Patents

Literature

65results about How to "Minimal dimension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

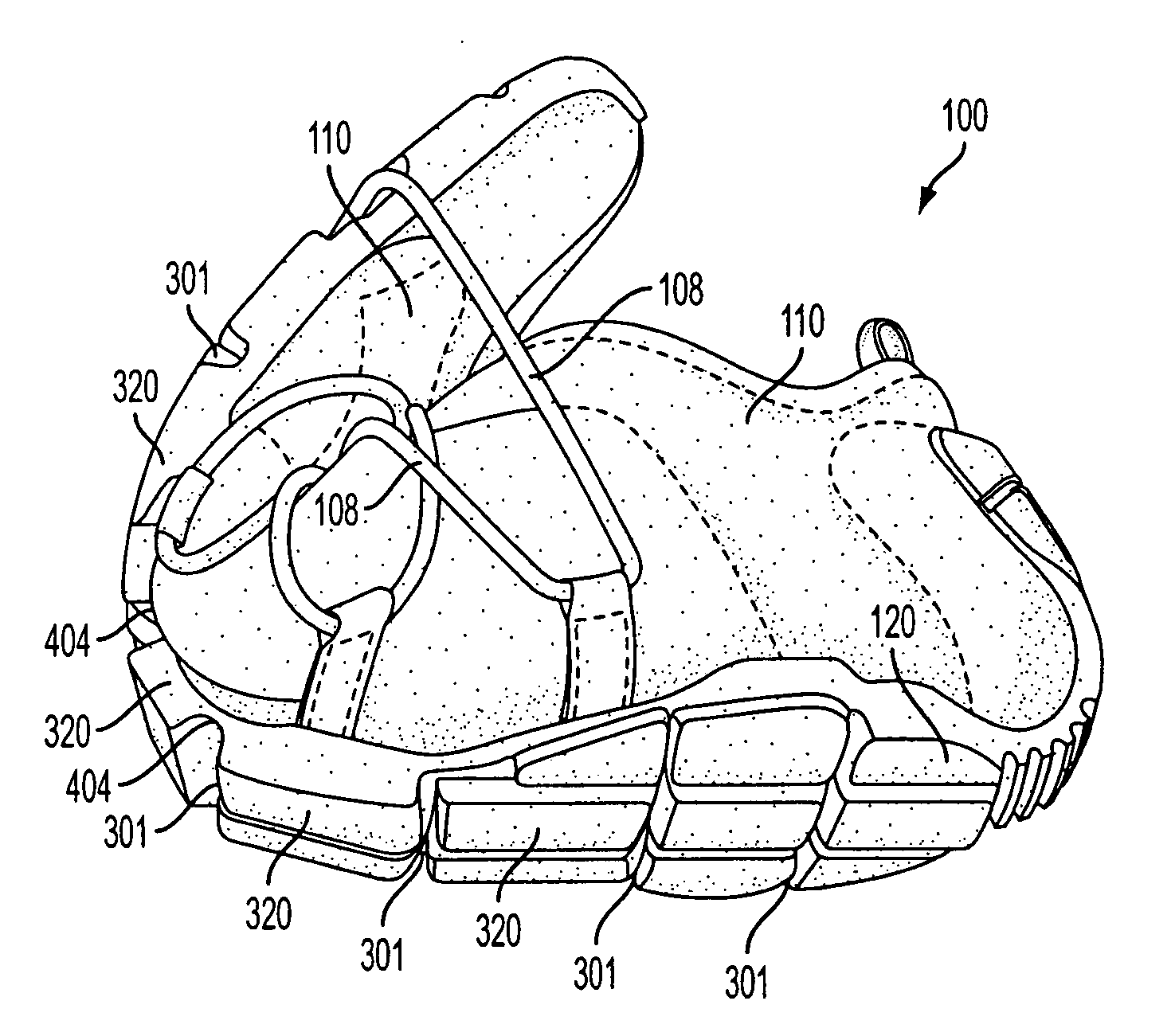

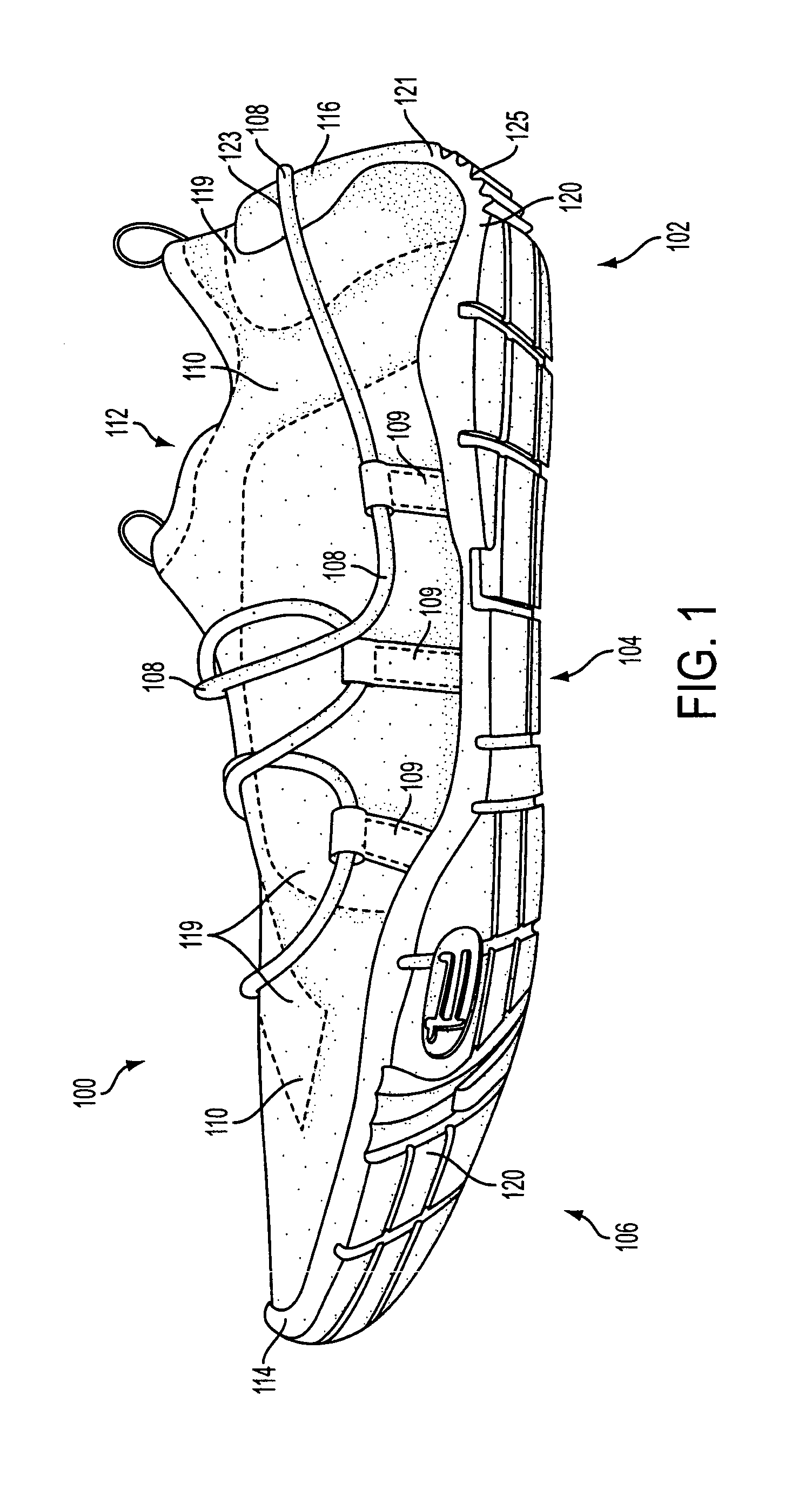

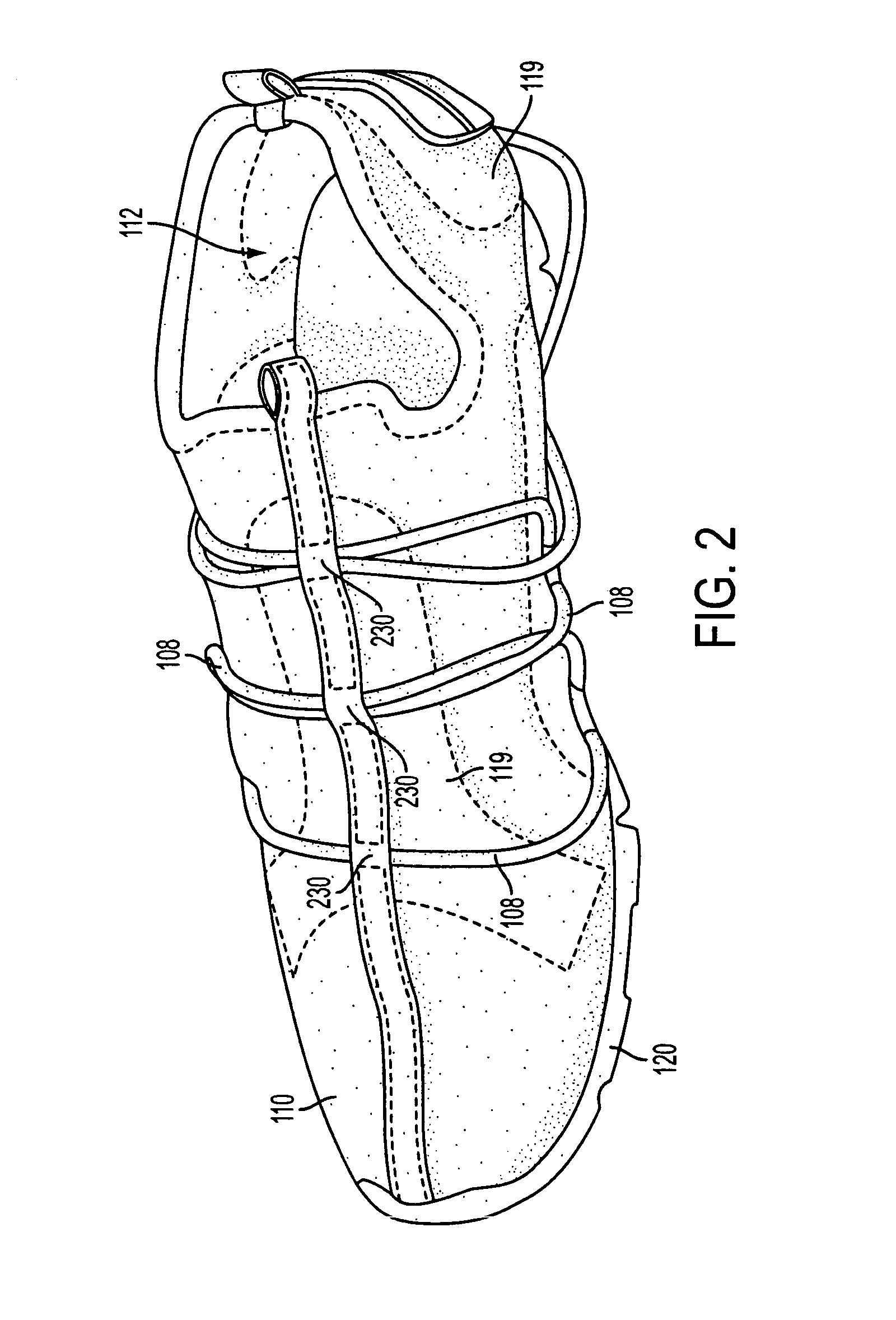

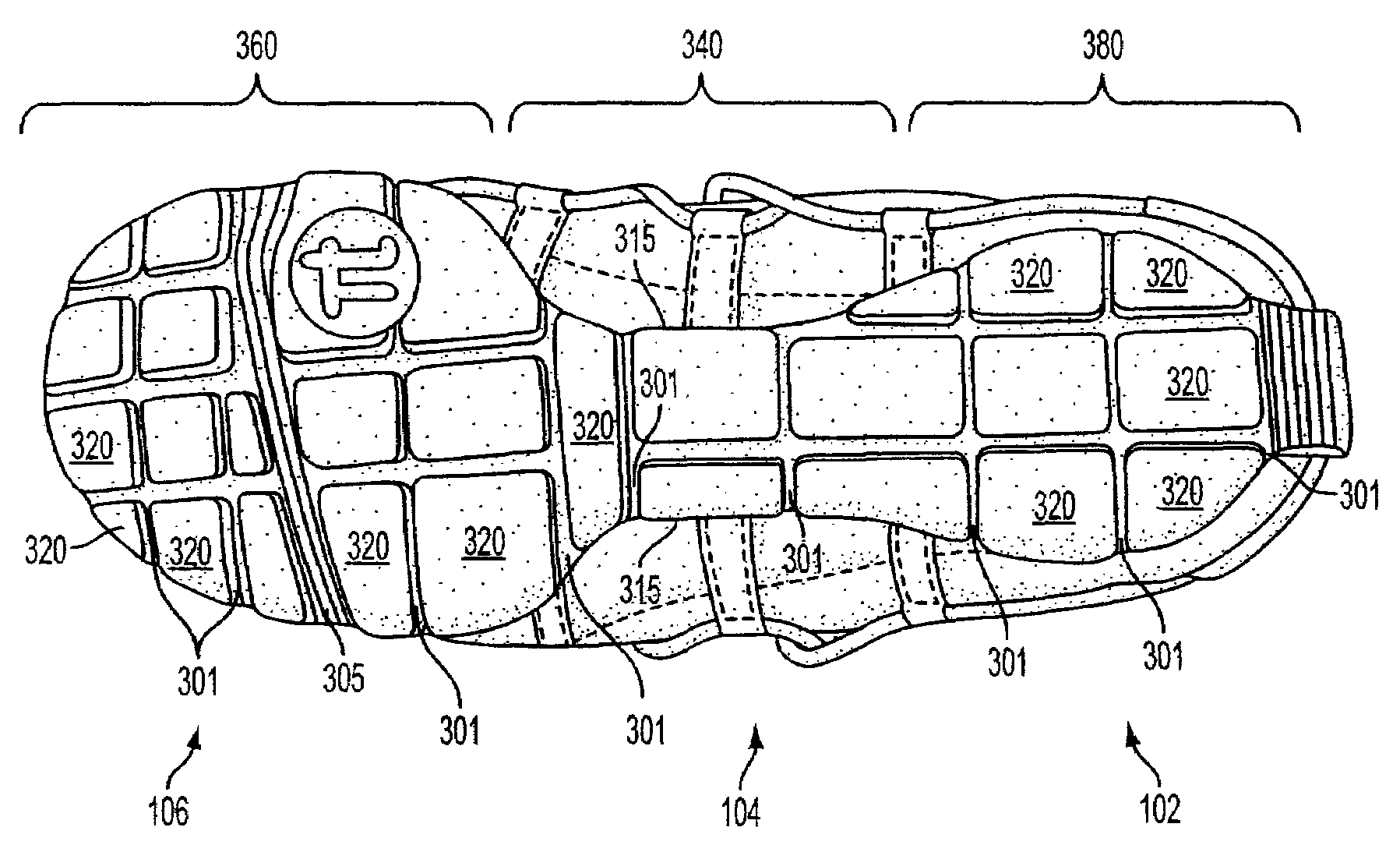

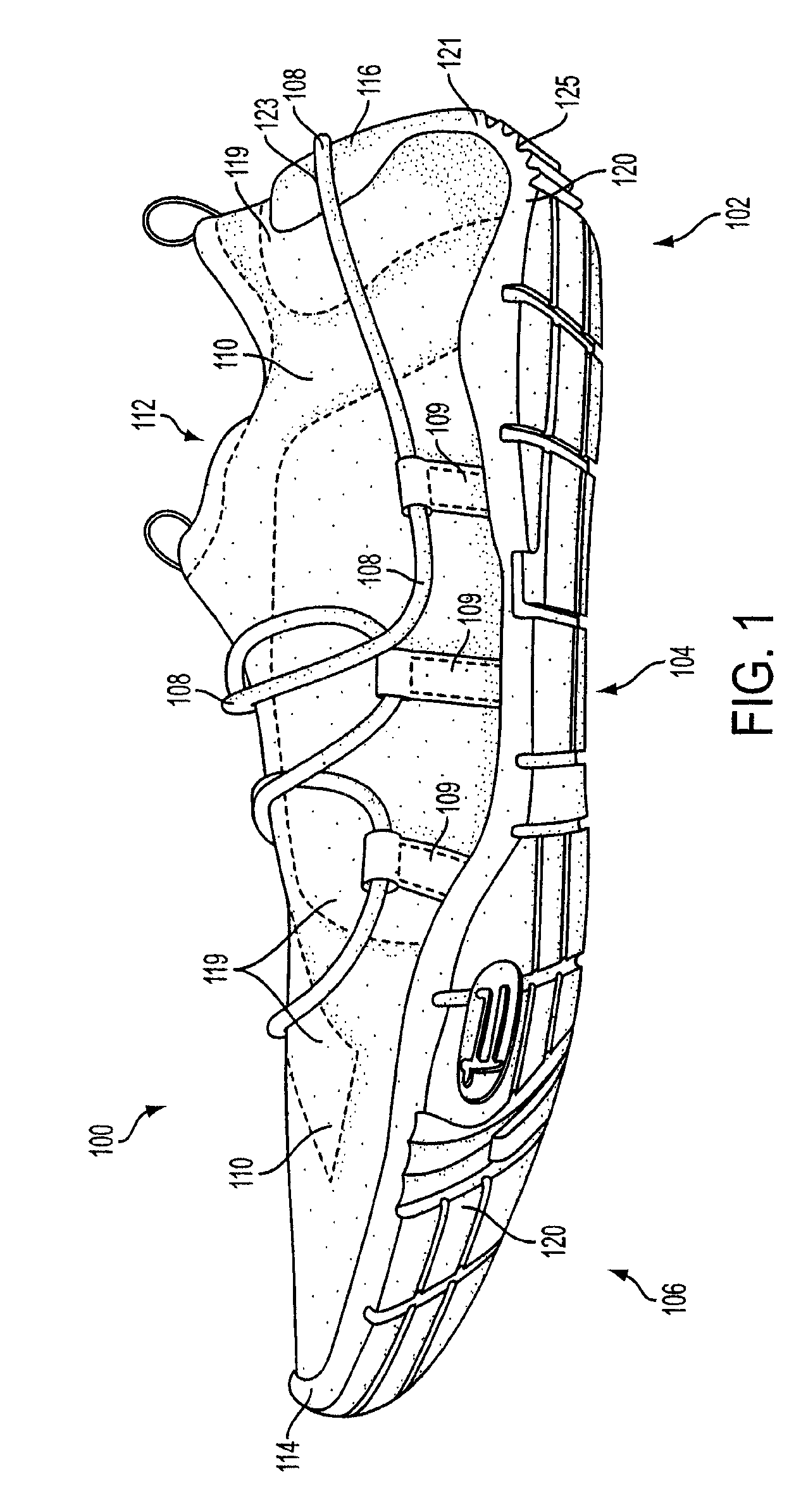

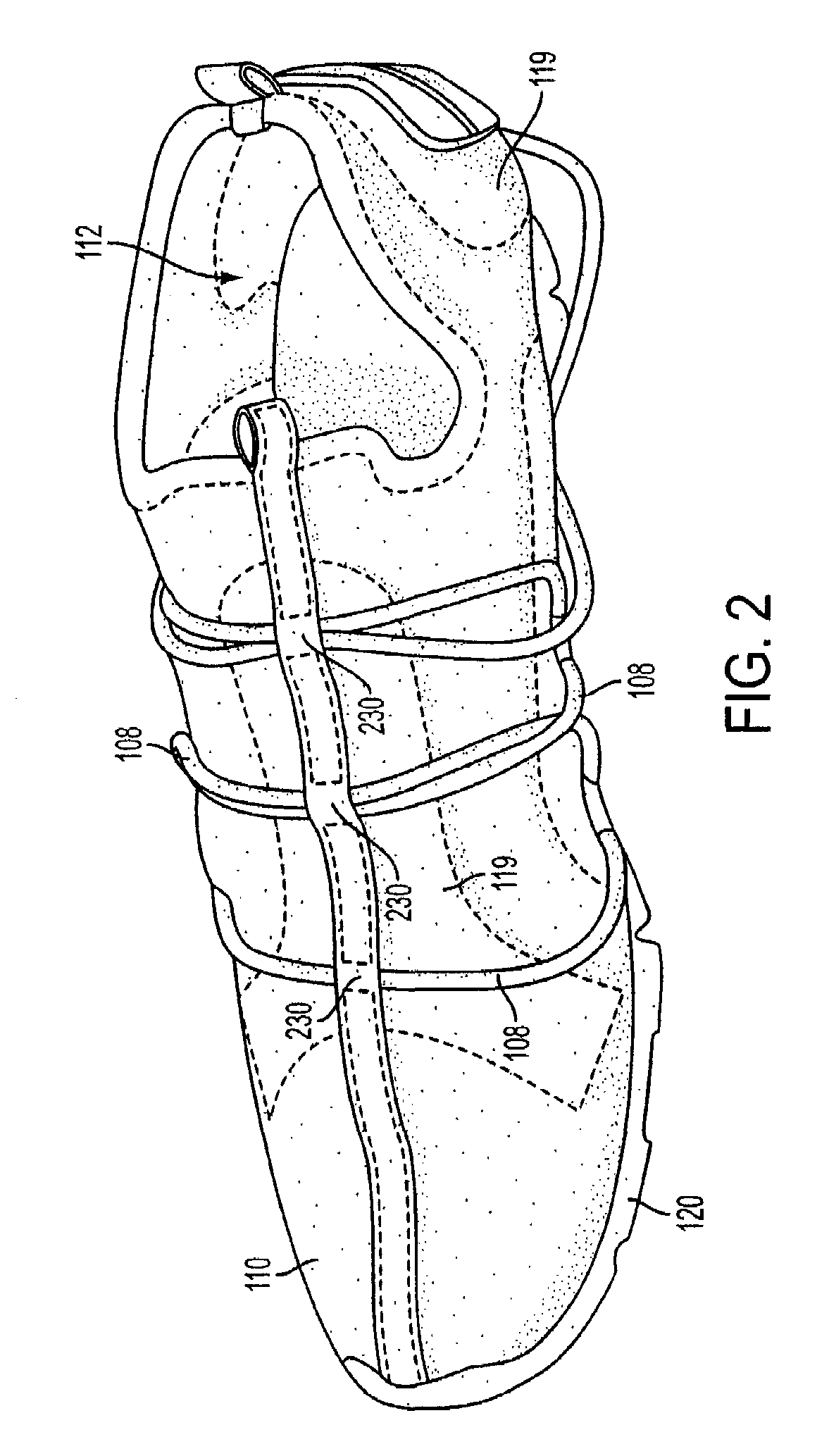

Collapsible shoe

InactiveUS7168190B1Easy to storeConvenient saleSolesAc-dc conversionEngineeringMechanical engineering

An article of footwear including an upper formed of a flexible upper material and a sole formed of a flexible sole material, wherein the sole is rolled, folded, or collapsed onto itself to reduce the volume of the article of footwear. The article of footwear in a collapsed state can then be packaged in a container. This container can be dispensed by a vending machine in a convenient urban area.

Owner:REEBOK

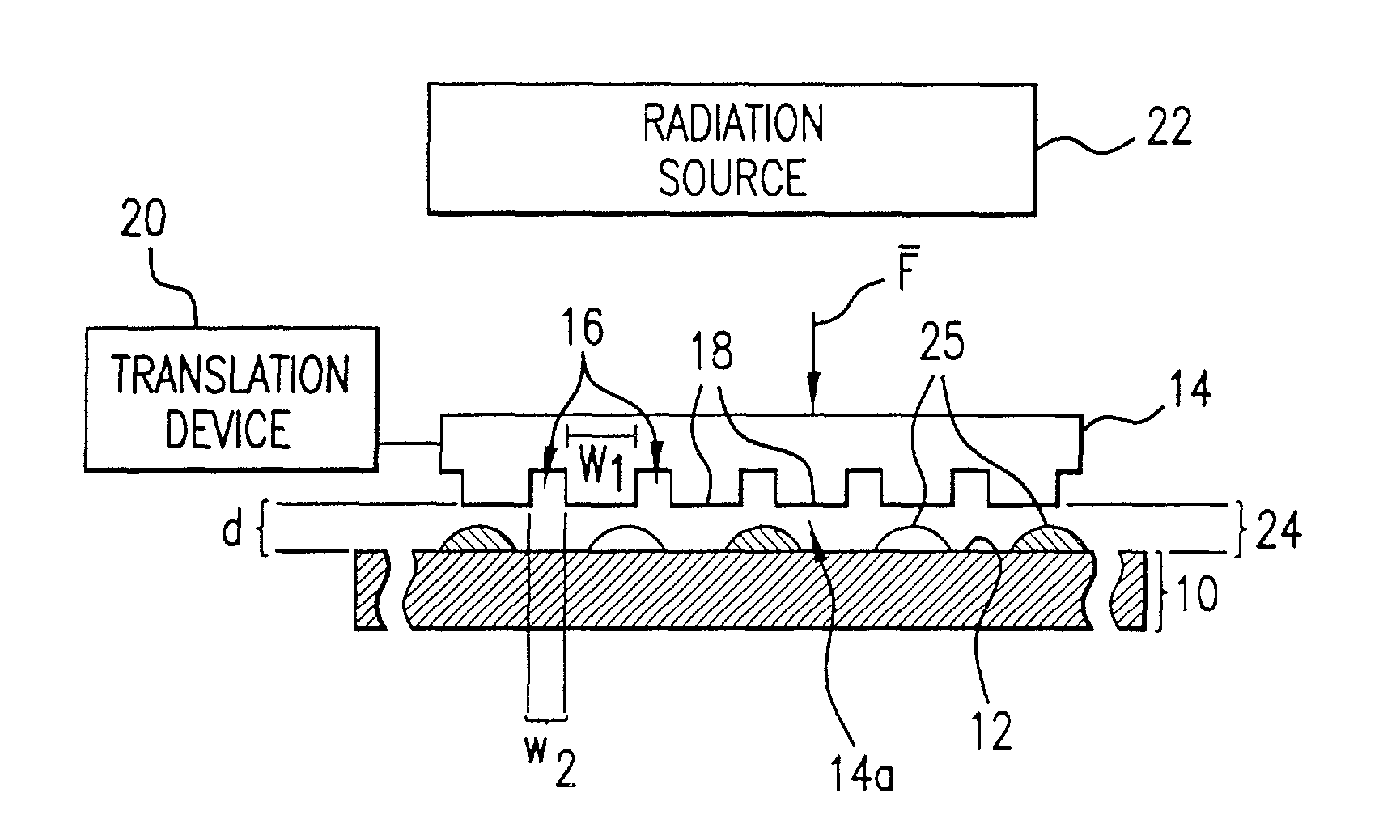

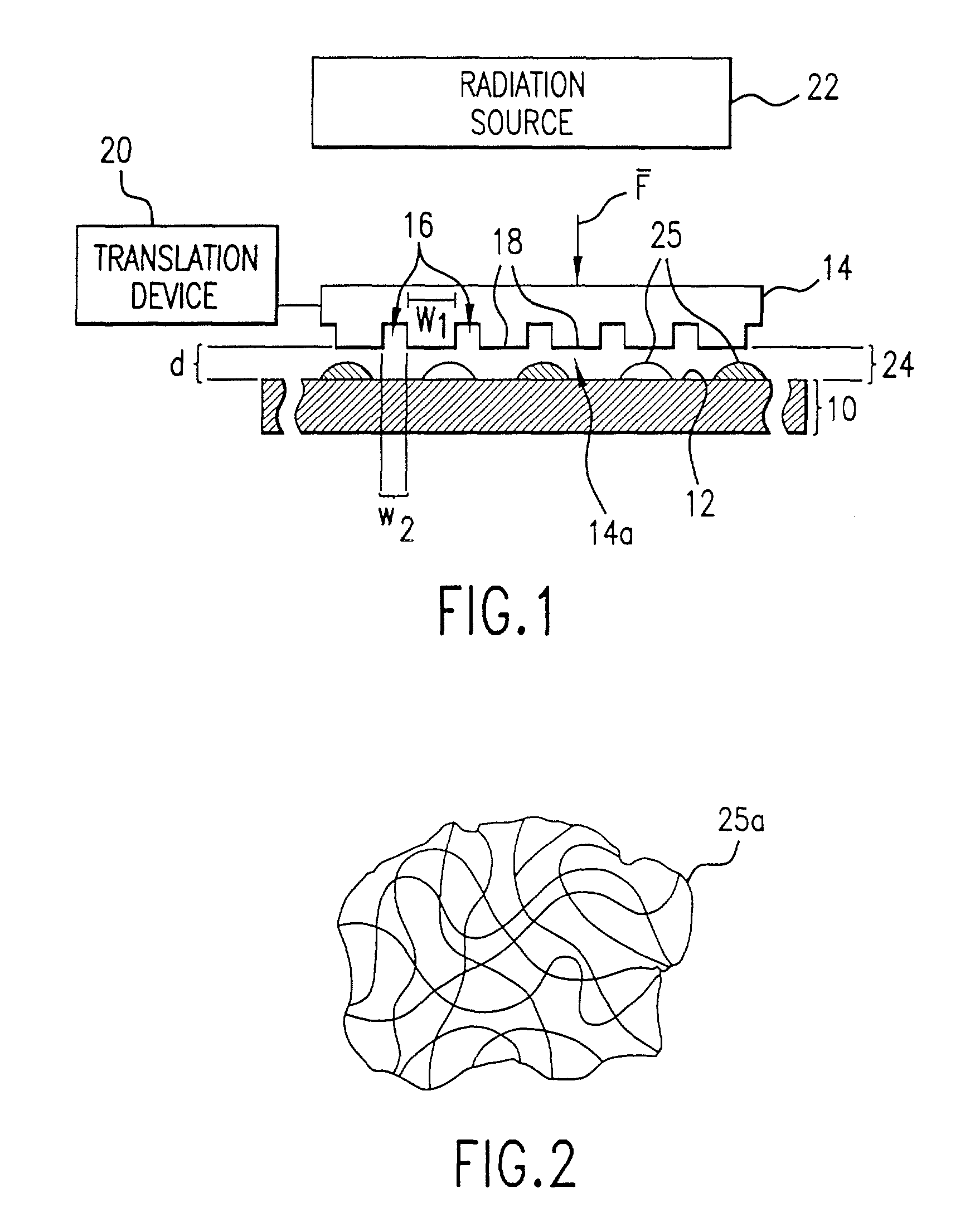

Method to arrange features on a substrate to replicate features having minimal dimensional variability

ActiveUS8349241B2Minimizing dimensional variabilityMinimizing thickness variationDecorative surface effectsNanoinformaticsFill factorVolumetric Mass Density

The present invention is directed to a method of and a mold for arranging features on a substrate to replicate the features with minimal dimensional variability. The method includes arranging features on a layer to minimize thickness variations in the layer that are attributable to density variations of the plurality of features on the layer. The features are transferred into an underlying substrate. It is believed that by forming the features so as to define a uniform fill factor in the layer, the thickness variations may be reduced, if not abrogated. To that end, one method in accordance with the present invention includes forming a flowable material on the substrate. Thereafter, a plurality of features is formed in a region of the flowable material. The plurality of features are arranged to provide a substantially uniform fill factor in the region.

Owner:MOLECULAR IMPRINTS

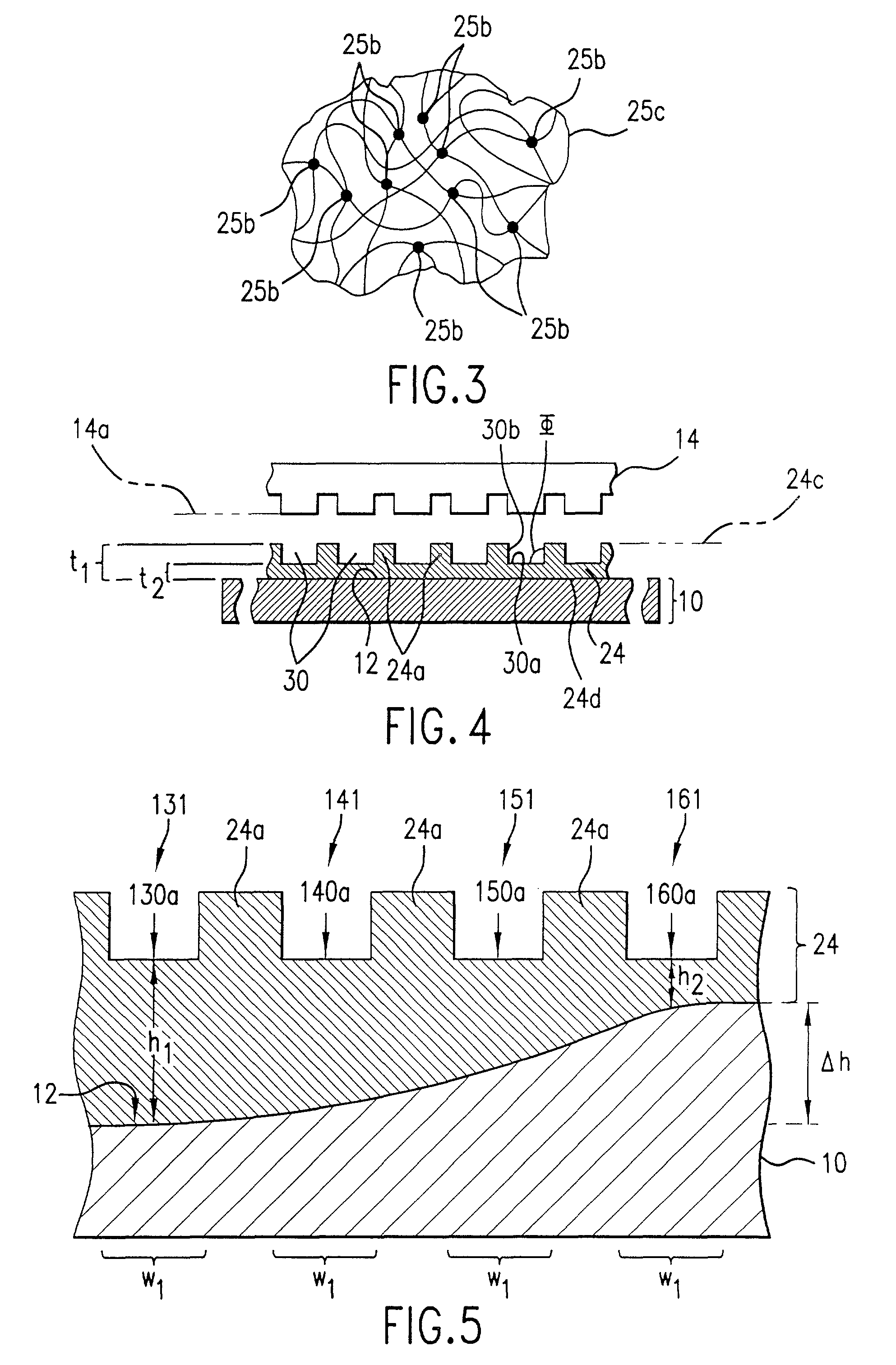

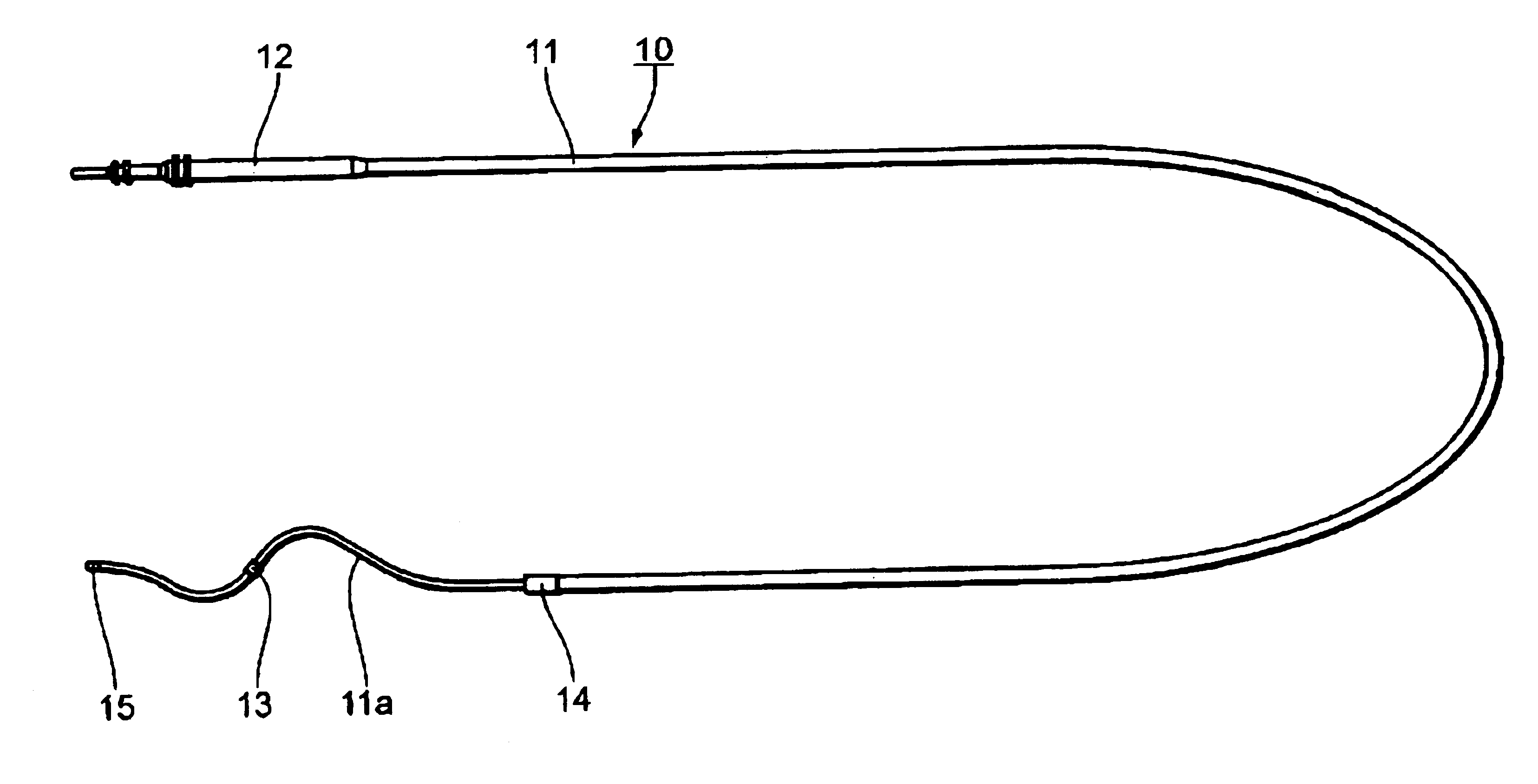

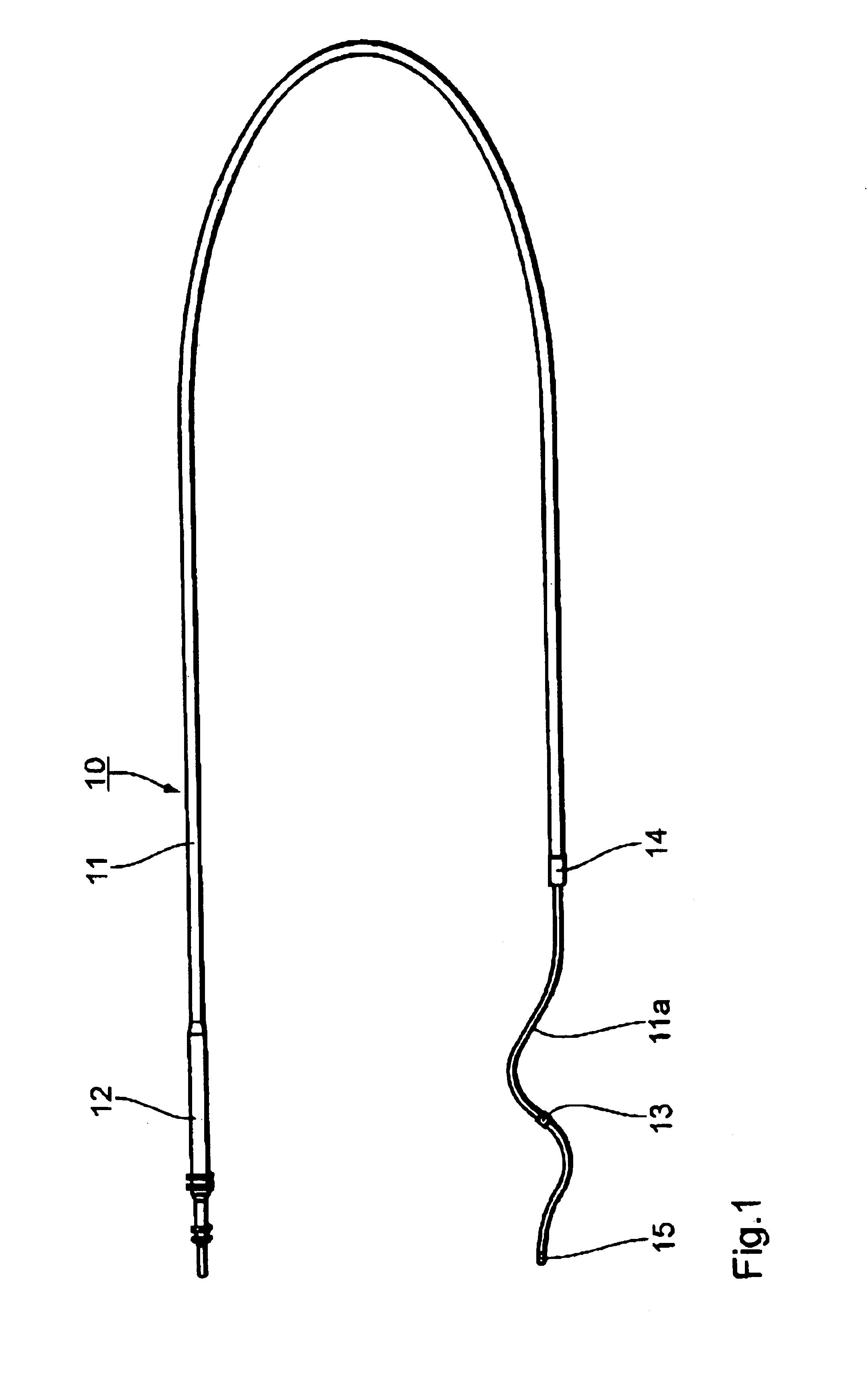

Vessel electrode line

InactiveUS6882886B1High stressIncrease flexibilityTransvascular endocardial electrodesExternal electrodesEngineeringBlood vessel

A vessel electrode line (10) for pacemaker stimulation and / or for sensing cardiac actions in the region of the atrium has an oblong base body (11) that receives at least one electrode supply line, and at least one electrode (13, 14) that is mounted on the base body, with the effective diameter of the electrode(s) being nearly identical to the diameter of the base body, and with fixing elements (11a) that essentially do not act as an electrode, and particularly have at least a partial insulating surface, being provided for fixedly positioning the electrode(s) with respect to the vessel wall.

