Patents

Literature

72results about How to "Avoid meshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

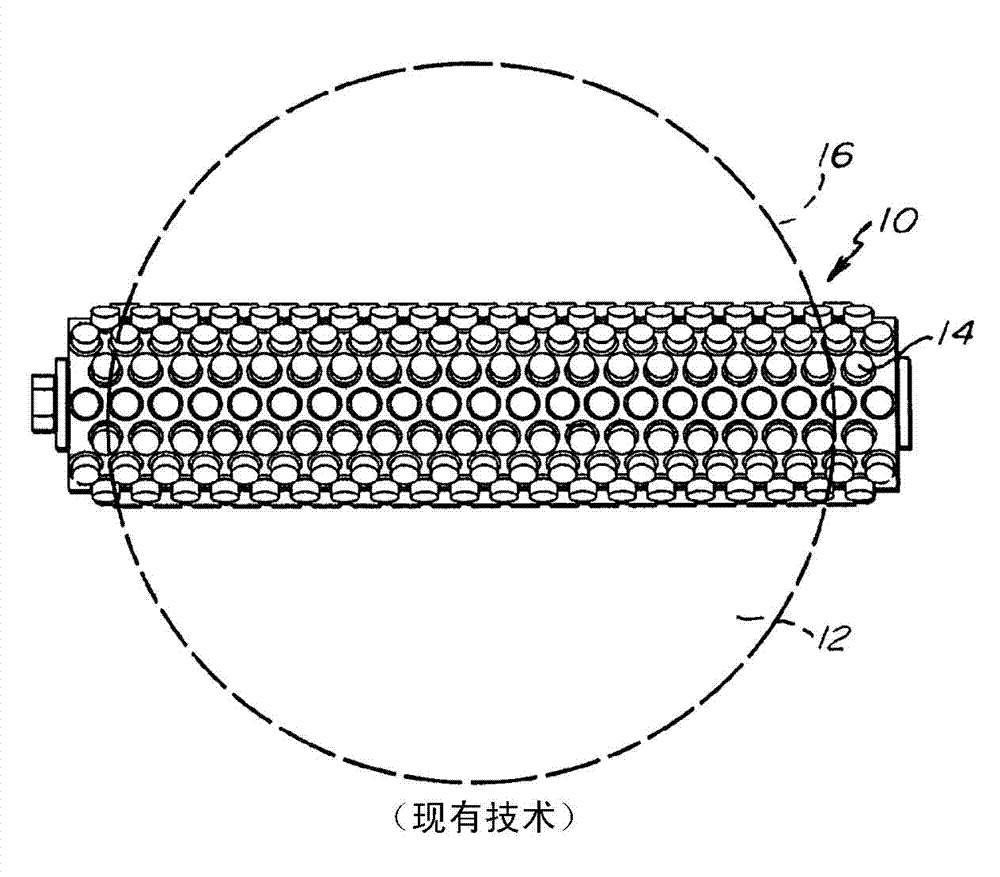

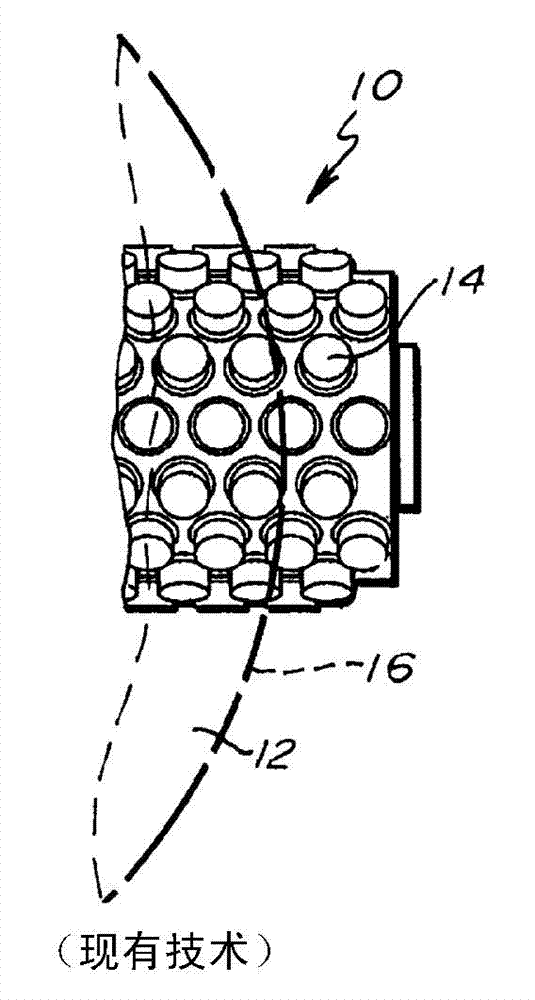

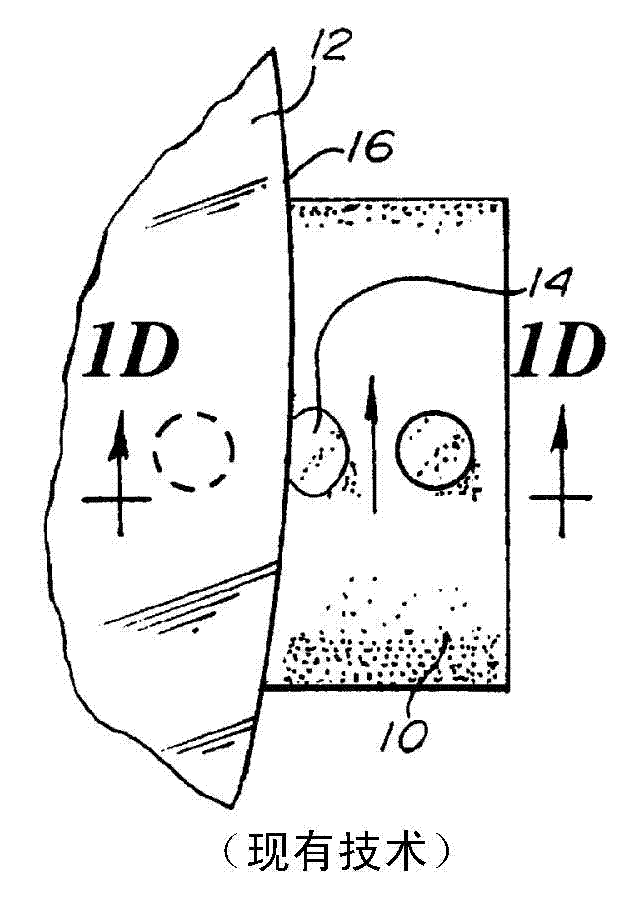

Post-CMP cleaning brush

InactiveCN102792424AMinimize damageAvoid meshingSemiconductor/solid-state device manufacturingAnatomyBiomedical engineering

Embodiments of the invention include a CMP brush that has a combination of central nodules at an inner region of the brush and one or more edge nodules at an end region of the brush where the central nodules and edge nodules are in a staggered or matched arrangement with each other and an upper surface of each edge nodule on the brush has the same or a greater contact area than an upper surface of a central nodule. The area of contact of the upper surface of each edge nodule with the substrate edge region is the same or greater than the area of contact of the upper surface of a central nodule with the substrate center region.

Owner:ENTEGRIS INC

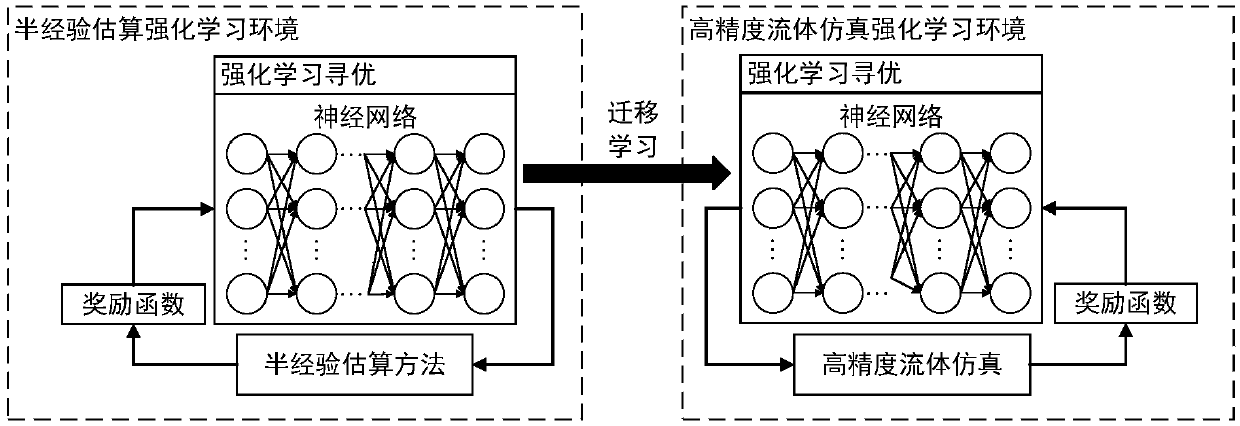

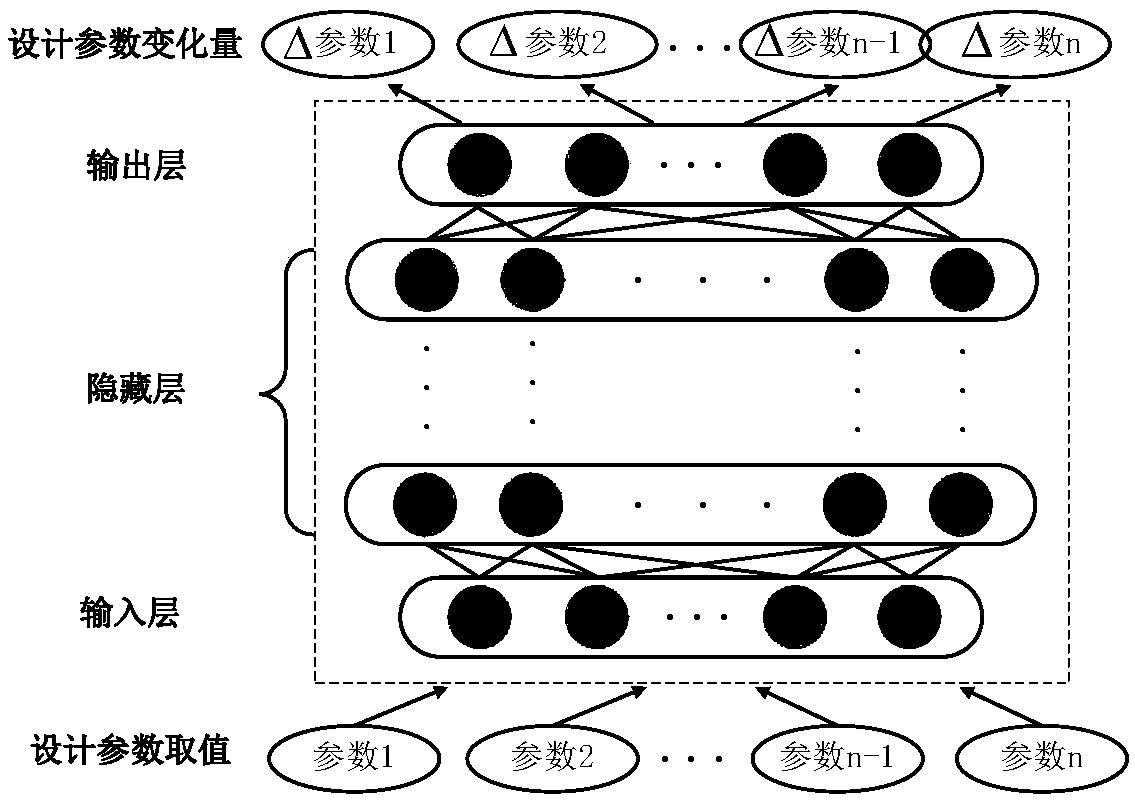

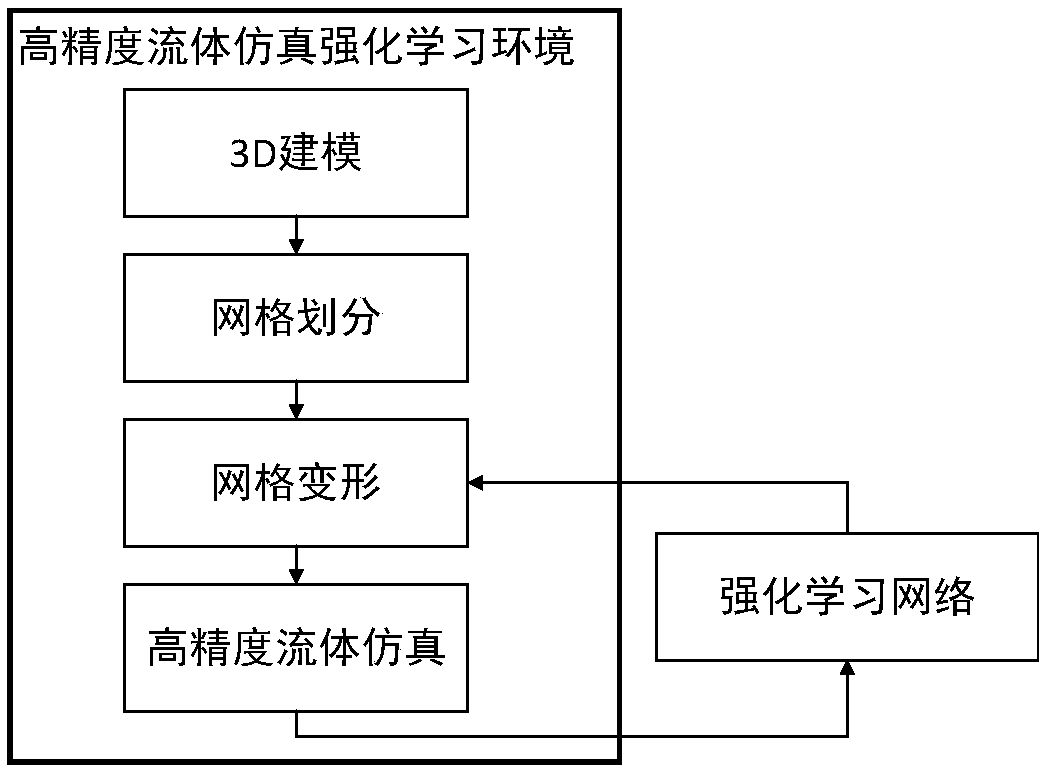

Aircraft full-automatic pneumatic optimization method based on reinforcement learning and transfer learning

ActiveCN109614631AAvoid duplicationAvoid meshingSustainable transportationDesign optimisation/simulationLocal optimumEstimation methods

The invention discloses an aircraft full-automatic aerodynamic optimization method based on reinforcement learning and transfer learning. The method is used for solving the problem that an existing pneumatic optimization method is prone to falling into local optimization or low in convergence speed, manual intervention is excluded in the final high-precision optimization stage through the optimization method, and the optimization efficiency is further improved. According to the technical scheme, firstly, a reinforcement learning environment based on semi-empirical estimation and high-precisionfluid simulation is established; a reinforcement learning neural network is constructed; a reward function is set, the global optimization capability of reinforcement learning is utilized; in the network training process, optimization experience is extracted from a semi-experience estimation method and stored in network parameters; then, another reinforcement learning neural network is constructed, migration learning is used for migrating the extracted optimization experience to the network, then the network is applied to aerodynamic optimization based on high-precision fluid simulation, andfinally, high-precision design parameters with excellent aerodynamic performance are obtained by training the network. Compared with a background technology method, the method has the advantages thatthe convergence speed is increased, the strong global optimization capability is realized, and the engineering value for high-precision pneumatic optimization is very high.

Owner:TSINGHUA UNIV

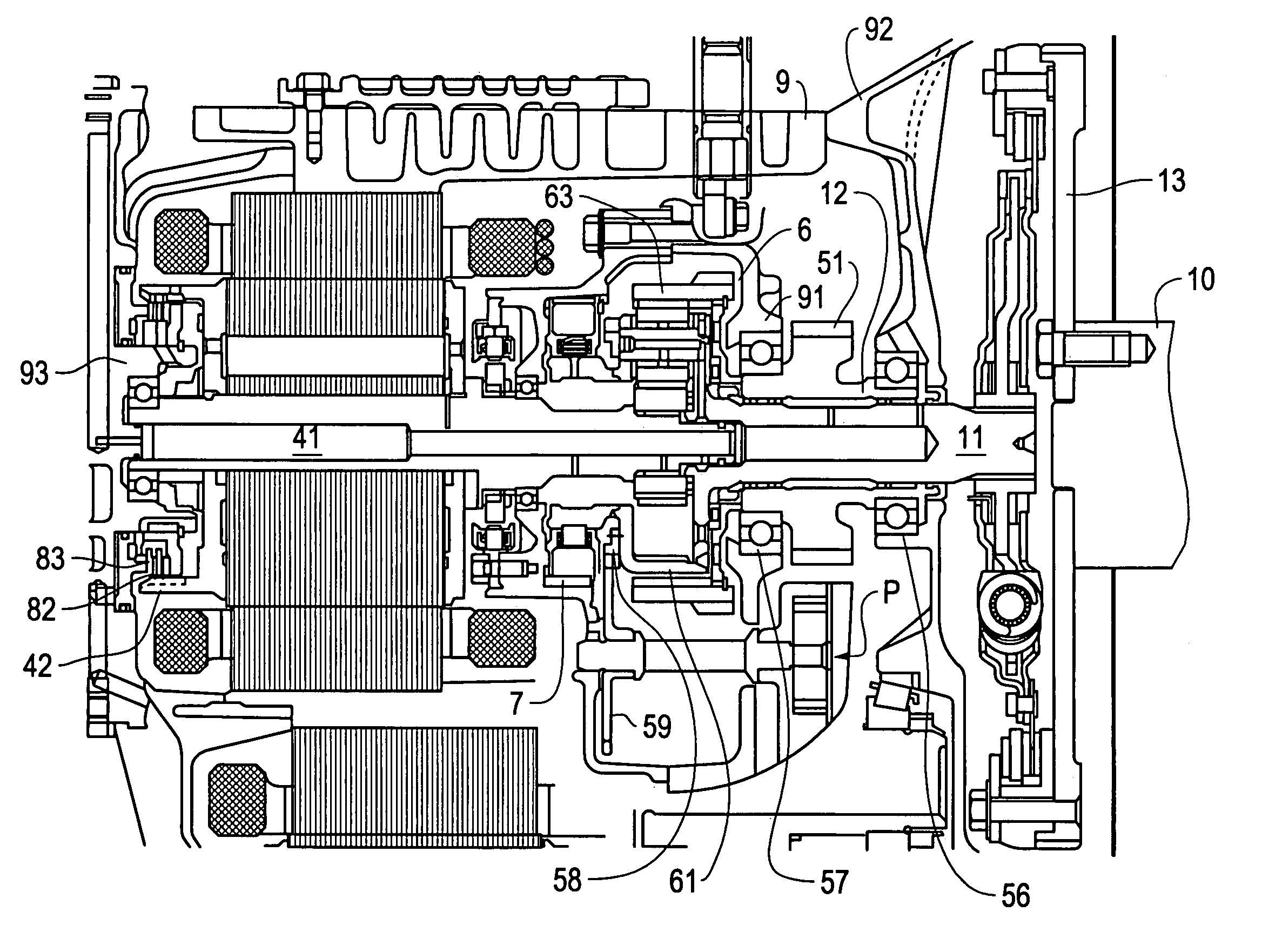

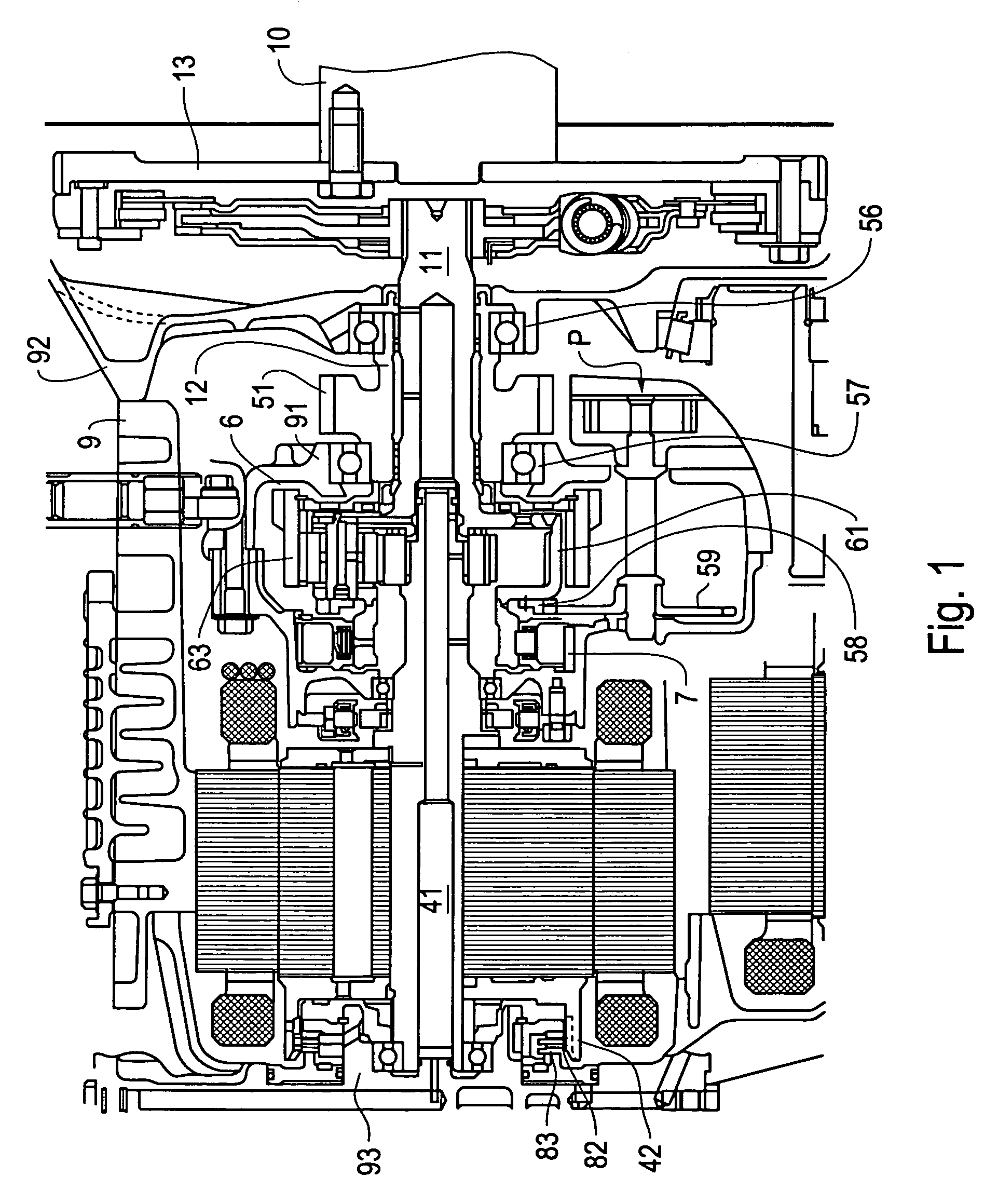

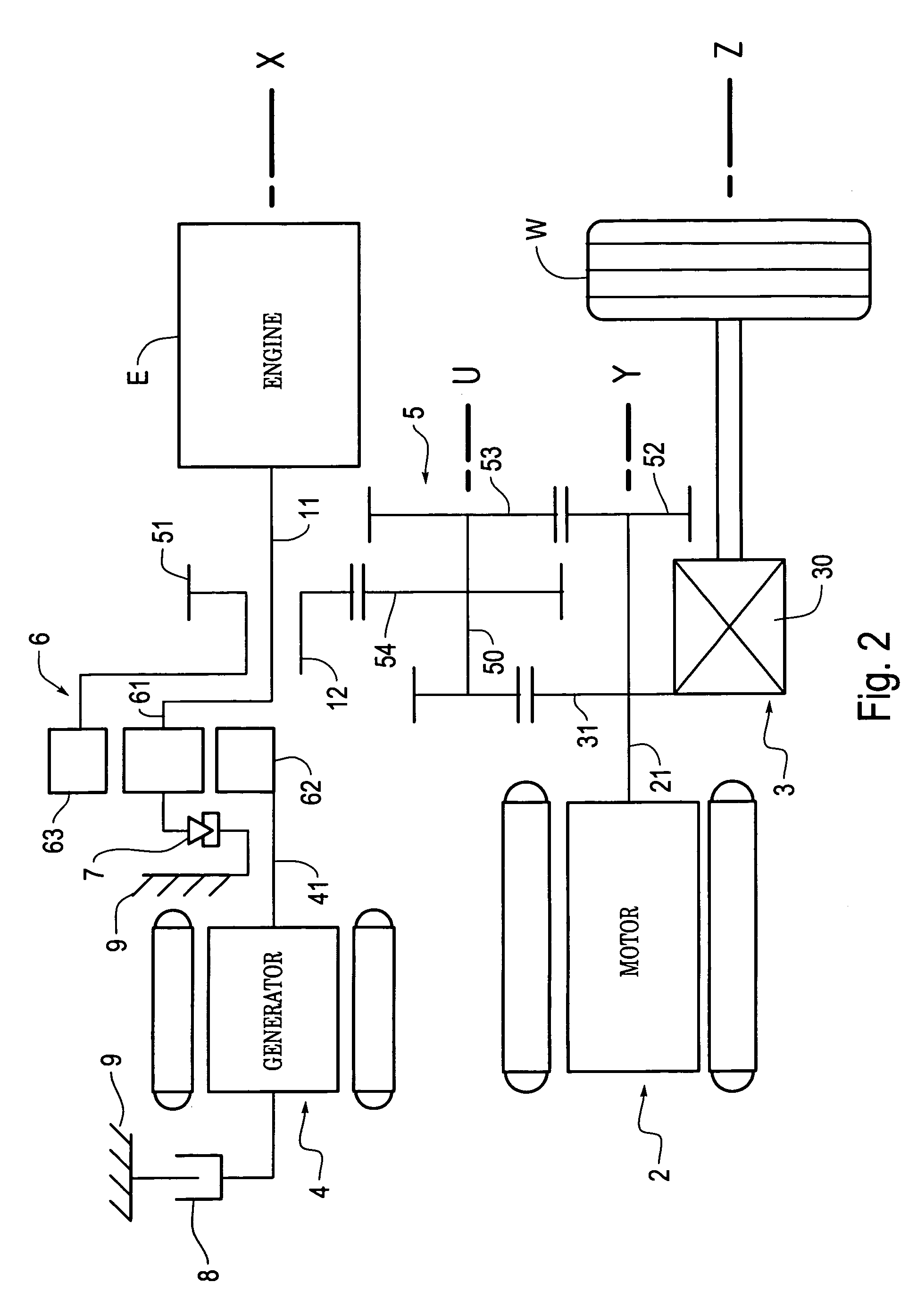

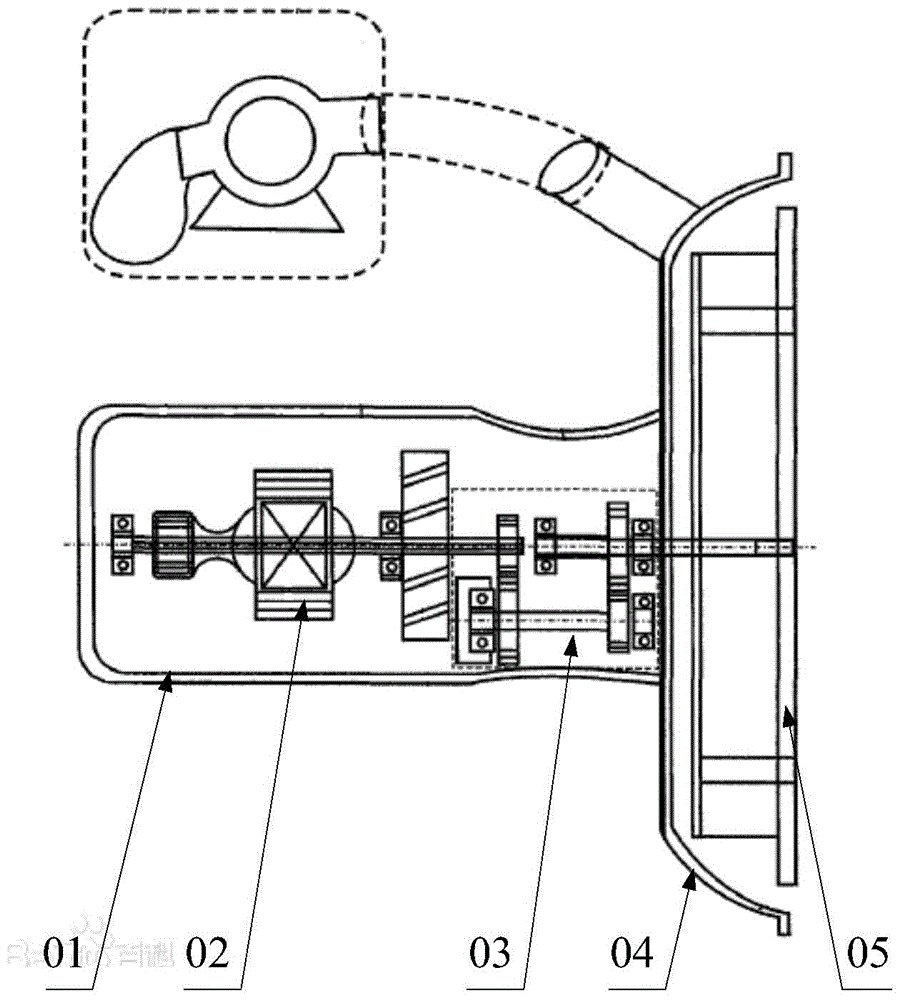

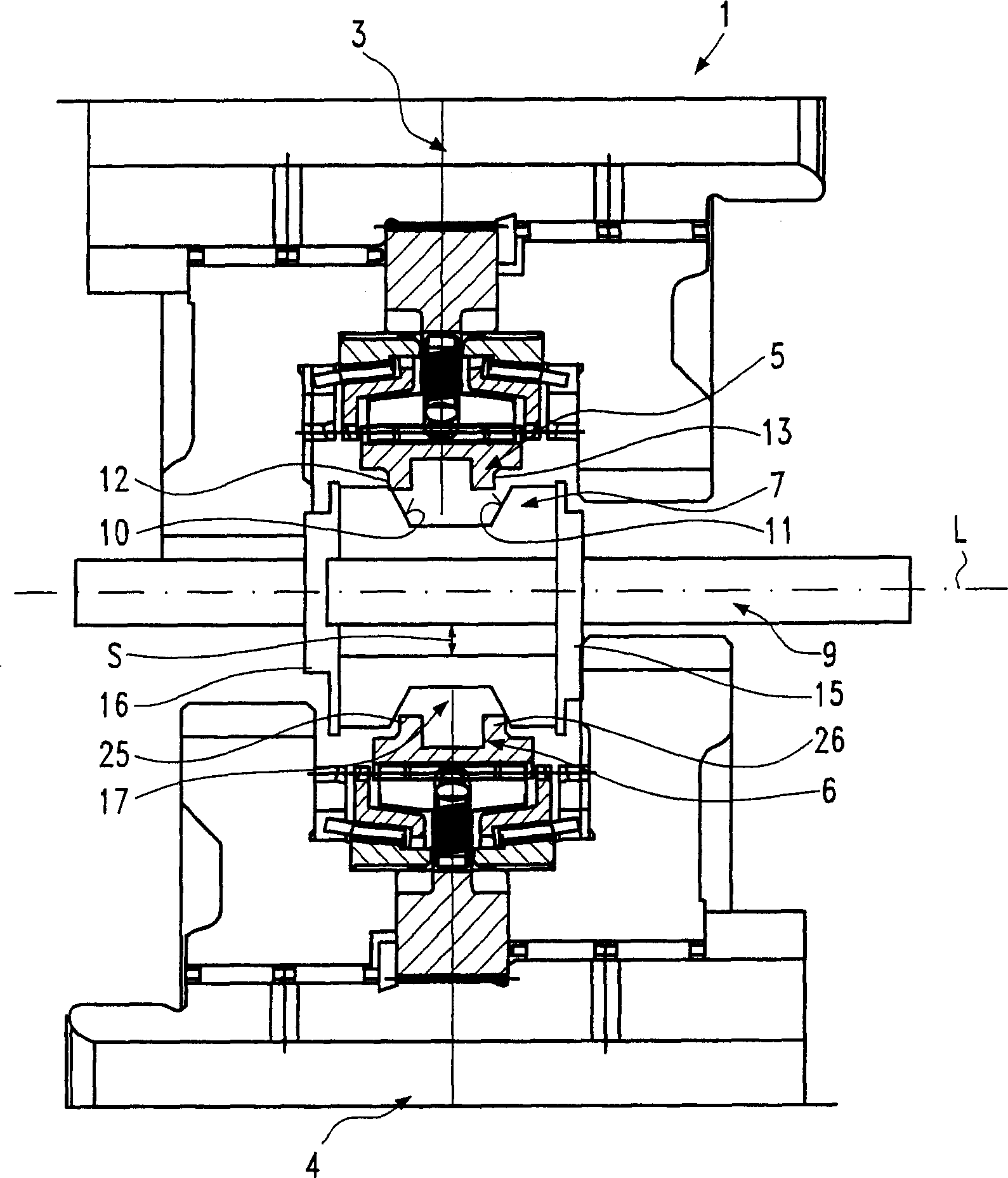

Drive unit equipped with electrical motor

InactiveUS7033296B2Prevent rotationAvoid noiseHybrid vehiclesElectric propulsion mountingEngineeringElectric motor

A drive unit equipped with an electric motor including an input shaft that is connected to an engine, an electric motor shaft, a counter output shaft, and a planetary gear set, wherein the input shaft and the counter output shaft are connected respectively, on one side of the planetary gear set, to two other elements which are different from an element with which the electric motor shaft is connected, an outer circumference of both edge portions of the counter output shaft is supported by a drive unit case, and an outer circumference of the input shaft is supported by an inner circumference of the counter output shaft by the drive unit case through the counter output shaft.

