Patents

Literature

317 results about "Mutual solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

As the temperature rises, both liquids become more soluble in each other. They reach a mutual solubility temperature or critical solution temperature. Above that point, the mixture becomes homogeneous. Below that point, the mixture separates into two layers.

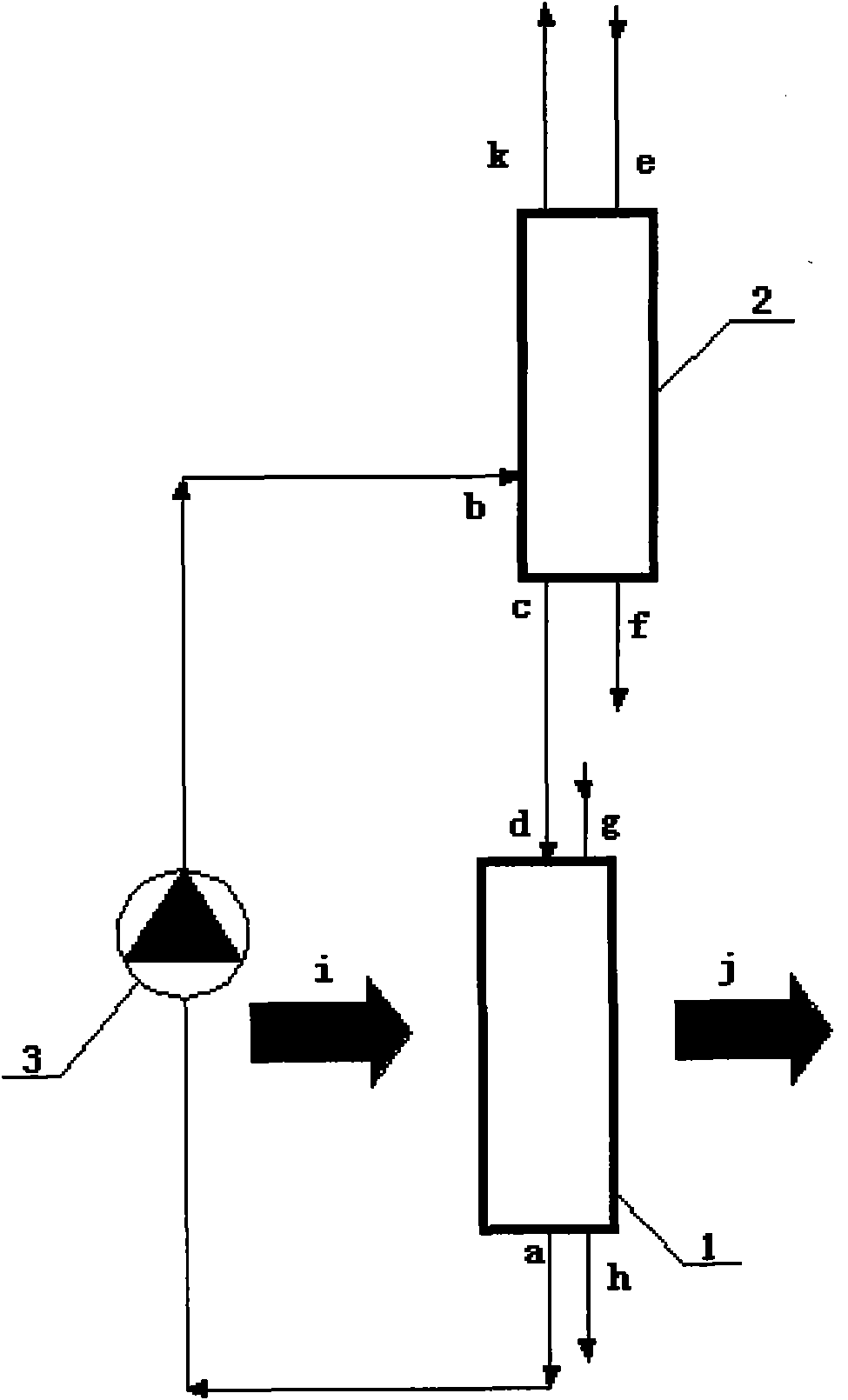

Dehumidizer for air dehumidification, air dehumidification method and device

InactiveCN102335545AEfficient removalQuick removalLighting and heating apparatusDispersed particle separationLithium chlorideWater vapor

The invention discloses a dehumidizer for air dehumidification. The dehumidizer provided by the invention is an ionic liquid solution formed by dissolving an ionic liquid in water, wherein the ionic liquid is formed by organic positive ions and inorganic negative ions, and the melting point of the ionic liquid is close to or is lower than room temperature. In addition, the invention further discloses a method and a device for air dehumidification by the adoption of the above dehumidizer. In comparison with traditional salting liquids (lithium bromide, lithium chloride and calcium chloride aqueous solutions and the like), the dehumidizer provided by the invention has the following advantages: 1) the applied ionic liquid solution is in the liquid state at normal temperature, is intermiscible with water, and will not be crystallized during operation, so as to guarantee the reliable operation of a system; 2) the applied ionic liquid solution has similar or lower water vapor pressure than a traditional dehumidifying salting liquid so as to raise the dehumidifying efficiency; 3) the applied ionic liquid solution will not corrode metal equipment such as steel equipment such that the equipment has low cost and long service life; 4) the dehumidizer has nonvolatility so as to reduce the environmental pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

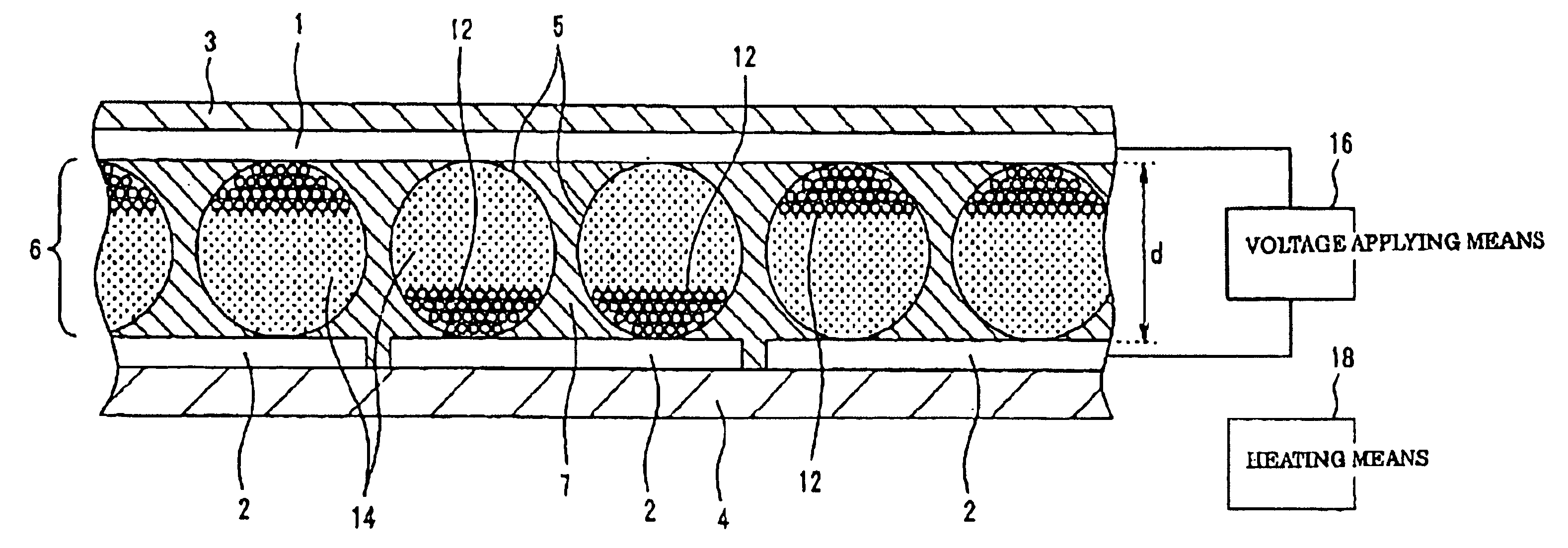

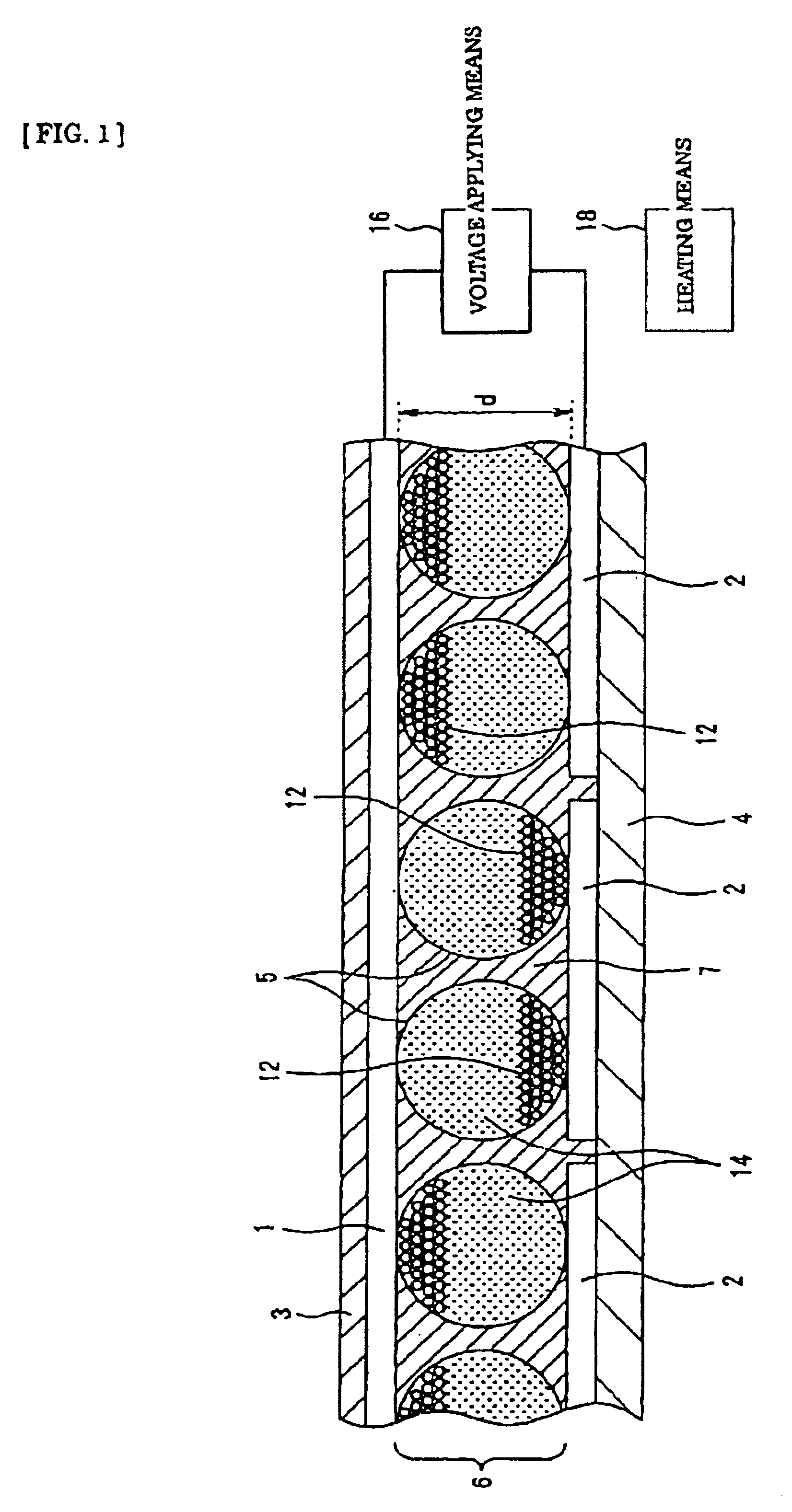

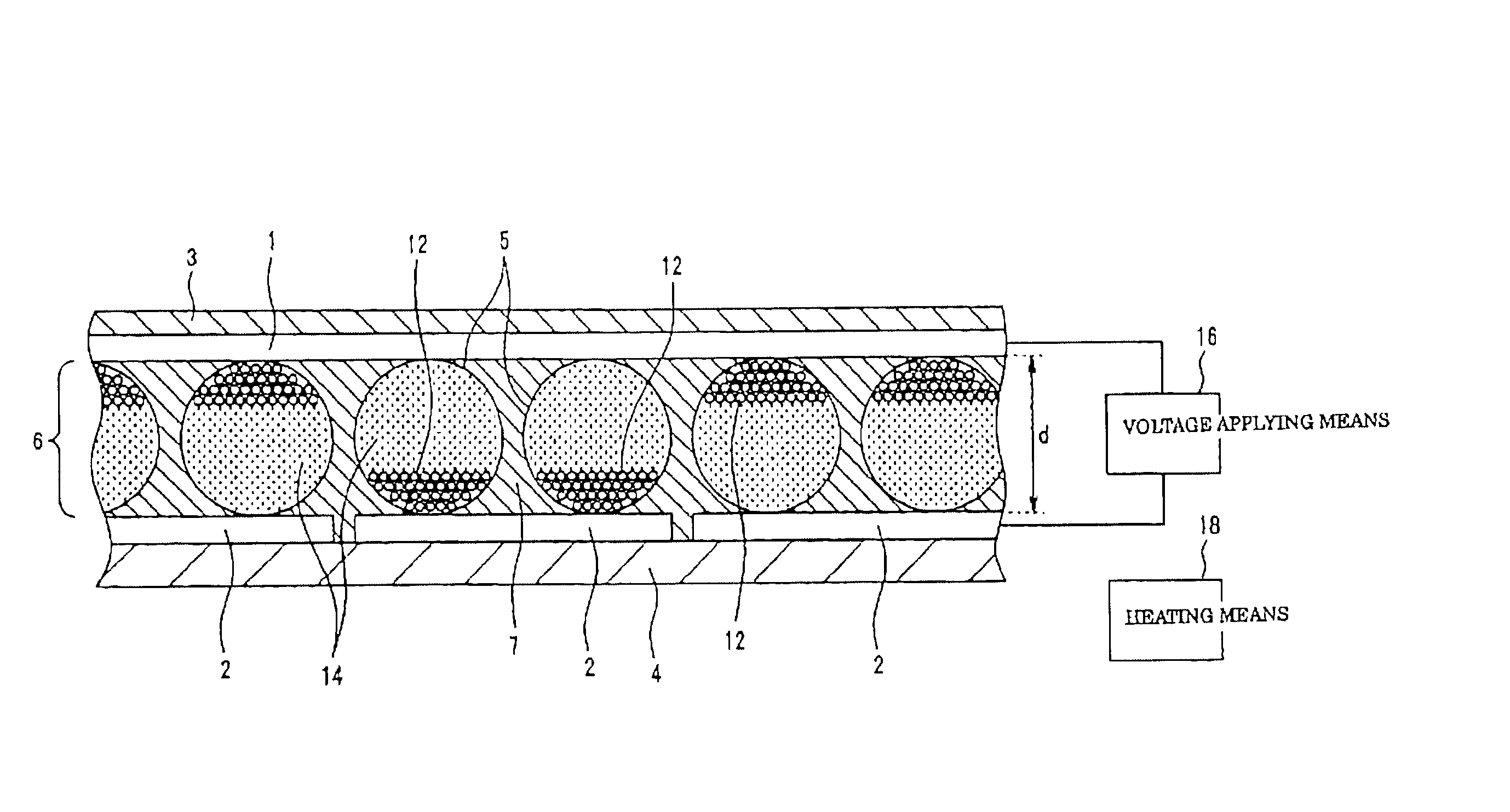

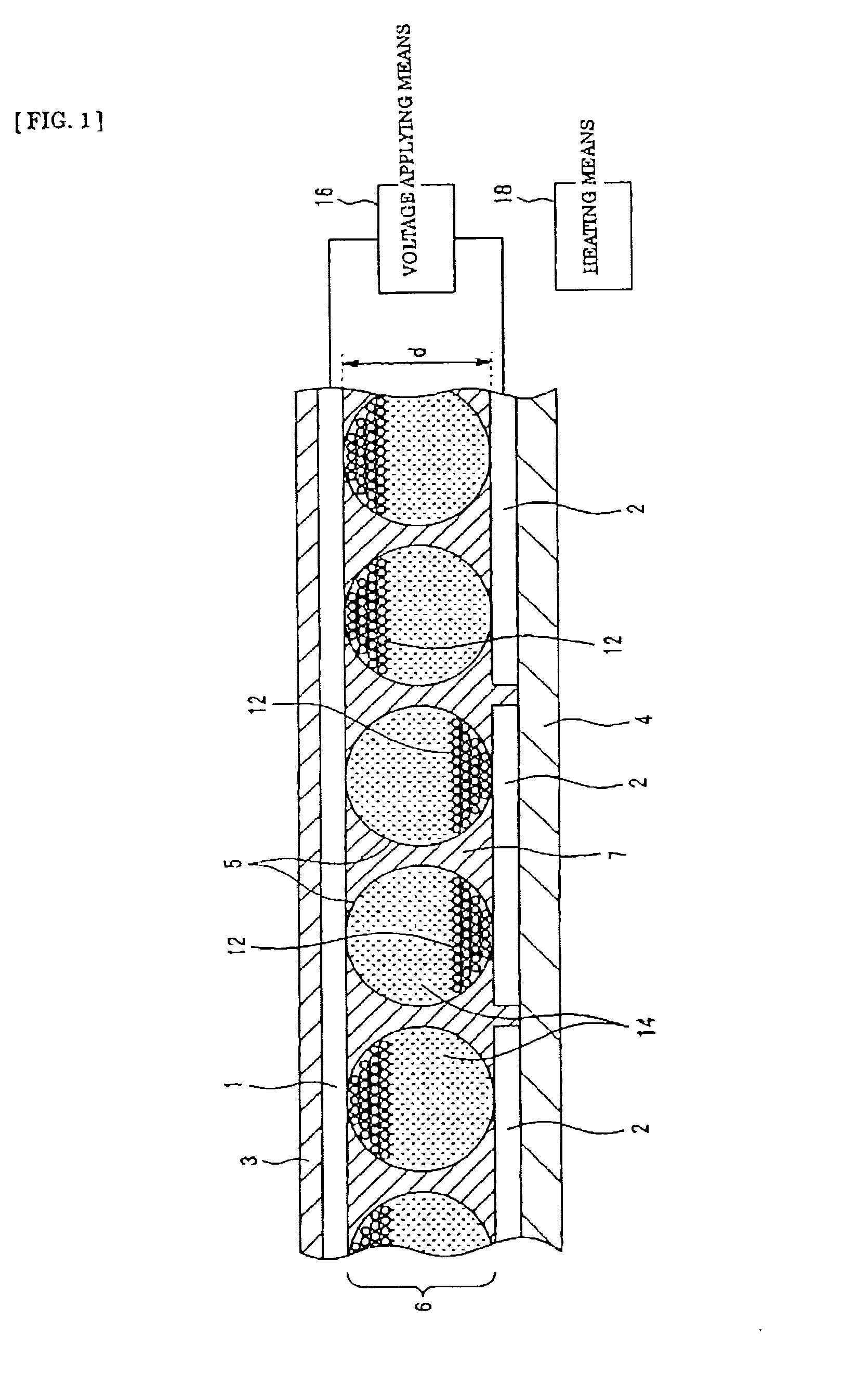

Electrophoretic device, driving method of electrophoretic device, and electronic apparatus

InactiveUS6788450B2Improving visibility and contrast characteristicMaintenance conditionStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresisEngineering

Owner:E INK CORPORATION

Electrophoretic device, driving method of electrophoretic device, and electronic apparatus

InactiveUS20020150827A1Excellent characteristicsImprove visibilityLiquid crystal compositionsMaterial analysis by electric/magnetic meansElectrophoresisEngineering

There is provided an electrophoretic device which comprises an electrophoretic layer containing dispersion medium and electrophoretic particles dispersed in the dispersion medium, controls the position of the electrophoretic particles according to the electric potential applied to electrodes, and can maintain the electrophoretic particles at a desired position for a long time by using the dispersion medium formed of mixture consisting of a plurality of substances having small mutual solubility.

