Patents

Literature

77results about How to "Rapid rise in temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

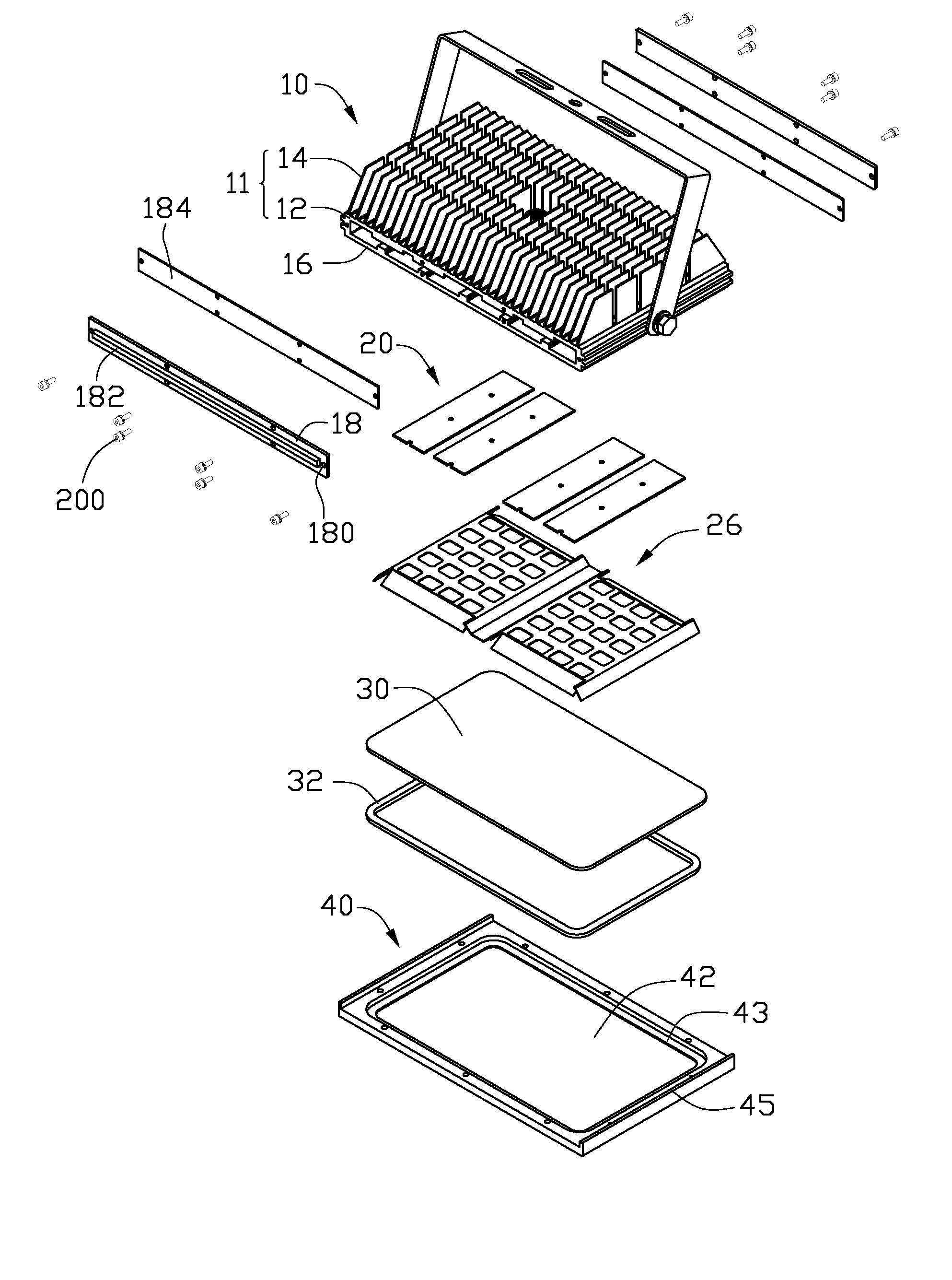

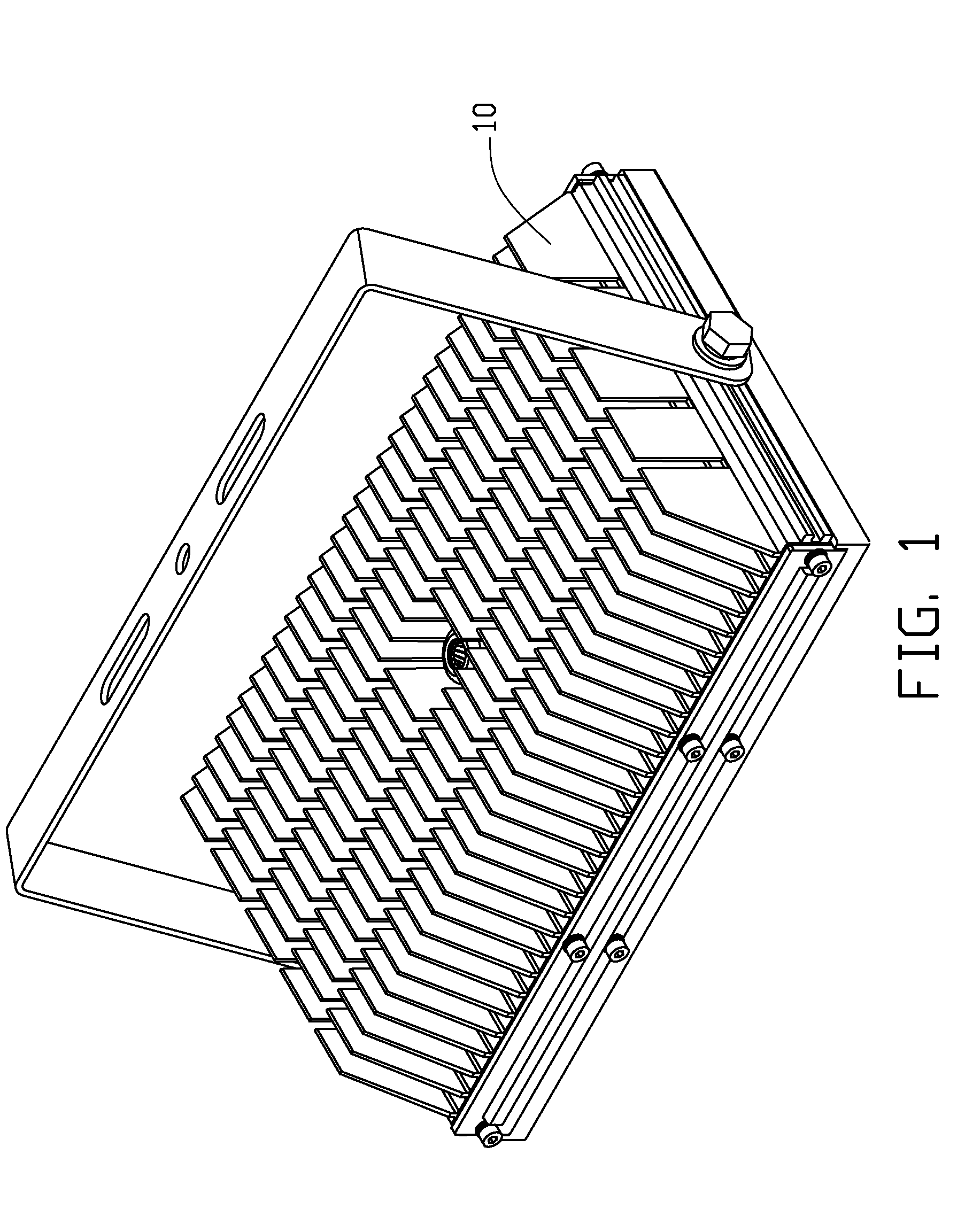

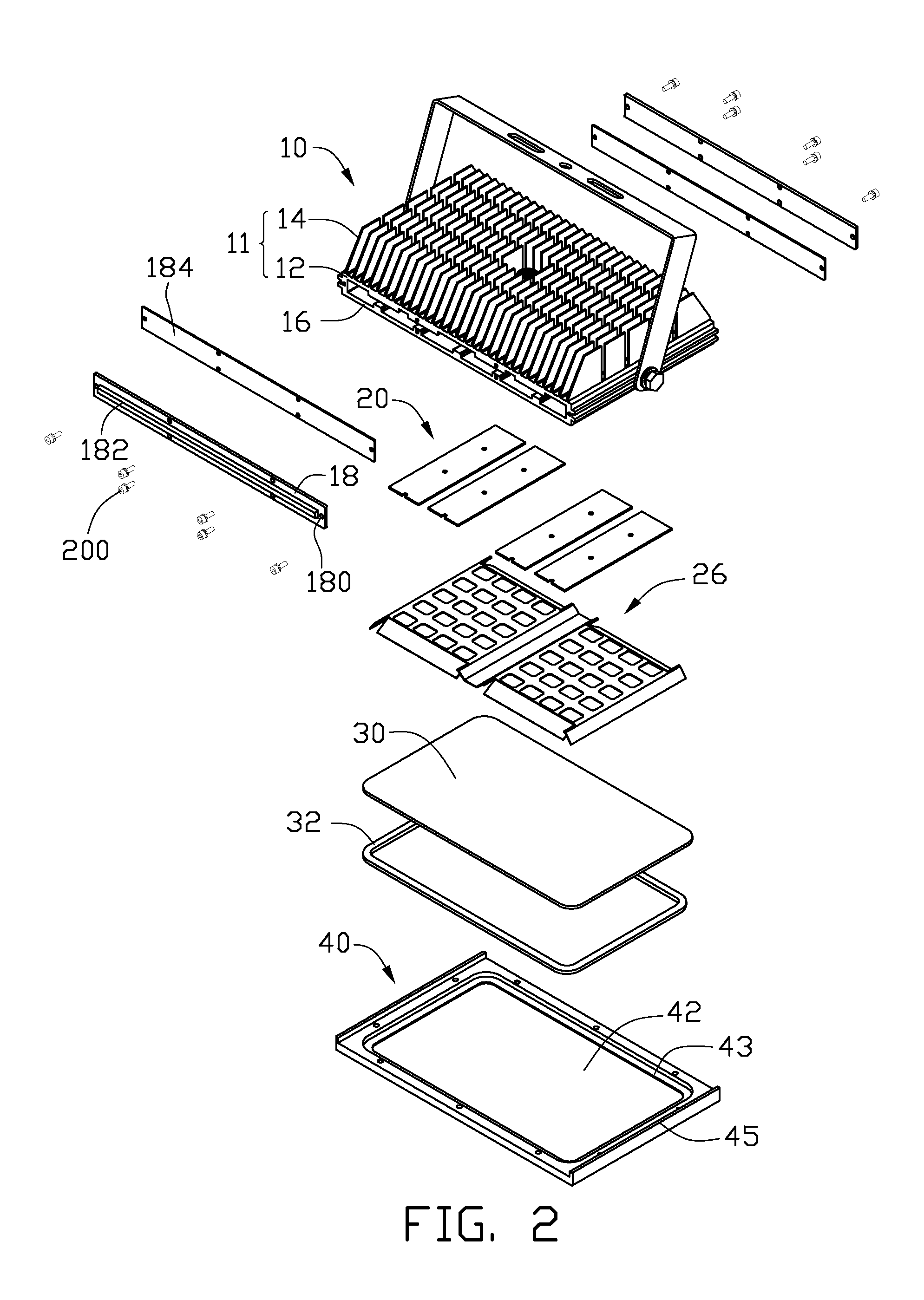

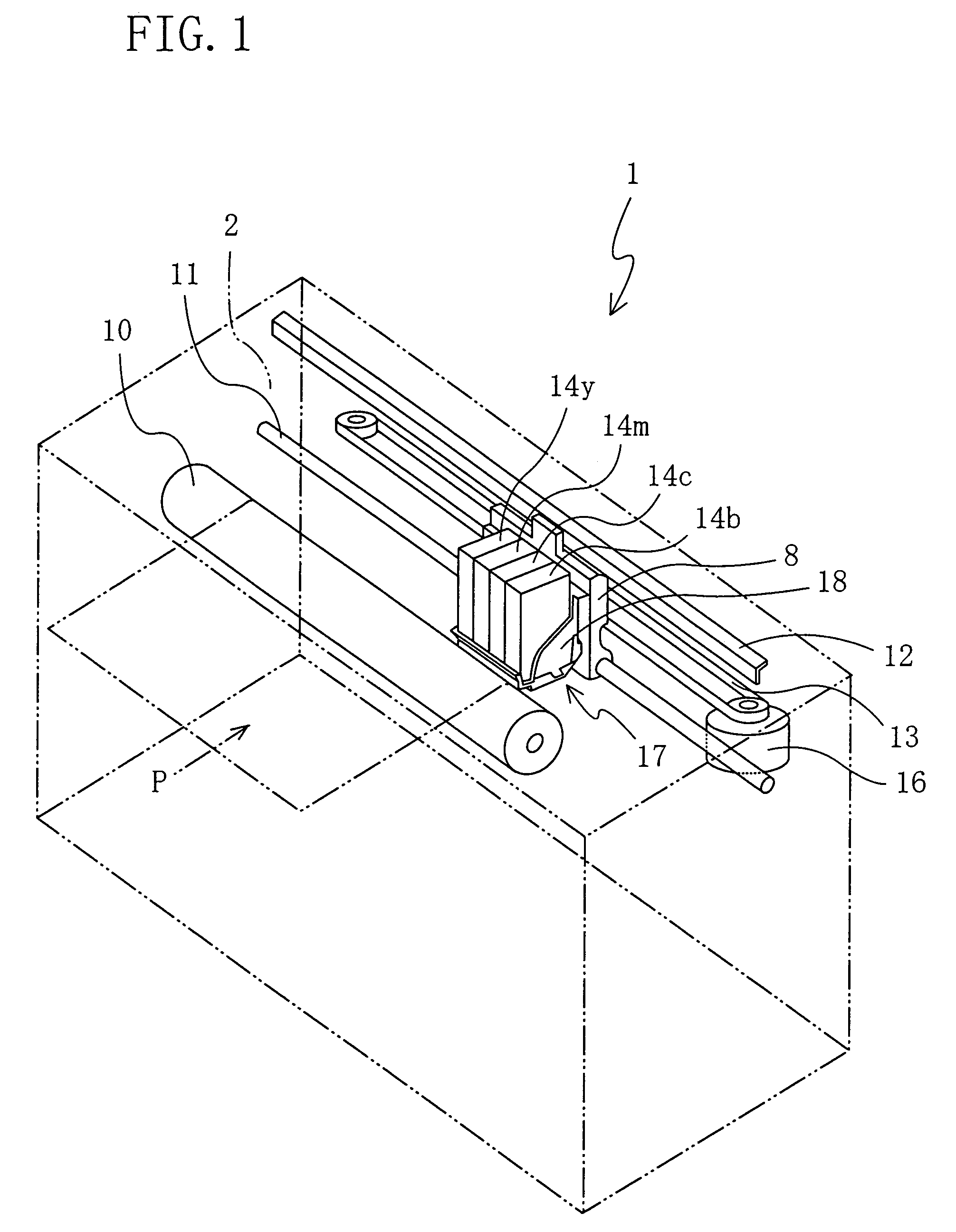

LED lamp

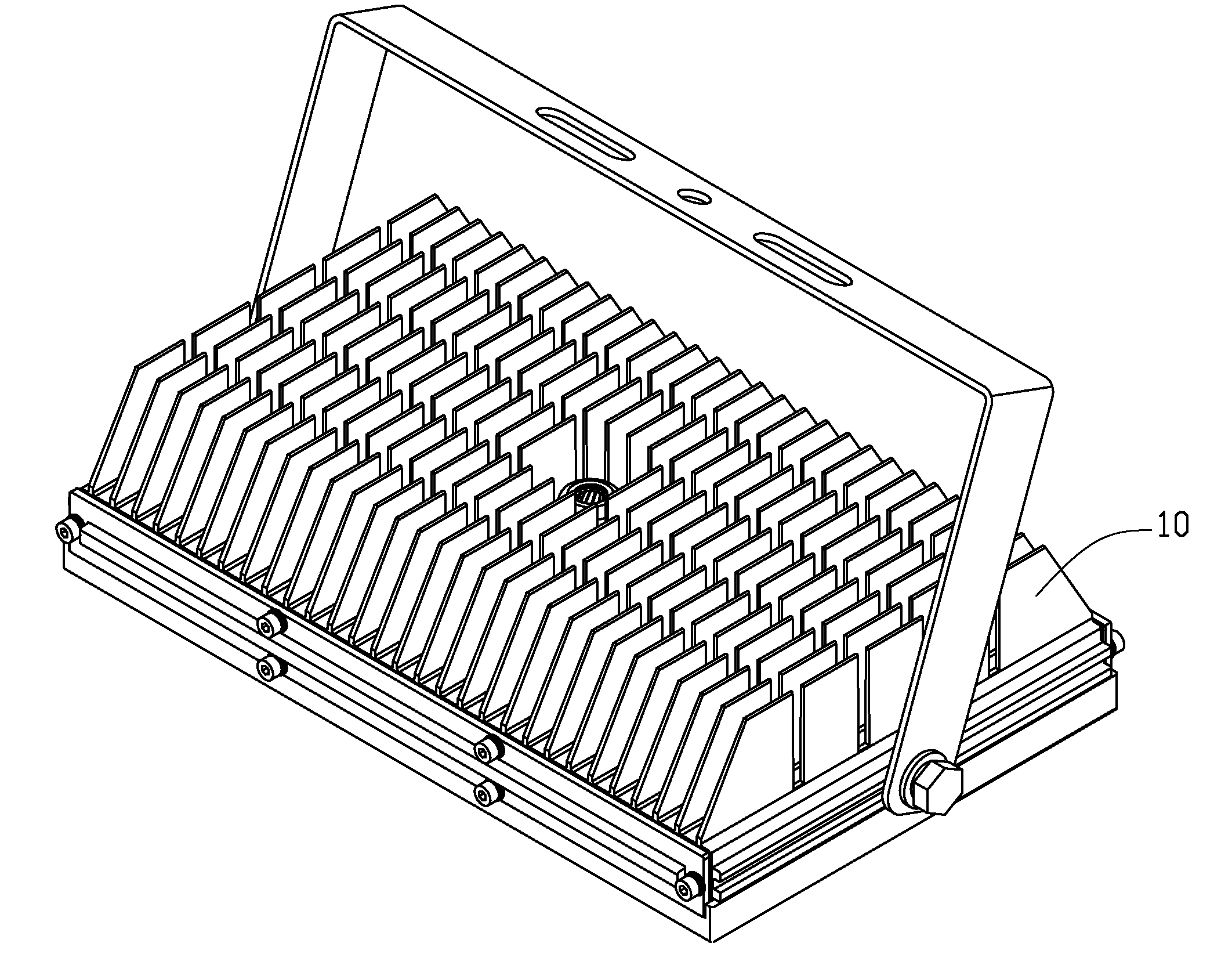

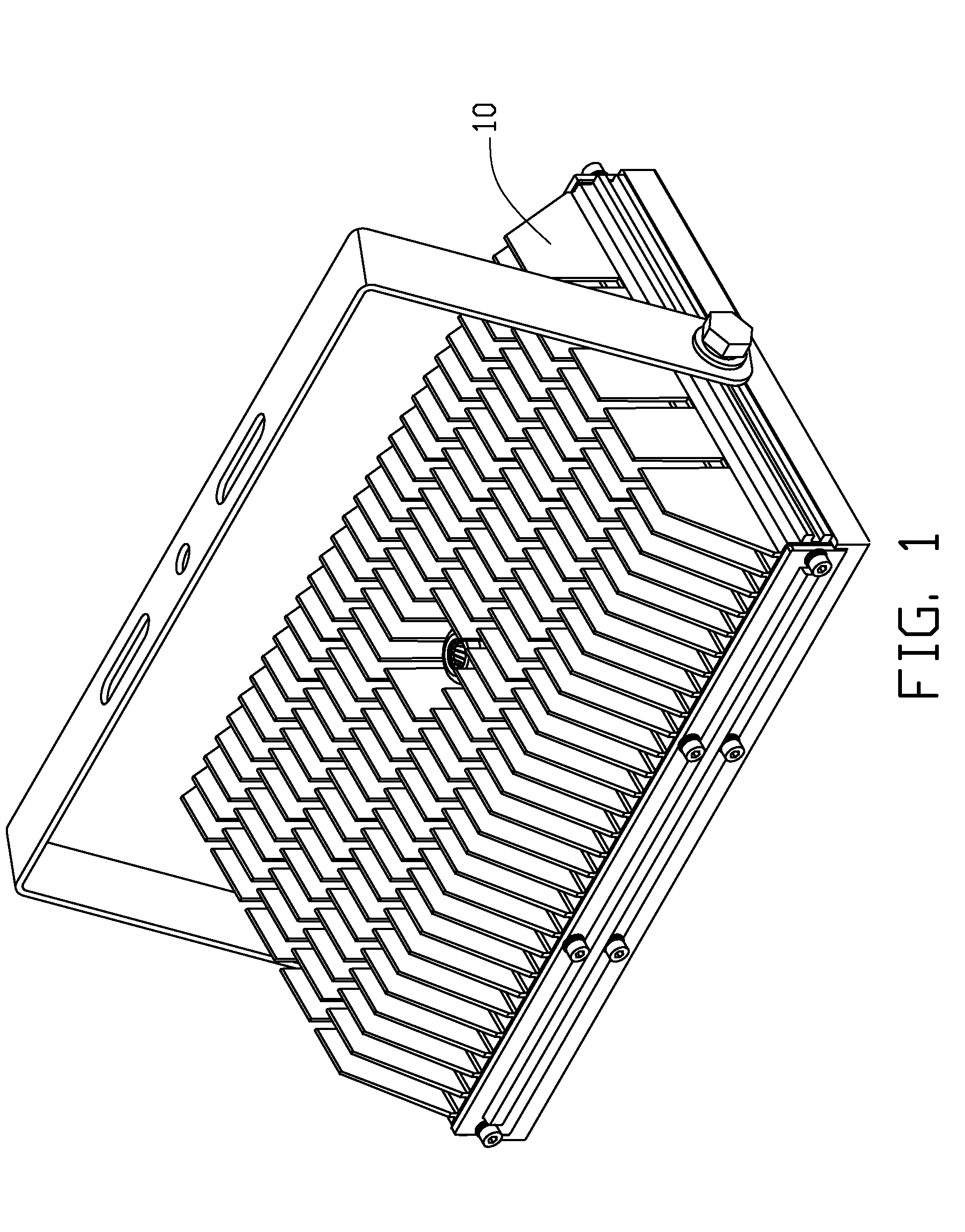

InactiveUS20100296287A1Rapid rise in temperatureHighly effectivePlanar light sourcesPoint-like light sourceEngineeringLED lamp

An LED lamp includes a monolithic housing made of metal extrusion and comprising a heat sink and a receiving portion integrally extending from a bottom of the heat sink, a plurality of LED modules attached to the heat sink, a cover covering the LED modules and a supporting bracket mounted on the housing. The heat sink includes a planar base and a plurality of fins extending from a top face of the base. The receiving portion includes a frame defining a window at a center thereof and two sidewalls interconnecting the frame and the base. The frame, the sidewalls and the base cooperatively define a receiving chamber for accommodating the LED modules therein. The LED modules are attached to the base and located corresponding to the window of the frame. The cover is mounted on a bottom of the frame and correspondingly covers the window.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

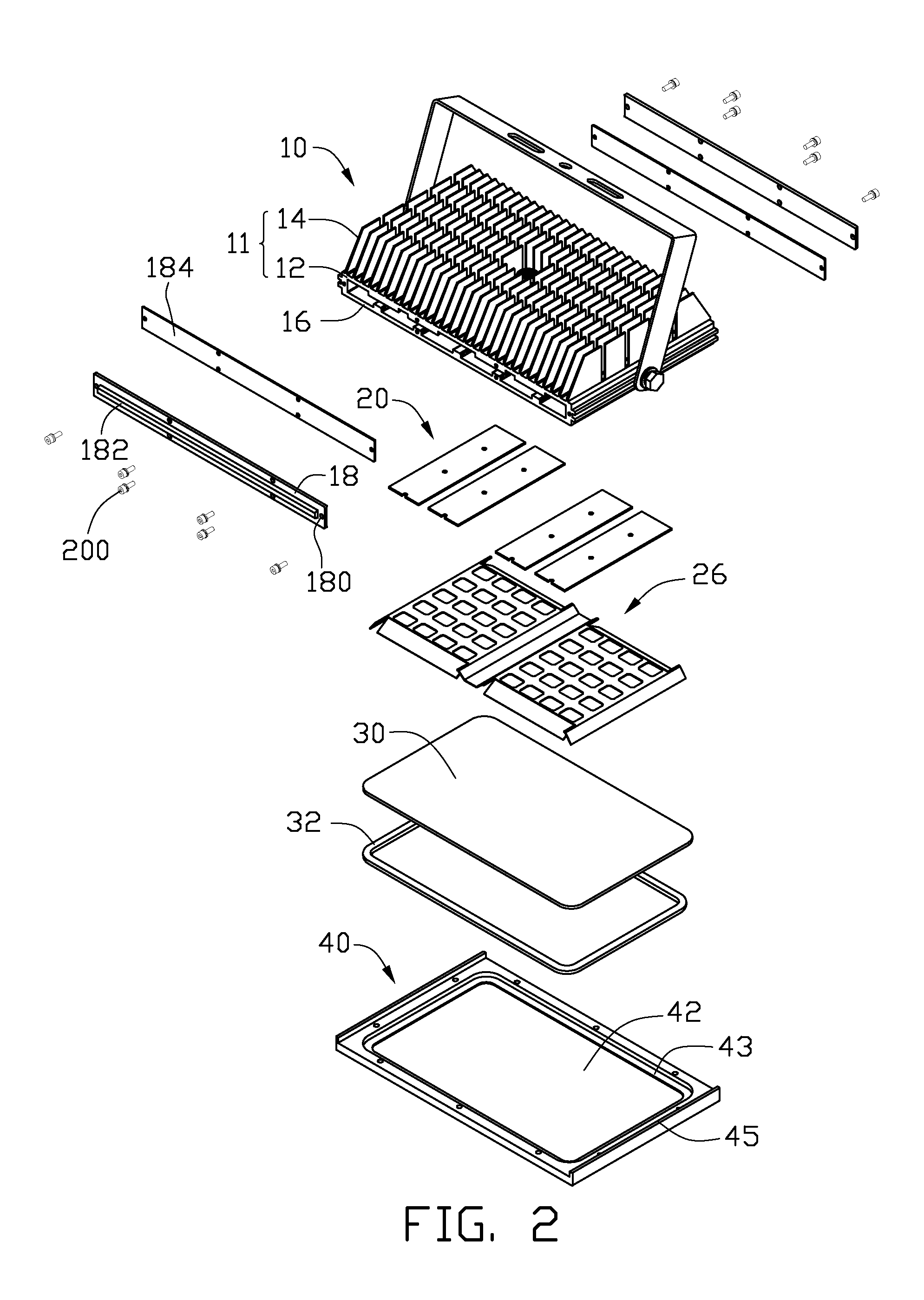

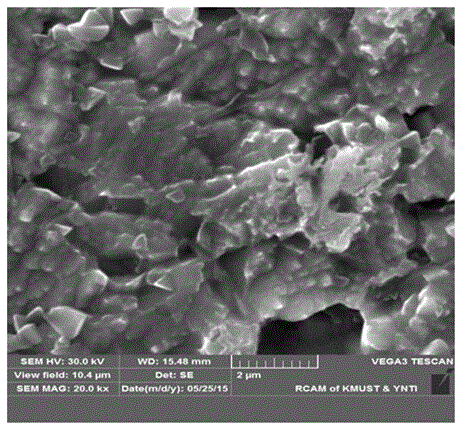

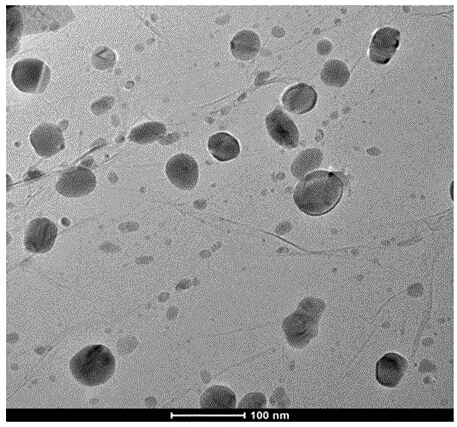

Preparation method of graphene-reinforced copper-based composite

ActiveCN105624445AImprove performanceEasy to organizeTransportation and packagingMetal-working apparatusSlurryCobalt

The invention discloses a preparation method of a graphene-reinforced copper-based composite and belongs to the field of preparation of high-strength and high-conductivity composites. The method comprises steps as follows: graphene, nano copper powder and cobalt powder in the required mass ratio are mixed in absolute ethyl alcohol, the mixture is physically dispersed under electromagnetic stirring, and then physically dispersed mixed slurry is added to a ball milling tank for mechanical ball milling; after evenly mixed slurry is centrifugally dried, obtained mixed powder is annealed and then subjected to hot-pressing SPS (spark plasma sintering) forming; an obtained block blank is annealed and then subjected to hot extrusion, and the graphene-reinforced copper-based composite is obtained. The graphene-reinforced copper-based composite prepared through the method has the good mechanical property, uniform structure and good heat and electricity conductivity.

