Patents

Literature

938results about How to "The preparation process is mature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

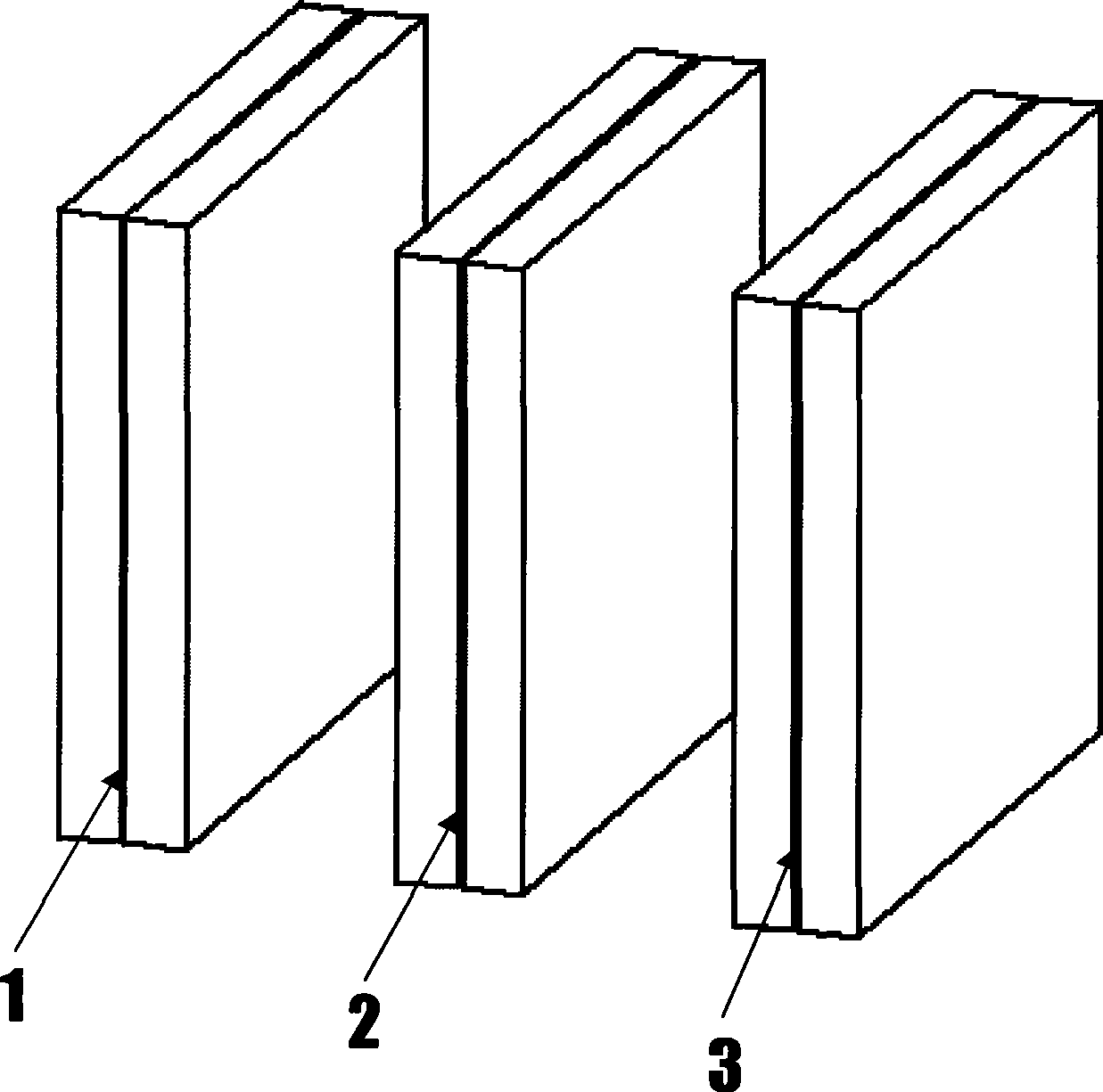

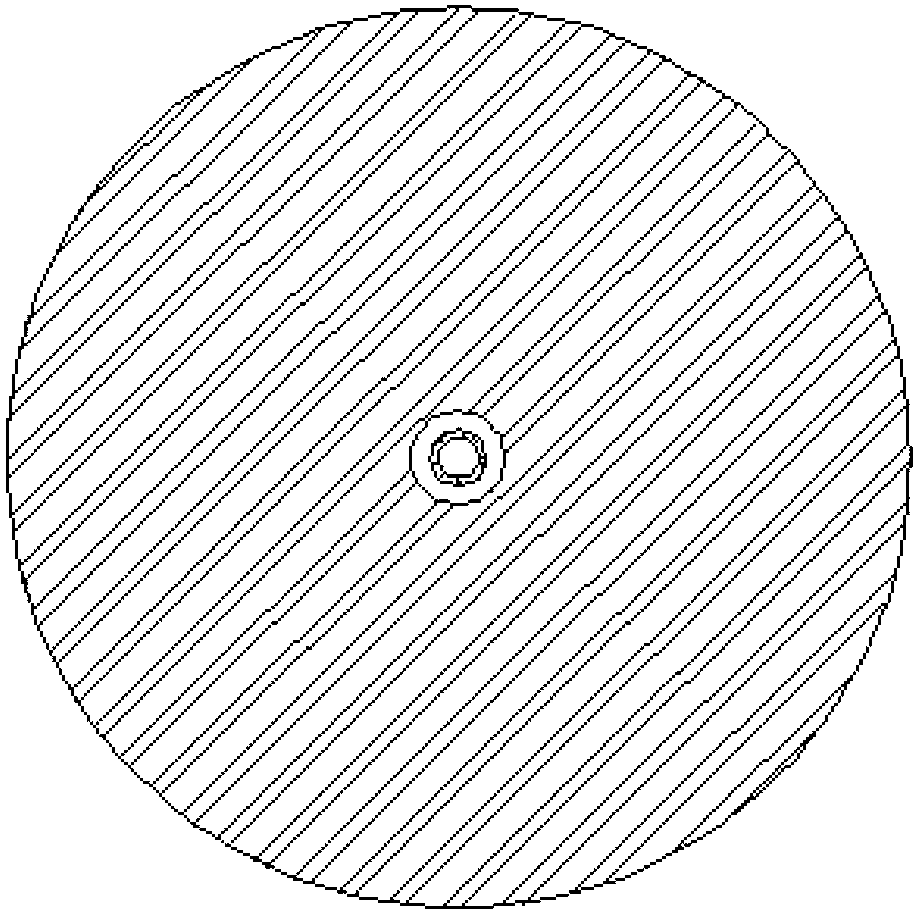

Radar and infrared compatible stealthy material and preparation method thereof

ActiveCN102179968AAchieve broadband absorbing performanceReduce IR emissivityLaminationLamination apparatusGlass fiberScreen printing

