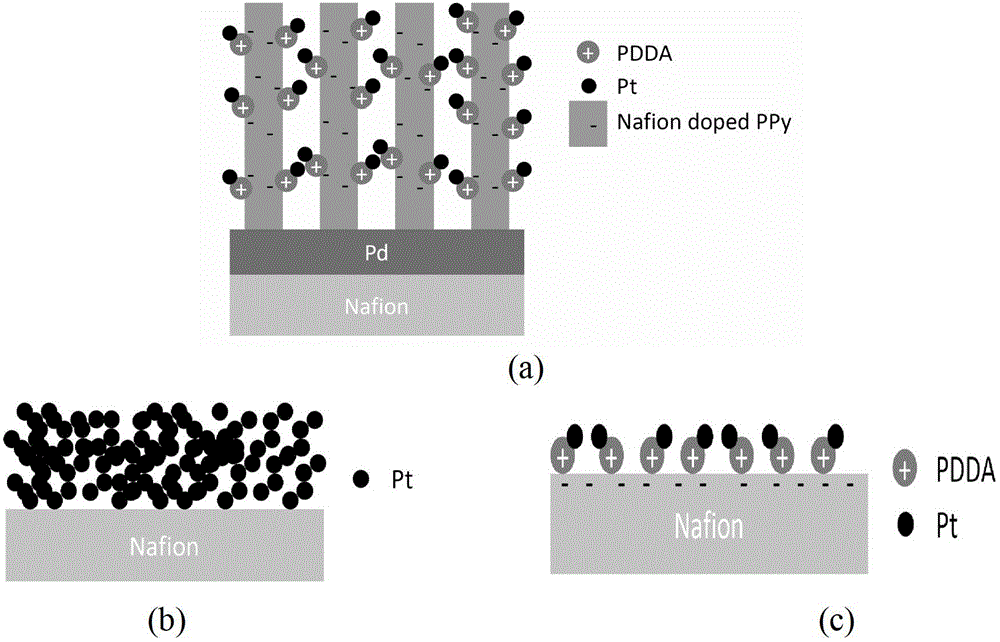

Novel ordering membrane electrode and preparation method and application thereof

A membrane electrode, electrodeposition technology, applied in battery electrodes, circuits, fuel cells, etc., can solve the problems of low overall performance and little practicality, achieve low catalyst loading, increase effective utilization area, fuel penetration low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