Owner:KUNMING UNIV OF SCI & TECH

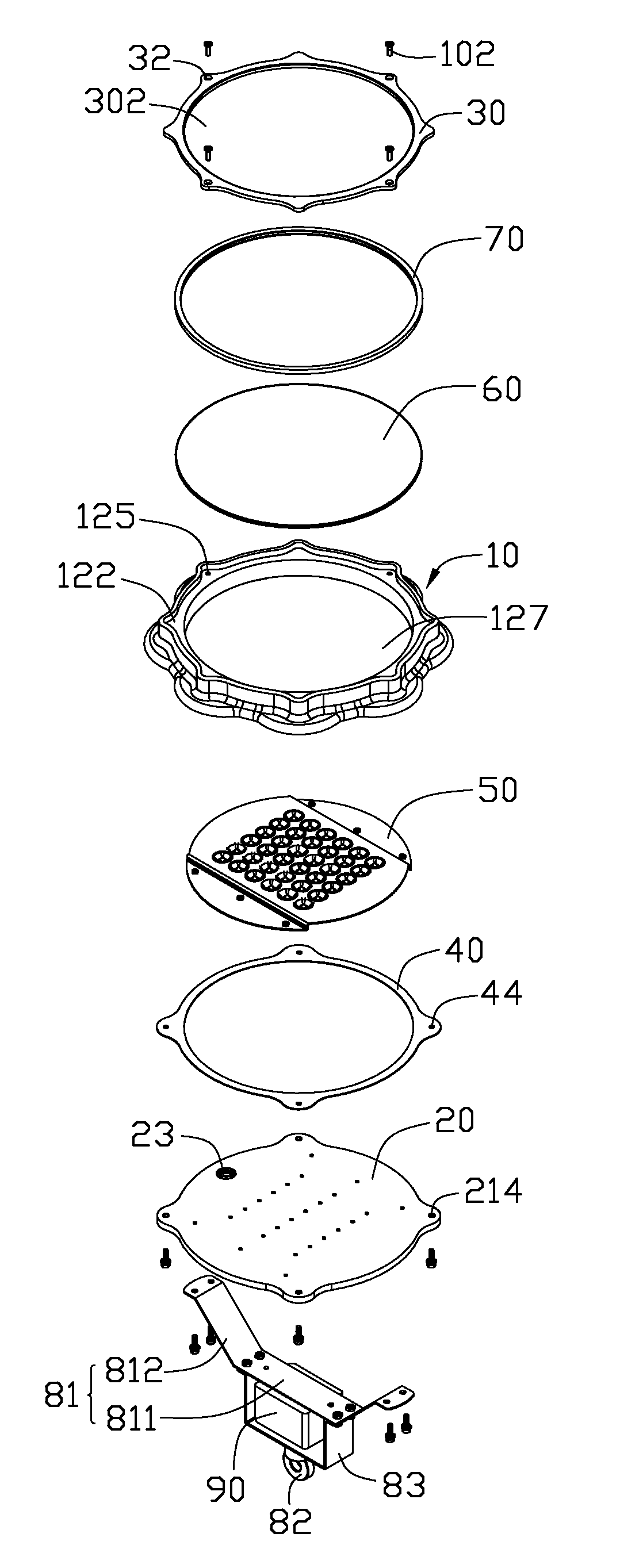

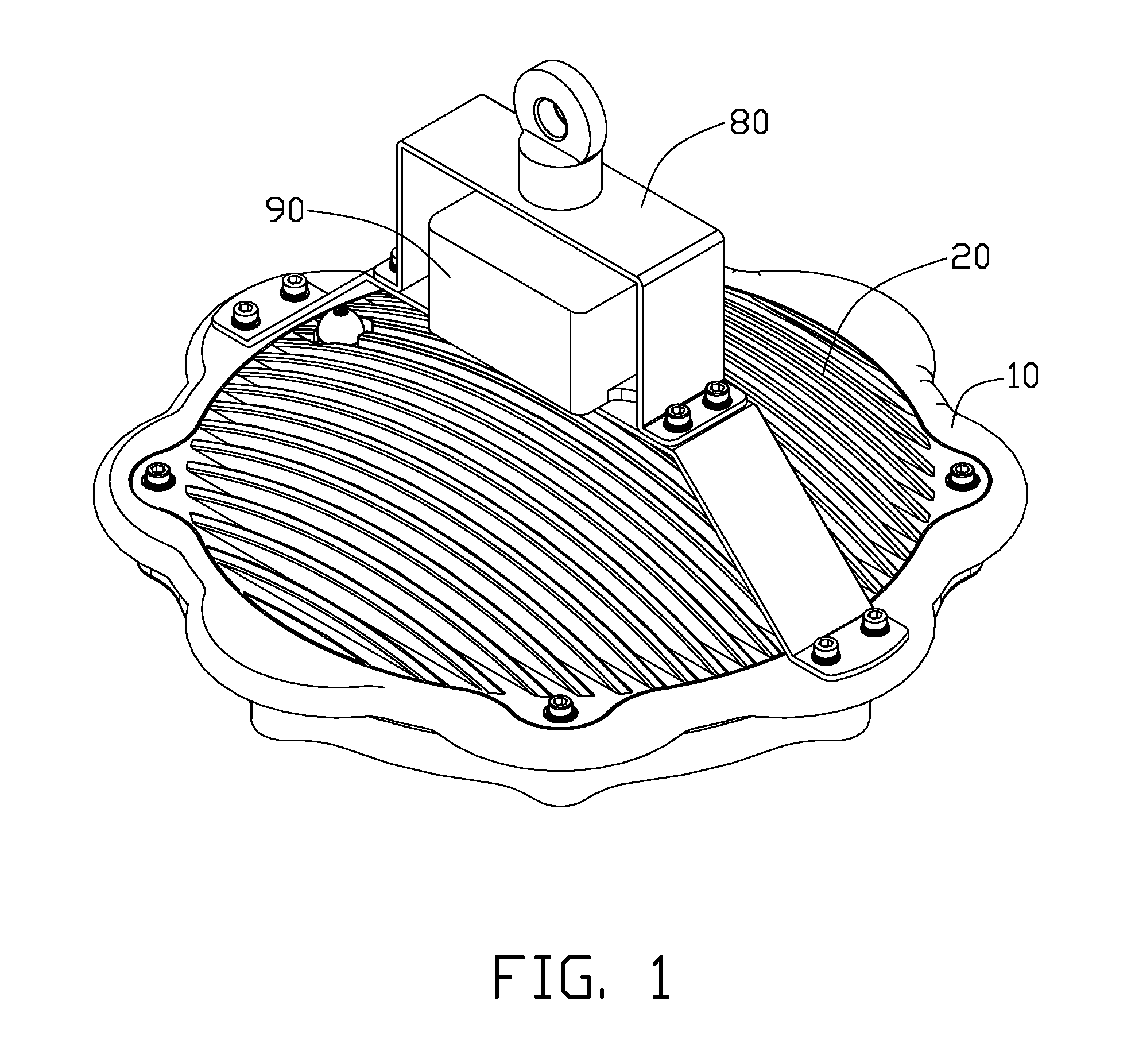

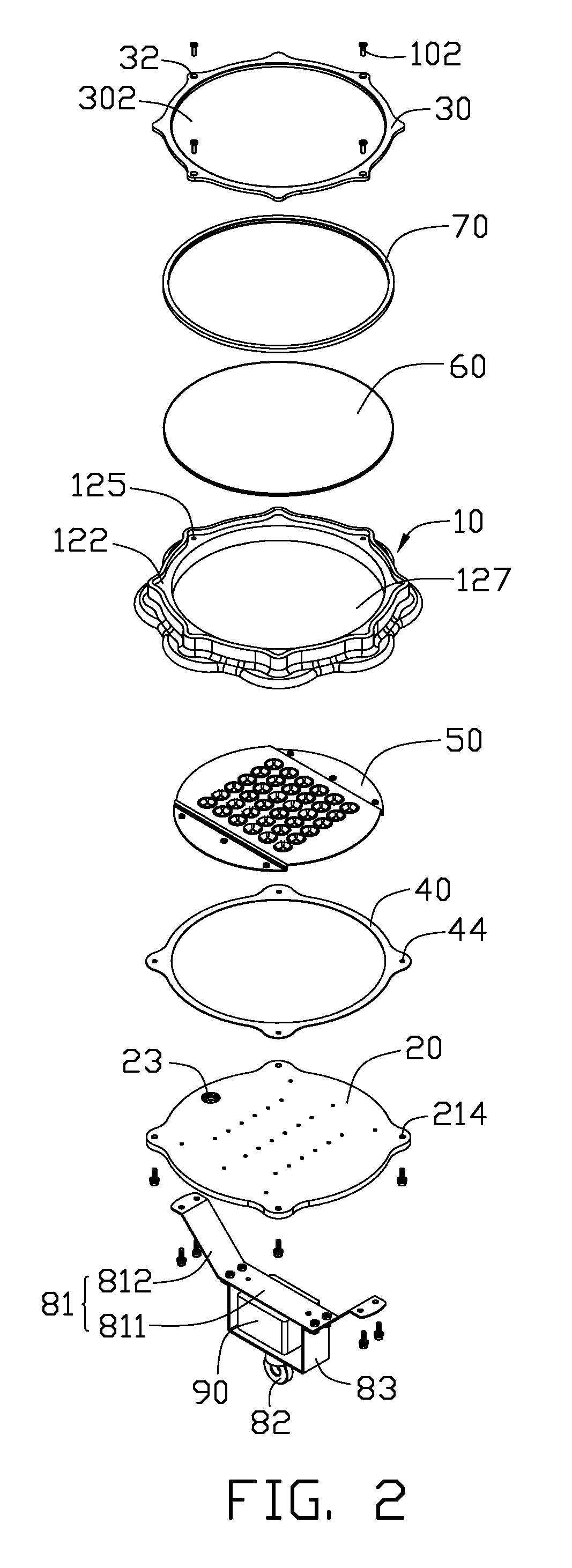

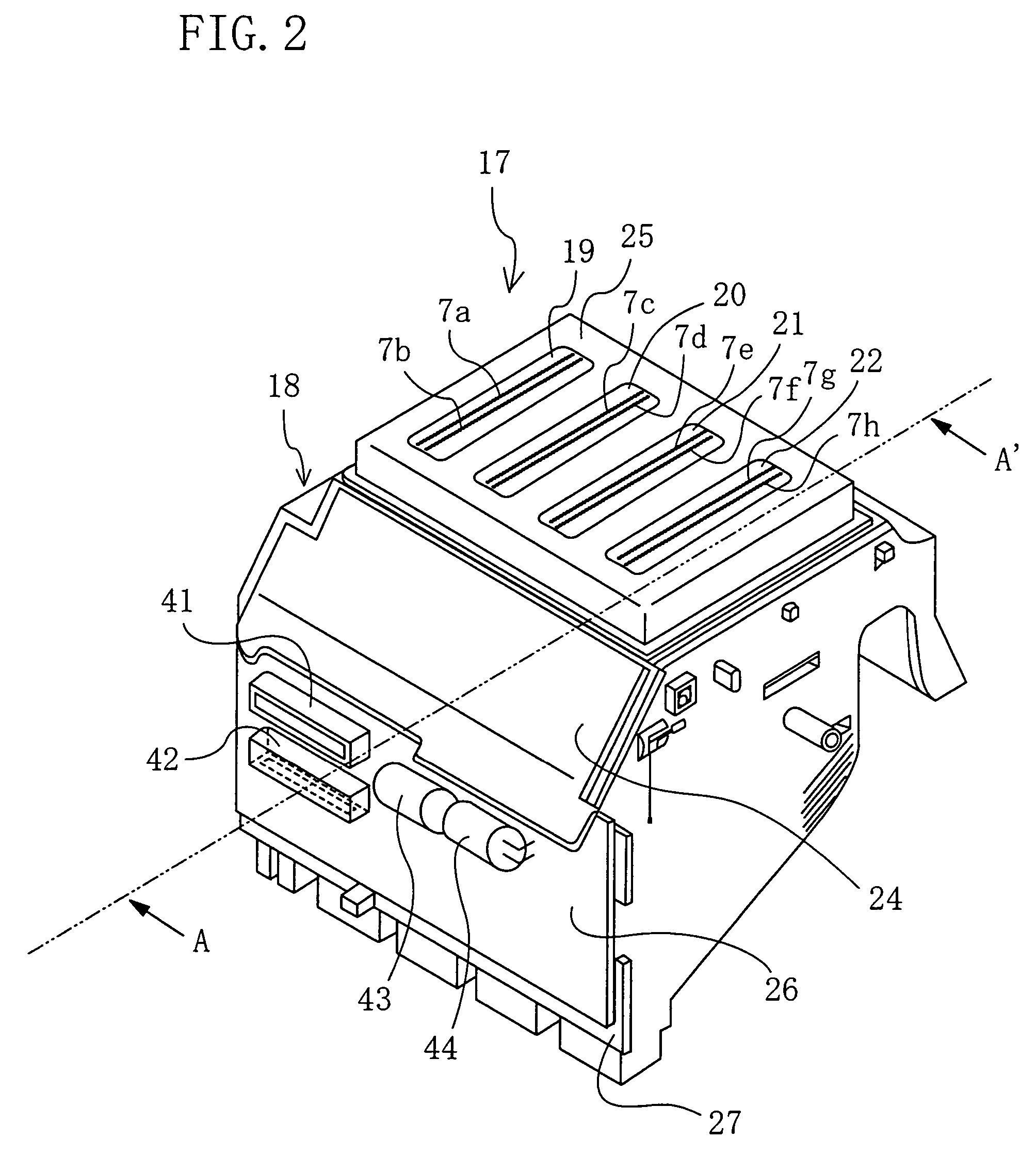

Compact LED lamp having heat dissipation structure

InactiveUS7753556B1Rapid rise in temperatureHighly effectiveLighting support devicesPoint-like light sourceLED lampRetaining ring

An LED lamp includes a body comprising a supporting ring and a holding ring. A heat sink cover is mounted to a top surface of the supporting ring to cover a top end of the body. The heat sink cover comprises a plate and a plurality of fins formed on a top surface thereof. An LED module is received in the body and mounted to a bottom surface of the plate. A transparent envelope is mounted to the holding ring to cover a bottom end of the body. A retaining ring is mounted to a bottom surface of the holding ring to secure the transparent envelope in position. A suspension device is mounted to the heat sink cover. A power module is disposed in the suspension device.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

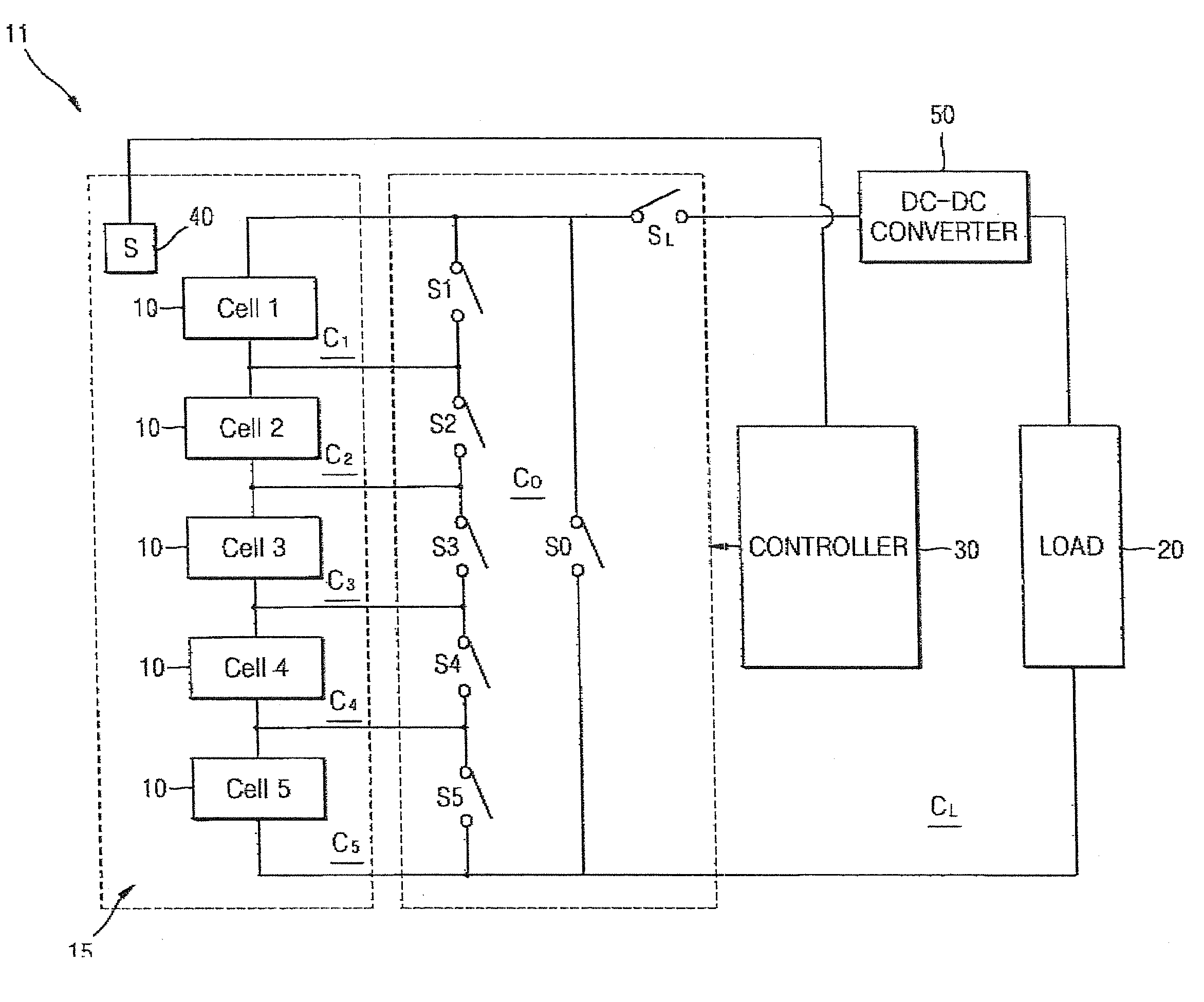

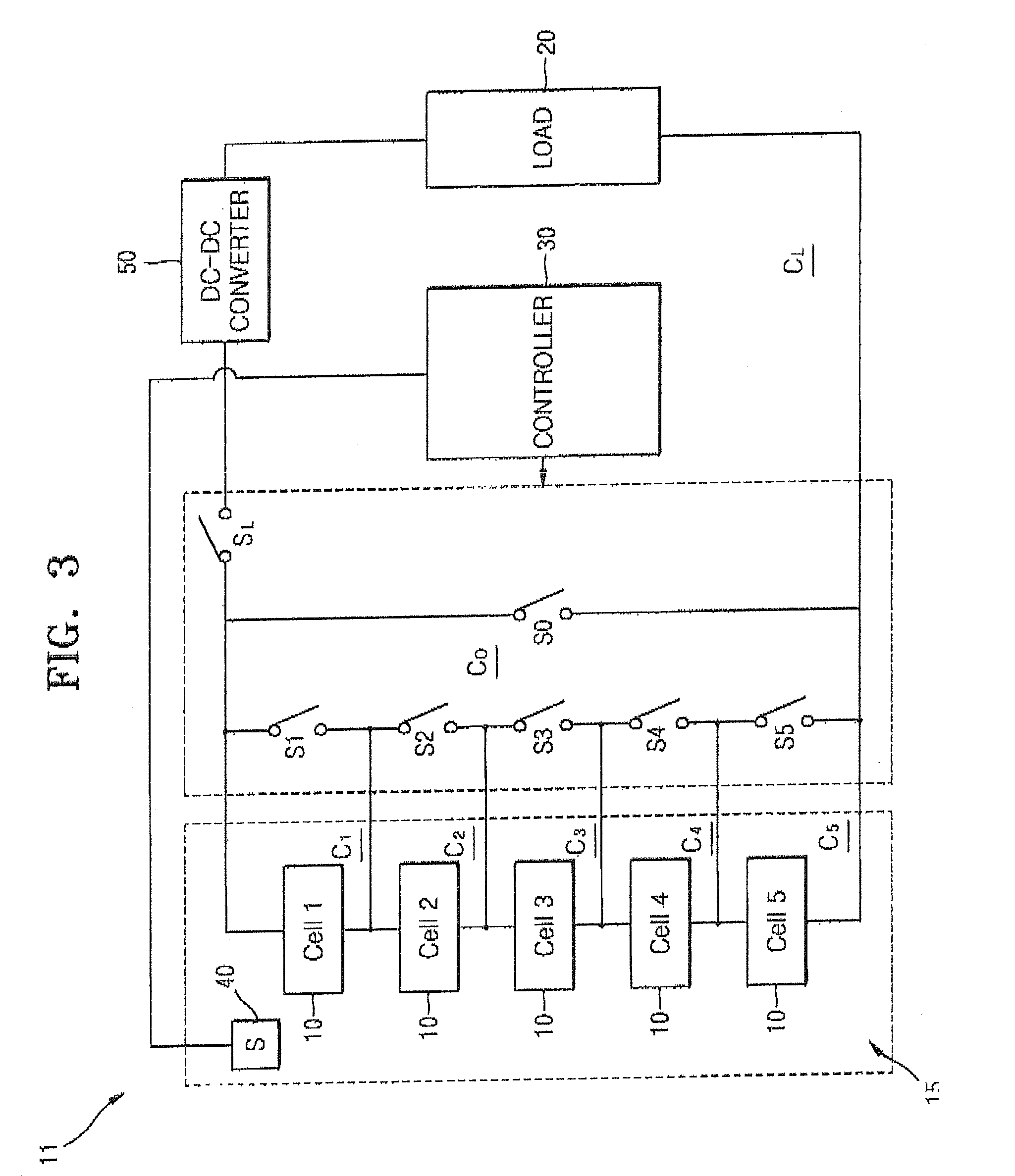

Fuel cell system and method of operating the same

InactiveUS20080090111A1Increase temperatureRapid rise in temperatureFuel cell heat exchangeTemperature controlLoad circuit

A fuel cell system to rapidly increase the temperature of unit cells. The fuel cell system includes; a plurality of current generating unit cells; a load circuit to supply the current to a load; a short circuit to connect the cells to an electrically closed loop without passing through the load; a thermo sensor to measure the temperature of the cells, and a controller that controls the delivery of the current to the load circuit and the short circuit, according to the temperature measured by the thermo sensor. The fuel cell system can rapidly increase the temperature of the unit cells when the temperature of the unit cells is below an operating temperature, thereby reducing the time required for the fuel cell to generate a stable output voltage.

Owner:SAMSUNG SDI CO LTD

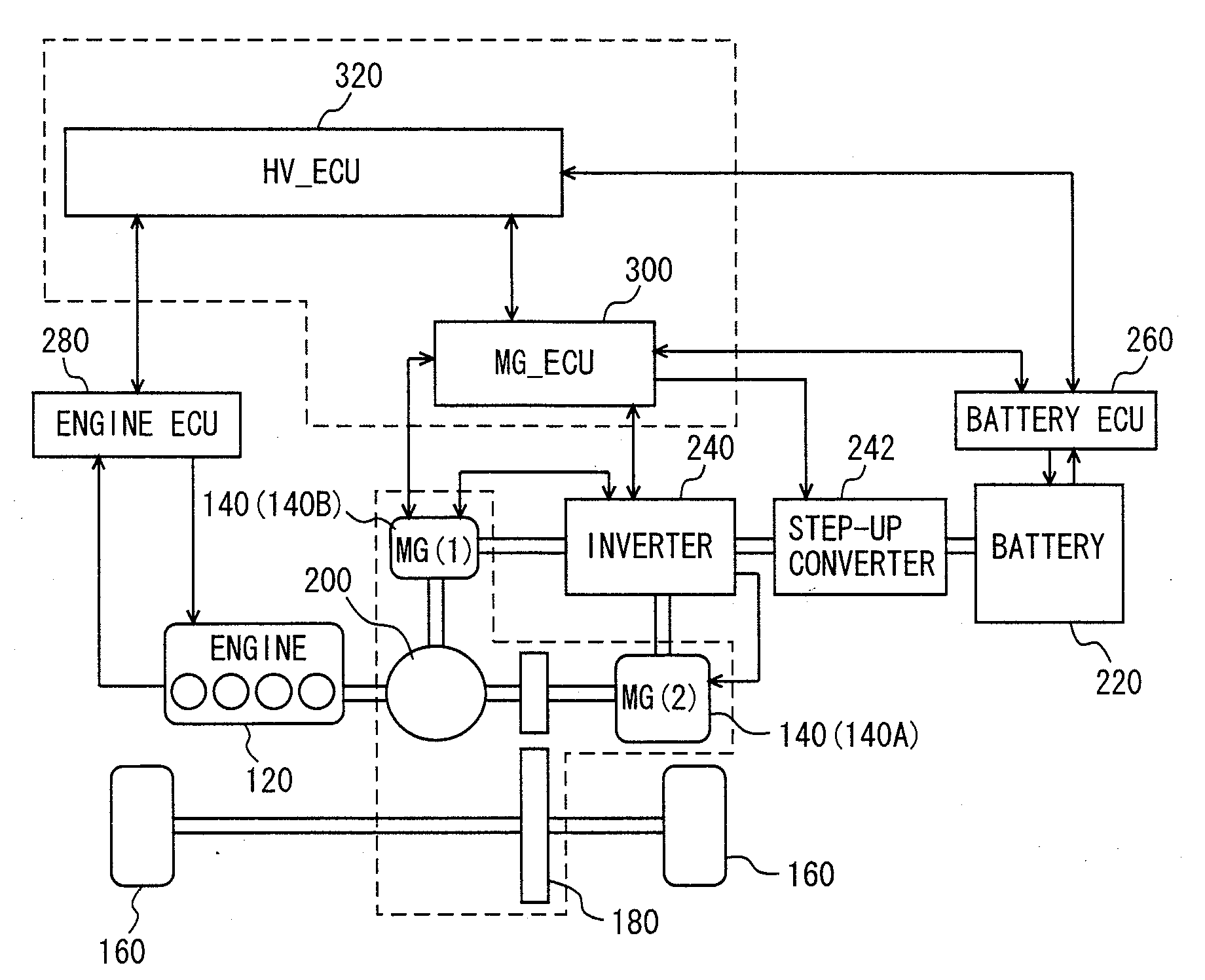

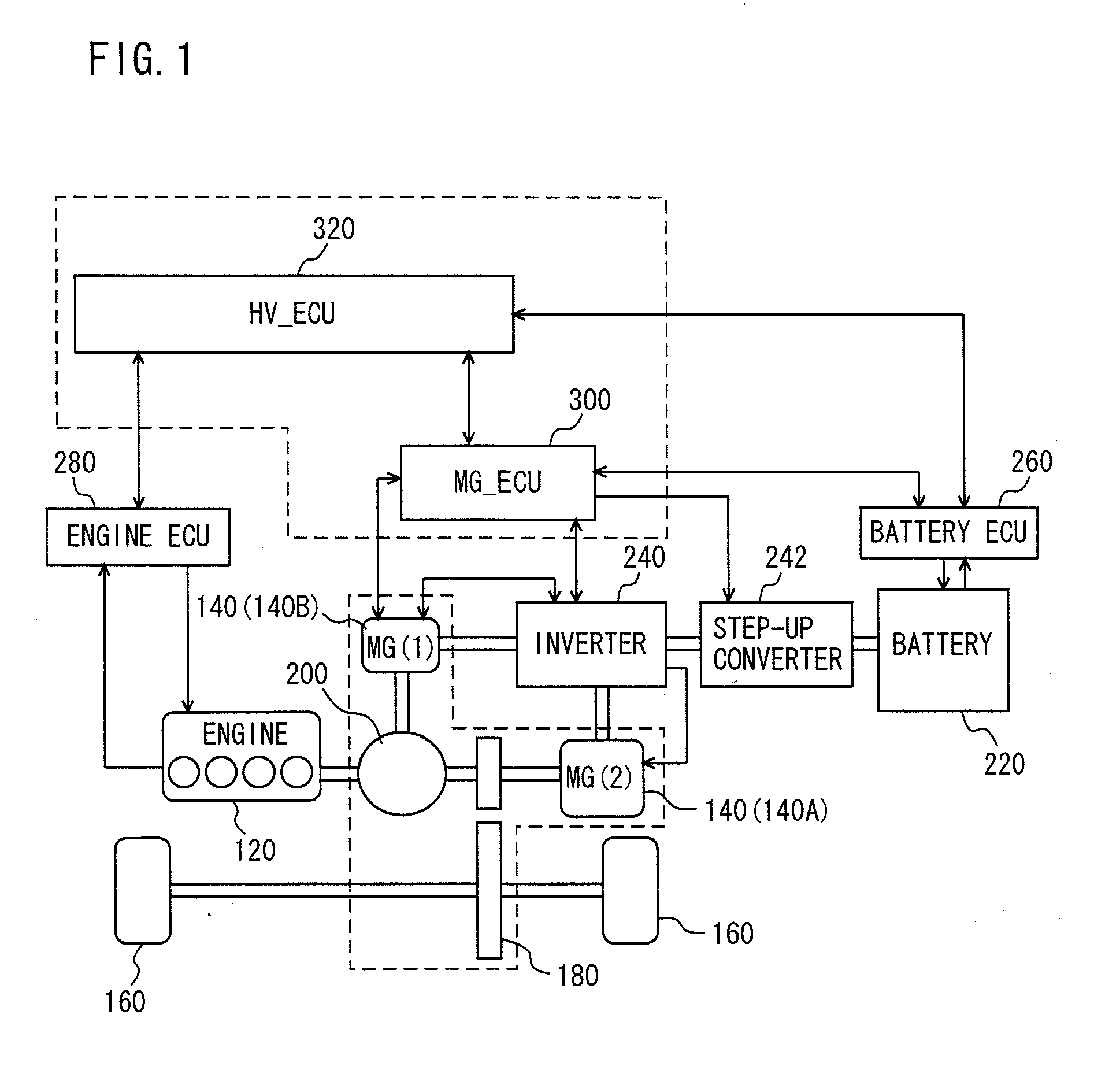

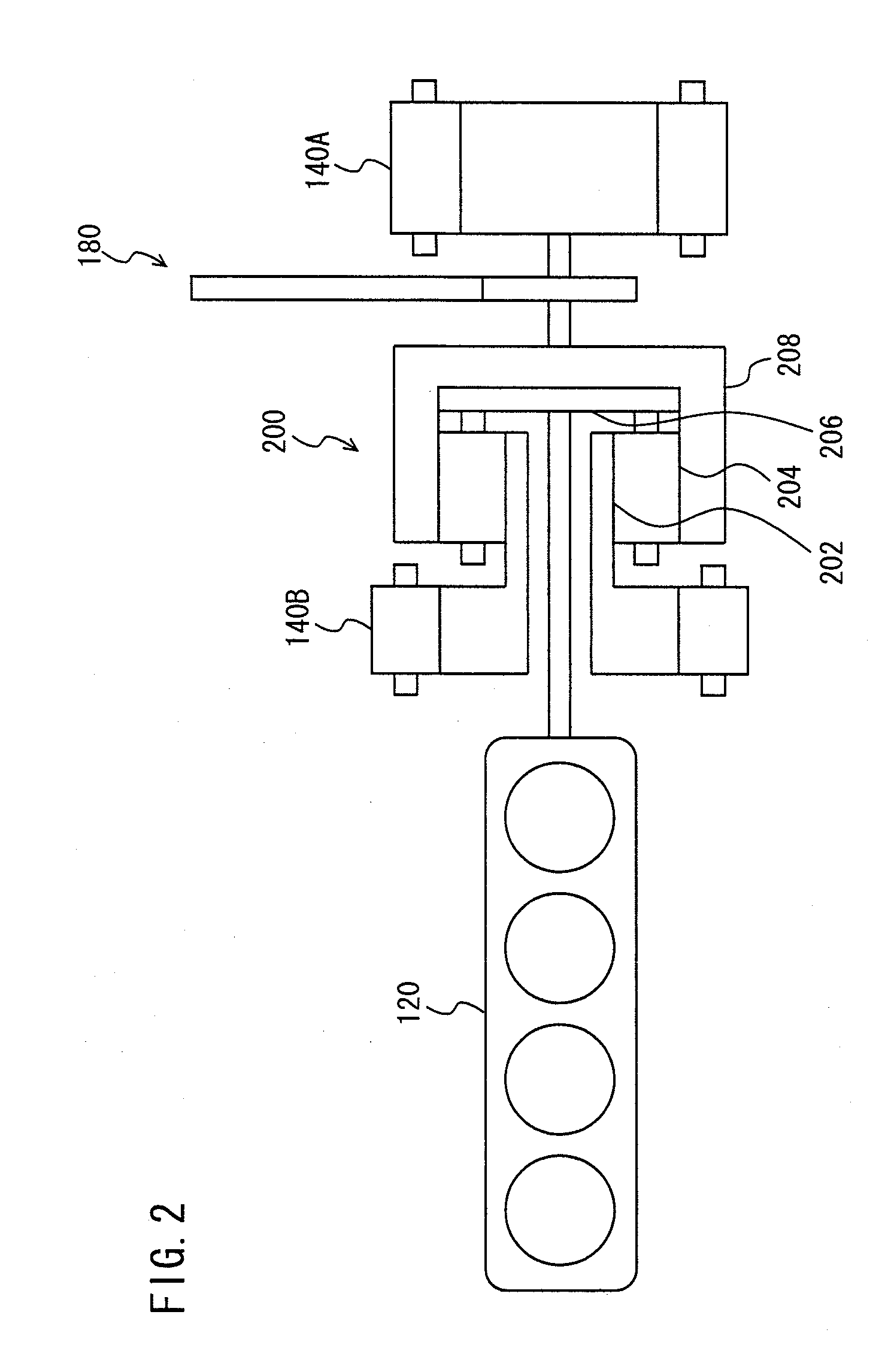

Catalyst temperature increasing apparatus for hybrid vehicle

ActiveUS20100043414A1Low efficiencyRapid rise in temperatureHybrid vehiclesInternal combustion piston enginesHeat resistanceEngineering

An ECU executes a program including: detecting a catalyst temperature T upon start of an engine; outputting an instruction signal to drive a power module, which is disposed in contact with an outer surface of a catalyst and is high in heat resistance, with a low efficiency upon determination that the catalyst temperature need be increased; and outputting a valve opening instruction signal to a switch valve in a cooling system in such a manner as not to allow a coolant to flow in a coolant pipeline interposed between the power module and an electric part low in heat resistance.

