Patents

Literature

33results about How to "Easy to recycle separately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

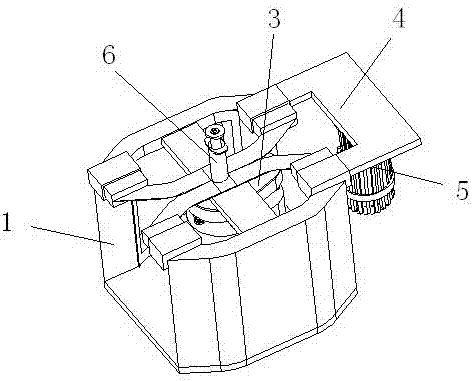

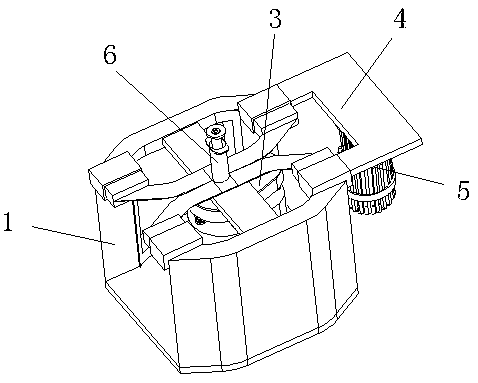

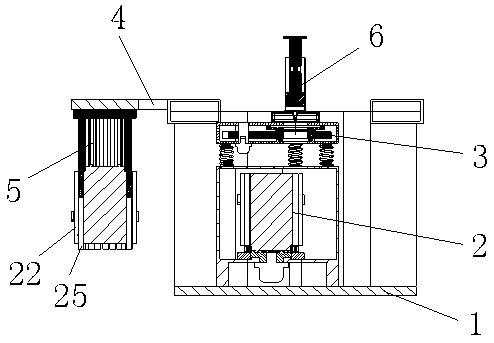

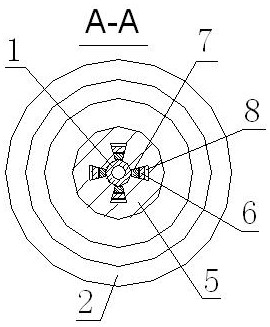

Medical portable syringe needle recoverer for clinical usage

ActiveCN107485765AEasy to useHigh degree of automationInfusion needlesSyringe needleBiomedical engineering

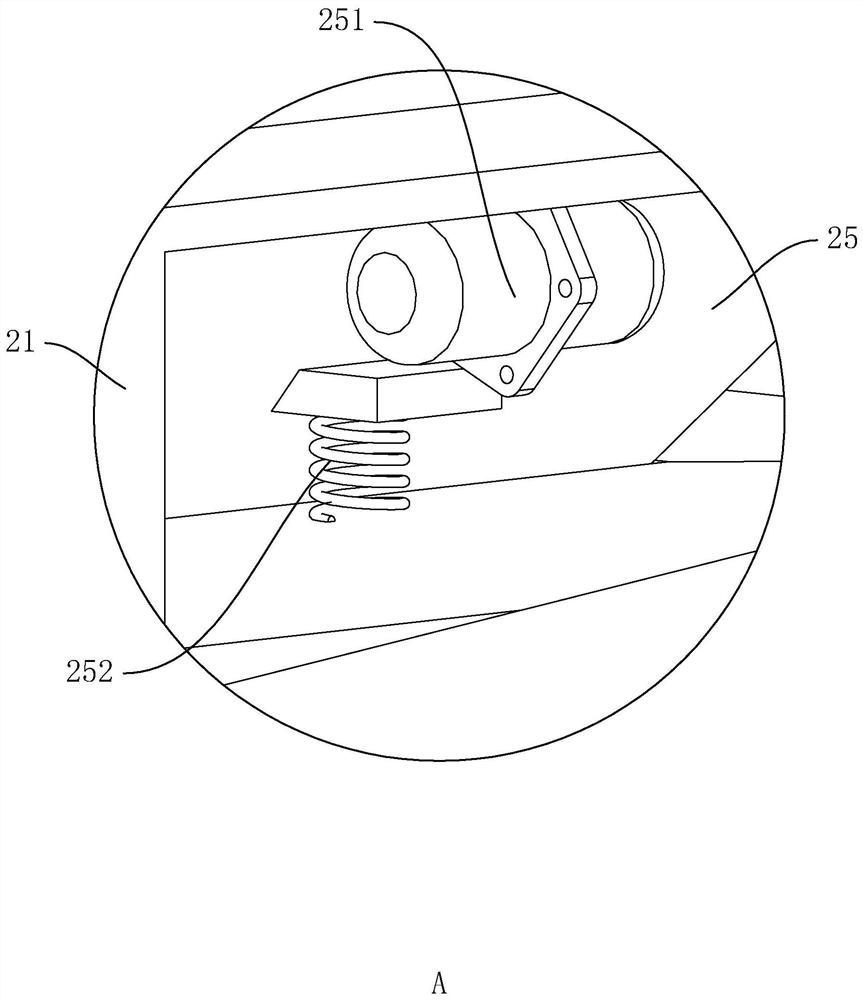

The invention discloses a medical portable syringe needle recoverer for clinical usage. The recoverer includes a splint device, a syringe needle pulling device and a syringe needle collecting device, wherein the splint device includes a rack base, two support plates symmetrically arranged above the rack base and two splint fixing mechanisms which are symmetrically and fixedly arranged on the inner sides of the upper portions of the two support plates respectively and used for fixing and clamping a needle cap in a syringe needle assembly; the rack base is successively provided with the syringe needle pulling device and the syringe needle collecting device which are positioned under the two splint fixing mechanisms from top to bottom, the syringe needle pulling device is used for clamping and pulling out a metal syringe needle fixedly inserted in the bottom of the needle cap, and the syringe needle collecting device is used for collecting the metal syringe needles pulled out by the syringe needle pulling device. The medical portable syringe needle recoverer for the clinical usage has the advantages of being small in overall occupied space, convenient to carry, high in automation degree, convenient to operate and use, environment-friendly and capable of well recovering the medical syringe needles alone.