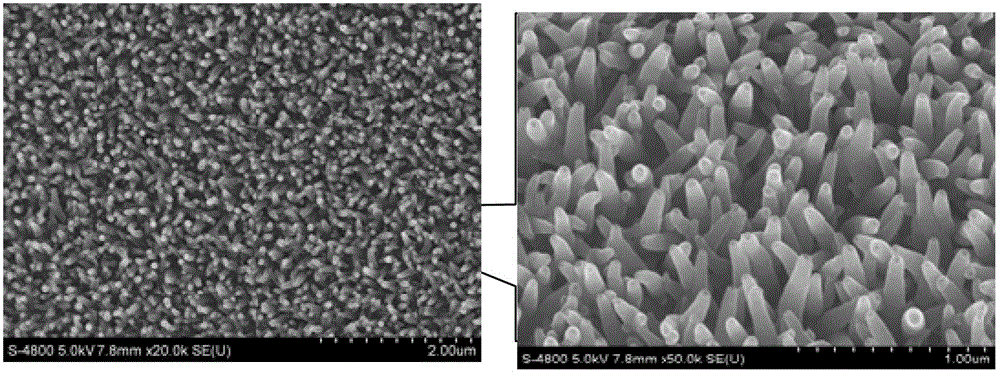

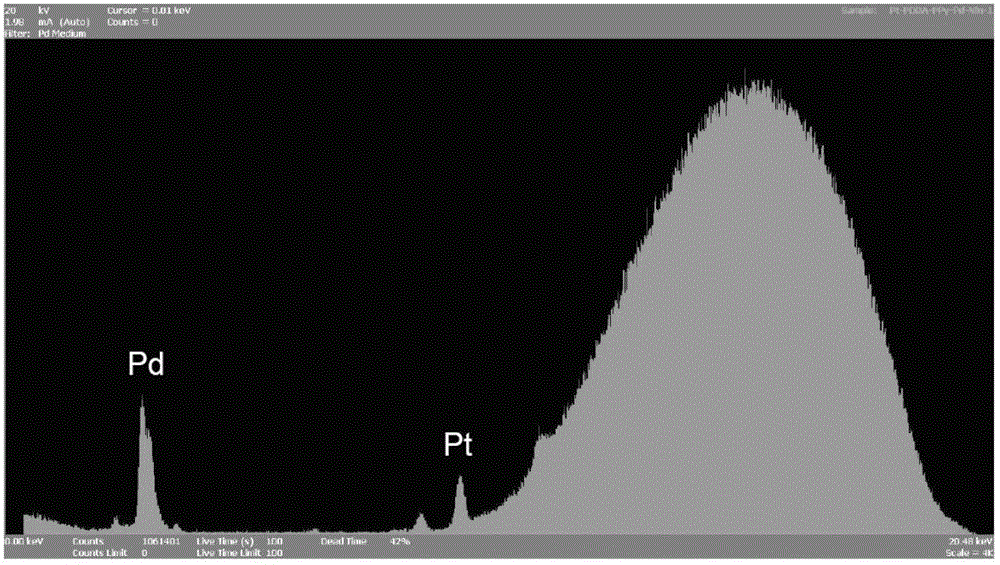

Embodiment 1

[0056] 1) Preparation of composite electrolyte membrane:

[0057] Will Membrane at 3wt.%H 2 o 2 solution, treated in a water bath at 80°C for 1 hour, rinsed with deionized water and placed in In the activation solution for 5min, take it out and rinse it with deionized water, then place it in After 5 minutes in the sensitization solution, take out the deionized water to rinse, and repeat the above steps 6 times. The surface prepared with highly active Pd core After filming, attach it to the surface of a piece of ABS plastic, and then cover it with an ABS plastic frame with a hollow in the middle, and the other side of the ABS plastic also covers a plastic frame with a closed bottom, and seal the two ABS plastics with PTFE waterproof material. space around the frame. Place the above device in the In the electroless plating solution, after 30 minutes, A uniform and firm metal Pd film is formed on the surface of the film, and the waterproof material is removed and th...

Embodiment 2

[0067] 1) Preparation of composite electrolyte membrane:

[0068] Will Membrane at 3wt.%H 2 o 2 solution, treated in a water bath at 80°C for 1 hour, rinsed with deionized water and placed in In the activation solution for 5min, take it out and rinse it with deionized water, then place it in After 5 minutes in the sensitization solution, take out the deionized water to rinse, and repeat the above steps 6 times. The surface prepared with highly active Pd core After filming, attach it to the surface of a piece of ABS plastic, and then cover it with an ABS plastic frame with a hollow in the middle, and the other side of the ABS plastic also covers a plastic frame with a closed bottom, and seal the two ABS plastics with PTFE waterproof material. space around the frame. Place the above device in the In the electroless plating solution, after 30 minutes, A uniform and firm metal Pd film is formed on the surface of the film, and the waterproof material is removed and th...

Embodiment 3

[0077] 1) Preparation of composite electrolyte membrane:

[0078] Will Membrane at 3wt.%H 2 o 2 solution, treated in a water bath at 80°C for 1 hour, rinsed with deionized water and placed in In the activation solution for 5min, take it out and rinse it with deionized water, then place it in After 5 minutes in the sensitization solution, take out the deionized water to rinse, and repeat the above steps 6 times. The surface prepared with highly active Pd core After filming, attach it to the surface of a piece of ABS plastic, and then cover it with an ABS plastic frame with a hollow in the middle, and the other side of the ABS plastic also covers a plastic frame with a closed bottom, and seal the two ABS plastics with PTFE waterproof material. space around the frame. Place the above device in the In the electroless plating solution, after 30 minutes, A uniform and firm metal Pd film is formed on the surface of the film, and the waterproof material is removed and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com