Patents

Literature

57 results about "Differential heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Differential heat of solution. The partial derivative of the total heat of solution with respect to the molal concentration of one component of the solution, when the concentration of the other component or components, the pressure, and the temperature are held constant.

Deposition sensor based on differential heat flux measurement

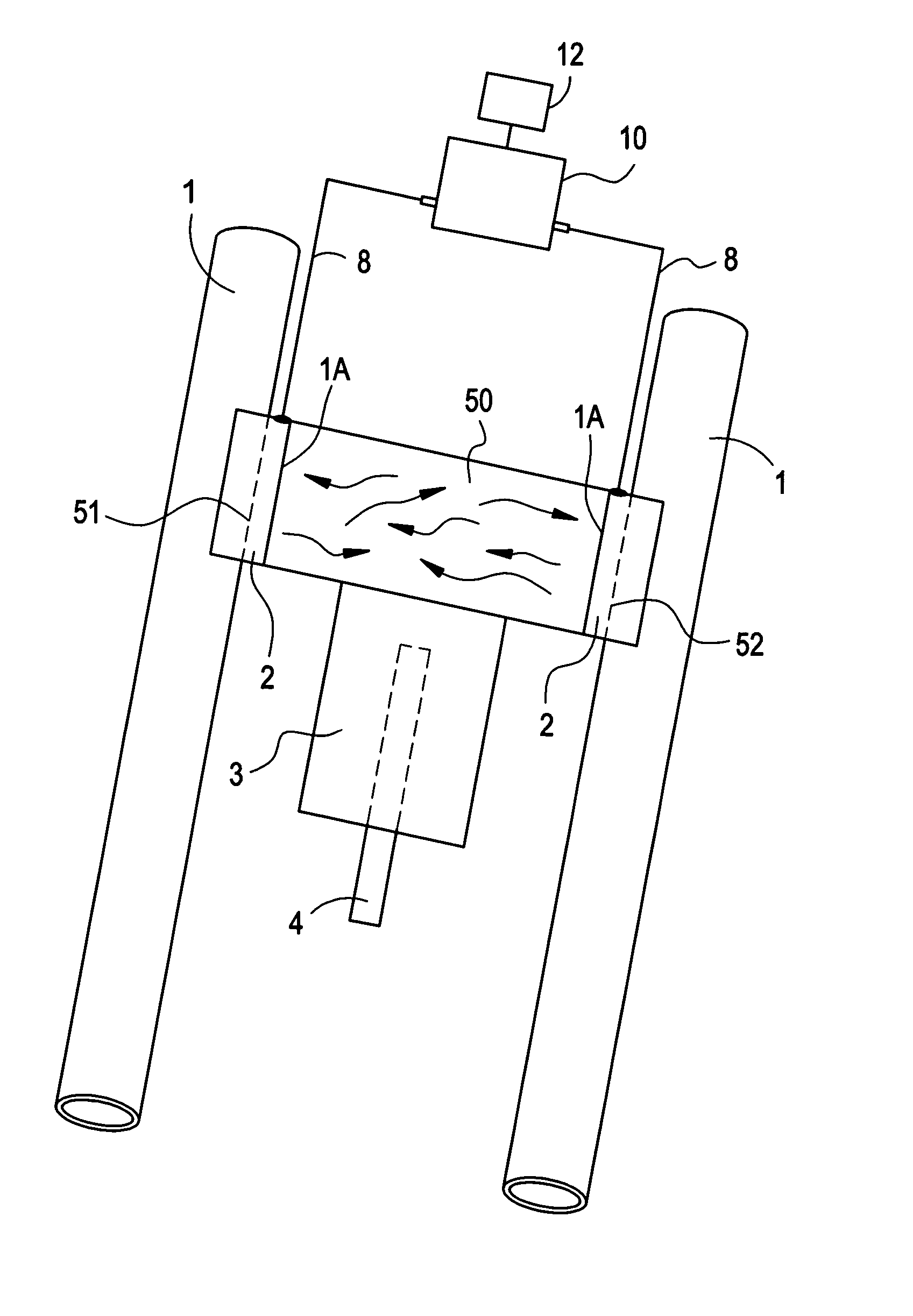

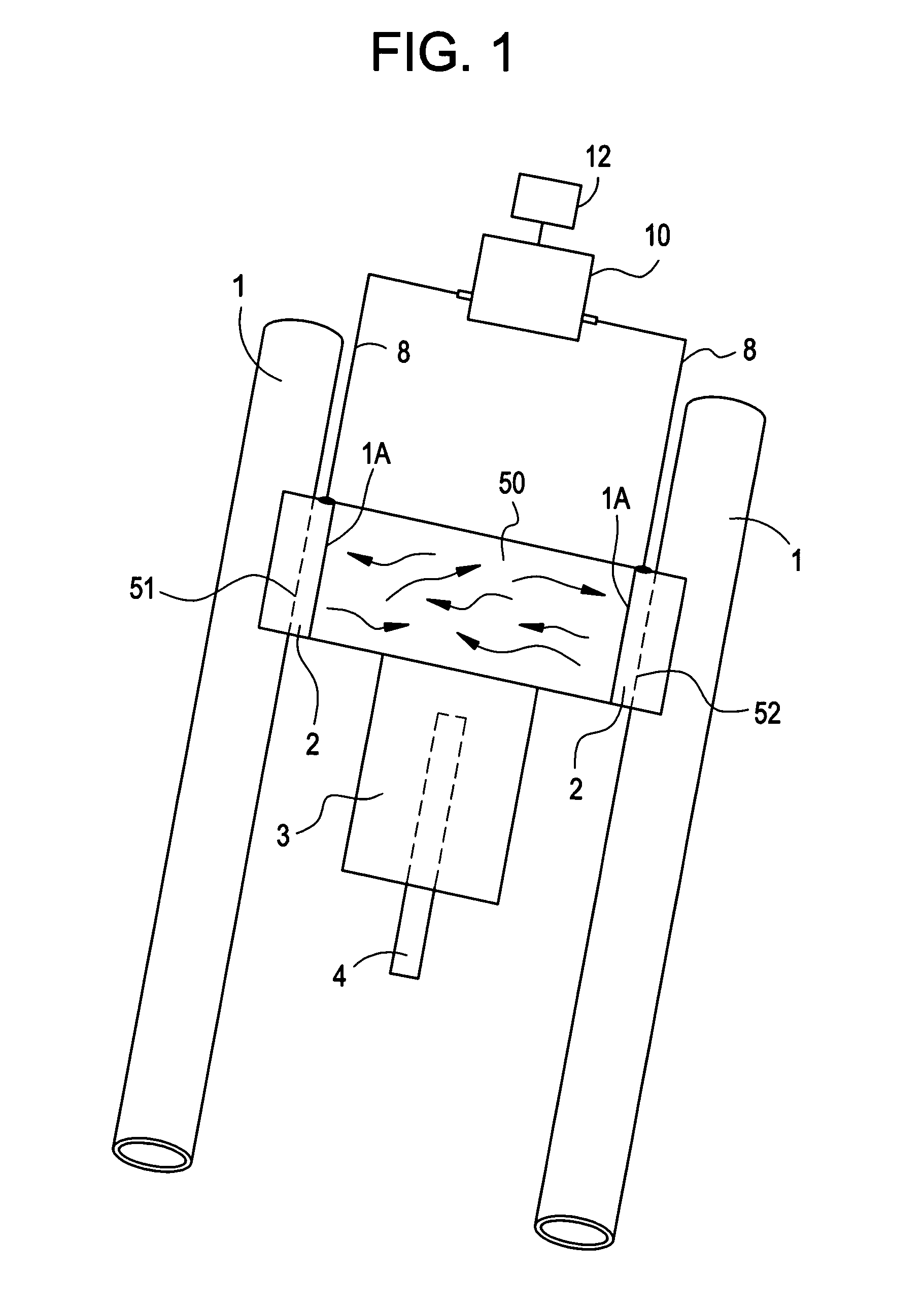

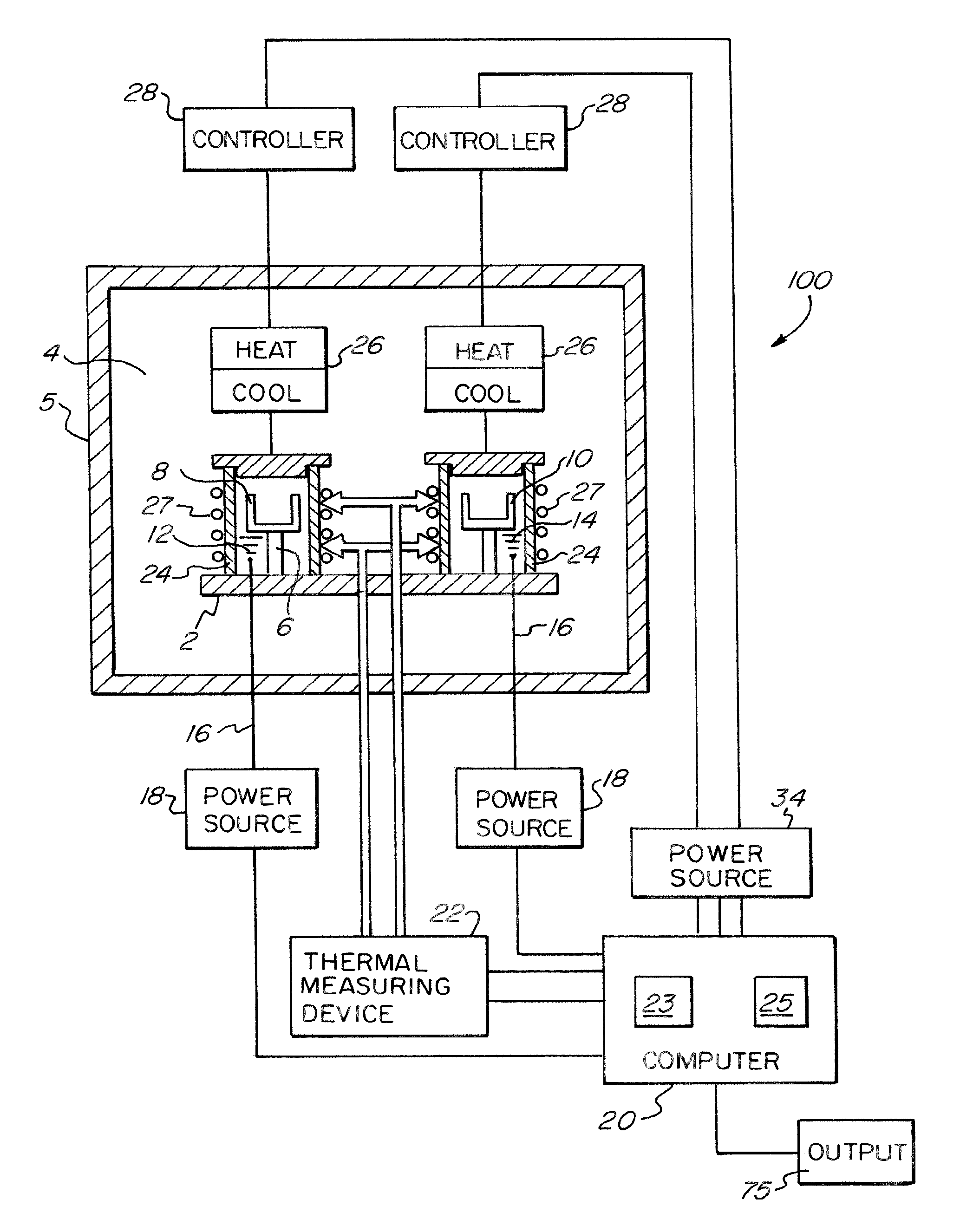

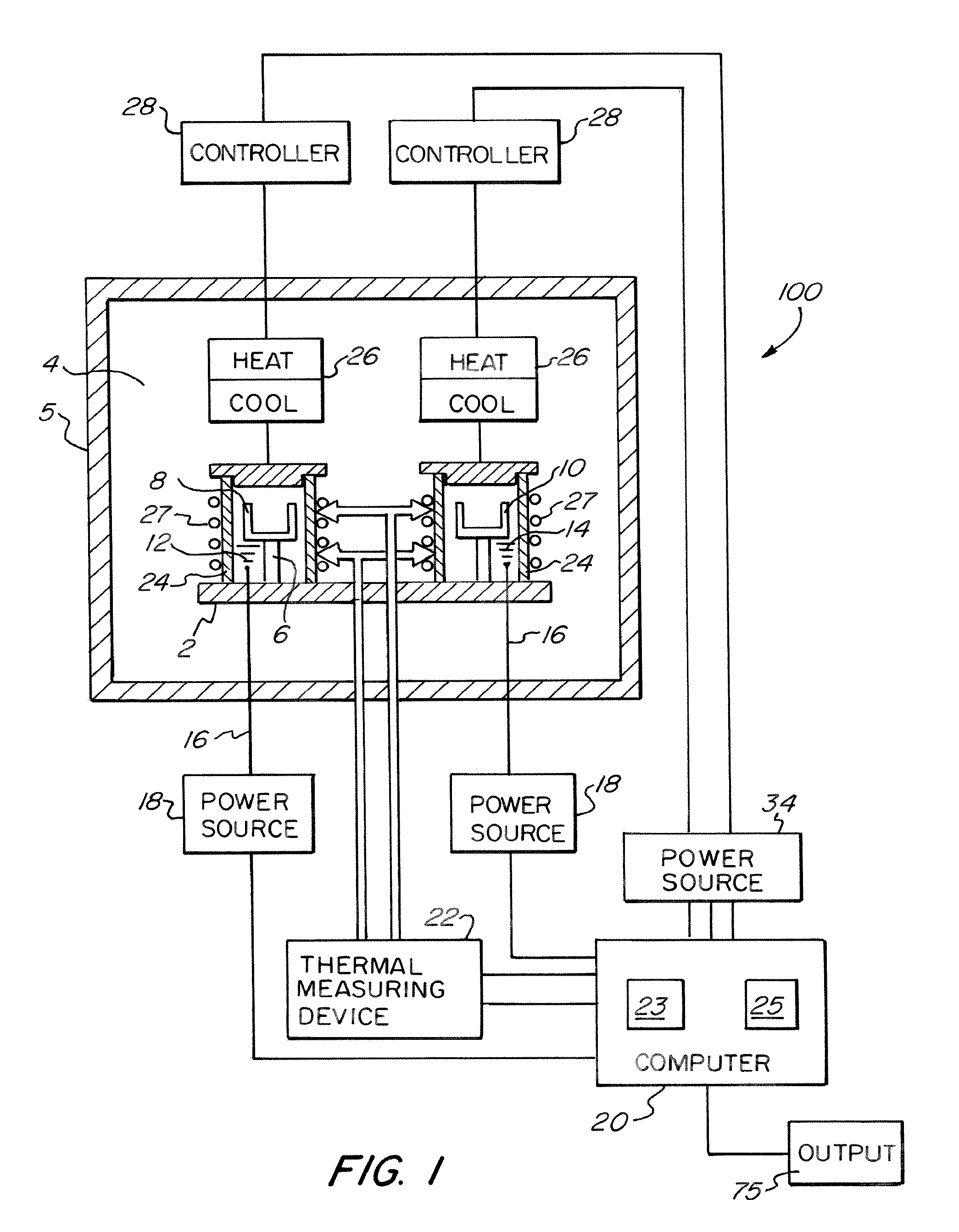

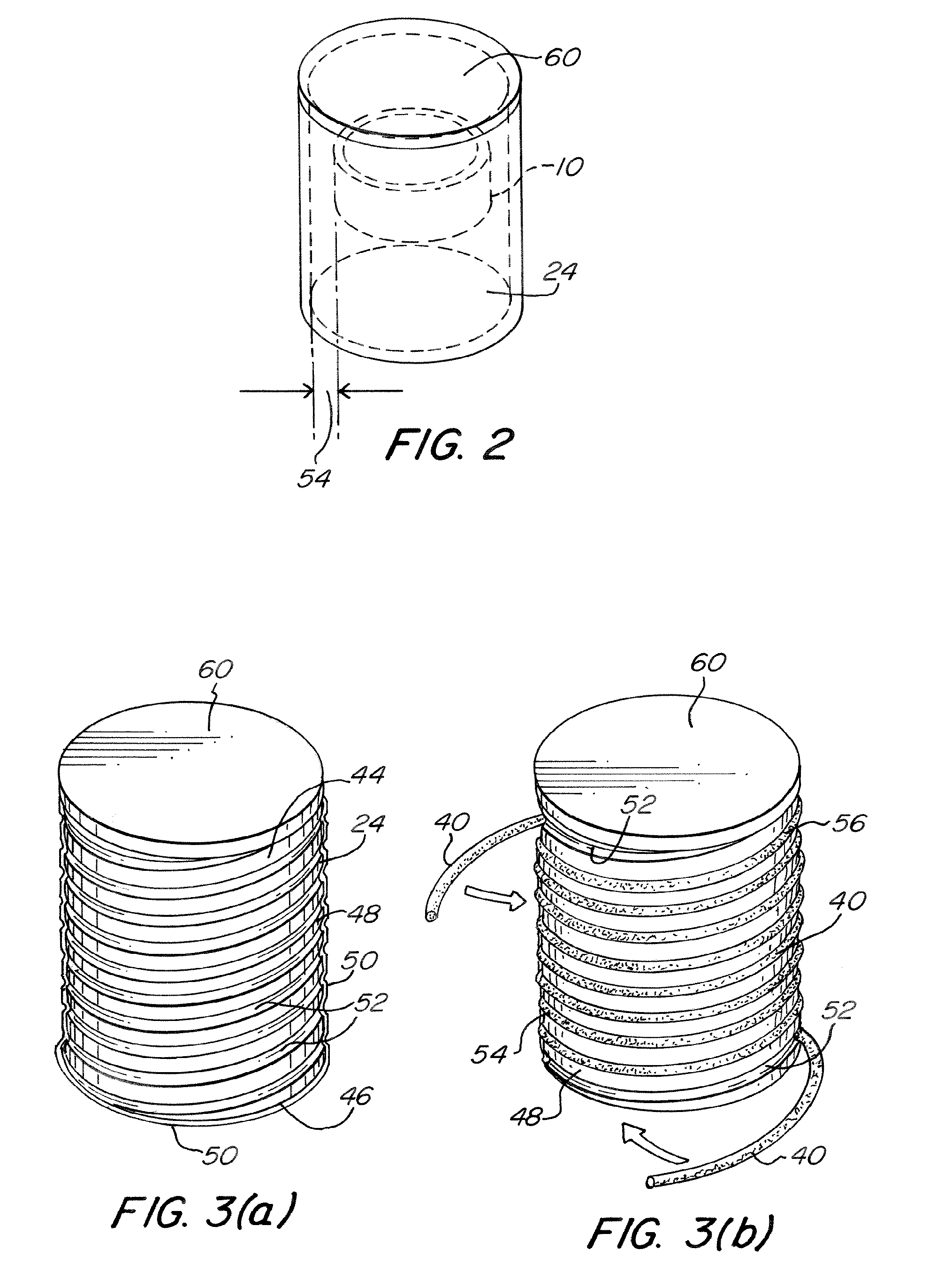

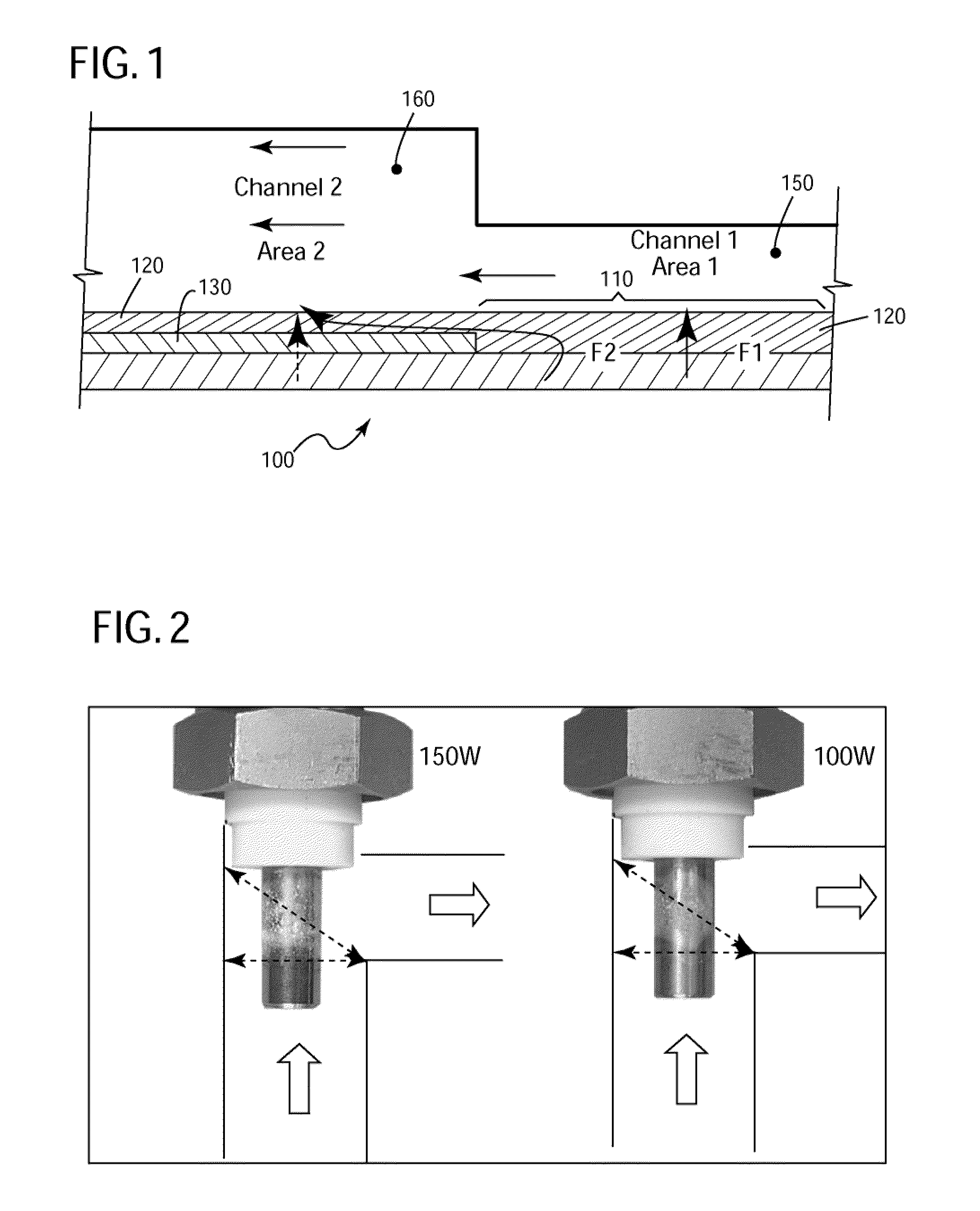

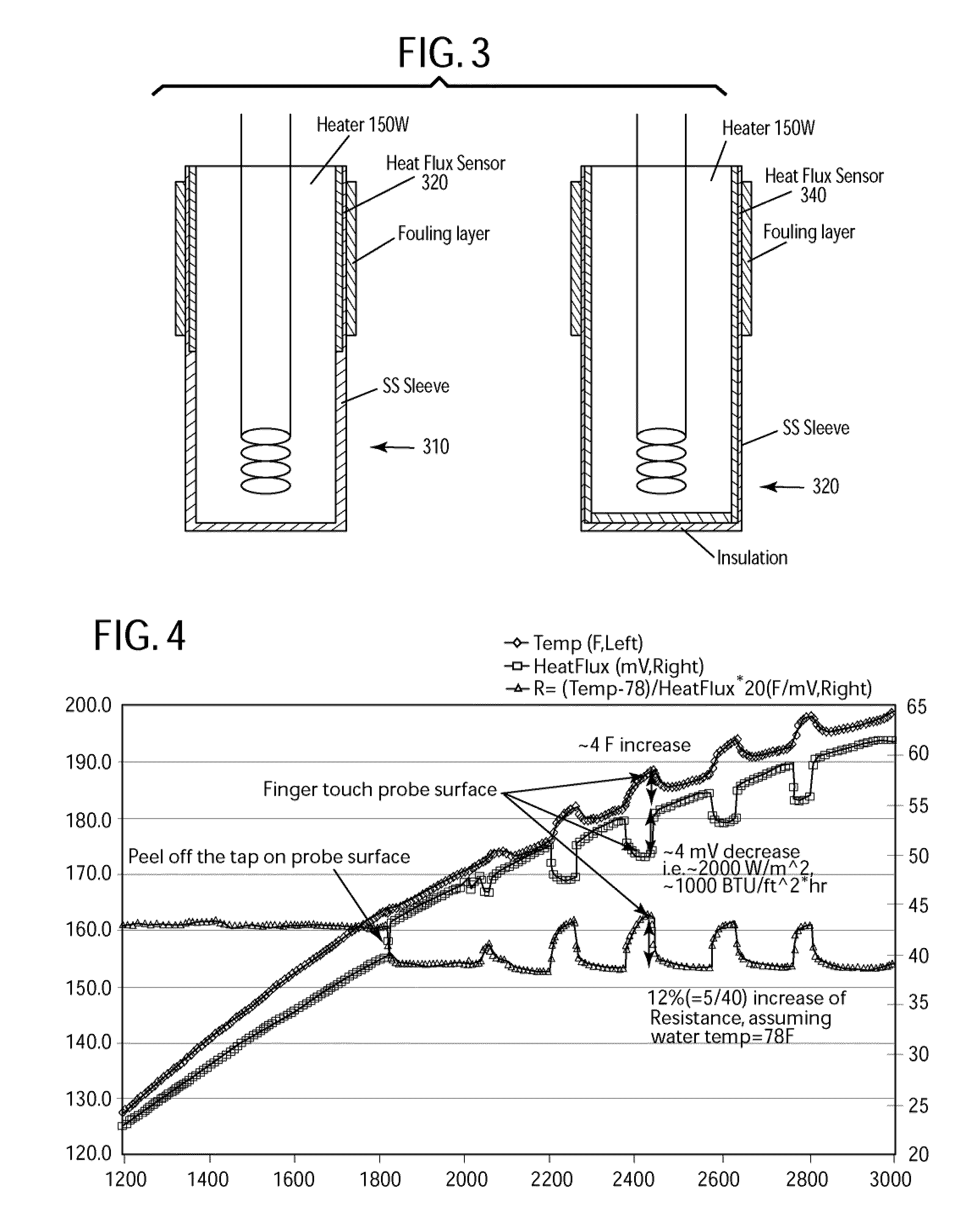

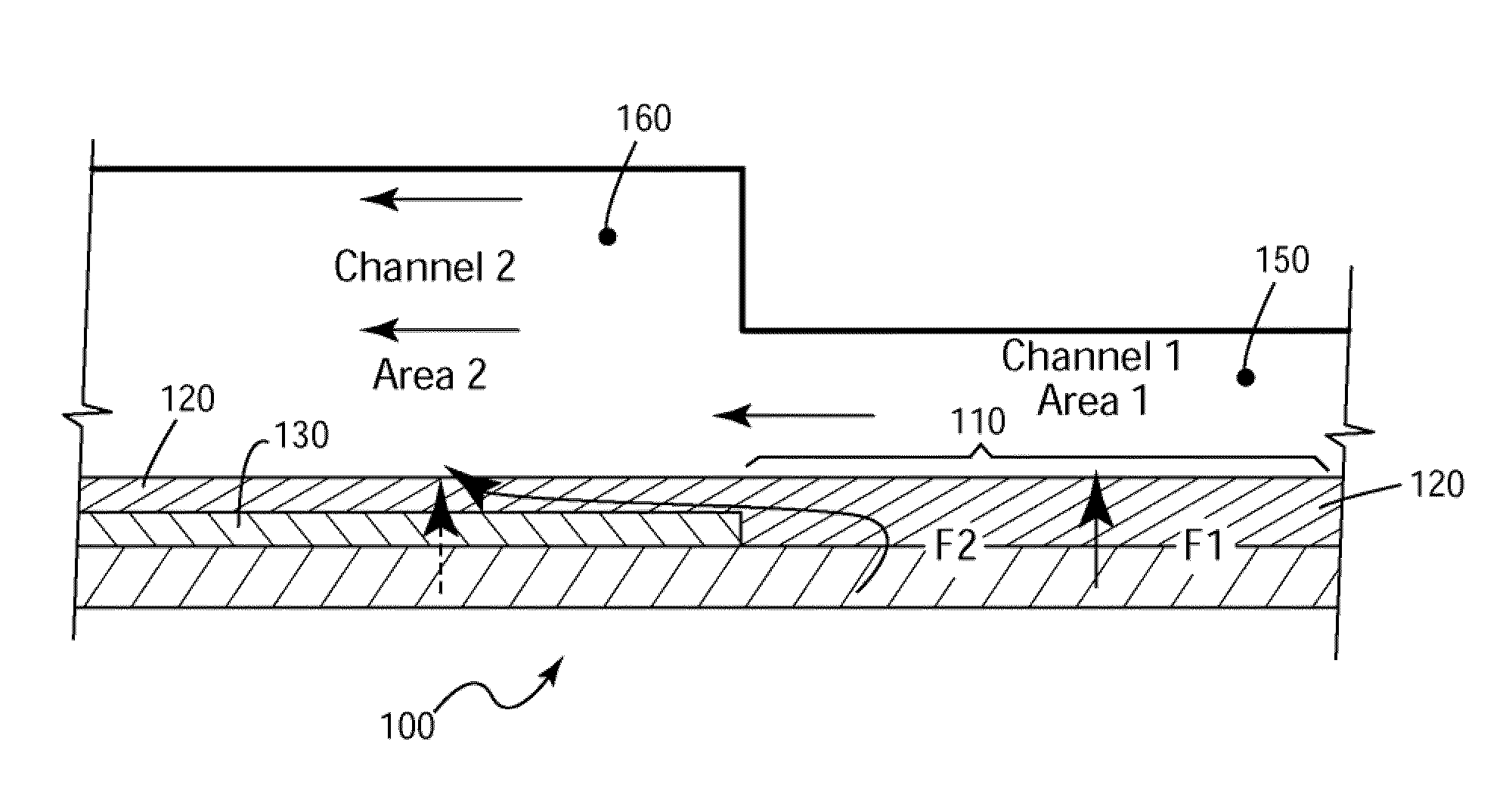

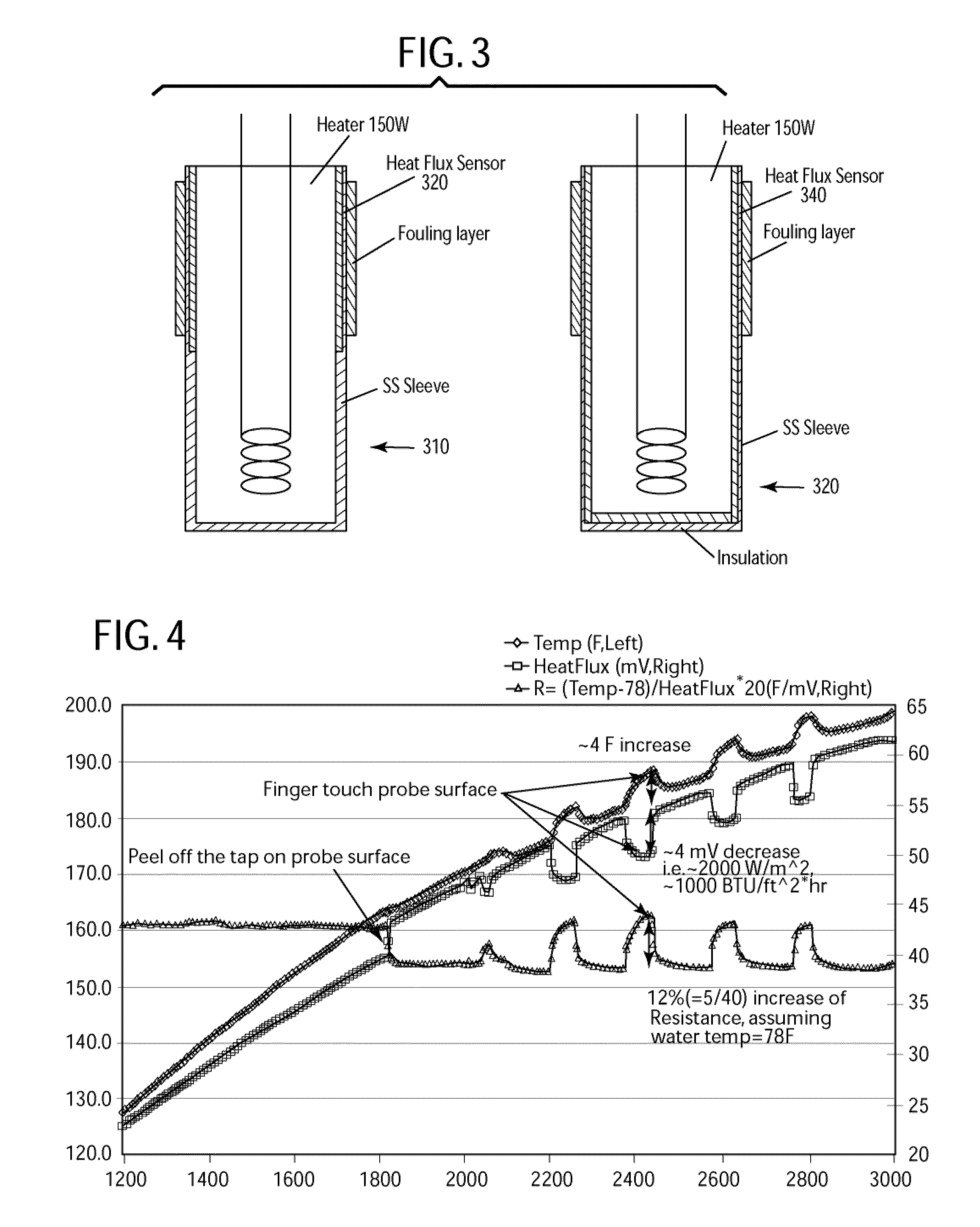

An apparatus and method for the monitoring and measurement of chemical and / or biological deposition in heat exchangers and other fluid processing vessels. The new and original sensing system includes at least two hollow fluid vessels conductively mounted across a constant heat transfer path. Thin film heat flux sensors are attached to a heat transfer surface of the vessels in order to measure changes in differential heat flux that occur when deposition begins to accumulate in the vessel. In this way, it is shown that differential heat flux measurements can be used to detect and measure the early onset of chemical and / or biological deposition.

