Patents

Literature

144results about How to "Compact size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

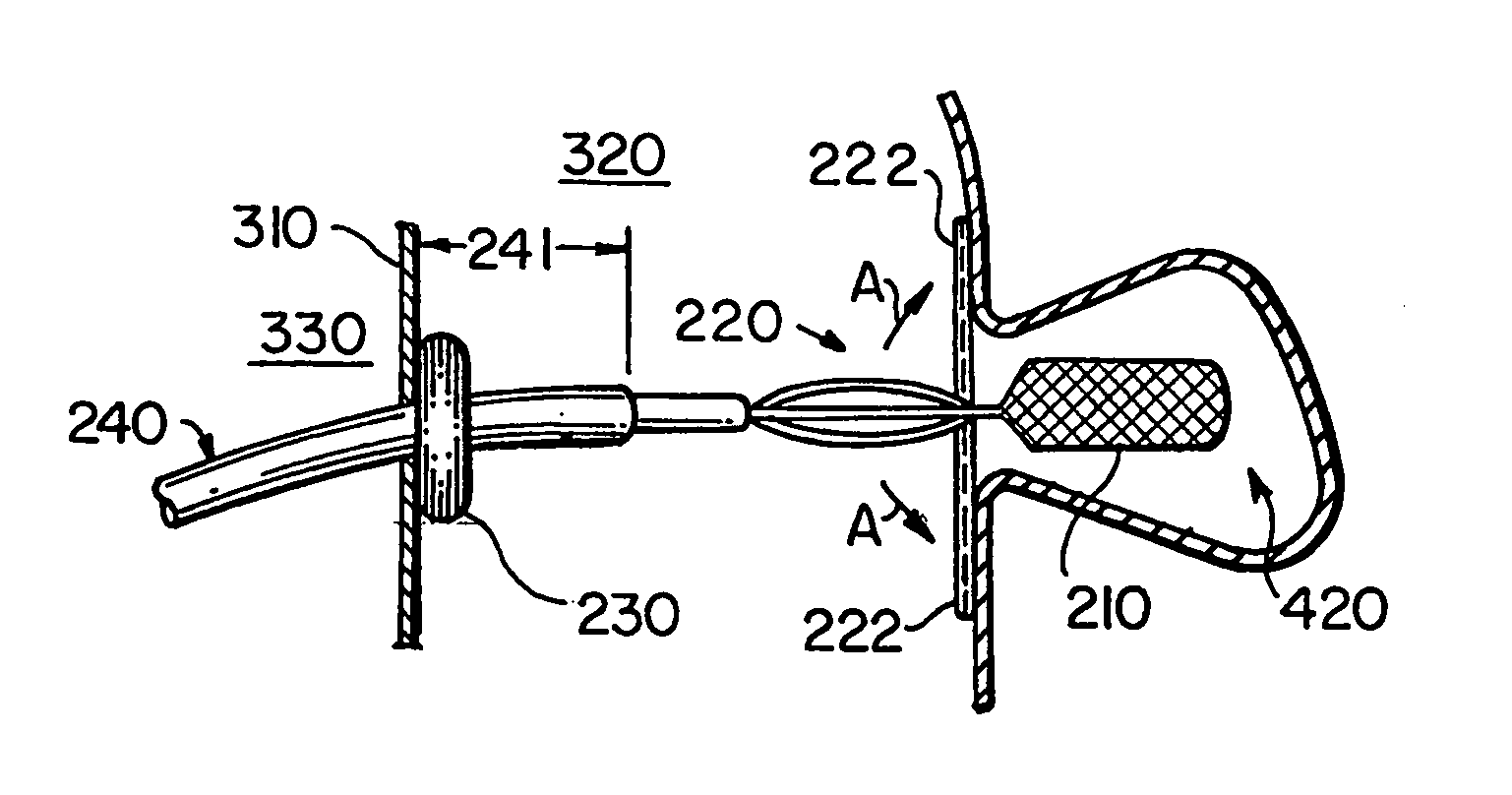

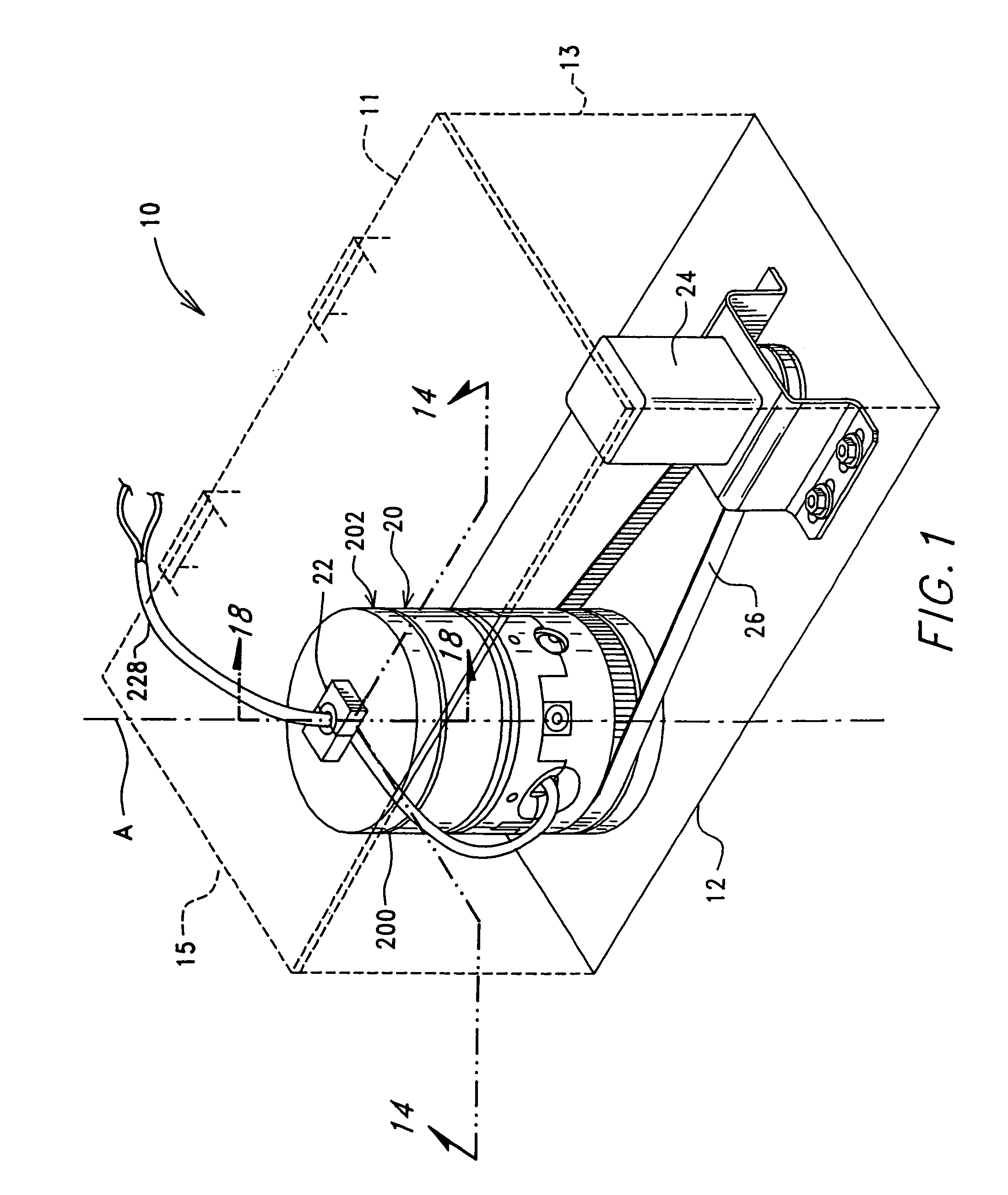

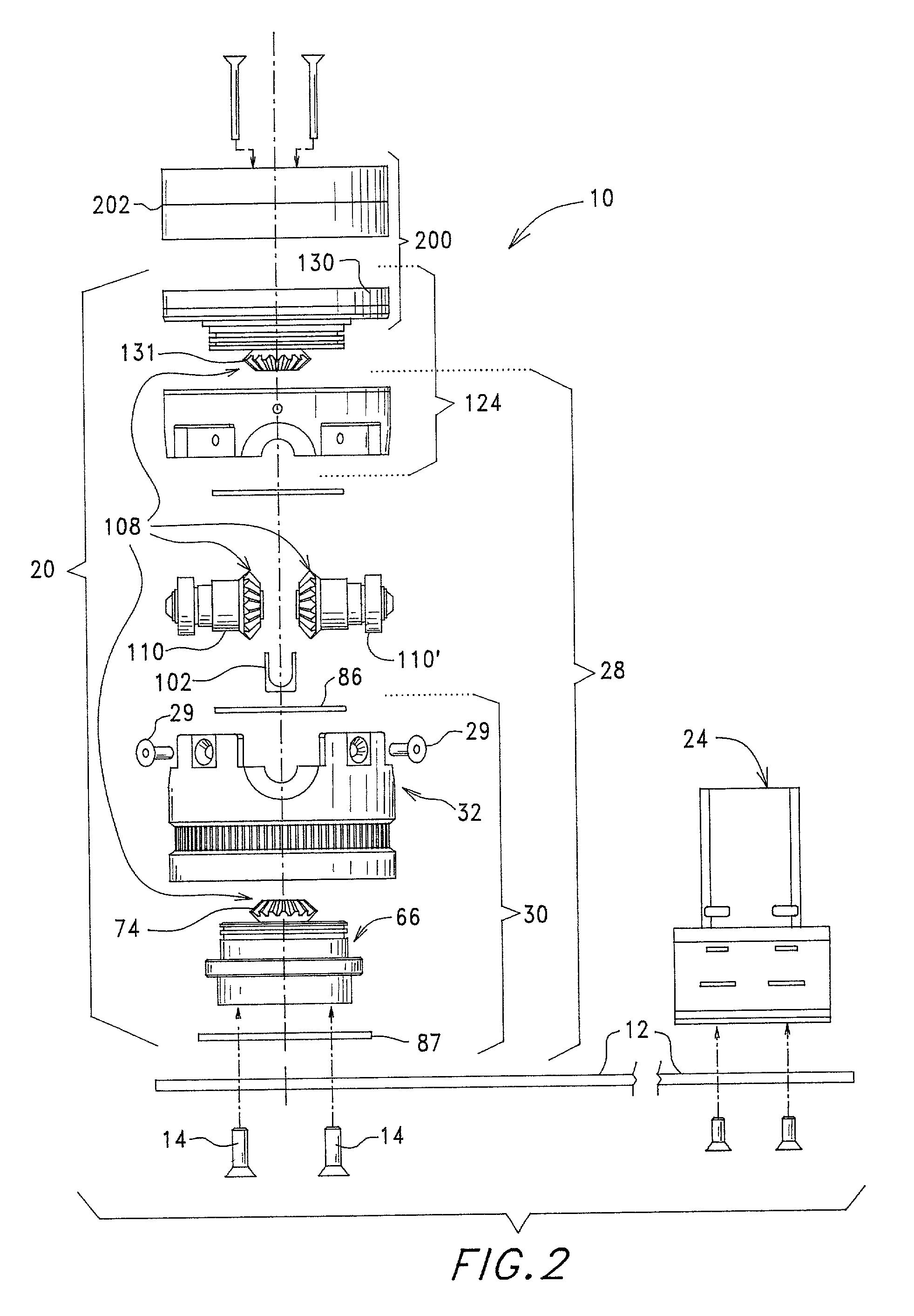

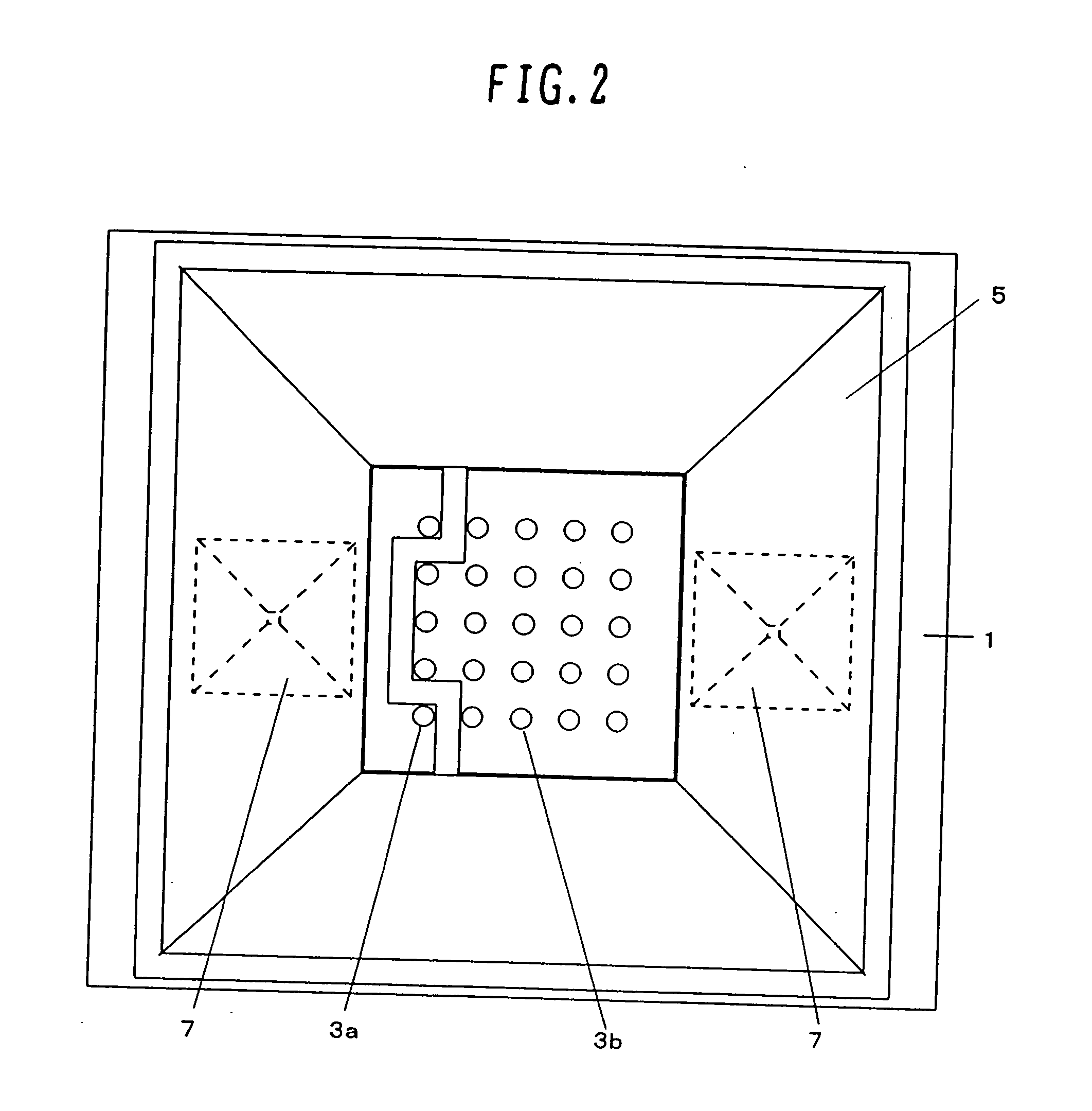

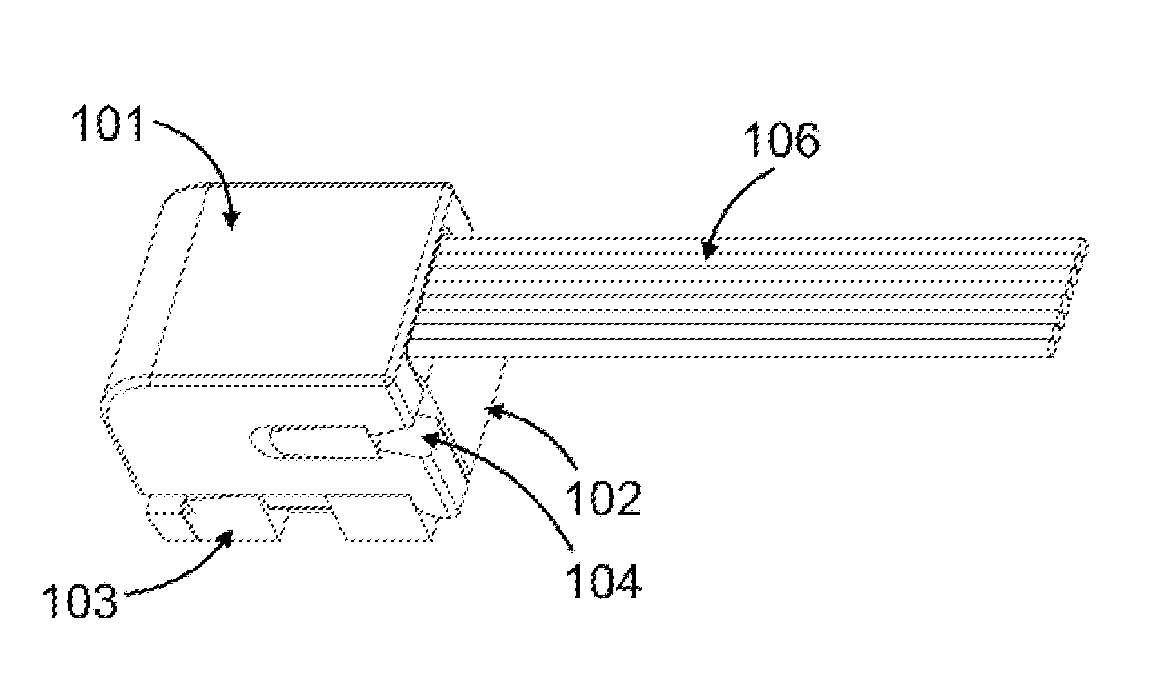

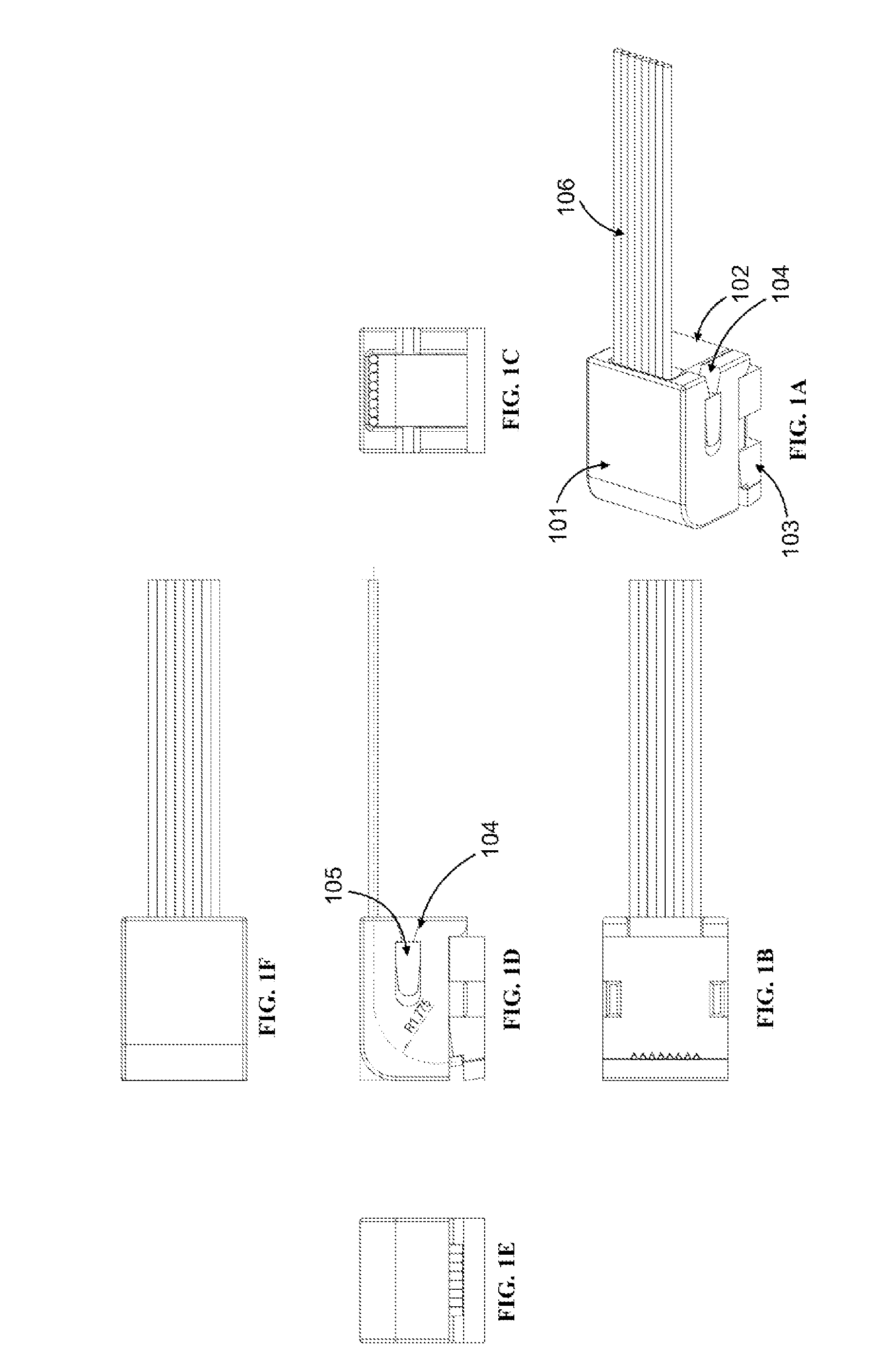

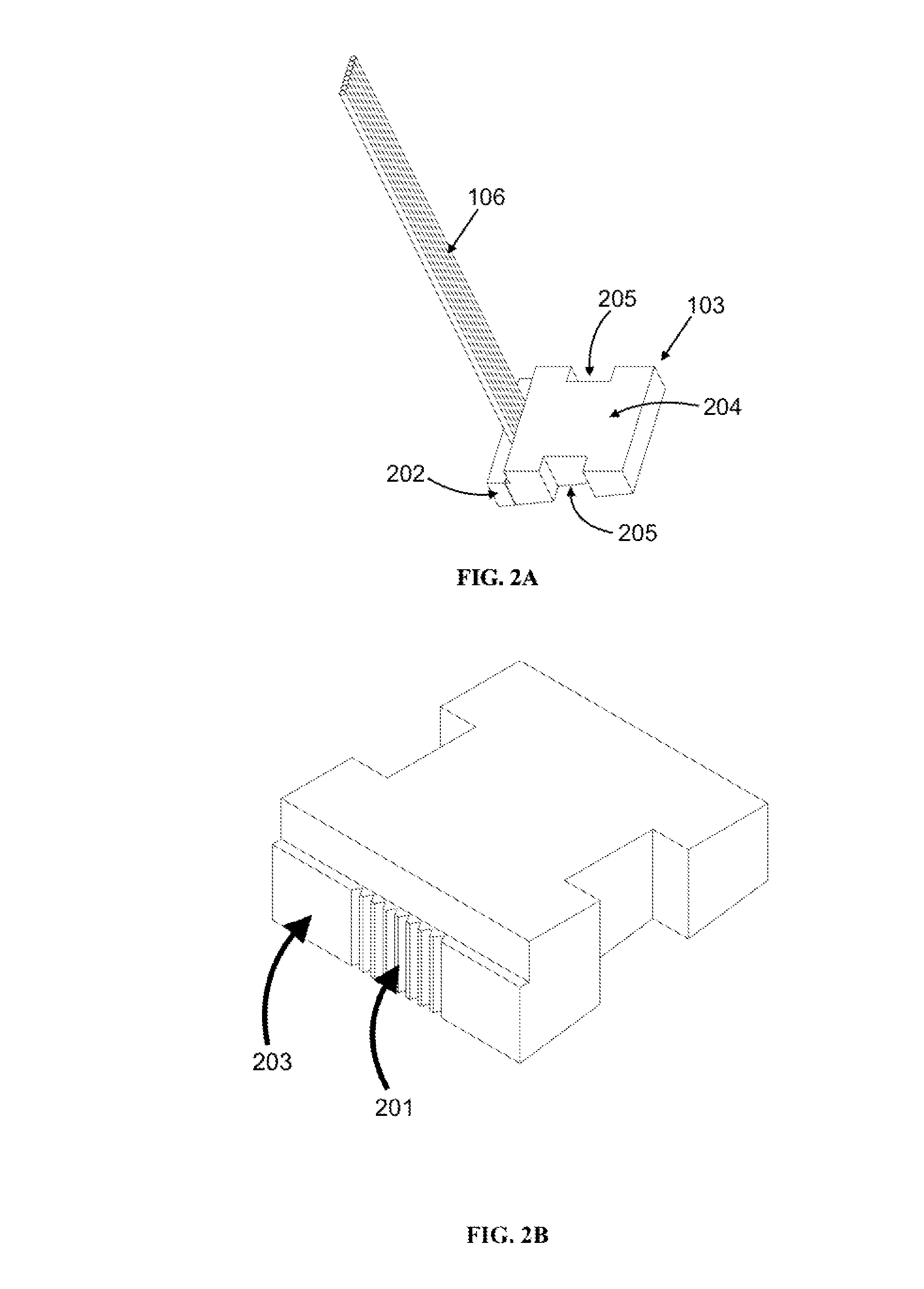

Apparatus for implanting devices in atrial appendages

InactiveUS7169164B2Secure positioningCompact sizeSurgical needlesHeart defibrillatorsCatheterization deviceAtrial Appendage

The invention provides a delivery system for placing devices in atrial appendages. The system includes a catheterization apparatus having a tubular structure with one or more nested tubes, wires, and shafts. The tubes establish a passageway for moving a device through a body's vasculature and heart into an atrial appendage. An expandable positioning guide is disposed on the distal end of a tube passing through the apparatus. The positioning guide is expanded in situ to engage atrial wall surfaces proximate to the atrial appendage for mechanical support. The deployed positioning guide mechanically stabilizes the device delivery passageway. A shaft passing through the tubes transports the device through the passageway to the atrial appendage.The system includes catheterization apparatus for transseptal delivery of the devices. An outer tube or sheath in the apparatus is used to penetrate and traverse the septum. An expandable securement device is disposed toward an end of the sheath. The securement device is expanded in situ to engage surface portions of the traversed septum to restrain further inadvertent movement of the septum-traversing sheath.

Owner:BOSTON SCI SCIMED INC

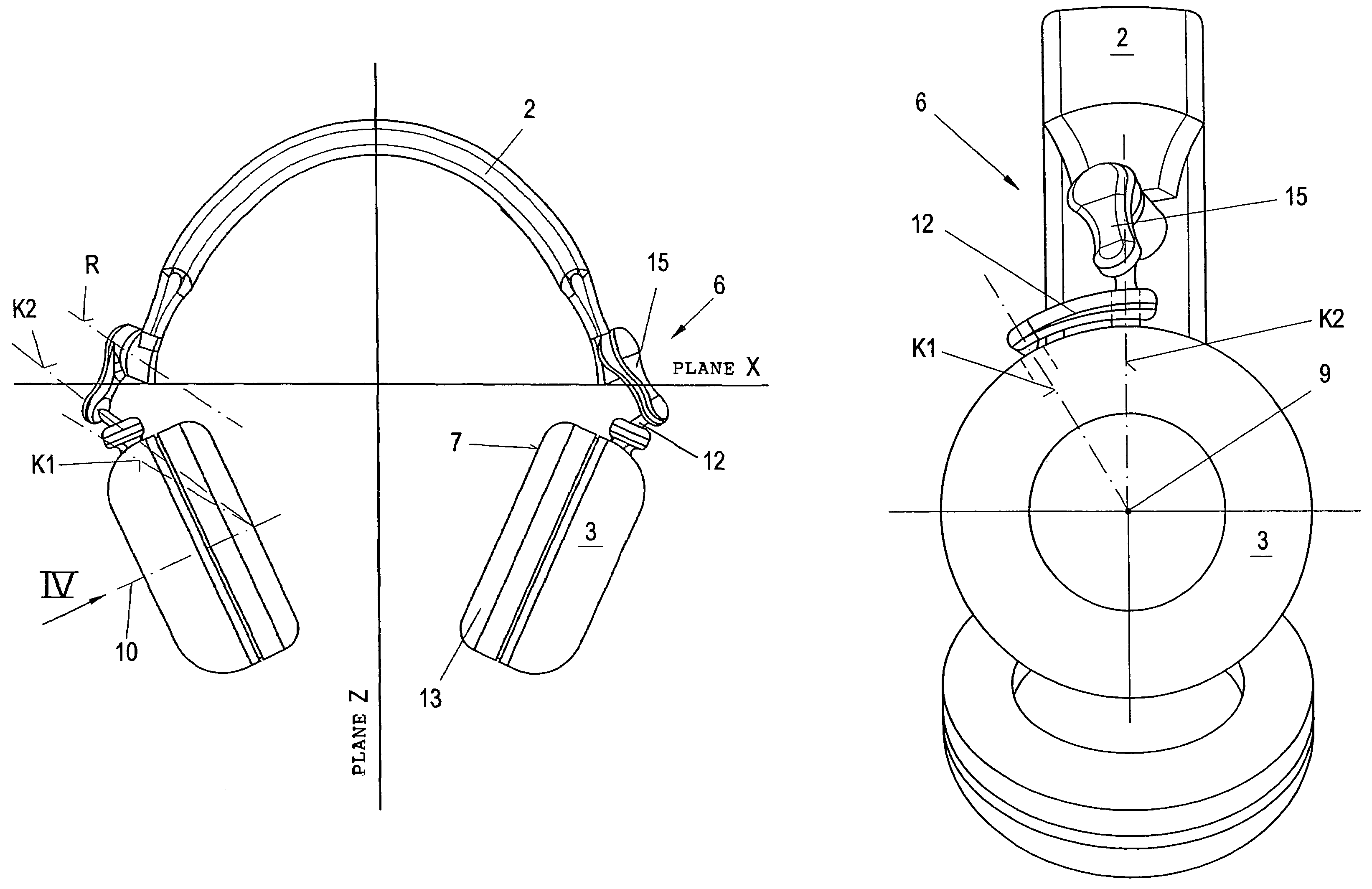

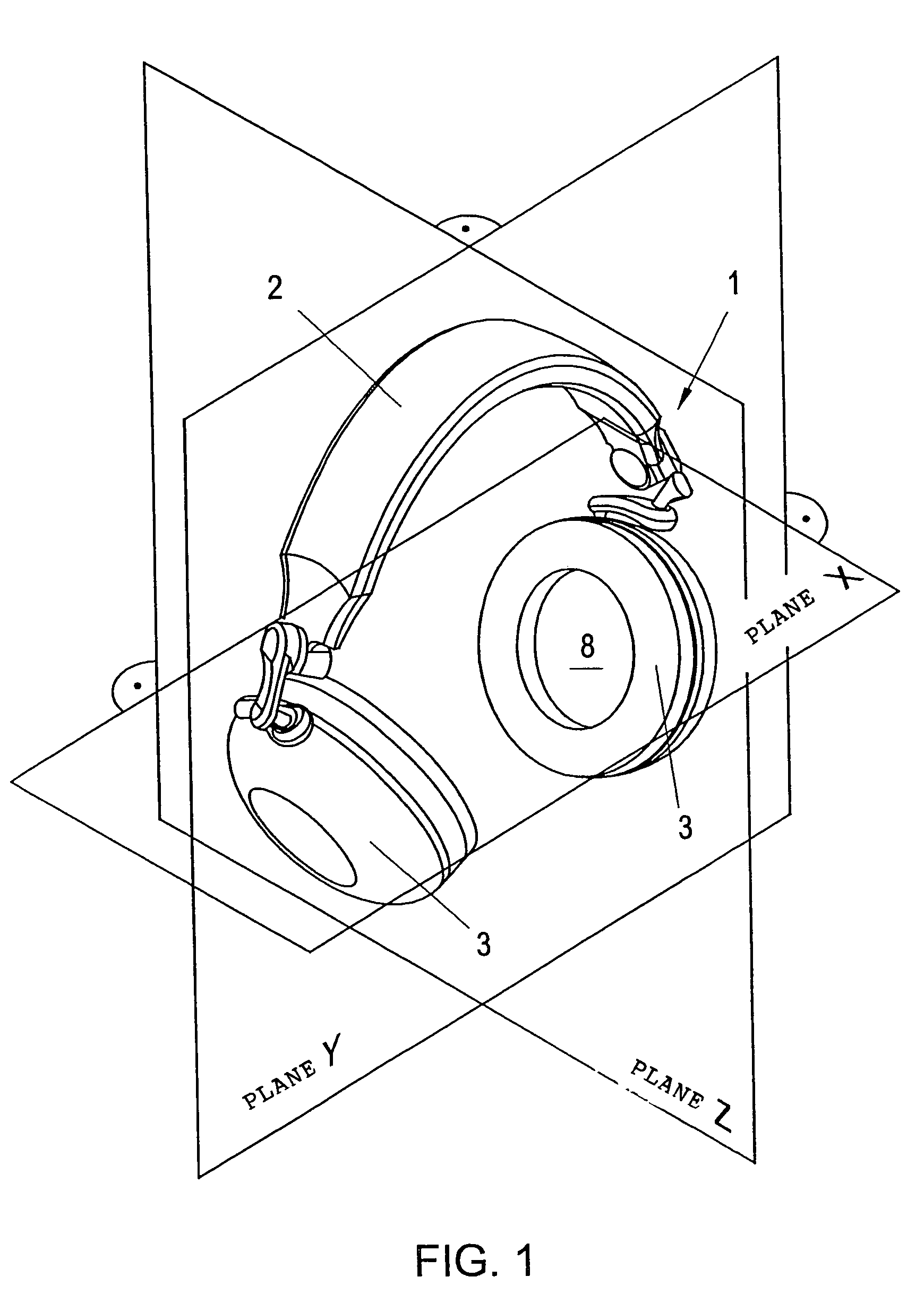

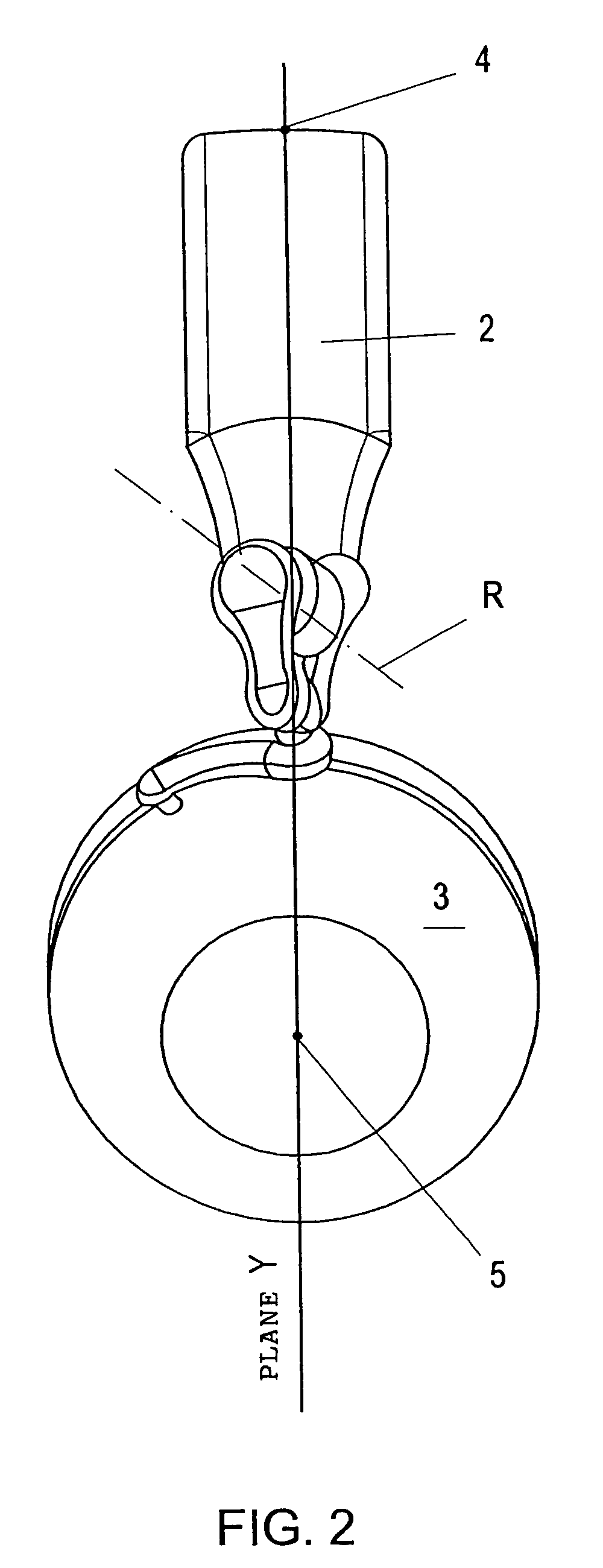

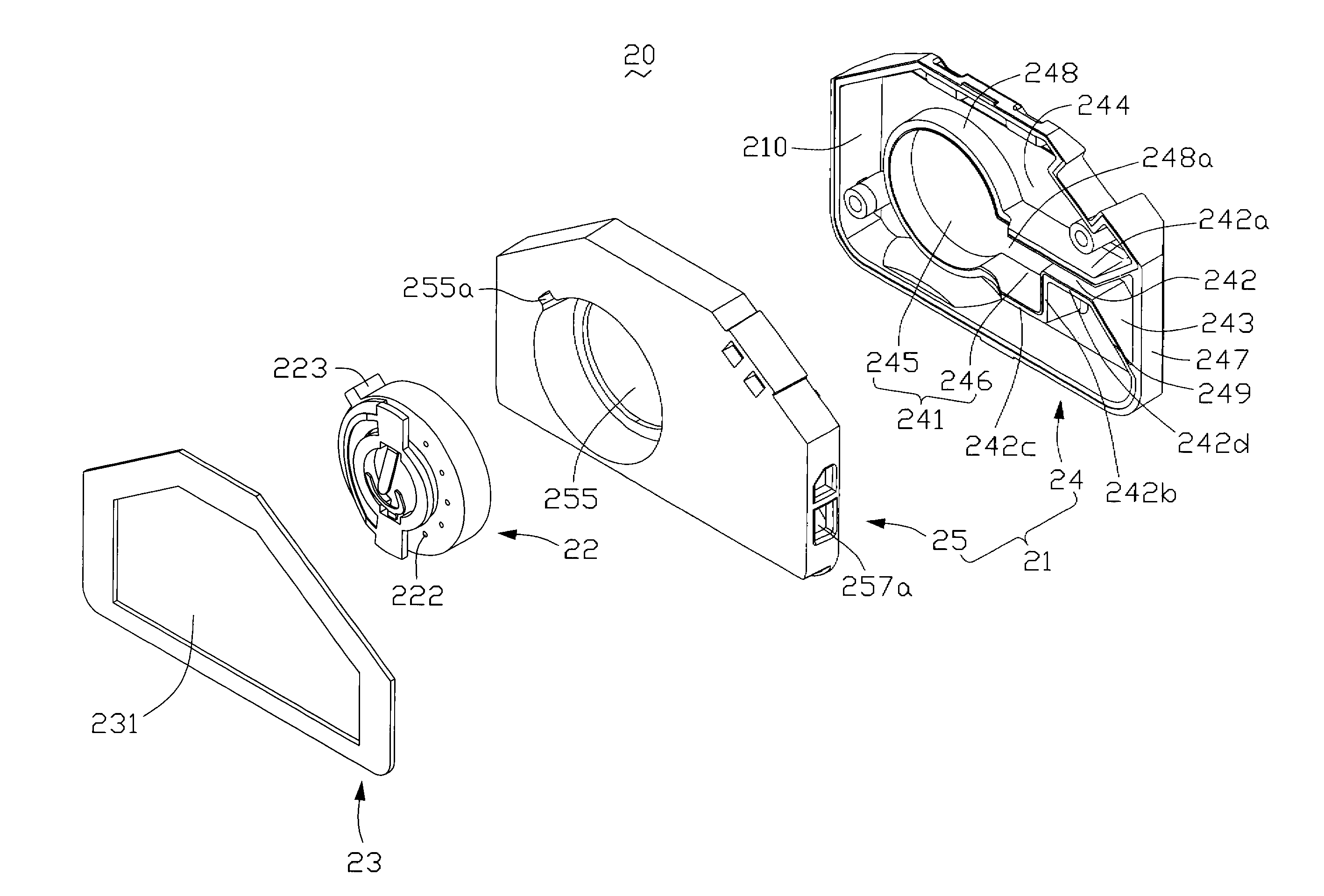

Headphone

ActiveUS7172052B2Compact configurationCompact sizeHeadphones for stereophonic communicationNon-optical adjunctsHandsetEngineering