Owner:TOYOTA JIDOSHA KK

LED lamp

InactiveUS8021024B2Rapid rise in temperatureHighly effectivePlanar light sourcesLighting support devicesLED lampHeat spreader

An LED lamp includes a monolithic housing made of metal extrusion and comprising a heat sink and a receiving portion integrally extending from a bottom of the heat sink, a plurality of LED modules attached to the heat sink, a cover covering the LED modules and a supporting bracket mounted on the housing. The heat sink includes a planar base and a plurality of fins extending from a top face of the base. The receiving portion includes a frame defining a window at a center thereof and two sidewalls interconnecting the frame and the base. The frame, the sidewalls and the base cooperatively define a receiving chamber for accommodating the LED modules therein. The LED modules are attached to the base and located corresponding to the window of the frame. The cover is mounted on a bottom of the frame and correspondingly covers the window.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

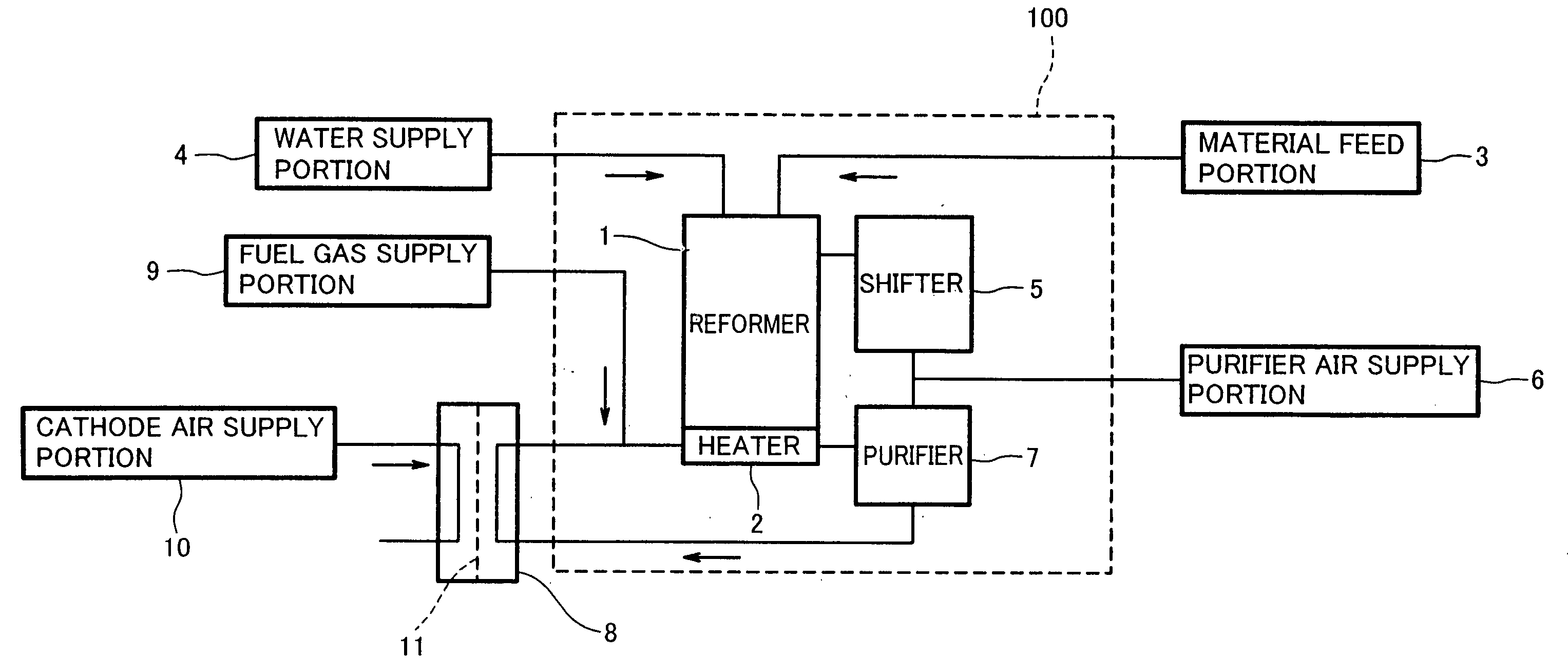

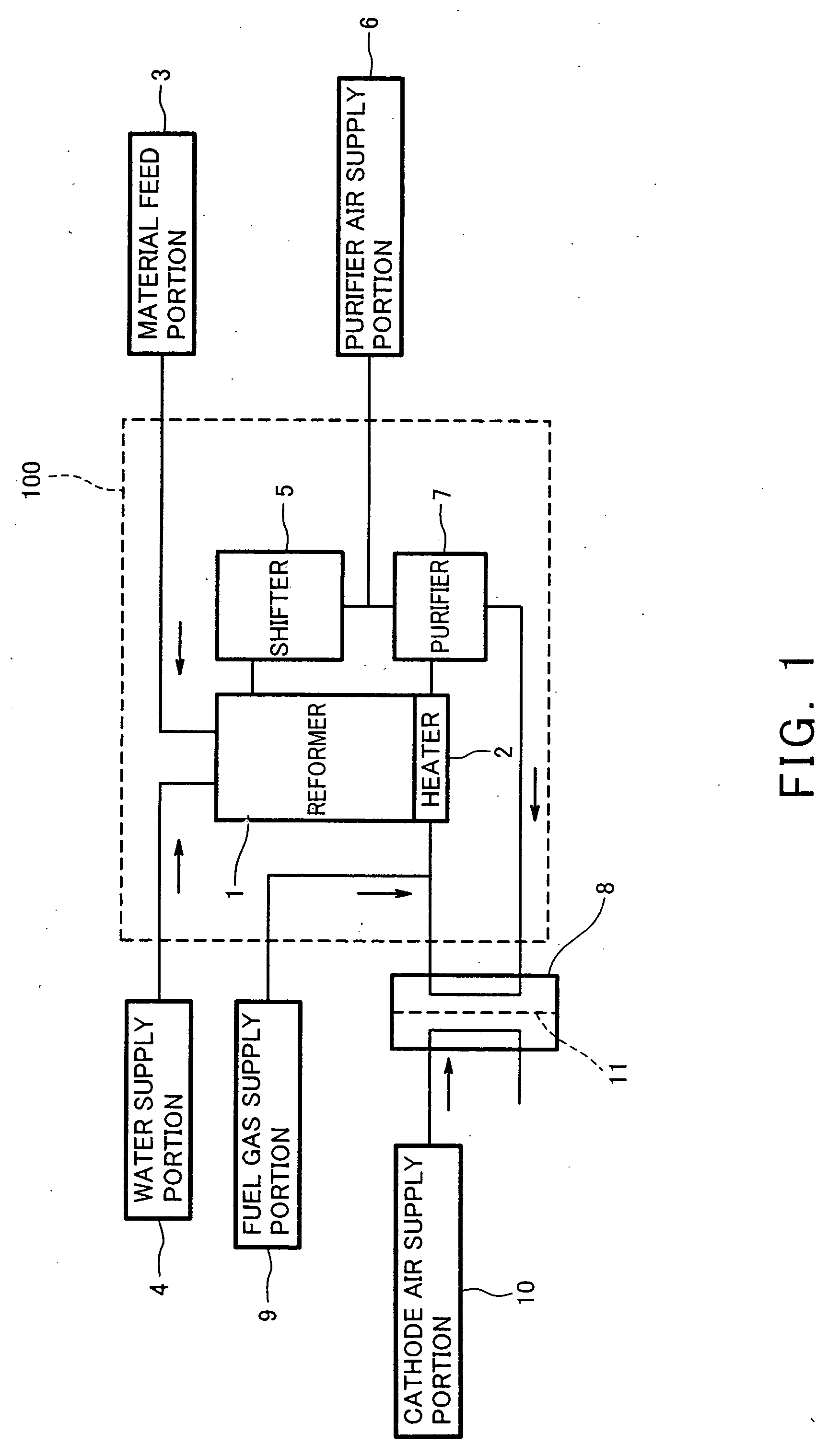

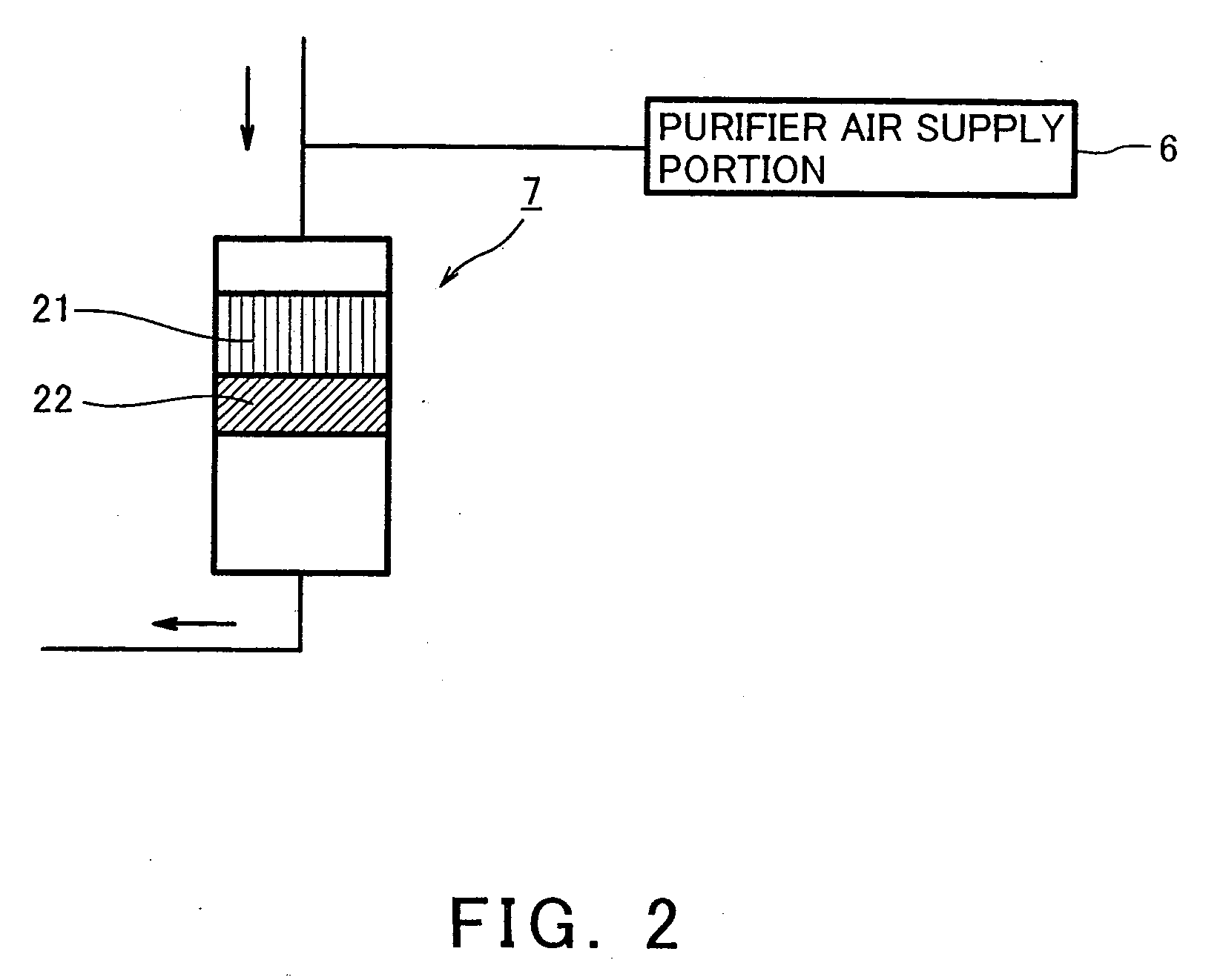

Hydrogen generator and fuel cell system

InactiveUS20040241509A1Rapid rise in temperatureHydrogen separation using solid contactChemical industryFuel cellsHydrogen

A hydrogen generator comprises a reformer configured to generate a reformed gas containing at least hydrogen and carbon monoxide; a gas supply portion configured to supply an oxidization gas containing oxygen; a purifier configured to reduce a concentration of carbon monoxide contained in the reformed gas in such a manner that a mixture gas containing the reformed gas and the oxidization gas flows through the purifier such that the mixture gas flows through a catalyst body within the purifier to allow the carbon monoxide and the oxygen contained in the mixture gas to react with each other, wherein the purifier has a first catalyst body that selectively oxidizes the carbon monoxide and a second catalyst body which is lower in CO selectivity and lower in temperature of oxidization reaction than the first catalyst body, and the second catalyst body is disposed in parallel with the first catalyst body and on a downstream side of the first catalyst body or adjacent the first catalyst body in a flow of the mixture gas.

Owner:PANASONIC CORP

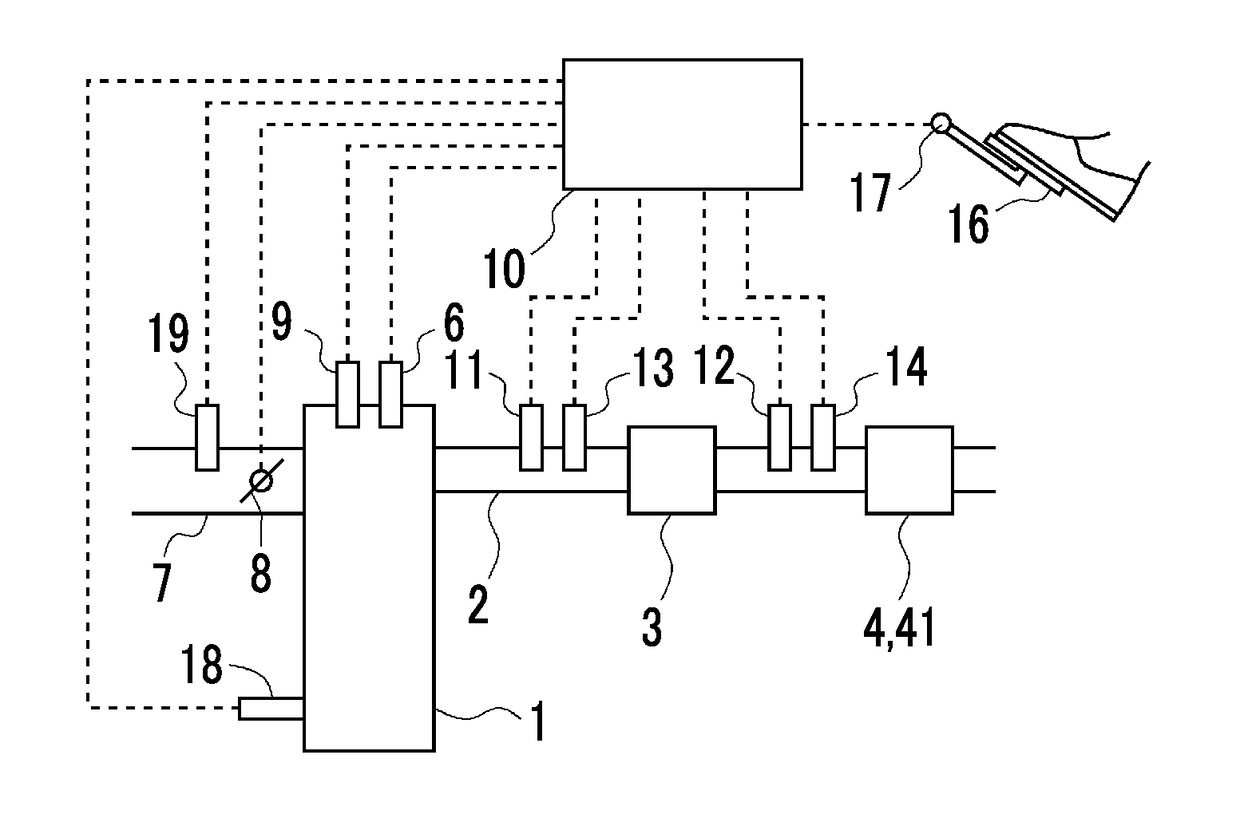

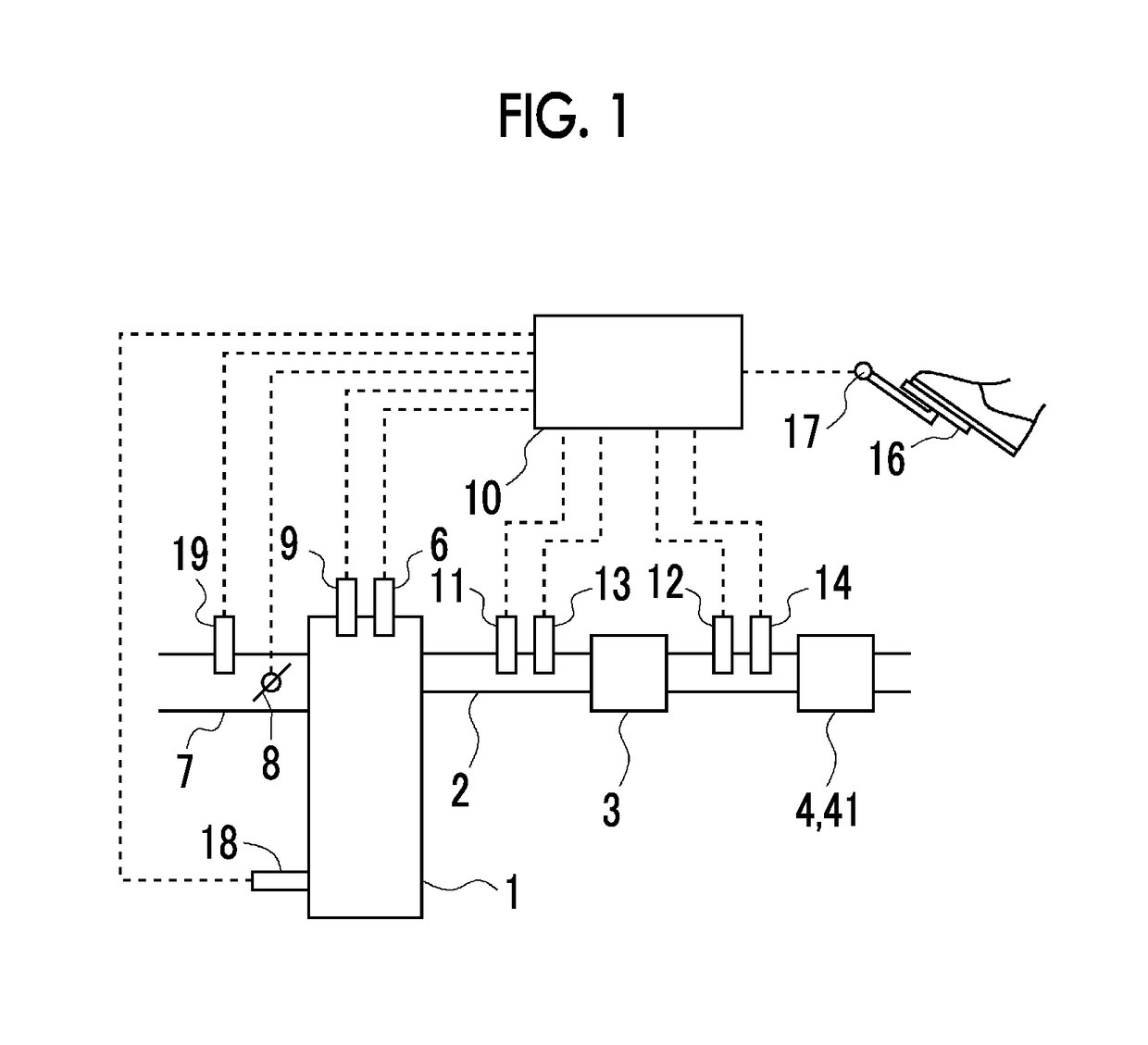

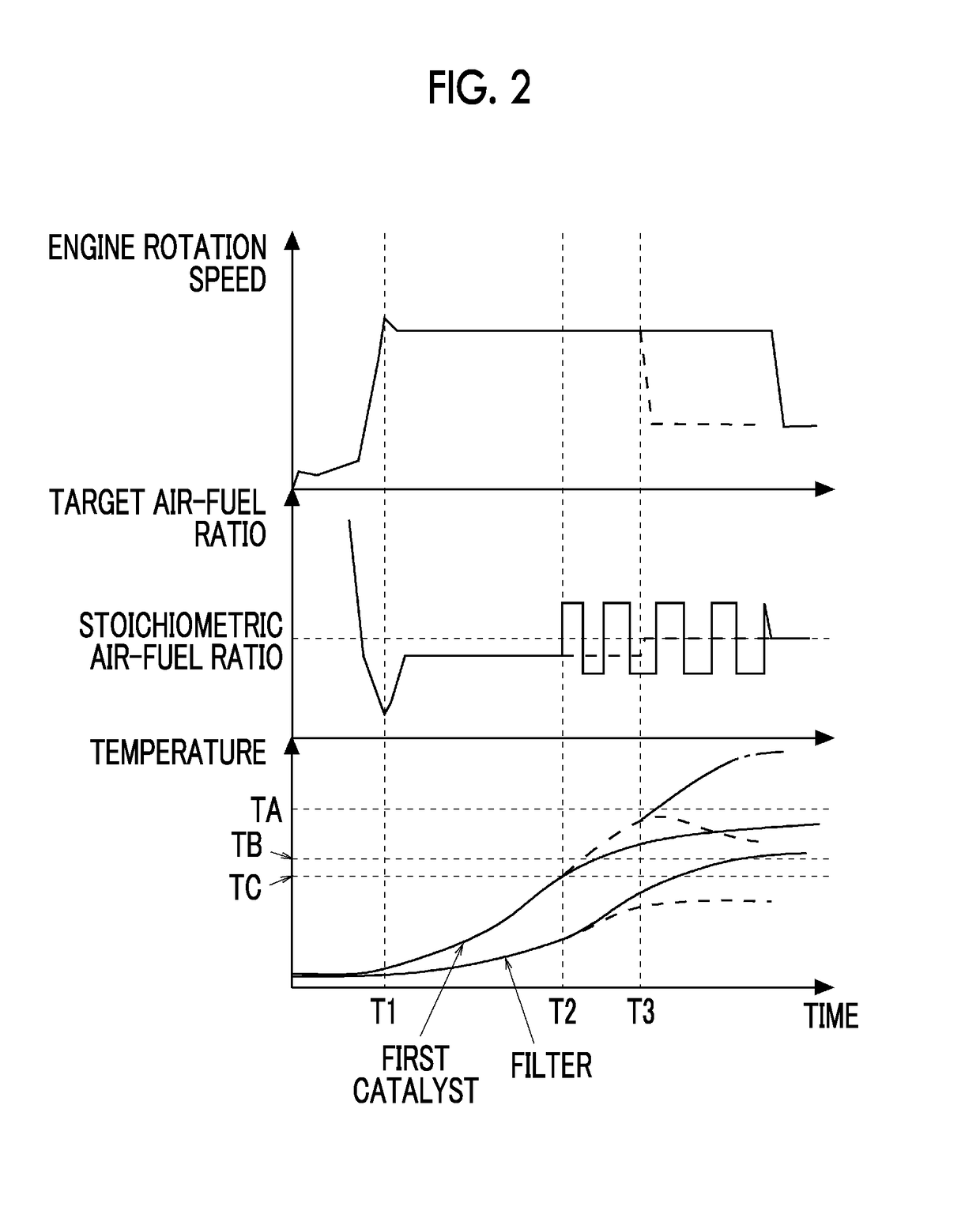

Exhaust gas control apparatus for internal combustion engine and exhaust gas control method for internal combustion engine

InactiveUS20180202336A1Rapid rise in temperatureElectrical controlInternal combustion piston enginesEngineeringControl theory

An exhaust gas control apparatus includes a first catalyst, a filter, and an electronic control unit. The electronic control unit is configured to alternately execute lean control and rich control multiple times. The lean control is control for, over a period longer than a period from when a target air-fuel ratio is set to a predetermined lean air-fuel ratio until an air-fuel ratio of exhaust gas flowing out from the first catalyst becomes greater than the stoichiometric air-fuel ratio, setting the target air-fuel ratio to the predetermined lean air-fuel ratio. The rich control is control for, over a period longer than a period from when the target air-fuel ratio is set to a predetermined rich air-fuel ratio until the air-fuel ratio of exhaust gas flowing out from the first catalyst becomes smaller than the stoichiometric air-fuel ratio, setting the target air-fuel ratio to the predetermined rich air-fuel ratio.

Owner:TOYOTA JIDOSHA KK

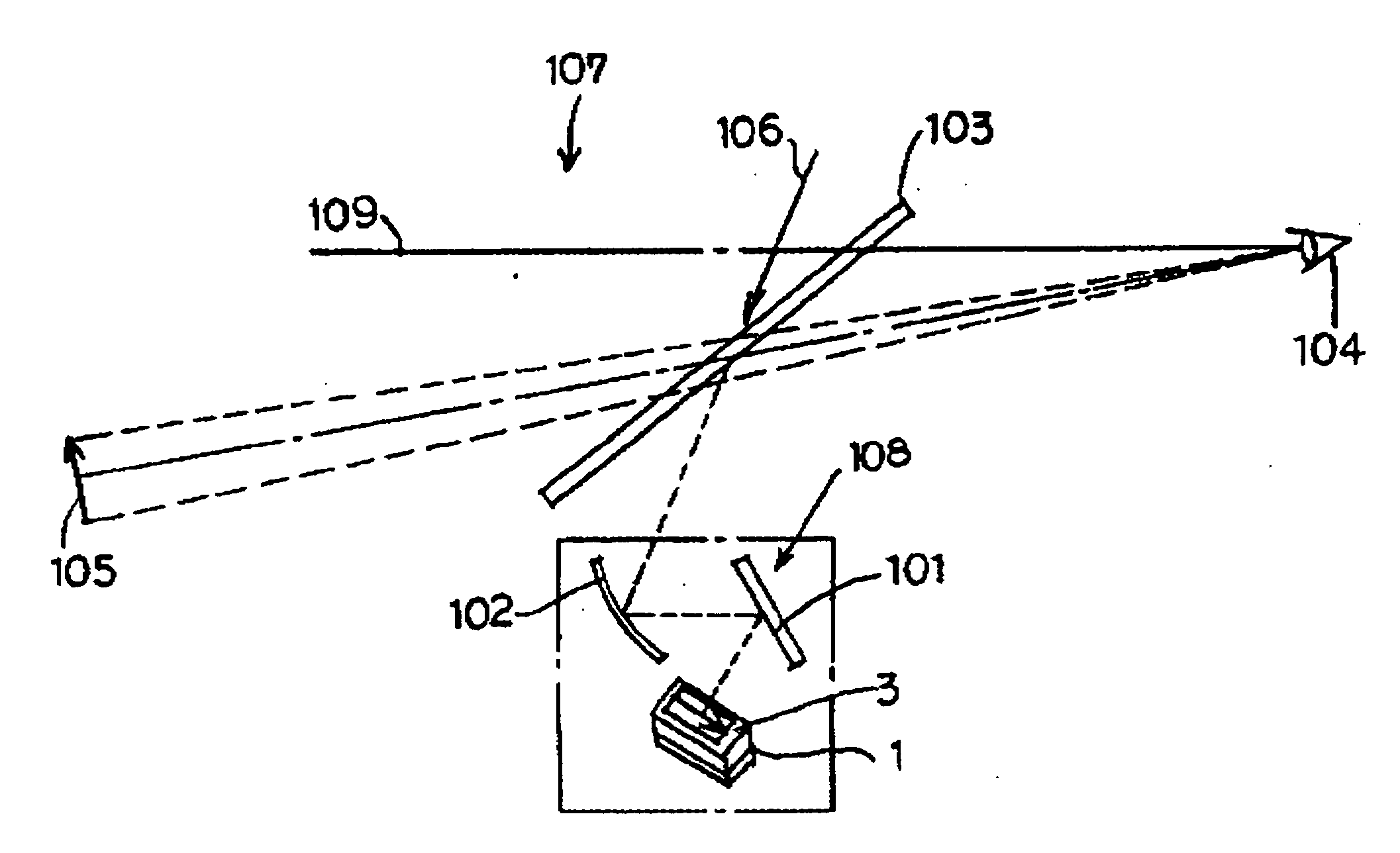

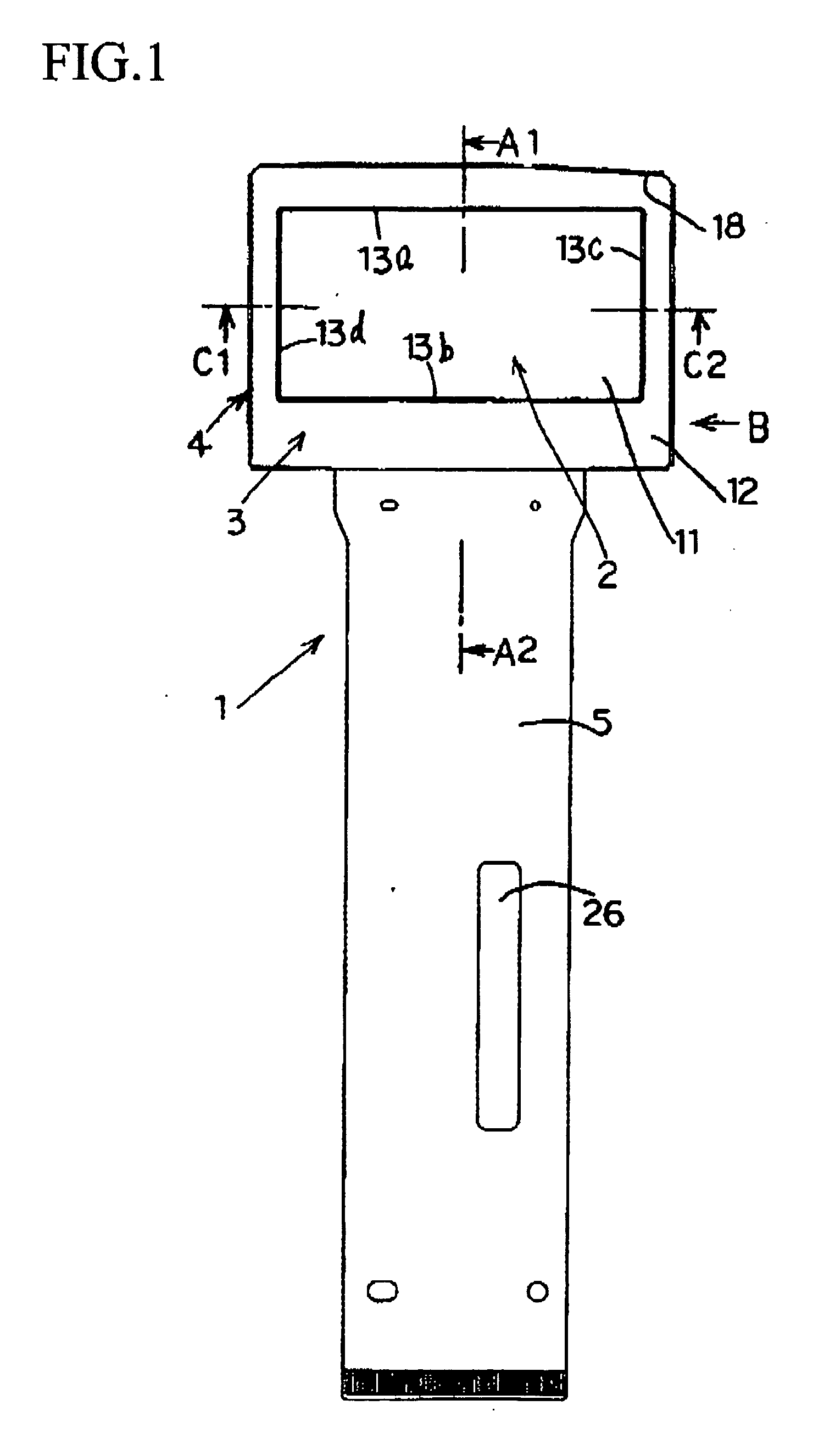

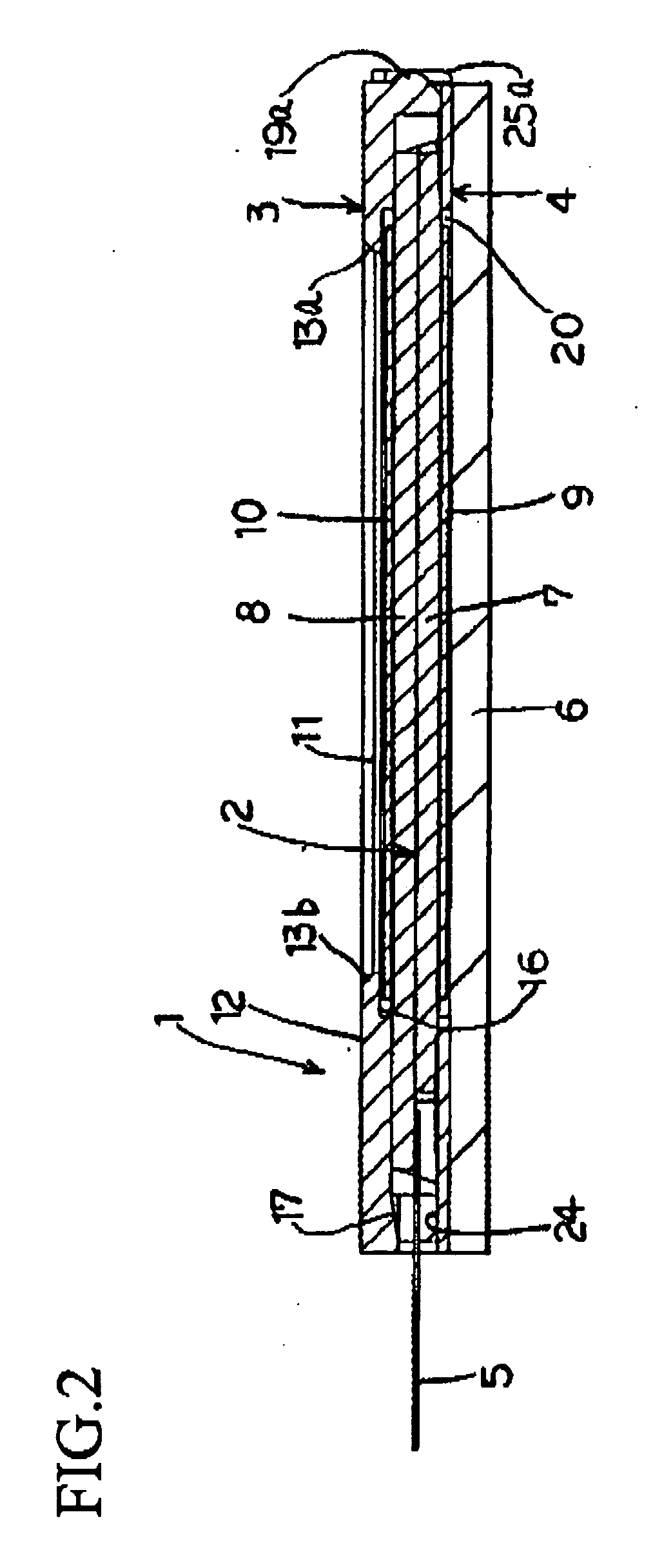

Liquid crystal display device and head-up display using it

InactiveUS20070164955A1Improve thermal conductivityFast heat conductionStatic indicating devicesDiffusing elementsHead-up displayMiniaturization

Provided is a liquid crystal display device that can be produced at low costs, can achieve miniaturization, and can offer clear virtual images. The liquid crystal display device is provided with: a frame body that is so disposed as to cover a top face of a liquid crystal cell, that has a first opening so formed as to face the top face of the liquid crystal cell, and that has a picture frame-shaped member formed around the first opening; a frame that is fixed to the frame body and that has a second opening so formed as to face a back face of the liquid crystal cell; and a light source that illuminates the liquid crystal cell via the second opening of the frame. Here, a top face of the picture frame-shaped member of the frame body is so designed that light is diffusely reflected therefrom.