Owner:BL TECH INC

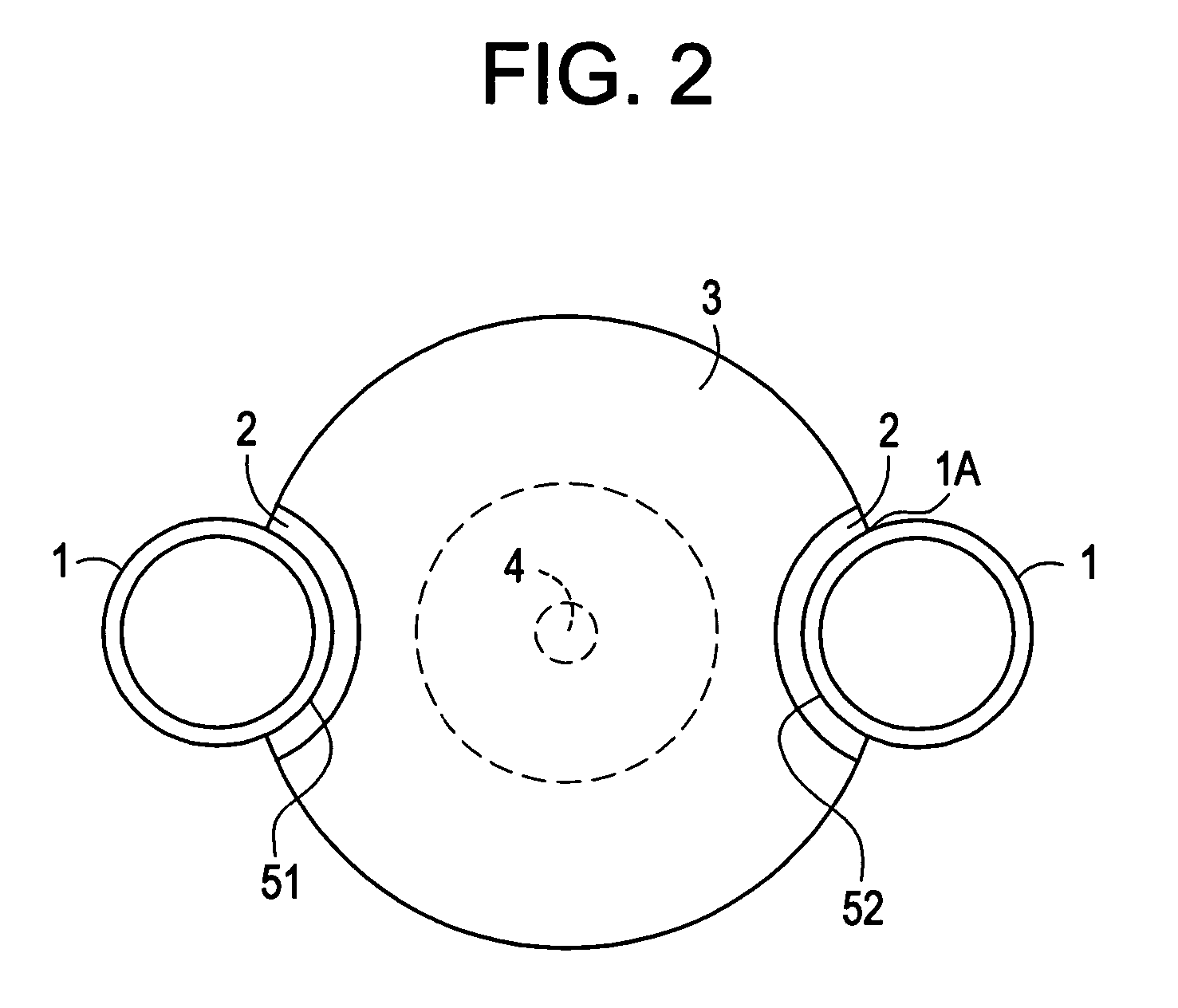

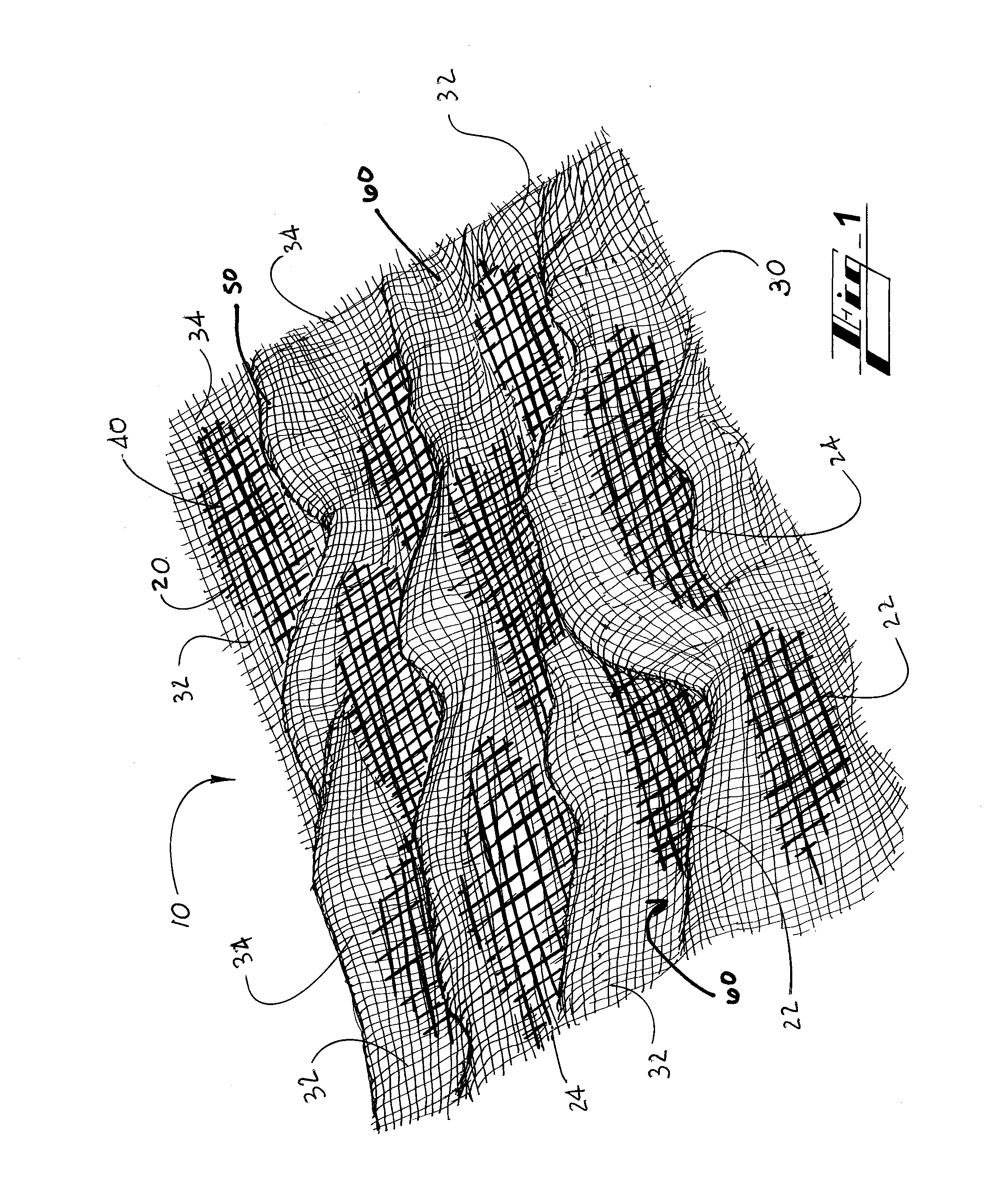

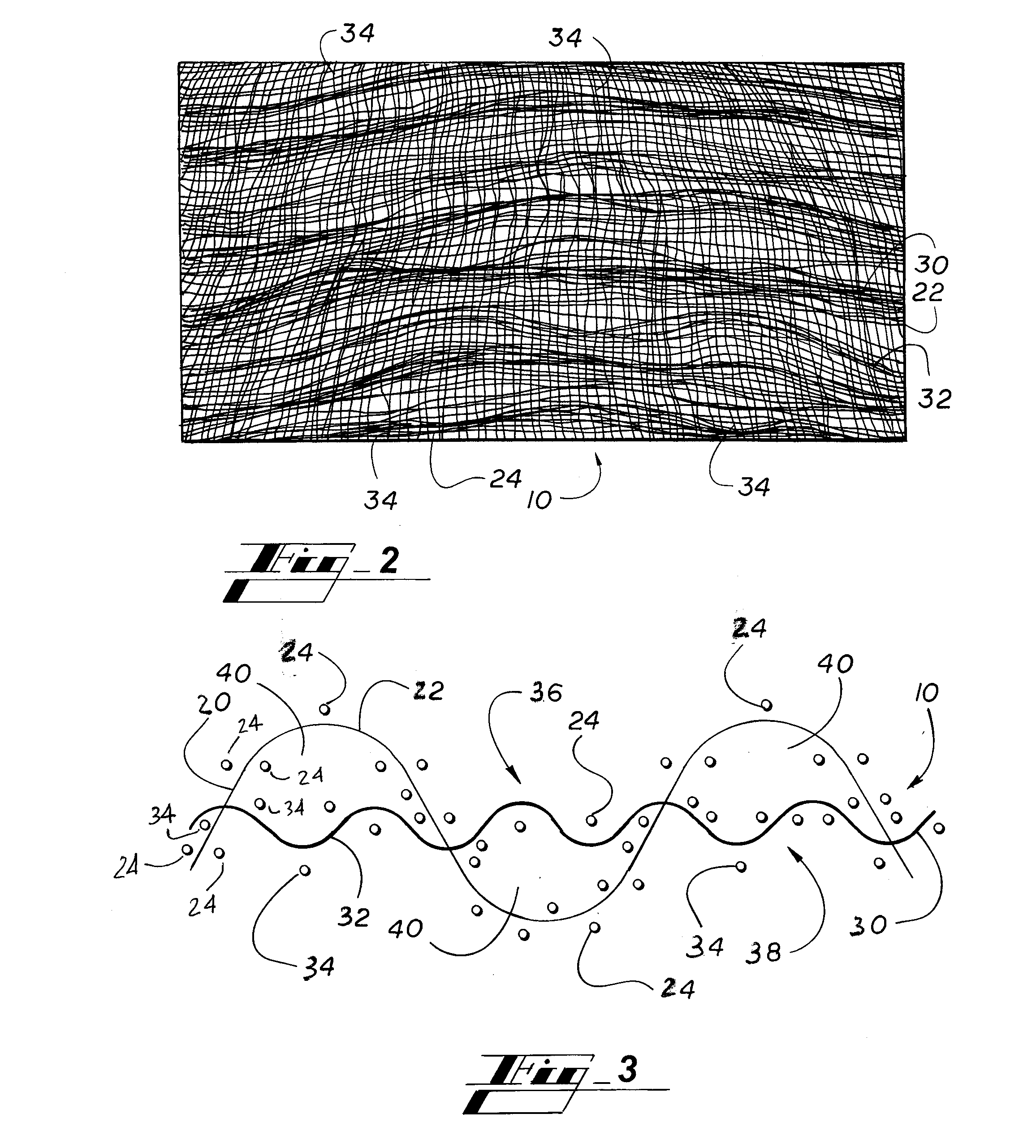

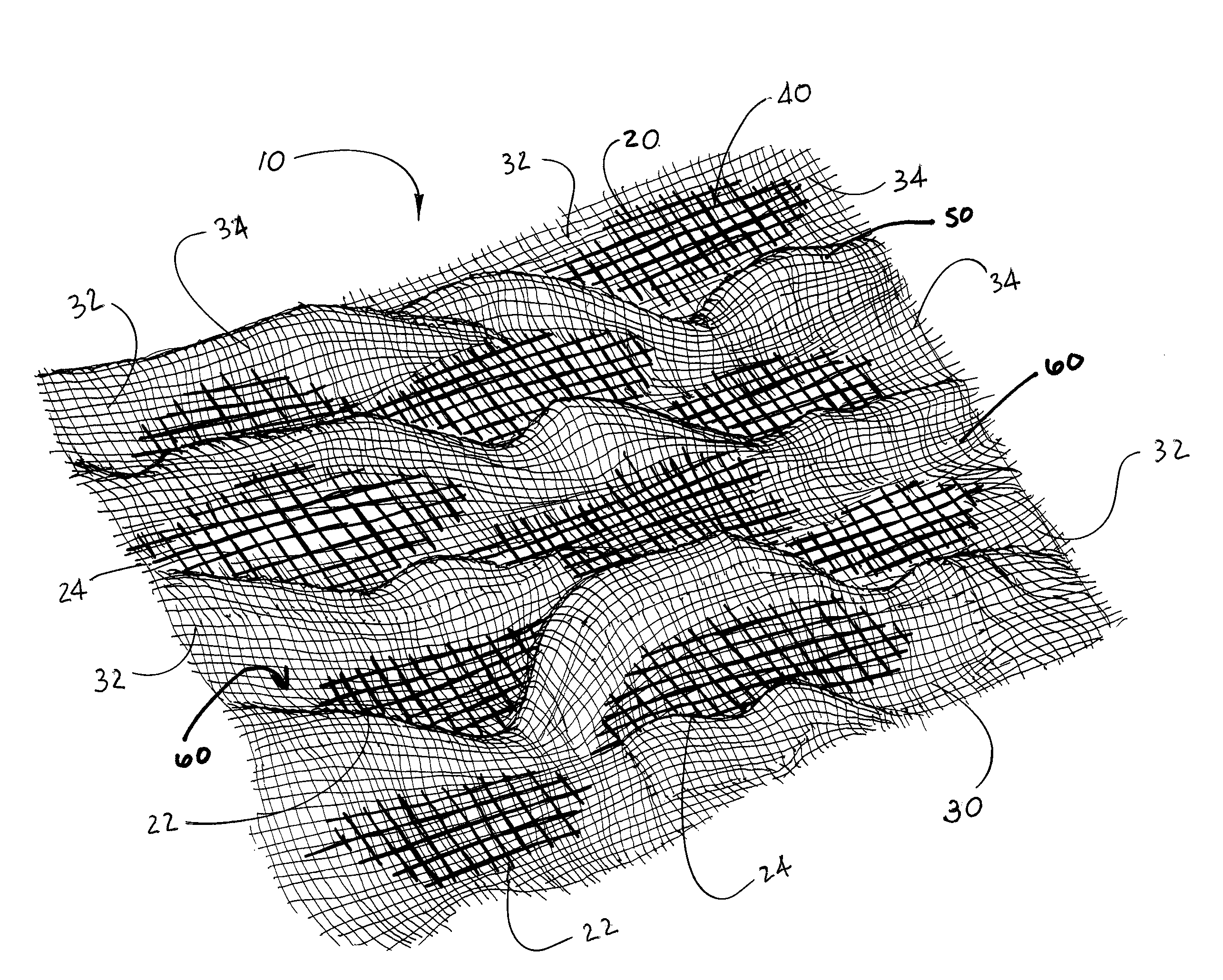

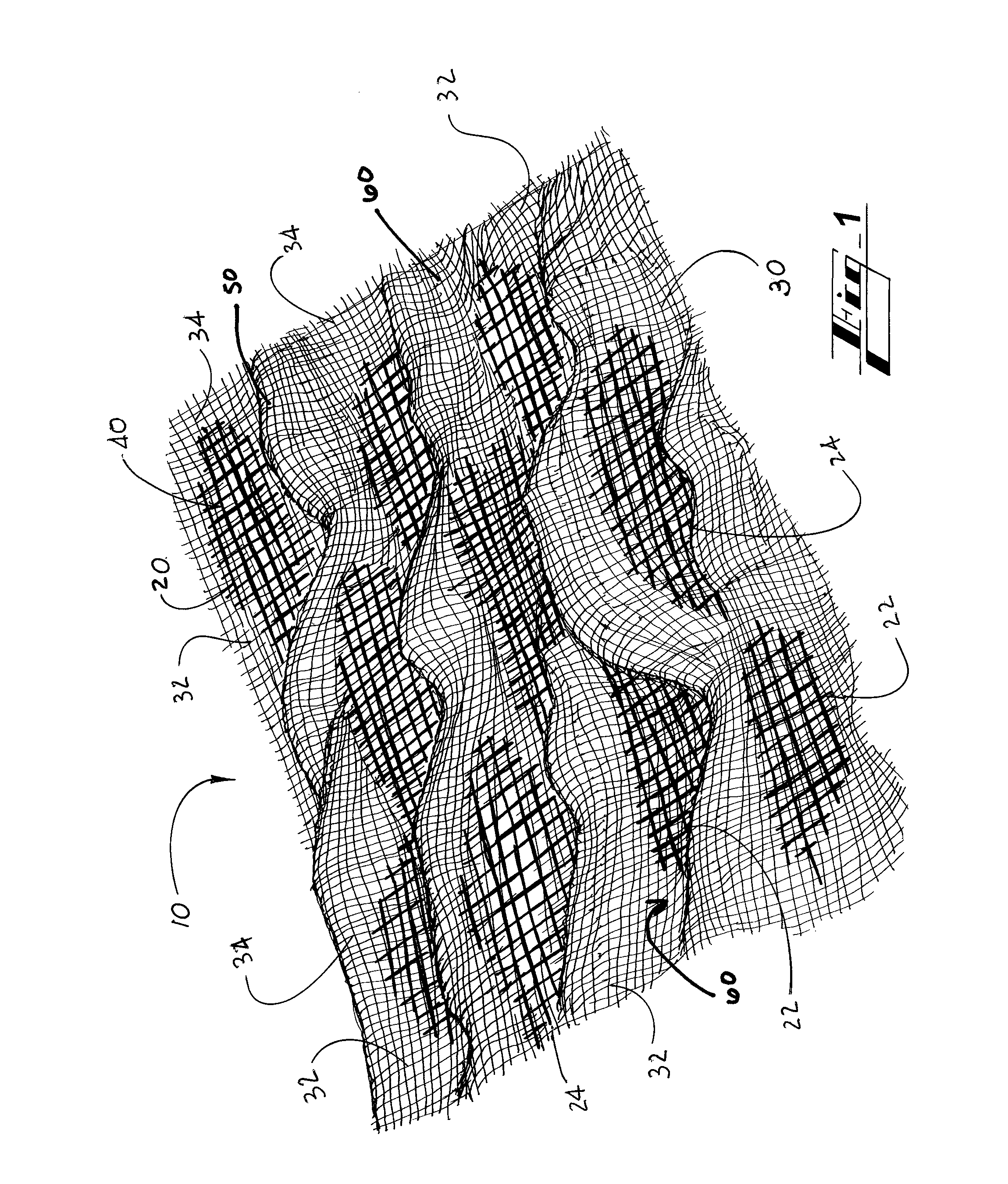

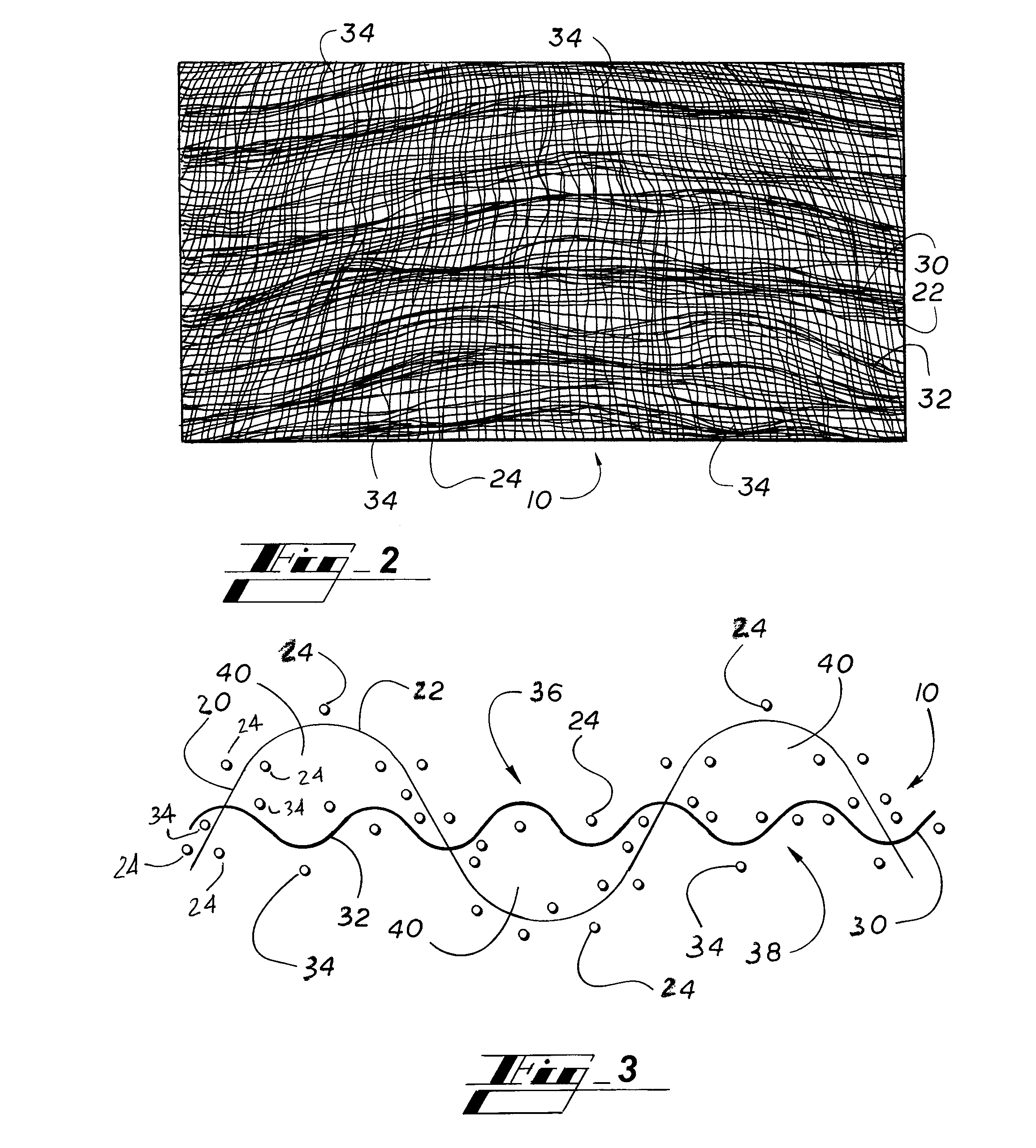

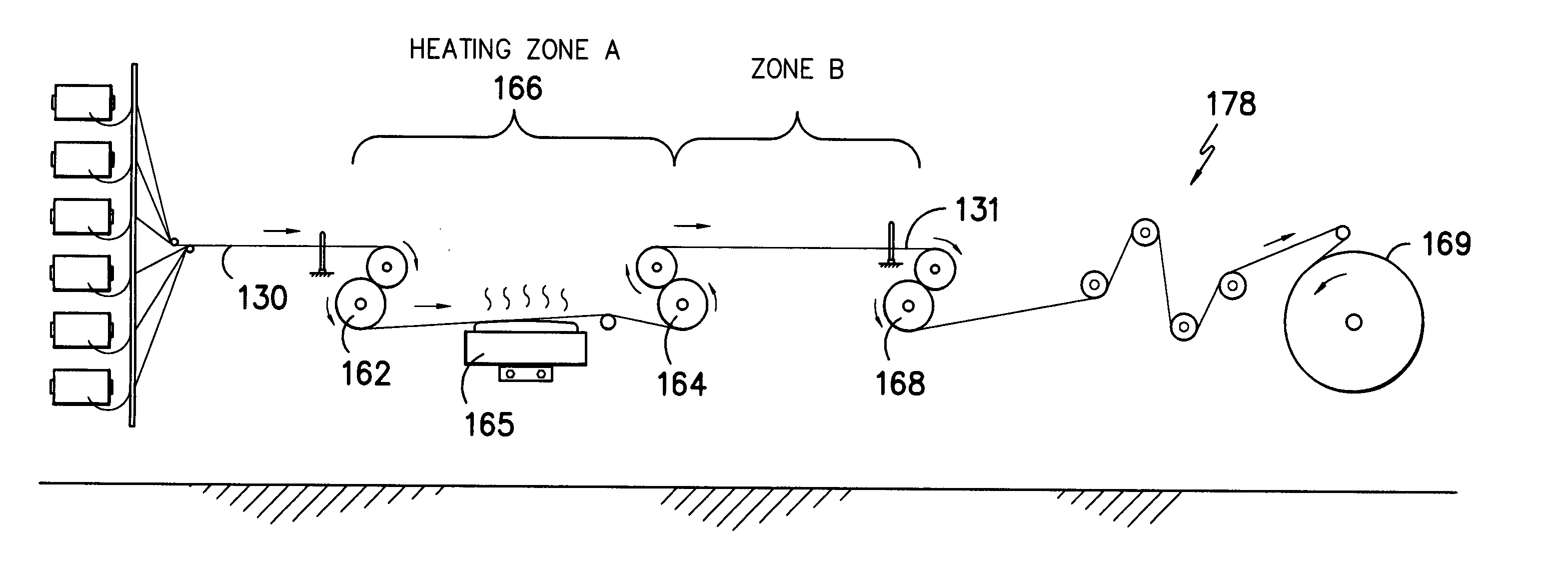

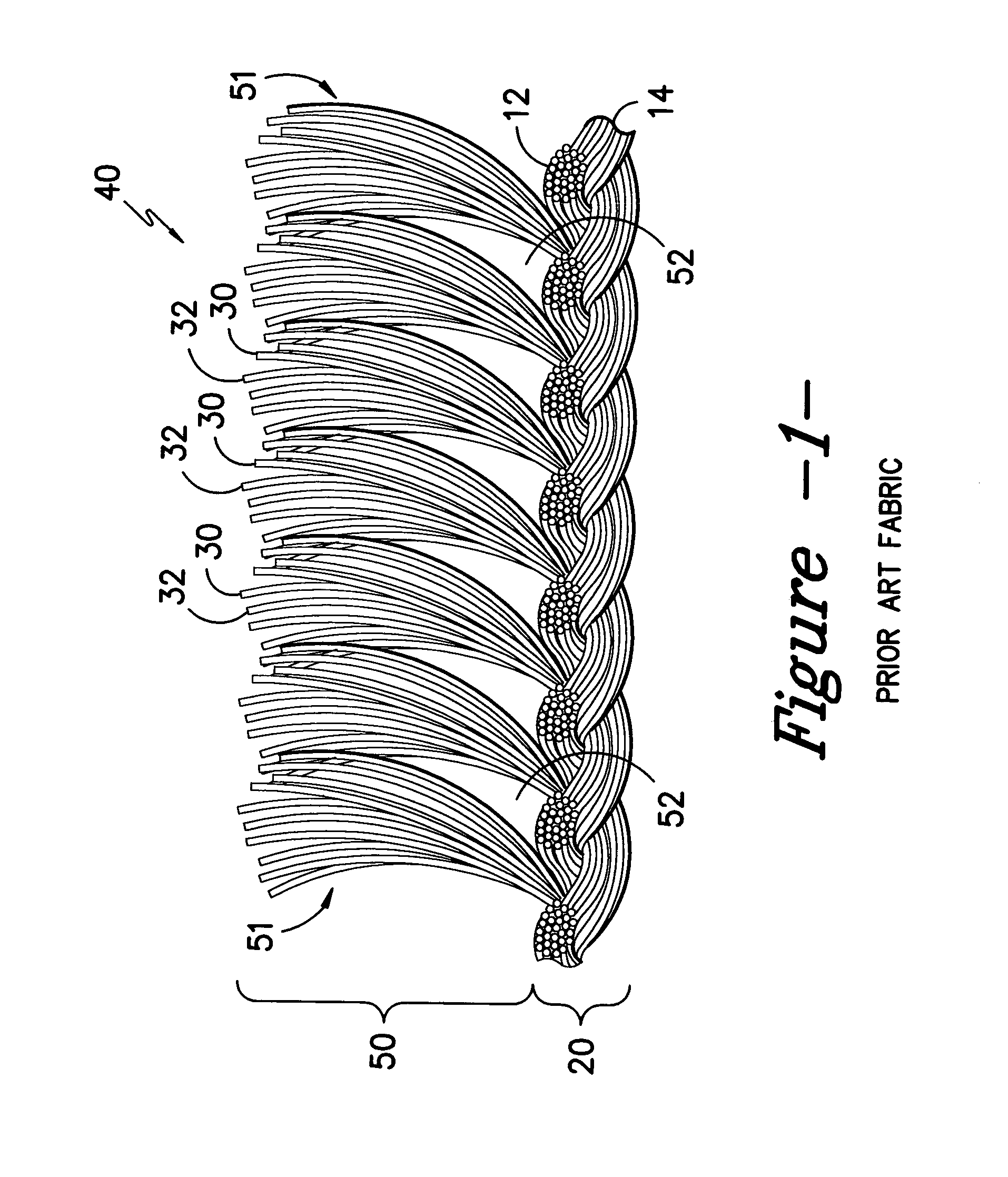

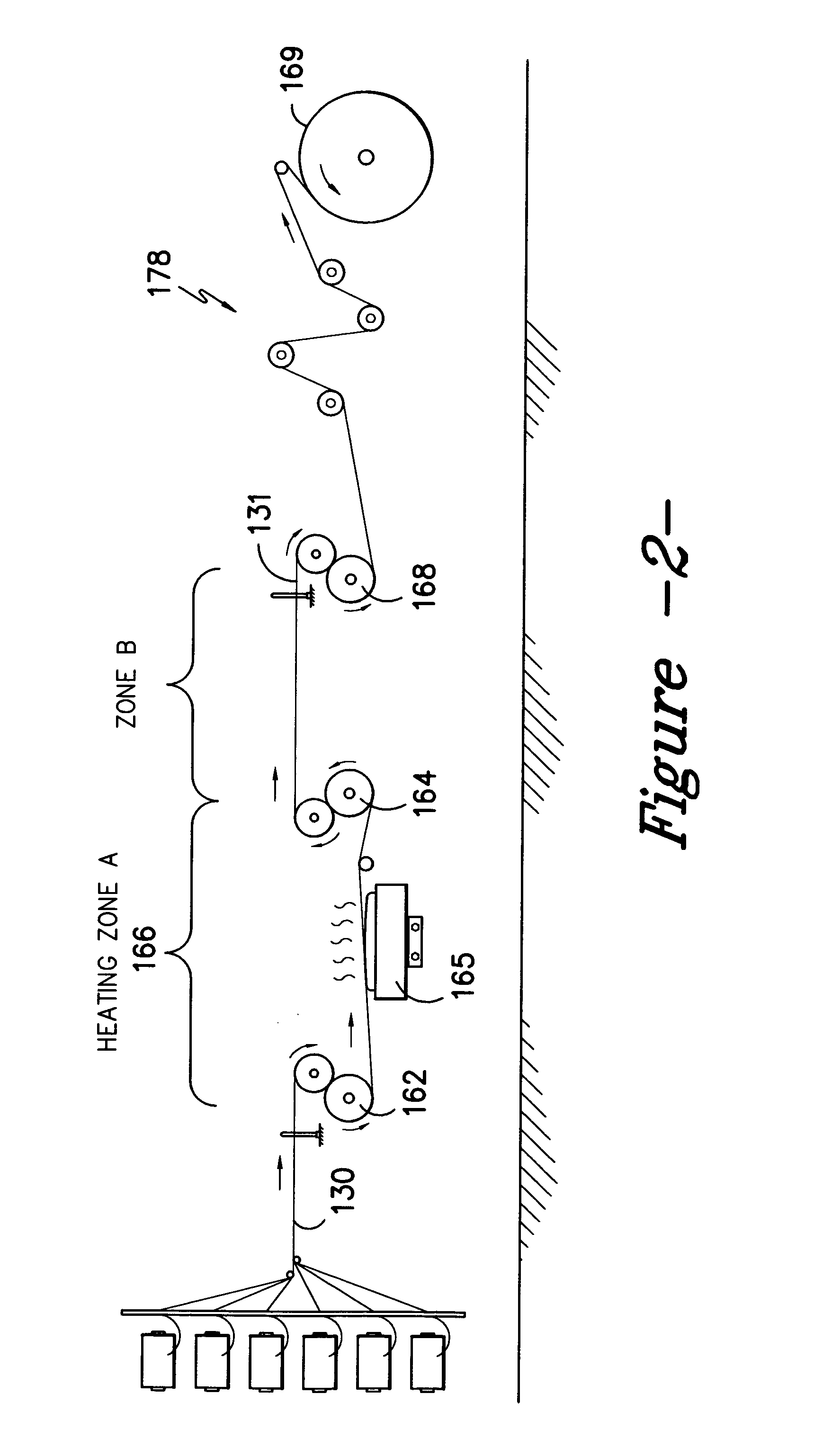

Turf reinforcement erosion control mat

A bi-layer, woven geotextile fabric has interwoven first and second layers. The first layer is over and under woven through the second layer in a pre-determined pattern so that the first layer has portions which face a first side of the second layer and portions which face a second side of the second layer. Monofilaments in the warp direction of the first layer have a pre-determined differential heat shrinkage characteristic that is greater than the monofilaments in the warp direction of the second layer. Closed cells defined by the pattern of the over and under weave are disposed on the first and second sides of the second layer. Shrinkage of the monofilaments in the warp direction of the first layer provide for a separation of a portion of the second layer from the first layer at the cells.

Owner:NICOLON CORP

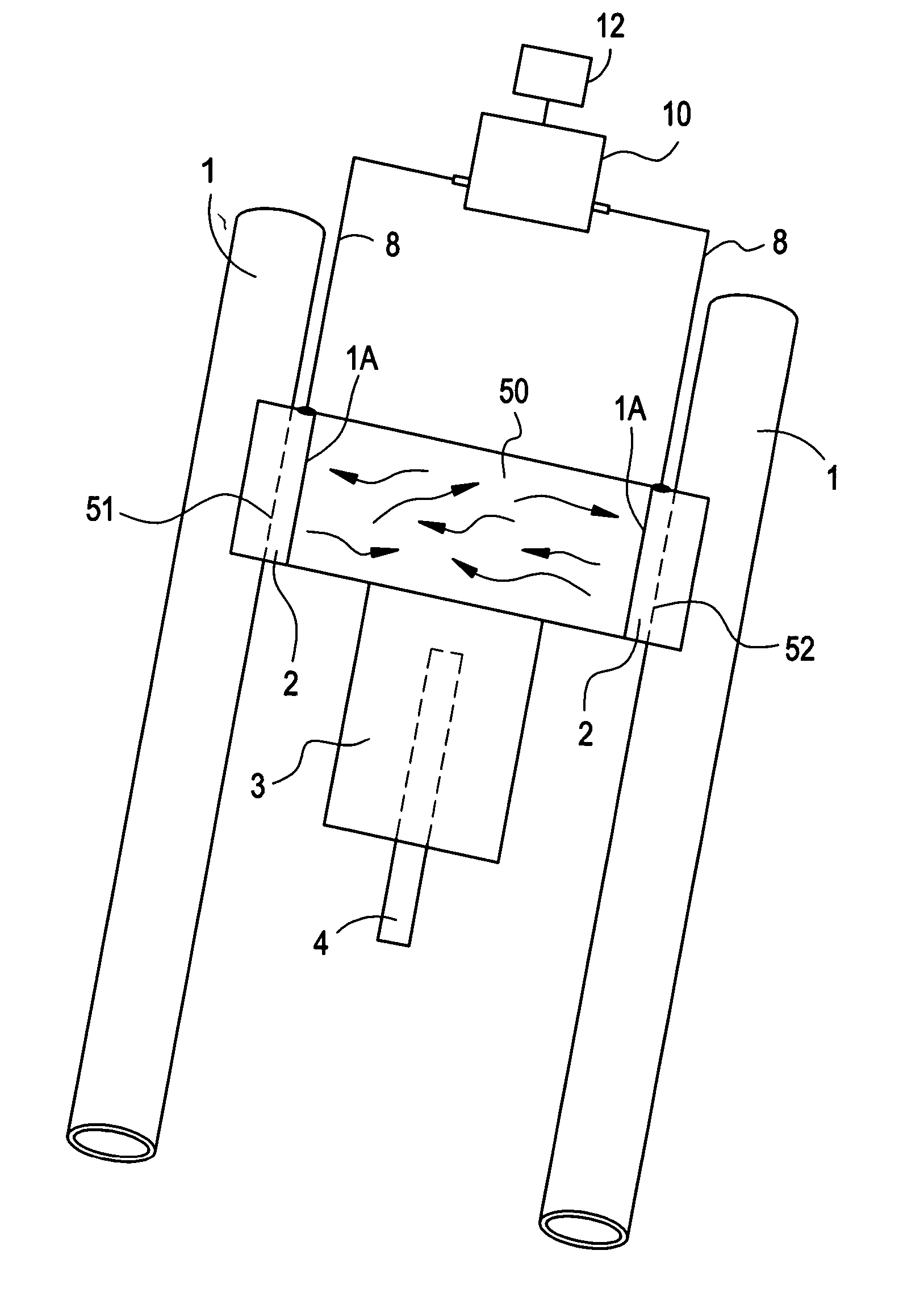

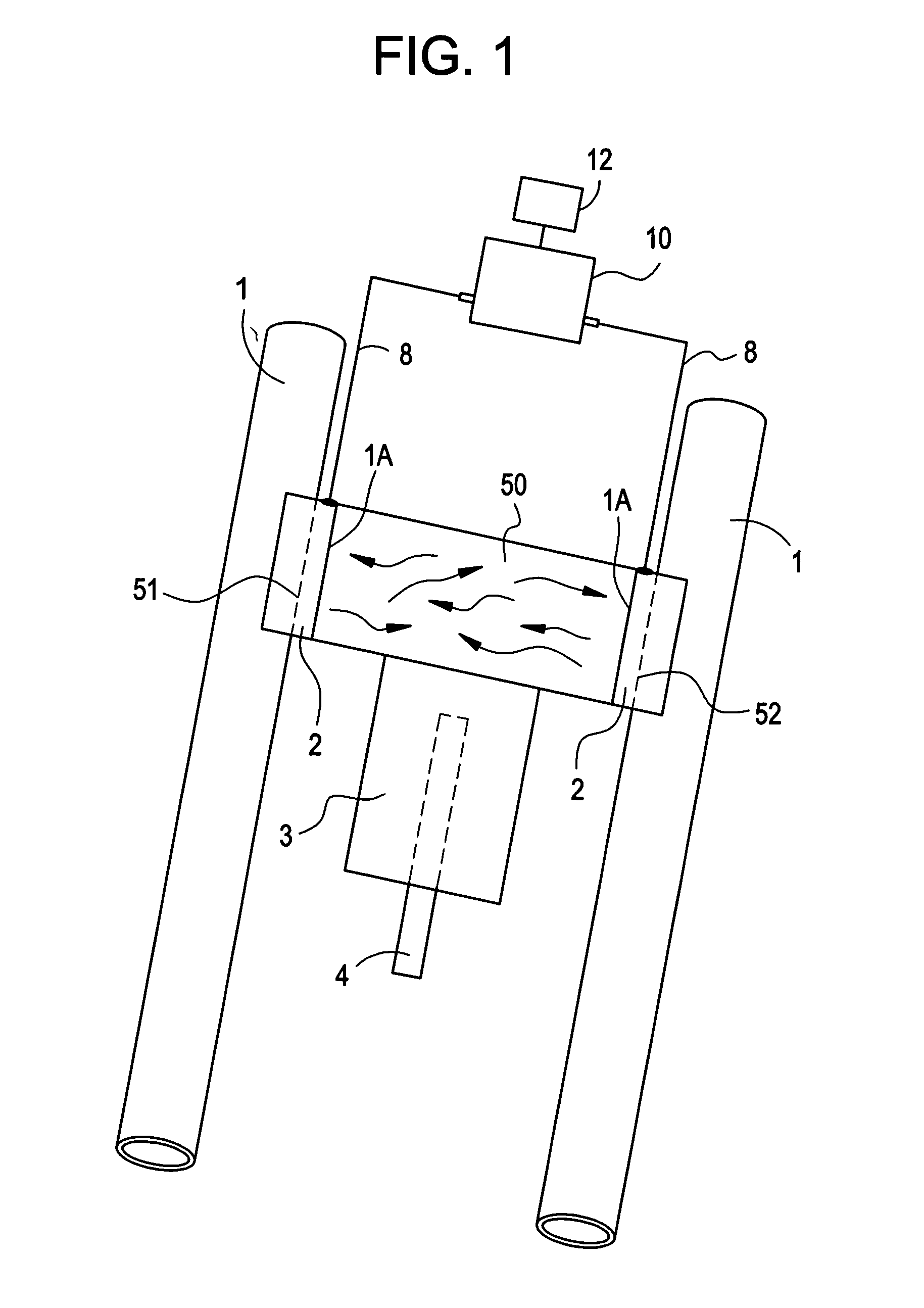

Deposition sensor based on differential heat flux measurement

ActiveUS20050105583A1Thermometer detailsMaterial thermal conductivityEarly onsetCompound (substance)

An apparatus and method for the monitoring and measurement of chemical and / or biological deposition in heat exchangers and other fluid processing vessels. The new and original sensing system includes at least two hollow fluid vessels conductively mounted across a constant heat transfer path. Thin film heat flux sensors are attached to a heat transfer surface of the vessels in order to measure changes in differential heat flux that occur when deposition begins to accumulate in the vessel. In this way, it is shown that differential heat flux measurements can be used to detect and measure the early onset of chemical and / or biological deposition.