Owner:E INK CORPORATION

Multifunctional alcohol fuel additives

InactiveCN101285010ABoost octanePowerfulLiquid carbonaceous fuelsFuel additivesAlcohol fuelEngineering

The invention relates to a multifunctional alcohol fuel additive, aiming at resolving such technical problems existing in prior alcohol fuel as the mutual solubility, the power performance and the stability are poor, cleaning degrees of oil products and fuel oil system are poor and the corrosion and the air resistance of methanol gasoline can not be effectively handled. The additive comprises following components in portion by volume: 50 to 60 portions of cosolvent, 5 to 10 portions of corrosion inhibitor, 0 to 30 portions of detergent dispersant, 0 to 10 portions of rubber plasticizer and 0 to 15 portions of vapor pressure inhibitor. The additive has the advantages of high octane value, strong power performance, good stability, desirable mutual solubility, environmental protection and energy conservation, and can effectively inhibit metallic corrosion, improve the cleanness of oil products and resolve the problems of air resistance.

Owner:山西丰喜新能源开发有限公司

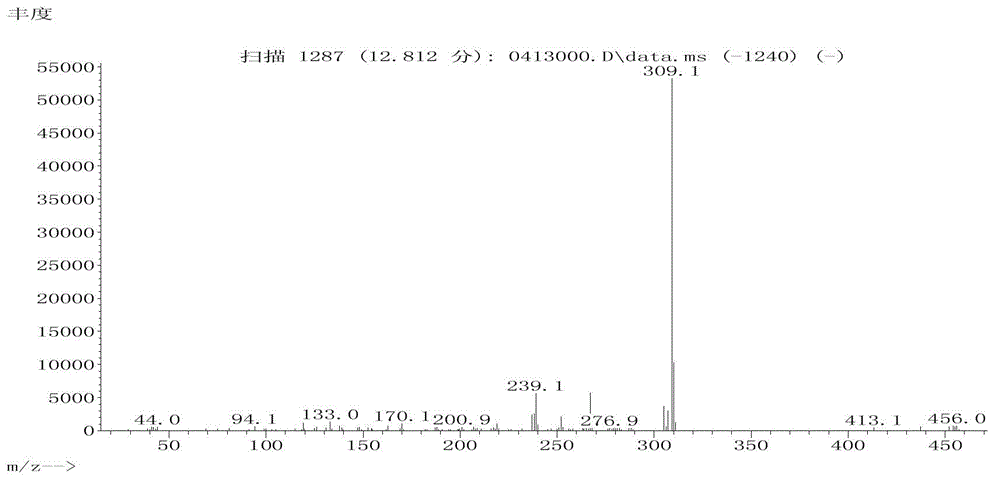

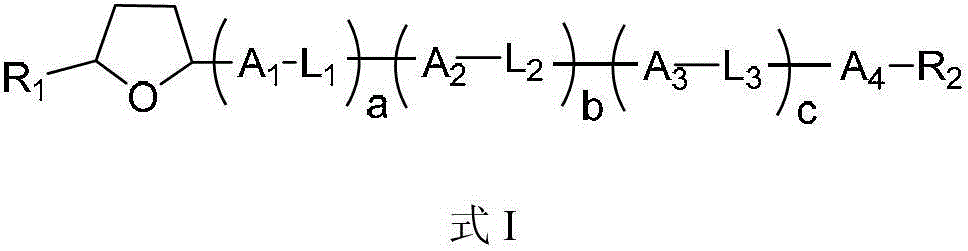

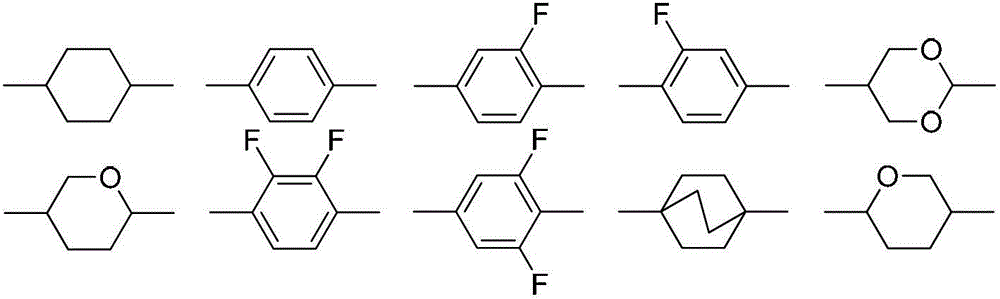

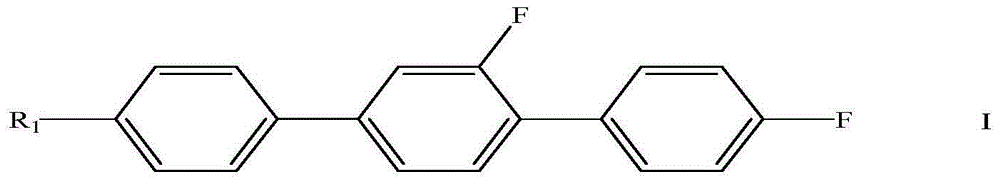

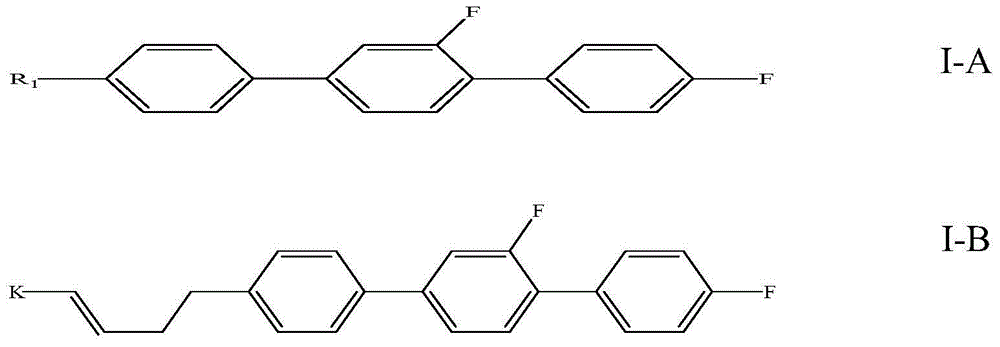

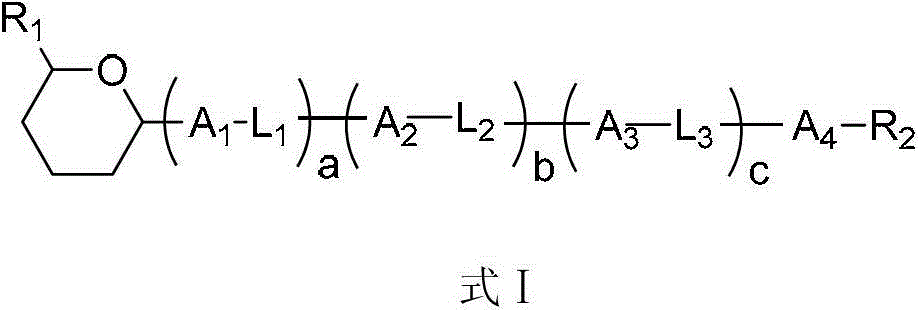

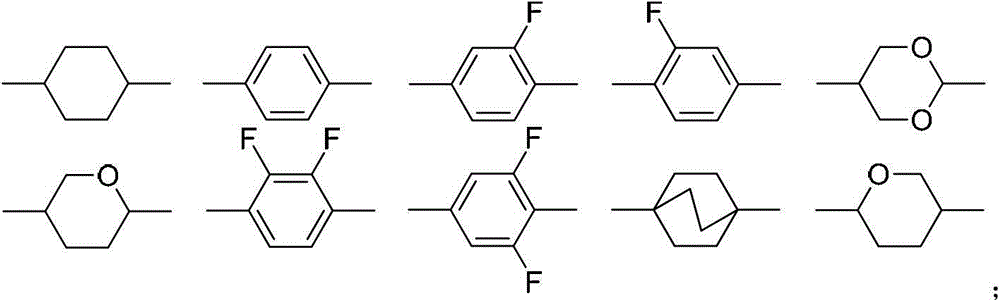

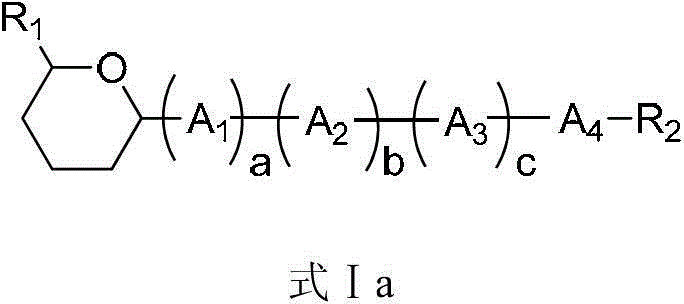

Liquid crystal compounds containing tetrahydrofuran structure

ActiveCN103333139AImprove stabilityQuick responseLiquid crystal compositionsOrganic chemistryMutual solubilityLiquid-crystal display

The invention discloses liquid crystal compounds containing tetrahydrofuran structure, and a preparation method and application thereof. The structural general formula of the compounds is disclosed as Formula I. The compounds have the advantages of stable structure, wide liquid-crystal-state temperature range and favorable low-temperature mutual solubility, can implement low threshold voltage and low rotary viscosity gamma 1 when being used in optical devices, and can improve the properties of the liquid crystal composition material and display device, thereby having an important meaning in quick response of display devices. The liquid crystal composition containing the compounds can be used for preparing liquid crystal displays with low drive voltage, wide temperature range and high response speed.