Owner:EPSON IMAGING DEVICES CORP

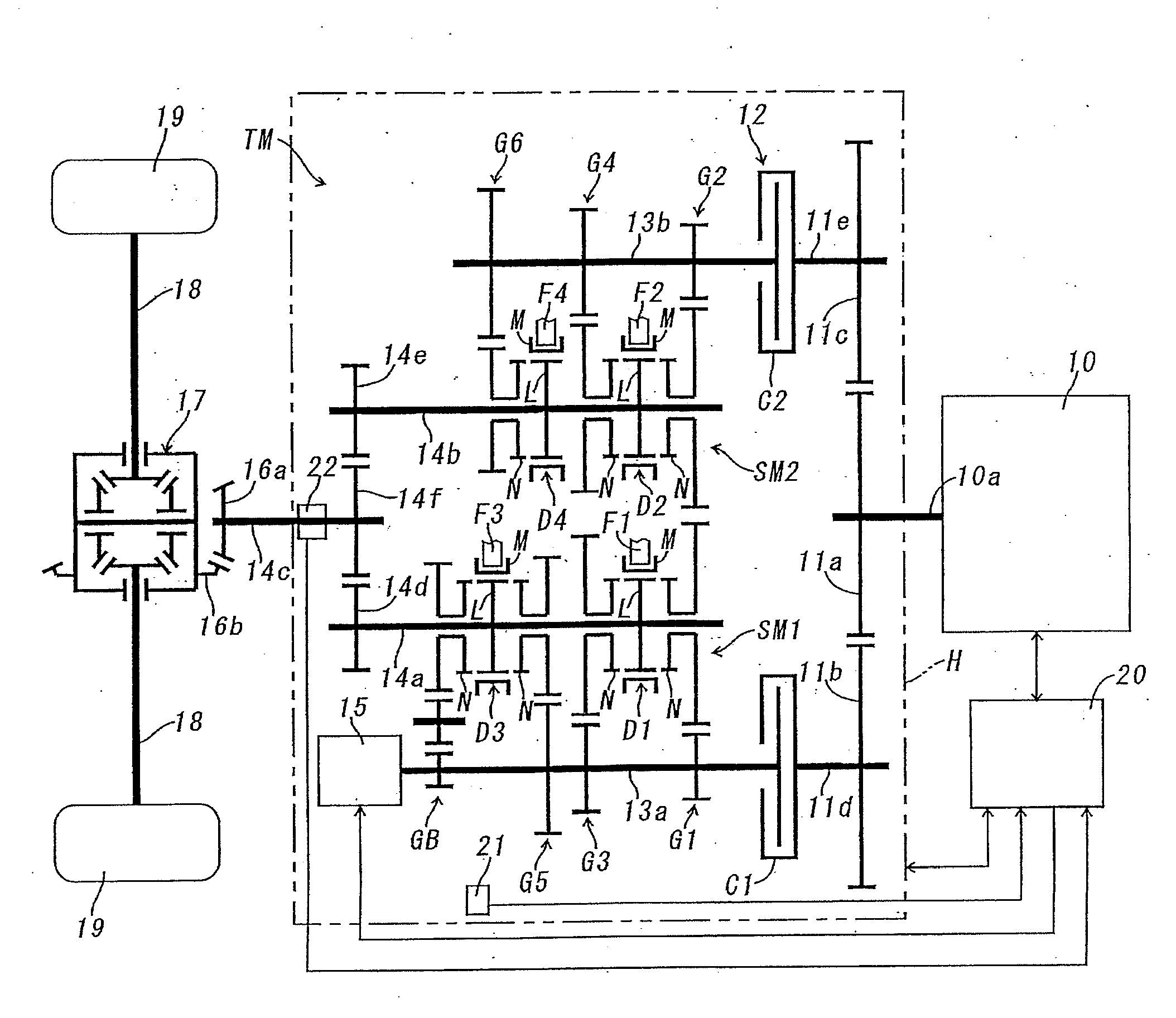

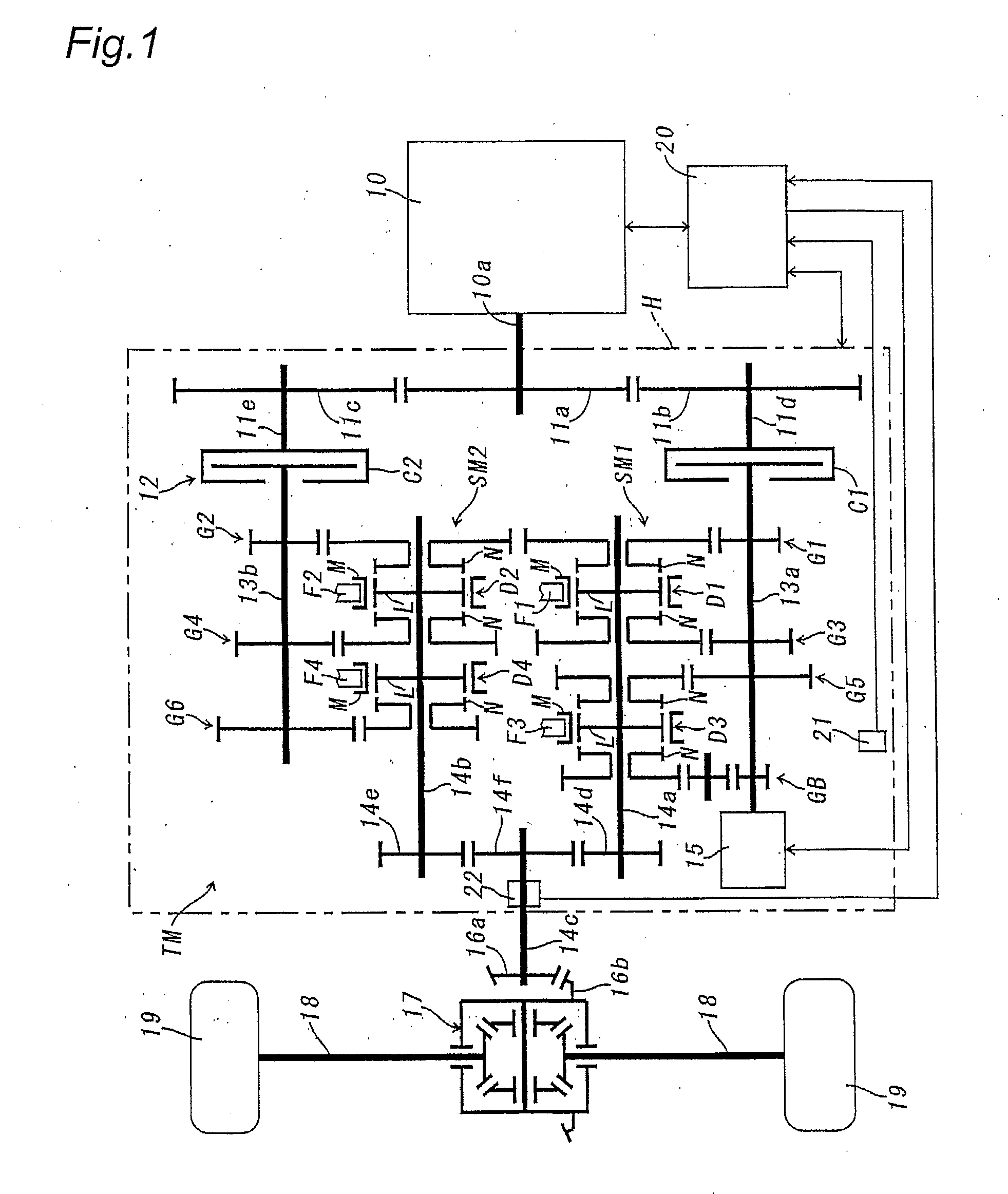

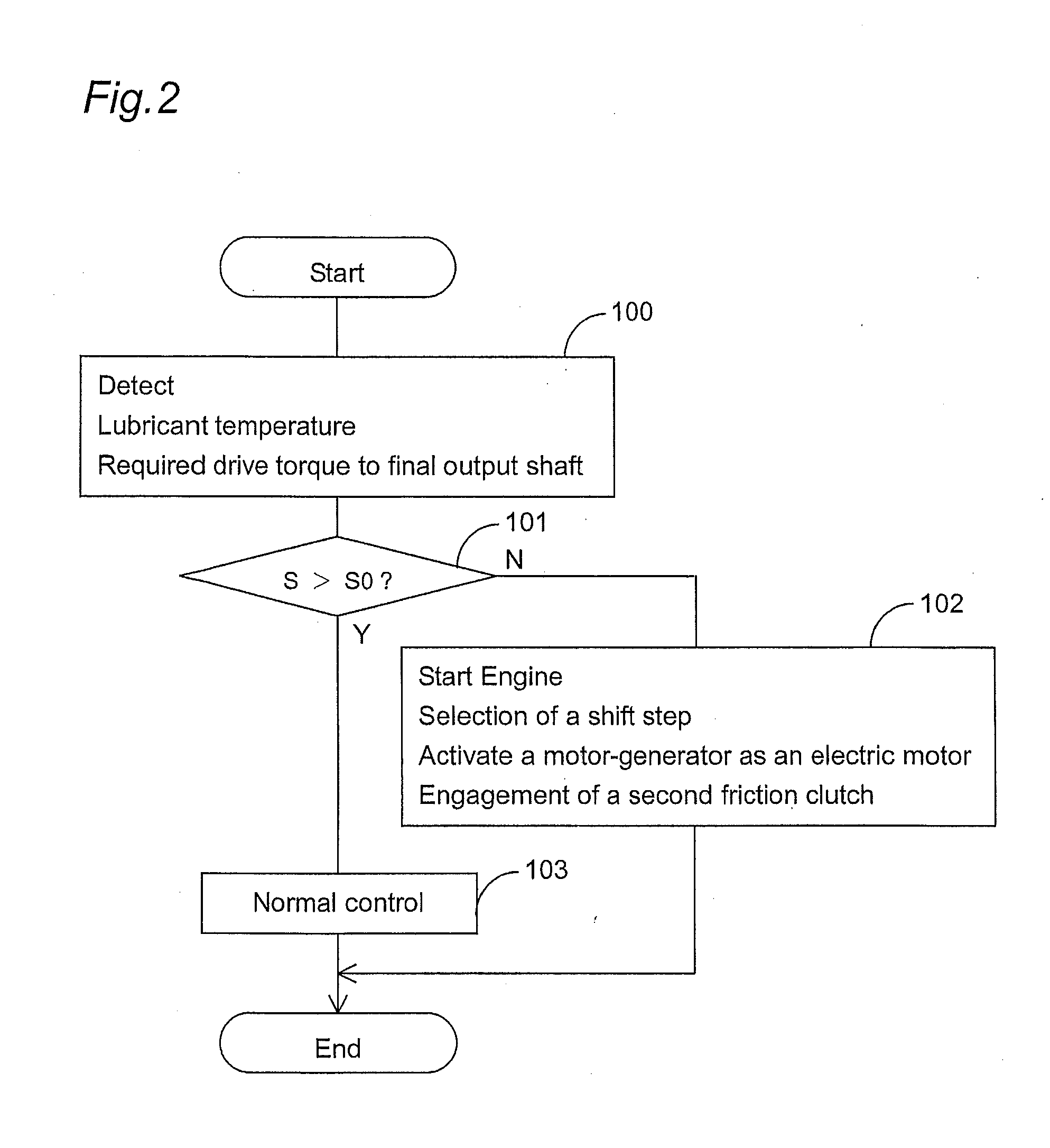

Control system of hybrid power drive apparatus

InactiveUS20110174557A1Increase heatRapid rise in temperatureHybrid vehiclesVehicle sub-unit featuresLower limitControl system

[Subject]To rapidly rise a temperature of lubricant in a transmission housing of a hybrid drive power apparatus when the lubricant temperature is lower than a preset lower limit value.[Solution]A control system of a hybrid drive power apparatus of the type which comprises a transmission housing provided therein with a first input shaft to be applied with drive power from an engine through a first friction clutch and a second input shaft to be applied with the drive power of the engine through a second friction clutch, first and second gear-shift mechanisms respectively assembled with the first and second input shafts, a final output shaft in drive connection with each output shaft of the gear-shift mechanisms, a motor-generator in drive connection with the first input shaft or the second input shaft, and a driven mechanism in drive connection with the final output shaft, wherein the control system includes a temperature sensor for detecting a temperature of lubricant stored in the transmission housing, and control means for selecting a shift-step in the first or second gear-shift mechanism assembled with the input shaft in drive connection with the motor-generator when the lubricant temperature detected by the sensor is lower than a preset lower limit value so that drive torque larger than that required for driving the driven mechanism is transferred to the final output shaft, for activating the motor-generator as an electric motor after selection of the shift-step , and for engaging the first or second friction clutch so that the drive torque of the engine is transferred to the final output shaft through a gear set at the selected shift-step in the first or second gear-shift mechanism.

