Patents

Literature

41results about How to "Good fiber opening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

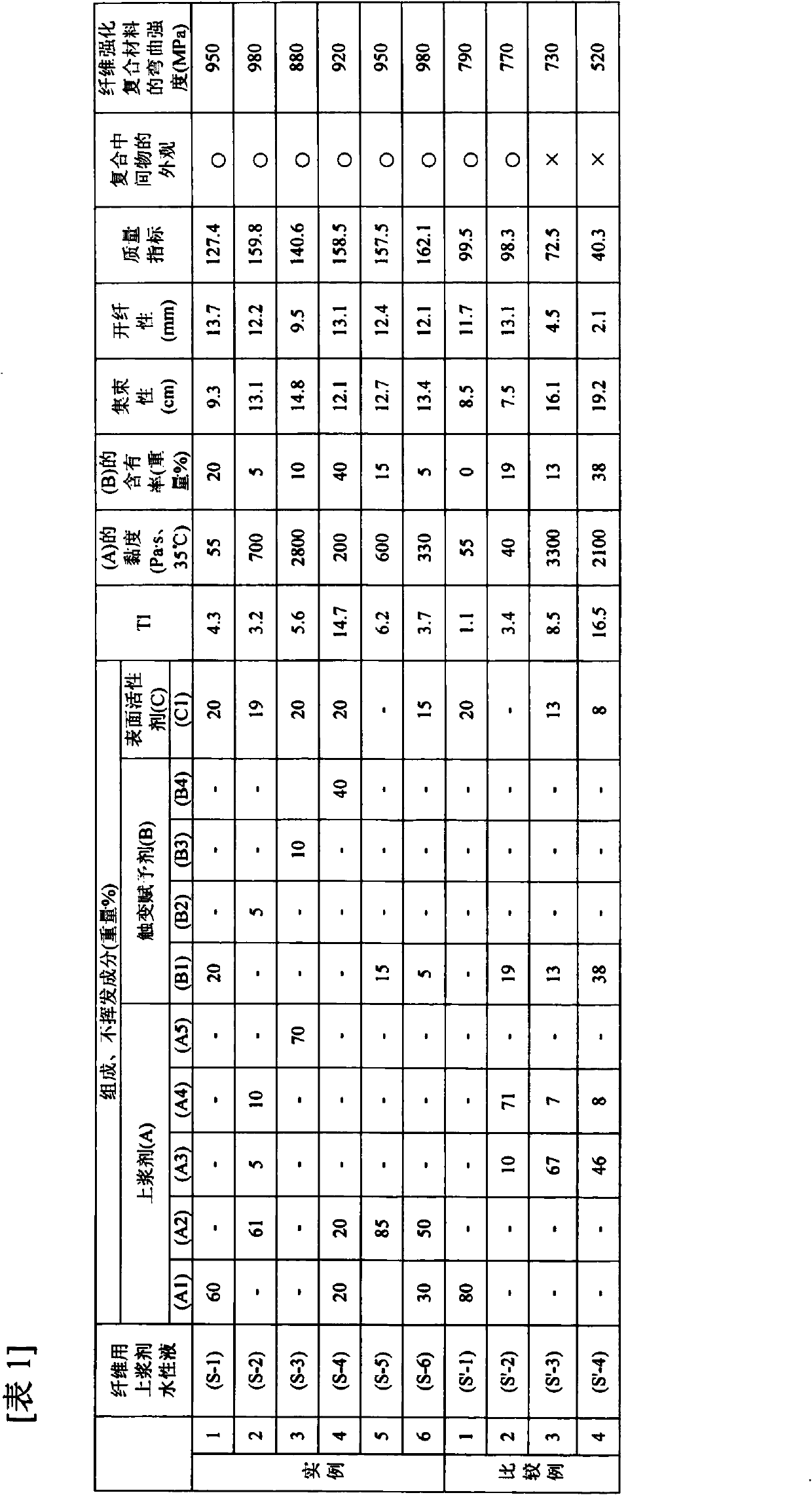

Fiber sizing agent composition

InactiveCN103797183AEasy to bundleGood fiber opening effectCarbon fibresThin material handlingEpoxyFiber bundle

Provided is a fiber sizing agent capable of imparting sufficient sizing properties and fiber spreading properties to reinforced fiber bundles for producing fiber-reinforced composite materials. A fiber sizing agent composition (E) which contains a fiber sizing agent (A), said fiber sizing agent having a viscosity at 35oC of 50-3,000 Pas, and has a thixotropic index of 3-15. As the sizing agent (A), an epoxy resin, a polyester rein, a polyurethane resin, a polyether resin and a vinyl ester resin are preferred.

Owner:SANYO CHEM IND LTD

Cellulose fiber and manufacturing process therefor, cellulose fiber aggregate and cellulose fiber composite material

ActiveCN103429622AGood fiber opening effectHigh transparencyPaper/cardboardArtificial filaments from cellulose derivativesCellulose fiberFibrous composites

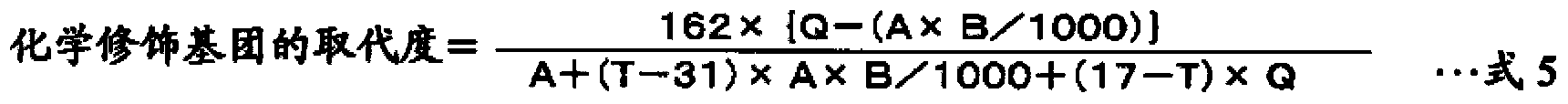

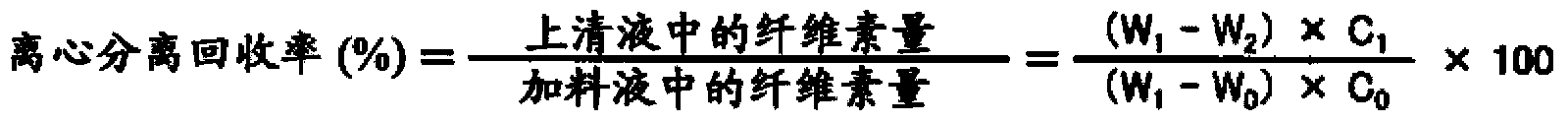

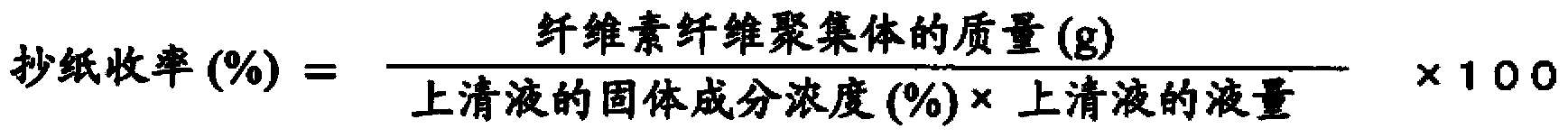

The present invention pertains to a cellulose fiber in which some of the hydroxyl groups of the cellulose are substituted with carboxyl and / or formyl in an amount of 0.1mmol / g or more relative to the weight of the cellulose fiber and are further substituted with a chemically modifying group other than carboxyl and formyl.

Owner:OJI HLDG CORP

Method for producing weft-knitting suede fabric

The invention, which belongs to the technical field of the textile fabric, provides a method for producing weft-knitting suede fabric. The method comprises the following steps: (1), weaving is carried out; to be specific, weft knitting is carried out on 20% to 26% of T400 high stretch yarn and 74 to 80% of sea-island filaments to form fabric; (2), washing is carried out; (3), splitting is carried out; to be specific, the processed fabric is put into a solution including caustic soda and an M-1100 splitting agent, wherein the bath ratio is 1 to 15-20 and the temperature is 90 to 92 DEG C; (4), singeing is carried out; to be specific, the fabric is processed by flame quickly to burn fuzz formed on the surface of a piece of greige cloth, wherein the flame temperature of the fuzz burning is 900 to 1000 DEG C; (5), dyeing is carried out; (6), drying is carried out; (7), sanding is carried out; and (8), drying and sizing are carried out. The product produced based on the method has advantages of high coverage, soft feeling, high lustrousness and flexibility, substantially improved fabric performance, simple production process, high production efficiency, and low cost.

Owner:TONGXIANG HUIQUAN TEXTILE CO LTD

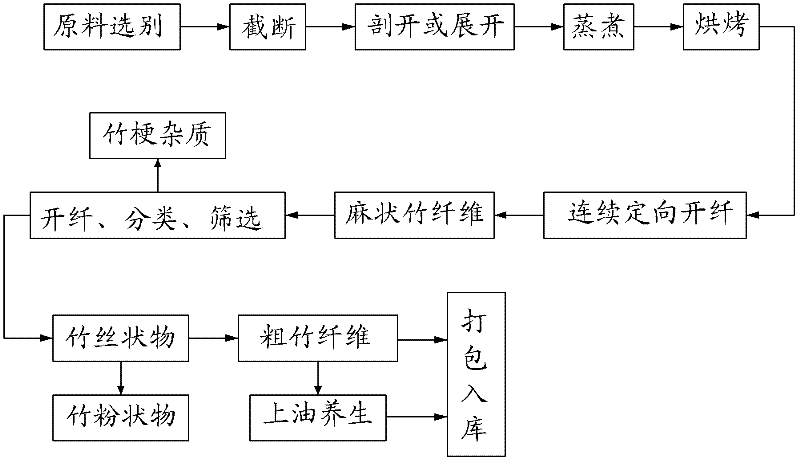

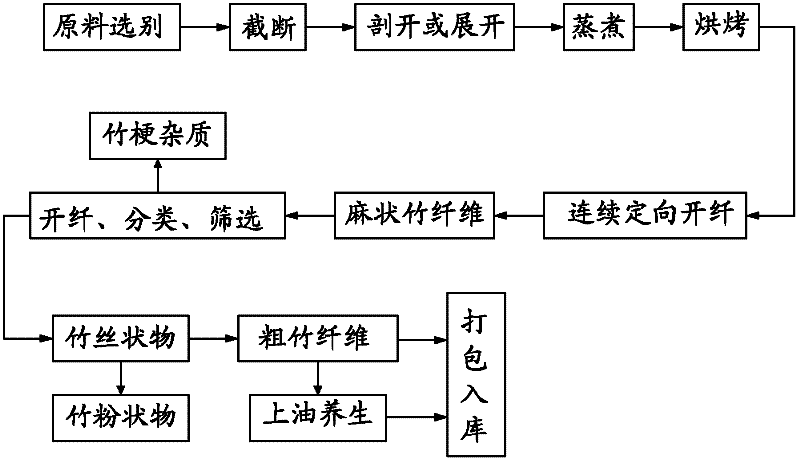

Non-pollution production method of bamboo fibers

ActiveCN102517642AEfficient productionNo harmVegetable materialMechanical fibre separationFiberPollution

The invention provides a non-pollution production method of bamboo fibers, wherein the method is used for producing coarse bamboo fibers with lengths of 60-120 mm and diameters of 0.18-0.35 mm. the method comprises the steps of: firstly, selecting the raw materials; and then, cutting the bamboos into regulated lengths; splitting or flattening the bamboos; adding a reusable neutral softening solution in the bamboos to stew and soften the bamboos; roasting the softened bamboos on a drying machine; directionally opening fibers from the roasted bamboos; drying the bamboos, opening fibers for the second time, classifying and sorting to obtain bamboo fibers with stable quality. The method of the invention has the advantages of non waste liquid drainage during the production process, simple technique, high production efficiency, reliable product quality, and capability of greatly improving the fiber yield and reducing the production cost, so that the method is an ideal method for producing bamboo fibers.

Owner:ZHEJIANG FORESTRY UNIVERSITY

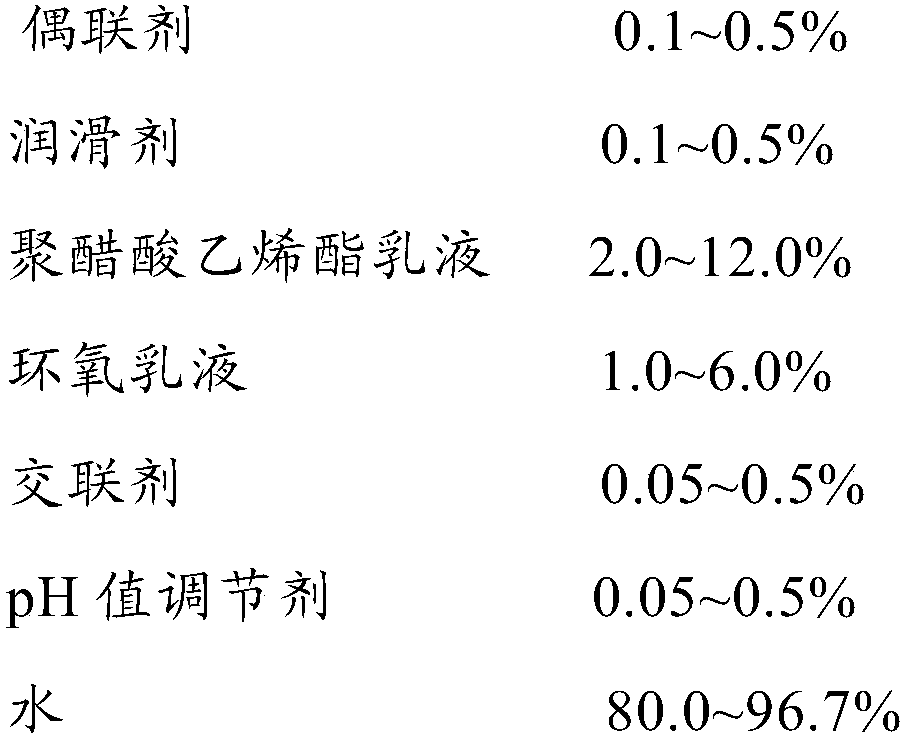

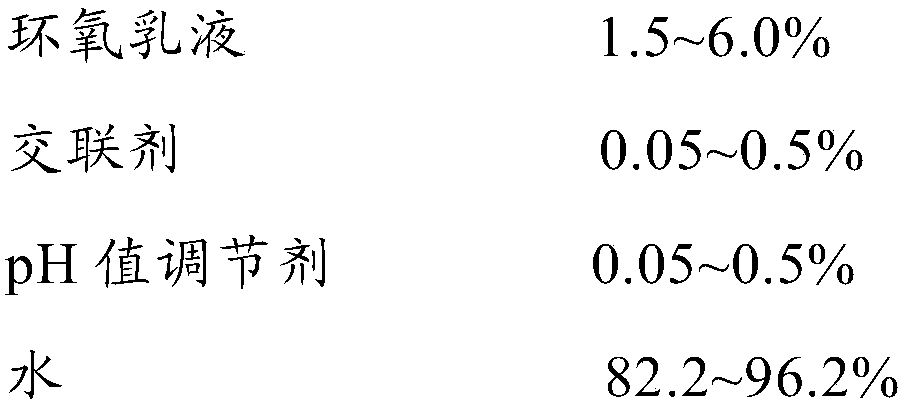

Glass fiber sizing agent and application thereof

The invention provides a glass fiber sizing agent. The glass fiber sizing agent is prepared from the following components in mass by percentage: 0.1 to 0.5% of coupling agent, 0.1 to 0.5% of lubricant, 2.0 to 12.0% of polyvinyl acetate emulsion, 1.0 to 6.0% of epoxy emulsion, 0.05 to 0.5% of crosslinking agent, 0.05 to 0.5% of pH adjusting agent, and 80.0 to 96.7% of water. The epoxy emulsion is abisphenol A type epoxy resin emulsion, and the polyvinyl acetate emulsion comprises a crosslinked polyvinyl acetate and a plasticized modified polyvinyl acetate, wherein the mass ratio of the crosslinked polyvinyl acetate and the plasticized modified polyvinyl acetate is (1 to 1) to (5 to 1). By using the sizing agent of the invention, the produced glass fiber yarn can not only improve the colorand breaking strength of the yarn, but also effectively improve the fluidity of the glass fiber and improve the compatibility with a matrix resin, and an SMC material for a sewage degrading tank obtained by reinforcing the glass fiber sizing agent can be improved has the advantages of uniform glass fiber distribution, smooth surface, high product yield and good mechanical properties.

