Patents

Literature

65results about How to "Easy to promote and use in industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

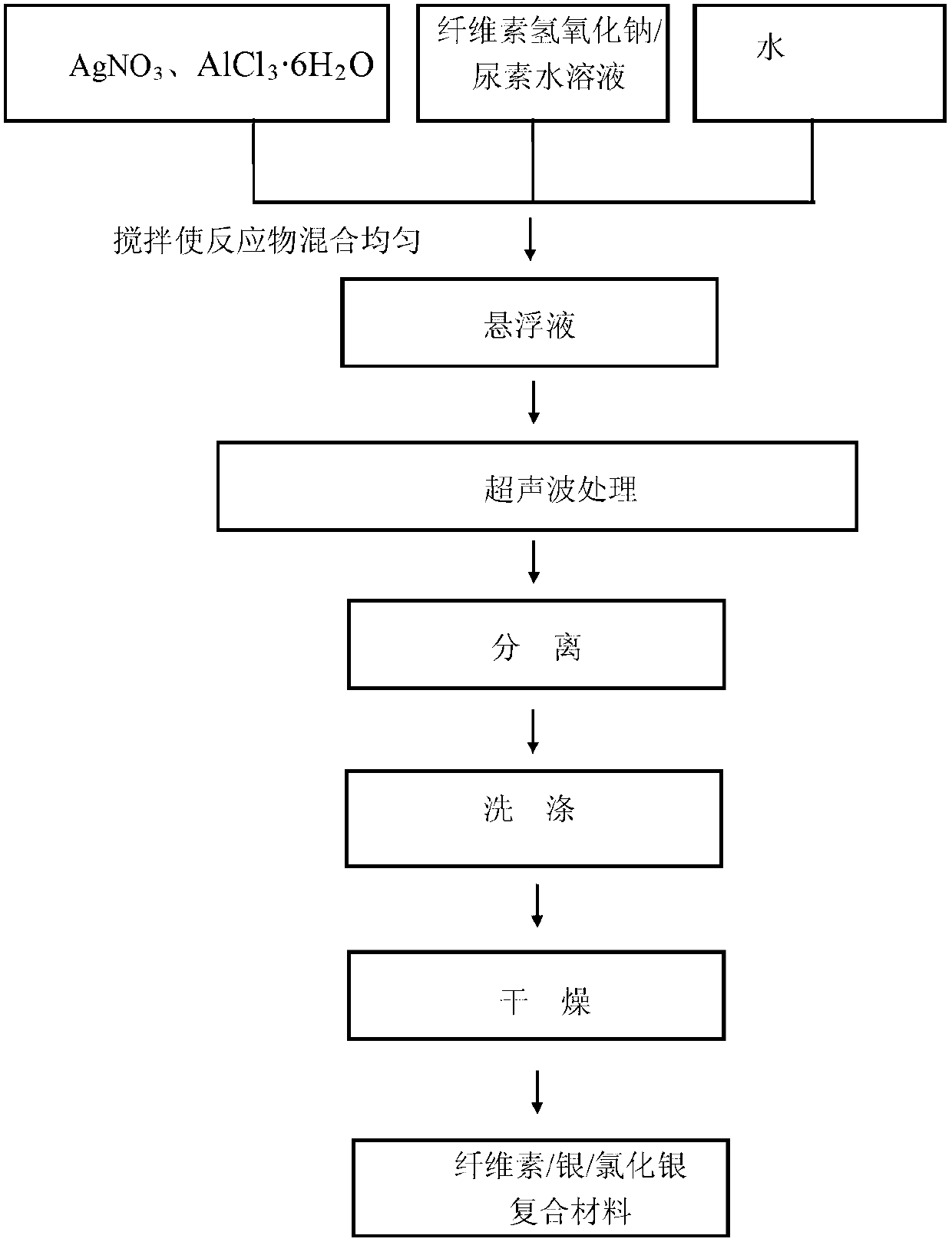

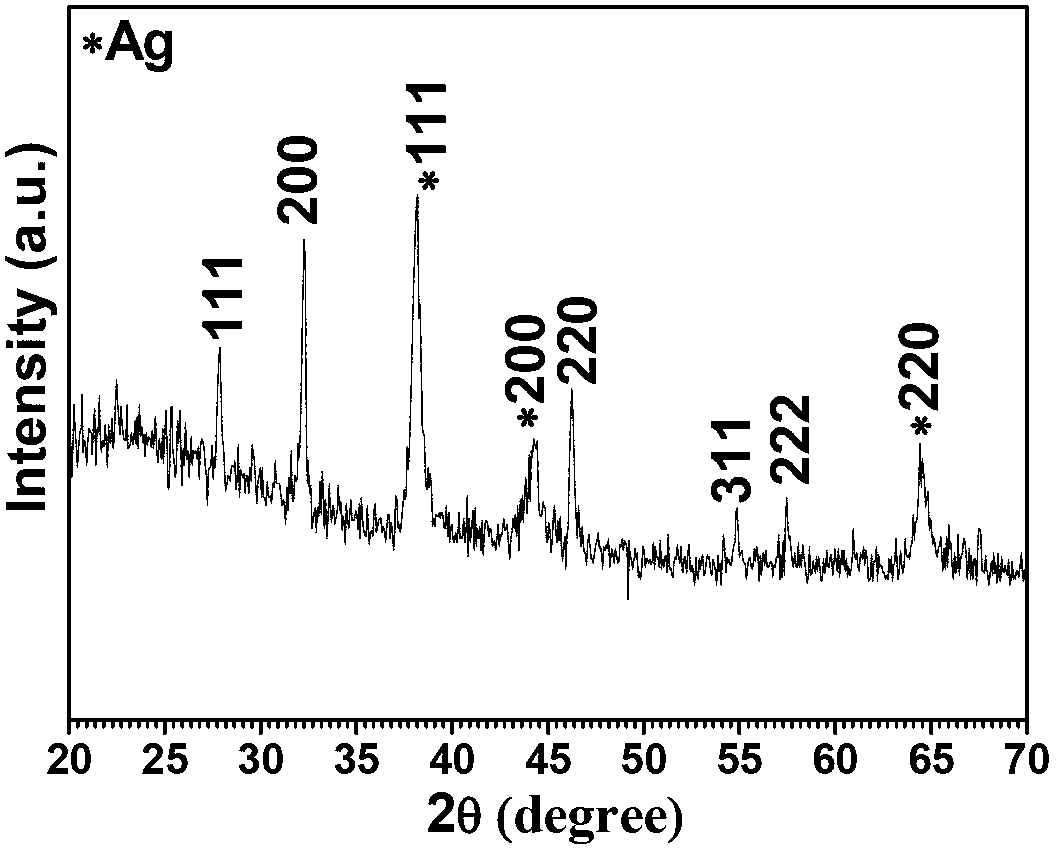

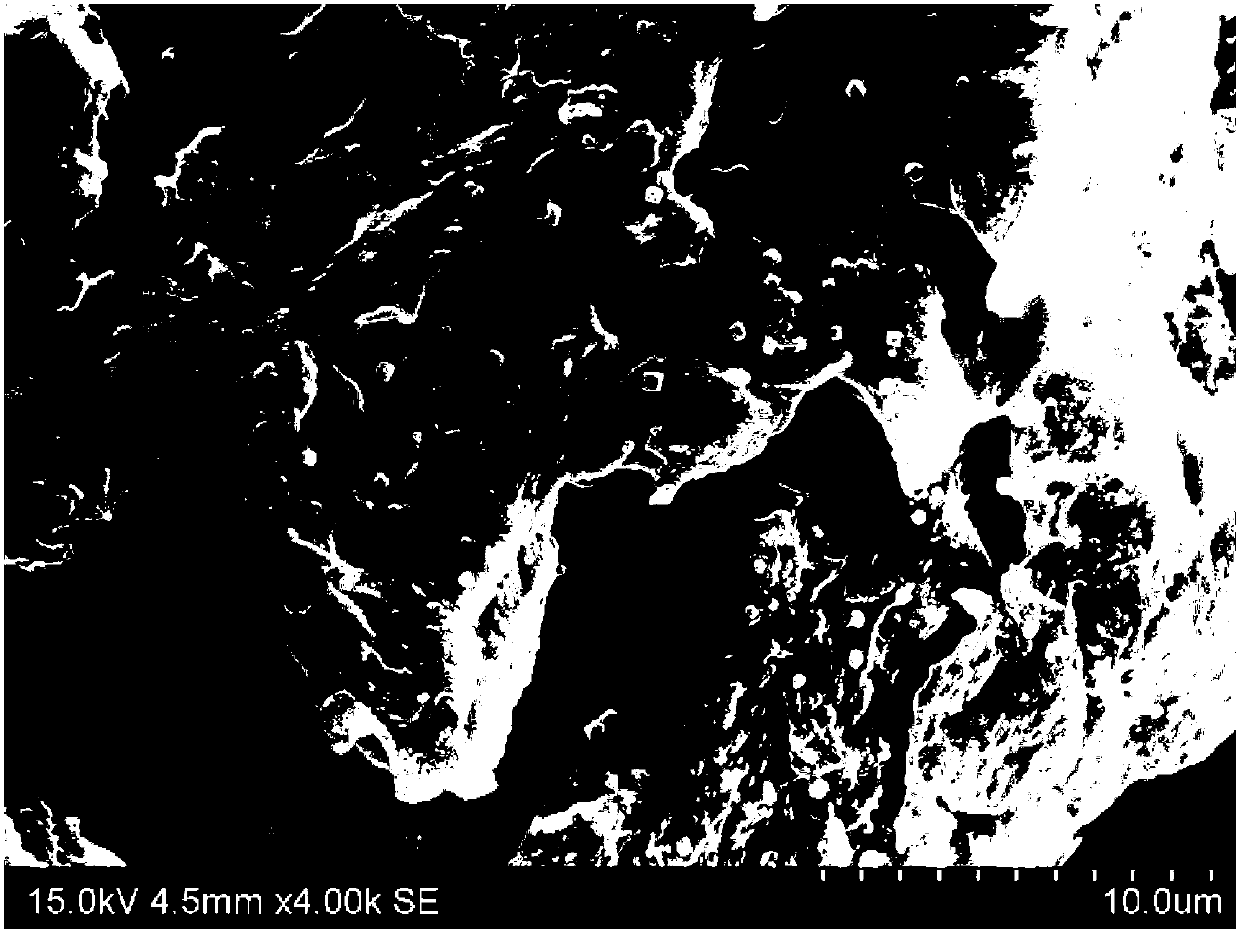

Cellulose/sliver/silver chloride composite material and preparation method thereof

The invention provides a cellulose / silver chloride composite material and a preparation method thereof. The cellulose / silver chloride composite material is quickly prepared by adopting microcrystalline cellulose, sliver salt and chlorine compound as the materials, adopting water as solvent and adopting an ultrasonic-wave treatment method. The cellulose / silver chloride composite material prepared by the preparation method disclosed by the invention is uniform in silver / silver chloride nanometer particle, capable of being uniformly distributed on a cellulose substrate and is extensive in application prospect in the antibacterial filed and the photocatalysis filed. Moreover, according to the preparation method disclosed by the invention, the materials are cheap, the process is simple, the operation is convenient, the preparation is quick and the process conditions are easy to control, so that the production process is greatly simplified, the time is saved and the cost is reduced. Meanwhile, the preparation method is free of any expensive and complex equipment and is beneficial to the industrial popularization.