Owner:BEIJING CHENGZHI YONGHUA DISPLAY TECHNOLOGY CO LTD

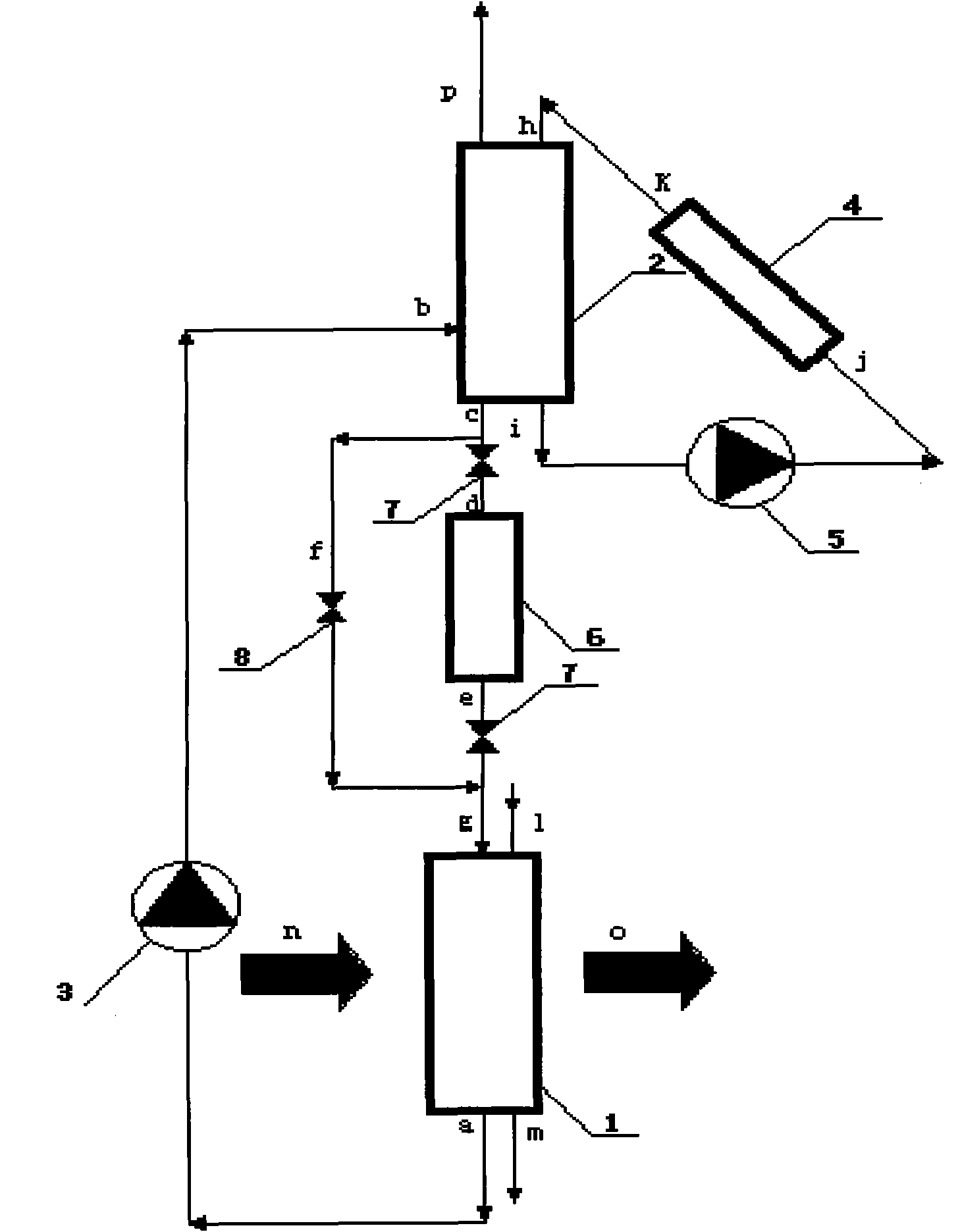

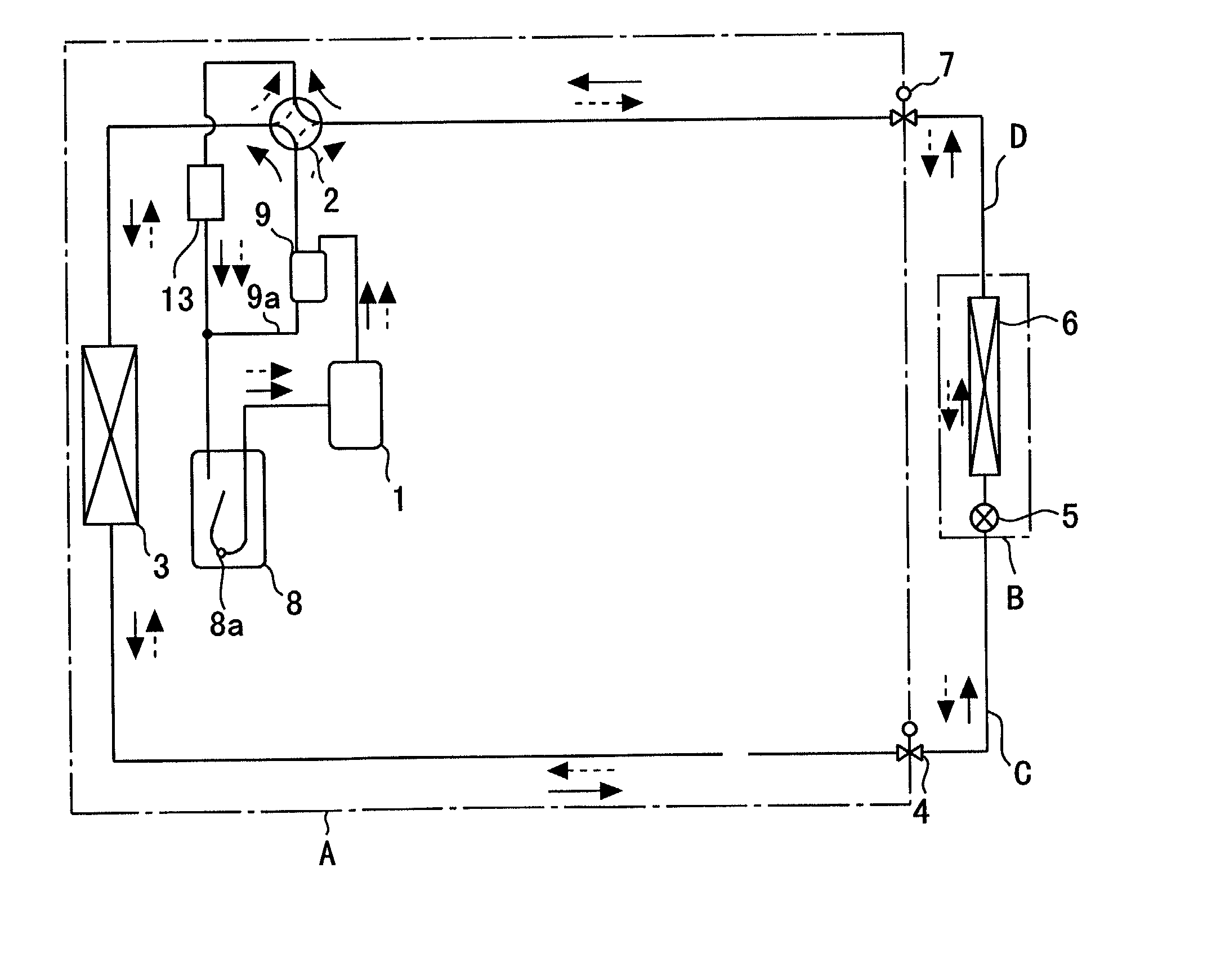

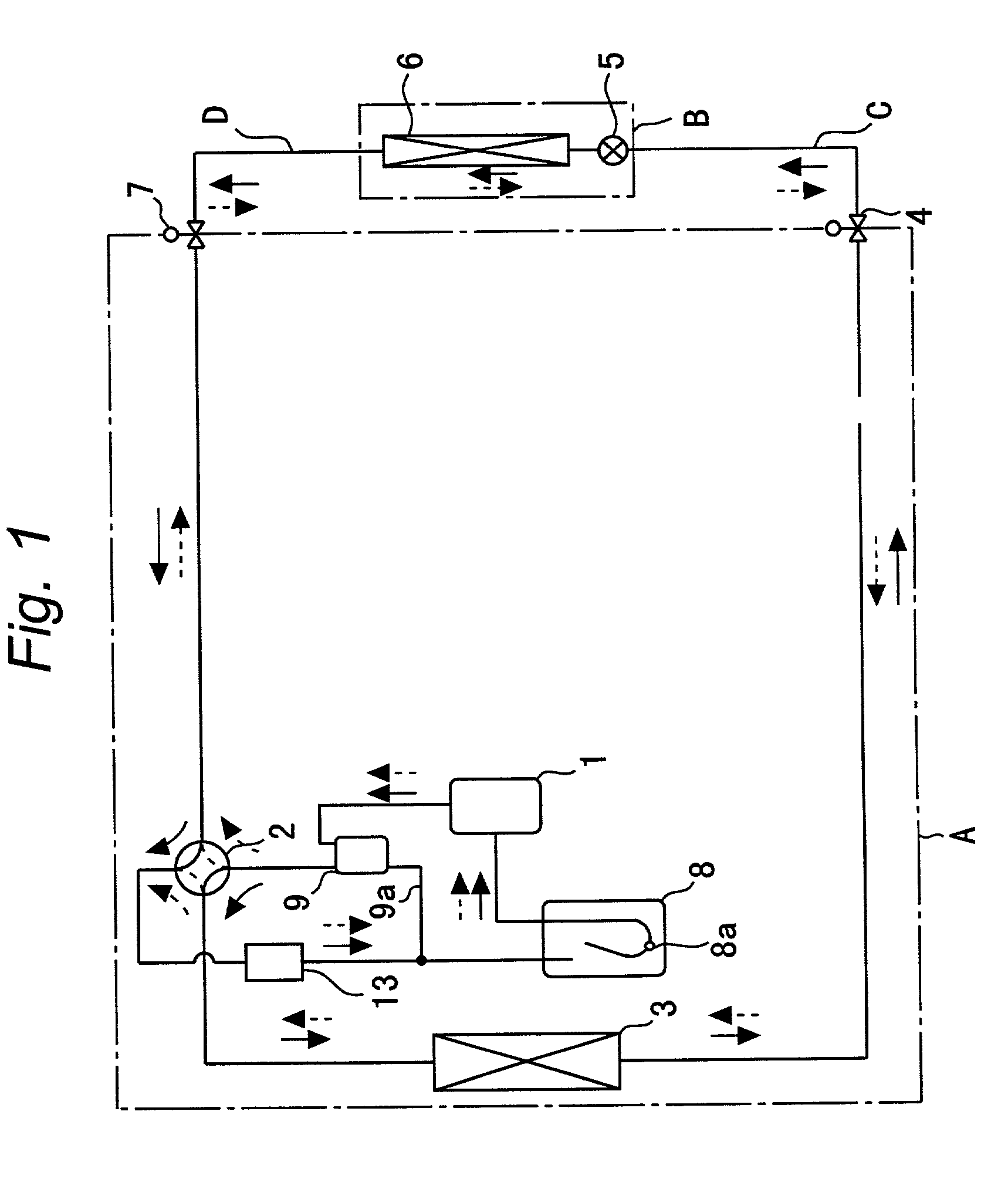

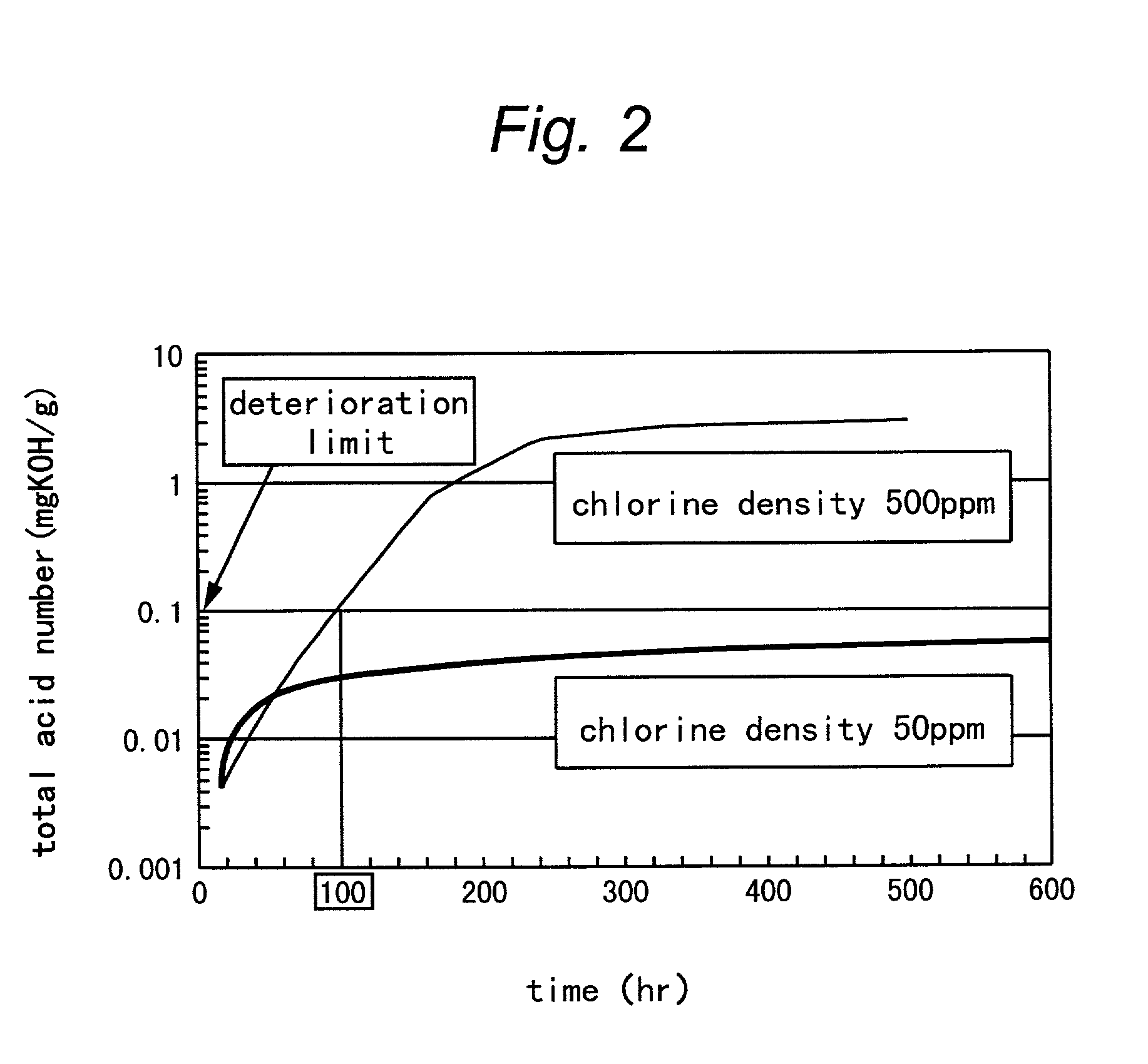

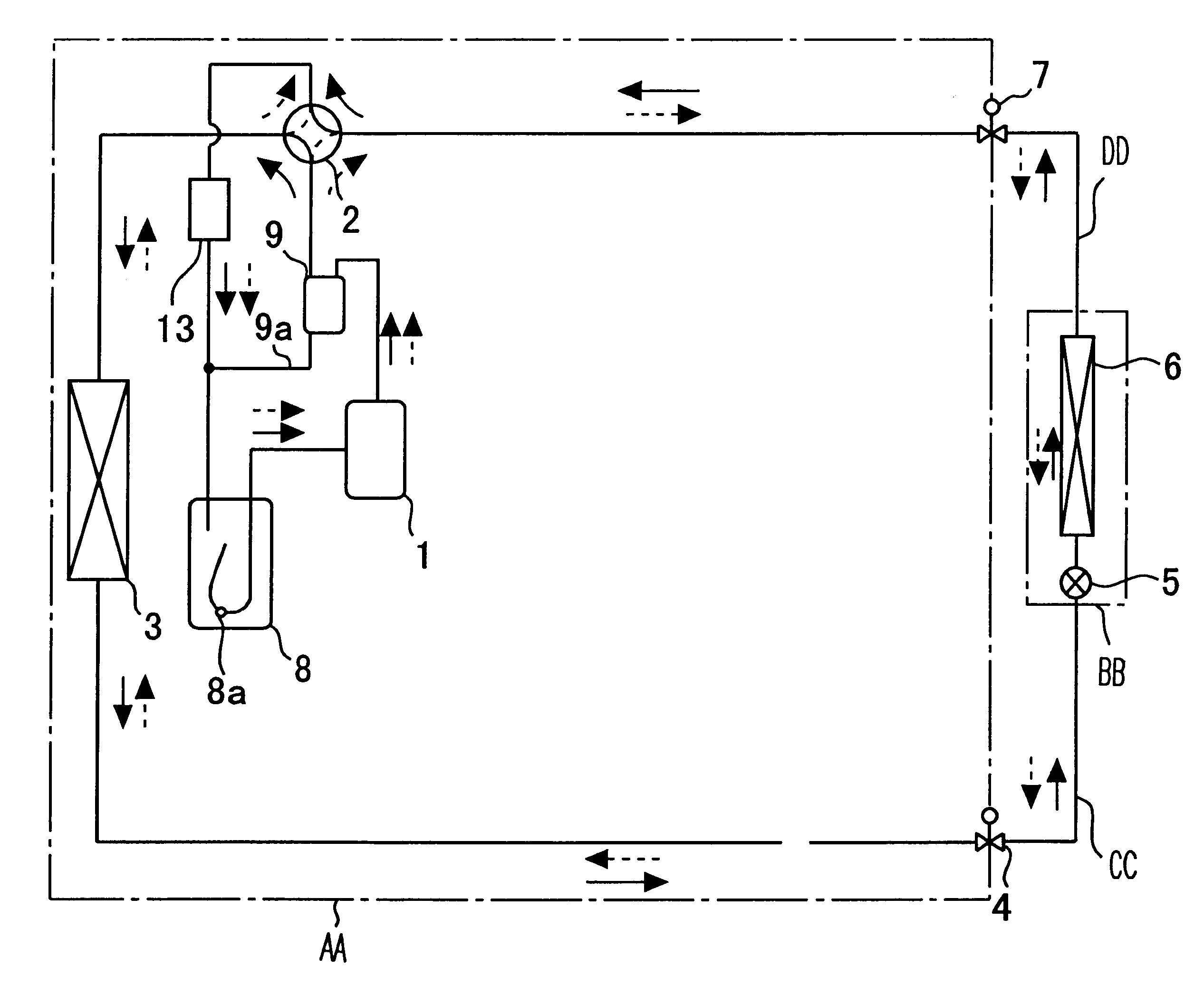

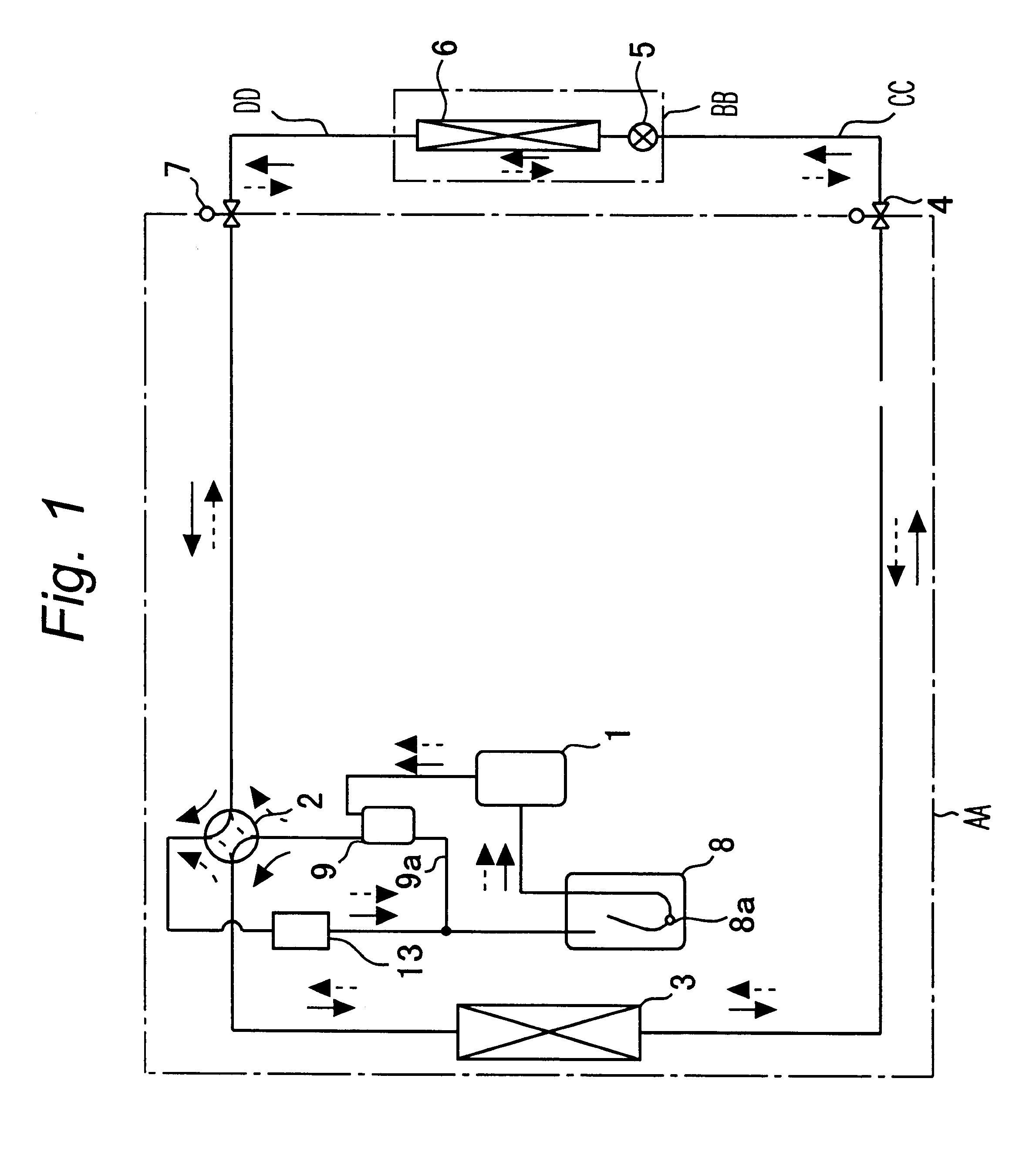

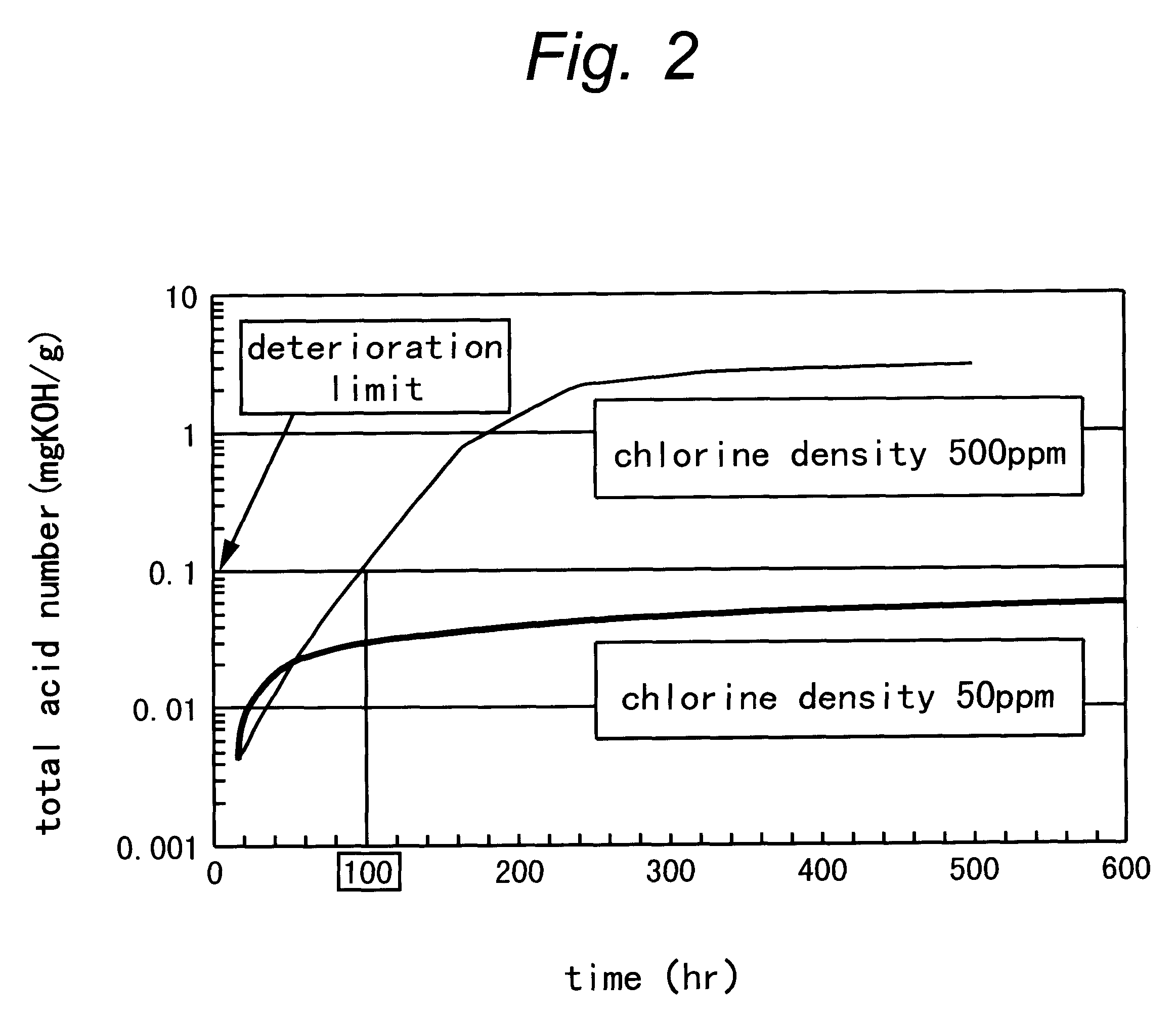

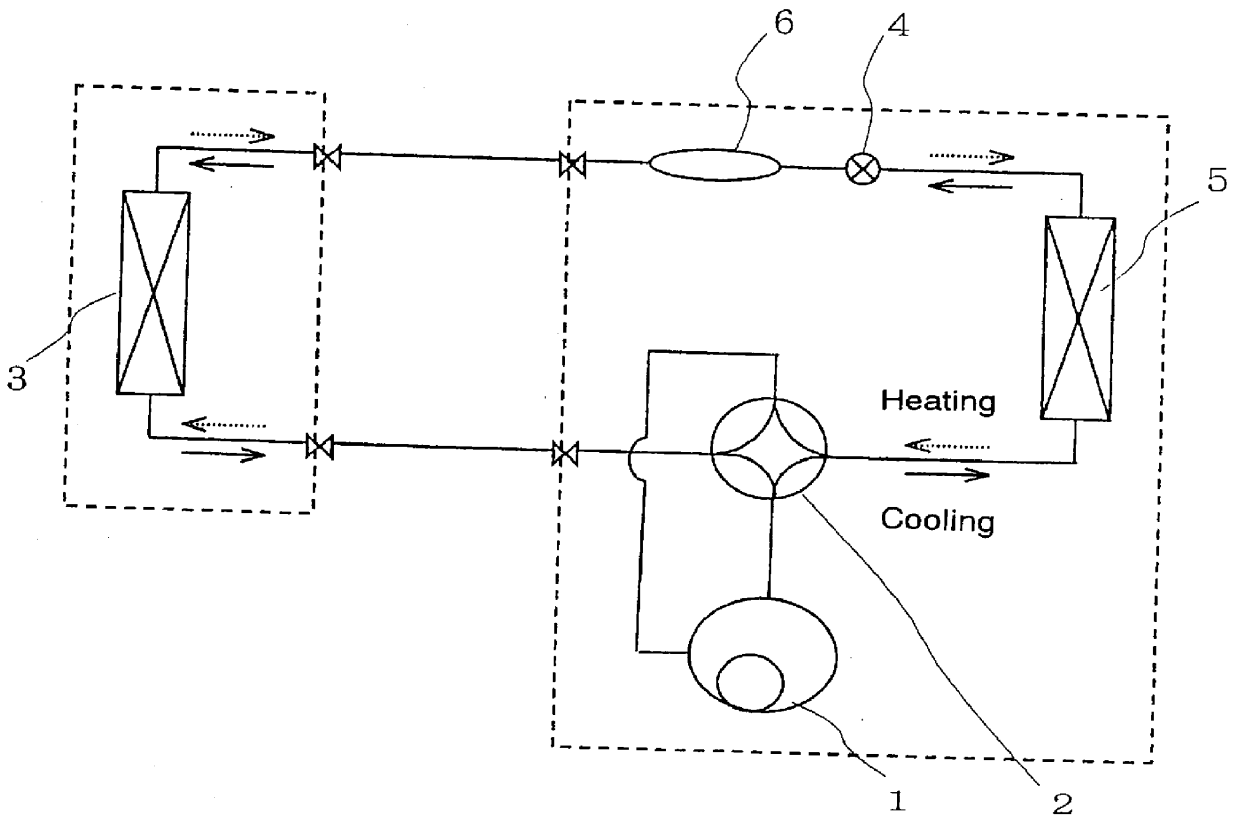

Refrigeration system, and method of updating and operating the same

A heat source unit and refrigerant used in an existing refrigeration system are replaced with new refrigerant and a new heat source unit which employs the new refrigerant and is equipped with an oil separator and extraneous-matter trapping means. An indoor unit of the existing refrigeration system may be used, in its present form, or replaced with a new indoor unit. Further, connecting pipes used for the existing refrigeration are reused. After replacement of refrigerant, the refrigeration system performs an ordinary operation after having performed a cleaning operation. The extraneous-matter trapping means is provided in a refrigerant pipe close to the heat source unit or in a bypass channel connected to the refrigerant pipe close to the heat source unit. Alternatively, only the heat source unit of the existing refrigeration system is replaced with a new one, and there is employed refrigeration oil which has no mutual solubility with respect to HFC or has very low mutual solubility.

Owner:MITSUBISHI ELECTRIC CORP

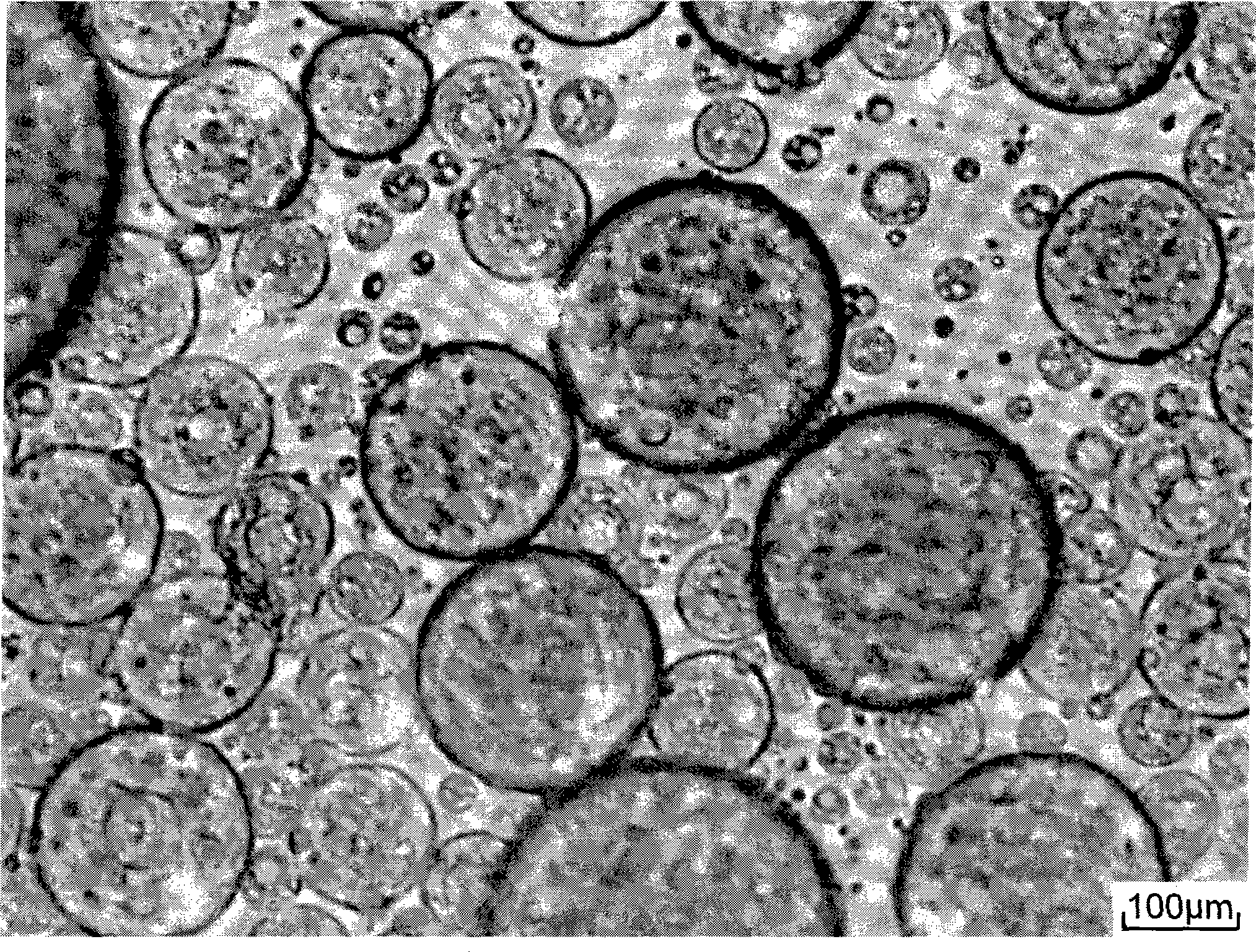

Microcapsule preparation method

InactiveCN101362067AOvercoming not easy to disperseSolve deficiencies that are not easy to disperseMicroballoon preparationMicrocapsule preparationOrganic solventSolvent evaporation

The invention relates to a preparation method of microcapsules. A used organic compound is soluble in a medium-polarity organic solvent mutually soluble with water, but insoluble in both water and a non-polarity (or weak-polarity) solvent mutually insoluble with water. The organic compound is taken as core material and dissolved with wall material in a mixed solvent formed by a medium-polarity organic solvent mutually soluble with water and an organic solvent mutually insoluble with water, and then a combined method of phase separation and solvent evaporation is carried out to prepare the microcapsules of the organic compound. The preparation method has simple process, is liable to be magnified, friendly to the environment and capable of cutting cost and recovering the solvents.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

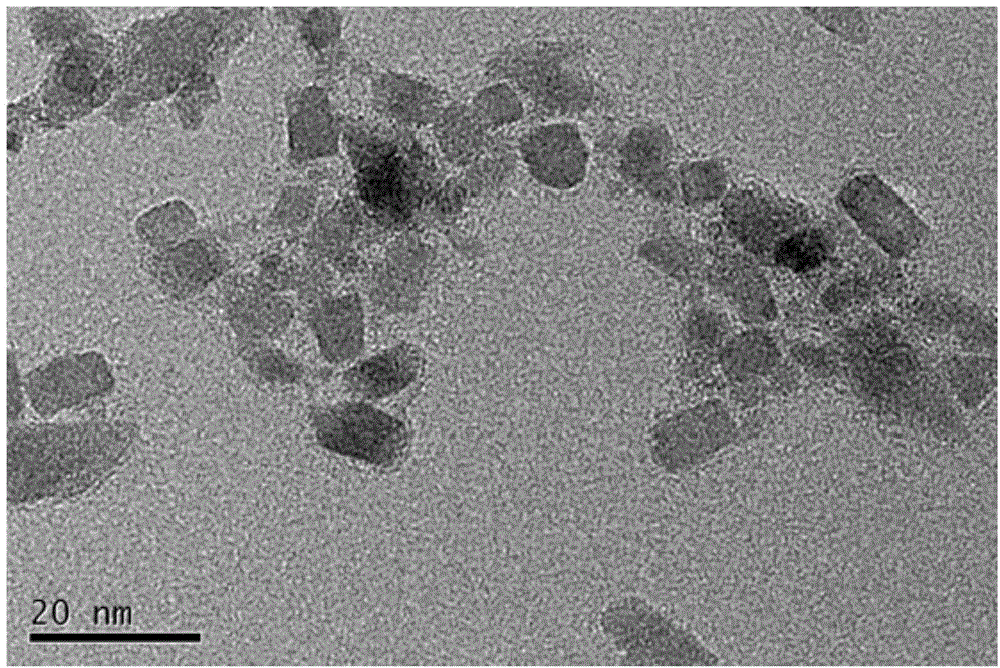

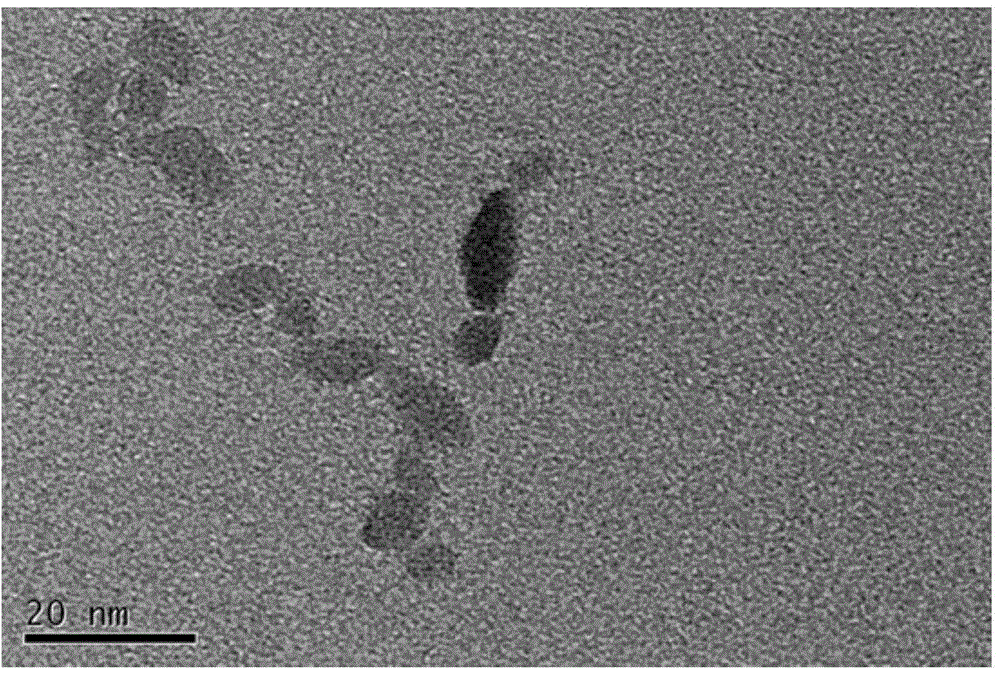

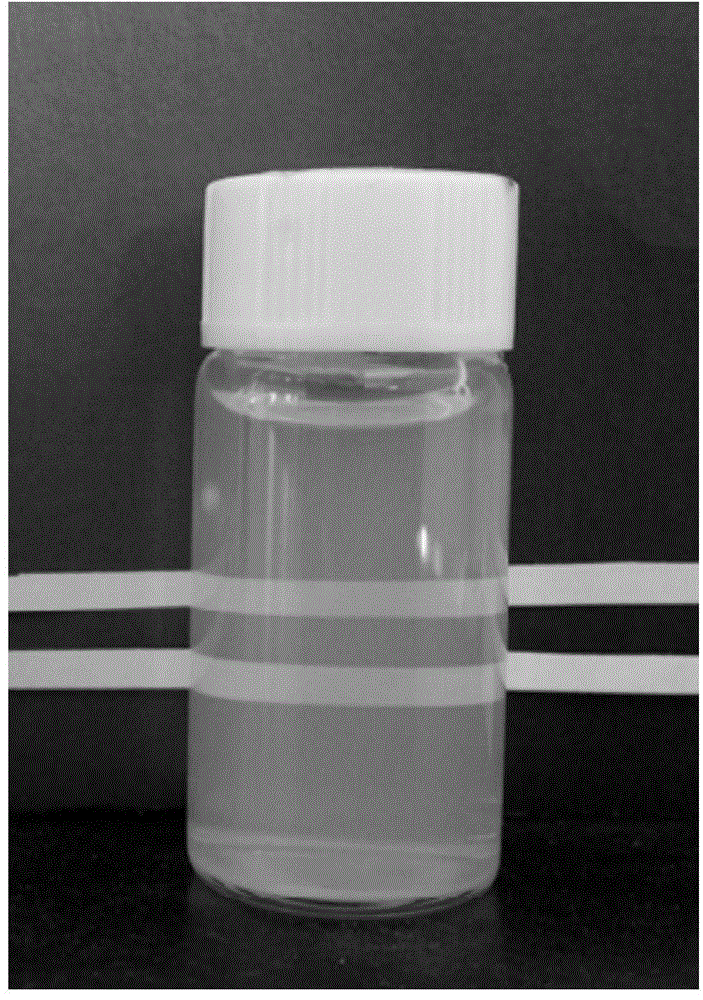

