Preparation method and application of bipolar plate

A bipolar plate and unipolar plate technology, applied in the field of bipolar plate preparation, can solve the problems of high electrical conductivity and high thermal conductivity, and achieve the effects of high electrical conductivity, excellent mechanical strength, and good performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

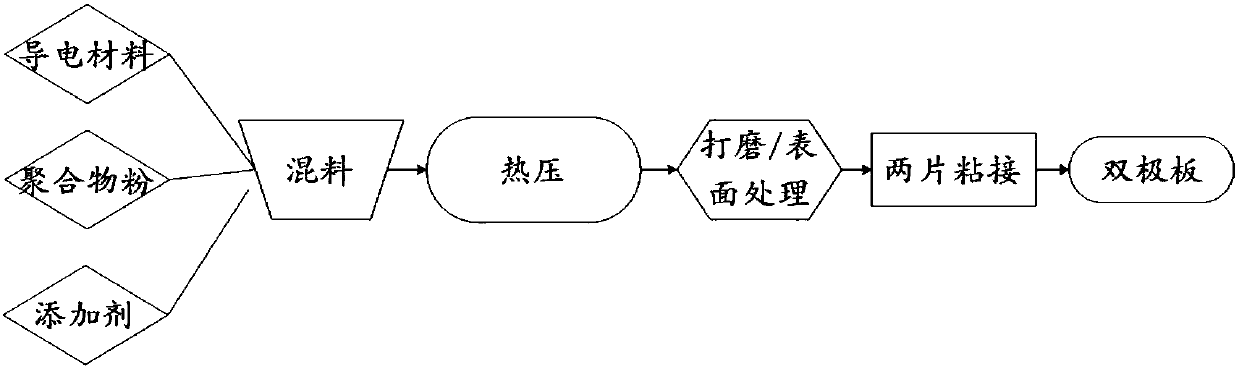

Method used

Image

Examples

Embodiment 1

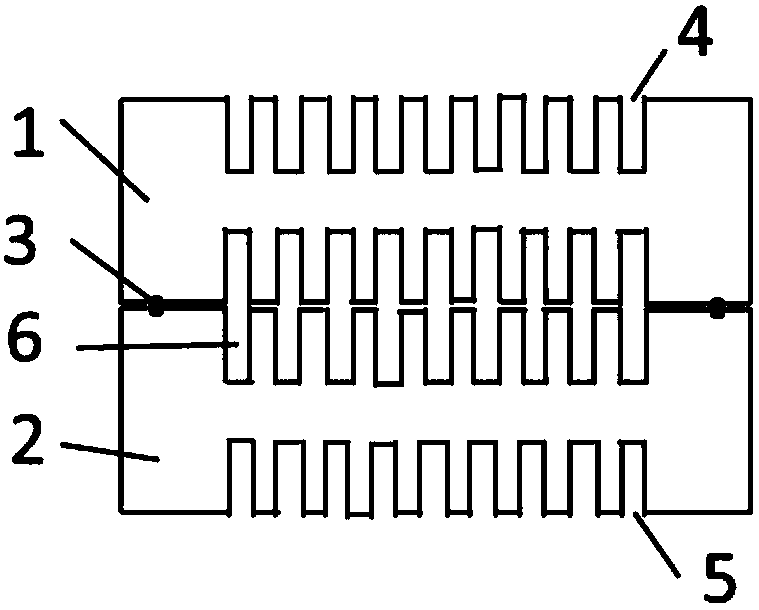

[0055] Mix 79.7% graphite powder, 20% polypropylene polymer, and 0.3% calcium stearate evenly, and then evenly distribute them in the hot-pressing mold. The hot-pressing mold is a mold with runners. Under pressure, gradually increase the temperature to 160°C, then gradually increase the pressure to 40MPa, continue to raise the temperature to 230°C, keep the pressure at 230°C for 1min, then cool down, release the pressure after the temperature drops to 80°C, open the mold, and demould successfully , take out the plate. Cut 3 strips of 4cm×1cm from different positions on the plate, use the four-probe method to measure the horizontal conductivity of the plate, and finally take the average value of the 3 pieces to measure the area specific resistance of the unipolar plate 22mΩ·cm 2 ;Cut four samples of 4cm×4cm size from different positions on the pole plate, and use the four-electrode method to characterize the vertical conductivity of the pole plate at 1000psi. The average valu...

Embodiment 2

[0057] Mix 80% of high-conductivity carbon black, 15% of polyethylene terephthalate, 4.5% of carbon nanotubes and 0.5% of zinc stearate, and spread them evenly in the hot pressing mold, first at 10MPa Under the pre-compression pressure, gradually increase the temperature to 150°C, then increase the pressure to 45MPa, continue to raise the temperature to 250°C, keep the pressure at 250°C for 3 minutes, then cool down, release the pressure after the temperature drops to 70°C, open the mold, and successfully release mold, take out the plate. Using the same method as in Example 1 to characterize the prepared pole plate, the measured area specific resistance of the monopolar plate is 23mΩ cm 2 , the vertical conductivity is 42S / cm; the flexural strength measured by the three-point method is 63MPa.

Embodiment 3

[0059] Mix 85% graphite powder, 13% polyphenylene sulfide polymer and 2% ground carbon nanofiber evenly, and then evenly distribute them in the hot-pressing mold. At first, a layer of flake graphite powder is evenly spread on the bottom of the mold, and the raw materials are placed After being inside the mold, sprinkle a layer of flake graphite powder evenly on the surface, and then close the mold, first gradually increase the temperature to 200°C under the pre-compression pressure of 10MPa, then gradually pressurize to 40MPa, continue to heat up to 370°C, 370°C Keep the pressure at ℃ for 30s, and then cool down. After the temperature drops to 150℃, open the mold, demould successfully, and take out the polar plate. Using the same method as in Example 1 to characterize the prepared polar plate, the measured area specific resistance of the unipolar plate is 17mΩ cm 2 , the vertical conductivity is 47S / cm; the flexural strength measured by the three-point method is 66MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com