Titanium dioxide nano thread, belt and tube block array and preparation method thereof

A titanium dioxide and nanowire technology, which is applied in the directions of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of single nanotube array, complex preparation process and high equipment requirements, and achieves good process repeatability and simple equipment. , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

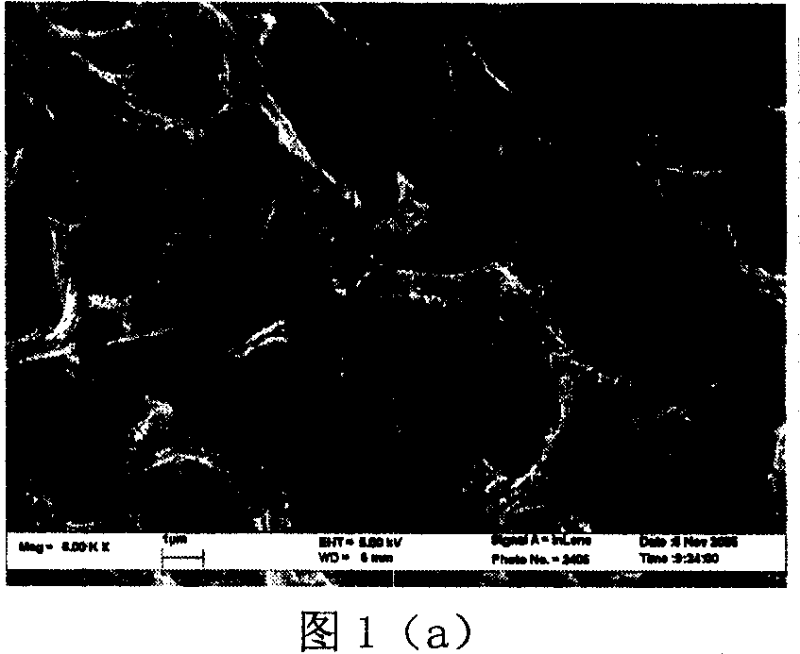

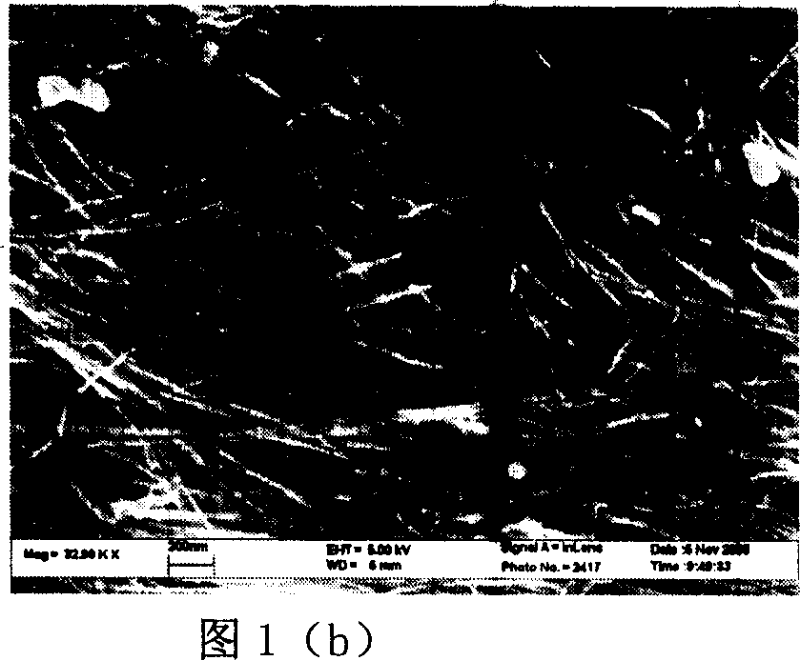

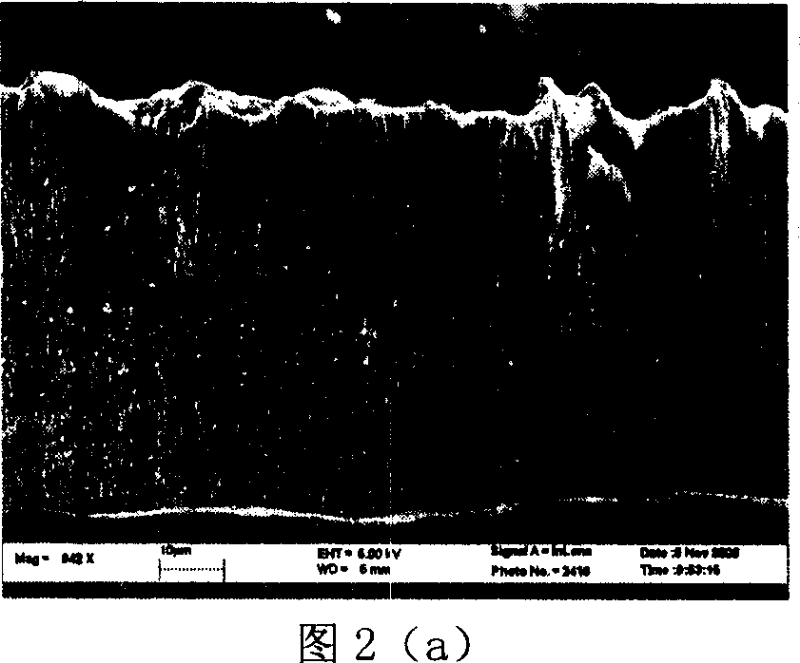

[0019] Titanium dioxide nanowires, ribbons, and tube block arrays of 10mm×10mm were prepared with high-purity titanium foil.

[0020] The first step, the preparation of the substrate

[0021] Cut the high-purity titanium foil into 10mm×10mm sheets, seal the back with epoxy resin, degrease with acetone and ethanol in sequence, clean with deionized water, and then put hydrogen with a volume ratio of 1:1:2. Carry out chemical polishing in the mixed solution of hydrofluoric acid, nitric acid and deionized water, then wash with ethanol and deionized water respectively, and finally blow dry with nitrogen, and set aside;

[0022] The second step, preparation of titanium dioxide nanowires, ribbons, and tube block arrays

[0023] The high-purity titanium foil prepared in the first step is used as the anode, and the platinum sheet is used as the cathode, and they are placed in the reactor upright. The distance between the two poles should be 50mm, and a concentration of 0.25wt% fluorid...

Embodiment 2

[0029] Titanium dioxide nanowires, ribbons, and tube block arrays of 10mm×10mm were prepared with high-purity titanium foil.

[0030] The first step, the preparation of the substrate