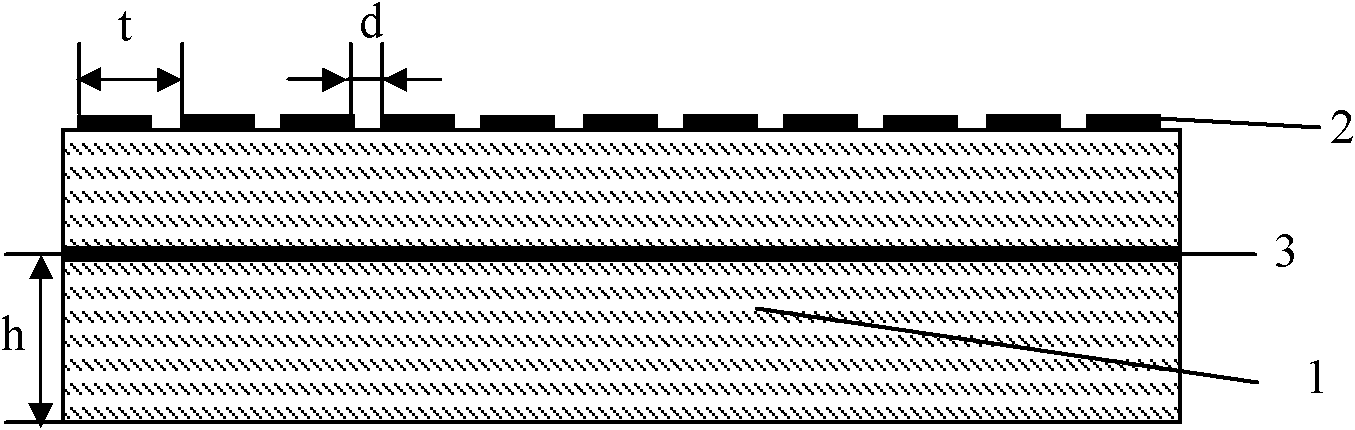

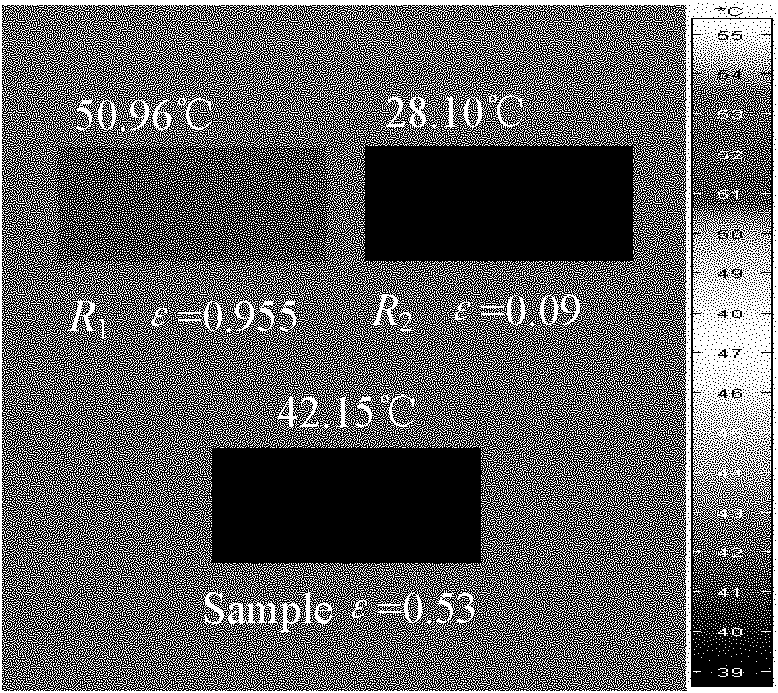

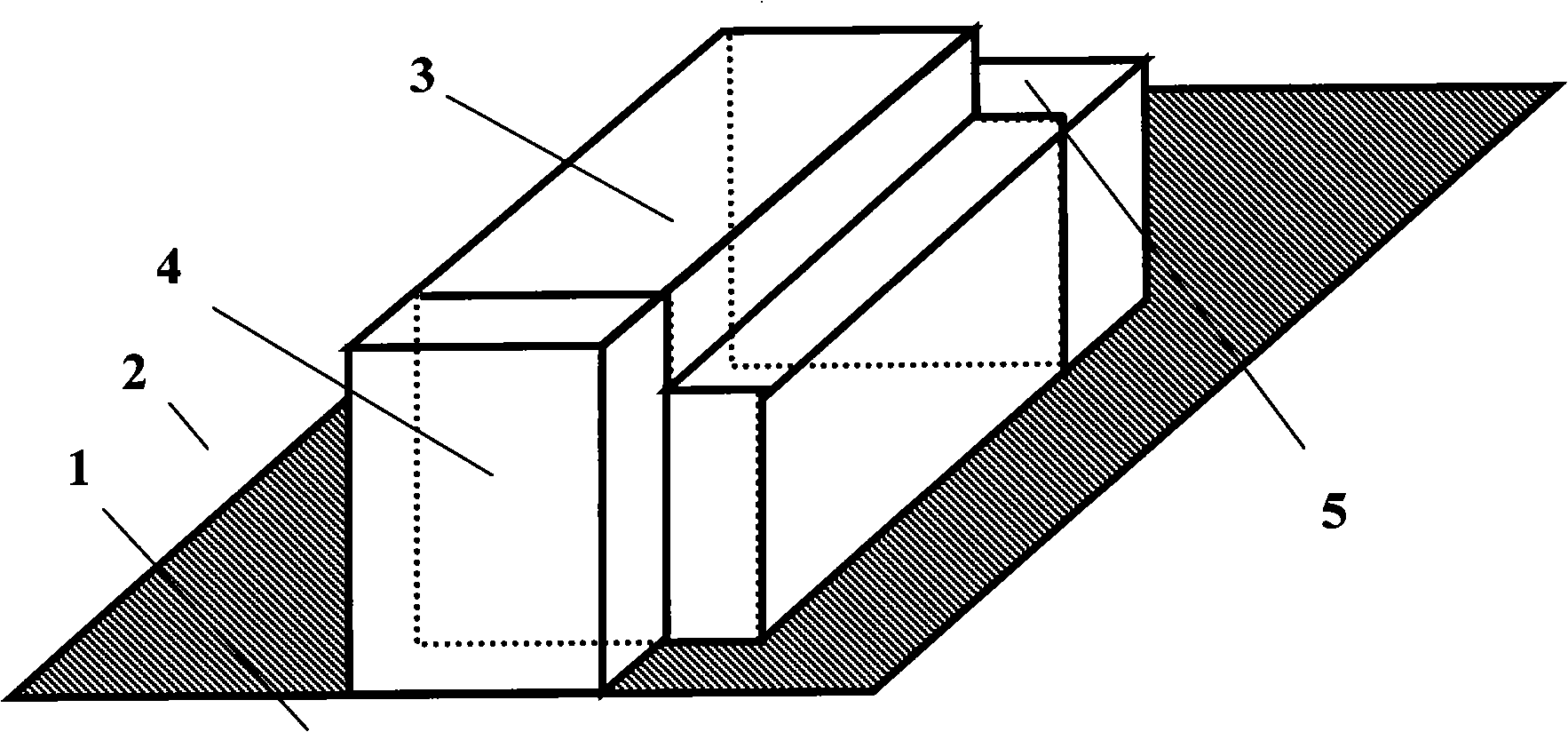

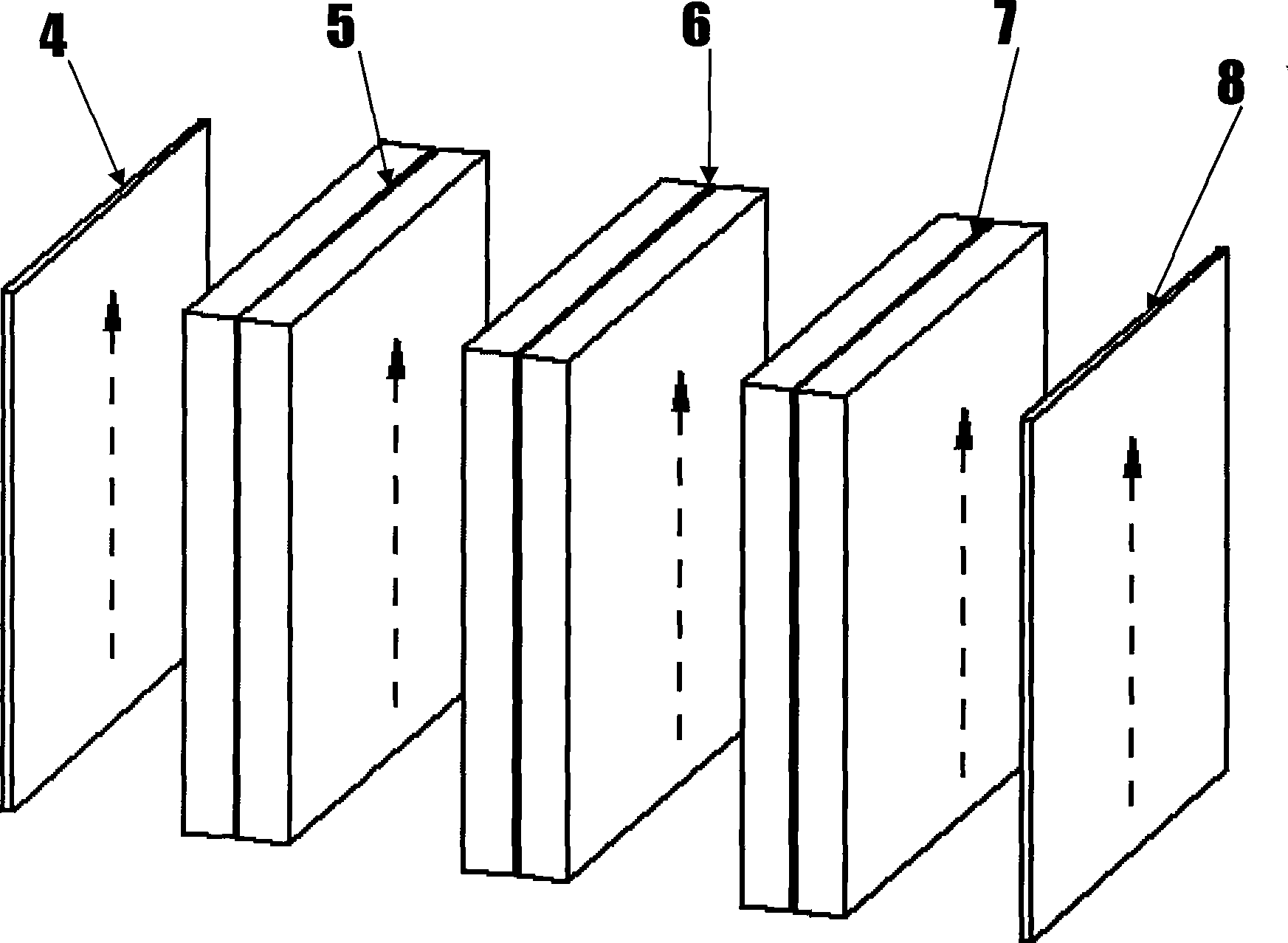

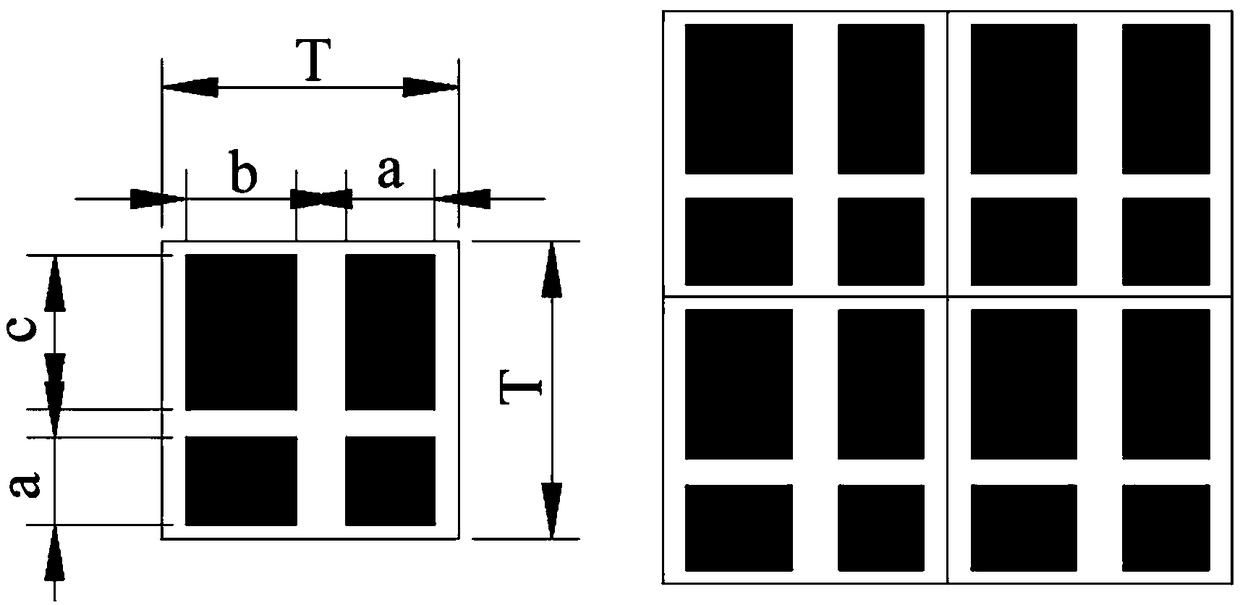

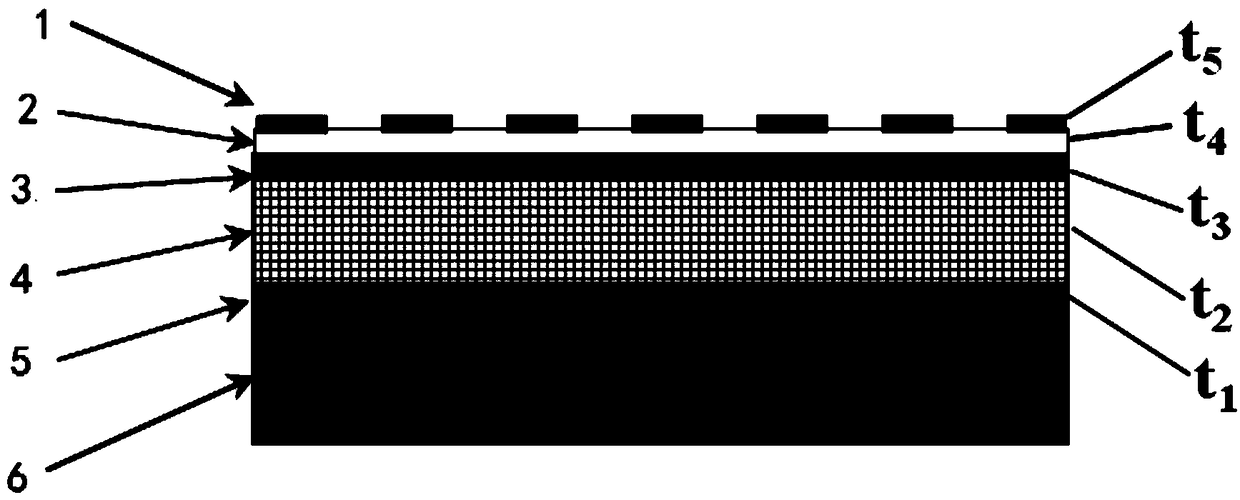

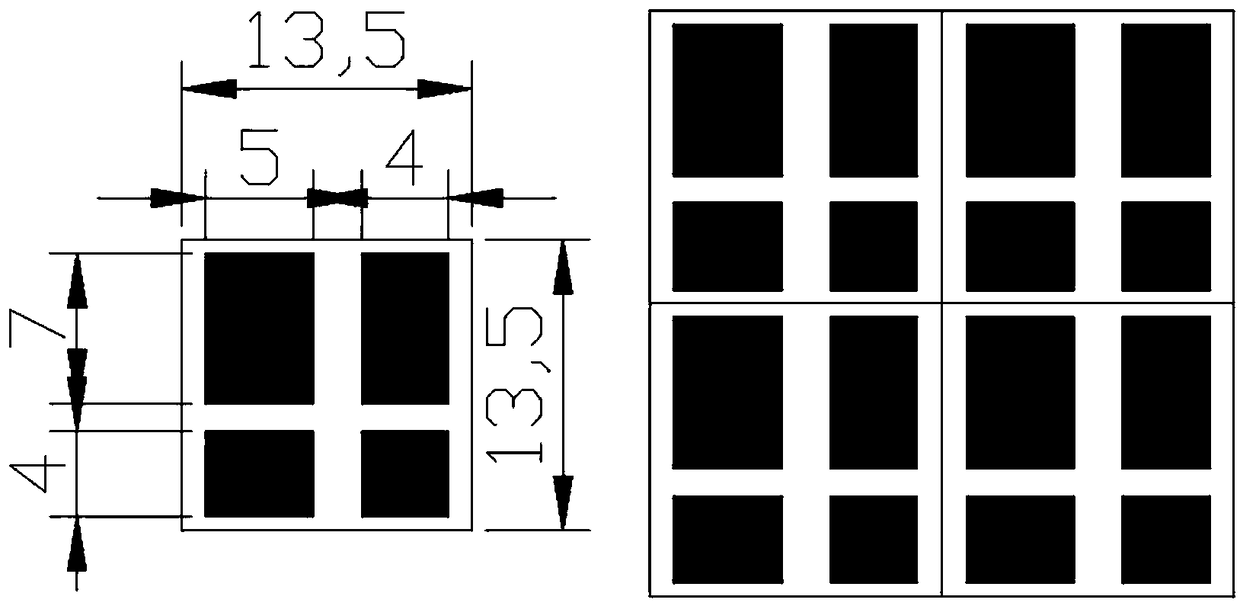

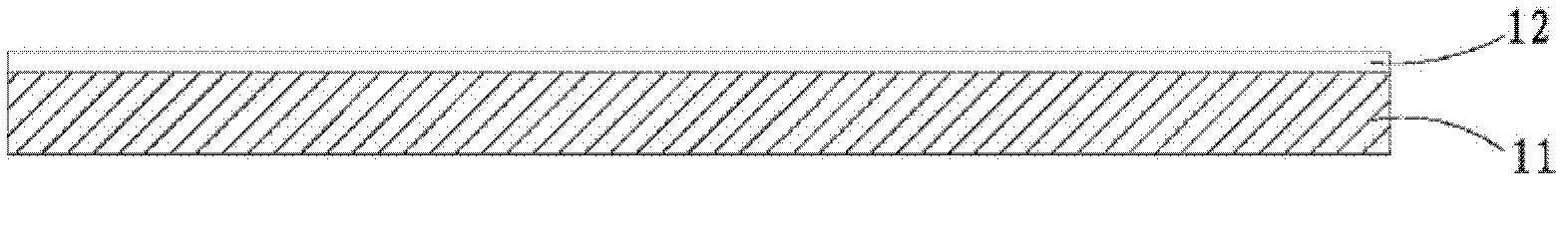

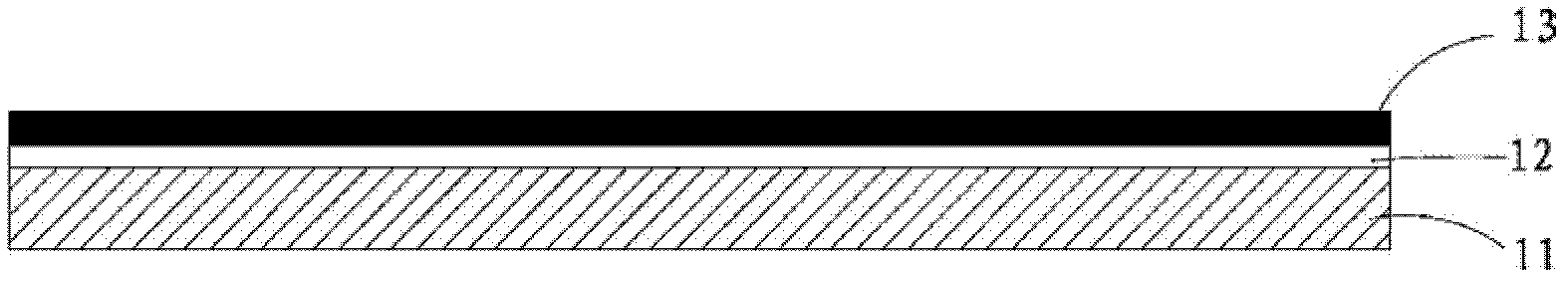

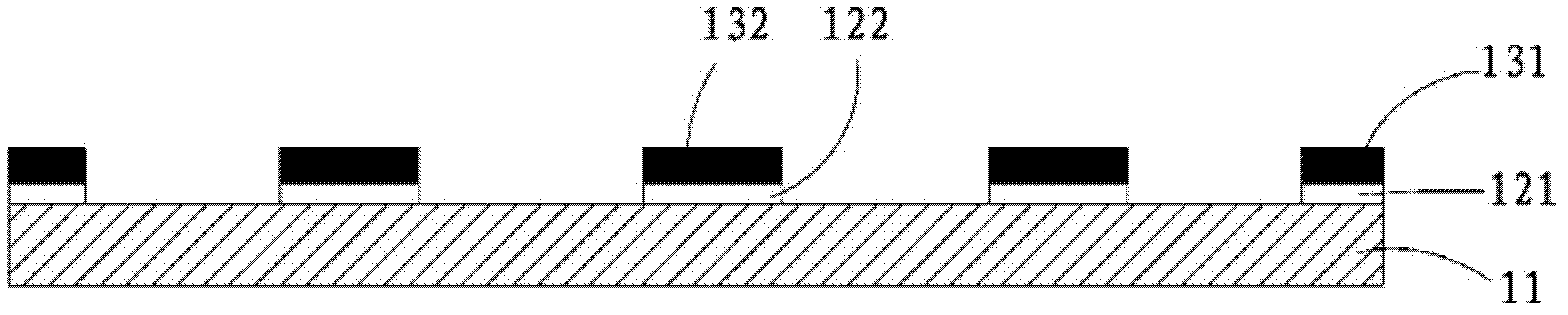

The invention discloses a radar and infrared compatible stealthy material and a preparation method thereof. The compatible stealthy material is mainly formed by compounding a radar wave absorbing structural layer and an infrared stealthy functional layer, wherein the radar wave absorbing structural layer is made of a glass fiber reinforced glass steel composite material; and the infrared stealthy functional layer is a capacitive frequency selective surface. The preparation method comprises the following steps of: preparing the capacitive frequency selective surface by a printed circuit board (PCB) process; preparing a layer of resistance sheet on glass fiber plain cloth by using conductive carbon slurry through a screen printing process; preparing the glass fiber reinforced glass steel composite material by using epoxy resin as a base material and the glass fiber plain cloth as a reinforcing material through a resin forming process; and curing to make the capacitive frequency selective surface compounded and superposed so as to obtain the radar and infrared compatible stealthy material. The compatible stealthy material has a simple structure and low cost, is convenient to prepare, and has the duplex characteristics of high reflection of an infrared wave band and high permeation of a radar wave band.

Owner:NAT UNIV OF DEFENSE TECH

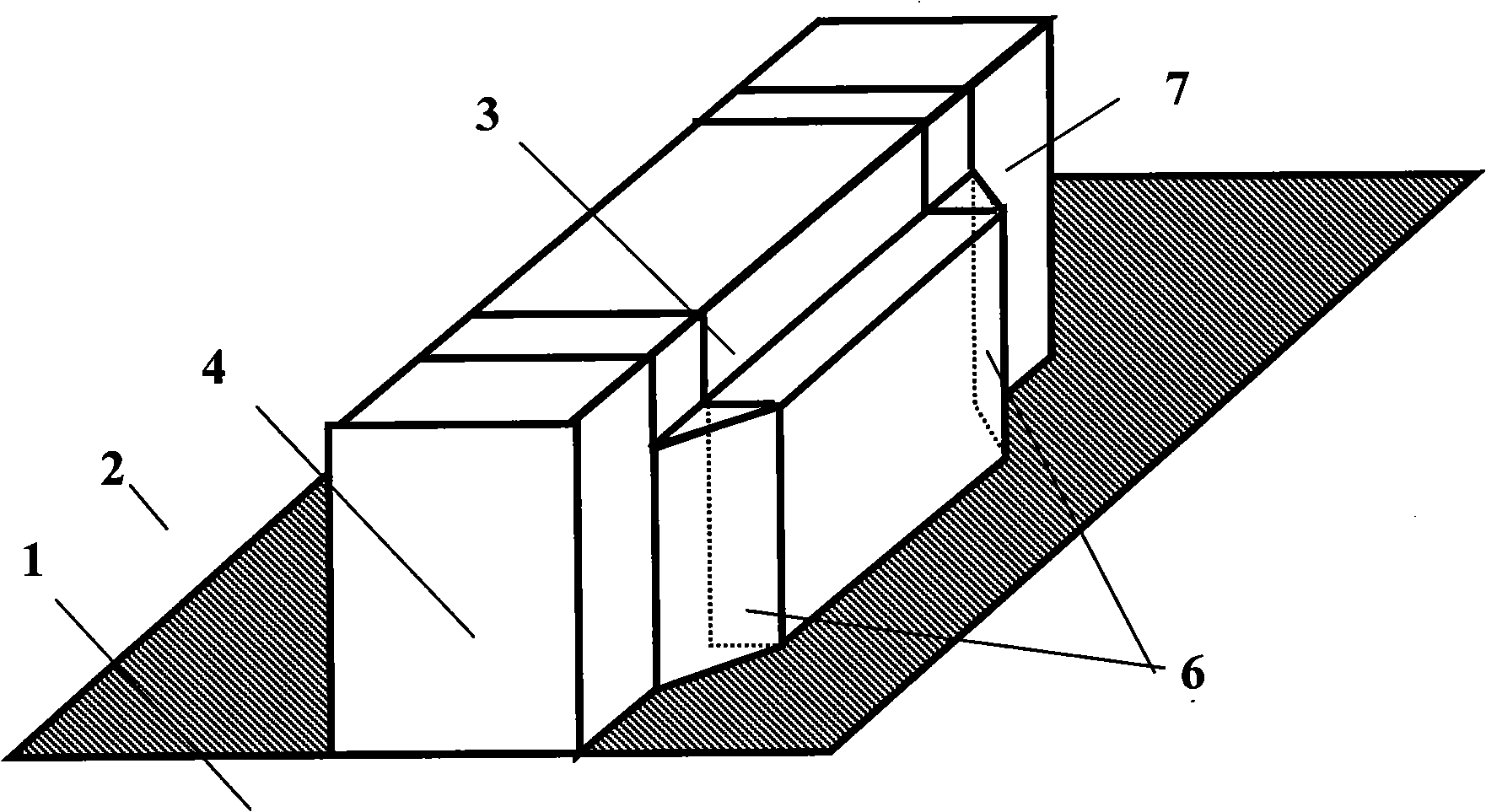

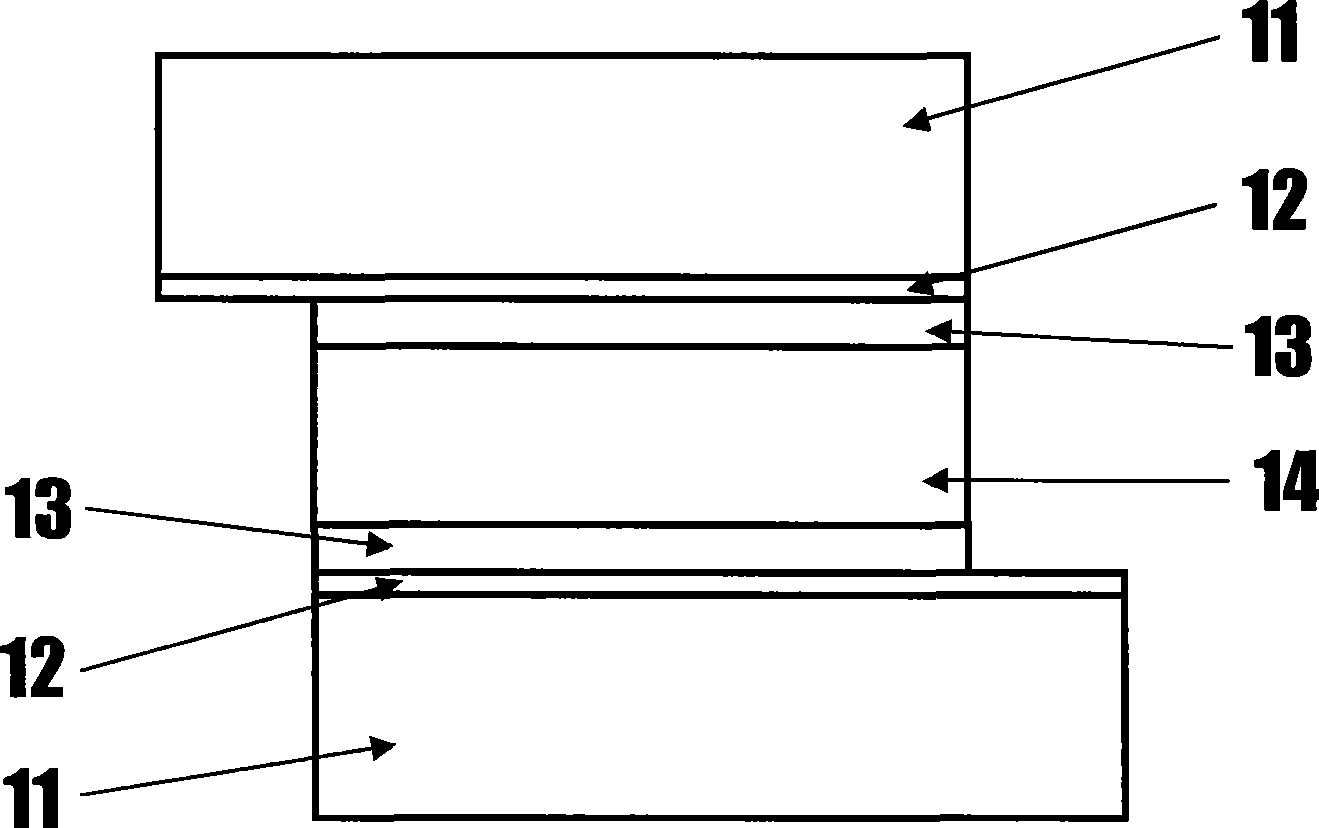

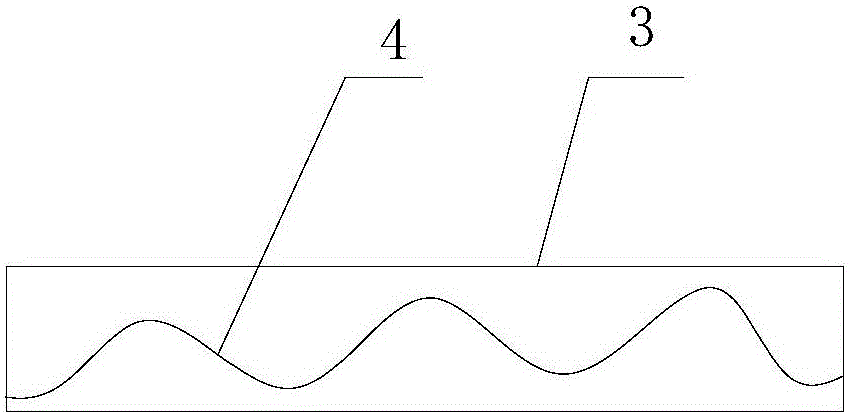

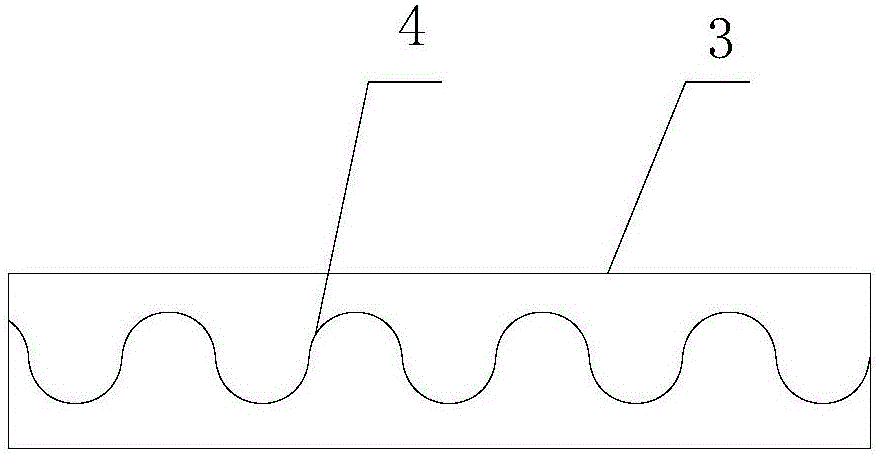

Waveguide type polarization mode converter

InactiveCN101320113AWide range of size variationsSimple structureCoupling light guidesWaveguideOptical integrated circuit

The invention discloses a waveguide type polarized mode converter, which is composed of a conventional dielectric waveguide which contains a substrate layer, a covering layer and a core layer; wherein, the core layer is formed by that the head and the tail of an L-shaped conversion waveguide are respectively connected with a rectangular input waveguide and a rectangular output waveguide which has a different dimension with the input waveguide, and also can be formed by that the head and the tail of the L-shaped conversion waveguide are respectively connected with a rectangular input waveguide and a rectangular output waveguide which has the same dimension as the input waveguide through a conical transition waveguide. The converter can realize the polarized mode conversion between the rectangular waveguides with different dimensions or same dimensions. The input waveguides which are processes by the polarized conversion have wide dimensional variation range, and the single mode conditions are easy to satisfy. The converter has simple structure, the required fabrication technology is mature, the dimension is compact, the polarized conversion efficiency is high, the frequency range is wide and is easy to be integrated, and the converter can be widely applied to the optical integrated circuits which are operated in the single polarized mode.

Owner:ZHEJIANG UNIV

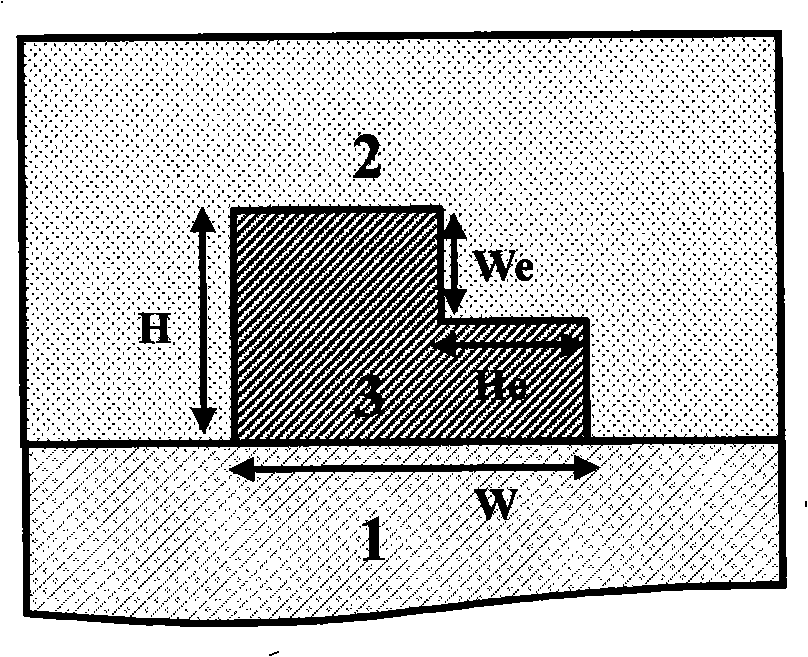

Aqueous lithium (sodium) ion battery mixed negative material

InactiveCN104779394AThe preparation process is matureReduce manufacturing costElectrode manufacturing processesAlkaline earth metalShortest distance

The invention belongs to the technical field of batteries, and particularly relates to an aqueous lithium (sodium) ion battery mixed negative material. The mixed negative material is prepared by mixing three materials including ion embedded type compounds, conductive materials, organic compounds capable of reversibly storing alkali metal or alkaline earth metal ions or high-molecular polymers in a certain mass proportion; a mixing way comprises the steps of in-situ growth and direct mechanical mixing of all the composition parts. An aqueous lithium (sodium) ion battery assembled by using the mixed electrode material as a negative electrode has the characteristics of long cycle life, high power, high security, low cost and no environment pollution, and is particularly suitable for power batteries used in short-distance electromobiles and energy storage batteries used in smart power grids.

