Polycondensation kettle for falling film outside vertical tube

A technology of polycondensation reaction and tube arrangement, which is applied in the direction of pressure vessels used in chemical processes, can solve the problems that the reaction of high-viscosity materials cannot be carried out, and achieve the effects of uniform film formation, improved reaction efficiency, and increased film-forming area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

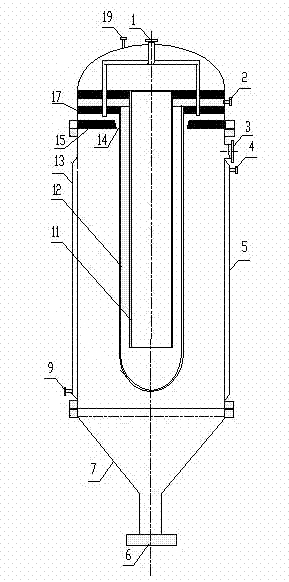

[0012] A falling film polycondensation reaction kettle with tubes and tubes, comprising: a vertical shell 13, a head and a cone 7 connected to the upper and lower ends of the vertical shell 13 respectively, and the feed port 1 and the heating medium inlet 19 are located at On the top of the head, the discharge port 6 is located at the bottom of the cone 7, and the vacuum port 3 is located on the upper part of the vertical shell 13; the feed port 1 is directly connected to the lower tube plate 15 and the middle tube plate 17 through the pipeline The material buffer zone is connected; the tubes 12 are located in the center of the vertical shell 13, and there is at least one tube 12, which is connected to the middle tube plate 17 and communicated with the heating medium outlet 2; between the tubes 12 and the lower tube plate 15 There is an annular gap 14 between them, and the milling teeth are evenly arranged at the film-forming part of the annular gap 14; the central tube 11 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com