Owner:AISIN AI CO LTD +2

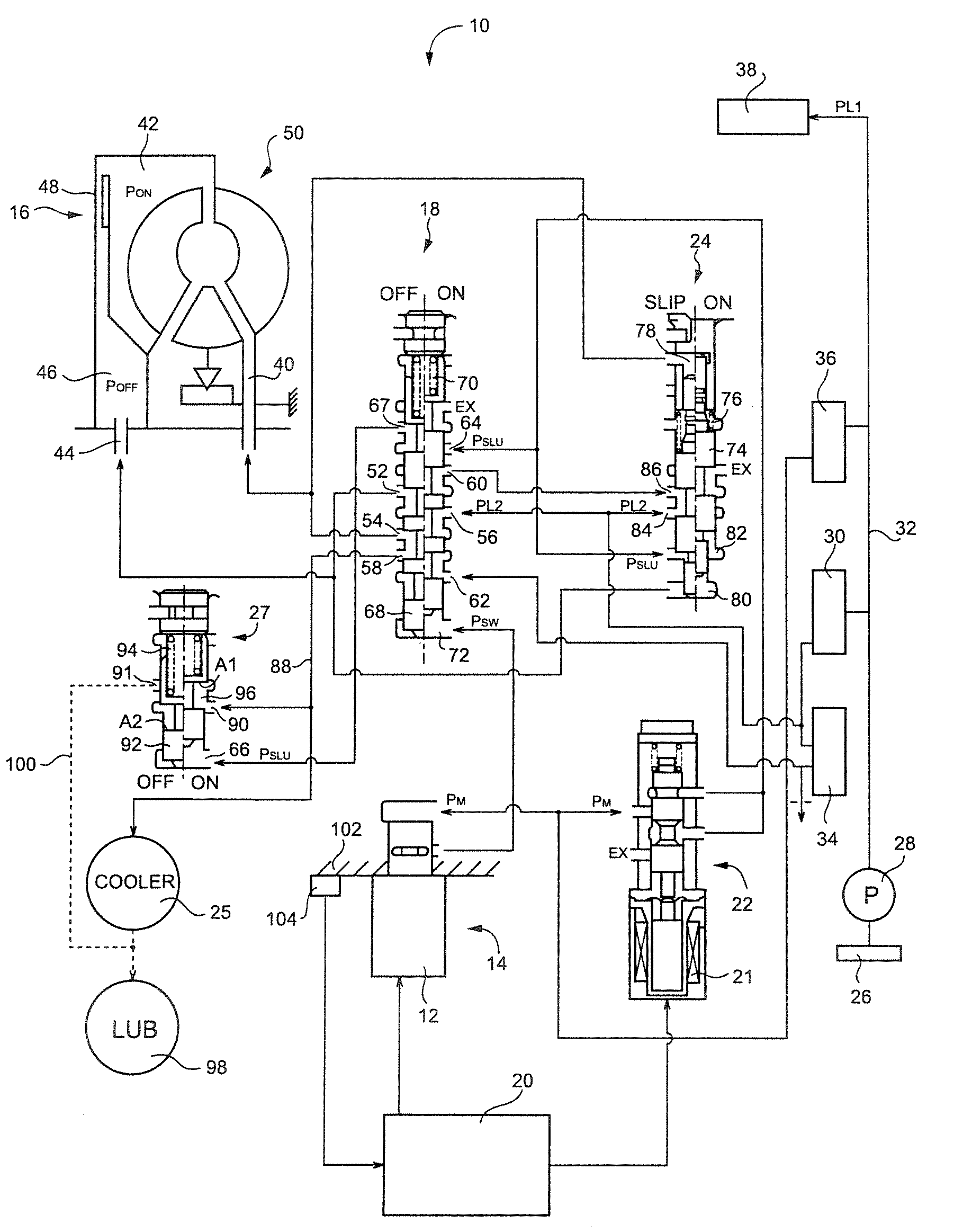

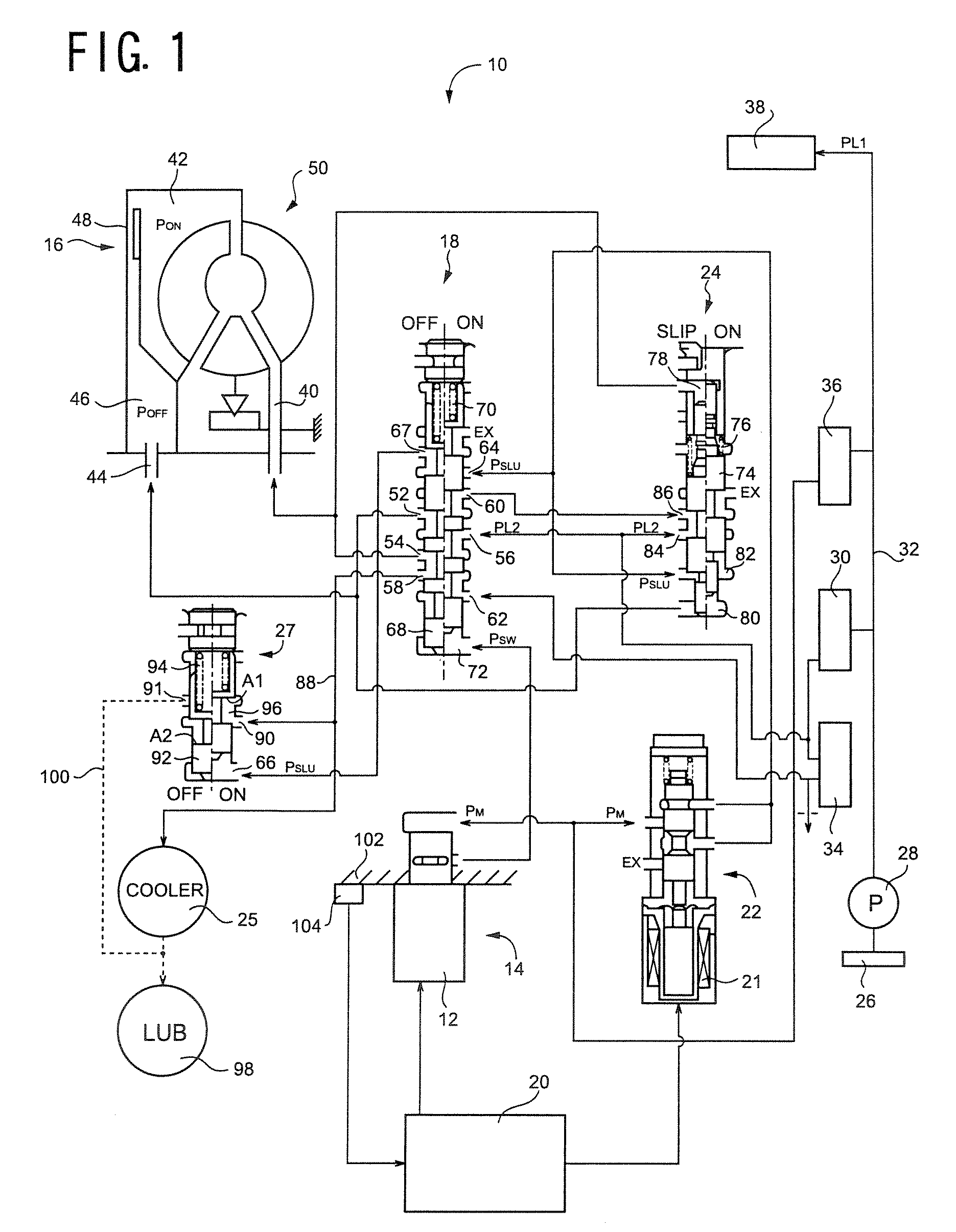

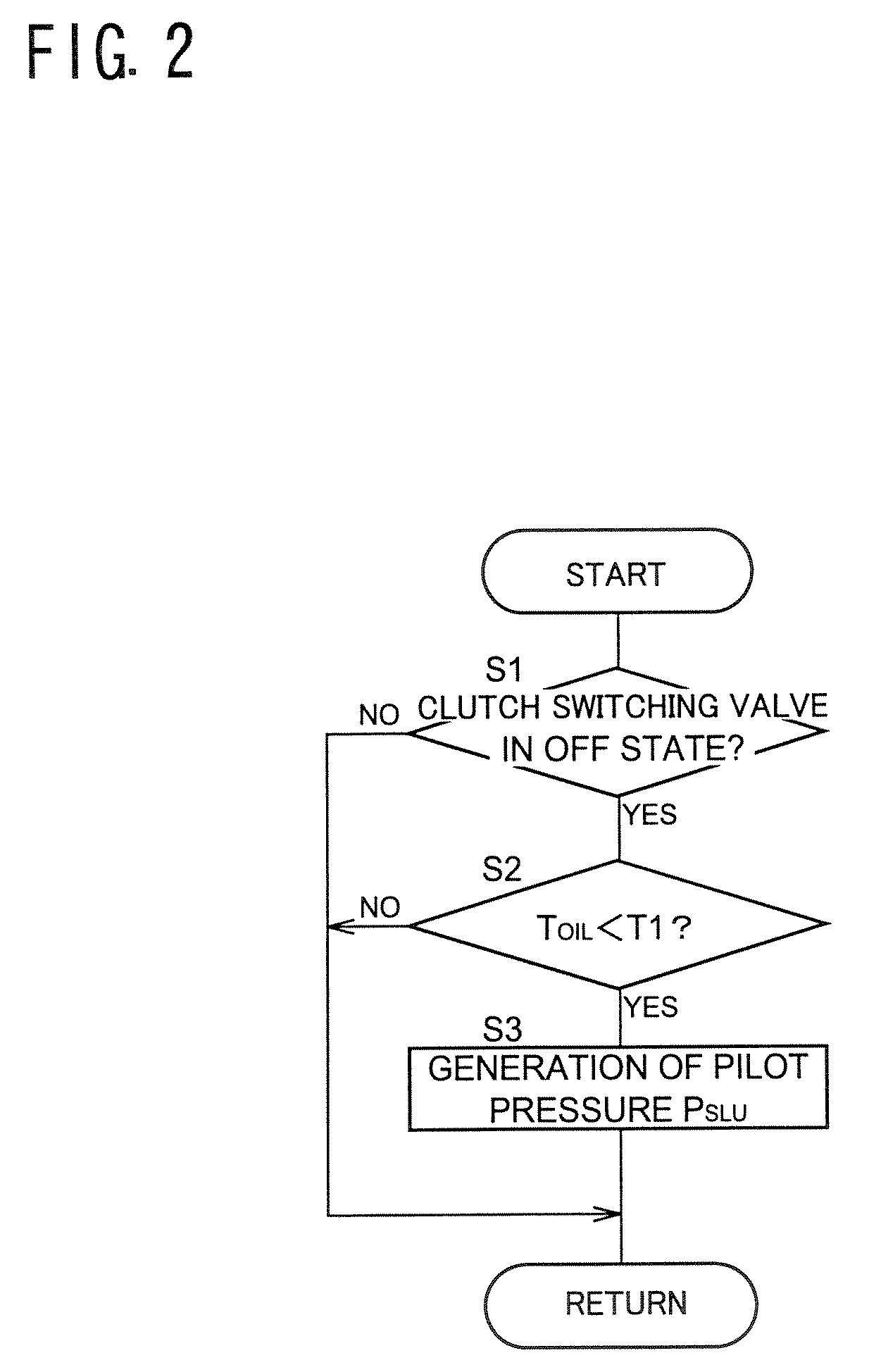

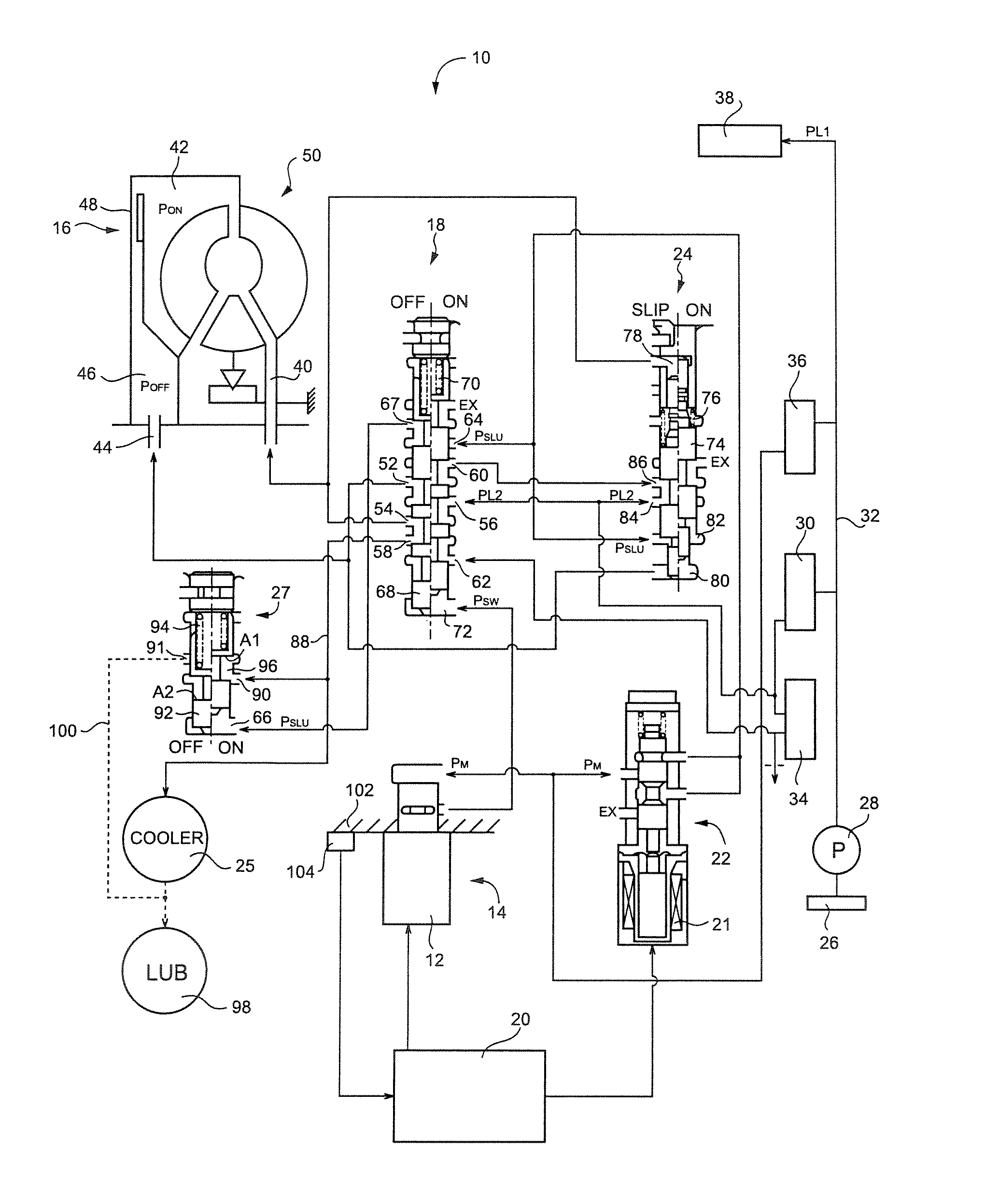

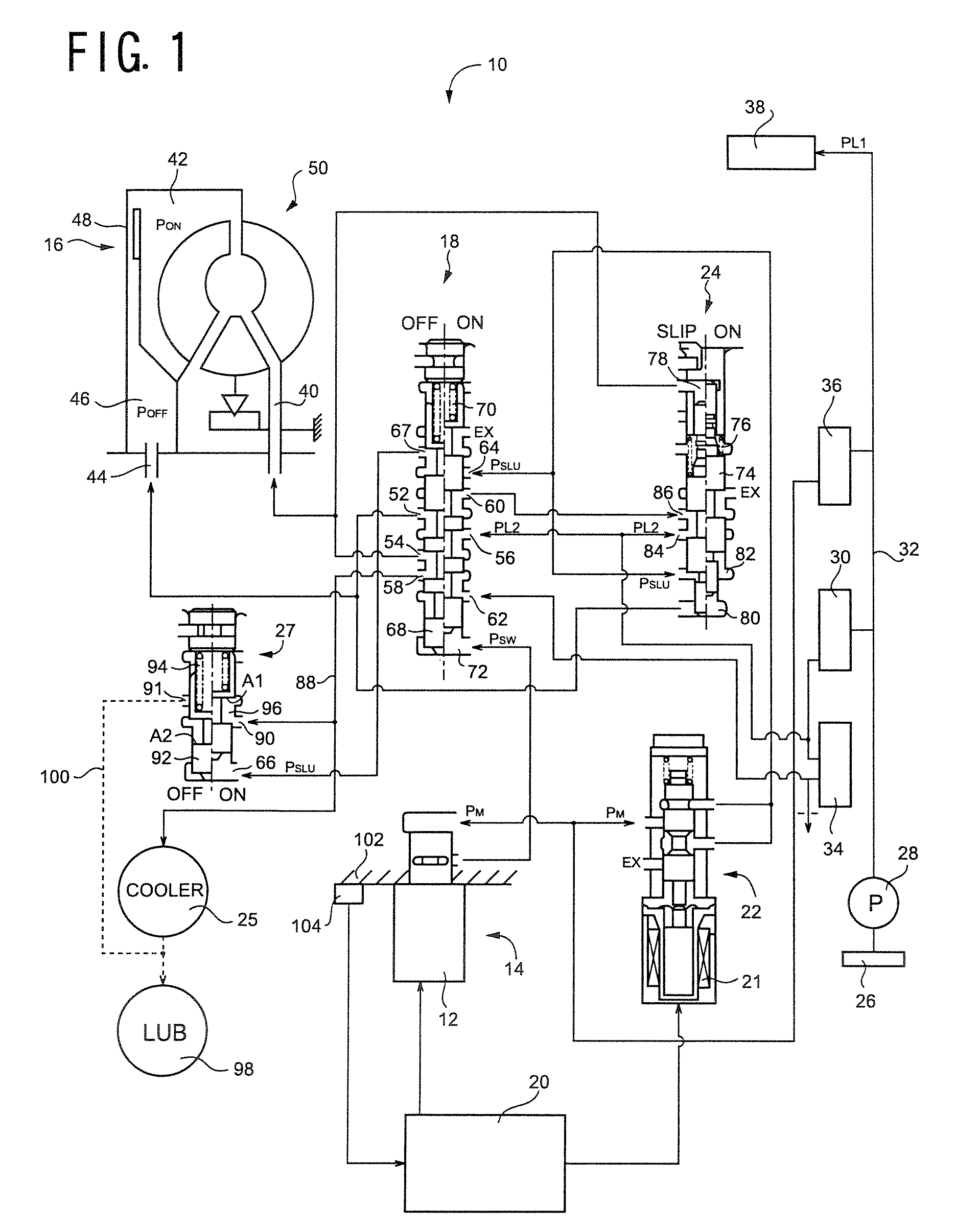

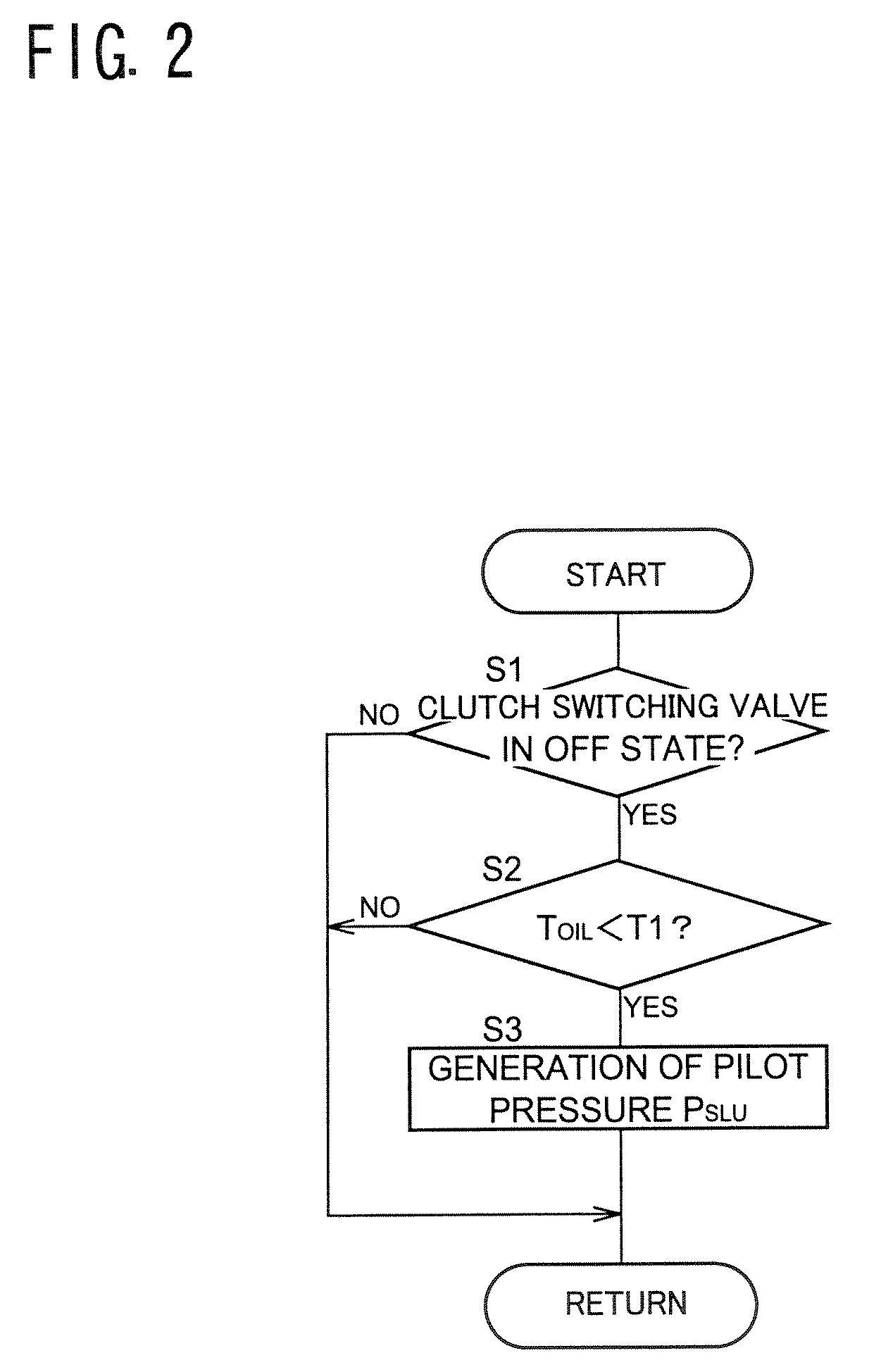

Hydraulic control apparatus for vehicular fluid- actuated power transmitting device provided with lock-up clutch

InactiveUS20070186981A1Excessive rise of pressureEasy to provideThermometer detailsValve members for heating/coolingLower limitWorking fluid

A hydraulic control apparatus for a vehicular fluid-actuated power transmitting device provided with a lock-up clutch and an oil cooler, the lock-up clutch being operable between an engaged state and a released state according to a difference between pressures of a working fluid in an engaging fluid chamber and a releasing fluid chamber, the oil cooler being connected to a fluid passage communicating with the engaging and releasing fluid chambers, and operable to cool the working fluid, the hydraulic control apparatus including an oil cooler by-pass valve operable to permit the working fluid to by-pass the oil cooler, and a low-temperature by-pass device operable to open the oil cooler by-pass valve, for permitting the working fluid to by-passes the oil cooler, when a temperature of the working fluid is lower than a predetermined lower limit.

Owner:TOYOTA JIDOSHA KK

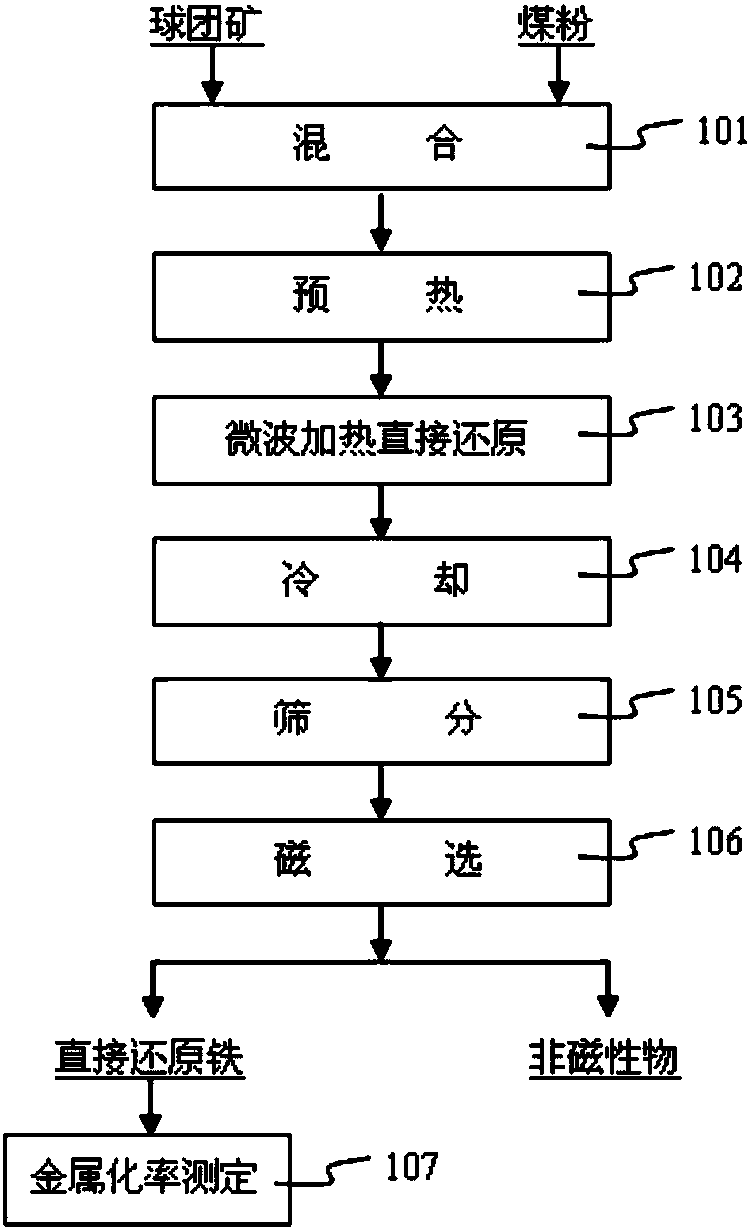

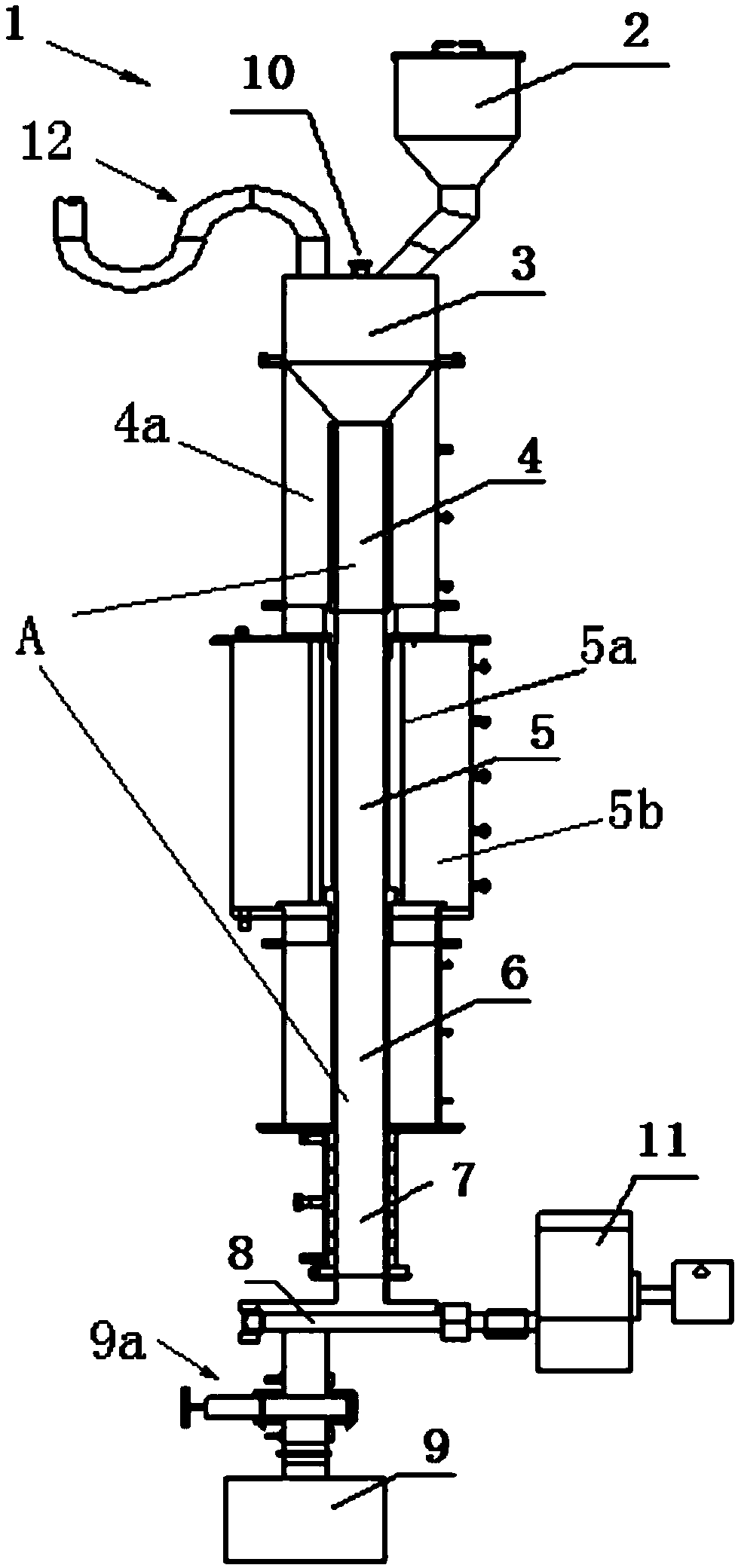

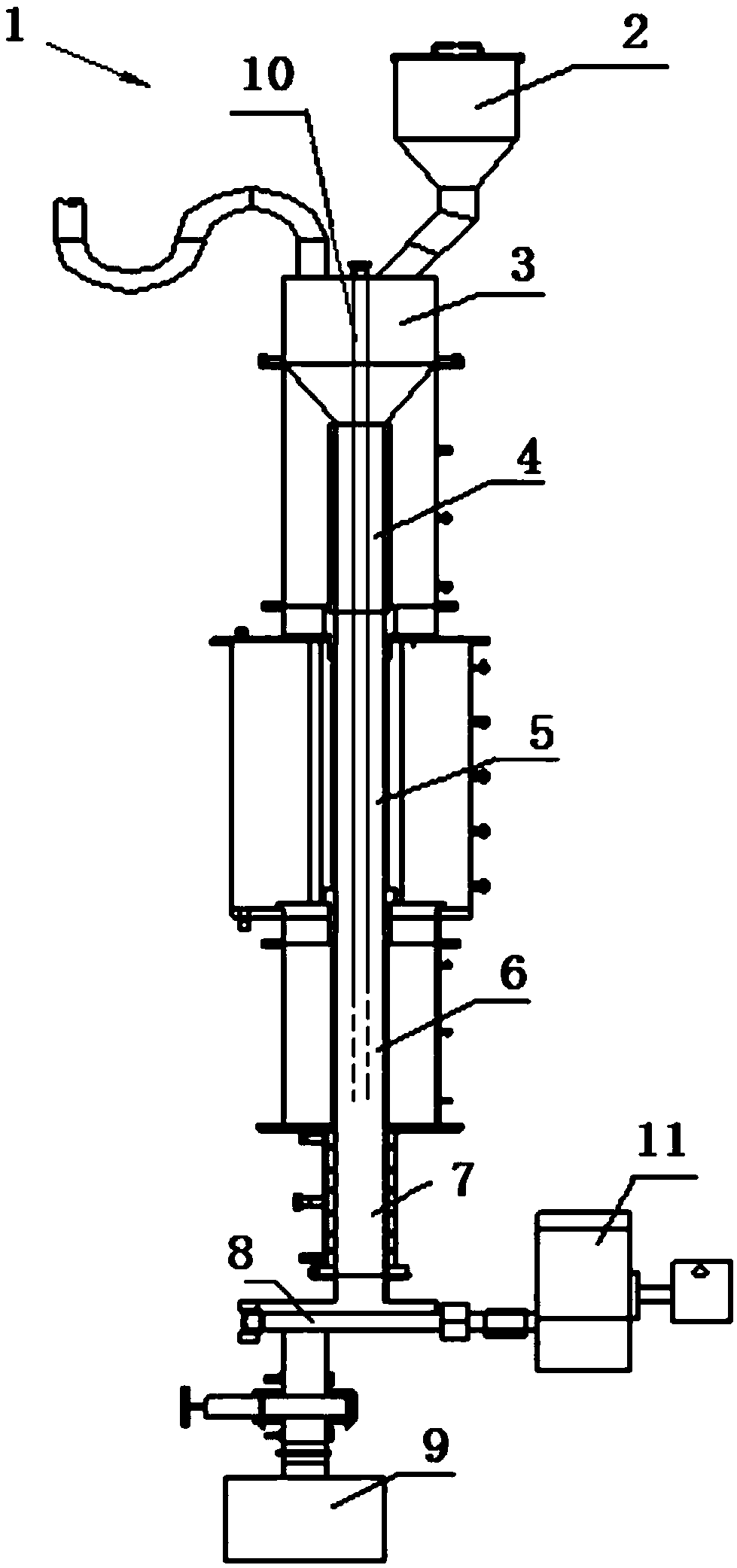

Direct reduced iron production method and device

ActiveCN107779536AImprove use valueQuick restoreShaft furnaceProcess efficiency improvementChemical reactionReaction temperature

The invention relates to a microwave shaft furnace direct reduction process adopting pellets and coal powder. According to the process, direct reduced iron is produced from raw material pellets and external matched material coal powder in a continuous microwave shaft furnace, selection heating, rapid heating, volume heating, activated metallurgical chemical reaction and other features of the microwave are fully utilized, gasification of fixed carbon is accelerated, and iron oxide is further reduced, so that the reduction temperature is lowered and the reaction time is shortened. The coal powder can serve as both a reducing agent and a heating element in the process, a gas-solid-heat exchange step is simplified, energy is saved and emission is reduced. The process contains low free oxygen content, and can produce CO with high purity of 95% or above; and the process is compact in structure, high in metallization degree, which is 94-98%, low in carbon content, which is less than 0.2%, andis low in quality requirements on coal powder, thereby being an environment-friendly iron making process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Hydraulic control apparatus for vehicular fluid-actuated power transmitting device provided with lock-up clutch

InactiveUS7617676B2Rapid rise in temperatureReduce controlThermometer detailsRotary clutchesLower limitWorking fluid

A hydraulic control apparatus for a vehicular fluid-actuated power transmitting device provided with a lock-up clutch and an oil cooler, the lock-up clutch being operable between an engaged state and a released state according to a difference between pressures of a working fluid in an engaging fluid chamber and a releasing fluid chamber, the oil cooler being connected to a fluid passage communicating with the engaging and releasing fluid chambers, and operable to cool the working fluid, the hydraulic control apparatus including an oil cooler by-pass valve operable to permit the working fluid to by-pass the oil cooler, and a low-temperature by-pass device operable to open the oil cooler by-pass valve, for permitting the working fluid to by-passes the oil cooler, when a temperature of the working fluid is lower than a predetermined lower limit.

Owner:TOYOTA JIDOSHA KK

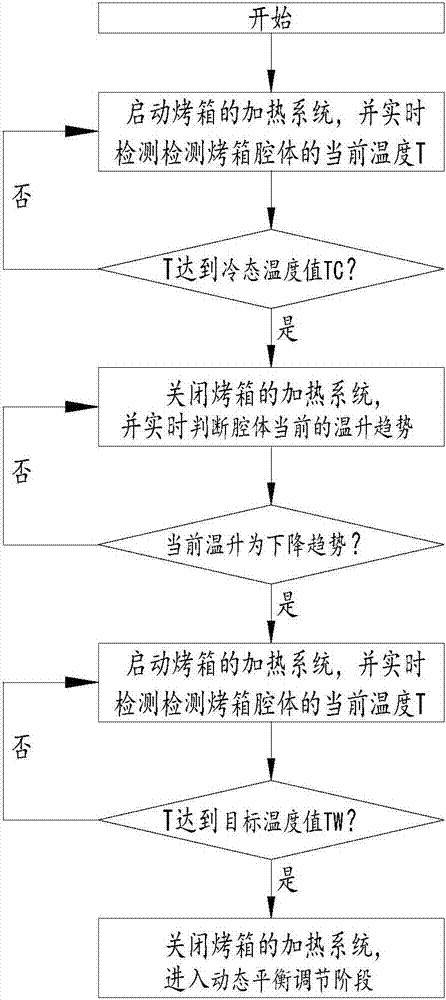

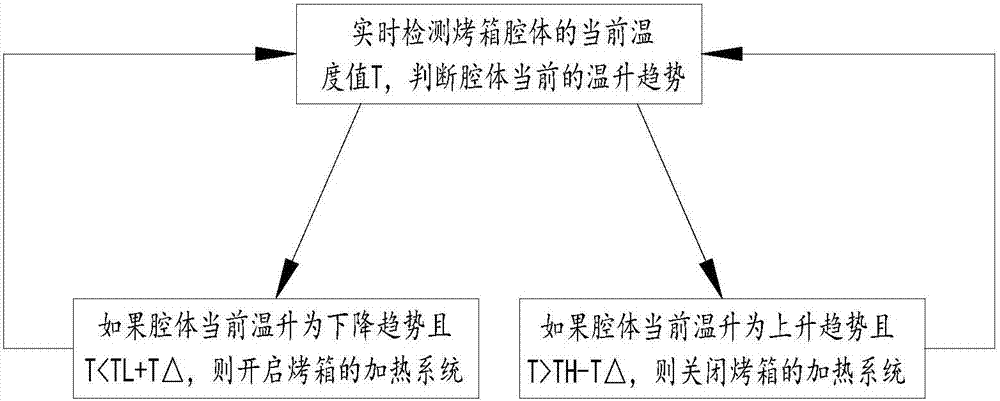

Baking oven temperature control method

ActiveCN106951012AAffect the baking effectAvoid the phenomenon of baking failureTemperatue controlCooking & bakingTemperature control

The invention discloses a baking oven temperature control method, and relates to the technical field of kitchen electric appliances. The baking oven temperature control method comprises a dynamic balance adjusting phase control step. The dynamic balance adjusting phase control step comprises the steps that step one, the current temperature value T of a baking oven cavity is detected, the current temperature value T is compared with a preset upper threshold temperature value TH and a lower threshold temperature value TL, the heating system of the baking oven is turned on when T<TL and the heating system of the baking oven is turned off when T>TH; and step two, the current temperature value T of the baking oven cavity is detected in real time and the current temperature rising trend of the cavity is judged; the heating system of the baking oven is turned on if the current temperature rising of the cavity is in the downtrend and T<TL+Tdelta; and the heating system of the baking oven is turned off if the current temperature rising of the cavity is in the uptrend and T>TH-Tdelta, wherein TL<=TL+Tdelta<TH-Tdelta<=TH, and Tdelta is the temperature compensating value. According to the technical scheme, accurate control of the temperature of the baking oven cavity can be realized.

Owner:JOYOUNG CO LTD

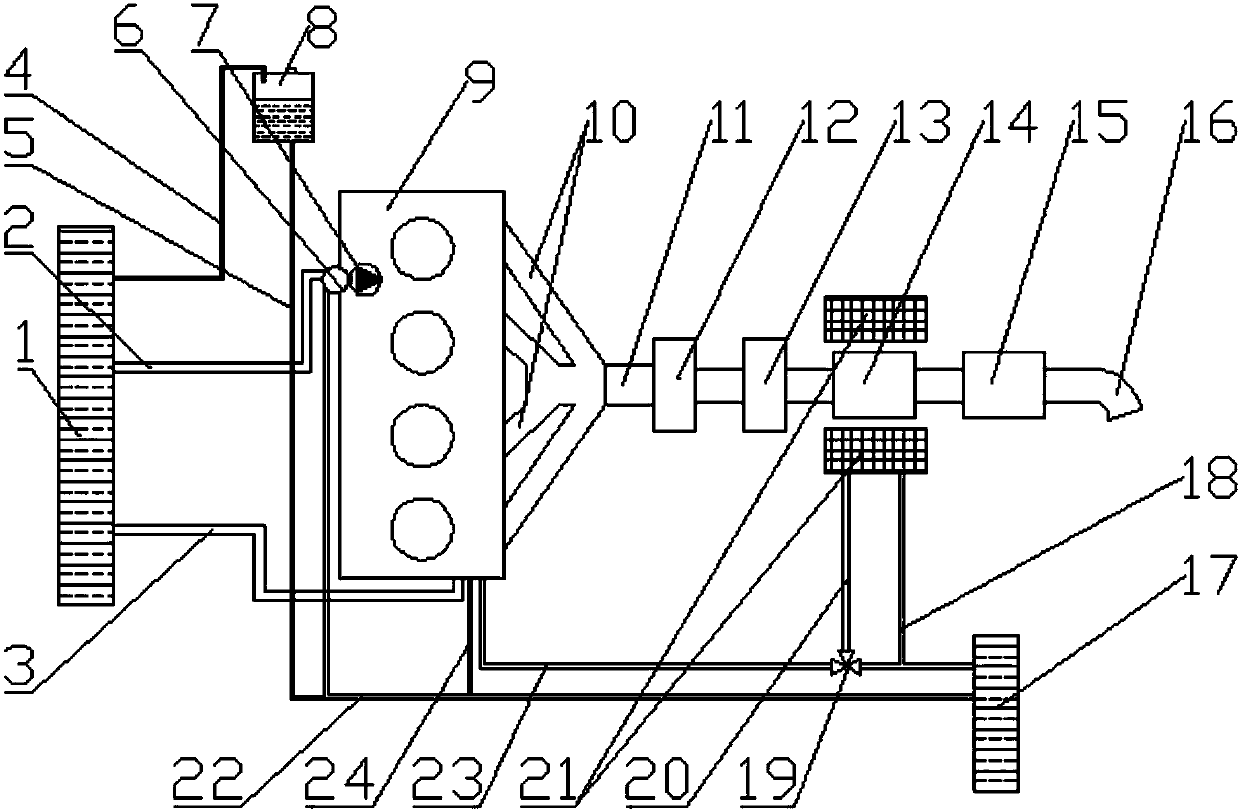

Vehicle engine rapid warming-up system

PendingCN107869417AEasy to wearExtended service lifeAir-treating devicesCoolant flow controlPollutant emissionsThermostat

The invention provides a vehicle engine rapid warming-up system. An engine communicates with a main radiator through an engine water return pipe and an engine water outlet pipe, a thermostat valve anda water pump are connected with the position between the engine water return pipe and the engine, the engine communicates with a warm wind radiator through a warm wind water inlet pipe and a warm wind water return pipe, the warm wind water return pipe communicates with the thermostat valve, and a heat exchanger communicates with the warm wind water inlet pipe through a heat exchanger water inletpipe and a heat exchanger water outlet pipe. According to the vehicle engine rapid warming-up system, small-circulation cooling liquid is heated by utilizing exhaust gas generated by burning of the engine, rapid warming-up of the engine can be achieved, oil consumption and pollutant discharge are reduced, abrasion of the engine at the starting stage is reduced, the engine is protected, and the service life of the engine is prolonged.