Owner:AKG ACOUSTICS

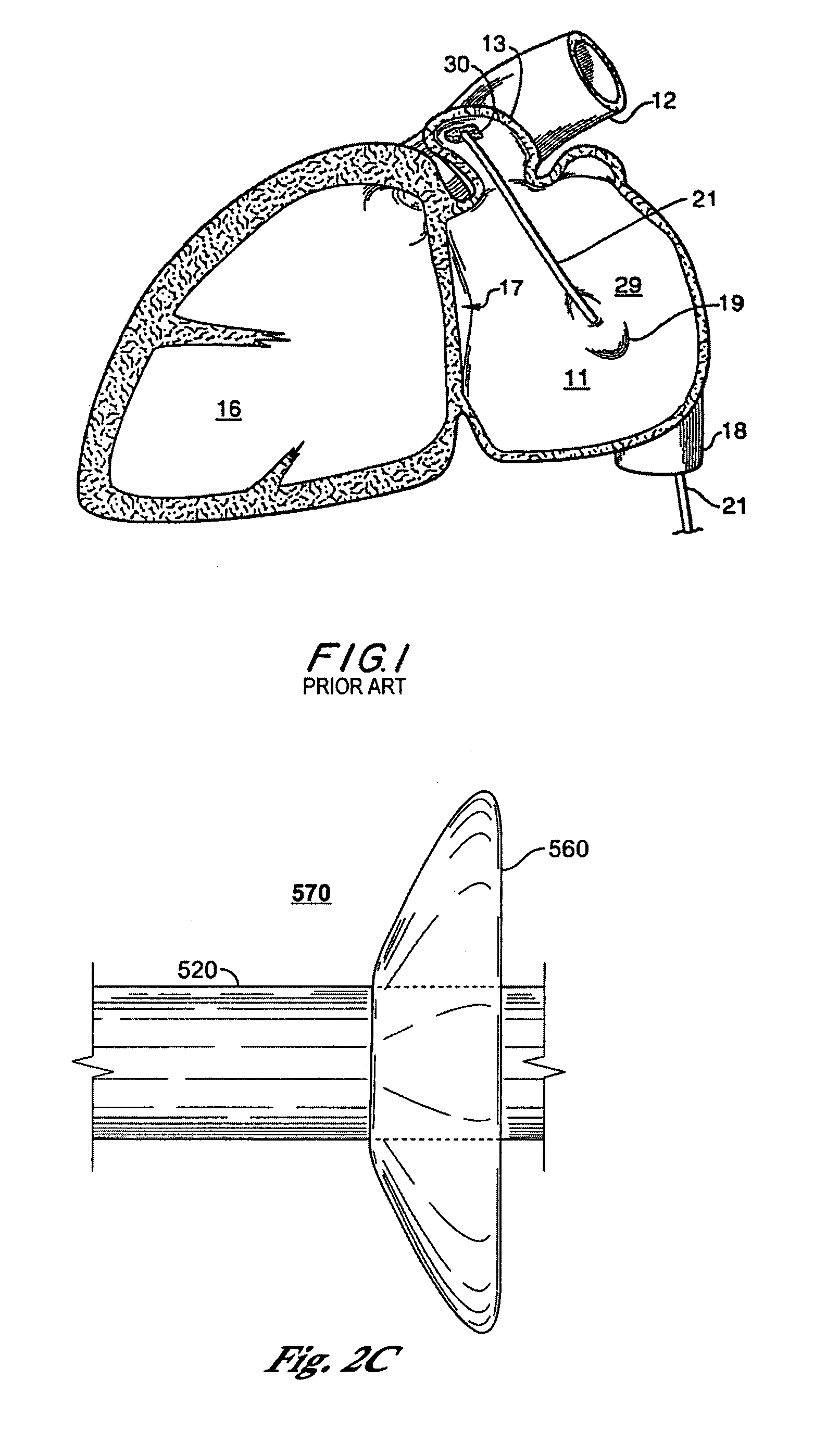

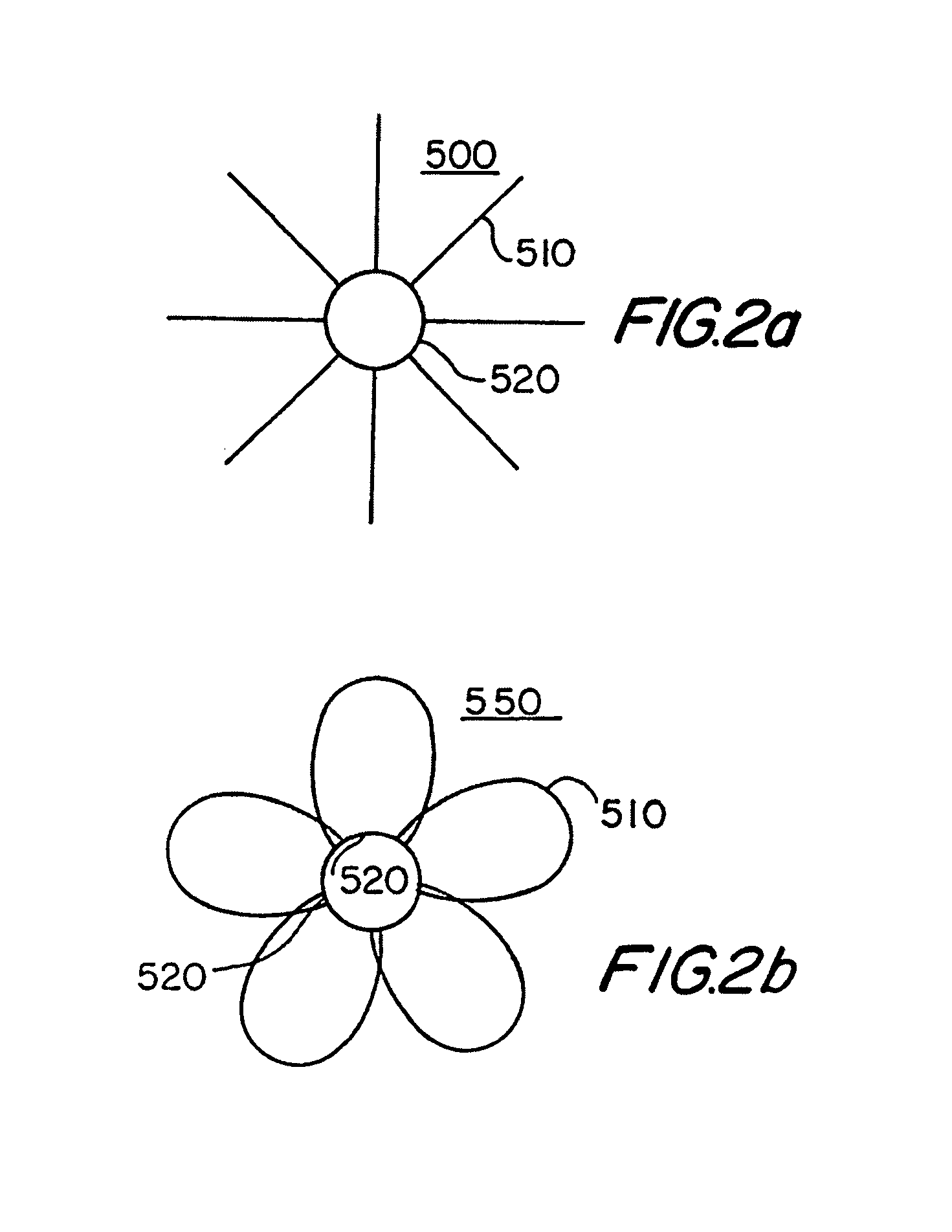

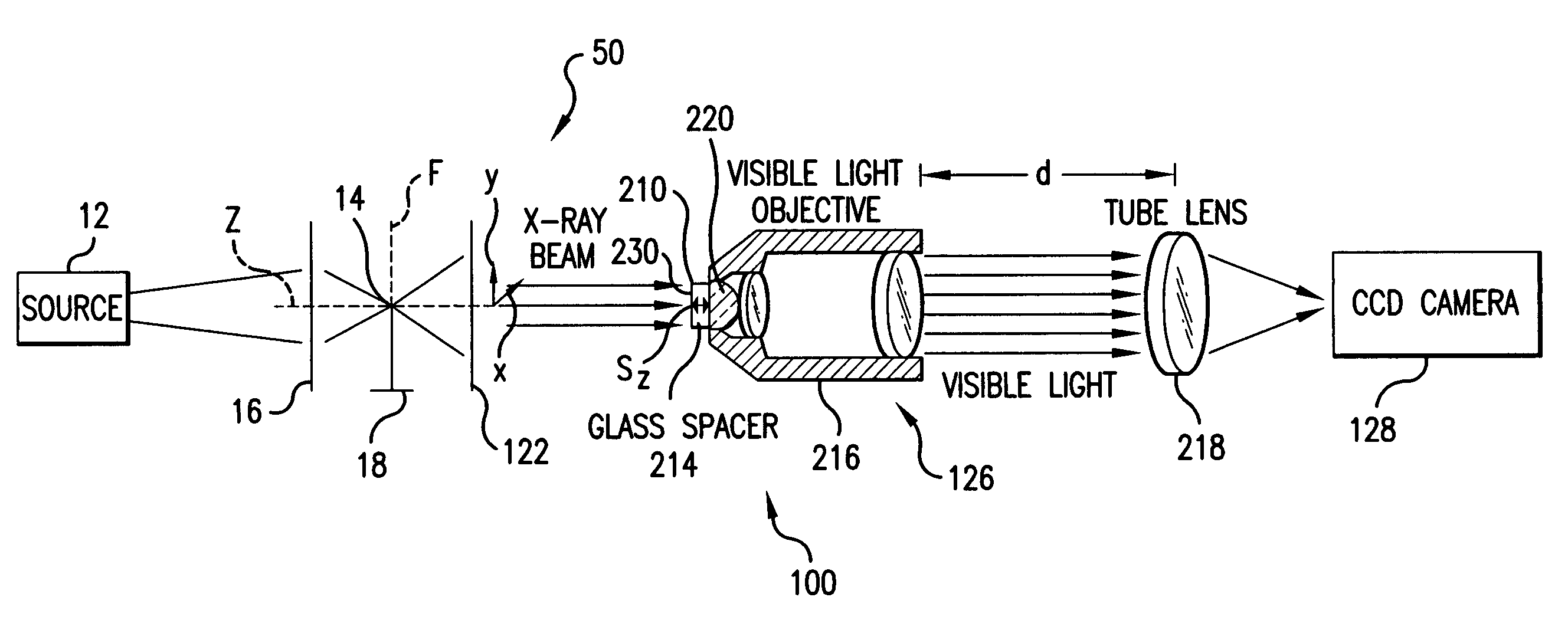

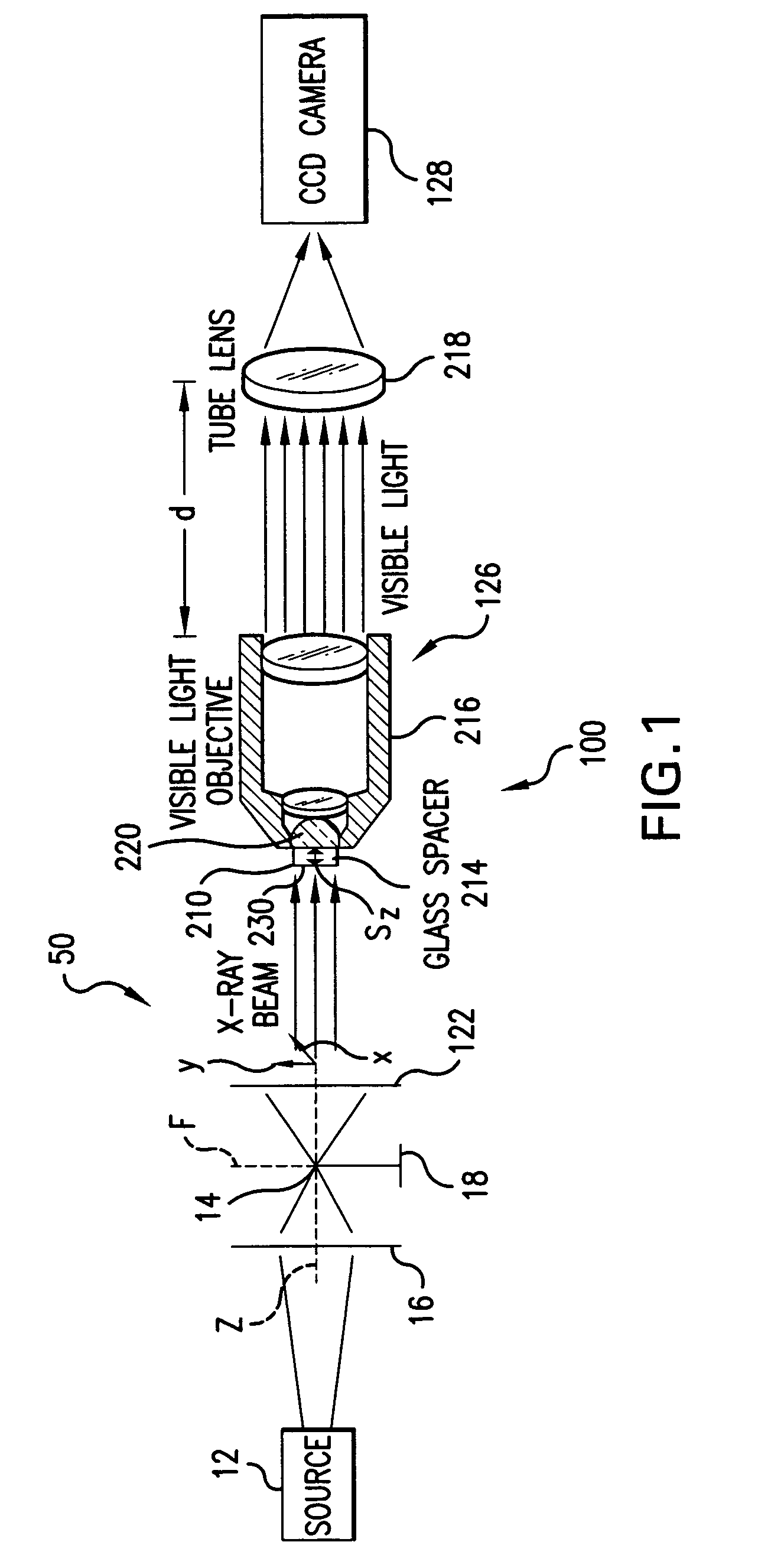

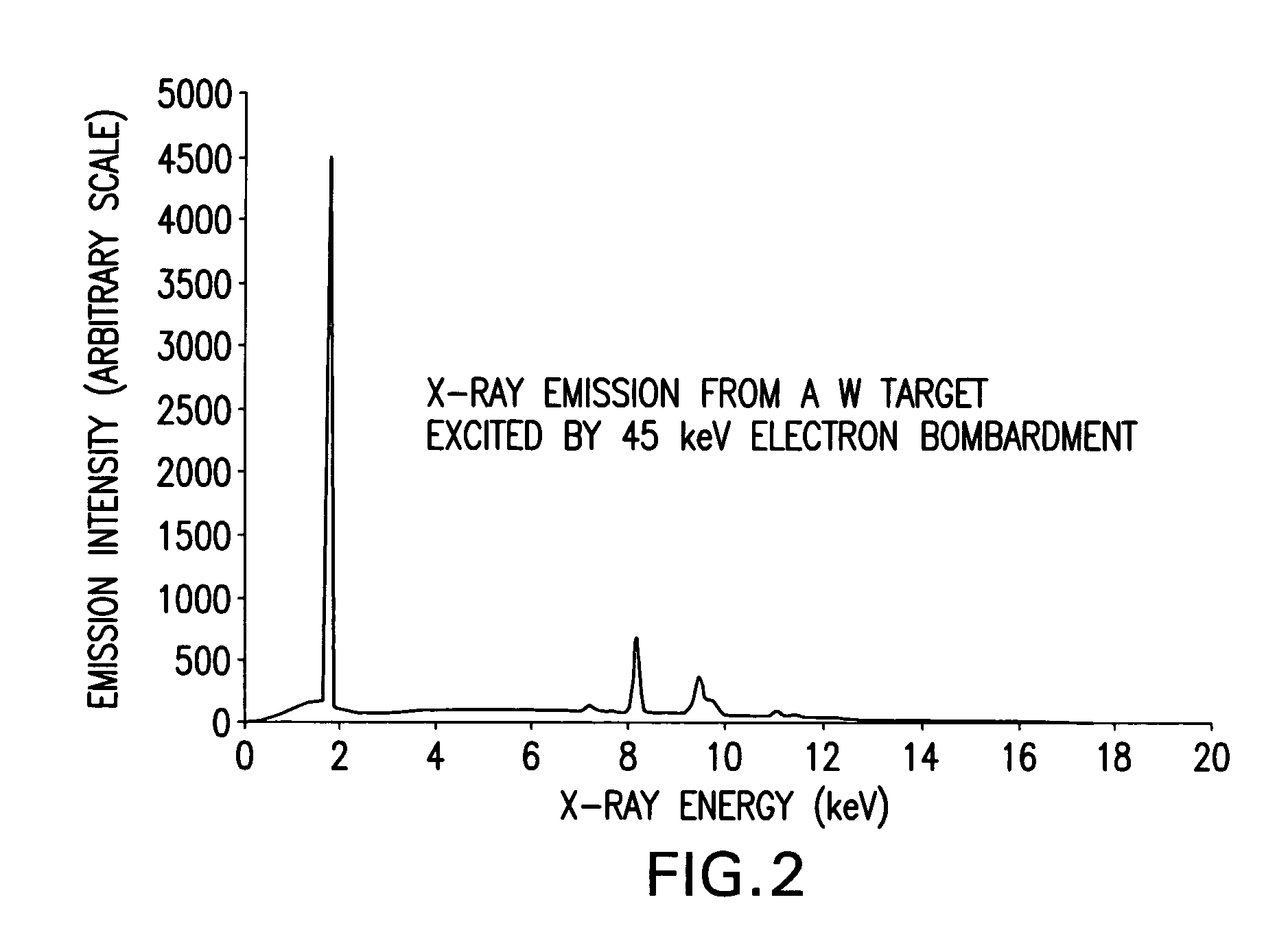

Scintillator optical system and method of manufacture

ActiveUS7057187B1Compact sizeAppropriate sizePhotometryFluorescence/phosphorescenceMicrometerImage resolution

A scintillated CCD detector system for imaging x rays uses x-rays having a photon energy in the range of 1 to 20 keV. The detector differs from existing systems in that it provides extremely high resolution of better than a micrometer, and high detection quantum efficiency of up to 95%. The design of this detector also allows it to function as an energy filter to remove high-energy x-rays. This detector is useful in a wide range of applications including x-ray imaging, spectroscopy, and diffraction. The scintillator optical system has scintillator material with a lens system for collecting the light that is generated in the scintillator material. A substrate is used for spacing the scintillator material from the lens system.

Owner:CARL ZEISS X RAY MICROSCOPY

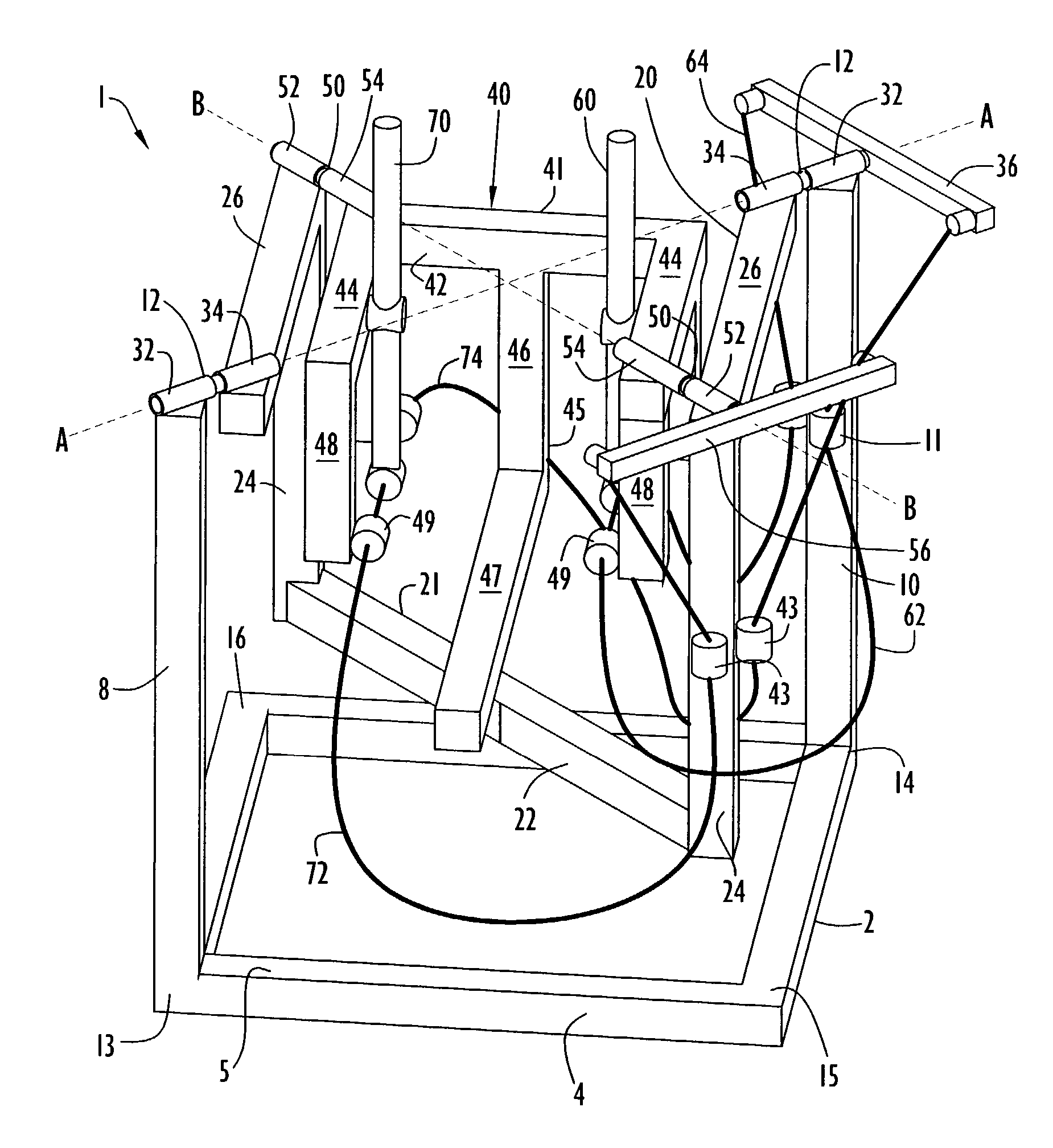

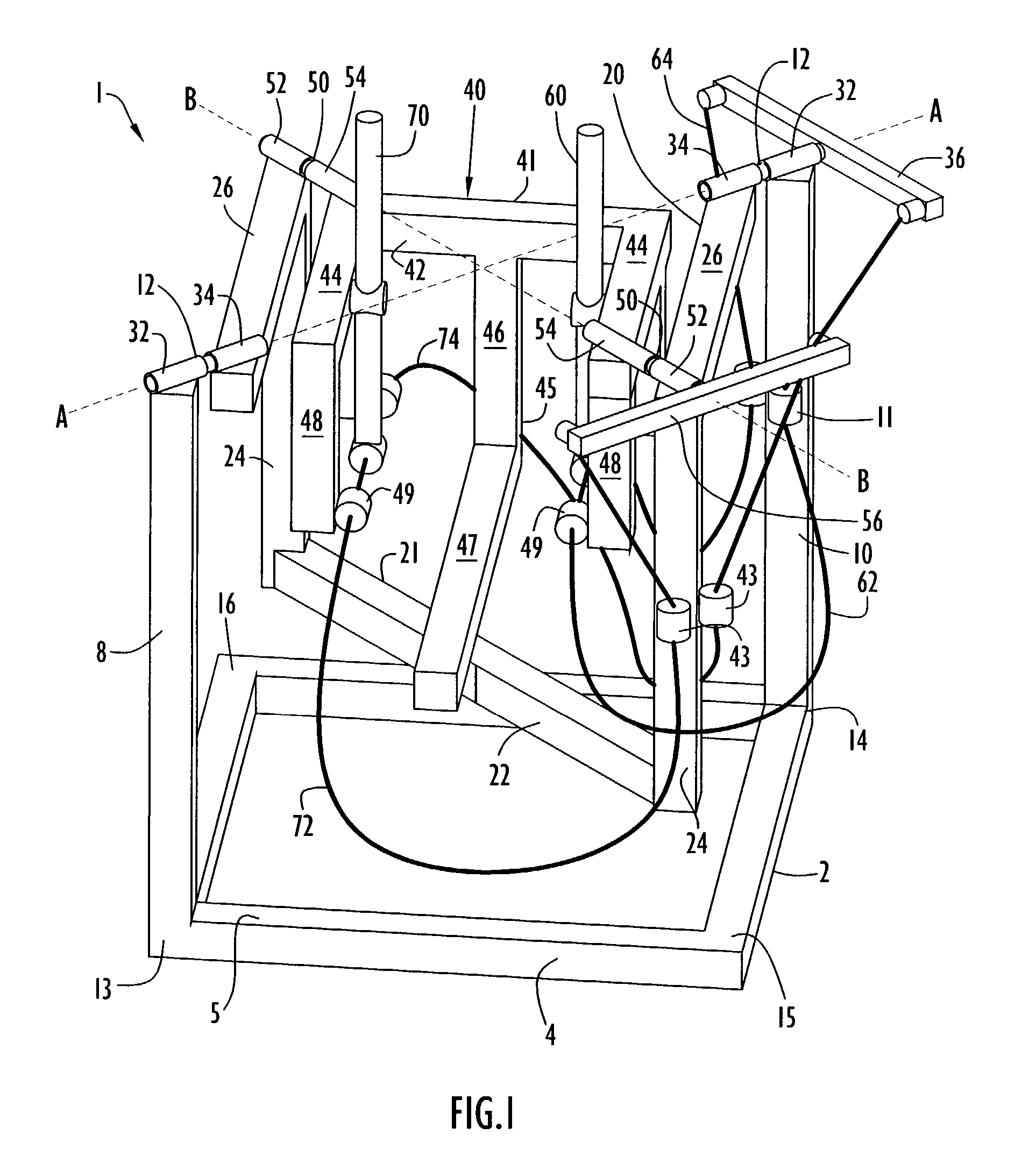

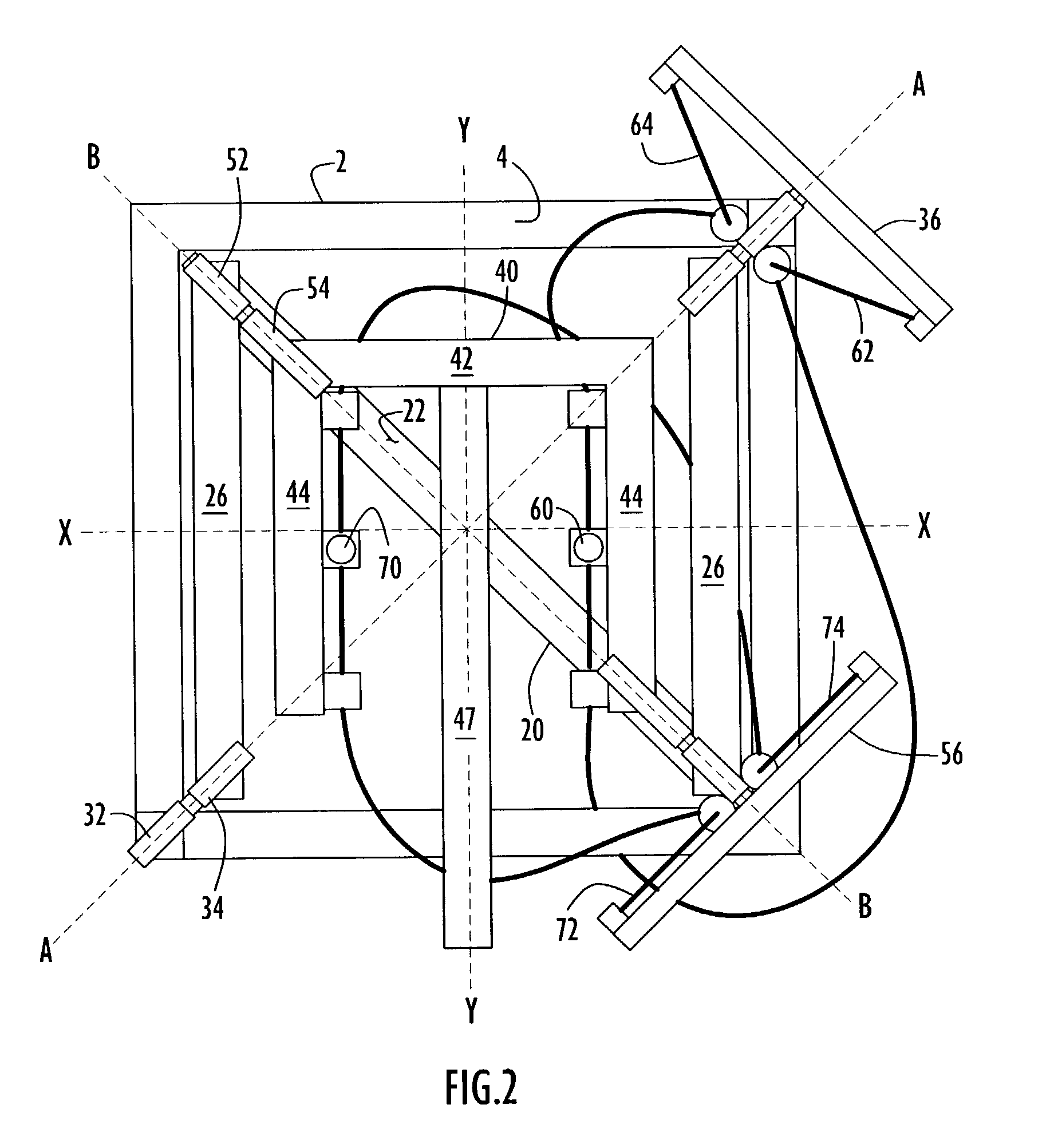

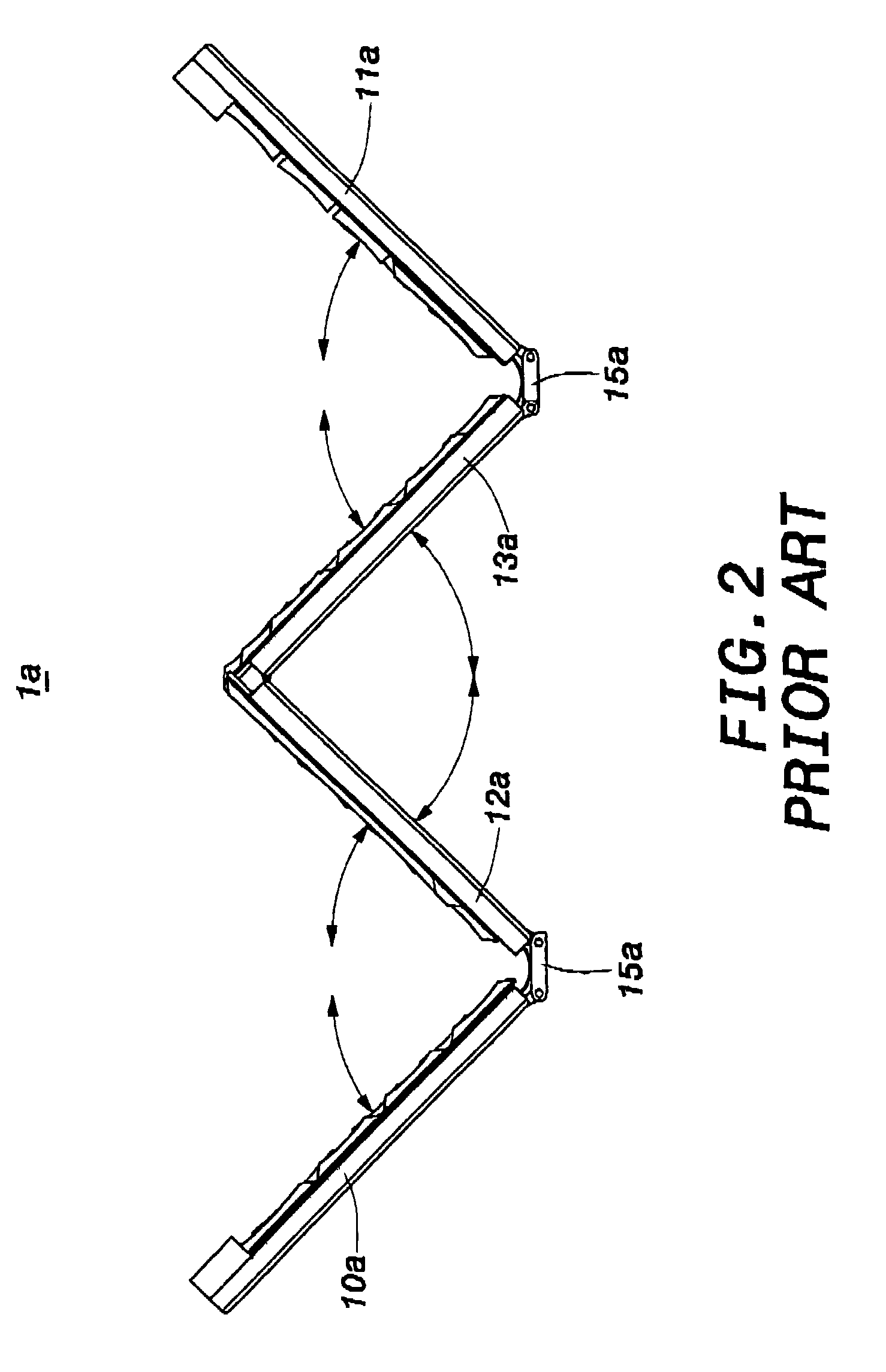

Motion platform system and method of rotating a motion platform about plural axes

InactiveUS7033176B2Compact sizeEasy user manipulationCosmonautic condition simulationsAmusementsEngineering

A motion platform system includes a support and a motion platform supported by the support and rotatable about a plurality of bearing axes. The motion platform is further rotatable with respect to the support about at least one axis that is offset from the plurality of bearing axes. The motion platform may include an intermediate frame supported by the support, where the intermediate frame is rotatable about a first bearing axis with respect to the support. The motion platform may further include an inner frame supported by the intermediate frame, where the inner frame is rotatable about a second bearing axis with respect to the intermediate frame. Rotations of the inner and intermediate frames about the first and second bearing axes facilitate rotation of the inner frame with respect to the support about at least one axis offset from the bearing axes.