Transparent nanometer zirconium dioxide liquid phase dispersoid, and preparation method and application thereof

ActiveCN106277049ALong-term stable and uniform dispersionOvercome the problem of easy reunionNanotechnologyZirconium oxidesOrganic solventWater soluble

The invention discloses transparent nanometer zirconium dioxide liquid phase dispersoid, and a preparation method and application thereof. The dispersoid comprises liquid phase media and nanometer zirconium dioxide particles, wherein the nanometer zirconium dioxide particles are uniformly dispersed into liquid phase media; the solid content of the dispersoid is 1 weight percent to 50 weight percent; the one-dimensional dimension of the nanometer zirconium dioxide particles is 1 to 12nm; the liquid phase media are water, organic solvents, a mixture of water-soluble organic solvents and water, or a mixture of different organic solvents. The nanometer zirconium dioxide in the product has high crystallinity degree; the particle diameter is small; the distribution is uniform; any surfactant is not contained; the purity is high; the dispersion effect is good; no sedimentation occurs after the still standing for 6 months or longer. The product prepared by the method does not need any treatment, and is directly the transparent nanometer zirconium dioxide liquid phase dispersoid; any substance does not need to be added for dispersion assistance; the problems of easy agglomeration, poor dispersibility and poor optical performance of the composite material are solved; higher application performance and wider application ranges are given to the product.

Owner:BEIJING UNIV OF CHEM TECH

Refrigeration system, and method of updating and operating the same

A heat source unit and refrigerant used in an existing refrigeration system are replaced with new refrigerant and a new heat source unit which employs the new refrigerant and is equipped with an oil separator and extraneous-matter trapping device. An indoor unit of the existing refrigeration system may be used, in its present form, or replaced with a new indoor unit. Further, connecting pipes used for the existing refrigeration are reused. After replacement of refrigerant, the refrigeration system performs an ordinary operation after having performed a cleaning operation. The extraneous-matter trapping device is provided in a refrigerant pipe close to the heat source unit or in a bypass channel connected to the refrigerant pipe close to the heat source unit. Alternatively, only the heat source unit of the existing refrigeration system is replaced with a new one, and there is employed refrigeration oil which has no mutual solubility with respect to HFC or has very low mutual solubility.

