Patents

Literature

750results about How to "Good process repeatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

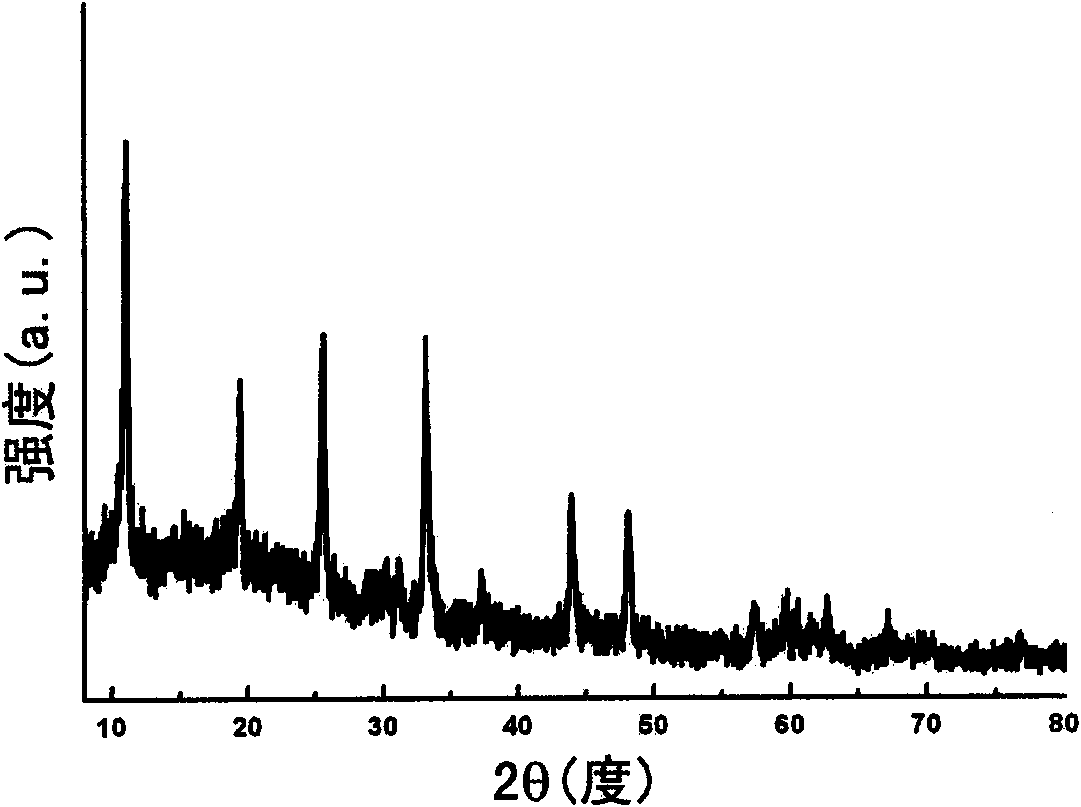

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

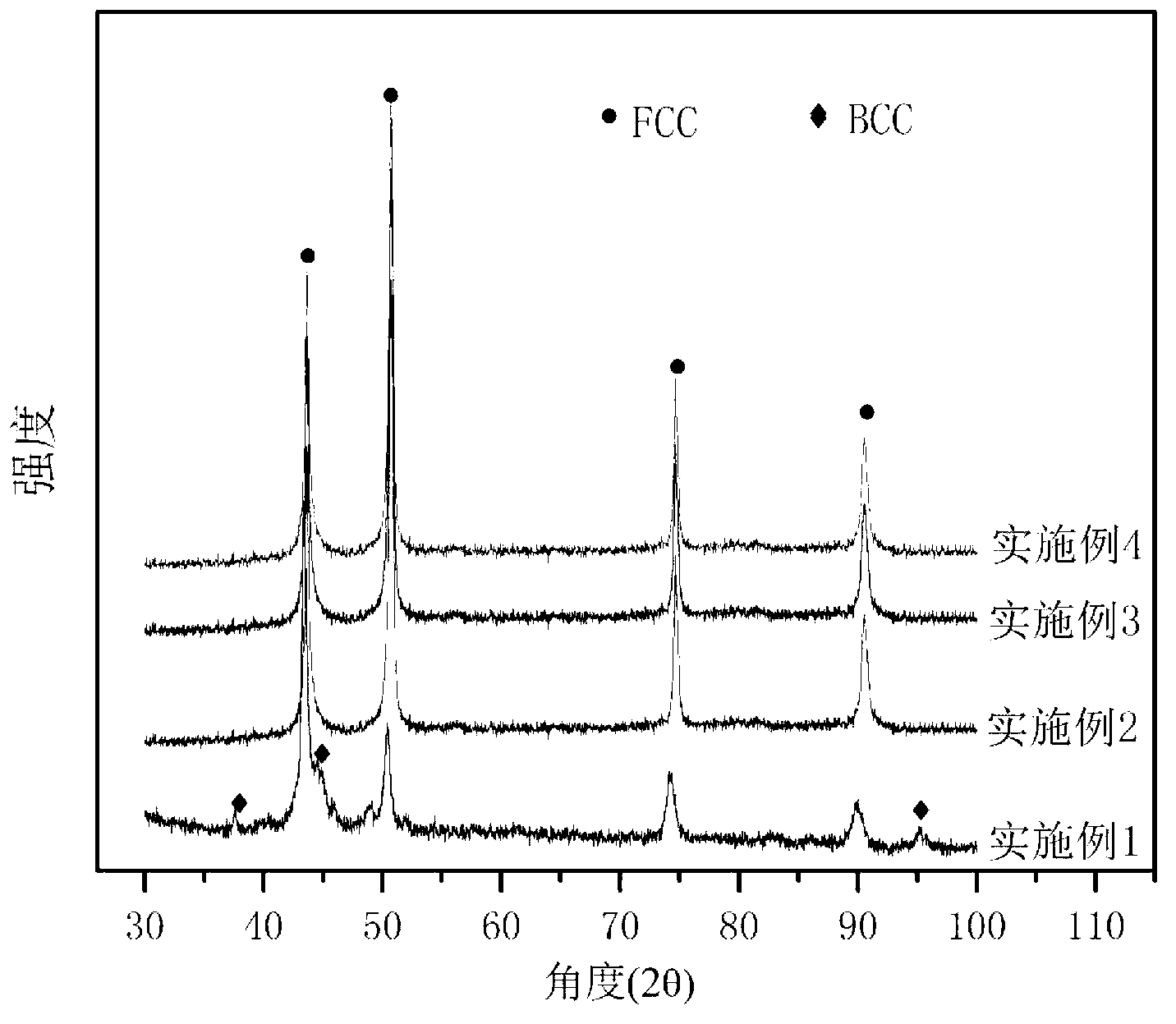

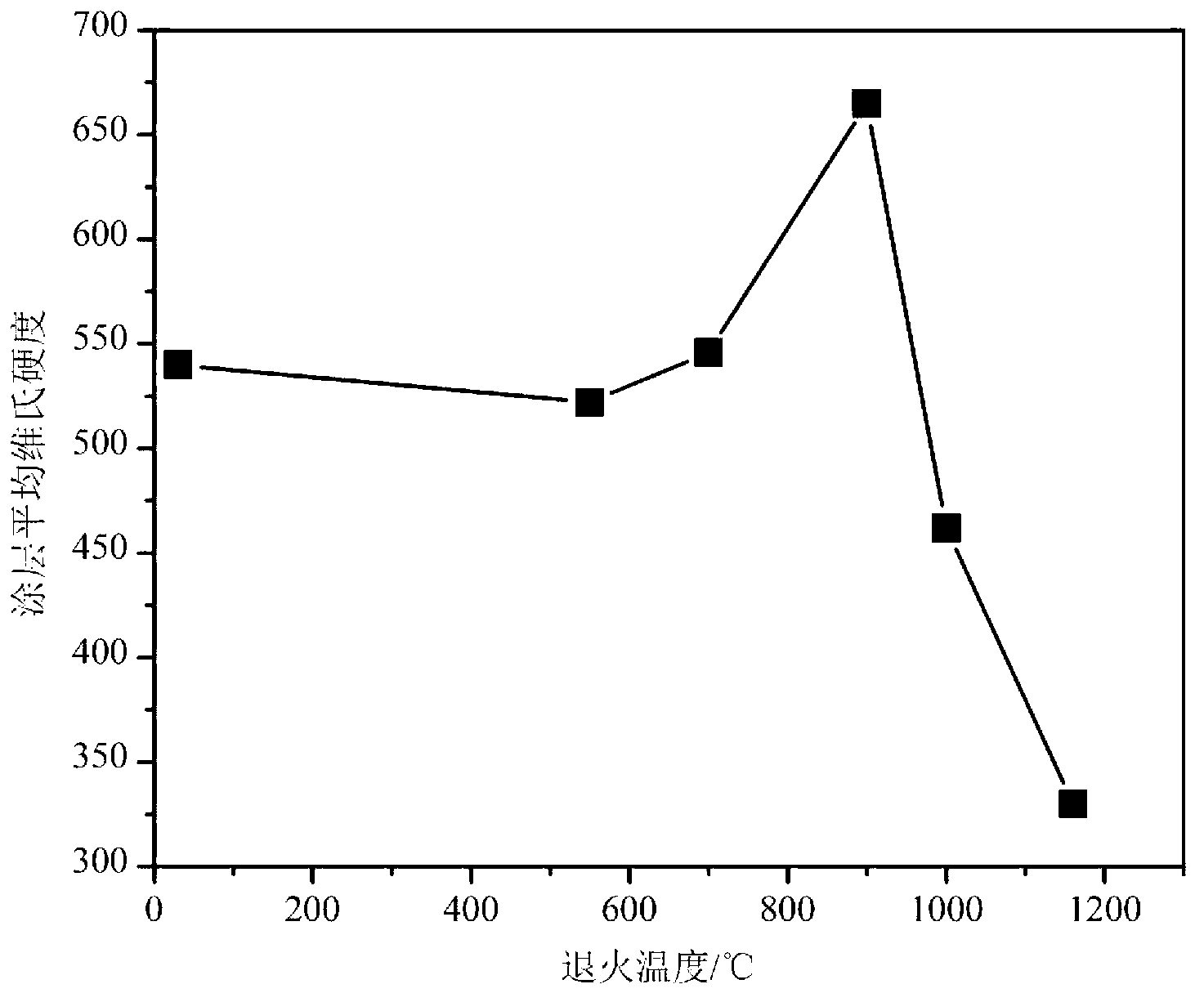

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

Synthesis of several metal selenides and tellurides as semiconductor material

InactiveCN1384047AOvercome the problems of high temperature, highly toxic raw materials, complicated process, etc.Low reaction temperatureSemiconductor/solid-state device manufacturingBinary selenium/tellurium compoundsSemiconductor materialsHydroxylamine

By using the soluble salt of transition metalz Zn, Cd, Pb, Mn, Co, Ni, Cu, Ag, Sb and Bi, selenious acid or its solutl salt, or antimonous acid or its soluble salt as raw material, and hydrazine hydrate, sodium borohydride, potassium borohydride, hydroxylamine or hydrazine sulfate as reductant, and through hydrothermal reduction reaction at 100-200 deg.c in a sealed container for 2 hr to 5 days, selenides or tellurides of the said metals as semiconductor material may be synthesized. Unlike available synthesis process, which needs high temperature, toxic feedstock and complex technological course, the present invention has the advantages of low-cost material, simple apparatus, easy control, good technological reproducibility, stable product quality, etc.

Owner:TSINGHUA UNIV

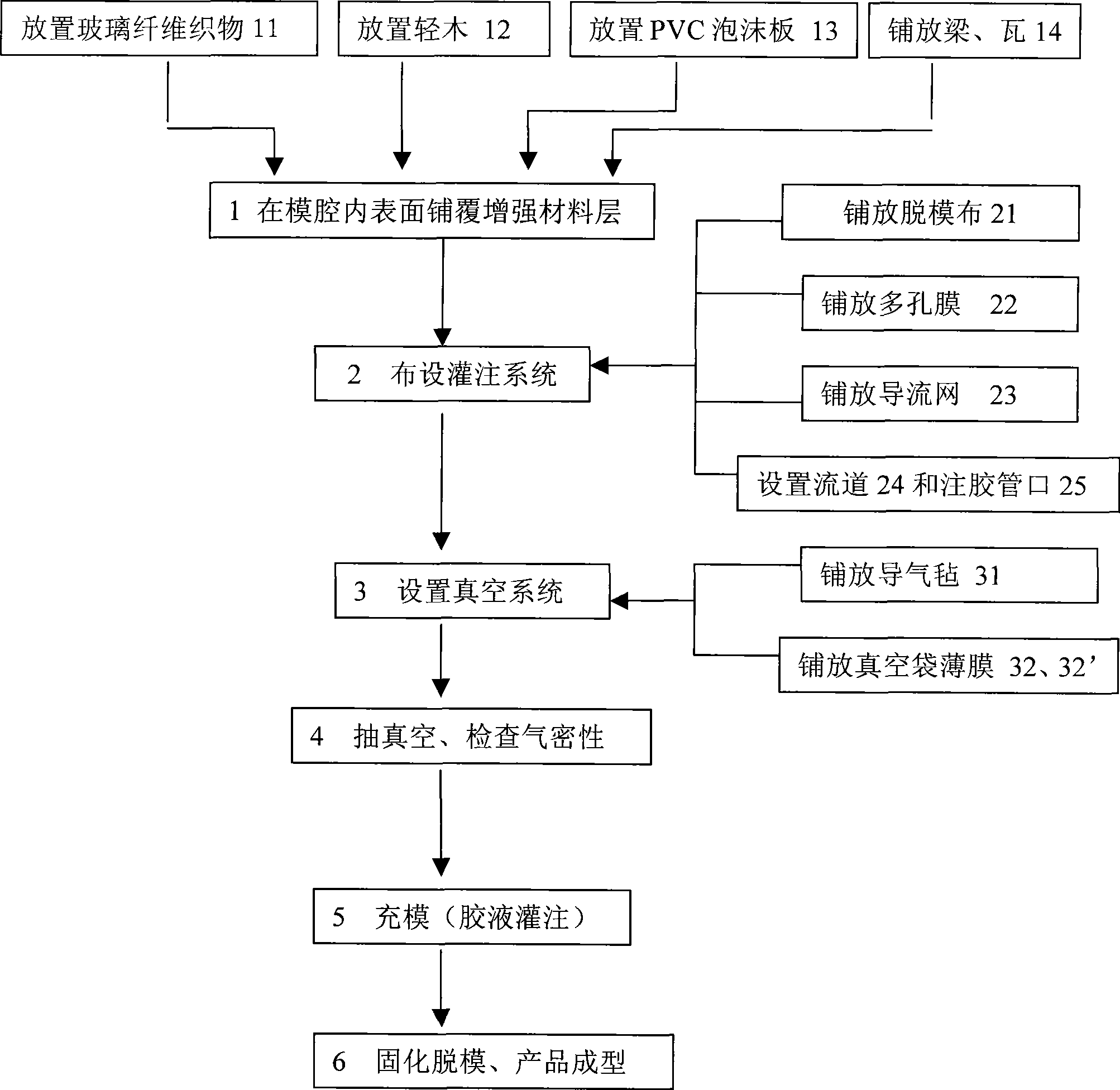

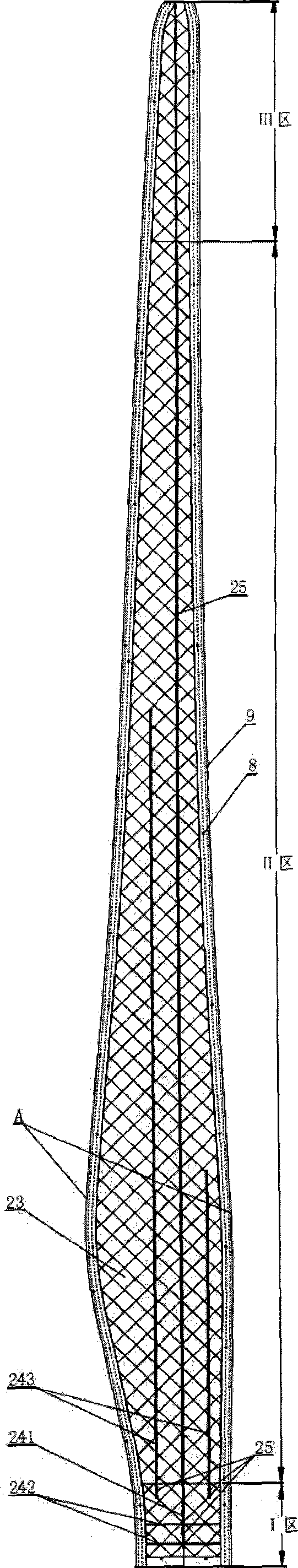

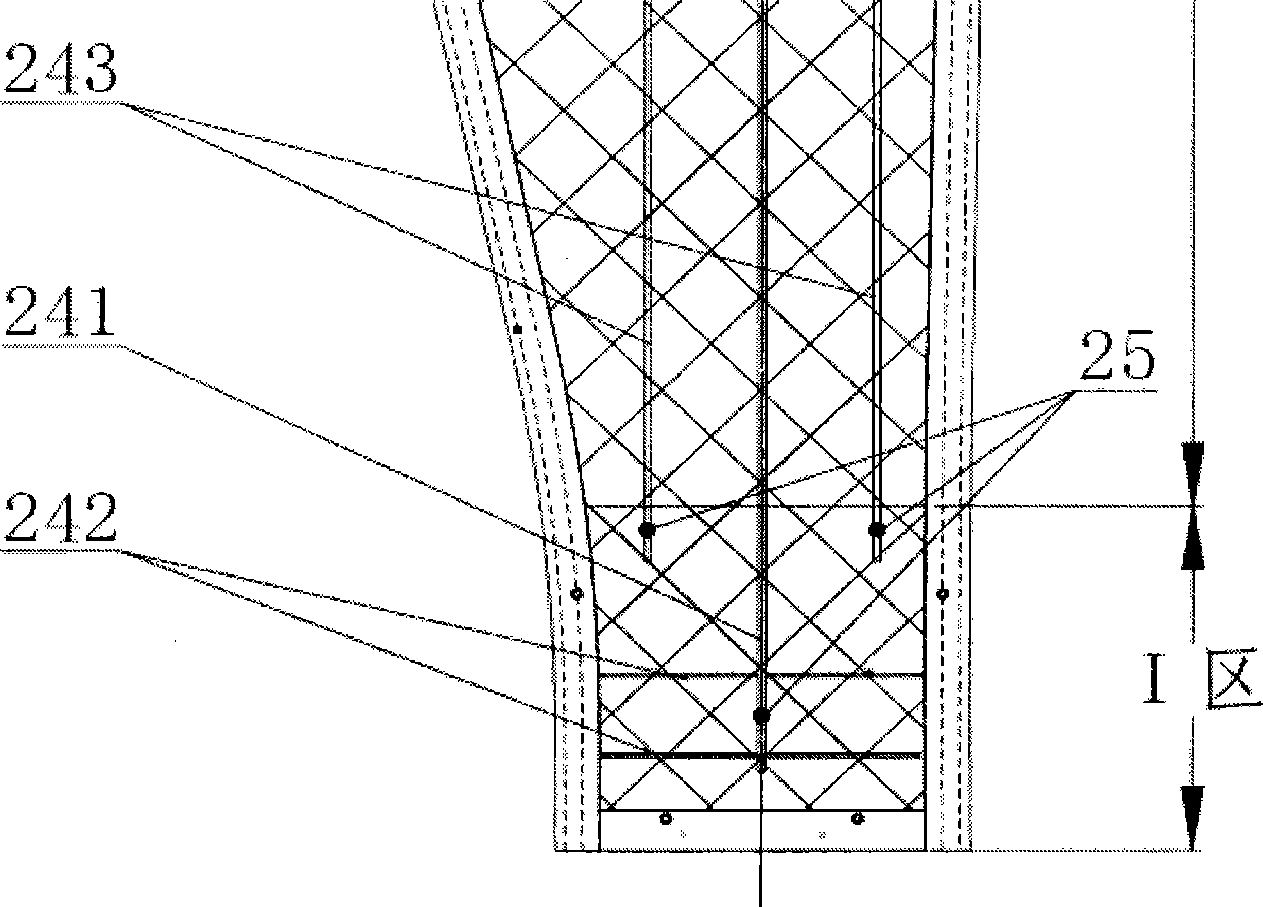

Megawatt level composite material wind electricity blade vacuum guiding and forming technique

ActiveCN101456256AHarm reductionImprove molding efficiencyFinal product manufactureDomestic articlesElectricityTurbine blade

The invention discloses a vacuum infusion forming process for a megawatt grade composite material wind turbine blade. The process comprises a step of spreading and cladding reinforced material layers in an upper mold cavity and a lower mold cavity of a mould of the blade respectively and a step of solidification, demoulding and product forming, and is characterized by comprises the following steps between the two steps: 1)distributing injection systems on the surfaces of the reinforced material layers; 2) distributing vacuum systems on the outer surface of the injection systems spread and covered with flow channels in the step 1); 3) checking the airtight performance of an vacuumizing opening; 4) mould filling ( filling rubber liquid); and 5), solidification, demoulding and product forming. The vacuum infusion process can complete mould filling in 1.5 hours, improves the forming efficiency of large blades, saves special equipment and achieves low production costs. Products formed by the process are uniform in quality distribution and good in process repeatability, and can reduce volatilization of harmful gases and environmental pollution and ensure heath of operators and are easy to promote and use compared with a hand lay up process and a wet spreading process.