Owner:JUSHI GRP CO

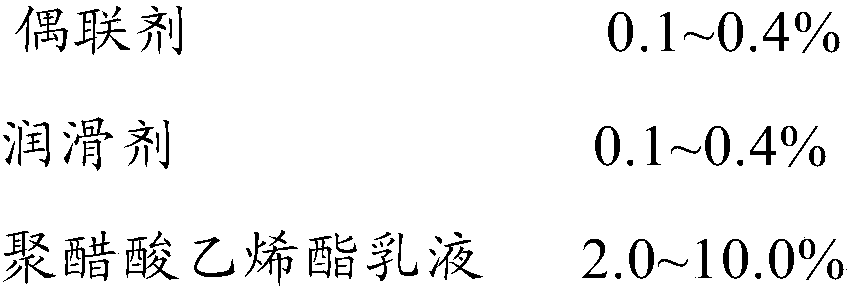

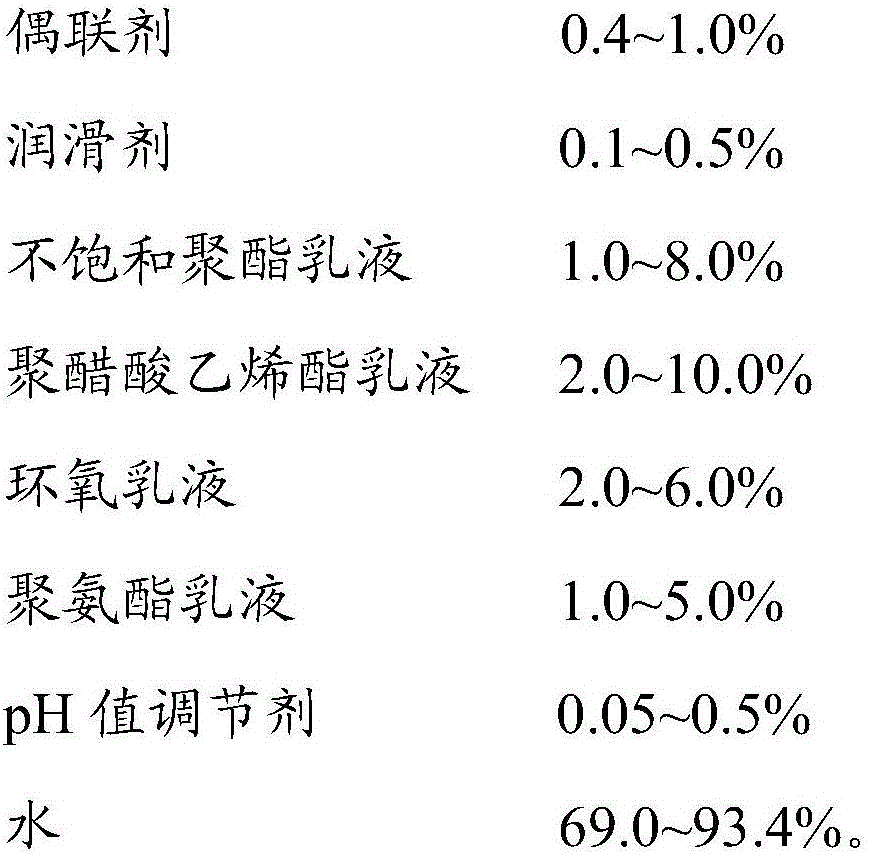

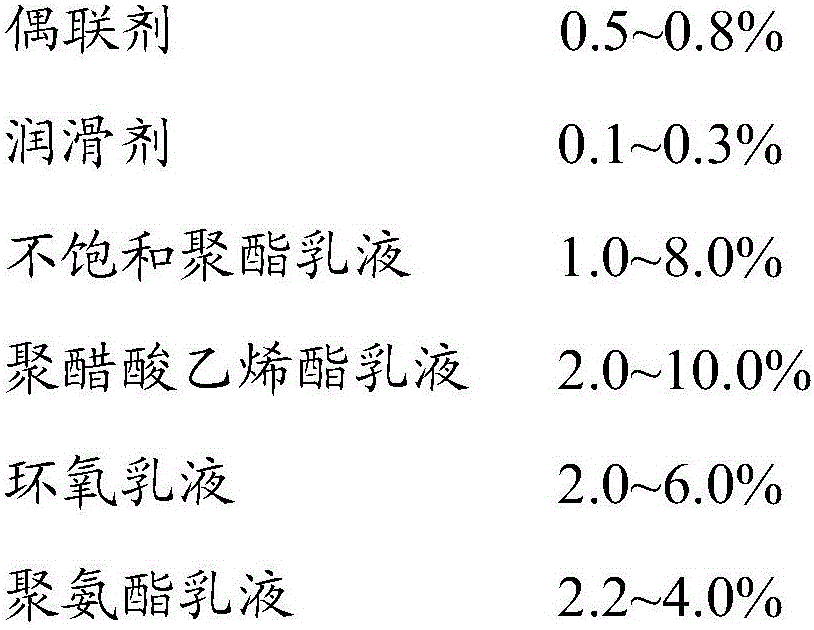

Glass fiber impregnating compound and application thereof

Owner:JUSHI GRP CO

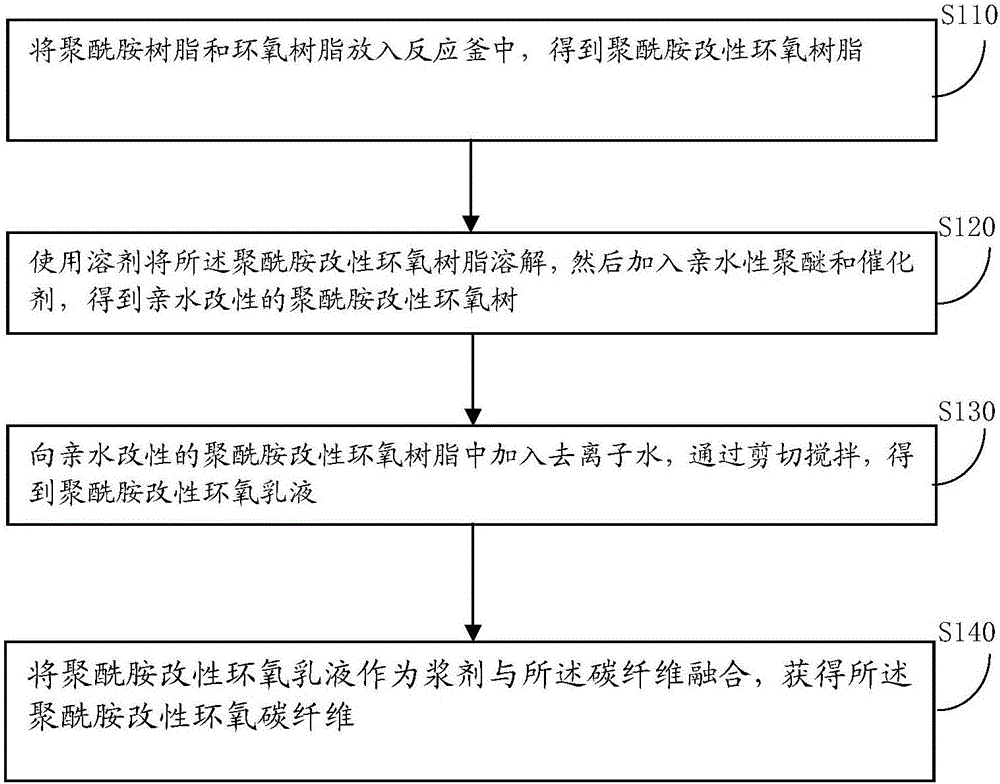

Preparation method of polyamide-modified epoxy carbon fiber

InactiveCN106637984AImprove performanceEasy to bundleCarbon fibresLiquid repellent fibresFiberBreaking strength

The application provides a preparation method of polyamide-modified epoxy carbon fiber, and relates to the field of preparation of carbon fiber / epoxy composite materials. The method comprises the steps of putting polyamide resin and epoxy resin into a reaction kettle to obtain polyamide-modified epoxy resin; dissolving the polyamide-modified epoxy resin by using a solvent, and then adding hydrophilic polyether and a catalyst to obtain hydrophilic modification polyamide-modified epoxy resin; adding deionized water into the hydrophilic modification polyamide-modified epoxy resin, shearing and stirring to obtain polyamide-modified epoxy emulsion; finally, carrying out sizing treatment on carbon fiber by taking the polyamide-modified epoxy emulsion as a sizing agent so as to obtain the polyamide-modified epoxy surface modification carbon fiber. The preparation method solves the problems that the modification method in the existing carbon fiber production is complicated in conditions and hard in control of treatment time, so that the modulus and breaking strength of the carbon fiber are easily reduced, and the performance of a carbon fiber composite material is greatly reduced accordingly.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

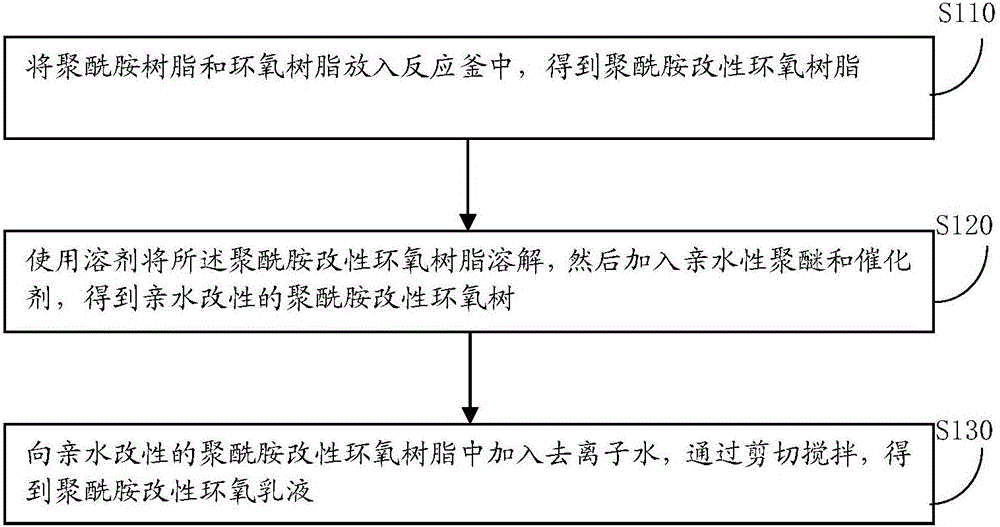

Preparation method for polyamide-modified epoxy resin emulsion

The invention provides a preparation method for polyamide-modified epoxy resin emulsion, and relates to the field of preparation of carbon fibre sizing agent emulsion. The method comprises the following steps: placing polyamide resin and epoxy resin into a reaction kettle to obtain polyamide-modified epoxy resin; dissolving the polyamide-modified epoxy resin by using a solvent; then, adding a hydrophilic polyether and a catalyst to obtain hydrophilic modified polyamide-modified epoxy resin; adding deionized water into the hydrophilic modified polyamide-modified epoxy resin; shearing and stirring to obtain the polyamide-modified epoxy resin emulsion. The deficiencies of poor heat resistance and toughness of a sizing agent used in the prior art are overcome; the polyamide-modified epoxy resin emulsion has high heat resistance and high toughness; when the polyamide-modified epoxy resin emulsion is used as a carbon fibre sizing agent, the technical effects of excellent bundling property, splitting property and wettability with the epoxy resin can be provided for fibre bundles.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

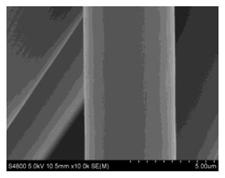

Preparation method of polyacrylonitrile-based carbon fiber precursor

ActiveCN104088029AImprove raw silk performance and quality stabilityOptimal Control StructureMonocomponent synthetic polymer artificial filamentPolyacrylonitrileHeat setting

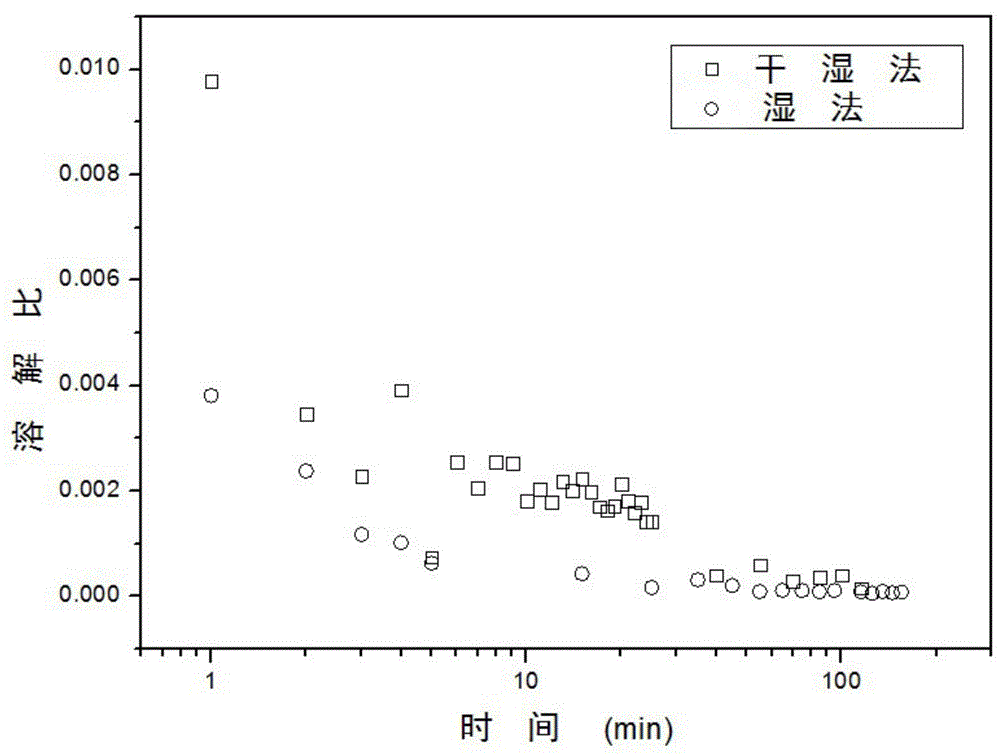

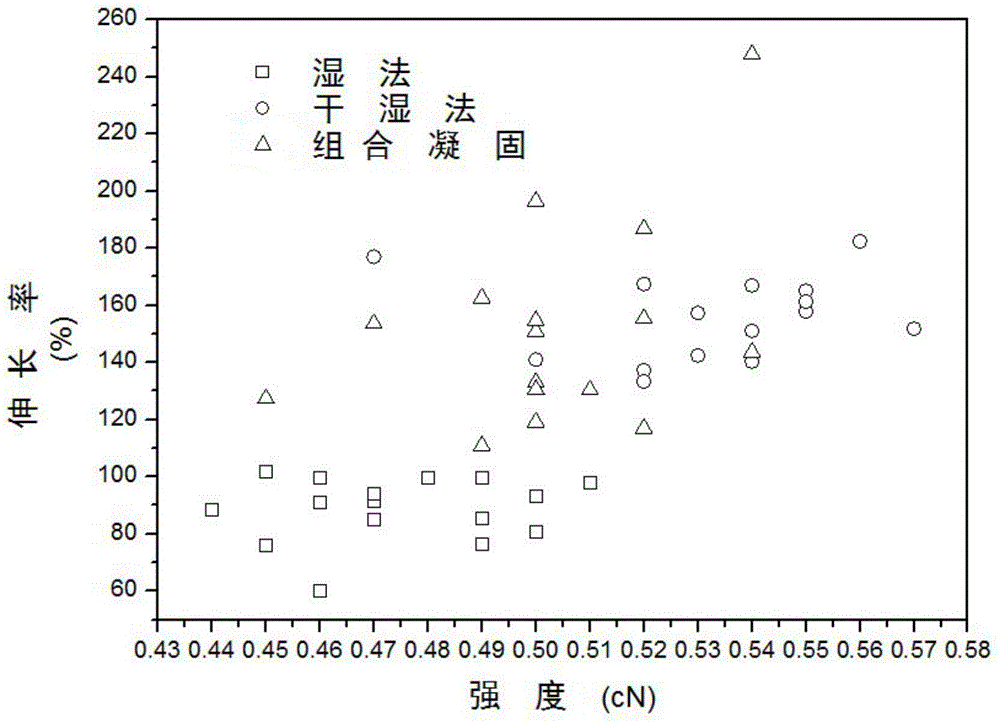

The invention relates to a preparation method of a polyacrylonitrile-based carbon fiber precursor; after filament-out of a polyacrylonitrile spinning solution, the polyacrylonitrile spinning solution enters into a stage of non solidification bath, and then enters into a composite solidification molding process of a solidification bath. The preparation method specifically includes the following steps: after solidification molding of the polyacrylonitrile spinning solution by the composite solidification molding process, successive drafting, water washing, oiling, drying, steam drafting or boiling water drafting, heat setting, drying, and filament collection. The preparation method can overcome the shortcomings of a traditional wet and dry process and wet process, and is conducive to the control of raw filament cortex structure. By use of the process, a spinning speed more than 300m / min can be achieved, the obtained raw filament has a surface groove structure similar with that of a wet-method raw filament, is soft in hand feeling and good in splitting property, and the carbonized strength is higher than 5.8GPa. The preparation method belongs to the technical field of preparation methods of the polyacrylonitrile-based carbon fiber precursor.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