Owner:BIOTRONIK MESS UND THERAPIEGERAETE GMBH & CO

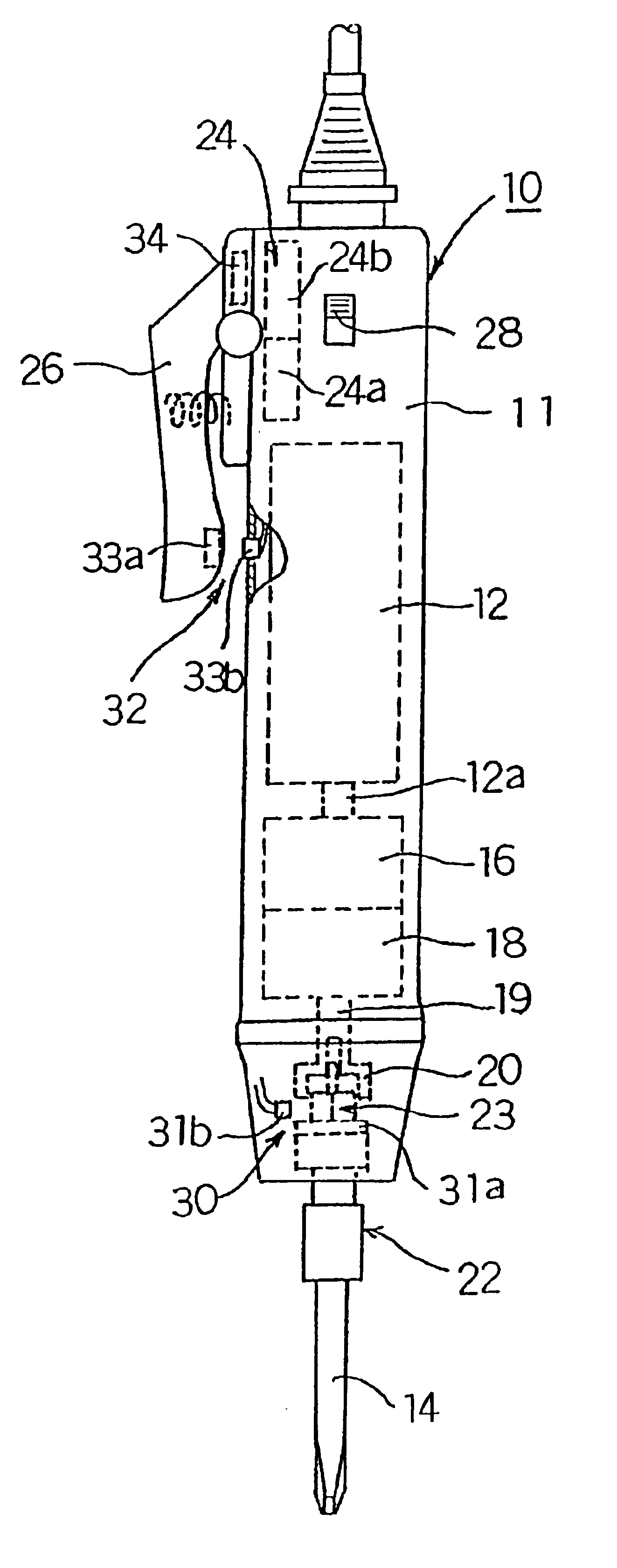

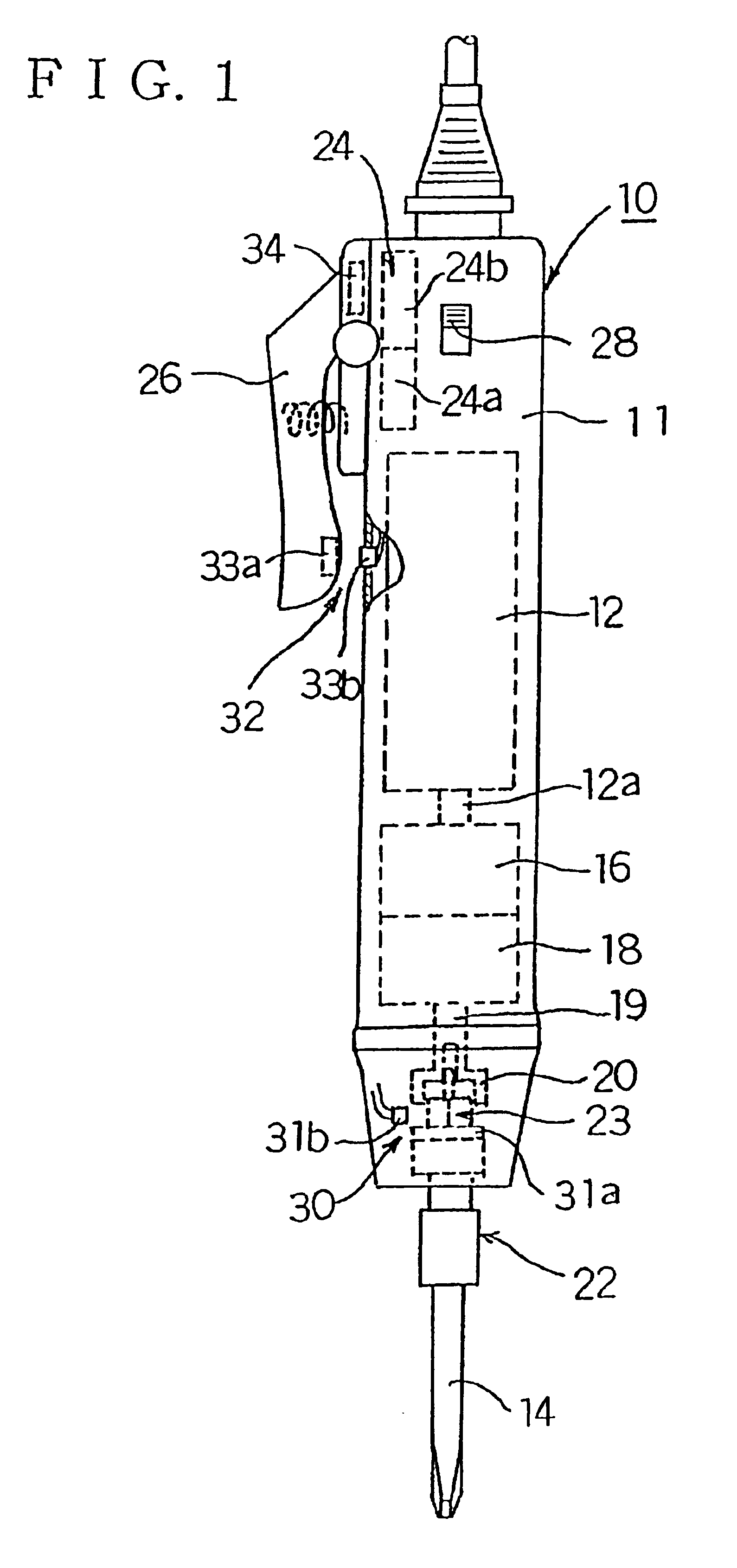

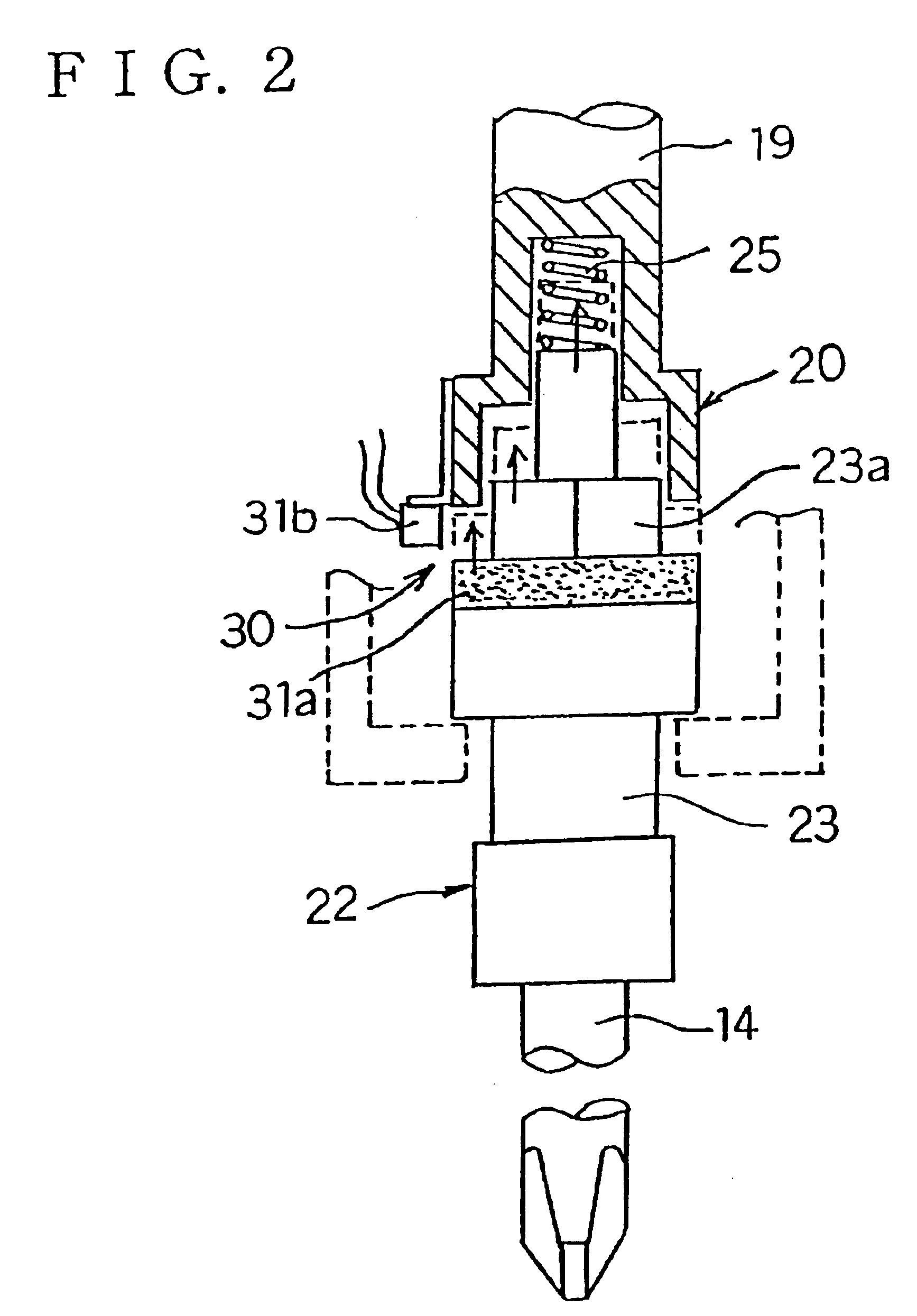

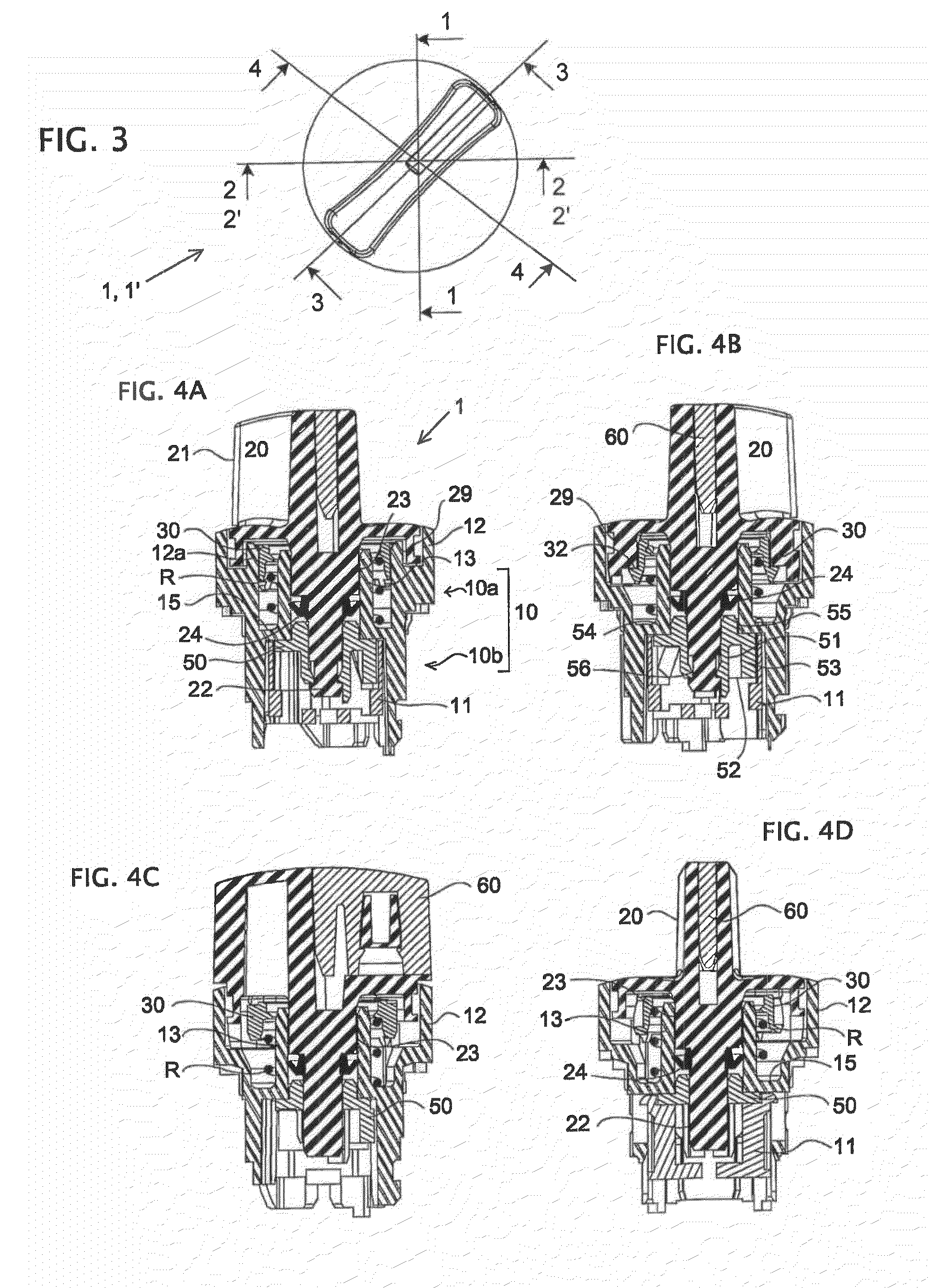

Electric rotational tool driving switch system

InactiveUS6923268B2Easy to operateImprove securityDerricks/mastsOperator-supported drilling machinesOperational systemPower circuits

An electric or power rotational tool including a driving switch of a push operating system that switches the electric motor ON when the rotational tool contacts a work object such as a screw, etc. and is displaced by being pressed, and a driving switch of a lever operating system that switches the electric motor ON when a switch lever installed in the grip portion of the electric rotational tool is displaced by being pressed. Each of the driving switches is constructed by a combination of a magnet and a magnetic sensor, and the magnetic sensor is connected to the power circuit of the electric motor, so that either one of operating systems is selected; and the driving of the electric motor is initiated by switching the power circuit ON through a magnetism sensing action of the magnetic sensor of the selected operating system.

