Method for removing sulfur-containing compound from catalytically cracked gasoline by using polyglycol extraction process

A technology for catalytic cracking of gasoline and polyethylene glycol, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of no treatment, and achieve the effects of low operating cost, simple operation, and simple and convenient solvent recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Use n-octane + thiophene (simulated gasoline ①, sulfur content: 995ppm), n-octane + benzothiophene (simulated gasoline ②, sulfur content: 1006ppm) to constitute the simulation system of FCC gasoline middle and heavy fractions;

[0014] 2. Weigh a certain mass of simulated gasoline and polyethylene glycol 400, so that the mass ratio of the agent to oil is 1, 1.5, 2, 2.5 and 3, respectively, add them to the container, and put them into the container at a temperature of 30°C, 40°C, 50°C and Shake at a constant temperature in a water bath at 60°C for 30 minutes to fully mix the two phases, and then separate the two phases after standing at a constant temperature for 15 minutes;

[0015] 3. Take the upper gasoline phase for sulfur content analysis, and calculate the apparent partition coefficient and sulfur removal rate, and the results are shown in Table 1 and Table 2, respectively.

[0016] 30℃

[0017] 30℃

Embodiment 2

[0019] 1. Add thiophene and benzothiophene (simulated gasoline ③) to n-octane in a certain proportion, so that the sulfur in thiophene and the sulfur in benzothiophene each account for about 50% of the total sulfur, and the total sulfur content is 1143ppm ;

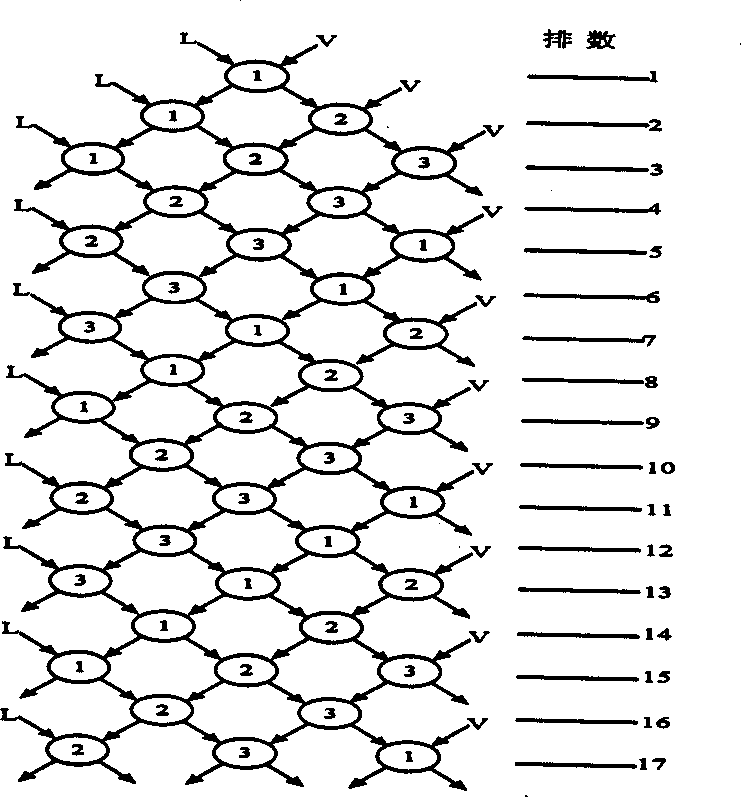

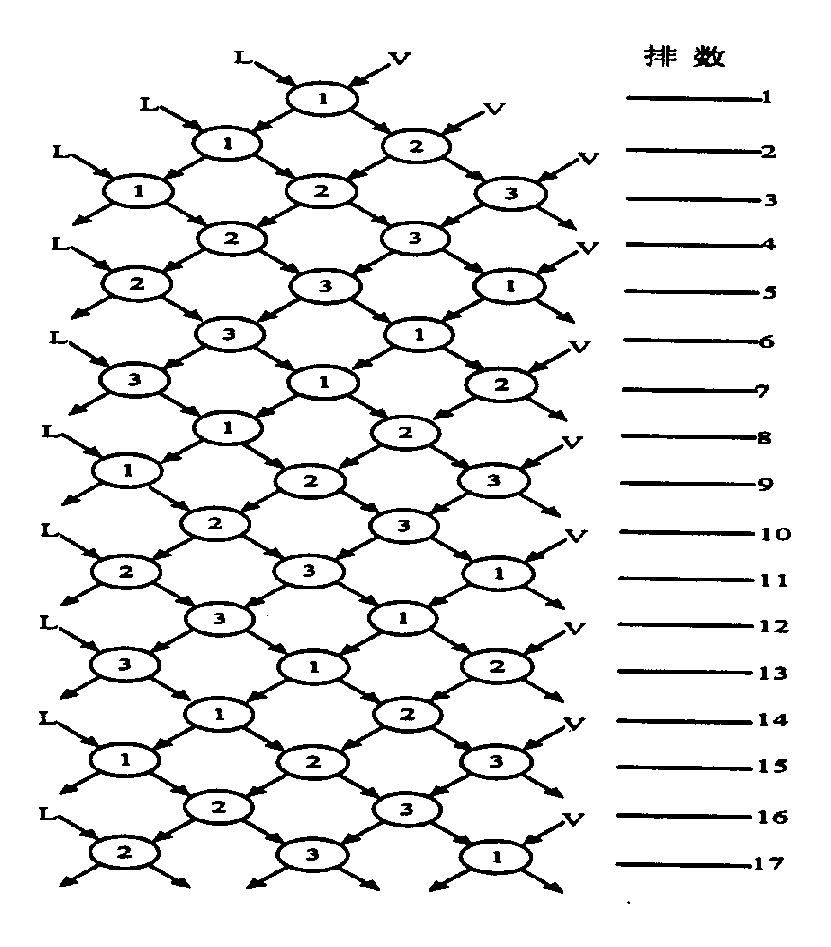

[0020] 2. Carry out three-stage cross-current extraction for simulated gasoline ③ at a solvent-oil mass ratio of 1:1, and a three-stage counter-current extraction at a solvent-oil mass ratio of 1.5:1. The extraction temperatures are 30°C, 40°C, and 50°C, respectively. ℃ and 60℃;

[0021] 3. Measure the sulfur content of the gasoline phase after the three-stage extraction, and calculate the sulfur removal rate. The results are shown in Table 3.

[0022] Way

Embodiment 3

[0024] 1. The unsweetened FCC gasoline of Shengli Refinery of Qilu Petrochemical Company was fractionated at 120°C, leaving the middle and heavy fractions with a boiling point higher than 120°C, and the measured sulfur content was 938ppm;

[0025] 2. Weigh a certain mass of actual gasoline and polyethylene glycol 400, so that the mass ratio of the agent to oil is 1, 1.5, 2, 2.5 and 3, respectively, add them to the container, and add them to the container at temperatures of 30°C, 40°C, 50°C and Shake at a constant temperature in a water bath at 60°C for 30 minutes to fully mix the two phases, and then separate the two phases after standing at a constant temperature for 15 minutes;

[0026] 3. Take the upper gasoline phase for sulfur content analysis, and calculate the apparent partition coefficient and sulfur removal rate, the results are shown in Table 4 respectively;

[0027] 4. According to the apparent partition coefficient obtained above, calculate the sulfur content and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com