Owner:BEIJING FORESTRY UNIVERSITY

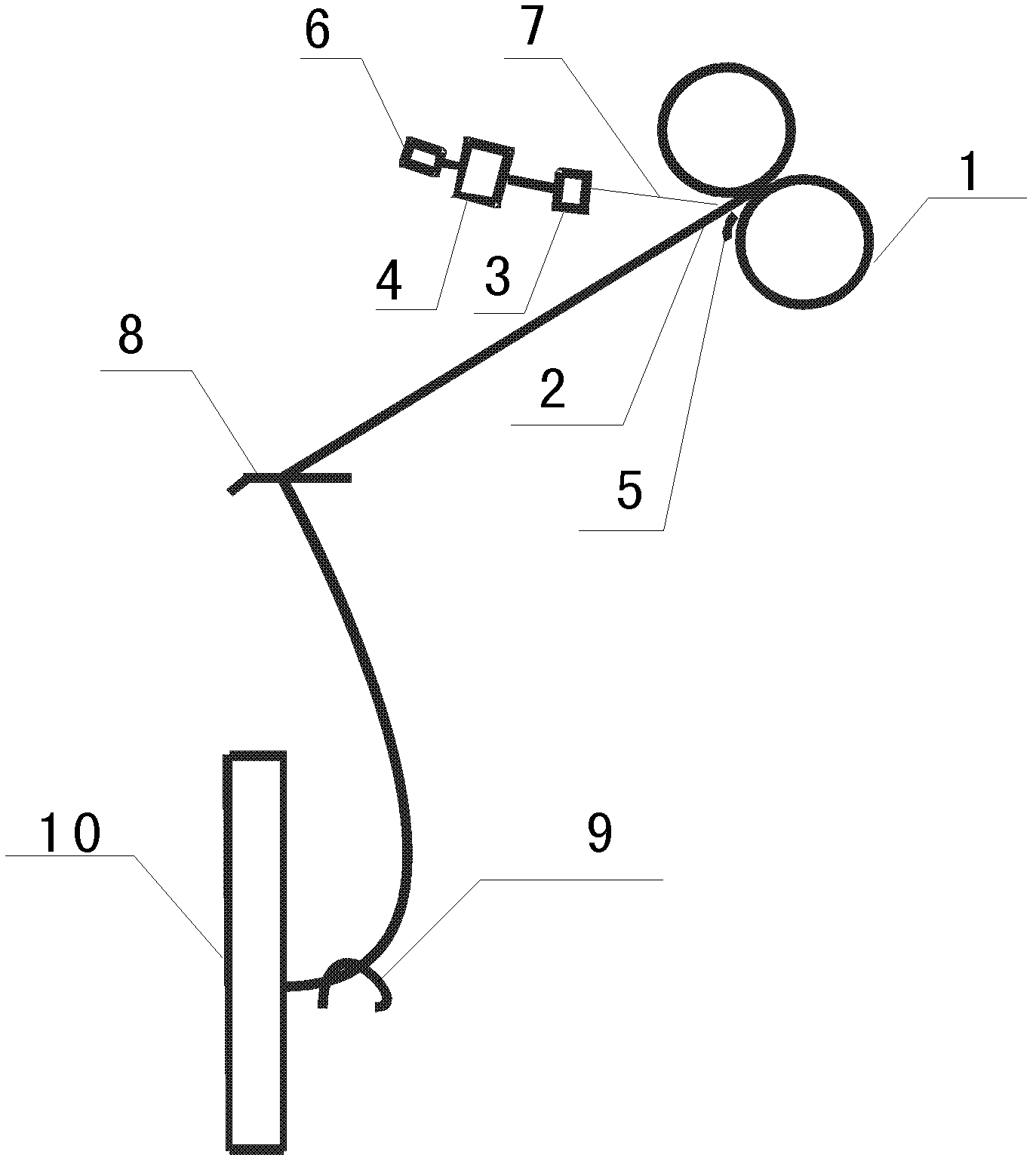

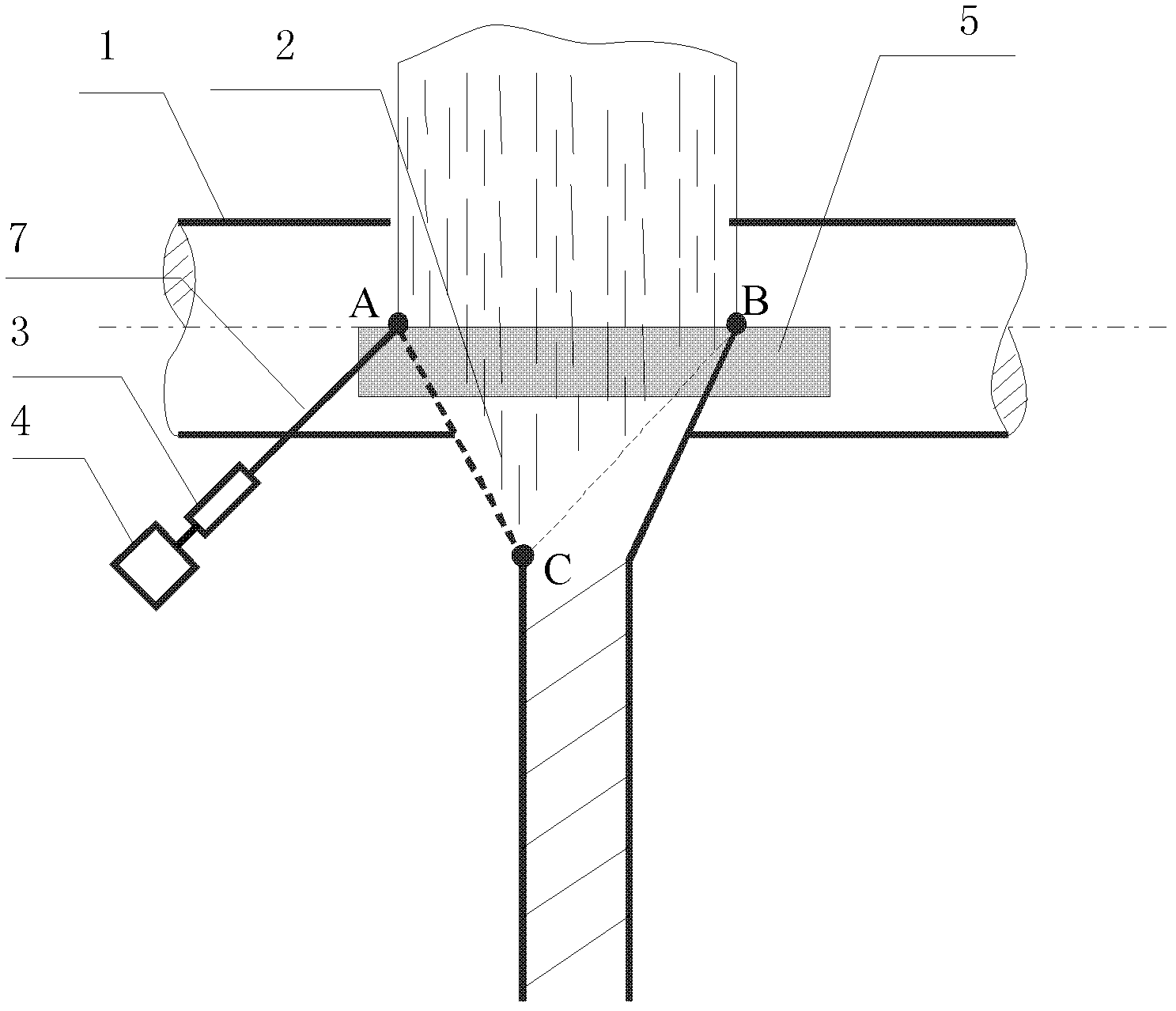

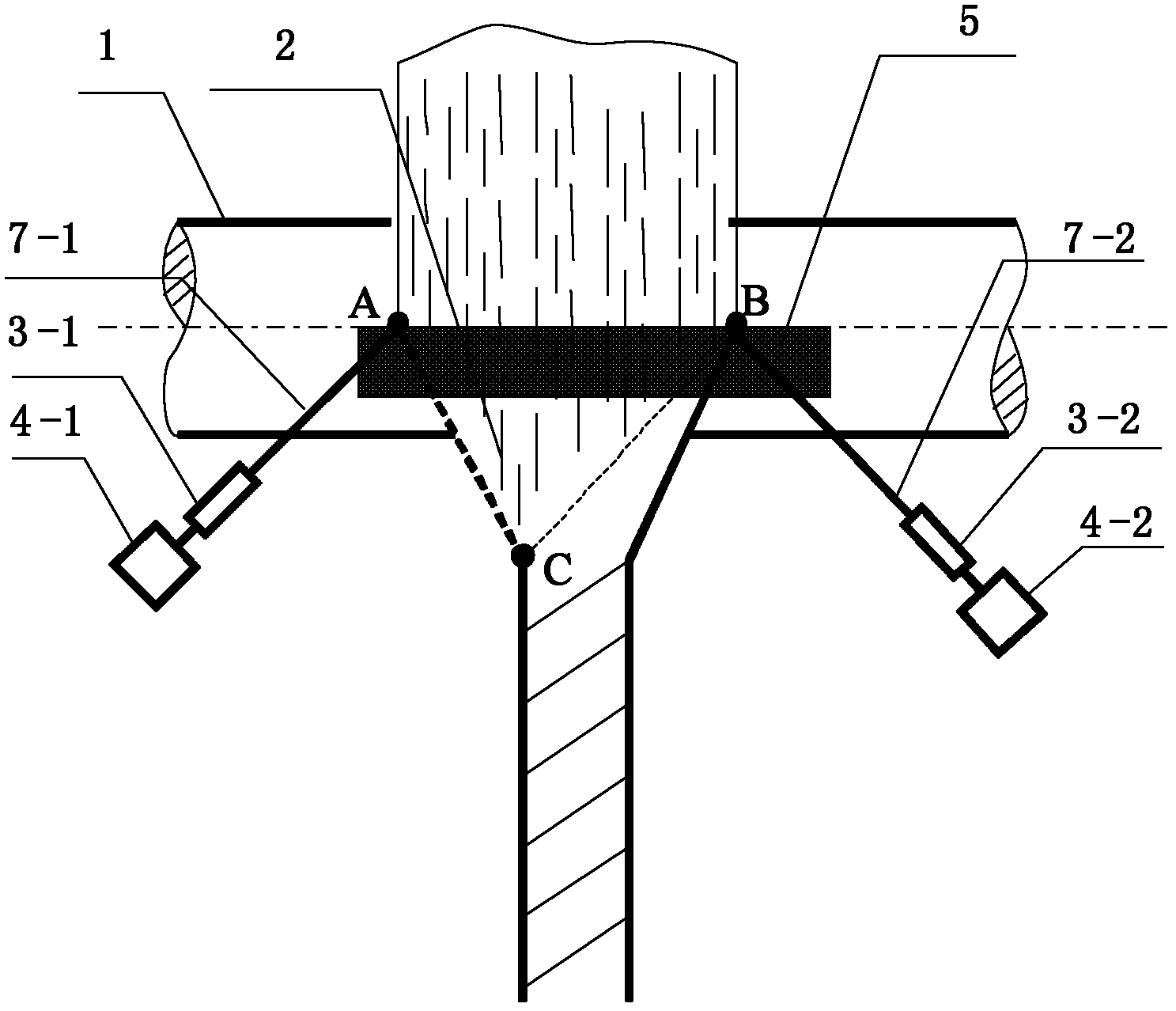

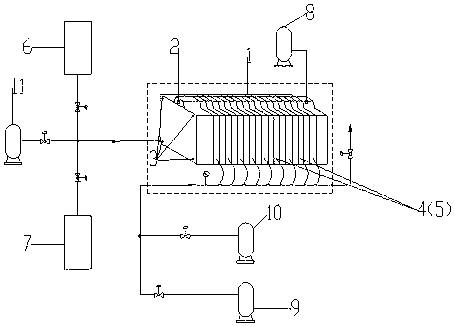

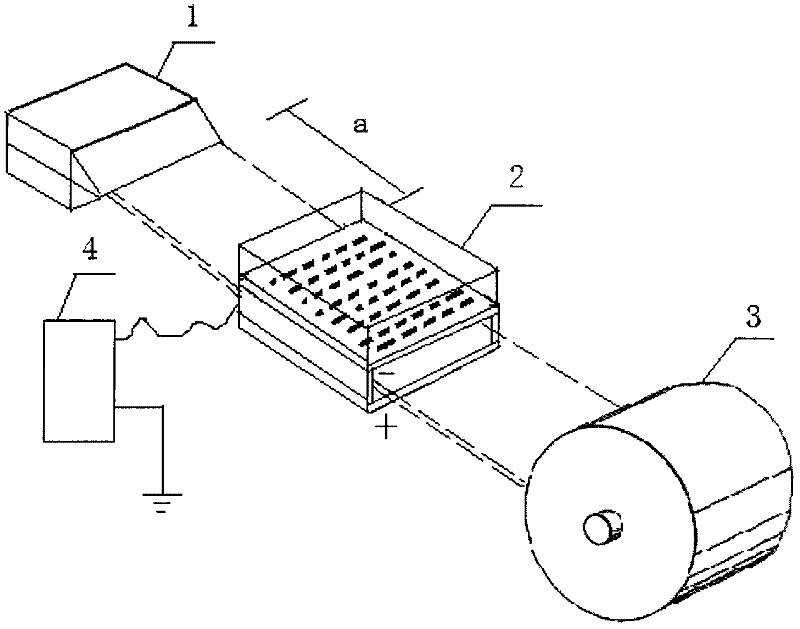

Clean electrospinning method

The invention provides a clean electrospinning method, which comprises, on each drafting assembly of a ring spinning frame, drafting rove by the drafter of the ring spinning frame to output strands from a front roller, entering a twisting triangular zone, twisting, injecting spinning liquid into a capillary spinneret via a liquid flow controller, connecting the spinning liquid to a positive electrode of a high-voltage power source, connecting a polar plate to a negative electrode of the high-voltage power source, forming a high-voltage electric field between the capillary spinneret and the polar plate, stretching the spinning liquid extruded from the capillary spinneret into microscale or nanoscale fine filaments under the action of the high-voltage electric field, twisting the fine filaments with the strands together in the twisting triangular zone, winding on a yarn bobbin via a guide and a traveler, and making into yarn. The capillary spinneret and the liquid flow controller are arranged at the upper inclined side of the triangular zone, and the grounding polar plate is arranged under the triangular zone. The method provided by the invention can decrease hairiness of the yarn, improve strength of the yarn, and lower cost, and is suitable for fields of cotton spinning, flax spinning, wool spinning and silk spinning.

Owner:HUBEI FENGSHU THREAD MFG

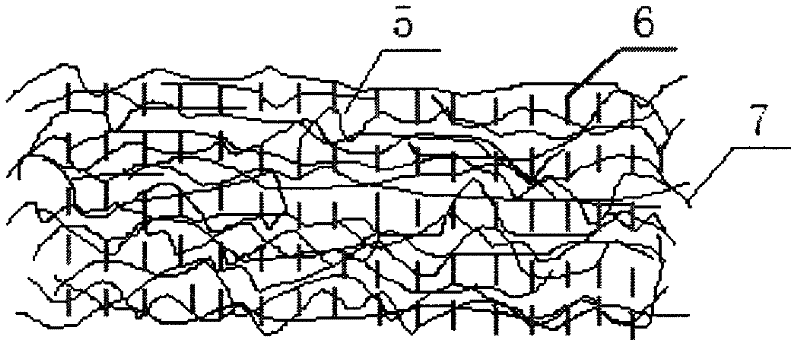

Multifunctional waffle cotton thermal batting and preparation method thereof

A multi-functional honeycomb cotton warm-keeping floc, which includes a surface fiber web, a middle layer fiber web, and an inner layer fiber web from top to bottom, wherein the middle layer fiber web is honeycomb cotton formed by carding and then vertically laid. The surface fiber web and the inner layer fiber web are fiber webs that are carded or air-laid and then cross-laid. An upper bonded fiber web can be added between the surface layer fiber web and the middle layer fiber web. A lower bonded fiber net can be added between the layer fiber nets, and evenly distributed thin magnets are embedded on the top surface of the middle layer fiber net. During production, each fiber web is prepared first, then compounded into one, and finally dried, cooled, and wound to obtain a finished product. This design is not only strong in warmth retention, good in elasticity, and capable of withstanding relatively large tensile forces in the horizontal direction, but also has antibacterial and magnetic therapy functions, and is easy to popularize and apply.

Owner:孙福胜

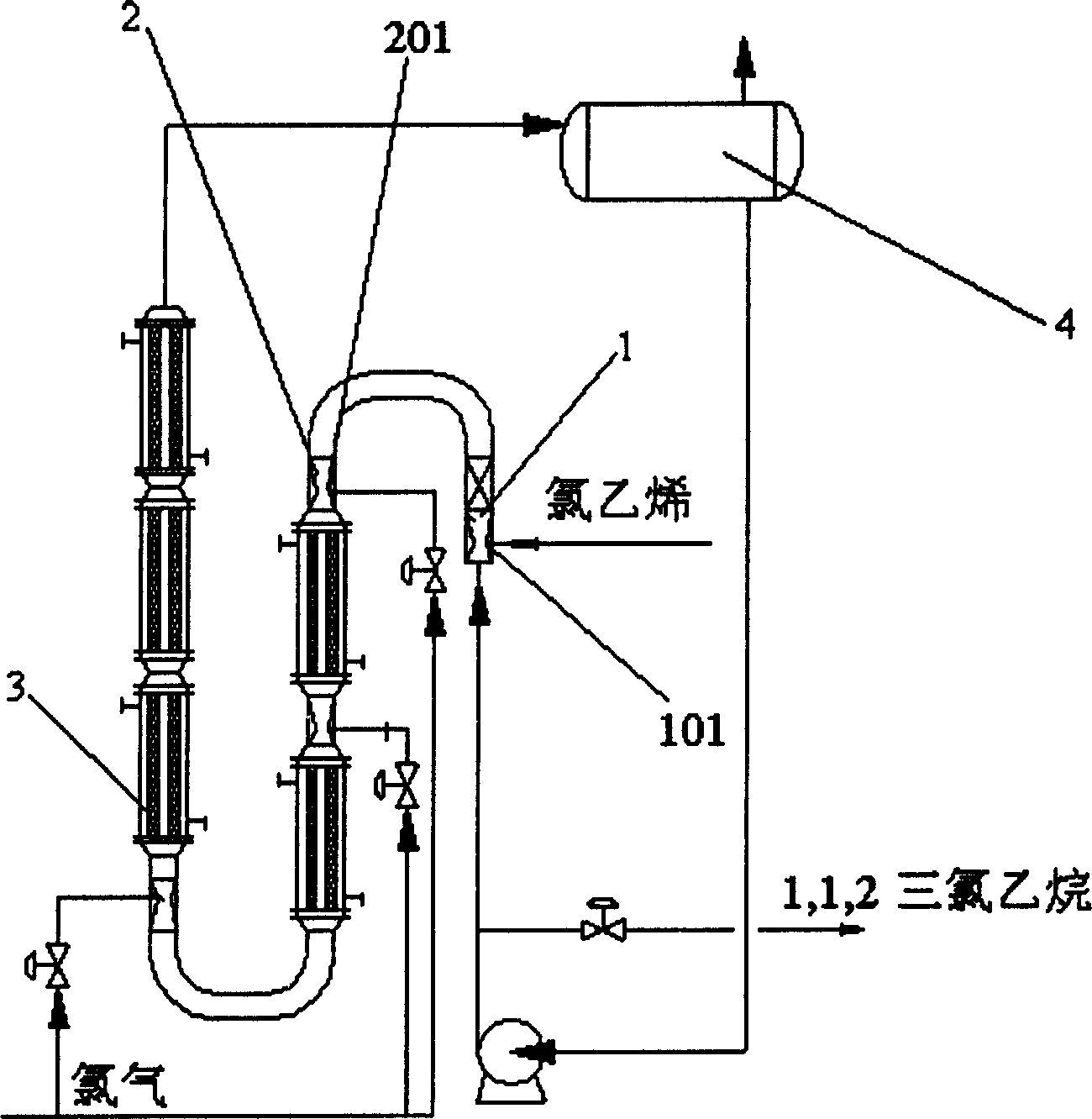

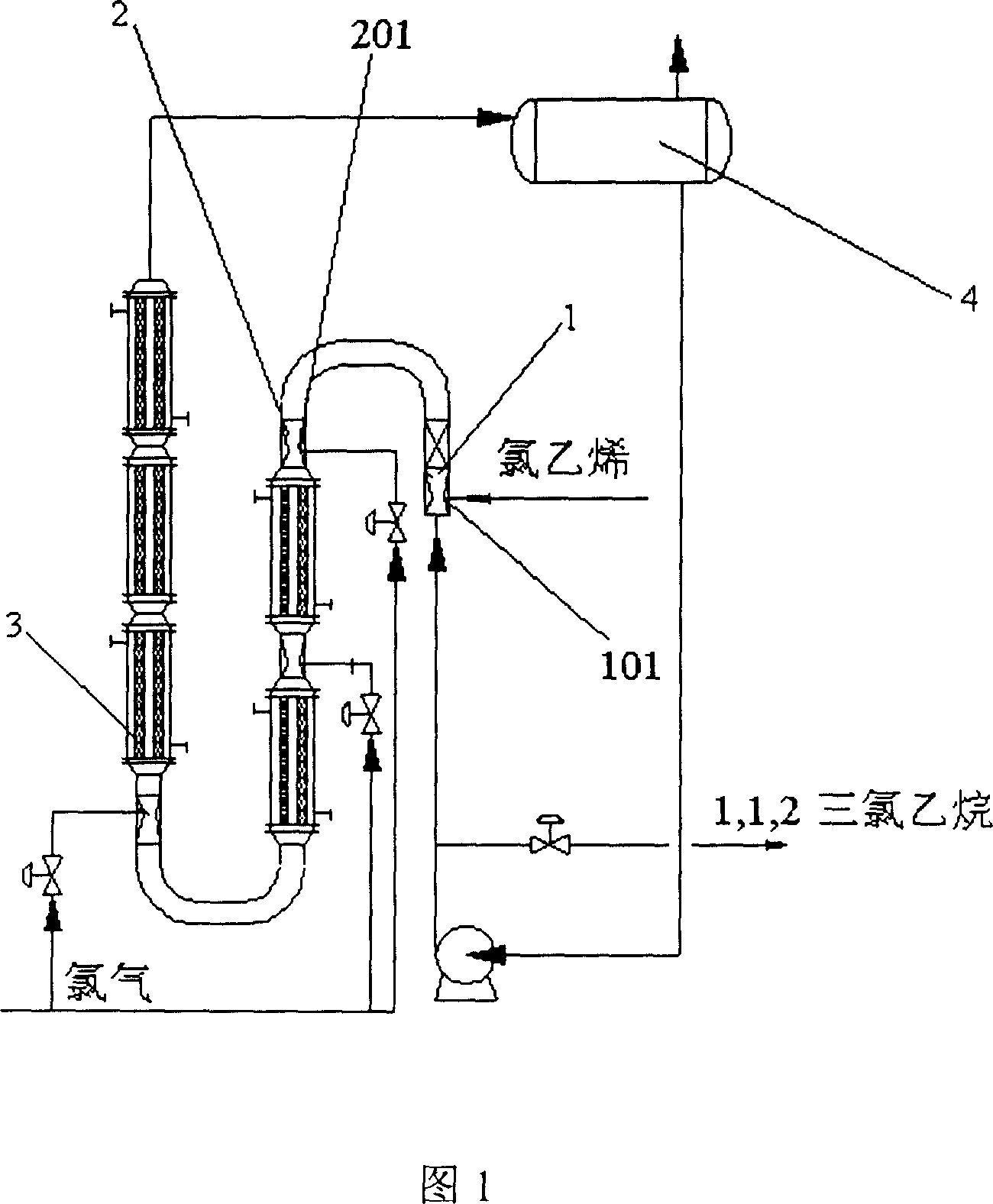

Process for preparing 1,1,2 trichloroethylane

ActiveCN1793093ASimple equipment structureEasy to operatePreparation by halogen additionMain channelChemistry

The invention discloses a method to make 1,1,2 trichloroethane. It includes the following steps: using 1,1,2 trichloroethane as circling medium sending to the first mixing spraying device, the vinyl chloride would be absorbed into the first mixing area of the first mixing spraying device through, and vinyl chloride dissolving in the 1,1,2 trichloroethane would be sent to the second spaying device, and the chlorine would be absorbed at the mixing area of the second mixing spraying device. The vinyl chloride would take reaction with chloride in the mixing area of the second mixing spraying device and coming into the main channel reactor to continue reacting to form 1,1,2 trichloroethane, the result would be separated in the separator and coming into the post section. The invention is simple structure, easy to operate, and the conversion of vinyl chloride could reach to 98%.

Owner:SHANGHAI CHLOR ALKALI CHEM

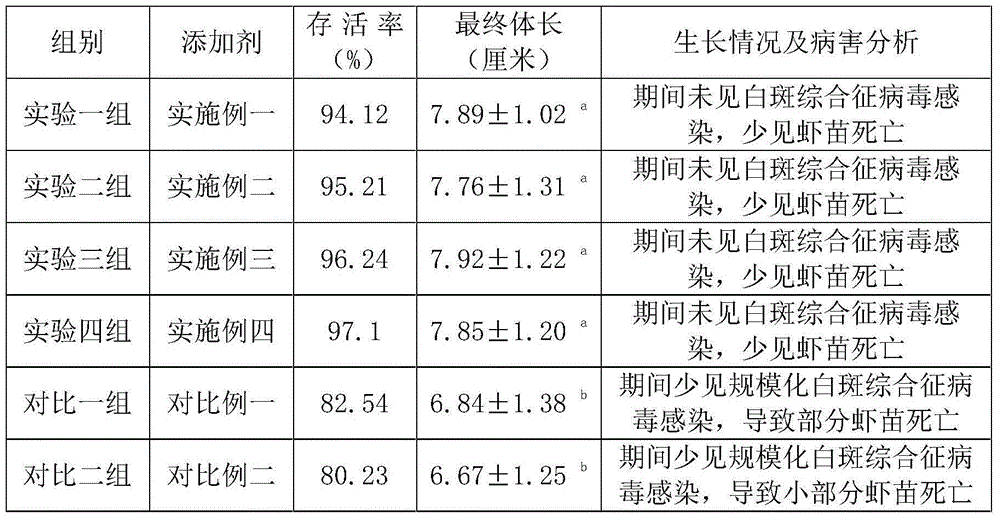

Feed additive capable of reducing white spot syndrome virus disease of penaeus vannamei boone

InactiveCN104664164AImprove qualityReduce white spot syndrome virus diseaseAnimal feeding stuffAntiviralsVitamin CPrawn

The invention discloses a feed additive capable of reducing the white spot syndrome virus disease of penaeus vannamei boone. The feed additive comprises the following components in parts by weight: 0.5-2 parts of photosynthetic bacteria, 0.2-1.5 parts of bacillus subtilis, 1-3 parts of glucose, 2-4 parts of Chinese honey locust, 3-7 parts of purple perilla, 5-7 parts of green tangerine peel, 1-4 parts of cassia twig, 3-7 parts of white paeony roots, 0.01-0.5 part of vitamin C, 0.01-0.05 part of vitamin K and 15-20 parts of a carrier. 0.1-1 percent by weight of the feed additive disclosed by the invention is added into a conventional mixed feed for a prawn, and the obtained feed can be used for feeding the penaeus vannamei boone. By the adoption of the feed additive disclosed by the invention, the occurrence of the white spot syndrome virus disease in the cultivation process of the penaeus vannamei boone can be remarkably reduced, the cultivation survival rate is improved, the quality of a prawn body is improved, the water quality is improved, and the economical and ecological benefits are increased.