Owner:AISIN AW CO LTD

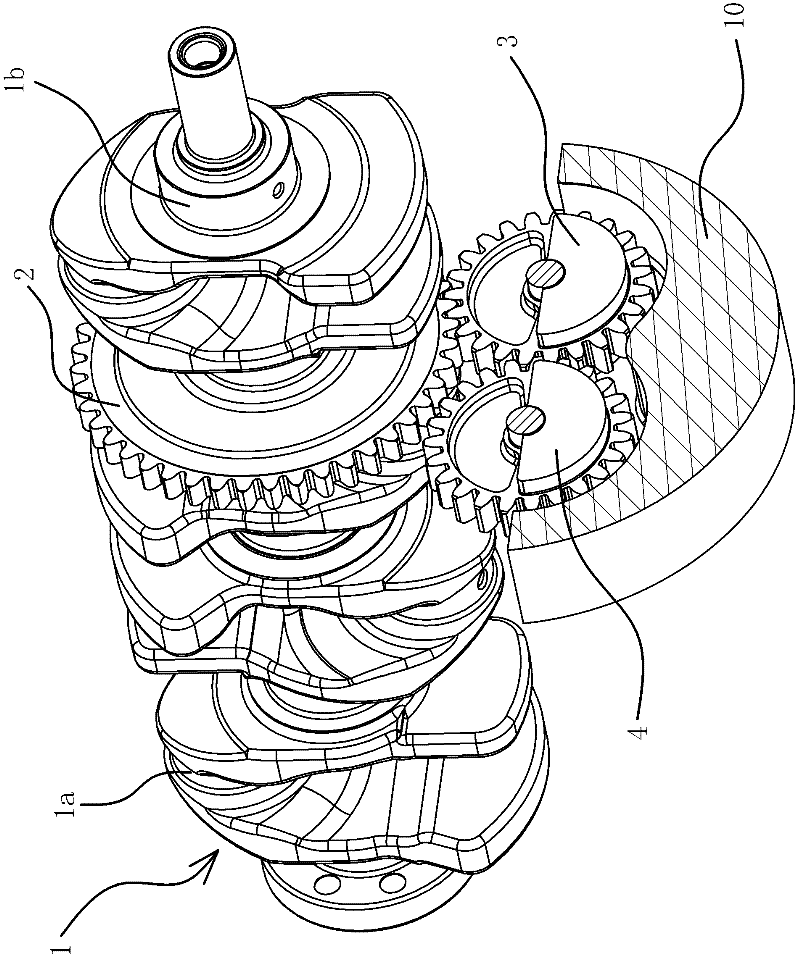

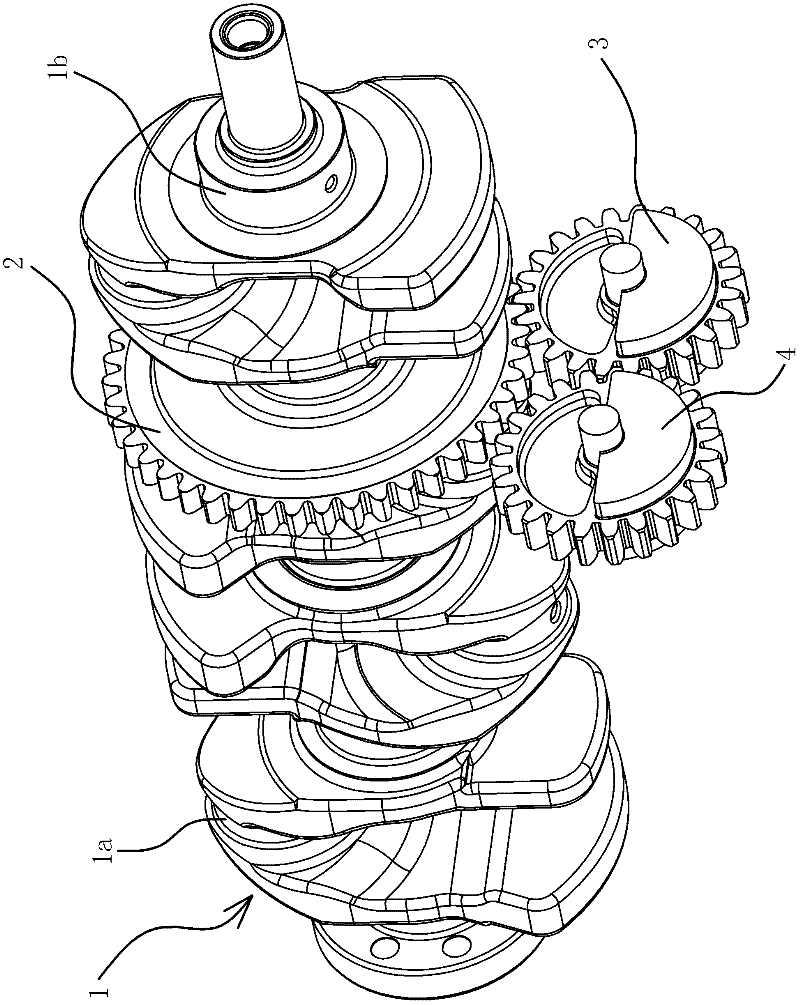

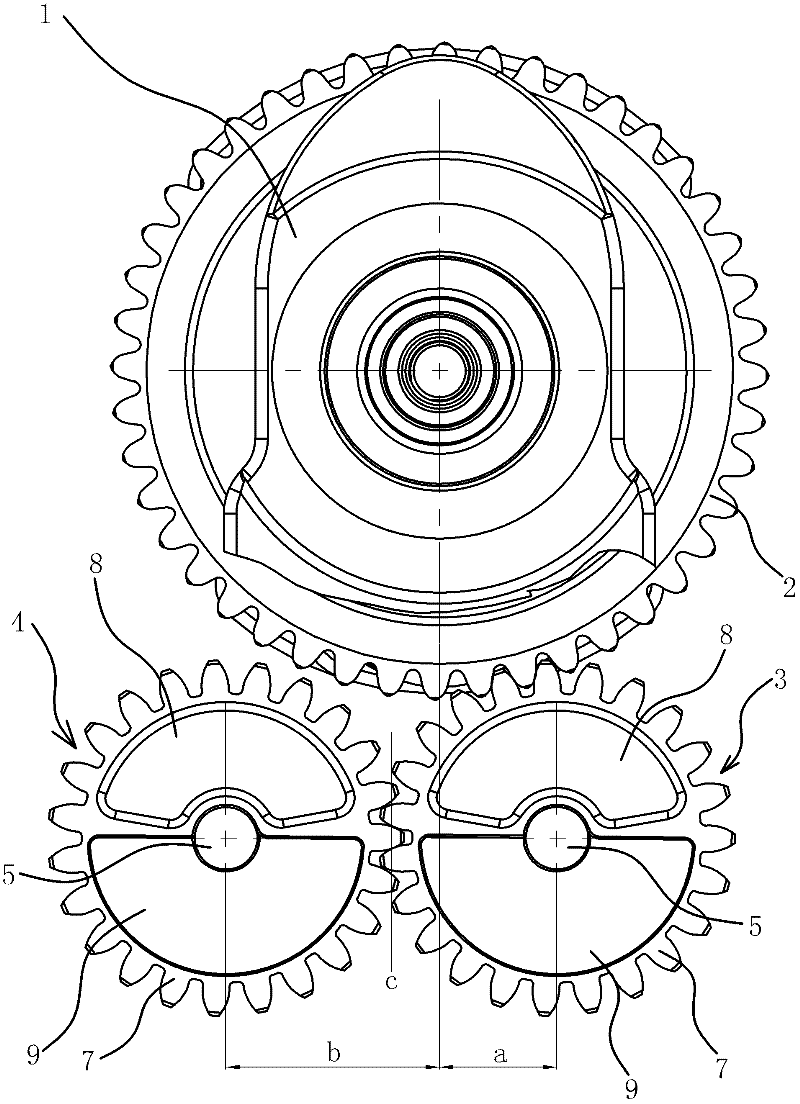

Double-shaft balance device of engine

InactiveCN102537205ANo lateral forceReduce axial sizeInertia force compensationMechanical engineering technologyEngineering

The invention provides a double-shaft balance device of an engine, which belongs to the technical field of mechanical engineering and resolves the technical problems of engine vibration and noise caused by vibration of the existing automobile. The double-shaft balance device of the engine comprises a driving gear fixed on a crank shaft and a first balance shaft and a second balance shaft which are arranged on the lateral side of the crank shaft and are parallel relative to a main journal of the crank shaft. The first balance shaft and the second balance shaft are respectively provided with a tooth portion, a shaft portion and a balance portion. The balance portion is arranged between the tooth portion and the shaft portion, and the weight of an area on one side of the balance portion relative to a radial line of the tooth portion is smaller than the weight of an area on the other side. The tooth portion of the first balance shaft is meshed with the tooth portion of the second balance shaft, and the tooth portion of the first balance shaft is meshed with the driving gear. The balance portion of the first balance shaft and the balance portion of the second balance shaft are symmetrically arranged relative to the meshing face of the first balance shaft and the second balance shaft. The double-shaft balance device facilitates integral machine arrangement and has the advantages of being compact in structure and small in size and saving cost.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

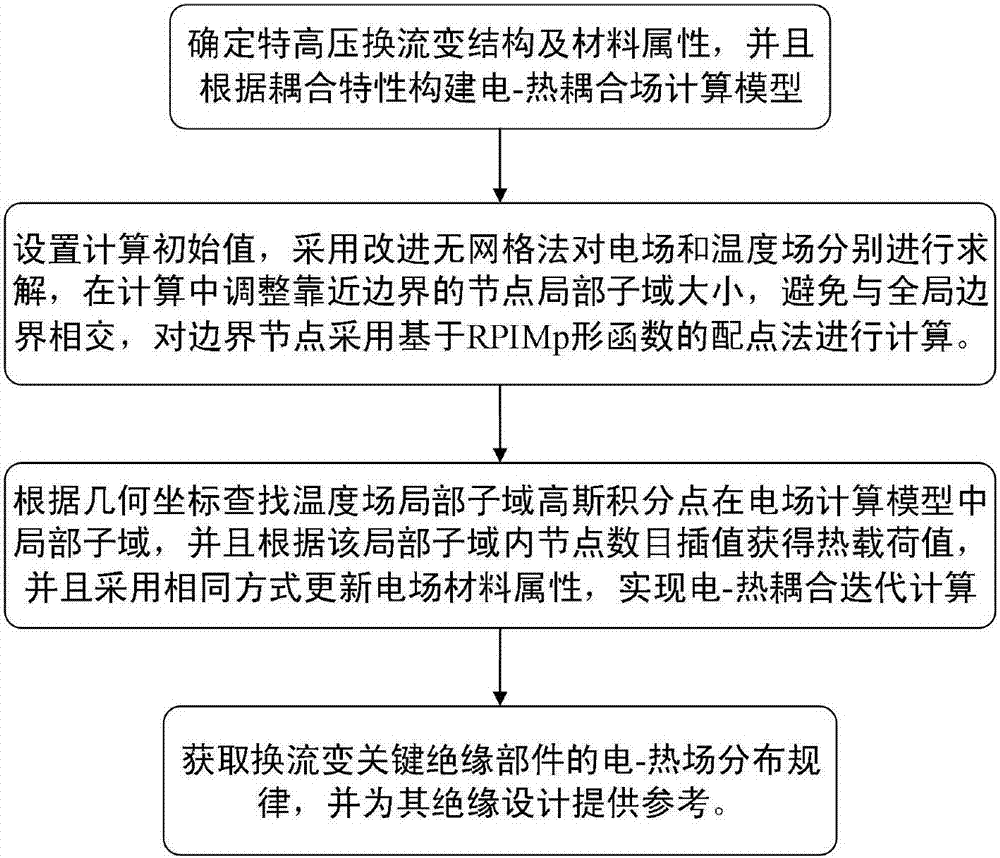

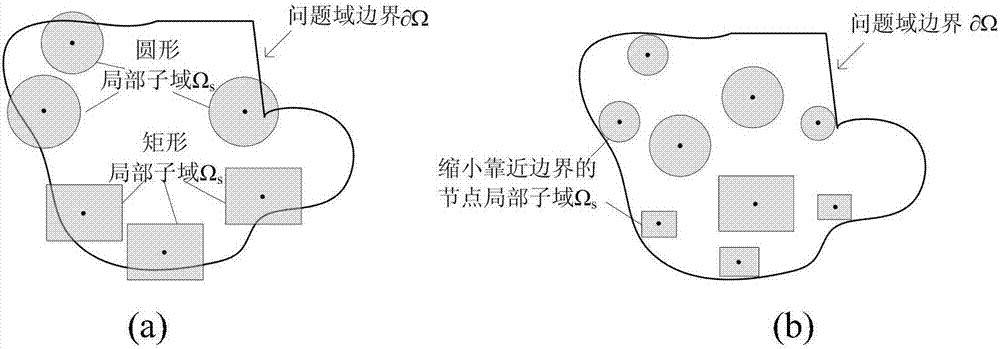

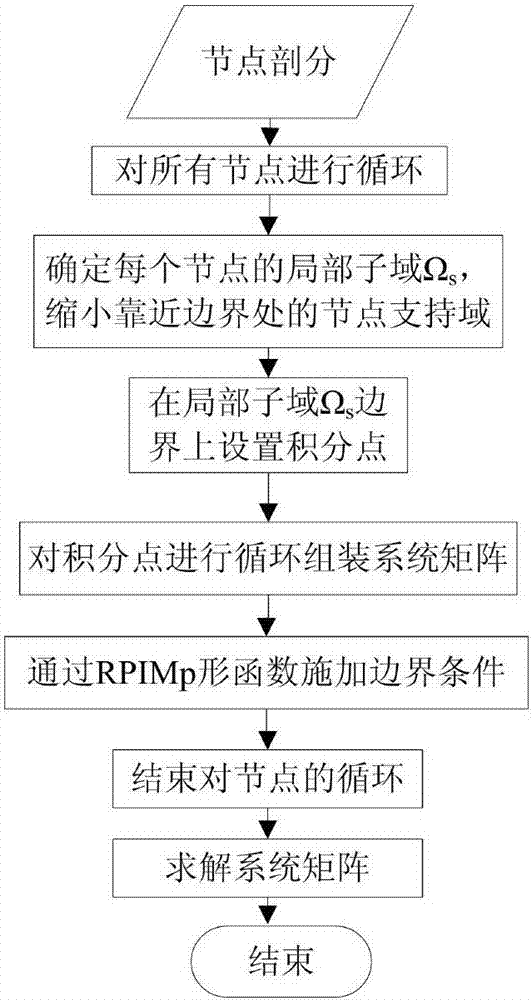

Converter transformer electric-thermal coupling field calculation method based on improved meshless method

ActiveCN107992664AAvoid meshingSmall amount of calculationDesign optimisation/simulationSpecial data processing applicationsData transmissionElectric field

The invention provides a converter transformer electric-thermal coupling field calculation method based on an improved meshless method. The method includes the steps that a mathematical nonlinear model of extreme high voltage converter transformer insulating oiled paper materials is determined, and a two-dimensional axial symmetric nonlinear electric-thermal coupling field calculation model is determined; the improved meshless method is used for calculating a converter transformer electric-thermal coupling field, modes of model point distribution are adjusted through self-adaption according tosizes, and the electric field and temperature field of a converter transformer are calculated respectively; the sizes of local sub-fields are adjusted in the vicinity of calculation boundary areas toprevent the local sub-fields from intersecting with global boundaries, and the point distribution method is used for calculation on the global boundaries; in the coupling data transmission process between the electric field and the temperature field, when a thermal load of the temperature field needs to be calculated, the gauss integral points of the local sub-fields of the temperature field andthe local sub-fields in an electric field calculation model are searched for according to geometric coordinates, and the thermal load is obtained according to the node number interpolations in the local sub-fields; electric field material properties are updated, and the iterative calculation and the distribution law acquisition of the converter transformer electric-thermal coupling field are obtained. The method improves calculation time and accuracy.

Owner:CHONGQING UNIV

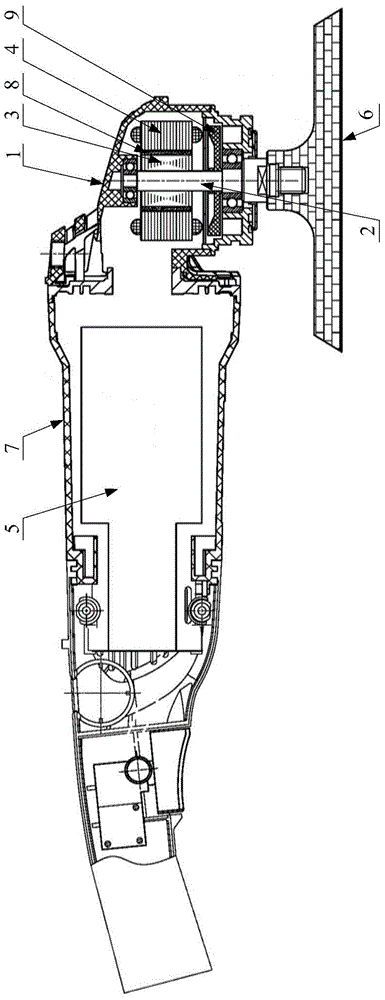

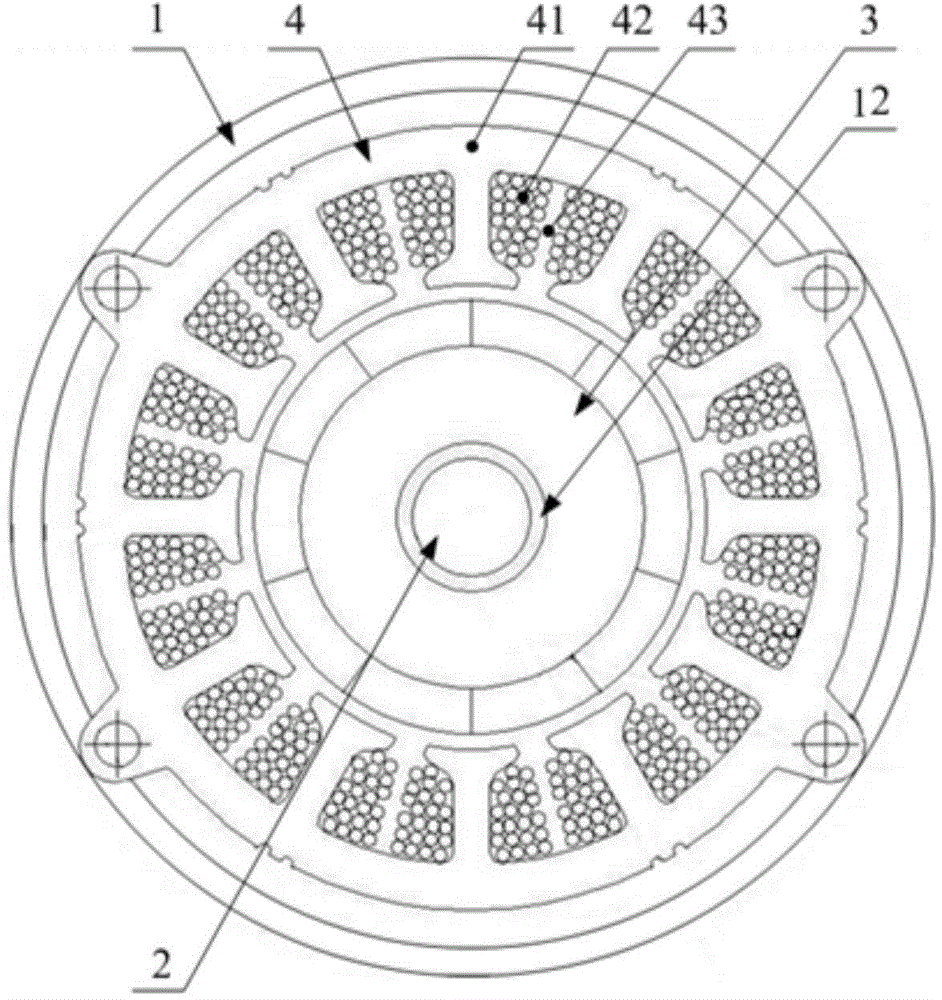

Wall surface grinding machine

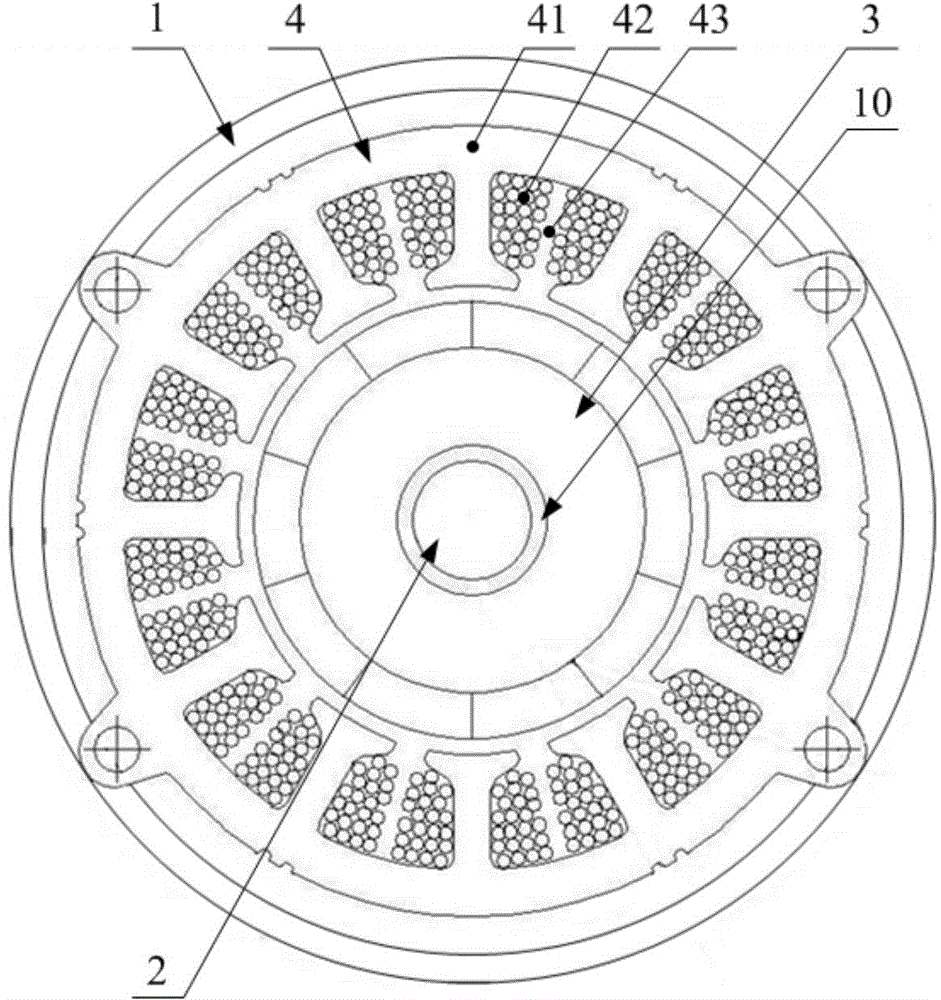

InactiveCN105127853AReduce volumeReduce weightPlane surface grinding machinesGrinding/polishing safety devicesBrushless motorsDrive shaft

The invention discloses a wall surface grinding machine. The wall surface grinding machine comprises a shell. A high-power-density brushless motor and a controller of the high-power-density brushless motor are arranged in the shell. The high-power-density brushless motor comprises a rotor shaft arranged in the shell in a rotating mode. The rotor shaft and a drive shaft of a grinding plate of the wall surface grinding machine are coaxially arranged and are of an integral structure. The controller is arranged on one side, away from the grinding plate, of the high-power-density brushless motor. The grinding plate is covered with a dedusting protection cover. A dust collection pipeline connected with an external dust collection device is arranged on the dedusting protection cover which is connected with the shell. The axis of the rotor shaft is perpendicular to the operation face of the grinding plate and passes the circle center of the grinding plate. By means of the wall surface grinding machine, generation of carbon powder is avoided, and environmental pollution is avoided. It is avoided that a transmission device is arranged in the shell, the service life is prolonged, the energy loss is reduced, the output efficiency is improved, noise and vibration are reduced, the complex meshed installation of transmission gears is avoided, the size and the weight are decreased, and assembling is convenient.

Owner:ZHEJIANG LVDONG MOTOR TECH CO LTD

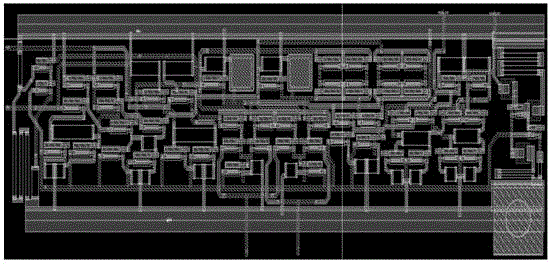

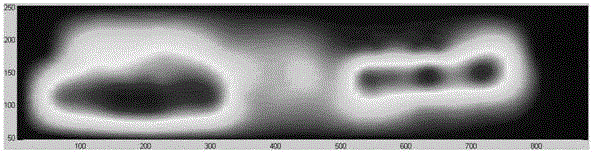

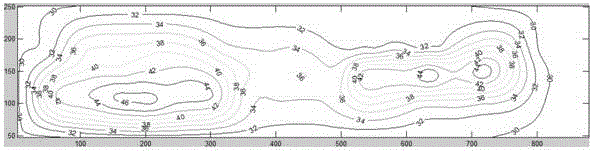

HBT (heterojunction bipolar transistor) circuit chip temperature analysis method based on MATLAB (matrix laboratory) programming

ActiveCN104679964AAvoid the time-consuming and labor-intensive shortcomings of manually inputting power consumptionEnables temperature analysisSpecial data processing applicationsStable stateElement analysis

The invention discloses an HBT (heterojunction bipolar transistor) circuit chip temperature analysis method based on MATLAB (matrix laboratory) programming. The method mainly solves the problems of small circuit scale and complicated manual input power consumption of the traditional finite element analysis method. The method comprises the following major steps that 1, the geometric dimension of an HBT device and the material heat conductivity are obtained; 2, the device is subjected to modeling, and in addition, the single device is subjected to finite element temperature analysis; 3, the temperature distribution of each device is subjected to function fitting; 4, circuit software is used for simulation, the power consumption of each device is obtained, and is marked on a territory; 5, a GDSII format territory file is exported, and then, the format is converted into a DXF format; 6, the MATLAB programming is used, the coordinate and the power consumption of the devices on the territory are extracted, the work temperature of each device is calculated, and a temperature distribution figure is made. The HBT circuit chip temperature analysis method has the advantages that the method can be used for the integrated circuit physical design time and can be used for predicting the stable state temperature of the HBT device in the work process of the circuit and the hotspot positions on the territory, and the work stability of the circuit is improved.