Owner:NINTENDO CO LTD AND NINTENDO OF AMERICA INC

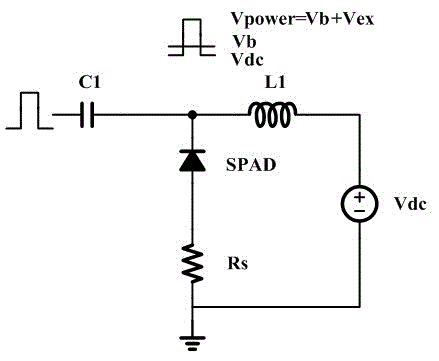

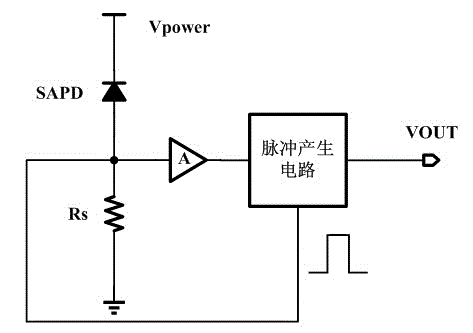

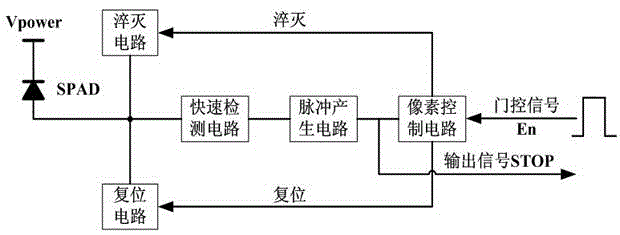

Integrated gating active quenching/restoring circuit

InactiveCN103148950AReduce detection noiseImprove reliabilityInstrumentsCounting rateSingle-photon avalanche diode

The invention discloses an integrated gating active quenching / restoring circuit. The integrated gating active quenching / restoring circuit comprises a quick detection circuit, a pulse generation circuit, a pixel control circuit, a quenching circuit and a restoring circuit, wherein the quick detection circuit is used for processing a detected anode current signal of an SPAD (Single Photon Avalanche Diode) into a pulse signal, the pulse signal can be output through the pulse generation circuit, the pixel control circuit is controlled by an output signal and a gating signal of the pulse generation circuit, the restoring circuit and the quenching circuit are respectively controlled by outputs of the pixel generation circuit, outputs of the restoring circuit and the quenching circuit can be fed back to an anode of the SPAD, and the restoring and the quenching of the SPAD can be controlled. According to the integrated gating active quenching / restoring circuit disclosed by the invention, by adopting a gating control method, the dark counting rate of the SPAD can be effectively reduced, the quenching time can be controlled by the pulse generation circuit, and the integrated gating active quenching / restoring circuit has the advantages of compact area and low power consumption.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

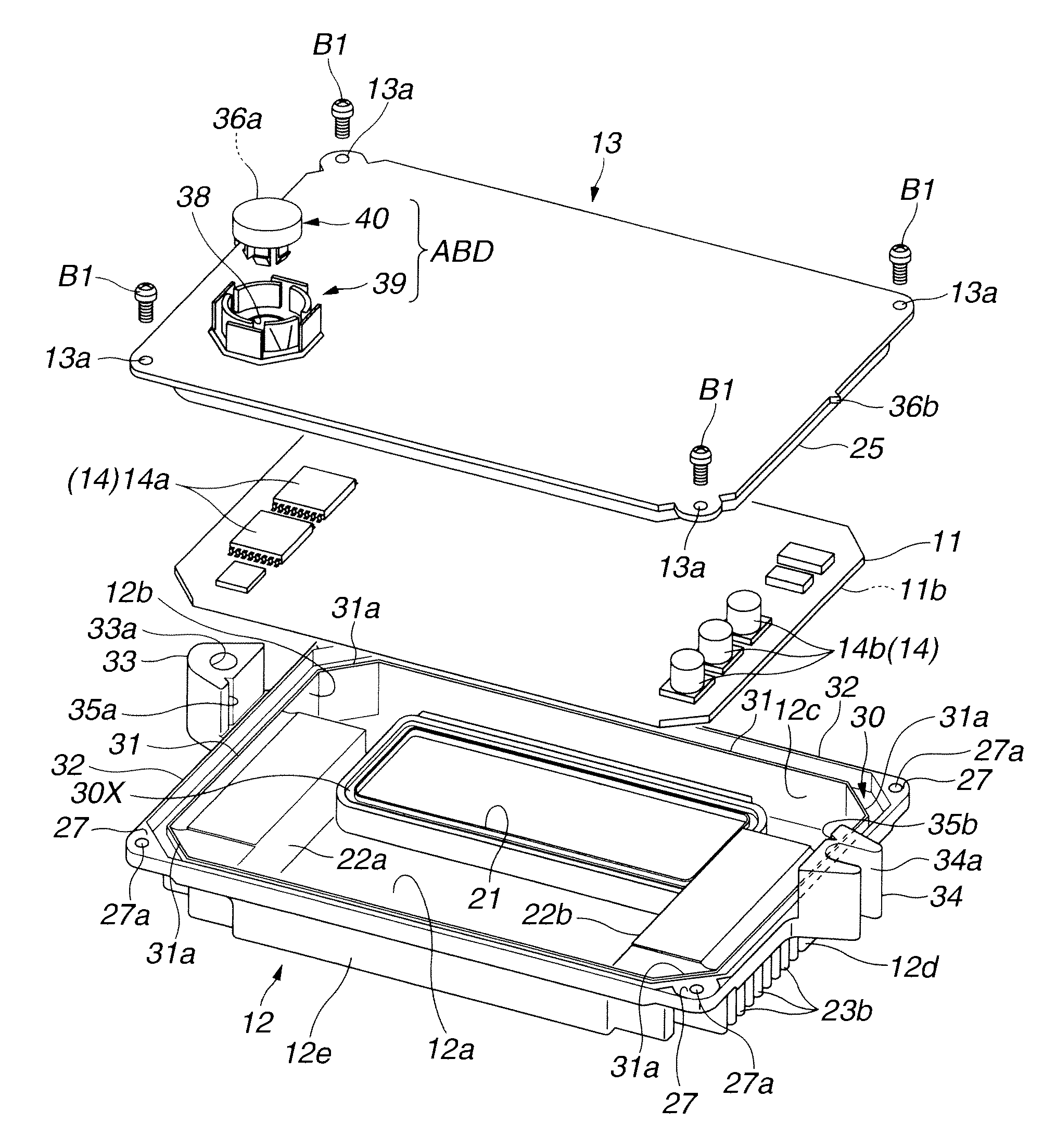

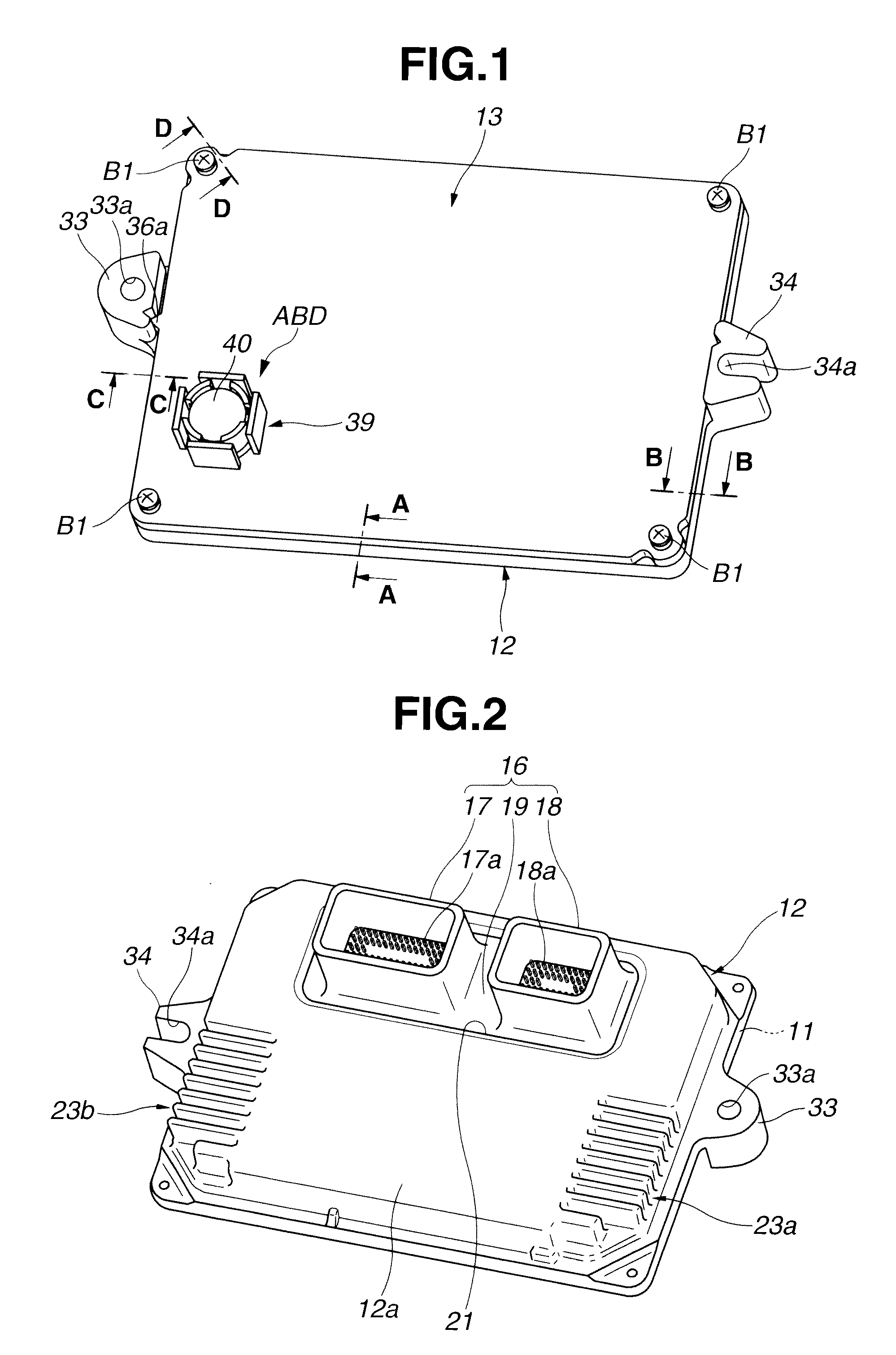

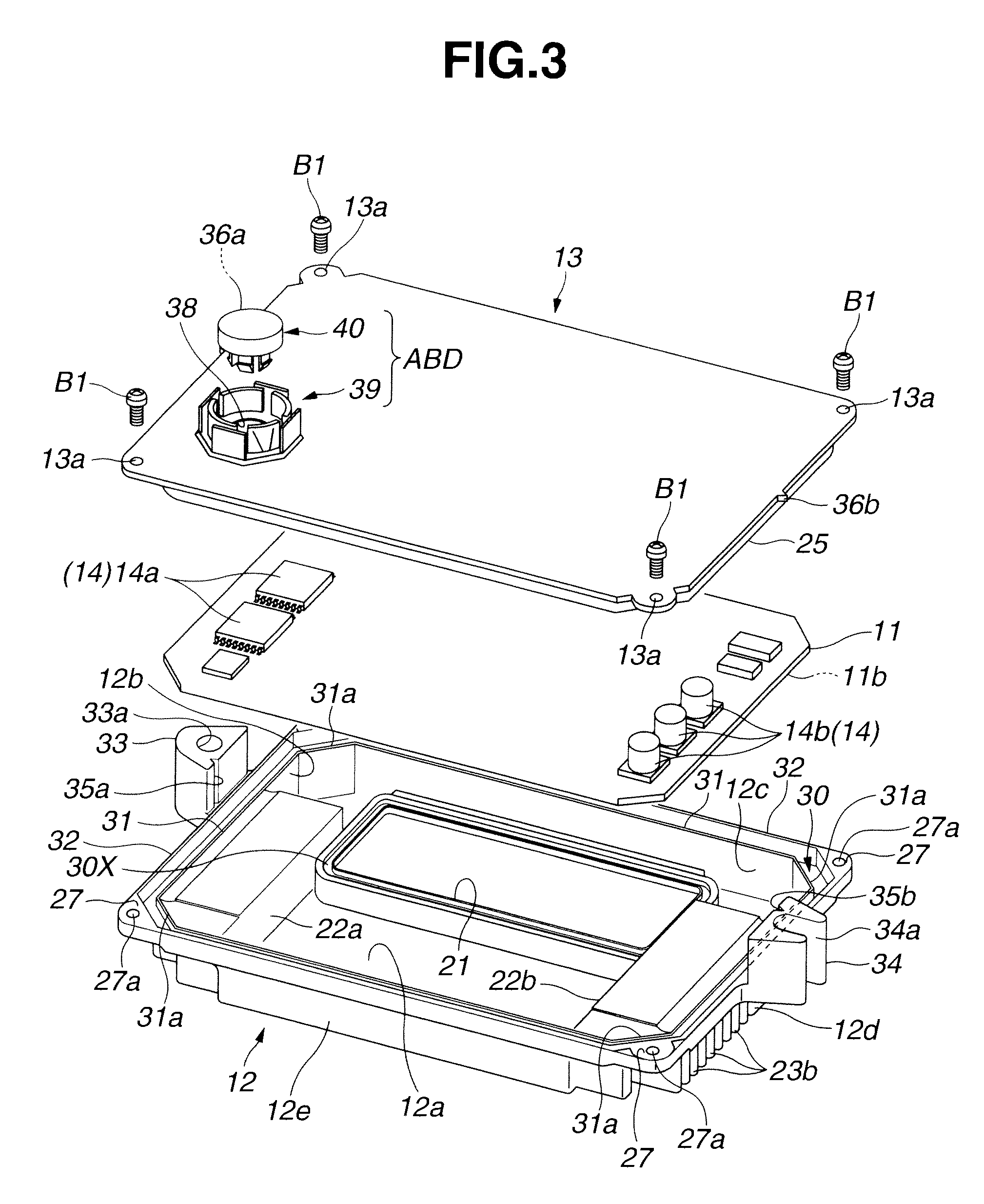

Electrical control unit

ActiveUS20120320544A1Compact sizeSmall sizeCasings with connectors and PCBSupport structure mountingElectrical controlEngineering

An electrical control unit comprises a case having a groove on a first contact surface thereof, a cover having a protrusion on a second contact surface thereof, a printed wiring board received in a board receiving space defined between the case and the cover, and an adhesive received in the groove, wherein when the cover is put on the case having the protrusion inserted into the groove, the adhesive in a still soft condition is forced to move toward a space between the first and second contact surfaces for bonding the same, and wherein when the printed wiring board is properly put in the board receiving space, a peripheral outer surface of the board serves as an extra part of an inside wall of the groove.

Owner:HITACHI ASTEMO LTD

Autologous platelet gel having beneficial geometric shapes and methods of making the same

InactiveUS6942880B1Compact sizeQuantity maximizationSurgical adhesivesOther blood circulation devicesTOOTH EXTRACTIONSNormal platelet morphology

The present invention relates to the production of platelet gels formed into beneficial geometric shapes. Specifically the present invention provides a simpler way to introduce platelet gel for specific uses, such as into the cavity of a gum left after a tooth extraction. Molds of predetermined shapes are provided for forming the desired shape.

Owner:ARTERIOCYTE MEDICAL SYST

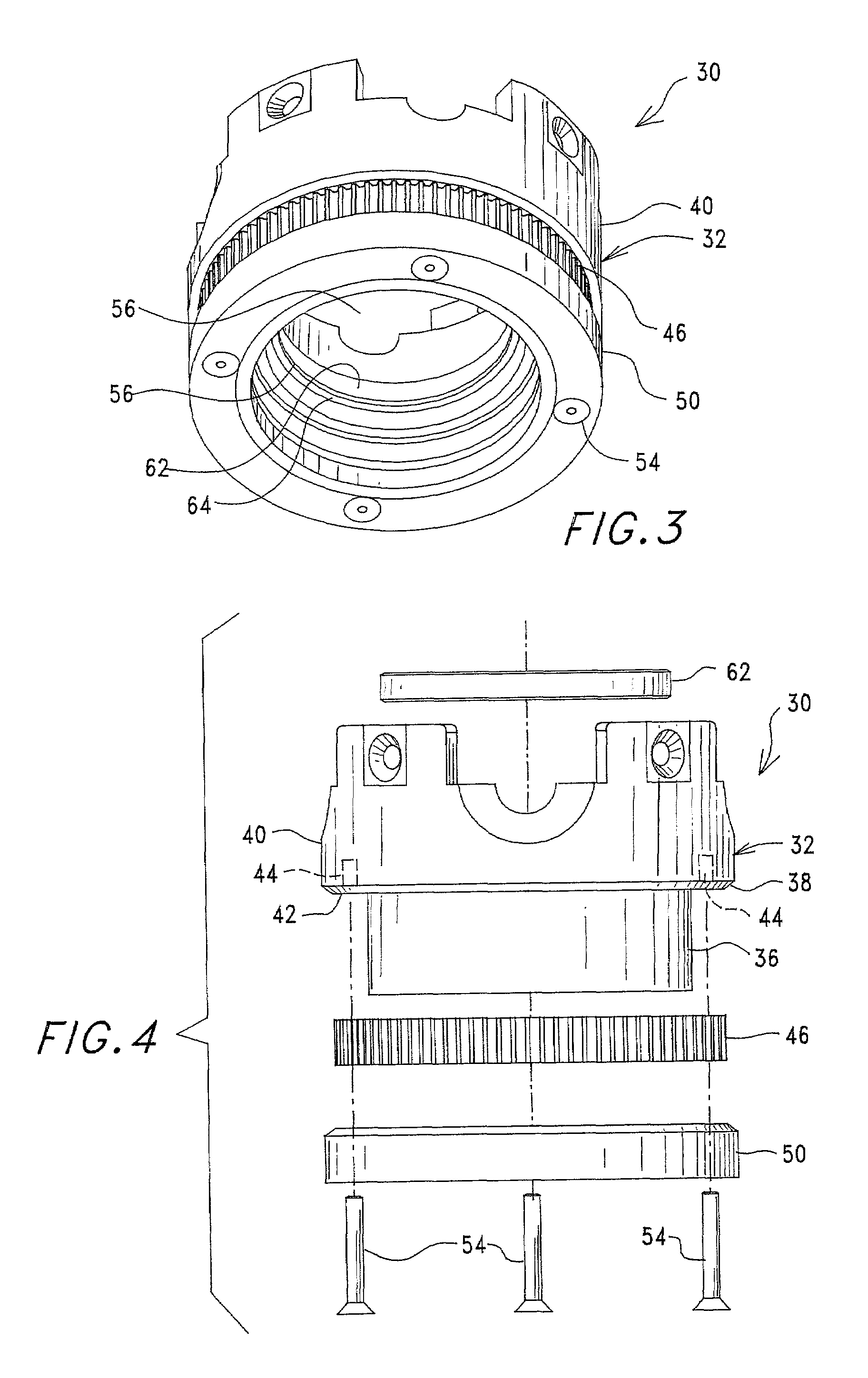

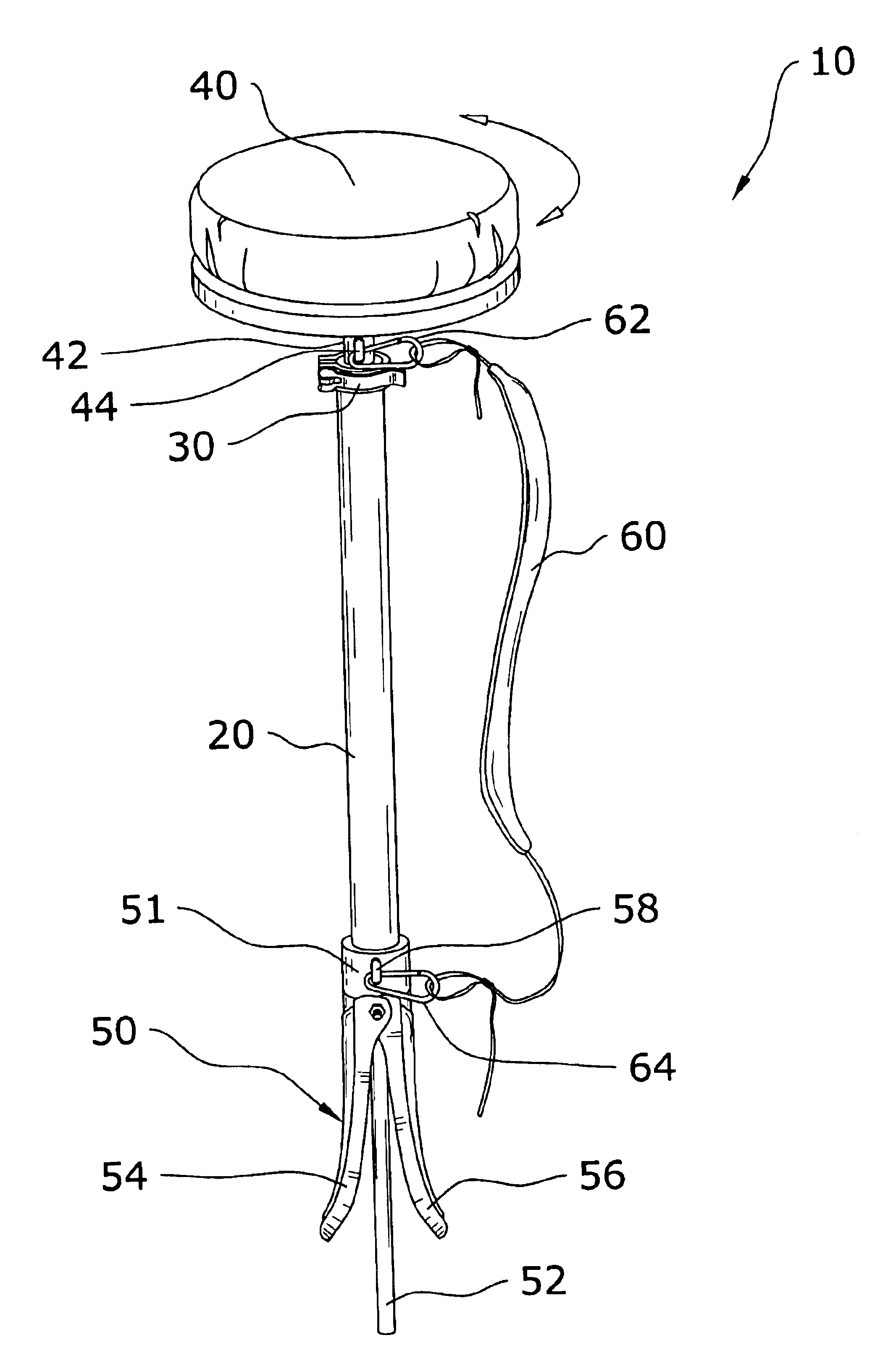

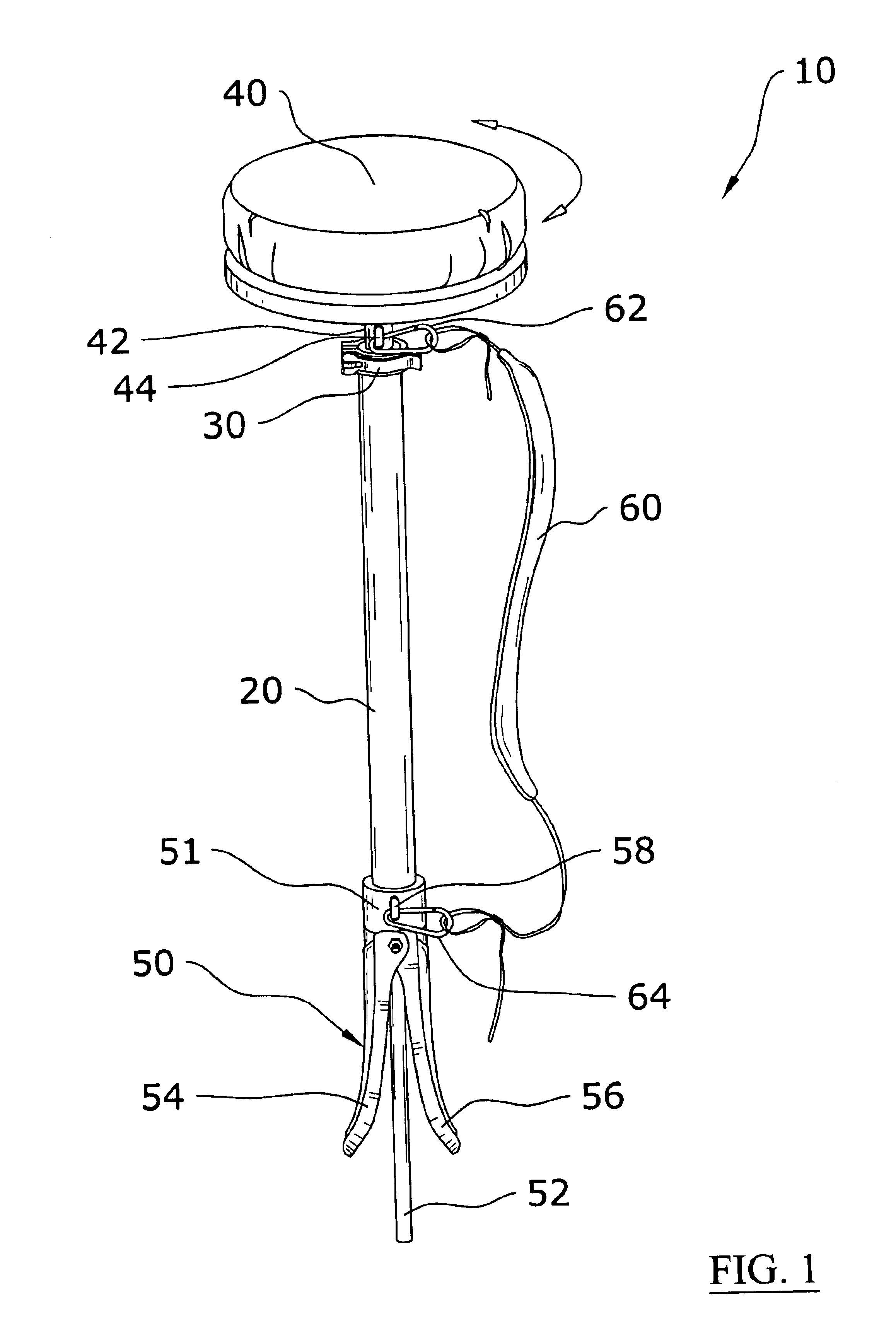

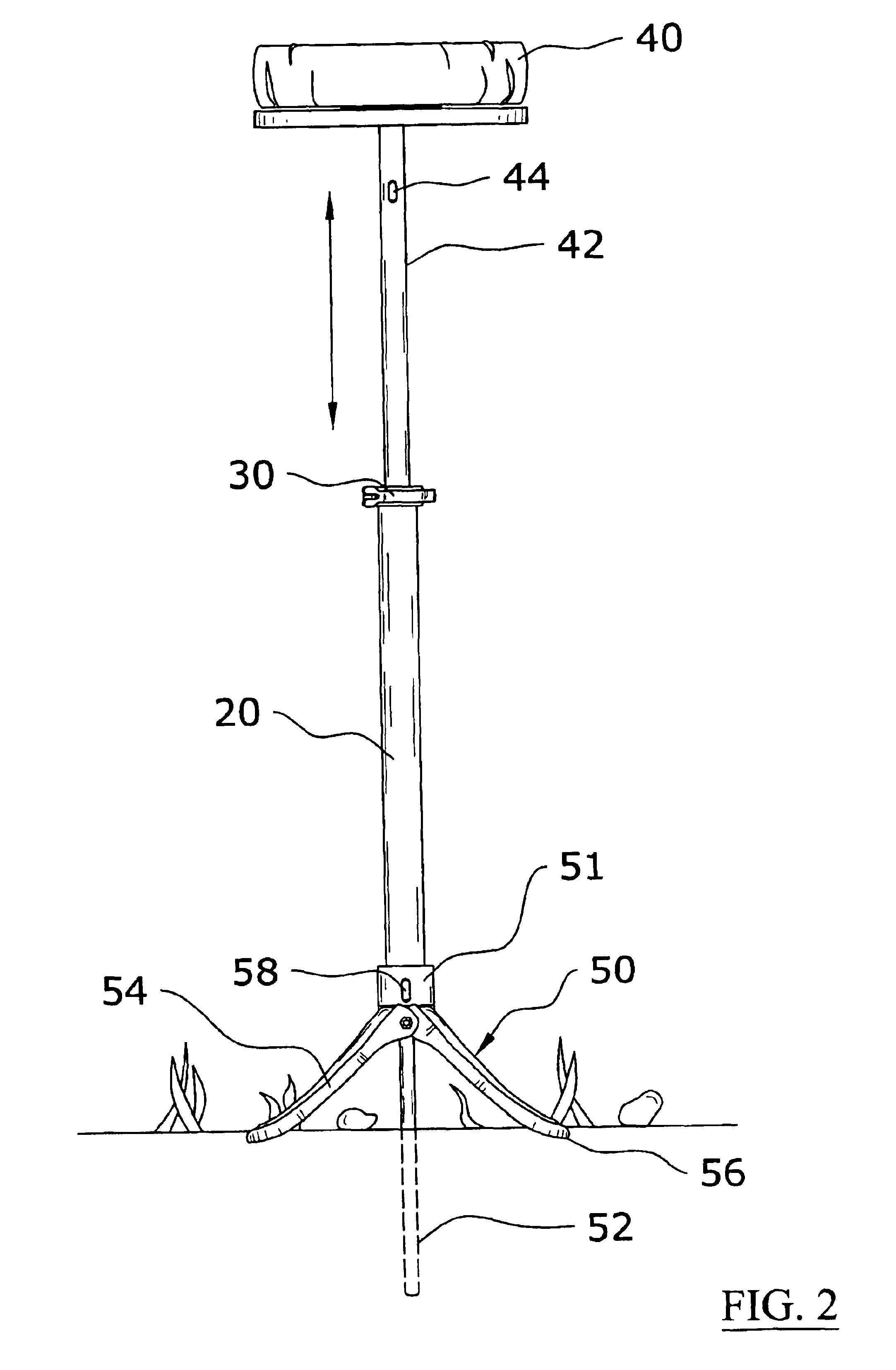

Outdoor stool system

InactiveUS6893097B1Compact sizeEasily transportVehicle seatsFoldable chairEngineeringStorage structure

An outdoor stool system for providing a portable seating structure capable of being utilized in various ground surface conditions. The outdoor stool system includes an elongate support member, a seat shaft slidably positioned within the support member, a seat member attached to the seat shaft, and a self-deploying base support that has a compact storage structure. The base support is comprised of a spike member along with a first member and a second member pivotally attached to a lower collar. The first member and the second member pivotally extend outwardly when the spike member is inserted into a ground surface thereby providing positional support to the seat structure.

