Patents

Literature

151 results about "Microwave resonance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave ovens and resonance in molecules. Like all other objects molecules have a resonant frequency. This means that they vibrate wildly when a certain input frequency is applied to them in just the same way that a child's swing will build up large oscillations if it is pushed at just the right rate.

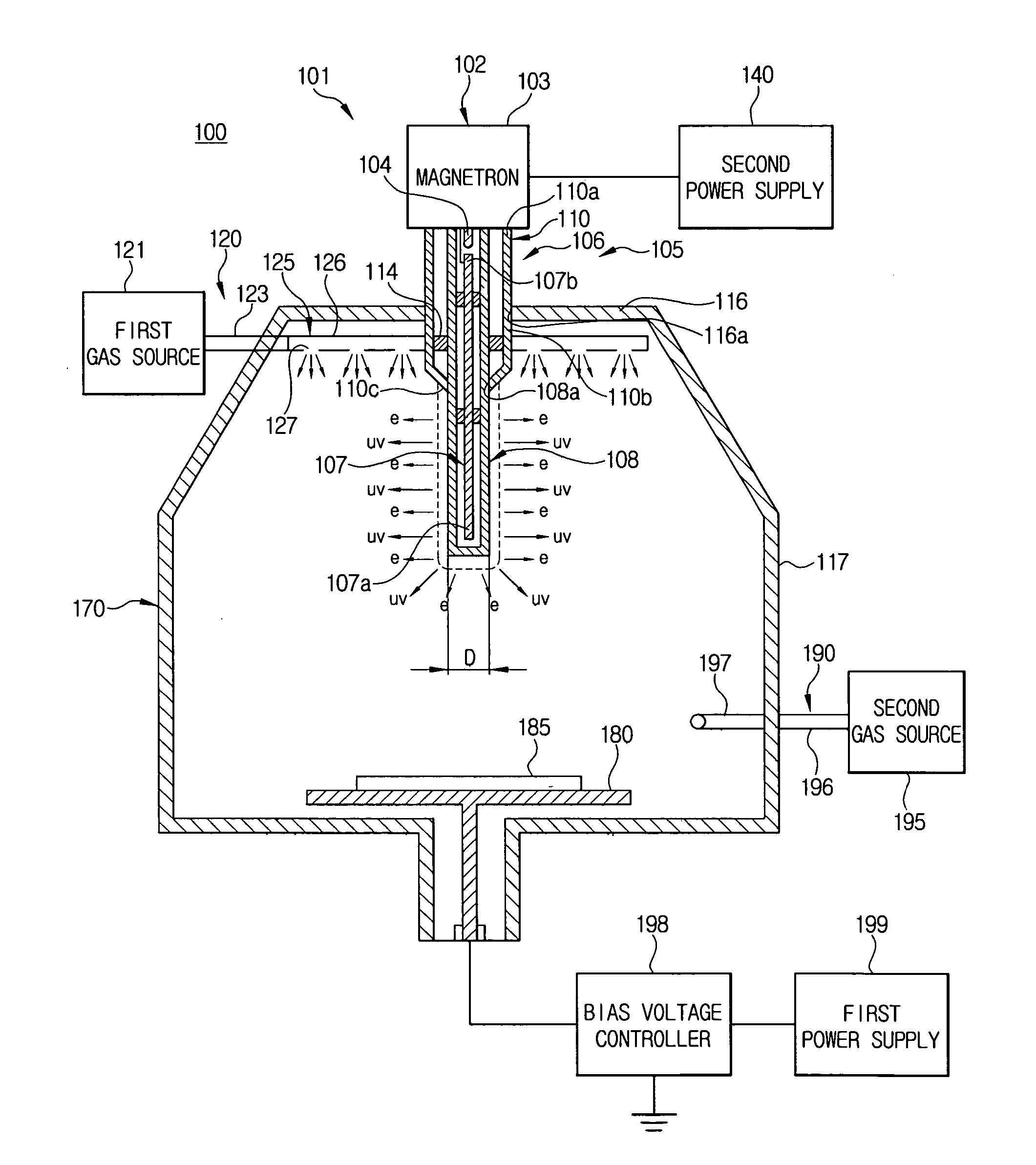

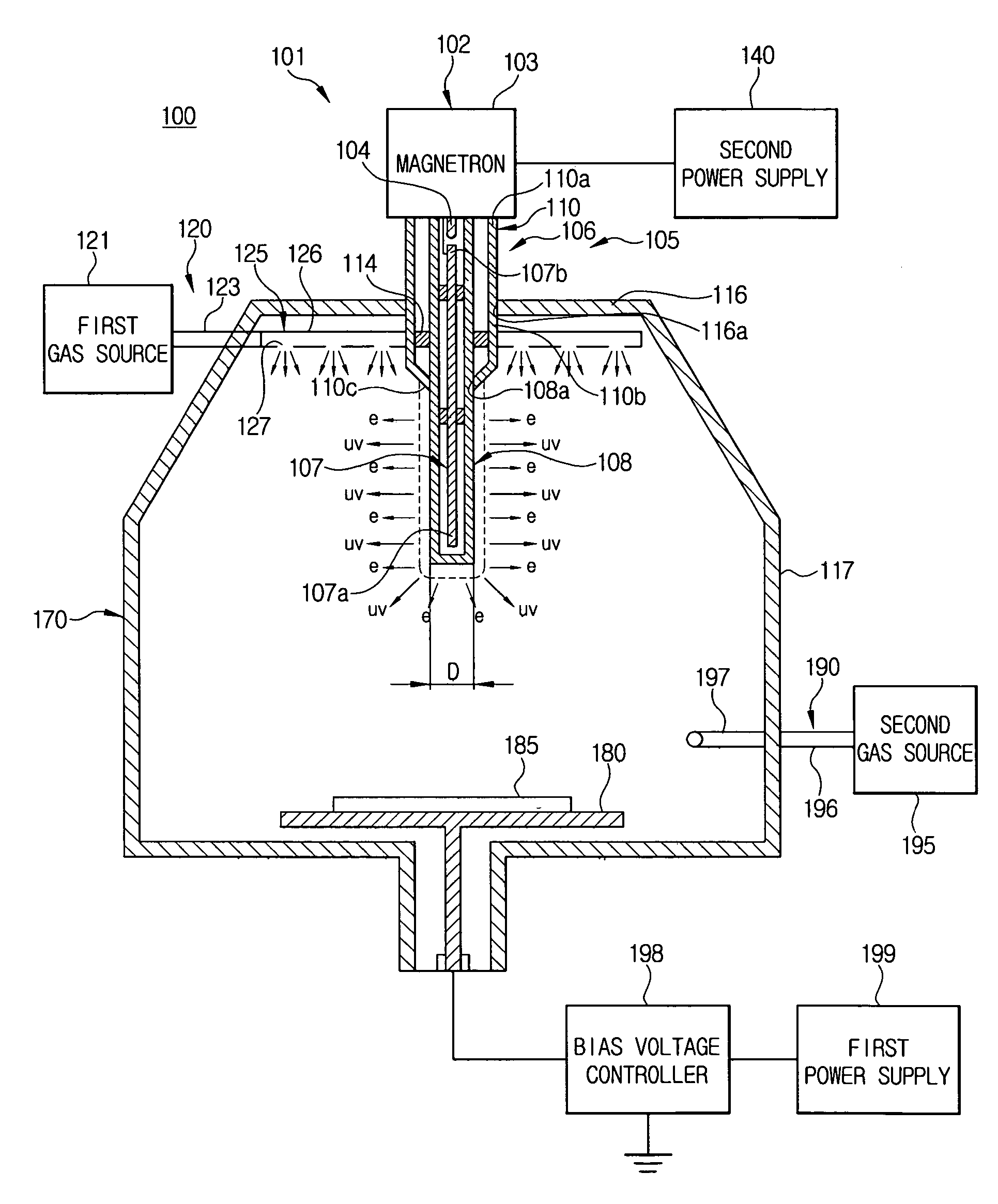

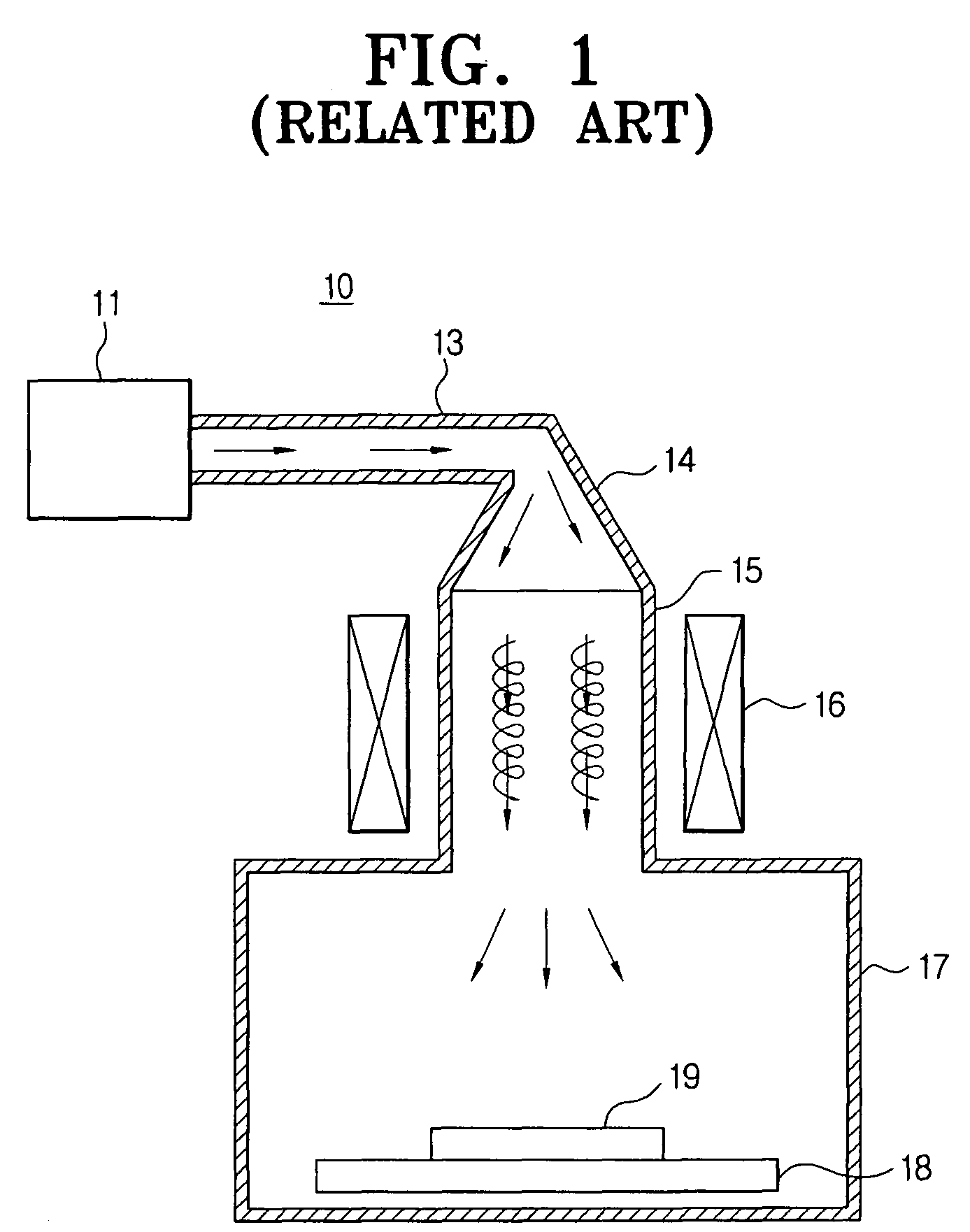

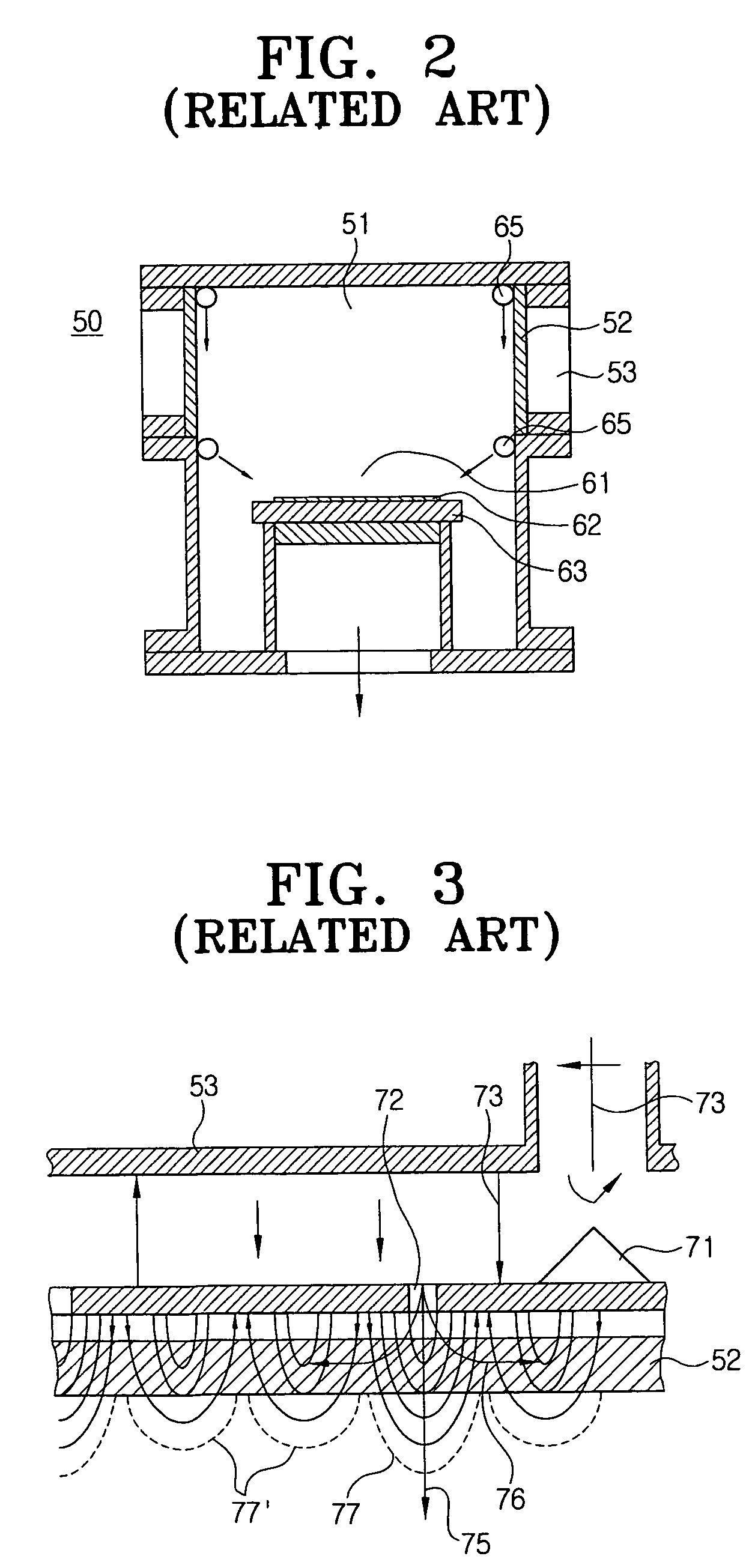

Microwave resonance plasma generating apparatus and plasma processing system having the same

ActiveUS20070045244A1Increase plasma producing efficiencySimple structureElectric discharge tubesElectric arc lampsHigh energyCoaxial waveguides

A microwave resonance plasma generating apparatus, a plasma processing system having the same and a method of generating a microwave resonance plasma are provided. The apparatus includes a microwave generating unit which generates a microwave, and a plasma producing unit which produces electrons and photons of high energy using the microwave generated from the microwave generating unit. The plasma producing unit includes a coaxial waveguide having an inner electrode disposed adjacent to the microwave generating unit, an outer electrode connected to the microwave generating unit and disposed to coaxially surround a portion of the inner electrode, the outer electrode being shorter than the inner electrode, and a dielectric tube disposed between the inner electrode and the outer electrode to insulate between the inner electrode and the outer electrode. The coaxial waveguide utilizes a principle of “cut or truncated electrode of coaxial waveguide” and a resonance phenomenon of Langmiur.

Owner:SAMSUNG ELECTRONICS CO LTD

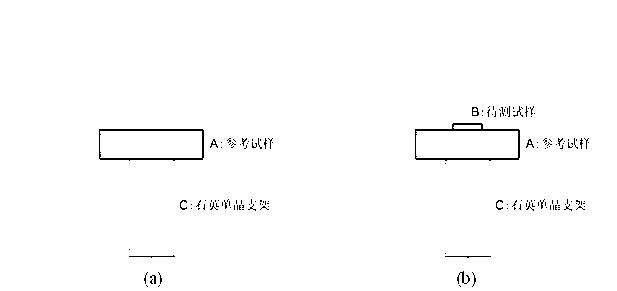

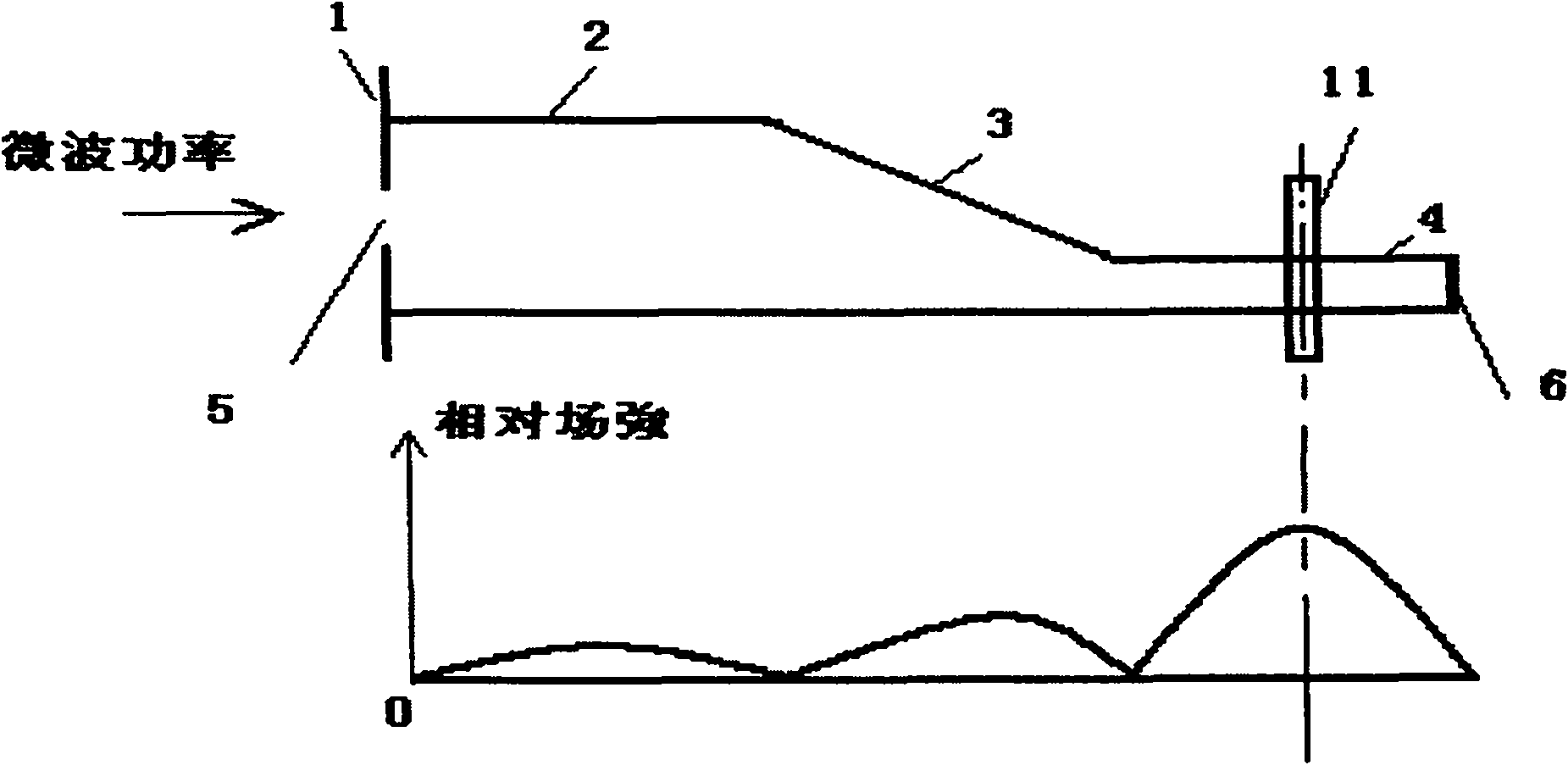

Method for testing microwave dielectric property of high-loss dielectric substance

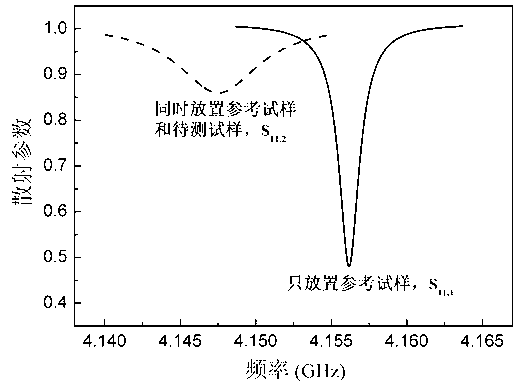

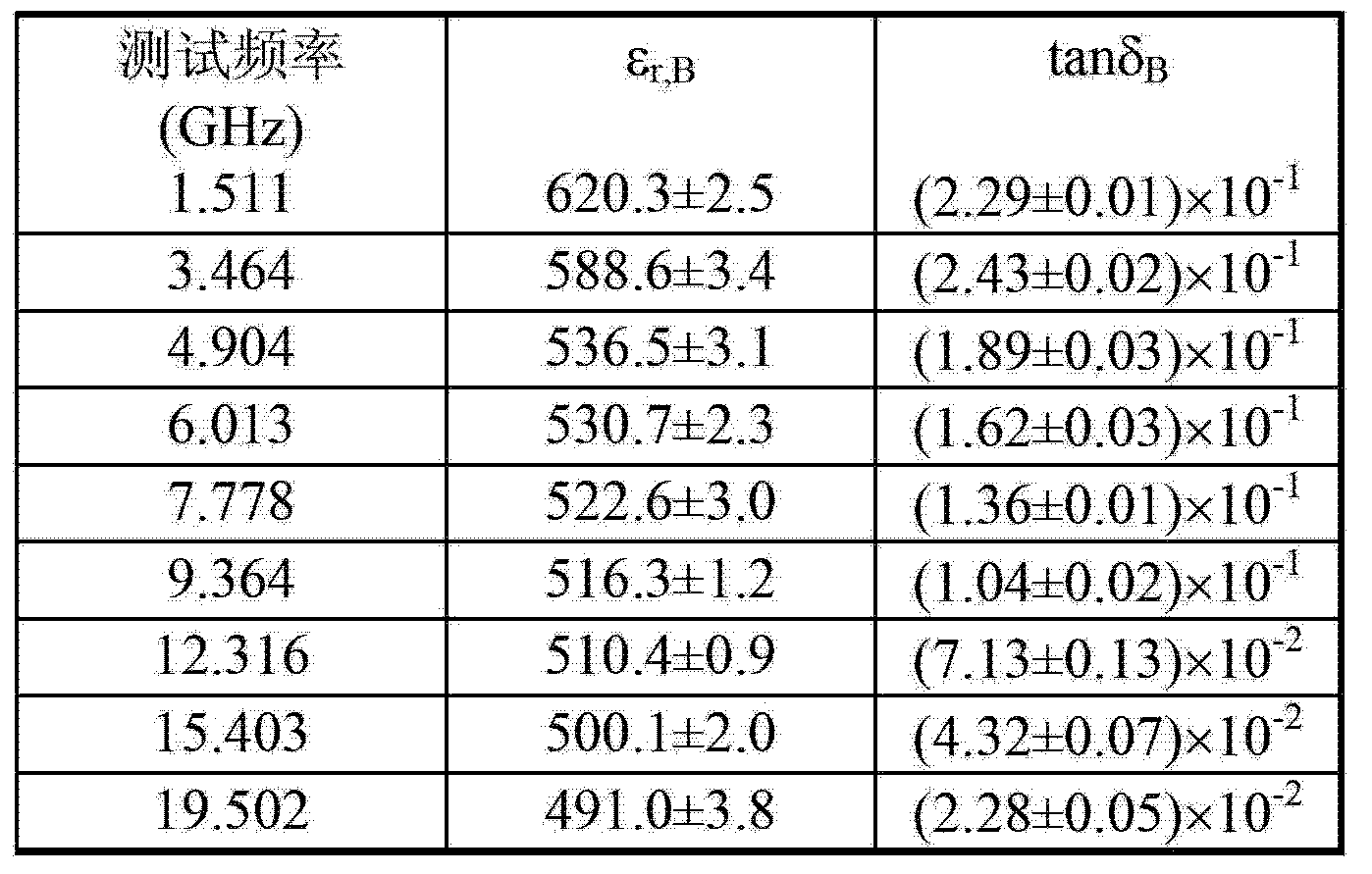

ActiveCN102798766AOvercome the defect of low test accuracyReduce lossResistance/reactance/impedenceReference sampleElement analysis

The invention discloses a method for testing microwave dielectric property of a high-loss dielectric substance. According to the method, a small-size sample to be tested is used, and a large-size and low-loss reference sample is introduced, so that the high loss of the sample to be tested is reduced, and the resonance peak is ensured to be observed. According to the changes of the resonance peak of a TE01 delta model when only the reference sample is arranged in a resonant cavity and the reference sample and the sample to be tested are simultaneously arranged in the resonant cavity, and the distribution of an electromagnetic field under the two conditions can be simulated by using finite element analysis, so that the dielectric constant and the dielectric loss of the sample to be tested at the resonance frequency can be obtained. According to the method, the characteristics of high test precision of the microwave resonance method is utilized, and the influence on the distribution of the electromagnetic field caused by the introduction of the sample to be tested, is considered, so that the defects of low precision of other conventional methods can be overcome from the test principle, and the accurate test of the microwave dielectric property of the high-loss substance can be realized. Meanwhile, the resonance frequency is decided by the reference sample with large size, so that the frequency conversion test can be realized by changing the dielectric constant or the size of the reference sample.

Owner:ZHEJIANG UNIV

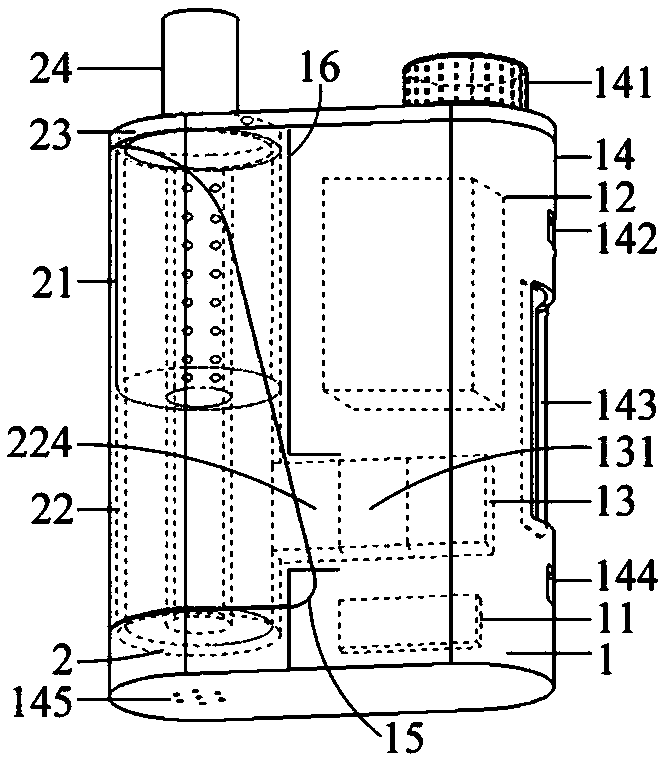

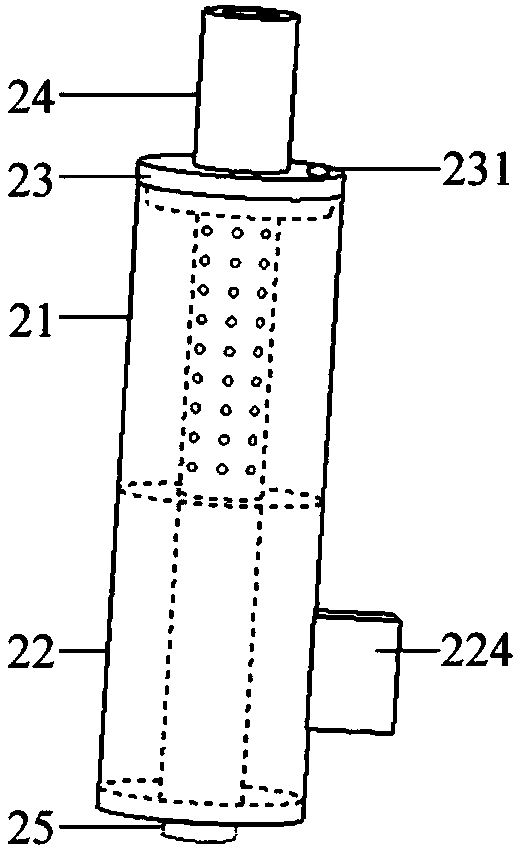

Electronic cigarette for atomizing by microwave resonance

InactiveCN108552613AAvoiding the Risk of Patent InfringementIncrease energy densityTobacco devicesTarMicrowave resonance

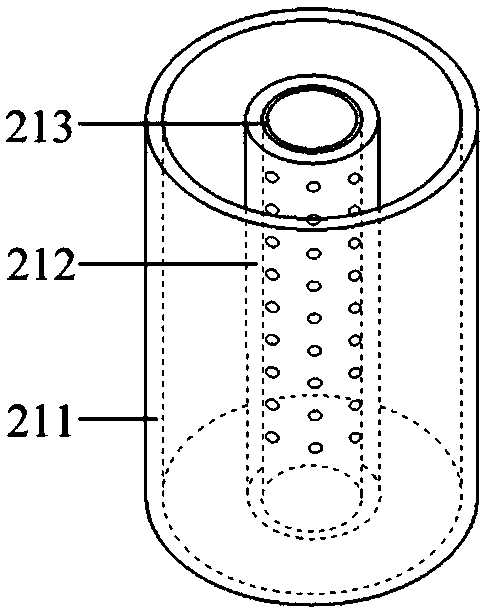

The invention discloses an electronic cigarette (1) for atomizing by microwave resonance, comprising a main shell (14), a battery (11), a controller (12) and a microwave generator (13) which are located in the main shell (14), and an accommodating chamber (16) used for placing a microwave resonance atomizer (2), wherein a gear switch (141) capable of performing microwave power strength adjustment,a master control switch (142), a display screen (143) and a charging interface (144) are arranged on the outer wall of the main shell (14), and an air inlet (145) is formed in the bottom of the outerwall of the main shell (14); the microwave resonance atomizer (2) comprises a tar storage unit (21), an atomizing unit (22), an upper cover plate (23), a suction nozzle (24) and a base (25) used forfixing the microwave resonance atomizer (2) in the accommodating chamber (16); and the microwave resonance atomizer (2) is enveloped by a detachable auxiliary shell (15). The atomizing mechanism of the electronic cigarette disclosed by the invention is different from that of electrothermic type electric cigarettes, and the electronic cigarette disclosed by the invention has the advantages of beinginstant in heating, high in efficiency, and good in thermal uniformity, realizing non-contact atomizing, and being capable of realizing low temperature sterilization of tobacco tar.