Owner:BL TECH INC

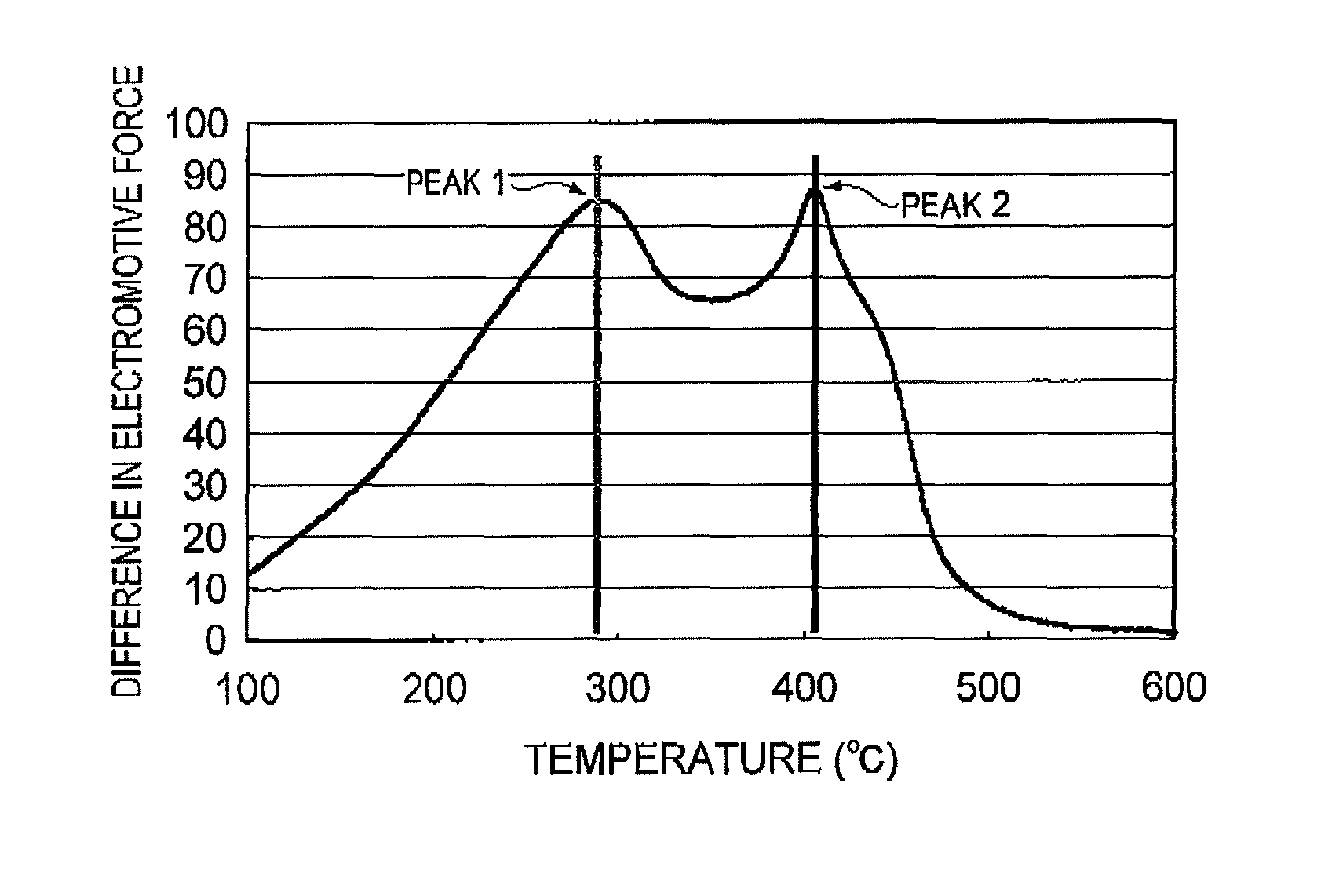

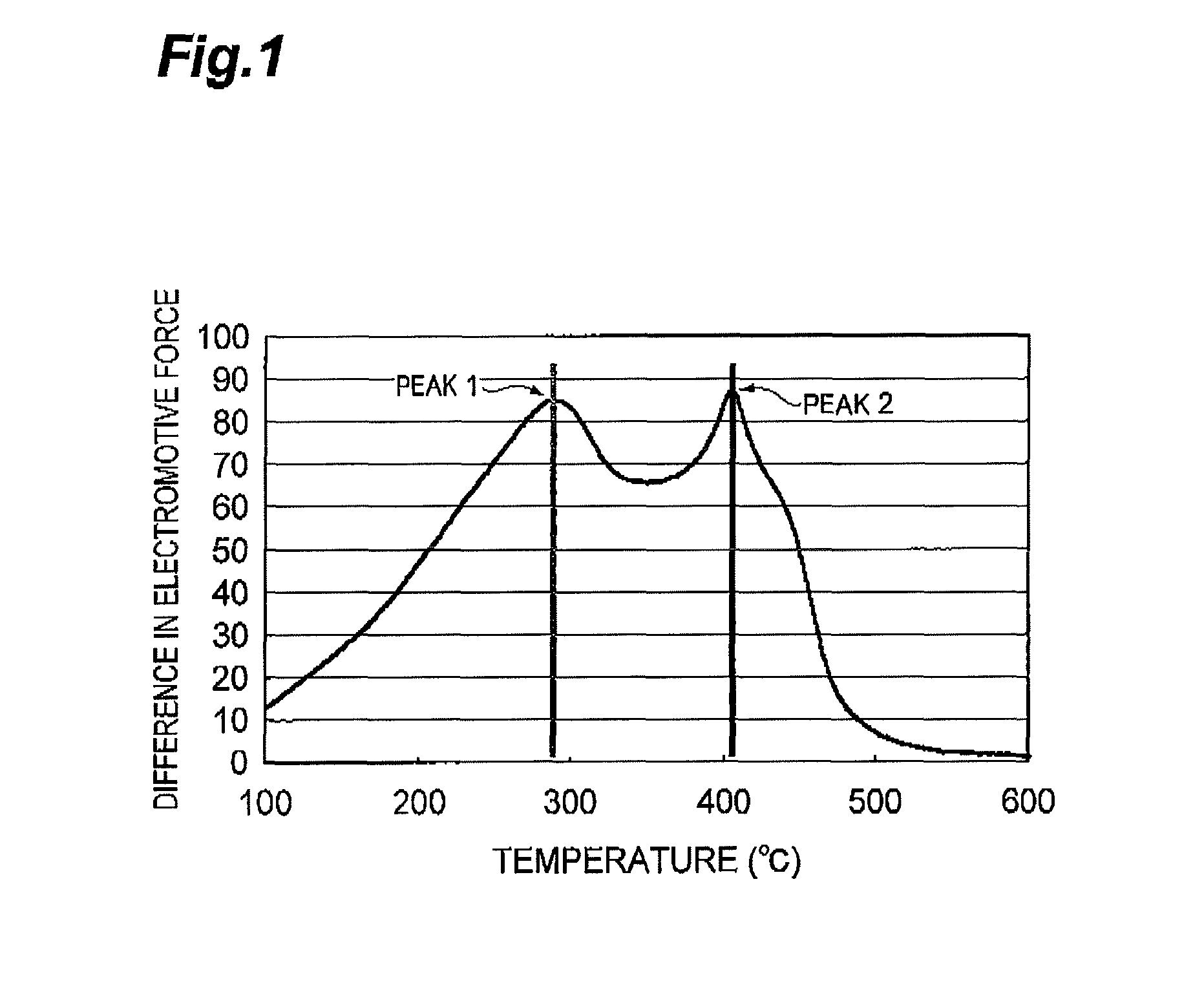

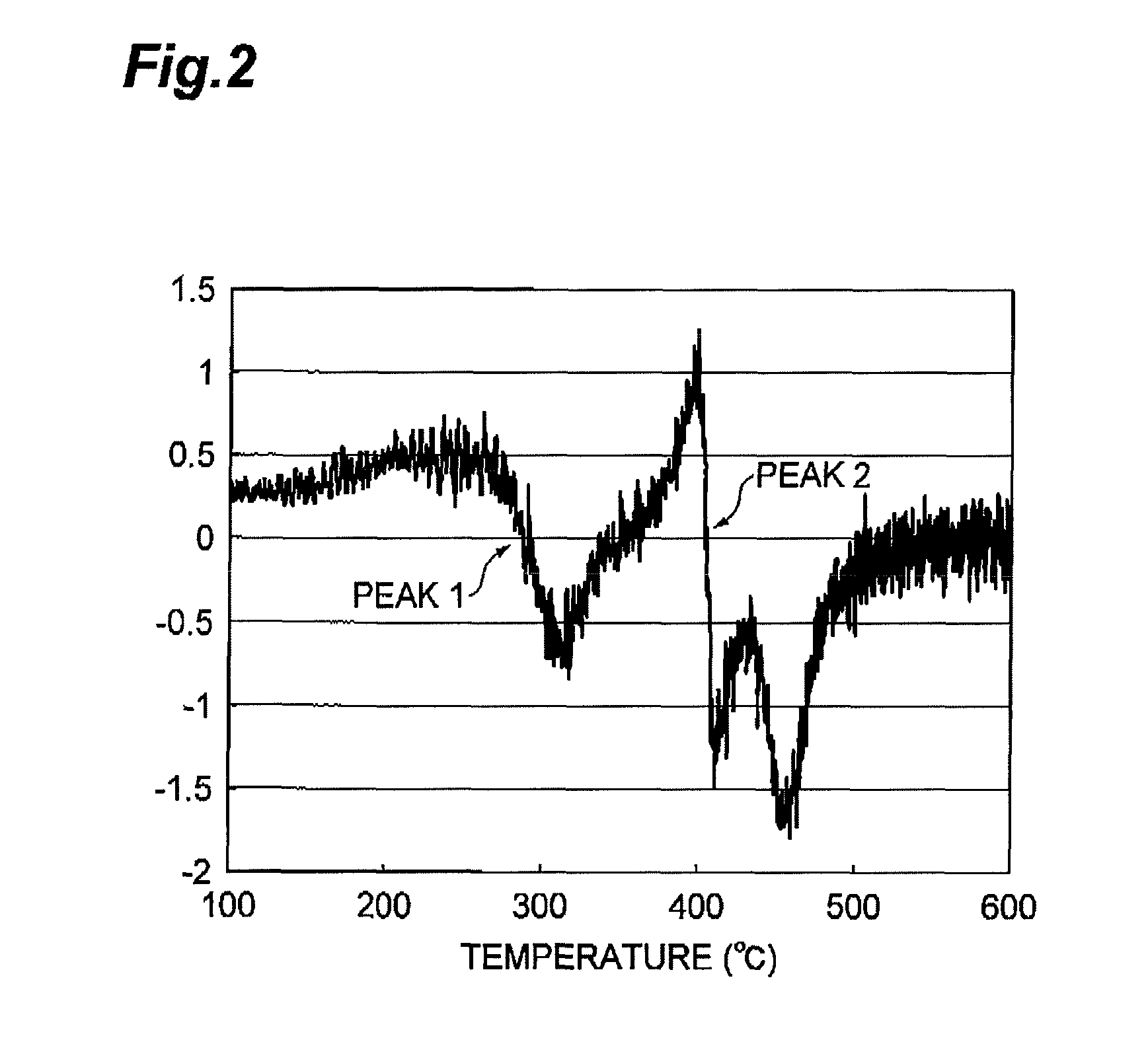

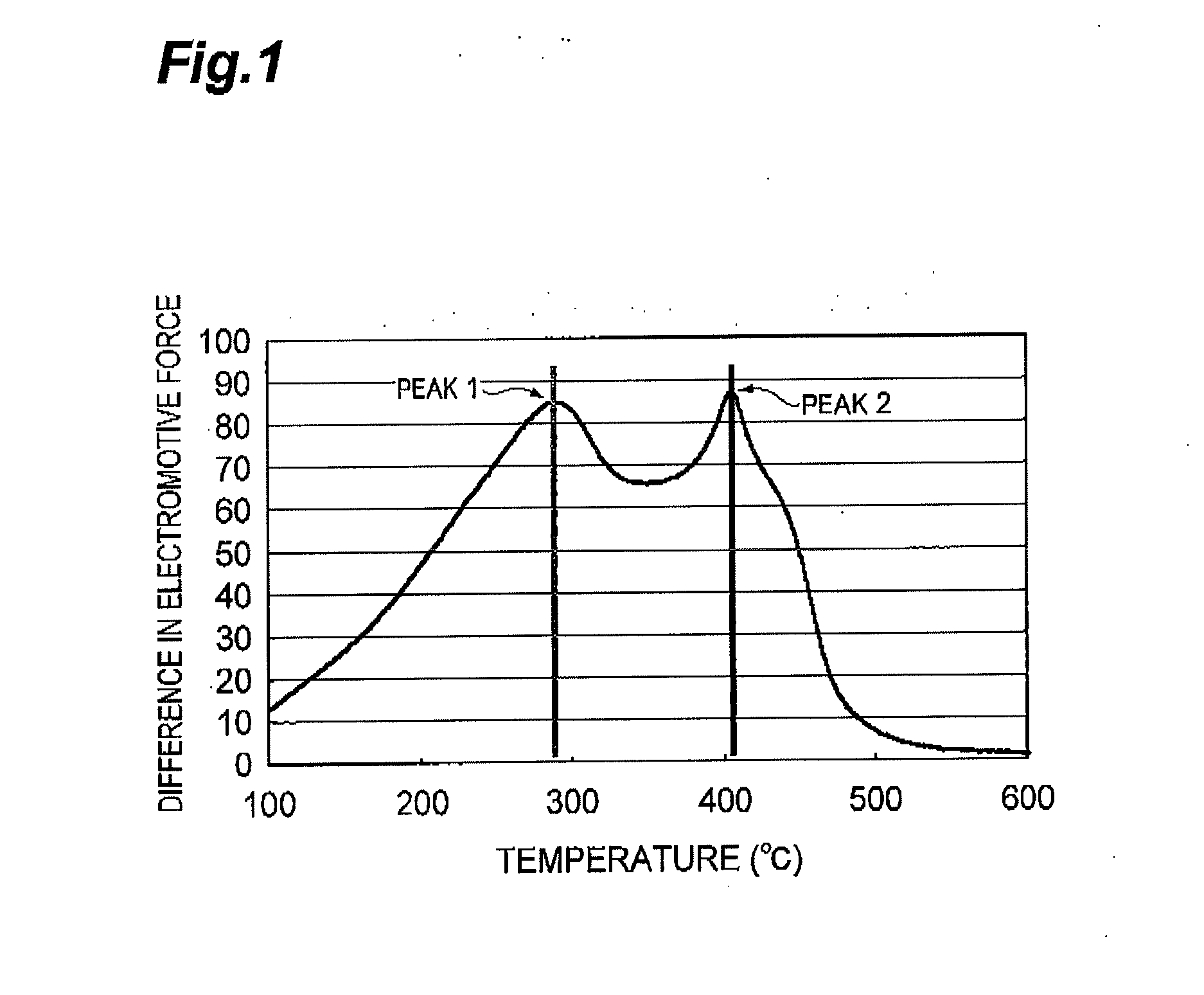

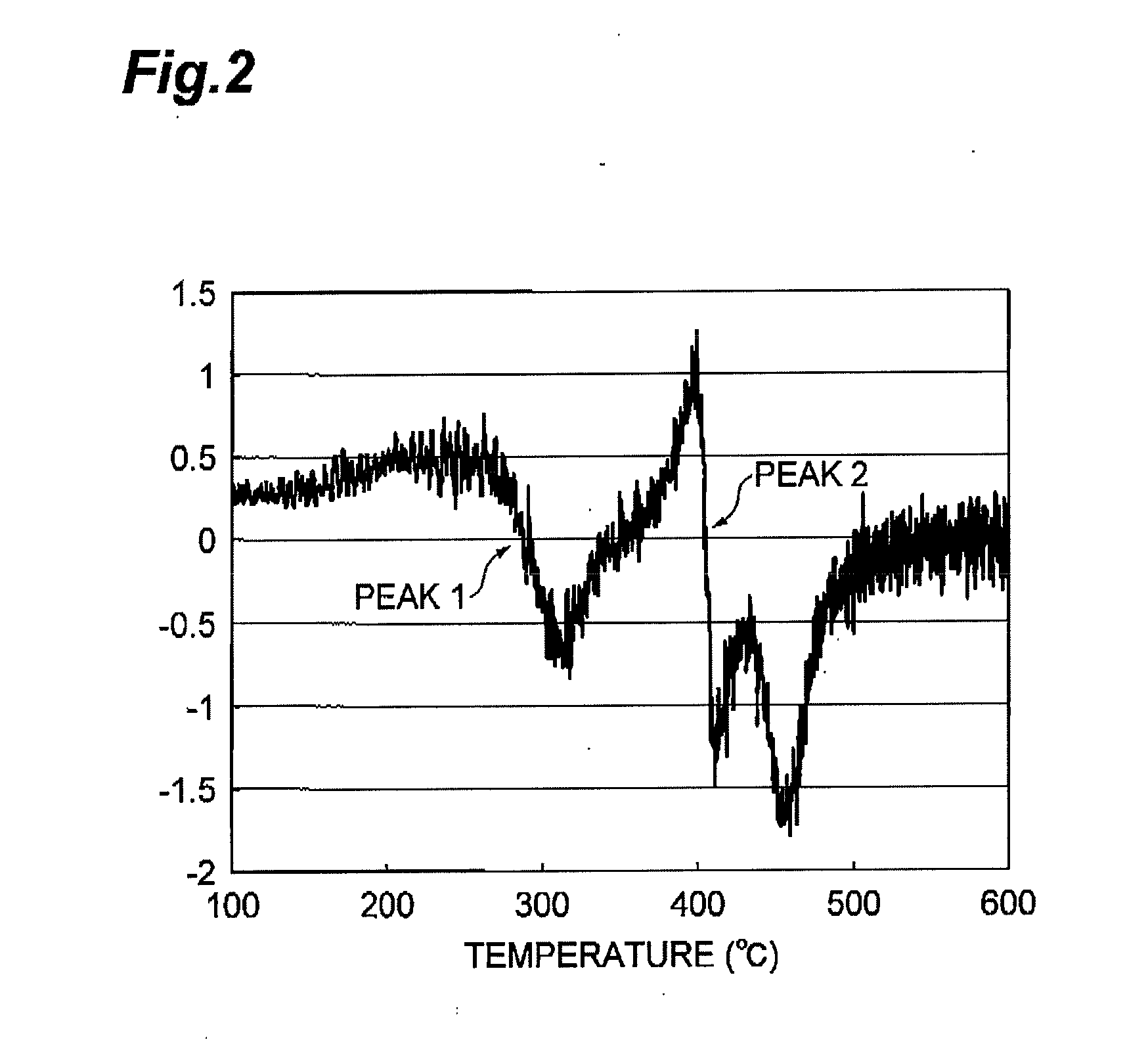

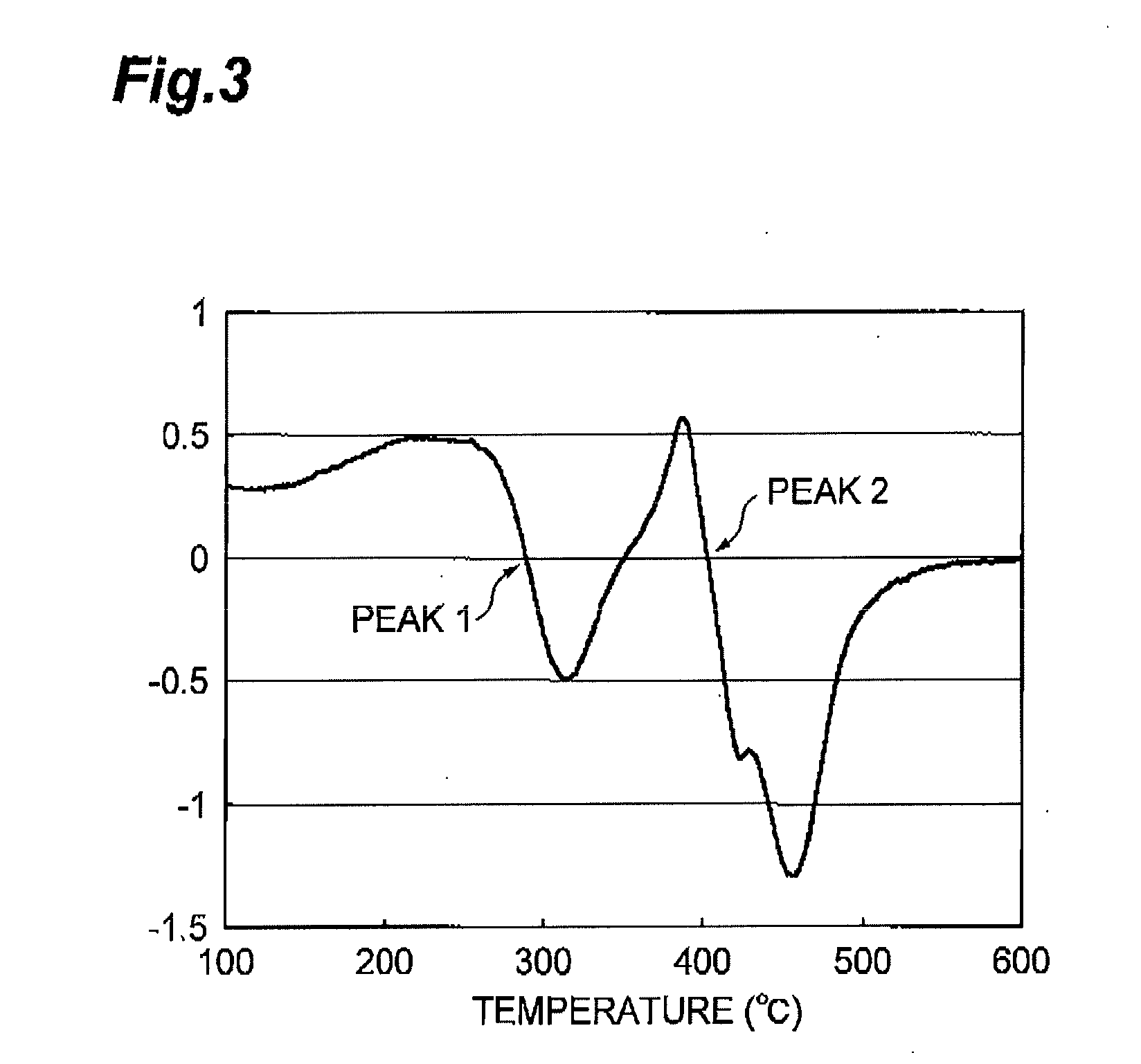

Process for producing regenerated hydrotreating catalyst and process for producing petrochemical product

InactiveUS8722558B2Easy to produceSolve the lack of activityCoke ovensTreatment with hydrotreatment processesPetrochemicalElectromotive force

Provided is a process for producing a regenerated hydrotreating catalyst by regenerating a spent hydrotreating catalyst in a prescribed temperature range, wherein the prescribed temperature range is a temperature range of T1−30° C. or more and T2+30° C. or less, as determined by subjecting the spent hydrotreating catalyst to a differential thermal analysis, converting a differential heat in a measuring temperature range of 100° C. or more and 600° C. or less to a difference in electromotive force, differentiating the converted value twice by temperature to provide a smallest extreme value and a second smallest extreme value, and representing a temperature corresponding to the extreme value on the lower-temperature side as T1 and a temperature corresponding to the extreme value on the higher-temperature side as T2.

Owner:JX NIPPON OIL & ENERGY CORP

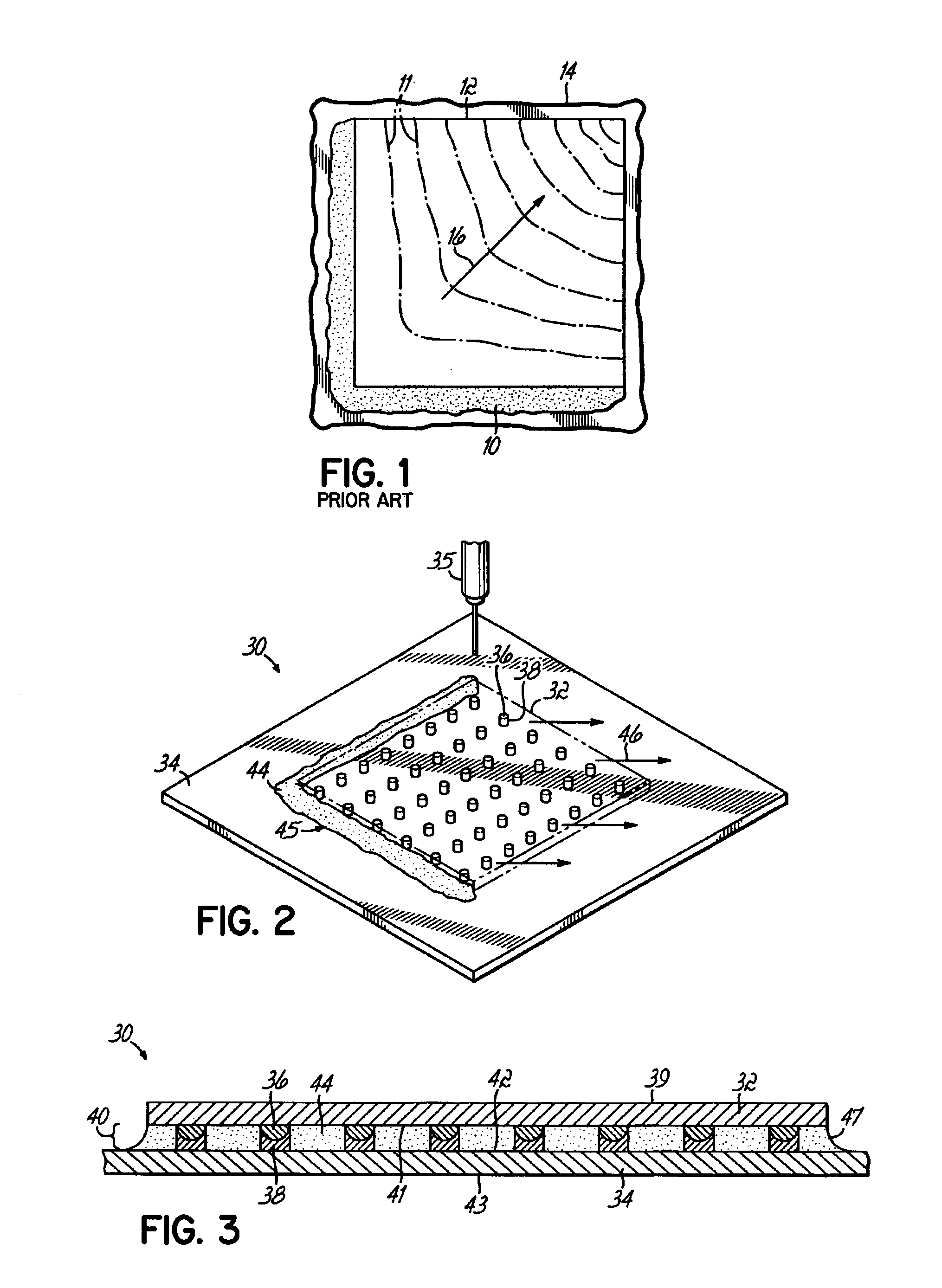

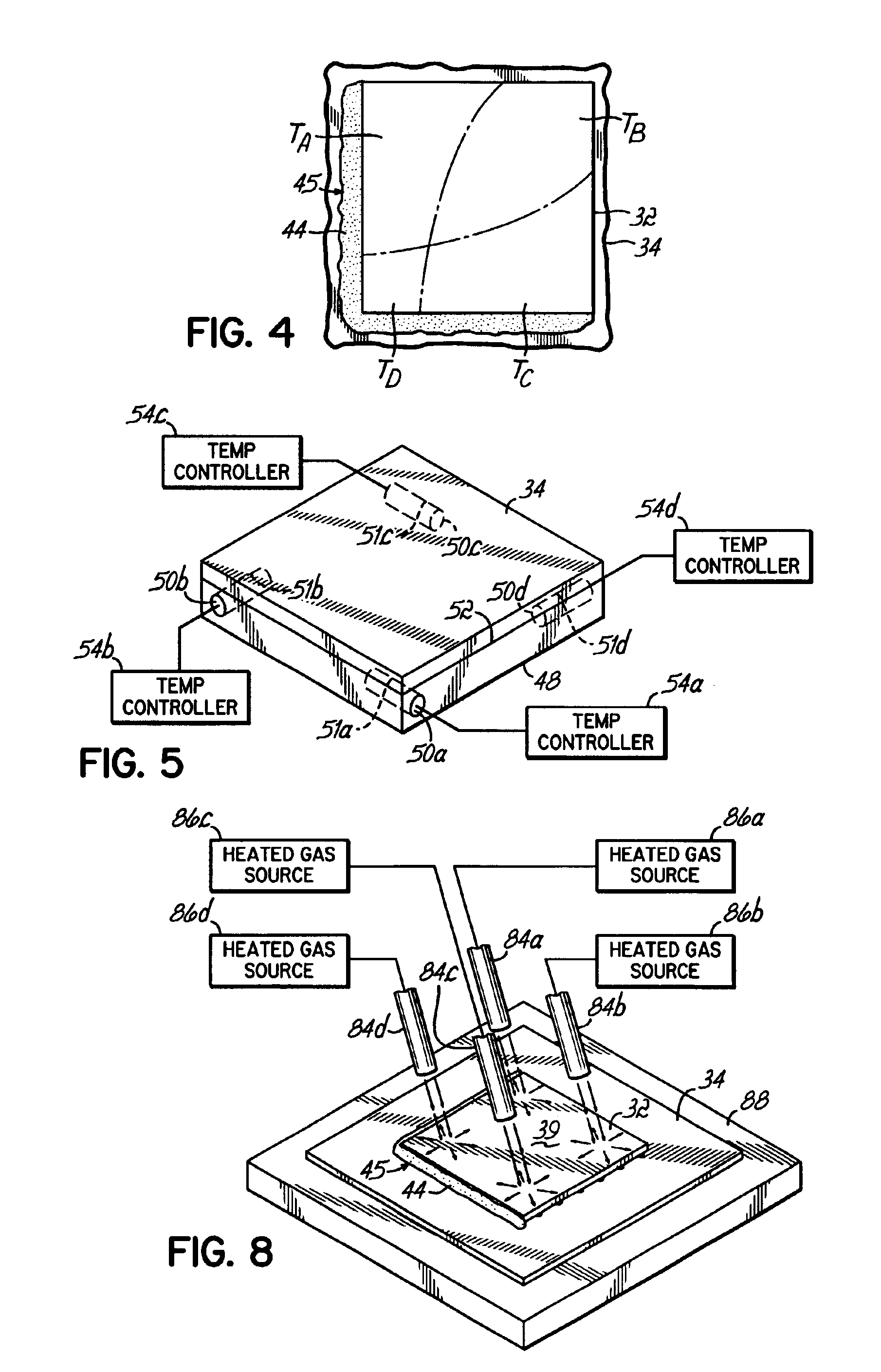

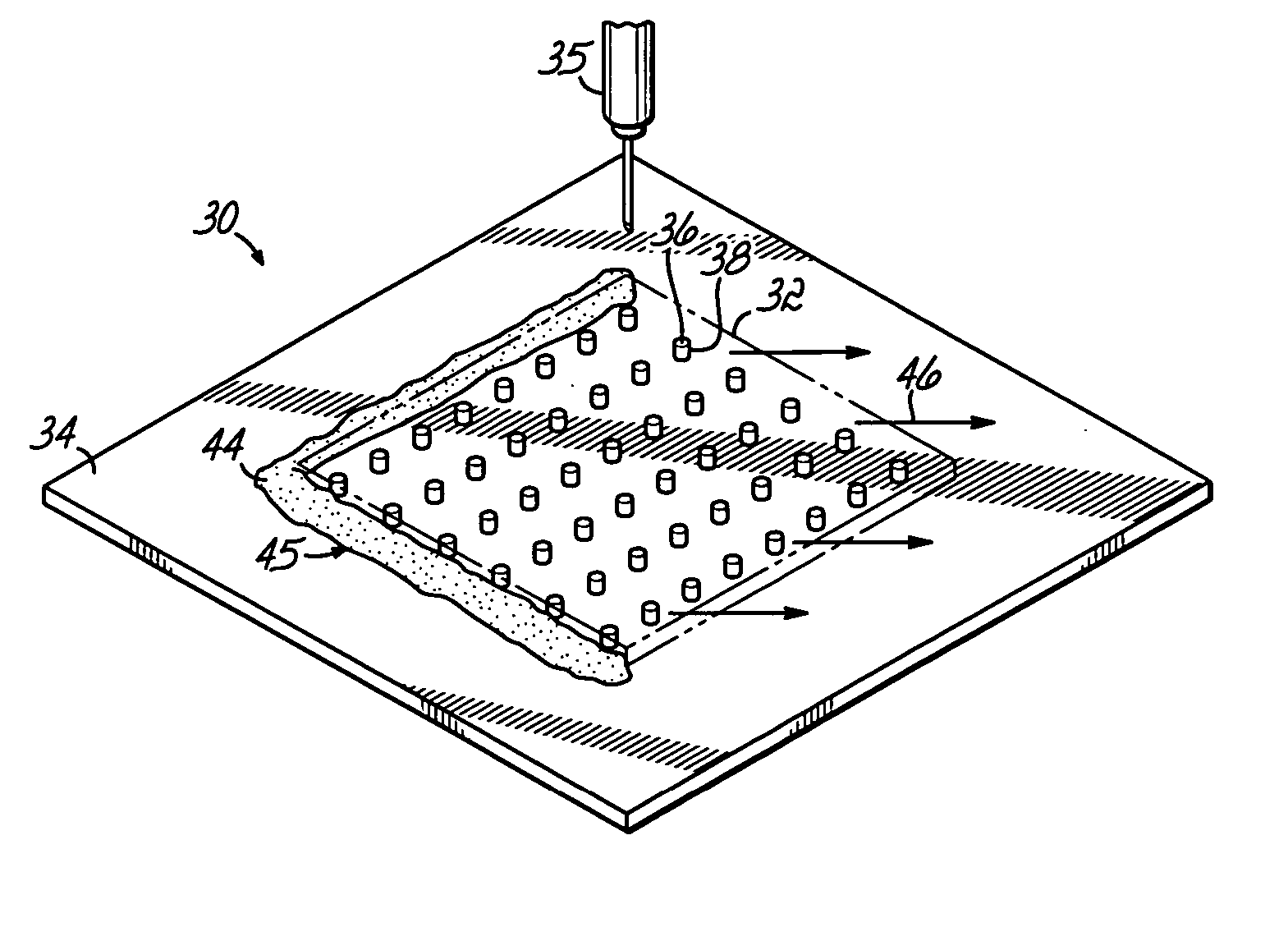

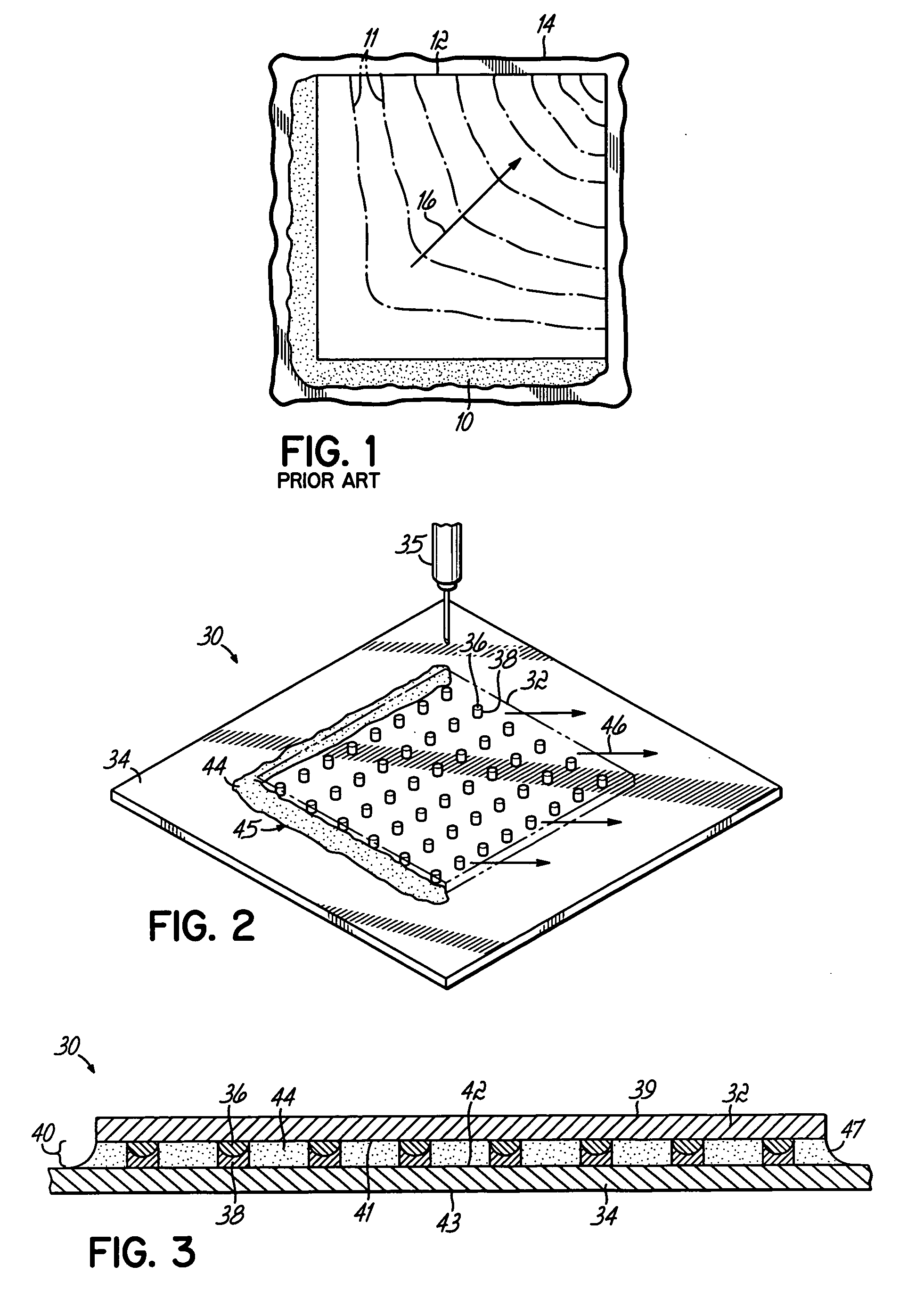

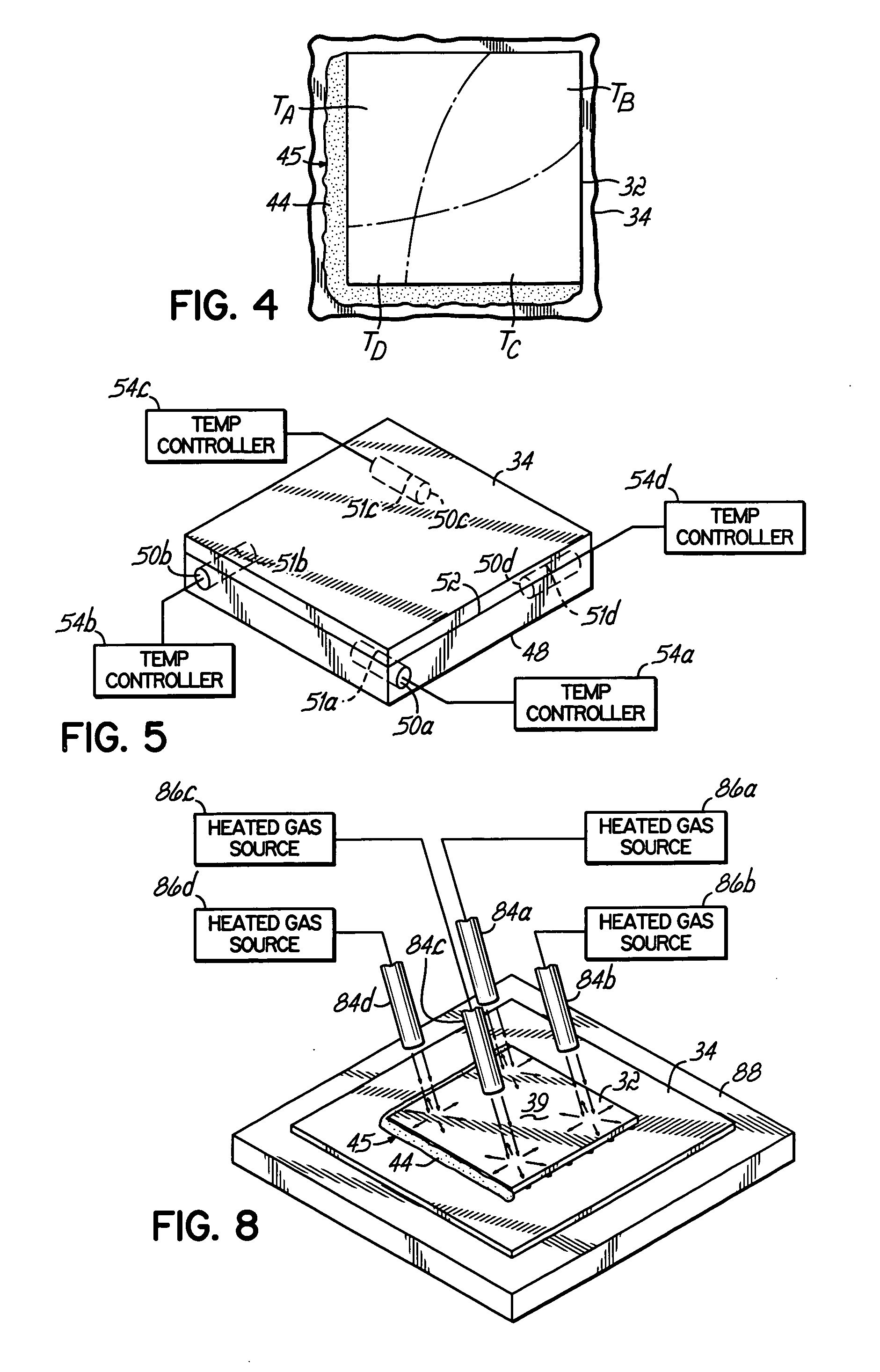

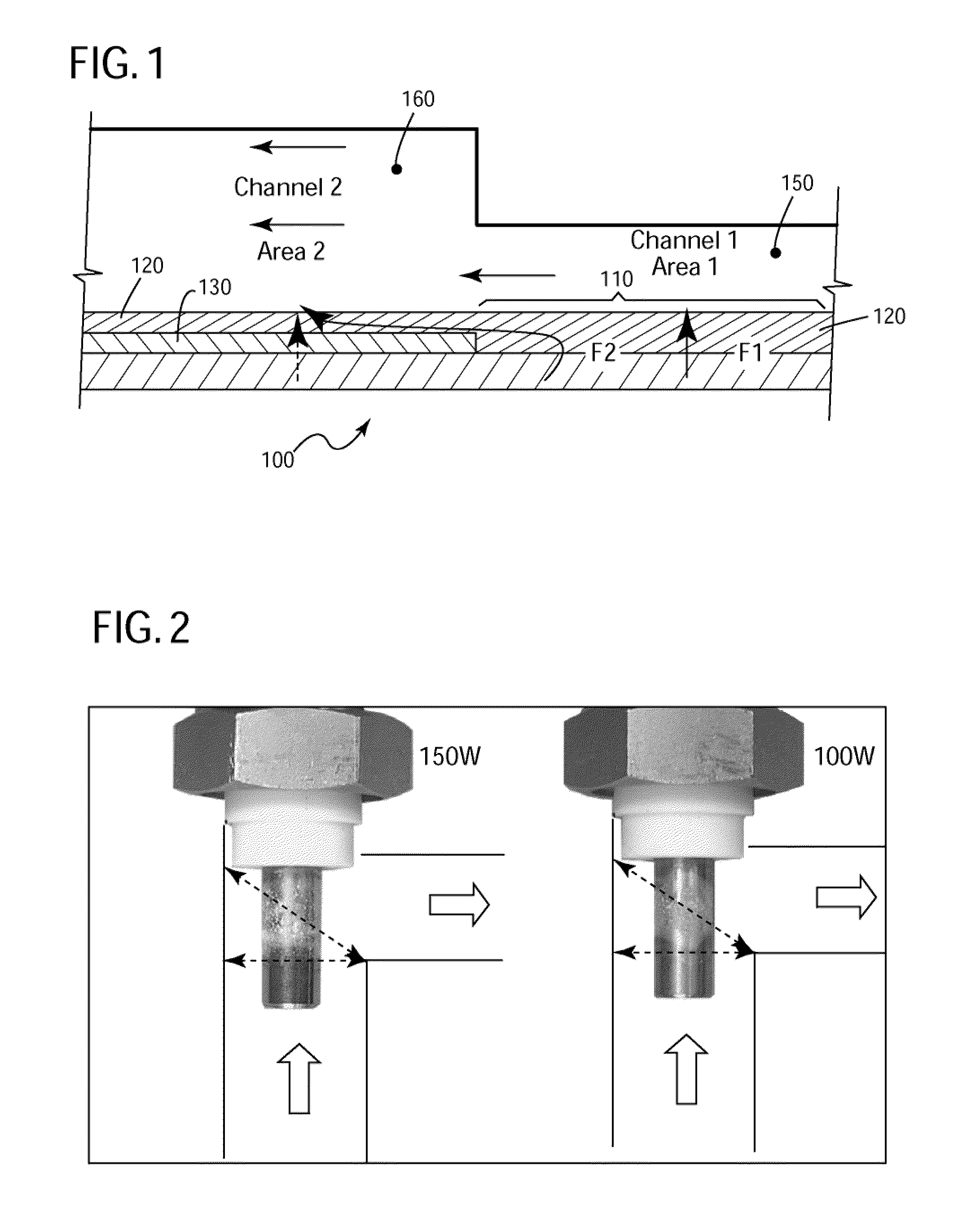

Method and apparatus for underfilling semiconductor devices

InactiveUS6861278B2Reduce incidenceLow viscositySemiconductor/solid-state device detailsSolid-state devicesSealantHeat energy

A method and apparatus for underfilling a gap between a multi-sided die and a substrate with an encapsulant material. The die and / or the substrate is heated non-uniformly by a heat source to generate a temperature gradient therein. The heated one of the die and the substrate transfers heat energy in proportion to the temperature gradient to the encapsulant material moving in the gap. The differential heat transfer steers, guides or otherwise directs the movement of the encapsulant material in the gap. The temperature gradient may be established with heat transferred from the heat source to the die and / or the substrate by conduction, convection, or radiation. The temperature gradient may be dynamically varied as the encapsulant material moves into the gap.

