Patents

Literature

67 results about "Unit Density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The number of arbitrary units of something contained in a specific volume.

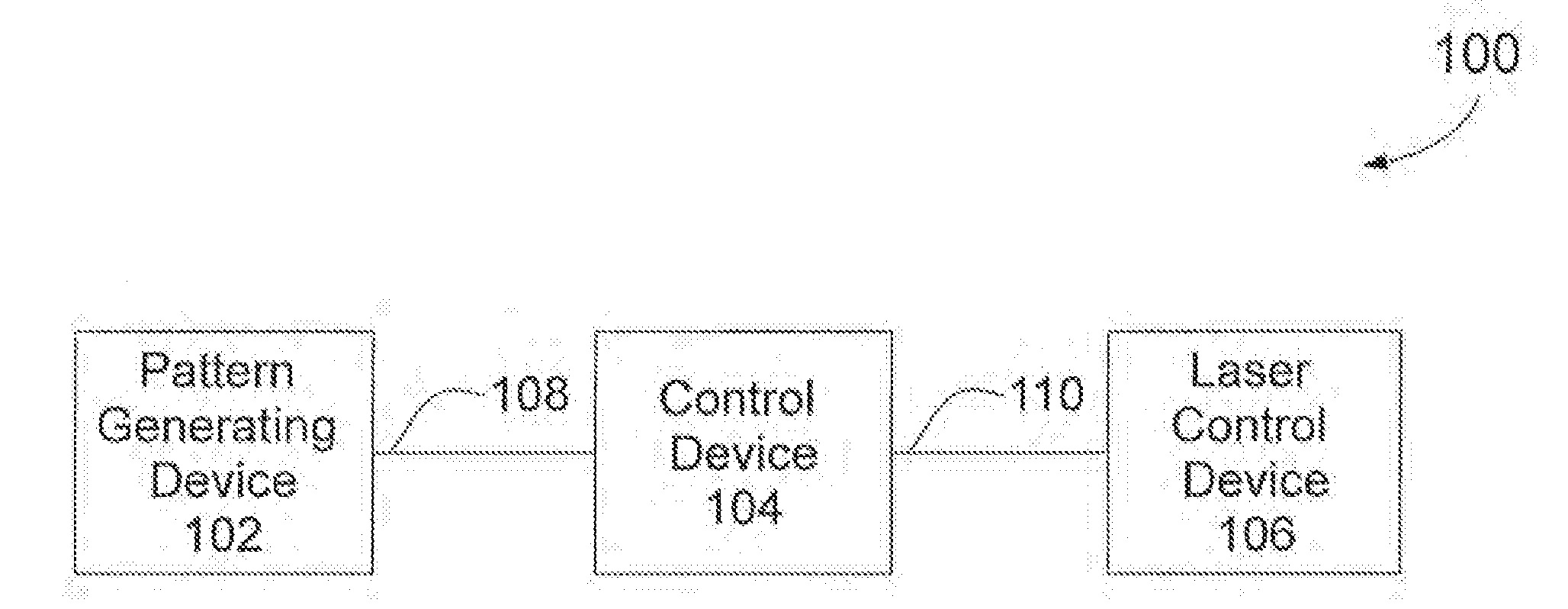

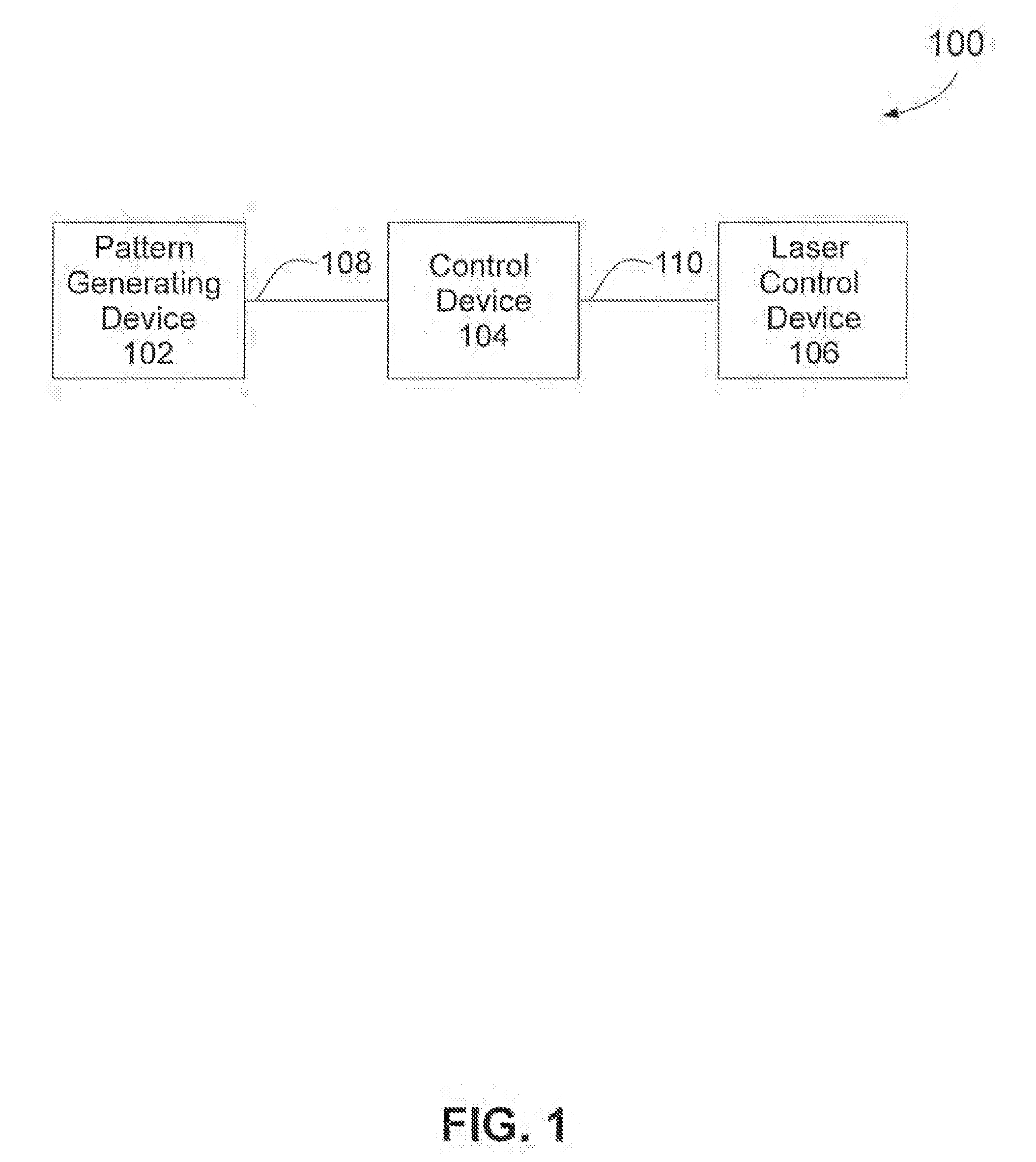

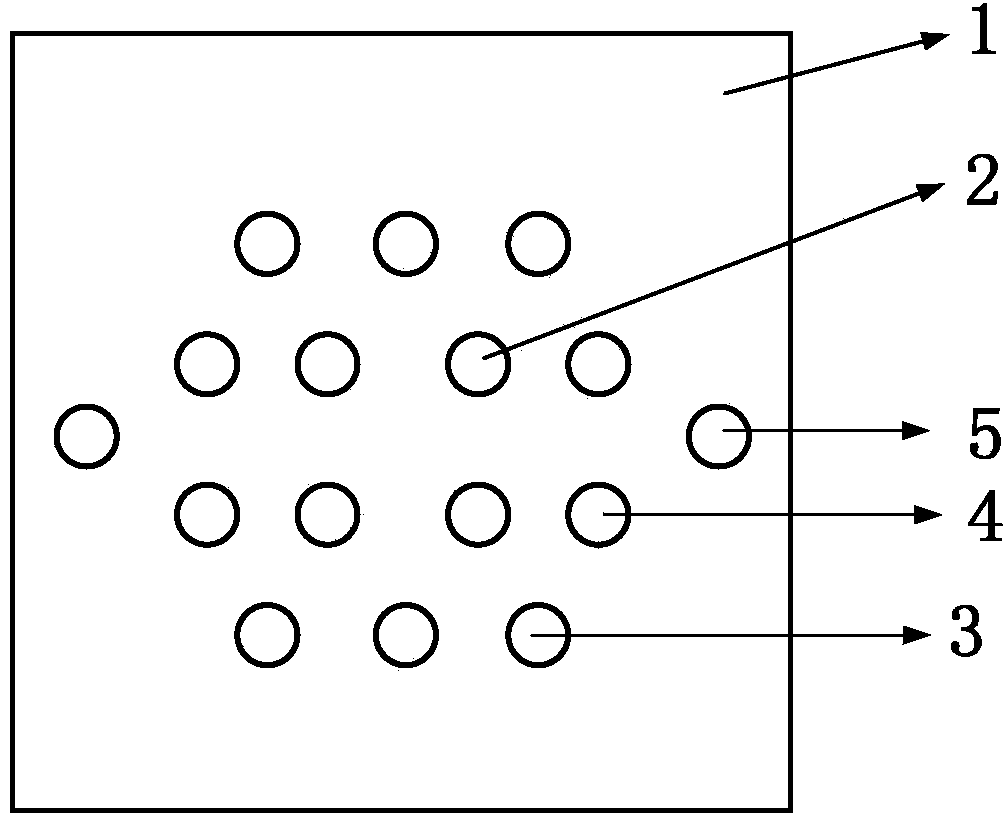

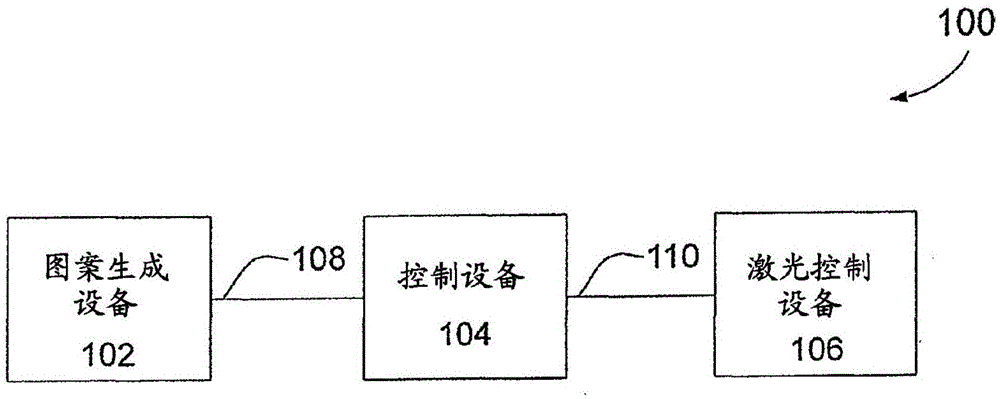

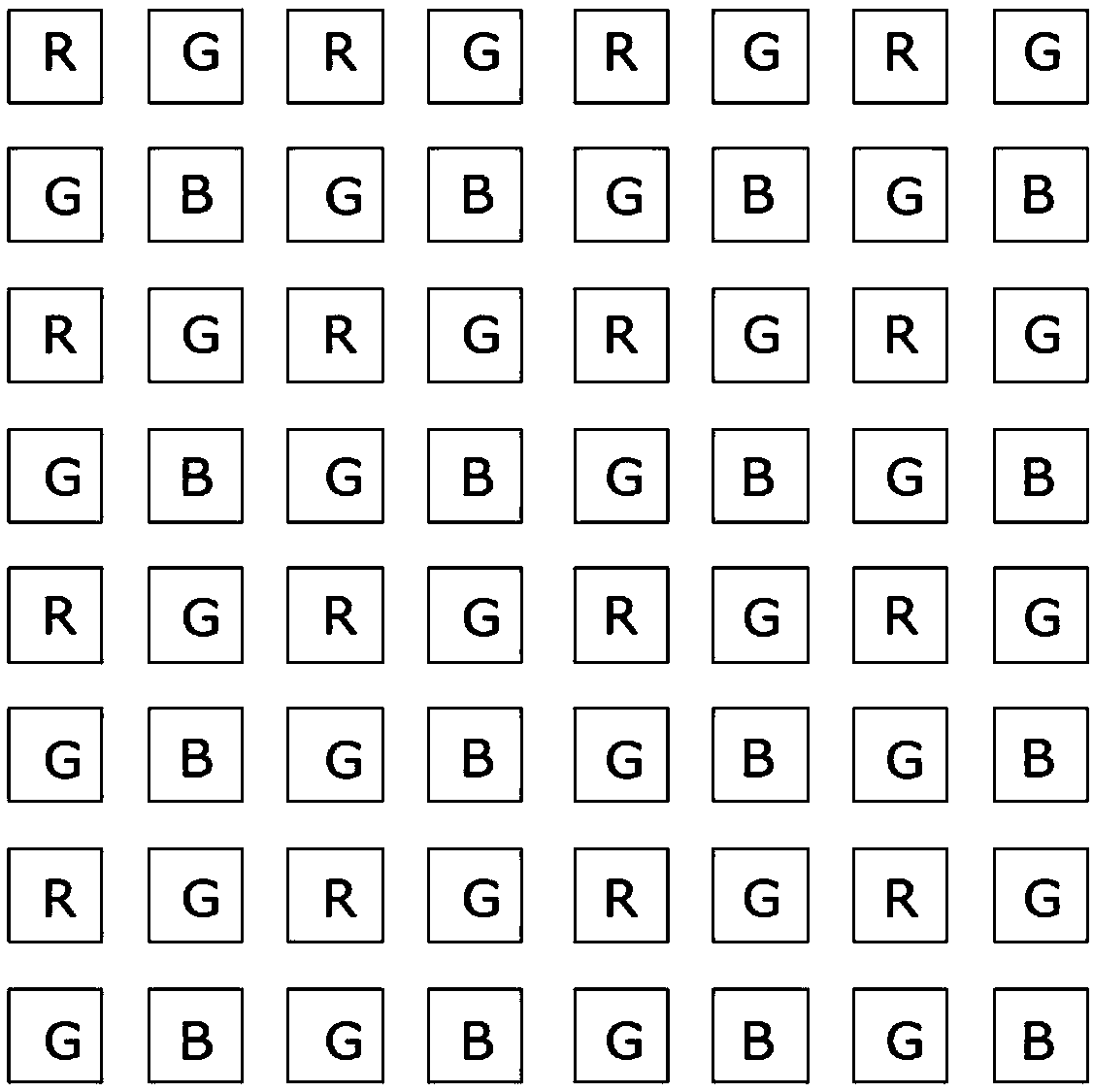

System and method of generating a pattern used to process a surface of a fabric through laser irradiation, and fabric created thereby

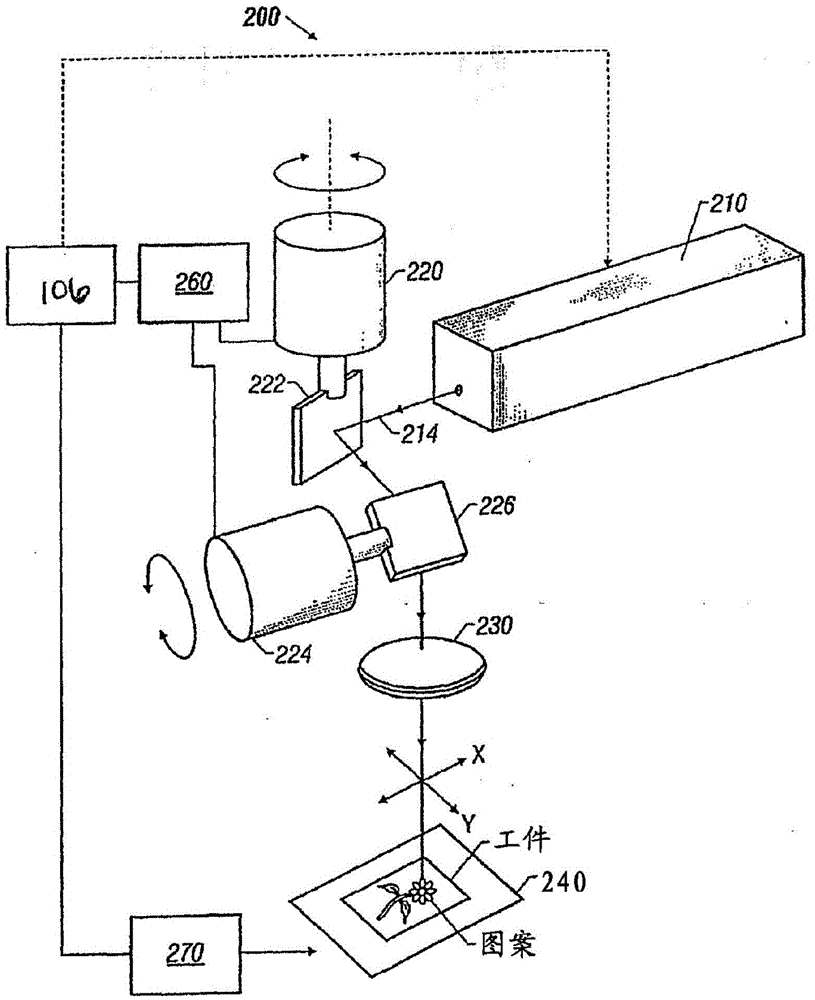

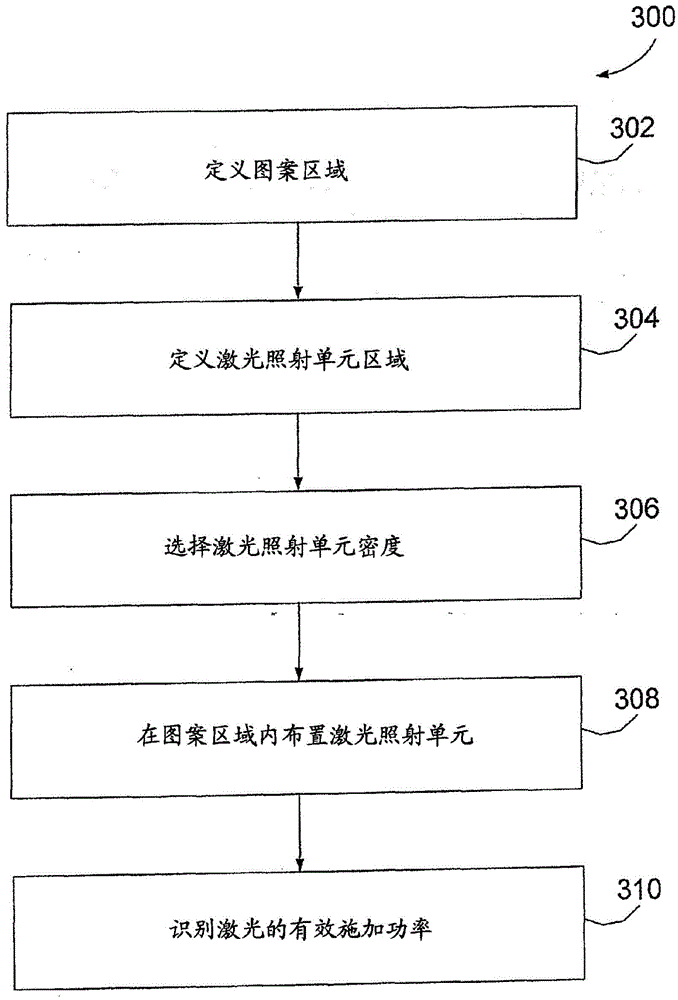

A method is provided of generating a pattern image used to form a pattern on a surface of a fabric using laser irradiation. A plurality of parameters associated with laser irradiation units are input into a user interface. The parameters include an area parameter, a laser irradiation unit density parameter, optionally a discontinuity parameter, and a dye removal parameter. A plurality of laser irradiation units arranged in a pattern area of a user interface based on computer processing of the inputted plurality of parameters is received for viewing at the user interface. The laser irradiation units collectively establish the pattern image for viewing by the user.

Owner:REVOLAZE LLC

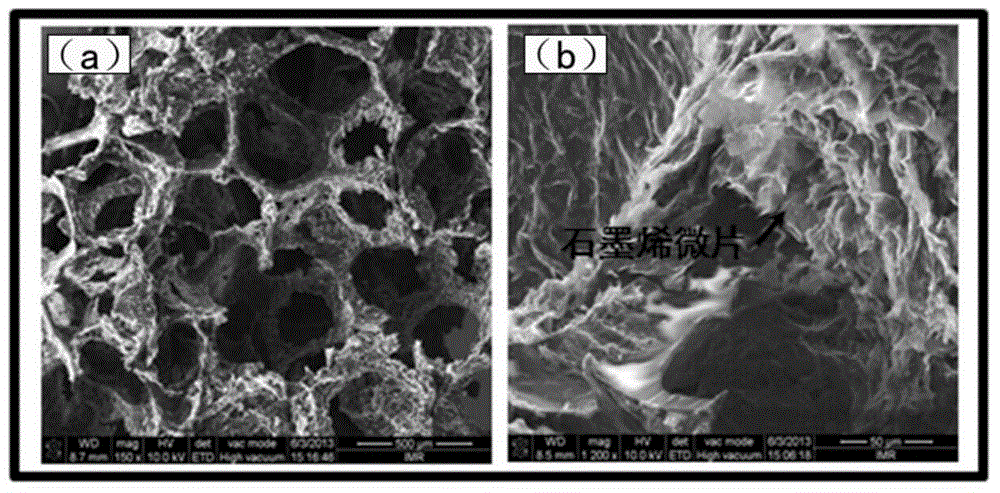

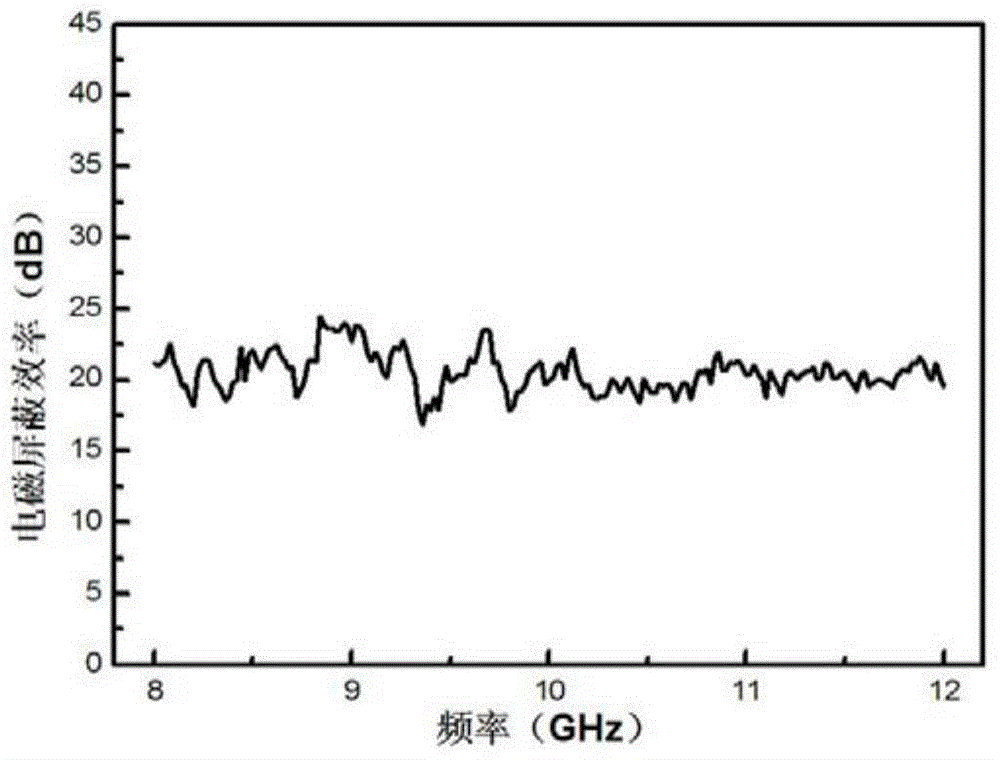

Application of graphene composite material electromagnetic shielding material

ActiveCN105694427AGood electromagnetic shieldingImprove flexibilityElectromagnetic shieldingElectromagnetic radiation

The invention discloses an application of a graphene composite material as an electromagnetic shielding material, and belongs to the technical field of new materials and applications thereof. The graphene composite material with isotropic and three dimensional connected conductive network skeleton is prepared through uniformly coating the surface of a foam sponge skeleton with a graphene material by compounding graphene and foam sponge. The electromagnetic shielding performance of the material is excellent, and the electromagnetic shielding effectiveness of the material with the thickness of 1.5mm can reach 40dB. The material can bear 80% compression deformation, has good flexibility and elasticity, and has a density of about 0.05g / cm<3>, and the unit density electromagnetic shielding effectiveness can reach 800dB.cm<3> / g. The material can effectively shield electromagnetic radiation interference, improve the reliability of electronic products and prolong the service life of the electronic products as an electromagnetic shielding material. The graphene composite material has characteristics of massive preparation by adopting an industrial method, low cost, light weight and high efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

