Glass fiber cloth and processing method for preparing glass fiber cloth from low-dielectric glass fiber filaments

A technology of glass fiber cloth and glass fiber yarn, which is applied in the processing field of glass fiber cloth, can solve the problems of influence of glass fiber cloth properties, damage to the integrity of glass fiber cloth, and limited fiber splitting effect, so as to achieve the best fiber splitting effect and satisfy The effect of high frequency and high speed and low dissipation factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

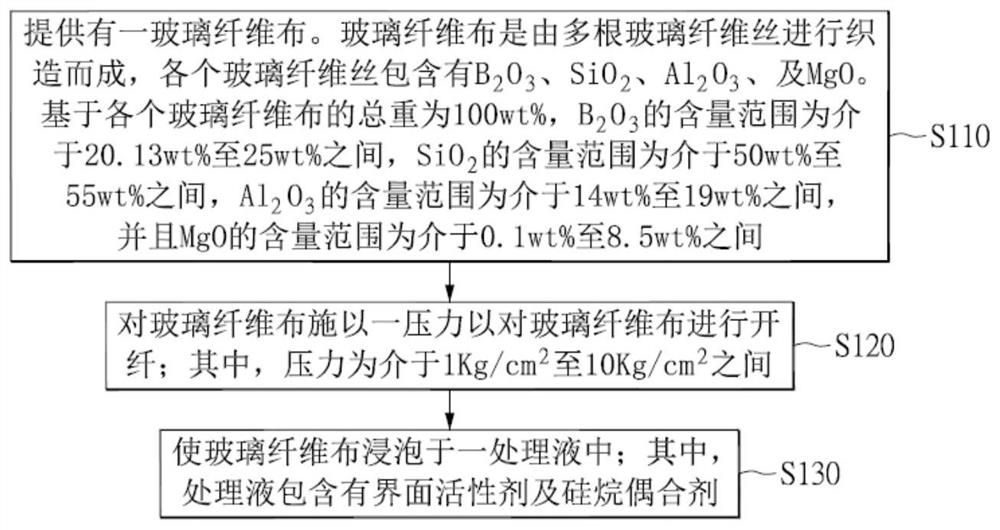

Method used

Image

Examples

Embodiment 1

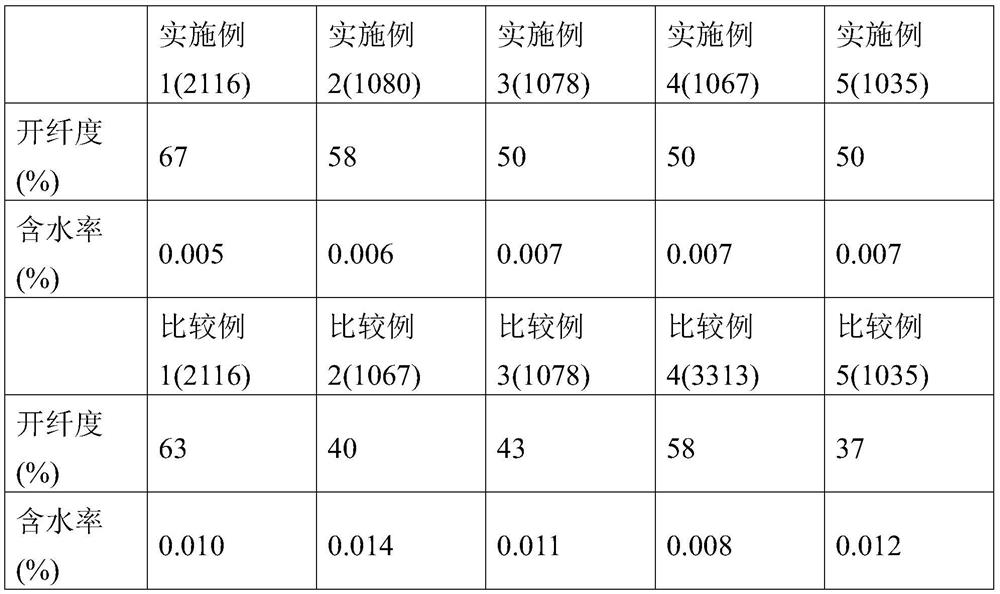

[0032] Example 1: A glass fiber cloth (such as 2116 cloth) is subjected to the processing method of the glass fiber cloth made of low-dielectric glass fiber filaments, and the product is obtained by heating and drying. In the treatment liquid, the silane coupling agent is methacryloxypropyl trimethoxysilane (manufactured by Dow Corning Co., Ltd.; OFS6030), and the surfactant is polyethanol phenol ether, partial fluorine Alcohol replaces ethylene glycol and polyoxypropylene polyoxyethylene ether.

Embodiment 2

[0033] Embodiment 2: A glass fiber cloth (such as 1080 kinds of cloth) implements the processing method of the glass fiber cloth made of low-dielectric glass fiber yarn, and heats and dries, and then utilizes high-pressure water to carry out fiber opening treatment to obtain products. In the treatment liquid, the silane coupling agent is methacryloxypropyl trimethoxysilane (manufactured by Dow Corning Co., Ltd.; OFS6030), and the surfactant is polyethanol phenol ether, partial fluorine Alcohol replaces ethylene glycol and polyoxypropylene polyoxyethylene ether.

Embodiment 3

[0034] Embodiment 3: Implement the processing method of glass fiber cloth made of low-dielectric glass fiber filaments on a glass fiber cloth (such as 1078 cloth), and perform heating and drying treatment to obtain a product. In the treatment liquid, the silane coupling agent is methacryloxypropyl trimethoxysilane (manufactured by Dow Corning Co., Ltd.; OFS6030), and the surfactant is polyethanol phenol ether, partial fluorine Alcohol replaces ethylene glycol and polyoxypropylene polyoxyethylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com