Owner:MITSUBISHI ELECTRIC CORP

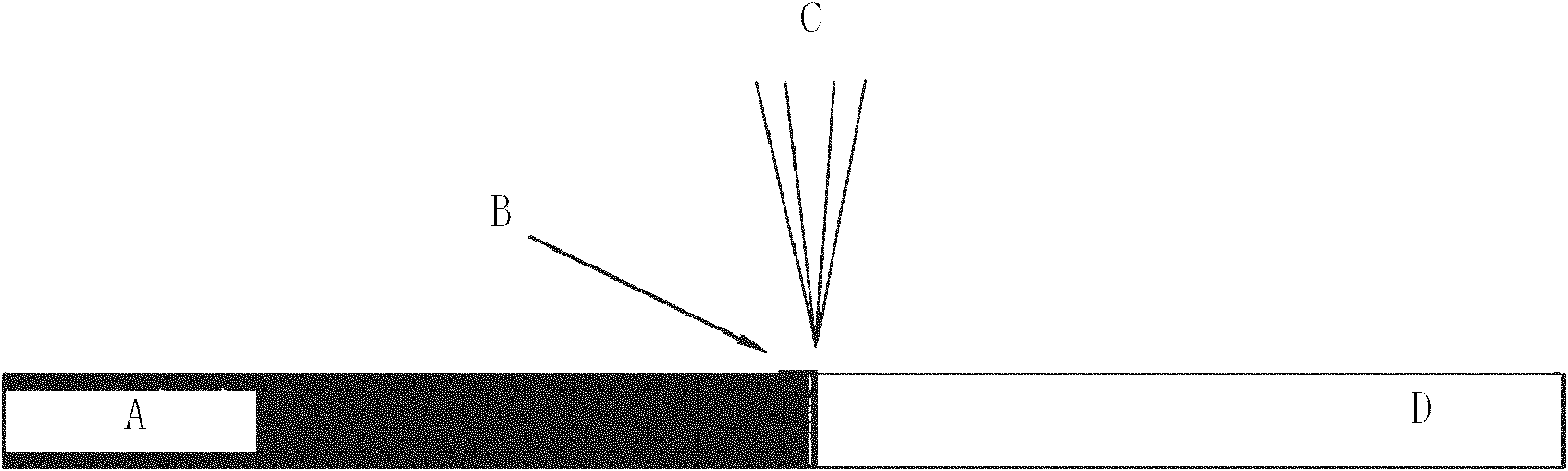

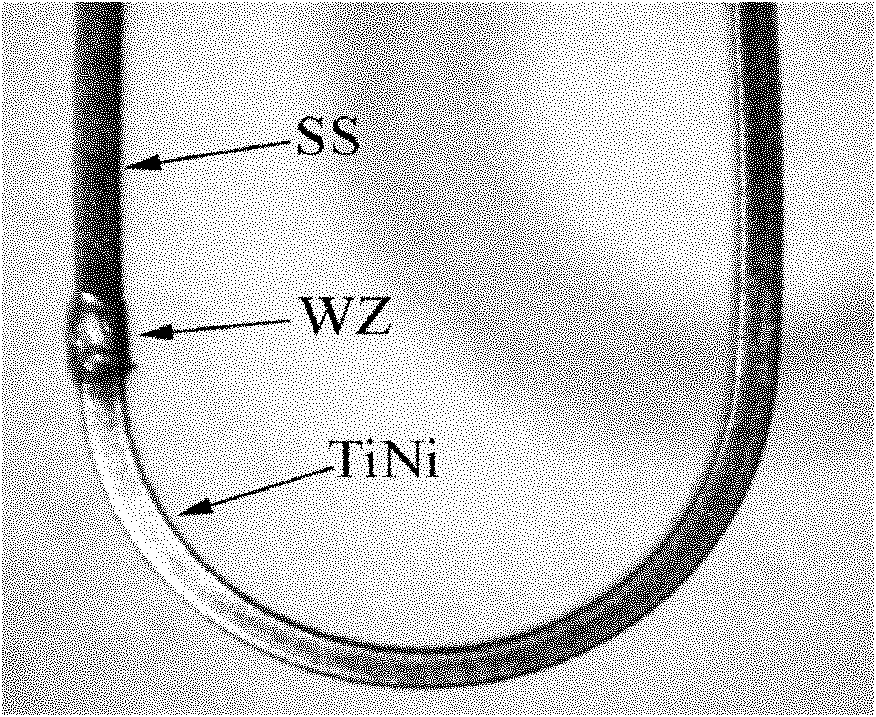

Method for connecting TiNi shape memory alloy and austenitic stainless steel heterogenetic material

InactiveCN102152017AHigh strengthHigh tensile strengthWelding/soldering/cutting articlesWelding apparatusShape-memory alloyAustenite

The invention relates to a method for connecting a TiNi shape memory alloy and an austenitic stainless steel heterogenetic material, and belongs to a heterogenetic material connection technology. In the method, aiming at the welding problem of the TiNi shape memory alloy and the austenitic stainless steel heterogenetic material, on the basis of the characteristics of limitless mutual solubility of copper and nickel, finite solid solubility of copper and titanium, iron and chromium, higher strength and plasticity of copper solid solution, lower brittleness of a copper-titanium intermetallic compound and the like, the copper solid solution can be extracted from a welding line region and the brittle intermetallic compounds can be reduced by adopting a pure copper packing material (a copper middle layer or a copper welding wire) and reducing the penetration ratio of a TiNi alloy base material, so the strength and flexibility of a welding joint between the TiNi shape memory alloy and the stainless steel heterogenetic material. The method comprises the following processes of: adding the pure copper middle layer (pure copper welding wire), adjusting the position of a heat source, protecting a welding region, and melting and welding.

Owner:JILIN UNIV

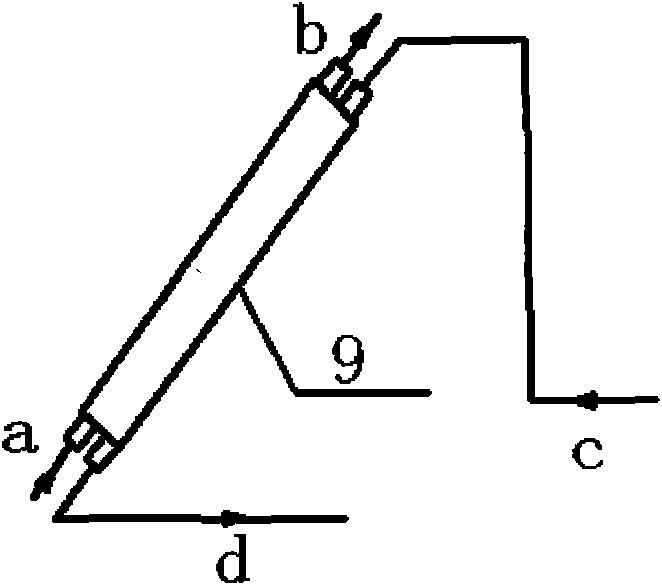

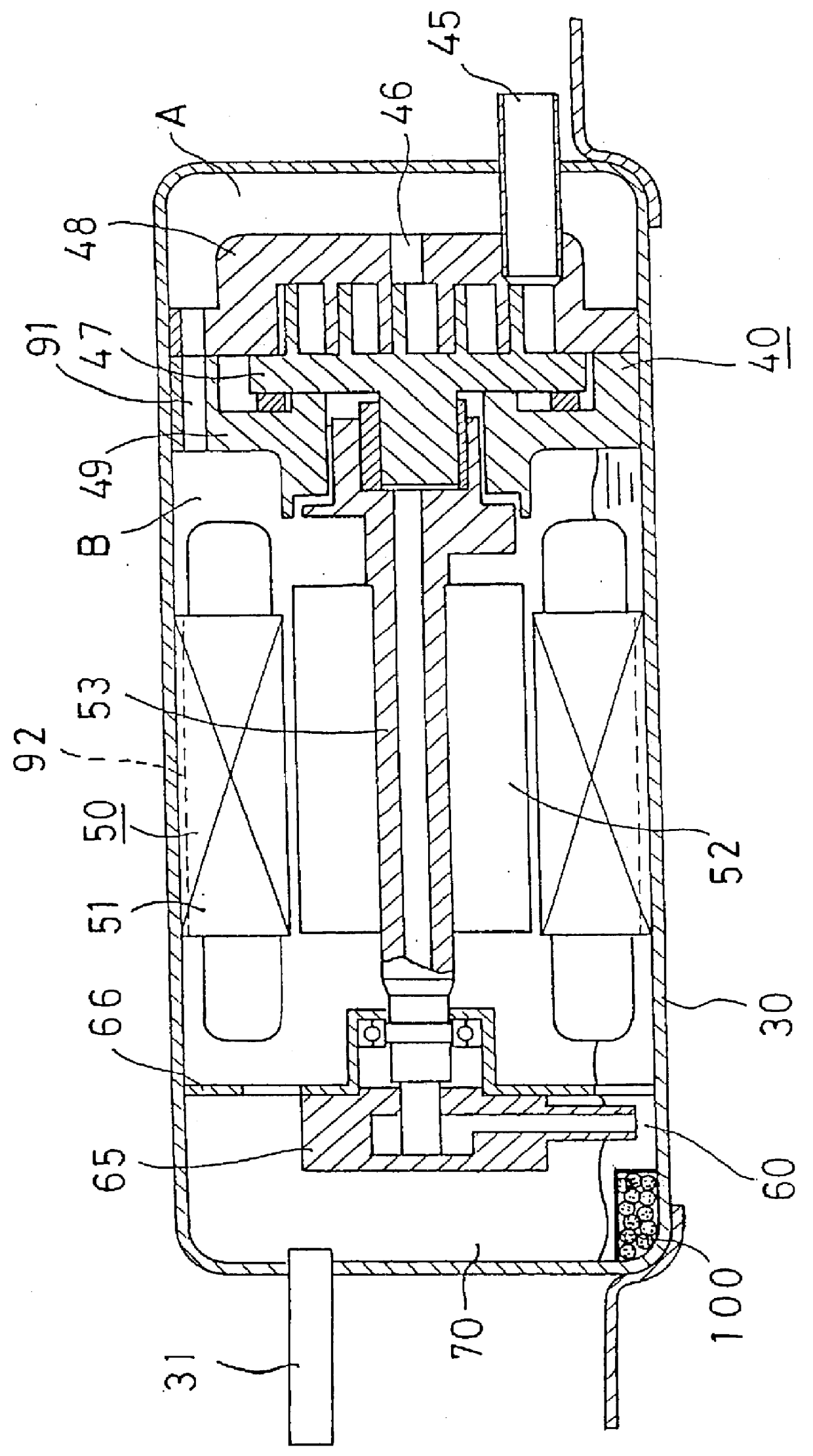

Apparatus having refrigeration cycle

InactiveUS6044660AReduce the amount requiredReduce refrigerantCompressorCompression machines with non-reversible cycleEngineeringRefrigeration

In an apparatus having a refrigeration cycle, the refrigeration cycle is formed by annularly connecting a compressor, a condenser, an expansion device and an evaporator with one another, the apparatus uses propane, isobutane or ethane as a refrigerant, and uses refrigerating machine oil having less mutual solubility with the refrigerant, and a dryer is provided in the refrigeration cycle for absorbing water. In stead of the dryer, an additive which reacts with water may be included in said refrigerating machine oil. With this arrangement, the amount of the refrigerant can be reduced, and the long term reliability of the apparatus can be obtained.

Owner:PANASONIC CORP

Method for enhancing oxidation resistance of edible vegetable oil or fish oil by using natural antioxidant

InactiveCN104911027AImprove stabilityImprove antioxidant capacityFatty substance preservation using additivesOil and greaseVegetable oil

The invention discloses a method for enhancing oxidation resistance of edible vegetable oil or fish oil by using a natural antioxidant, which comprises the following step: dissolving the natural antioxidant powder (polyphenol compounds, such as tea polyphenols and carnosic acid) in high-polarity oil (propanediol octanoate) while assisting dissolution with an ultrasonic vortex instrument, wherein the dissolution required lime is directly proportional to the dissolved amount. The natural antioxidant high-load grease has favorable mutual solubility with edible vegetable oil and fish oil, and the addition amount is 10-4000 ppm, thereby obtaining favorable oxidation resistance effect.

Owner:JIANGSU FUSHENG BIOTECH CO LTD

Biologically active composition

A biologically active stick composition comprising a biologically active agent dissolved in a carrier system including an unsaturated fatty acid alcohol in mutual dissolution with an alkylene glycol as a solvent for said biologically active agent and a stiffening agent therefor, said stiffening agent imparting stick consistency to the composition, said alkylene glycol preferably being present in an amount of more than 12%. The composition can be prepared by dissolving the active agent in the solvent, combining the solution with the stiffening agent and shaping the formulation into a stick. The composition is especially intended for use as a medicament, preferably in the treatment of dermatological conditions, where it has been found to possess outstanding bioavailability properties.

Owner:JAGOTEC AG

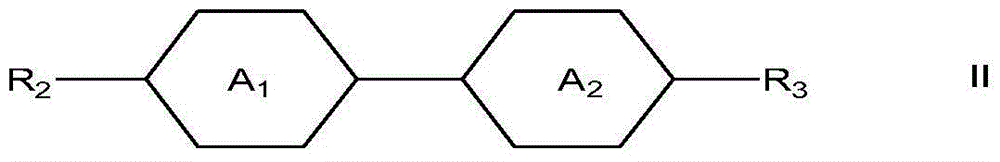

Quick-response liquid crystal composition

ActiveCN104593002ALow rotational viscosityLarge elastic constantLiquid crystal compositionsIn planeCrystallography

The invention relates to a liquid crystal composition which comprises the following components in parts by weight: 1-30 parts of compound disclosed as general formula I and 10-70 parts of compound disclosed as general formula II. The liquid crystal composition has the advantages of low rotary viscosity, high elastic constant, favorable low-temperature mutual solubility and high response speed, can be used for multiple display modes of quick-response liquid crystal display, and can obviously improve the display effect of the liquid crystal display device in TN (twisted nematic), IPS (in-plane switching) or FFS (fringe field switching)-mode display devices.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

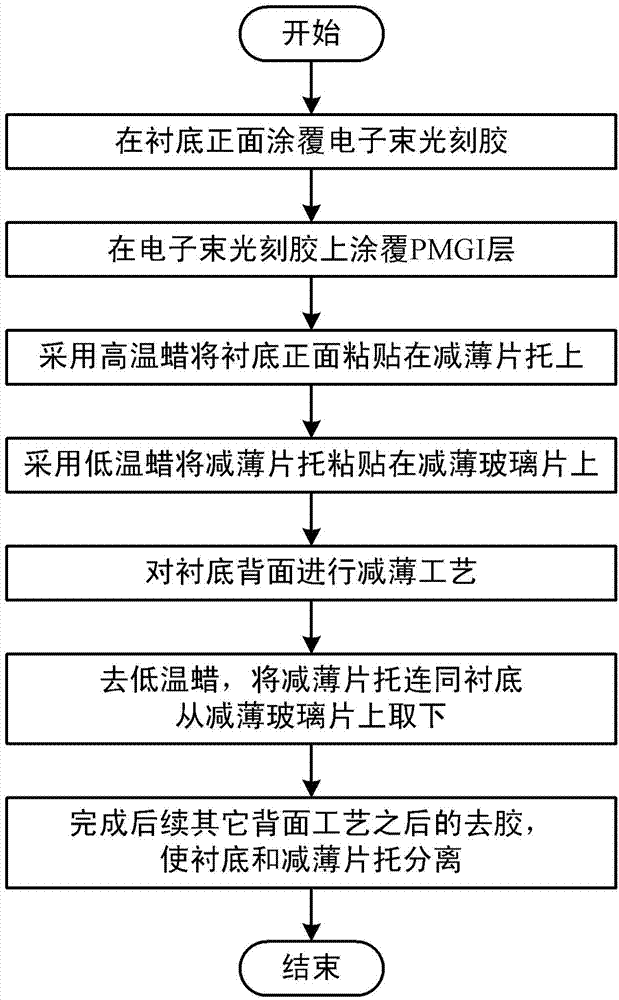

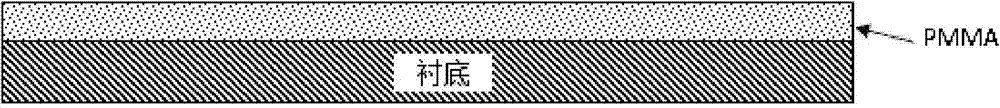

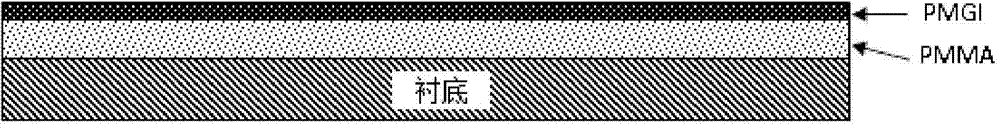

Sheet bonding method in substrate thinning technique

InactiveCN103489755AAvoid integration problemsImprove processing efficiencySolid-state devicesSemiconductor/solid-state device manufacturingWaxOptoelectronics

The invention discloses a sheet bonding method in a substrate thinning technique, which comprises the following steps: coating an electron beam photoresist on the front surface of a substrate; coating a PMGI layer on the electron beam photoresist; bonding the front surface of the substrate onto a thinning sheet support by using high temperature wax; bonding the thinning sheet support onto a thinning glass sheet by using low temperature wax; carrying out thinning technique on the back surface of the substrate; removing the low temperature wax, and taking the thinning sheet support with the substrate off the thinning glass sheet; and completing subsequent photoresist removal after other back surface techniques, and separating the substrate from the thinning sheet support. The method effectively solves the problem of mutual solubility between the photoresist and high temperature wax, and enhances the technical efficiency and technical yield of the thinning technique.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

