Gantry fermented grain automatic loading machine and loading method

A gantry-type retort-loading technology, which is applied in the directions of conveyor, loading/unloading, transportation and packaging, etc. It can solve the problems of inability to simulate quantitative discharge, uniform distribution of materials, inability to judge the height of retort material surface, and affect the production cost of liquor, etc. problems, to achieve the effect of reducing equipment cost investment, improving the effect of retort, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

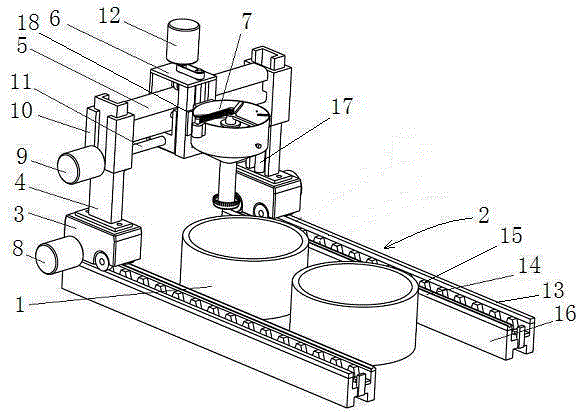

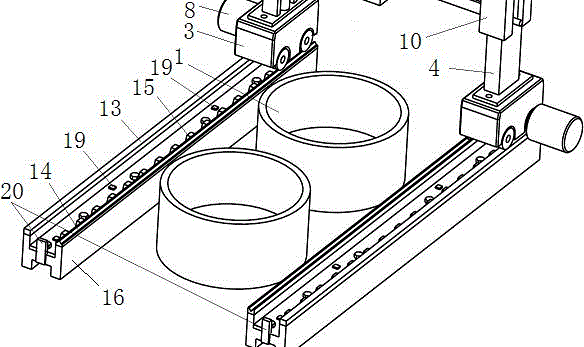

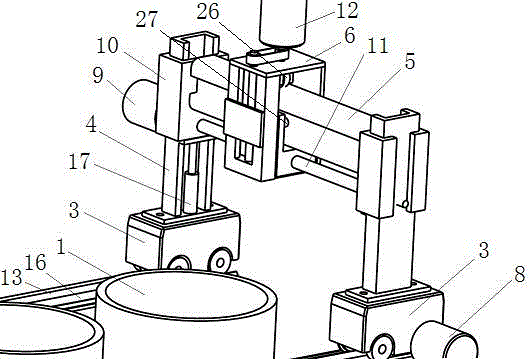

[0034] like Figure 1~5 A gantry-type automatic retort loading machine for wine fermented grains shown includes a gantry retort loading robot, a retort loading actuator 7, a binocular visual recognition system, and a control system composed of an industrial computer and a PLC programmable logic controller.

[0035]The gantry retort robot is composed of two horizontal guide rails 2, two columns 4, a beam 5 and a ram 6. The two guide rails 2 are respectively arranged on both sides of the retort bucket 1, and each guide rail 2 includes an H-shaped Base 16, the protrusions on both sides of the upper end surface of the base 16 are respectively provided with a flat guide rail 13 and a V-shaped guide rail 14, a rack 15 is provided in the groove on the upper end surface of the base 16, and a pulley 3 is provided at the lower end of the column 4 , the pulley 3 is equipped with wheels that cooperate with the flat guide rail 13 and the V-shaped guide rail 14 respectively, and a gear that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com