A method for preparing nanocellulose liquid crystal microgrid film by two-dimensional confined self-organization

A nano-cellulose and micro-grid technology, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve problems such as the inability to realize the precise control of CNC microstructure, and achieve the effects of industrial promotion and use, precise microstructure, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

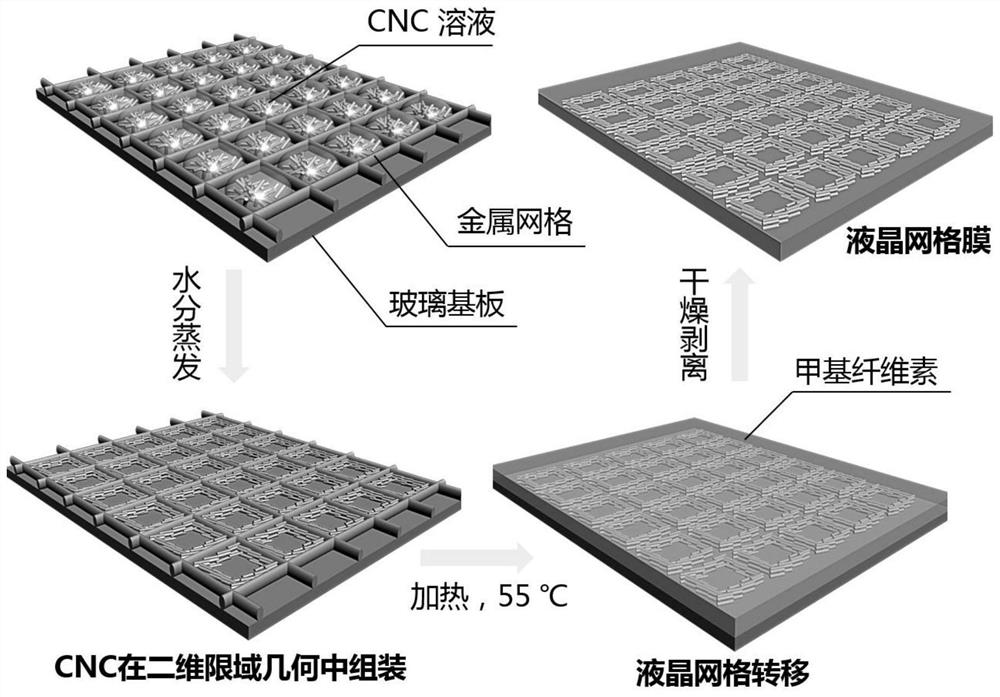

[0043] 1) Set the aperture to 610*610μm 2 The metal micro-grid was tiled on the glass substrate, and then the mass fraction of 1wt% cellulose nanocrystal (CNC) aqueous solution was added dropwise on the metal micro-grid, so that each grid hole was filled with the CNC solution, and finally the Scrape off the excess CNC solution on the surface of the metal microgrid on the glass slide;

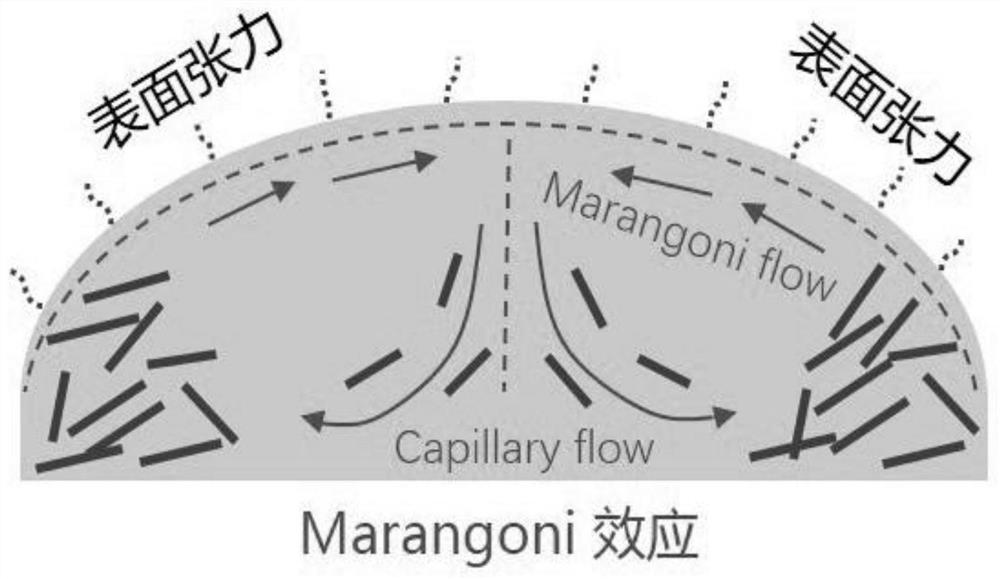

[0044] 2) Place the substrate and the metal microgrid at room temperature to dry naturally. Driven by the evaporation of water, the CNC gradually migrates to the grid boundary in the metal microgrid on the substrate and deposits down to form nanocellulose liquid crystal microgrid;

[0045] 3) Remove the metal microgrid, apply a 25wt% methylcellulose solution on the liquid crystal microgrid, dry it at 55°C for 1.5h, and then peel off the methylcellulose film from the substrate After that, a nanocellulose liquid crystal microgrid film with high mechanical strength (tensile stress 110 MPa), excel...