Owner:拓尔微电子股份有限公司

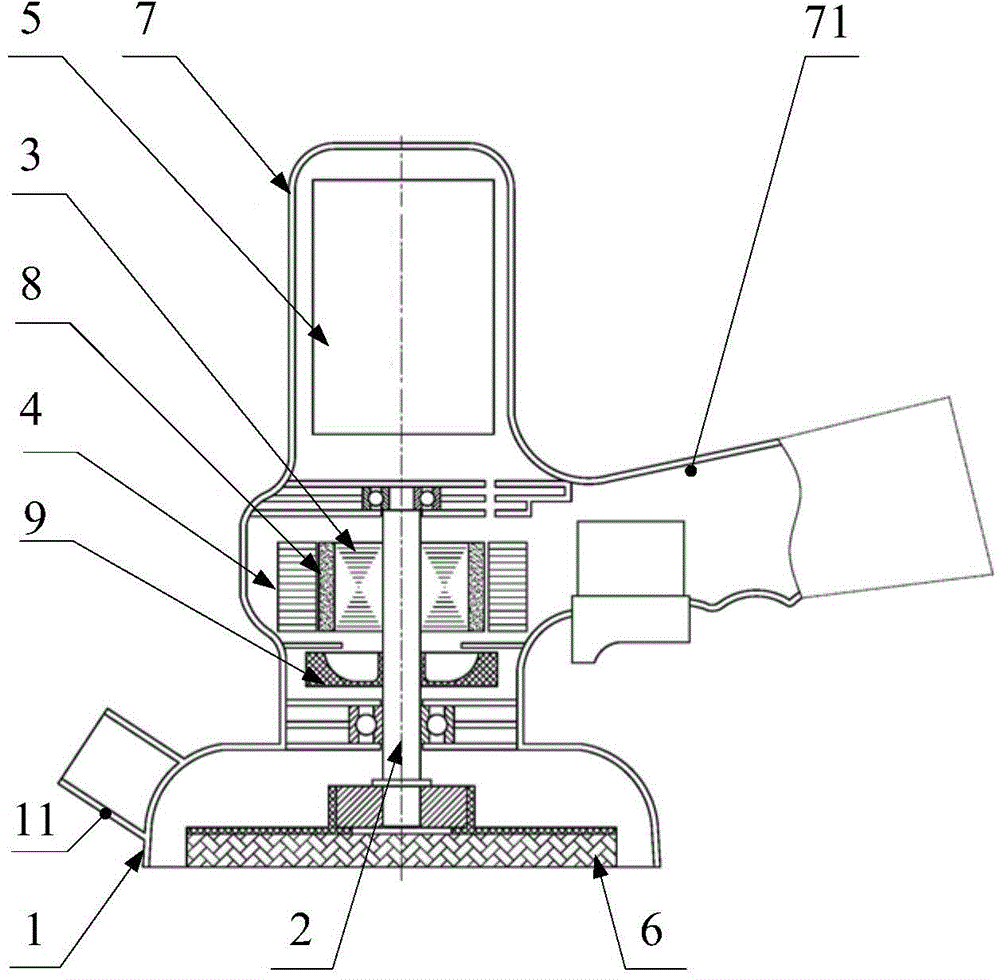

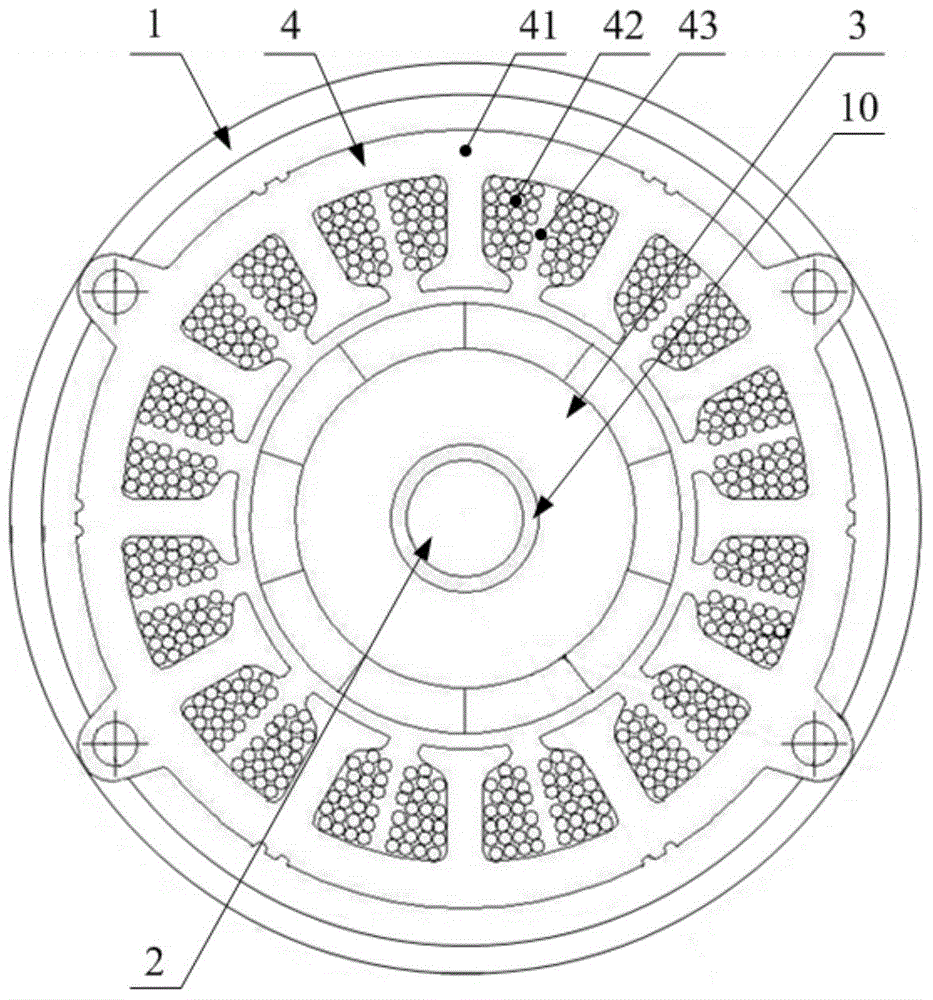

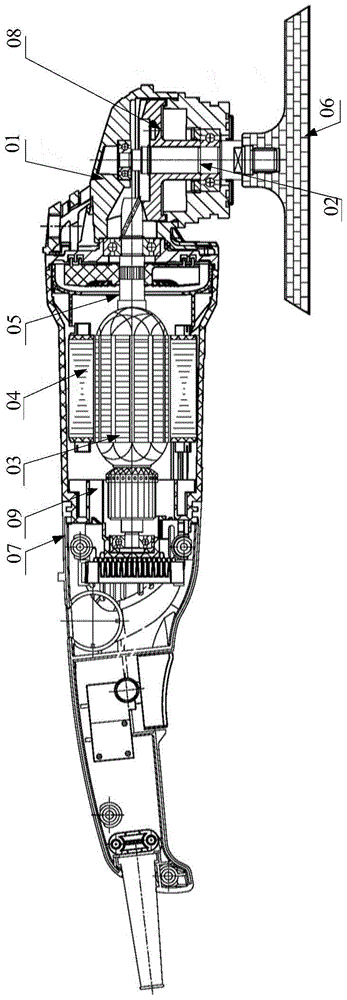

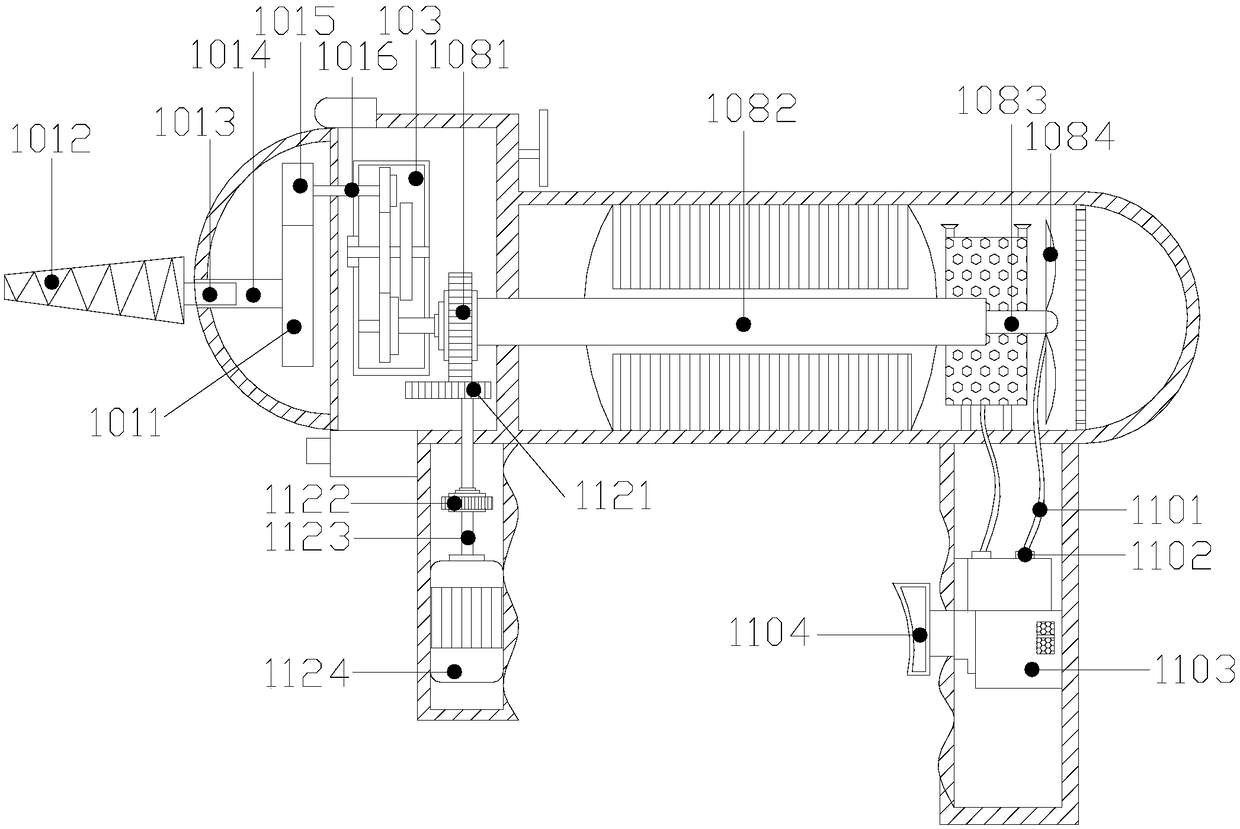

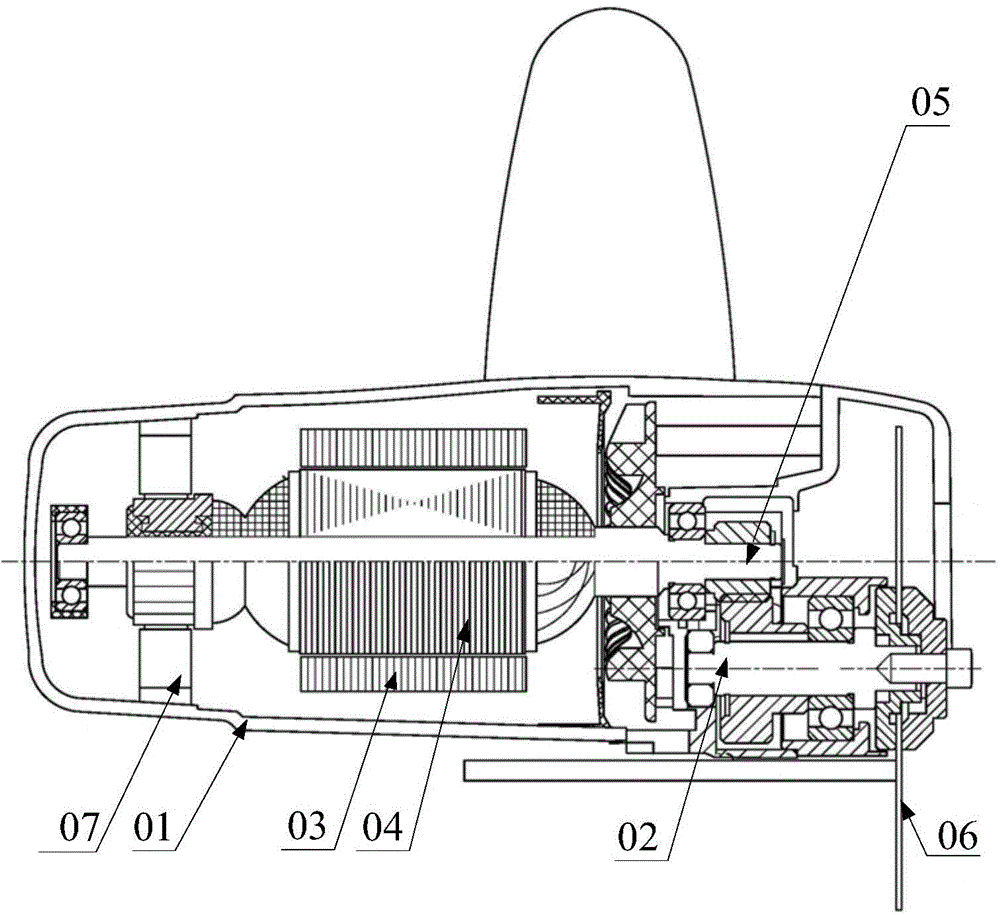

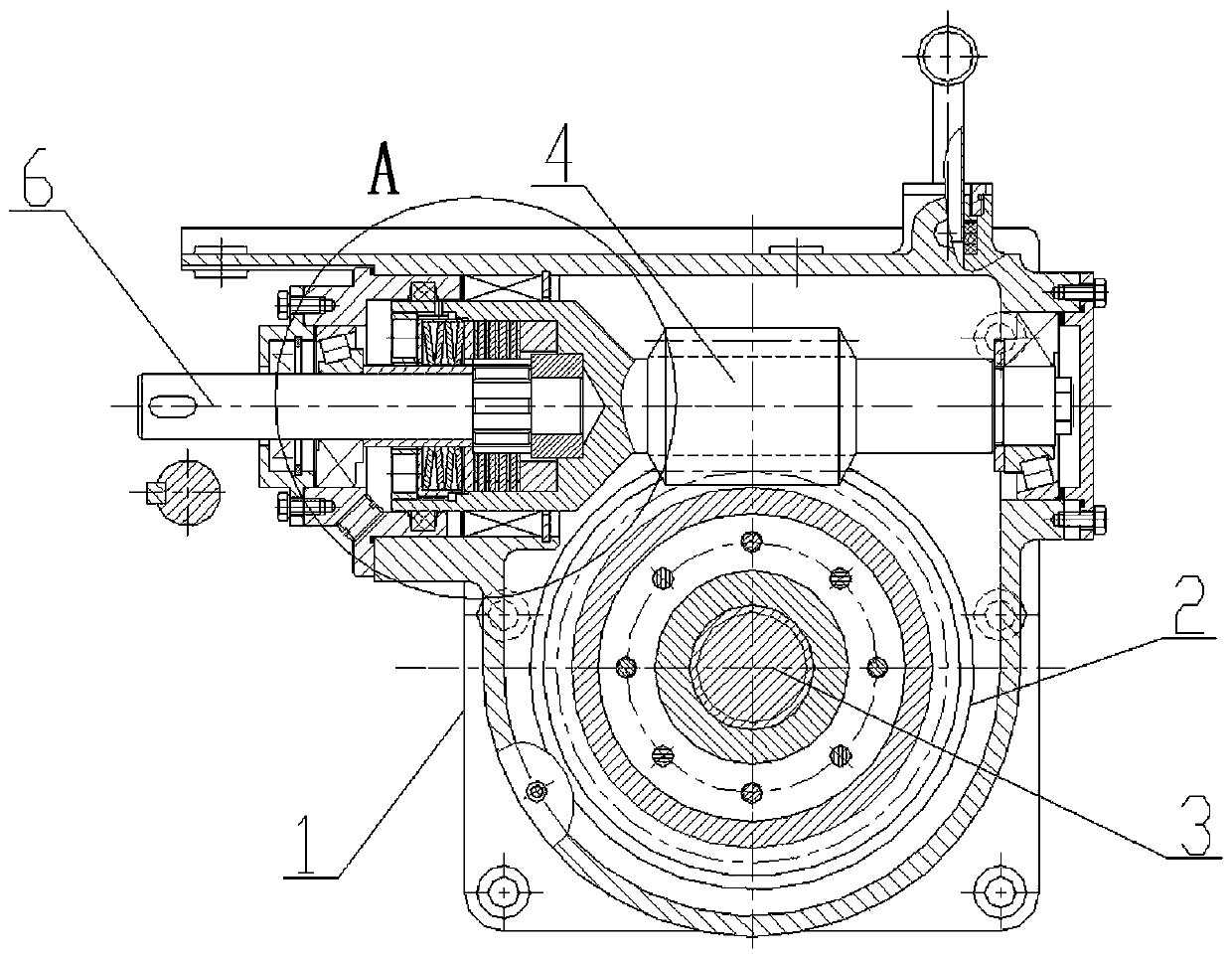

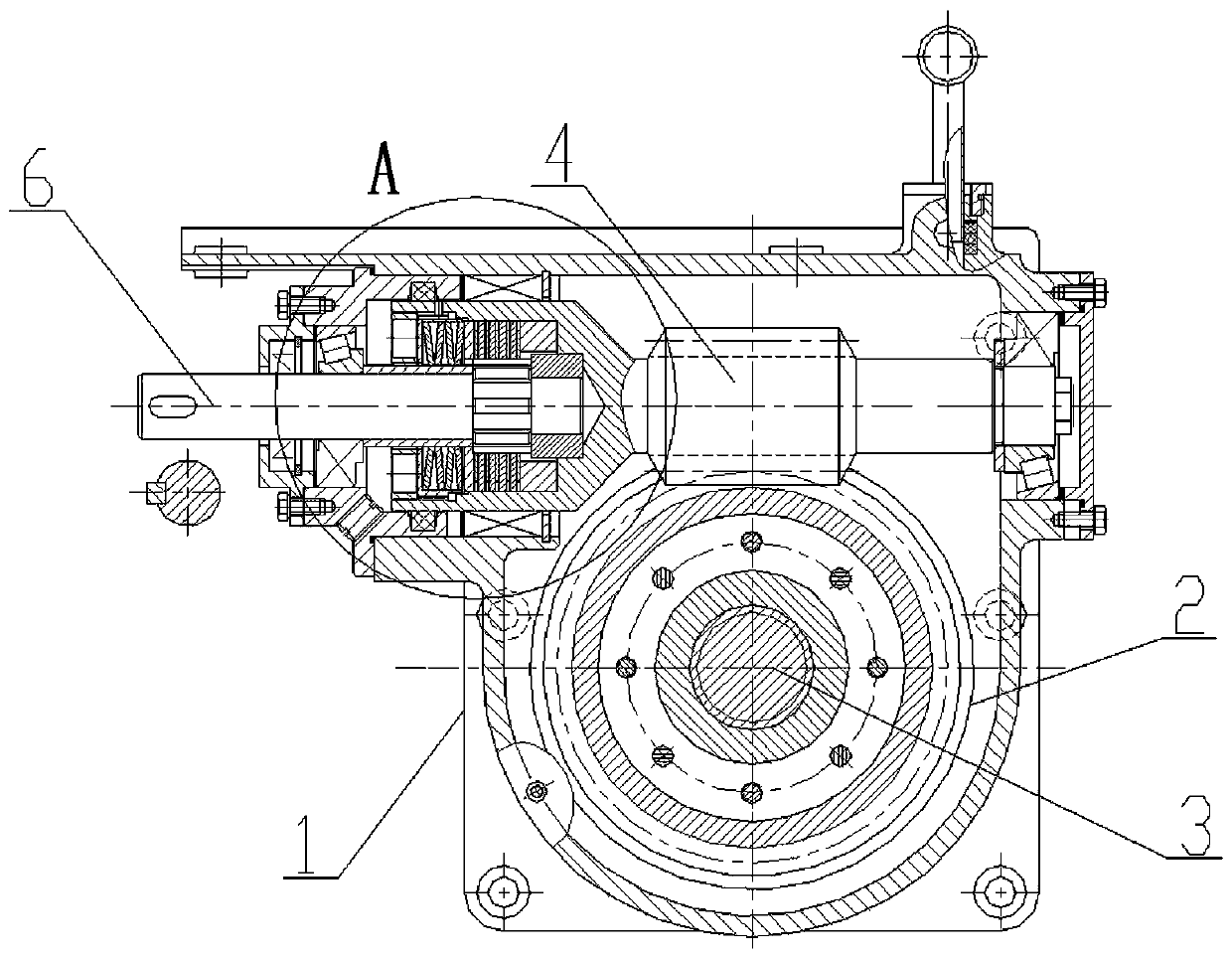

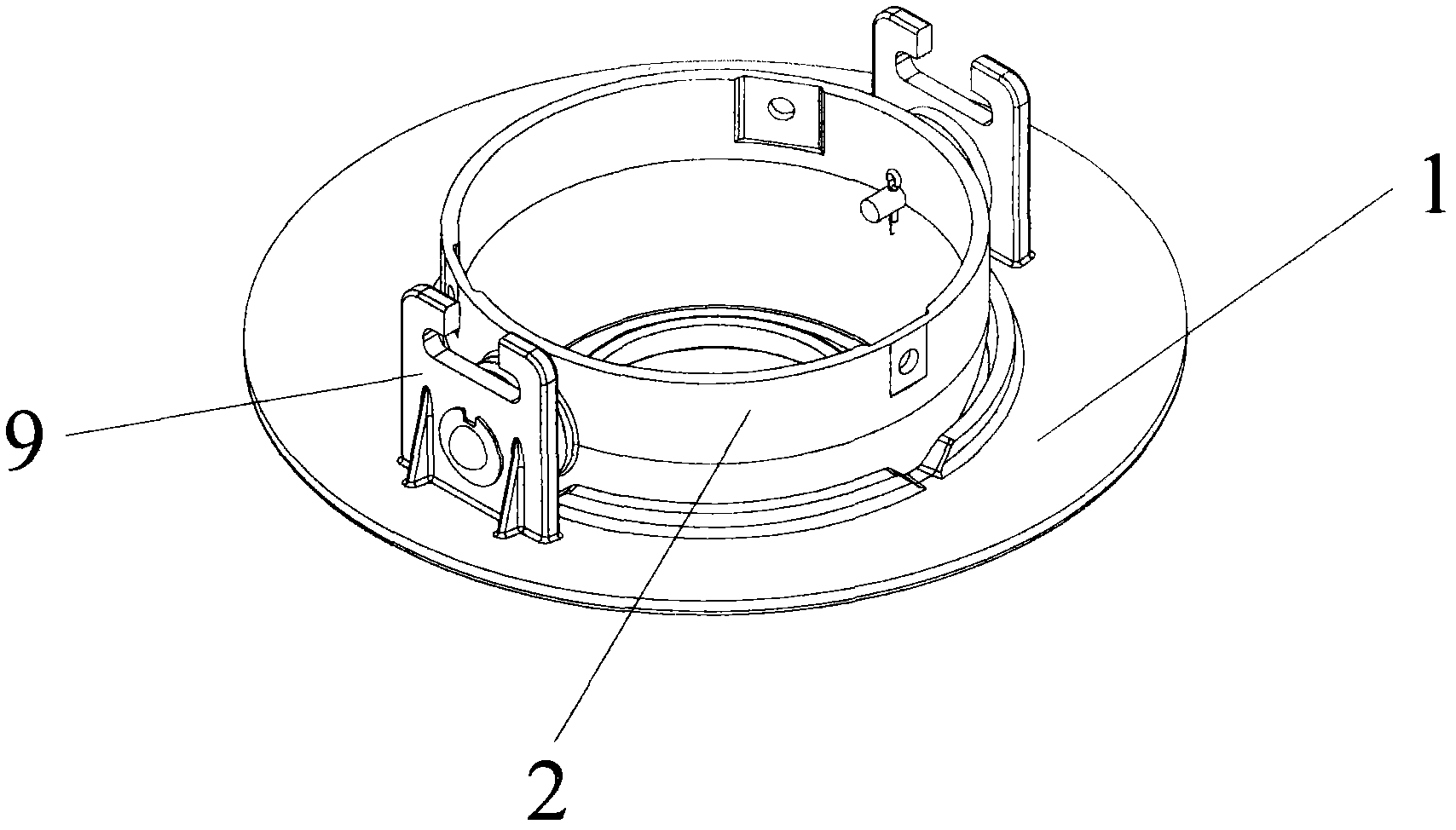

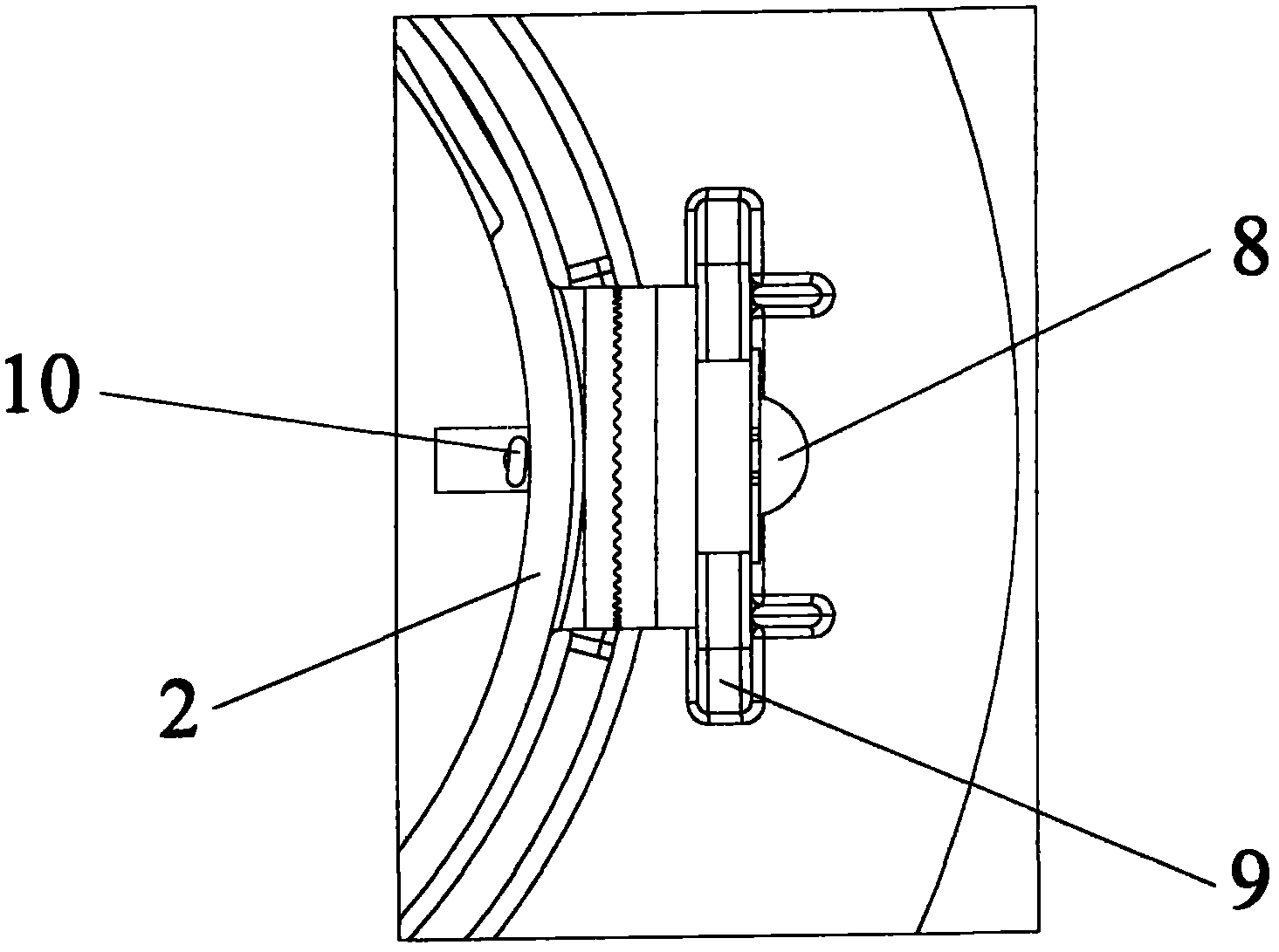

Polishing machine

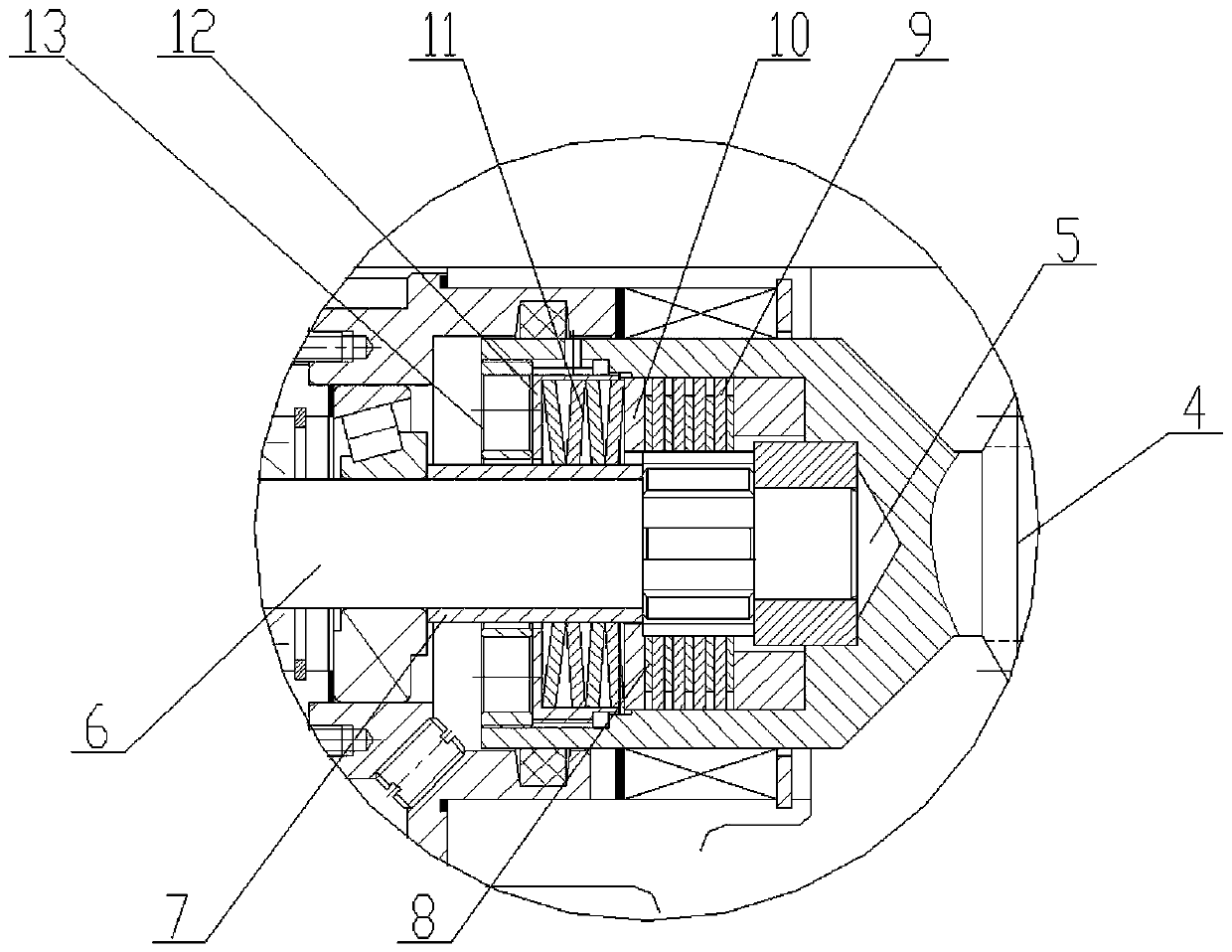

InactiveCN105215951AEasy to useReduce volumeMagnetic circuit stationary partsPortable power-driven toolsBrushless motorsDrive shaft

The invention discloses a polishing machine. The polishing machine comprises a machine shell (7) and a head shell (1) arranged at the top end of the machine shell (7), wherein a high-power-density brushless motor is arranged in the head shell (1); a controller (5) of the high-power-density brushless motor is arranged in the machine shell (7); the high-power-density brushless motor comprises a rotor shaft (2) rotationally arranged on the head shell (1), and the rotor shaft (2) and a driving shaft of a polishing rotary disc (6) of the polishing machine are coaxially arranged and are of an integrated structure. The axis of the rotor shaft (2) is perpendicular to the operation surface of the polishing rotary disc (6) and passes through the circle center of the polishing rotary disc (6). According to the polishing machine, the service life of the device is prolonged, generation of carbon powder is avoided, and environmental pollution is avoided. A transmission device is arranged in the machine shell, the service life is prolonged, energy consumption is lowered, output efficiency is improved, and noise and vibration are lowered. The trouble of engagement installation of transmission gears is omitted, the size and weight of the polishing machine are effectively reduced, and the polishing machine can be assembled conveniently.

