Patents

Literature

44results about How to "High heating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

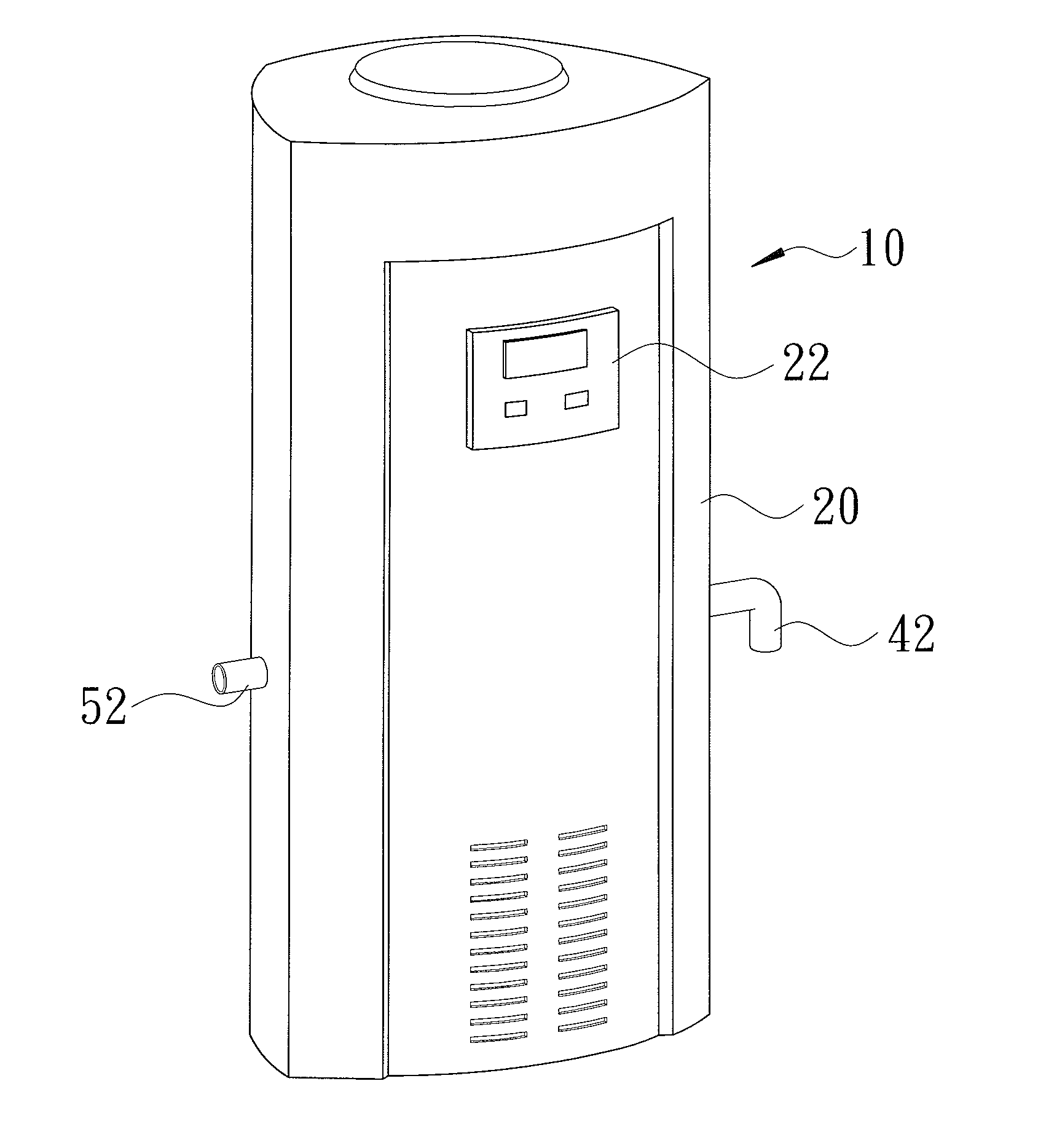

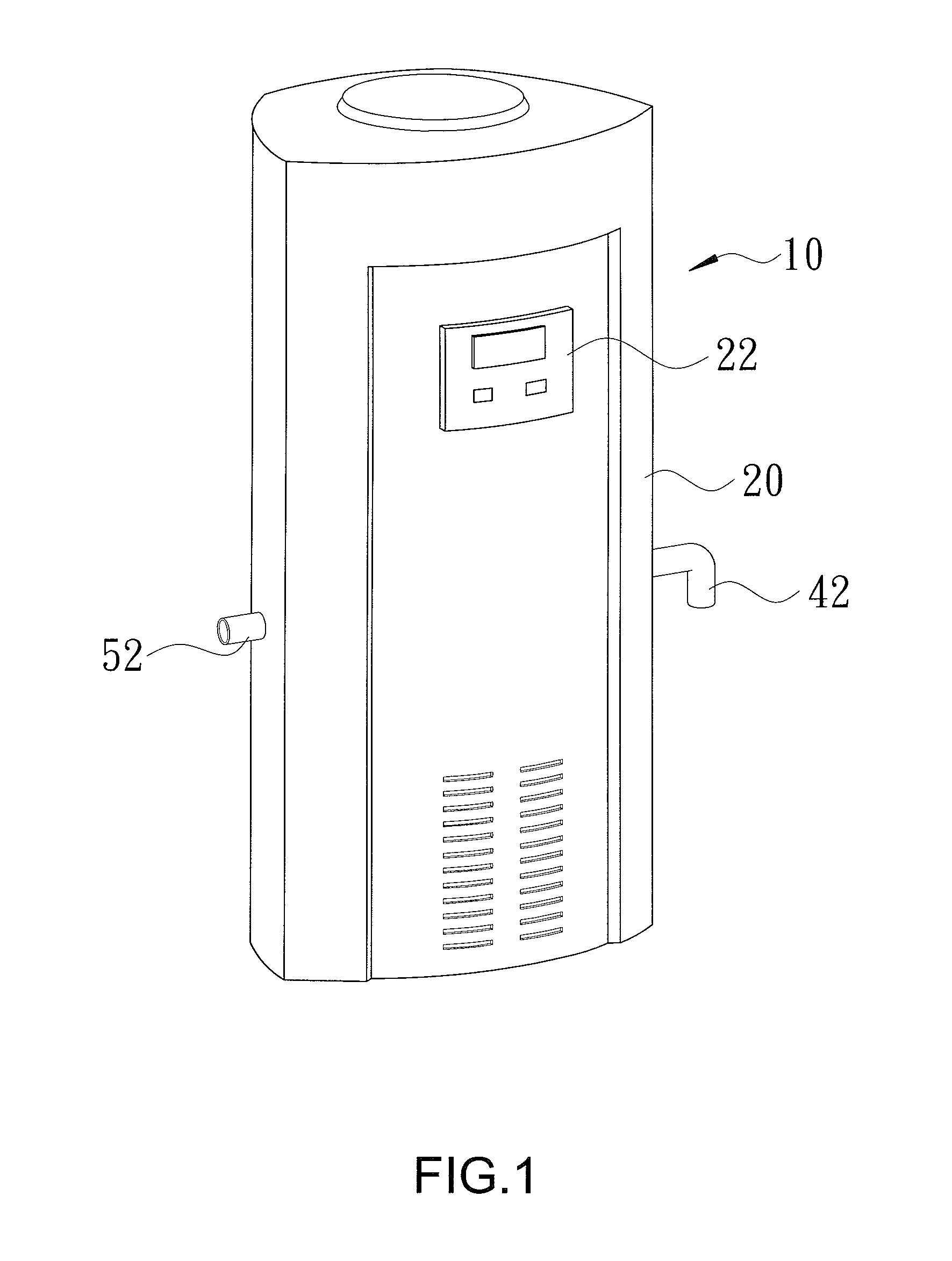

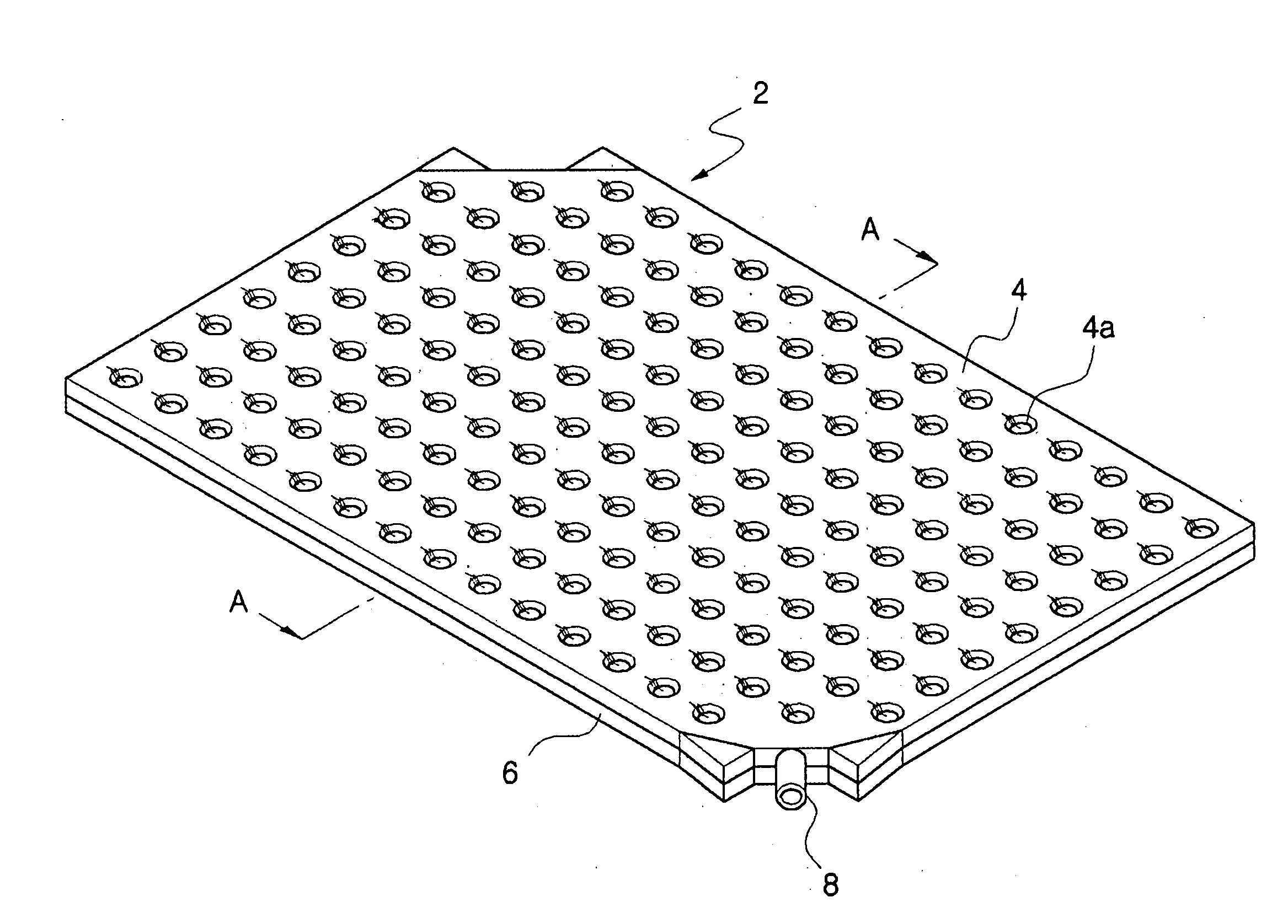

High-Efficiency Water Boiling Device

InactiveUS20120061382A1High heating efficiencyHigh utilization safetyDomestic stoves or rangesSpace heating and ventilationInduction heaterHigh frequency

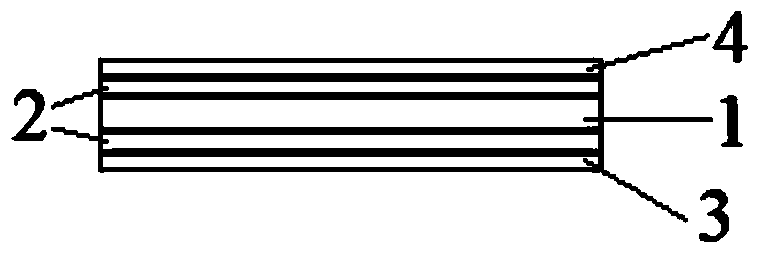

A water boiling device includes a heat tank unit received in a machine body, a high frequency induction heater, and a heat pipe unit. Heat tank unit includes first and second heating tanks in communication with each other. Outside water can flow into first and second heating tanks. The high frequency induction heater includes a heat pipe induction coil and first and second induction coils. The heat pipe unit includes first and second heating pipes. An upper section of each heating pipe is received in one of heating tanks, and a lower section of each heating pipe extends out of heating tanks and is inserted into heat pipe induction coil. The first and second heating tanks will heat up to heat the water in first and second heating tanks when a high frequency current is passed through the heat pipe induction coil and first and second induction coils.

Owner:YANG SHUN CHI +4

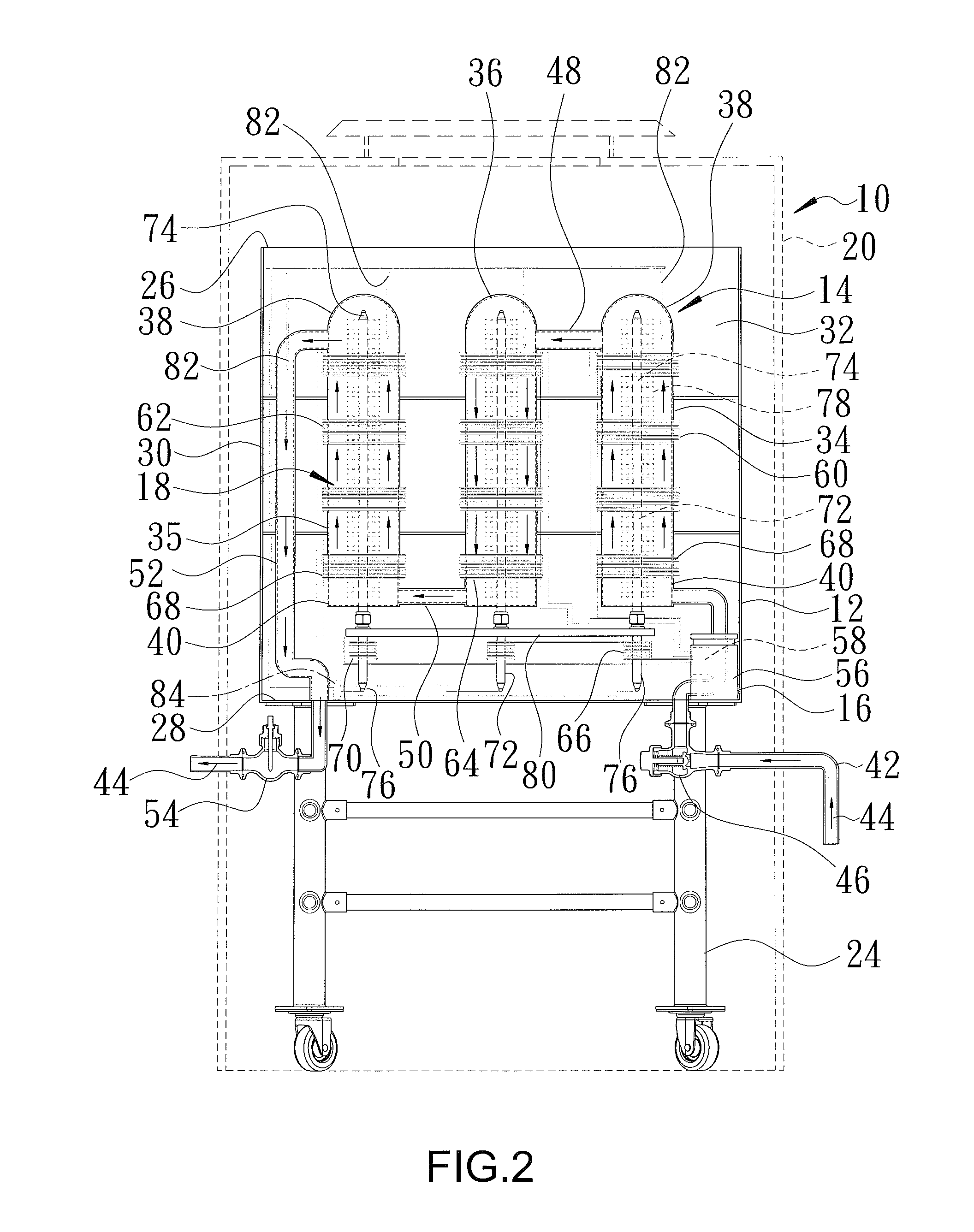

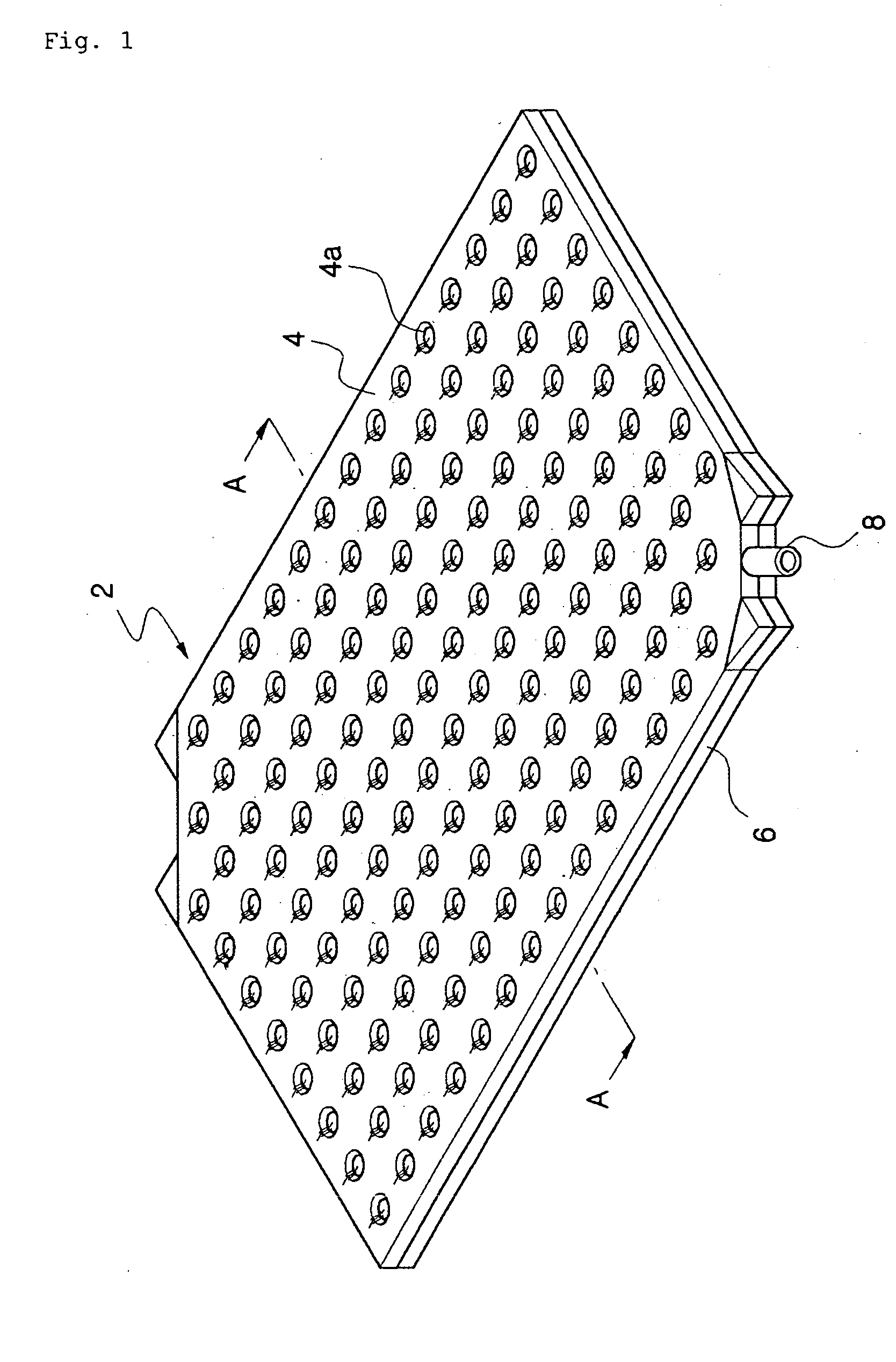

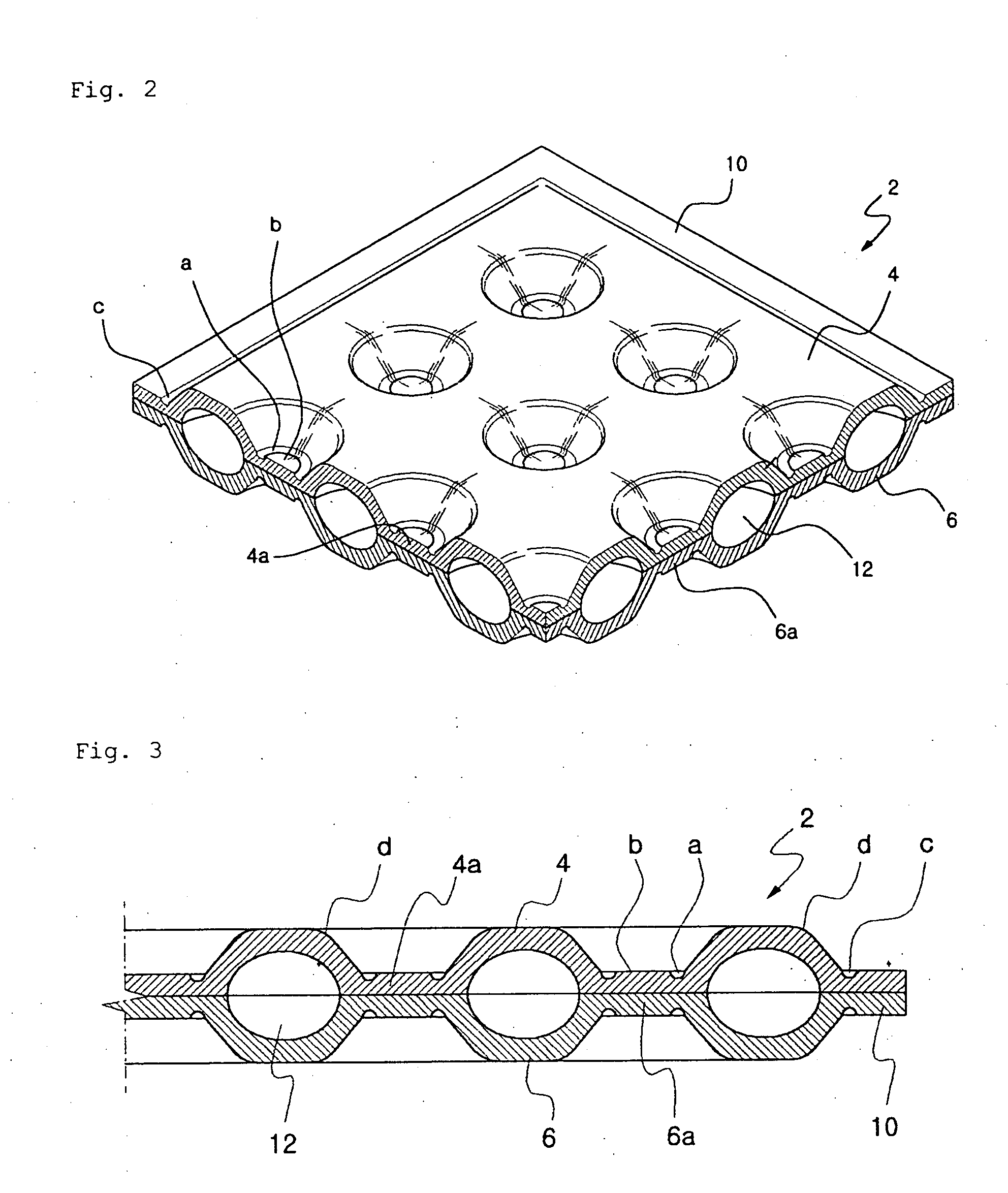

Plate-shaped heating panel in which connecting members are fastened by bolts and nuts

InactiveUS20060000588A1High heating efficiencyReduction of fuel expenseStationary conduit assembliesSustainable buildingsBonding strengthElectrical and Electronics engineering

Disclosed herein is a plate-shaped heating panel having connecting members fastened to each other by means of bolts and nuts. The heating panel comprises upper and lower plates integrally formed to face each other so as to form an inner fluid pathway in which heating water flows, a plurality of connecting members, each symmetrically extending from the upper and lower plates toward the lower and upper plates, respectively, and connecting the upper and lower plates to each other, the inner fluid pathway formed inside of the plate by means of the plurality of connecting members, and two fluid communication portions for supplying and discharging the heating water, wherein one or more connecting members adjacent to the fluid communication portions are punctured such that punctured portions of the connecting members are fastened to each other by means of bolts and nuts. Accordingly, a bonding strength of the heating panel is enhanced, and even though the crack is generated, the crack is forced to change in its progressing direction and is prevented from spreading, thereby enhancing the pressure resistance of the heating panel.