Owner:NORDSON CORP

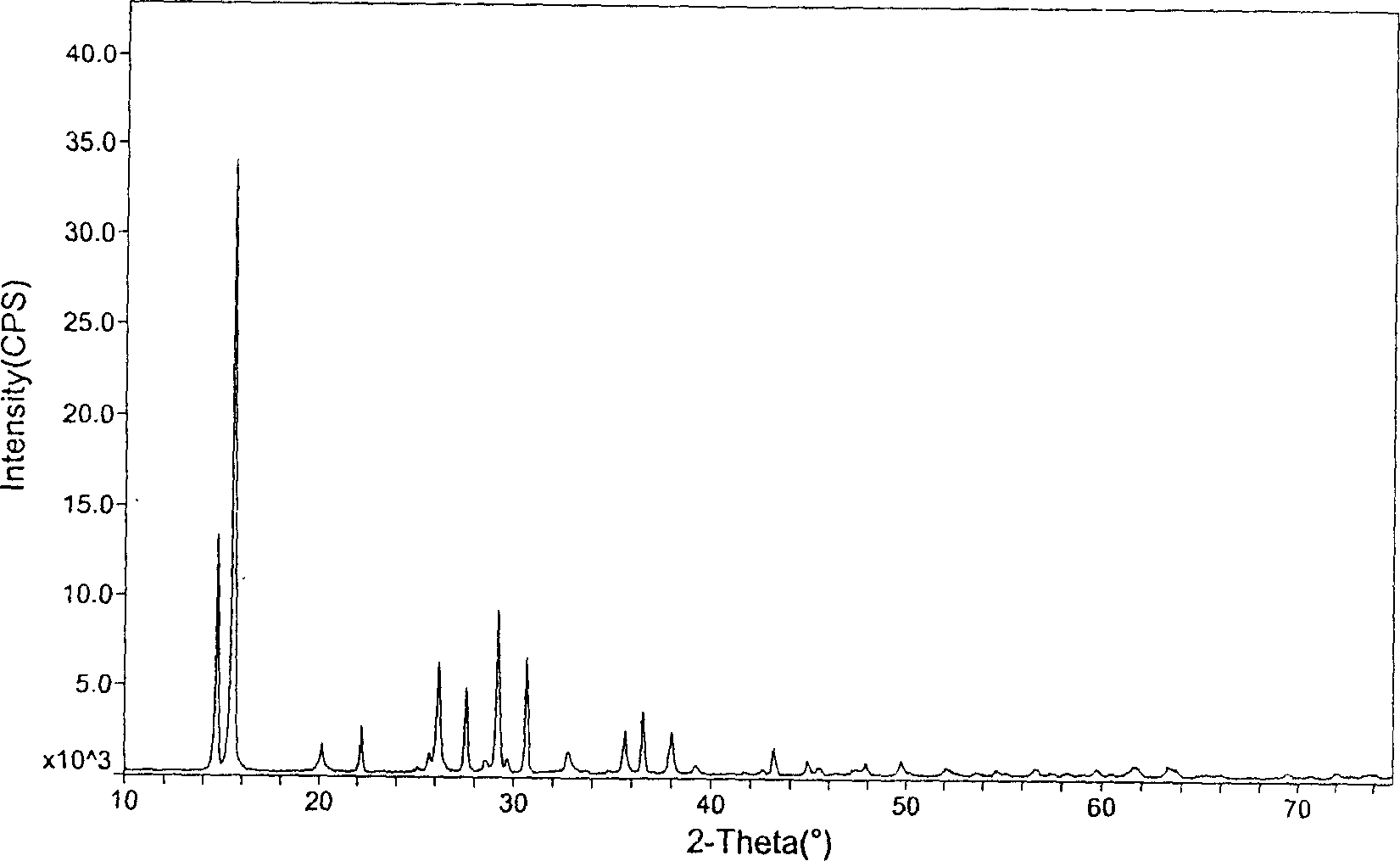

Method for preparing and detecting crystallization II type ammonium polyphosphate

The invention provides a process for preparing inorganic highly performance combustion inhibitor crystallization II type ammonium polyphosphate, which comprises selecting equal mol of phosphorus pentoxide and ammonium monohydric phosphate, under 150-350 deg. C, charging ammonium sulfate, melamine or ammonium hydrogen carbonate polycondensation agent, mixing, liquating, crystallizing, and disintegrating at the presence of ammonia gas atmosphere, thus obtaining crystallization II type polyphosphoric acid (APP-II). The method for detecting crystallization II type ammonium polyphosphate consists of measuring crystallization form of the APP-II through X-ray diffraction analysis, measuring polymerization degree of the APP-II through nuclear magnetic resonance method, measuring the decomposition temperature of the APP-II through heat weight / differential heat synchronization analytic method.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD

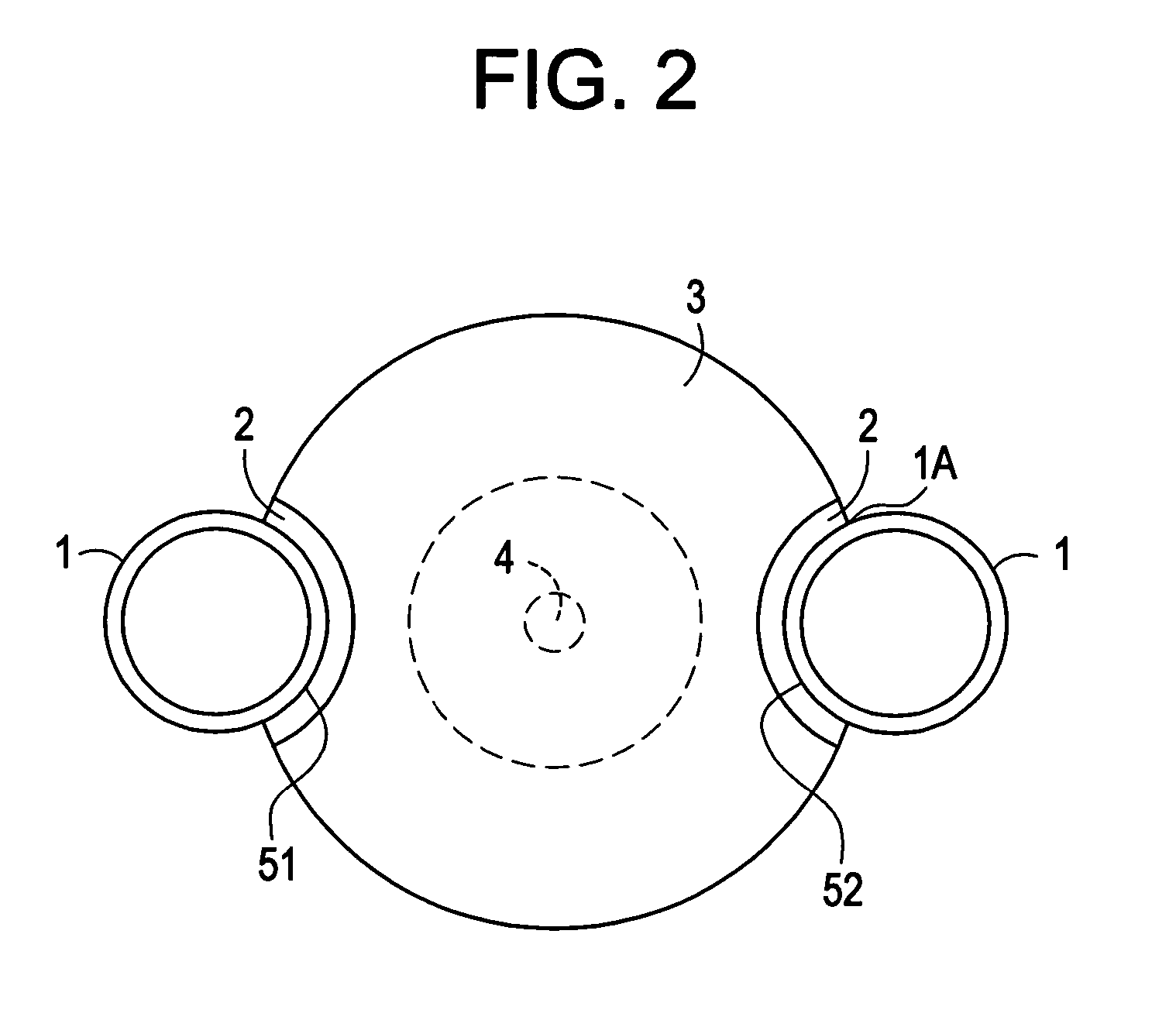

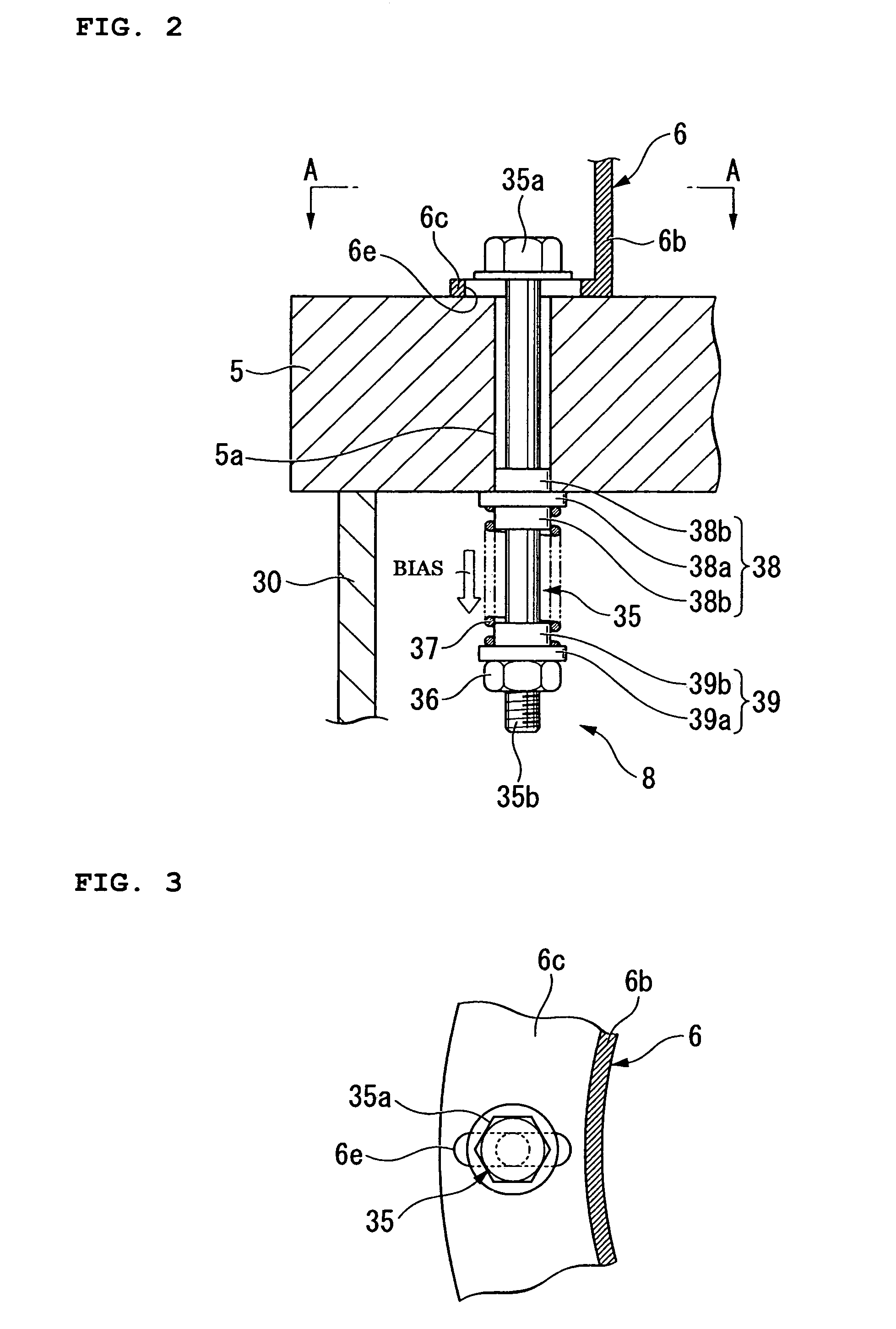

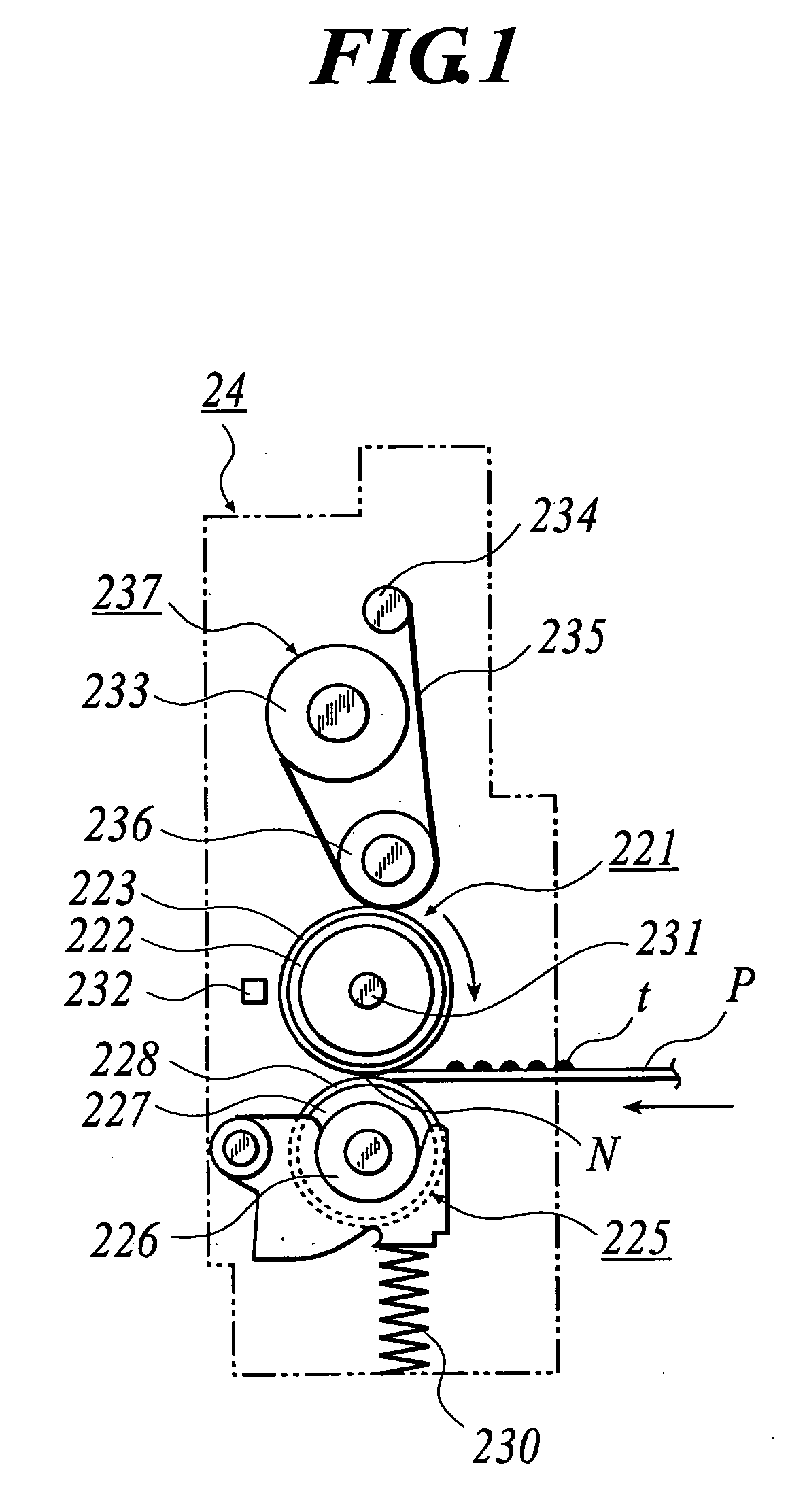

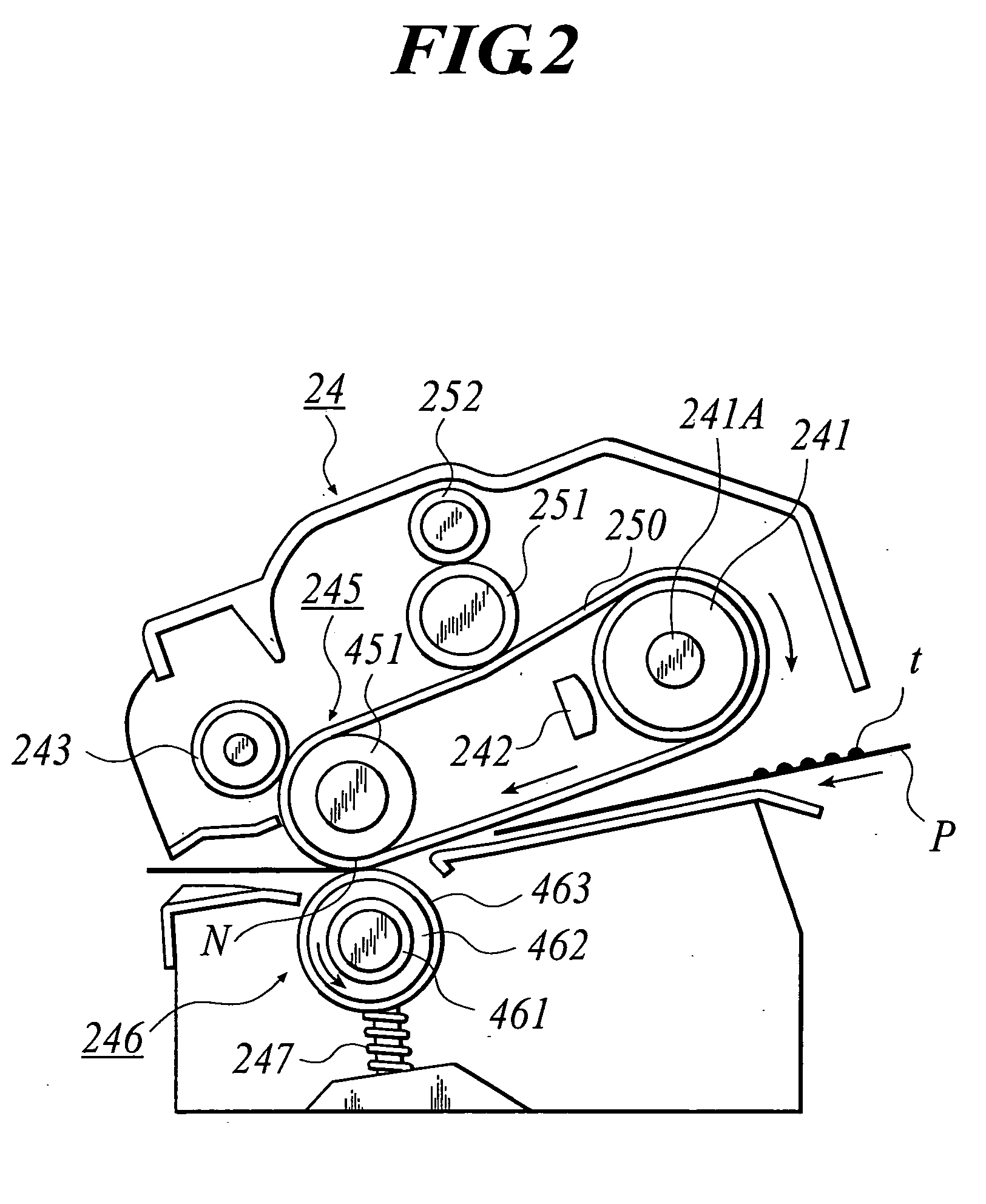

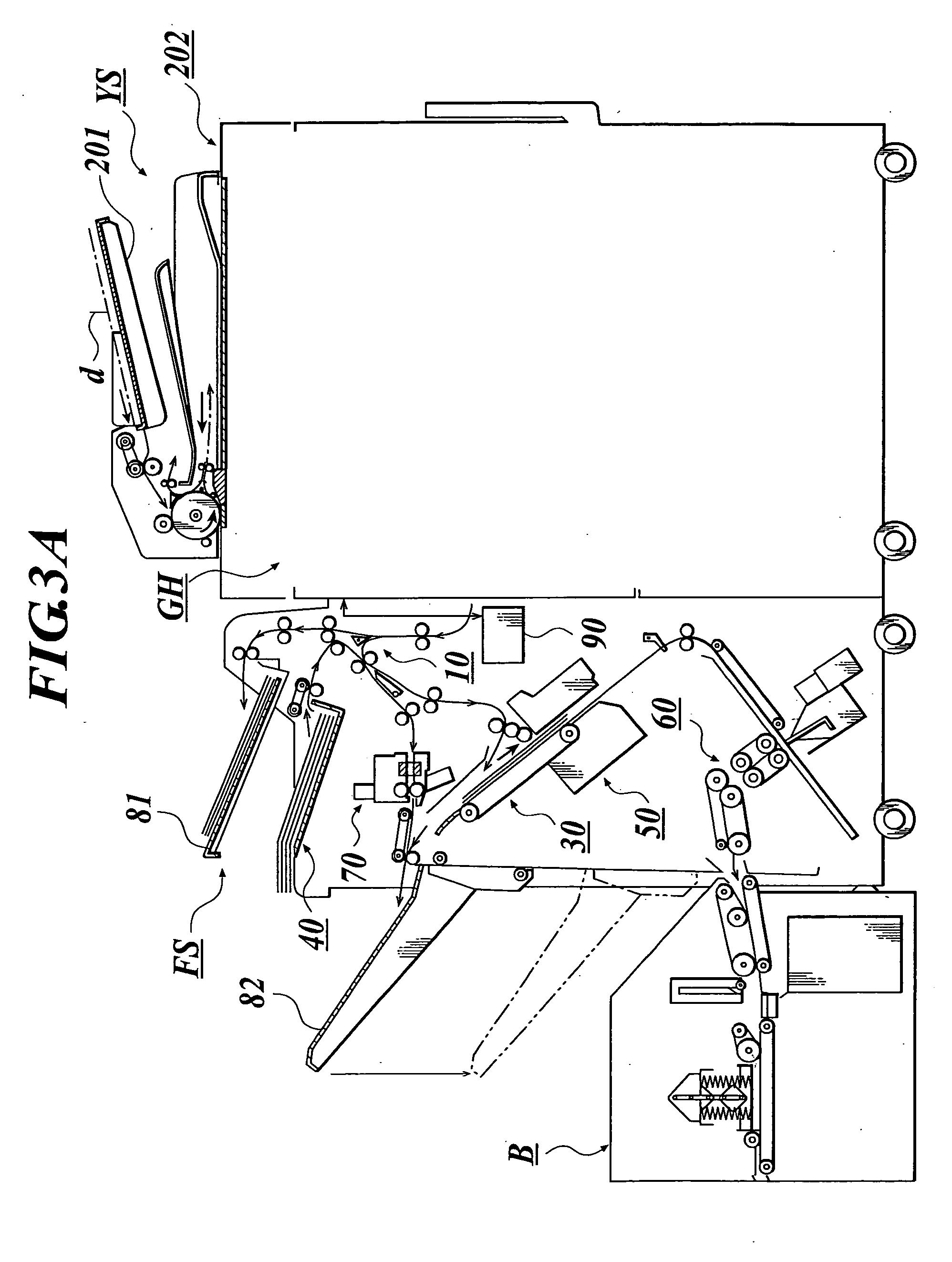

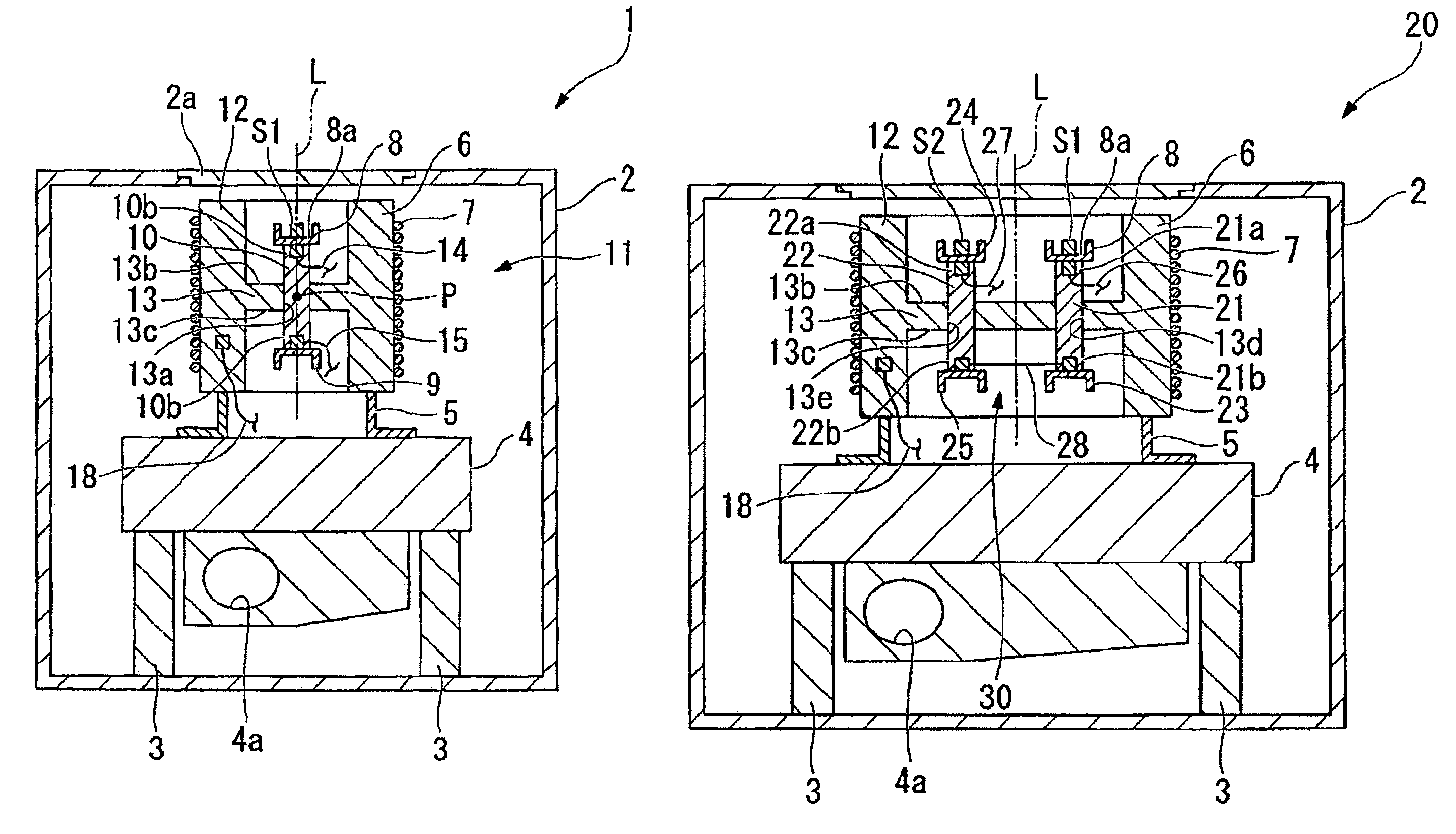

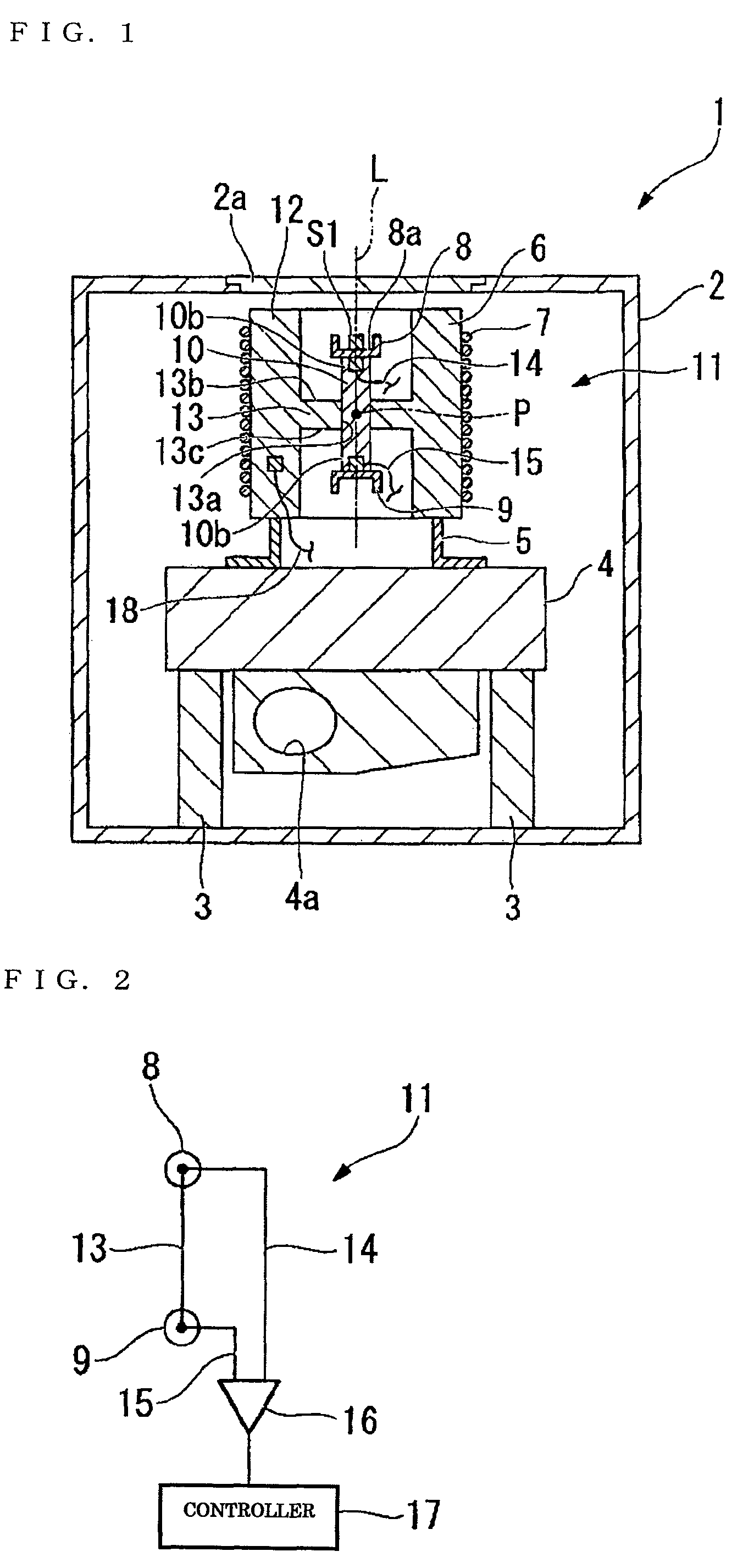

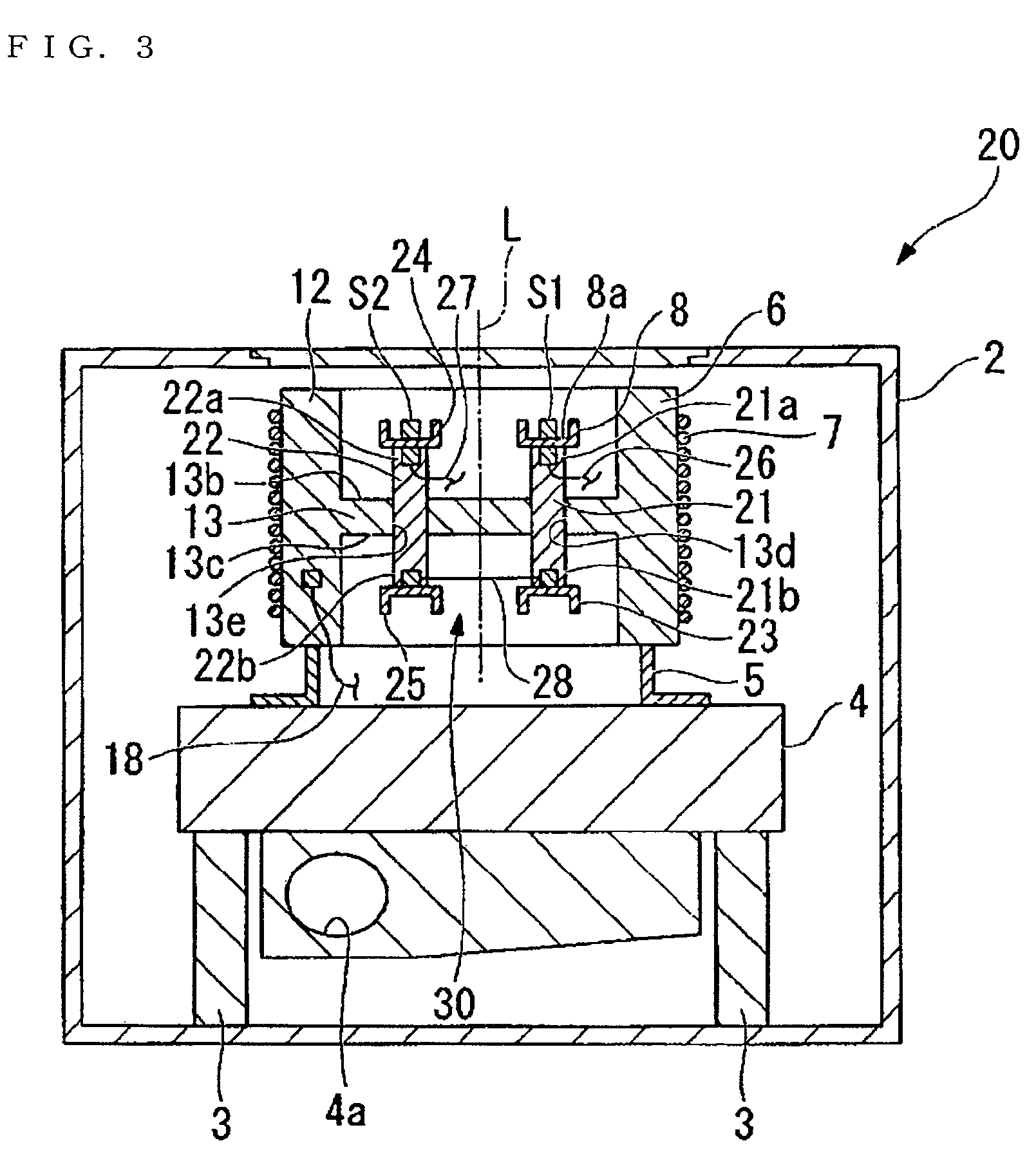

Differential scanning calorimeter

InactiveUS20070189357A1Avoid temperature riseAvoid changeThermometerMaterial thermal analysisElectrical resistance and conductanceHeat flow