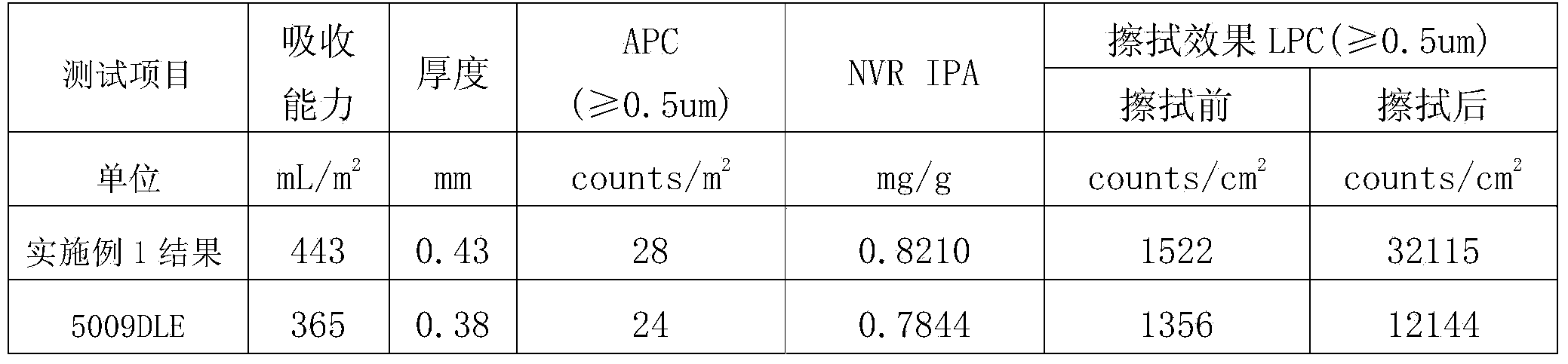

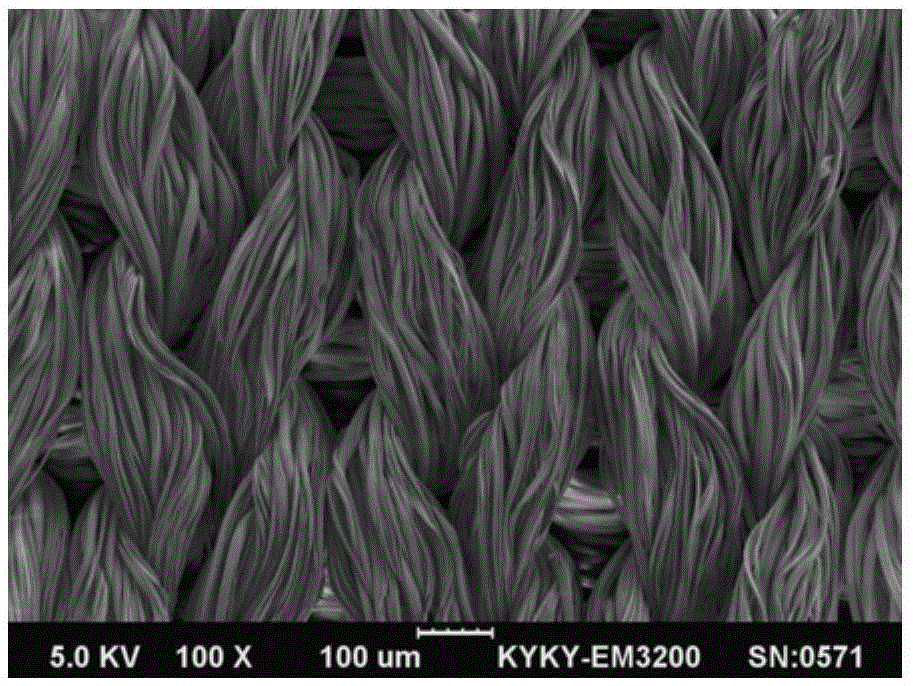

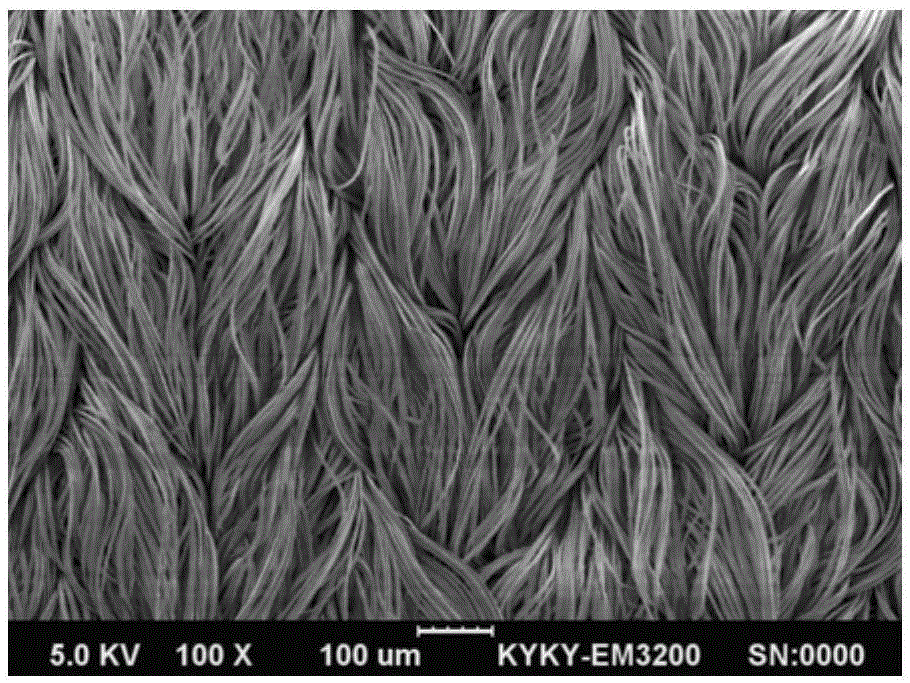

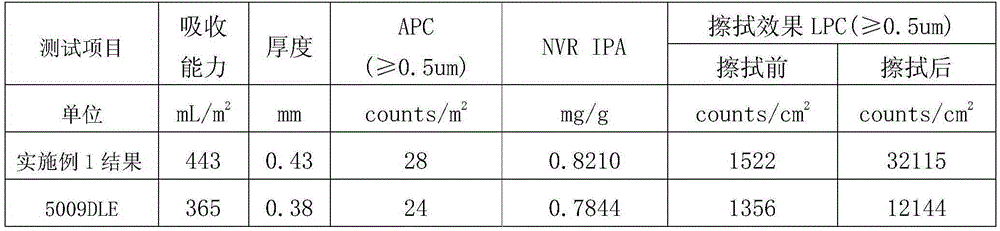

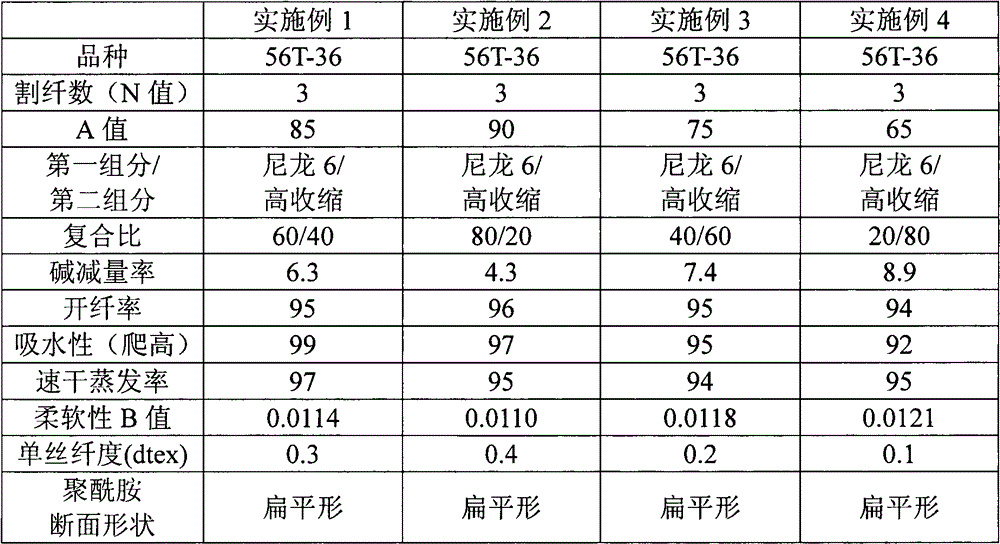

Dustless cloth with high shrinkage and high dust removing efficiency as well as production method thereof

ActiveCN104074043AGood fiber opening effectStrengthen the strength of fiber openingFibre typesDry-cleaning apparatus for textilesGramPolyester

The invention provides a production method of dustless cloth with high shrinkage and high dust removing efficiency as well as the produced dustless cloth. The production method comprises the following main steps: polyester / nylon superfine fiber yarns are woven to gray cloth by using a knitting machine; the gram weight of the produced gray cloth is 130-180 g / m2; the gray cloth is poured in a dye vat by the bath ratio of 1: 5-7; penetrating agent, sodium hydroxide, EDTA-4Na and degreasing agent are added in the dye vat; the gray cloth is cleaned in a manner of discharging while washing; acetic acid is added for cleaning again; splitting agent is added for treating, and the cleaning is performed; soaping agent is added; and the gray cloth is cleaned again in the manner of discharging while washing. According to the production method of the dustless cloth with high shrinkage and high dust removing efficiency provided by the invention, the produced dustless cloth has excellent absorbability and good dust and dirt removing effect.