Owner:CHINA TOBACCO YUNNAN IND

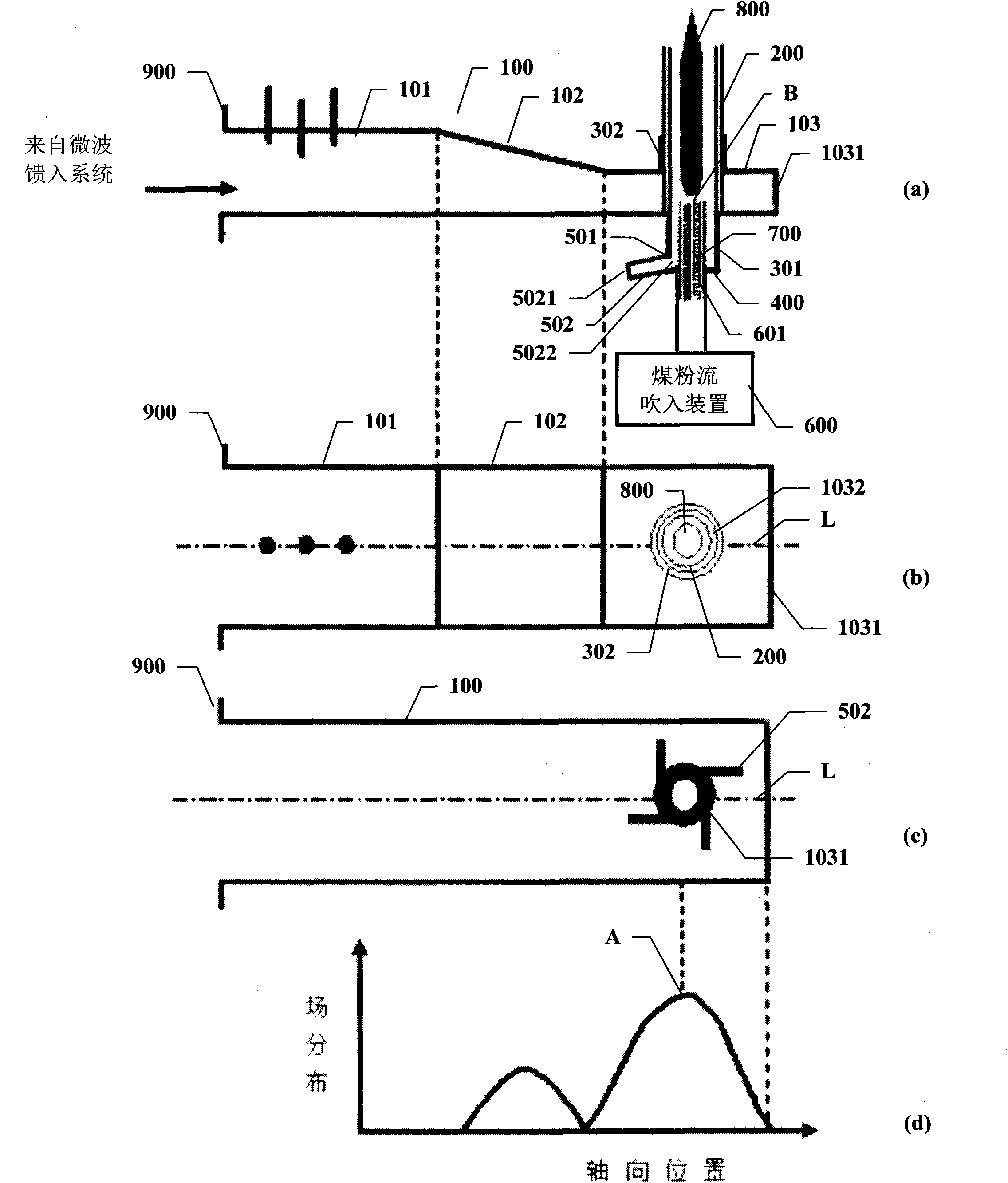

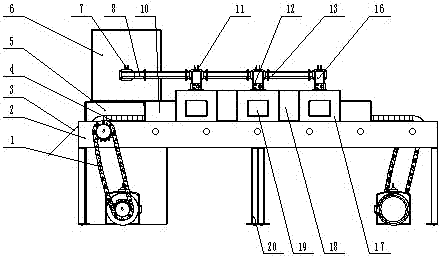

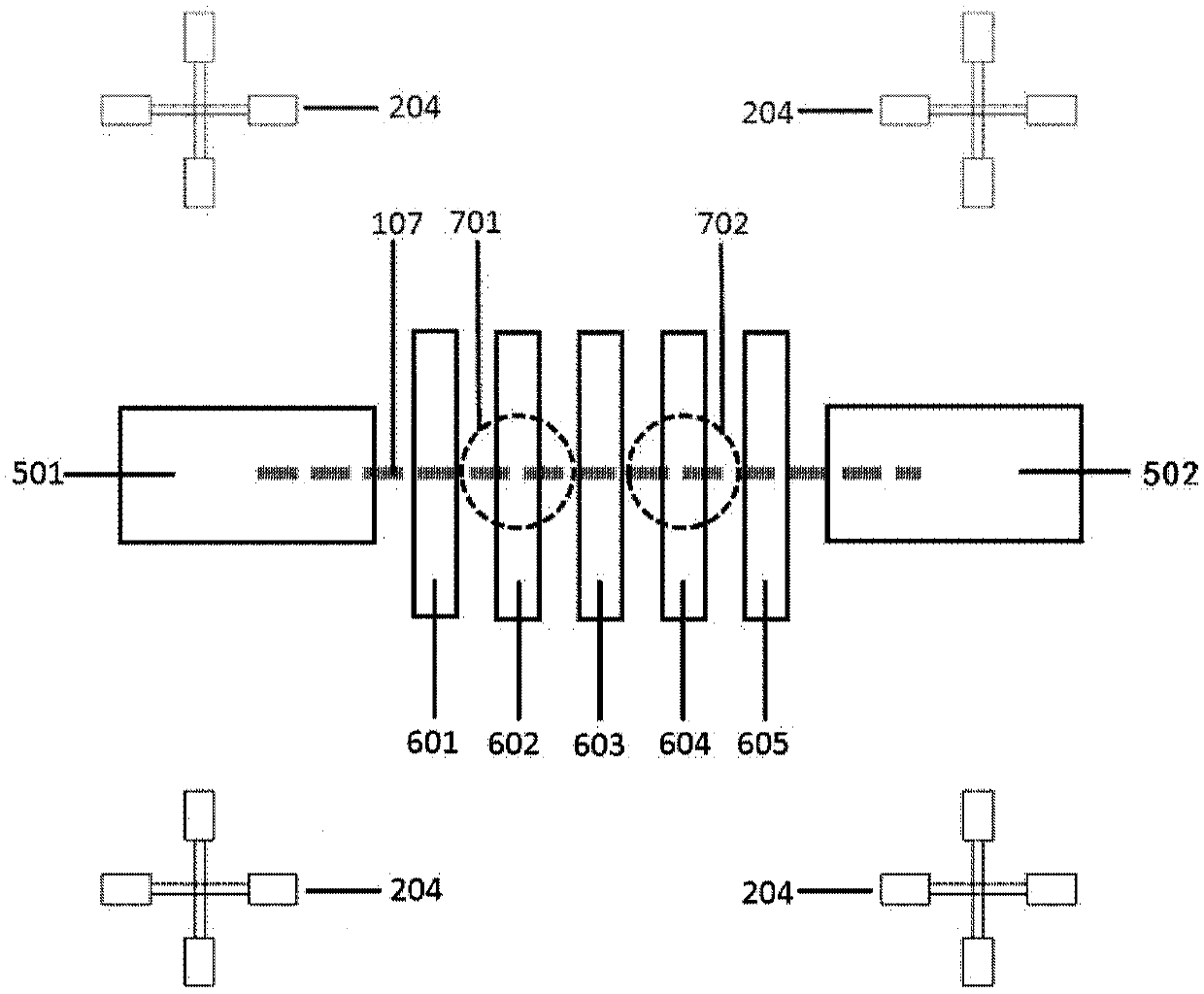

Microwave electron cyclotron resonance plasma chemistry gas phase sedimentation device

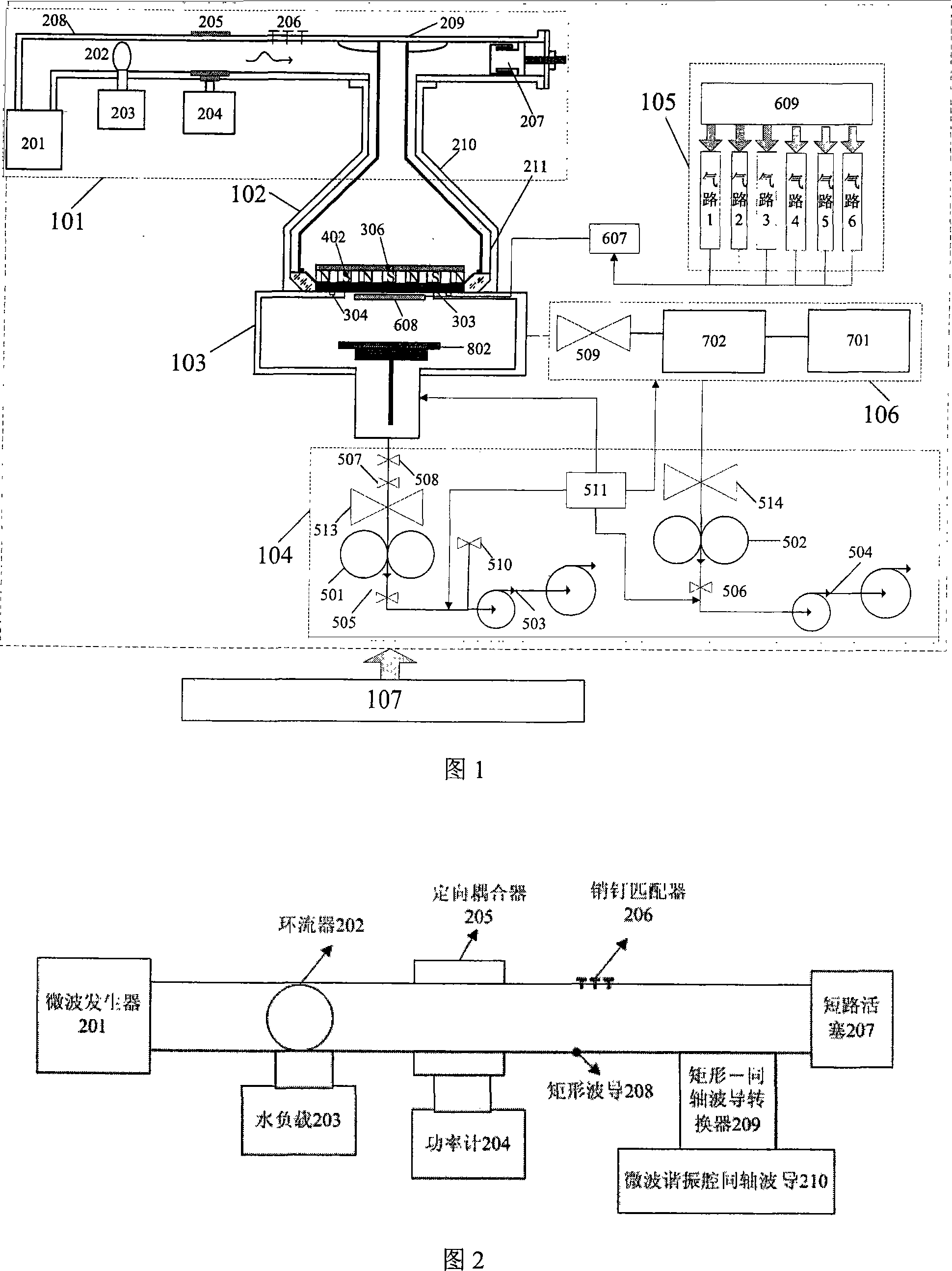

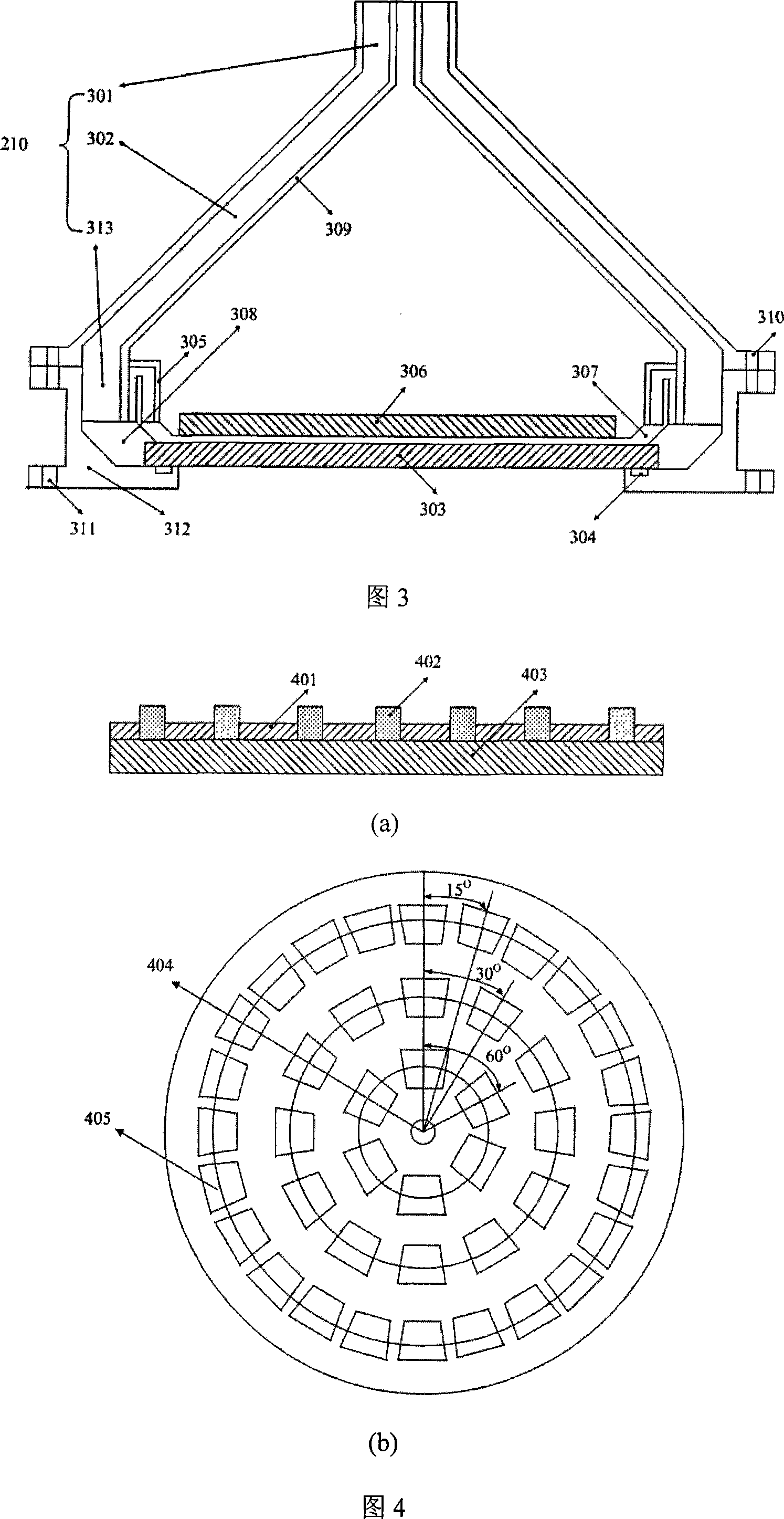

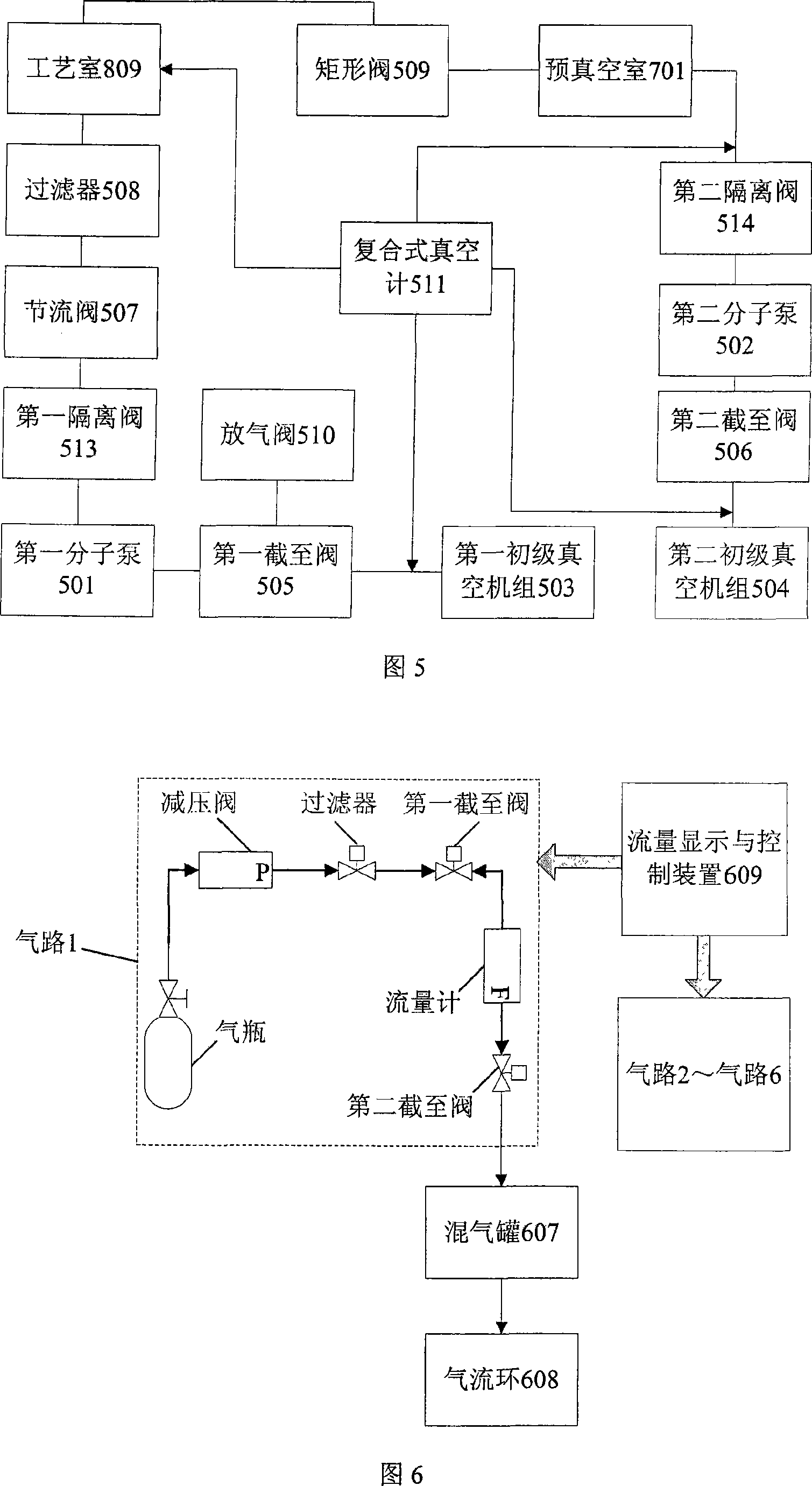

InactiveCN101144155AReduce volumeReduce power consumptionChemical vapor deposition coatingGas phaseMicrowave resonance

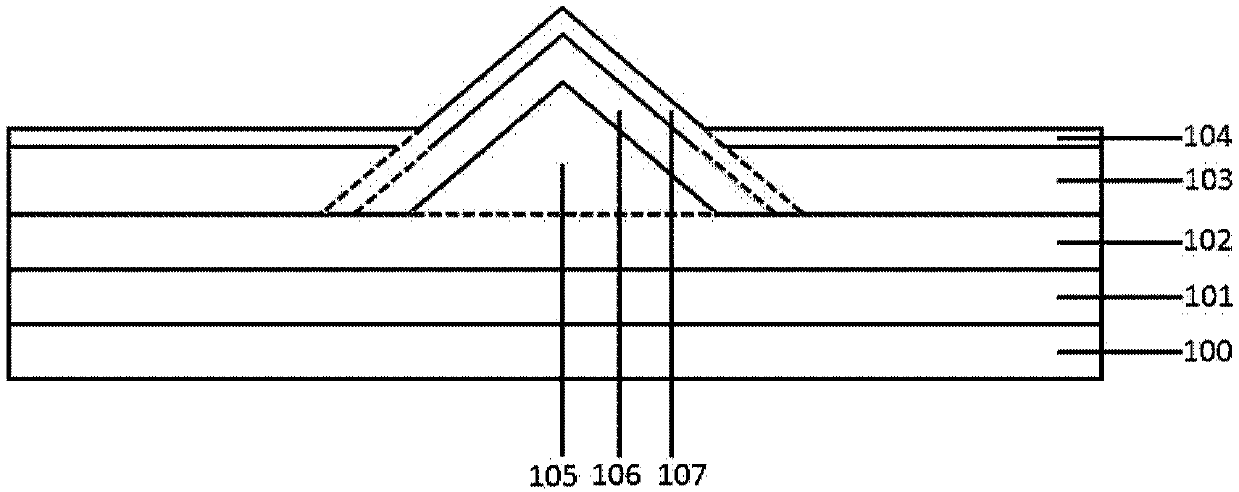

The present invention discloses microwave electron cyclotron resonance plasma body chemical vapor deposition equipment, which comprises a microwave power source and a transmission system 101, a microwave resonance cavity 102, a coating chamber and a specimen stage system 103, a vacuum system 104, a gas circuit system 105, an automatic sheet transmission system 106, and a controlling system 107, wherein, magnetic field devices 306 which are lined at equal intervals are arranged in the microwave resonance cavity; the specimen stage system is arranged inside the coating chamber; the microwave resonance cavity, the vacuum system, and the automatic sheet transmission system are respectively connected with a coating chamber 809, the microwave power source and the transmission system are connected with the microwave resonance cavity; a controlling software is solidified in the host computer of the controlling system; the working states of the microwave power source and the transmission system, the coating chamber and the specimen stage system, the vacuum system, and the gas circuit system are respectively controlled through interfaces, and thus the deposition technological process of a film is completed. The present invention has the advantages that the big area uniformity is good, the deposition rate is high, the automaticity and the production efficiency are high, the reliability is good, the power loss is small, and the stability and the repeatability are good.

Owner:XIDIAN UNIV

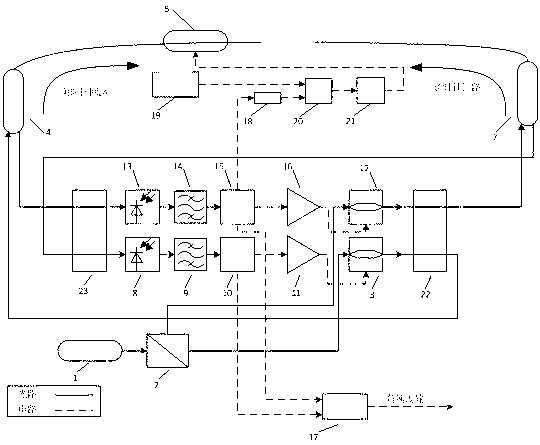

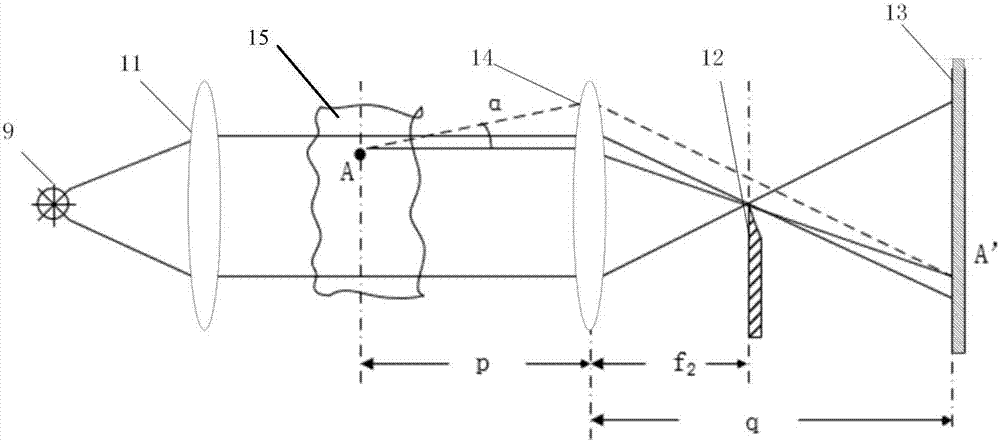

Non-local-oscillator low-phase-noise microwave signal optical frequency-doubling generation device and method

ActiveCN107395284ARealize generationTunable microwave signal frequencyRing-type electromagnetic networksElectromagnetic transmittersPhase noiseMicrowave resonance

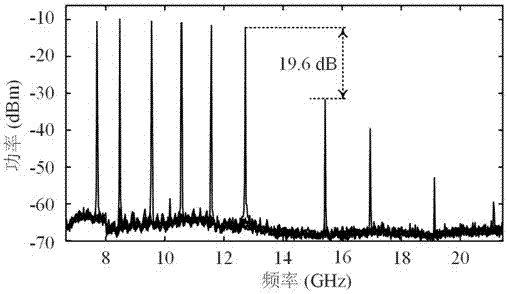

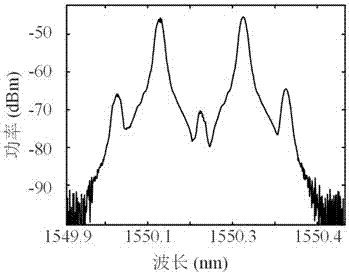

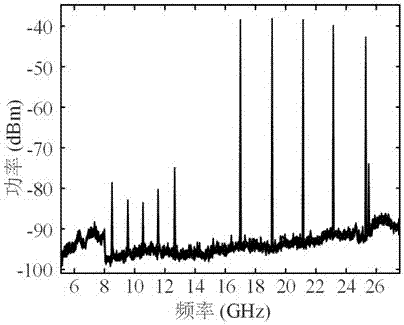

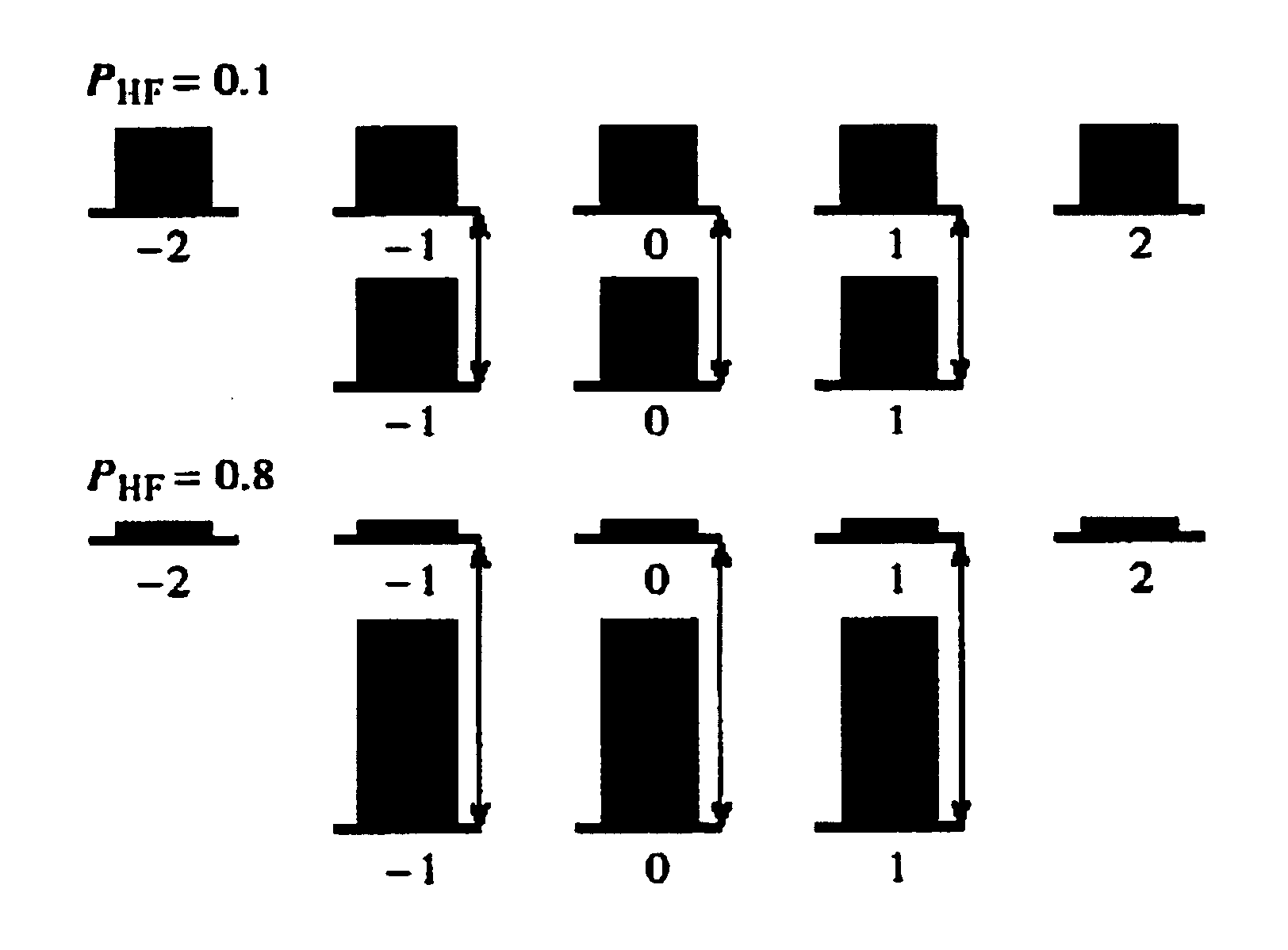

The invention discloses a non-local-oscillator low-phase-noise microwave signal optical frequency-doubling generation device and method, and belongs to the technical field of microwave signal generation. According to the device and the method, a narrow-band microwave photonic filter is formed by utilizing an equivalent phase modulation characteristic of one double parallel Mach-Zehnder modulator (DP-MZM) integrated in a polarized multiplexed double parallel Mach-Zehnder modulator (DP-QPSK modulator) and a phase shifting fiber bragg grating (PS-FBG); and in an optoelectronic oscillator, generation of a frequency tunable low-phase-noise microwave resonance signal is implemented. Signal frequency doubling of the generated microwave resonance signal is implemented by the other DP-MZM integrated in the DP-QPSK modulator so as to generate a high-frequency microwave signal. The non-local-oscillator low-phase-noise microwave signal optical frequency-doubling generation device and method disclosed by the invention can overcome the defect of limitation of the electronic bottleneck of an electronic system in the aspect of generating the high-frequency low-phase-noise microwave signal, and implement generation of the low-phase-noise microwave signal with a magnitude of dozens of GHz and even hundreds of GHz.