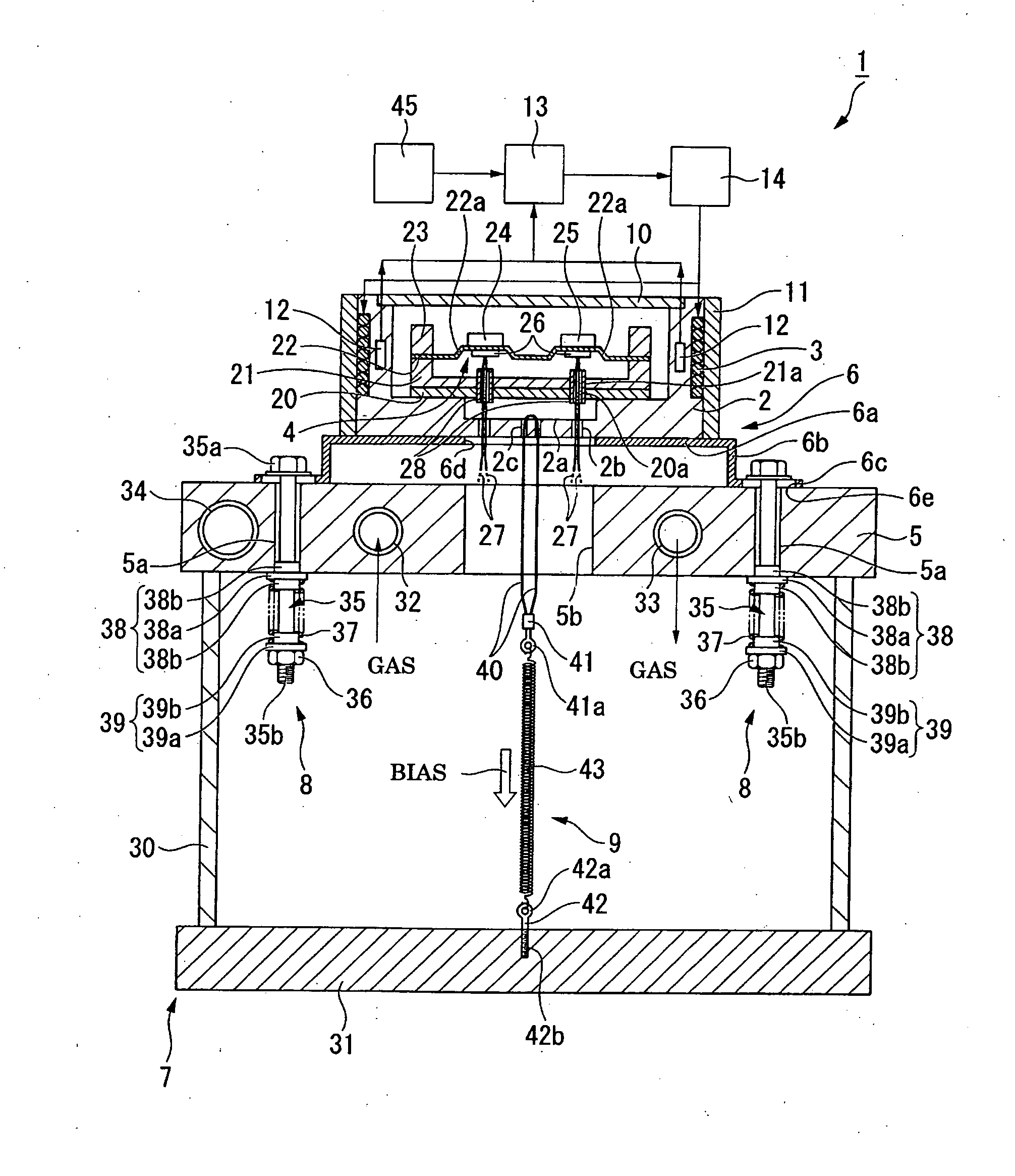

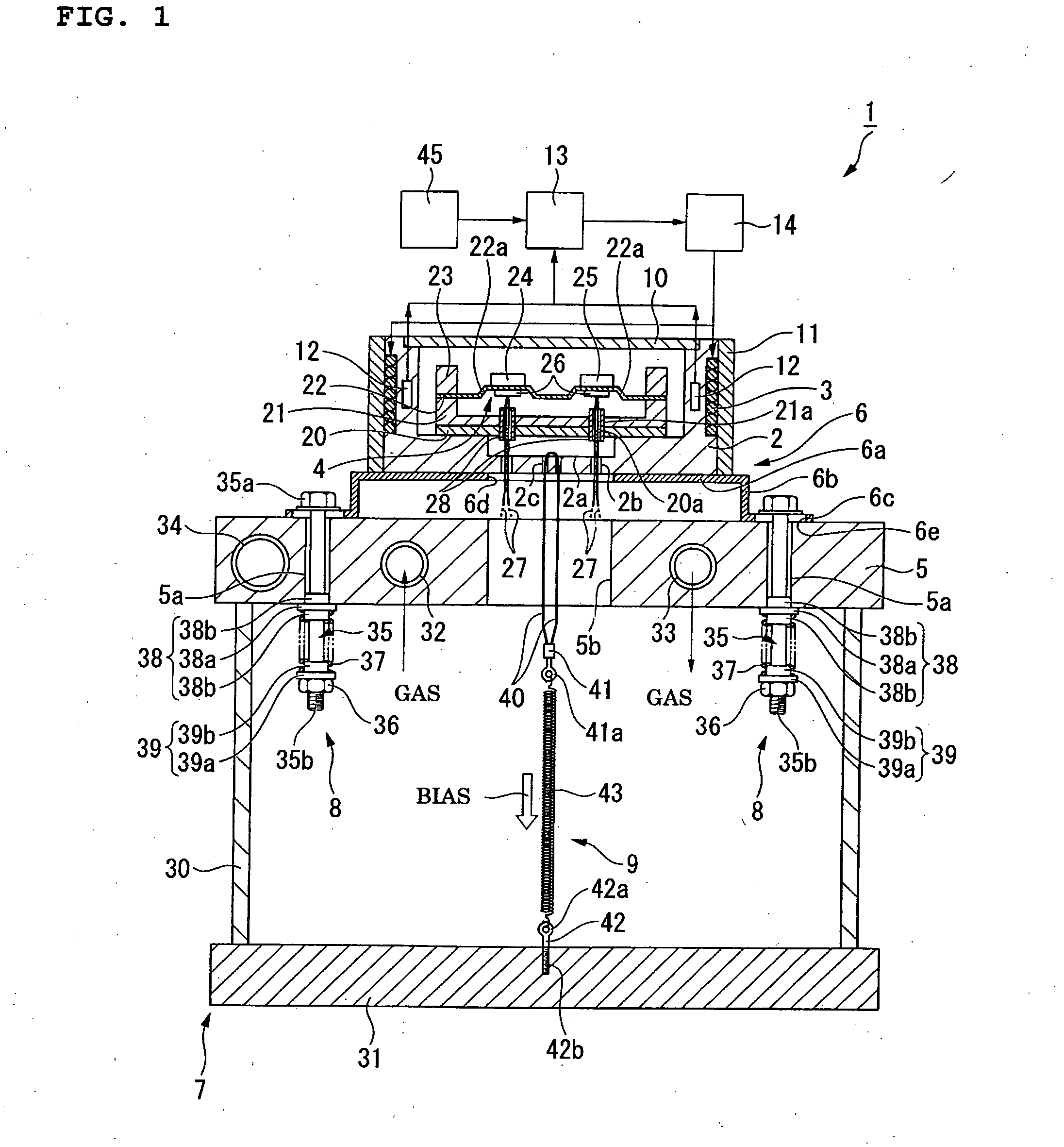

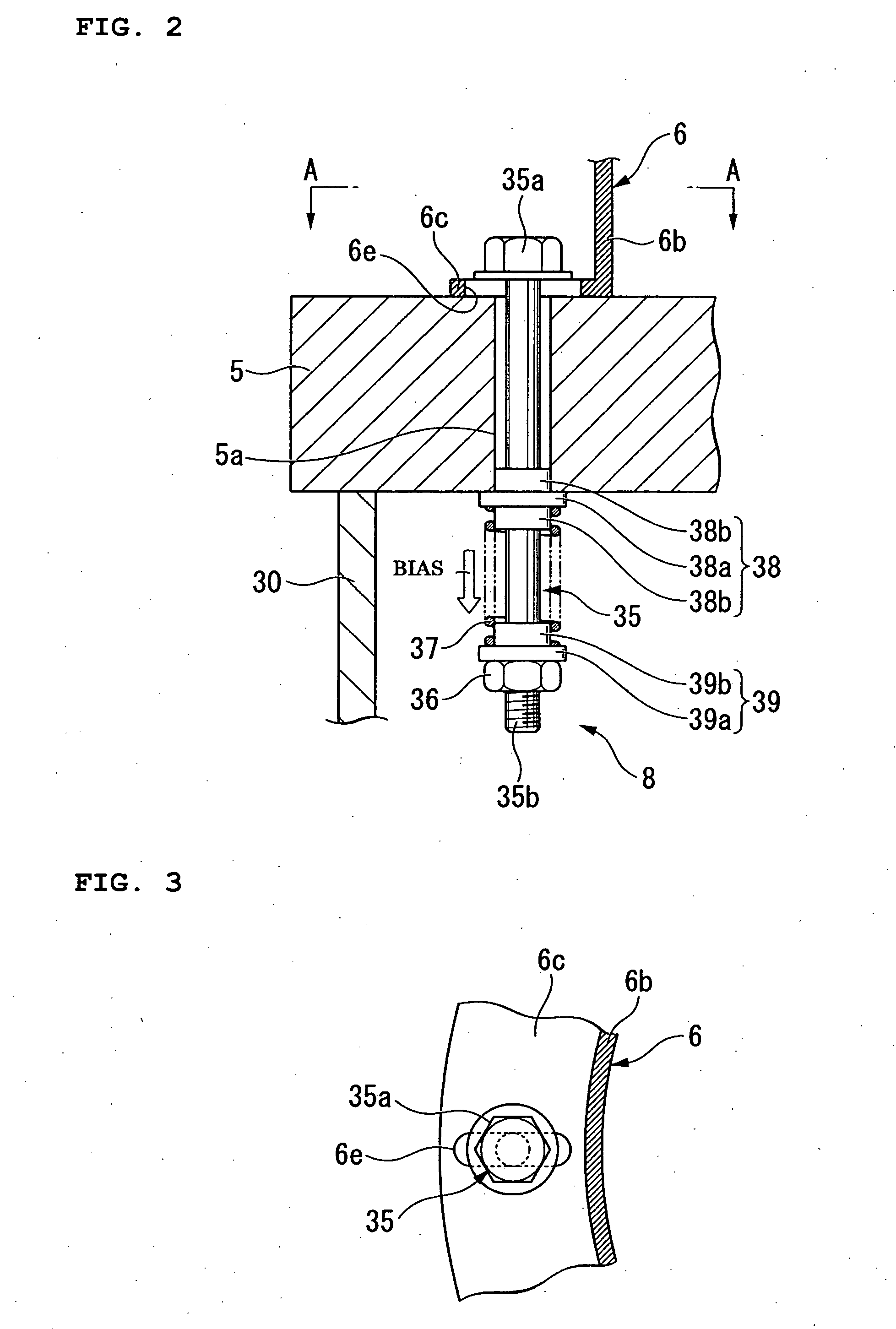

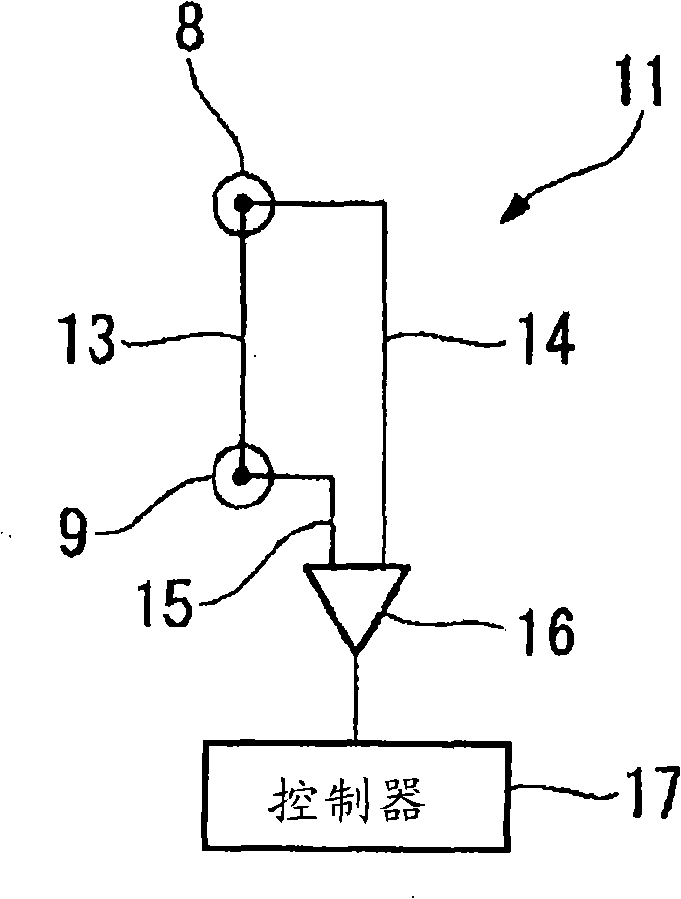

There is provided a differential scanning calorimeter possessing an accommodation chamber accommodating a sample to be measured and a reference material, a heater heating the accommodation chamber, a differential heat flow detector outputting a temperature difference between the sample to be measured and the reference material as a heat flow difference signal, a cooling block cooling-controlled to a predetermined temperature, a heat resistor which mechanically connects the cooling block and the accommodation chamber and forms a heat flow path between both, a first fixation means which fixes the heat resistor to the cooling block by pressing the former while being biased by a constant elastic force, and a second fixation means which fixes the accommodation chamber to the heat resistor by pressing the former while being biased by a constant elastic force.

Owner:HITACHI HIGH TECH SCI CORP

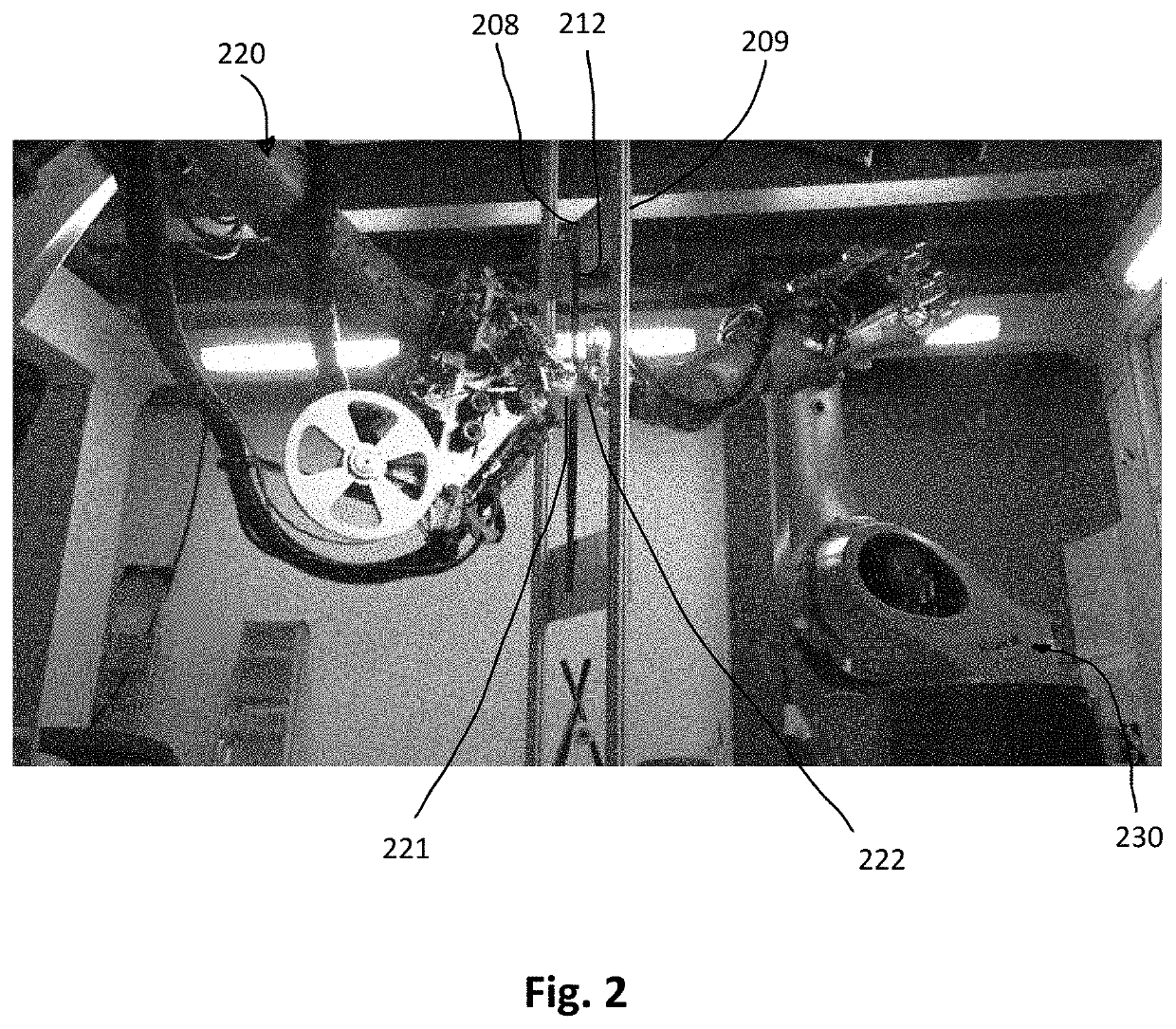

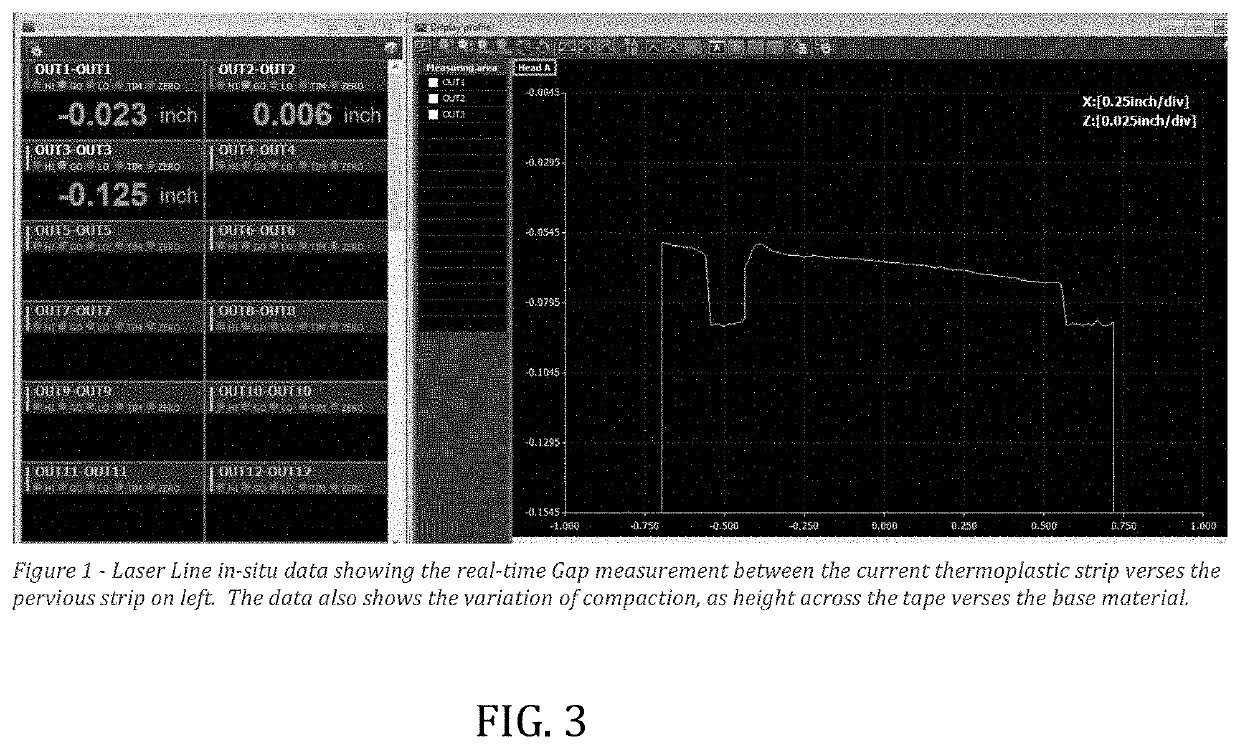

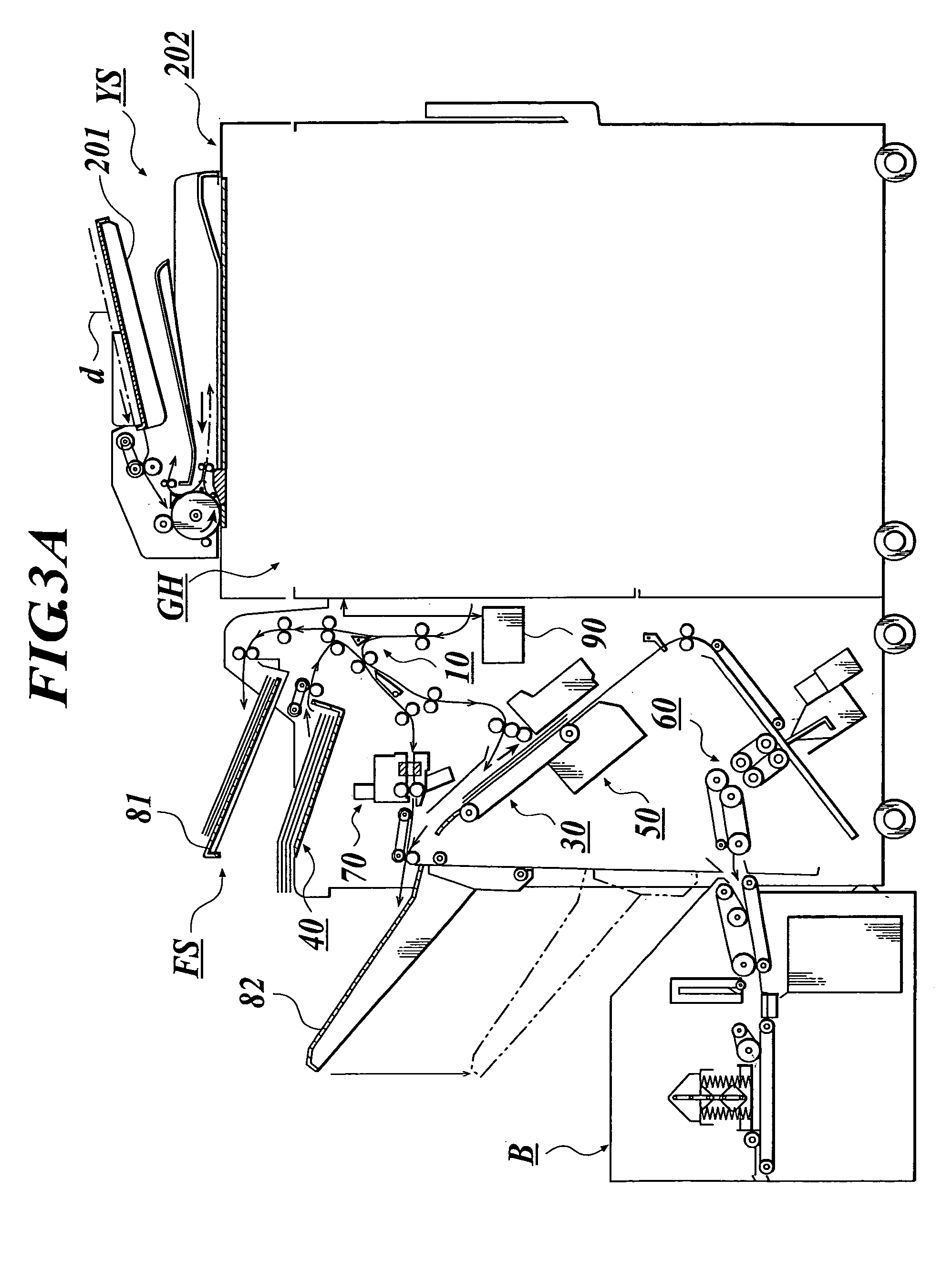

In-situ monitoring of thermoformable composites

ActiveUS20200230899A1Low costShorten the timeInvestigating composite materialsOptically investigating flaws/contaminationHeat fluxThermoforming

A method and system for determining the quality and configuration of a structure that is constructed from a thermoformable material, such as a thermoplastic or thermoset material, and in particular thermoplastic composite tapes, where heat is applied to cure the thermoformable material. The quality of the build is monitored during the construction of the structure by determining the differential heat flux in the material as it cools from its elevated temperature. The system and method also may determine the location of defects in a structure being constructed so that remedial measures may be taken or production operations halted to address the defect. A transient thermal effect is applied to the structure being monitored, such as the thermoformable material being applied, which may be implemented from the applied heating of the thermoformable construction application process or additional heating.

Owner:TYSON II JOHN

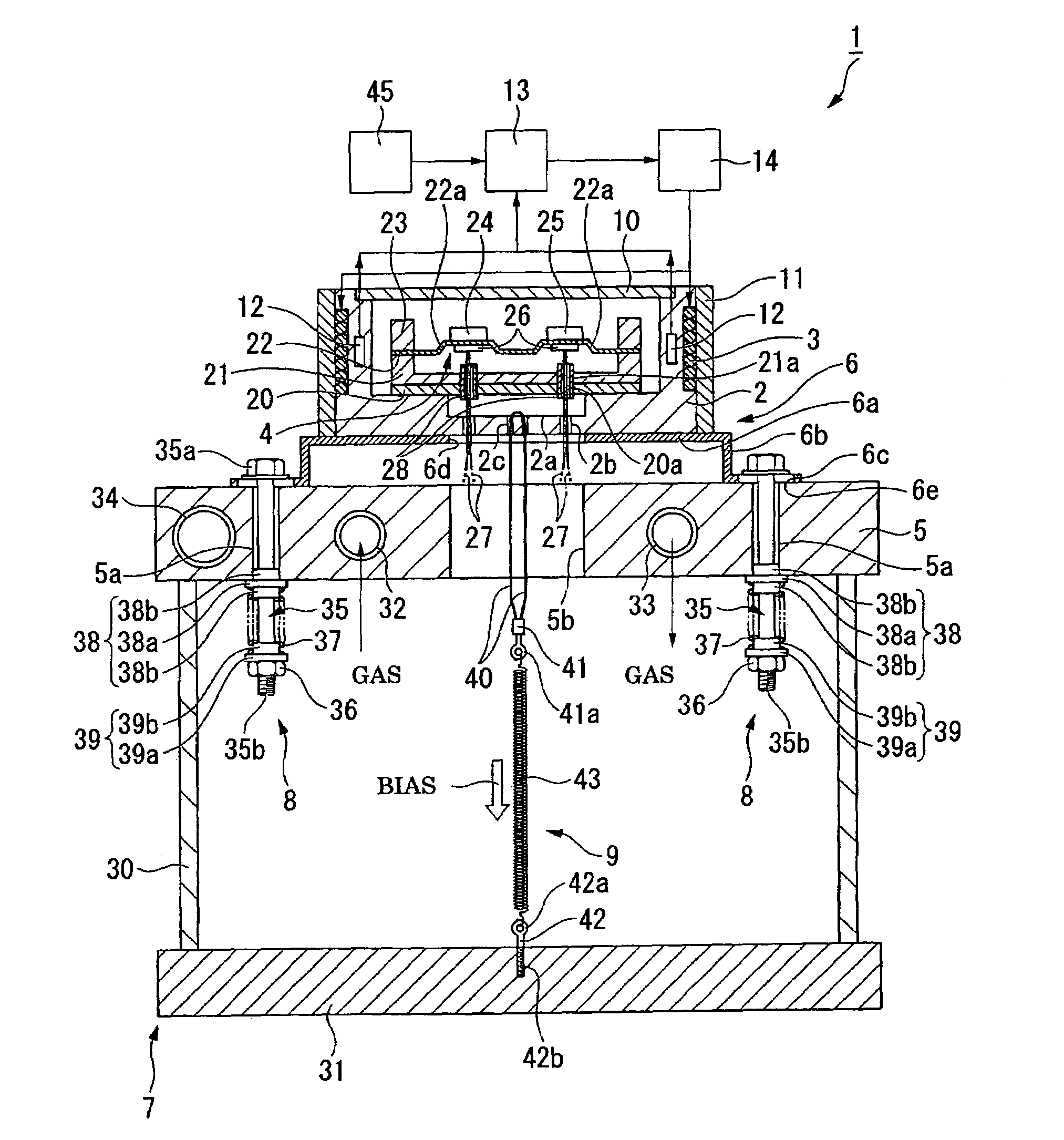

Differential scanning calorimeter

InactiveUS7455449B2Easy to produceAnalysis can be performedMaterial heat developmentThermometerHeat flowEngineering

There is provided a differential scanning calorimeter possessing an accommodation chamber accommodating a sample to be measured and a reference material, a heater heating the accommodation chamber, a differential heat flow detector outputting a temperature difference between the sample to be measured and the reference material as a heat flow difference signal, a cooling block cooling-controlled to a predetermined temperature, a heat resistor which mechanically connects the cooling block and the accommodation chamber and forms a heat flow path between both, a first fixation means which fixes the heat resistor to the cooling block by pressing the former while being biased by a constant elastic force, and a second fixation means which fixes the accommodation chamber to the heat resistor by pressing the former while being biased by a constant elastic force.

Owner:HITACHI HIGH TECH SCI CORP

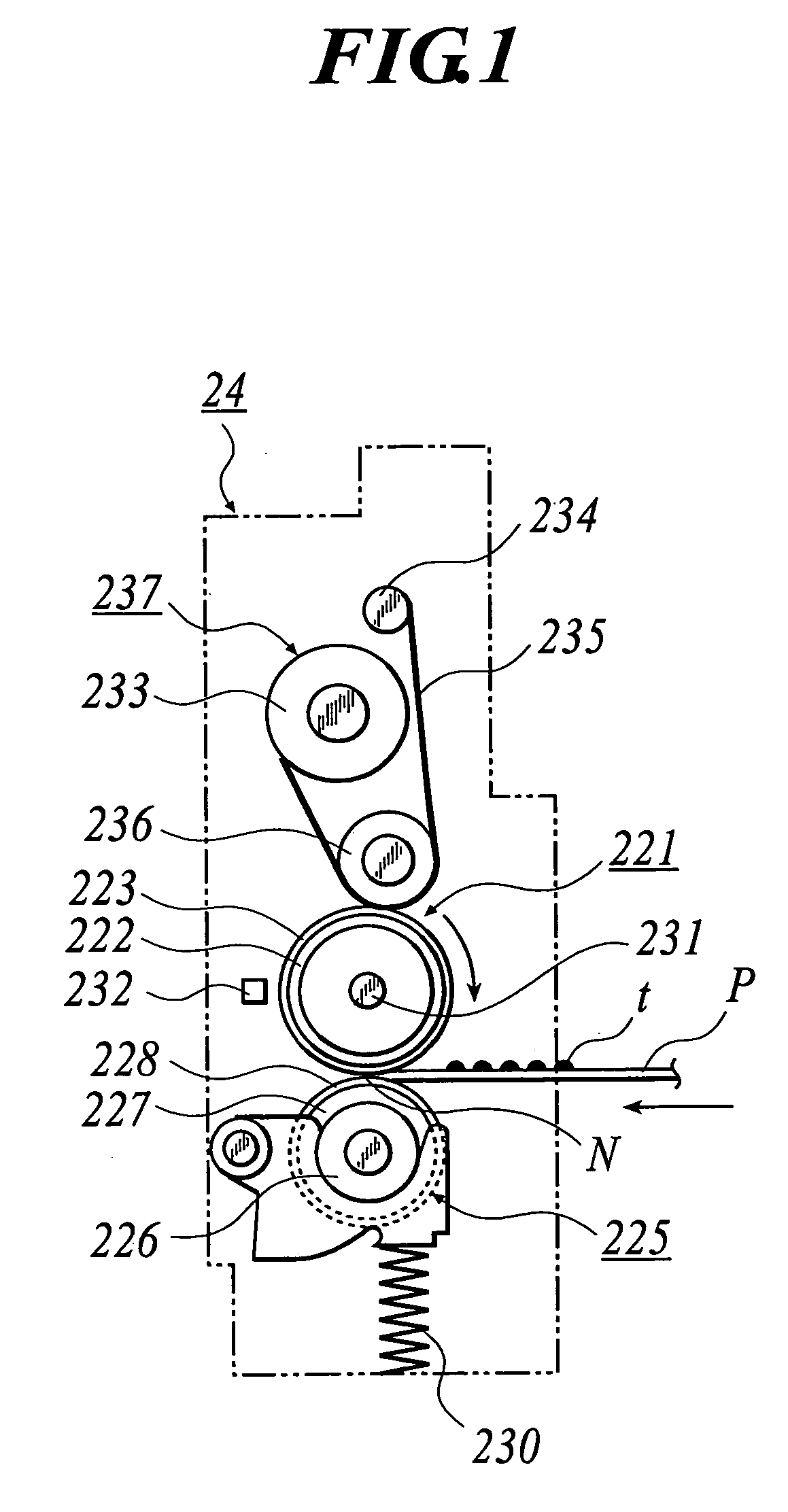

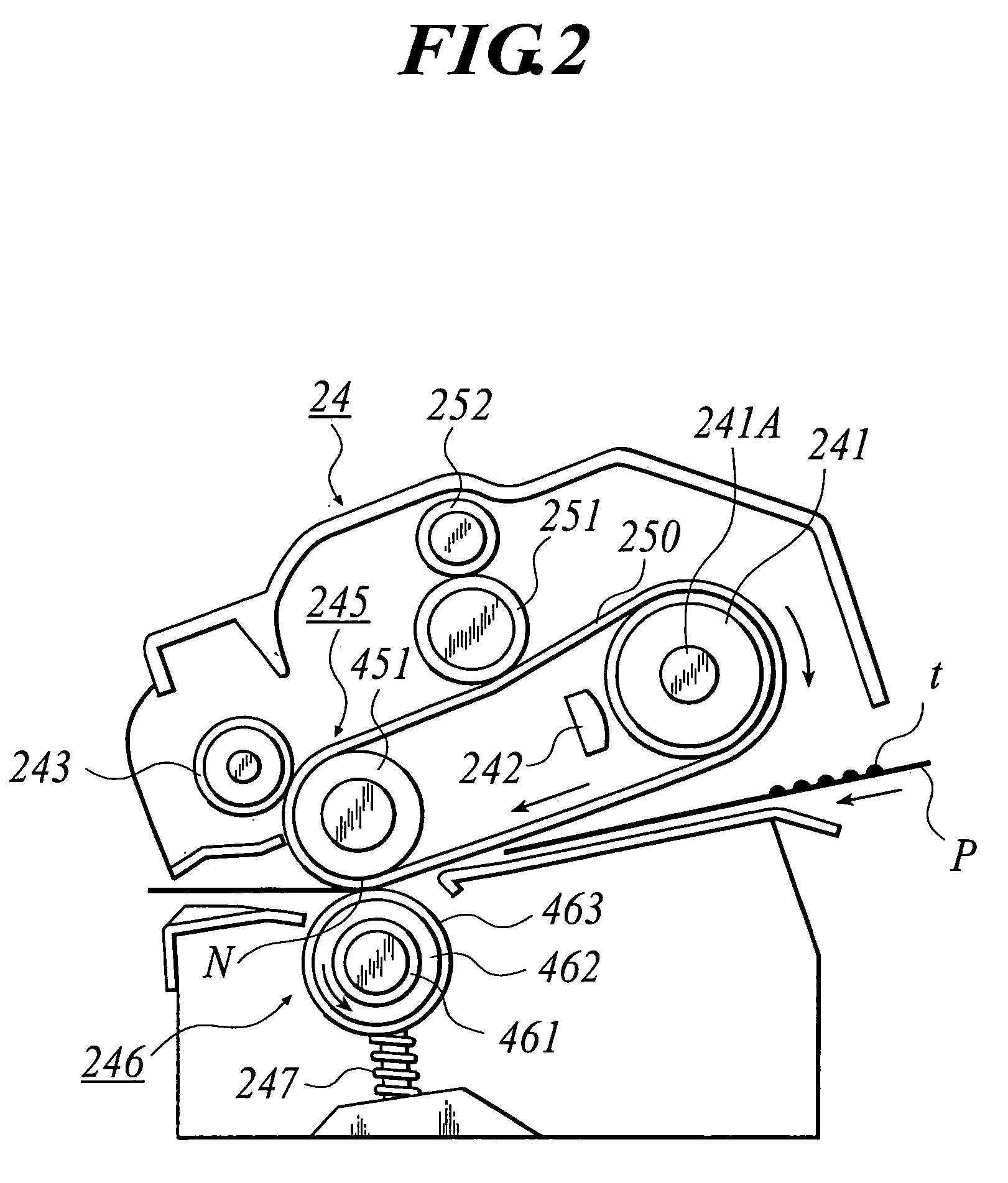

Toner for electrostatic charge image development and image forming method

ActiveUS20050175919A1Sticking and the like easily occurAnti-sticking property of images one another is highDevelopersElectrographic processes using charge patternImage formationEngineering

A toner includes at least a crystalline compound, a binding resin and coloring agent, wherein a differential heat quantity curve measured by a differential scanning calorimeter (DSC) has a clear endothermic peak at 50 to 100° C. in a first temperature rising process, and in a second temperature rising process, a peak area of the endothermic peak is reduced by ⅓ or less with respect to the peak area of the endothermic peak in the first temperature rising process. An image forming method employs the toner.