Owner:CATARC AUTOMOTIVE TEST CENT TIANJIN CO LTD +1

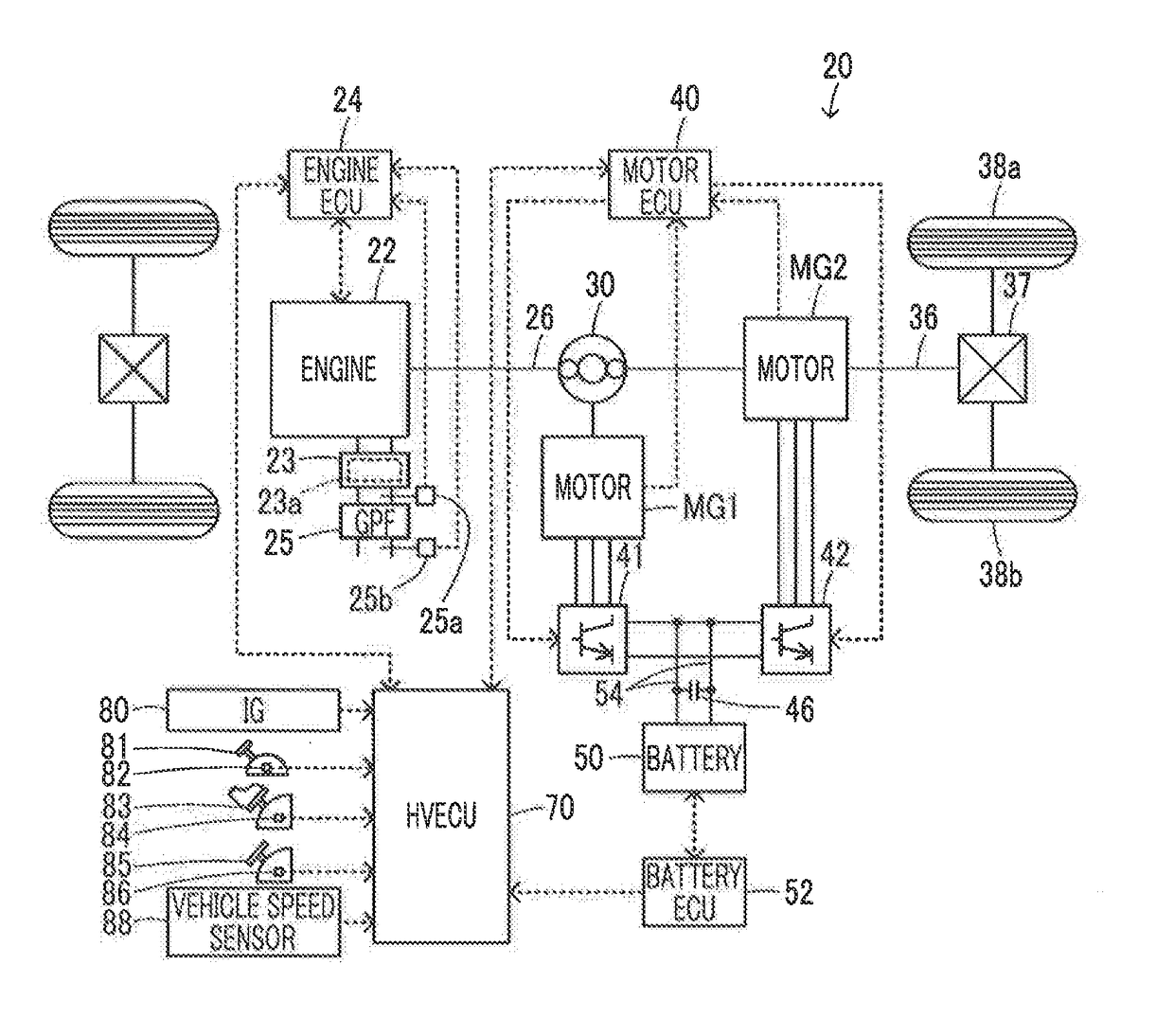

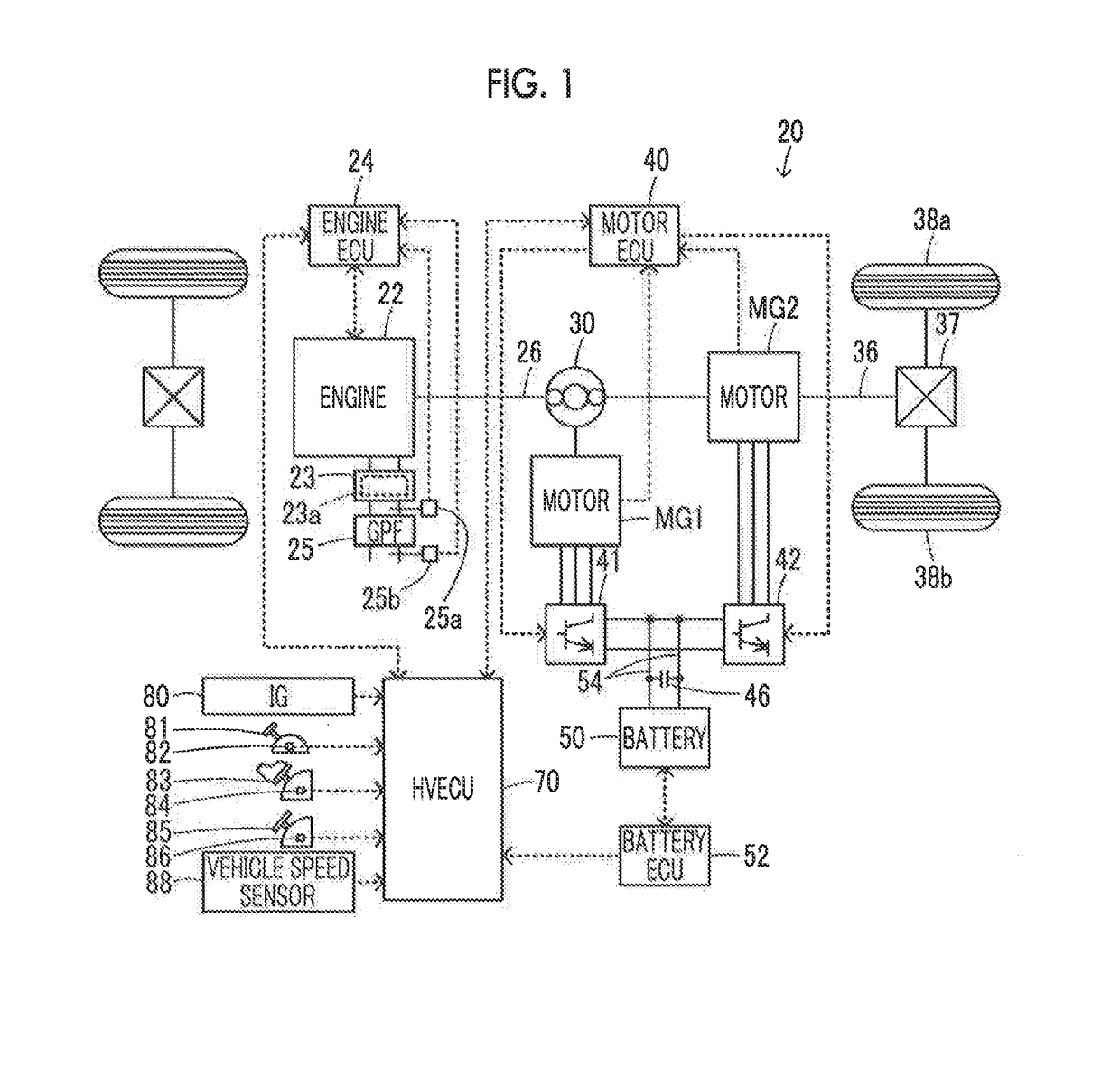

Hybrid vehicle and control method for hybrid vehicle

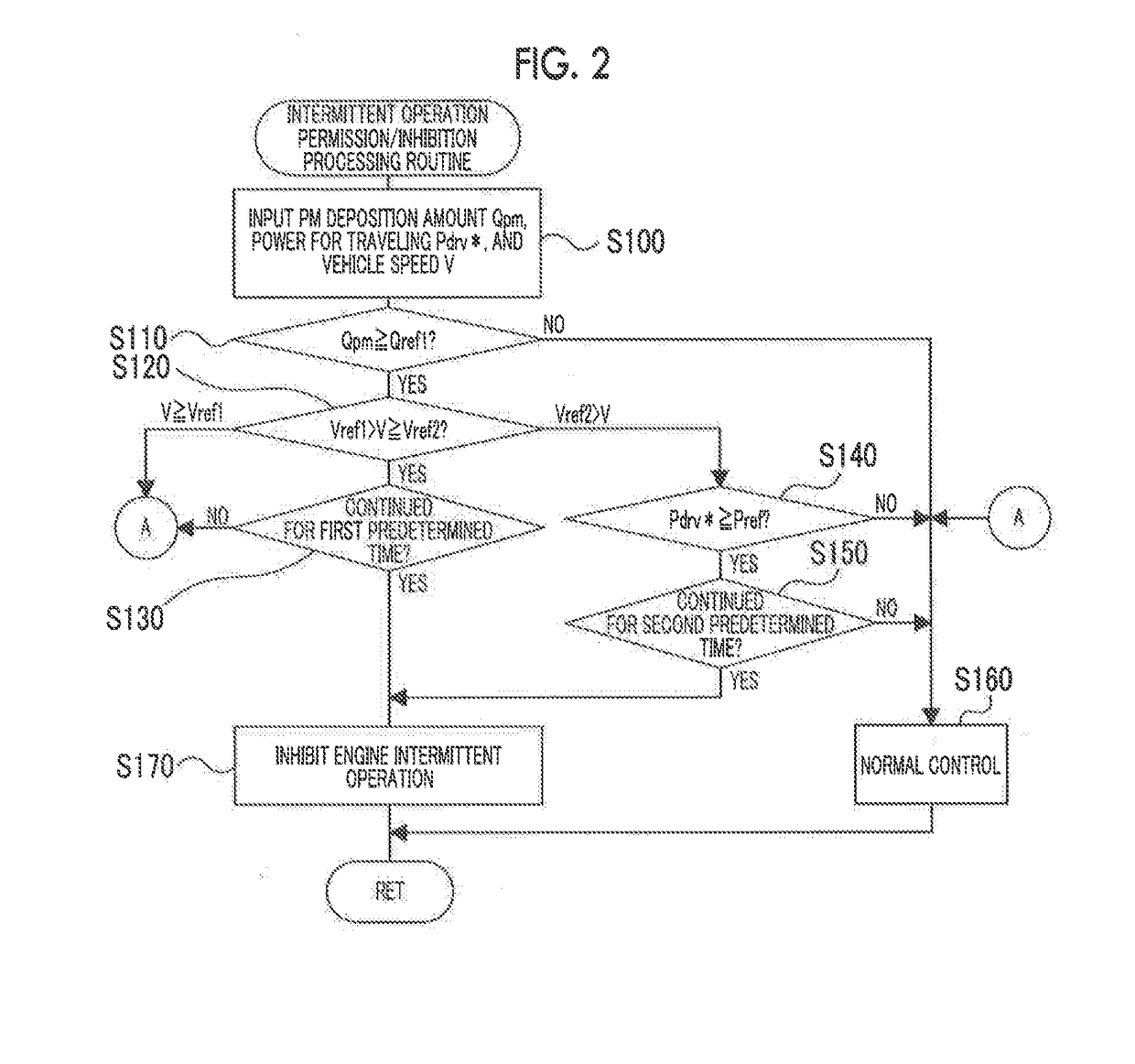

InactiveUS20180099656A1Increase opportunitiesRapid rise in temperatureHybrid vehiclesElectrical controlParticulatesHybrid vehicle

A hybrid vehicle includes an engine that has a particulate matter filter, a motor, and an electronic control unit. The electronic control unit is configured to control the engine and the motor such that an intermittent operation of the engine is permitted and the hybrid vehicle travels with required power when a vehicle speed is lower than a first predetermined vehicle speed. The electronic control unit is configured to inhibit the intermittent operation of the engine when a deposition amount of particulate matters is equal to or greater than a first deposition amount and a state in which the vehicle speed is equal to or higher than a second predetermined vehicle speed and is lower than the first predetermined vehicle speed is continued for a first predetermined time.

Owner:TOYOTA JIDOSHA KK

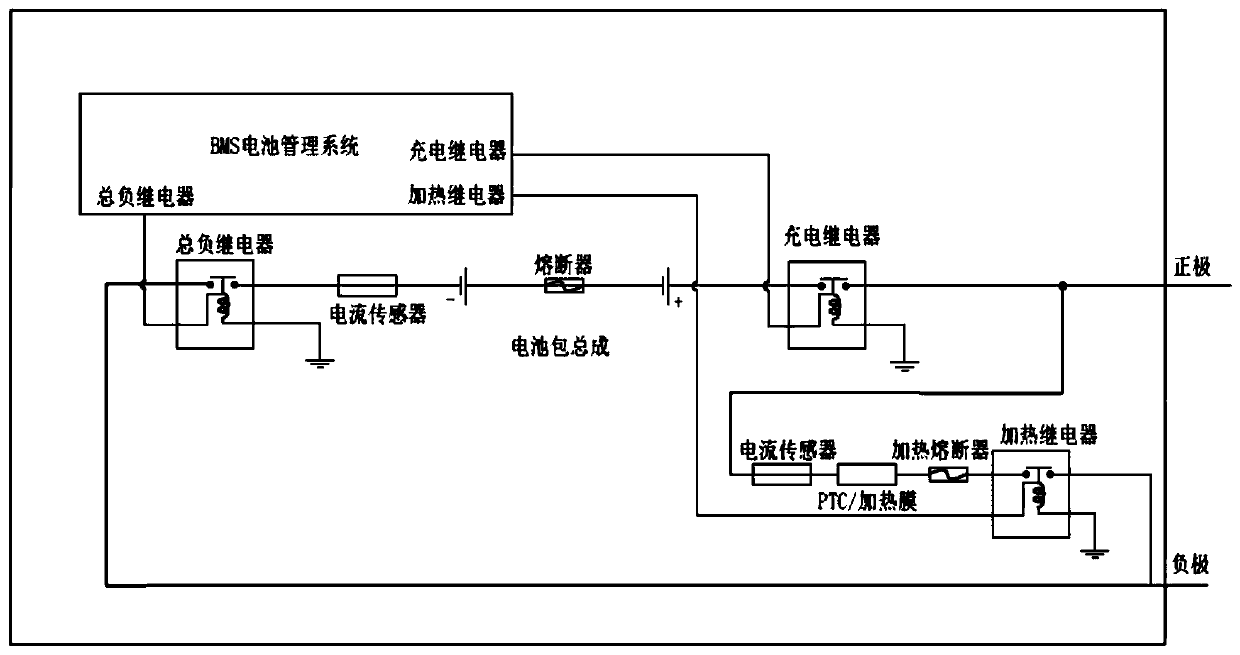

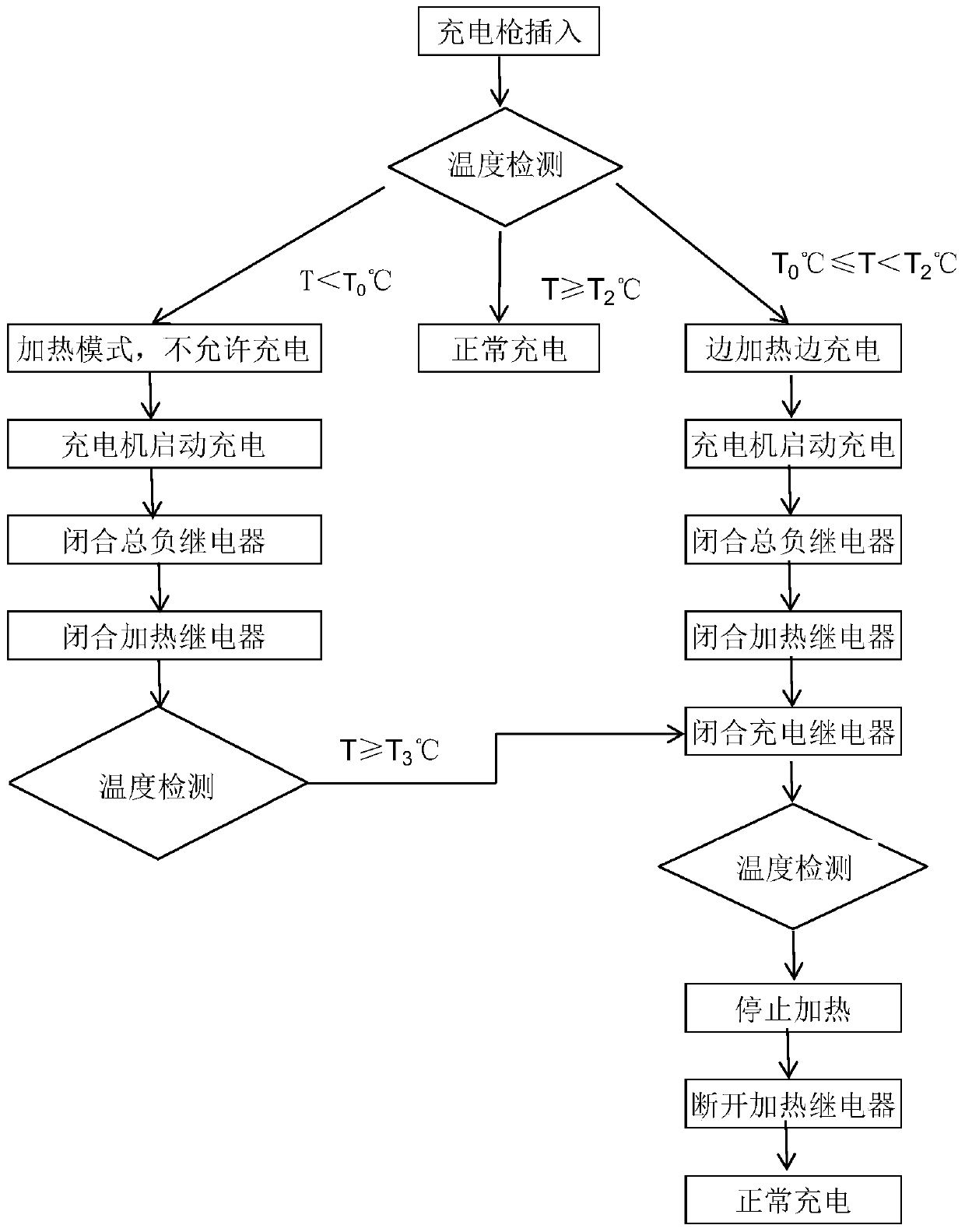

Power battery system and charging method for optimizing heating strategy through low-temperature charging

ActiveCN110635183AIncrease temperatureRapid rise in temperatureBatteries circuit arrangementsSecondary cells charging/dischargingPower batteryEngineering

The invention relates to the technical field of electric vehicle charging and discloses a power battery system and a charging method for optimizing a heating strategy through low-temperature charging.When the power battery system is charged under a low-temperature condition, temperature rising is achieved through a heating system, when the temperature reaches an allowable low-current charging state, heating and charging are performed at the same time, the temperature of the power battery system is increased through heat generated by the heating system, reaction heat and joule heat of the power battery system, the temperature of the power battery system rises rapidly and is in the rated continuous large-current charging process rapidly, and the charging time under the low-temperature condition is shortened. The power battery system is advantaged in that a heating stopping temperature point is determined as a balance point of the heat release amount of a power battery and heat generatedby the heating system, a problem that the heating system is repeatedly started due to continuous temperature drop after the heating system is stopped is solved, and the effects of short charging timeunder the low-temperature condition and repeated heating system starting prevention are achieved.

Owner:骆驼集团武汉光谷研发中心有限公司

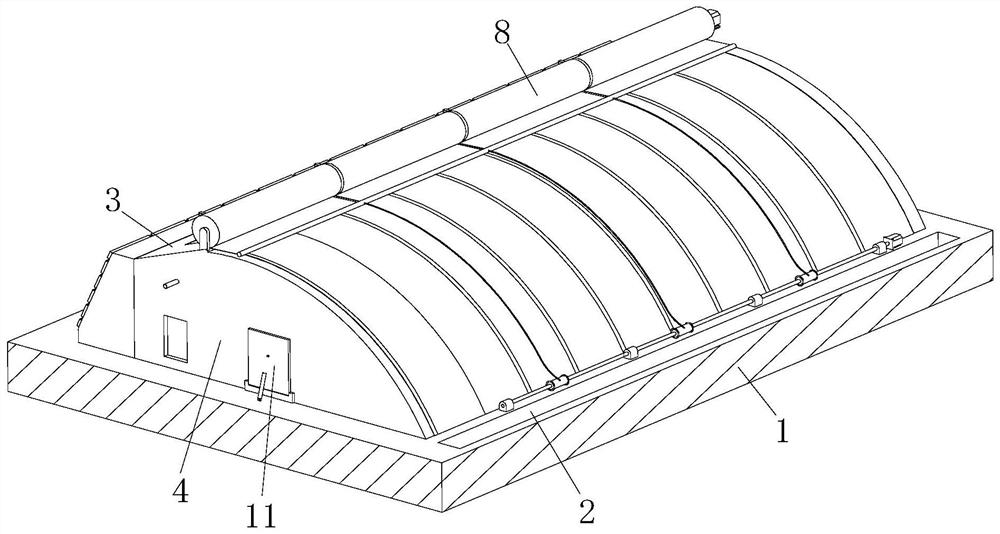

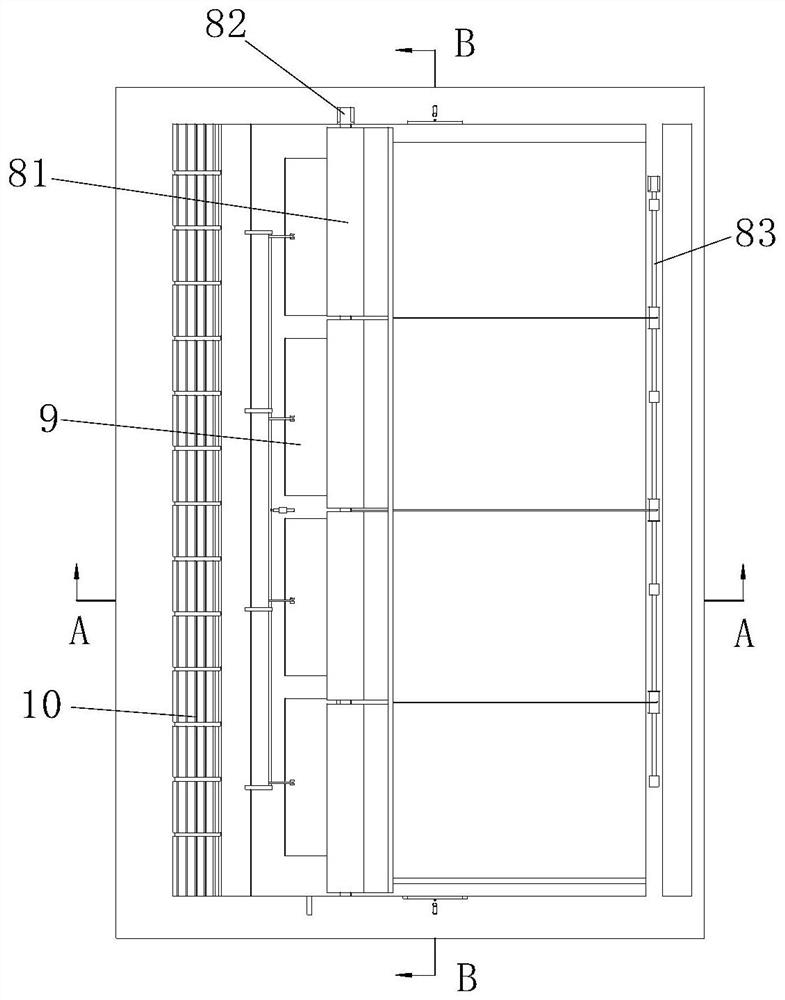

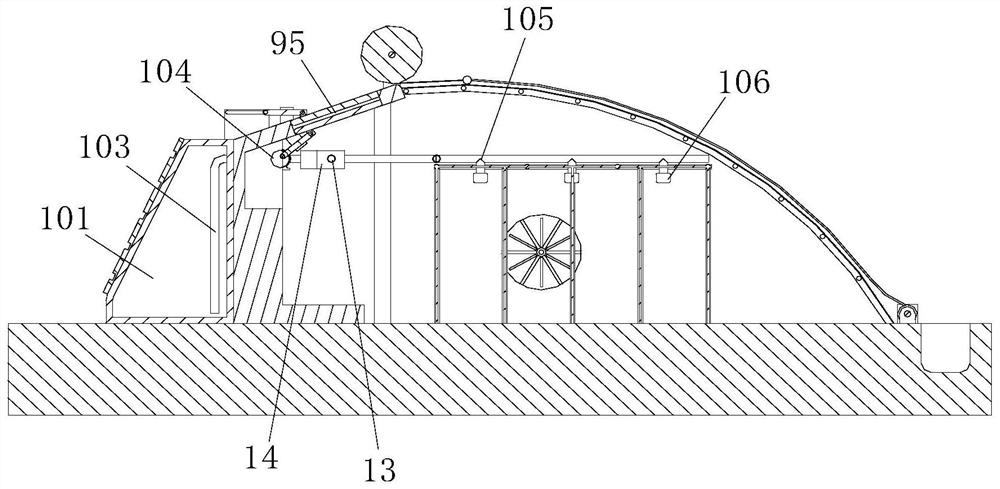

Automatic constant-temperature grape greenhouse

InactiveCN111788967AImprove qualityPromote photosynthesisClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention discloses an automatic constant-temperature grape greenhouse, which relates to the technical field of grape planting and comprises a grape planting field, a cold-proof ditch, a rear wallbody, a side wall body, an arch-shaped frame and a heat insulation film, a closed grape planting cavity is formed among the rear wall body, the side wall body, the grape planting field and the heat insulation film, and a heat insulation mechanism and an illumination supplementing mechanism are arranged at the upper end of the rear wall body. The illumination supplementing mechanism is arranged onthe side of the heat insulation mechanism, a rapid heating mechanism used for increasing the temperature rising speed in the heat preservation film is arranged on one side of the rear wall, and a cooling mechanism is arranged in the grape planting cavity and comprises an air inlet assembly and two exhaust assemblies. A grape trellis, a controller and a plurality of temperature sensors are furtherarranged in the grape planting cavity, wherein the controller and the temperature sensors are installed on the grape trellis. Through the arrangement of the illumination supplementing mechanism and the rapid heating mechanism, the photosynthesis duration and effect of grape plants are improved, and the growth quality of grapes is improved.

Owner:威海神山葡萄科技股份有限公司

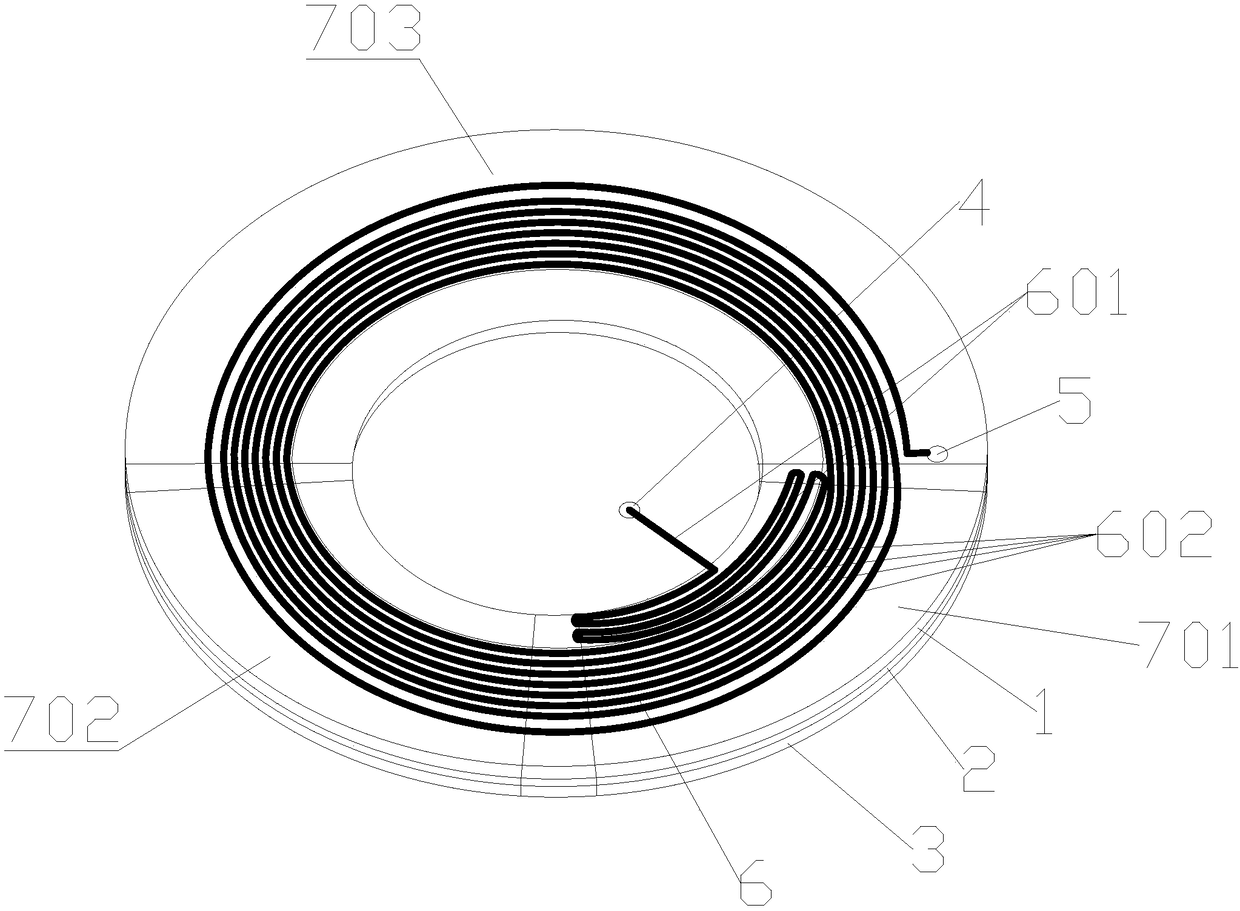

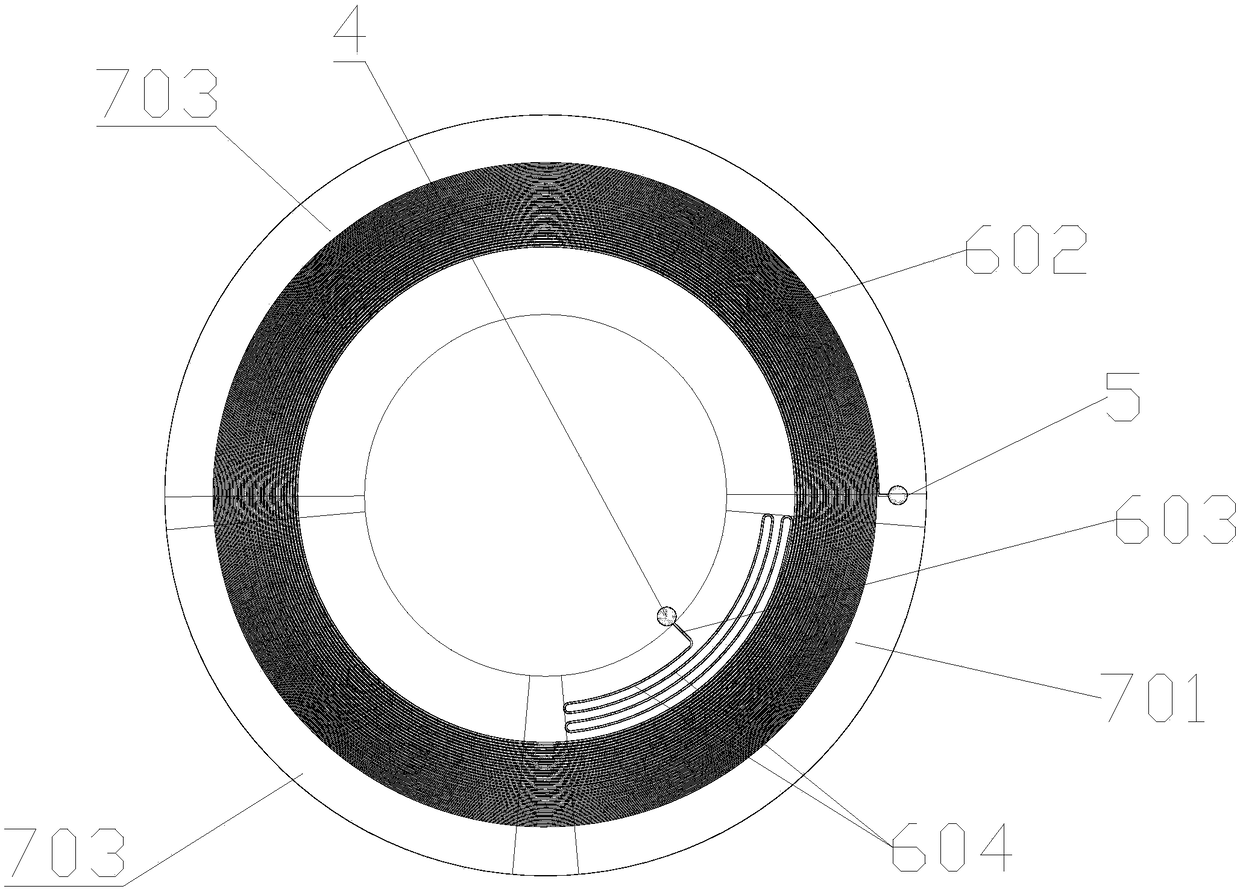

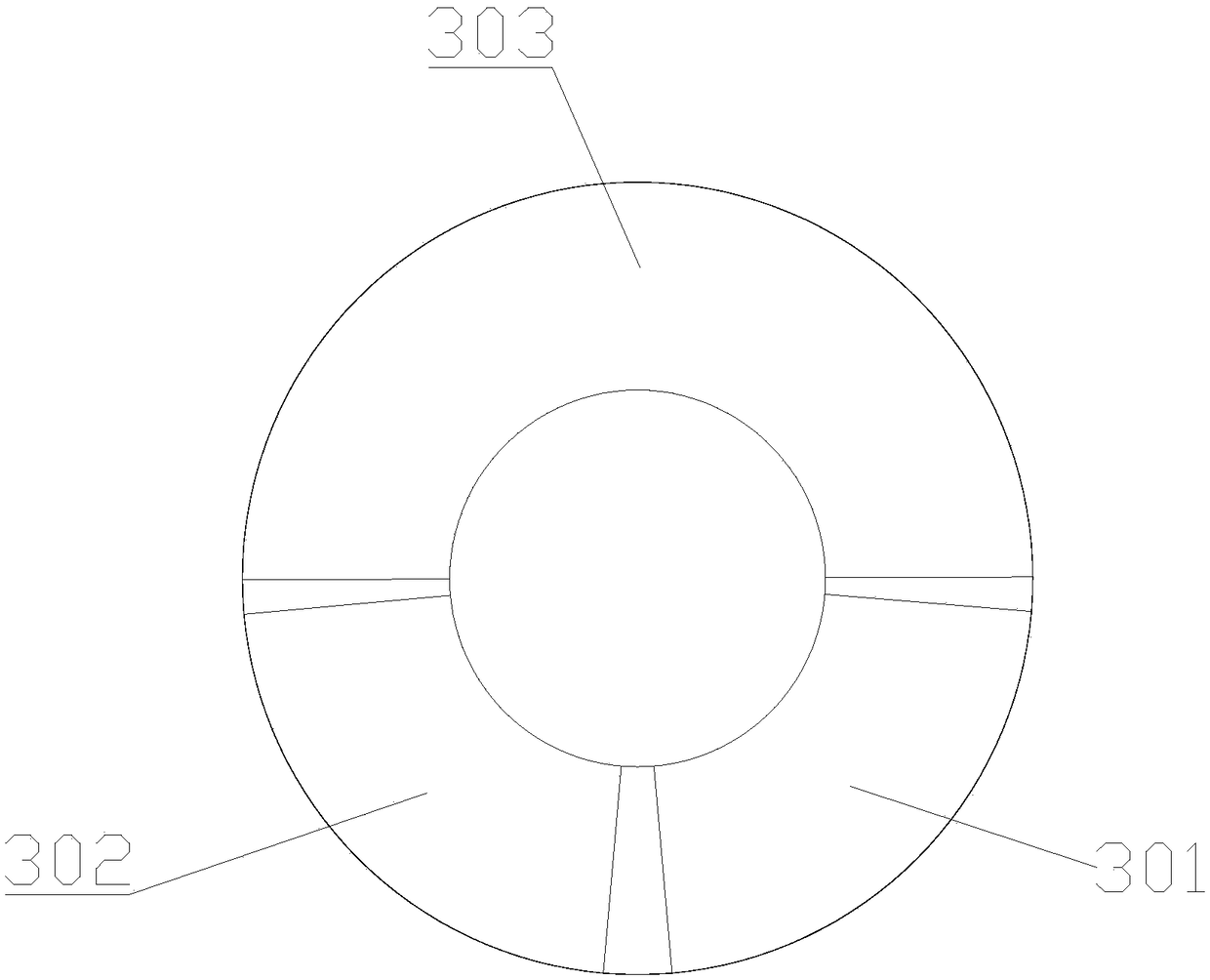

Spiral-type variable-cross-section micro fluidic PCR chip, and manufacturing method thereof

ActiveCN108277154ASmall structure sizeReduce volumeBioreactor/fermenter combinationsHeating or cooling apparatusTemperature controlPcr chip

The invention provides a spiral-type variable-cross-section micro fluidic PCR chip, and a manufacturing method thereof. The spiral-type variable-cross-section micro fluidic PCR chip comprises a reaction system and a temperature control system; the reaction system comprises a base sheet and a cover sheet connected via bonding; a base sheet channel is arranged in the base sheet; the base sheet channel comprises a constant cross section channel and a spiral-type variable-cross-section channel; the spiral-type variable-cross-section channel is designed to be spiral taking the center of the base sheet as the circle center; the size of the cross section of the spiral-type variable-cross-section channel is reduced gradually with increasing of the length. The spiral-type variable-cross-section micro fluidic PCR chip is small in size, is portable, is capable of realizing high degree integration of a plurality of PCR reaction auxiliary equipment. According to the spiral-type variable-cross-section micro fluidic PCR chip, the base sheet can be divided into three temperature zones; three temperature zone constant temperature independent control is adopted by the temperature control system, andthe uniformity control of the temperature zones is improved using thermal conductive elements, so that requirements of the PCR reaction on high speed accurate temperature increasing and reducing control of the temperature control system can be reduced.