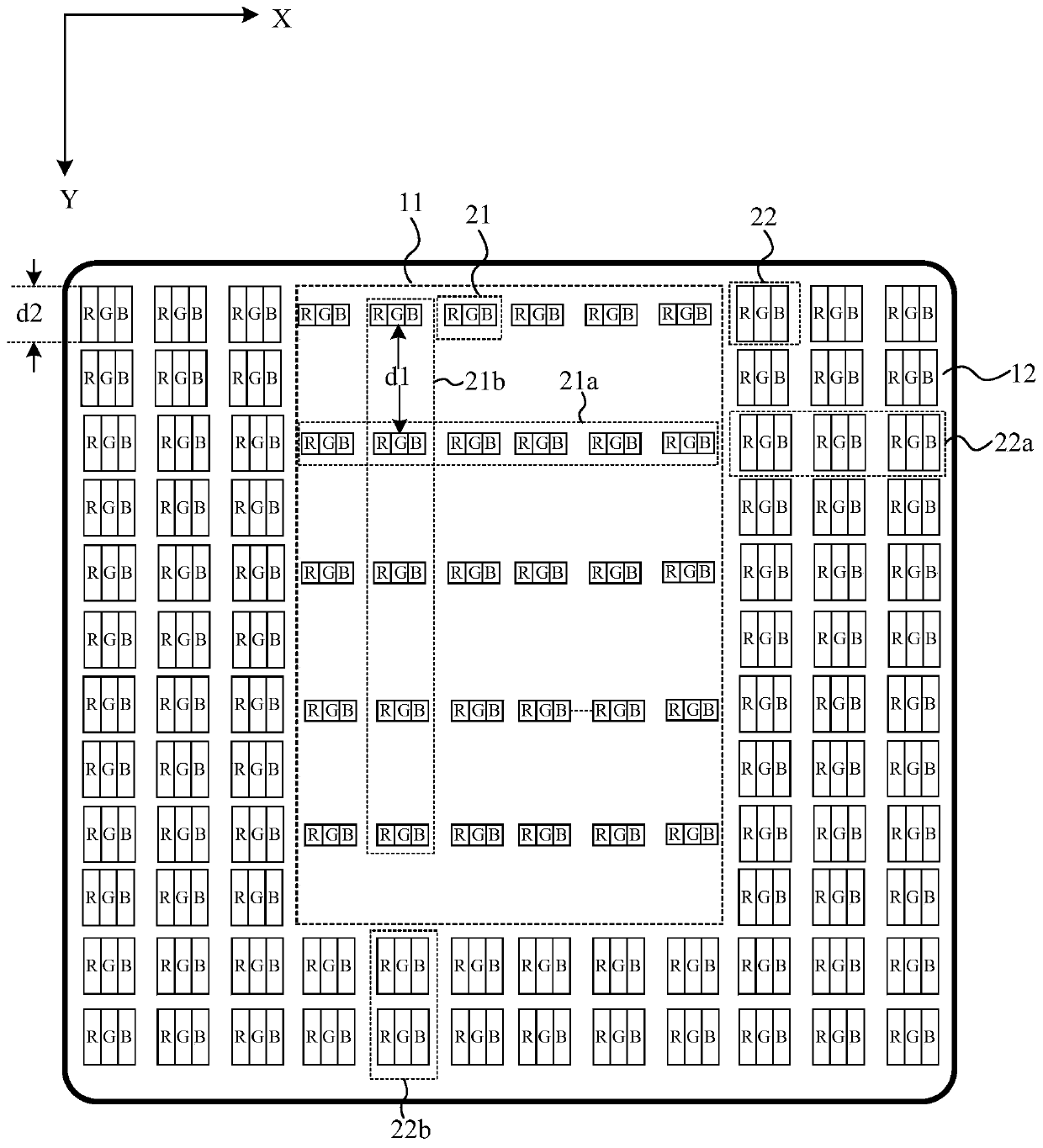

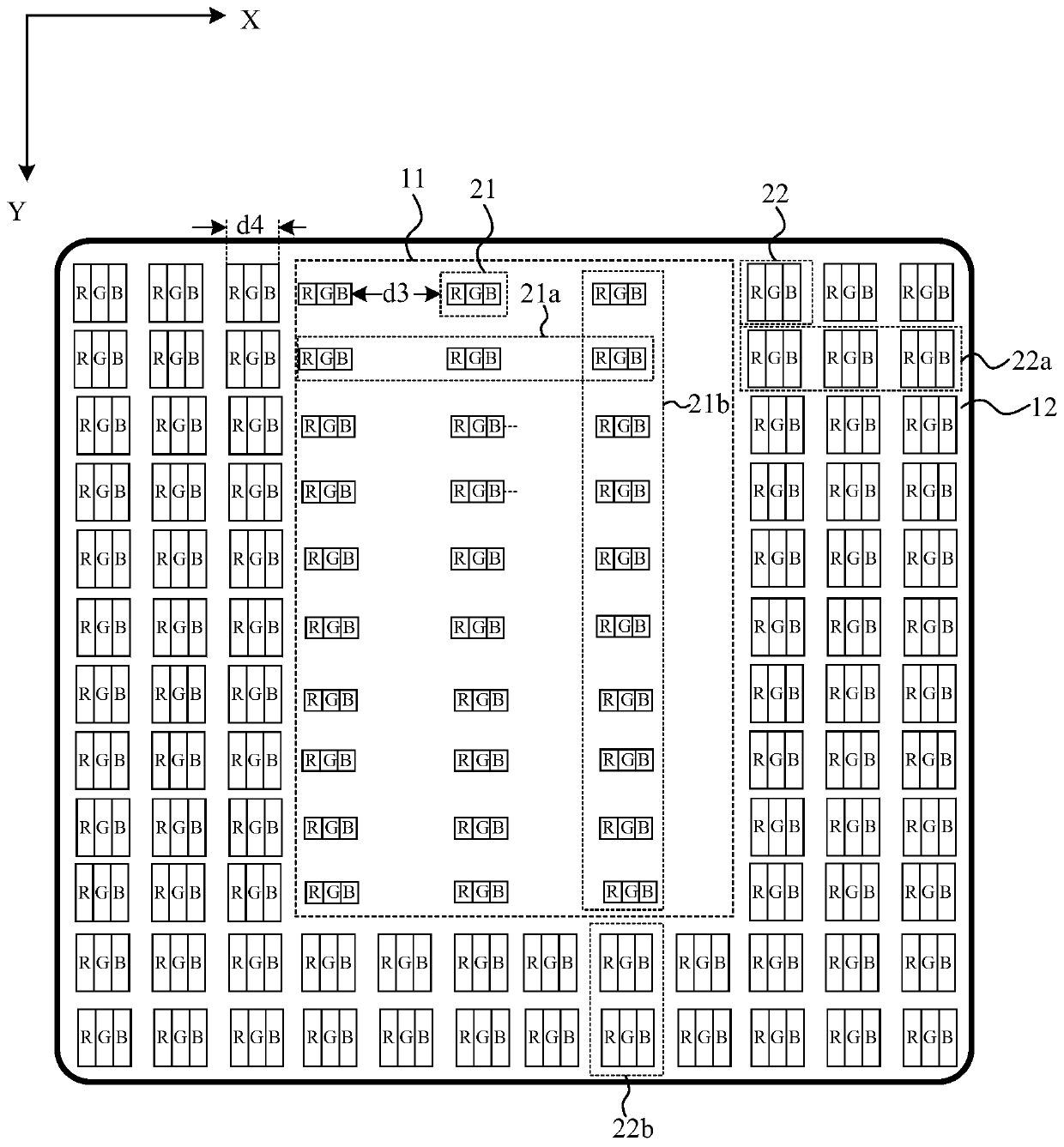

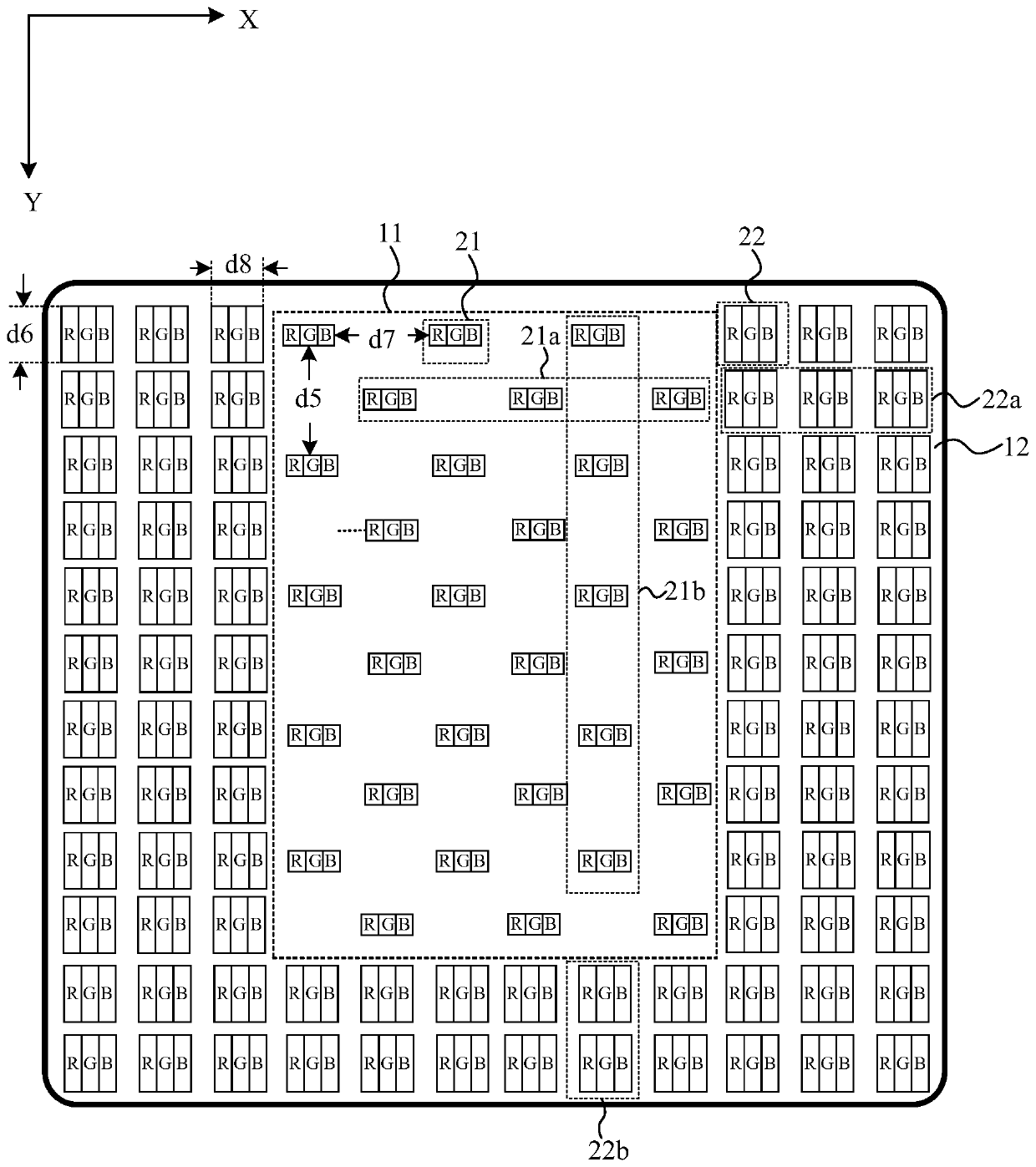

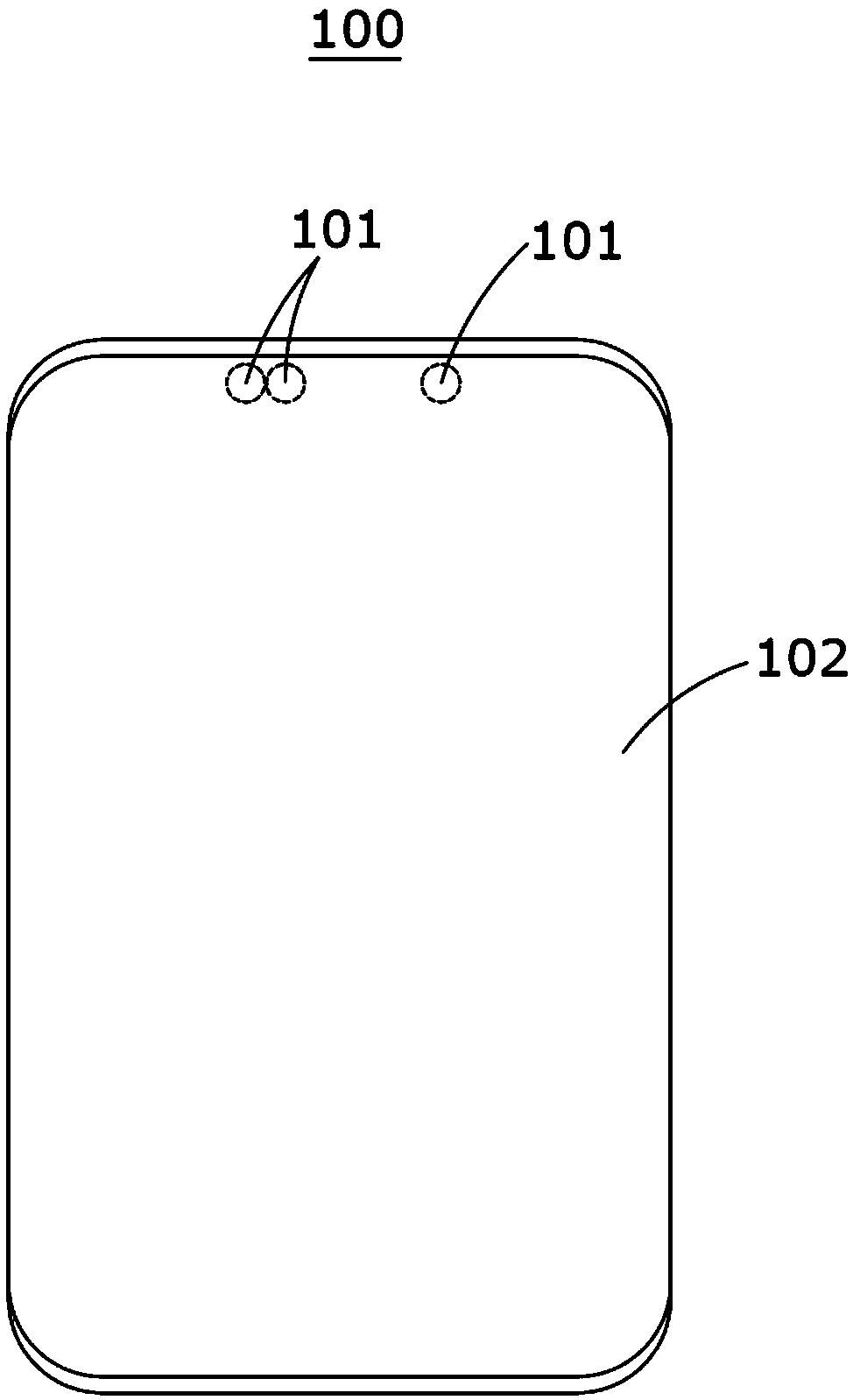

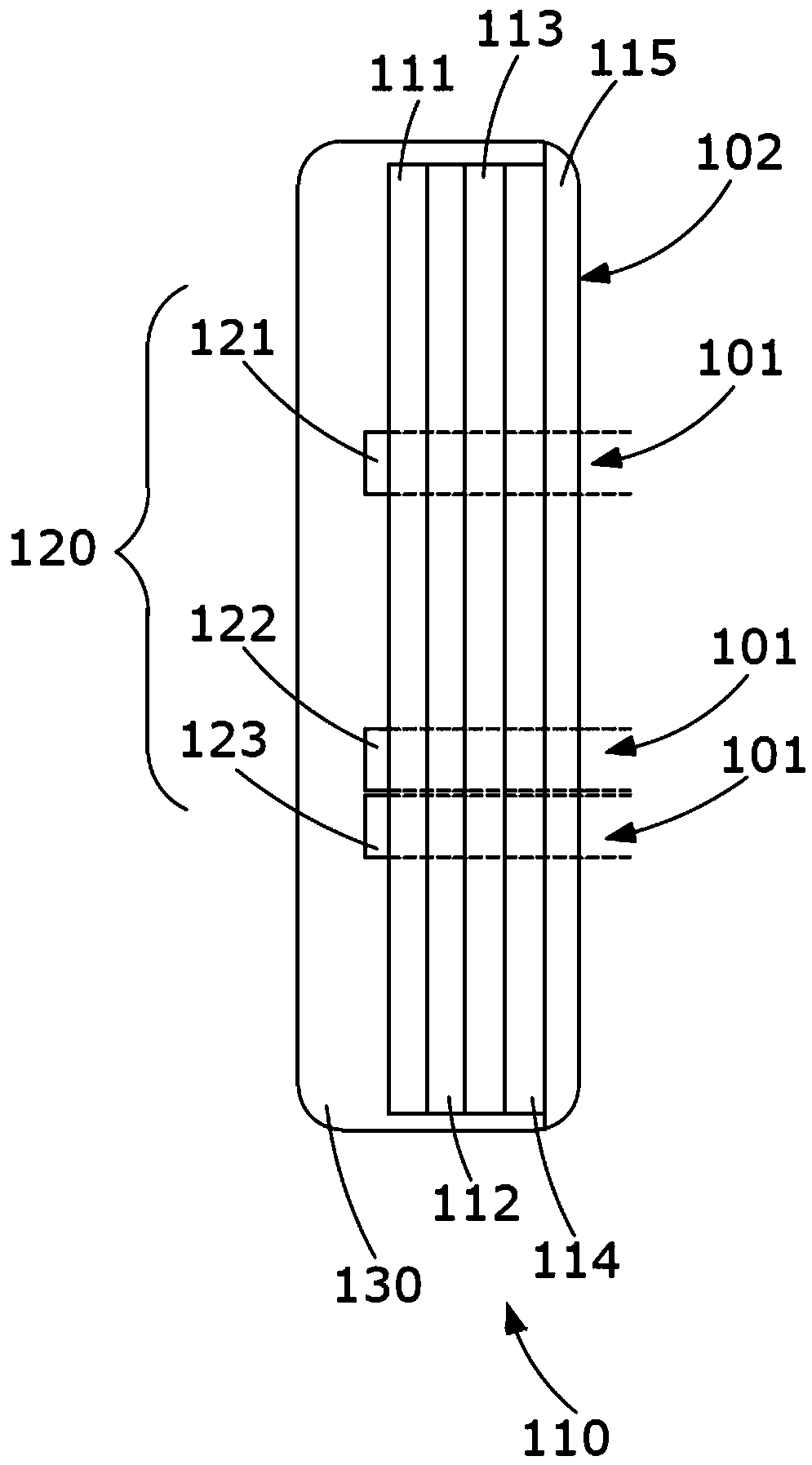

Display panel and display device

ActiveCN109950288AGood light transmissionEasy to useSolid-state devicesSemiconductor devicesDisplay deviceComputer science

The embodiment of the invention discloses a display panel and a display device. The display panel includes a first display area and a second display area. The first display area is multiplexed into asensor reserved area. The first display area includes a plurality of first pixel units. The second display area includes a plurality of second pixel units. The first pixel units include micro light-emitting diode pixel units, and the second pixel units include organic light-emitting diode pixel units. The pixel unit density of the first pixel units is smaller than that of the second pixel units. By using the above technical solution, the micro light-emitting diode pixel units are used in the first display area to ensure that the first display area can display normally or allow light to pass. At the same time, the pixel unit density of the first pixel units is smaller than that of the second pixel units, the good light transmission effect of the first display area is ensured, and the good use effect of a sensor is ensured.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

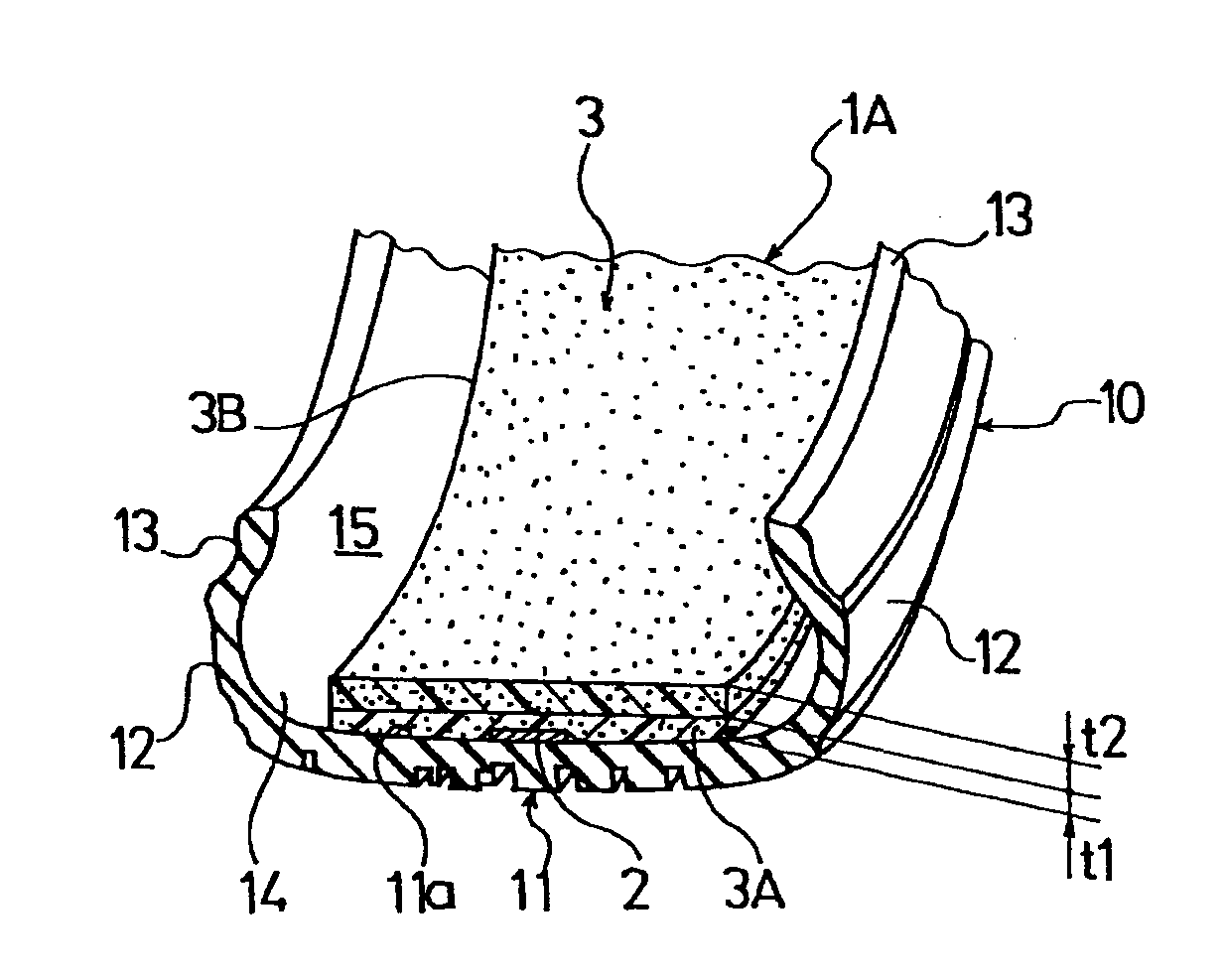

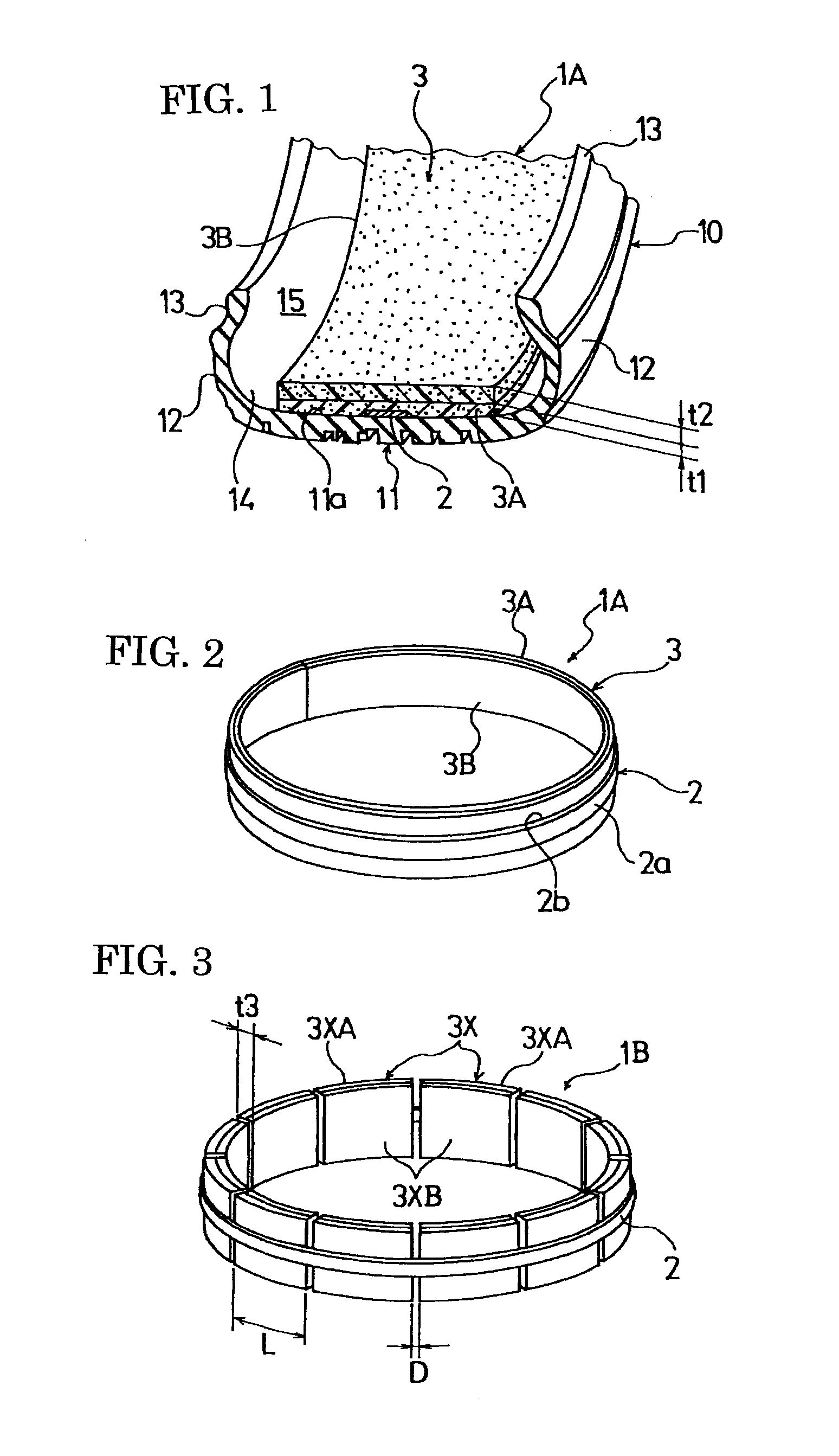

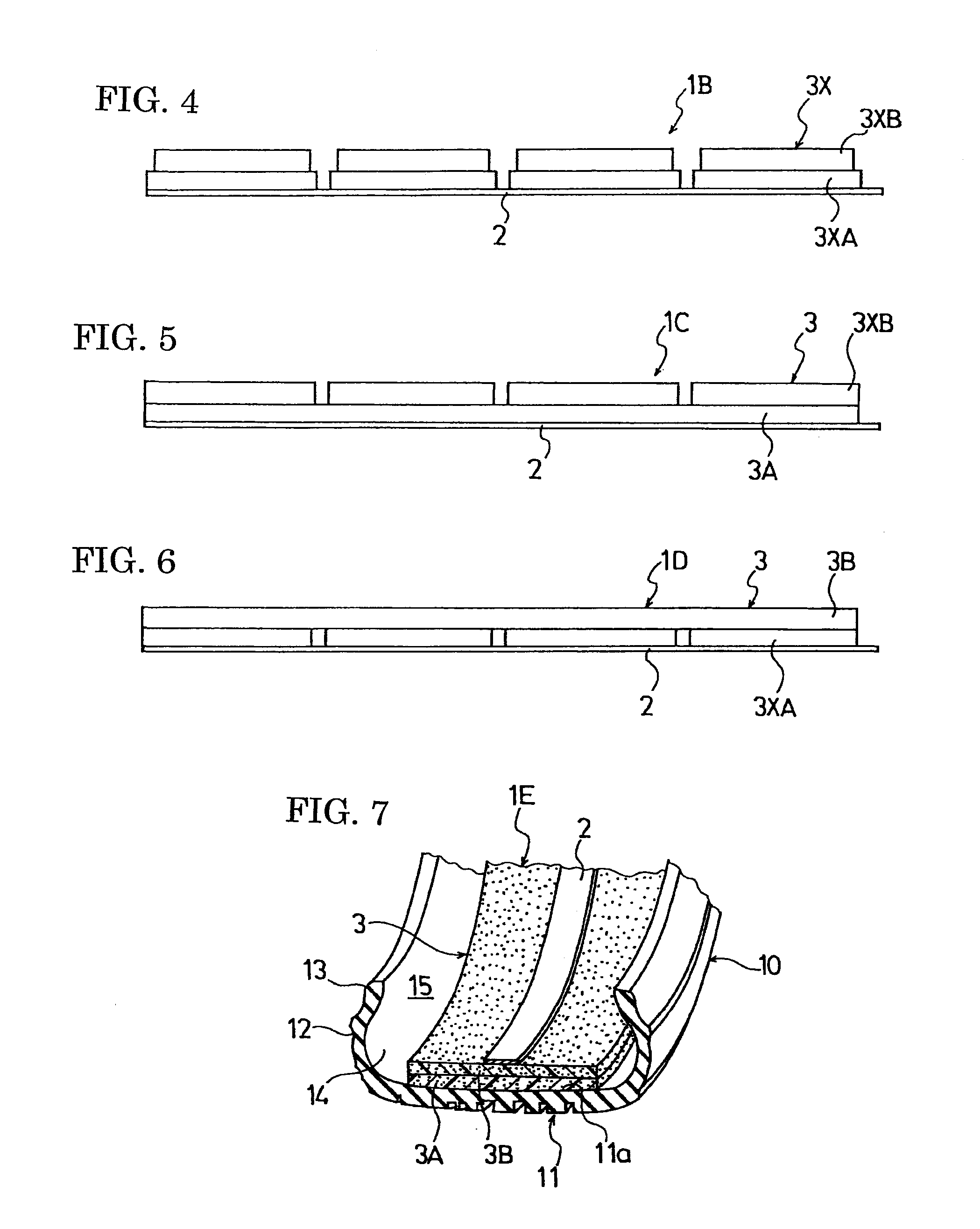

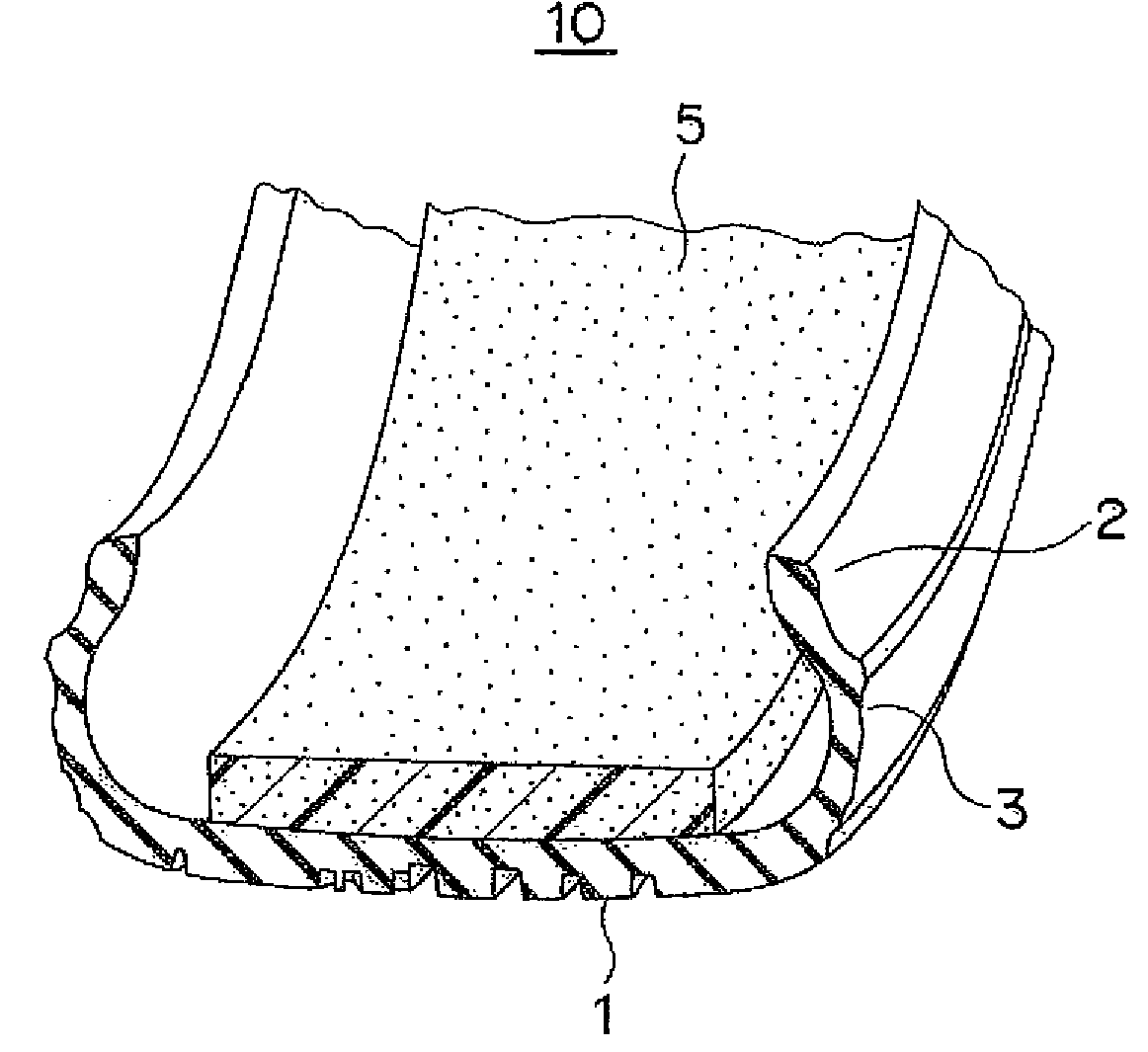

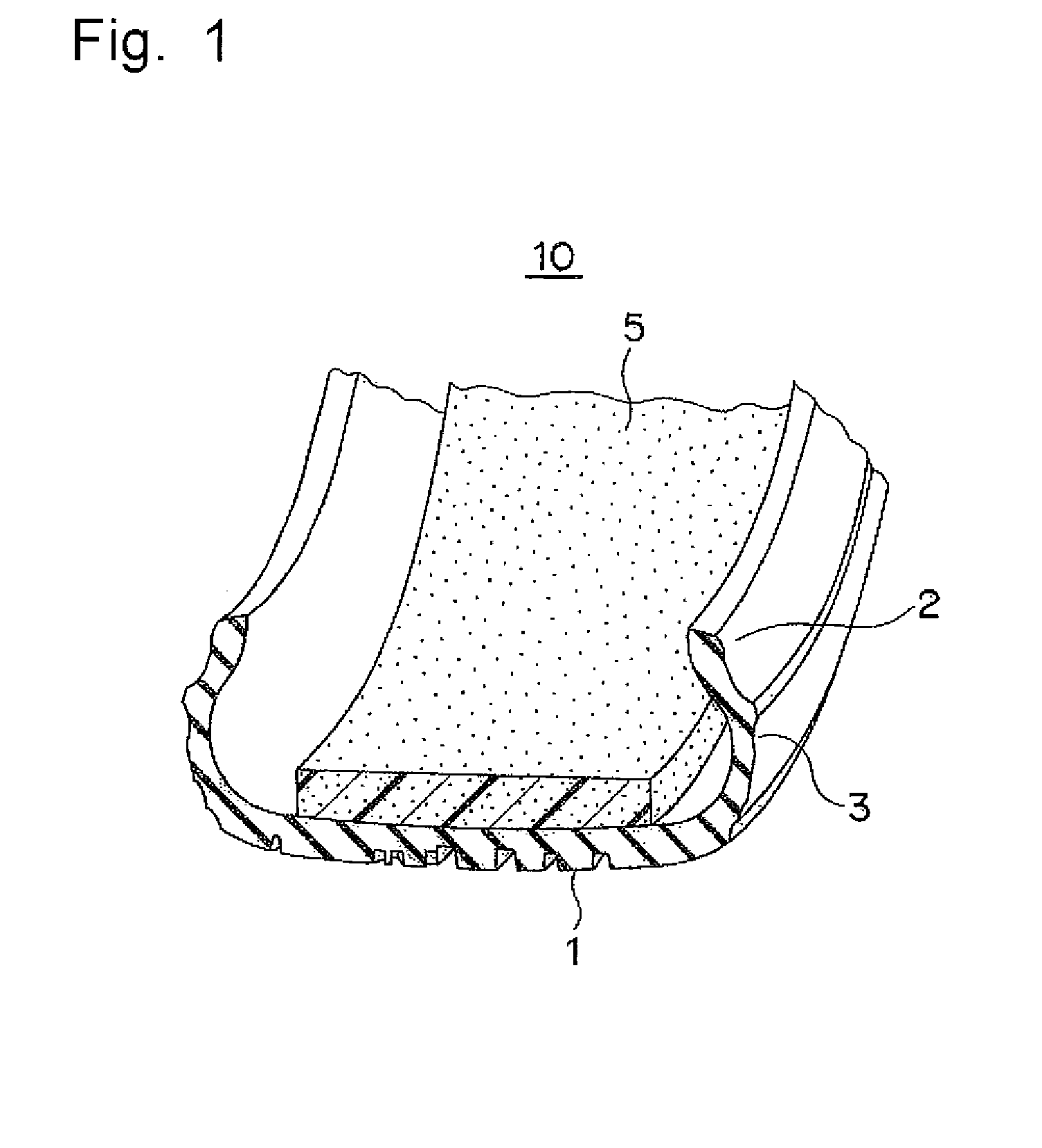

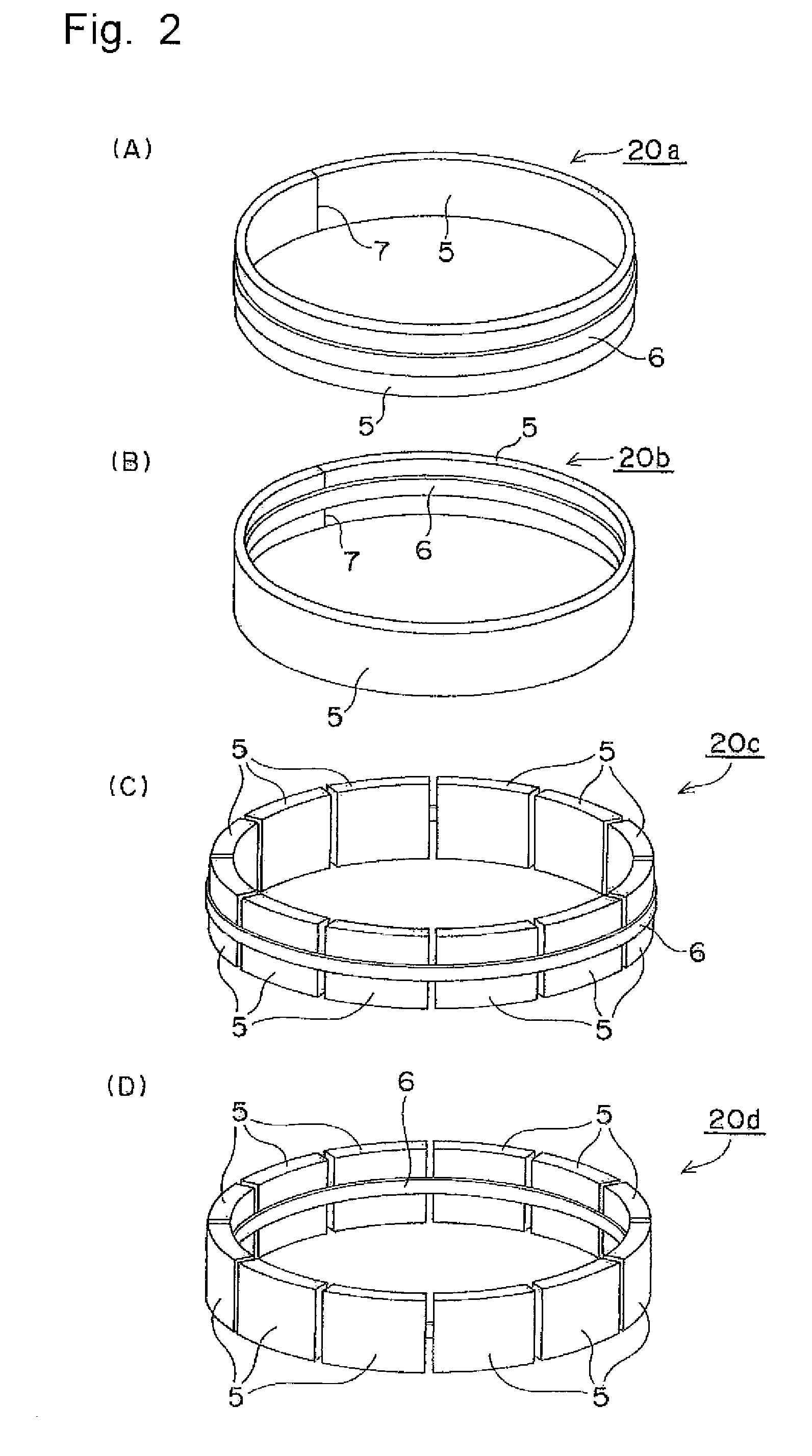

Tire noise reduction device and pneumatic tire

ActiveUS20100012243A1Low densityReduce the total massInflatable tyresWheelsEngineeringVolumetric Mass Density

There is provided a tire noise reduction device and a pneumatic tire, in which weight can be reduced while sound absorbing characteristics are maintained and durability is improved.The tire noise reduction device 1A of the present invention includes a sound absorbing member 3 of flexible polyurethane foam to be attached to an inner surface of a tire facing a cavity of the tire. The sound absorbing member 3 comprises a first sound absorbing layer 3A placed on a tire inner surface side thereof. The first sound absorbing layer 3A has a tear strength (N / cm) per unit density (kg / m3) which is equal to or more than 0.30. The second sound absorbing layer 3B has a density which is lower than that of the first sound absorbing layer 3A.

