A catalytic diesel conversion process

A technology for catalyzing diesel oil and process, which is applied in petroleum industry, molecular sieve catalyst, hydrotreating process, etc. It can solve unfavorable hydrogenation conversion to produce high-octane gasoline, strong saturation ability of gasoline components, and reduce hydrogenation of gasoline components Saturation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

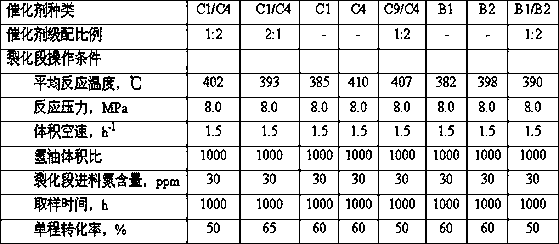

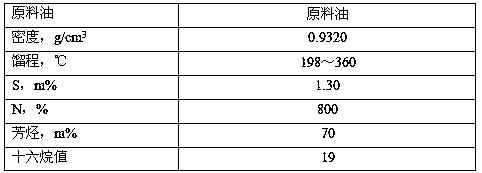

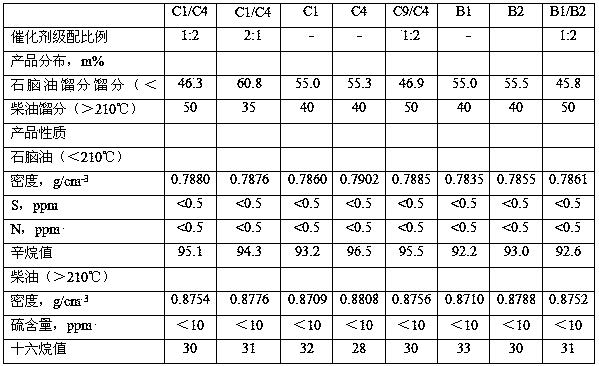

Examples

Embodiment 1

[0043] (1) Configure NaNO 3 Aqueous solution, NaNO 3 Concentration in Na 2 O is calculated as 8g / 100ml;

[0044] (2) NaNO obtained in step 1 3 The aqueous solution is impregnated with industrially produced macroporous alumina powder at a liquid / solid ratio of 3:1 for 2 hours, filtered and then roasted at 120°C for 2 hours and at 550°C for 3 hours;

[0045] (3) Take 40g of alumina obtained in step (2), 80g of industrially produced modified Y molecular sieve, MoO 320g was mixed with 20g of nickel nitrate, added 4g / 100ml of dilute nitric acid, mixed and rolled in a mixer until it could be extruded, extruded and shaped on an extruder, dried and calcined to obtain catalyst C1.

Embodiment 2

[0047] (1) Configure Mg(NO 3 ) 2 Aqueous solution, Mg(NO 3 ) 2 Concentration calculated as MgO is 4g / 100ml;

[0048] (2) The Mg(NO 3 ) 2 The aqueous solution is impregnated with industrially produced macroporous alumina powder at a liquid / solid ratio of 2:1 for 2 hours, filtered and then roasted at 110°C for 4 hours and at 500°C for 4 hours;

[0049] (3) Mix 30g of alumina obtained in step (2) with 90g of industrially produced modified Y molecular sieve, add 4g / 100ml of dilute nitric acid, mix and roll in a mixer until it can be extruded, and extrude it on an extruder to obtain carrier;

[0050] (4) Configure Mo-Ni impregnation solution, MoO 3 1. Basic nickel carbonate is added to distilled water to prepare a partial Mo-Ni impregnation solution, and the MoO is adjusted in the mixed solution by the oxide of the metal salt. 3 23g / 100ml, nickel oxide 8g / 100ml;

[0051] (5) Take the Mo-Ni impregnation solution obtained in step (4), impregnate the catalyst support obtained...

Embodiment 3

[0053] (1) Configure KNO 3 Aqueous solution, KNO 3 Concentration in Na 2 O is calculated as 10g / 100ml;

[0054] (2) NaNO obtained in step 1 3 The aqueous solution is impregnated with industrially produced macroporous alumina powder at a liquid / solid ratio of 2:1 for 2 hours, filtered and then roasted at 110°C for 4 hours and at 500°C for 4 hours;

[0055] (3) Take 50g of alumina obtained in step (2), 100g of industrially produced modified Y molecular sieve, 25g of metatungstic acid and 20g of nickel nitrate, mix them, add 4g / 100ml of dilute nitric acid, mix and roll in a mixer until it can be extruded shape, extruded on the extruder, shaped, dried and calcined to obtain the catalyst C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com