Owner:EBENSPERGER ALAN H +1

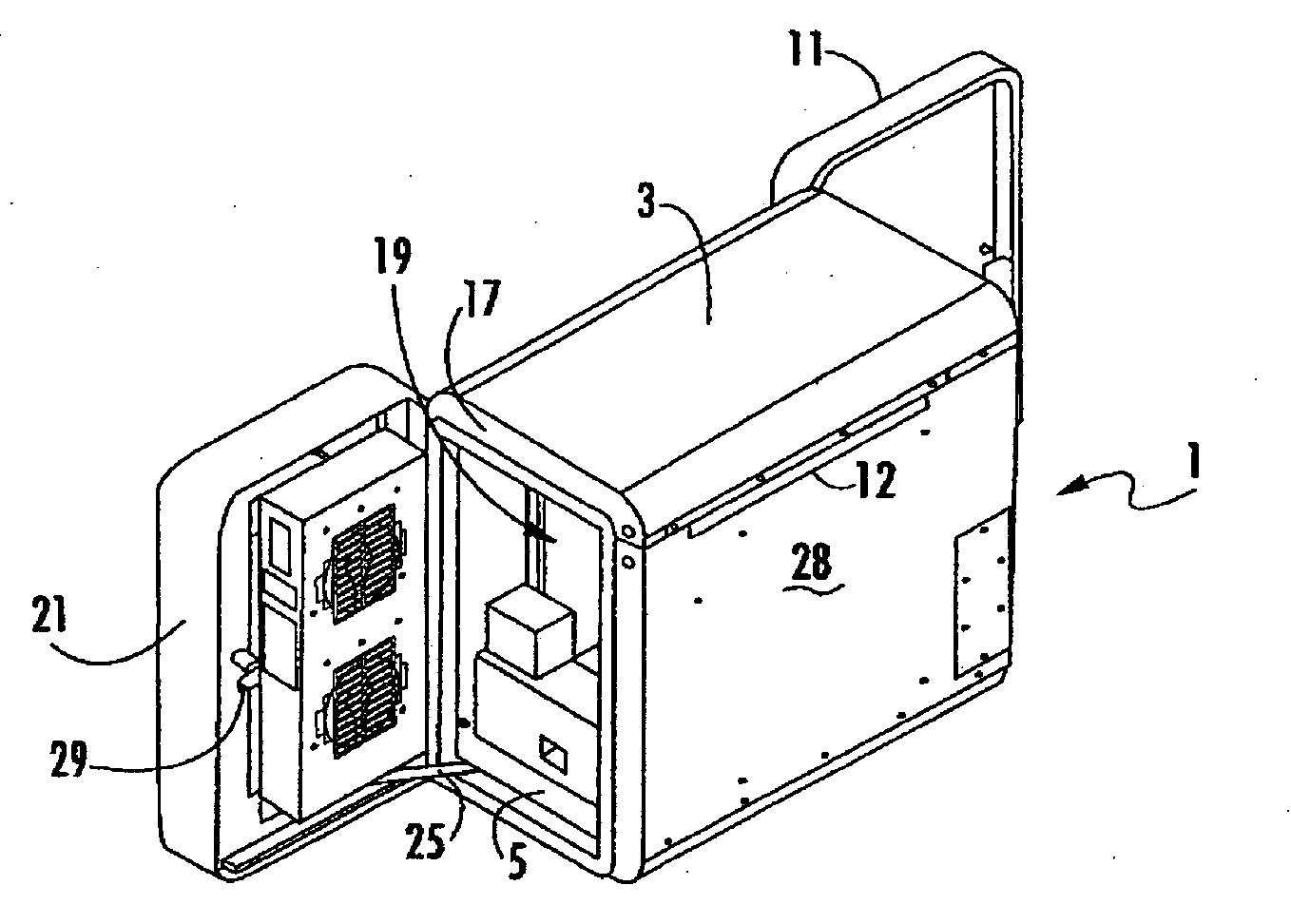

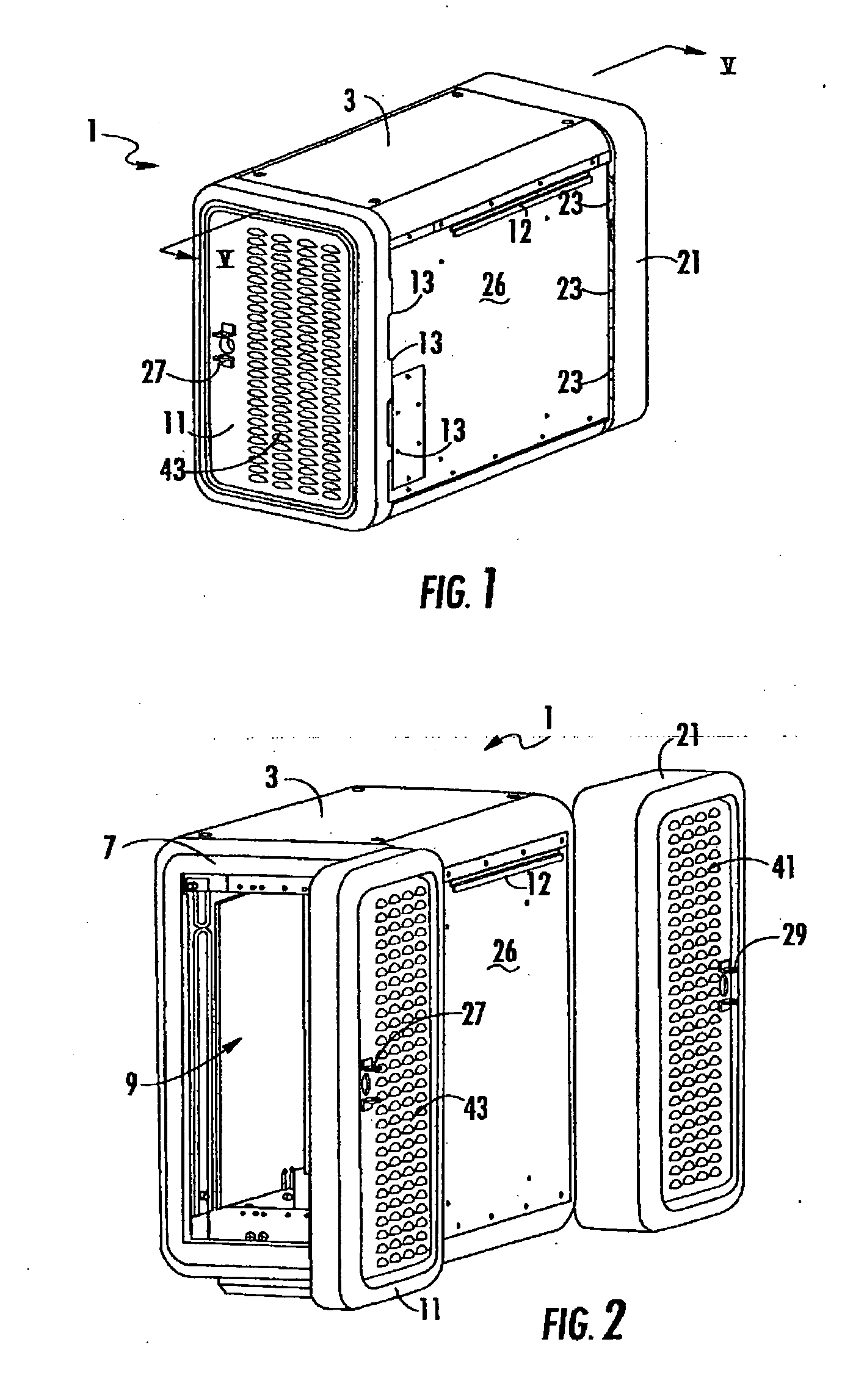

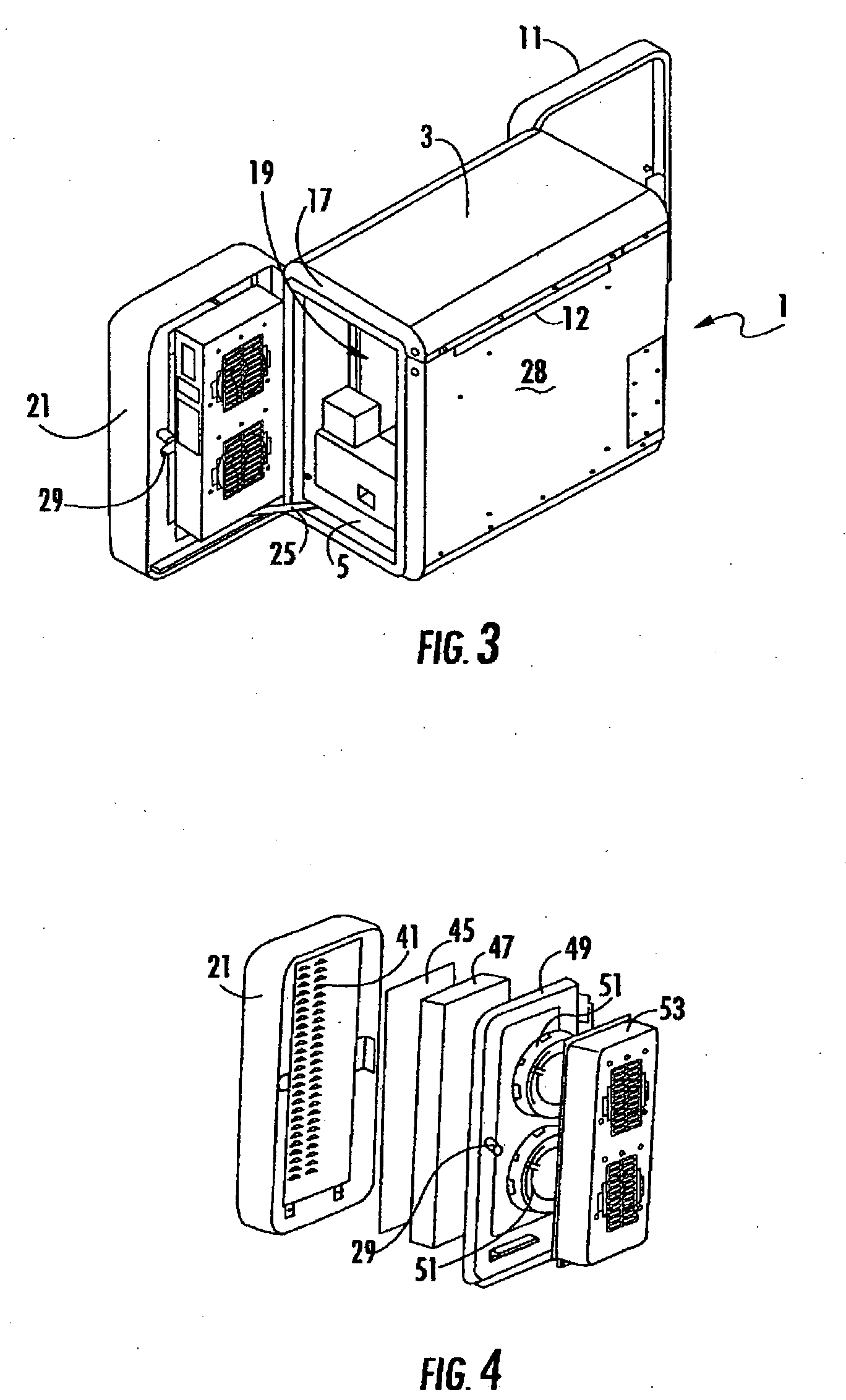

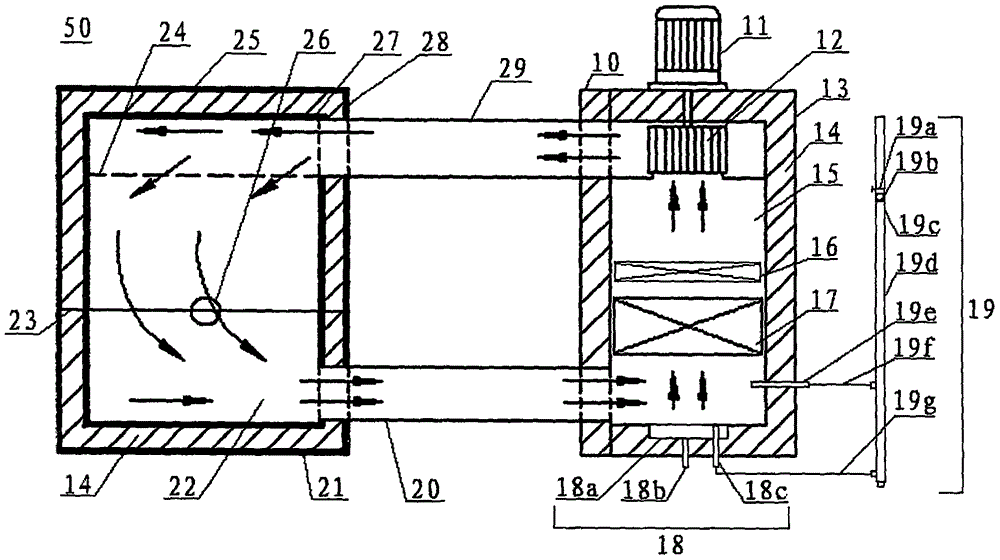

Outside plant telecommunications cabinet direct air cooling system

ActiveUS20080239668A1Compact sizeIncrease electron densityDomestic cooling apparatusLighting and heating apparatusAir cooling systemAirflow

An outdoor equipment cabinet includes a housing with an equipment compartment therein. An intake air vent and an exit air vent are formed in the housing. A fan is mounted within the housing for pulling air into the intake air vent, moving an air stream through the equipment compartment, and pushing air out of the exit air vent. A membrane is disposed adjacent the intake air vent. The membrane allows air to pass therethrough, but resists the passage of water and contaminants therethrough. In some embodiments, a baffling plate is disposed to direct the air stream within the equipment compartment, and / or the fan speed is controlled by a temperature sensor, and / or a clogging of the membrane is monitored and reported, and / or the intake air vent is located in a first door and the exit air vent is located in a second door of the cabinet.

Owner:COMMSCOPE INC

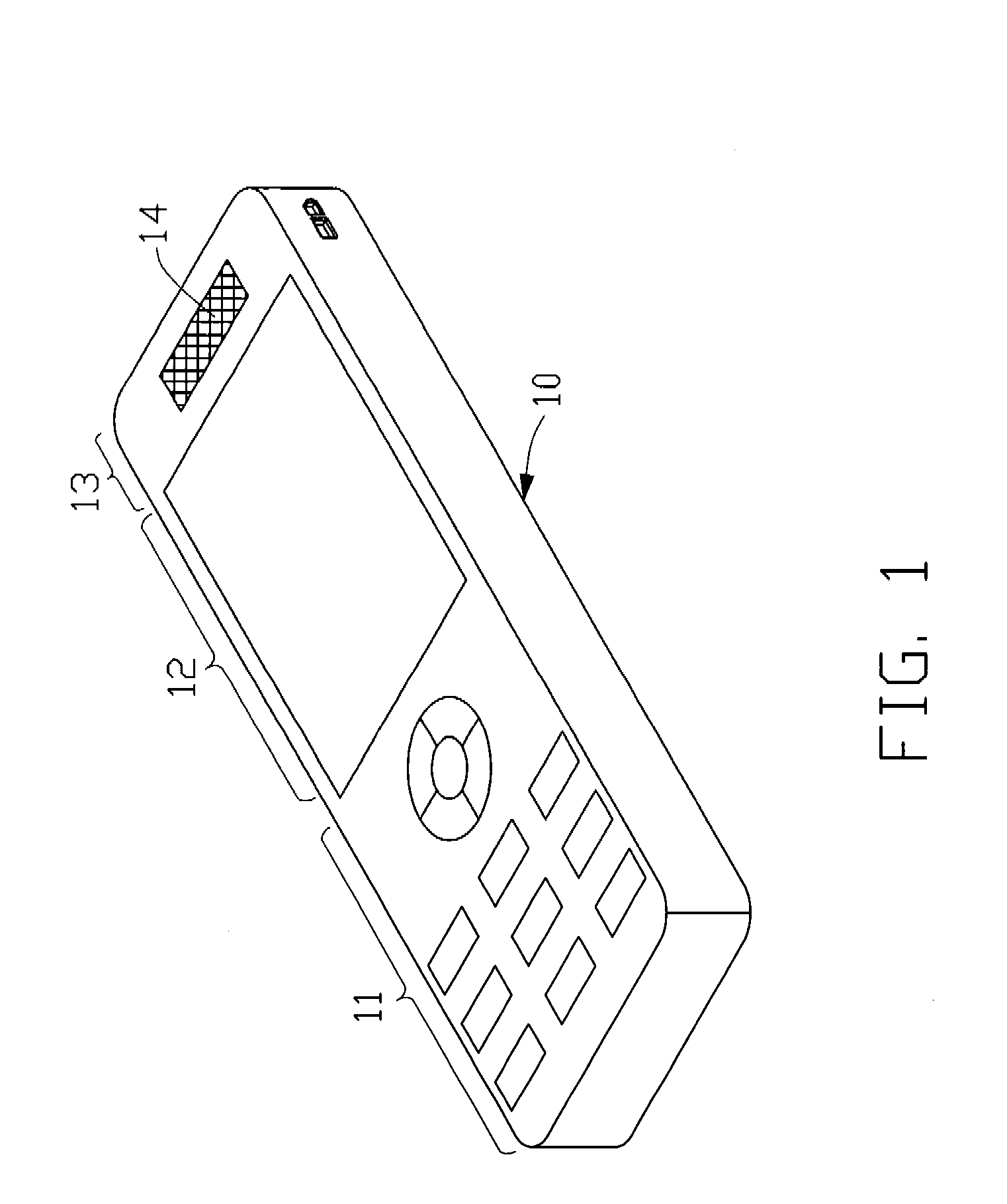

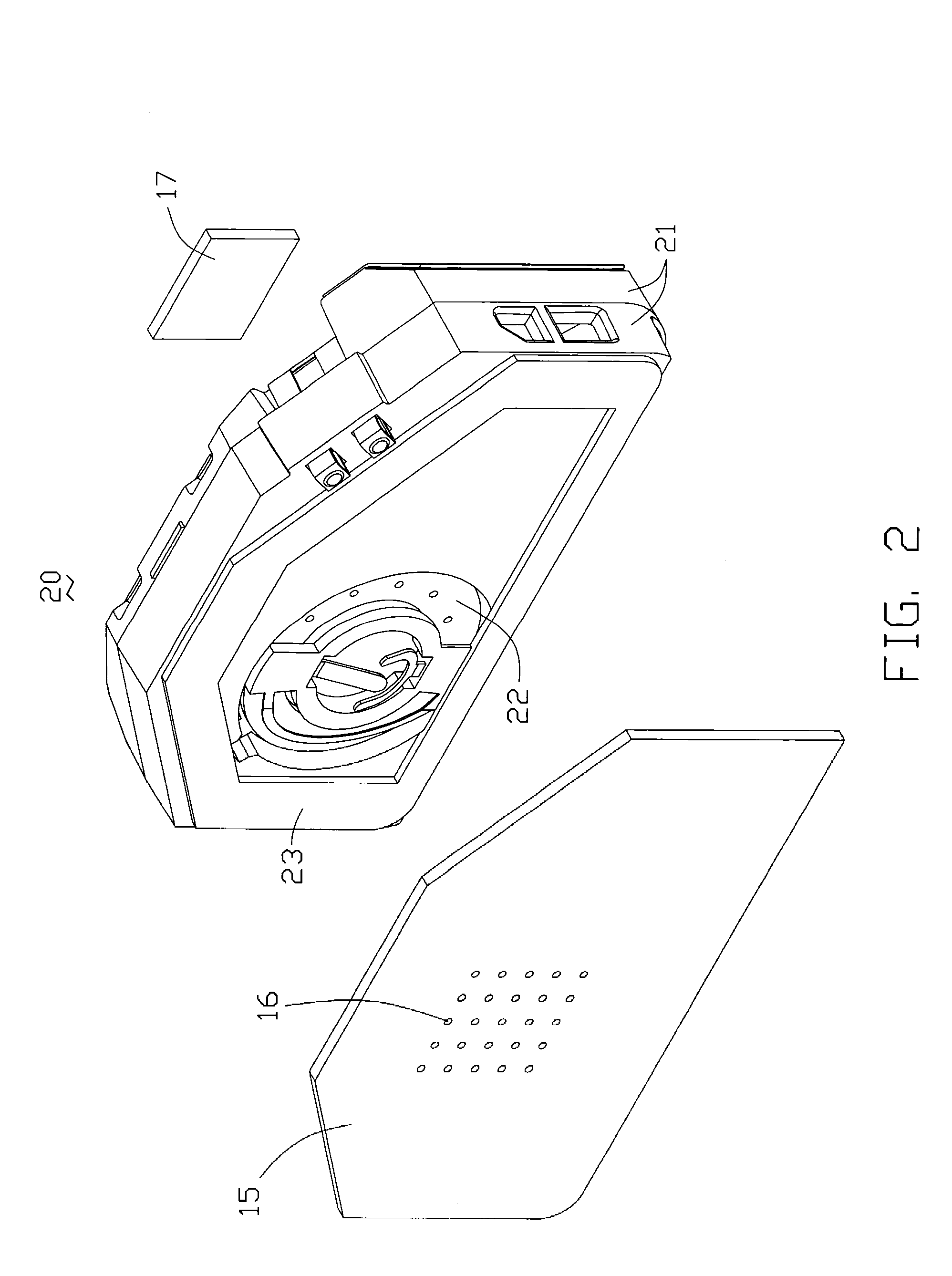

Speaker set and mobile phone incorporating the same

InactiveUS20070242848A1Good sound qualityCompact sizeSingle transducer incorporationSubstation equipmentLoudspeakerPrinted circuit board

A mobile phone and an acoustic box structure thereof are provided. The mobile phone includes a shell containing a printed circuit board (PCB) and a hidden antenna therein. The acoustic box structure is disposed between the PCB and the hidden antenna. The acoustic box structure includes a main body, a loudspeaker accommodated in the main body and a frame located between the PCB and the main body. Due to the design of the frame, a hermetic space is framed between the PCB and the main body, thereby preventing sound waves generated by the loudspeaker from leaking out via a gap between the main body and the PCB. Furthermore, the frame made of shockproof materials decreases the resonant transfer between the PCB and the loudspeaker. Consequently, the quality of the sound made by the mobile phone is improved.

Owner:HON HAI PRECISION IND CO LTD

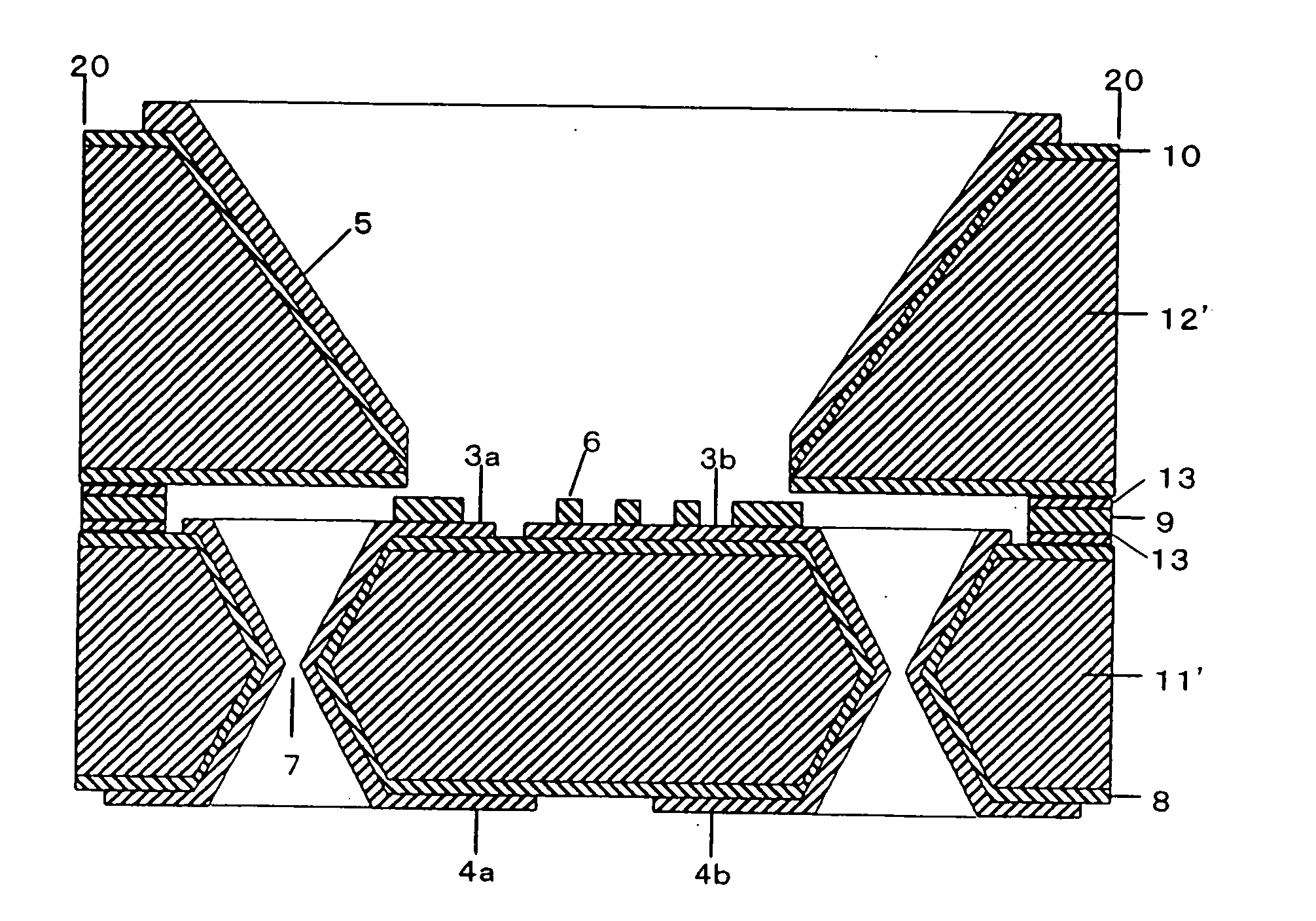

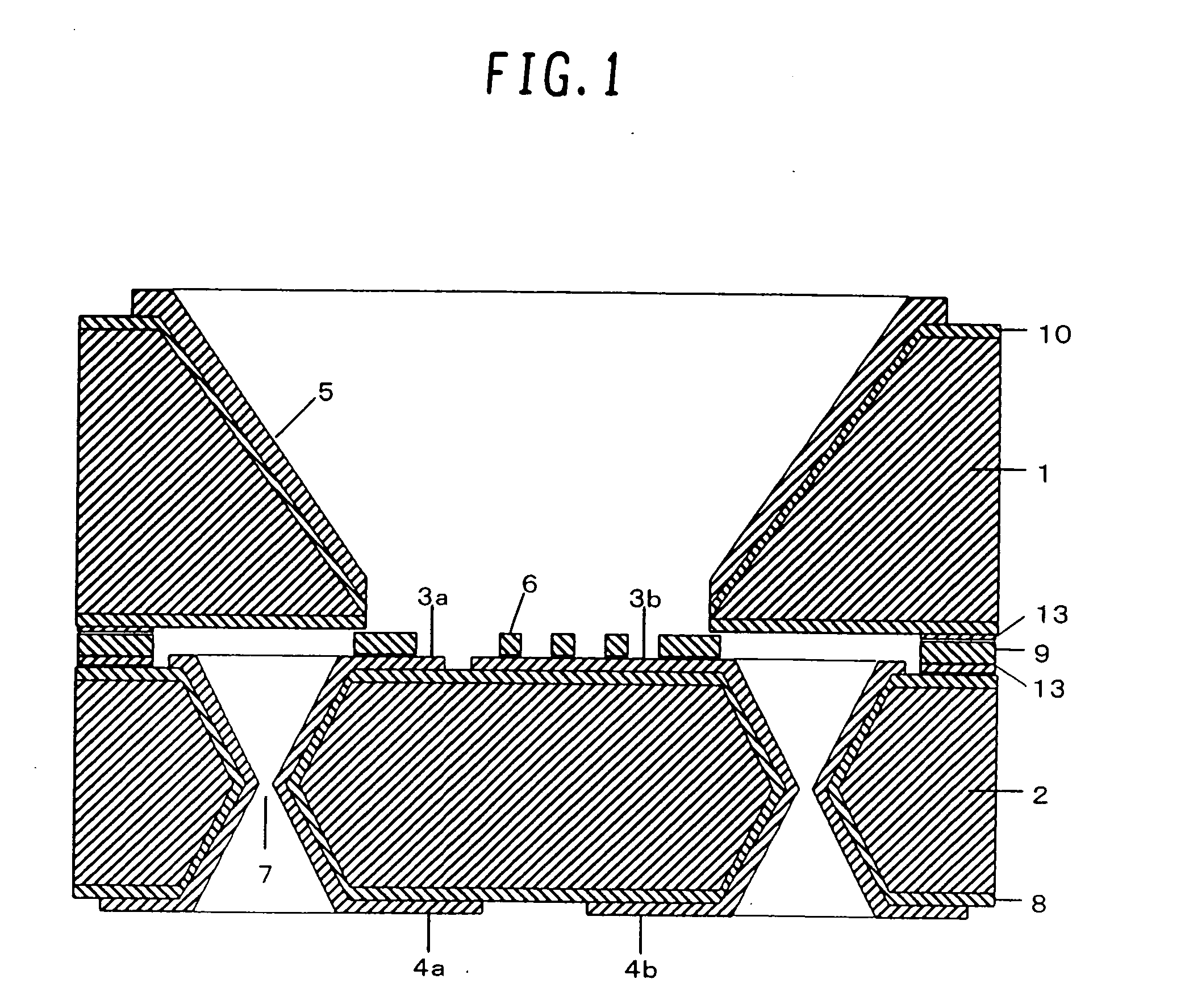

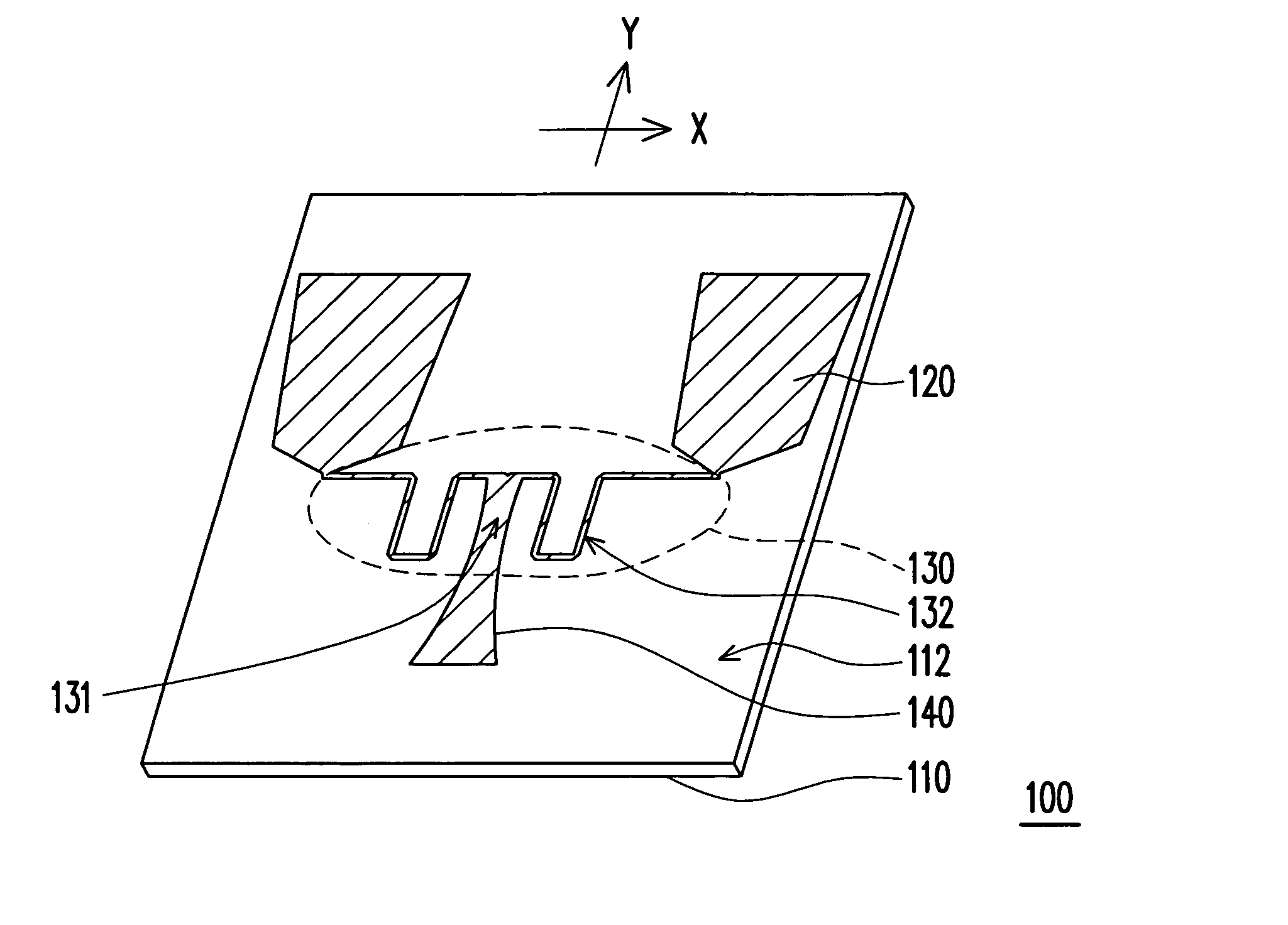

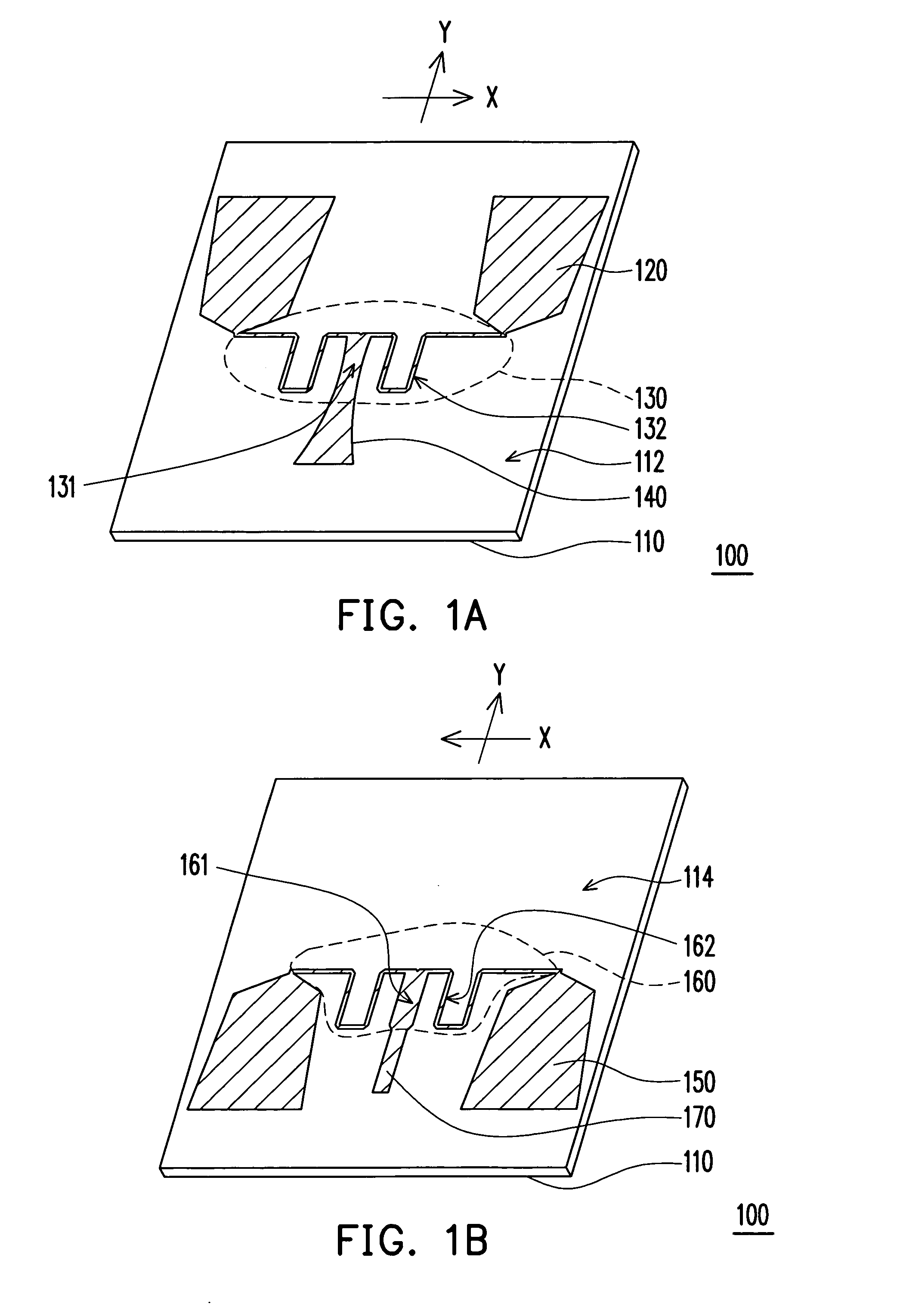

Submount for light emitting diode and its manufacturing method

ActiveUS20060054910A1Compact sizeSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPhysicsLight-emitting diode

A submount for a light emitting diode and its manufacturing method, the submount including a reflector and having a compact size. The submount for the light emitting diode comprises a Si base substrate having input / output terminals formed on a front side thereof, and a Si reflector having a sloped through hole and a reflecting film formed at least on a slope defining the through hole. The Si reflector is mounted on the Si base substrate and is fixedly joined to the Si base substrate. The Si reflector and the Si base substrate are joined to each other by a thin film solder.