Owner:SINOMATECH WIND POWER BLADE

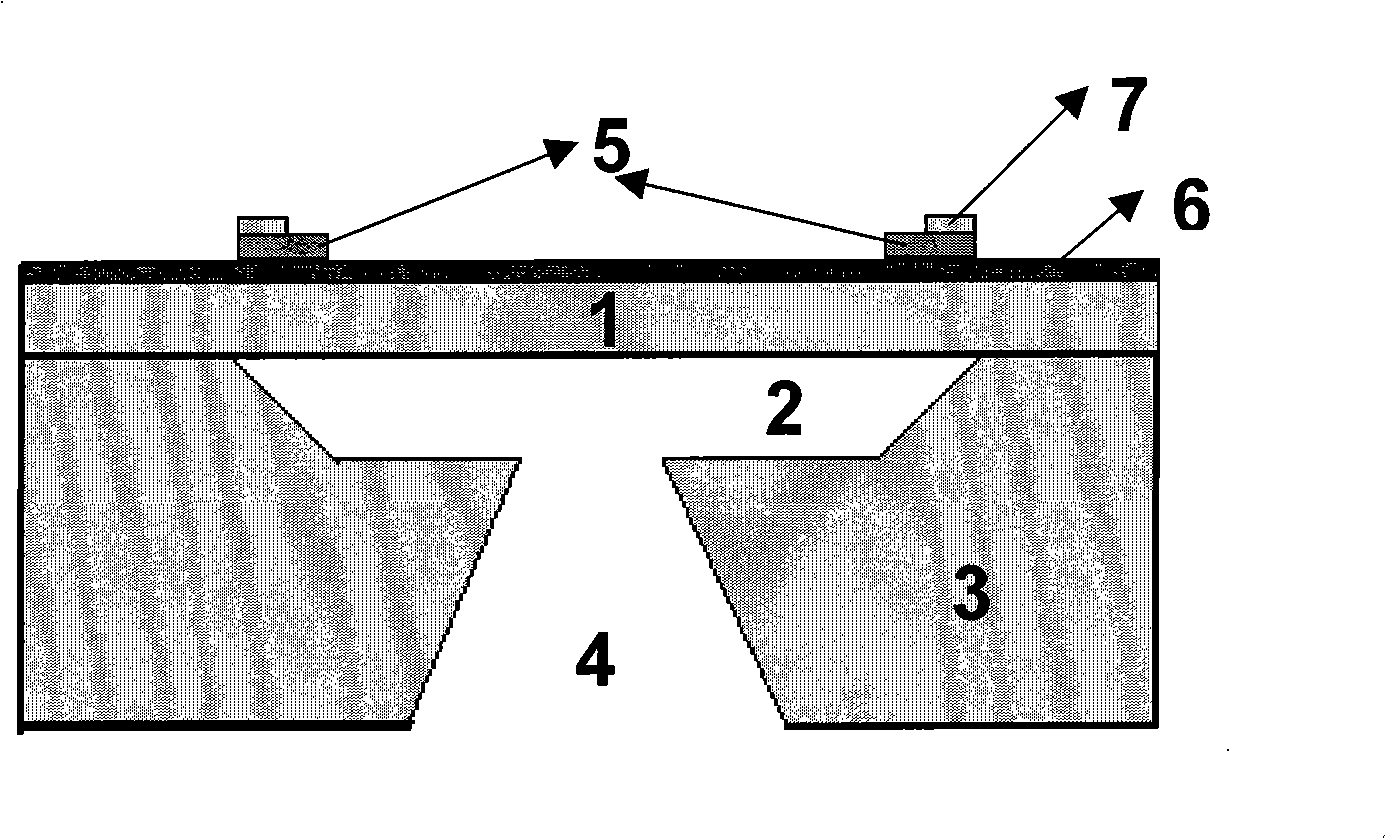

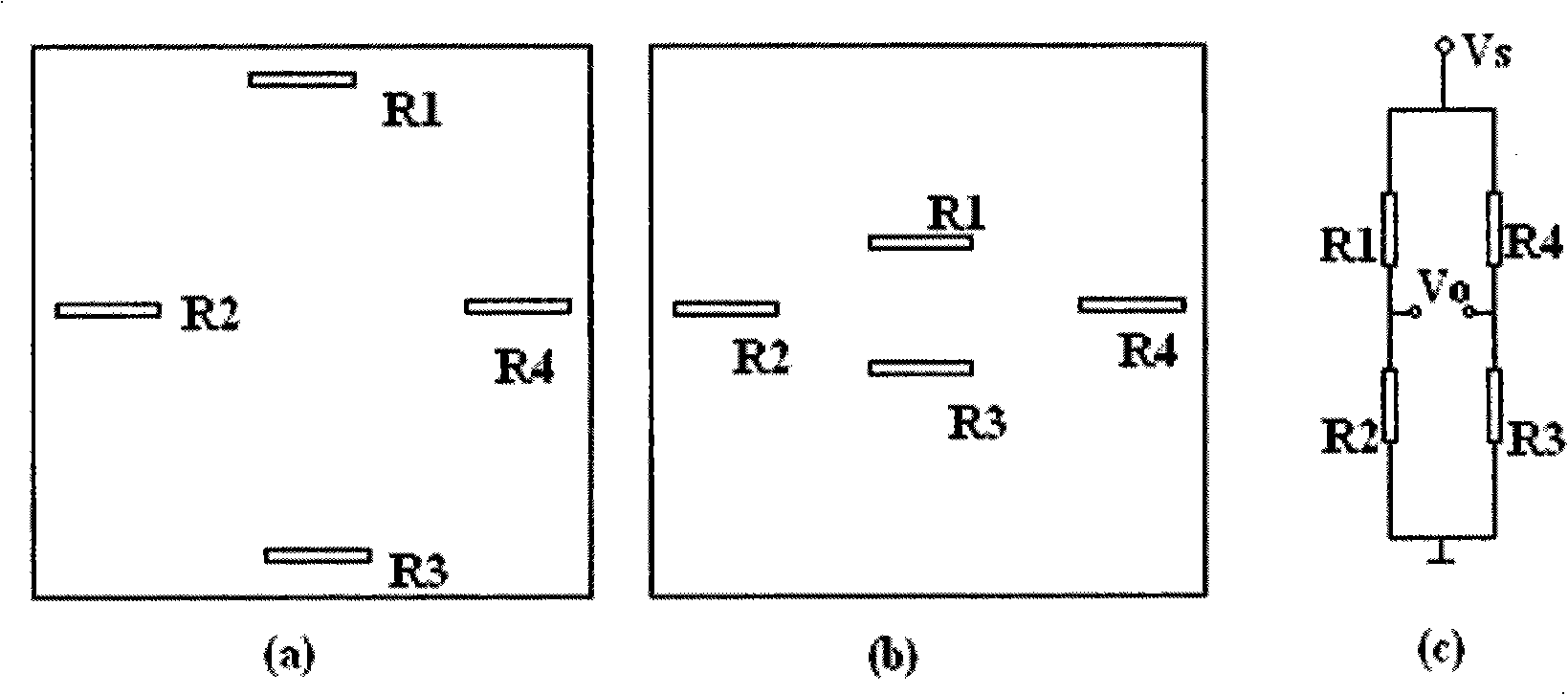

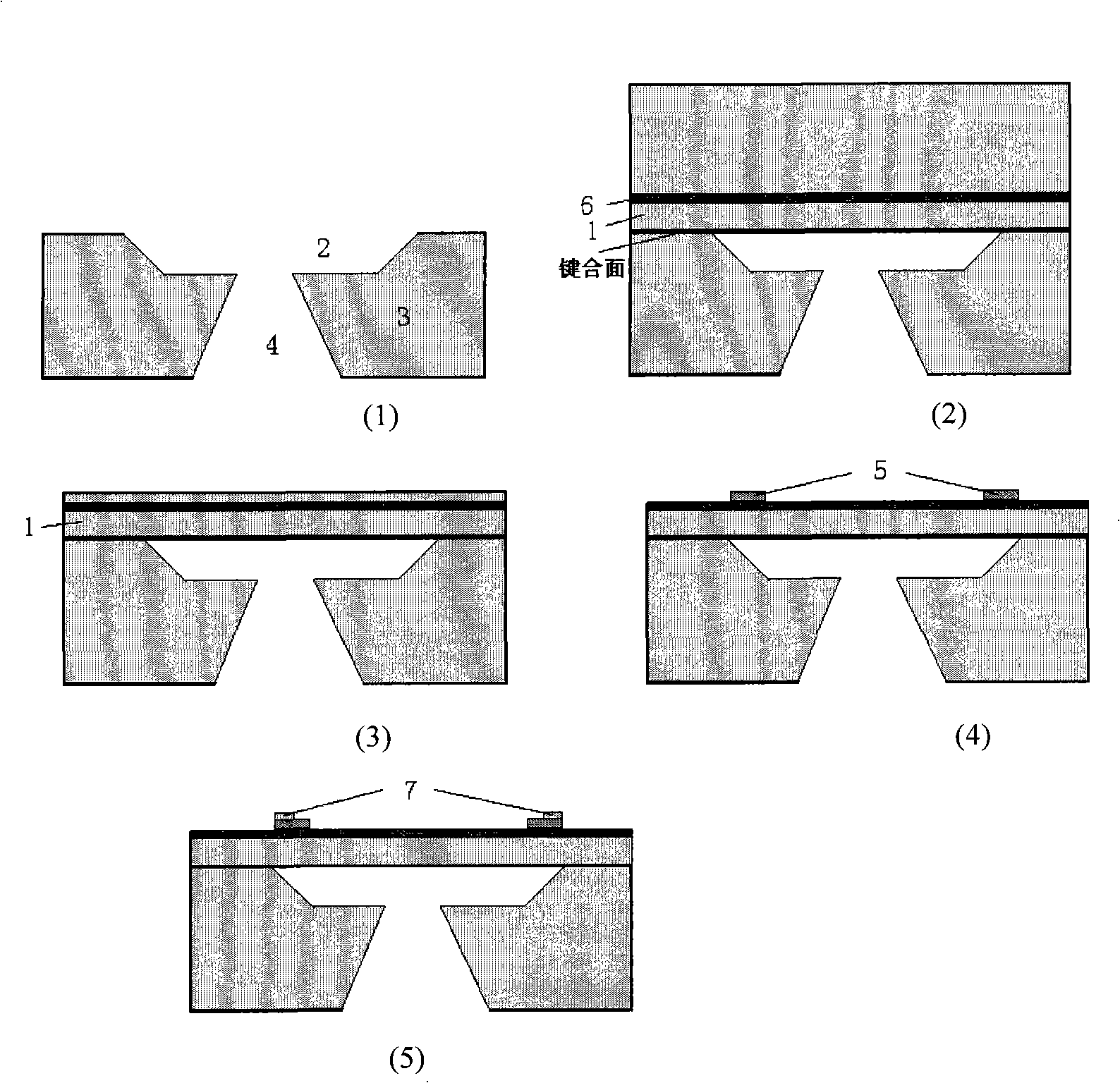

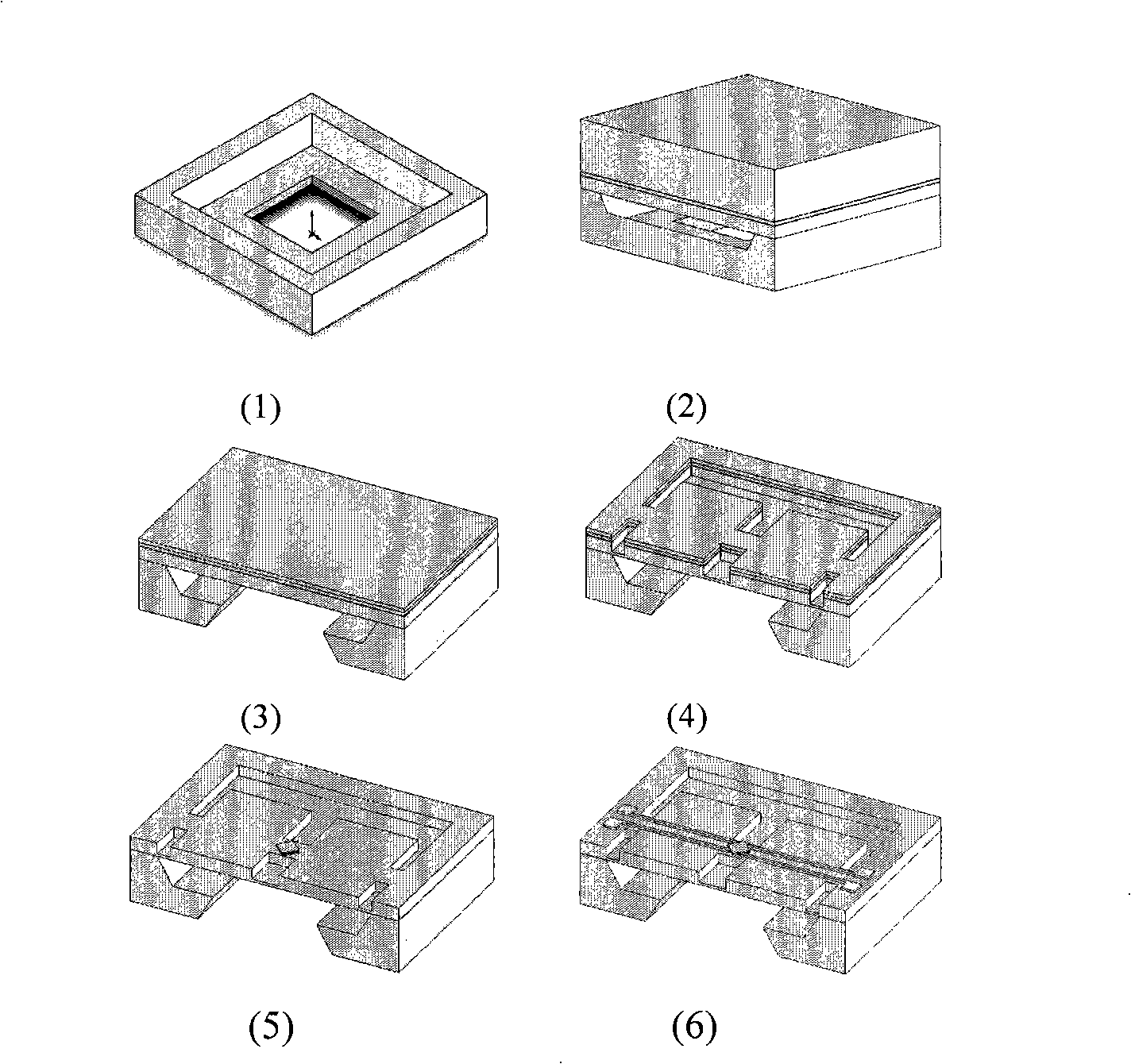

Si-Si bonding isolator upper silicon high-temperature pressure sensor chip and manufacture method

InactiveCN101266176AIncrease flexibilityReduce residual stressTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysicsBuried oxide

The invention relates to a high-temperature press sensor of silicon-silicon-bonded-based silicon on an insulator (SOI) and a producing method, belonging to the field of sensor chip, characterized in that a shallow slot and a gas vent on a support silicon substrate are all formed through anisotropic etch; suitable depth of the shallow slot can be obtained by controlling etching time so as to accomplish over-voltage protection for the device; the support silicon substrate is bonded with an inverted SOI chip; a piezoresistor is produced on the top layer of silicon after reducing and polishing the back of the SOI chip. The device can operate normally at high temperature using SOI buried oxide layer for isolation of sensitive component and elastic component.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Nucleocapsid energizing agent for propelling agent and method for preparing same

InactiveCN101549289ASimple ingredientsLow priceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive agentVacuum drying

The present invention discloses a nucleocapsid energizing agent for propelling agent and a method for preparing same, the energizing agent is a nucleocapsid structure energizing agent that carbon is encapsulated on a metallic oxide surfaced. The preparing method includes steps as follows: selecting one or some raw materials: address sugar, diose or soluble polysaccharide to mix according with random weight rate for confecting water solution 50-1500g / L, adding the surfactant or dispersant into the water solution, then adding the metallic oxide powder, the metallic oxide weight is 1-60% of the raw material total weight, the surfactants or dispersants weight is 0-4.5% of the metallic oxide weight, ultrasounding or stirring to distribute evenly, heating in 100-260 DEG C during 1-72 hours; reducing the product temperature to a room temperature, washing, centrifuging, removing the water-soluble impurity again and again, then vacuum drying for obtaining the nucleocapsid energizing agent. The nucleocapsid energizing agent has better compatibility with other component of the propelling agent, and has simple preparing technique, low cost, green process and is easy to mass production.

Owner:WUHAN UNIV

High-entropy alloy powder for 3D (three-dimensional) printing and method for preparing high-entropy alloy coating by using high-entropy alloy powder

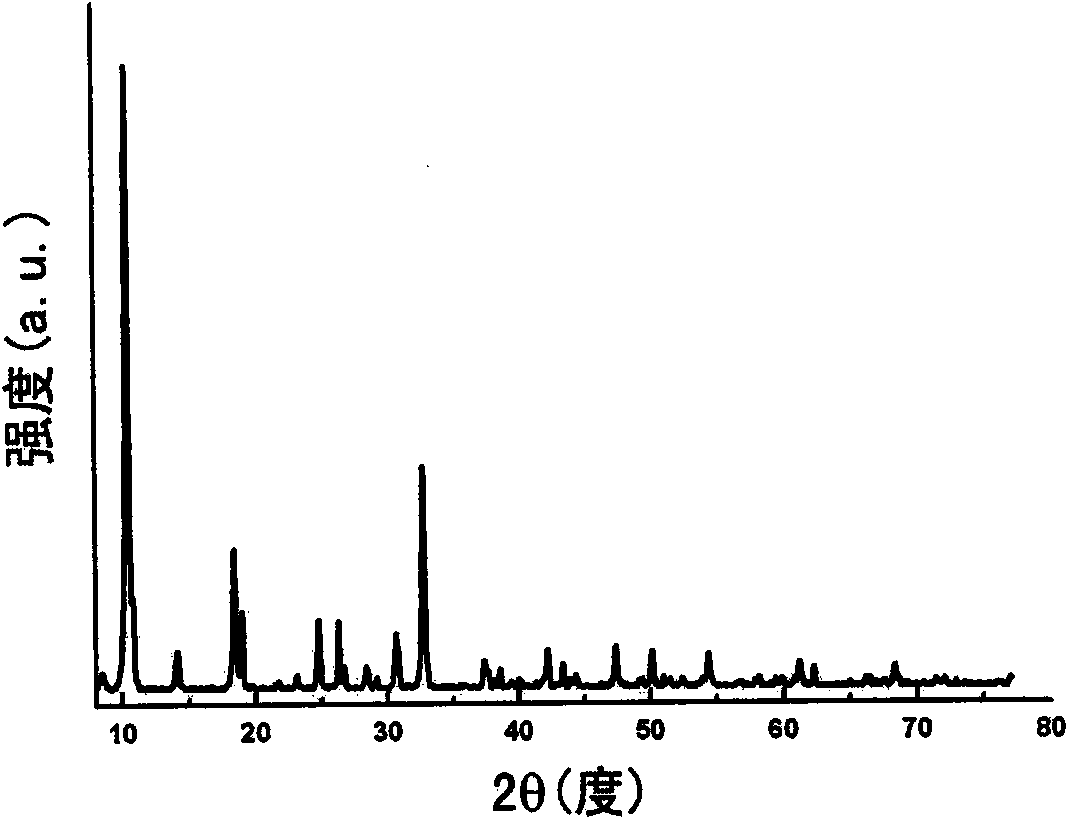

ActiveCN104841930AImprove performanceScientifically optimize the ratioIncreasing energy efficiencySelective laser sinteringHigh entropy alloys

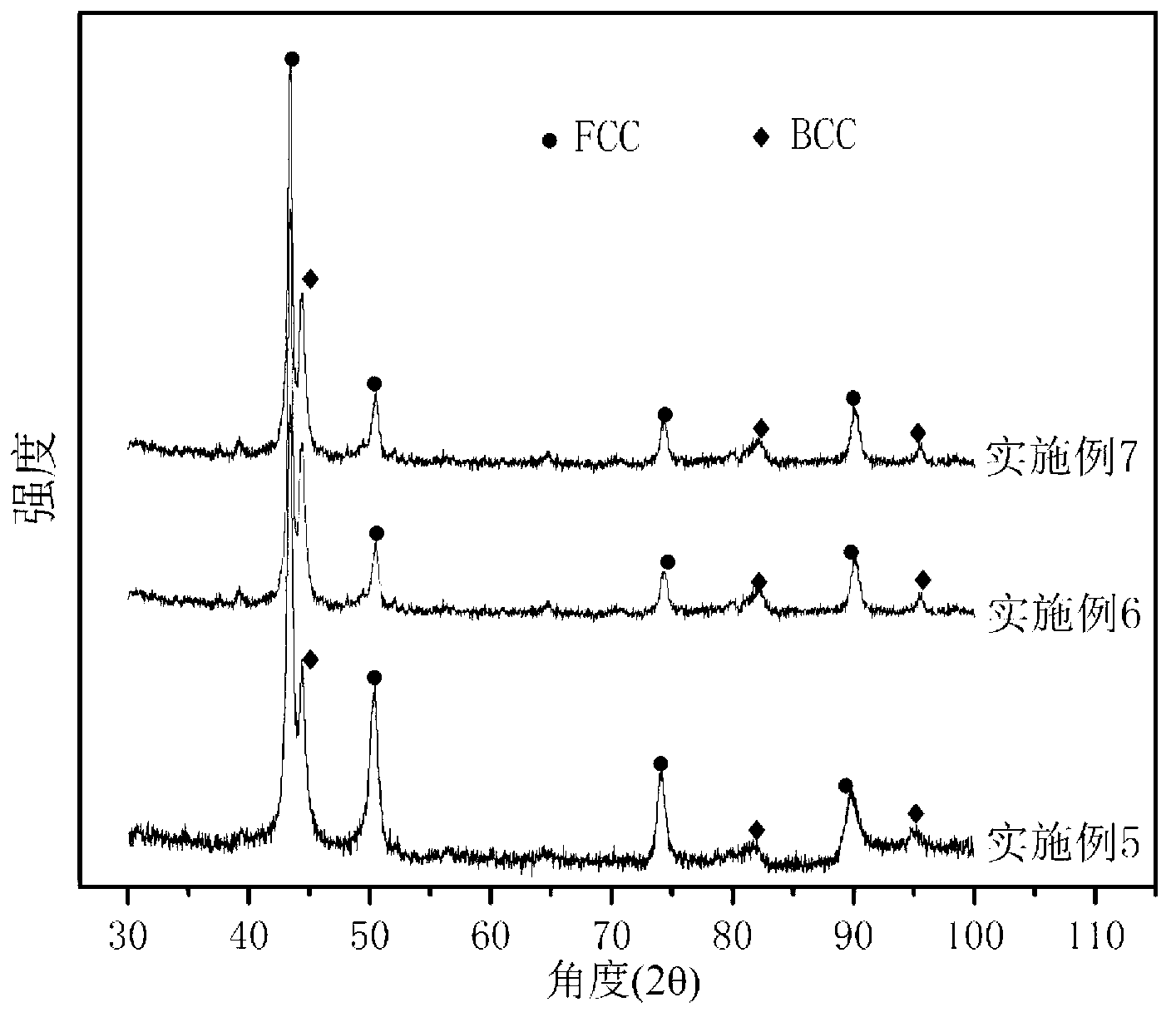

The invention provides high-entropy alloy powder for 3D (three-dimensional) printing and a method for preparing a high-entropy alloy coating by using the high-entropy alloy powder, and belongs to the technical field of coating preparation. By the high-entropy alloy powder, the wear resistance of the existing powder materials for 3D printing is improved. The high-entropy alloy powder is prepared by using the following ingredients in atomic percentage by weight: 16%-25% of Ni, 16%-25% of Co, 16%-25% of Cr, 16%-25% of Ti and 16%-25% of V. The preparation method comprises the following steps of (1) performing ball-mill mixing on raw materials to obtain mixed powder; (2) grinding and cleaning a matrix; and (3) placing the mixed powder in a powder feeder of 3D printing equipment and sintering the mixed powder on the surface of the matrix to form the high-entropy alloy coating by using selective laser. The NiCoCrTiV coating is prepared by selective laser sintering and has the advantages of high hardness, wear resistance, corrosion resistance and the like. The high-entropy alloy powder for 3D printing and the method for preparing the high-entropy alloy coating by using the high-entropy alloy powder can be widely used in the field of 3D printing.

Owner:HARBIN ENG UNIV

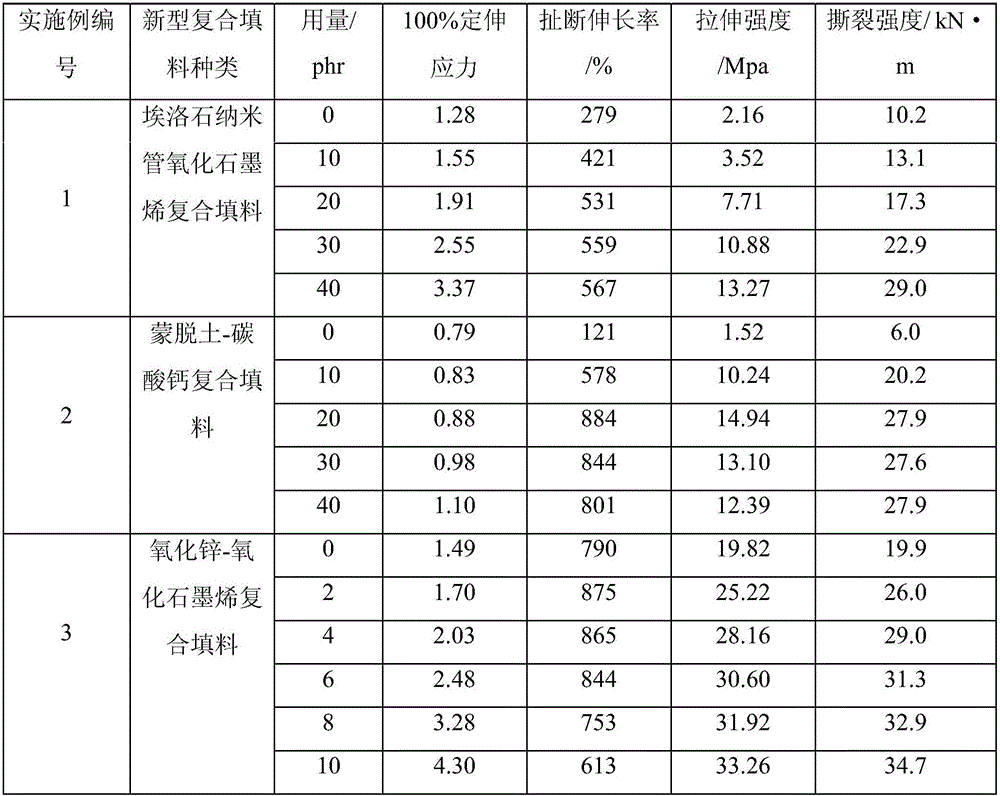

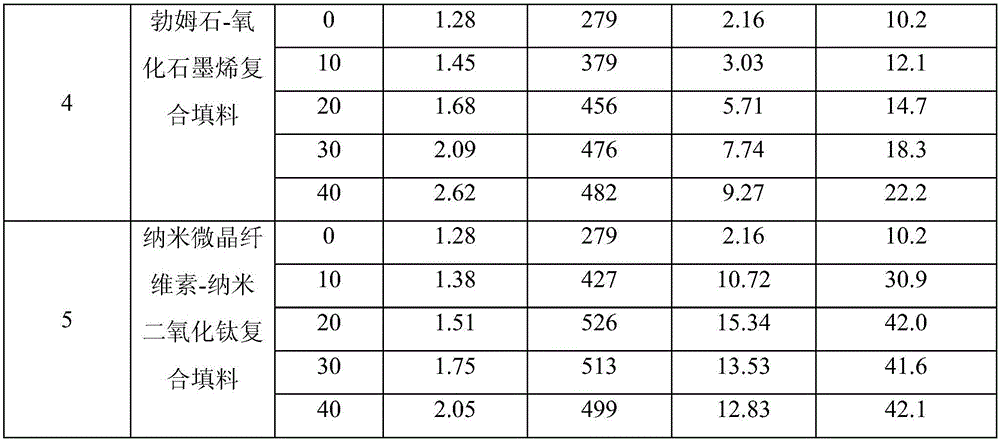

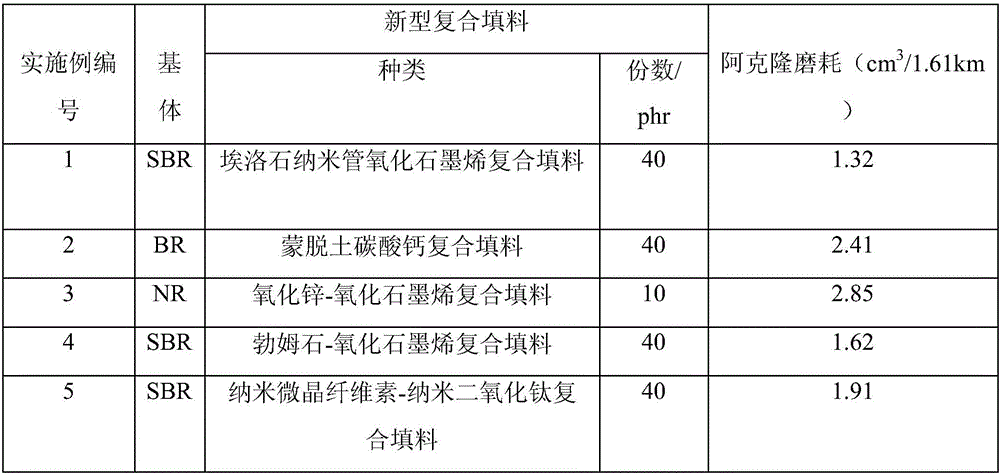

Novel rubber compound stuffing preparing method based on mercapto-alkene chemical reaction

The invention discloses a novel rubber compound stuffing preparing method based on mercapto-alkene chemical reaction. The preparing method comprises the following steps of using rubber common stuffing as a raw material, ultrasonically processing two kinds of stuffing to be compounded in solvents respectively to enable the stuffing to be evenly scattered, enabling a silane coupling agent containing double bonds and mercapto groups to react with hydroxide radicals or other oxygen-containing groups in structures of the two kinds of stuffing respectively to obtain the double bonds and two kinds of mercapto-group silane coupling agent modified stuffing, ultrasonically scattering the double bonds and the two kinds of double-bond mercapto-group silane coupling agent modified stuffing in a solvent, adding a photoinitiator, triggering the mercapto-alkene chemical reaction through exposure of ultraviolet light, connecting the two kinds of stuffing through chemical bonds, then centrifuging or filtering and separating, drying, smashing and sieving to obtain novel rubber compound stuffing. According to the preparing method, the stuffing is firstly modified through the silane coupling agent, and then the two kinds of stuffing are compounded in a chemical bond mode through the high-efficiency mercapto-alkene chemical reaction to obtain the novel rubber compound stuffing. In addition, the preparing method belongs to pioneering researches.

