Automatic equal volume distribution device for cluster distillation reflux liquid

A distribution device and reflux liquid technology, applied in the field of rectification, can solve the problems that glass equipment can no longer be used, and the requirements for equal distribution of N tower tubes cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

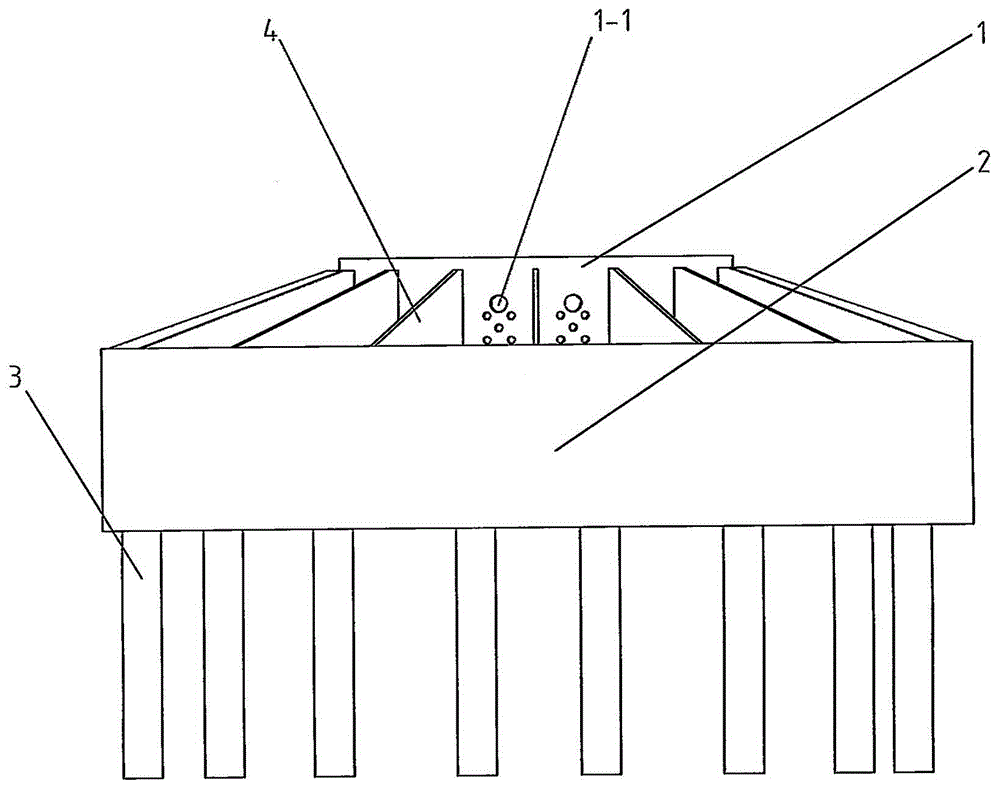

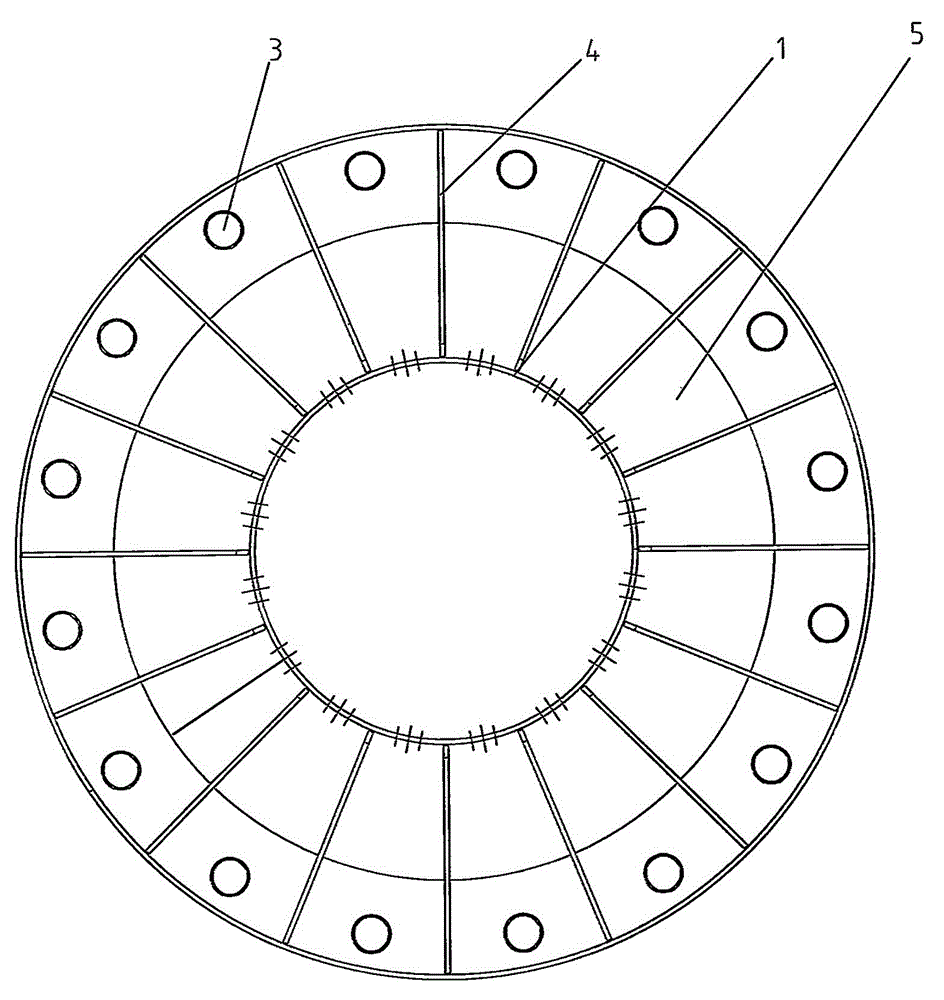

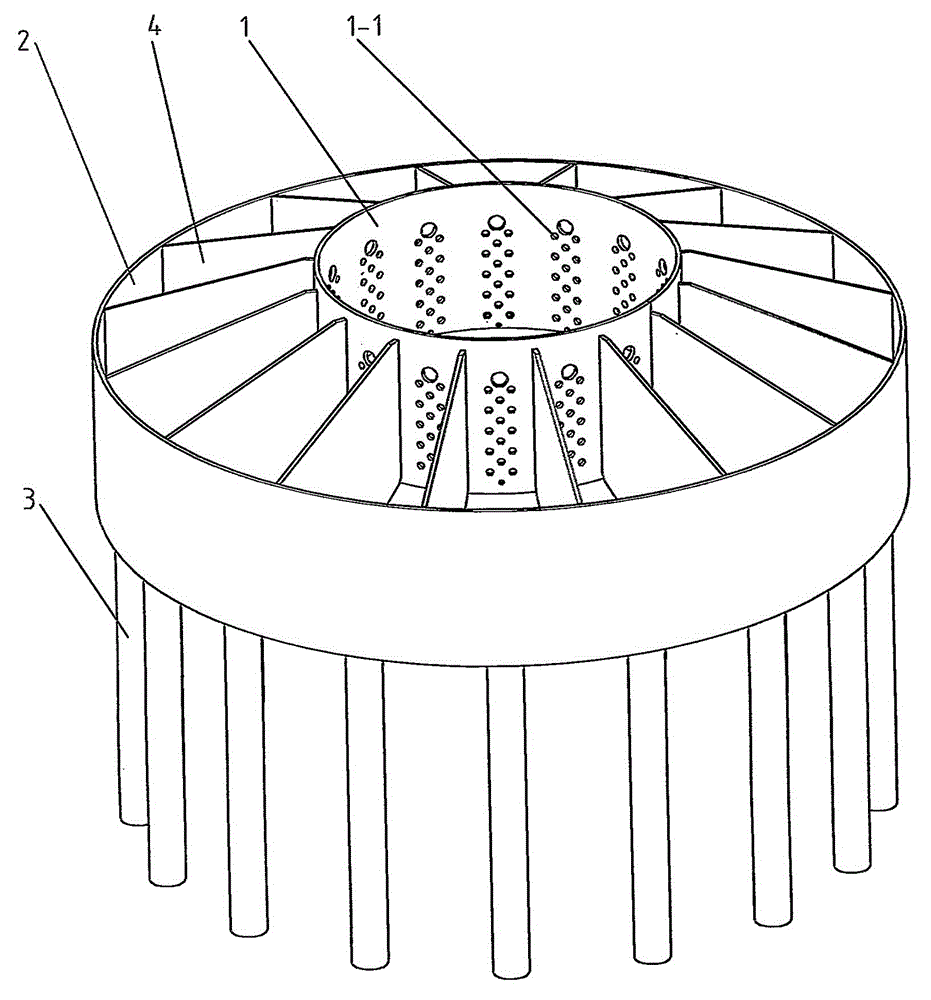

[0014] Such as Figure 1~3 As shown, a cluster rectification reflux liquid automatic equivalent distribution device, it includes the outer tank wall 2, the reflux liquid inner tank 1 connected to the reflux liquid feeding pipe and a plurality of reflux liquid guide pipes 3, the outer tank wall 2 is located The periphery of the reflux liquid inner tank 1, and between the outer tank wall 2 and the wall plate of the reflux liquid inner tank 1 are connected with a plurality of partitions 4 that are radially evenly distributed with the center of the reflux liquid inner tank 1 as the center of the circle. A reflux liquid sub-groove 5 is formed between adjacent partitions 4, and the same arrangement of flow hole groups 1- 1, and the liquid flow hole grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com