Owner:李奇元

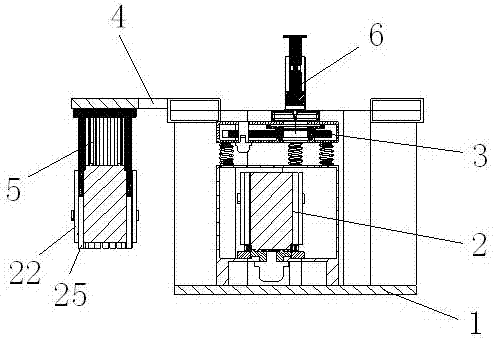

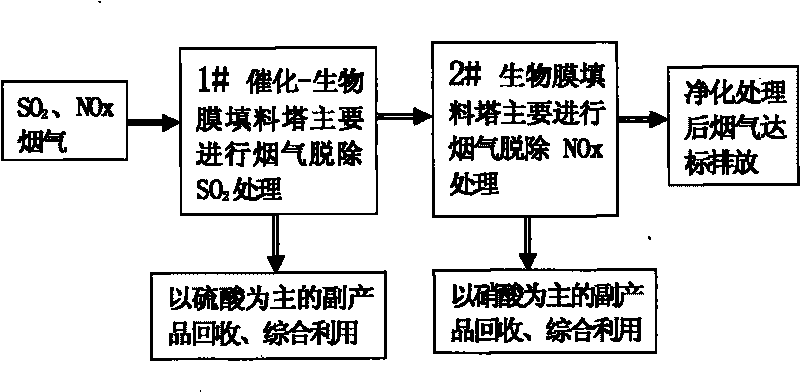

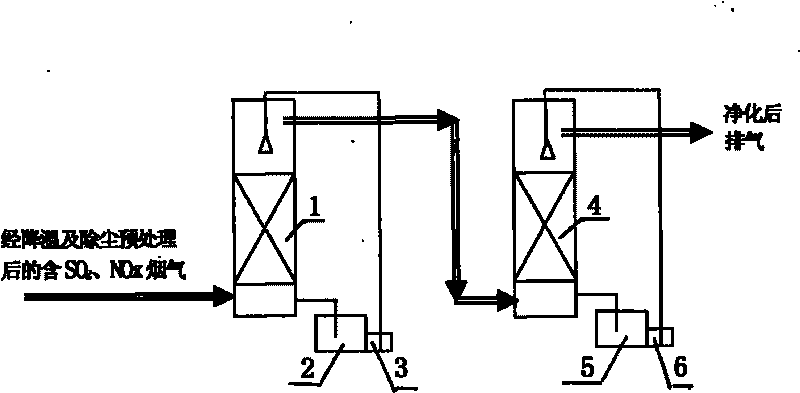

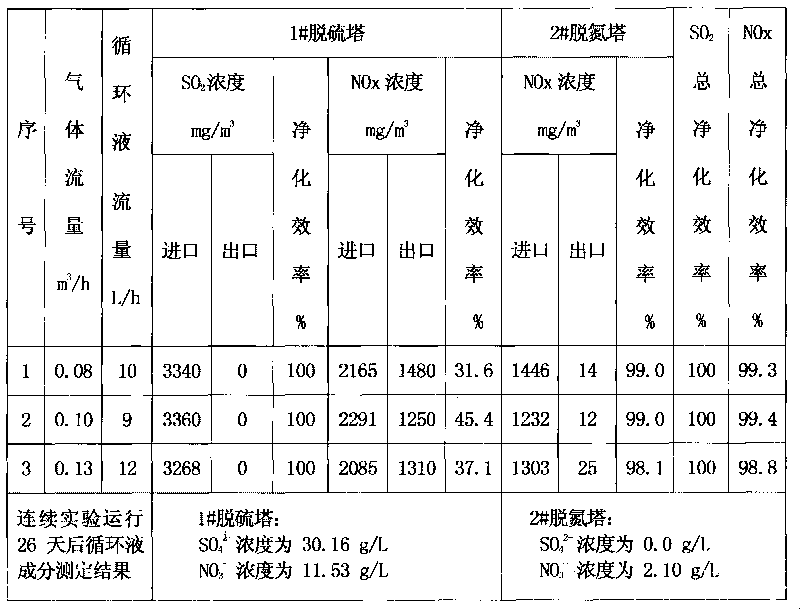

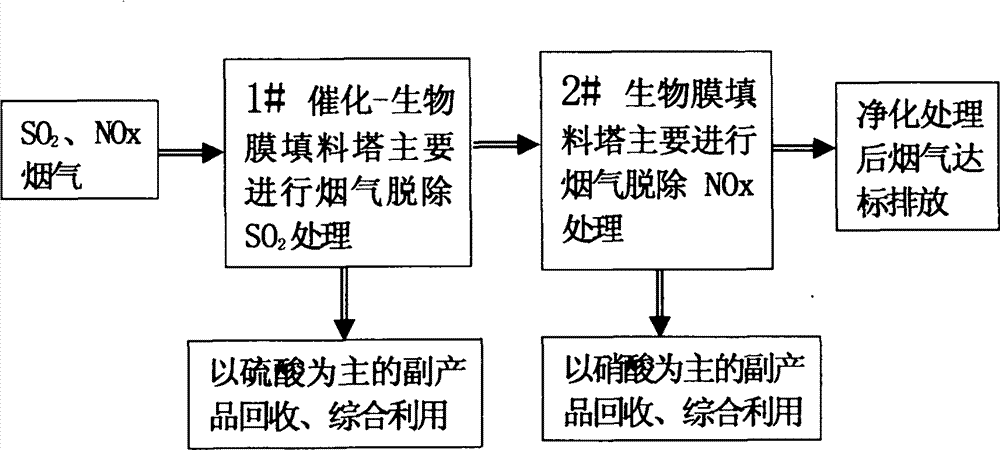

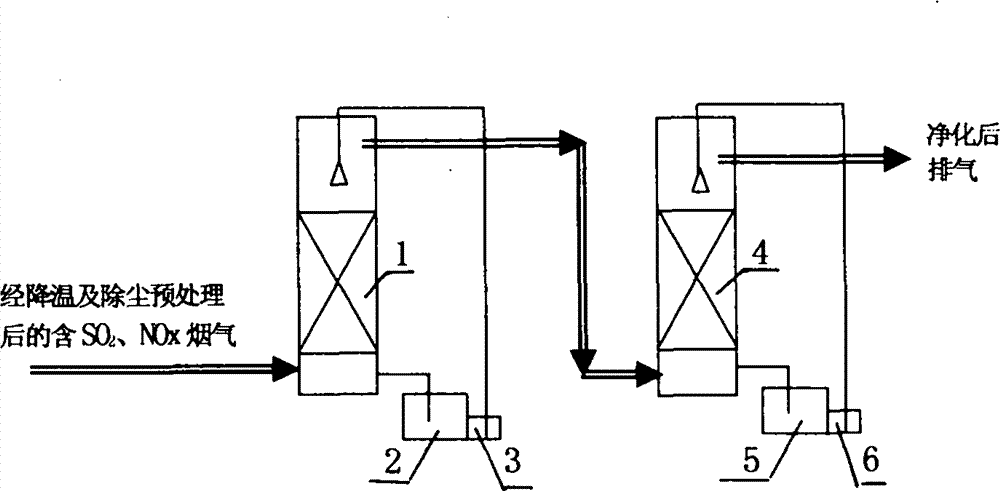

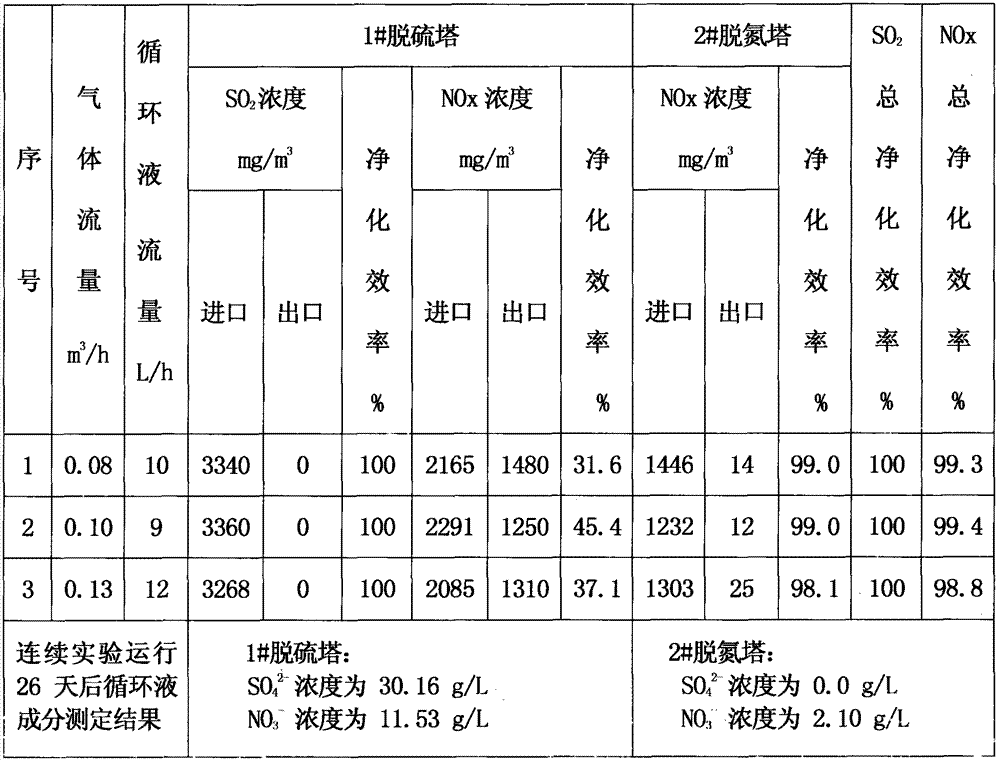

Method for simultaneously removing sulfur dioxide and nitrogen oxide in exhaust gas by twin tower tandem catalysis-biomembrane packing tower system

InactiveCN101708415AGood purification effectEasy to recycle separatelyDispersed particle separationAir quality improvementPh bufferingCatalytic oxidation

The invention provides a twin tower tandem exhaust gas purifying processing combination device which adopts a biomembrane packing tower system utilizing catalytic oxidant cyclically spraying liquid in the front and a biomembrane packing tower system utilizing pH buffering agent cyclically spraying liquid in the rear, which can carry out purifying processing to simultaneously remove the SQ2 and the NOx in the exhaust gas and to obtain by-products, namely, the utilizable sulphuric acid and nitrating acid products. The invention is characterized in that desulphuricants and denitrifier complex bacteria with the performance of simultaneously removing SQ2 and NOx in the exhaust gas under the conditions of liquid-phase catalyzed oxidation and pH acid environment can be obtained by screening and culturing and domesticating, and the composite bacteria biofilm to manufacture the biomembrane packing tower which is arranged in the tandem front end and is mainly used for removing SQ2; and the biomembrane packing tower which is mainly used for removing NOx in the rear is manufactured by adopting the denitrifier complex bacteria biofilm with the performance of removing NOx in the exhaust gas under the condition of pH neutral environment through screening and culturing and domesticating.