Owner:任芳芳

Leaf surface resistance and control agent for blocking heavy metal accumulation and preparation method thereof

InactiveCN111528236AWith accumulationReduce the degree of impactPlant growth regulatorsBiocideMicrobial agentChaff

The invention discloses and provides a leaf surface resistance and control agent for blocking heavy metal accumulation and a preparation method thereof. The leaf surface resistance and control agent is prepared from the following components in parts by weight: 1-3 parts of borax, 5-9 parts of nano silicon dioxide, 10-17 parts of carbon nano tubes, 5-8 parts of a surfactant, 18-31 parts of tea seedcake, 7-9 parts of dunaliella, 13-22 parts of flammulina velutipes fungus chaff, 3-5 parts of betel nut tree sawdust, 9-13 parts of a microbial agent, 3-4.5 parts of orange peel powder, 8-13 parts ofdistillers' grains, 7-10 parts of artemisia apiacea leaves, 25-43 parts of tea saponin, 1-3 parts of citric acid, 12-28 parts of amino acids, 6-11 parts of humic acid and 1000-1500 parts of deionizedwater. The leaf surface resistance and control agent prepared from the raw materials can prevent plants from absorbing heavy metals in air and soil and prevent the heavy metals from damaging the plants. Meanwhile, according to the preparation method of the leaf surface resistance and control agent for blocking heavy metal accumulation, effective components in the raw materials can be fully utilized, and the method is easy to operate and beneficial to industrial promotion.

Owner:武汉市秀谷科技有限公司

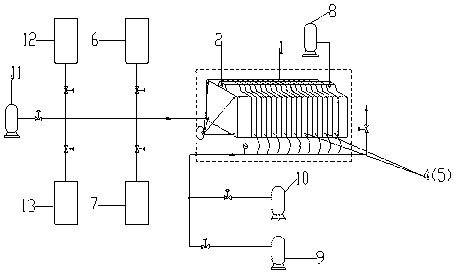

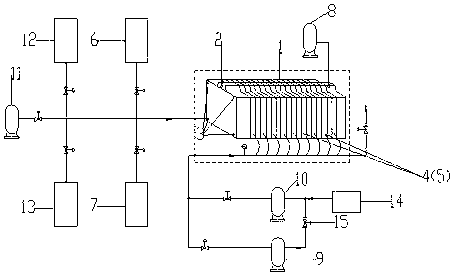

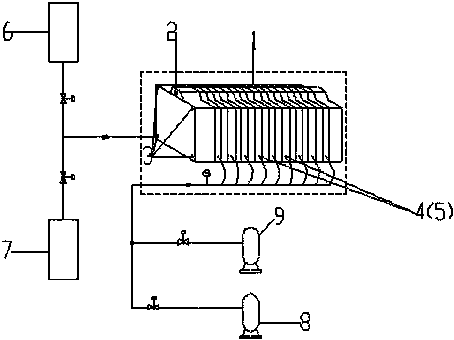

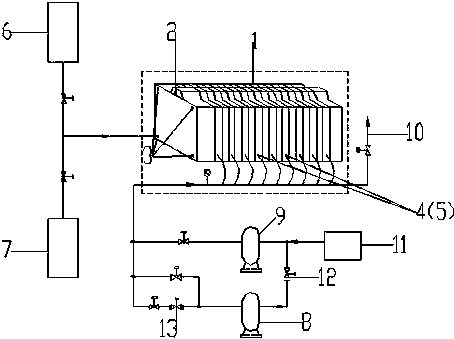

Multi-section acid leaching, washing and pressure filtration metal extraction process and integrated device thereof

ActiveCN103343223AAvoid cloggingAvoiding the Problem of Contaminating Diaphragm Filter Press ClothsProcess efficiency improvementInlet channelSlag

The invention discloses a multi-section acid leaching, washing and pressure filtration metal extraction process. The multi-section acid leaching, washing and pressure filtration metal extraction process comprises the following steps of: pressurizing and injecting a metal acid leaching solution into a filter chamber of a diaphragm filter press to get a filter cake, and pre-pressing the filter cake at 0.2MPa-0.6MPa; performing two-section acid leaching on the filter cake by two-section acid under a pre-pressed state; continuously washing the filter cake subjected to acid leaching by a one-section washing solution under the pre-pressed state; introducing gas below 70 DEG C to one side of the washed filter cake for gas blowing under the pre-pressed state; introducing gas into a material inlet channel for back blowing under the pre-pressed state after the gas blowing is ended; and performing high-pressure pressure filtration on substances in the filter chamber after the back blowing is ended, and unloading slag. On the basis, the invention further discloses a device for the process. The process and the device are used for extracting metal compounds from ore in a wet electrolytic industry.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