Owner:FUDAN UNIV

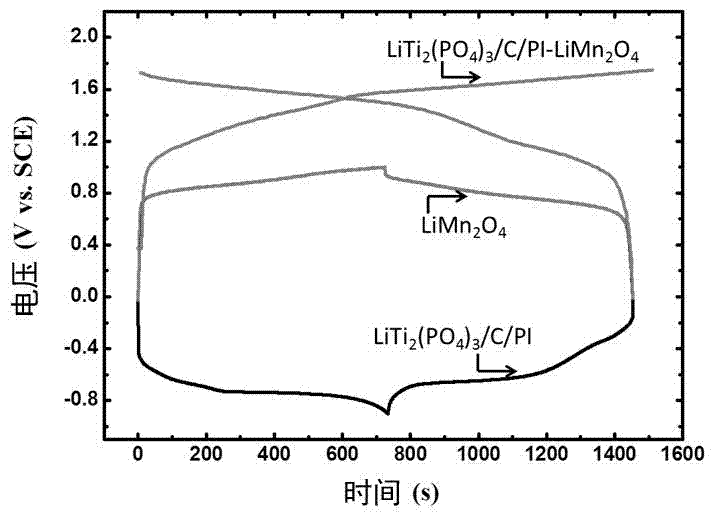

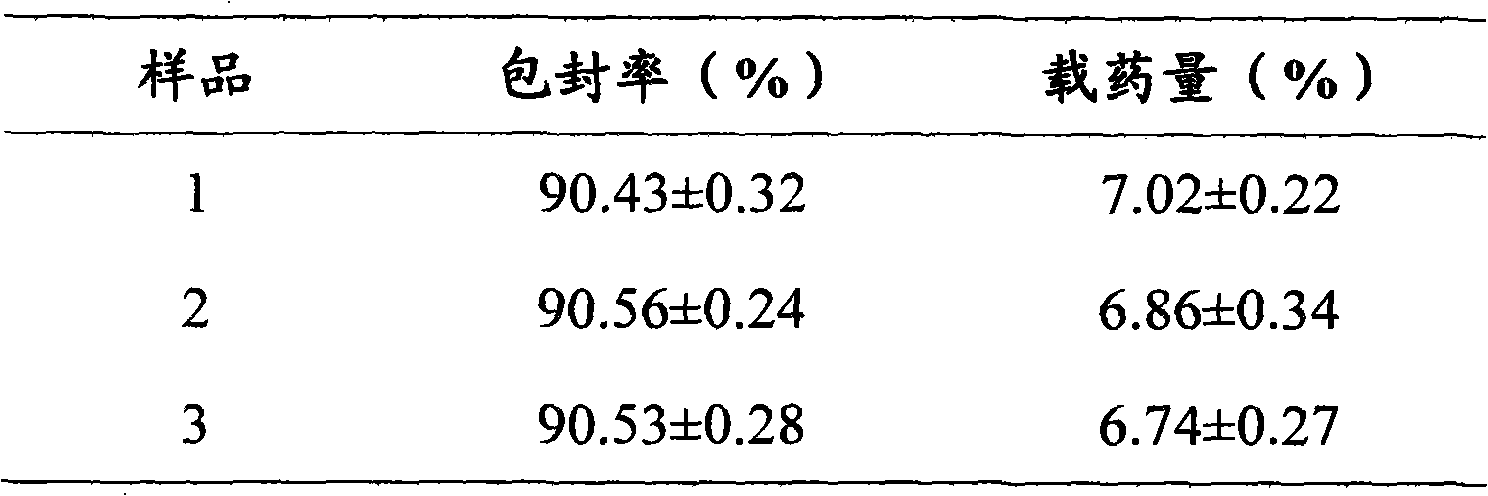

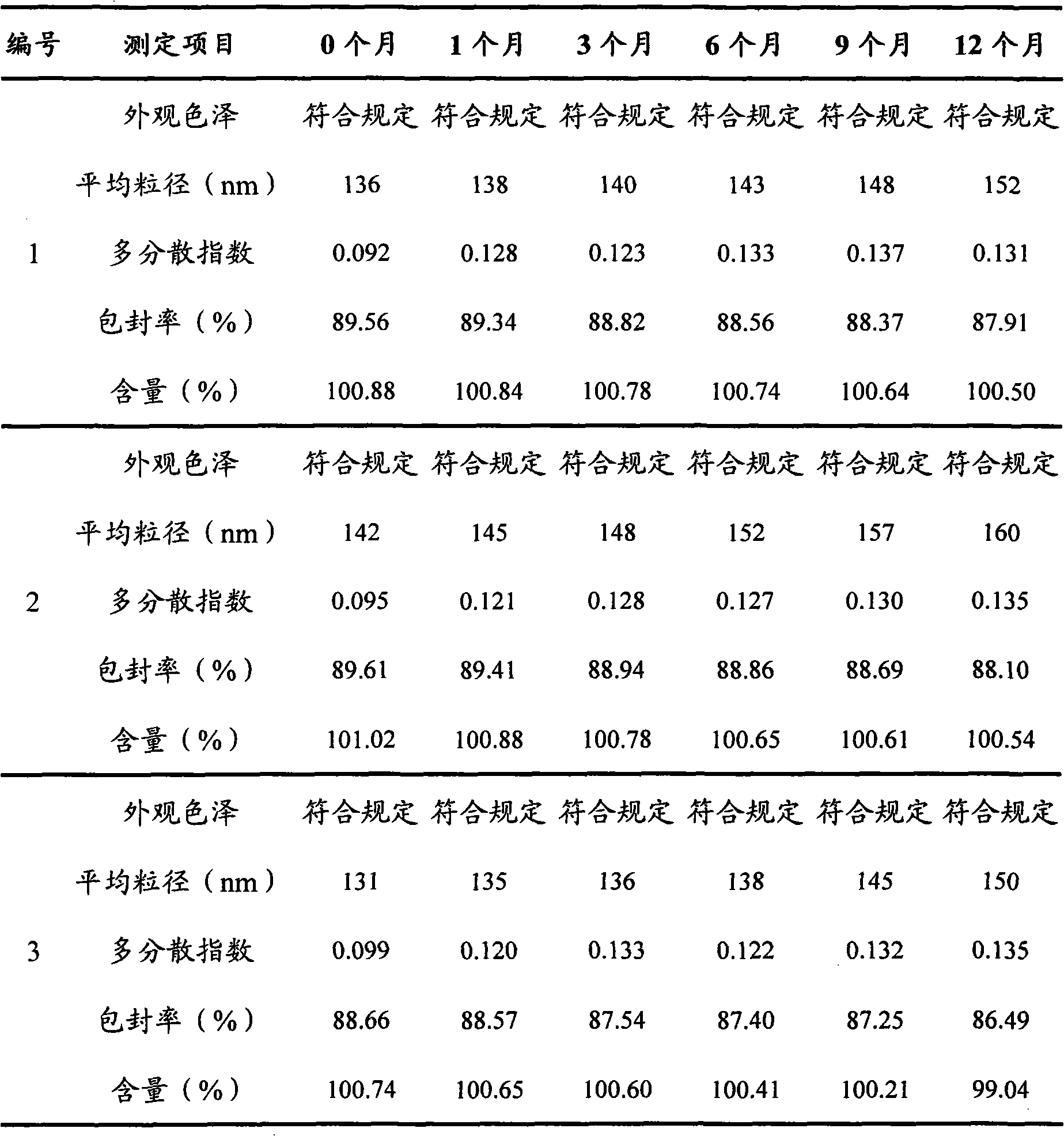

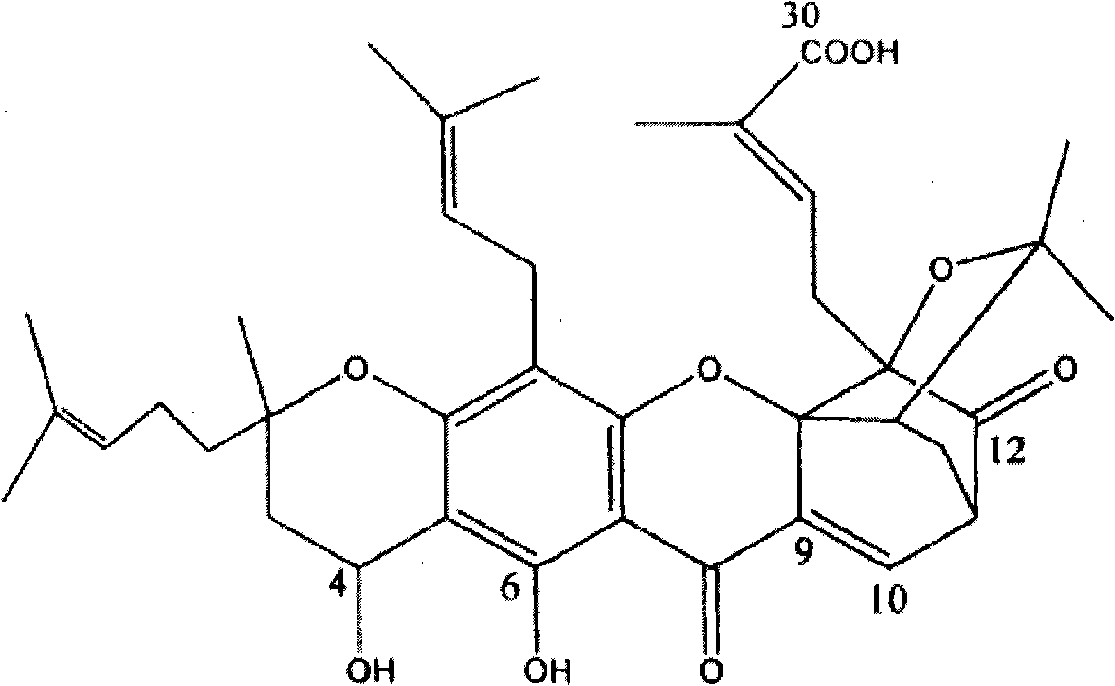

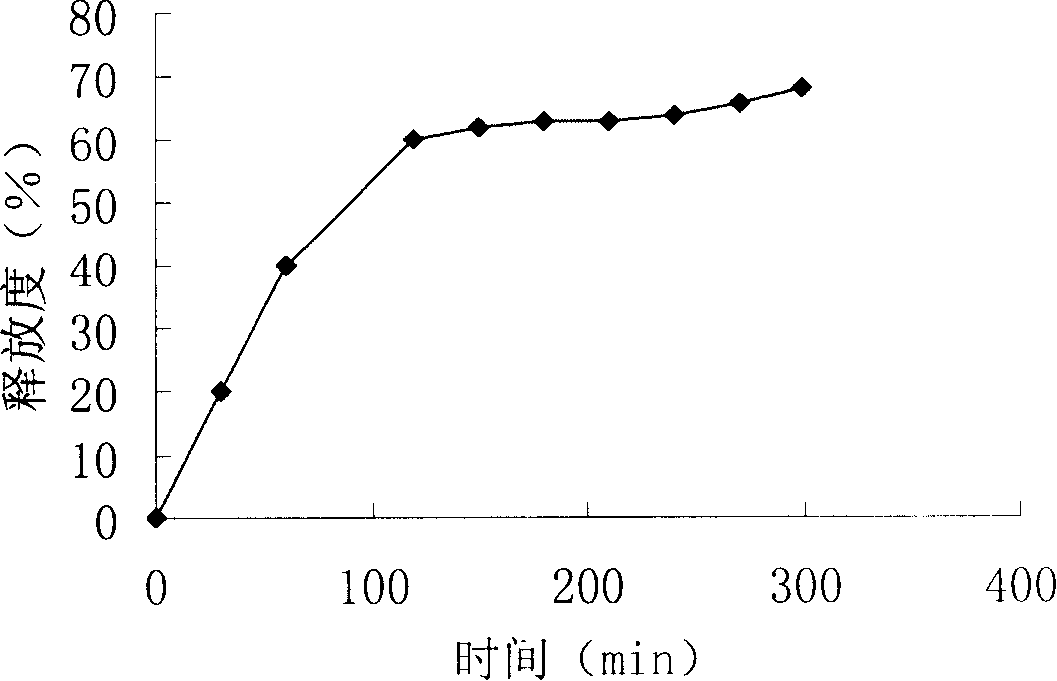

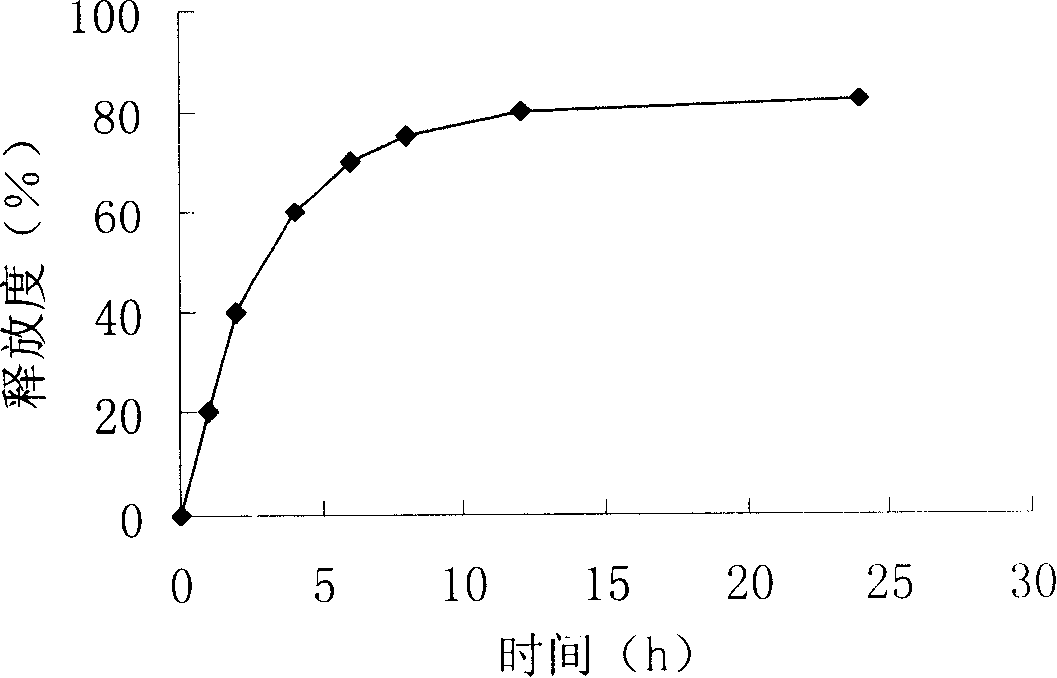

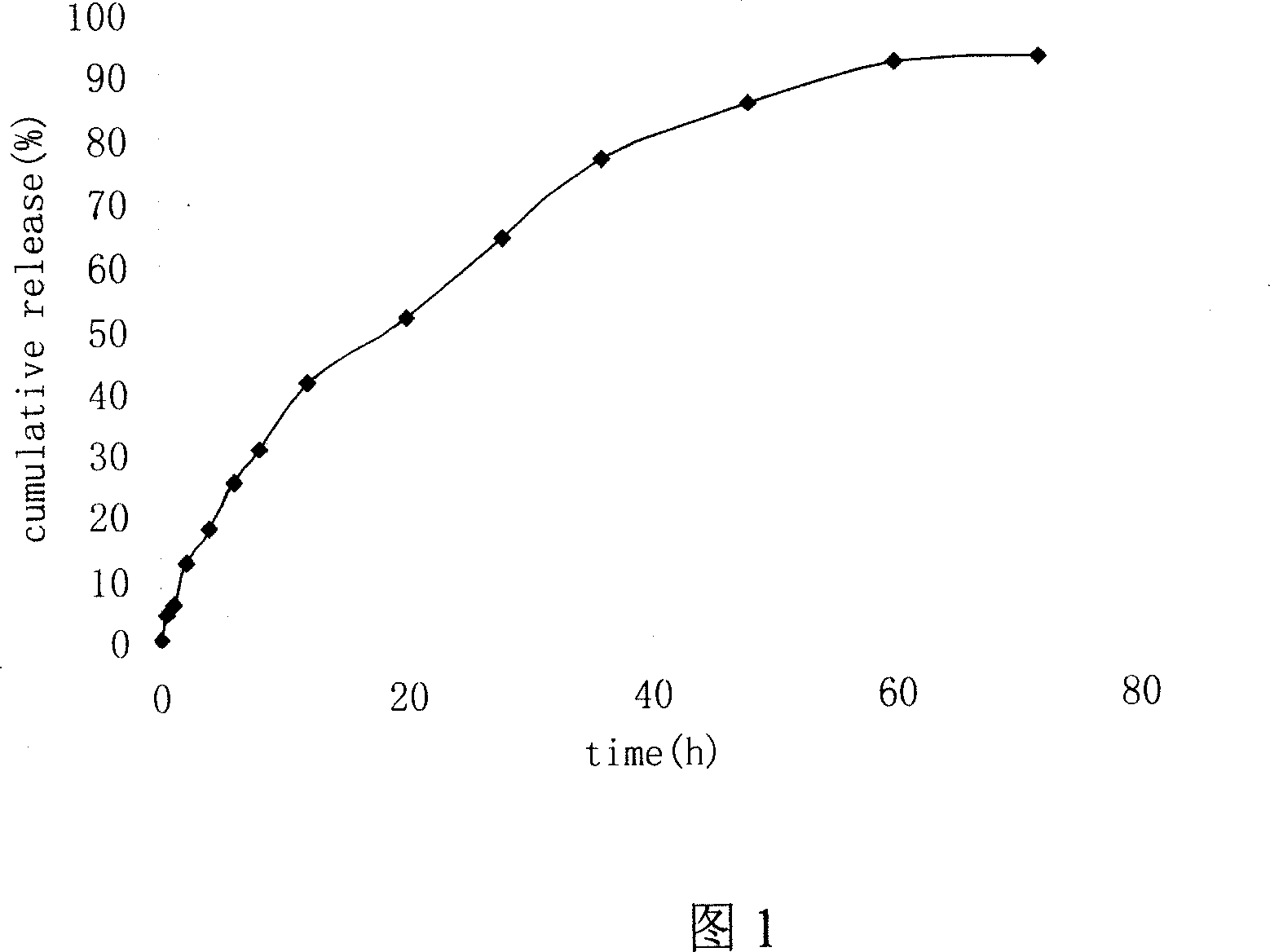

Long-circulating solid lipid docetaxel nanoparticles and preparation method thereof

InactiveCN101653414AGood water solubilityImprove stabilityOrganic active ingredientsAntineoplastic agentsLipid formationSolubility

The invention discloses long-circulating solid lipid docetaxel nanoparticles and a preparation method thereof. The long-circulating solid lipid docetaxel nanoparticles comprise the following materialsin therapeutic effective dose: docetaxel, lipid materials, long-circulating auxiliary materials and an emulsifier. The long-circulating solid lipid docetaxel nanoparticles have small particle size, high encapsulation rate and good stability, and not only improve the solubility and the stability of the docetaxel, reduce the toxicity of the docetaxel, but also prolong the circulating time of a medicament in blood, and improve the therapeutic index of the medicament, so that the preparation has the characteristics of low toxicity, low allergy, high efficiency and targeting in clinical application.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Third level Fabry-Perot cavity type tunable ray filter system

InactiveCN101533159AThe preparation process is matureWide filter spectrumNon-linear opticsPhysicsPolarizer

The invention discloses a third level Fabry-Perot cavity type tunable ray filter system, comprising two structures. The first structure comprises three Fabry-Perot cavities, wherein, the Fabry-Perot cavities are electrically tunable; the second structure comprises a polarizer, the three Fabry-Perot cavities and an analyzer, wherein, the Fabry-Perot cavities have the tunable effect only on the linearly polarized light which goes through the polarizer. The invention realizes continuously adjustable narrowband light-filtering within the wide spectral range by the reasonable design of the three Fabry-Perot cavities, the Fabry-Perot cavities have mature fabrication process, and the implementation of the whole system is convenient. The invention further has the characteristics of large aperture, simple assembling, wide light-filtering spectrum range and high spectral resolution, and can be applied in the fields of remote sensing, biomedicine, astronomical observation and the like.

Owner:ZHEJIANG UNIV

Slag glass ceramic pipe and preparation method thereof

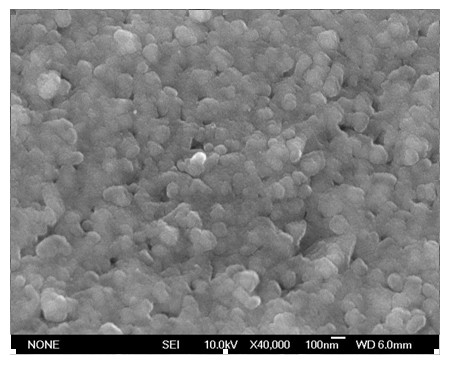

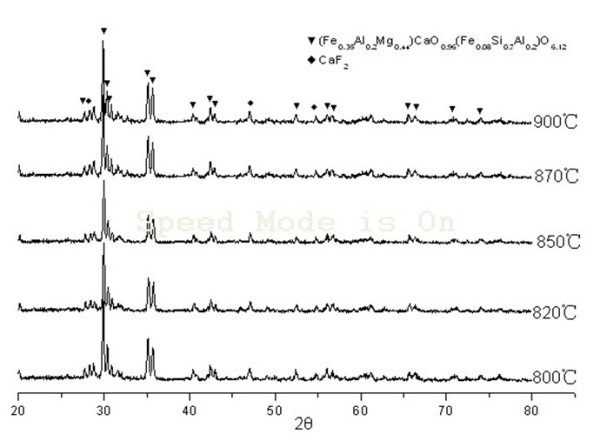

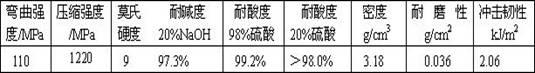

The invention relates to a glass ceramic pipe and a preparation method thereof. The glass ceramic pipe is prepared from the following raw materials in percentage by weight: 20 to 40 percent of coal ash, 20 to 50 percent of slag obtained by separating Baiyunebo tailings again, 0 to 40 percent of blast furnace slag or steel slag, 15 to 30 percent of quartz sand, 2 to 5 percent of sodium carbonate, 2 to 7 percent of borax, 0 to 5 percent of dolomite or lime stone, and 0 to 6 percent of albite or potash feldspar; and the preparation method comprises the following steps of: measuring the raw materials according to the ratio and then adding into a ball-milling mixing machine and mixing uniformly and melting the mixture at the temperature of between 1,350 and 1,450 DEG C; and performing centrifugal casting and molding; annealing, coring and crystallizing the molded pipe, and reducing the temperature at a speed of 1 to 5 DEG / min to the temperature of less than 100 DEG C and then discharging. The product has good performance, the abrasive resistance of the product is three times higher than that of a glass-ceramic tube, the weight of the product is only one third that of a glass-ceramic composite tube, the service life of the product is 3 to 5 times that of the glass-ceramic composite tube, and the cost performance of the product is high. The utilization rate of industrial waste residue in the raw materials is more than and equal to 70 percent, and the pipe is energy-saving and environment-friendly, has low production cost, is suitable for large-scale industrial production and has a wide application range.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

High-temperature-resistant radar and infrared compatible stealth coating and preparation method thereof

ActiveCN108212722ARealize integrationThe overall thickness is thinPretreated surfacesCoatingsLayered structureTemperature resistance

The invention relates to a high-temperature-resistant radar and infrared compatible stealth coating and a preparation method thereof. The high-temperature-resistant radar and infrared compatible stealth coating is of a layered structure, and sequentially comprises a metal bonding layer, a ceramic wave absorbing layer, a chip resistance type high-temperature periodic structure layer, a ceramic isolation layer and an infrared low-emissivity frequency selective surface layer from inside to outside; and the chip resistance type high-temperature periodic structure layer is a high-temperature resistance coating which is arranged in a periodic characteristic mode, and the infrared low-emissivity frequency selective surface layer is a high-temperature conductor coating which is arranged in a periodic characteristic mode. According to the radar and infrared compatible stealth coating, integration of the radar stealth function and the infrared stealth function is effectively achieved, the coating has both the radar stealth effect and the infrared stealth effect, and the defects that a traditional radar stealth coating cannot be compatible with the infrared stealth function, and the wave absorbing performance is not ideal are overcome; and the preparation method is simple and relatively mature, and is easy for large-scale production and application.