Owner:TOTSU KATSUYUKI

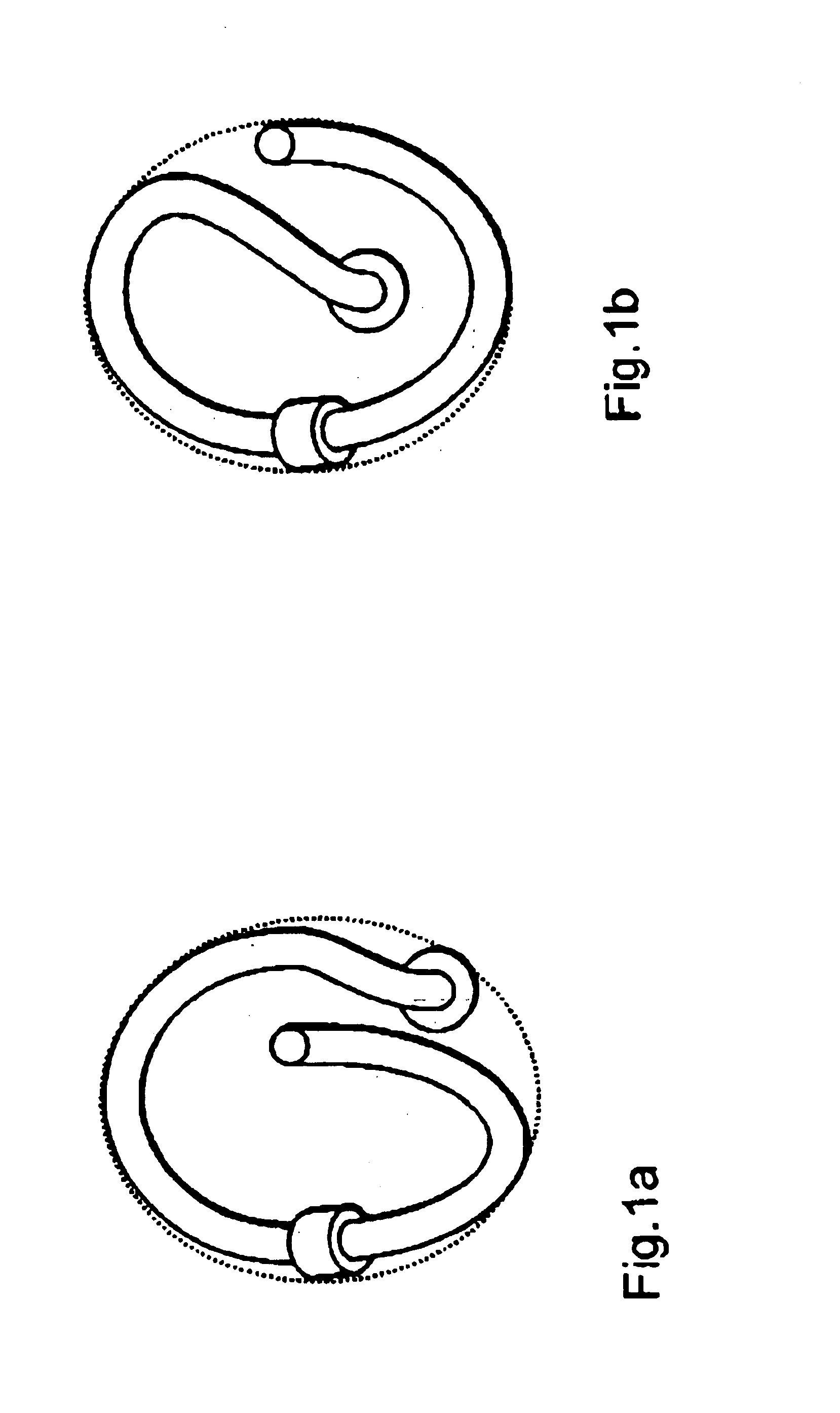

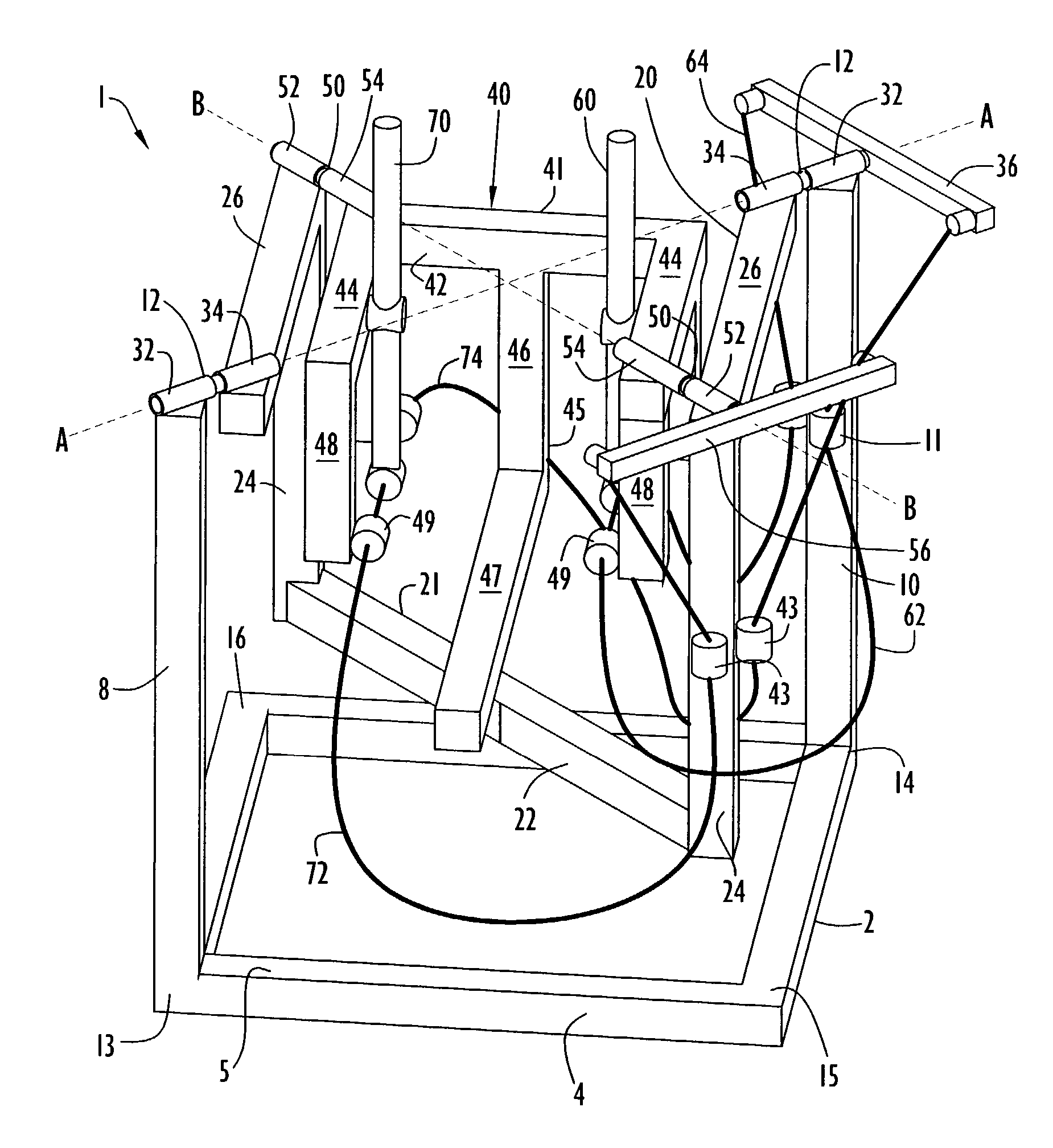

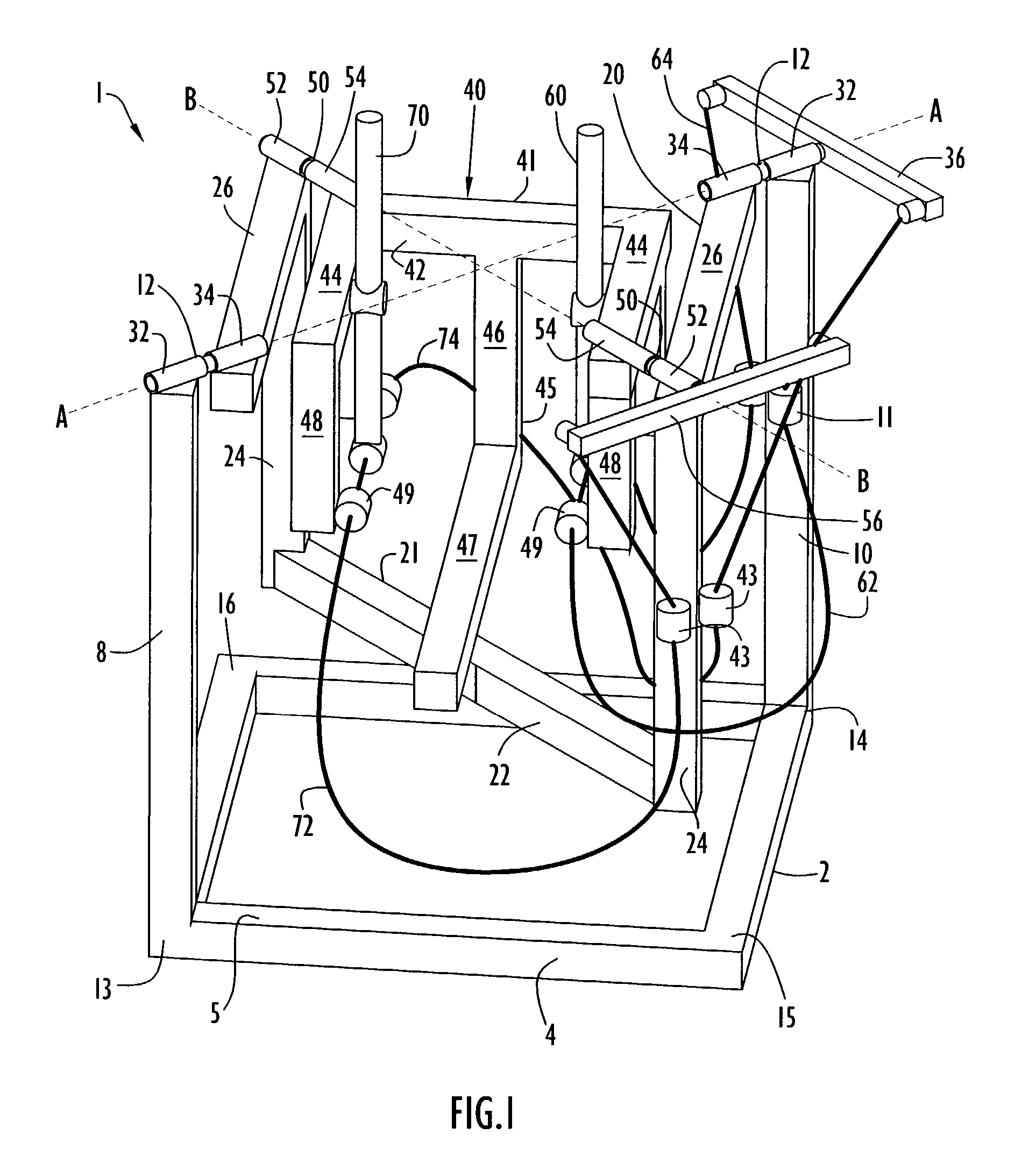

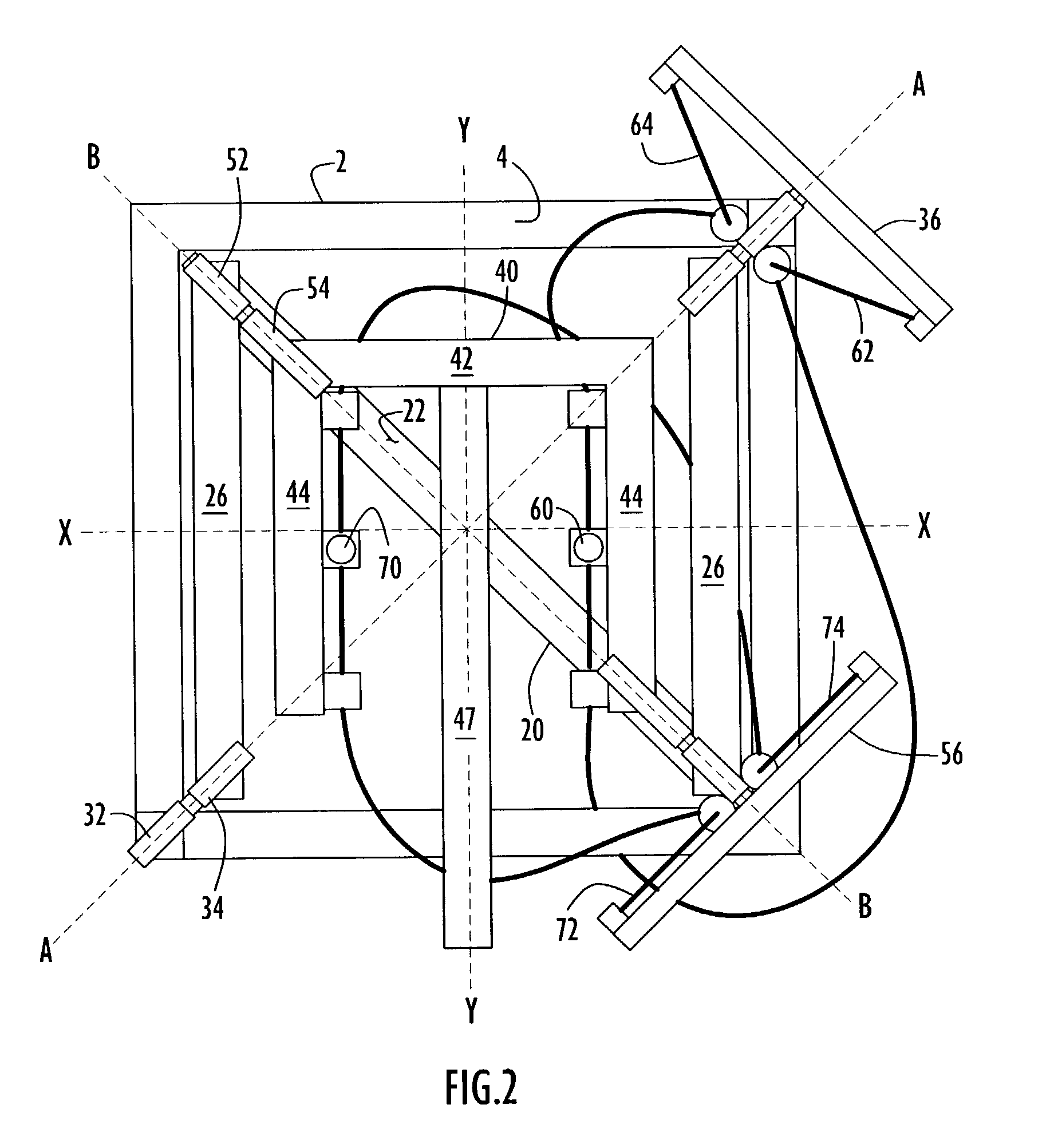

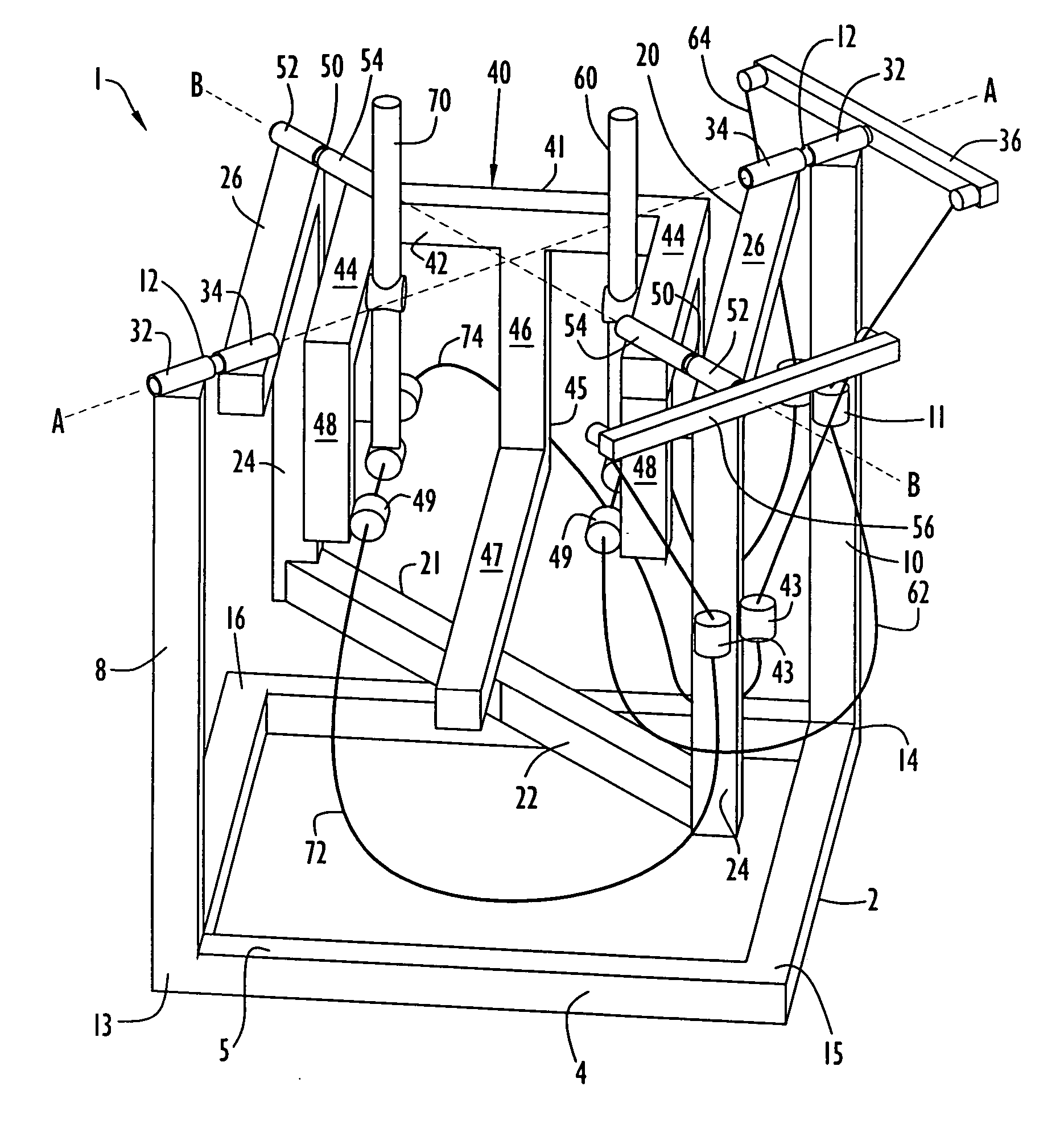

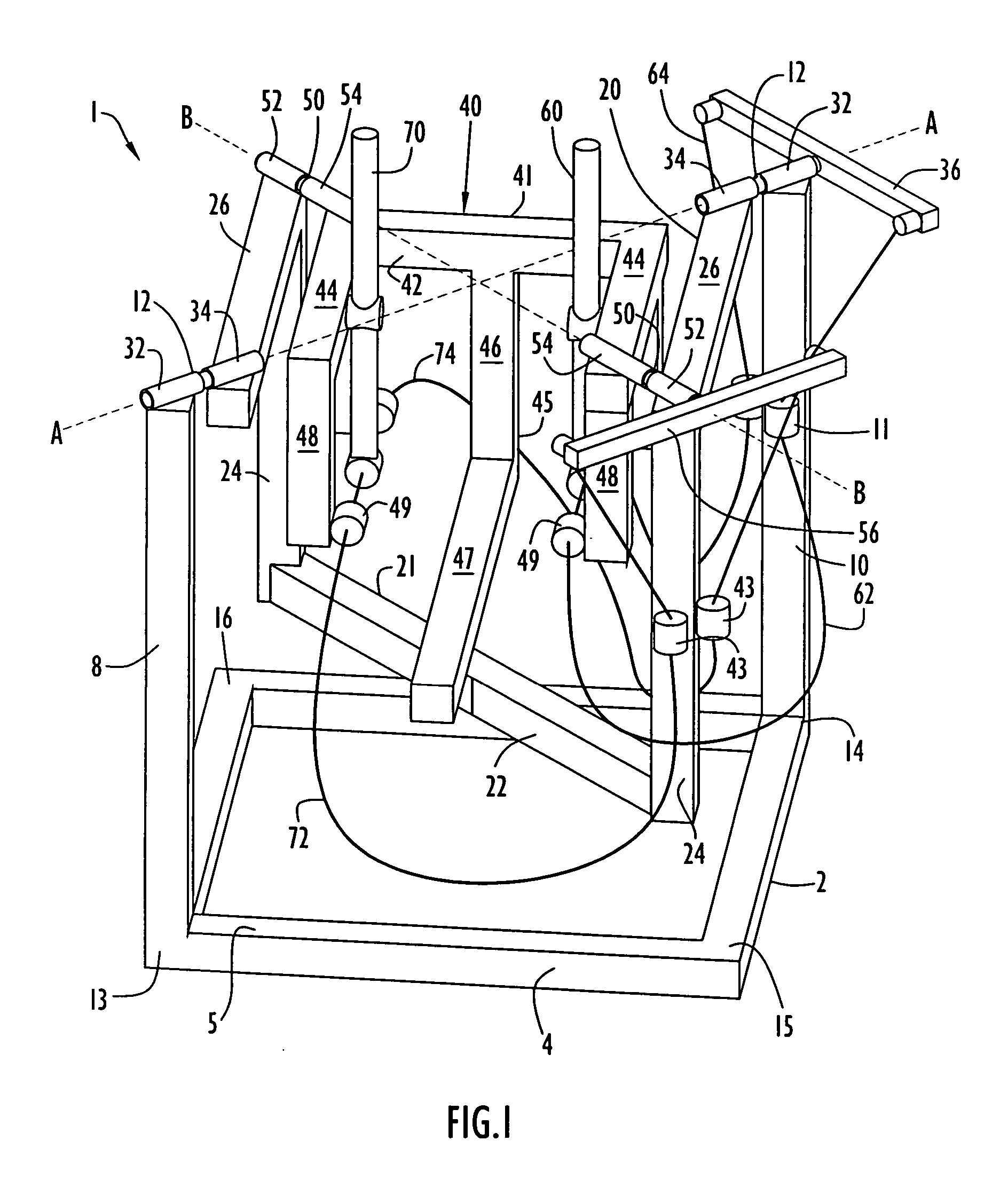

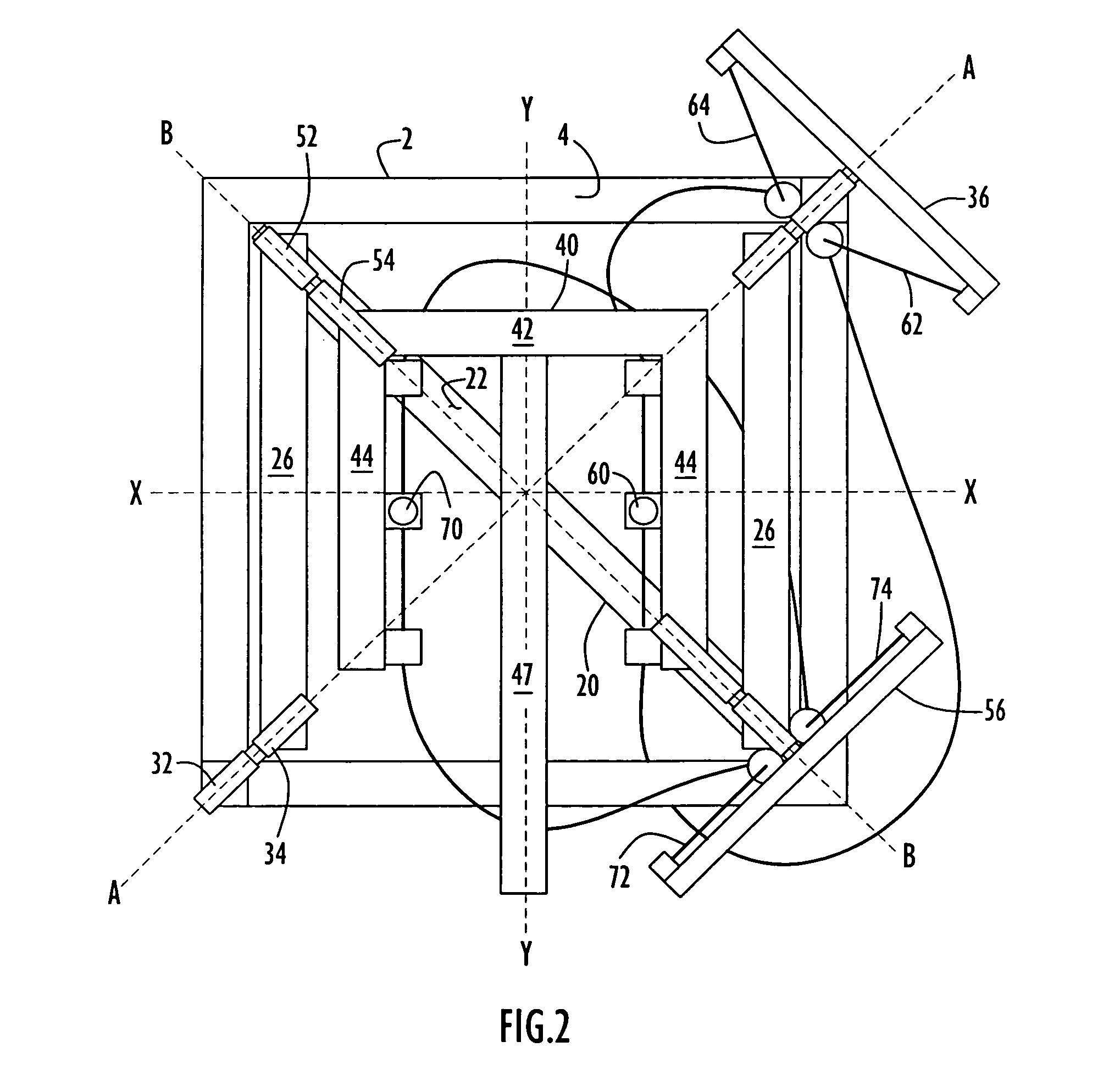

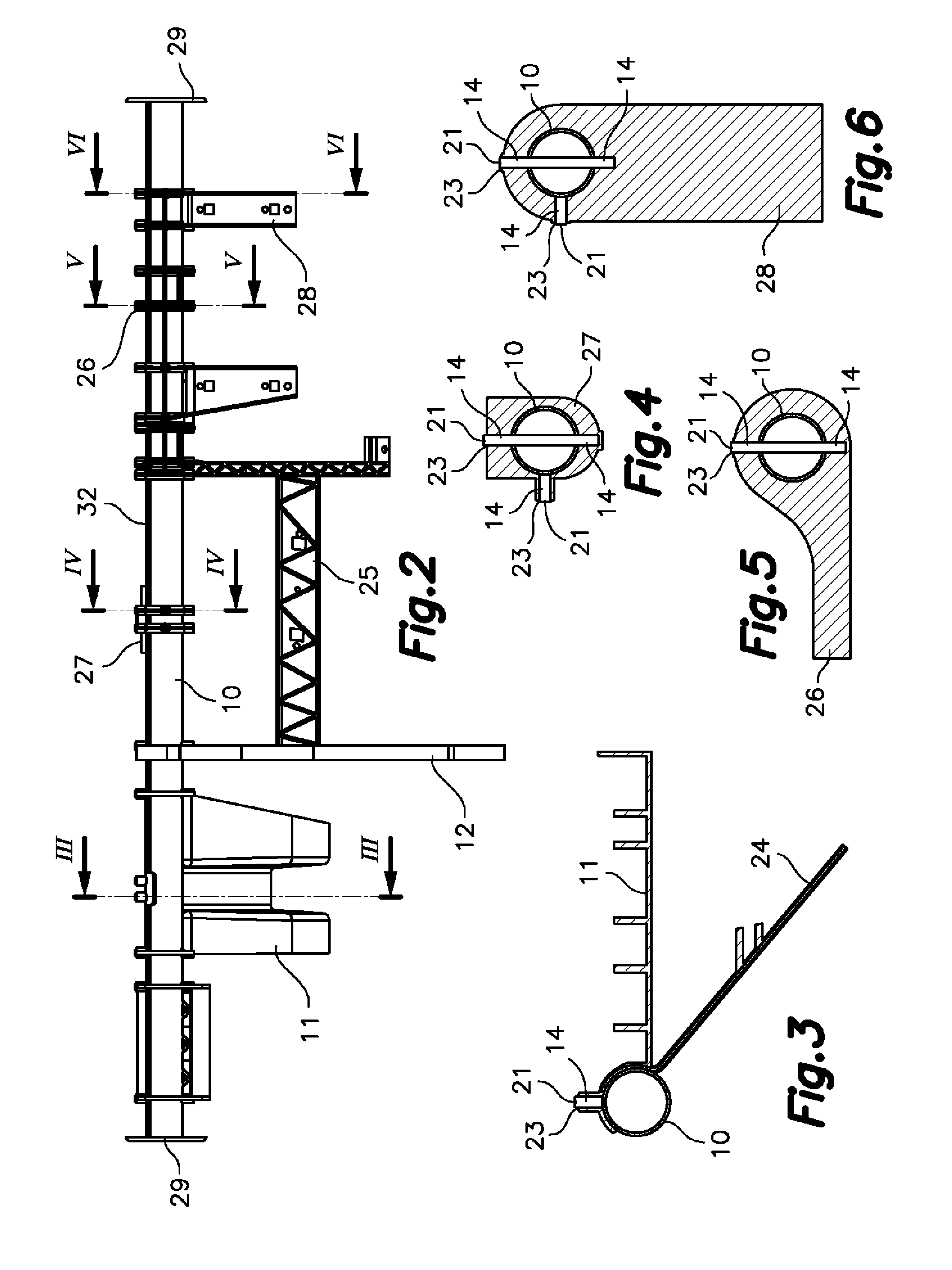

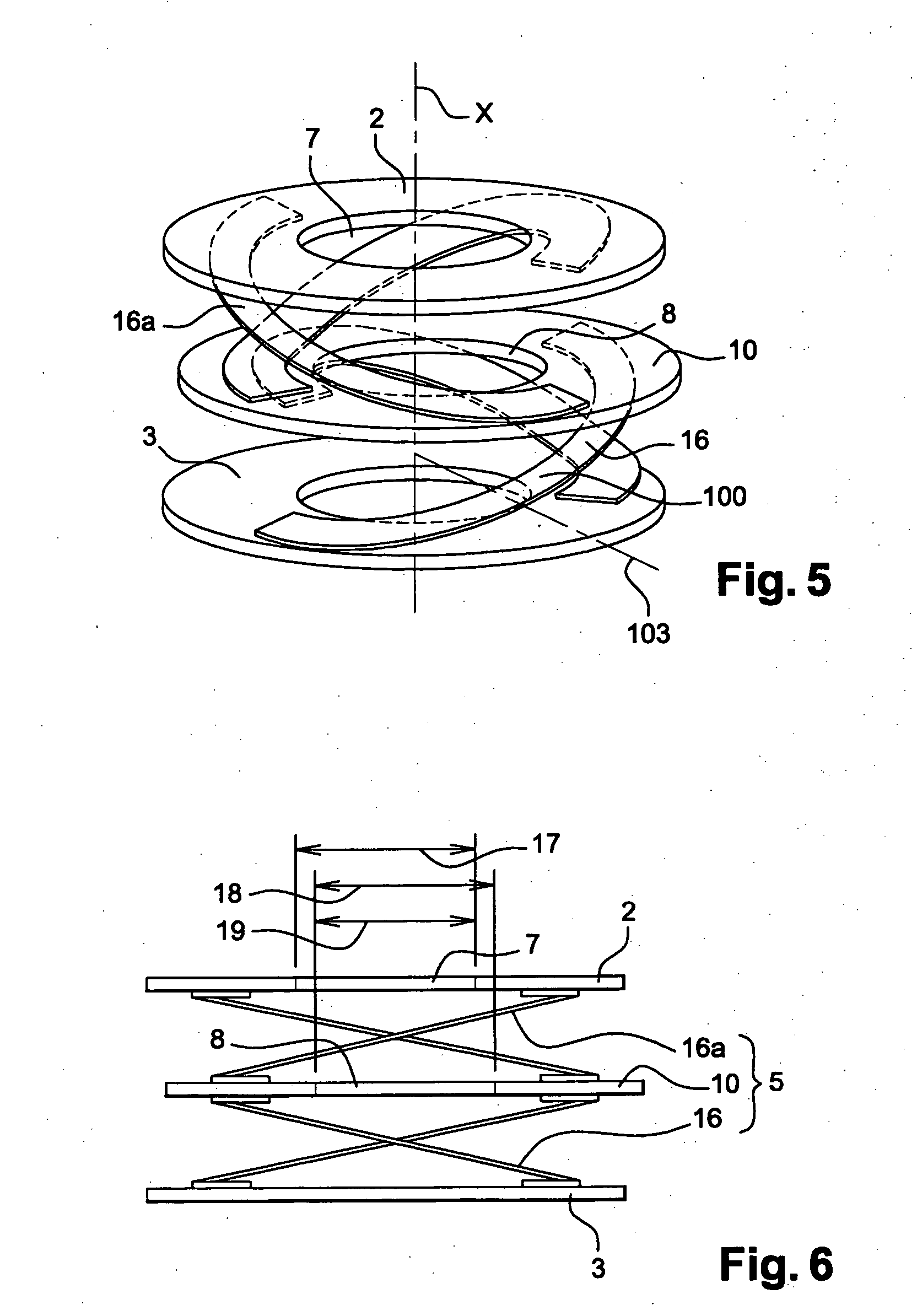

Motion platform system and method of rotating a motion platform about plural axes

InactiveUS7033176B2Compact sizeEasy user manipulationCosmonautic condition simulationsAmusementsEngineering

A motion platform system includes a support and a motion platform supported by the support and rotatable about a plurality of bearing axes. The motion platform is further rotatable with respect to the support about at least one axis that is offset from the plurality of bearing axes. The motion platform may include an intermediate frame supported by the support, where the intermediate frame is rotatable about a first bearing axis with respect to the support. The motion platform may further include an inner frame supported by the intermediate frame, where the inner frame is rotatable about a second bearing axis with respect to the intermediate frame. Rotations of the inner and intermediate frames about the first and second bearing axes facilitate rotation of the inner frame with respect to the support about at least one axis offset from the bearing axes.

Owner:NINTENDO CO LTD AND NINTENDO OF AMERICA INC

Motion platform system and method of rotating a motion platform about plural axes

InactiveUS20060211543A1Small sizeEasy user manipulationCosmonautic condition simulationsAmusementsEngineering

A motion platform system includes a support and a motion platform supported by the support and rotatable about a plurality of bearing axes. The motion platform is further rotatable with respect to the support about at least one axis that is offset from the plurality of bearing axes. The motion platform may include an intermediate frame supported by the support, where the intermediate frame is rotatable about a first bearing axis with respect to the support. The motion platform may further include an inner frame supported by the intermediate frame, where the inner frame is rotatable about a second bearing axis with respect to the intermediate frame. Rotations of the inner and intermediate frames about the first and second bearing axes facilitate rotation of the inner frame with respect to the support about at least one axis offset from the bearing axes.

Owner:NINTENDO CO LTD AND NINTENDO OF AMERICA INC

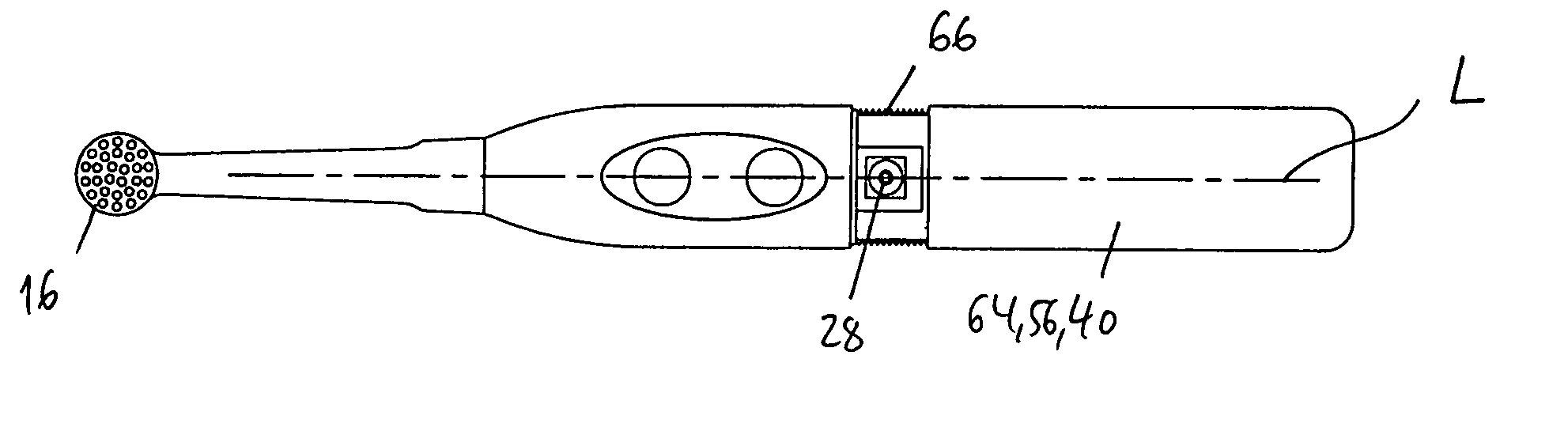

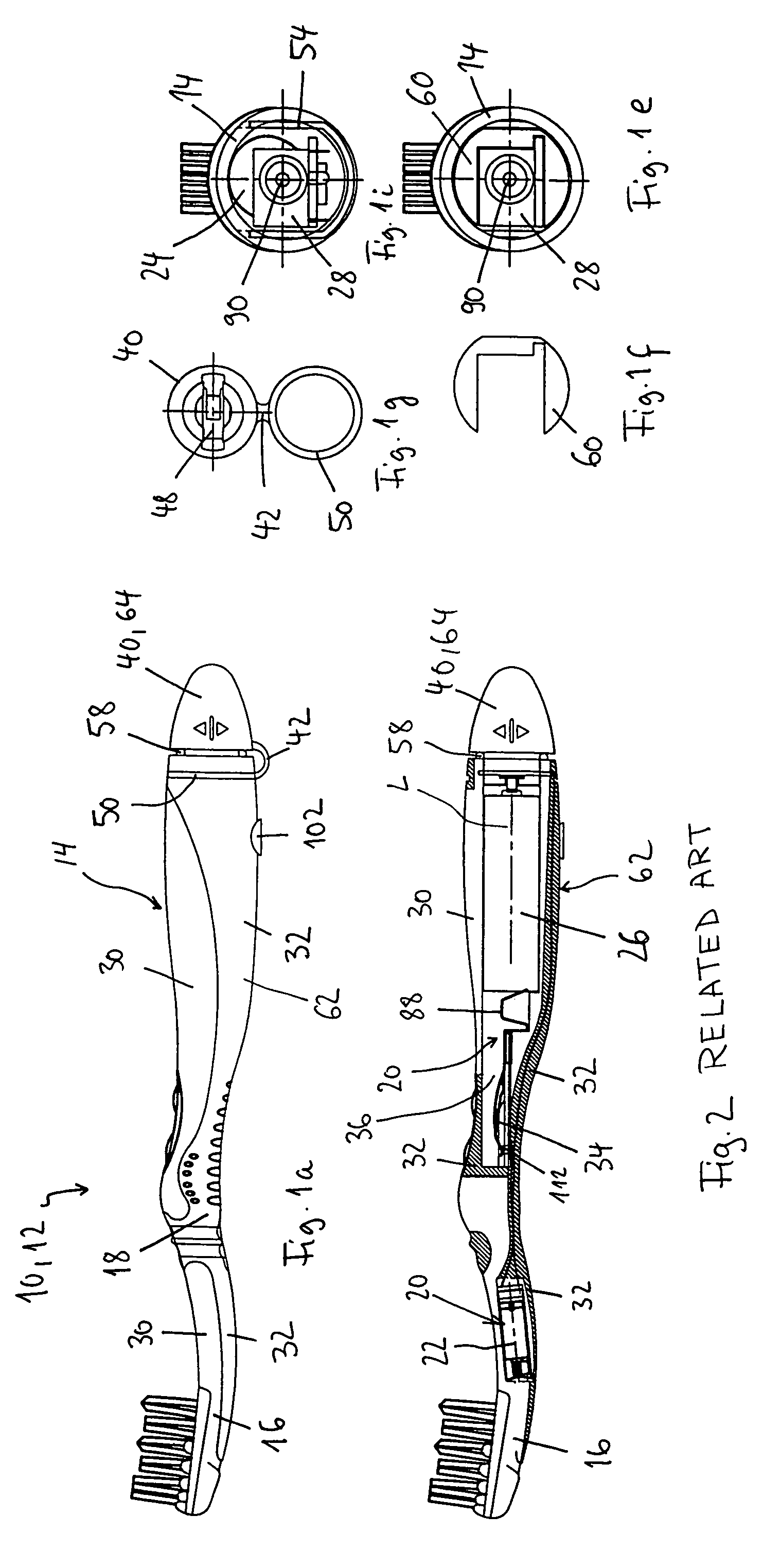

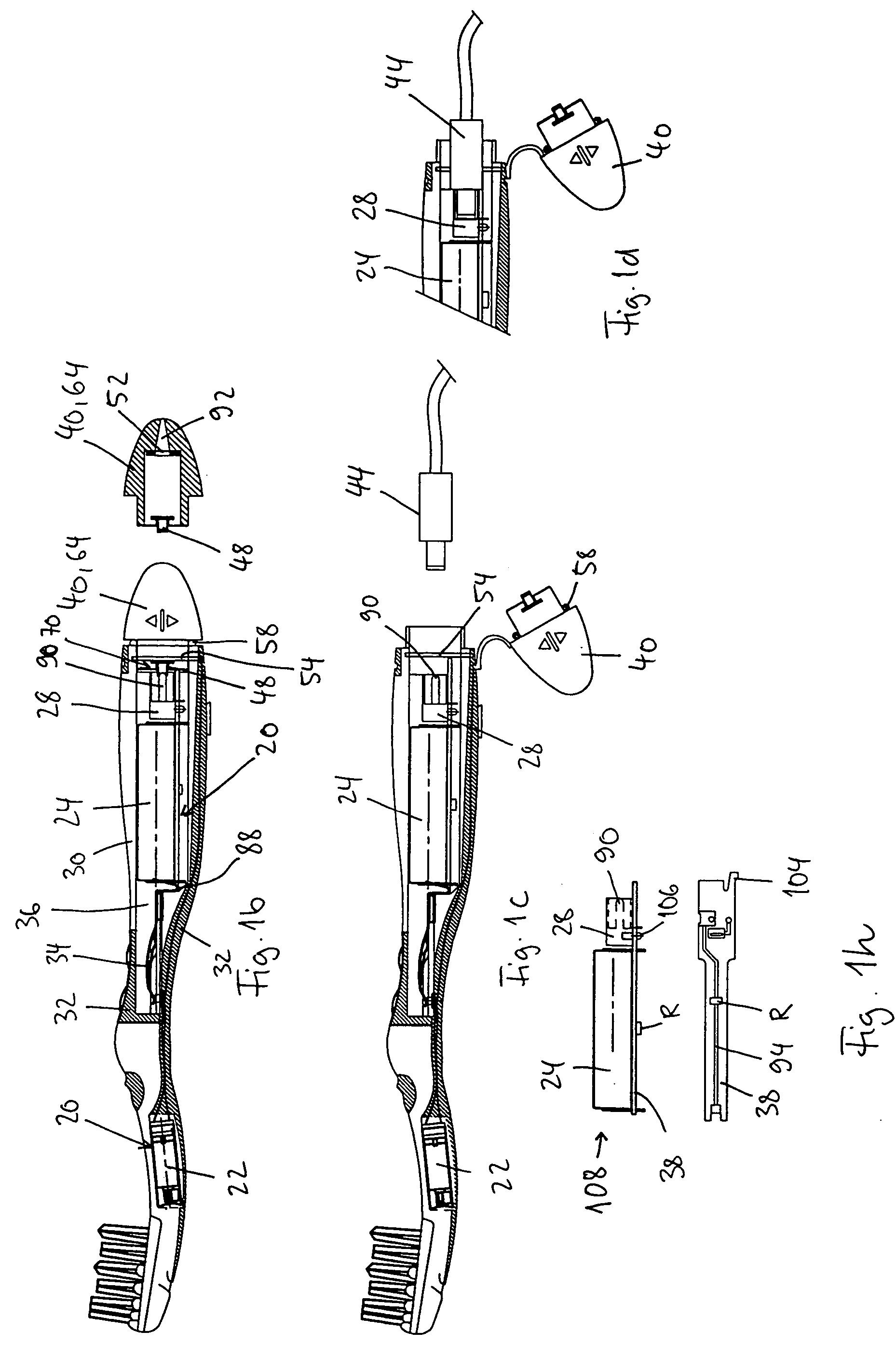

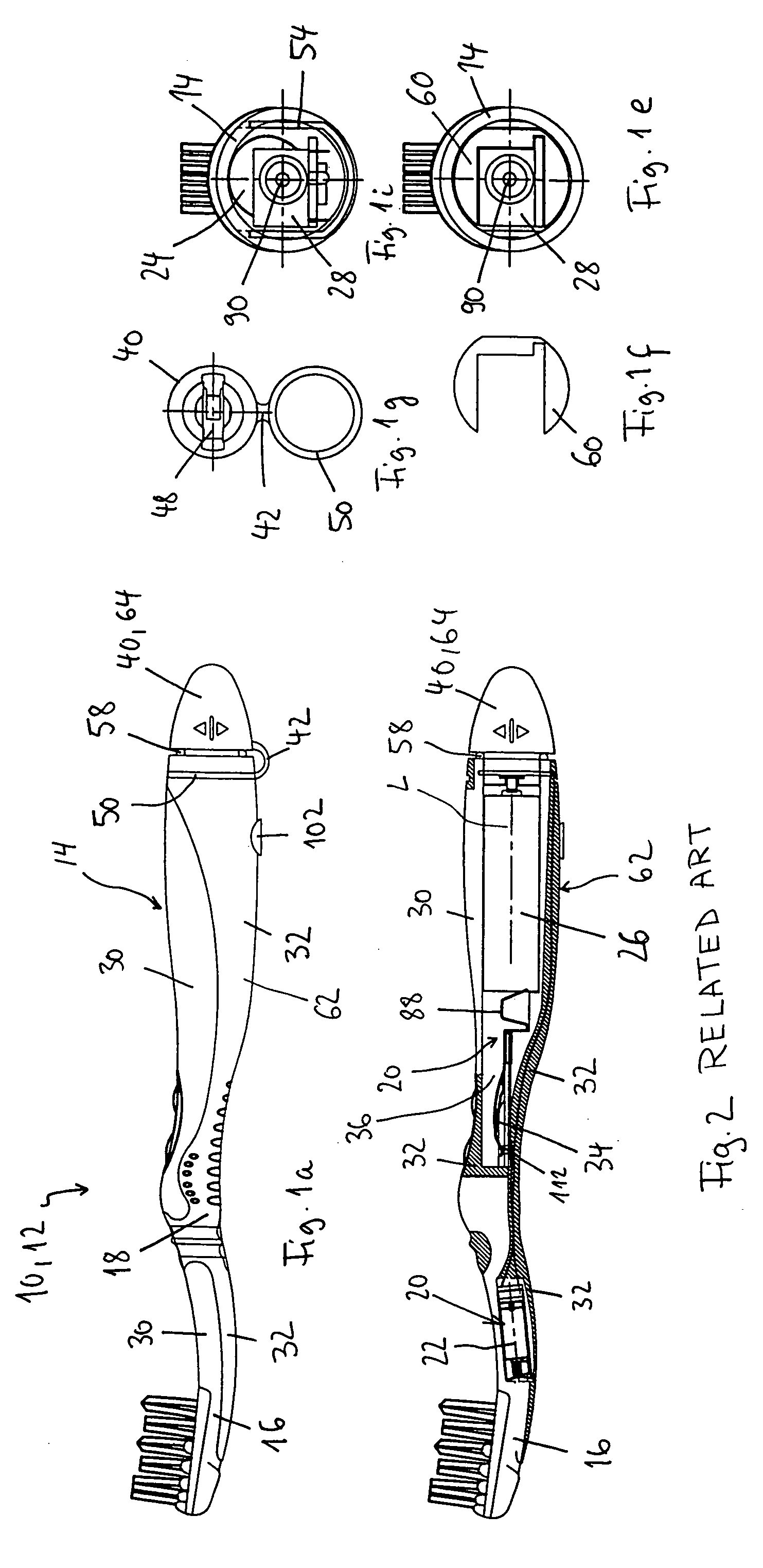

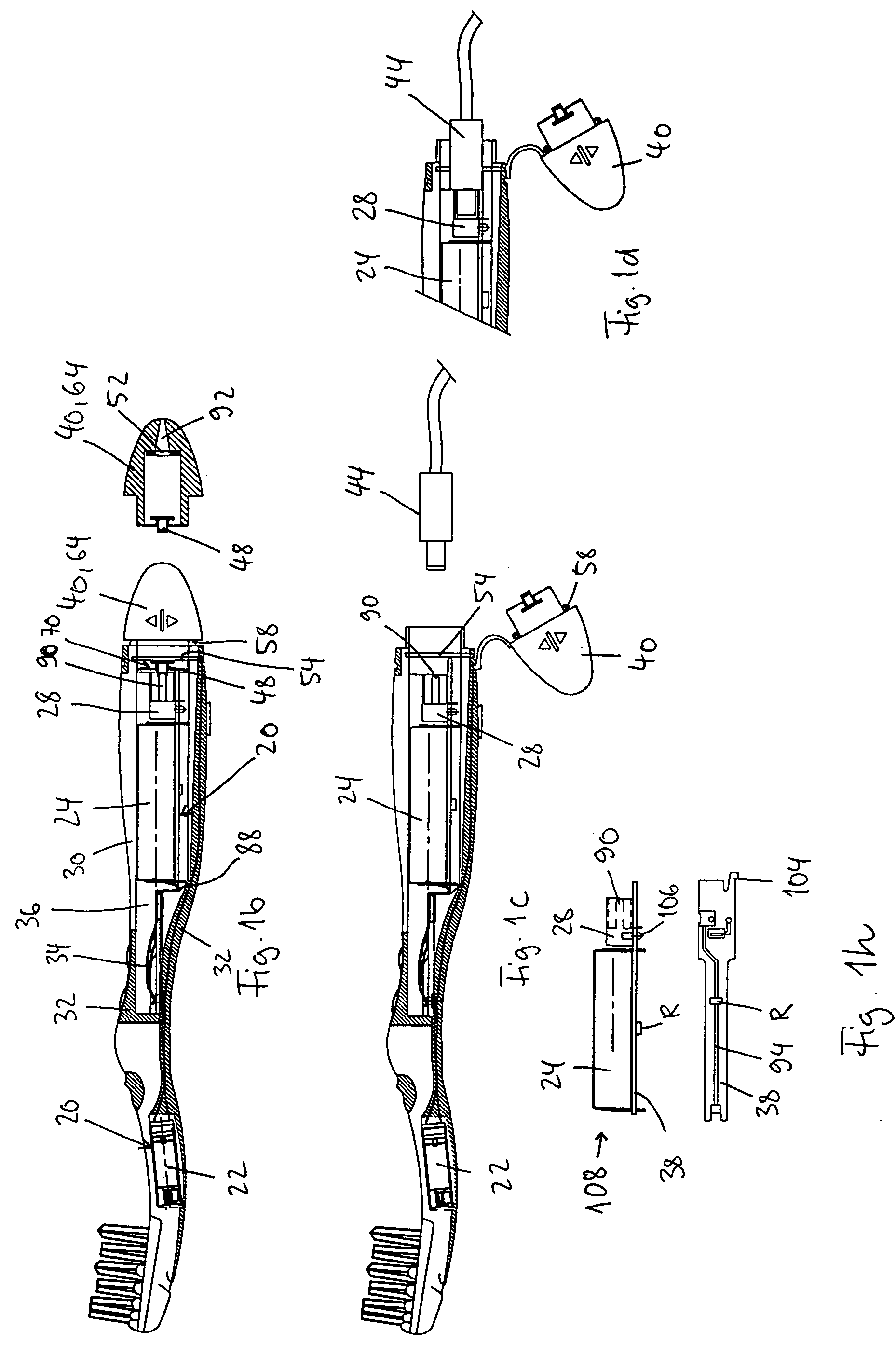

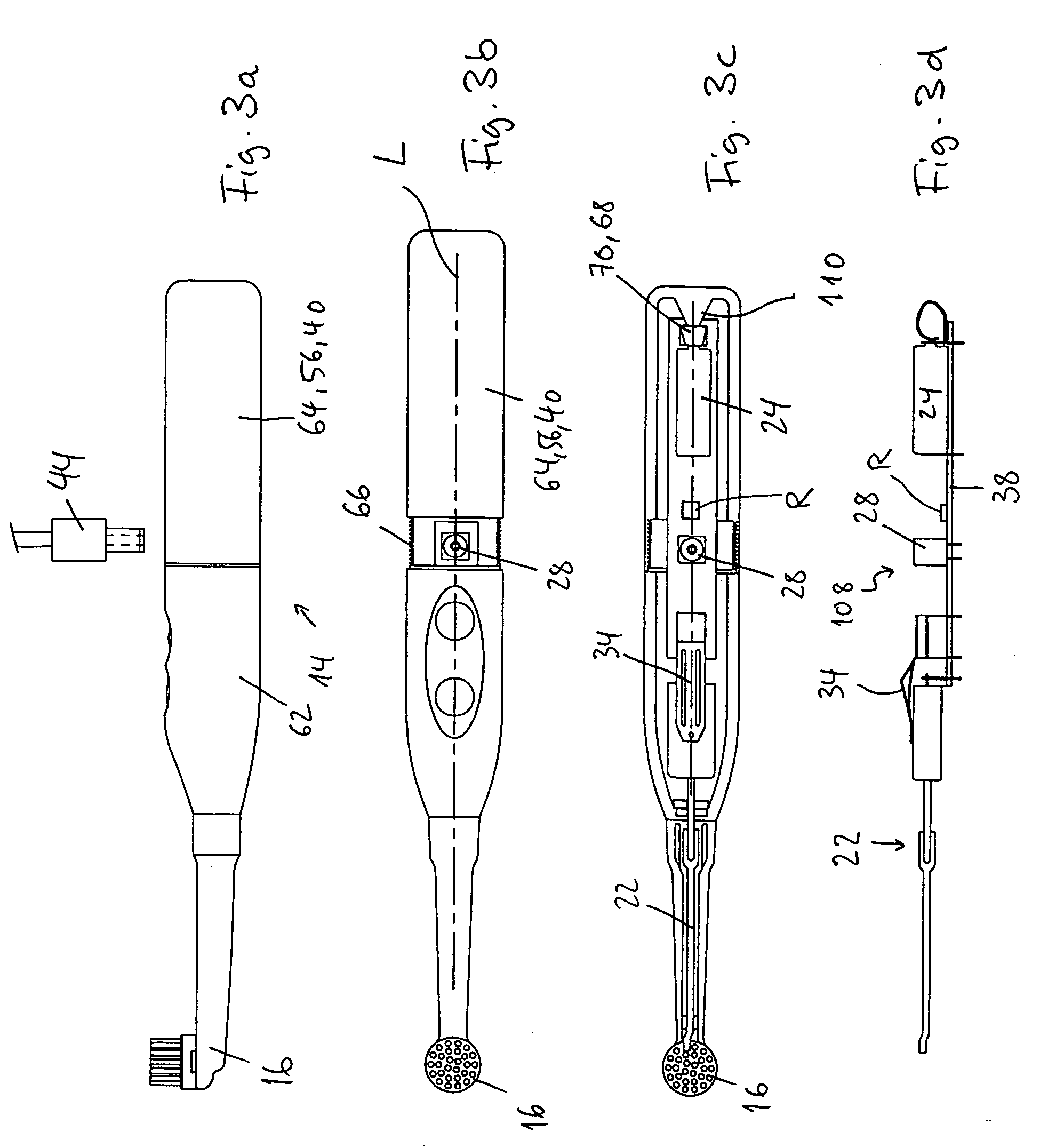

Rechargeable toothbrush having a sealed position and an open position for exposing a contact element for charging

ActiveUS7049790B2Minimal dimensionCost-effectiveBatteries circuit arrangementsSecondary cellsContact elementElectrical and Electronics engineering

Owner:TRISA HLDG AG

Collapsible shoe

InactiveUS7637035B1Easy to storeConvenient saleSolesShoe lace fasteningsEngineeringMechanical engineering