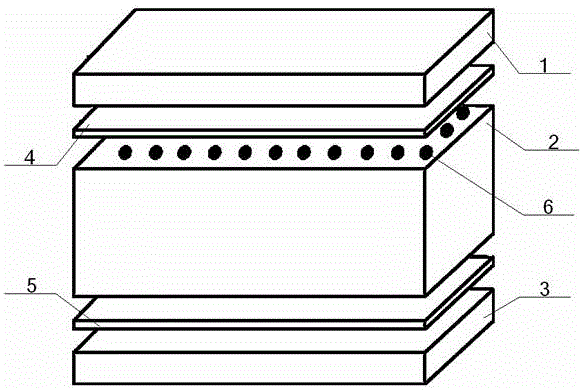

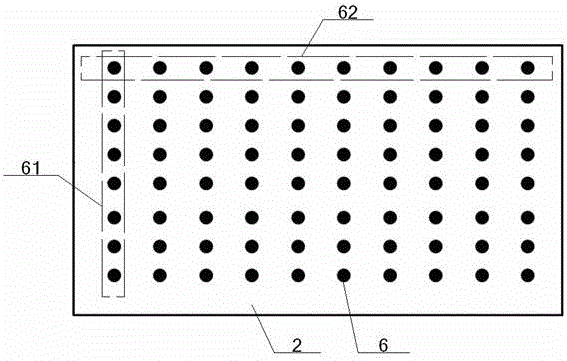

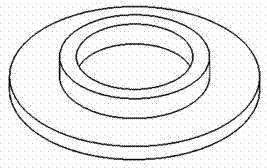

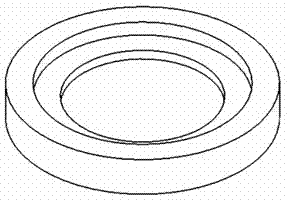

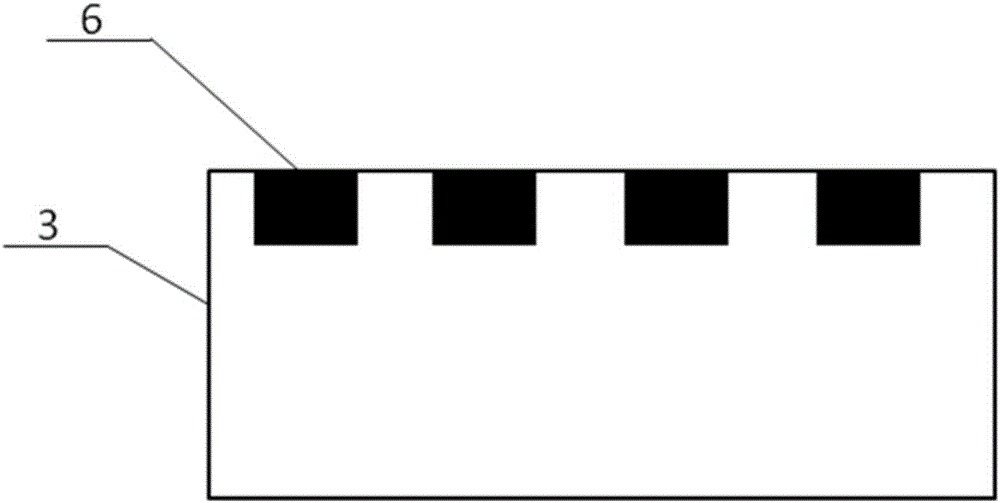

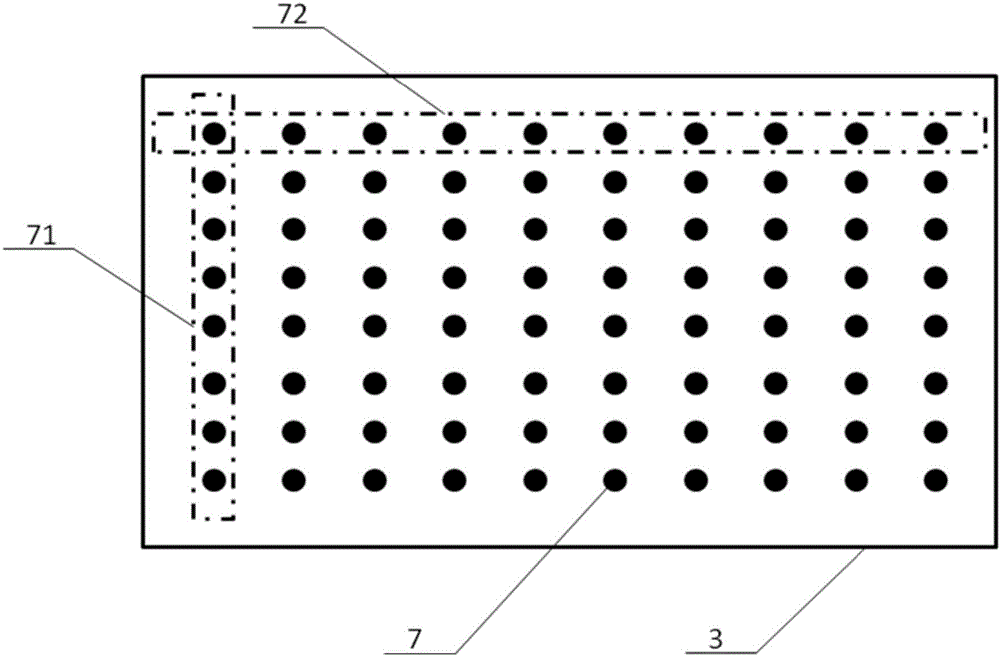

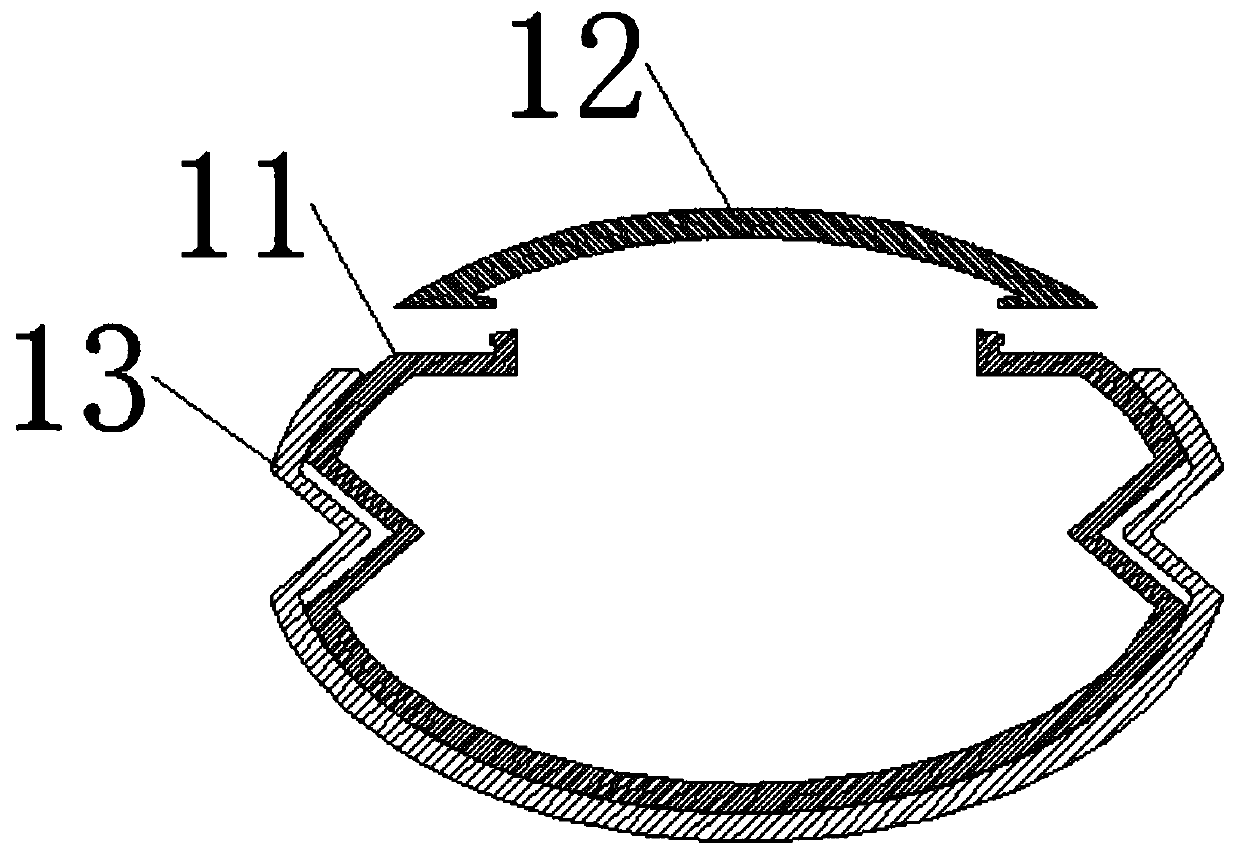

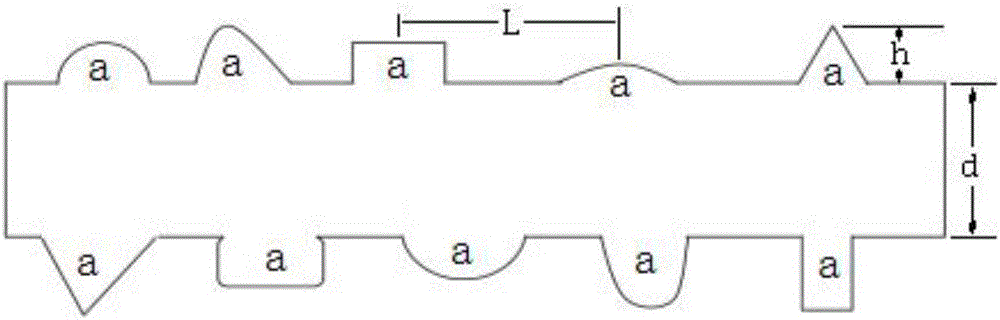

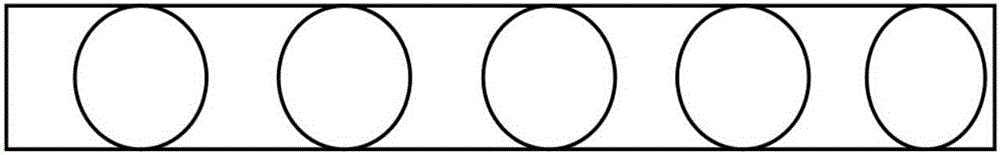

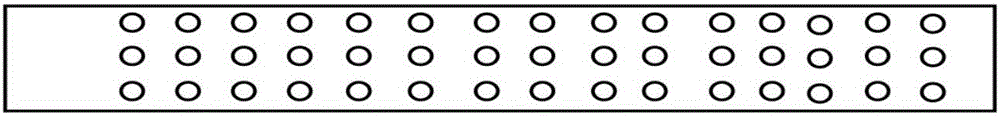

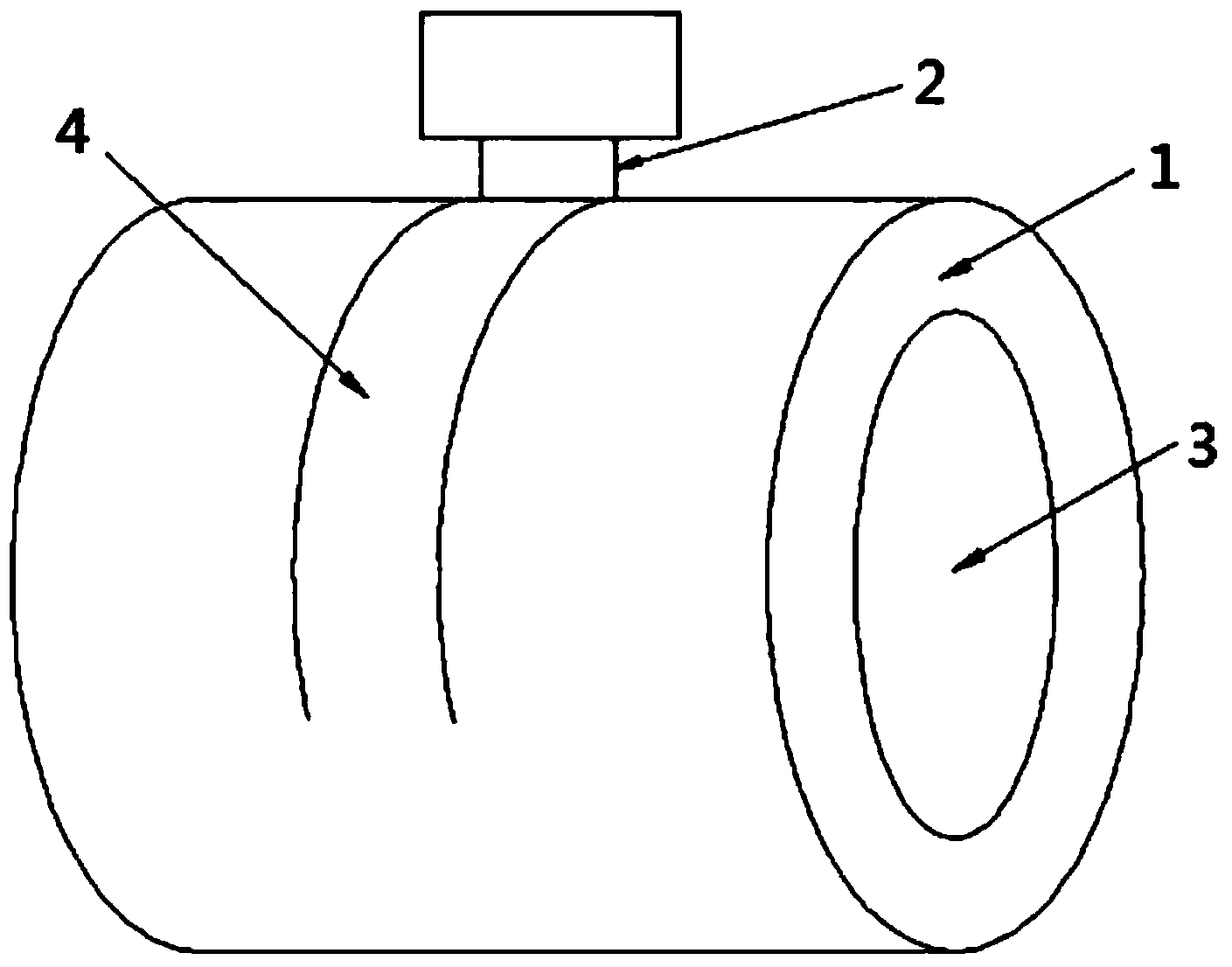

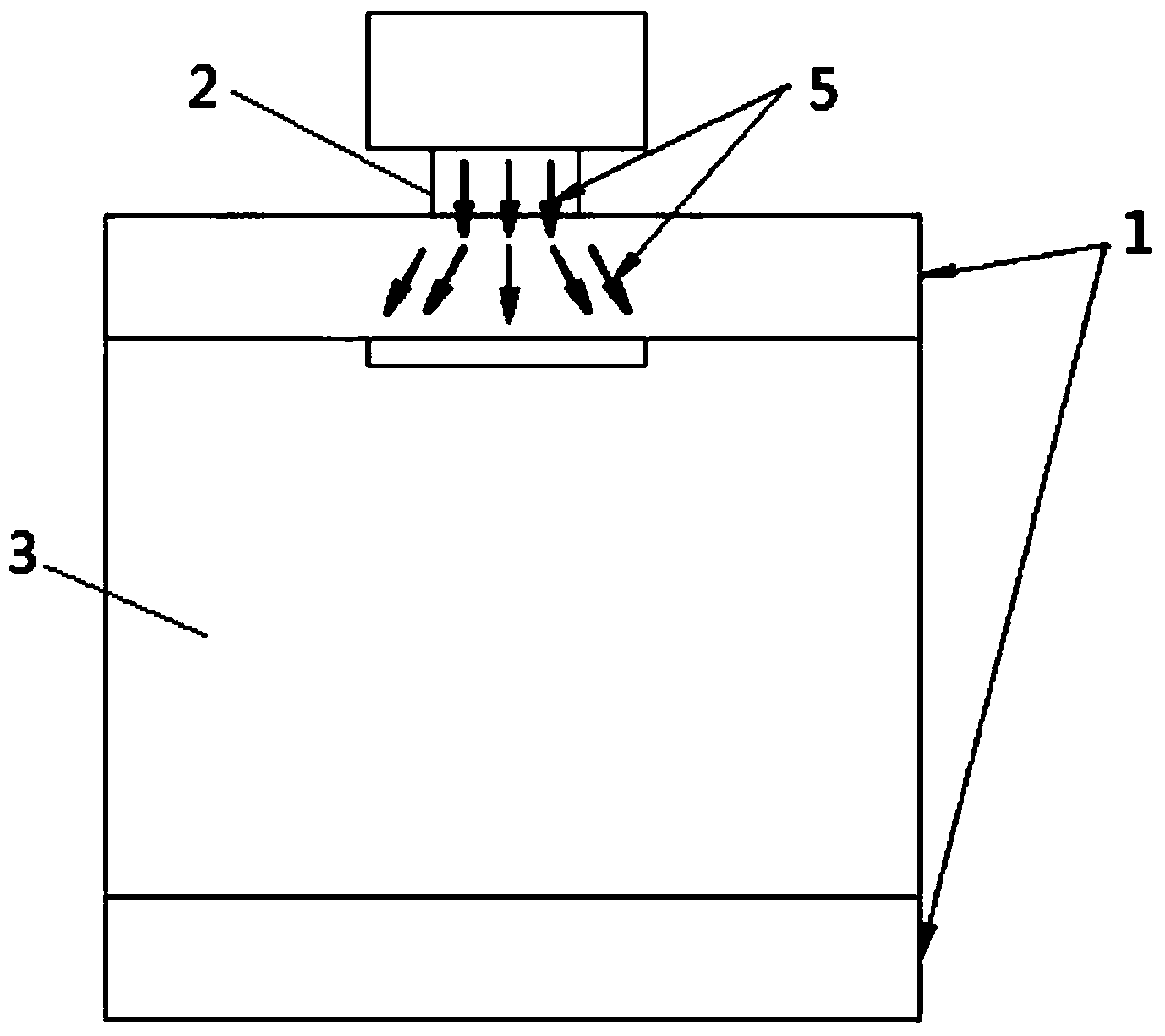

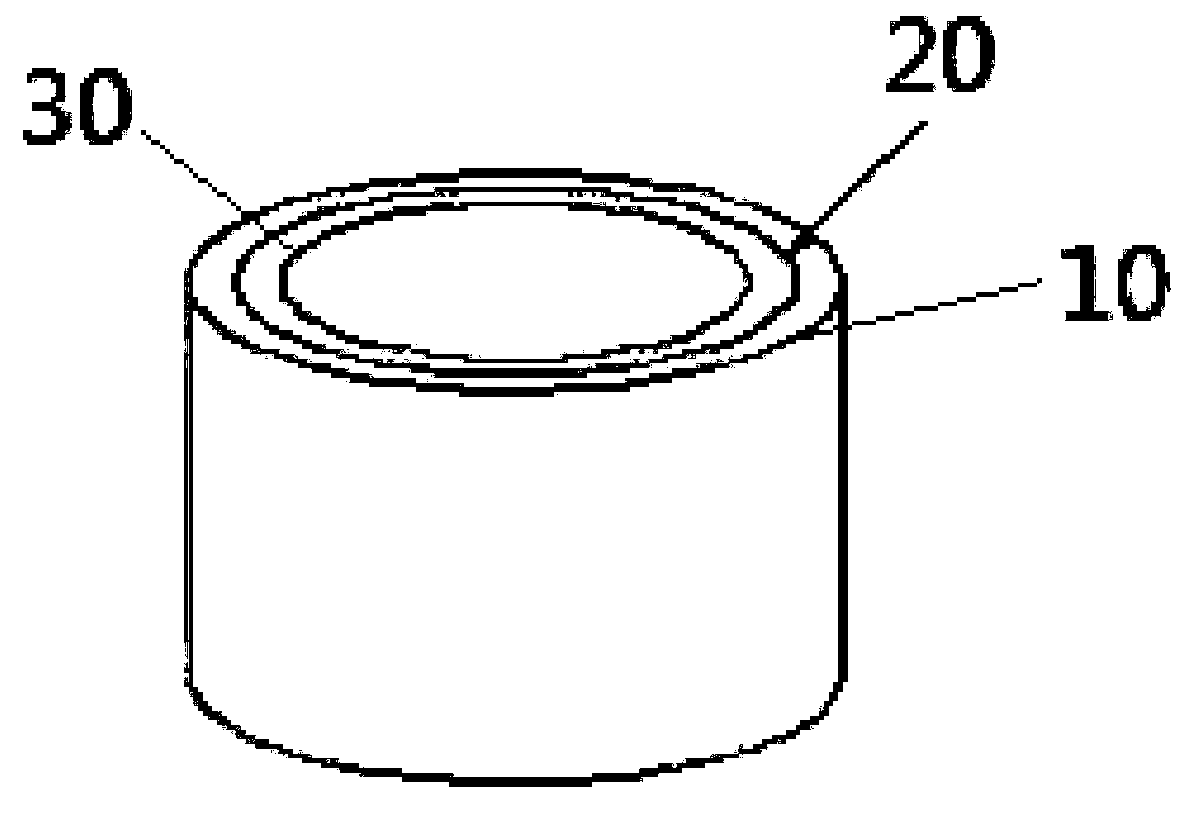

Integral annular three-dimensional fabric and weaving method thereof

The invention discloses an integral annular three-dimensional fabric and a weaving method thereof. The fabric is in a completely integral three-dimensional yarn interweaving structure, and is not laminated or lapped; the yarns inside an xoy plane where the annular direction and the radial direction of the fabric are positioned and the yarns in z direction are all in the states of extension, wherein the yarns inside the xoy plane can be orientated at any angle according to design requirements, and no interweaving point is formed among each layer of yarns; the yarns in z direction are vertical to the yarns inside the xoy plane, and are interweaved with the yarns inside the xoy plane so that each layer of yarns are restricted into an integral annular three-dimensional fabric. The weaving method comprises the following steps of: (1) designing and preplacing a steel pipe array; (2) penetrating and inserting a steel sheet; (3) threading the yarns inside the xoy plane; (4) and leading the yarns in z direction to replace all steel pipes till the integral annular three-dimensional fabric is weaved completely.

Owner:TIANJIN POLYTECHNIC UNIV

Process for preparing 1,1,2 trichloroethylane

ActiveCN100335450CGood effectSimple structurePreparation by halogen additionVapor–liquid separatorMain channel

The invention discloses a method to make 1,1,2 trichloroethane. It includes the following steps: using 1,1,2 trichloroethane as circling medium sending to the first mixing spraying device, the vinyl chloride would be absorbed into the first mixing area of the first mixing spraying device through, and vinyl chloride dissolving in the 1,1,2 trichloroethane would be sent to the second spaying device, and the chlorine would be absorbed at the mixing area of the second mixing spraying device. The vinyl chloride would take reaction with chloride in the mixing area of the second mixing spraying device and coming into the main channel reactor to continue reacting to form 1,1,2 trichloroethane, the result would be separated in the separator and coming into the post section. The invention is simple structure, easy to operate, and the conversion of vinyl chloride could reach to 98%.

Owner:SHANGHAI CHLOR ALKALI CHEM

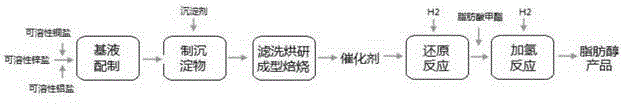

Catalyst applied to medium-pressure liquid-phase hydrogenation of fatty acid methyl ester for preparation of fatty alcohol

InactiveCN106140172AFew types of componentsReduce the impactOrganic compound preparationHydroxy compound preparationPtru catalystCopper oxide

The invention discloses a catalyst applied to medium-pressure liquid-phase hydrogenation of fatty acid methyl ester for preparation of fatty alcohol. The catalyst consists of the following components (in percentage by weight): 10 to 60 percent of copper oxide, 5 to 40 percent of zinc oxide and 0 to 80 percent of alumina. According to the catalyst applied to medium-pressure liquid-phase hydrogenation of the fatty acid methyl ester for preparation of the fatty alcohol, the copper oxide is a main catalytic active component, the zinc oxide is a catalyst promoter component, and alumina is either a catalyst promoter component or a carrier. Each component synergistically acts to achieve high catalytic activity, high selectivity and high stability. Moreover, the catalyst applied to medium-pressure liquid-phase hydrogenation of the fatty acid methyl ester for preparation of the fatty alcohol contains fewer types of components, and each component has less influence and pollution to the environment, so that good environmental benefits are created. The catalyst applied to medium-pressure liquid-phase hydrogenation of the fatty acid methyl ester for preparation of the fatty alcohol is very applied to a process for catalytically hydrogenating the fatty acid methyl ester to prepare the fatty alcohol, is suitable to be industrially popularized and applied, and has broad industrial application prospect.

Owner:南京博明科技有限责任公司 +2

Multifunctional filling non-woven cloth and manufacturing method thereof

InactiveCN106048884AGood warmth retentionImproves warmth and elasticityPattern makingDigestive systemHoneycombAirflow

The invention relates to a multifunctional filling non-woven cloth which comprises a surface fiber web, an upper bonding fiber web, a middle fiber web, a lower bonding fiber web and an inner fiber web sequentially from top to bottom, wherein the middle fiber web is honeycomb cotton formed by carding webs and vertical laying the webs, the surface fiber web and the inner fiber web are fiber webs formed by carding or air laying webs and intersecting laying the webs, the upper bonding fiber web and the lower bonding fiber web are fiber webs formed by carding or air laying short fiber with low melting points, lavender fills in grooves carved in the upper surface of the middle fiber web, and uniformly distributed thin magnets are embedded in the lower surface of the middle fiber web. The finished product is made through steps of preparing fiber webs, fibre web grooving, embedding thin magnets, compositing fiber webs, drying, cooling, filling lavender and reeling. The multifunctional filling non-woven cloth has the advantages of good warmth retention and elasticity performance and can bear relatively large horizontal pulling force. The multifunctional filling non-woven cloth has medicinal anti-bacteria and magnetic therapy functions and is easy for popularization and application.

Owner:WUHAN TEXTILE UNIV

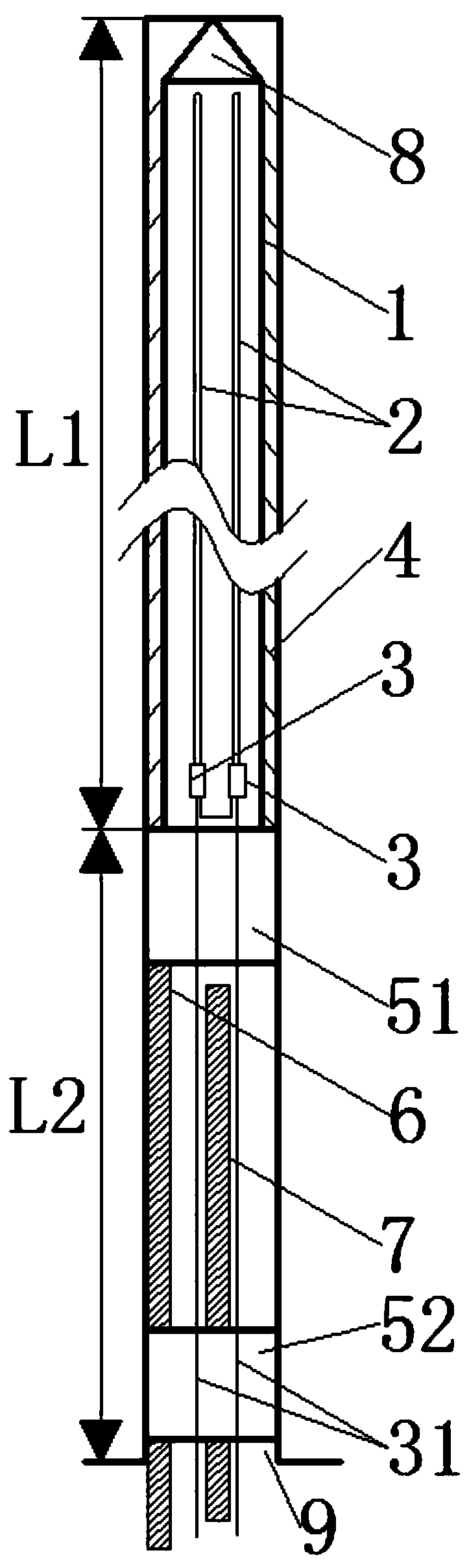

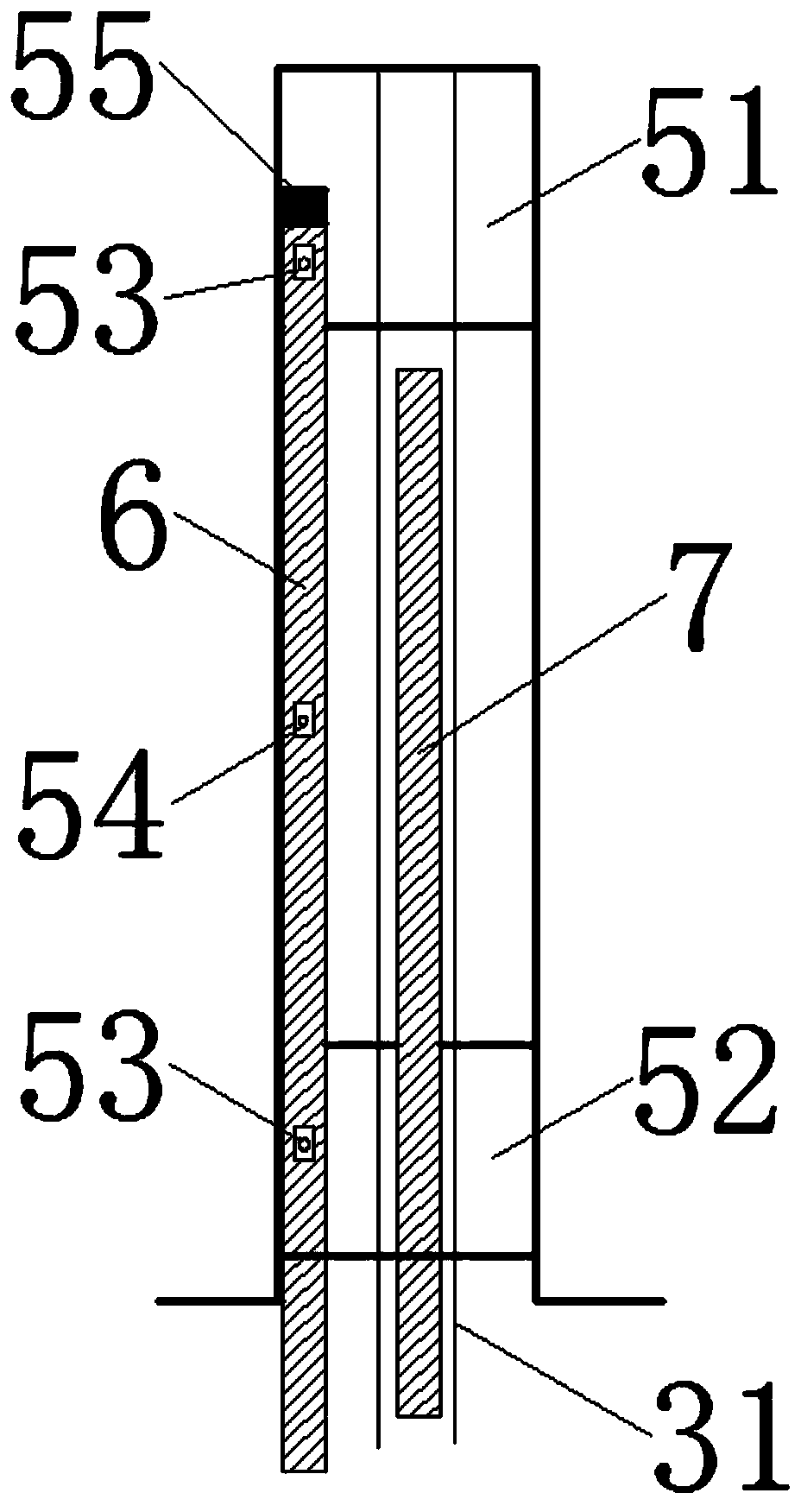

Deep hole blasting charging hole sealing device and using method thereof

The invention provides a deep hole blasting charging hole sealing device and a using method thereof. The deep hole blasting charging hole sealing device comprises a blasting tube, a detonating cord, an electric detonator, a hole sealing bag, a grouting tube and an exhaust slurry return tube; the blasting tube comprises a plurality of pipeline units which are tightly connected end to end; the detonating cord is arranged in the blasting tube; the electric detonator is located at one end of the detonating cord at the tail part of the blasting tube and is connected with the electric detonator; thehole sealing bag comprises a first hole sealing bag and a second hole sealing bag, and a grouting area is formed in a space between the first hole sealing bag and the second hole sealing bag; one endof the grouting tube penetrates through the second hole sealing bag and is inserted into the first hole sealing bag through the grouting area; and one end of the exhaust slurry return tube penetratesthrough the second hole sealing bag and enters the grouting area. The deep hole blasting charging hole sealing device is convenient to construct and operate, time-saving, labor-saving, low in cost, capable of greatly improving the construction efficiency, and high in hole sealing quality and safety, normal initiation is ensured, and blasting punching and blown-out shot are avoided.

