Preparation method of polyacrylonitrile-based carbon fiber precursor

A polyacrylonitrile-based carbon fiber, polyacrylonitrile spinning technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problems affecting spinning stability, fiber interference, dry and wet Solve problems such as process overflow and improve the performance and quality stability of raw silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

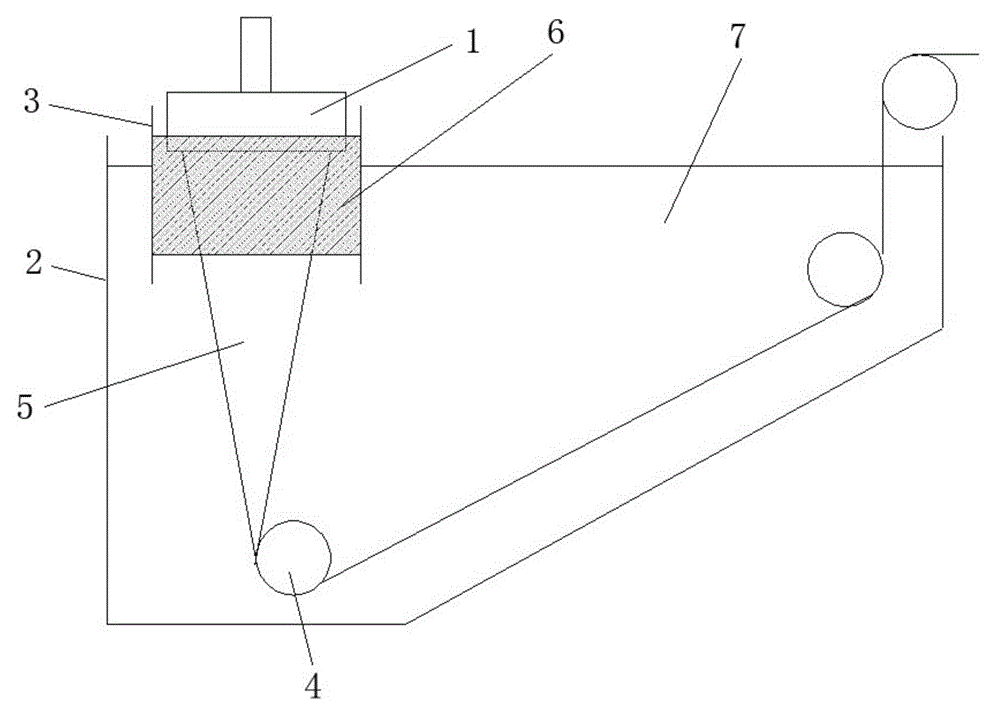

[0031] This embodiment adopts 3-stage gradient coagulation, and the first-stage coagulation bath is as image 3 As shown, wherein the non-coagulating bath is simethicone oil with a viscosity of 10 cP.s, the coagulating bath is a 65% DMSO (dimethyl sulfoxide) aqueous solution, and the temperature is 45° C. The spinning dope is a DMSO solution of an acrylonitrile-itaconic acid binary copolymer, and the molar ratio of itaconic acid units to acrylonitrile units in the copolymer is 0.45:100. Use a transparent cylinder to isolate the non-coagulation bath from the coagulation bath (the components of the non-coagulation bath and the coagulation bath are immiscible with each other, the mutual solubility is very small, and their influence can be almost ignored, so there is no need to physically separate the two in the up and down direction open), cylinder length 50cm. The hole diameter of the spinneret is 0.1mm. After the wire drawing is successful, slowly add simethicone oil into the ...

Embodiment 2

[0038] In this embodiment, n-heptane is used as the non-coagulation bath, and the rest of the parts not mentioned are the same as in Embodiment 1.

[0039] After carbonization, the linear density is 0.066, the bulk density is 1.801, the tensile strength is 6.4GPa, the modulus is 265GPa, and the elongation at break is 2.3%.