Owner:REEBOK

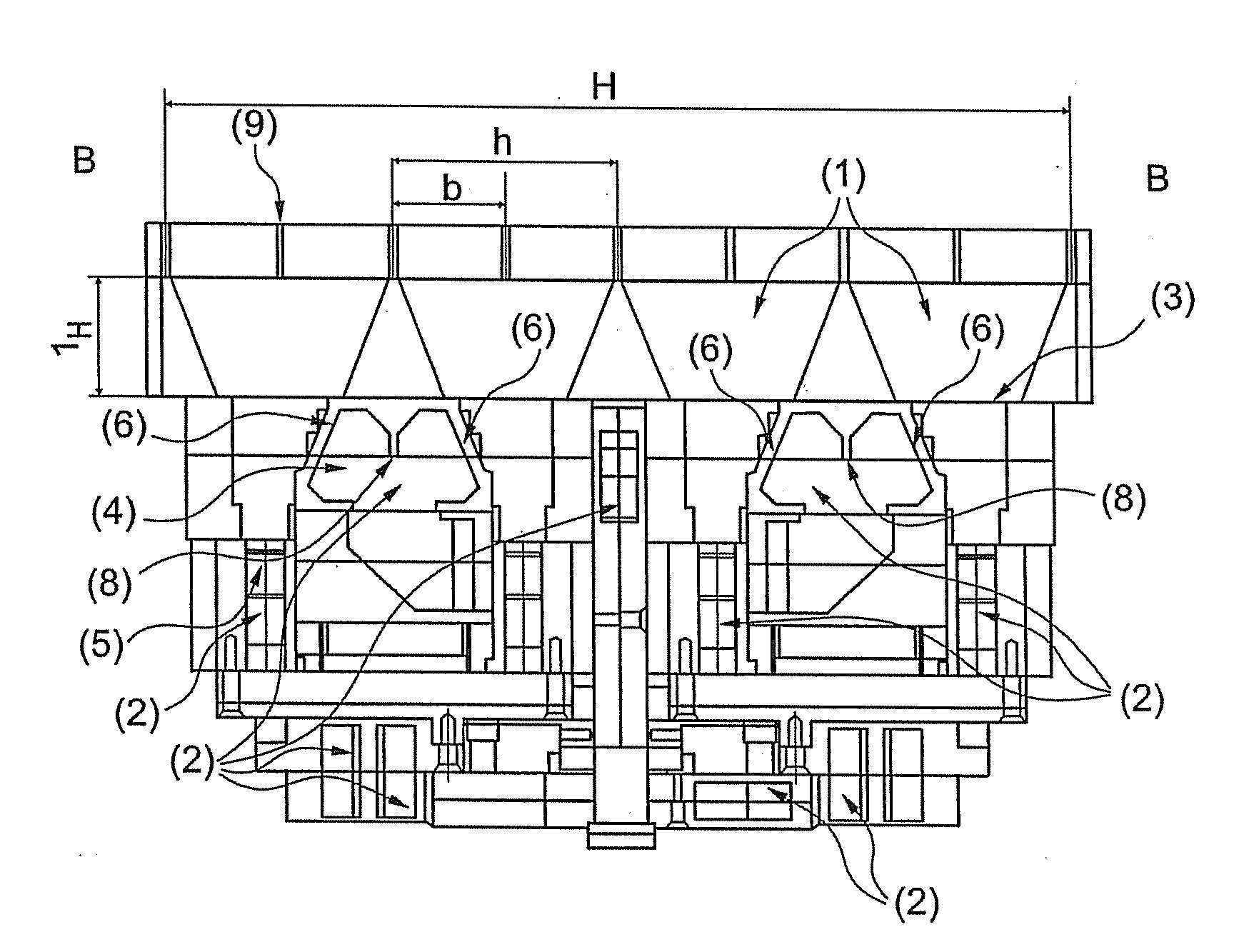

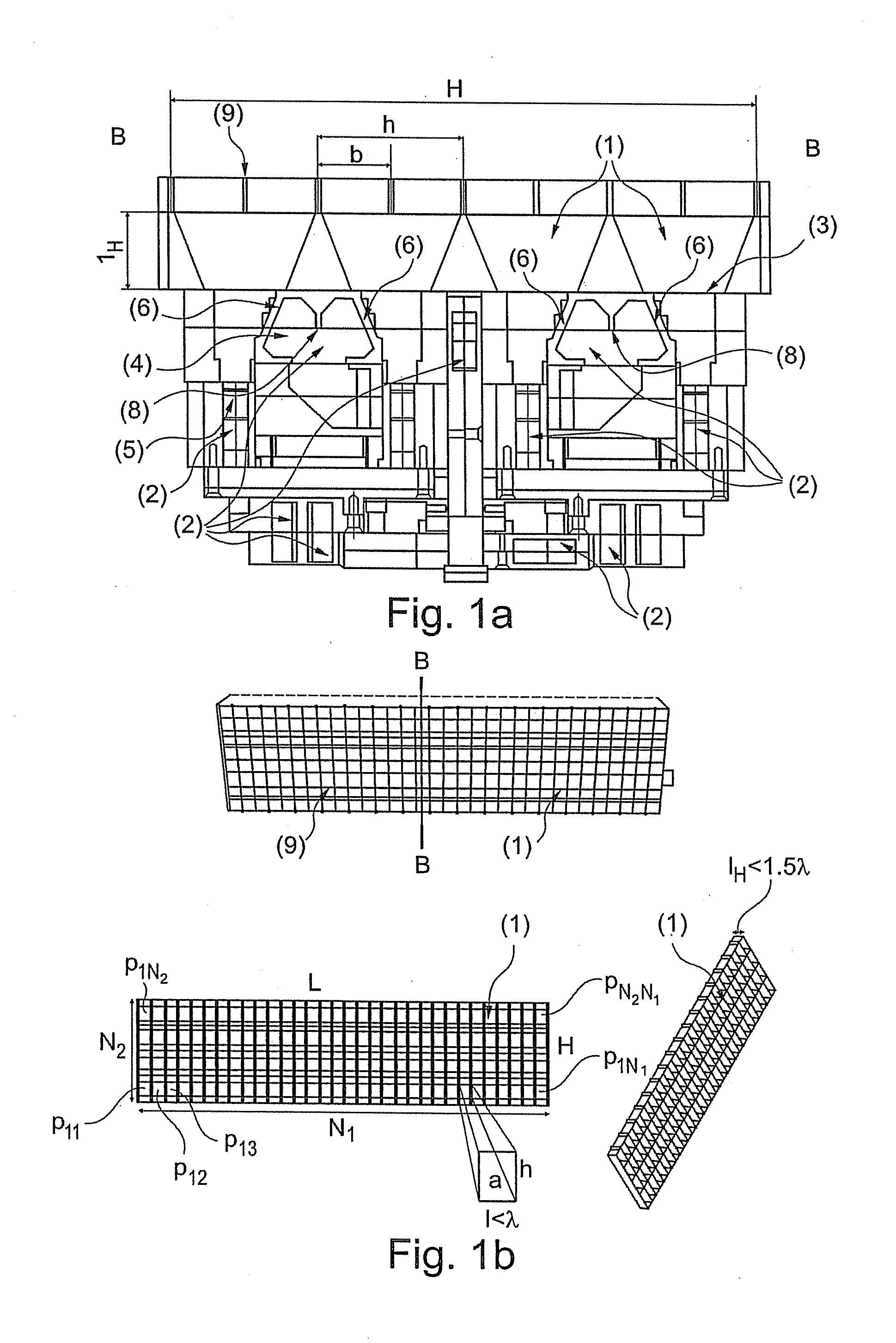

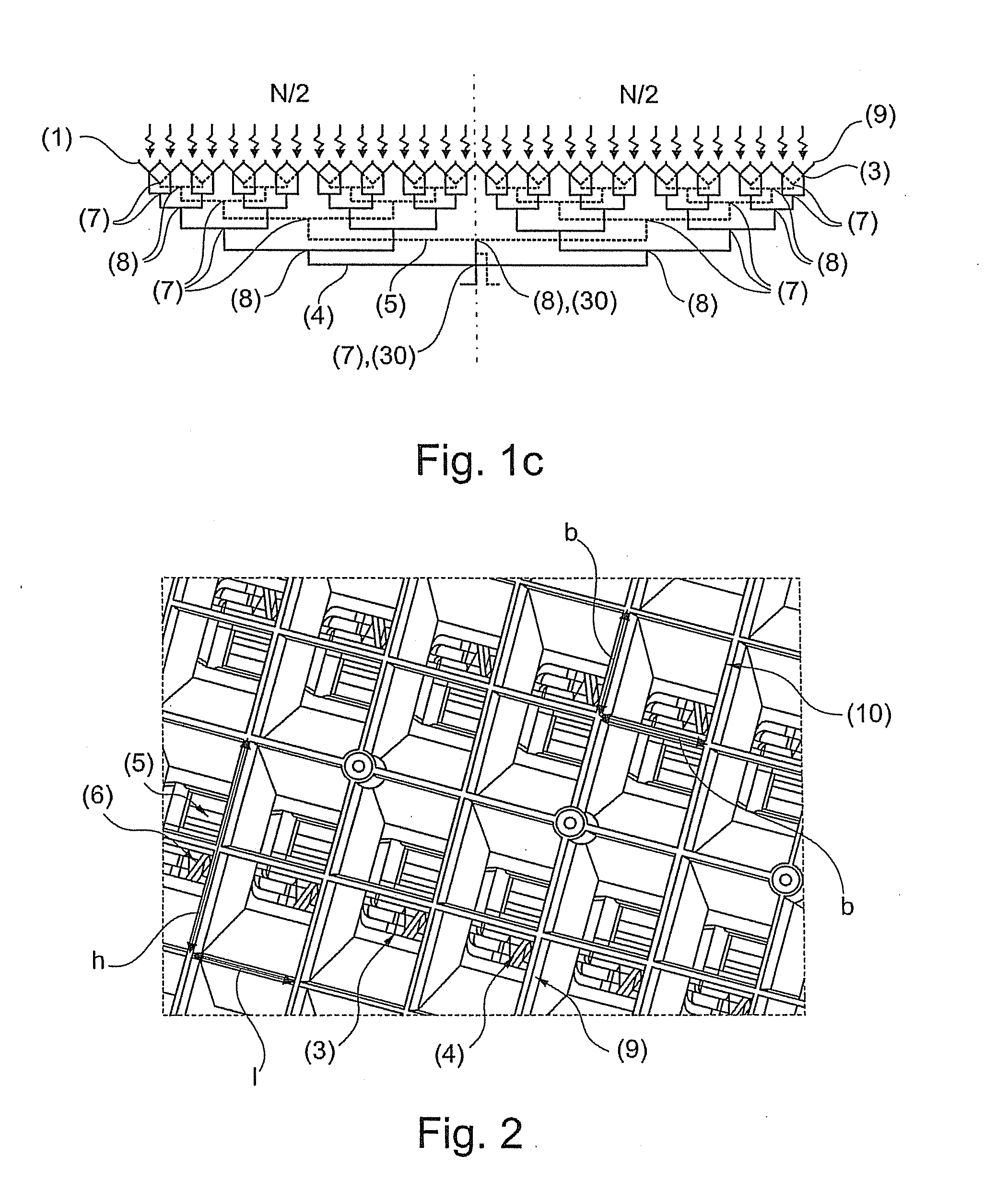

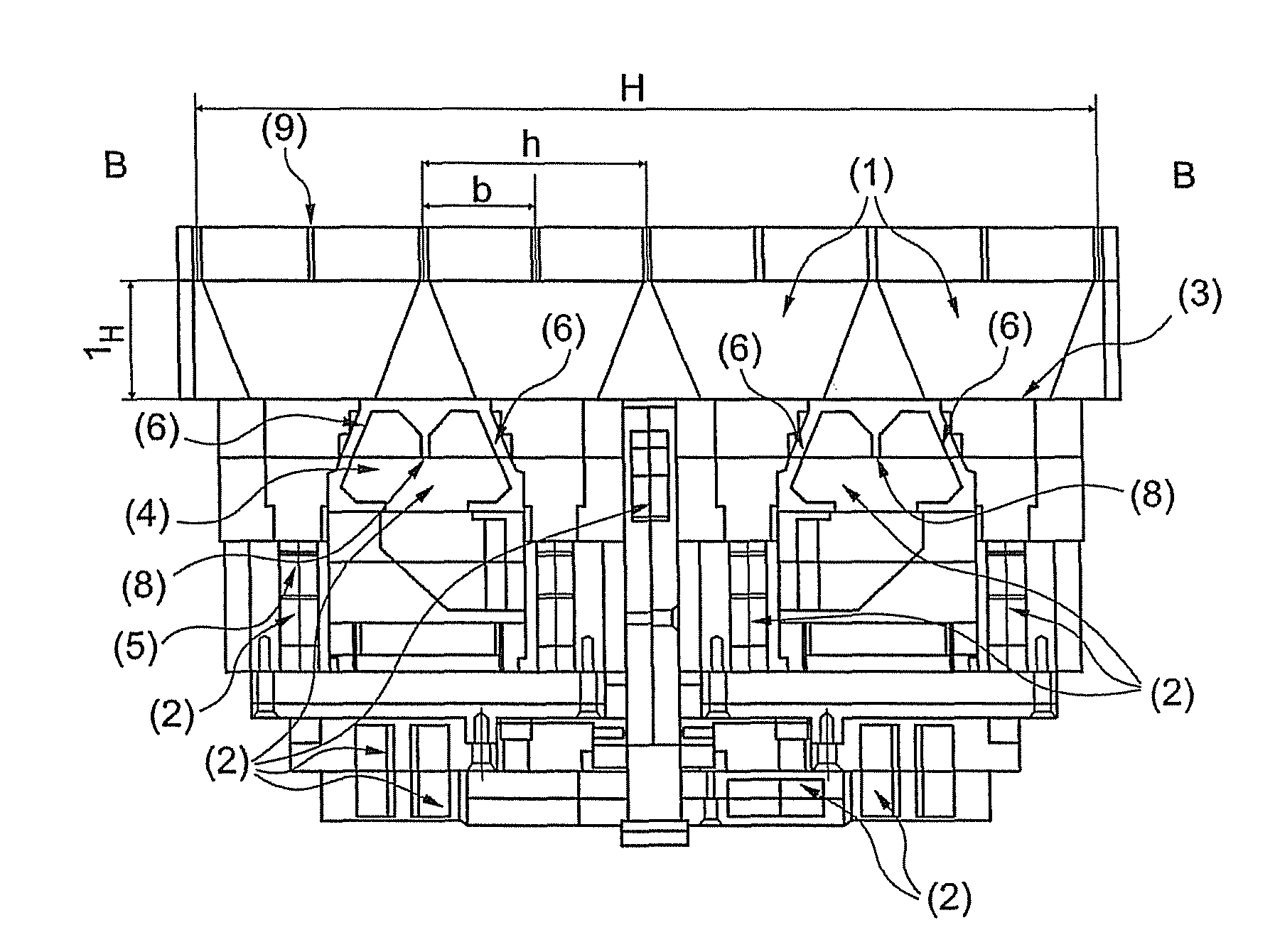

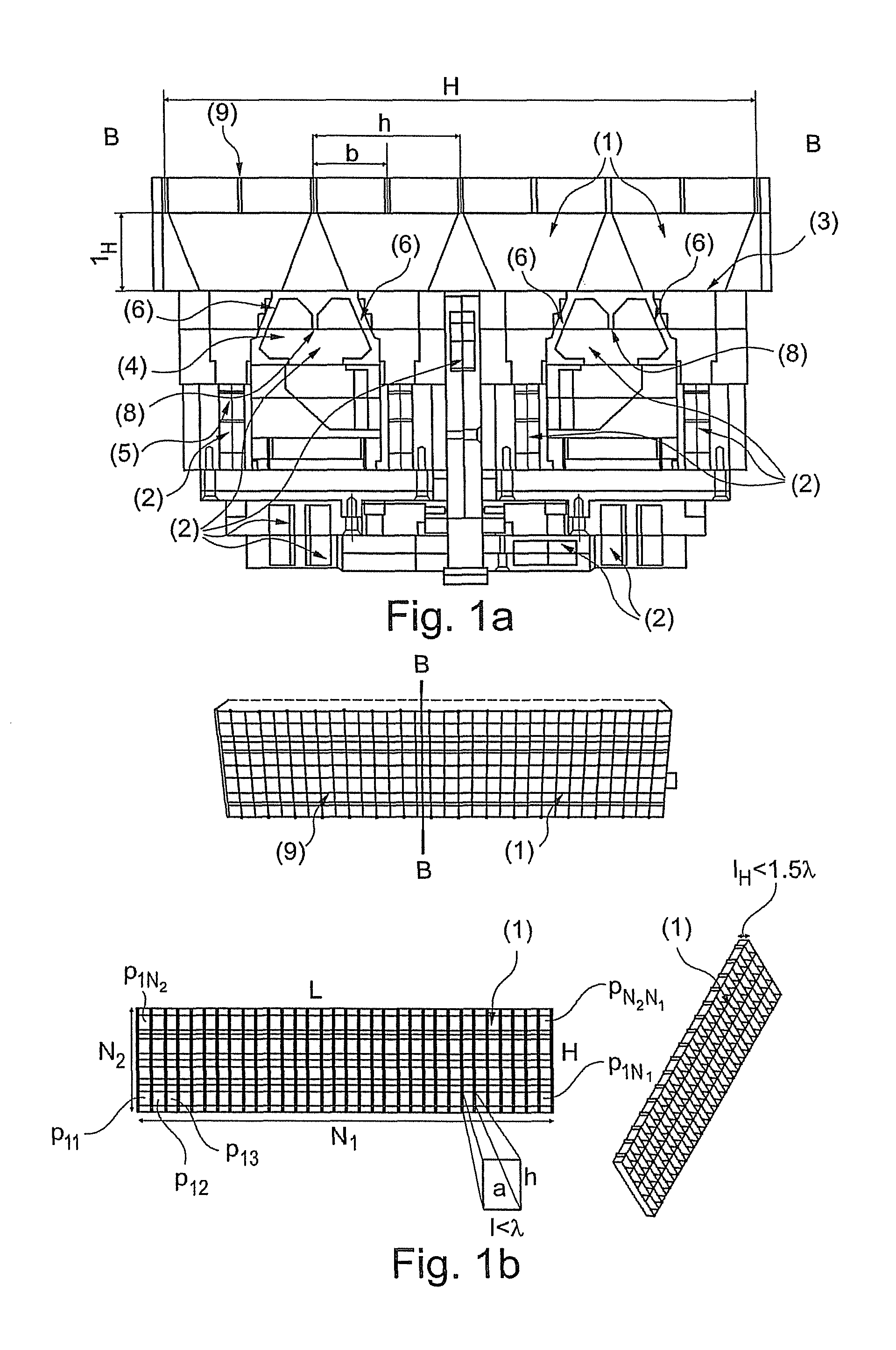

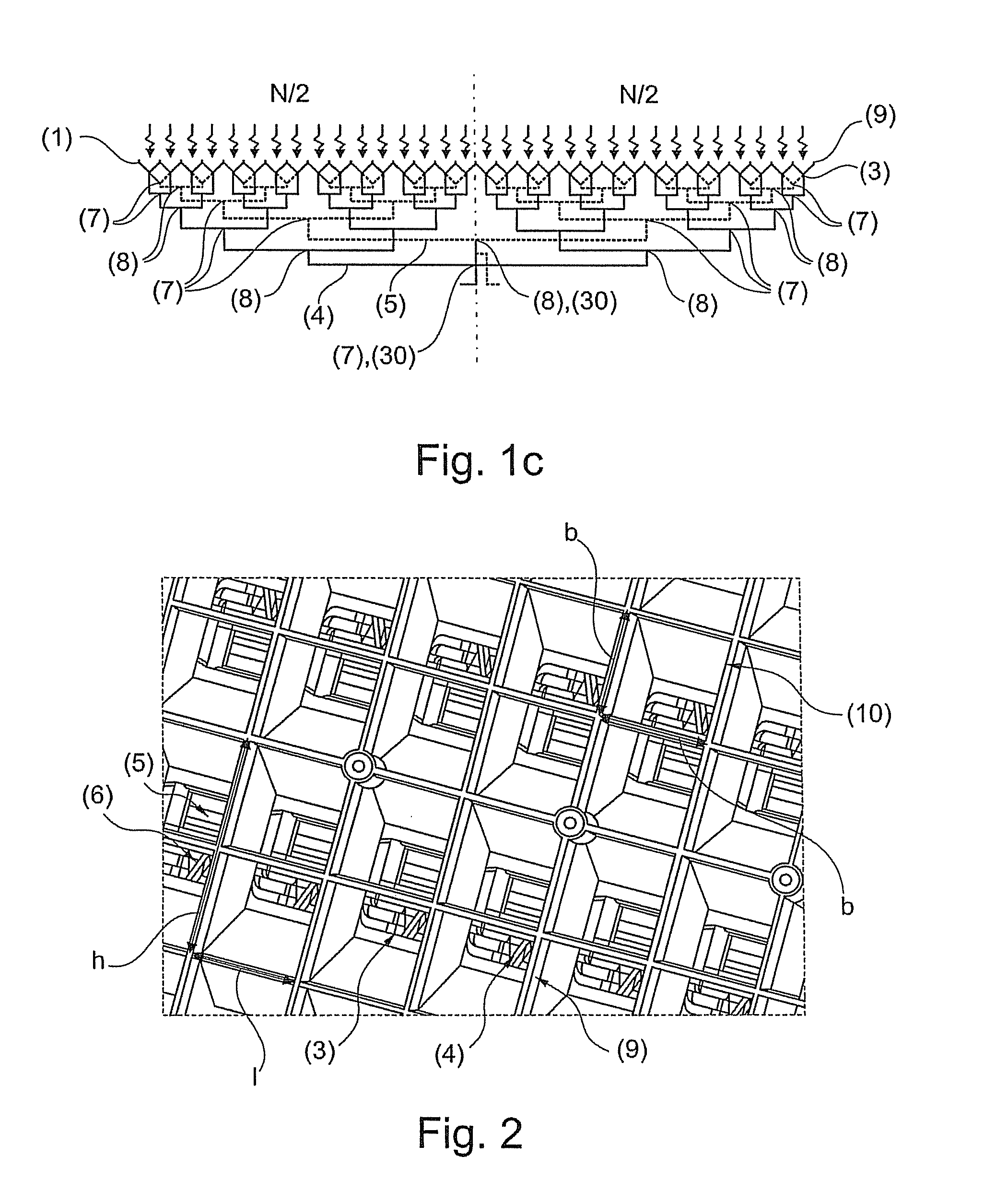

Broadband antenna system for satellite communication

ActiveUS20110267250A1Precise alignmentMinimal dimensionWaveguide hornsAntenna arraysPhysicsHorn antenna

An antenna for broadband satellite communication including an array of primary horn antenna elements which are connected to one another by a waveguide feed network.

Owner:QEST QUANTENELEKTRONISCHE SYST

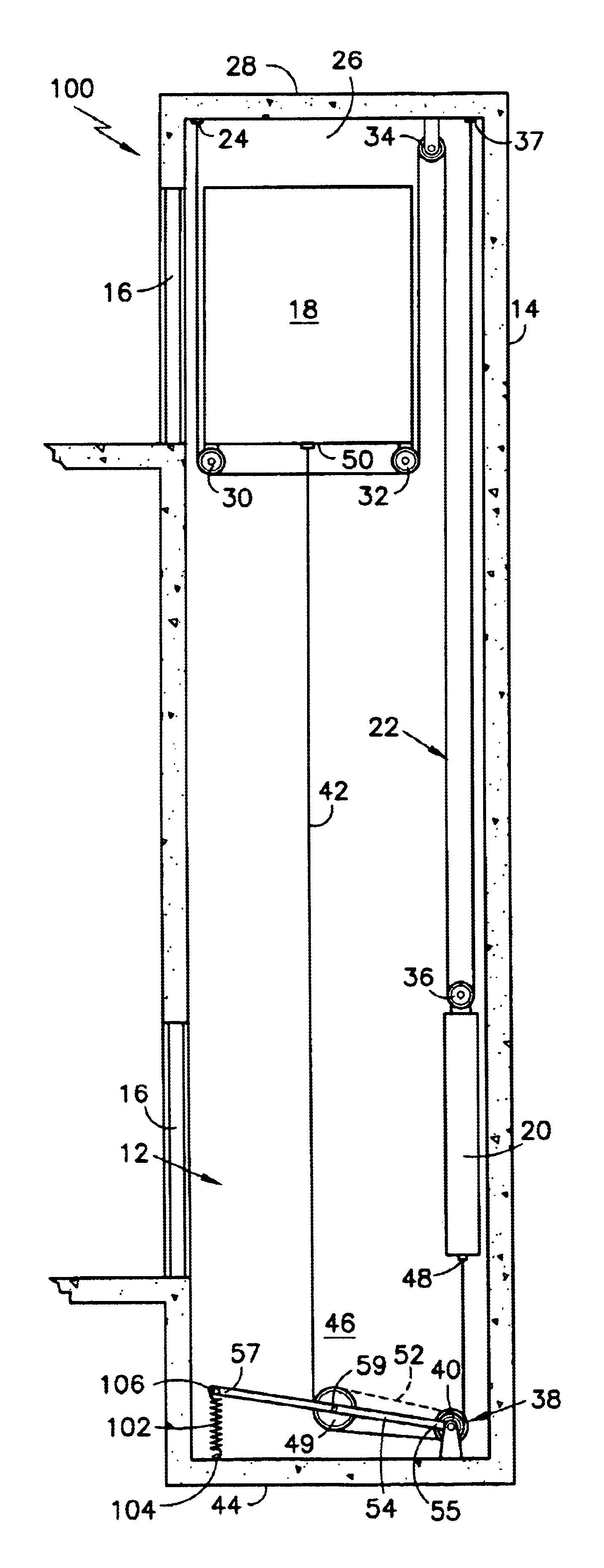

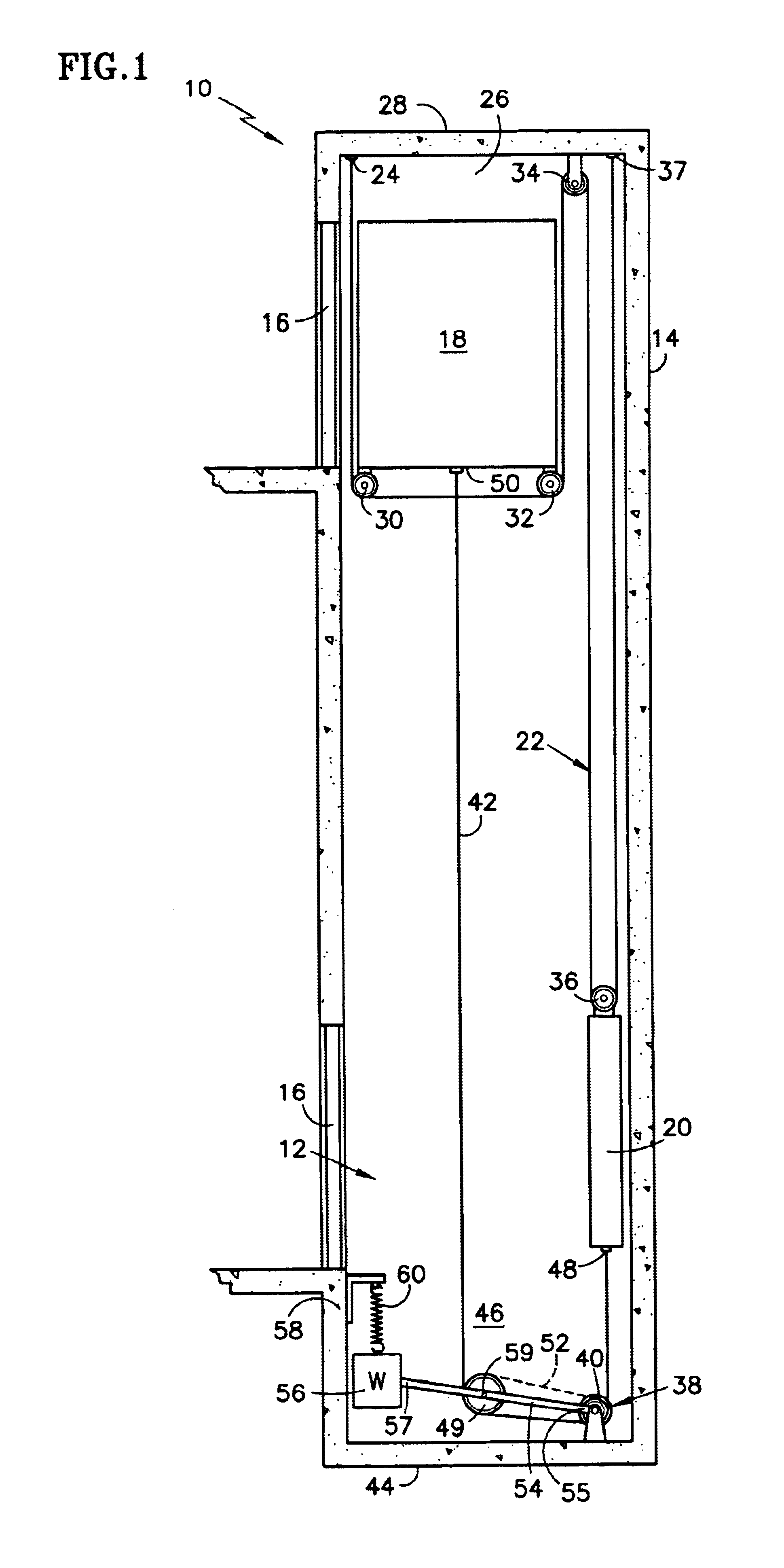

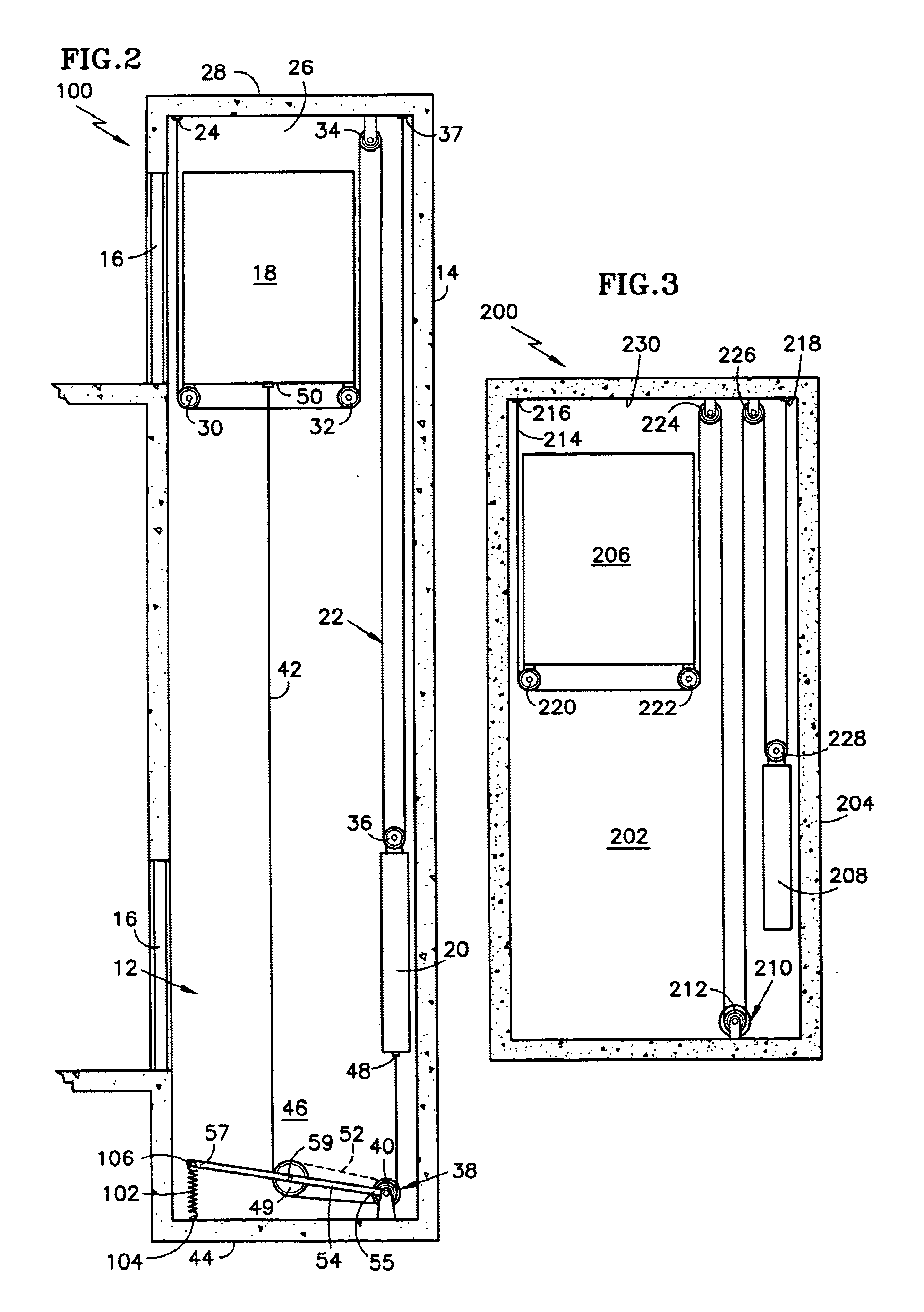

Elevator system having drive motor located below the elevator car

InactiveUS6860367B1Reduce space and construction costMinimal dimensionElevatorsBuilding liftsAutomotive engineeringDrive motor

An elevator system includes an elevator hoistway defined in a surrounding structure, such as a building. An elevator car and counterweight are located in the hoistway. A drive motor and associated drive sheave are disposed at a bottom portion of the hoistway. The drive motor is coupled to the elevator car and the counterweight via at least one flat rope for moving the elevator car upwardly and downwardly along the hoistway.

Owner:OTIS ELEVATOR CO

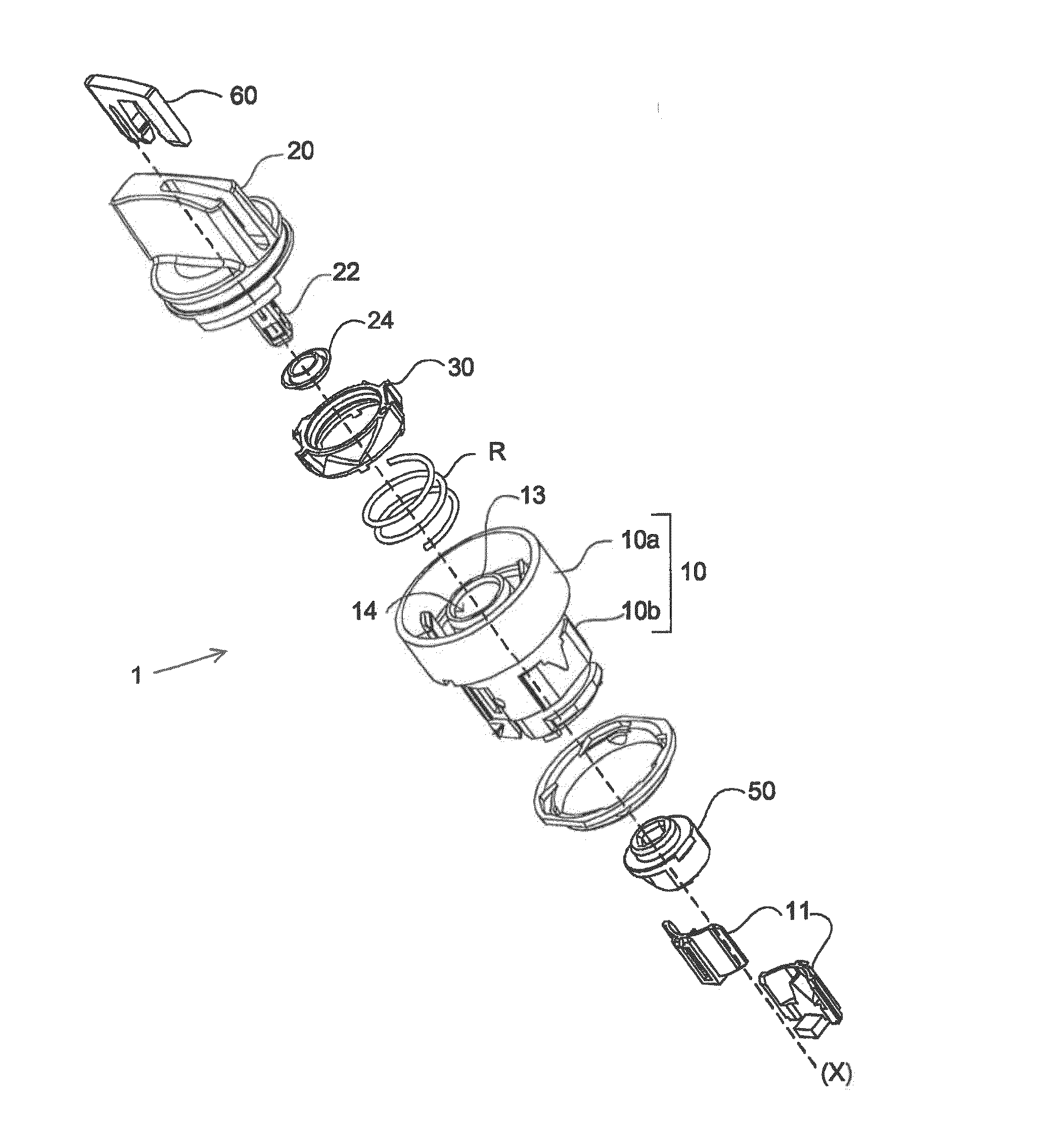

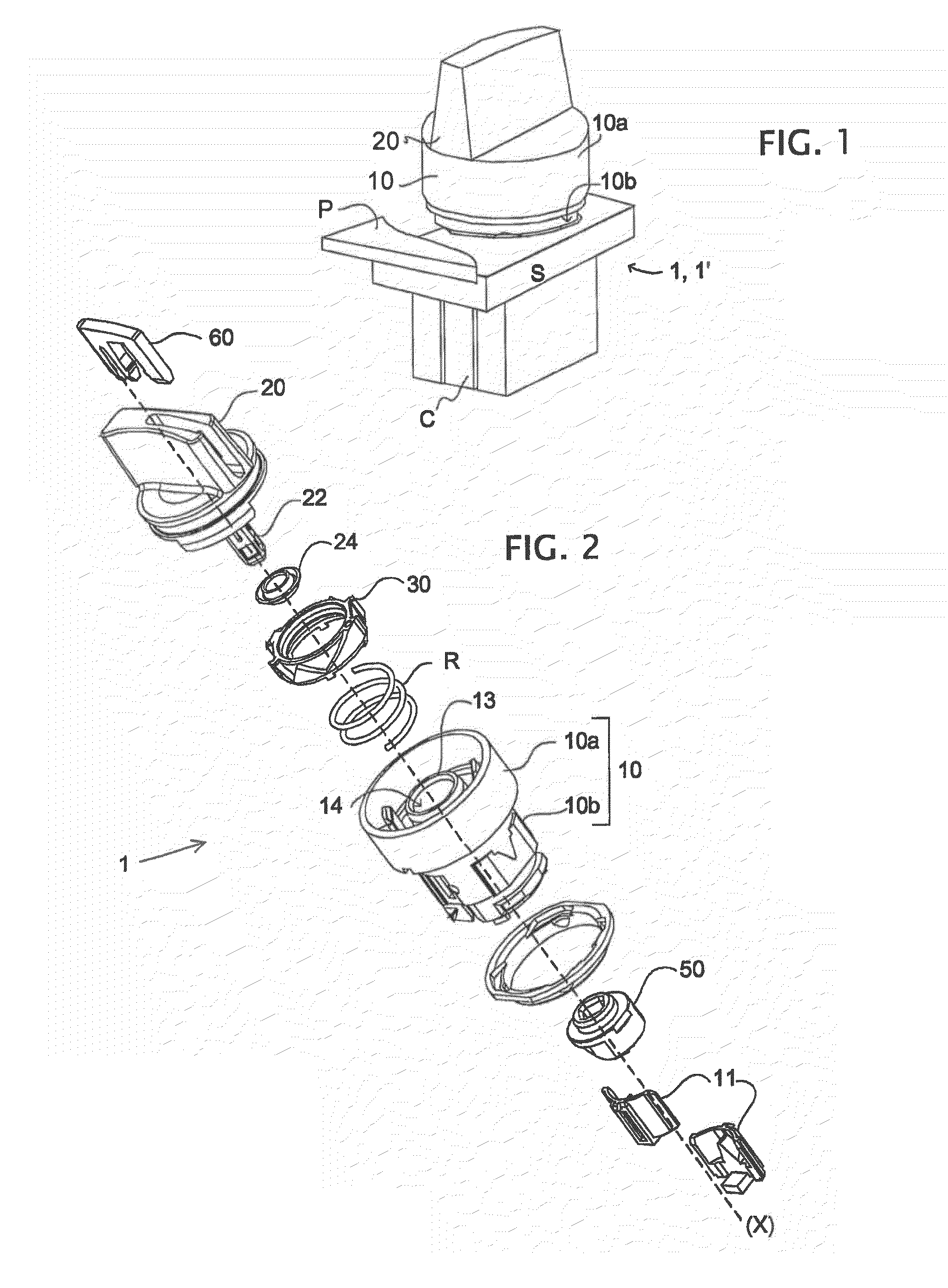

Rotary knob for electrical system

A rotary knob for an electrical system includes a body containing a rotary maneuvering member which actuates a cam-driving part and bears one or more electrical units. A cup is defined between an outer cylindrical flange of the body and an inner cylindrical sleeve, and contains a spring either of a helical type for urging a sliding ring separate from the driving part, or of a torsion type to return the maneuvering member. The ring provides a sensitivity function. The cylindrical sleeve defines in a central opening thereof a centering seat of the shank of the maneuvering member.

Owner:SCHNEIDER ELECTRIC IND SAS

Broadband antenna system for satellite communication

An antenna for broadband satellite communication including an array of primary horn antenna elements which are connected to one another by a waveguide feed network.

Owner:QEST QUANTENELEKTRONISCHE SYST TUBINGEN GMBH

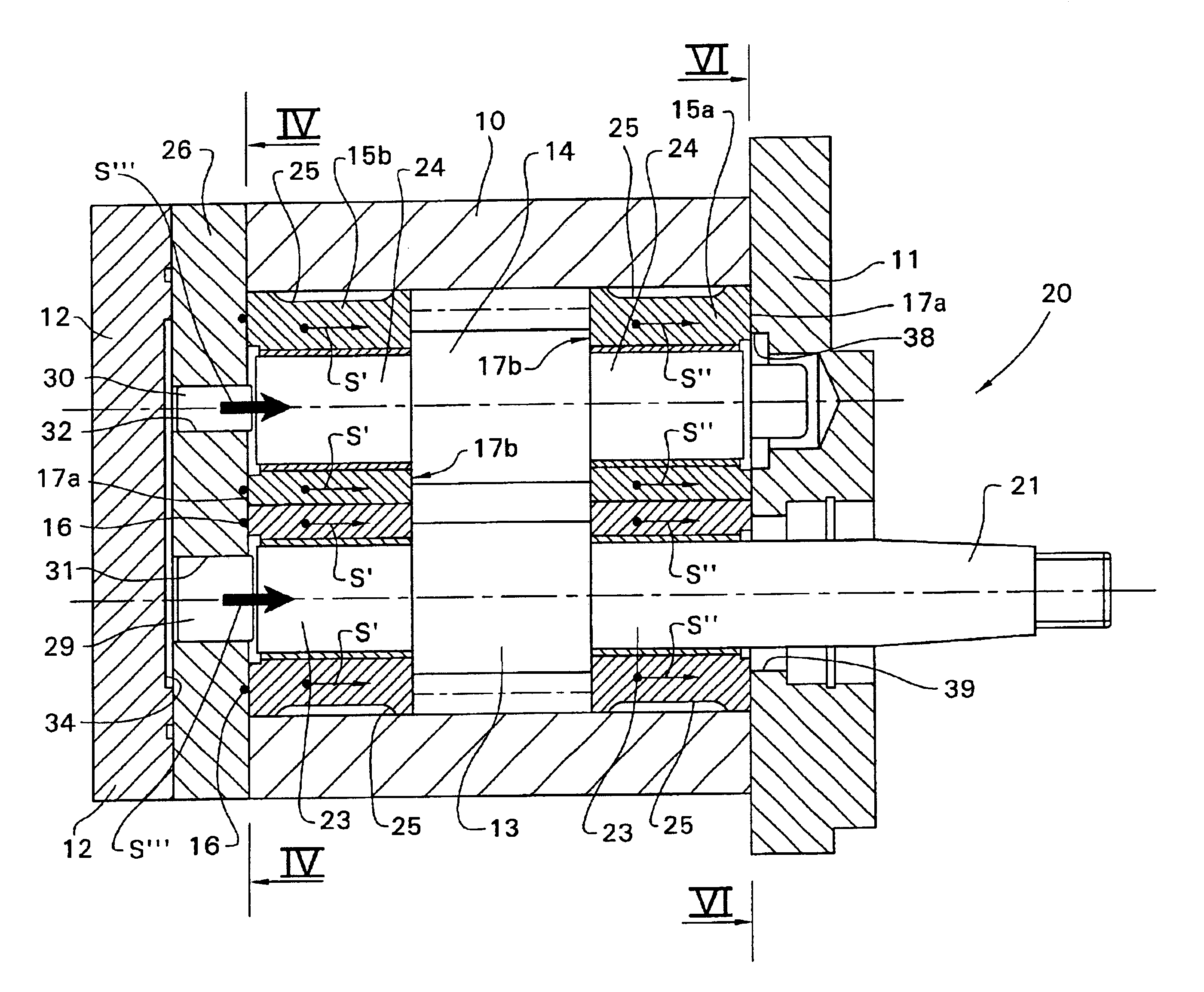

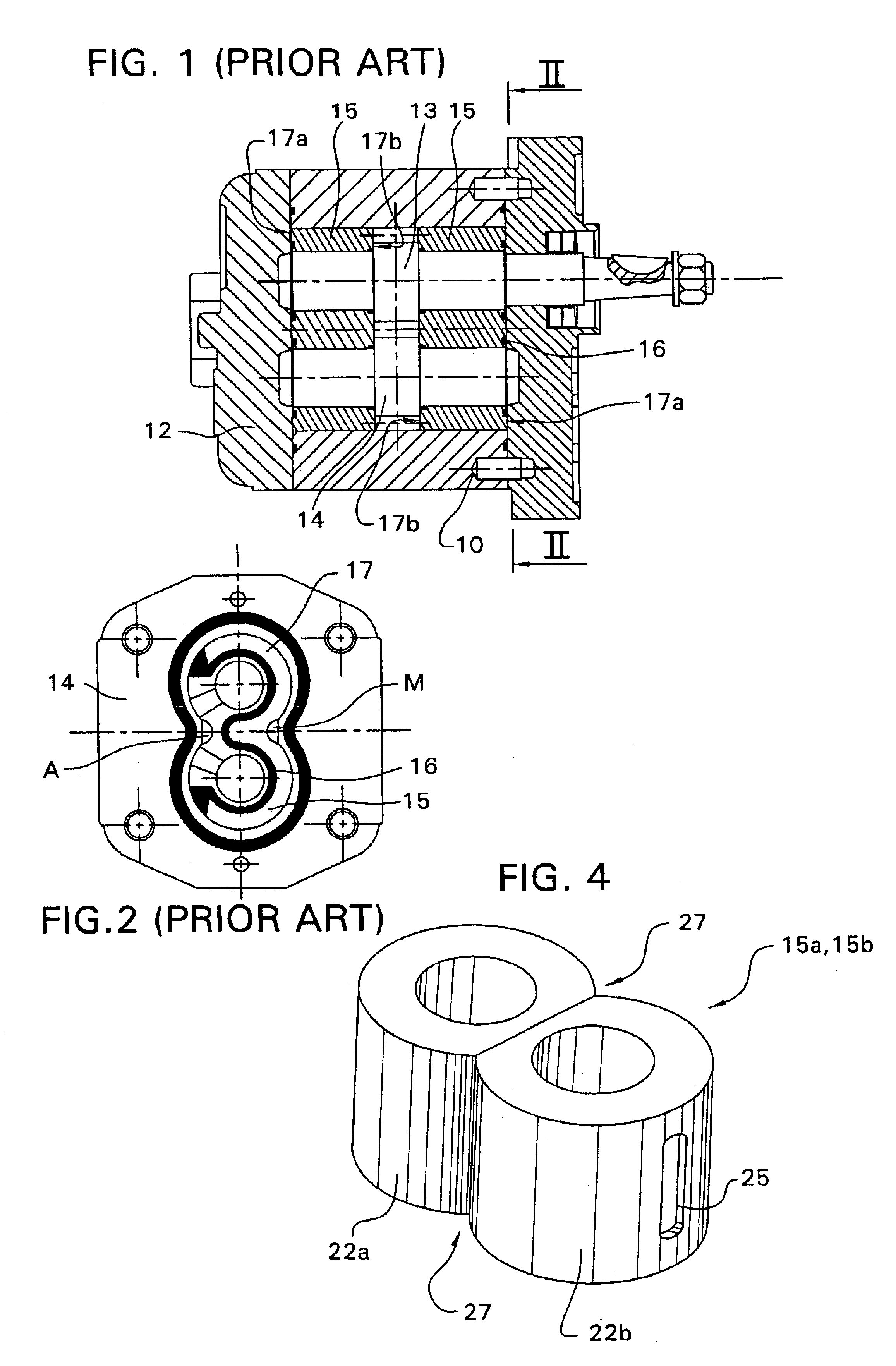

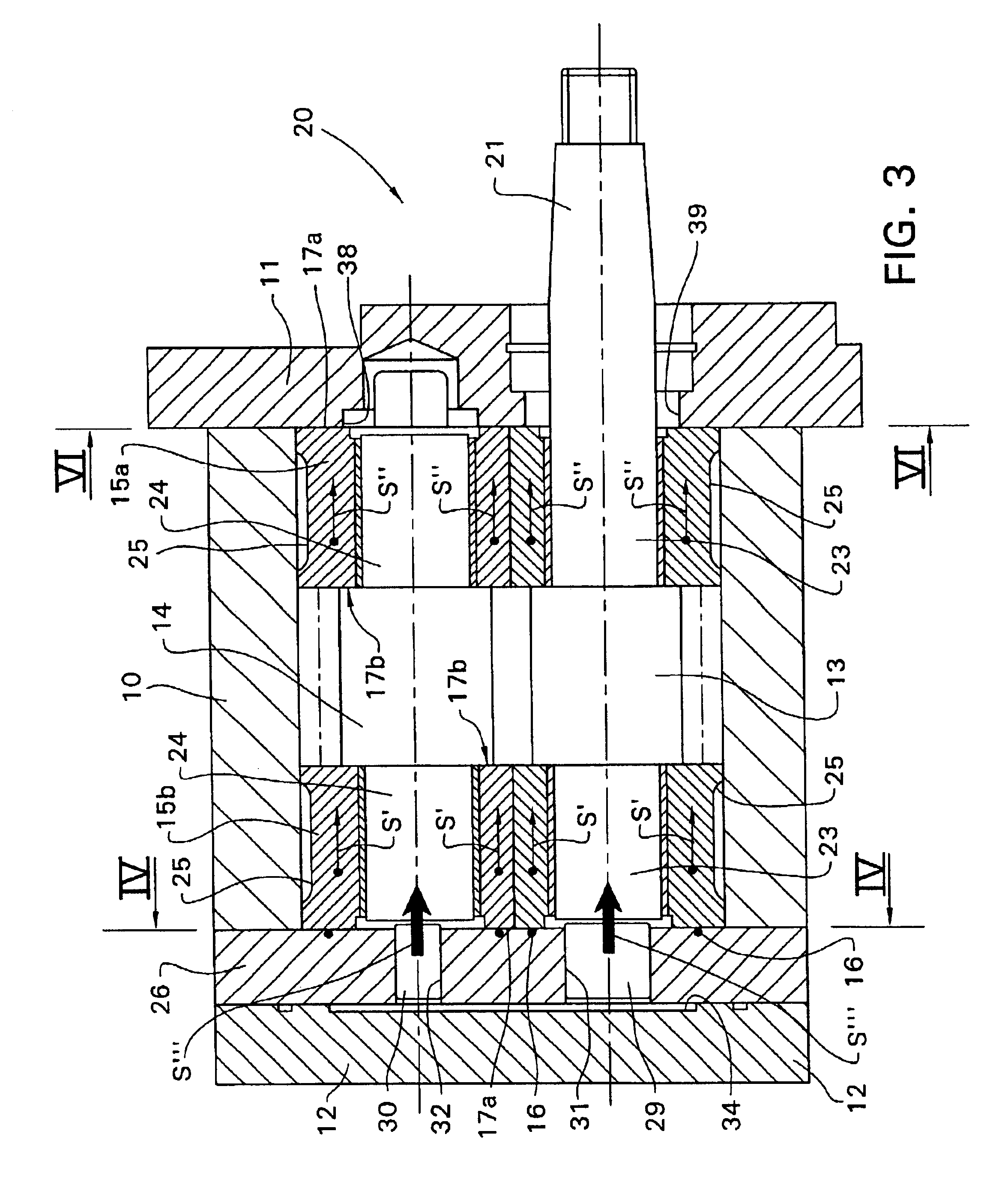

Positive-displacement rotary pump

InactiveUS6887055B2Minimal dimensionPrecise positioningOscillating piston enginesSealing arrangement for pumpsRotary pumpEngineering

A positive-displacement rotary pump comprising a pair of meshing gears (13, 14) or rotors, consisting of a driving gear and a driven gear, contained in a shell (10) having an output opening and an intake opening for a fluid. The gears (13, 14) include shafts (23, 24) which are supported by bushings (15a, 15b) having two faces (17a, 17b) which are subjected, in use, to pressures which bring about an axial load on the bushing itself, wherein the resultant of the axial loads (S′, S″) on the two bushings has a predetermined direction so as to move the bushings (15a, 15b) and the gears (13, 14) as a whole into close abutment with a predetermined reference plane (VI—VI).

