Silicon pressure transducer chip and method based on silicon-silicon linking and silicon-on-insulating layer

A sensor chip, silicon-silicon bond technology, applied to the process for producing decorative surface effects, piezoelectric/electrostrictive/magnetostrictive devices, measurement of the properties and forces of piezoelectric resistance materials, etc., can solve the problem It is difficult to ensure the uniformity of the film and other problems, so as to achieve the effect of ensuring long-term stability, good process repeatability and stability, and product yield guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

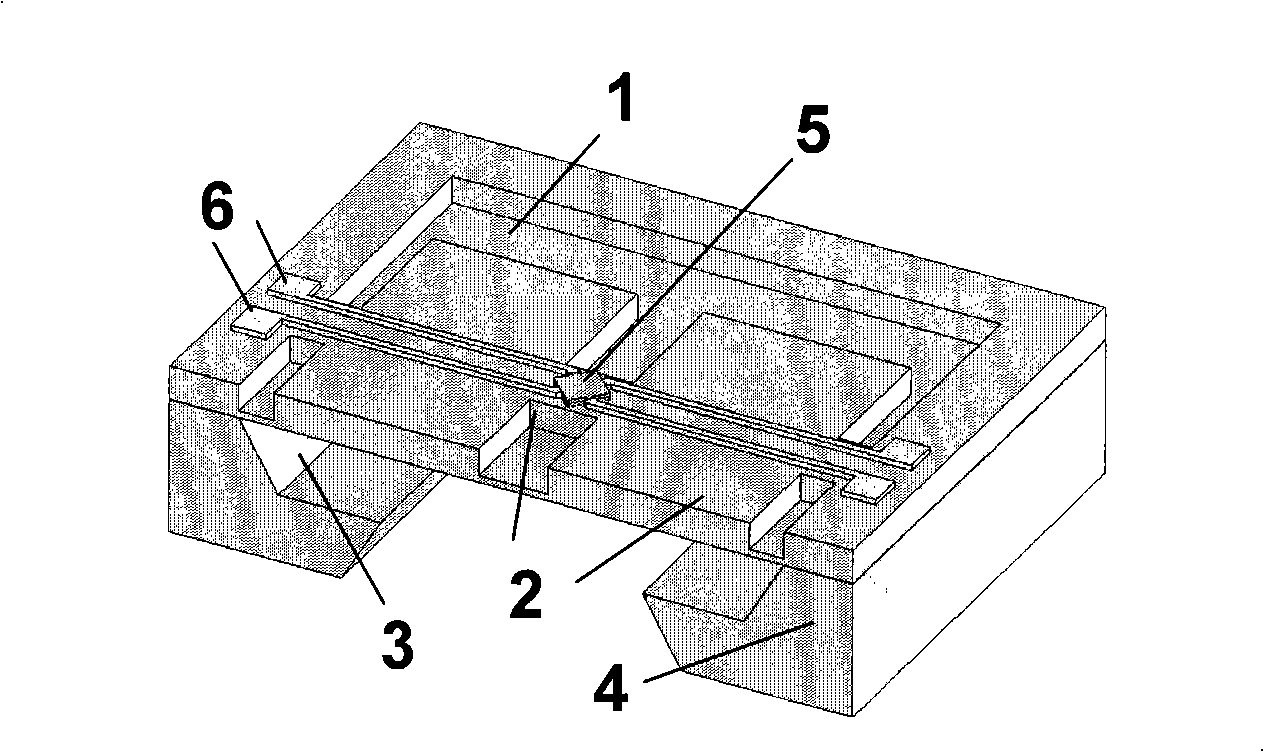

[0019] The following examples will help to understand the present invention, but do not limit the content of the present invention. The manufacturing method of the pressure sensor chip based on silicon-silicon bonding and silicon-on-insulator suitable for the 1KPa range:

[0020] Use 4-inch 450μm N-type (100) double-polished single-crystal silicon wafers with a resistivity of 1-10ohm.cm, and 4-inch P-type double-polished SOI wafers. The thickness of the top silicon layer and the buried layer are 30μm and 1μm respectively. Silicon resistivity 1-10ohm.cm.