Owner:EAST CHINA NORMAL UNIV

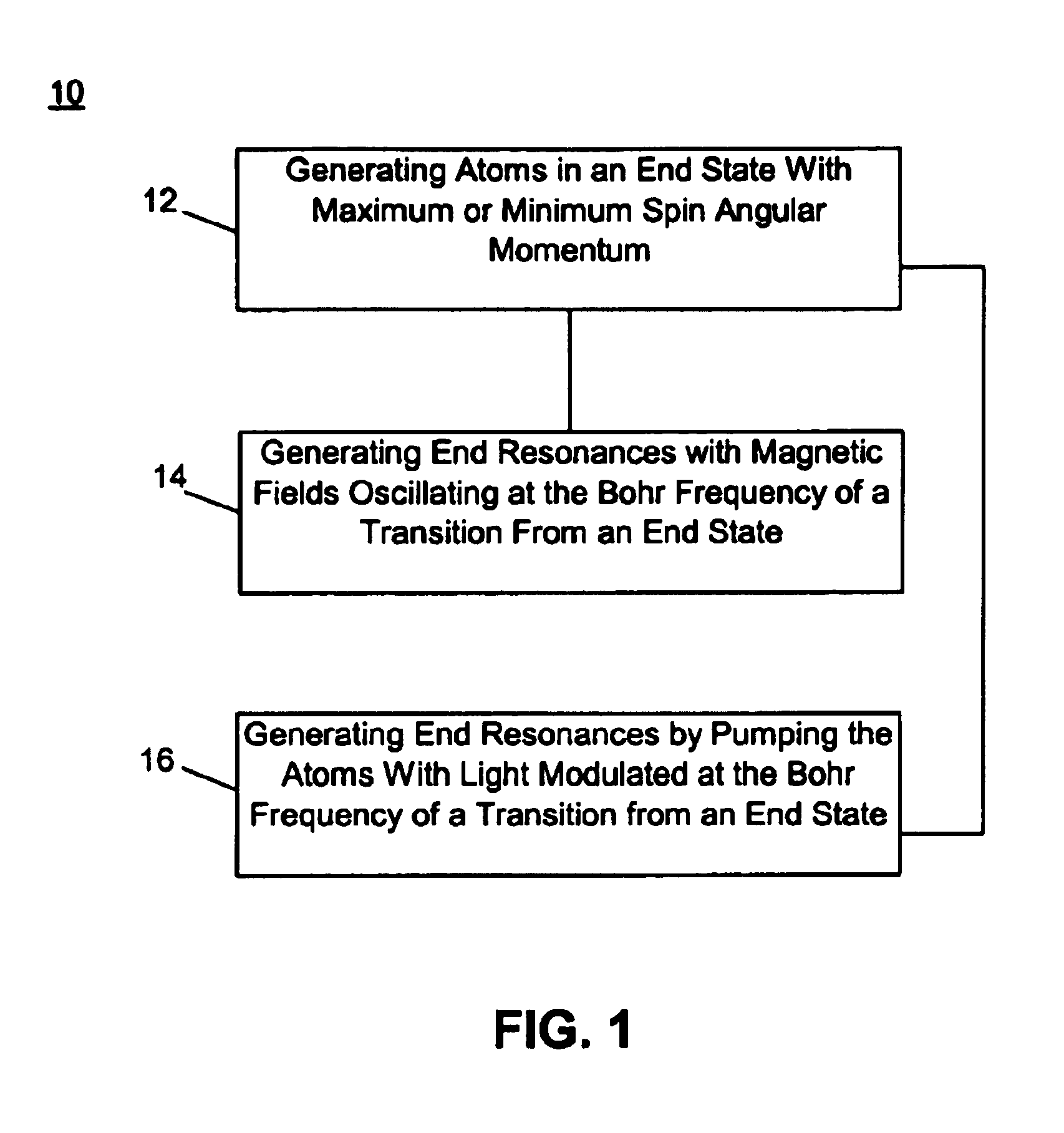

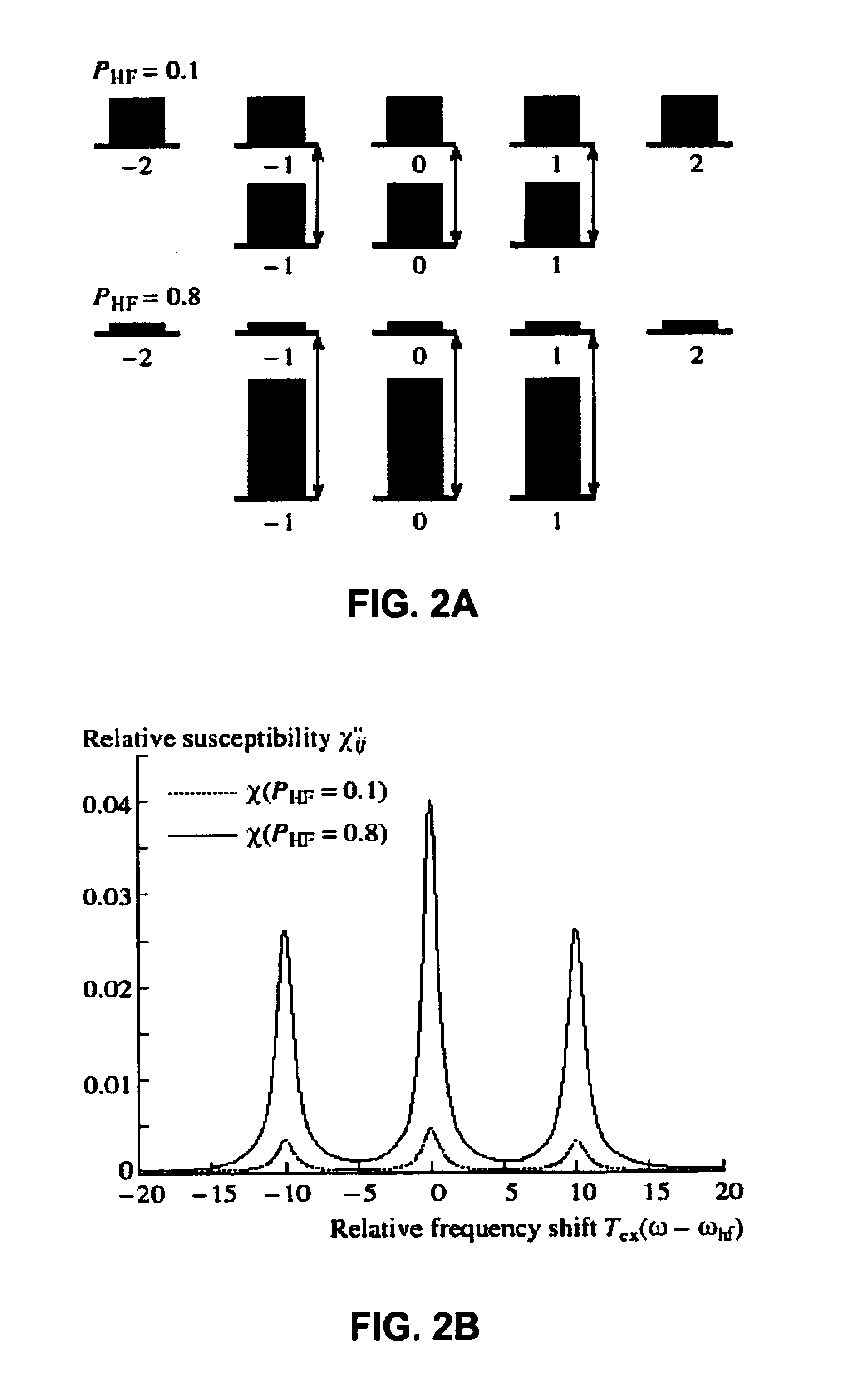

Method and system for operating an atomic clock with reduced spin-exchange broadening of atomic clock resonances

ActiveUS6919770B2Improve signal-to-noise ratioReduce the valueApparatus using atomic clocksPulse automatic controlSpin angular momentum of lightSpins

The present invention relates to a method and system for using end resonances of highly spin-polarized alkali metal vapors for an atomic clock, magnetometer or other system. A left end resonance involves a transition from the quantum state of minimum spin angular momentum along the direction of the magnetic field. A right end resonance involves a transition from the quantum state of maximum spin angular momentum along the direction of the magnetic field. For each quantum state of extreme spin there are two end resonances, a microwave resonance and a Zeeman resonance. The microwave resonance is especially useful for atomic clocks, but it can also be used in magnetometers. The low frequency Zeeman resonance is useful for magnetometers.

Owner:PRINCETON UNIV

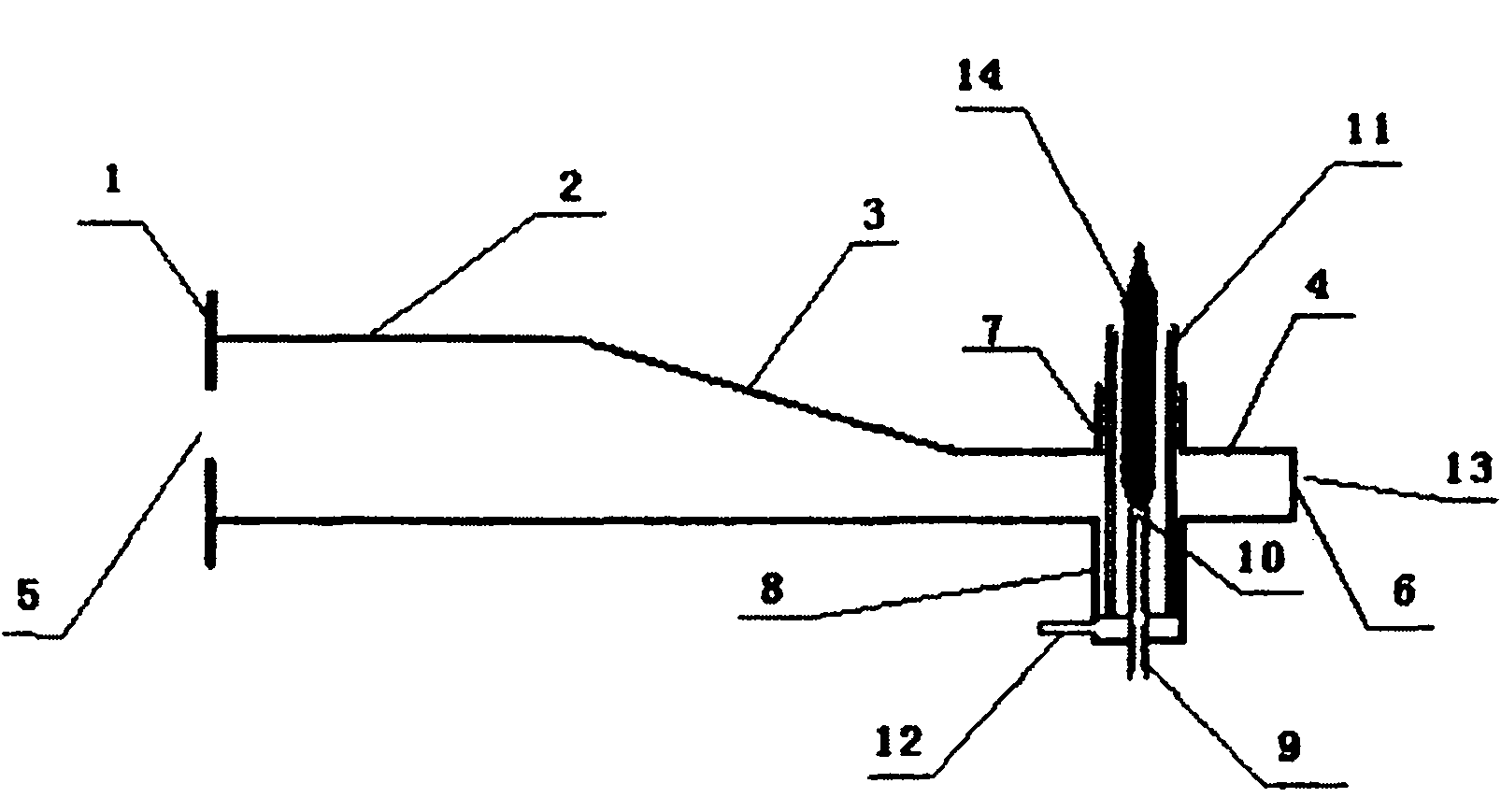

Microwave plasma ignition device

InactiveCN101852444APlay a role in combustionPlay a role in stabilizing combustionIncandescent ignitionPlasma techniqueElectrical conductorCoaxial line

The invention discloses a microwave plasma ignition device, which comprises a microwave resonance cavity, a quartz glass tube plasma generating area, a tangential air supply device and a coal dust flow blowing-in device. The coal dust flow blowing-in device axially blows coal dust flow into the microwave plasma generating area in a quartz glass tube; when the input microwave power exceeds a critical value, the microwave plasma generating area generates initial ionization under the excitation of micro coal dust in the coal dust flow, and the initial ionization is transited to the whole quartz glass tube through avalanche effect so as to form a microwave plasma torch. Meanwhile, the coal dust flow is ignited to form a coal dust microwave plasma torch and is blown out from the upper end of the quartz glass tube along the axial direction of the quartz glass tube. The coal dust and the microwave plasma are mutually acted so as to raise the temperature of the output torch of the ignition device, increase the ignition, combustion support and combustion stabilization capabilities of the microwave plasma ignition device and meanwhile overcome the defects that the microwave plasma torch is excited by coaxial inner conductors in the microwave plasma generating area and the high-temperature plasma torch melts the coaxial inner conductors due to long time.

Owner:白野 +1

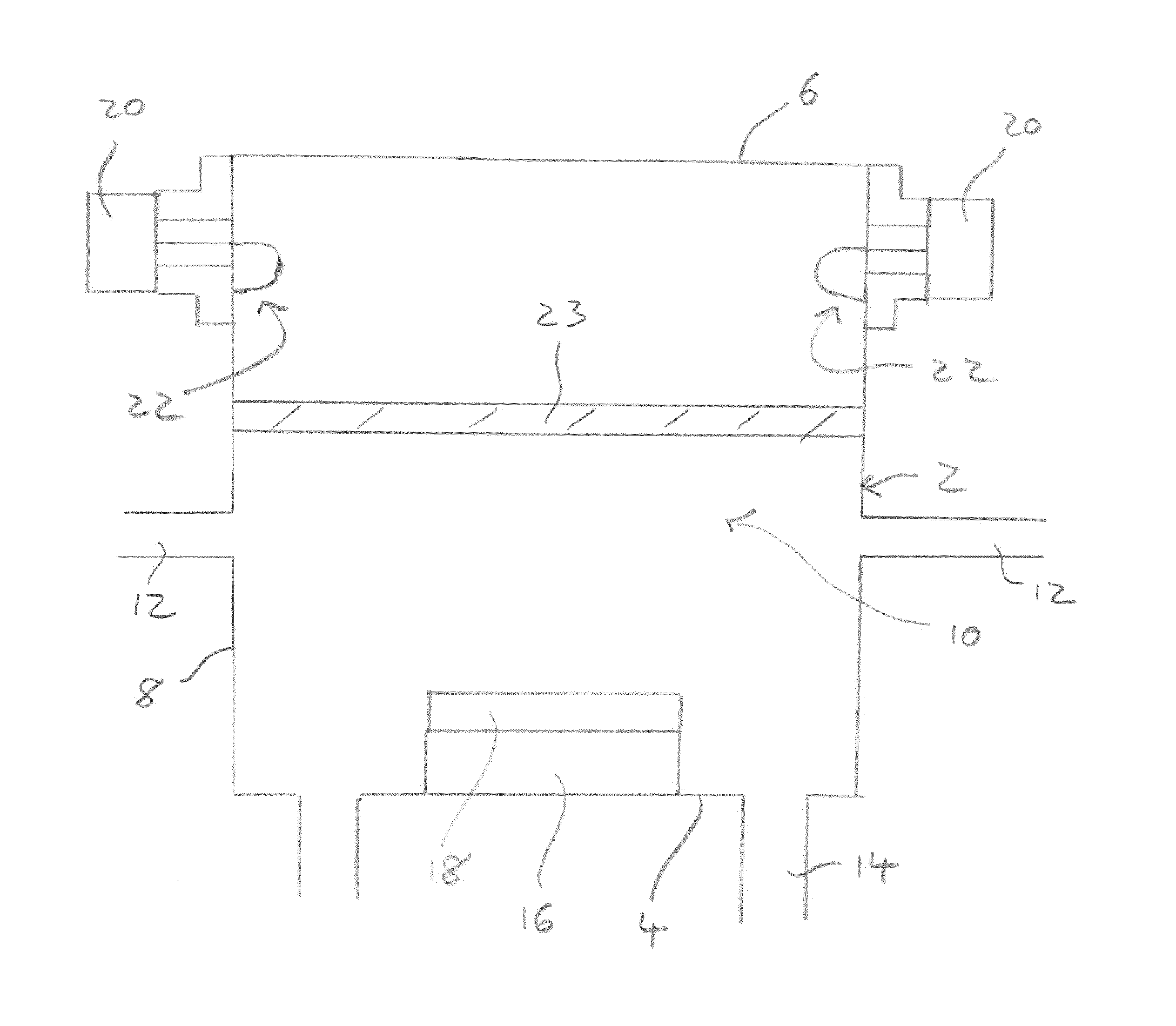

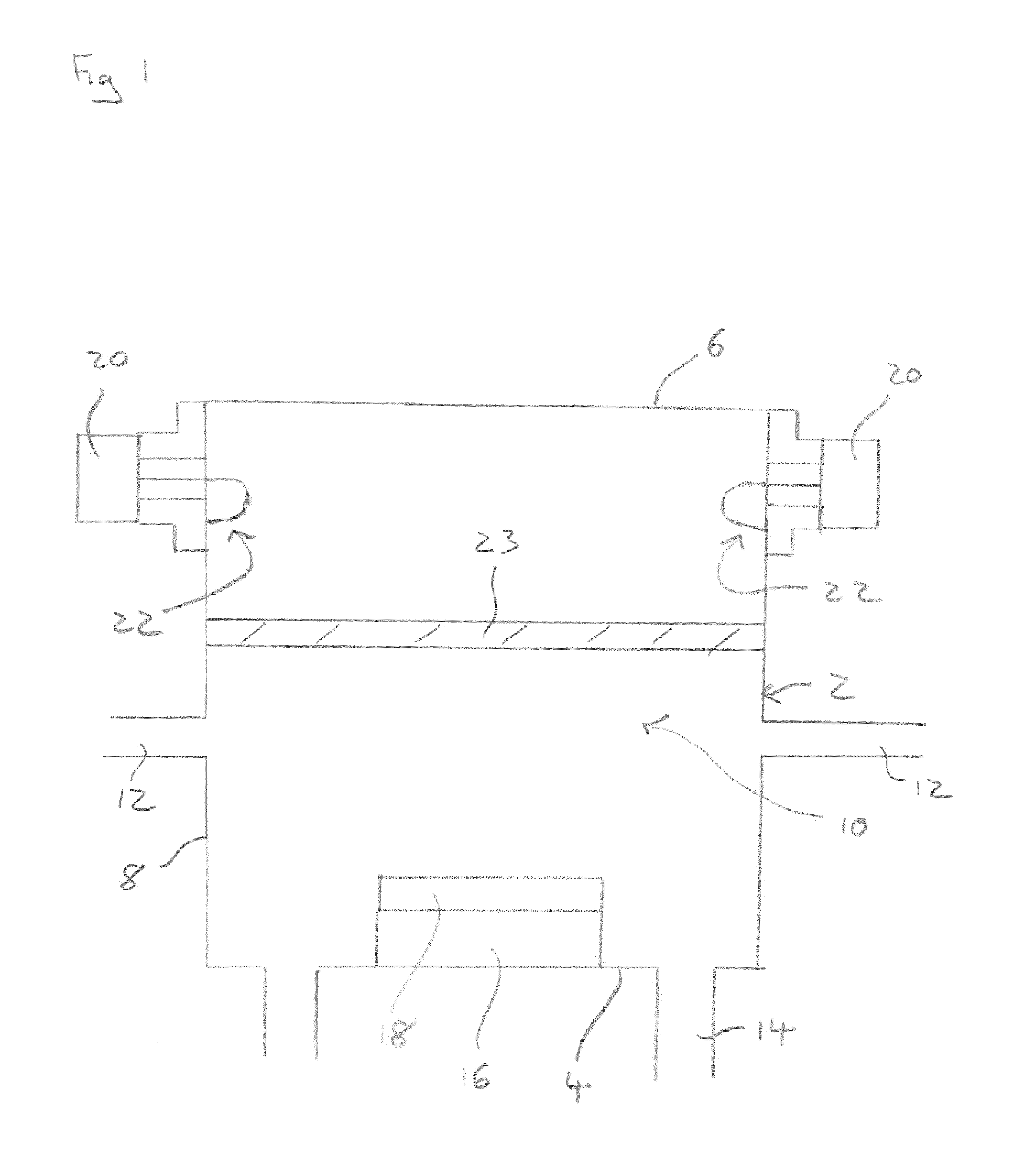

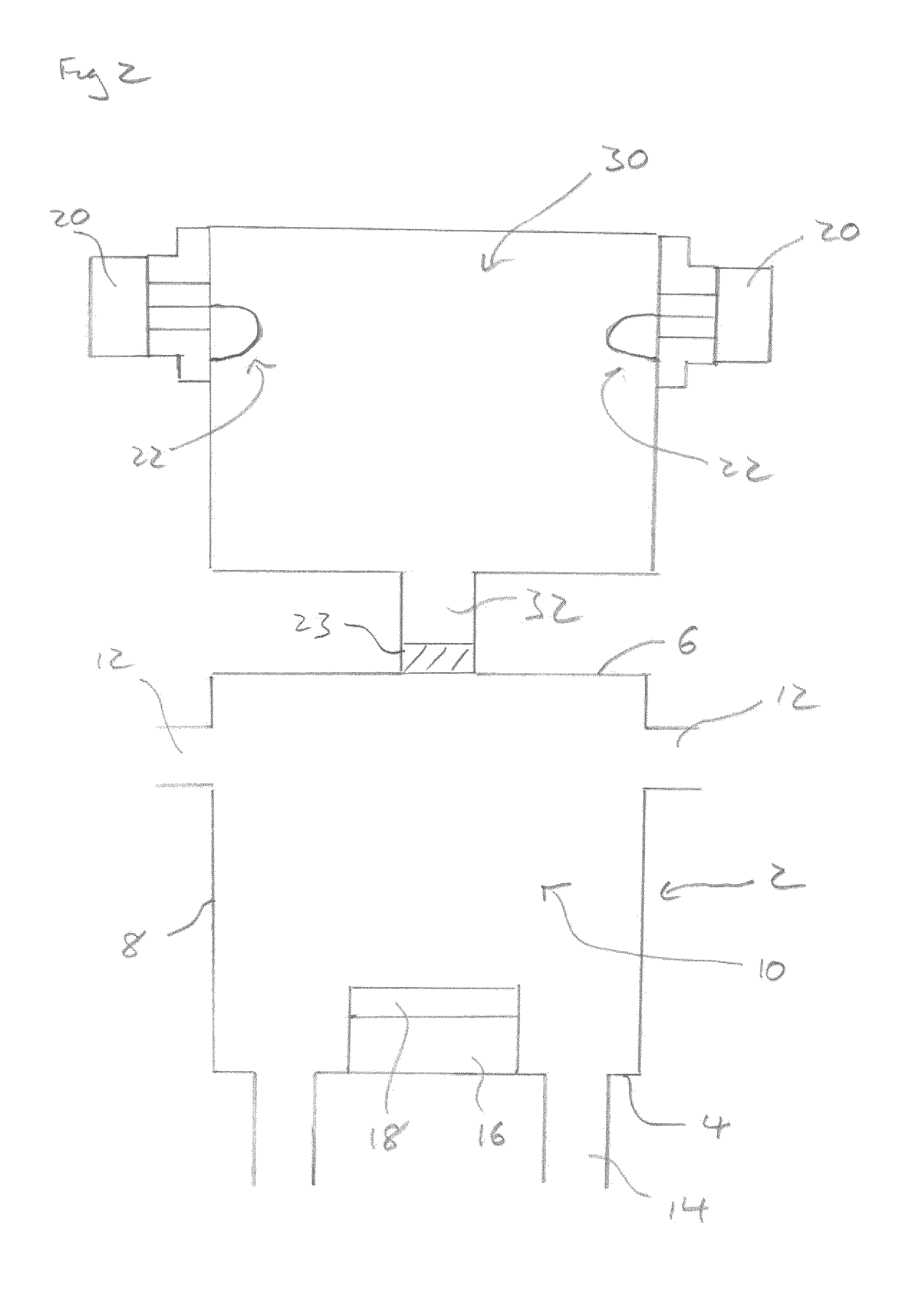

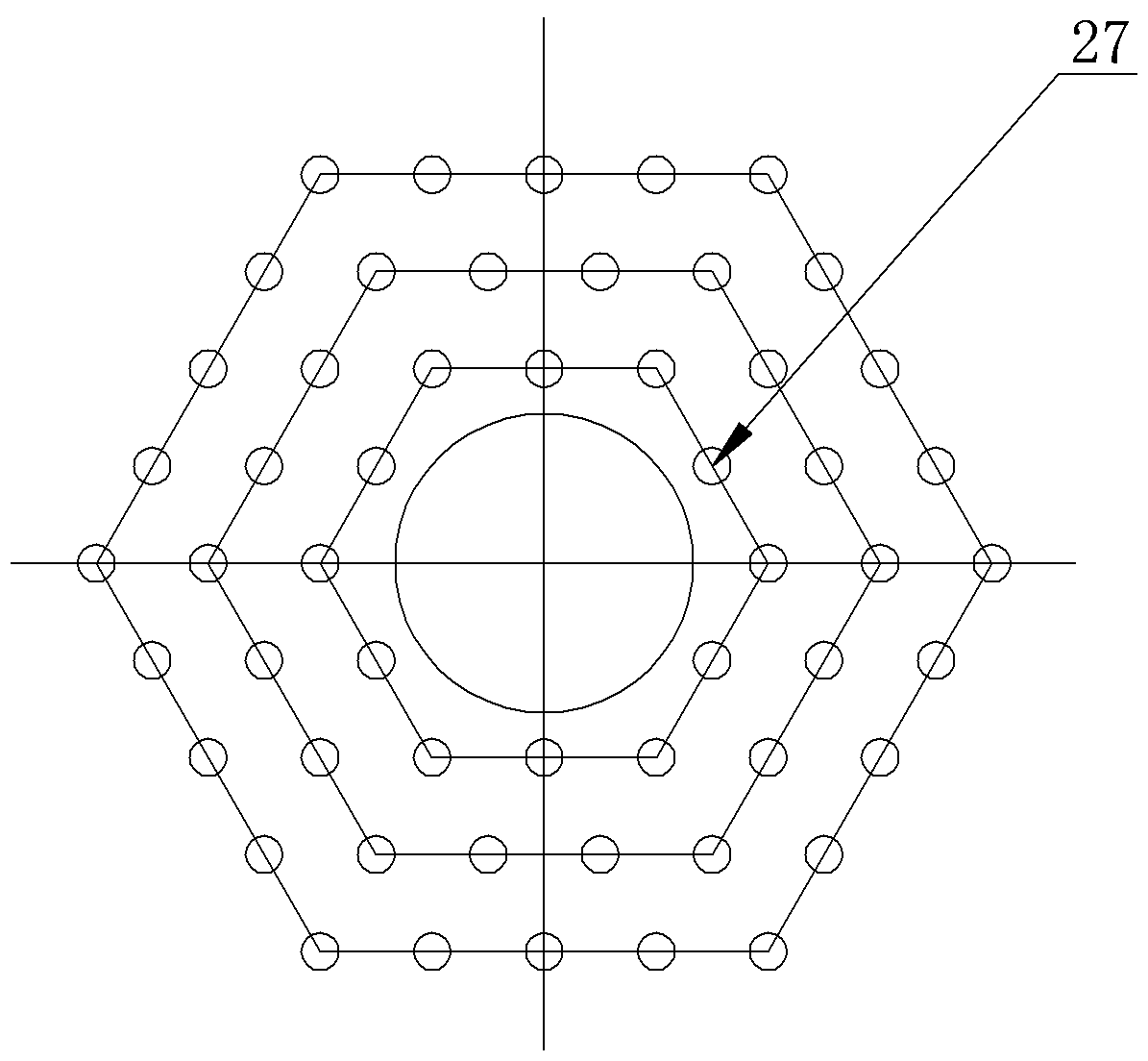

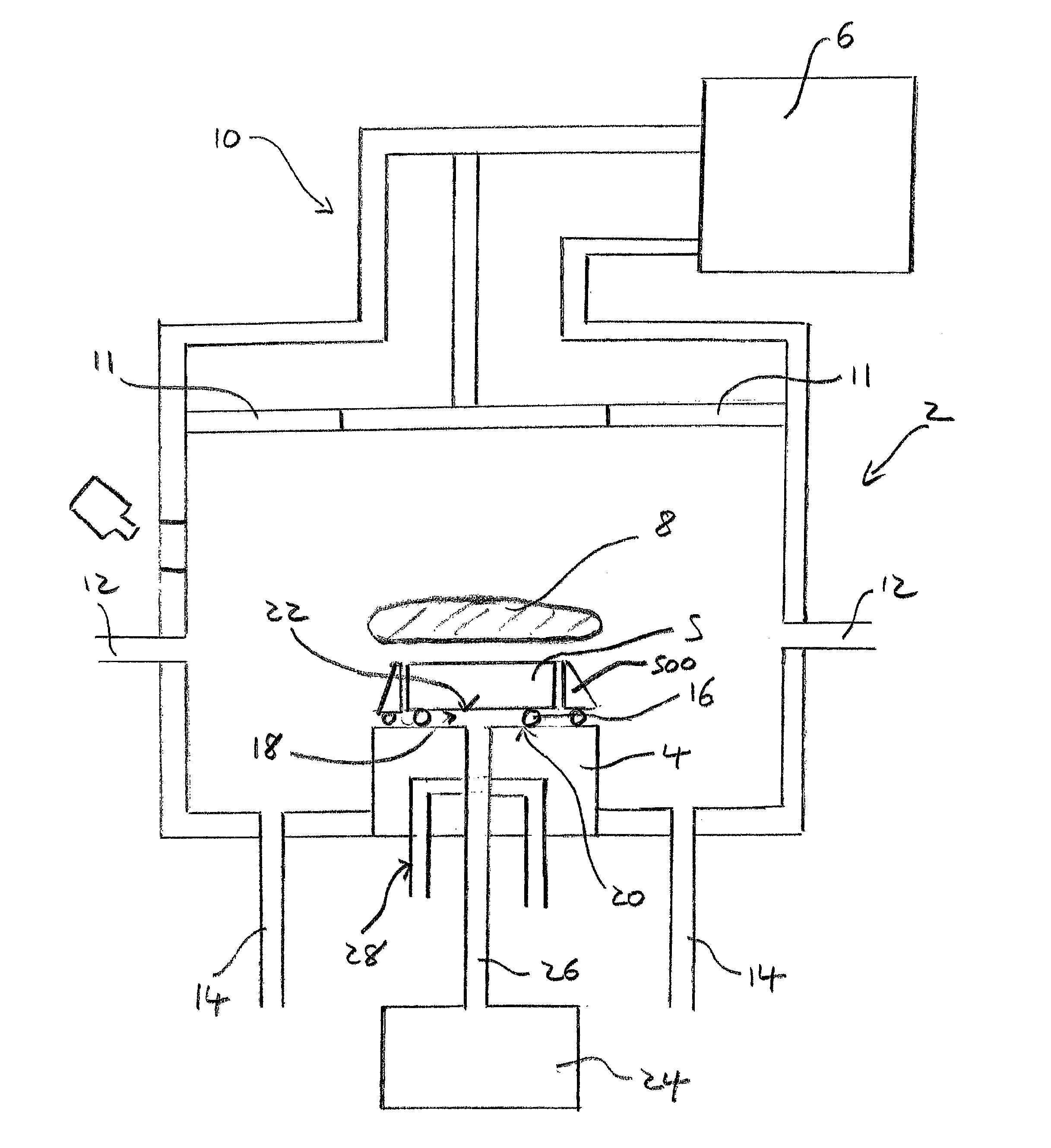

A microwave plasma reactor for manufacturing synthetic diamond material

ActiveUS20170040145A1Reduce yieldPolycrystalline material growthElectric discharge tubesResonant cavityGas phase

A microwave plasma reactor for manufacturing synthetic diamond material via chemical vapour deposition, the microwave plasma reactor comprising: a plasma chamber defining a resonant cavity for supporting a primary microwave resonance mode having a primary microwave resonance mode frequency f; a plurality of microwave sources coupled to the plasma chamber for generating and feeding microwaves having a total microwave power Pτ into the plasma chamber; a gas flow system for feeding process gases into the plasma chamber and removing them therefrom; and a substrate holder disposed in the plasma chamber and comprising a supporting surface for supporting a substrate on which the synthetic diamond material is to be deposited in use, wherein the plurality of microwave sources are configured to couple at least 30% of the total microwave power Pτ into the plasma chamber in the primary microwave resonance mode frequency f, and wherein at least some of the plurality of microwave sources are solid state microwave sources.