Owner:河源市锦扬新材料有限公司

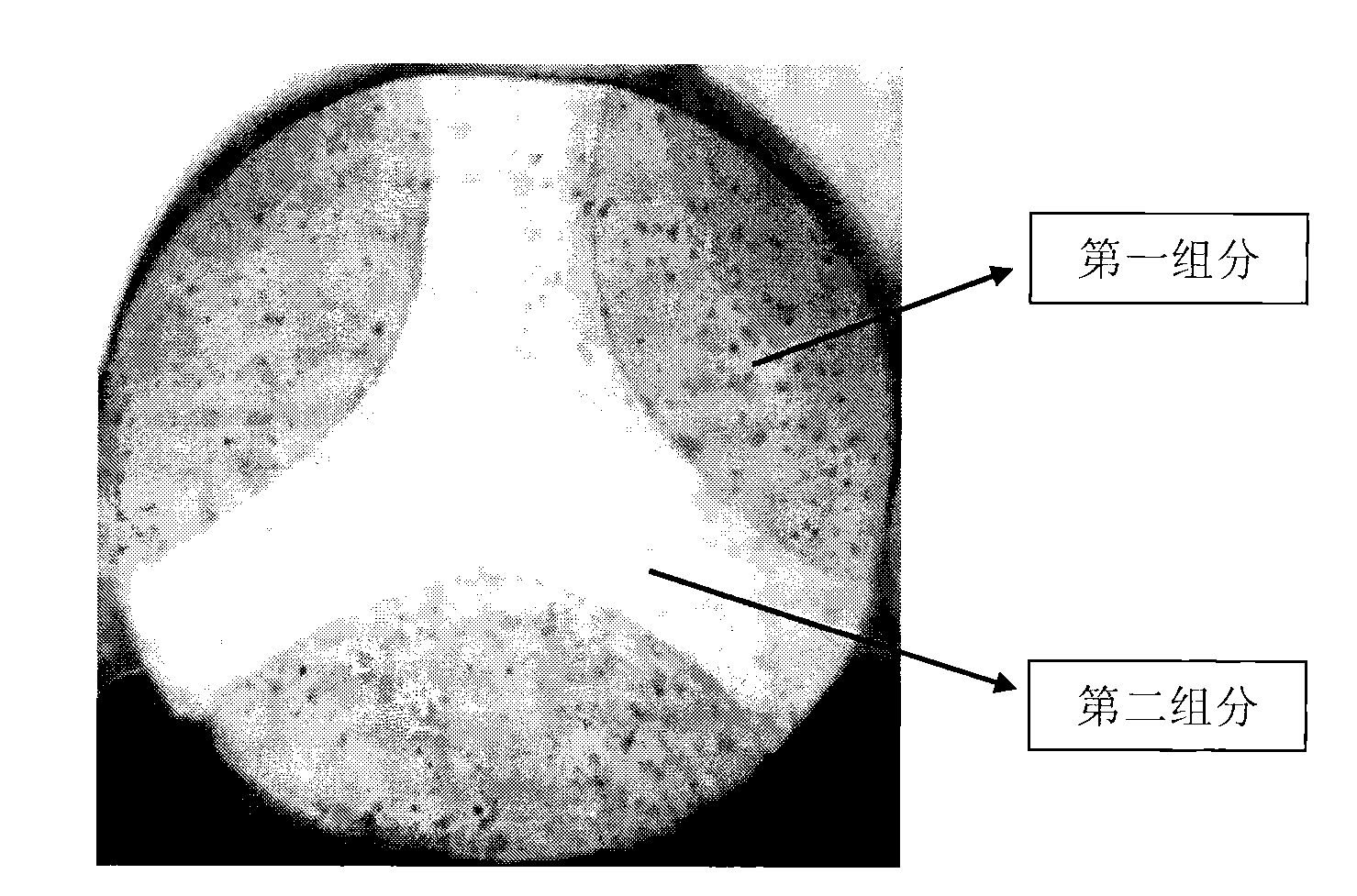

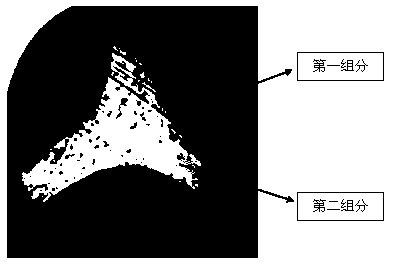

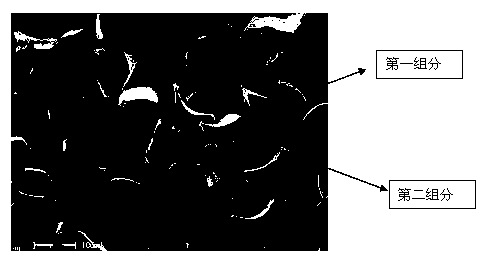

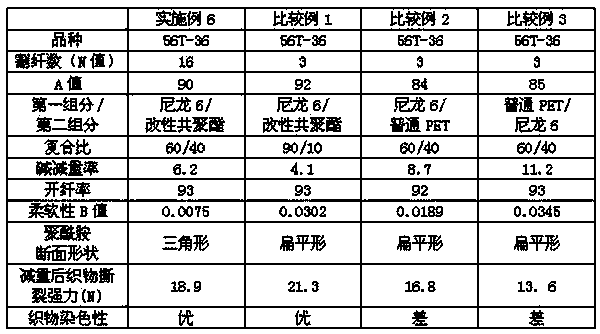

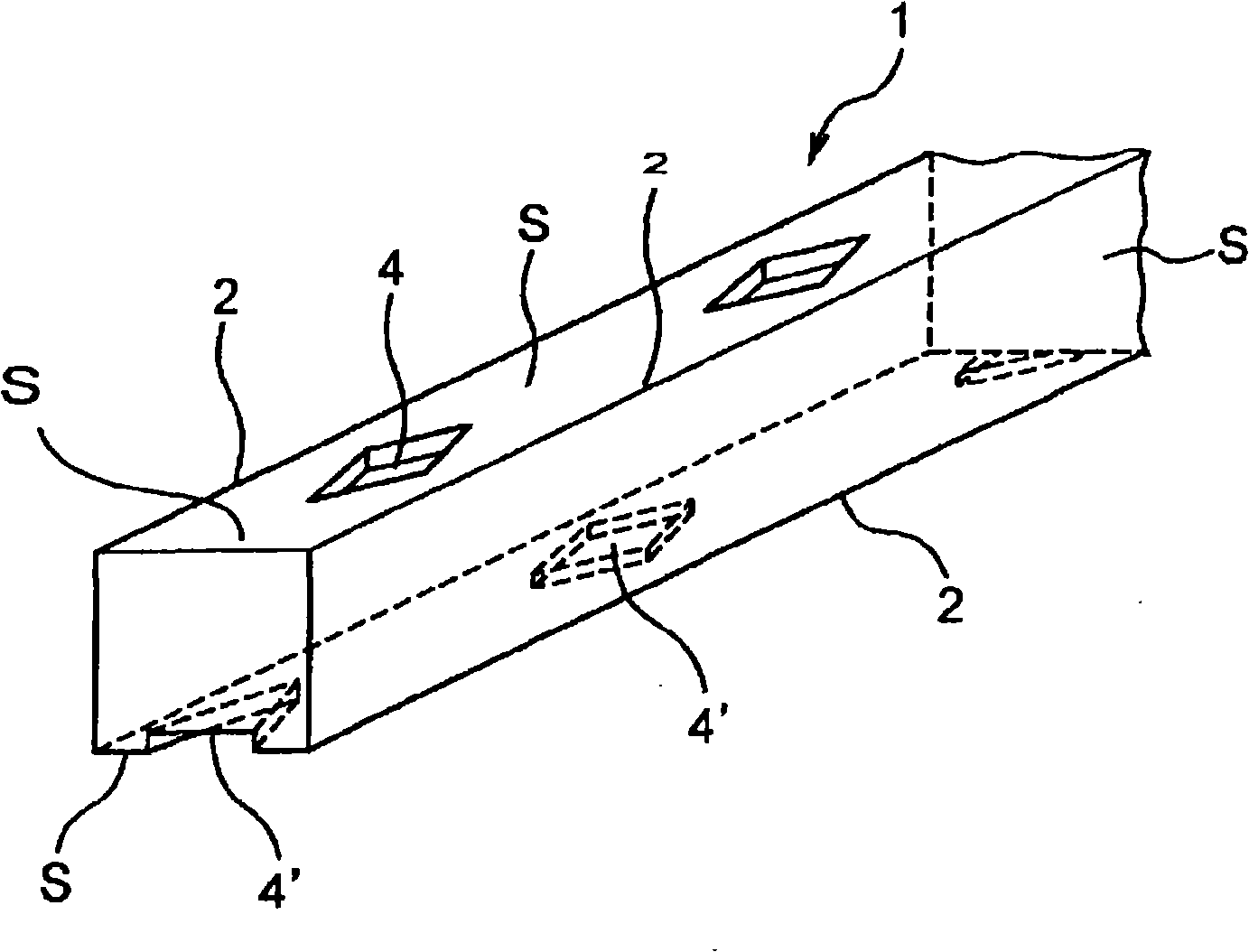

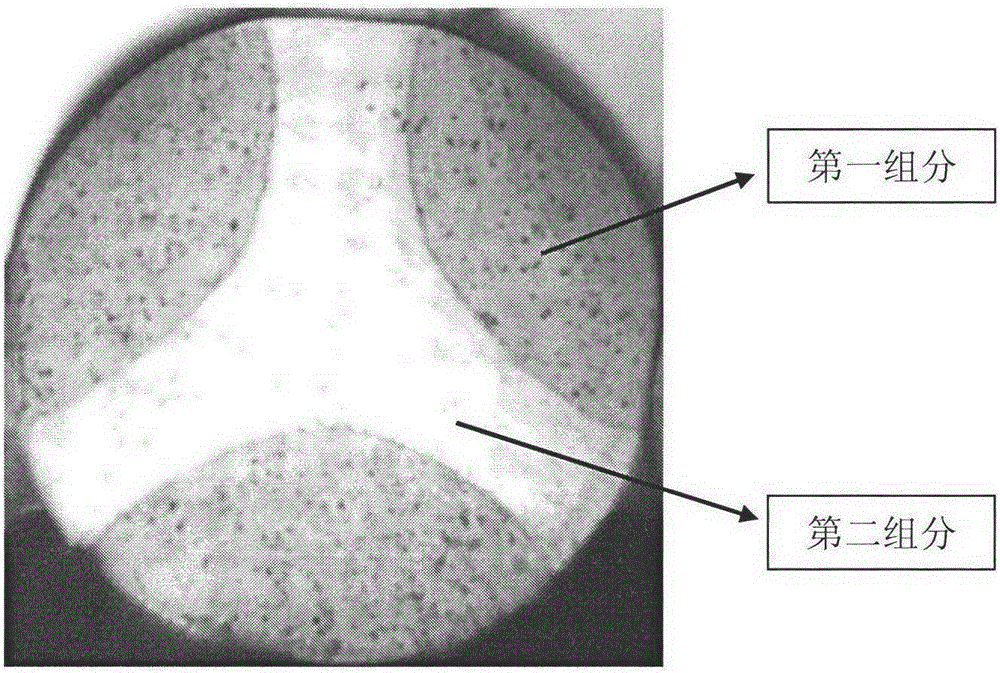

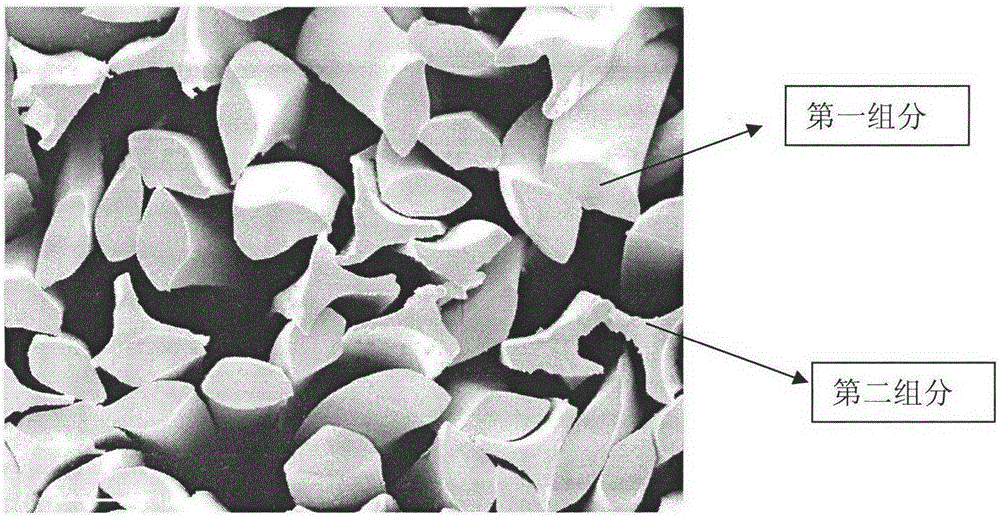

Split composite fiber and ultrafine fiber fabric

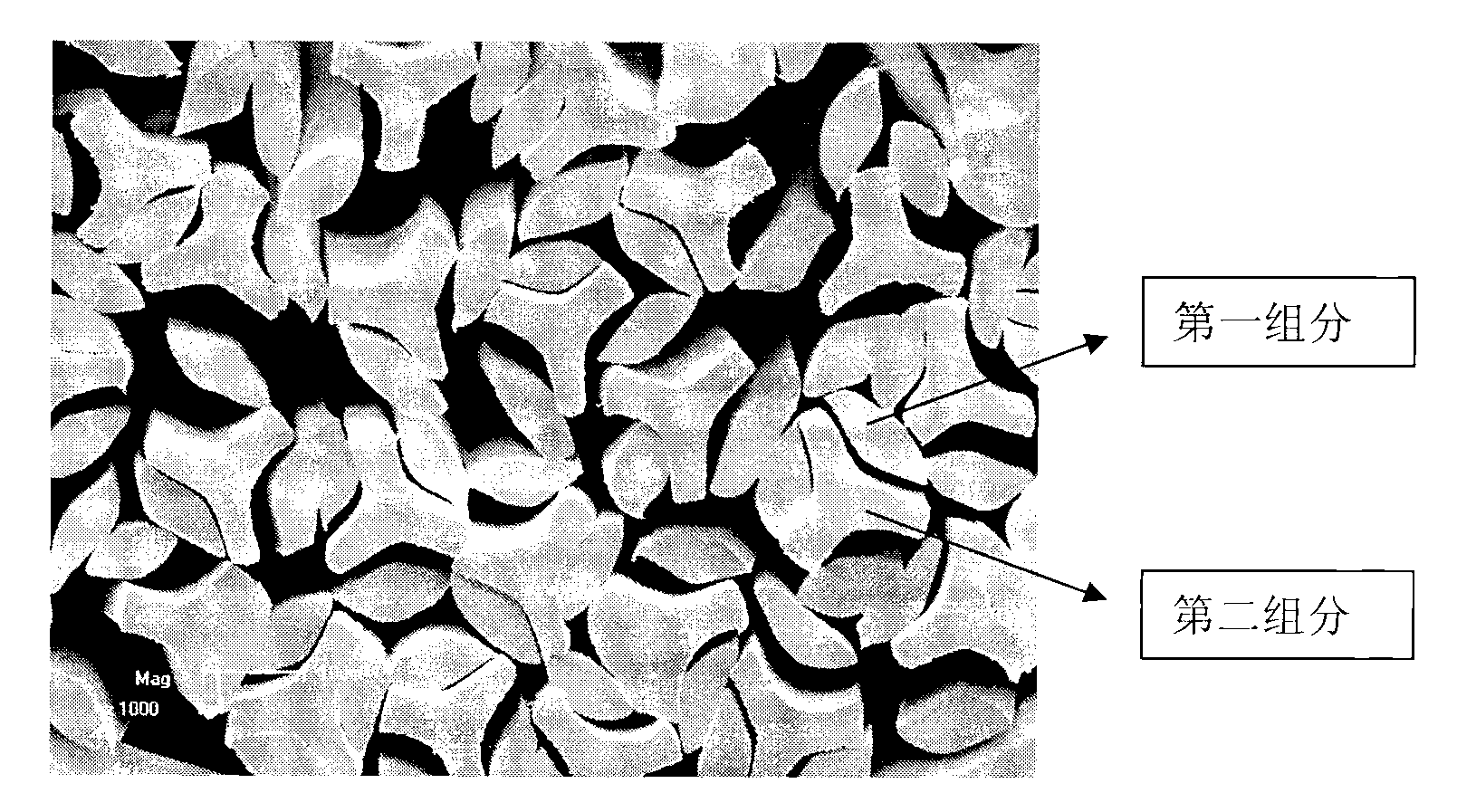

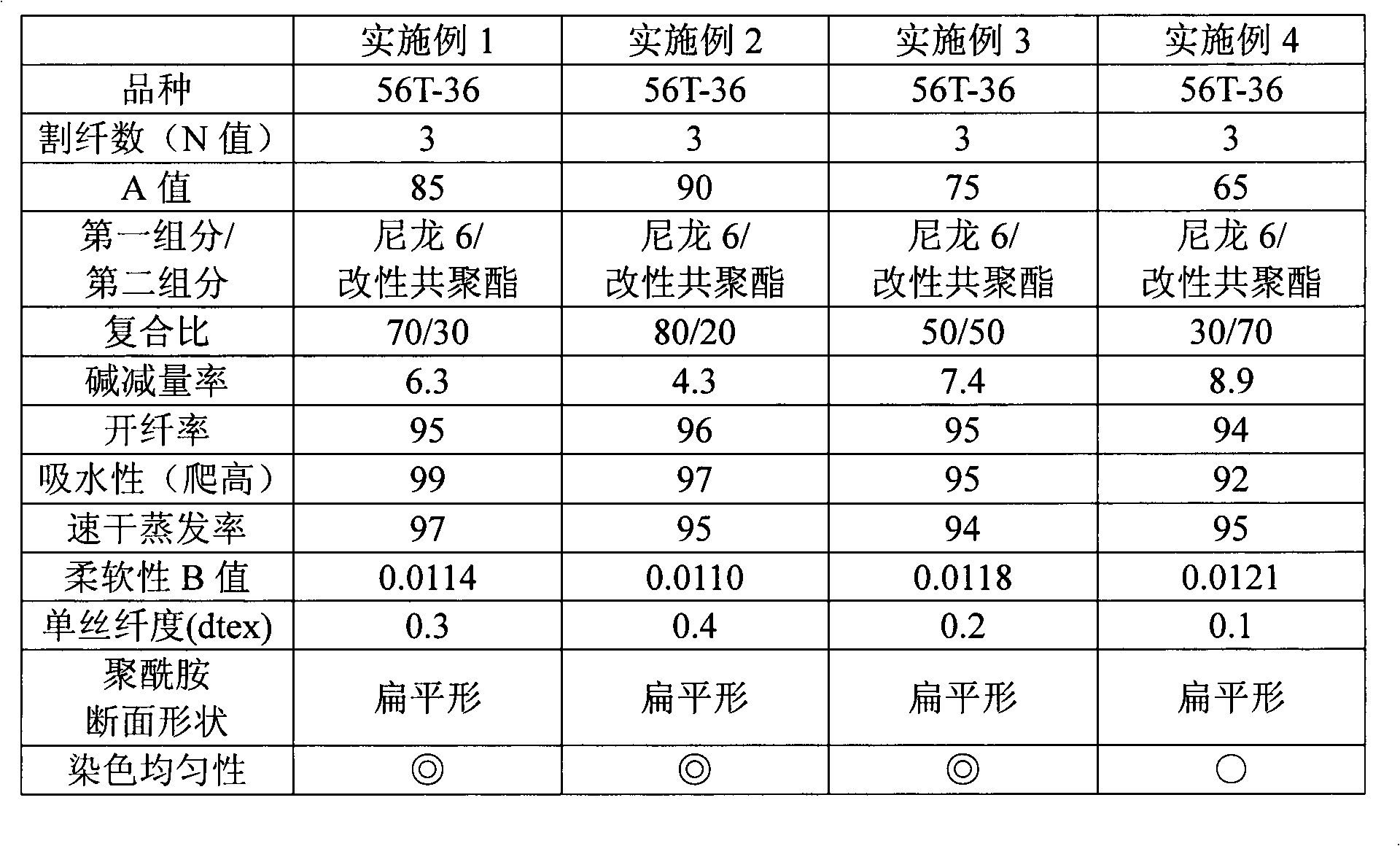

InactiveCN103122499AReduce productionLower requirementConjugated synthetic polymer artificial filamentsPolyamideCopolyester

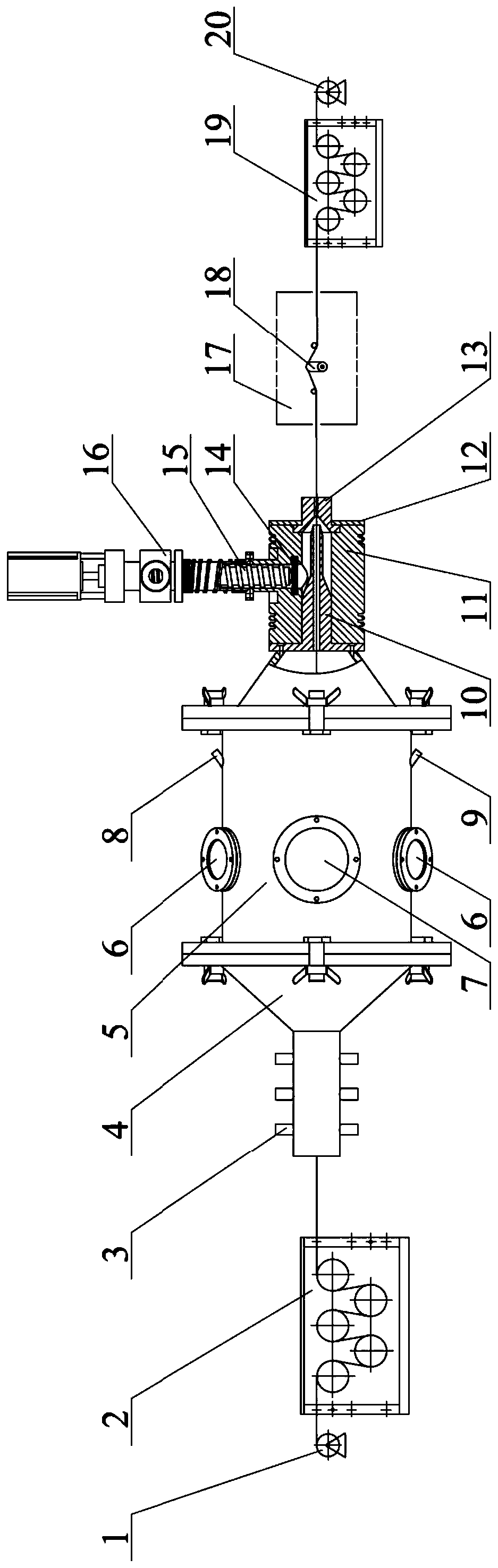

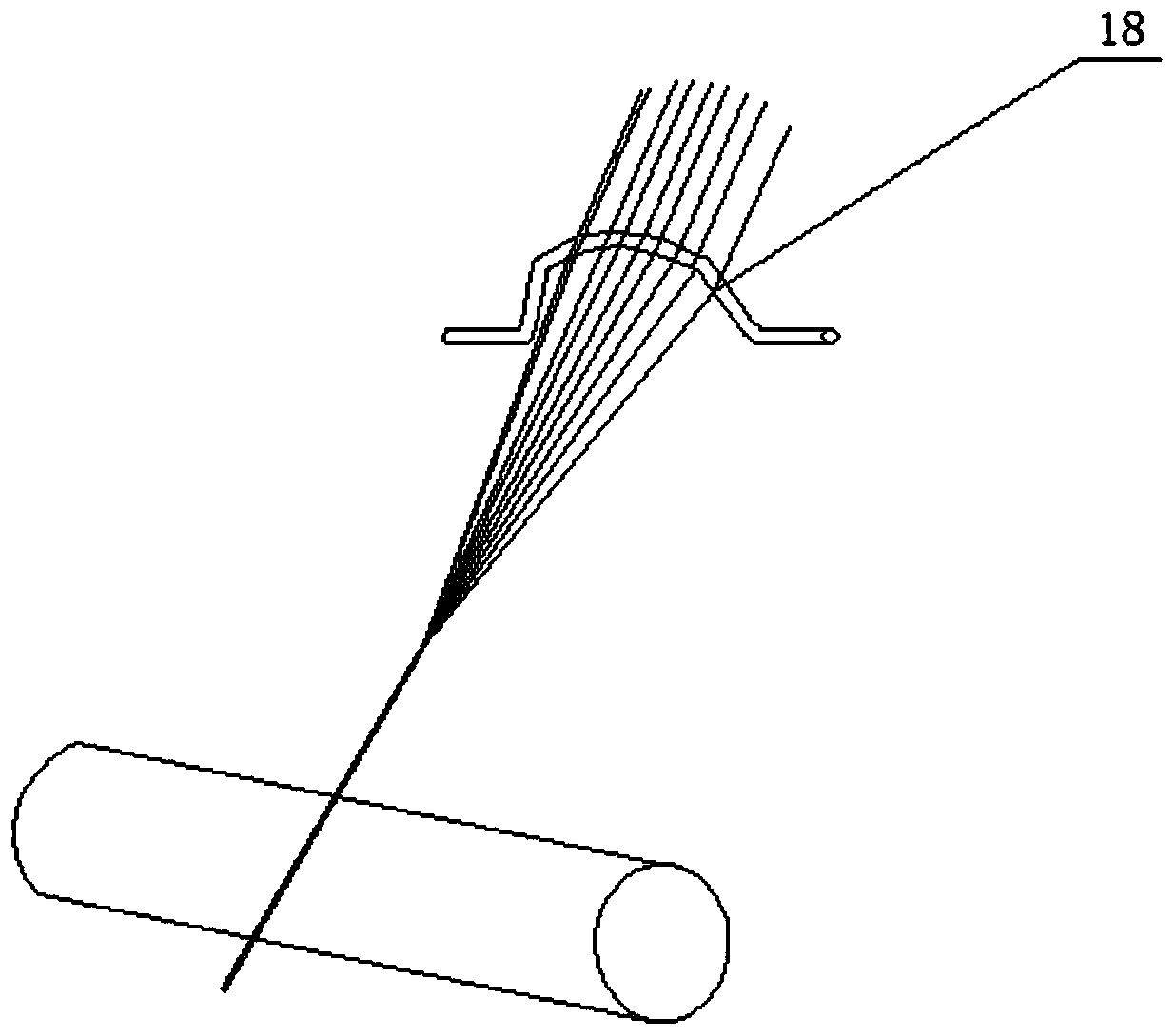

The invention discloses a split composite fiber which comprises fatty polyamide and modified copolyester. The fatty polyamide is used as a first component, the modified copolyester is used as a second component, and the weight ratio of the first component to the second component ranges from 80%:20% to 20%:80%; the second component is distributed on the cross section of a composite fiber in a continuous phase manner and divides the first component, and the first component is distributed on the cross section of the composite fiber in a discontinuous phase manner. The split composite fiber has the advantages that the fatty polyamide and the modified copolyester are subjected to composite spinning to obtain the split composite fiber, and can be sufficiently peeled off after a fabric manufactured by the split composite fiber is subjected to aqueous alkali de-weighting treatment, so that the ultrafine fiber fabric is obtained, and the ultrafine fiber fabric can be dyed uniformly, has wicking and quick-dry properties and feels soft.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

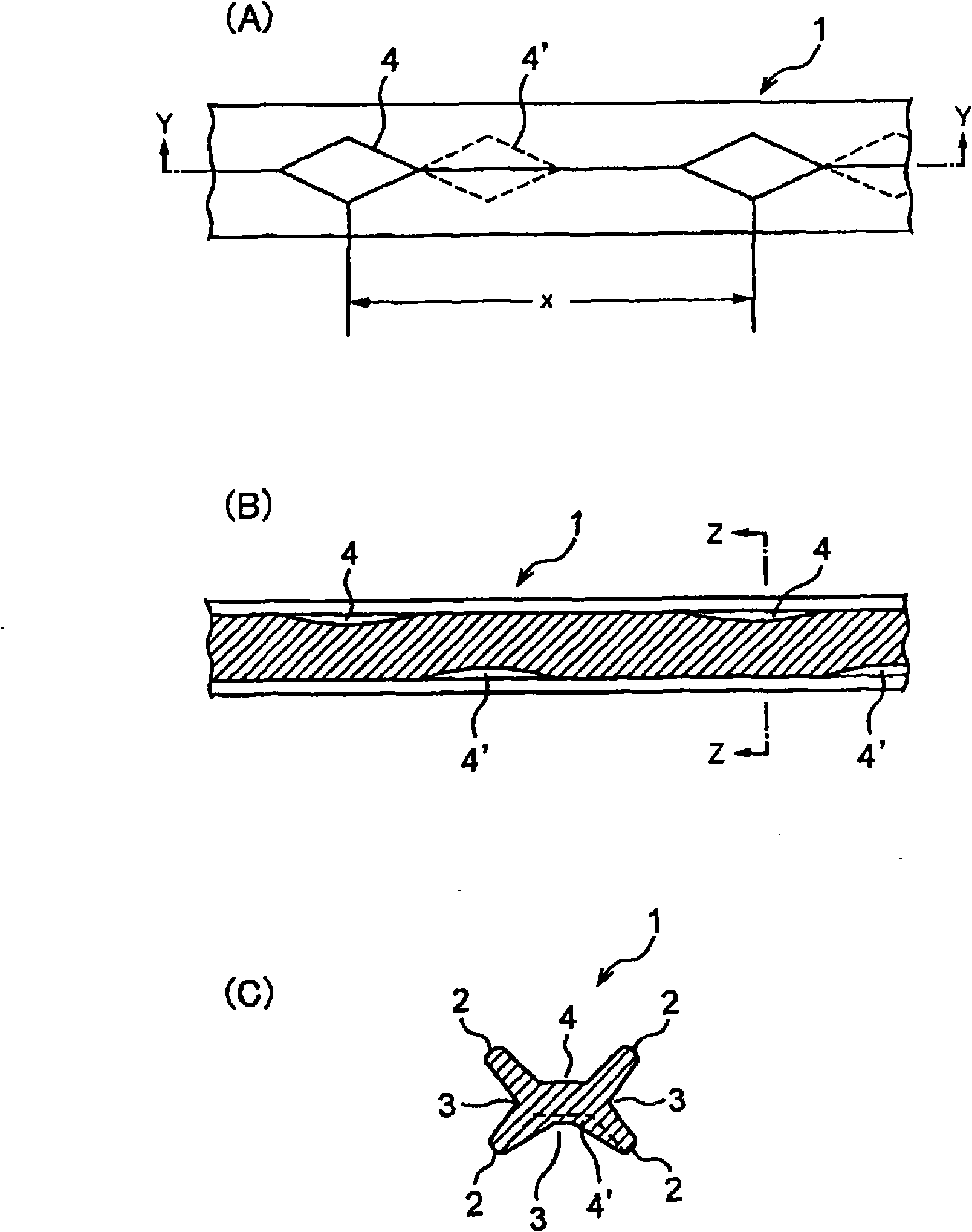

Plushed fabric and stuffed toy using the same

A plushed fabric has a unique, soft touch, which is different from that of a natural fur and has never seen up to now, that is, the plushed fabric is gentle and nice to touch, is free from see-through feeling in using it, is good in following property for a curved face, is less prone to the falling of yarns, and is capable of having a clear color and has good property in opening of a pile yarn, and a stuffed toy using the plushed fabric. The plushed fabric comprising piles having a single yarn fineness of 0.1 to 4 dtex, with the proviso that 80 to 100 wt % of single yarns constituting the piles have a fineness of 0.1 to 2.2 dtex.