Owner:KONICA MINOLTA INC

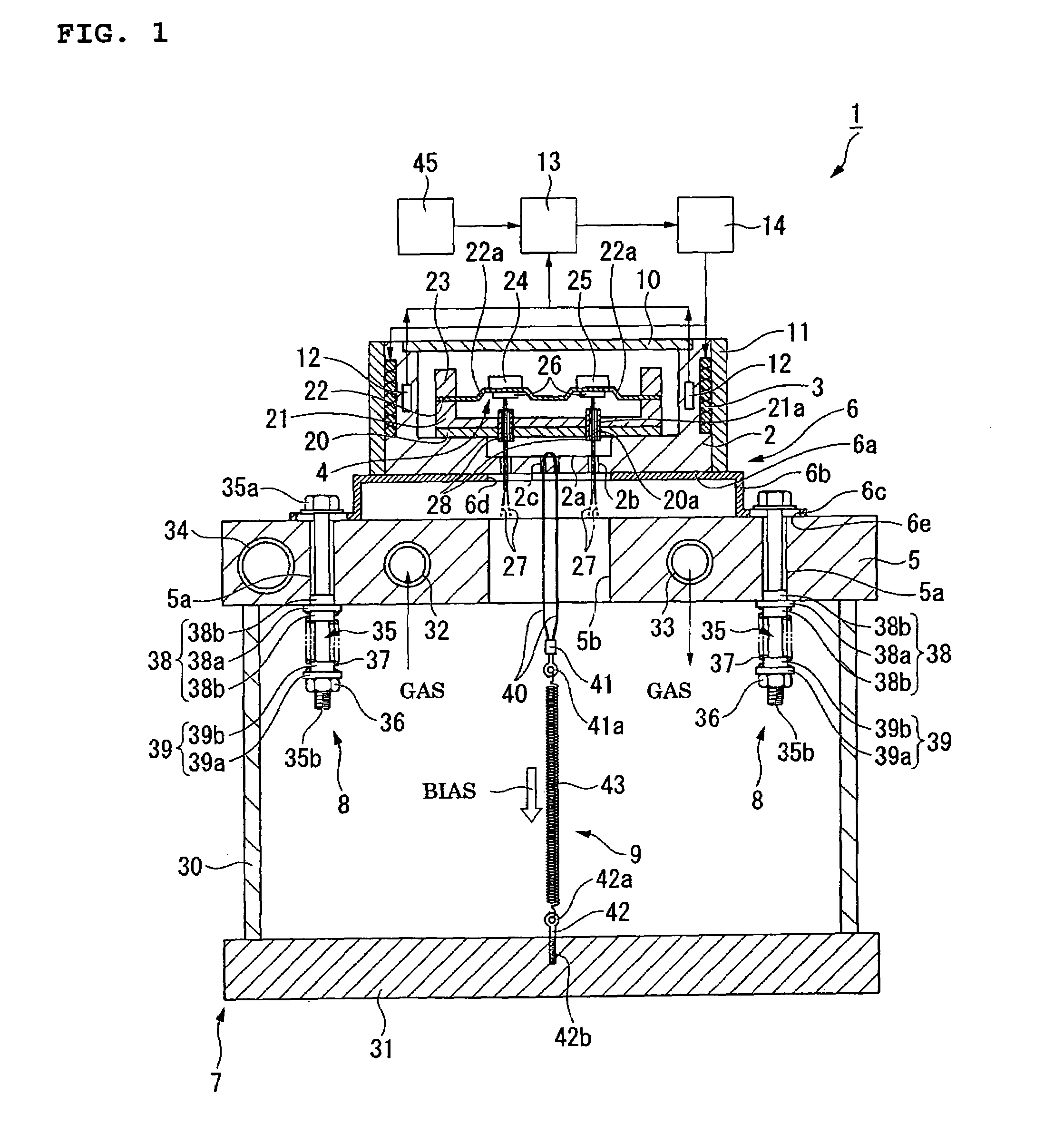

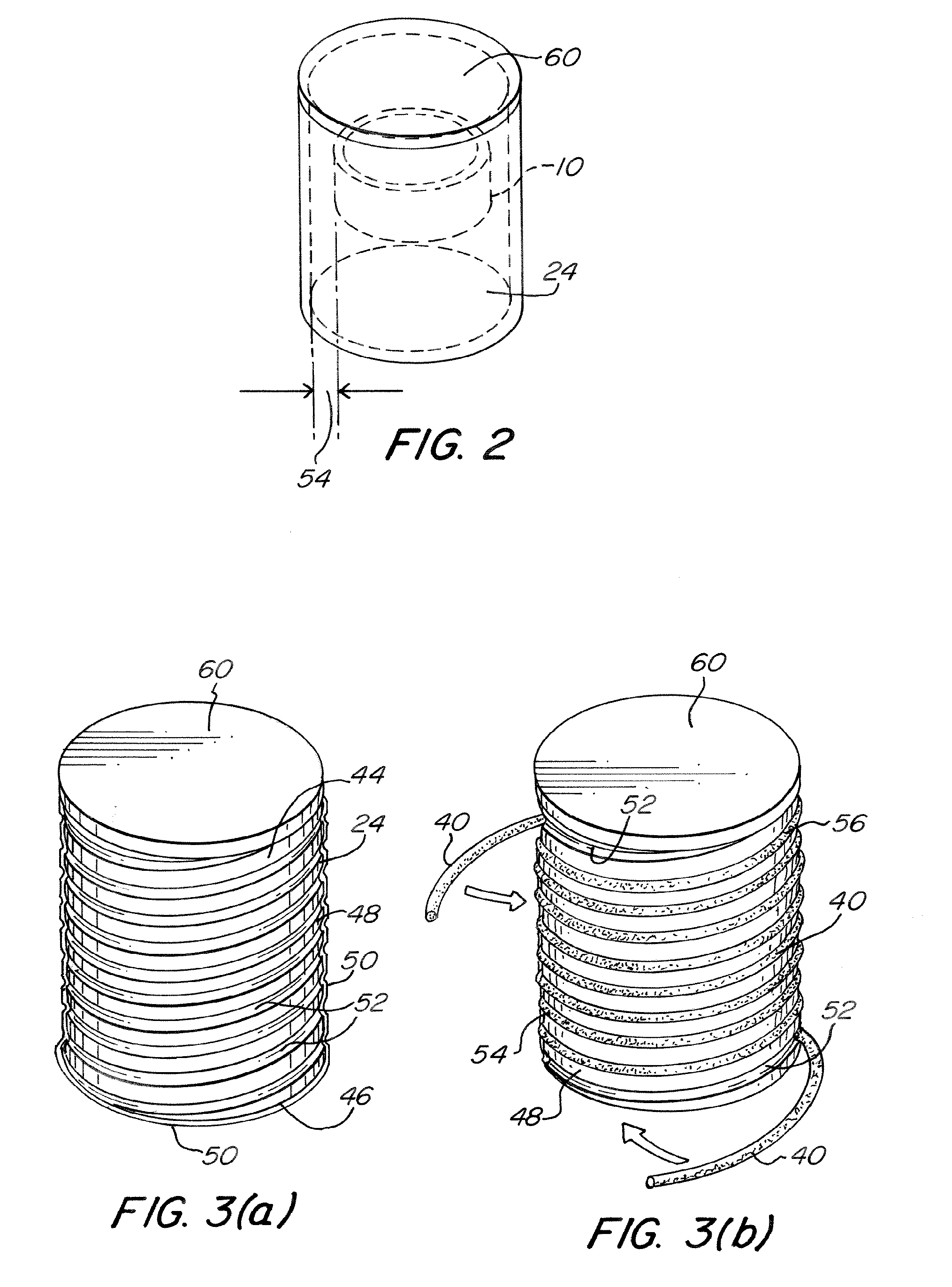

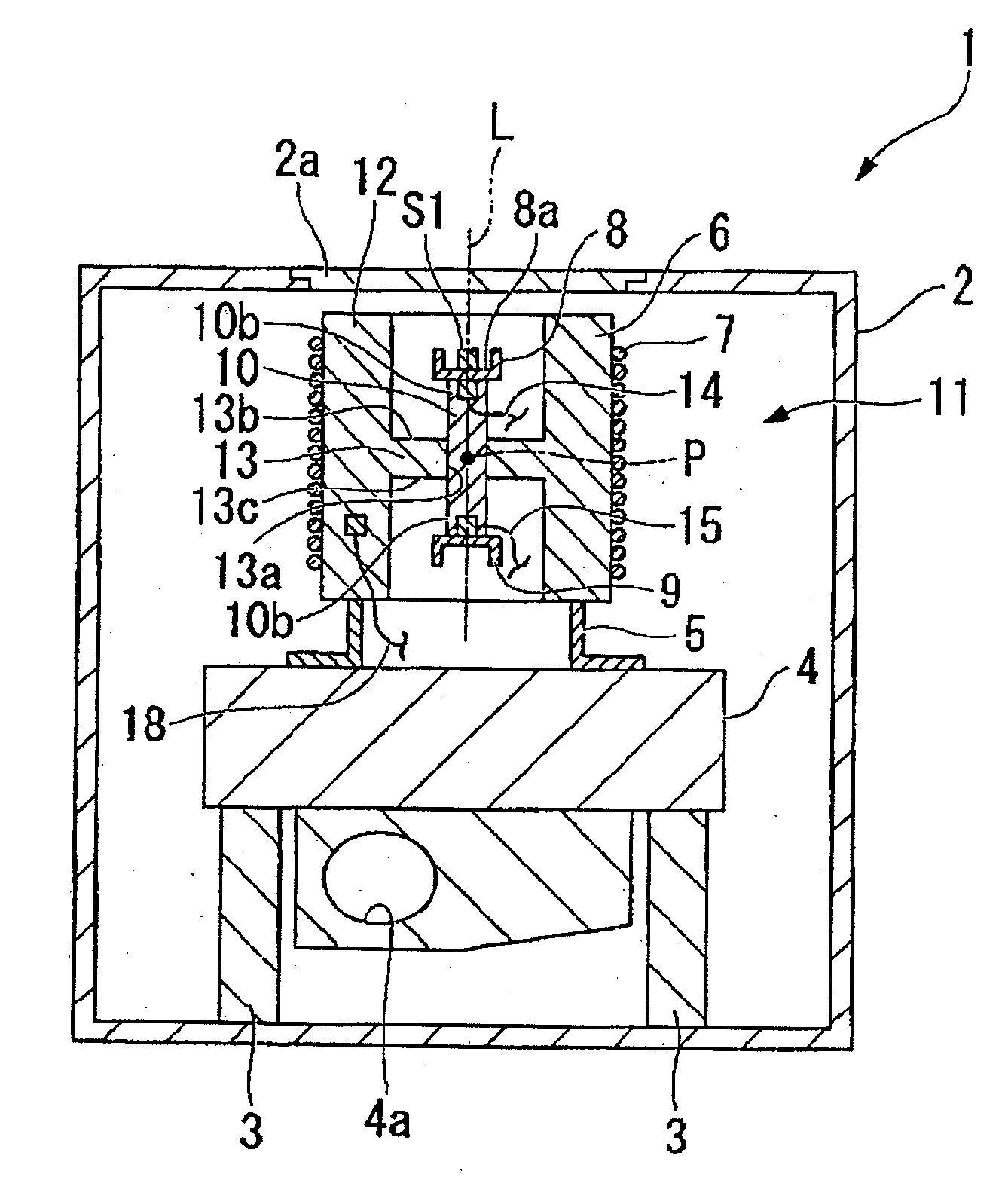

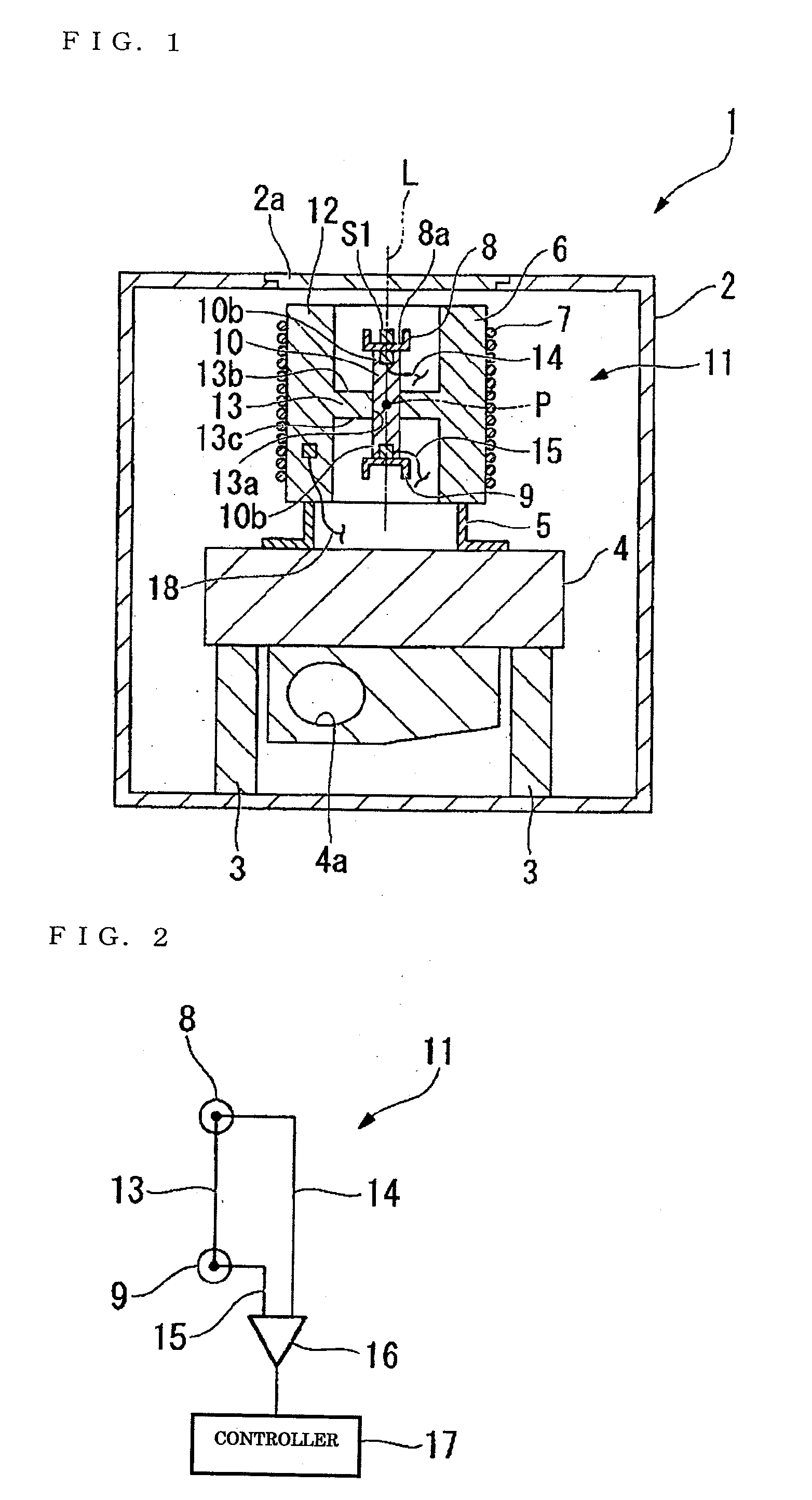

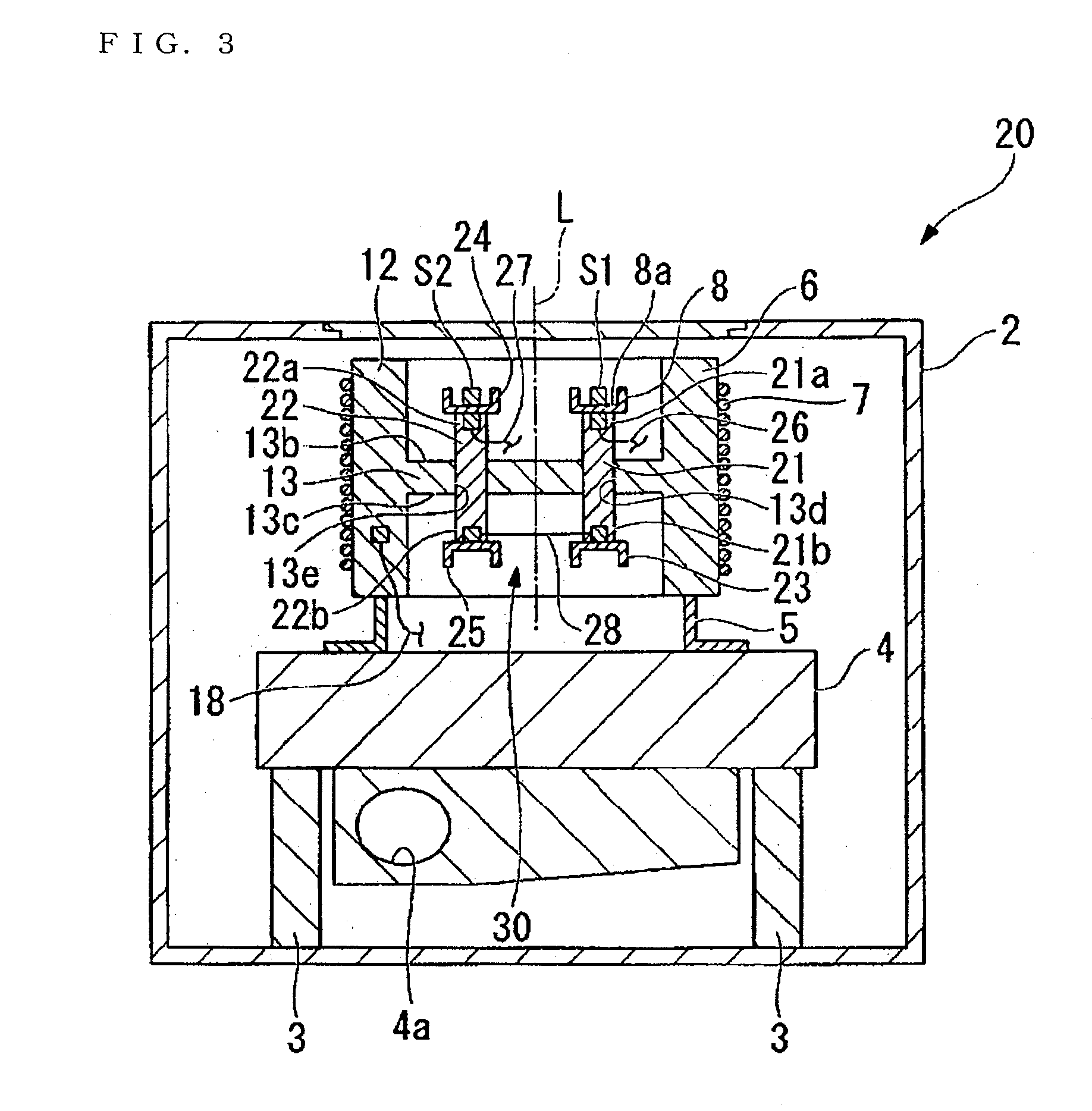

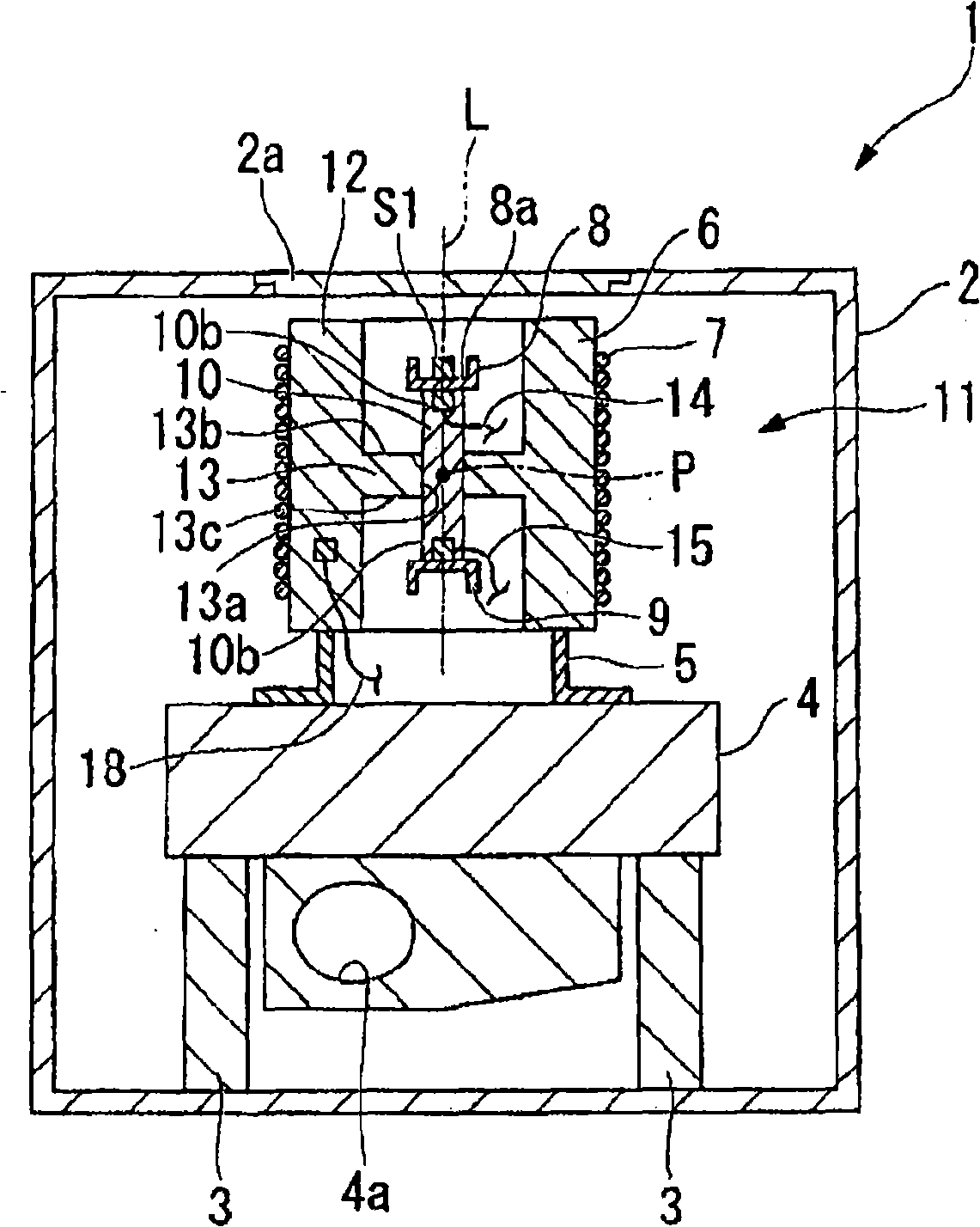

Differential scanning calorimeter

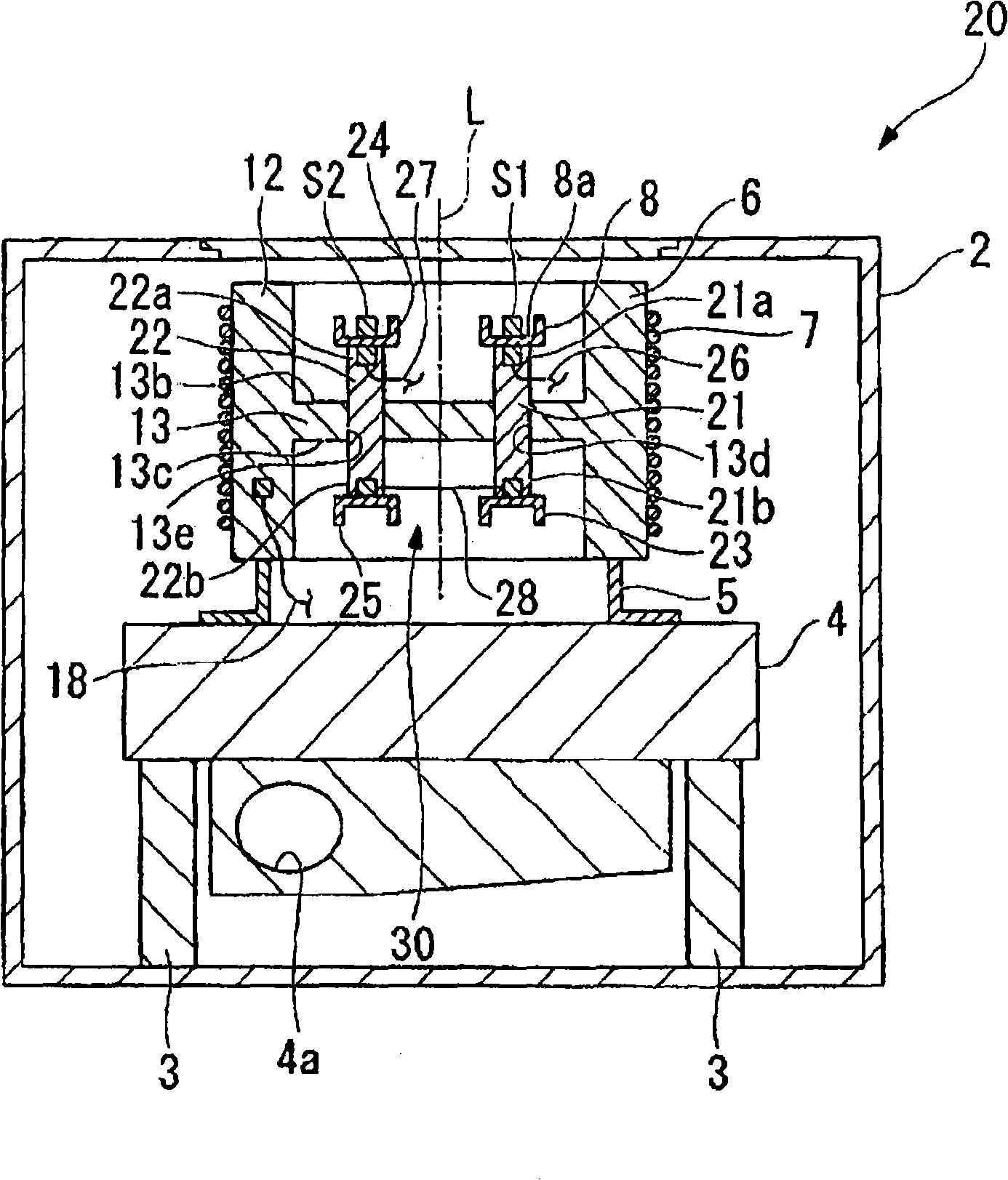

InactiveUS7802916B2Reduce decreaseImprove thermal conductivityThermometer detailsMaterial heat developmentHeat resistanceEngineering

There is provided a differential scanning calorimeter for exactly measuring a calorie variation of the measured sample on the basis of the temperature difference between sample container and the reference container without the influence of the heat irregularity incoming from the surroundings and the noise components. The differential scanning calorimeter includes a heating furnace of an approximately H-shaped section having an approximately drum-shaped wall part and an approximately plate-shaped heat inflow part, a heater disposed outside the wall part so as to heat the heating furnace, a approximately bar-shaped heat-resistance member that is arranged along the center axis L of the wall part, that protrudes from both sides of the heat inflow part by an approximately equal length, that is made of a material heat conductivity lower than that of the material of the heating furnace, a sample container disposed at one end of the heat-resistance member, a reference container disposed at the other end of the heat-resistance member, and a differential heat flow detector measuring a difference between the temperature of the sample container and the temperature of the reference container as a measured value.

Owner:HITACHI HIGH TECH SCI CORP

Turf reinforcement erosion control mat

A bi-layer, woven geotextile fabric has interwoven first and second layers. The first layer is over and under woven through the second layer in a pre-determined pattern so that the first layer has portions which face a first side of the second layer and portions which face a second side of the second layer. Monofilaments in the warp direction of the first layer have a pre-determined differential heat shrinkage characteristic that is greater than the monofilaments in the warp direction of the second layer. Closed cells defined by the pattern of the over and under weave are disposed on the first and second sides of the second layer. Shrinkage of the monofilaments in the warp direction of the first layer provide for a separation of a portion of the second layer from the first layer at the cells.

Owner:NICOLON CORP

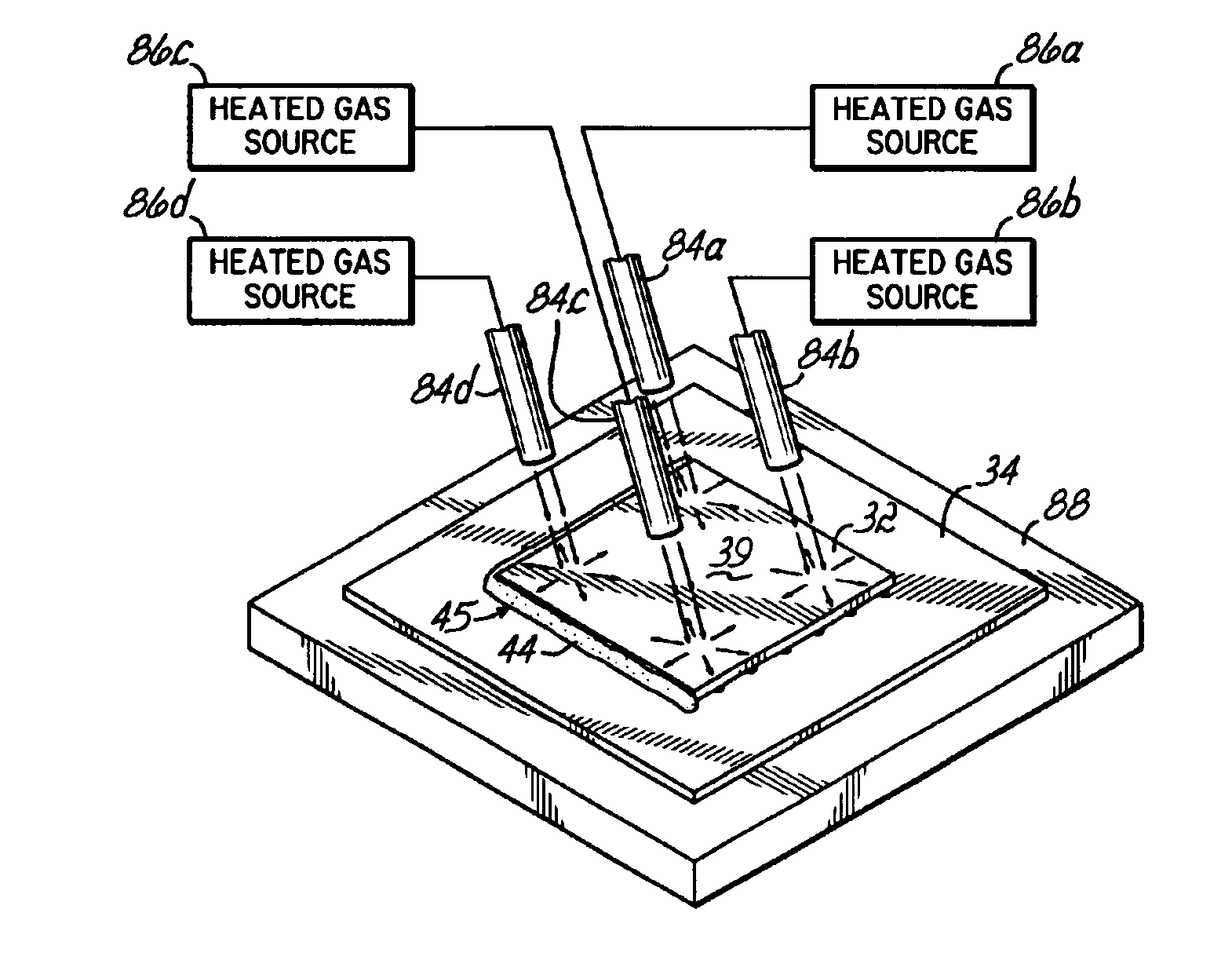

Method and apparatus for underfilling semiconductor devices

InactiveUS20050161846A1Reduce incidenceLarge space to underfillSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialSealant

A method and apparatus for underfilling a gap between a multi-sided die and a substrate with an encapsulant material. The die and / or the substrate is heated non-uniformly by a heat source to generate a temperature gradient therein. The heated one of the die and the substrate transfers heat energy in proportion to the temperature gradient to the encapsulant material moving in the gap. The differential heat transfer steers, guides or otherwise directs the movement of the encapsulant material in the gap. The temperature gradient may be established with heat transferred from the heat source to the die and / or the substrate by conduction, convection, or radiation. The temperature gradient may be dynamically varied as the encapsulant material moves into the gap.

Owner:NORDSON CORP

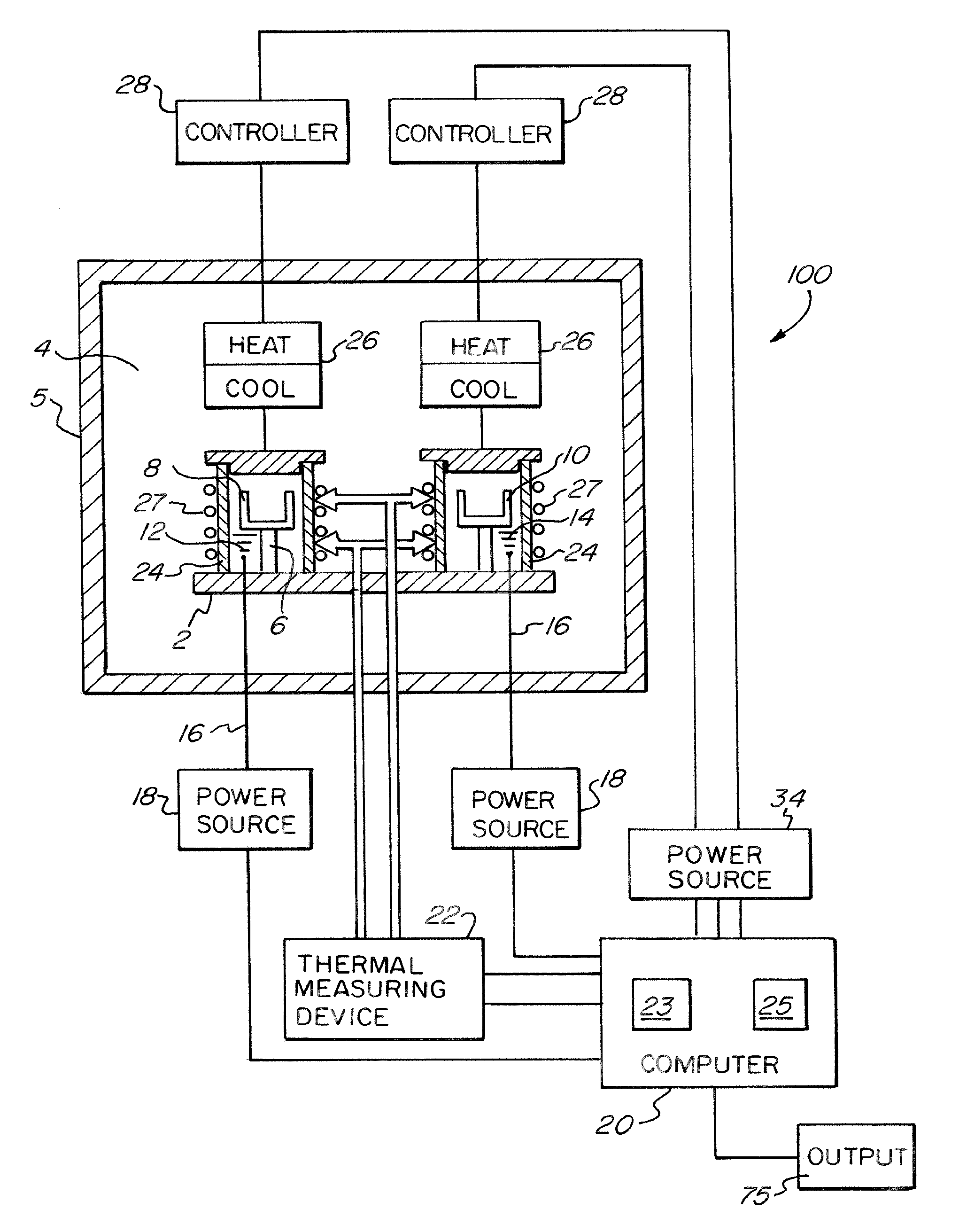

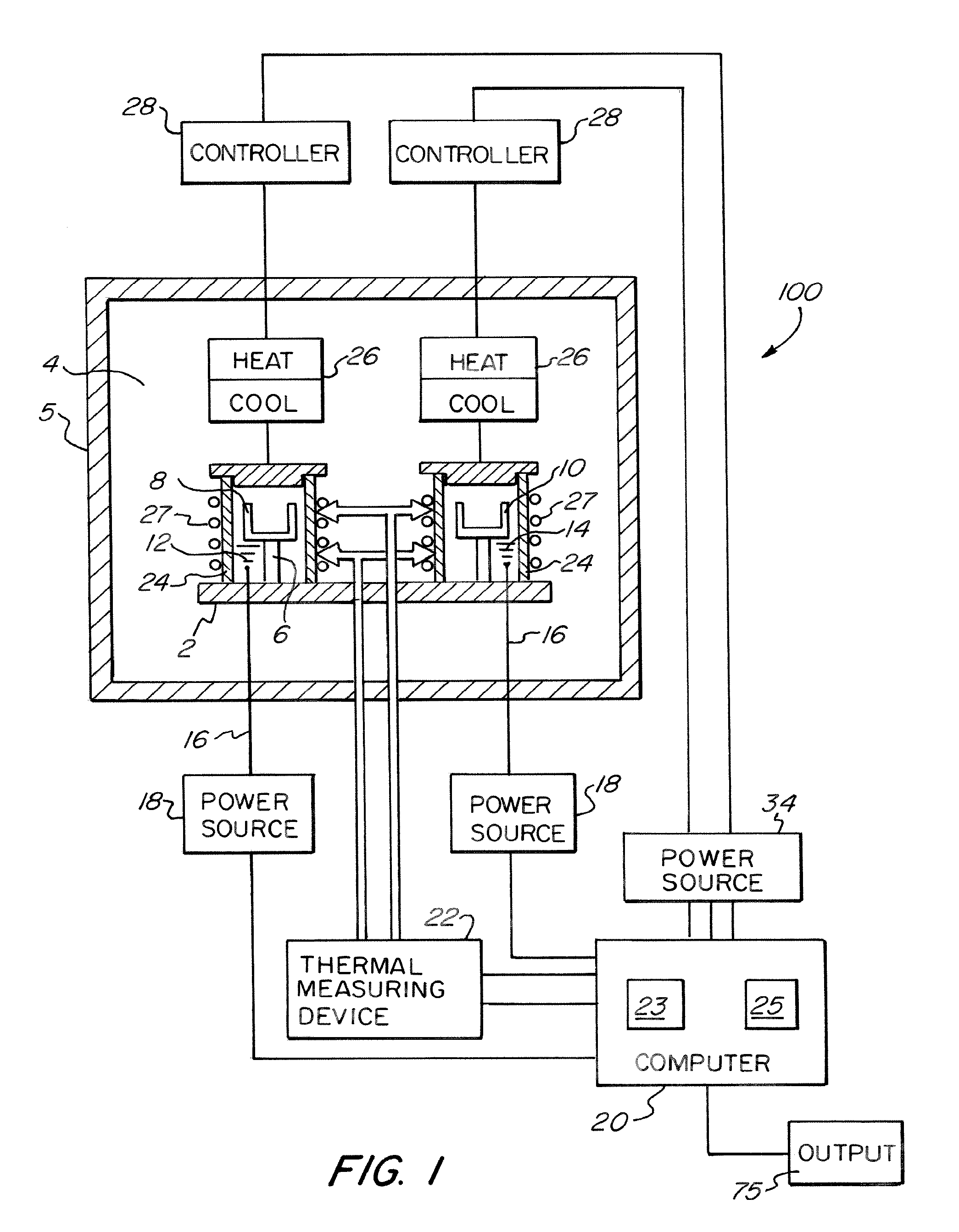

Differential Scanning Calorimeter (DSC) With Temperature Controlled Furnace

A differential scanning calorimeter apparatus includes reference and sample cells and controlled temperature shields. The temperature of the shields is controlled such that baseline curvature is reduced by eliminating heat flow from the furnaces to their surroundings (quasi adiabatic conditions) and by controlling heat flow through a well defined solid state heat resistance between the furnaces and a temperature controlled heat sink. The temperature of each shield can be controlled independently to reduce differential heat flow over the whole temperature range of the scan, or maintained at a constant temperature for conventional power compensated DSC operation. The temperature / time profile for each shield can be controlled according to actual furnace temperature, obtained from an empty run, or stored in the computer memory and recalled for sample measurements.