Owner:ELEMENT SIX TECH LTD

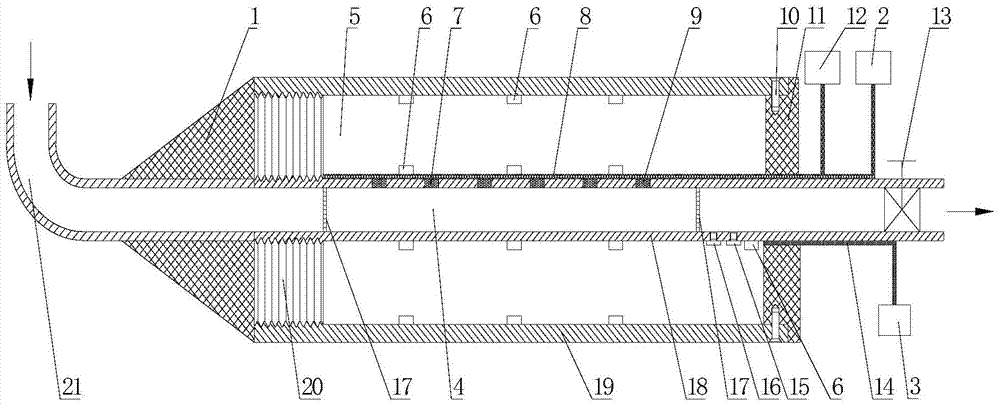

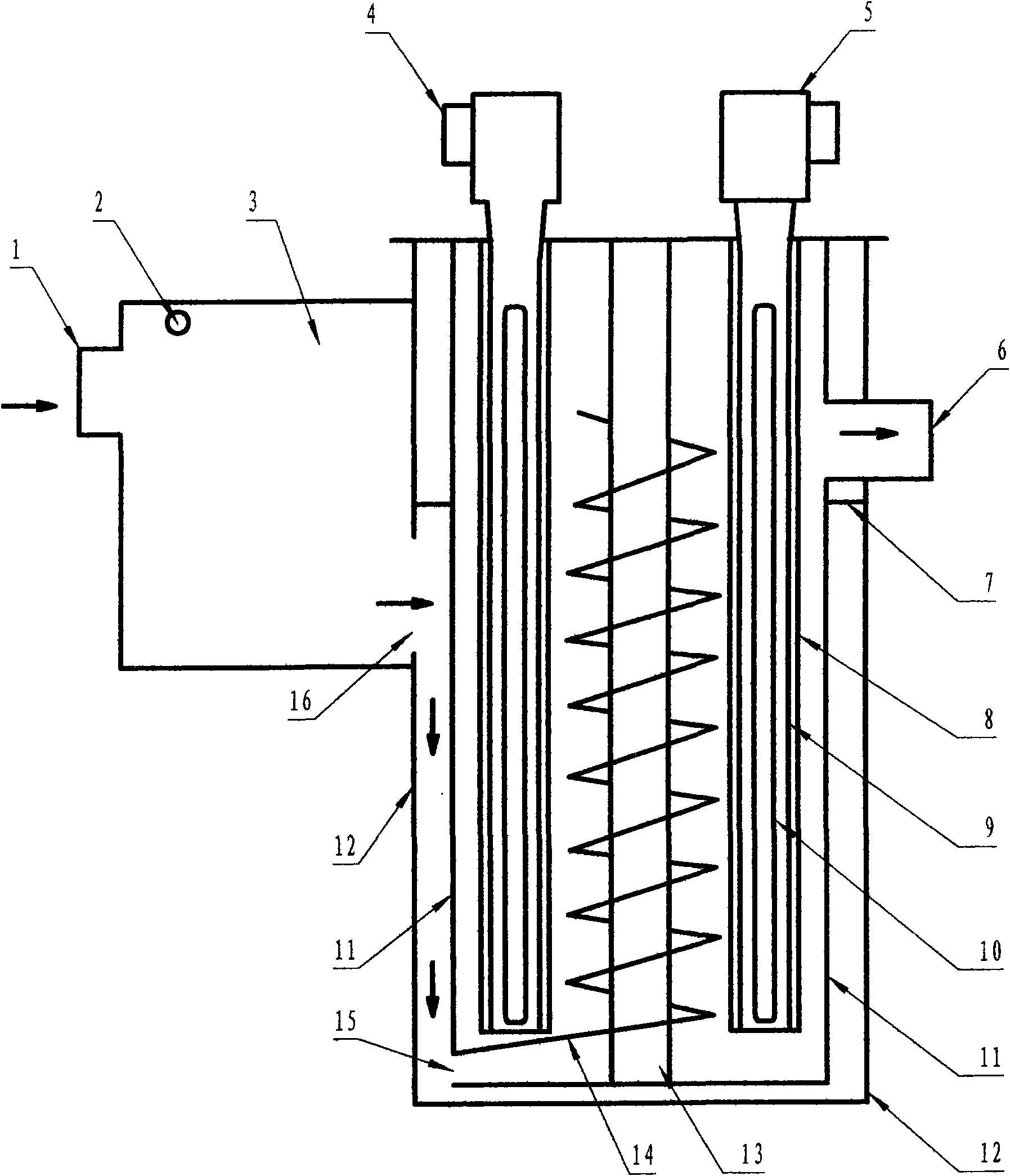

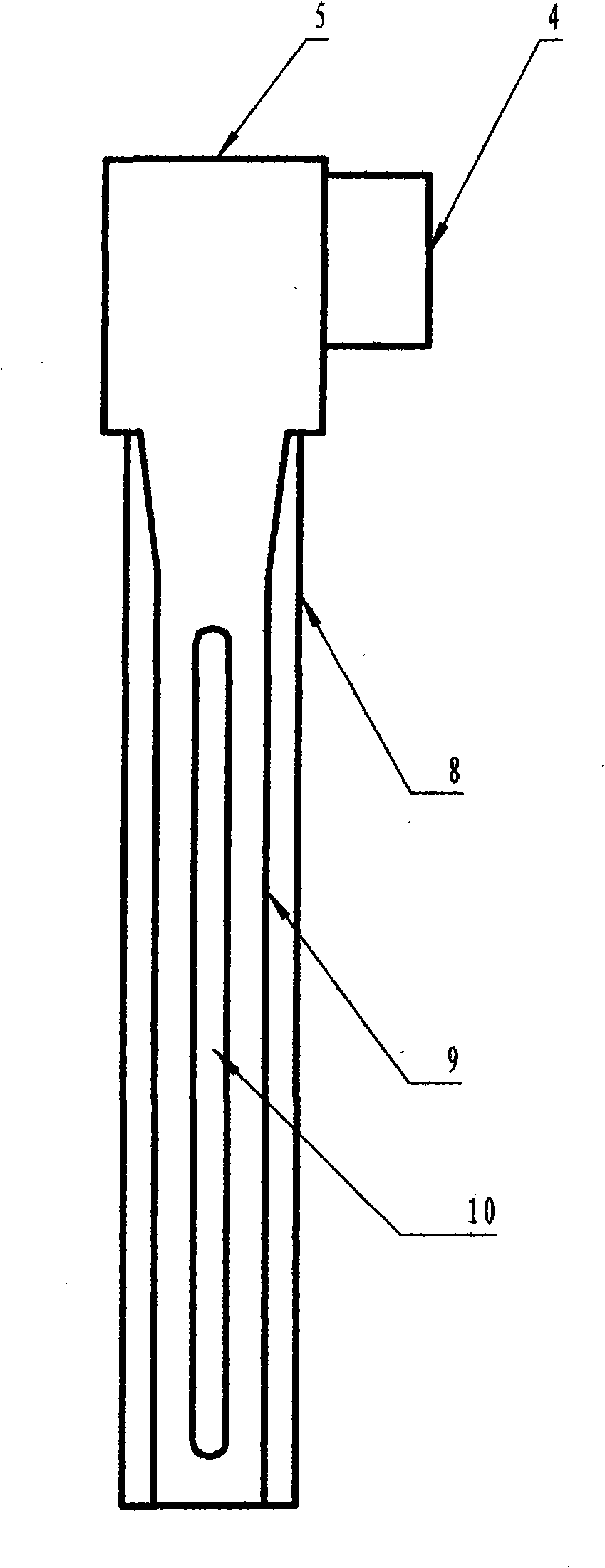

Flowing wet vapor humidity measurement probe based on microwave heating and measurement method thereof

InactiveCN103940851AShorten the lengthAccurate measurementMaterial moisture contentCoaxial lineData acquisition

The invention discloses a flowing wet vapor humidity measurement probe based on microwave heating and a measurement method of the probe. The probe is characterized in that flowing wet vapor is heated to form superheated vapor through microwaves, and then measurement on the wet vapor humidity is achieved. The wet vapor probe mainly comprises a sampling probe, a microwave heating section, a microwave source, a control circuit, temperature and pressure sensors and a data acquisition system, wherein the sampling probe is aligned to the flowing direction of wet vapor so as to achieve isokinetic sampling; microwaves generated from the microwave source are transmitted into a microwave resonance cavity through a coaxial line; moisture and vapor in flowing wet vapor inside the resonance cavity can simultaneously absorb microwave energy so as to be rapidly heated to form superheated vapor; data measured by the temperature and pressure sensors are displayed, processed and output through the data acquisition system, and then measurement on the humidity of flowing wet vapor is achieved. The probe is applicable to measurement on the humidity of flowing wet vapor at various flowing speeds, and in particular to measurement on the humidity of wet vapor inside a turbine.

Owner:XI AN JIAOTONG UNIV

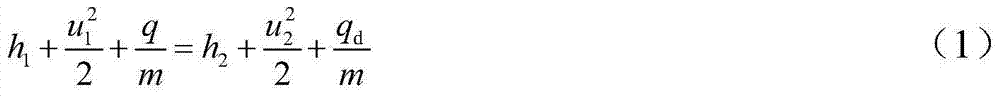

Tunable rounding cavity type high-power microwave plasma chemical vapor deposition device

ActiveCN108624870AEnhanced couplingImprove feedFinal product manufactureChemical vapor deposition coatingDistributed structureMicrowave resonance

The invention discloses a tunable rounding cavity type high-power microwave plasma chemical vapor deposition device which is composed of a microwave resonance cavity main body, a mode converter and amicrowave electric field adjusting system. According to the chemical vapor deposition device, by means of the rounding cavity type cavity, a sample table, the mode converter and an adjusting structurethereof, the problems of low microwave input power, the poor focusing ability, shortage of perfect adjusting measures and the too close distance between a unifying part and plasma existing in variousexisting devices can be effectively solved, gas is input from the top and output from the bottom, the multi-hole array distributing structure of a flow uniformizing ring and a buffering bin is adopted, uniformity of gas flow and distribution in a resonance cavity and on the surface of a base piece can be effectively is improved, and deposition efficiency and uniformity of a deposition diamond film are further improved. The device can achieve efficient deposition of large-area and high-quality diamond film under high power.

Owner:CHENGDU NEWMAN HERUI MICROWAVE TECH CO LTD

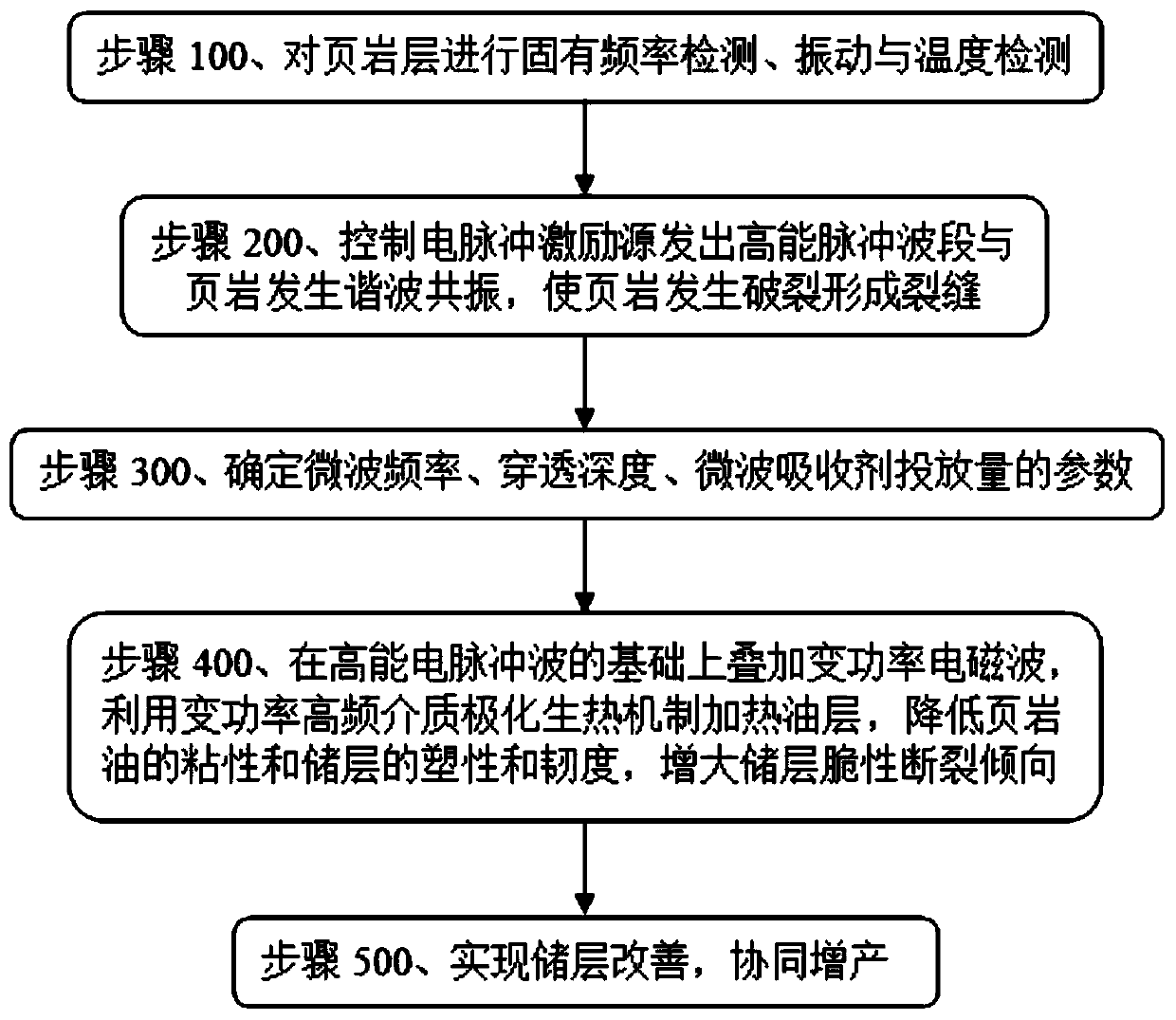

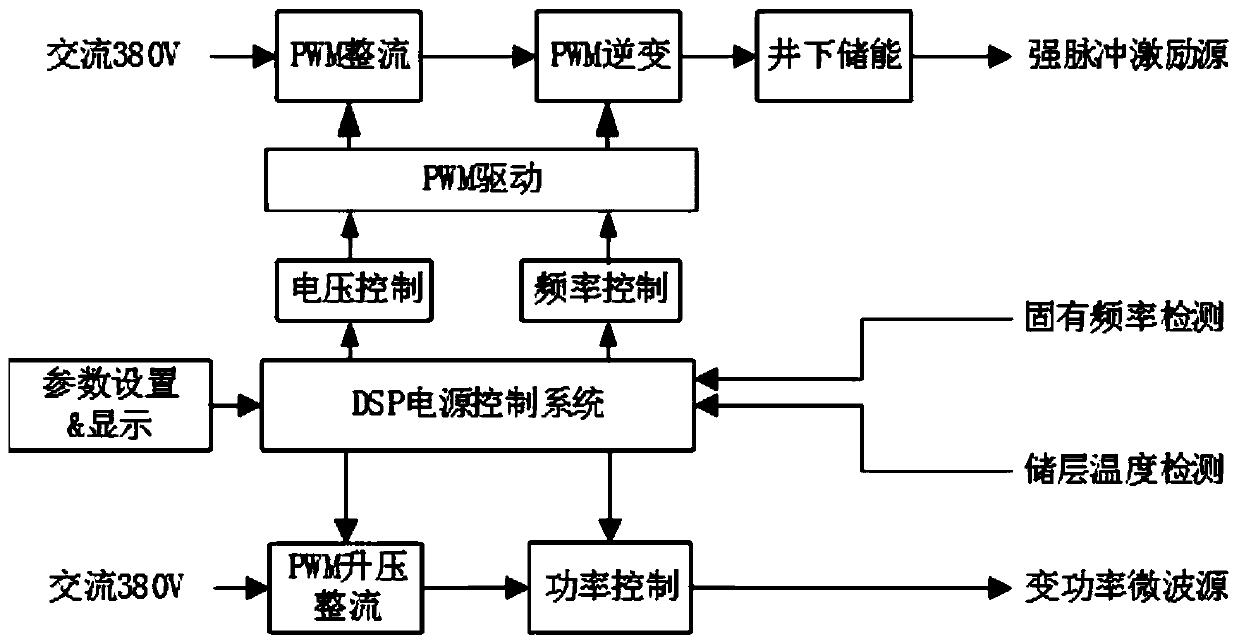

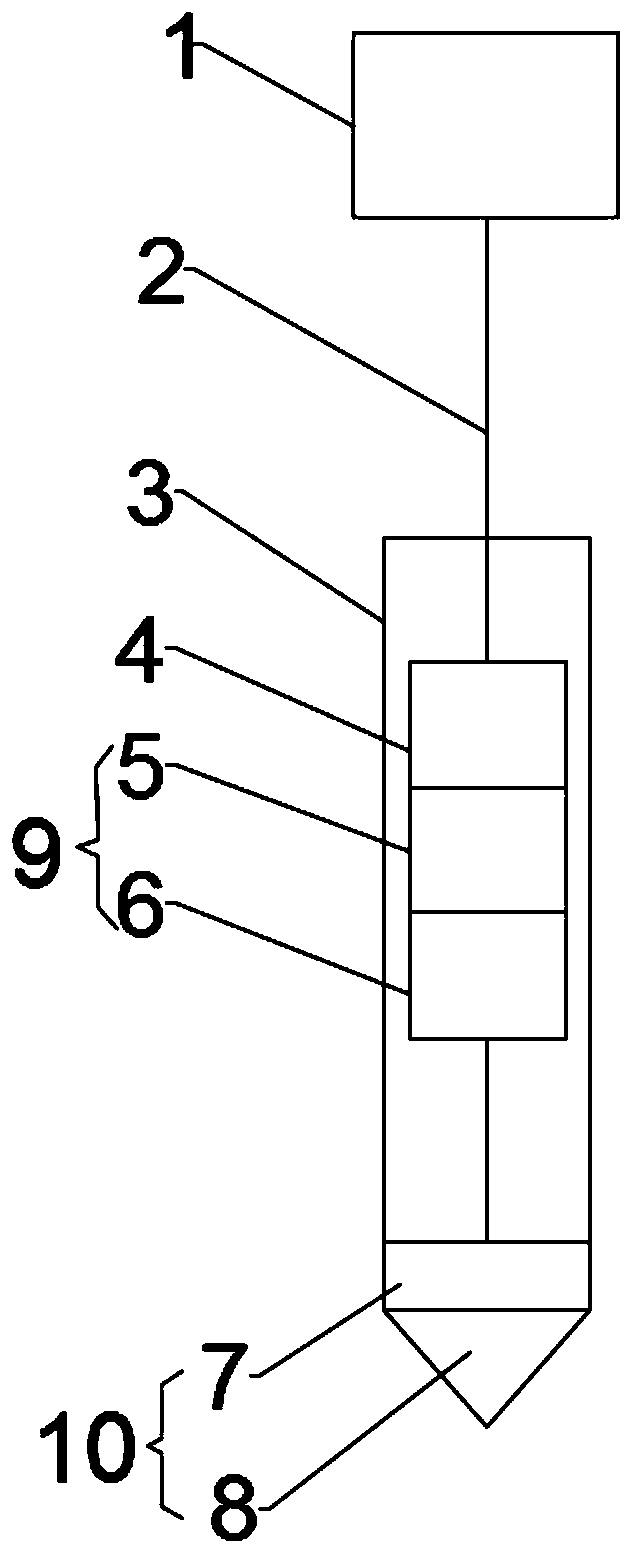

Shale oil and gas microwave resonance impact collaborative production-increasing technical method

ActiveCN110485959AReduce pollutionReduce energy consumptionFluid removalVibration devicesFrequency spectrumHigh energy

The embodiment of the invention discloses a shale oil and gas microwave resonance impact collaborative production-increasing technical method. The shale oil and gas microwave resonance impact collaborative production-increasing technical method comprises the following steps that S100, a shale bed is subjected to inherent frequency detection and vibration and temperature detection; S200, an electric pulse excitation source is controlled to emit a high-energy pulse wave band to be subjected to harmonic resonance with shale, and thus the shale cracks to form a crack; S300, the microwave frequency, the penetration depth and the microwave absorbent delivery quantity are determined; S400, variable-power electromagnetic waves are superimposed on the basis of high-energy electric pulse waves, an oil reservoir is heated through a variable-power high-frequency medium polarization heat-generation mechanism, the viscosity of shale oil and the plasticity and toughness of the reservoir are lowered,and the reservoir brittle rupture tendency is enlarged; and S500, the reservoir is improved, and collaborative production-increasing is realized. The advantages of an electromagnetic wave heating production-increasing technology and a frequency spectrum resonance impact production-increasing technology are combined, the high-energy impact waves with the inherent frequency of the target reservoir are superimposed on the electromagnetic wave heating basis, and the characteristics of low pollution, low energy consumption and the like are realized.

Owner:OIL & GAS SURVEY CGS

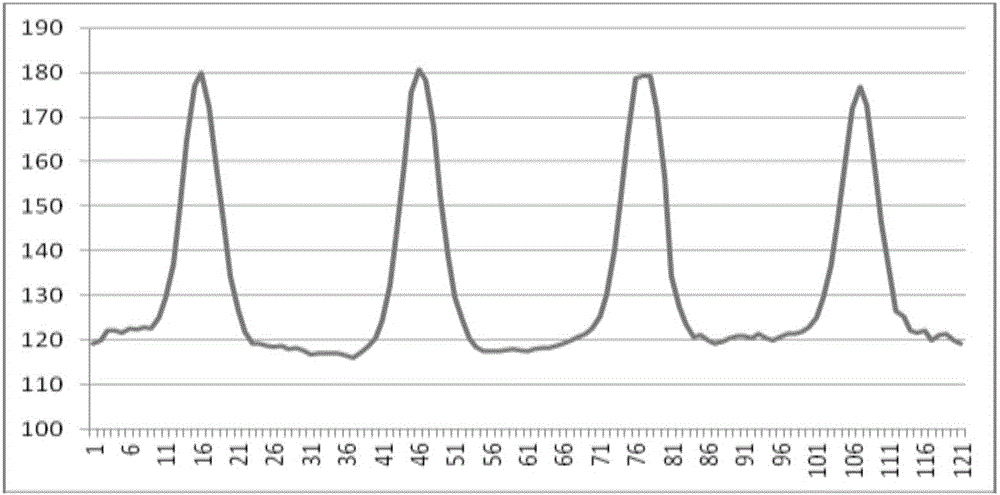

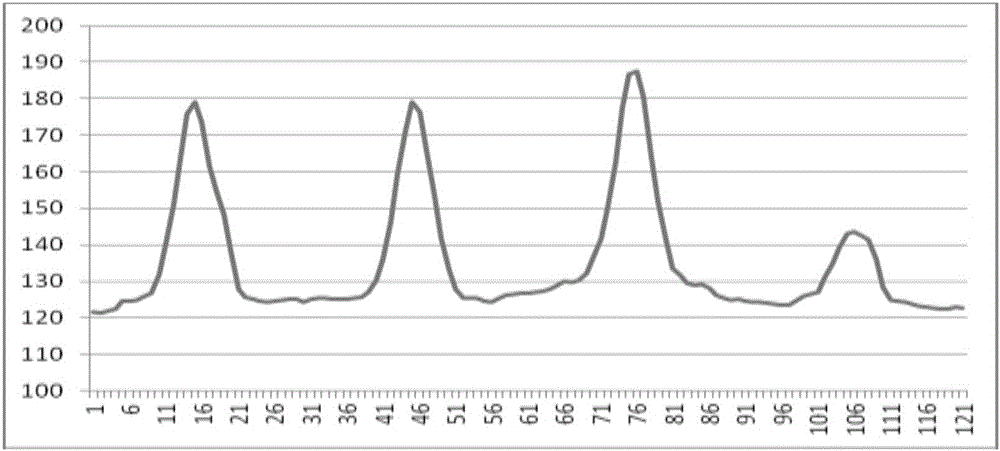

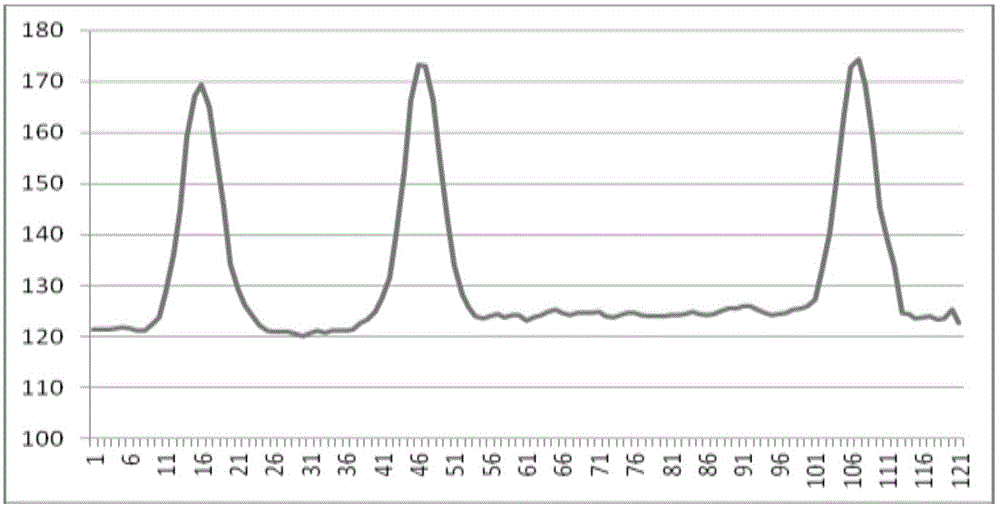

Microwave determination method for breakable beads in breakable bead filter rod

ActiveCN105866140AAccurately measure damageOvercome labor intensityFlaw detection using microwavesUsing wave/particle radiation meansDensity curveHorizontal axis

The invention discloses a microwave determination method for breakable beads in a breakable bead filter rod. The microwave determination method comprises the following steps: collecting breakable bead samples, and measuring the diameters Db of the breakable beads; collecting a breakable bead filter rod sample, measuring the density rholij of the part which does not contain the breakable bead of the filter rod, and finding out the maximum value rholmax of rholij; measuring the density rholij of the part containing the breakable beads of the filter rod, finding out the maximum value rohbihmax of the unit density of the part in which each breakable bead is located, and finding out the minimum value rhomin of rohbihmax; measuring the density of the breakable bead filter rod by virtue of a microwave resonance method by taking the length of 1mm or less as a measurement unit, and drawing a density curve of the breakable bead filter rod by taking the length as a horizontal axis and the density as a vertical axis; and reflecting the existence the breakable bead by virtue of the appearance of a peak value in the curve, reflecting the position offset of the breakable bead by virtue of the corresponding length of the peak value, and reflecting the damage condition of the breakable bead by virtues of the variation of the peak value. The microwave determination method is simple, the operation is easy, and the existence, position offset and damage condition of the breakable bead in the breakable bead filter rod can be accurately determined.

Owner:CHINA TOBACCO SHANDONG IND

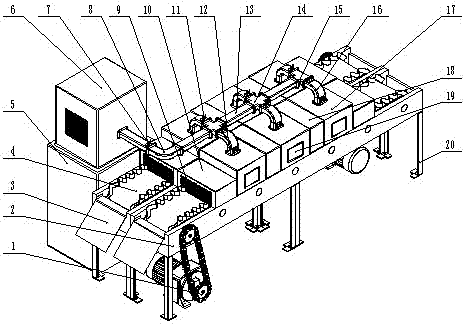

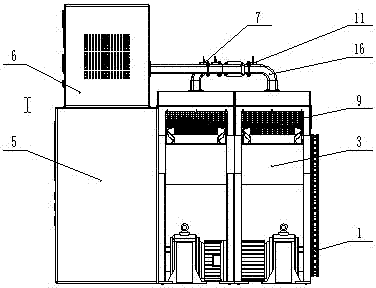

Dual-belt type microwave quick sterilizing device

PendingCN107535796AReduce in quantityImprove securityFood processingFood preservationResonant cavityBelt speed

The invention belongs to the technical field of food processing, and relates to a dual-belt type microwave quick sterilizing device. The dual-belt type microwave quick sterilizing device comprises a dual-conveyer-belt transporting device (4). The dual-belt type microwave quick sterilizing device is characterized in that the belt speed of the dual-conveyer-belt transporting device (4) can be adjusted according to different materials; sterilizing resonance cavities (17) are arranged on a single conveyer belt, and are mutually independent; a vertical wave guide pipe (16) communicates with the corresponding sterilizing resonance cavity (17); an independent microwave adjusting switch (12) and a microwave detecting device (11) are arranged on the vertical wave guide pipe (16), and the sterilizing process of each sterilizing resonance cavity can be controlled through a microwave master console (5), and the number of the microwave resonance cavities (17) can be increased and reduced to changethe microwave sterilization efficiency. The dual-belt type microwave quick sterilizing device disclosed by the invention is reasonable in structure, energy-saving, low in consumption, is suitable forfoods of different sizes and kinds, economical and practical, safe and environmental-friendly.