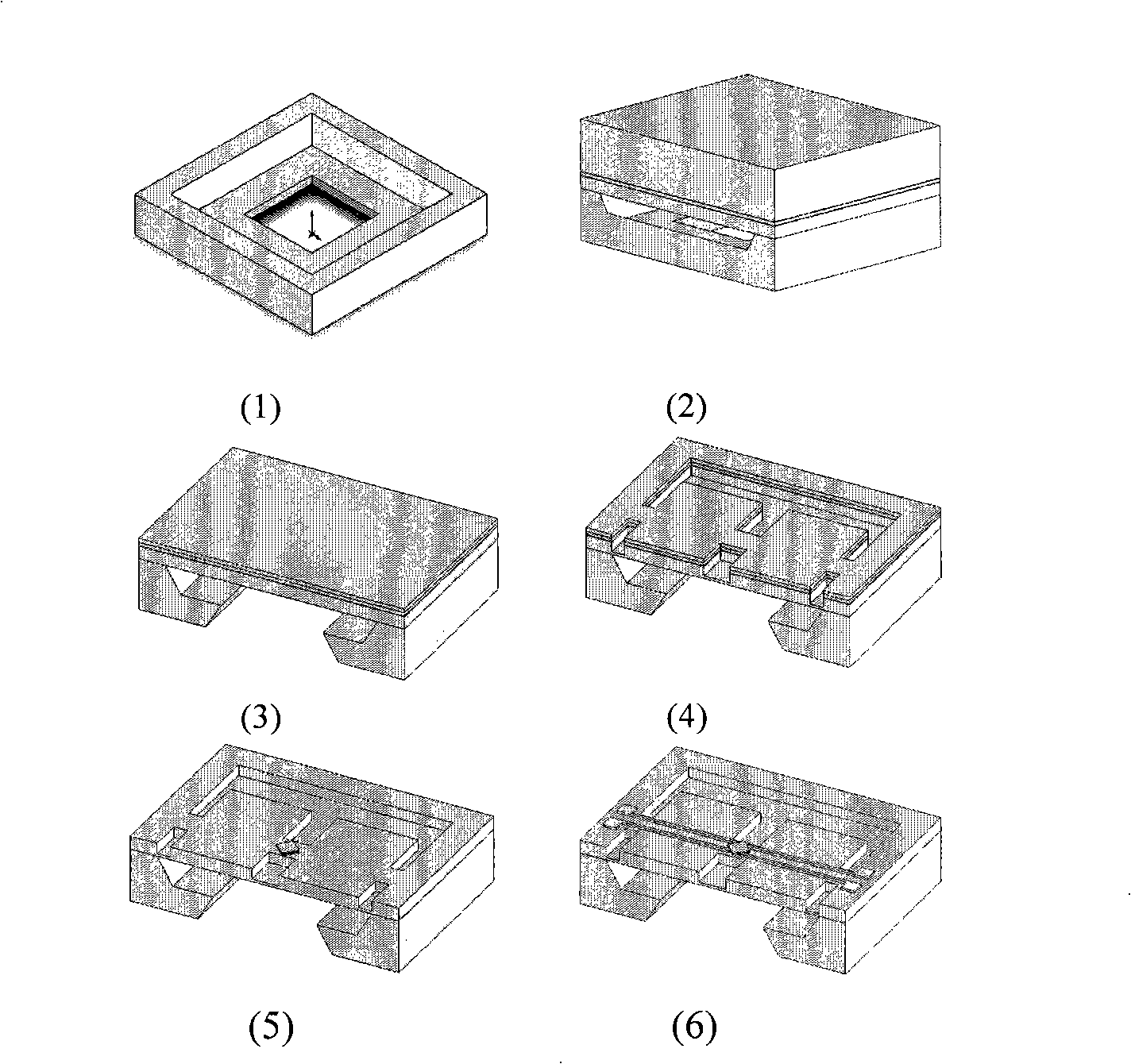

[0021] 1. The silicon wafer is cleaned and then oxidized, and shallow grooves and air guide holes are etched in the potassium hydroxide solution. The depth of the shallow grooves is 15 μm, such as figure 2 as shown in (1);