Owner:SOUTH CHINA UNIV OF TECH

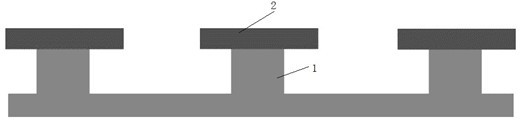

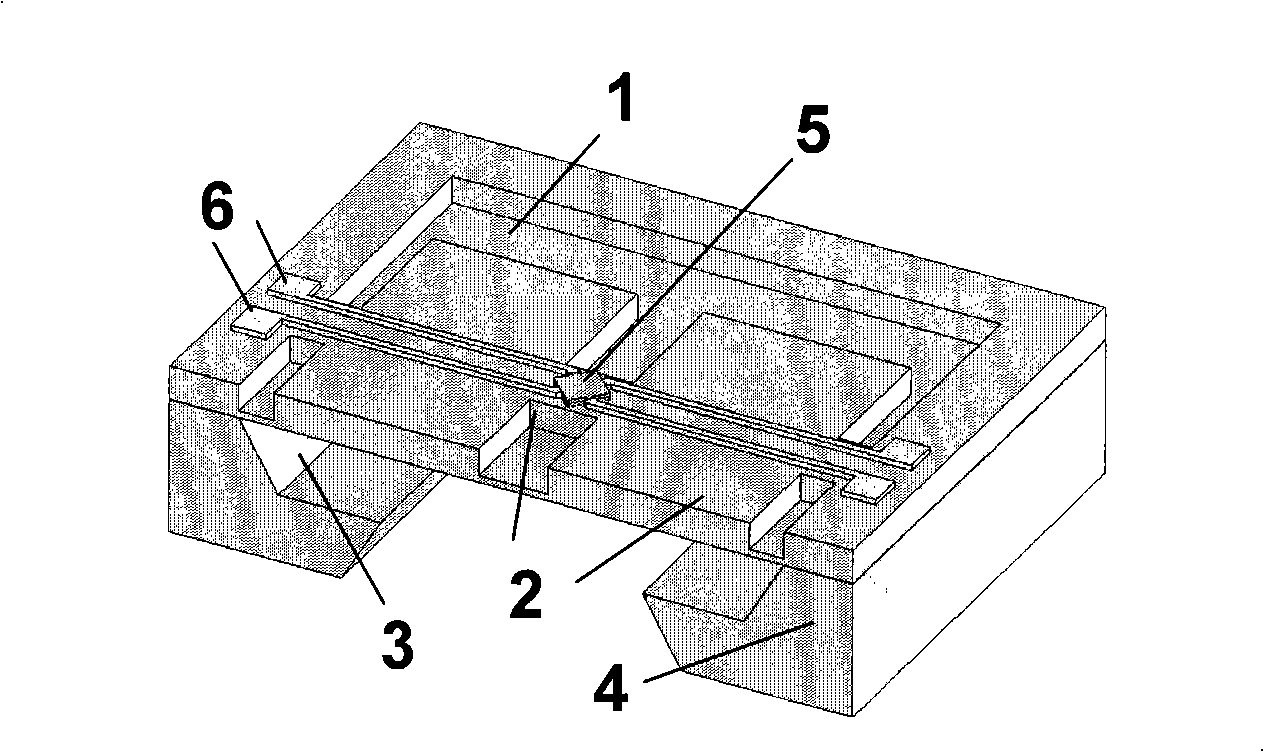

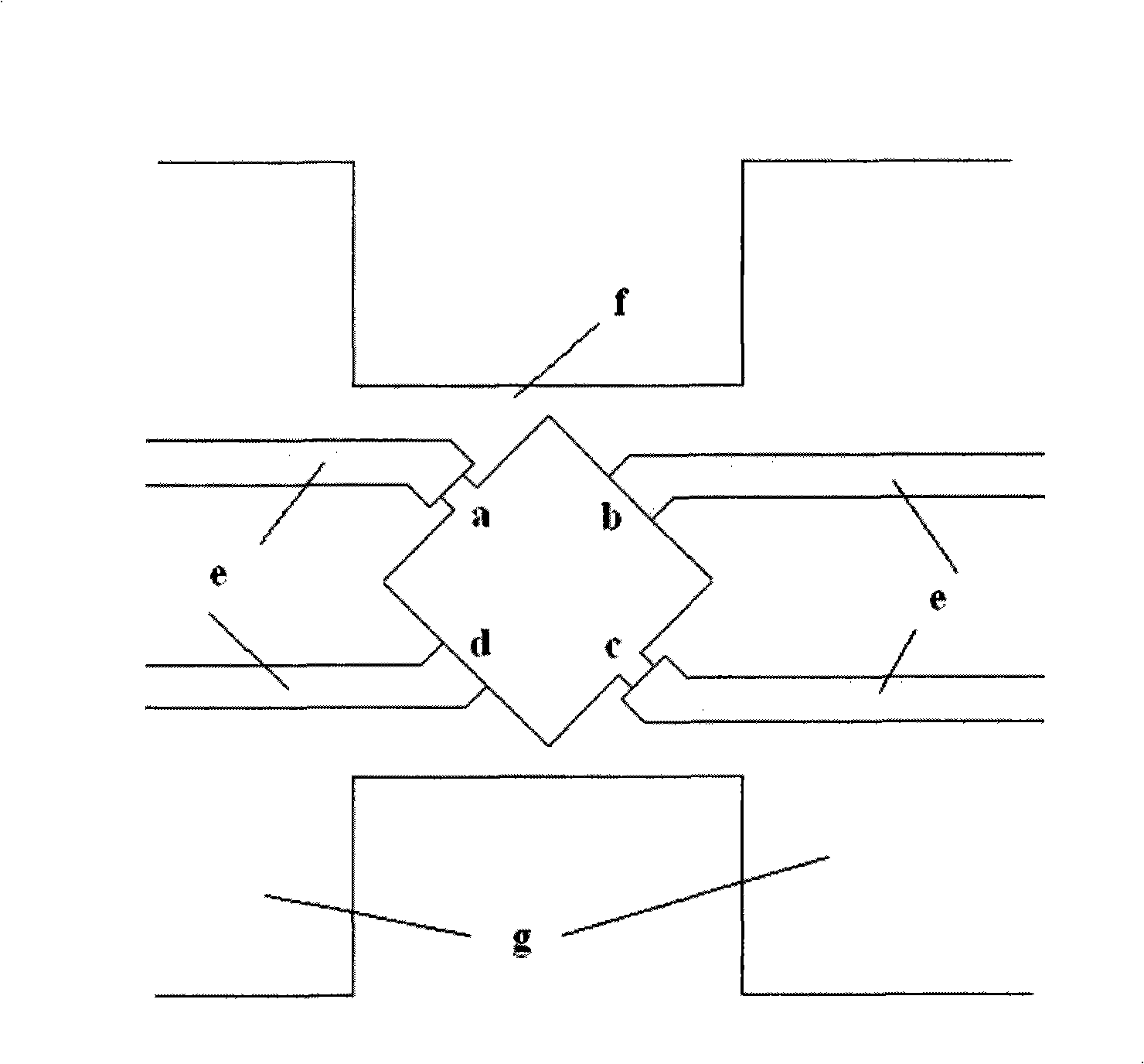

Water and oil repellency surface microstructure and manufacturing method thereof

InactiveCN102427083AImprove mechanical stabilityGood process repeatabilitySemi-permeable membranesFixed microstructural devicesIonMolecular self-assembly

The invention discloses a water and oil repellency surface microstructure which comprises a substrate and a T type micro-nanometer structure etched on the substrate, wherein the T type micro-nanometer structure comprises a vertical part and a transverse part which is arranged at the top end of the vertical part. A manufacturing technology of a water and oil repellency surface comprises the steps of substrate cleaning, mask pattern transfer, XeF2 gaseous phase etching process or DRIE (Deep Reactive Ion Etching) etching process, chemical vapor deposition or perfluorination silane monomer self-assembly, thereby the water and oil repellency surface microstructure with high mechanical stability, good technology repeatability and controlled geometric structure is obtained.

Owner:SUN YAT SEN UNIV

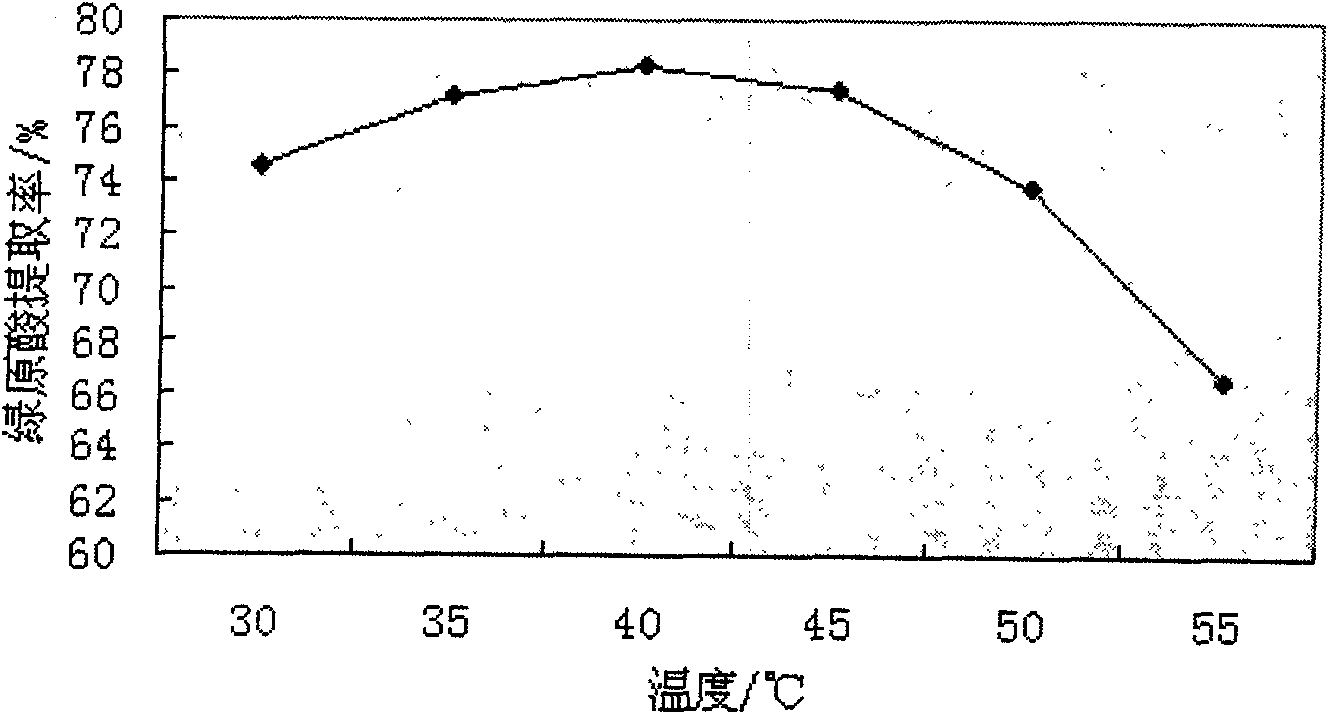

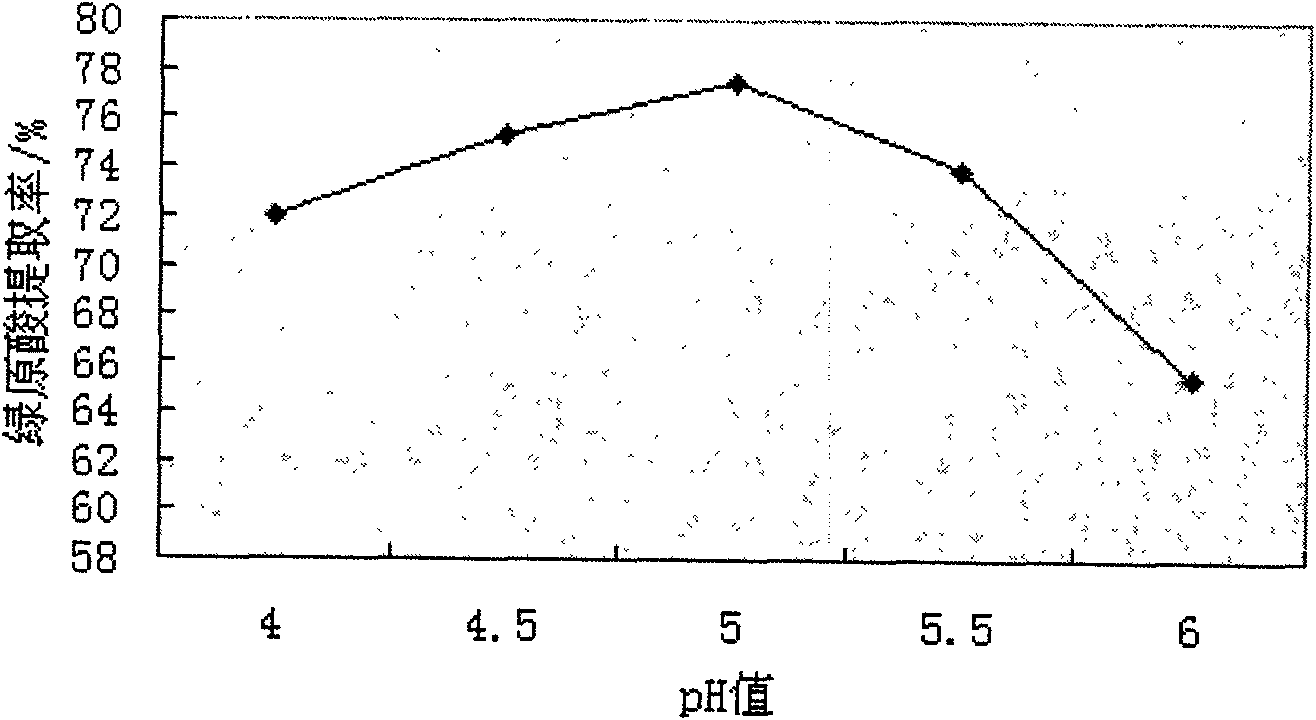

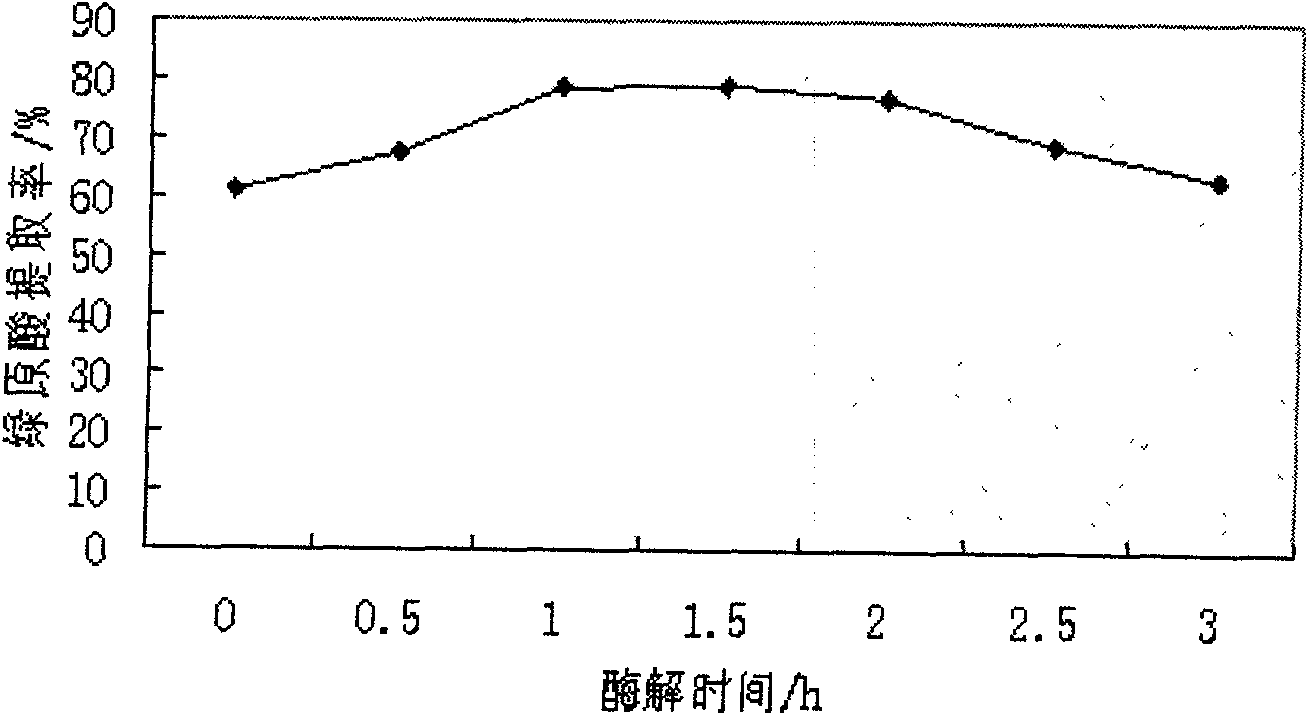

Method for extracting chlorogenic acid from honeysuckle by using compound enzyme method

InactiveCN101830804AGood process repeatabilityThe result is stableCarboxylic acid esters separation/purificationPectinaseChlorogenic acid

The invention relates to a method for extracting chlorogenic acid from honeysuckle by using a compound enzyme method and researches a novel process for extracting a main medicinal effective component of the chlorogenic acid from the honeysuckle by a cellulose and pectinase compounding enzyme method. Through a single factor experiment and an orthogonal test, optimal process conditions for extracting the chlorogenic acid from the honeysuckle by using the compound enzyme method can be optimized: the enzymolysis temperature is 45DEG C, the pH is 4.5, the compound ratio of the cellulose to the pectinase is 1.0:0.3 and the enzymolysis time is 1.5 hours. The test result shows that the process repeatability is favorable and the result is stable. The extraction rate of the chlorogenic acid extracted from the honeysuckle by using the compound enzyme method can reach 83.06 percent which is improved by 16.93 percent in comparison with the extraction rate of the chlorogenic acid extracted by using a water extraction process.

Owner:ZHONGXIN PHARMA FACTORY OF TIANJIN ZHONGXIN PHARMA GROUP

Smelting production method of low activation martensitic steel for fusion reactor

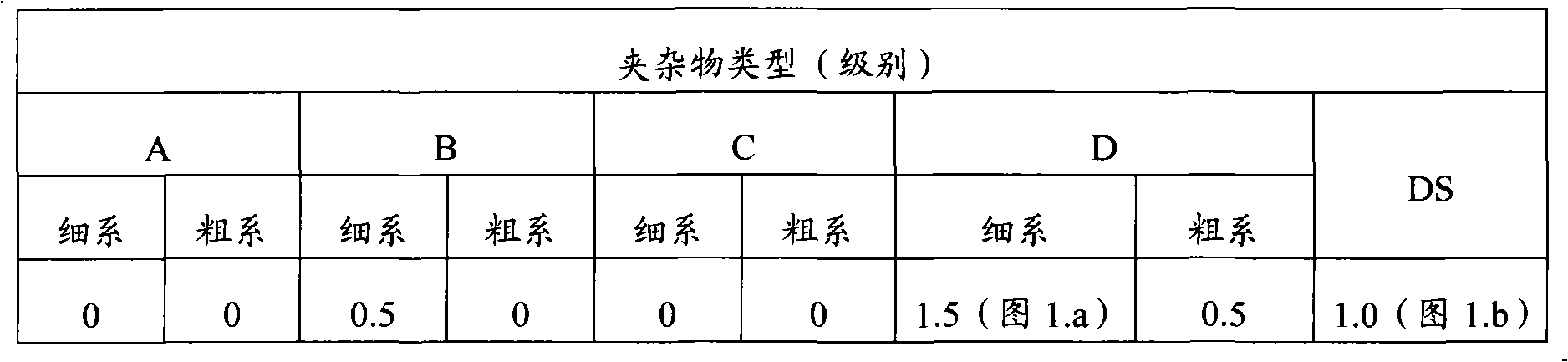

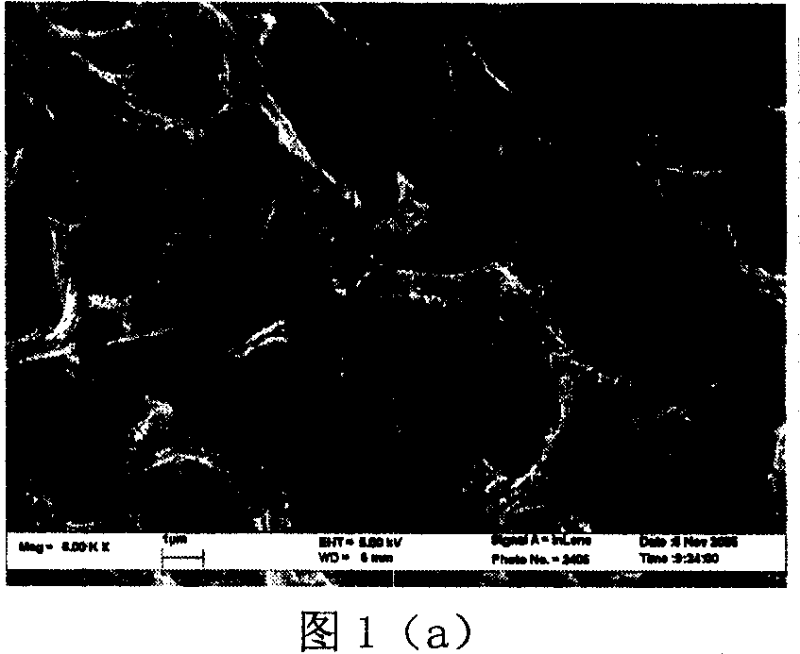

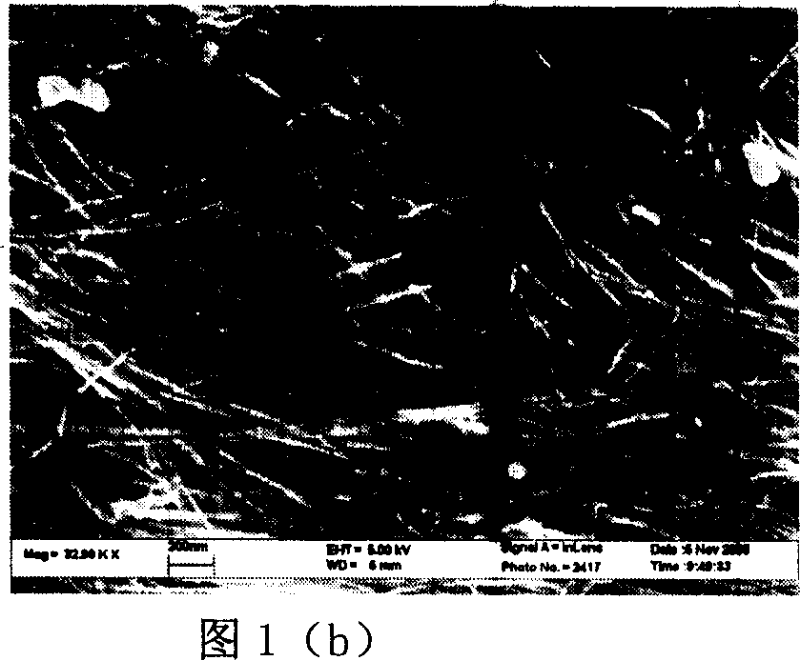

InactiveCN101328522AReduce manufacturing costMeet the design requirementsIncreasing energy efficiencyQuality levelSteel bar

The invention relates to a method for producing a low-activation martensitic steel for a fusion reactor by melting. The method comprises: step one, a charging material is smelted in a vacuum induction furnace: (1) when a vacuum degree is between 0.1 and 10 Pa, argon gas is passed through the vacuum induction furnace till the vacuum degree is between 0.005 and 0.08MPa, and a smelting temperature is between 1450 and 1650 DEG C; (2) alloys are added in sequence: firstly, pure Fe is melted; Cr and W are added into the furnace; then Ta and V are added into the furnace, and finally C and Mn are added into the furnace; simultaneously, the level of an oxygen content in the pure Fe is observed; before Cr is added, a little of C is added into the furnace for carrying out deoxidation treatment; (3) on-line detection is carried out to the compositions of alloy elements; the alloy elements are added according to a detection result; and (4) after the compositions are qualified, a mixture is cast under the vacuum at a casting temperature of between 1450 and 1550 DEG C. Step two, according to the compositions and the inner quality level of a cast ingot which is obtained by vacuum induction and melting, whether the cast ingot is remelted and refined in a vacuum electroslag remelting furnace or a common electroslag remelting furnace with argon protection. Step three, a needed CLAM steel bar material is prepared by the production of forging, cogging and hot rolling. The method has the characteristics of simple smelting operation, stable process and low production cost; the compositions and impurities of the produced CLAM steel meet the design requirement; and the method has no aliquation of the compositions and tissues and high degree of purity and is suitable for the application of the fusion reactor.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

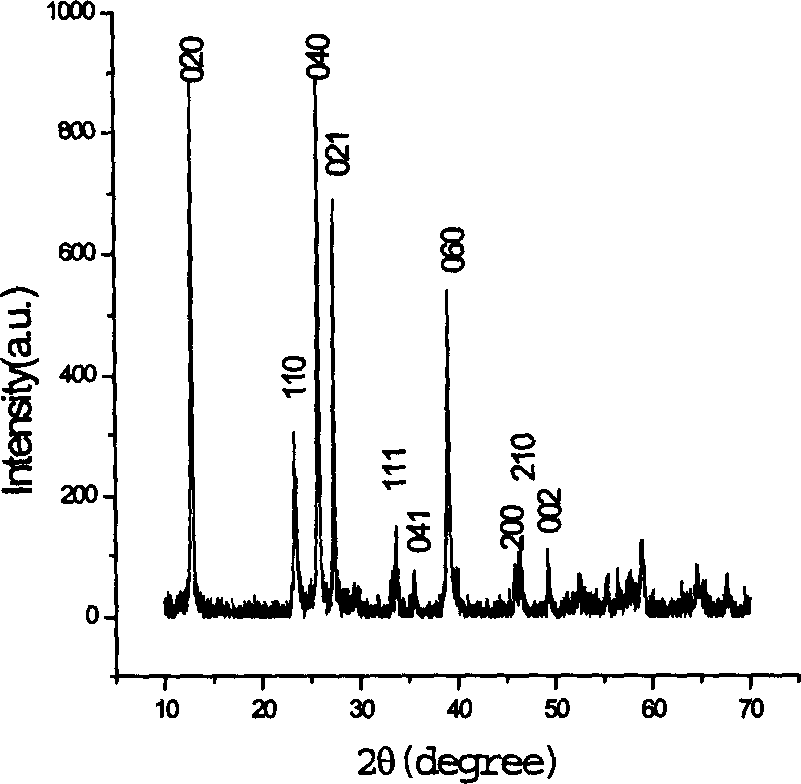

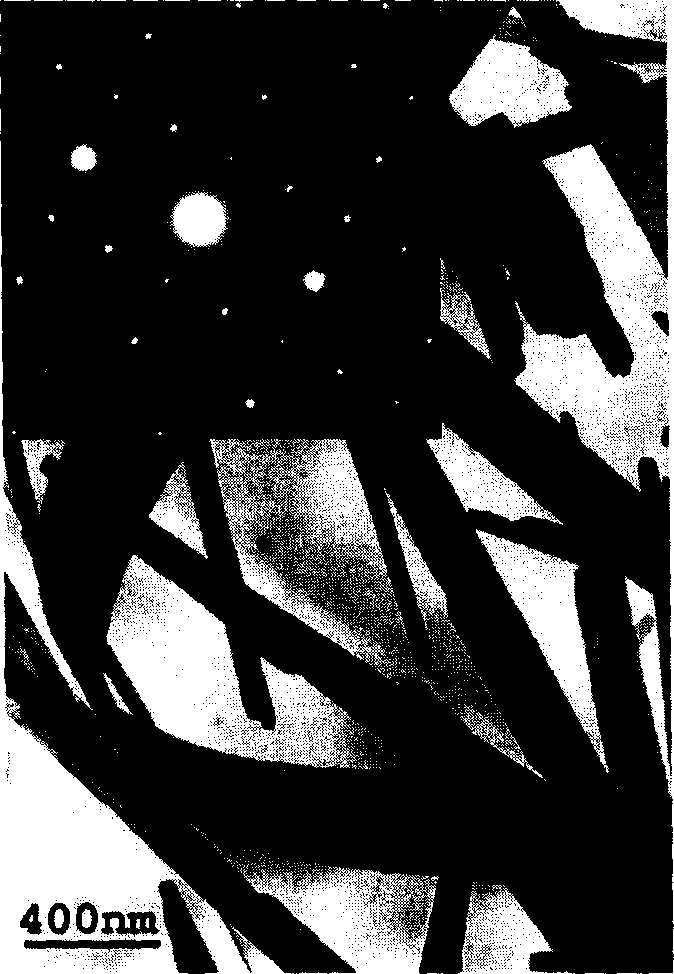

Titanium dioxide nano thread, belt and tube block array and preparation method thereof