Owner:NANJING JIANGDAO INST OF ENVIRONMENT RES CO LTD

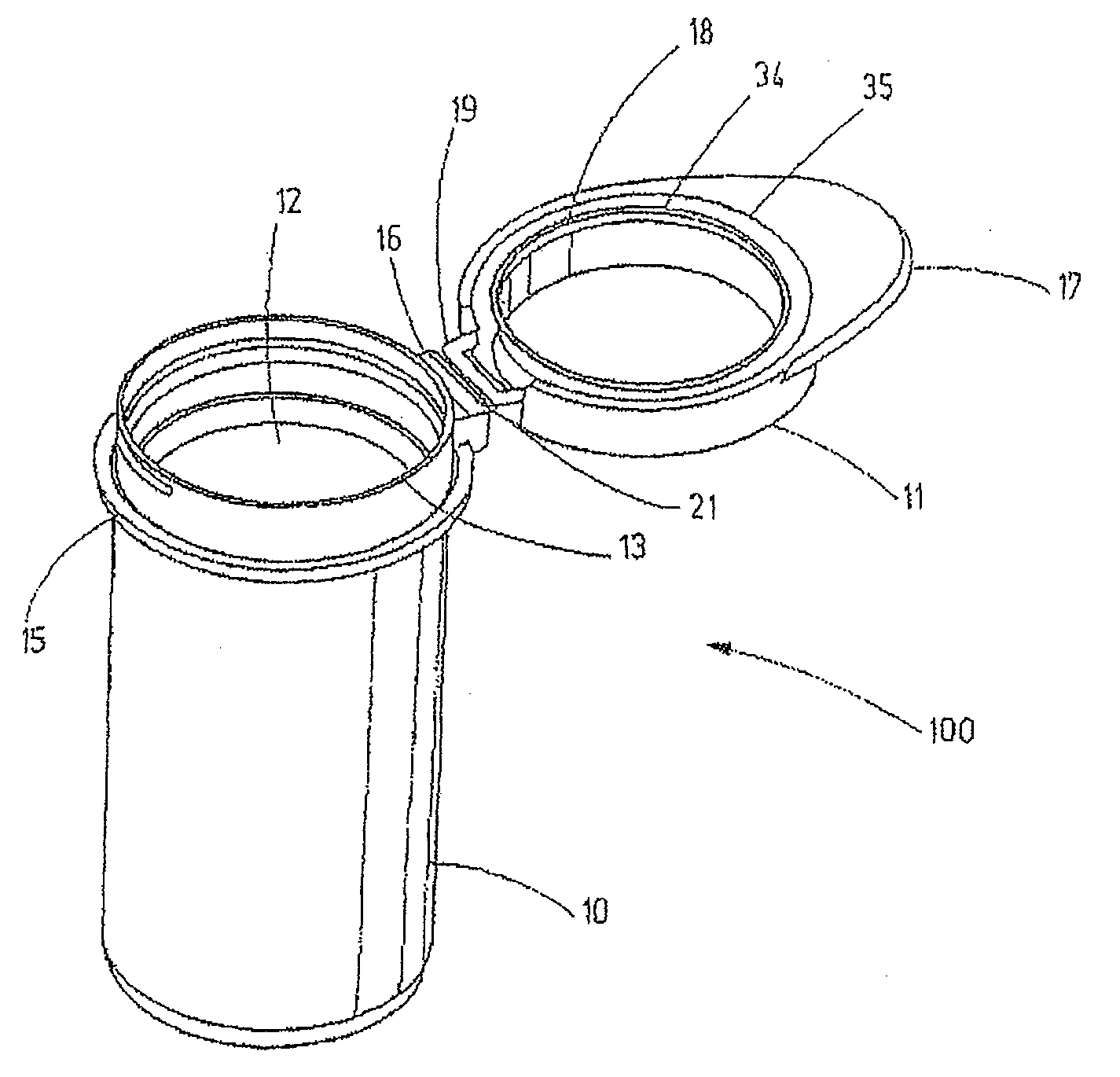

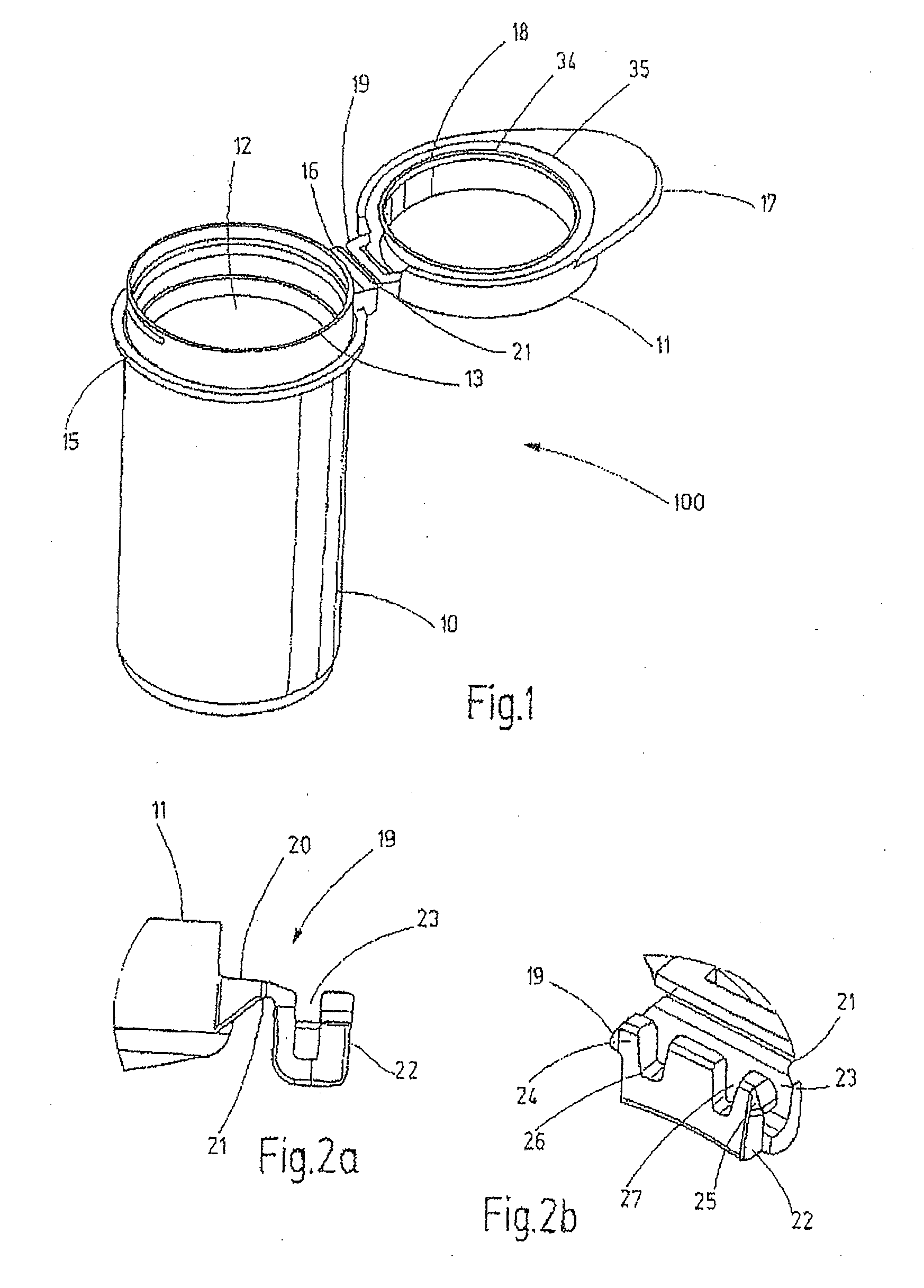