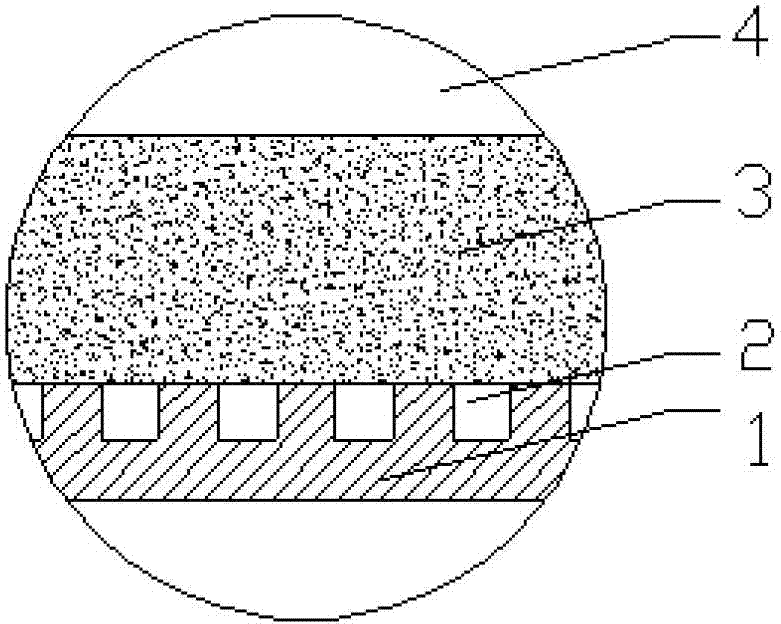

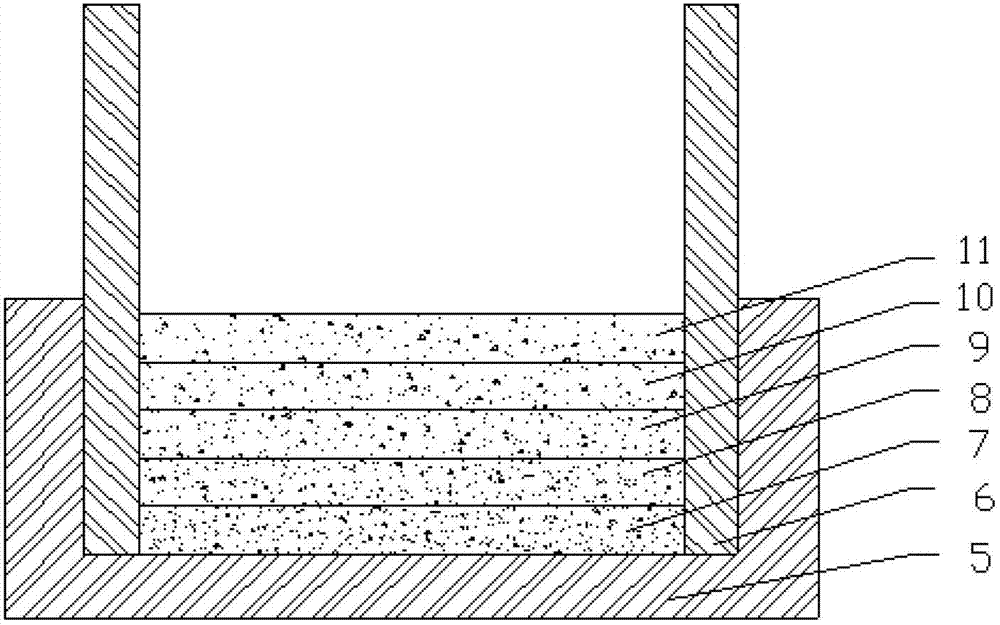

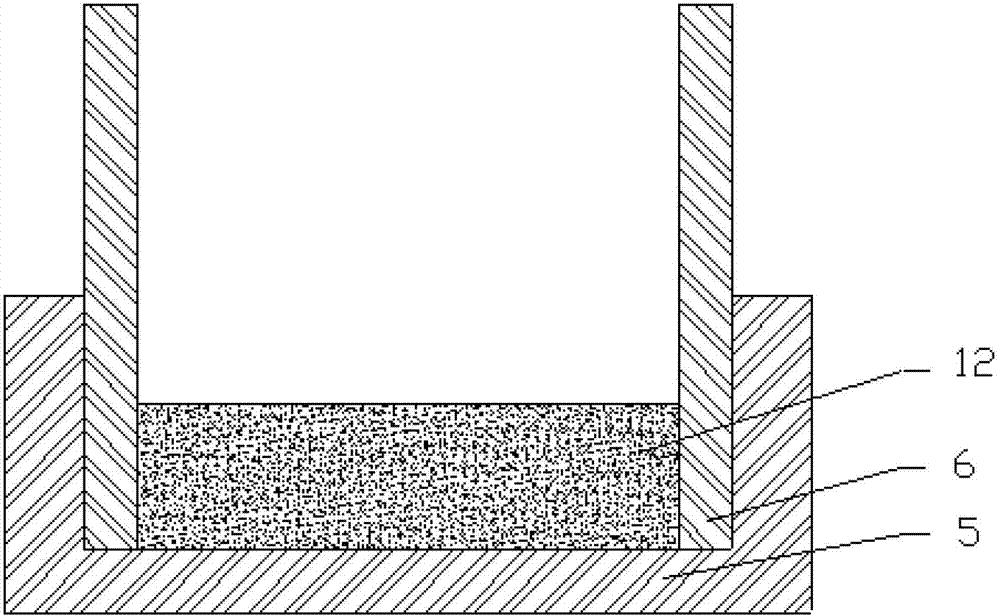

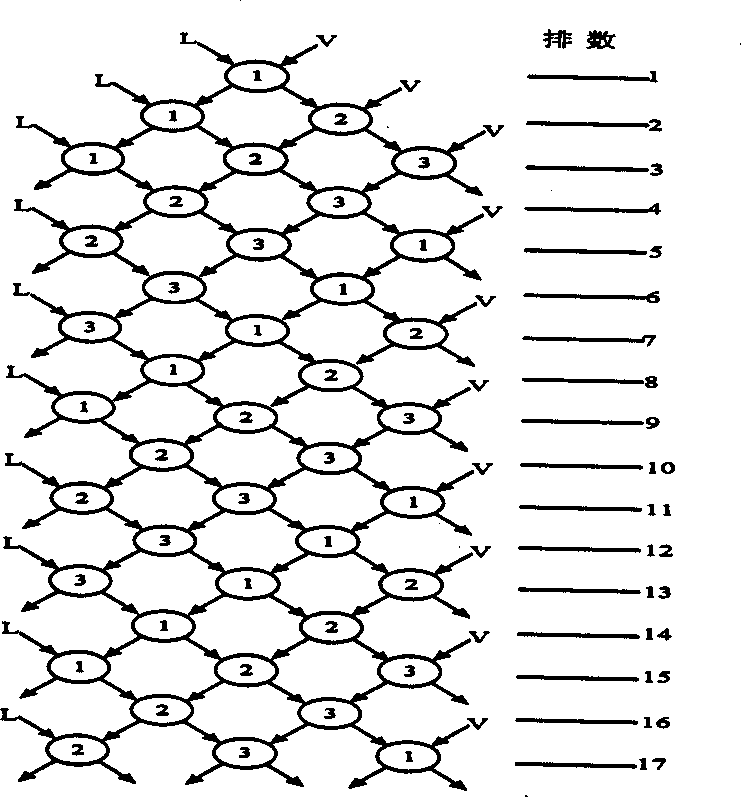

Composite capillary core with differential thermal coefficients for loop heat pipe and preparation method of composite capillary core

ActiveCN102901390AEasy to makeImprove heat transfer performanceIndirect heat exchangersAviationPowder mixture

The invention relates to a composite capillary core with differential thermal coefficients for a loop heat pipe and a preparation method of the composite capillary core. A thermal coefficient of the composite capillary core close to an evaporator side of the loop heat pipe is higher than that of the composite capillary core close to a compensator liquid side of the loop heat pipe. The preparation method of the composite capillary core with differential thermal coefficients comprises the following steps of: selecting sintering material matrix metal powders with an infinite mutual solubility and preparing a powder mixture with different mass proportions; filling the mixed powder mixture with different mass proportions in a mould layer by layer; carrying out cold press moulding on the powder mixture after the powder mixture is filled in the mould to form the shape and size required by a capillary core; and at last, sintering the powder mixture to prepare the composite capillary core with differential thermal coefficients. Since the composite capillary core has differential thermal coefficients, the heat transfer performance of the loop heat pipe can be favorably improved and heat control requirements of the loop heat pipe with performances of large heat transfer power and long-distance transmission can be met; and the composite capillary core with differential thermal coefficients can be used for developing efficient loop heat pipes and can be applied to the fields such as aviation heat control and ground electronic equipment cooling and the like.

Owner:SHANDONG UNIV

Method for preparing rubber powder masterbatch capable of quickly dispersing modified asphalt

The invention provides a method for preparing a rubber powder masterbatch capable of quickly dispersing modified asphalt and belongs to the technical field of asphalt modification. The prior art has the problems of poor mutual solubility of rubber powder and asphalt, complex preparation process, and the like. The method comprises the following steps that: by weight portion, 100 portions of rubber powder, 50 to 200 portions of asphalt, 10 to 40 portions of modifying agent and 10 to 20 portions of wax are put into a rubber refining machine to be mixed at a temperature of between 60 and 80 DEG C for 15 to 35 minutes, and then extruded and granulated to prepare the masterbatch with high rubber powder content. The rubber powder masterbatch can be directly applied to the material mixing stage, and be dispersed in the asphalt within one minute at a temperature below 200 DEG C with excellent modification effect.

Owner:BEIJING UNIV OF CHEM TECH

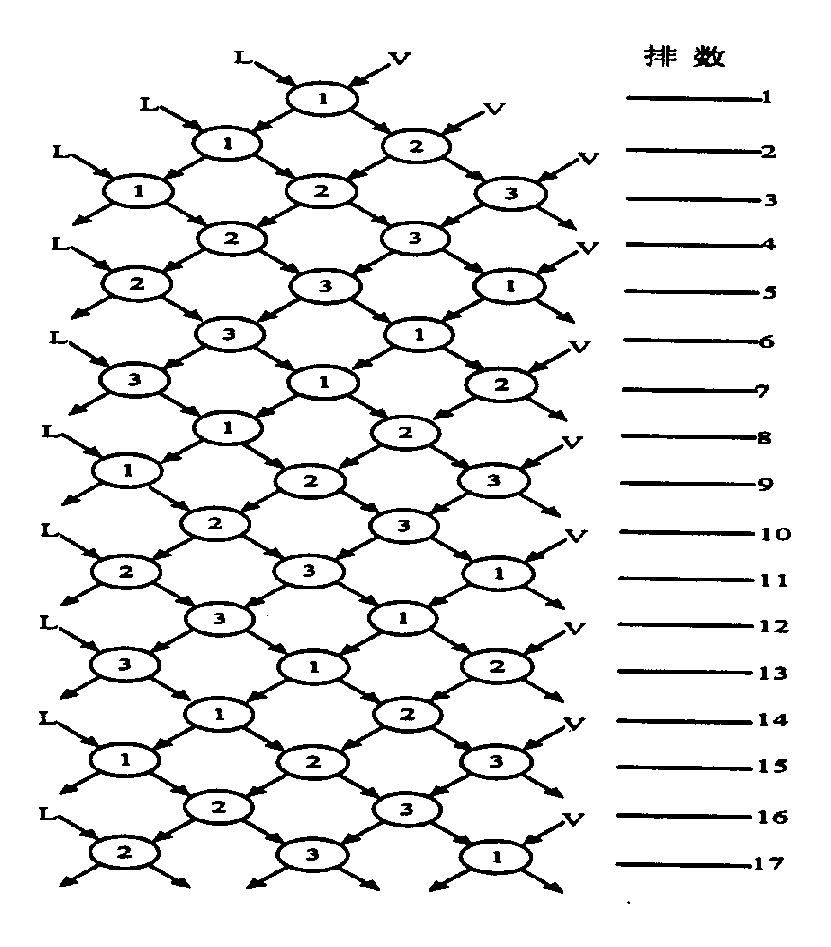

Method for removing sulfur-containing compound from catalytically cracked gasoline by using polyglycol extraction process

InactiveCN1341698AOctane reductionImprove desulfurization efficiencyHydrocarbon oils refiningPEG 400Mass ratio

The present invention uses polyglycol 400 as desulfurizing solvent to make multi-stage countercurrent extraction of gasoline. The mass ratio of extracting agent and gasoline is 1-3.5:1. Extracting temp. is 20-70 deg.C. Extracting time is 10-50 min. and constant temperature standing time is 10-30 min. Then. the gasoline phase taken out is the desulfurized gasoline. Said invented solvent possesses the advantages of high desulfurizing efficiency, less toxicity, low mutual solubility with gasoline, simple and convenient for recovering solvent. As compared with hydrogenation process said invented extraction process features small equipoment investment, low cost and simple operation. The loss in octane number of the treated gasoline is small.

Owner:TSINGHUA UNIV

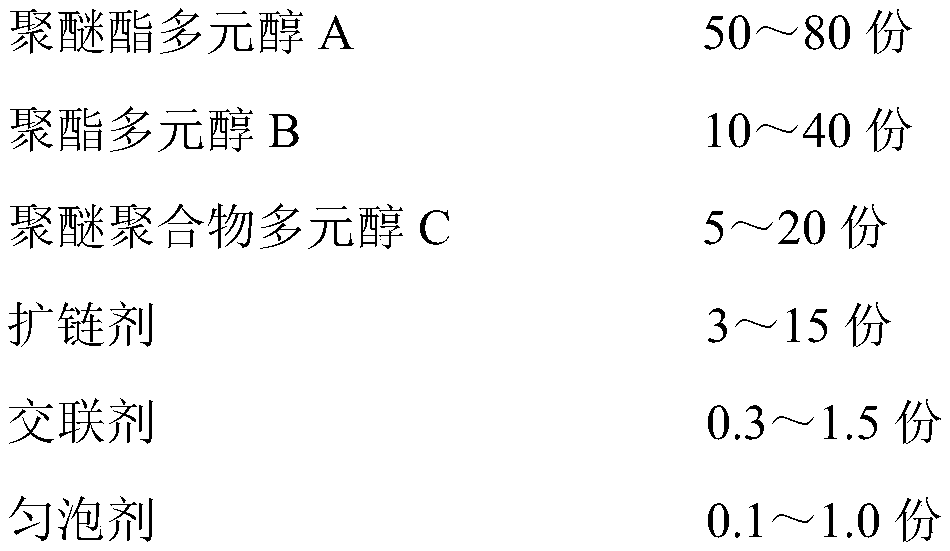

Low-temperature-resistant low-density polyurethane sole product composition material and preparation method thereof

InactiveCN109265641AImprove low temperature resistanceSolve miscibility issuesSolesPolyesterCross-link

The invention belongs to the technical field of polyurethane elastomers, and particularly relates to a low-temperature-resistant low-density polyurethane sole product composition material and a preparation method thereof. The composition material comprises a component A and a component B according to a weight ratio of 100:65-105, wherein the raw materials of the component A comprise polyether ester polyol A, polyester polyol B, polyether polymer polyol C, a chain extender, a cross-linking agent, a foam stabilizer, a catalyst and a foaming agent, the component B is polyol-modified isocyanate, and the NCO content is 18-25%. According to the present invention, with the application of the combination material to prepare the low-temperature-resistant low-density polyurethane sole, the problem of mutual solubility of polyester and polyether in the material A is effectively solved, and the added polyether polymer polyol can be purchased at a reasonable price on the market so as not to increase the raw material cost; and the low density sole prepared according to the composition material has excellent low-temperature resistance.

Owner:SHANDONG INOV POLYURETHANE

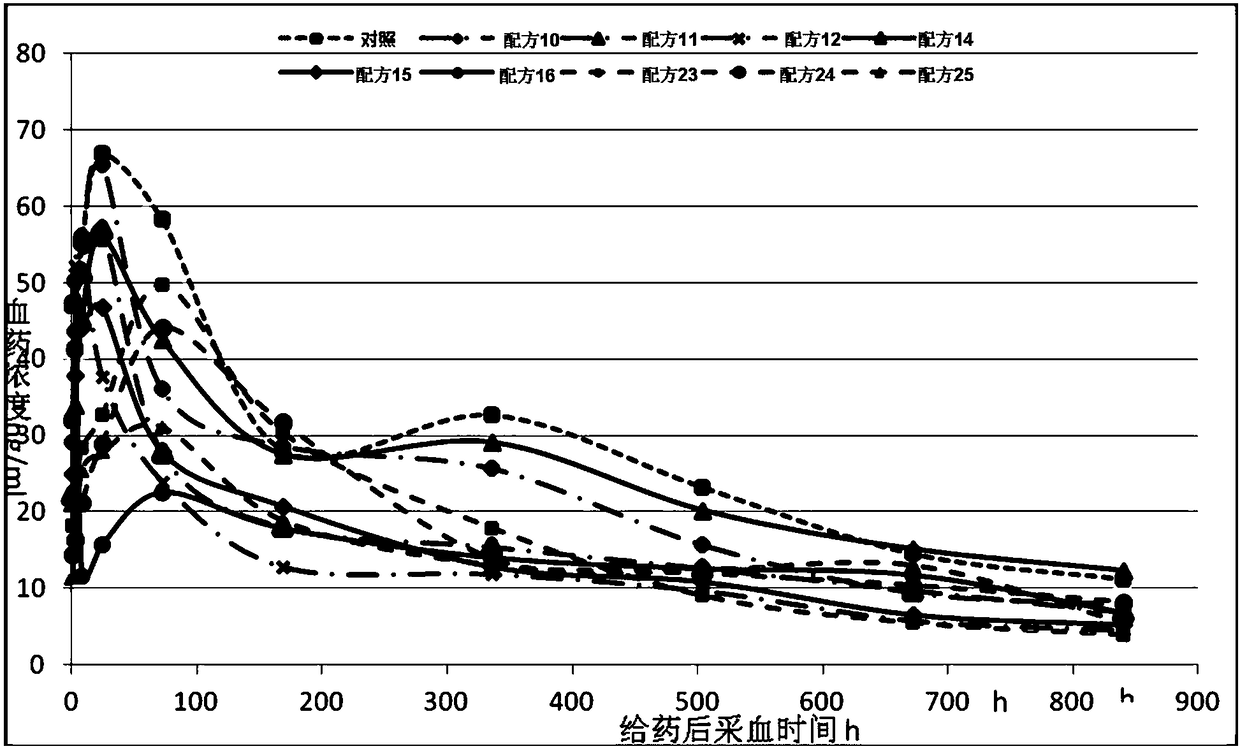

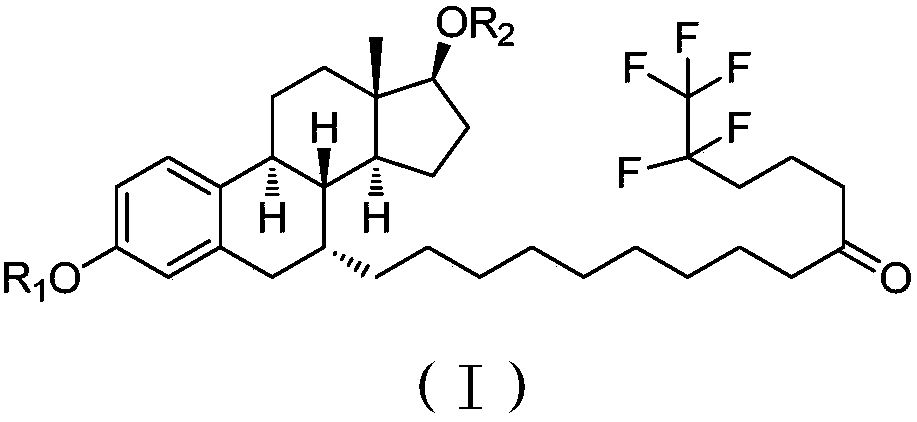

Long acting drug delivery system for treating breast cancer and preparation method and applications thereof

InactiveCN108159055AEnsure safetyIncrease concentrationOrganic active ingredientsPharmaceutical delivery mechanismProcainePhospholipid

The invention provides a long acting drug delivery system, which comprises fulvestrant or derivatives thereof and takes phospholipid as a sustained release material. The invention mainly discloses a high concentration formula of fulvestrant or derivatives thereof. The main component is fulvestrant or derivatives thereof. The sustained release material is different phospholipids or a mixture of phospholipids and different kinds of plant oil. The solvent is at least one of ethanol, ethyl lactate, 1,2-propylene glycol, and ethyl acetate. The analgesic is benzyl alcohol, lidocaine, procaine, or ropivacaine. The viscosity of the formula is 20-45 mPa.s, and the concentration of the formula is 60-300 mg / mL. The antioxidant of the formula is Ve, lipoic acid, and the like. The phospholipids can increase mutual solubility and has a sustained release function. The preparation is prepared in an aseptic filtration mode.