Owner:NAT UNIV OF DEFENSE TECH

Method for manufacturing EO-grade flame-proof, abrasion-proof, mildew resistant and moisture-proof veneer overlay wood veneer

InactiveCN101367219AThe preparation process is matureIncrease productivityAldehyde/ketone condensation polymer adhesivesWood veneer joiningMoistureMasking agent

The invention relates to a method for manufacturing E0 grade veneer overlaid plywood with inflaming retardance, abrasion resistance, rot resistance and moisture protection. The method comprises the following steps: selecting a dried veneer; rubberizing the veneer in two sides; assembling after rubberizing, with veneer structure layers being odd number; carrying out prepressing treatment after assembly; carrying out hot pressing treatment after the prepressing treatment; entering naturally cooling, depositing and sanding after the hot pressing treatment; coating masking agent, which is to apply aldehydeless gummy masking agent on a baseplate of the plywood to cover color difference of the baseplate surface to lead the baseplate surface to be in light yellow; applying E0 grade urea-formaldehyde resin adhesive on the baseplate by a pasting machine after the masking agent is dried; and pasting veneer on the baseplate, and carrying out abrasion-resistant treatment to the surface after hot pressing. The method has the advantages that the veneer overlaid plywood is an environment-friendly decoration material reaching E0 grade, has the functions of inflaming retardance, rot resistance, moisture protection and abrasion resistance, achieves the bonding strength of national standard, has mature manufacturing process, can implement industrial production so as to greatly improve the production efficiency and ensure product quality, and is convenient for popularization and application.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD +1

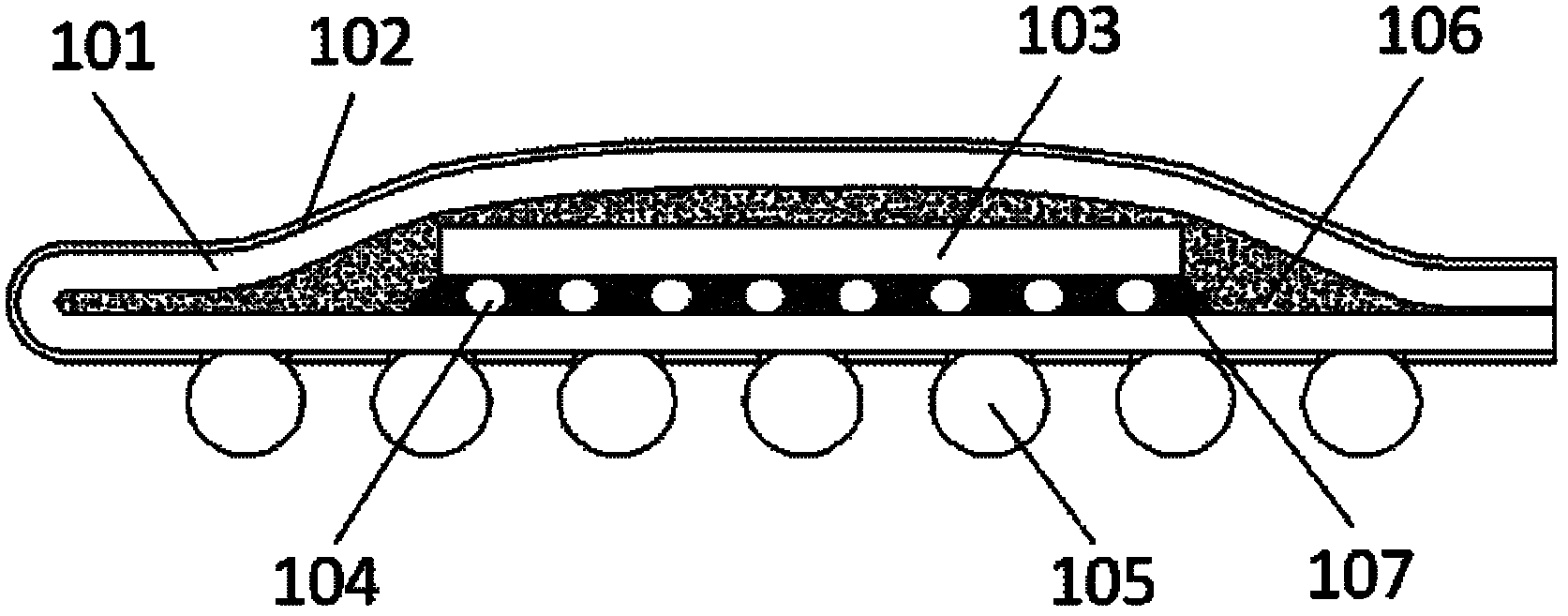

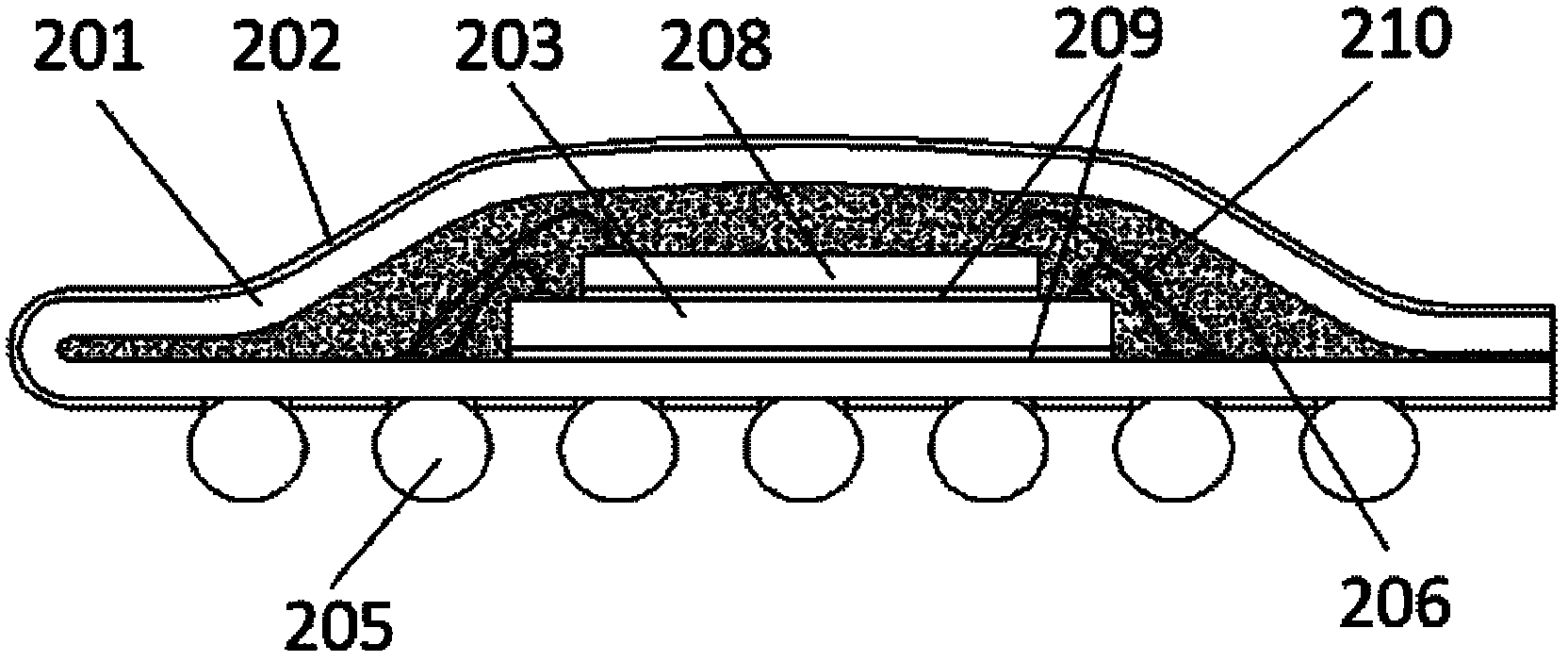

Flexible substrate package-based shielding structure and manufacturing process thereof

InactiveCN102254898AAchieve shieldingGuarantee the quality of signal transmissionMagnetic/electric field screeningSemiconductor/solid-state device detailsAdhesiveMiniaturization

The invention relates to a flexible substrate package-based shielding structure and a manufacturing process thereof. The shielding structure comprises a flexible substrate which is coated on a component, wherein a potting adhesive is filled between the flexible substrate and the component; at least one shielding layer is coated on the flexible substrate; the shielding layer is grounded or connected with a power supply; a plurality of packaging pins are arranged on an outer surface of the flexible substrate with the shielding layer; the packaging pins are electrically connected with the flexible substrate; and the flexible substrate is interconnected with a printed circuit board through the packaging pins. For the flexible substrate package-based shielding structure, the manufacturing process is basically mature, the packaging weight is light, and the sensitivity of a miniature packaging system can be effectively improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

High-resilience urethane elastic fiber as well as preparation method thereof

ActiveCN103436983AHigh reboundImprove the degree of microphase separation of soft and hard segmentsMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberEthylenediamine

The invention relates to a preparation method of a high-resilience urethane elastic fiber. The preparation method comprises the following steps: (1) mixing raw materials, namely, polytetramethylene ether glycol (PTMEG) and 4, 4-diphenylmethane diisocyanate (MDI) to carry out reaction so as to obtain a prepolymer; (2) adding a certain amount of a mixed diamine chain extender into the prepolymer to form polymer liquor; (3) quickly adding polyamine (the number of functional groups is greater than 2) into the polymer liquor while stirring to carry out reaction so as to form polyurethaneurea liquor; (5) carrying out reaction on MDI and polyether polyhydric alcohol and blocking with ethanediamine to prepare oligomers; (6) blending nano attapulgite with the oligomers to prepare a prepreg; and (7) mixing the polyurethaneurea liquor with the prepreg to prepare a spinning dope, and spinning to form the high-resilience urethane elastic fiber. The preparation method of the high-resilience urethane elastic fiber provided by the invention satisfies the demands on the high-resilience urethane elastic fiber in certain special fields, and the resilience of the urethane elastic fiber is improved.

Owner:ZHEJIANG HUAFENG SPANDEX

Preparation method and application of lycium barbarum fermented and concentrated juice

InactiveCN103704557AGreat tasteAdd flavorFood thermal treatmentYeast food ingredientsMaillard reactionAdditive ingredient

The invention particularly discloses a preparation method and the application of lycium barbarum fermented and concentrated juice. The method comprises the following steps: fermenting lycium barbarum with beneficial compound lactobacillus; performing natural placement and fermentation under the conditions of controlled temperature and controlled time; filtering and centrifuging fermented juice at high speed to obtain lycium barbarum fermented juice; performing film evaporation and concentration under the reduced pressure to obtain a lycium barbarum fermented and concentrated juice product. Lycium barbarum fermented powder can be prepared by performing spray drying or freeze drying, crushing and screening on the lycium barbarum fermented and concentrated juice product. According to the method, the previous section of the fermentation process is the fermentation process of the beneficial compound lactobacillus, and the subsequent section of the fermentation process is the process of temperature-control natural fermentation, namely the Maillard reaction; by the combination of probiotics and natural fermentation, the prepared product is good in taste and flavor, has rich nutritional ingredients, and can be applied to products of wine, soft drinks, solid drinks, seasonings, food and health food.

Owner:徐州绿之野生物食品有限公司

Novel electrode lead capacitive screen manufacturing method and its product and touch screen terminal

ActiveCN102279684AThere will be no disconnectionPrecise thickness controlInput/output processes for data processingPolyesterCapacitance

The invention is applicable to the technical field of touch screen production and provides a method for manufacturing a novel electrode lead capacitive screen, the novel electrode lead capacitive screen and a touch screen terminal. The method comprises the following steps of: (1) preparing an indium tin oxide (ITO) conductive film on a polyester (PET) base film; (2) preparing a copper film on the ITO conductive film by using a magnetically-controlled splutter coating method; (3) manufacturing ITO patterns, and forming an edge copper electrode lead at one time; (4) selectively etching the copper film on the middle ITO pattern, and reserving the ITO pattern to obtain PET thin film structures; and (5) sequentially adhering two PET thin film structures which are obtained in the step (4) and a piece of panel glass by using an optical adhesive to obtain the novel electrode lead capacitive screen. In the method for manufacturing the novel electrode lead capacitive screen provided by the invention, the magnetically-controlled splutter coating method is adopted to replace a silk-screening silver paste process to manufacture an electrode lead of a capacitive screen with mature technical means; and by the method, the good rate for manufacturing the capacitive screen having a film-film structure can be greatly improved, so that the manufacturing cost of the capacitive screen is saved.

Owner:深圳豪威显示科技有限公司

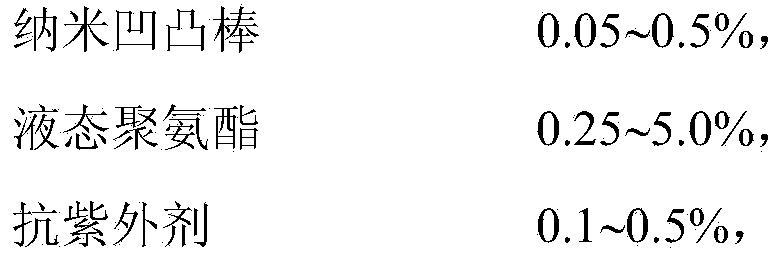

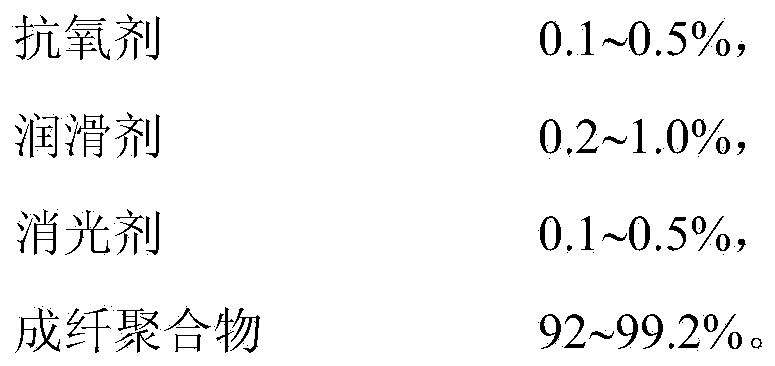

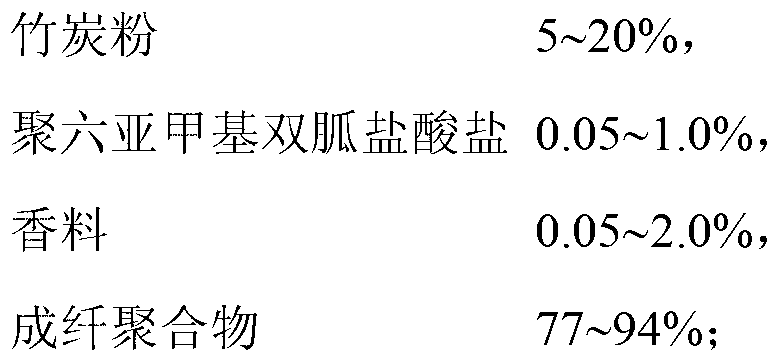

Antibacterial spandex fiber and preparation method thereof

InactiveCN104726961AWith antibacterial functionEasy to useWet spinning methodsConjugated synthetic polymer artificial filamentsAntioxidantAntibacterial agent

The invention discloses an antibacterial spandex fiber and a preparation method thereof. The antibacterial spandex fiber is prepared by combining a wrapper and a core part, wherein the section of the fiber is solid; the material of the core material is a polyurethane slice for melt spinning; the wrapper comprises the following raw materials in percentage by mass: 0.1-0.2% of a silver ion compound, 0.1-0.5% of an ultraviolet screening agent, 0.1-0.55 of an antioxidant,0.2-1.0% of a lubricant, 0.1-0.5% of a matting agent and 97.3-99.4% of fiber forming aggregate. The preparation method of the antibacterial spandex fiber comprises the following steps: 1 manufacturing an antibacterial spandex core part by a melt spinning technique according to the formula ratio; 2 manufacturing an antibacterial spandex wrapper by a wet-dry spinning technology according to the ratio; and 3 spinning by wet-dry spinning equipment and process through a special spinneret assembly, and thus preparing the antibacterial spandex fiber by a special coagulating bath. The preparation method of the antibacterial spandex fiber is simple in process; the antibacterial agent is low in amount, economical and practical; and the prepared antibacterial spandex fiber is stable and uniform in performance, broad-spectrum antibacterial and lasting in antibacterial effect.

Owner:ZHEJIANG HUAFENG SPANDEX

Health-care spandex fiber and preparation method thereof

ActiveCN103194819AGuaranteed stabilityGuaranteed physical propertiesFilament forming substance formingMelt spinning methodsMoistureMelt spinning

The invention provides a health-care spandex fiber which is formed by combining a wrapper and a core part, wherein the section of the fiber is solid; the mass percentage of the core part accounts for 30-70% of that of the fiber and the mass percentage of the wrapper accounts for 30-70% of that of the fiber; and a preparation method of the health-care spandex fiber comprises the following steps of: 1, preparing a health-care spandex core part by utilizing a melt spinning technology according to a formula proportion; 2, preparing a health-care spandex fiber wrapper by utilizing a dry-method spinning technology according to the proportion; and 3, spinning by utilizing a special spinneret plate combined piece through a conventional dry-method spinning equipment process so as to obtain a health-care spandex. The health-care spandex disclosed by the invention has the effects of eliminating the peculiar smell, absorbing the moisture and proofing moulds, and inhibiting bacteria and expelling parasites; the health-care spandex can be contacted with a human body to remove the humidity and absorb the sweat so as to accelerate the blood circulation and the metabolism of the human body and relieve fatigues; and the health-care spandex also has the aroma of plant essences, and furthermore is good in utilization performance and can meet the requirements on homespun in processes of spinning, weaving, dyeing and finishing.

Owner:ZHEJIANG HUAFENG SPANDEX

Neo-gambogic acid SLN (solid lipid nanoparticle) and preparation method thereof

InactiveCN101947204ALow toxicityImprove tolerancePowder deliveryOrganic non-active ingredientsLipid formationSolubility

The invention relates to a neo-gambogic acid SLN (solid lipid nanoparticle) and a preparation method thereof. The neo-gambogic acid SLN comprises a therapeutically effective amount of neo-gambogic acid, medicinal phosphatide, a surfactant and a lipid material. In the invention, the neo-gambogic acid is prepared into SLNs (solid lipid nanoparticles), thereby improving the solubility of the neo-gambogic acid, reducing the irritability, improving the bioavailability, and prolonging the action time of medicaments in a human body, in addition, the neo-gambogic acid SLNs can be gathered partially in the human body so as to play the targeted action of the SLNs and exert the anti-cancer therapeutic action of the SLNs better.