Owner:SHIHEZI UNIVERSITY

Disinfection well for ultraviolet sewage treatment by using microwaves

InactiveCN101676221AIncrease contact timeNot affected by timeWater/sewage treatment by irradiationUltraviolet lightsWater flow

The invention is applied to ultraviolet sewage treatment in the field of environmental protection. Lamp tubes, the conventional equipment for ultraviolet sewage treatment, have low electrode efficiency and short lives, have large floor areas because of using open channels for flowing and have poor effects. The invention adopts the microwaves sent out by magnetrons as the energy sources. The ultraviolet quartz lamp tubes are arranged in a cylindrical microwave resonance cavity body, are filled with mercury and protective gases, emit ultraviolet light under microwave excitation, have no electrodes and have long lives. A facility for current to flow in and out, with a cylindrical well type structure, and a spiral diversion facility installed in the facility for current to flow in and out canenable water to be fully contacted with the ultraviolet rays, thus obtaining good sterilization effects. The floor area of the invention is only a small percentage of that of the conventional equipment for ultraviolet sewage treatment.

Owner:吕志敏

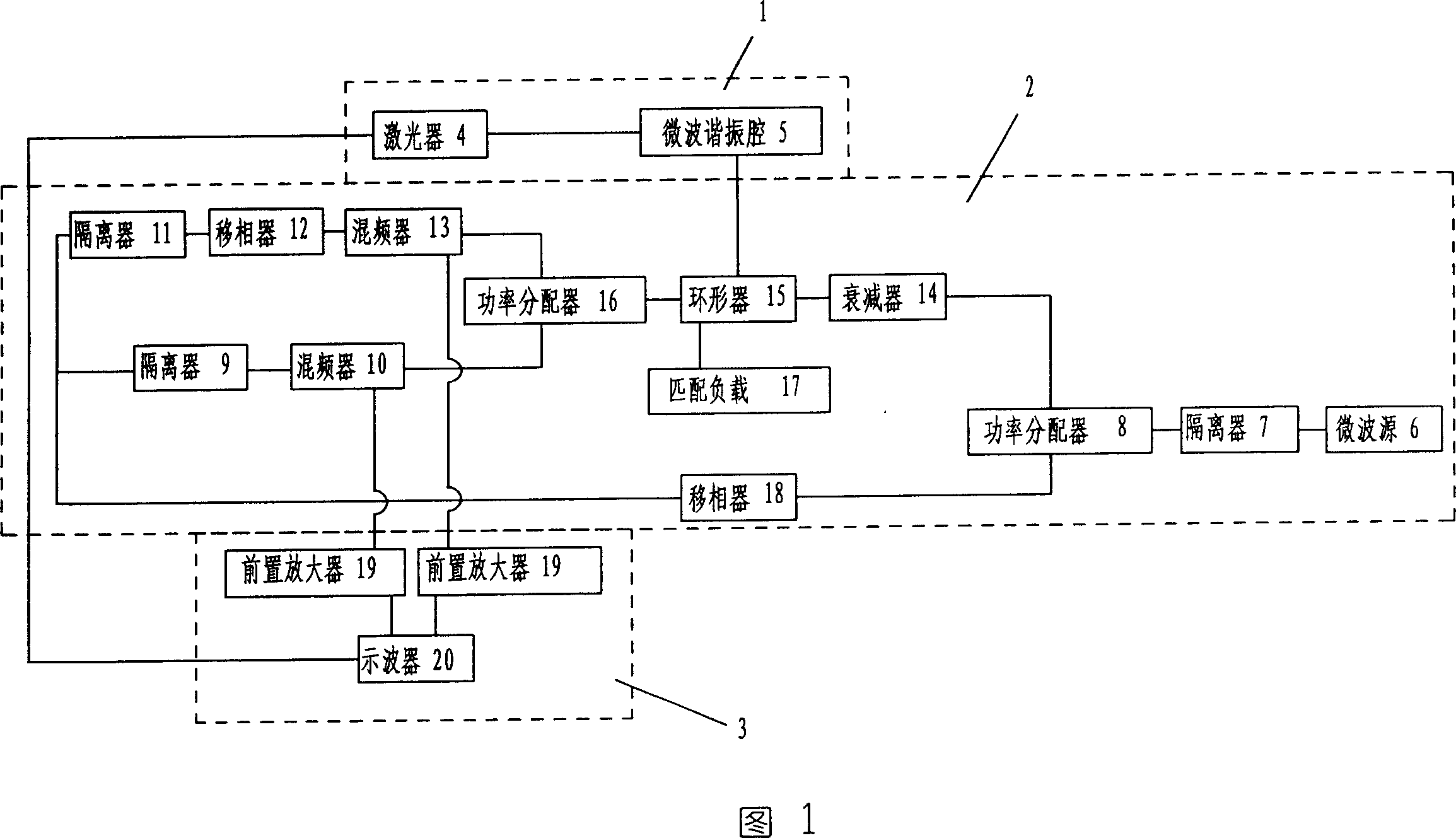

Photoelectron characteristic detecting method for thin-layer microcrystal medium material and device thereof

InactiveCN101017145ARealize real-time non-destructive measurementMaterial analysis using wave/particle radiationAnalysis by material excitationDiffusionImage resolution

This invention relates to one film transistor medium material photo electron property test method and device, which comprises the following scheme: micro source giving out two paths of micro wave with one for reference signal and other for detection signals into microwave vibration chamber; using laser to light microwave resonance chamber dielectric materials; reflecting detection signals from the chamber into two balance frequency mixture devices; the device makes use of the mixture of the signals by use of phase sensitive technique to isolate micro wave absorptive signals and diffusion signals converted into voltage change; outputting voltage change into computer to get freedom and beam signal range attuning curve.

Owner:HEBEI UNIVERSITY

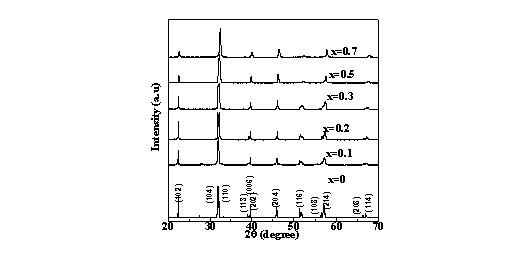

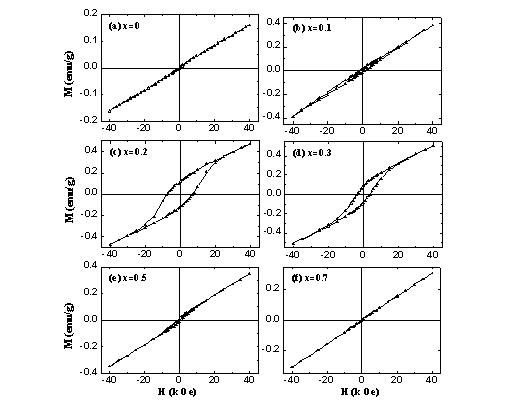

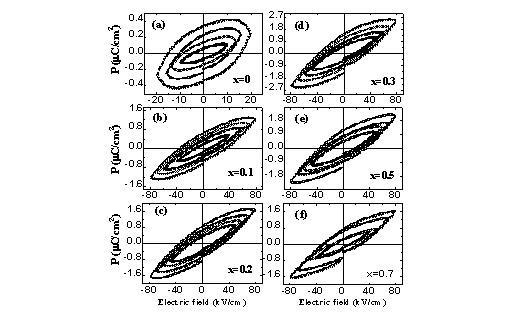

BiFeO3-Bi0.5Na0.5TiO3 base multiferroic solid solution ceramic and preparation method thereof

InactiveCN101941838AReduce leakage currentFerroelectric/ferromagnetic coexistence at room temperatureMicrowave resonanceTableting

The invention belongs to the technical field of information functional materials and in particular relates to BiFeO3-Bi0.5Na0.5TiO3 base multiferroic solid solution ceramic and a preparation method thereof. The preparation method comprises the following steps of: dissolving bismuth nitrate and ferric nitrate in a citric acid solution to form a transparent BiFeO3 solution; dissolving butyl titanate, bismuth nitrate and sodium nitrate into the citric acid solution to form a transparent Bi0.5Na0.5TiO3 solution; mixing the BiFeO3 solution and the Bi0.5Na0.5TiO3 solution by a certain molar ratio and then regulating the pH value to 7-7.5 with ammonia water; aging, dewatering and drying the mixed solution to form black xerogel; grinding the xerogel and carrying out heat treatment to remove organic matters to obtain precursor powder; and grinding, tabletting and sintering the precursor powder to obtain the BiFeO3-Bi0.5Na0.5TiO3 base multiferric solid solution ceramic. The BiFeO3-Bi0.5Na0.5TiO3 base multiferric solid solution ceramic has the characteristics of single phase structure, low leakage current, ferroelectric / ferromagnetic coexistence at room temperature, and the like and has wideapplication prospect in the aspects of manufacturing emerging spin valve devices, magnetoelectric storages, magnetoelectric sensors and microwave resonance devices.

Owner:HUAZHONG UNIV OF SCI & TECH

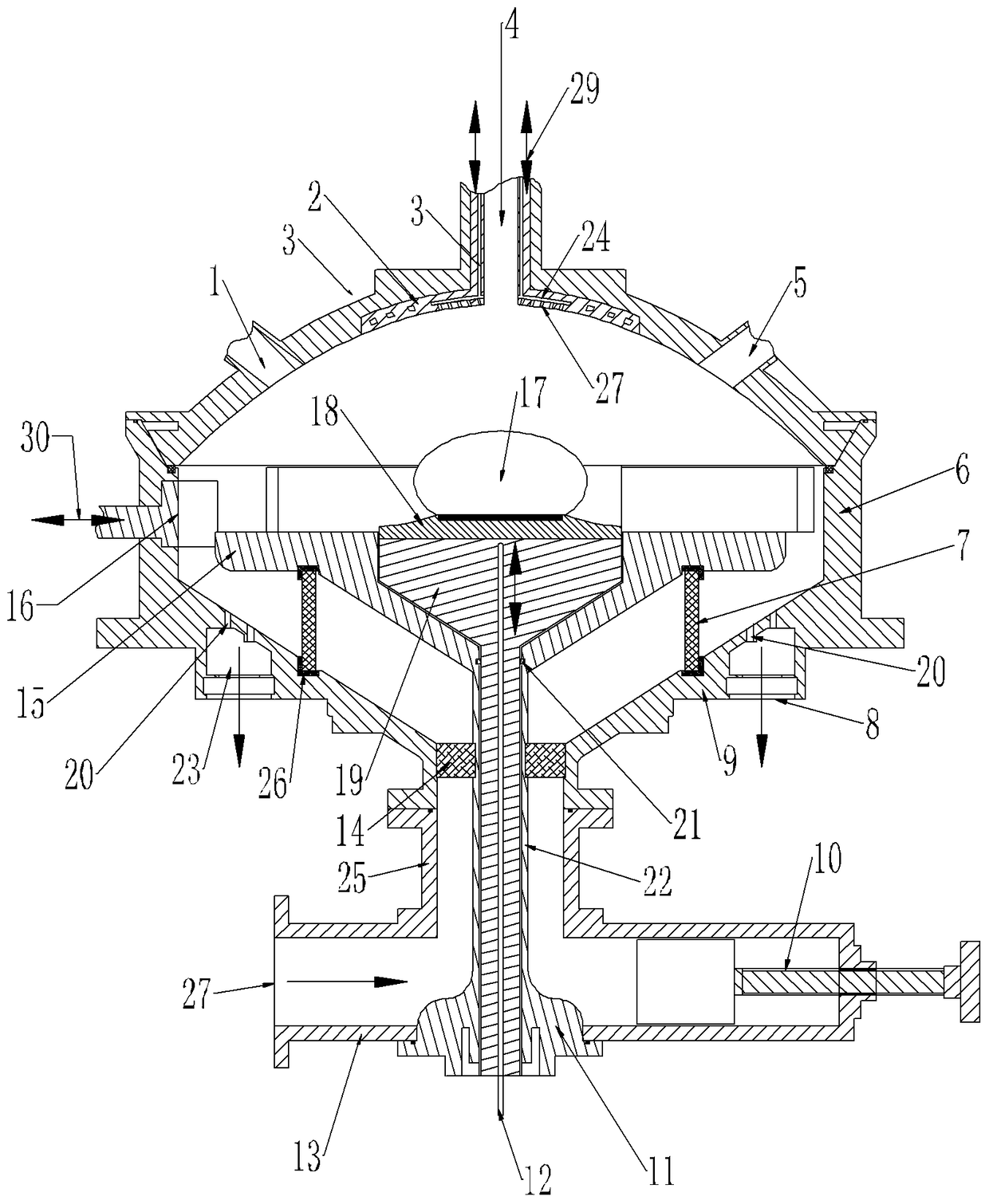

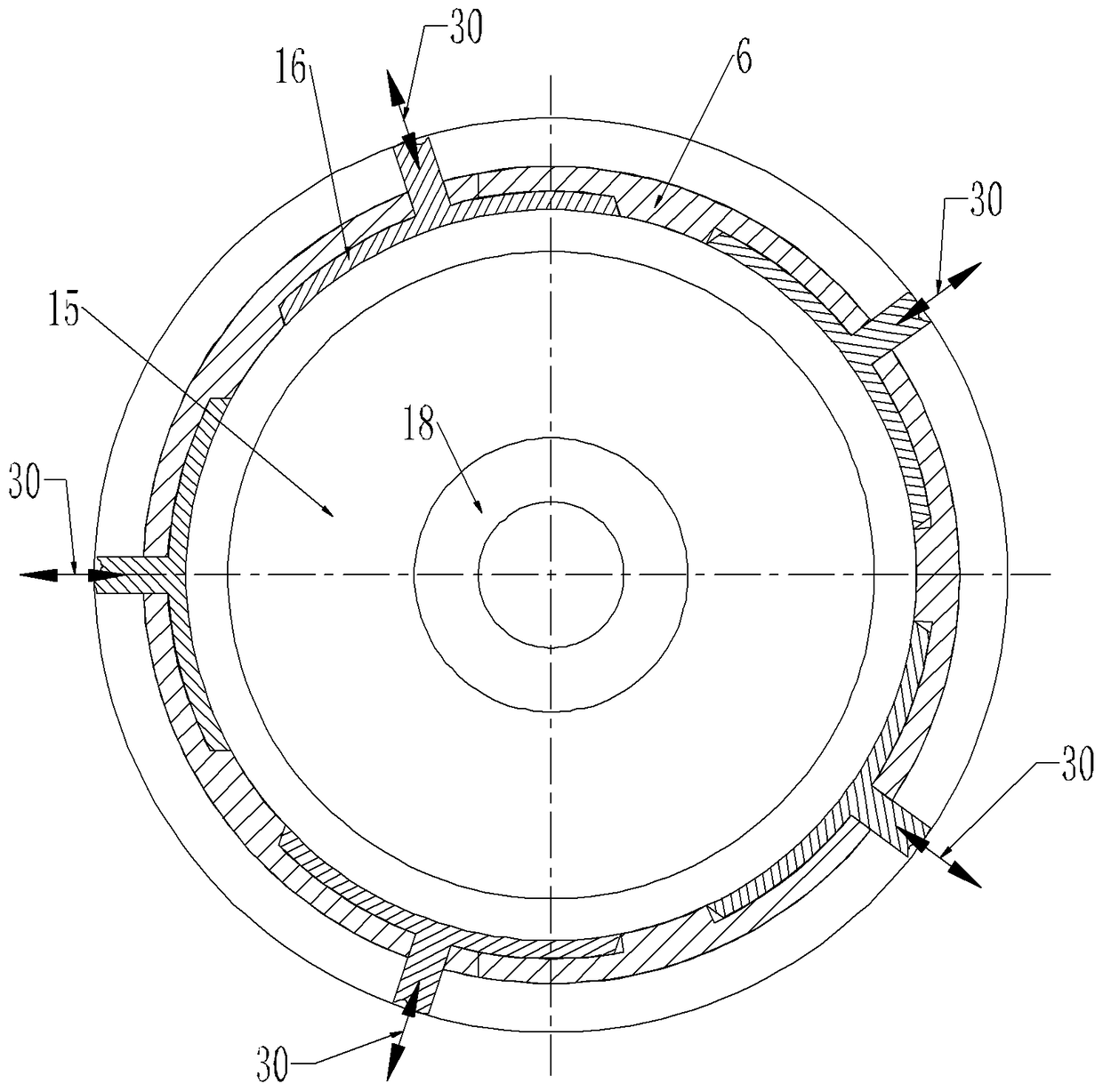

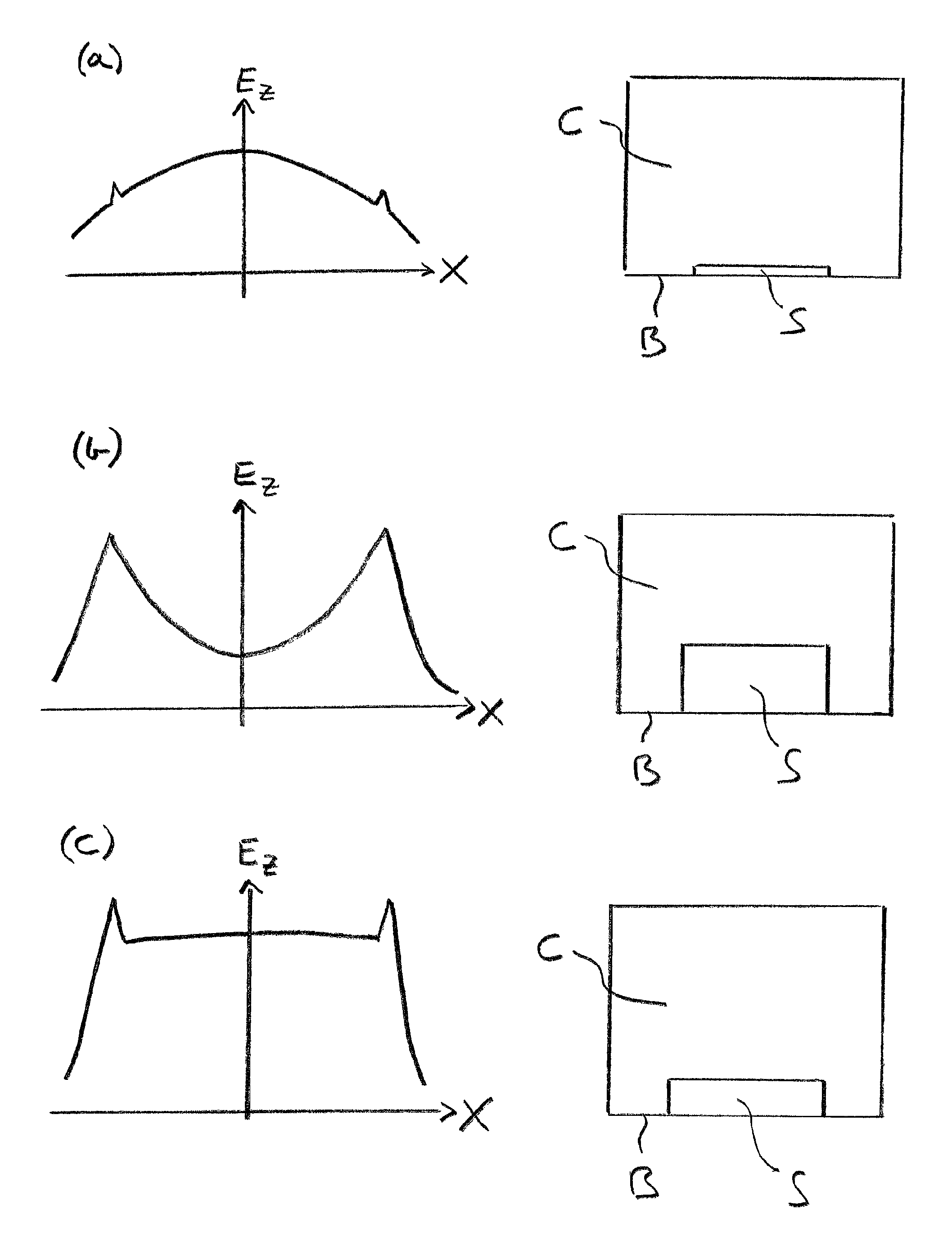

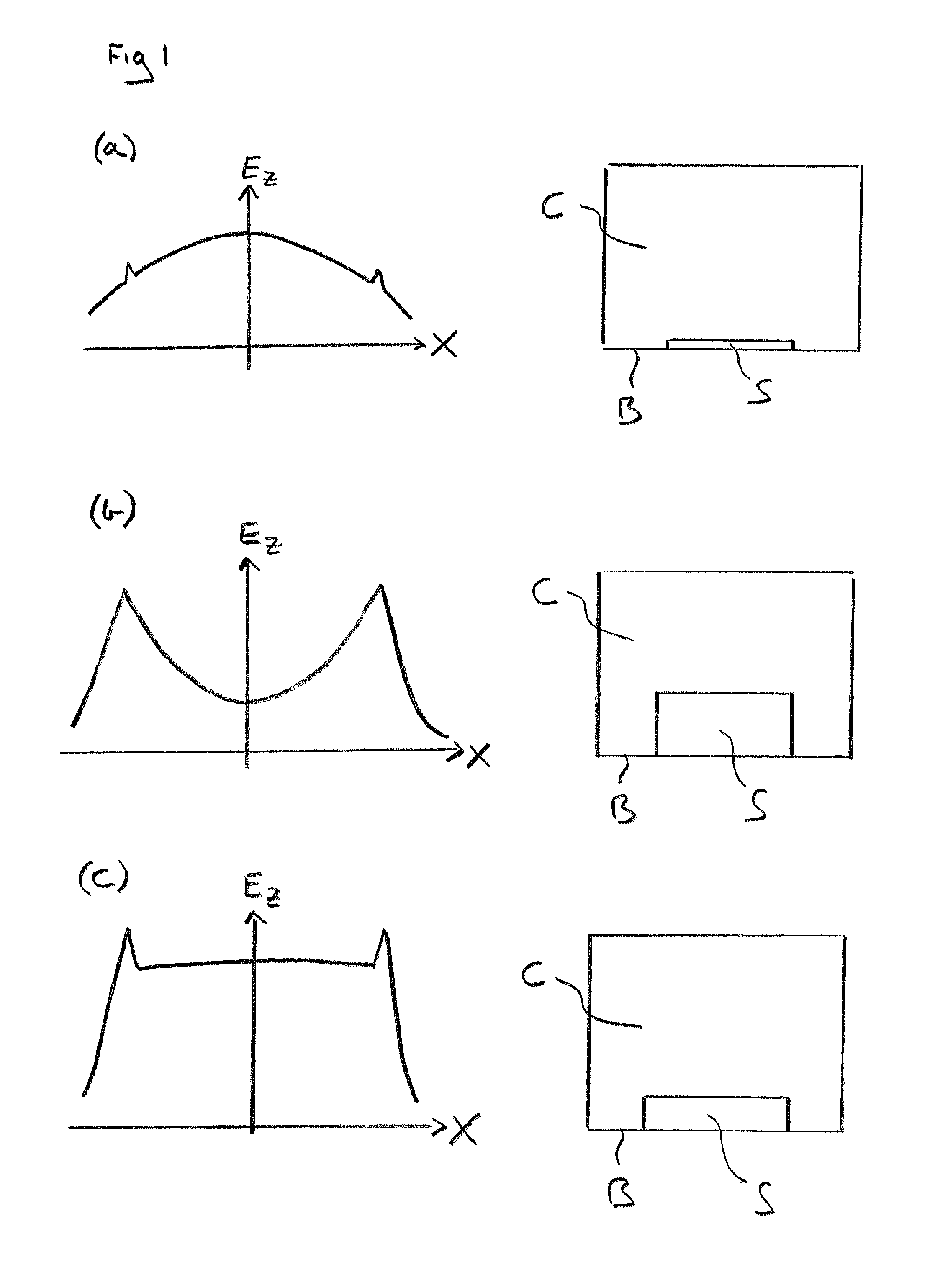

Microwave plasma reactors and substrates for synthetic diamond manufacture

ActiveUS20140234556A1Increase the electric field strengthPolycrystalline material growthElectric discharge tubesCouplingMicrowave resonance

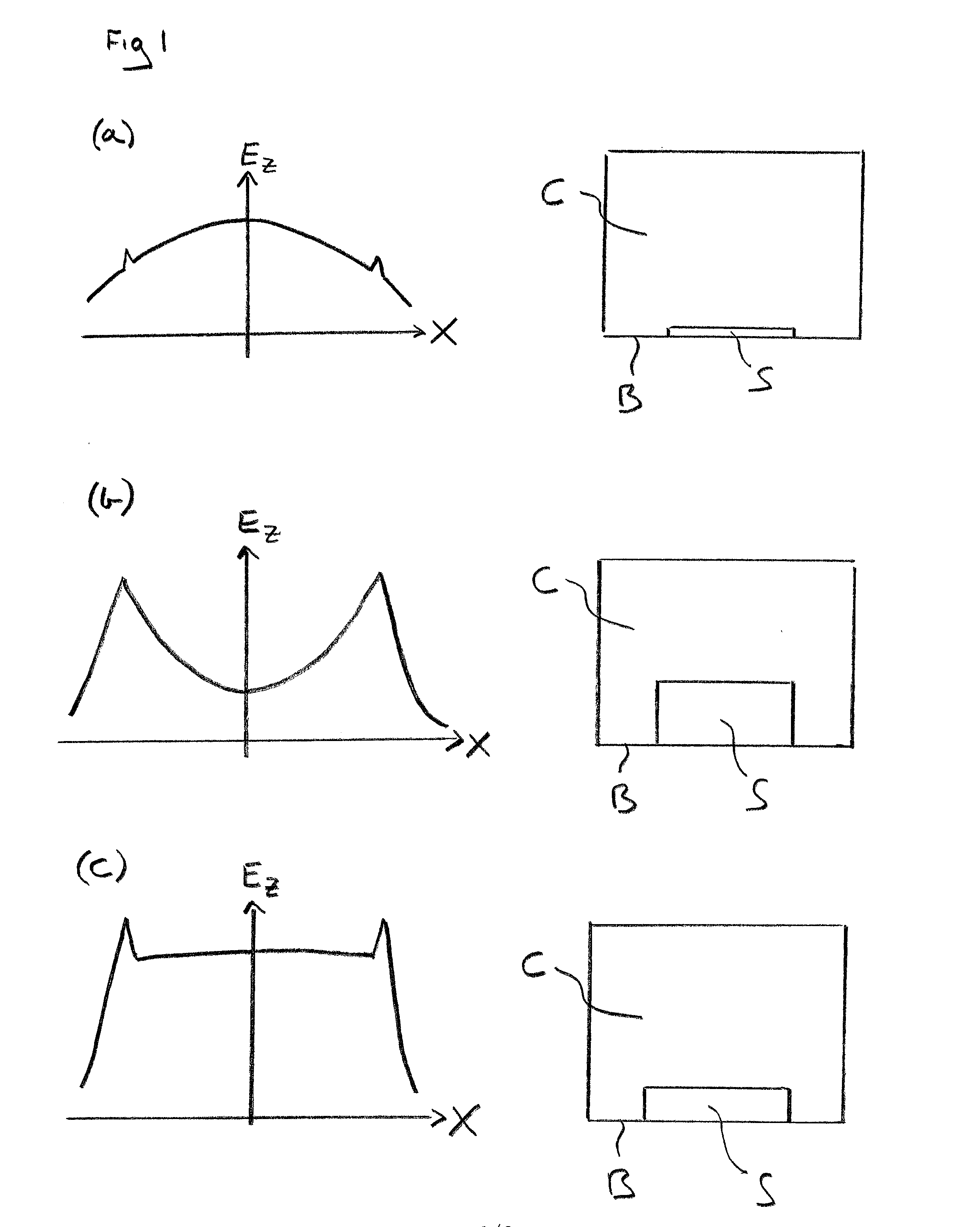

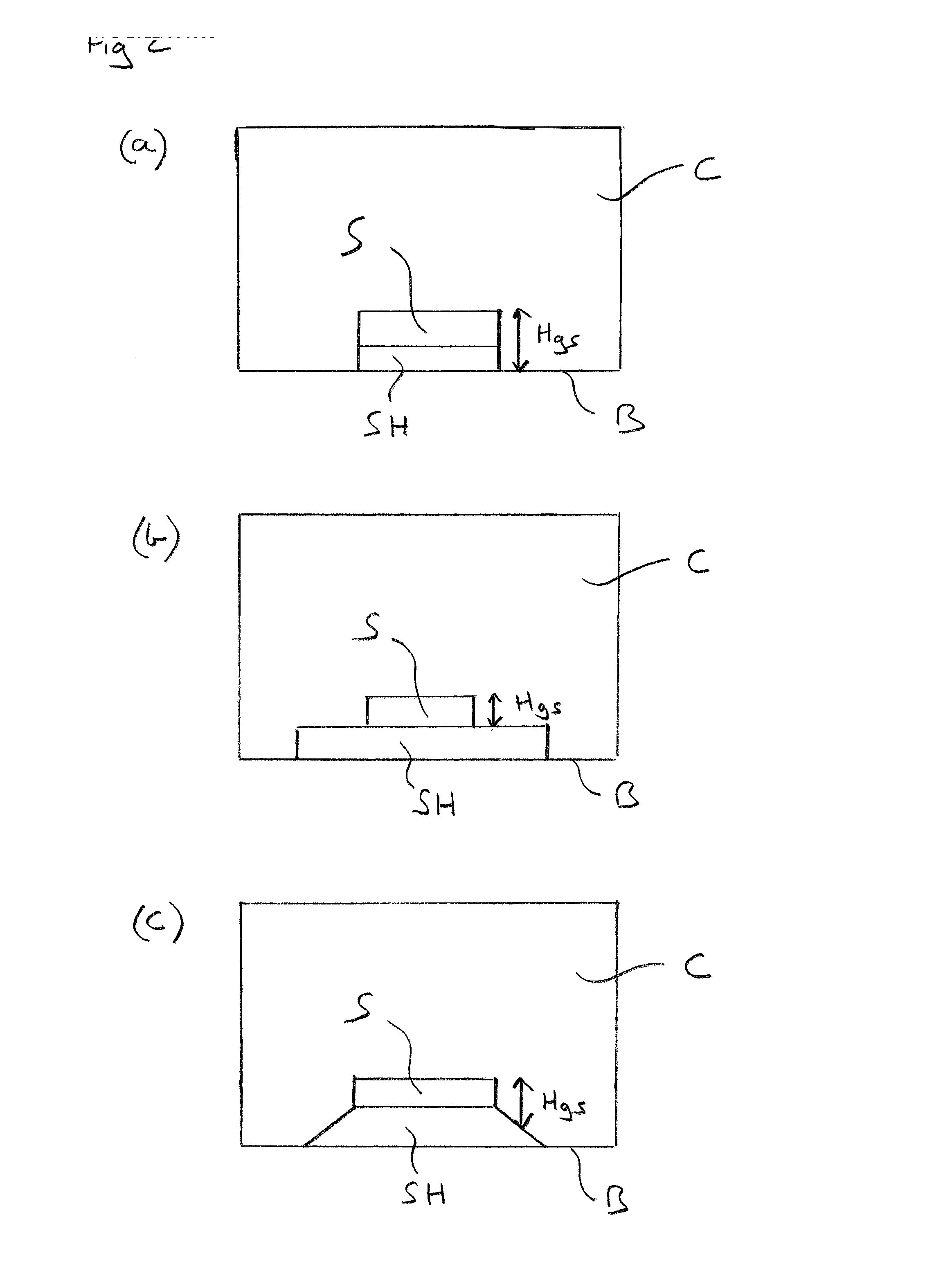

A microwave plasma reactor for manufacturing synthetic diamond material via chemical vapour deposition, the microwave plasma reactor comprising: a microwave generator configured to generate microwaves at a frequency f; a plasma chamber comprising a base, a top plate, and a side wall extending from said base to said top plate defining a resonance cavity for supporting a microwave resonance mode between the base and the top plate; a microwave coupling configuration for feeding microwaves from the microwave generator into the plasma chamber; a gas flow system for feeding process gases into the plasma chamber and removing them therefrom; a substrate holder disposed in the plasma chamber and comprising a supporting surface for supporting a substrate; and a substrate disposed on the supporting surface, the substrate having a growth surface on which the synthetic diamond material is to be deposited in use, wherein the substrate dimensions and location within the resonance cavity are selected to generate a localized axisymmetric Ez electric field profile across the growth surface in use, the localized axisymmetric Ez electric field profile comprising a substantially flat central portion bound by a ring of higher electric field, the substantially flat central portion extending over at least 60% of an area of the growth surface of the substrate and having an Ez electric field variation of no more than ±10% of a central Ez electric field strength, the ring of higher electric field being disposed around the central portion and having a peak Ez electric field strength in a range 10% to 50% higher than the central Ez electric field strength.