Owner:ZHEJIANG LVDONG MOTOR TECH CO LTD

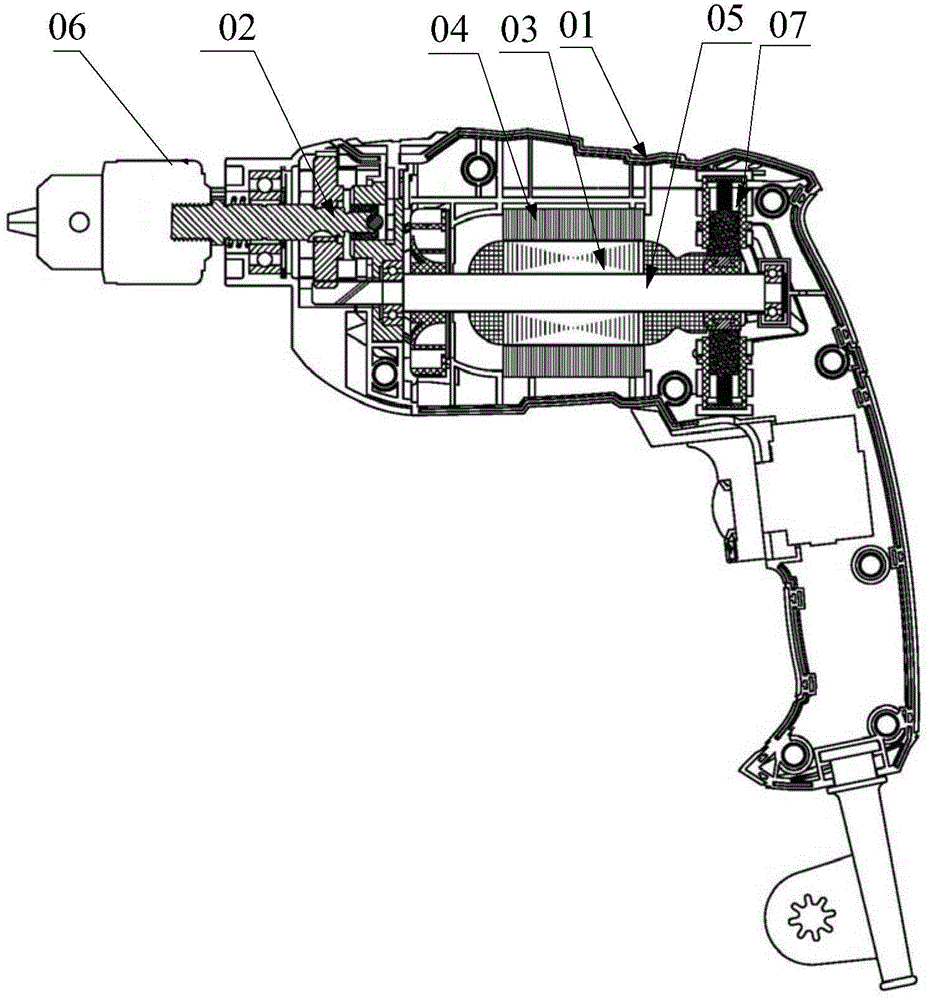

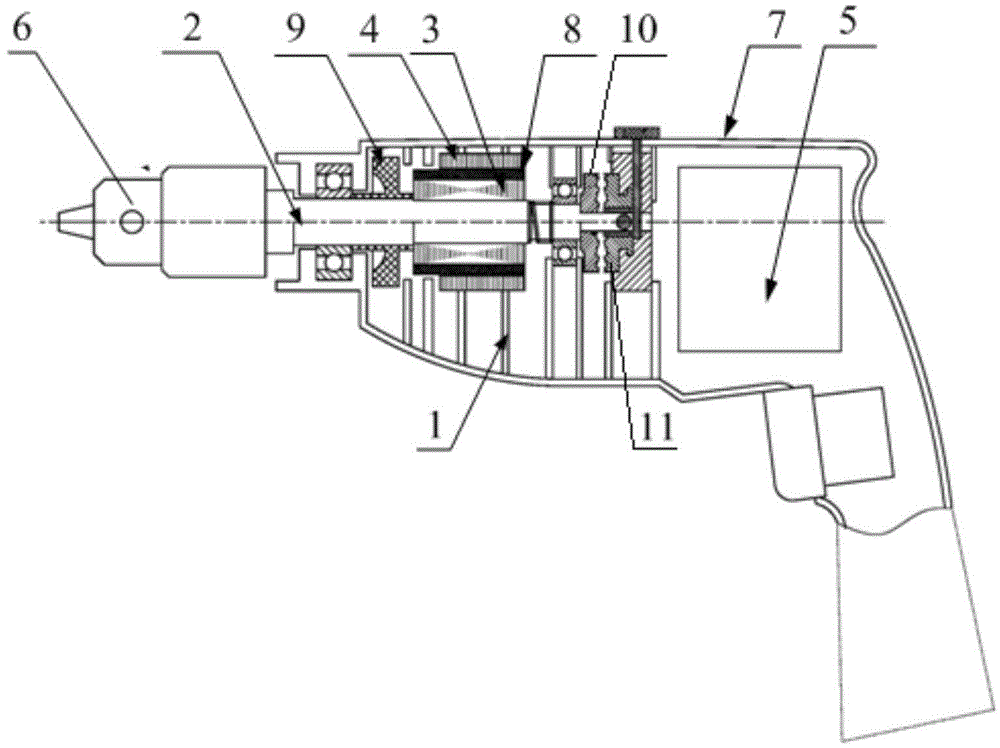

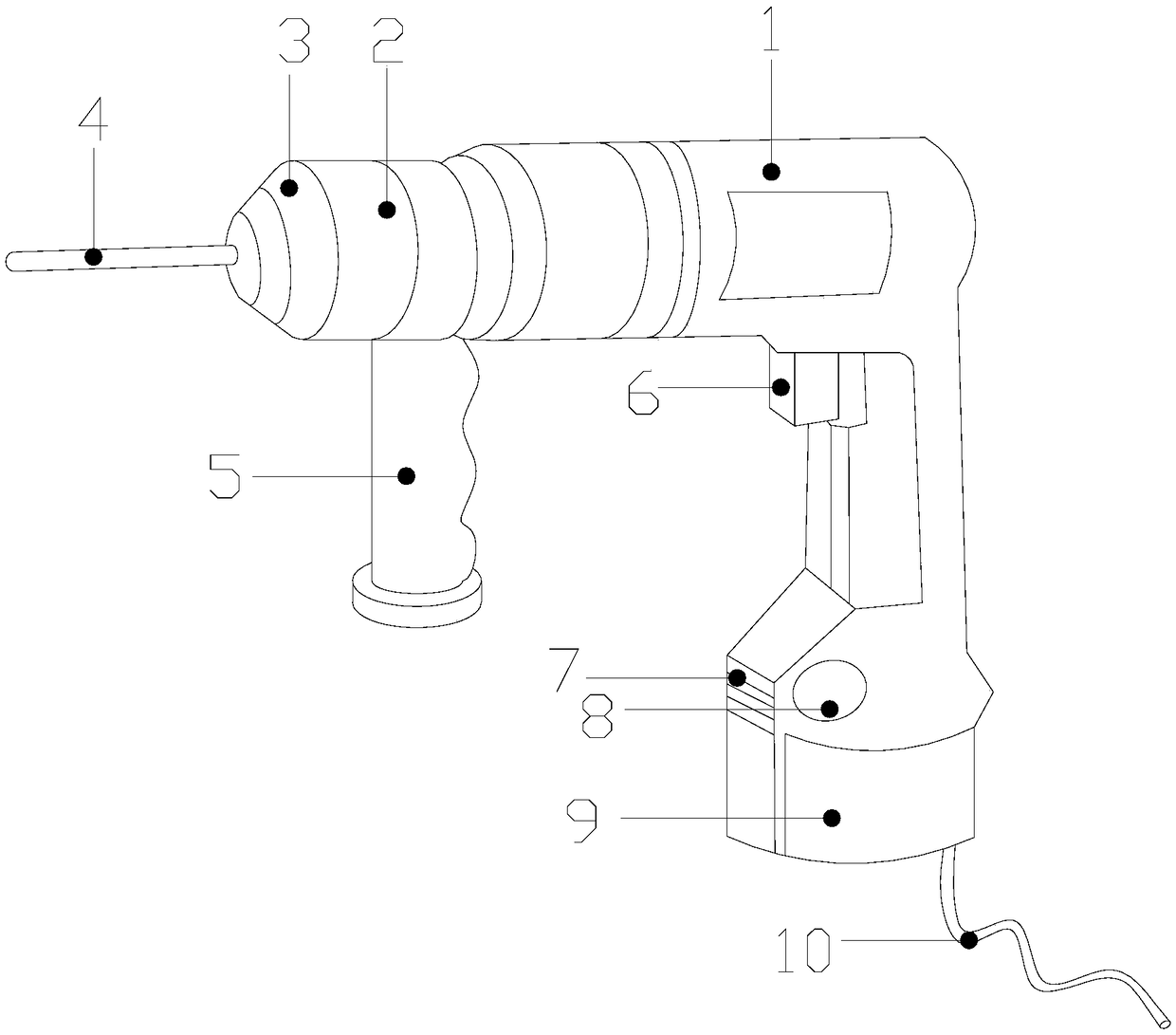

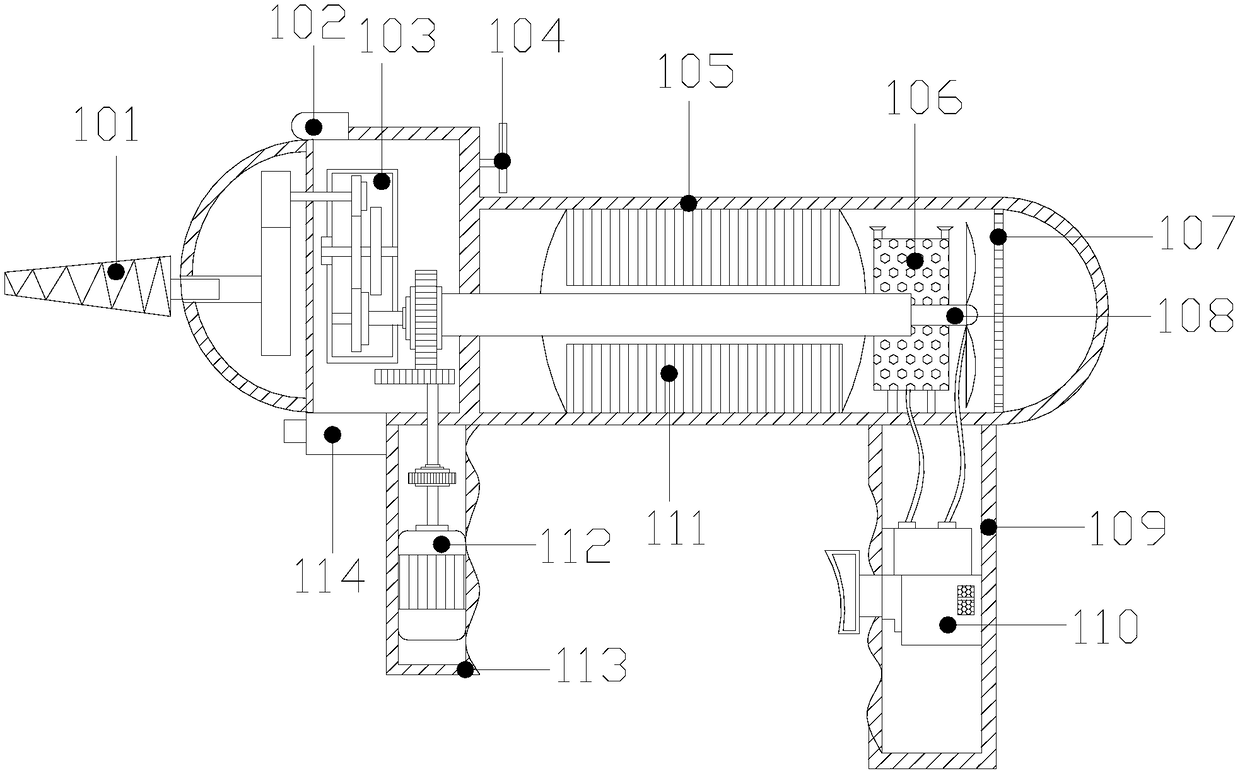

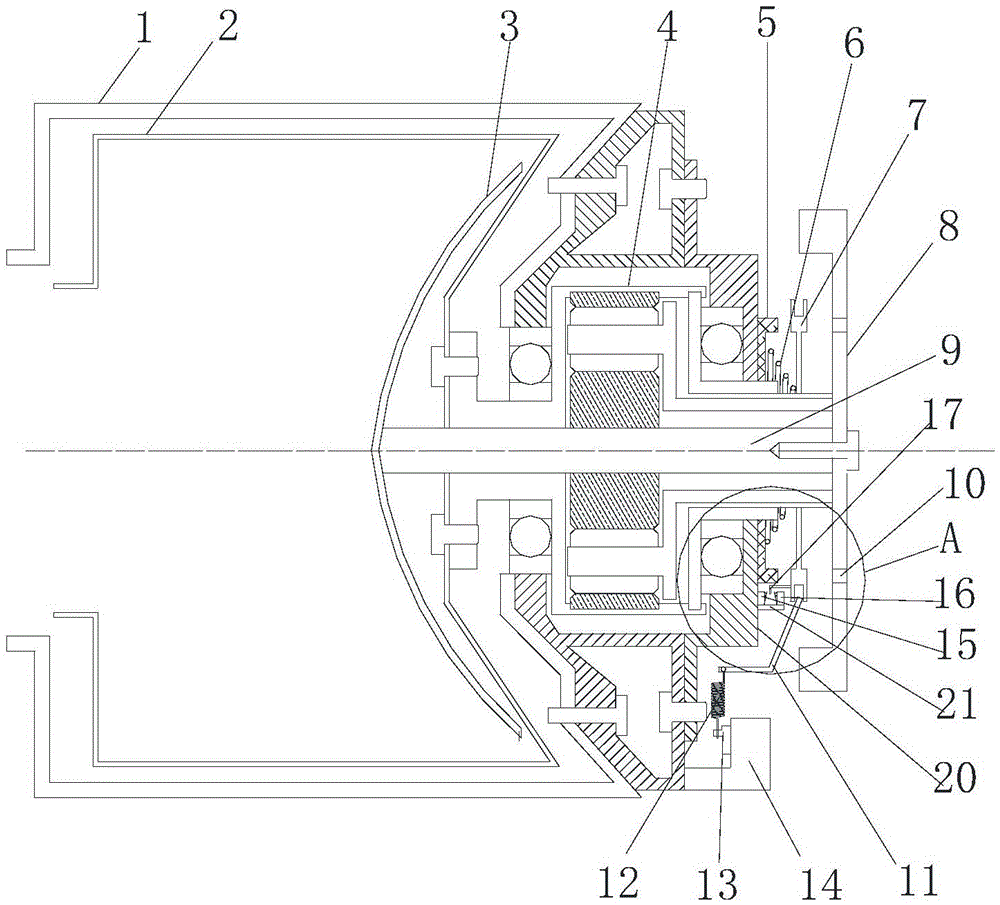

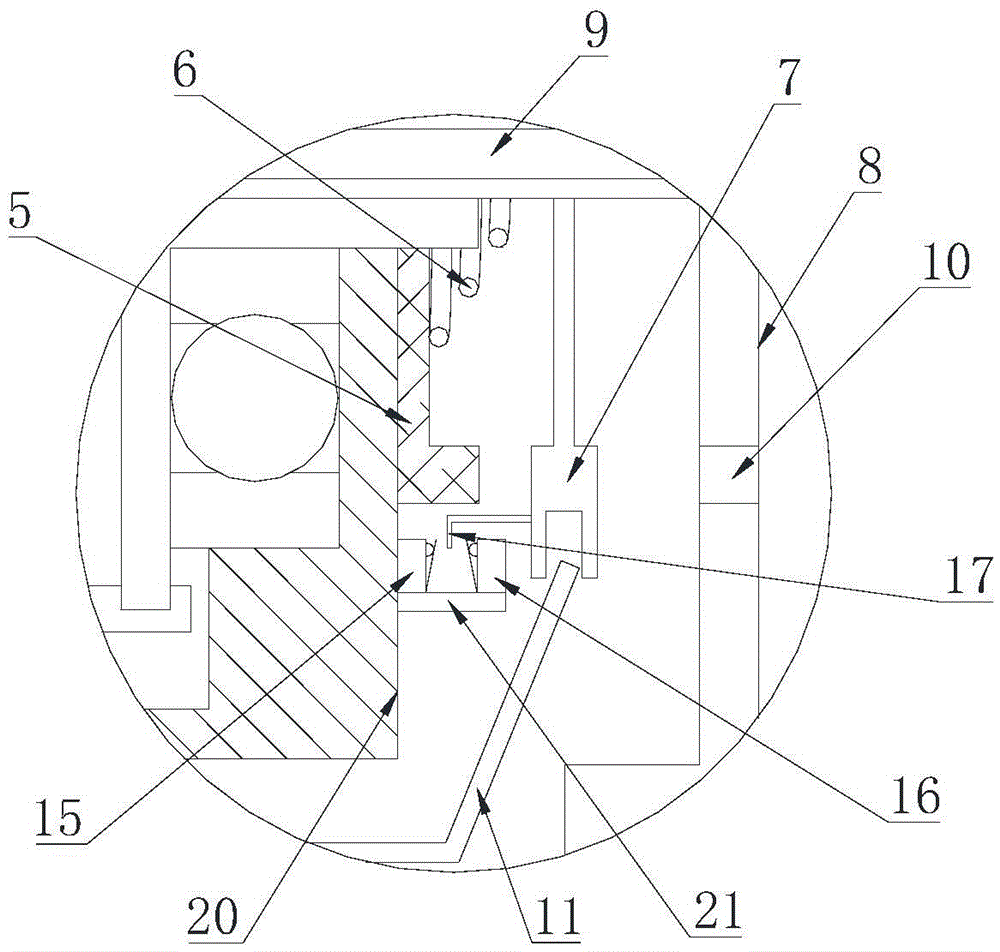

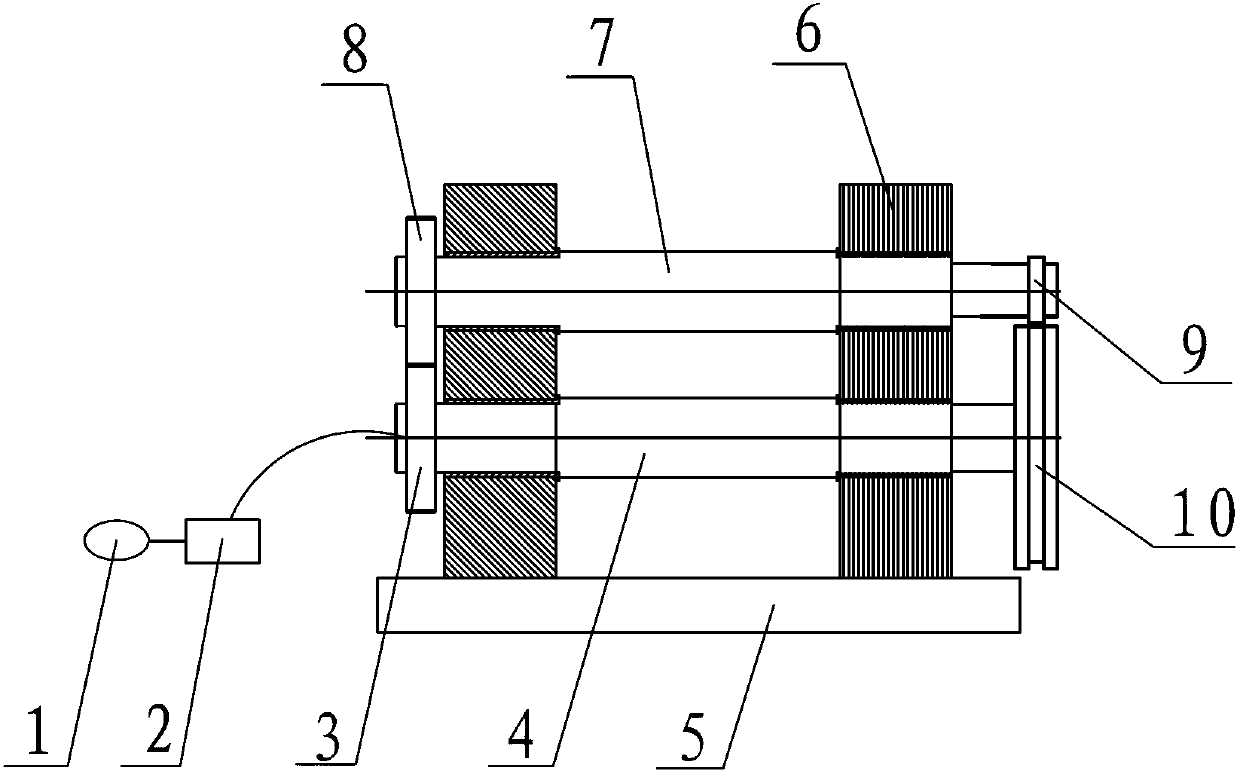

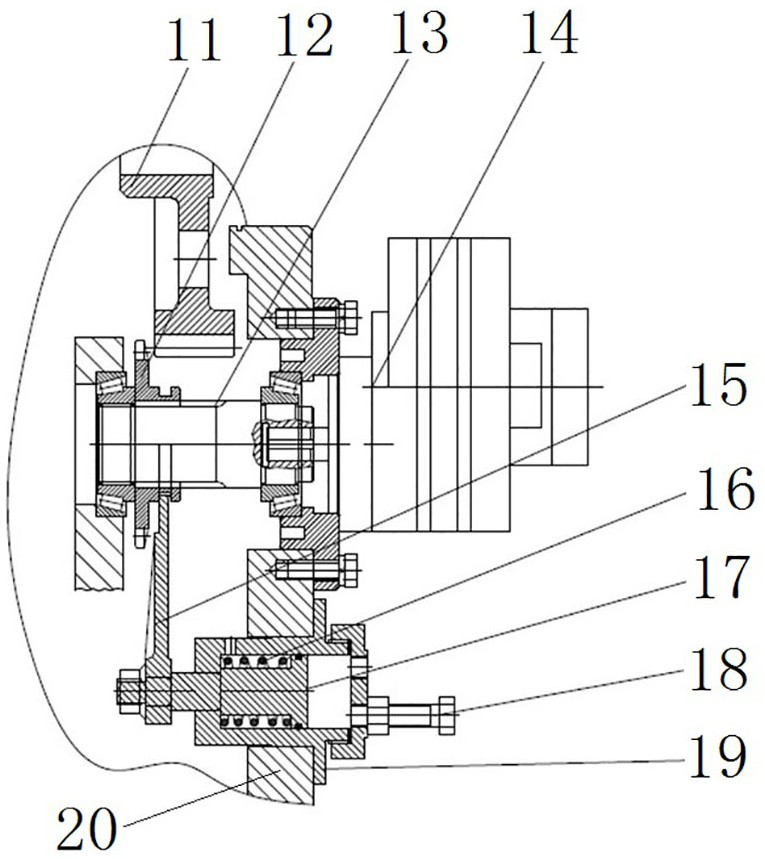

Percussion drill

InactiveCN105305721AEasy to useReduce volumeMechanical energy handlingPortable drilling machinesBrushless motorsEngineering

The invention discloses a percussion drill. The percussion drill comprises a case; a supporting part and a high power density brushless motor erected on the supporting part are arranged in the case; a controller of the high power density brushless motor is arranged in the case; the high power density brushless motor comprises a rotor shaft rotationally arranged in the supporting part; a chuck of the percussion drill is fixed at one end of the rotor shaft; an impact movable gear is arranged at the other end, far from the chuck, of the rotor shaft; and an impact static gear, arranged corresponding to the impact movable gear, is arranged in the case. According to the percussion drill provided by the invention, the service life of the percussion drill is prolonged; the generation of carbon powder is avoided, and environmental pollution is avoided; and a transmission apparatus arranged in the case is avoided, so that the service life of the percussion drill is prolonged, the energy consumption is reduced, the output efficiency is improved, the noise and the vibration are reduced, the trouble in engagement installation of the transmission gears is avoided, the volume and the weight of the percussion drill are effectively reduced, and convenience is brought for the assembling of the percussion drill.

Owner:ZHEJIANG LVDONG MOTOR TECH CO LTD

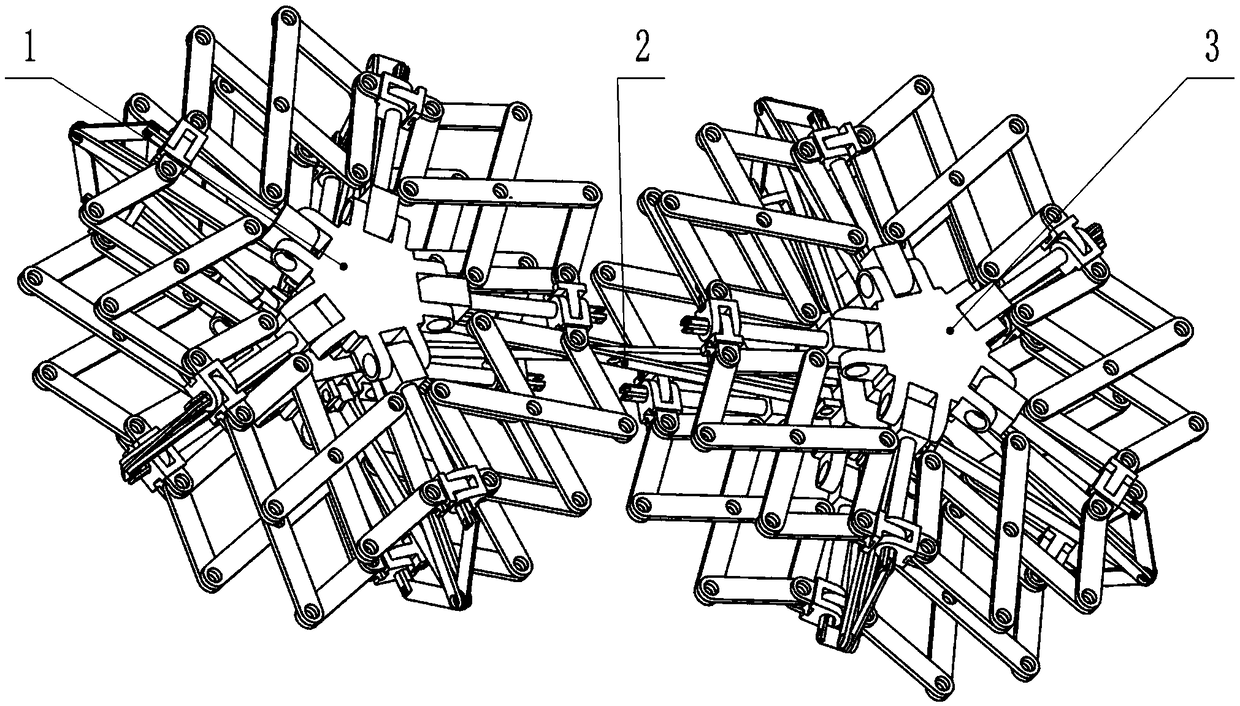

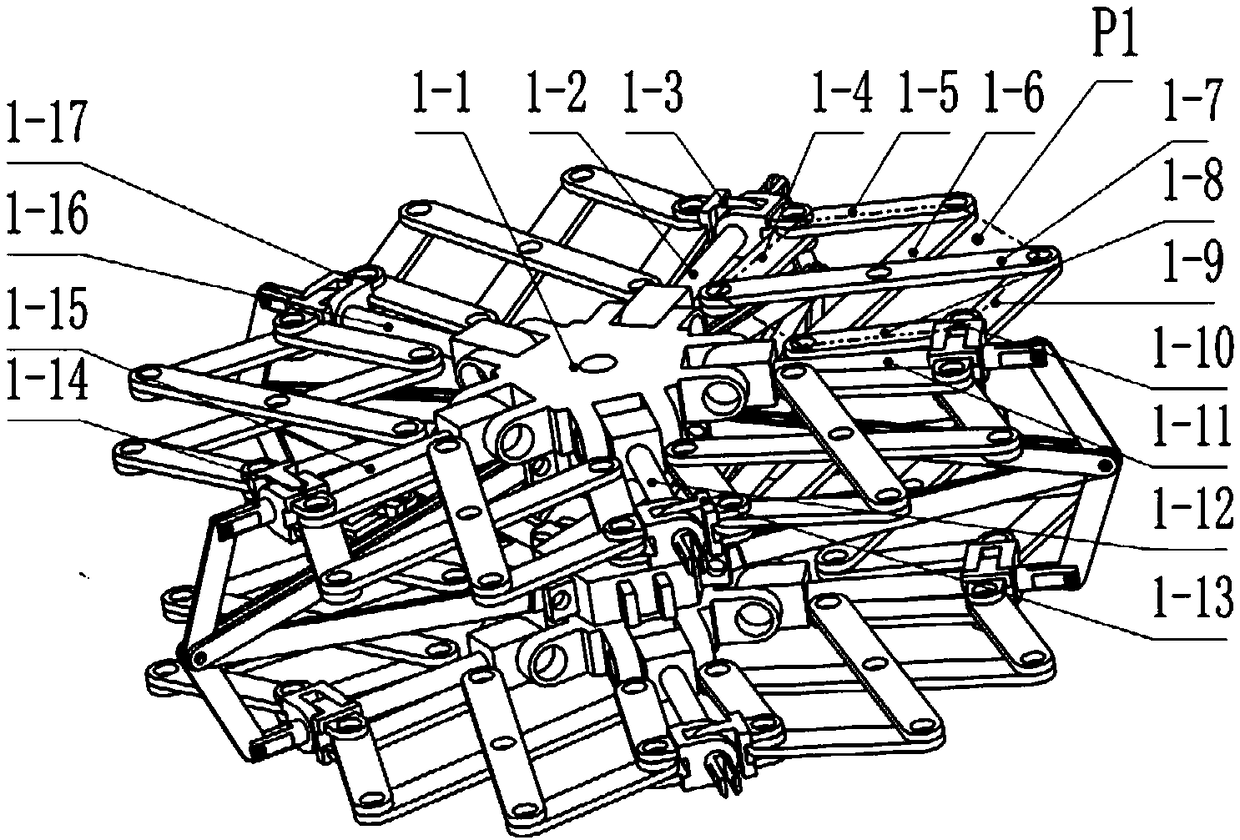

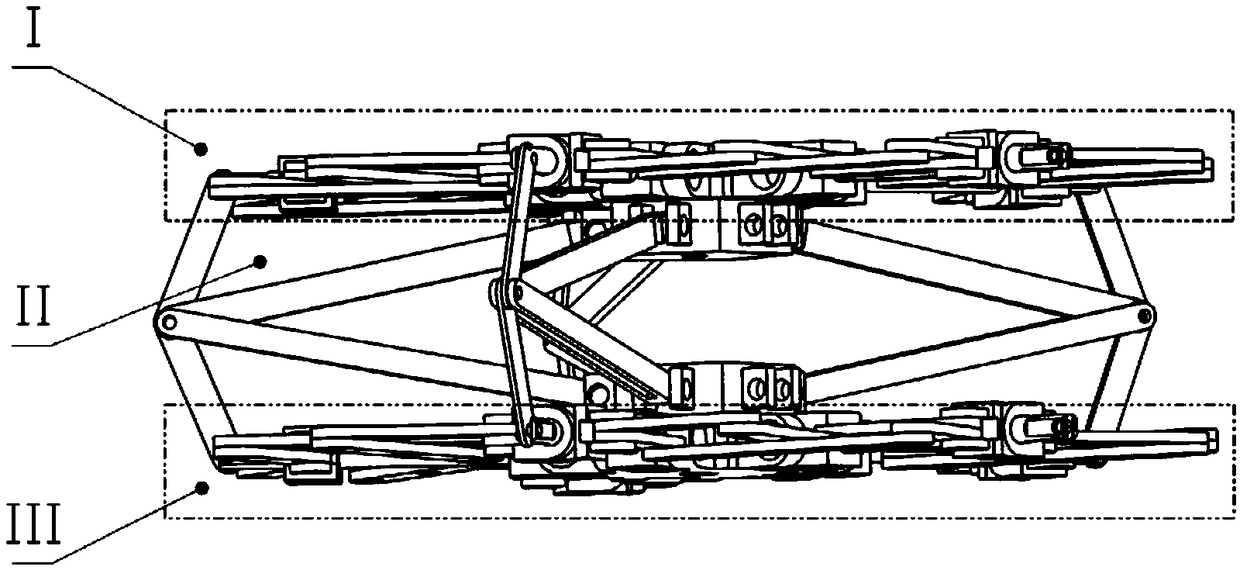

A two-layer deployable antenna mechanism based on diamond deployable element scissors

ActiveCN109103560AAvoid meshingReduce manufacturing costCollapsable antennas meansMechanical engineeringComponent type

A two-layer deployable antenna mechanism based on diamond deployable element scissors is provided. A first diamond deployable unit is connected to a second diamond deployable unit through a shearing fork bar, the shearing fork bar includes a first shearing fork bar and a second shearing fork bar, the first diamond-shaped deployable unit includes a first layer of deployable units, a second layer ofdeployable units and a support member, the first-layer deployable unit is composed of a first frame, a bracket bar, a hinge and a small diamond unit, and the support member includes a first group ofsupport members, a second group of support members, a third group of support members and a fourth group of support members, and the support members support the first-layer deployable unit and the second-layer deployable unit up and down. The mechanism has the characteristics of large folding ratio, large structural rigidity, good stability, low manufacturing cost and few component types, and is suitable for the field of space satellite plane transmitting antenna and the like.

Owner:GUANGXI UNIV

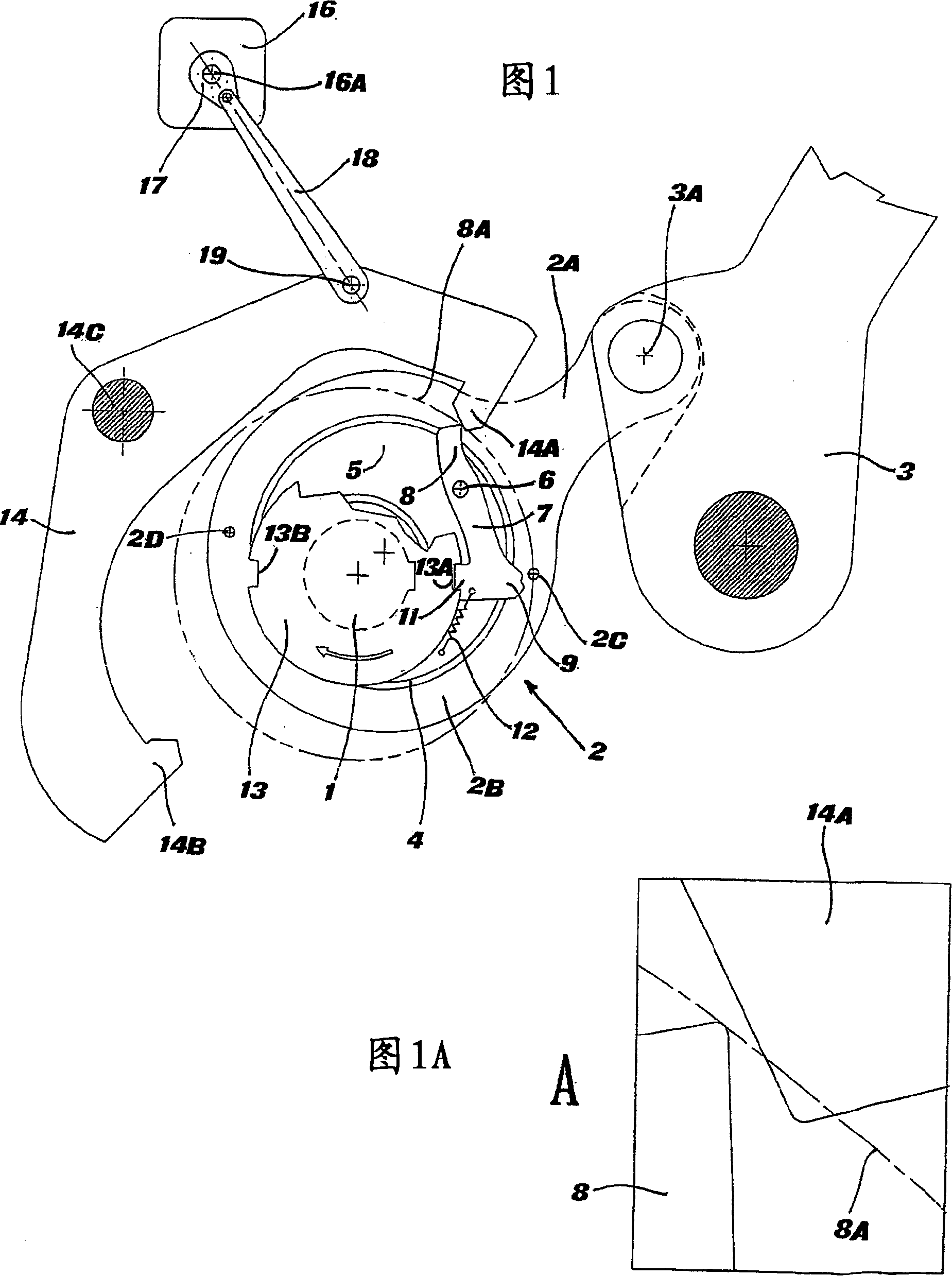

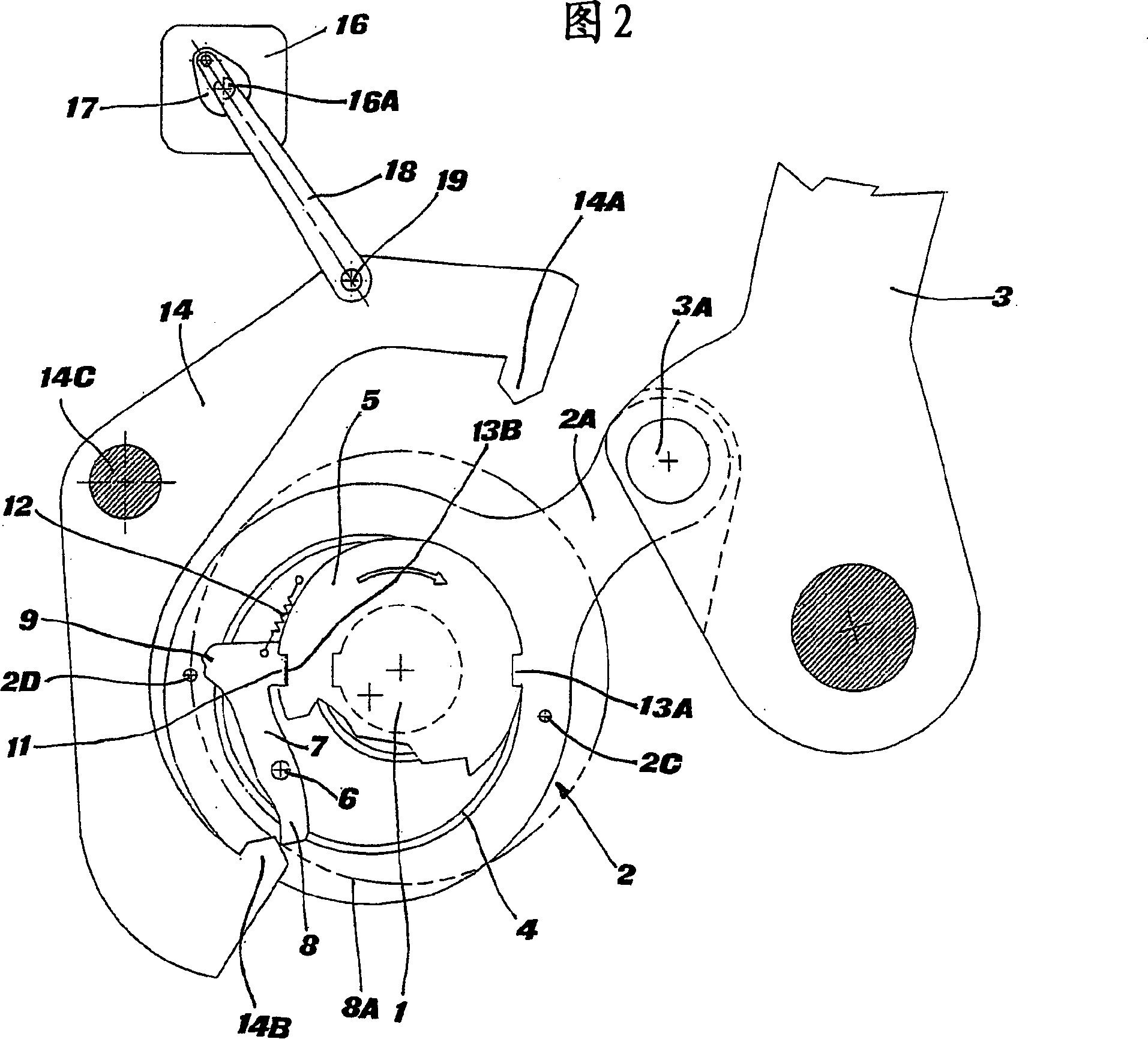

Device for carrying out the programming of rotary dobbies in weaving machines

The present invention provides a device for carrying out the programming of rotary dobbies for the operation of heald frames in weaving looms, of the type in which the control rods (3) of the heald frames are operated by connecting rods (2) each mounted on an eccentric ring (5) rotating with respect to the main shaft (1) of the dobby, said device comprising, for each frame, a C-shaped lever (14) caused to oscillate about a fixed point (14C) so that the toothed ends (14A, 14B) of the same lever position themselves either along or outside the trajectory of the end (8) opposite to the toothed end (11) of a selection lever (7), in order to cause or prevent the engagement of the selection lever with a rotating disc (13), characterised in that positive controls are provided causing the C-shaped operating levers (14) to oscillate, said positive controls being synchronised with the rotation of the loom main shaft and obtained, independently for each heald frame, by means of a rotary electric motor.