Owner:MORSELLI MARIO ANTONIO

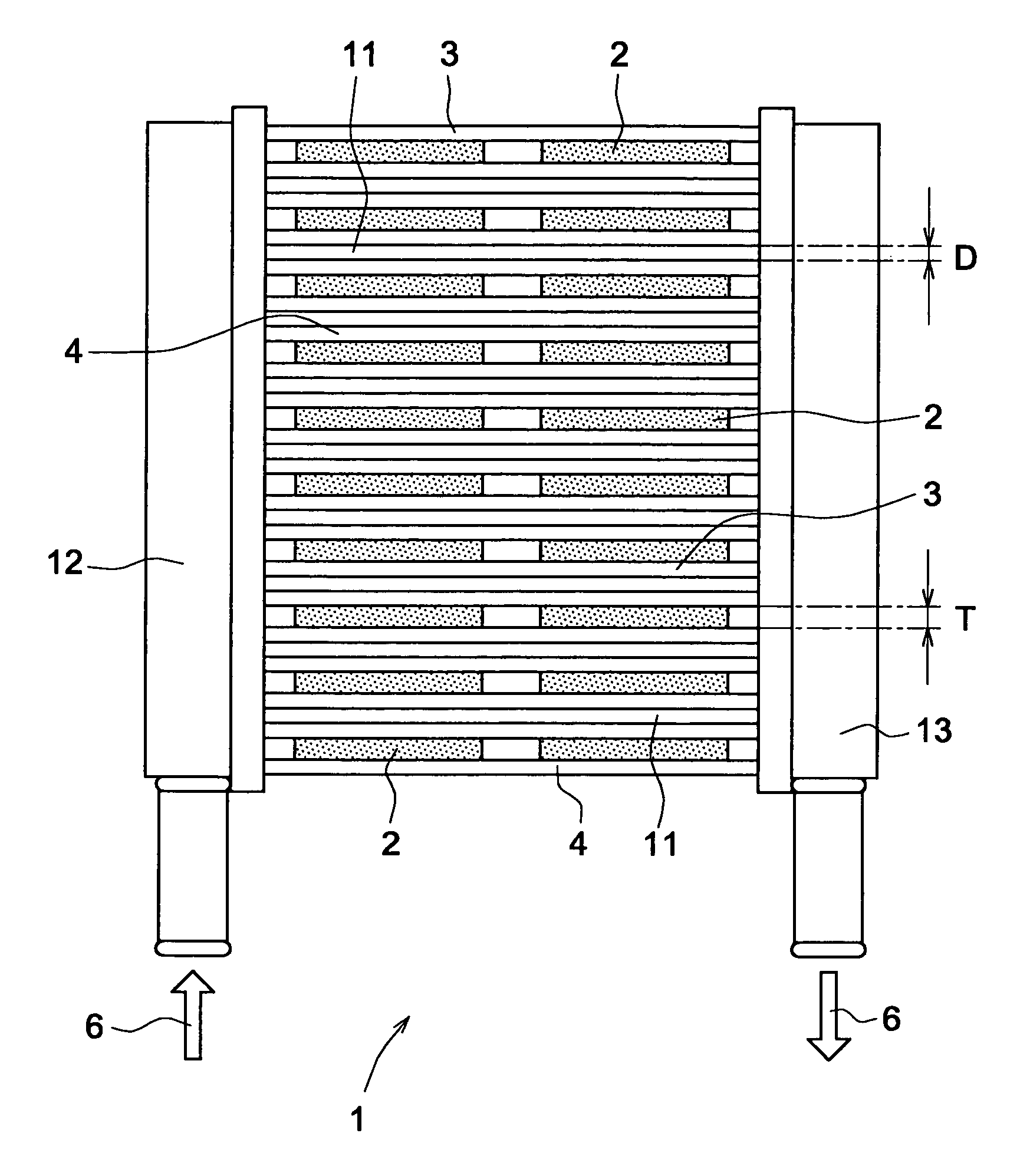

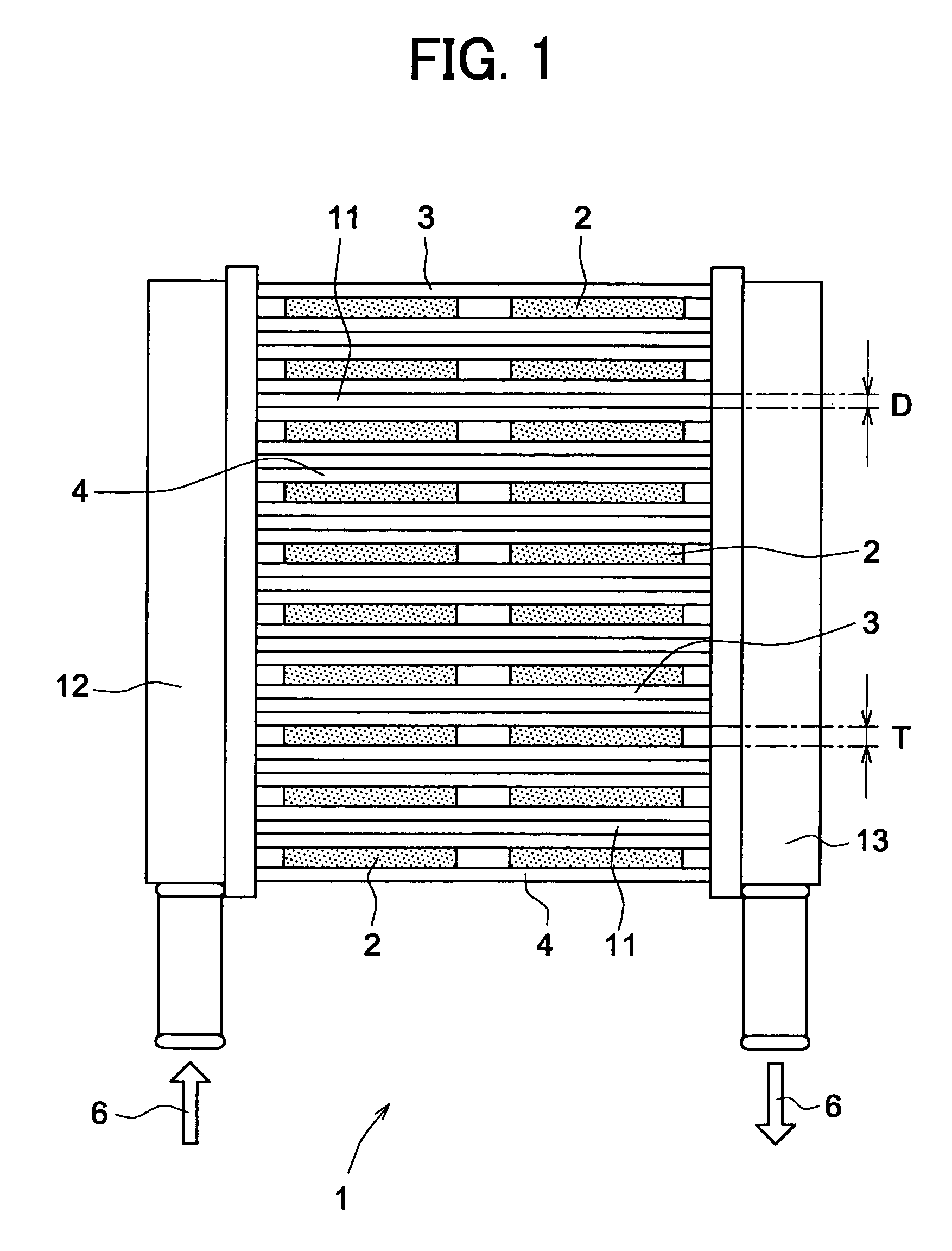

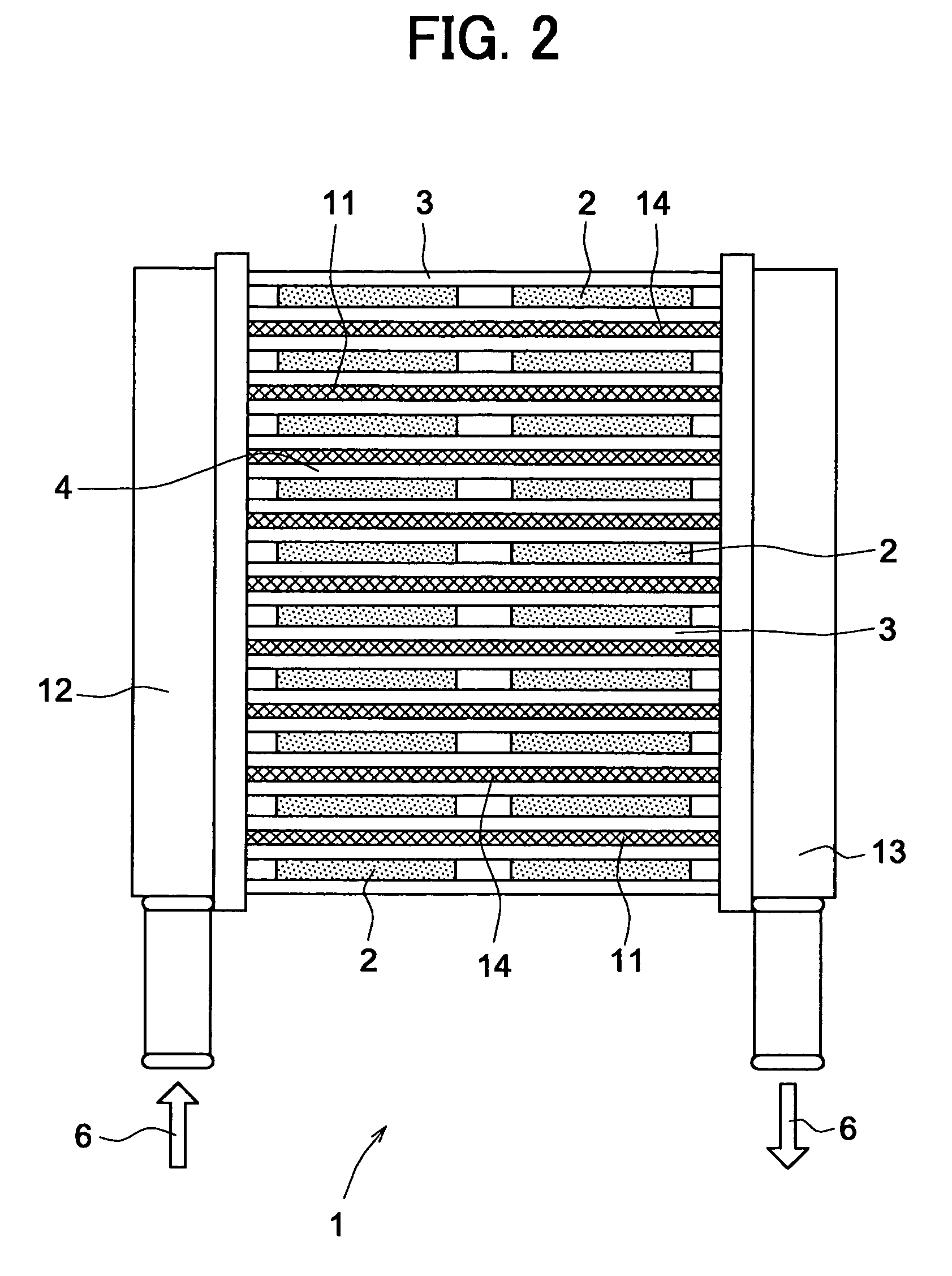

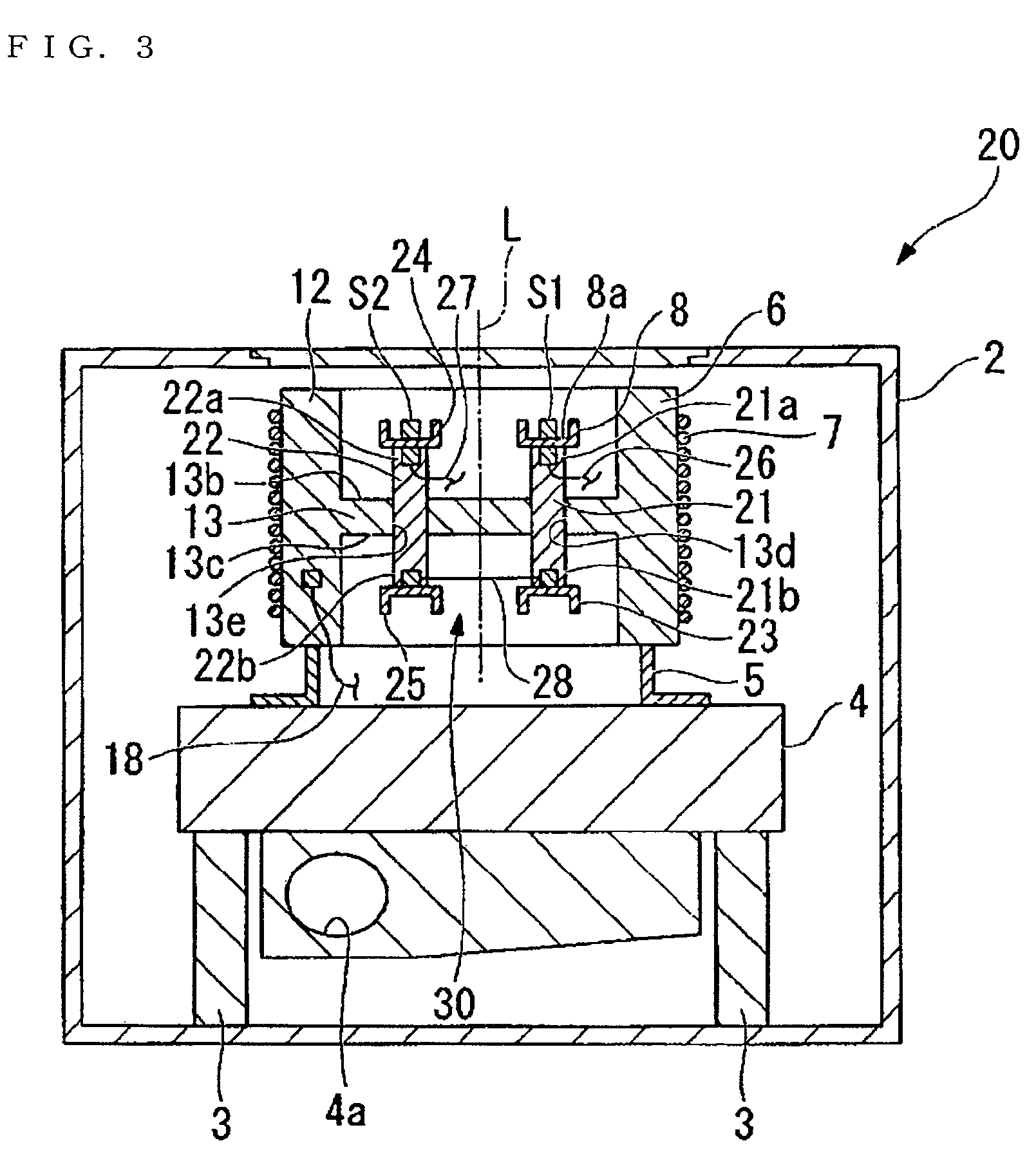

Cooler for cooling electric part

ActiveUS7245493B2Improve cooling effectMinimal dimensionDigital data processing detailsSemiconductor/solid-state device detailsEngineeringCooling pipe

Owner:DENSO CORP

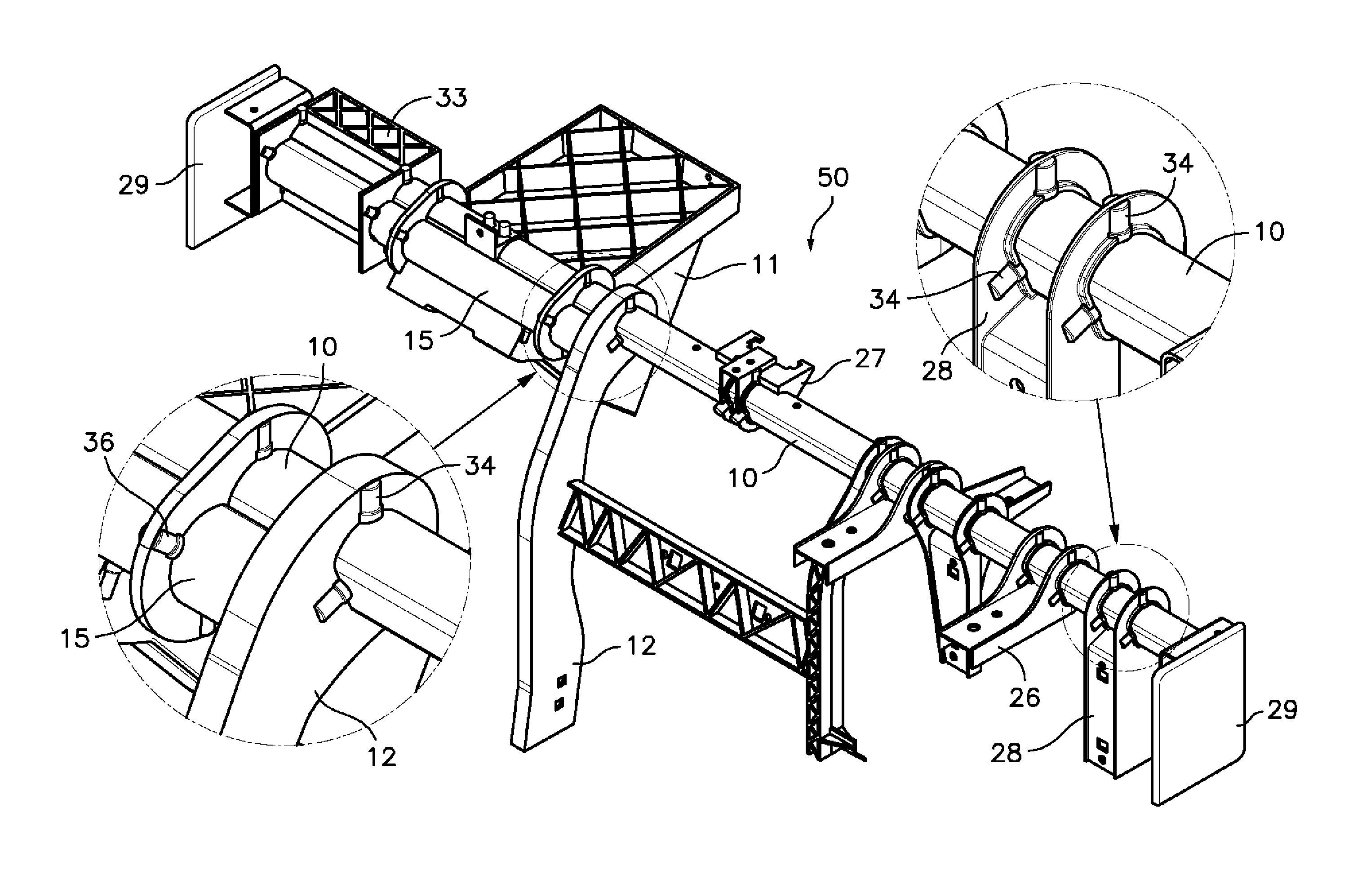

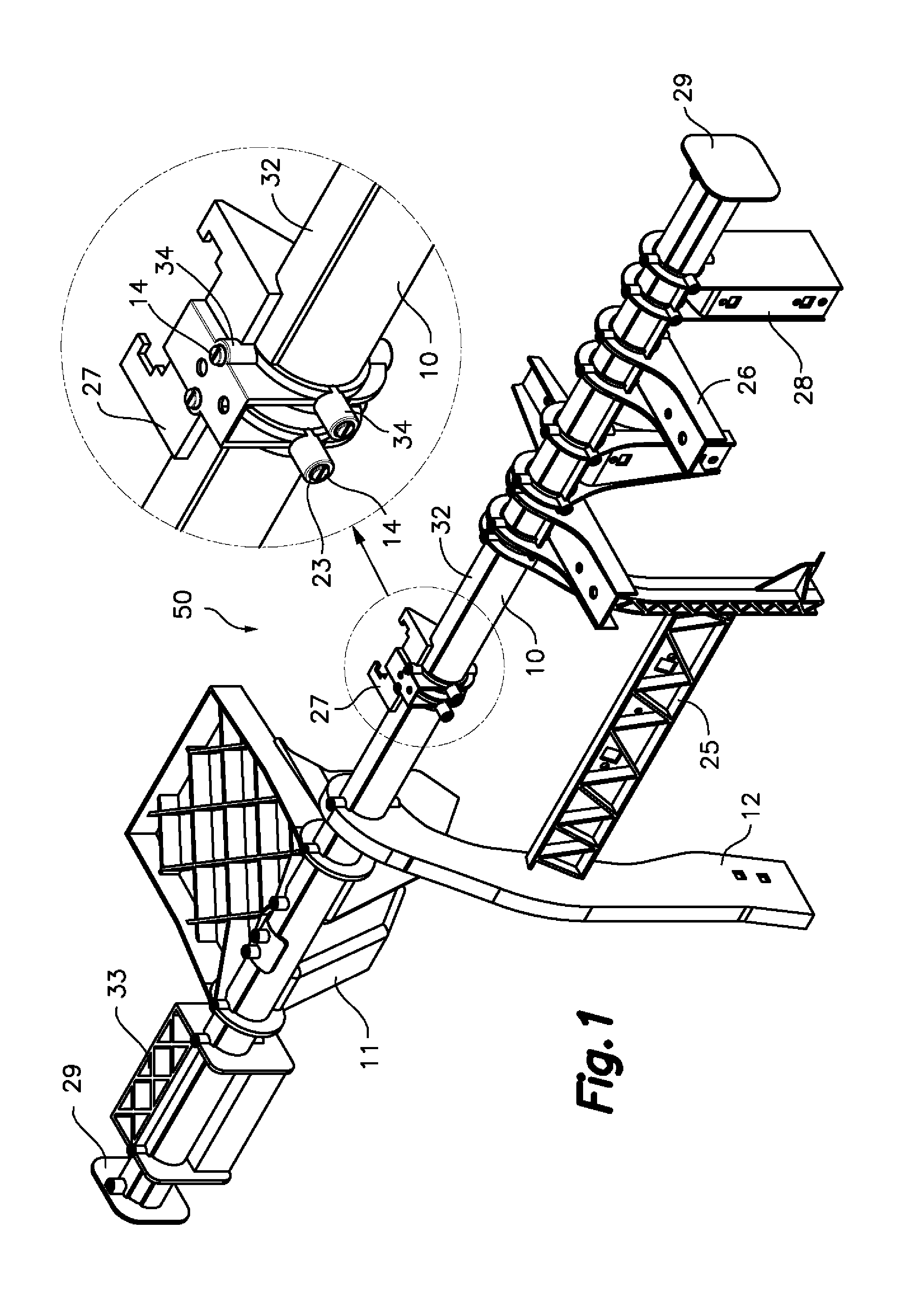

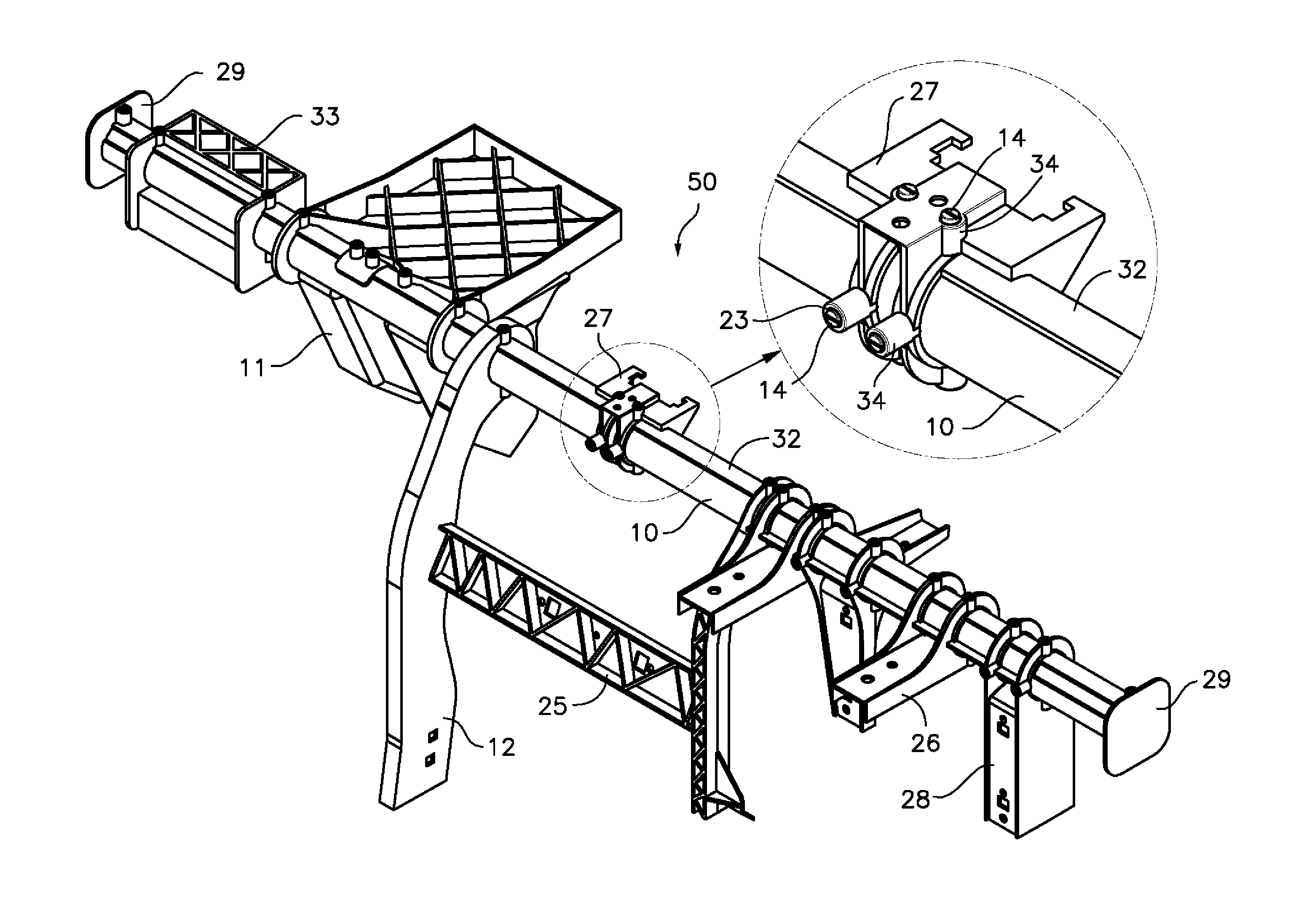

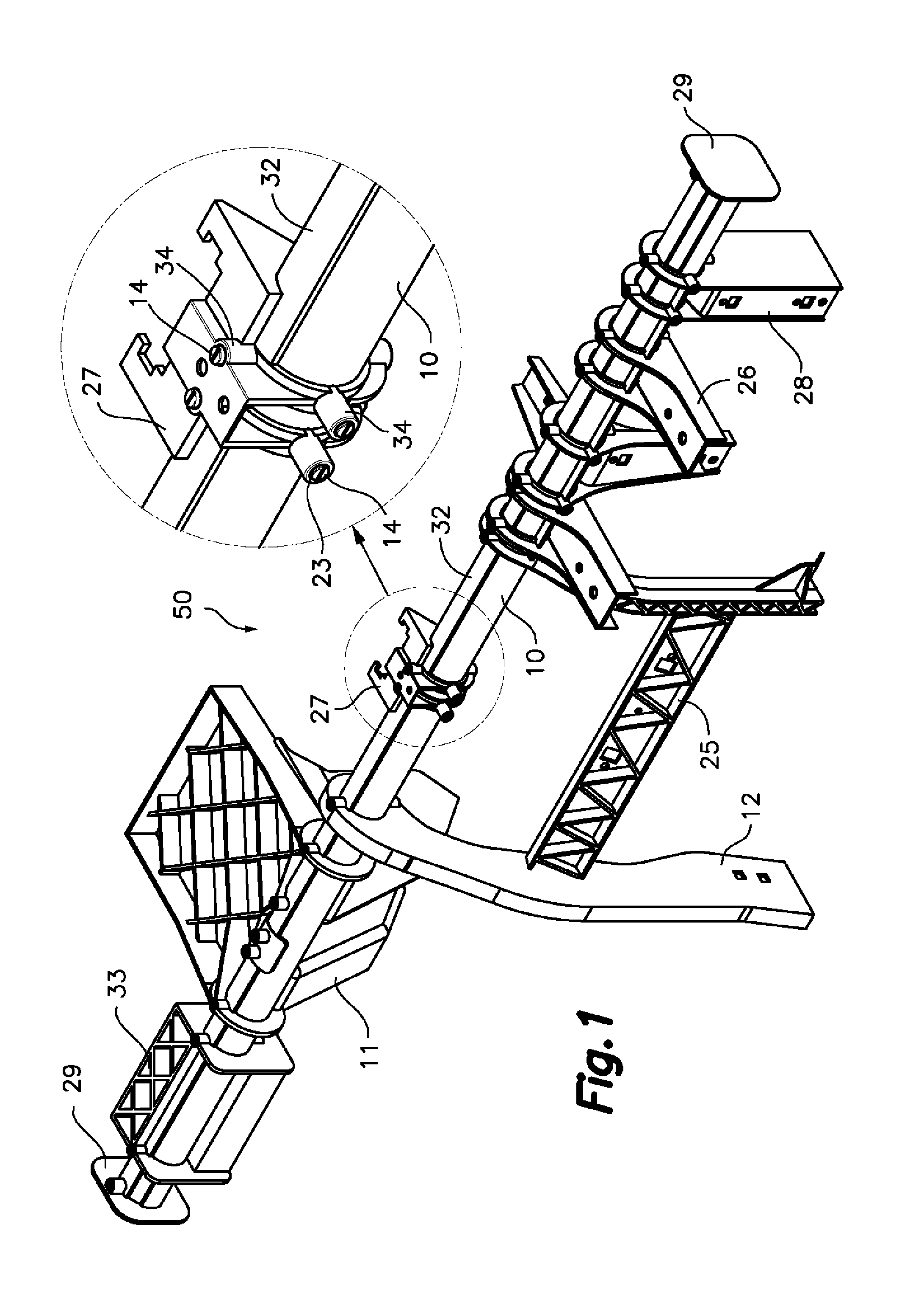

Metal-plastic hybrid support structure applicable to a dashboard support of a vehicle

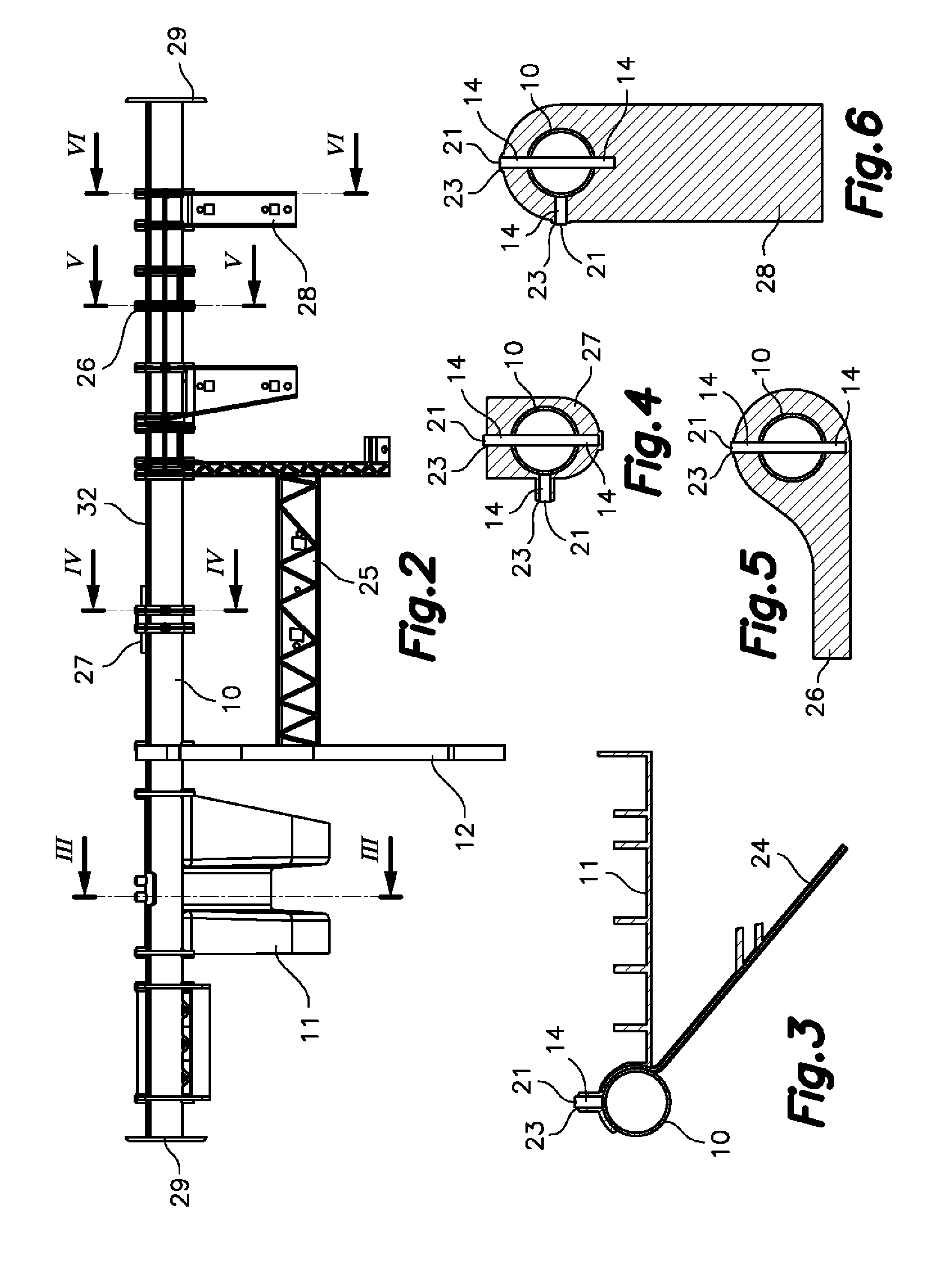

ActiveUS8919855B2Easy to separateReduce manufacturing costVehicle seatsSuperstructure subunitsMobile vehicleDashboard

The invention relates to a metal-plastic hybrid support structure applicable to a dashboard support of a vehicle, wherein the hybrid support structure comprises a metal tubular body (10) having a closed cross section profile and suitable length to be assembled between two elements of a frame of an automotive vehicle, a plurality of projecting metal fastening elements (14) distributed along said metal tubular body (10) and fixed thereto, and a plastic body defining a plurality of plastic functional elements (11, 12) overmolded on different separate regions of the metal tubular body (10), each plastic functional element (11, 12) embedding at least one of the projecting metal fastening elements (14). In one embodiment, the projecting metal fastening elements (14) are stems with outer screw threading.

