Patents

Literature

145results about How to "Improve the distillation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

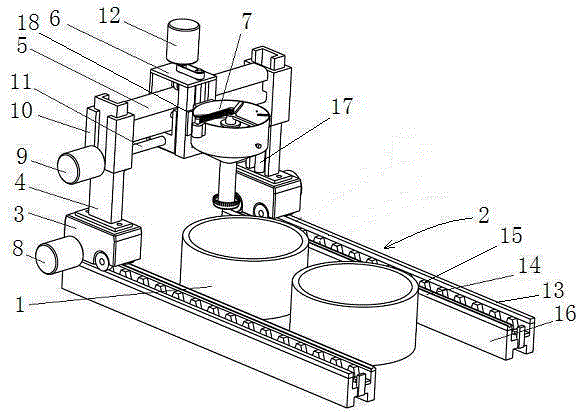

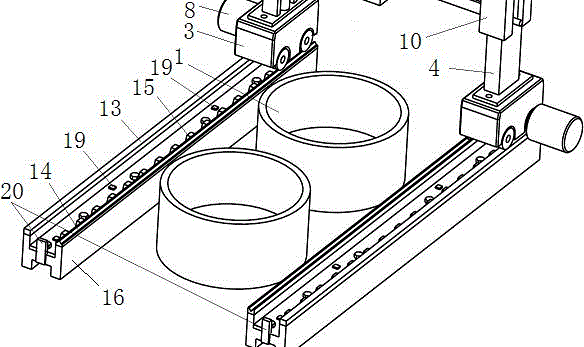

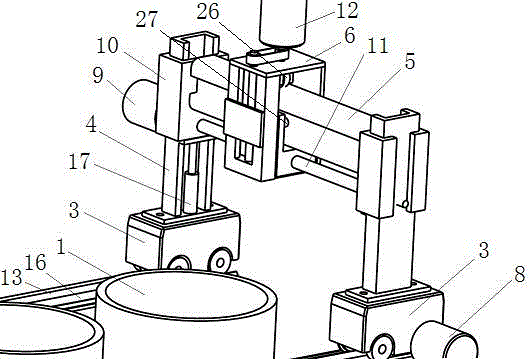

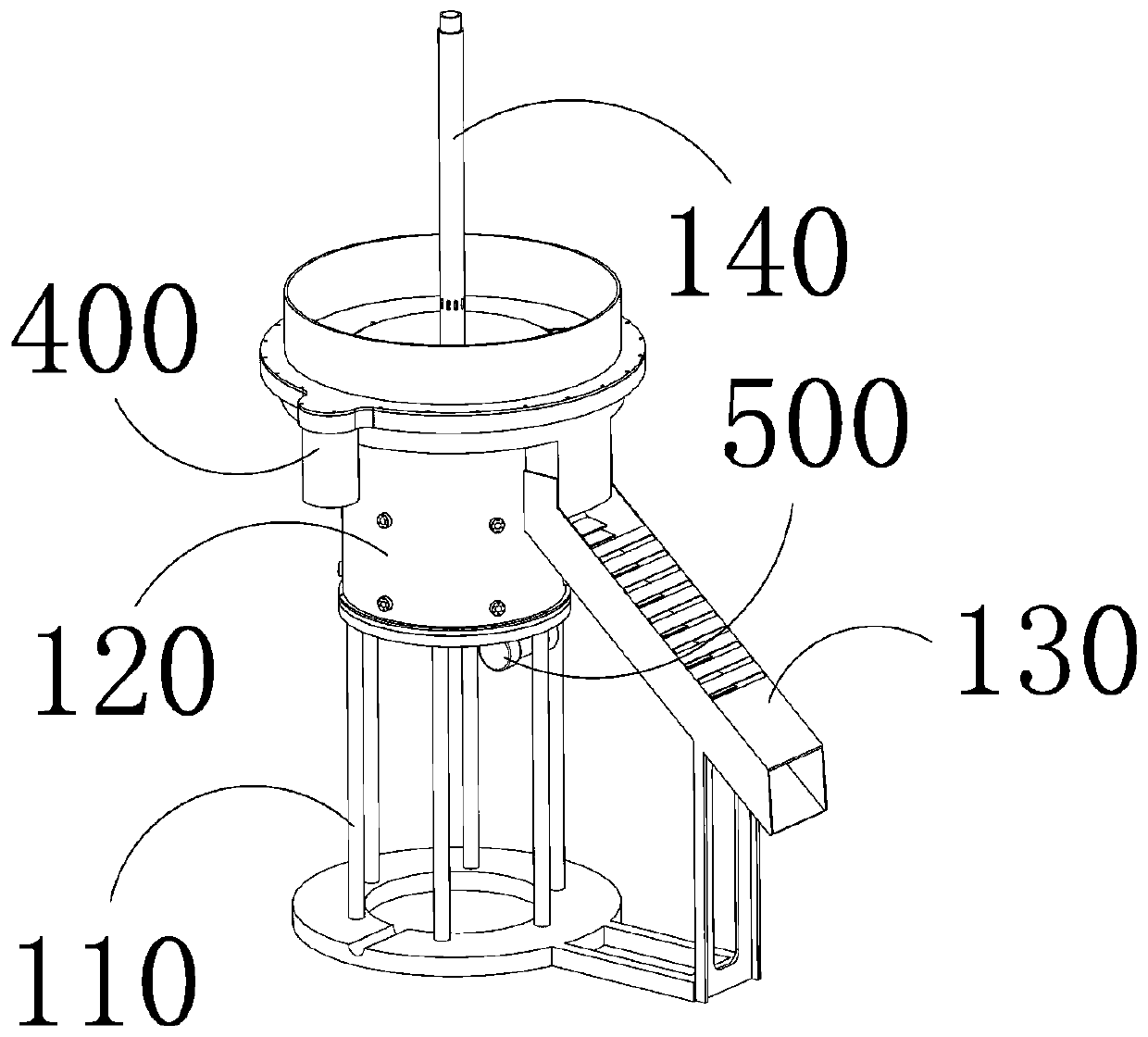

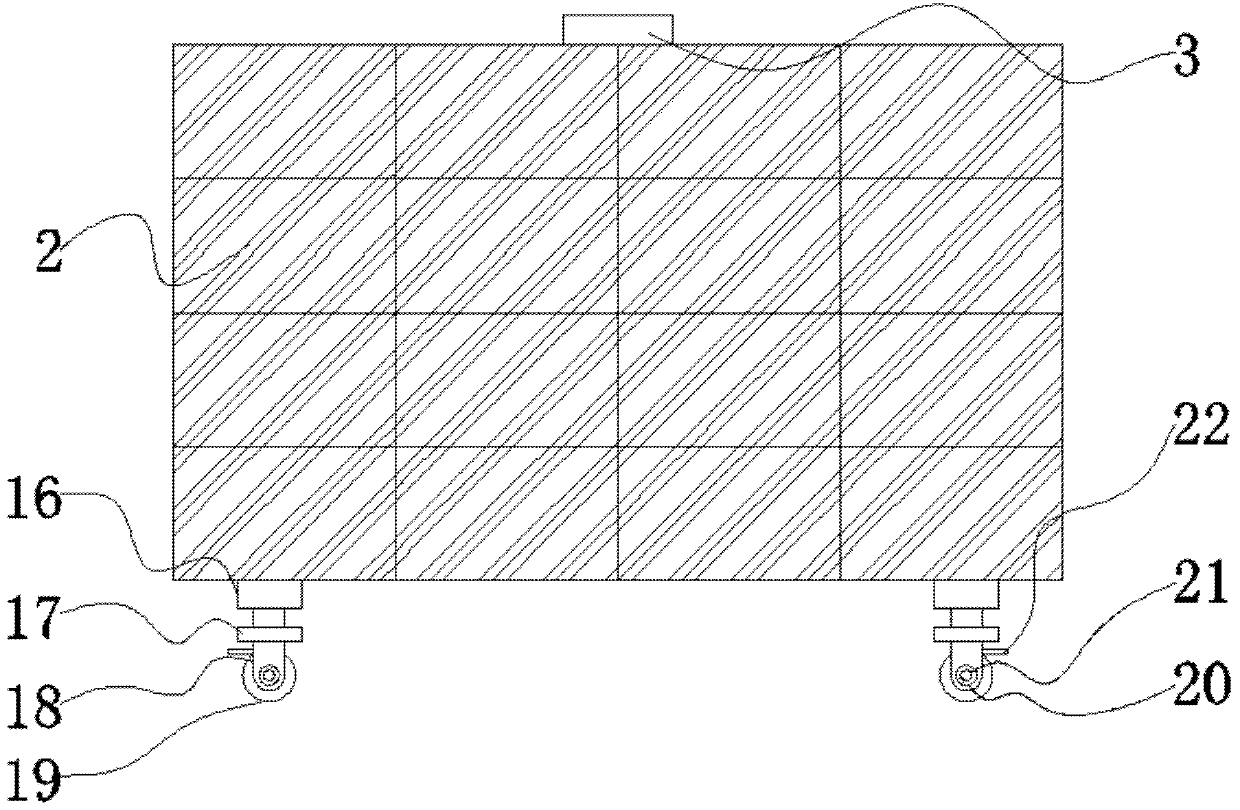

Gantry fermented grain automatic loading machine and loading method

InactiveCN104816954AIncrease loading capacityLower performance requirementsConveyorsAlcoholic beverage preparationSteam pressureControl system

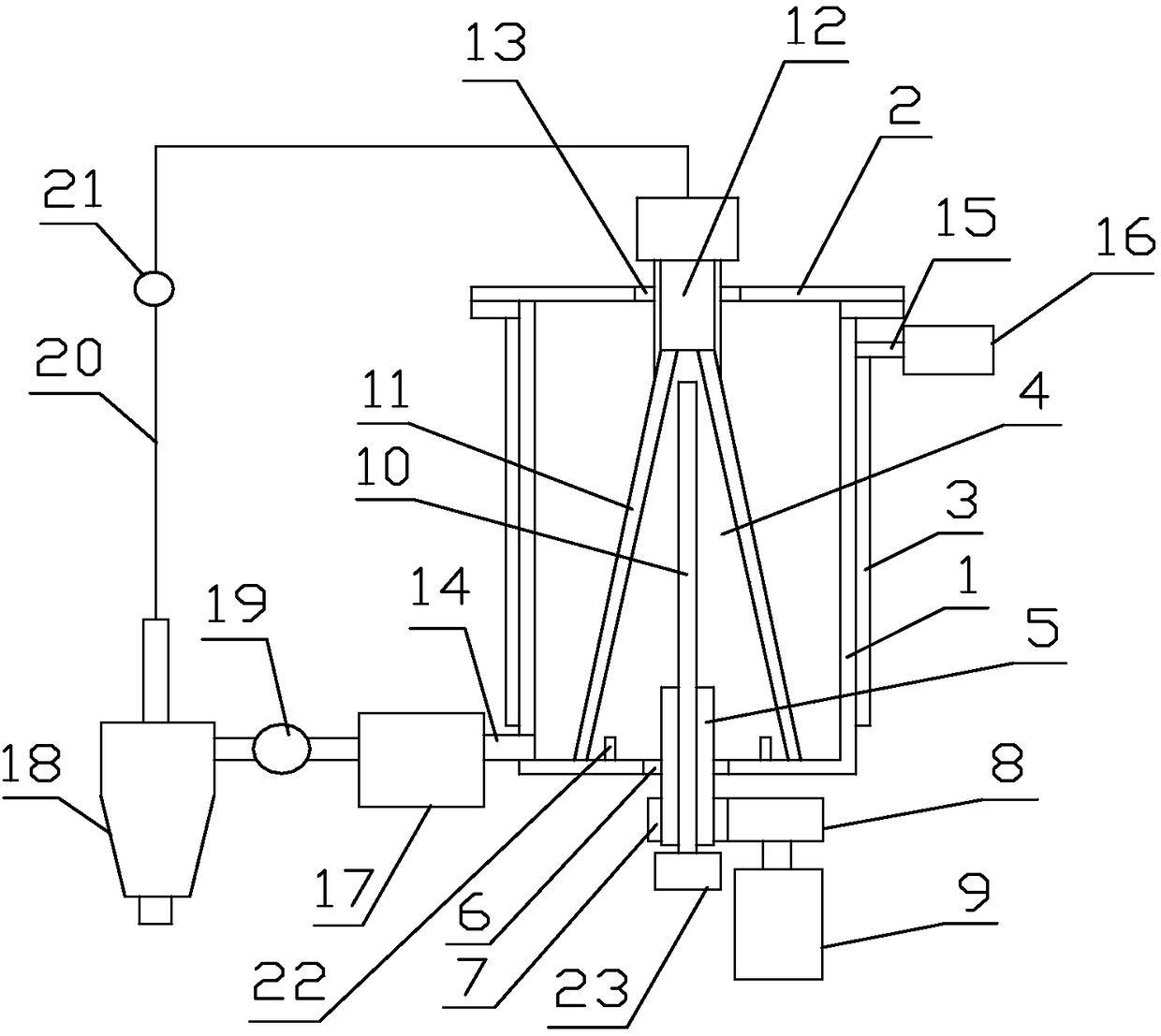

The invention discloses a gantry fermented grain automatic loading machine. The gantry fermented grain automatic loading machine comprises a gantry fermented grain loading robot, a fermented grain loading execution mechanism, a binocular vision identifying system and a control system, wherein the gantry fermented grain loading robot consists of two horizontal guide rails, two stand columns, a cross beam and a ram; the fermented grain loading execution mechanism is mounted on the ram; and the binocular vision identifying system comprises a steam running identification thermal infrared imager and a height identification thermal infrared imager, whose output ends are connected to an input end of the control system. The gantry fermented grain loading robot is excellent in loading capacity, and the performance requirement of the robot can be reduced, so that the equipment cost investment is reduced; the guide rails consisting of a flat guide rail, a V-shaped guide rail and a rack composition are adopted to bear the position deviation caused by slight displacement generated in the fermented grain loading motion process, so that the material distributing and feeding accuracy is guaranteed, and the distilling effect is improved; and the binocular vision identifying system is adopted to obtain the material surface temperature distribution and height, so that fermented grains are uniform to prevent the air way blockage and the steam pressure, and the distillation effect is guaranteed.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

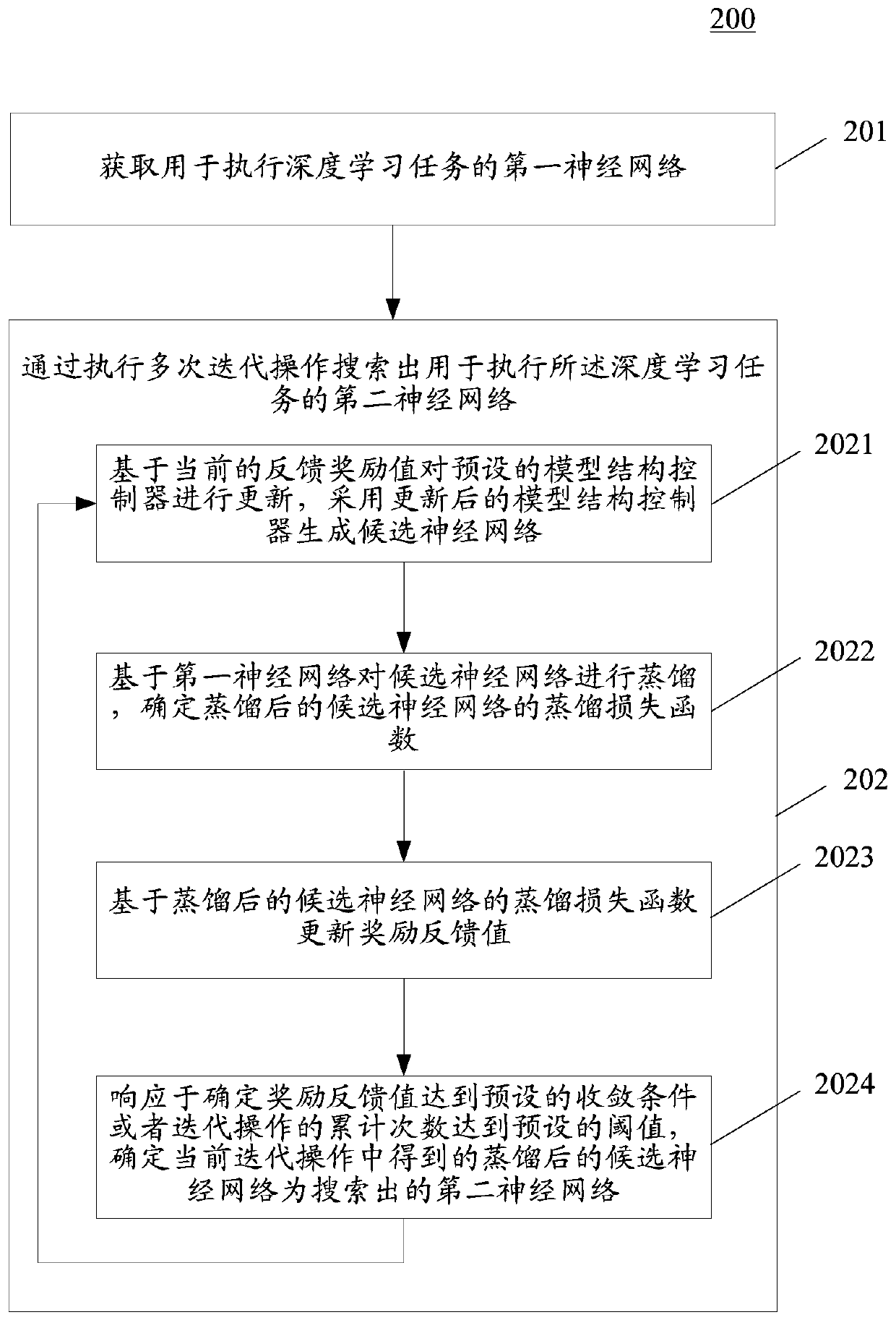

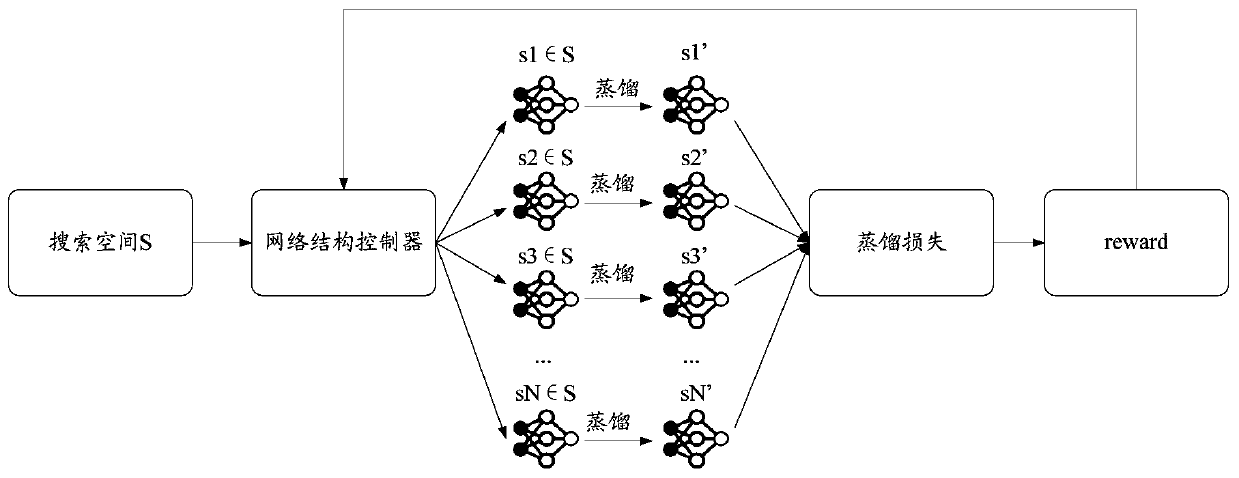

Model generation method and device

PendingCN110766142AImprove the distillation effectReduce consumptionNeural architecturesNeural learning methodsEngineeringNetwork model

The invention relates to the technical field of artificial intelligence. The embodiment of the invention provides a model generation method and device. The method comprises the steps of obtaining a first neural network used for executing a deep learning task; searching a second neural network by executing multiple iterative operations; wherein the iterative operation comprises the steps of updating a preset model structure controller based on a current feedback reward value, and generating a candidate neural network by adopting the updated model structure controller; distilling the candidate neural network based on the first neural network, and determining a distillation loss function of the distilled candidate neural network; updating a reward feedback value based on a distillation loss function of the distilled candidate neural network; and determining the distilled candidate neural network obtained in the current iterative operation as the searched second neural network in responseto the determination that the reward feedback value reaches a preset convergence condition or the cumulative number of the iterative operations reaches a preset number threshold. According to the method, the neural network model structure suitable for distillation can be automatically searched.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