Owner:NAT UNIV OF DEFENSE TECH

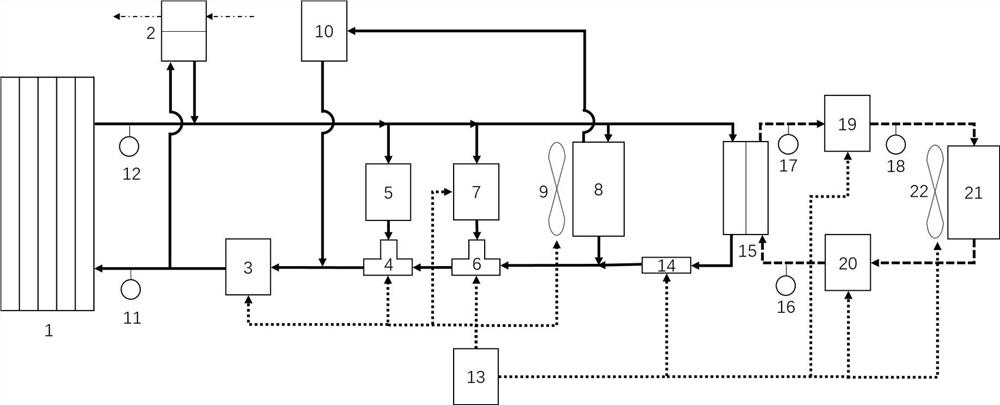

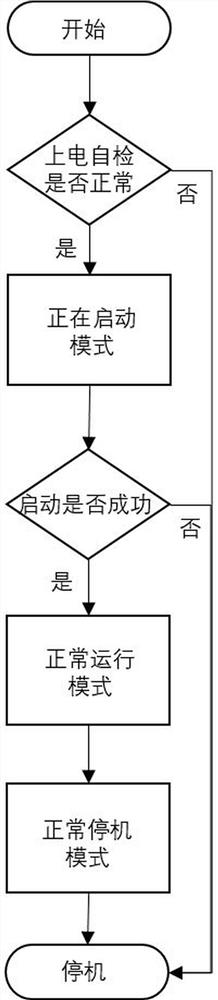

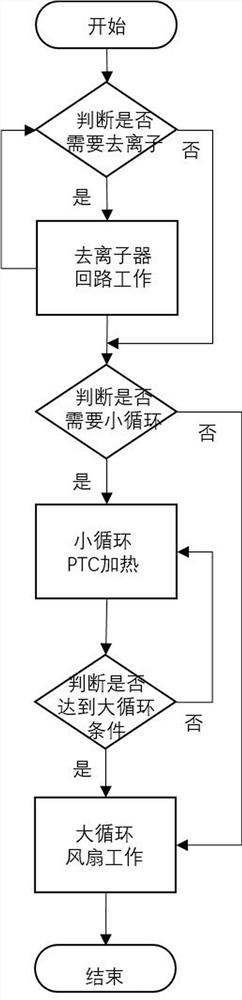

Fuel cell thermal management system and control method thereof

PendingCN114335624AConsider comfortTaking energy efficiency into considerationFuel cell heat exchangeThermodynamicsFuel cells

According to the fuel cell thermal management system and the control method thereof, the energy utilization rate and the comfort of a passenger compartment are both considered on the premise that the appropriate temperature of the fuel cell is maintained, meanwhile, the water heating system and the cooling system use independent pipelines, the water heating system can be freely arranged, cheaper fluid is selected as a working medium, and the energy consumption is reduced. The deionizer can work at any time according to needs, flow resistance caused when the deionizer does not need to work is avoided, on the basis that a cooling system and a water heating system are comprehensively considered, the working condition is divided into a plurality of sub-working conditions, the working condition in starting is open-loop control, rapid temperature rising is achieved, and the working condition in normal operation is closed-loop control. According to the method, in particular, feedforward and feedback combined control is adopted, an initial control parameter is not simply set as a fixed value any more, a variable feedforward value is determined according to working conditions, and therefore the overshoot is more accurately reduced.

Owner:郑州意昂新能源汽车科技有限公司

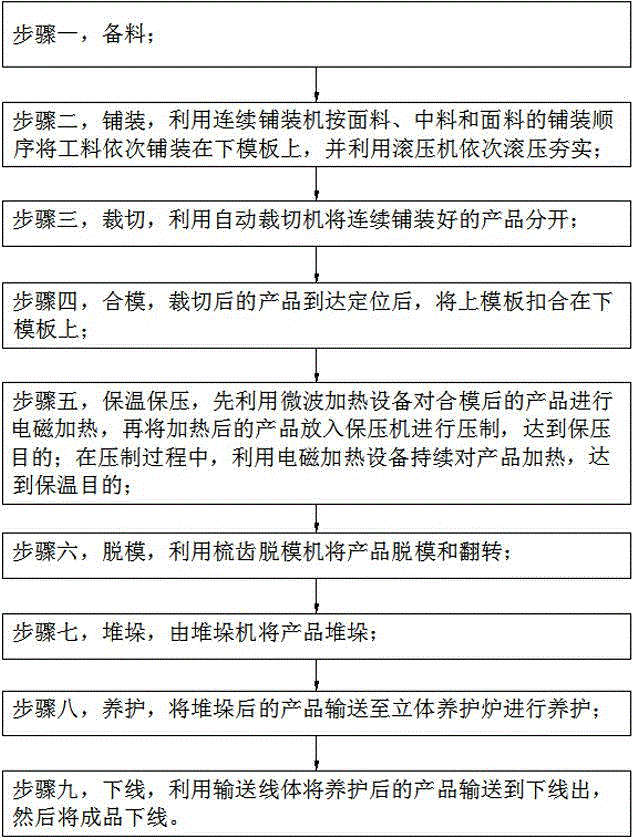

Technology for producing magnesium plate

InactiveCN104400886AImprove heating efficiencyReduce energy consumptionDischarging arrangementAuxillary shaping apparatusMicrowaveElectromagnetic heating

The invention discloses a technology for producing a magnesium plate. The technology comprises the following few steps: material preparing; paving, wherein a continuous paving machine is utilized for sequentially paving labor and materials on a lower template according to the paving sequence of surface materials, middle materials and surface materials, and a roller press is utilized for sequentially carrying out rolling and tamping; cutting; die assembly; heat preservation and pressure maintenance, wherein a microwave heating device is utilized for carrying out electromagnetic heating on products after die assembly, then, the heated products are put into a pressure maintaining machine to be pressed, and the pressure maintaining aim is achieved; in the pressing process, an electromagnetic heating device is utilized for continuously heating the products, and the heat preservation aim is achieved; die releasing; stacking; maintaining, wherein the stacked products are conveyed to a three-dimensional curing furnace to be cured; and offline operation. According to the technology for producing the magnesium plate, in the heat preservation and pressure maintenance processes, the microwave heating device is utilized for replacing a traditional hot oil furnace and has the advantages of being high in heating efficiency and high in rising and facilitating temperature adjustment; due to the fact that the hot oil furnace is not needed, floor space of the device can be reduced; the cost is reduced; and the safety is improved.

Owner:SHENZHEN NARI TECH

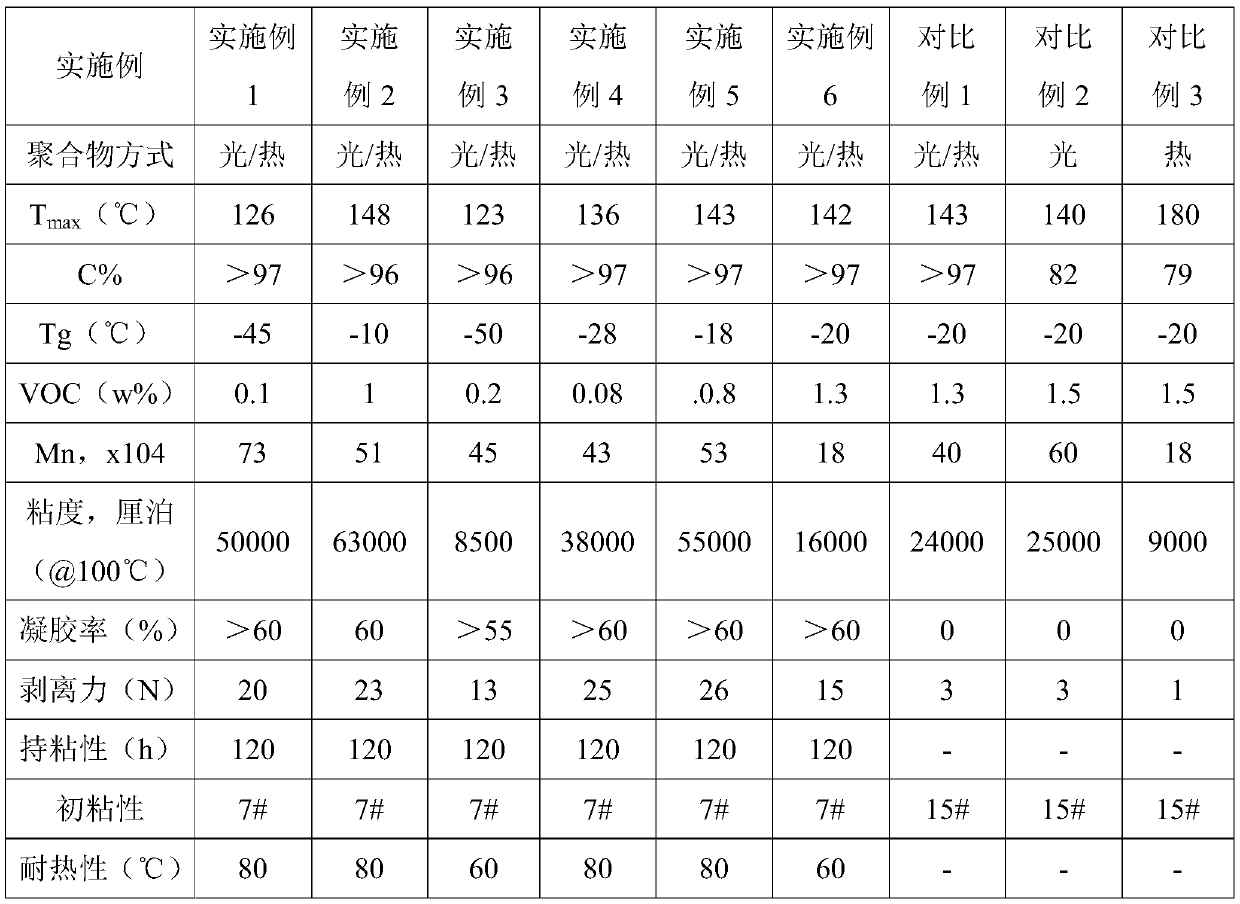

Photo-thermal free radical polymerization preparation method and application of vinyl polymer

InactiveCN110423304ARapid rise in temperatureShort reaction timeEster polymer adhesivesN-vinyl-pyrrolidone polymer adhesivesPolymer scienceReaction temperature

The invention discloses a photo-thermal free radical polymerization preparation method of a vinyl polymer and an application of the polymer. The method uses a photo / thermal composite initiator to initiate polymerization of a vinyl monomer, firstly a photoinitiated polymerization reaction is performed, and a thermal polymerization reaction is performed after the thermal polymerization reaction temperature is achieved. The method for preparing the vinyl polymer provided by the invention can reduce energy consumption, reduce reaction time, and improve production efficiency, and the product has amore uniform structure, better performance, a lower gelation rate or even no gel and a higher conversion rate of the monomer; and the vinyl polymer prepared by the method can be used for coating and photocrosslinking products.

Owner:成都辉聚光电材料有限公司

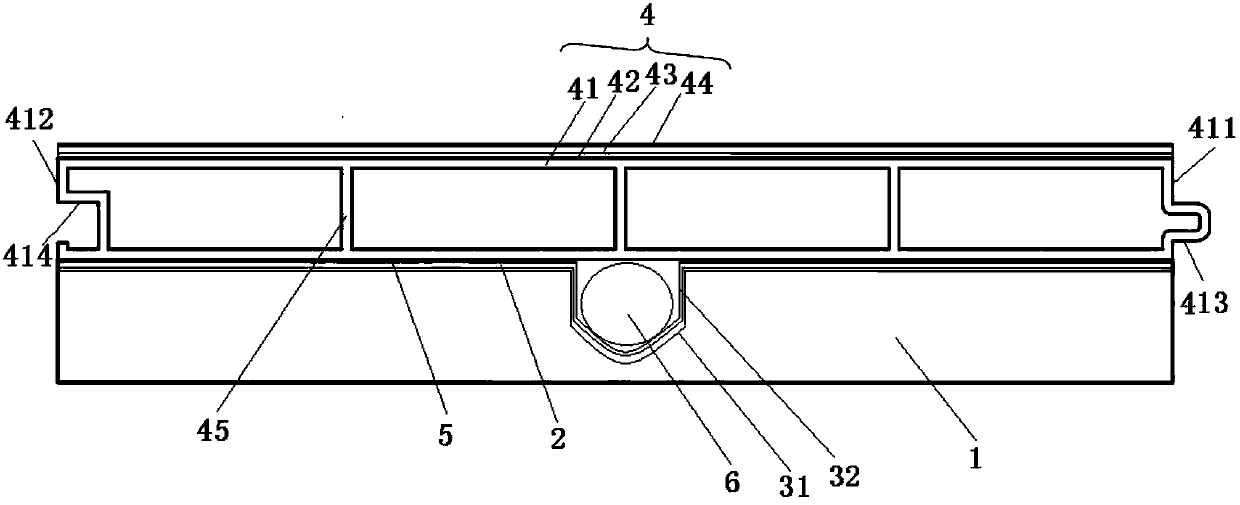

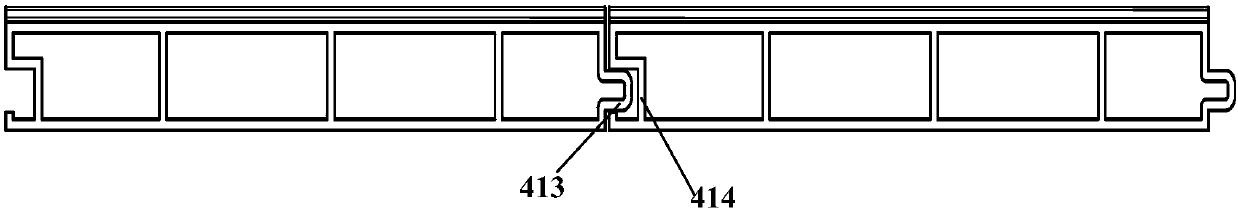

Aluminum-wood water heating system and paving method thereof

PendingCN108036385AShort thermal pathFast heat conductionCovering/liningsLighting and heating apparatusWater pipeSolid wood

The invention discloses an aluminum-wood water heating system and a paving method thereof. The aluminum-wood water heating system comprises a heat preservation plate, a reflecting film, a cyclic heating water pipe and an aluminum-wood composite floor. The reflecting film is laid on the heat preservation plate. Linear or arc-shaped heat preservation plate grooves are formed in the heat preservationplate. Linear or arc-shaped reflecting grooves are formed in the reflecting film and matched with the heat preservation plate grooves. The cyclic heating water pipe is located in the reflecting filmgrooves. The aluminum-wood composite floor is laid on the top of the reflecting film. The aluminum-wood composite floor comprises an aluminum alloy base plate, a first PUR glue layer and a solid woodplate. The first PUR glue layer and the solid wood layer are sequentially laid on the top of the aluminum alloy base plate. The solid wood plate is bonded and connected to the aluminum alloy base plate through the first PUR glue layer. The aluminum-wood water heating system is fast in heat conduction, the room temperature can be raised rapidly during a short time, the laid floor is free of cracking or deformation, the stability is good, the safety and reliability are high, and the aluminum-wood water heating system has the characteristic of being convenient to disassemble and assemble.

Owner:金华意萨曼新材料科技有限公司

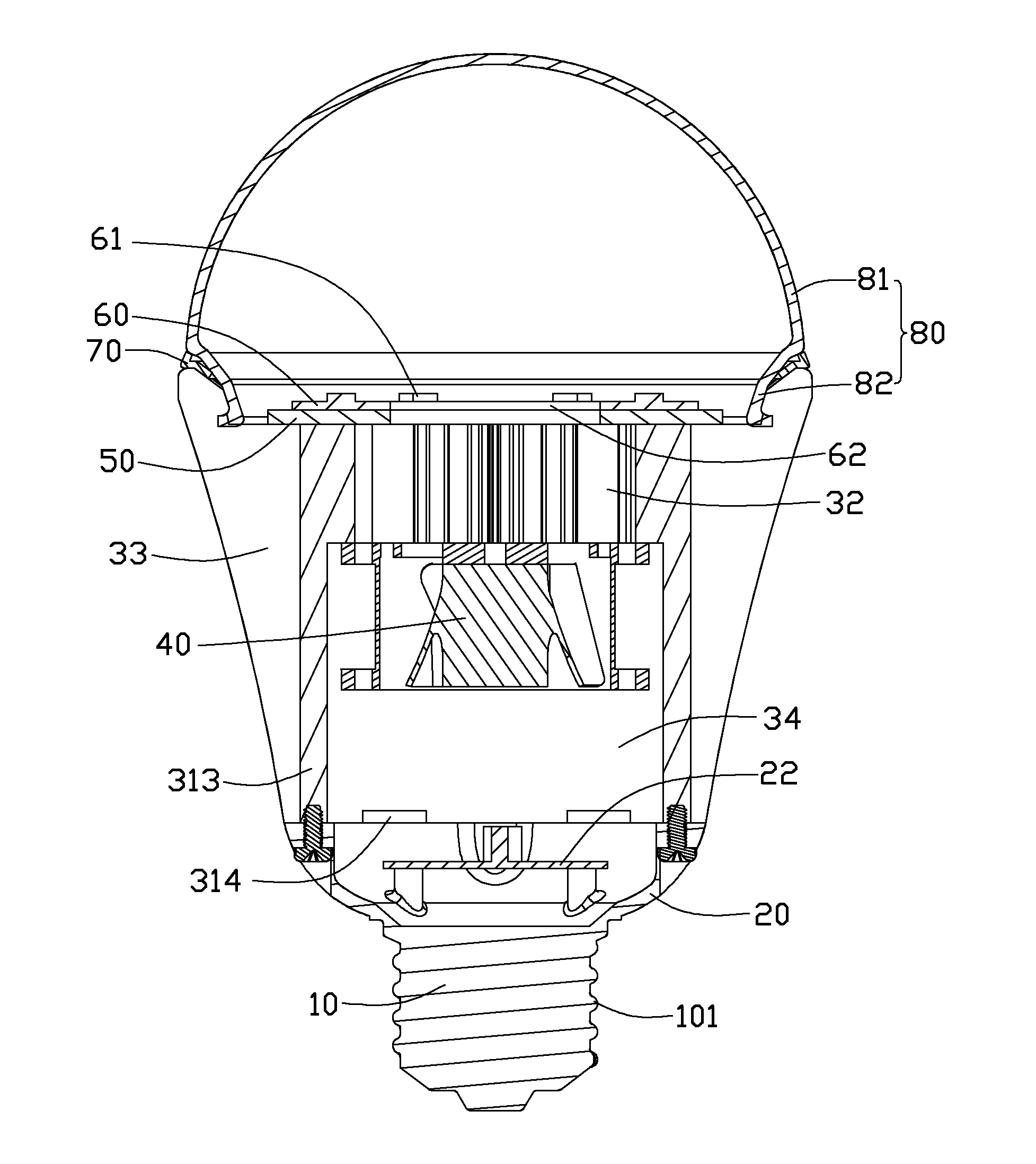

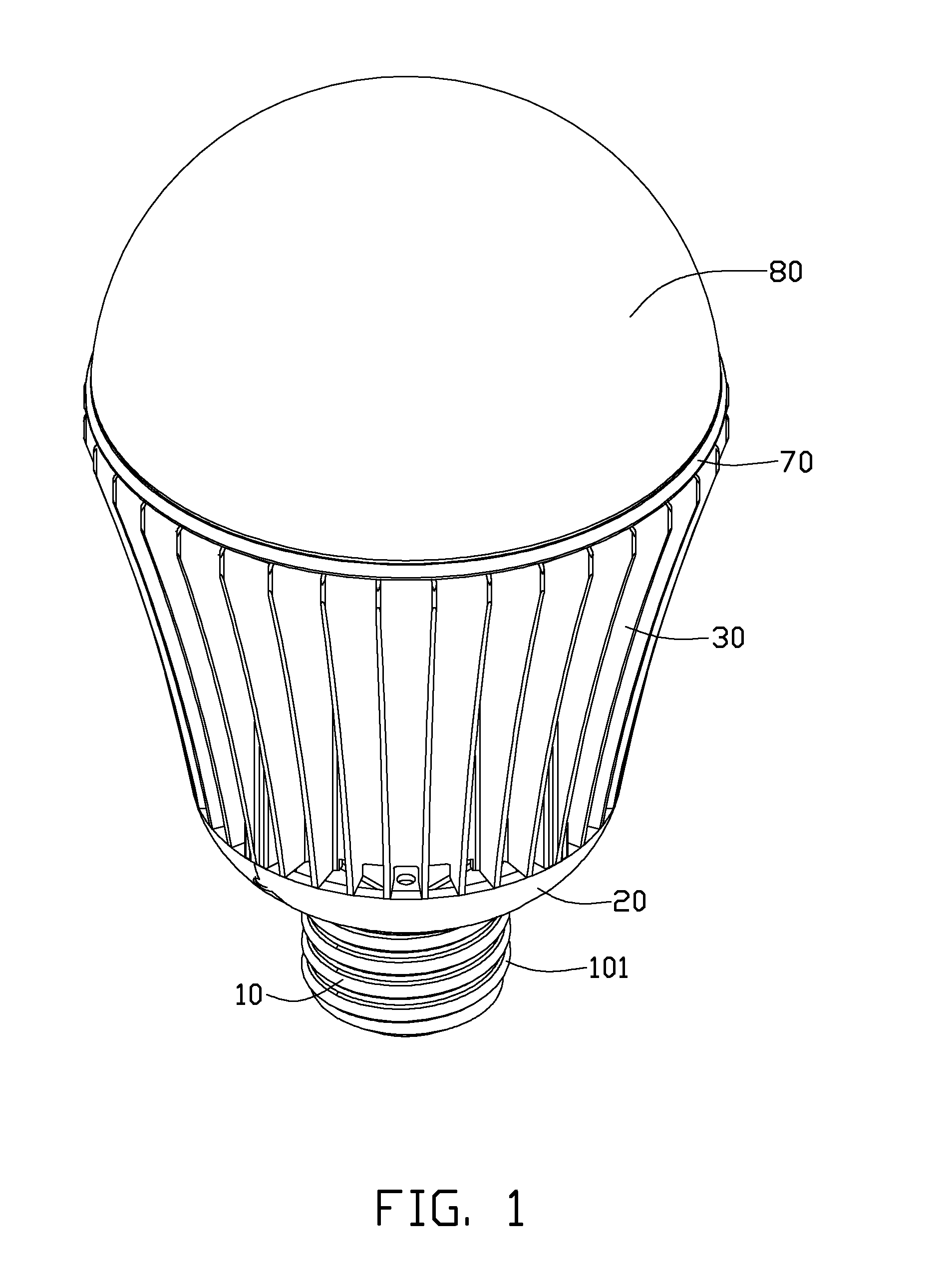

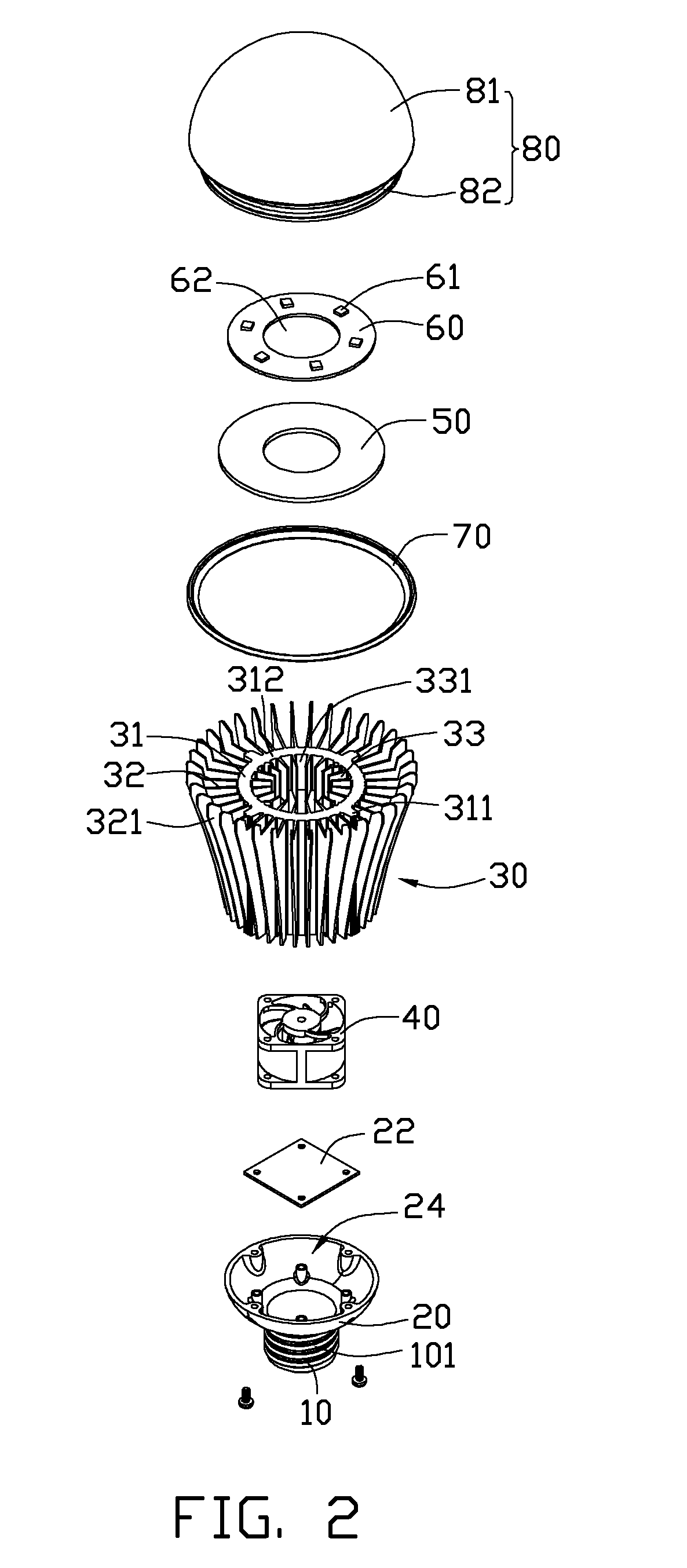

LED bulb

InactiveUS20120161624A1Rapid rise in temperaturePoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

An LED bulb includes a connector for electrically connecting with a power supply, a heat sink disposed on the connector, an LED module mounted the heat sink, and an envelope secured to the heat sink and covering the LED module. The heat sink includes a tubular body, a plurality of first fins extending outwardly from an outer circumference of the tubular body, and a plurality of second fins extending inwardly from an inner circumference of the tubular body.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

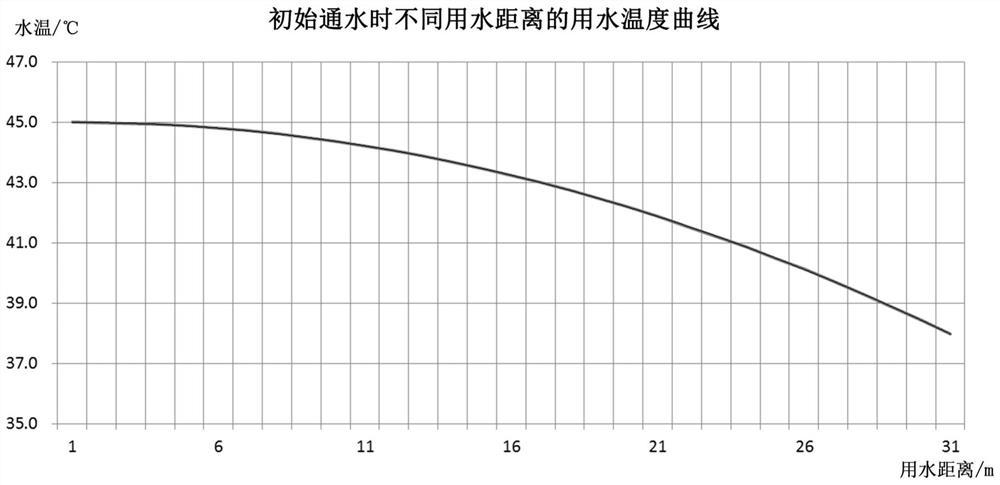

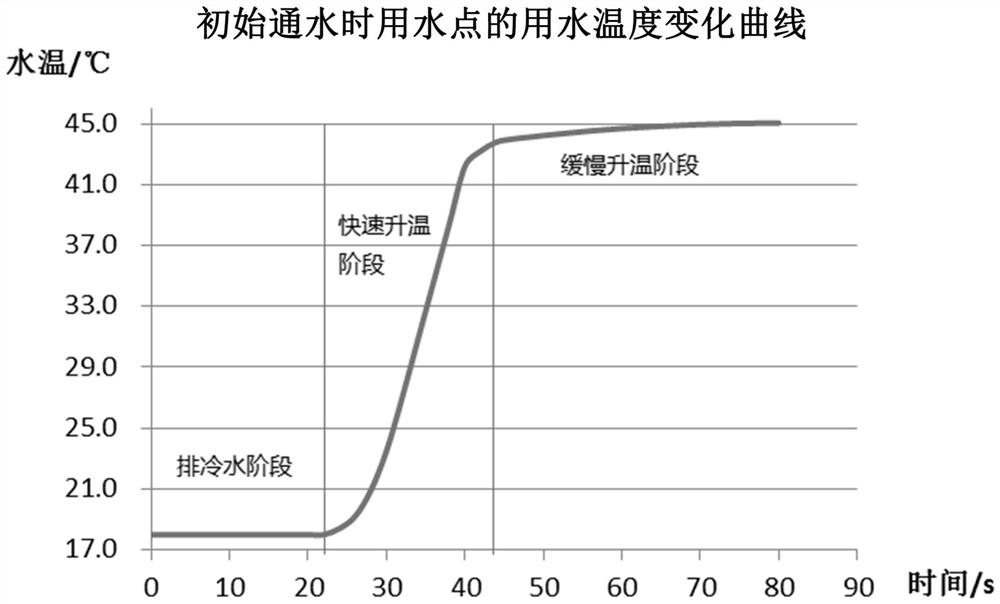

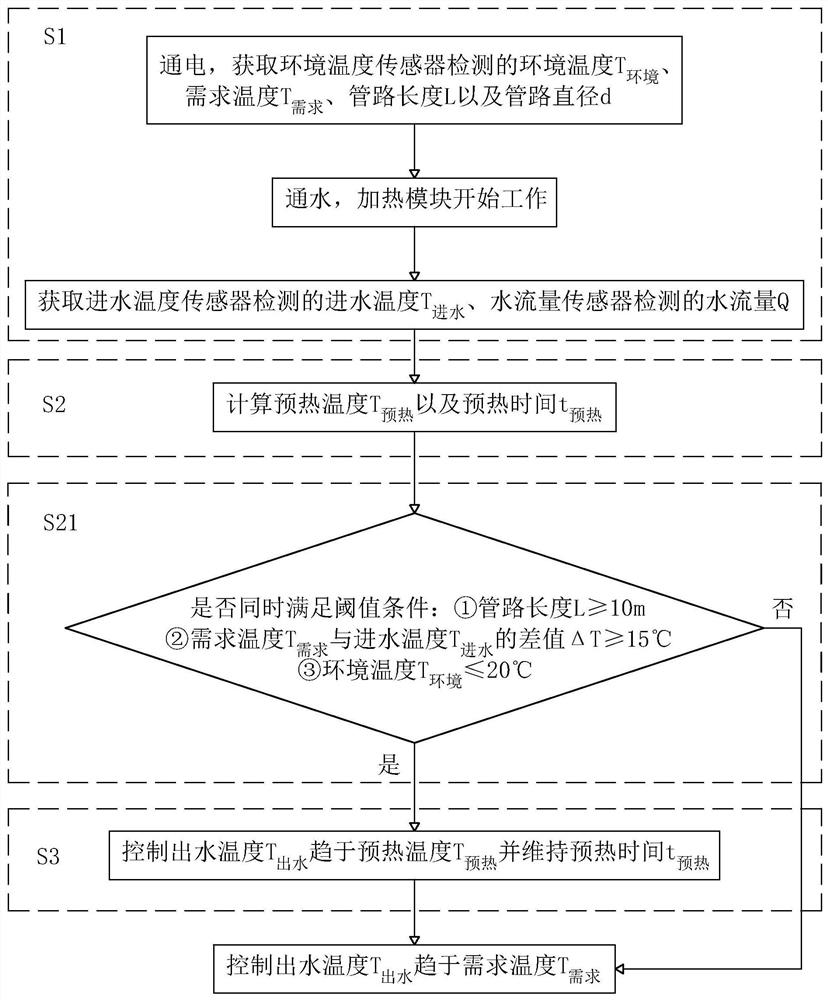

Water outlet temperature compensation method for water heater, and water heater

ActiveCN112283954ARapid rise in temperatureSmall temperature differenceFluid heatersWater useThermodynamics

The invention discloses a water outlet temperature compensation method for a water heater, and the water heater. The water outlet temperature compensation method for the water heater comprises the following steps: S1, required temperature and water delivery change influence parameters are obtained; S2, a preheating temperature and preheating time are calculated according to the required temperature and the water delivery change influence parameters; and S3, the water outlet temperature is controlled according to the preheating temperature and the preheating time. According to the required temperature and the water delivery temperature change influence parameters, the proper preheating temperature and preheating time are calculated, and then the water outlet temperature is controlled according to the preheating temperature and the preheating time, so that the water outlet temperature of the water heater tends to the preheating temperature and lasts for the preheating time during initialwater supply, the preheating temperature is higher than the required temperature, so that hot water output by the water heater carries more heat so as to compensate part of heat absorbed by the pipeline, the temperature of the pipeline can be rapidly increased, the time for enabling the water temperature to meet the required temperature is shortened, and realization for the effect of rapidly reducing the temperature difference between the water temperature and the required temperature is facilitated.