Owner:YOKOHAMA RUBBER CO LTD

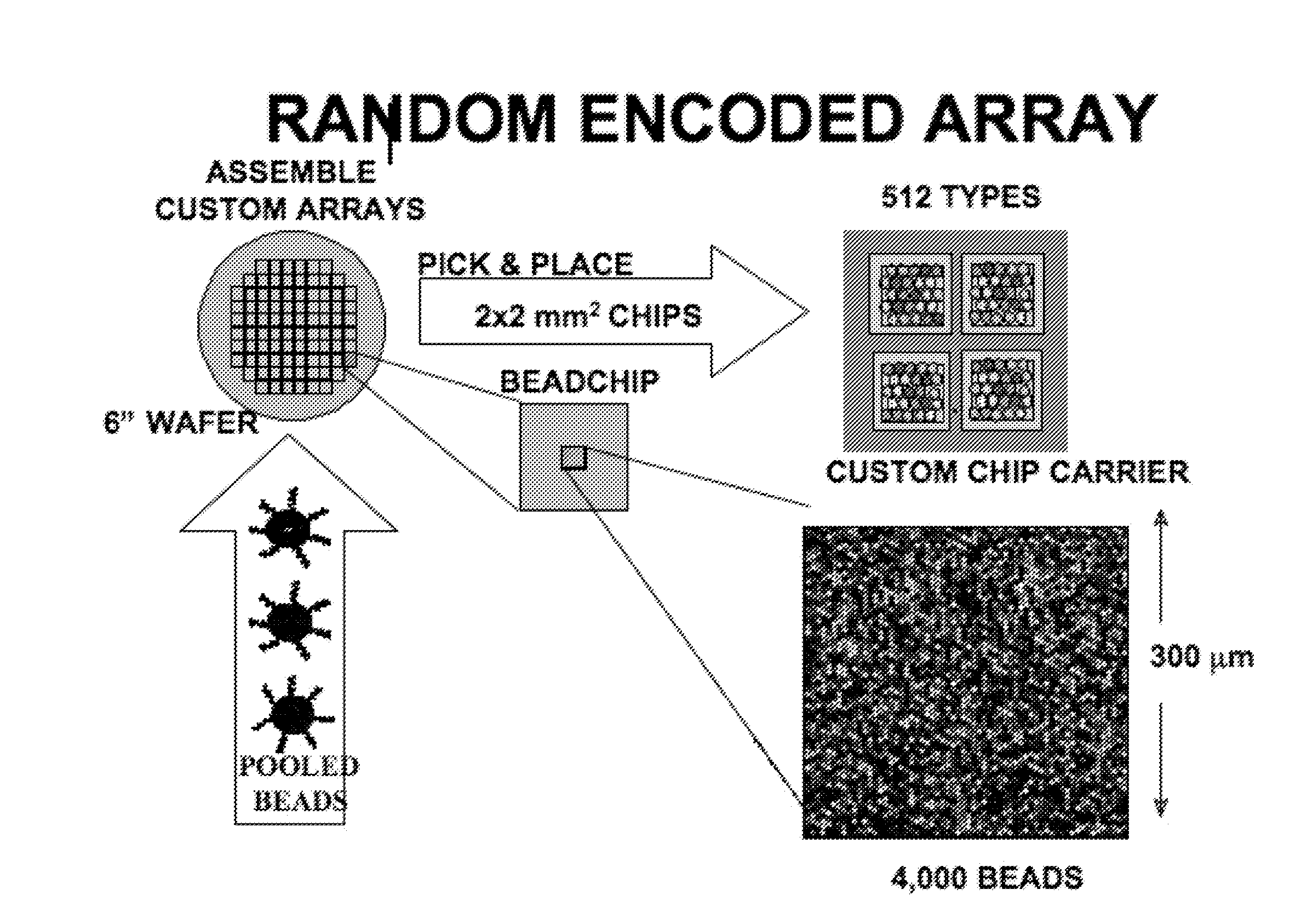

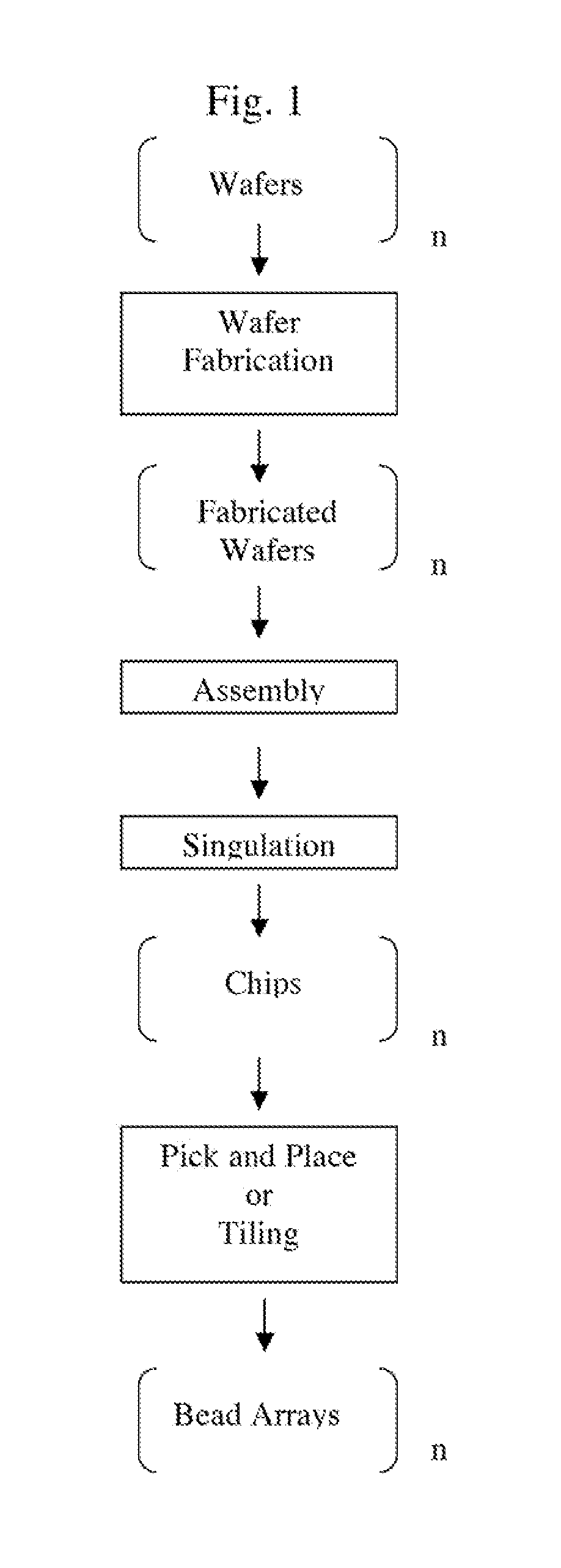

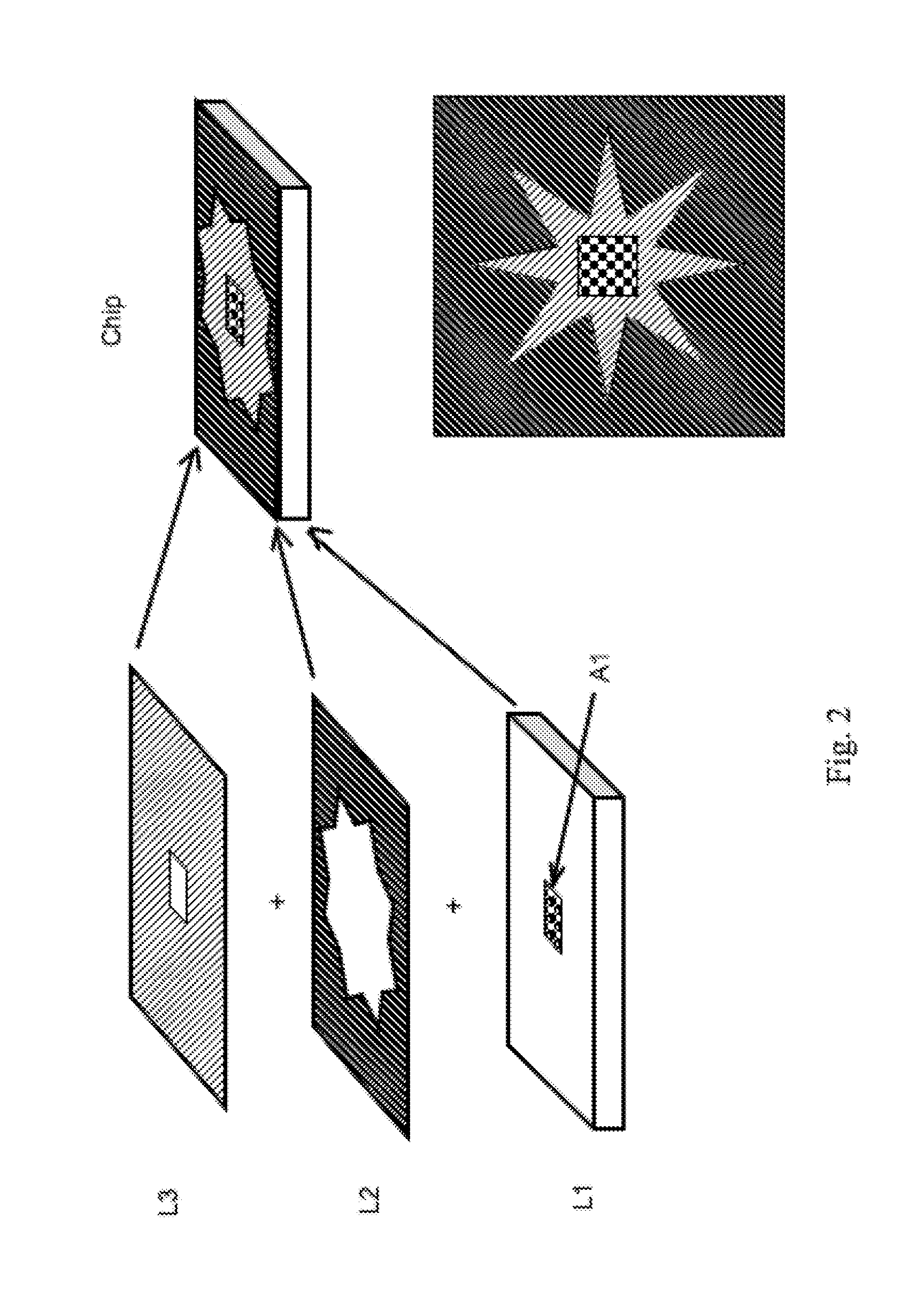

Quality control method for making a biochip displaying an encoded bead array

InactiveUS20080123089A1Improve performanceHigh densityBioreactor/fermenter combinationsSequential/parallel process reactionsAnalyteQuality control

This invention provides high unit density arrays of microparticles and methods of assembling such arrays. The microparticles in the arrays may be functionalized with chemical or biological entities specific to a given target analyte. The high unit density arrays of this invention are formed on chips which may be combined to form multichip arrays according to the methods described herein. The chips and / or multichip arrays of this invention are useful for chemical and biological assays.

Owner:BIOARRAY SOLUTIONS

Flexible polyurethane foam for tires, noise reducing device and tire

InactiveUS20090053492A1Damage suppressionLight weightWith separate inflatable insertsLayered productsVolumetric Mass DensityEngineering

The present invention is to provide a flexible polyurethane foam for tires that can effectively suppress damages, such as chips and cracks, and deformation, such as compression (permanent set in fatigue), even when attached to an inner face of a tire by using a band member.A flexible polyurethane foam for tires 5 which is attached to a gap between a tire and a wheel rim, wherein a density is in the range from 7 to 40 kg / m3 and a tear strength (N / cm) per unit density (kg / m3) is 0.30 or more, a noise reducing device with the flexible polyurethane foam for tires 5 fixed to a ring-shaped band member, and a tire 10 with the noise reducing device attached thereto.

Owner:THE YOKOHAMA RUBBER CO LTD +1

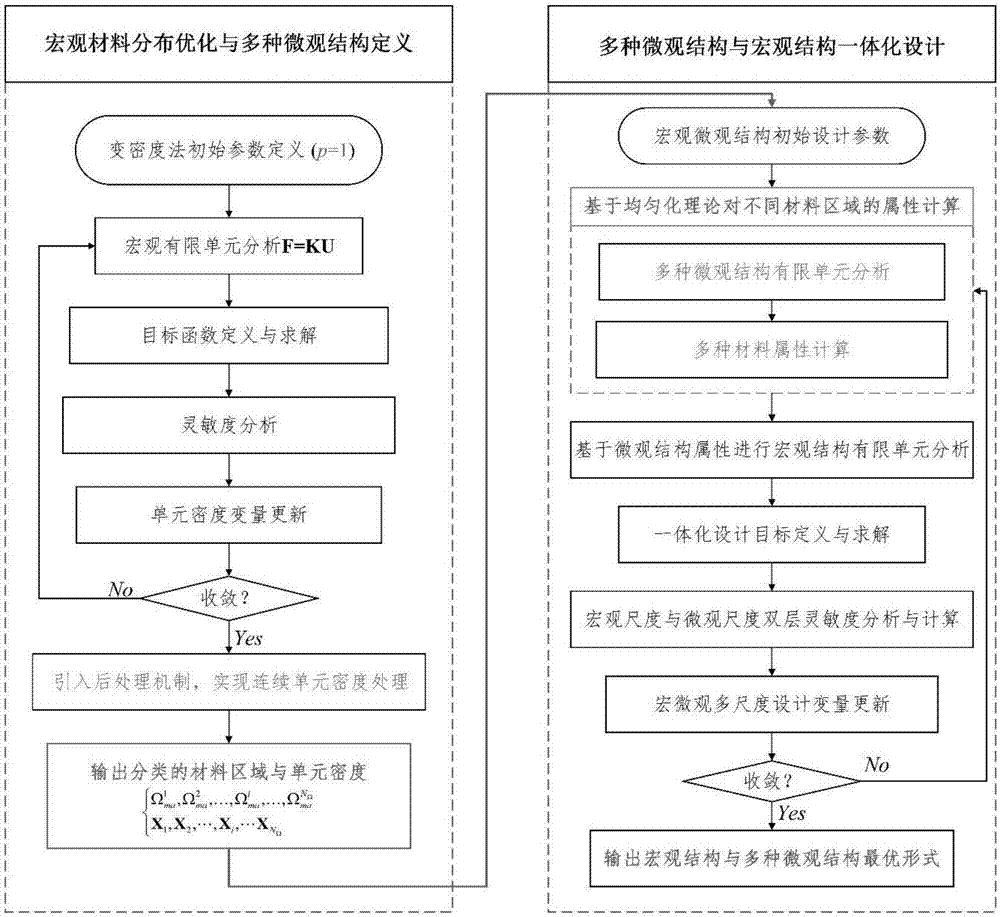

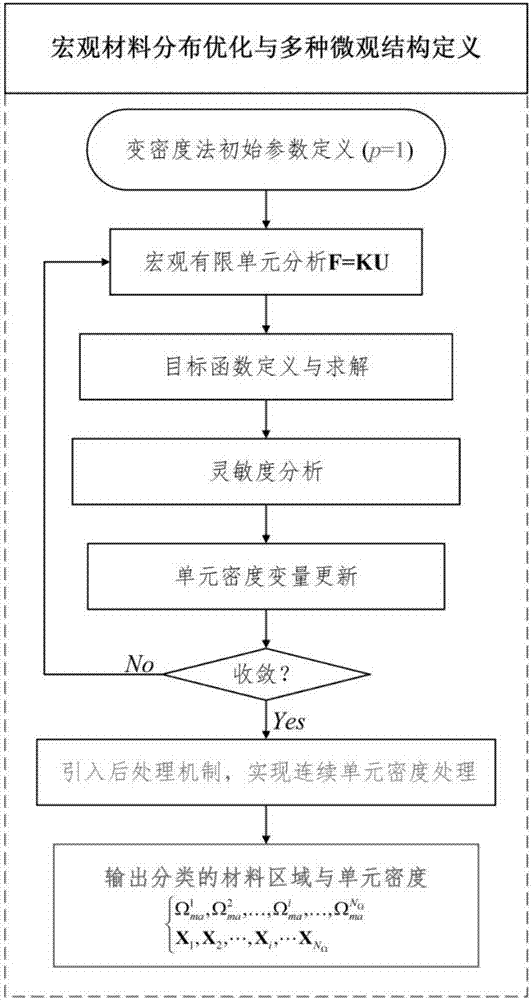

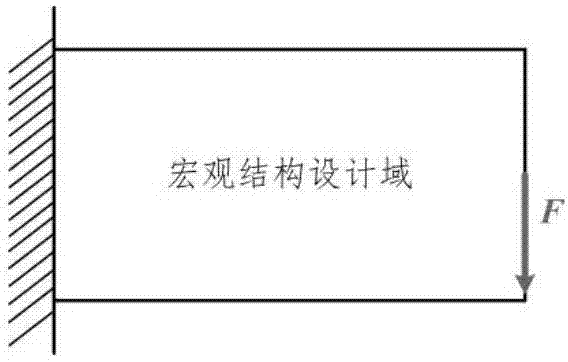

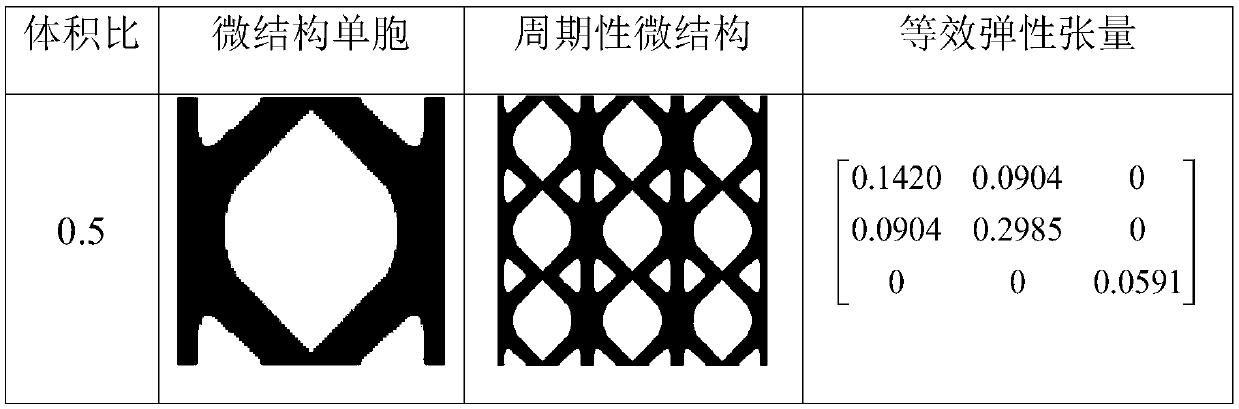

Multi-microstructure-oriented material structure integrated construction method

ActiveCN107391855ASimple designGuaranteed coupling effectGeometric CADSpecial data processing applicationsMacroscopic scaleTopology optimization

The invention belongs to the technical field of structural optimization and discloses a multi-microstructure-oriented material structure integrated construction method. According to continuously changing material distribution and unit density which are obtained through a traditional variable density method, a material area is divided and subjected to unit density grouping on the basis of a post-processing mechanism, definition and dividing of areas, with different material attributes, in a macrostructure are achieved, and various microstructures in the macrostructure are defined; a material structure integrated design model is established on the basis of a parameterized level set topological optimization method and the homogenization theory, that is, integrated design is carried out according to various defined microstructures and the macrostructure, the parallel design of the macroscopic structure and the microstructures is achieved, and under a given constraint condition, the performance of the overall structure is optimal.

Owner:HUAZHONG UNIV OF SCI & TECH

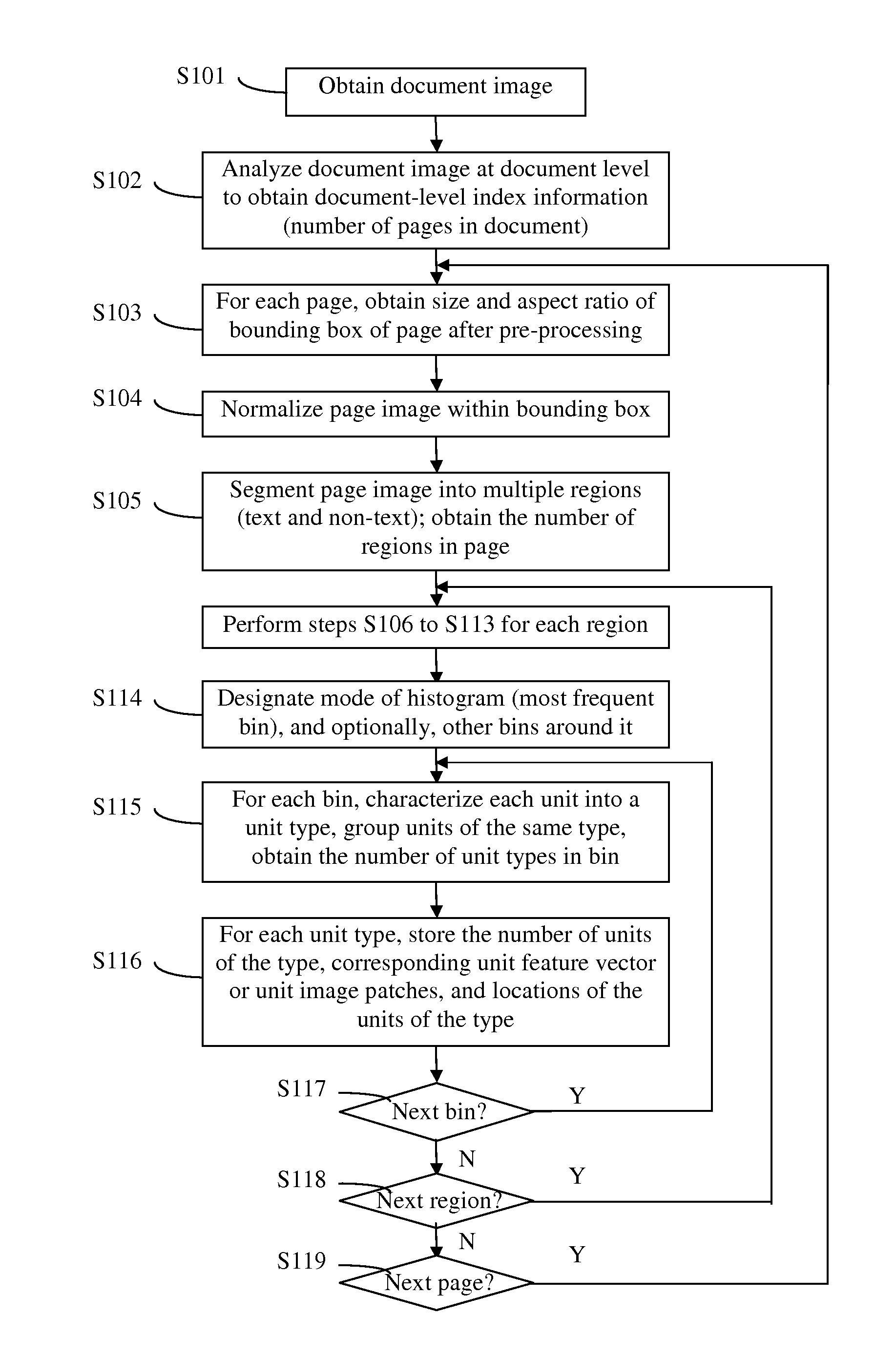

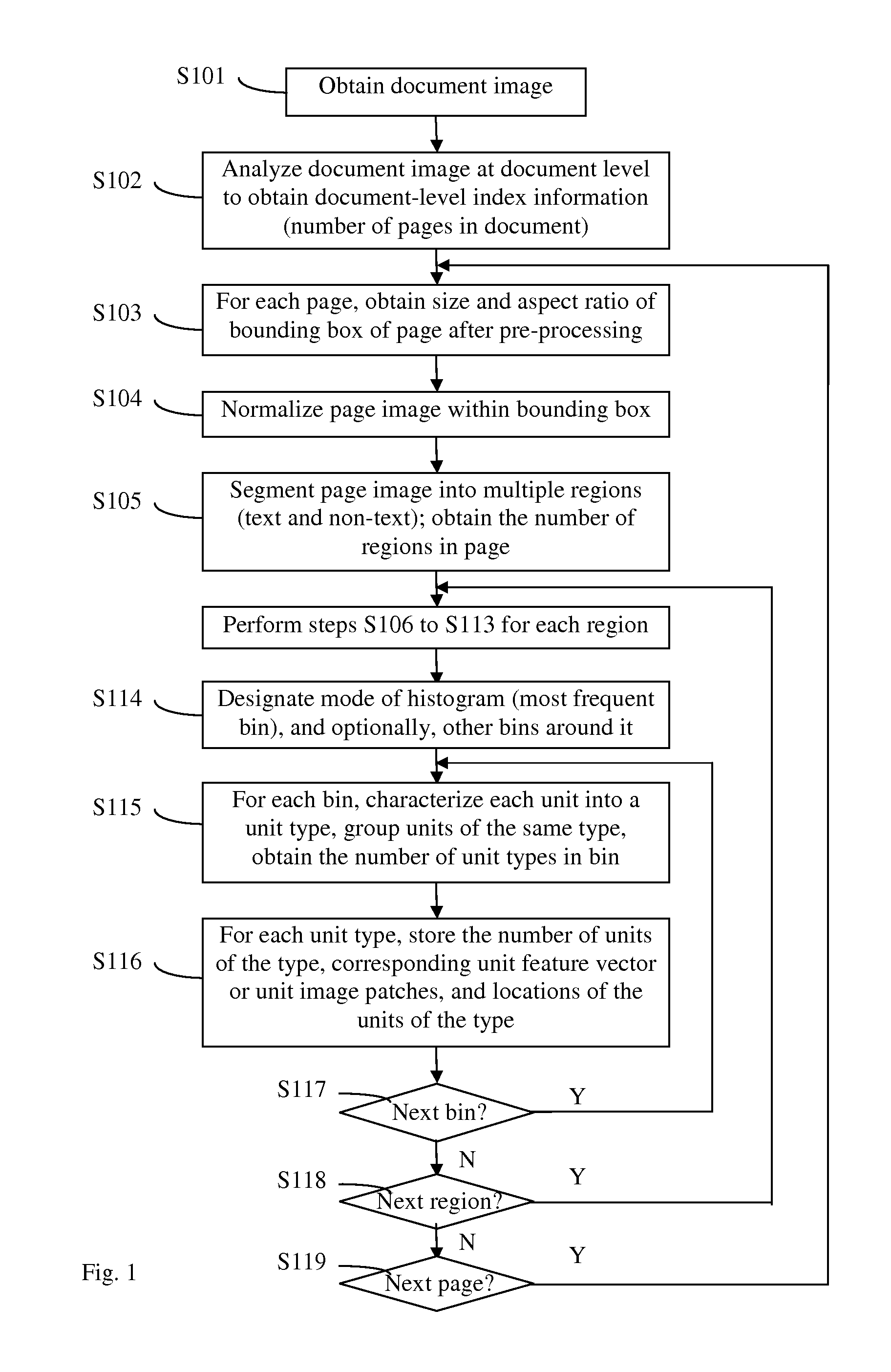

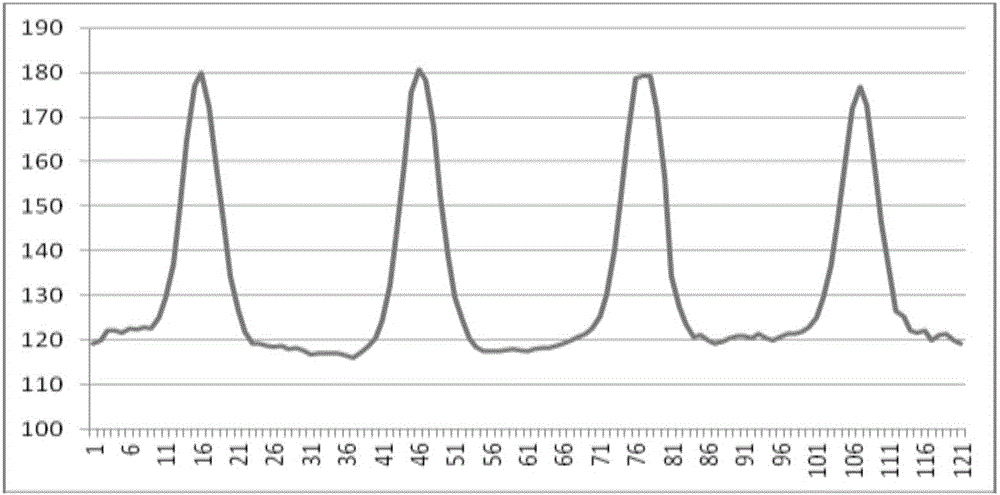

Method and apparatus for document image indexing and retrieval using multi-level document image structure and local features

ActiveUS20130170749A1Efficient and reliableReliable methodSpecial data processing applicationsCharacter recognitionImage structureHistogram

An image based document index and retrieval method is described. During document indexing, each source document is analyzed to generate index information at document, page, region and unit levels. Region and unit level index information is generated by segmenting each text region into units, constructing unit length or unit density histograms, and analyzing the units in a few most frequent bins of the histogram. The index information and the source document images are stored in a database. During document retrieval, a target document is analyzed to generate target index information in the same way as during document indexing. The target index information is compared to stored index information in a progressive manner (from higher to lower levels) to identify source documents with index information that matches the target index information. Fuzzy logic is used in the comparison steps to increase the robustness of the document retrieval.