Owner:IP FIRST

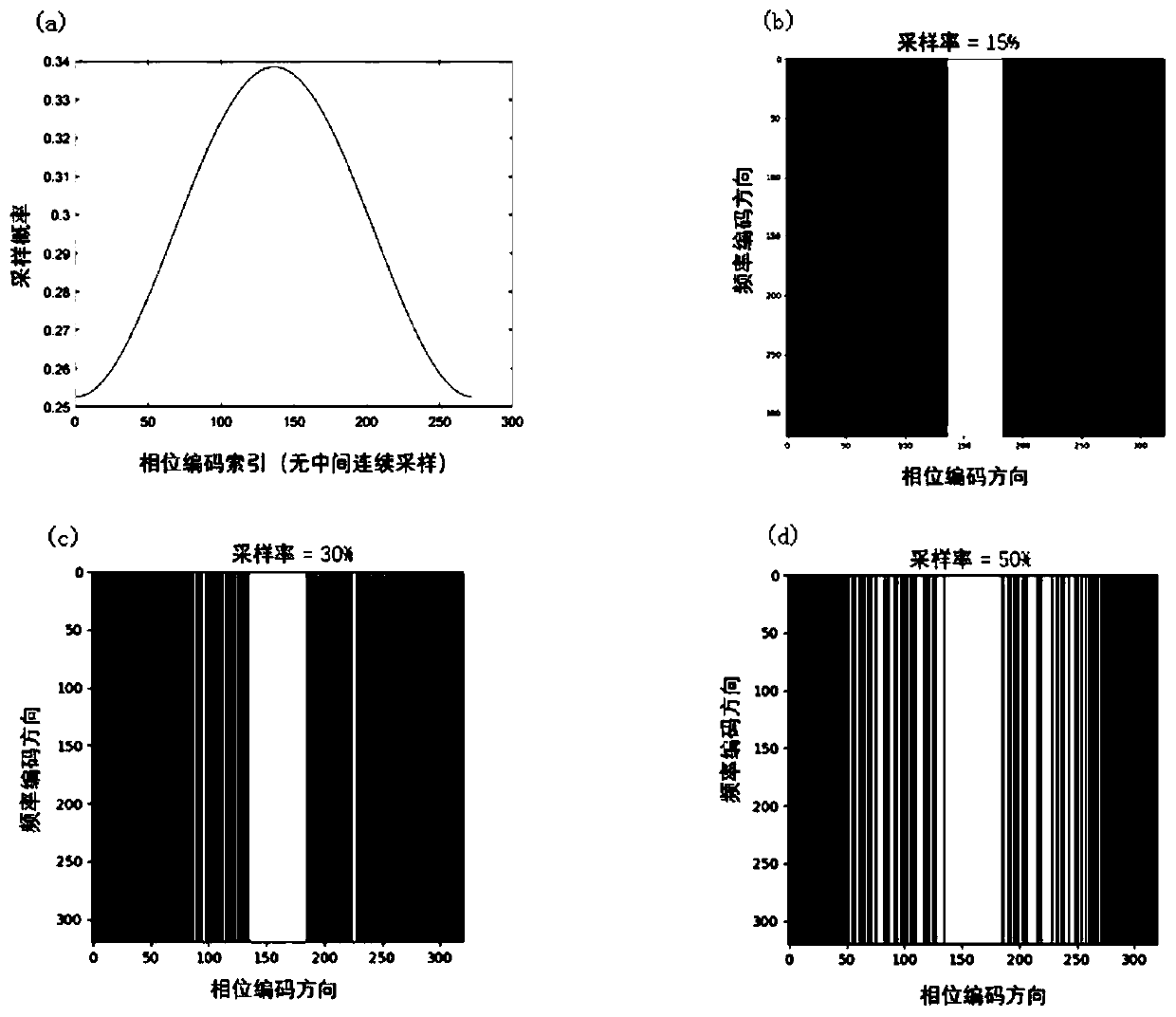

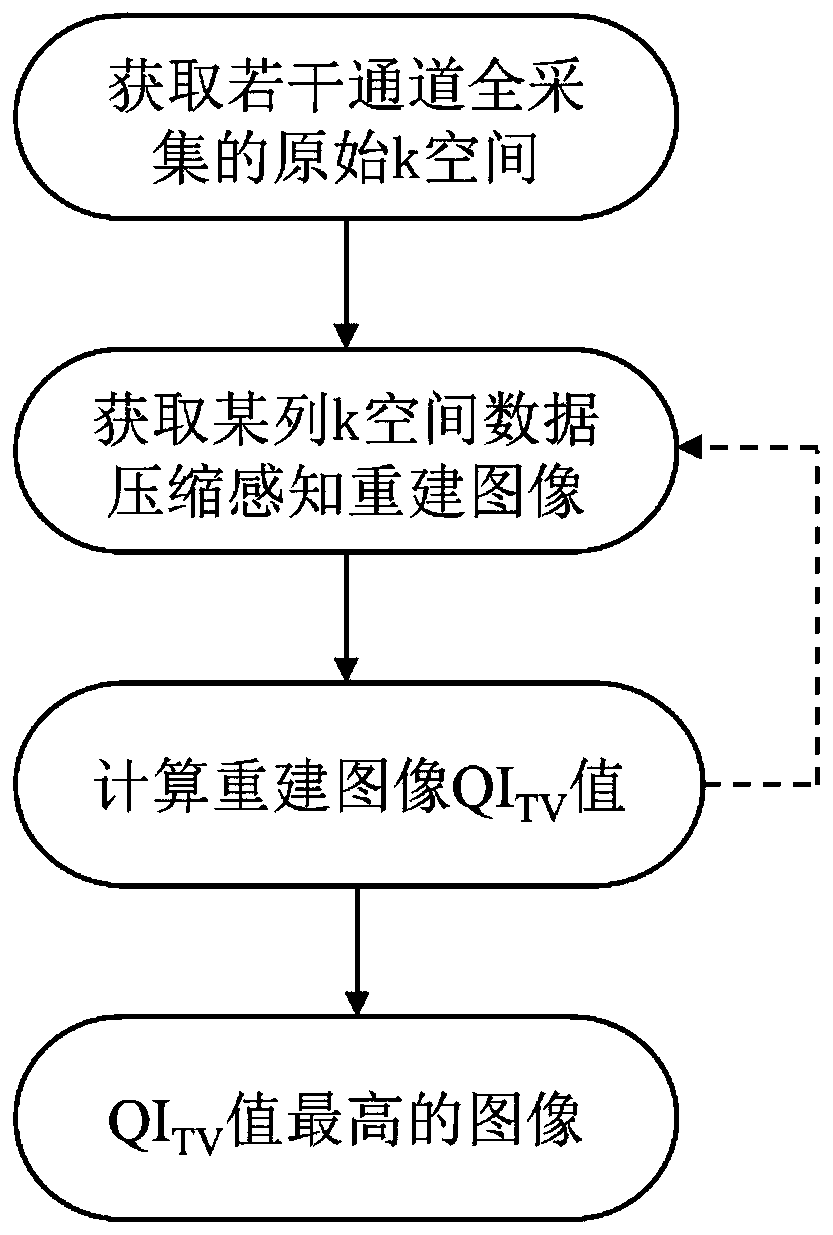

Method for removing magnetic resonance head image motion artifacts

PendingCN110652296AAvoid meshingQuality improvementDiagnostic recording/measuringMeasurements using NMR imaging systemsImaging qualityK-space

The invention discloses a method for removing magnetic resonance head image motion artifacts.. Non-reference image qualitative assessment indexes QITV in the method are used for reflecting image quality. The method comprises the steps of constructing k space data after sampling each time through contraction perception, calculating QITV value of reconstructed images, by observing the change trend of the image QITV value, finding the time when patients make motion in the magnetic resonance screening process, and using k space data without motion to reconstruct contraction perception so as to optimize fully-collected motion artifact images. The image quality of the magnetic resonance motion artifacts can be effectively improved, so that clinical application of magnetic resonance images can bepromoted.

Owner:EAST CHINA NORMAL UNIV

Electric drill device capable of measuring while drilling

InactiveCN108422009ATimely evacuationAvoid meshingDrilling/boring measurement devicesPortable power-driven toolsPower flowCoupling

The invention discloses an electric drill device capable of measuring while drilling. The electric drill device structurally comprises a high-efficiency electronic mechanism, a dust suction pipe, a dust suction opening, a drill bit, a handle, a power switch, an exhaust outlet, a vacuum cleaner, a dust box and a power line, the right side of the dust suction pipe are fixedly welded to the left sideof the high-efficiency electronic mechanism, and the dust suction pipe and the high-efficiency electronic mechanism are embedded together; the right side of the dust suction opening is fixedly fastened to the left side of the dust suction pipe and the dust suction opening and the dust suction pipe are of an integrated molding structure. The electric drill device is capable of dispersing heat generated during work timely and effectively. When a propulsive force is excessively large, a spiral bit stops rotating, and at this time, the current of a motor rises instantaneously, which is likely tocause hidden danger. If the force is over large when the device is propelled, a fourth gear and a first coupler are disengaged, and then the device needs to be powered off and restarted, thereby preventing direct engagement between a rotating fourth gear and the stationary first coupler, avoiding the occurrence of tooth collision, and further avoiding damage to the device and potential safety hazard caused by excessive current.

Owner:莆田市荔城区秋妹电子商务有限公司

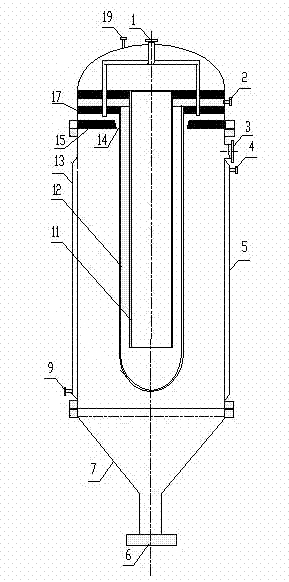

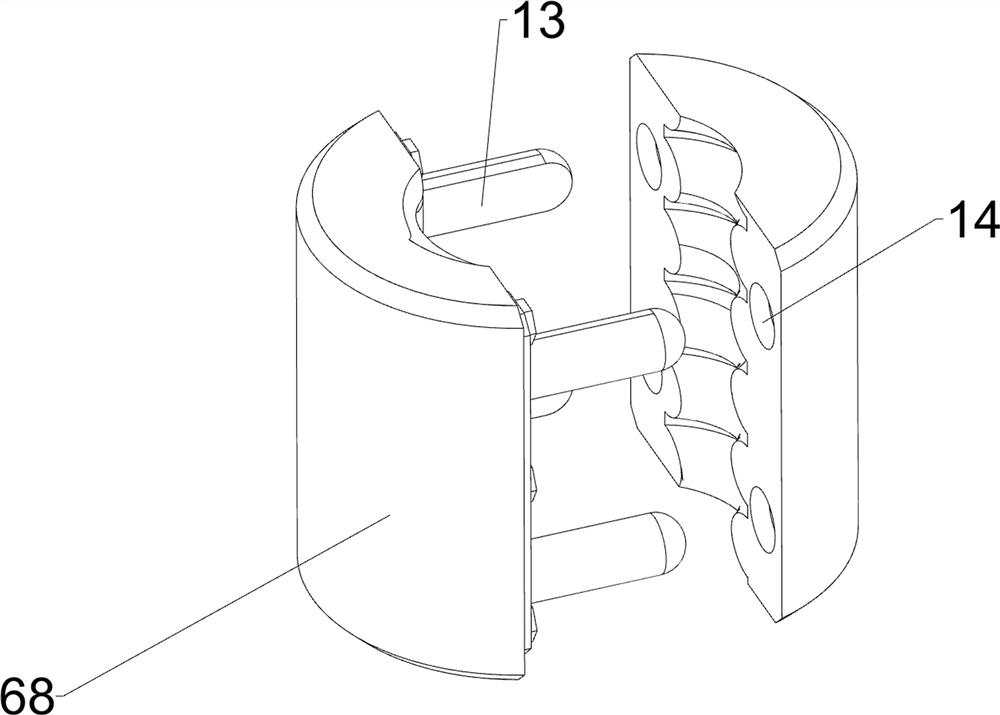

Polycondensation kettle for falling film outside vertical tube

ActiveCN102746499BNo cloggingUniform film formationPressure vessels for chemical processVertical tubeVacuum pumping

The invention relates to a polycondensation kettle for a falling film outside a vertical tube. The kettle comprises a vertical casing (13); a head and a cone (7) are connected to the upper end and the lower end of the vertical casing (13) respectively; a feed inlet (1) and a heating medium inlet (19) are arranged at the top of the head; a discharge port (6) is arranged at the bottom of the cone (7); a vacuum pumping port (3) is arranged on the upper portion of the vertical casing (13); the feed inlet (1) is communicated with a buffer area between a lower tube plate (15) and a middle tube plate (17) through a pipeline; the vertical tube (12) is arranged in the center of the vertical casing (13), connected with the middle tube plate (17), and communicated with a heating medium outlet (2); and an annular gap (14) is reserved between the vertical tube (12) and the lower tube plate (15), and a central tube (11) arranged in the vertical tube (12) is communicated with the heating medium inlet (19). The polycondensation kettle has the advantages that the film formation of the materials is even, the reaction efficiency can be improved, and the kettle can be used for production of highly viscous polymers such as polyethylene terephthalate (PET).