Owner:HITACHI KYOWA ENG +1

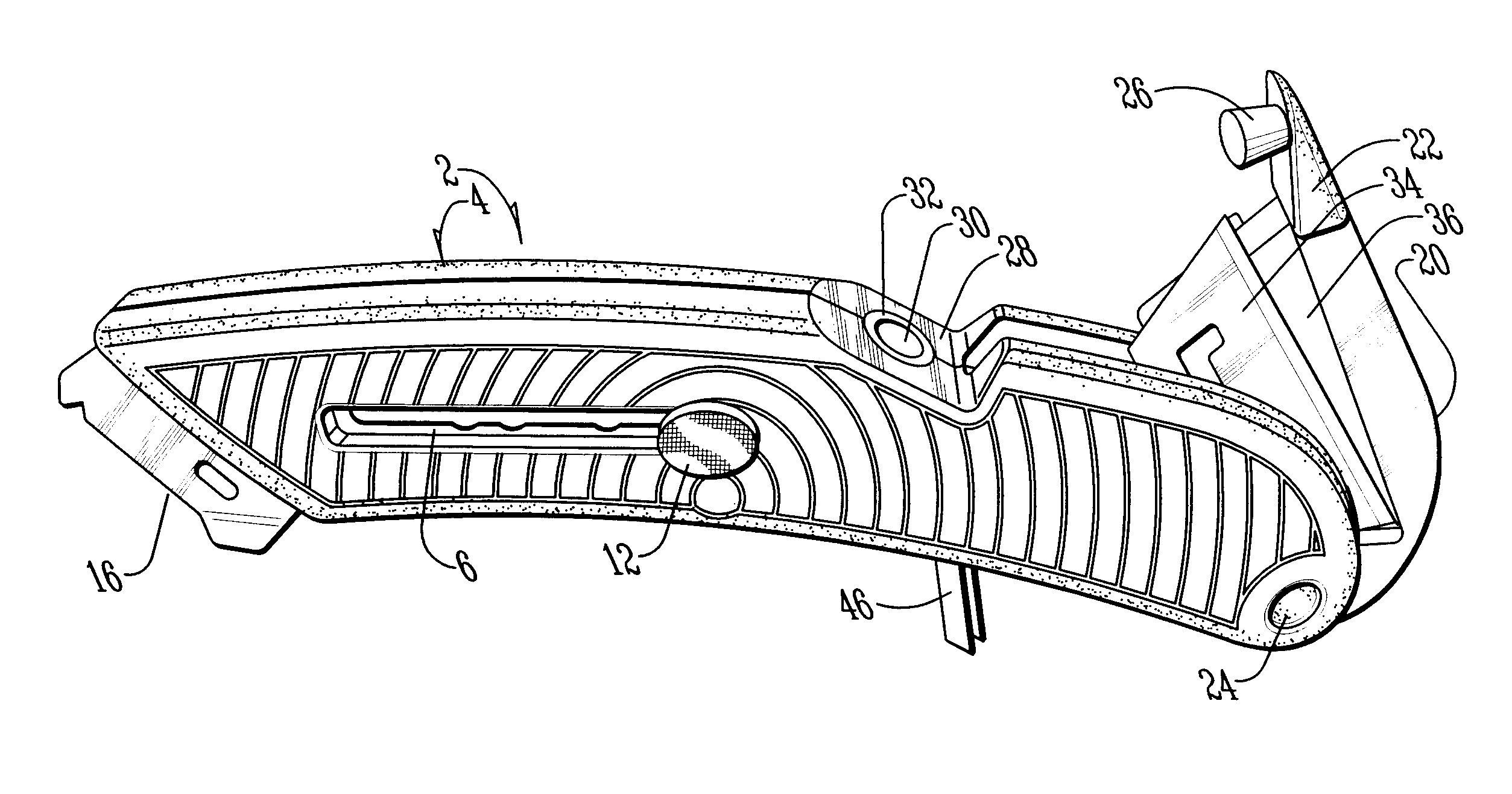

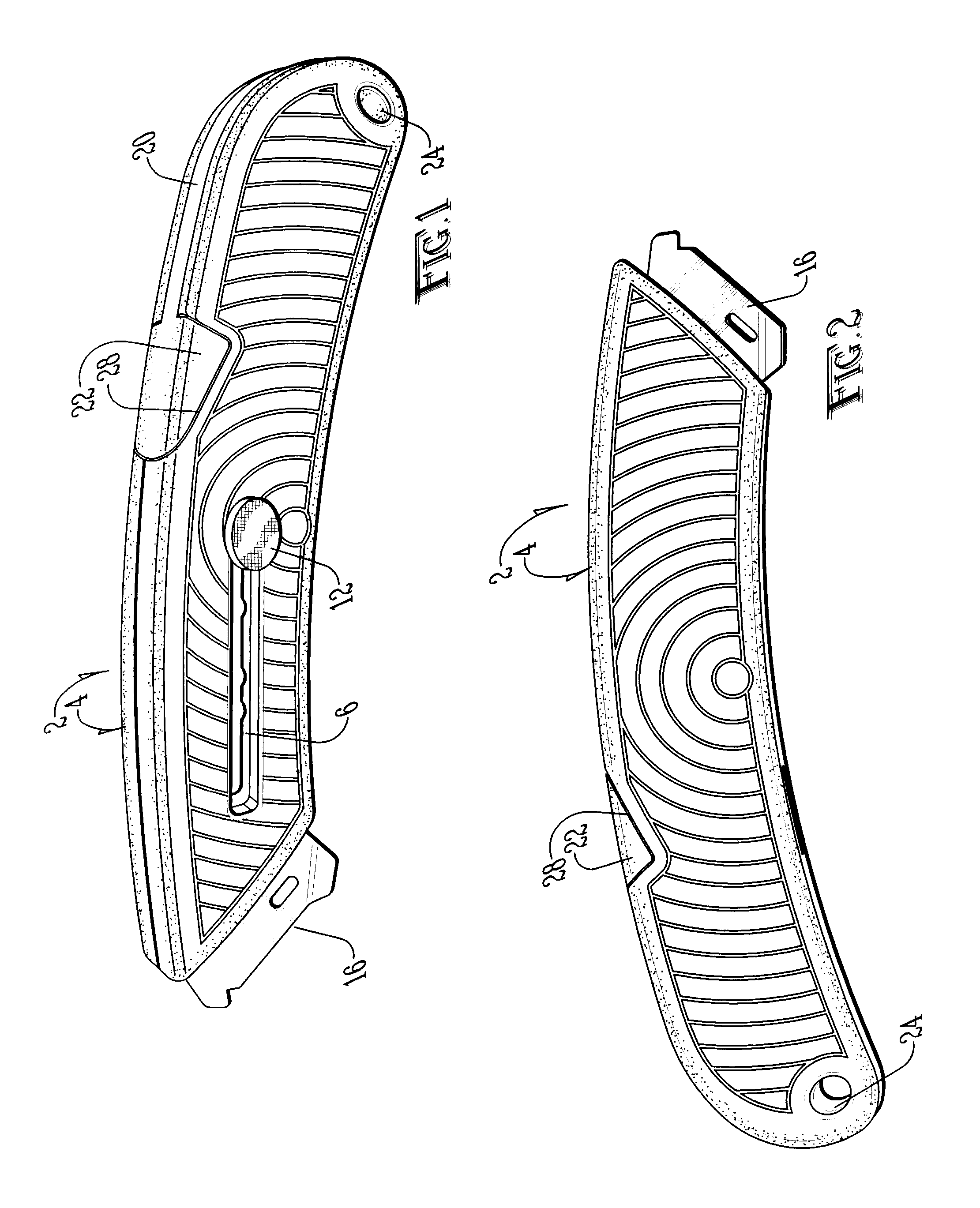

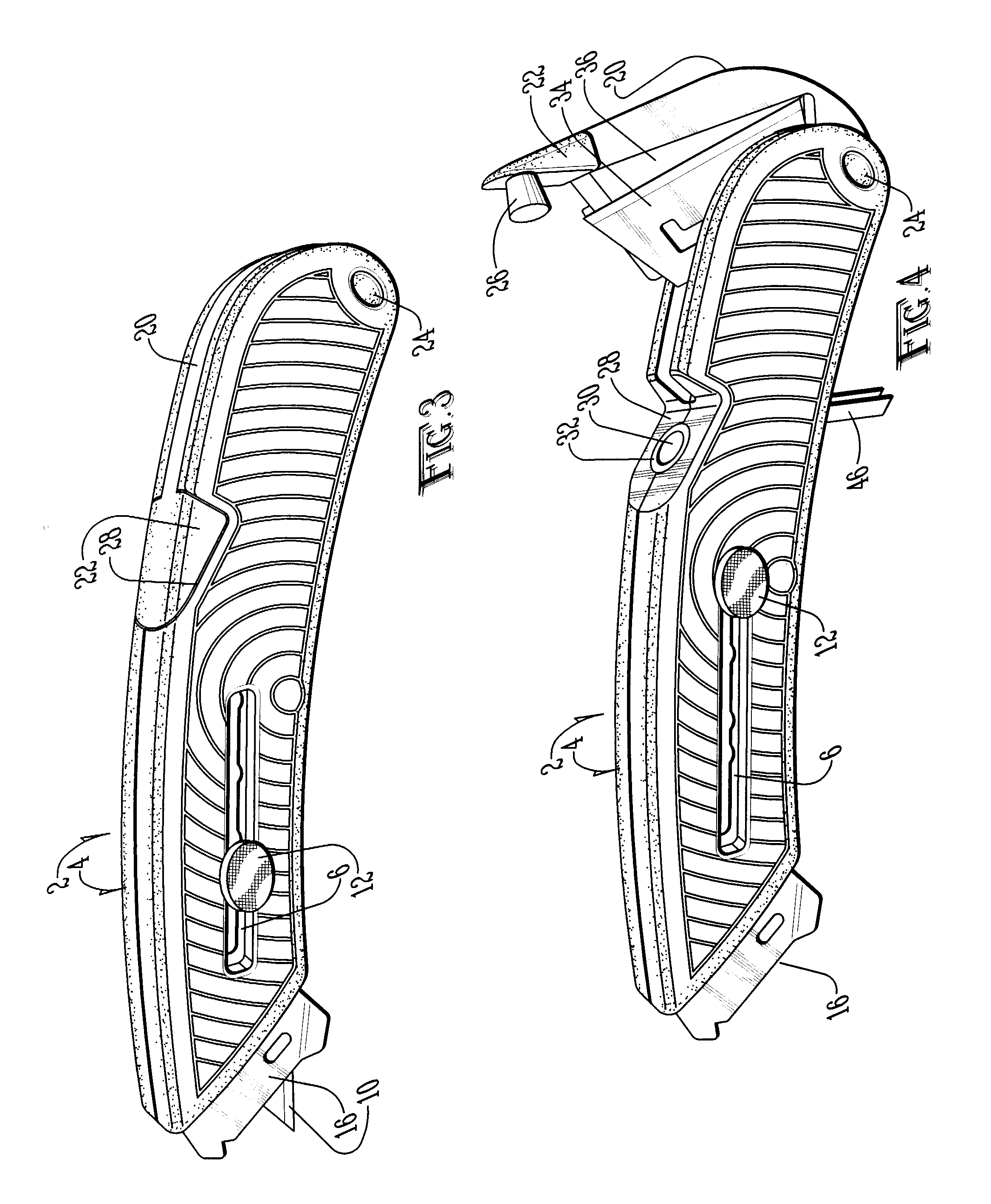

Utility knife with integrated hole punch

InactiveUS20080086895A1Compact sizeComfortable to carryThrusting weaponsWeapon componentsKnife bladesEngineering

A utility knife in accordance with the present invention combines a cutting tool and a hole punch into a single compact, efficient tool. The utility knife includes a recess into which the cutting blade is retracted and another recess to store a hole punch. The hole punch pivots from one end the body so that a piece of material to be punched can be placed between the hole punch and the body. The hole punch is pivoted towards the body to punch through the material. The punch mechanism pushes confetti from the material into a confetti storage cavity within the body. A user can open the confetti storage door to discard the confetti stored within the body. The present invention also allows a user to store extra cutting blades within a recess in the hole punch arm.

Owner:PARKS THOMAS JERALD

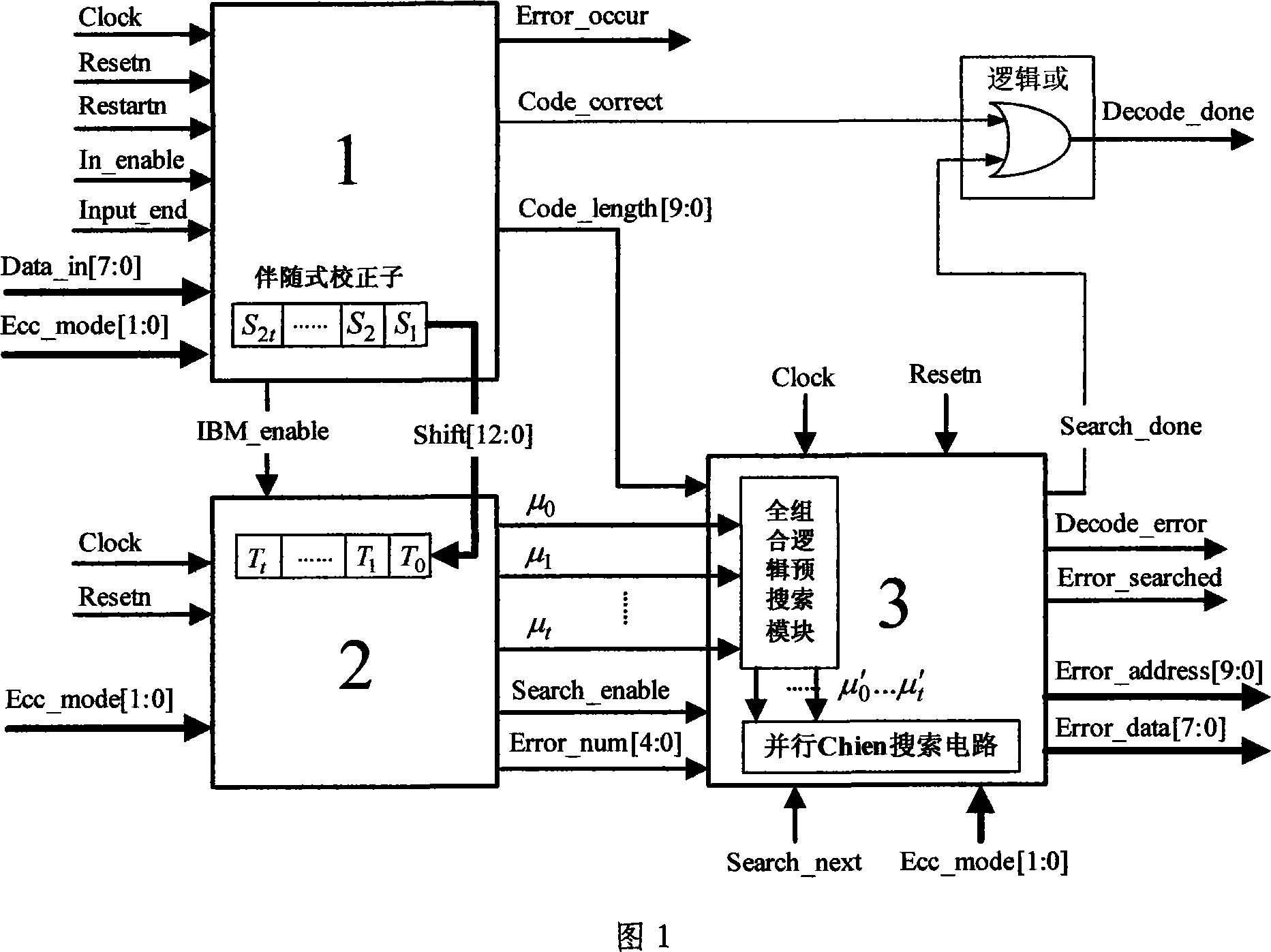

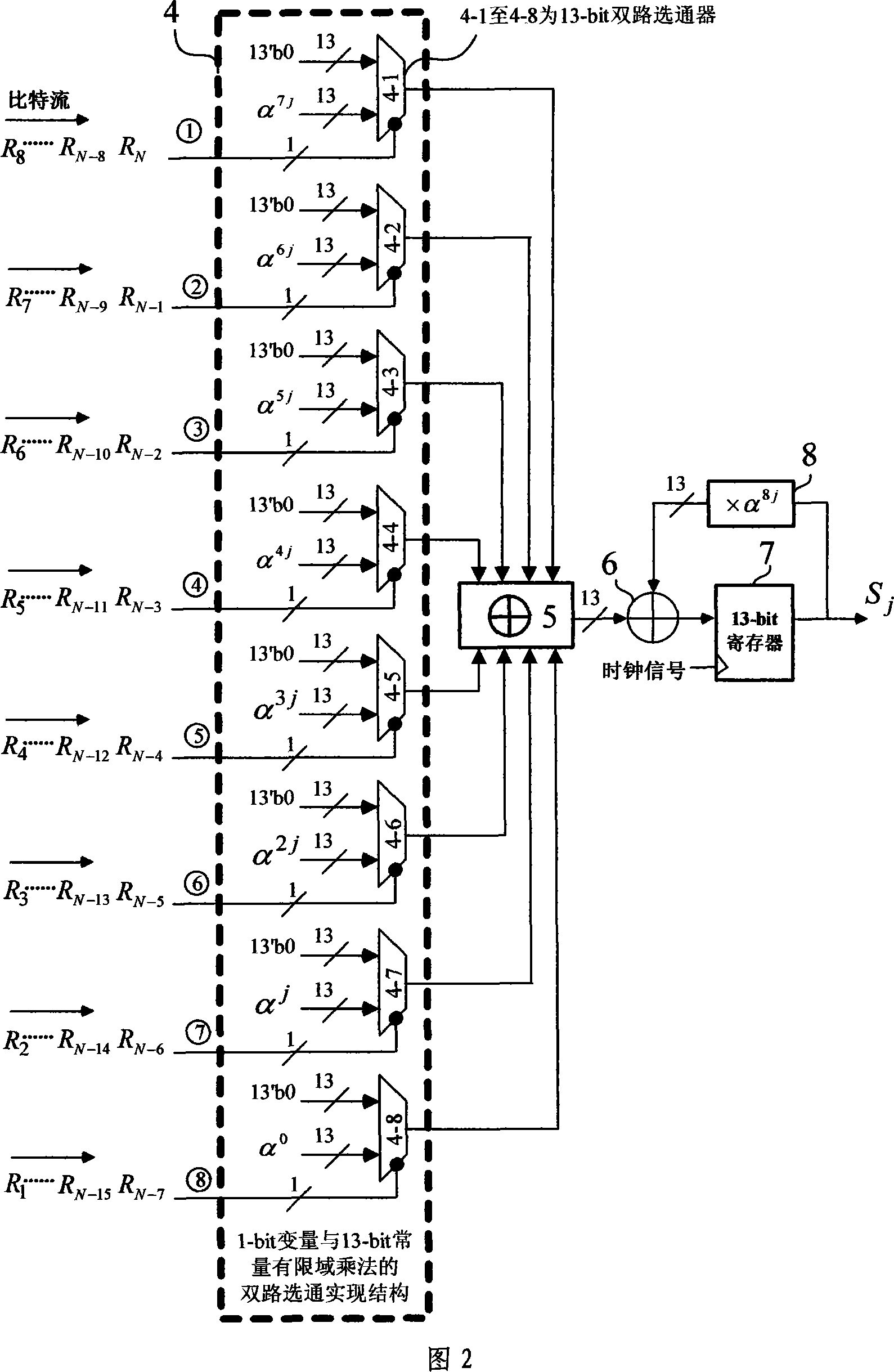

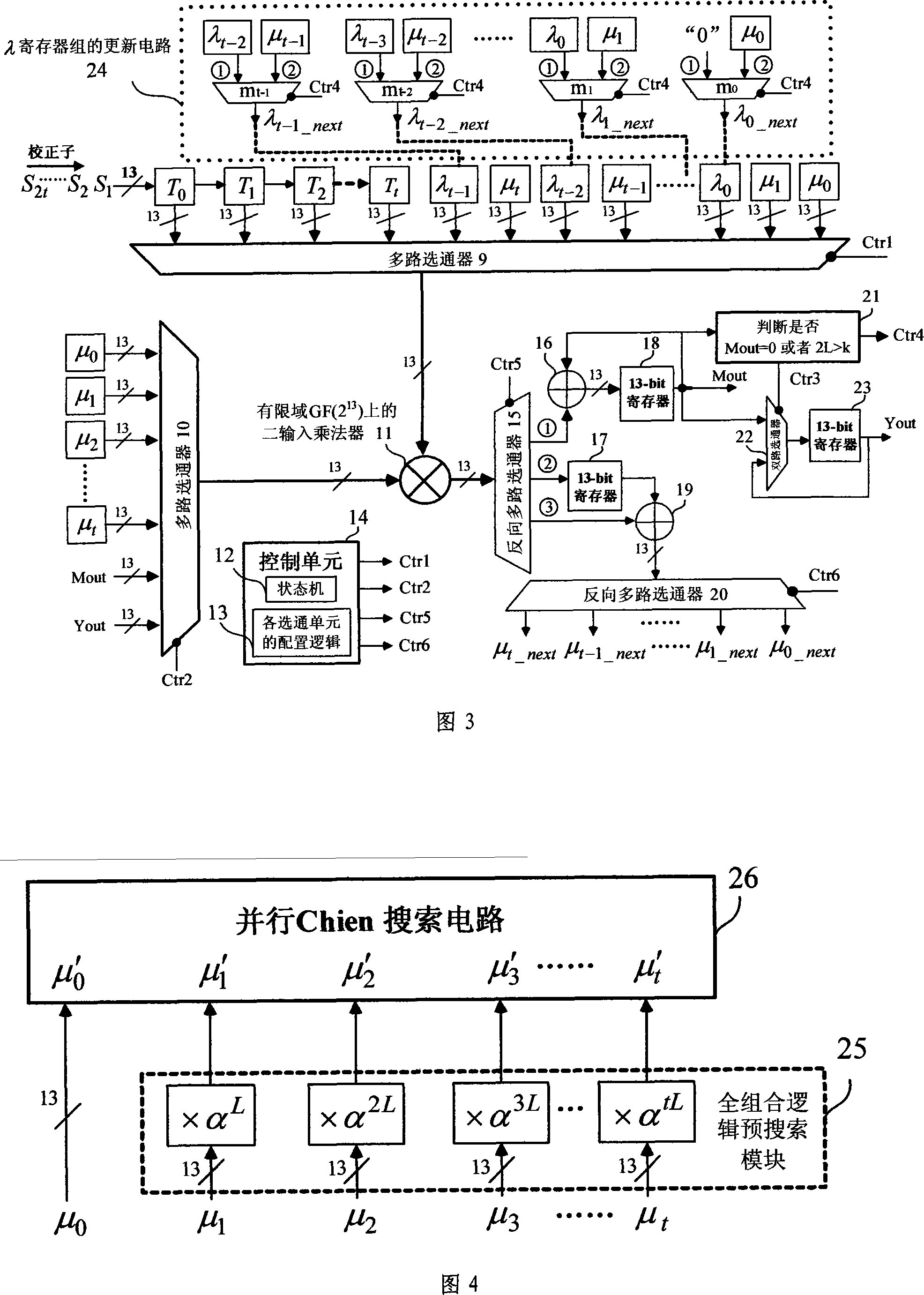

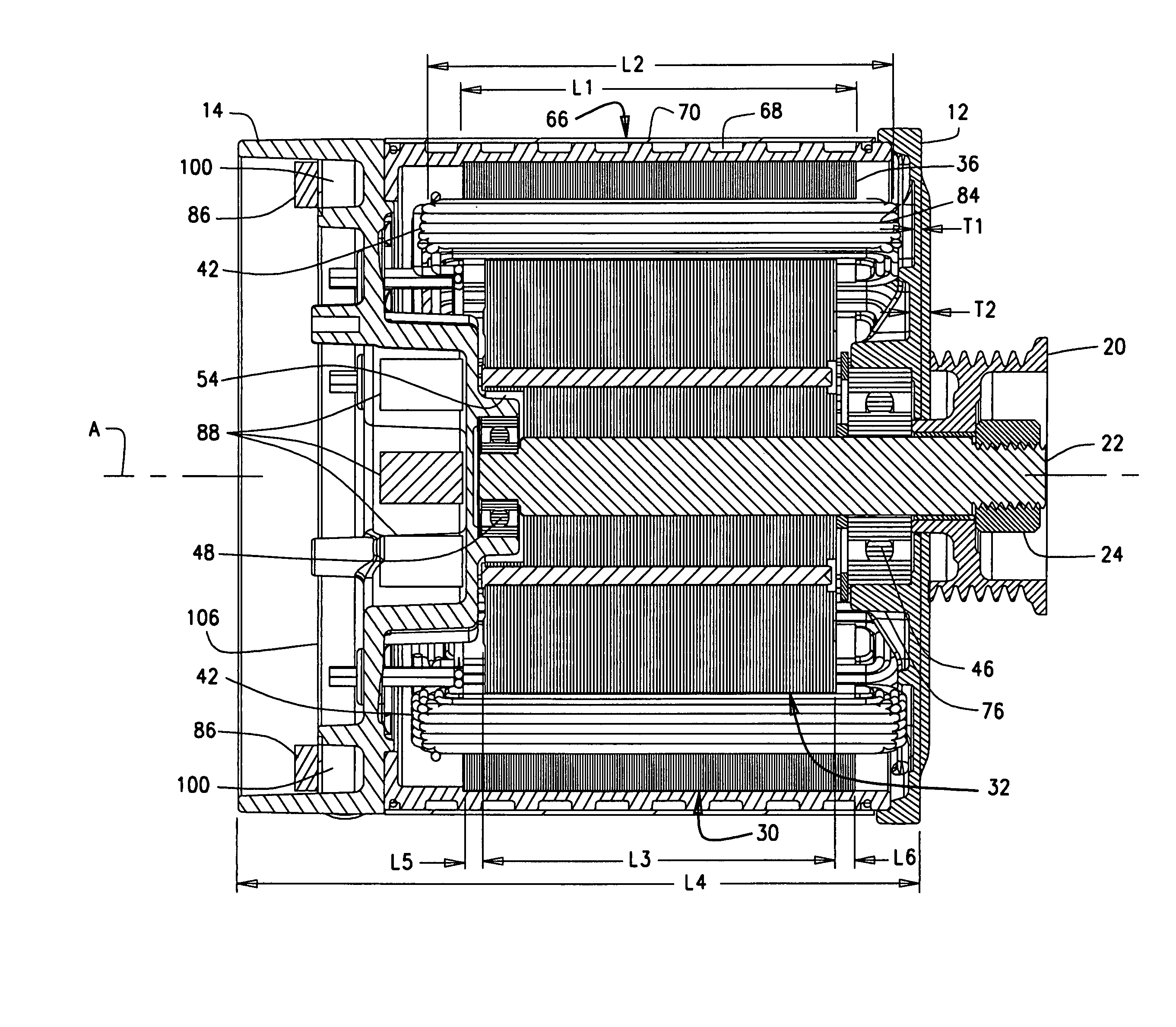

Area compact type BCH paralleling decoding circuit supporting pre searching

A compact BCH parallel decoding circuit which supports preview search works on a finite field GF(2<13>). The parallel decoding circuit comprises a syndrome arithmetic circuit(1), a realizing circuit(2)with multiple shoots in one round for IBM wrong position multinomial iterative computation in the finite field GF(2<13>), a wrong address search circuit(3) provided with a totally combined logic pre-search module and a multifunctional configurable data interface(27)of an encoder. Compared with prior art, the decoding circuit has the advantages that the hardware is of low degree of complexity, the circuit area is compact and the decoding circuit is low in cost; data throughput is high and wrong address research is quick; the interface is simple in design and is practical and multi-functional; correcting performance can be flexibly configured according to the length of the check element and is free from the change of the code length.

Owner:NATIONZ TECH INC

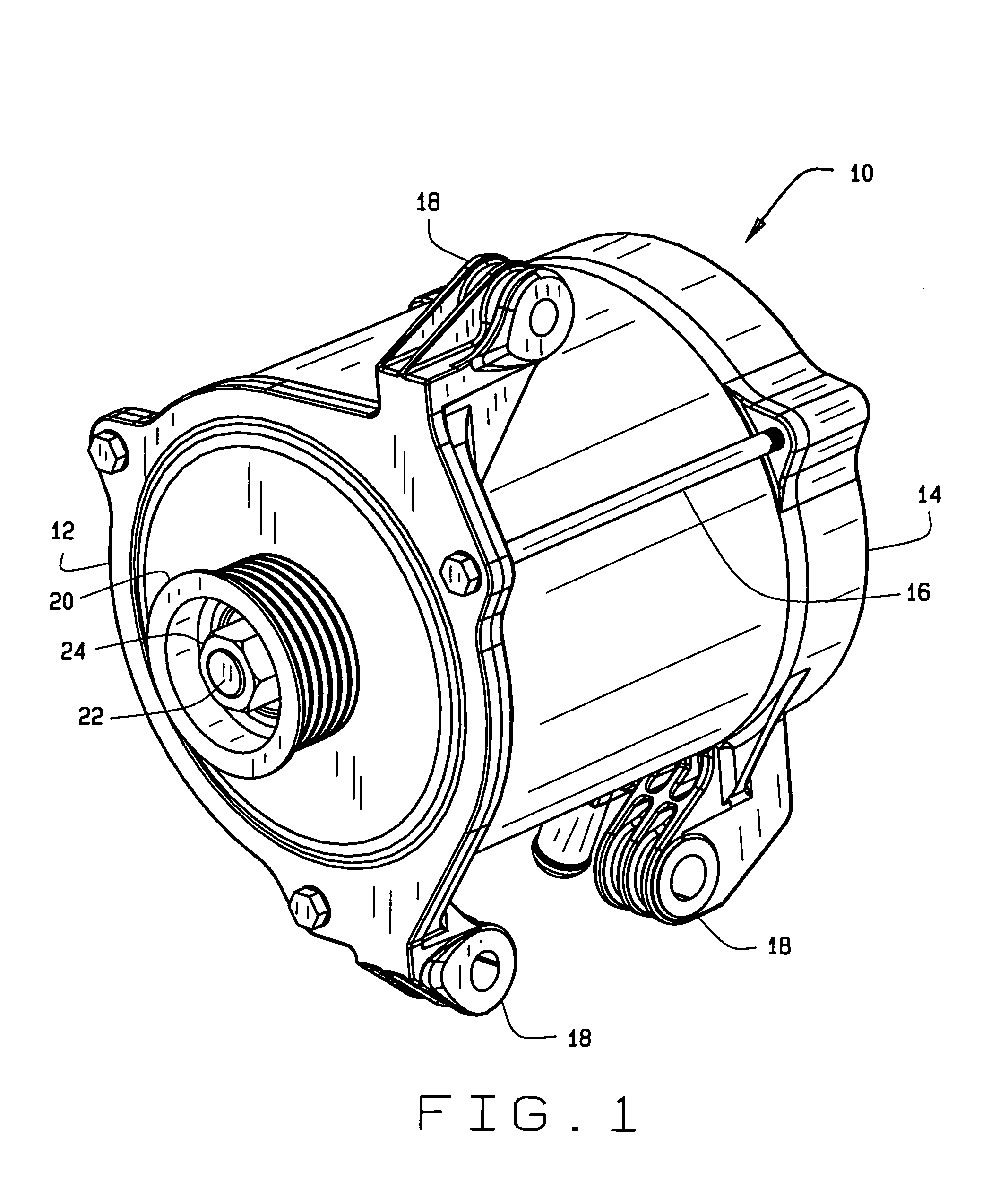

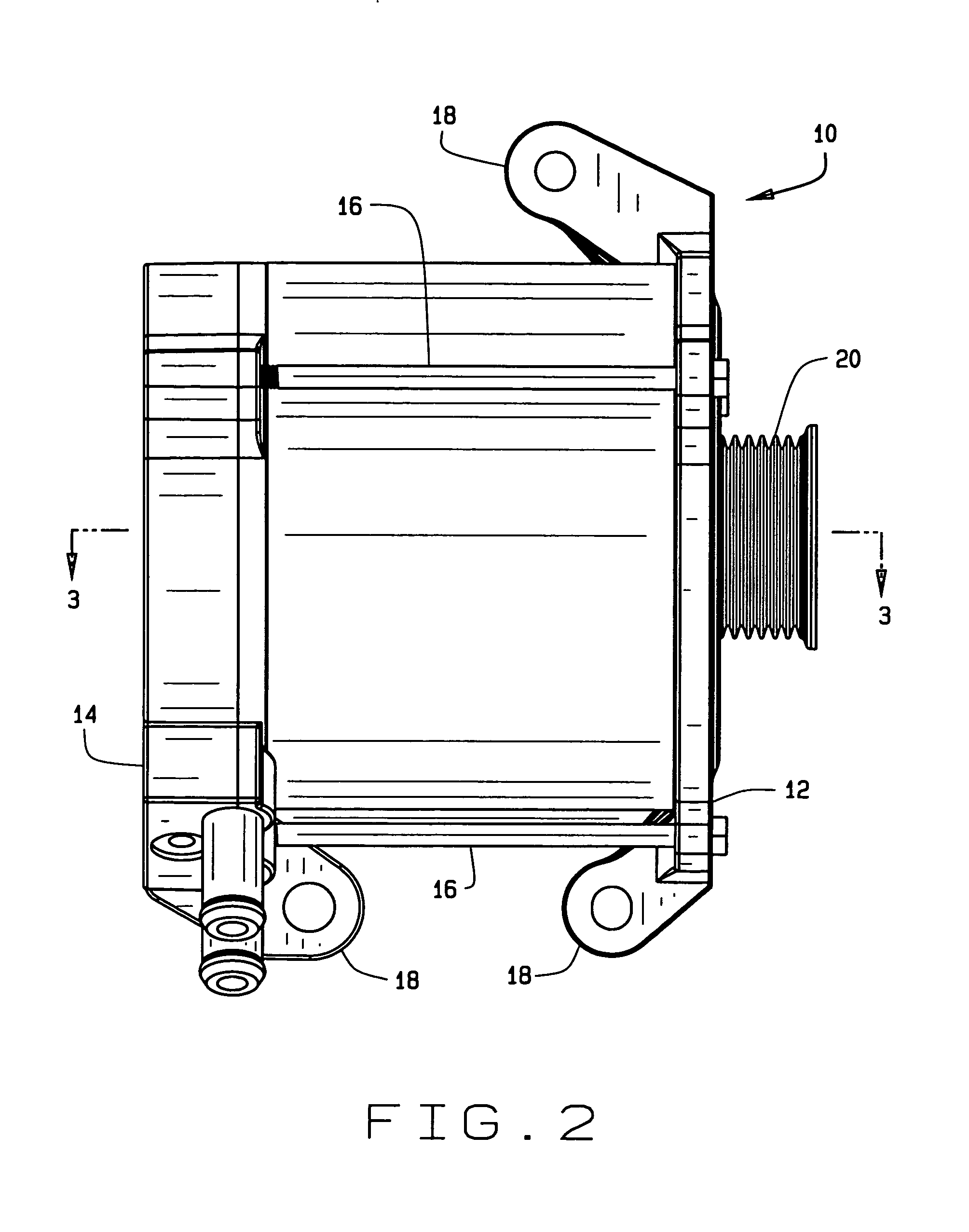

Compact dynamoelectric machine

ActiveUS20050174007A1Compact sizeEfficient in operationWindingsMagnetic circuit rotating partsStatorEngineering

A compact dynamoelectric machine having a rotor with a length which is less than the length of a corresponding stator core. The rotor is rotatable on a shaft supported by bearings, with at least one of the bearings being positioned longitudinally within the stator core. Two endshields define opposite ends of the machine. One of the endshields is configured for holding electronic components in arrangement integrated with the machine.