Owner:河南力行科创矿山技术开发有限公司

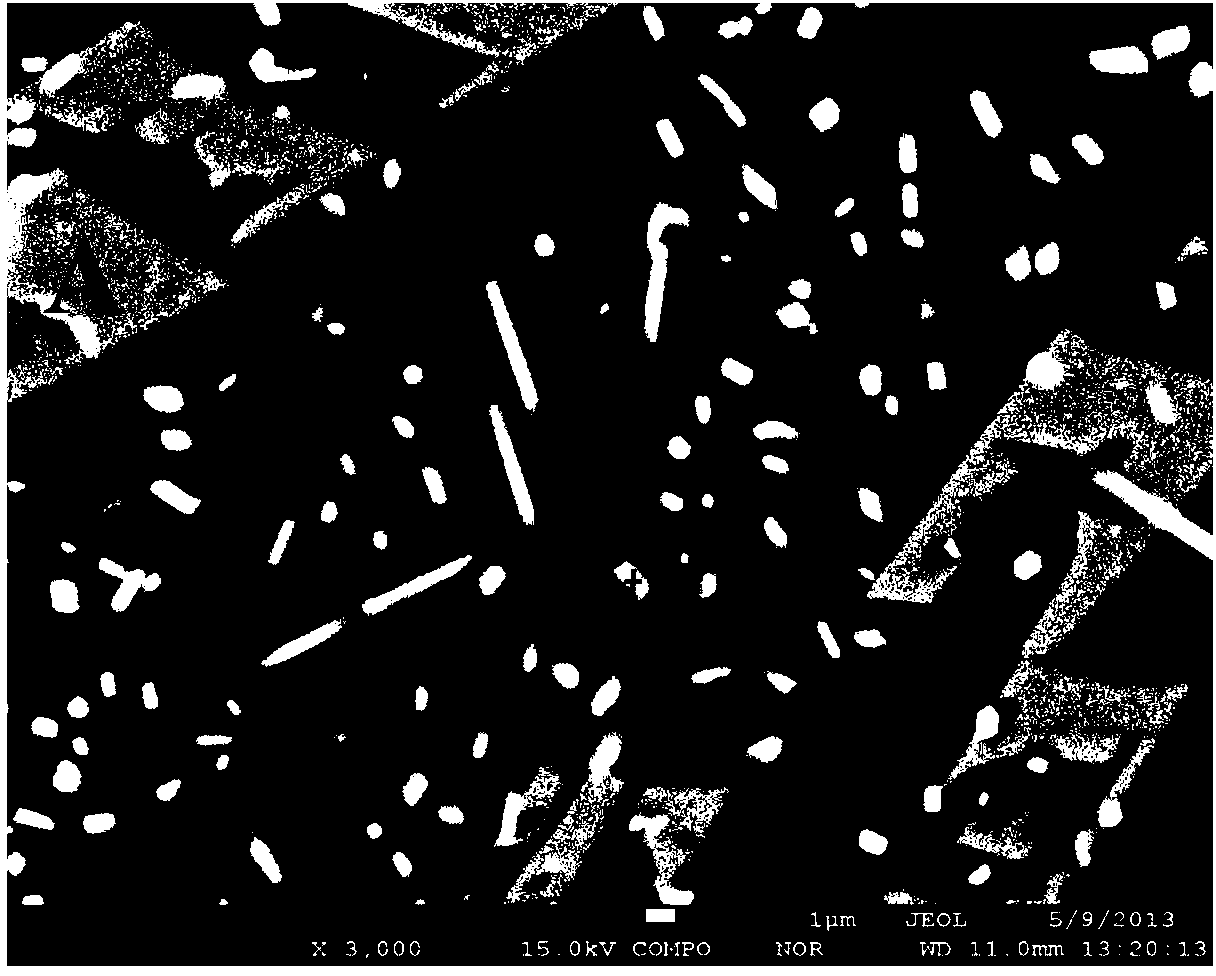

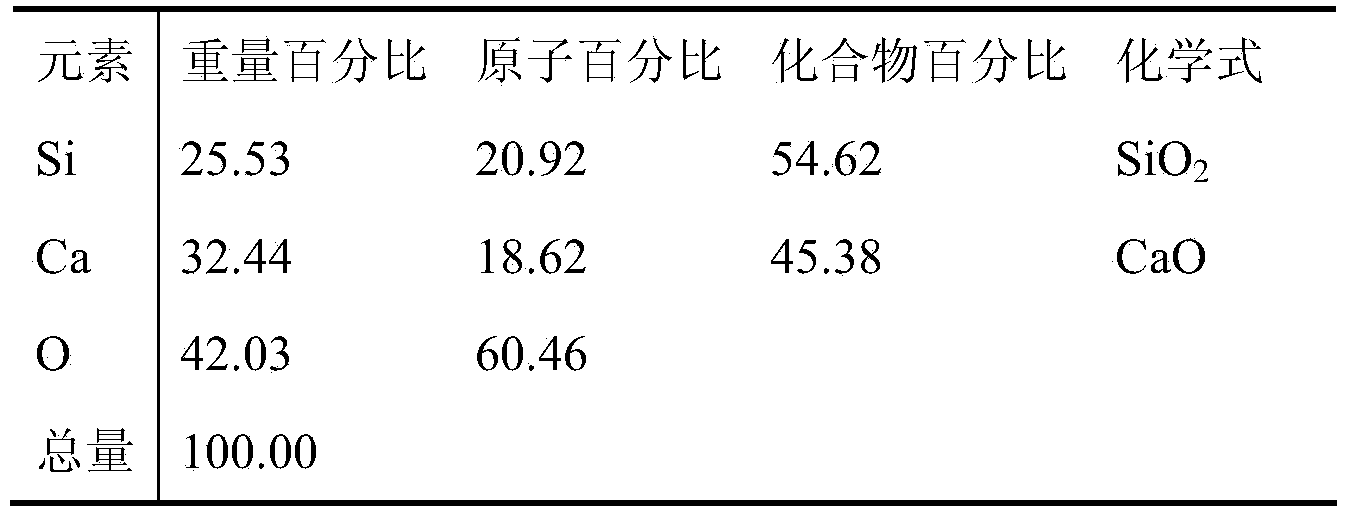

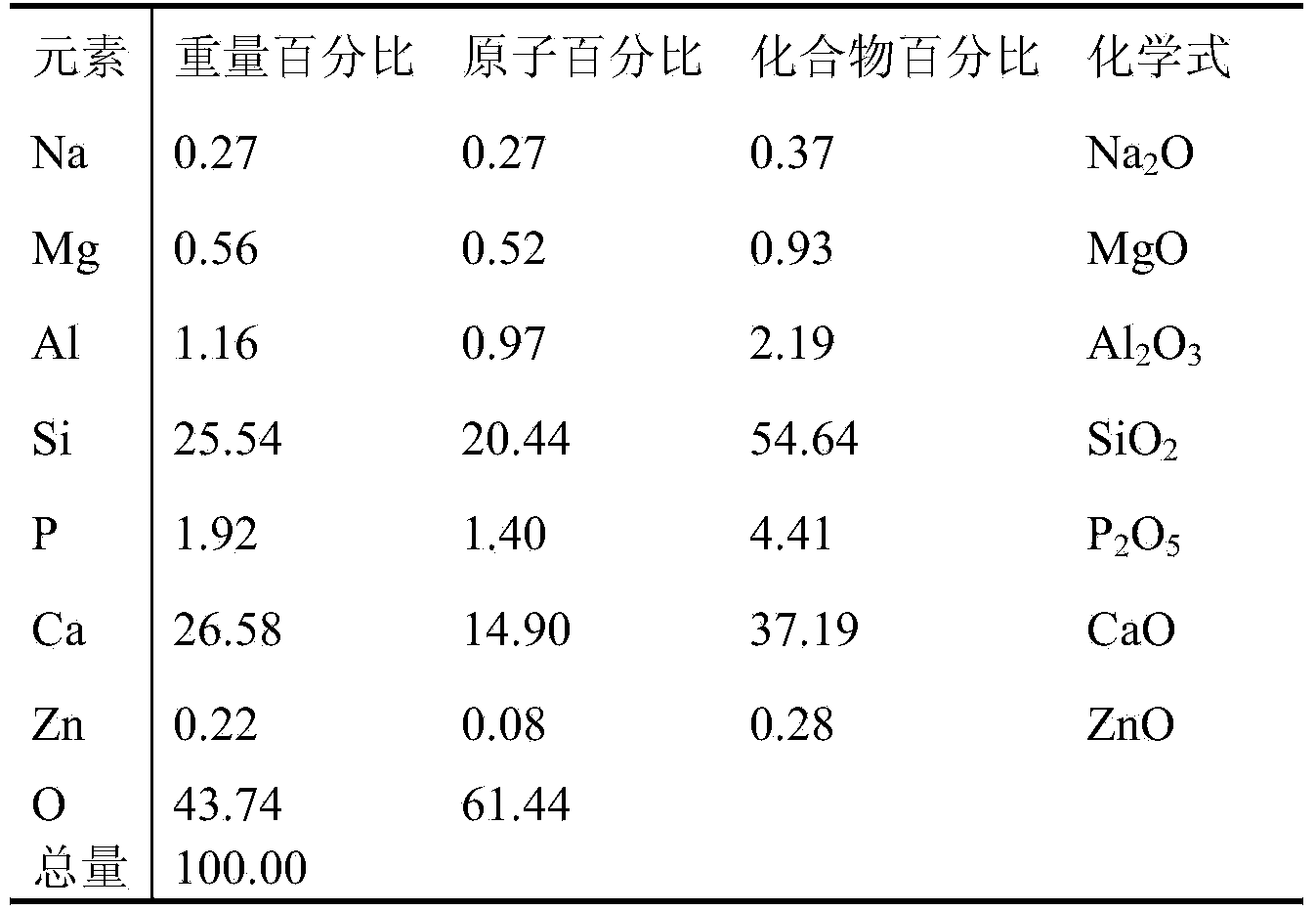

Beige tooth microcrystalline glass compounded by frits of wollastonite and apatite

The invention discloses a beige tooth microcrystalline glass compounded by frits of wollastonite and apatite. The beige tooth microcrystalline glass is prepared through a sintering method after smashing and mixing white microcrystalline glass frits in a single wollastonite crystalline phase and beige microcrystalline glass frits in a single apatite crystalline phase, the bending strength of the prepared material is less than or equal to 80 Mpa, the Vickers hardness tested by an FM-700 type microhardness tester is less than or equal to 5.80 GPa (HV 0.5). According to the invention, through the adjustment of frit composition proportion and the mixing ratio of the two types of frits, microcrystalline glass similar to teeth of different crowds in color can be prepared; under the premise that the constituent ratio in a unitary system is not needed to be adjusted, the mechanical property and the color of the microcrystalline glass can be adjusted through changing the mixing ratio of the mixing frits,; the preparation technology requirements are low; industrialized popularization and application are facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

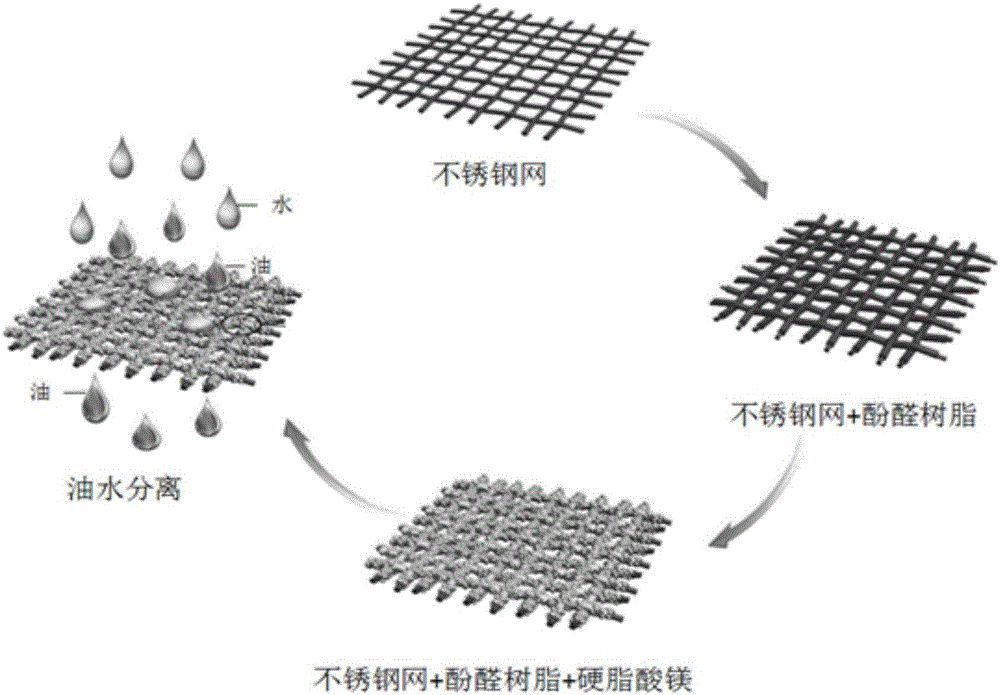

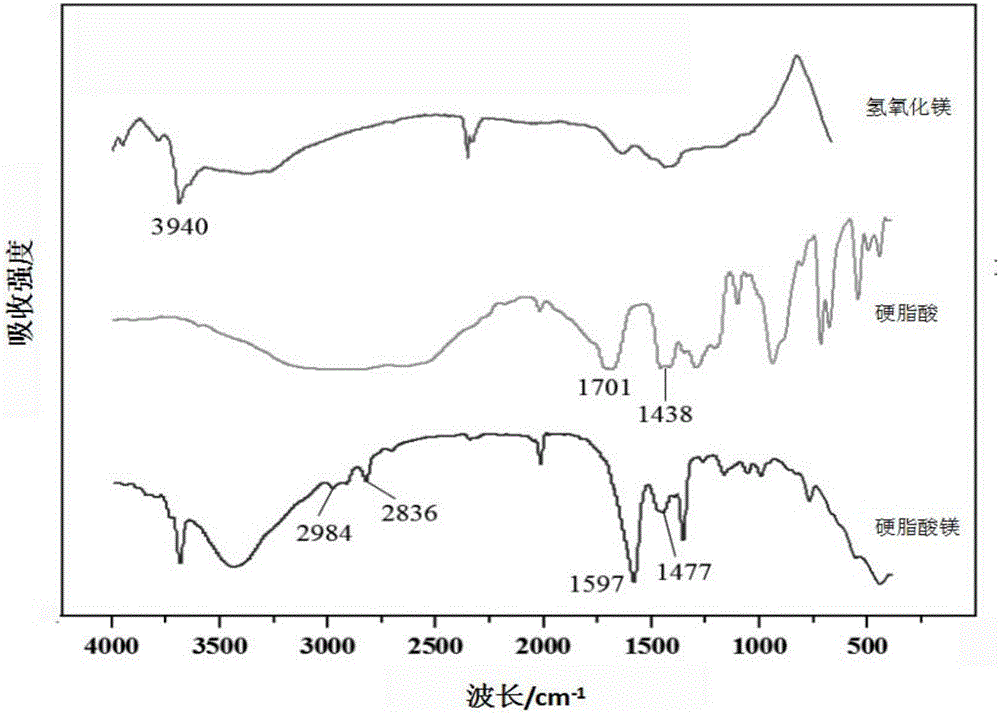

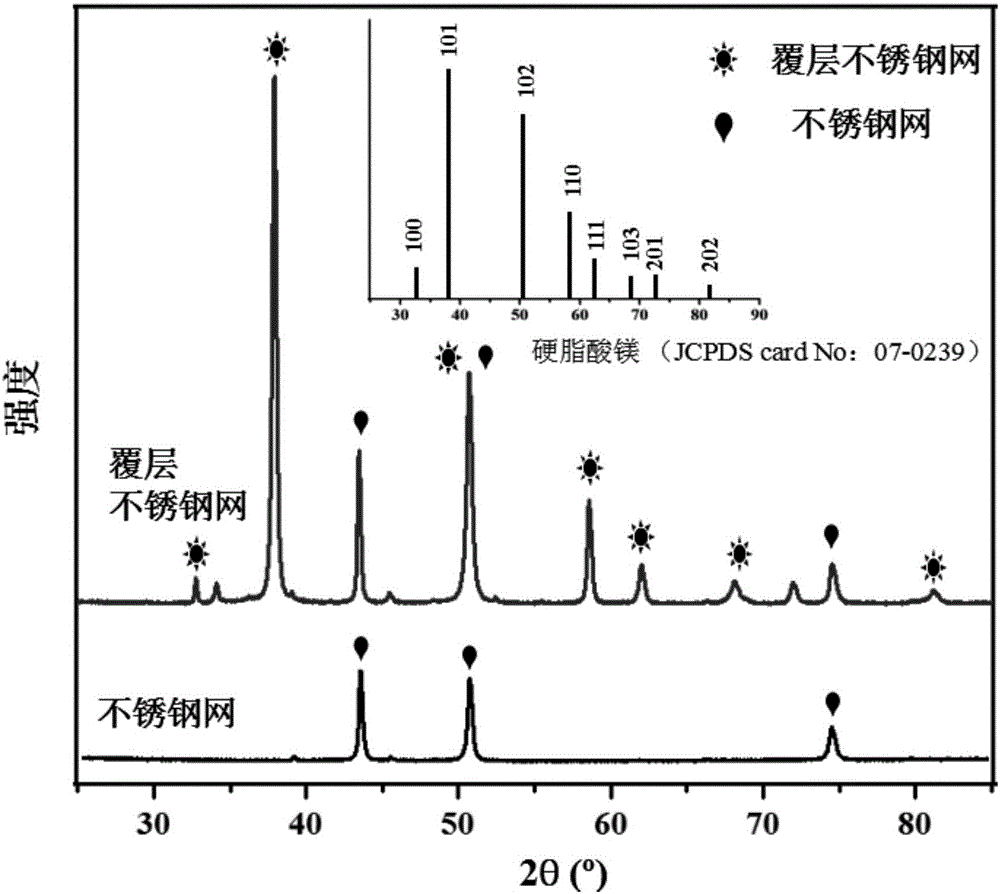

Hydrophobic material and preparation method thereof

ActiveCN106833253ASimple methodGood physical and mechanical propertiesCoatingsOil waterHydrophobic surfaces

The invention discloses a hydrophobic material and a preparation method thereof. The hydrophobic material comprises a base material and a hydrophobic surface coating layer, wherein the surface coating layer contains magnesium hydroxide (Mg(OH)2) powder and phenolic resin. The preparation method of the hydrophobic material is simple, and the prepared hydrophobic material is wide in application range and can still preserve good self-cleaning property and relatively high oil-water separation efficiency under complex physical conditions.

Owner:BEIJING FORESTRY UNIVERSITY

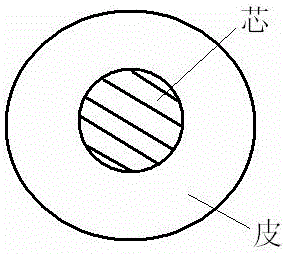

Ultrahigh molecular weight polyethylene fiber flat wire and preparation method thereof

InactiveCN106149068AImprove adhesionIncrease exerciseArtificial filament physical treatmentWet spinning methodsPolymer scienceSolvent

The invention belongs to the technical field of composite materials, and discloses an ultrahigh molecular weight polyethylene fiber flat wire and a preparation method thereof. The preparation method comprises the steps of adding ultrahigh molecular weight polyethylene powder and an additive into a solvent to prepare suspension mixed liquid, heating for swelling at the temperature of 100-150 DEG C, then injecting the product into a twin-screw extruder for extruding, and cooling to form a primary gel fiber; pressing the primary gel fiber by using a press roller, and forming a ribbon silk having a pit structure so as to obtain a primary flat silk fiber; prestretching and winding the obtained primary flat silk fiber, then extracting, drying and carrying out super multiple thermal drawing to obtain the ultrahigh molecular weight polyethylene fiber flat wire. According to the preparation method, the pit structure is pressed on the surface of the ultrahigh molecular weight polyethylene fiber flat wire by means of the press roller, i.e., a mechanical method, so that the adhesive property of an ultrahigh molecular weight polyethylene fiber surface is improved; the ultrahigh molecular weight polyethylene fiber flat wire is simple and environmental-friendly in preparation technology, easy in control of production process and low in requirements for production equipment, thus being easy in industrial popularization and use.