Owner:LG CHEM LTD

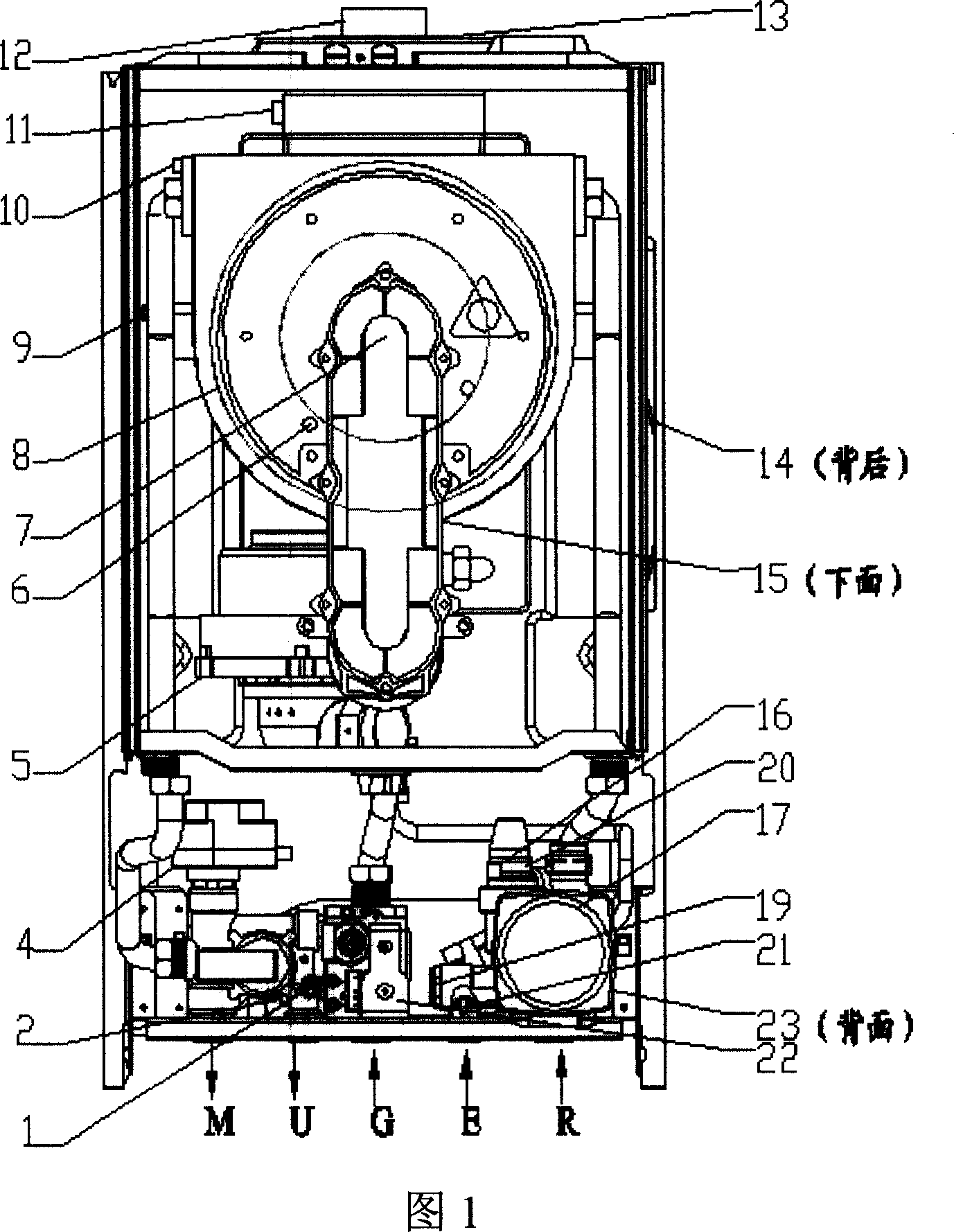

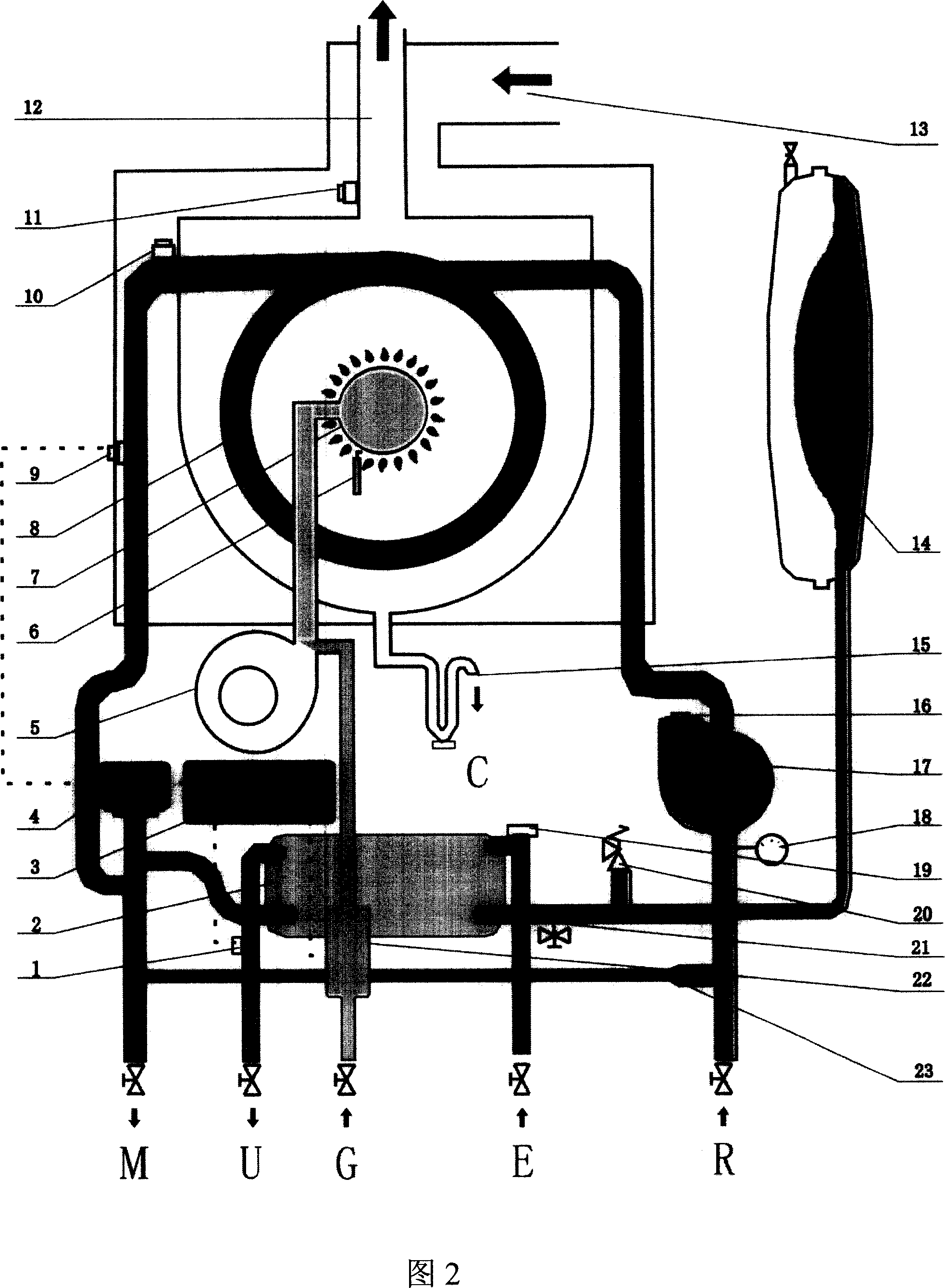

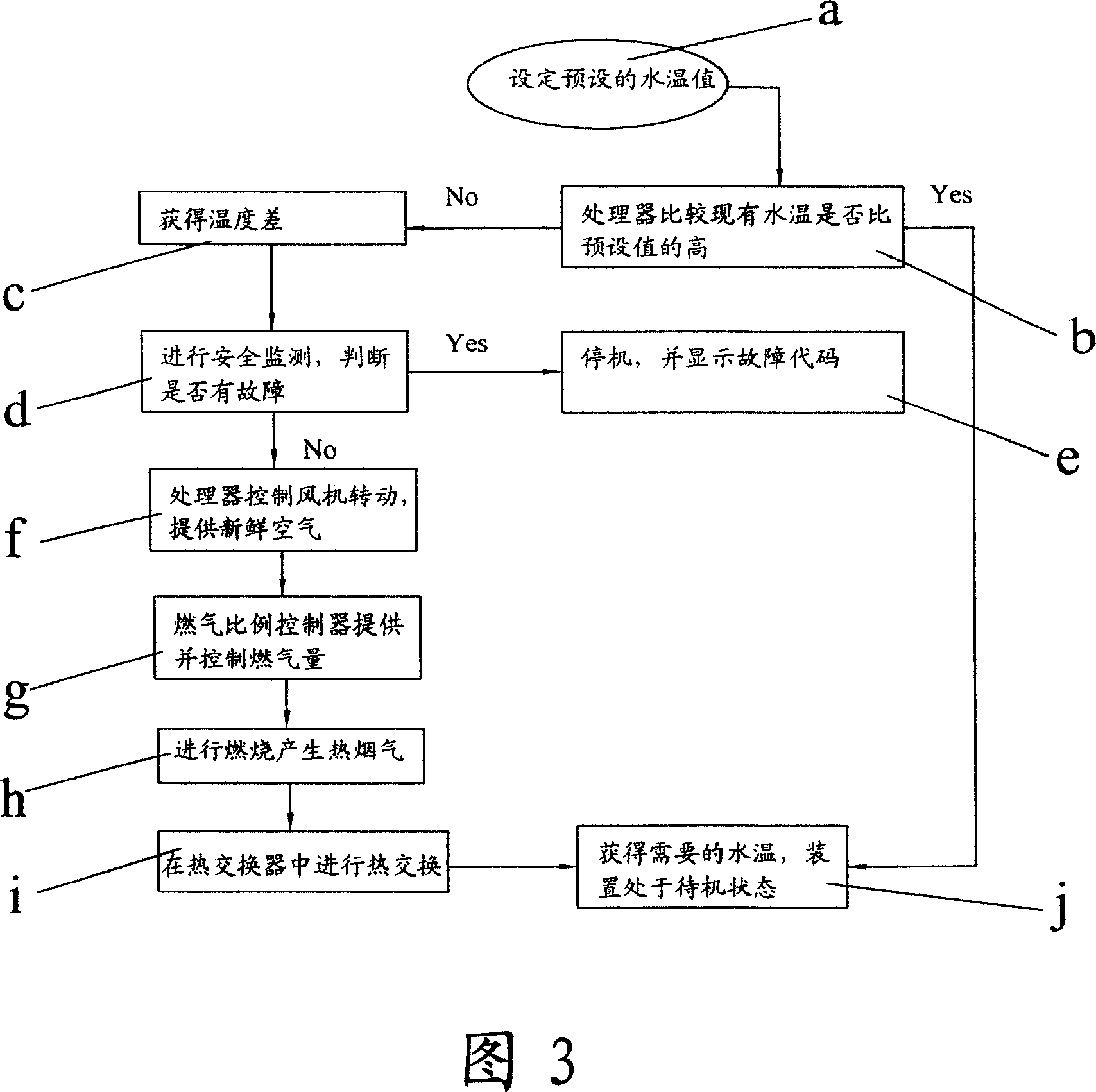

Full pre-mix condensing heating hot-water dual-purpose device

ActiveCN101118127AHigh heating efficiencyEnergy savingStationary conduit assembliesWater heatersEngineeringThermal efficiency

The present invention relates to a whole premixing condensing space heating and water heating double duty device, which comprises a burning generating part, a cyclical delivering part, a heat exchanging part and a control part. The burning generating part comprises a whole premixing burner and a fuel gas and air ratio controller, the heat exchanging part realizes the heat exchanging of fume and water, and comprises a condensing heat exchanger and a plate type heat exchanger, the cyclical delivering part comprises a fume exhaust pipe, an air inlet pipe, a condensate water discharging pipe and a water circulating pump and a blower fan, realizes air and fuel gas delivering for the burning generating part, and the hot fume discharging, deliveries hot fume and water to the heat exchanging part, and discharges low-temperature fume and high-temperature water; the control part is arranged in the whole premixing condensing space heating and water heating double duty device, and comprises a processor controlling each part work flow, and sensors are arranged at the cyclical delivering part, the heat exchanging part and the burning generating part, thus the purposes of thermal efficiency improving and foul gas discharging reduction are realized.

Owner:HAIER GRP CORP +1

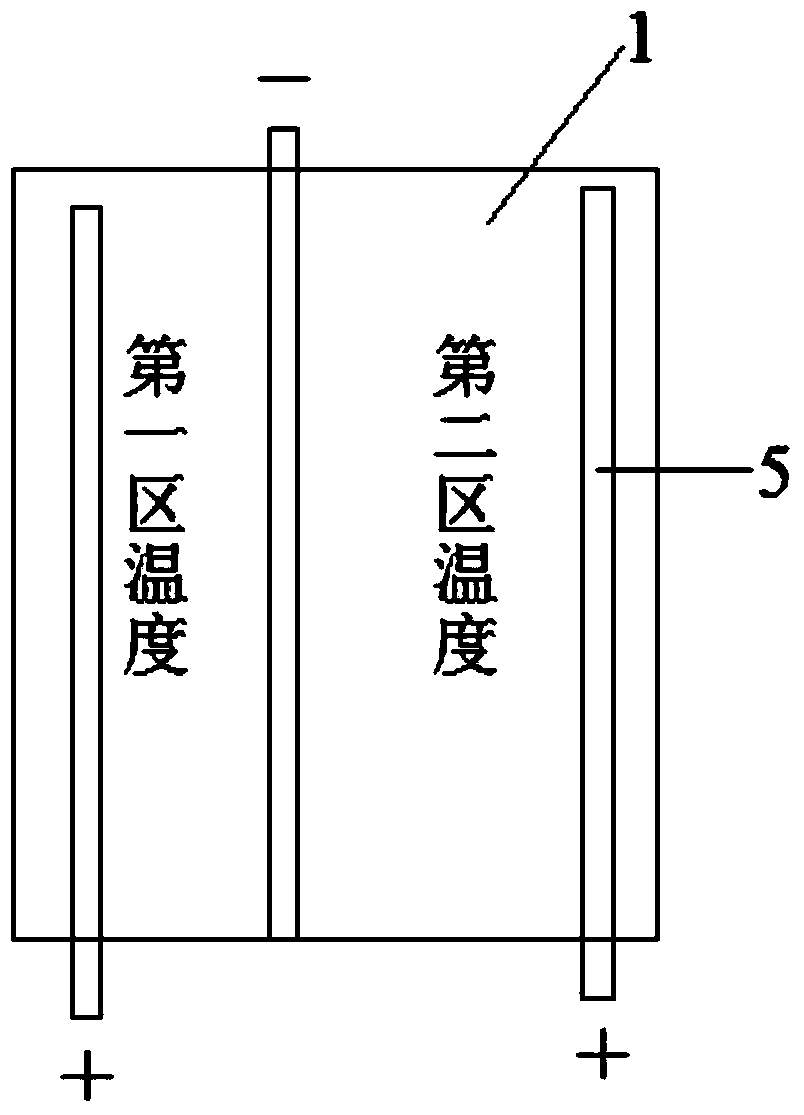

Infrared carbon crystal electronic heating panel and processing method thereof

ActiveCN103763796ASolve the heat resistance temperatureSolve efficiency problemsLaminationLamination apparatusEpoxyCopper wire

The invention discloses an infrared carbon crystal electronic heating panel. The infrared carbon crystal electronic heating panel comprises a carbon crystal heating sheet which is composed of superconducting resin and non-woven glass fiber cloth. The two surfaces of the carbon crystal heating sheet are respectively covered with an insulating layer, the insulating layer on one surface of the carbon crystal heating sheet is covered with a reflective coating layer, and the insulating layer on the other surface of the carbon crystal heating sheet is covered with a protective layer. A plurality of copper wire electrodes are arranged between the carbon crystal heating sheet and the insulating layers. The superconducting resin is composed of the following raw materials, by weight, 100 parts of fire resistance high temperature resistance epoxy resin, 31-100 parts of superconducting carbon crystal powder, 10-50 parts of organic filler, 3.1-3.8 parts of curing agents and 200-430 parts of acetone. A processing method of the heating panel includes the steps that the above raw materials are weighed, so that the superconducting resin is made, the heating sheet and a heating panel semi-finished product are prepared, and finally a heating panel finished product is manufactured. By means of the infrared carbon crystal electronic heating panel and the processing method thereof, the problems that an existing heating panel is low in heat-resistance temperature and heating efficiency and cannot obtain different temperature distribution areas on one heating panel are solved, and the infrared carbon crystal electronic heating panel is large in heating power, high in heat-resistance temperature and long in service life.

Owner:郭长奇

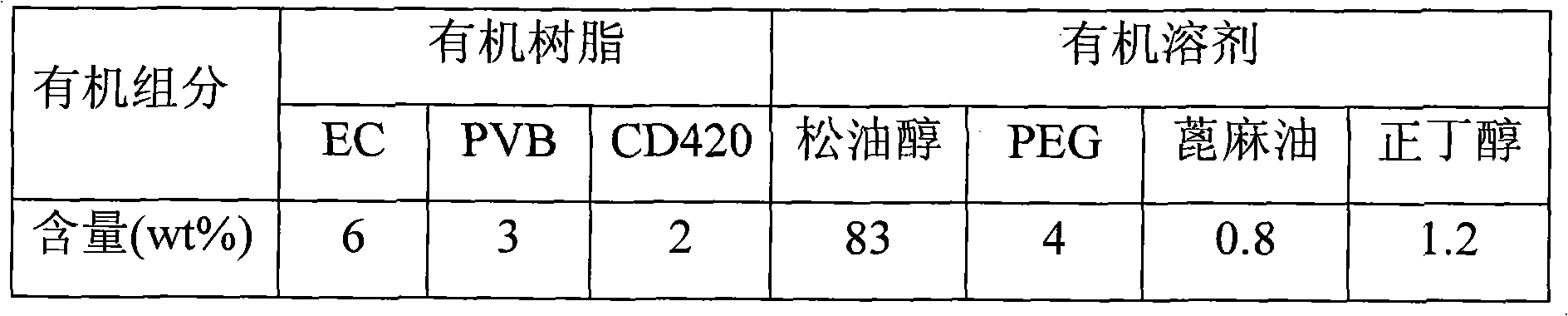

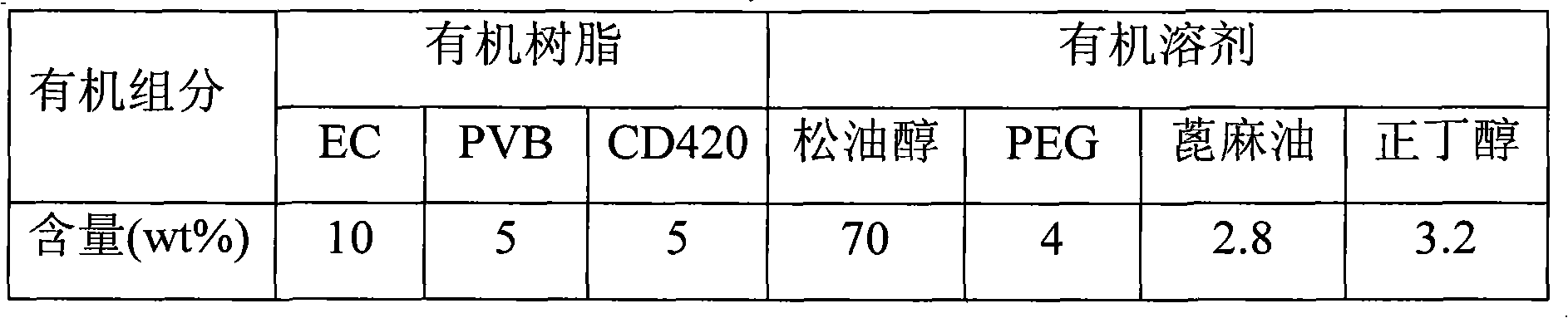

Rare-Earth Doped Semiconductor Infrared Radiation Thick-Film Electronic Paste and Preparation Method Therefor

InactiveUS20190007998A1High heating efficiencyImprove heating efficiencyHeating element materialsHeating efficiencyOrganic solvent

A rare-earth doped semiconductor infrared radiation thick-film electronic paste and a preparation method therefor. The electronic paste comprises, in parts by weight, 10%-90% of organic vehicle and 10%-90% of functional phase. The organic vehicle comprises, in parts by weight, 50%-95% of organic solvent, 1%-40% of thickener, and 0%-5% of organic aid. The functional phase comprises, in parts by weight, 40%-95% of rare-earth doped infrared radiation semiconductor material, 5%-60% of conductor material, and 0%-20% of functional additive. The electronic paste features a wide range of selectable base materials, a wide heating temperature range, high heating efficiency, and a heating body of low temperature, and can implement bidirectional conversion of heat to electricity and electricity to heat. The preparation method comprises: a. mixing a thickener, an organic aid, and an organic solvent to prepare an organic vehicle; b. mixing the organic vehicle and a functional phase, and grinding the mixture to prepare an electronic paste; and c. printing the electronic paste onto a substrate by means of screen printing, and curing or sintering same to form a film.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

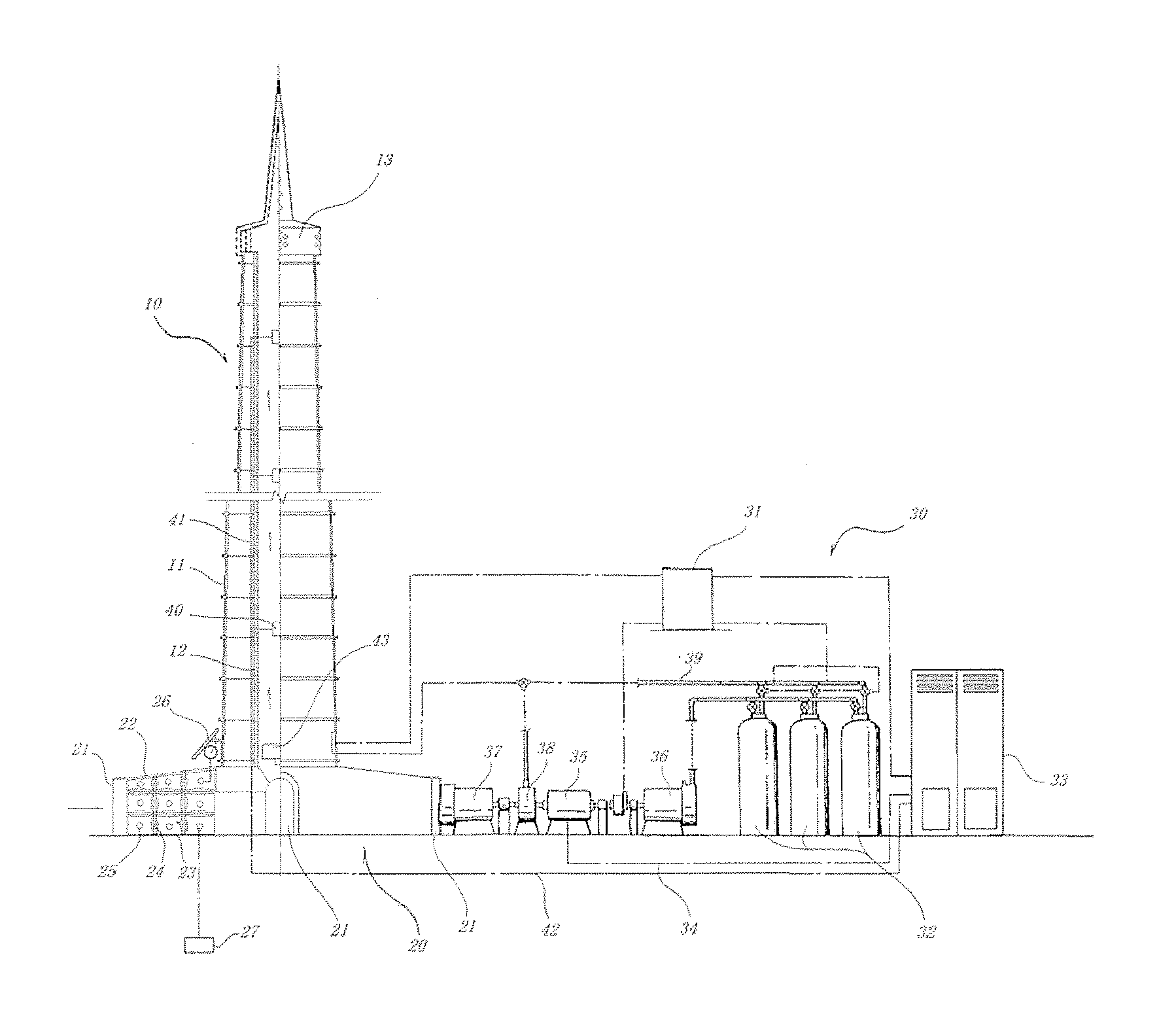

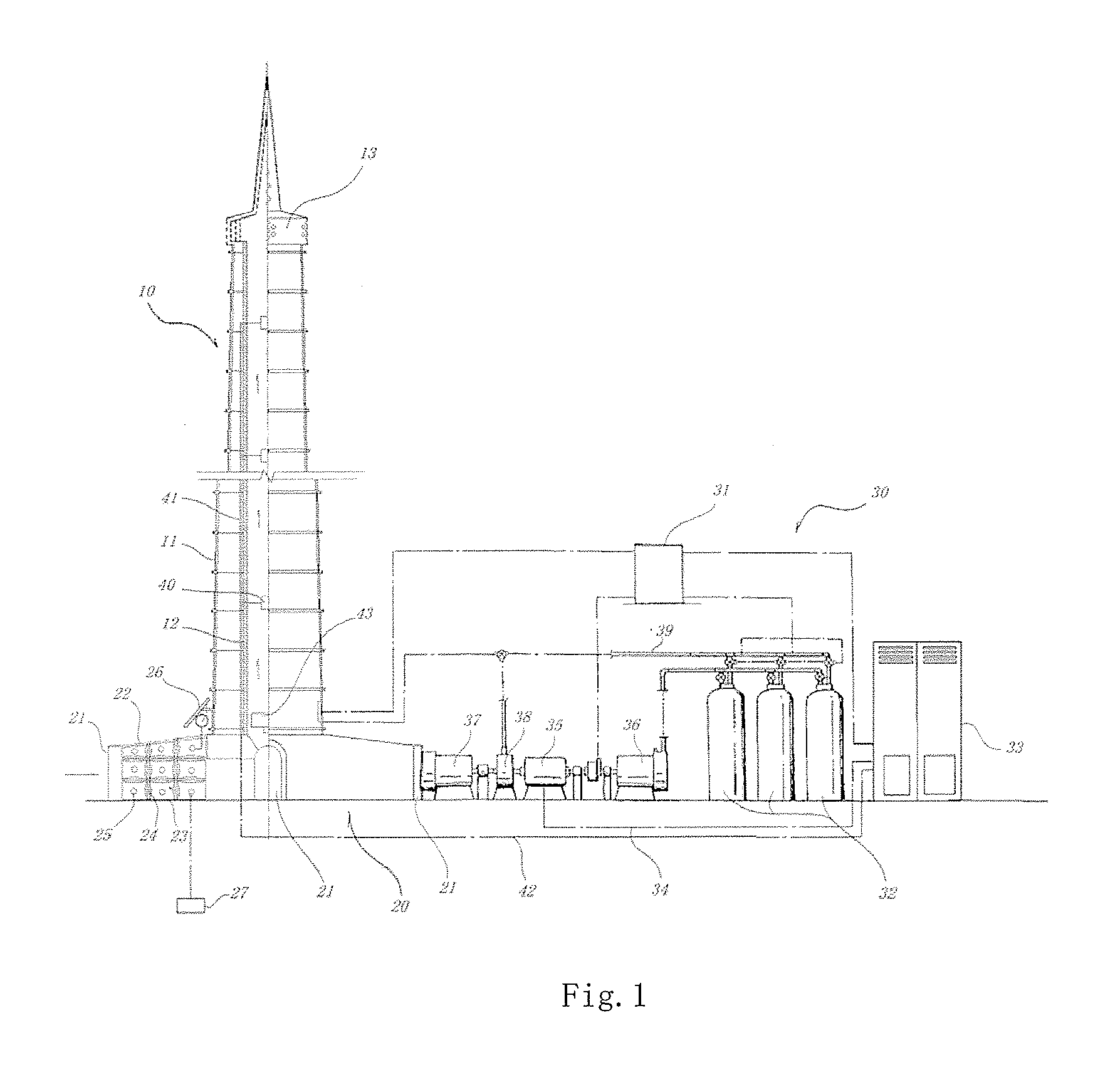

Storage energy generation method utilizing natural energy and generation system thereof

InactiveUS20140196456A1High heating efficiencyHigh air velocity and pressureGas turbine plantsHydro energy generationAutomotive engineeringPower grid

A storage energy generation method utilizing natural energy and a generation system thereof generates electricity through natural energy such as wind power or solar energy and then compresses air, or directly compresses air, then generates electricity to an electric grid through the compressed air which is deemed as a power resource. An electric station utilizing integrated energy generates electricity to drive an air compression device, further then produces compressed air as an energy storage medium and stores compressed air in an air storage device, and then regards the compressed air as a main or auxiliary driving energy to other electric stations, such that a function of stabilizing and adjusting peak load can be realized.