InactiveCN101037225AEasy to controlGood process repeatabilityIndividual molecule manipulationTitanium dioxideSolar cellPt element

The present invention provides a titanium dioxide nanometer thread, strip and tube block array, and a preparation method of the same, which relates to a nanometer material and a preparation method of the same. A high purity titanium foil serves as a substrate; a mixture solution of ethylene glycol and fluorination ammonification with a content of 0.1~0.5 wt%; a titanium dioxide nanometer thread, strip and pipe block array, which has a nanometer thread, strip blended fasciculation substance of 1~20 micron at the upper end and a regular nanometer tube array at the lower part, is formed vertically at the substrate by constant pressure anodisation. The preparation method comprises the steps of that: the substrate serves as the anode, the platinum serves as the cathode, the distance between the anode and the cathode is 10~50 mm, the voltage is 10~60 V, the reaction time is 30~3000 min; the obtained product is roasted for 1~3 hours at 240~600 DEG C, and is cooled in the furnace, thereby the titanium dioxide nanometer thread, strip and tube block array is obtained. The method has a simple equipment, an excellent repetitiveness for technology, a steady quality of product, and can be used for the fields of photocatalysis, photolysis water, solar cell and spinning electron.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Realizing method of novel enhancement type AlGaN/GaN HEMT device

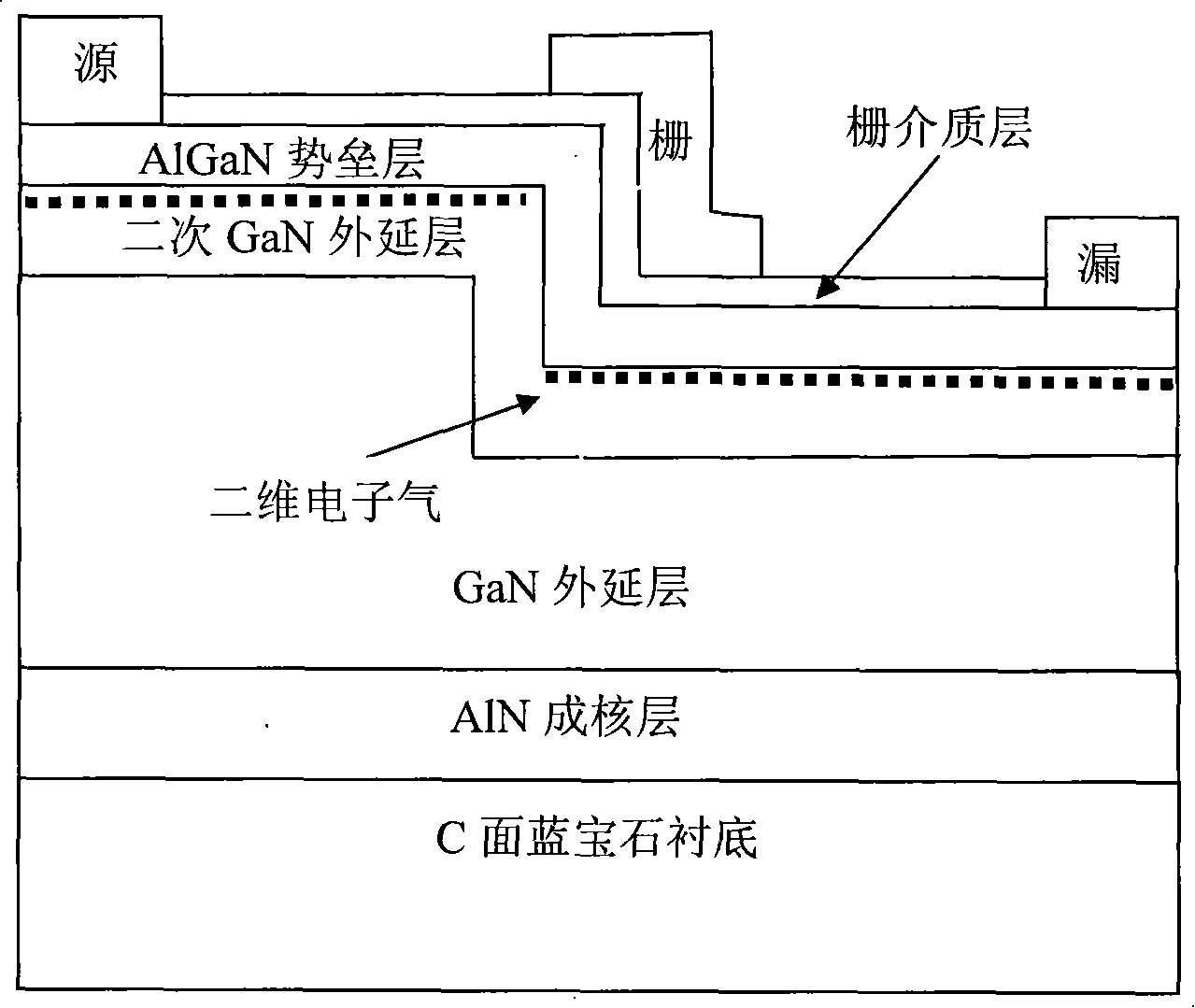

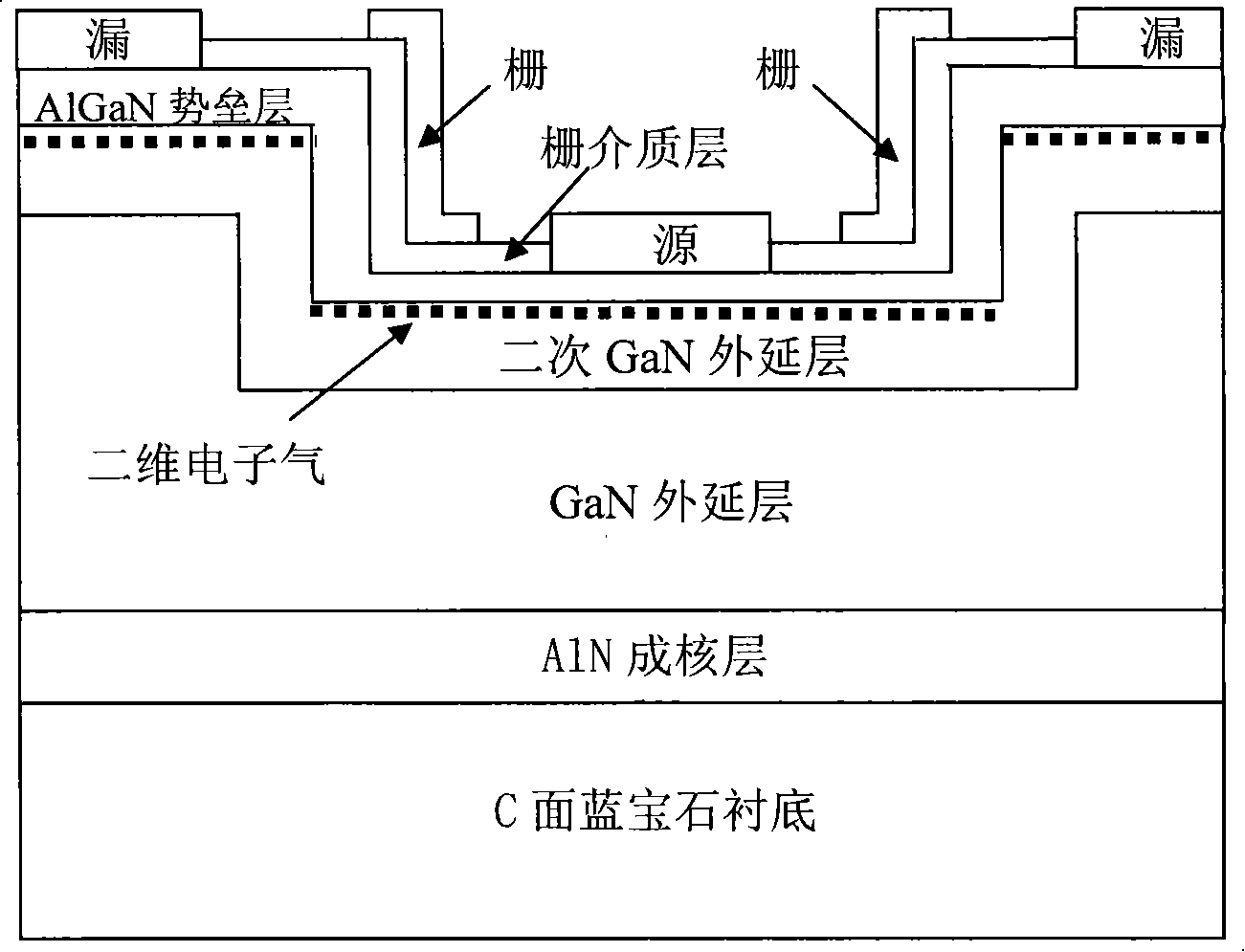

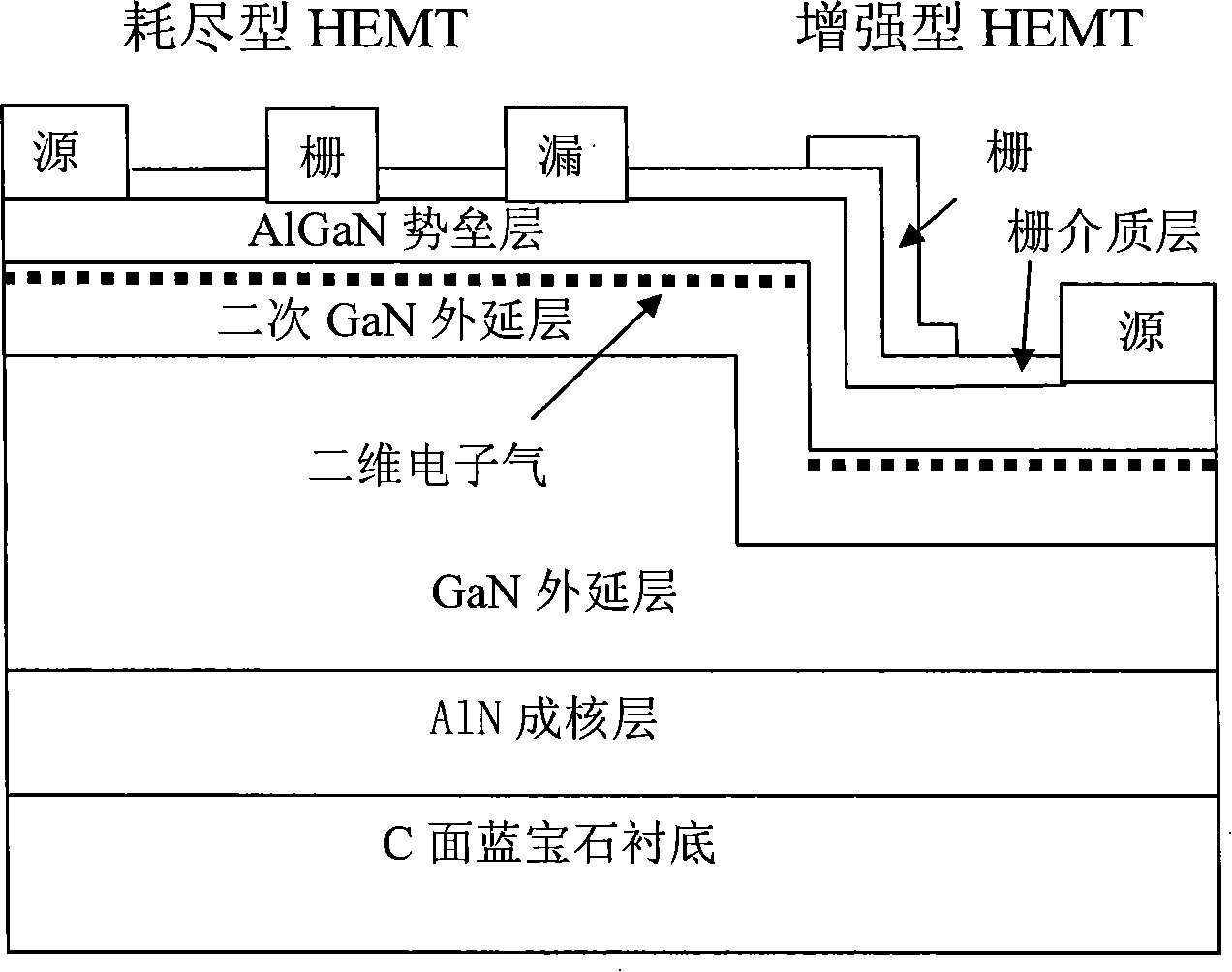

InactiveCN101252088AHigh depletion rateRaise the threshold voltageSemiconductor/solid-state device manufacturingHeterojunctionElectron

The invention discloses a realization method for a novel enhancement type AlGaN / GaN HEMT device, relating to the microelectronic technical field. The realization method has low cost, simple technique, good repeatability, high reliability and small damage on materials. The enhancement type HEMT device with high threshold voltage and nano-sized effective channel length can be obtained. The invention adopts the method of etching a table top after growth of an AlN nucleating layer and a GaN epitaxial layer and before growth of a secondary GaN epitaxial layer and an AlGaN layer to make heterojunction materials on the side face of the table top grow along the nonpolarized direction, thereby the air density of two-dimensional electrons in the heterojunction materials on the side face of the table top is greatly reduced. A grid electrode of the device is produced on the side face of the table top; under the condition of no additional voltage on the grid electrode, a conductive channel can not be switched on or weakly switched on; under the condition of certain additional positive bias on the grid electrode, the conductive channel is switched on. The invention can be used in a high-temperature high-frequency high-power situation, a high-power switch and a digital circuit.