Owner:ELEMENT SIX LTD

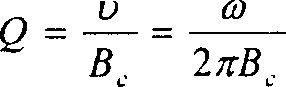

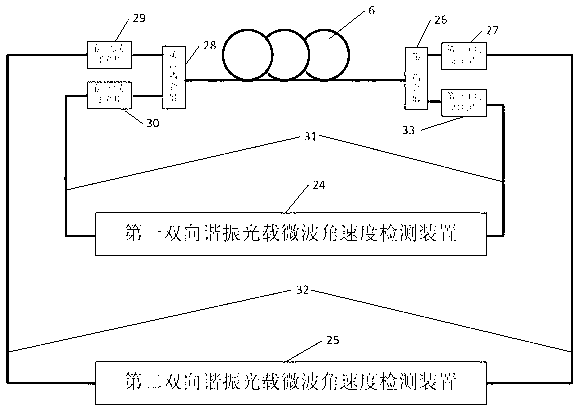

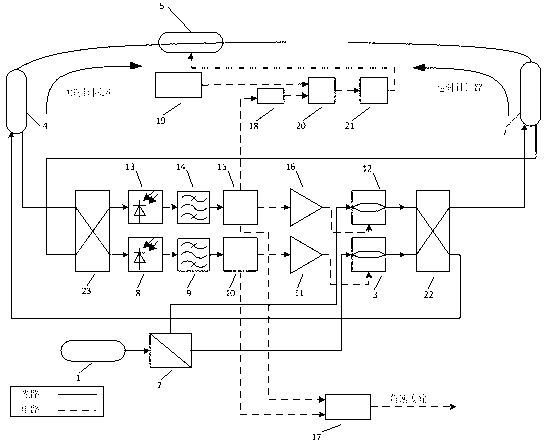

Method for detecting angular velocity through adopting one-loop two-way bidirectional resonant optical microwaves

ActiveCN103267521AHighly stable resonant frequencyHigh measurement accuracySagnac effect gyrometersGyroscopeAngular velocity

The invention discloses a method for detecting the angular velocity through adopting one-loop two-way bidirectional resonant optical microwaves. The method can be realized through a one-loop two-way bidirectional resonant optical microwave gyroscope, the one-loop two-way bidirectional resonant optical microwave gyroscope includes two two-way bidirectional resonant optical microwave angular velocity measuring devices sharing one fiber loop to form two optical microwave resonance loops, and the two-way angular velocity measuring devices alternatively work. The alternative work mode of the two-way angular velocity measuring devices is adopted in the invention to guarantee the measuring continuity in order to solve a measuring discontinuity problem appearing in the locking frequency switching process of one-way bidirectional resonant optical microwave angular velocity measuring devices. The method disclosed in the invention guarantees the angular velocity measuring continuity and increases the measuring precision.

Owner:ZHEJIANG UNIV

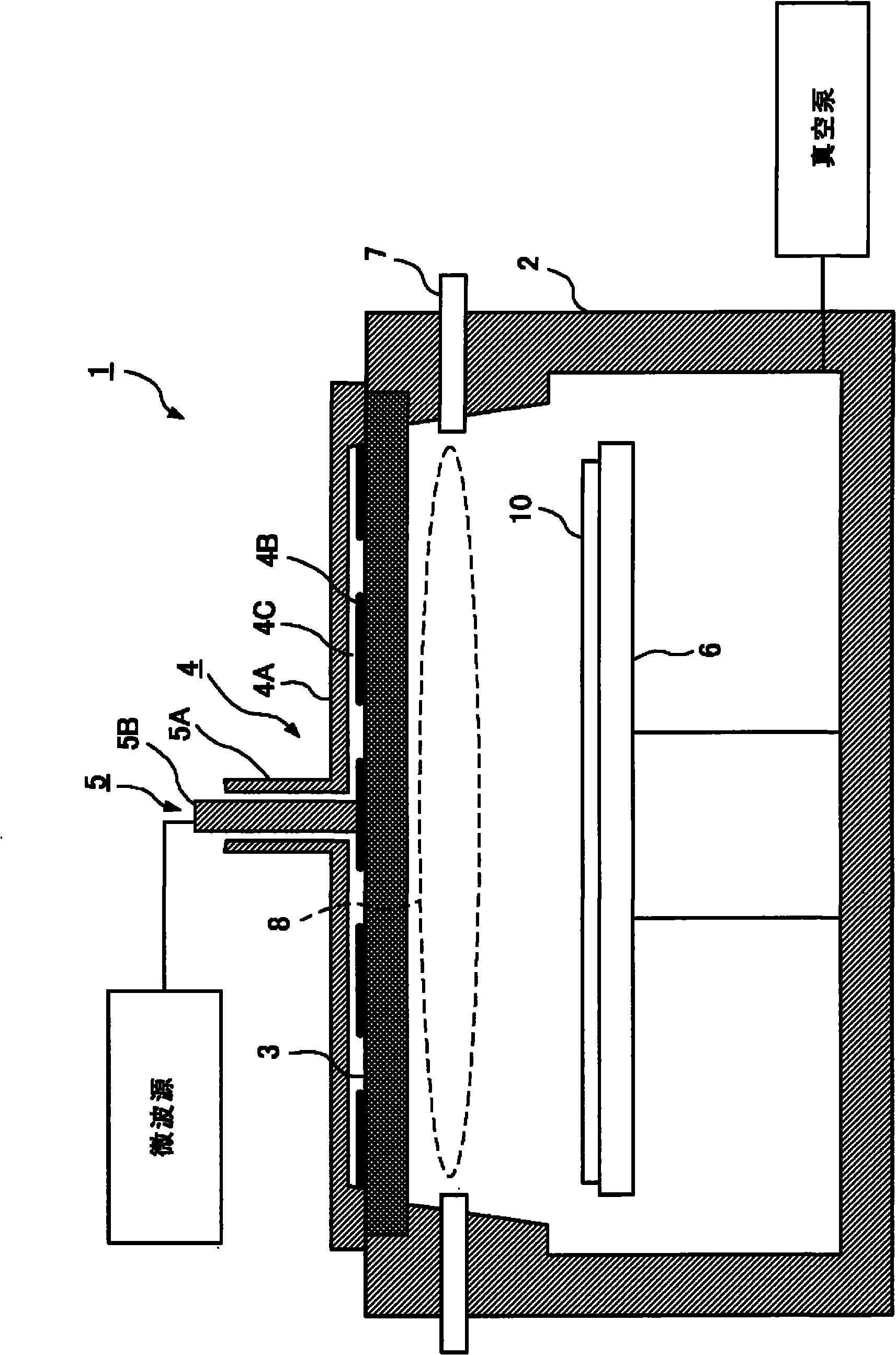

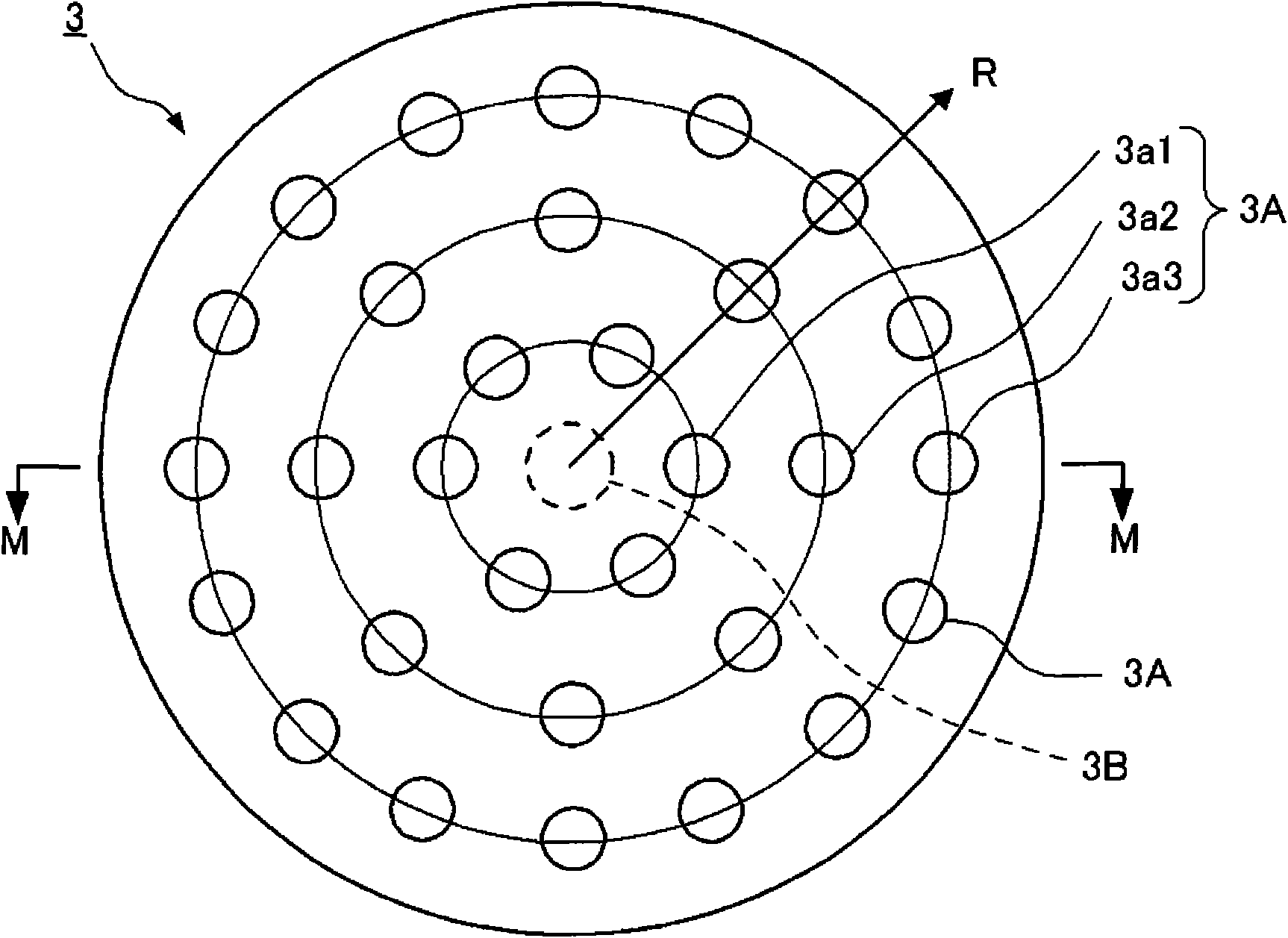

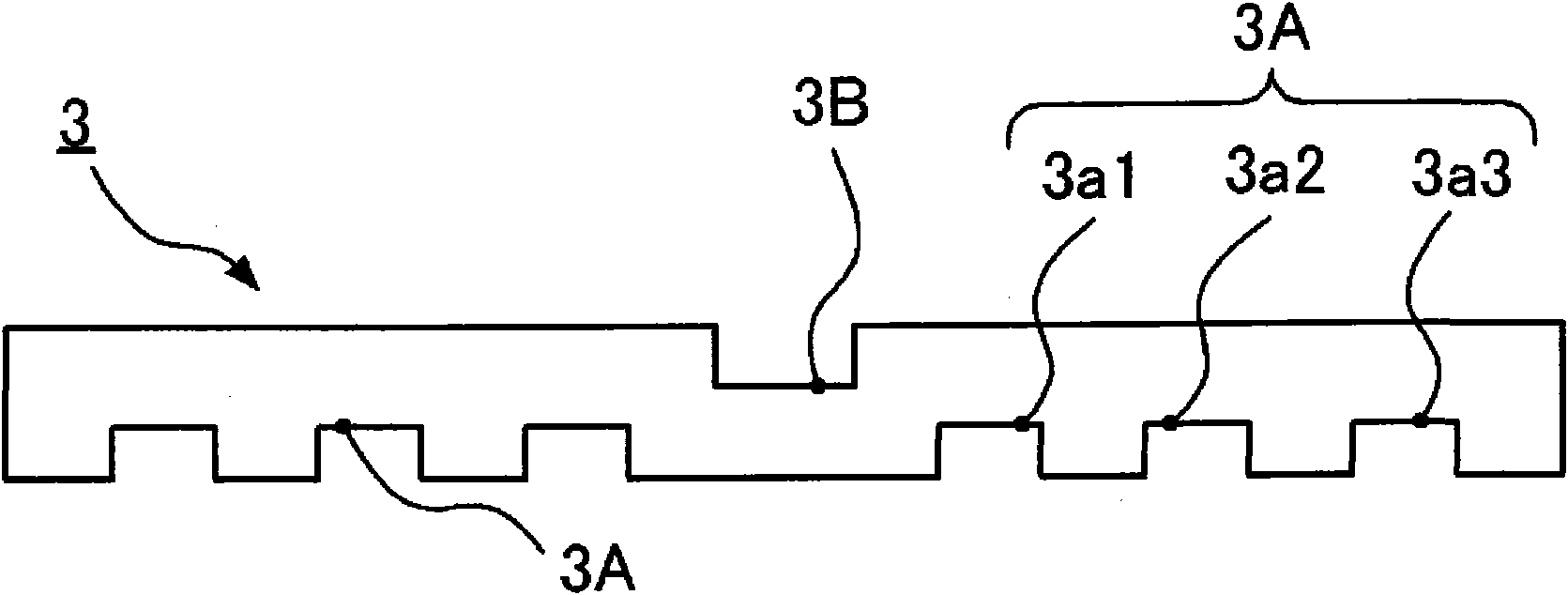

Top board of microwave plasma processing device, plasma processing device and plasma processing method

InactiveCN101953236APlasma mode stableElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMicrowave resonance

A plasma generation chamber of a plasma processing device is covered by a top board (3). The top board (3) is provided with concave portions (3A) made on a surface facing a side of the plasma generation chamber and concave portions (3B) made at the central portion on the reverse side surface. Antennas are coupled on the top board (3). The antennas are connected with waveguides. When a microwave is supplied through the waveguides, the supplied microwave travels between the antennas in the radial direction and is radiated from slots of the antennas. The microwave travels through the top board (3), has a polarized wave surface and forms a circular polarized wave as a whole. In this event microwave resonance absorption occurs at the side surfaces of the concave portions (3A) made at the top board (3) and the microwave travels on a single mode in the inside of the concave portions (3A). Strong plasma is formed in each inside of the multiple concave portions (3A), so that a stabilized plasma mode is yielded at the top board (3).

Owner:TOKYO ELECTRON LTD

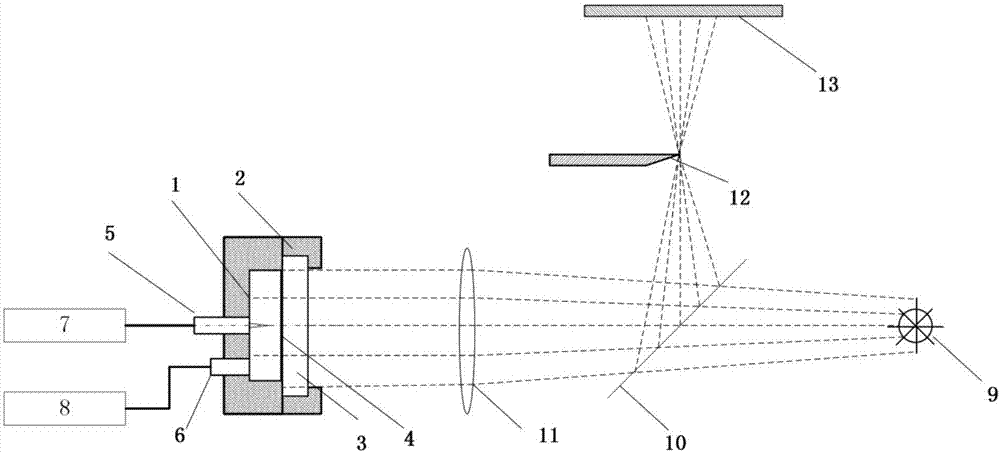

System for visualizing the cavity-inside microwave ignition and combustion process

ActiveCN107290133AIncrease profitBreakthrough in Energy Saving and Emission Reduction TechnologyOptical apparatus testingOptical elementsEngineeringMicrowave burn

The system for visualizing the cavity-inside microwave ignition and combustion process provided by the present invention belongs to the field of microwave ignition and microwave combustion and includes a microwave ignition device and a microwave ignition visualizing device located on one side of the microwave ignition device. The microwave ignition device comprises a microwave coupler and a gas preparing valve's U-shaped upper cover arranged respectively on the center of the top end and the edge part; a microwave burning chamber formed by a flat lower end cover with a transparent conducting layer of quartz glass on one side embedded right in the center wherein the upper end cover top end's inside is a mirror face. The microwave ignition visualizing device comprises a white light source generator coaxially arranged with the quartz glass, a convex lens, a half-transparent and half-reflective lens, a coaxially arranged knife edge and an imaging screen, wherein the knife edge is located at a focal point where the convex lens is converged with the half-transparent and half-reflective lens. The system can ensure the good reflection characteristic and the microwave resonance mode of the microwave in the cavity, avoids the external leakage of the microwave, and ensures the visible light from the outside to penetrate the cavity. The whole process of the microwave ignition in the combustion cavity is visually observed through the schlieren method.

Owner:清普莱斯(苏州)环保科技有限公司

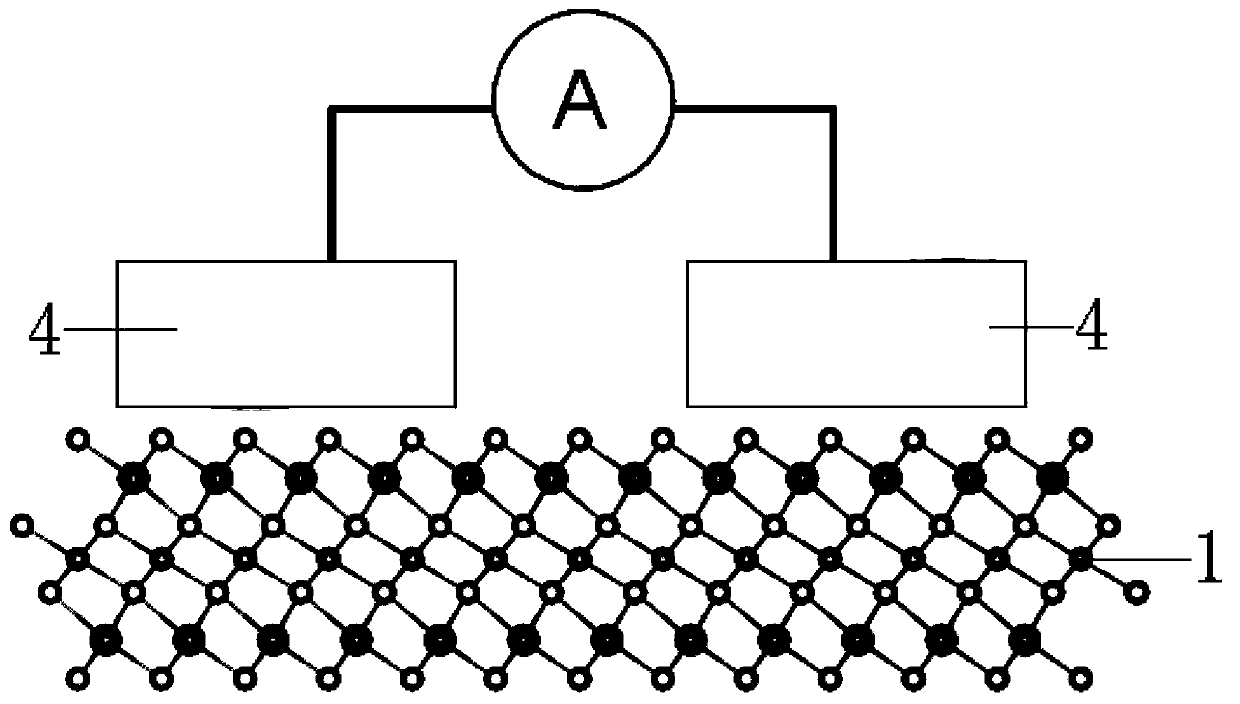

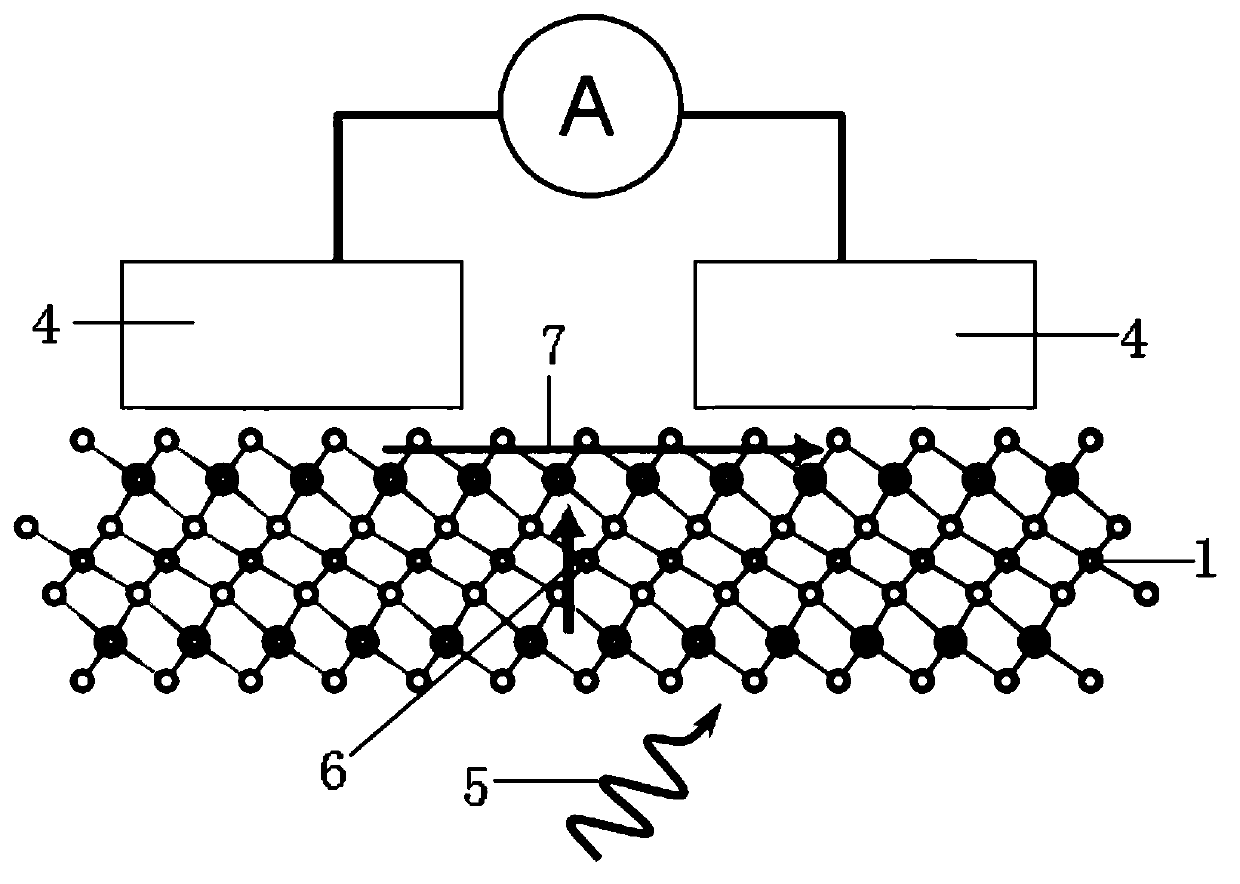

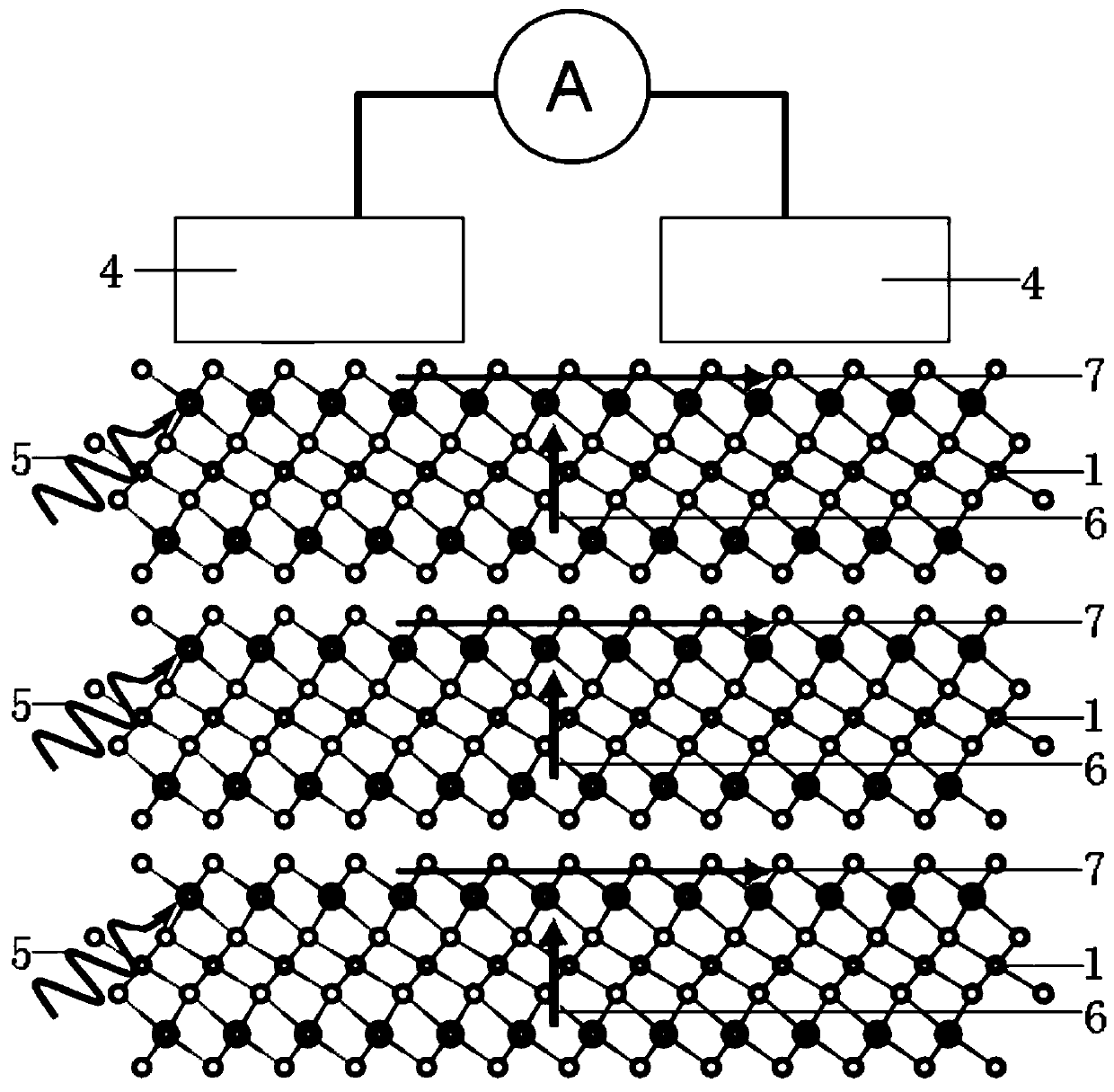

Passive low-power-consumption microwave detection method and device, and preparation method

ActiveCN110726736AReduce power consumptionMaterial analysis using microwave meansMagnetic-field-controlled resistorsLow dissipationMicrowave resonance

The invention discloses a passive low-power-consumption microwave detection method and a passive low-power-consumption microwave detection device, and a preparation method. The passive low-power-consumption microwave detection method is characterized in that: an antiferromagnetic topological insulator layer is prepared, under microwave energy, spin precession occurs in the antiferromagnetic topological insulator layer to generate a spin current, due to a spin momentum locking feature of a topological surface state, a directional charge flow can be generated spontaneously on the surface if thespin current; and passive low-power-consumption detection of microwave can be achieved through detection of the charge flow by an electrode. The passive low-power-consumption microwave detection method of the invention has the beneficial effects that: multiple antiferromagnetic topological insulator layers can be regarded as being formed by periodic stacking of a double-layer structure consistingof an antiferromagnetic layer and a topological insulator layer, thus microwave detection sensitivity is increased in multiples; the topological surface state shows strong robustness and low-dissipation current transmission characteristic, thereby reducing power consumption of microwave detection; the passive low-power-consumption microwave detection method not only takes full advantage of the strong robustness and an unique electric transmission characteristic showed by the topological surface state, but also takes advantage of microwave resonance of the antiferromagnetic layer, thereby enabling the structure to achieve passive low-power-consumption microwave detection.