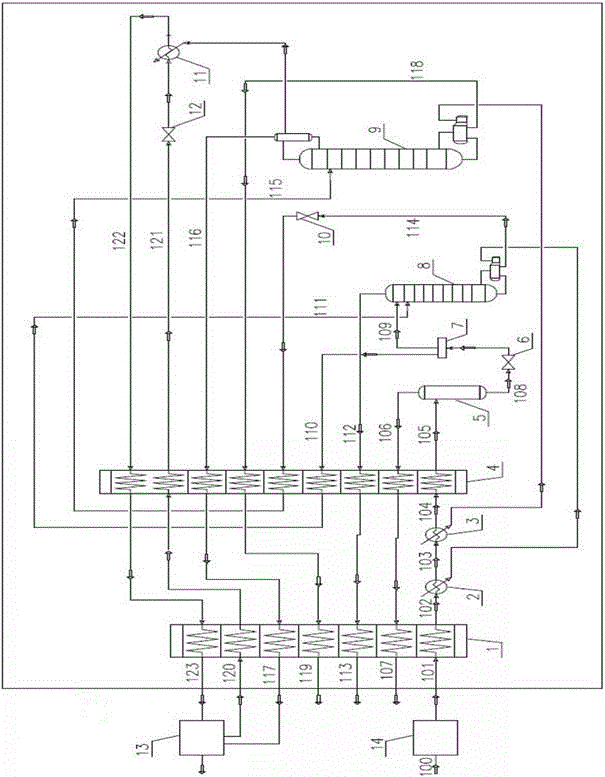

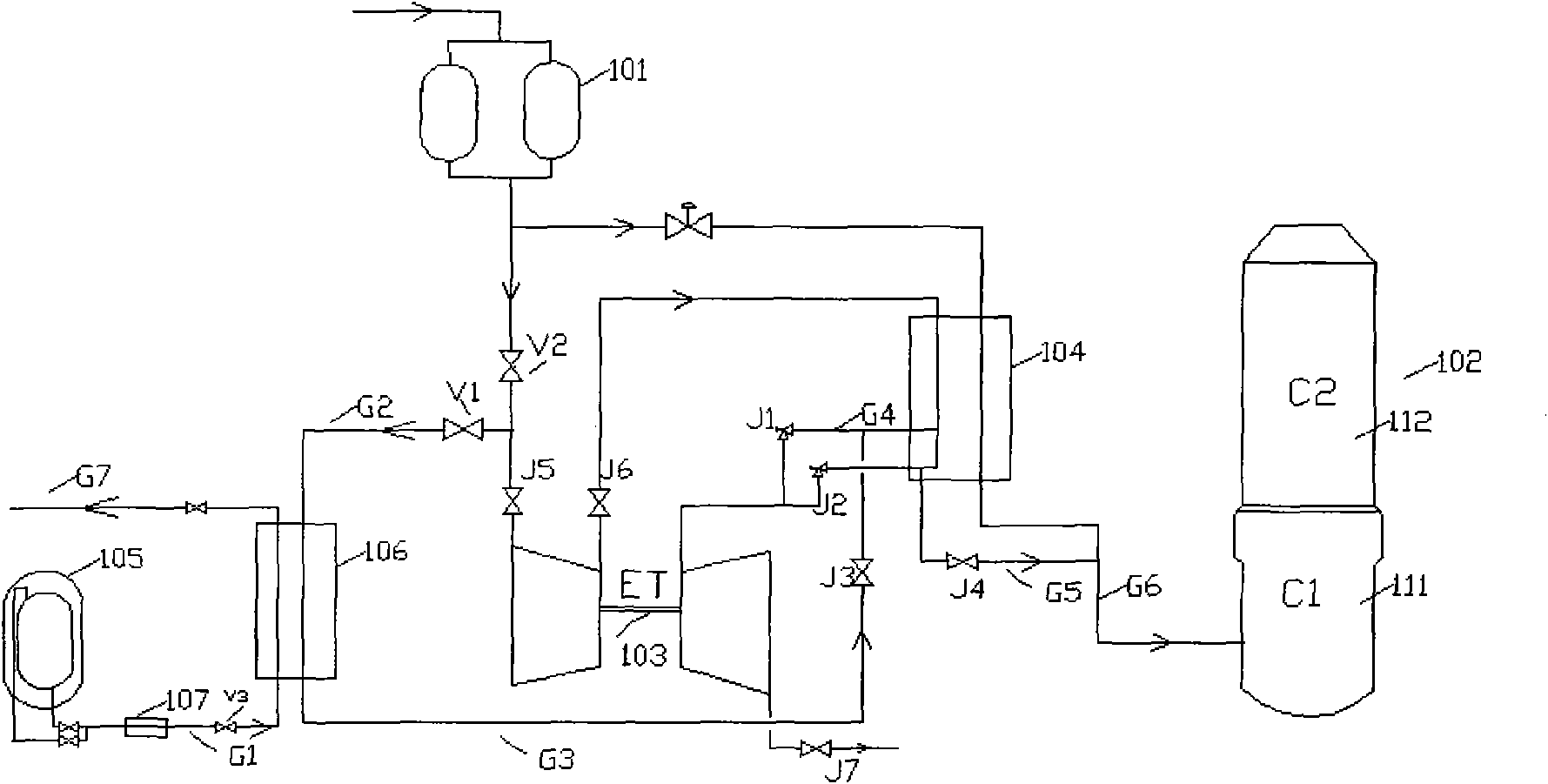

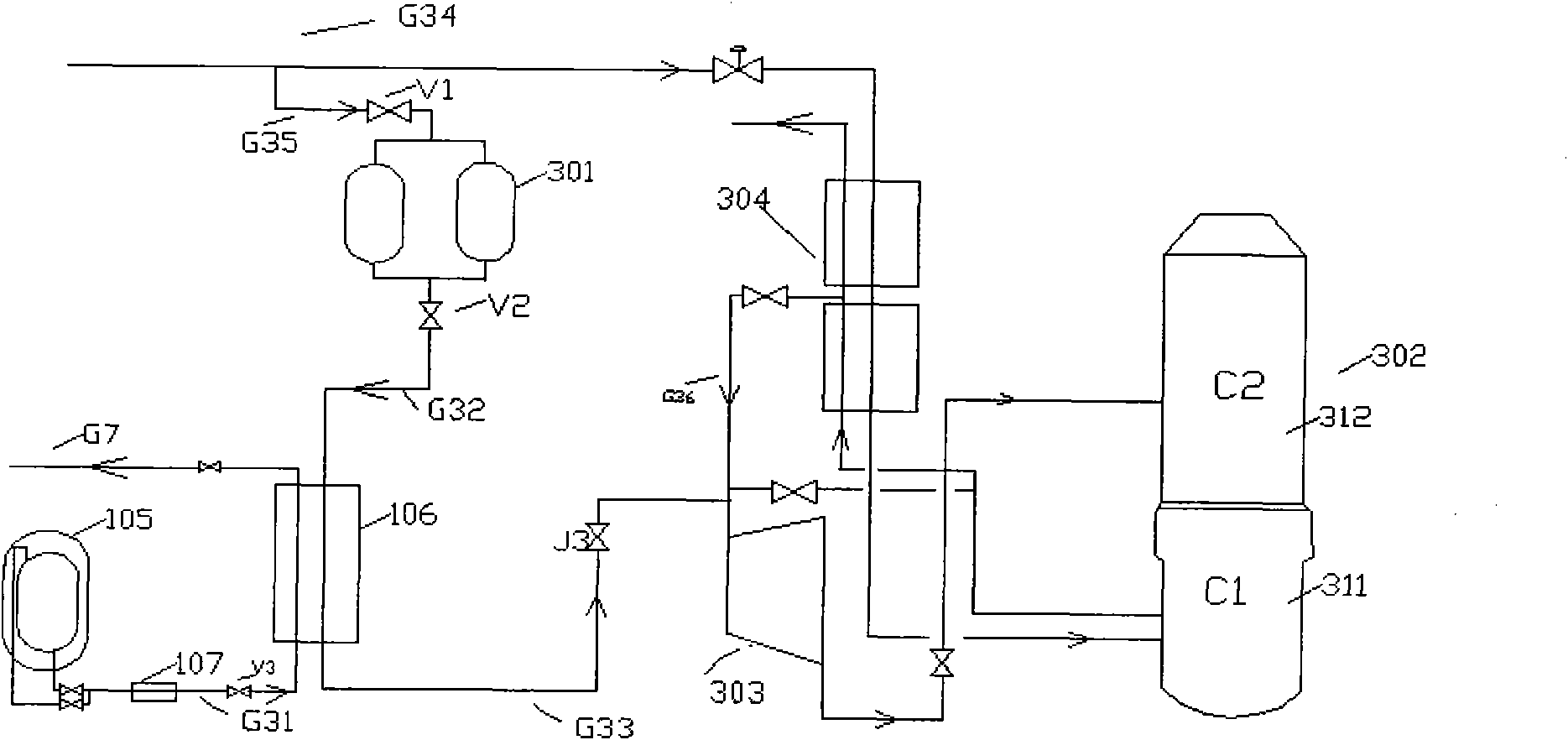

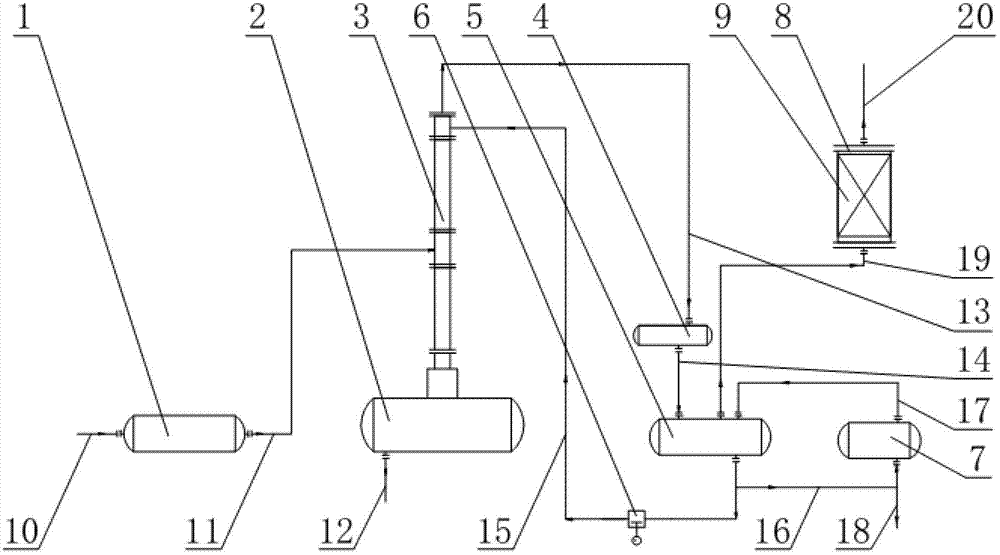

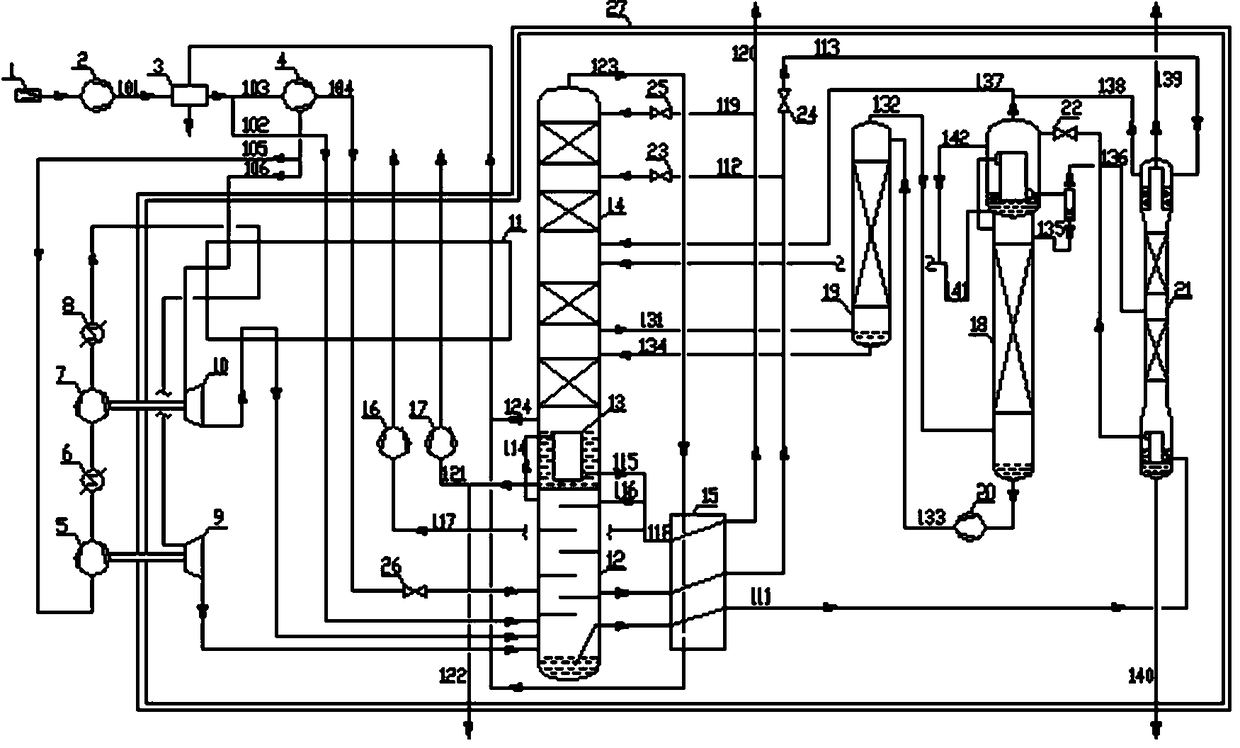

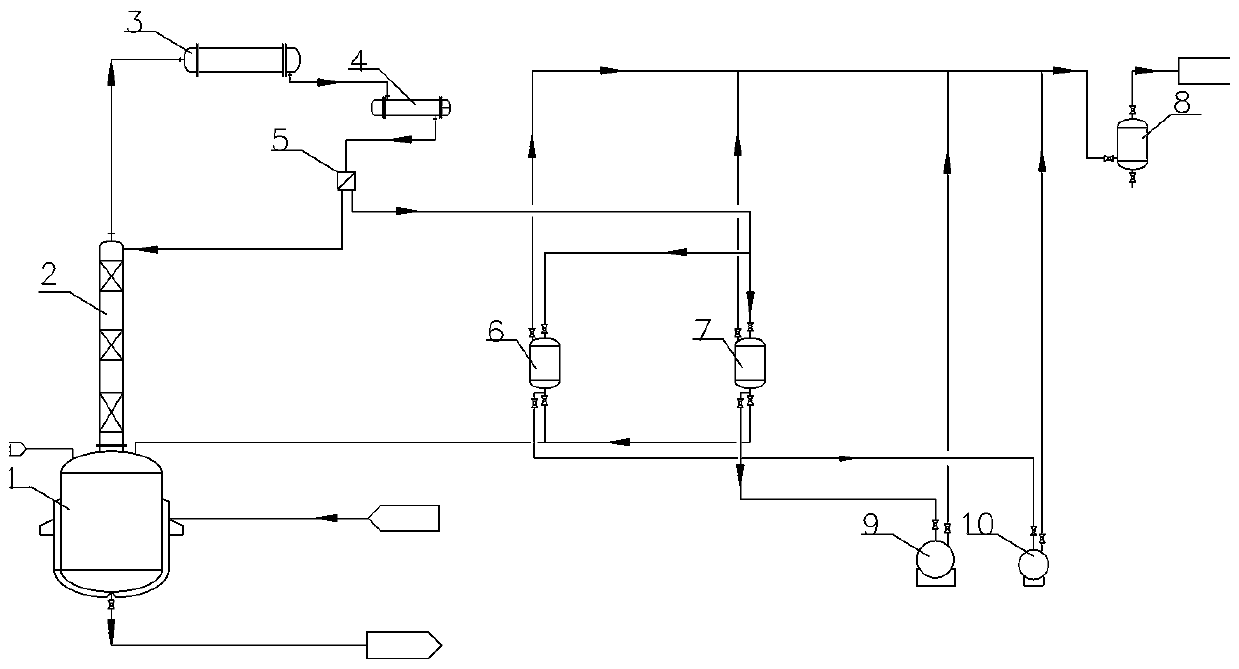

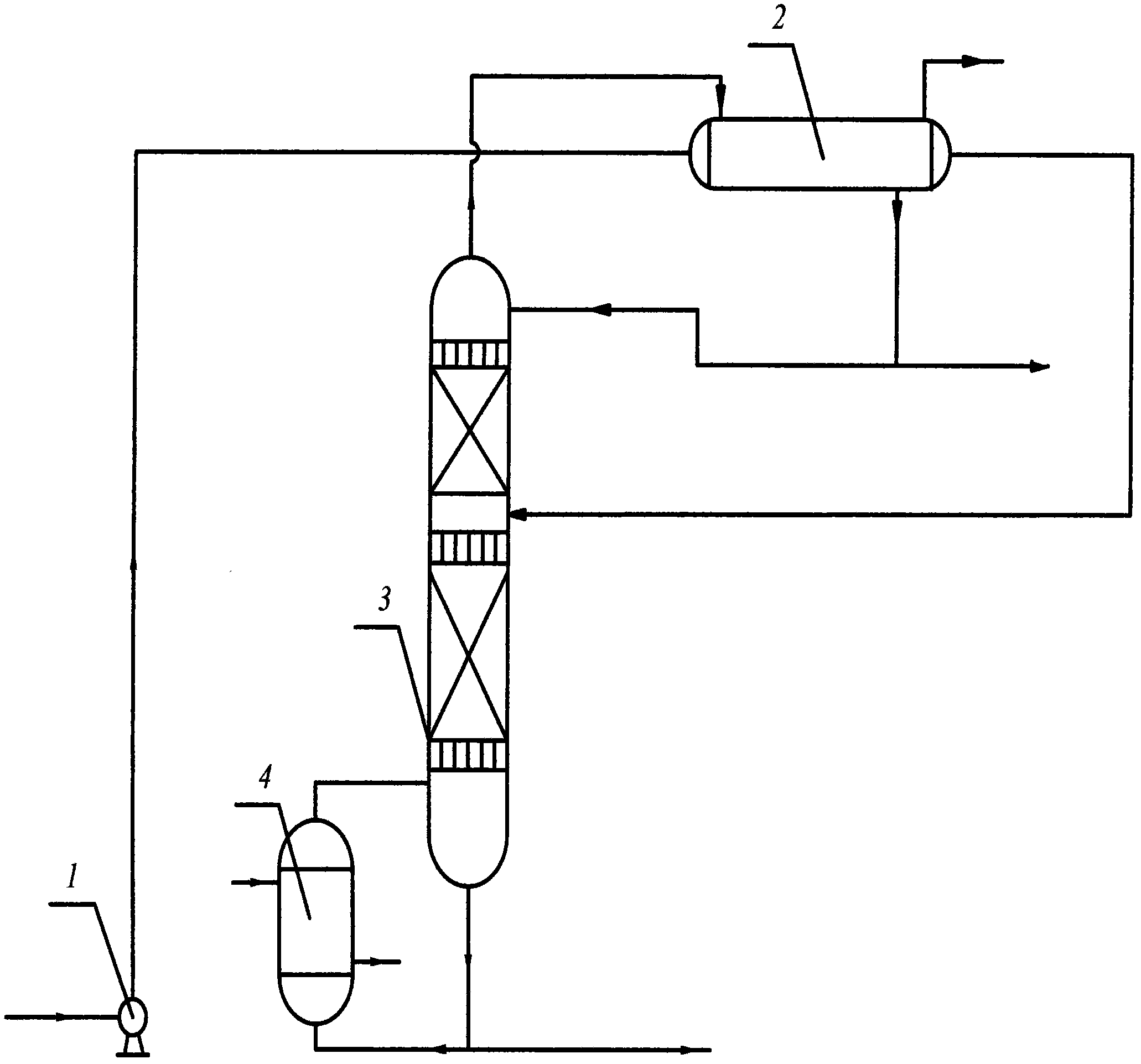

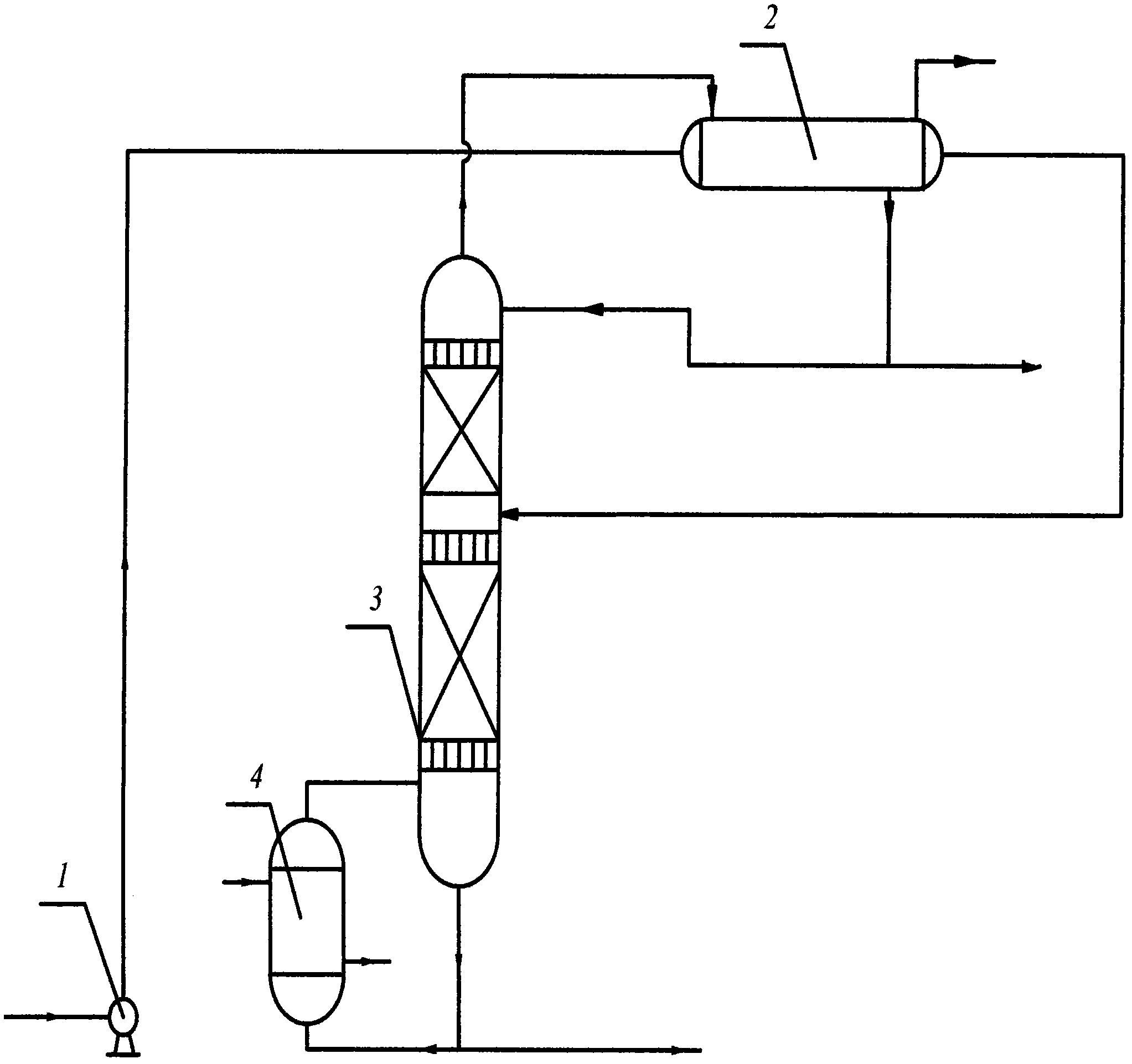

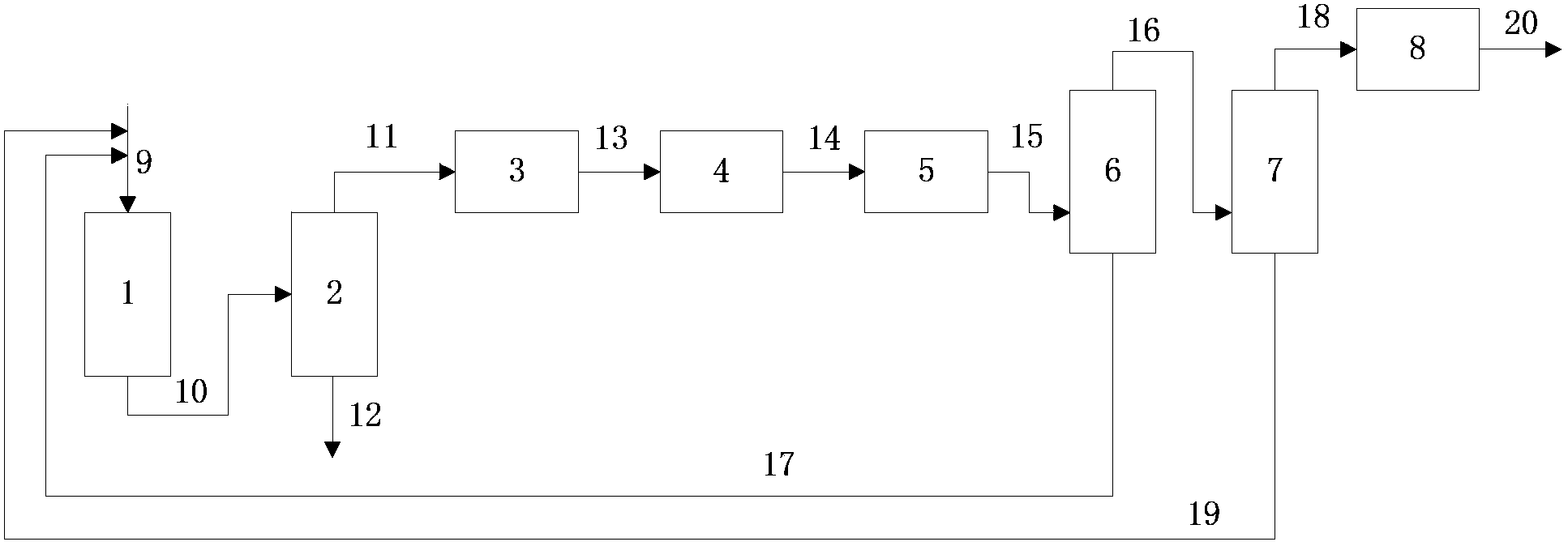

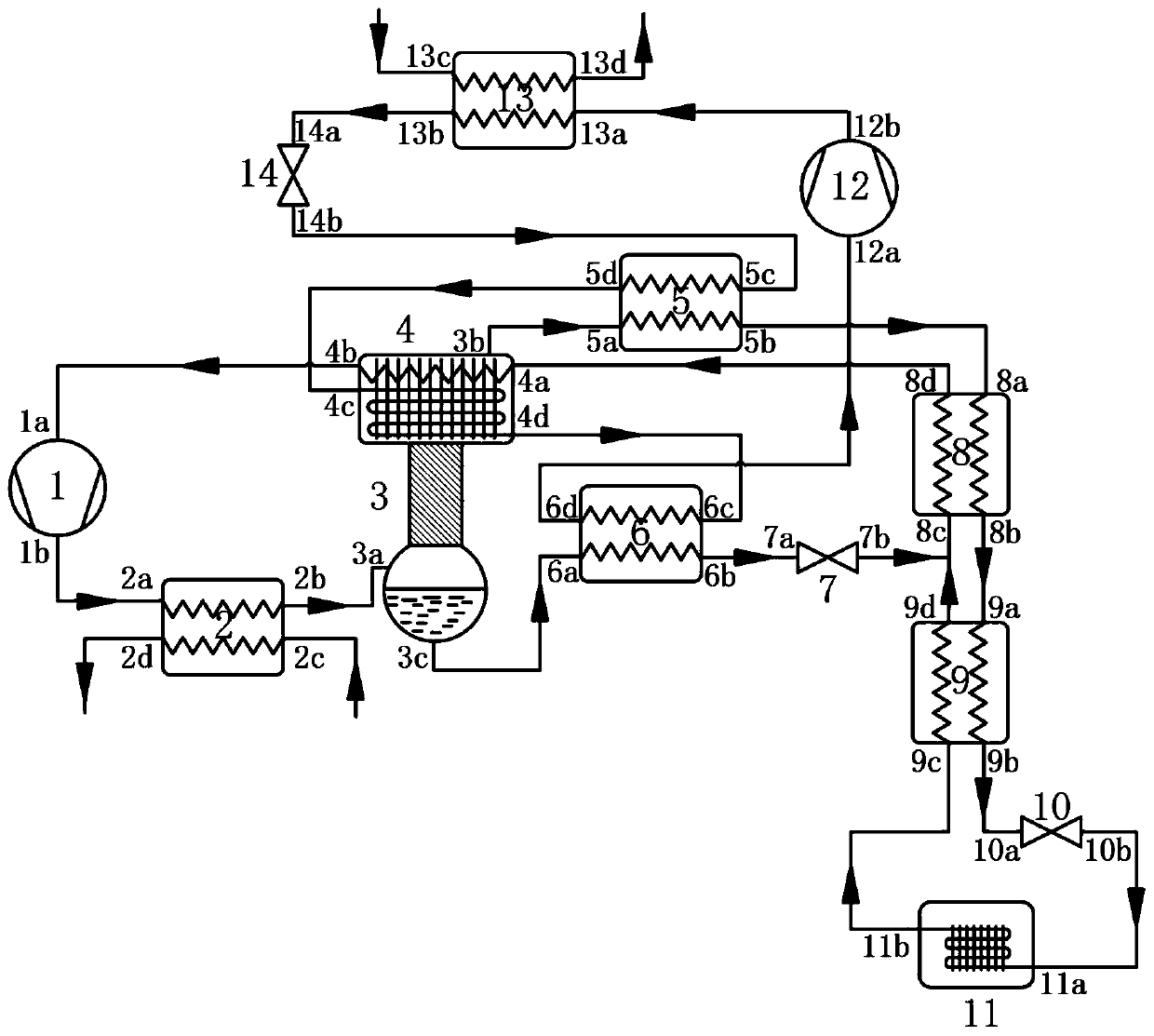

System and method of preparing hydrogen rich gas and carbon monoxide from synthesis gas