Owner:彭代银 +4

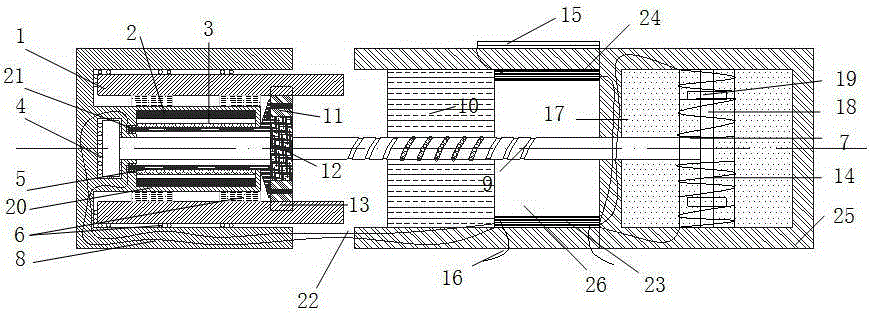

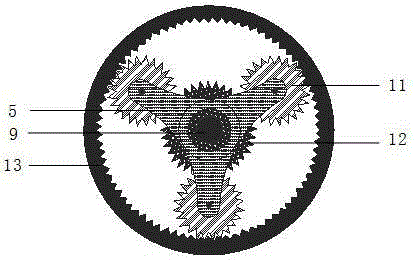

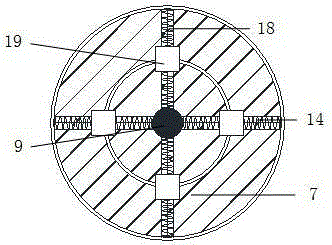

Variable rotating equivalent inertia mass damper

ActiveCN105221622AExtended use timeTransmission concept is clearInertia effect dampersModal damping ratioViscous damping

The invention relates to a variable rotating equivalent inertia mass damper which comprises a primary energy consumption element, a horizontal moving / rotating conversion device, a speed changing device, a secondary energy consumption element, a rotating mass unit, a control chip, circuits and the like. Through the horizontal moving / rotating conversion device, relative horizontal movement at the two ends of the damper is converted into high-speed rotation of a transmission shaft; through the speed changing device and the secondary energy consumption element, the transmission ratio, namely equivalent inertia mass is controlled; the primary energy consumption element and the secondary energy consumption element are adjusted in real time so that a needed equivalent viscous damping value can be reached. According to the variable rotating equivalent inertia mass damper, the equivalent inertia mass and viscous damping of the damper can be adjusted in real time to reach the needed optimum values; meanwhile, harvesting and storing of part of vibration energy are achieved so that part of electric energy needed by the control circuit and a working state indicating device can be provided. Through preliminary analysis, the modal damping ratio which is multiple times that of a traditional oil damper can be provided, and the variable rotating equivalent inertia mass damper can be applied to (but not limited to) vibration control of buildings, bridges, bridge cables, vehicles and the like and has good engineering application prospects.

Owner:TONGJI UNIV

Donepezils compound long-acting slow-releasing and controlled-releasing composition and preparation method thereof

InactiveCN101167697AReduce releaseImprove compliancePowder deliveryNervous disorderDonepezilProcess equipment

The invention discloses a long-acting sustained controlled release formulation of donepezil-like composition and a process for preparation. The composition is in the shape of micro-granular. According to the measurement by weight, the invention contains donepezil-like compounds 0.5-5 parts, carrier material of the sustained controlled release formulation 1-500 parts, and further contains other common excipient in pharmacy. The composition is used for anti senile dementia. The frequency of donepezil-like compounds is reduced, and the periodic time of administering medicament is prolonged, the compliance and conformability of the patient are improved, and the bioavailability and the therapeutic index of the donepezil are promoted. Meanwhile the invention discloses a plurality of processes for the preparation of long-acting sustained controlled release formulation of donepezil-like compounds. The process for preparation is flexible. Common processing equipment and commercial scale can be adopted. The production efficiency is high and the quality keeps steady. The invention can be directly or secondly used for making injection or medicament for oral administration.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Nanometer solid taxol lipoid particle and its prepn process

InactiveCN1931156ALow toxicityImprove toleranceOrganic active ingredientsPowder deliveryCancer cellActive agent

The present invention provides one kind of nanometer solid taxol lipoid particle capable of being used for injection and oral taking and its solid preparation, and features that taxol matter is coated with carrier material and surfactant so as to prepare nanometer solid taxol lipoid particle with small size, high coating rate, high stability, low toxicity and easy surface modification. The nanometer solid taxol lipoid particle has raised targeting effect on cancer cell, enhanced tumor cell killing effect, high curative effect, less toxic side effect, and reduced medicine resistance. The present invention also provides several preparation processes of nanometer solid taxol lipoid particle, and the preparation processes are simple, low in cost and suitable for industrial production.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

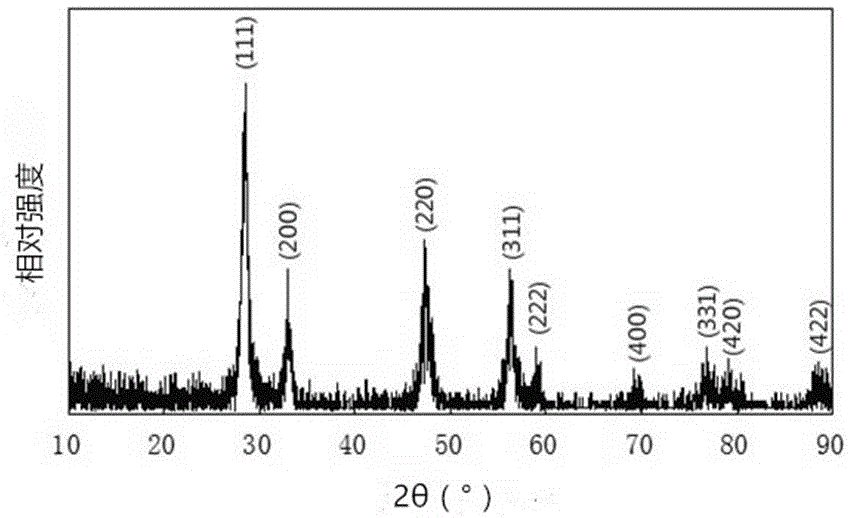

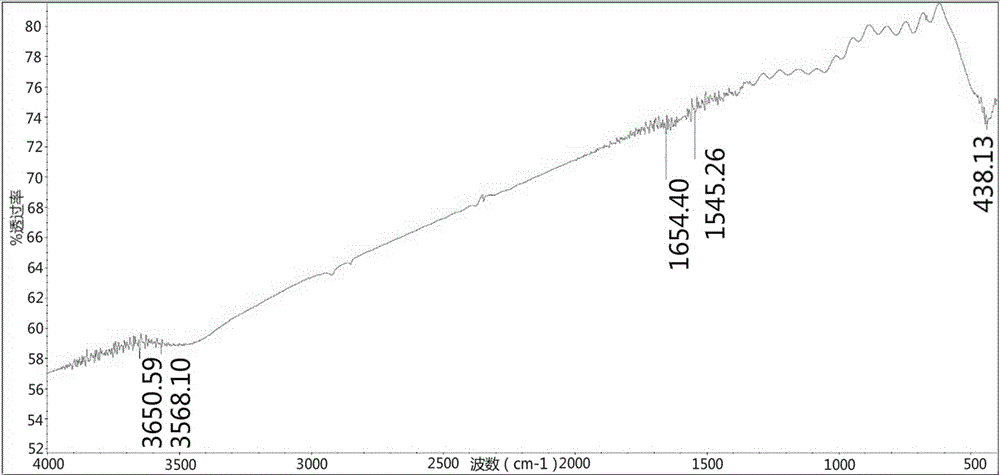

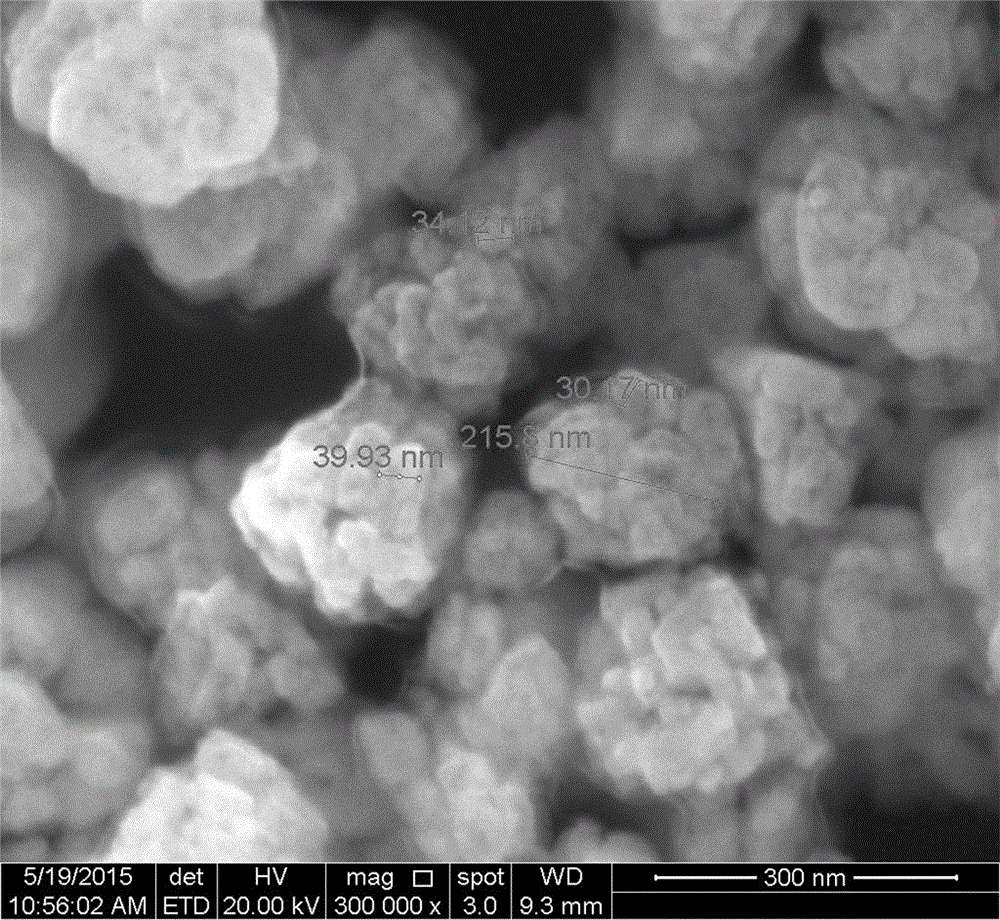

Mesoporous flower-shaped CeO2, as well as preparation method and application thereof

InactiveCN105731515AThe preparation process is matureEasy to operateRare earth metal oxides/hydroxidesMaterial nanotechnologyCeriumHigh pressure

The invention belongs to the technical field of water treatment, and relates to mesoporous flower-shaped CeO2, a preparation method thereof and an application thereof as mimic oxidase to degrade wastewater containing reactive light yellow. The mesoporous flower-shaped CeO2 is a hollow type crystal consisting of a plurality of small particles with an average particle diameter of 214 nm. The preparation method comprises the following steps: firstly, by adopting CeCl3.7H2O as a cerium source, adopting urea as a precipitator and adopting PVP as a surfactant, preparing a CeO2 precursor under high pressure at a high temperature through a hydrothermal method; and roasting the precursor at a high temperature, thereby preparing a light yellow CeO2 nano material. According to the TMB chromogenic reaction, the prepared CeO2 has characteristics of mimic enzyme. The mesoporous flower-shaped CeO2 is used for reactive light yellow catalytic degradation reaction, so that the degradation rate of the reactive light yellow can be about 95% under the optimum proportion condition, and therefore, the mesoporous flower-shaped CeO2 has relatively good application prospects.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

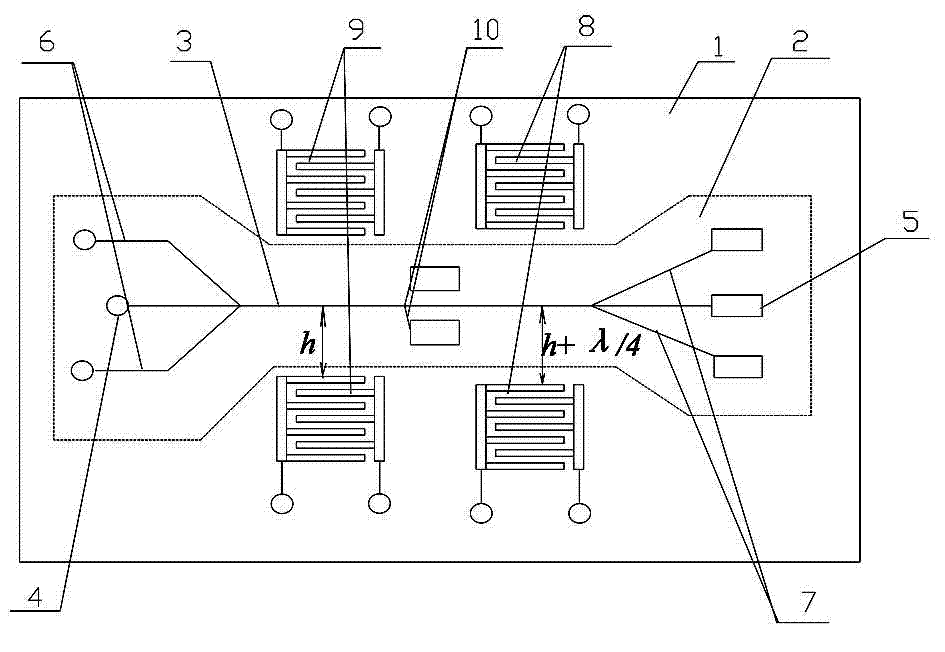

Surface acoustic micro-fluidic chip for tumor cell separation

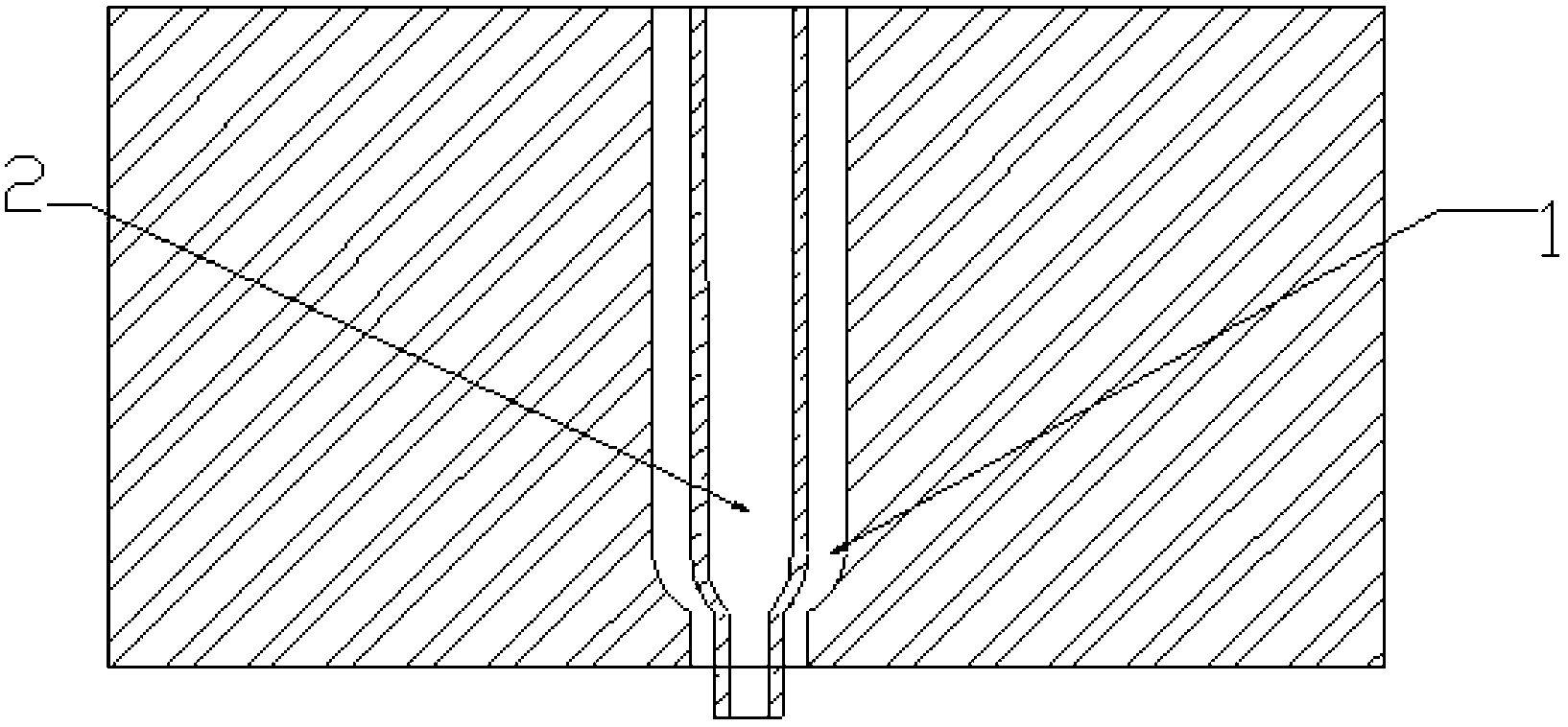

InactiveCN103667051ALow costThe preparation process is matureBiomass after-treatmentStress based microorganism growth stimulationStanding waveMicro fluidic

The invention discloses a surface acoustic micro-fluidic chip for tumor cell separation. The chip comprises a substrate, and a cover plate adhered on the substrate and provided with a micro-channel, wherein the micro-channel comprises a middle channel with an inlet and an outlet; cell sap injection channels connected with the inlet are arranged on two sides of the inlet; cell collection channels connected with the outlet are arranged on two sides of the outlet; two pairs of interdigital converters with identical frequencies and sound intensities are sequentially deposited on the substrate on two sides of the middle channel between the injection channel and the collection channel; the distance from the second pair of the interdigital converters to the middle channel is a quarter of surface wave length larger than that from the first pair of the interdigital converters to the middle channel; and small cell collection channels are symmetrically arranged on two sides of the middle channel between the two pairs of the interdigital converters. The chip has the advantages that a standing wave surface sound wave technology is realized, efficient, economic and pollution-free separation of tumor cell (CTCs) is realized, simultaneously the chip is low in cost, and the preparation technology is mature.

Owner:河南省医药科学研究院

Additive for electronic cigarette liquid, and preparation method thereof

ActiveCN104531351AIncreased roasted aromaExtended service lifeTobacco treatmentEssential-oils/perfumesBiochemical engineeringElectronic cigarette

The invention relates to the technical field of electronic cigarette preparation, and specifically relates to an additive for electronic cigarette liquid, and a preparation method thereof. The electronic cigarette liquid additive preparation method comprises the steps of raw material pretreatment, solvent leaching, solid-liquid separation, reduced-pressure concentration, molecular distillation, and the like. The method is developed based on problems of weak smoke incense and poor mouthfeel of existing electronic cigarettes in the market. As a result of detection experiments, with the additive, electronic cigarette baking incense can be substantially improved, such that the aroma and mouthfeel of the electronic cigarette are closer to those of traditional cigarettes. Also, doses of other essences and flavorings can be reduced, such that a safety risk caused by large doses of essences and flavorings is avoided. Therefore, the additive and the preparation method have good technical effects. With the additive, electronic cigarette service life can be prolonged. The preparation process is mature and is easy to operate, and production cost is relatively low. Therefore, the additive and the method have good practical popularization significance.

Owner:CHINA TOBACCO HENAN IND

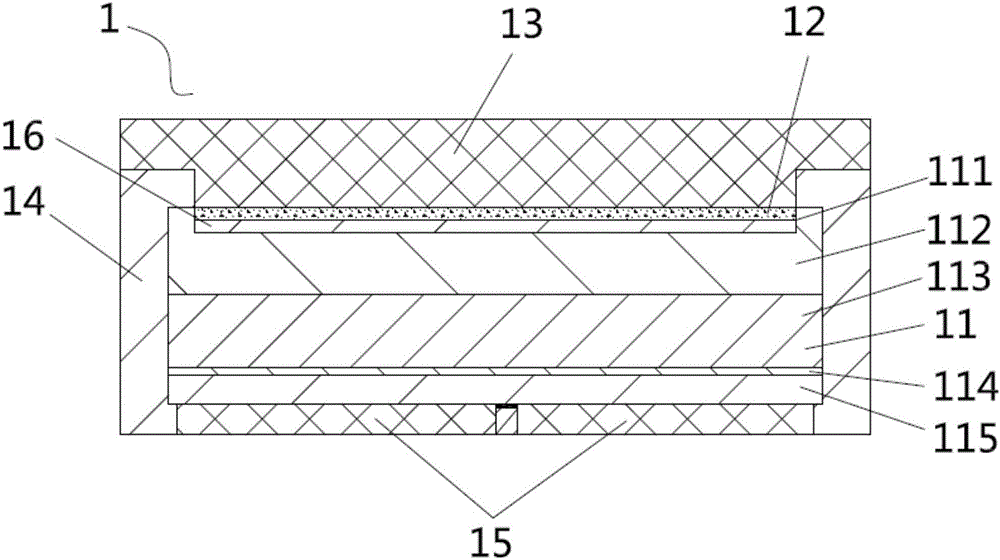

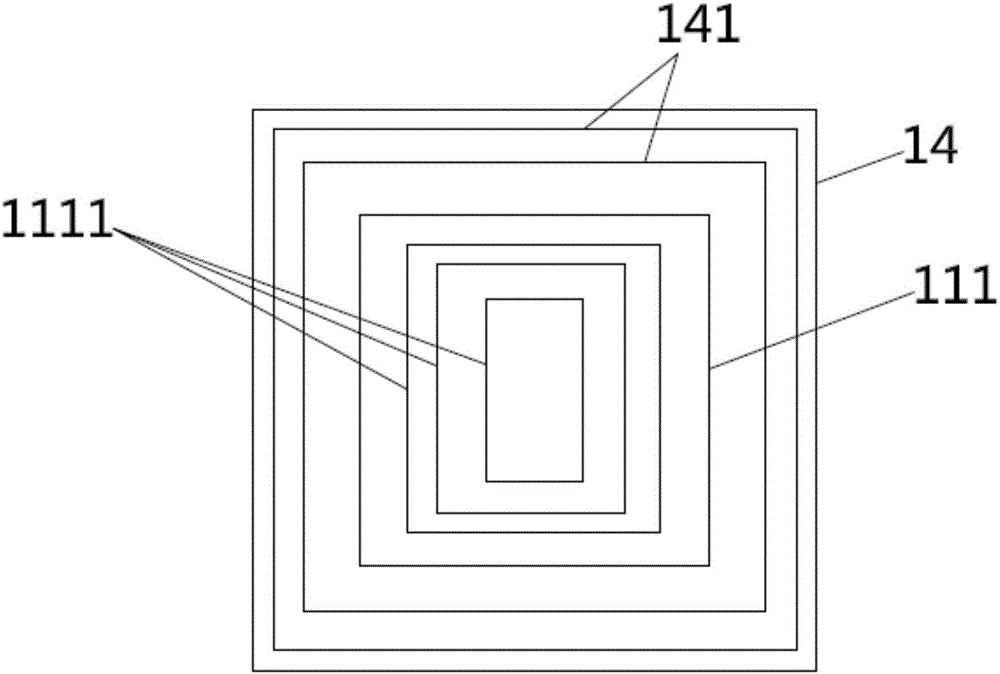

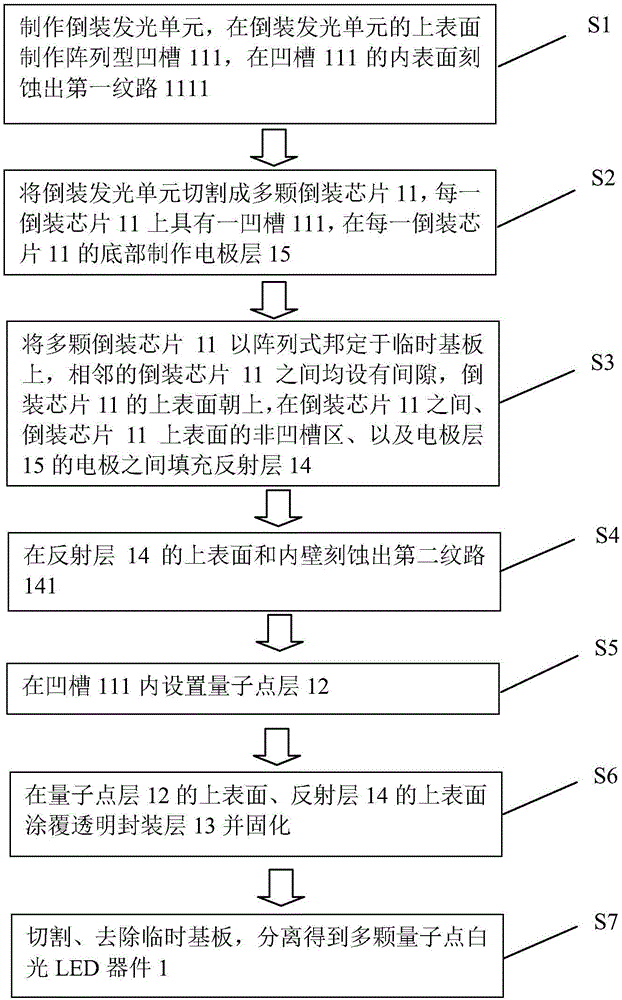

Quantum dot white light LED device and preparation method therefor

ActiveCN106505134AImprove reliabilityExtended service lifeSemiconductor devicesQuantum dotReflective layer