Owner:KONICA MINOLTA LAB U S A INC

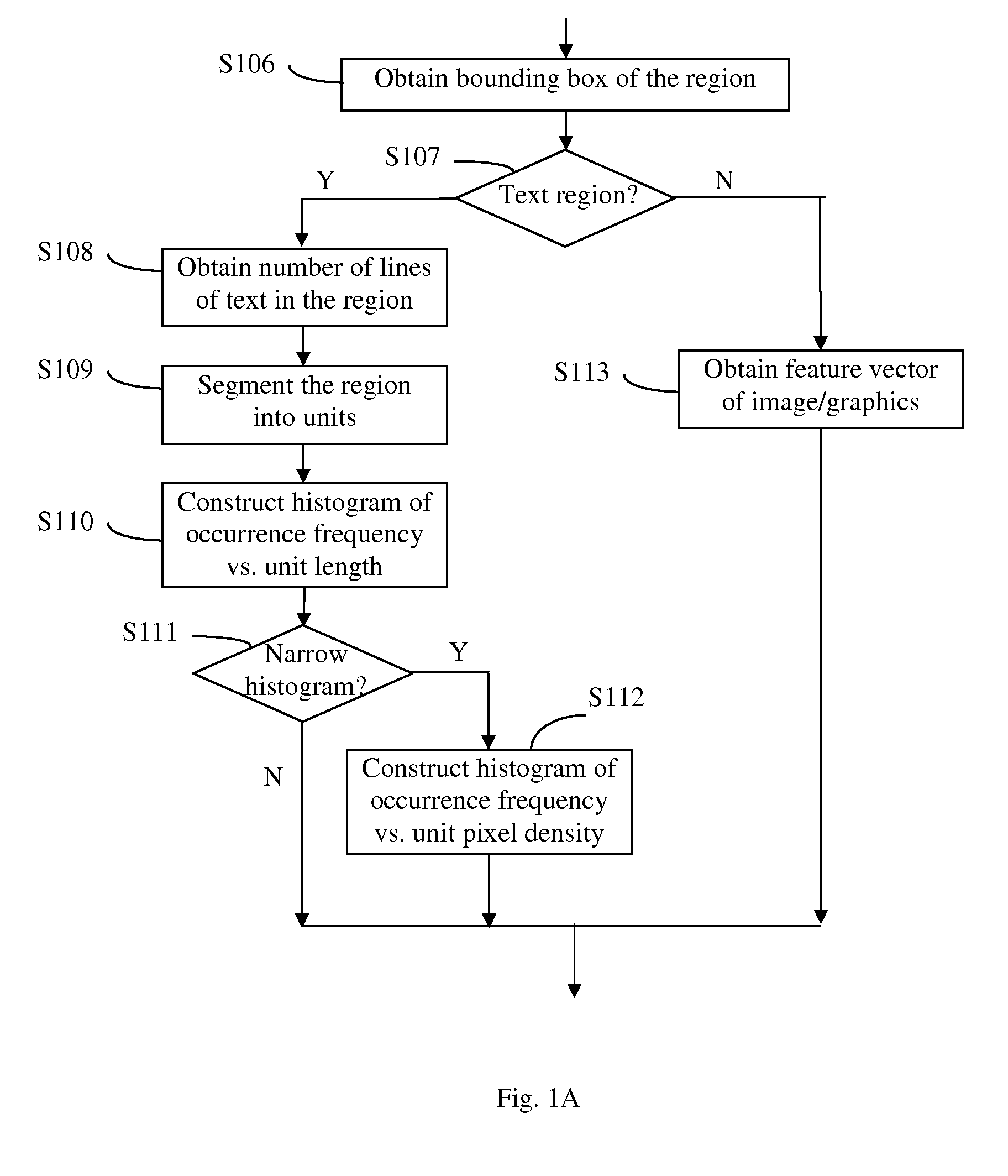

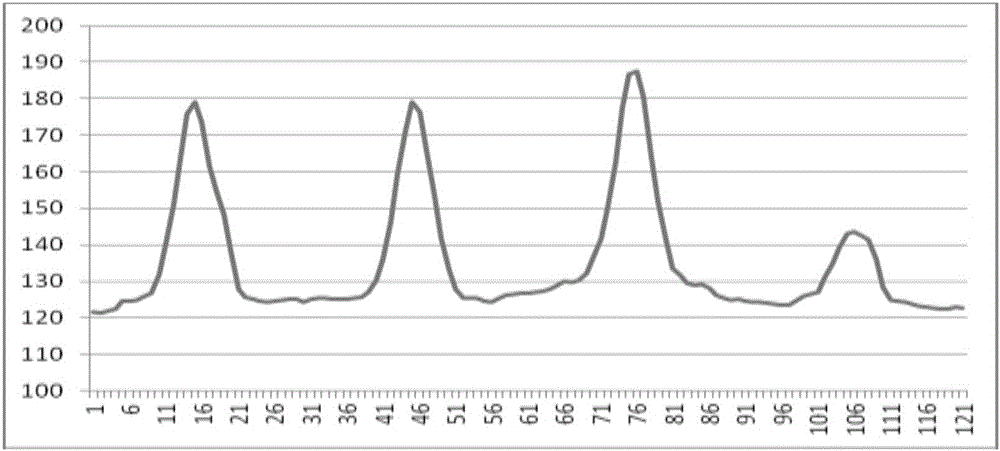

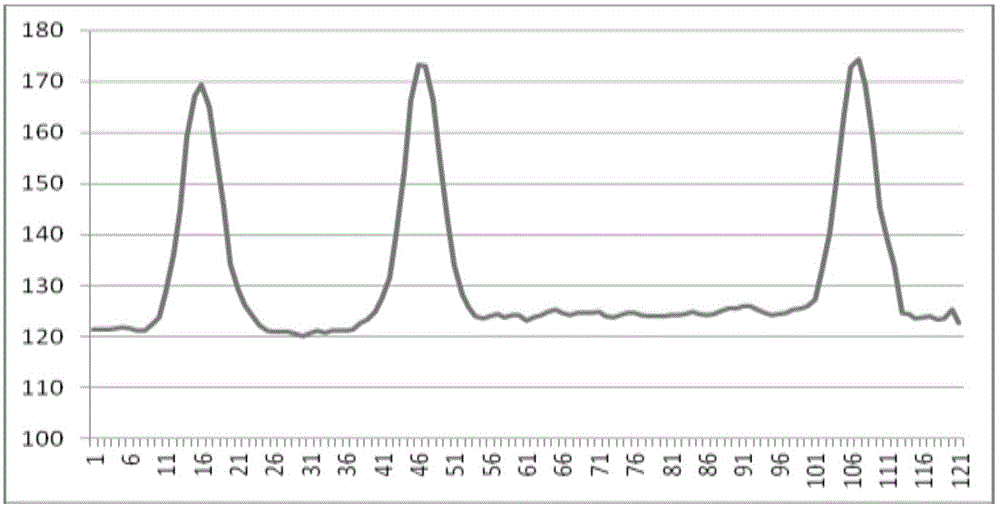

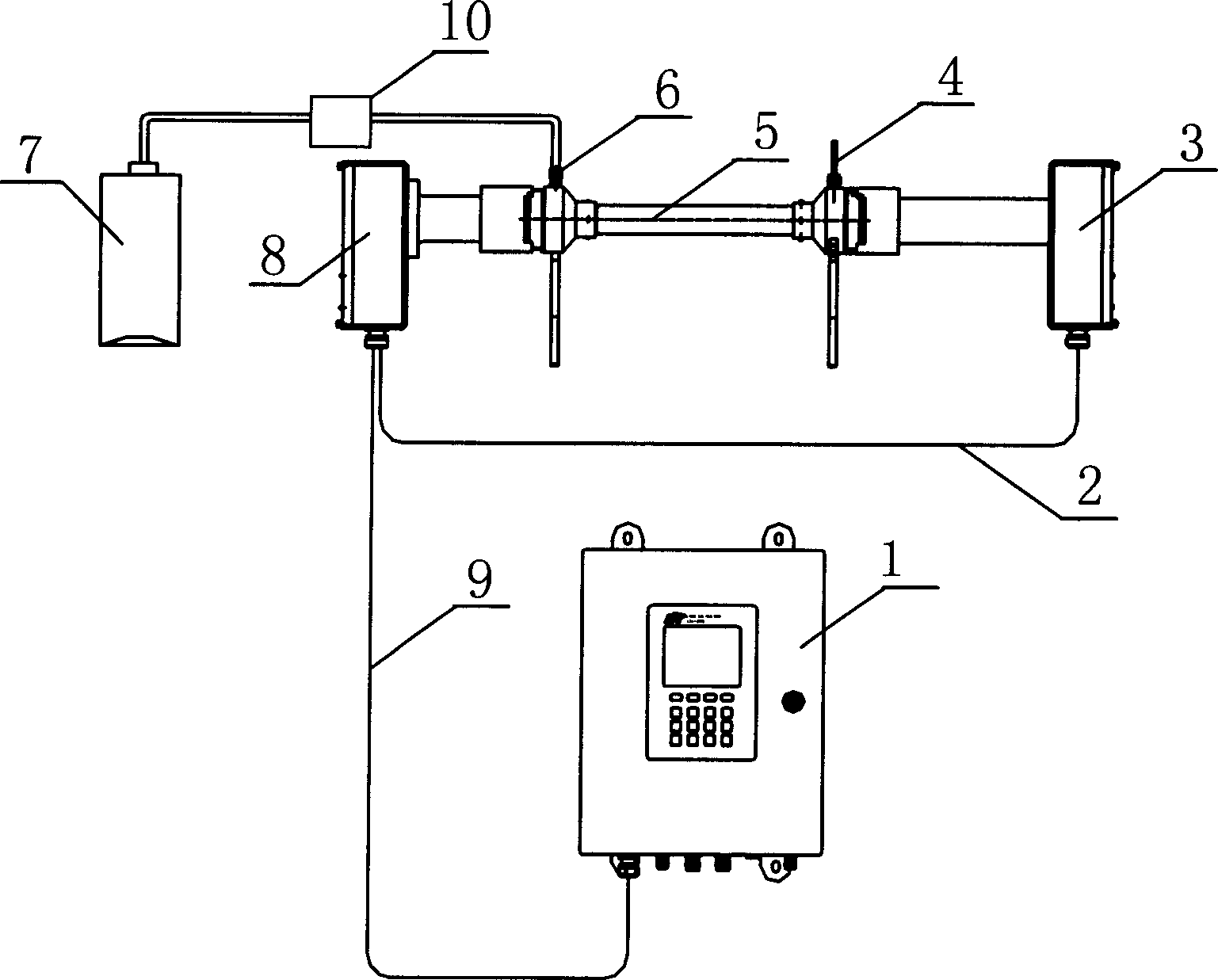

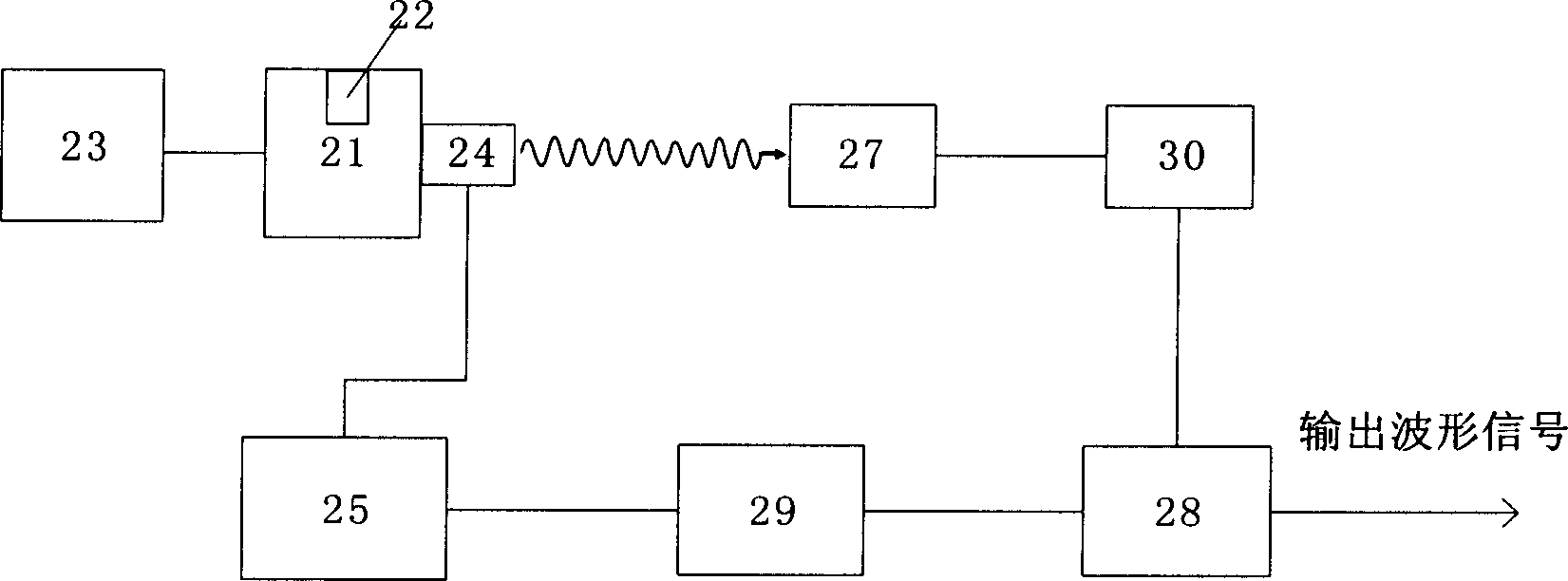

Microwave determination method for breakable beads in breakable bead filter rod

ActiveCN105866140AAccurately measure damageOvercome labor intensityFlaw detection using microwavesUsing wave/particle radiation meansDensity curveHorizontal axis

The invention discloses a microwave determination method for breakable beads in a breakable bead filter rod. The microwave determination method comprises the following steps: collecting breakable bead samples, and measuring the diameters Db of the breakable beads; collecting a breakable bead filter rod sample, measuring the density rholij of the part which does not contain the breakable bead of the filter rod, and finding out the maximum value rholmax of rholij; measuring the density rholij of the part containing the breakable beads of the filter rod, finding out the maximum value rohbihmax of the unit density of the part in which each breakable bead is located, and finding out the minimum value rhomin of rohbihmax; measuring the density of the breakable bead filter rod by virtue of a microwave resonance method by taking the length of 1mm or less as a measurement unit, and drawing a density curve of the breakable bead filter rod by taking the length as a horizontal axis and the density as a vertical axis; and reflecting the existence the breakable bead by virtue of the appearance of a peak value in the curve, reflecting the position offset of the breakable bead by virtue of the corresponding length of the peak value, and reflecting the damage condition of the breakable bead by virtues of the variation of the peak value. The microwave determination method is simple, the operation is easy, and the existence, position offset and damage condition of the breakable bead in the breakable bead filter rod can be accurately determined.

Owner:CHINA TOBACCO SHANDONG IND

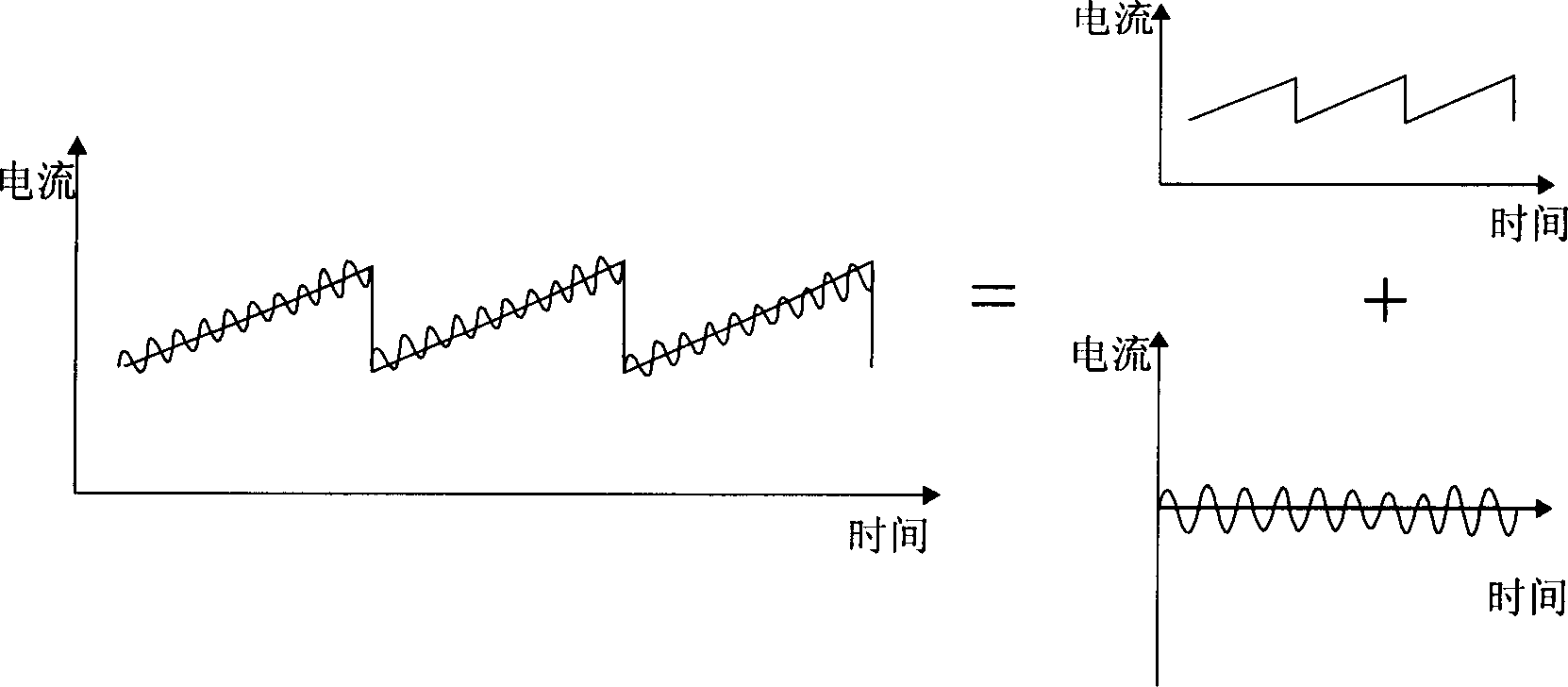

Scaling method of laser gas analysis system

ActiveCN1804585AEasy dischargeSimple processing capacityColor/spectral properties measurementsComplex mathematical operationsGas analysisOptical pathlength

The invention discloses a method for labeling a laser gas analyzing system, which adopts modulated absorption spectrum technology and comprises the following steps: a. choosing the spectral line II of the replacing gas in the output frequency range; b. choosing the work parameter when the laser is labeling; c. obtaining the function relation f2 (P, T, ªŽ) of the output signal density and pressure, temperature, absorption spectrum linear function of unit density and unit optical path of the replacing gas; d. obtaining f1(P, T, ªŽ) of the spectral line I of the system and f2(P, T, ªŽ) dispersed value ratio of spectral line II; e. modulating the replacing gas to obtain the label factor K on spectral line I and storing it in the signal analyzing unit.

Owner:FOCUSED PHOTONICS

Structural topology optimization method based on material field reduction stage expansion

ActiveCN110110413AAvoid dependencyAvoiding Checkerboard Formatting IssuesGeometric CADDesign optimisation/simulationSeries expansionTopology design

The invention discloses a structure topology optimization method based on material field reduction series expansion, and solves the problem of low calculation efficiency caused by too many design variables and need of relative density or sensitivity filtering measures in traditional density method topology optimization. The method comprises the following steps: a bounded material field consideringcorrelation is defined; a spectral decomposition method is adopted to perform transform to obtain a linear combination of a series of undetermined coefficients, the undetermined coefficients are usedas design variables, an optimization model is constructed based on a unit density interpolation model, a gradient class or non-gradient class optimization algorithm is adopted to solve a topologicaloptimization problem, and then a topological configuration with a clear boundary is obtained efficiently. According to the method, the number of design variables in density method topology optimization can be greatly reduced, and meanwhile, the method has the natural advantage of completely avoiding grid dependence and chessboard format problems. The method also inherits the advantages of simple density method form, convenience in engineering popularization and the like, the optimization solving speed is high, and the research and development efficiency of the innovative topological design ofthe complex equipment structure can be ensured.

Owner:DALIAN UNIV OF TECH

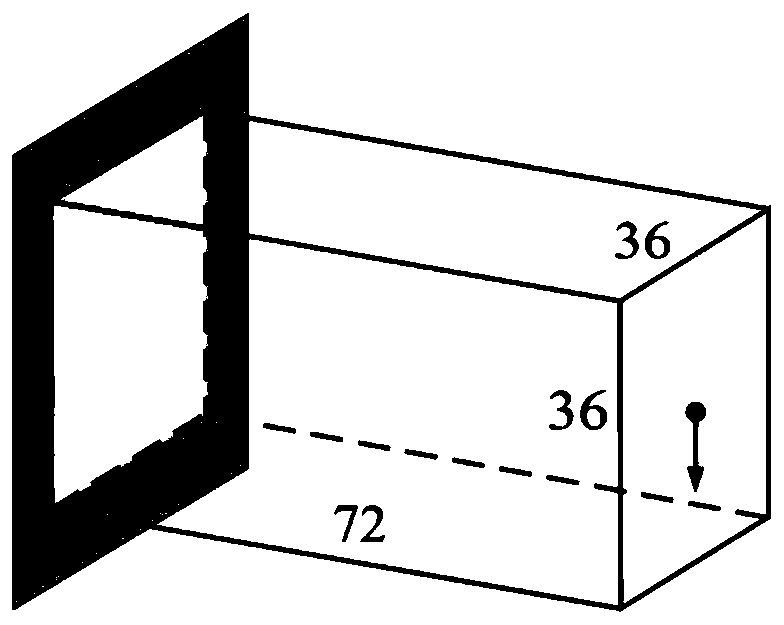

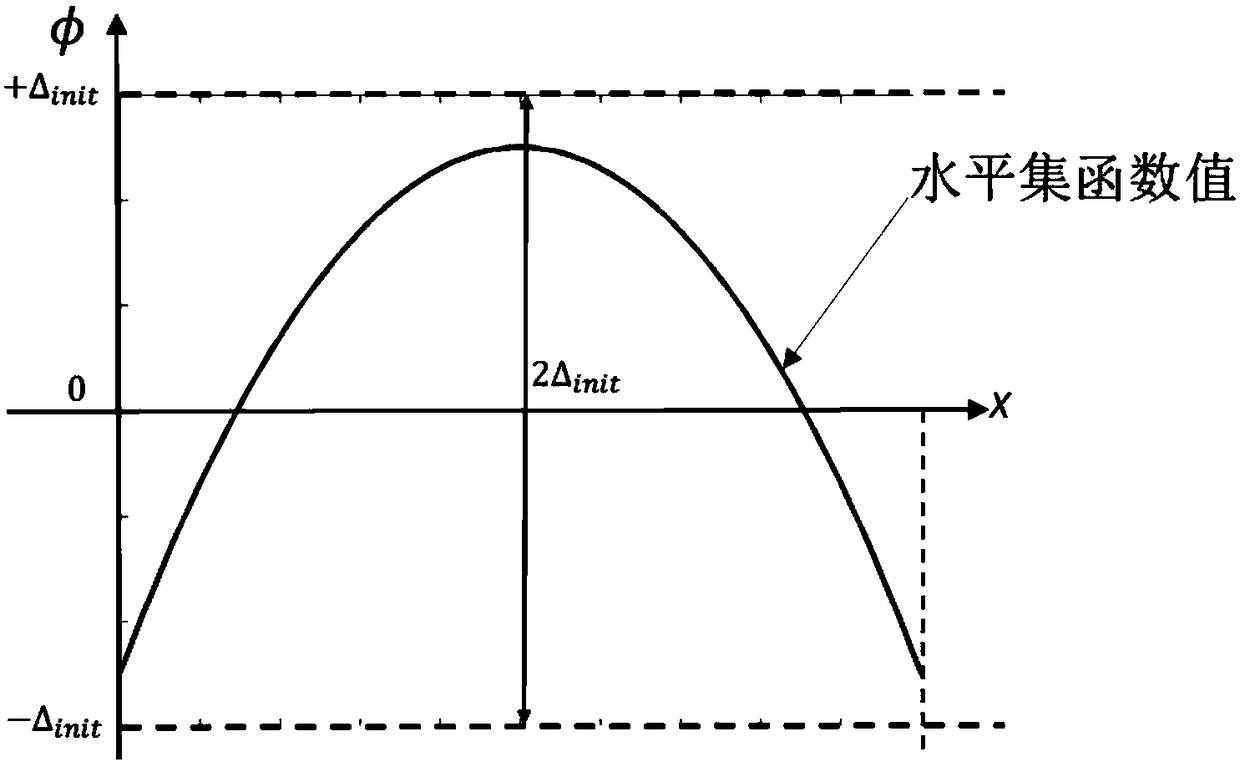

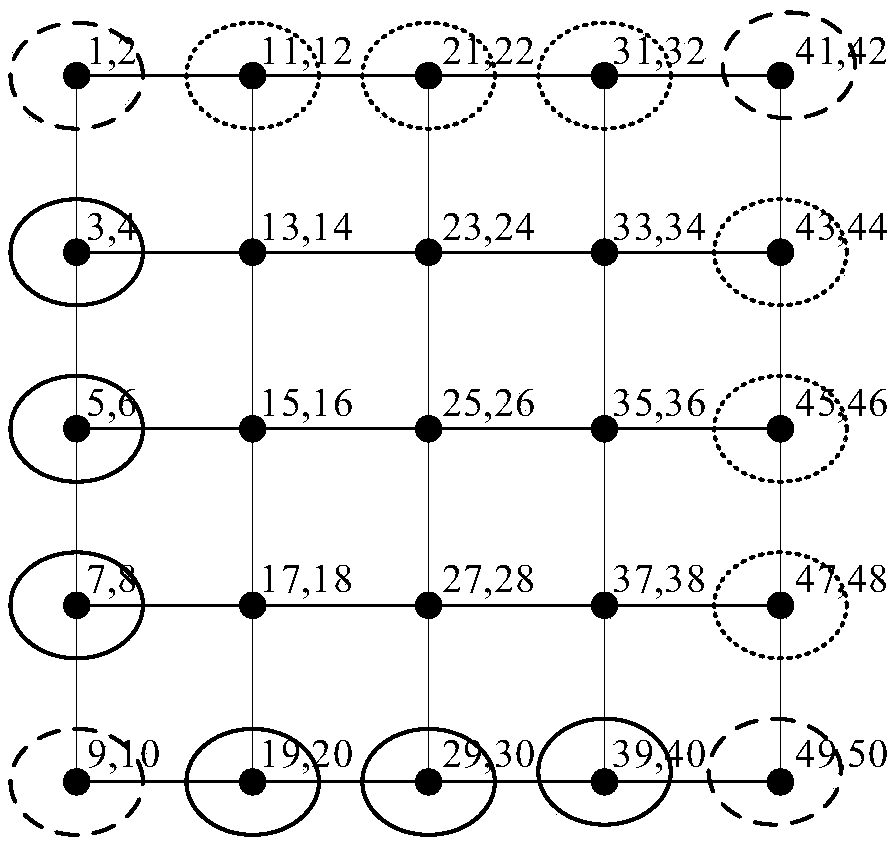

Structure topology optimization method

ActiveCN109190233AClear Boundary Structural DesignContinuous topological evolutionGeometric CADDesign optimisation/simulationElement analysisTopology optimization

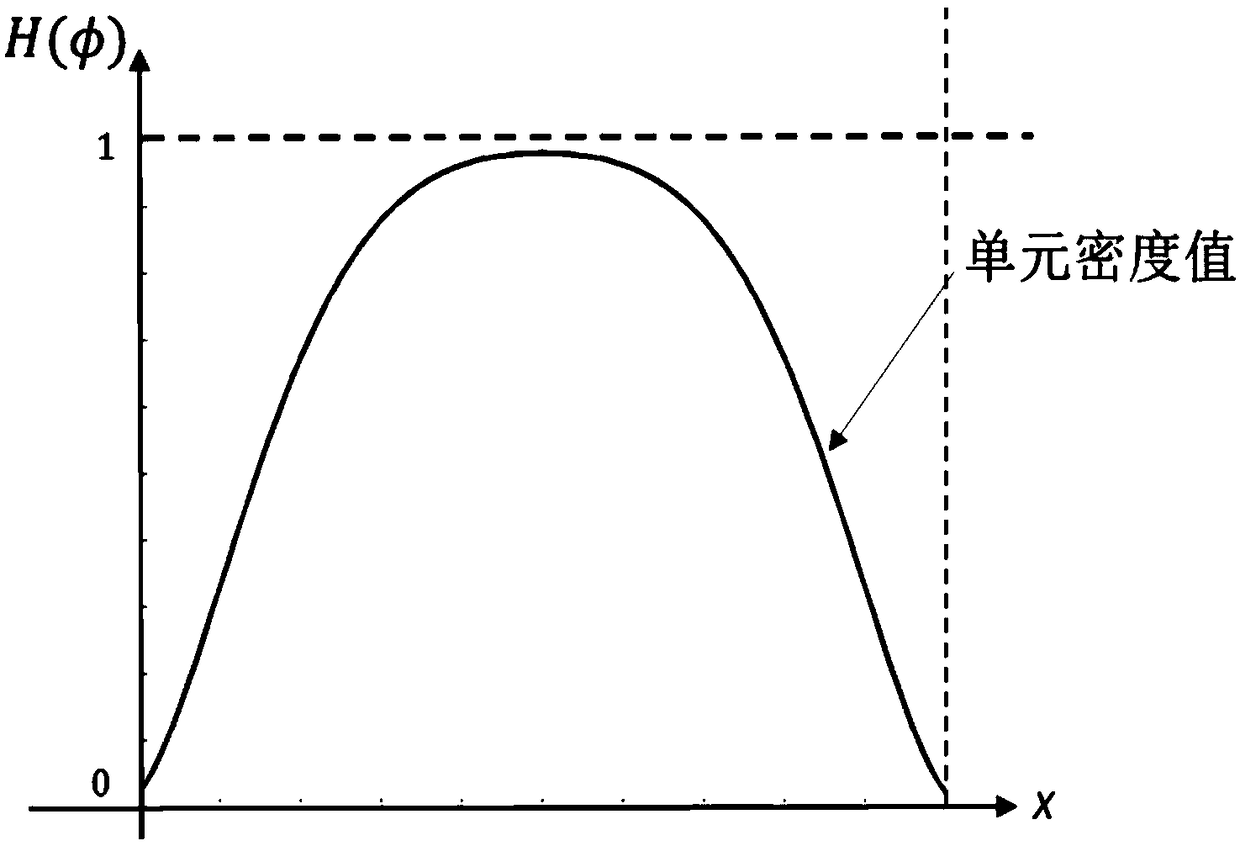

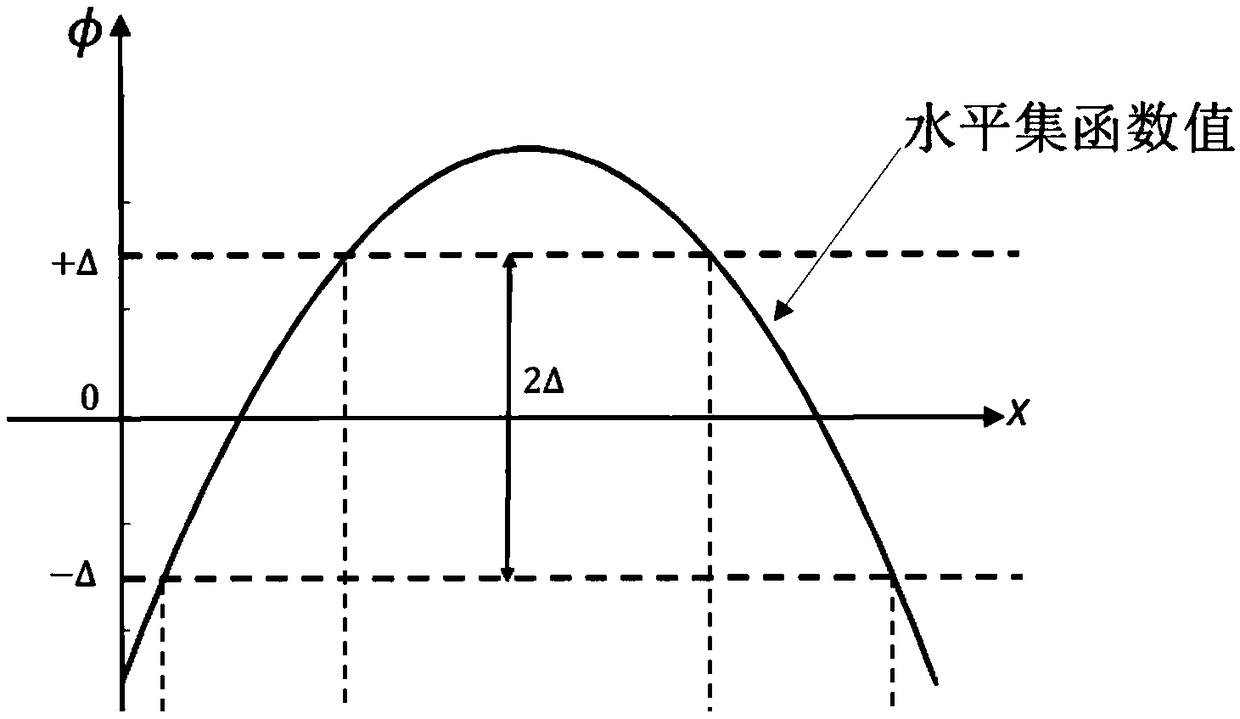

The invention discloses a structure topology optimization method, comprising the following steps: defining an initial structure and a corresponding level set function; averagely interpolating the current node level set function value phi N to obtain the initial level set function value phi of each element; introducing the concept of level set band with adjustable width and the parameter delta usedto control the intermediate density range, and processing the value phi of the level set function by the mapping function with parameter delta to get the unit density value H (phi) in the range of 0-1 to obtain the topological structure containing the intermediate density; carrying out finite element analysis of the topological structure, and updating the value phi N of the node level set function; carrying out iteration and convergence judgment to get the structure design with clear boundary; outputting optimization results. The invention can realize continuous topology evolution, solve boundary-related optimization problems, ensure physical manufacturability of optimization results, obtain reasonable structure topology, and finally obtain structure design with clear boundary expressed by zero-level set when converging.