The invention relates to a system and a method of preparing hydrogen rich gas and carbon monoxide from synthesis gas. The system mainly comprises a synthesis gas purifying unit, a low-temperature liquefying separation unit and a CO product compressor, wherein the low-temperature liquefying separation unit is composed of a first plate-fin heat exchanger, a second plate-fin heat exchanger, a flash separator, a high-pressure rectification tower and a low-pressure rectification tower; a first evaporator is arranged at the bottom of the high-pressure rectification tower; a second evaporator is arranged at the bottom of the low-pressure rectification tower; and a first condenser is arranged at the top part of the low-pressure rectification tower. The system and the method are strong in adaptability to raw gas, little in equipment and small in investment, lower the requirement for impurities of the synthesis gas, eliminate a nitrogen compressor and an expander, increase the hydrogen recovery rate of a device and reduce the processing load of PSA or a membrane separation system.

Owner:KAIFENG AIR SEPARATION GROUP

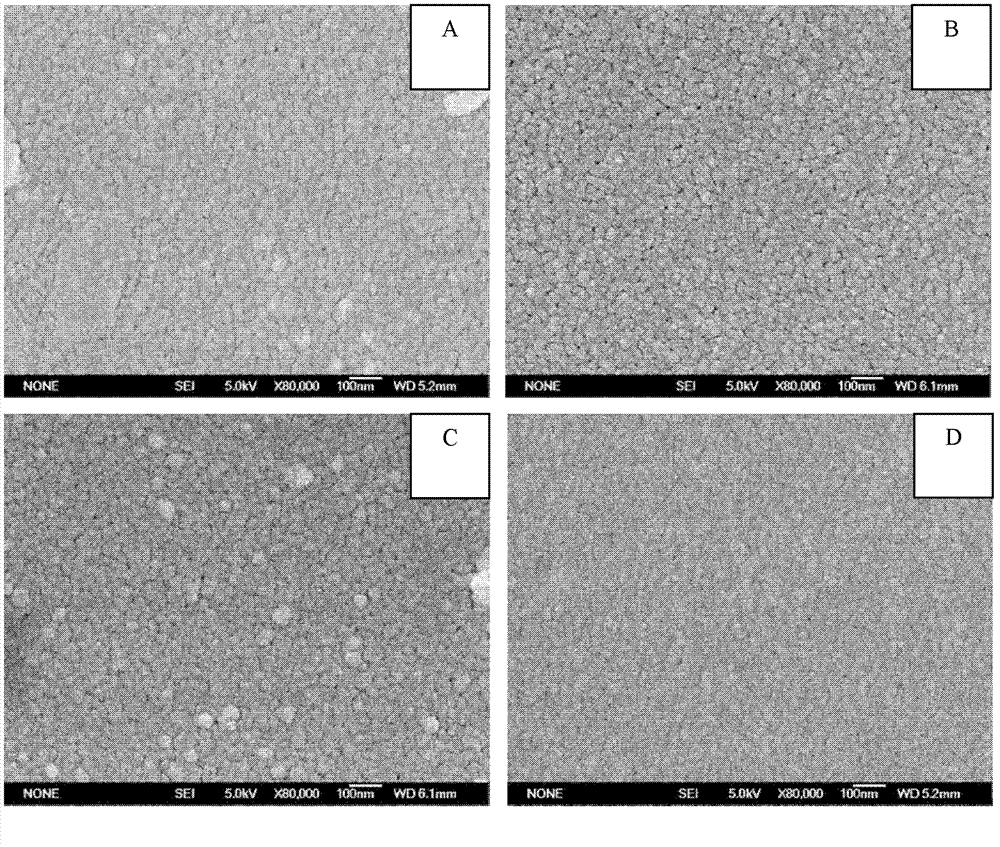

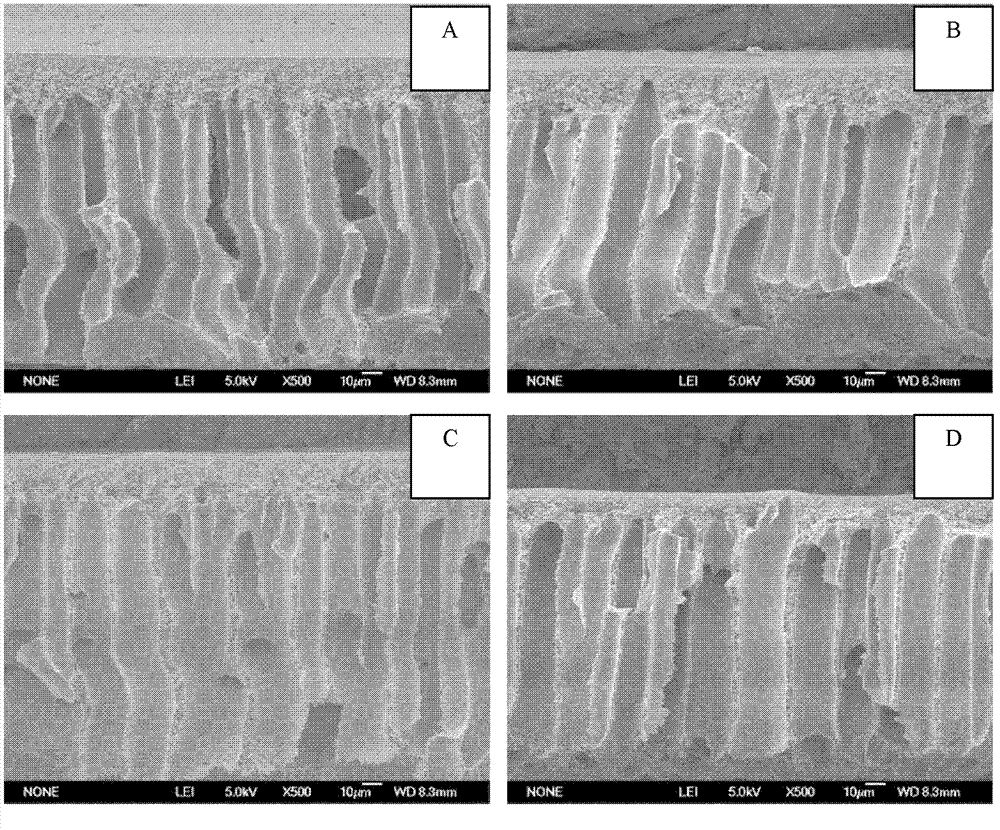

Polyether sulfone porous membrane for membrane distillation process and preparation method thereof

ActiveCN102698618AExcellent Membrane Distillation PerformanceThe film making process is simpleDistillationPorous membraneMembrane distillation

The invention provides a polyether sulfone porous membrane for a membrane distillation process and a preparation method of the polyether sulfone porous membrane, wherein before the polyether sulfone porous membrane for the membrane distillation process is prepared, no hydrophobic modification treatment on polyether sulfone body material is carried out, and no hydrophobic modification treatment on the membrane is carried out after membrane is prepared. The preparation method comprises the following steps: firstly preparing a wet polyether sulfone porous membrane by a lyotropic phase transformation method, and then drying the wet membrane so as to prepare the polyether sulfone porous membrane for the membrane distillation process. The polyether sulfone porous membrane provided by the invention has the advantages that membrane distillation flux is stable and high, the preparation method is mature and simple, the cost is low, the amplification is easy, and the application prospects in the fields such as desalination of seawater and bitter saline water, concentration of biological macromolecular solution and concentration of sugar-containing liquid are broad.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

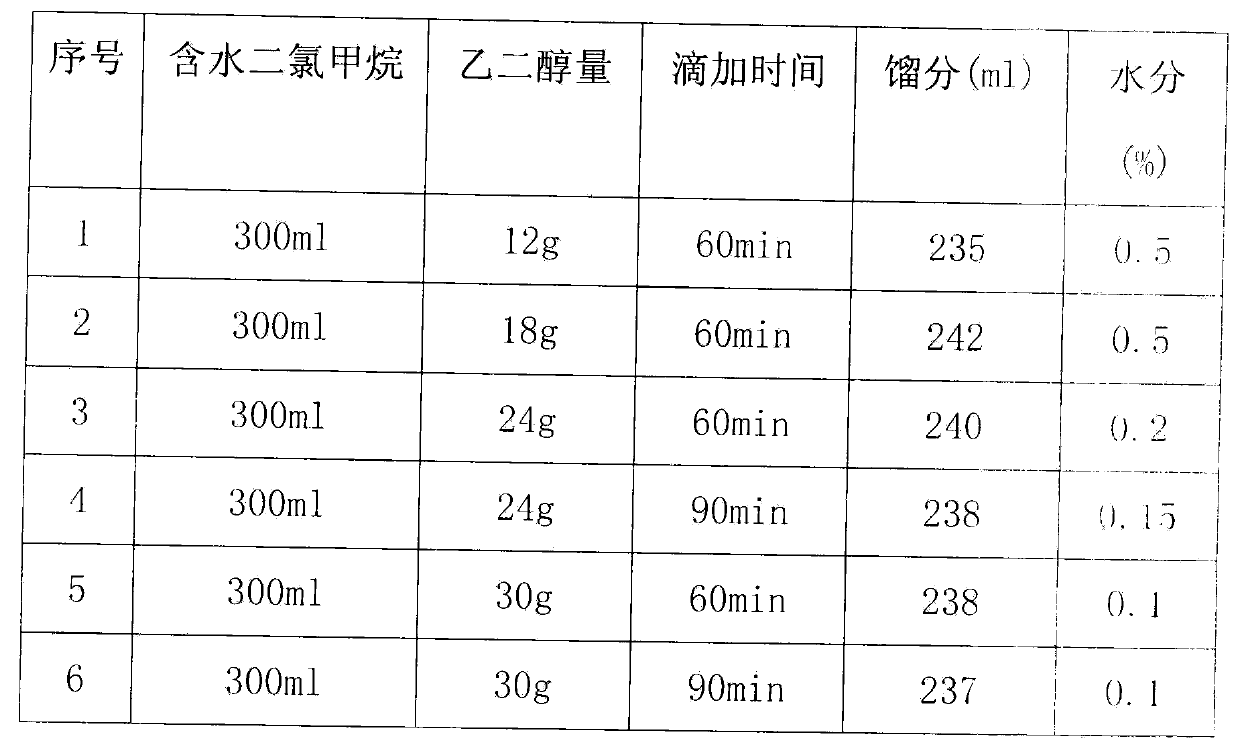

Method for recovering dichloromethane

InactiveCN103553868ASolve the problem that it is difficult to keep the water content below 0.5%Reduce moistureHalogenated hydrocarbon preparationEnvironmental engineeringGlycol synthesis

The invention discloses a method for recovering dichloromethane. Ethylene glycol is added to the dichloromethane, and is treated through a rectifying tower, so that the moisture of the dichloromethane is separated and purified to below 0.5%. By adopting the method for recovering the dichloromethane, which is disclosed by the invention, the problem that the dichloromethane and water are azeotropic together in the prior art to cause that the moisture of the dichloromethane cannot be easily kept below 0.5% even if the rectifying tower is utilized is solved. The dichloromethane has a significant rectification effect and is low in moisture by adding the ethylene glycol, and can be directly recovered and reused.

Owner:ANHUI LANGXI LIANKE IND

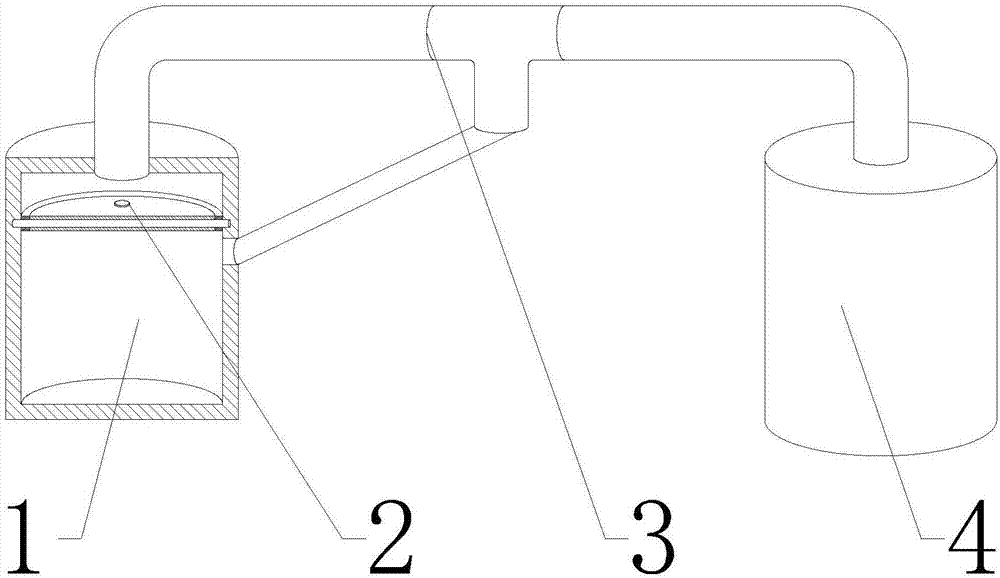

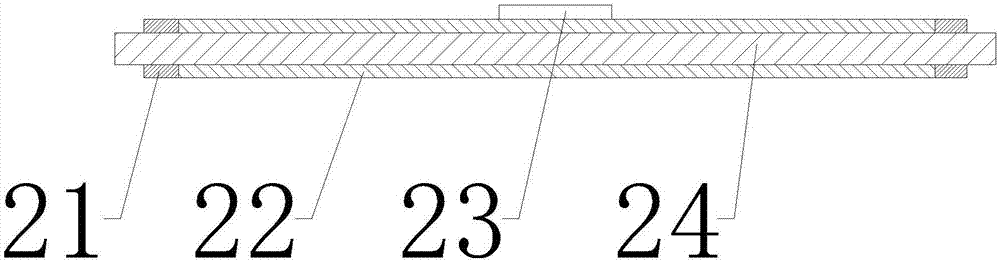

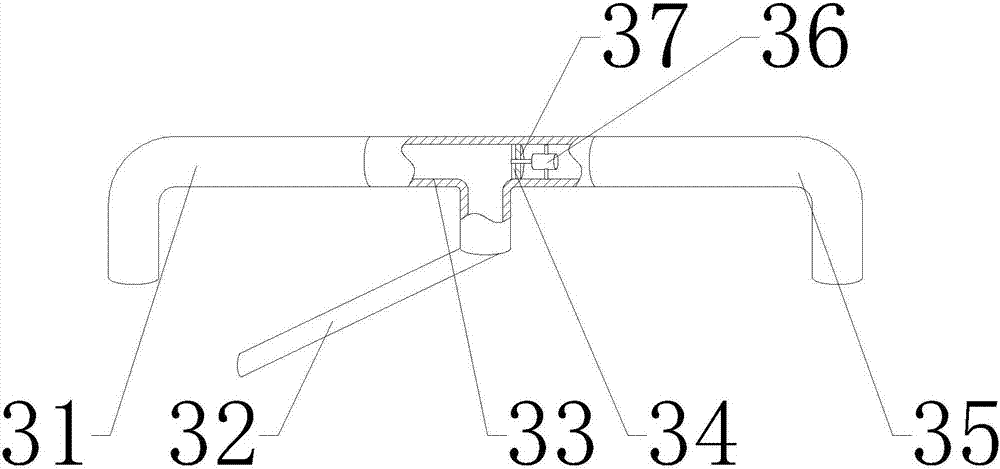

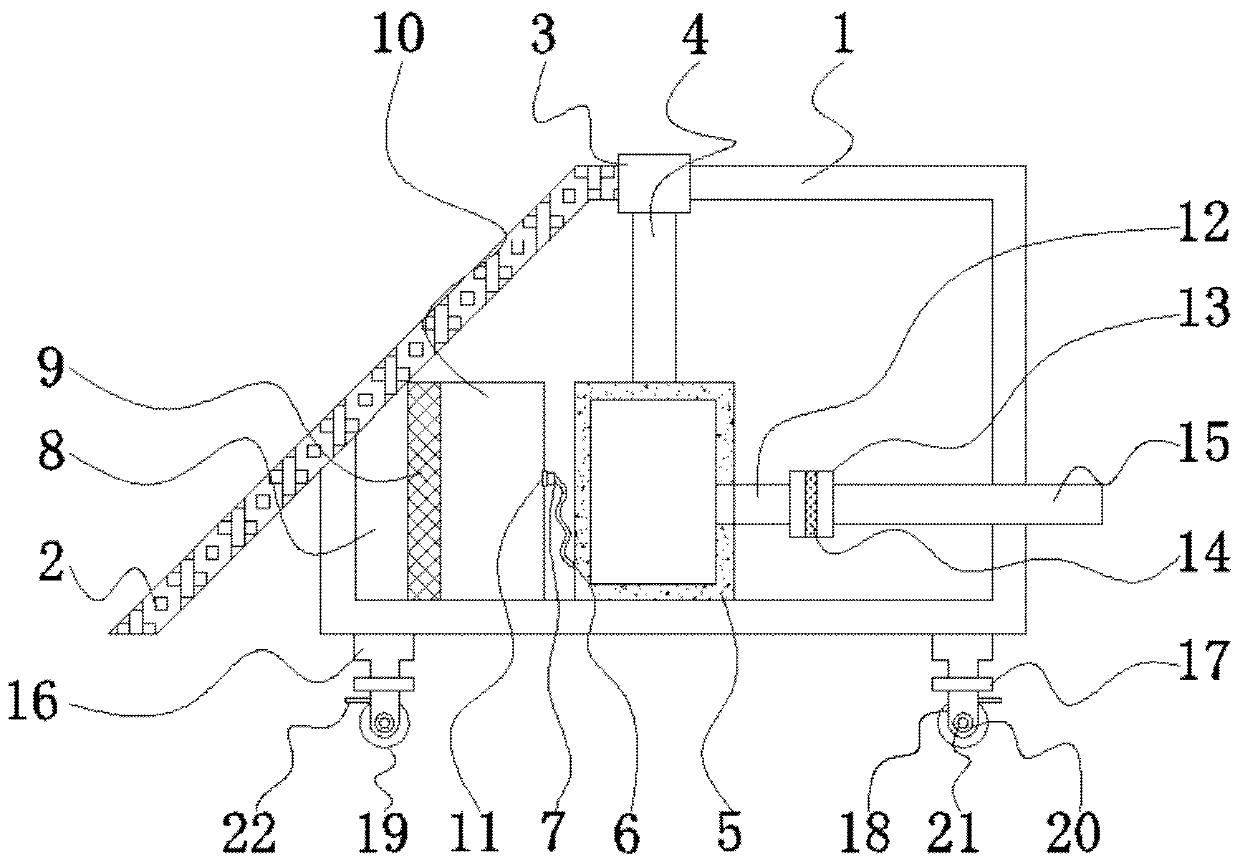

Oxygen generator

InactiveCN102030314ASmall running resistanceReduce power consumptionSolidificationLiquefactionMolecular sieveLiquid storage tank

The invention provides an oxygen generator, comprising an expanding device, a main heat exchanger and a main tower; the oxygen generator further comprises a molecular sieve purifier, a low-temperature liquid storage tank and a high-pressure heat exchanger; after the air is purified by the molecular sieve purifier, a part of the air is subjected to temperature reduction by a mainboard-type heat exchanger and inputted to the main tower, and the other part of the air is inputted to the high-pressure heat exchanger to exchange heat with the liquid in the low-temperature liquid storage tank in thehigh-pressure heat exchanger and then inputted to a lower tower; the liquid from the low-temperature liquid storage tank exchanges heat in the high-pressure heat exchanger and then changes into gas state, and is outputted by a first gas pipe. The oxygen generator of the invention can meet the demands of gas products of users through the high-pressure heat exchanger, and simultaneously can recovercool energy of the liquid simultaneously; the oxygen generator is beneficial for saving energy, and can reduce the operation resistance of the main heat exchanger and power consumption amount of a compressor, simultaneously can enhance the rectifying effect of the main tower and output of the oxygen and argon in the unit time, and can reduce energy consumption.