Owner:NIDEC SR DRIVES

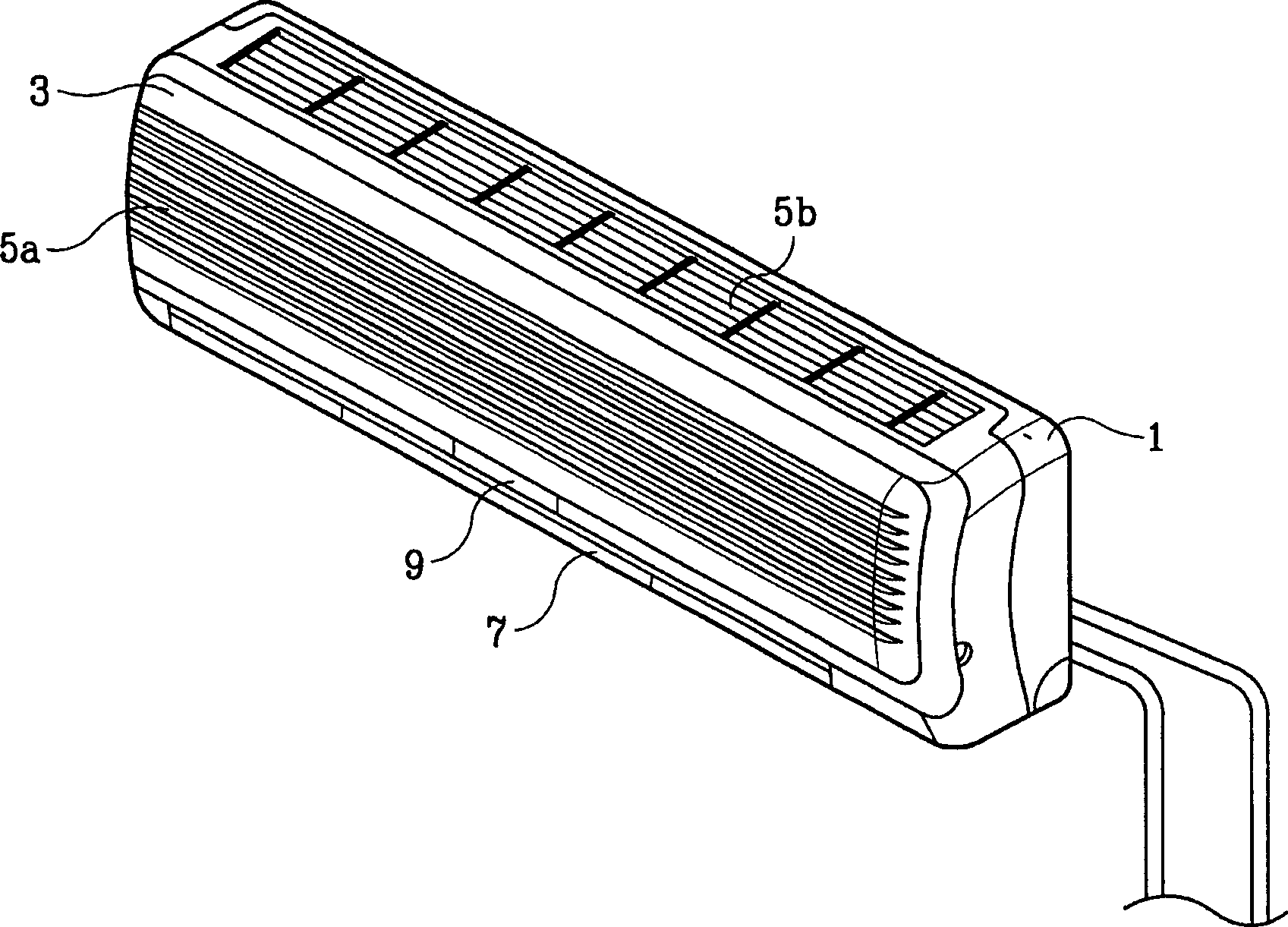

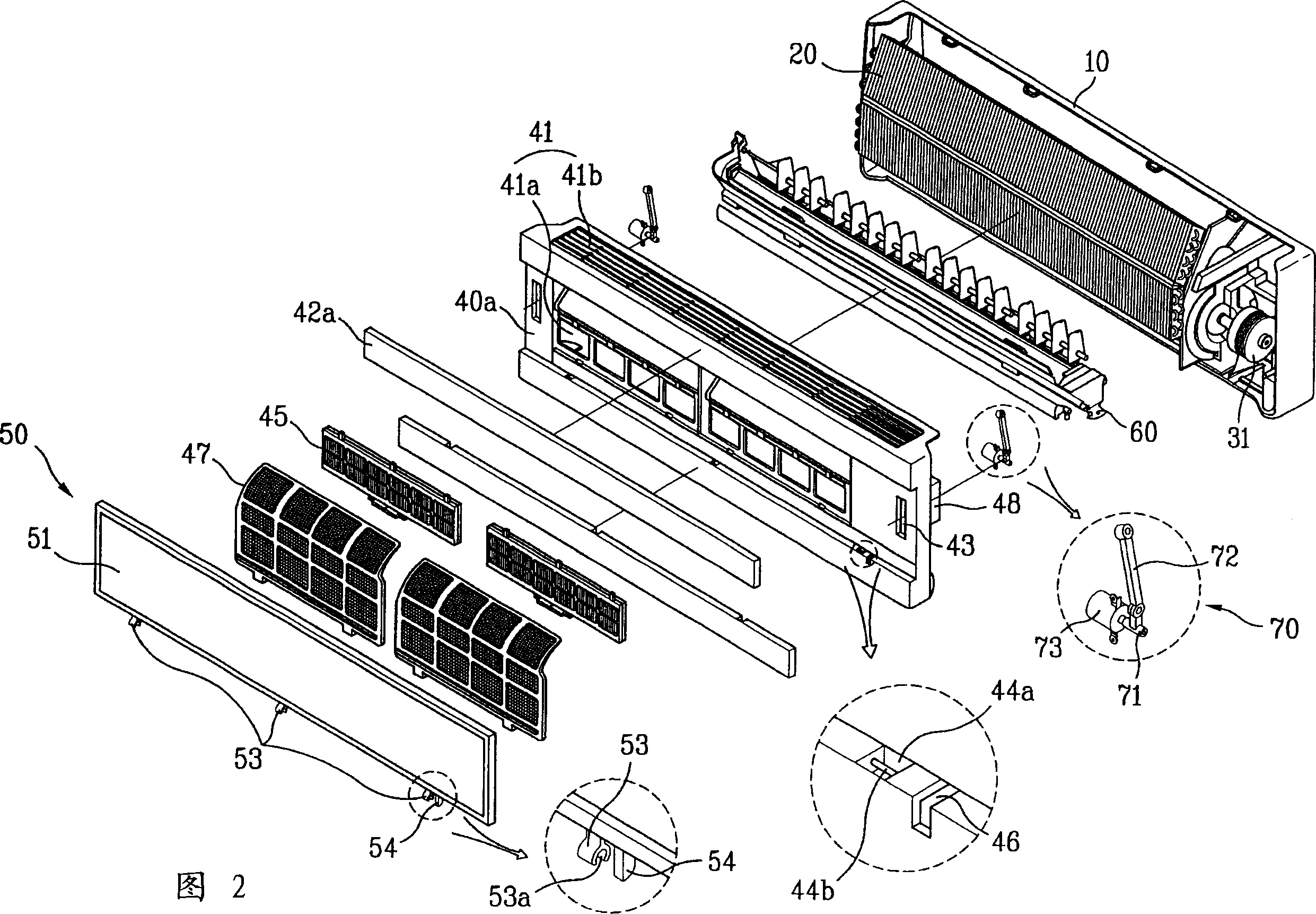

Air conditioner

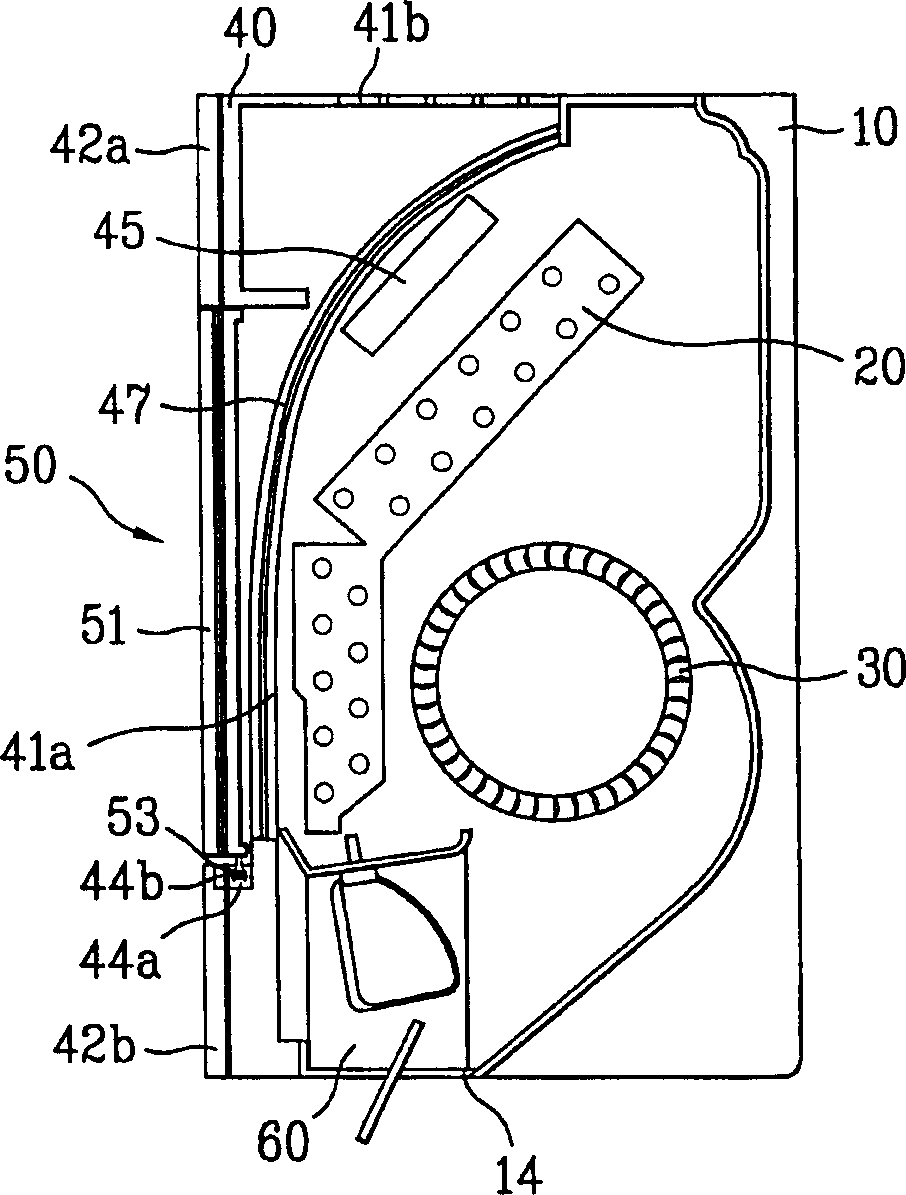

InactiveCN1401944ACompact sizeEasy to identify informationMechanical apparatusSpace heating and ventilation safety systemsIndoor airEngineering

An air-conditioner is disclosed, which has a small size with a more sophisticated appearance and provides more various information to a user. The air-conditioner includes a main chassis (10) for receiving various components, a heat exchanger (20) being installed inside the main chassis (10) for exchanging heat with room air, a blow fan (30) being installed inside the main chassis (10) for sucking in and blowing out the room air, a front panel (40) being attached to the front side of the main chassis (10) and having an intake inlet (41a) at its front face to make air flowed into the heat exchanger (20), and an display panel (50) detachably installed on the front face of the front panel (40) revolvably so as to selectively close / open the intake inlet (41a) and displaying various information.

Owner:INTELLECTUAL DISCOVERY CO LTD

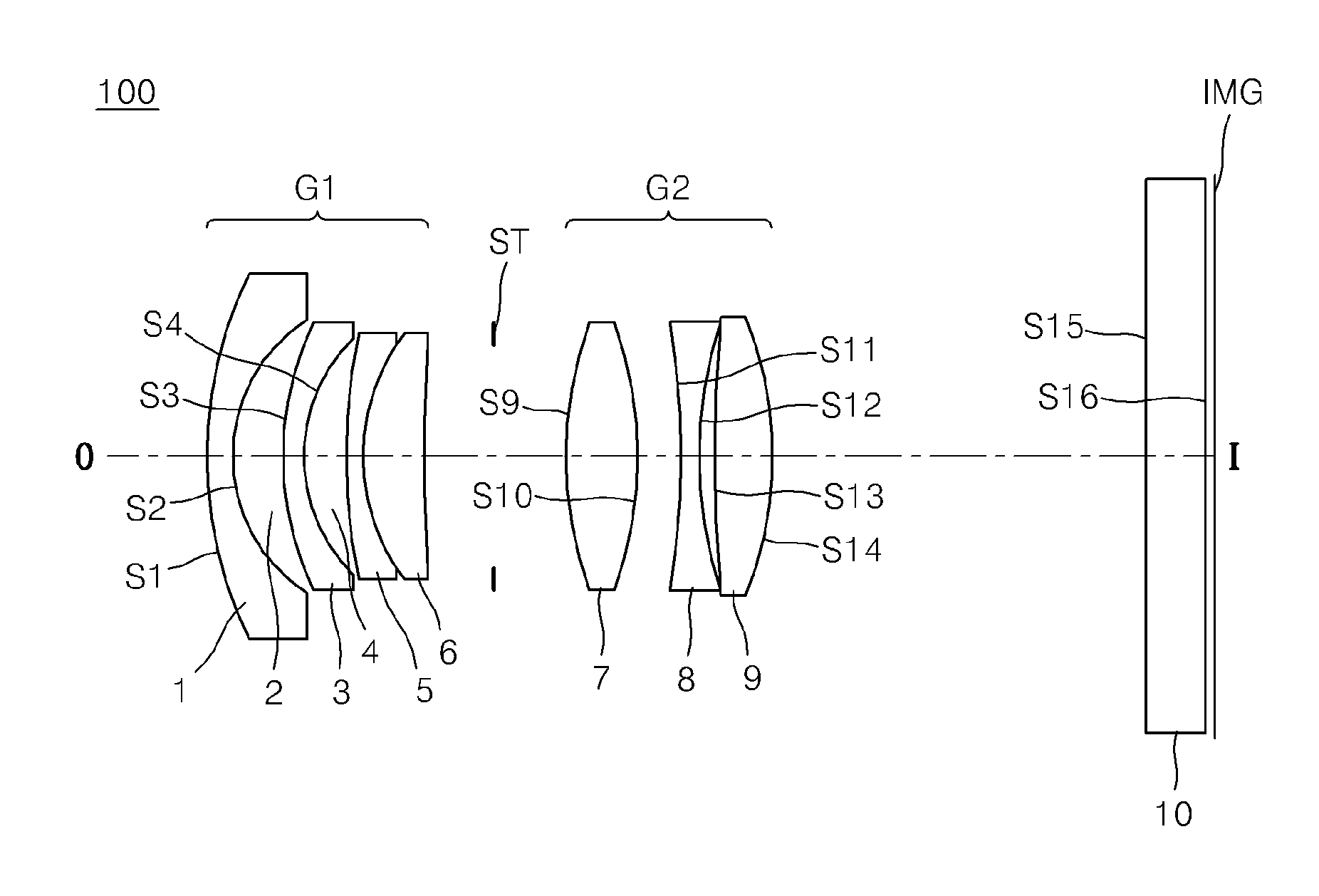

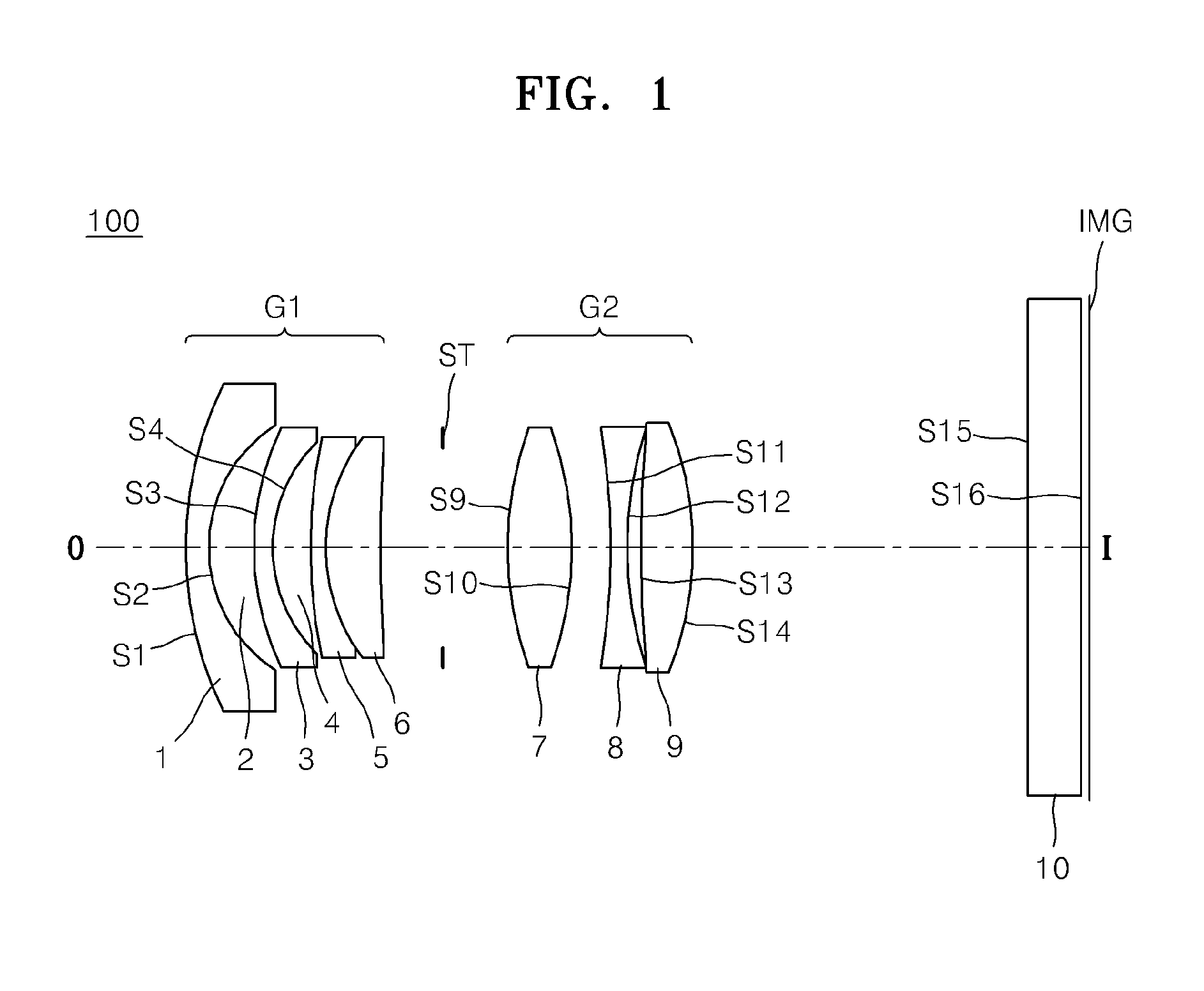

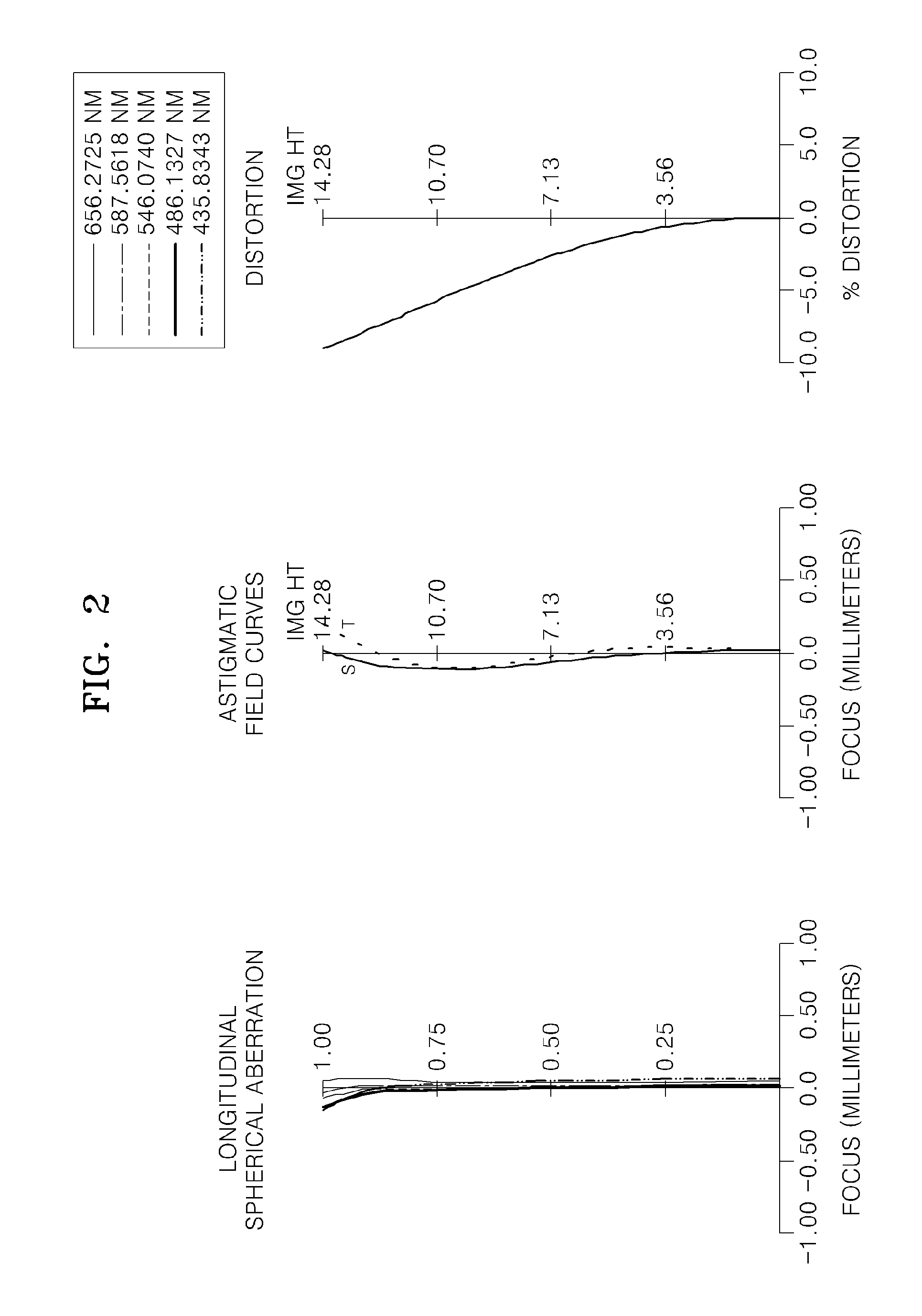

Single focus lens system and photographing apparatus including the same

A single focus lens system and a photographing apparatus including the single focus lens system are disclosed. A single focus lens system is provided that includes a first lens group having a negative refractive power, a stop, and a second lens group having a positive refractive power, sequentially arranged in order from an object side, wherein the first lens group comprises first and second air lenses having a negative refractive power, a meniscus shape and a convex surface toward the object side, and the second lens group comprises a lens that has a positive refractive power, is disposed closest to the object side, and has a convex surface toward the object side.

Owner:SAMSUNG ELECTRONICS CO LTD

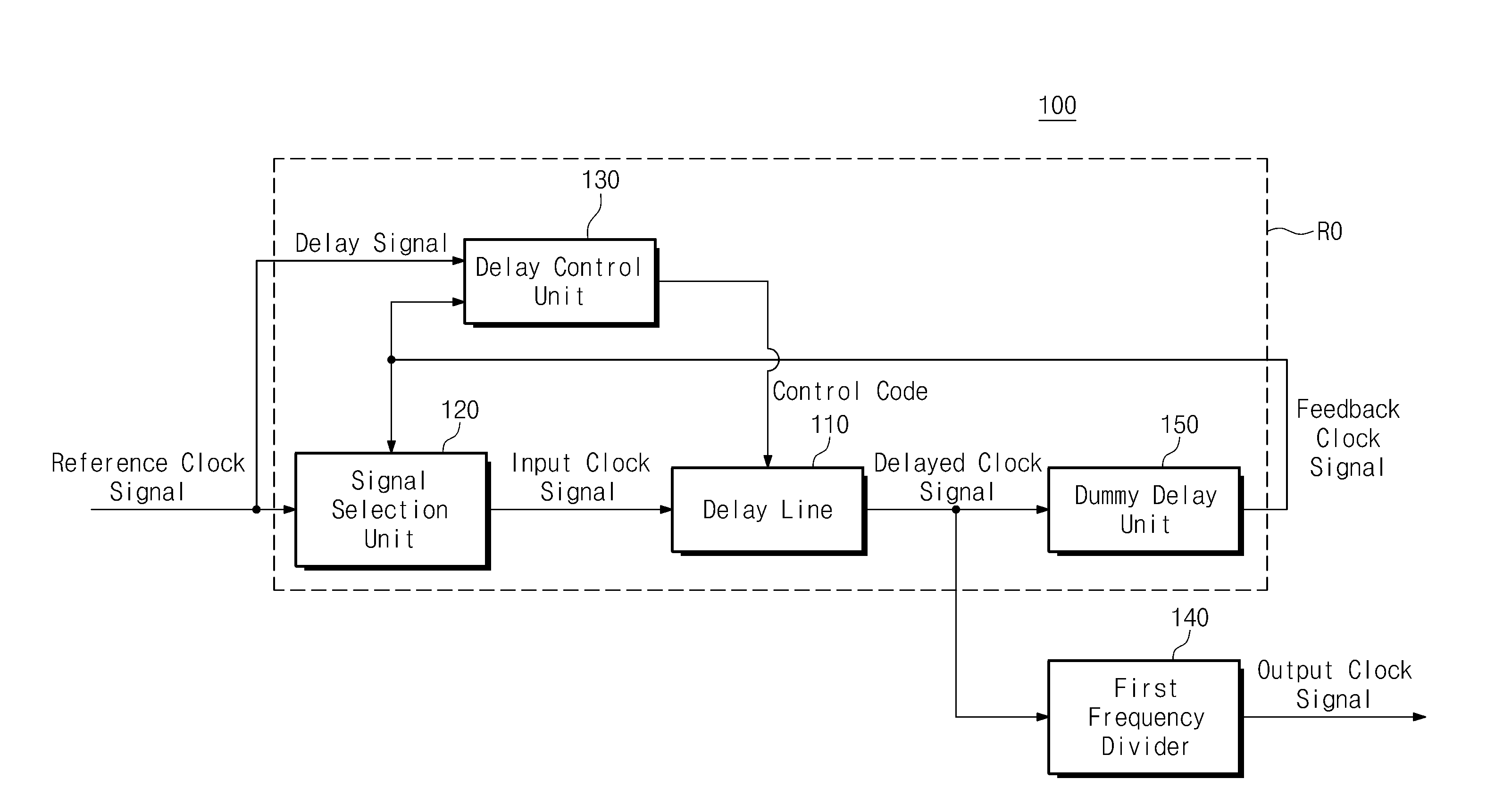

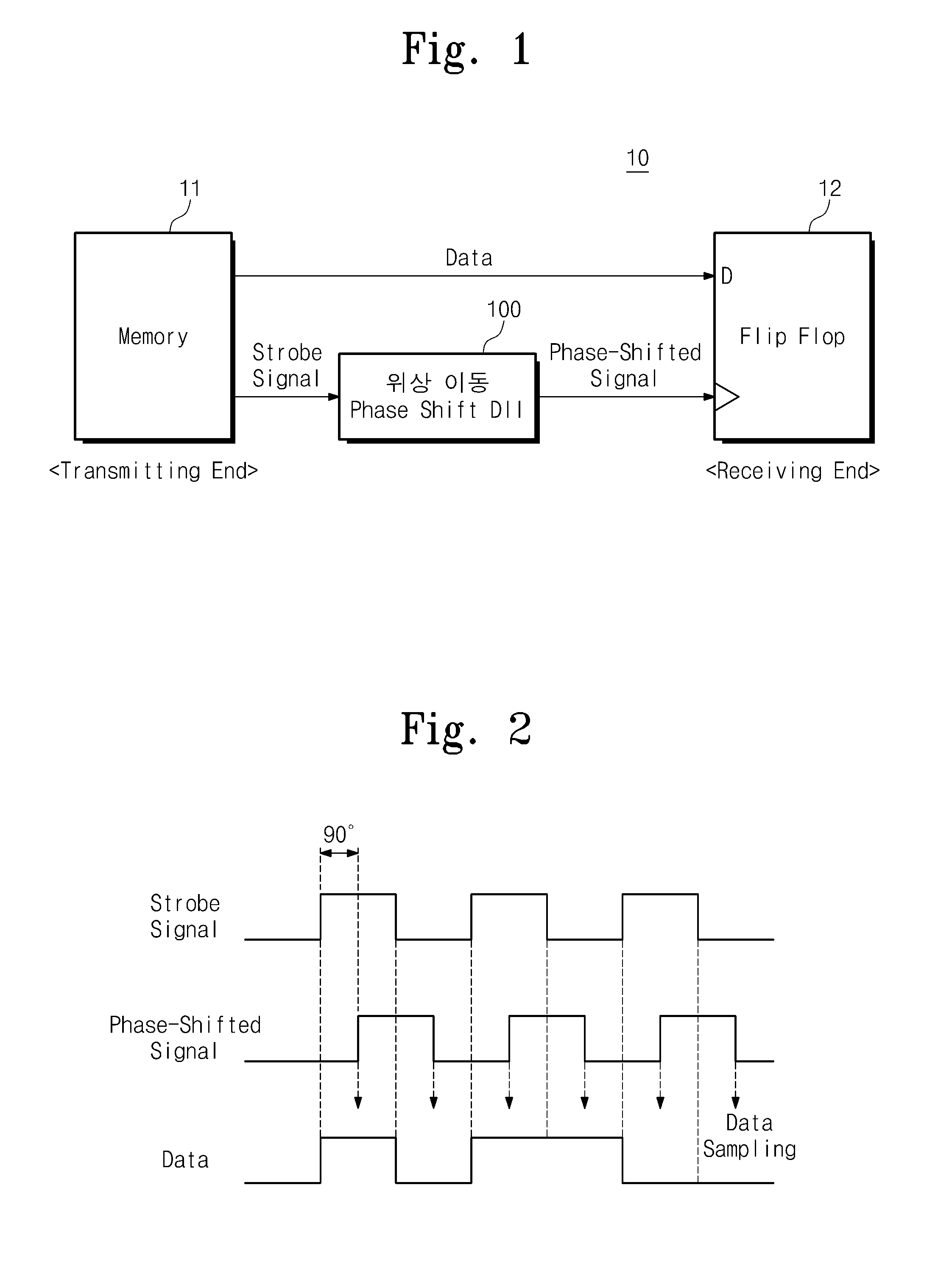

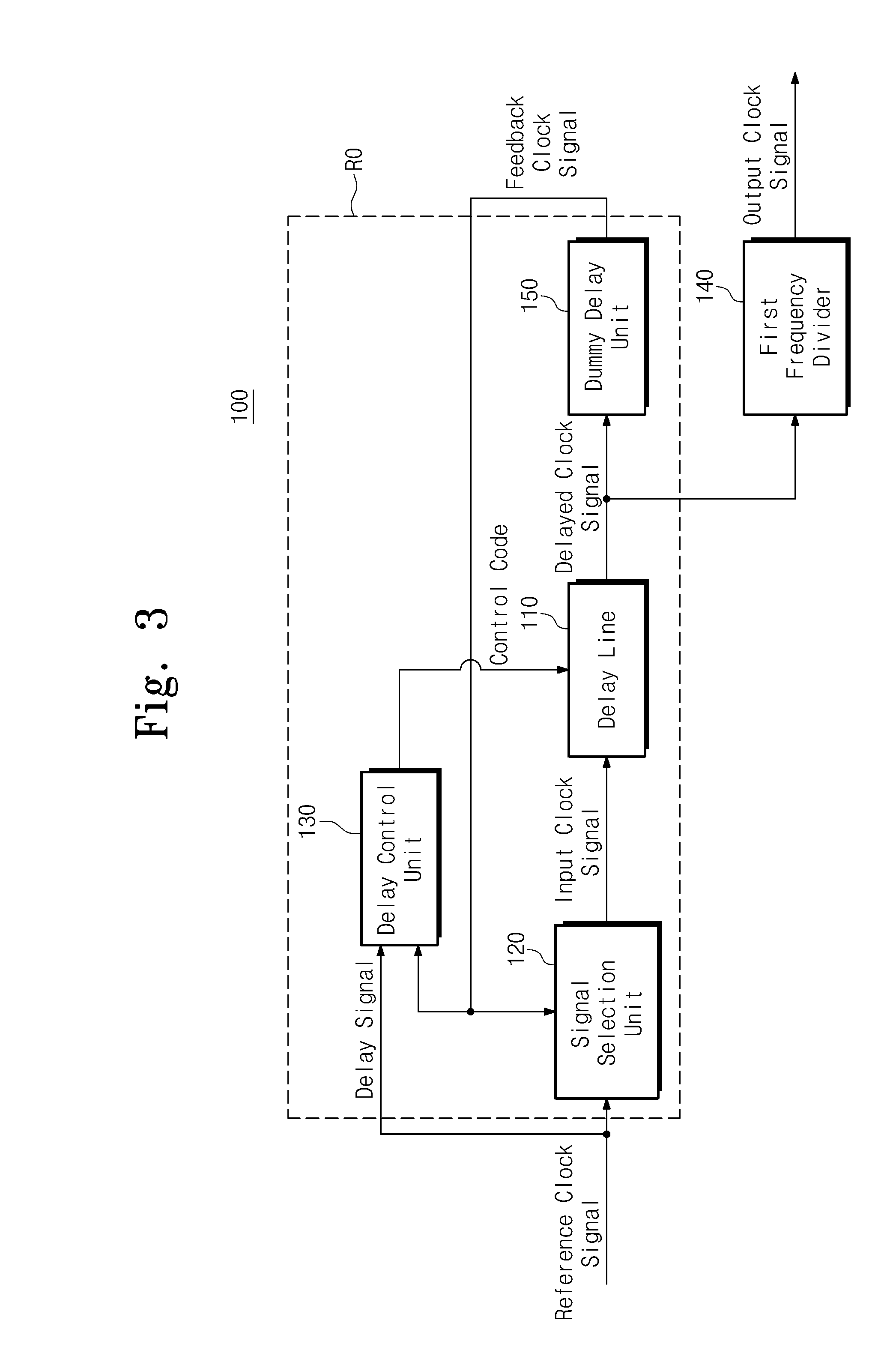

Delay locked loop and method of generating clock

ActiveUS20140203854A1Compact sizeLow power consumptionPulse automatic controlDigital storageDelay-locked loopClock signal

Provided is a delay locked loop (DLL) including a ring oscillator (RO) including a delay line to delay a reference clock signal and generate a delayed clock signal, wherein the RO circulates, through the delay line, a feedback clock signal corresponding to the delayed clock signal to synchronize N cycles of the feedback clock signal with a cycle of the reference clock signal (where N is an integer number equal to or larger than 2); and a first frequency divider dividing the frequency of the delayed clock signal by 1 / N (where N is an integer number equal to or larger than 2) to generate an output clock signal.

Owner:IND ACADEMIC COOP FOUNDATION YONSEI UNIV

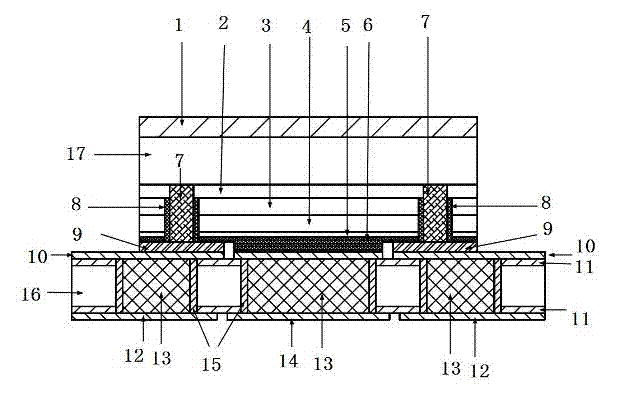

Light emitting diode (LED) based on silicon substrate through hole technology flip chip and manufacturing process of LED

ActiveCN102769086AUniform fluorescent layerCompact sizeSemiconductor devicesThrough-hole technologyWafer-level packaging

The invention relates to a light emitting diode (LED) based on a silicon substrate through hole technology flip chip and a manufacturing process of the LED. The LED provided by the invention comprises a fluorescent layer, an n-type current expansion layer, a luminous layer, a p-type current expansion layer, a metal light reflecting layer, a p-type electrode bonding pad, a metal through hole, an insulating layer, an n-type electrode bonding pad, a silicon substrate circuit layer, a silicon substrate insulating layer, a silicon substrate, a silicon substrate negative electrode, a silicon substrate negative electrode metal through hole, a silicon substrate positive electrode metal through hole, a silicon substrate positive electrode bonding pad, a silicon substrate through hole insulating layer and a chip sapphire substrate. Aiming at the structural defects existing in the current high-power LED, the invention provides the LED based on the silicon substrate through hole technology flip chip and the manufacturing process of the LED, through hole electrodes are respectively manufactured on a flip LED chip and a silicon substrate through an etching technology or a laser technology, and co-crystallization welding is carried out so that packaging is finished. An LED device provided by the invention is free of gold wire bonding, and the technology is beneficial to the development of large-scale wafer level packaging and is used for improving the heat dissipation performance by through holes as well as improving the reliability in packaging an LED chip.