Owner:ASAHI KASEI KK

Polyester peach skin imitation finishing technology for terylene and regenerated cellulose fiber interweaved fabric

InactiveCN109629265AShort processReduce equipment corrosionDyeing processVegetal fibresChemistryPolyester

The invention discloses a polyester peach skin imitation finishing technology for a terylene and regenerated cellulose fiber interweaved fabric. For now, according to existing polyester peach skin imitation finishing for a regenerated cellulose terylene fabric, fiber opening treatment is firstly conducted generally, under the effect of strong acid such as concentrated sulfuric acid, macromolecularchain segments of regenerated cellulose fiber is broken into short molecular chains, and the purposes of increasing naps and improving softness, drapability and appearance are achieved; due to the operation, one dyeing and finishing process is added, and the production cost is increased. The polyester peach skin imitation finishing technology comprises the following steps that S1, fiber opening and dyeing of terylene components in one bath; S2, san washing; S3, reactive dyeing of regenerated cellulose components; S4, soaking and softening. According to the technology, the fiber opening step and the step of disperse dyeing of the terylene components are innovatively combined and completed in one bath in one step, the ideal fiber opening effect is achieved, the technology processes are shortened, and fiber opening in one bath cannot influence the colored light and color yield of disperse dyeing severely.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

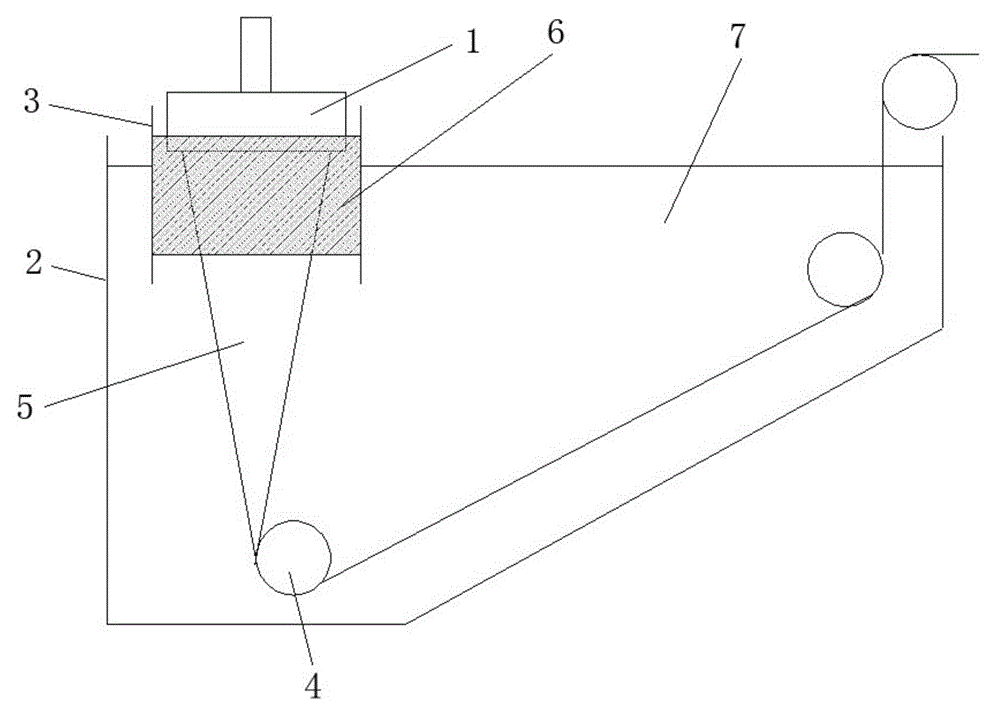

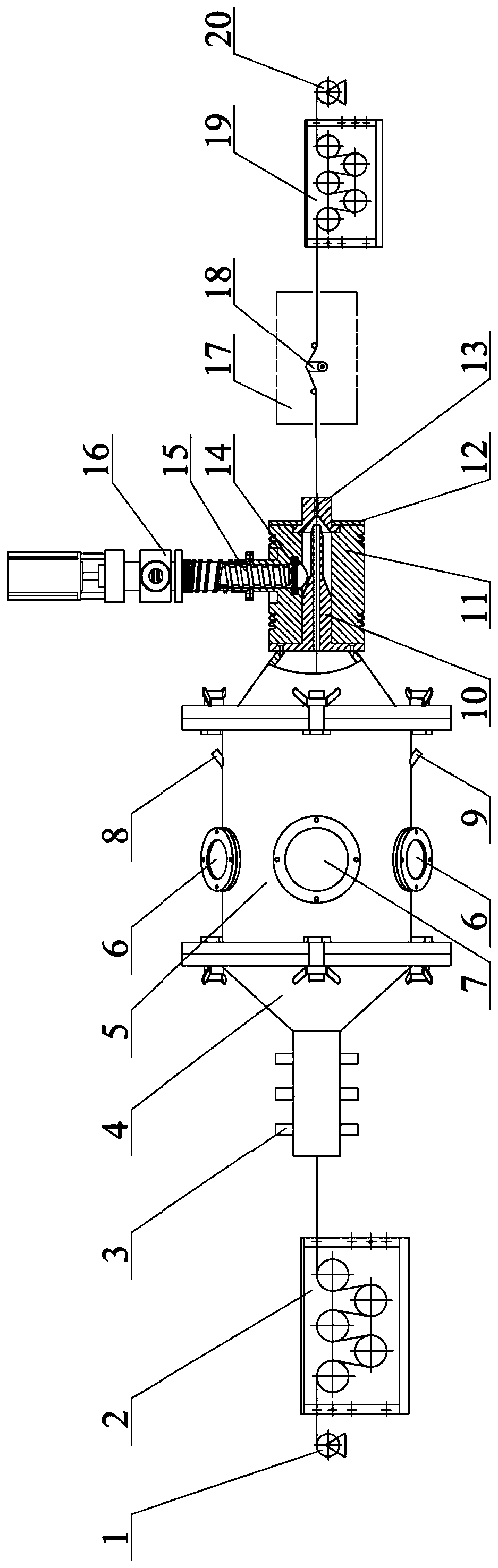

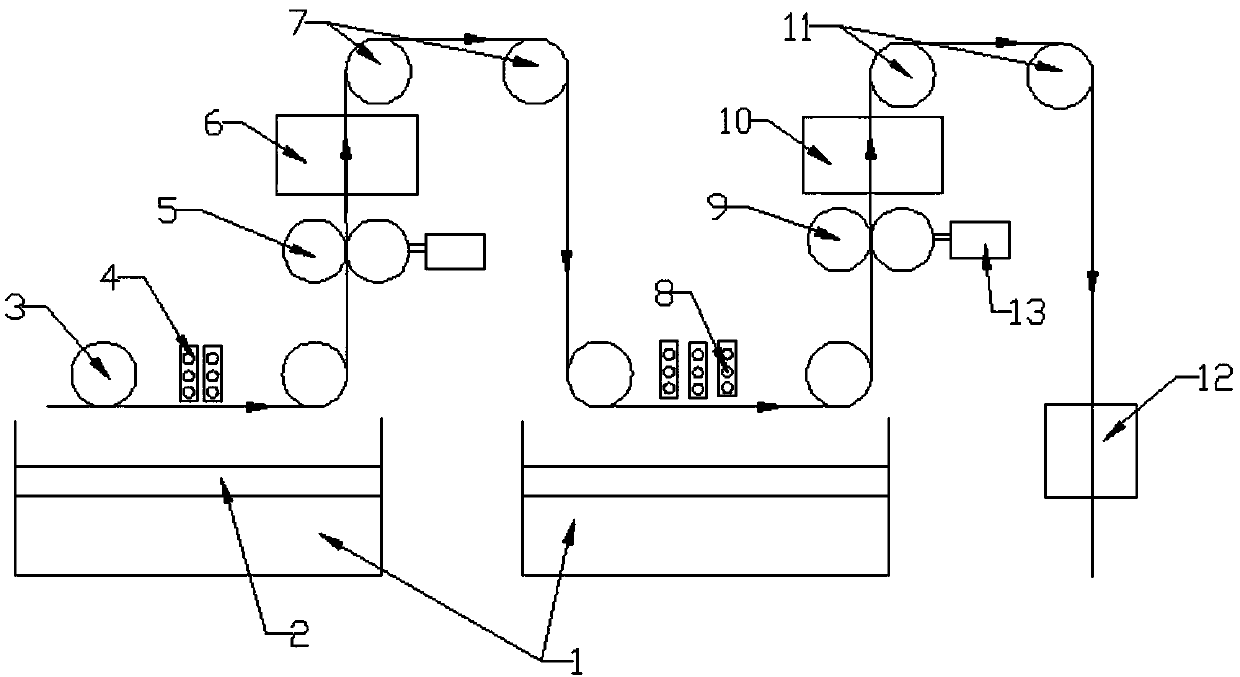

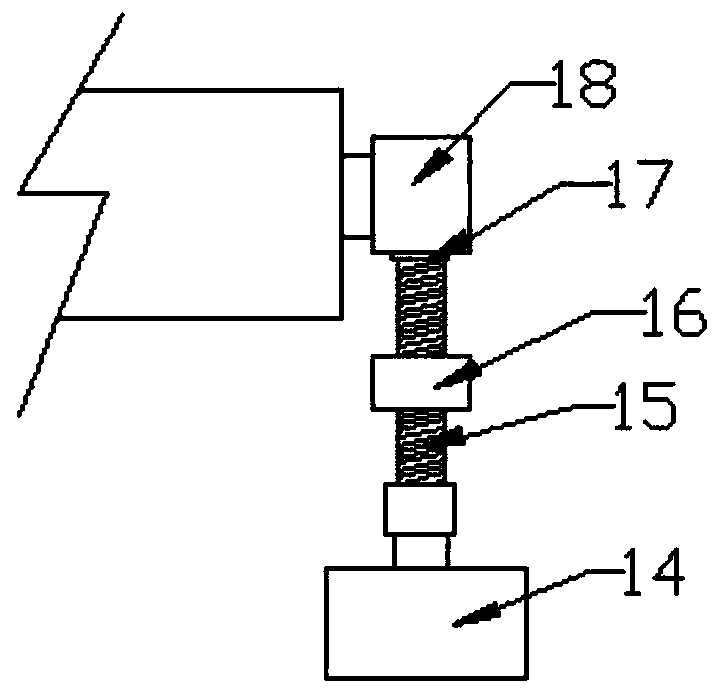

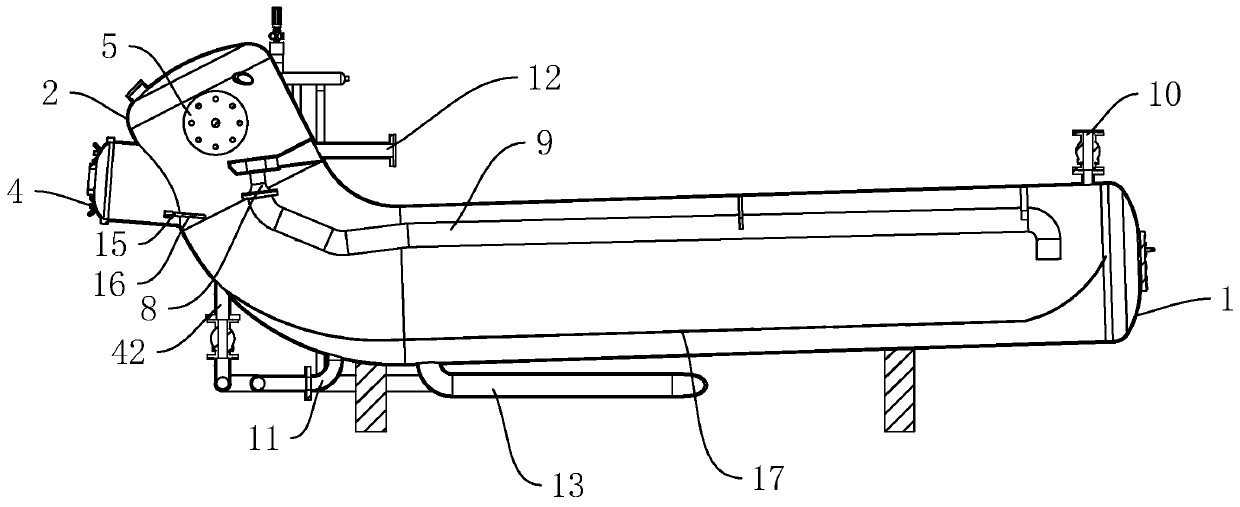

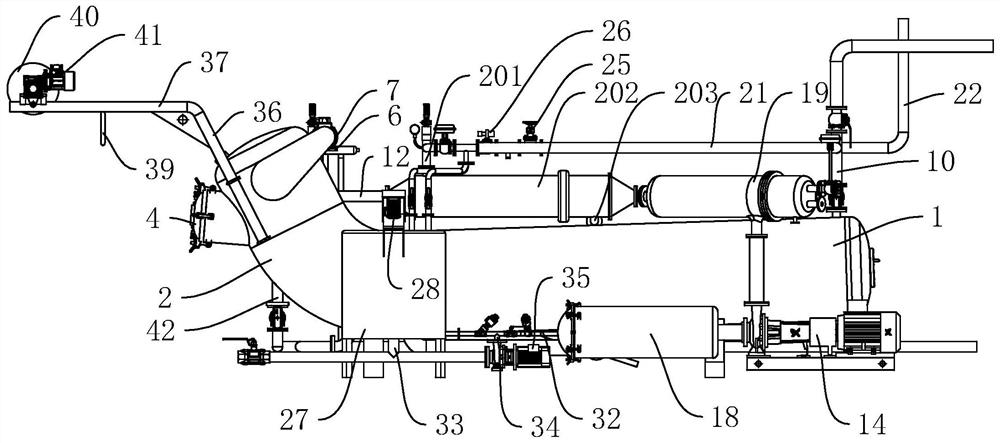

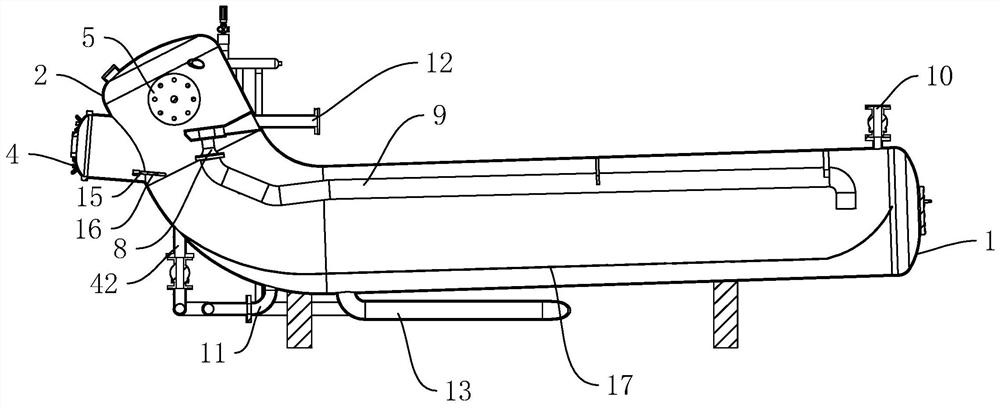

Carbon fiber laser graphitizing sizing equipment and method

ActiveCN110042583AGood fiber opening effectImprove wear resistancePhysical treatmentCarbon fibresCarbon fibersEngineering

The invention discloses carbon fiber laser graphitizing sizing equipment and method. The equipment is mainly composed of a silk releasing device, a drafting device A, a gas seal end cover, a graphitizing furnace body, a coating machine head, an extruder, a drying device, a drafting device B and a silk collecting device. The devices are sequentially arranged, the gas seal end cover is fixed to theleft end of the graphitizing furnace body through a bolt, the right end of the graphitizing furnace body is connected with the sizing coating machine head, the side face of the coating machine head isconnected with the small extruder, and the drying device, the drafting device B and the silk collecting device are sequentially mounted on the right side of the coating machine head. An outlet of a graphitizing furnace is directly connected with the coating machine head, inert gas sealing on the outlet is omitted, and the use amount of argon is saved. An extruded sizing agent has uniform and dense texture and is tightly attached to the surfaces of fibers, due to sizing in the pressure environment, the skinning performance of the sizing agent is better than the soaking effect in a sizing agenttank, skin films on the surfaces of the fibers are denser, and the performance of a prepared composite is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

Split type composite fiber and superfine fiber fabric prepared by same

InactiveCN103422190AEliminate fiber formation difficultiesGood alkali resistanceFilament/thread formingConjugated synthetic polymer artificial filamentsCopolyesterSide chain

The invention discloses a split type composite fiber. The fiber is composed of aliphatic polyamide as a first component and modified copolyester as a second component, wherein the second component is the modified copolyester prepared by copolymerizing aliphatic dibasic alcohol as a third monomer and with a side chain and having the carbon atom number of six or less; the second component is distributed on the cross section of the composite fiber in a continuous phase manner and splits the first component, and the first component is distributed on the cross section of the composite fiber in a discontinuous phase manner. The split type composite fiber containing aliphatic polyamide and modified copolyester is obtained by adopting a composite spinning method, and the composite fiber further forms a fabric; after the fabric is subjected to aqueous alkali decrement treatment, the two components can be fully stripped so as to form a superfine fiber fabric; and the superfine fiber fabric can be dyed under a normal pressure, has water absorption and quick-drying properties, soft hand feeling and higher tear strength, and achieves wide application in the clothing field.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