Owner:XIDIAN UNIV

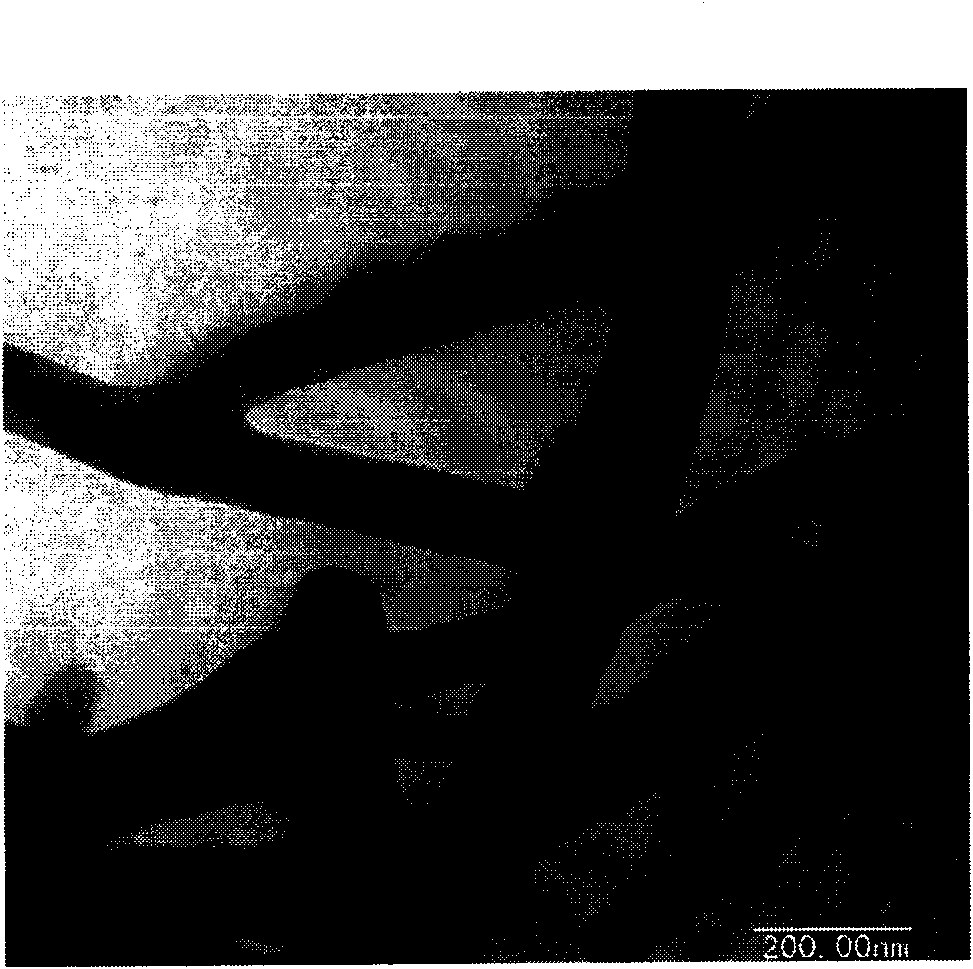

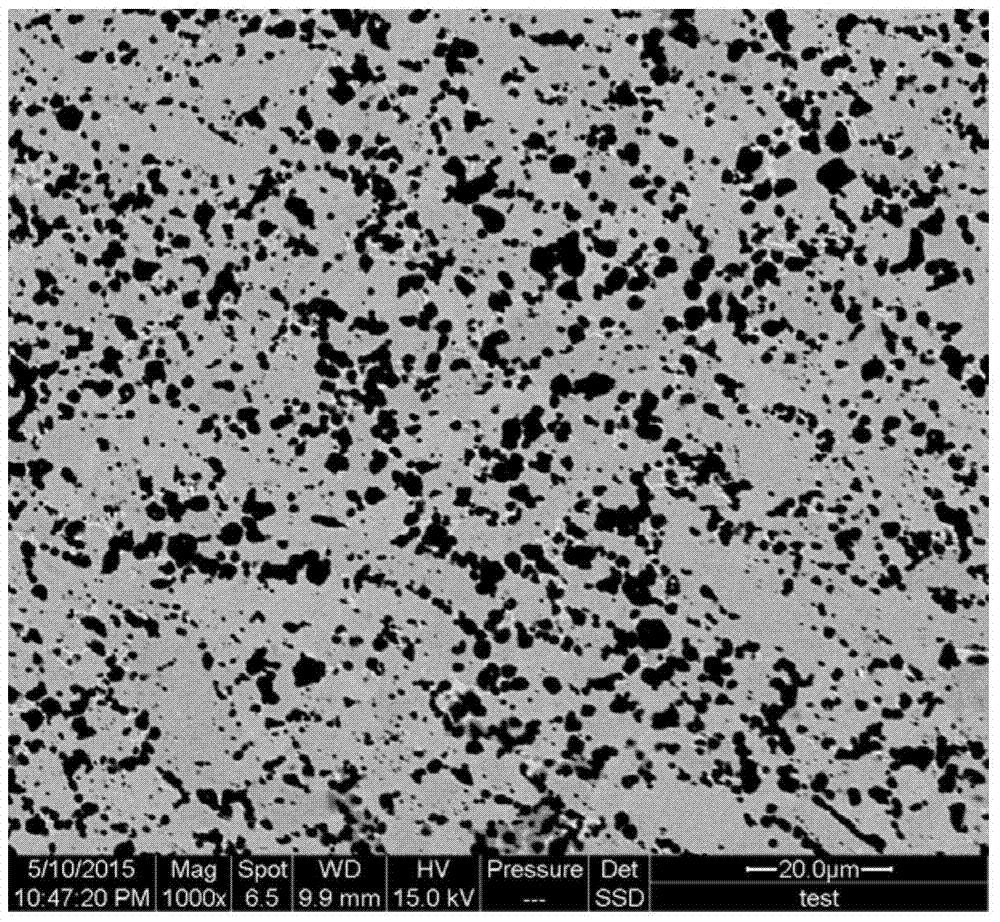

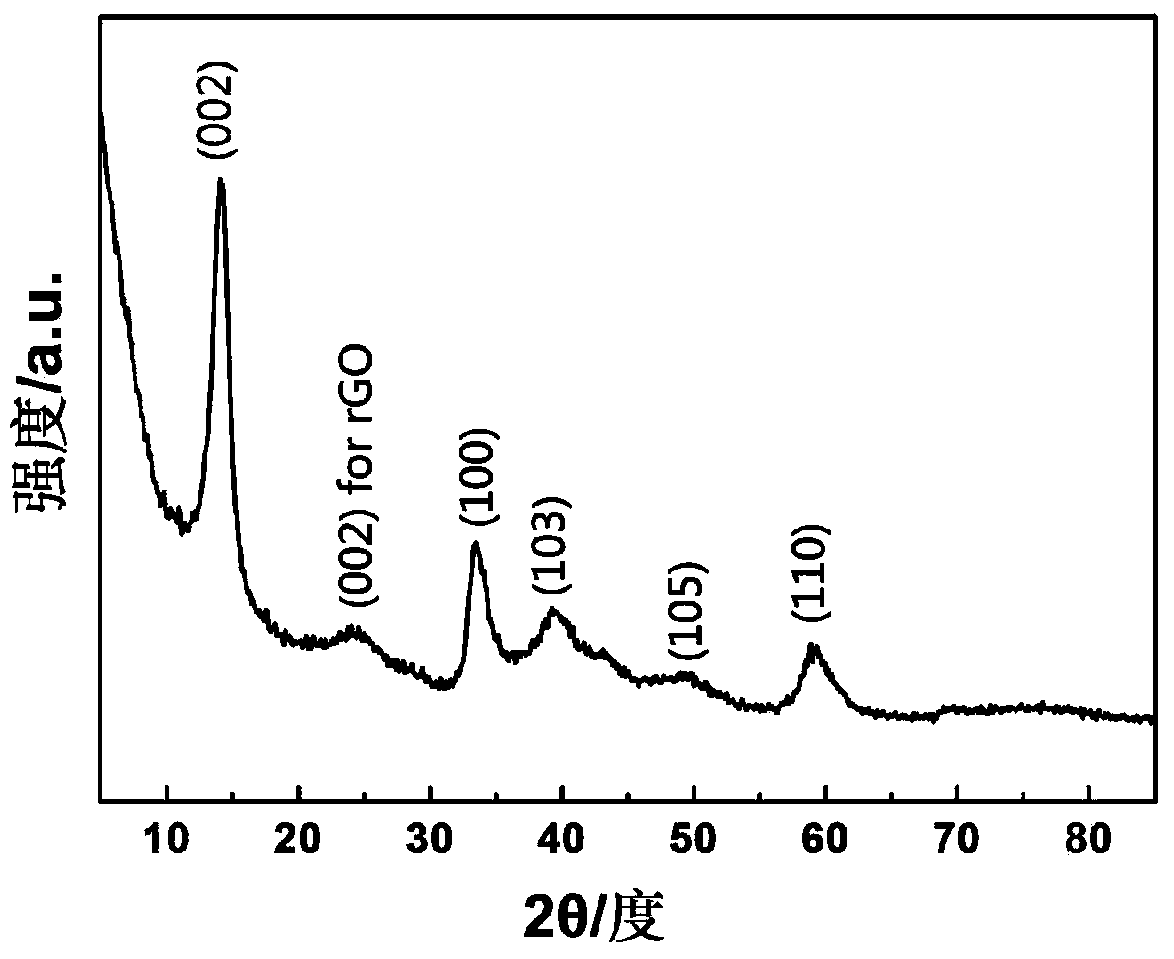

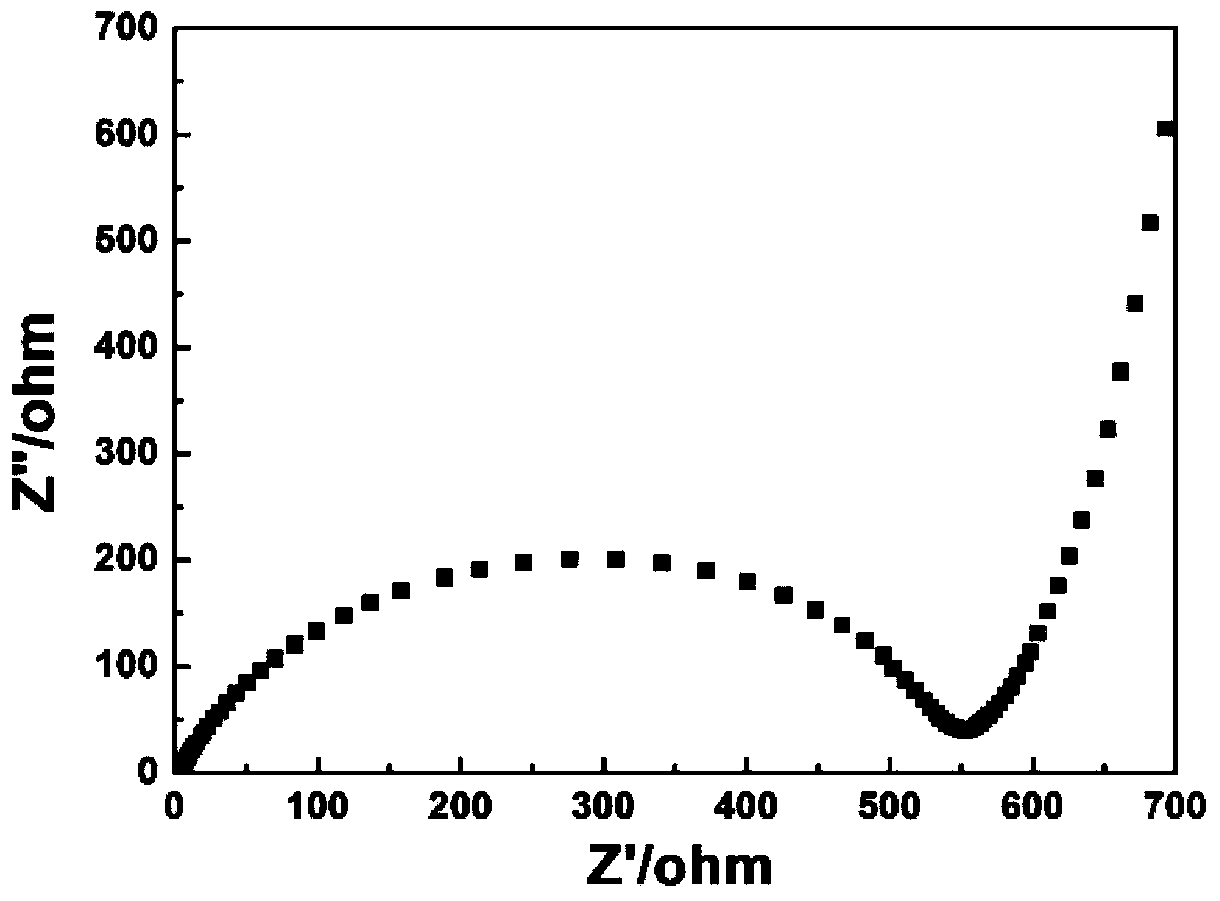

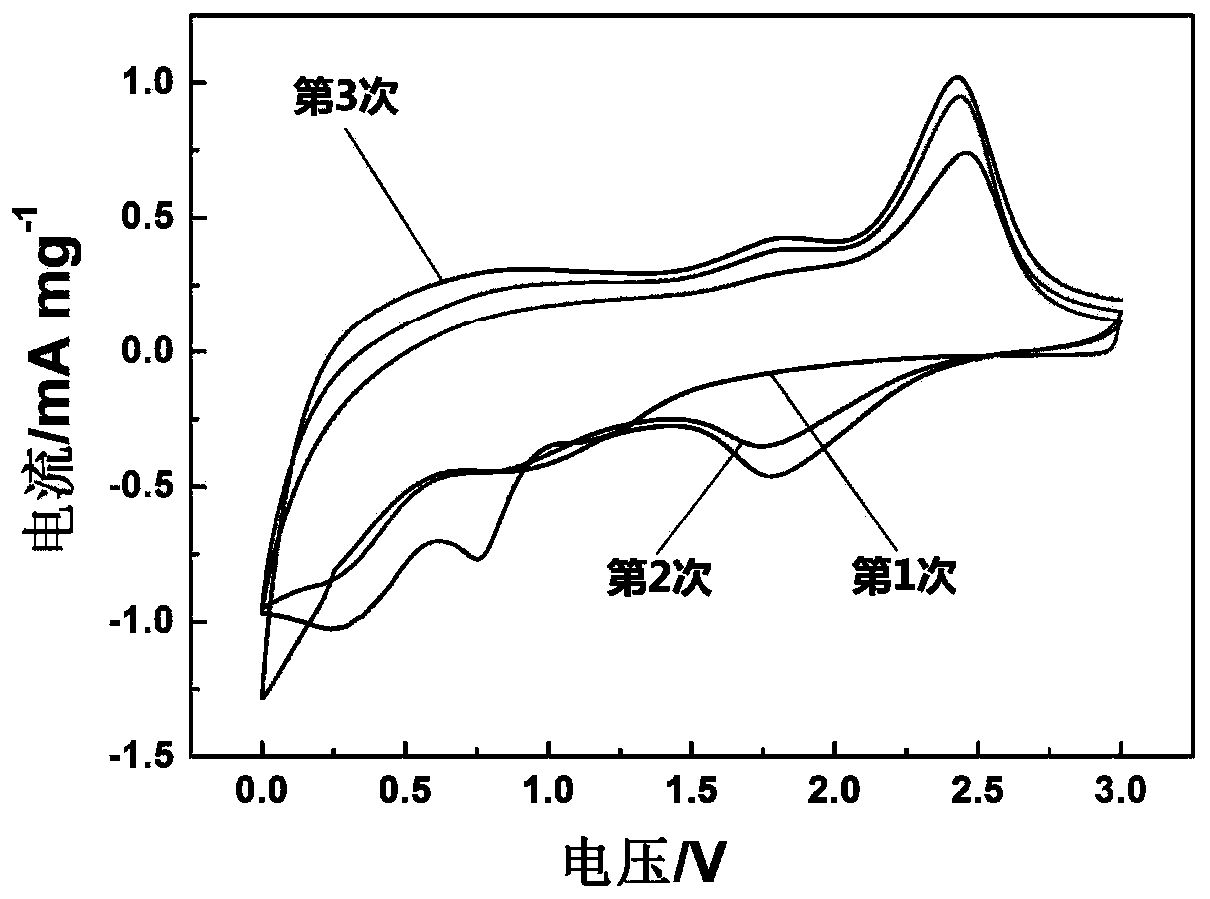

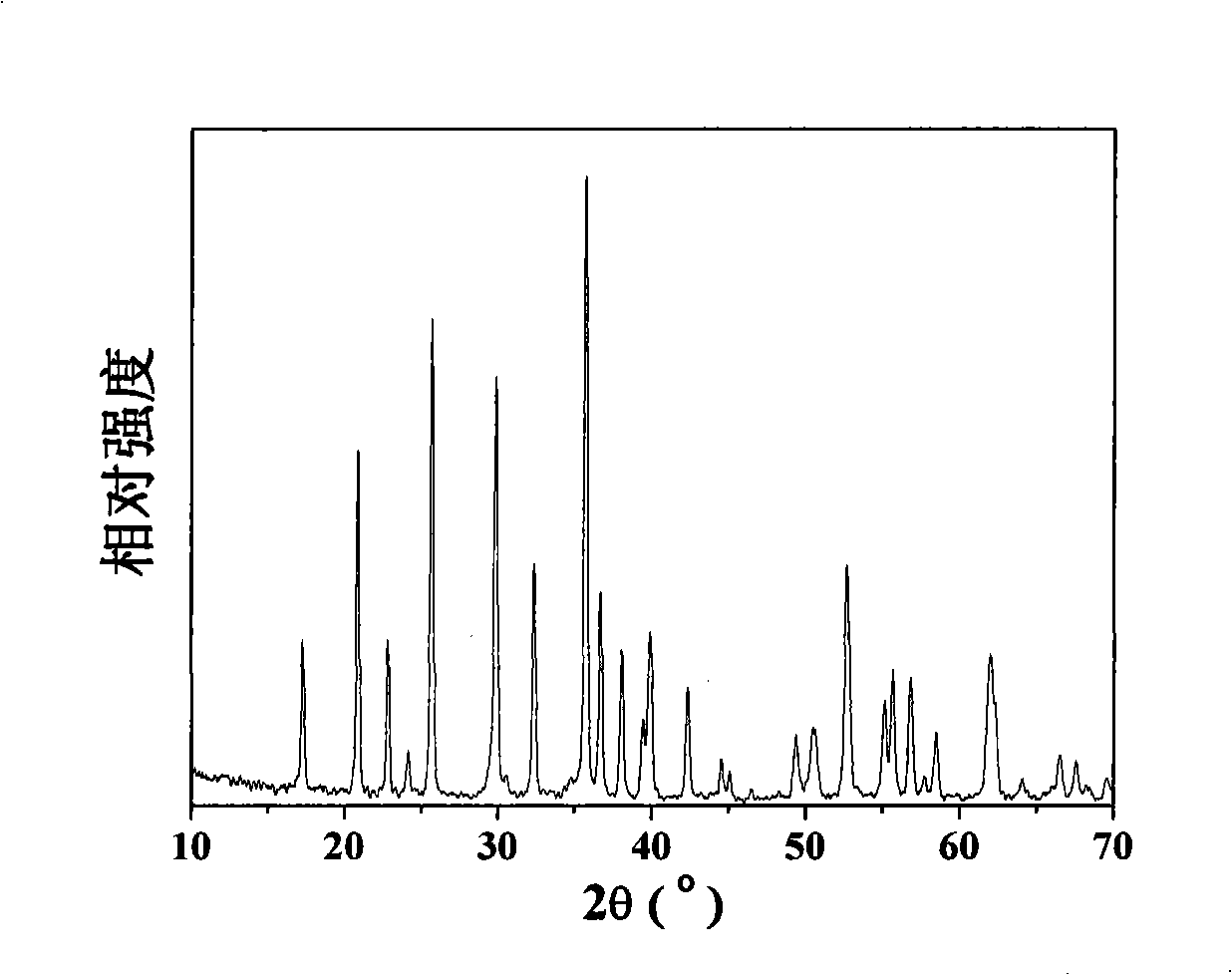

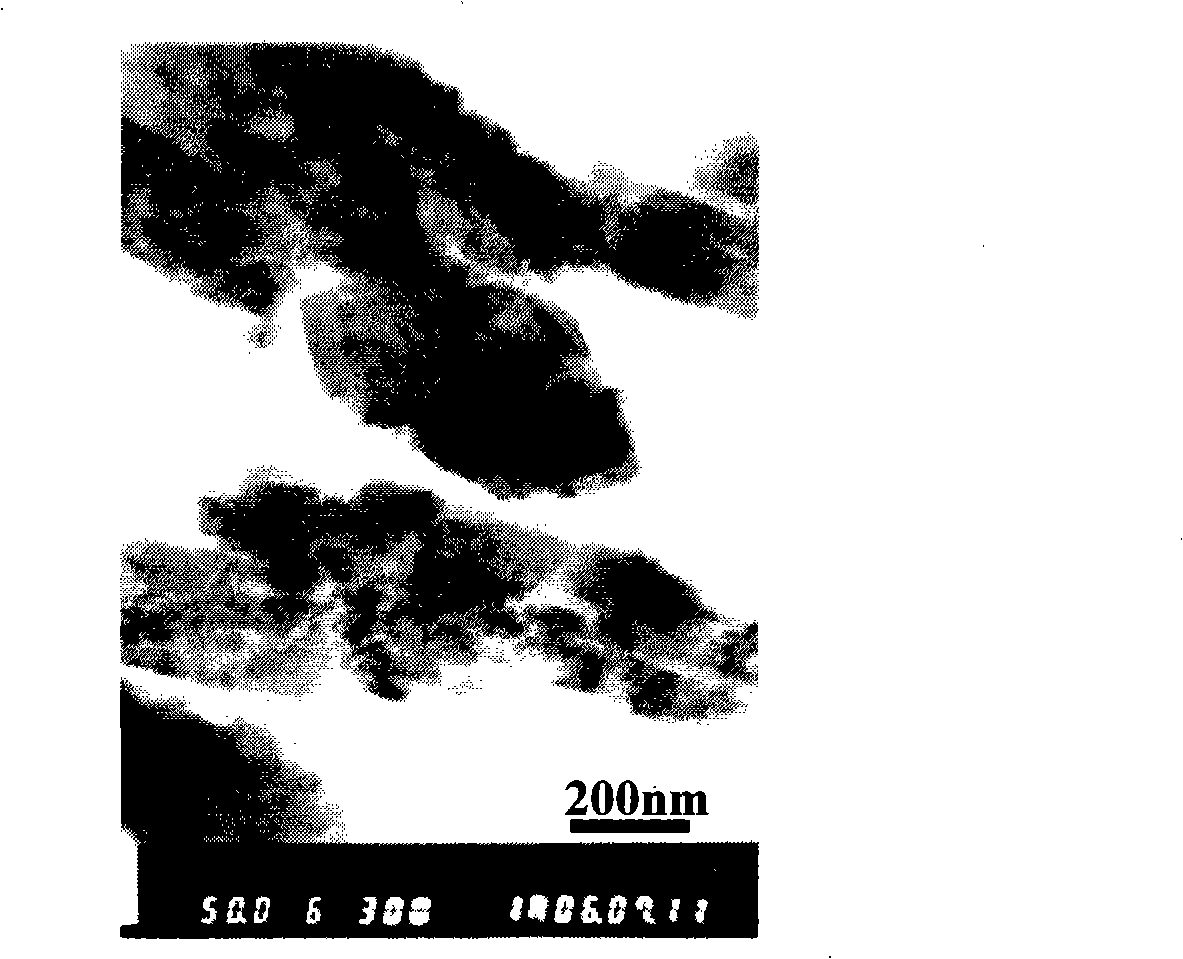

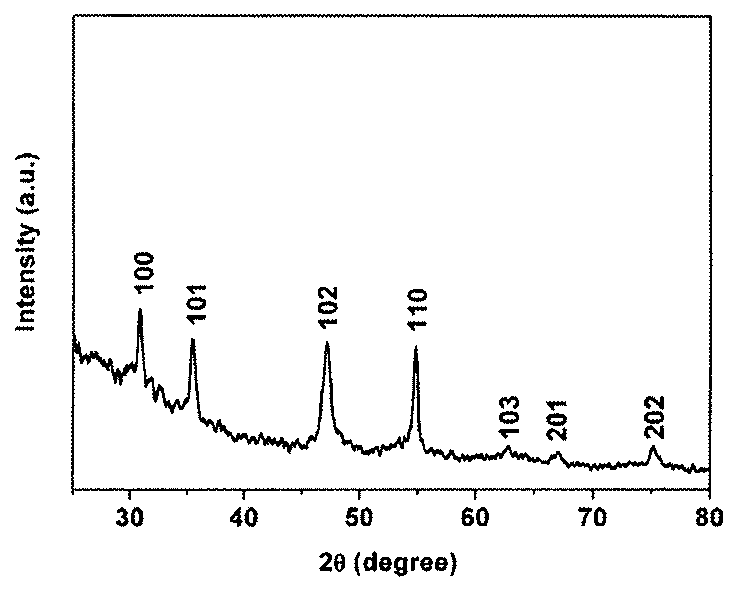

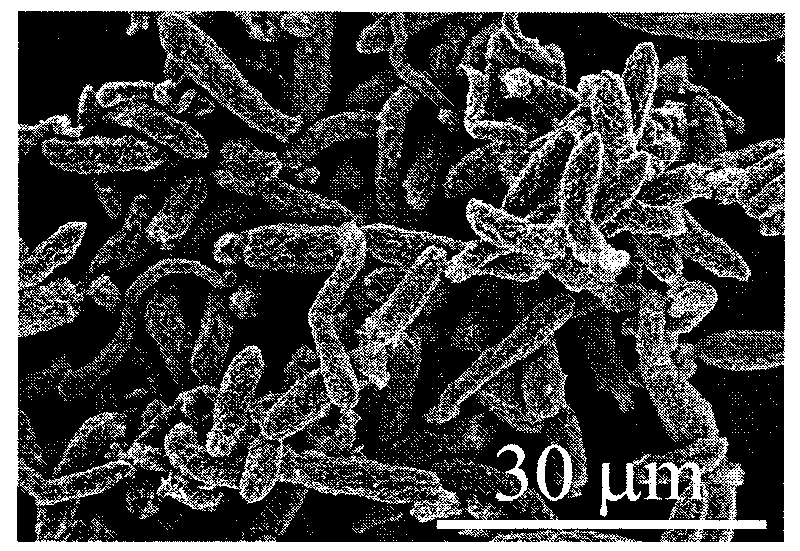

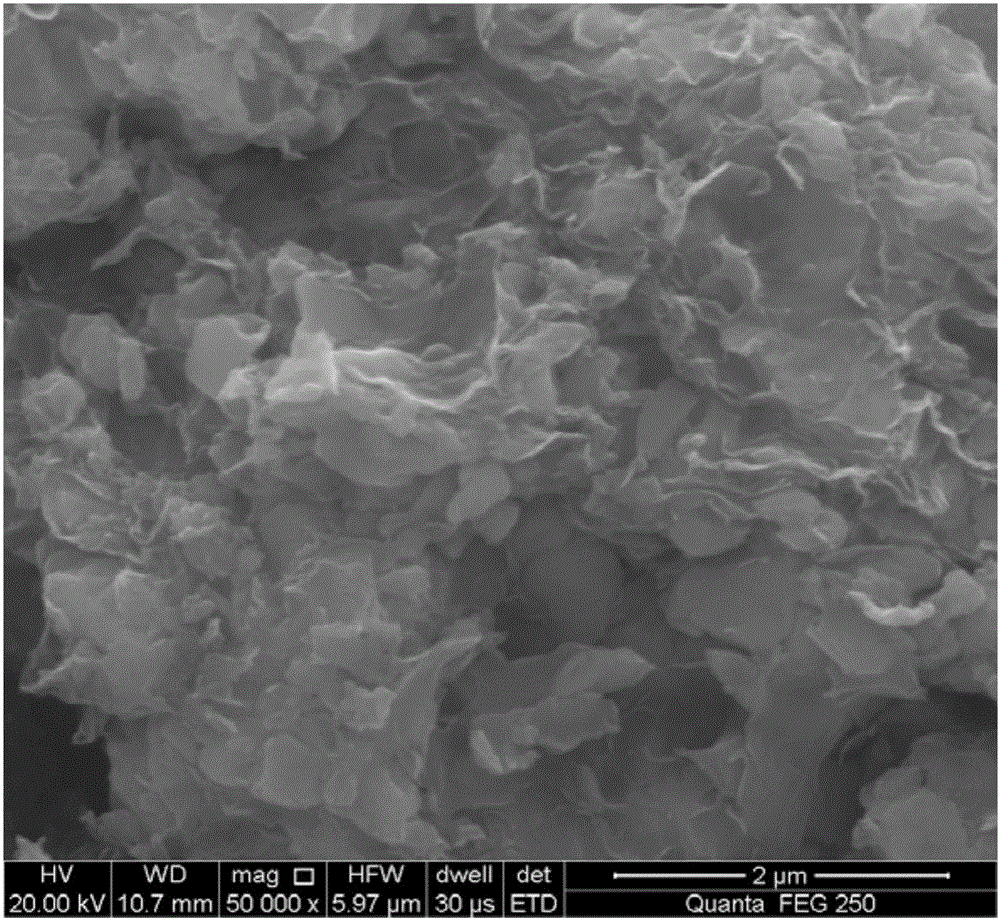

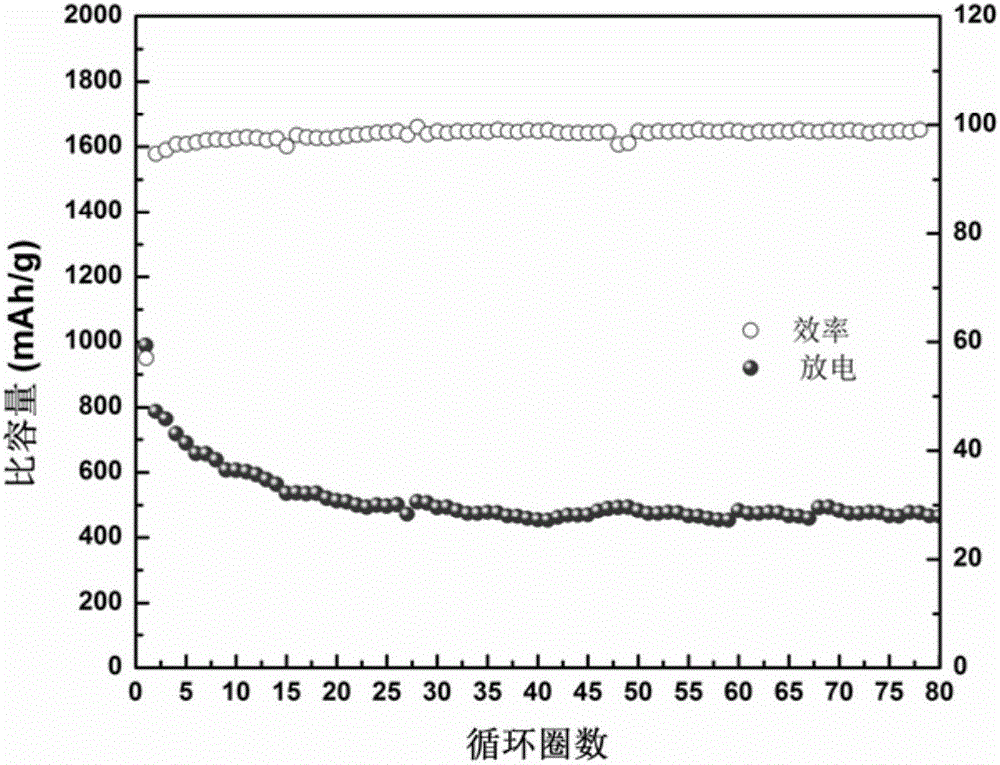

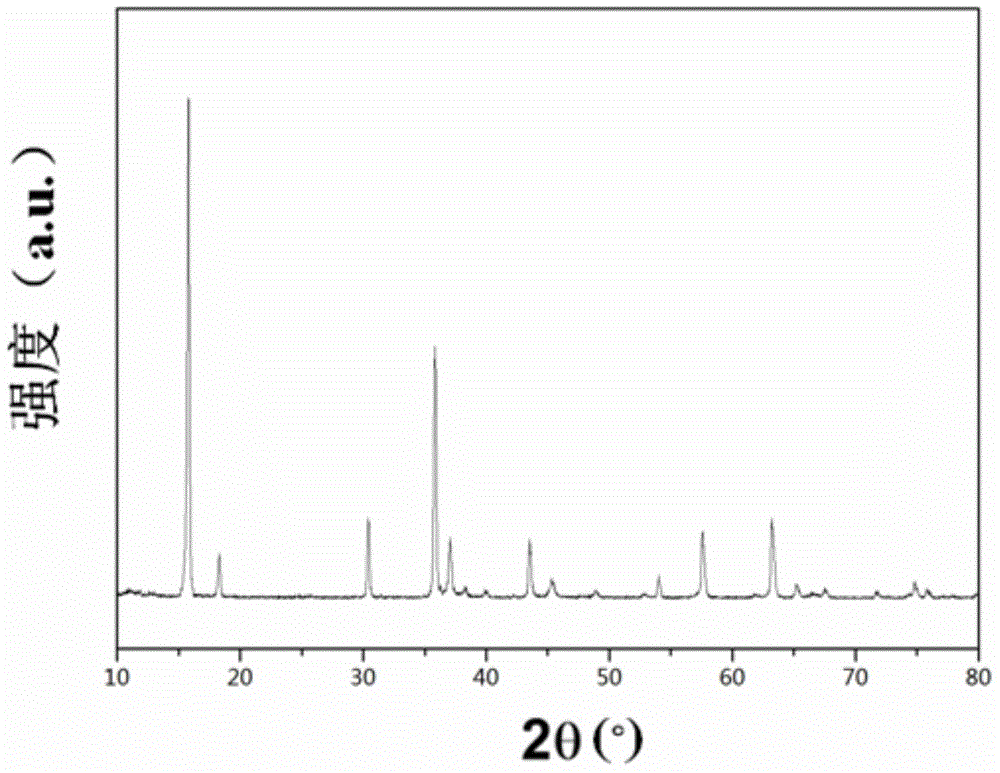

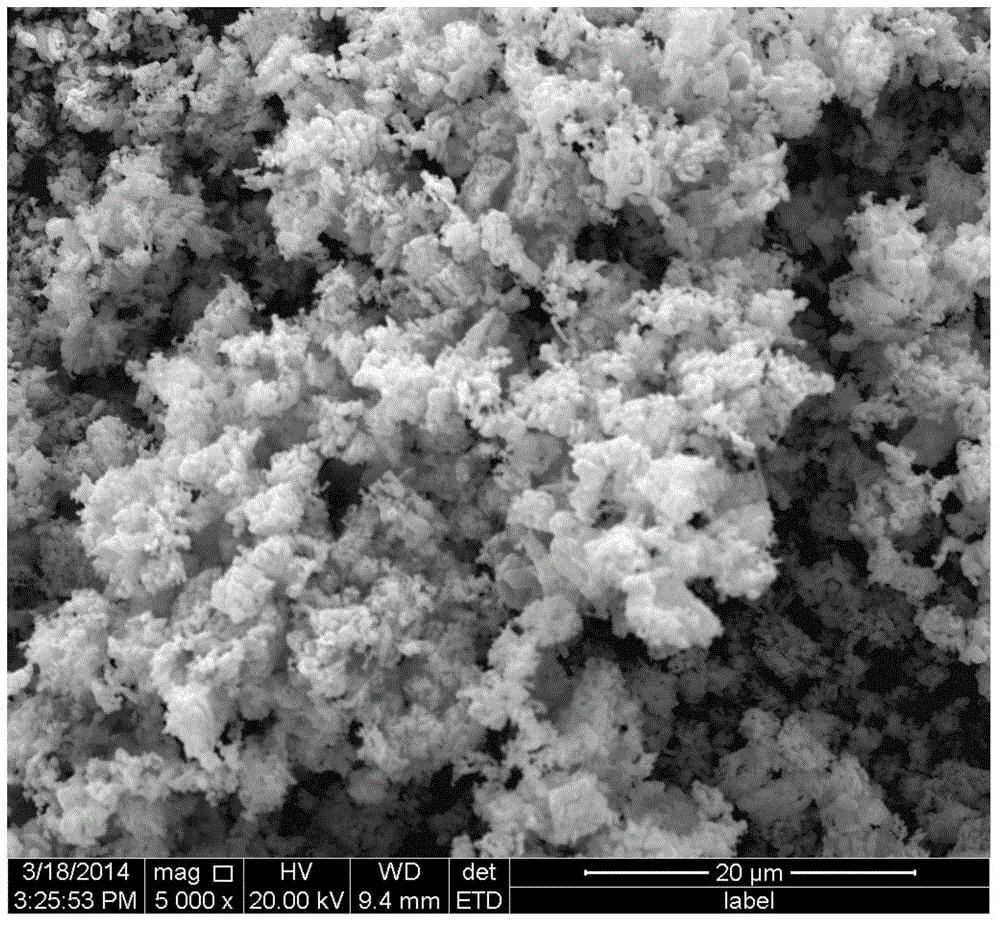

Molybdenum disulfide/graphene (MoS2/rGo) lithium ion battery negative electrode material and preparation method of material

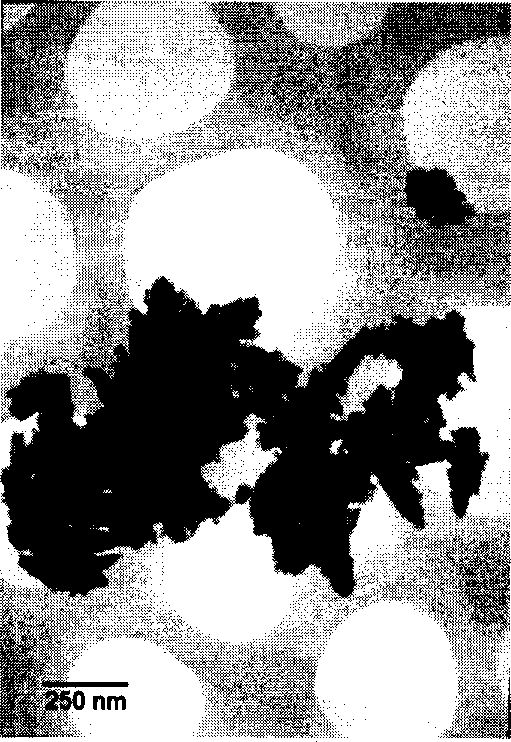

InactiveCN103904334AThe method is simple and reliableGood process repeatabilityCell electrodesSecondary cellsCvd grapheneGraphite oxide

The invention discloses a molybdenum disulfide / graphene (MoS2 / rGo) lithium ion battery negative electrode material and a preparation method of the material. The MoS2 / rGo composite material is prepared by a hydrothermal method, and the prepared half-battery is tested to be high in specific capacity and stable in circulation performance. The method is simple and reliable, good in process repeatability and high in operability. The preparation method comprises the following steps of (1) taking proper amount of sodium molybdate, thiourea and graphene oxide as raw materials, (2) preparing a sample by the hydrothermal method, and (3) filtering, washing and carrying out vacuum drying to obtain the needed product.

