A kind of preparation method of high viscosity index lubricating oil base oil

A lubricating oil base oil, high viscosity technology, applied in the field of oil refining, can solve the problems of low viscosity, product yield loss, etc., to achieve the effect of ensuring yield, reducing the possibility of excessive cracking, and avoiding excessive yield loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

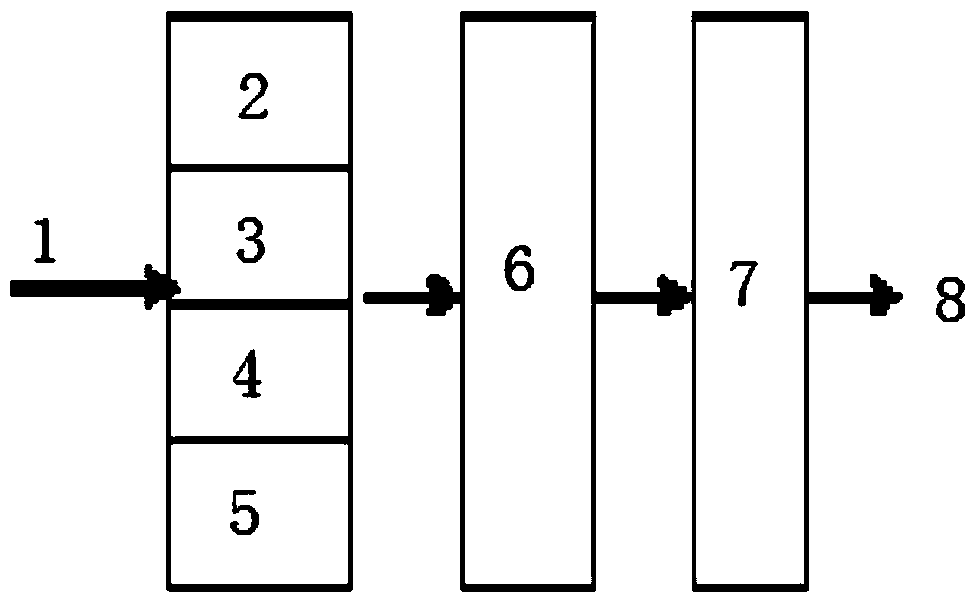

[0024] The invention provides a kind of preparation method of high viscosity index lubricating oil base oil, and the method comprises:

[0025] (1) The raw oil and the hydrogen-containing stream are introduced into the isomerization depreciation reaction zone for reaction to obtain the oil converted from isomerized wax, wherein the isomerization depreciation reaction zone includes at least two sequentially loaded hydrofining catalysts and a catalyst bed of heterogeneous depressing catalyst;

[0026] (2) introducing the isomerized wax conversion product oil into a supplementary refining reaction zone containing a hydrorefining catalyst for reaction to obtain a hydrorefining product oil; and

[0027] (3) introducing the hydrorefined oil into a separation zone for separation.

[0028] In the method of the present invention, at least two stages of hydrofining catalysts are added in the isomerization depressing reaction zone, so that the aromatics, naphthenes and polycyclic naphth...

Embodiment 1

[0074] In this example, a hydrocracking tail oil is used as a raw material, and its properties are shown in Table 1.

[0075] according to figure 1 The process flow processes the raw material. The catalysts are: the first hydrofinishing reaction unit and the second hydrofinishing reaction unit of the isomerism depreciation reaction zone are loaded with hydrofinishing catalyst I, the first isomerism depreciation reaction unit and the second isomerism depreciation reaction The unit is filled with isomerization depreciation catalyst I, and the catalyst loading volume ratio of the first hydrofinishing reaction unit, the first isomerization depreciation reaction unit, the second hydrofinishing reaction unit and the second isomerization depreciation reaction unit is 2 : 4: 1: 3, see Table 2 for operating conditions. Table 3 shows the changes in hydrocarbon composition in the isomerization depreciation reaction zone, and see Table 4 for the properties of lubricating base oil produc...

Embodiment 2

[0091] In this example, a hydrotreated distillate is used as a raw material, and its properties are shown in Table 6.

[0092] according to figure 1 The process flow processes the raw material. The catalysts are: the first hydrofinishing reaction unit and the second hydrofinishing reaction unit of the isomerism depreciation reaction zone are loaded with hydrofinishing catalyst I, the first isomerism depreciation reaction unit and the second isomerism depreciation reaction The unit is filled with isomerization depreciation catalyst I, and the catalyst loading volume ratio of the first hydrofinishing reaction unit, the first isomerization depreciation reaction unit, the second hydrofinishing reaction unit and the second isomerization depreciation reaction unit is 2 :6:2:3, see Table 7 for operating conditions. Table 8 shows the change of hydrocarbon composition in the isomerization depreciation reaction zone, and the properties of lubricating base oil products separated in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com