Owner:ZHEJIANG UNIFULL IND FIBER

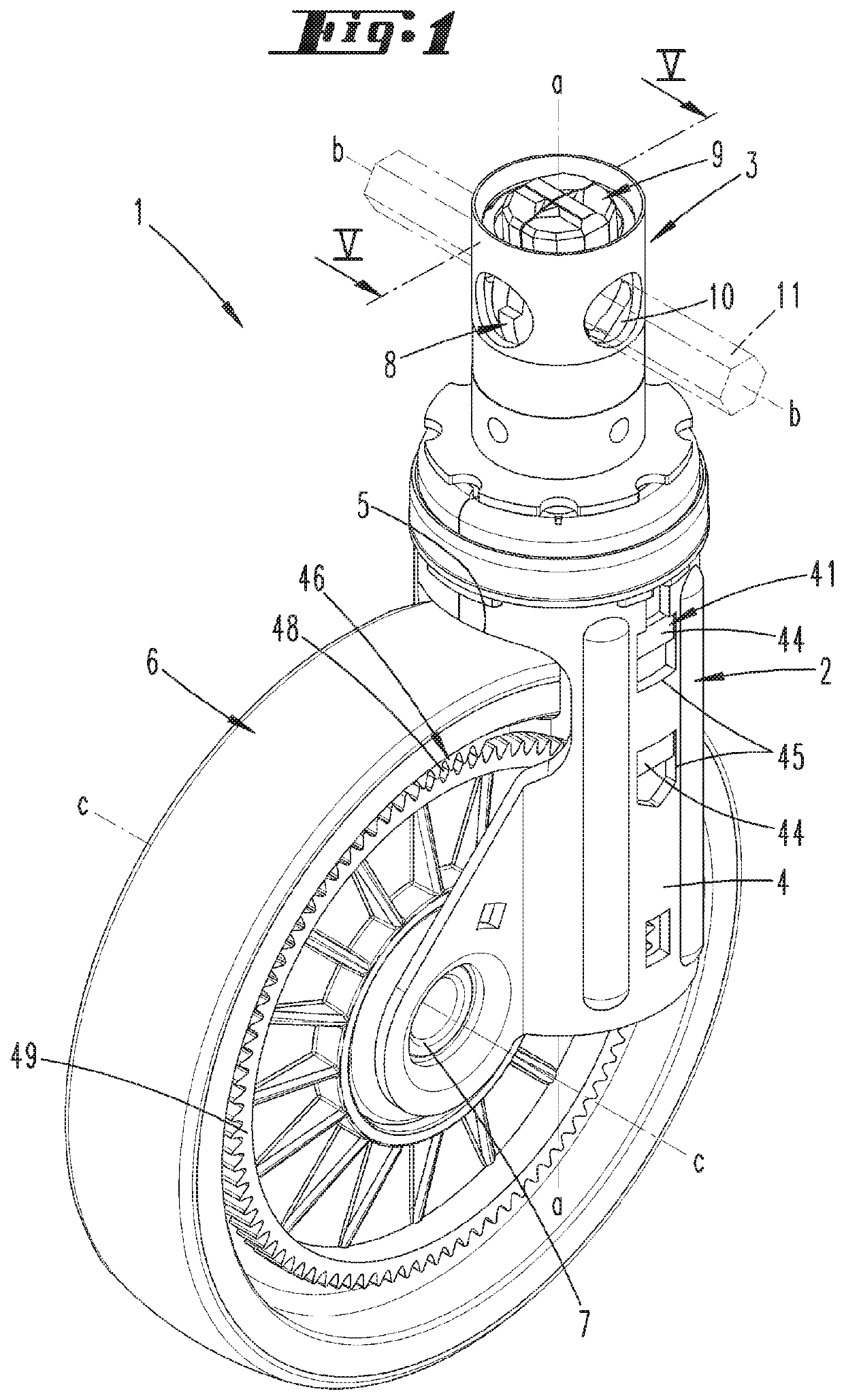

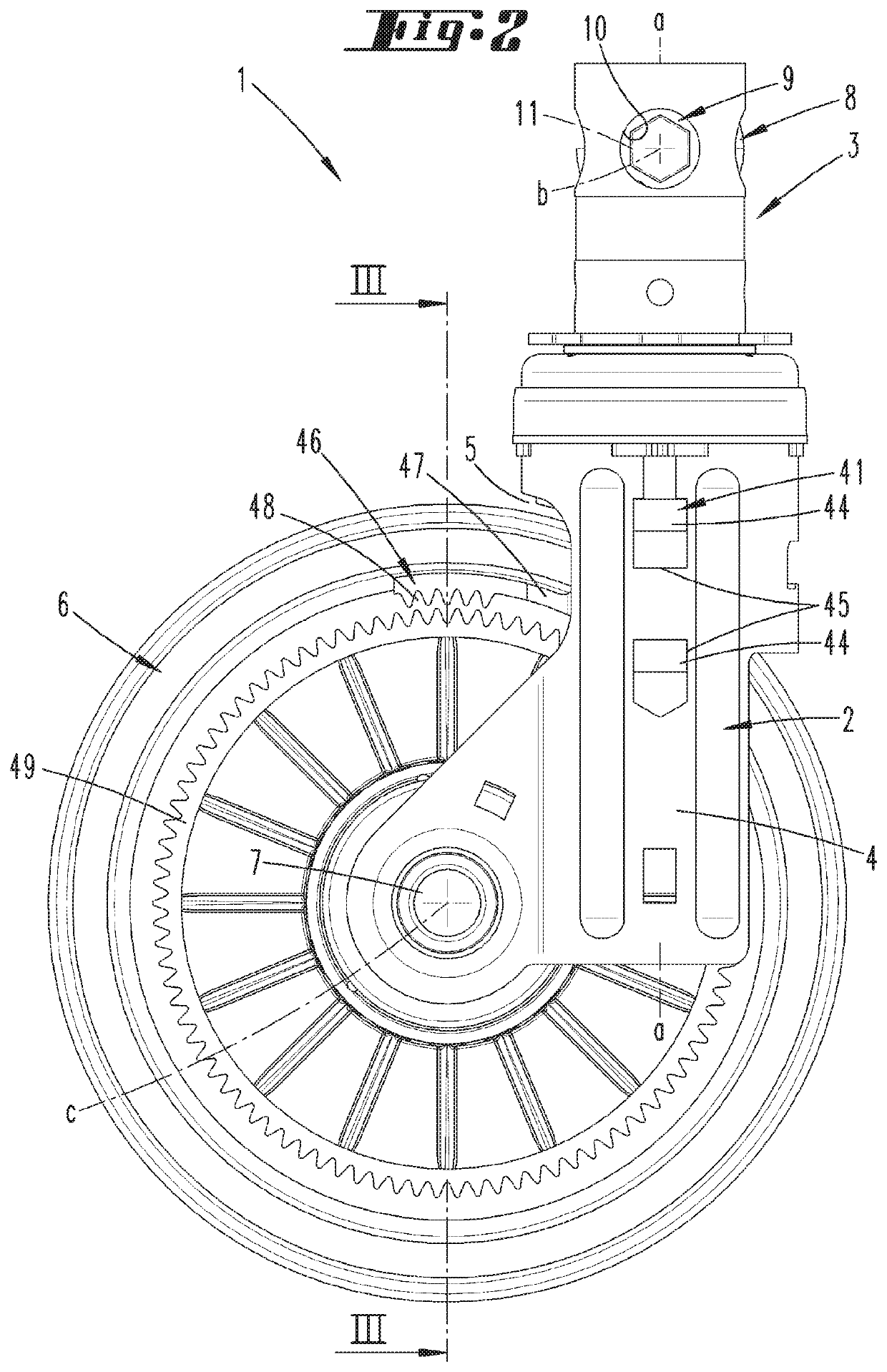

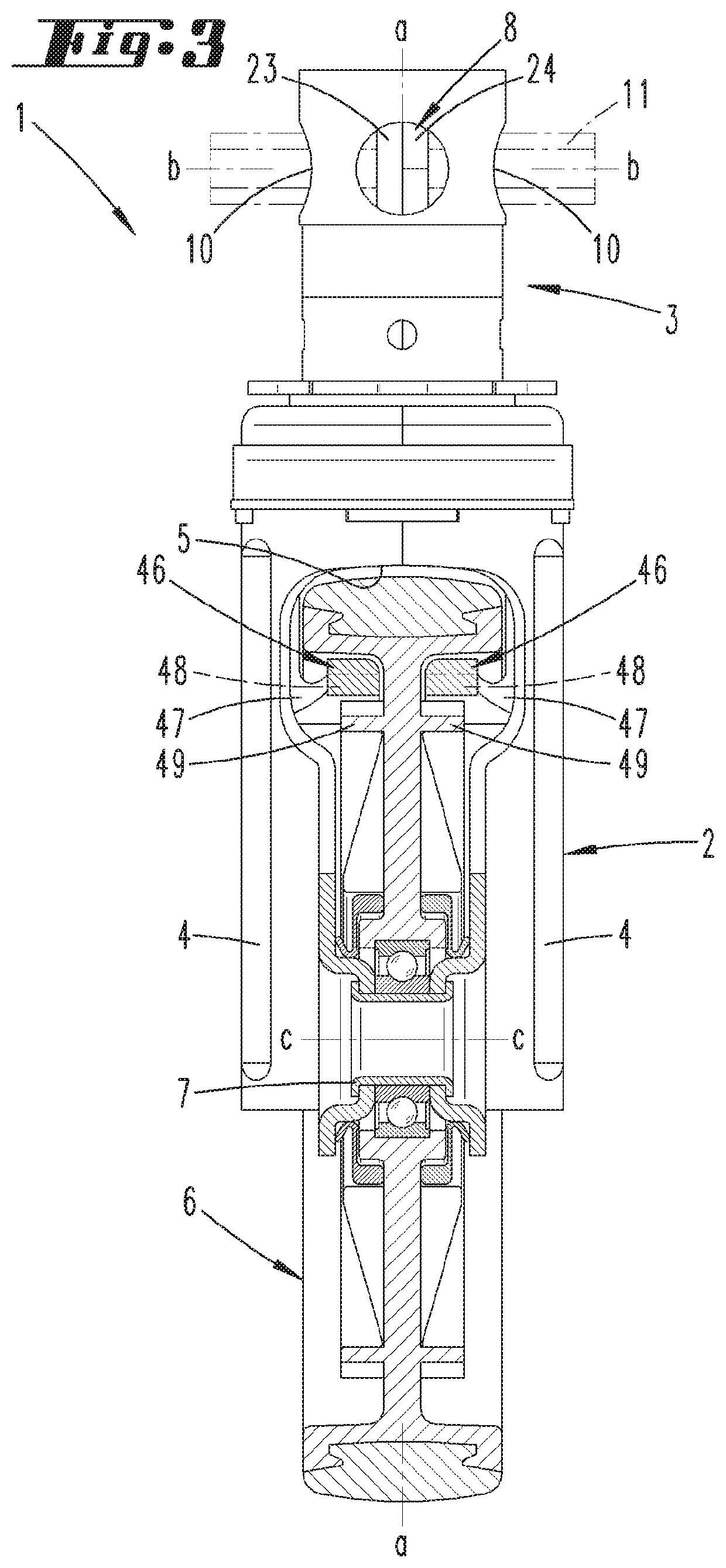

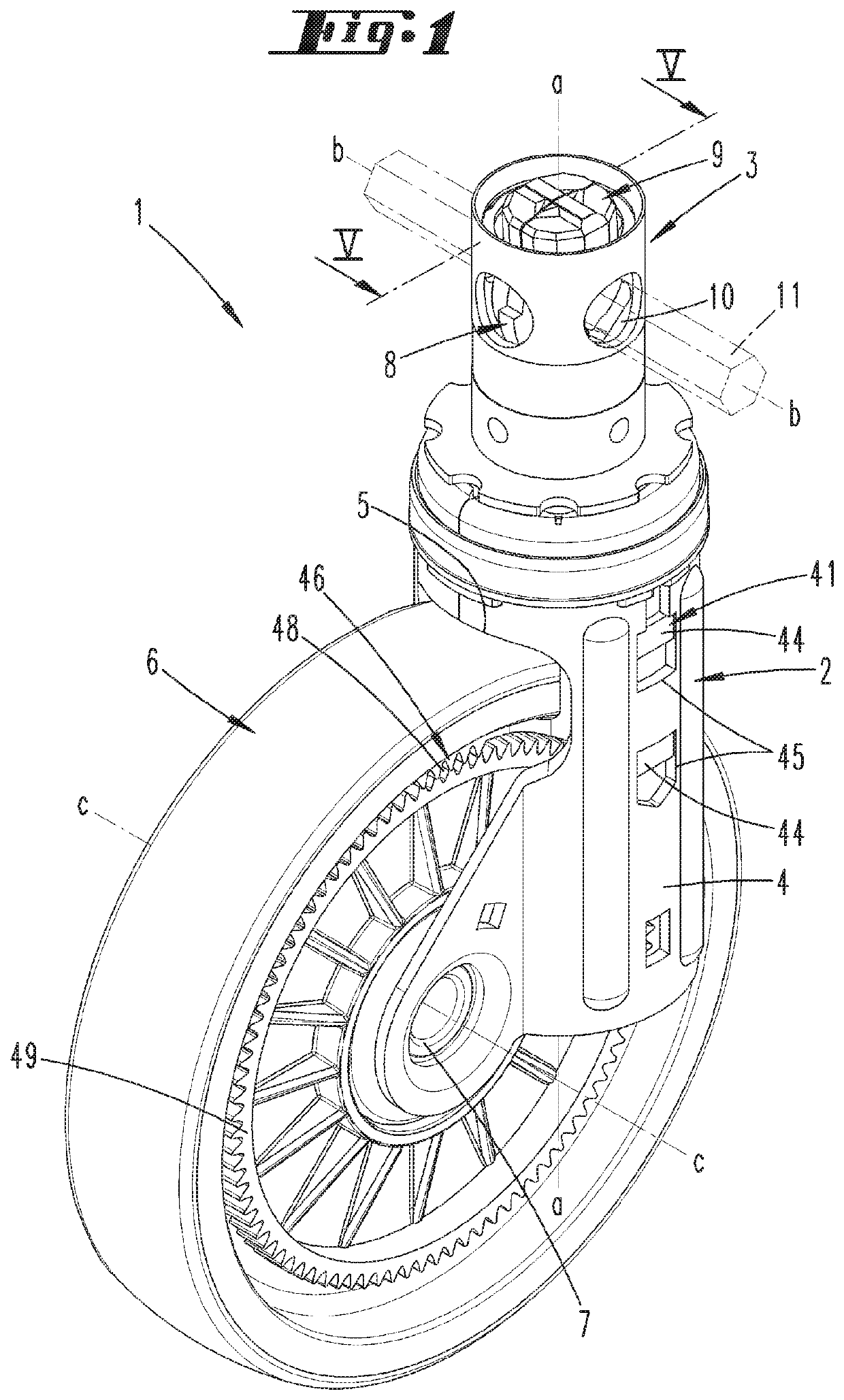

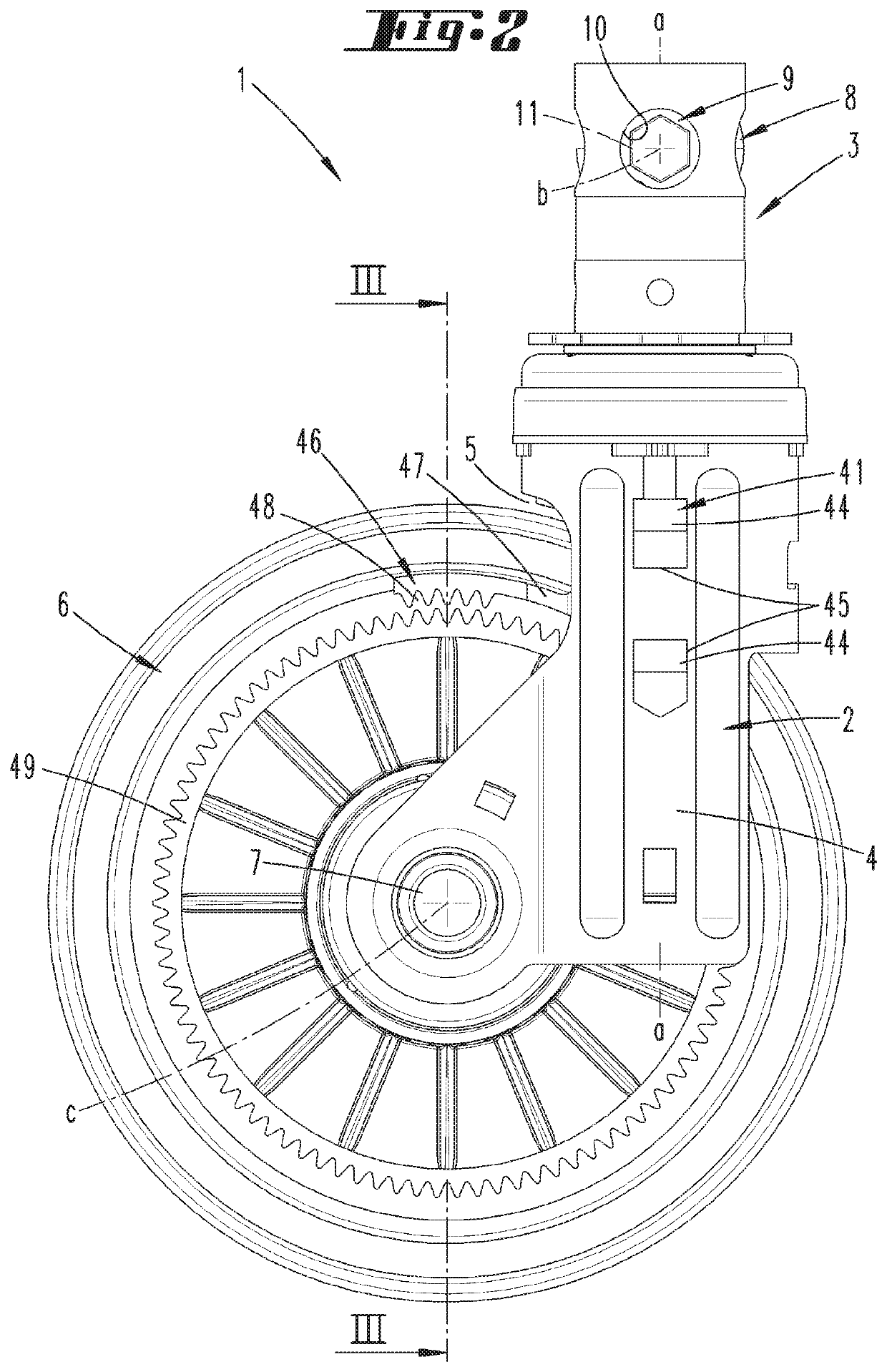

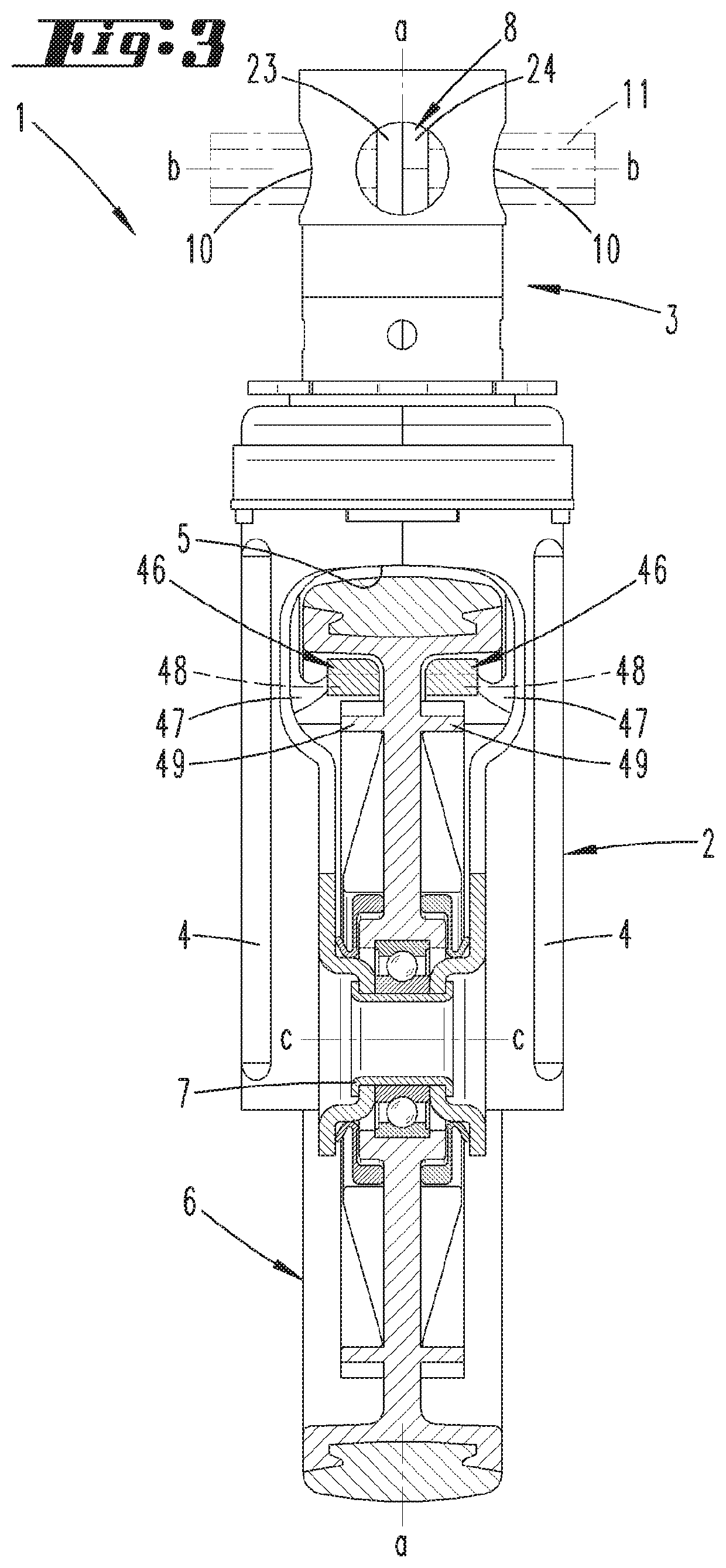

Caster comprising a running wheel

A caster includes a running wheel, a fork and an assembly journal, wherein the fork is pivotable in relation to the assembly journal and a braking device is arranged in the fork and can be displaced into the braking position via a tappet actuated by a trip cam. A direction lock can be set without a braking action on the running wheel. Two tappets are movable independently of each other, wherein only the direction lock without a braking action can be set via one of the tappets. Another caster includes a running wheel, a fork and an assembly journal, wherein a braking device is provided in the fork and can be displaced into the braking position via a trip cam. The braking device has a first braking part for friction-locking action on the running wheel and a second braking part for the interlocking lock of the running wheel.

Owner:TENTE

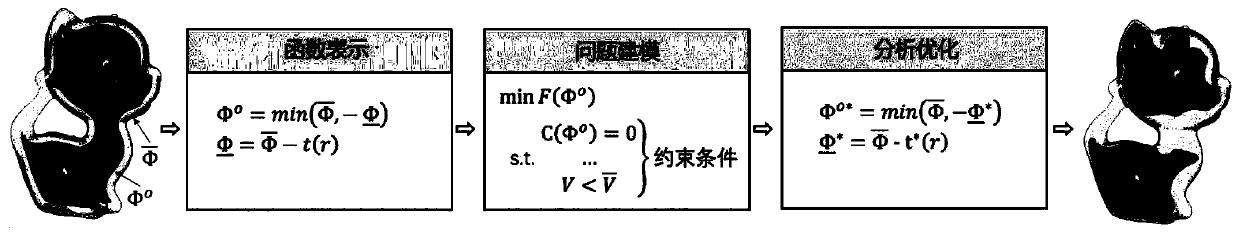

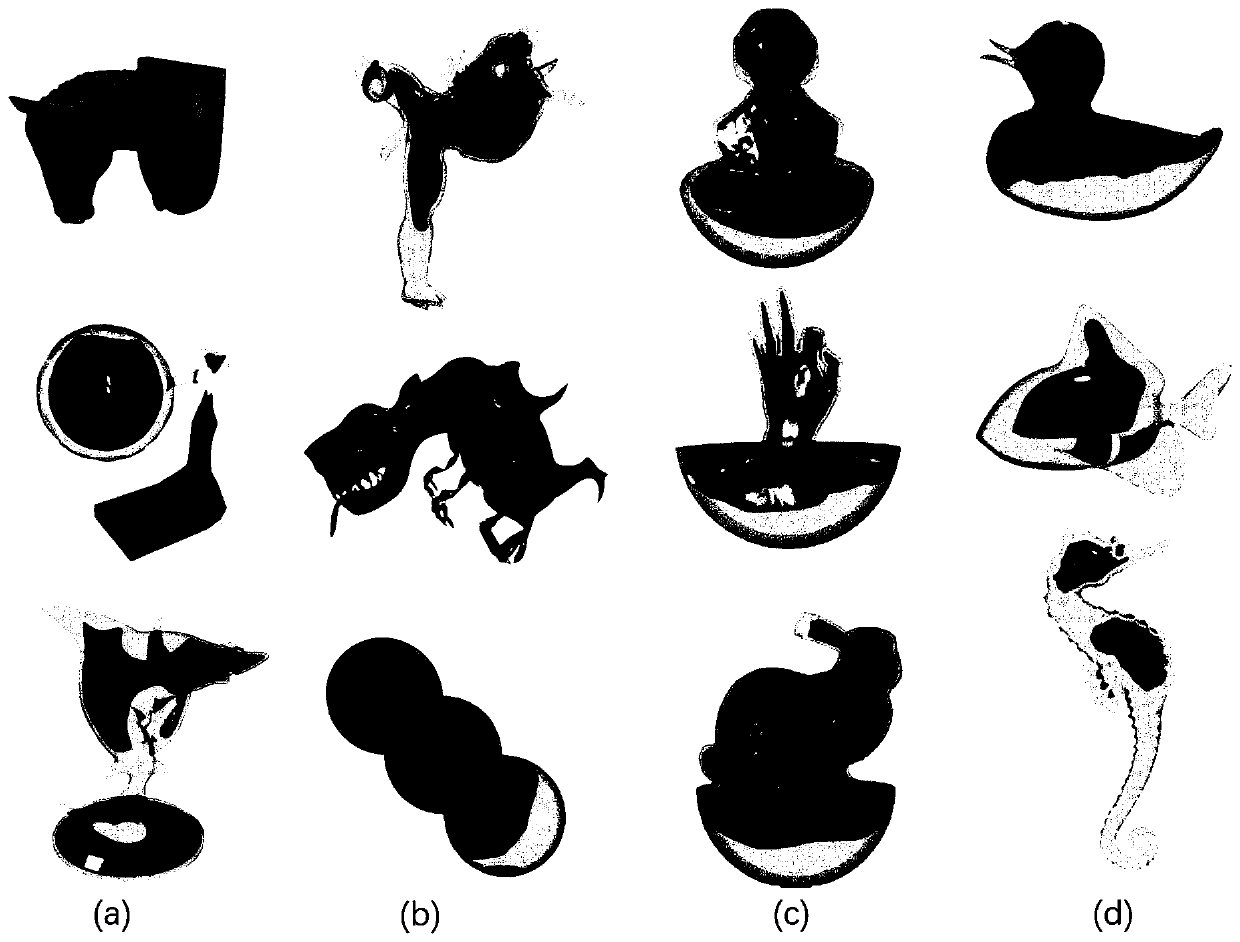

3D model internal hole digging type lightweight method based on function representation

ActiveCN111368477AImprove standing stabilityReduce designGeometric CADAdditive manufacturing apparatus3d shapesAlgorithm

The invention discloses a 3D shape internal hole digging type lightweight method based on function representation, and belongs to the field of computer aided design. The method comprises the followingsteps: firstly, expressing and exploring effective shape optimization analytical calculation by utilizing a function, then designing a stress structure of a 3D model by constructing an energy function model under given external condition constraints, modeling an object mass center, standing stability, tumbler design and suspension problems, and giving out a corresponding discretization form; andfinally, respectively carrying out geometric optimization on the modeling problems to obtain the internal shape of the optimized object under a given constraint condition. According to the method, thedesign and optimization period of the hole structure is greatly shortened, and a theoretically optimal result can be given. According to the method, the internal cavities of the obtained model are smoother and are not limited by the number of the cavities, the object model has a lower centroid, more materials are saved, and the consumed time in the aspects of design and optimization is shorter.

Owner:DALIAN UNIV OF TECH

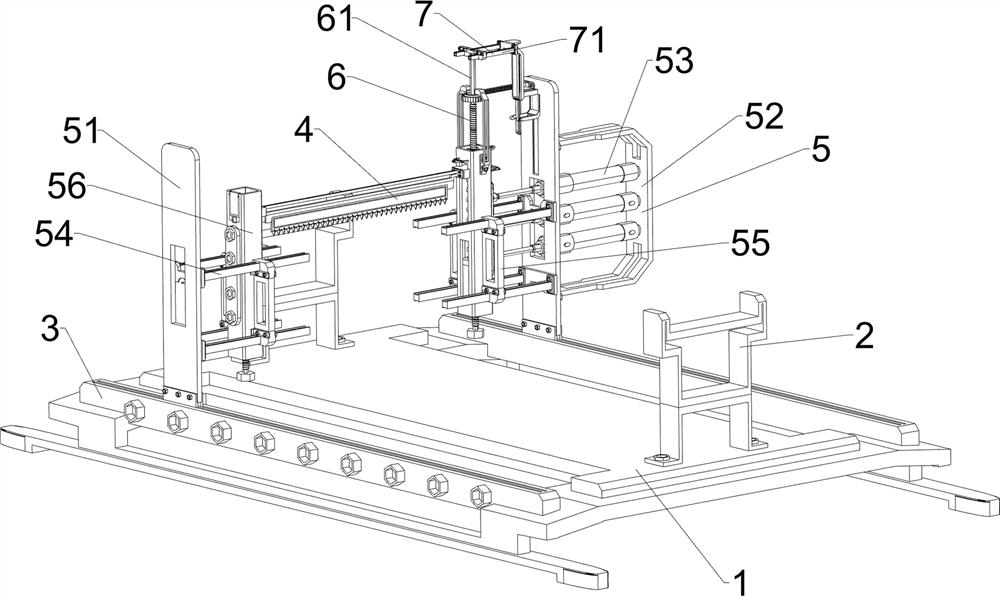

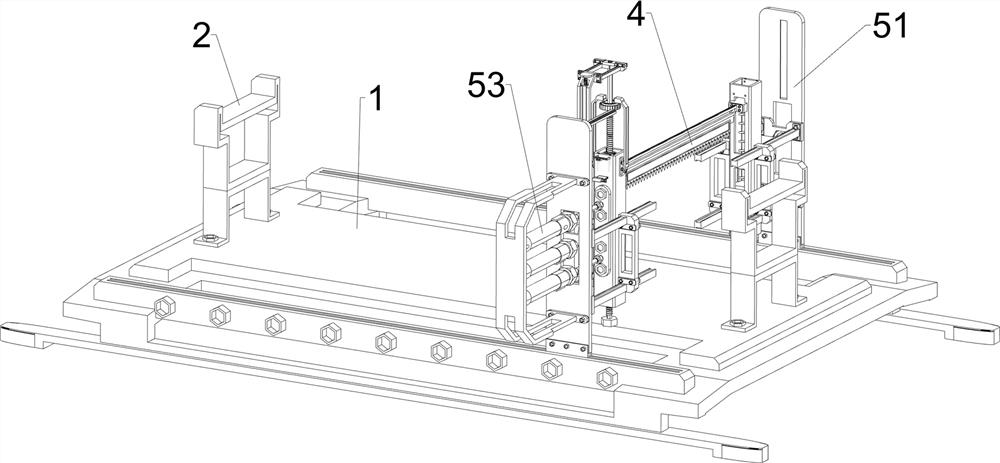

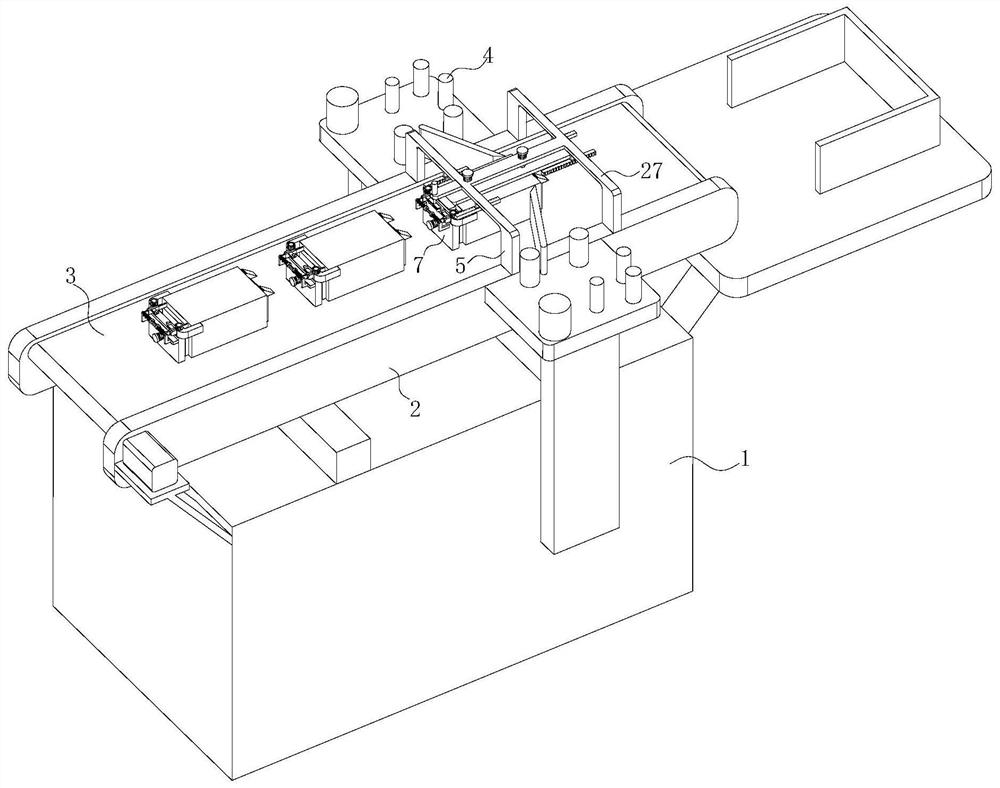

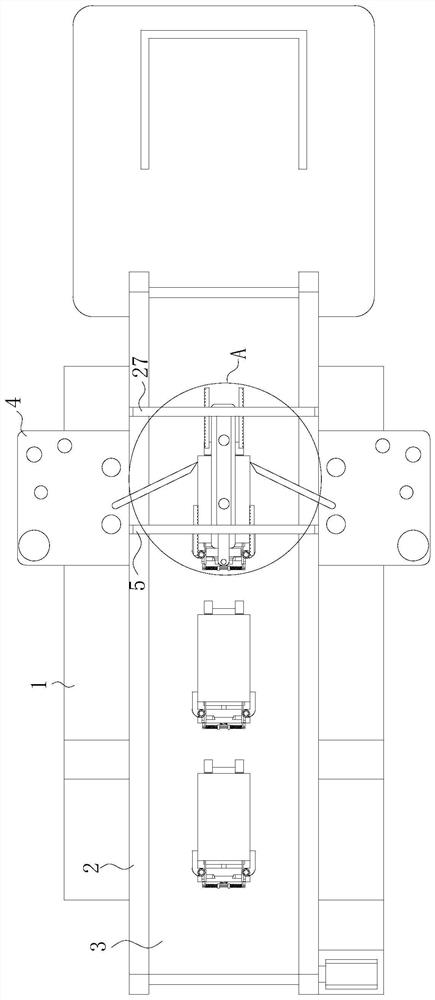

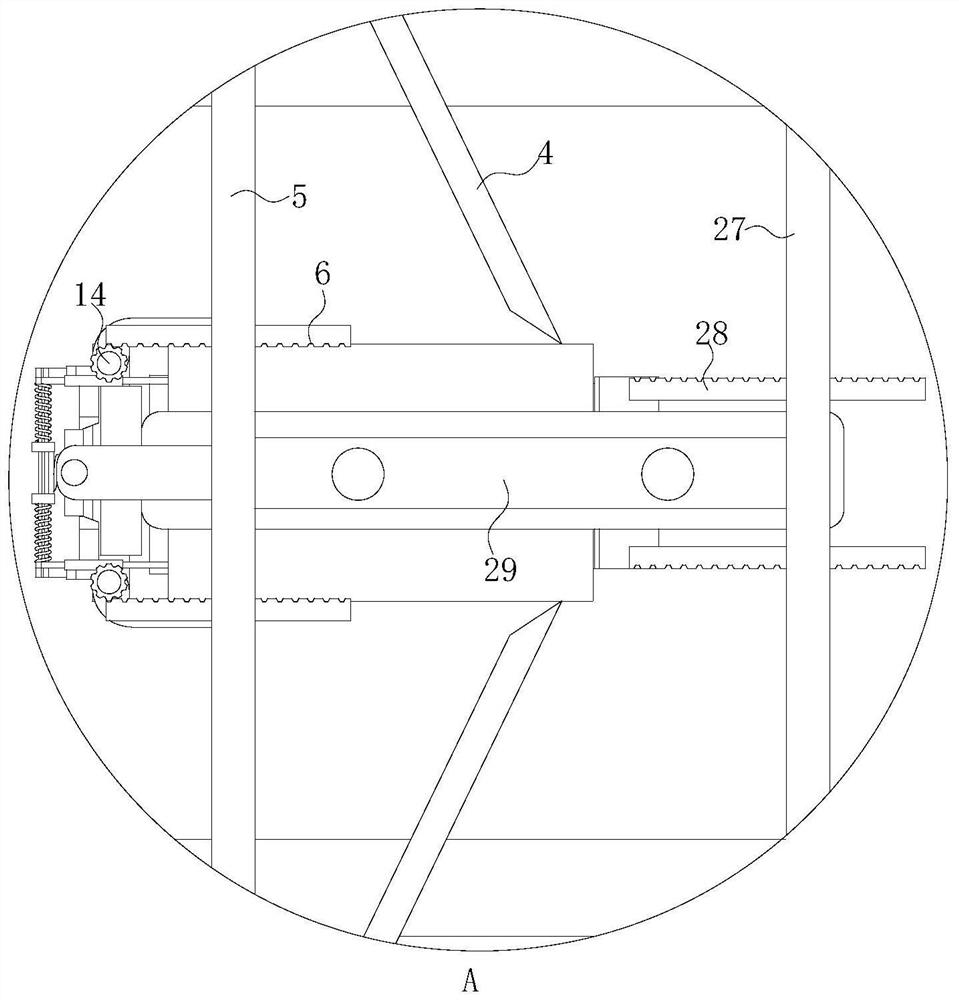

Adjustable cutting equipment for plate processing

ActiveCN114290080AAvoid meshingFeeding apparatusLarge fixed membersEngineeringStructural engineering

The invention relates to adjustable cutting equipment, in particular to adjustable cutting equipment for plate processing. According to the adjustable cutting equipment for plate machining, the cutting position of a plate can be adjusted according to requirements, and the adjustable cutting equipment is convenient to use. Adjustable cutting equipment for plate processing comprises a base, placing frames, guide rails and the like, the placing frames used for placing plates are fixedly connected to the middles of the left side and the right side of the top of the base, and the guide rails are fixedly connected to the top of the base in a front-back symmetry mode. A plate is placed between the two containing frames, when the driving mechanism is pulled to move left and right to drive the cutting knife to move left and right to the position needing to be cut through the reset mechanism, pulling of the driving mechanism is stopped, the driving mechanism is started to drive the cutting knife to move front and back through the reset mechanism, and the reset mechanism enables the cutting knife to move downwards intermittently; and the cutting knife moves downwards and moves front and back to cut the plate, so that the cutting position of the plate can be adjusted according to requirements, and convenience is achieved.

Owner:SHANDONG HONGXING NEW MATERIAL TECH CO LTD

Double-side labeling machine for packaging

The invention discloses a double-side labeling machine for packaging, and belongs to the technical field of double-side labeling machines. The double-side labeling machine for packaging comprises a rack, two first fixed plates are fixedly connected to the top of the rack, and a conveying belt is jointly in transmission connection between the two first fixed plates. According to the double-side labeling machine for packaging provided by the invention, when double side faces of a carton are labeled every time, the periphery of the carton is positioned at the accurate labeling position through a positioning mechanism and a pressing mechanism, the carton is prevented from deviating in the conveying process, the pressing mechanism is used in cooperation to press an L-shaped clamping block to clamp the carton, it is guaranteed that a first rack can drive a first gear and the L-shaped clamping block to rotate every time, the L-shaped clamping block is completely separated from the side wall of the carton and is matched with a front labeling device and a rear labeling device to label at the same time, when the L-shaped clamping block is separated, the accuracy of the front position and the rear position of the carton can still be kept, the L-shaped clamping block is prevented from making contact with the labeling machine, the labeling machine is protected, and the requirement for labeling the whole side wall of the carton can be met.

Owner:东莞市欧尚自动化设备科技有限公司

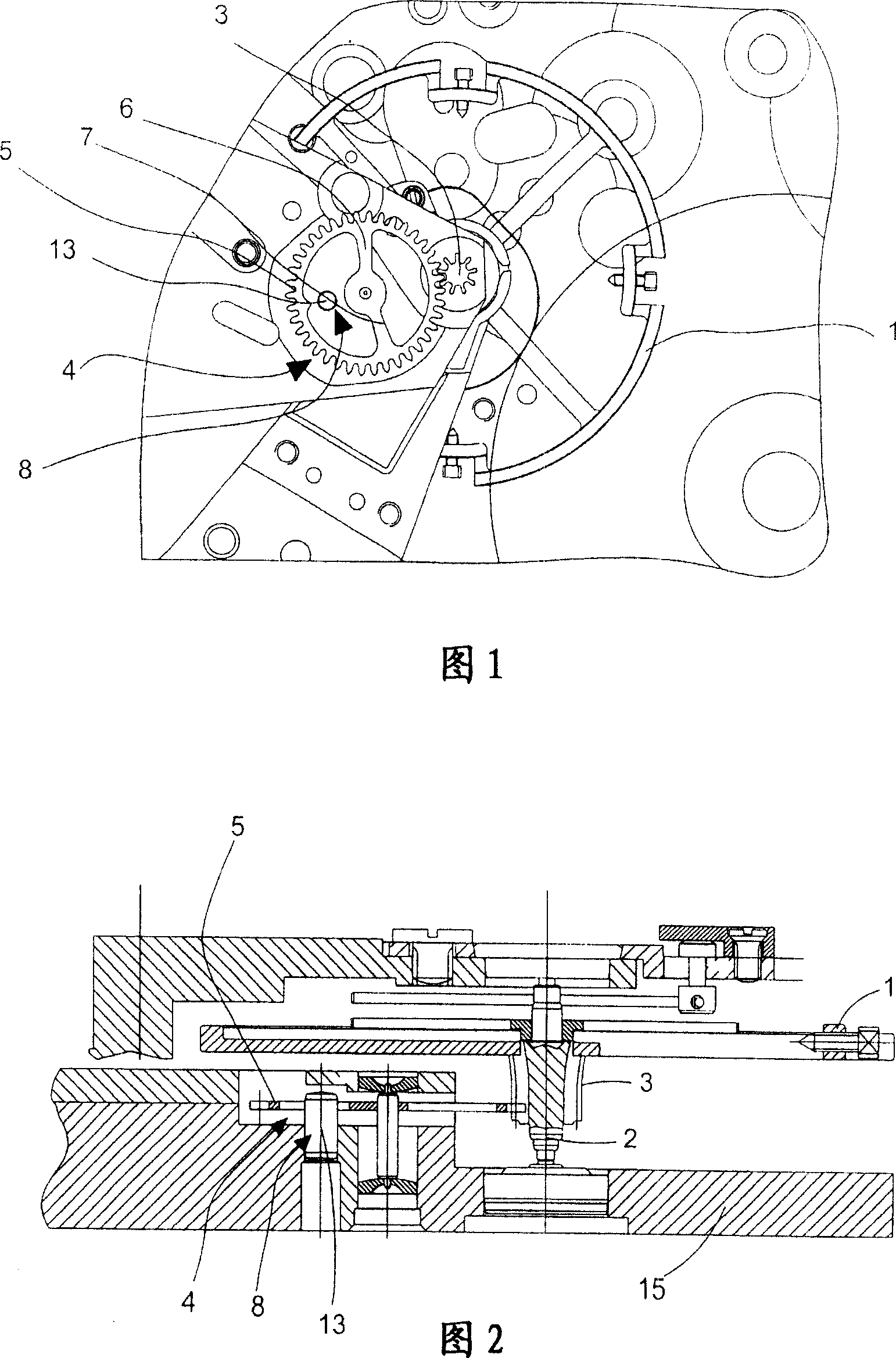

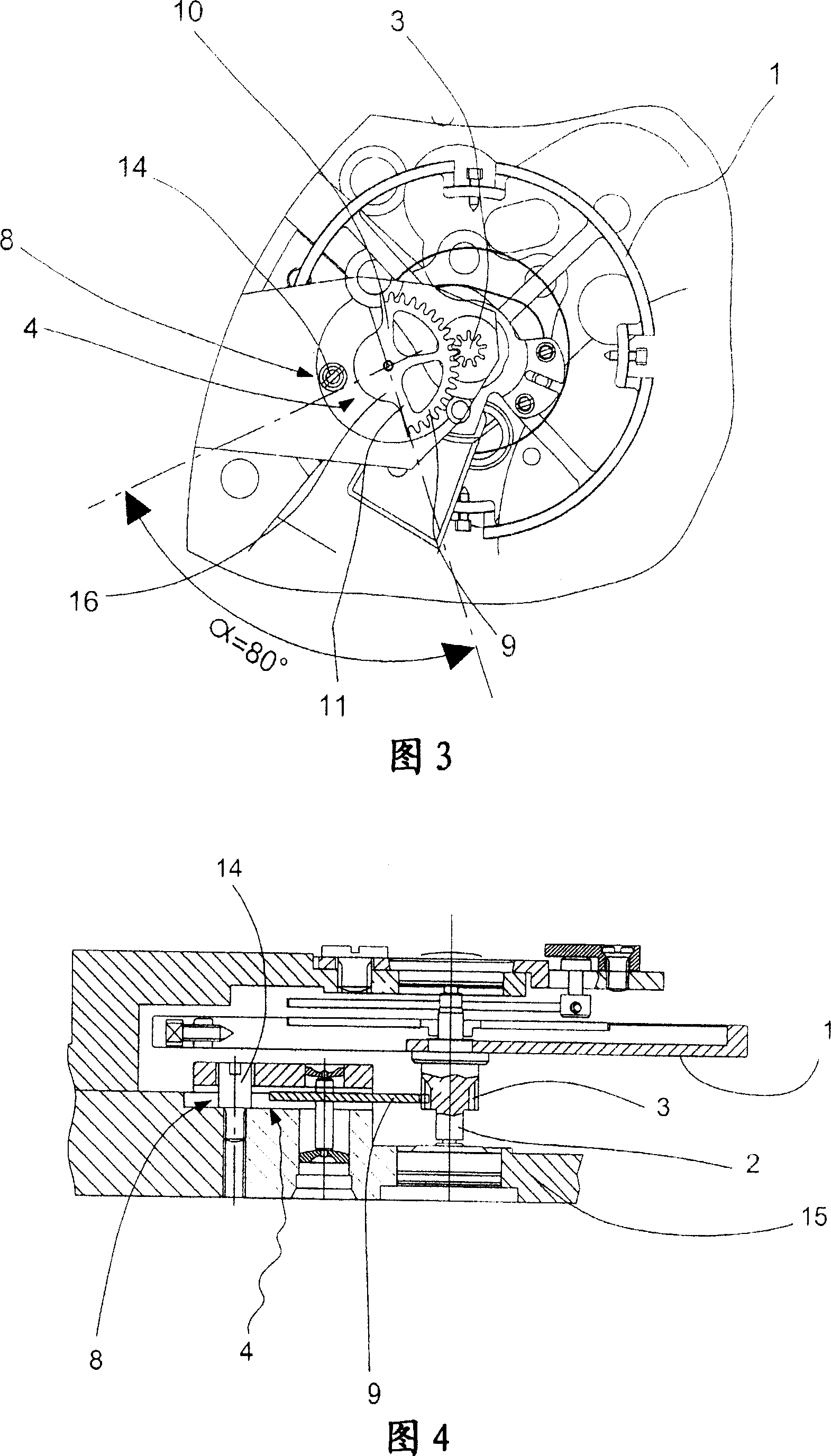

Anti-tripping device for timepiece escapement

The anti-trip device for a timepiece escapement essentially includes a sprung balance ( 1 ), this device preventing the angular extension of said balance beyond a normal angle of rotation. The device is characterized in that the arbour ( 2 ) fitted to the balance ( 1 ) is provided with a pinion ( 3 ) meshing with means ( 4 ) preventing said balance from rotating beyond said normal angle of rotation, whatever the direction of said rotation.