Owner:CHINABEST HOME APPLIANCE

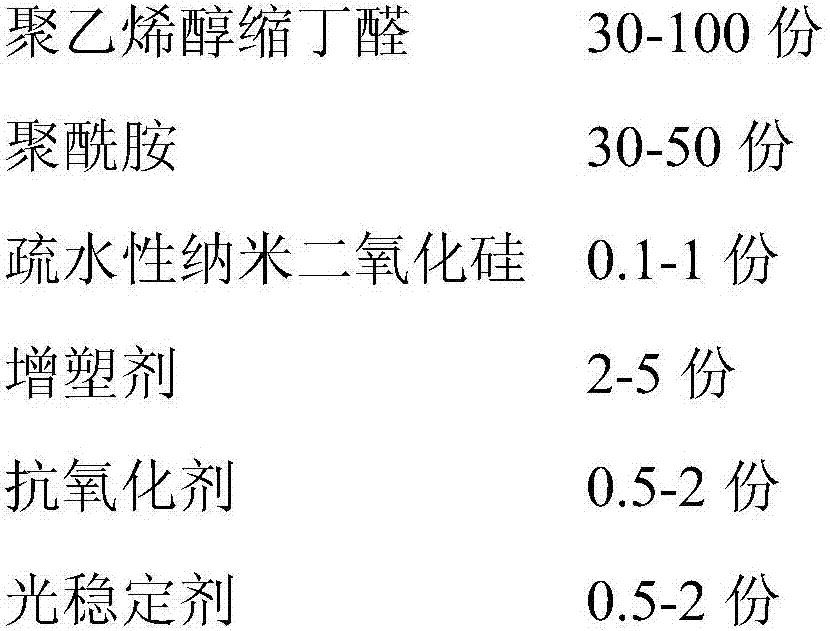

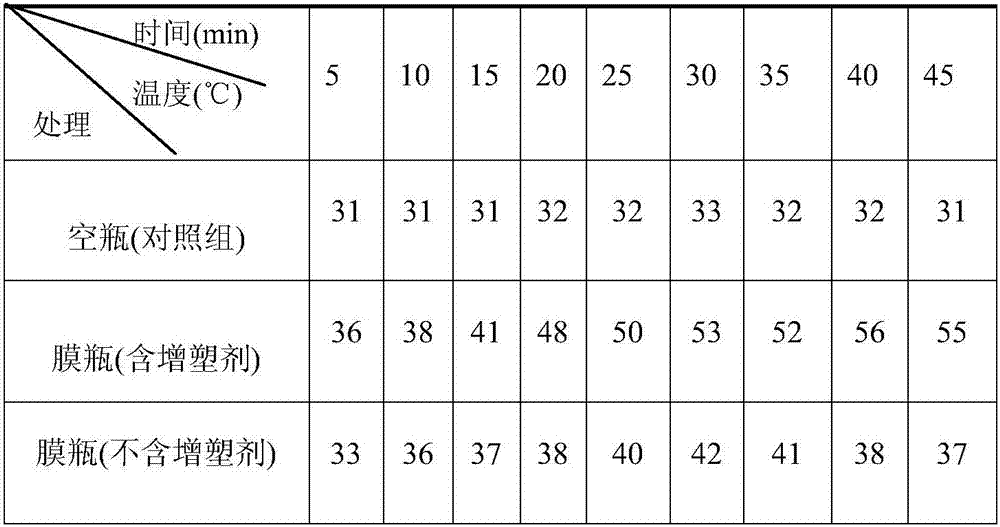

Quick liquid film forming agent capable of preventing pine wilt disease spreading

The invention discloses a quick liquid film forming agent capable of preventing pine wilt disease spreading. The quick liquid film forming agent is characterized by being prepared from 100 parts of polyvinyl butyral, 40 parts of polyamide, 1 part of hydrophobic nano silica, 5 parts of a plasticizer, 1 part of an antioxidant, 1 part of a light stabilizer, 1 part of a light absorbent and 85 parts of a solvent. A sealing film formed by the quick liquid film forming agent on dead pine wood can produce the greenhouse effect under sunlight, the temperature in the film can increase to 50 DEG C or above, and pine wood nematode and monochamus alternatus larvae in the dead wood can be killed effectively. The ratio composition is more reasonable and targeted, and the waterproof effect of the liquid film forming agent can be improved by adding the hydrophobic nano silica; the liquid film forming agent forms a film more quickly and more compactly due to addition of the plasticizer, the film forming time is effectively shortened, the sealing effect of the sealing film is enhanced, and the temperature in the film can be increased.

Owner:HANSHAN NORMAL UNIV

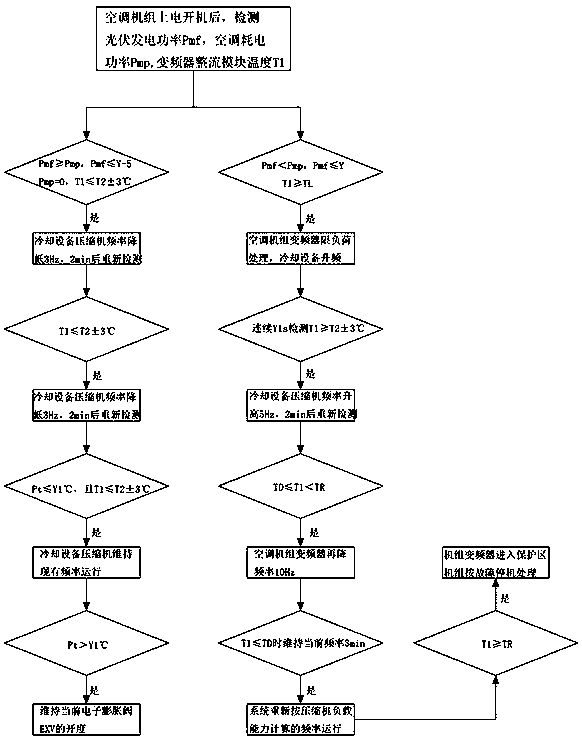

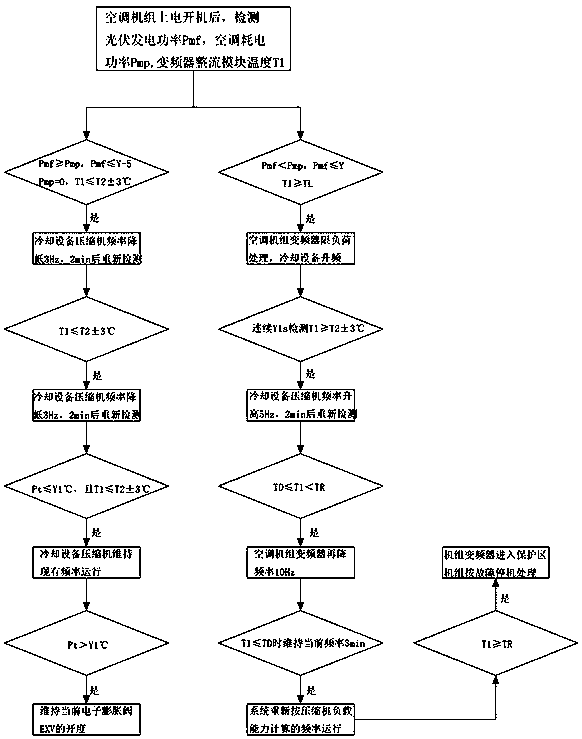

Photovoltaic direct-drive variable-frequency air conditioner control method, computer readable storage medium and air conditioner

ActiveCN111174369AImprove reliabilityPrecise control of circulation volumeMechanical apparatusSpace heating and ventilation safety systemsFrequency changerControl engineering

The invention provides a photovoltaic direct-drive variable-frequency air conditioner control method, a computer readable storage medium and an air conditioner. The photovoltaic direct-drive variable-frequency air conditioner control method is characterized in that after an air-conditioning unit is powered on, the photovoltaic power generation efficiency and the air-conditioning power consumptionare detected in real time, calculated and analyzed; the heat generation situation of a frequency converter rectification module is preliminarily judged, and then the temperature of the frequency converter rectification module is detected; and the running parameters of an air-conditioning unit frequency converter and cooling equipment are adjusted according to the temperature of the frequency converter rectification module. The photovoltaic direct-drive variable-frequency air conditioner control method, the computer readable storage medium and the air conditioner have the beneficial effects that the air-conditioning compressor load dynamic and photovoltaic generated power matching situation can be judged through power detection; the running of the air-conditioning unit and the cooling equipment can be adaptively adjusted aiming at the photovoltaic high-load running and photovoltaic low-load running situations; the circulating mass of a coolant can be precisely controlled, and thus the undercooling and overheating adjustment can be avoided; accordingly, the safe and stable running of a photovoltaic direct-drive frequency converter can be guaranteed; and meanwhile, the reliability ofthe cooling equipment can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

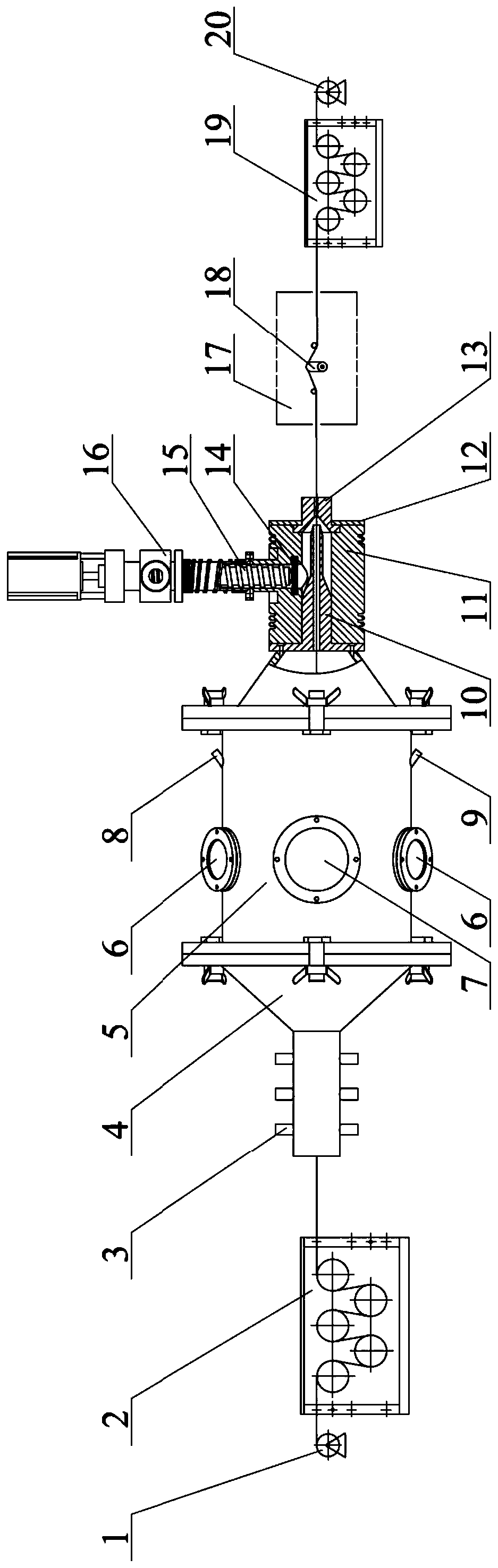

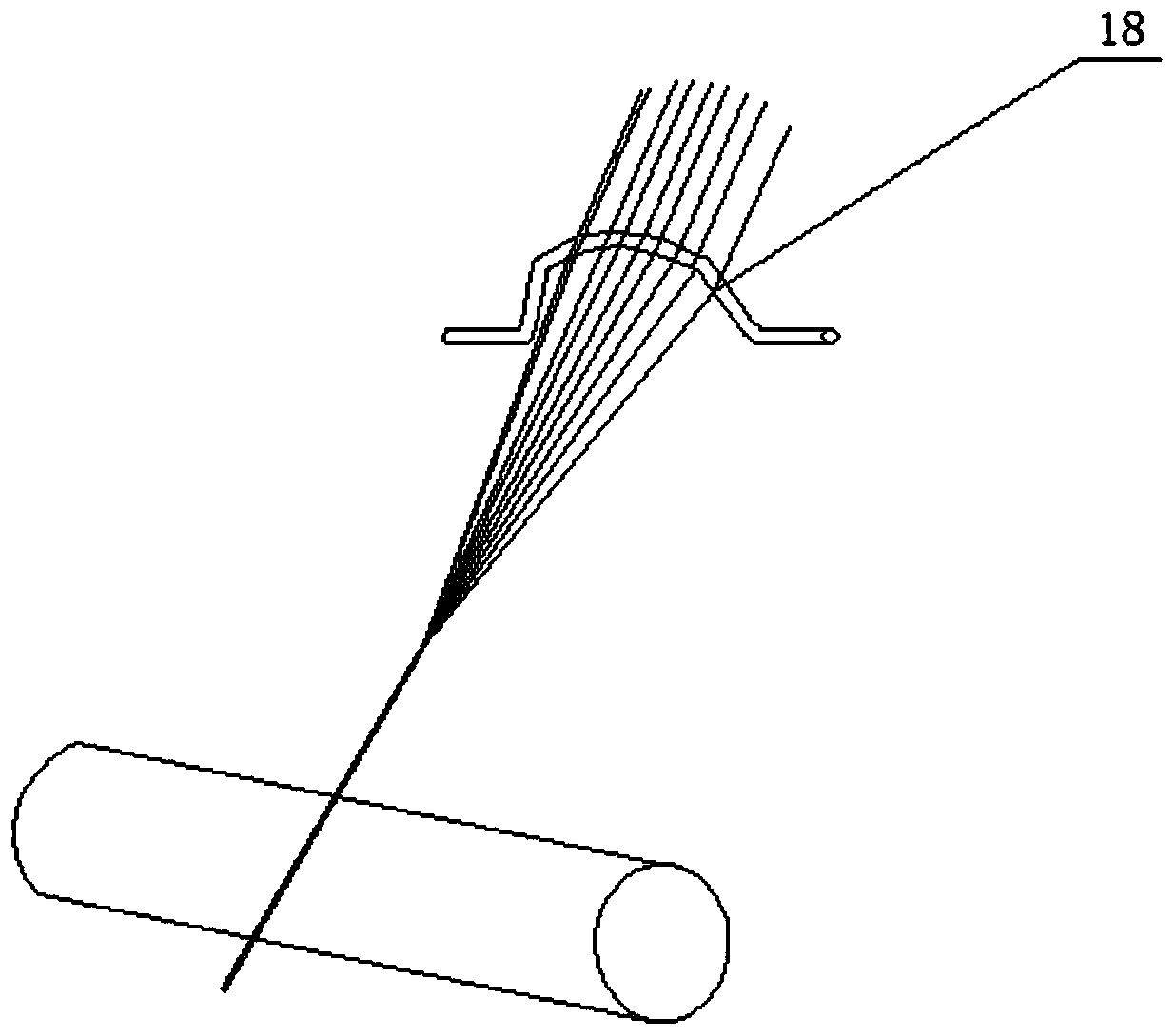

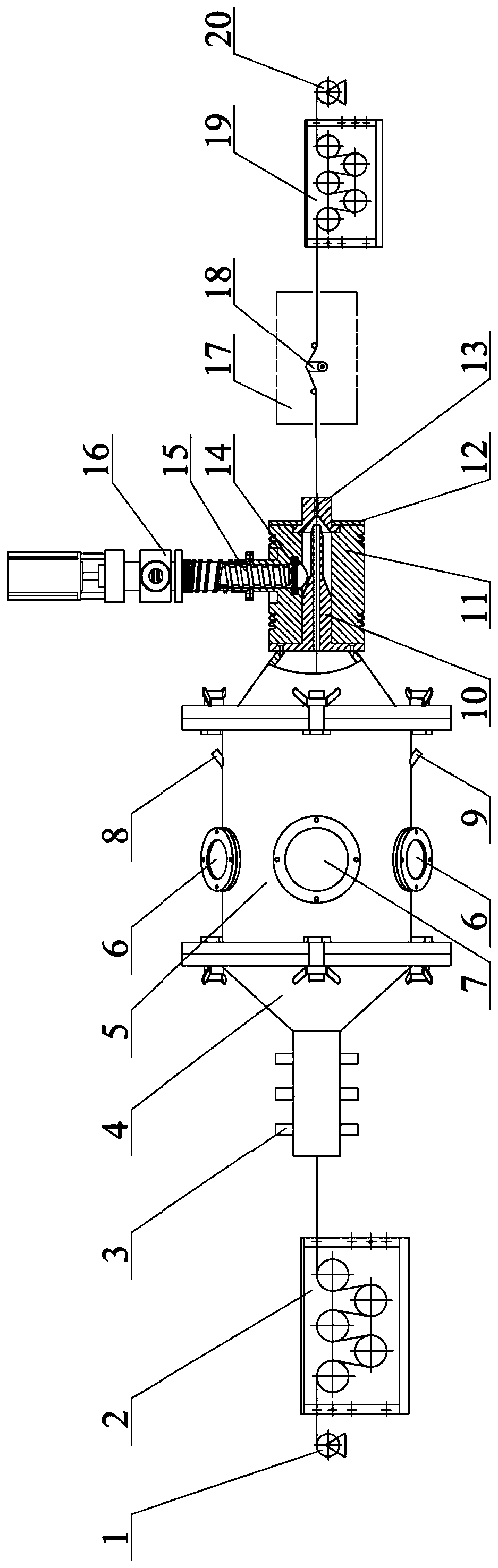

Carbon fiber laser graphitizing sizing equipment and method

ActiveCN110042583AGood fiber opening effectImprove wear resistancePhysical treatmentCarbon fibresCarbon fibersEngineering

The invention discloses carbon fiber laser graphitizing sizing equipment and method. The equipment is mainly composed of a silk releasing device, a drafting device A, a gas seal end cover, a graphitizing furnace body, a coating machine head, an extruder, a drying device, a drafting device B and a silk collecting device. The devices are sequentially arranged, the gas seal end cover is fixed to theleft end of the graphitizing furnace body through a bolt, the right end of the graphitizing furnace body is connected with the sizing coating machine head, the side face of the coating machine head isconnected with the small extruder, and the drying device, the drafting device B and the silk collecting device are sequentially mounted on the right side of the coating machine head. An outlet of a graphitizing furnace is directly connected with the coating machine head, inert gas sealing on the outlet is omitted, and the use amount of argon is saved. An extruded sizing agent has uniform and dense texture and is tightly attached to the surfaces of fibers, due to sizing in the pressure environment, the skinning performance of the sizing agent is better than the soaking effect in a sizing agenttank, skin films on the surfaces of the fibers are denser, and the performance of a prepared composite is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

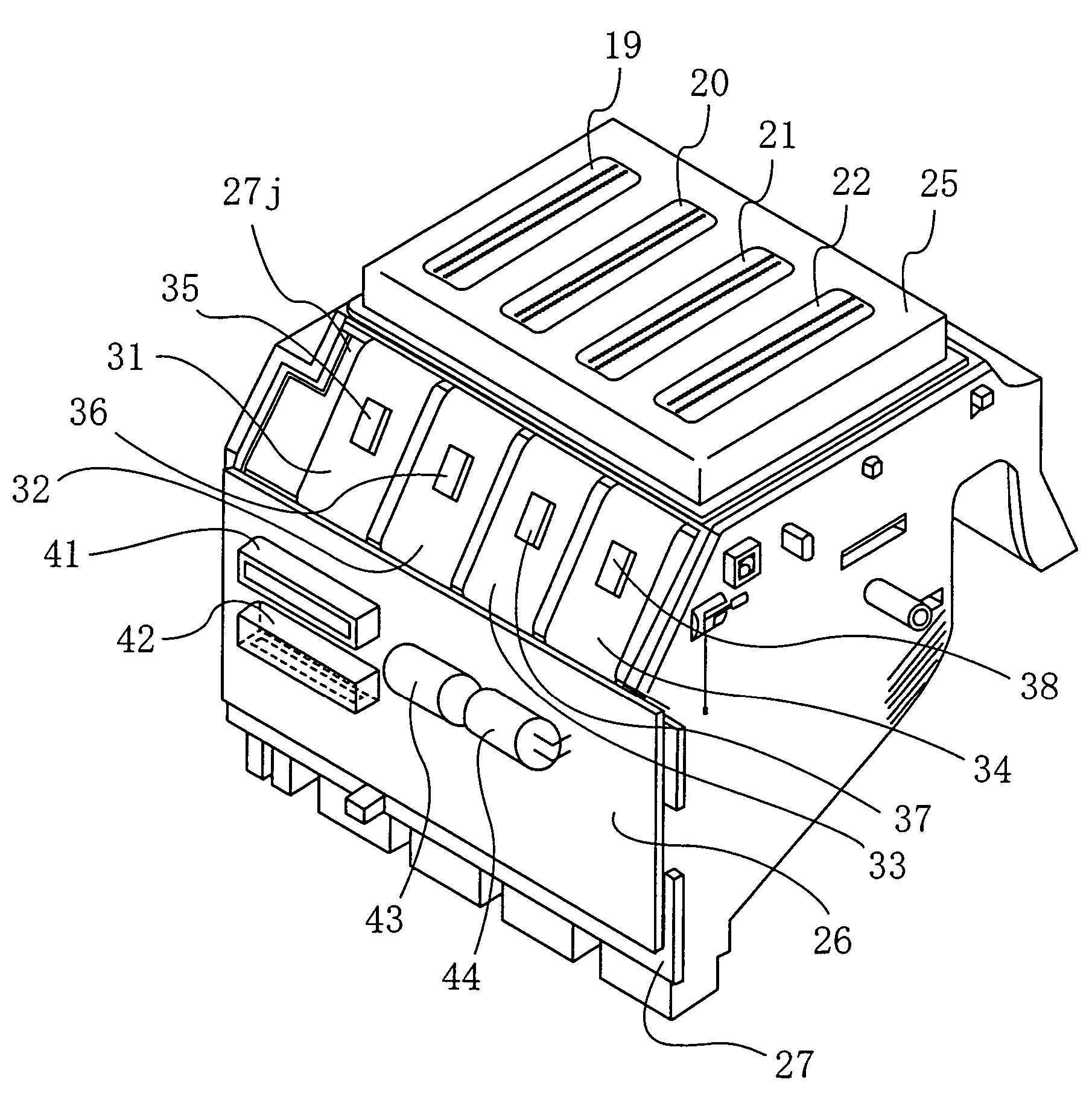

Recording apparatus

ActiveUS7252358B2High heat conductivityEfficient heat dissipationInking apparatusPrinted circuits structural associationsEngineeringHead holder

A recording apparatus comprising: a printing head which has a plurality of recording elements and performs recording on the recording medium; a head holder which holds the printing head; a flexible wiring board comprising a flexible insulating band and a plurality of conductive wires and a driver element for actuating the printing head, which are provided on the flexible insulating band; and a heatsink for releasing heat generated by the driver element, wherein the heatsink is disposed between the flexible wiring board and the head holder.

Owner:BROTHER KOGYO KK

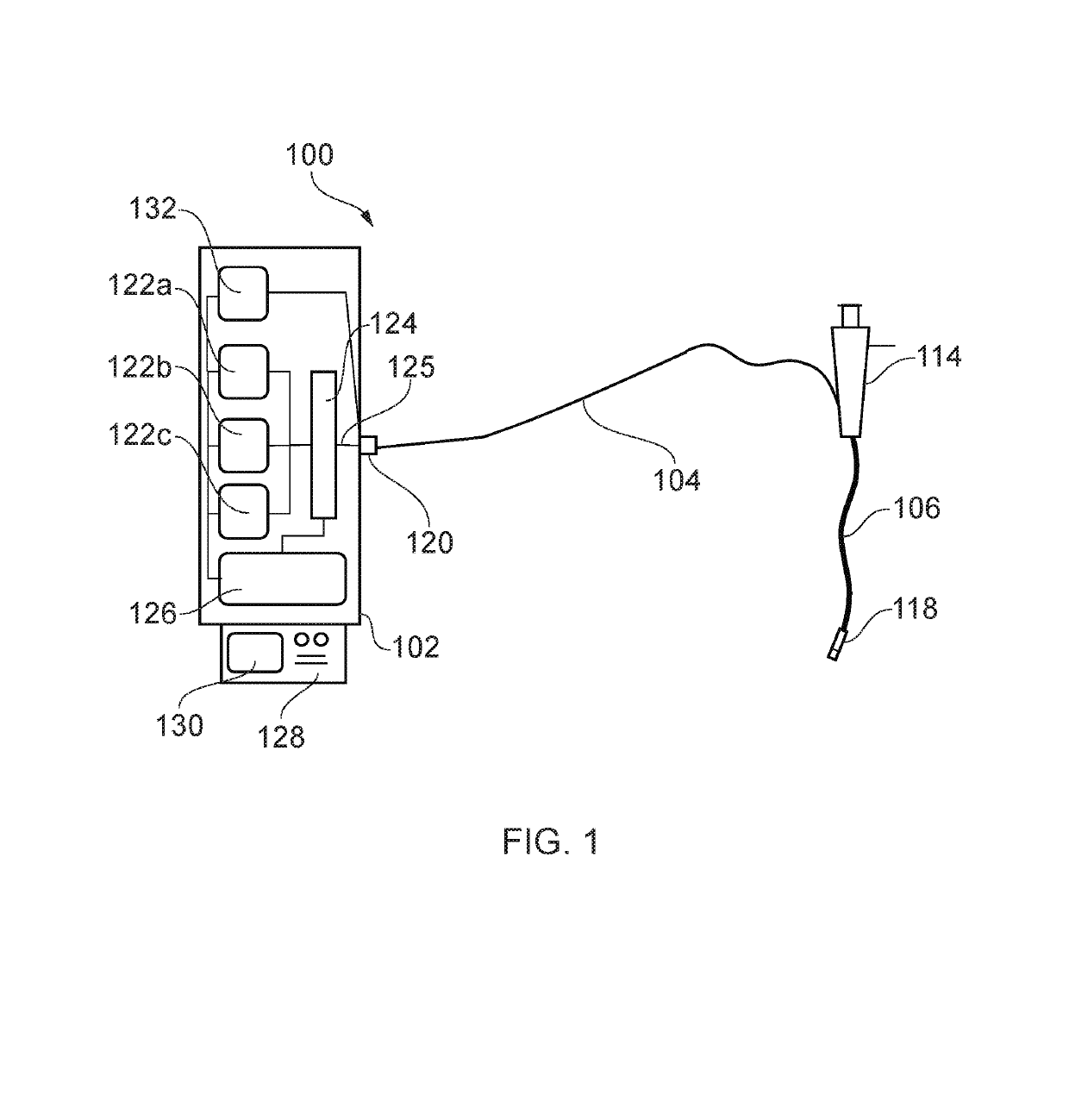

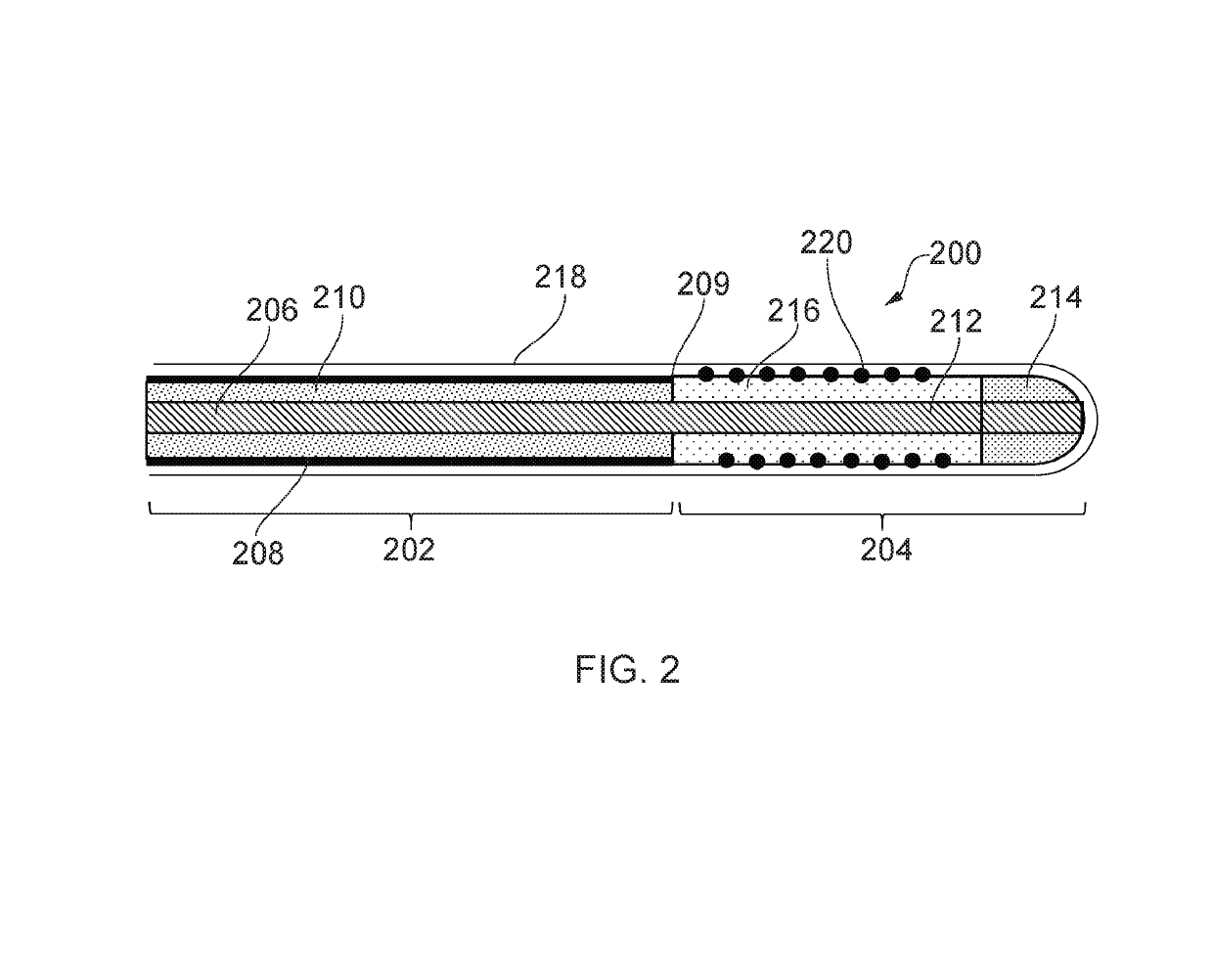

Electrosurgical instrument

ActiveUS20190201095A1Faster and more localised heatingFaster and more heatingCatheterSurgical instruments using microwavesElectricityCoaxial cable

An electrosurgical instrument with a radiating tip portion having a relative permeability and / or relative permittivity that is selected to provide an electrical length for the radiating tip portion that enables effective delivery into biological tissue of microwave EM energy supplied thereto, at two or more frequencies of choice. The instrument has a radiating tip portion disposed to receive microwave EM energy from a coaxial cable, the radiating tip portion having a first effective relative permeability at a first frequency and a second effective relative permeability at a second frequency.

Owner:CREO MEDICAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com