Owner:BEIJING XIANGTIAN HUACHUANG AERODYNAMIC FORCE TECH RES INST

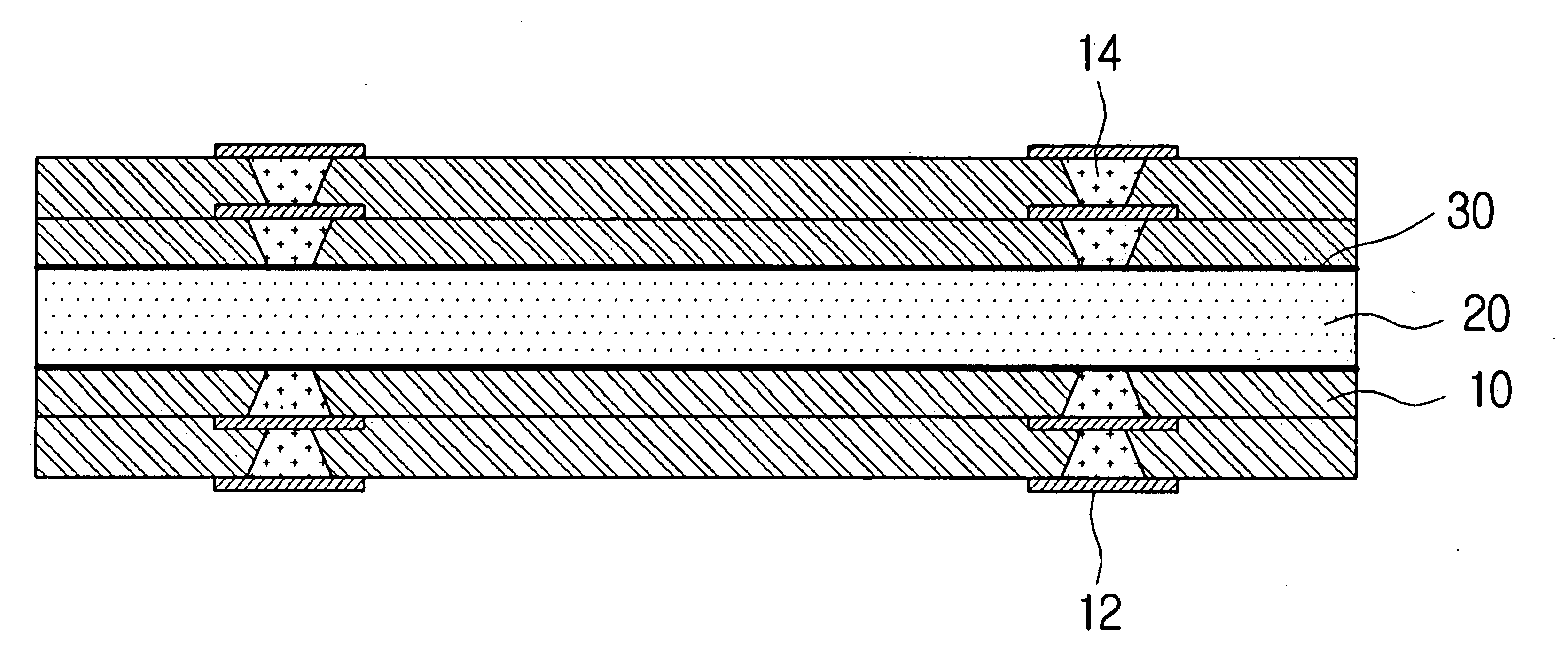

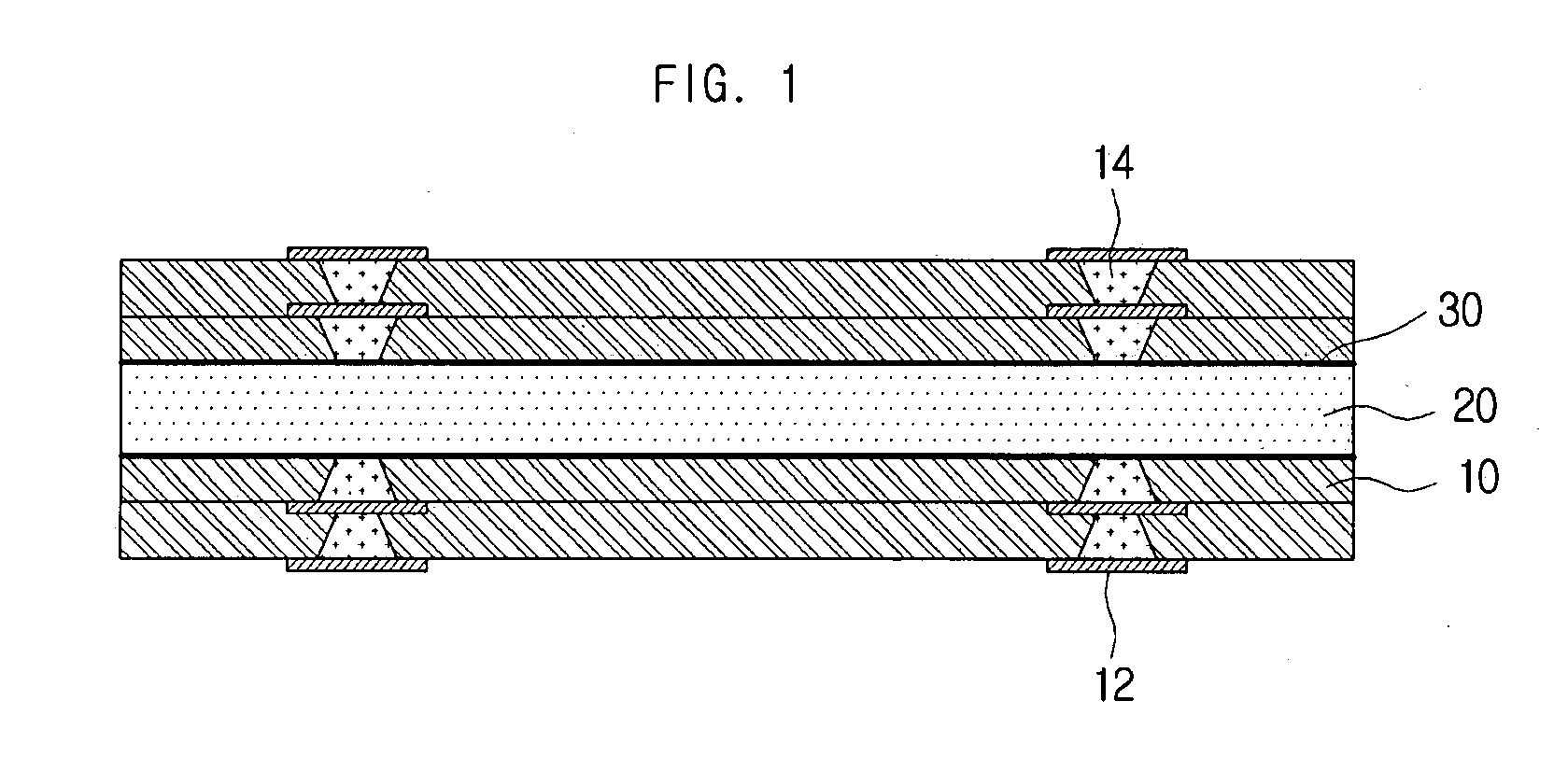

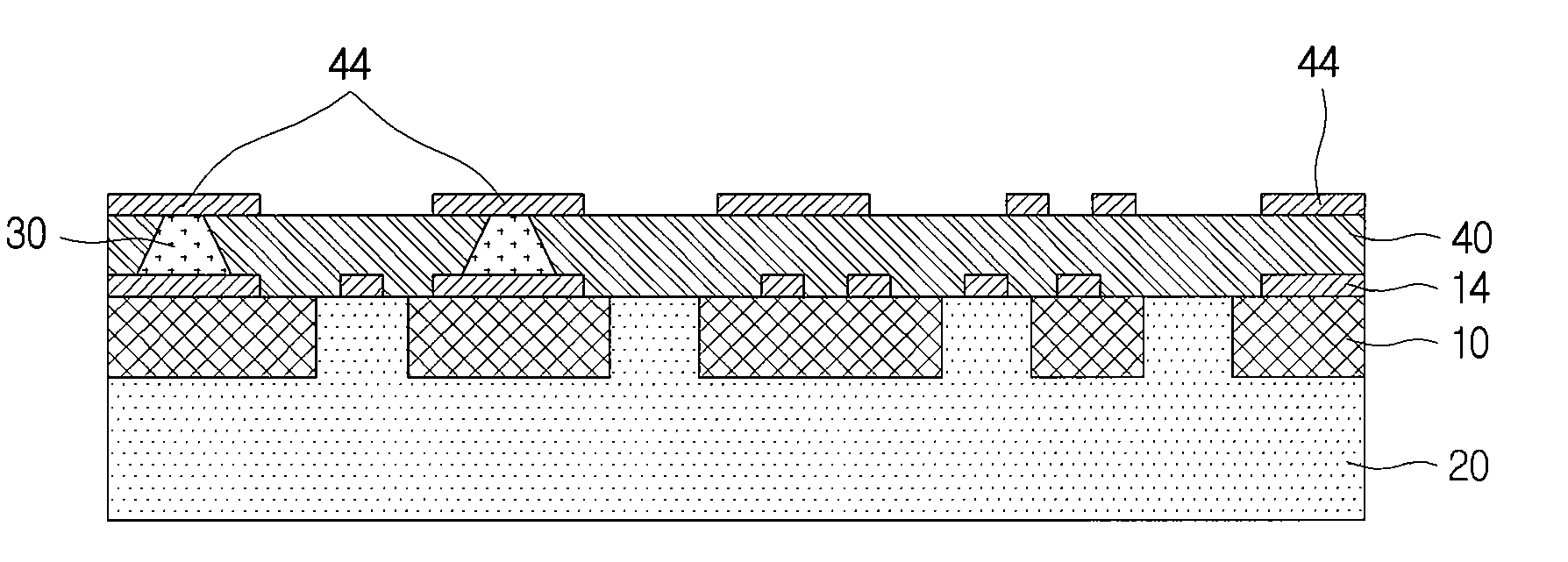

Printed circuit board and method for manufacturing thereof

InactiveUS20080121414A1High heating efficiencyHigh thermal conductivityPrinted circuit aspectsConductive pattern formationPrinted circuit boardCoating

A printed circuit board and a method of manufacturing thereof are disclosed. With a printed circuit board comprising an insulating layer; a circuit pattern formed on one side of the insulating layer; an inter-layer conductive part joining with the insulating layer by passing through the insulating layer, and electrically connected to the circuit pattern; a heat dissipating layer laminated on the other side of the insulating layer; and a heat dissipating coating layer interposed between the insulating layer and the heat dissipating layer, and connected with the inter-layer conductive part, the heat contained in the insulating layer may be delivered to the heat dissipating layer effectively and the efficiency of heat dissipation may be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Heating electrode paste, heating electrode and planar oxygen sensor comprising heating electrode

ActiveCN102376378ALow resistivityHigh heating efficiencyMaterial analysis by electric/magnetic meansNon-conductive material with dispersed conductive materialHeating efficiencySilicon oxide

The invention provides a heating electrode paste, which comprises an inorganic powder and an organic paste carrier, wherein the inorganic powder comprises tantalum silicide, niobium alloy, aluminum oxide and silicon oxide. The invention also provides a heating electrode obtained by sintering the heating electrode paste and a planar oxygen sensor comprising the heating electrode. In the heating electrode paste provided by the invention, the tantalum silicide and the niobium alloy are adopted, thereby, the heating efficiency is very high, and the cost is lower.

Owner:BYD CO LTD

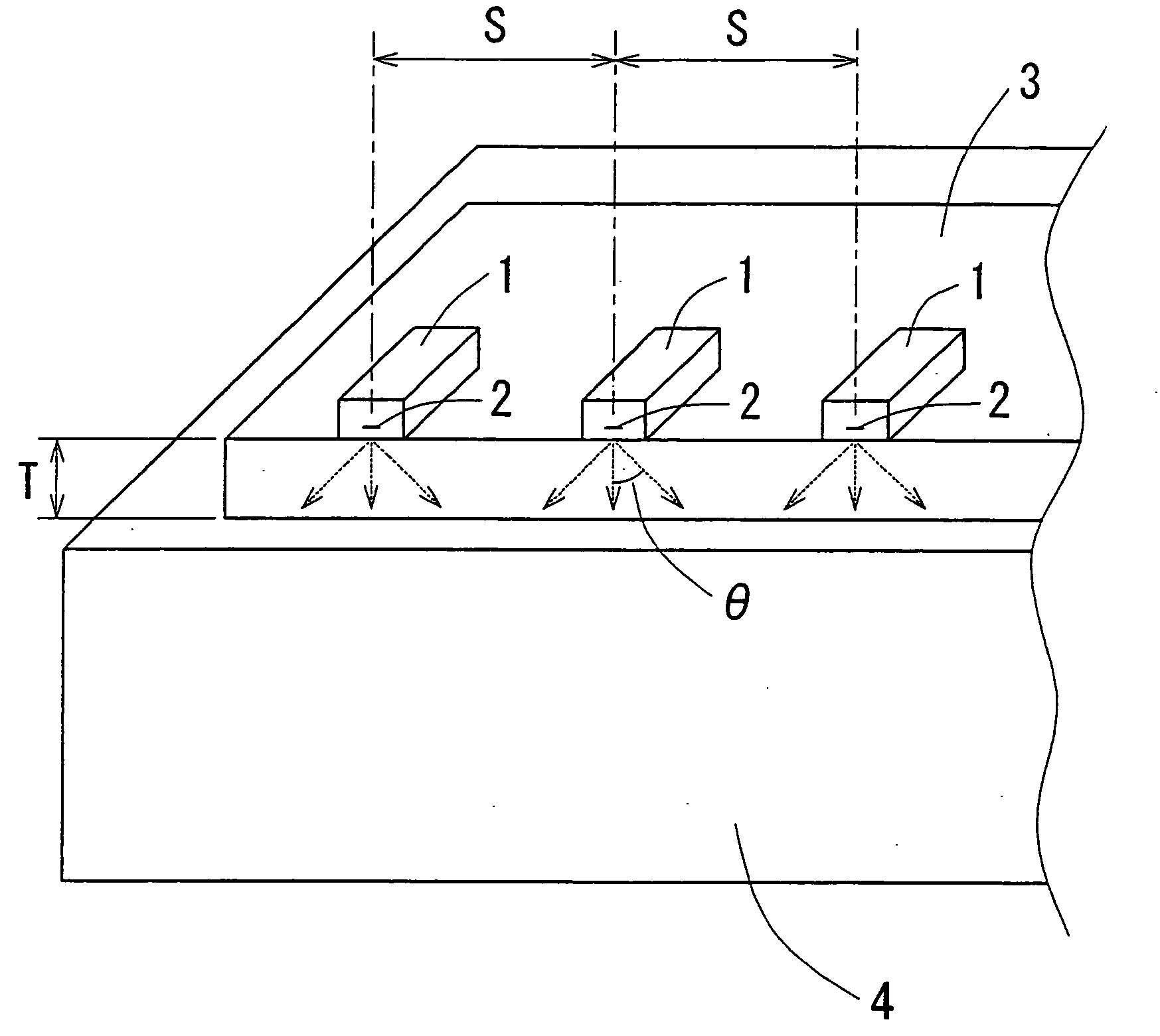

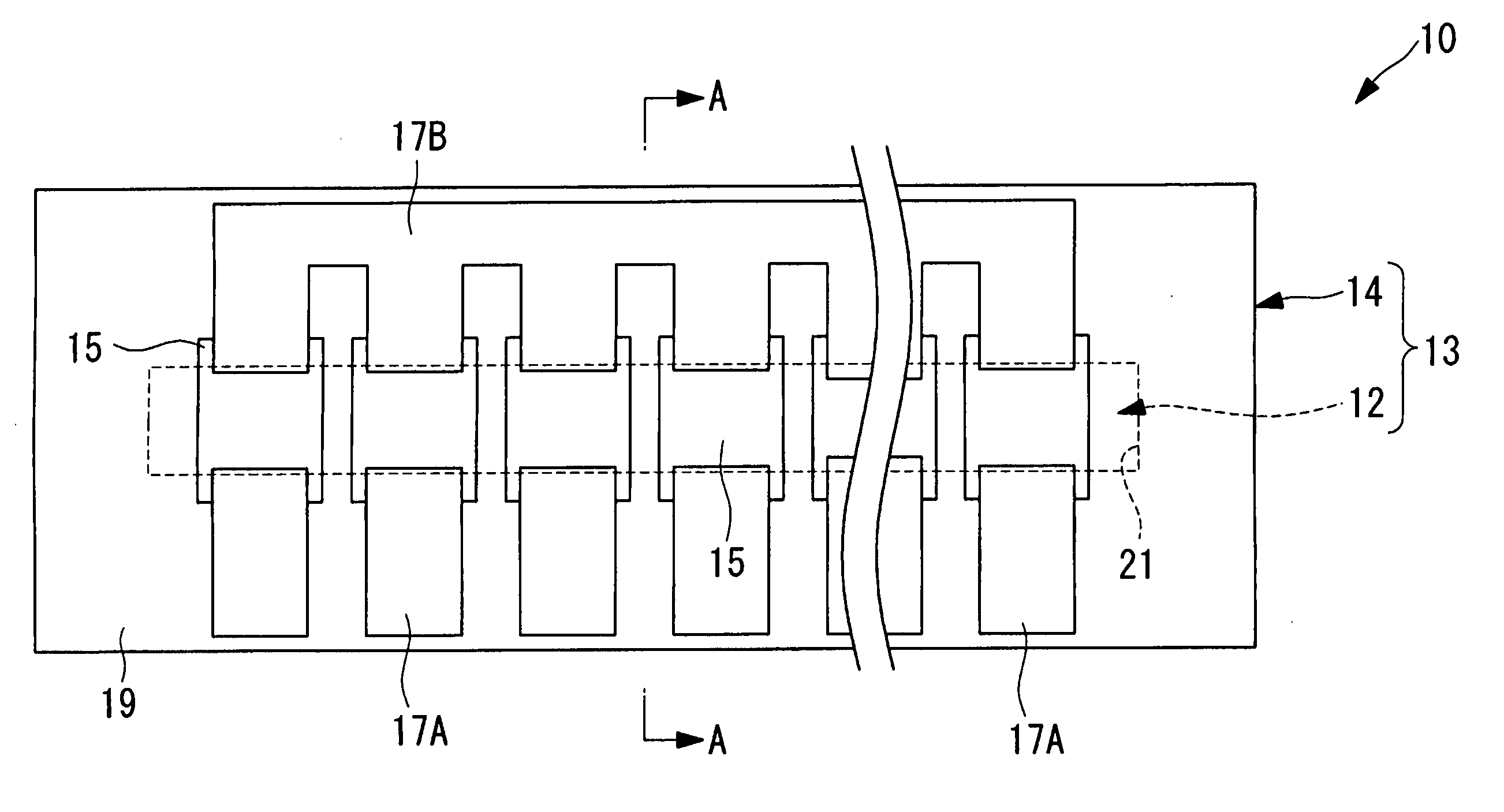

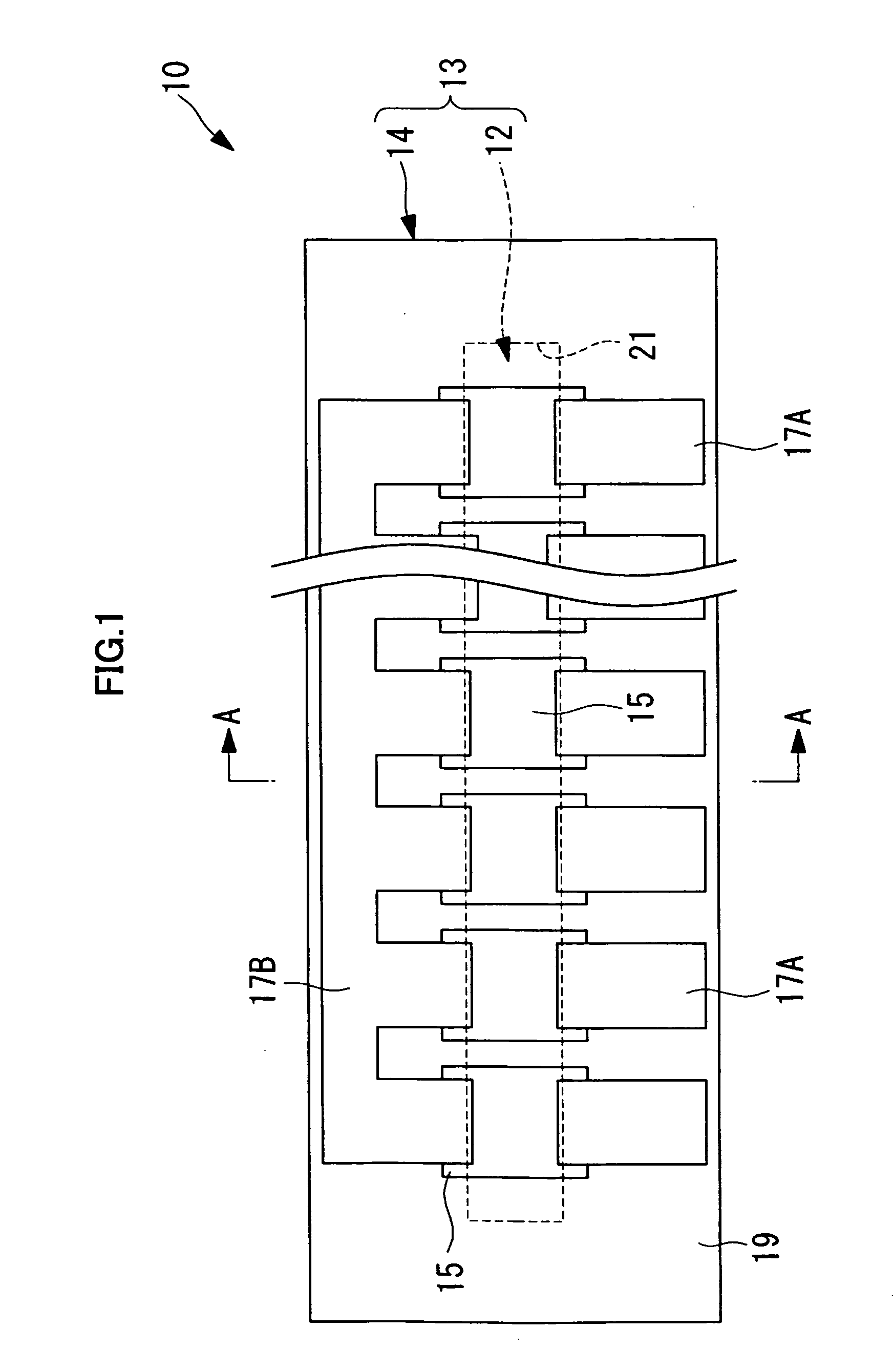

Semiconductor laser array device

InactiveUS20050286592A1High heating efficiencyGood process yieldSemiconductor laser arrangementsLaser arrangementsLaser arrayHeat spreader

A semiconductor laser array device for outputting a higher power includes: a plurality of semiconductor laser chips, arranged in a predetermined pitch; a submount for mounting each semiconductor laser chip; and a heat sink for dissipating heat from the semiconductor laser chip through the submount; wherein a distance S between the centers of the chips and a thickness T of the submount satisfy the following inequality: 2×T≦S≦10×T, whereby improving efficiency of heat dissipation with a good process yield.

Owner:MITSUBISHI ELECTRIC CORP

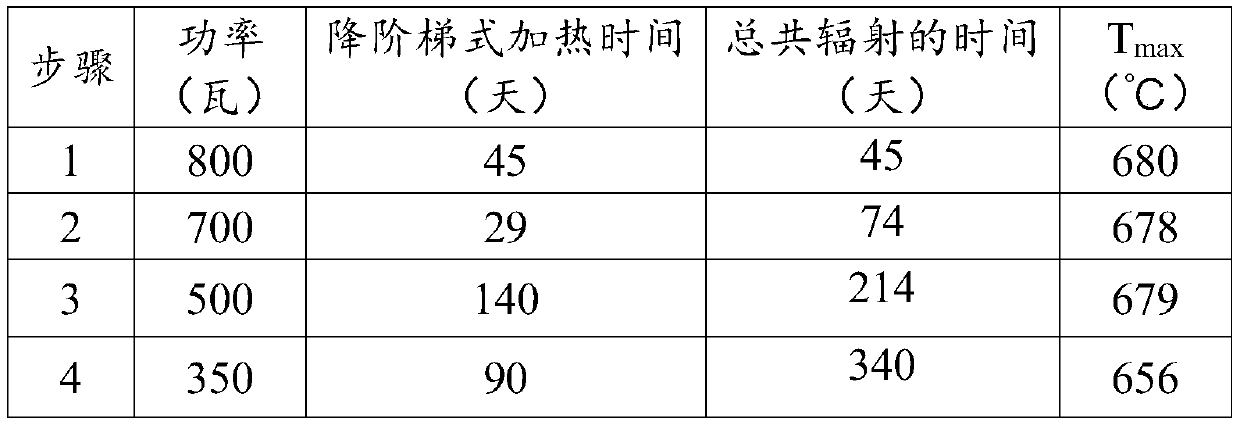

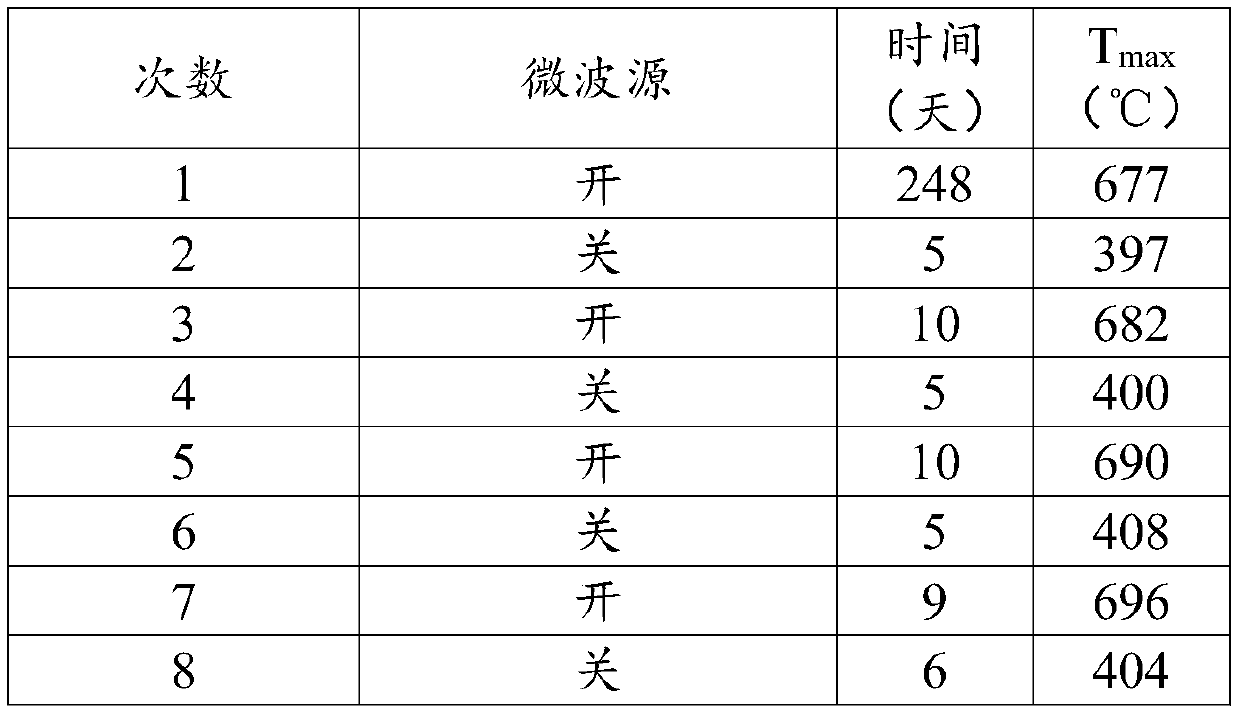

Microwave step-down in-situ heating method for mining oil shale

A microwave step-down in-situ heating method for mining oil shale includes the following steps: (1) setting a microwave heating well on an oil shale ore layer, wherein the microwave heating well is located at the center of an oil and gas export crack; and (2) after a temperature sensor monitors that the temperature of the microwave heating well reaches the upper limit, reducing the microwave powerin a stepwise manner so as to radiately heat the oil shale ore layer, so that the generated oil and gas are exported through the oil and gas export crack. The method adopts the heating mode of step-down type microwave heating for oil shale, not only takes advantage of the easy control of microwave power, but also is a high-efficiency heating method with higher efficiency than an intermittent microwave heating mode.

Owner:SOUTHWEST PETROLEUM UNIV

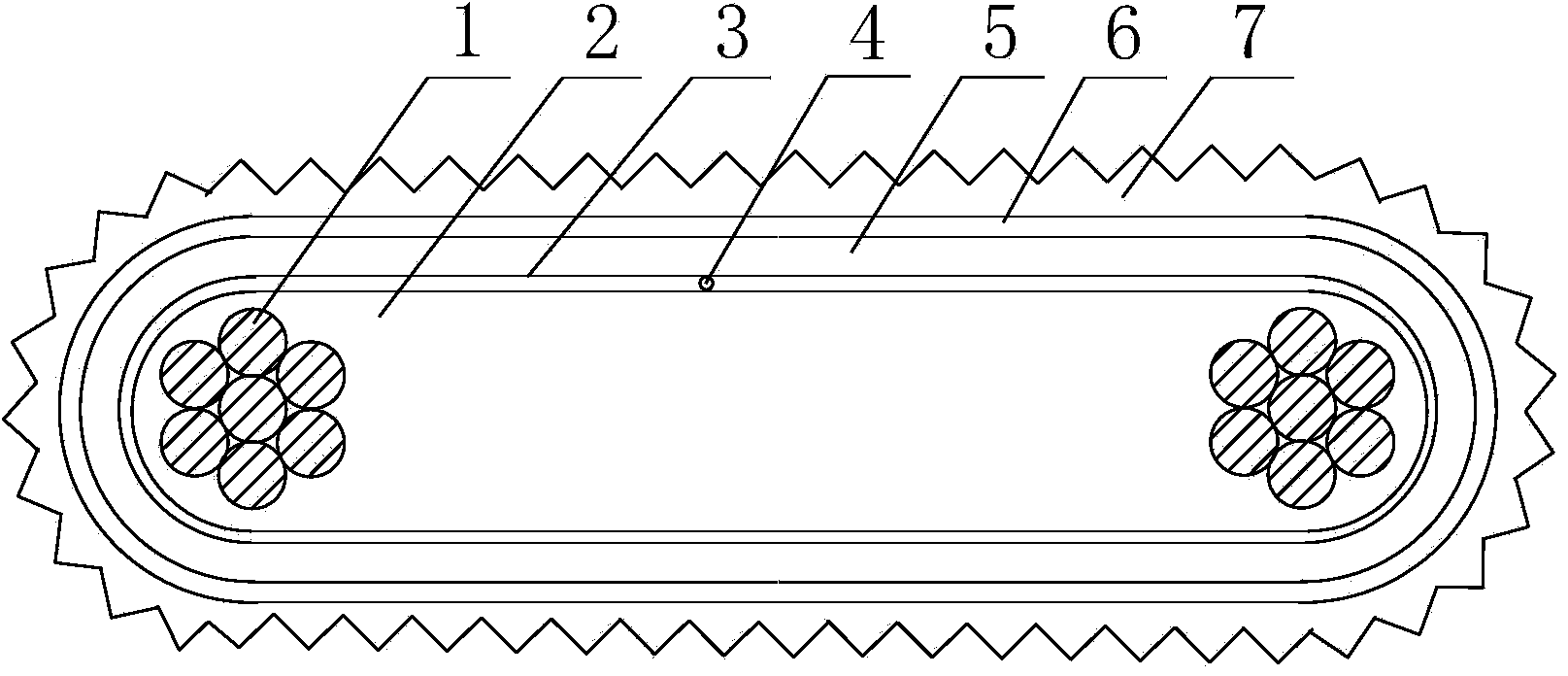

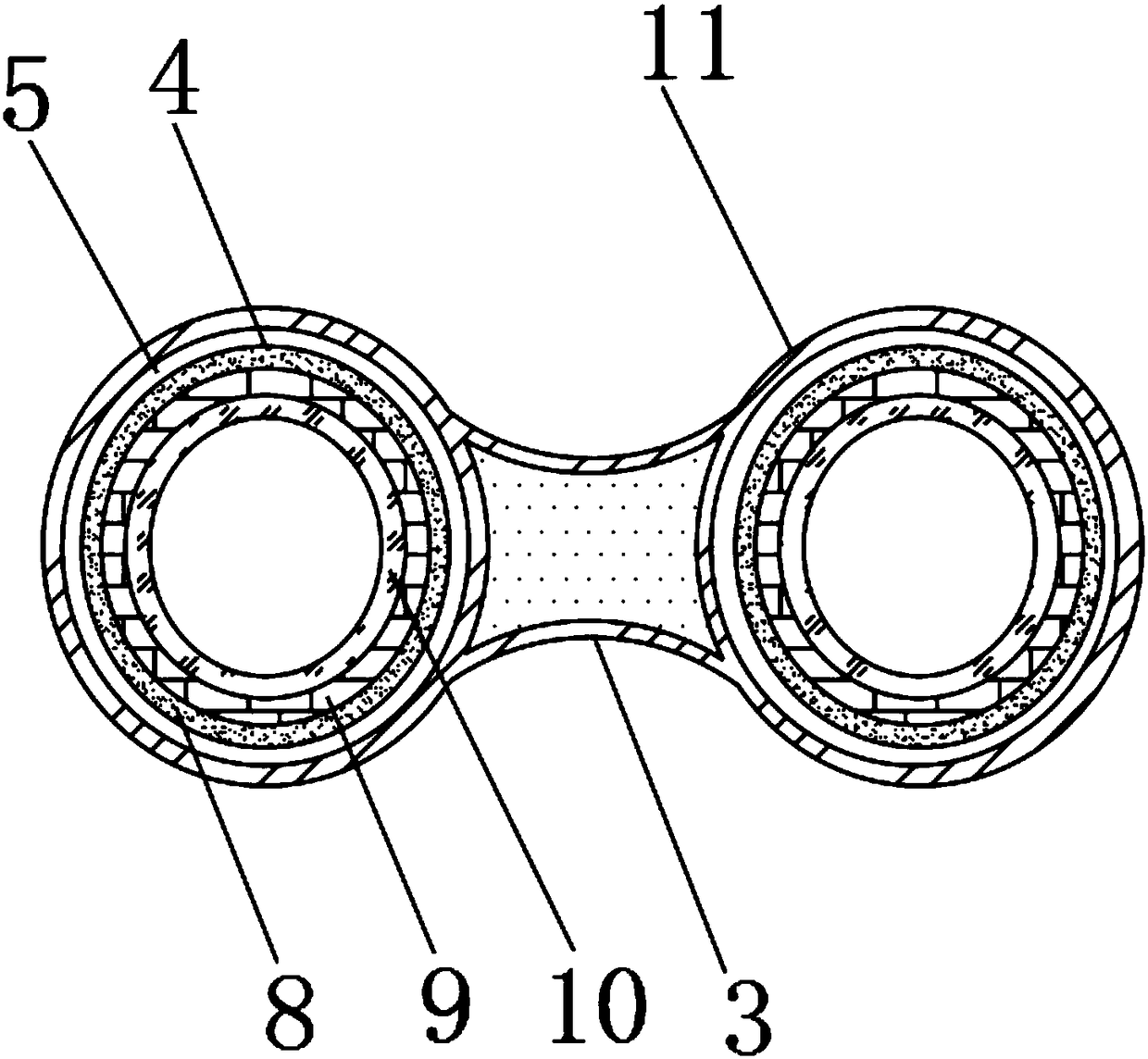

Anti-corrosion and anti-explosion self-temperature-control electric tracing band

The invention discloses an anti-corrosion and anti-explosion self-temperature-control electric tracing band. The anti-corrosion and anti-explosion self-temperature-control electric tracing band comprises a PTC material core which is internally provided with two wires, the PTC material core is wrapped by a single-face metal and plastic composite belt which is internally provided with a drainage wire, the plastic layer of the single-face metal and plastic composite belt faces inwards, and the metal layer of the single-face metal and plastic composite belt faces outwards. The metal and plastic composite belt is wrapped by an insulating layer, the insulating layer is wrapped by a braided shield layer, the braided shield layer is wrapped by a restrictive coating, and the periphery of the restrictive coating is provided with a plicated texture. The anti-corrosion and anti-explosion self-temperature-control electric tracing band is simple in structure and good in electromagnetic shielding performance and can be used safely under the high-temperature environment.

