Method and equipment for comprehensive recycling treatment on organic silicon slag slurry

A technology of organic silicon slag slurry, recycling and processing, applied in the direction of silicon organic compounds, silicon compounds, organic chemistry, etc., can solve the problems of cumbersome workload, environmental pollution, waste of resources, etc., to increase distillation effect, improve heat transfer efficiency, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

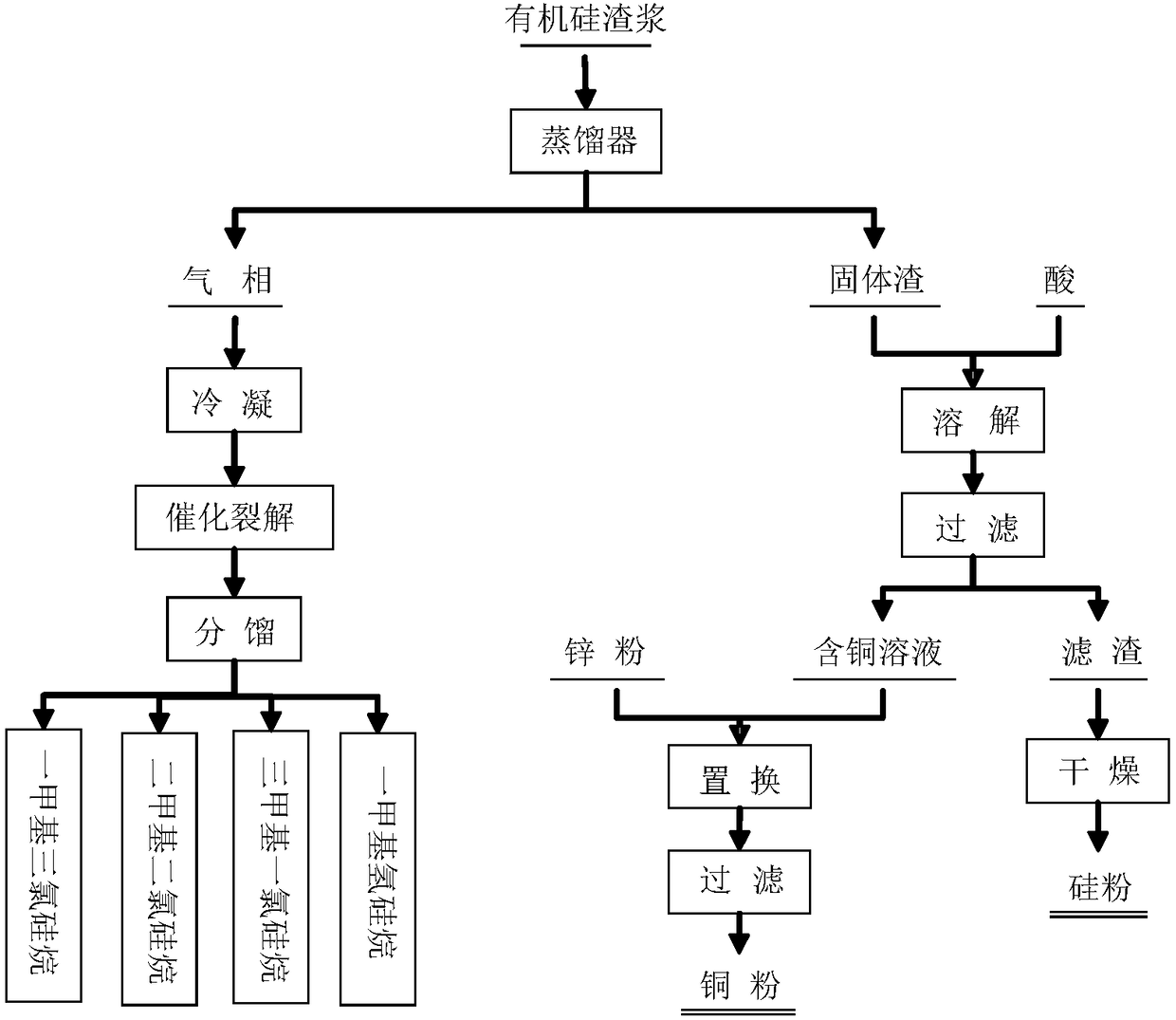

[0040] like figure 1 As shown, a method for comprehensive recovery and treatment of organic silicon slag, the specific operation is: the organic silicon slag is separated by a distiller to obtain a high-boiling gas phase and solid slag; the solid slag is dissolved by adding acid, and the dissolved liquid-solid ratio is 1:5 , the dissolution time is 10 hours, and the dissolution temperature is 20°C; after the dissolution is completed, filter and separate the copper-containing solution and filter residue, and the filter residue is washed and dried to obtain silicon powder; add zinc in an amount that is 1.1 times the theoretical amount of zinc powder required to replace copper with the copper-containing solution The powder was subjected to a replacement reaction, and metal copper powder was obtained by filtration; the gas phase of the high boiler separated by the distiller was condensed, and 400 g of the condensed material was added to a 500 mL round-bottomed three-necked flask, a...

Embodiment 2

[0042] A method for comprehensive recovery and treatment of organic silicon slag, the specific operation is: the organic silicon slag is separated by a distiller to obtain a high-boiling gas phase and solid slag; the solid slag is dissolved by adding acid, the dissolved liquid-solid ratio is 1:1, and the dissolution time 5h, the melting temperature is 60°C. After the dissolution is completed, filter to separate the copper-containing solution and filter residue, and the filter residue is washed and dried to obtain silicon powder; add zinc powder according to 1.3 times the theoretical amount of zinc powder required for copper-containing solution to replace copper for replacement reaction, and filter to obtain metal copper powder Condensate the gaseous phase of the high boilers obtained by the separation of the distiller, get 400g of material after condensation and join in a 500mL round-bottomed three-necked flask, add catalyst tri-n-butylamine 20g therein, and control the feed ra...

Embodiment 3

[0044] A method for comprehensive recovery and treatment of organic silicon slag, the specific operation is: the organic silicon slag is separated by a distiller to obtain a high-boiling gas phase and solid slag; the solid slag is dissolved by adding acid, the dissolved liquid-solid ratio is 5:1, and the dissolution time is 5:1. 0.5h, the melting temperature is 90°C. After the dissolution is completed, filter and separate the copper-containing solution and filter residue, and the filter residue is washed and dried to obtain silicon powder; add zinc powder according to 1.2 times the theoretical amount of zinc powder required for copper-containing solution to replace copper for replacement reaction, and filter to obtain metal copper powder Condensate the gaseous phase of the high boilers obtained by the separation of the distiller, get 400 g of the condensed material and add it to a 500 mL round-bottomed three-neck flask, add catalyst tri-n-butylamine 10 g therein, and control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com