Owner:XIAN LIBANG PHARMA TECH

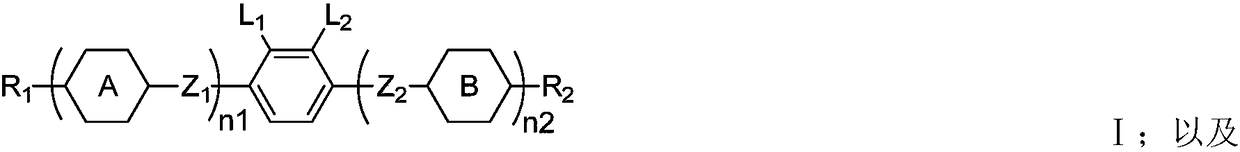

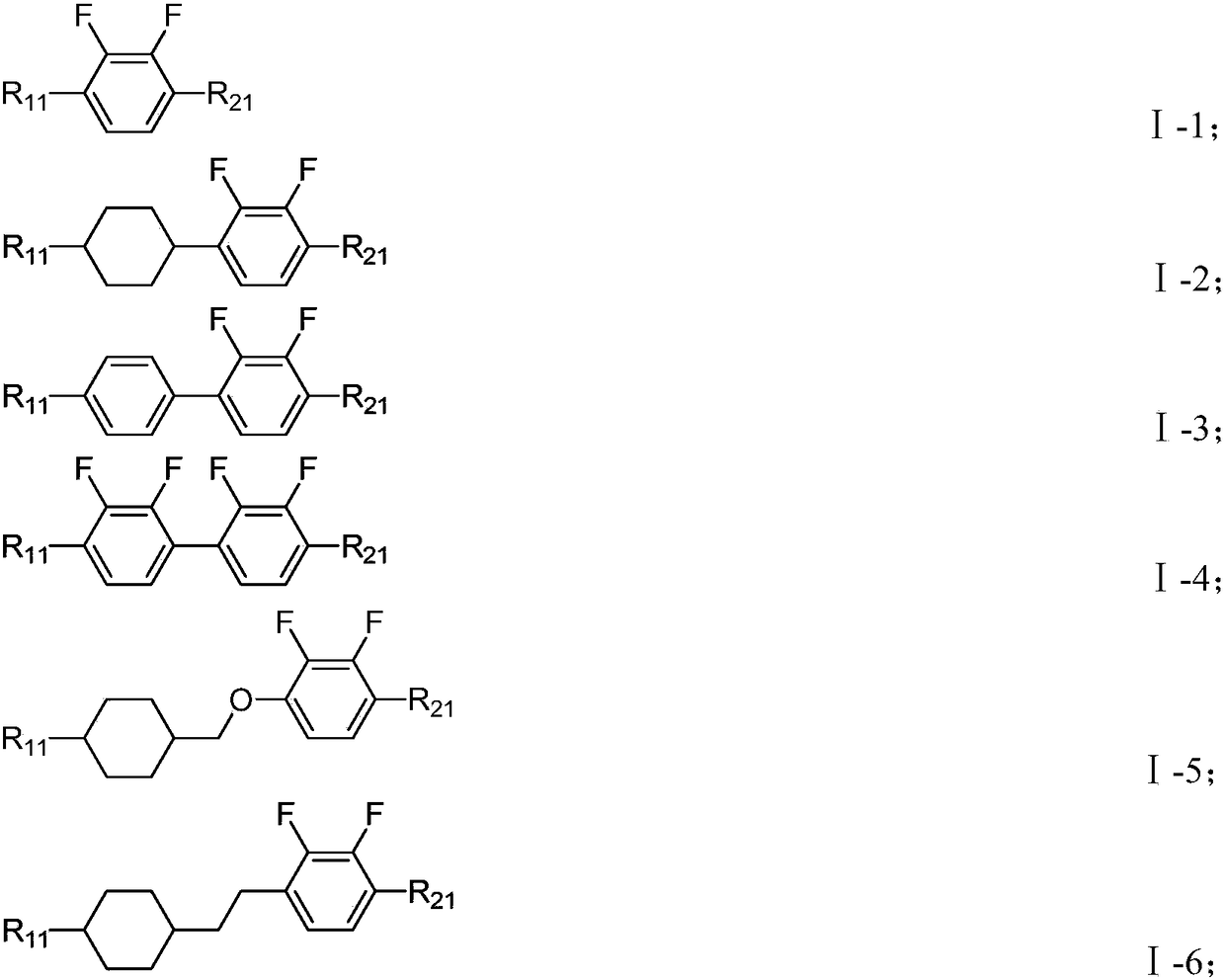

Liquid crystal composition and application thereof

PendingCN109181713AAppropriate optical anisotropyLow Dielectric AnisotropyLiquid crystal compositionsNon-linear opticsCrystallographyDielectric anisotropy

The invention discloses a liquid crystal composition and an application thereof. The liquid crystal composition comprises at least one compound of formula I, and at least one compound of formula II. The liquid crystal composition provided by the present invention has suitable optical anisotropy and has a relatively large elastic constants K11 and K33 while a relatively high clearing point, relatively low dielectric anisotropy, and good low-temperature mutual solubility are maintained. When the liquid crystal composition is applied to a liquid crystal display, the liquid crystal composition canhave the advantages of fast response, high contrast, large temperature width and the like.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Preparation method of Si-C-N ceramic precursor

The invention discloses a preparation method of a Si-C-N ceramic precursor. The preparation method comprises the following steps of: dissolving silicon-containing chlorosilane in an organic solvent which in immiscible with water, carrying out ammonolysis by virtue of aqueous alkali of a compounding containing -NH-, separating oil phase from water phase, and rotatably evaporating the oil phase at the boiling temperature of the organic solvent, to obtain liquid polysilazane; and putting the liquid polysilazane in a three-opening flask, and in the presence of N2, Ar or vacuum atmosphere, and continuously carrying out curing reaction for 12-72 hours at the temperature of 50-250DEG C, wherein the obtained solid product is the Si-C-N ceramic precursor. According to the preparation method, interfacial polymerization is adopted, so that the influence of byproducts on the purification and yield of polysilazane can be avoided, the reaction working procedures can be simplified, and the reaction time can be shortened; and the reaction process is easy to control, the synthesis yield reaches up to 90%, the product is high in purity, and a pyrolysis product is good in high temperature resistance and oxidation resistance.

Owner:ZHEJIANG SCI-TECH UNIV

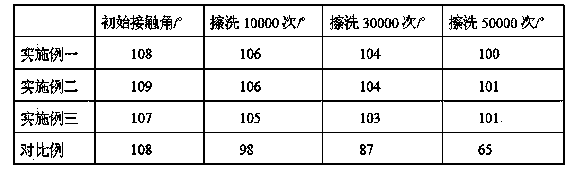

Preparation method of hydrophobing agent

The invention relates to a preparation method of a high-durability hydrophobing agent, which comprises the following steps: (1) hydrolysis of long-chain fluoroalkyl low-surface-energy substances: adding long-chain fluoroalkyl low-surface-energy substances, a catalyst and water into an organic solvent, and stirring so that the long-chain fluoroalkyl low-surface-energy substances have the activity of reacting with hydroxy group; and (2) extraction: adding a perfluoro solvent into the system, extracting the hydrolyzed long-chain fluoroalkyl low-surface-energy substances into the perfluoro solvent by utilizing favorable solubility of the long-chain fluoroalkyl low-surface-energy substances in the perfluoro solvent, and removing the supernatant liquid, thereby obtaining the hydrophobing agent. The invention also provides a preparation method of hydrophobic glass with high performance, which comprises the following step: preparation of hydrophobic film layer: coating the hydrophobing agent on the surface of the glass to prepare the hydrophobic film layer, thereby obtaining the hydrophobic glass. The perfluoro solvent can improve the solubility of the long-chain fluoroalkyl low-surface-energy substances and prevent the long-chain fluoroalkyl low-surface-energy substances from polymerization and crystallization; and the perfluoro solvent is hardly dissolved in water, thereby avoiding water in the system, enhancing the reaction density between the long-chain fluoroalkyl low-surface-energy substances and the hydroxy group on the glass surface, and improving the durability of the hydrophobic film layer.

Owner:CHERY AUTOMOBILE CO LTD

Composition for underground modification, viscosity reduction and catalysis of crude oil

ActiveCN103878024AEasy to operateLow costCatalytic crackingOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventPetroleum product

The invention provides a composition for underground modification, viscosity reduction and catalysis of crude oil. The composition comprises the following components in percentage by weight: 30wt%-50wt% ofcatalysts, 45wt%-70wt% of solvent and 0.1wt%-1wt% of solubilizer, wherein the sum of the weight percentages of the components is 100%; the catalyst is organic metal salt, the solvent comprises an organic solvent and / or a petroleum product, and the solubilizer is a surfactant. According to the composition, water is taken as a medium to be injected into an oil deposit, so that the operation is simple, and the costs for the catalysis, modification and viscosity reduction of thickened oil can be effectively reduced; after entering the oil deposit, the composition can be well mutually dissolved with the crude oil, so that the catalysis efficiency can be effectively increased.

Owner:PETROCHINA CO LTD

Liquid crystal compounds containing 2-alkyltetrahydropyrane structure, and preparation method and application thereof

InactiveCN103333146AImprove stabilityQuick responseLiquid crystal compositionsOrganic chemistryLiquid-crystal displayDisplay device

The invention discloses liquid crystal compounds containing 2-alkyltetrahydropyrane structure, and a preparation method and application thereof. The structural general formula of the compounds is disclosed as Formula I. The compounds have the advantages of stable structure, wide liquid-crystal-state temperature range, favorable low-temperature mutual solubility and high clearing point, can implement low threshold voltage and low rotary viscosity gamma 1 when being used in optical devices, and can improve the properties of the liquid crystal composition material and display device, thereby having an important meaning in quick response of display devices. The liquid crystal composition containing the compounds can be used for preparing liquid crystal displays with low drive voltage, wide temperature range and high response speed.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

Additive for improving wettability of pulverized coal

InactiveCN101735794AImprove wettabilityEffective dispersionDrilling compositionRoom temperatureEthanolamines

The invention relates to an additive for improving the wettability of pulverized coal, which comprises the following components in percentage by weight: 15 to 40 percent of organic sulfoacid, 10 to 25 percent of fatty alcohol-polyoxyethylene ether, 14 to 35 percent of low-level fatty alcohol, 2 to 15 percent of ethanolamine and 31 to 53 percent of water. The additive is prepared by directly mixing the components at room temperature, can be directly added into liquid for the fracture reformation of coal-bed gas fields, and has mutual solubility with other additives and good compatibility, and is easy to disperse; and the using coal-bed temperature is between 0 and 80 DEG C, the using mass concentration of the additive is between 0.5 to 5 percent, and the additive effectively solves the problem of the effect of the output of the pulverized coal on the energy output of coal-bed gas wells, and promotes the high and stable yield of the coal-bed gas wells.