Owner:PERKINELMER U S LLC

Differential scanning calorimeter (DSC) with temperature controlled furnace

A differential scanning calorimeter apparatus includes reference and sample cells and controlled temperature shields. The temperature of the shields is controlled such that baseline curvature is reduced by eliminating heat flow from the furnaces to their surroundings (quasi adiabatic conditions) and by controlling heat flow through a well defined solid state heat resistance between the furnaces and a temperature controlled heat sink. The temperature of each shield can be controlled independently to reduce differential heat flow over the whole temperature range of the scan, or maintained at a constant temperature for conventional power compensated DSC operation. The temperature / time profile for each shield can be controlled according to actual furnace temperature, obtained from an empty run, or stored in the computer memory and recalled for sample measurements.

Owner:PERKINELMER U S LLC

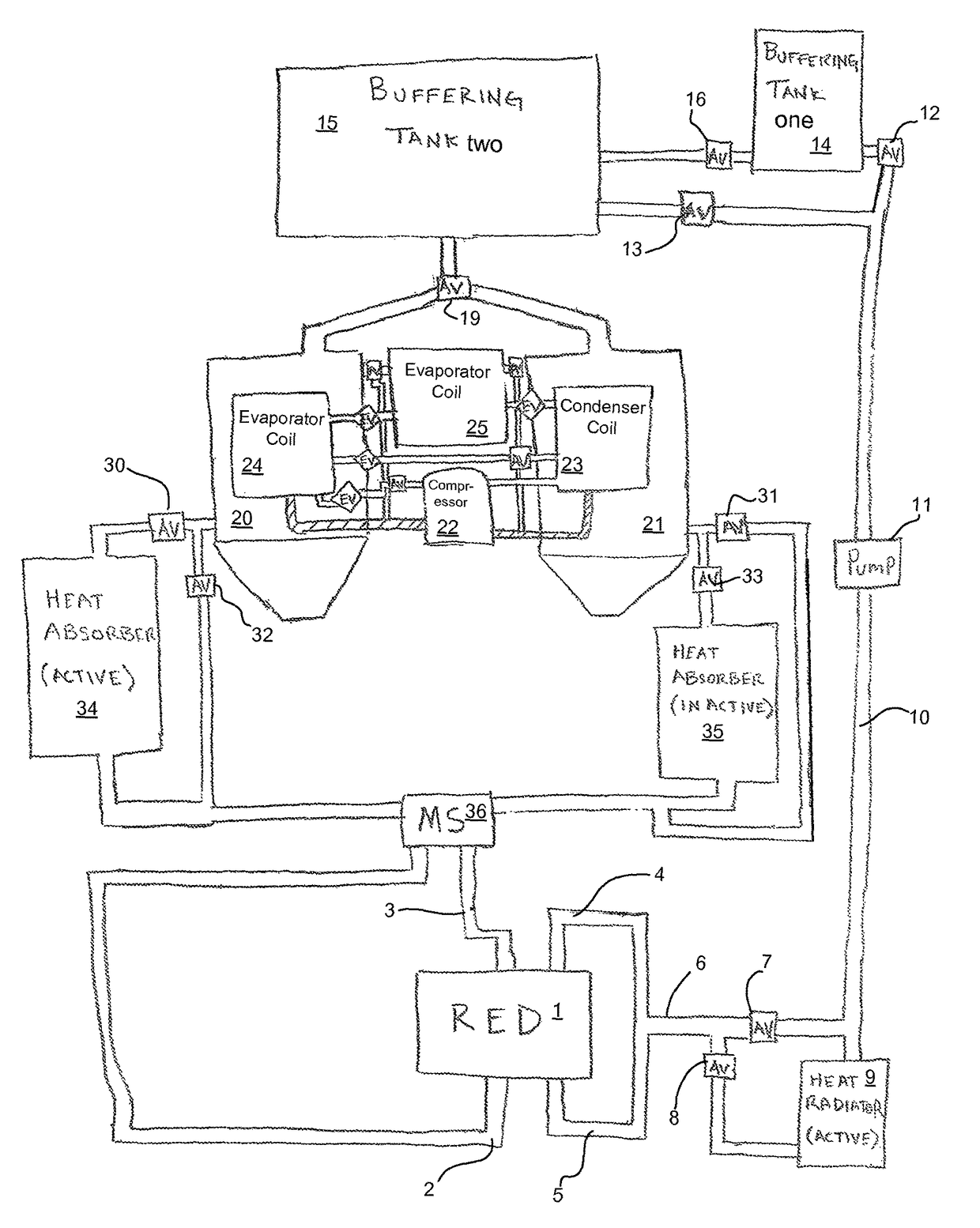

Ionic air cooling device

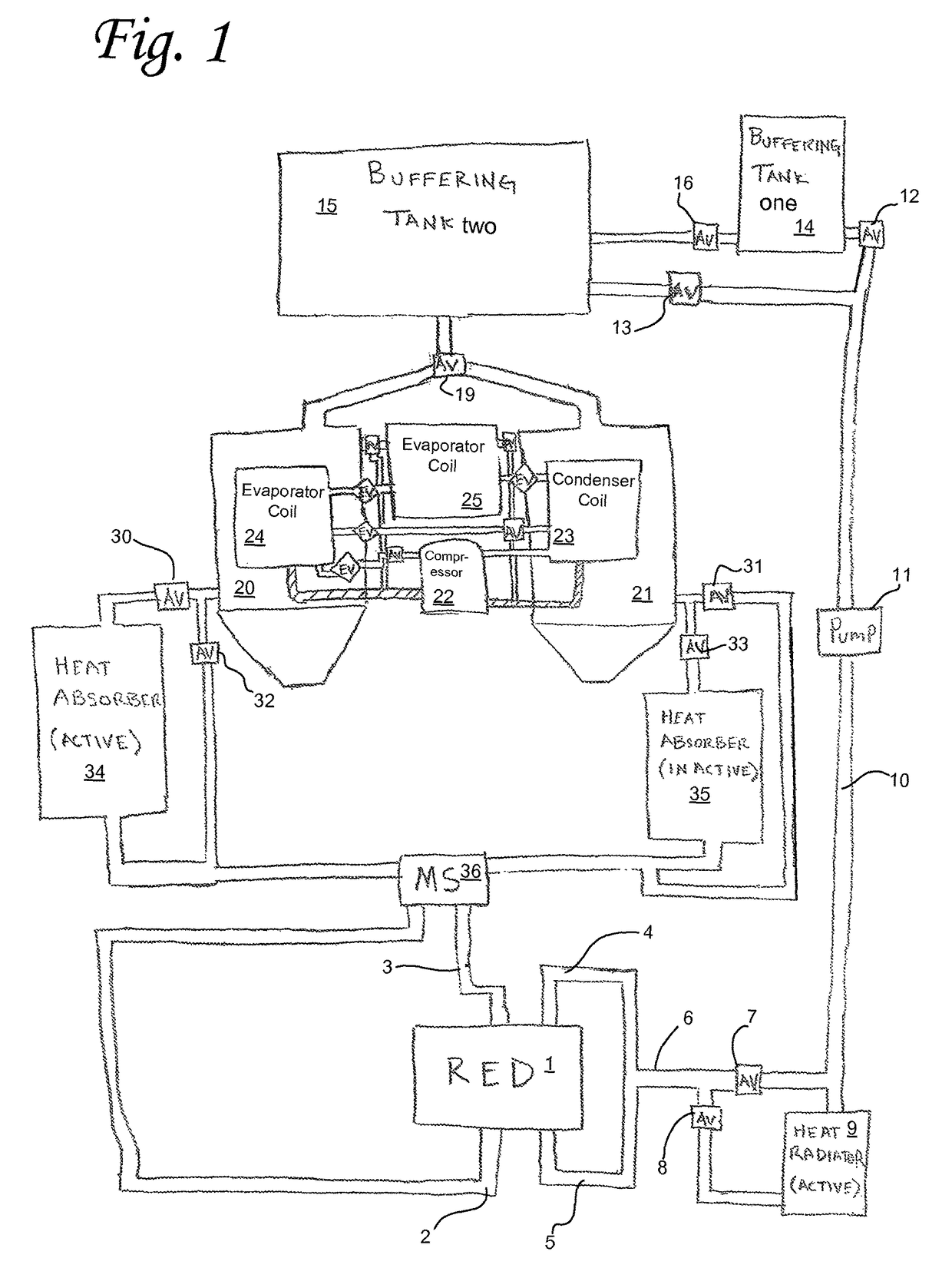

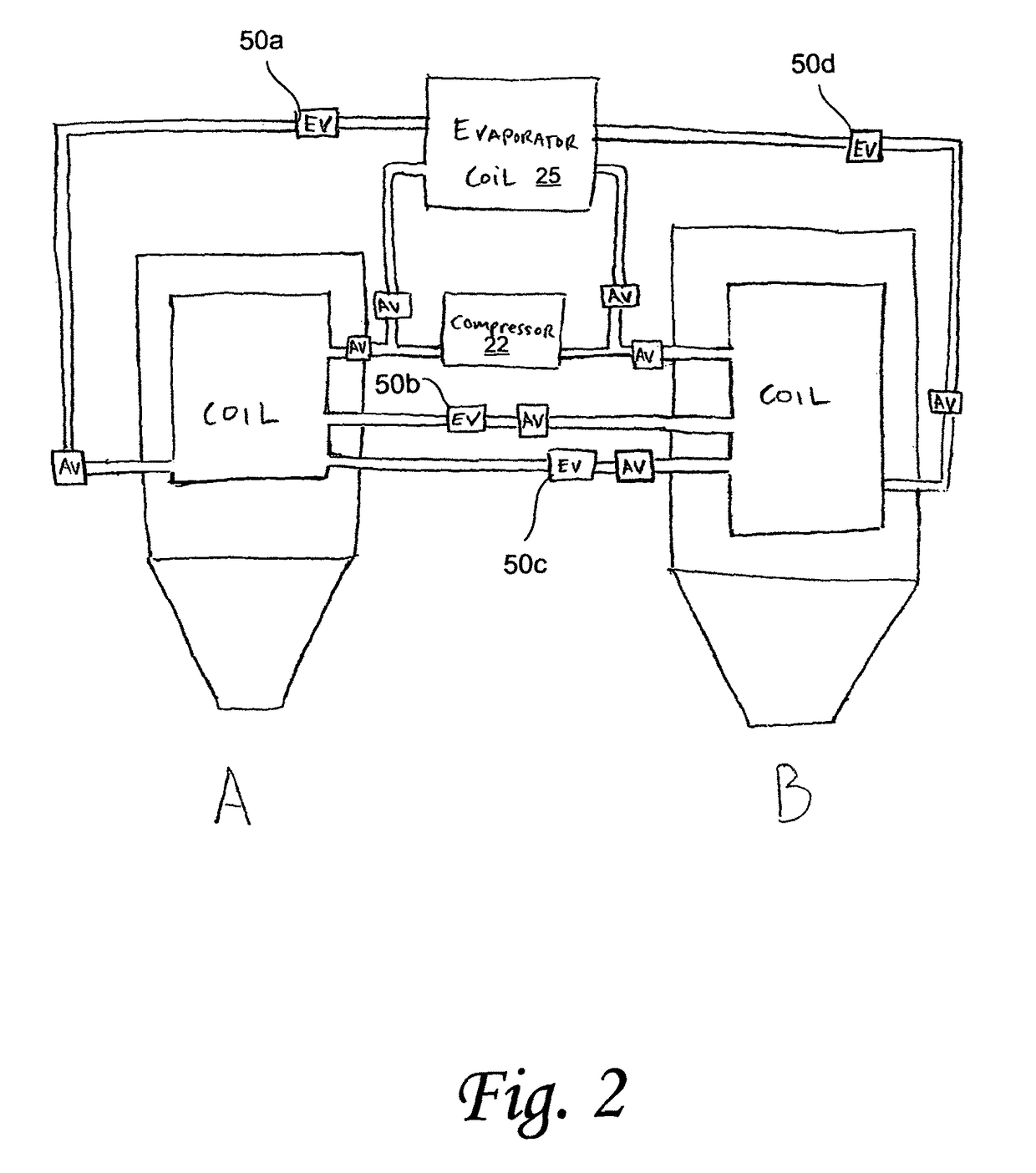

ActiveUS9851129B1Inhibit productionSpeed up the processHeat pumpsDispersed particle separationClosed loopCooling effect

An ionic air cooling device comprising a salinity differential heat engine using a heat pump as the primary heat source and the mechanism by which the temperature differential is achieved. A closed loop thermodynamic cycle which produces a high thermodynamic efficiency in heat to energy conversion with a low temperature differential between the high and low sides, in addition to a net ambient temperature cooling effect by directly or indirectly converting ambient temperature / environmental low grade heat to electricity or potential kinetic energy or mechanical work. An ionic air cooling device which uses a salinity differential heat engine in which the heat energy can be converted to kinetic or electrical energy by means of pressure retarded osmosis, pressurized gas through volume confinement, or reversed electro dialysis.

Owner:TANNER DAVID JOHN

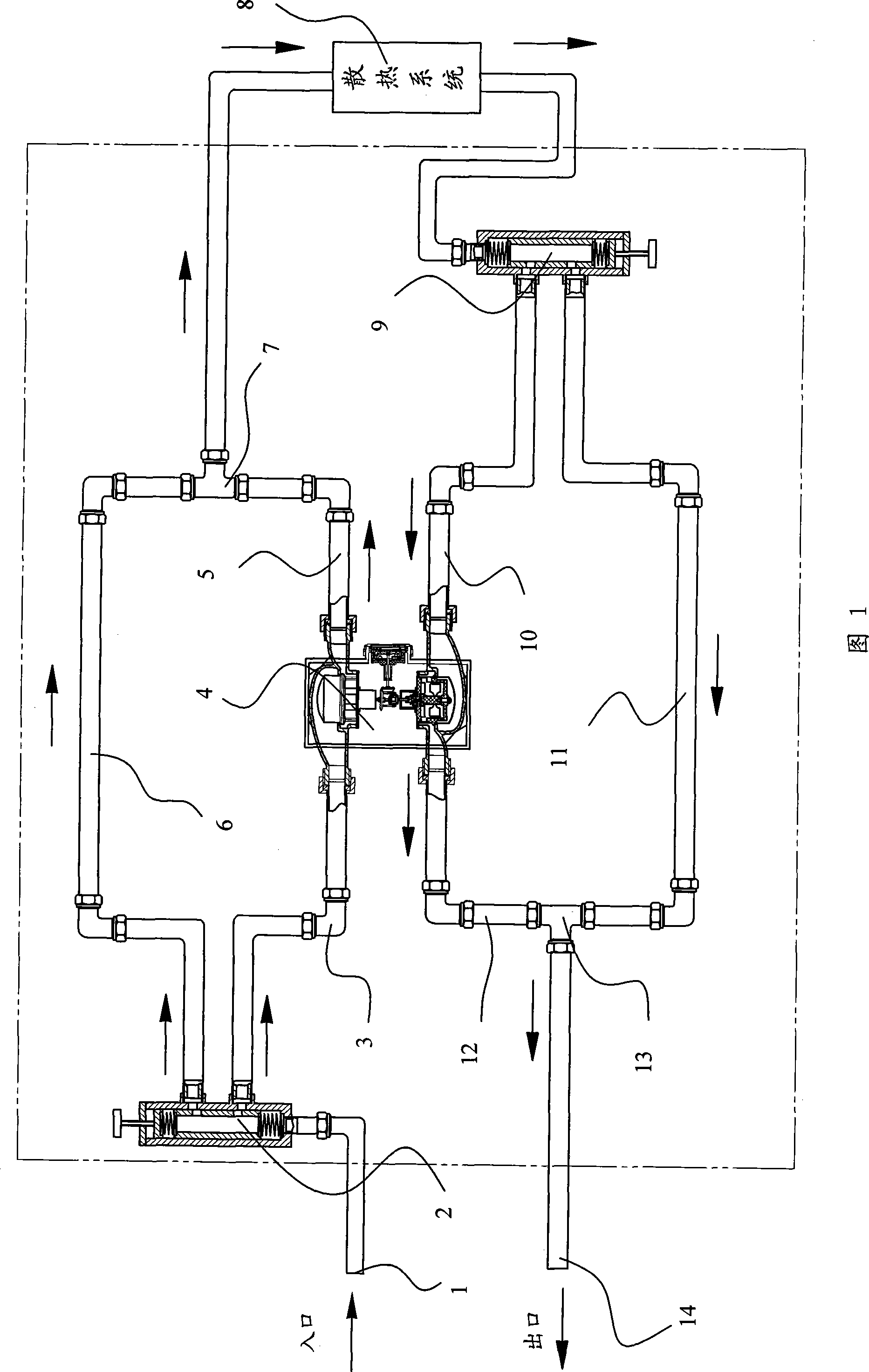

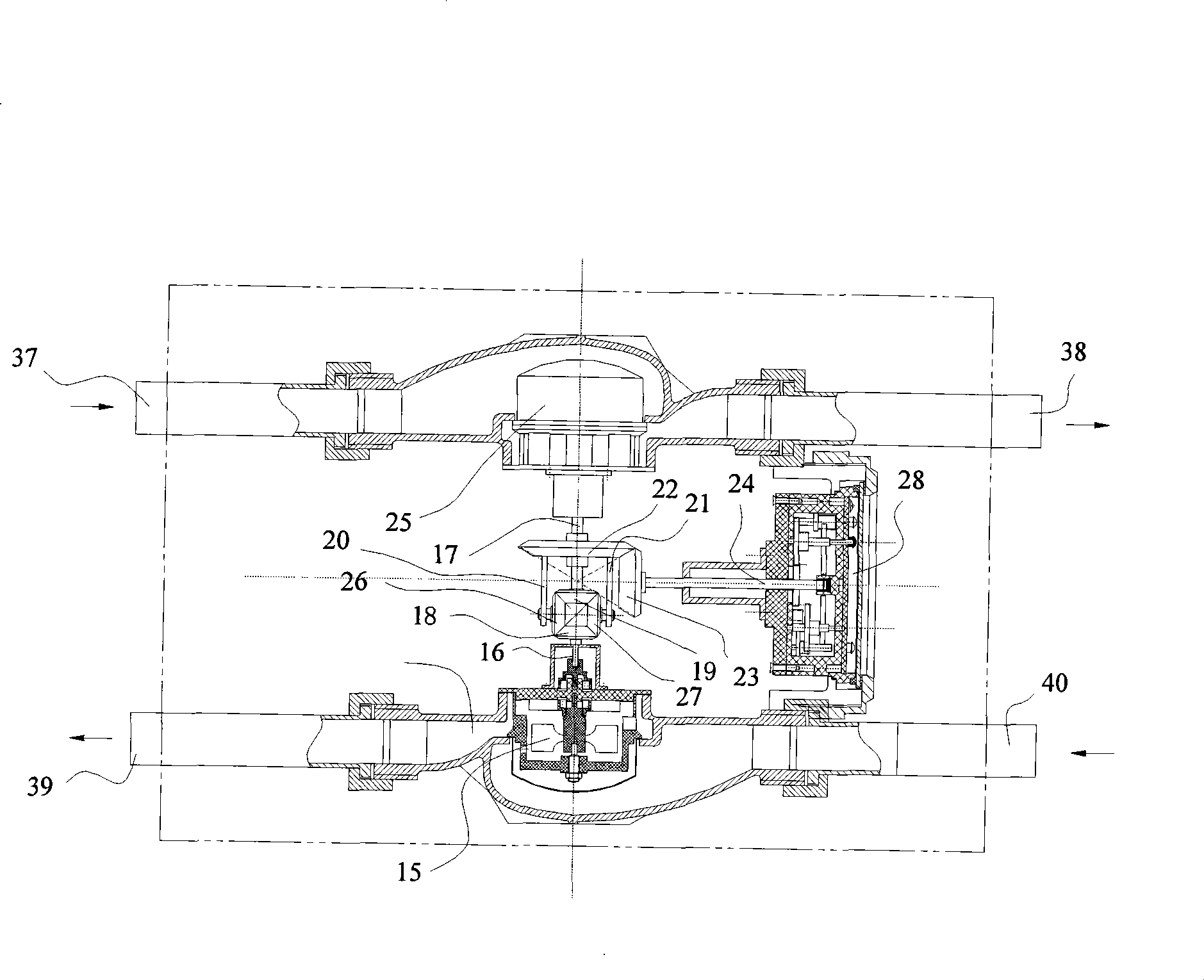

Flow distributor and differential heat meter using the flow distributor

InactiveCN101387353AWith temperature-length memory functionOperating means/releasing devices for valvesMultiple way valvesDistributorStreamflow

The invention relates to a flow distributor, which comprises a valve body, a sliding valve core and an adjusting component, wherein one end face of the valve body is provided with a medium inlet, the side wall of the valve body is provided with two external outlets, the side wall of the sliding valve core is provided with two internal outlets, the adjusting component is a temperature-length memory spring positioned in an inner cavity of the valve body, the sliding valve core can be attached to the inner cavity of the valve body and moved under the control of the memory spring, the two external outlets and the two internal outlets are parallelograms which have the same section shape and the same sectional area, the first external outlet can be completely coincided with the first internal outlet, and the second external outlet can be completely coincided with the second internal outlet. The flow distributor is not supplied by power, can be used singly, and can form a passive element together with other components.

Owner:BEIJING UNION UNIVERSITY

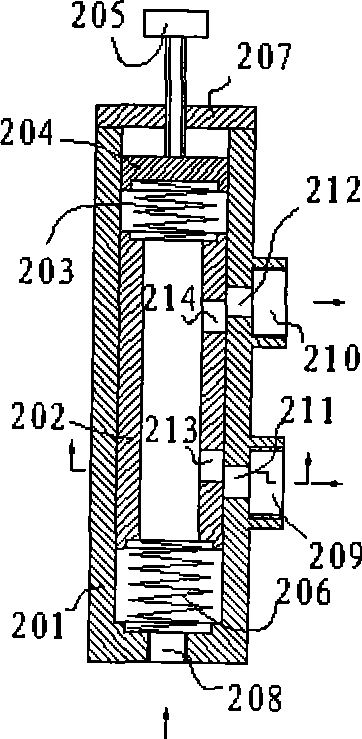

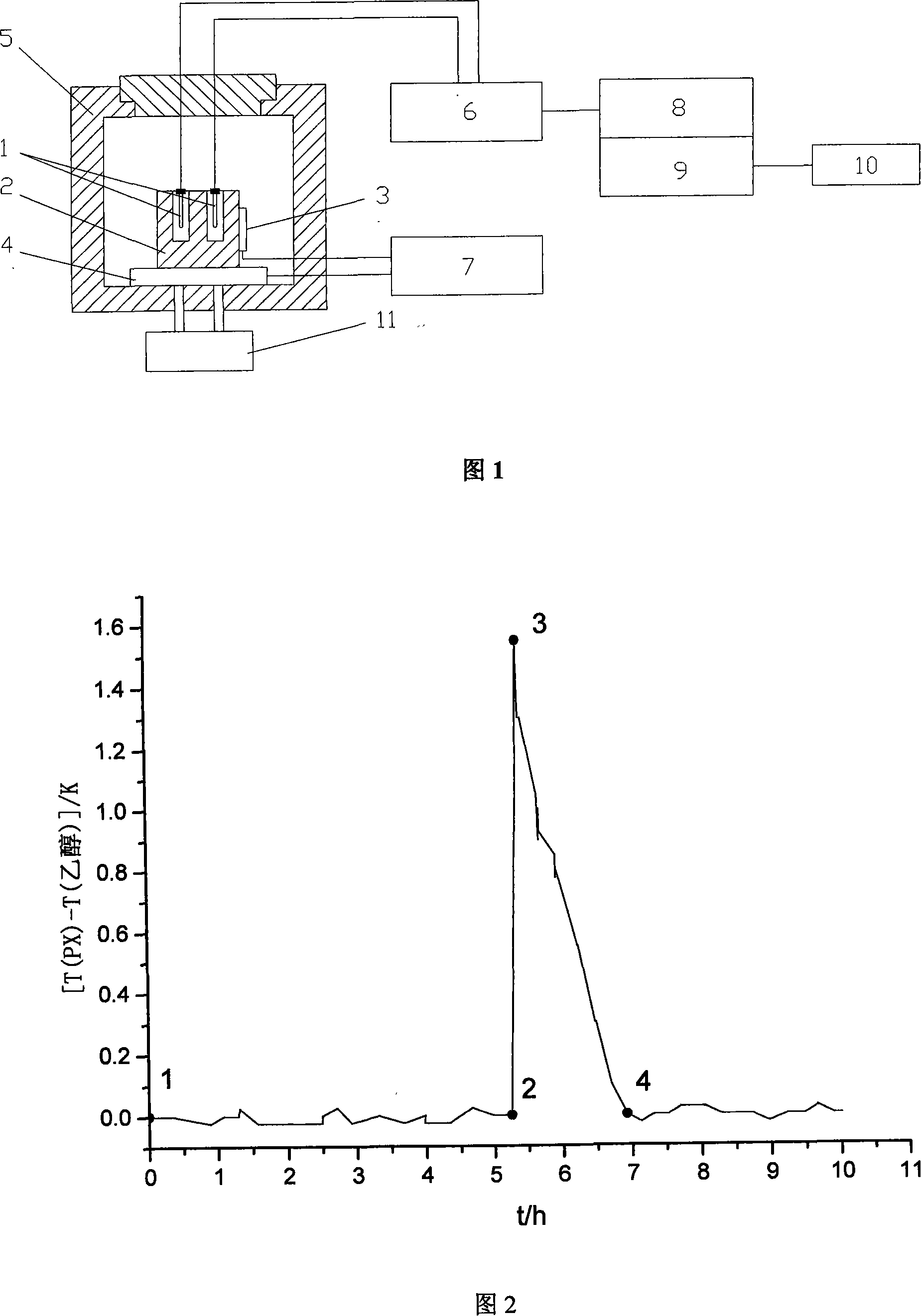

Peltier low temperature differential heat analyzer

The invention pertains to the technical field of thermal analysis and test, in particular to a Peltire low-temperature micro thermal analyzer, which comprises sensors, crystallizer, a hot pump chip, a sealer, a temperature / heat flow measuring device, a temperature / heat flow measuring and power controller, an A / D converter, and a digital processor, etc. The sealer is hollow in the middle, the sensor, crystallizer and the chip are in the sealer, the chip is located at the bottom of the sealer, the crystallizer is above the chip; the top of the crystallizer is provided with a recess, in which a sensor is placed; at one side of the crystallizer, a sensor is provided, which is connected with a wire with the temperature / heat flow measuring and power controller, and is connected with a wire with the temperature / heat flow measuring device; another end of the temperature / heat flow measuring device is connected with the A / D converter, which is connected with a computer that is connected with a printer. The invention is of high measuring accuracy, is highly automatic, can be used for studying the nucleation principle of crystal of organic system such as DNA, protein, polymers and medicines, etc., for studying solid-liquid phase balancing and crystallizing principle, etc.

Owner:TONGJI UNIV

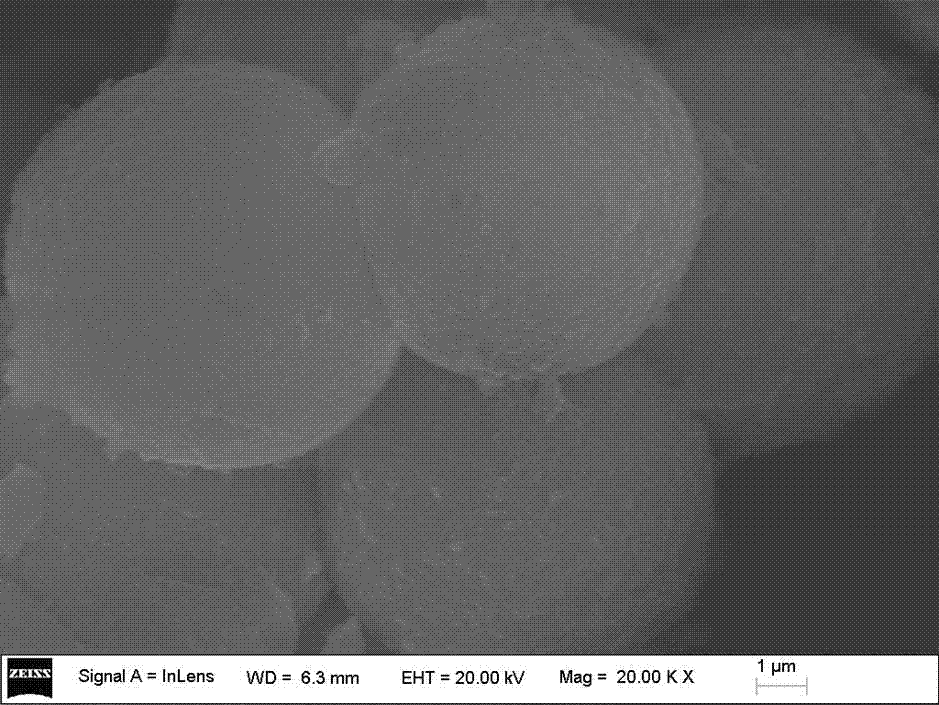

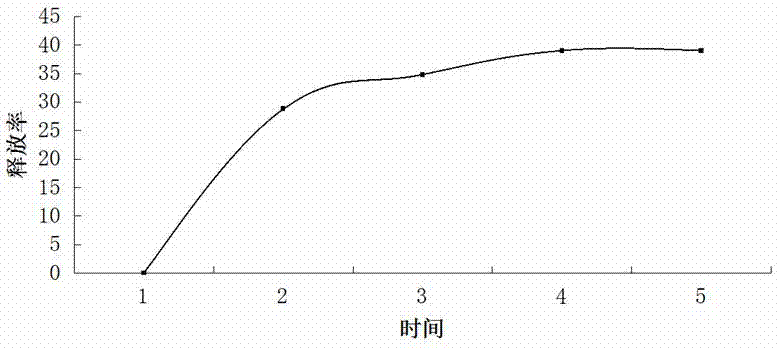

Preparation method for silicon dioxide aerogel microsphere coated ammonium persulfate delaying gel-breaking agent

InactiveCN107304356ASolve the defect of poor heat resistanceImprove stabilityDrilling compositionMaterial defectMicrosphere

The invention provides a preparation method of ammonium persulfate delayed breaker coated with silica airgel microspheres, by using silica airgel instead of polymer material as the coating material of ammonium persulfate, It solves the defect of poor heat resistance of polymer materials, realizes the delayed release of the breaker, improves the stability and safety of the ammonium persulfate breaker in fracturing construction, prolongs the operation time, and ensures The crack construction can be carried out safely and smoothly.

Owner:BEIJING UNIV OF CHEM TECH

Differential Scanning Calorimeter

InactiveUS20080151962A1Reduce decreaseImprove thermal conductivityThermometer detailsMaterial heat developmentHeat resistanceEngineering

There is provided a differential scanning calorimeter for exactly measuring a calorie variation of the measured sample on the basis of the temperature difference between sample container and the reference container without the influence of the heat irregularity incoming from the surroundings and the noise components. The differential scanning calorimeter includes a heating furnace of an approximately H-shaped section having an approximately drum-shaped wall part and an approximately plate-shaped heat inflow part, a heater disposed outside the wall part so as to heat the heating furnace, a approximately bar-shaped heat-resistance member that is arranged along the center axis L of the wall part, that protrudes from both sides of the heat inflow part by an approximately equal length, that is made of a material heat conductivity lower than that of the material of the heating furnace, a sample container disposed at one end of the heat-resistance member, a reference container disposed at the other end of the heat-resistance member, and a differential heat flow detector measuring a difference between the temperature of the sample container and the temperature of the reference container as a measured value.

Owner:HITACHI HIGH TECH SCI CORP

Toner for electrostatic charge image development and image forming method

ActiveUS7186492B2Sticking and the like easily occurAnti-sticking property of images one another is highDevelopersElectrographic processes using charge patternImage formationEngineering

A toner includes at least a crystalline compound, a binding resin and coloring agent, wherein a differential heat quantity curve measured by a differential scanning calorimeter (DSC) has a clear endothermic peak at 50 to 100° C. in a first temperature rising process, and in a second temperature rising process, a peak area of the endothermic peak is reduced by ⅓ or less with respect to the peak area of the endothermic peak in the first temperature rising process. An image forming method employs the toner.

Owner:KONICA MINOLTA INC

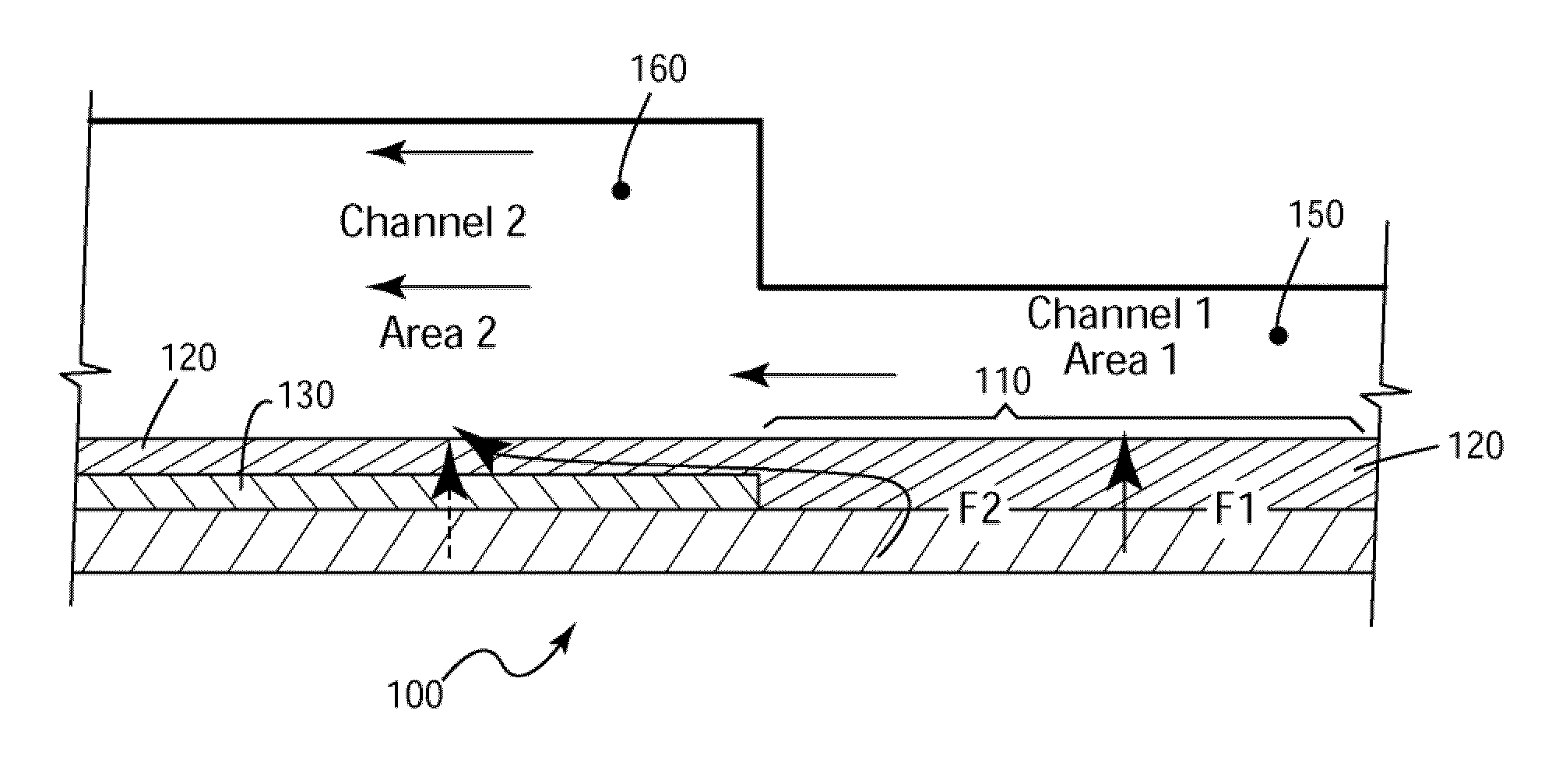

Deposition sensor based on differential heat transfer resistance

ActiveUS8517600B2Weather/light/corrosion resistanceMaterial heat developmentFluid transportThin metal

A system and method are disclosed wherein differential heat transfer resistances are used to effectively and efficiently detect the early onset of deposit accumulation in industrial fluid processes and fluid transport vehicles.According to one embodiment, a probe is provided in conjunction with a heat source, a water source and a probe. The probe is comprised of a heat transfer surface, a first part of which is covered only by a thin metal layer. The second or remaining portion of the heat transfer surface is covered by a heat flux sensor and a thin metal layer. The metal layers of both the first and second areas of the probe are connected, and water flows across the full heat transfer surface. Deposition forms on a portion of the heat transfer surface as a result of slow water flow and elevated water temperature. The temperatures of the heat source, water source, and heat flux are measured. The deposition rate as a rate of change of heat transfer resistance is measured.