Owner:SOUTHEAST UNIV

Silicon pressure transducer chip and method based on silicon-silicon linking and silicon-on-insulating layer

InactiveCN101271028AReduce residual stressImplement overvoltage protectionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLinearitySilicon on insulator

The invention relates to a pressure sensor chip based on silicon direction bonding and silicon on insulator and a manufacturing method thereof, and belongs to the field of sensor chips. The invention is characterized in that a shallow slot and a gas port on a supporting silicon wafer are formed through anisotropy corrosion, and appropriate shallow slot depth obtained by controlling the corrosion time can realize over pressure protection of parts. A silicon direct bonding technology bonds the supporting wafer and a reversed SOI wafer, realizes a beam-membrane structure on the SOI after lapping and polishing to improve the sensitivity and linearity of the parts; manufactures force sensing resistance elements on the processed beam; adopts the oxidation buried layer of the SOI to solve insulation and isolation of the sensing elements and elastic elements; and improves the long-termed reliability and adaptability under high temperature of the parts. The SOP high-sensitivity pressure sensor chip based on the bonding technology has the advantages of controllable process, excellent repeatability and high finished product rate.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

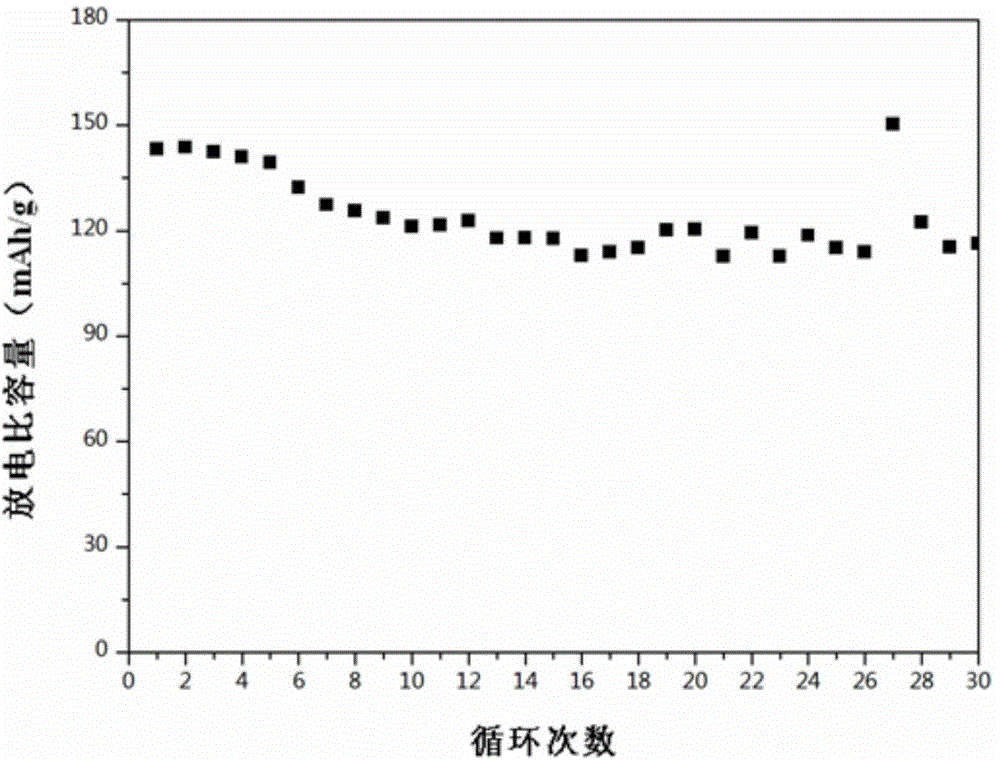

Lithium iron phosphate anode material for lithium ion battery and modification method

InactiveCN101315981AUniform structureEasy to processElectrode manufacturing processesChemical/physical/physico-chemical processesSolid state reaction methodLithium-ion battery

The invention provides a lithium iron phosphate anode material used for lithium ion batteries; the lithium iron phosphate which is prepared by a water heating method is taken as a precursor which is then uniformly mixed with a conductive matter precursor and metal ion salt, and finally baked in inert gas to obtain the lithium iron phosphate anode material which is coated by the conductive matter and doped by the metal ions. Compared with a pure solid phase reaction method, the method of the invention has small energy dissipation, the chemical uniformity of the synchronized outcome is good, the dimension and the appearance of the outcome are uniform, and the electromechanical performance and the processing performance have good stability and repeatability. Compared with the a pure water heating method, as the coating of the conductive matter, the doping and modifying performance of the metal ions are added during the anaphase, the electric conductivity of the material is greatly improved, and the high magnification electromechanical performance of the material is excellent; wherein, under the 10C discharging magnification, the discharging content of the lithium iron phosphate anode material with the copper ion doped is kept at 107mAh / g. After circulation for 50 times, the discharging content of the material is kept unchangeable basically, which can certify that the material has good circulation performance.

Owner:HEFEI UNIV OF TECH

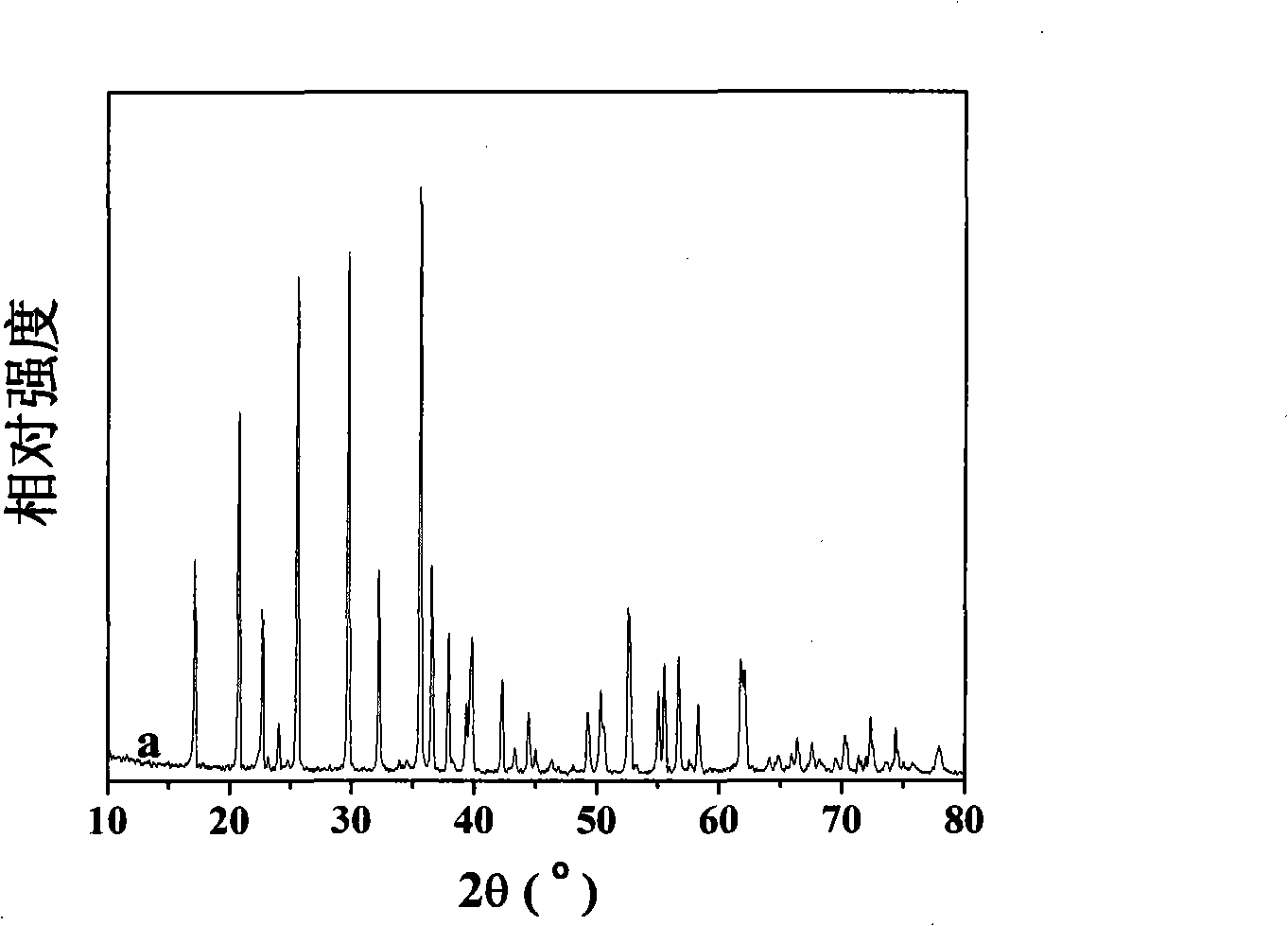

Process for synthesizing nano band of MoO3 monocrystal

A process for synthesizing nanoband of MoO3 monocrystal includes dissolving soluble molybdate and perchloric acid in water, and hydrothermal reaction at 100-200 deg.C while controlling the concentration of H ions (10mol / L[H]>0.01mol / L) and the speed of dropping acid (10mL / min>V7 0.1mL / m). Its advantages are unique ize and shape of product, and high output rate.

Owner:TSINGHUA UNIV

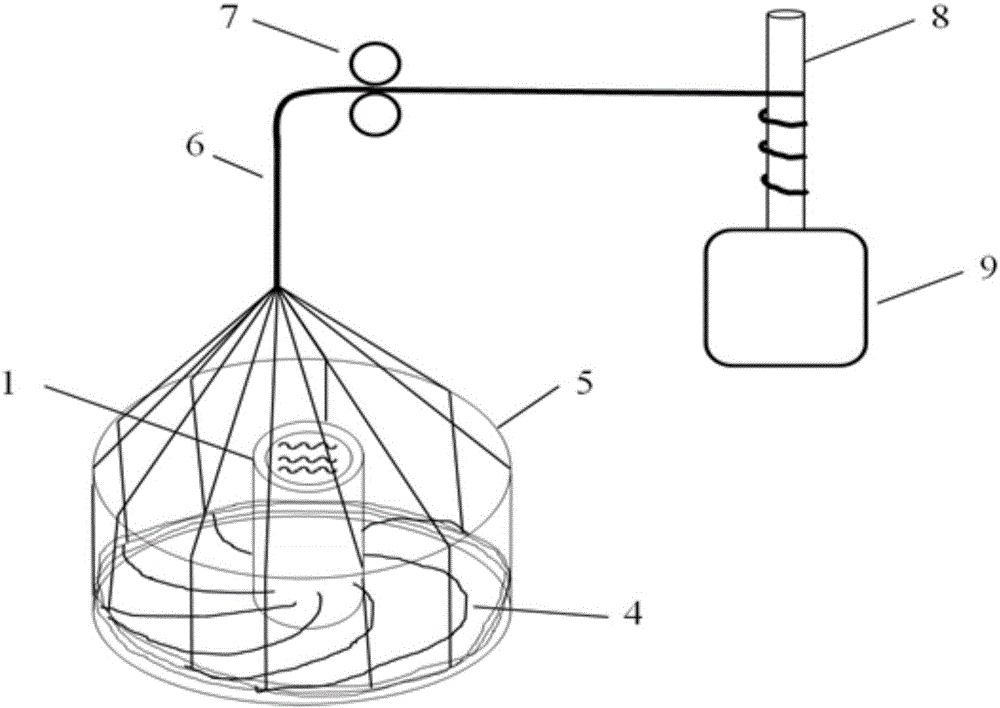

High-speed centrifugal spinning device for producing nanofiber yarn in one-step shaping and production method of nanofiber yarn

InactiveCN105887223AImprove mechanical propertiesIncrease productionArtificial thread manufacturing machinesFilament/thread formingYarnFiber

The invention discloses a high-speed centrifugal spinning device for producing nanofiber yarn. The high-speed centrifugal spinning device is characterized by comprising a hollow rotating centrifugal column, a rotating cylinder collector, a roller, a winding unit and a transmission gear; a plurality of spray nozzles are arranged in the outer wall of the rotating centrifugal column, and the spray nozzles are communicated with a central cavity of the rotating centrifugal column through radial channels in the rotating centrifugal column; the rotating cylinder collector is located on the outer periphery of the rotating centrifugal column; the roller is located on the upper side of the rotating cylinder collector; the winding unit is located at the rear end of the roller, and the transmission gear drives the winding unit to rotate. The invention further discloses a production method of the nanofiber yarn. According to the advantages of the high-speed centrifugal spinning device in producing the nanofiber yarn, and spinning of the collector is combined technically, the nanofiber yarn which is controllable and highly oriented is obtained; the yield is greatly increased as compared with that of the nanofiber yarn obtained by other production methods, spinning quality is greatly improved, mechanical property of the nanofiber yarn is enhanced, machining reproducibility is good, and good industrial production prospect is achieved.

Owner:JIANGNAN UNIV

Method for preparing three-dimensional macroporous metal phosphide

The invention relates to a method for preparing a three-dimensional macroporous metal phosphide by heat treatment of foam metal, and belongs to the technical field of preparation processes of inorganic materials. According to the method disclosed by the invention, a mechanical mixture of red phosphorus and the foam metal is taken as a precursor, and the three-dimensional macroporous metal phosphide is prepared by utilizing the reaction of the red phosphorus and metal particles. The method has the advantages of simplicity in operation, good process repeatability, stable product quality, and suitability for large-scale production.

Owner:TIANJIN POLYTECHNIC UNIV

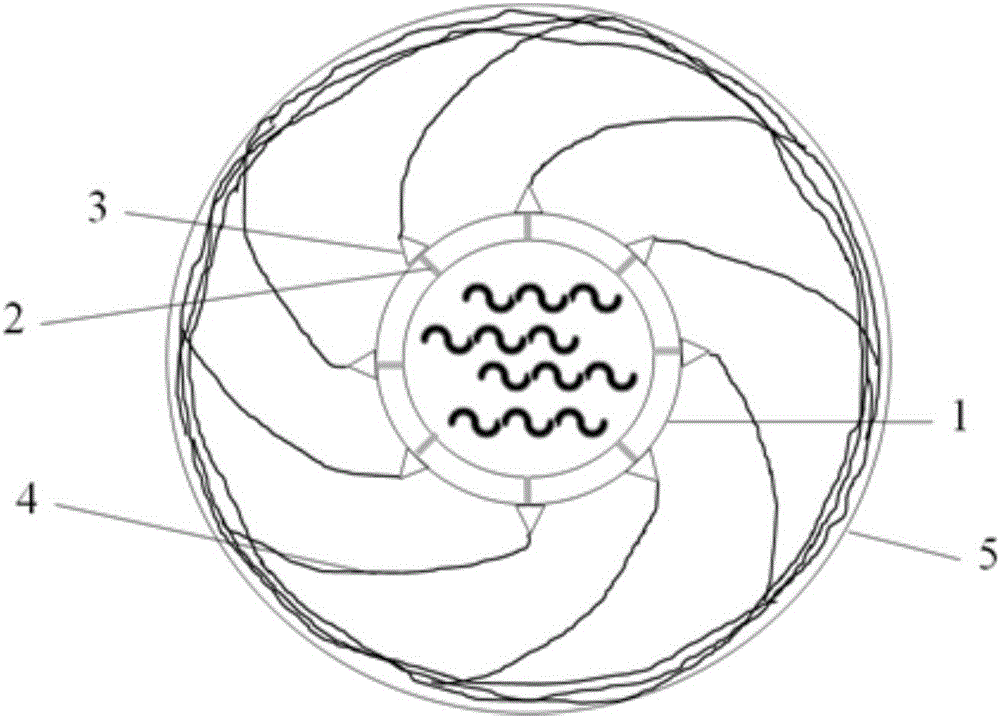

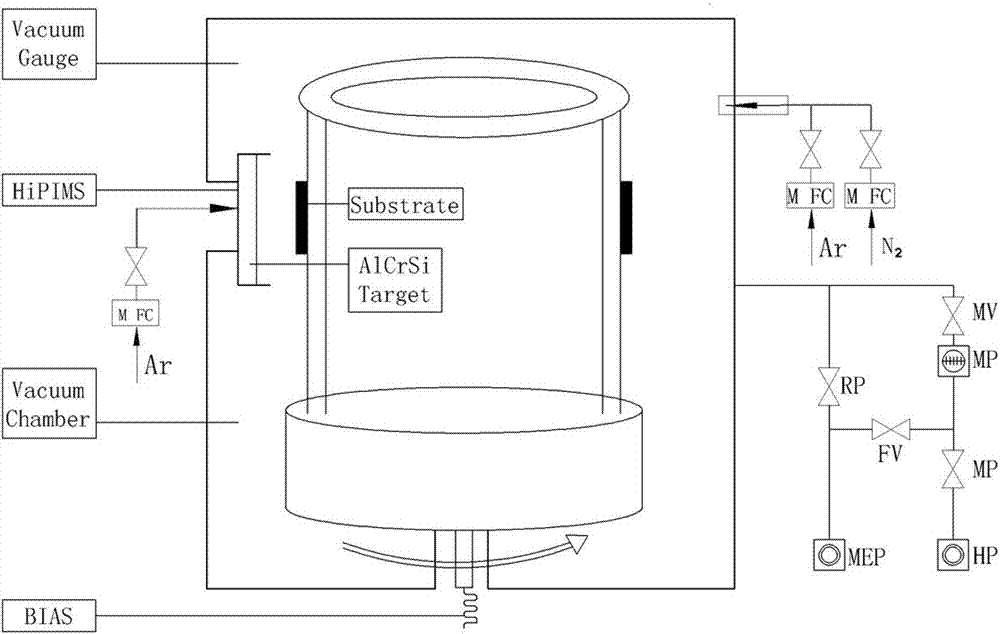

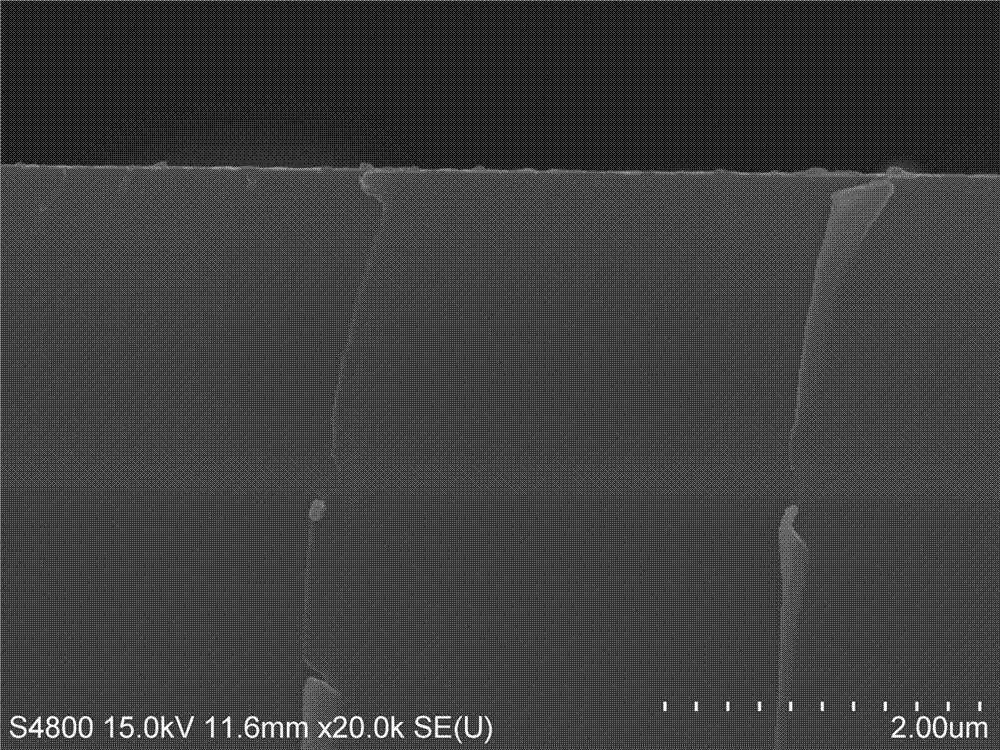

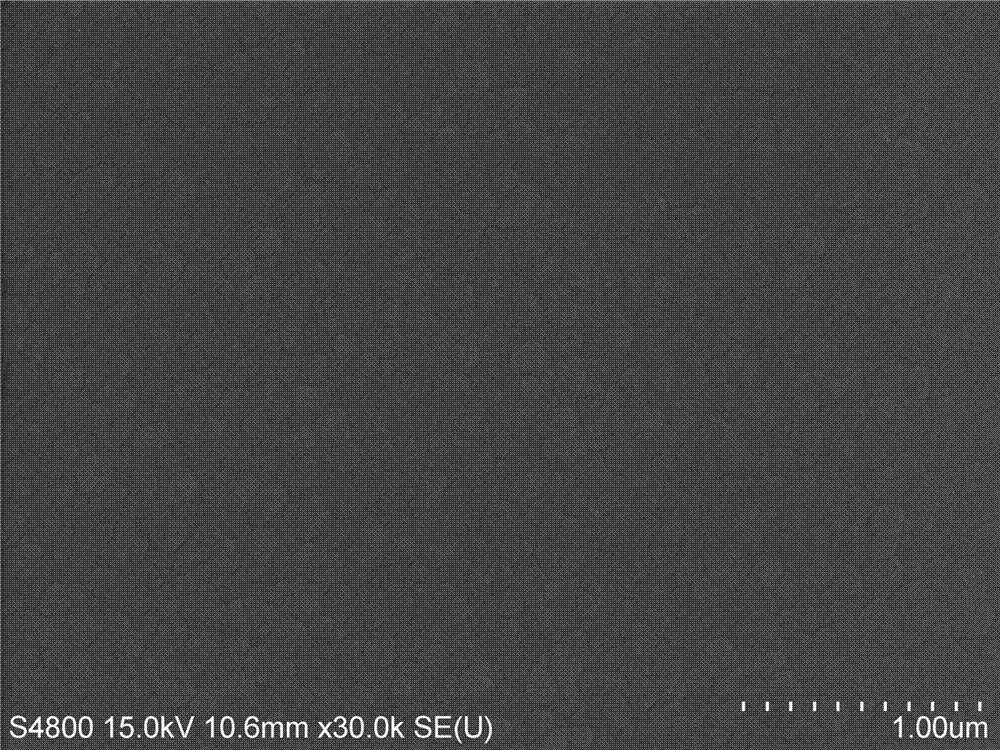

Preparing technology for high-aluminum-content ultra-dense Al-Cr-Si-N coating

ActiveCN106987816AImprove antioxidant capacityInhibited DiffusionVacuum evaporation coatingSputtering coatingAlloyMaterials science

The invention relates to a nano composite coating and a preparing technology thereof, in particular to a preparing technology for a high-aluminum-content ultra-dense Al-Cr-Si-N nano composite coating. An Al-Cr-Si-N nano composite coating is deposited on a metal or alloy base body through the high-power pulse magnetron sputtering technology. An Al-Cr-Si alloy target is selected as a target material, wherein the atomic ratio of Al to Cr to Si is 6:3:1, purity is 99.8 wt.%, and the size is 300 x 100 x 5 mm; before film coating, inflation of Ar is conducted firstly, striking is conducted at the bias voltage of -800 V, high-power pulse magnetron sputtering of the Al-Cr-Si target is conducted, and bombardment cleaning is conducted on the surface of the base body. Then, the bias voltage is reduced to -30 V, an Al-Cr-Si transition layer is deposited, then inflation of the reaction gas N2 is conducted finally, and deposition of the Al-Cr-Si-N coating is started. The related preparing technology for the high-aluminum-content ultra-dense Al-Cr-Si-N nano composite coating is simple, repeatability is good, and industrial production is easy. The prepared Al-Cr-Si-N coating is high in hardness, good in tenacity, low in internal stress and excellent in abrasion resisting performance; and the coating organization structure is extremely dense and is firmly combined with the base body, and the high-temperature oxidation resisting capability is high.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Low temperature coefficient, low loss and high saturated flux density ferrite material and preparing method

InactiveCN1587193AReduce lossLow costInorganic material magnetismVolumetric Mass DensityRepeatability

The present invention discloses one kind of ferrite material with low temperature coefficient, low loss and high saturated flux density and its preparation process. It is mainly spinel type structure and consists of Fe2O3 45-52 mol%, ZnO 20-35 mol%, CuO 5-15 mol%, MnO 1-3 mol%, and NiO 10-18 mol%. The preparation process includes the following steps: mixing material; pre-sintering; adding impurity; secondary ball milling; forming and sintering. The ferrite material has CuO and Mn3O4 to replace NiO and thus lowered material cost, lower pre-sintering temperature and sintering temperature and thus low power consumption, low requirement in sintering apparatus and low production cost; relatively wide pre-sintering temperature range and sintering temperature range, no need of protecting atmosphere, high technological repeatability and product consistency.