Owner:安徽华海特种电缆集团有限公司

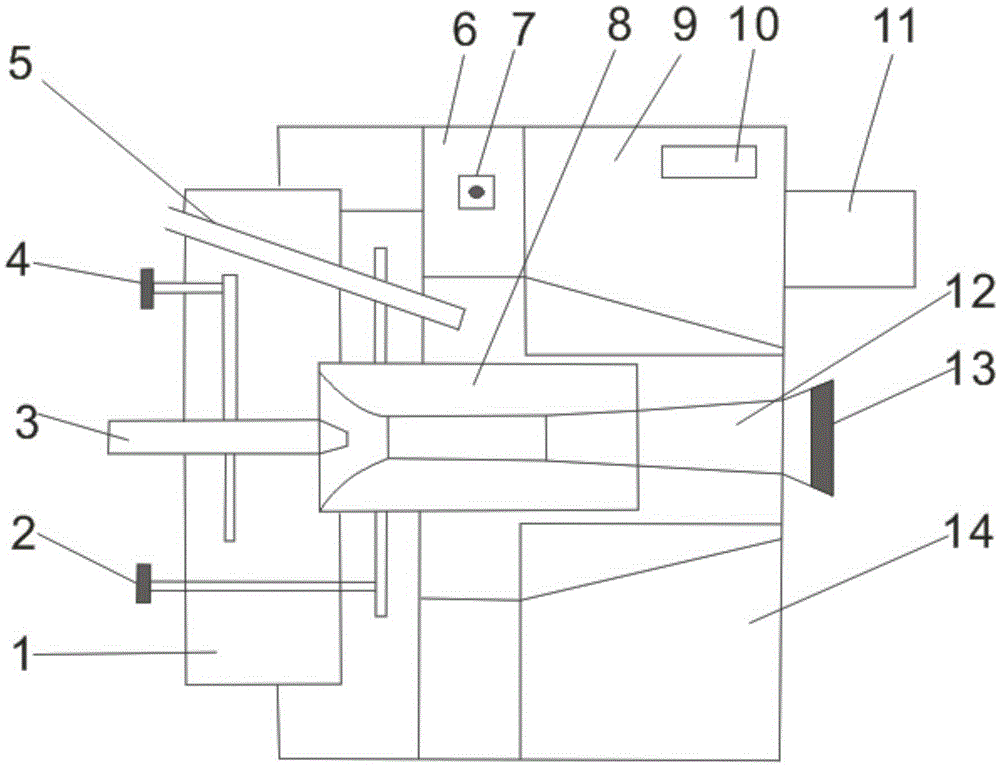

Novel energy-saving and environment-friendly combustion engine

InactiveCN105402731AReduce consumptionFast heatingFuel supply regulationIndirect carbon-dioxide mitigationBrickSprayer

The invention relates to the field of environmental protection technology and particularly relates to a novel energy-saving and environment-friendly combustion engine, which comprises a muffler, a primary air port, a secondary air port, a nozzle, an igniter, an injector, a sprayer, a plum blossom-type flue brick, a nameplate, a motor, a combustion cylinder, an air pressure switch, a control box and an ignition transformer. The injector and the sprayer are directly connected to form an integral structure. The nozzle and the motor are directly connected and are positioned right in front of the muffler. The nameplate is arranged on the left upper part of an instrument. The igniter is arranged in front of the muffler. The combustion cylinder is directly connected with the ignition transformer and is right above the sprayer. According to the technical scheme of the invention, through reasonably organizing the combustion process, the above combustion engine is more energy-saving, more environment-friendly, higher in combustion efficiency, stable in combustion, good in flame performance, strong in radiation capability, high in heat recovery capability, small in noise, less in amount of noxious gas and smoke, convenient to use, simple in design, low in cost and worth to popularize and use widely during the working process.

Owner:TIANJN TAIFENG XINGYE TECH CO LTD

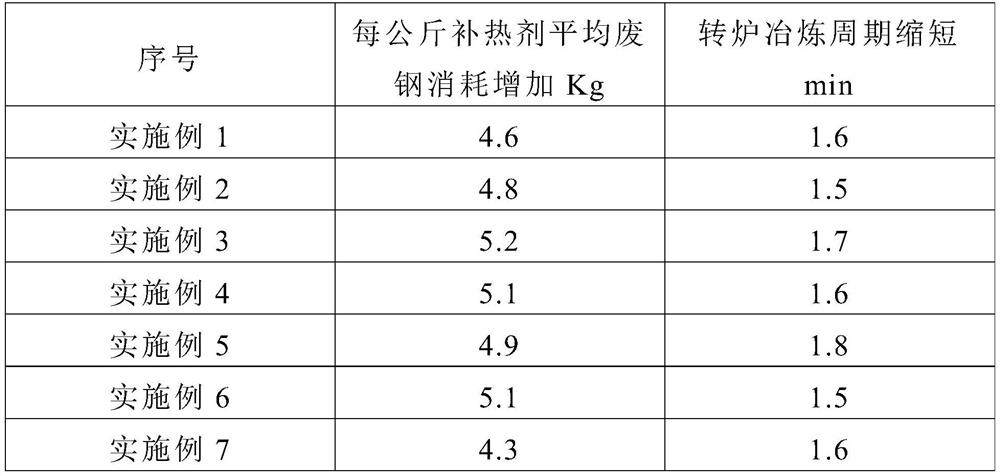

Converter large scrap ratio smelting composite slagging heat supplementing agent and preparation and use method thereof

ActiveCN114686643AOxidative combustion heat value is highLow content of harmful elementsProcess efficiency improvementSteelmakingSodium stearate

The invention relates to the technical field of converter steelmaking, and discloses a converter large scrap ratio smelting composite slagging heat supplementing agent which is prepared from the following raw materials in percentage by weight: 55-60% of silicon-aluminum-calcium-carbon alloy, 10-15% of sintered calcium aluminate, 5-10% of wood charcoal, 5-10% of sintered return mine, 10-15% of manganese ore, 5-10% of light-burned dolomite and 0.3-0.5% of sodium stearate. The invention further discloses a preparation method and a use method of the converter large scrap ratio smelting composite slagging heat supplementing agent. The converter large scrap ratio smelting composite slagging heat supplementing agent and the preparation and use method thereof have the advantages that converter oxygen blowing combustion is stable, heat supplementing efficiency is high, heat supplementing cost is low, converter slagging speed is high, dephosphorization efficiency is high, and the content of harmful elements and residual elements in molten steel is not increased; and the purpose of high-quality, high-efficiency, low-cost and low-carbon green smelting of the converter with large scrap ratio is