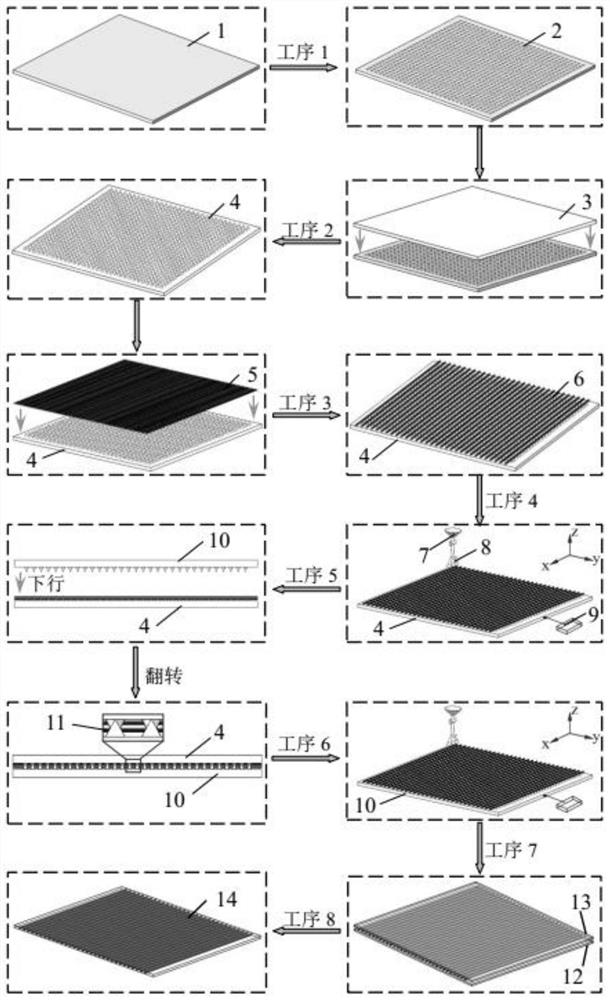

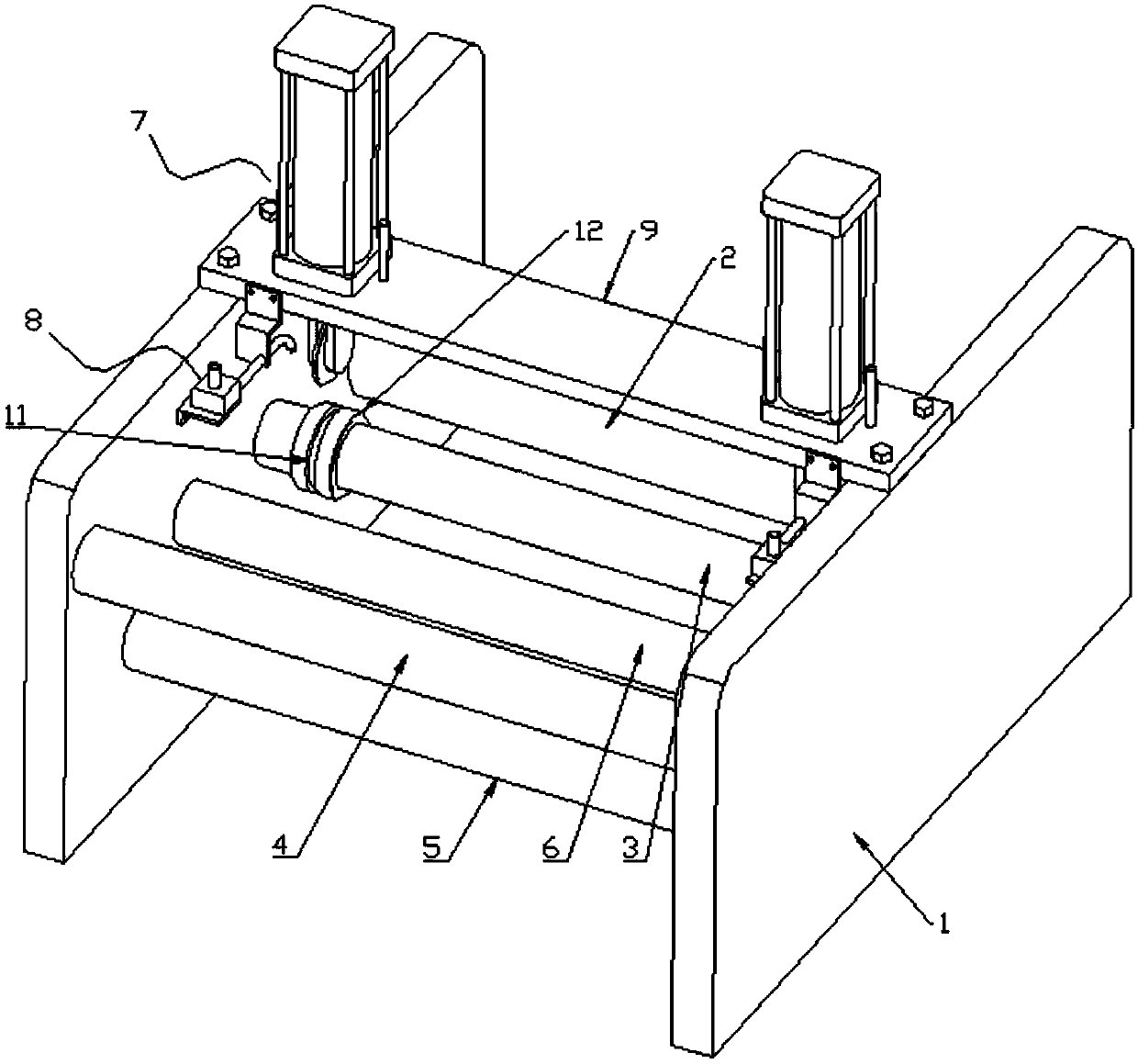

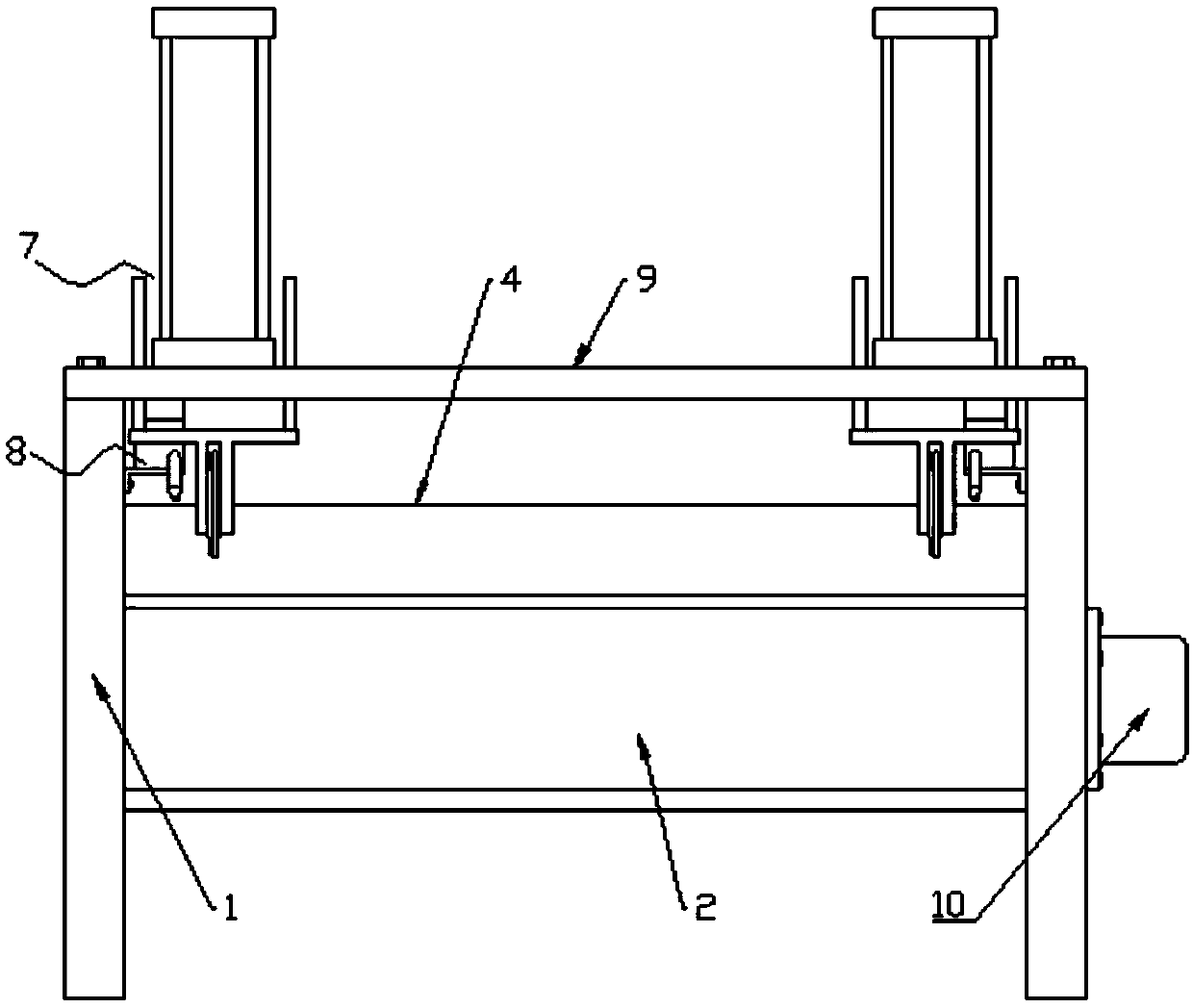

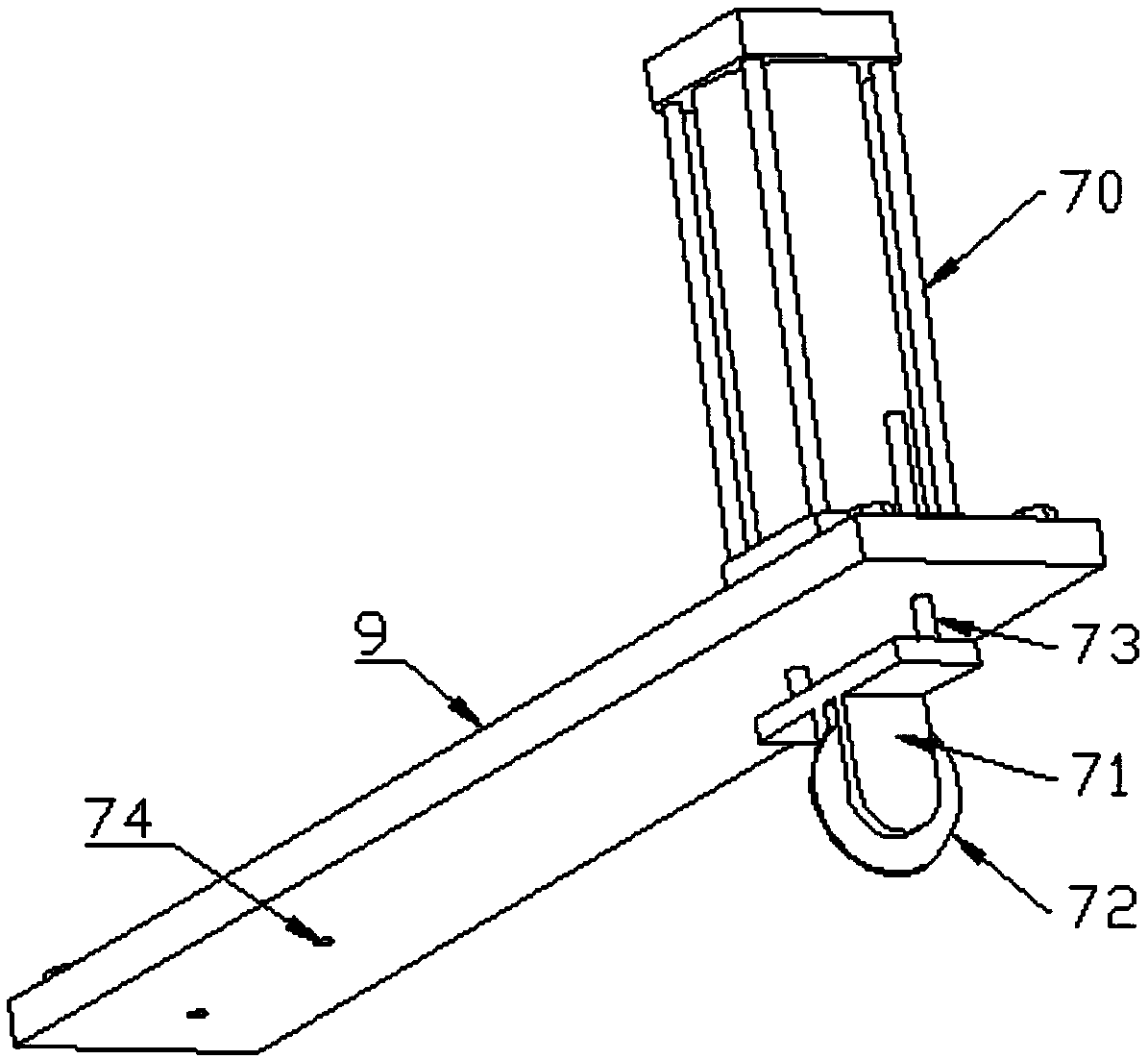

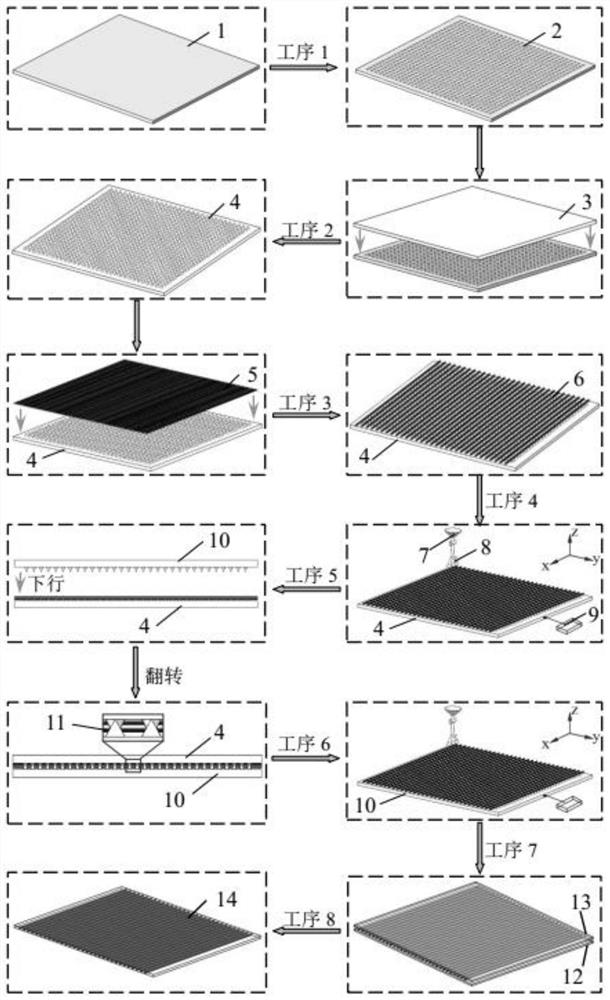

Preparation method of ultrathin continuous fiber reinforced thermoplastic prepreg

The invention provides a preparation method of an ultrathin continuous fiber reinforced thermoplastic prepreg. The preparation method comprises the following steps of processing a metal mold with micro-taper hole array characteristics, duplicating a splitting plate with micro-taper bulge array characteristics, conducting primary splitting on ultrathin fiber cloth, conducting vibrating and powder scattering on matrix resin powder, conducting secondary splitting, conducting primary overturning for homogenizing the powder, conducting secondary overturning for replacing a mold, conducting vacuum heating and melting and carrying out hot-press molding. Array taper holes are machined in the surface of the metal mold, a high-performance thermoplastic PEEK resin thin plate is used for duplicating the splitting plate with the micro-taper bulge array characteristics, full splitting of the ultrathin continuous reinforced fiber cloth is achieved, and the splitting effect is good; and in cooperationwith two times of high-frequency low-amplitude vibration powder spreading of a flow-controllable three-dimensional movable discharge spout and the splitting plate, uniform distribution of the matrixresin powder in the reinforced fiber cloth is achieved, and the problem that it is difficult to make a molten resin matrix go deep into continuous fiber bundles is effectively solved.

Owner:JIANGSU UNIV

Carpet edge cutting mechanism with water spraying function

The invention discloses a carpet edge cutting mechanism with a water spraying function, and relates to the field of machinery. The carpet edge cutting mechanism with the water spraying function comprises a rack, a drive roll, an edge cutting roll, an edge cutting mechanism, a water spraying mechanism and a plurality of driven rolls; the drive roll, the edge cutting roll and a plurality of the driven rolls are rotatably connected to the interior of the rack, the edge cutting roll is located between the drive roll and the driven rolls, and one end of the drive roll is connected to a driving motor; the edge cutting roll is symmetrically provided with two annular sleeves, and each annular sleeve is provided with an annular cutter groove; and a transverse bracket is installed on the top of therack and located over the edge cutting roll. According to the carpet edge cutting mechanism with the water spraying function, the structure is simple, cutting work of leftover materials in the automobile carpet processing process is achieved through the edge cutting mechanism, the tensile force is enough, and the cutting precision is high; and through the water spraying mechanism, the leftover materials on the side can be wetted while automobile carpet edge cutting is conducted, the water flow can be adjusted through an electromagnetic valve, the water spraying width also can be adjusted, therefore, water spraying is uniform, and the fiber opening effect is good.