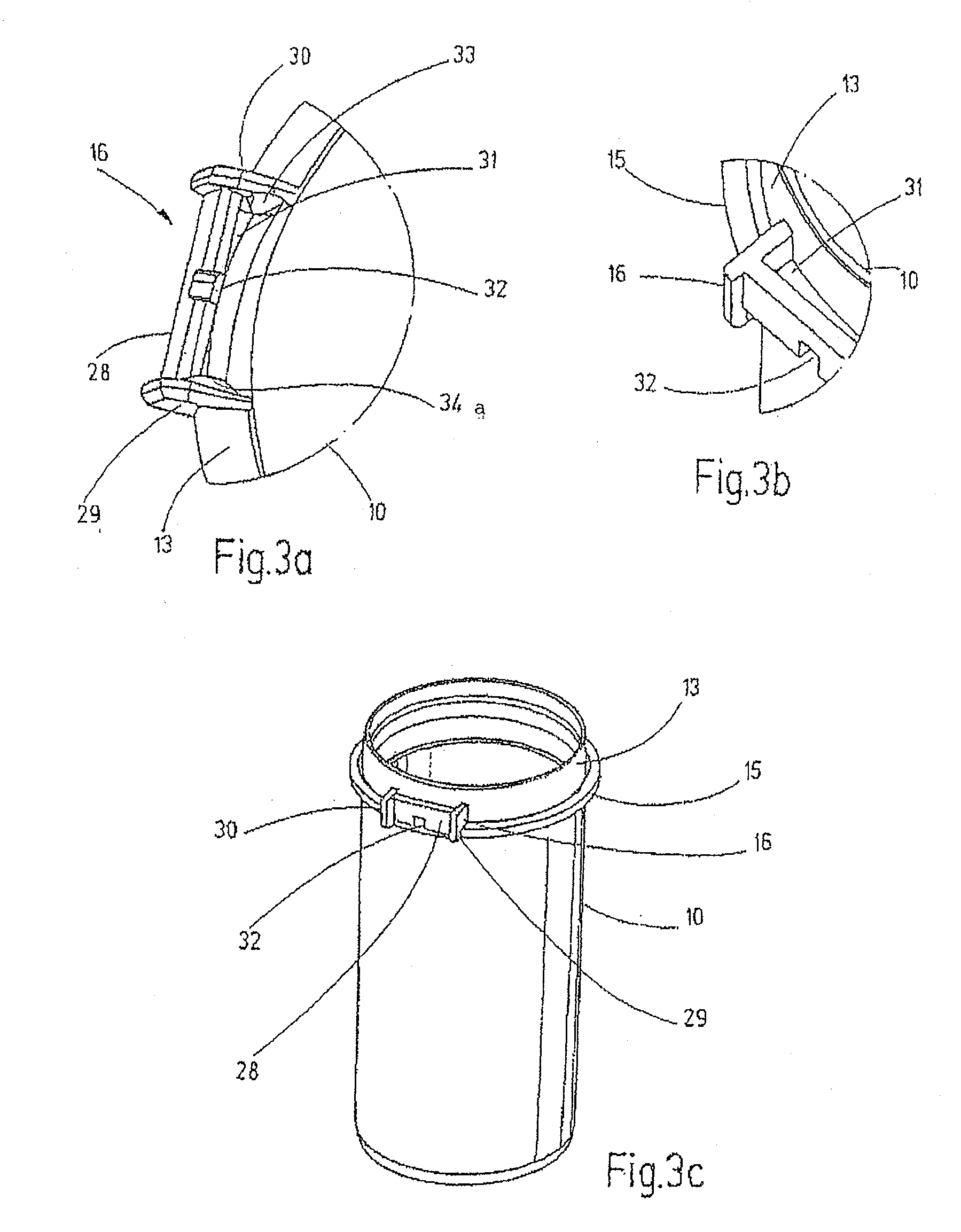

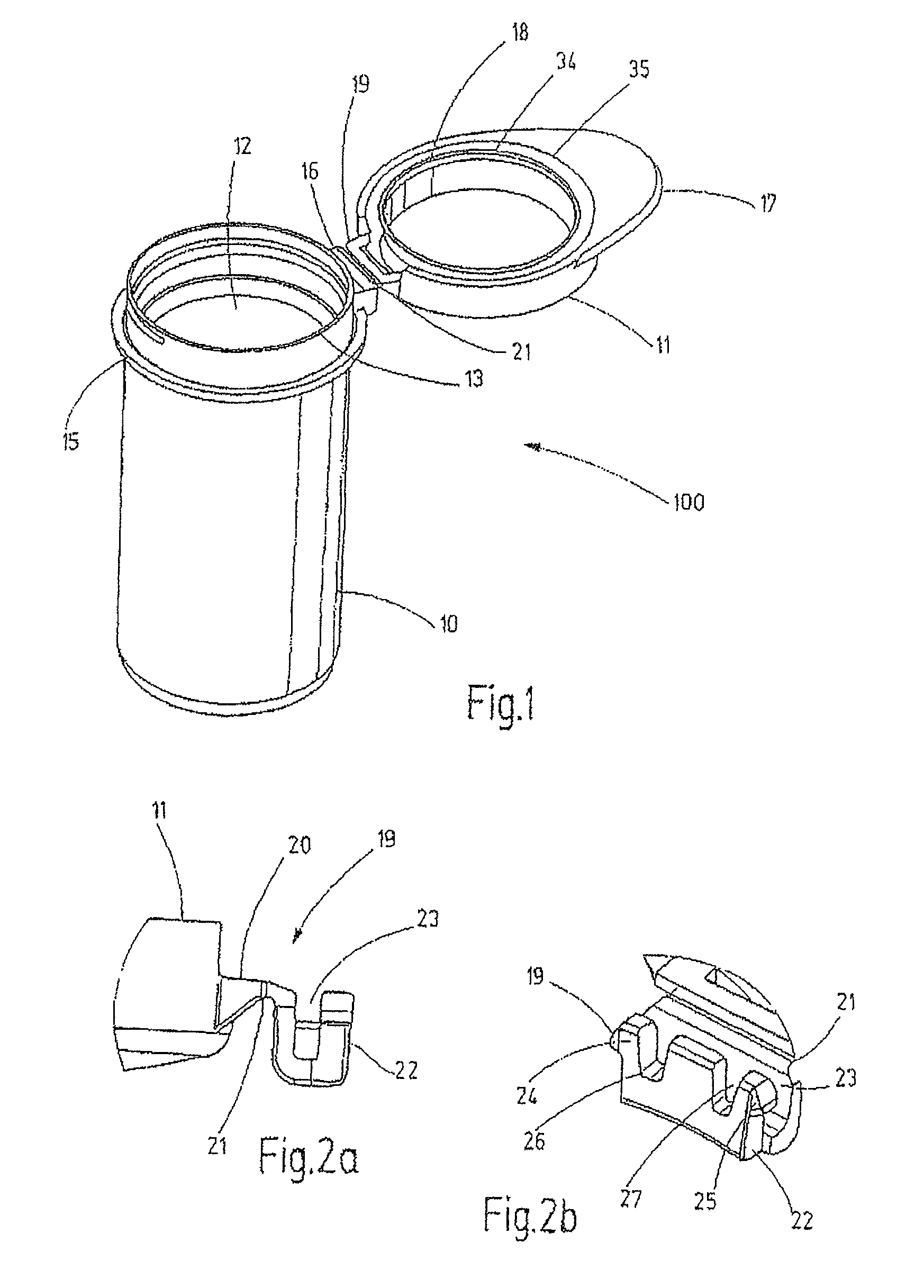

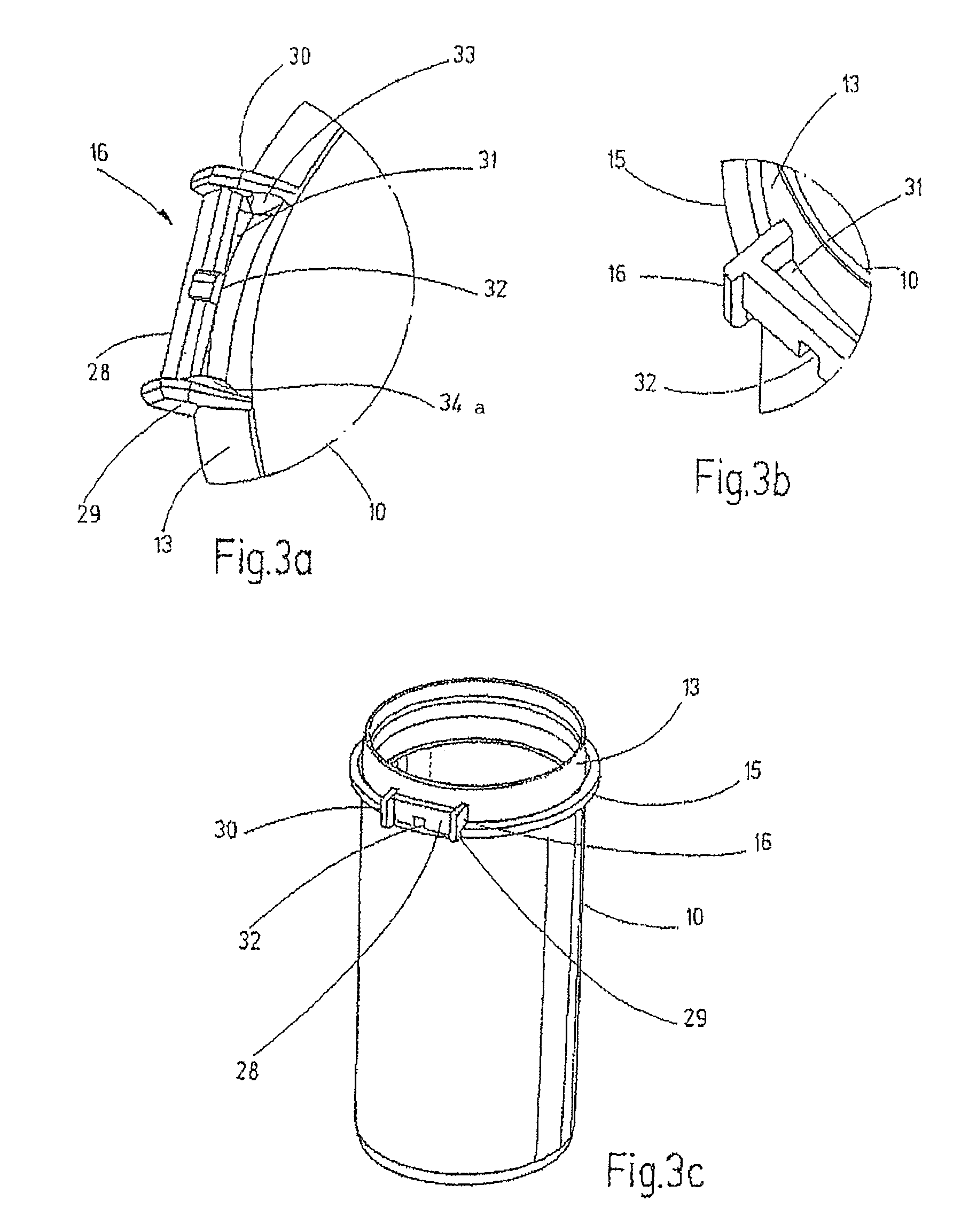

Container

ActiveUS20100051636A1Prevent disengagementImprove sealingLidsNon-removalbe lids/coversEngineeringMechanical engineering