Owner:武汉钢铁有限公司

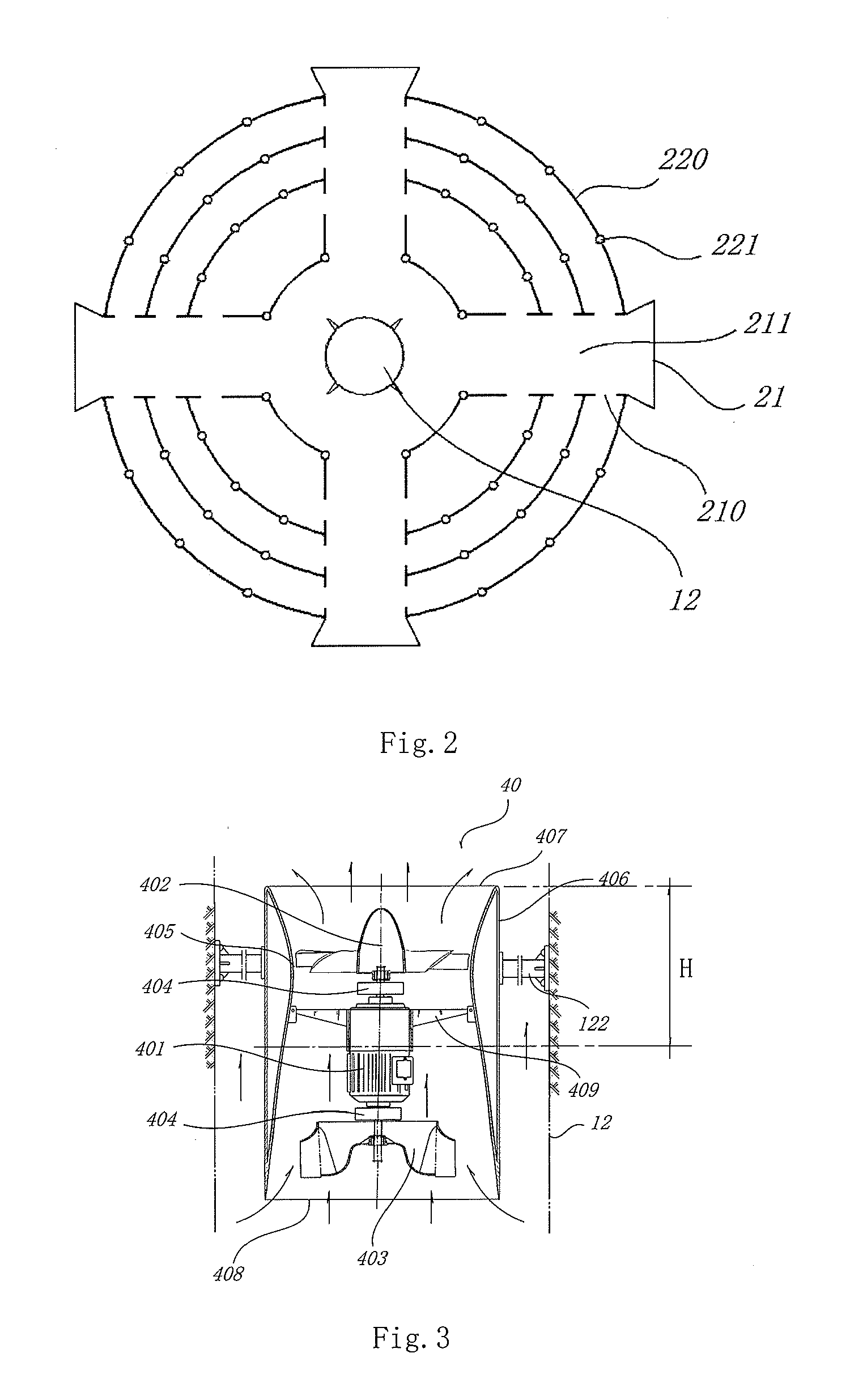

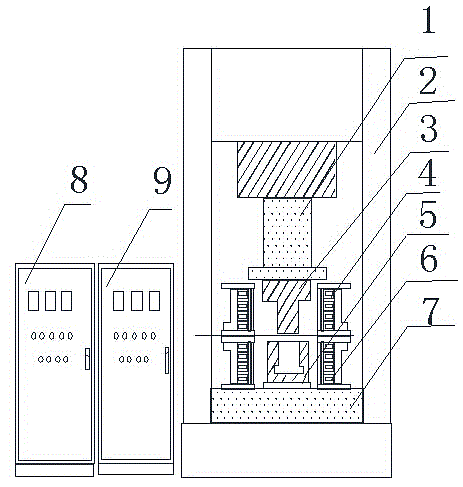

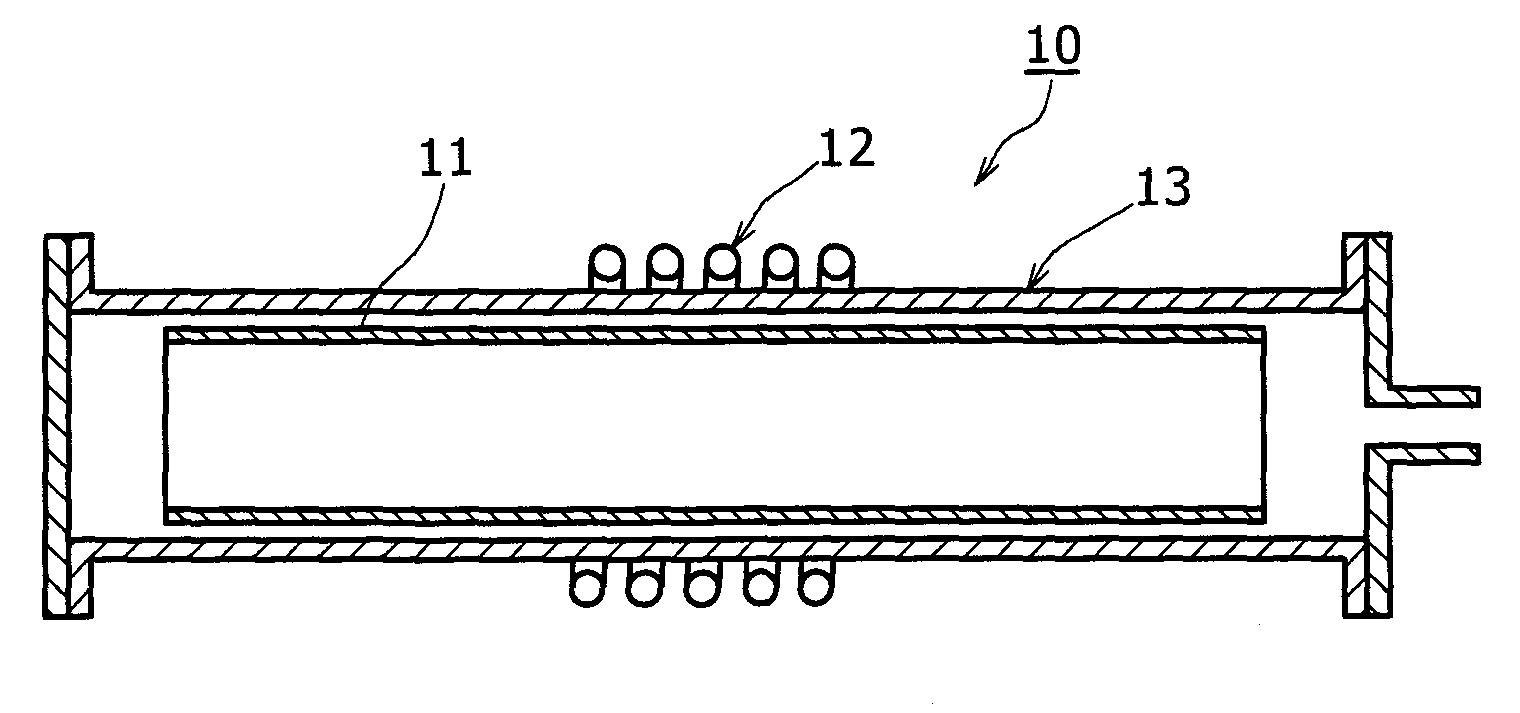

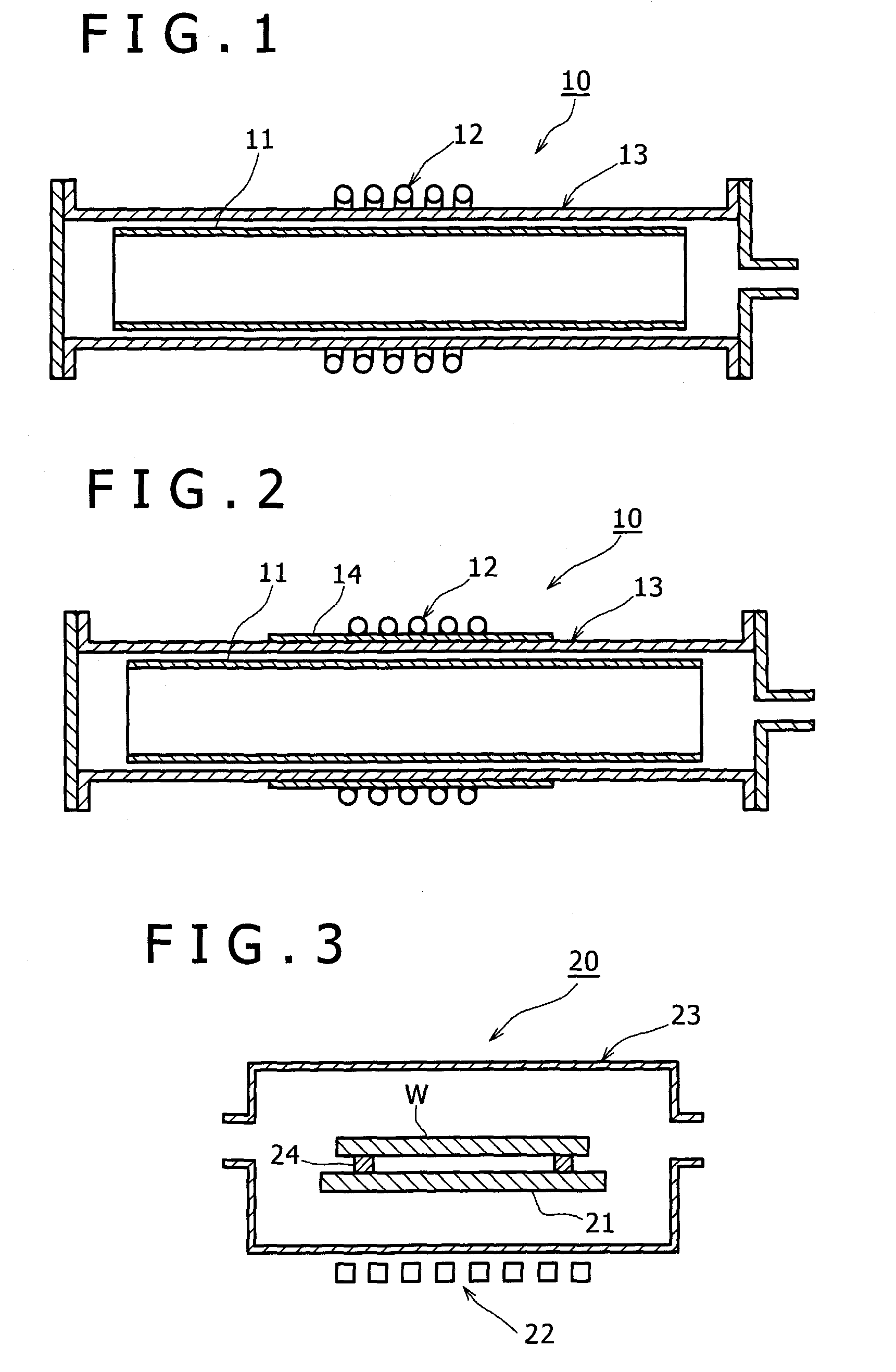

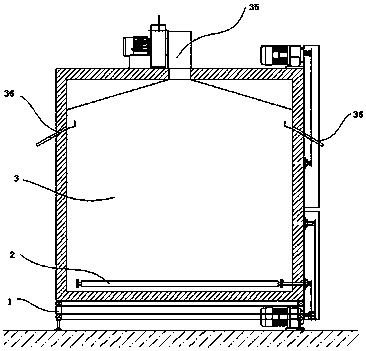

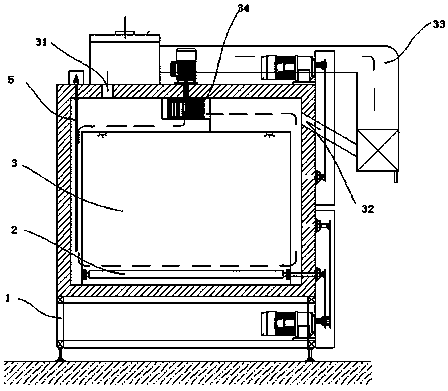

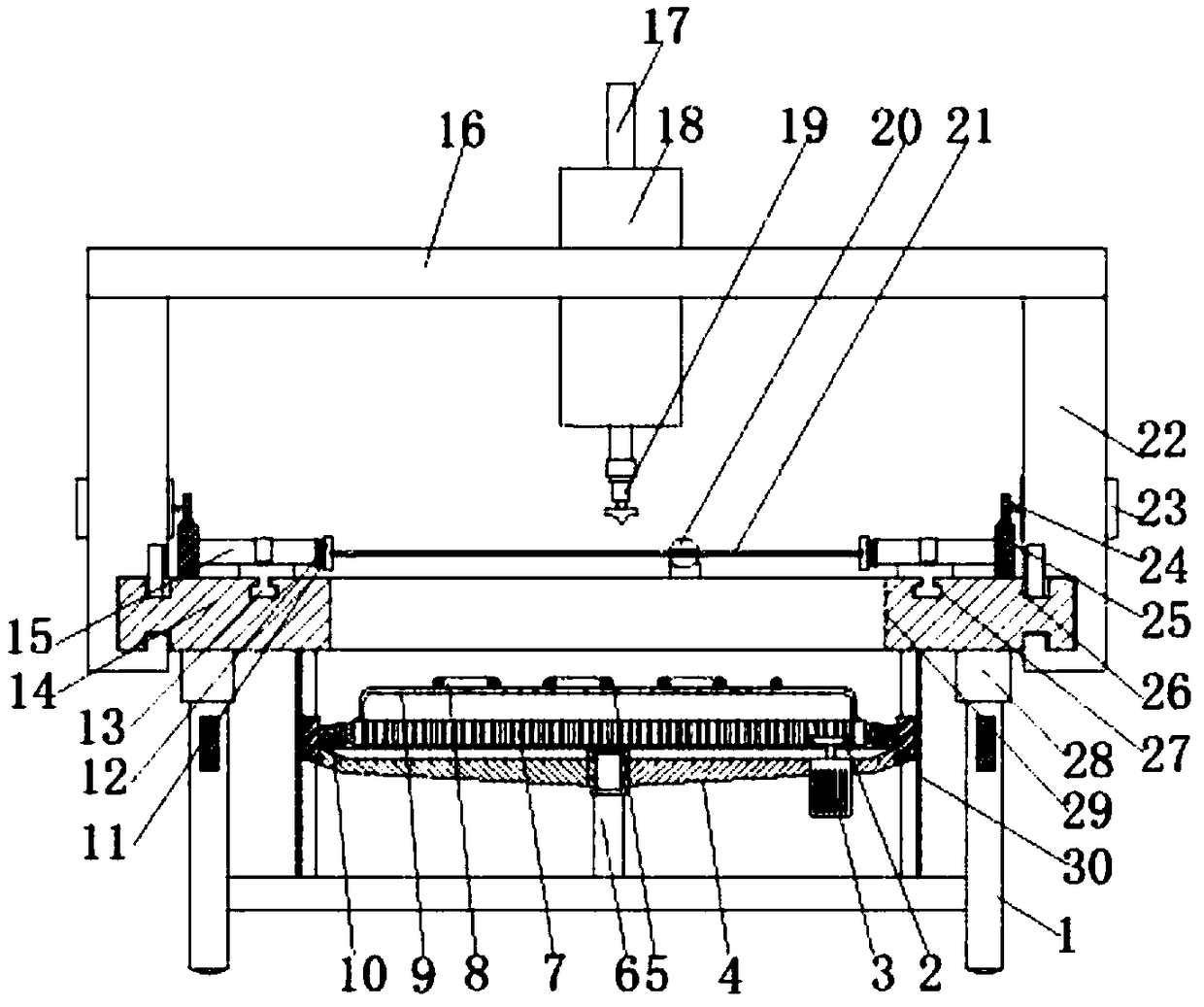

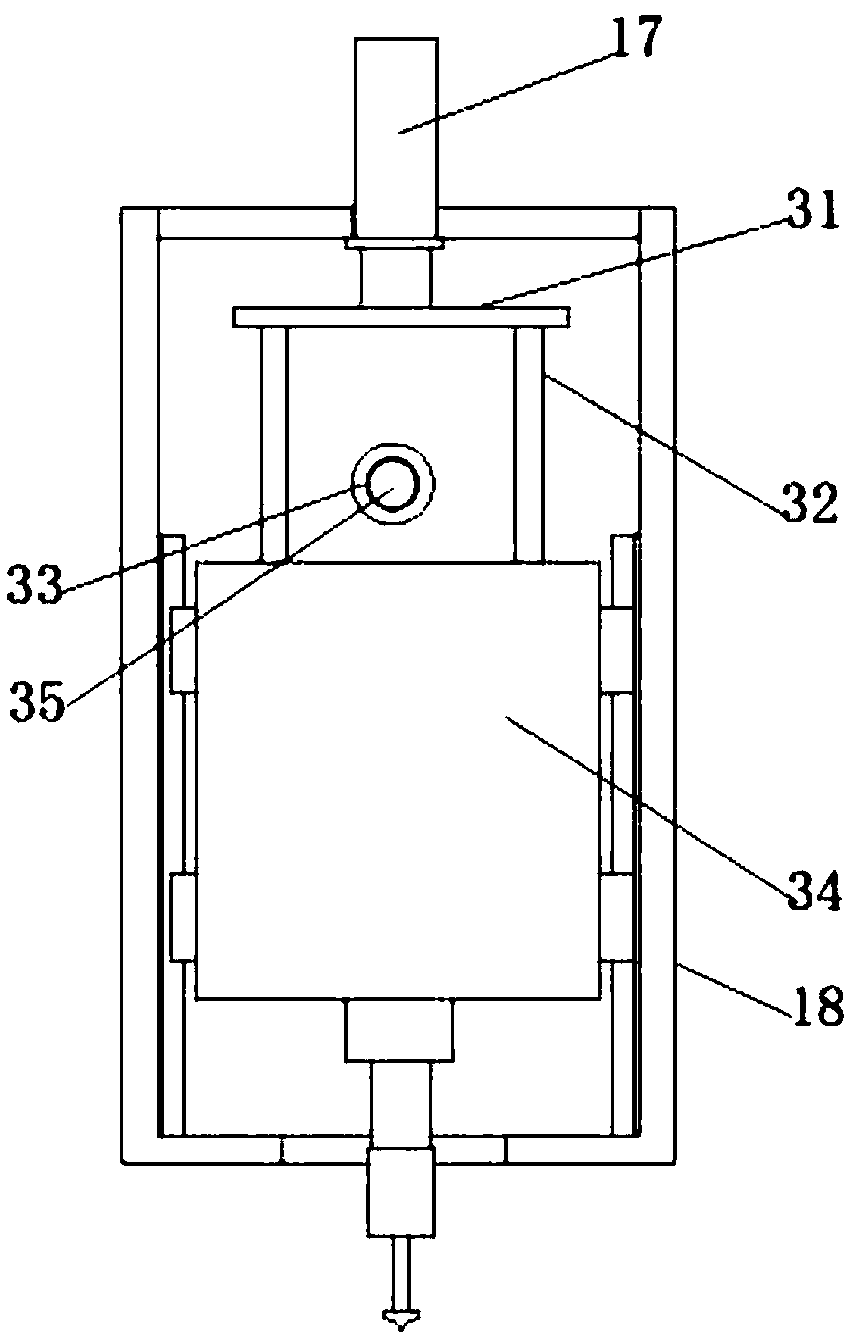

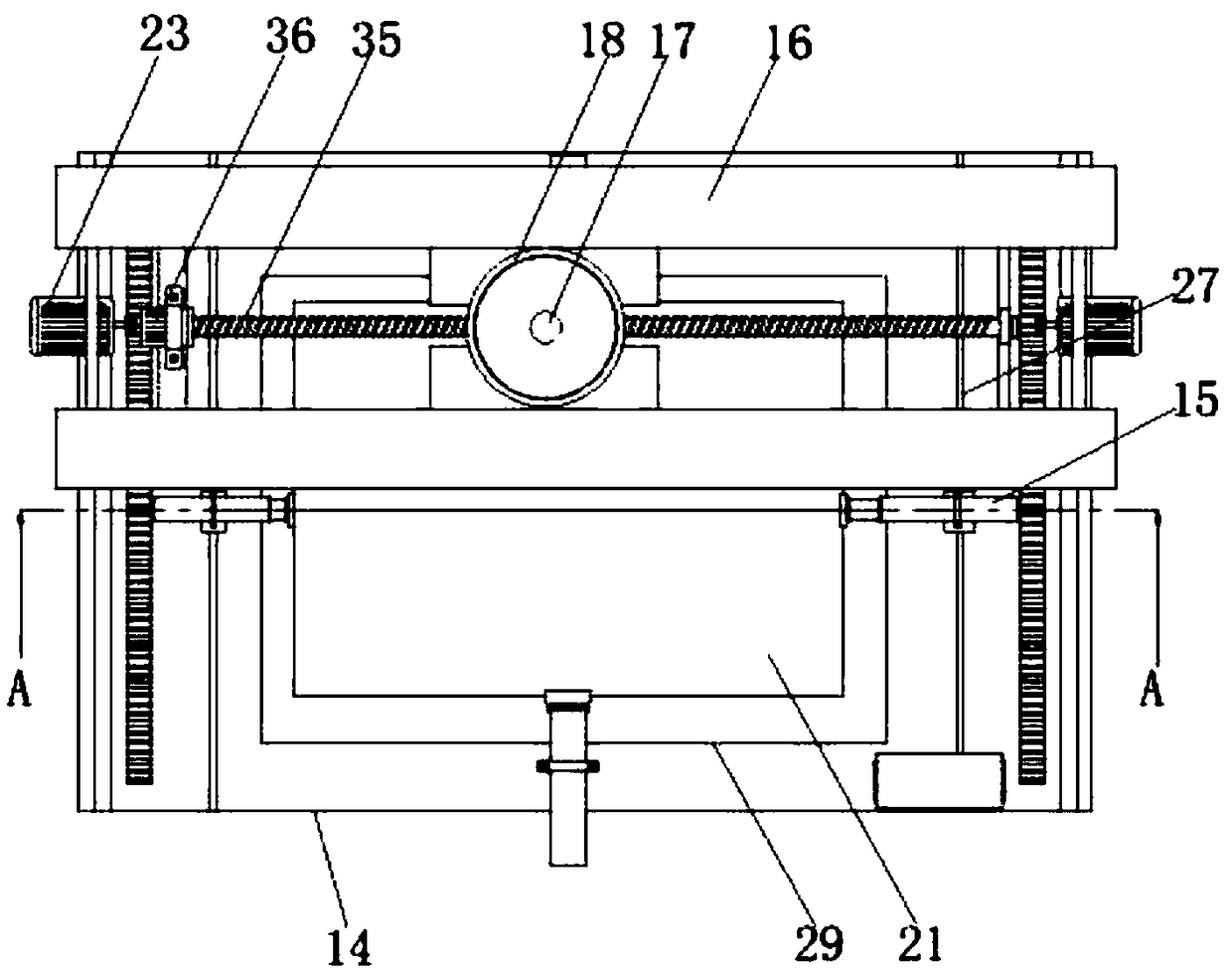

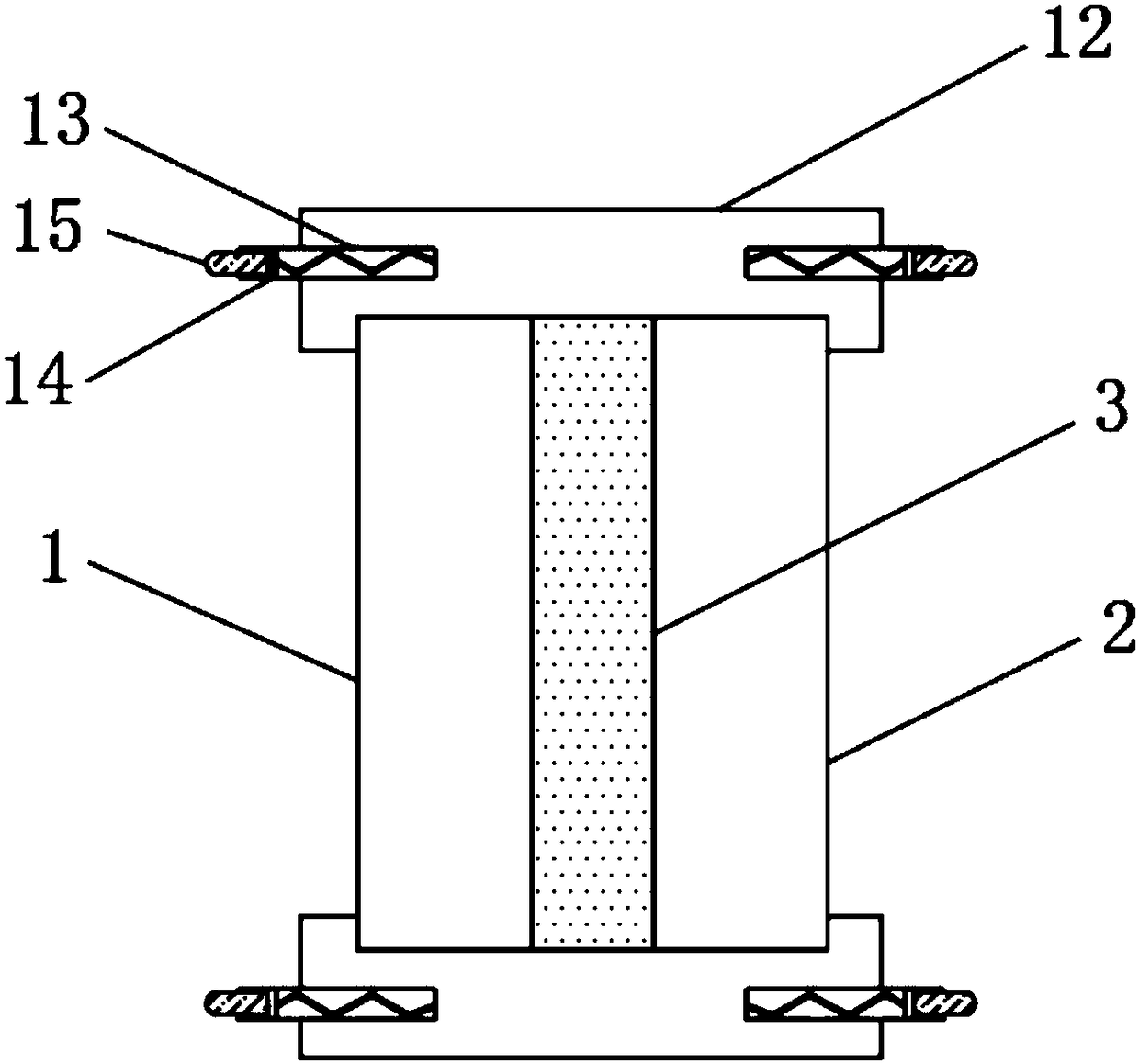

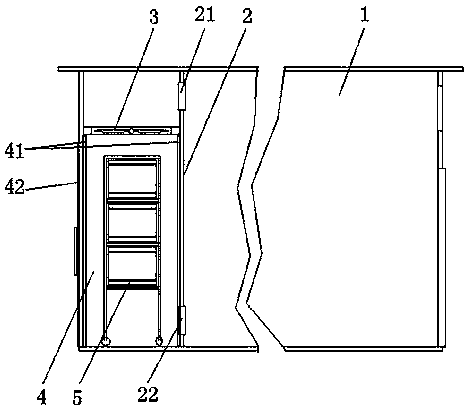

All-solid-state variable-frequency induction heating device for isothermal forging upper and lower molds and heating method

ActiveCN104690204AHigh heating efficiencyGreat energy saving potentialForging/hammering/pressing machinesHeating/cooling devicesPotential energyHeating time

The invention provides an all-solid-state variable-frequency induction heating device for isothermal forging upper and lower molds (of which the diameters Phi are 900-2,000 mm) and a heating method. The all-solid-state variable-frequency induction heating device comprises an oil press upper die head, an oil press upright column, an isothermal forging upper mold, an upper mold induction heating furnace, an isothermal forging lower mold, a lower mold induction heating furnace, an oil press lower carriage, a 1# all-solid-state variable-frequency induction power supply and a 2# all-solid-state variable-frequency induction power supply. The all-solid-state variable-frequency induction heating device has the advantage that the heating time of the isothermal forging molds (of which the diameters Phi are 900-2,000 mm) is shortened to 4 to 8 hours, the heating efficiency is improved, the potential energy-saving effect is great, the production efficiency is improved, the molds are heated uniformly and long in service life, the quality of product is improved, the maintenance cost is reduced, and the all-solid-state variable-frequency induction heating device has an obvious technical and economic benefit.

Owner:朱兴发

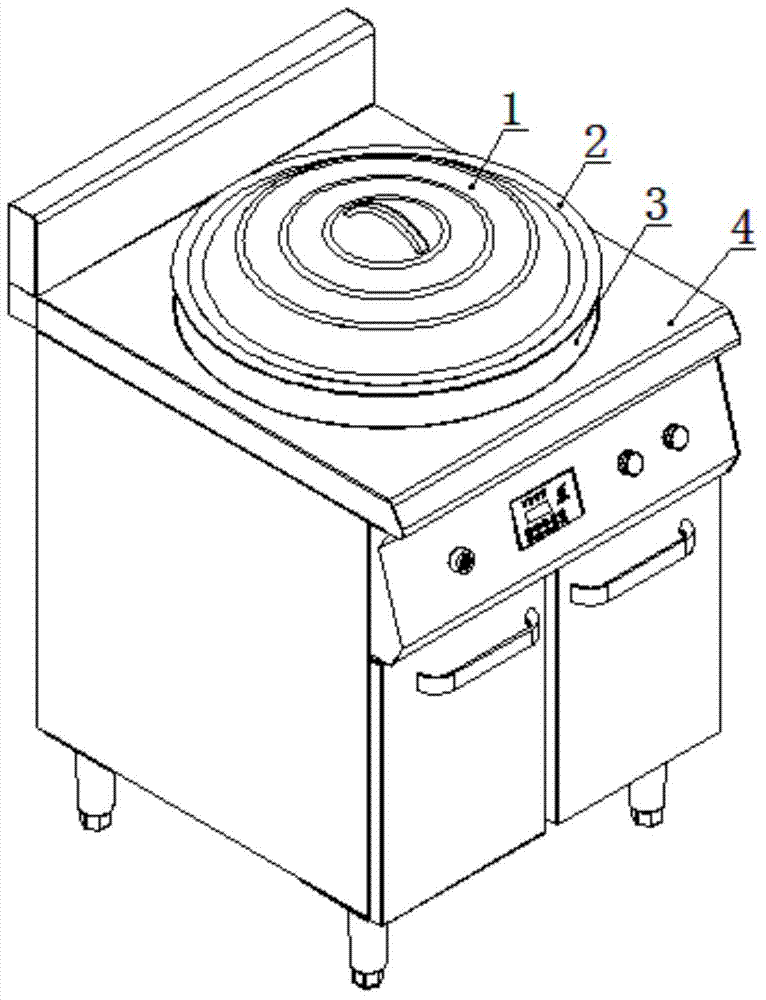

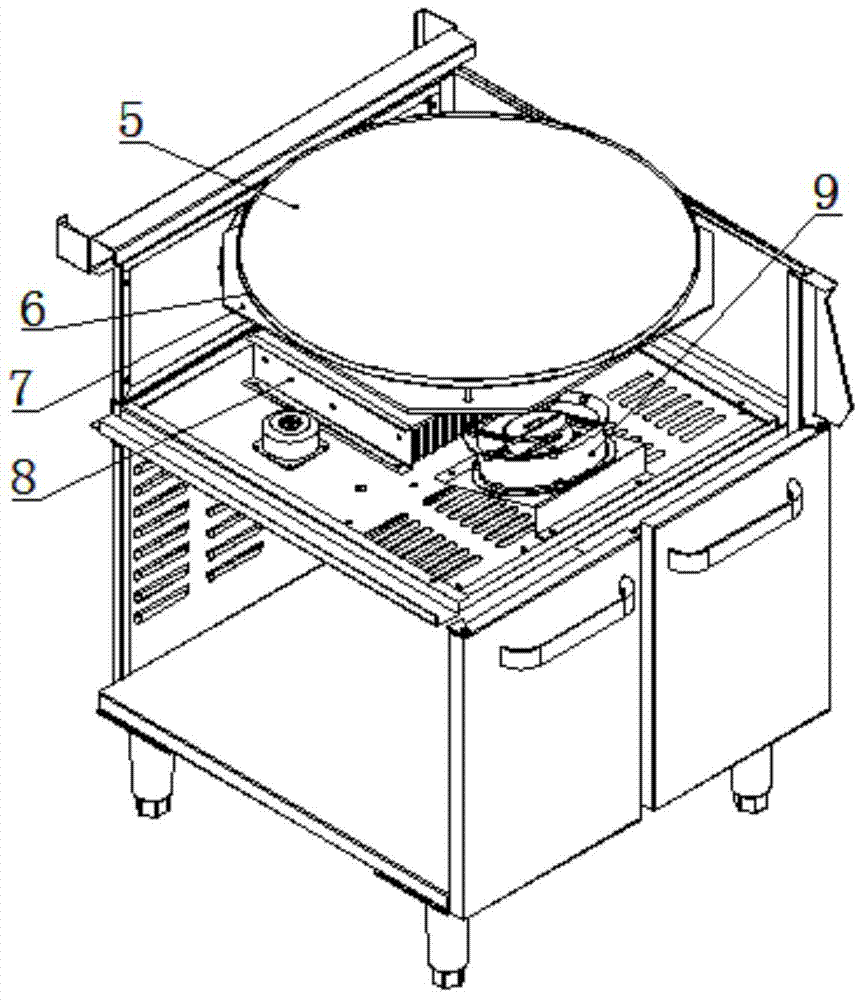

Electromagnetic induction frying-stove energy-saving device

InactiveCN104771090AHigh heating efficiencyImprove energy savingDomestic stoves or rangesLighting and heating apparatusElectromagnetic shieldingElectromagnetic heating

The invention discloses an electromagnetic induction frying-stove energy-saving drive. The electromagnetic induction frying-stove energy-saving device comprises a shell, a pot cover, a frying pan, a pot frame and a microcrystal glass, wherein a mica plate is arranged under the bottom of the microcrystal glass in a lining manner, an electromagnetic coil disc is installed on the bottom of the mica plate, a separation plate is installed inside the shell, an electromagnetic heating core is installed on the separation plate, and the electromagnetic heating core is connected with the electromagnetic coil disc by virtue a high-temperature conducting wire; the pot frame is installed on the shell and arranged above the microcrystal glass, and the frying pot is arranged on the pot frame. The electromagnetic heating way is used for heating the frying pot, so that the electromagnetic induction frying-stove energy-saving device has advantages of safety in use, environmental protection, energy conservation and time conservation.

Owner:HEFEI SHUNCHANG ELECTROMAGNETIC INDUCTION TECH

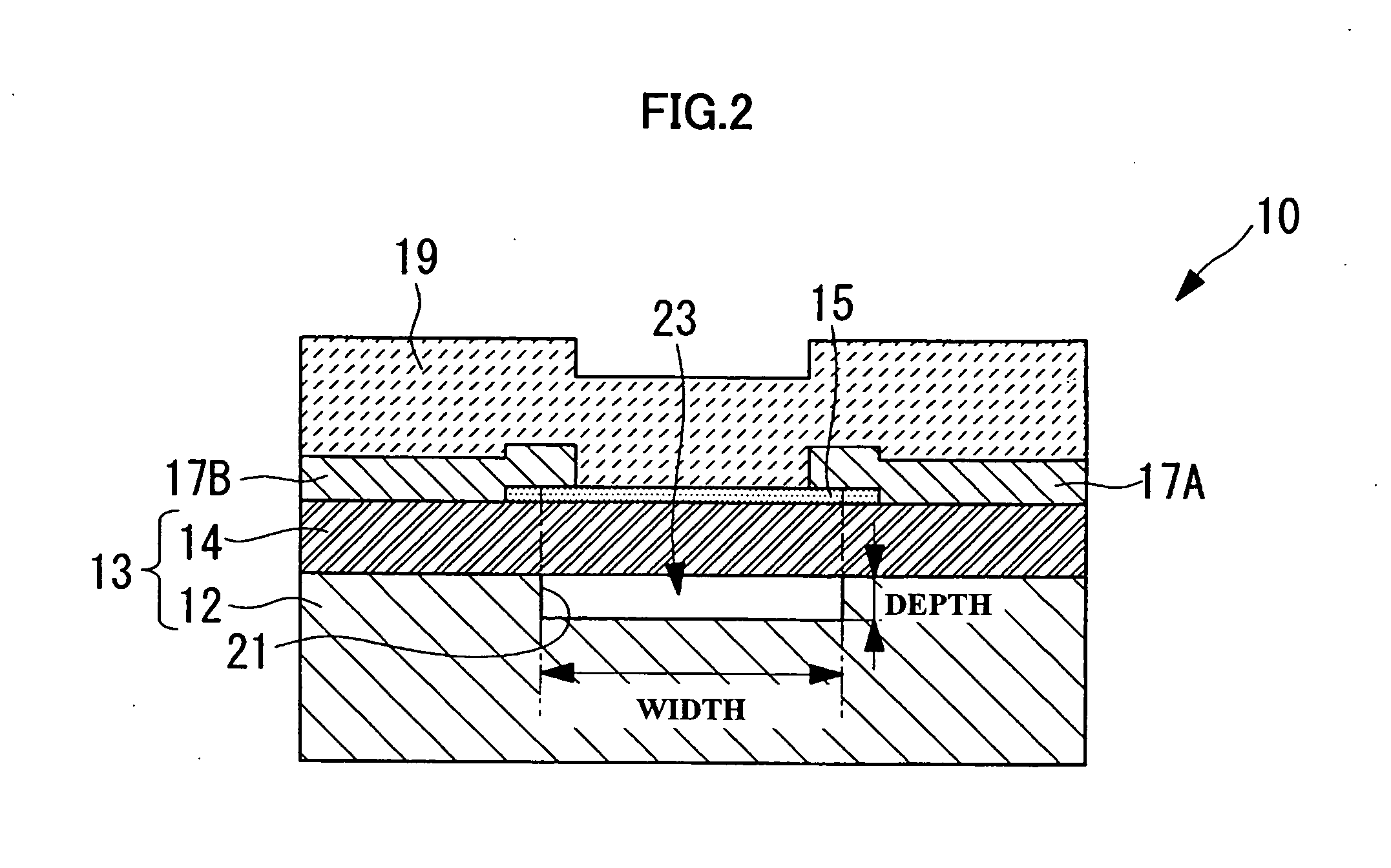

Method of manufacturing thermal head

InactiveUS20120073122A1Good accuracyHigh heating efficiencyResistor manufacturePrintingEngineeringResistor

A method of manufacturing a thermal head, comprising: forming a concave portion opened in one surface of at least one of a support substrate and an upper substrate to be disposed on the support substrate in a stacked state, the support substrate and the upper substrate each being of a plate shape; measuring a width dimension of the concave portion; bonding the support substrate and the upper substrate to each other in the stacked state so as to close an opening of the concave portion; forming a heating resistor on a surface of the upper substrate bonded onto the support substrate, in a region opposed to the concave portion; and forming a protective film for covering and protecting the heating resistor on the upper substrate, at a thickness which is set based on the width dimension of the concave portion and a thickness dimension of the upper substrate.

Owner:SEIKO INSTR INC

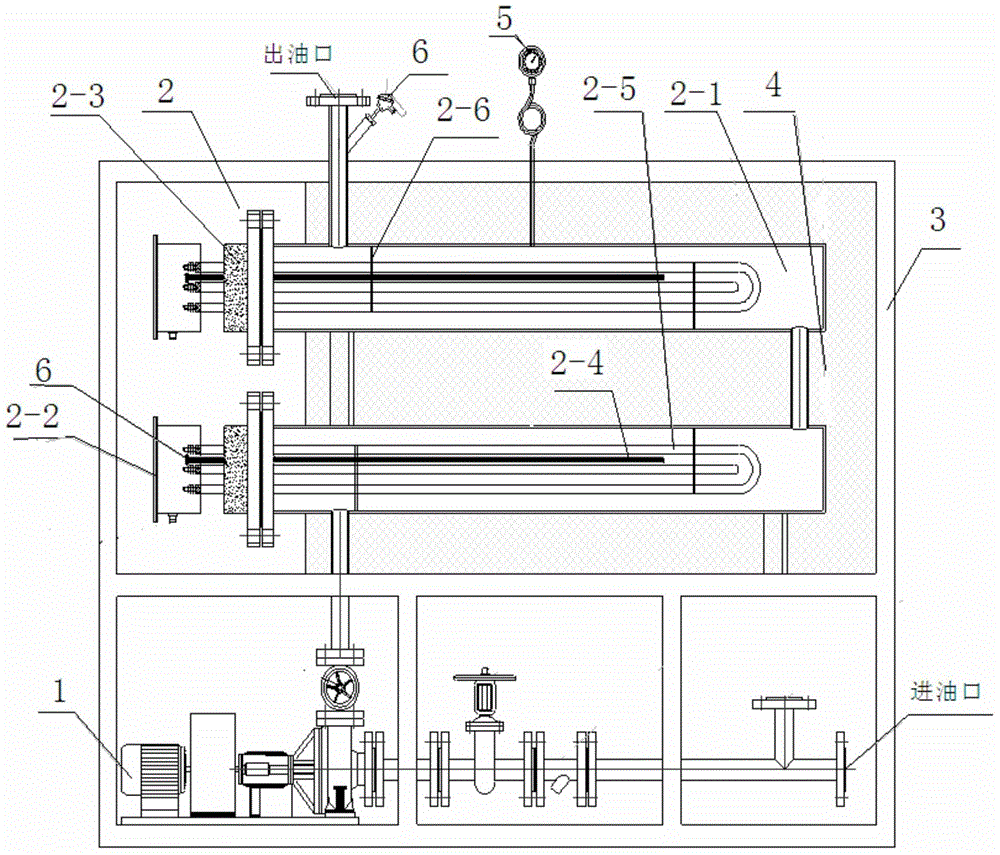

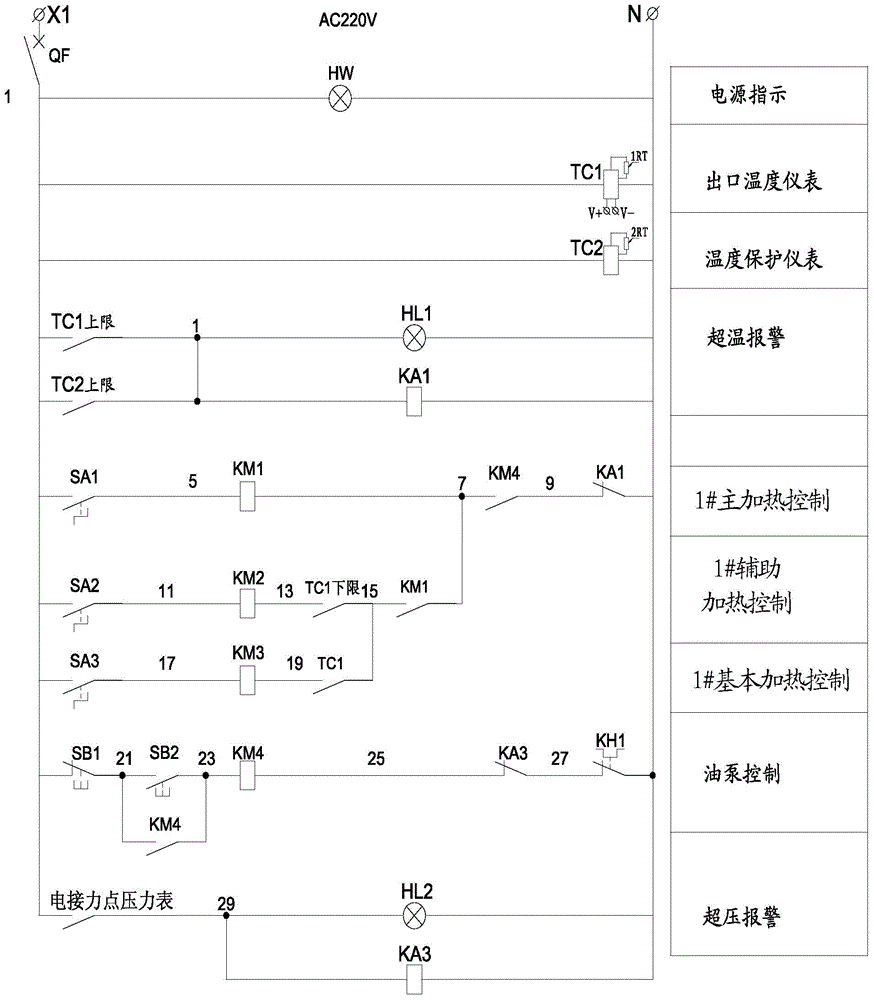

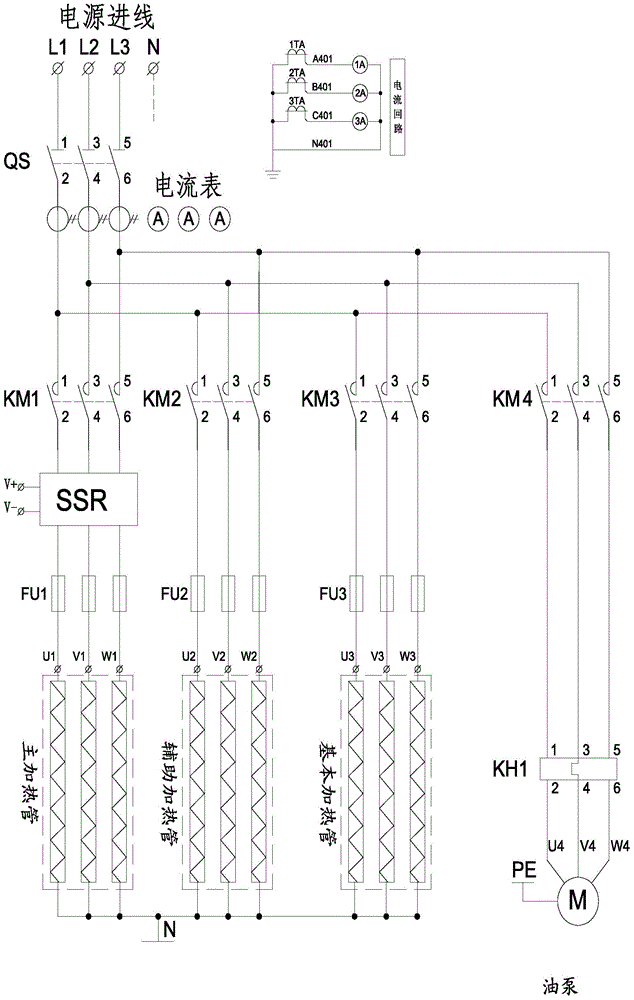

Single-pump conduction oil heating system

ActiveCN104019548ASlow down the temperature dissipationThe temperature dissipated reachesStorage heatersHeating effectEngineering

The invention discloses a single-pump conduction oil heating system. The single-pump conduction oil heating system comprises a hot oil pump, more than one heating element and a control unit, wherein the heating elements are arranged in a heat insulation box; heat insulation cotton is filled in the gaps between the heating elements and the heat insulation box; each heating element comprises an oil storage cavity, an anti-explosion box, a heat insulating layer, a temperature tube, more than one heating tube and more than one guide plate. The single-pump conduction oil heating system has a simple structure, is accurate in heating control, has high efficiency of the heating mode and good temperature uniformity of the heating effects, is energy-saving and environment-friendly and reduces the production cost.