Owner:SOUTH CHINA UNIV OF TECH

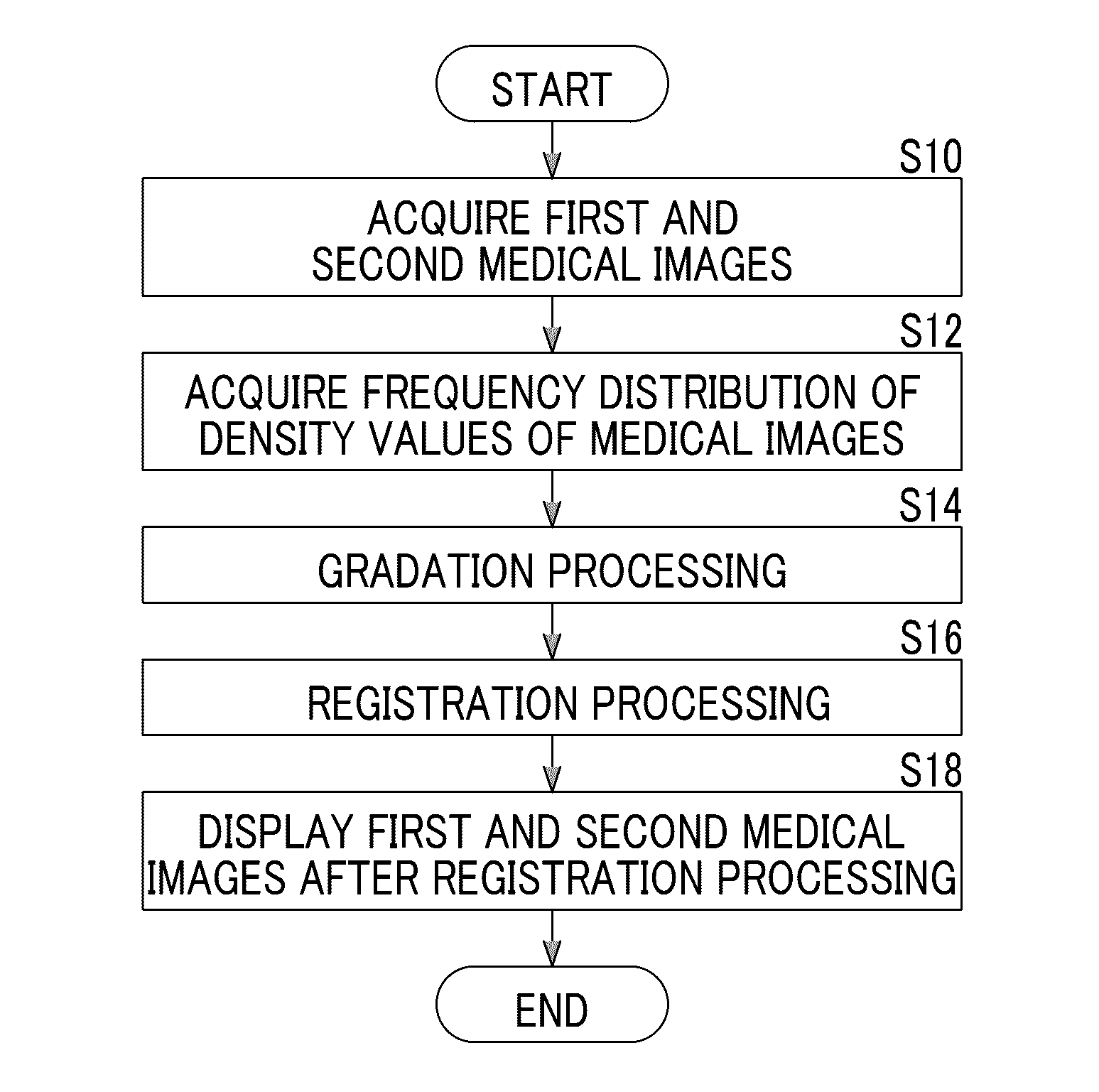

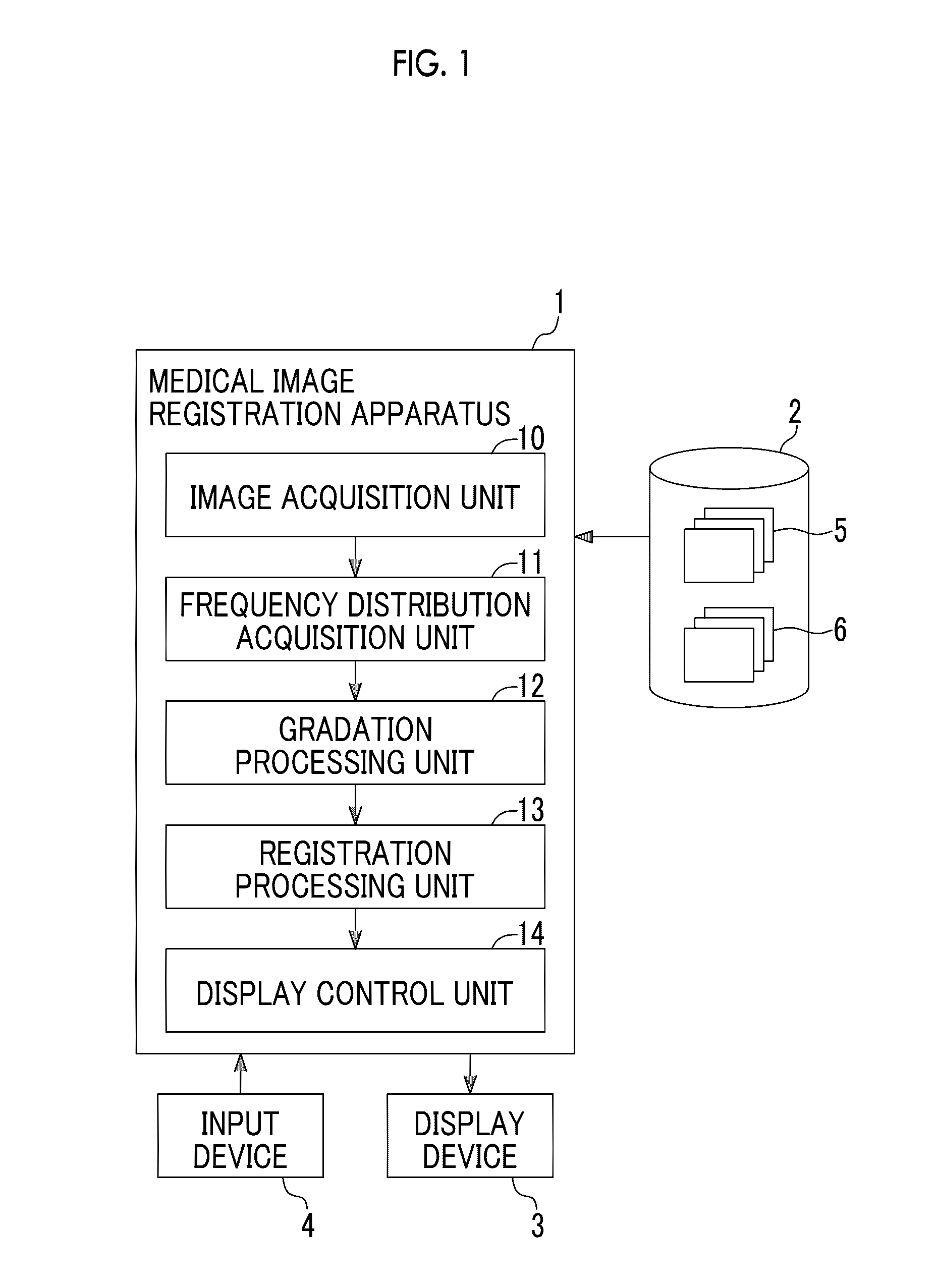

Medical image registration apparatus, medical image registration method, and medical image registration program

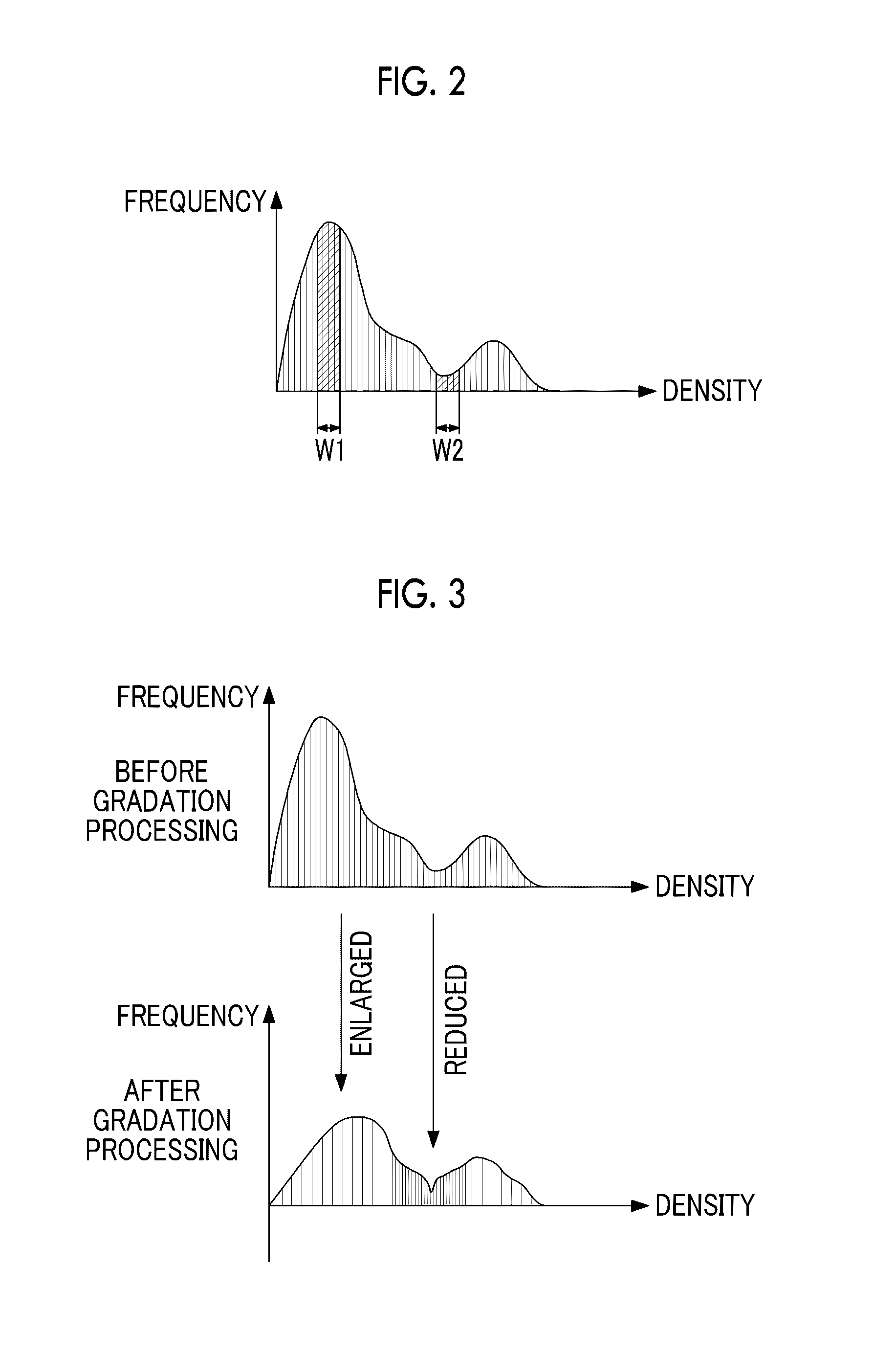

InactiveUS20160292844A1Reduce widthMutual information in the registration method using a joint histogram is reducedImage enhancementImage analysisComputer scienceMedical treatment

The medical image registration apparatus includes: a frequency distribution acquisition unit that acquires the frequency distribution of the density value of at least one of first and second medical images obtained by imaging the same subject; a gradation processing unit that performs gradation processing for increasing the frequency distribution in a density range where the number of pixels included in the unit density width is relatively large, of the acquired frequency distribution, and reducing the frequency distribution in a density range where the number of pixels included in the unit density width is relatively small, of the acquired frequency distribution, for at least the one medical image; and a registration processing unit that performs registration processing for matching the anatomical position of the subject included in the first medical image with the anatomical position of the subject included in the second medical image for the first and second medical images.

Owner:FUJIFILM CORP

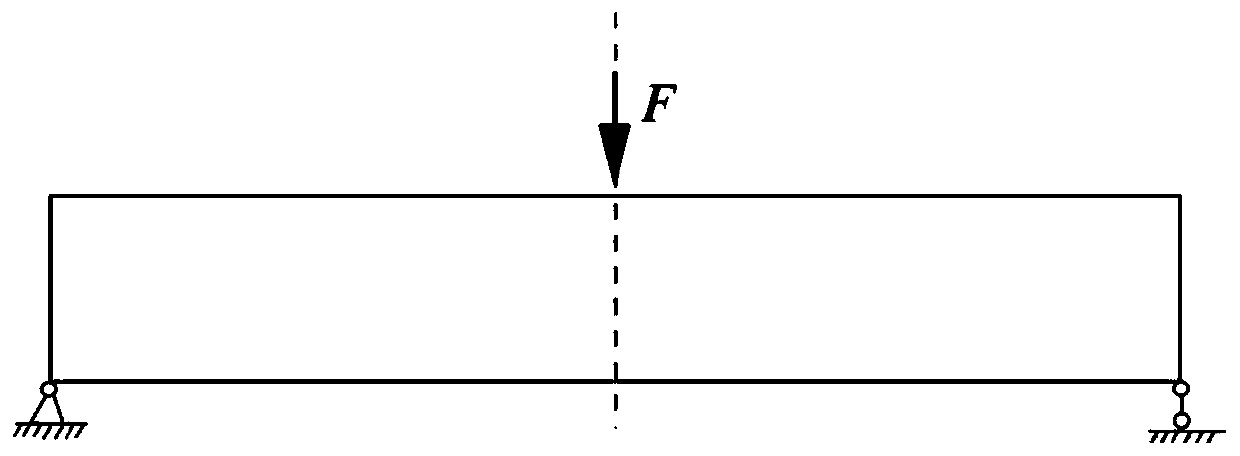

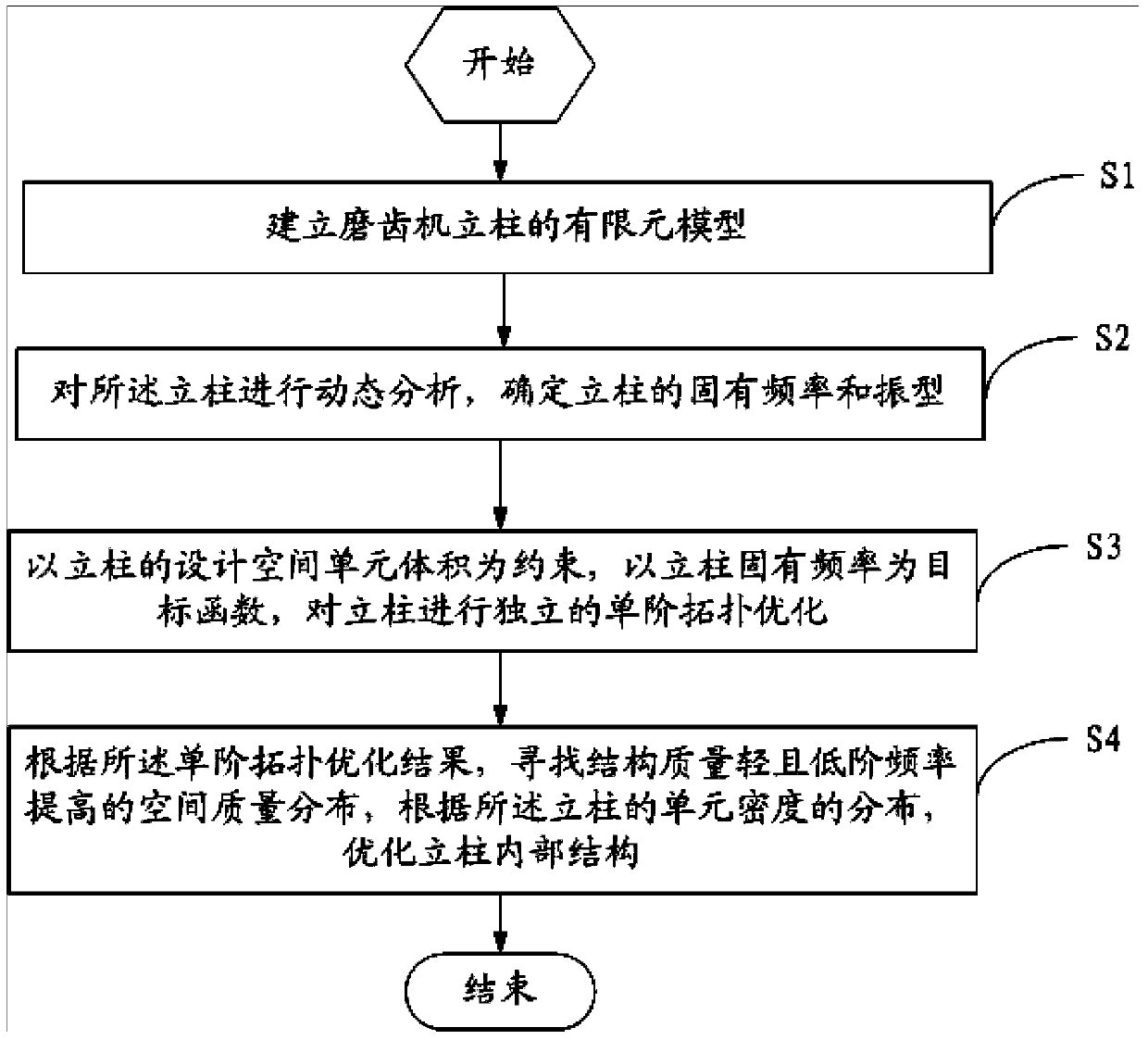

Structure optimization design method for gear grinding machine stand column on basis of dynamic characteristic analysis

InactiveCN103995914AReasonable forceBest distributionSpecial data processing applicationsMachine toolUnit Density

The invention provides a structure optimization design method for a gear grinding machine stand column on basis of dynamic characteristic analysis. A finite element model of the gear grinding machine stand column is established; dynamic analysis is carried out on the stand column and the inherent frequency and vibration mode of the stand column are determined; independent single-order topology optimization is conducted on the stand column with the design space unit volume of the stand column as a constraint and the inherent frequency of the stand column as an objective function; according to the single-order topology optimization result, space quality distribution with light structure quality and improved low-order frequency is searched for, and the internal structure of the stand column is optimized according to distribution of unit density of the stand column. Stress distribution of the structure of a gear grinding machine is more reasonable, the optimal distribution condition of materials is obtained, and the materials are economical. In addition, analysis and design stages of a machine tool structure are applied, repeated prototype testing and scheme correction operations are reduced, the design cycle is shortened, development cost is lowered, and efficiency and high quality are achieved in structural design of a machine tool with theoretical basses as guidance.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

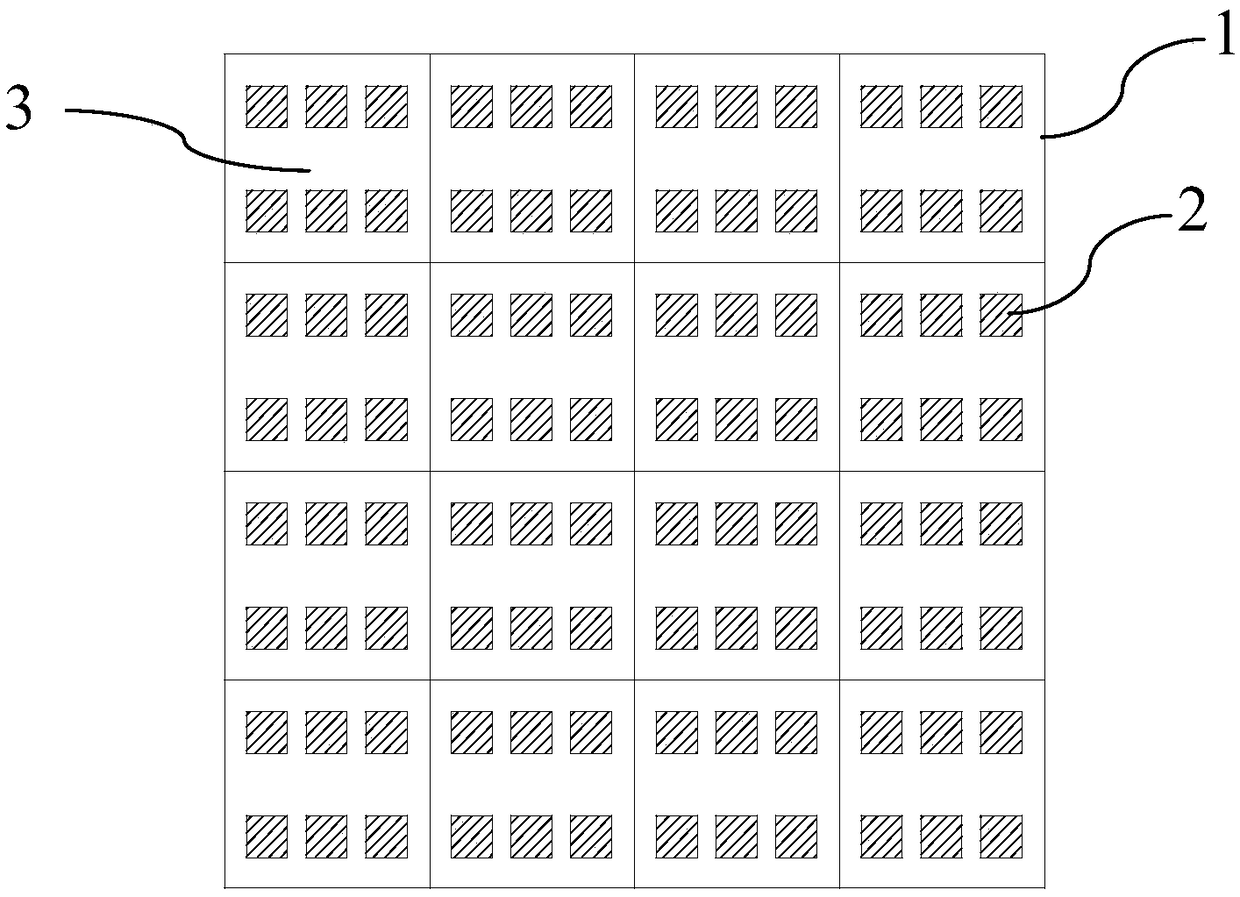

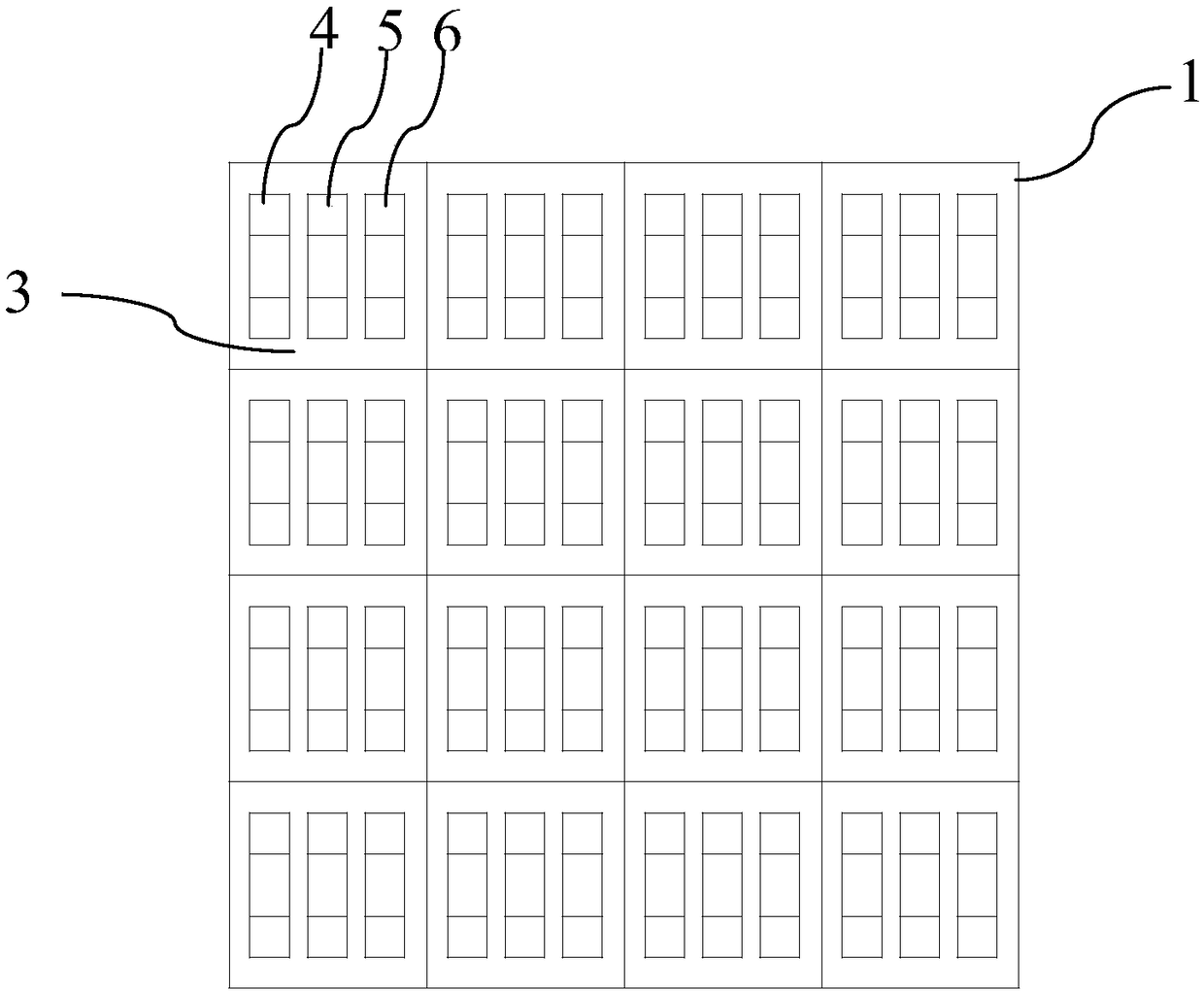

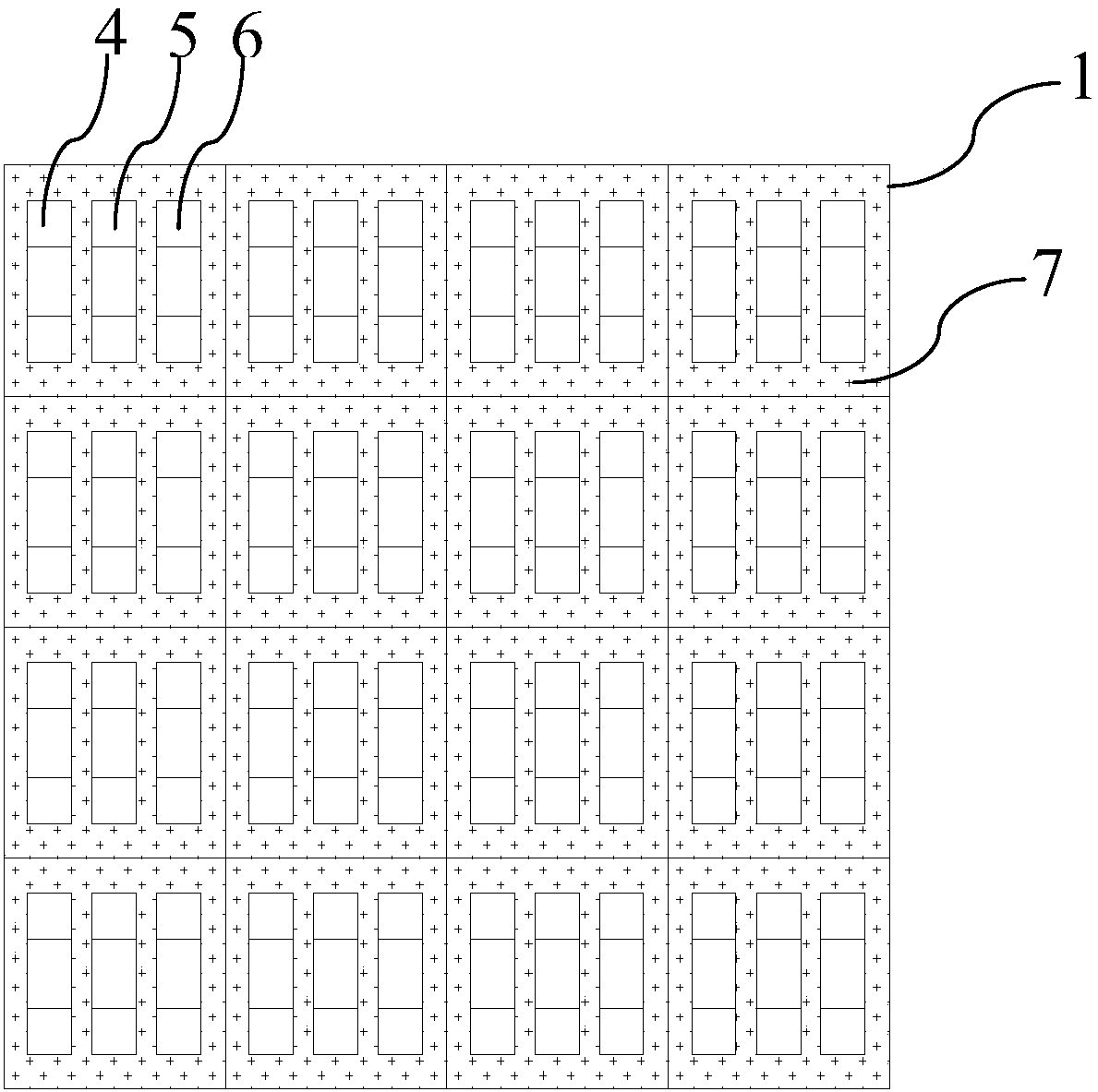

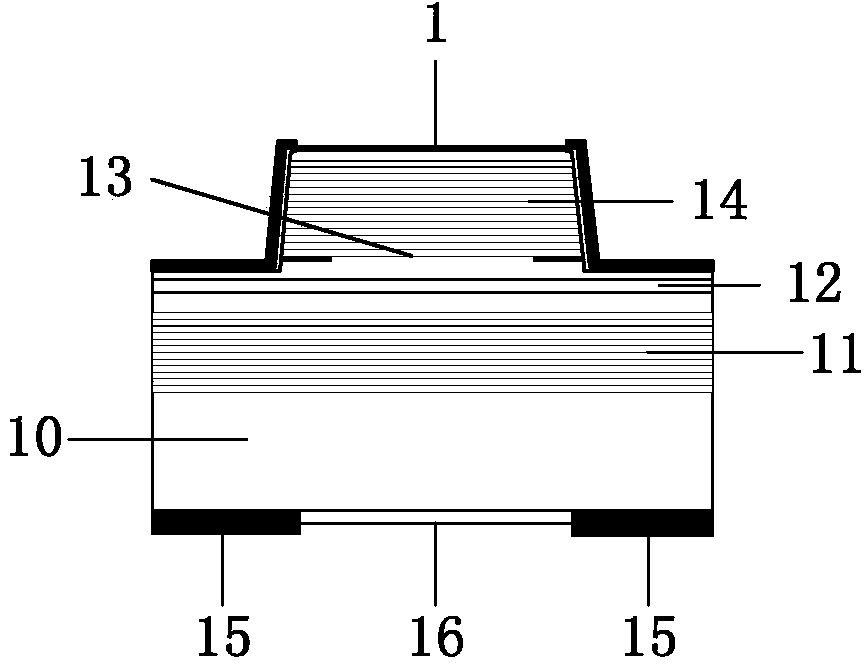

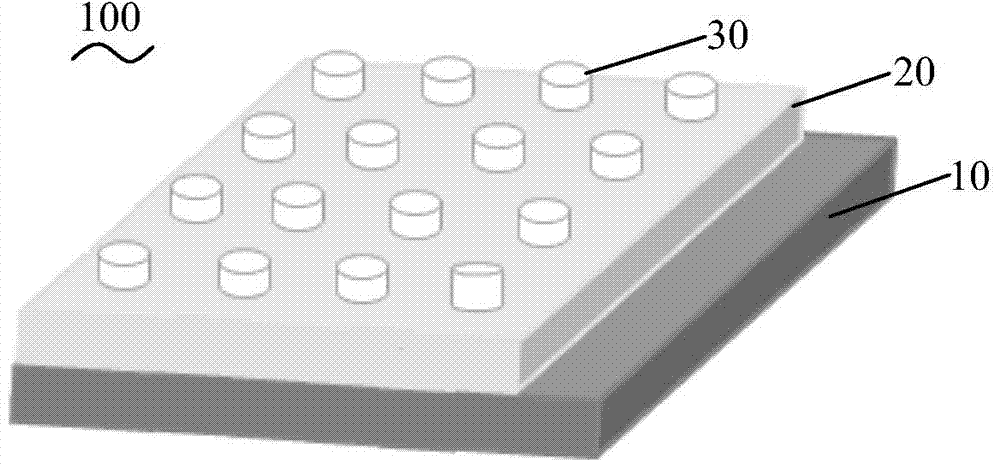

Package structure of micro LED display module

InactiveCN108400220AReduce gapSmall sizeSolid-state devicesSemiconductor devicesUnit sizeLED display

The invention discloses a package structure of a micro LED display module. The package structure comprises a circuit board, multiple light-emitting units, and a transparent package layer; each light-emitting unit comprises a first flip blue-light chip, a flip green-light chip and a second flip blue-light chip; the first flip blue-light chip, the flip green-light chip and the second flip blue-lightchip are orderly fixed on the circuit board, the gaps between the light-emitting units, between the first flip blue-light chip and the flip green-light chip, and between the flip green-light chip andthe second flip blue-light chip are filled by using filing layers; a red fluorescent layer is coated on the first flip blue-light chip or the second flip blue-light chip; and the transparent packagelayer wraps the whole surface of the circuit board and the light-emitting units. The package structure disclosed by the invention reduces the gaps among the LED particles when a surface mount device is in mounting, the single light-emitting unit size is greatly reduced to the micron order, the light-emitting unit density is improved, and the final display resolution is improved; and the problem ofthe thermal drift color aberration of the display screen is improved.