Owner:AIRNOV INC

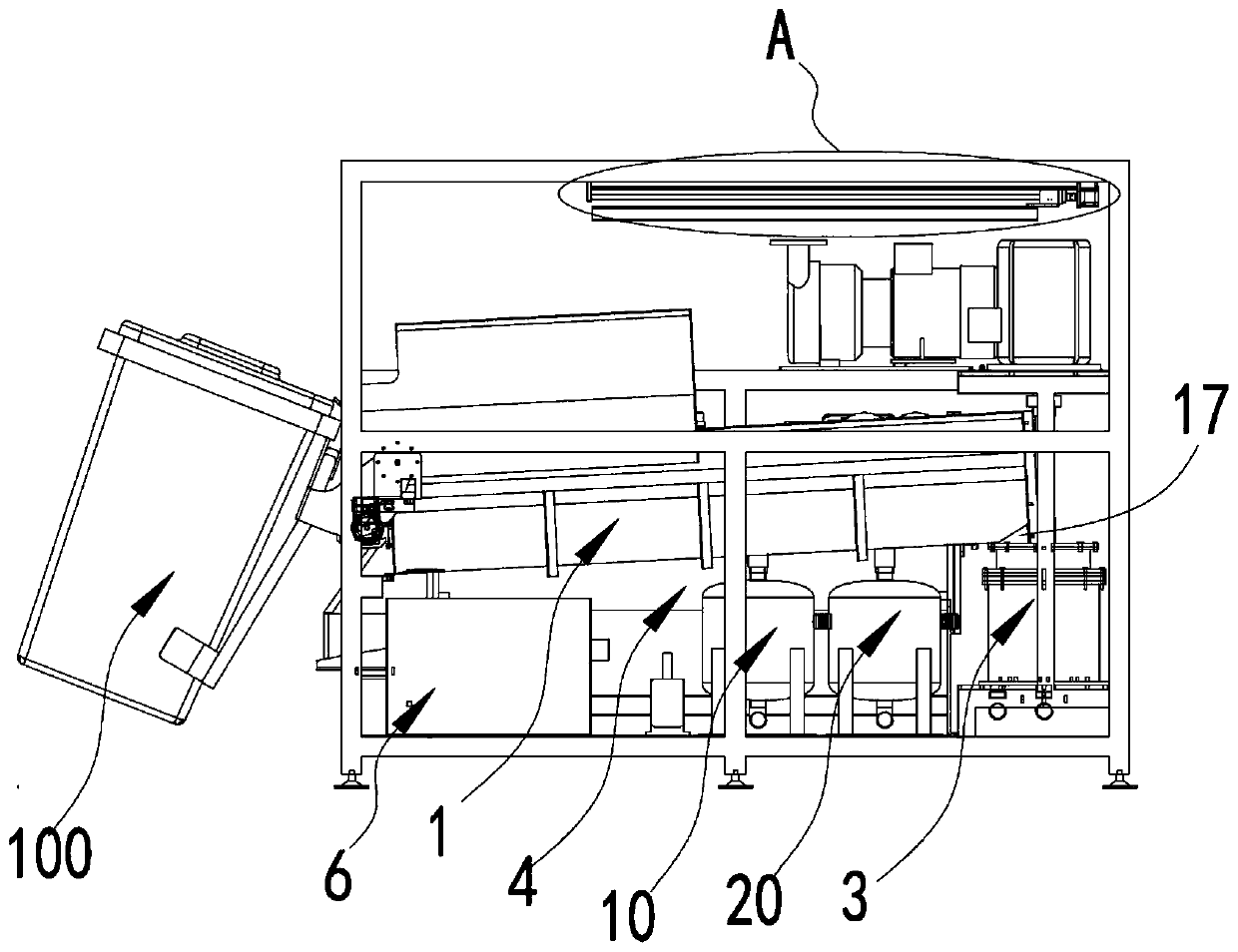

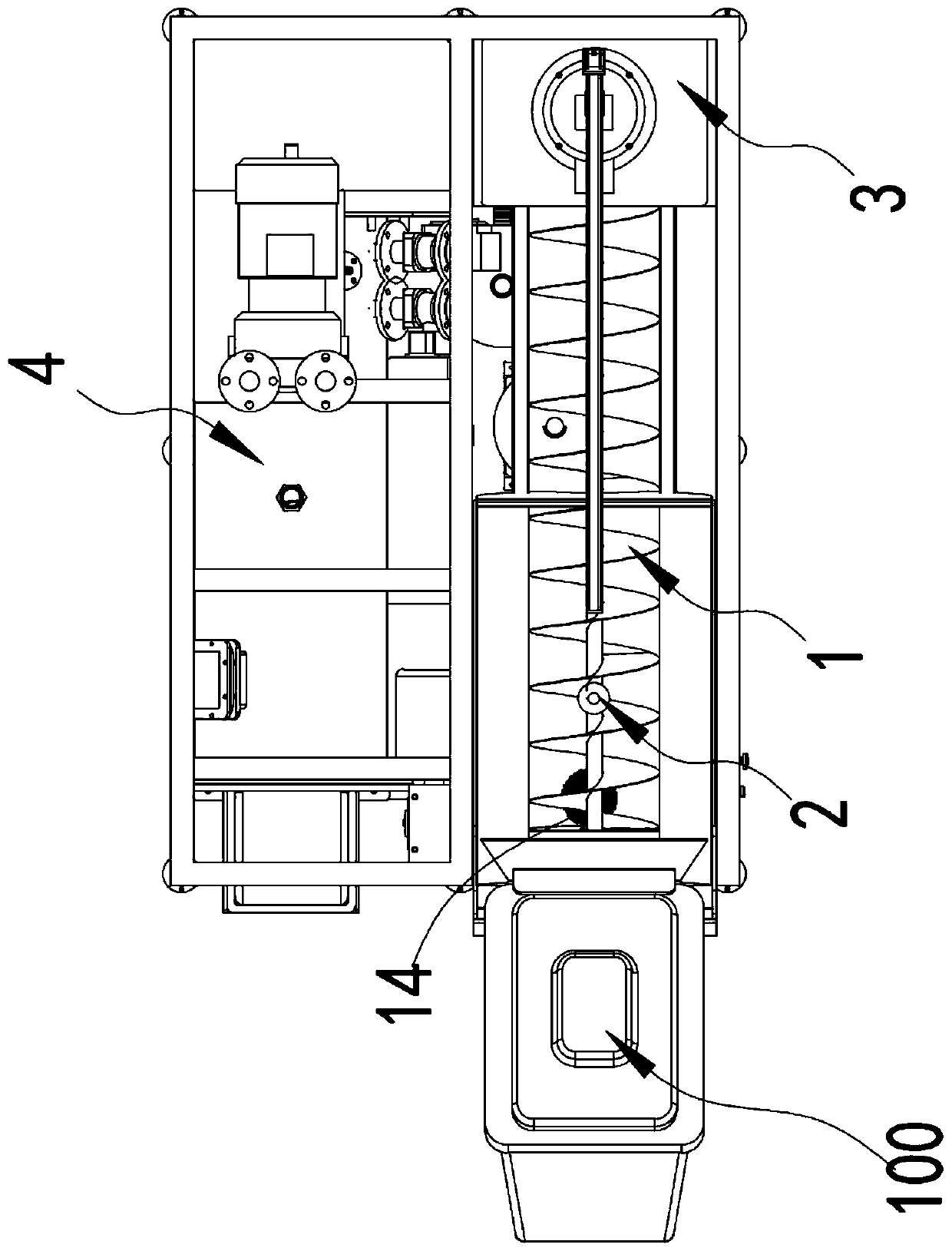