Owner:NANJING UNIV

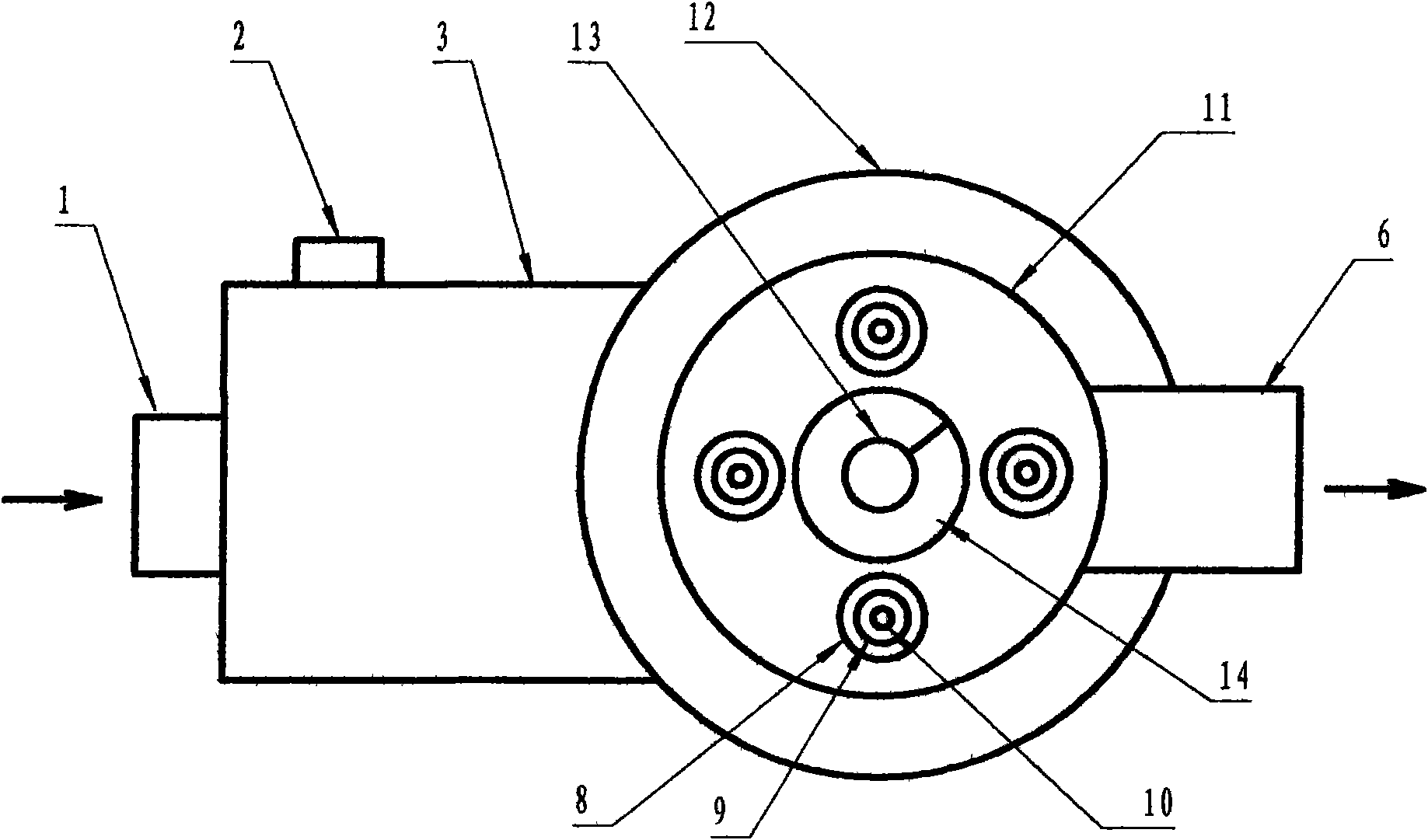

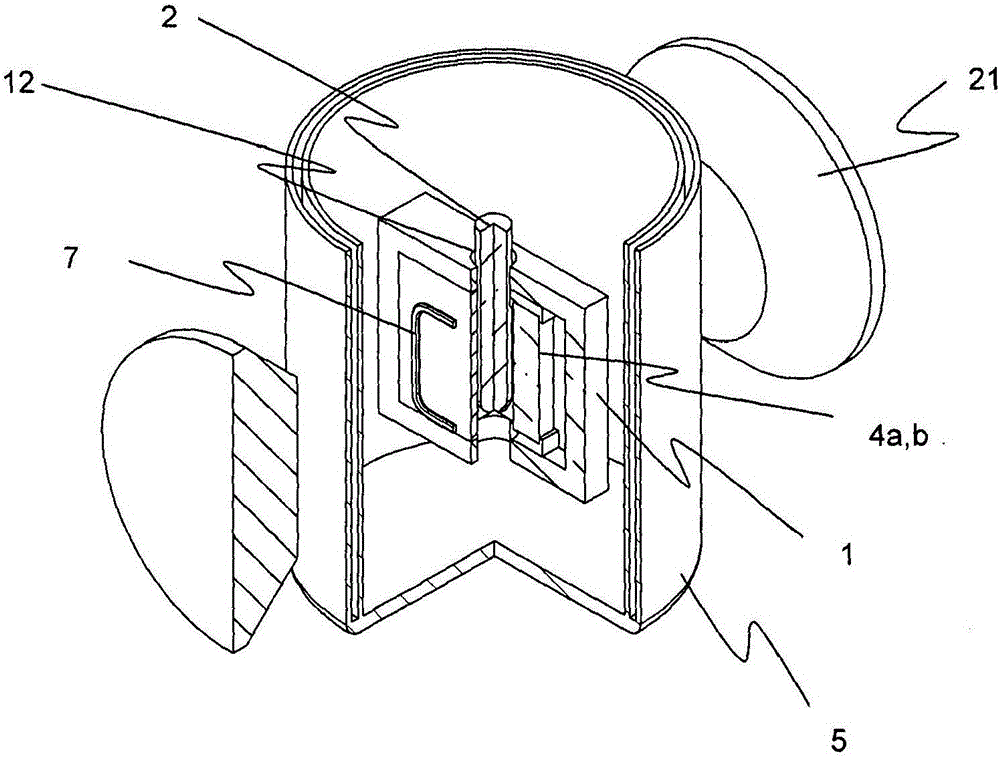

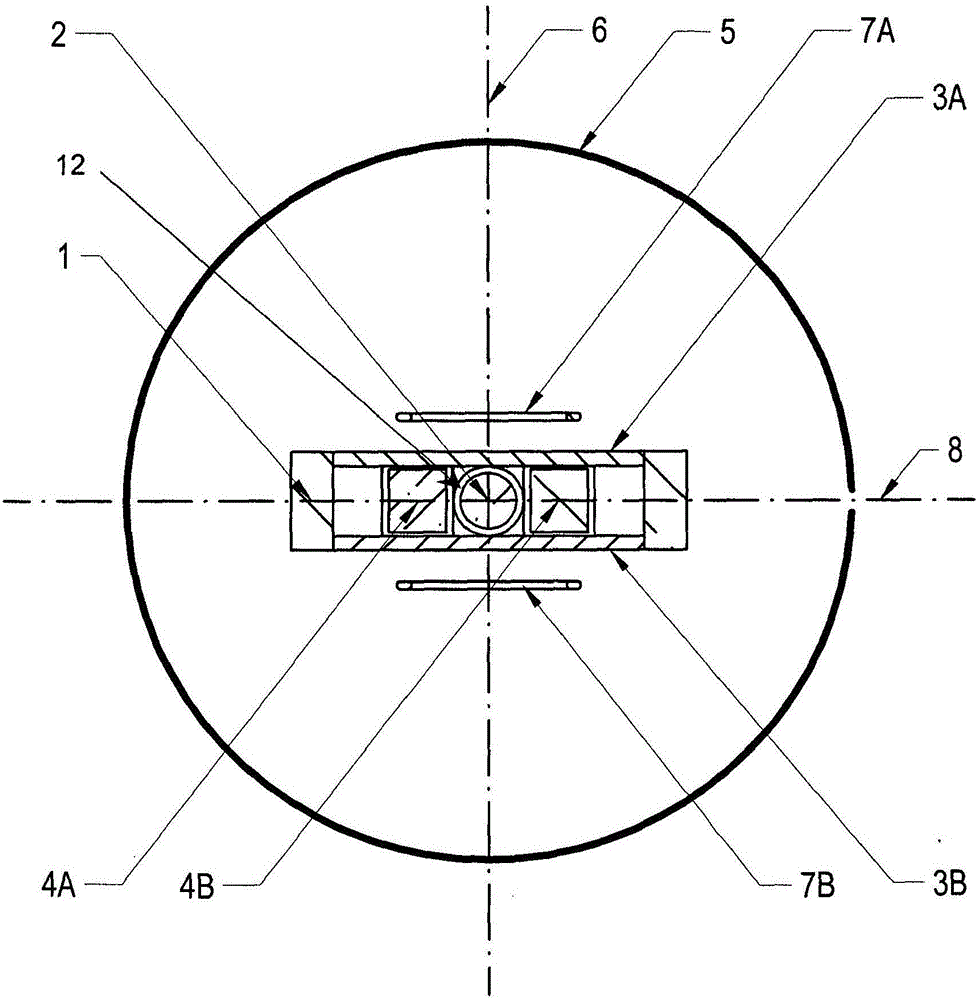

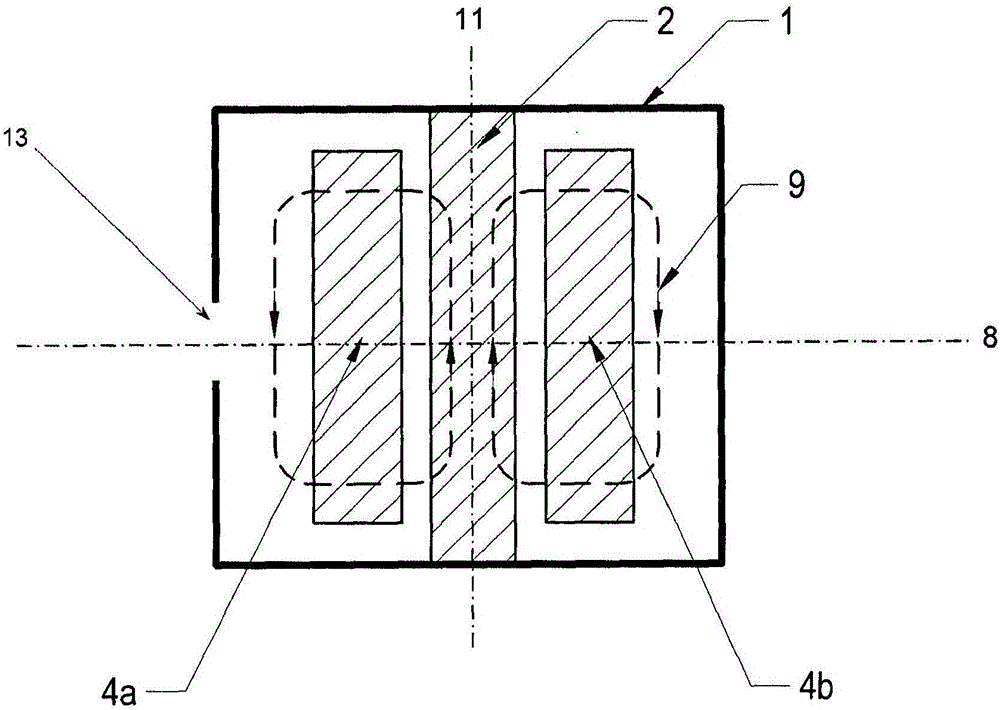

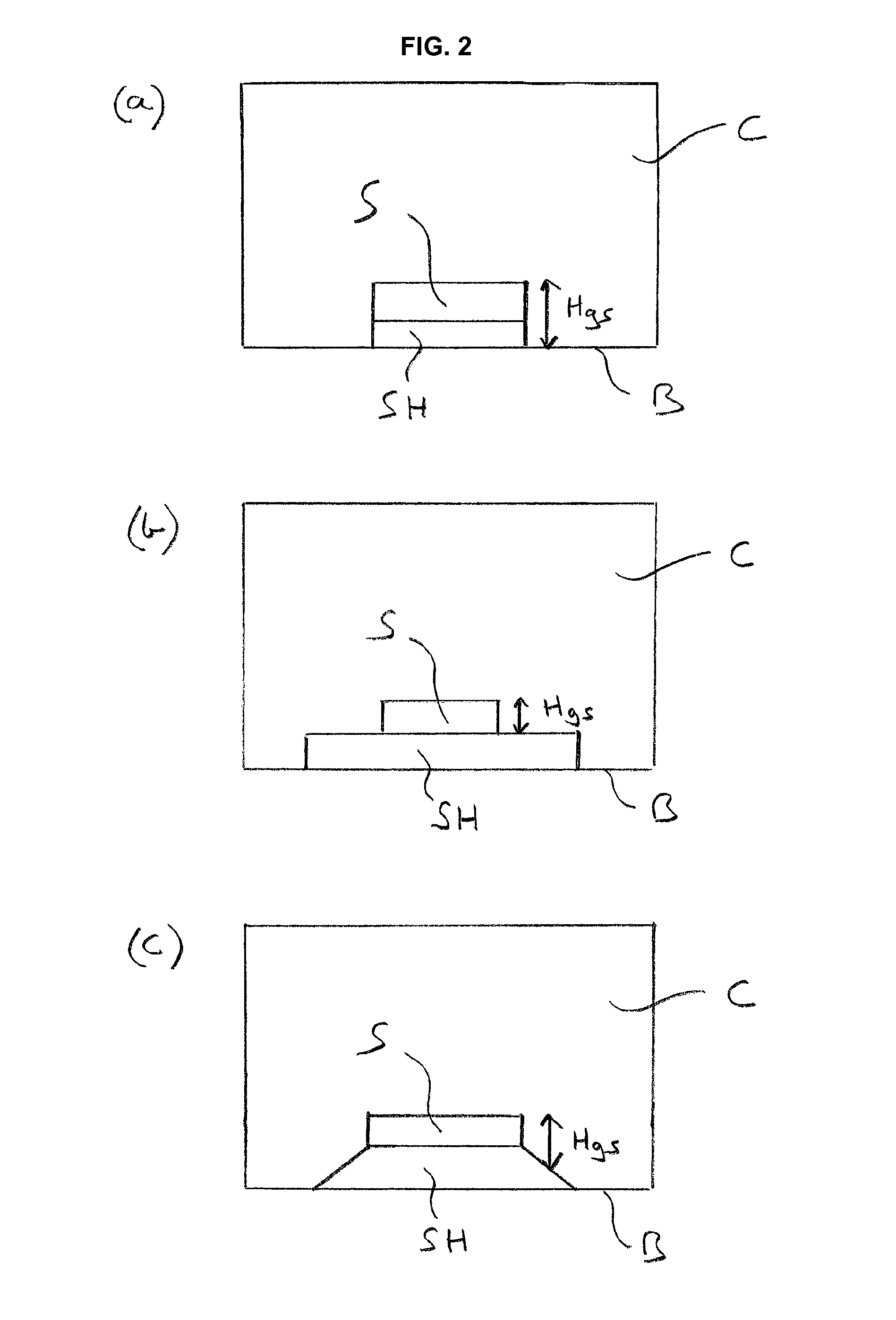

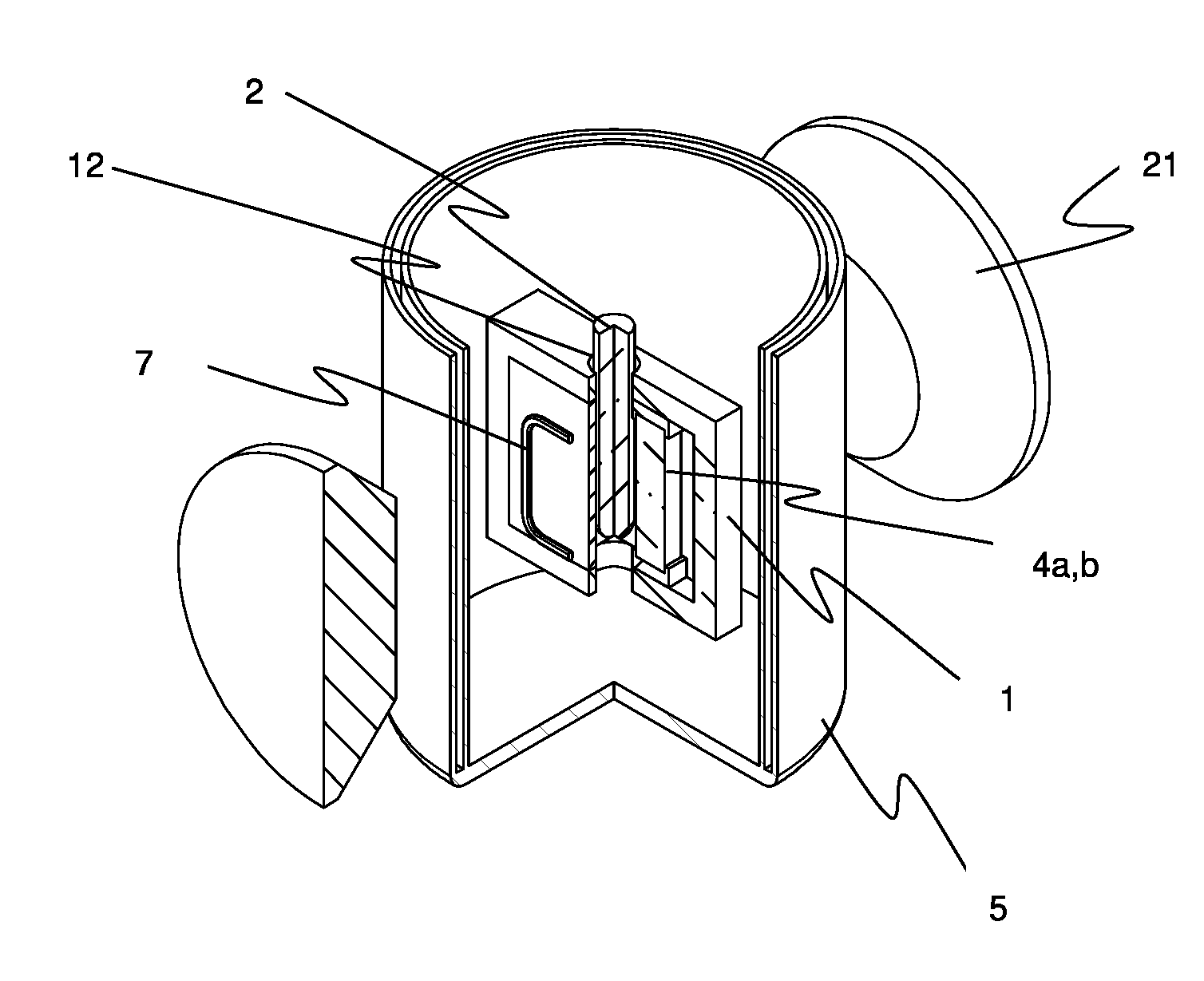

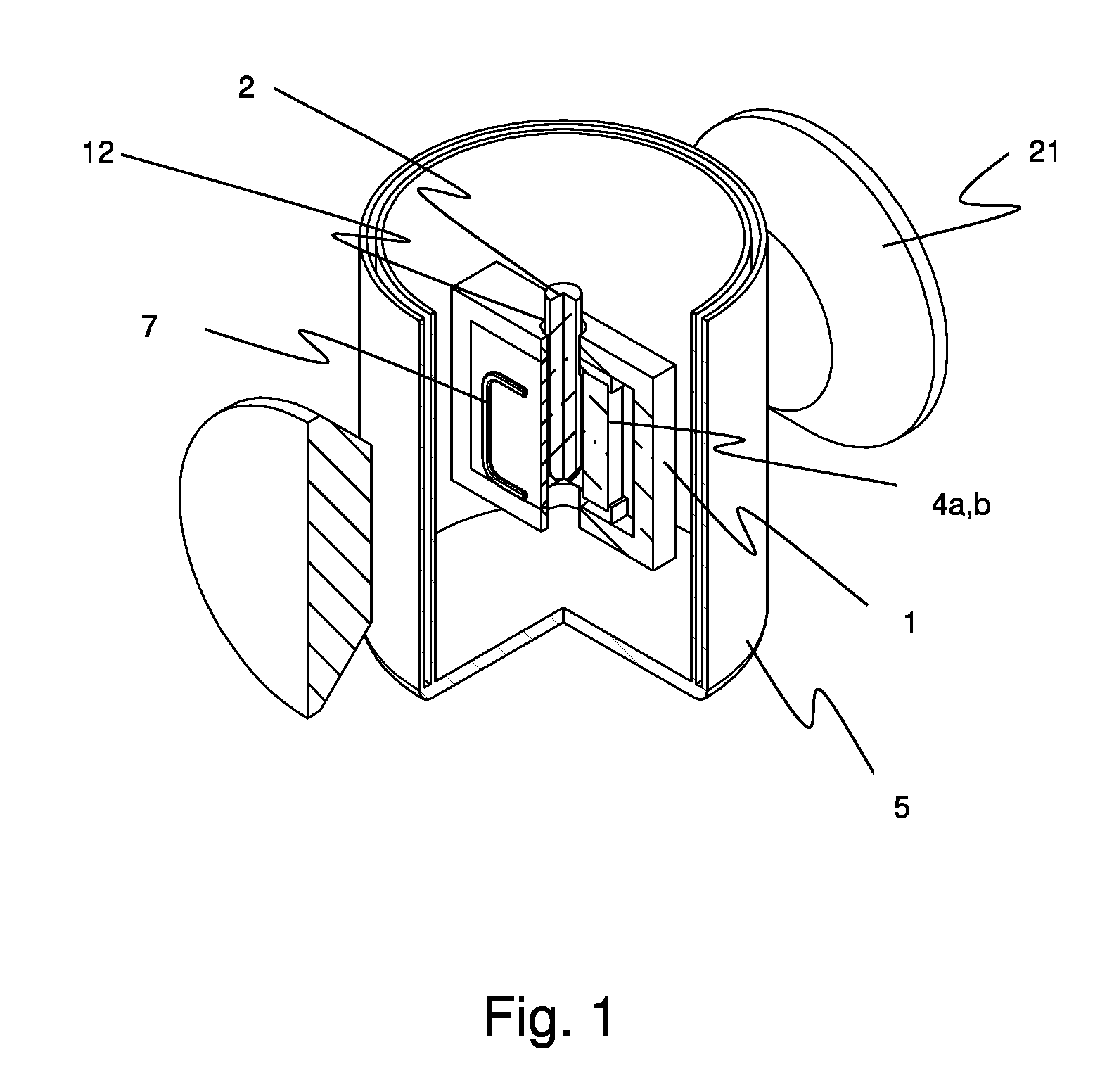

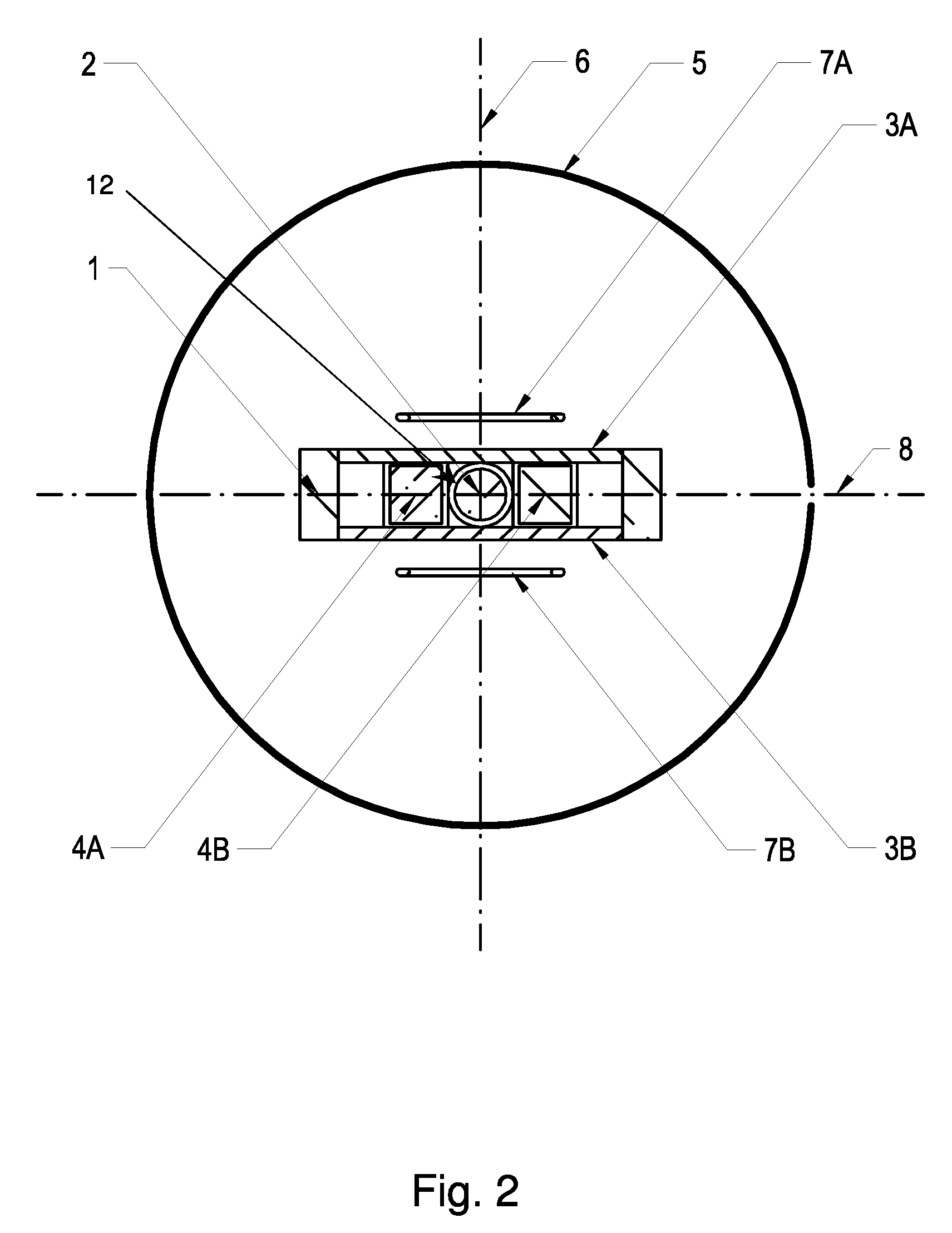

EPR microwave cavity for small magnet airgaps

The present invention relates to an EPR microwave cavity for small magnet airgaps. A microwave resonator for an EPR probe head has a metal cavity body for supporting an electromagnetic microwave resonance mode, the electromagnetic microwave resonance mode having an even number of local maxima of microwave electric field energy, the metal cavity body having an opening for inserting a smaple tube to a center position of the resonator, wherein a center of the opening and a center position of the resonator define an x-axis, the metal cavity body also having an opening for transmitting microwave radiation into the resonator; and two substantially identical dielectric elements located symmetrically with respect to an E-field nodal plane containing the x-axis and a z-axis perpendicular to the x-axis, wherein each dielectric element is geometrically formed and positioned to provide an equal overlap with a local maximum of the microwave electric field energy. The microwave resonant cavity has a thin planar shape for an EPR probe head. The resonator is loaded with two dielectric elements, of identical shape and physical properties, placed symmetrically relative to the central EPR sample.