Owner:BARCELONA TECHN CENT

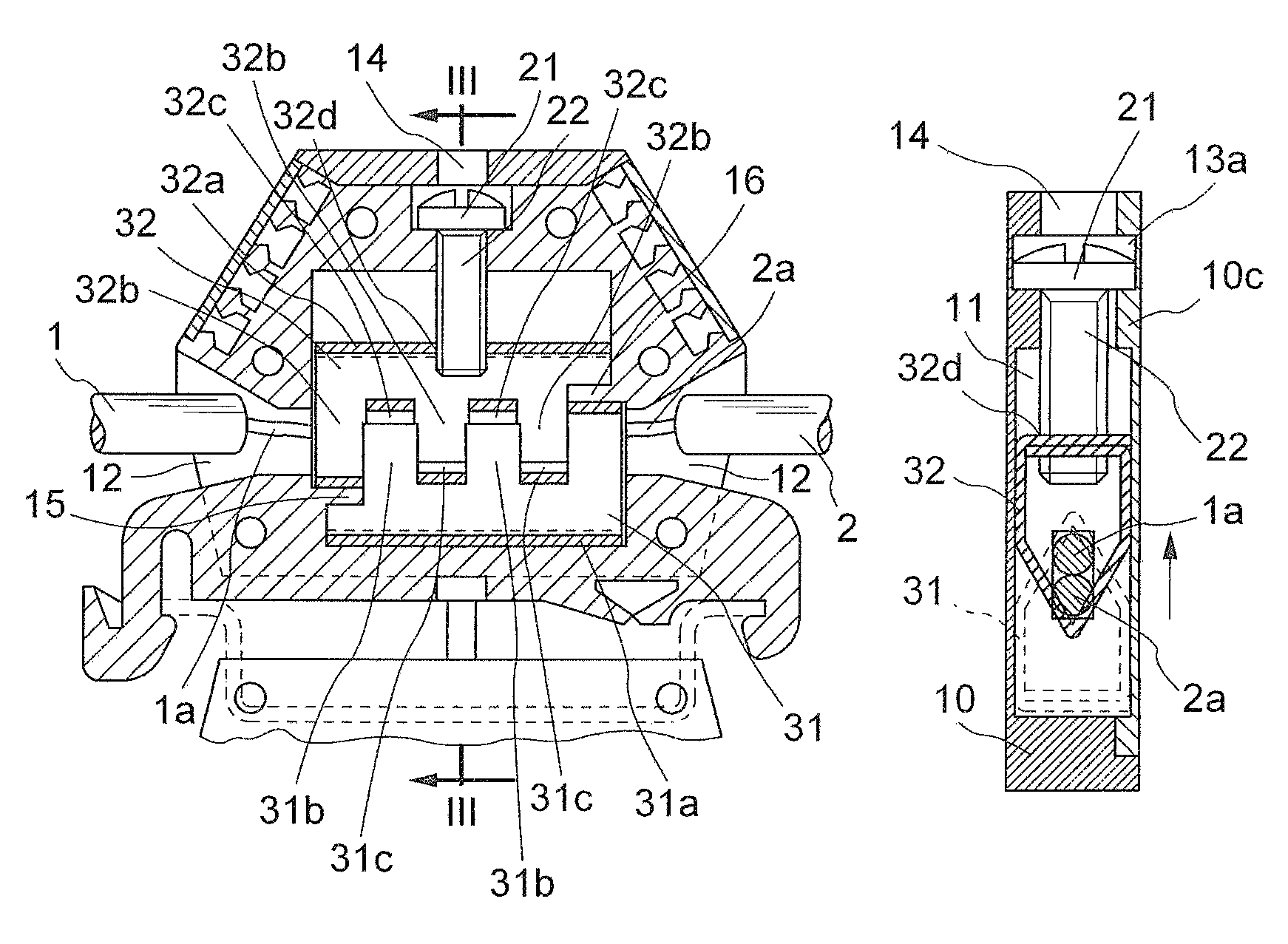

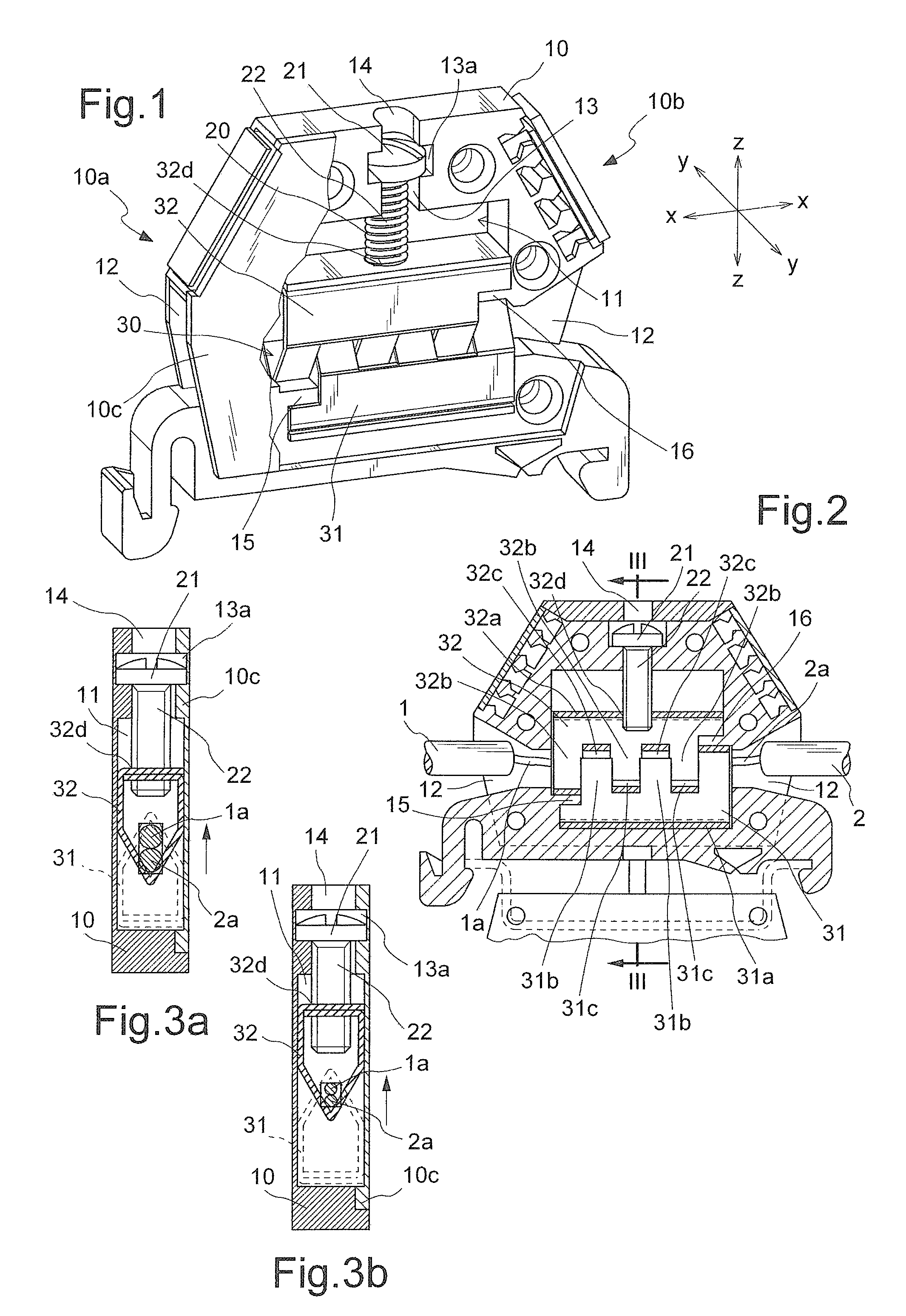

Terminal Block for Connecting Electric Cables

ActiveUS7438606B2Easy and inexpensive to produceEasy and inexpensive to and assembleContact member manufacturingClamped/spring connectionsEngineeringElectric cables

Terminal block comprising a body having, formed internally, a chamber for housing a clamp for retaining the ends of electric cables or wire, which can be operated by an operating mechanism, at least two openings for introducing said wires, at least one opening for access to the operating mechanism, the clamp consisting of at least two jaws which are situated opposite each other in the direction (Z-Z) transverse to the longitudinal direction of the electric wires and respectively comprising at least one base and at least one pair of lugs which are discontinuous in the longitudinal direction (X-X) so as to define respective seats suitable for engagement in the vertical direction (Z-Z) with corresponding lugs of the other jaw and each of the lugs having a cross-section substantially in the form of an isosceles triangle.

Owner:MORSETTITALA

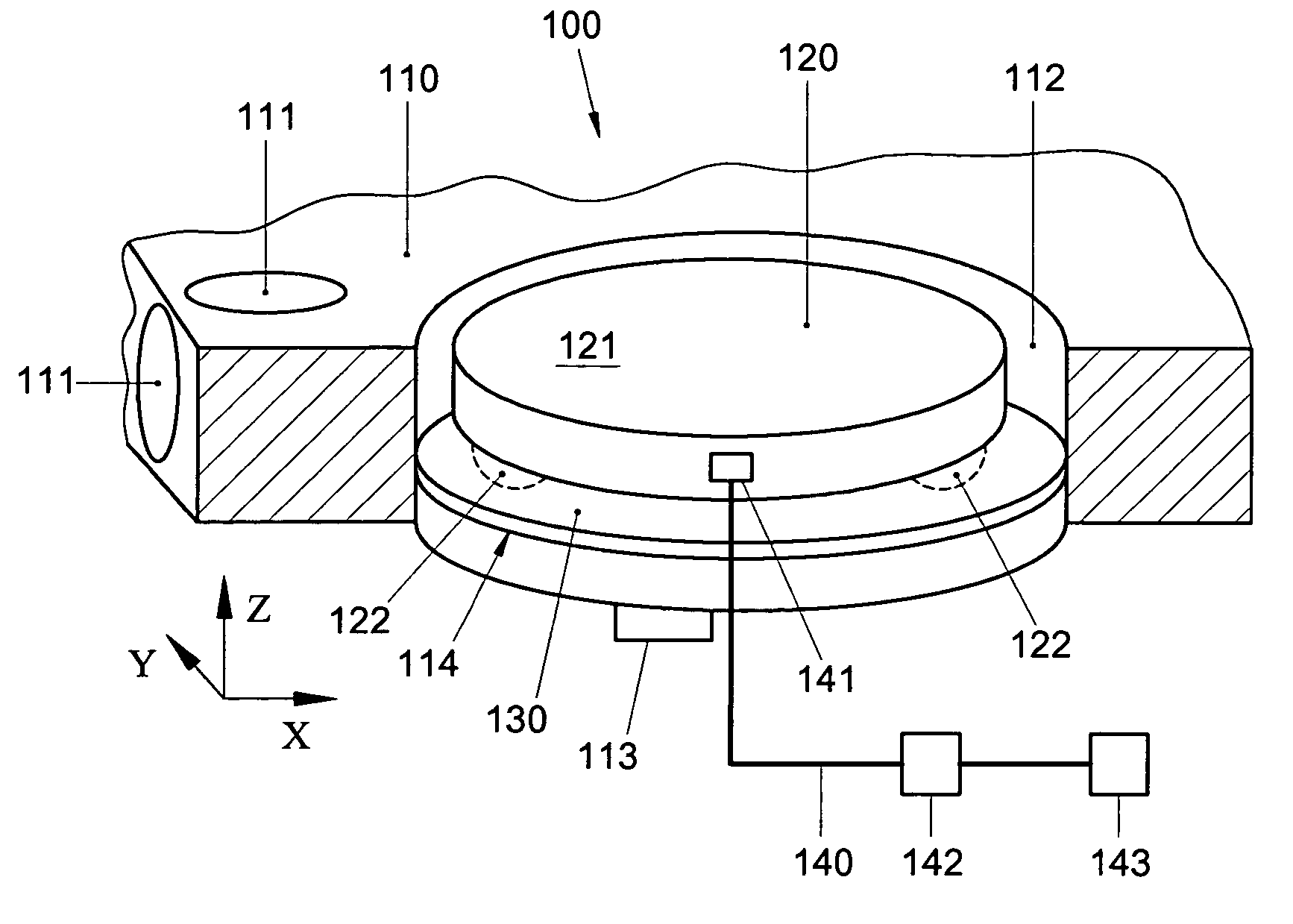

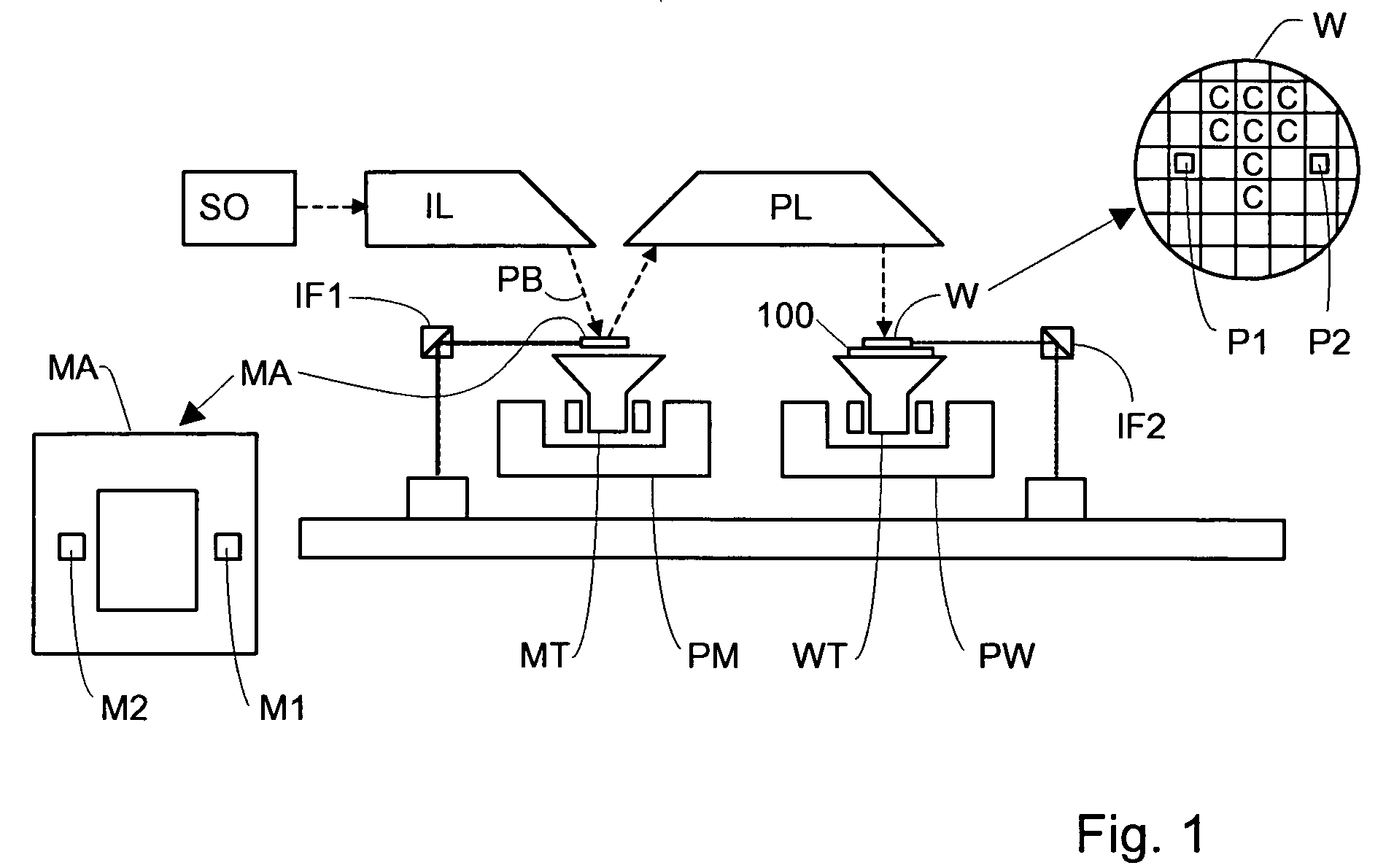

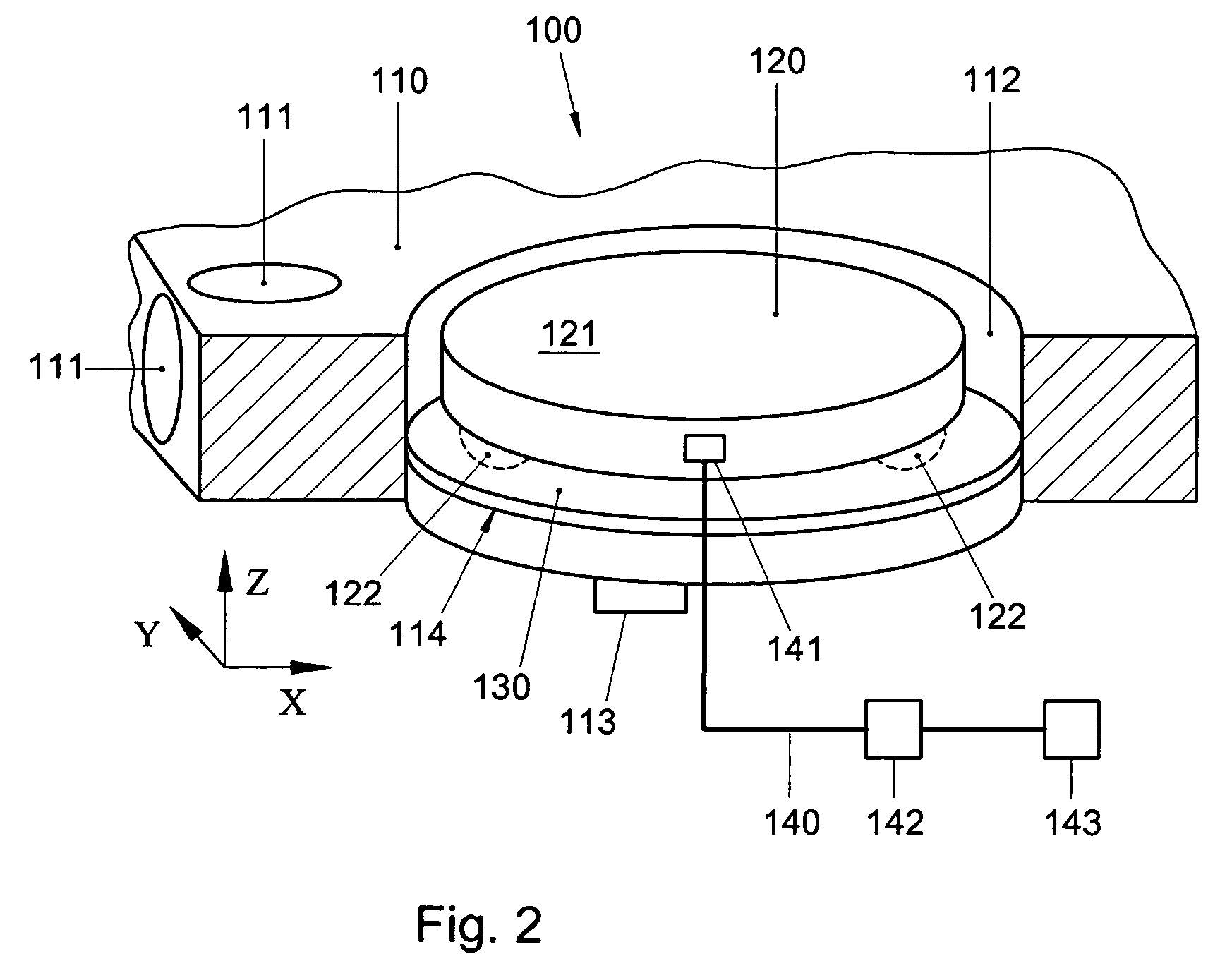

Lithographic apparatus and device manufacturing method

InactiveUS7119884B2Improve accuracyPrecise positioningSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringDegrees of freedom

A lithographic apparatus includes an illumination system for providing a beam of radiation and a support structure for supporting a patterning device. The patterning device serves to impart the beam with a pattern in its cross-section. The lithographic apparatus includes a substrate table for holding a substrate and a projection system for projecting the patterned beam onto a target portion of the substrate. The apparatus has a chuck system for supporting an object, such as the substrate or the patterning device, in the lithographic apparatus. The chuck system includes a chuck for supporting the object, a frame for supporting the chuck, and a chuck support structure for supporting the chuck relative to the frame. The chuck support structure includes at least one flexure element, which flexure element is flexible in at least one degree of freedom and is coupled to the chuck and the frame.

Owner:ASML NETHERLANDS BV

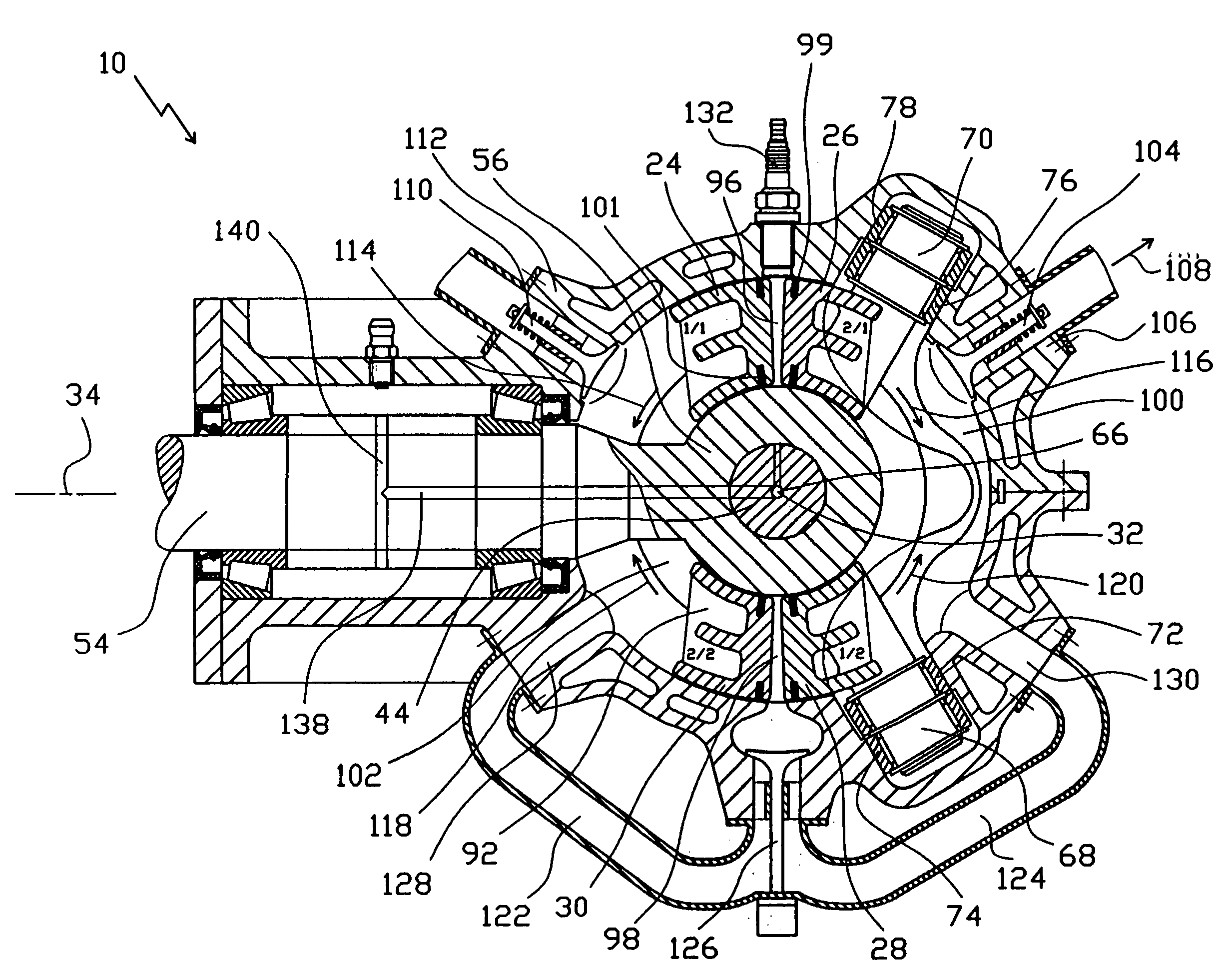

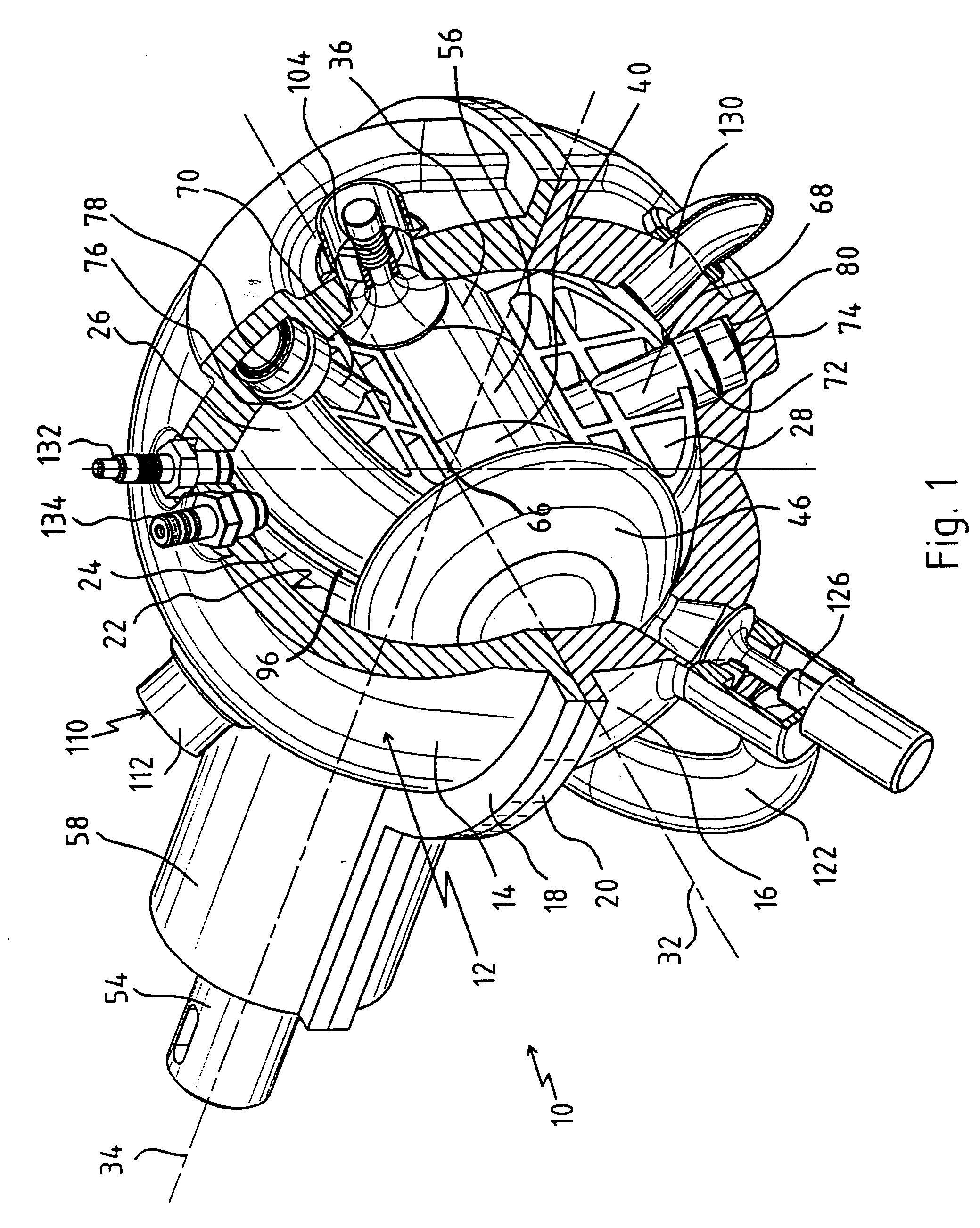

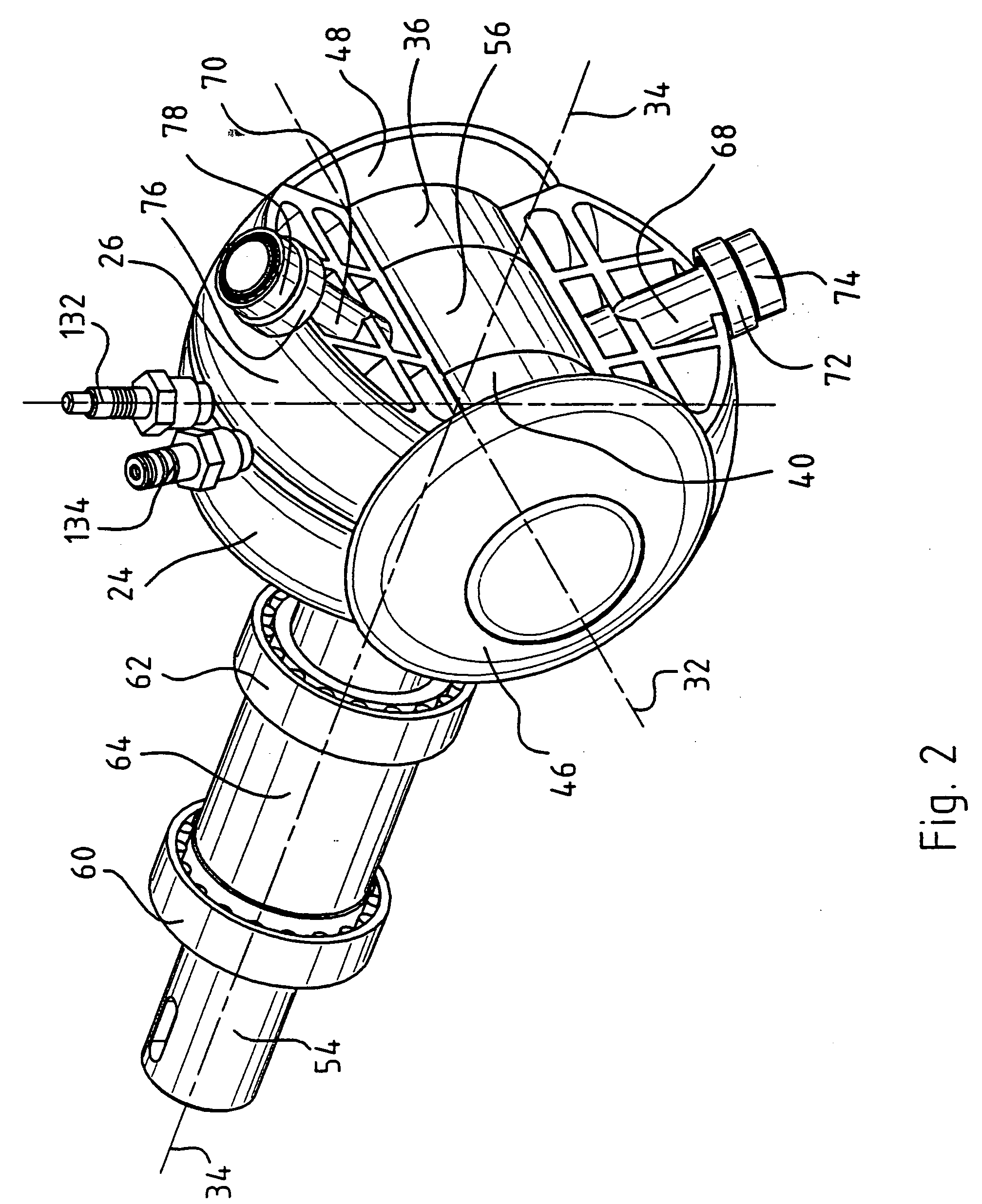

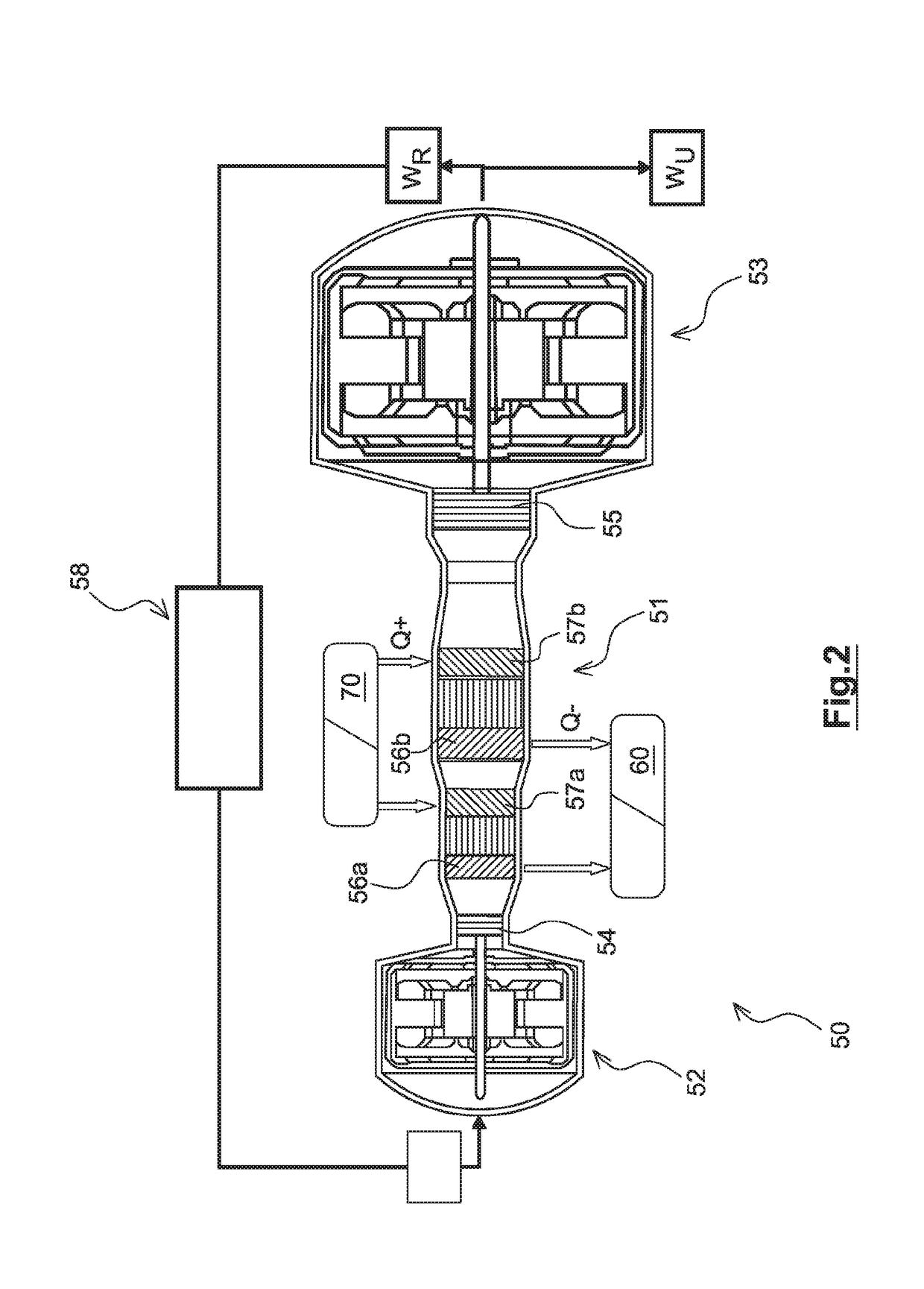

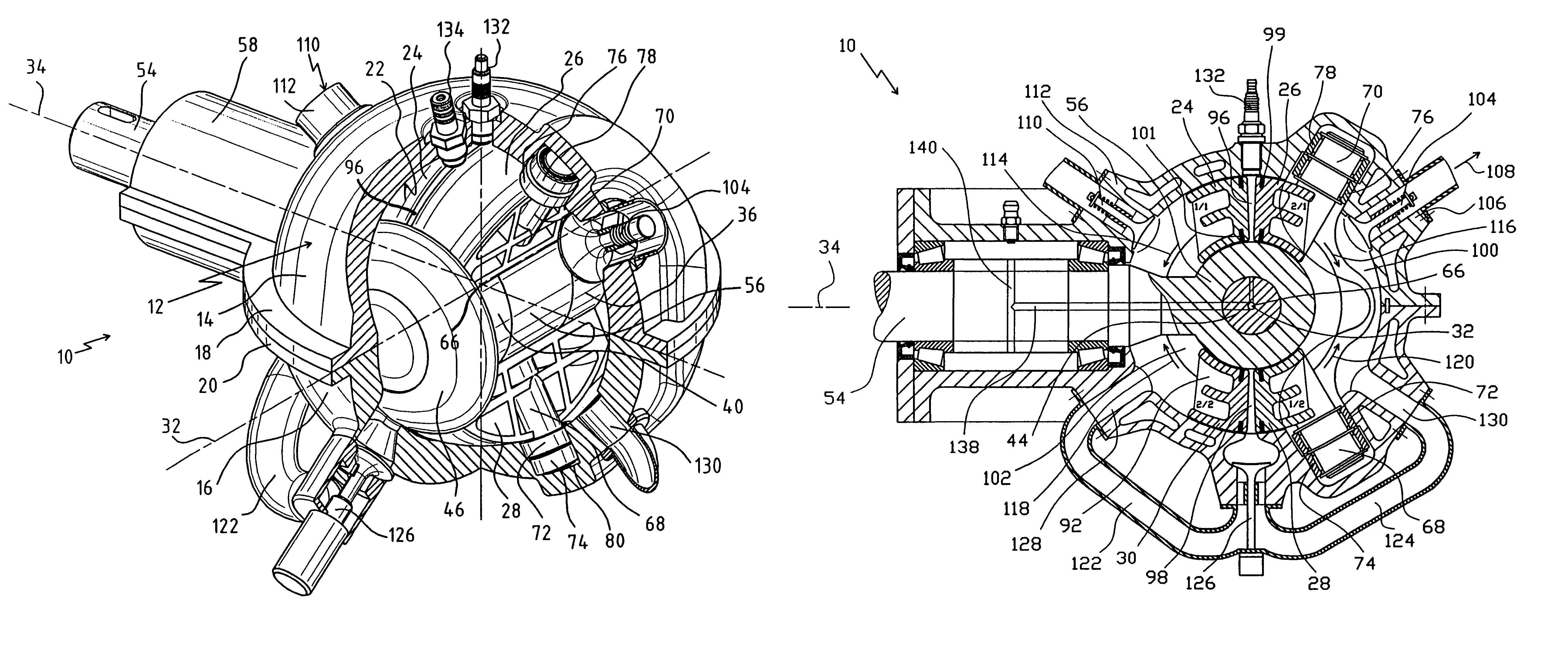

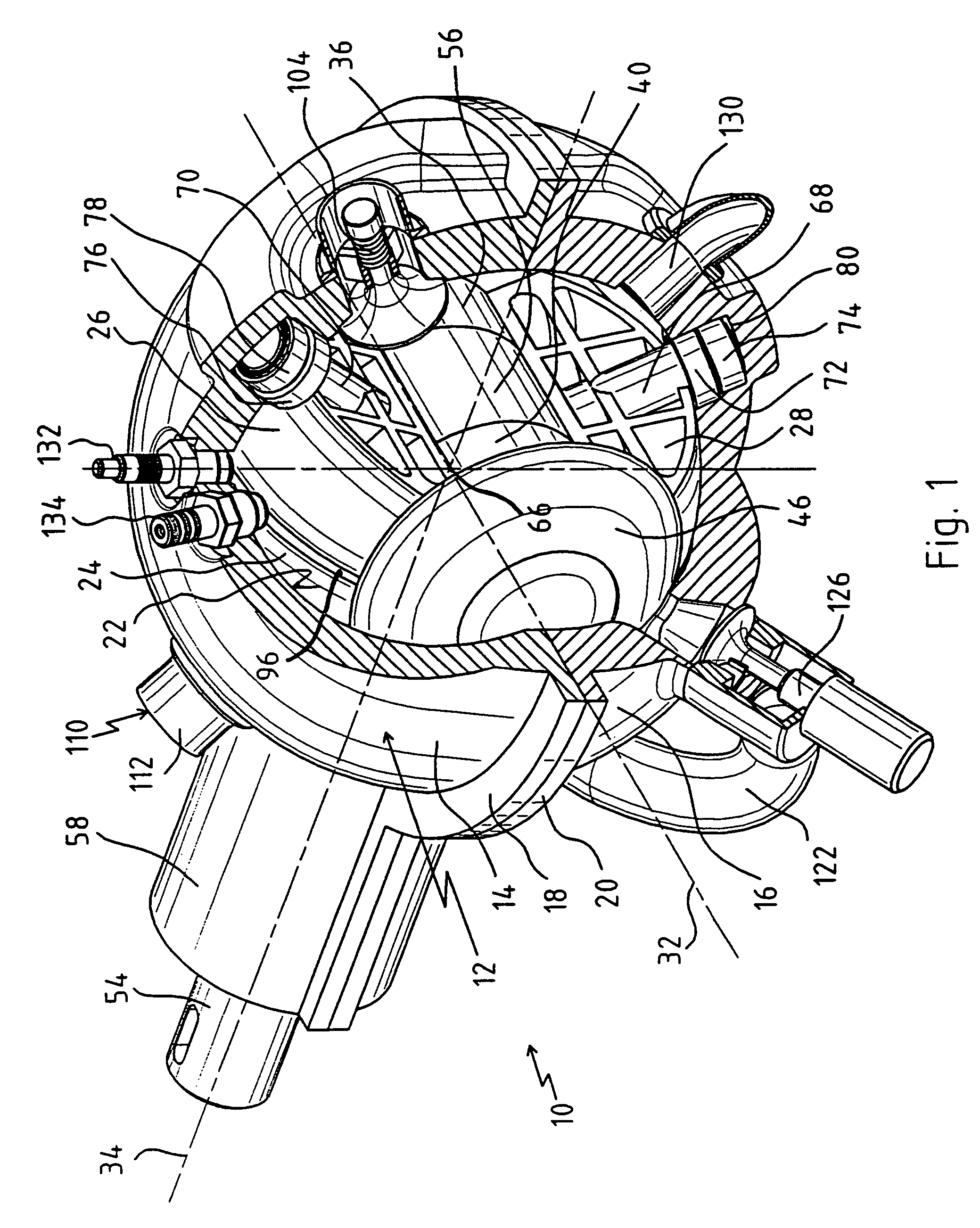

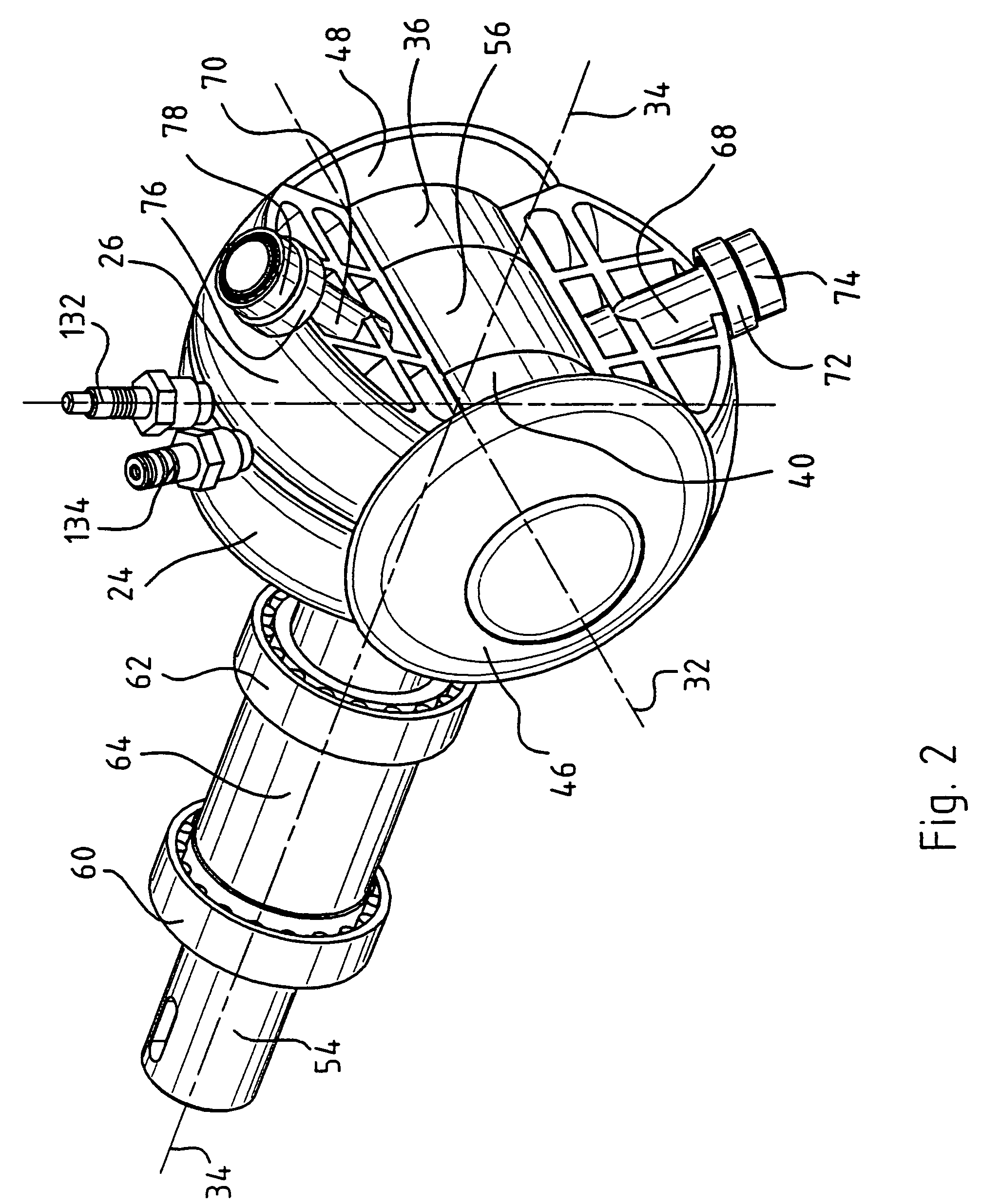

Oscillating piston machine

InactiveUS20050008515A1Enhanced interactionQuieter runningOscillating piston pumpsInternal combustion piston enginesEngineeringPiston

An oscillating piston machine comprises a plurality of pistons which are arranged in a housing, rotate together in the housing about an axis of rotation which is essentially central in the housing and is fixed to the housing, and execute reciprocating oscillating movements about a respective oscillation axis as they rotate in the housing, in each case two adjacent pistons executing oscillating movements in opposite directions. The housing is of spherical construction on the inside, the oscillation axes of the pistons being formed by a common oscillation axis which run essentially through the center of the housing.