Owner:ZHEJIANG UNIV

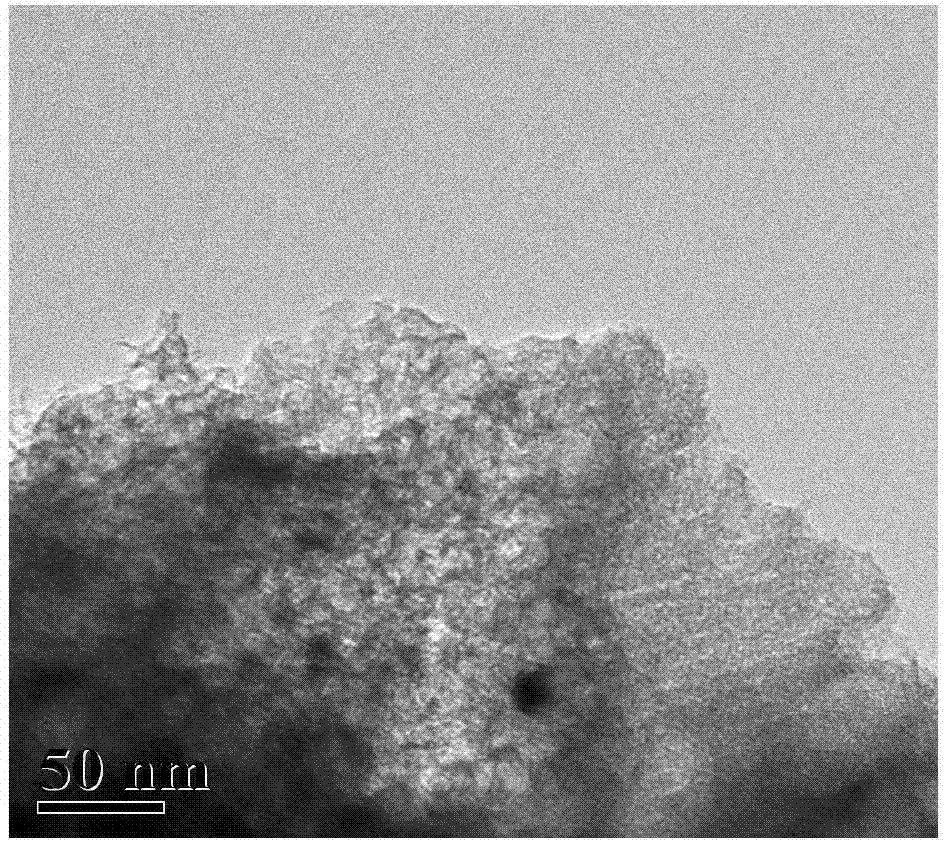

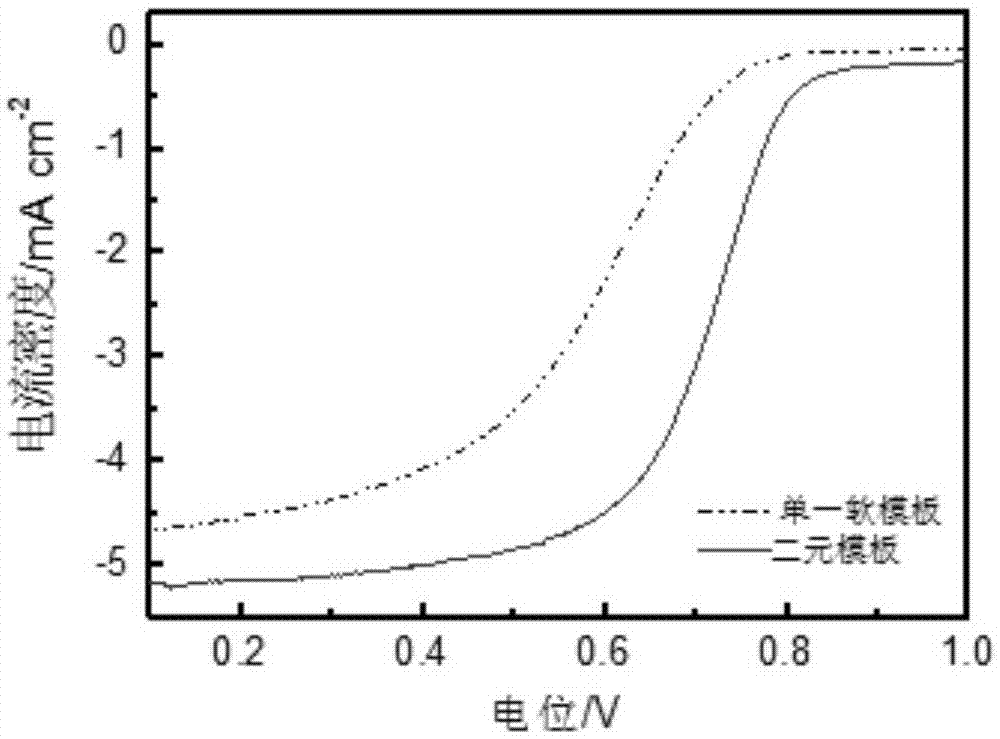

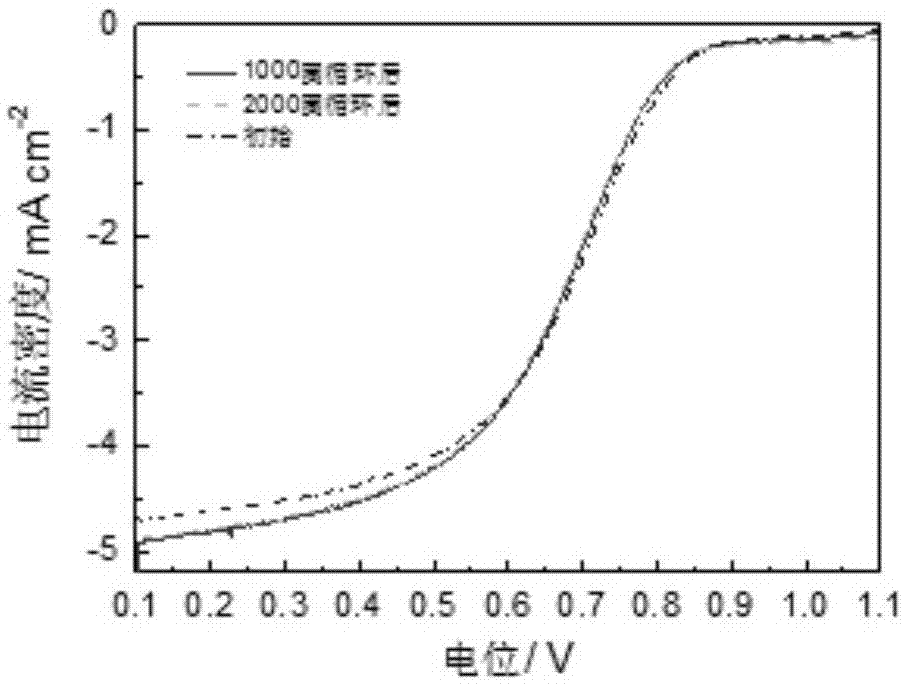

Preparation of nitrogen-doped orderly-graded mesoporous carbon catalyst as well as carbon catalyst and application of carbon catalyst

ActiveCN106861740AHigh active specific surfaceEnhanced mass transferPhysical/chemical process catalystsCell electrodesEtchingOxygen

The invention discloses a preparation method of a nitrogen-doped orderly-graded mesoporous carbon catalyst and application of the nitrogen-doped orderly-graded mesoporous carbon catalyst to proton exchange membrane fuel cells. The catalyst is prepared though a binary mixing template method; a triblock copolymer is used as a soft template agent and one or more of a Y-type molecular sieve, an MCM-41 molecular sieve and a ZSM-5 molecular sieve are used as a hard template agent; soluble resin is used as a carbon source; in a preparation process, a transition metal salt is added and a transition metal element is introduced in situ; meanwhile, a nitrogen element is introduced through roasting in an ammonia atmosphere. The nitrogen-doped orderly-graded mesoporous carbon material provided by the invention has an ordered mesoporous structure (with the size of 3nm to 5nm) generated by soft template induction and a three-dimensional through mesoporous structure (with the size of 10nm to 50nm) generated by hard template etching, has a high-activity specific surface and good mass-transferring performance and has excellent oxygen reduction catalysis performance and good electrochemical stability. By adopting the carbon material provided by the invention, application of the binary mixing template method to preparation of an oxygen reduction carbon-based catalyst is realized for the first time; meanwhile, the carbon material has the advantages of good process repeatability, low cost, good environmental friendliness and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nitrogen fertilizer stabilizer composition and preparation method thereof

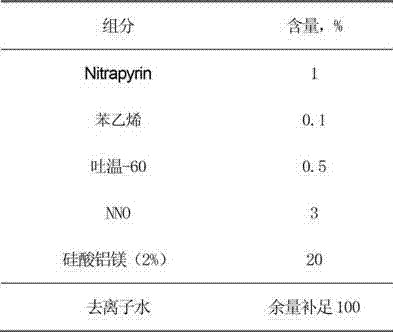

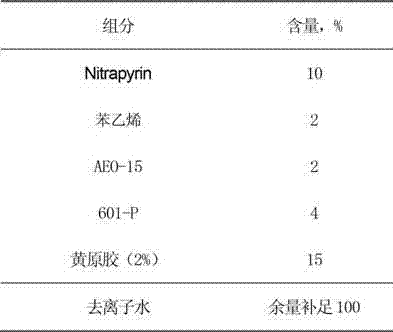

InactiveCN103044137AImprove efficiencyImprove compatibilityFertilizer mixturesNitrapyrinNitrogen fertilizer

The invention discloses a nitrogen fertilizer stabilizer composition. The nitrogen fertilizer stabilizer composition comprises the following components in part by weight: 1-60 parts of nitrapyrin, 1-15 parts of wall material, 2-10 parts of emulsifier, 0.05-0.3 parts of viscosity regulator, 2-10 parts of dispersing agent and 0.1-100 parts of water. The invention further provides a preparation method of the nitrogen fertilizer stabilizer composition. The preparation method of the nitrogen fertilizer stabilizer composition comprises the following steps of: heating and melting active components, adding the macromolecular wall material, and stirring uniformly; adding a mother liquid containing the active components and the wall material into an emulsifier-containing water solution under a shearing condition, and emulsifying into an oil-in-water state; and controlling grain size as required, wherein the nitrogen fertilizer stabilizer composition can be in a liquid or solid state; and liquid drops containing the active components react with water molecules to form the macromolecular wall material. Through addition of a nitrapyrin product, the nitrogen fertilizer stabilizer composition can improve the using efficiency of an ordinary nitrogen fertilizer by decreasing nitrogen leaching and denitrification, is good in compatibility with a variety of fertilizers, pesticides, weedicides and bactericides, and can be mixed therewith for application.

Owner:南通联农佳田作物科技有限公司

Preparation method of cobalt sulfide micro tube with hiberarchy structure

InactiveCN101746837ALarge specific surface areaHigh specific capacitanceSemi-permeable membranesFixed microstructural devicesEthylenediamineSynthesis methods

The invention belongs to an inorganic chemical synthesis method and in particular relates to a preparation method of a cobalt sulfide micro tube with hiberarchy structure; in the invention, water-soluble cobalt salt is used as a metal source, thioacetamide is used as a sulphur source, ethanediamine is used as metal chelating agent, and cetyl trimethylammonium bromide CTAB is used as a template agent, in a closed reactor, hydro-thermal reaction is carried out under a certain temperature condition, so as to synthesize the micron tube-like cobalt sulfide with the hiberarchy structure, the outer diameter of the tube is about 1.5micron, the thickness of the tube wall is about 400nm, the average length is about 15micron, the tube wall is a nanoscale hexagonal sheet, and the length and the thickness of the sheet are 90nm and 22nm respectively; the synthesis method has the advantages of cheap and easy-obtaining raw material, simple equipment, low reaction temperature and good process repeatability and overcomes the problem of environment pollution caused by organic solvent in the previous synthesis method; the obtained product has wide application prospect in the field of biology, catalysis and material science and the like.

Owner:NORTHEAST NORMAL UNIVERSITY

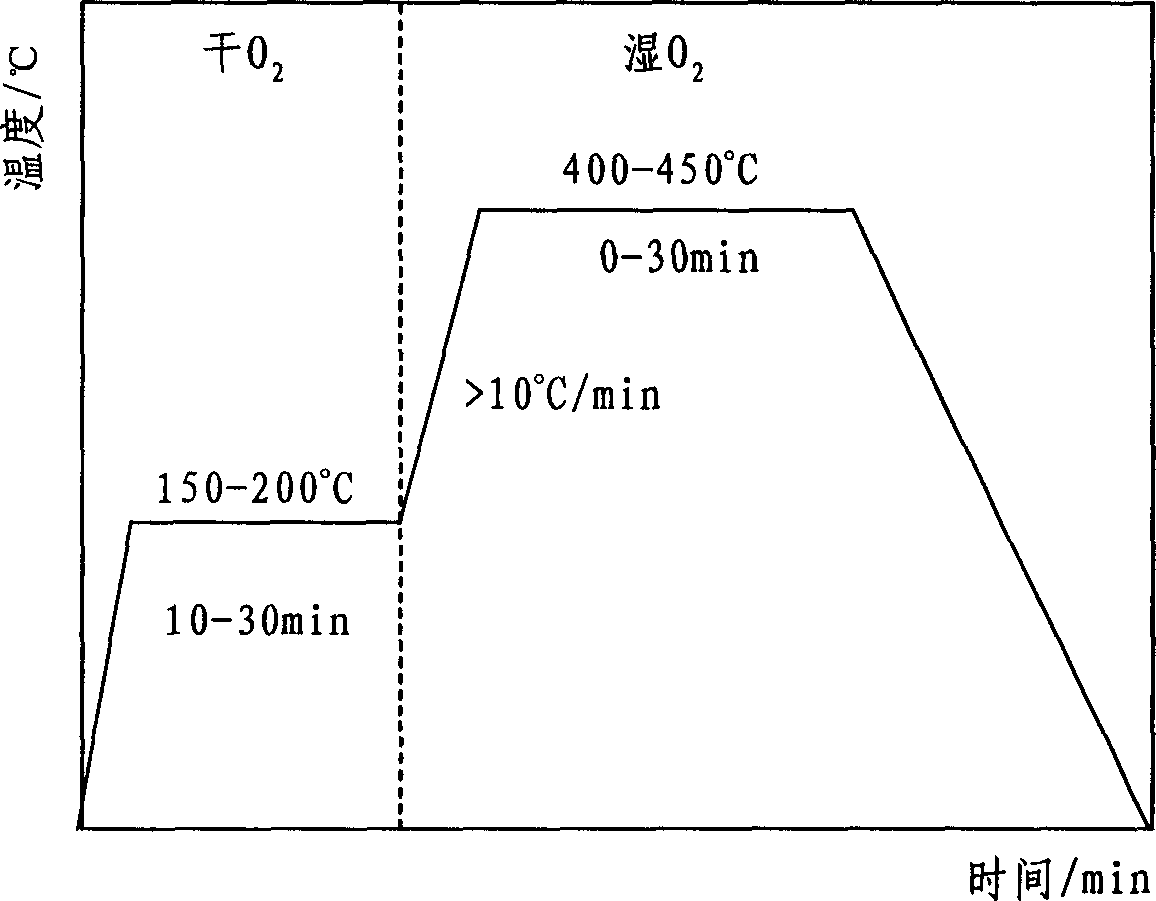

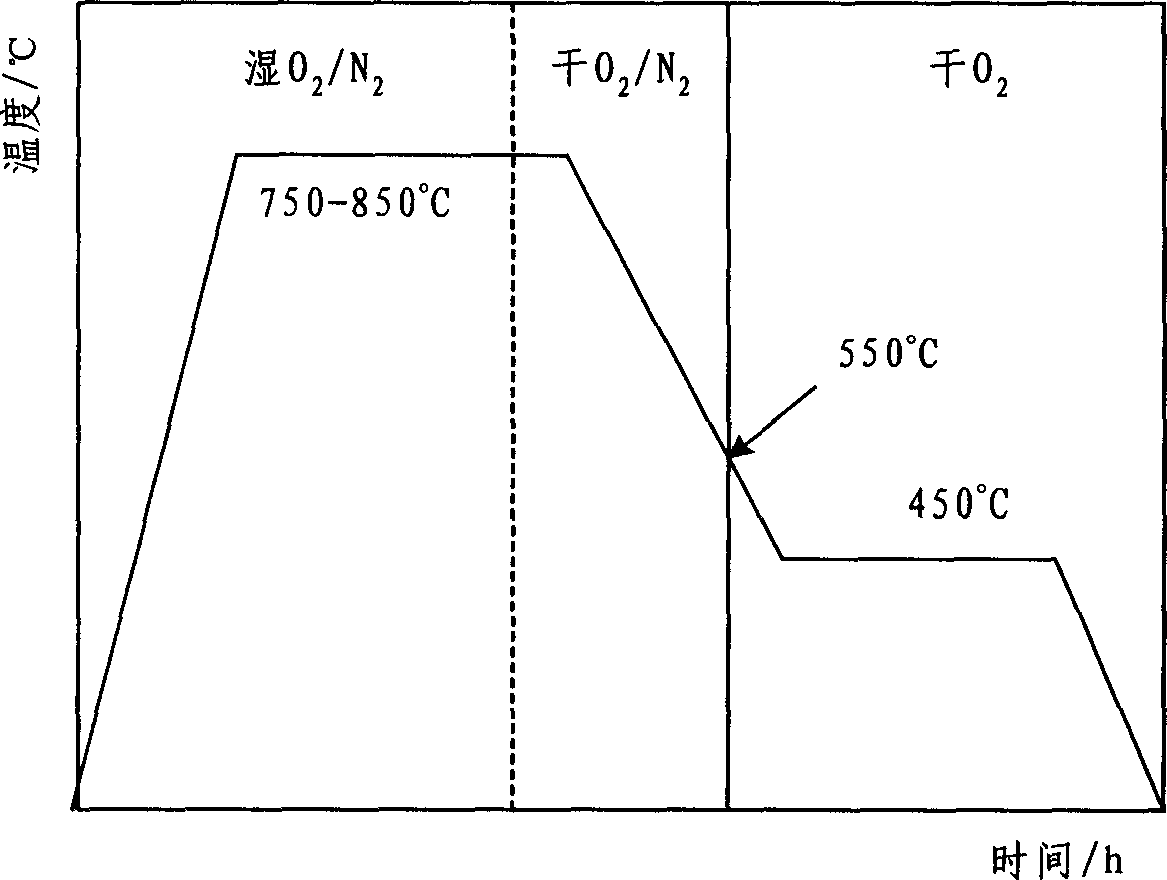

Collosol of yttrium barium cupper oxygen superconducting film and process for preparing high temp. superconducting film thereof

InactiveCN1792806AShorten heat treatment timeEasy to makeSuperconductors/hyperconductorsSuperconductor devicesPolymer scienceOxygen

A sol of the Y-Ba-Cu-O (YBCO) superconductor film is proportionally prepared from yttrium acetate, barium acetate, copper acetate, trifluoroacetic acid, water, alpha-methylacrylic acid, divinyltriamine and methanol. A process for preparing the high-temp superconductor film from said sol is also disclosed.

Owner:XIAN UNIV OF TECH

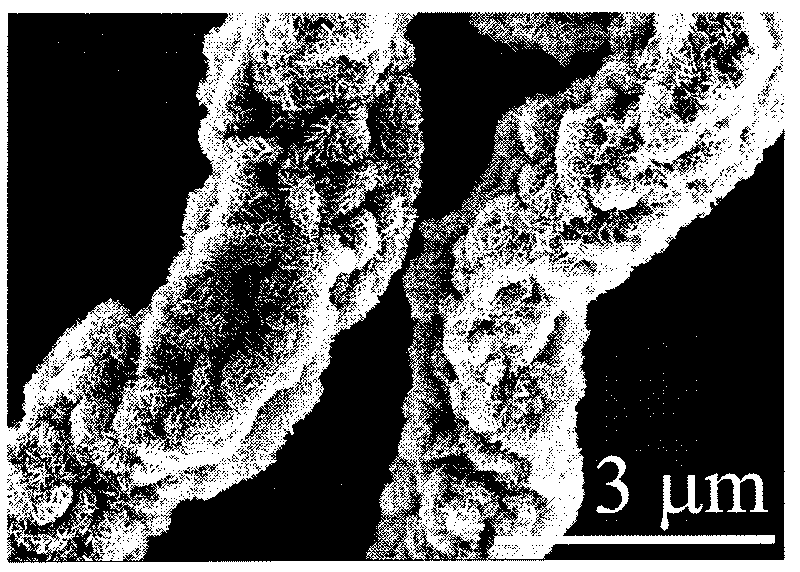

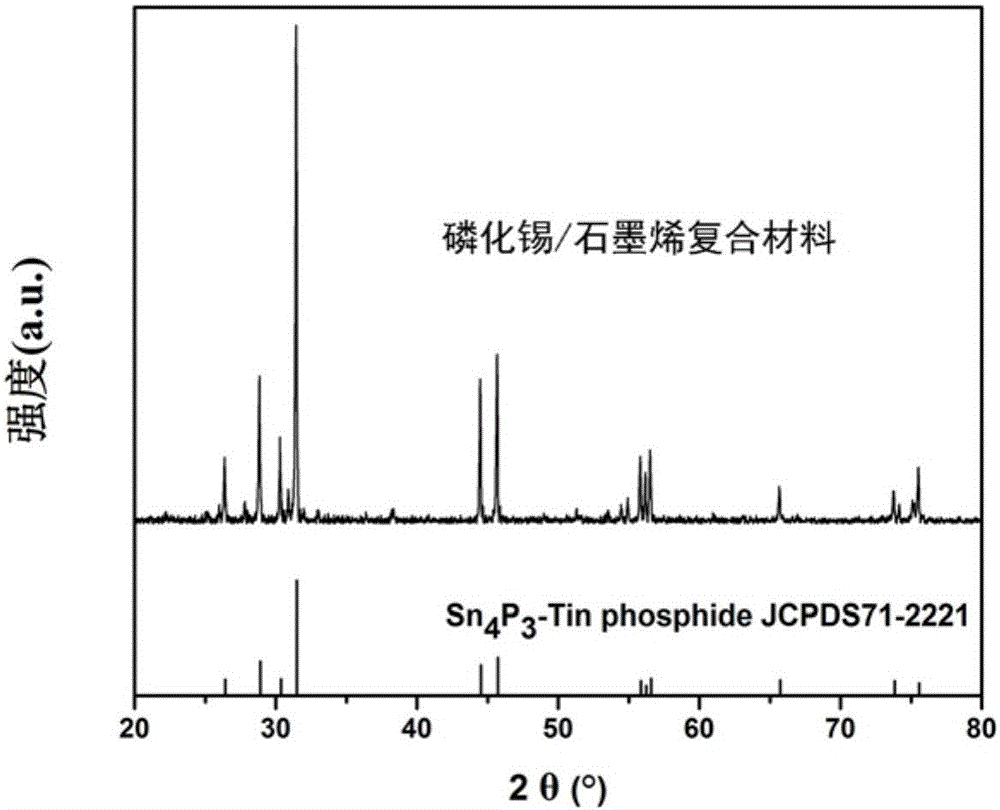

Stannic phosphide/graphene composite cathode material for sodium-ion battery and preparation method thereof

InactiveCN105006551AHigh charge and discharge capacityImproved magnification performanceCell electrodesSecondary cellsChemical reactionHigh energy

The invention discloses a stannic phosphide / graphene composite cathode material for a sodium-ion battery and a preparation method thereof. The composite cathode material is a three-dimensional structure material formed by wrapping the surfaces of nano stannic phosphide particles with flake graphite. The preparation method comprises the steps of adding metal tin powder, phosphorus powder and grinding balls into a ball milling jar of a high-energy ball milling machine, performing chemical reaction while ball milling under the protection of inert gas or nitrogen atmosphere to obtain the nano stannic phosphide particles, then adding graphene dispersion liquid into the ball milling jar, further performing ball milling to enable the surfaces of the nano stannic phosphide particles to be evenly wrapped by the graphene, and arranging a ball milling product in an inert gas or nitrogen protection environment to perform heat processing so as to obtain the stannic phosphide / graphene composite cathode material. A testing result shows that the composite cathode material has very high charging-discharging specific capacity and stable circulating performance after the composite material serving as the cathode material for the sodium-ion battery is prepared into a half battery. The preparation method of the composite material is simple, reliable and good in process repeatability and in operability, is environmentally friendly and is suitable for industrial production.

Owner:CENT SOUTH UNIV

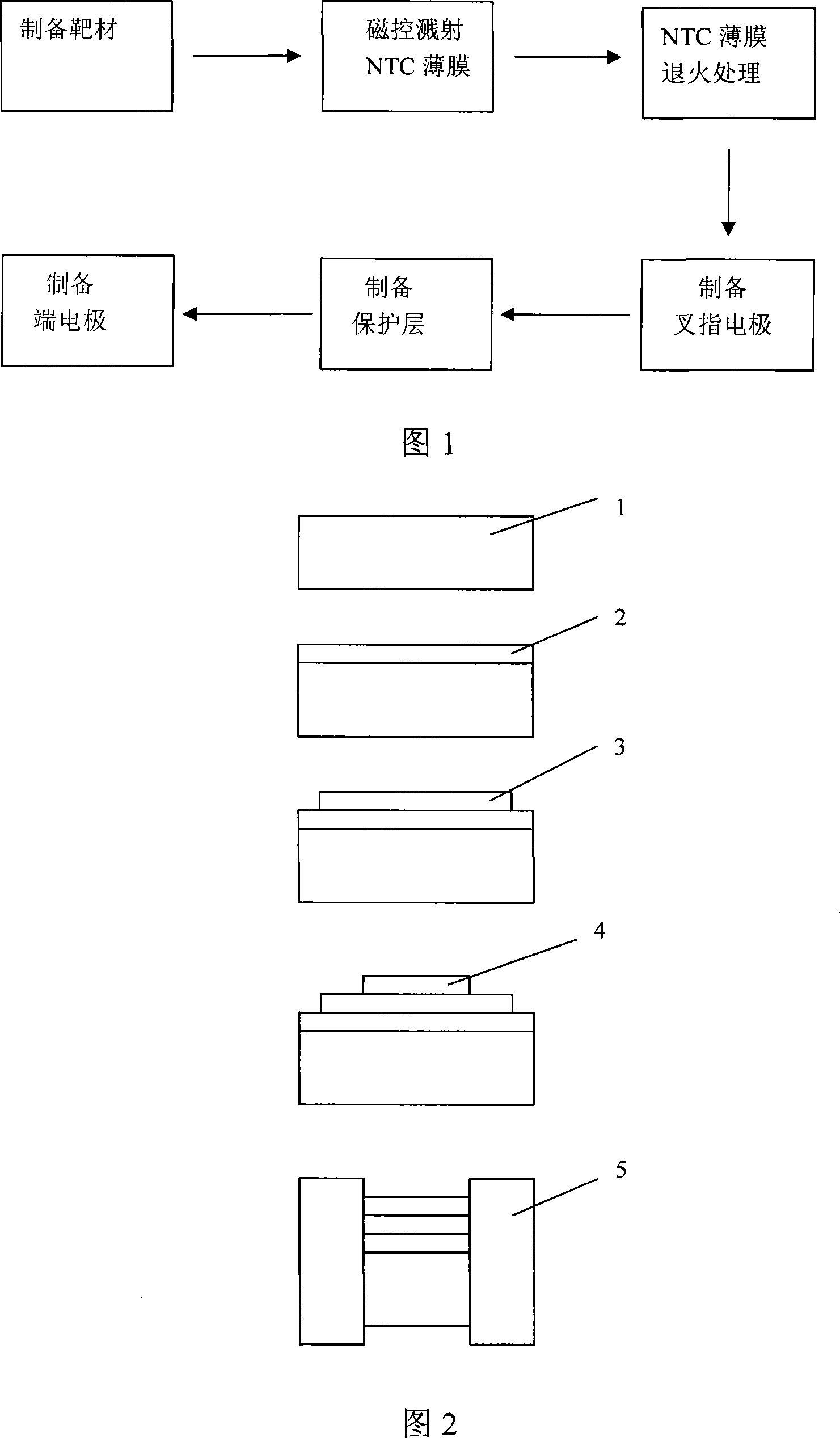

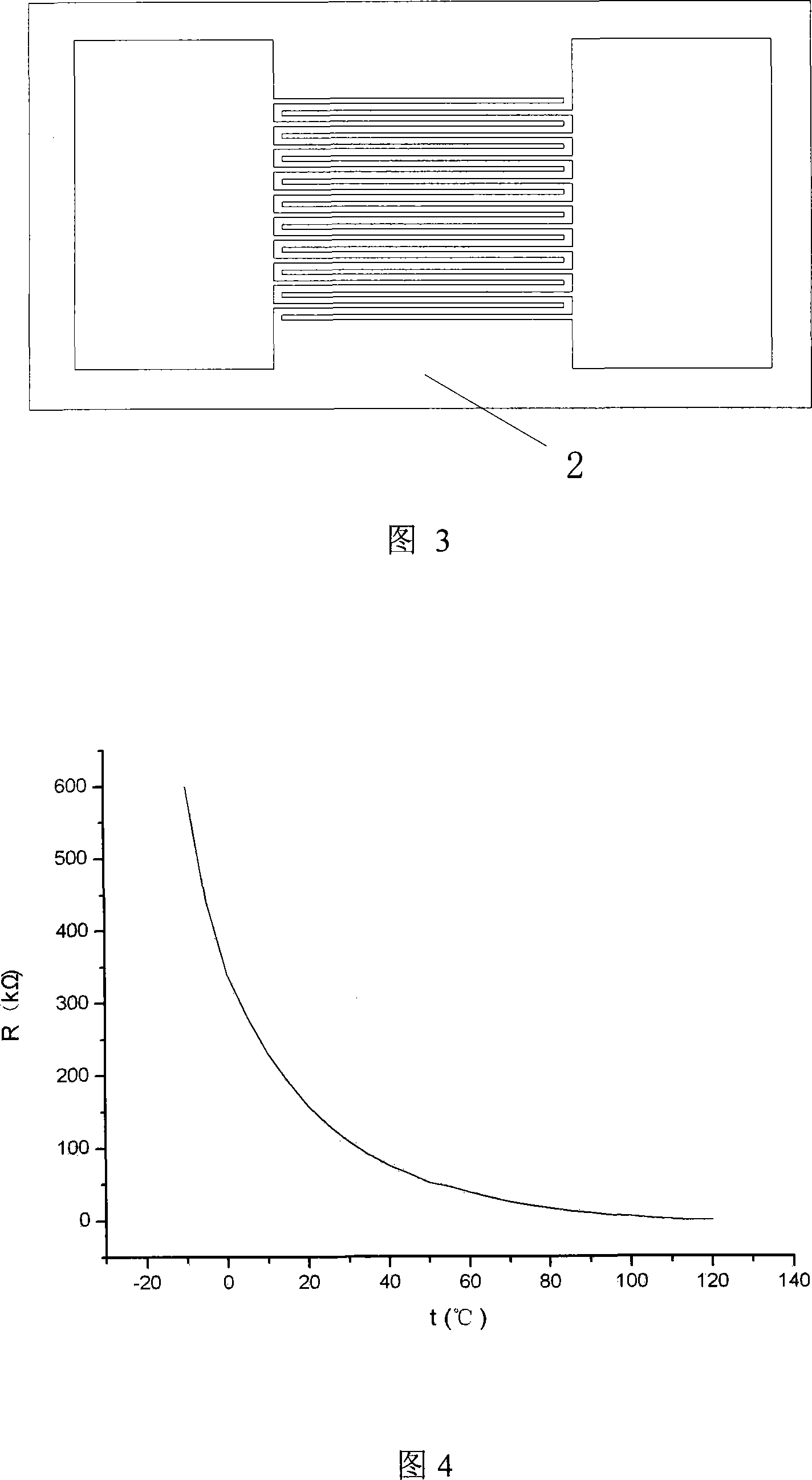

NTC film heat sensitive resistance and its making method

InactiveCN101241786AGood process repeatabilityImprove long-term stabilityNegative temperature coefficient thermistorsElectrical resistance and conductanceHeat sensitive