Owner:BL TECH INC

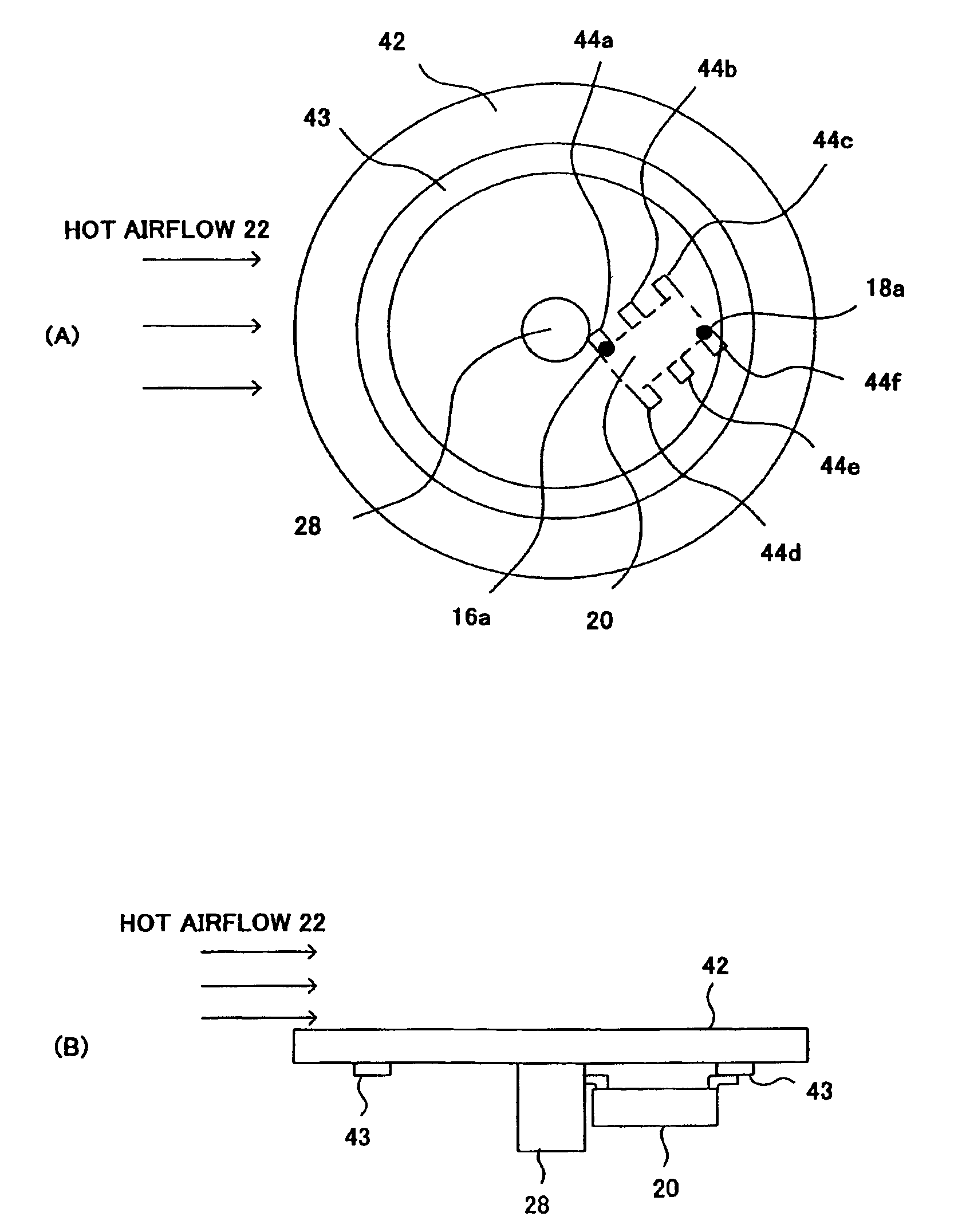

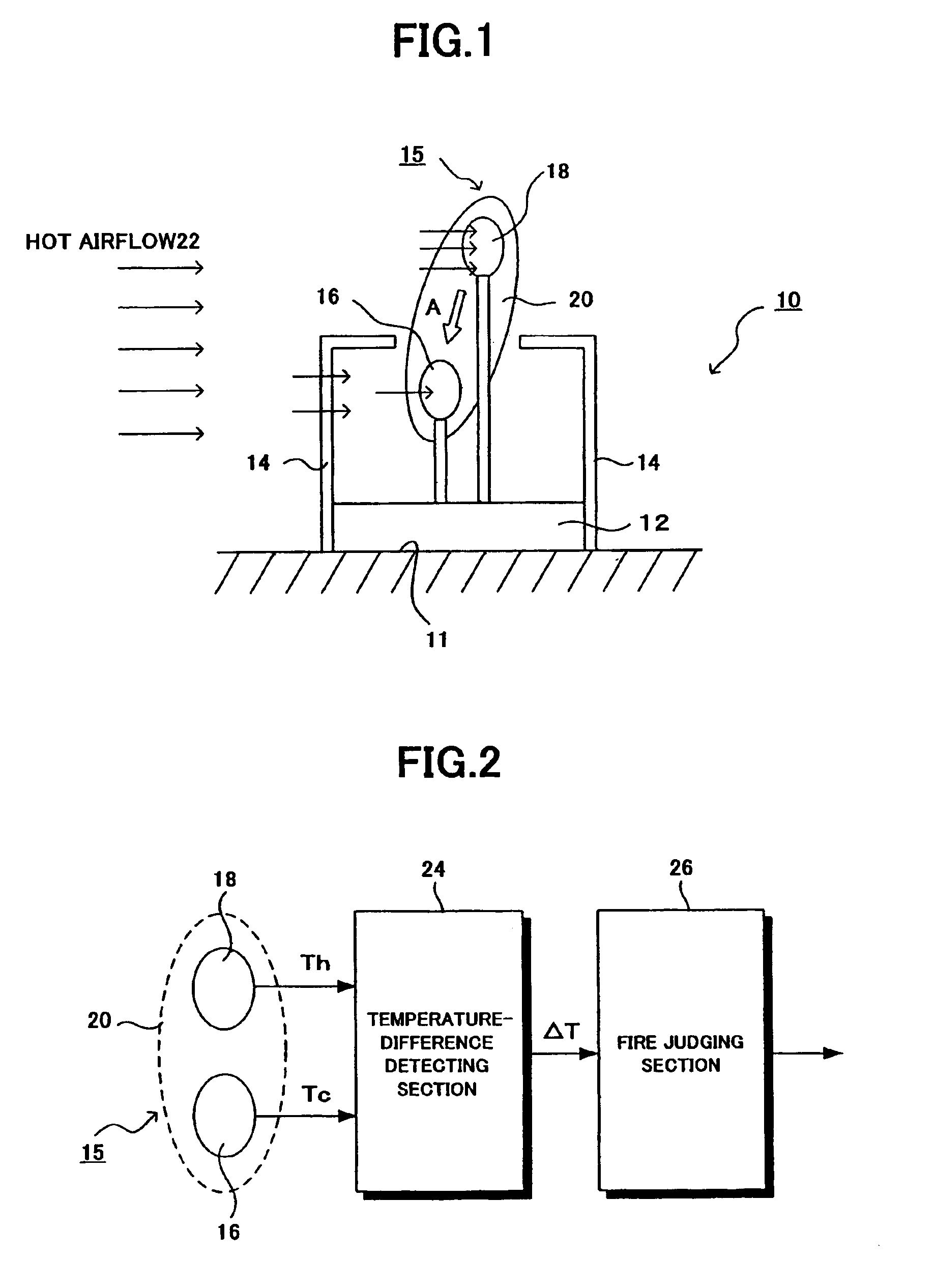

Fire heat sensor

InactiveUS6917296B2Eliminating signal processingReduce dependenceFire alarm electric actuationCalorimeterEngineeringThermal perception

A fire heat sensor comprising a high-temperature detecting portion provided with a temperature detecting element which exhibits a fast heat response to a rise in ambient temperature, and a low-temperature detecting portion provided with a temperature detecting element which exhibits a slow heat response to a rise in ambient temperature. The fire heat sensor further comprises a resin member by which the high-temperature detecting portion and the low-temperature detecting portion are integrally formed so that heat energy is transferred from the temperature detecting element of the high-temperature detecting portion to the temperature detecting element of the low-temperature detecting portion. In the fire heat sensor, differential heat sensing is performed based on temperatures detected by the low-temperature detecting portion and the high-temperature detecting portion.

Owner:HOCHIKI CORP

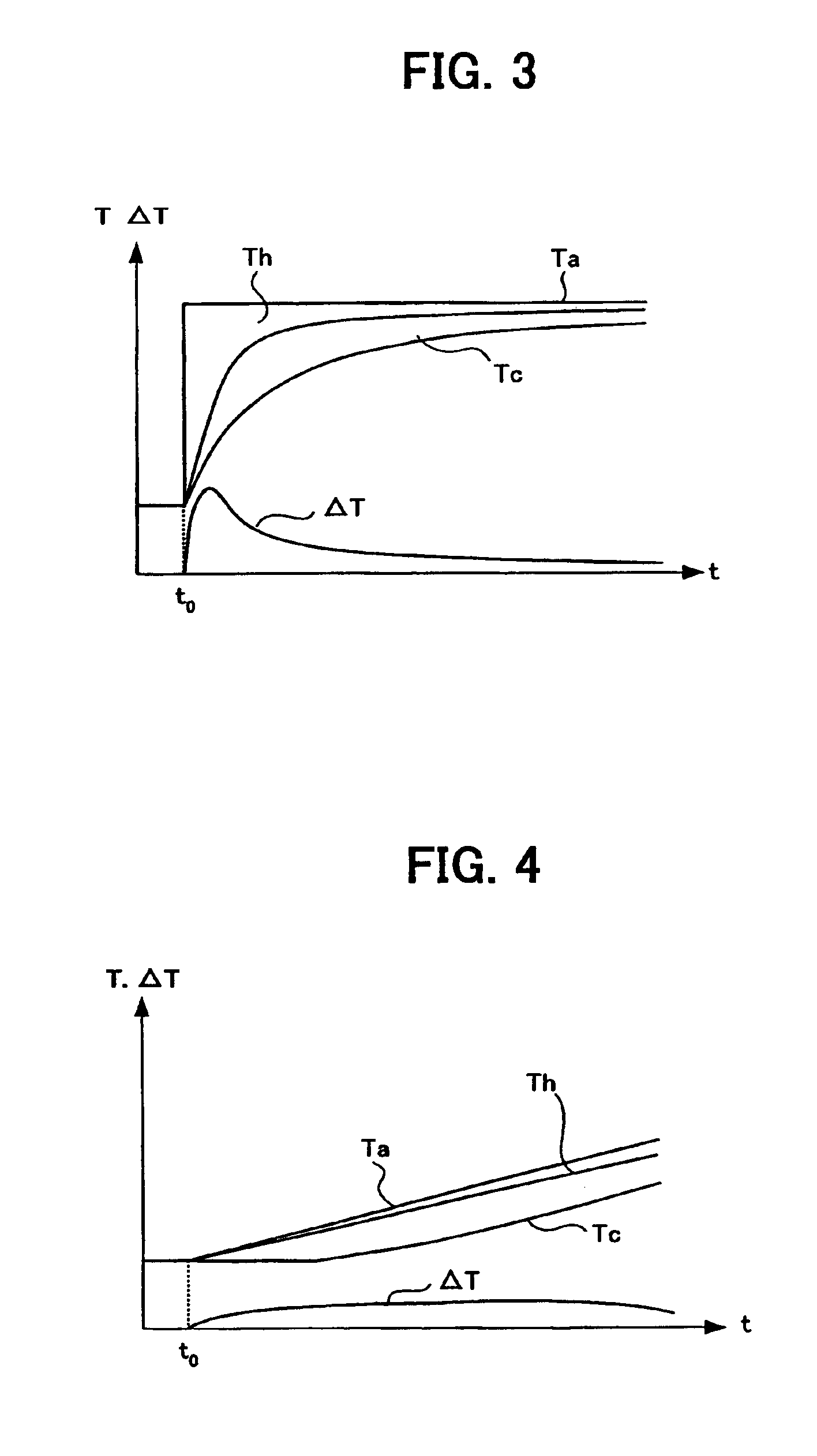

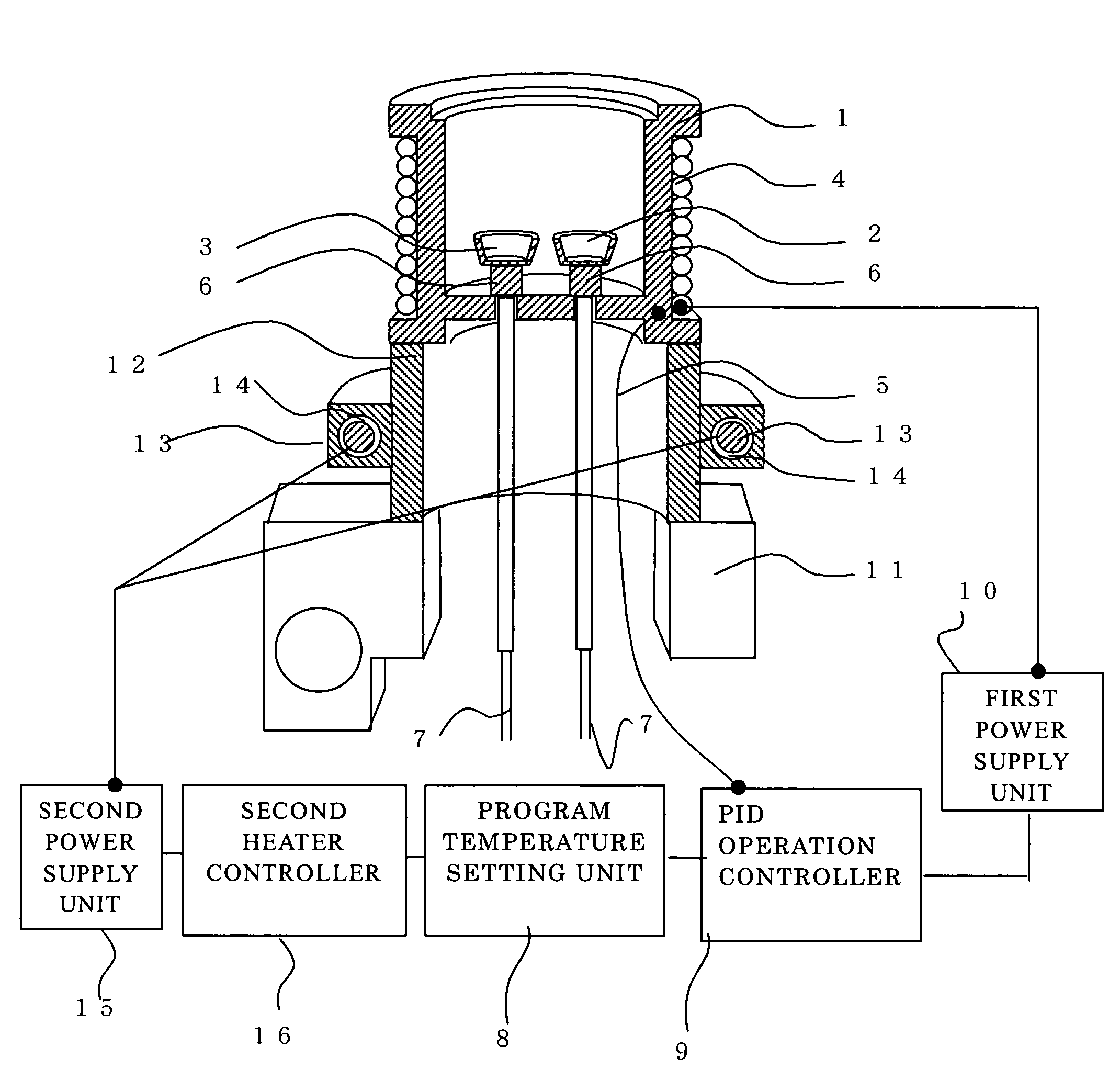

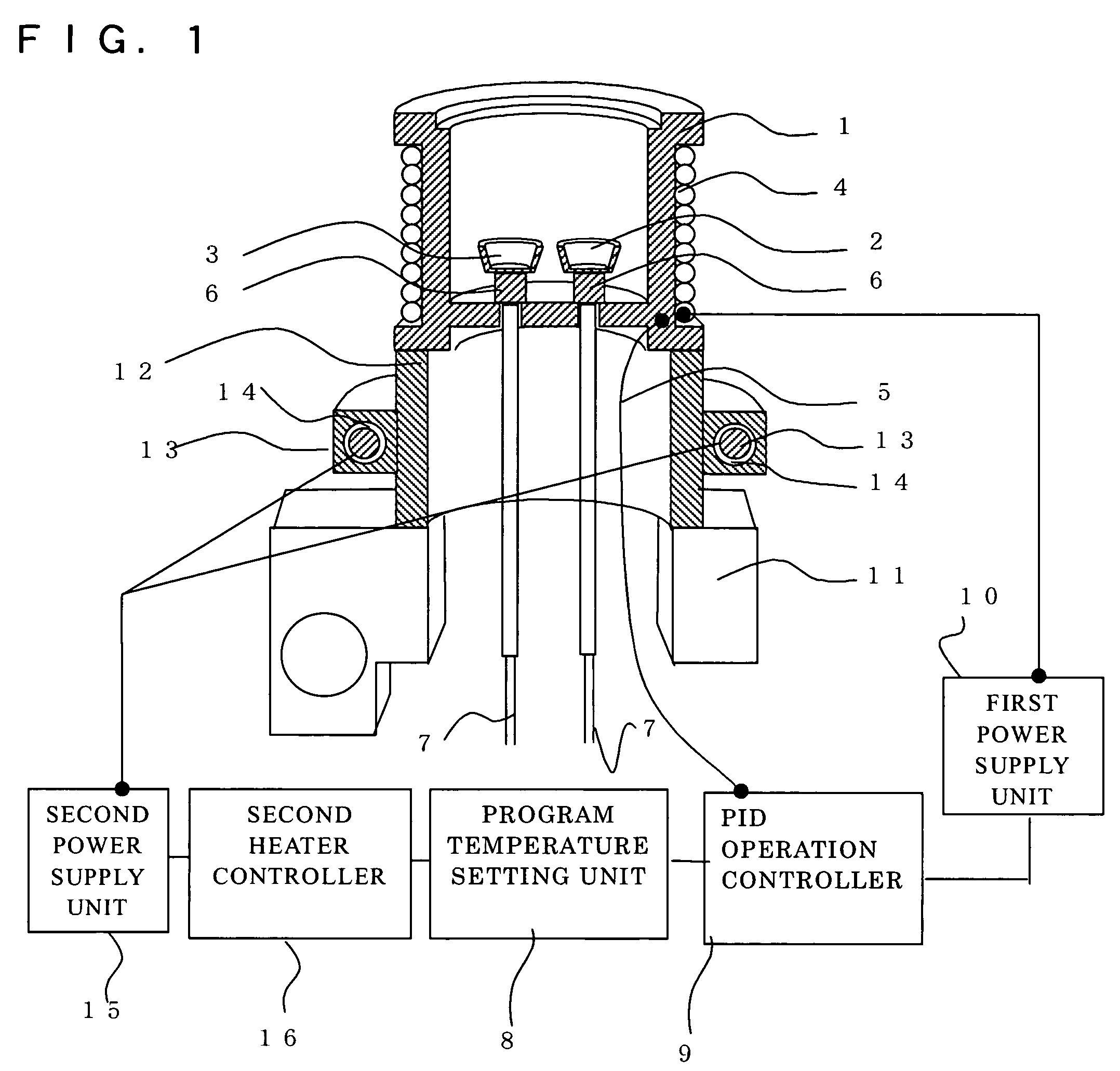

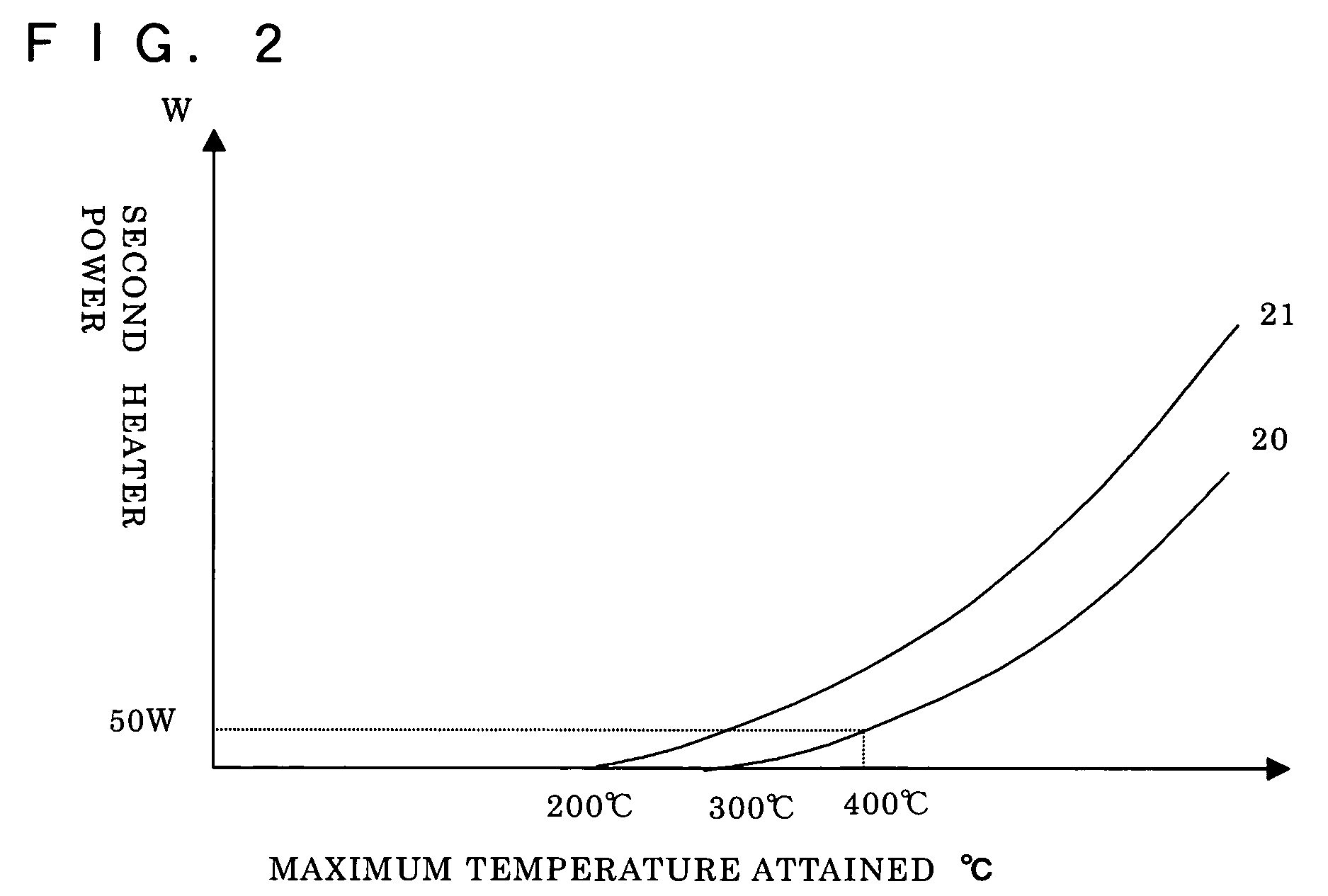

Differential scanning calorimeter with a second heater

A differential scanning calorimeter has a heat sink for accommodating therein a measurement sample and a reference material, and a differential heat flow detector that detects a temperature difference between the sample and the reference material. A cooling mechanism cools the heat sink, and a thermoconductor is disposed between the cooling mechanism and the heat sink and forms a heat flow path between the two. A first heater heats the heat sink, and a second heater heats the thermoconductor to thereby heat the heat sink. The second heater begins operating before the first heater nears its rated maximum output power.

Owner:HITACHI HIGH TECH SCI CORP

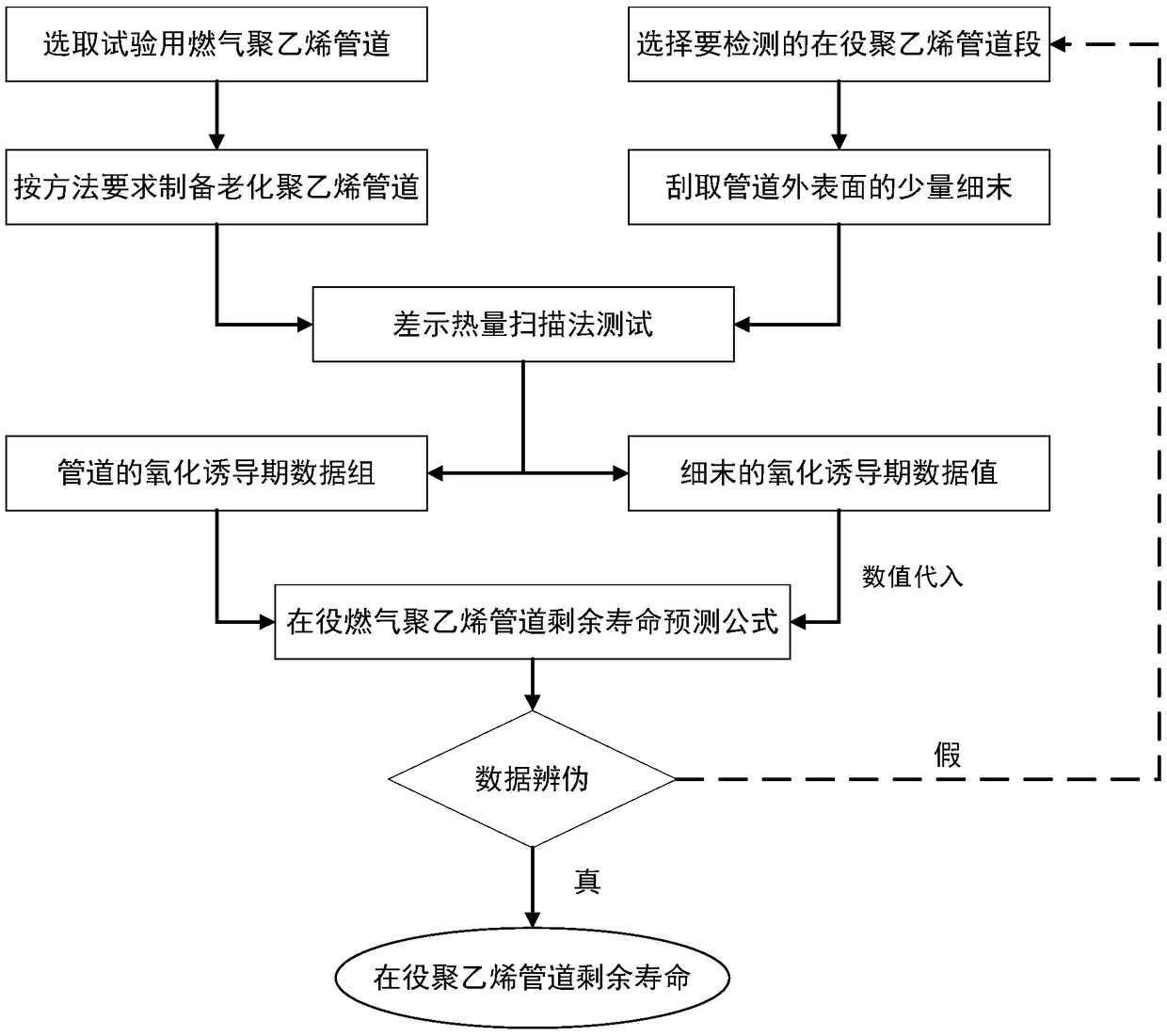

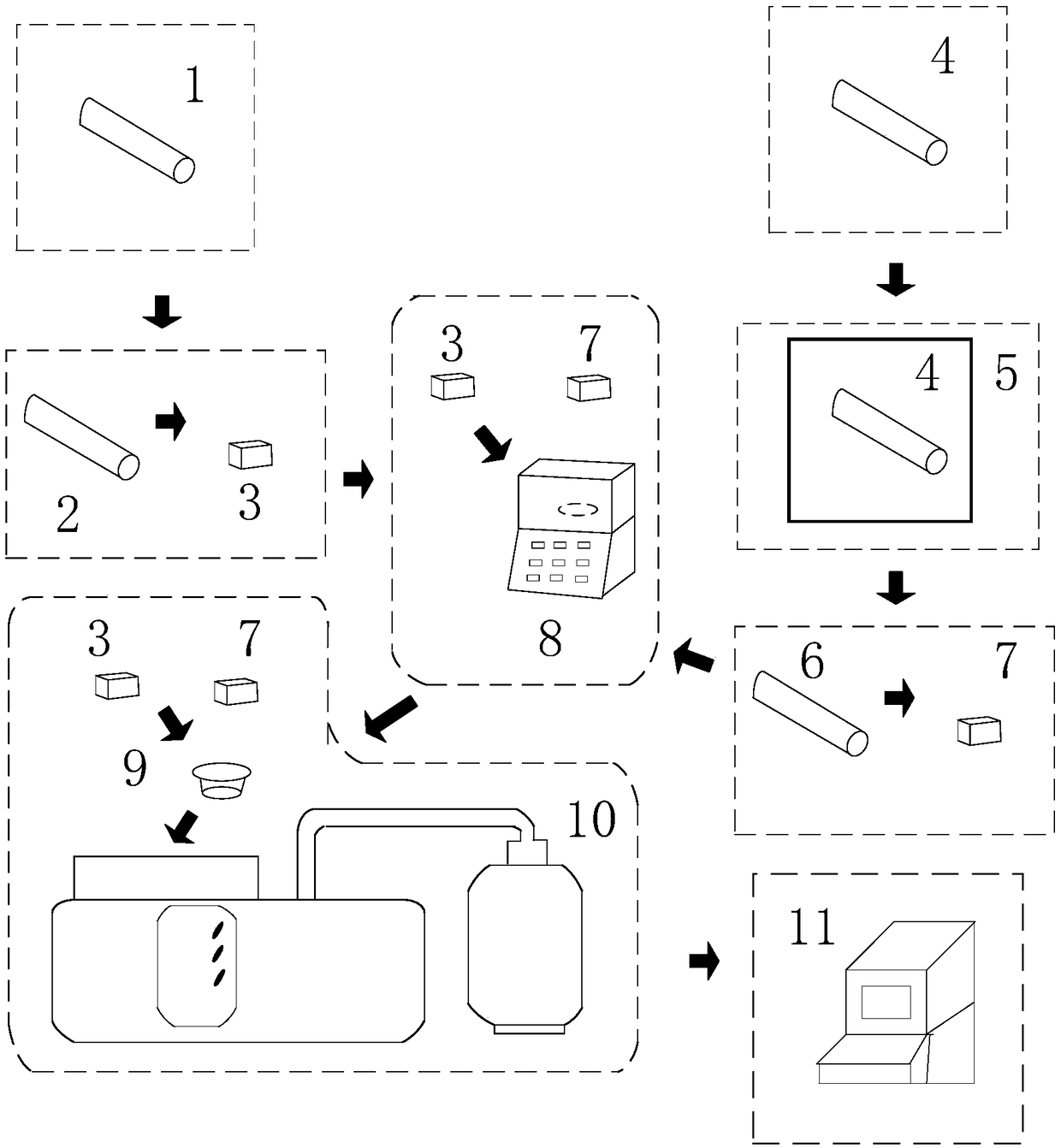

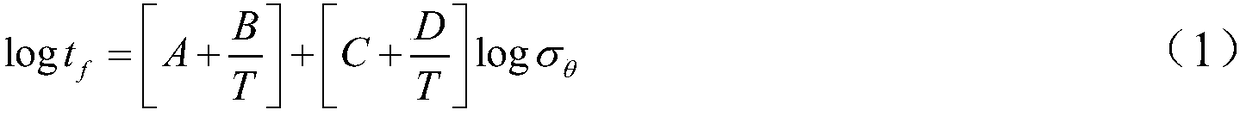

Method for predicting residual life of in-service gas polyethylene pipelines

ActiveCN109164138ALow skill level requiredEasy to operateWeather/light/corrosion resistanceMaterial heat developmentMethod testData set

The invention discloses a method for predicting residual life of in-service gas polyethylene pipelines, and belongs to the technical field of polyethylene pipeline life prediction. According to the method, an accelerated ageing experiment is carried out on a polyethylene pipeline having the same mark with an in-service polyethylene pipeline to prepare an aged polyethylene pipeline according to method requirements, and the ageing time, the temperature and the pressure are recorded; and a differential heat scanning method is used for testing an oxidation induction period of the aged polyethylenepipeline, and an oxidation induction period data set is recorded to obtain a residual life prediction formula (as shown in the specification); and finally, a few smalls are scraped from the surface of the in-service polyethylene pipeline to carry out a differential heat scanning method test, and an obtained oxidation induction period numerical value is substituted into the a0 of the residual lifeprediction formula to carry out calculation so as to predict the residual life of the gas polyethylene pipeline under operation state. The life prediction method does not influence the normal operation of urban gas polyethylene pipelines, is simple and time-saving, has a certain data distinguishing ability and is capable of providing technical support for the safe operation of in-service gas polyethylene pipelines.

Owner:BEIJING JIAOTONG UNIV

Process for producing regenerated hydrotreating catalyst and process for producing petrochemical product

InactiveUS20120160738A1Easy to produceSolve the lack of activityCoke ovensTreatment with hydrotreatment processesPetrochemicalElectromotive force

Provided is a process for producing a regenerated hydrotreating catalyst by regenerating a spent hydrotreating catalyst in a prescribed temperature range, wherein the prescribed temperature range is a temperature range of T1−30° C. or more and T2+30° C. or less, as determined by subjecting the spent hydrotreating catalyst to a differential thermal analysis, converting a differential heat in a measuring temperature range of 100° C. or more and 600° C. or less to a difference in electromotive force, differentiating the converted value twice by temperature to provide a smallest extreme value and a second smallest extreme value, and representing a temperature corresponding to the extreme value on the lower-temperature side as T1 and a temperature corresponding to the extreme value on the higher-temperature side as T2.

Owner:JX NIPPON OIL & ENERGY CORP

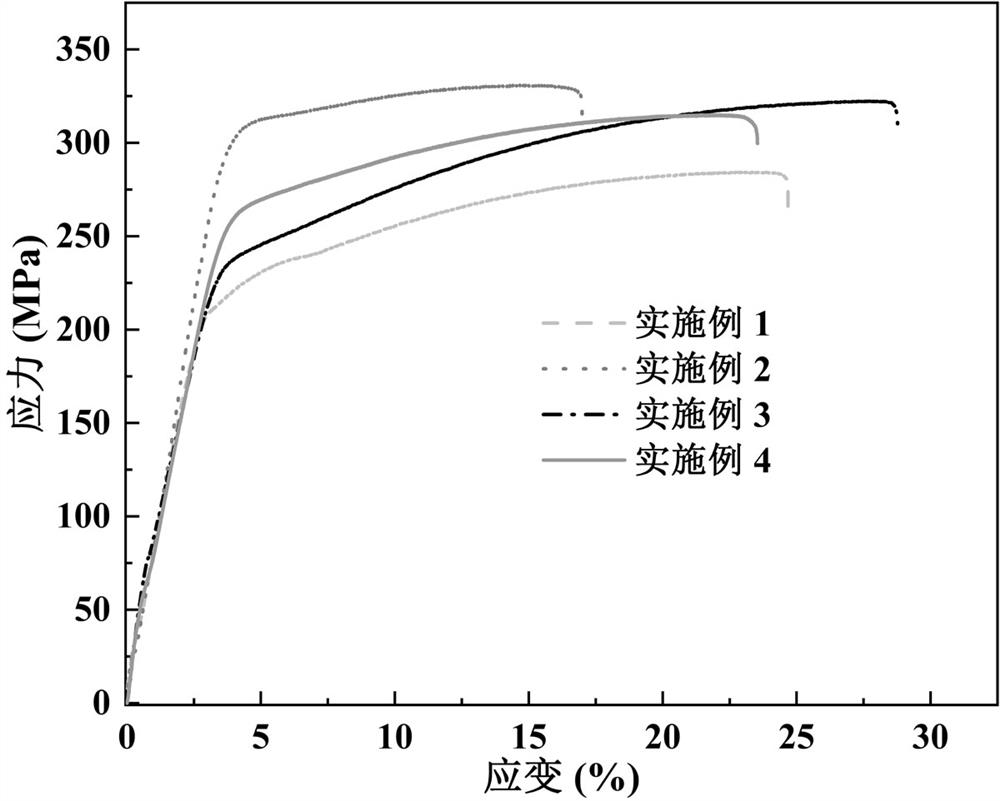

Differential thermal forming method for preparing high-strength and high-toughness magnesium alloy

The invention provides a differential thermal forming method for preparing a high-strength and high-toughness magnesium alloy. The differential thermal forming method aims at only heating a forming die at the deformation temperature without heating an alloy sample. After heat preservation is conducted for a determined time, an alloy blank at the room temperature is placed in the heated forming die, and stable deformation is achieved. The differential thermal forming method comprises the steps that (1) burdening is conducted; (2) preheating is conducted, specifically, a dried magnesium ingot, tin particles, a zinc block and an Mg-Zr intermediate alloy are preheated for 30-35min at the temperature of 200-250 DEG C; (3) smelting and casting are conducted, and a cast alloy is obtained; (4) heat treatment is conducted and comprises solution treatment and aging treatment; (5) and (6) extrusion forming is conducted; and (7) and (8) differential thermal equal-channel corner extrusion forming is conducted. The forming method serves as the core, and differential thermal equal-channel corner extrusion stable forming is successfully achieved. The tensile strength of the alloy exceeds 300MPa, the ductility is close to 30%, excellent comprehensive mechanical performance is obtained, and good strength and plasticity matching is achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Differential scanning calorimeter

There is provided a differential scanning calorimeter for exactly measuring a calorie variation of the measured sample on the basis of the temperature difference between sample container and the reference container without the influence of the heat irregularity incoming from the surroundings and the noise components. The differential scanning calorimeter includes a heating furnace of an approximately H-shaped section having an approximately drum-shaped wall part and an approximately plate-shaped heat inflow part, a heater disposed outside the wall part so as to heat the heating furnace, a approximately bar-shaped heat-resistance member that is arranged along the center axis L of the wall part, that protrudes from both sides of the heat inflow part by an approximately equal length, that is made of a material heat conductivity lower than that of the material of the heating furnace, a sample container disposed at one end of the heat-resistance member, a reference container disposed at the other end of the heat-resistance member, and a differential heat flow detector measuring a difference between the temperature of the sample container and the temperature of the reference container as a measured value.

Owner:HITACHI HIGH TECH SCI CORP

Deposition sensor based on differential heat transfer resistance

ActiveUS20110096807A1Weather/light/corrosion resistanceMaterial heat developmentFluid transportThin metal

A system and method are disclosed wherein differential heat transfer resistances are used to effectively and efficiently detect the early onset of deposit accumulation in industrial fluid processes and fluid transport vehicles.According to one embodiment, a probe is provided in conjunction with a heat source, a water source and a probe. The probe is comprised of a heat transfer surface, a first part of which is covered only by a thin metal layer. The second or remaining portion of the heat transfer surface is covered by a heat flux sensor and a thin metal layer. The metal layers of both the first and second areas of the probe are connected, and water flows across the full heat transfer surface. Deposition forms on a portion of the heat transfer surface as a result of slow water flow and elevated water temperature. The temperatures of the heat source, water source, and heat flux are measured. The deposition rate as a rate of change of heat transfer resistance is measured.

Owner:BL TECH INC

Method of making pile fabric

A pile fabric may be employed in automotive, furniture upholstery and other applications. Pile surfaces on such fabrics may be provided in tufts, or collections of fiber bundles, arranged in rows upon a base portion. Fabrics and methods of making fabrics which minimize the average amount of void space between respective tufts or rows are disclosed. Fabrics which provide more effective overall fabric coverage upon base portions of the fabric are described. A method of “heat shocking” fibers during the drawing of said fibers to pre-stress the fiber and thereby produce a fabric having greater bloom or bulk is disclosed. Providing differential heat history to predetermined portions of the fiber may be a suitable manner of obtaining a fiber which can be used to form a fabric having greater bulk.

Owner:SAGE AUTOMOTIVE INTERIORS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com