Owner:JIANGSU WENRUN OPTOELECTRONICS

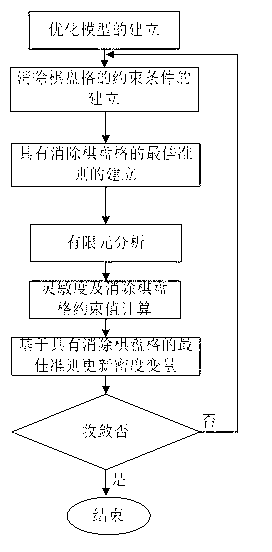

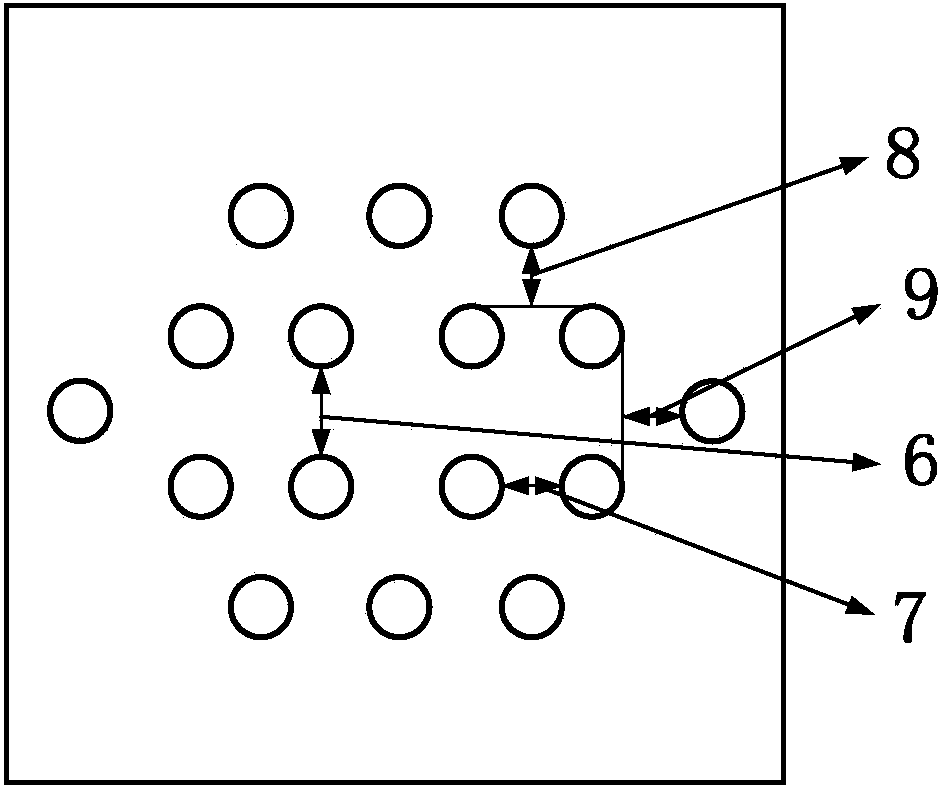

Method for extracting no-checkerboard topological diagram from compliant mechanism

ActiveCN103020361AOvercome the checkerboard problemImprove the phenomenon of the middle unitSpecial data processing applicationsCompliant mechanismComputation complexity

The invention discloses a method for extracting a no-checkerboard topological diagram from a compliant mechanism. The method comprises the following steps of: establishing a compliant mechanism topology optimization model with volume constraints; carrying out checkerboard analysis on the topological diagram, and establishing constraint conditions for checkerboard eliminating based on the basis; establishing optimum updating rules with design variables for checkerboard eliminating; and processing until the no-checkerboard topological diagram is extracted from the compliant mechanism. The method for extracting the no-checkerboard topological diagram from the compliant mechanism has the advantages that the problem of checkerboard caused during SIMP (Solid Isotropic Material with Penalization)-method-based design variable relaxation can be effectively solved, and then, the no-checkerboard topological diagram is extracted from the compliant mechanism; unit density in a design domain is not required for being smoothened, so that the intermediate unit phenomenon in topology optimization results can be greatly improved; and the constraint conditions for checkerboard eliminating are only applied between a lower-density unit in a checkerboard area and a unit, with the density higher than or equal to a given threshold, in a neighbor area of the checkerboard area, so that the computational complexity is low.

Owner:SOUTH CHINA UNIV OF TECH

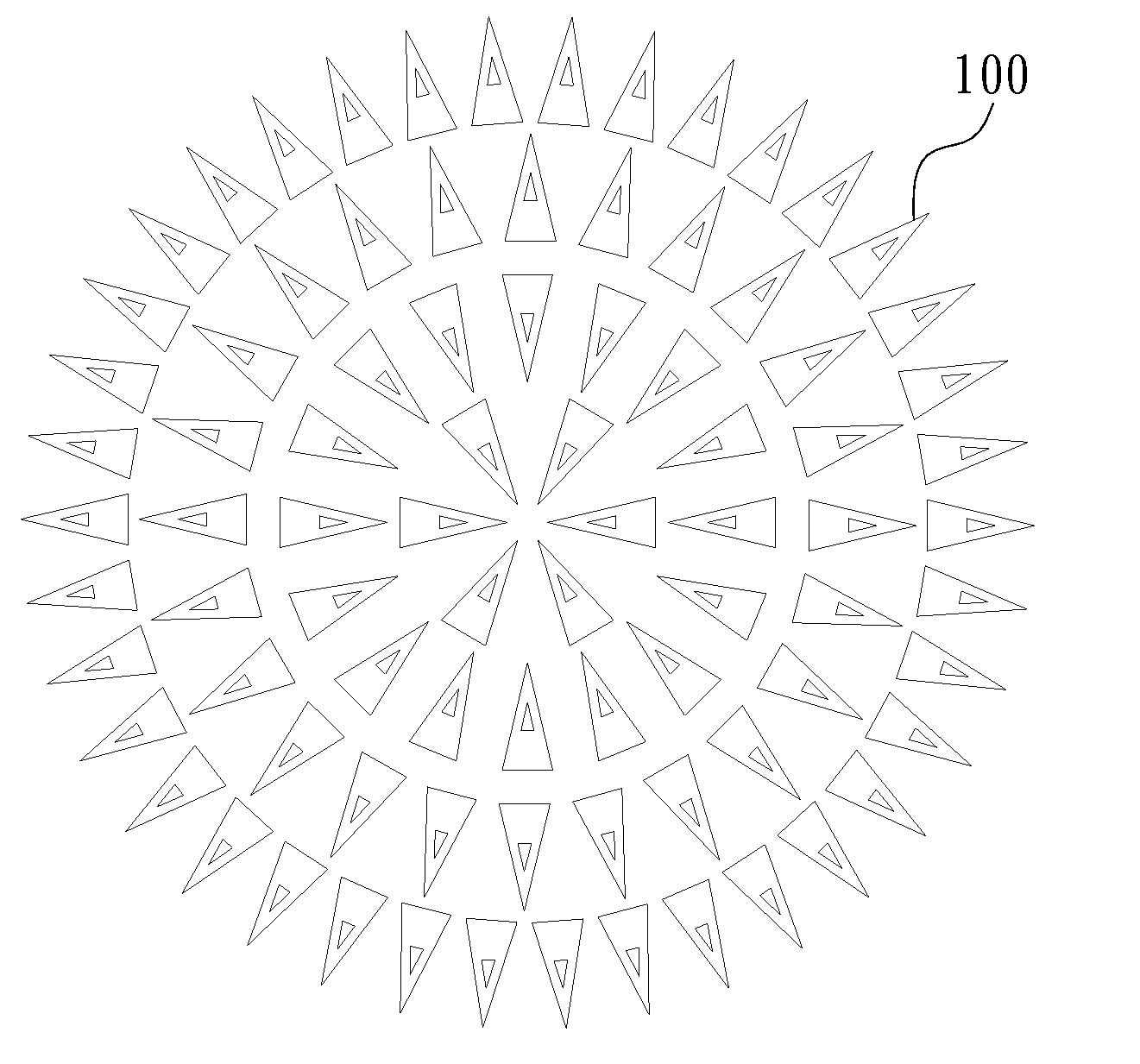

Two-dimensional vertical cavity surface emitting laser array

ActiveCN103730833AImprove output performanceReduce thermal crosstalkLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserCoupling

The invention discloses a two-dimensional vertical cavity surface emitting laser array. The two-dimensional vertical cavity surface emitting laser array comprises a surface electrode and n unit laser devices, wherein n is an integer which is larger than 3; the unit laser devices are distributed on the surface electrode; the unit laser devices comprise (n-2) <2> central area unit laser devices, (n-1) * 2 horizontal peripheral unit laser devices, (n-2) * 2 vertical peripheral unit laser devices and two edge unit laser devices; the active area diameter of every unit laser device is d and the light aperture of every unit laser device is r. According to the two-dimensional vertical cavity surface emitting laser array, the arrangement mode which is similar to a rhombus is adopted and accordingly the thermal crosstalk is low and the unit density is large in the same surface electrode area, the temperatures of the unit laser devices are uniformly distributed at different coupling positions, the integral temperature of the array is low, the thermal effect of a high power vertical cavity surface emitting laser array is significantly improved, the output performance of the devices is improved, and the application fields of lasers are extended.

Owner:HI TECH OPTOELECTRONICS

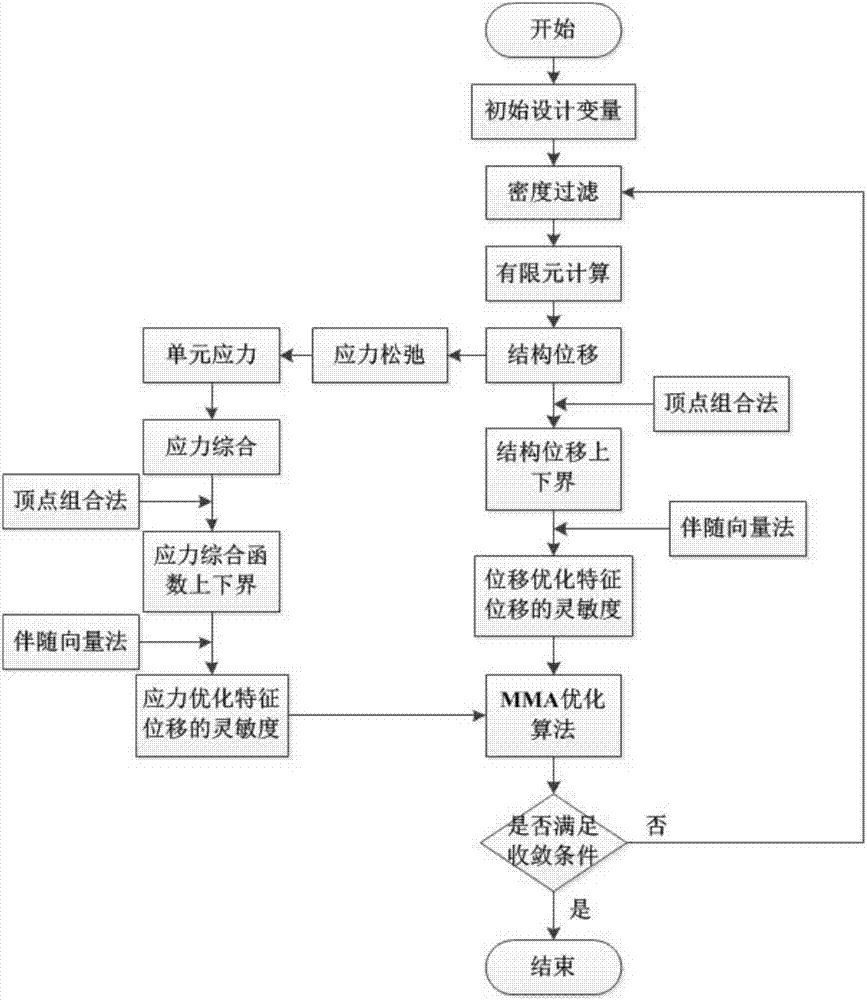

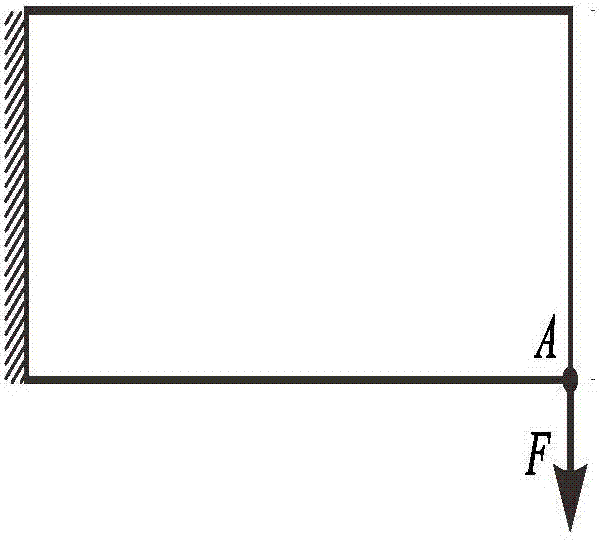

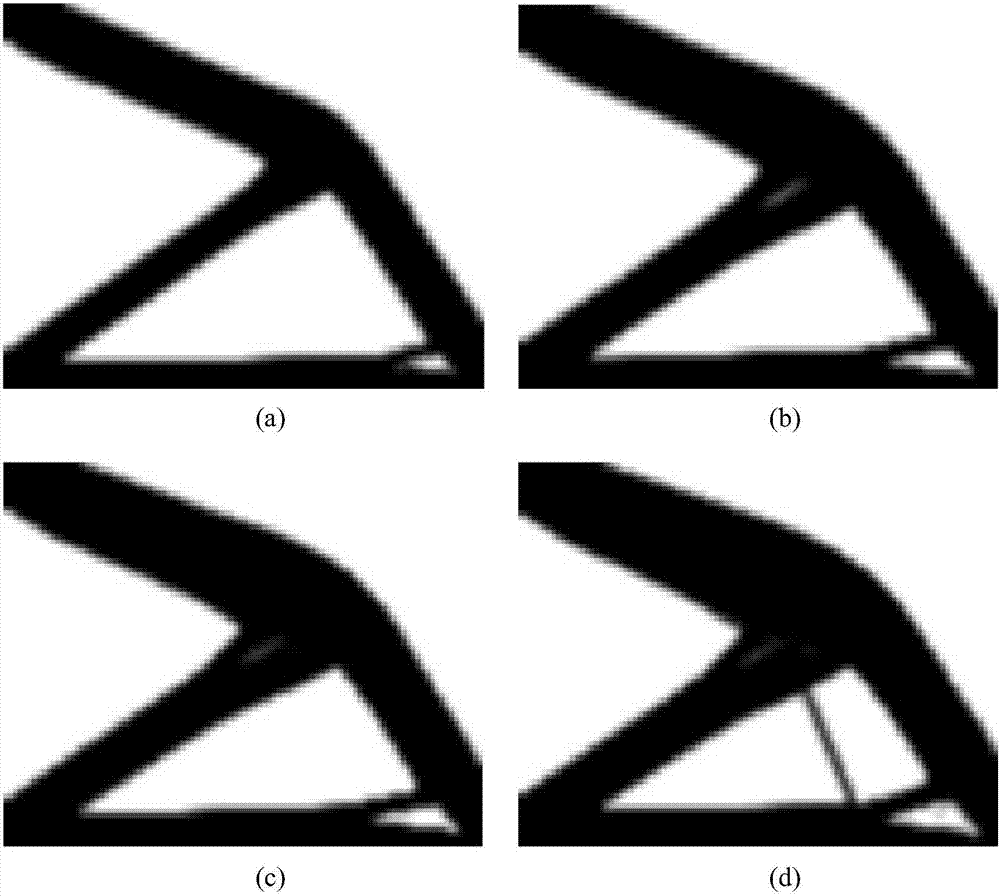

Continuum structure reliability topological optimization method under displacement and global stress mixed constraint

ActiveCN108009381ATake security into considerationSmall sample size requirementDesign optimisation/simulationSpecial data processing applicationsTopology optimizationConvergence problem

The invention discloses a continuum structure non-probability reliability topological optimization method under displacement and global stress mixed constraint. According to the method, first, a density filtering method is adopted to obtain unit density through design variables; second, a relaxation rule is adopted to calculate displacement and stress of a structure, and stress integration function constraint is utilized to process global stress; third, a vertex combination method is utilized to obtain an upper bound and a lower bound of a displacement and stress integration function; fourth,optimal feature displacement is adopted to replace non-probability reliability indexes to solve a convergence problem, and an adjoint vector method and a composite function derivation rule are adoptedto solve sensitivity of the optimal feature displacement; and last, a mobile progression method is adopted to perform iterative computation till a corresponding convergence condition is met, and an optimal design scheme meeting reliability constraint is obtained. Through the method, the influence of uncertainty on stiffness and strength performance of the continuum structure is reasonably represented in the topological optimization design process, effective weight reduction can be realized, and it is ensured that the design is secure and economical.

Owner:BEIHANG UNIV

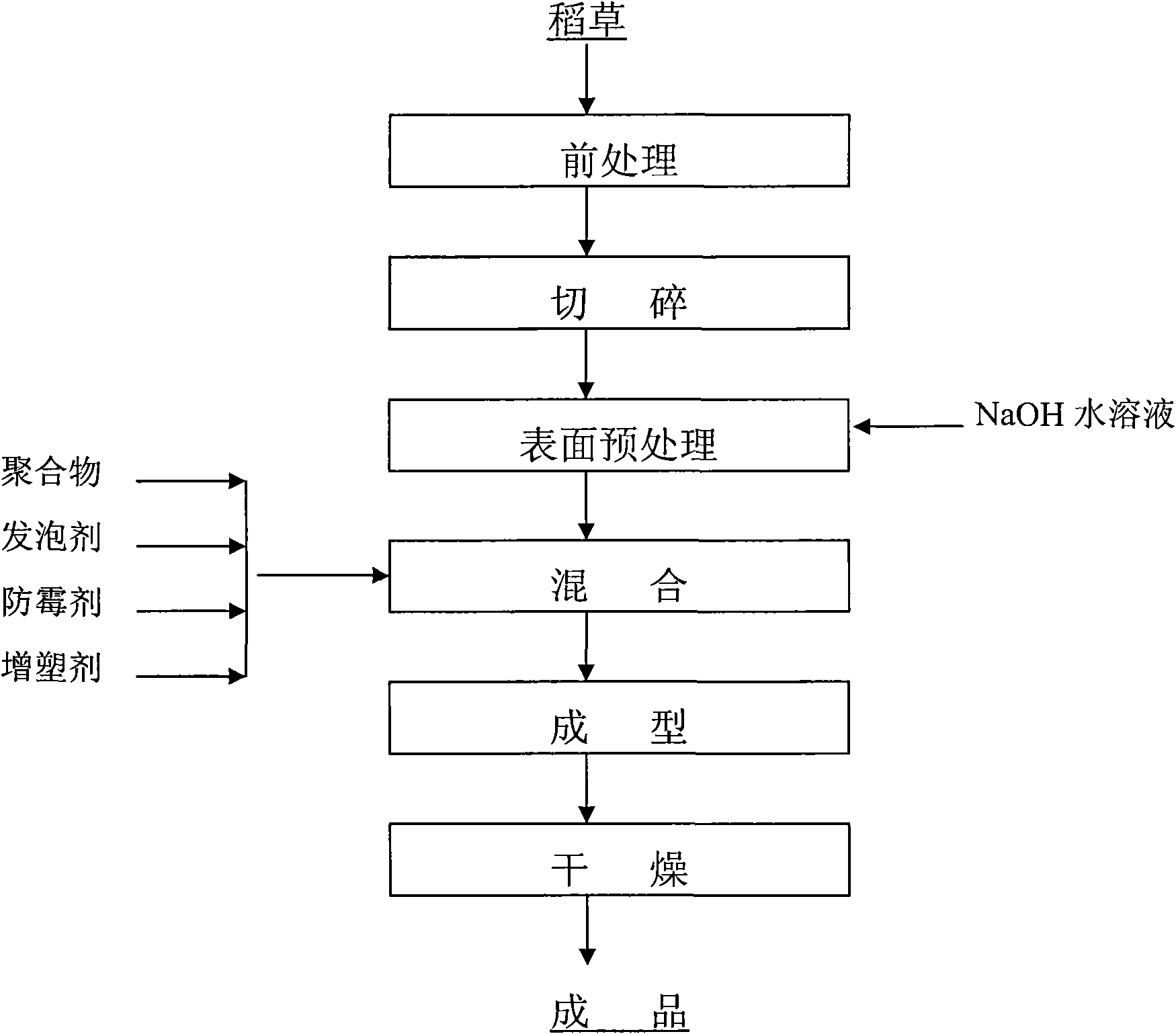

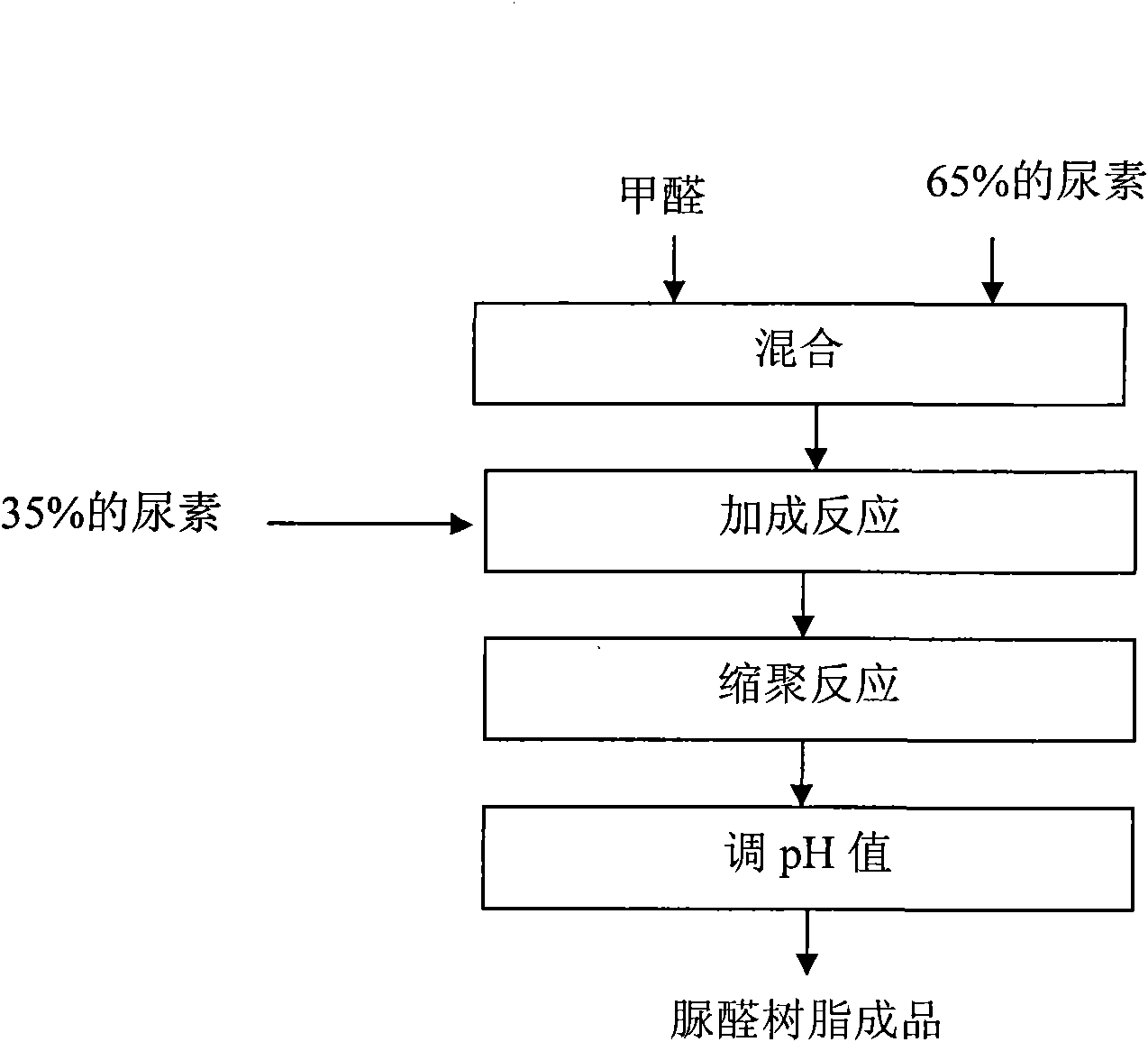

Technology for preparing composite package cushioning material from rice straw fibers

The invention discloses technology for preparing a composite package cushioning material from rice straw fibers. The technology comprises the following technological steps of: (1) pretreating, namely drying and removing impurities; (2) cutting up, namely cutting the rice straw obtained in the step (1) into straw particles with the diameter of 5 to 8mm, and mixing with partial fine rice straw fibers which are cut into the diameter of around 0.1mm and the length of 5mm; (3) performing surface pretreatment, namely soaking for 10 minutes by using aqueous solution of NaOH, filtering and drying for later use; (4) mixing, namely adding polymer into the mixed fibers subjected to surface treatment according to a mass ratio of 2-5:6-9, and adding a proper amount of mildew preventive and foaming agent for uniformly mixing; (5) molding, namely adding the uniformly mixed mixture into a mold, molding and demolding; and (6) drying. The invention also discloses a formula and technology for preparing 35 percent urea resin. The urea resin is a raw material for preparing the polymer in the composite package cushioning material prepared from the rice straw fibers. The technology for preparing the composite package cushioning material has the advantages of simple process flow and no side products. The produced finished product has the advantages of good degradation performance, good elastic resilience, high unit density and compression strength, and low density.

Owner:MYS GRP CO LTD

System and method of generating a pattern used to process a surface of a fabric through laser irradiation, and fabric created thereby

A method of generating a pattern used to process a surface of a fabric through laser irradiation is provided. The method includes the steps of defining a pattern area having an array of pixels. A laser irradiation unit area is defined where the laser irradiation unit area includes at least one pixel. A laser irradiation unit density associated with the pattern area can be selected where the irradiation unit density corresponds to a number of laser irradiation unit indicators included in the pattern area. A plurality of laser irradiation unit indicators are arranged within the pattern area based on the laser irradiation unit density and the defined laser irradiation unit area. An effective applied power of the laser is identified for each of the plurality of laser irradiation unit indicators.

Owner:REVOLAZE LLC

Electronic equipment

PendingCN109215525AImprove experienceTelevision system detailsColor television detailsComputer graphics (images)Electric equipment

An electronic device includes a display screen having a first region corresponding to at least a portion of the functional module and a second region excluding the first region, the pixel unit densityof the first region being smaller than the pixel unit density of the second region. The display screen includes a plurality of pixel units and a functional module disposed on the back of the displayscreen. The front side of the electronic device of the present invention has more areas for display and has a better user experience.

Owner:SHENZHEN FUSHI TECH CO LTD

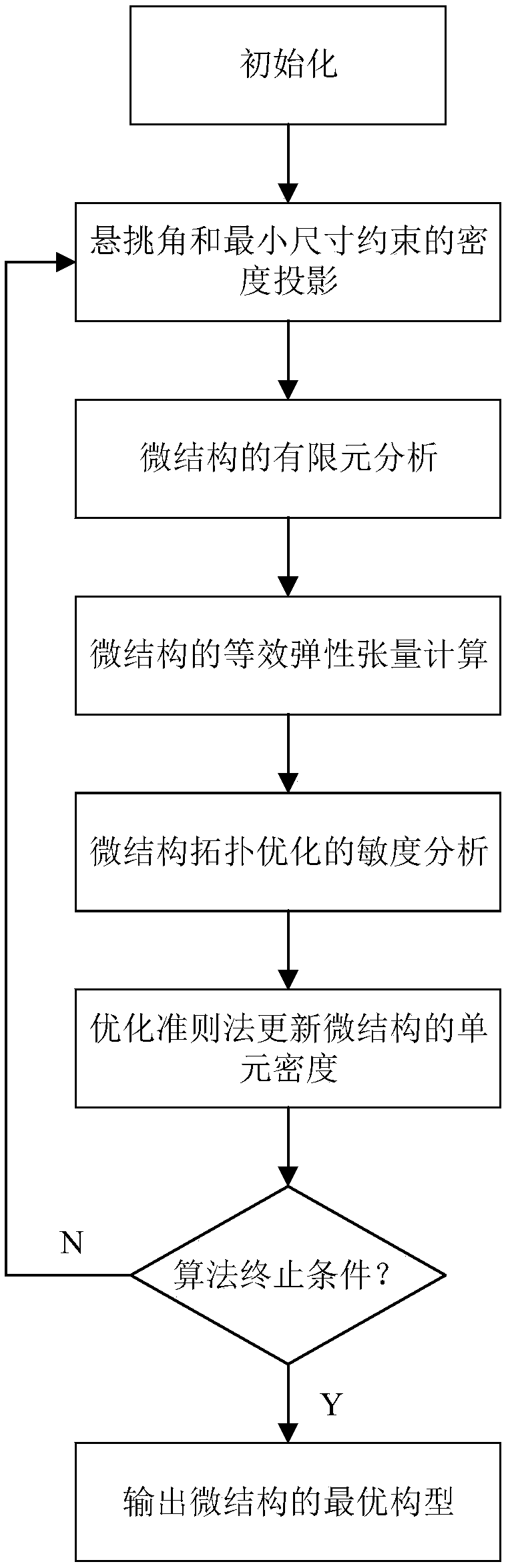

A self-supporting microstructure topology optimization method considering overhung angles and minimum size constraints

ActiveCN109002598AEasy to processAvoid fine feature size structuresGeometric CADDesign optimisation/simulationElastic tensorTopology optimization

The invention belongs to the technical field related to structural optimization design, and discloses a self-supporting microstructure topology optimization method considering overhung angles and minimum size constraints. The method comprises the following steps: (1) initializing relative unit density of micro-structure, material volume fraction, material attribute parameter and optimization algorithm parameter; (2) projecting the relative unit density of the microstructure to a density constrained by a cantilever angle and a minimum size, and obtaining a displacement field of the microstructure; (3) obtaining the equivalent elastic tensor of the microstructure, and carrying out sensitivity analysis on the topology optimization model of the microstructure, and then constructing an optimization criterion to update the relative unit density of the microstructure; (4) judging whether the current relative cell density satisfies the iterative convergence condition, and if so, outputting theoptimal microstructure configuration; Otherwise go to step (2). The invention does not depend on engineering experience, has high flexibility, and ensures that the microstructure has self-supportingproperty and also has better macroscopic equivalent performance.