The present invention provides a thin-film thermosensitive resistor and the preparing method thereof and especially relates to the preparing for the thermosensitive material and the device. The invention comprises a resistor body and an internal electrode and an end electrode which are connected with the resistor body. The invention is characterized in that the resistor body is a NTC film. The invention has the beneficial effects of good technique repeatability of the device, less environmental pollution of the technique, long-term stability, short responsive time and high precision.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Sodium-rich cathode material of sodium ion battery, preparation method of sodium-rich cathode material and sodium ion battery

InactiveCN105226264AImprove electrochemical performanceHigh discharge specific capacityCell electrodesSecondary cellsAir atmosphereNickel salt

The invention discloses a sodium-rich cathode material of a sodium ion battery, a preparation method of the sodium-rich cathode material and the sodium ion battery. The method comprises the following steps of: (1) mixing a nickel salt solution, a cobalt salt solution, a manganese salt solution, an oxalate solution and a sodium salt solution under stirring, wherein in a mixing condition, the ratio of the total mole number of Ni<2+>, Co<2+>, Mn<2+> and Na<+> in the mixed solution to the mole number of oxalate ions is (0.8-1):1; (2) carrying out hydrothermal reaction on the mixed solution in a sealed environment, and then carrying out cooling, solid-liquid separation, washing and drying to obtain a precursor; and (3) calcining the precursor in an air atmosphere to obtain the sodium-rich cathode material of the sodium ion battery. By means of the sodium-rich cathode material of the sodium ion battery, obtained according to the preparation method, high-capacity charging and discharging of the sodium ion battery can be achieved, and moreover, the sodium ion battery has excellent cycling stability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for quickly manufacturing titanium alloy artificial biological joint

ActiveCN105268977ASolve the problem of personal matchingGood biocompatibilityTurbinesOther manufacturing equipments/toolsBiological adaptationBiocompatibility Testing

The invention provides a method for quickly manufacturing a titanium alloy artificial biological joint. A three-dimensional model of an affected part joint in the body of a patient is obtained through CT scanning, and the model is amplified in a corresponding proportion according to a contraction ratio; then, an elastic cavity negative mould of the joint is quickly manufactured through 3D printing, titanium alloy powder is evenly and loosely contained in the cavity negative mould in the argon environment and sealed, and a porous titanium alloy joint blank is manufactured through high-pressure cold isostatic pressing; titanium alloy slurry in different particle sizes and even in the nano scale is sprayed to the surface of the blank to build a porosity gradient surface layer; and then, the joint blank is biologically modified through biological agent slurry, the blank is subjected to vacuum drying, degreasing and sintering after surface treatment, and the porous titanium alloy artificial biological joint is obtained. According to personal data, the appearance of the joint is customized, and the joint is good in biological adaptation. Through porosity gradient structural design and biological modification, the joint is good in biocompatibility. Through an oxygen control means, the joint is small in impurity content and high in performance. The production period is short, process stability is high, repeatability is good, and cost is low.

Owner:UNIV OF SCI & TECH BEIJING

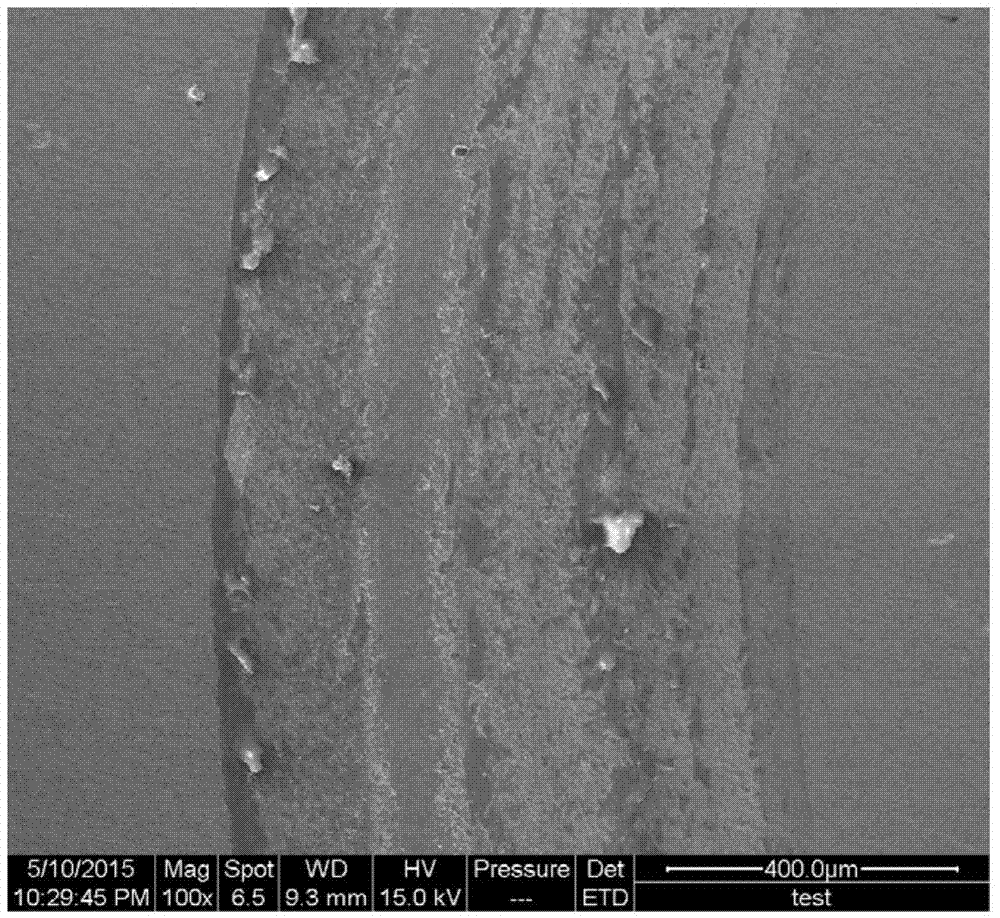

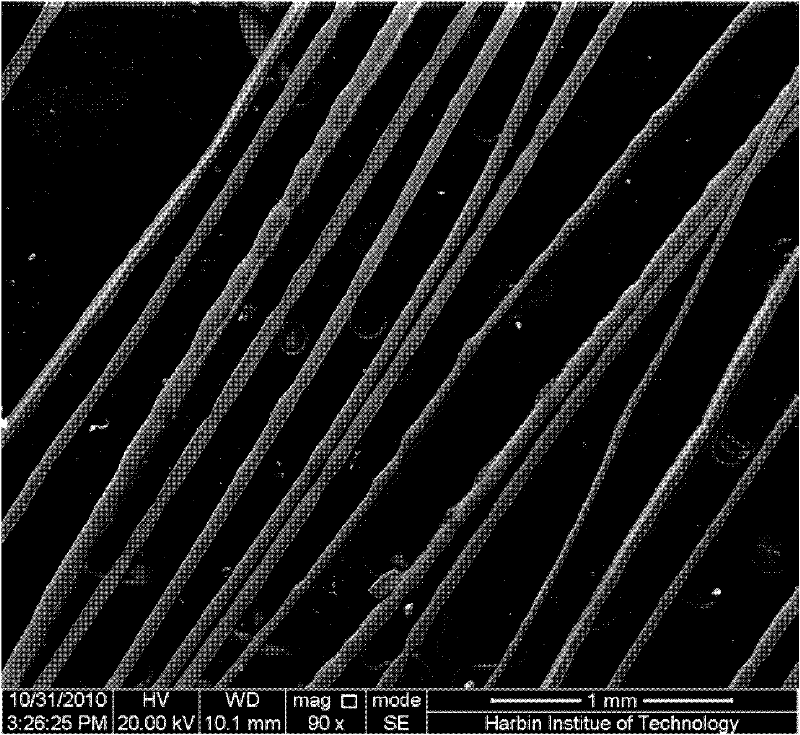

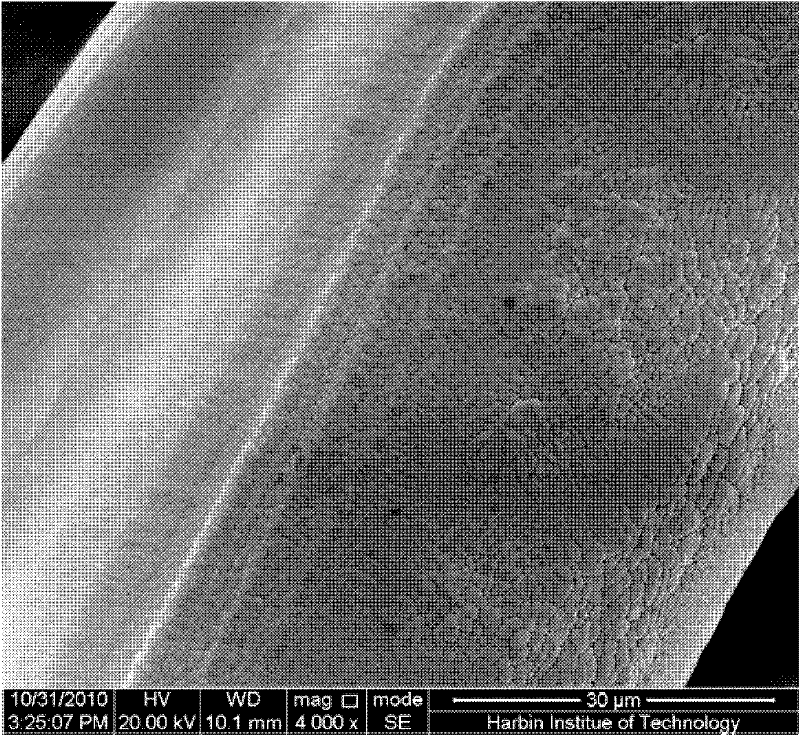

Method for preparing Ni-Mn-Ga ferromagnetic shape memory alloy continuous fibers by adopting spinning method

The invention discloses a method for preparing Ni-Mn-Ga ferromagnetic shape memory alloy continuous fibers by adopting a spinning method, and relates to a preparation method of Ni-Mn-Ga ferromagnetic shape memory alloy continuous fibers. The method solves the problems that the conventional glass coating method for preparing the Ni-Mn-Ga fibers has low production efficiency and poor process repeatability and bare fibers cannot be directly obtained. The method comprises the following steps of: putting Ni-Mn-Ga alloy ingots into a crucible of a device for preparing metallic amorphous wires, charging argon protection gas into a cavity, starting a metallic roller, heating the crucible, controlling the crucible to move to the metal roller after the alloy is smelted, and spinning the metal into the fibers when the high-speed rotating metal roller is in contact with the molten metal. The length of the prepared fibers reaches 1 to 10 centimeters, the diameter of the fibers is 30 to 80 microns, and the size of the fibers is uniform. The components of the fibers are uniform and consistent with the adopted alloy ingot components. The preparation method has high production efficiency and good process repeatability, the bare fibers can be directly obtained, and good surface state is kept.

Owner:HARBIN INST OF TECH

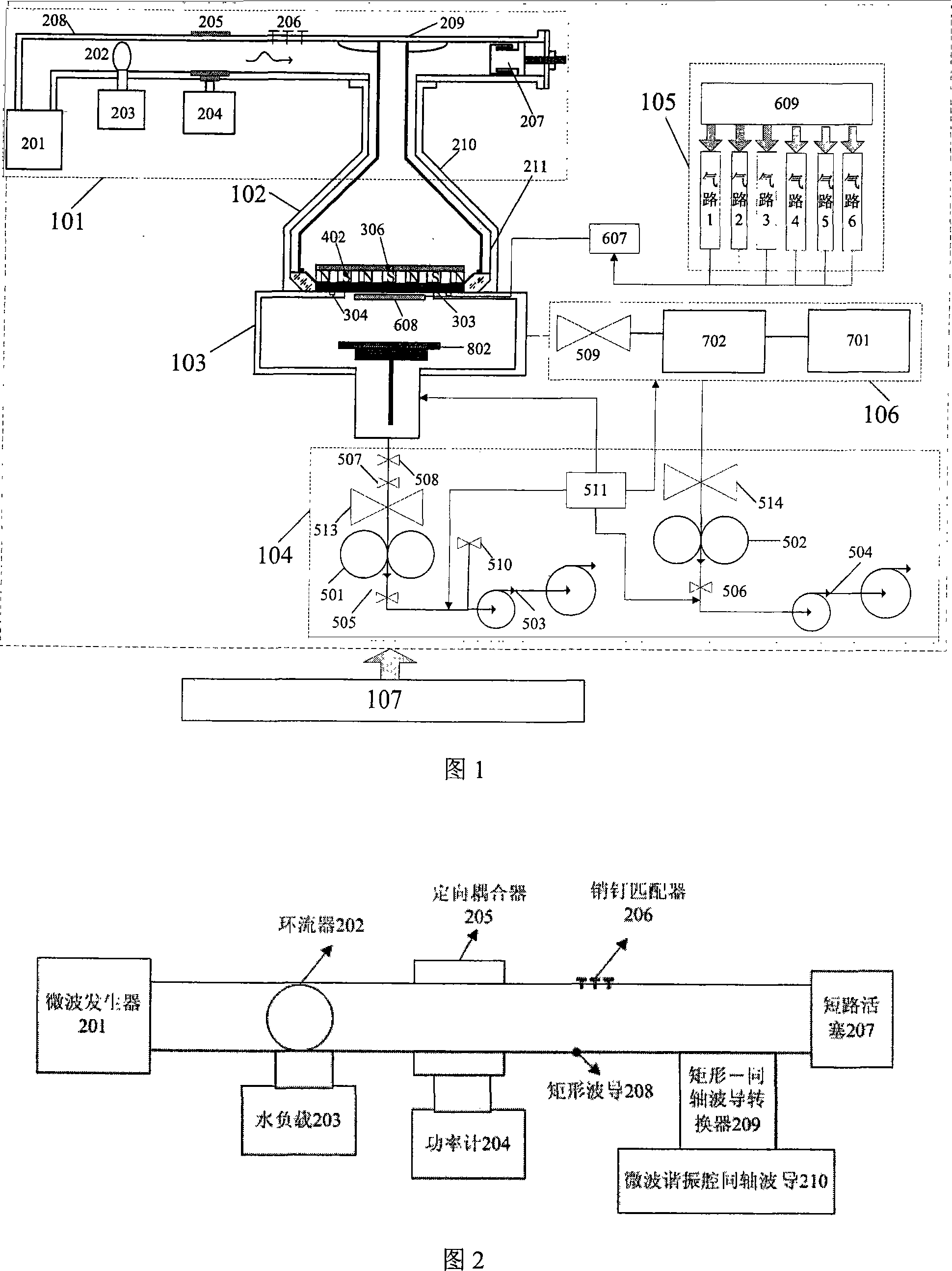

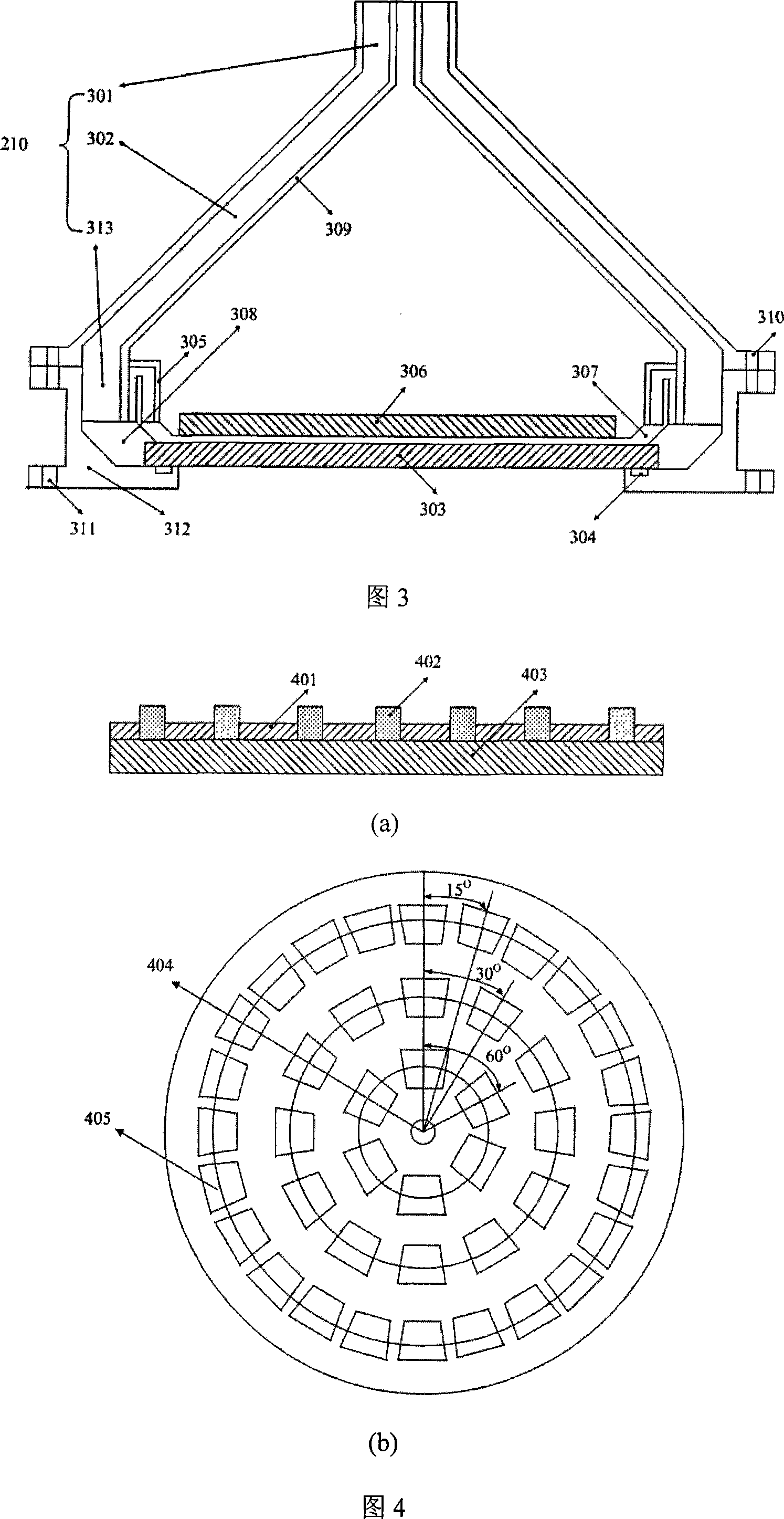

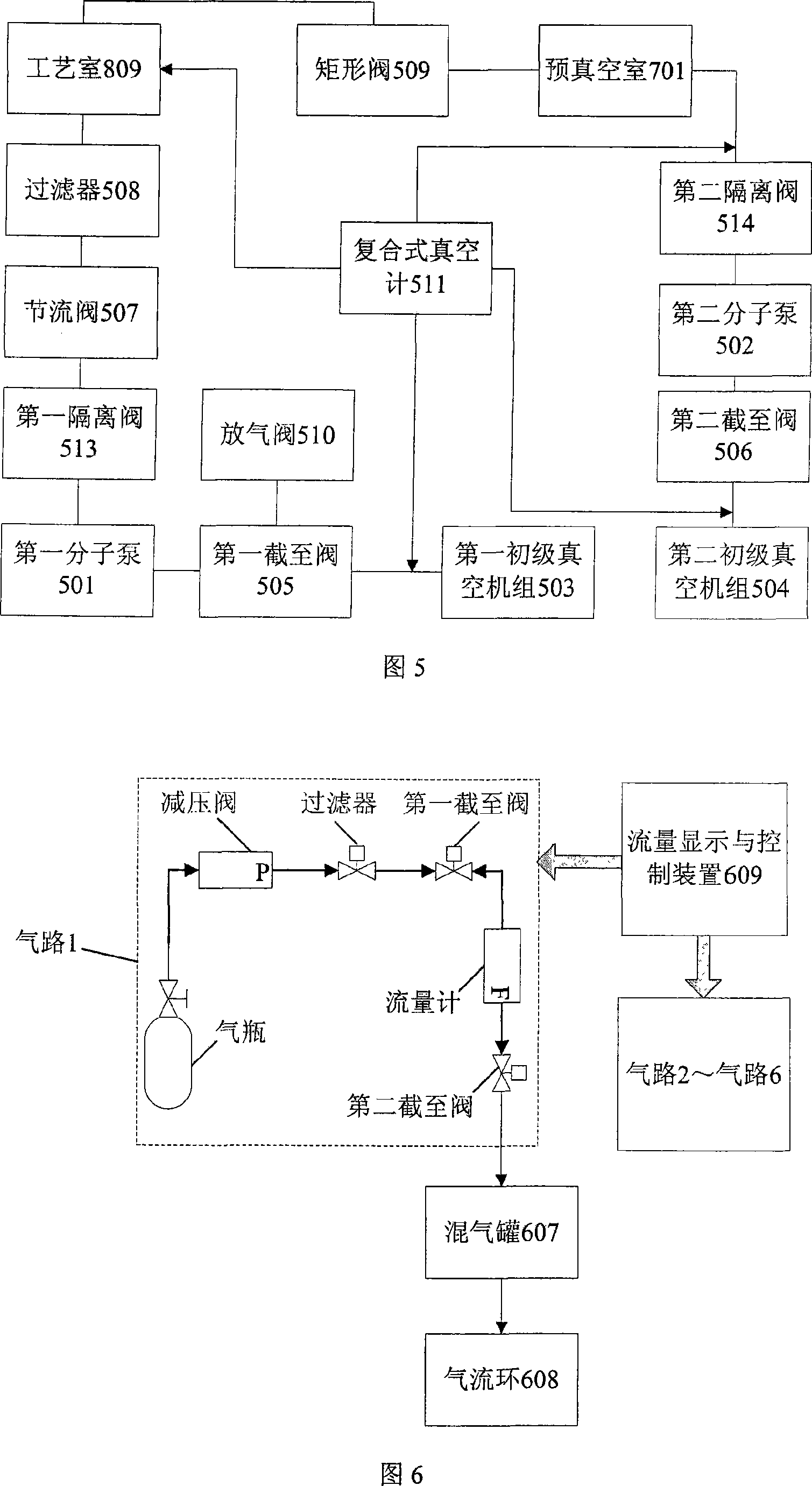

Microwave electron cyclotron resonance plasma chemistry gas phase sedimentation device

InactiveCN101144155AReduce volumeReduce power consumptionChemical vapor deposition coatingGas phaseMicrowave resonance

The present invention discloses microwave electron cyclotron resonance plasma body chemical vapor deposition equipment, which comprises a microwave power source and a transmission system 101, a microwave resonance cavity 102, a coating chamber and a specimen stage system 103, a vacuum system 104, a gas circuit system 105, an automatic sheet transmission system 106, and a controlling system 107, wherein, magnetic field devices 306 which are lined at equal intervals are arranged in the microwave resonance cavity; the specimen stage system is arranged inside the coating chamber; the microwave resonance cavity, the vacuum system, and the automatic sheet transmission system are respectively connected with a coating chamber 809, the microwave power source and the transmission system are connected with the microwave resonance cavity; a controlling software is solidified in the host computer of the controlling system; the working states of the microwave power source and the transmission system, the coating chamber and the specimen stage system, the vacuum system, and the gas circuit system are respectively controlled through interfaces, and thus the deposition technological process of a film is completed. The present invention has the advantages that the big area uniformity is good, the deposition rate is high, the automaticity and the production efficiency are high, the reliability is good, the power loss is small, and the stability and the repeatability are good.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com