Owner:HUTTLIN HERBERT

Metal-plastic hybrid support structure applicable to a dashboard support of a vehicle

ActiveUS20120032044A1Inexpensive to manufactureEasily separateCandle holdersLighting support devicesEngineeringMechanical engineering

Owner:BARCELONA TECHN CENT

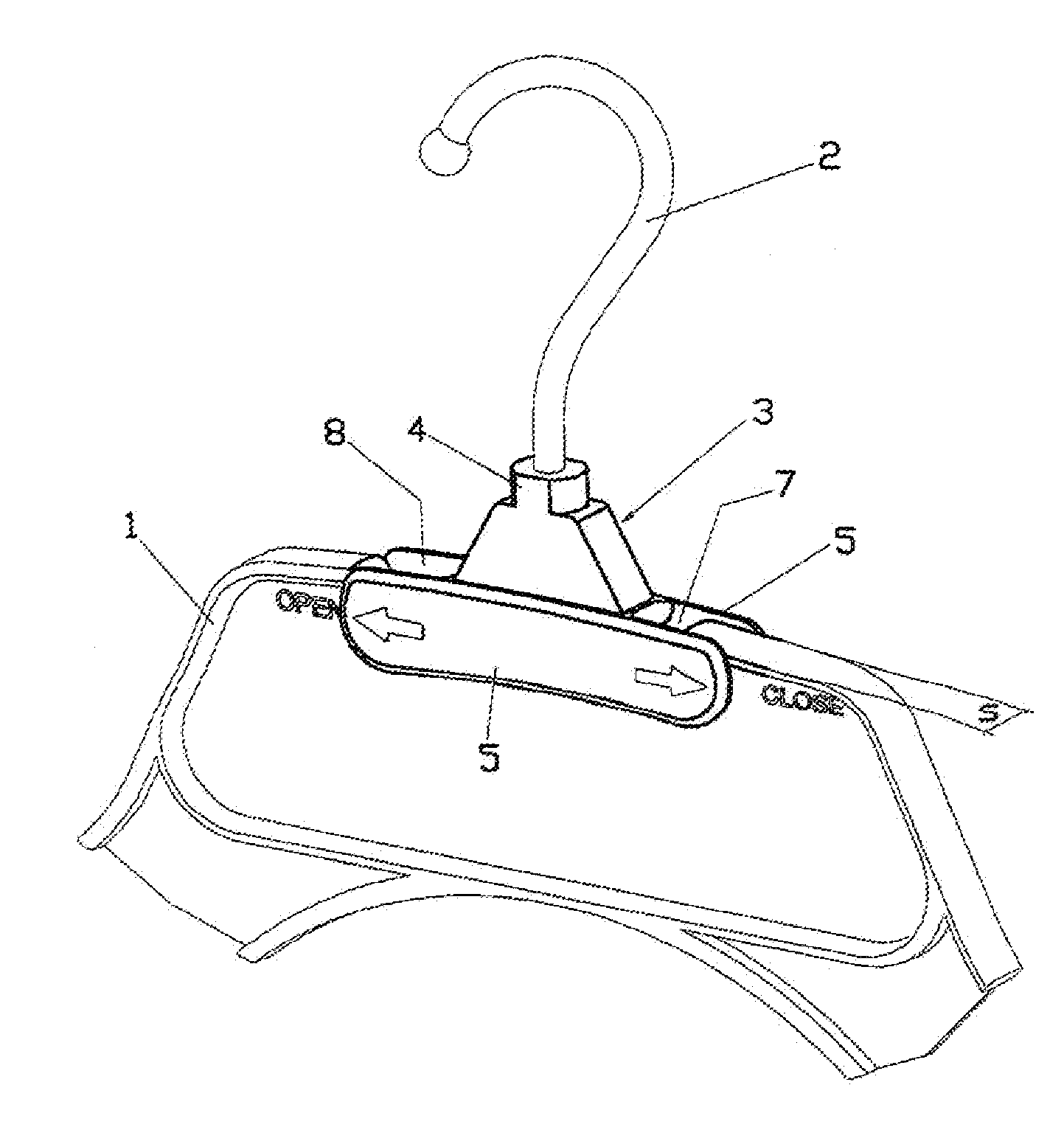

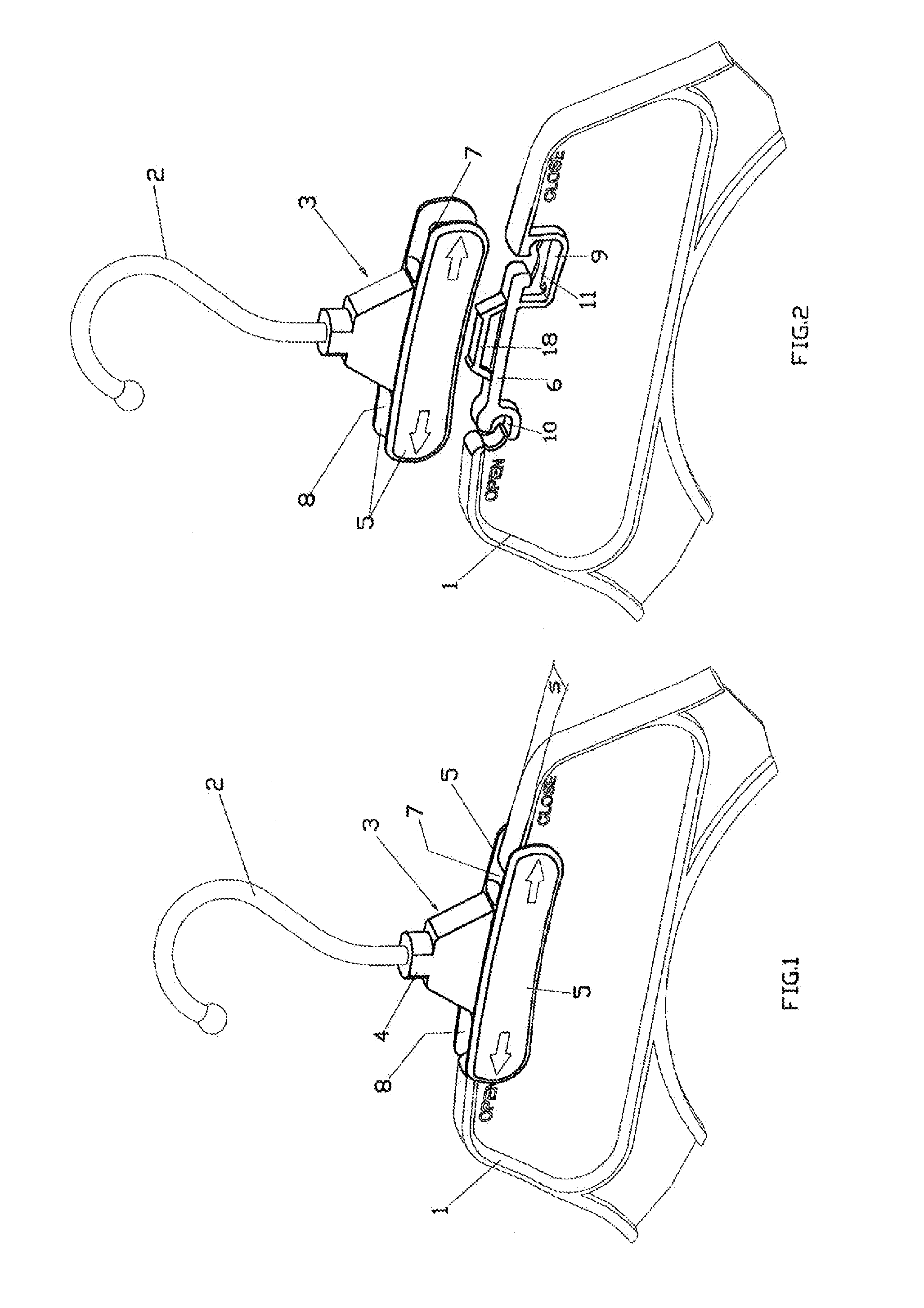

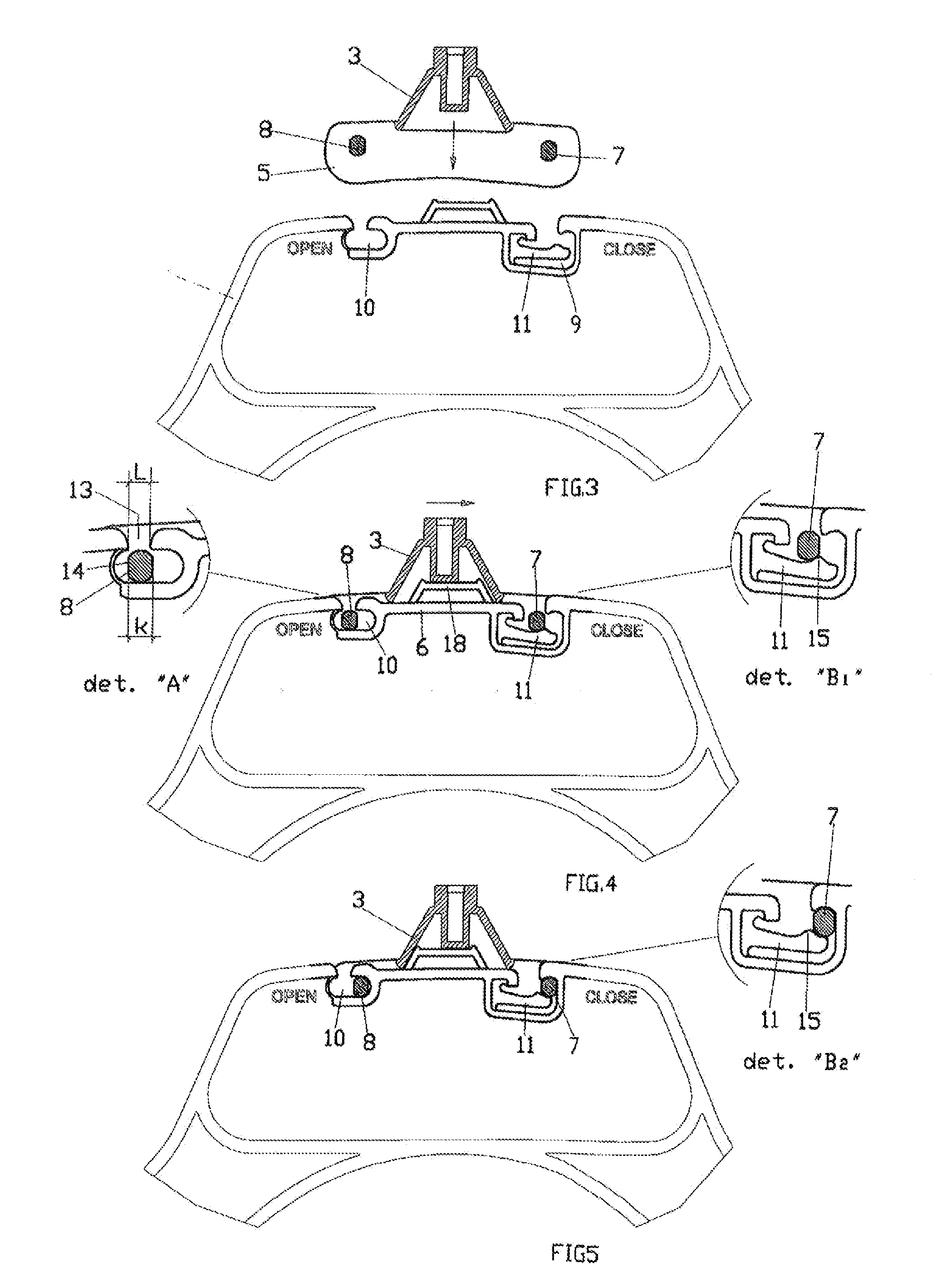

Hanger with foldable/removable hook

InactiveUS20140252048A1Minimal dimensionSimple processApparel holdersGarmentsMechanical resistanceEngineering

Disclosed herein is a hanger with a foldable / removable hook, of the type that is made up of an arched body and a projecting crook-shaped hook, provided with a base, which allows the removably hooking of said hook on said body, as well as a rotation thereof, with reference to the position of normal use thereof, from vertical to horizontal and vice versa, i.e. from perpendicular to parallel with respect to the arched body. In addition, when said hook is raised, so as to allow the hanger to assume a normal configuration, it has the same mechanical resistance of a common hanger with fixed hook.

Owner:MAINETTI SPA

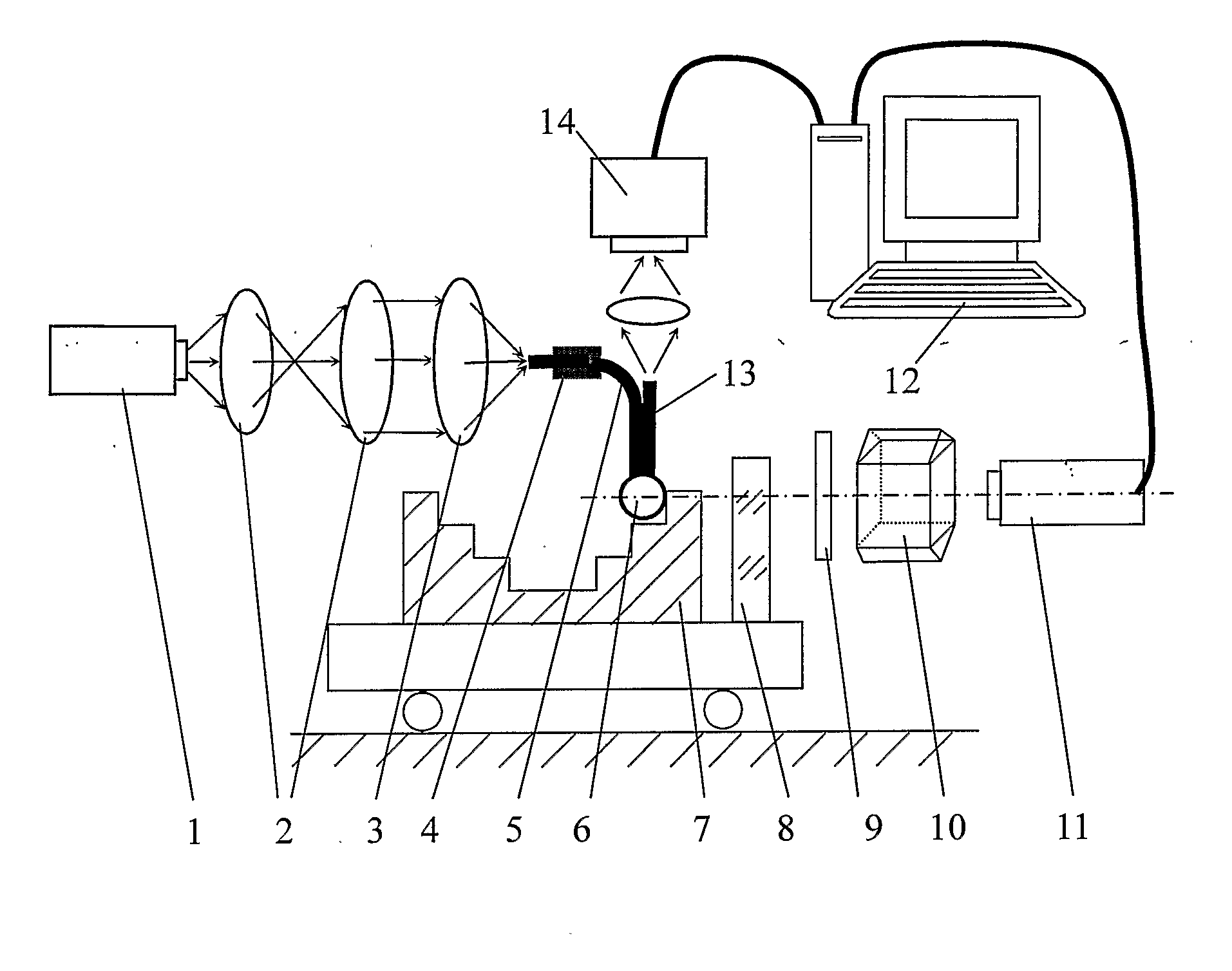

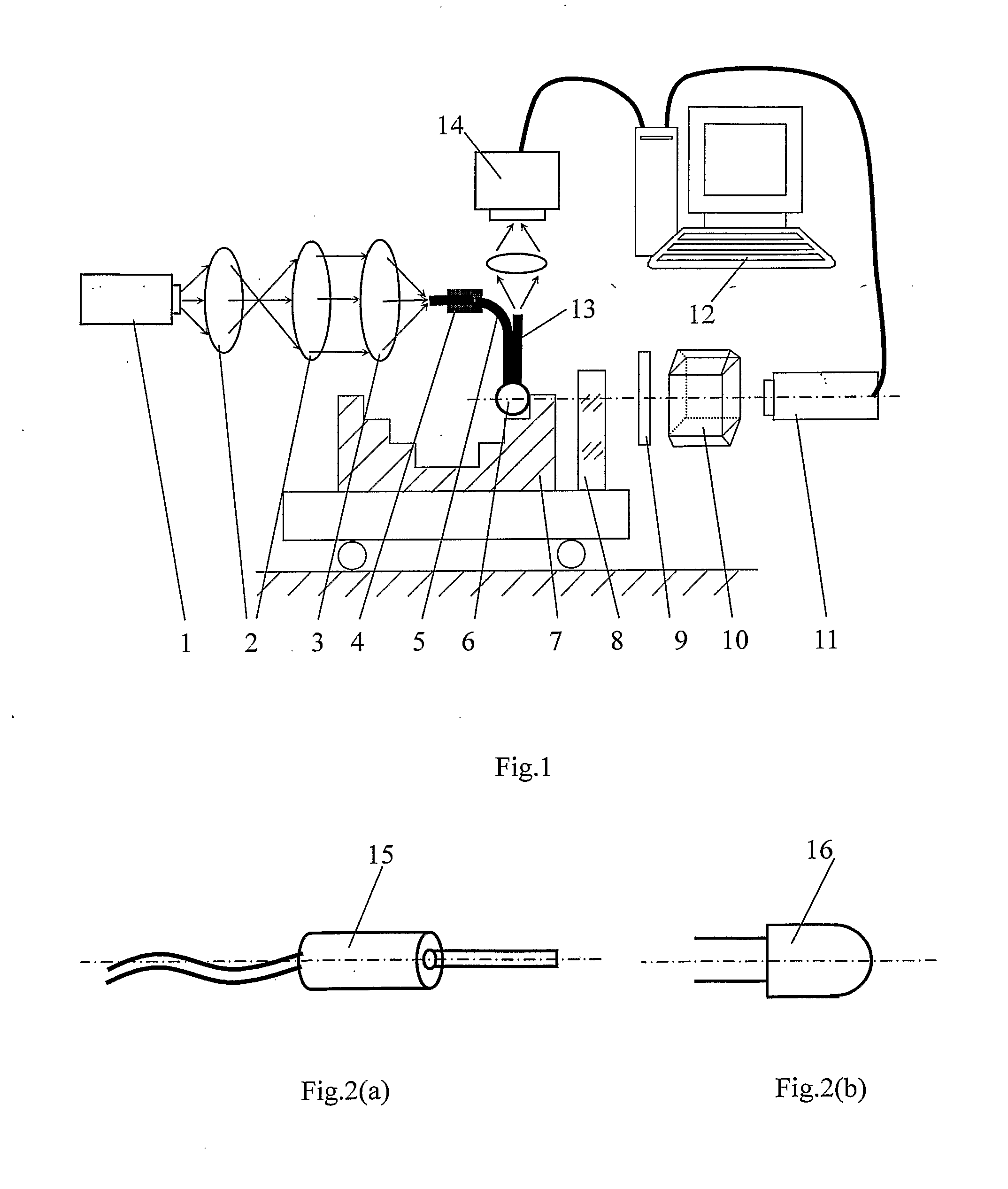

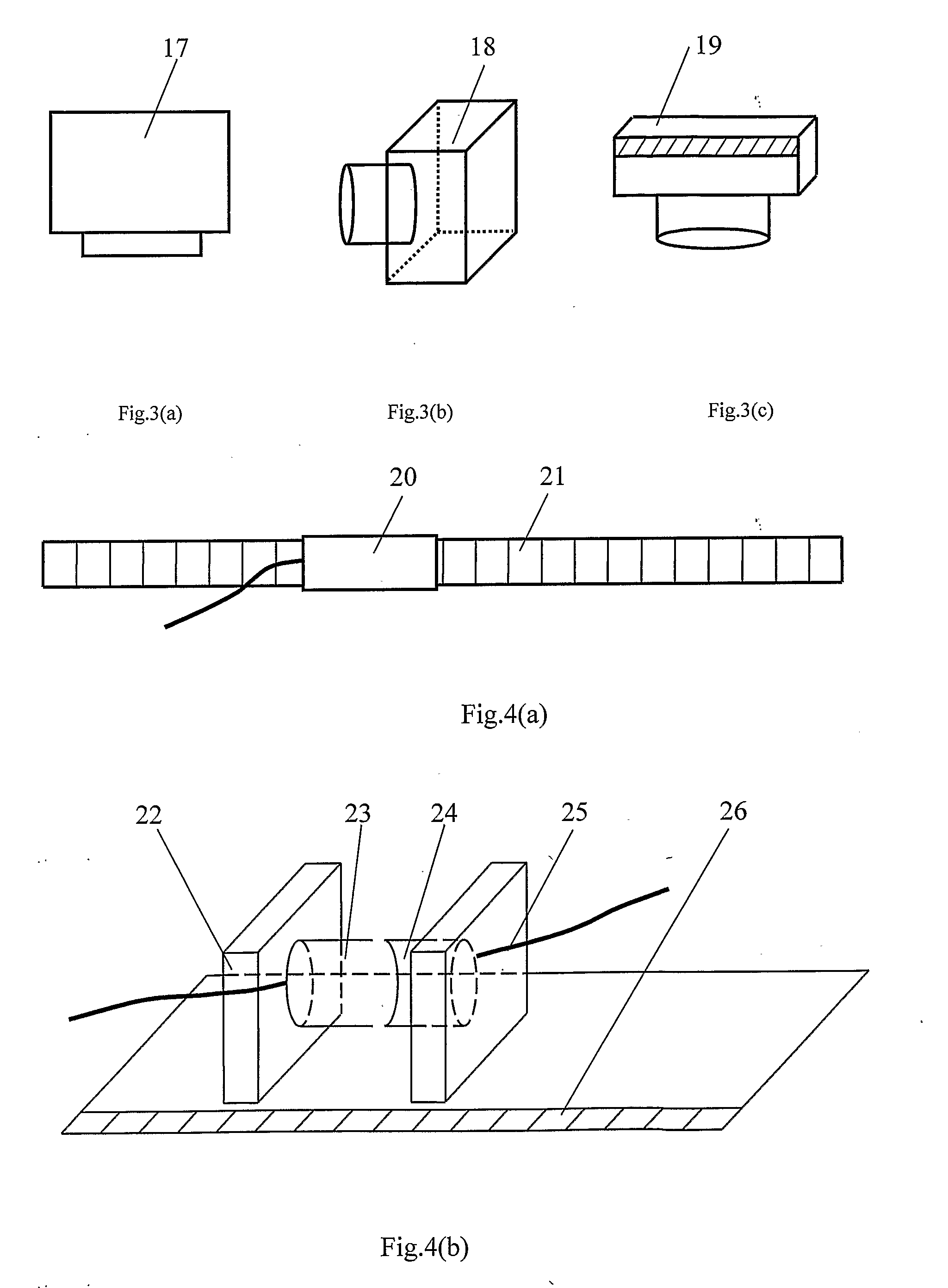

Micro-Cavity Measuring Equipment and Method Based on Double Optical Fiber Coupling

InactiveUS20080209746A1Light signalMinimal dimensionMaterial analysis by optical meansUsing optical meansStopped workAutomatic control

A micro-cavity measuring equipment based on double optical fiber coupling includes a sight and transmitter, a controller, and a length measuring device. The equipment detects small changes in the position of an object with respect to a probe from a moment when the sight and transmitter starts working to another moment when the sight and transmitter stops working. The controller has a program to automatically control the whole measuring process. The measuring equipment is characterized in that the sight and transmitter consists of a laser unit, a data collecting and processing unit, and a double optical fiber coupling unit with its ends of incident and effluent optical fibers fixed on a coupler. A micro-cavity measuring method based on double optical fiber coupling consists of the following steps: inserting the probe into the micro-cavity and moving it in the measuring direction; sending signals to the length measuring device by the sight and transmitter to cause the length measuring device to record the corresponding position of the probe when the probe is contact with the sides of the micro-cavity; and then calculating the dimensions of the micro-cavity.

Owner:TAN JIUBIN +1

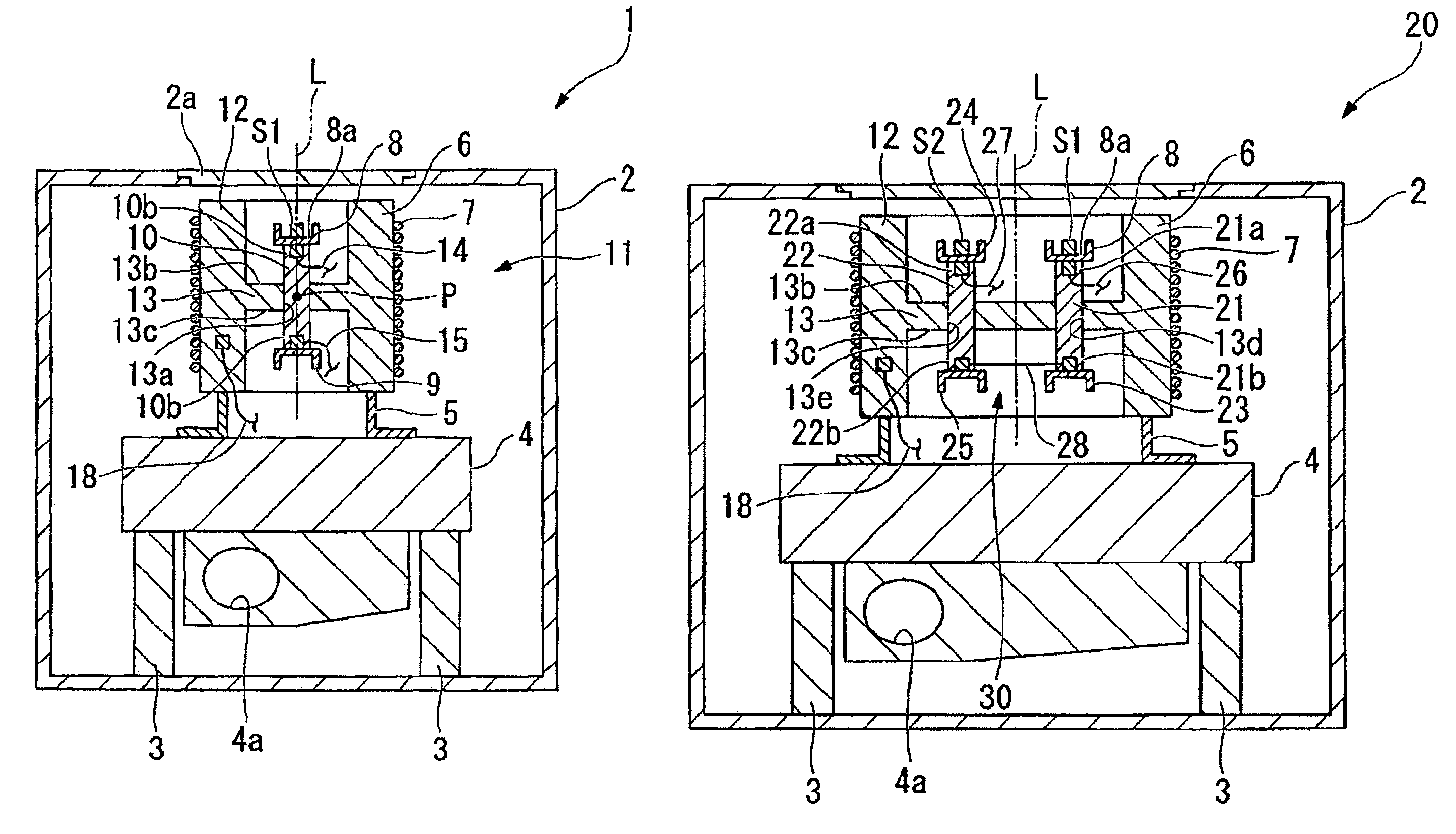

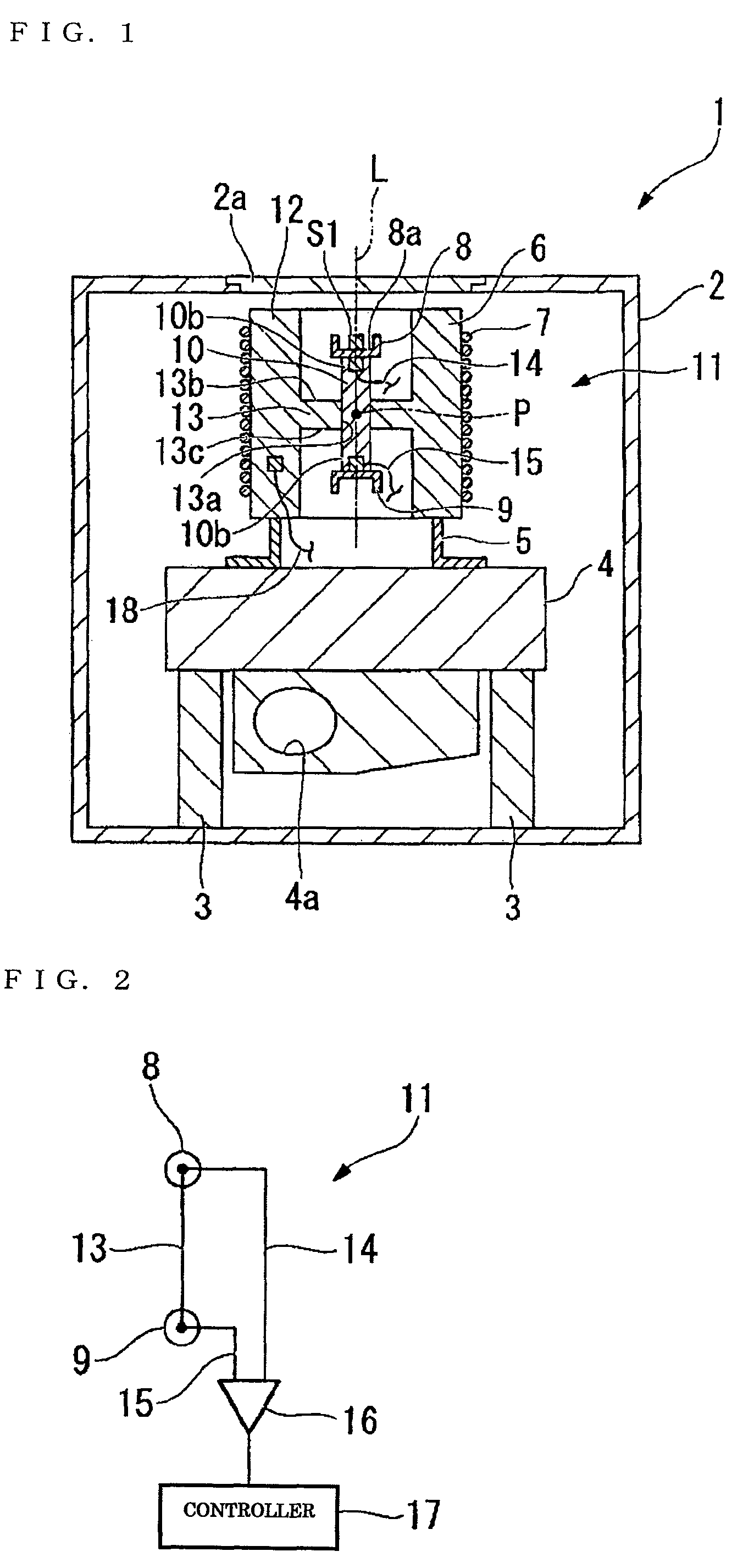

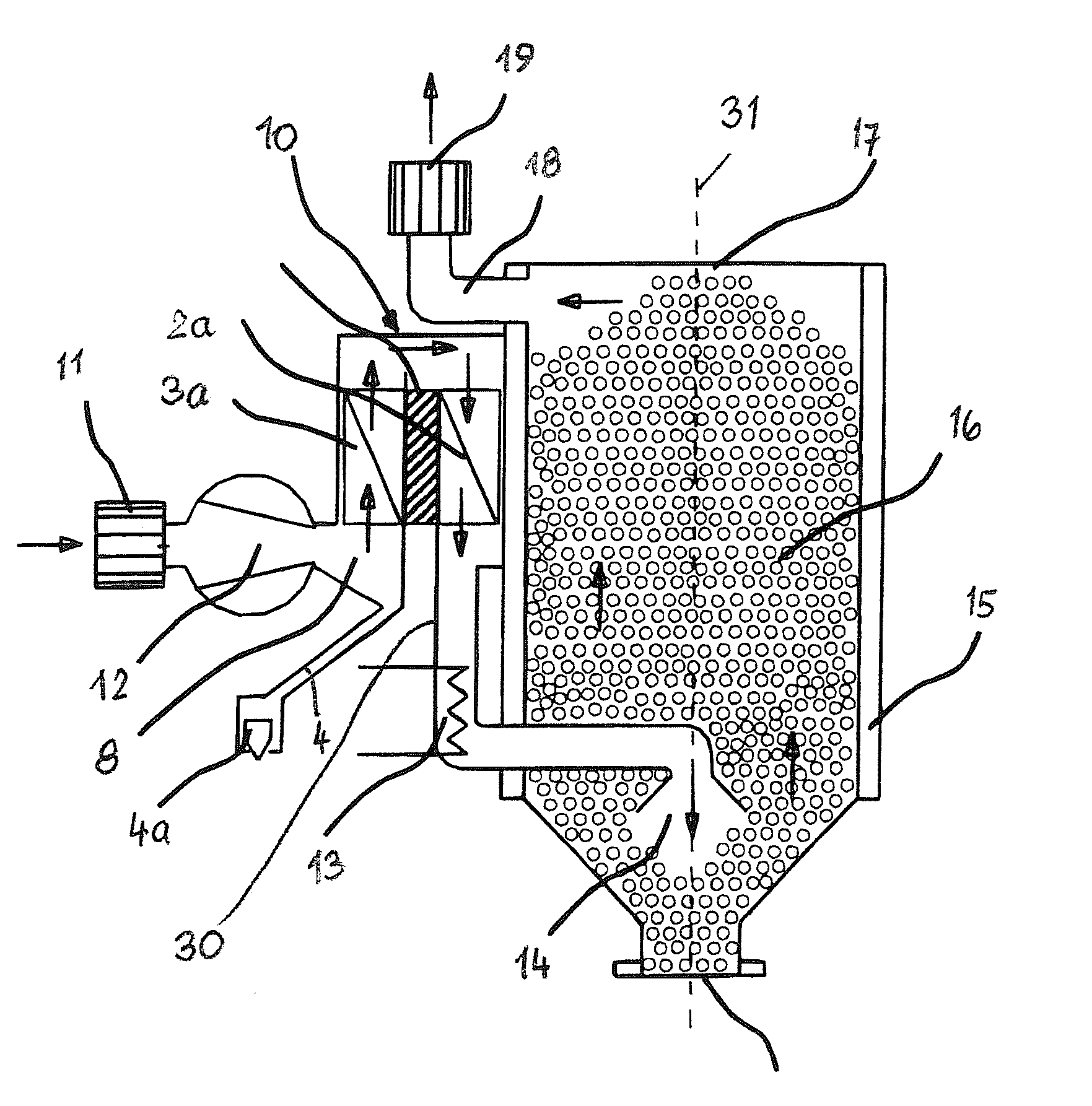

Differential scanning calorimeter

InactiveUS7802916B2Reduce decreaseImprove thermal conductivityThermometer detailsMaterial heat developmentHeat resistanceEngineering

There is provided a differential scanning calorimeter for exactly measuring a calorie variation of the measured sample on the basis of the temperature difference between sample container and the reference container without the influence of the heat irregularity incoming from the surroundings and the noise components. The differential scanning calorimeter includes a heating furnace of an approximately H-shaped section having an approximately drum-shaped wall part and an approximately plate-shaped heat inflow part, a heater disposed outside the wall part so as to heat the heating furnace, a approximately bar-shaped heat-resistance member that is arranged along the center axis L of the wall part, that protrudes from both sides of the heat inflow part by an approximately equal length, that is made of a material heat conductivity lower than that of the material of the heating furnace, a sample container disposed at one end of the heat-resistance member, a reference container disposed at the other end of the heat-resistance member, and a differential heat flow detector measuring a difference between the temperature of the sample container and the temperature of the reference container as a measured value.