Owner:芜湖市韩源众科汽车新材料有限公司

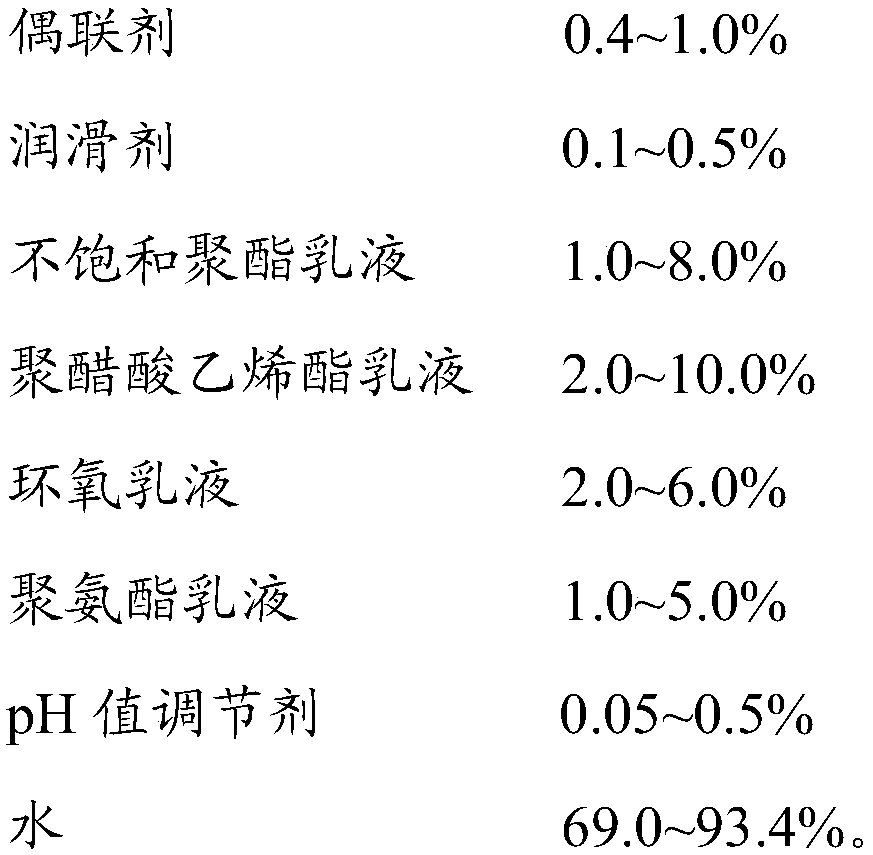

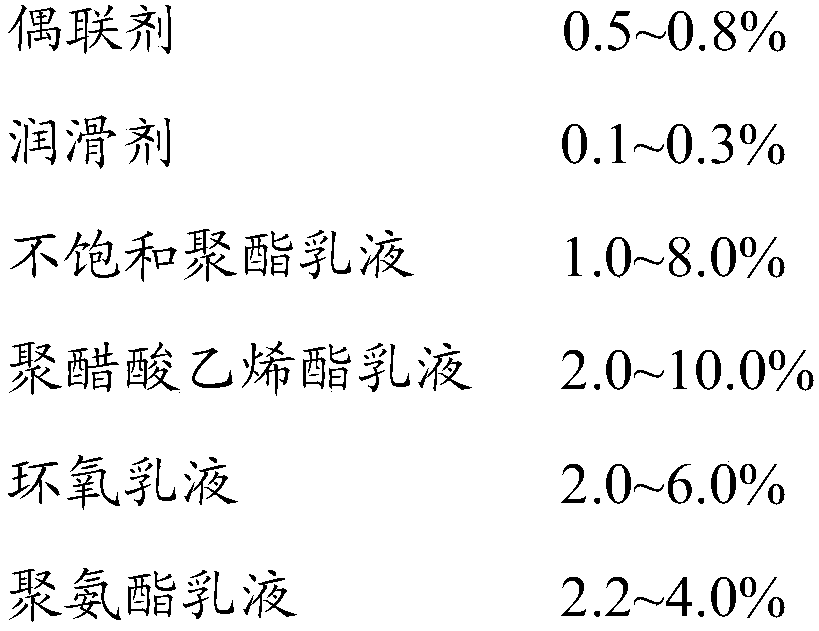

A kind of glass fiber sizing agent and its application

Owner:JUSHI GRP CO

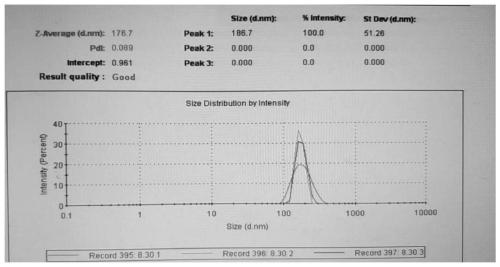

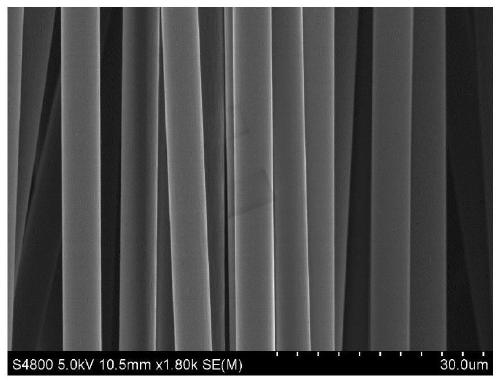

A kind of water-based epoxy sizing agent and preparation method thereof

ActiveCN109868654BEasy to bundleGood fiber opening effectCarbon fibresPolymer scienceInterlaminar shear

The invention discloses a water-based-epoxy sizing agent and a preparing method thereof. The water-based-epoxy sizing agent is prepared from, by weight, 100 parts of epoxy resin, 10-30 parts of a hyperbranched emulsifying agent, 1-5 parts of an auxiliary emulsifying agent, 1-5 parts of a dispersing agent and 100-300 parts of deionized water. A hyperbranched structure of a modified epoxy emulsifying agent has a large quantity of holes, the holes are added into the epoxy resin, the viscosity of a system can be reduced, and the grain size of emulsion can be decreased in the phase transformation process to improve wetting of the sizing agent to the surface of a carbon fiber. According to the water-based-epoxy sizing agent and the preparing method thereof, the solvent problem caused by the large viscosity in a traditional emulsification epoxy process is solved, the grain size of the sizing agent prepared with the method is 200 nm or below, the sizing agent can be evenly spread on the surface of the carbon fiber, and the carbon simultaneously has good bundling and splitting properties accordingly. The interlaminar shear strength of an epoxy composite material prepared from the carbon fiber sized through the sizing agent can be 70 MPa or above.

Owner:BEIJING UNIV OF CHEM TECH

Reinforcing short fiber for cement molding

InactiveCN101516800AFull fixation capacityGood fiber opening effectSpinnerette packsFilament/thread formingFiberMaterials science

A reinforcing short fiber for cement molding, consisting of an oriented fiber composed mainly of a synthetic resin, which fiber in its cross-section configuration is roughly a polygon having three or more projecting portions, at least one side portion of the polygon provided with depressed portions with given intervals along the longitudinal direction of the fiber. The reinforcing short fiber for cement molding, as a reinforcing short fiber for cement molding in civil engineering, construction work, etc., has satisfactory fixing power with cement paste and, at charging and mixing, exhibits good spreadability and good dispersibility in concrete.

Owner:UBE NITTO KASEI CO LTD

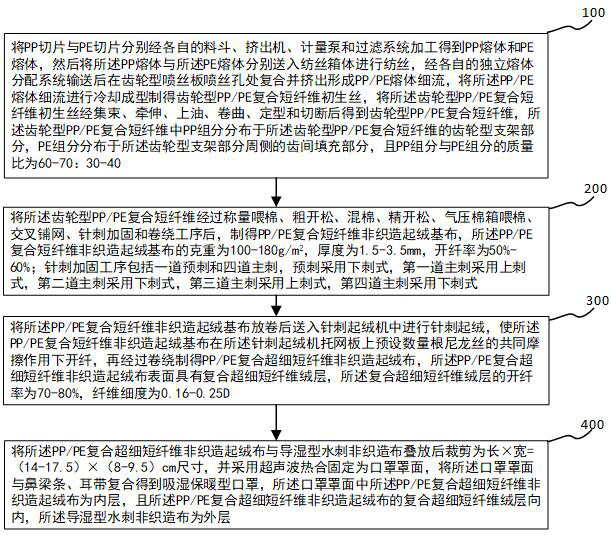

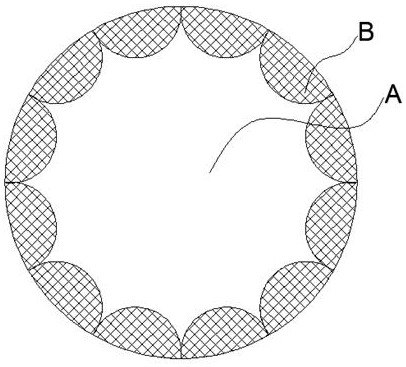

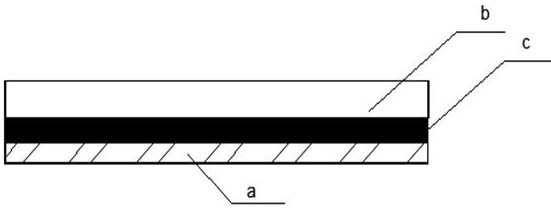

Moisture-absorbing and warm-keeping type mask and preparation method thereof

ActiveCN113103700AReduce difficultyReduce energy consumptionProtective equipmentSynthetic resin layered productsFiberMoisture absorption

The invention discloses a moisture-absorbing and warm-keeping type mask and a preparation method thereof, and relates to the technical field of articles of daily use. According to the moisture-absorbing and warm-keeping type mask, through preparation of gear type PP / PE composite short fibers, setting of pre-needling and main needling process parameters in the needling reinforcing process and setting of needling raising process parameters, prepared PP / PE composite superfine short fiber non-woven raising cloth has the high splitting rate; the further prepared moisture-absorbing and warm-keeping type mask has a gradient layer-by-layer filtering effect and is high in filtering efficiency, good in air permeability and good in moisture absorbing and guiding performance, and meanwhile the warm keeping performance is further improved through the composite superfine short fiber fleece layer of the PP / PE composite superfine short fiber non-woven fleece. The moisture-absorbing and warm-keeping type mask has the efficient filtering performance, the moisture absorption and conduction performance and the warm keeping performance, and the technical effects that the warm keeping performance of the mask is improved, and the man-machine relation of the mask to a user wearing glasses in winter is improved are achieved.