The invention discloses a quantum dot white light LED device. The quantum dot white light LED device comprises a flip chip, a quantum dot layer, a transparent packaging layer, a reflective layer and an electrode layer, wherein a groove is formed in the upper surface of the flip chip; first lines are arranged on the inner surface of the groove; the quantum dot layer is arranged in the groove; the electrode layer is arranged at the bottom of the flip chip; the reflective layer coats the side wall of the flip chip, a non-groove region on the upper surface of the flip chip, and the side wall of the electrode layer; the spaces between electrodes of the electrode layer is filled with the reflective layer; second lines are arranged on the upper surface and the inner wall of the reflective layer; and the exposed region of the quantum dot layer and the upper surface of the reflective layer are coated with the transparent packaging layer. The invention also correspondingly discloses a preparation method for the quantum dot white light LED device. The quantum dot white light LED device is high in airtight property, excellent in heat dissipation, high in reliability, and high in color rendering; and the preparation method is free of a packaging link, simple in preparation process and easy to implement, mature, and high in preparation efficiency.

Owner:APT ELECTRONICS

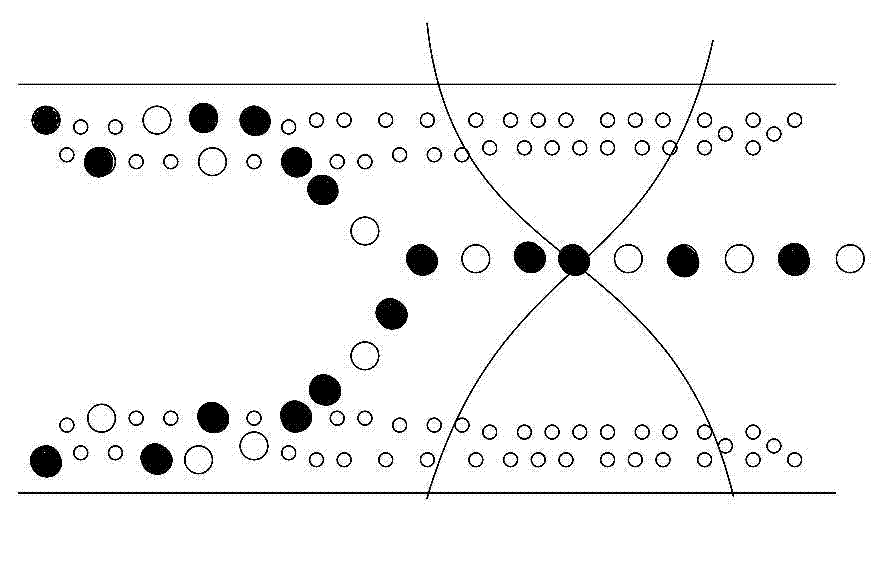

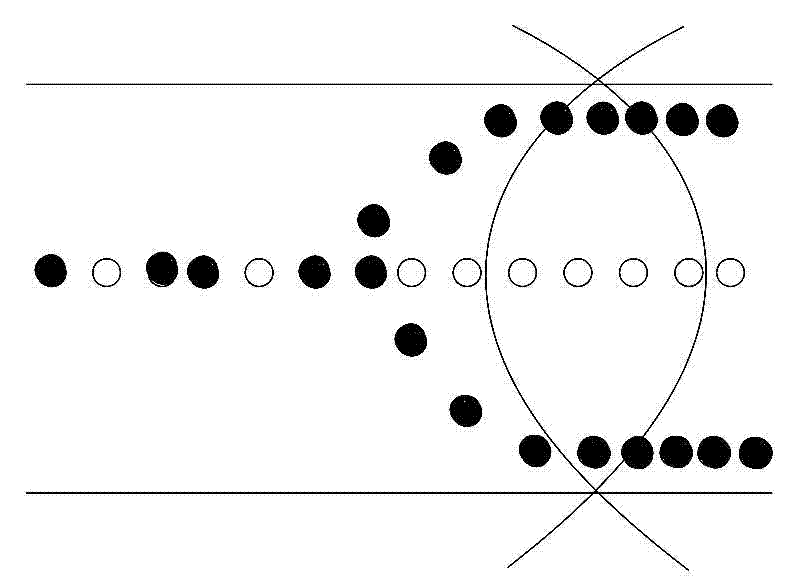

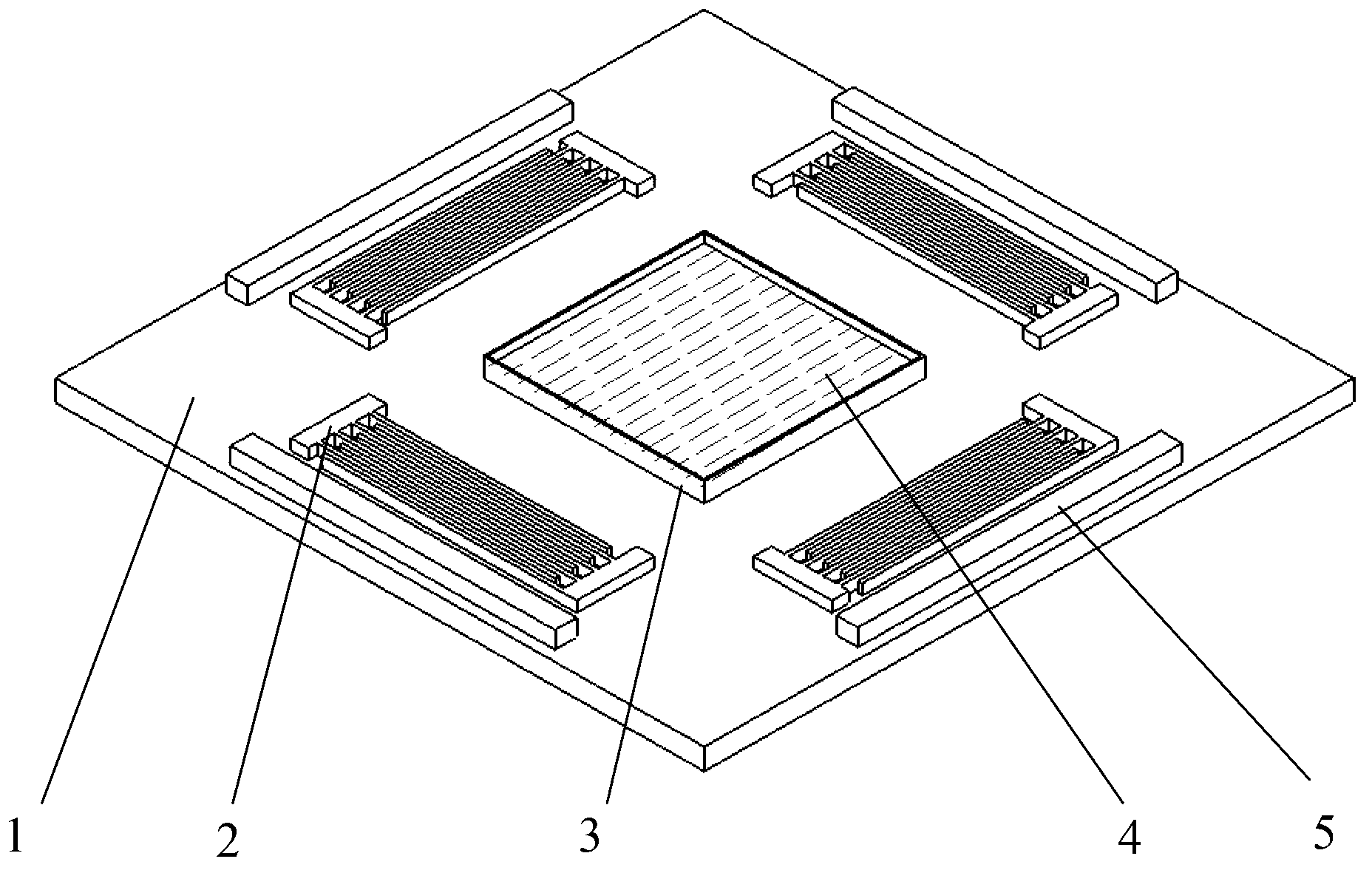

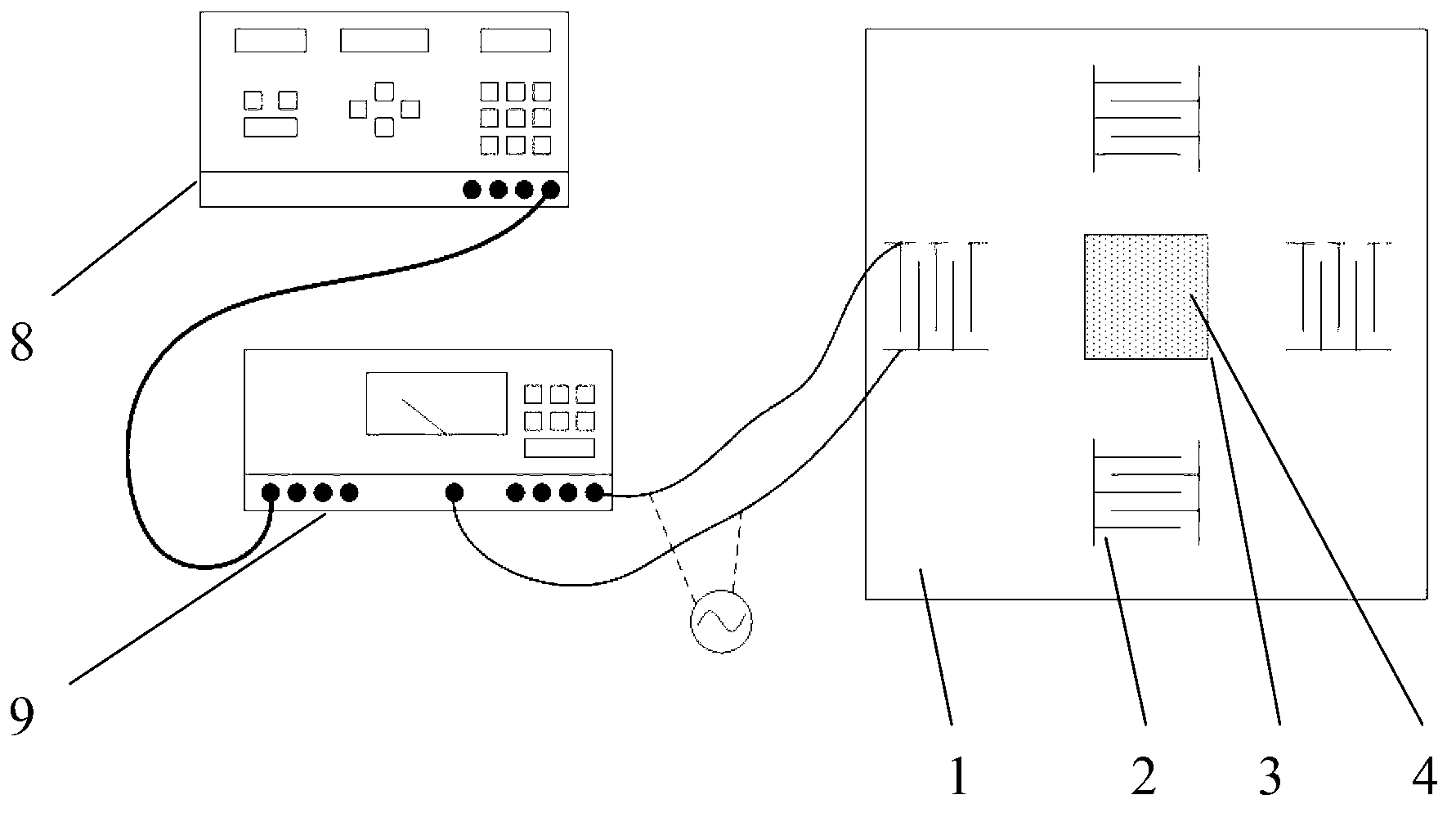

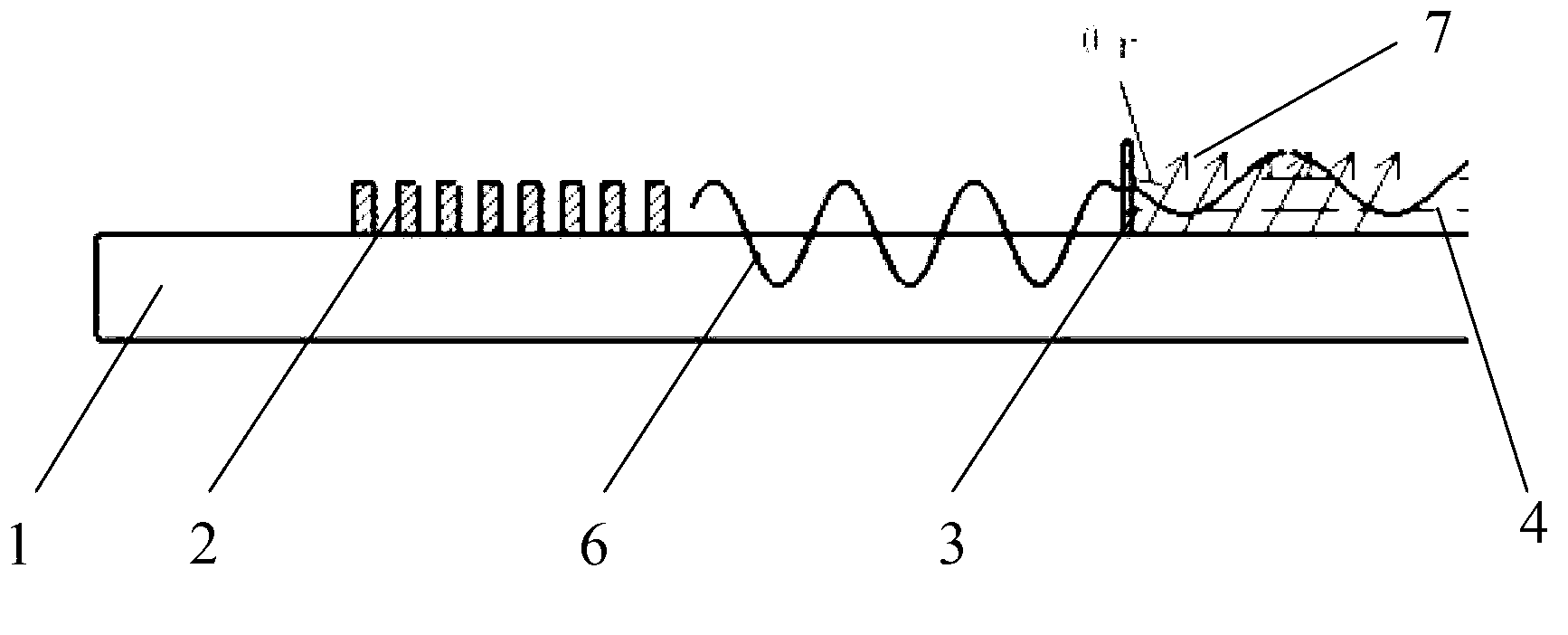

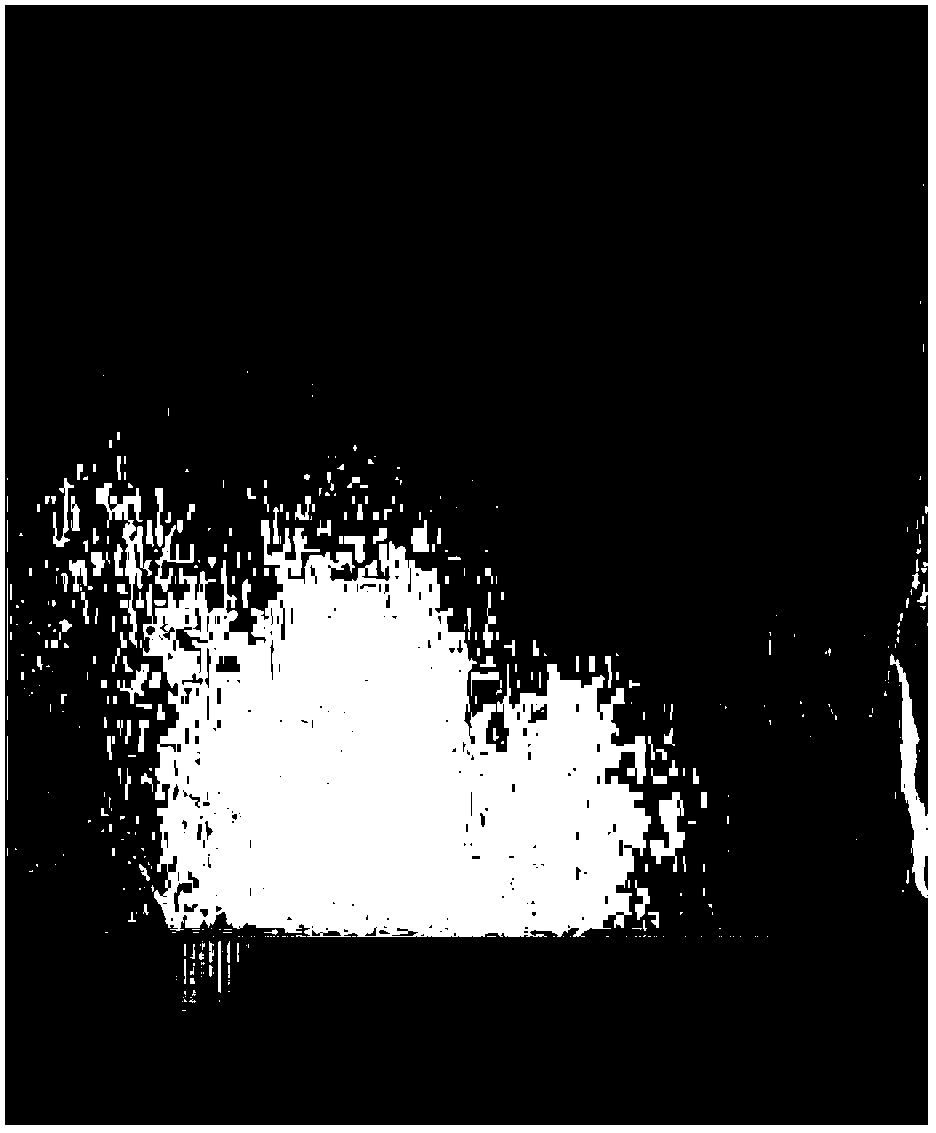

Microarray die-free forming device based on surface acoustic wave and forming method

The invention discloses a microarray die-free forming device based on a surface acoustic wave and a forming method. The technical scheme is that a square piezoelectric matrix plate is provided with two pairs of interdigital transducers in a photoetching manner, each pair of interdigital transducers is symmetrically arranged with a center shaft of the square piezoelectric matrix plate as an axis, a square glass fluid tank is placed in the middle of the piezoelectric matrix plate and adhered to the piezoelectric matrix plate, and a formed liquid-state material is accommodated in the glass fluid tank. An ultrasonic surface wave is transmitted in the piezoelectric matrix plate, the energy of the ultrasonic surface wave is leaked into the formed liquid-state material within a certain angles to form a sound field, a signal generator and a power amplifier are adjusted to change amplitude values, frequency and phases of the ultrasonic surface wave, so that a required stable microarray structure is formed on the surface of the formed liquid-state material, and the microarray structure is cured and formed through ultraviolet irradiation. The microarray die-free forming device based on the surface acoustic wave and the forming method have the advantages that the sound field is adopted to manufacture the surface microarray structure through rapid forming in the liquid-state material, the die is not required, the manufacturing process is simple, the equipment requirement is low, the operation is simple and convenient, the production cost is low, and the material usage rate and the production efficiency are high.

