Graphene polymerized nano energy heating sheet and preparation method thereof

A technology of graphene and heating sheet, which is applied in the field of graphene polymerized nano-energy heating sheet and its preparation, which can solve the problems of unguaranteed heating temperature, carbon fiber heat attenuation, and potential safety hazards, so as to improve heating efficiency and rapid temperature rise , Improve the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

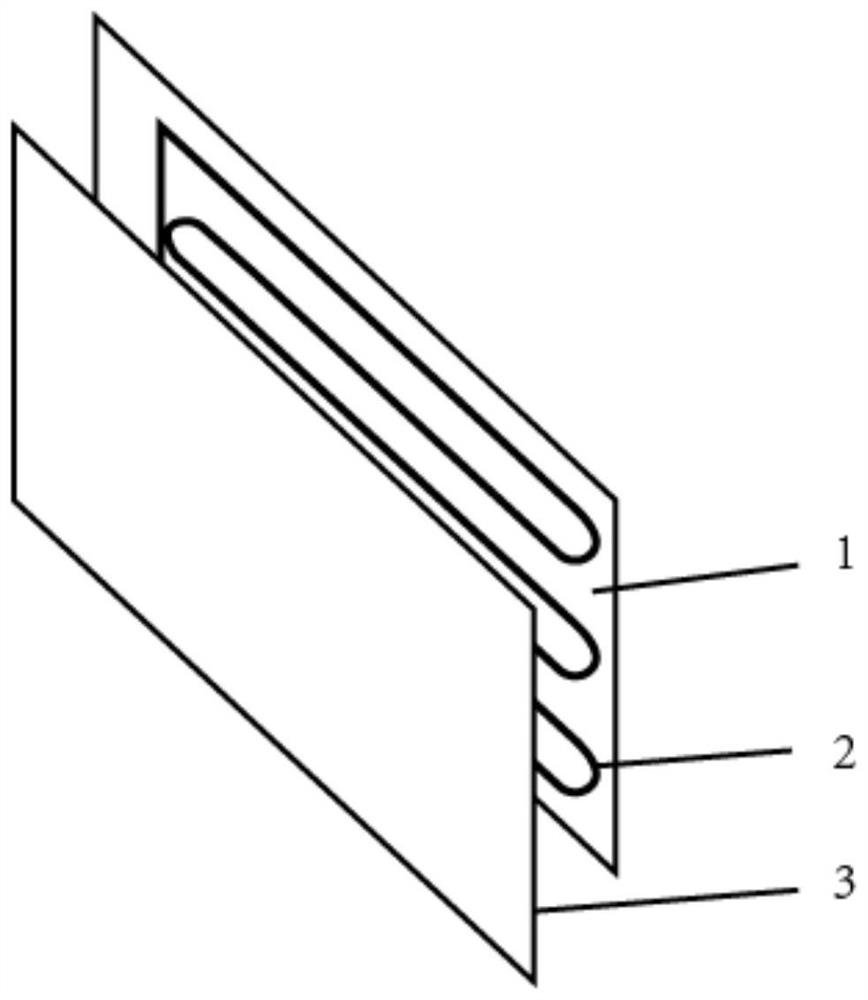

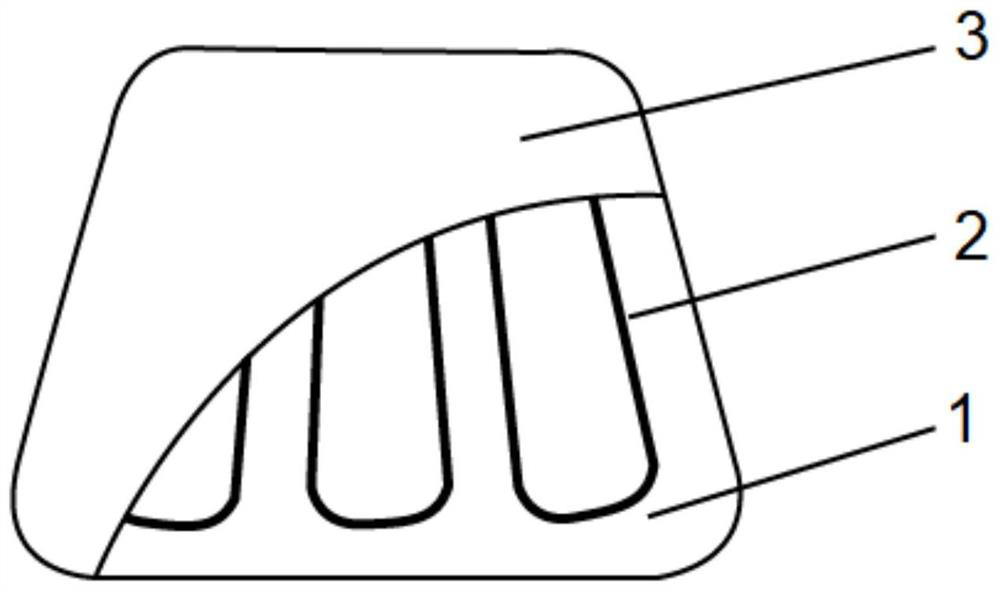

[0064] The preparation method of the graphene-polymerized nano-energy heating sheet is characterized in that it sequentially includes the preparation of the fiber composite fabric 1 and the fiber composite fabric 2 3, the preparation of the heating wire 2, and the preparation of the graphene-polymerized nano-energy heating sheet.

[0065] The preparation of the fiber composite fabric 1 and the fiber composite fabric 2 3 comprises the following steps:

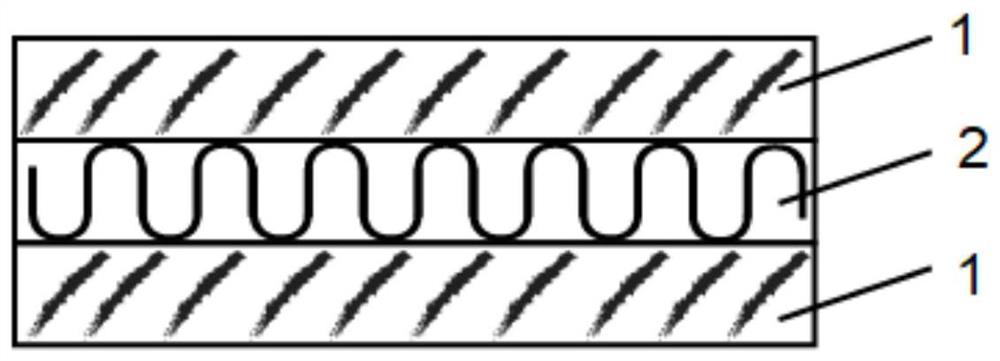

[0066] (1) Preparation of the spinning solution of the hydrophobic bottom layer 11 and the hydrophobic top layer 13: adding multi-walled carbon nanotubes into a mixed solvent, ultrasonic treatment for 3-5 hours, then adding polyvinylidene fluoride to dissolve, and continuously stirring at room temperature for 4-5 hours, After adding the flame retardant, continue to stir continuously for 5-6h to obtain the spinning solution of the hydrophobic bottom layer 11 and the hydrophobic top layer 13; 1.2-1.5wt% of the mass fraction, the a...

Embodiment 2

[0077] The preparation method of the graphene-polymerized nano-energy heating sheet is characterized in that it sequentially includes the preparation of the fiber composite fabric 1 and the fiber composite fabric 2 3, the preparation of the heating wire 2, and the preparation of the graphene-polymerized nano-energy heating sheet.

[0078] The preparation of the fiber composite fabric 1 and the fiber composite fabric 2 3 comprises the following steps:

[0079] (1) Preparation of the spinning solution of the hydrophobic bottom layer 11 and the hydrophobic top layer 13: adding multi-walled carbon nanotubes into a mixed solvent, ultrasonic treatment for 3-5 hours, then adding polyvinylidene fluoride to dissolve, and continuously stirring at room temperature for 4-5 hours, After adding the flame retardant, continue to stir continuously for 5-6h to obtain the spinning solution of the hydrophobic bottom layer 11 and the hydrophobic top layer 13; 1.2-1.5wt% of the mass fraction, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com