Owner:JIAXING UNIV

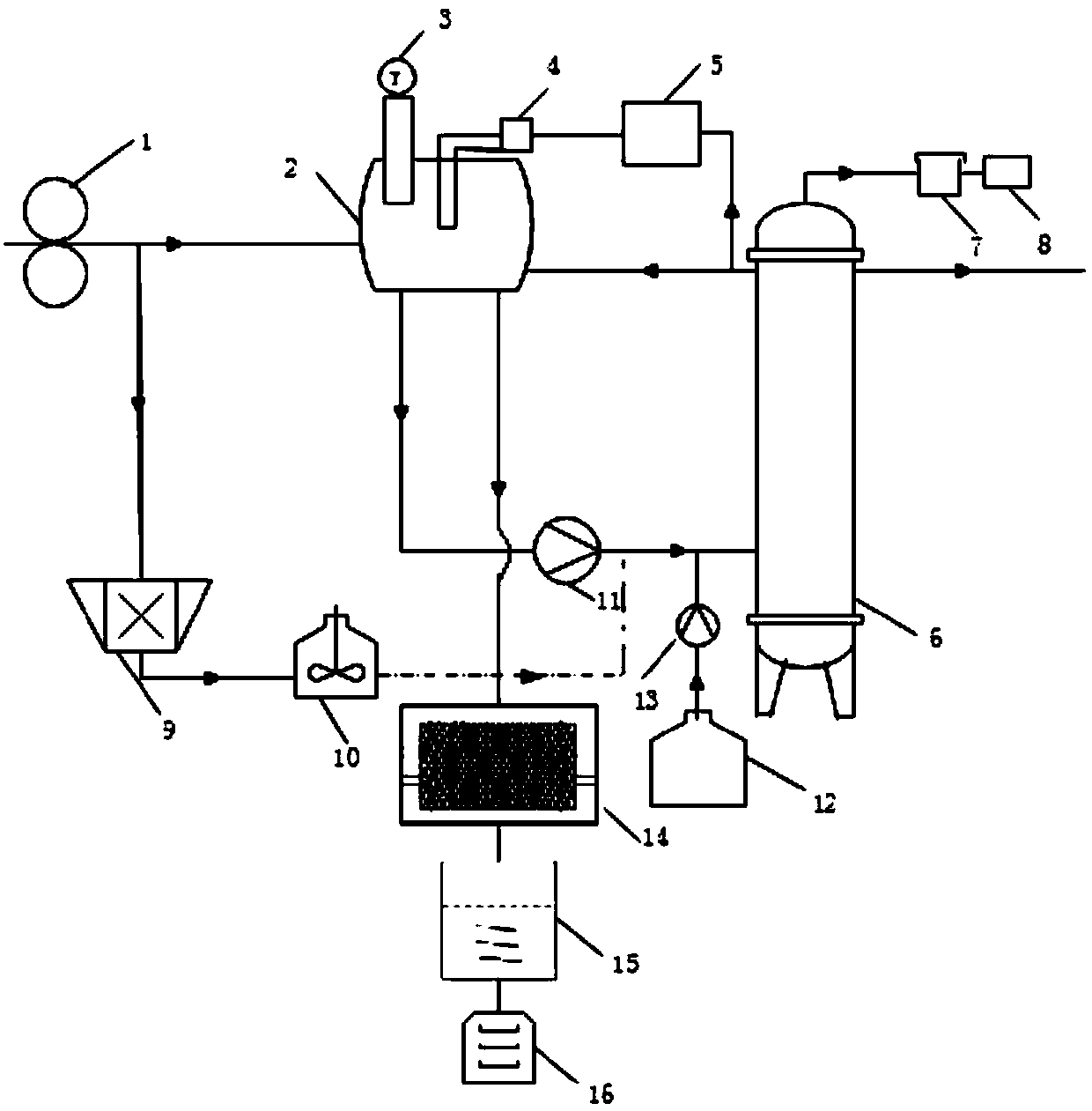

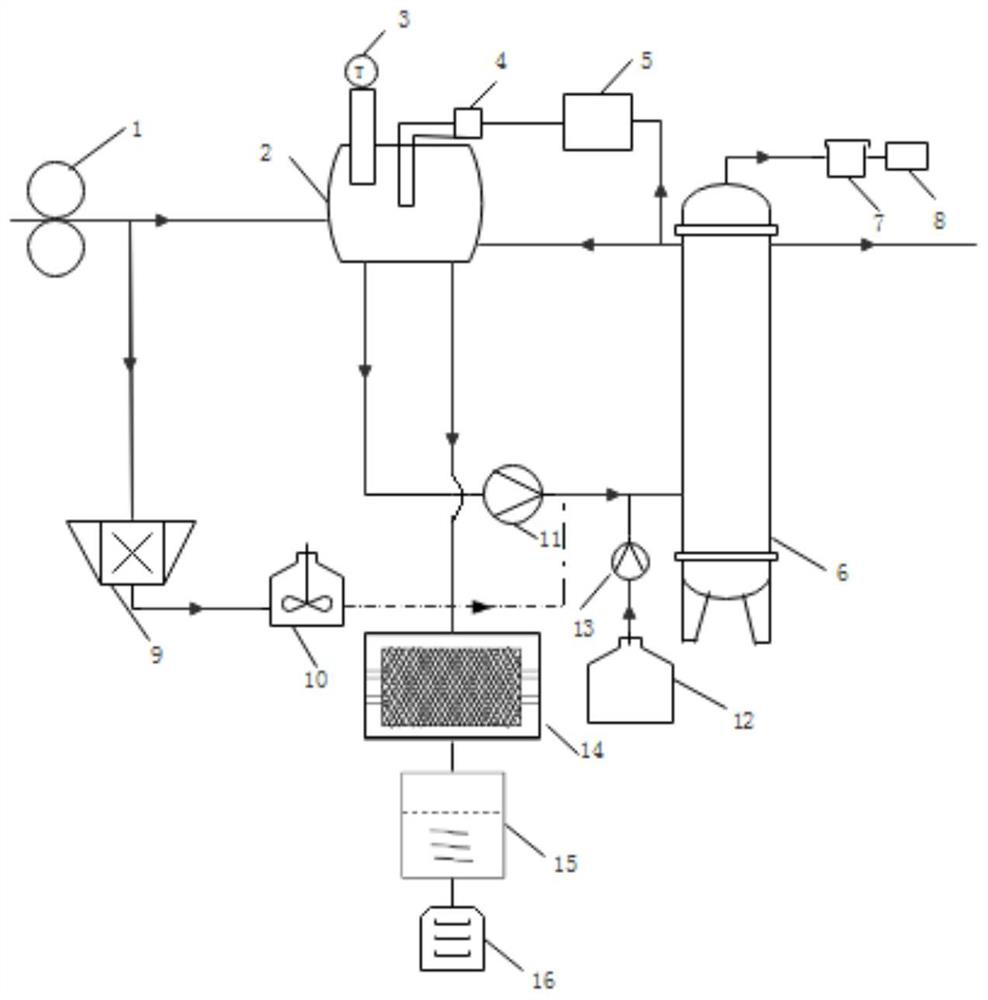

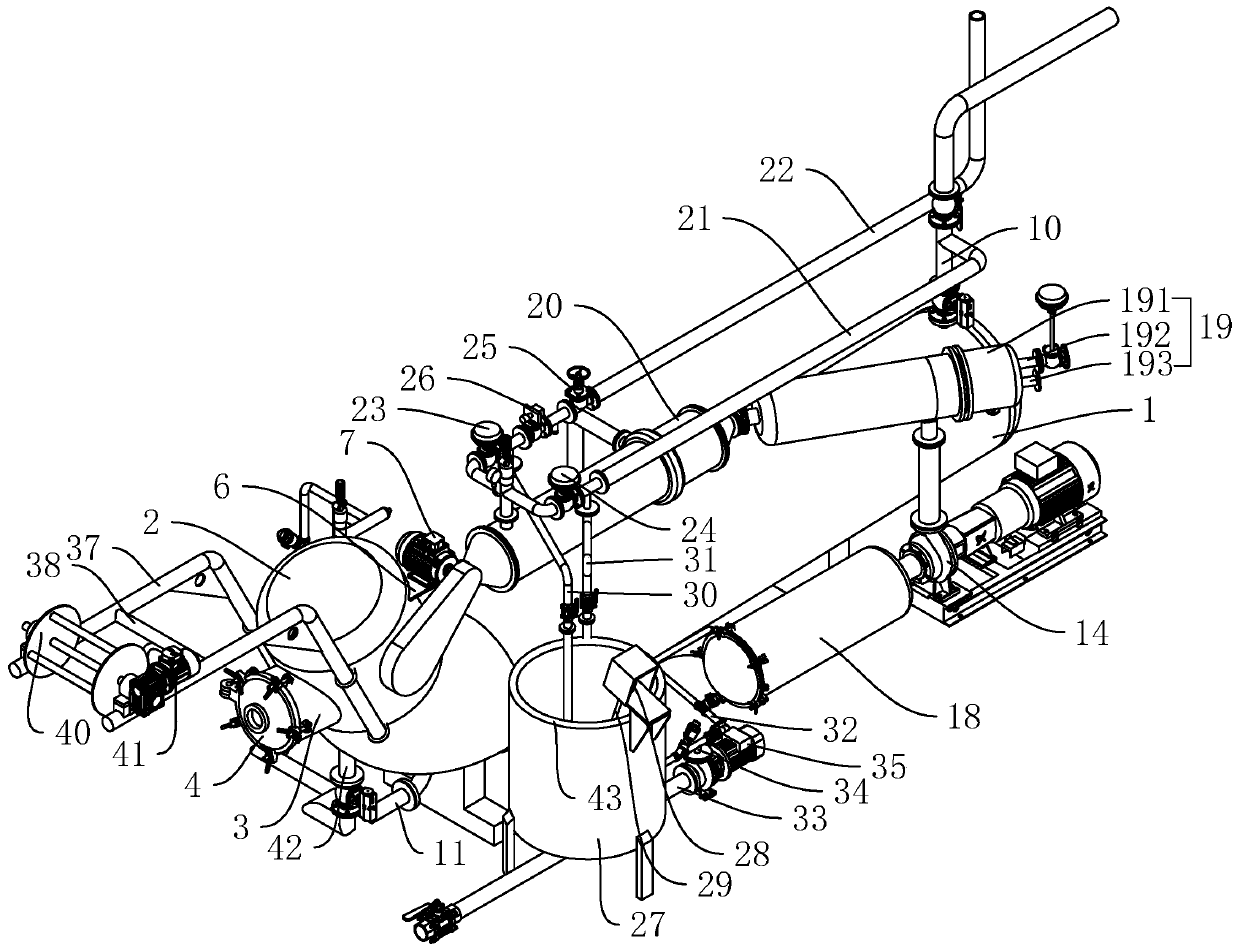

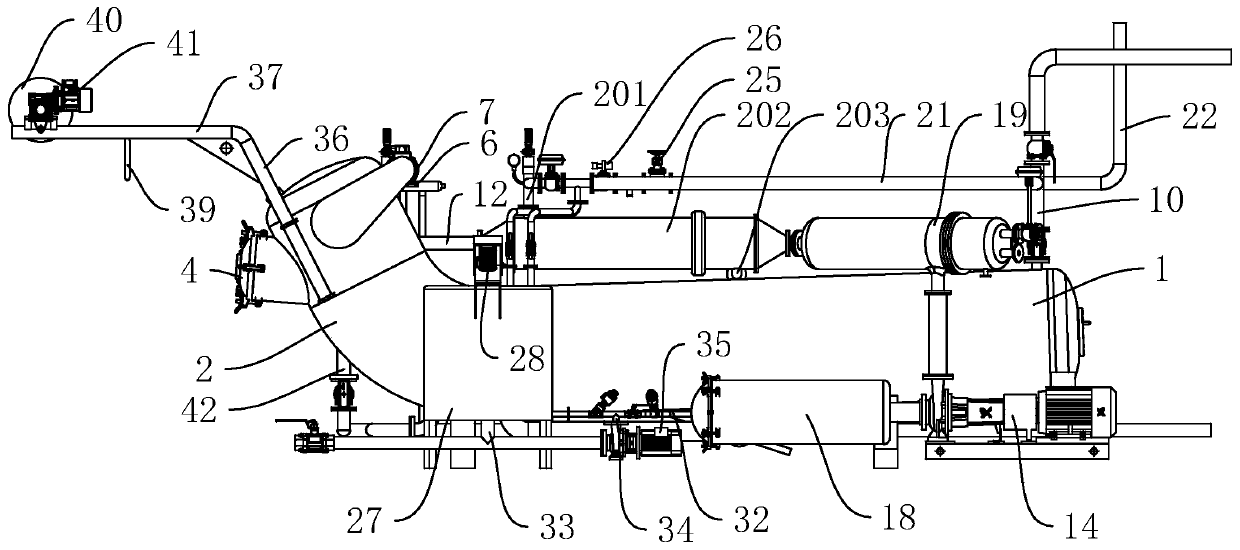

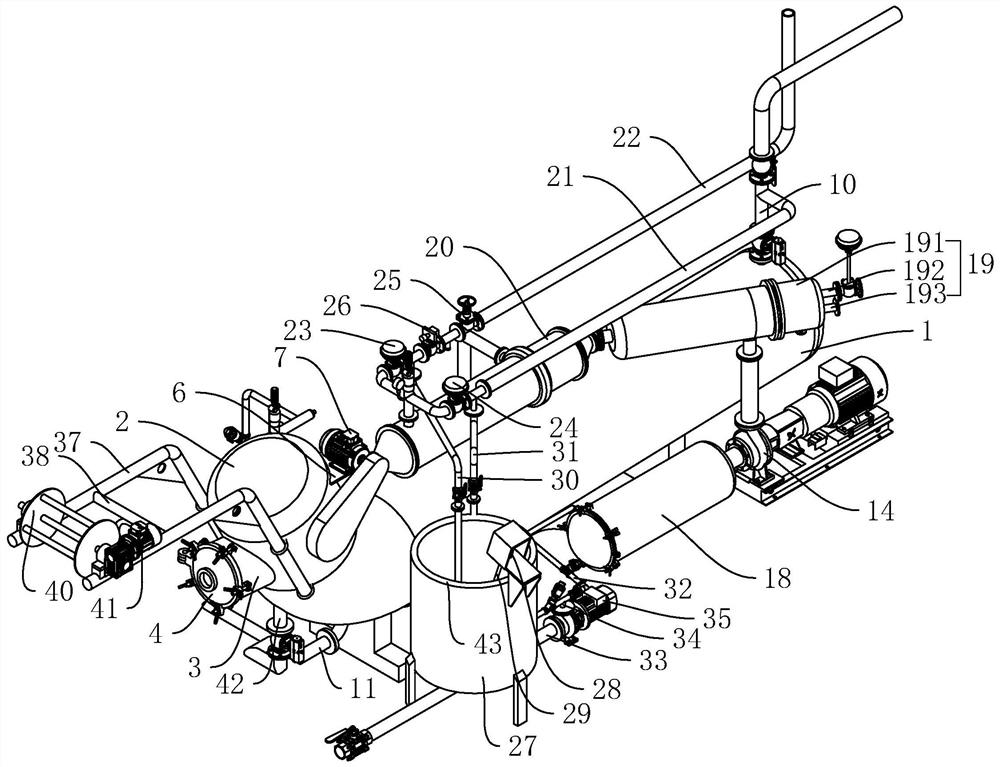

Ramie biological degumming device and degumming method

ActiveCN109537065ASimple processProcess environmental protectionBacteriological rettingAlkalinityEnvironmental engineering

The invention provides a ramie biological degumming device which comprises a ramie stripping machine, a ramie stalk smashing machine, a ramie biological degumming tank, a ramie stalk dissolving pool,an anaerobic bioreactor, a nutrition pool, an effluent alkalinity regulating pool and a biogas storage tank, wherein a discharge port of the ramie stripping machine is connected with a feeding port ofthe ramie biological degumming tank; waste of the ramie stripping machine is connected with the ramie stalk smashing machine; the discharge of the ramie stalk smashing machine is stored in the effluent alkalinity regulating pool; the ramie stalk dissolving pool is connected with a water inlet of the anaerobic bioreactor; the nutrient pool is connected with the water inlet of the anaerobic bioreactor; an outer circulation port of the anaerobic bioreactor is connected with the water inlet of the ramie biological degumming tank; an exhaust port of the anaerobic bioreactor is connected with the biogas storage tank; a water outlet of the ramie biological degumming tank is connected with the water inlet of the anaerobic bioreactor; and the water outlet of the anaerobic bioreactor is connected with the effluent alkalinity regulating pool. The ramie biological degumming device has the advantages of green and environmental protection, low cost and simple process.

Owner:DONGHUA UNIV

A kind of high-shrinkage and high-efficiency dust-free dust-free cloth and its production method

ActiveCN104074043BGood fiber opening effectFine clothFibre typesDry-cleaning apparatus for textilesPolyesterYarn

The invention provides a production method of dustless cloth with high shrinkage and high dust removing efficiency as well as the produced dustless cloth. The production method comprises the following main steps: polyester / nylon superfine fiber yarns are woven to gray cloth by using a knitting machine; the gram weight of the produced gray cloth is 130-180 g / m2; the gray cloth is poured in a dye vat by the bath ratio of 1: 5-7; penetrating agent, sodium hydroxide, EDTA-4Na and degreasing agent are added in the dye vat; the gray cloth is cleaned in a manner of discharging while washing; acetic acid is added for cleaning again; splitting agent is added for treating, and the cleaning is performed; soaping agent is added; and the gray cloth is cleaned again in the manner of discharging while washing. According to the production method of the dustless cloth with high shrinkage and high dust removing efficiency provided by the invention, the produced dustless cloth has excellent absorbability and good dust and dirt removing effect.

Owner:河源市锦扬新材料有限公司

A kind of ramie biological degumming device and degumming method

ActiveCN109537065BSimple processProcess environmental protectionBacteriological rettingEnvironmental engineeringBioreactor

The invention provides a ramie biological degumming device, which includes a ramie peeling machine, a ramie stalk grinder, a ramie biological degumming tank, a ramie stalk dissolving pool, an anaerobic bioreactor, a nutrient pool, an outlet water alkalinity adjustment pool, and biogas storage tank; the discharge port of the ramie stripping machine is connected with the feed port of the ramie biological degumming tank, the waste of the ramie stripping machine is connected with the ramie stalk grinder, and the output of the ramie stalk grinder is stored in the water outlet The alkalinity dissolution pool, the ramie stalk dissolution pool is connected to the water inlet of the anaerobic bioreactor, the nutrient pool is connected to the water inlet of the anaerobic bioreactor, the external circulation port of the anaerobic bioreactor is connected to the inlet of the ramie biological degumming tank The water port is connected, the exhaust port of the anaerobic bioreactor is connected to the biogas storage tank, the water outlet of the ramie biological degumming tank is connected to the water inlet of the anaerobic bioreactor, and the water outlet of the anaerobic bioreactor is connected to the effluent alkalinity adjustment tank connect. The invention has the advantages of environmental protection, low cost and simple process.

Owner:DONGHUA UNIV

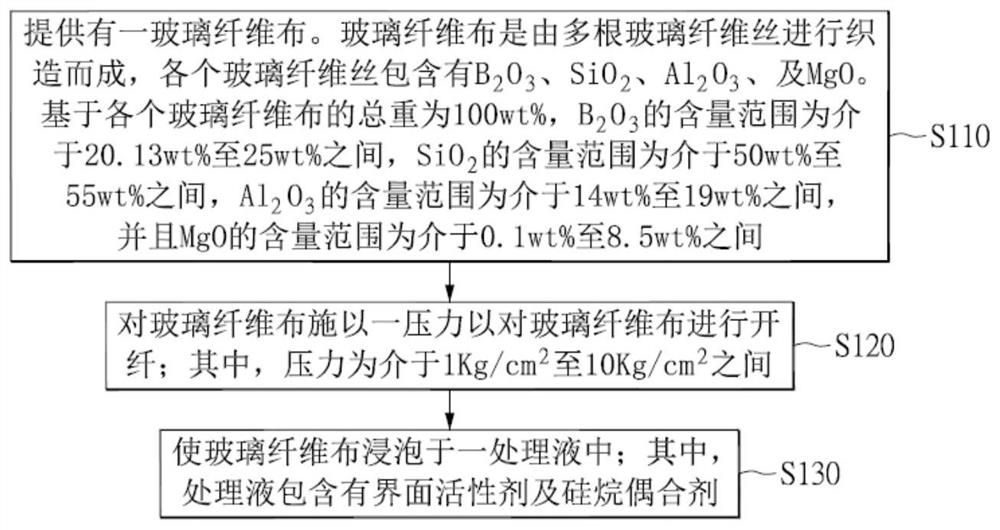

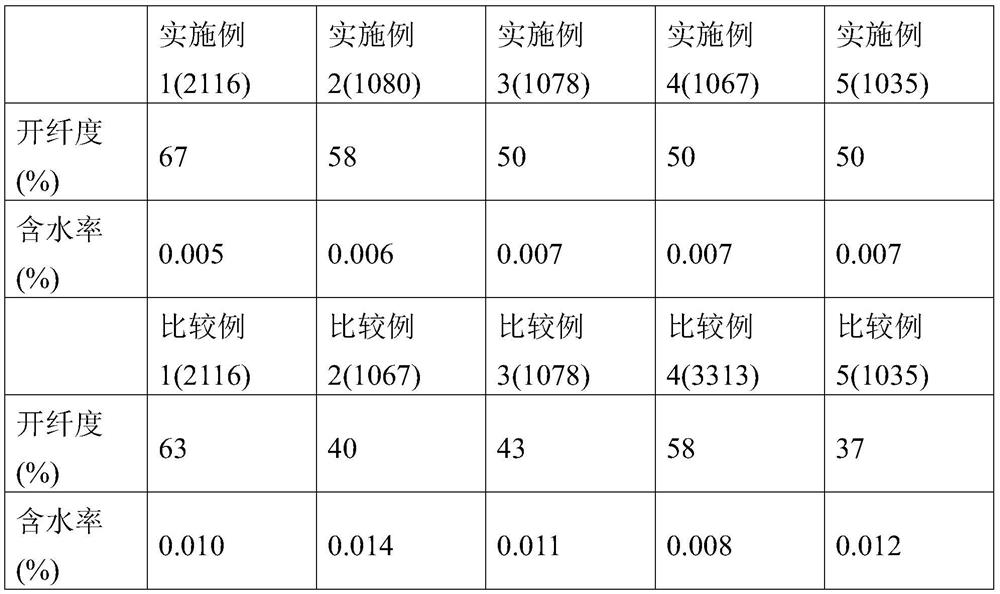

Splitting method for ultrathin electronic grade glass fiber cloth

InactiveCN109594255AIncrease warp and weft widthAvoid distortionFibre treatmentTextile treatment machine partsSilanesHigh pressure

The invention discloses a splitting method for ultrathin electronic grade glass fiber cloth. Two times of horizontal needle-punching methods are adopted for high-pressure splitting, fitness between rubber press rolls is adjusted by a press wheel fitness adjusting device, so that good splitting effect on the ultrathin glass fiber cloth is realized, meanwhile, through combination with expanding andshaping treatment of the ultrathin glass fiber cloth and special silane formula for impregnating the ultrathin glass fiber cloth, the high-performance ultrathin glass fiber cloth can be obtained, warpand weft width of the ultrathin glass fiber cloth is increased, weft twist is avoided, physical indexes such as impregnation time and air permeability are reduced, and the technical requirements of high-end copper-clad plate customers for HDI processes, IC package substrate processes and environment-friendly and halogen-free processes can be met.

Owner:LINZHOU GUANGYUAN NEW MATERIAL TECH

Mechanical splitting process of poly/nylon superfine fiber dustproof cloth

ActiveCN110042599AGood fiber opening effectAvoid damageLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine arrangementsSpray nozzleFiber

The invention discloses a mechanical splitting process of poly / nylon superfine fiber dustproof cloth, and relates to the technical field of dustproof cloth splitting. The process includes the following steps that 1, one end of the poly / nylon superfine fiber dustproof cloth is wound around a cloth lifting roller and stretches into a spray nozzle, water is injected into a barrel body, the head and the tail of the poly / nylon superfine fiber dustproof cloth are sewn in the barrel body, and gray cloth is annular; 2, the barrel body is sealed, the poly / nylon superfine fiber dustproof cloth is kept in circulation motion, the interior of the barrel body is heated to 130 DEG C at a constant speed, heat preservation is carried out for 40-50 min, the interior of the barrel body is heated to 160 DEG Cat a constant speed, and heat preservation is carried out for 40-50 min; 3, the temperature in the barrel body is reduced to 130 DEG C, heat preservation is carried out for 40-50 min, the temperatureis reduced to 80 DEG C or below, water is drained, and pressure is released; 4, the poly / nylon superfine fiber dustproof cloth is taken out, and after the poly / nylon superfine fiber dustproof cloth is dried and shaped, the split poly / nylon superfine fiber dustproof cloth is obtained. The process has the advantages that the splitting effect is good, the weight loss ratio of fibers is low, and thedrainage amount of waste water is reduced.

Owner:厦门保视丽无尘科技有限公司

A split type composite fiber and the superfine fiber fabric prepared therefrom

InactiveCN103122500BReduce productionLower requirementFilament/thread formingConjugated synthetic polymer artificial filamentsPolyamideCopolyester

The invention discloses a split composite fiber which comprises fatty polyamide and modified copolyester. The fatty polyamide is used as a first component, the modified copolyester is used as a second component, the weight ratio of the first component to the second component ranges from 80%:20% to 20%:80%, the second component is distributed on the cross section of a composite fiber in a continuous phase manner and divides the first component, and the first component is distributed on the cross section of the composite fiber in a discontinuous phase manner. The split composite fiber has the advantages that the fatty polyamide and the modified copolyester are subjected to composite spinning to obtain the split composite fiber, and can sufficiently peeled off after a fabric manufactured from the split composite fiber is subjected to aqueous alkali de-weighting treatment, so that the ultrafine fiber fabric can be obtained, and the ultrafine fiber fabric has wicking and quick-dry properties and feels soft.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Glass fiber cloth and processing method for preparing glass fiber cloth from low-dielectric glass fiber filaments

PendingCN114517351ALow dielectric constantLow Dissipation FactorWoven fabricsGlass fiberPolymer science

The invention discloses glass fiber cloth and a processing method of the glass fiber cloth made of low-dielectric glass fiber filaments. The glass fiber cloth is formed by weaving a plurality of glass fiber filaments. And each of the glass fiber filaments contains B2O3, SiO2, Al2O3, and MgO. Based on 100 wt% of the total weight of the glass fiber filaments, the content of B2O3 ranges from 20.13 wt% to 25 wt%, the content of SiO2 ranges from 50 wt% to 55 wt%, the content of Al2O3 ranges from 14 wt% to 19 wt%, and the content of MgO ranges from 0.1 wt% to 8.5 wt%. Therefore, the glass fiber cloth has a low dielectric constant and a low loss factor so as to meet the application requirements of high frequency and high speed.

Owner:NANYA PLASTICS CORP

A preparation method of ultra-thin continuous fiber reinforced thermoplastic prepreg

The invention provides a method for preparing an ultra-thin continuous fiber reinforced thermoplastic prepreg, which includes processing a metal mold with a micro-cone hole array feature, remanufacturing a fiber-spread board with a micro-cone protrusion array feature, and initial opening of an ultra-thin fiber cloth. Vibration dusting of fiber and matrix resin powder, second fiber opening, first turning to even powder, second turning to mold conversion, vacuum heating and melting and hot pressing. An array of tapered holes is processed on the surface of the metal mold, and the high-performance thermoplastic PEEK resin sheet is used to reproduce the fiber-spreading board with the characteristics of a micro-conical protrusion array, so as to realize the full fiber-opening and fiber-opening effect of the ultra-thin continuous reinforced fiber cloth. Good; with the three-coordinate movable nozzle with controllable flow and two high-frequency and low-amplitude vibration dusting of the expanded fiberboard, the matrix resin powder can be evenly distributed inside the reinforced fiber cloth, which effectively solves the problem of the penetration of the molten resin matrix into the continuous fiber. Difficult problems within the bundle.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com