Differential thermal forming method for preparing high-strength and high-toughness magnesium alloy

A magnesium alloy and differential heat technology, applied in the field of magnesium alloy materials and their deformation processing, can solve problems such as the wide application of unfavorable alloys, the increase of rare earth elements to increase the cost of alloy preparation, and achieve precise control of microstructure, improvement of alloy preparation efficiency, grain size The effect of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Taking the equal channel angular extrusion deformation as an example, the specific steps are as follows:

[0048] (1) Ingredients: Alloy raw materials are high-purity magnesium ingot (99.95%), high-purity zinc block (99.995%, 50 mm), high-purity tin particles (99.99%, Φ2×5 mm), Mg-30 wt.%Zr master alloy. Firstly weigh the original material slightly higher than the alloy composition, then polish the oxide film on its surface (except for high-purity tin particles) until a clean and non-oxidized surface appears and the quality of the composition is consistent with the stated composition (error is less than 0.01 g), and finally clean the original material , dry for later use;

[0049] (2) Preheating: Preheat the dried magnesium ingots, high-purity tin particles, zinc blocks and Mg-30 wt.%Zr master alloy at 200-250°C for 30-35 min. In addition, the stainless steel crucible and stainless steel casting mold for melting are all preheated and kept at this temperature...

Embodiment 2

[0054] Embodiment 2: In this embodiment, steps (1), (2), (3), and (4) are the same as in Embodiment 1.

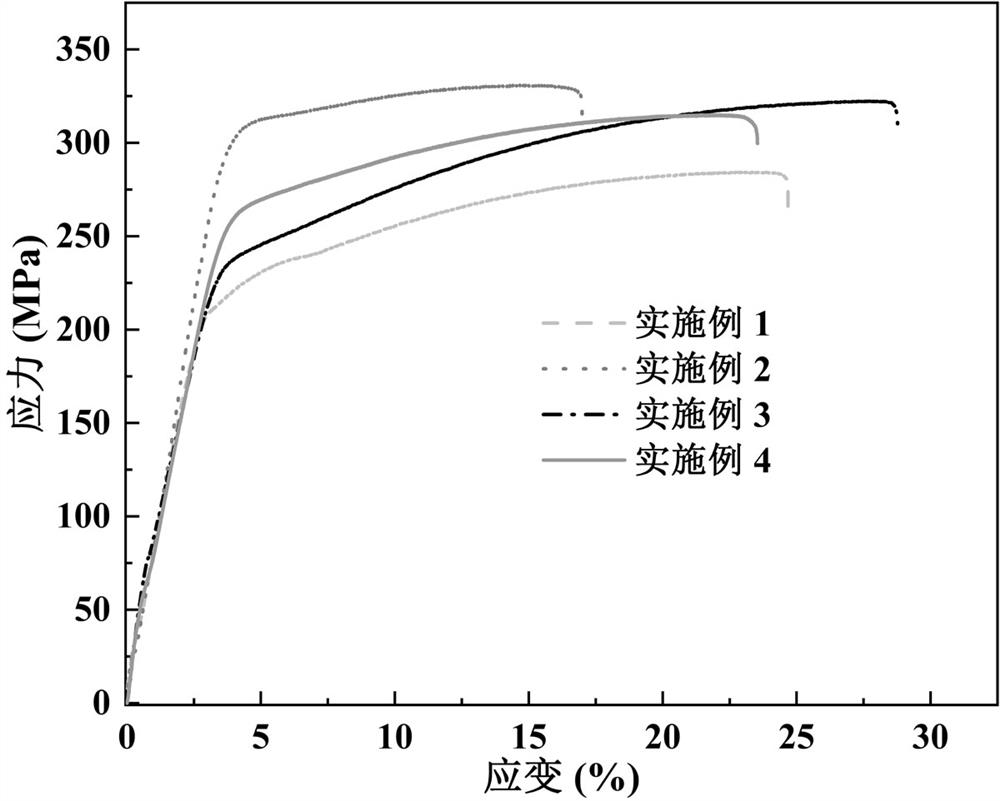

[0055] The difference between this example and Example 1 is that the alloy obtained in step (4) is deformed by four passes of differential heat equal channel angular extrusion. At room temperature, the alloy sample and the equal channel angular extrusion die were simultaneously coated with high-purity graphite mixed with a small amount of synthetic engine oil, and then only the extrusion die was heated to 300 °C, and the alloy sample was not heated. After the temperature is stable, keep it warm for 30 min; after the heat preservation is over, put the alloy sample at room temperature into the mold for four passes of extrusion deformation. The extrusion speed is 12 mm / s, the channel angle is 120°, and the deformation path is Bc path. After extrusion, the sample was air-cooled to room temperature to obtain a four-pass deformed alloy. The alloy has a tensile strength of 331 M...

Embodiment 3

[0056] Embodiment 3: In this implementation, steps (1), (2), and (3) are the same as in Embodiment 1.

[0057] The difference with embodiment 1 is:

[0058] (4) Heat treatment: The cast alloy obtained in (3) is subjected to heat treatment, including solution heat treatment and aging heat treatment. The solid solution heat treatment process is to keep the cast alloy at 400 °C for 12 h, and then put the sample into 25 °C water for quenching to obtain a solid solution (T4) alloy; the aging heat treatment process is to heat the solid solution alloy at 300 ℃ for 10 h, and then air-cooled to room temperature to obtain a heat-treated (T6) alloy;

[0059] (5) Extrusion forming: The heat-treated (T6) alloy (h=10-15 mm, d=40 mm) obtained in (4) is subjected to forward extrusion forming. At room temperature, the positive extrusion die was coated with high-purity graphite mixed with a small amount of synthetic motor oil, and heated to 300°C. After the temperature stabilized, it was kept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com