Owner:ZHEJIANG UNIV

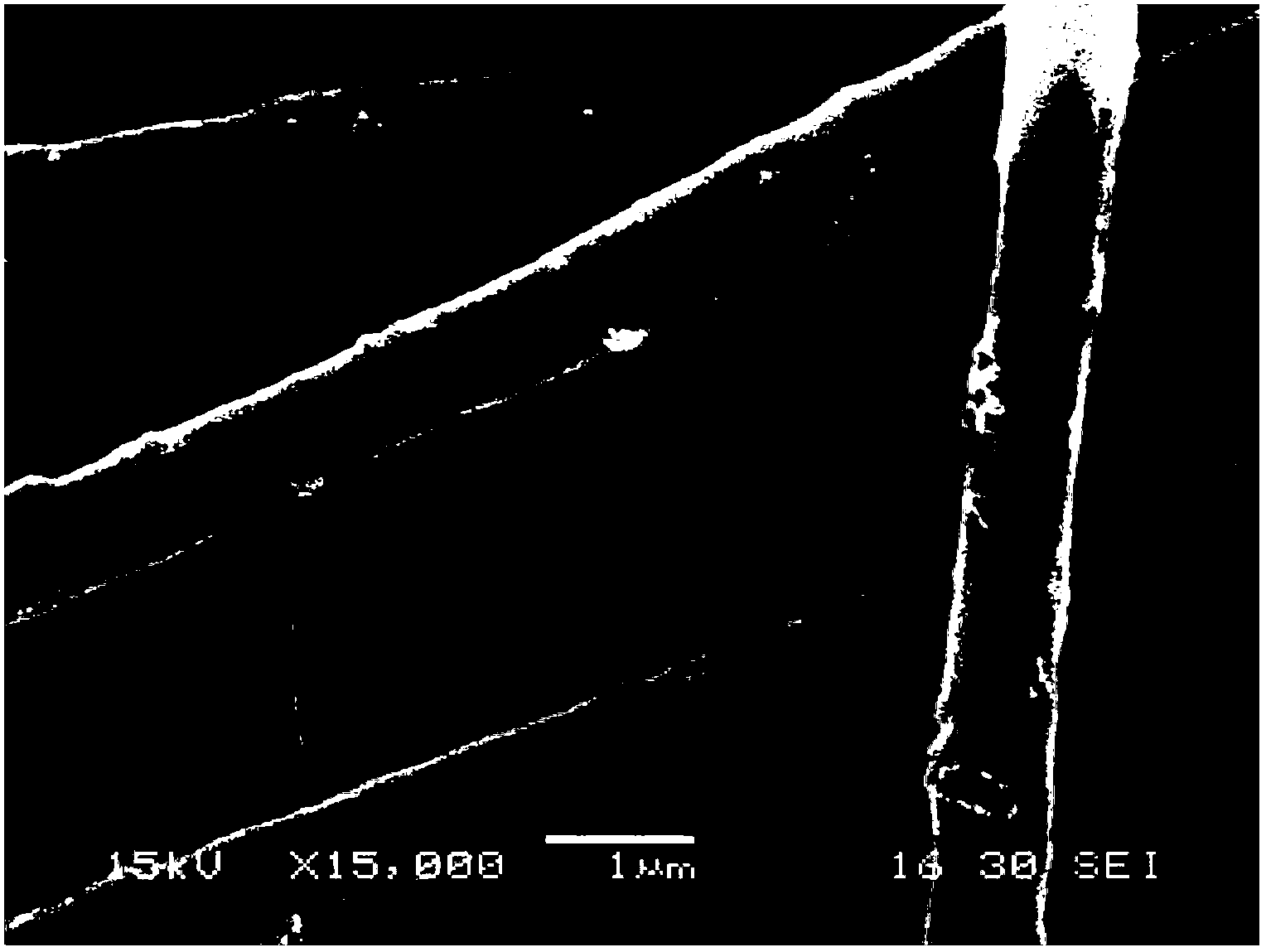

Preparation method of polymer nanofiber membrane containing perfluorinated sulfonic acid

InactiveCN103469352AOutstanding FeaturesHighlight significant progressFilament/thread formingConjugated synthetic polymer artificial filamentsPorosityN dimethylformamide

The invention relates to a preparation method of a polymer nanofiber membrane containing perfluorinated sulfonic acid. The method comprises four steps: (1) preparing an organic solution containing perfluorinated sulfonic acid and dispersed polymers, by using N, N-dimethylformamide, N, N-dimethylacetamide or dimethyl sulfoxide as a solvent; (2) adding organic small molecular alcohol or an inorganic nanoparticle additive into the above organic solution to prepare an organic blend solution containing perfluorinated sulfonic acid or an organic-inorganic suspended system; (3) preparing a polymer or polymer inorganic nanofiber membrane containing perfluorinated sulfonic acid; and (4) subjecting the obtained nanofiber membrane to acid and alkali treatment to obtain a porous nanofiber membrane with rough surface. The invention has the characteristics of mature and simple preparation process; and the obtained perfluorinated sulfonic acid nanofiber membrane has uniform and controllable distribution of size, high specific surface area, high porosity, good mechanical properties, and overcomes the defects of a traditional perfluorinated sulfonic acid membrane, such as easy swelling in a wet state and easy brittle cracking in a dry state.

Owner:EAST CHINA UNIV OF SCI & TECH

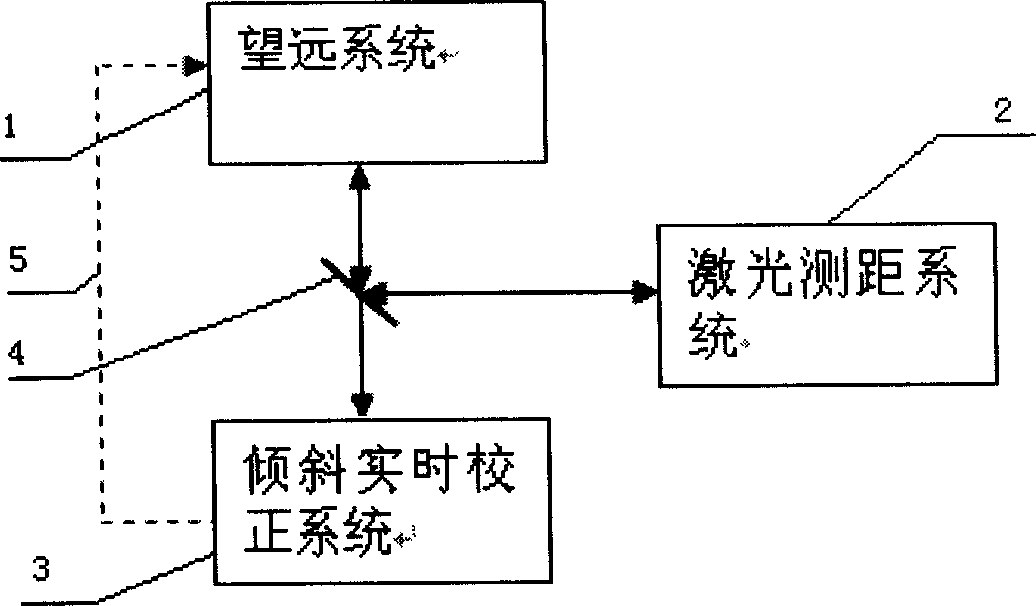

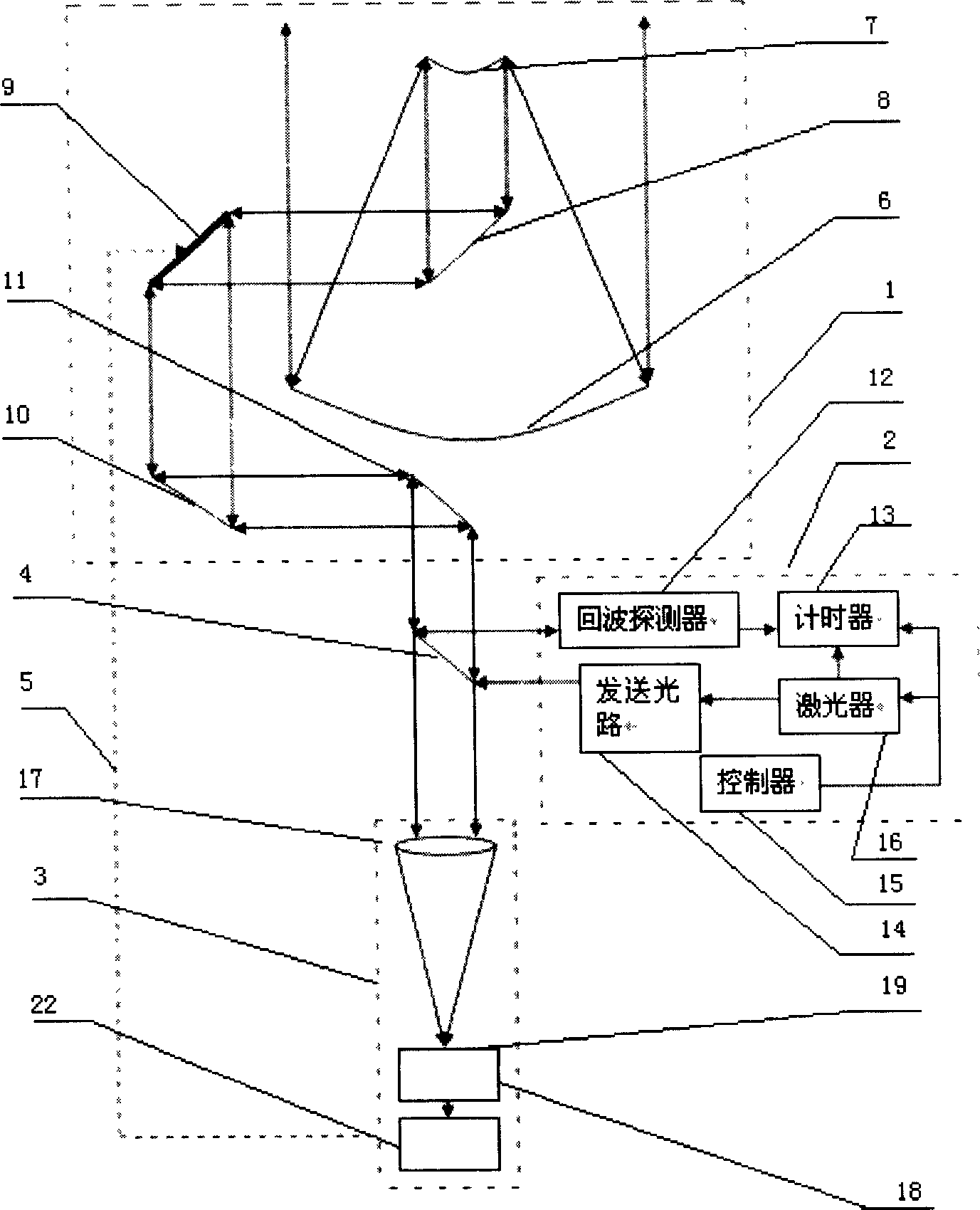

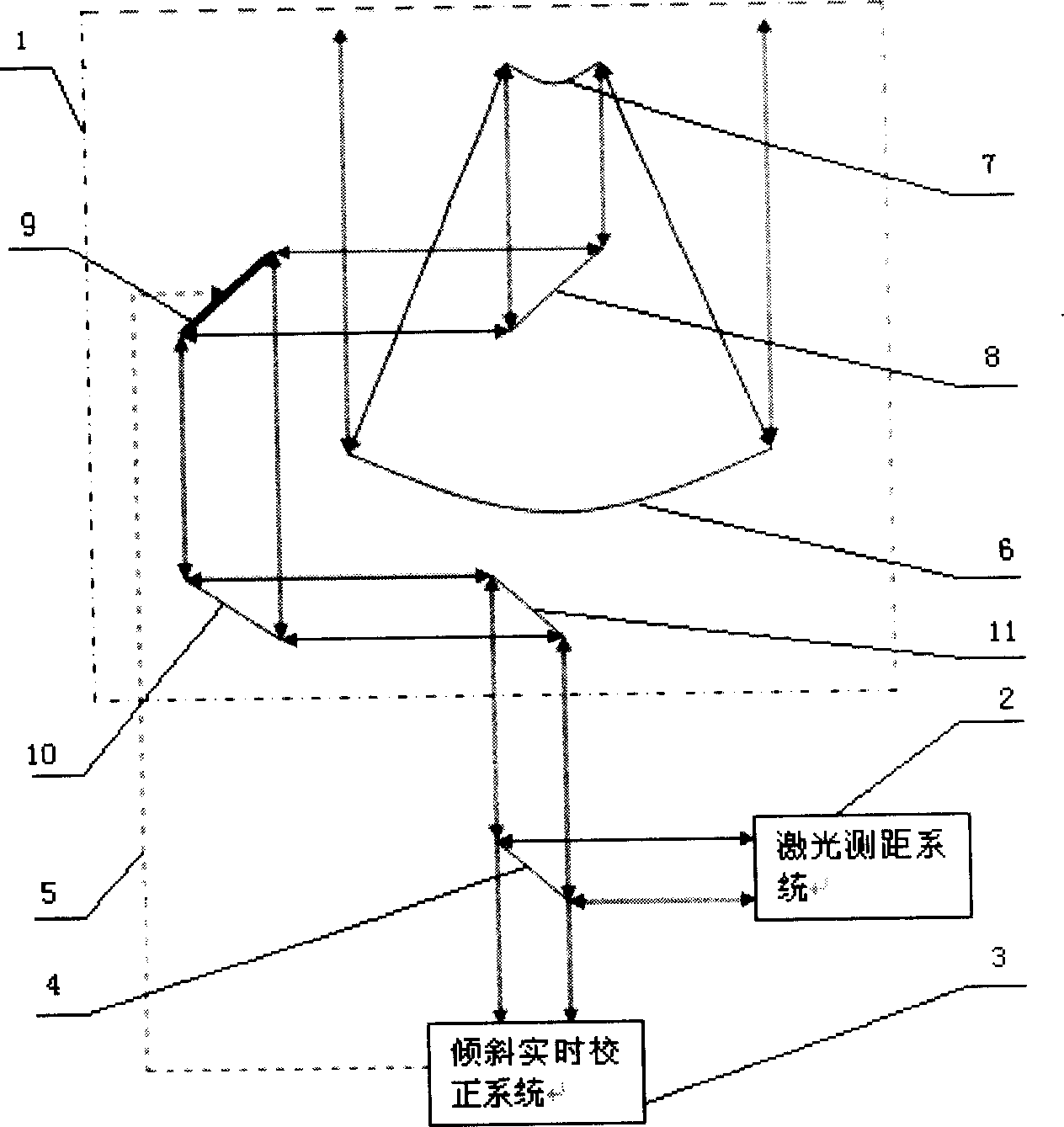

Satellite laser range-measurement system based on tilt correction

InactiveCN1831559AHigh precisionAchieve real-time closed-loop correctionElectromagnetic wave reradiationSatellite laser rangingControl signal

A satellite laser distance measurement system based on tilt calibration is featured as setting high speed tilt reflector in telescoping unit, using tilt tracking transducer to carry out wave front detection on light wave received by receiving telescope, outputting calibration control signal to high speed tilt mirror in telescope by high speed processor after error signal is restored, starting up satellite laser distance measurement system in telescoping unit to send out laser with specific wavelength for carrying out satellite laser distance measurement after tilt closed loop real time calibration is finished.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