Owner:JIANGSU ZONRE MECHANICAL EQUIP

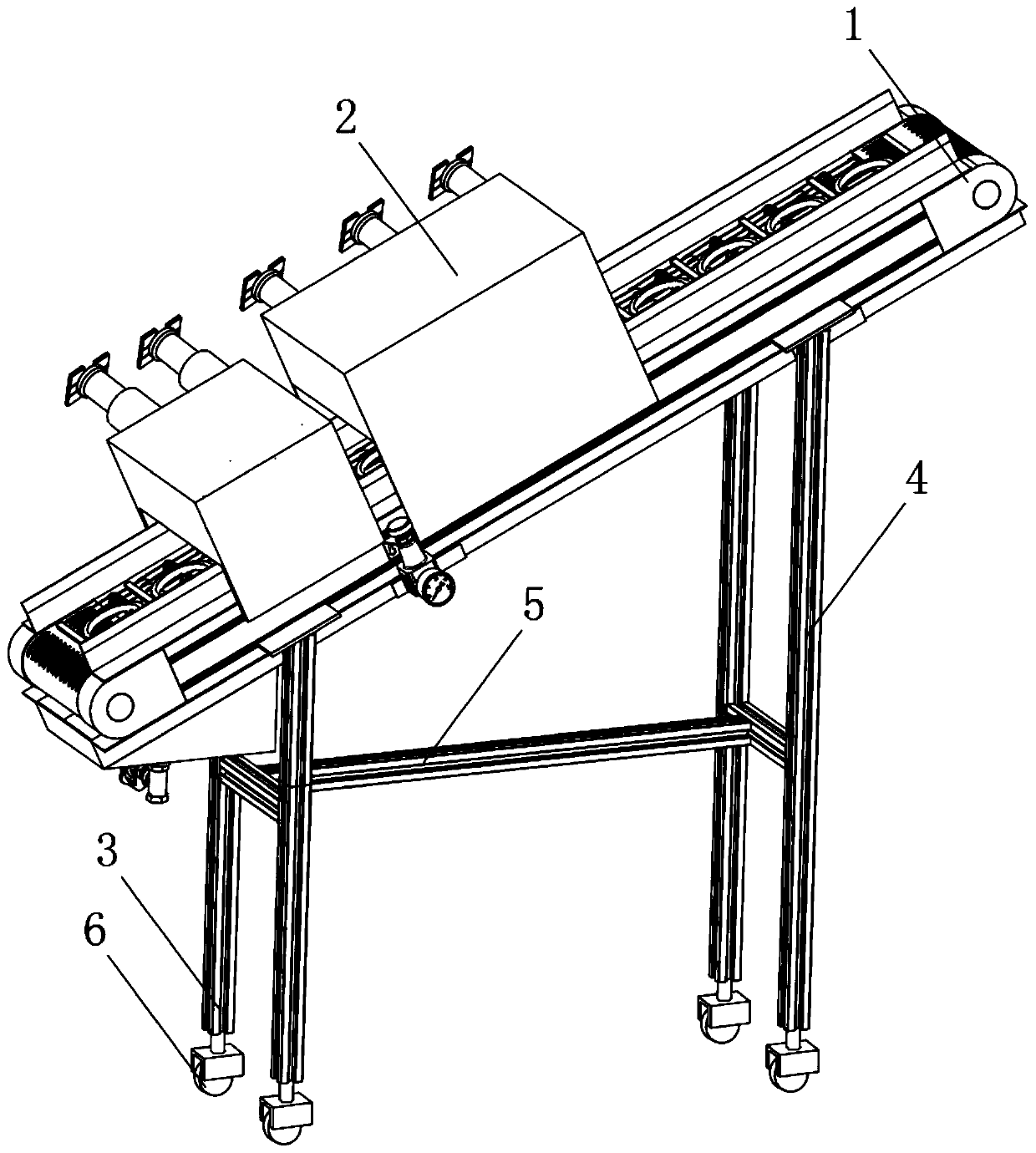

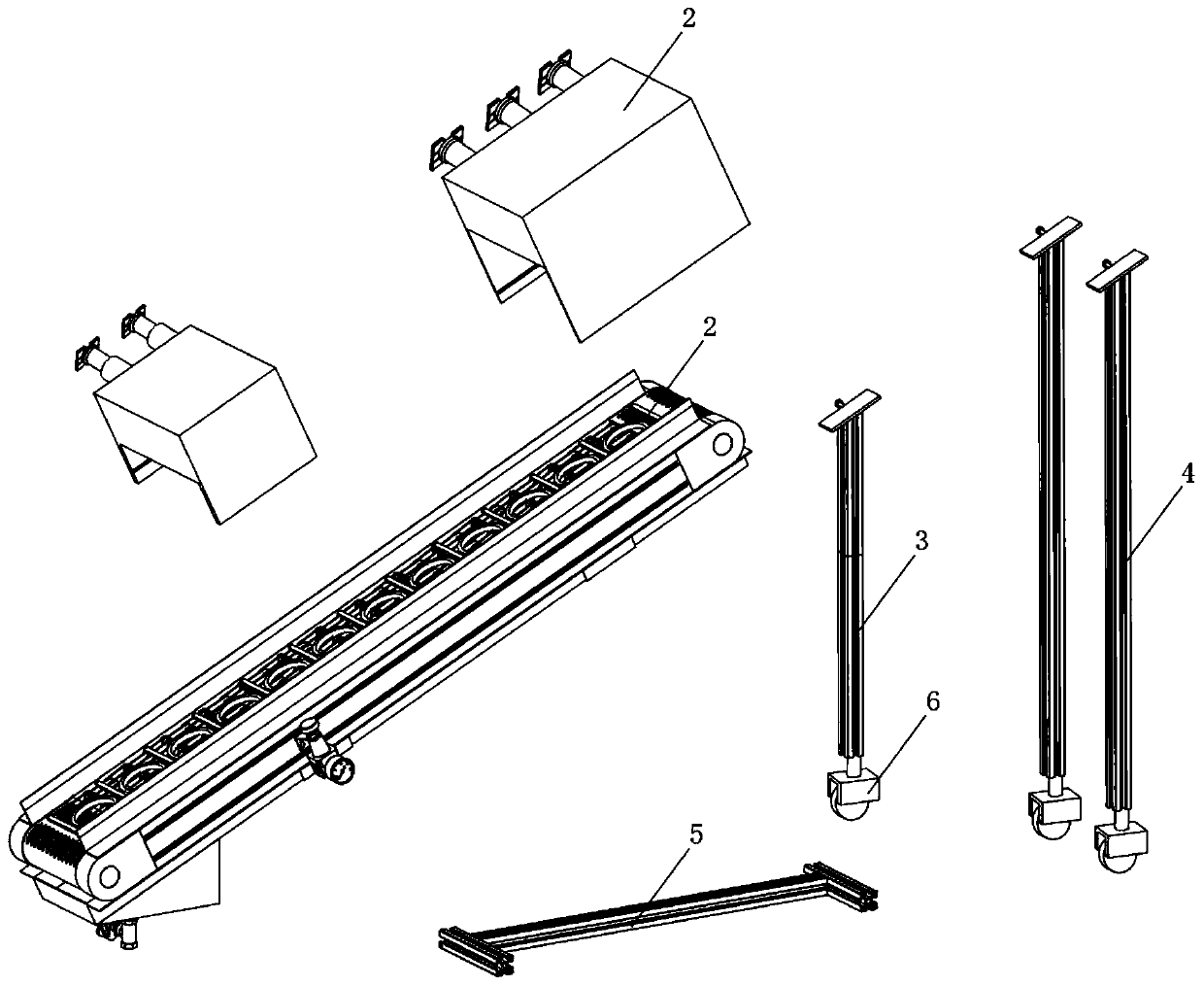

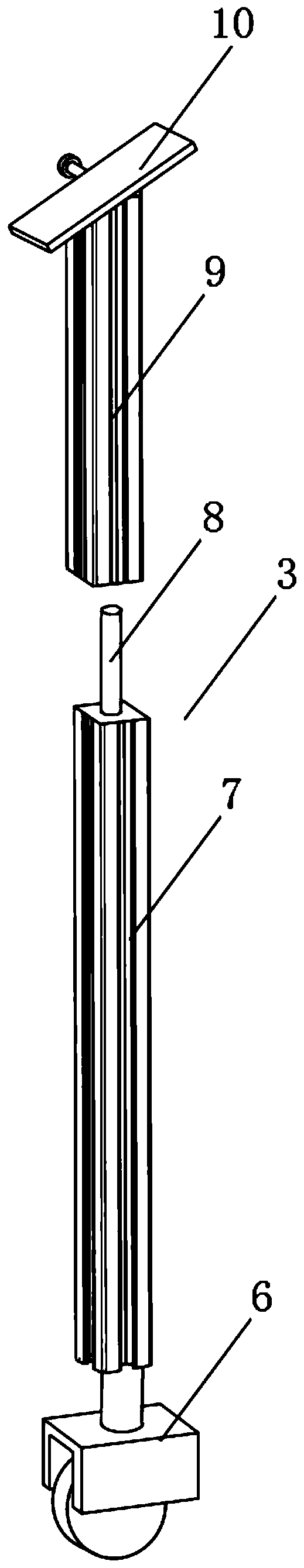

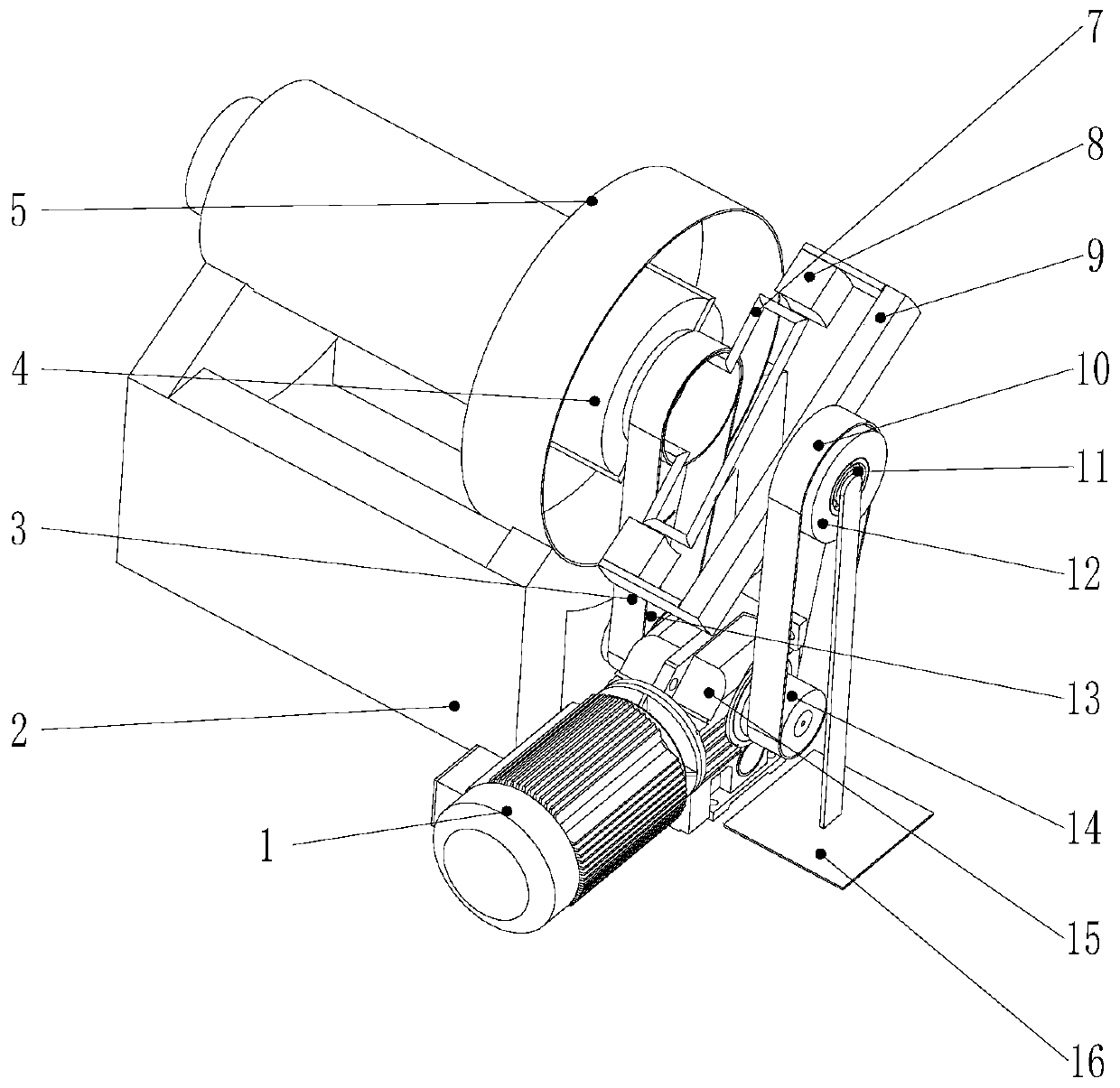

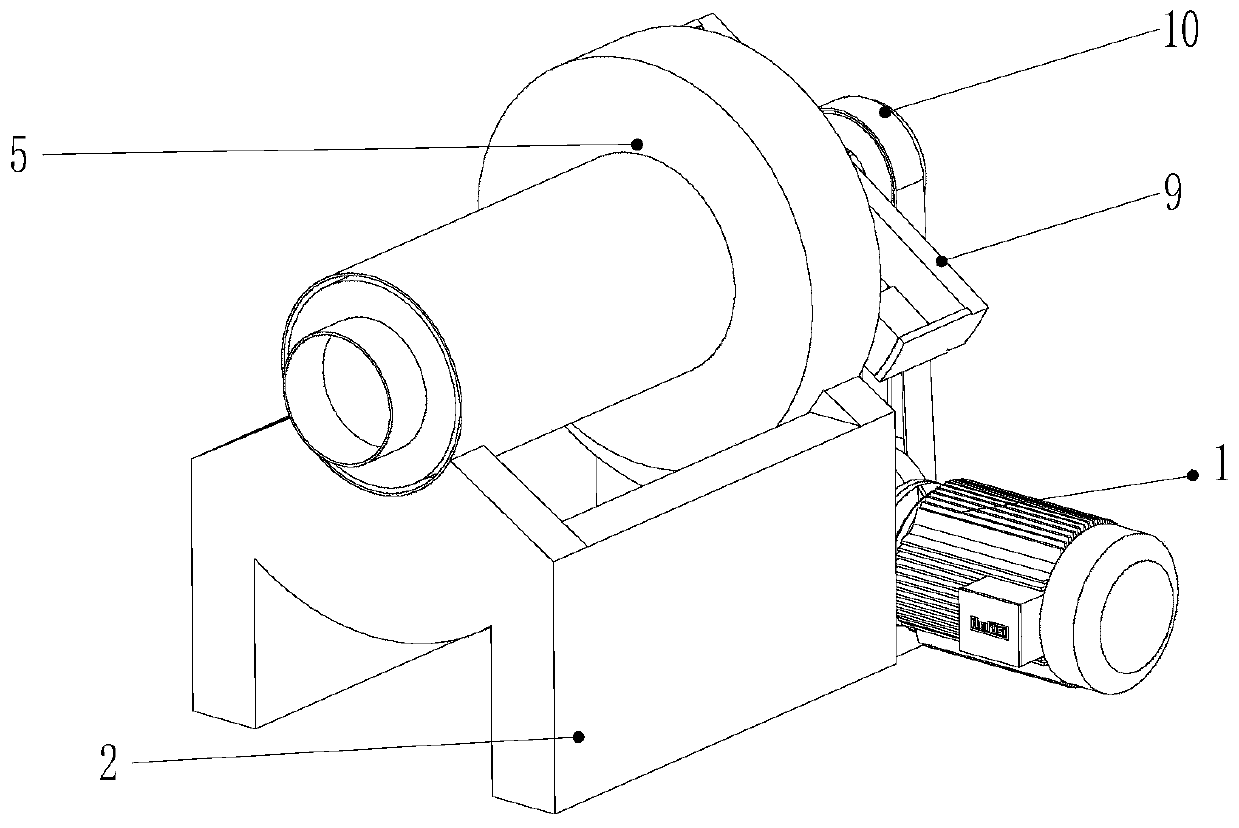

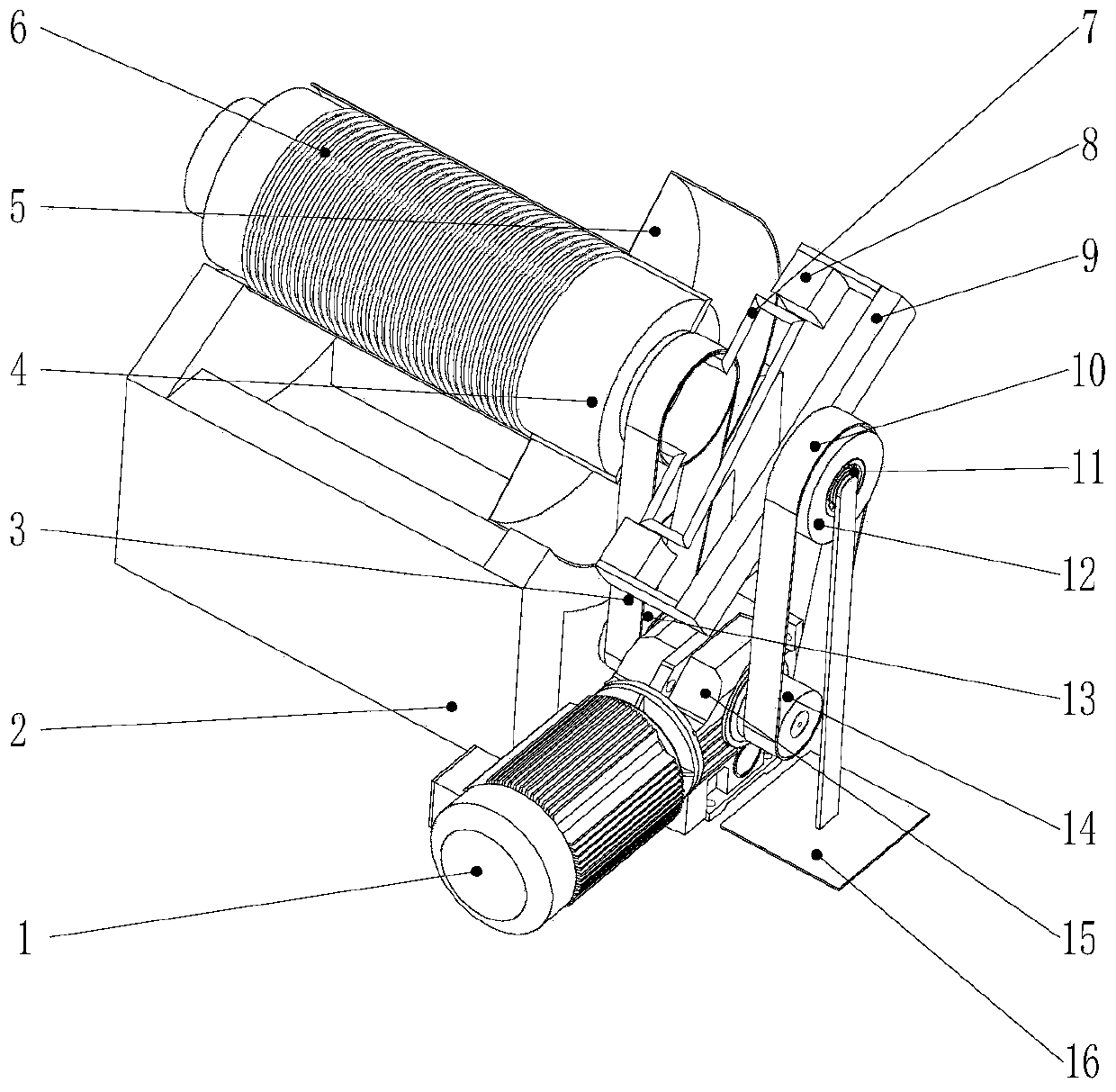

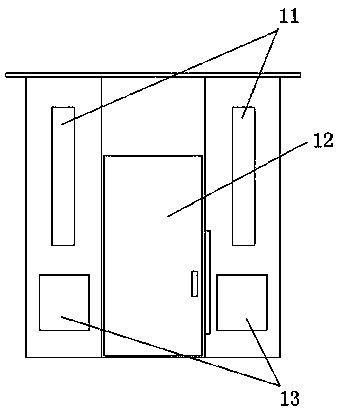

Greenhouse planting warm air equipment for seedling raising and heating and operation method thereof

ActiveCN110249865AReduce friction lossRegulatory activity is smoothClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention discloses greenhouse planting warm air equipment for seedling raising and heating and an operation method thereof. The equipment comprises a supporting platform, sleeving discs, extending platforms and supporting rods, wherein the supporting platform is obliquely arranged, and the sleeving discs sleeve the supporting platform. The equipment has the advantages that the equipment movably blows warm air into a greenhouse, so that the coverage of an area into which the warm air is blown in the greenhouse is more uniform and comprehensive, the heating quality of the equipment for the greenhouse is improved, the working automation degree of the equipment is higher at the same time, and time and labor are saved when the equipment is used. The sleeving discs are connected into screw holes in the two ends of each mounting ring through the bottoms of two screw bolts respectively, the sleeving discs and the supporting platform are connected during mounting, and it is ensured that people can mount any sleeving disc of different sizes to heat greenhouses according to the actual heating demands of the greenhouses different in area, so that the use flexibility is guaranteed.

Owner:山东润鹏种苗有限公司

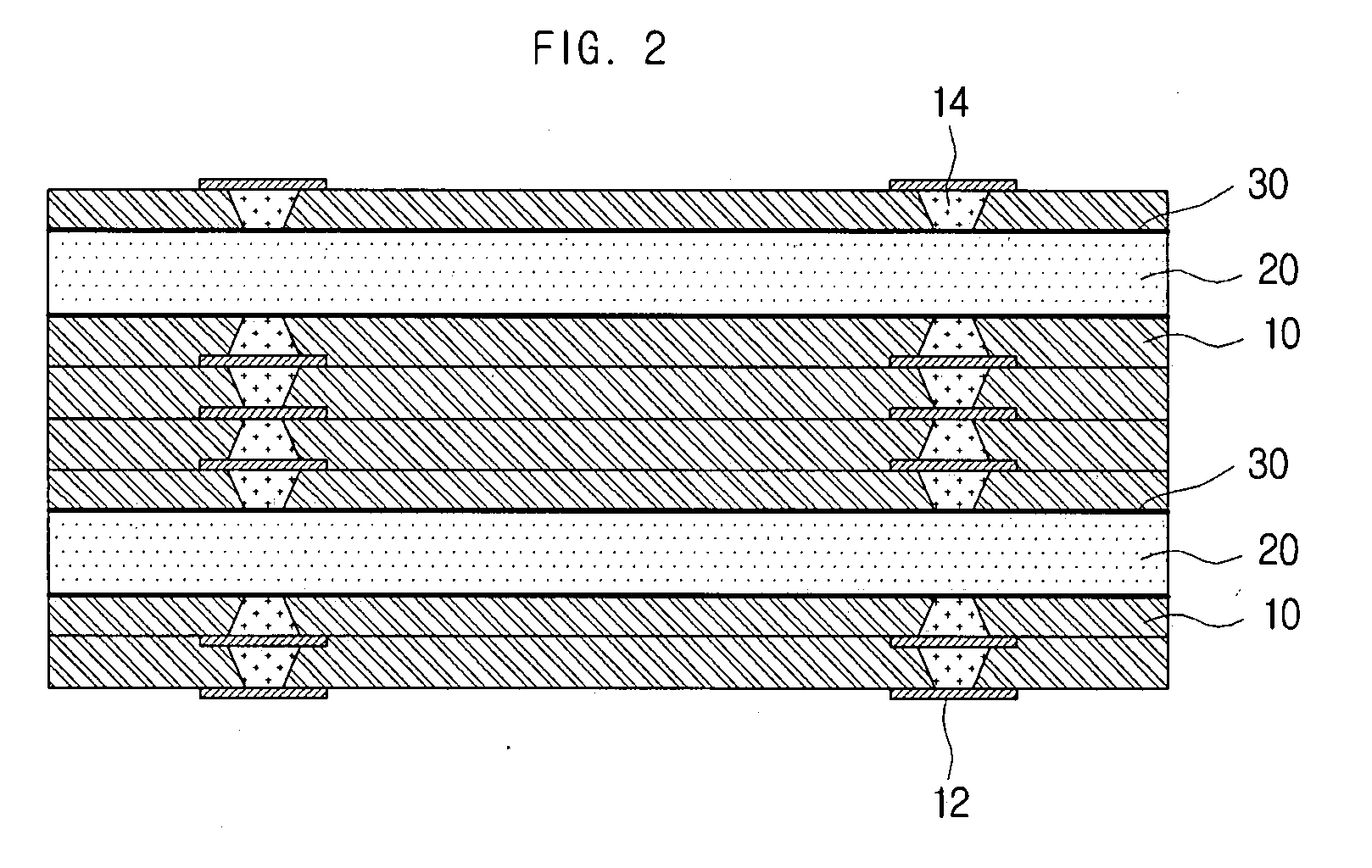

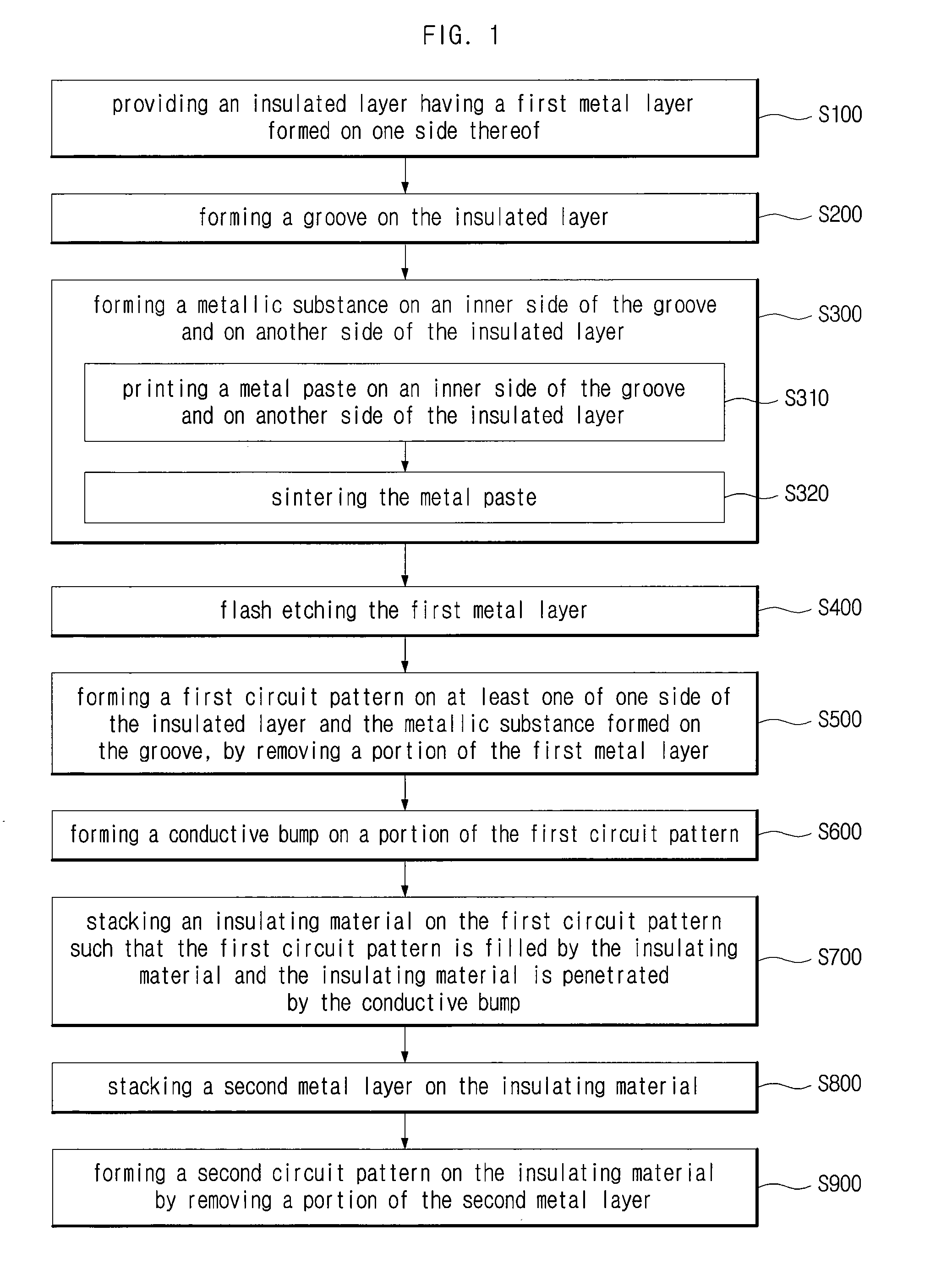

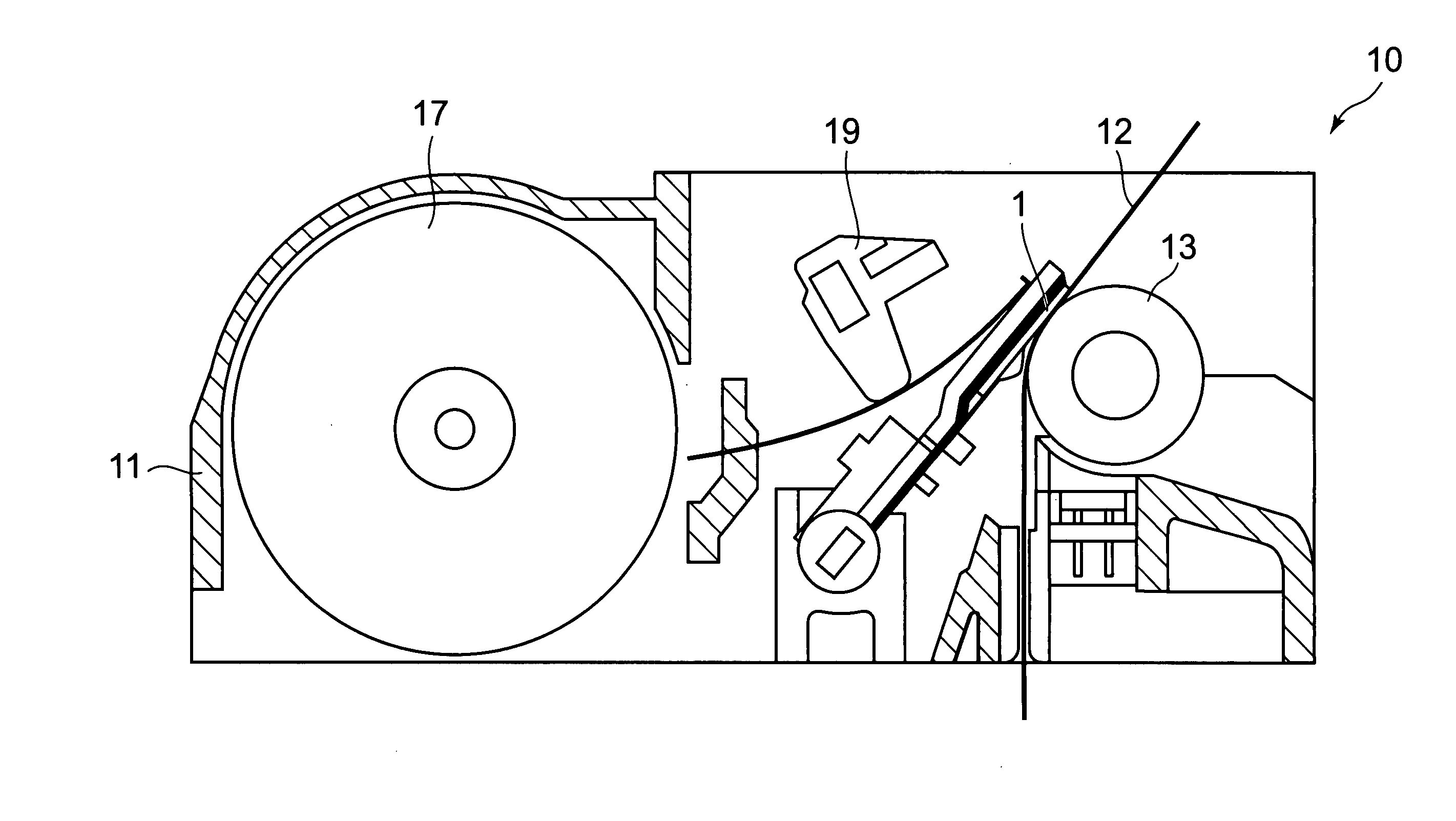

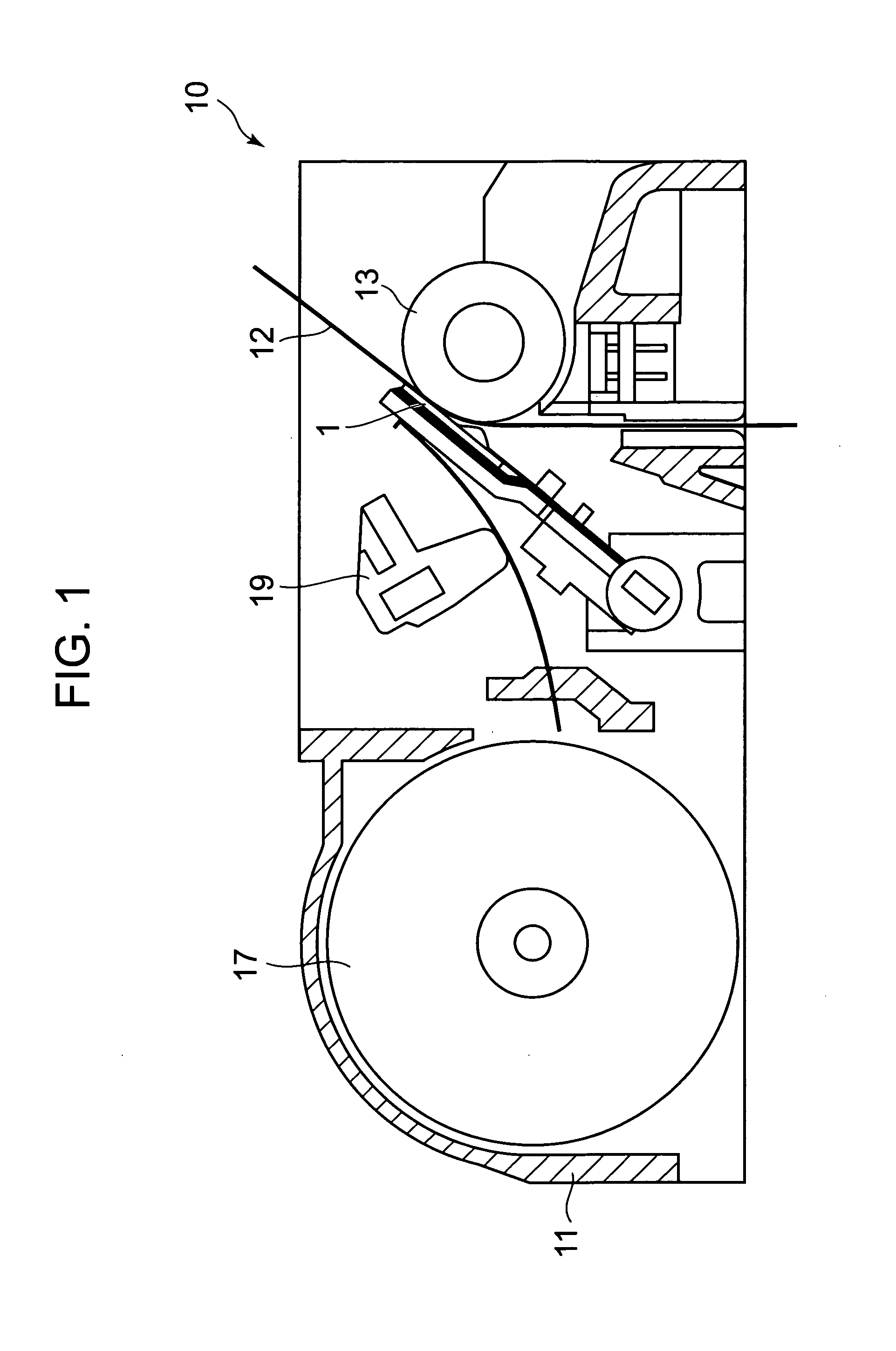

Printed circuit board and manufacturing method thereof

InactiveUS20090321109A1High heating efficiencyPrinted circuit assemblingNanoinformaticsPrinted circuit boardEngineering

A printed circuit board and a method for manufacturing the printed circuit board are disclosed. The method can include; providing an insulated layer, in which a first metal layer is formed on one side of the insulated layer; forming a groove on the insulated layer; forming a metallic substance on an inner side of the groove and on another side of the insulated layer; and forming a first circuit pattern on at least one of one side of the insulated layer and the metallic substance formed on the groove by removing a portion of the first metal layer. The present invention provides the printed circuit board having a high efficiency of heat emission by disposing a heat sink in direct contact with a board and the method of manufacturing the printed circuit board.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Manufacturing method for a thermal head

InactiveUS20100115760A1Easily formHigh heating efficiencyPrinted circuit assemblingContact member manufacturingHeating efficiencyThin sheet

Provided is a manufacturing method for a thermal head, which enables to manufacture a thermal head having high heating efficiency and stable quality. The manufacturing method for a thermal head includes: a concave portion forming step of forming a hollow concave portion and a marking concave portion having a depth larger than a depth of the hollow concave portion on one surface of a thin plate glass; a bonding step of bonding a supporting plate onto the one surface of the thin plate glass, in which the hollow concave portion and the marking concave portion are formed in the concave portion forming step; a thinning step of thinning the thin plate glass onto which the supporting plate is bonded in the bonding step until the marking concave portion extends through the substrate from a side of a back surface opposite to the one surface; and a heating resistor forming step of forming a heating resistor on the back surface of the thin plate glass thinned in the thinning step so as to be opposed to the hollow concave portion.