Owner:HUAZHONG UNIV OF SCI & TECH

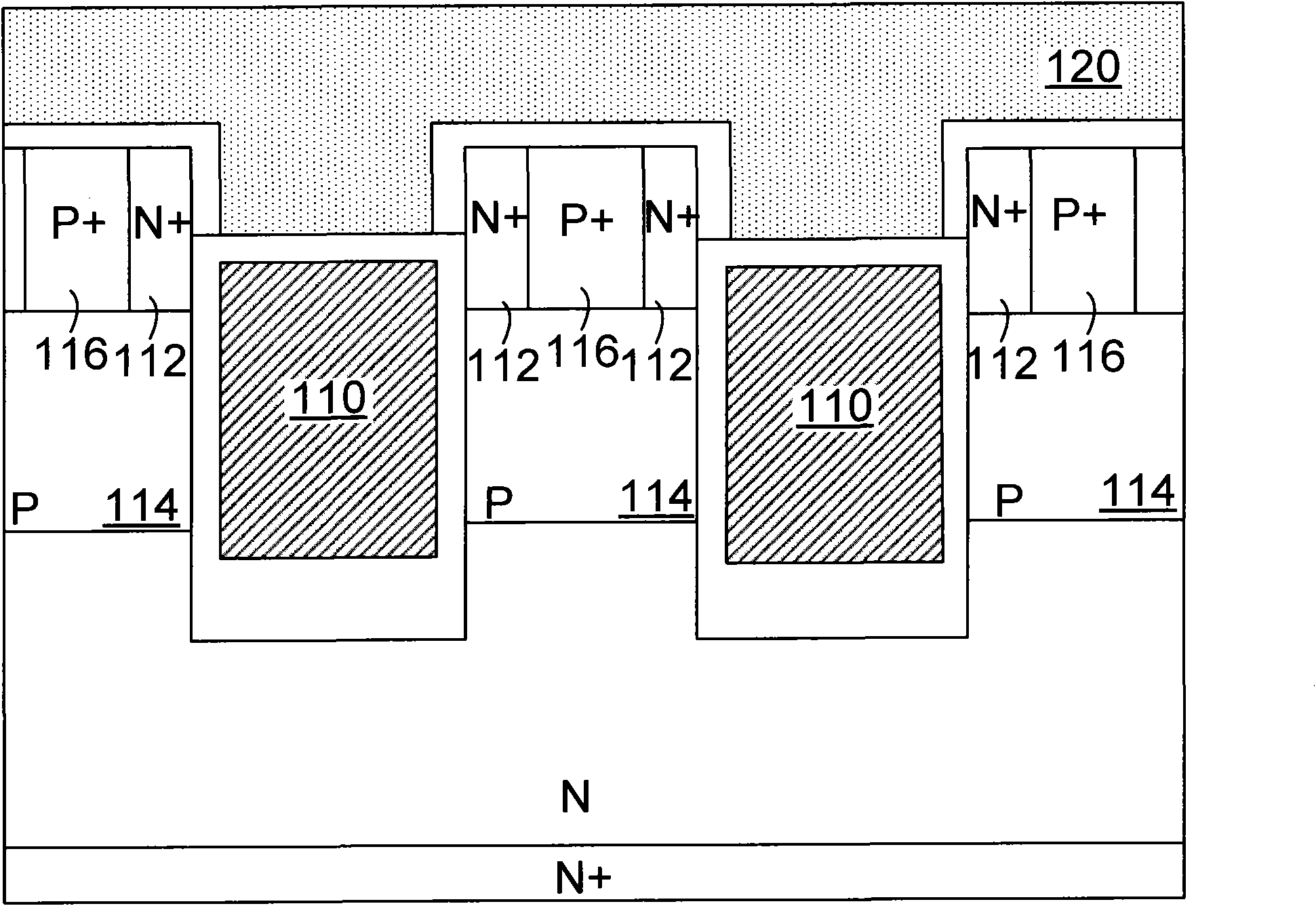

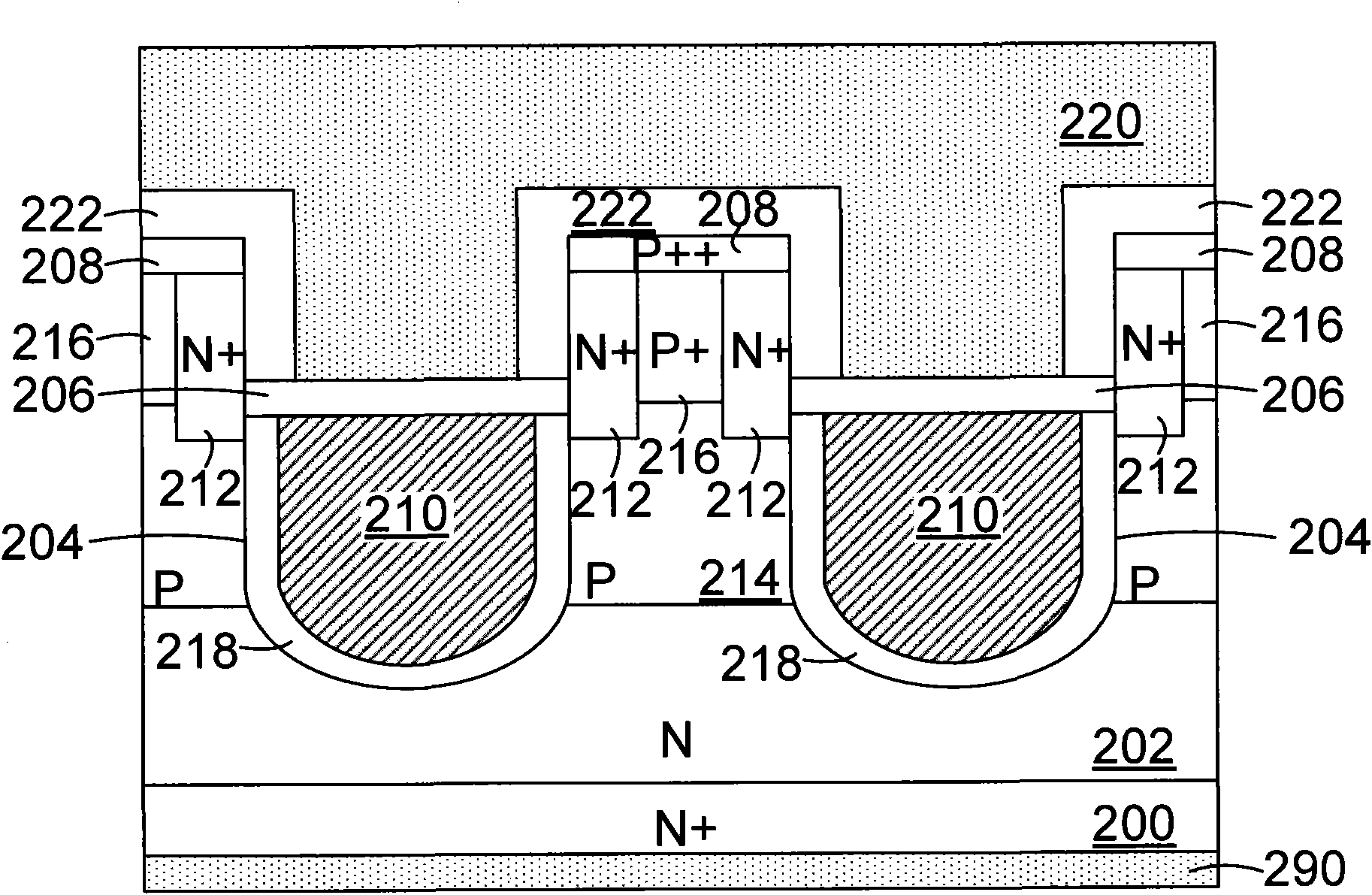

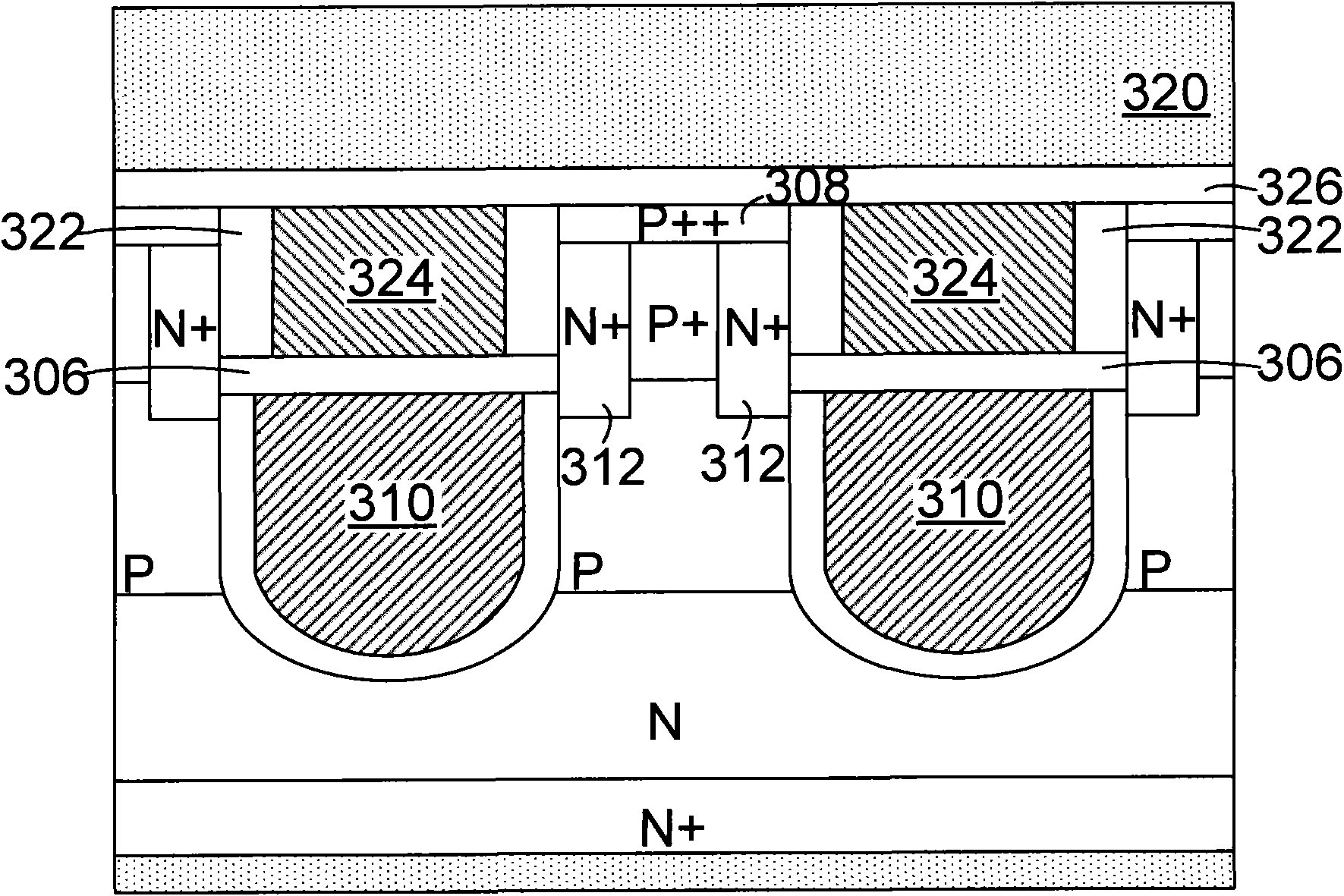

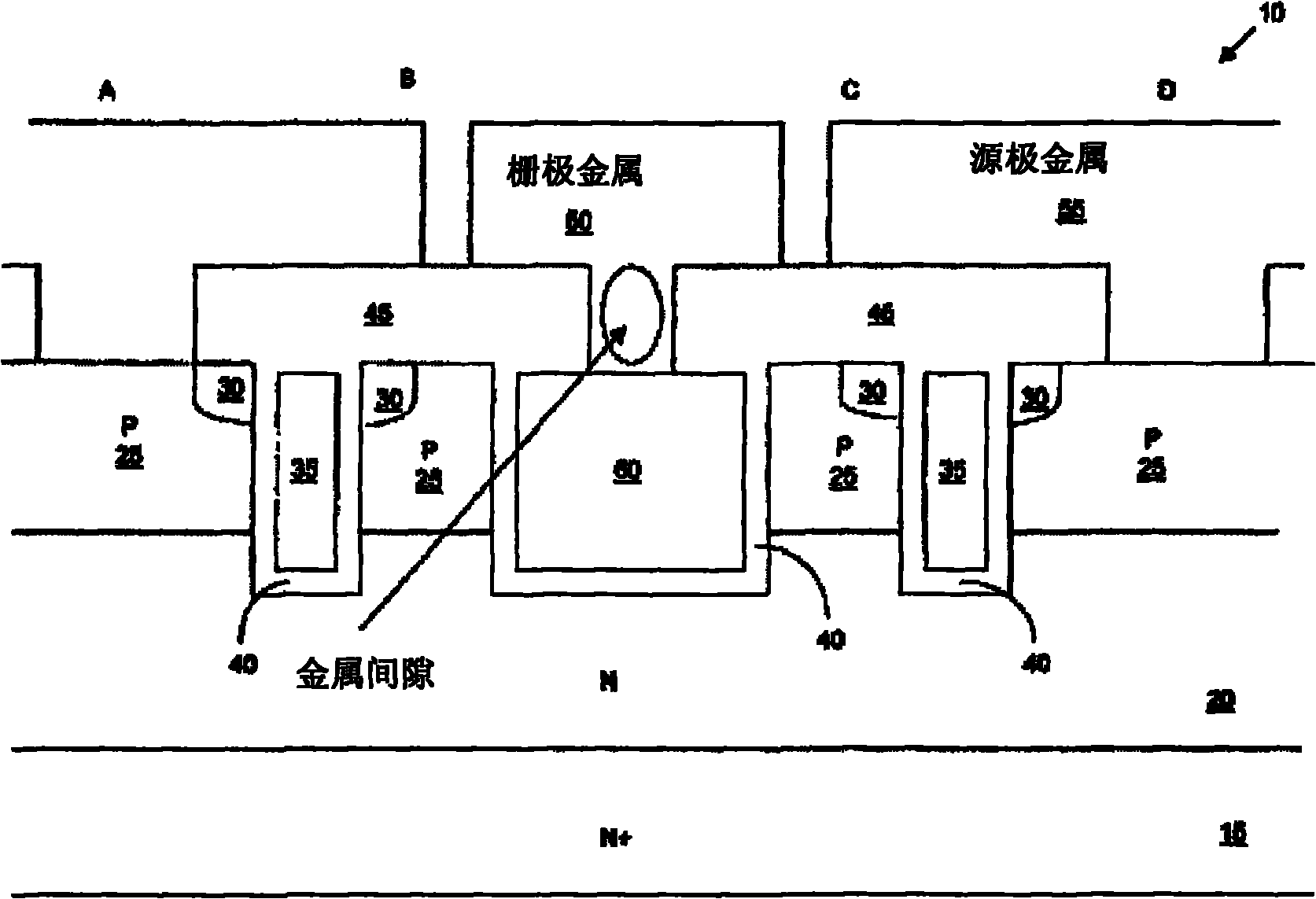

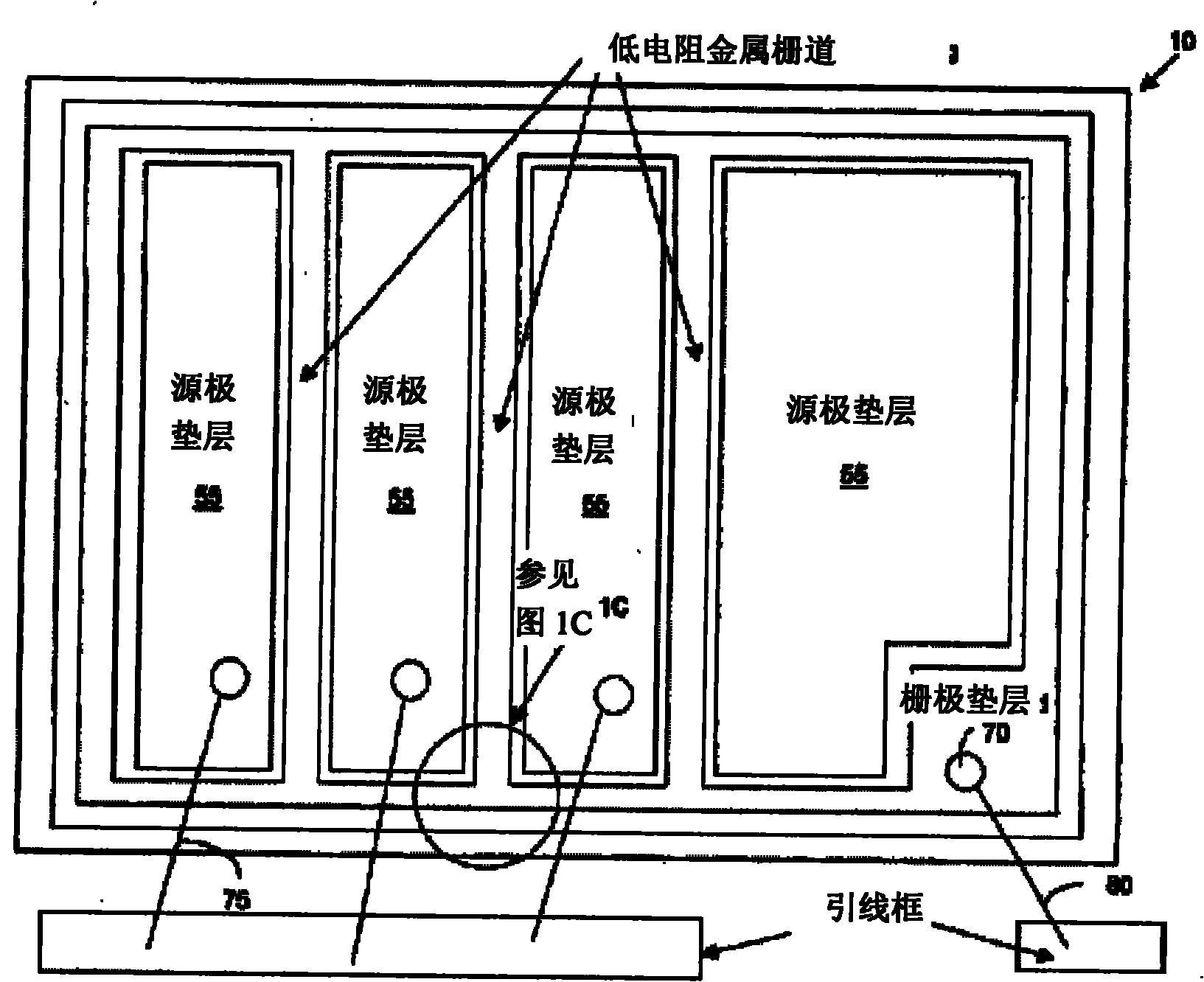

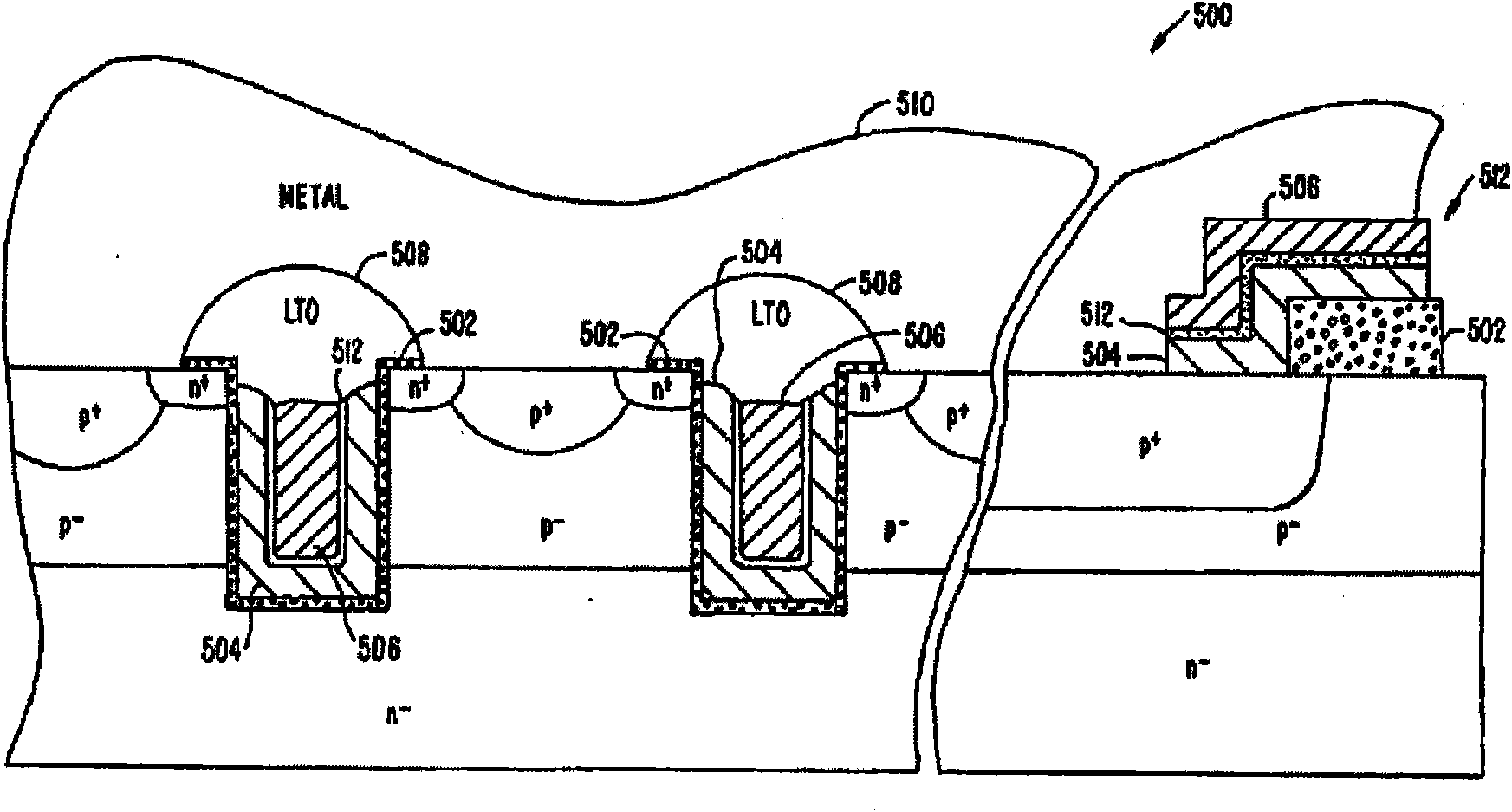

Trench metal-oxide semiconductor field effect transistor (MOSFET) and manufacture method thereof

InactiveCN102097434ASmall sizeDecreased avalanche breakdown characteristicsTransistorSemiconductor/solid-state device manufacturingTrench mosfetField-effect transistor

The invention discloses a trench metal-oxide semiconductor field effect transistor (MOSFET) and a manufacture method thereof. A heavily doped contact region is arranged at the top of a table between two adjacent trench grids in an epitaxial layer in the structure. The trench MOSFET provided by the invention can be used for effectively avoiding the problem of drop of the avalanche breakdown characteristic while improving the unit density of the device.

Owner:FORCE MOS TECH CO LTD

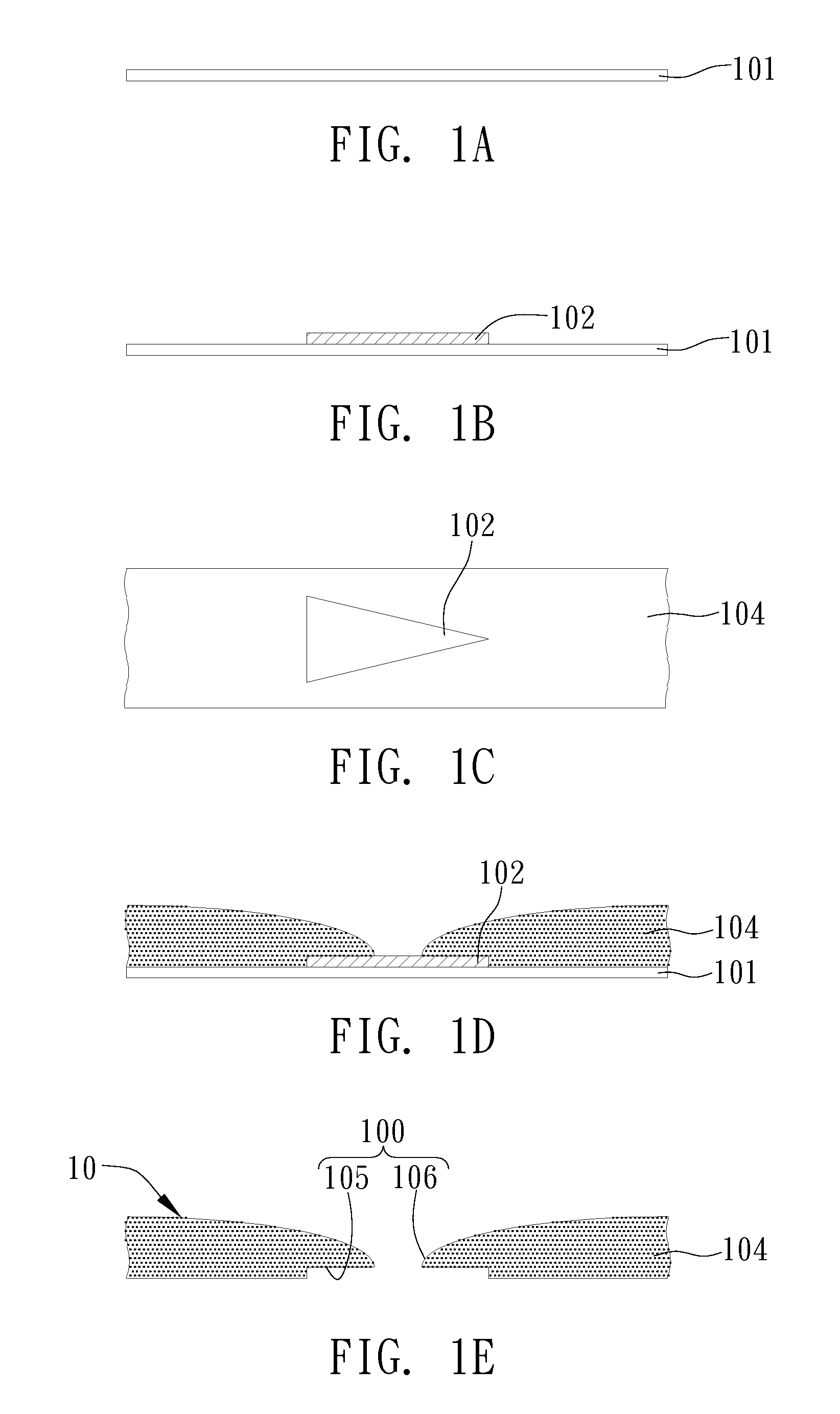

Nozzle plate of a spray apparatus and fabrication method thereof

InactiveUS20090242661A1Reduce in quantityLower the volumeWriting implementsMovable spraying apparatusMiniaturizationVolumetric Mass Density

A nozzle plate for use with a spray apparatus and a fabrication method thereof are provided. The nozzle plate has a plurality of orifices each including an inlet end and an outlet end. The inlet end and the outlet end have a geometrical structure with mirror symmetry and a centroid with positional deviation from a pattern center. The pattern center is the center of an imaginary circle circumscribed about the geometrical structure. The geometrical structure controls the propagation direction of liquid spray, expands the nebulizing range per unit density of orifices, enables product miniaturization, and saves energy.

Owner:IND TECH RES INST

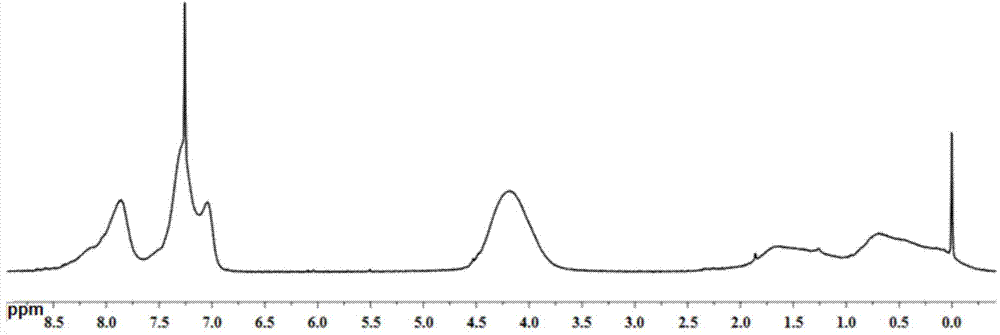

Ternary system electric storage material and preparation and application thereof

InactiveCN103497176AIncrease information storage capacityImprove stabilityOrganic chemistrySolid-state devicesChemical structureElectricity

The invention discloses a ternary system electric storage material and preparation and application of the ternary system electric storage material. The chemical structure general formula of the ternary system electric storage material is , wherein x ranges from 5 to 9, y ranges from 1 to 5, the number-average molecular weight ranges from 11000 to 13000, the molecular weight distribution ranges from 1.4 to 1.6, and R is -Br or -H or -NO2 or -N(CH2CH3)2. The ternary system electric storage material has the high performance of having the ultrahigh electrical information storage intensity, and the information storage capacity of the material is greatly improved. Meanwhile, a ternary system storage device can be obtained based on the ternary system electric storage material, the preparation method is simple and high in efficiency, the obtained ternary system data storage device is high in stability, the data memory space in a unit intensity increases exponentially in comparison with the data memory space based on '0' and '1' binary data storage, and therefore the ternary system electric storage material has great value in ultrahigh density data storage application of the next generation.

Owner:SUZHOU UNIV

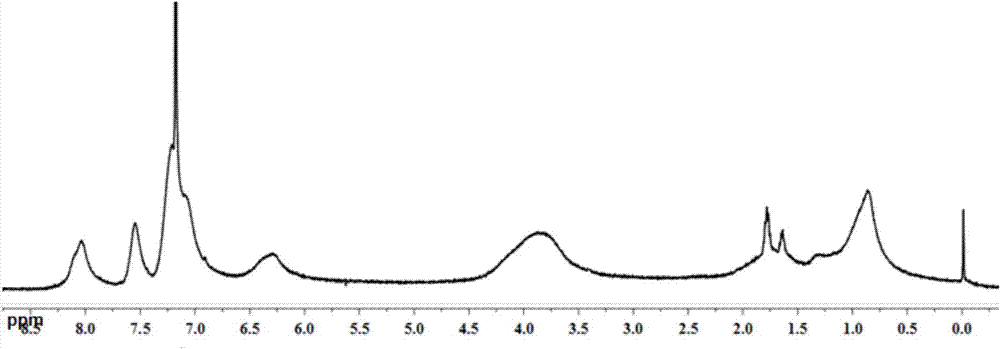

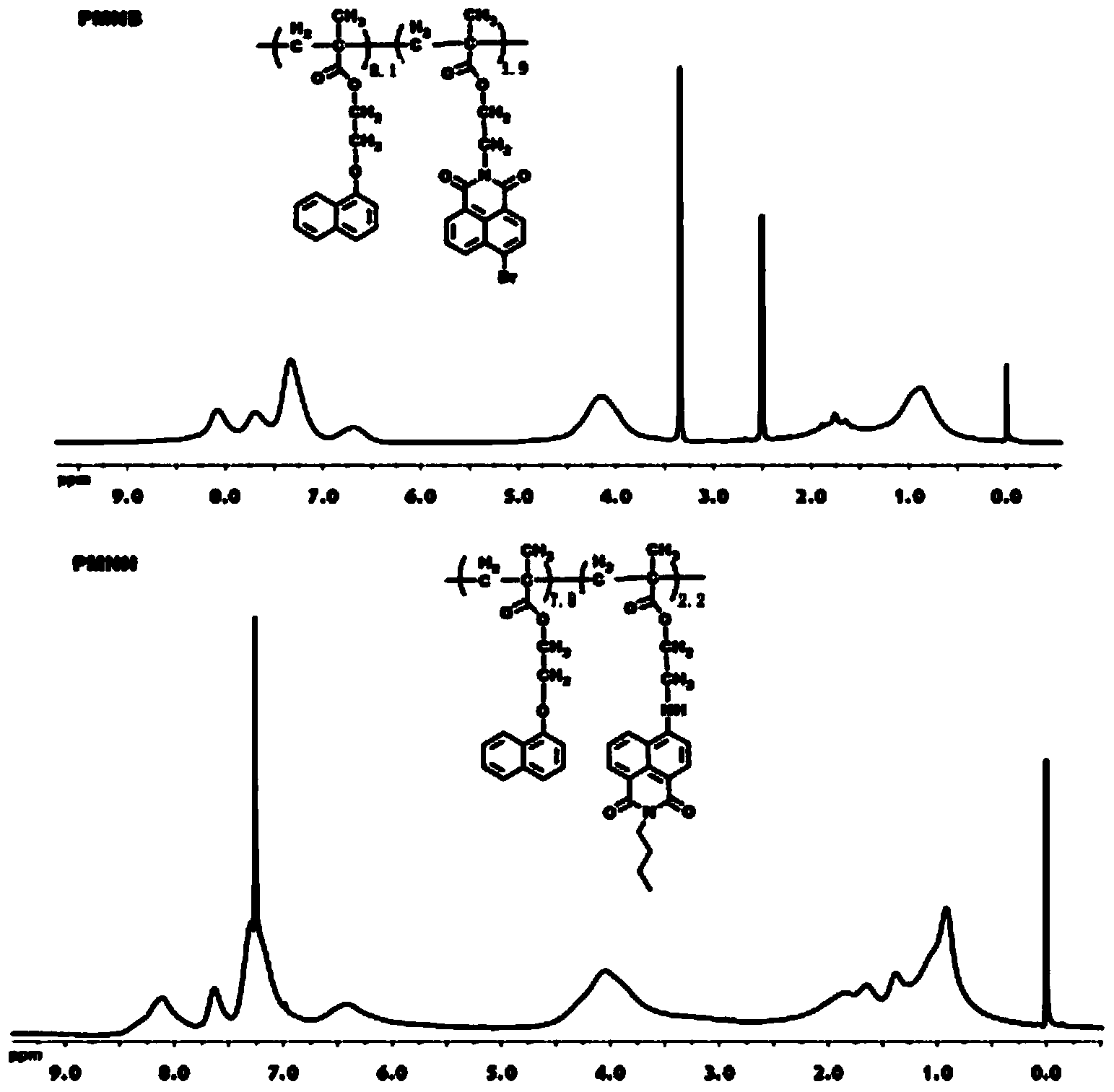

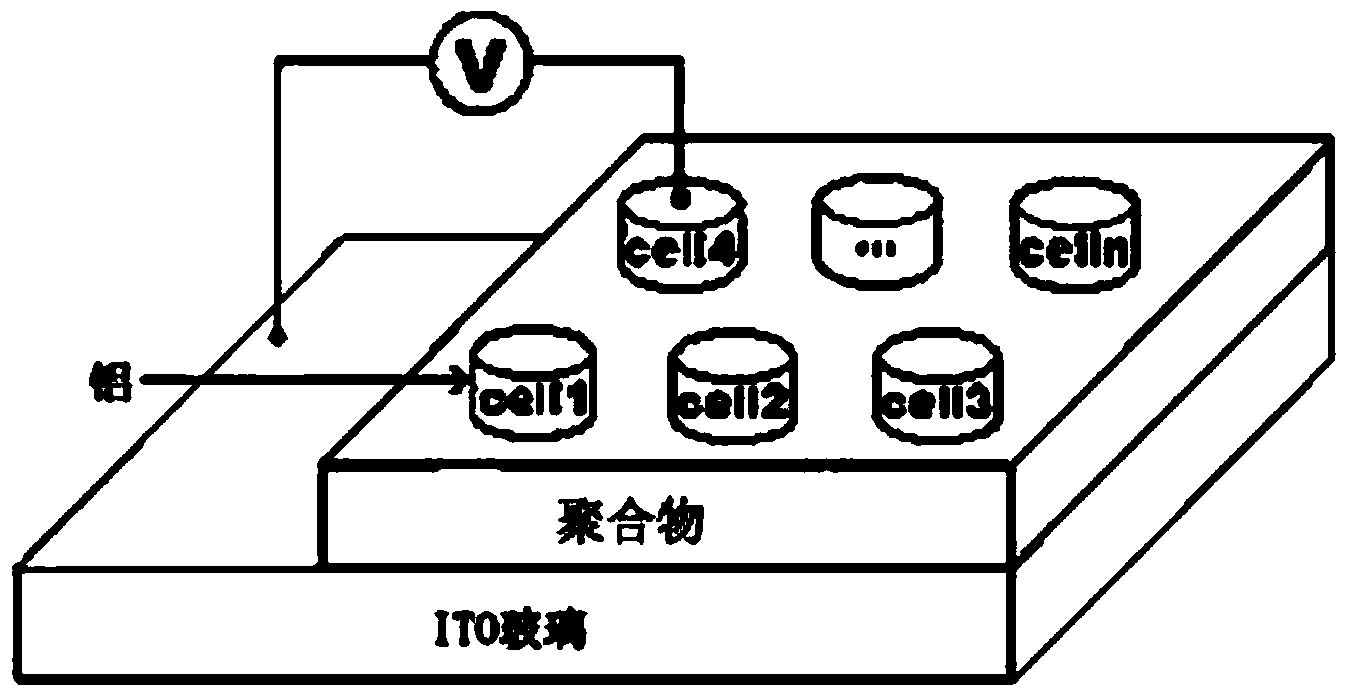

Novel copolymer based on naphthalene nucleus, preparation method thereof and ternary electric storage device prepared therefrom

InactiveCN103554351AThe preparation process is matureImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmElectricity

The invention discloses ternary electric storage materials PMNB and PMNN prepared from a novel copolymer based on a naphthalene nucleus which is used as a functional group, wherein x is not less than 7.5 and less than 10, and y is greater than 0 and not greater than 2.5. The PMNB and PMNN disclosed by the invention are simple in synthesis process; a ternary data storage device with a sandwich structure of bottom electrode / organic film / top electrode is prepared from the PMNB and PMNN, the preparation process is mature, the device has stable performance, a data storage amount in a unit density exponentially grows compared with '0' and '1' binary data storage, and the ternary data storage device has a great value in future ultrahigh-density data storage applications.