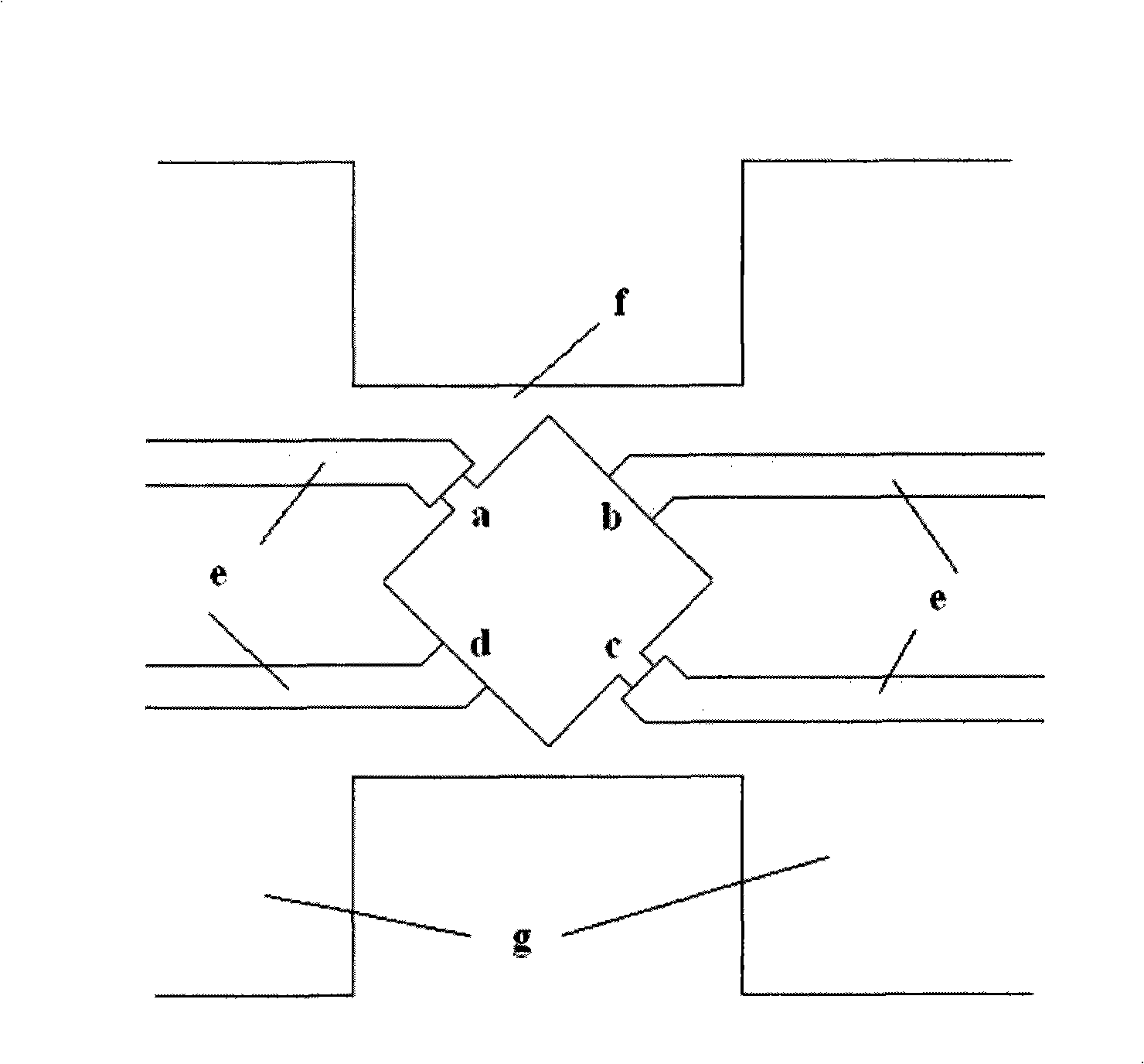

[0022] 2. SOI wafers and silicon wafers are bonded on the shallow groove surface. Use 400°C vacuum in the bonding machine, pressurize 2bar for 20 minutes, and then dry oxygen in a 1200°C high-temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com