Owner:SEIKO INSTR INC

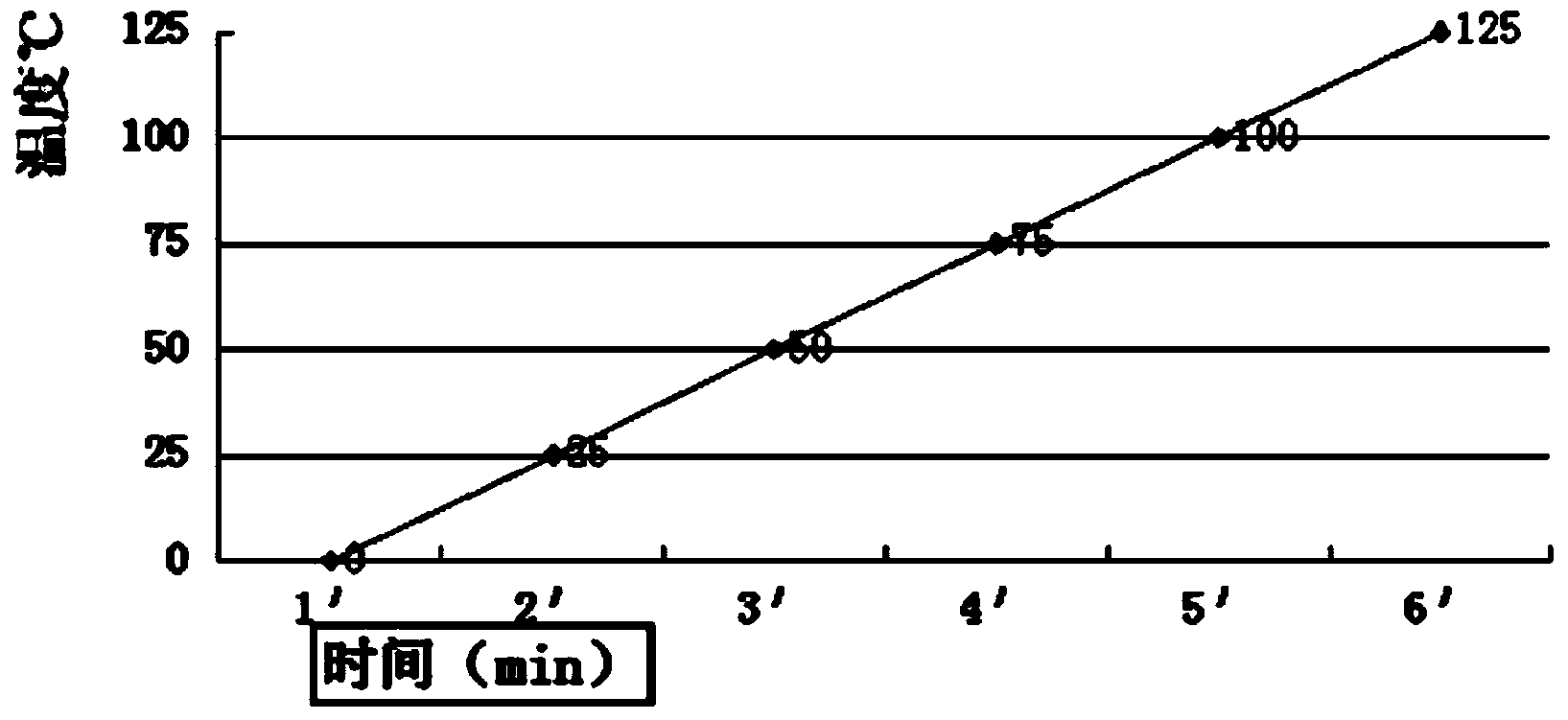

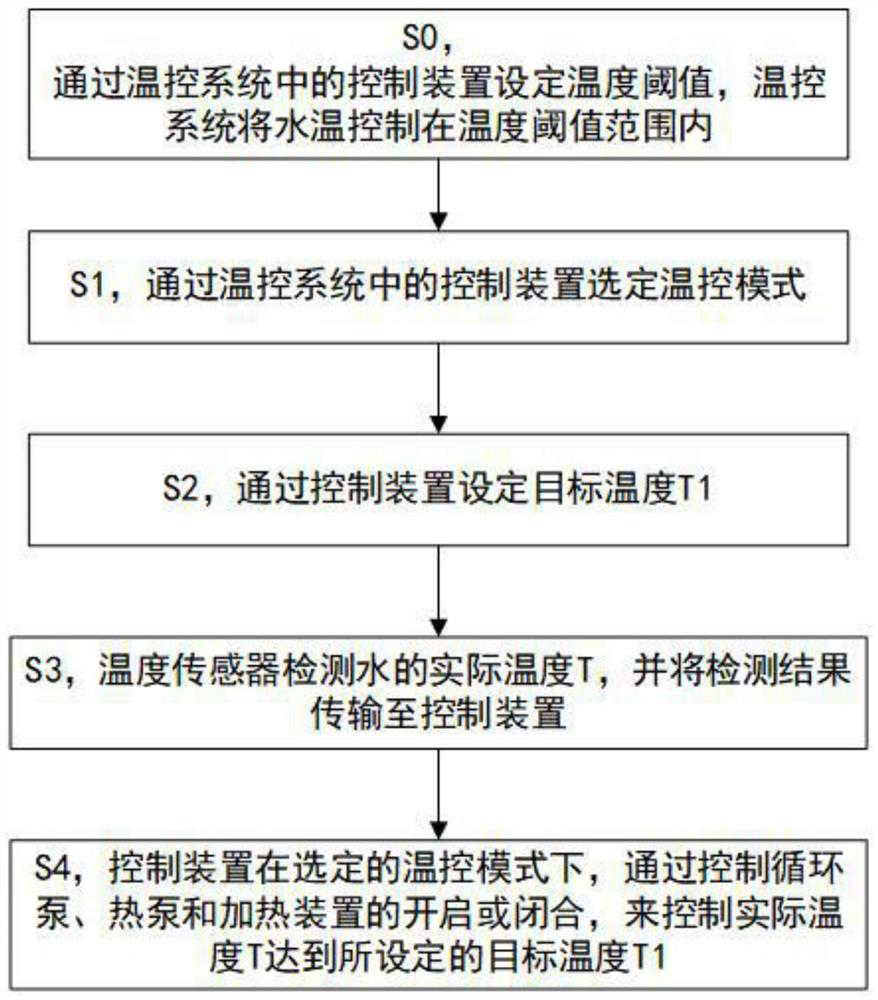

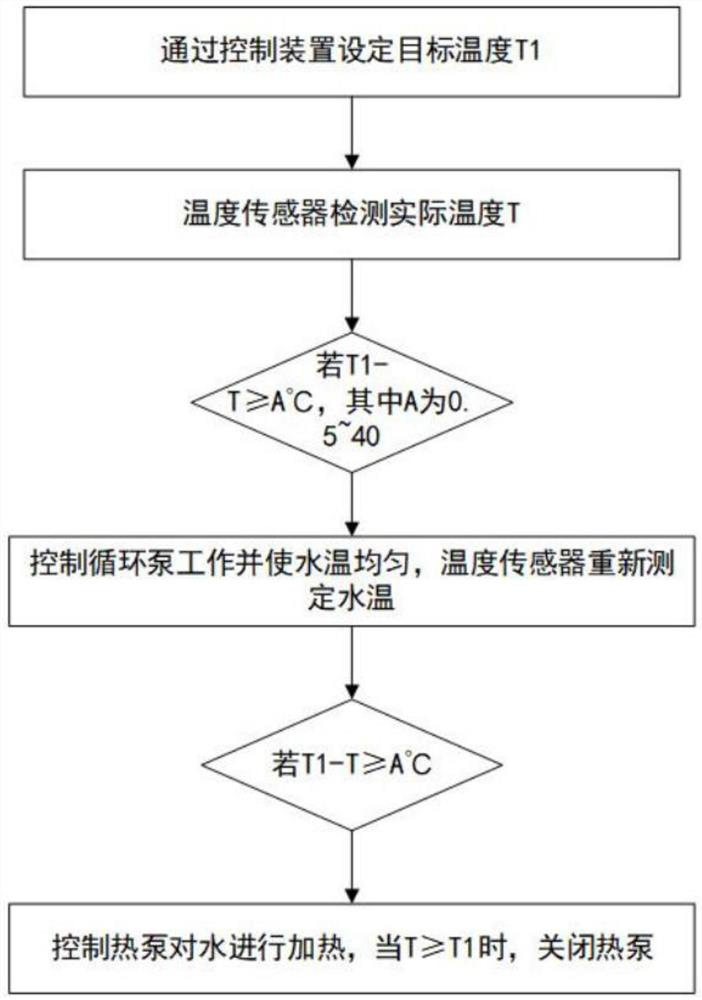

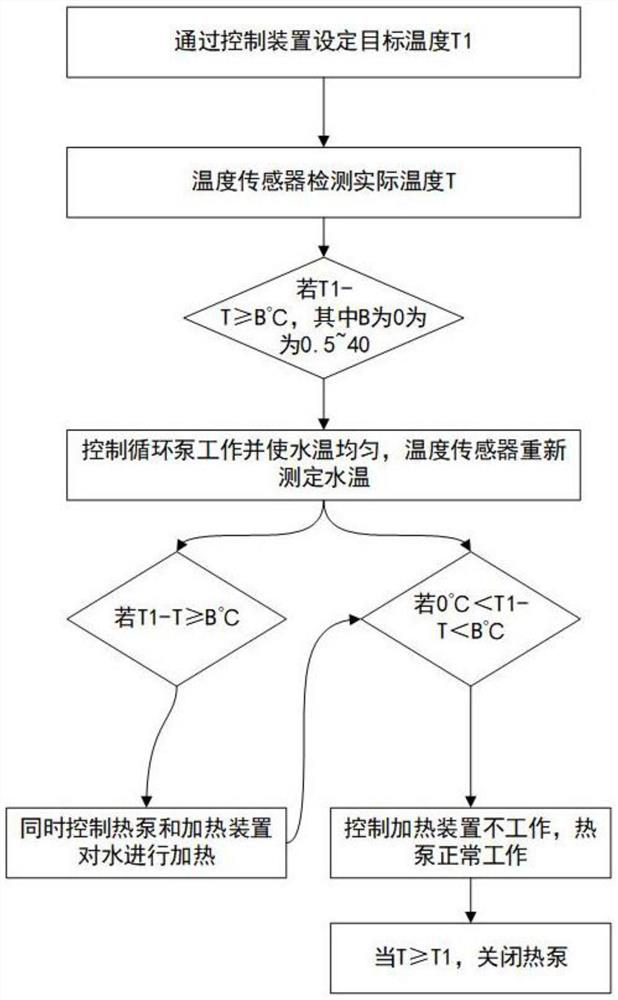

Method for controlling water temperature by multi-mode temperature control system

InactiveCN112394759AHigh heating efficiencyImprove heating efficiencyAuxillary controllers with auxillary heating devicesTemperature control modeEngineering

The invention relates to the technical field of temperature control, in particular to a method for controlling water temperature by a multi-mode temperature control system, which comprises the following steps that: S1, a temperature control mode is selected through a control device in the temperature control system; S2, a target temperature T1 is set through the control device; S3, a temperature sensor detects the actual temperature T of the water and transmits a detection result to the control device; and S4, in the selected temperature control mode, the control device controls the actual temperature T to reach the set target temperature T1 by controlling a circulating pump, a heat pump and a heating device to be started or stopped. According to the method for controlling the water temperature by a multi-mode temperature control system, different use requirements of users can be met, and the heating efficiency can be improved; and the temperature control system only controls the temperature in the temperature control mode selected by the user, so that different requirements of the user on energy saving or rapid heating or intelligent heating are met.

Owner:FOSHAN SHUIJINGDAO LEISURE EQUIP

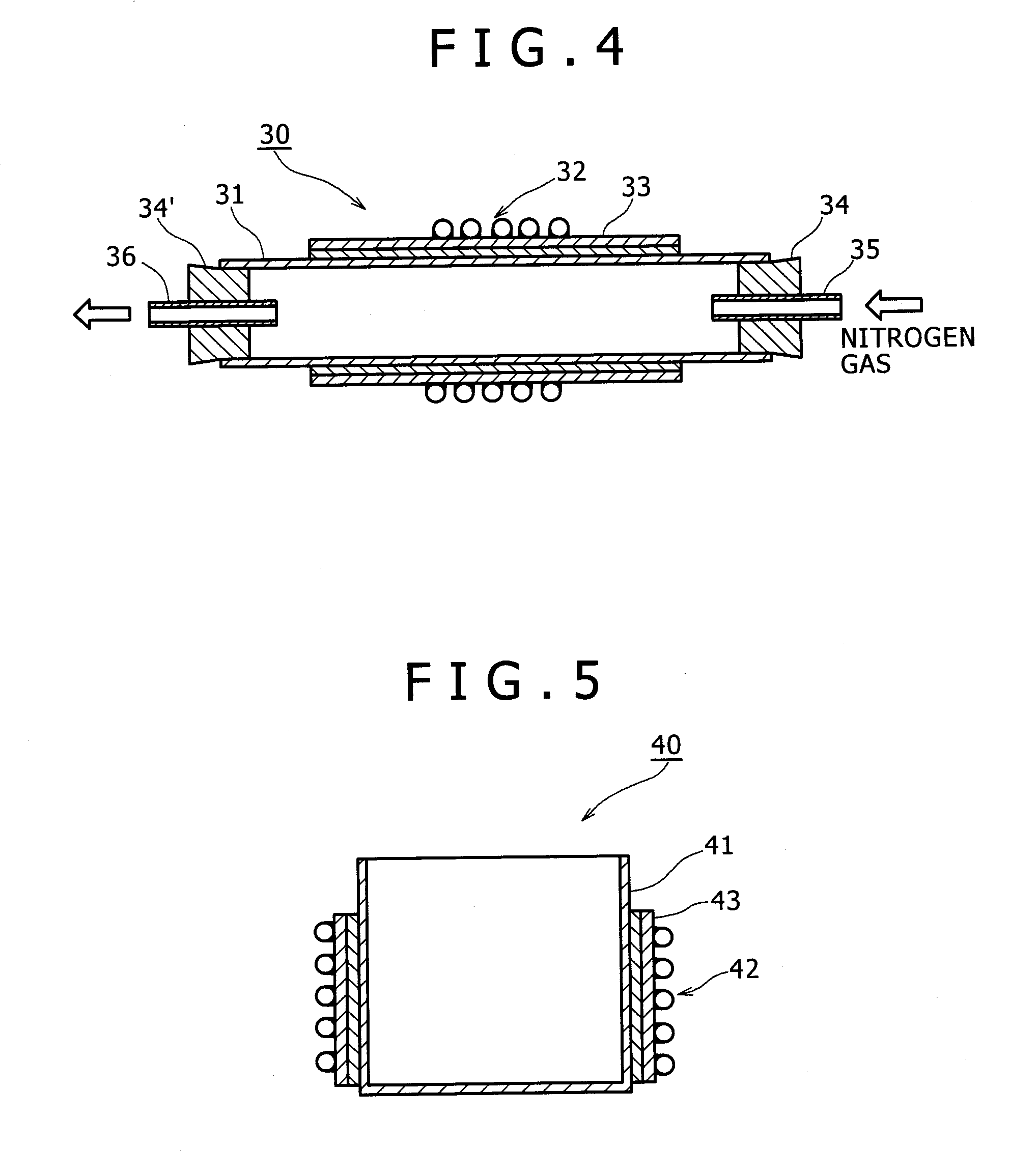

Induction heating element made of glassy carbon, heating device and heater

InactiveUS20090071953A1Well-balanced mannerHigh heating efficiencyInduction heatingSemiconductor/solid-state device manufacturingElectromagnetic inductionHeating efficiency

A glass-like carbon induction heating element having high heating efficiency and a heating apparatus are provided. A glass-like carbon induction heating element, which inductively generates heat by electromagnetic induction, has an infrared radiation characteristic that a ratio (E1 / E2) of infrared radiation intensity (E1) of an opposed face to an object-to-be-heated to infrared radiation intensity (E2) of a non-opposed face to the object-to-be-heated exceeds 1.2. A heating apparatus has the glass-like carbon induction heating element, and a high frequency induction coil that is disposed outside the glass-like carbon induction heating element for allowing the glass-like carbon induction heating element to inductively generate heat, wherein the high frequency induction coil is applied with a current so that the object-to-be-heated is heated by infrared rays radiated from the glass-like carbon induction heating element.

Owner:KOBE STEEL LTD

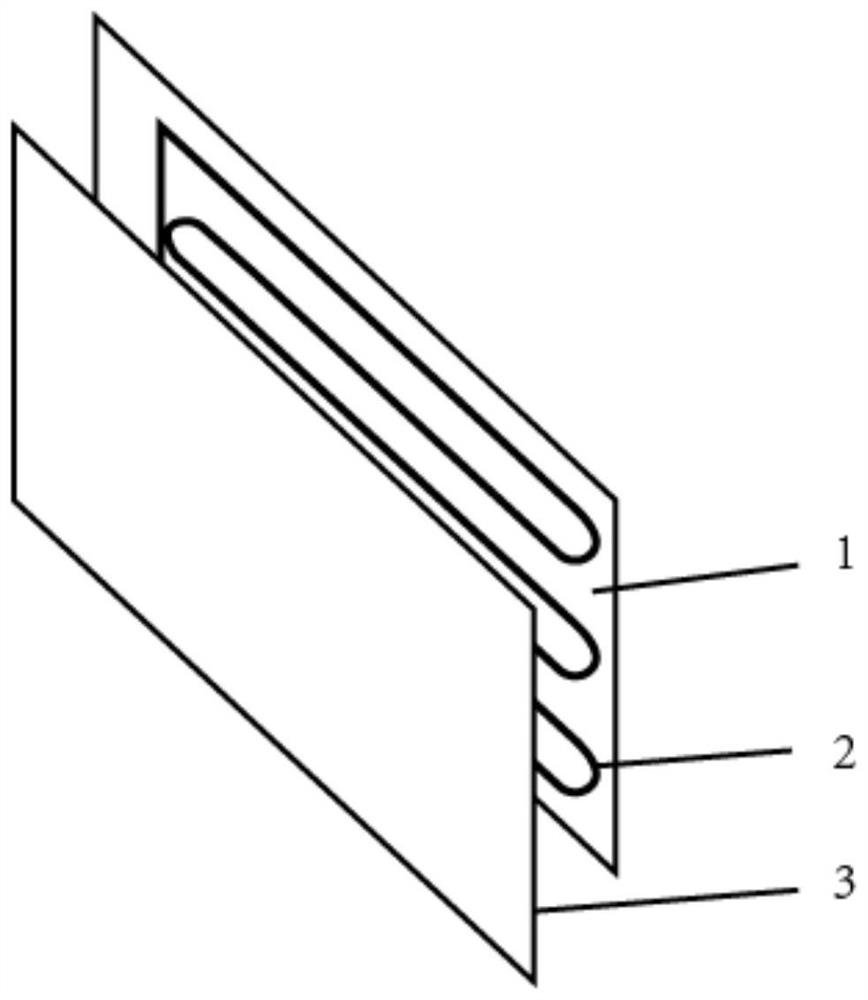

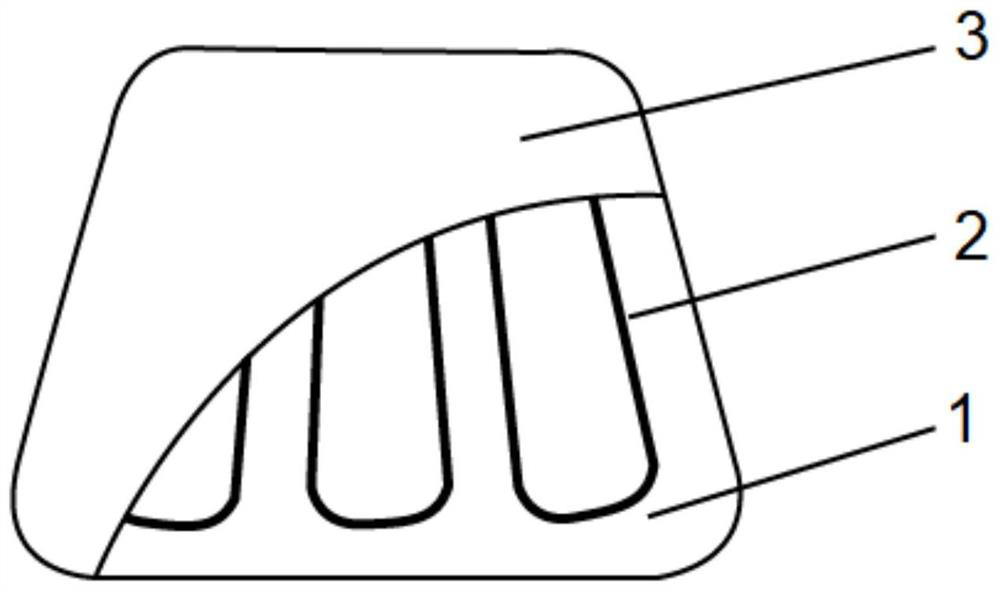

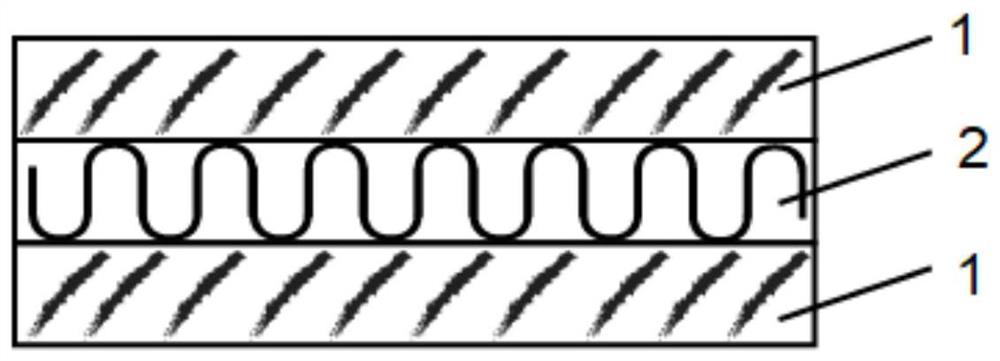

Graphene polymerized nano energy heating sheet and preparation method thereof

PendingCN111918425AReasonable structural designHigh heating efficiencyHeating element materialsHuman healthPolymer chemistry

The invention relates to a graphene polymerization nanometer energy heating sheet and a preparation method thereof. The graphene polymerization nanometer energy heating sheet comprises a fiber composite fabric 1, a heating filament and a fiber composite fabric 2 from inside to outside, wherein the heating filament is embroidered on the fiber composite fabric 1 in a circuitous winding shape througha computer embroidery mode, the first fiber composite fabric is tightly connected with the second fiber composite fabric in a gluing mode, and the heating wire is clamped between the first fiber composite fabric and the second fiber composite fabric. According to the graphene polymerization nanometer energy heating sheet and the preparation method thereof, the structure design is reasonable, theheating effect is good, the heat conduction speed is high, the temperature rise is rapid, the electricity is not conducted, the service life is long, water, electric shock and fire are prevented, thesafety is high, far infrared waves and negative oxygen ions are released, radiation is avoided, human health is facilitated, the preparation method is simple, the flexibility is high, and the application prospect is good.