Owner:SUZHOU UNIV

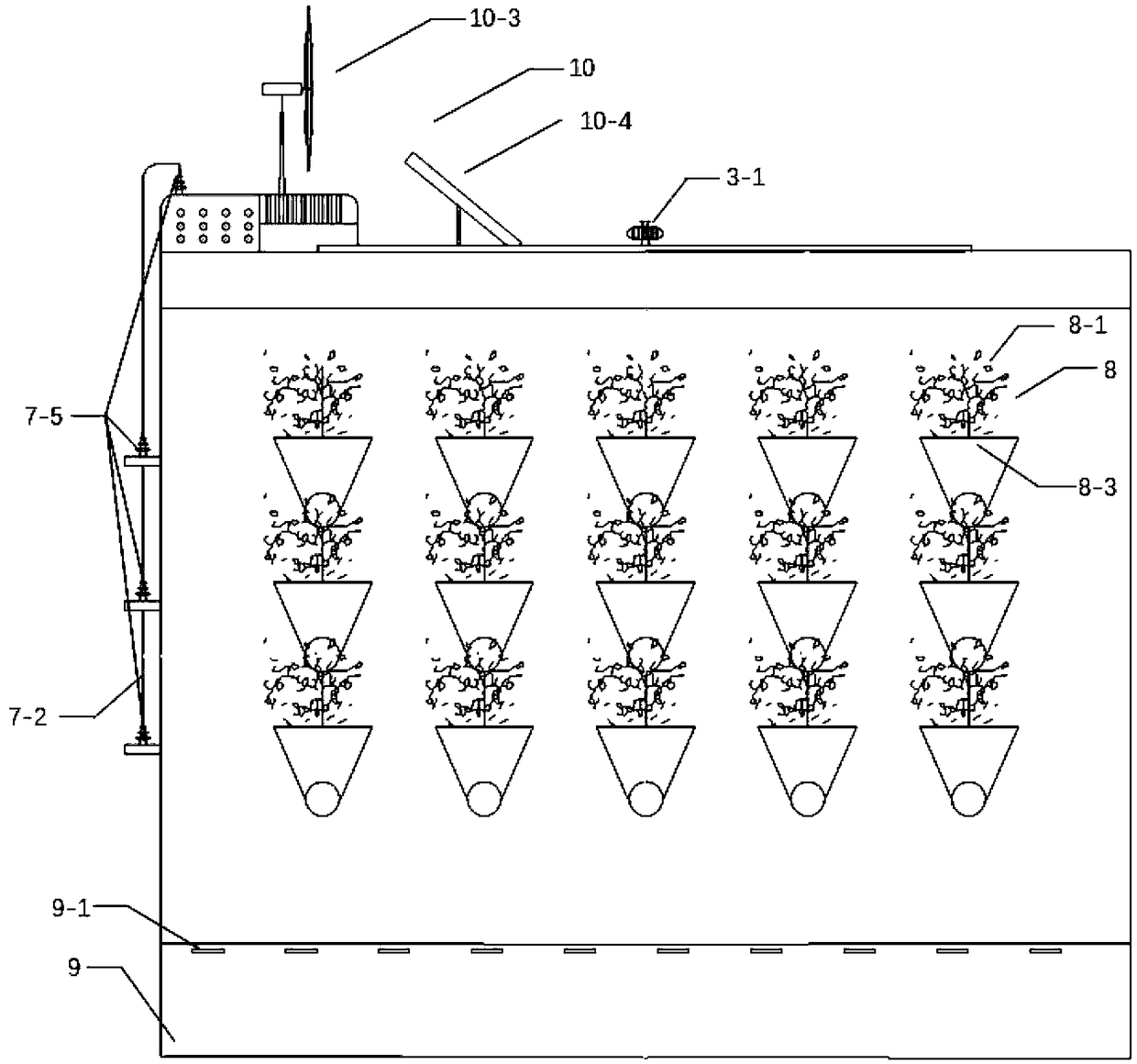

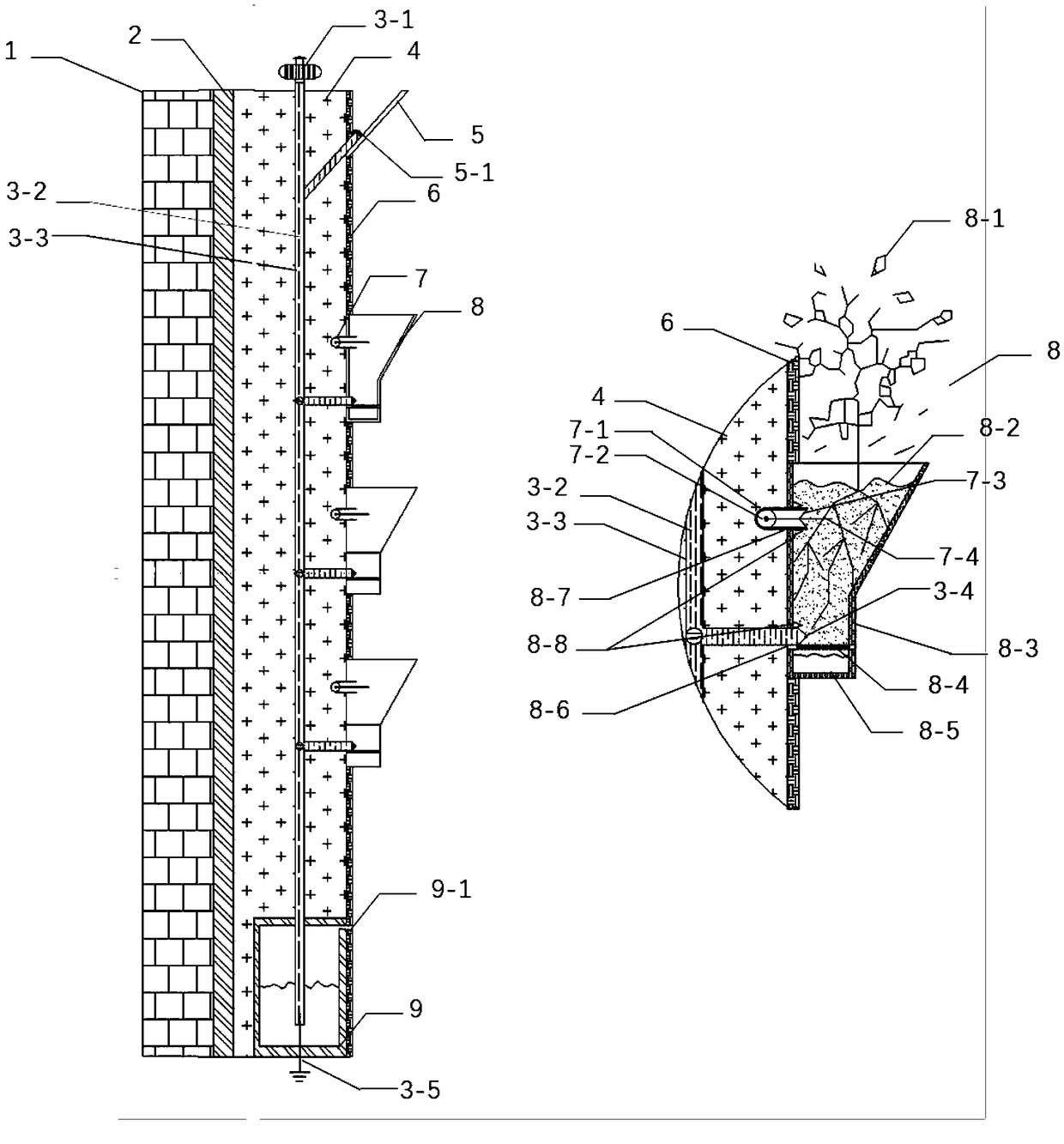

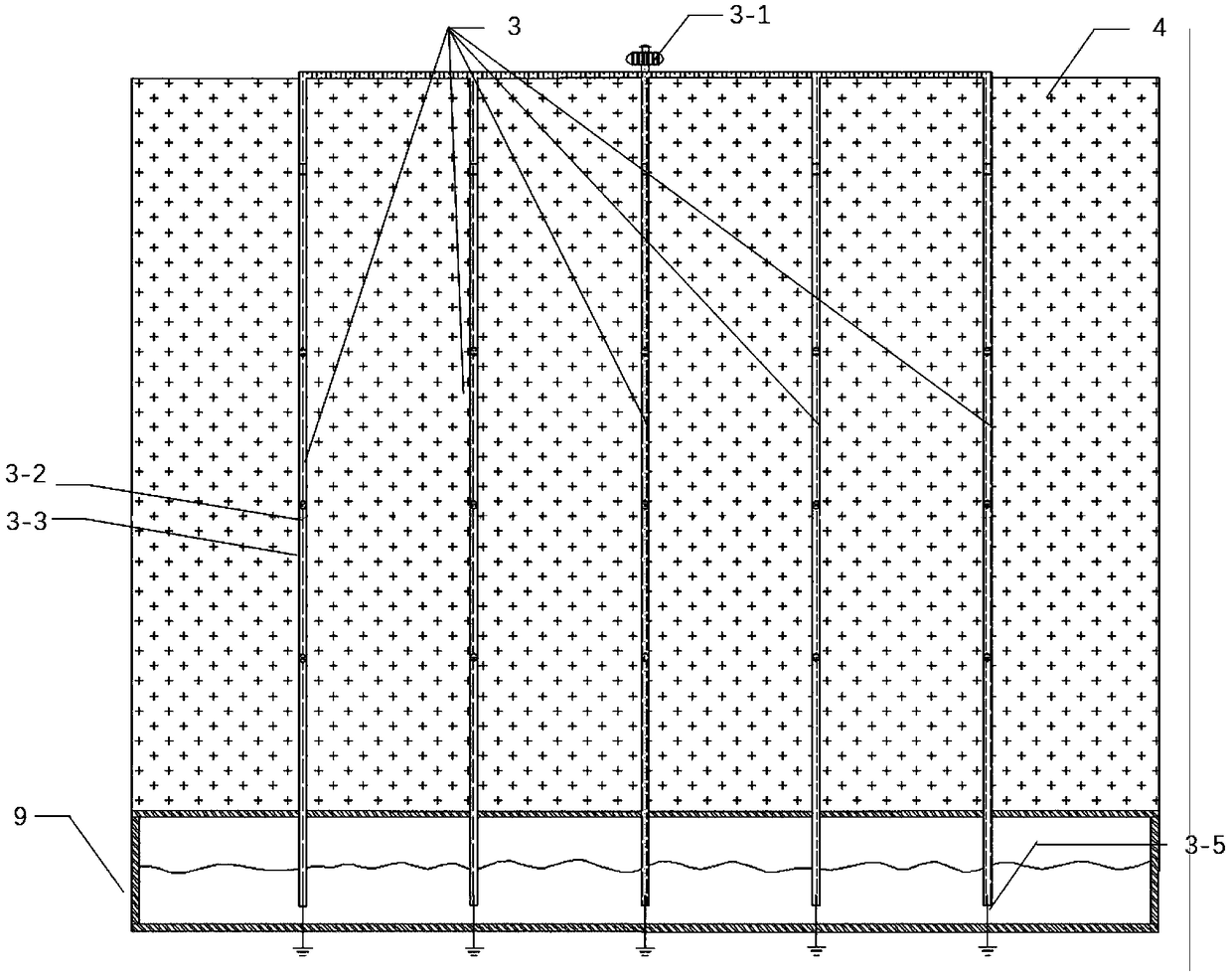

Environment-friendly building wall system

ActiveCN109113208AImprove purification effectSave energyGeneral water supply conservationWallsSystems designInsulation layer

The invention discloses an environment-friendly building wall system. The environment-friendly building wall system comprises an outer wall, a ventilation and water-replenishing system, a discharge system, a rainwater collection tank, a rainwater storage chamber and an electric control system. The outer wall is composed of a wall body, a moisture-proof layer, a light concrete layer, a heat insulation layer and a plant layer sequentially from inside to outside; the rainwater collection tank is arranged at the position, close to the exterior, of the top of the heat insulation layer of the outerwall; and the rainwater storage chamber is formed in the bottom of the light concrete layer of the outer wall. According to the environment-friendly building wall system, the technology that negativeion generation by plants is promoted through electric simulation is applied to the plant outer wall of an environment-friendly building creatively, the unique system design is adopted to solve the problems of installation, construction, water replenishing and power supply of the plant outer wall, the technology that negative ion generation by the plants is promoted through electric simulation andthe plant outer wall can be utilized to build a small environment with clean air and the suitable temperature outside the building, the air purification capability of the plant wall in unit area and unit density is improved, and the environment-friendly building has the environment-friendly and energy-saving effects.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Trench type semiconductor power device with low gate resistance and preparation method thereof

ActiveCN101826551ALower Internal Gate ResistanceIncrease cell densitySemiconductor/solid-state device manufacturingSemiconductor devicesLow voltageTitanium nitride

The invention relates to a trench type semiconductor power device with low gate resistance and a preparation method thereof, the semiconductor power device comprises an embedded trench type gate (250) with a titanium / titanium nitride / tungsten plug, an NSG layer (270) is arranged at the top, the arrangement of the embedded trench type gate (250) is that a standard trench gate is matched with the embedded trench type gate, or 10 standard trench gates are matched with the embedded trench type gate; and the number of the embedded trench type gate (250) is inversely proportional to the width of the unit standard trench gate and inversely proportional to the required gate resistance. The device and the preparation method thereof can reduce the internal gate resistance, simultaneously not affectthe improvement of the unit density, simplify the manufacture and be applicable to mass production. The trench type semiconductor power device can be used for a variety of trench type metal oxide semiconductor field effect transistors, such as P type and N type low-voltage devices and high-voltage devices, P type and N type IGBT, high-voltage integrated circuits and the like.

Owner:M-MOS半导体香港有限公司

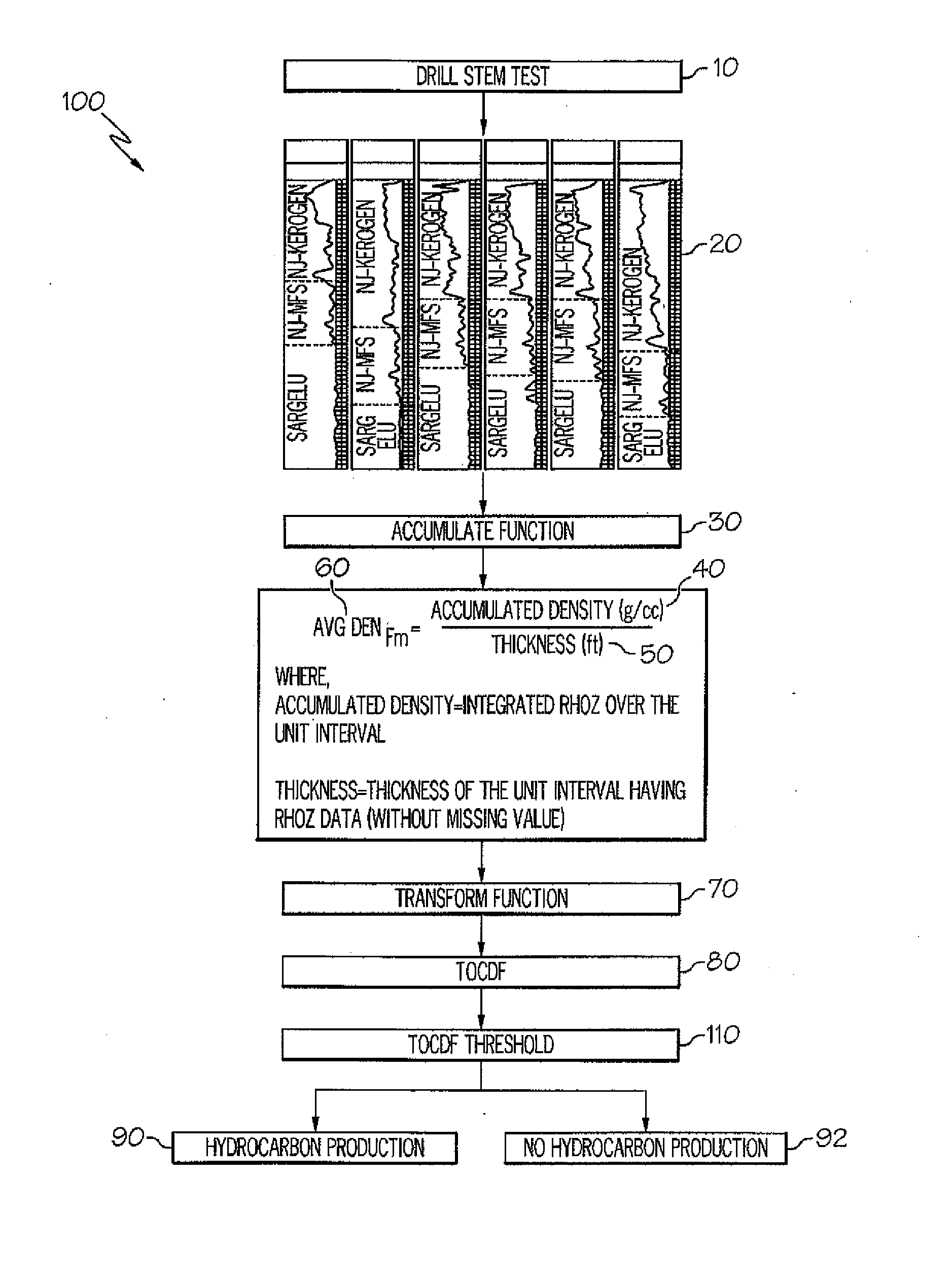

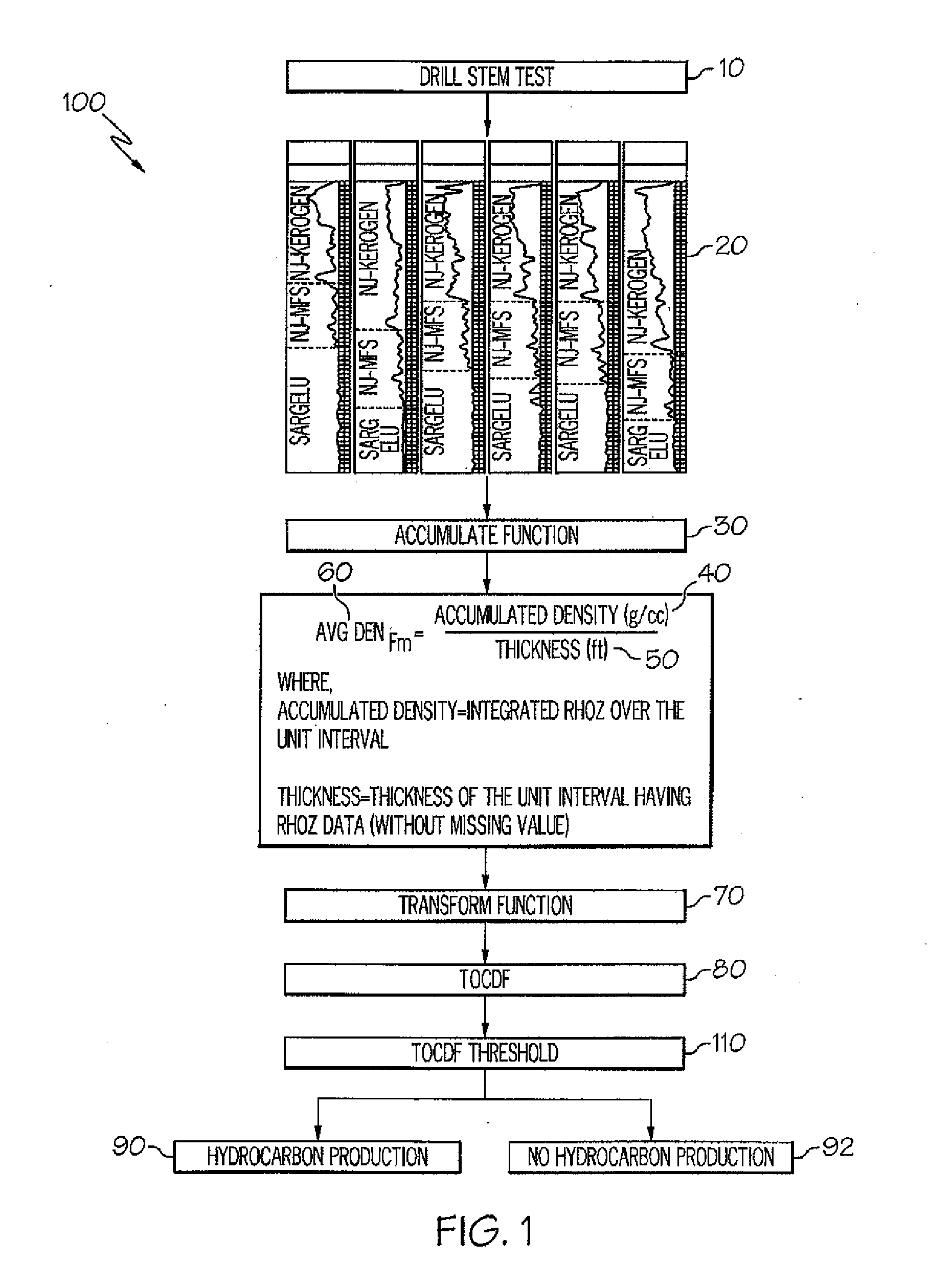

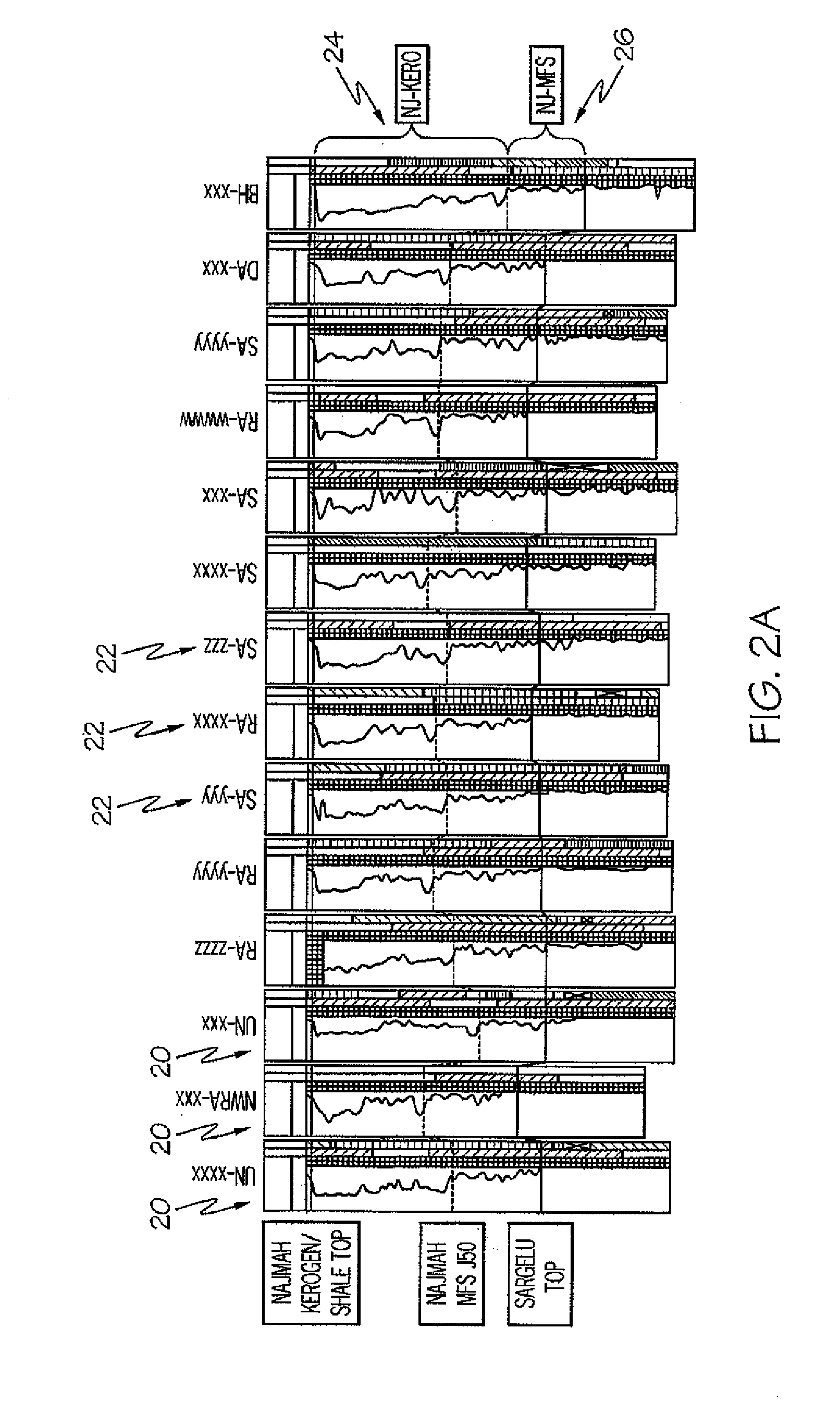

System and method for determining the production of wells

InactiveUS20140100797A1Efficient well site planningGeomodellingSpecial data processing applicationsDensity basedEngineering

According to one embodiment, a system for determining hydrocarbon production may be disclosed. The system may include one or more processors and a memory comprising logic. The memory comprising logic may be operable to determine an accumulated unit density of a reservoir unit from a density log. The memory comprising logic may be further operable to determine a thickness of the reservoir unit and determine a density footage of the reservoir unit based on the accumulated density and the thickness. The memory comprising logic may also be operable to generate a total organic carbon content per density footage based on the density footage. In accordance with certain embodiments, the memory comprising logic may be operable to determine a potential production of hydrocarbons based on the total organic carbon content per density footage of the reservoir unit.

Owner:KUWAIT OIL K S C

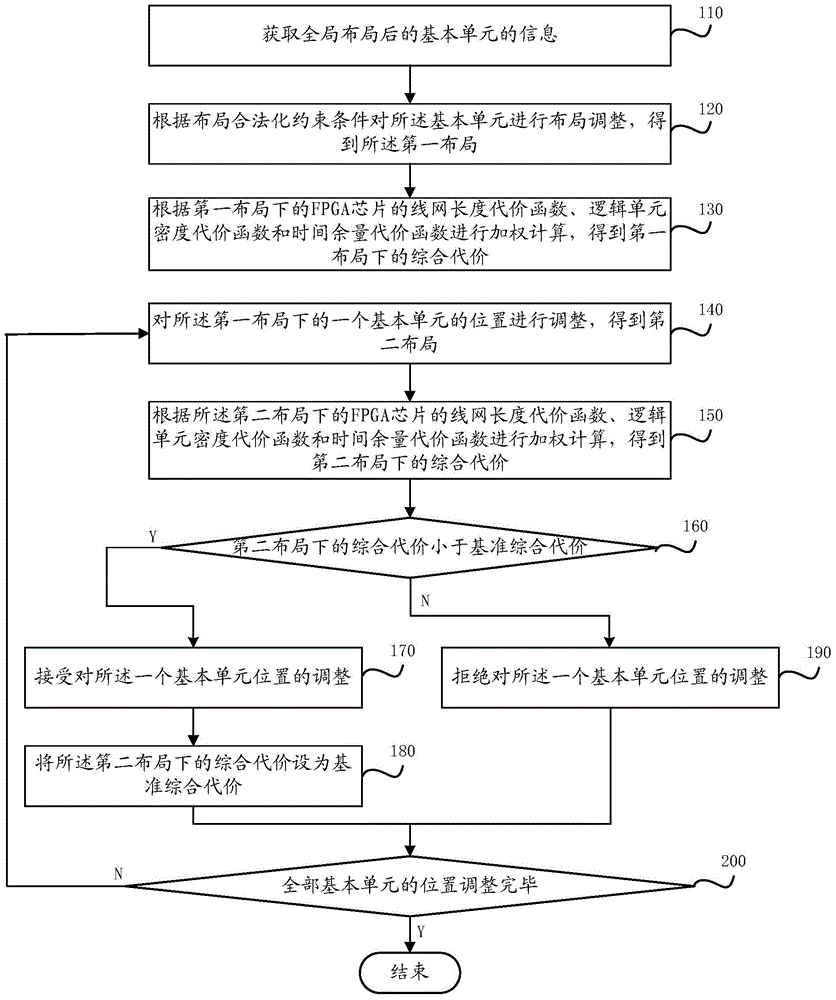

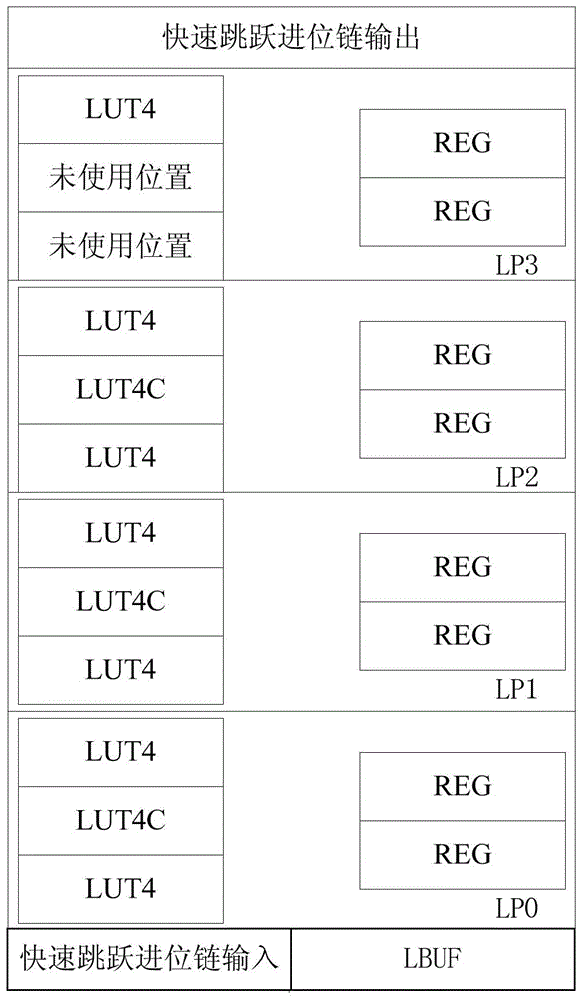

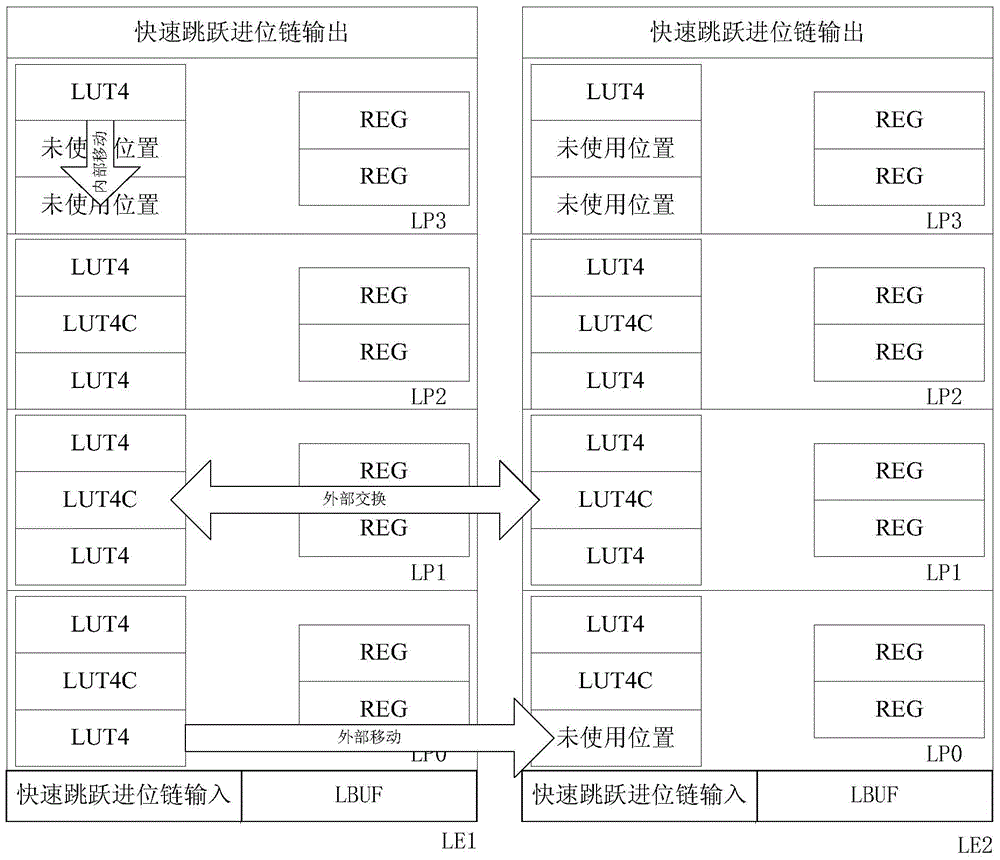

Optimization method for local layout of FPGA chips

ActiveCN104699867AOptimize layoutTaking into account the efficiency of layout optimizationSpecial data processing applicationsTiming marginLogic cell

The invention relates to an optimization method for local layout of FPGA chips. The method comprises the following steps: carrying out weighting calculation according to the wire network length cost function, logical unit density cost function and time margin cost function of the FPGA chips under a first layout to obtain comprehensive cost under the first layout; setting the comprehensive cost under the first layout to be reference comprehensive cost; adjusting the position of a basic unit under the first layout to obtain a second layout; carrying out weighting calculation according to the wire network length cost function, logical unit density cost function and time margin cost function of the FPGA chips under the second layout to obtain comprehensive cost under the second layout; when the comprehensive cost under the second layout is smaller than the reference comprehensive cost, receiving the adjustment for the position of one basic unit; setting the comprehensive cost under the second layout to be the reference comprehensive cost; adjusting the position of the next basic unit under the first layout.

Owner:CAPITAL MICROELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com