Embodiment 2

[0050] In addition to changing step 1) the aperture of the metal microgrid to 450*450μm 2 、310*310μm 2 、250*250μm 2 , and others were prepared according to the same preparation steps as in Example 1 to prepare a nanocellulose liquid crystal microgrid film.

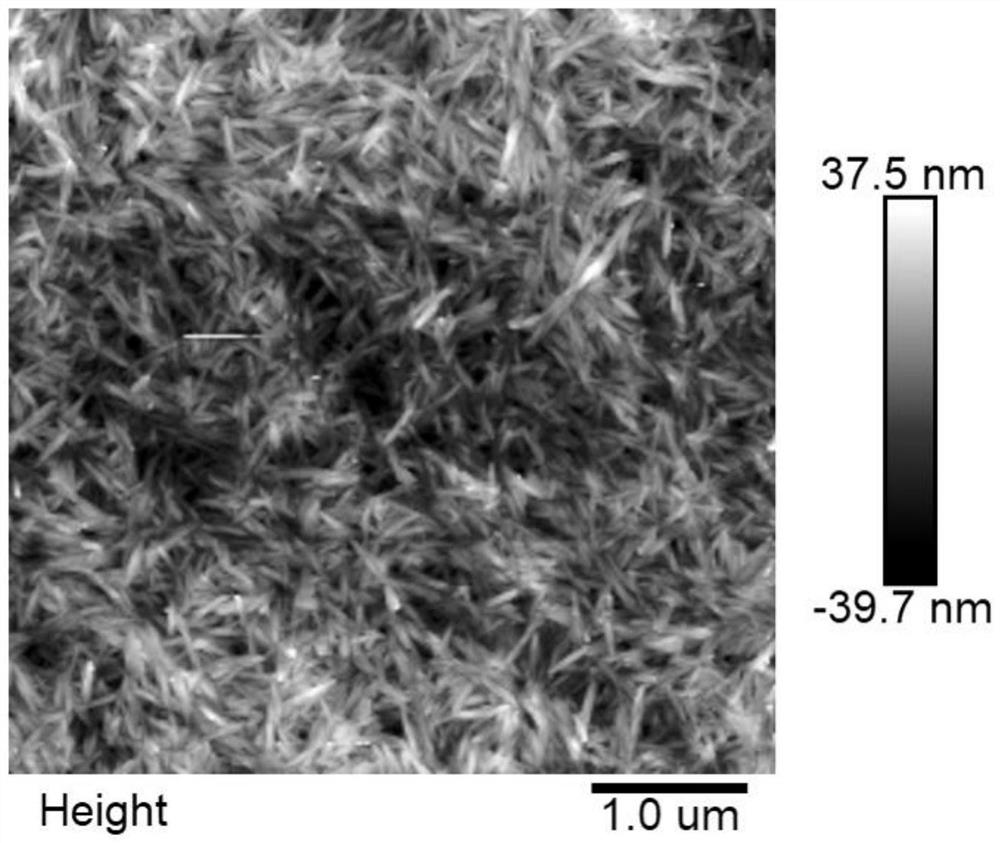

[0051] The inside of the microgrid of the nanocellulose liquid crystal microgrid film obtained in Comparative Example 1 has regular concentric circle color bands ( Figure 4 ), the internal morphology of the microgrid obtained by embodiment 2 of the nanocellulose liquid crystal microgrid film decreases with the grid size, the concentric circles of color bands disappear, and the arrangement of the CNC appears inhomogeneous. The aperture is 450*450μm 2 The concentration of CNC inside the liquid crystal micro-grid gradually decreases from the center to the boundary, the concentric circle color band remains, and the arrangement of CNC is uniform; the aperture is 310*310μm 2 When the concentration of CNC inside the liquid c...

Embodiment 3

[0054] Except for changing the mass fraction of CNC in step 1) to 2 wt%, the same preparation steps as in Example 1 were used to prepare a nanocellulose liquid crystal microgrid film.

[0055] Compared with the highly transparent nanocellulose liquid crystal microgrid film obtained in Example 1, the transparency of the nanocellulose liquid crystal microgrid film obtained in Example 3 was reduced to 79%. This is because the high concentration of CNC increases the thickness of CNC inside the microgrid in the liquid crystal microgrid film, which affects the light transmittance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com