Owner:MONTRES BREGUET

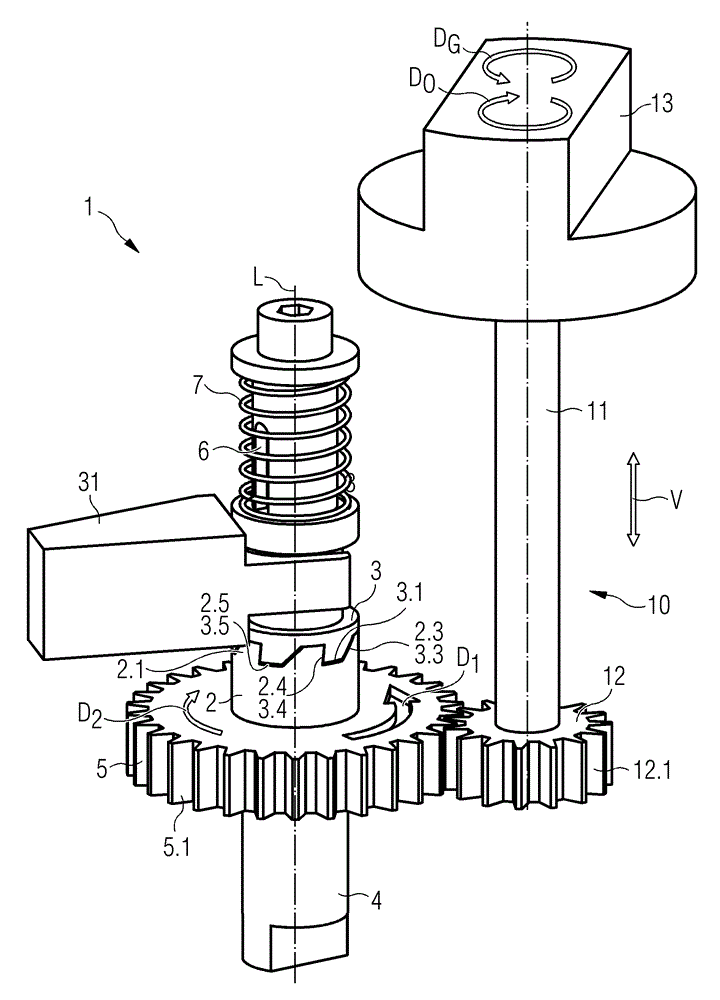

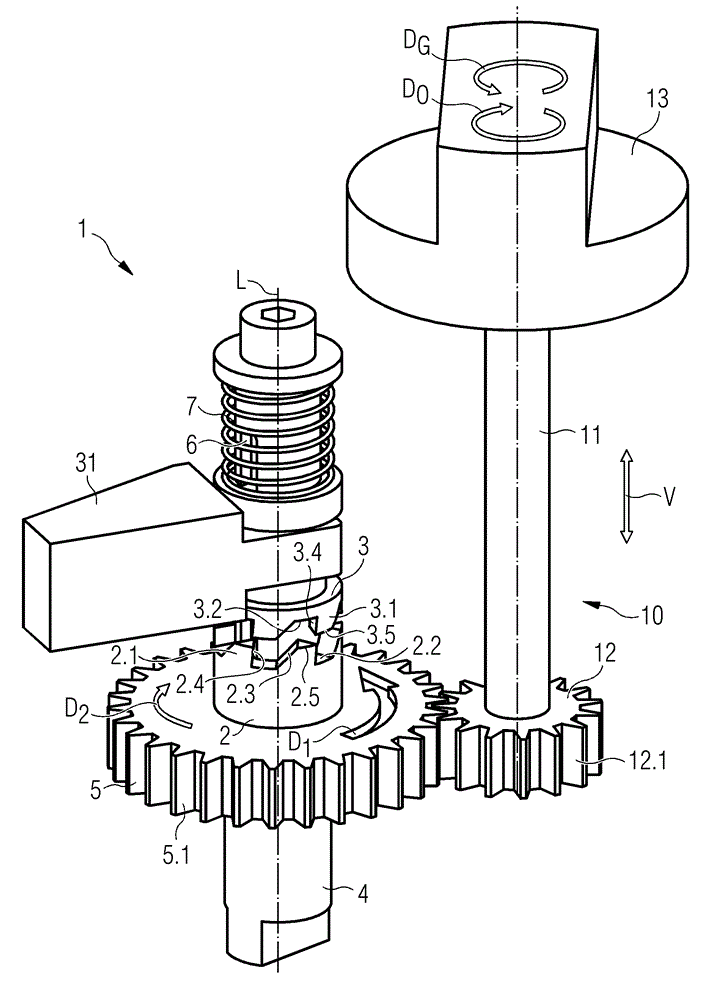

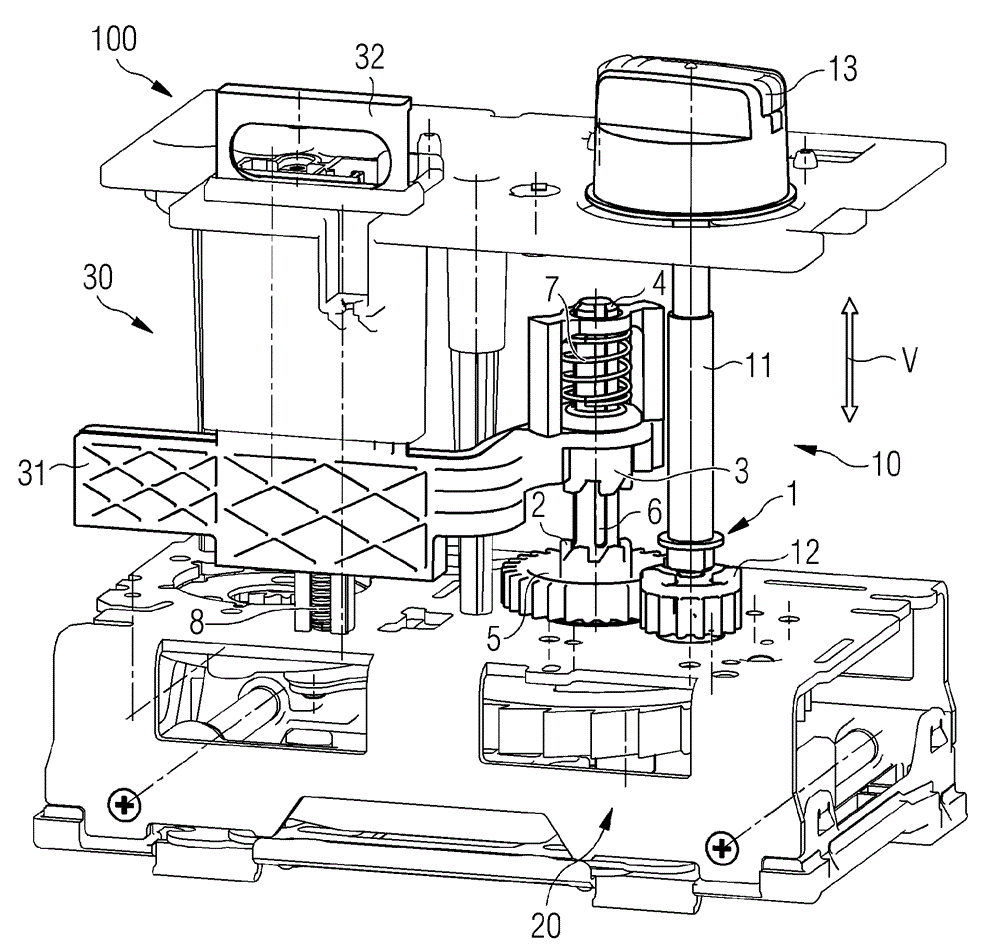

Transmission device for a compact circuit breaker for the transfer of torque and actuating means of a compact circuit breaker

InactiveCN105023778AAvoid meshingHandy deliveryContact driving mechanismsProtective switch operating/release mechanismsDrive shaftEngineering

The present invention relates to a transmission device for circuit breakers for transmitting a torque from a manually operated manually activate, deactivate and / or induction of actuating means on a driven transmission shaft to activate, deactivate and / or induction of the compact circuit breaker, wherein the transmission device includes the drive shaft and at least two transmission devices meshed together, and the first transmission device the first rotatable drive shaft is arranged in the delivery device and the second transmission connects with the drive shaft during transmitting the torque and is movable relative to the first transmission is arranged in a trennposition. The present invention also relates to a operating gear to enable, disable and / or cause a compact circuit breaker and circuit breakers.

Owner:SIEMENS AG

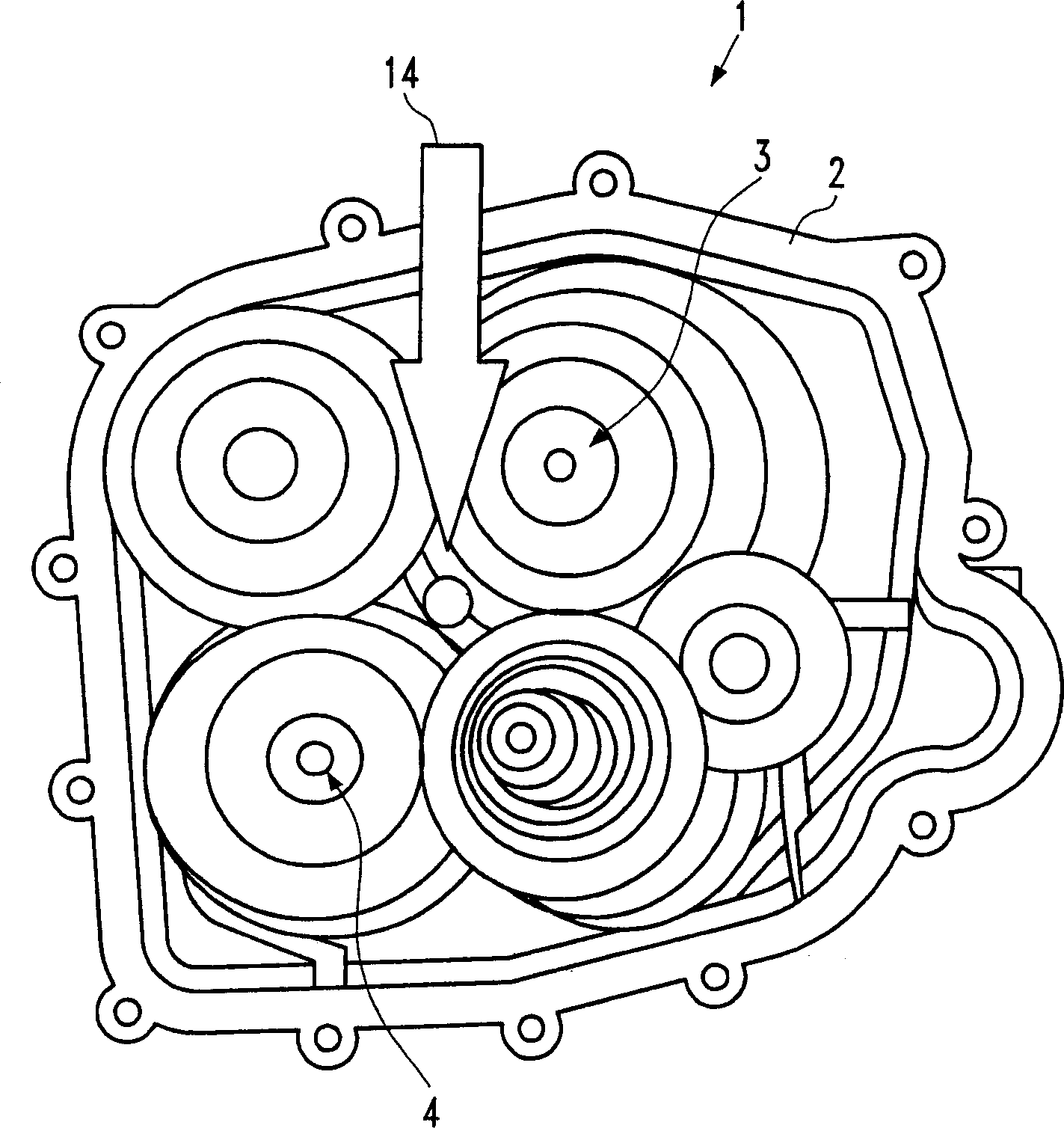

Gear-change device

InactiveCN1900560AAvoid meshingPrevent wrong gear changesGearboxesGearing controlAxial displacementGear wheel

The present invention relates to a gear-change device ( 1 ) comprising a transmission housing ( 2 ), at least two neighboring gear shafts ( 3, 4 ) arranged in the transmission housing, and a respective gear-change sleeve ( 5, 6 ) per gear shaft ( 3, 4 ), wherein at least one locking element ( 7; 8 ) is arranged on a guide means ( 9 ) supported on the transmission housing ( 2 ), and by displacement of one ( 5 ) of the gear-change sleeves ( 5, 6 ) the respectively other one ( 6 ) of the gear-change sleeves ( 5, 6 ) is locked against an axial displacement on the gear shaft ( 4 ) thereof out of the neutral position.

Owner:HOERBIGER DRIVETRAIN MECHATRONICS B A

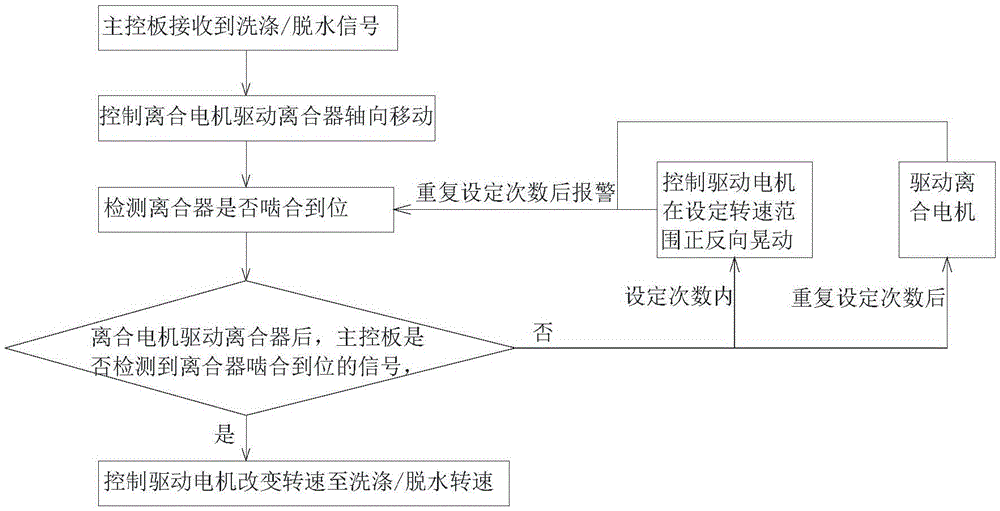

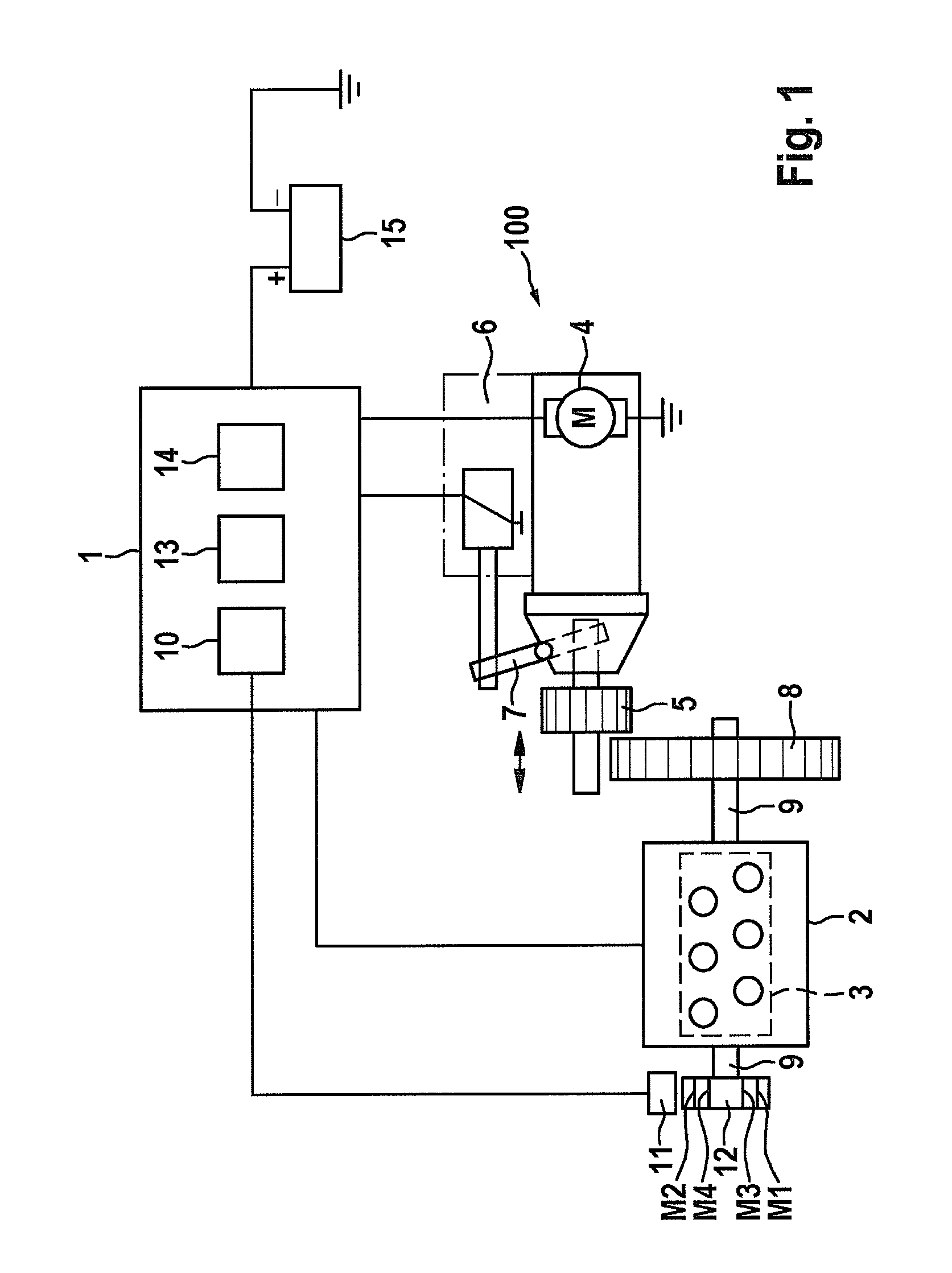

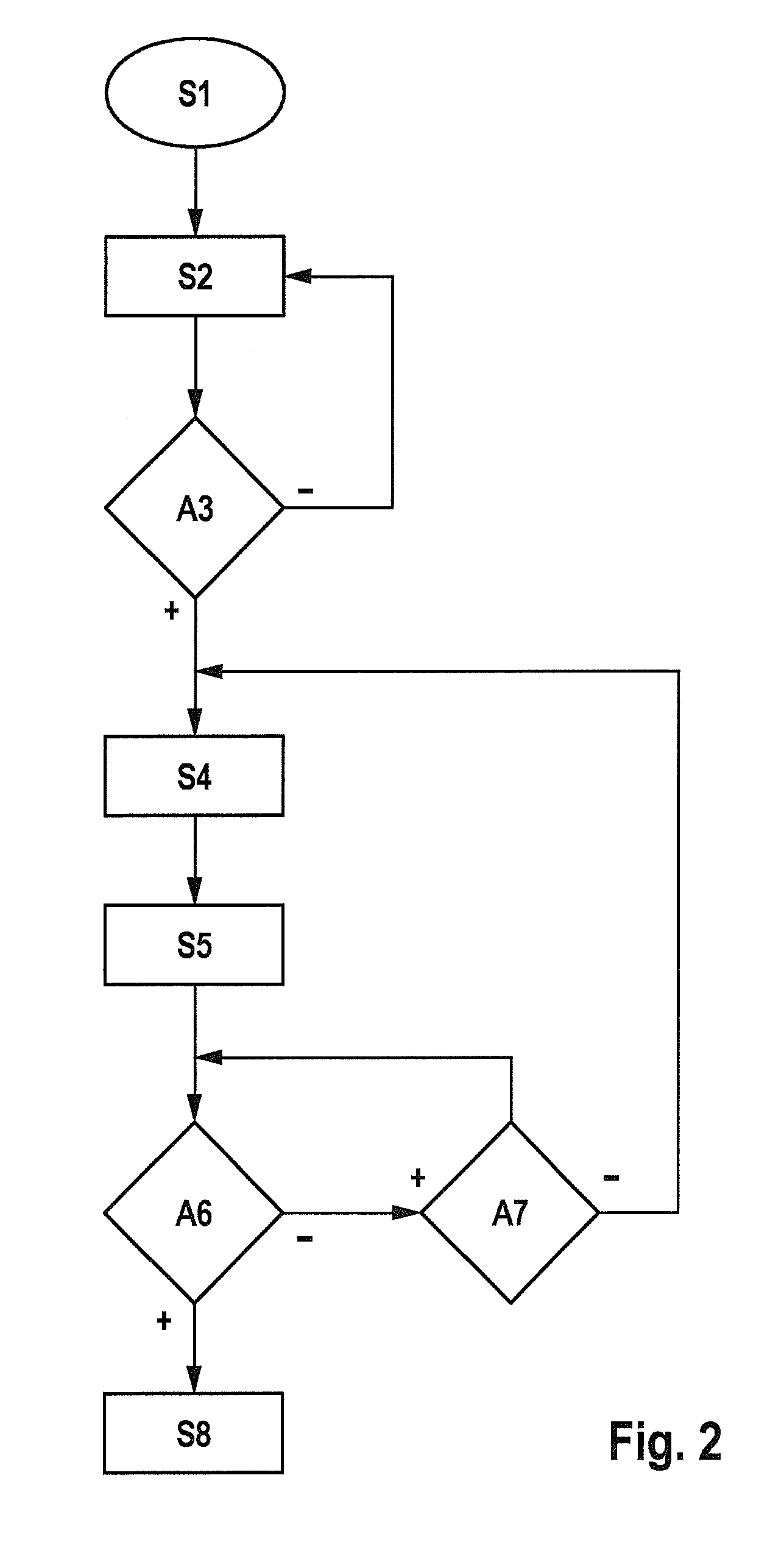

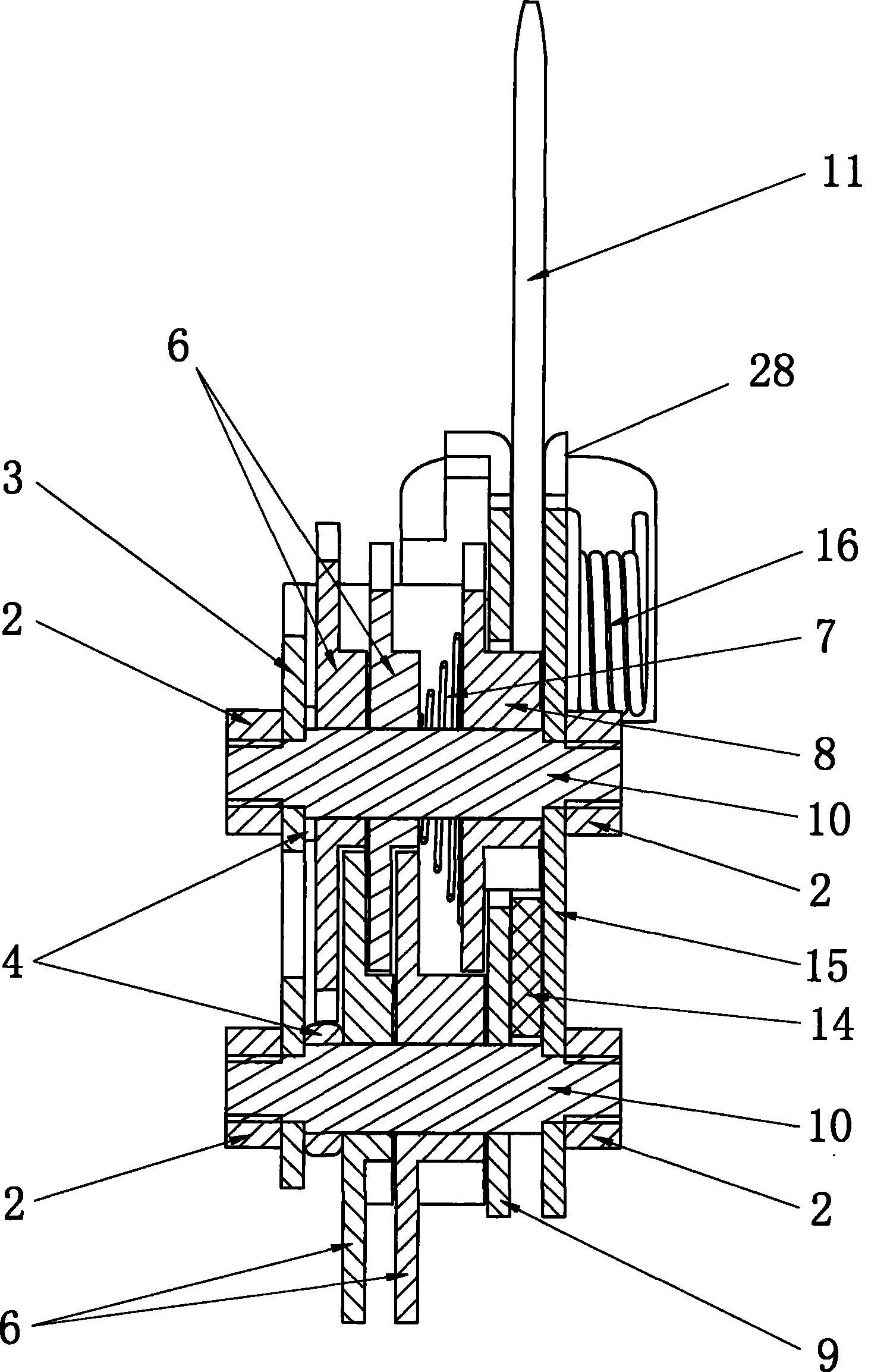

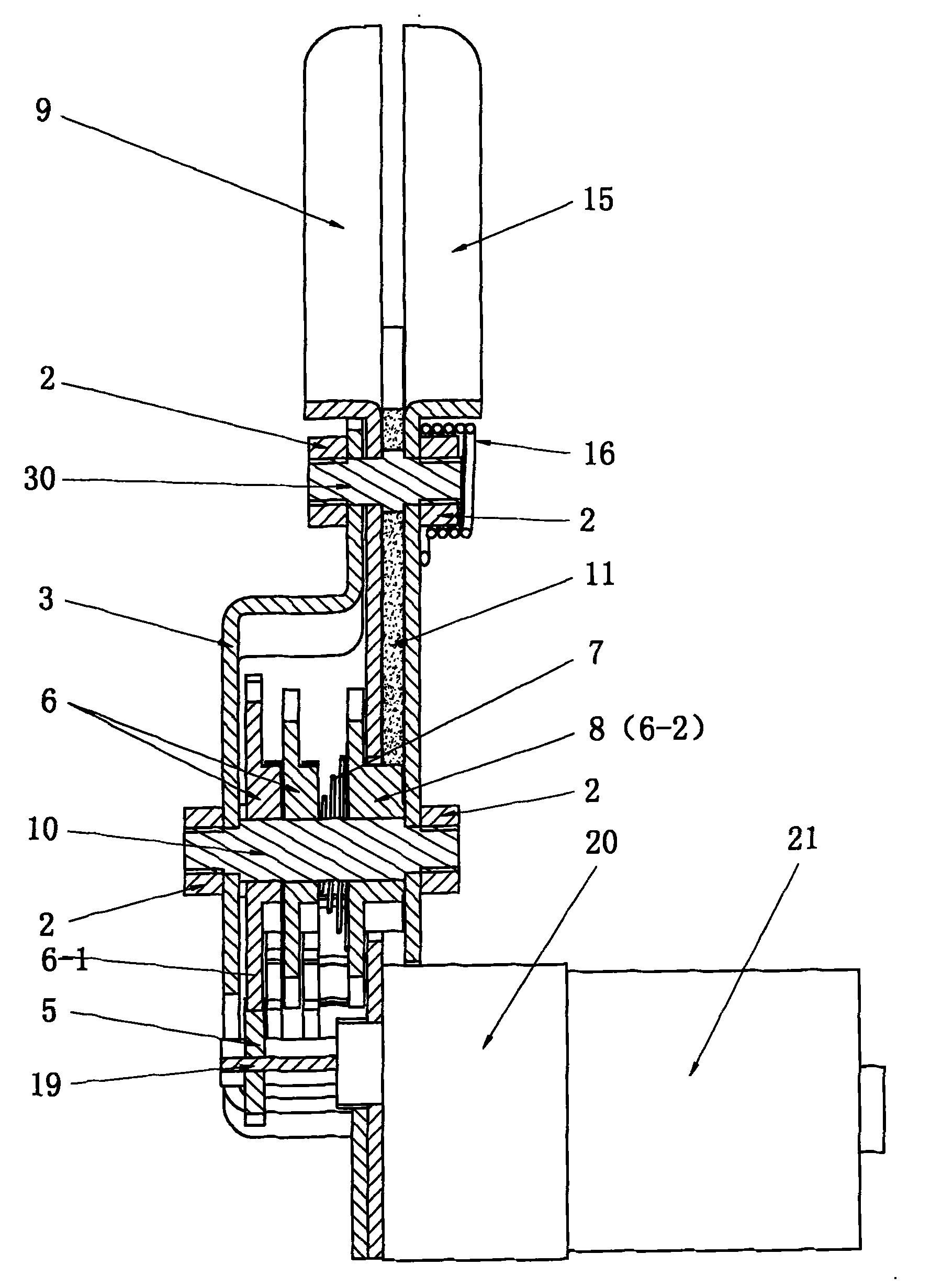

Washing machine speed reducing clutch control method, speed reducing clutch and washing machine

ActiveCN106592163AAvoid meshingOther washing machinesTextiles and paperClutch controlReciprocating motion

The invention relates to a washing machine speed reducing clutch control method, a speed reducing clutch and a washing machine. The control method includes that step 1, a mainboard receives a washing or dewatering signal, and a clutch motor is controlled to drive a clutch to move axially; step 2, whether the clutch is meshed in place or not is detected, after the clutch motor runs in place, if a signal indicating that the clutch is meshed in place is detected by the mainboard, a driving motor is controlled to change rotating speed to washing or dewatering rotating speed, and if the signal indicating that the clutch is meshed in place is not detected by the mainboard, the driving motor is controlled to be in forward-backward reciprocating motion within a set rotating speed range to promote meshing of the clutch.