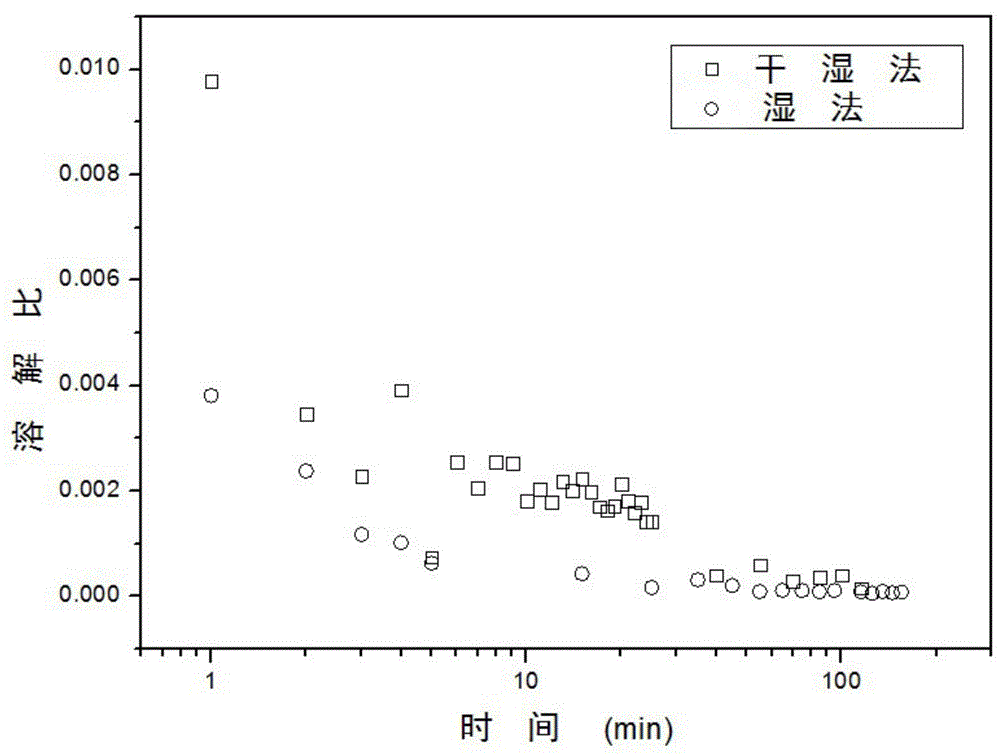

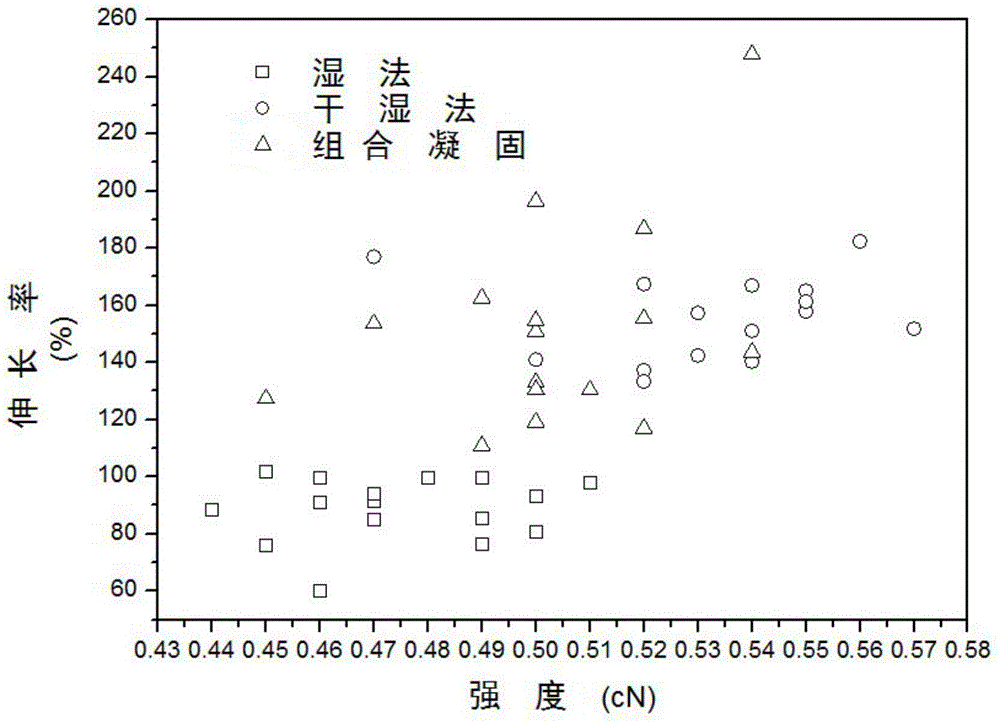

[0040] The following is to compare the wet spinning process with the combined coagulation molding process of the present invention:

[0041] The hole diameter of the spinneret is 0.055mm, the three-stage gradient coagulation, the first-stage coagulation bath draft is 0.97, and the spinning speed is 150m / min. All the other unmentioned parts are the same as in Embodiment 1.

[0042] The SEM characterization of the obtained precursor surface is as follows: Figure 6a and Figure 6b shown. After carbonization, the linear density is 0.063, the bulk density is 1.786, the tensile strength is 4.9GPa, the modulus is 268GPa, and the elongation at break is 2.0%. ...

Embodiment 3

[0045] The spinning stock solution is a DMSO solution of acrylonitrile-itaconic acid-methyl acrylate terpolymer, the molar ratio of itaconic acid unit to acrylonitrile unit in the copolymer is 0.45:100, and the molar ratio of methyl acrylate unit to acrylonitrile unit The ratio is 0.55:100. Others are the same as embodiment one.

[0046] The linear density of the obtained precursor after carbonization is 0.066, the bulk density is 1.805, the tensile strength is 5.5GPa, the modulus is 275GPa, and the elongation at break is 2.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com