Owner:中国石油集团廊坊科学技术研究院有限公司 +1

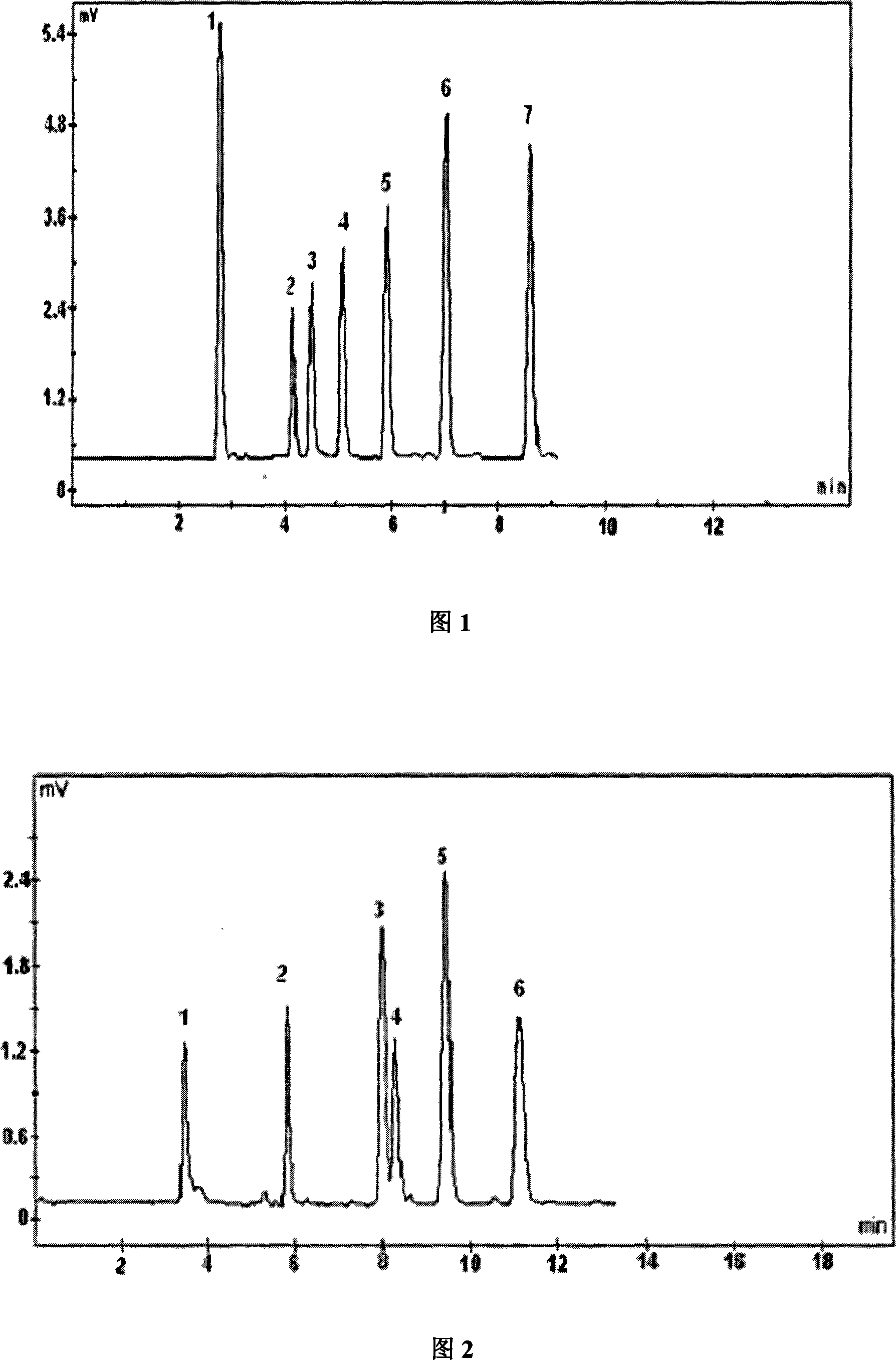

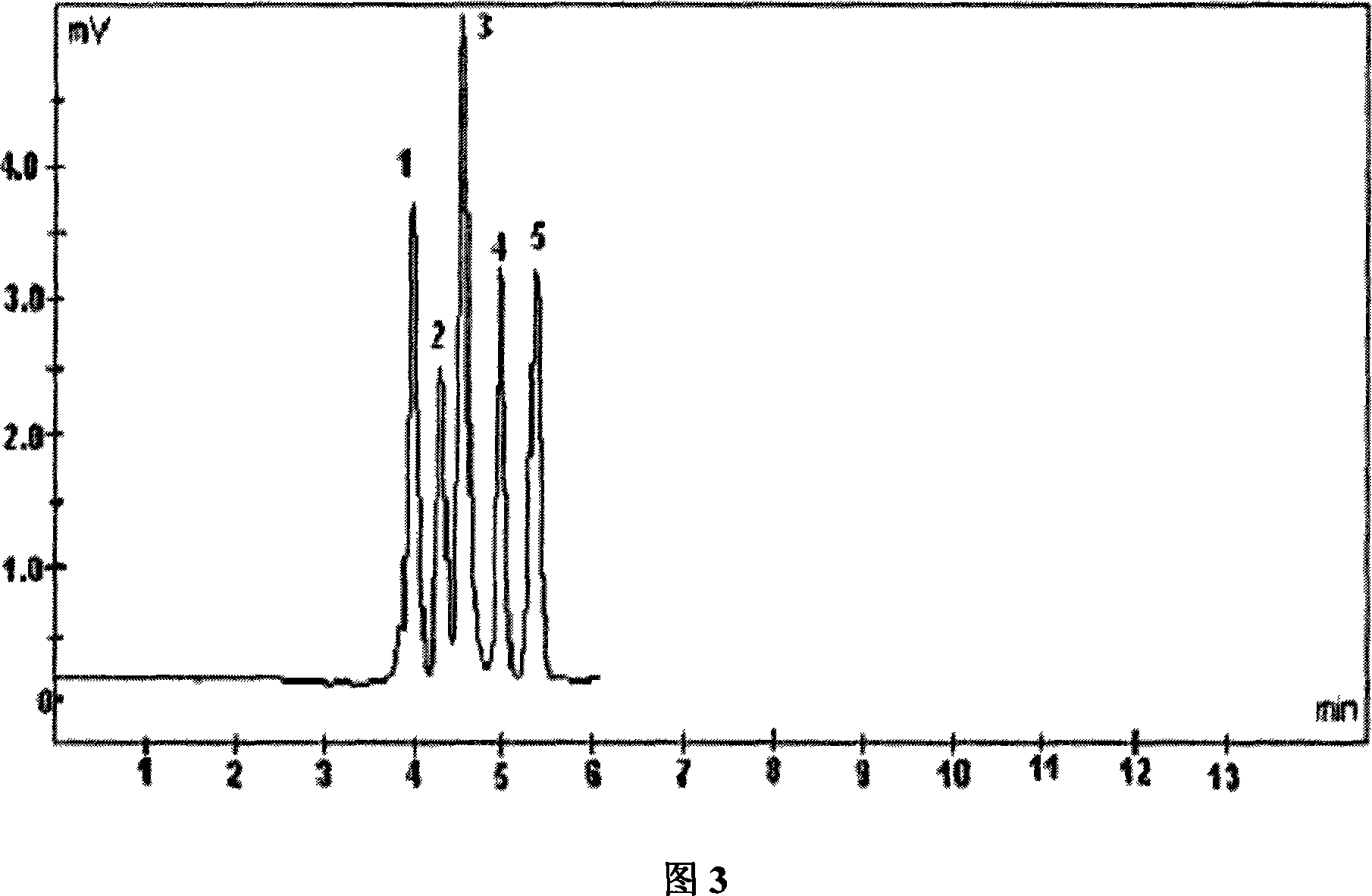

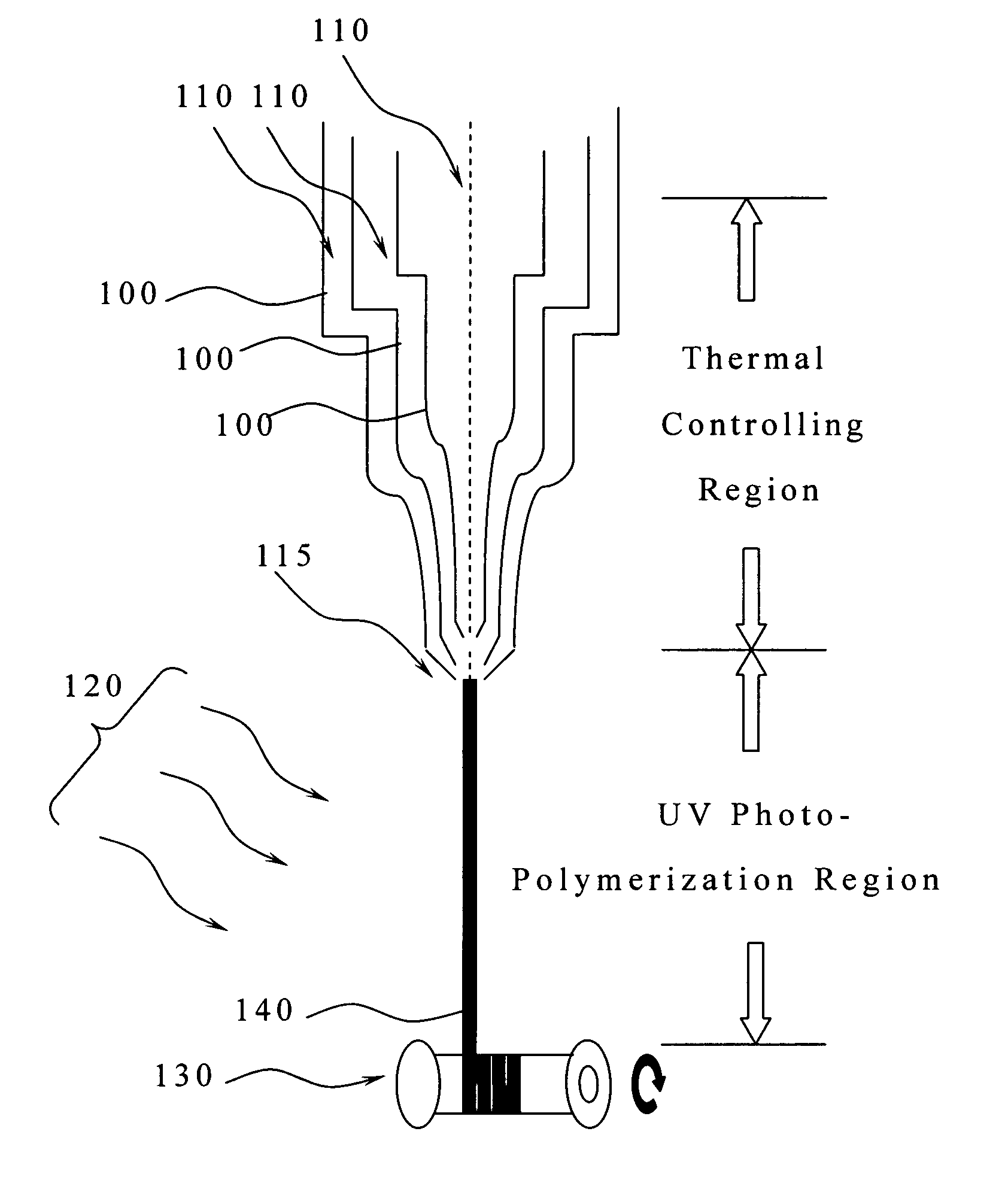

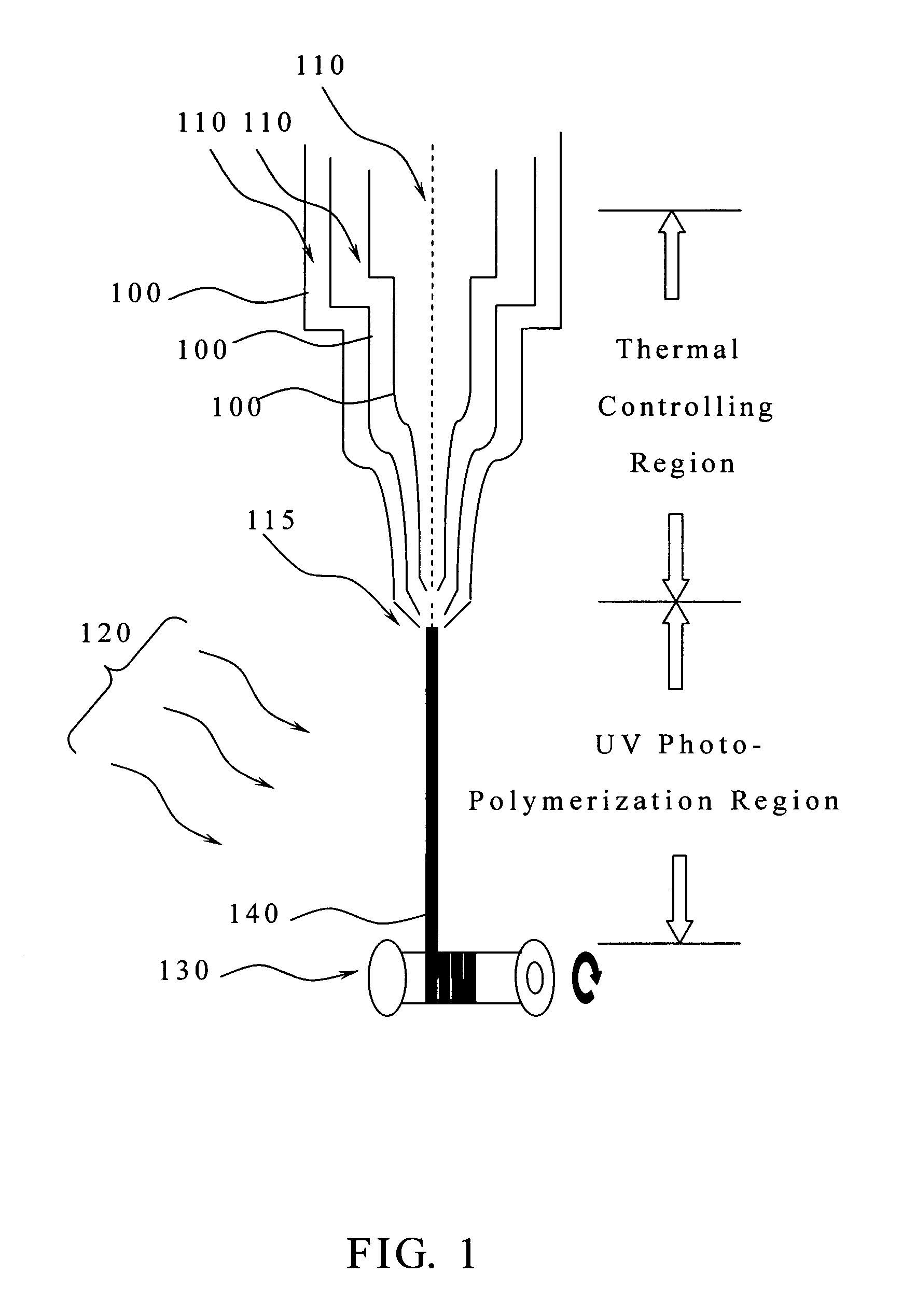

Formula of raw material of reversed phase ion exchange electrochromatography column, and preparation method

InactiveCN101091913ASolve miscibility issuesMeet continuous and rapid separation requirementsOther chemical processesElectricityElectrochromatography

The invention provides a raw material formula of the anti-phase ion exchange electricity chromatographic column: ionic compound monomer; neutral compound monomer; initiator; the hole-making. According to the above raw material formula, the neutral compound monomer and the ionic compound monomer carries on the polyreaction in the capillary vessel, joins the hole-making and the initiator in the polyreaction, then prepares the anti-pjase ion exchange electricity chromatographic column. The invention has solved the mutual solubility question which between the ionic compound monomer and the neutral monomer, may satisfies the continuously sharp separation request of the neutrality, acidity and alkaline matter; the pillar has good insightful performance, is suitable to the high concentrated buffer salt system; when preparing, no longer need to burn the plug on the two ends of the pillar, also has avoided the difficulty of filling up the pillar.

Owner:FUZHOU UNIV

Liquid environment protection fuel and its preparing method

The liquid environment protecting fuel is prepared through mixing methanol or ethanol in 9-40 wt%, with viscosity improver 7-13 wt%, smoke and smell eliminating agent 1-3.6 wt%, cosolvent-pour point reducer 1-11.2 wt%, antioxidant 0.1-0.5 wt% and combustion improving cleaning agent 0-2 wt% via slight stirring, mixing the mixture with diesel oil in 40-77 wt% via slight stirring; and reaction at rest state for 6-12 hr. The liquid fuel has easy-to-obtain material, low cost, good mutual solubility, full combustion and less exhausted waste.

Owner:陈胜军

Gradient refrective-index plastic rod and method for making the same

InactiveUS20050151286A1High refractive indexGood refractive indexMaterial nanotechnologyOptical fibre with graded refractive index core/claddingNanoparticleRefractive index

A gradient refractive-index (GRIN) plastic rod comprises a monomer, a surfactant monomer (surfmer), and nanoparticles. The surfmer, which keeps nanoparticles and polymers in a good mutual solubility, can increase a content of nanoparticles, and thus overcome a problem of the resulting opaque plastic rod caused by introducing nanoparticles in the prior art. Moreover, nanoparticles can increase a difference of refractive index, the numerical aperture and a transmission efficiency of the GRIN plastic rod.

Owner:NAT CHENG KUNG UNIV

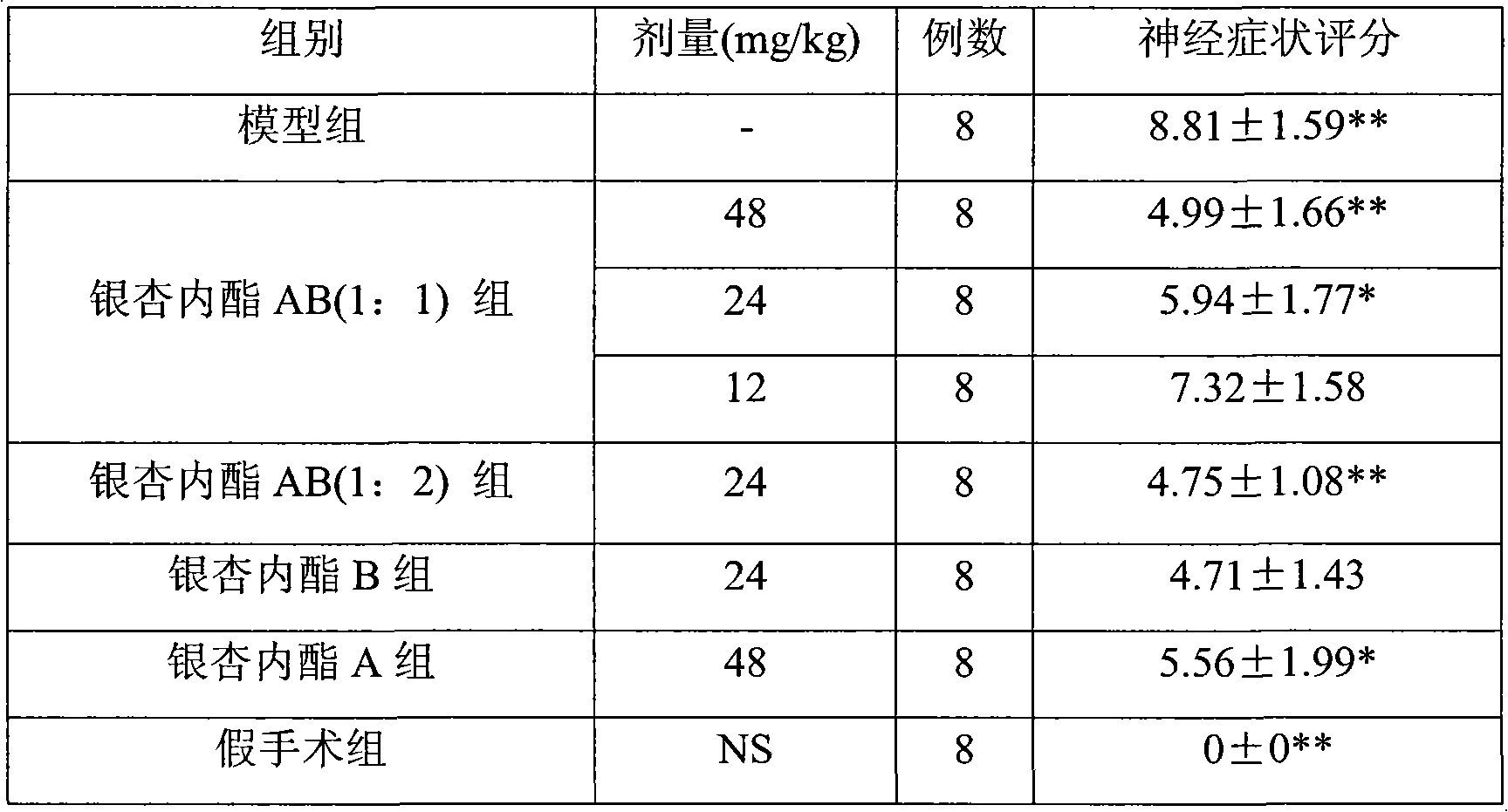

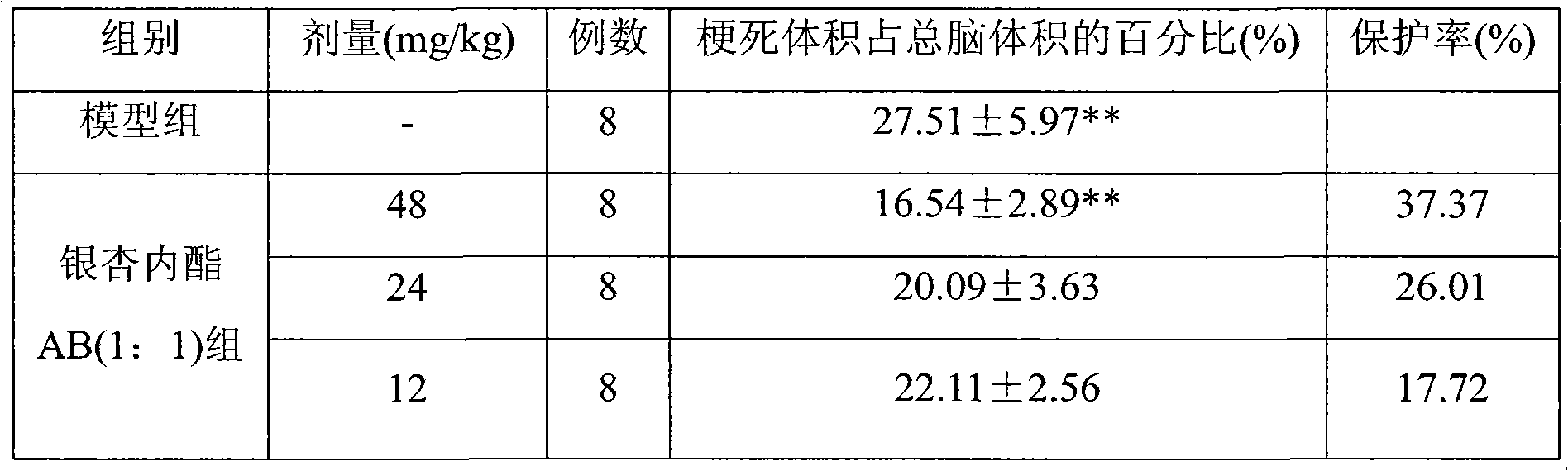

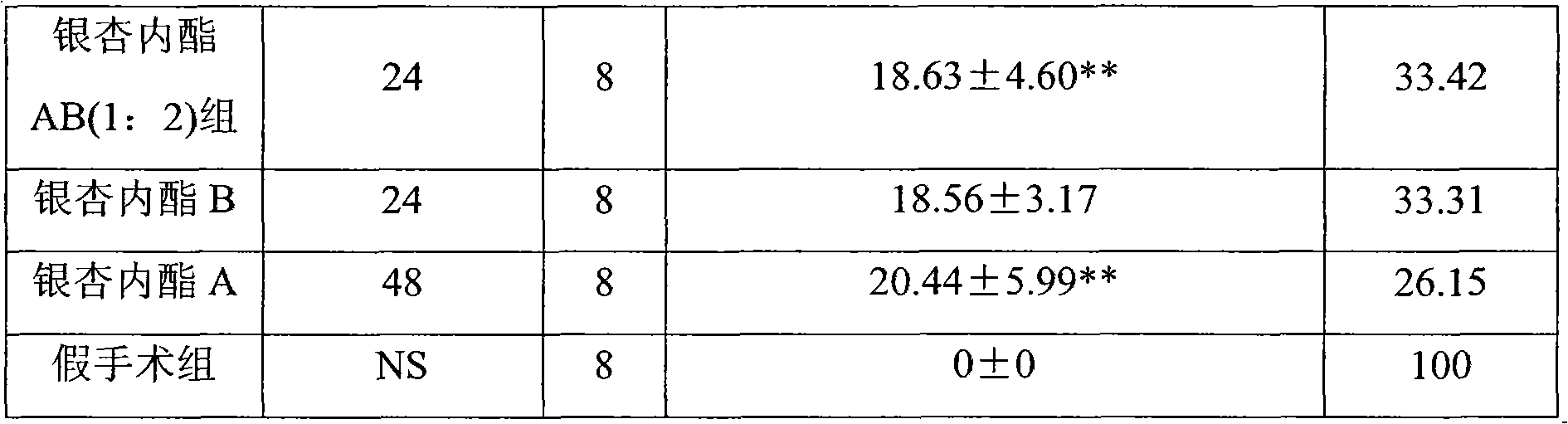

Bilobalide A, B compound injection and preparation method and application thereof

InactiveCN101249085AImprove solubilityImprove expiration dateOrganic active ingredientsPharmaceutical delivery mechanismAdjuvantMedicine

The invention relates to a ginkgolide injection and a preparation method thereof. The ginkgolide injection contains an active component and adjuvant for injection, wherein the active component is composed of ginkgolide A and ginkgolide B. Experimental studies shows that the preparation containing the combination of ginkgolide A and ginkgolide B has synergic effect and excellent mutual solubility thereof, increases the solubility of ginkgolide B and improves stability at a low temperature. Tests prove that the inventive ginkgolide injection has improved stability at a low temperature, so that the shelf life, safety and effectiveness of the injection in cold areas are improved.

Owner:广州艾格生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com