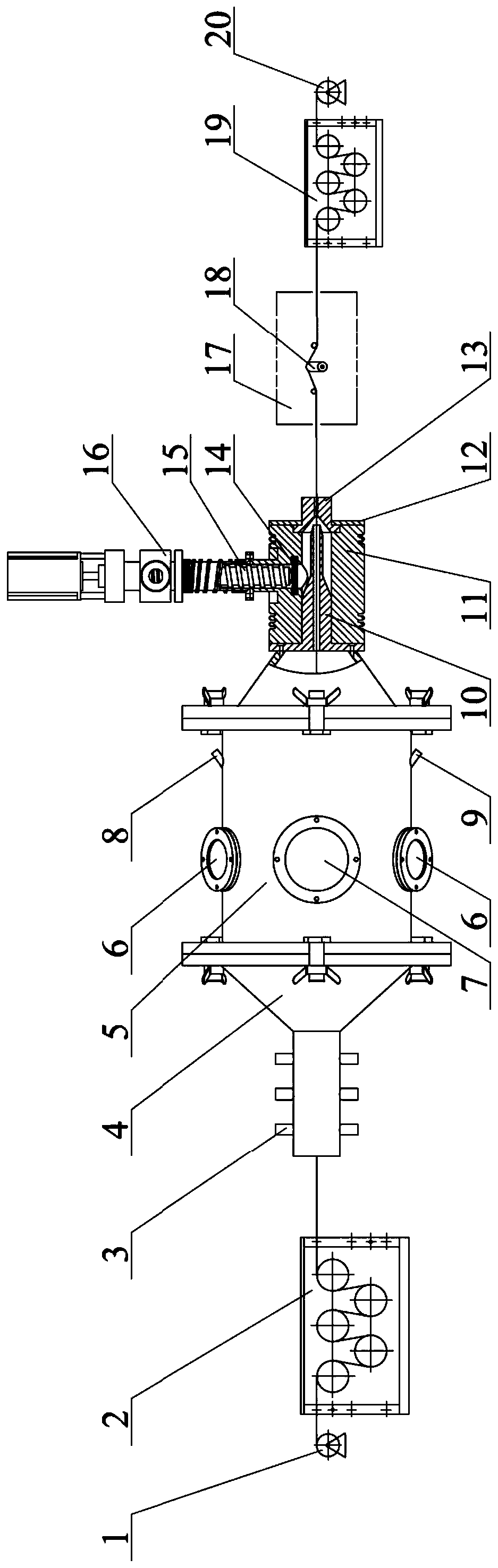

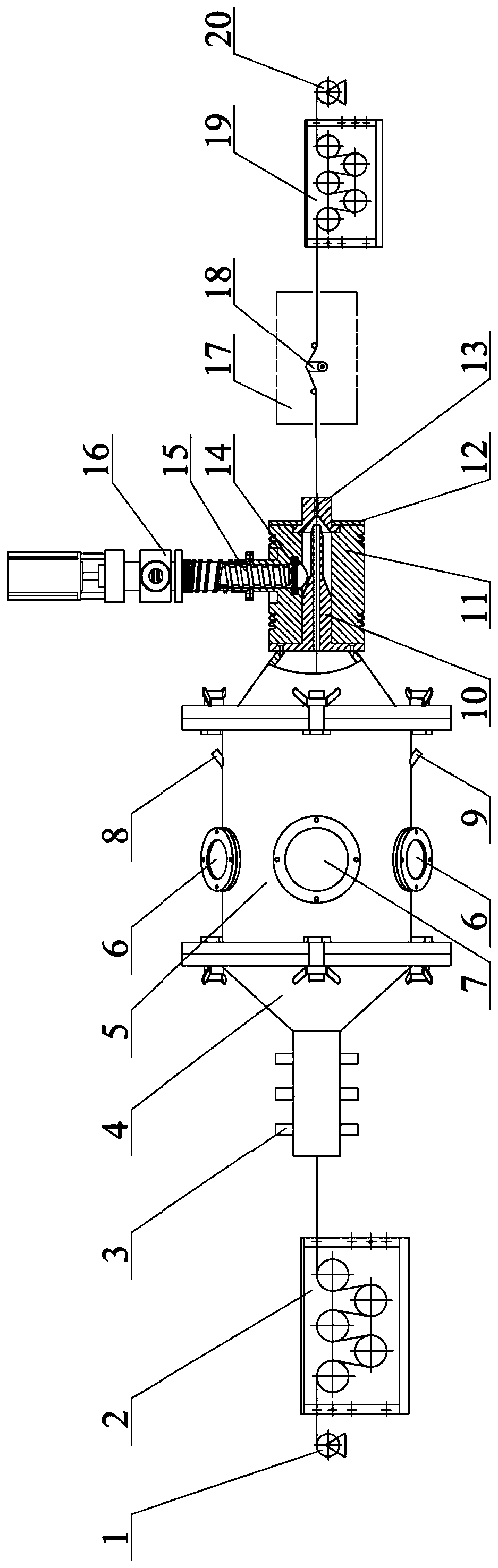

Carbon fiber laser graphitizing sizing equipment and method

A carbon fiber and graphitization technology, applied in the direction of carbon fiber, fiber processing, textile material processing equipment configuration, etc., can solve the problems of being susceptible to air pollution, uneven sizing, poor fiber opening, etc., to increase wear resistance, heating point control Precise, controllable preparation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0029]Components of emulsified sizing agent: (1) main agent: bisphenol A epoxy resin, (2) diluent: ethylene glycol monoethyl ether, (3) emulsifier: aromatic nonionic emulsifier, (4) lubricant Agent: butyl stearate, (5) solvent: water. Among them, the materials (1), (2), (3), and (4) are stirred and mixed at a high speed, and mixed uniformly at 50-60°C, and then (5) is added, the stirring speed is reduced, and the mixture is fully stirred and mixed below 40°C. Make it uniform, carry out emulsification and phase inversion, and obtain a milky white emulsion sizing agent.

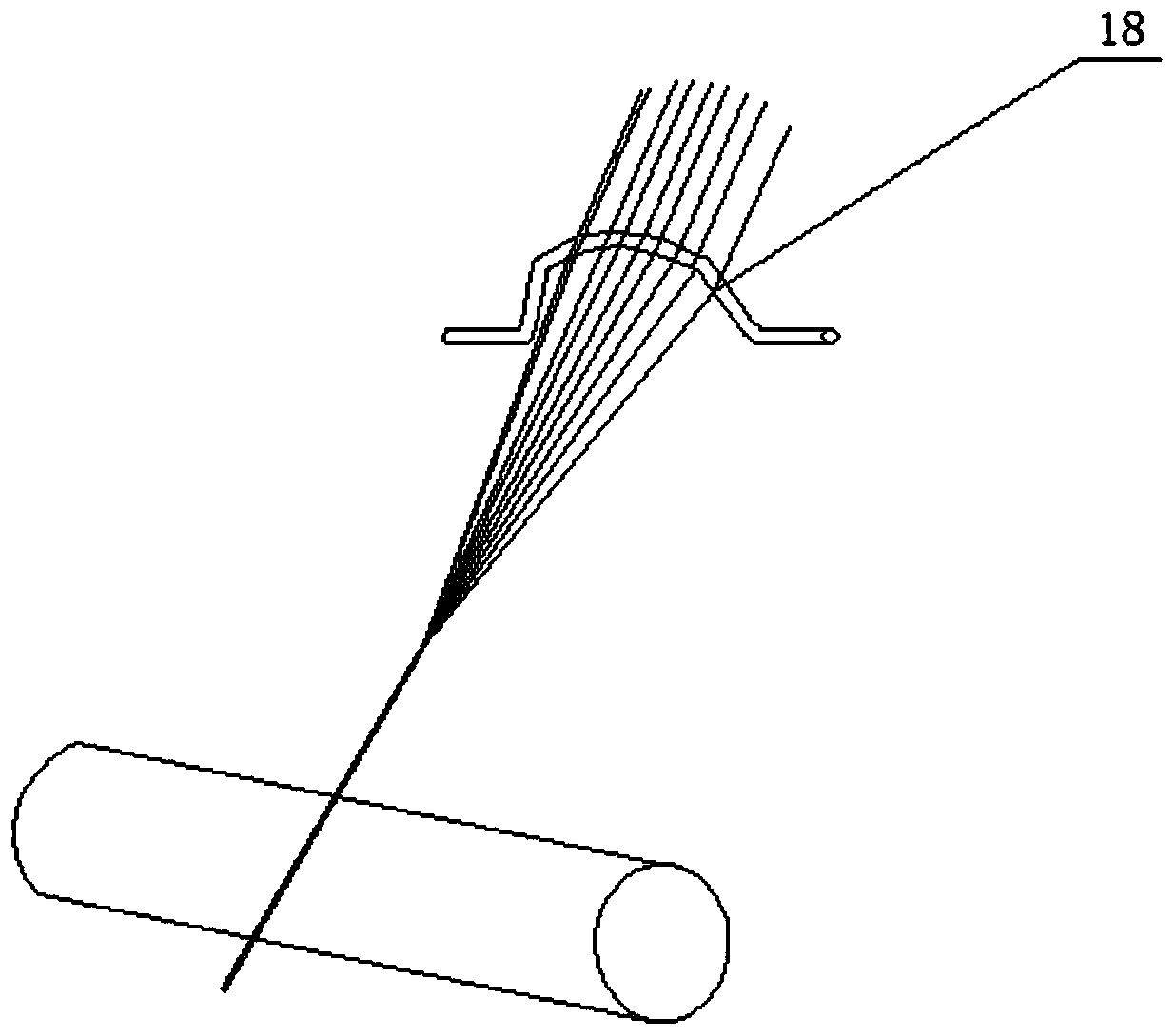

[0030] PAN-based carbon fiber is used, and the speed ratio rollers of the traction device A2 and traction device B19 are subjected to the drafting force. The wire speed is 60mm / min, and the wire inlet of the gas-sealed end cover 4 enters the main body of the graphitization furnace 5, and the argon gas After passing through the argon purifier, enter the graphitization furnace through the inlet 9, the inlet pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com