Owner:HITACHI HIGH TECH SCI CORP

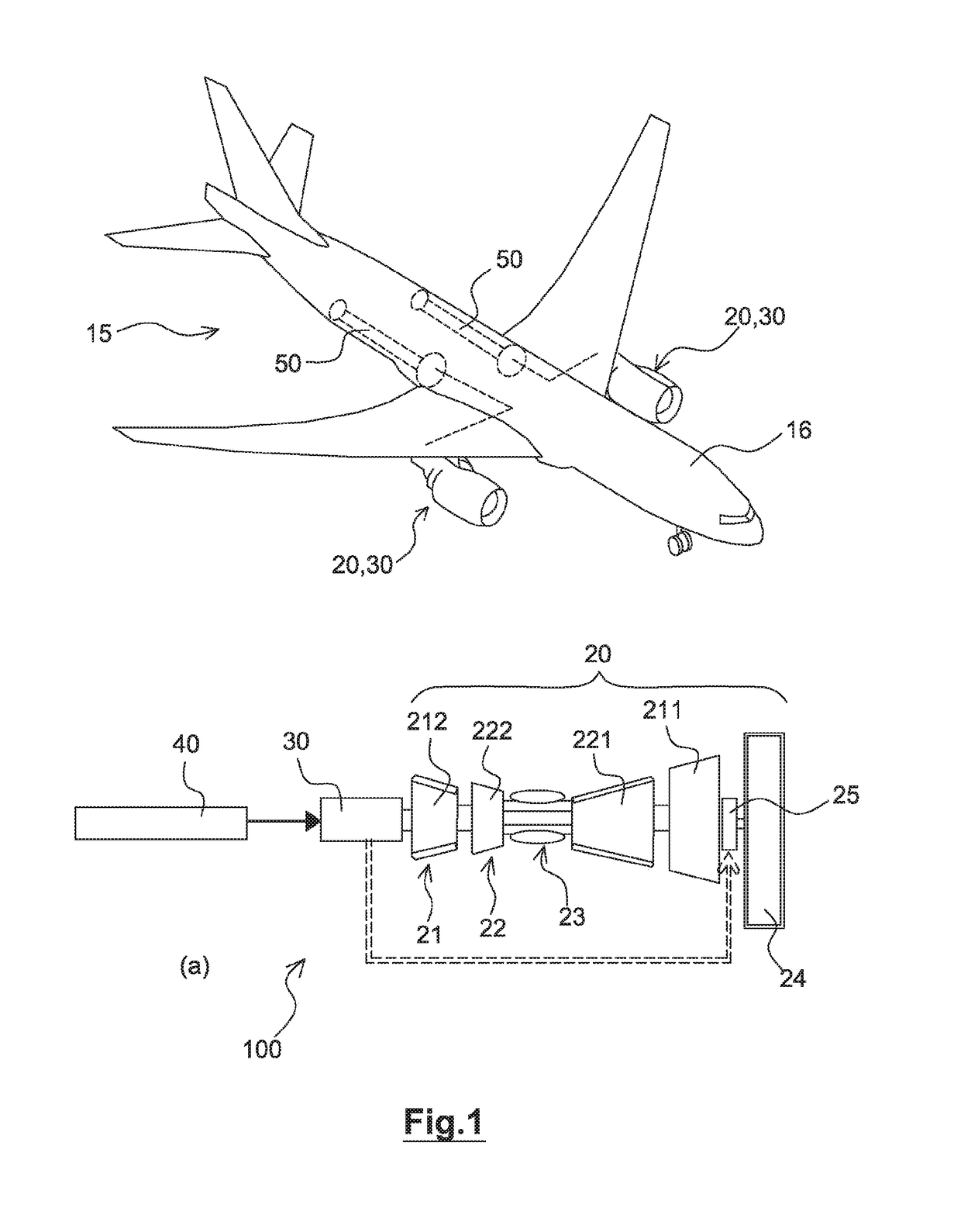

Hybrid power or thrust generator and vehicle including such a generator

InactiveUS20180363564A1Easily variableIncrease productionPower installationsEfficient propulsion technologiesElectricityAlternator

A hybrid power or thrust generator including at least one thermodynamic turbine engine and at least one electric power generator. An electric power generator is electrically connected to at least one electric motor, mechanically and rotatably coupled to one or more rotating portions of the thermodynamic turbine engine, and the electric power generator operates simultaneously with the thermodynamic engine so as to supply the electric motor(s) to reduce the power drawn from the turbines of the thermodynamic turbine engine in operation. The electric power generator may comprise a thermoacoustic engine driving a linear electric alternator. The generator is advantageously implemented in a vehicle, such as an aircraft.

Owner:AIRBUS SAS

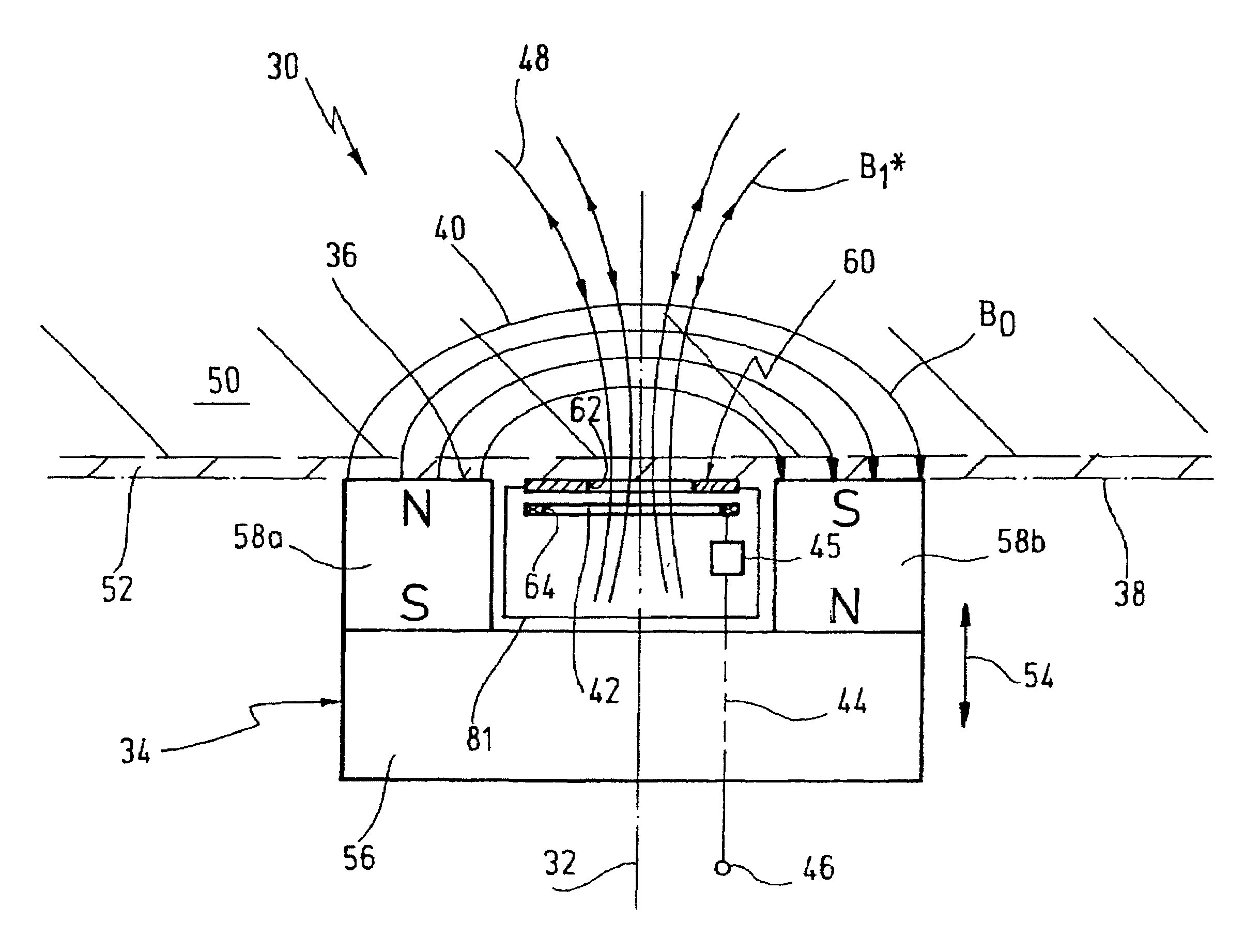

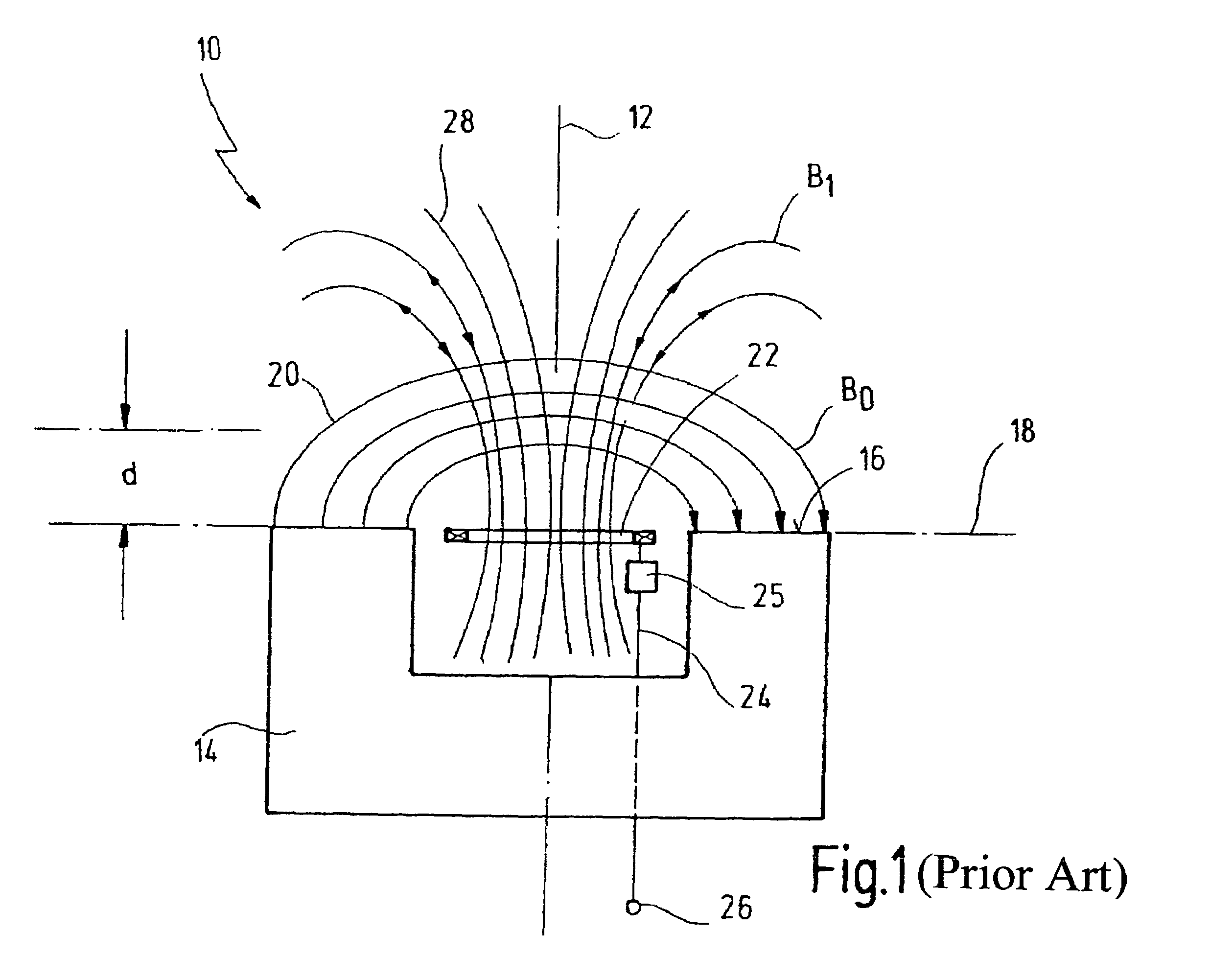

Probe head for nuclear magnetic resonance measurements

ActiveUS7271589B2Robust designEasy to operateMagnetic measurementsMaterial analysis by using resonanceNMR - Nuclear magnetic resonanceRadio frequency

A probe head for nuclear magnetic resonance measurements in an area of a surface of a measuring object is disclosed. The probe head comprises first means for generating a static magnetic field extending at least partially parallel to the surface, second means for generating a radio frequency magnetic field having components extending perpendicular to the surface, and third means for amplifying a radio frequency magnetic field effective within the measuring object. The third means are configured as an aperture and are located between the second means and the surface.

Owner:BRUKER BIOSPIN

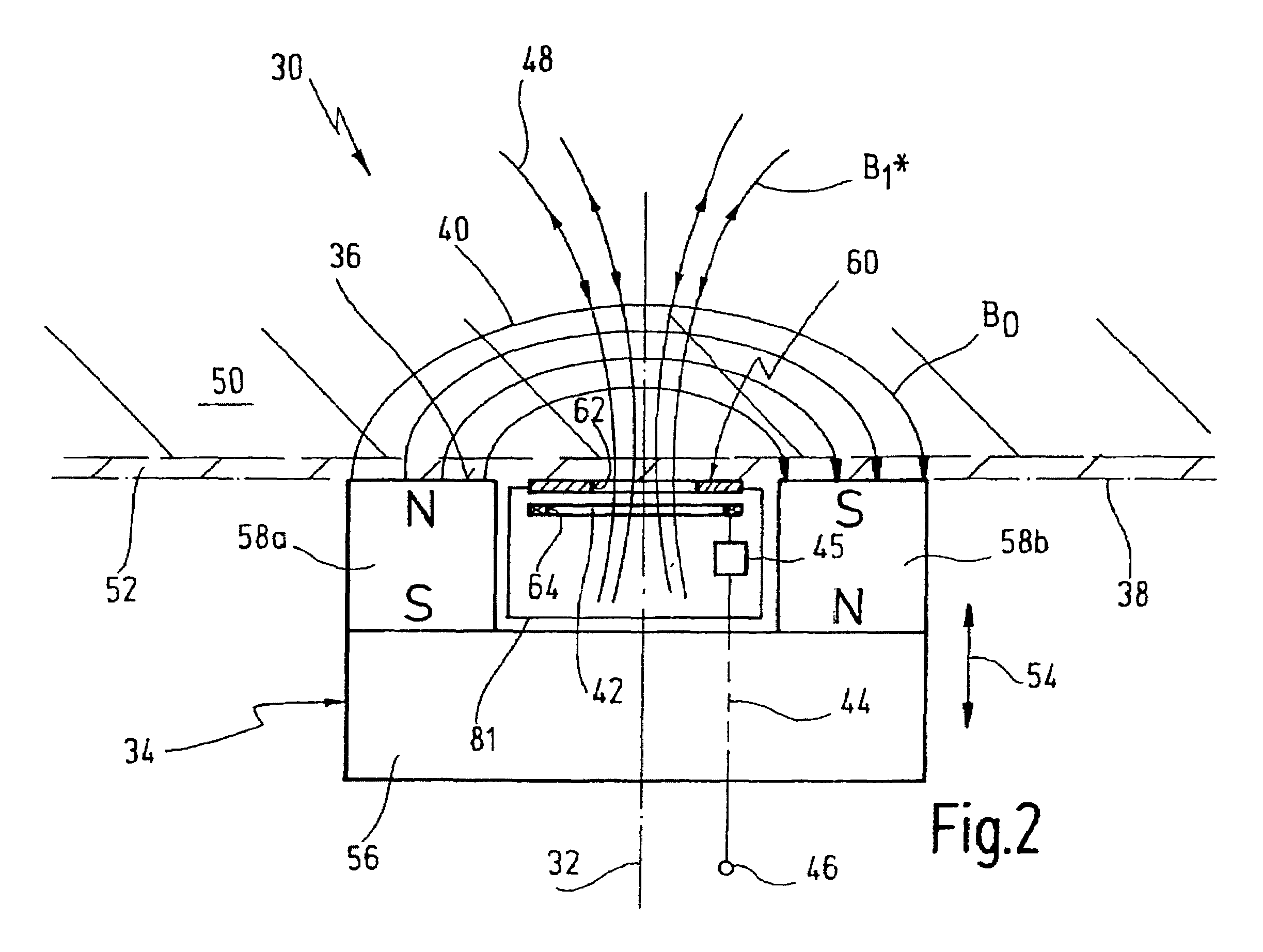

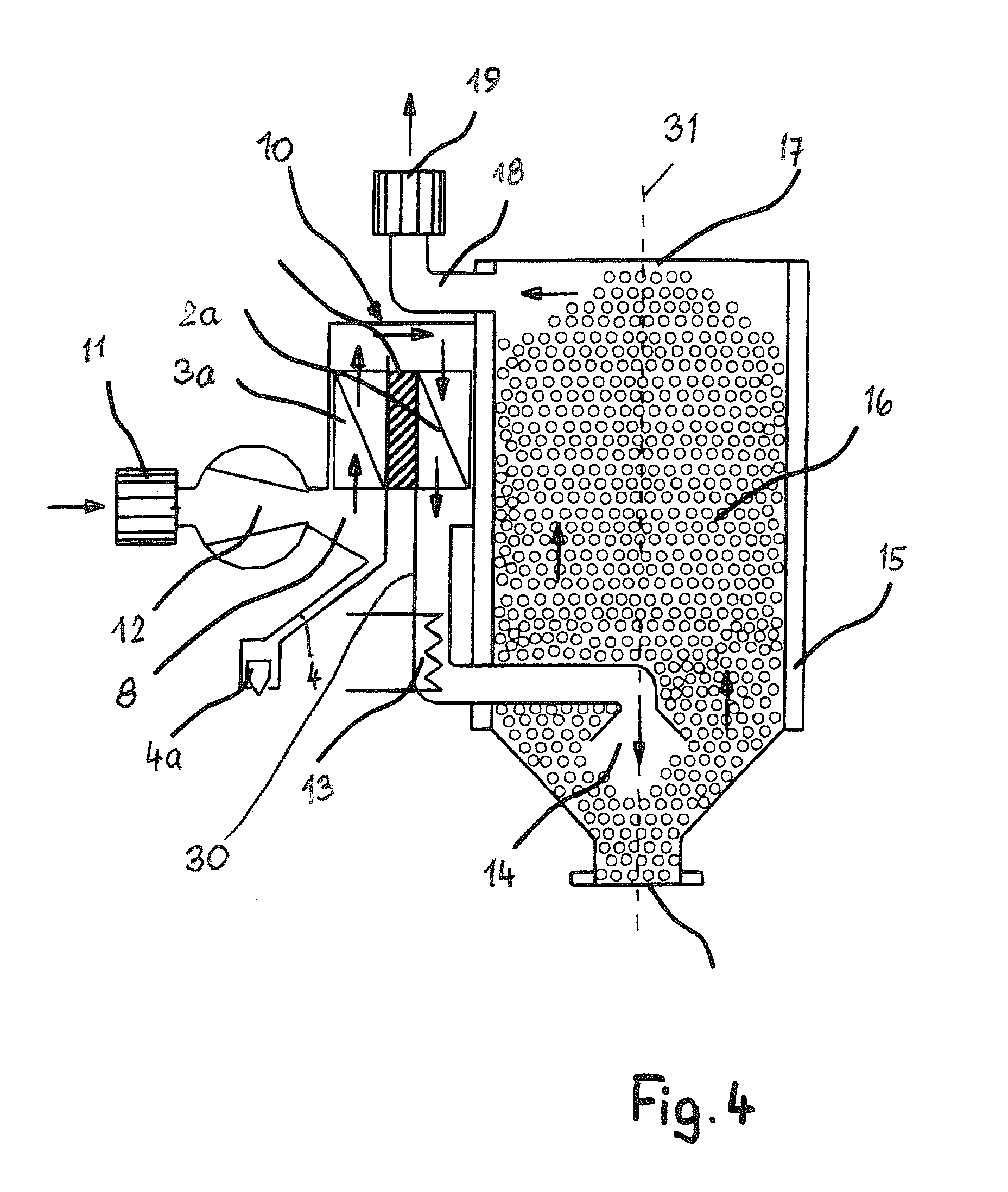

Device for Drying Bulk Material in at least one Storage Container

InactiveUS20110283554A1Increase temperature differenceSave energyDrying solid materials with heatGranular material dryingCold sidePulp and paper industry

Before being processed, bulk material is dried in a storage container. A drying medium such as air is passed through the bulk material for drying. The drying medium heats the bulk material and removes moisture at the same time. For dehumidifying the drying medium, a dehumidifying unit with a Peltier device is provided whose cold side and whose hot side are positioned within the flow path of the drying medium. The drying medium loaded with moisture is passed across the cold side and dehumidified. The hot side of the Peltier device is used to preheat the dehumidified drying medium.

Owner:MOTAN HLDG

Toothbrush and process for producing the same

ActiveUS20050104556A1Guaranteed uptimeImplementation is particularly straightforwardBatteries circuit arrangementsBrush bodiesInterior spaceEngineering

An electric toothbrush includes a rechargeable energy store which is arranged in an inner space in the body of the toothbrush. The inner space is sealed by a primary sealing element against splash water and other detrimental influences. At least one contact element for an external power supply unit produces an electrically conductive connection to the energy store. The contact element is located either within the inner space, the primary sealing element being removable for charging purposes, or outside the inner space, in which case it is optionally protected by an additional secondary sealing element. The invention also relates to a process for producing such a toothbrush.

Owner:TRISA HLDG AG

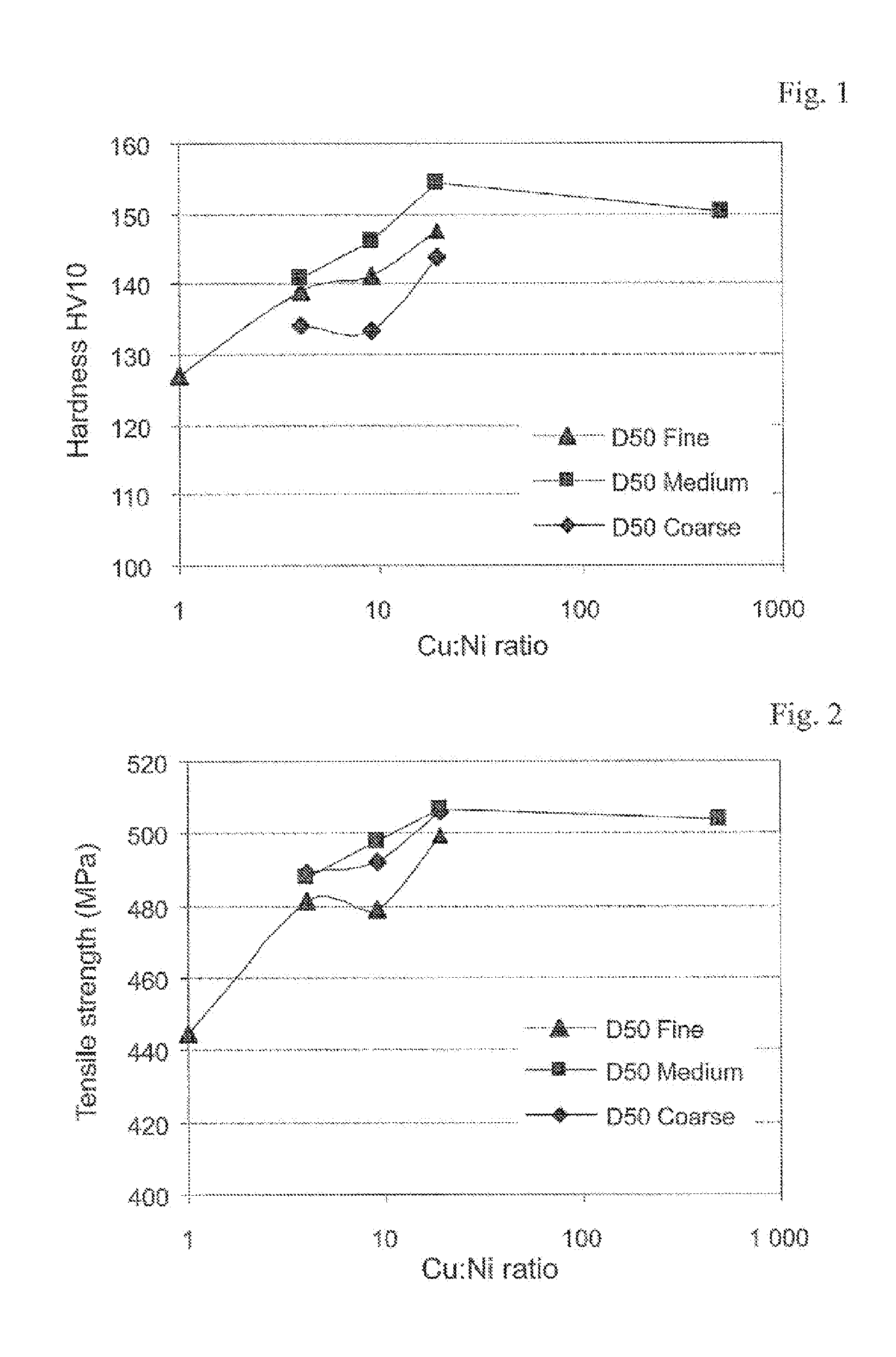

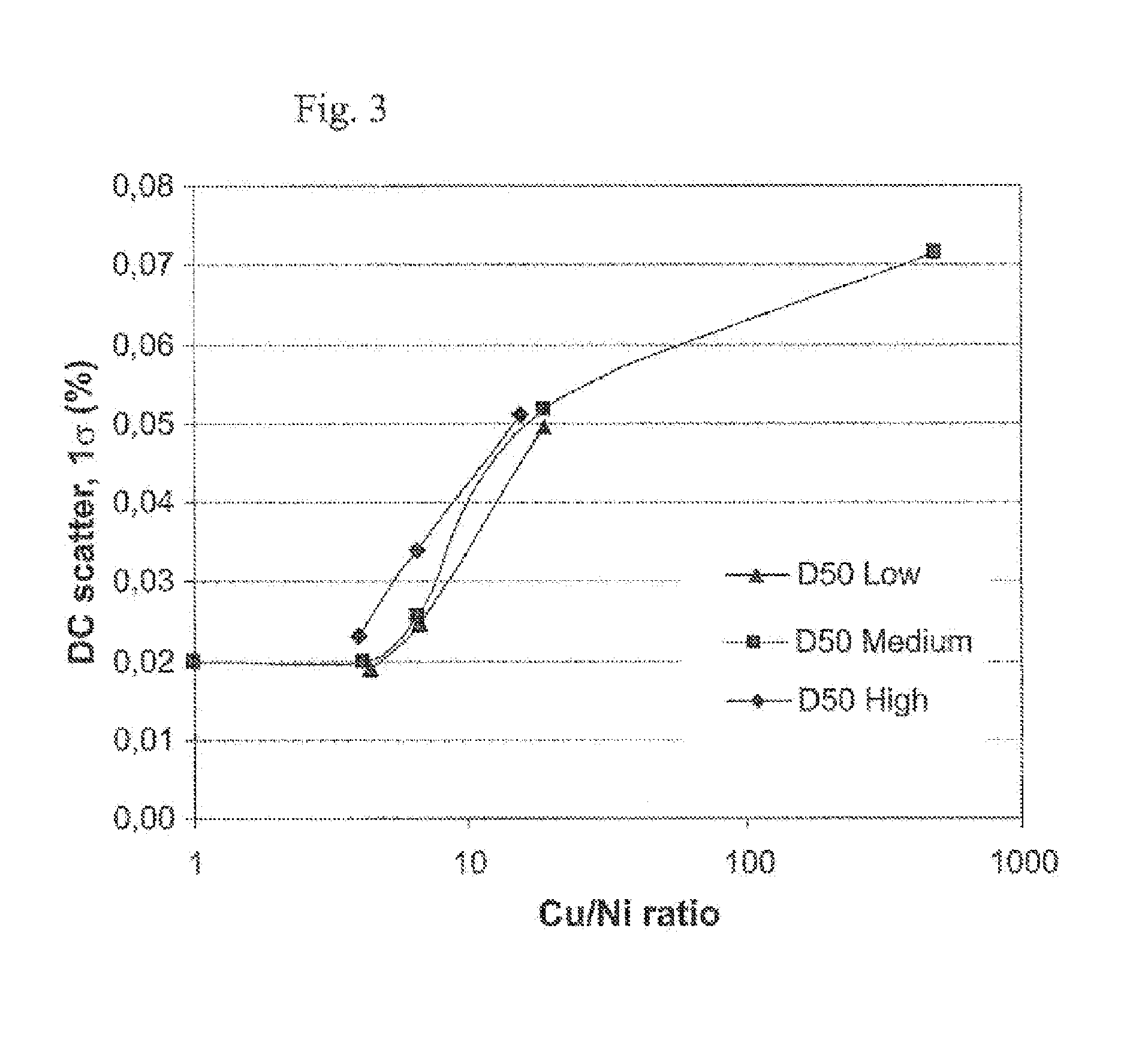

Method of producing a diffusion alloyed iron or iron-based powder, a diffusion alloyed powder, a composition including the diffusion alloyed powder, and a compacted and sintered part produced from the composition

InactiveUS20110252922A1Reduce swellingReduce impactMetal-working apparatusCoatingsAlloyReducing atmosphere

A method is provided for producing a diffusion alloyed powder consisting of an iron or iron-based core powder having particles of an alloying powder containing Cu and Ni bonded to the surface of the core particles, comprising providing a unitary alloying powder capable of forming particles of a Cu and Ni containing alloy, mixing the unitary alloying powder with the core powder, and heating the mixed powders in a non-oxidizing or reducing atmosphere to a temperature of 500-1000° C. during a period of 10-120 minutes to convert the alloying powder into a Cu and Ni containing alloy, so as to diffusion bond particles of the Cu and Ni alloy to the surface of the iron or iron-based core powder. The alloying powder may be a Cu and Ni alloy, oxide, carbonate or other suitable compound that on heating will form a Cu and Ni alloy. Preferably, the total content of Cu and Ni is at most 20 wt %, the particle size distribution of the Cu and Ni alloying powder is such that D50 is less than 15 μm, and the ratio Cu / Ni in wt % is between 9 / 1 and 3 / 1. The compacted and sintered parts produced from the diffusion alloyed iron-based powder present a minimum of variation of dimensional change from component to component.

Owner:HOGANAS AB

Retaining device

InactiveUS20050167557A1Easy to installMinimal dimensionSleeve/socket jointsFlexible coversEngineeringLower face

A retaining device for an object including a plate incorporating an aperture allowing the insertion and withdrawal of the object. A lower face of the plate is attached to a support by a connecting arrangement, and a separation movement between the plate and the support causes deformation of the connecting arrangement so as to form a sleeve around the object. Walls of the connecting arrangement are preferably defined radially relative to the object and facilitate its protection. The device can be advantageously mounted inside a case capable of accommodating the object.

Owner:LOREAL SA

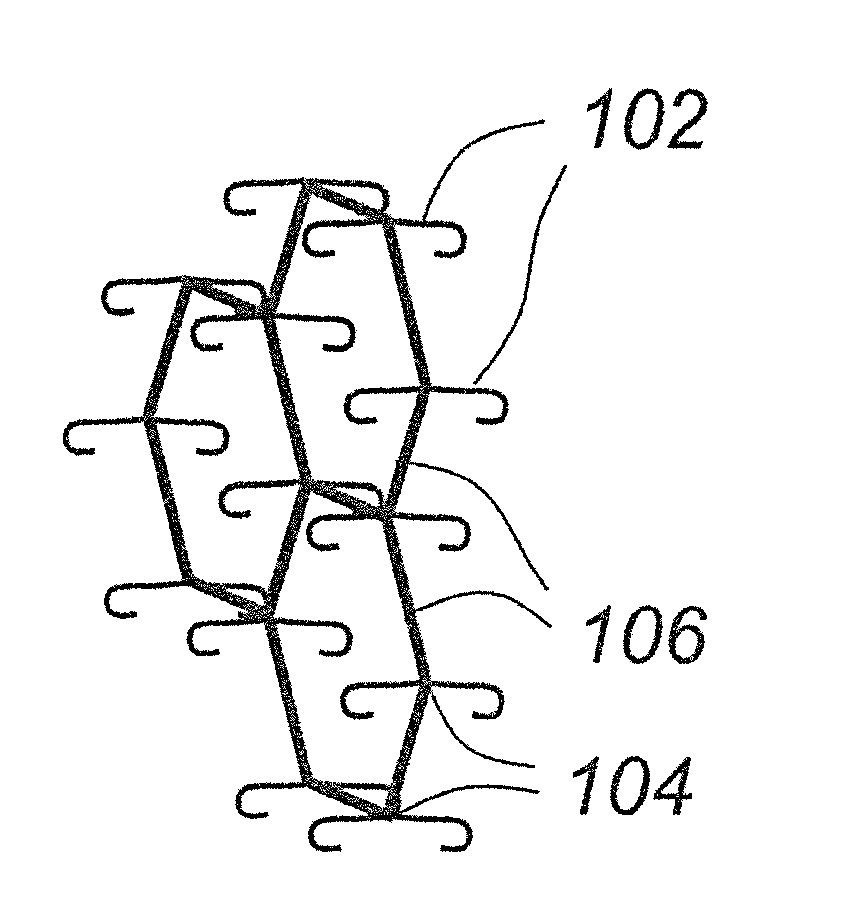

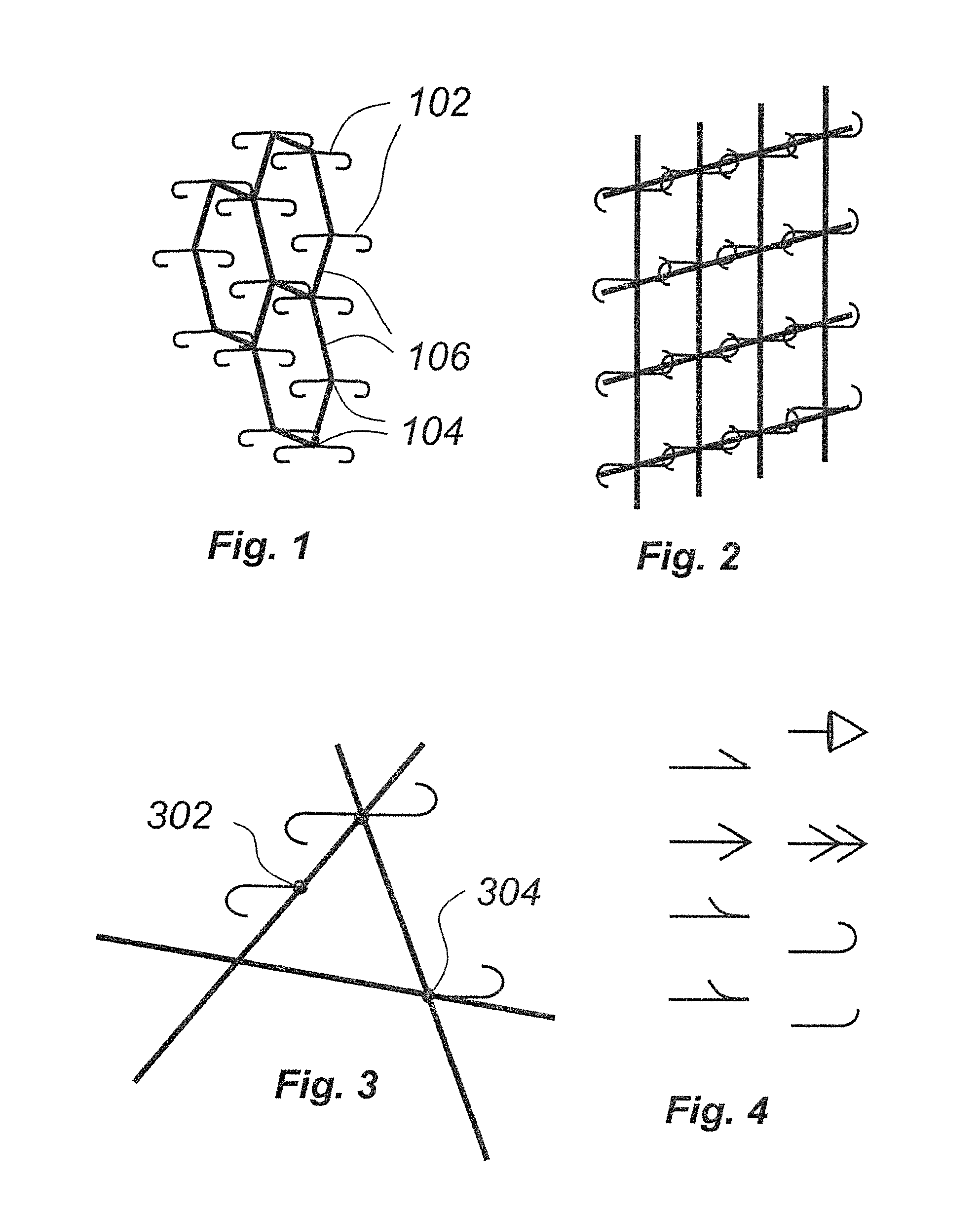

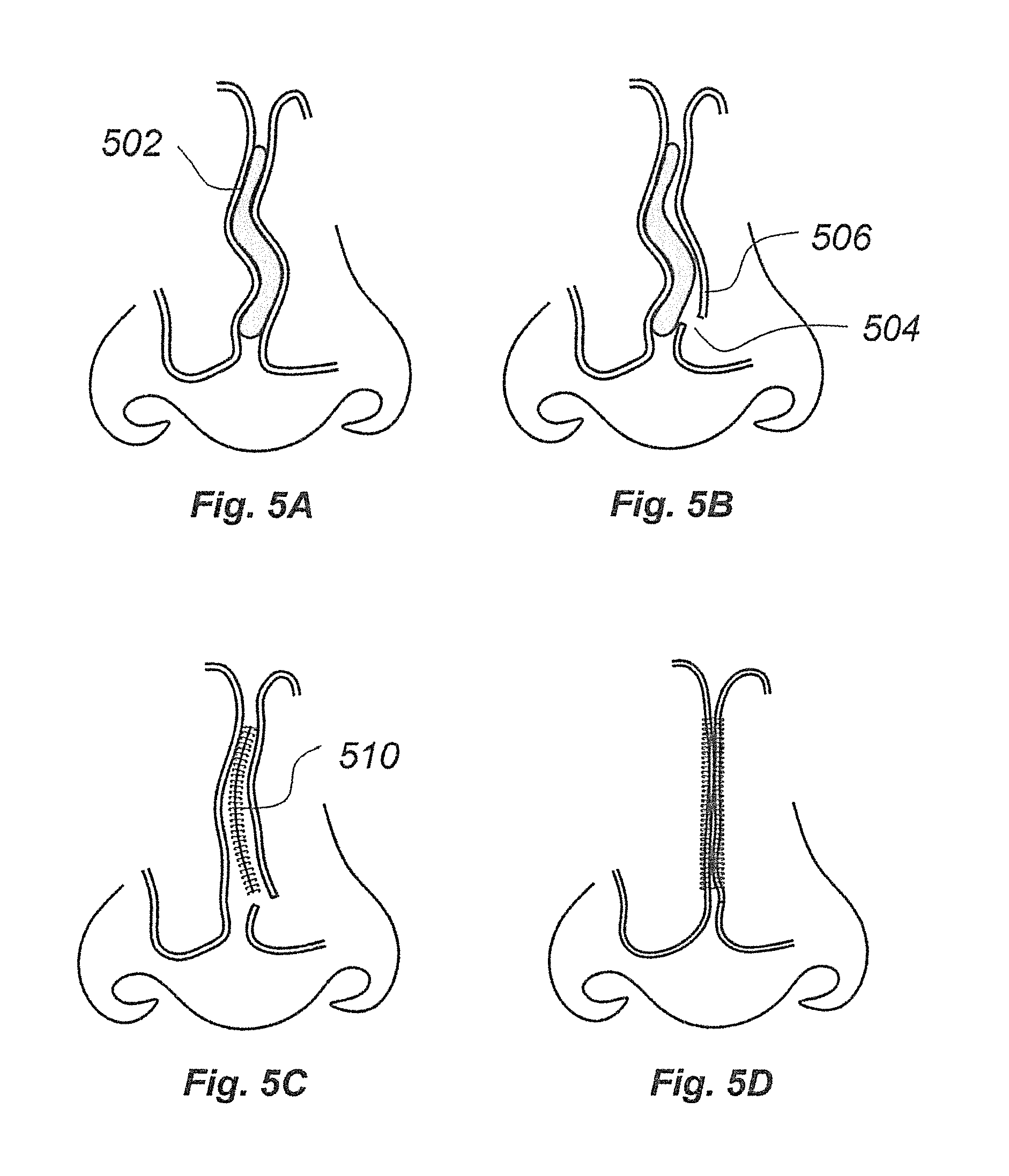

Bioresorbable septoplasty closure implant

InactiveUS20160287367A1Minimal dimensionNose implantsCosmetic implantsBiomedical engineeringSeptoplasty

A bioresorbable implant and associated method for use in conjunction with septoplasty procedure comprises a thin, at least partially flexible mesh sheet constructed with struts of material intersecting at points defining openings entirely through the mesh sheet, and wherein the sheet defines a plane with opposing side surfaces. A plurality of projections extend away from the sheet on both side surfaces thereof. The openings through the mesh sheet have minimum dimensions in the range of 2 to 8 mm, and the projections have a length in the range of 1 to 5 mm. The openings in the mesh sheet may define regular polygons, whereby the struts may have minimum dimensions in the range of 2 to 8 mm. The projections may extend from the intersections of the struts, directly from the struts, or both from the intersections and the struts. A method of performing septoplasty in accordance with the invention is also disclosed.

Owner:RONTAL DANIEL A

Oscillating piston machine

InactiveUS7563086B2Reduce frictionMore compactOscillating piston pumpsInternal combustion piston enginesEngineeringPiston

Owner:HUTTLIN HERBERT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com