Owner:SHANGHAI UNIV

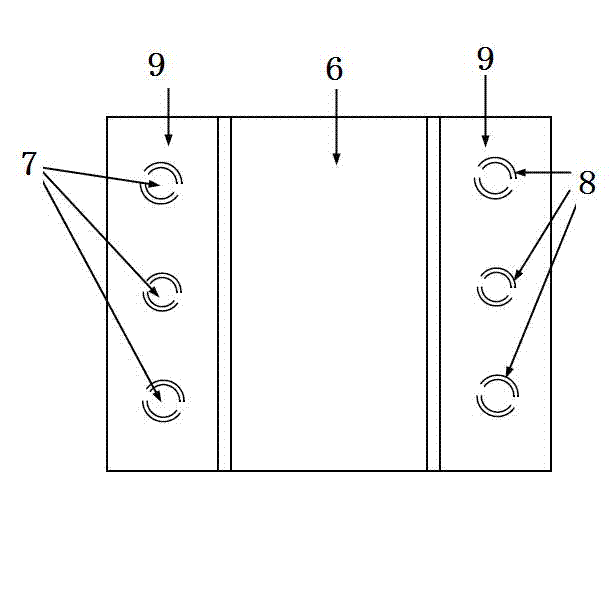

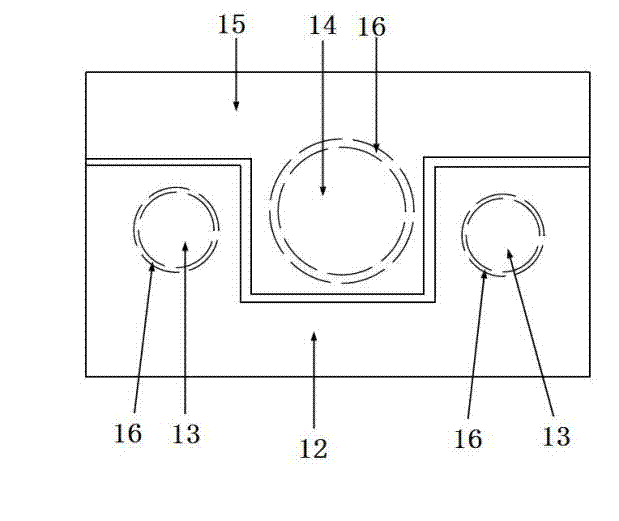

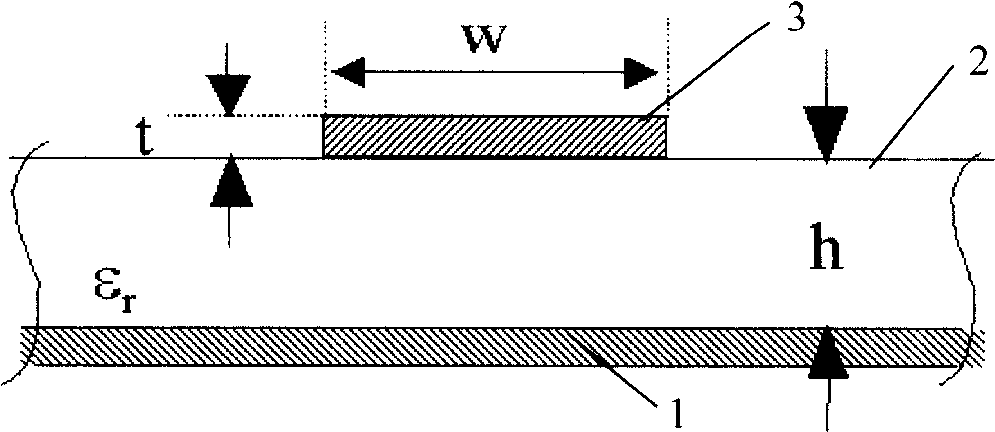

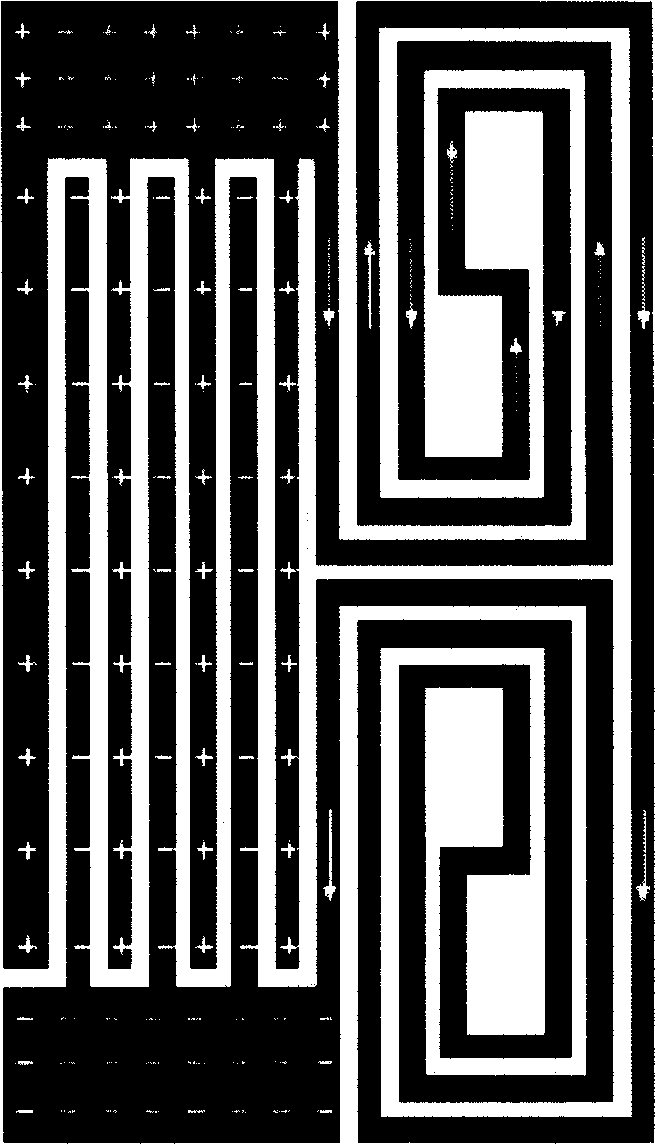

Planar superconducting microstrip resonator

The invention relates to a planar superconducting microstrip resonator which comprises a microstrip line comprising an upper-layer superconducting film, a lower-layer superconducting film and a monocrystal medium positioned between the upper-layer and the lower-layer superconducting films, finger-inserting capacitors, a double-helix curved inductor and a blocky capacitor formed together with the ground, wherein the finger-inserting capacitors are parallel to the double-helix curved inductor, and the finger-inserting capacitors are connected with the double-helix curved inductor in parallel, and the finger-inserting capacitors and the double-helix curved inductor which are connected in parallel are connected with the blocky capacitor in series. The planar superconducting microstrip resonator has small volume and less electromagnetic radiation. The planar superconducting microstrip resonator can be used for designing and manufacturing a narrowband superconducting band-pass filter with high performance.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

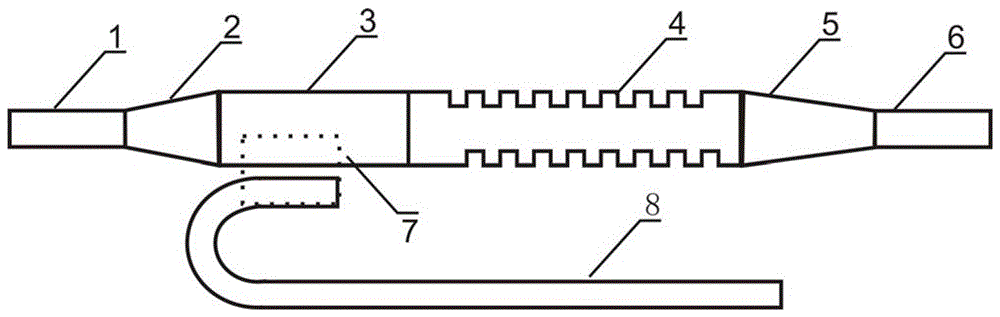

Optical fiber connector with optical path direction changer

InactiveUS20160291261A1Compact sizeSmall sizeCoupling light guidesOptical fiber connectorOptical path

An optical path direction changing optical fiber connector, comprising: a base having an optical fiber mechanical splice at one edge of the base for securing a first end of an optical fiber ribbon; a retention block having a curved surface for guiding a portion of the optical fiber ribbon laid upon thereof, wherein the curved surface curving from a first end to a second end of the optical fiber ribbon such that the first end being at a bending angle to the second end of the optical fiber ribbon, wherein the curved guiding surface having a curvature radius of no more than approximately 2 mm, and wherein the retention block being positioned on top of the base; and a cover for covering the retention block and retaining the portions of the optical fiber ribbon laid upon the curved guiding surface of the retention block.

Owner:SENKO ADVANCED COMPONENTS HK

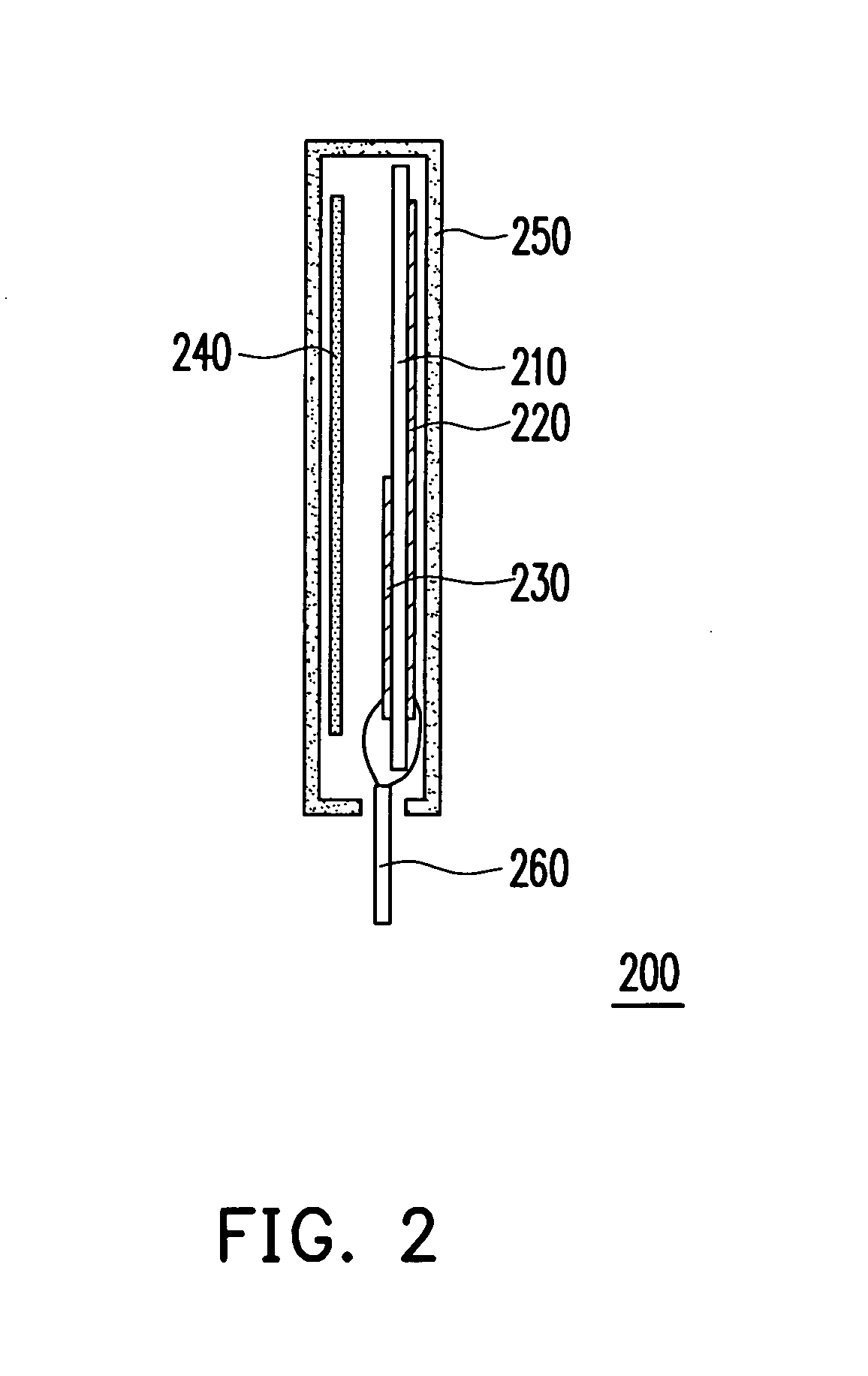

Ultra-wideband directional antenna

InactiveUS20060273976A1Compact sizeSuitable be applyAntenna arraysIndoor communication adaptationStanding waveBroadband

An ultra-wideband directional antenna is disclosed, including a dielectric substrate, and antenna elements, symmetrical microstrip lines and baluns on front and back surfaces of the dielectric substrate. Each end of the symmetrical microstrip line is connected to two antenna elements. Wherein, a width of the antenna elements increases gradually outwards from sides of the antenna elements connected to the symmetrical microstrip lines. One end of the balun is connected to the middle segment of the symmetrical microstrip lines, and the other end of the balun is connected to an antenna feeding port. The ultra-wideband directional antenna with thin and compact size has a broadband property with respect to VSWR and a radiation pattern and is suitable for indoor application.

Owner:CORETRONIC

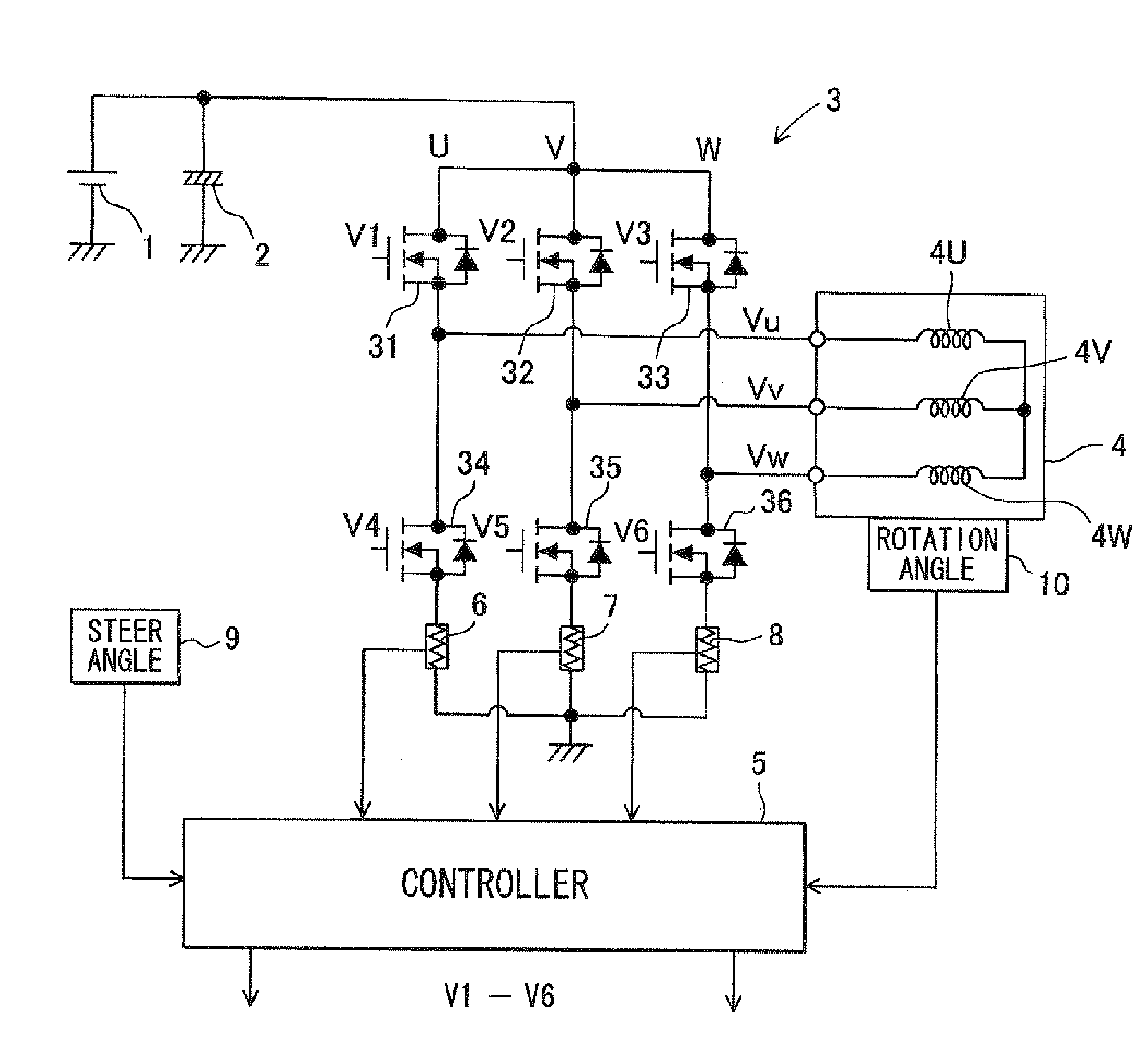

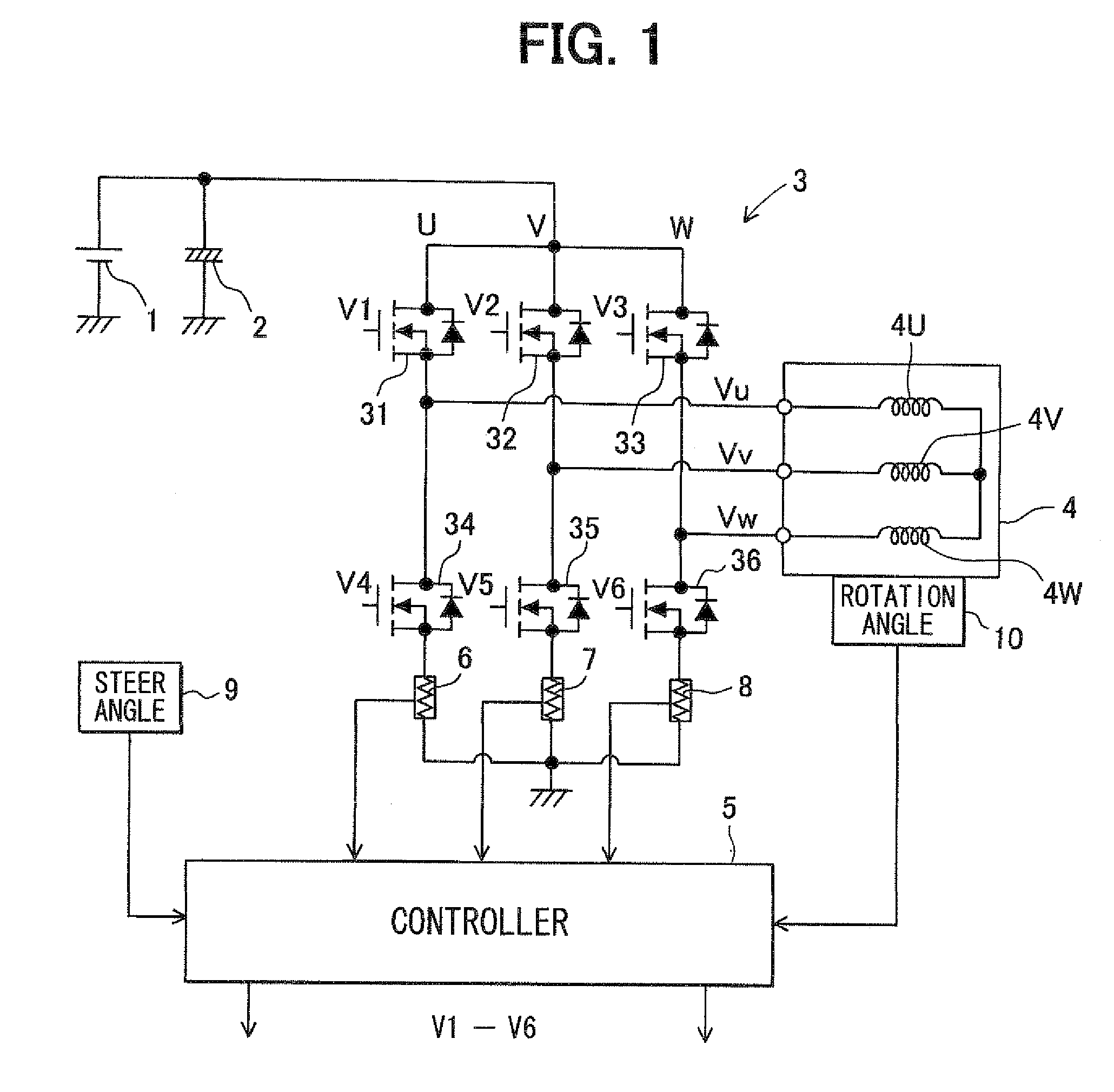

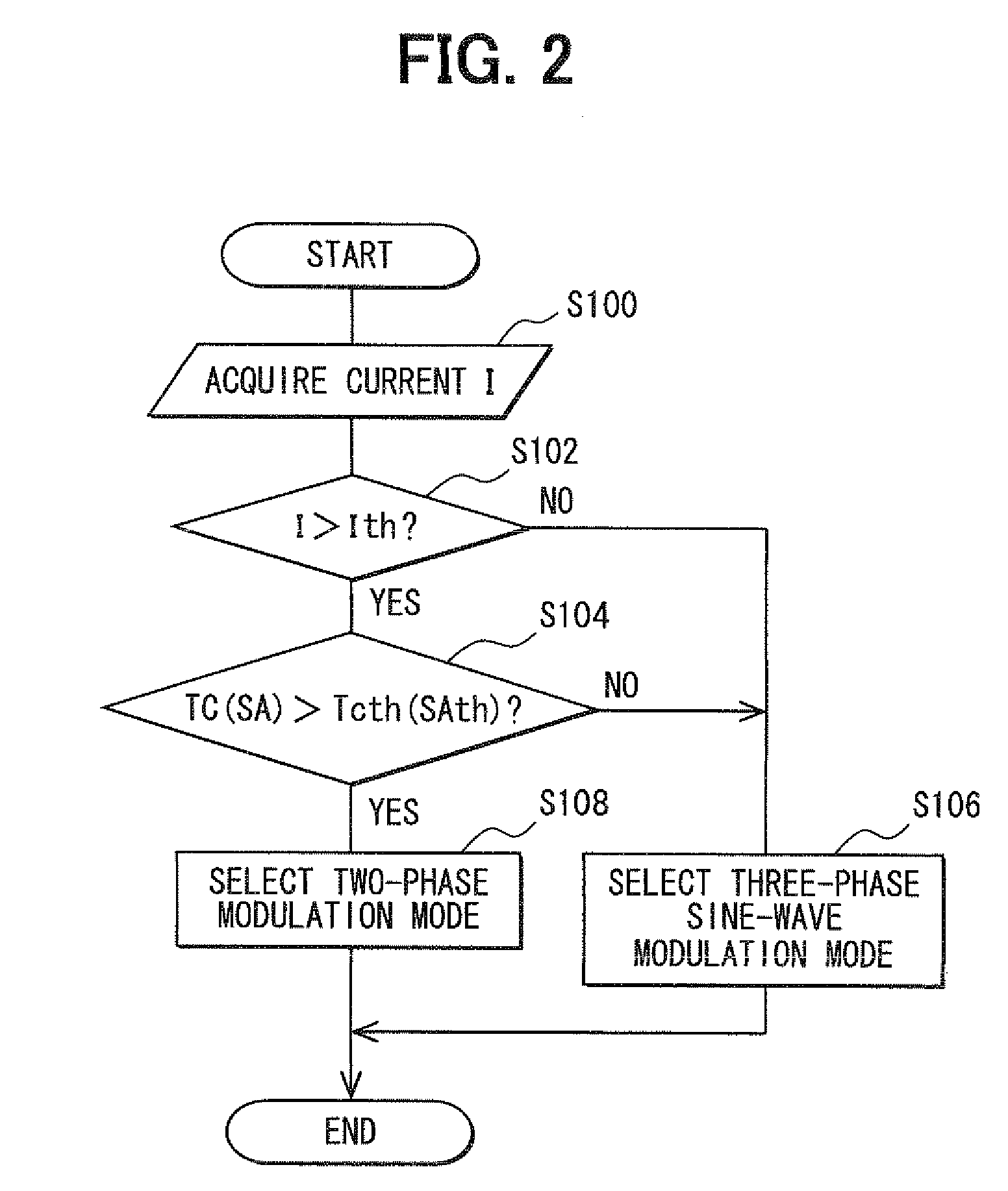

Motor drive apparatus and method for electric power steering system

ActiveUS20090200975A1Compact sizeImprove responseTorque ripple controlDC motor speed/torque controlPhase modulationMotor drive

In a motor drive apparatus for an EPS motor, which provides steering assist torque in an electric power steering system, a three-phase inverter applies three phase-voltages to the EPS motor, and a controller controls the three-phase inverter. The controller drives the EPS motor by implementing a two-phase modulation method and a three-phase modulation method, when at least one of the assist torque, a steering angle acceleration and a function value of a predetermined function is greater and less than a predetermined threshold value indicative of a rapid steering operation, respectively.

Owner:DENSO CORP

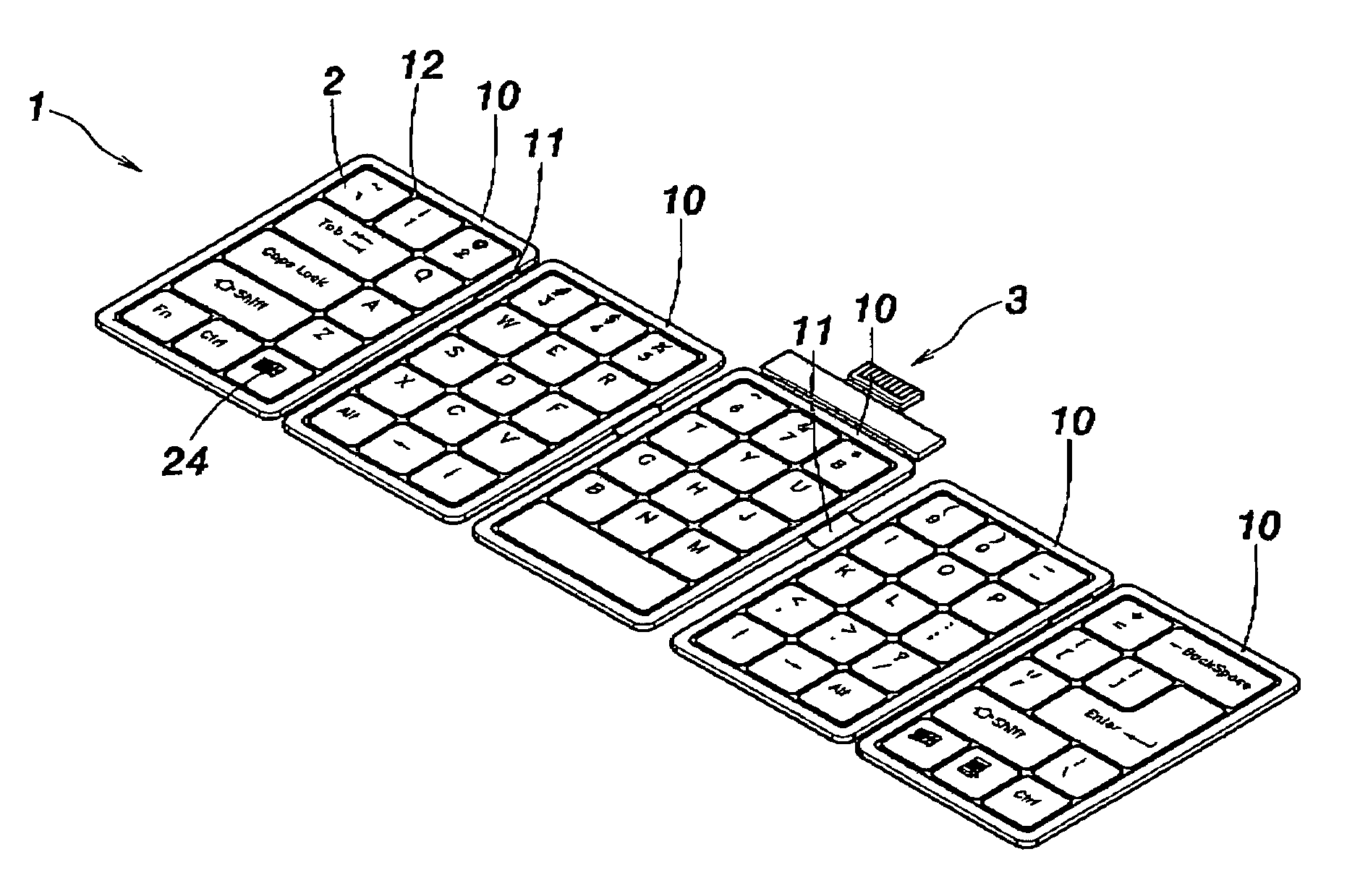

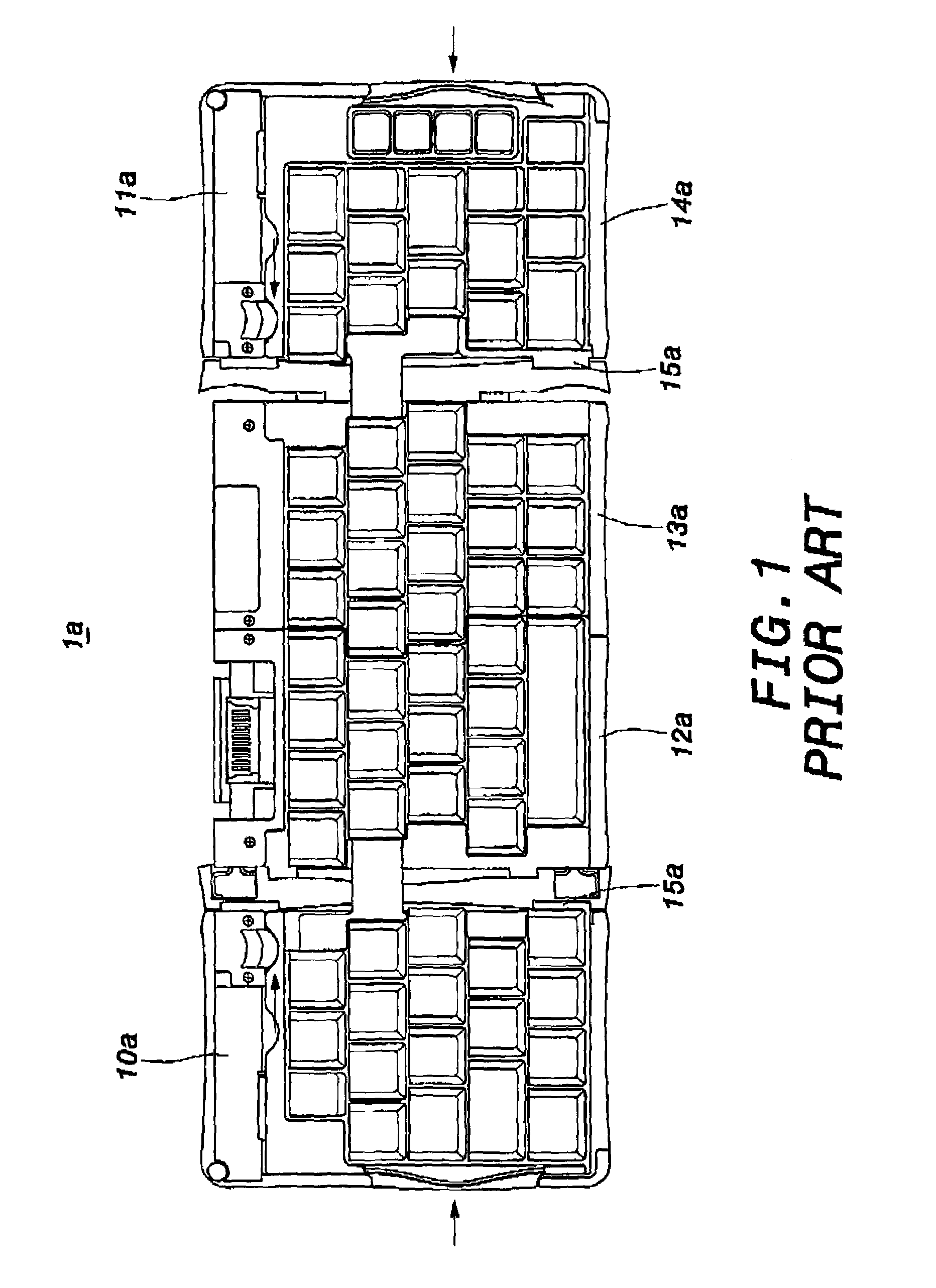

Foldable keyboard

InactiveUS6967831B2Compact sizeSmall sizeInput/output for user-computer interactionEmergency casingsTouch panelEngineering

A foldable keyboard comprises a keyboard body, a circuit, and a plurality of flexible printed circuit. The keyboard body has a plurality of touch panels in serial connection. Each touch panel has a pair of conductive membranes being segmented into a plurality of blocks for generating a panel signal. The adjacent touch panels are connected by the flexible printed circuits so that the touch panels can be folded in a stacked way. The touch panels are segmented into a plurality of blocks. A plurality of legends is formed on the top surface or the bottom surface of the keyboard body. The legends respectively correspond to the blocks.

Owner:GULA CONSULTING LLC

Band-pass and band-stop filter based on anti-symmetric multimode Bragg light guide grating

The invention discloses a band-pass and band-stop filter based on an anti-symmetric multimode Bragg light guide grating. When TE light is input from a single-mode input waveguide, an input mode switcher switches the TE light to a TE-based mode of a multi-mode waveguide, the anti-symmetric multimode Bragg light guide grating reversely couples incident light with the wavelength meeting phase matching conditions into a TE first-order mode of the multi-mode waveguide, the mode is switched to a TE mode of a downlink single-mode waveguide when the light passes through a downlink coupling zone, the light is output from the output end of the downlink single-mode waveguide, and transmission light is switched to the TE mode of a single-mode output waveguide through an output mode switcher and is output from the output end of the single-mode output waveguide. The band-pass and band-stop filter simultaneously achieves band-pass and band-stop functions and can be applied to an optical interconnection system adopting on-chip high-density integration.

Owner:LONGYAN UNIV

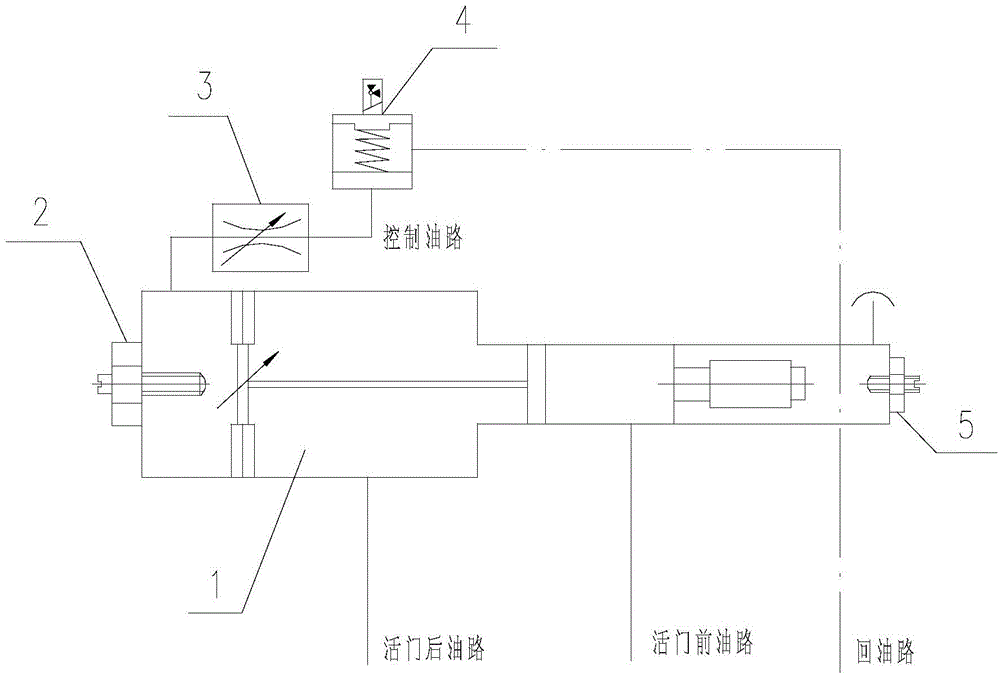

Fuel metering valve control system and fuel regulator

InactiveCN104314696AHigh precisionCompact sizeElectrical controlMachines/enginesControl systemSolenoid valve

The invention discloses a fuel metering valve control system which comprises a metering valve comprising a regulating valve core, a minimum flow limiter and a maximum flow limiter which are arranged at the two ends of the metering valve respectively, a Q value regulator connected with the metering valve, a digital pulse solenoid valve connected with the Q value regulator, and a controller used for controlling the digital pulse solenoid valve to generate high-frequency motion for enabling the regulating valve core to move to a maximum flow limiting screw to increase the oil supply quantity when judging that the oil pressure in the control cavity of the metering valve is higher than the oil pressure at the front part of the metering valve. According to the fuel metering valve control system disclosed by the embodiment of the invention, the oil supply precision of a fuel regulator can be improved, the response speed of the fuel regulator can be increased, the service life of the fuel regulator can be prolonged; the fuel metering valve control system has the advantages of simple structure and simplicity for matching, and is relatively good in usability. The invention further discloses the fuel regulator.