Owner:杜金明

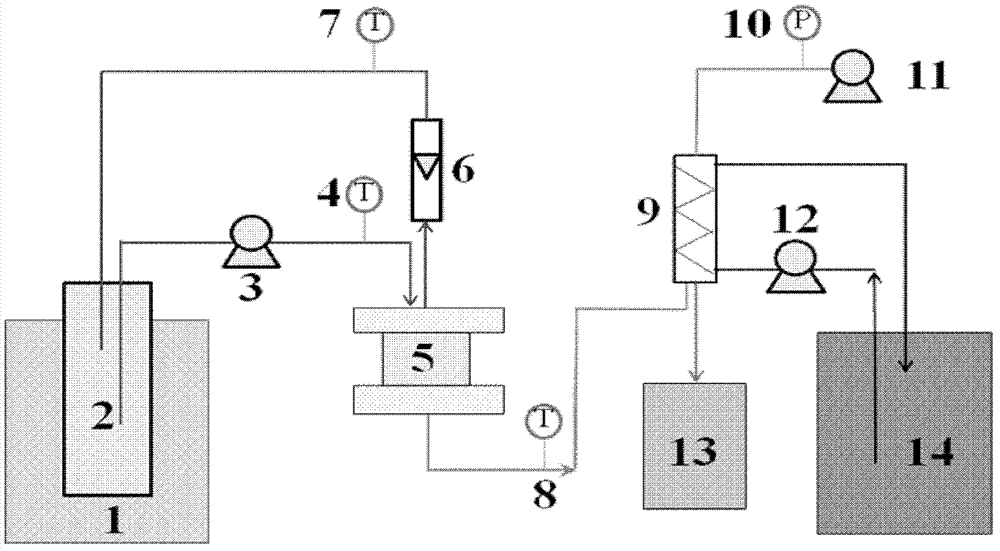

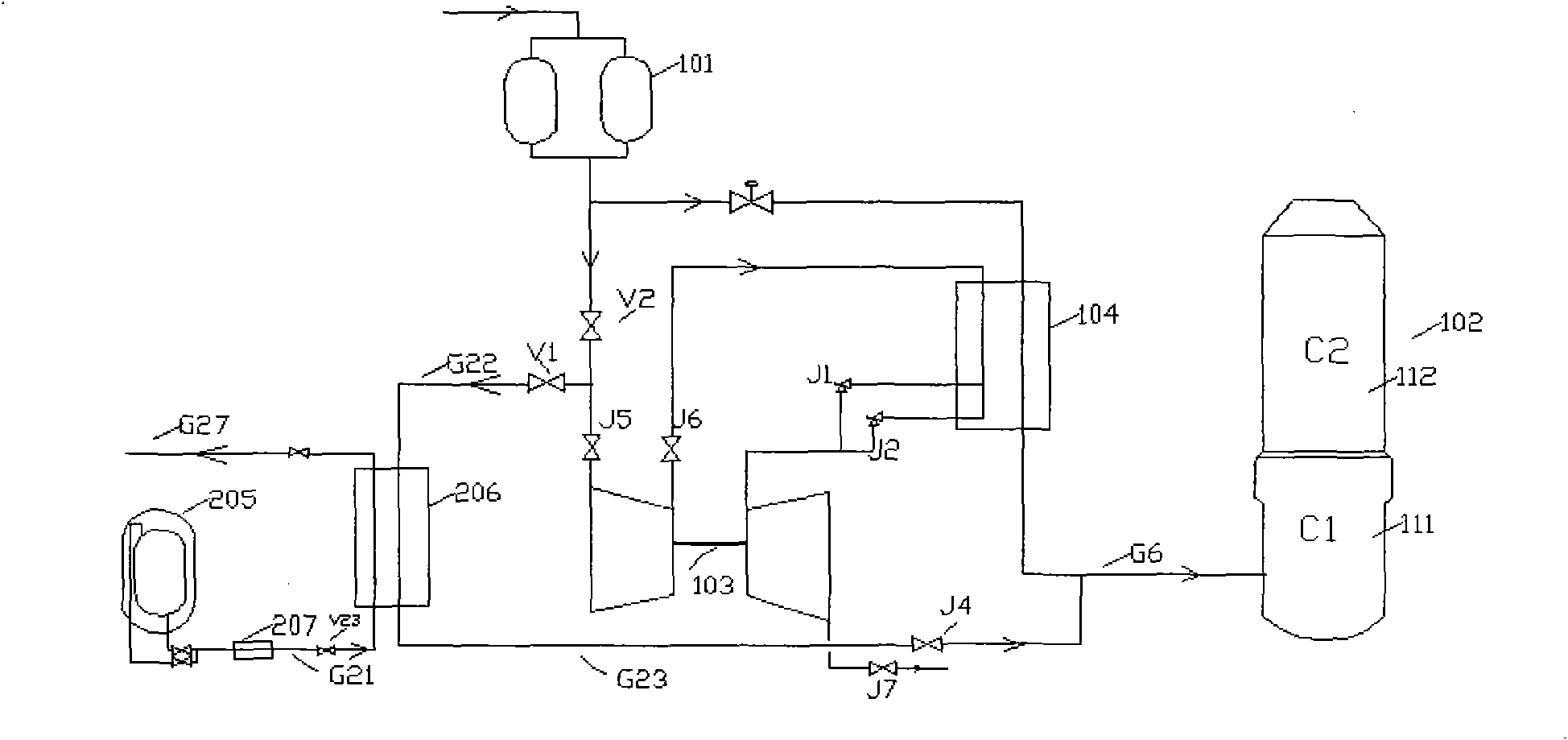

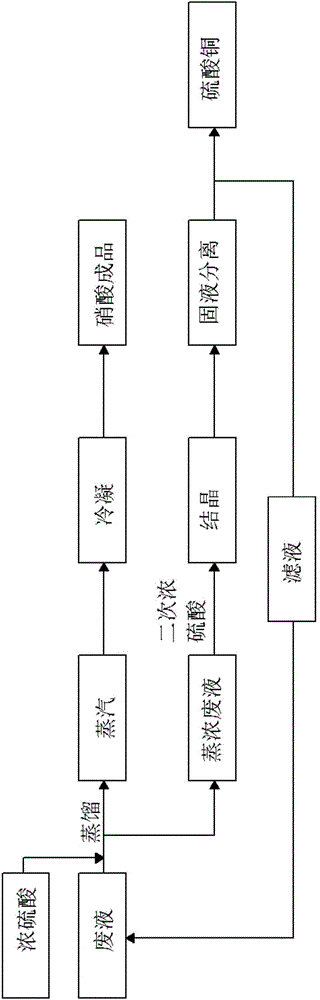

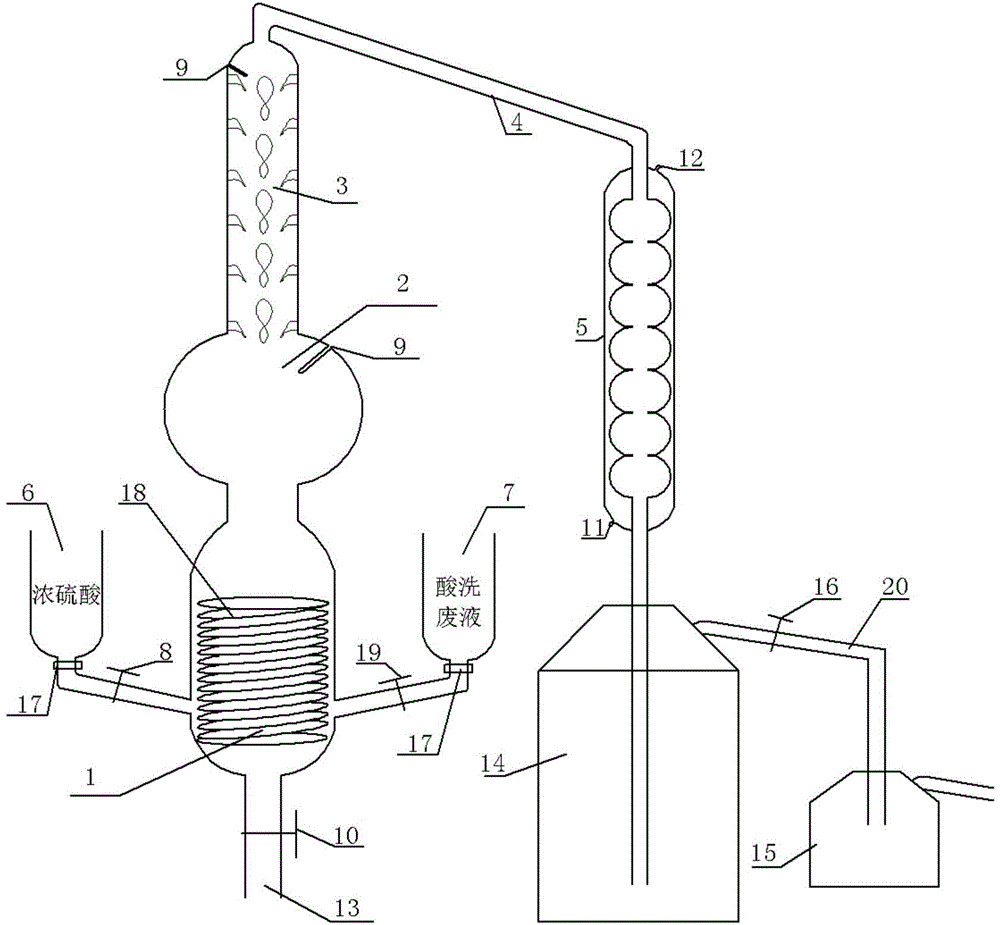

Device for recycling nitric acid from waste liquor containing copper nitrate and use method of device

InactiveCN104085865AConcentration controllableImprove the distillation effectWater/sewage treatment by heatingCopper sulfatesDistillationCopper nitrate

The invention discloses a device for recycling nitric acid from waste liquor containing copper nitrate. Repeated addition of concentrated sulphuric acid or adoption of a reverse extraction technology is not needed, cost and space occupied by equipment are saved, operation steps are simplified, resource optimization is realized, design is simple and reasonable, and control is easy. The device for recycling nitric acid from the waste liquor containing copper nitrate comprises a concentrated sulphuric acid storage tank and an acid pickling waste liquor storage tank and is characterized in that a metering pump is respectively arranged at the outlet of the bottom of each of the concentrated sulphuric acid storage tank and the acid pickling waste liquor storage tank and is respectively communicated to the inner cavity of a heating unit, a heating wire is arranged in the inner cavity of the heating unit, a crystal outlet pipeline is arranged at the bottom of the heating unit, a distillation flask and a rectifying unit are sequentially arranged at the outlet in the upper part of the heating unit, the outlet in the upper part of the distillation flask is communicated with the inlet in the lower part of the rectifying unit, the outlet in the upper part of the rectifying unit is externally connected with an inner cavity inlet in the upper part of a condensation unit, an inner cavity outlet in the lower part of the condensation unit is connected to the lower part of a nitric acid finished product tank by virtue of a guide pipe, and flowing cold water is filled in the outer cavity of the condensation unit.

