EPR microwave cavity for small magnet airgaps

A microwave and cavity technology, applied in the direction of using electron paramagnetic resonance for measurement, electrical components, measurement of magnetic variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

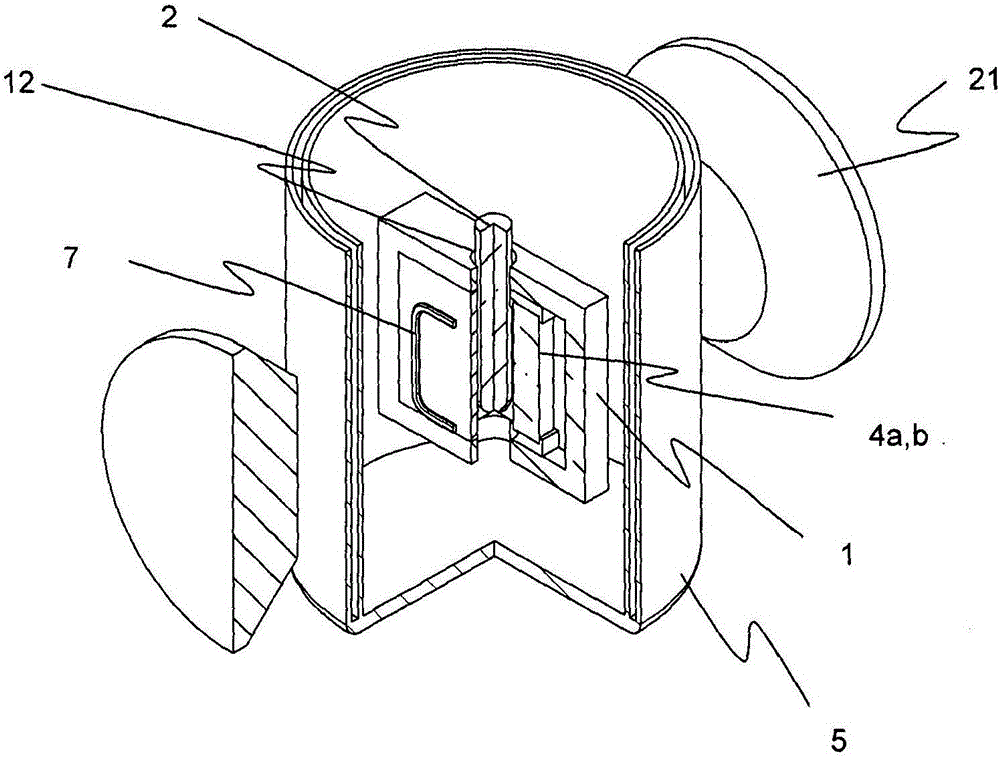

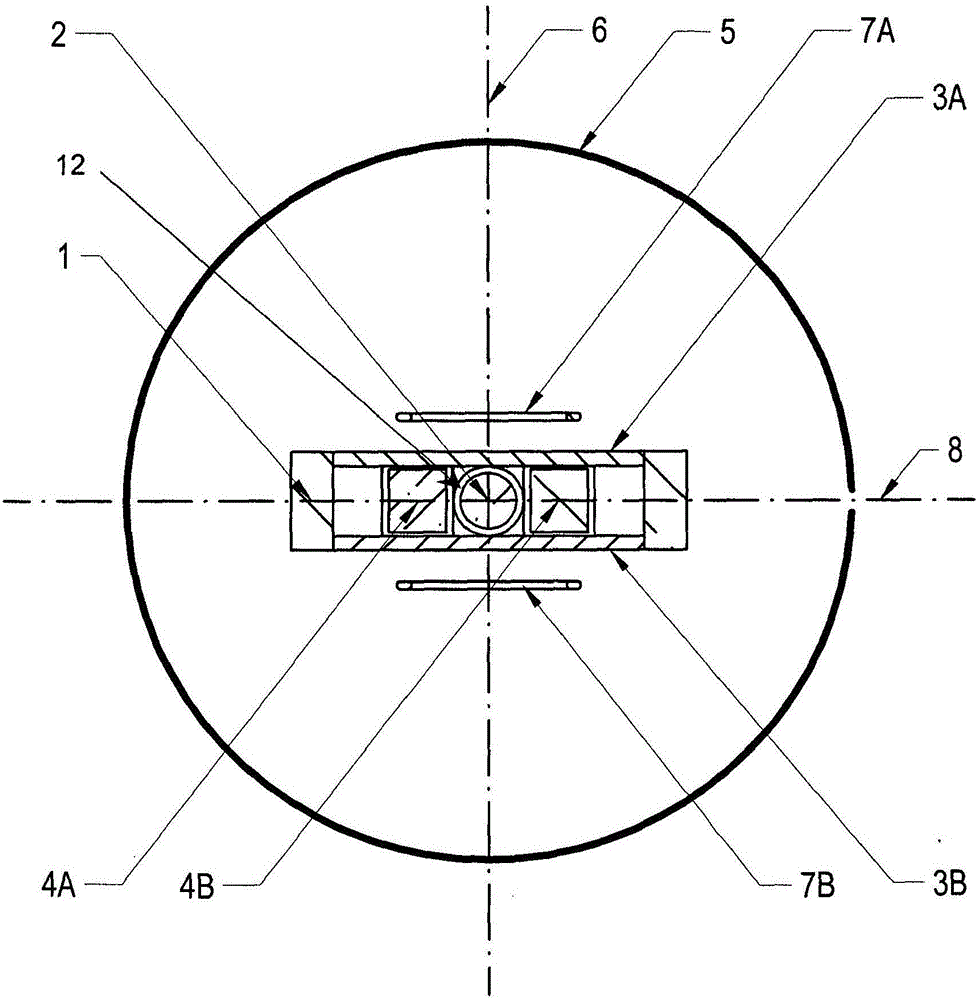

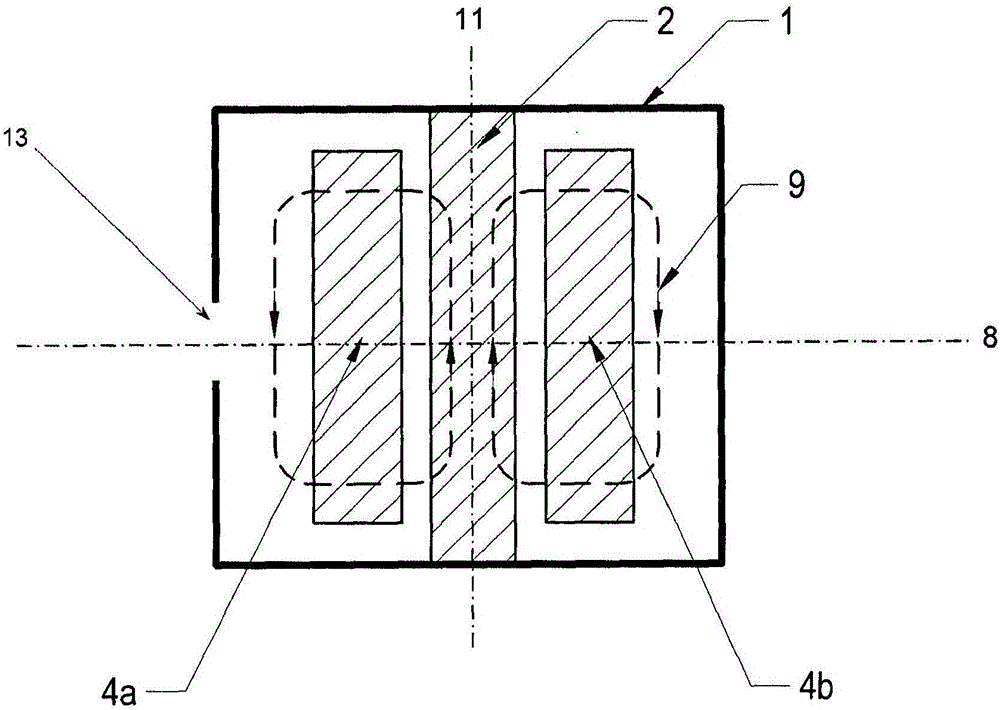

[0052] exist figure 1 A simplified example of a novel EPR experimental setup according to the present invention is shown in . An EPR experiment showing a flat microwave cavity 1 loaded with dielectrics 4a,b, together with a variable temperature cryostat 5, the poles 21 of an external magnet forming the main static magnetic field and responsible for the formation of a modulated magnetic field throughout the EPR cavity and a paramagnetic sample 2 The modulating coil 7. Samples mostly consist of tubes that hold the substance to be measured. When describing the characteristics of the resonator in relation to the position of the sample, it is understood that this is equivalent to the space provided to accommodate the sample. All other details about the mechanical or standard implementation of microwaves (various supports, coaxial microwave launch lines and microwave coupling structures necessary to excite microwave resonances relevant to EPR use) are suppressed for clarity.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com