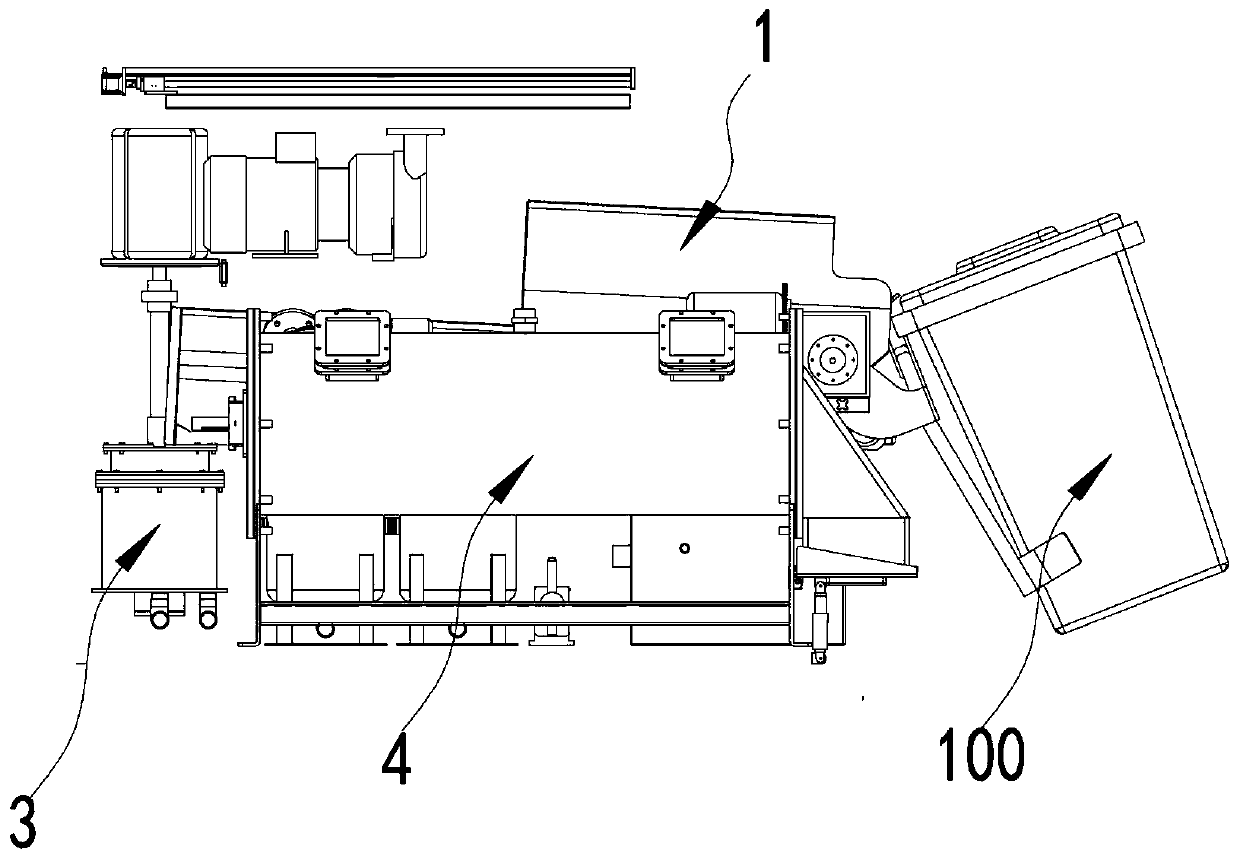

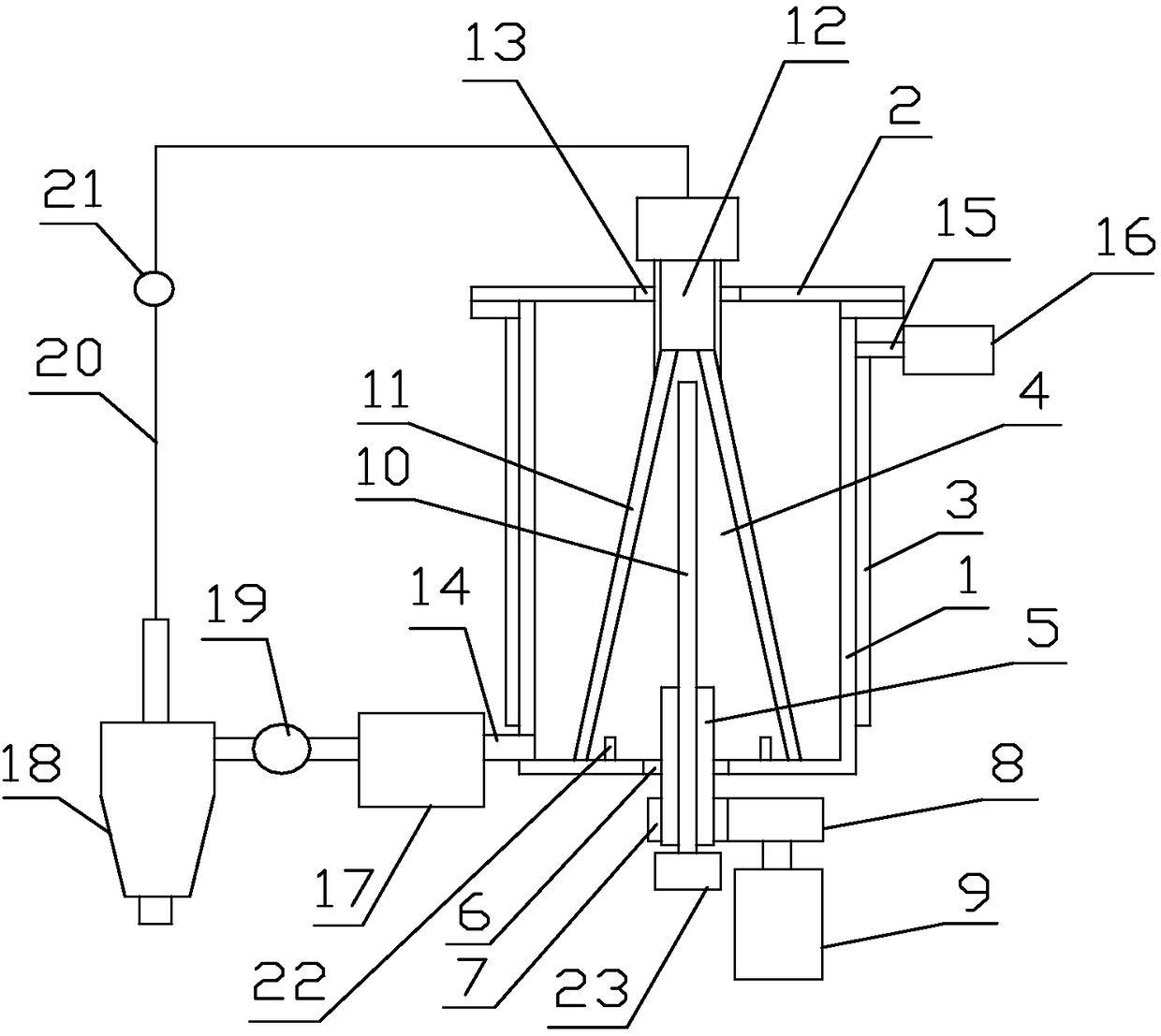

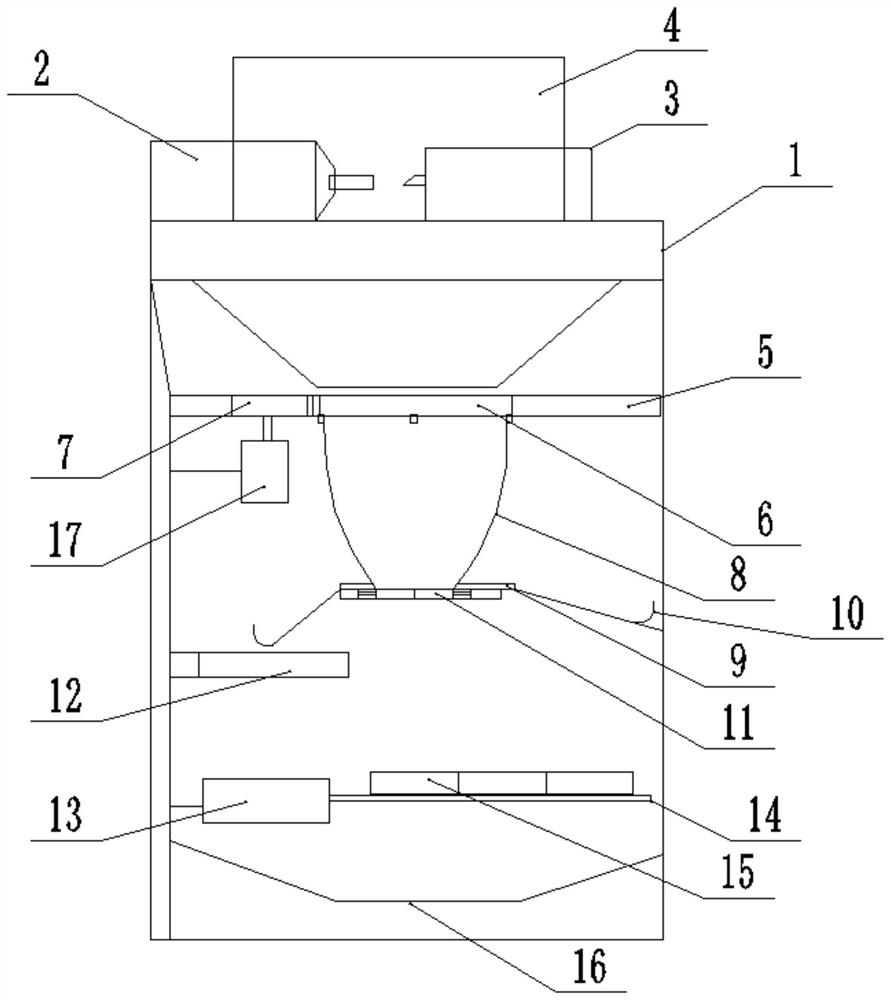