Owner:KUNSHAN MINGKUAN ENVIRONMENTAL & ENERGY SAVING TECH CO LTD

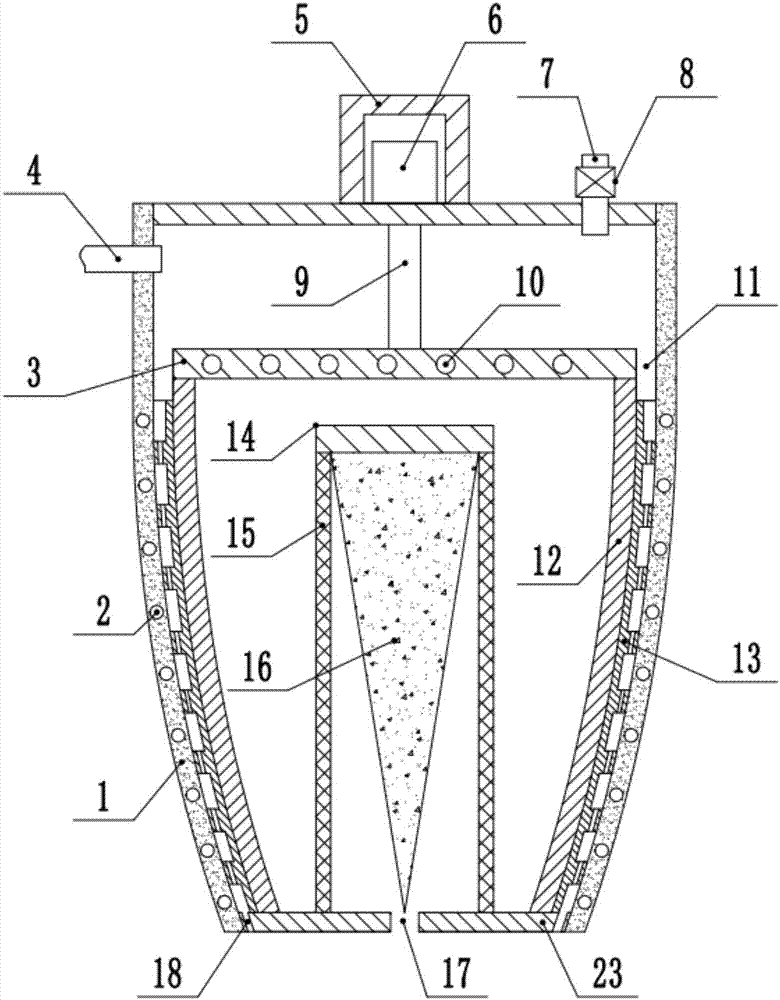

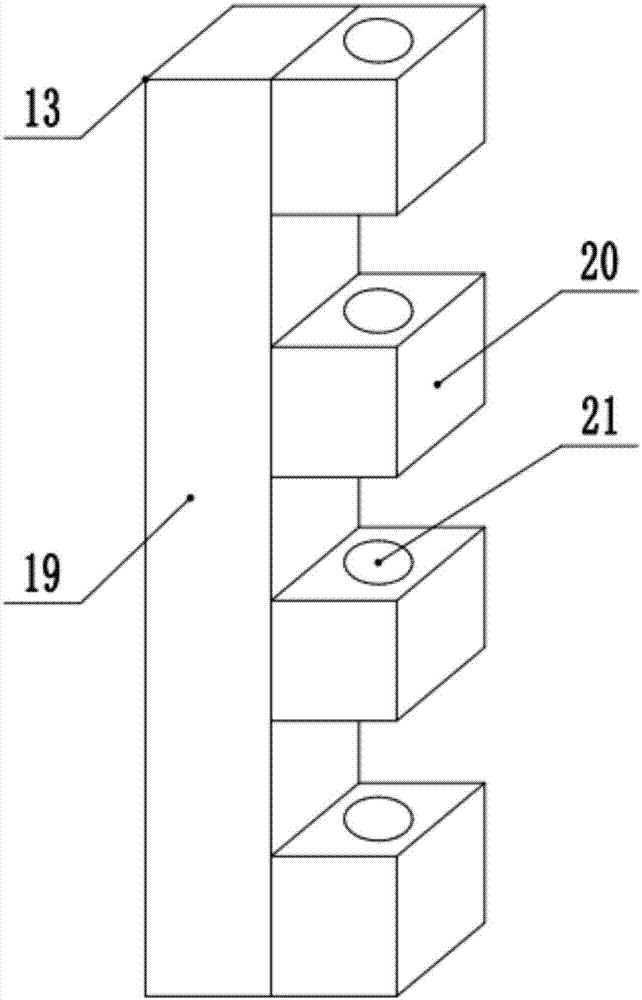

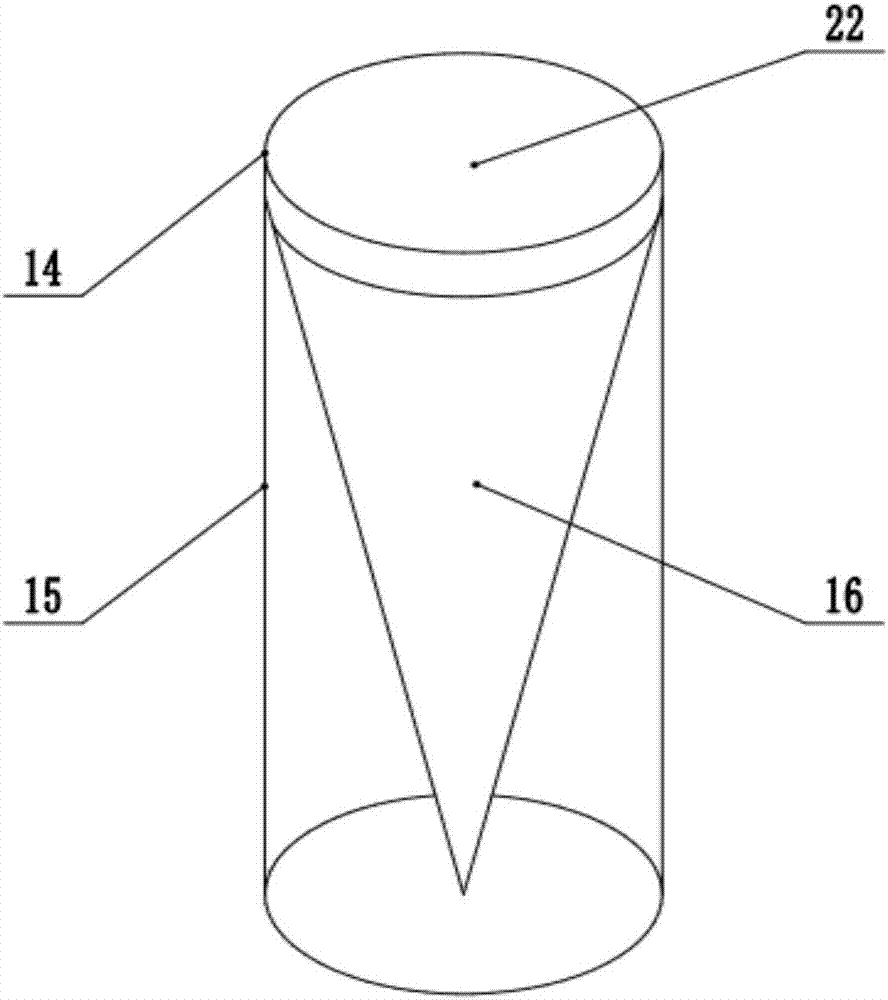

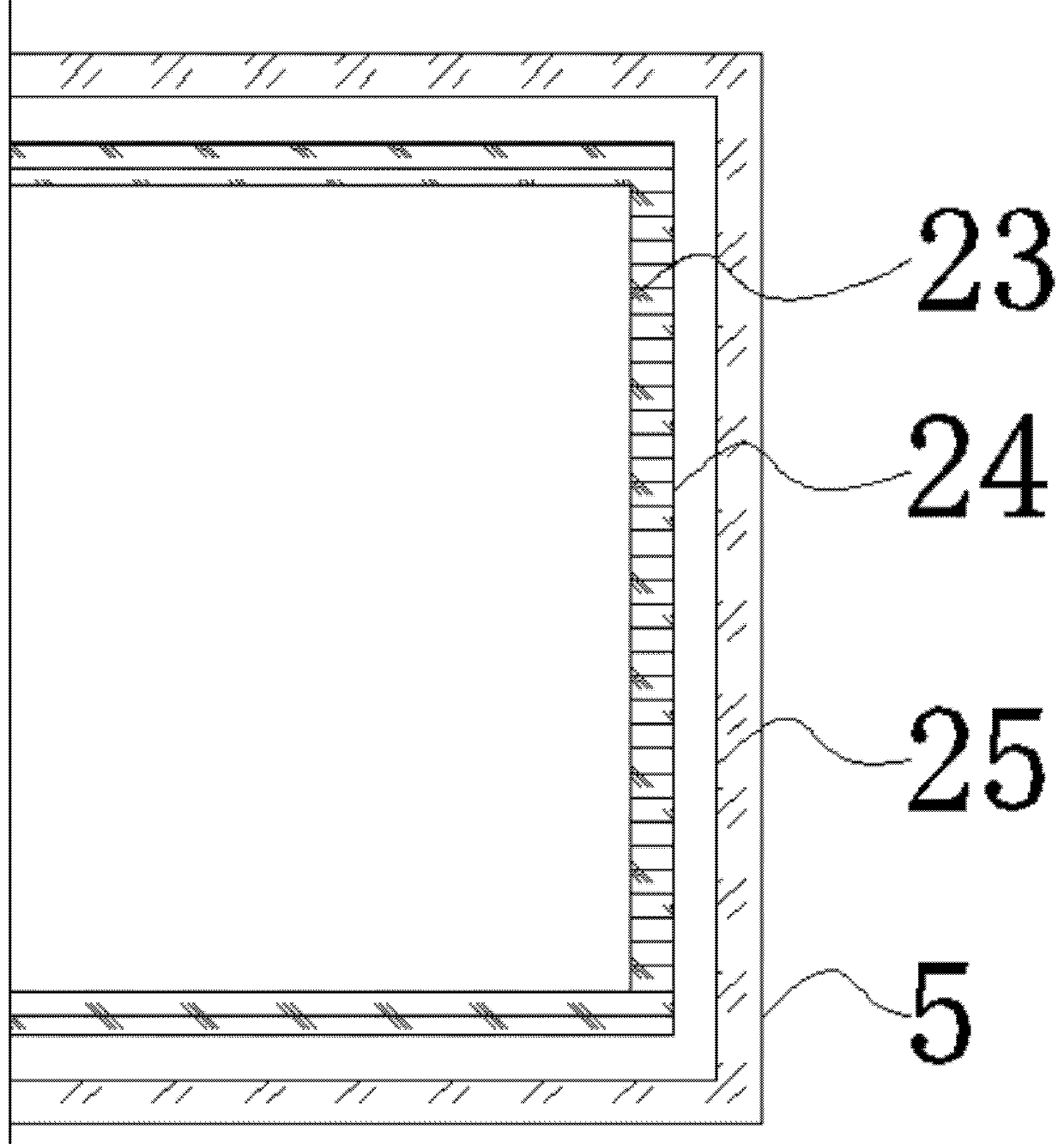

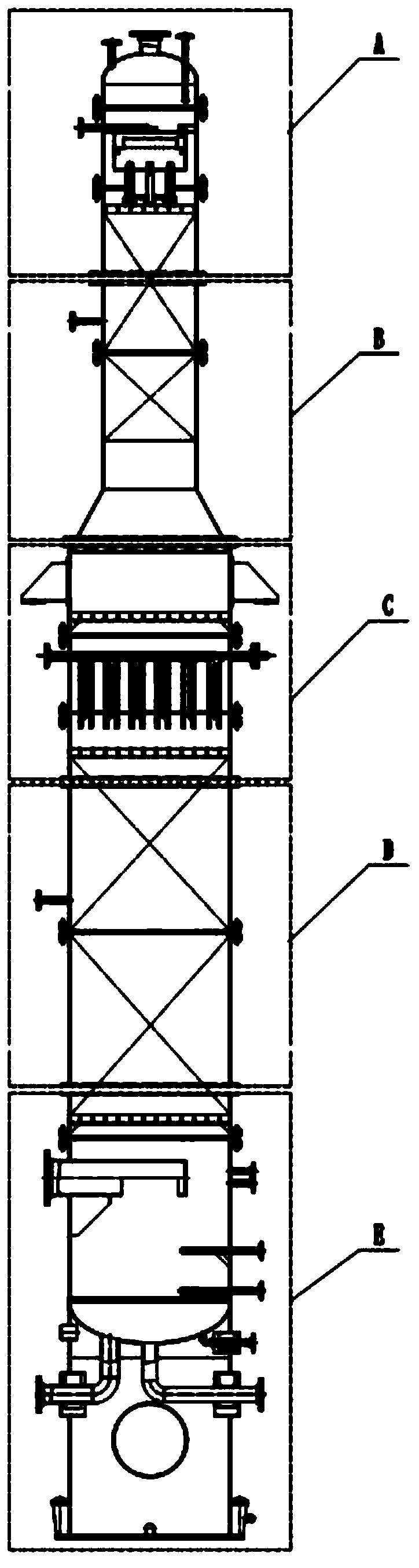

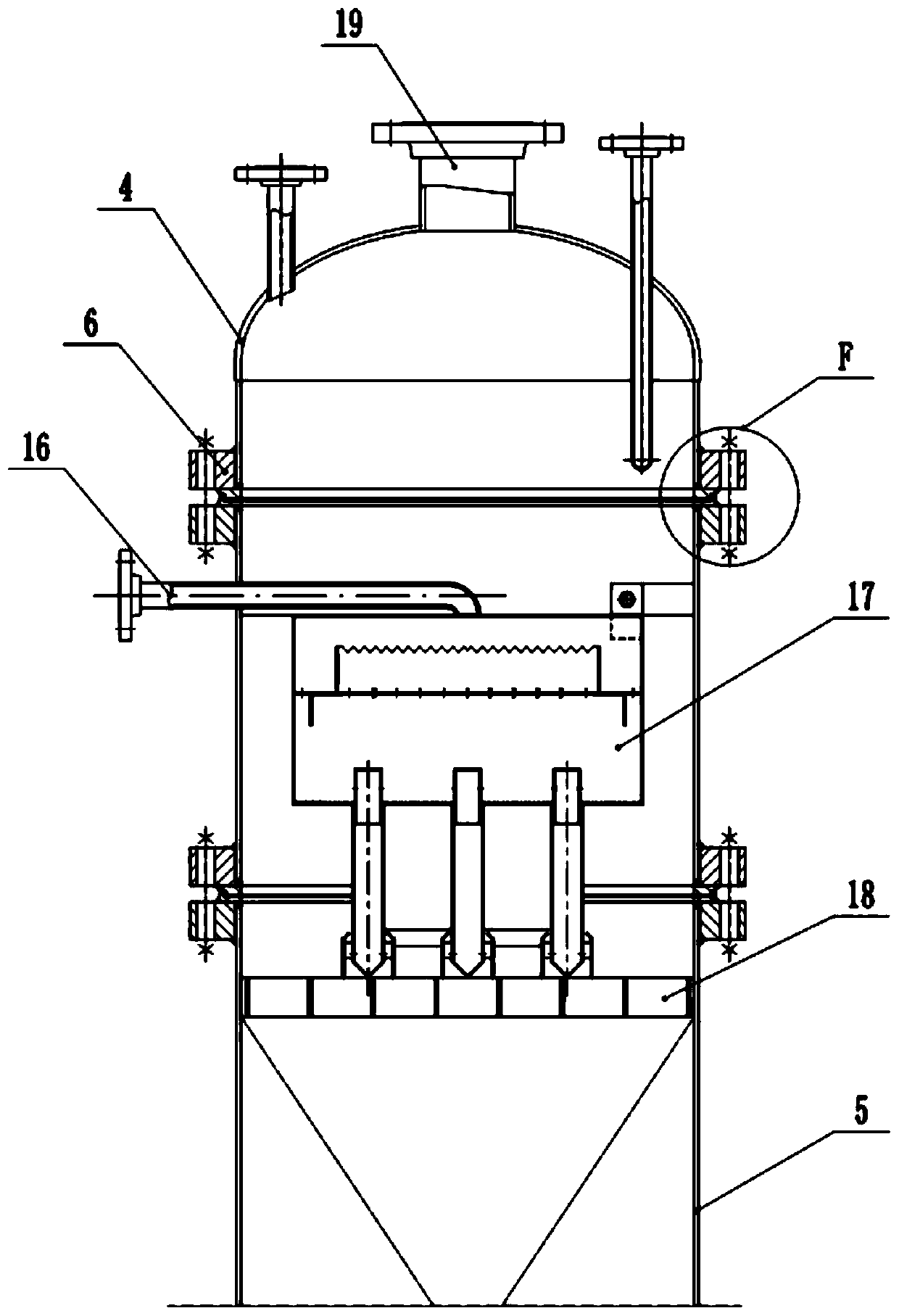

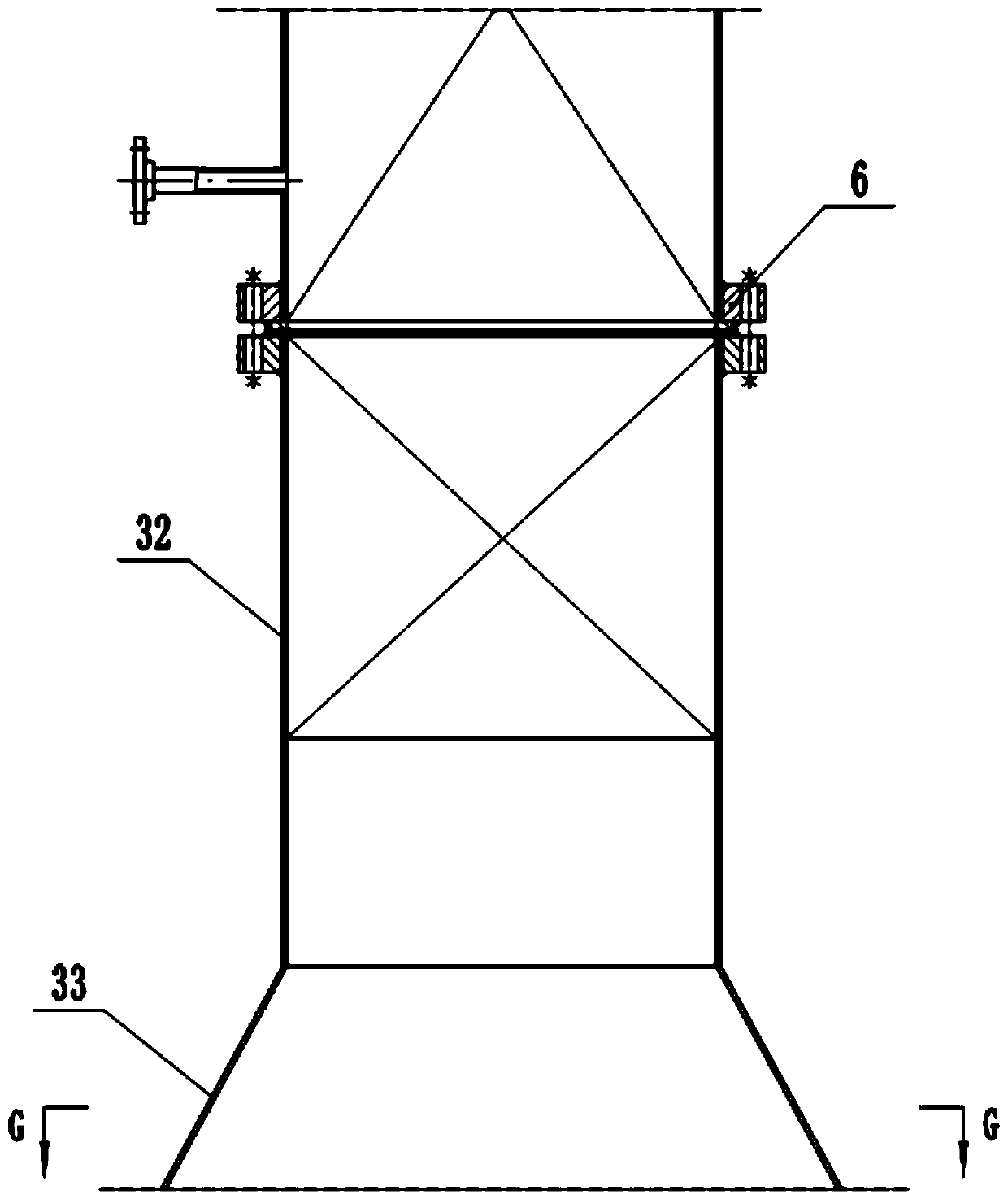

Scraper type molecular distillation device

The invention discloses a scraper type molecular distillation device, which comprises a body and a condenser; the body is provided with a partition, the partition is disc-shaped, and the partition divides the interior of the body into an upper cavity and a lower cavity; Two strip-shaped scrapers are installed symmetrically on the left and right sides of the bottom of the partition. The scraper is composed of a mounting plate and a number of scraping blocks, and the scraping blocks are fixed on the outer surface of the scraper through the mounting plate; The scrapers are equidistantly arranged, and the scrapers are close to the inner wall of the body, and the corresponding positions of each scraper are provided with through holes that can communicate with each other; the condenser is fixedly installed inside the lower cavity, and the condenser It consists of a filter screen and a condensation funnel. In the present invention, a scraper with several scrapers is arranged on the scraper, and each scraper is provided with a through hole that can communicate with each other at the corresponding position, so as to reduce the flow velocity of the mixed solution and make the mixed solution evenly spread on the device. On the inner wall, the distillation effect is improved.

Owner:惠安县泉联智能设备技术开发有限公司

Rectification and purification device and rectification and purification method for disulphide recovery in refinery plant

ActiveCN102949861AImprove the distillation effectSimple structureOrganic chemistryOrganic compound preparationEnvironmental resistancePurification methods

The invention relates to a rectification and purification device and a rectification and purification method for disulphide recovery in a refinery plant. The device comprises a heater, an evaporator, a rectification tower, a condenser, a product tank, a reflux pump, a metering tank and an adsorption tank. The device and the method haves the following beneficial effects: according to different boiling points of disulphides, the different disulphides can be separated out by virtue of a distillation method; according to the self demands of the refinery plant, the disulphides conforming to the requirements are recovered, most of dimethyl disulfide, methyl-ethyl disulfide and the like and minority alkaline liquor and catalysts are separated out, the disulphides with very high purity are recovered, the recovery purity is above 99.9%, the disulphide recovery rate is greater than or equal to 95%, the PH(Potential of Hydrogen) is equal to 7, the Na<+> content is less than 1mg / kg, and the Co content is less than 0.1mg / L; and meanwhile, the device has the characteristics of simple structure, low cost, low maintenance cost, safety, energy conservation, good disulphide rectification effect, environmental friendliness, economical efficiency, capability of adbsorbing harmful gas, and no pollution.

Owner:NINGBO ZHONGYI PETROCHEM TECH

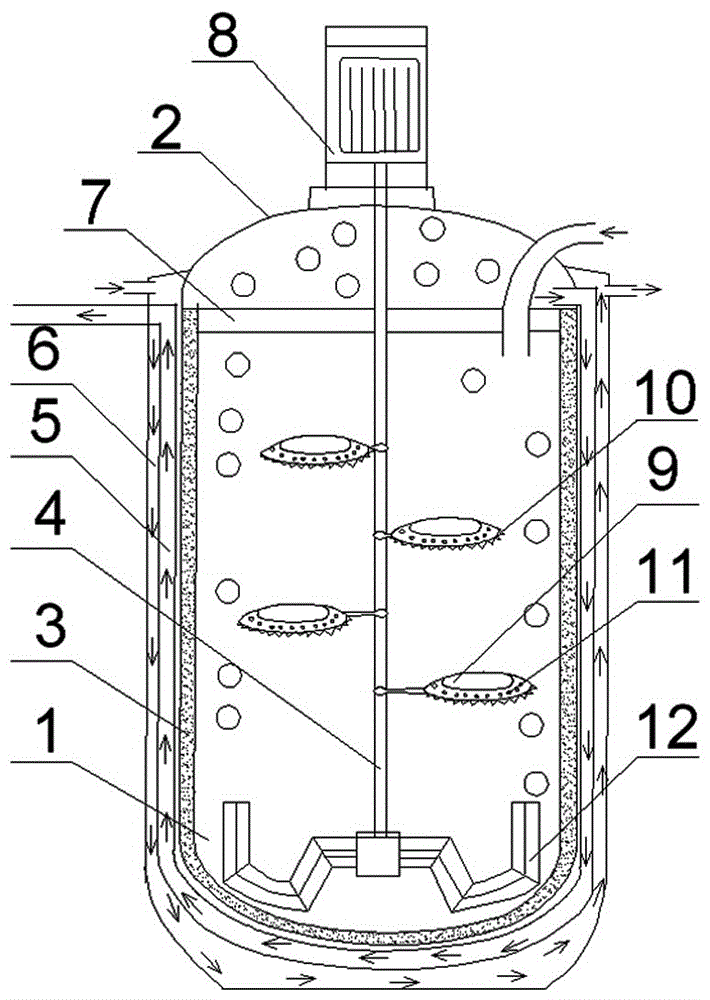

Liquid distillation device

InactiveCN106730971AStir quicklyImprove stirring efficiencyRotary stirring mixersTransportation and packagingDistillationEngineering

The invention discloses a liquid distillation device. The liquid distillation device comprises a tank body, wherein a discharging hole is formed in the bottom of the tank body; an upper sealing cover is connected above the tank body; a feeding hole is formed in the upper sealing cover; a distillation cavity is formed between the tank body and the upper sealing cover; a stirring tool is mounted at the center of the distillation cavity; the stirring tool is connected with a motor; the stirring tool mainly comprises a rotary shaft; a stirring blade is mounted at the bottom of the rotary shaft; a plurality of clamps are arranged in the middle of the rotary shaft; the distances among the plurality of clamps are equal; stirring discs are mounted on the clamps; a condensation device is arranged outside the tank body; the condensation device comprises a steam through pipe and a condensation channel; the steam through pipe is communicated with the tank body. According to the liquid distillation device, the stirring discs can be used for rapidly stirring distilled liquid at the upper part of the tank body; the stirring efficiency is improved and the distillation effect is accelerated.

Owner:成都兆丰斯诺科技有限公司

Air separation device for large liquid amount preparation and method

PendingCN108759311AGuaranteed uptimeSatisfy the cooling capacitySolidificationLiquefactionAir filterAir compressor

The invention relates to an air separation device for large liquid amount preparation and a method. The air separation device comprises an air filter, an air compressor, a purification unit, a supercharger, a high-low-temperature supercharged turbine expander and a cryogenic separation cold box unit. Compressed air directly undergoes heat exchange and then enters a lower tower partially, and undergoes supercharging by the supercharger and then is cooled and throttled to enter the lower tower partially, air pumping is carried out in the supercharger, the air undergoes double-supercharging double-expansion of the high-low-temperature supercharged turbine expander and then enters the lower tower, the product oxygen and the product nitrogen adopt a double-pump internal compression process, andan argon-making system adopts an oxygen-enriched liquid air total-reflux form. According to the disclosed method of the air separation device for large liquid amount preparation by cryogenic separation, the step of air pumping in the supercharger and the step of enabling the air to undergo double-supercharging double-expansion of the high-low-temperature supercharged turbine expander and then toenter the lower tower are adopted, the product oxygen and the product nitrogen adopt the double-pump internal compression process, and the argon-making system adopts the total-reflux form, so that therequirement of large liquid amount air separation large cooling capacity is well met, the circulation of the material flow is fully utilized, the equipment is reduced, the energy consumption is reduced, and the extraction rate is improved.

Owner:KAIFENG AIR SEPARATION GROUP

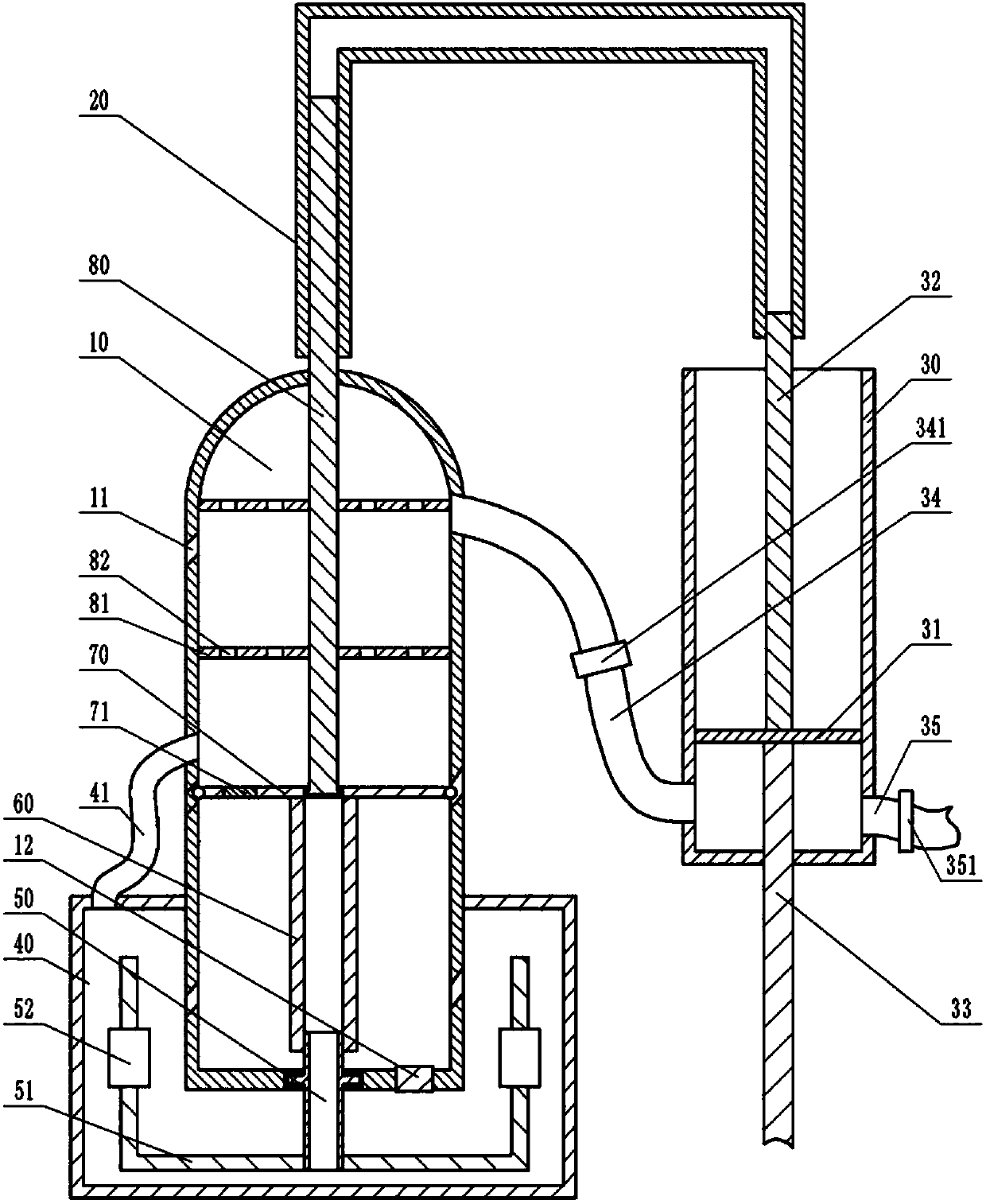

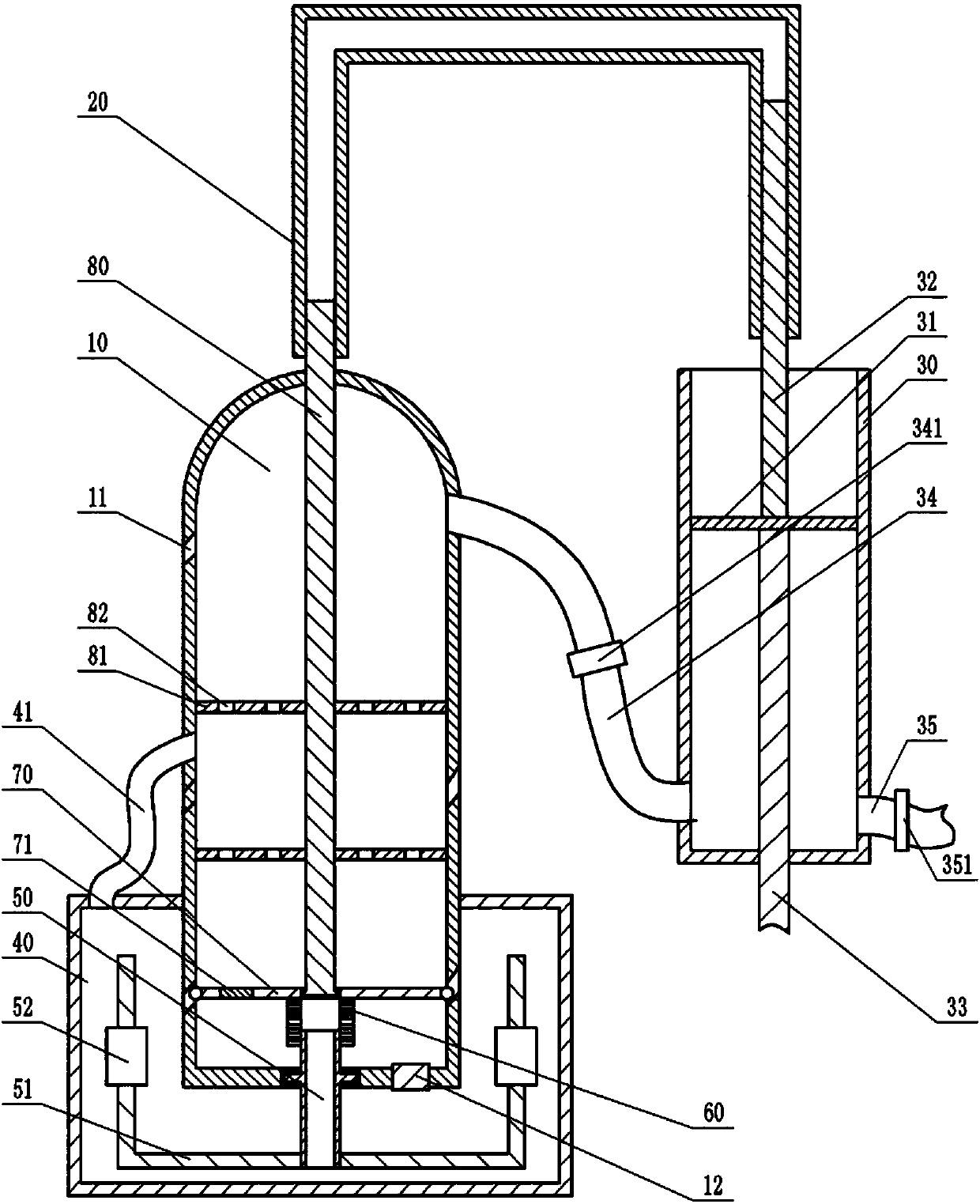

Method for alcohol distillation and extraction on fermented wine material

InactiveCN111218377AImprove loading and unloading efficiencyImprove the distillation effectAlcoholic beverage preparationAqua vitaeAlcohol

The invention discloses a method for alcohol distillation and extraction on a fermented wine material. The method comprises the steps that a jacking mechanism drives a wine material loading mechanismto rise until a bottom wine material loading assembly is located in a main housing, rest wine material loading assemblies are located outside the main housing, and then wine materials are dumped to the inner part of the main housing; the jacking mechanism drives the wine material loading mechanism to fall until the wine material loading assembly which is the second from bottom to top is located inthe main housing, and the rest wine material loading assemblies above the wine material loading assembly are located outside the main housing; the wine material is dumped into the main housing, and the operations are reciprocated; high-temperature vapour flows to the inner part of the main housing, and alcohol steam is traced to flow to condensing equipment; after distillation is completed, the jacking mechanism drives the wine material loading mechanism to slowly rise, and personnel stir the waste wine material to the inner part of a discharging housing through tools of scoops and the like;and besides, discharging structural members are assisted for pushing the waste wine materials in the discharging housing to a discharging cylinder, and the waste wine materials are finally led by a cylinder housing to be discharged.

Owner:六安七茗道机电科技有限公司

Process and device for purifying and recovering acetic acid waste liquid

PendingCN110183325AReduce productionReduce installation costsCarboxylic compound separation/purificationAcetic acidEconomic benefits

The invention provides a process and device for purifying and recovering acetic acid waste liquid. An acetic acid rectifying tower is connected with a rectifying kettle, the rectifying kettle is connected with a tower top primary condenser, the tower top primary condenser is connected with a tower top secondary condenser, the tower top secondary condenser is connected with a reflux ratio controller, the reflux ratio controller is connected with the rectifying kettle, the reflux ratio controller is connected with an acetic acid to-be-detected tank, the acetic acid to-be-detected tank is connected with a front fraction tank, and the acetic acid to-be-detected tank is connected with an acetic acid finished product tank. The bottom of the front fraction tank is divided into two channels, one channel is connected to a middle tank, and the other channel is connected to the acetic acid rectifying tower. By adopting the method, the concentration of the acetic acid with low concentration reaches 98.5% after the acetic acid with low concentration is concentrated, the waste liquid which is difficult to treat originally is changed into industrial-grade acetic acid, and thus, good economic benefits are obtained.