Owner:BEIJING POWER MACHINERY INST

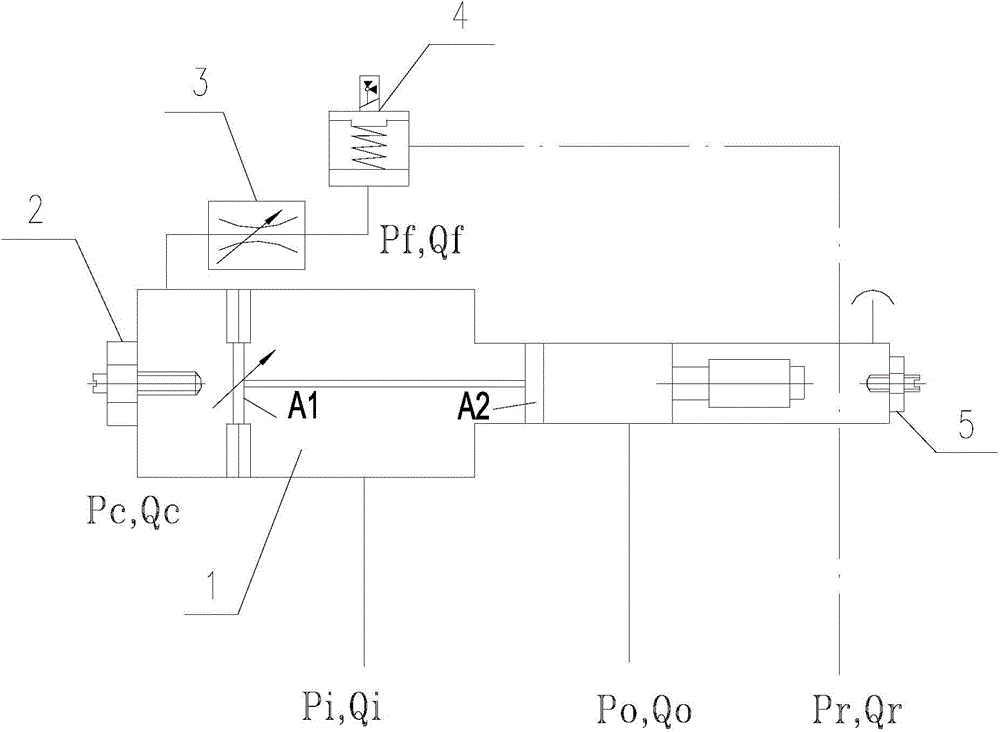

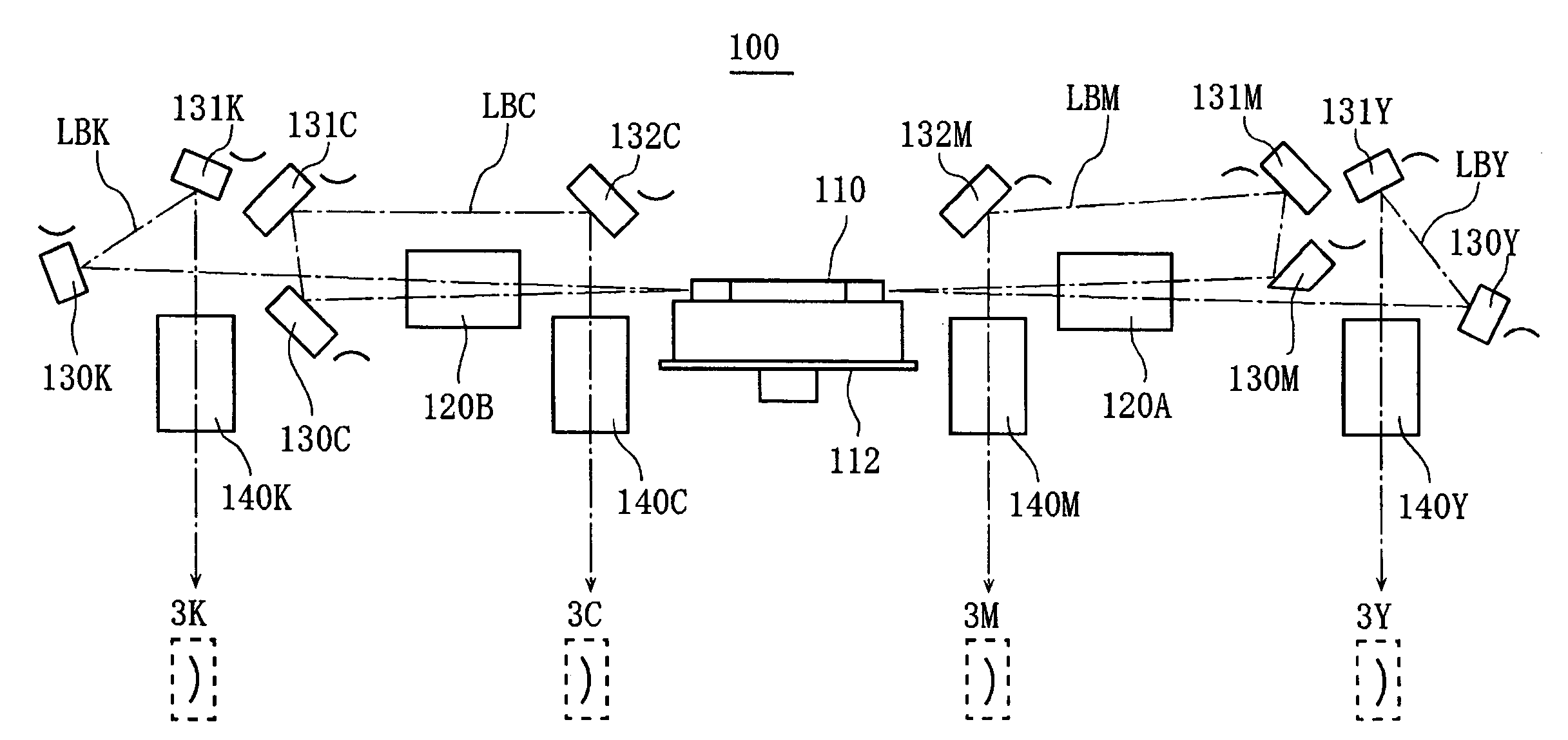

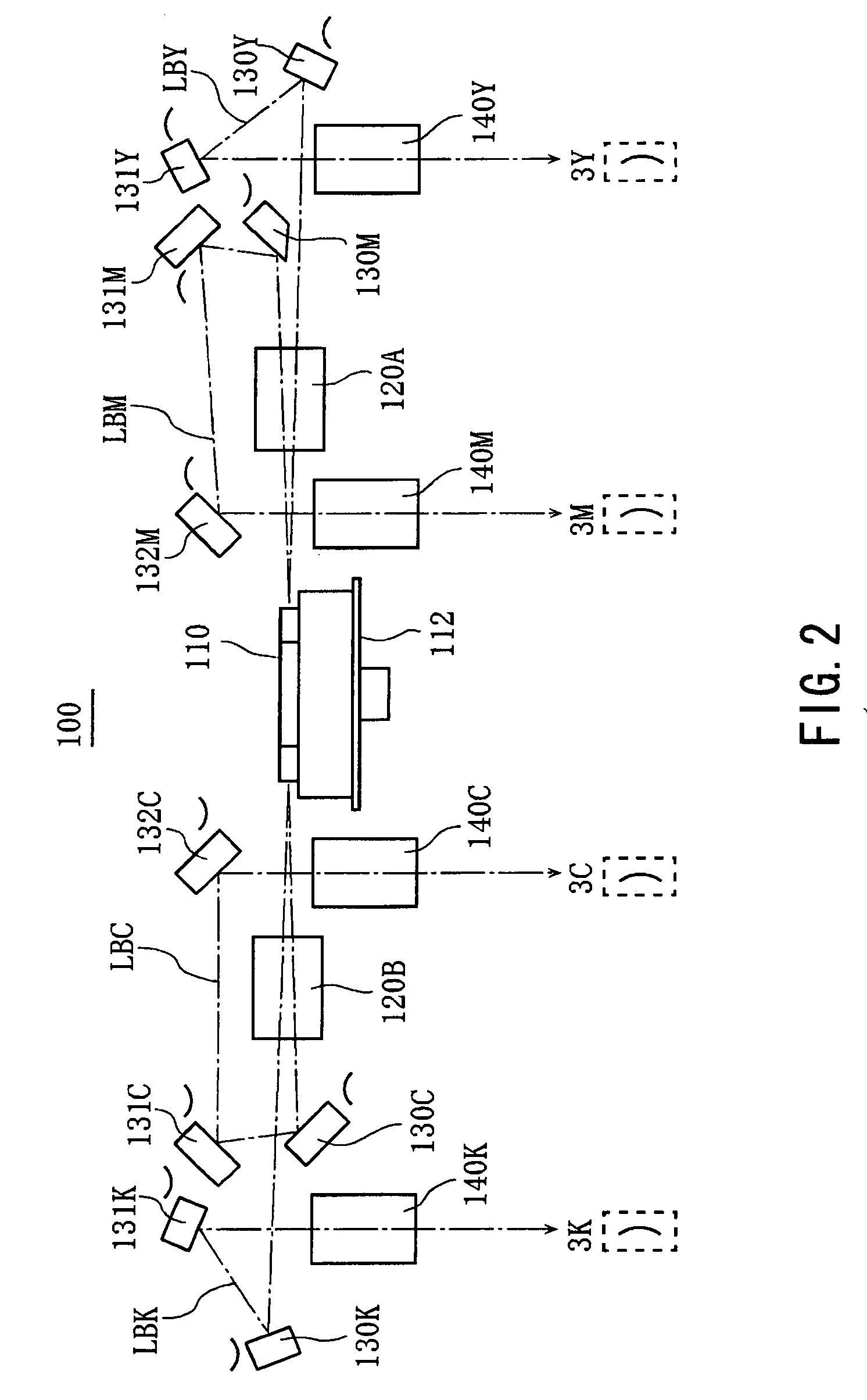

Image-forming device and scanning unit for use therein

ActiveUS20060017996A1Compact sizeSmall sizeInking apparatusOther printing apparatusLight sourceScan line

A scanning unit for use in an image-forming device includes, for example, four light sources that emit light beams corresponding to yellow, magenta, cyan and black images. The light beams are scanned over the corresponding photosensitive drum with the use of a single polygon mirror and four optical reflection systems each including reflection mirrors. The curved orientation of the scan lines on the photosensitive drum can be equalized for all four light beams by regulating the number of reflection mirrors, that is, by setting the number of reflection mirrors to an even number or an odd number.

Owner:BROTHER KOGYO KK

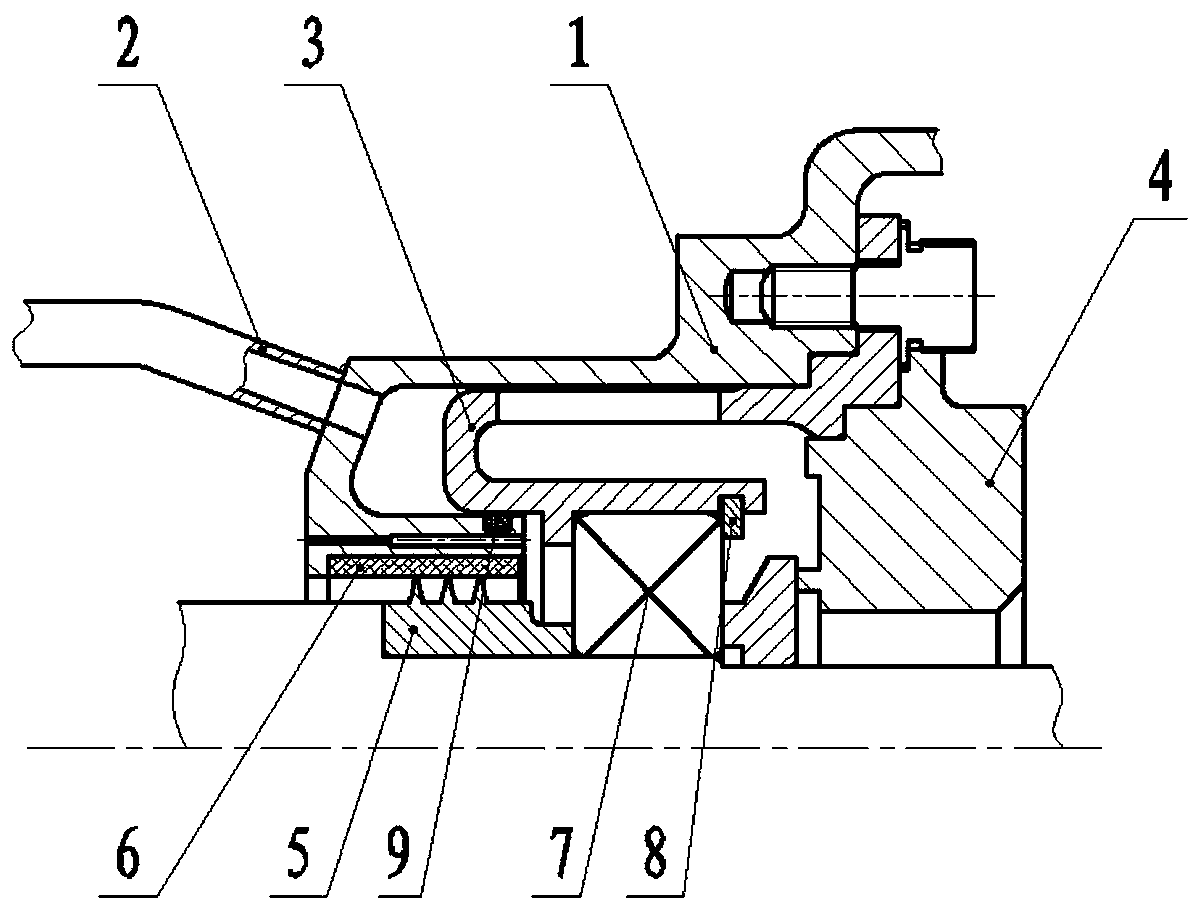

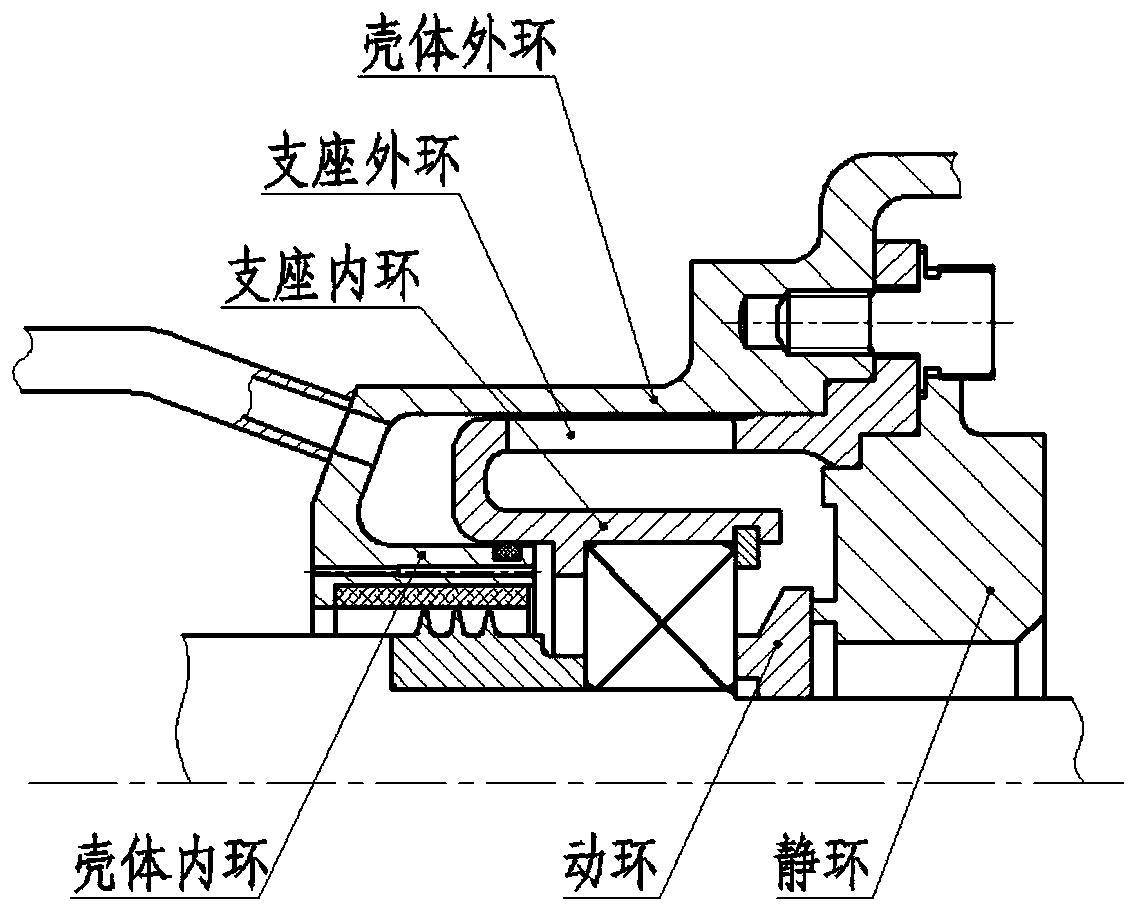

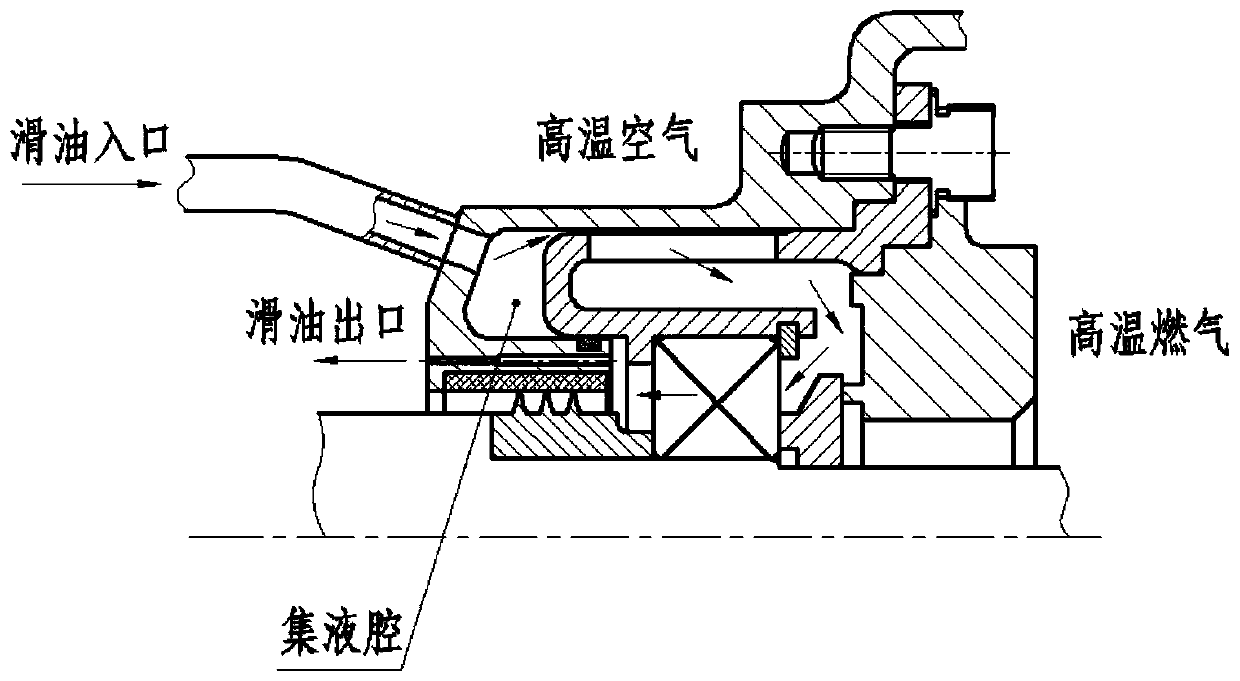

Mouse cage elastic support bearing cavity structure

ActiveCN110005545ACompact sizeGuaranteed to workEngine componentsRocket engine plantsEngineeringSmall hole

The invention relates to a mouse cage elastic support bearing cavity structure. The mouse cage elastic support bearing cavity structure comprises a shell provided with an oil inlet pipe, and a returntype mouse cage elastic support, a contact type end face sealing device, sliding oil seal grate teeth, a graphite ring, a bearing, a clamping ring, a rotating shaft and the like that are arranged in the shell; the return type mouse cage elastic support is installed in a ring groove of the shell, and the inner ring of the shell is provided with a plurality of small holes uniformly distributed in the circumference; and the contact end face sealing device is hermetically arranged at one end of the bearing cavity structure. In the working state, high-pressure lubricating oil enters the bearing cavity through the oil inlet pipe arranged on the shell, the contact-type end face sealing device and the bearing are sequentially cooled according to a preset flow path, and the cooled lubricating oil is discharged out of the bearing cavity through the small holes arranged in the inner ring of the shell, the bearing cavity is filled with lubricating oil under the throttling effect of the small holes, positive pressure of 0.6-0.7 MPa is formed, and therefore, the pressure condition of normal working of the contact type end face seal is met, the external high-temperature gas is isolated, and the normal working of the bearing cavity is ensured.

Owner:XIAN AEROSPACE PROPULSION INST

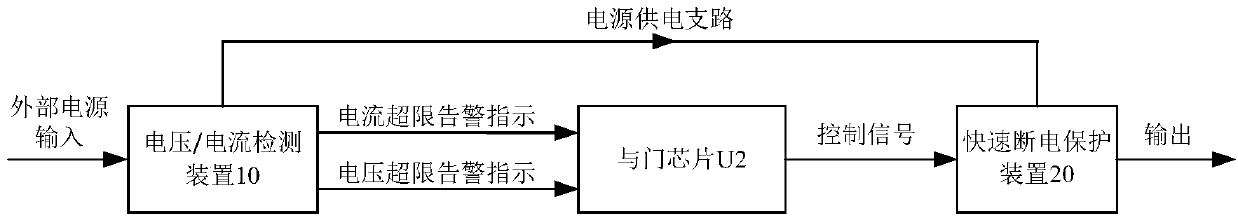

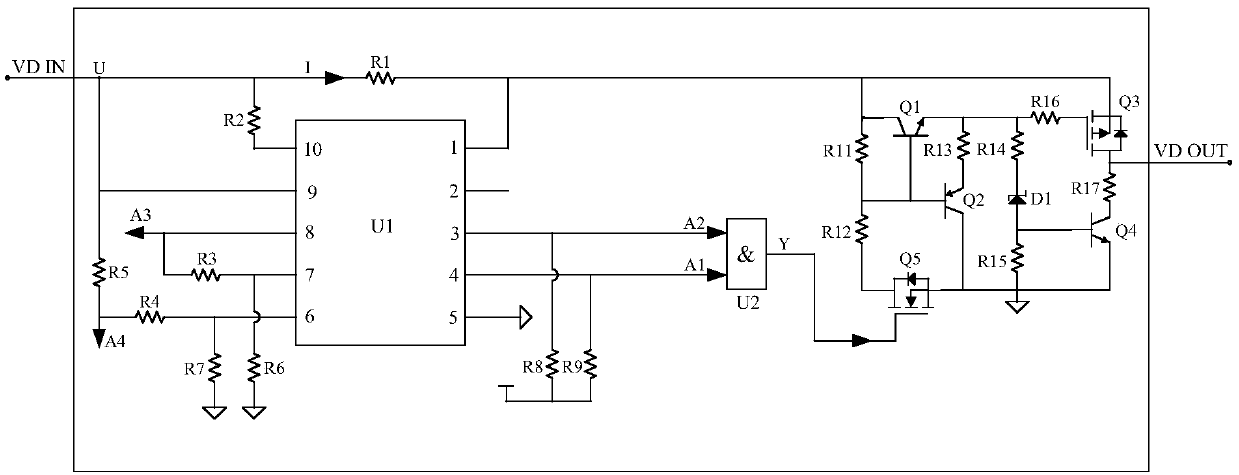

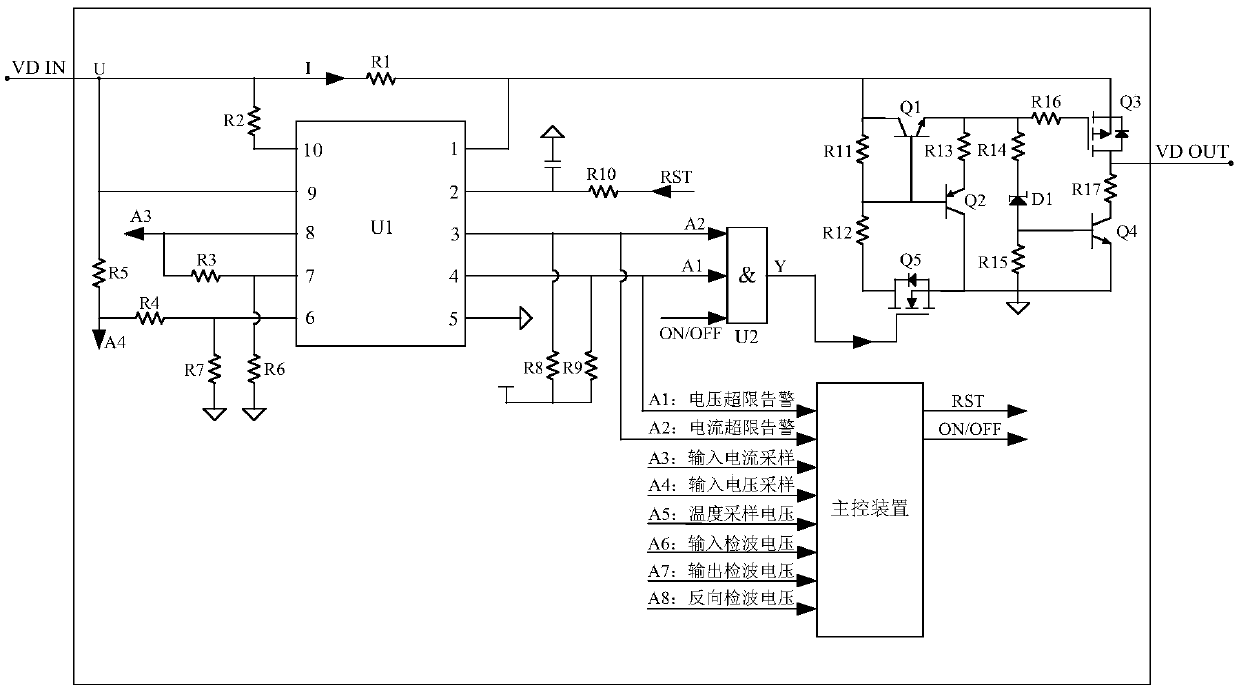

Radio-frequency power amplifier real-time monitoring and protecting circuit

ActiveCN109525206AAvoid failure situationsCompact sizeRadiofrequency circuit testingAmplifier protection circuit arrangementsAudio power amplifierControl signal

The embodiment of the invention relates to the circuit technical field, and discloses a radio-frequency power amplifier real-time monitoring and protecting circuit. The circuit comprises: a voltage / current detection device and a AND gate chip. The voltage / current detection device is used for: acquiring the working voltage and the working current of the power amplifier according to the voltage andthe current inputted by an external power supply; determining whether the working voltage of the power amplifier is over-limit or not, and outputting a voltage over-limit alarm level indication signalby the first output end of the voltage / current detection device; determining whether the working current of the power amplifier is over-limit or not, and outputting a current over-limit alarm level indication signal by the second output end of the voltage / current detection device. The AND gate chip outputs a control signal according to the two indication signals to control the power supply of theradio frequency power amplifier to be turned on and off by a rapid power-off protection device. According to the radio-frequency power amplifier real-time monitoring and protecting circuit, the powersupply of the radio-frequency power amplifier is directly controlled to be turned on and off without processing and judging by a master control device; the method has the advantages that the protection is rapid, the real-time performance is high, the circuit area is compact, the power consumption is low, and the like.

Owner:中科特思信息技术(深圳)有限公司

Condensation-controllable split type testing tank

ActiveCN106000483APrevent condensationCompact sizeHeating or cooling apparatusEnclosures/chambersVentilation ductHeating system

Owner:NAT INST OF METROLOGY CHINA +1

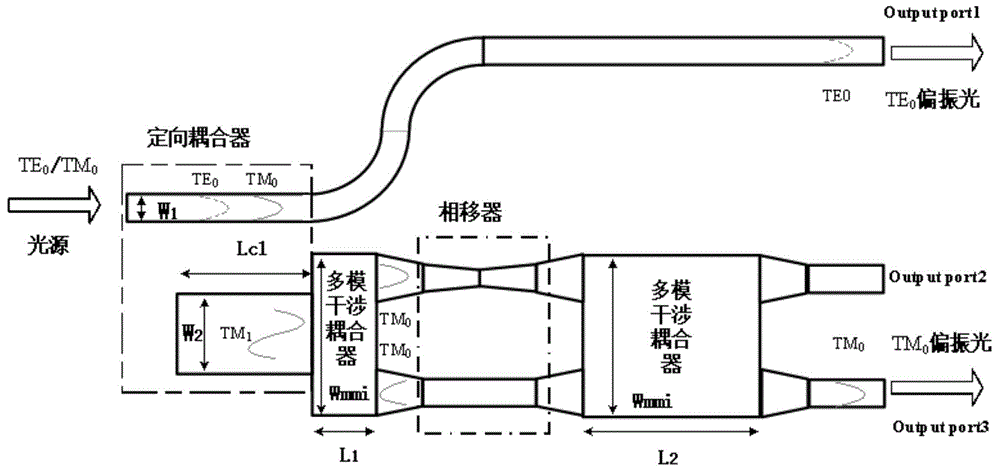

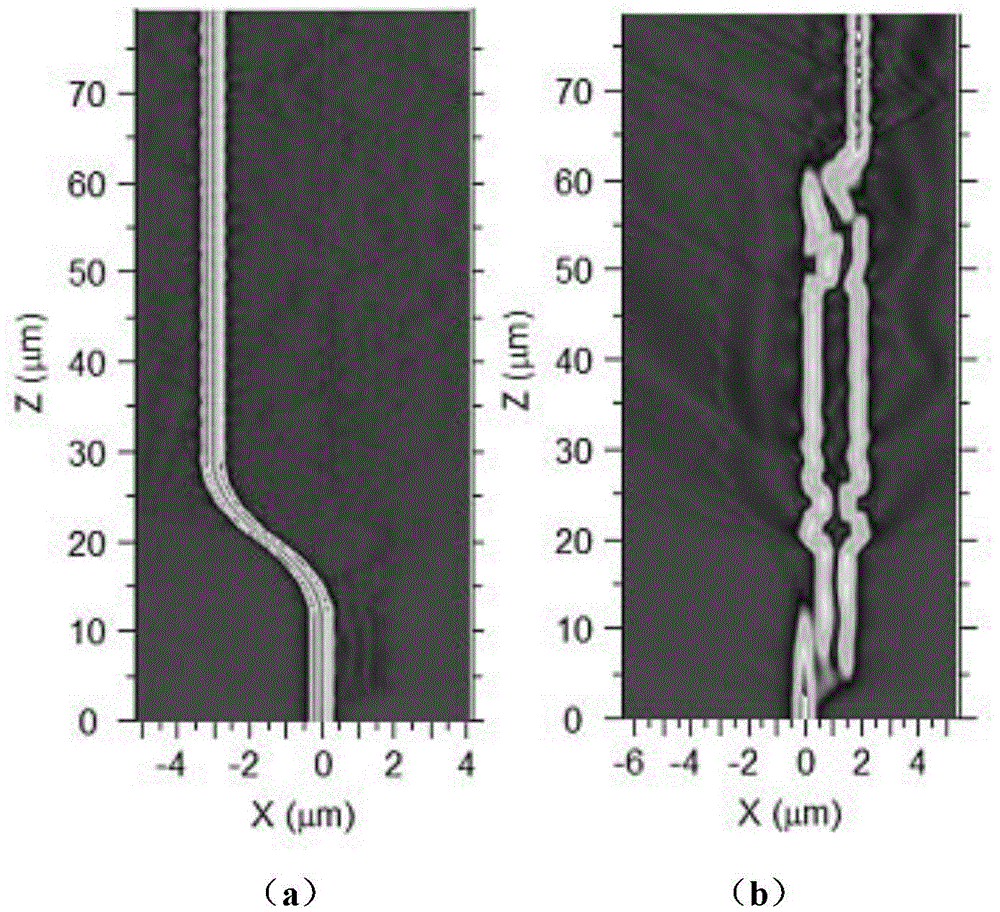

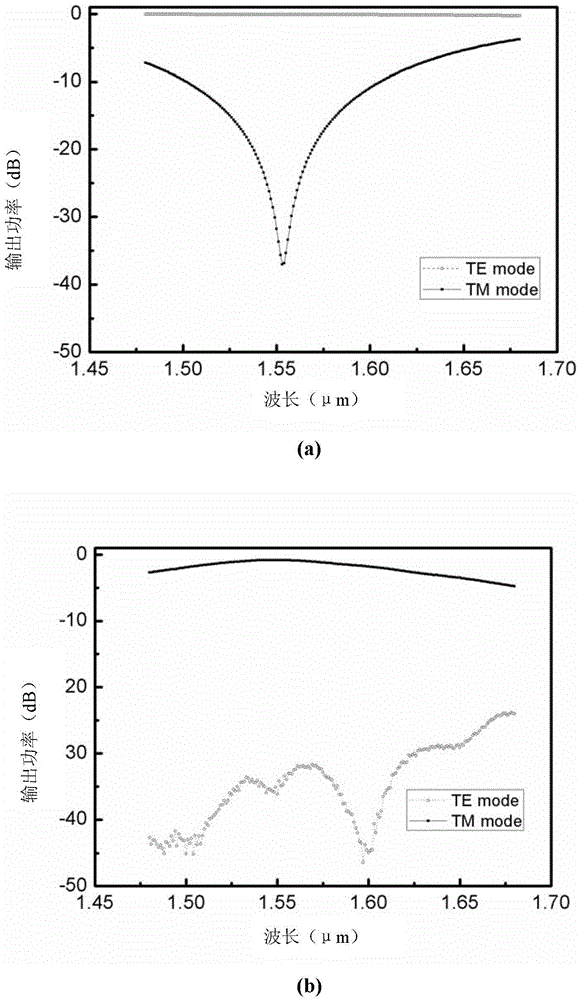

Light polarization beam splitter

The invention discloses a light polarization beam splitter. The light polarization beam splitter comprises an orientation coupler. The narrow waveguide of the orientation coupler receives an input light source and outputs TE0 light in the input light source, couples TM0 light in the input light source to wide waveguide and converts the TM0 light into TM1 light. The output end of the wide waveguide is connected with a first MMI coupler, and the first MMI coupler divides the input TM1 light into two beams of TM0 polarized light, wherein the two beams of TM0 polarized light are the same in power, and the phase difference of the two beams of TM0 polarized light is 180 degrees. The two output ends of the first MMI coupler are respectively connected with the input end of a second MMI coupler through a 90-degree phase shifter. One output end of the second MMI coupler serves as a TM0 polarized light output port. The equation of the length of the first MMI coupler is shown in the specification, and Lpi1 represents the beat length of the first MMI coupler. The second MMI coupler is an interference coupler. According to the light polarization beam splitter, a high-capacity monolithic integration chip can be achieved, and the light polarization beam splitter has the advantages that the bandwidth is very large, the extinction ratio is very high, and the loss is very low.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com