[0031] Cut the high-purity titanium foil into 10mm×10mm sheets, seal the back with epoxy resin, degrease with acetone and ethanol in sequence, clean with deionized water, and then put hydrogen with a volume ratio of 1:1:2. Carry out chemical polishing in the mixed solution of hydrofluoric acid, nitric acid and deionized water, then wash with ethanol and deionized water respectively, and finally blow dry with nitrogen, and set aside;

[0032] The second step, preparation of titanium dioxide nanowires, ribbons, and tube block arrays

[0033] The high-purity titanium foil prepared in the first step is used as the anode, and the platinum sheet is used as the cathode. They are placed in the reactor upright. The distance between the two poles should be 50mm, and a concentration of 0.25wt% fluoride T...

Embodiment 3

[0039] Titanium dioxide nanowires, ribbons, and tube block arrays of 10mm×10mm were prepared with high-purity titanium foil.

[0040] The first step, the preparation of the substrate

[0041] Cut the high-purity titanium foil into 10mm×10mm sheets, seal the back with epoxy resin, degrease with acetone and ethanol in sequence, clean with deionized water, and then put hydrogen with a volume ratio of 1:1:2. Carry out chemical polishing in the mixed solution of hydrofluoric acid, nitric acid and deionized water, then wash with ethanol and deionized water respectively, and finally blow dry with nitrogen, and set aside;

[0042] The second step, preparation of titanium dioxide nanowires, ribbons, and tube block arrays

[0043] The high-purity titanium foil prepared in the first step is used as the anode, and the platinum sheet is used as the cathode, and they are placed in the reactor upright. The distance between the two poles should be 50mm, and a concentration of 0.25wt% fluorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com