Owner:SOUTH CHINA UNIV OF TECH

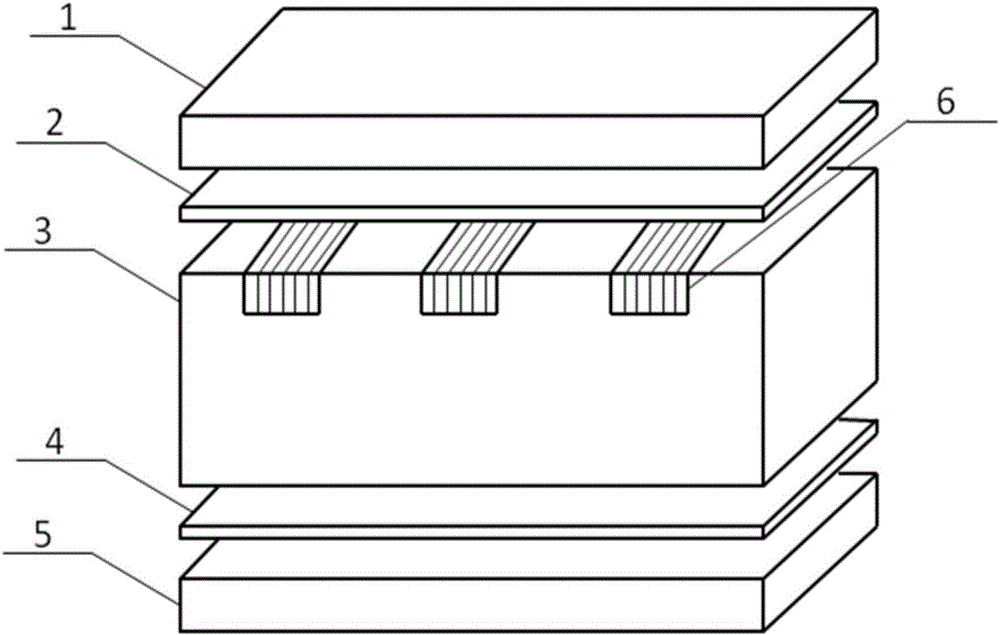

Composite copper bush and preparation method thereof

ActiveCN103909240AExtended service lifeImprove cooling efficiencyMetal layered productsThermal conductivityCooling efficiency

The invention discloses a composite copper bush for cooling. The composite copper bush comprises an outer copper bush, a horizontal high-heat-conductivity material layer and an inner copper bush which are laminated together closely and sequentially from outside to inside, the outer copper bush is prepared from chromium zirconium copper, and the outer copper bush is prepared from oxygen-free copper. The composite copper bush has high cooling efficiency, can improve performance of amorphous and nanocrystalline products, and can increase product percent of pass of amorphous and nanocrystalline belting equipment. The invention further discloses a preparation method of the composite copper bush.

Owner:GUANGZHOU QIDA MATERIAL & TECH

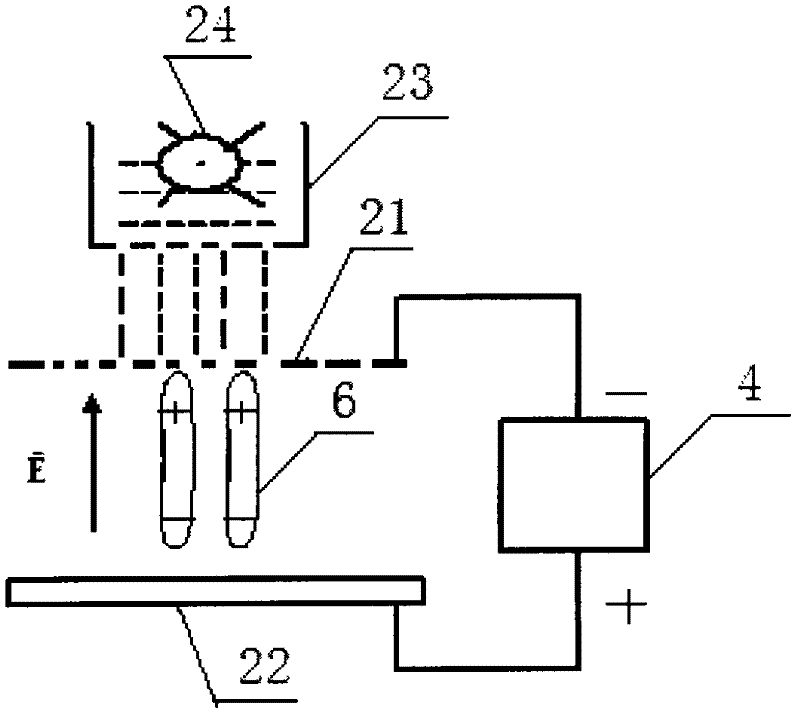

Production method of breathable melt-blown nonwoven fabrics

InactiveCN102517797AMature technologyGood warmth retentionNon-woven fabricsPolytetramethylene terephthalateMicrometer

The invention discloses a production method of breathable melt-blown nonwoven fabrics, which is used for producing polymer superfine fibers by means of well-known melt blowing. The method is characterized in that an electrostatic flocking box is arranged between a melt-blowing die head and a receiving device, superfine fibers pass through the electrostatic flocking box to be adhered with short fibers which perpendicularly fly down in the electrostatic flocking box under the action of an electrostatic field, and breathable melt-blown nonwoven fabrics are formed when the superfine fibers and the short fibers reach the receiving device. The polymer is one of polypropylene, polyester, polybutylene terephthalate, polytrimethylene terephthalate or mixture of the above materials. The short fibers are highly moisture absorbable, 2-20 micrometers in diameter and 3-15 micrometers in length, adding amount of the short fibers accounts for 5-30% of the total weight of the breathable melt-blown nonwoven fabric, and the short fibers are provided by a feeding mechanism. The flocking output voltage of the electrostatic flocking box ranges from 20KV to 60KV, the distance between the melt-blowing die head and the electrostatic flocking box ranges from 10cmm to 40cm, and the distance between an upper pole plate and a lower pole plate in the electrostatic flocking box ranges from 30cmm to 50cm.

Owner:TIANJIN POLYTECHNIC UNIV

Bacillus and application thereof

ActiveCN108865931AImprove thermal stabilityStrong heat resistanceBacteriaAnimal feeding stuffBacillus licheniformisMicrobiology

The invention discloses a bacillus. The strain is classified and named as bacillus licheniformis, is numbered as BLCC1-0441 and has been preserved at China Center for Type Culture Collection (CCTCC) on May 7, 2018; the address is Wuhan University, Wuhan, China; its preservation number is CCICC NO.: 2018253. The bacillus is capable of highly yielding alkaline phosphatase as well as efficiently fermenting, has excellent intestinal colonization performance and has an excellent application in chicken breeding.

Owner:山东宝来利来生物工程股份有限公司

Method for recovering noble metal from gold and silver converter waste magnesium brick

The invention relates to the technical field of noble metal recovery, in particular to a method for recovering noble metal from a gold and silver converter waste magnesium brick. The method comprises the working procedures of grinding a waste magnesium brick sample, performing flotation, performing gravity concentration on flotation tailings, performing flotation, performing gravity concentration, removing magnesium through hydrochloric acid, and the like. The problems that the concentrate cannot be fed into a furnace because of high magnesium content of the concentrate and the recovery rate is high when a gravity concentration method is singly used are solved; the problems that the concentration ratio of the concentrate is not high, the using amount of sulfuric acid is large, and leaching residue is difficultly filtered when a sulfuric acid leaching process is singly used are also solved. The magnesium oxide in the concentrate can be removed to the greatest degree by the method, the high-quality gold and silver concentrate is obtained, the gold recovery rate is more than 99 percent, the silver recovery rate is more than 98 percent, and the removing rate of magnesium oxide can be up to over 98 percent. The recovery rate is obviously higher than that of the other processes, the processing cost is relatively low, and the method is convenient to industrially popularize and use.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

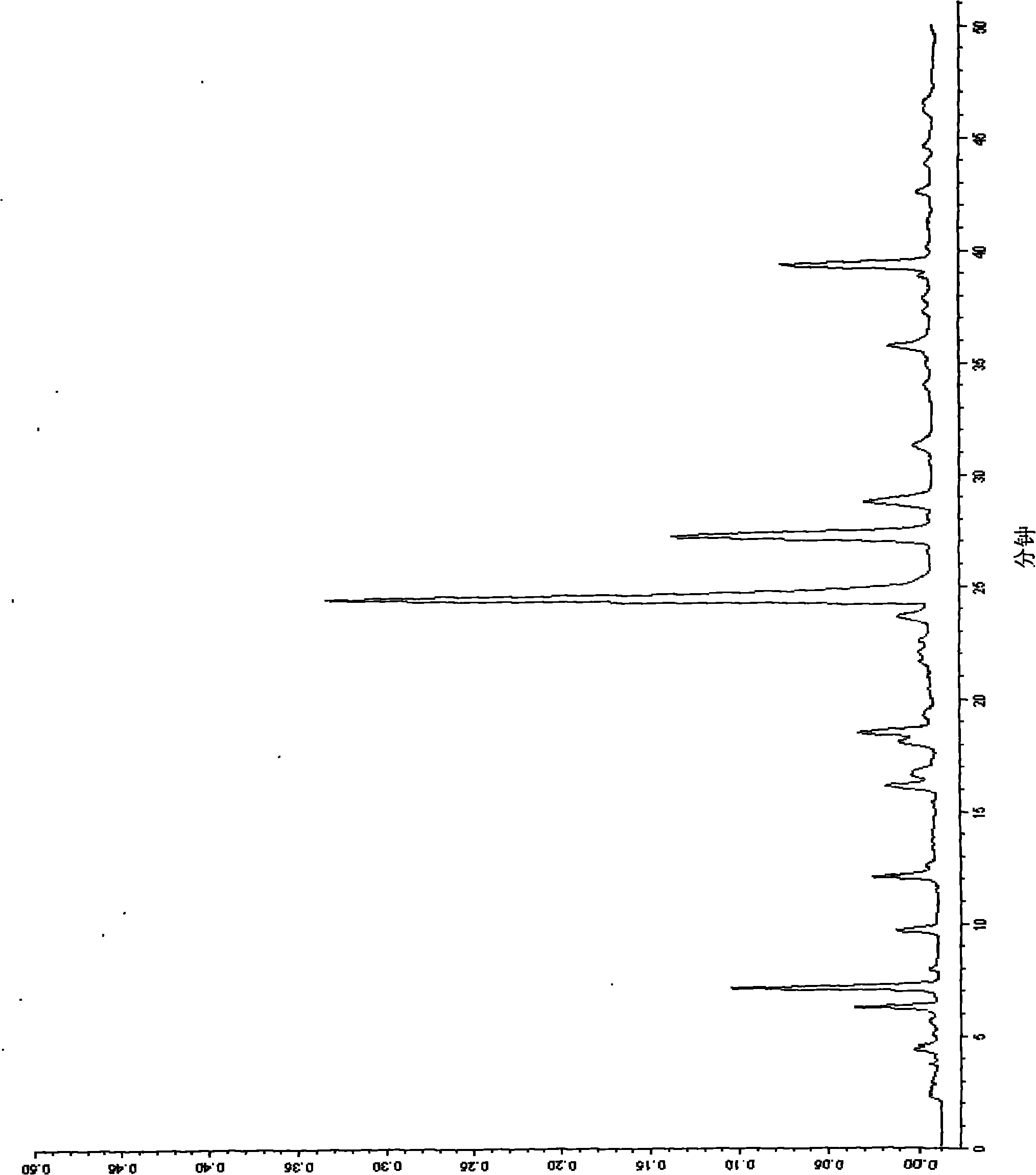

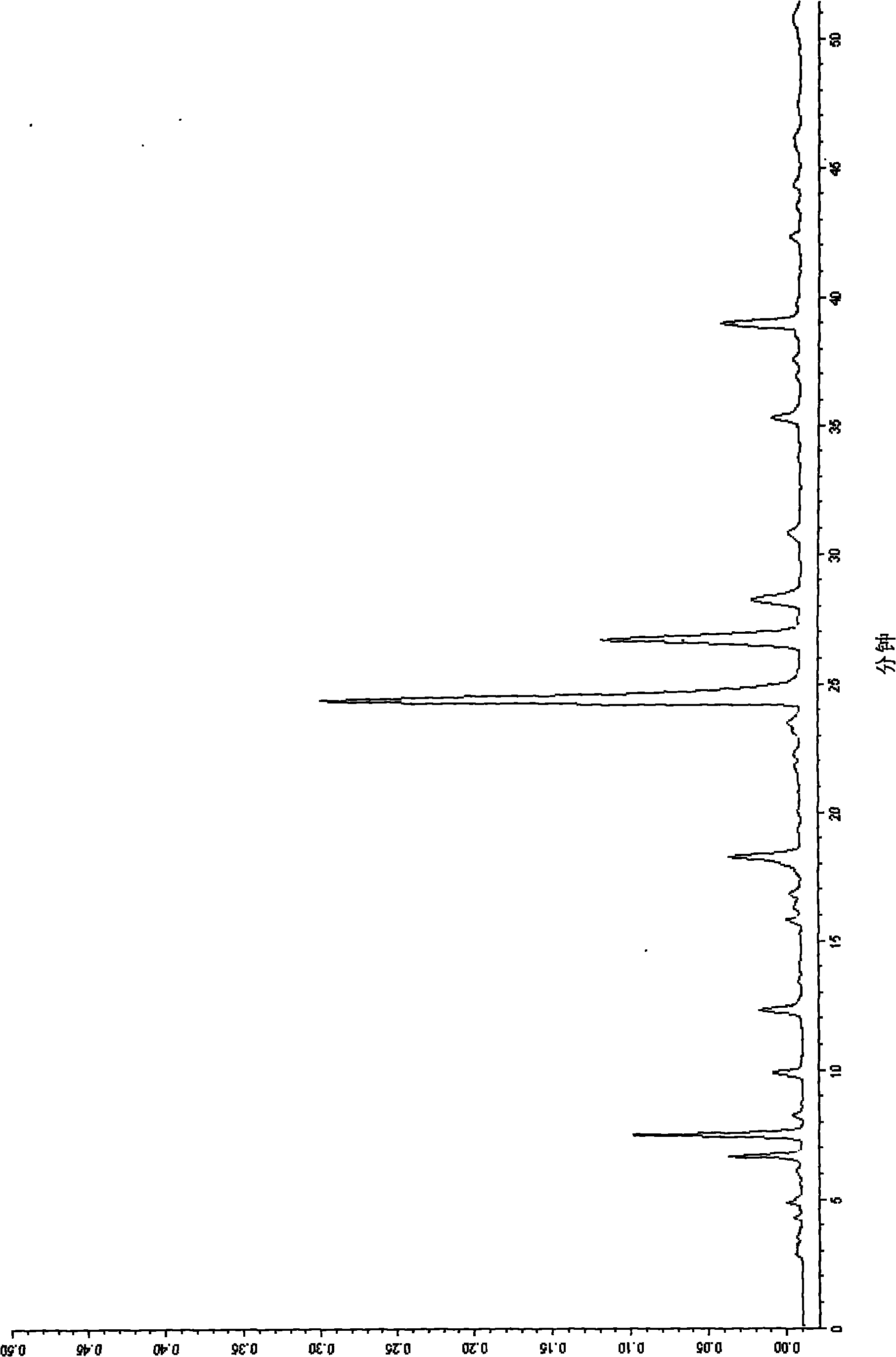

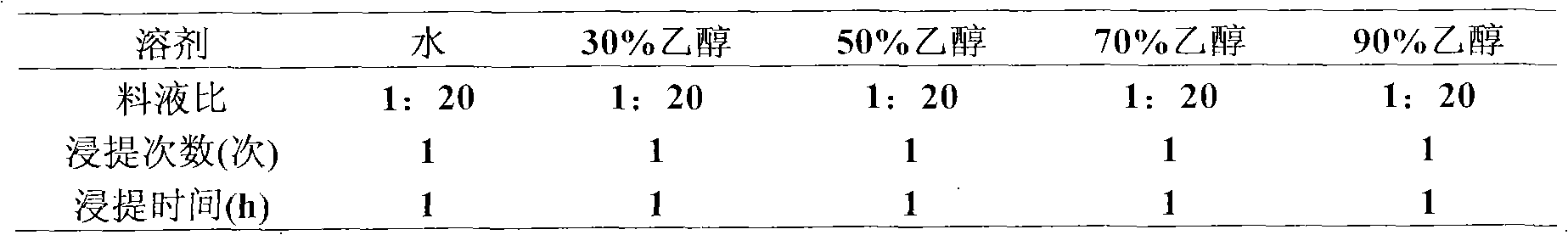

Method for clarifying green tea extract liquid

InactiveCN102144683AGuaranteed health functionImprove sensory qualityTea extractionCLARITYBULK ACTIVE INGREDIENT

The invention provides a method for clarifying a green tea extract liquid, and a ZTC1+1 II type clarifying agent is adopted for clarifying the green tea extract liquid. The invention further provides the green tea extract liquid prepared by the method. By adopting the clarifying method, the using amount of the ZTC1+1 II type natural clarifying agent for clarifying the green tea extract liquid is small, the cost is low, active ingredients can be effectively retained, the prepared green tea extract liquid has excellent taste and good clarity, and the clarifying method has low equipment requirement and is easy to perform industrial popularization and application.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