Owner:YICHANG SUPENG TECH CO LTD

Waste solvent oil separation process

ActiveCN107698420AHeating evenlyGuaranteed normal operationOrganic compound preparationDistillation purification/separationSteam pressureDistillation

The invention belongs to the technical field of solvent recovery and particularly discloses a waste solvent oil separation process. The waste solvent oil separation process comprises the following steps: (1) performing normal temperature distillation, namely performing normal temperature distillation on waste solvent oil by adopting a distilling apparatus, and distilling to obtain liquid containing xylene and n-butyl acetate; (2) performing magnetization treatment, namely pumping the liquid obtained in the step (1) into a closed magnetization pipe to perform circulating magnetization treatment, and circulating for 4-8 times; (3) performing intermittent fractionation, namely performing intermittent fractionation on the liquid obtained in the step (1) in a rectifying tower reactor, opening condensate water, connecting a heating power supply, and heating the tower reactor, wherein the rectification parameters are set as follows: the usage amount of circulation cooling water of 48-60m<3> / h, the steam pressure of 0.5-0.7MPa and steam consumption of 0.3-0.5t / h; (4) performing tail gas treatment. According to the process for separating waste solvent oil, the cost is low, the operation issimple, the waste solvent is subjected to repeated distillation operations, and the waste solvent can be effectively recycled.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

High-precision reduced-pressure distillation apparatus

InactiveCN107362565AReduce lossImprove the distillation effectVacuum distillation separationDistillationEngineering

The invention provides a high-precision decompression distillation device, which includes an annular sealing ring, a sealing baffle, a sealing cover, a connecting rod, an exhaust pipe, an inclined pipe, a tee pipe, a rotating blade, a condensation pipe, a waterproof motor and a filter screen. The annular sealing ring is assembled on the sealing baffle, the connecting rod is installed on the sealing baffle, the annular sealing ring is assembled on the connecting rod, the sealing cover is connected to the upper end of the sealing baffle, this design can be stirred, The right end of the exhaust pipe is connected to a three-way pipe, the lower end of the three-way pipe is provided with an inclined pipe, the right end of the three-way pipe is equipped with a condensation pipe, and a rotating blade, a waterproof motor and a filter screen are installed inside the three-way pipe. The waterproof motor is connected with the rotating blade through the filter net. This design can be used for filtering and circular distillation. The invention is easy to use and easy to operate, and can be stirred, filtered and circularly distilled.

Owner:RUIJIN RAGU TECH DEV

Water-saving solar concentrating type distillation seawater desalination device comprising RO (reverse osmosis) system

PendingCN109534585AIncrease light rateImprove conversion efficiencyBatteries circuit arrangementsGeneral water supply conservationDistillationEngineering

The invention discloses a water-saving solar concentrating type distillation seawater desalination device comprising a RO (reverse osmosis) system. The device comprises a frame, two sets of symmetrical fixing bases are fixedly connected to the bottom surface of the frame, a fixing block is fixedly connected to the bottom surface of each fixing base, a support is fixedly connected to the bottom surface of each fixing block, a gasket is arranged on the outer side surface of each support, a pin shaft is arranged in each support, a wheel is arranged on the lower portion of each support, and each wheel is fixedly hinged to the corresponding support through the corresponding pin shaft. According to the water-saving solar concentrating type distillation seawater desalination device comprising theRO (reverse osmosis) system, the wheels are arranged, under the action of the fixing bases, the supports, the fixing blocks, the gaskets, the pin shafts and brake pads, a solar cell panel group can be moved to a place where lighting is convenient, so that the illumination rate is improved, the solar cell panel group is arranged, and under the action of a solar controller, an inverter and a storage battery, the solar energy conversion efficiency is improved.

Owner:海南自贸区浩天能环境工程有限公司 +1

Separation method of 1,3-propylene glycol fermentation liquid

ActiveCN101875598AAccelerated precipitationSimple processOrganic compound preparationHydroxy compound separation/purificationDistillationFiltration

The invention relates to a separation method of 1,3-propylene glycol fermentation liquid, comprising the following steps: removing thallus in the fermentation liquid through centrifugation or membrane filtration to obtain clear liquid; carrying out evaporation concentration on the clear liquid into a half of one twelfth of the original volume to obtain mother liquid; adding one or more C1-C4 alcohol or C3-C5 ketone based on the volume ratio of 1:0.5-1:5, cooling to 30-35 DEG C, and then adding a seed crystal, wherein the mass of the seed crystal is 0.05-1% of that of the mother liquid; continuously cooling to minus10-10 DEG C with the velocity of 2-20 DEG C / h, separating out precipitate, extracting the clear liquid through a side line or filtering or removing the precipitate by centrifugation with the velocity of 1000-5000rpm, taking supernate, and then recovering the alcohol or the ketone by distillation or rectification; and finally decompressing and rectifying to obtain 1,3-propylene glycol. The separation method has simple process and operation, high product yield and high purity; and the method can be widely applied to producing the 1,3-propylene glycol product by a fermentation method.

Owner:PETROCHINA CO LTD

Method for producing high-purity optical isoamylol through decompression and rectification and technical process thereof

ActiveCN102010292AChanging the relative volatilityImprove the distillation effectOrganic compound preparationHydroxy compound preparationGas phaseReboiler

The invention relates to a method for producing high-purity optical isoamylol through decompression and rectification. The method comprises the following steps of: lowering the operating pressure of input materials to be separated through a vacuum system by using a decompression and rectification tower and a tower-top condenser; increasing the relative volatility of optical isoamylol and isoamylol; dividing the optical isoamylol and isoamylol passed through the decompression and rectification tower into a gas-phase substance at the tower top and a liquid-phase substance at the tower bottom under the heat and mass transferring function; and setting a thermosyphon reboiler at the bottom of the decompression and rectification tower so that the gas-phase substance and liquid-phase substance flow back and are in reverse multistage contact. The invention solves the technical problems of low separation efficiency, complex process, high processing cost, and the like in the traditional separation method.

Owner:QINGDAO UNIV OF SCI & TECH

Purification method for trifluoromethane

ActiveCN103896717ATo achieve the purpose of vaporizationImprove qualityPreparation by halogen replacementPurification methodsLatent heat

The invention provides a purification method for high-purity trifluoromethane. The method comprises the following steps: carrying out condensation and separation on a reaction product by using latent heat of a reaction raw material HCFC-22 and then carrying out two-stage rectification so as to obtain HFC-23 with content of more than 99.99%. The method provided by the invention enables the prepared product to have high purity and has the advantages of low energy consumption and smooth, steady and safe generation technology.

Owner:SINOCHEM LANTIAN +1

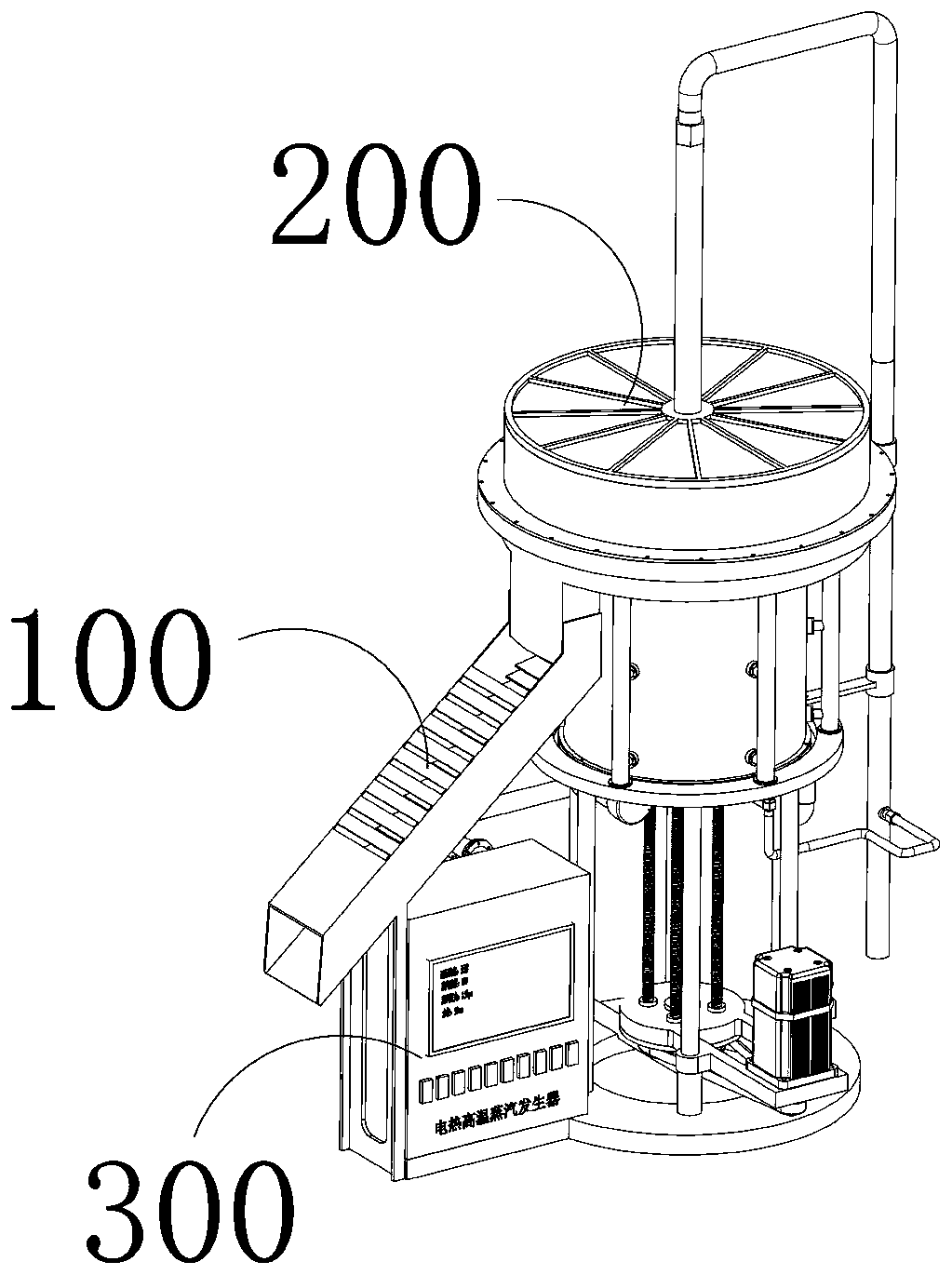

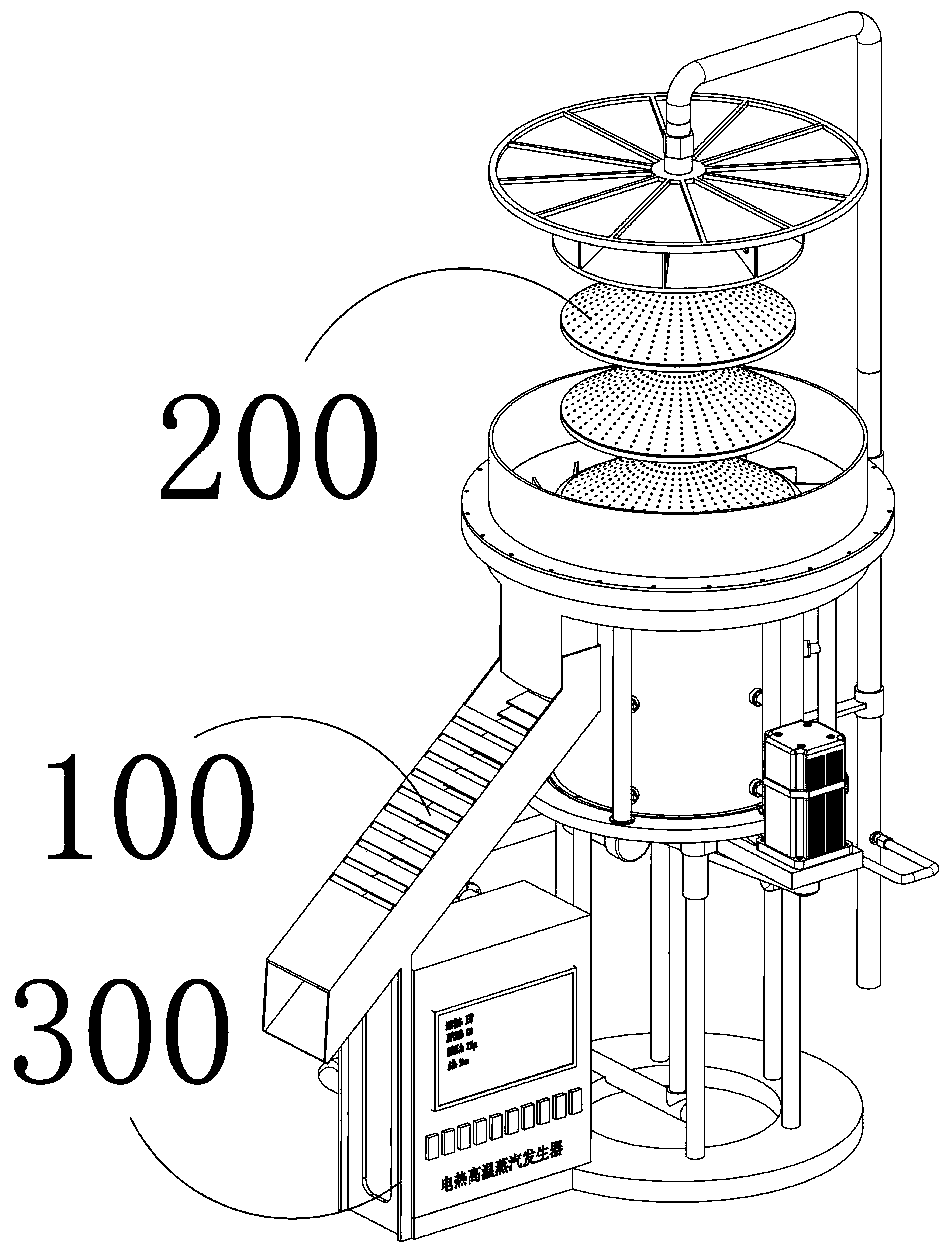

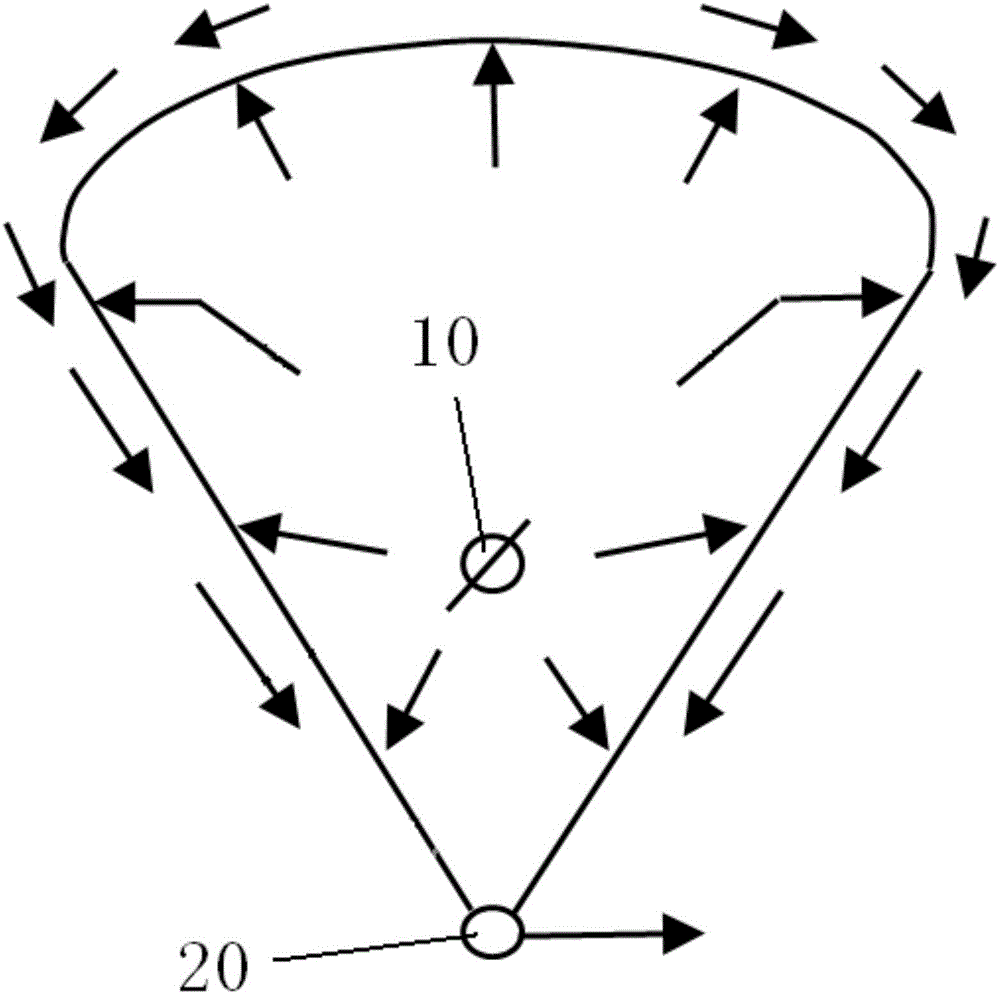

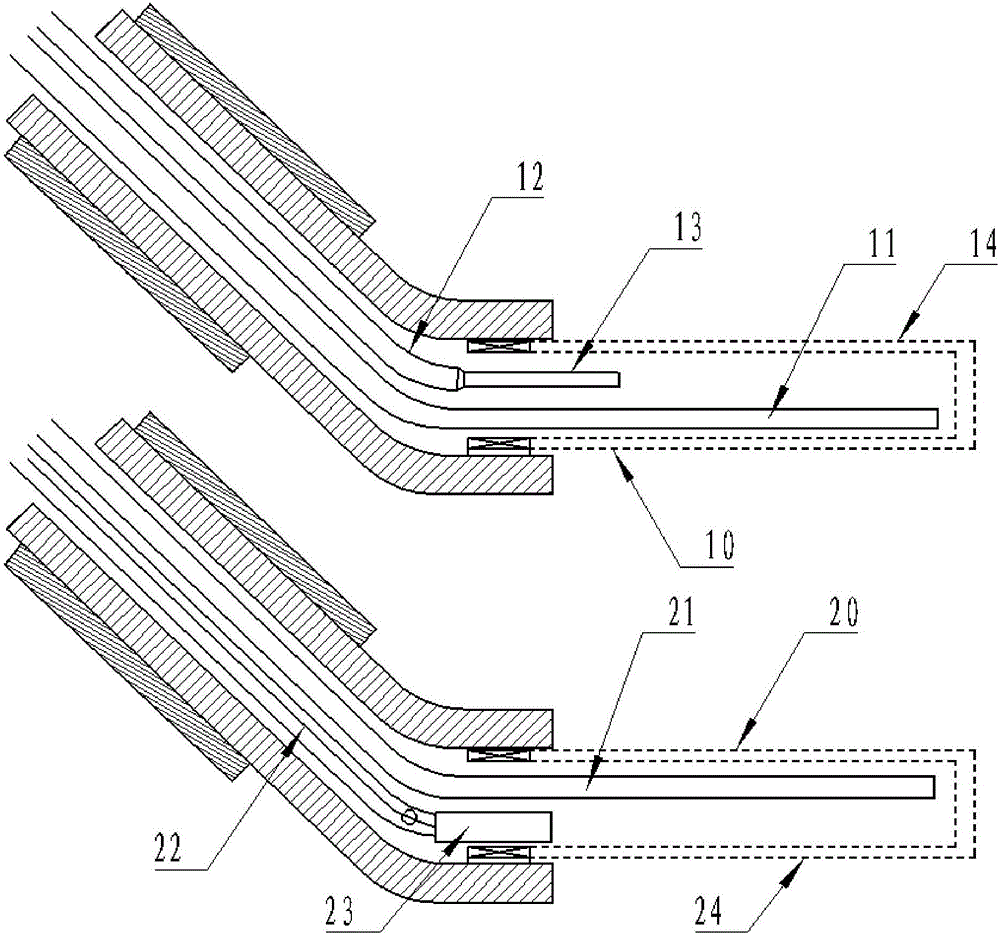

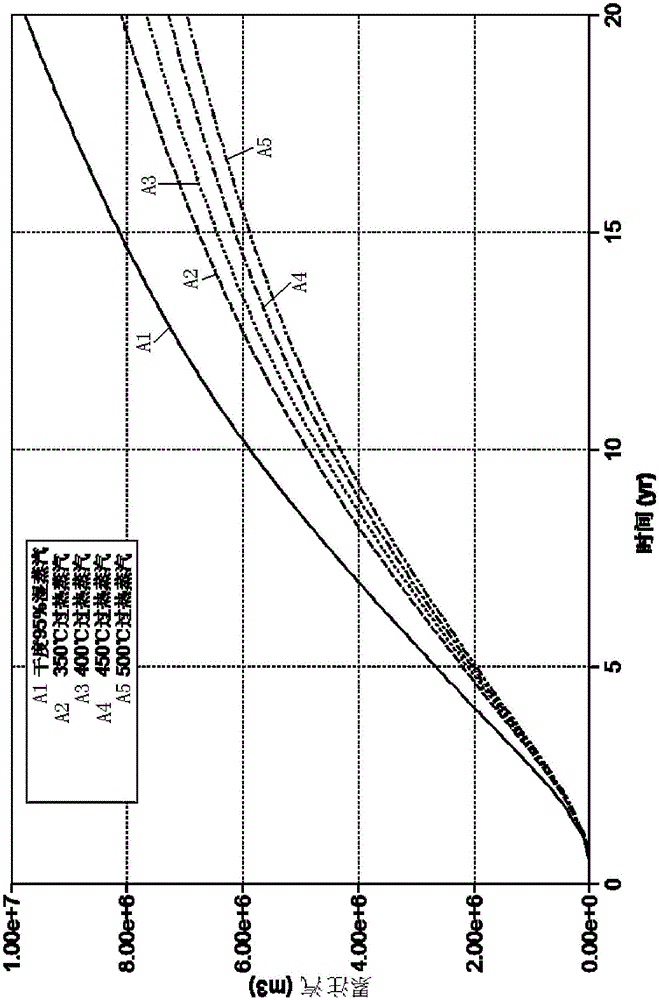

Dual-horizontal-well superheated steam assisted gravity oil drain well net and exploitation method

The invention provides a dual-horizontal-well superheated steam assisted gravity oil drain well net and an exploitation method. The dual-horizontal-well superheated steam assisted gravity oil drain well net comprises a first horizontal well (10) and a second horizontal well (20); a first long pipe column (11) and a first short pipe column (12) are arranged in the first horizontal well (10); and a second long pipe column (21) and a second short pipe column (22) are arranged in the second horizontal well (20). According to the dual-horizontal-well superheated steam assisted gravity oil drain well net and the exploitation method, a superheated steam assisted gravity oil drain mode is adopted, the problems that in the wet and saturated steam injection process, the heat utilization rate is low, the oil-steam ratio is low, and a reservoir stratum is damaged are solved, the heat utilization rate and the oil-steam ratio are increased, and the exploitation effects of a super heavy oil reservoir and a oil sand reservoir stratum are improved.