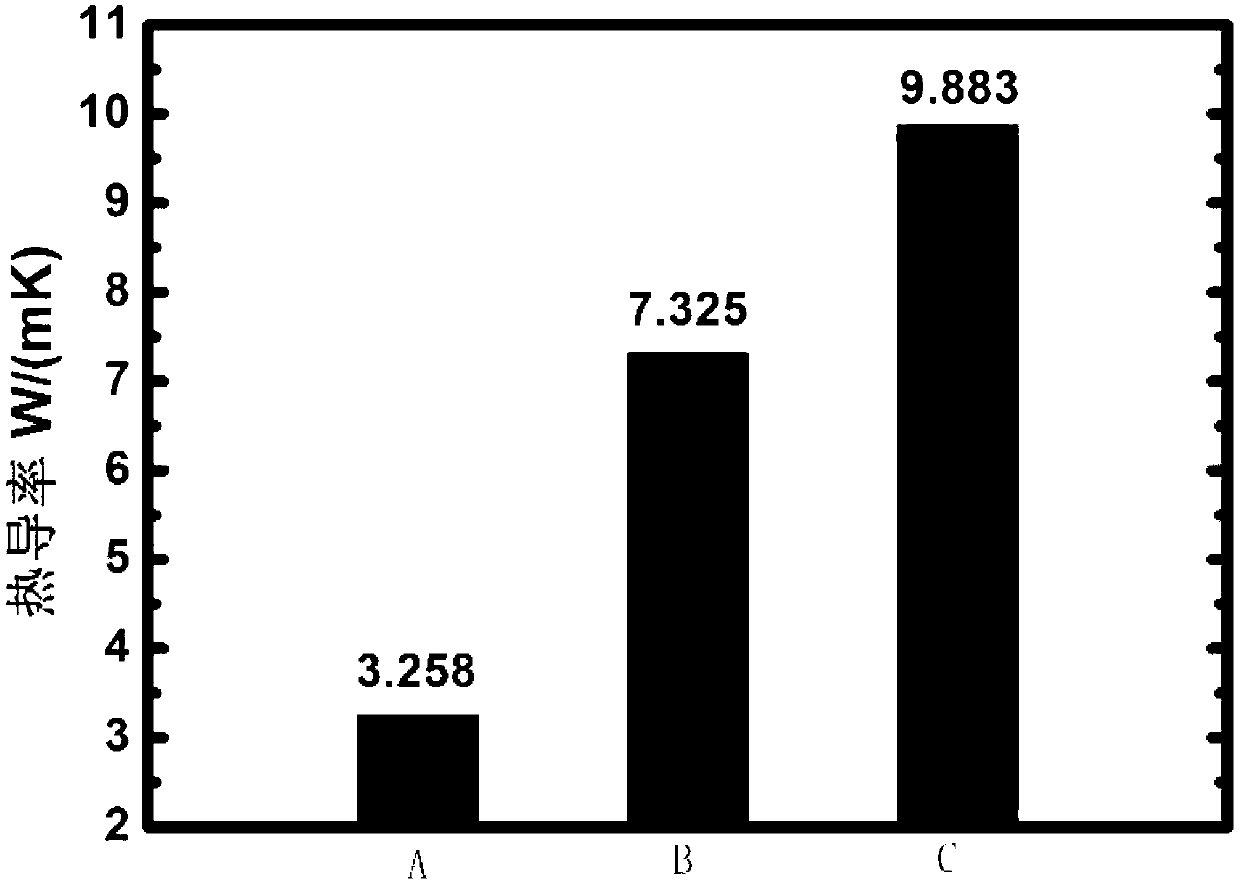

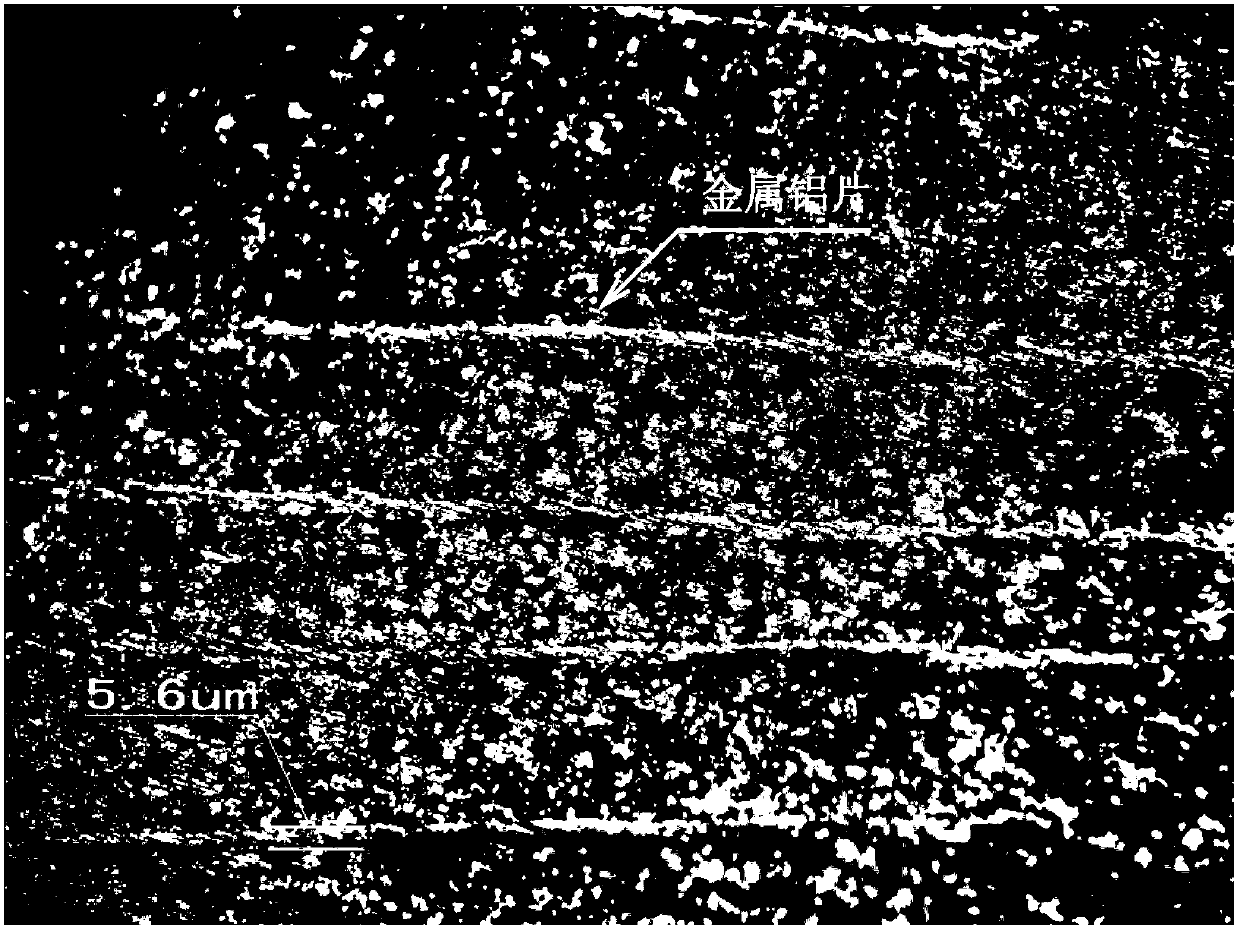

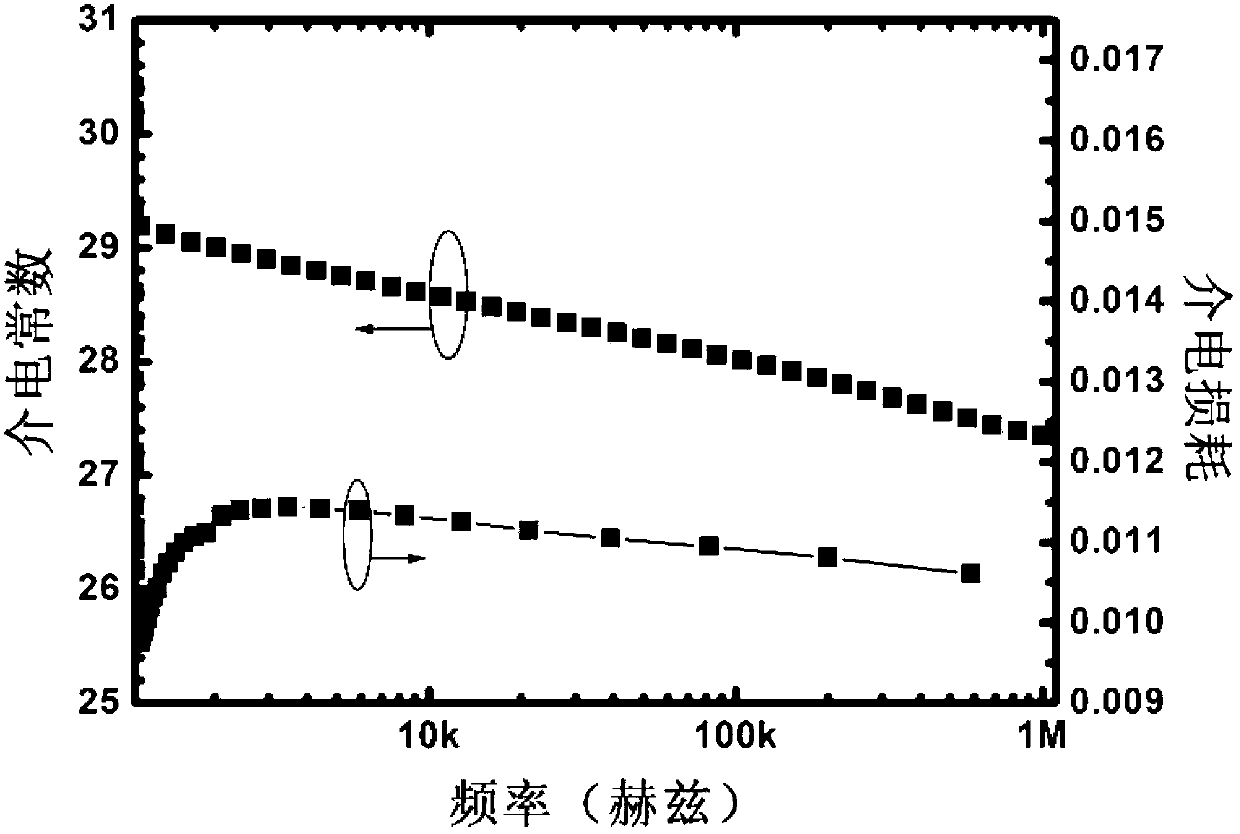

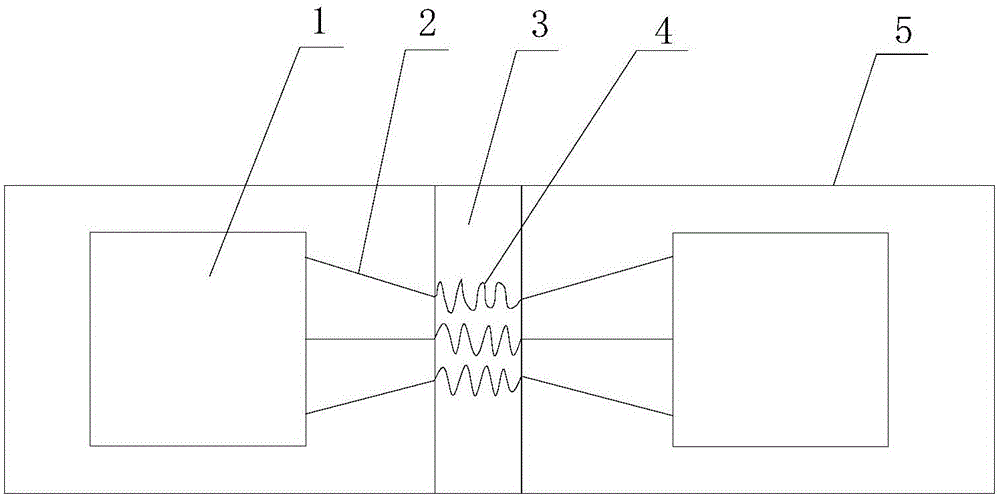

Polymer-matrix composite material and preparation method thereof

The invention provides a polymer-matrix composite material and a preparation method thereof, which belong to the technical field of preparation of electronic composite materials. The composite material is prepared from metal passivation fillers and polymer materials with different shapes, wherein the fillers are metal passivation particles and fibrous or platy metal with two grain sizes, which are matched with each other at a certain proportion, and according to the formula, the volume ratio of polymer is that the metal filler accounts for 1%-50% and the polymer accounts for 50%-99%. The composite material prepared from the metal passivation fillers with the different shapes and the polymer matrix has the advantages of high heat conductivity, low dielectric constant, low dielectric loss and the like. The preparation method has the characteristics of low heat treatment temperature, low cost and environment friendliness, and also has the characteristics of being simple to operate and suitable for industrial production.

Owner:XI AN JIAOTONG UNIV

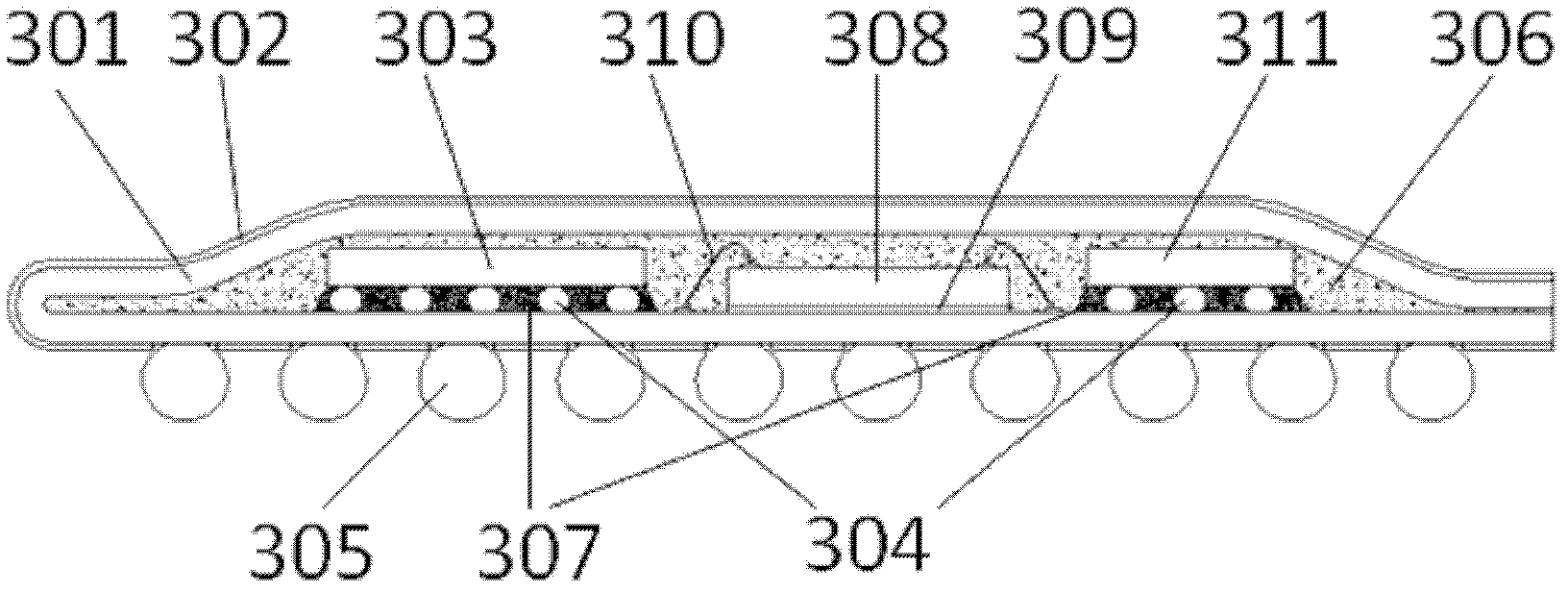

Packaging flexible substrate and packaging body

InactiveCN105047676ASimple structureThe preparation process is matureSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringBiomedical engineering

The invention relates to the technical field of display, and specifically relates to a packaging flexible substrate and a packaging body. The middle of the packaging flexible substrate is provided with a bending area. The two ends of the flexible substrate are respectively provided with a chip. Wires passing through the bending area are connected between the chips. Each wire is provided with a stress-resistant structure in a section corresponding to the bending area, and the stress-resistant structure is used to release anti-tensile and anti-compression stress when the bending area bends. Therefore, the reliability of the wires in the process of flexible substrate 3D stacked packaging bending is improved, and the problems greatly affecting the packaging performance and reliability, such as wire breakage or wire and substrate separation during use of the existing flexible substrate, are solved effectively. The packaging flexible substrate is simple in structure, convenient to operate, and suitable for popularization and application.

Owner:BOE TECH GRP CO LTD

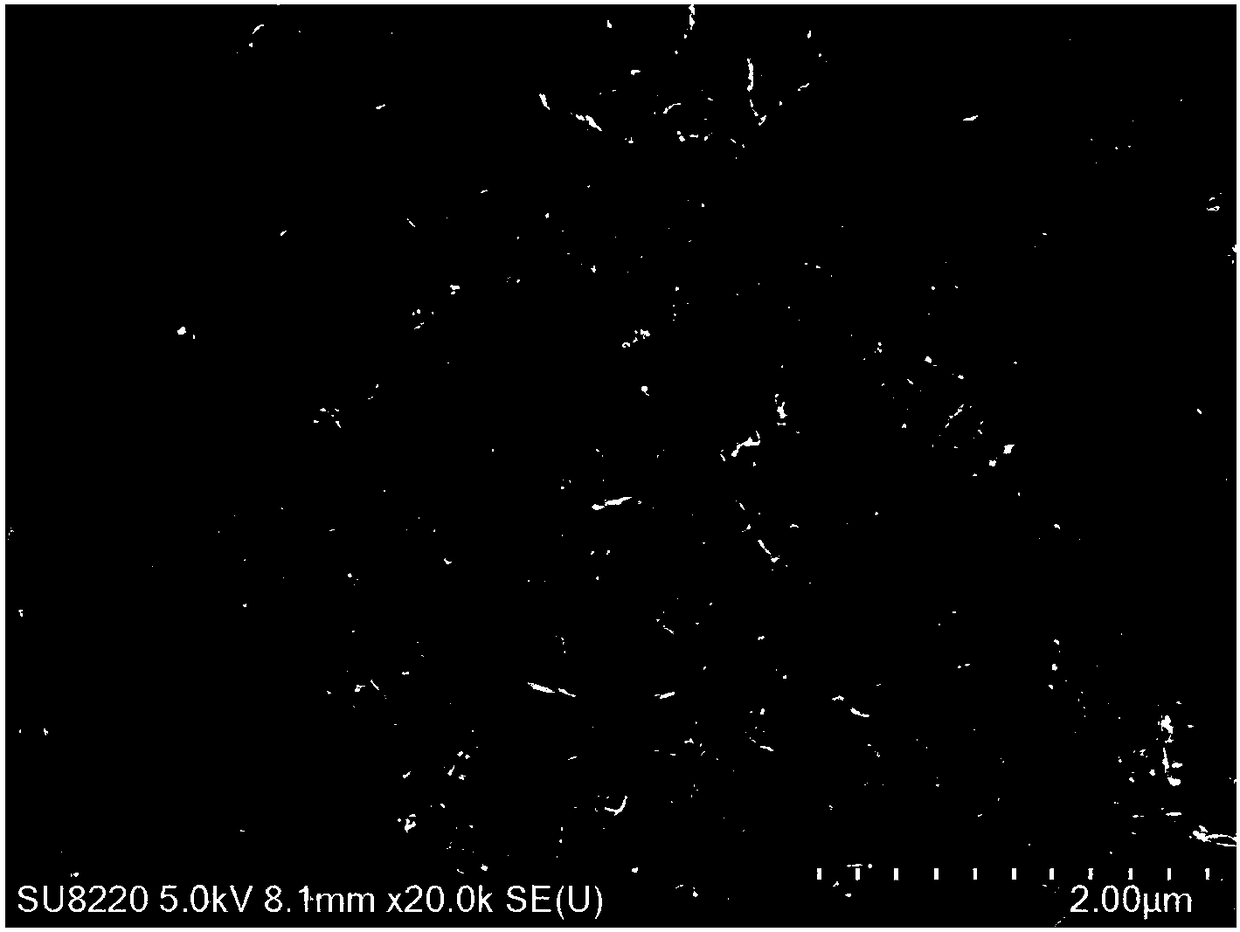

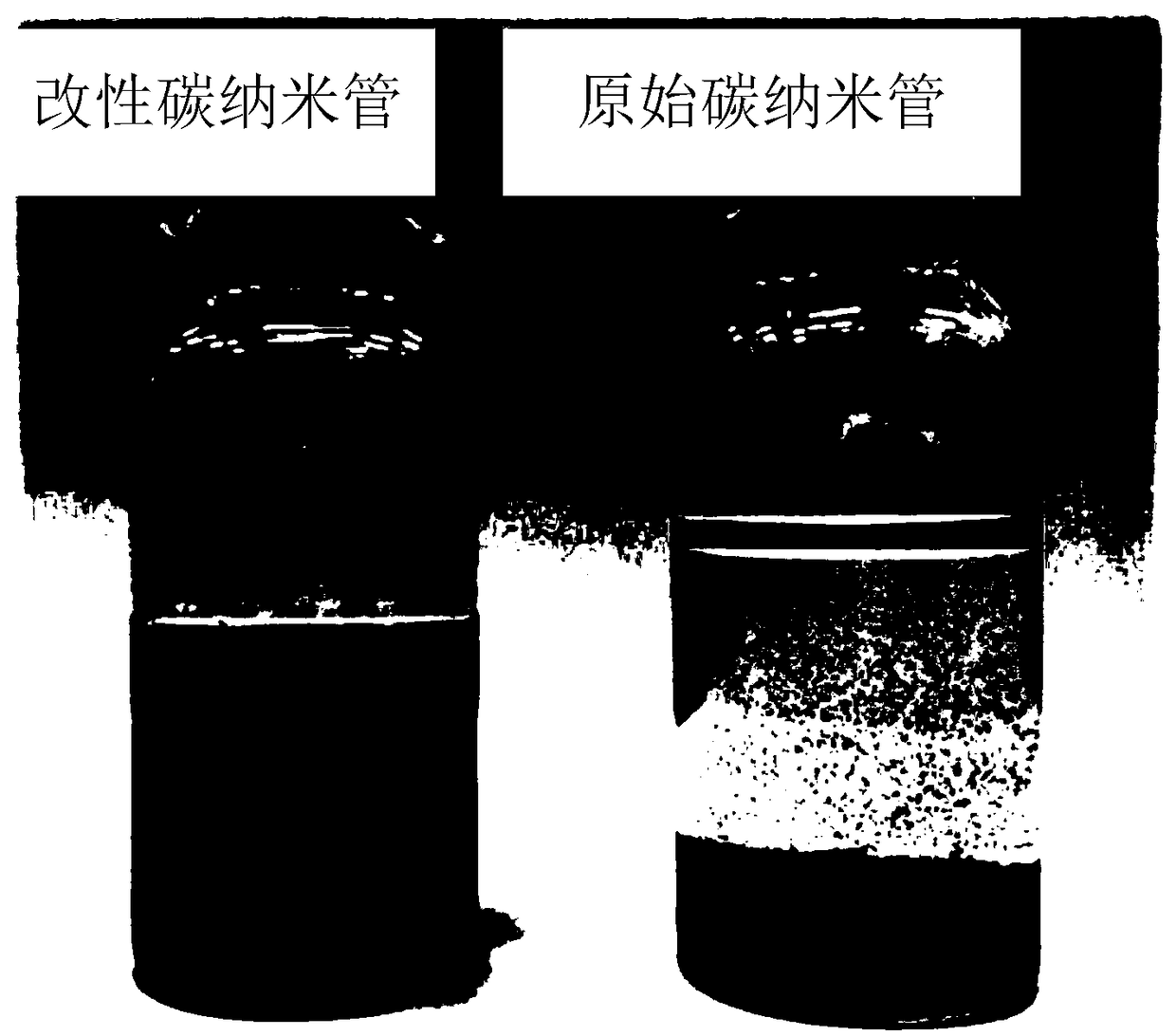

Method for efficiently dispersing carbon nano-tubes

ActiveCN108584918AImprove stabilityIncrease concentrationHeat-exchange elementsMulti-walled nanotubesHeat conductingConductive polymer

The invention discloses a method for efficiently dispersing carbon nano-tubes. The method comprises the steps: mixing the ingredients in parts by mass: 1-30 parts of carbon nano-tubes, 0.2-10 parts offunctionalized carbon nano-tubes and 400-1,200 parts of solvent, and adjusting the pH to 5 to 9; and carrying out ultrasonic dispersion, thereby obtaining a stable-dispersed carbon nano-tube dispersion, wherein the functionalized carbon nano-tubes are one or more of carboxylated carbon nano-tubes, hydroxylated carbon nano-tubes, aminated carbon nano-tubes, acylated-chlorinated carbon nano-tubes and sulfonated carbon nano-tubes. The method disclosed by the invention has the characteristics that the carbon nano-tube dispersion effect is good, the stability is high, the dispersion concentrationis high, the carbon nano-tubes are not destroyed and sheared, the surfactant is absent, the process flow and production cycle are short, and industrial production is easy to achieve; and the obtaineddispersion can be applied to the aspects of organic-inorganic nanocomposite materials such as heat-conducting coating materials, conducting polymers and supercapacitors.

Owner:SOUTH CHINA UNIV OF TECH

Composite nutritional body beautifying agent

ActiveCN101849669AThe preparation process is matureSimple preparation equipmentFood preparationFunctional foodNutrient

The invention relates to a composite nutritional body beautifying agent which has comprehensive and abundant nutrients, replenishes qi and blood after being eaten for a long time and has the special functions of nourishing and beautifying the body to females. The composite nutritional body beautifying agent is especially suitable for pregnant women, puerperae, ladies with valetudinarianism and all beauty-conscious ladies. The invention combines Chinese wolfberry, Chinese date, pawpaw, yam, radix puerariae, honey, soybean, milk, eggs, fish meal, licorice, ginger and brown sugar into a whole for the first time to realize the nutritional effect of beautifying the body. The invention can be prepared into various preparation forms with convenient eating and has simple process, abundance and easy purchase of raw materials, no any toxic or side reaction, obvious food therapy function of each component and high cognitive strength; and the invention can be used as functional food, medical auxiliary food, health-care food and even medicine for popularization.

Owner:永安康健药业(武汉)有限公司

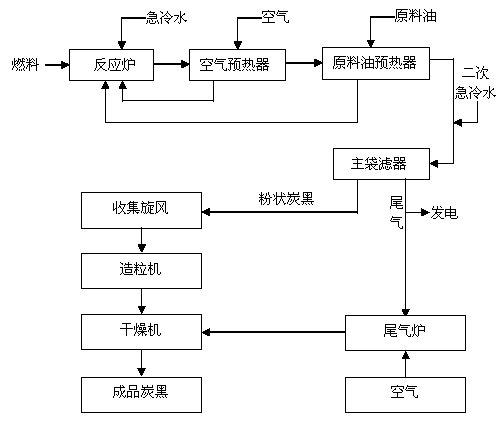

Low-themogenesis super-wear-resisting carbon black and production technology thereof

The invention provides low-themogenesis super-wear-resisting carbon black and a production technology thereof. According to the technical scheme, the production technology is characterized in that incomplete cracking reaction happens in a reaction furnace so as to generate carbon black exhaust gas by using anthracene oil or a mixture of anthracene oil and coal tar as raw oil and natural gas as fuel without addition of an additive, and the generated carbon black exhaust gas is subjected to post-treatment so as to obtain carbon black particles. The production technology has the most remarkable advantages that the natural gas is used as the fuel, the coal tar and the anthracene oil are mixed in appropriate proportions so as to obtain the raw oil, the adopted raw oil is reasonable in structure, and the carbon black product has relatively good quality and relatively high structure and is extremely small in particle sizes and narrowly distributed, so that vulcanized rubber of the carbon black has super-strong wear-resisting property; heat generated by the vulcanized rubber is relatively low. The powdery carbon black is produced by a micrometer pulverizer, a pelletizer and a drying machine. The production technology is mature and suitable for industrial production and has obvious economic benefits.

Owner:LONGXING CHEMICAL STOCK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com