Flexible measuring method for overflow particle size specification of ball mill grinding system

A measurement method, ball mill technology, applied in the direction of measurement devices, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of poor objectivity of measurement results, long feedback time of measurement results, and high price of particle size meters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

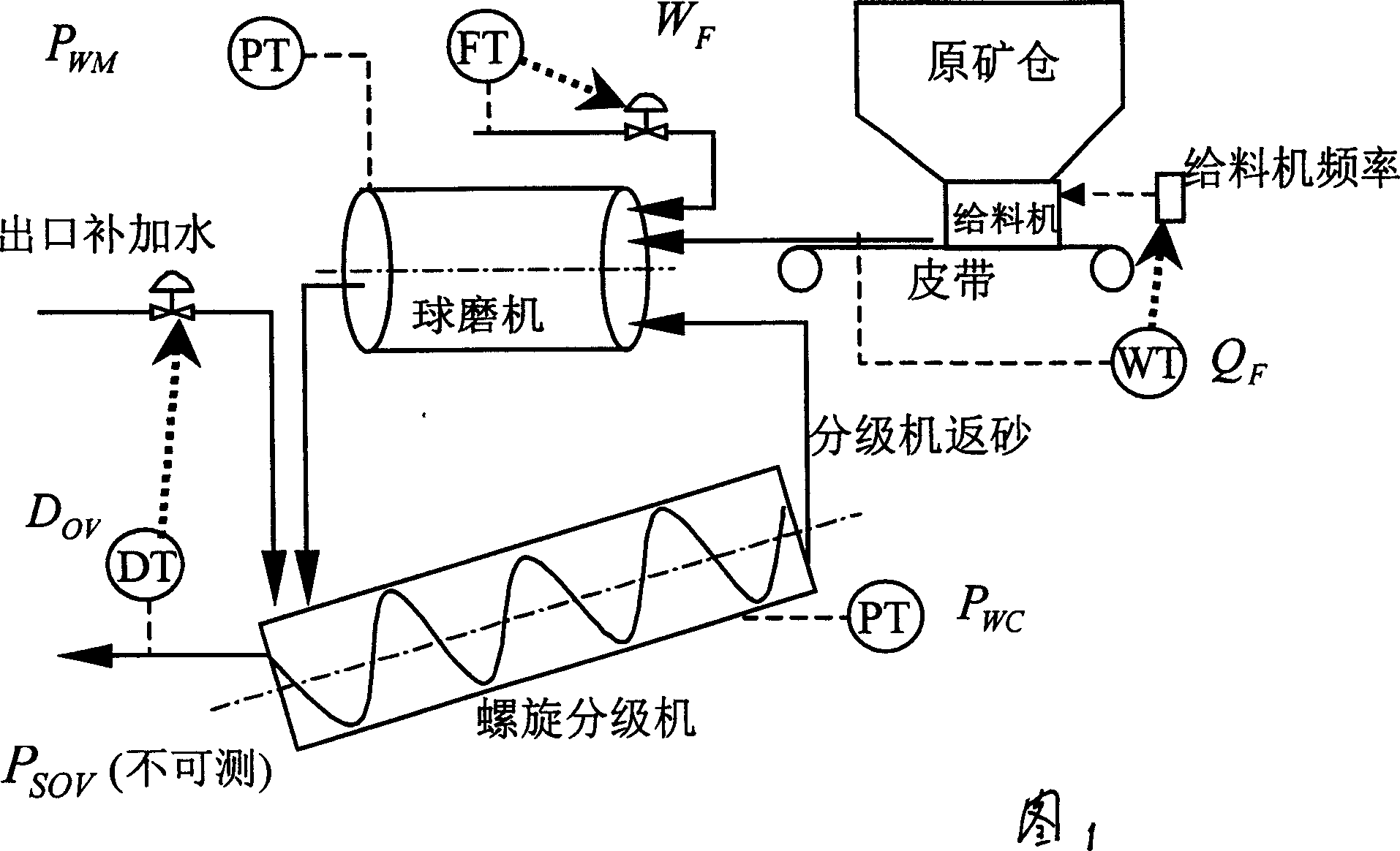

[0103] The embodiment of the present invention is a grinding series of the weak magnetic roasted ore of a large-scale iron ore concentrator. The main iron ores of this concentrator are pyrite and limonite, and the gangues are mainly barite, quartz, jasper and iron dolomite. The actual iron content of the ore is 33%. After sorting, the weak magnetic ore After the roasting process, it is transported to the weak magnetic separation cylinder silo. The schematic diagram of the grinding system is shown in Figure 1. The roasted ore in the weak magnetic separation cylinder silo is discharged by the electric vibration feeder, and then fed by the ore belt. The machine is sent into the ball mill, mixed with the additional water at the ball mill inlet, and ground into the ore pulp in the ball mill. This stage of grinding adopts a grid-type ball mill. Ball milling forms a closed circuit with primary ball milling. The overflow of the spiral classifier (that is, the final product of this pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com