Owner:PETROCHINA CO LTD

Efficient distillation equipment suitable for mass production of cinnamomum petrophilum oil

InactiveCN106167741AIncreased load-bearing capacityHigh strengthEssential-oils/perfumesDistillationHearth

The invention relates to the field of distillation equipment, in particular to efficient distillation equipment suitable for mass production of cinnamomum petrophilum oil. The distillation equipment for cinnamomum petrophilum can greatly increase one-time processing amount and increase distillation efficiency. The efficient distillation equipment comprises a hearth, a distillation pot is disposed on the hearth, a fuel inlet and an annular flue are arranged on the side face of the hearth, the annular flue is connected to a soot treatment device through a soot pipe,, a backflow pipe is arranged on the side all of the distillation pot, a multi-layer steaming drawer is disposed on the distillation pot, a steaming cover is arranged on the top layer of the steaming drawer, an air gathering port is arranged at the top of the steaming cover, a plurality of air holes are evenly distributed at the bottom of the steaming drawer, and lifting lugs are arranged on the peripheral surface of the distillation pot, the steaming drawer and the steaming cover. The efficient distillation equipment is suitable for mass production of cinnamomum petrophilum oil.

Owner:PENGXI MINXIN CINNAMOMUM SUBAVENIUM MIQ CO LTD

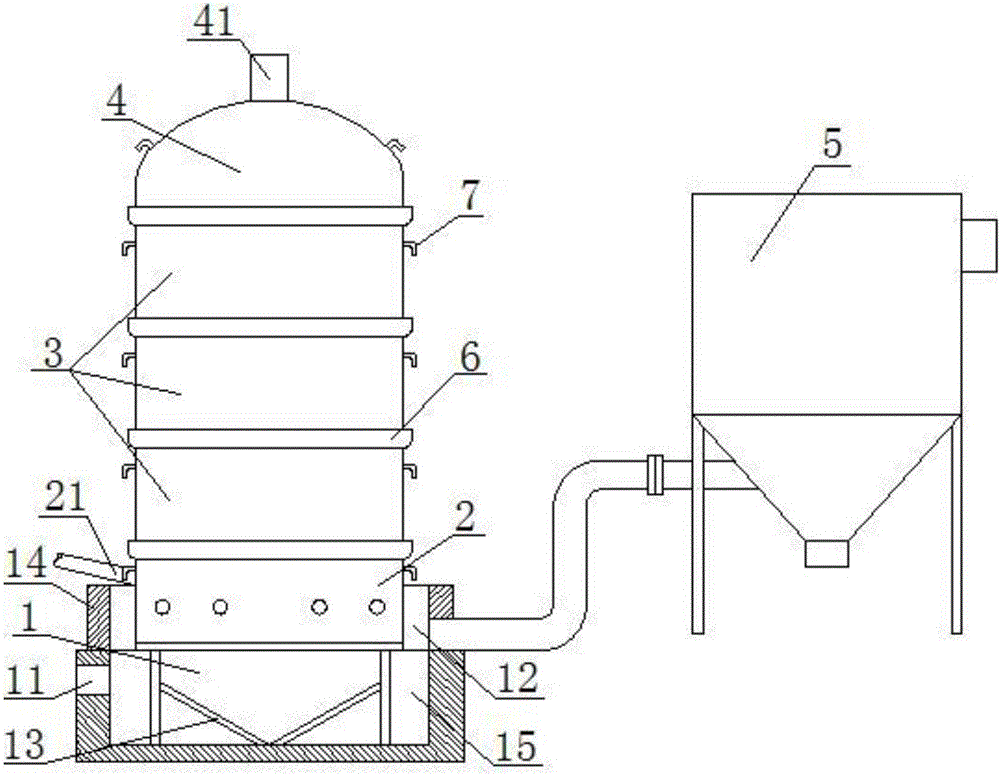

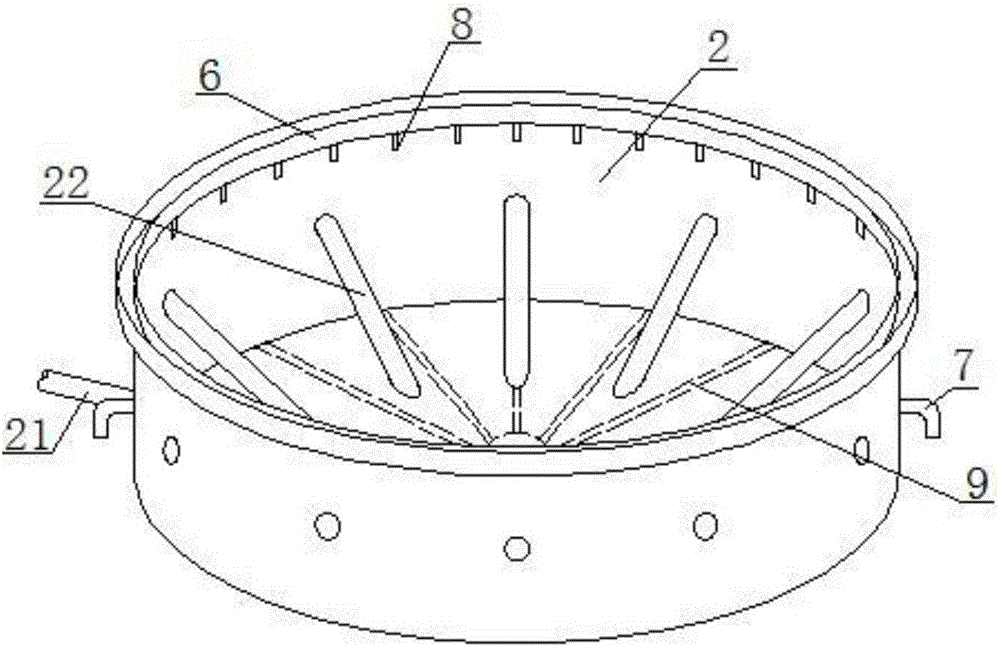

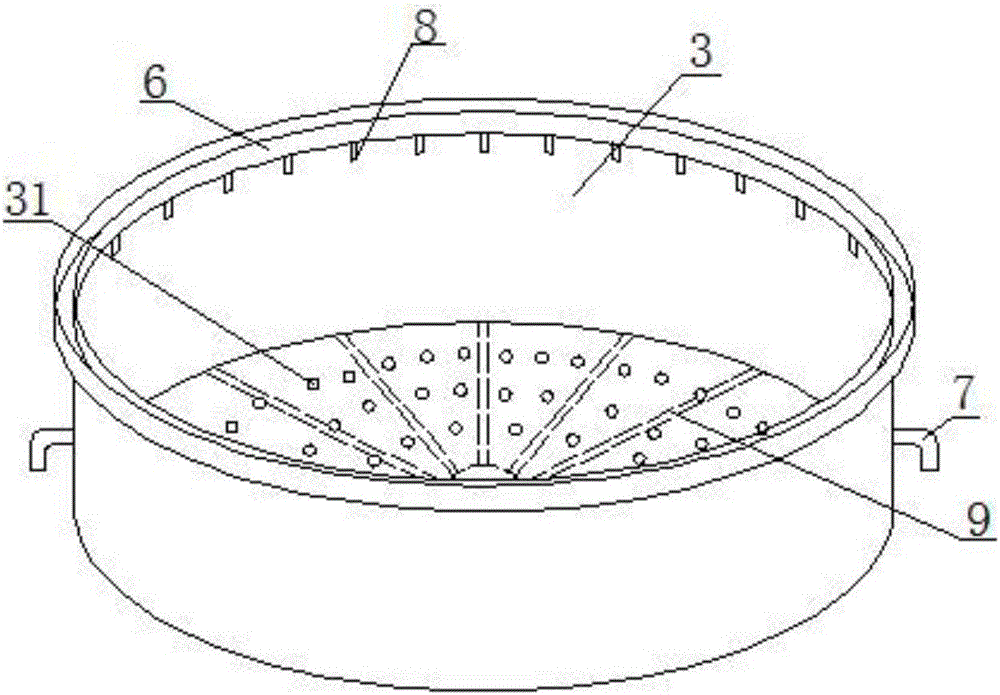

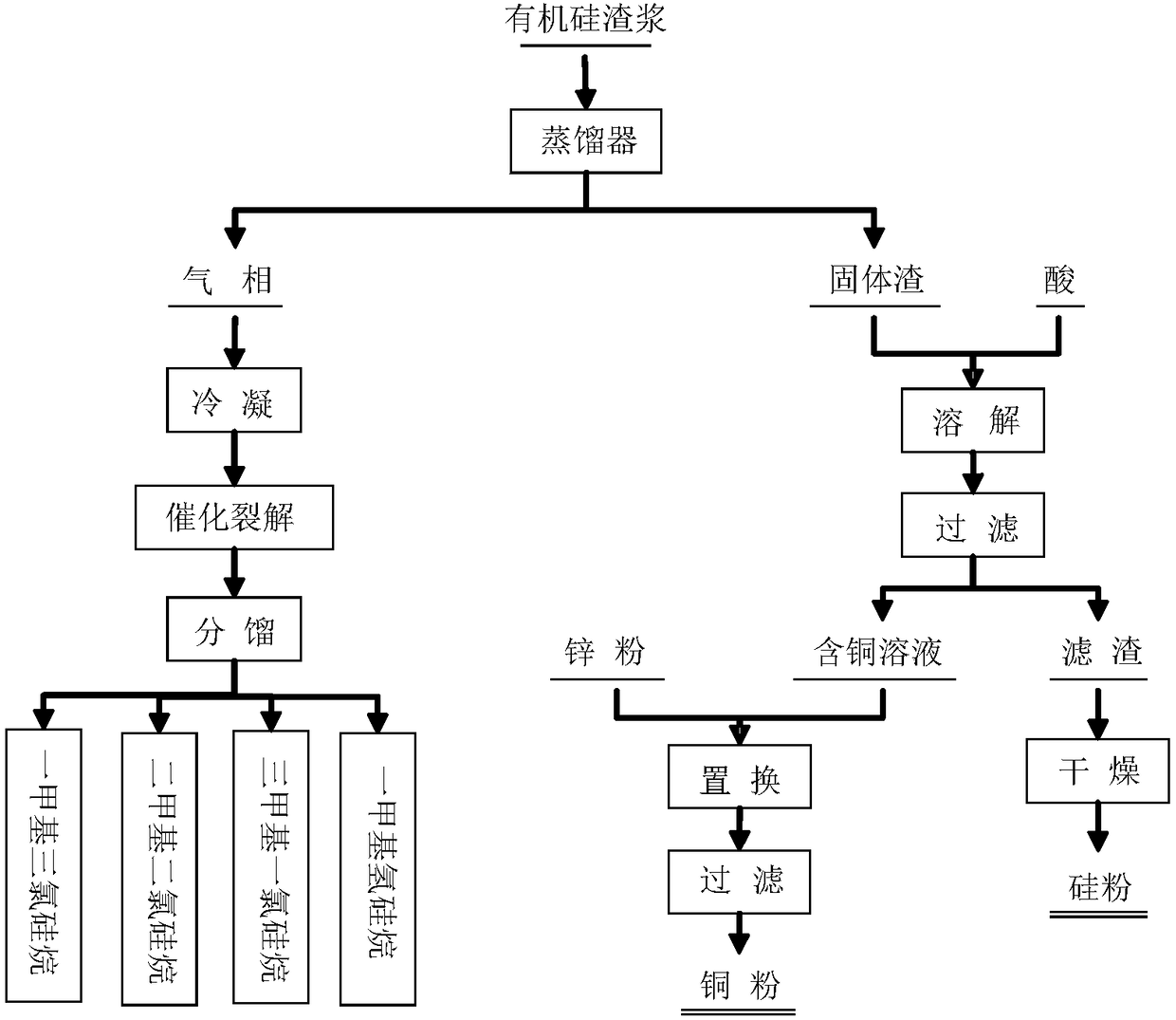

Method and equipment for comprehensive recycling treatment on organic silicon slag slurry

ActiveCN108558928AAchieve separationEasy to recycle separatelySilicon organic compoundsSilicon compoundsGas phaseSlag

The invention discloses a method and equipment for comprehensive recycling treatment on organic silicon slag slurry. The method comprises the following steps: 1, separating organic silicon slag slurryby using a distiller so as to obtain gas-phase high-boiling residues and solid residues; 2, dissolving the solid residues with an acid, and after dissolution is completed, carrying out filtration andseparation so as to obtain a copper-containing solution and filter residues; 3, washing the filter residues obtained in the step 2, and drying so as to obtain silicon powder; 4, putting zinc powder into the copper-containing solution separated in the step 2 to carry out replacement so as to obtain metallic copper powder; 5, condensing the gas-phase high-boiling residues obtained in the step 1 soas to obtain liquid high-boiling residues, and carrying out catalytic cracking on the liquid high-boiling residues with a catalyst; 6, carrying out fractionation on a gas phase obtained through catalytic cracking in the step 5, and collecting monomethyl trichlorolsilane, dimethyl diclorossilane, trimethylchlorosilane and monomethyl hydrosilane. By adopting the method and the equipment, copper andsilicon resources in organic silicon slag can be effectively recycled, thus being environmental-friendly and economic.

Owner:CHENGDU SILICON TECH CO LTD

Production technology of strong-flavor Chinese liquor

InactiveCN106929374AStrong fragranceSoft and sweet in the mouthAlcoholic beverage preparationYeastFlavor

The invention brings forward a production technology of strong-flavor Chinese liquor. The production technology comprises the following steps: weighing and treatment of main materials and auxiliary materials; burdening; steaming of materials; mixing with distiller's yeast; fermenting; distilling, etc. Through reasonable ratio of raw materials and technology improvement, liquor yield can reach 46.5%, the prepared Chinese liquor has fragrant flavor, total ester content can reach 2.88 g / L, the mouthfeel is soft and sweet, and the liquor quality is remarkably enhanced.

Owner:ANHUI YUNJIU GRP

Rose essential oil extraction device

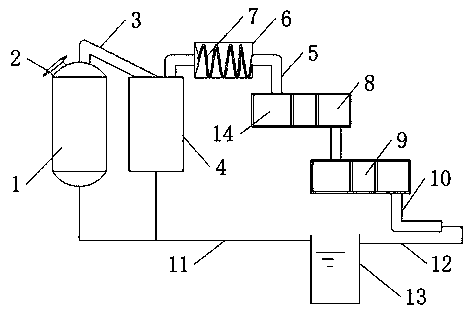

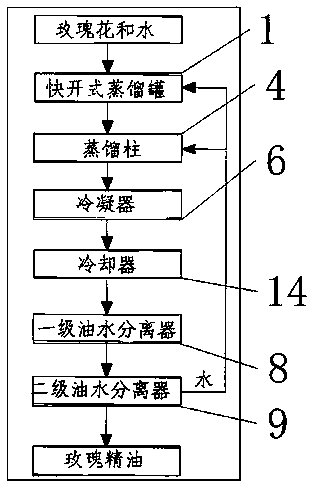

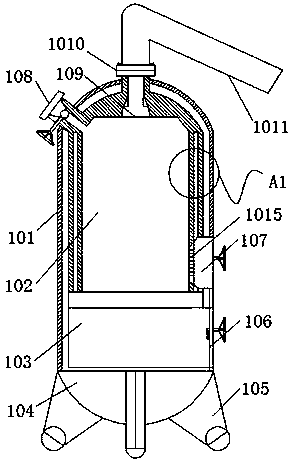

PendingCN108998244AImprove ease of useGood flow regulation functionEssential-oils/perfumesDistillation separationWater filterDistillation

The invention belongs to the field of essential oil extraction devices, and particularly relates to a rose essential oil extraction device. The device comprises a distillation tank; an intercepting pipe is arranged at the top of the distillation tank; a distillation column is arranged at the bottom end of one side of the intercepting pipe; end parts of the interception pipe are respectively embedded into the distillation tank and the distillation column; the distillation tank and the distillation column both communicate with the intercepting pipe; a condensation pipe is arranged at the top ofthe distillation column; a condenser is arranged in the middle of the condensation pipe; one side of the bottom end of the condensation pipe is provided with a cooler; the cooler the distillation column both communicate with the condensation pipe; a primary oil-water separator is arranged at the adjacent side of the cooler; a secondary oil-water separator is arranged at one end of the primary oil-water separator; the bottom of the secondary oil-water separator is provided with a water filter pipe; the end of the water filter pipe sleeves a collecting pipe; the secondary oil-water separator andthe collecting pipe both communicate with the water filter pipe; and a distilled water storage tank is arranged on the side face of the collecting pipe. The rose essential oil extraction device has the advantages that purification quality of essential oil is excellent, waste of water resources is avoided, the use is simple and convenient, and the like.

Owner:甘肃瑰隆生物科技有限公司

Dehydrating tower for recycling NMP waste liquid

InactiveCN111167146AIncrease in sizeEasy to installFractional distillationEnvironmental engineeringTower

The invention relates to the technical field of chemical equipment. The dehydrating tower for recycling NMP waste liquid comprises a tower base, a tower kettle, a tower body and a tower top which arefixedly connected in sequence, the bottom of the tower kettle communicates with a discharge pipe; the side wall of the tower kettle communicates with a steam pipe; the tower top communicates with a gas outlet; a filler is arranged in tower body; the tower body comprises a rectifying section and a stripping section; the rectifying section is positioned above the stripping section; the diameter of the rectifying section is 0.65-0.7 time the diameter of the stripping section; a feeding pipe is arranged on the stripping section; a liquid distributor positioned in the tower body is arranged at thefeeding pipe; a return pipe is arranged at the upper part of the rectifying section; and a reflux distributor positioned in the tower body is arranged at the return pipe. By the adoption of such a technical scheme, separation requirements on the NMP waste liquid can be met, products meeting purity requirements can be obtained, equipment size can be optimized, and equipment investment can be reduced.

Owner:重庆中润新材料股份有限公司

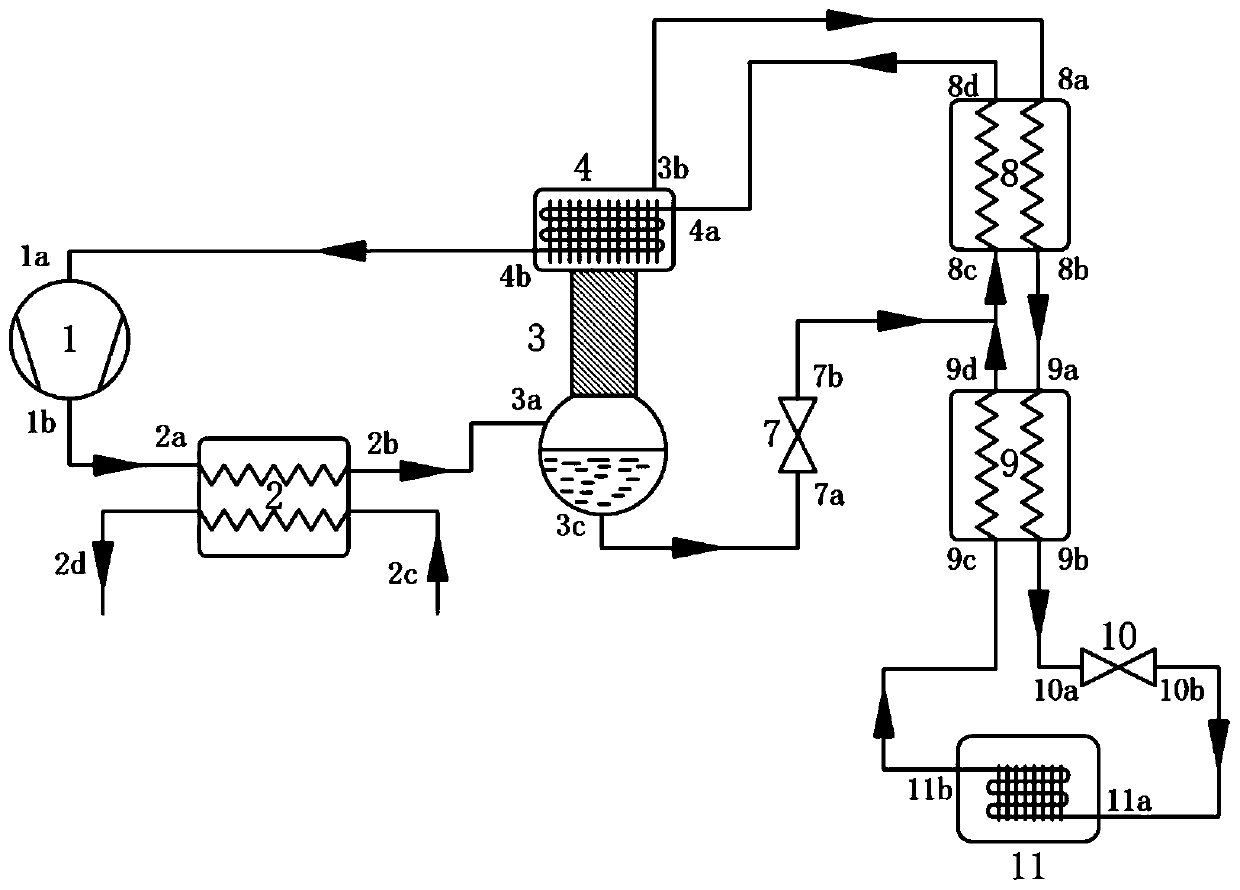

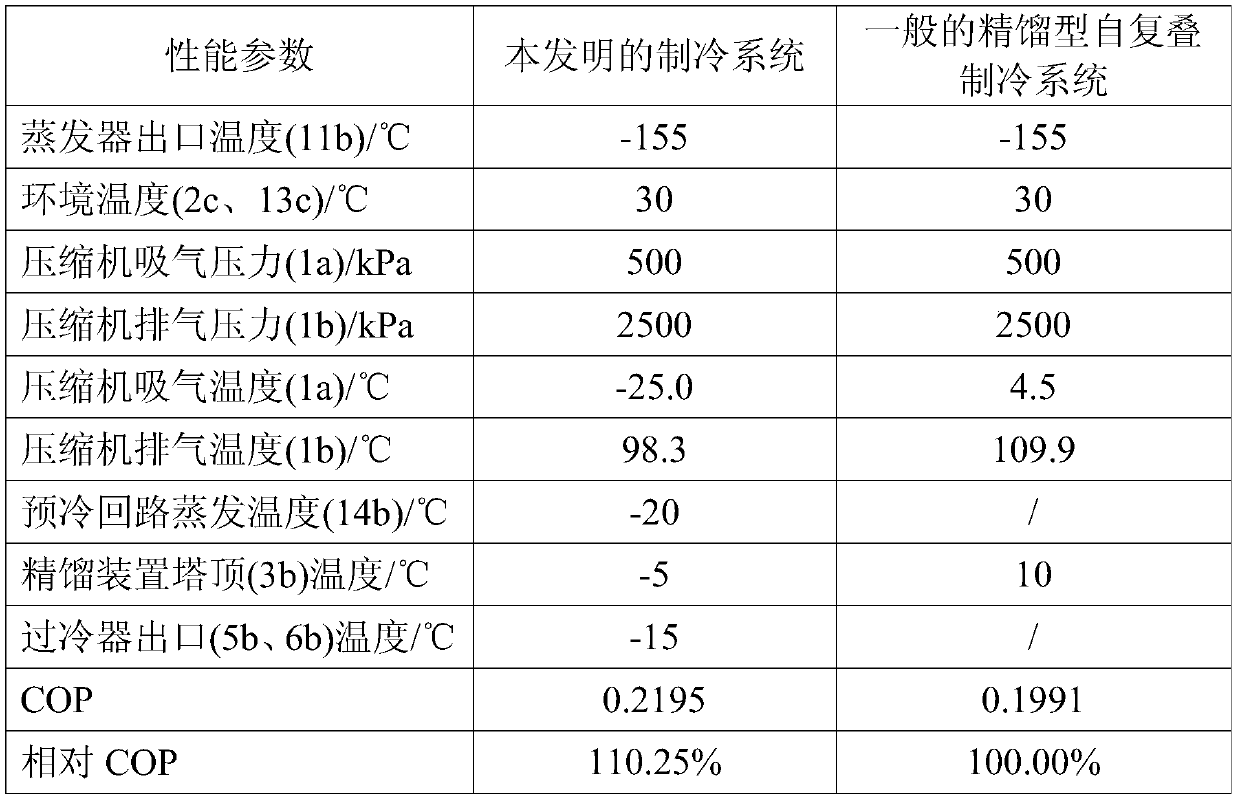

Rectification type auto-cascade refrigeration system with pre-cooling function

ActiveCN111043785AStable temperatureGuaranteed separation effectMechanical apparatusBoilers/analysersEngineeringTower

The invention relates to the technical field of refrigeration, and discloses a rectification type auto-cascade refrigeration system with a pre-cooling function. The system comprises a rectification type auto-cascade refrigeration loop and a pre-cooling loop, the pre-cooling loop is coupled with the rectification type auto-cascade refrigeration loop into a whole through a tower top subcooler, a tower top heat exchanger and a kettle bottom subcooler in the rectification type auto-cascade refrigeration loop; the cooling capacity is provided for the rectification process; the tower top temperatureof the rectifying device can be kept stable and at a target temperature; a separation effect and an oil removal effect in the rectification process are ensured; the capacity of the system for copingwith severe working conditions is enhanced, the supercooling degree is provided for working media of the tower top and the kettle bottom at the same time, the air suction temperature of a compressor is reduced, the operation working condition of the compressor is improved, reliable and stable system operation is guaranteed, the refrigeration performance coefficient of the system is increased, andthe operation cost is reduced.