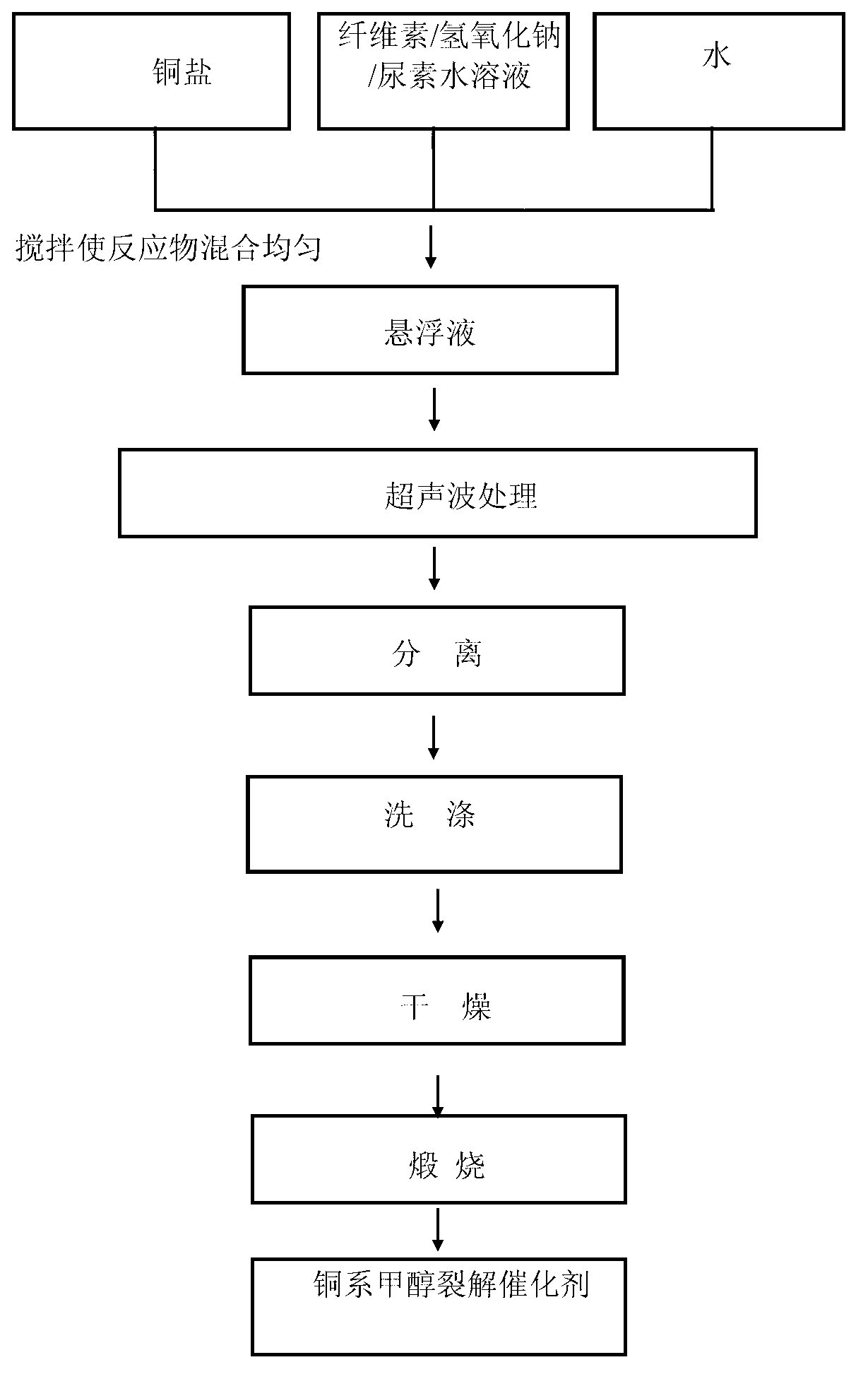

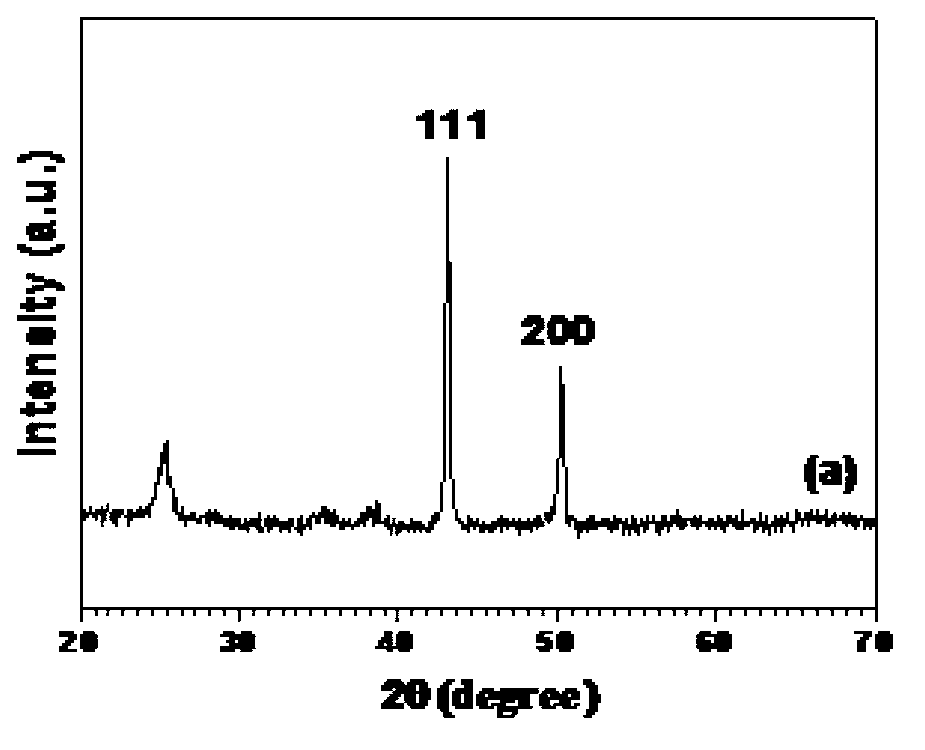

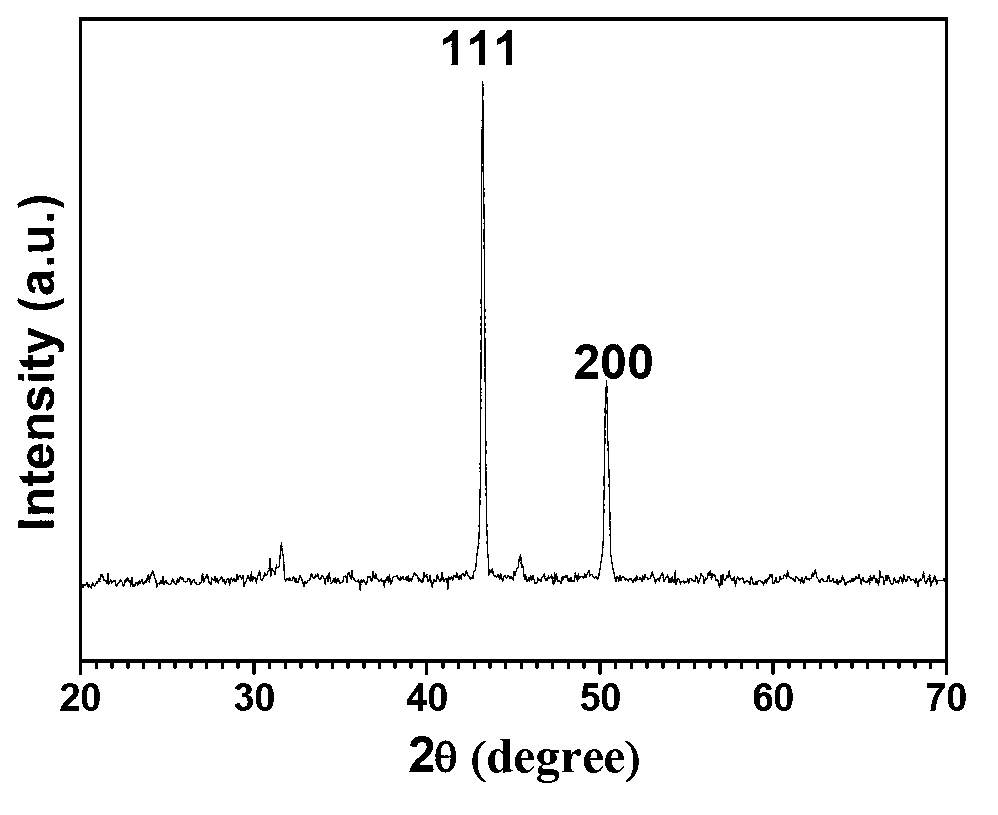

Methanol cracking catalyst and preparation method thereof

InactiveCN103157473ASimple ingredientsWide variety of sourcesHydrogenMetal/metal-oxides/metal-hydroxide catalystsSolventAqueous solution

The invention provides a methanol cracking catalyst and a preparation method thereof. The preparation method comprises the steps of: by taking copper salt and cellulose as raw materials and sodium hydroxide / urea water solution as a solvent, and carrying out fast preparing by adopting an ultrasonic treatment method; and preparing the methanol cracking catalyst by carrying out forging in inert atmosphere. The methanol cracking catalyst prepared by utilizing the preparation method has the advantages that the catalytic activity is strong, the selectivity and the stability are high, the methanol conversion rate is high, the selectivity of H2+CO in products is high, and the application prospect in the field of methanol catalytic cracking is wide.

Owner:BEIJING FORESTRY UNIVERSITY

Two-stage acid leaching washing pressure filtration process and device of metal acid leaching solution

ActiveCN103388073AHigh porosityGuaranteed Extraction EffectProcess efficiency improvementHigh pressureMaterials science

The invention discloses a two-stage acid leaching washing pressure filtration process of a metal acid leaching solution. The process comprises the following steps: 1) injecting the metal acid leaching solution into a filter chamber of a membrane filter press under pressure to obtain filter cakes, and pre-pressing the filter cakes under a pre-pressing pressure of 0.2-0.6MPa; 2) injecting acid into the filter chamber to perform two-stage acid leaching on the filter cakes under the pre-pressing state; 3) at the end of the two-stage acid leaching treatment, keeping the pre-pressing state and continuously injecting a washing solution into the filter chamber for washing the filter chamber; and 4) performing high-pressure press filtering on the substance in the filter chamber after the washing treatment is finished, and discharging the filter residues after the press filtering treatment is ended. On the basis of the two-stage acid leaching washing pressure filtration process, the invention also discloses a device for the process. The process and the device are applied to the wet electrolytic industry for extracting metal compounds from ores.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

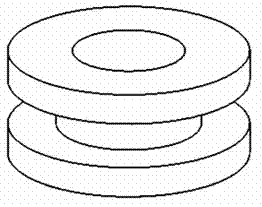

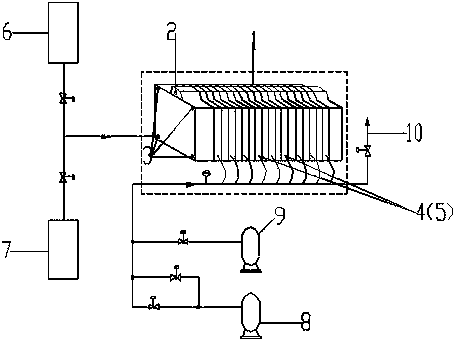

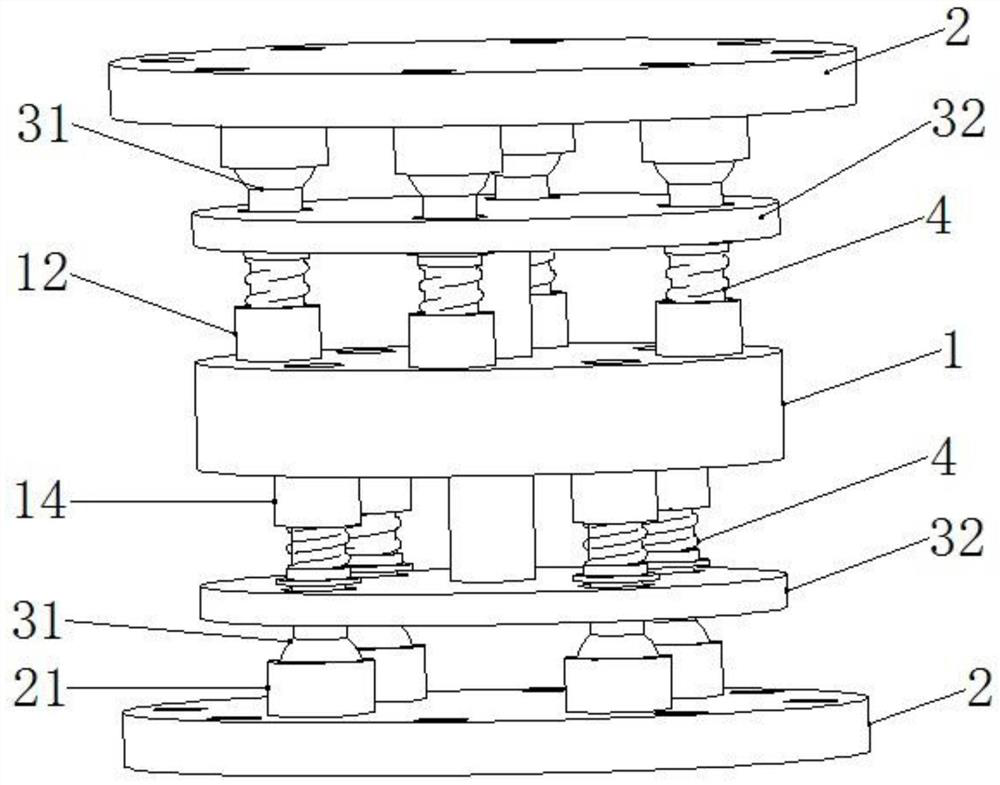

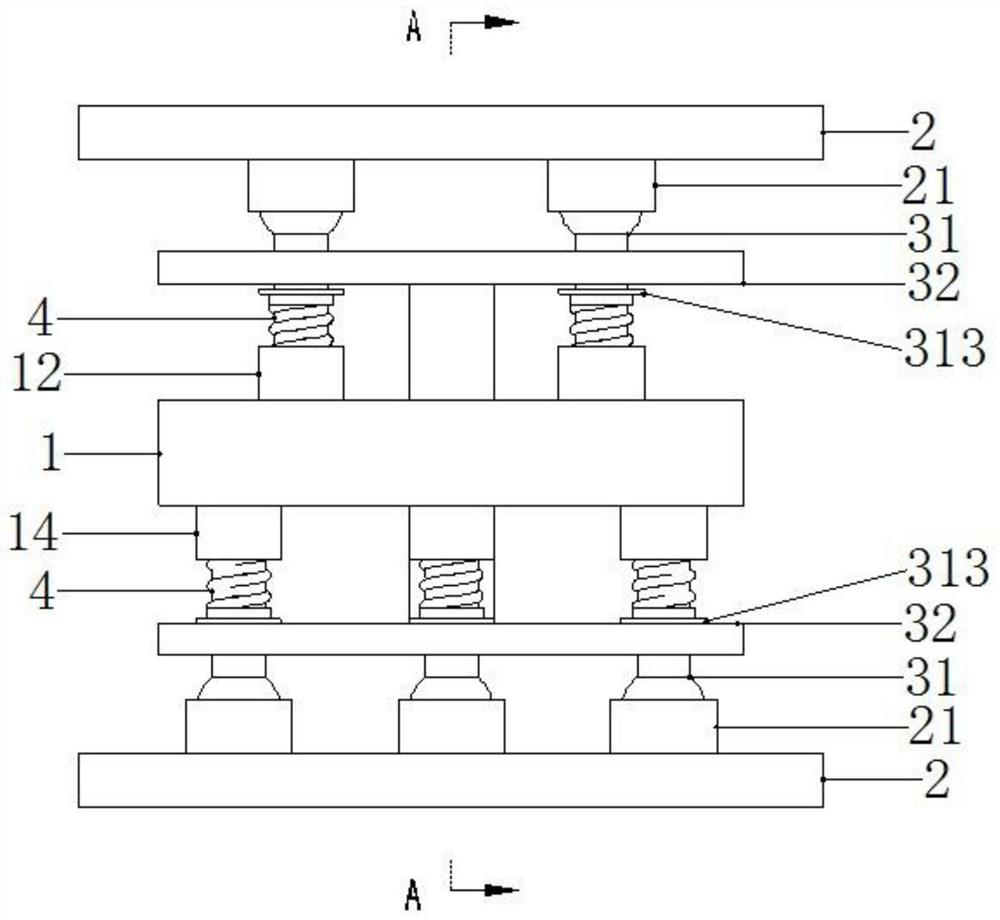

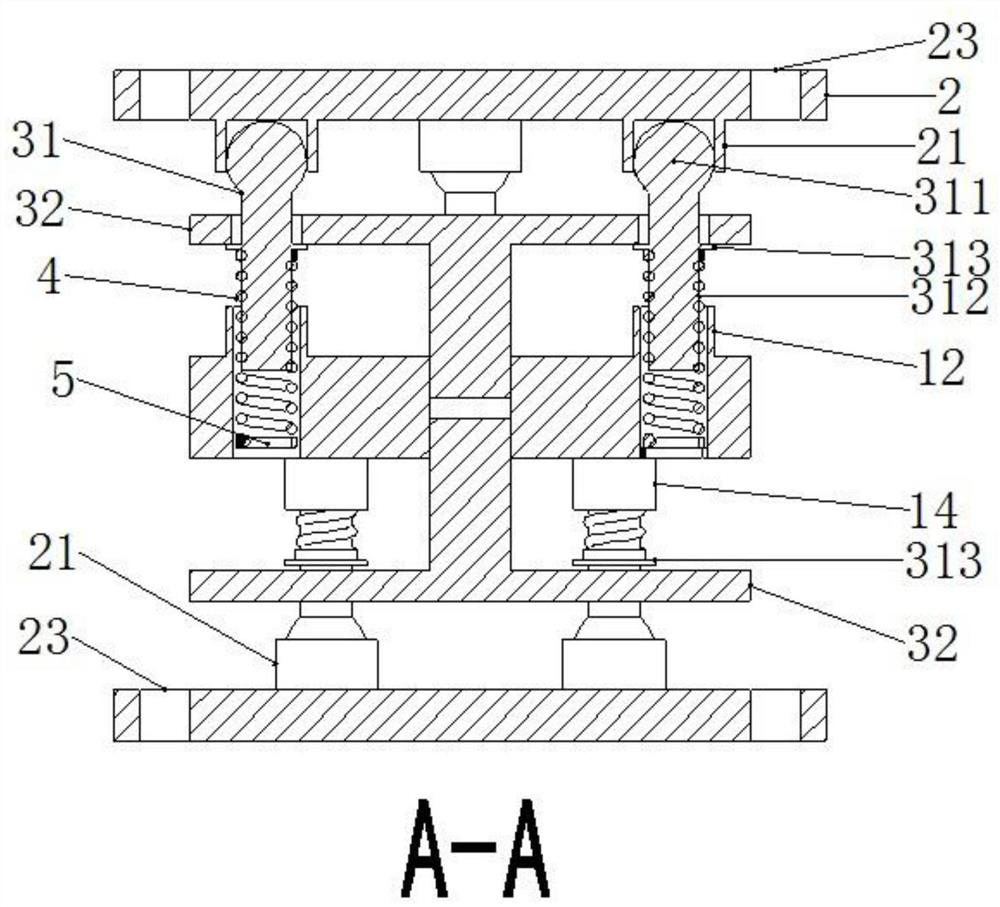

Transmission shaft connecting flange shock-absorbing protection device

PendingCN111828537AEliminate shockSimple structureNon-rotating vibration suppressionCouplings for rigid shaftsDrive shaftStructural engineering

The invention provides a transmission shaft connecting flange shock-absorbing protection device. The transmission shaft connecting flange shock-absorbing protection device includes a shock-absorbing disc, connecting discs, and shock-absorbing connectors; a through hole is arranged on the shock-absorbing disc, and a shock-absorbing spring is installed in the through hole; two connecting discs are arranged, and the two connecting discs are arranged oppositely above and below the shock-absorbing disc, which are a first connecting disc and a second connecting disc; a ball head hole is arranged oneach connecting disc; the two connecting discs are used for connecting a transmission shaft and a reducer; two shock-absorbing connectors are arranged, which are arranged oppositely along the two sides of the shock-absorbing disc; each shock-absorbing connector is arranged between the shock-absorbing disc and the connecting disc; one end of the shock-absorbing connector is installed in the ball head hole of the connecting disc, and the other end is installed in the through hole of the shock-absorbing disc, so as to be used for shock absorption by cooperating with a shock-absorbing spring; andthe shock-absorbing connectors are also connected to the shock-absorbing disc for transmitting torque. The transmission shaft connecting flange shock-absorbing protection device has a good shock-absorbing effect, can improve the operation stability and service life, has a simple structure, is convenient to install, and is convenient for industrialization promotion and use.