Owner:BRUKER BIOSPIN

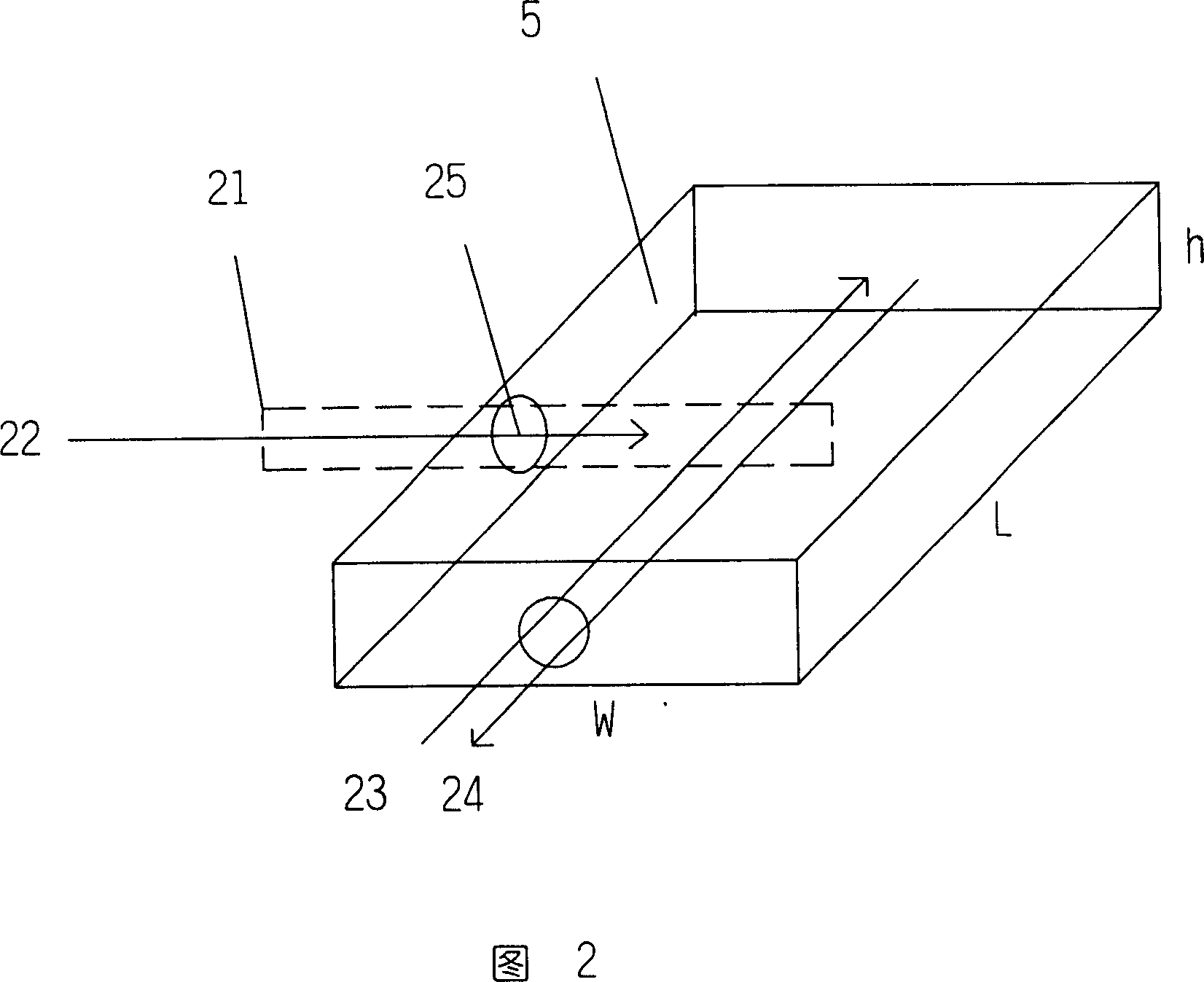

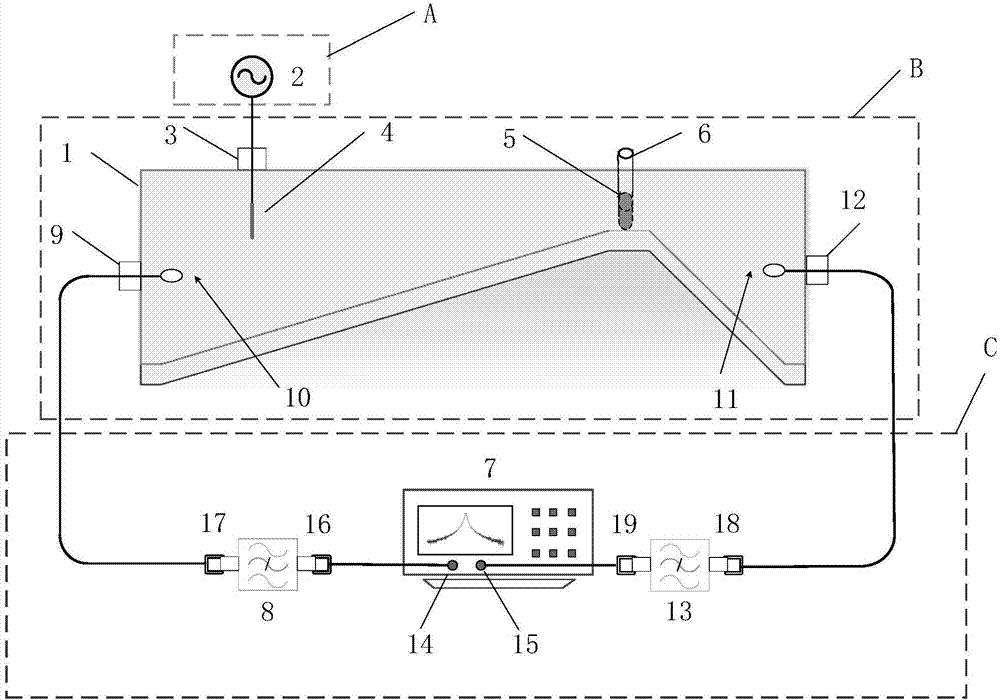

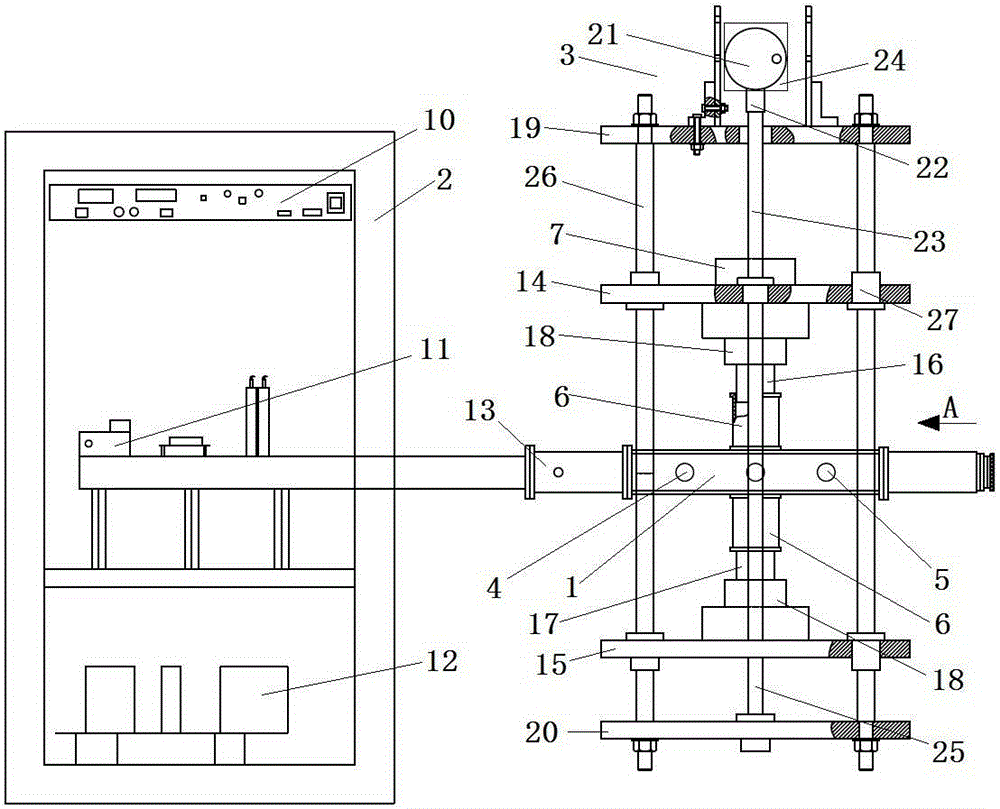

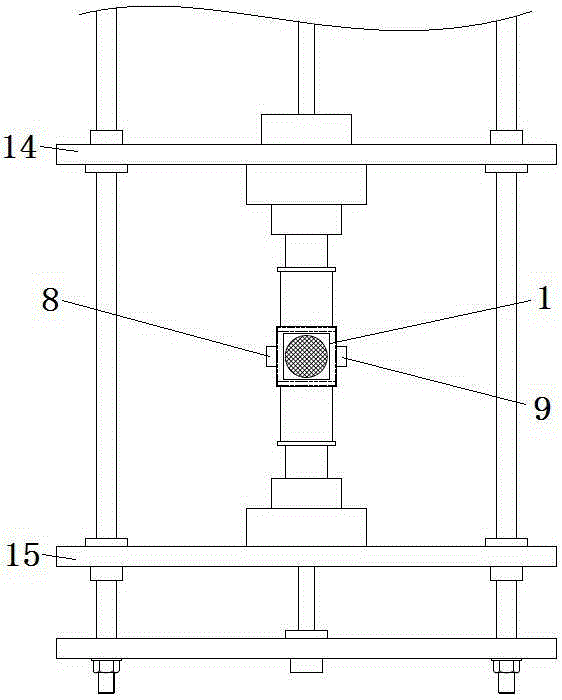

Research and test system and method of microwave dielectric characteristics of material in strong electromagnetic field environment

InactiveCN107202922AAvoid couplingReduce the impactResistance/reactance/impedenceTest powerSmall sample

The invention provides a research and test system and method of microwave dielectric characteristics of a material in a strong electromagnetic field environment. The system comprises three parts, a compression type resonant cavity excitation part A, a resonance system part B and a microwave resonance parameter extraction part C, wherein the compression type resonant cavity excitation part A comprises a signal source; the resonance system part B comprises a compression type resonance cavity, an SMA adapter, an electric probe and a coupling ring; the microwave resonance parameter extraction part C comprises a band stop filter and a vector network analyzer; the compression type resonance cavity can realize simulation of high-power environment experiments with a low-power source, and the cost of the experiment research through direct use of the high-power source is greatly reduced; introduction of the band stop filter enables an excitation power signal and a test power signal to be separated, accordingly, the research error of an experiment test can be deducted, and the reliability of test and research results is improved. The system can realize rapid test and research of a small sample at multi-frequency points, and the research and development cycle of a microwave material applied to a high-power microwave system is shortened.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

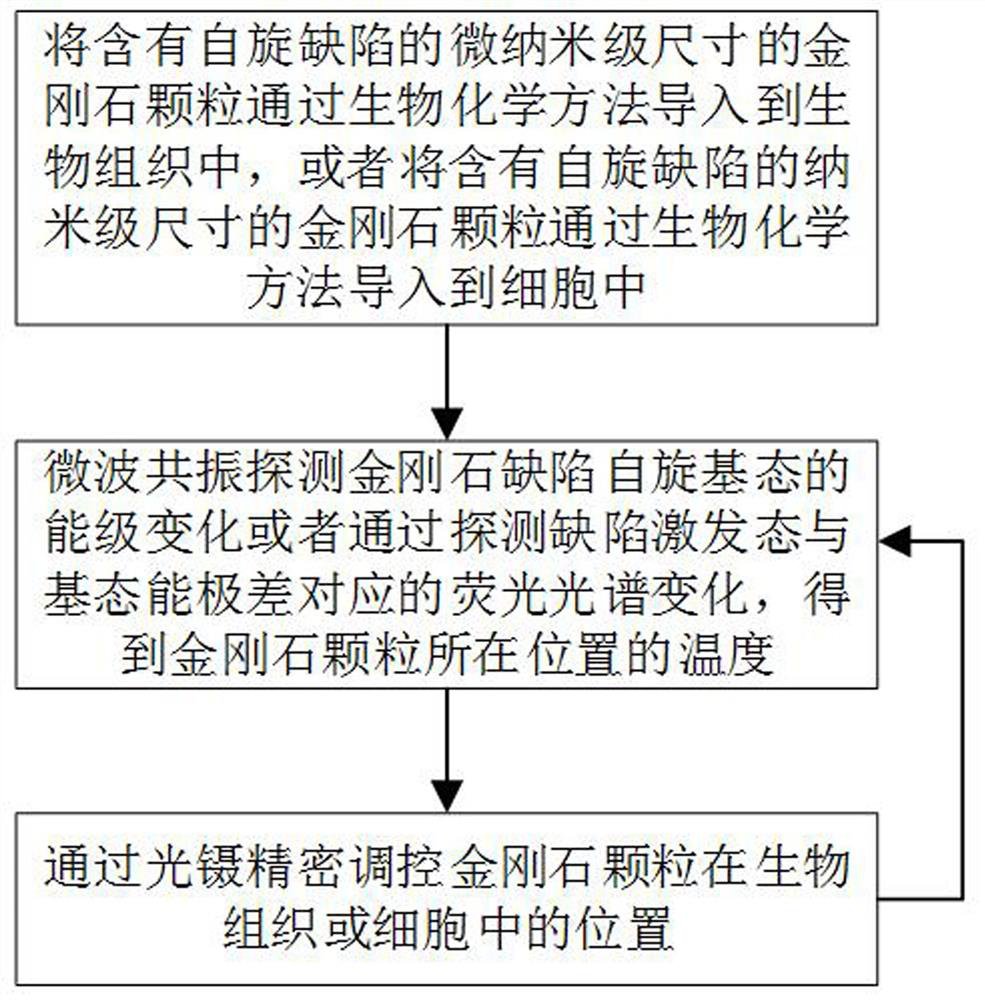

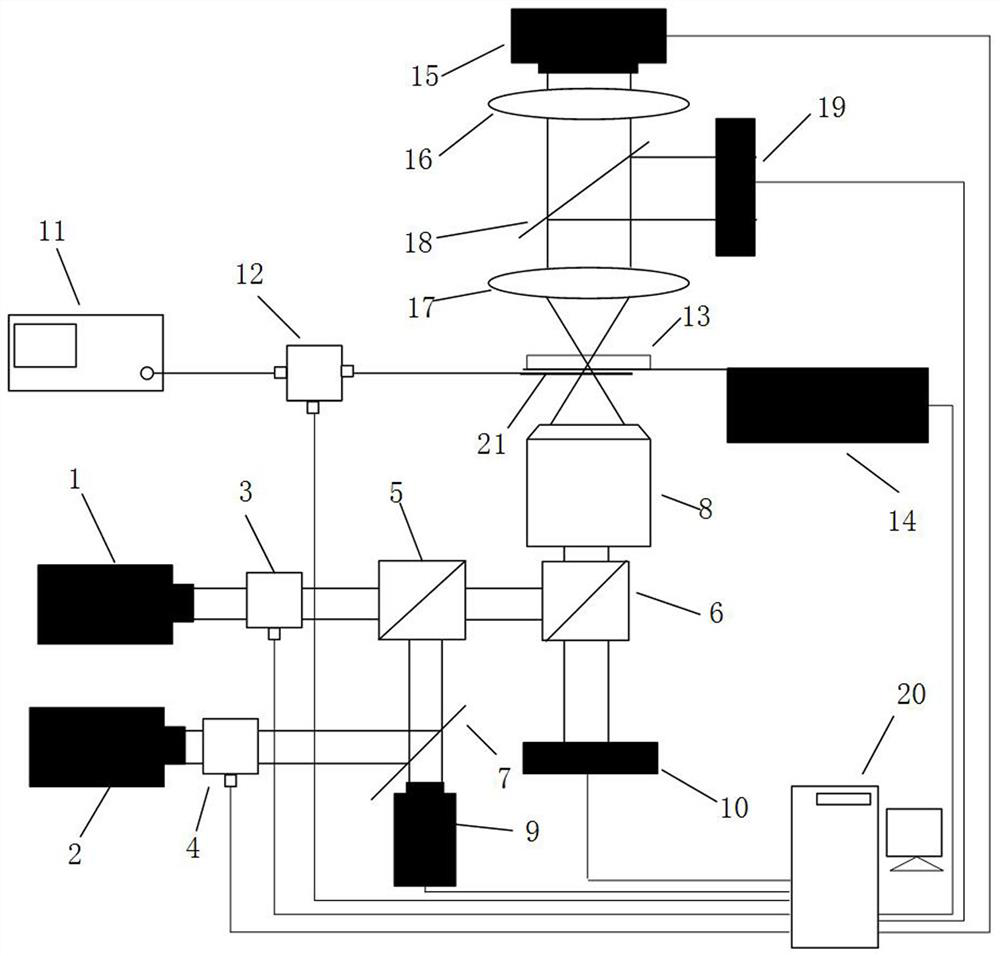

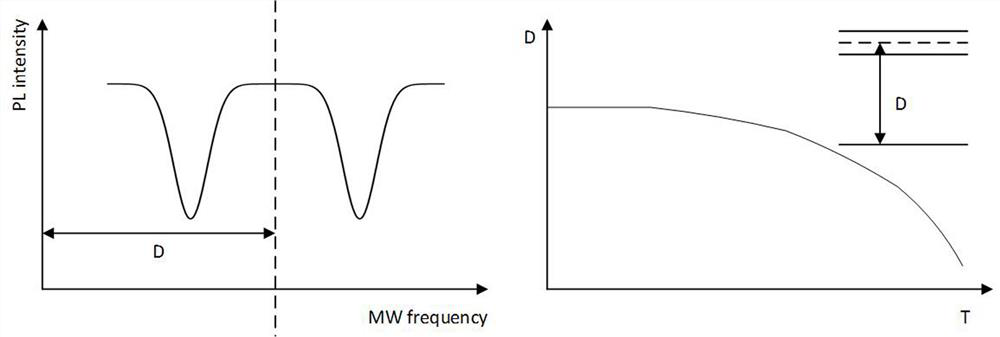

Method and device for measuring temperature of biological tissue or cell

ActiveCN111879434APosition is easy to controlReal-time location tracking temperature detectionThermometers using physical/chemical changesMicro nanoFluorescence spectra

The invention discloses a method and device for measuring the temperature of a biological tissue or a cell, and the method comprises the steps: guiding diamond particles which contain spin defects andare in a micro-nano size into the biological tissue through a biochemical method, or guiding the diamond particles which contain the spin defects and are in the nano size into the cell through the biochemical method; detecting the energy level change of the diamond defect spinning ground state through microwave resonance or detecting the fluorescence spectrum change corresponding to the energy range of the defect excited state and the ground state to obtain the temperature of the pis detectedosition where the diamond particles are located, and regulating and controlling the positions of the diamond particles in biological tissue or cells precisely through optical tweezers. and thus, obtaining the temperatures of different positions in the biological tissue or cells By means of the methodand device, micro-nano-scale real-time dynamic temperature tracking detection can be conducted on target biological tissue or cells.

Owner:ZHEJIANG LAB +1

CPT atomic clock control method

ActiveCN107404317AReduce volumeReduce power consumptionPulse automatic controlPreselected time interval producing apparatusTemperature controlControl system

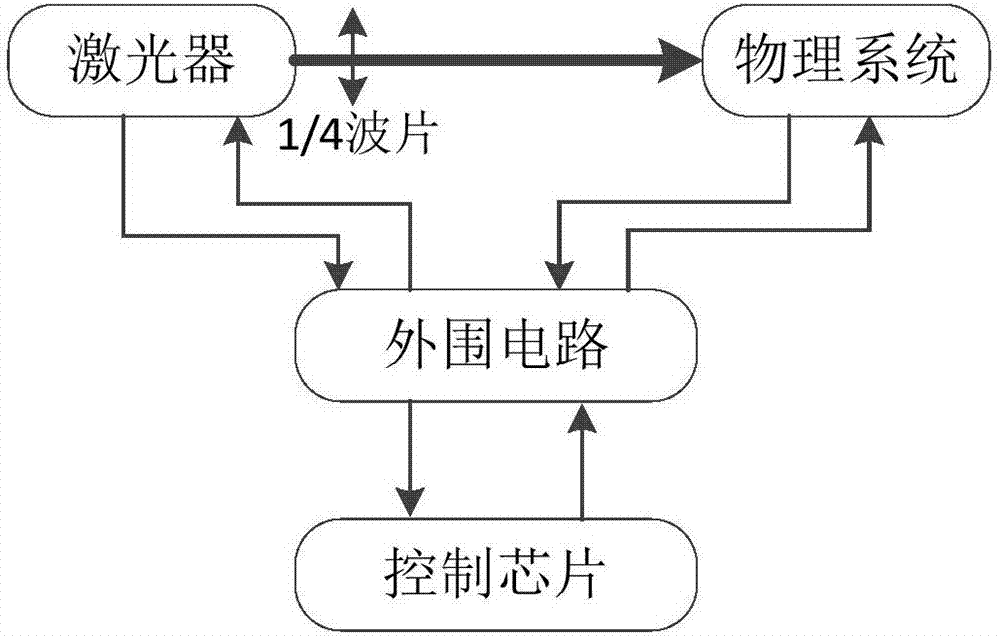

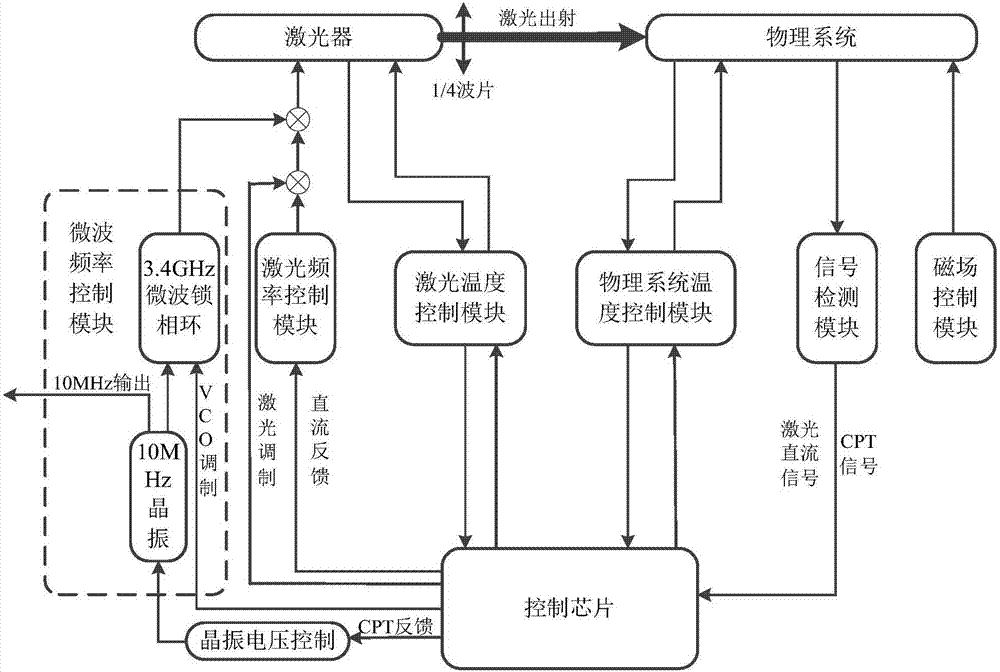

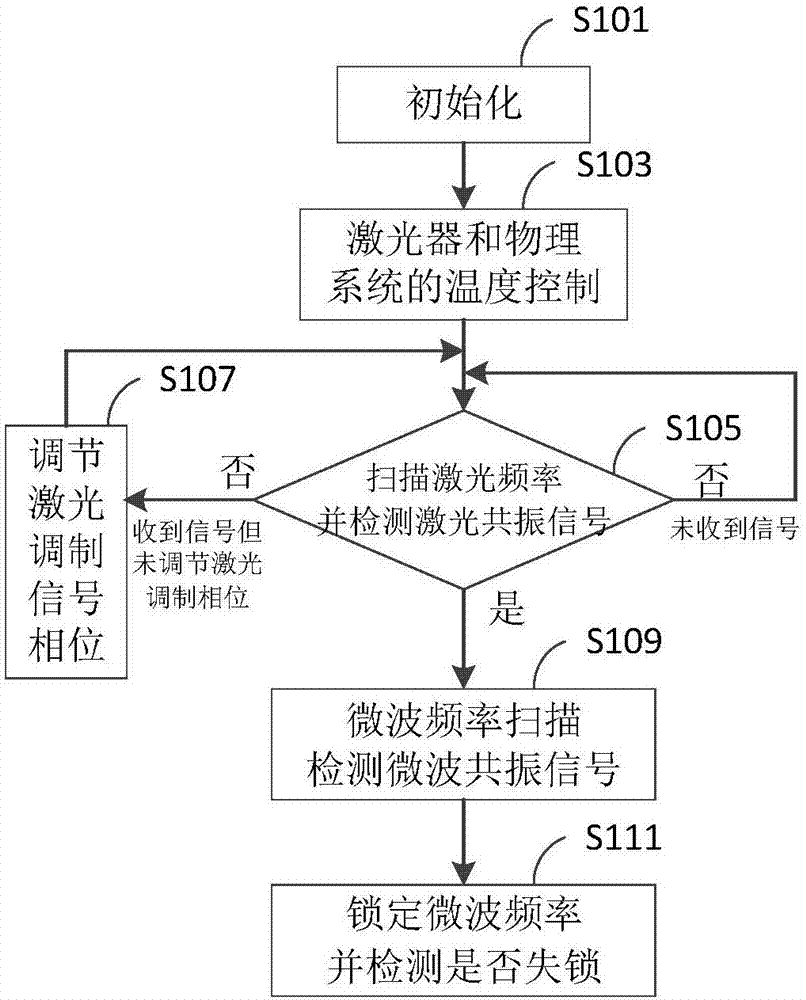

The invention discloses a CPT atomic clock control method. The method is executed by a CPT atomic clock control system. The system comprises a laser, a physical system, a microwave frequency control module, a laser frequency control module, a temperature control module, a signal detection module, a magnetic field control module and a control chip. The method comprises steps of initializing the control chip, the laser, the physical system and all control modules; controlling the temperature of the laser and the physical system; scanning laser frequencies and detecting laser resonance signals; adjusting phase position of laser modulation signals; scanning microwave frequencies and detecting microwave resonance signals; and locking the microwave frequencies, detecting whether the microwave frequencies are unlocked and repeatedly detecting and judging whether the microwave frequencies and the laser frequencies are unlocked.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

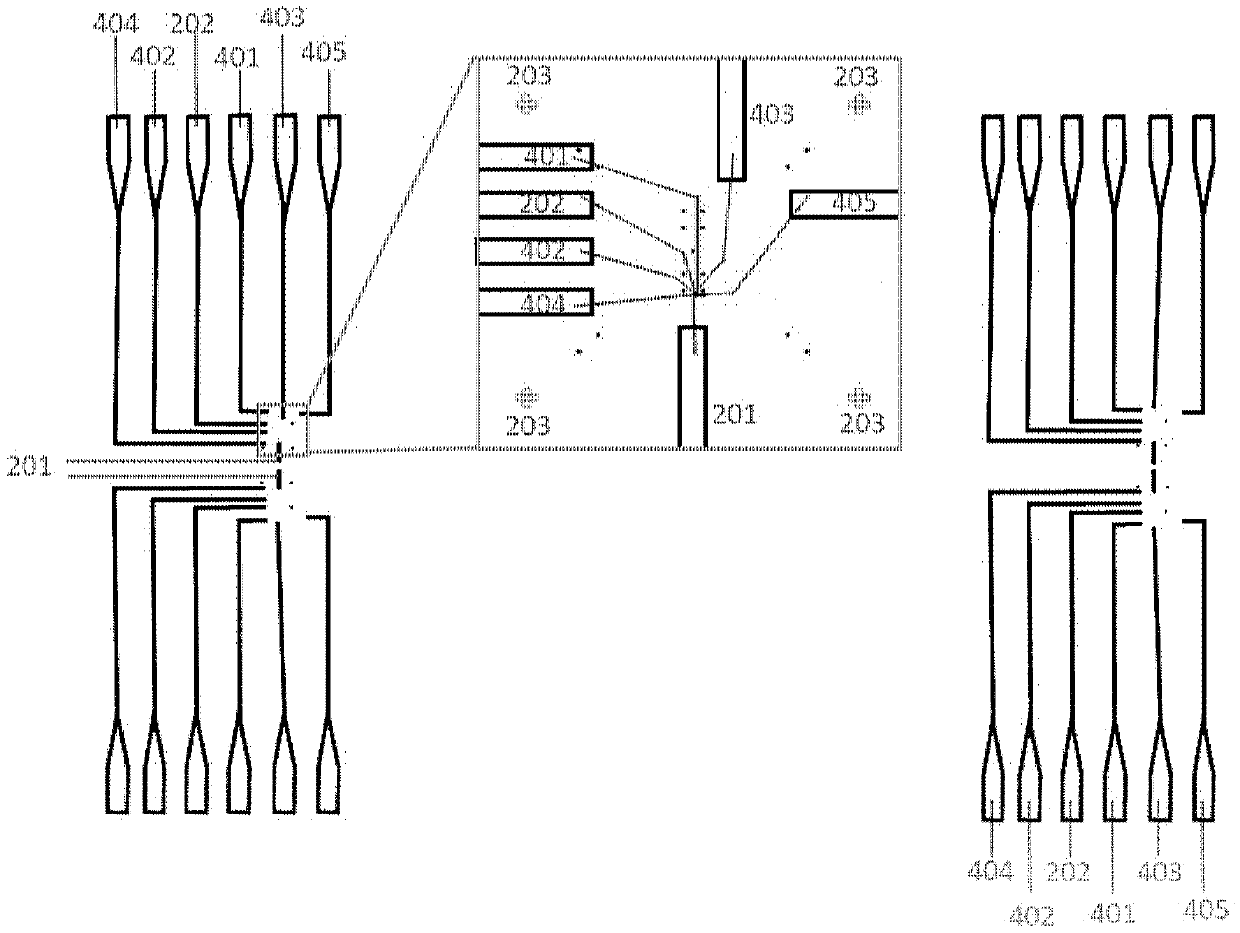

Device for coupling microwave resonance cavity with self-organization germanium-silicon nanowire quantum dots

PendingCN109616520ARealize functionThe process is simple and stableNanoinformaticsSemiconductor/solid-state device manufacturingNanowireCoupling

The invention discloses a device for coupling a microwave resonance cavity with self-organization germanium-silicon nanowire quantum dots. The device comprises a substrate structure, two or more self-organization germanium-silicon nanowire quantum dot electrode structures and a superconduction microwave resonance cavity structure, wherein the self-organization germanium-silicon nanowire quantum dot electrode structures are prepared on the substrate structure; the superconduction microwave resonance cavity structure is arranged on the substrate structure and coupled with the self-organization germanium-silicon nanowire quantum dot electrode structures. According to the device for coupling the microwave resonance cavity with self-organization germanium-silicon nanowire quantum dots, microwaves of the superconduction microwave resonance cavity are used as media, the multiple quantum dots can be coupled together and can be used as a quantum data bus for expansion and integration of a quantum chip, and a design through and a technical scheme are provided for constructing an expandable quantum chip with coupling of multiple quantum bit long ranges for a quantum computer.

Owner:UNIV OF SCI & TECH OF CHINA

Microwave plasma reactors and substrates for synthetic diamond manufacture

A microwave plasma reactor for manufacturing synthetic diamond material via chemical vapor deposition, the microwave plasma reactor comprising: a microwave generator configured to generate microwaves at a frequency f; a plasma chamber comprising a base, a top plate, and a side wall extending from said base to said top plate defining a resonance cavity for supporting a microwave resonance mode between the base and the top plate; a microwave coupling configuration for feeding microwaves from the microwave generator into the plasma chamber; a gas flow system for feeding process gases into the plasma chamber and removing them therefrom; a substrate holder disposed in the plasma chamber and comprising a supporting surface for supporting a substrate; and a substrate disposed on the supporting surface, the substrate having a growth surface on which the synthetic diamond material is to be deposited in use, wherein the substrate dimensions and location within the resonance cavity are selected to generate a localized axisymmetric Ez electric field profile across the growth surface in use, the localized axisymmetric Ez electric field profile comprising a substantially flat central portion bound by a ring of higher electric field, the substantially flat central portion extending over at least 60% of an area of the growth surface of the substrate and having an Ez electric field variation of no more than ±10% of a central Ez electric field strength, the ring of higher electric field being disposed around the central portion and having a peak Ez electric field strength in a range 10% to 50% higher than the central Ez electric field strength.

Owner:ELEMENT SIX LTD

EPR Microwave Cavity for Small Magnet Airgaps

ActiveUS20160274200A1Minimize impactEfficient couplingMeasurements using electron paramagnetic resonanceResonatorsNODALResonant cavity

A microwave resonator for an EPR probe head has a metal cavity body (1) supporting an electromagnetic microwave resonance mode. The metal cavity body (1) has an opening for inserting a sample tube (2) to a center position of the resonator. The center of the opening and the center position of the resonator define an x-axis. The cavity body also has an opening for transmitting microwave radiation into the resonator. Two dielectric elements (4a, 4b) are located symmetrically to the E-field nodal plane containing the x-axis and a z-axis perpendicular to the x-axis. Each dielectric element is geometrically formed and positioned such that it provides an equal overlap with a local maximum of the microwave electric field energy. The microwave resonant cavity has a thin planar shape and the resonator is loaded with two dielectric elements, placed symmetrically relative to the central EPR sample.

Owner:BRUKER BIOSPIN

Microwave hot-pressing sintering and brazing device and using method thereof

The invention relates to a microwave hot-pressing sintering and brazing device. The microwave hot-pressing sintering and brazing device comprises a microwave resonance cavity. A microwave generating device is connected to one side of the microwave resonance cavity. An adjustable total-reflection terminal device is connected to the other side of the microwave resonance cavity. A pressurization system used for applying pressure to a sample is further arranged on the microwave resonance cavity. The microwave resonance cavity of the microwave hot-pressing sintering and brazing device is of a rectangular structure of interlayer water cooling. A cooling water inlet and a cooling water outlet are formed in the outer wall of the microwave resonance cavity. The front portion, the rear portion, the upper portion and the lower portion of the microwave resonance cavity are each provided with a cylindrical attenuation waveguide which is communicated with the interior of the microwave resonance cavity and used for preventing microwave leakage. An optical fiber infrared temperature measuring sensor used for measuring thermal cycle is arranged in front of the microwave resonance cavity. The microwave hot-pressing sintering and brazing device is high in heating speed and capable of saving energy sources and achieving integration of microwave heating, pressurization and atmosphere protection.

Owner:FUZHOU UNIV

Microwave resonance plasma generating apparatus and plasma processing system having the same

ActiveUS8039772B2Producing efficiency can be increasedSimple structureElectric discharge tubesElectric arc lampsHigh energyCoaxial waveguides

A microwave resonance plasma generating apparatus, a plasma processing system having the same and a method of generating a microwave resonance plasma are provided. The apparatus includes a microwave generating unit which generates a microwave, and a plasma producing unit which produces electrons and photons of high energy using the microwave generated from the microwave generating unit. The plasma producing unit includes a coaxial waveguide having an inner electrode disposed adjacent to the microwave generating unit, an outer electrode connected to the microwave generating unit and disposed to coaxially surround a portion of the inner electrode, the outer electrode being shorter than the inner electrode, and a dielectric tube disposed between the inner electrode and the outer electrode to insulate between the inner electrode and the outer electrode. The coaxial waveguide utilizes a principle of “cut or truncated electrode of coaxial waveguide” and a resonance phenomenon of Langmiur.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com