Owner:ZHEJIANG UNIV

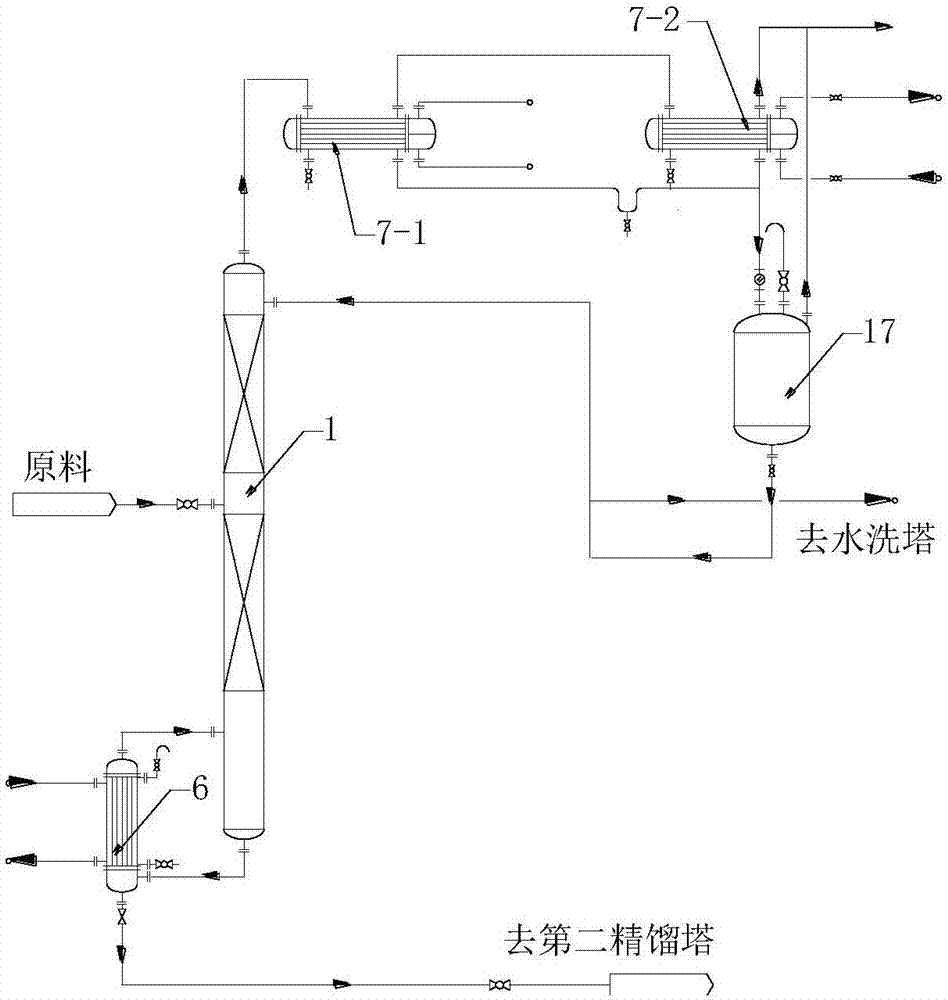

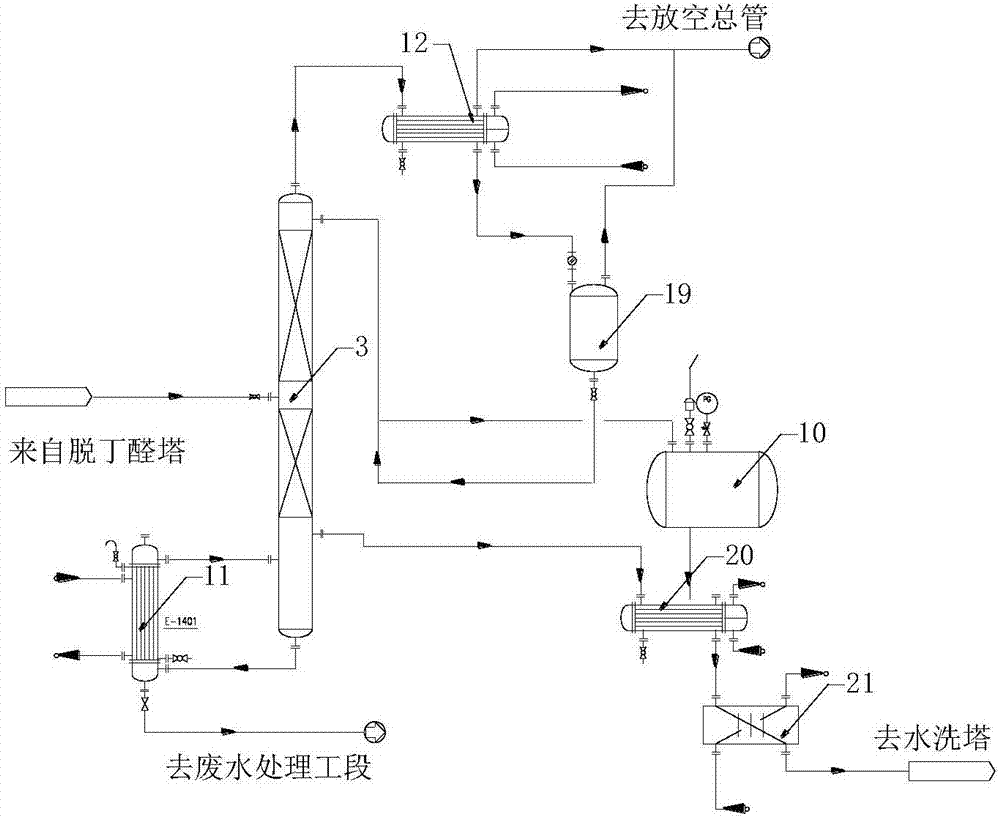

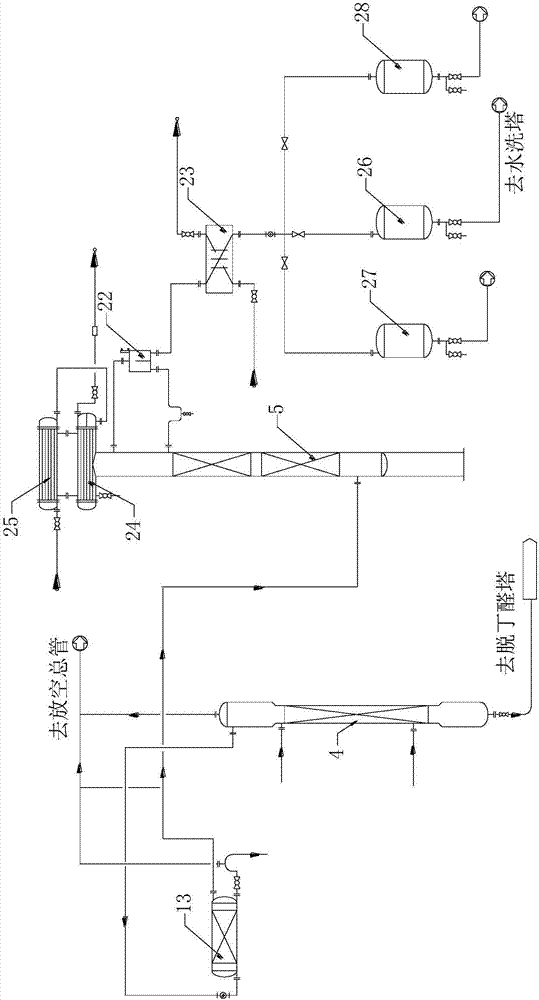

Technical method for separating butyraldehyde, ethanol and water mixture

ActiveCN107011141AEasy to operateEasy to separateOrganic compound preparationHydroxy compound preparationReboilerProcess engineering

The invention discloses a technical method for separating butyraldehyde, ethanol and water mixture. The method includes a butyraldehyde crude product separating technique, an ethanol separating technique, a water washing technique and a butyraldehyde refining technique. According to the technical scheme, a four-tower continuous rectification technique is adopted, wherein the enriched butyraldehyde is removed from a tower roof of a butyraldehyde removing tower; over 95% of ethanol product can be obtained at the roofs of a first rectification tower and a second rectification tower; a water washing tower is a fluid extraction tower, and the butyraldehyde crude product is obtained at the tower roof; the butyraldehyde crude product enters a third rectification tower to refine, and the butyraldehyde product is obtained. The whole continuous process is simple in operation, safe and controllable, good in separating effect, and suitable for industrial production; besides, a reverse three-effect rectification technique is also adopted according to the technical scheme; the steam at the first rectification tower roof is used as a hot source of a coupling reboiler of the butyraldehyde tower, and the steam at the second rectification tower roof is used as a hot source of a coupling reboiler of the first rectification tower. The steam usage and circular water usage are both reduced, the running cost is also reduced, the method is economical and environmentally friendly.

Owner:烟台国邦化工机械科技有限公司

Purification method for glacial acetic acid

ActiveCN104744233AImprove the distillation effectEasy to operateCarboxylic compound separation/purificationIodideOxide

The invention discloses a purification method for glacial acetic acid, which comprises the following steps: (1) treating crude glacial acetic acid by ozone contact to obtain a purified product; (2) adsorbing the purified product with a ZSM-5 molecular sieve; and (3) adding aliphatic tertiary amine or lactam into a product obtained after adsorption, placing the product and the aliphatic tertiary amine or lactam into rectification equipment, and rectifying the product and the aliphatic tertiary amine or lactam. According to the purification method, carbonyl impurities and other unsaturate and iodide impurities in the crude glacial acetic acid are removed by ozone contact first, then complexes or oxides formed by the carbonyl impurities, other unsaturate and iodide impurities and ozone are separated from acetic acid by the ZSM-5 molecular sieve, and finally the aliphatic tertiary amine or lactam is adopted as an extraction agent for rectification to improve the rectification effect. According to the method, operation procedures are simplified, the operation process is environment-friendly and the purity and yield of the product are guaranteed.

Owner:TAICANG HUSHI REAGENT

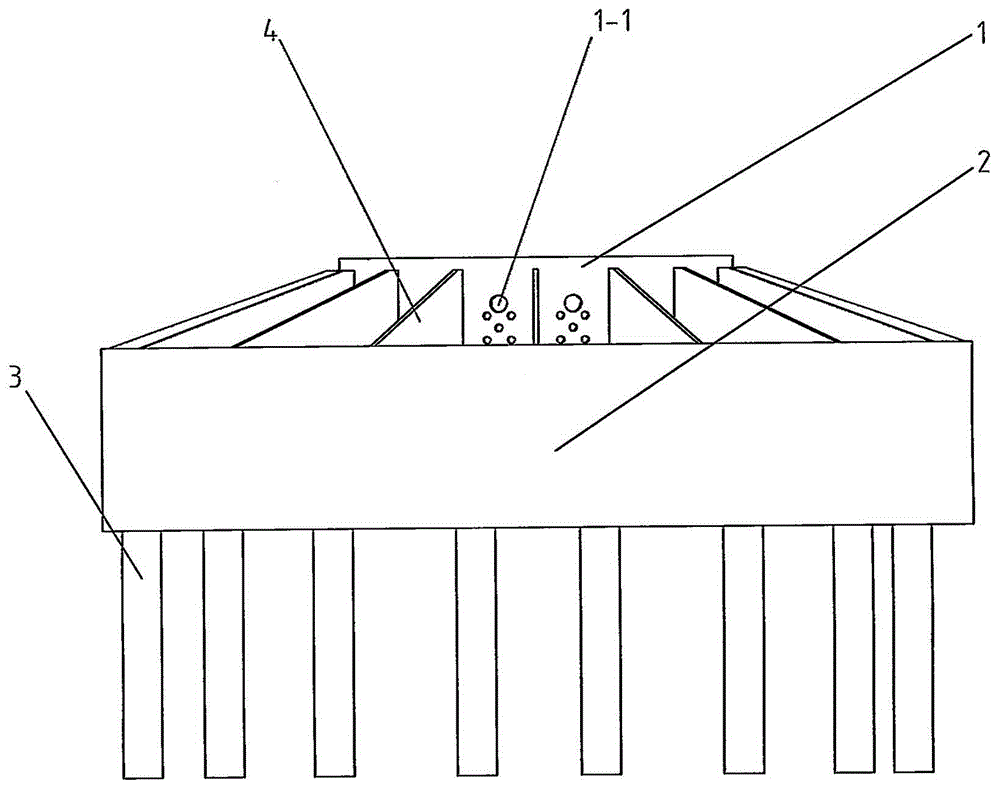

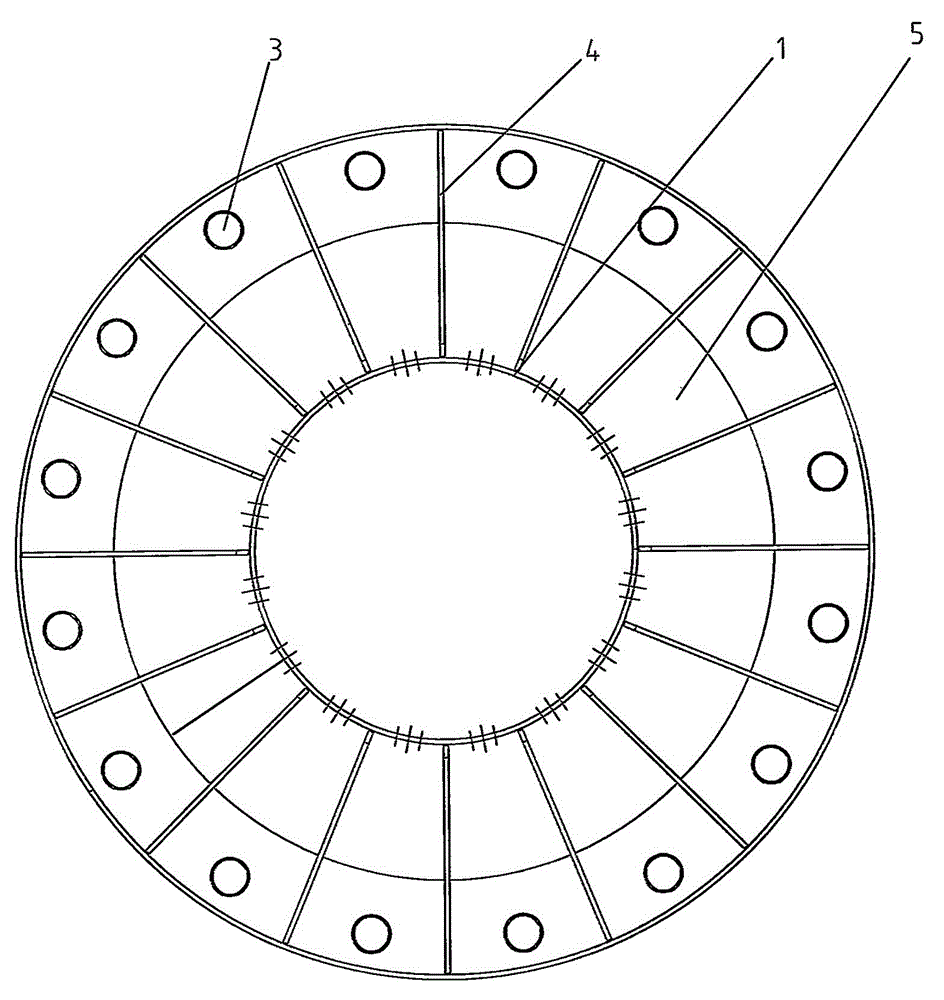

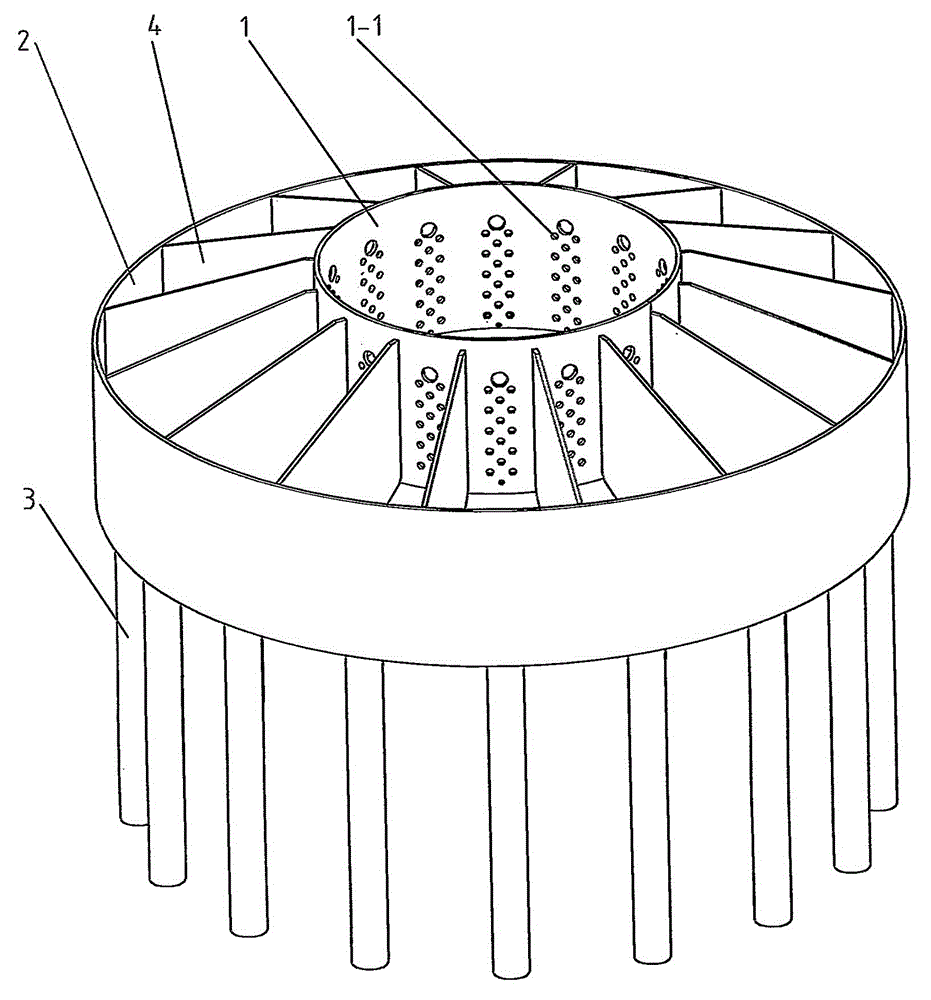

Automatic equal volume distribution device for cluster distillation reflux liquid

ActiveCN103920302BRealize automatic equal distributionGuarantee the normal operation of cluster distillationFractional distillationEngineeringTower

The invention discloses an automatic equivalent distributing device of cluster distillation reflux. The automatic equivalent distributing device of the cluster distillation reflux comprises an external groove wall, an inner reflux groove connected with a reflux discharge pipe, and a plurality of reflux flowing guide pipes; the external groove wall is positioned on the outer periphery of the inner reflux groove; a plurality of baffles which are distributed radially by taking the center of the inner reflux groove as a circle center is connected between the external groove wall and a wall plate of the inner reflux groove; reflux sub-grooves are formed between adjacent baffles; moreover, reflux flowing hole groups with the same arrangement are respectively formed in the wall plate of the inner reflux groove and corresponding parts of the corresponding reflux sub-grooves; additionally, the flow liquid hole groups are communicated with the inner sides of the corresponding reflux sub-grooves; the reflux flowing guide pipes are communicated with the bottoms of the outer side of the corresponding reflux inner groove. According to the device, the reflux is automatically and equivalently distributed to a plurality of distillation towers, so that the distillation effect is improved.

Owner:常州克罗蒂娜化工技术有限公司

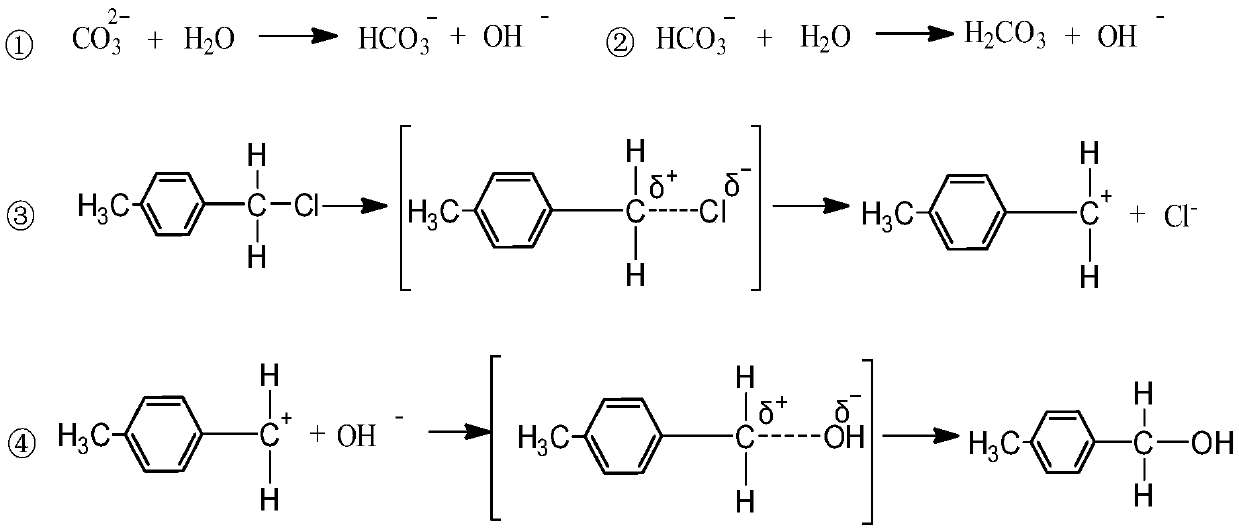

Preparation method of high-purity p-methyl benzyl alcohol

InactiveCN109734555AHigh speedLower reaction costOrganic compound preparationHydroxy compound preparationDicarbonateBenzyl chloride

The invention relates to a preparation method of high-purity p-methyl benzyl alcohol. The method comprises the following steps: carrying out the hydrolysis reaction for p-methyl benzyl chloride in a carbonate or bicarbonate saline solution under a pressure of 0.15 MPa to 0.2 MPa, wherein the pH value of the hydrolysis reaction is 7 to 9, the temperature of the hydrolysis reaction is 110 DEG C to 120 DEG C, and rectifying a crude product obtained in the hydrolysis reaction in a rectifying kettle to obtain high-purity p-methyl benzyl alcohol. The preparation method provided by the invention canbe directly applied to the industrial production, and has the advantages of high raw material conversion rate, high product purity, pollution-free reaction and environmental protection.

Owner:WUHAN GEYUAN FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com