Owner:SHANDONG IRON & STEEL CO LTD

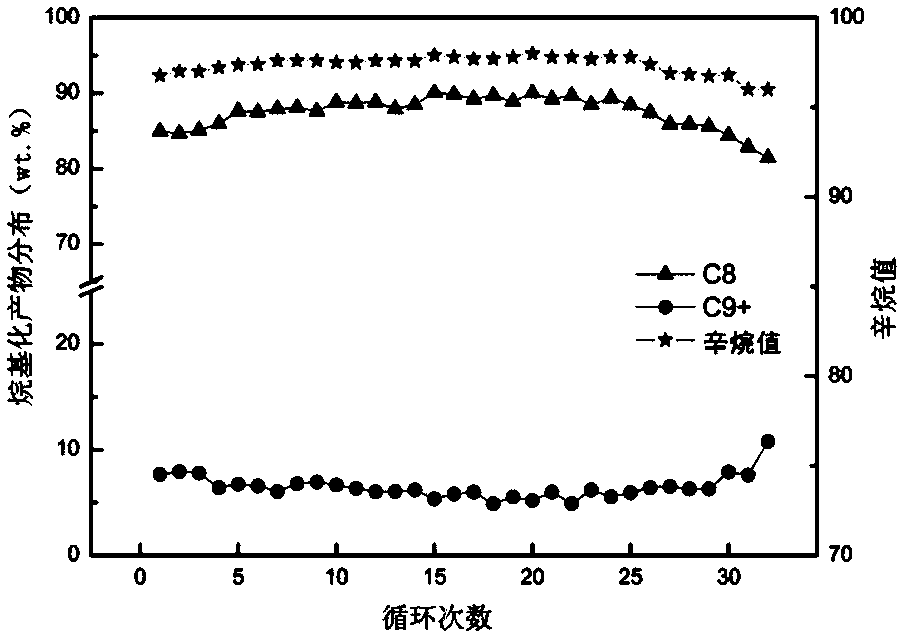

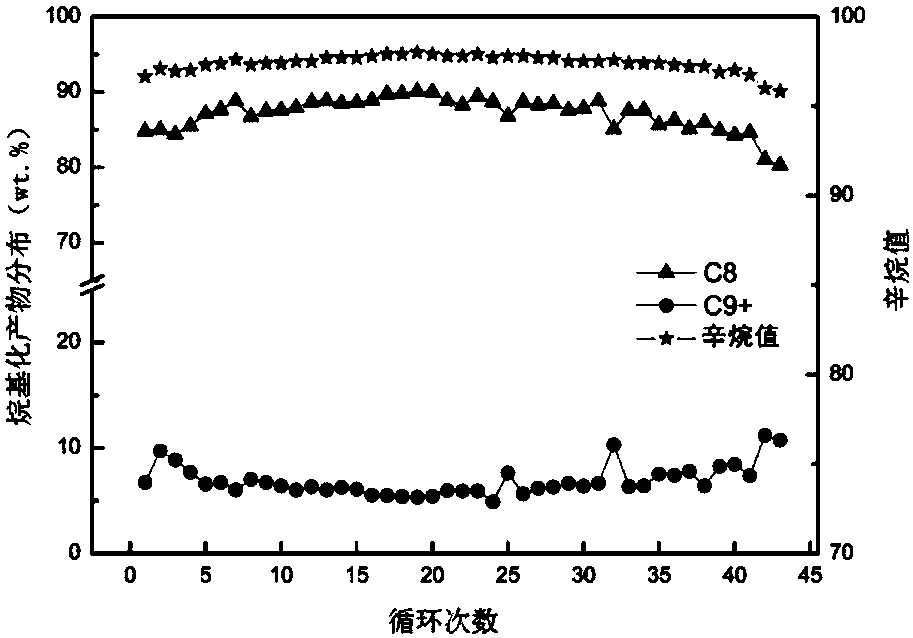

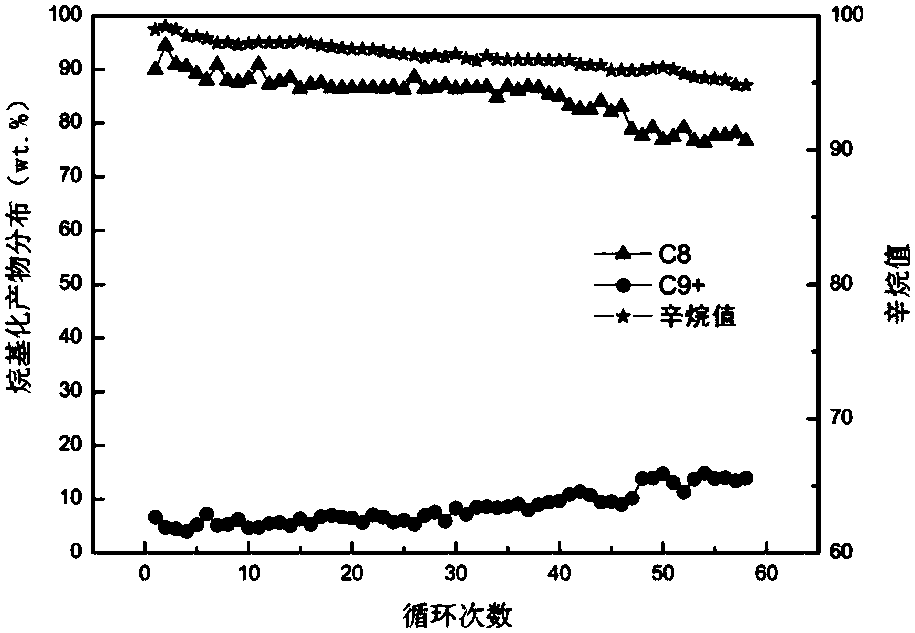

A kind of method that adamantyl ionic liquid promotes the catalytic production of alkylated gasoline

ActiveCN106635141BImprove stabilityImprove interface performanceOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionAlkyl transfer2-methylbutane

The invention relates to a production method of alkylation gasoline. According to the method, an adamantyl ion liquid modified strong acid is used as a catalyst, and low-carbon olefin and isobutane or isopentane are catalyzed to be subjected to direct addition, so as to generate highly branched isoparaffin. Cations of adamantyl ion liquid have a structure shown as the description, wherein R1, R2, R3, R4, R5 an R6 are the same or different C1 to C30 alkyl, and n is an integer from 0 to 8; anions of the adamantyl ion liquid comprise at least one of HSO4<->, CF3SO3<->, NTf<2->, H2PO4<->, PW12O40<3->, p-CH3-(C6H4)SO3<->, PMo12O40<3->, H2PW12O40<->, PF6<->, SBF6<-> and [B(HSO4)4]<->. According to the method for alkylating with the assistant catalysis of the adamantyl ion liquid, provided by the invention, the service life of the catalyst can be remarkably prolonged, and the selectivity and yield of a target product (trimethylpentane) are improved. The method has simple conditions and is simple and easy to operate, and industrialized popularization and application are facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Pesticide for orange

InactiveCN106472597ANo pollution in the processGood killing effectBiocideAnimal repellantsActive componentEcology

The invention discloses a pesticide for orange. The pesticide is prepared from the following components in parts by weight: 40-60 parts of pinellia tuber, 20-40 parts of honeysuckle flower, 10-20 parts of phellodendron bark, 5-15 parts of pokeweed, 10-20 parts of rhizoma acori graminei, 5-15 parts of safflower and 3-12 parts of eucommia. The pesticide has quick effect, difficult decomposition of active components and lasting effect, and reduces the consumption of pesticide and frequency of use of the pesticide; the pesticide formula is simple and easy for standardization and industrialized popularization and use; the pesticide has wide sources of raw materials, low cost, no chemical pesticide components, no public nuisance and no residue, greatly reduces environmental disruption and also reduces poisoning to an applicator in the process of application; the pesticide has broad range of disinsection, low environmental pollution, strong selectivity and low toxicity to people, livestock and native predators; and pests are difficult to generate chemical resistance, and the pesticide is green, healthy, environment-friendly and efficient.

Owner:开县朝国农业开发有限公司

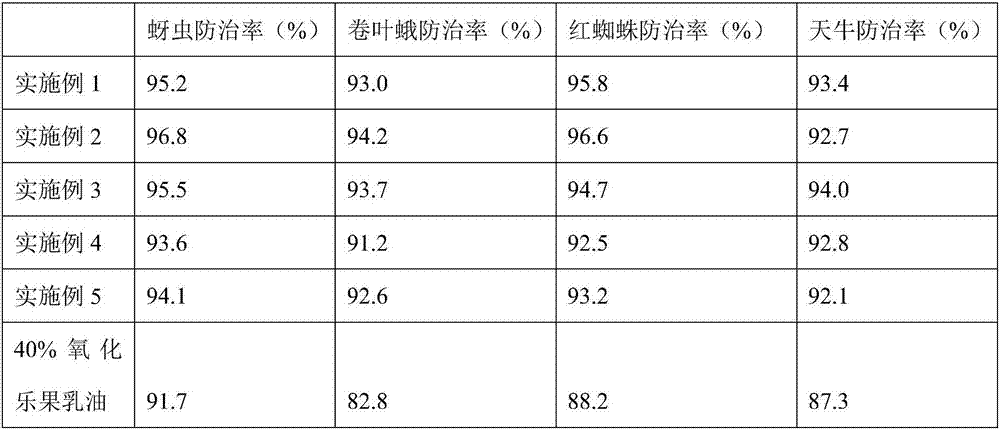

Environment-friendly high-effective citrus pesticide

InactiveCN107156194AFormulation ScienceSimple recipeBiocideDead animal preservationLimoniumDecomposition

The invention belongs to the field of plant pesticides, and particularly discloses an environment-friendly high-effective citrus pesticide. The pesticide includes, by weight, 15-20 parts of a primary extract of cicuta virosa, 12-17 parts of an extract of euphorbia helioscopia, 10-15 parts of an extract of tribulus terrestris, 8-13 parts of rotenone, 8-12 parts of polyaspartic acid, 4-9 parts of tea saponin, 6-10 parts of lemon, and 2-4 parts of nano-chitosan. The pesticide has scientific formula and reasonable compatibility, can quickly work, delays decomposition of active components and has durable effects, so that use amount and use frequency of the pesticide are reduced, and one-time kill rate can reach more than 90%. The pesticide highly reaches 96.8% and 96.6% in killing rates on aphids and red spider mites respectively; meanwhile, the pesticide is free of drug resistance to pests and can be used in 3-5 years.

Owner:嘉禾天奉富硒果业有限公司

Method for manufacturing bio-fuel from radix paeoniae alba extraction waste

InactiveCN106190396AReduced Humidity RequirementsIncrease production capacityBiofuelsSolid fuelsCombustionSulfur

The invention discloses a method for manufacturing bio-fuel from radix paeoniae alba extraction waste. The method includes steps of S1, drying radix paeoniae alba residues and then uniformly mixing the radix paeoniae alba residues and sawdust with one another to obtain mixtures; S2, pressing the mixtures to obtain bio-fuel lumps with the density of 0.8-1.2 kg / m<3>. The method for manufacturing the bio-fuel from the radix paeoniae alba extraction waste has the advantages that the bio-fuel manufactured by the aid of the method is easy to industrially produce and use, has high combustion values, is easy to clean and free of boiler corrosion and does not contain sulfur or phosphorus, and the costs can be reduced for enterprises.

Owner:NINGBO LIWAH PLANT EXTRACTION TECH

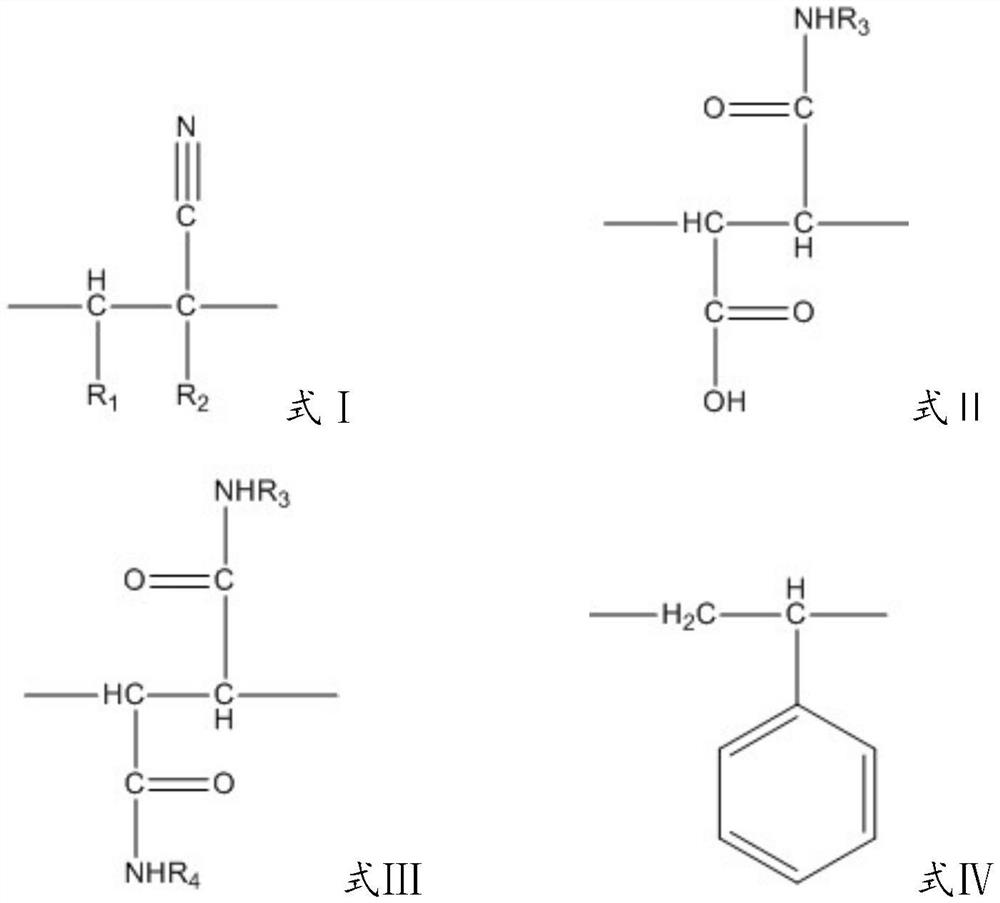

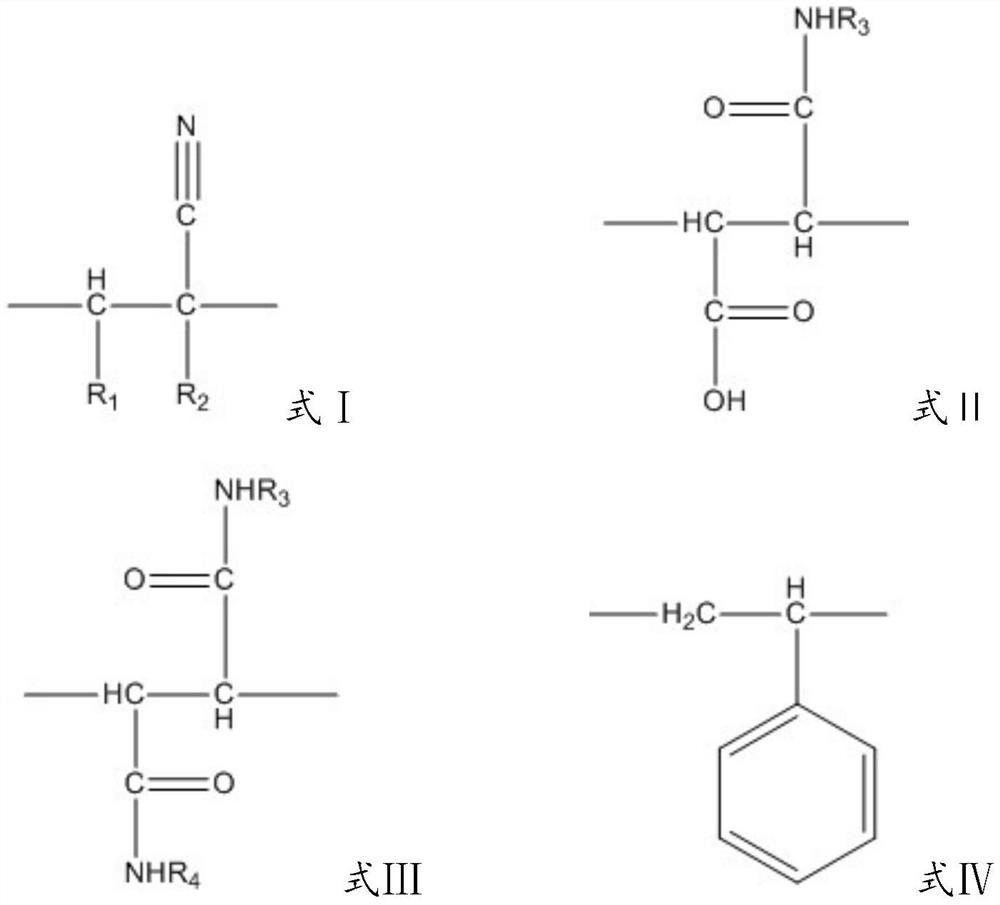

Polymer for crude oil pour point depressing and preparation method and application thereof

ActiveCN113444190AIncrease the degree of branchingLowering the freezing pointDrilling compositionPolymer scienceStructural unit

The invention discloses a polymer for crude oil pour point depressing and a preparation method and application thereof. The polymer comprises a structural unit A, a structural unit B and a structural unit C, wherein the structural unit A is a structural unit with the structure represented by a formula I, the structural unit B is a structural unit with the structure represented by a formula II or a formula III, and the structural unit C is a structural unit with the structure represented by a formula IV; and on the basis of the weight of the polymer, the weight percentage content of the structural unit A is 5%-25%, the weight percentage content of the structural unit B is 40%-85%, and the weight percentage content of the structural unit C is 10%-35%. The fumaric acid polymer in the polymer is good in rigidity and uniform in polar part distribution, and the long-chain structure of the fumaric acid polymer can act with wax crystals in the high-solidification-point crude oil; the amide structure is high in polarity, and the wax crystal structure can be better adjusted; and polar groups act with colloid and asphaltene in the high-solidification-point crude oil, and the solidification point of the crude oil is reduced.

Owner:DESHI ENERGY TECH GRP CO LTD +1

Antenna manufacturing method based on PDS technology, and antenna manufactured through antenna manufacturing method

InactiveCN108574139AThe printing process is simpleReduce foulingAntenna supports/mountingsRadiating elements structural formsState of artAdhesive

The invention relates to an antenna manufacturing method based on the PDS technology, and an antenna manufactured through the antenna manufacturing method. The method comprises the following steps: blending adhesive ink which is suitable for the coating of a glass or ceramic carrier; enabling a built-in NFC antenna circuit to be printed on the glass or ceramic carrier coated with the adhesive ink;performing the drying under the temperature of 60-250 DEG C, and forming a single-side NFC antenna circuit, thereby completing the manufacturing of the antenna. Compared with the prior art, the method is simple in technological step, does not need via holes, can reduce the working procedures and bad effects caused by the working procedures, saves the cost, improves the yield, can directly employa pogo pin, an elastic piece or a metal steamed bread contact feed point, facilitates the industrial popularization and application, and improves the work efficiency.

Owner:SHANGHAI DEMAN ELECTRONICS TECH +1

Novel compound fertilizer capable of increasing leaf lettuce yield

InactiveCN104803802AIncrease productionImprove the immunityBio-organic fraction processingOrganic fertiliser preparationDiseaseBiotechnology

The invention discloses a novel compound fertilizer capable of increasing a leaf lettuce yield. The novel compound fertilizer comprises the following components in parts by weight: 29-35 parts of corn stalks, 18-20 parts of soybean meal, 25-30 parts of rape seed cake powder, 12-15 parts of corn cob powder, 4-5 parts of actinomycetes and 3-4 parts of photosynthetic bacteria. The novel compound fertilizer contains a great amount of organic fertilizers, is added with a beneficial microbial flora, balanced and rich in nutrient, not only capable of increasing the yield of the lettuces and improving the quality of lettuces, but also capable of activating soil, improving the resistance of the leaf lettuces, reducing the diseases, and is green, efficient and environment-friendly.

Owner:湖州桑农生态农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com