Owner:元然(苏州)新能源科技有限公司

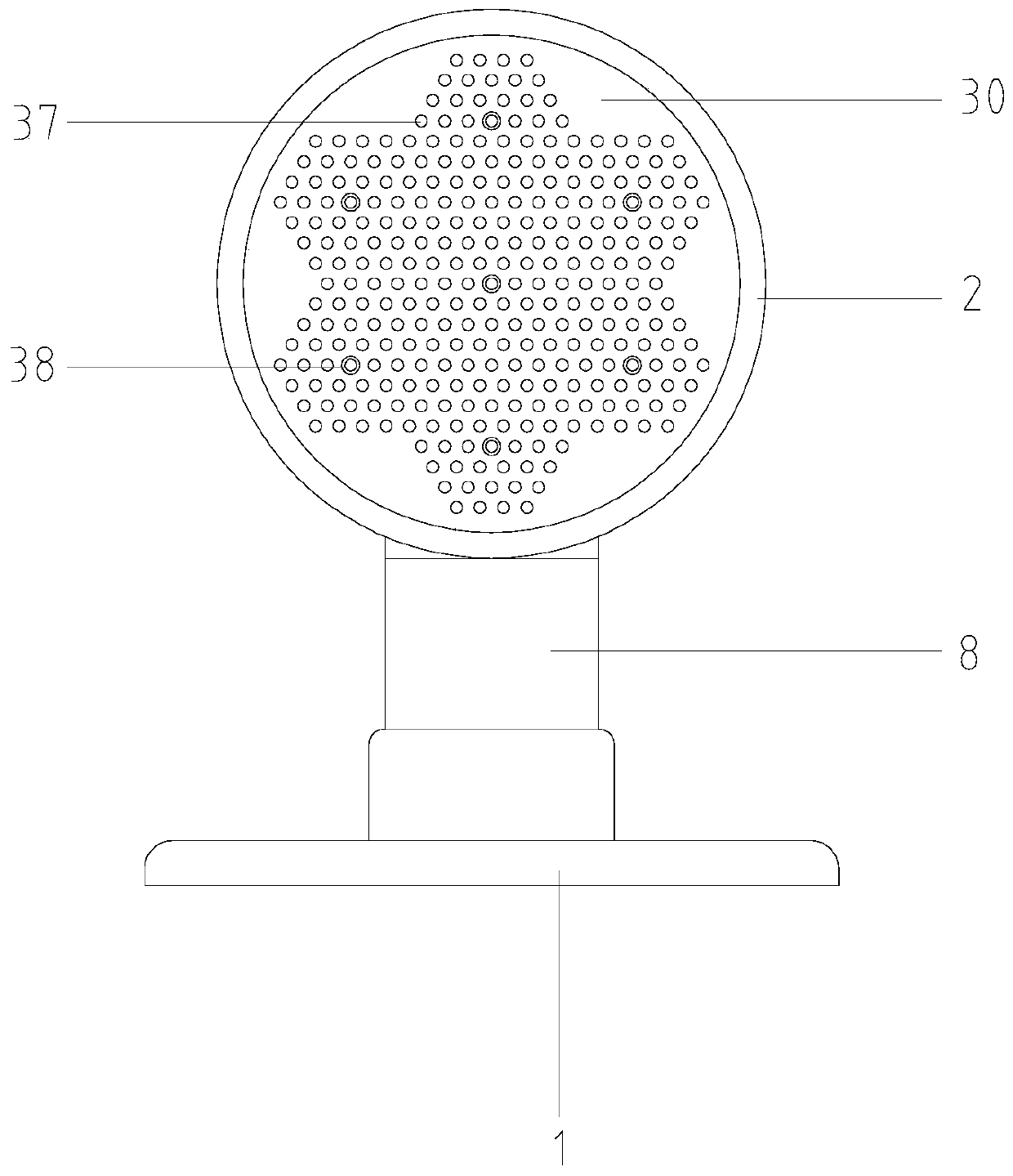

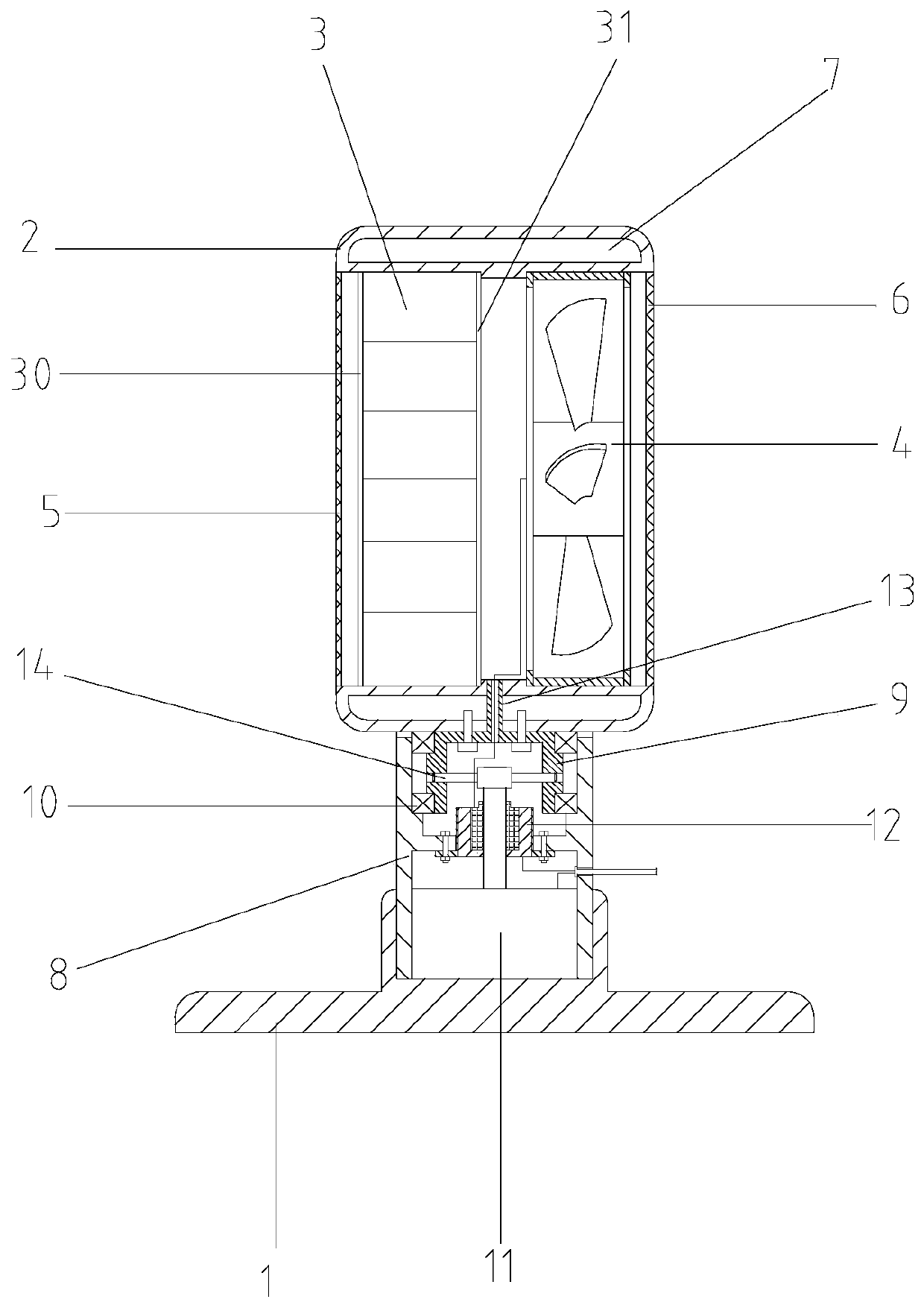

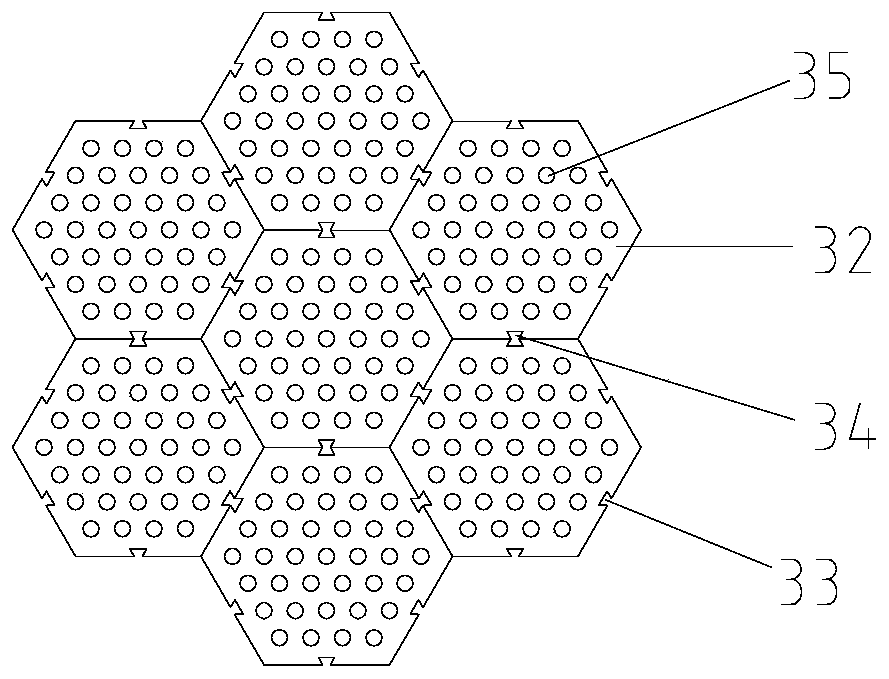

Microporous heater structure

ActiveCN111207439AHigh heating efficiencyLight in massHeating fuelLighting and heating apparatusGraphene coatingHeating efficiency

The invention relates to the technical field of heaters, and discloses a microporous heater structure. The microporous heater structure comprises a base and a shell arranged at the upper end of the base, a heater body is arranged in the shell and comprises a front electrode plate, a rear electrode plate and a plurality of ceramic membrane substrates, micropores are distributed in the ceramic membrane substrates and filled with graphene powder, the ceramic membrane substrates are each in a column shape, a plurality of heating through holes are evenly distributed in the two ends of each ceramicmembrane substrate, graphene coatings are arranged on the end faces of the ceramic membrane substrates and the inner walls of the heating through holes, the front electrode plate is electrically connected with the graphene coatings at the front ends of the ceramic membrane substrates, the rear electrode plate is electrically connected with the graphene coatings at the rear ends of the ceramic membrane substrates, receding through holes corresponding to the heating through holes one to one are formed in the front electrode plate and the rear electrode plate, a fan is arranged in the rear end ofthe shell, a front grid plate is arranged at the front end of the shell, and a rear grid plate is arranged at the rear end of the shell. The microporous heater structure has the beneficial effects ofbeing high in heating efficiency, low in weight and safe in using.

Owner:杭州慈源科技有限公司

Electromagnetic fixation machine with variable magnetic field

PendingCN110583813AReduced concentricity requirementsReduce processing costsPre-extraction tea treatmentInduction heating apparatusElectrical conductorDrive shaft

The invention discloses an electromagnetic fixation machine with a variable magnetic field. The machine comprises a driving motor, a frame, a first belt, a second belt, a roller, a shell, a spiral coil, a conductor, a permanent magnet, a permanent magnet fixing piece, a first driving belt wheel, a second driving belt wheel, a rotating disc, a supporting base and a reduction gearbox, the shell is horizontally arranged on the frame, the roller is sleeved by the shell, one end of the roller is provided with a driving shaft, and the outer side of the roller is provided with the spiral coil according to power requirements; the other end of the roller is provided with the conductor; and the permanent magnet fixing piece is fixed on the rotating disc, the rotating disc and the roller are coaxially arranged, the two permanent magnets are arranged at two ends of the permanent magnet fixing piece, and the N poles and the S poles of the two permanent magnets are arranged in opposite directions. The electromagnetic fixation machine adopts the permanent magnet as a stator, the driving motor drives the conductor attached to a roller as a rotor, the rotor continuously cuts different magnetic poles of the permanent magnet to generate alternating current, and the spiral coil is utilized to form a vortex electric field to heat the roller.

Owner:ZHEJIANG UNIV OF TECH

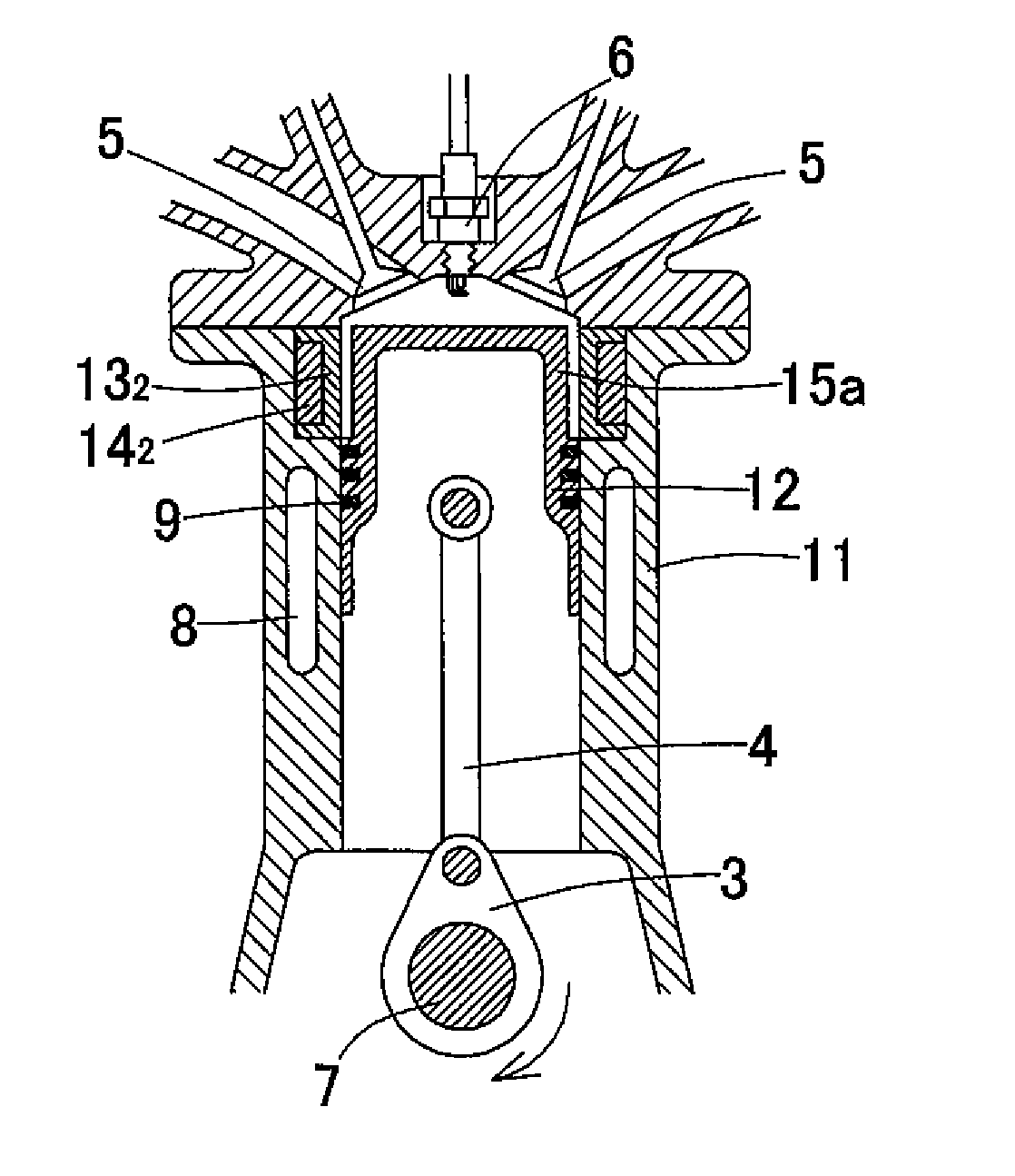

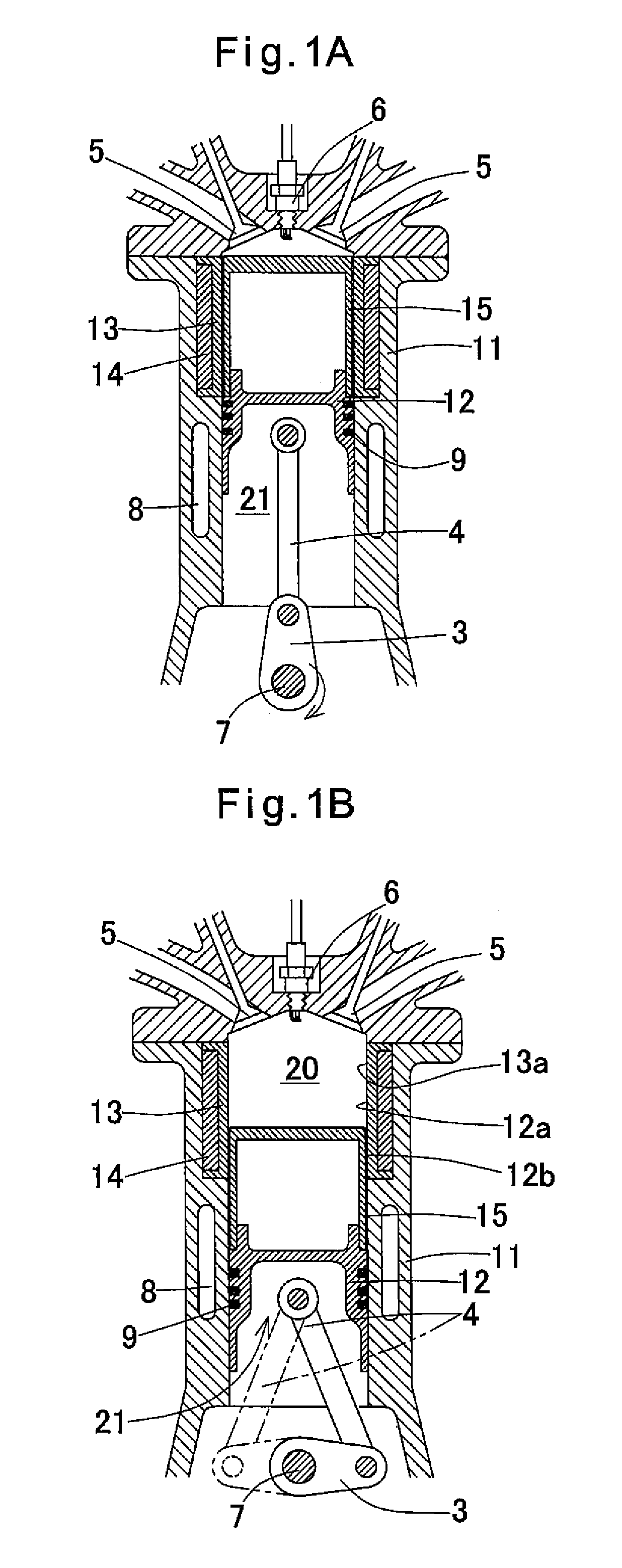

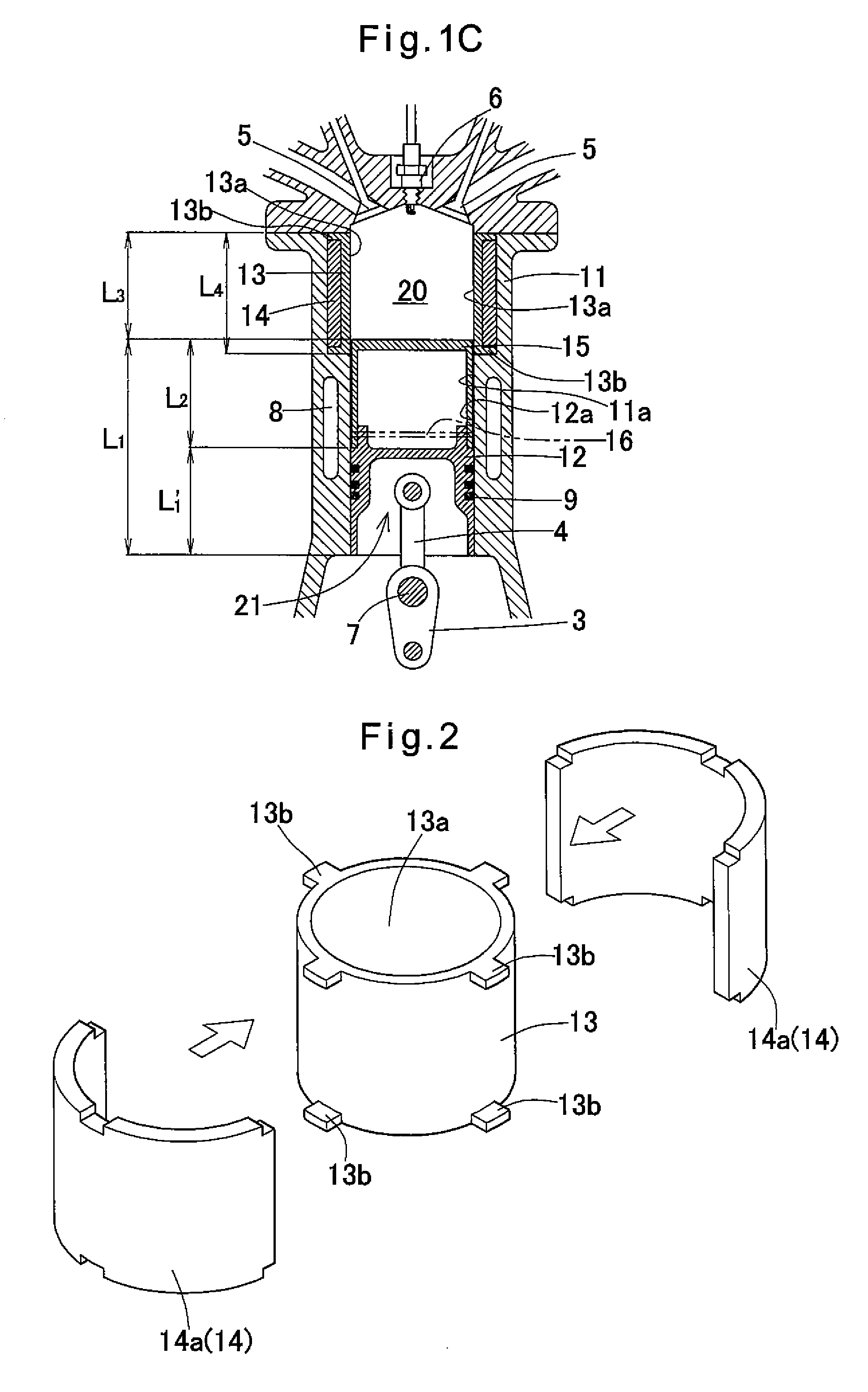

Piston type internal combustion engine

InactiveUS9255544B2Maximize heat efficiencyHigh heating efficiencyInternal combustion piston enginesCylinder headsPistonEngineering

An internal combustion engine includes a cylinder of which the interior is divided into two in the longitudinal direction. The lower chamber serves as a mechanical driving portion in which the piston is reciprocated. The upper chamber serves as a power portion in which combustion gas is drawn in, compressed, burned and exhausted. A cylindrical portion with a lid which moves into the power portion is continuously provided on top of the piston. A gap is defined between the cylindrical portion and the inner peripheral surface of the power portion of the cylinder. The inner peripheral surface of the power portion is defined by a heat shield tube fitted in the cylinder. A heat insulating tube is provided on the outer periphery of the heat shield tube.

Owner:TAKAHARA NOBUYA

Vulcanized heated wire

The invention relates to a vulcanized heated wire. The vulcanized heated wire is characterized by comprising a machine frame, a conveying module, heating modules, a plurality of heating chambers, thermal circulation systems, isolation doors and photoelectricity inductive switches. The photoelectricity inductive switches are arranged on two sides of the machine frame, the conveying module is arranged at the bottom of the machine frame, the heating chambers are sequentially arranged on the conveying module, the isolation doors are arranged between the heating chambers, the heating modules and the thermal circulation systems are arranged in the heating chambers, and the isolation doors are in communication connection with the photoelectricity inductive switches. According to the vulcanized heated wire, automatic production of vulcanized heating of products is realized, the working efficiency is high, and meanwhile, the production process is safe and reliable.

Owner:HUIZHOU BELLSAFE UP TECHNOOGY CO LTD

Drying device with deburring function for building material

ActiveCN108826910AIncrease the area of actionHigh heating efficiencyEdge grinding machinesDrying machines with non-progressive movementsBuilding materialProduction rate

The invention belongs to the technical field of building appliances, and particularly relates to a drying device with a deburring function for a building material. In allusion to problems that a drying process is long so that other working procedures, such as burring to a plate, cannot be performed, and a production rate is low, the following scheme is provided now. The drying device comprises a support frame and a plate body. The top end of the support frame is fixedly provided with a workbench through a bolt, and the upper surface and the lower surface at two sides of the workbench are provided with rectangular sliding chutes. A sliding frame is slidably connected in the rectangular sliding chutes at two sides of the workbench. The middle of the support frame is reserved with a bearing plate, and between the upper surface, adjacent to two sides, of the bearing plate and the lower surface of the workbench, four mutually parallel groove-shaped sliding rails with opposite openings are welded. The drying device is capable of stably fixing the building material to be processed on four clamping plates, conveniently performing deburring on the surface of the plate by machines, such as adeburring machine, at the top end, and performing the deburring on the other surface of the plate through rotating the plate.

Owner:CHONGQING VOCATIONAL INST OF ENG

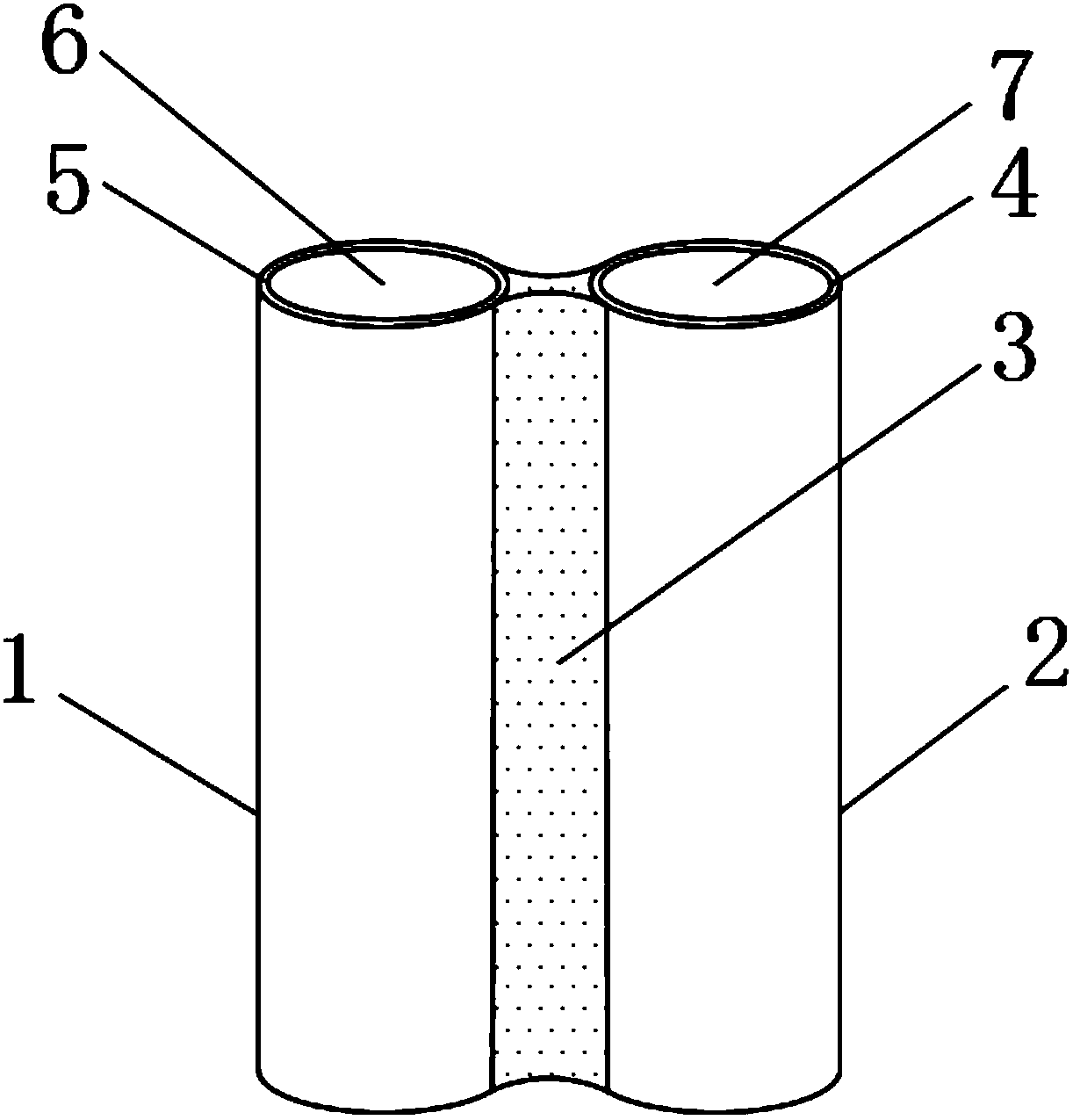

Double-hole quartz tube

InactiveCN108601117AHigh heating efficiencyReduce the number of installationsHeating element shapesEngineeringHeating efficiency

The invention discloses a double-hole quartz tube. The double-hole quartz tube comprises a first quartz tube, a second quartz tube is fixedly arranged at one side of the first quartz tube, a linking block is fixedly arranged between the first quartz tube and the second quartz tube, and a quartz tube inner wall is arranged in the second quartz tube; an annular cavity is arranged at inner surface ofthe first quartz tube, and a first through hole is arranged on the outer surface of the upper end of the first quartz tube. The double-hole quartz tube disclosed by the invention is provided with thejoining block, the limiting marble and a silicon pad, the first through hole and the second through hole can be connected in parallel to form the double-hole quartz tube; the double-hole quartz tubecan effectively increase the heating efficiency and is convenient for saving the mounting frequency of a user, thereby well clamping the equipment; the convenience is brought for mounting and dismounting the quartz tube by the user, thereby effectively preventing the heating inner tube from being damaged in the process of moving the quartz tube, and the better use prospect is brought.

Owner:DONGHAI COUNTY KAIKAI QUARTZ PROD CO LTD +1

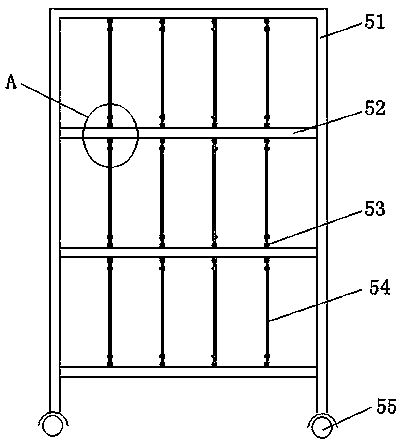

Environment-friendly dense electric tobacco curing room

PendingCN110447937AHigh heating efficiencyReduce the number of inputsTobacco preparationHeating filmElectric heating

The invention provides an environment-friendly dense electric tobacco curing room. The environment-friendly dense electric tobacco curing room comprises a tobacco curing chamber used for placing tobacco leaves, a heating chamber communicating with the tobacco curing chamber through an air flow channel, and a fan arranged in the heating chamber. The environment-friendly dense electric tobacco curing room is characterized in that an electric heating device is arranged in the heating chamber, the electric heating device comprises a plurality of electric heating bodies movably arranged on a fixingrack, each electric heating body comprises an electric heating film and a carrier attaching to the electric heating film, two ends of the elector heating film are provided with flexible conductive bars, a binding post is arranged on each flexible conductive bar, each binding post is connected with one end of a lead, and the other end of the lead is connected with a power supply or a controller after extending outwards. The efficient electric heating can be carried out on air in the heating chamber, the replacement of the electric heating bodies is convenient, the electric heating device is used alternately, so that the utilization ratio is high, the cost is low, the control is accurate, the purposes of cleanness, energy conservation and no pollution are realized, meanwhile, the number ofthe heating bodies can be flexibly adjusted, so that the heat loss can be reduced, the energy conservation and emission reduction effects are obvious, and the demands of various tobacco curing rooms are satisfied.

Owner:昆明飞泉环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com