Owner:HEFEI HAIER WASHING MACHINE

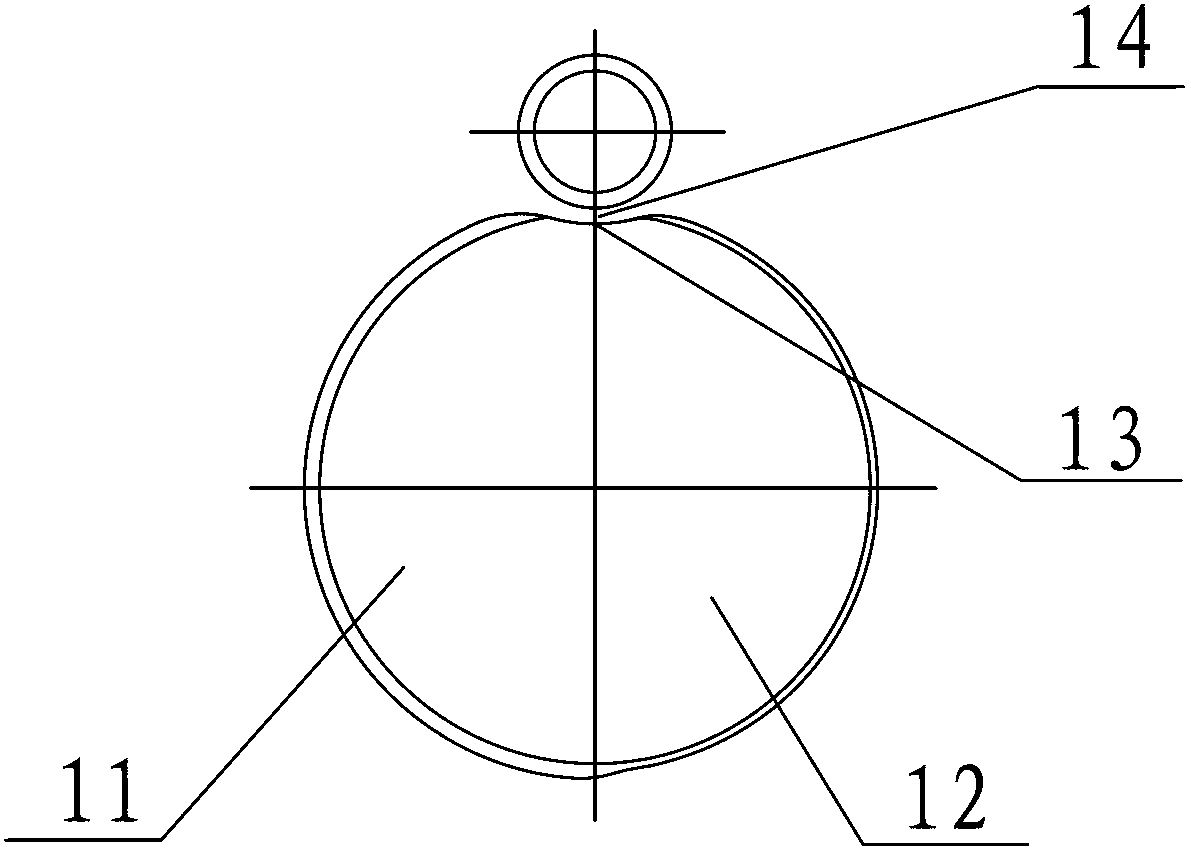

Automatic rib rolling machine

The invention relates to a rib rolling machine, and in particular relates to an automatic rib rolling machine which belongs to the field of manufacturing of filter devices. The automatic rib rolling machine is characterized in that a first transmission shaft (4) and a second transmission shaft (7) are fixedly arranged through fixed plates (6) installed on a base (5); the end, far from a second gear (8), of the second transmission shaft (7) is connected with a convex die (9), and the end, far from a first gear (3), of the first transmission shaft (4) is connected with a concave die (10); and the convex die and the concave die correspond to each other. The concave die is in a secondary advanced cam-like structure. With the adoption of a motor, through gear reduction, the two transmission shafts drive the convex and concave dies to rotate, and manual regulation is replaced by changing the radius of the concave die. In the anticlockwise rotating process, the convex and concave dies pass through a first semi-circle and a second semi-circle in sequence, a workpiece is prevented from being torn due to excessive rolling at one time. The two transmission shafts are fixedly arranged, so that the gear engagement problem is effectively avoided, the time is saved, and the labor intensity of workers is greatly reduced.

Owner:ZIBO YONGHUA FILTERS MAKE

Caster comprising a running wheel

A caster includes a running wheel, a fork and an assembly journal, wherein the fork is pivotable in relation to the assembly journal and a braking device is arranged in the fork and can be displaced into the braking position via a tappet actuated by a trip cam. A direction lock can be set without a braking action on the running wheel. Two tappets are movable independently of each other, wherein only the direction lock without a braking action can be set via one of the tappets. Another caster includes a running wheel, a fork and an assembly journal, wherein a braking device is provided in the fork and can be displaced into the braking position via a trip cam. The braking device has a first braking part for friction-locking action on the running wheel and a second braking part for the interlocking lock of the running wheel.

Owner:TENTE

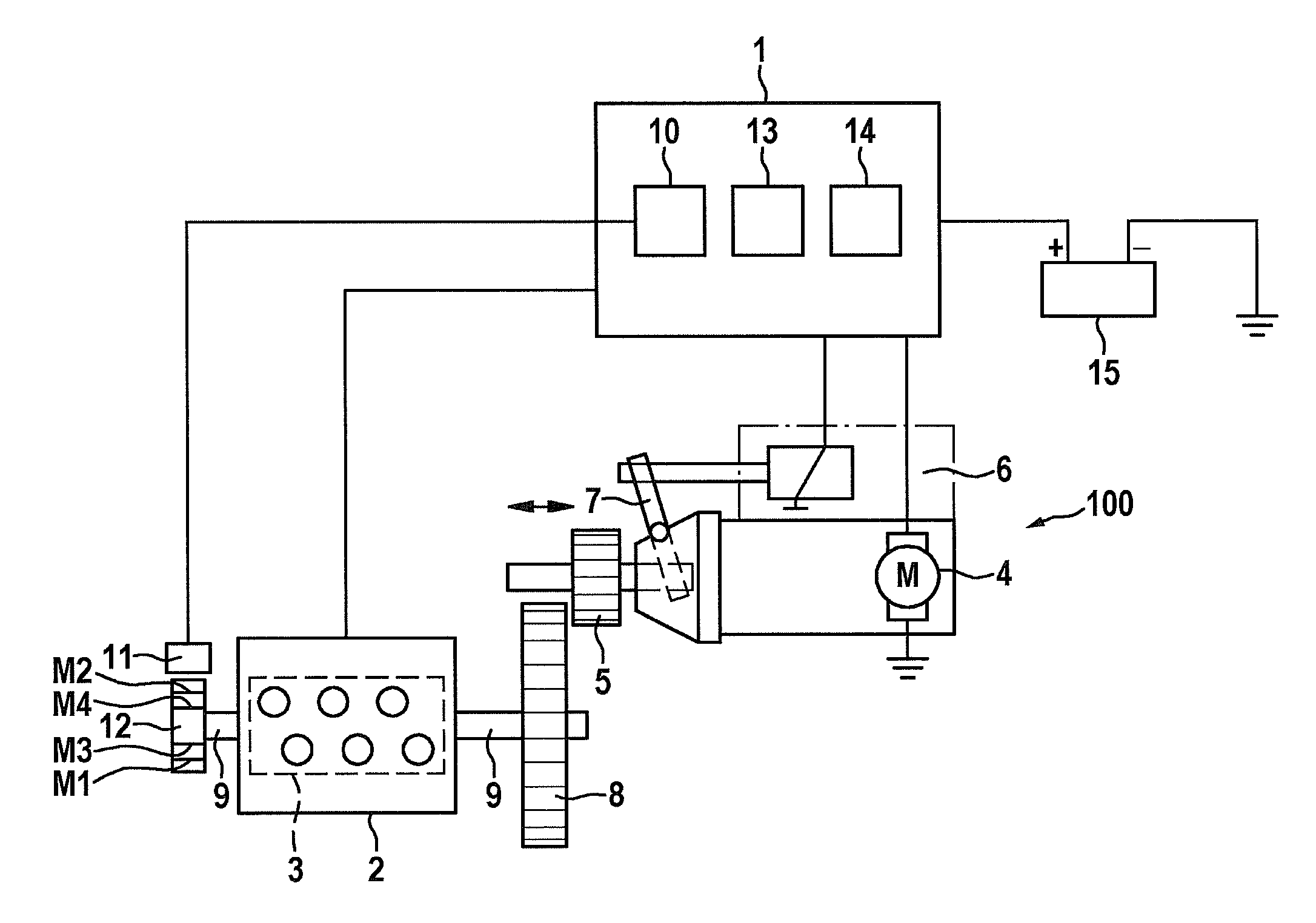

Control system and method for detecting the rotational speed of an internal combustion engine

InactiveUS9170176B2Improve accuracyLow sectionVehicle testingInternal-combustion engine testingSignal onExternal combustion engine

Owner:SEG AUTOMOTIVE GERMANY GMBH

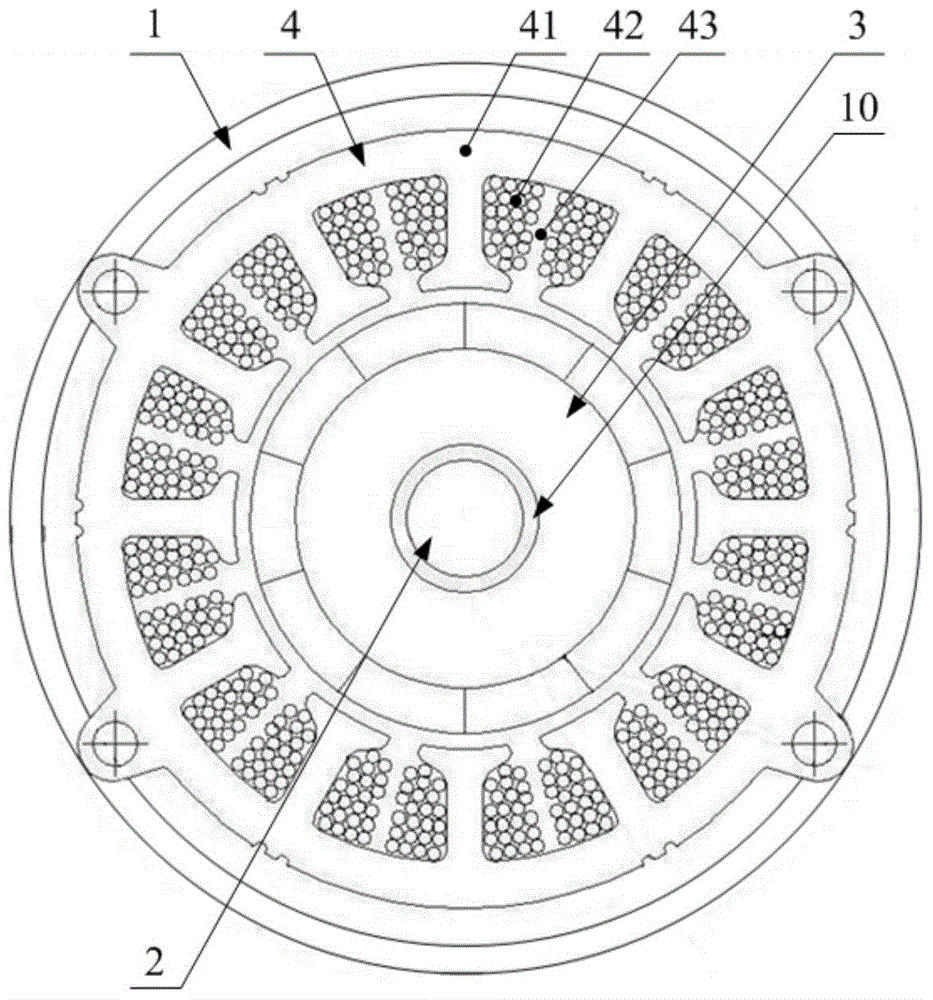

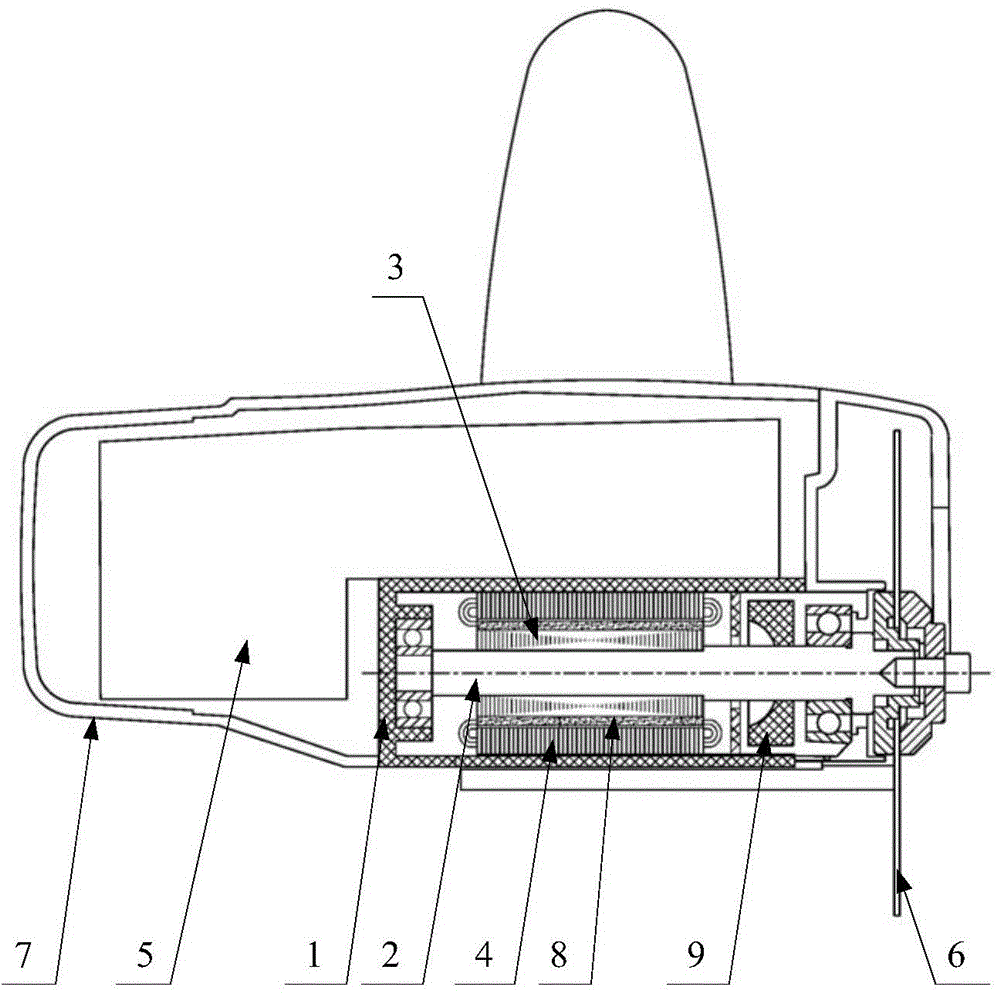

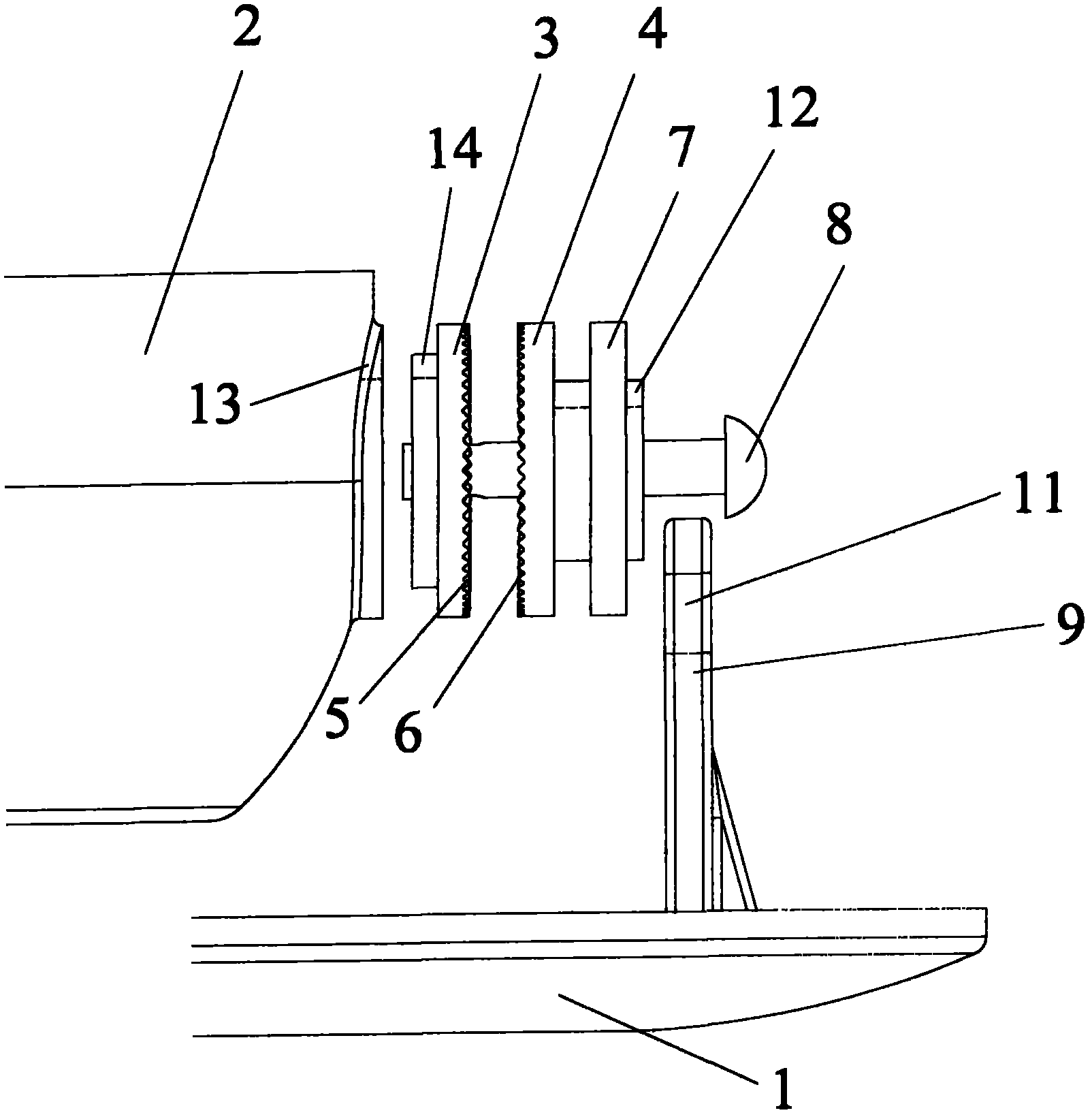

Marble cutting machine

InactiveCN105437160AAvoid meshingReduce noiseMagnetic circuit rotating partsPortable grinding machinesBrushless motorsDrive shaft

The invention discloses a marble cutting machine comprising a housing (7) and a motor casing (1) arranged in the housing (7) and fixed on the side wall of the housing (7); a high power density brushless motor is arranged in the motor casing (1), and a controller (5) thereof is arranged in the housing (7); the high power density brushless motor comprises a rotor shaft (2) arranged in the motor casing (1) in a rotary manner; the rotor shaft (2) is coaxially arranged with a drive shaft of a marble cutting blade (6) of the marble cutting machine so as to form an integrated structure; the axis of the rotor shaft (2) is perpendicular to the plane on which the marble cutting blade (6) is located, and penetrates the center of the marble cutting blade (5). The marble cutting machine can prevent carbon dust generation and environment pollution, can improve life and reduce energy cost, can improve output efficiency and reduce noises and vibration, can prevent transmission gear engagement installation complexity, can reduce size and weight, and the marble cutting machine can be conveniently assembled.

Owner:ZHEJIANG LVDONG MOTOR TECH CO LTD

Disc type overload protection anti-impact speed reducer

The invention relates to a disc type overload protection anti-impact speed reducer. The disc type overload protection anti-impact speed reducer comprises a box body, a worm wheel, an output shaft anda worm. A hollow shaft cavity is formed in the input end of the worm, the outer circumference of the hollow shaft cavity is supported on the box body through a bearing, the outer end of an input shaftis supported on the box body through a bearing, the inner end of the input shaft is coaxially rotationally supported in the hollow shaft cavity through a shaft sleeve or a bearing, multiple parallelcopper friction plates penetrate through the inner wall of the hollow shaft cavity through splines, multiple parallel steel friction plates penetrate through the input shaft through splines, the copper friction plates and the steel friction plates are sequentially attached alternately, an opening of the hollow shaft cavity is in threaded screwed connection with a pressure adjusting nut penetratingthrough the input shaft, and a disc spring abuts against the position between the inner end of the pressure adjusting nut and the steel friction plate or the copper friction plate at the outermost end. The disc type overload protection anti-impact speed reducer is compact in structure and convenient to adjust, protection of input impact and drive overload can be effectively taken into consideration, and the service safe life of the structure is guaranteed.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

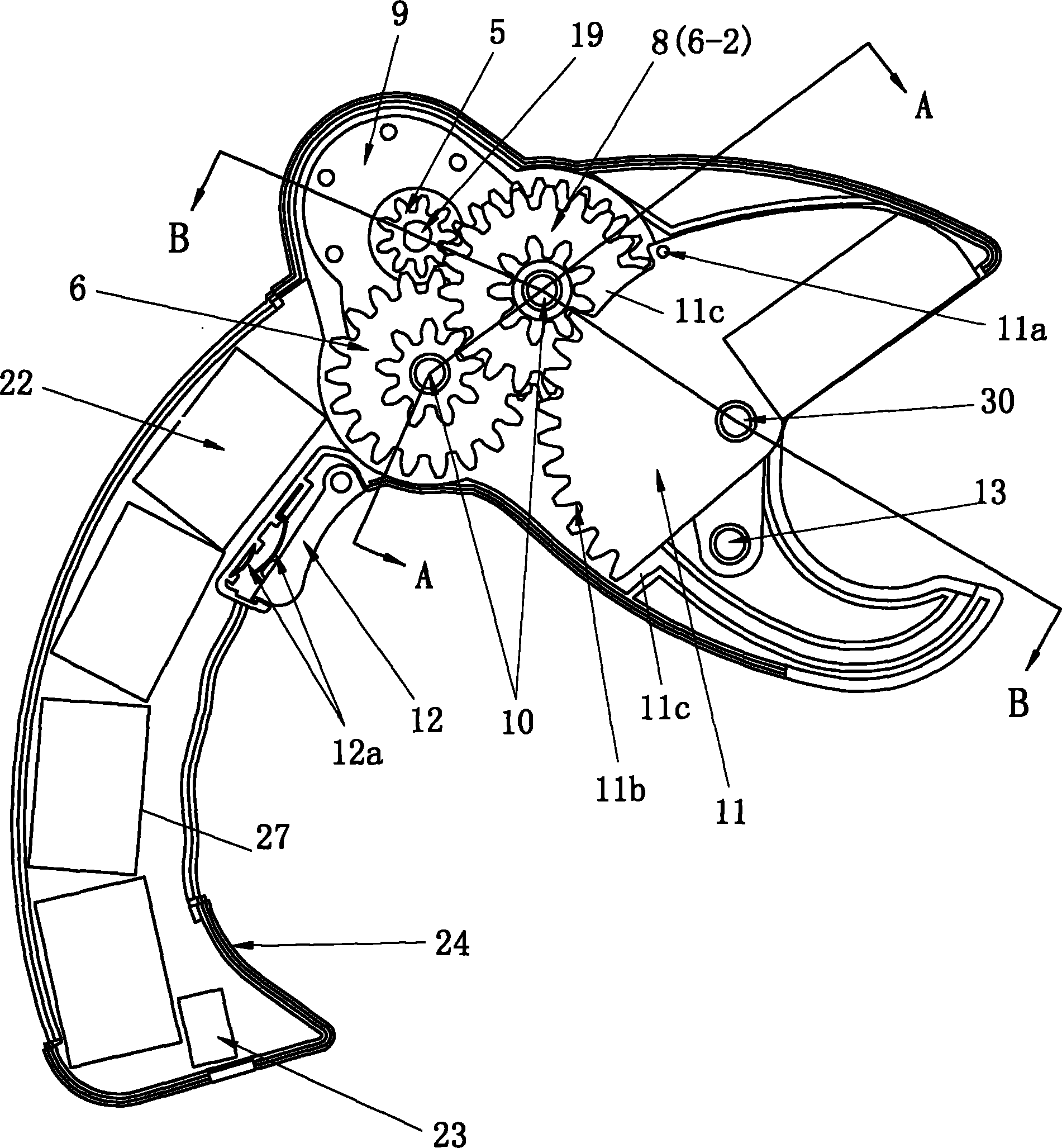

Quick retracting device in plastic tube cutting tool

The invention provides a quick retracting device in a plastic tube cutting tool. The device is characterized in that: the last gear of a transmission shifting mechanism in the electric cutter tool is a clutch gear, and is sleeved on a gear shaft and provided with a clutch spring capable of sliding the clutch gear left and right; correspondingly, the surface of a machine shell is provided with a button hole inside which a return button and a button spring are arranged; simultaneously, the side part of the return button is directly or indirectly contacted with the side surface of the clutch gear; when the return button is pressed down, the clutch gear is separated from the return button to be engaged with the local gear on the tail part of a cutter blade; and when the return button is released, the clutch gear is in engaged connection with the local gear on the tail part of the cutter blade, and the cutter blade is provided with a return elastic element capable of resetting the cutter blade. The device has the advantages of simple, practical and compact structure, small volume, and the realization of quick retraction of the cutter tool.

Owner:NINGBO JUFENG TOOLS IND

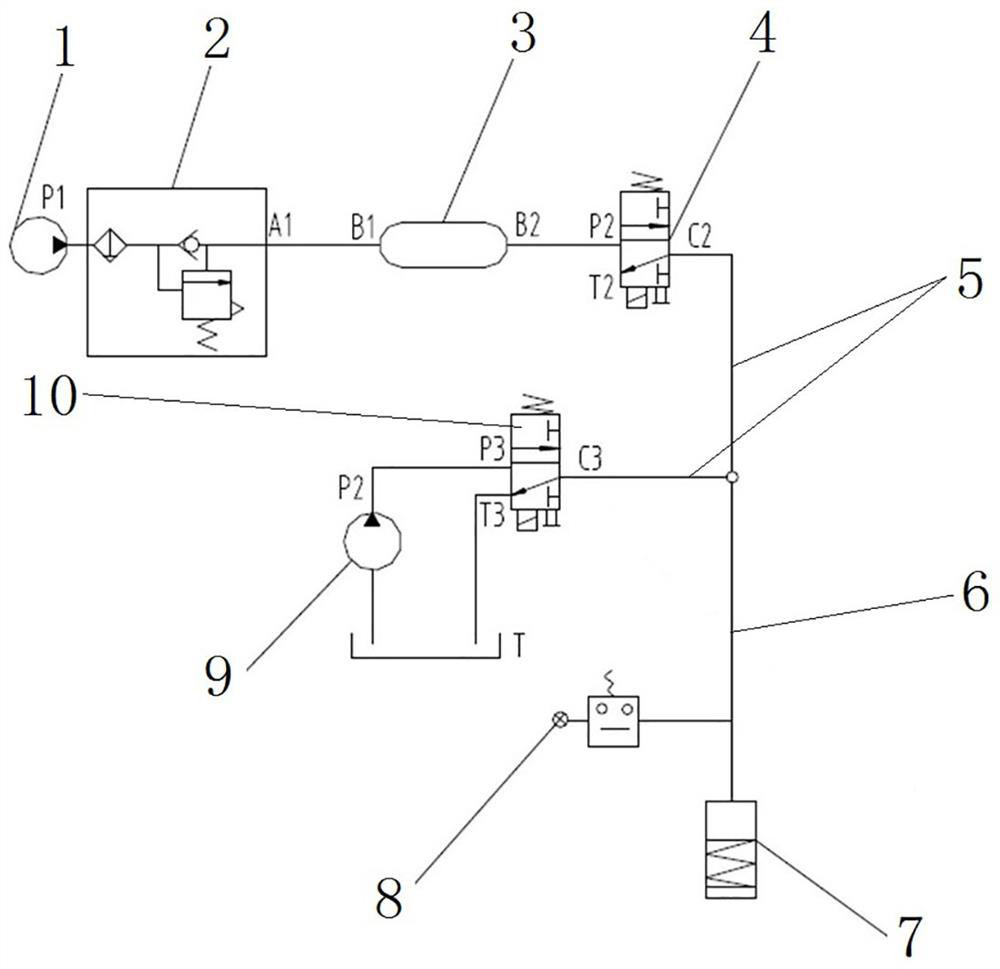

Dragging starting system and engineering equipment using same

ActiveCN113027655AAvoid meshingPower operated startersStarters with fluid-driven auxillary enginesGear wheelEngineering

The invention relates to a dragging starting system and engineering equipment using the same. The dragging starting system comprises an output gear, a dragging starting pump and a shifting fork, wherein a sliding gear is assembled on an input shaft of the dragging starting pump in a sliding mode; the shifting fork and the sliding gear are assembled together in a mode of relative rotation in the circumferential direction and relative fixation in the axial direction; the dragging starting system further comprises a piston cylinder and a piston driving mechanism, the piston cylinder comprises a cylinder body and a piston, and the telescopic end of the piston is fixedly connected with the shifting fork; the piston driving mechanism comprises an elastic piece and a fluid power source, and the elastic piece is used for driving the piston to move to a position where the sliding gear is meshed with the output gear; and the fluid power source is used for feeding fluid into the cylinder body so as to overcome the action of the elastic piece and enable the piston to move to a position where the sliding gear is separated from the output gear. According to the dragging starting system, meshing and separation of the sliding gear and the output gear can be completed only by controlling a valve structure, and the labor intensity is low.

Owner:ZHENGZHOU YUTONG HEAVY IND

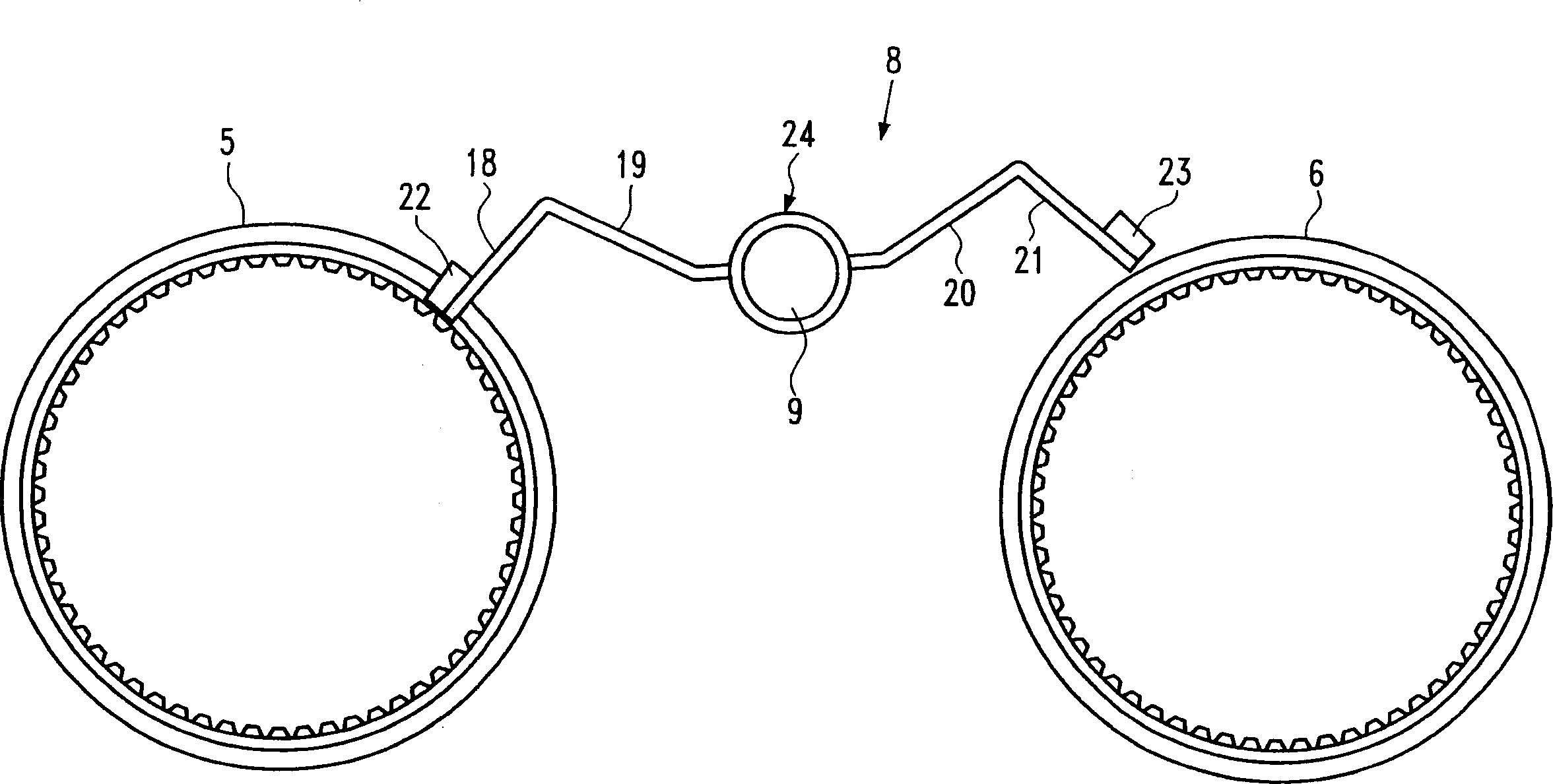

Rotatable fixing device and lighting equipment with same

InactiveCN102401355AExtended service lifeAchieve regulationLighting support devicesFixed installationEngineeringLight equipment

The invention relates to a rotatable fixing device for lighting equipment. The lighting equipment is provided with a fixedly arranged assembling ring (1) and a rotatable ring (2) which rotates relative to the assembling ring (1). The rotatable fixing device is provided with a first disc (3) which is connected with the rotatable ring (2) in an anti-torsion way and a second disc (4) which is connected with the assembling ring in an anti-torsion way, wherein the first disc (3) and the second disc (4) is respectively provided with a first tooth part (5) and a second tooth part (6). The locking of the rotating angle of the lighting equipment is realized through the engagement between the first tooth part (5) and the second tooth part (6), and the adjustment of the rotating angle of the lighting equipment is realized through the disengagement between the first tooth part (5) and the second tooth part (6). By using the rotatable fixing device, the lighting equipment can be reliably fixed at a preset illumination angle and the service life of the entire lighting equipment is not reduced when the times of angle adjustment are increased. Besides, the invention additionally relates to the lighting equipment with the rotatable fixing device.

Owner:OSRAM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com