Catalyst applied to medium-pressure liquid-phase hydrogenation of fatty acid methyl ester for preparation of fatty alcohol

A technology for fatty acid methyl ester and catalyst, which is applied in the field of catalyst production and application, can solve the problems of complex addition of components, difficult industrial application, complicated catalyst preparation, etc., and achieves the effects of easy industrialization and use, good industrial application prospects and good environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

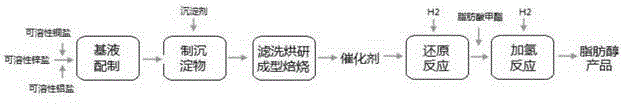

Image

Examples

example 1

[0036] (1) 90g of copper nitrate, 35g of zinc nitrate, and 76g of aluminum nitrate are dissolved in water to prepare a solution containing 12% of solute (total weight percentage).

[0037] (2) after the solution obtained in the step (1) is stirred and warmed up to 50° C., add dropwise a sodium carbonate solution containing 11% sodium carbonate (weight percent) to the solution, after the pH of the solution is adjusted to 8, aging for 4 hours, A sol-gel product is obtained, and a gel precipitate is obtained after part of the water is sucked out under negative pressure and vacuum.

[0038] (3) After filtering, washing and drying the product obtained in step (2), grind it into powder, add 10.7g of alumina and a small amount of graphite to mix evenly, and perform tablet molding. Roasting at 500° C. for 3 hours to obtain a catalyst for catalytic hydrogenation of fatty acid methyl ester to fatty alcohol.

[0039] The catalyzer that is used for fatty acid methyl ester catalytic hydro...

example 2

[0042] (1) 100g of copper nitrate, 40g of zinc nitrate, and 80g of aluminum nitrate are dissolved in water to prepare a solution containing 15% of solute (total weight percentage).

[0043] (2) after the solution obtained in the step (1) is stirred and warmed up to 50° C., add dropwise a sodium carbonate solution containing sodium carbonate (weight percent) 10% to the solution, after the pH of the solution is adjusted to 10, aging for 4 hours, A sol-gel product is obtained, and a gel precipitate is obtained after part of the water is sucked out under negative pressure and vacuum.

[0044] (3) Filter, wash and dry the product obtained in step (2), grind it into powder, add 11 g of alumina and a small amount of graphite to mix evenly, and perform tablet molding. Roasting at 400° C. for 4 hours to obtain a catalyst for catalytic hydrogenation of fatty acid methyl ester to fatty alcohol.

[0045]The catalyzer that is used for the catalytic hydrogenation of fatty acid methyl ester...

example 3

[0048] (1) 120g of copper nitrate, 50g of zinc nitrate, and 90g of aluminum nitrate are dissolved in water to prepare a solution containing 20% solute (total weight percentage).

[0049] (2) after the solution obtained in the step (1) is stirred and warmed up to 55° C., add dropwise a sodium carbonate solution containing 12% sodium carbonate (weight percentage) to the solution, after the pH of the solution is adjusted to 9, aging for 5 hours, A sol-gel product is obtained, and a gel precipitate is obtained after part of the water is sucked out under negative pressure and vacuum.

[0050] (3) After filtering, washing and drying the product obtained in step (2), grind it into powder, add 11.6g of alumina and a small amount of graphite to mix evenly, and perform tablet molding. Roasting at 450° C. for 4 hours to obtain a catalyst for catalytic hydrogenation of fatty acid methyl ester to fatty alcohol.

[0051] The catalyzer that is used for fatty acid methyl ester catalytic hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com