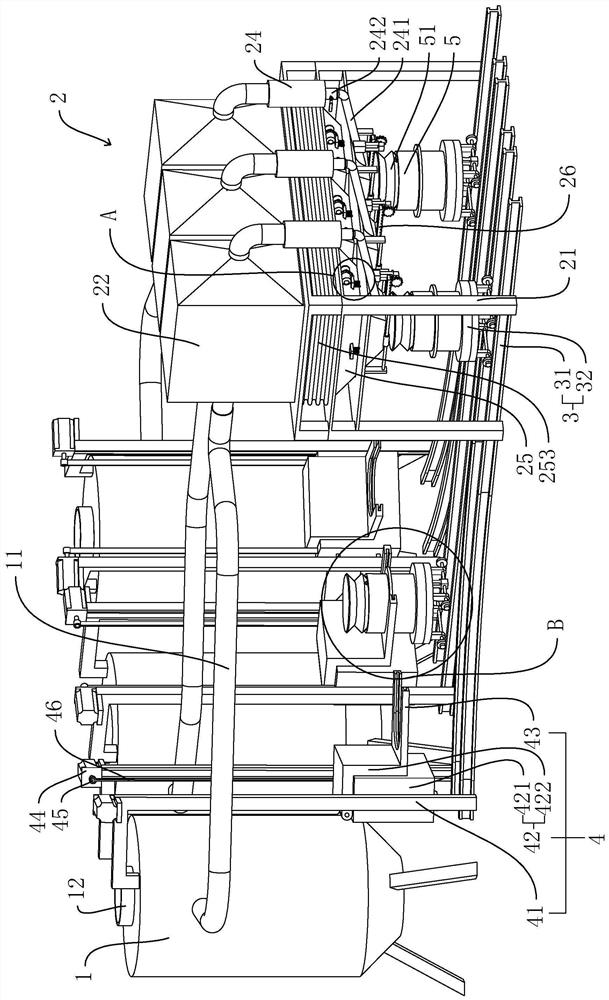

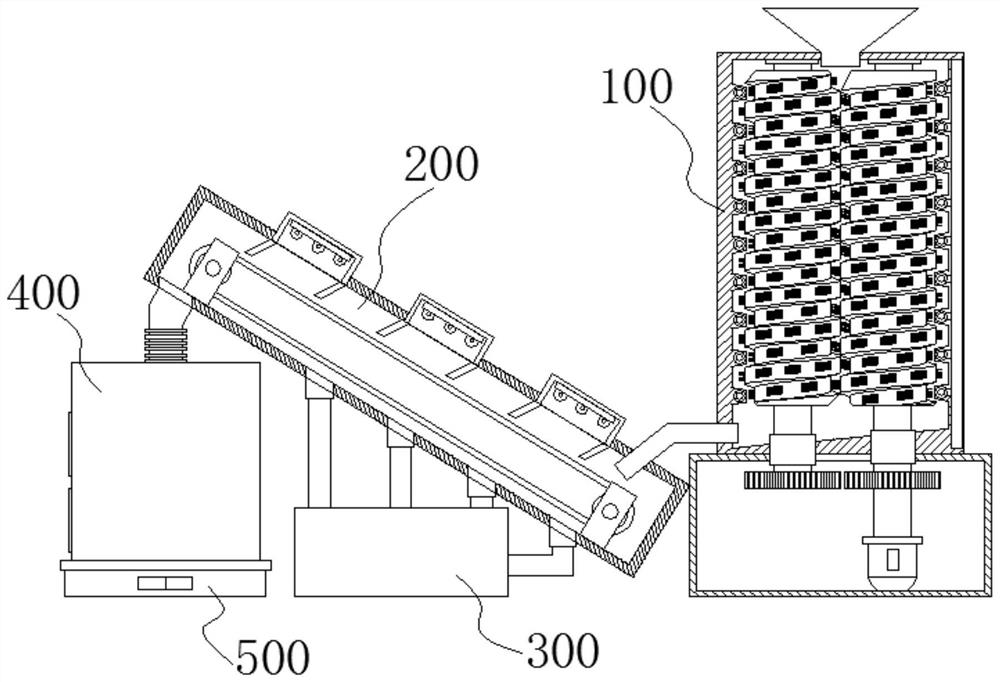

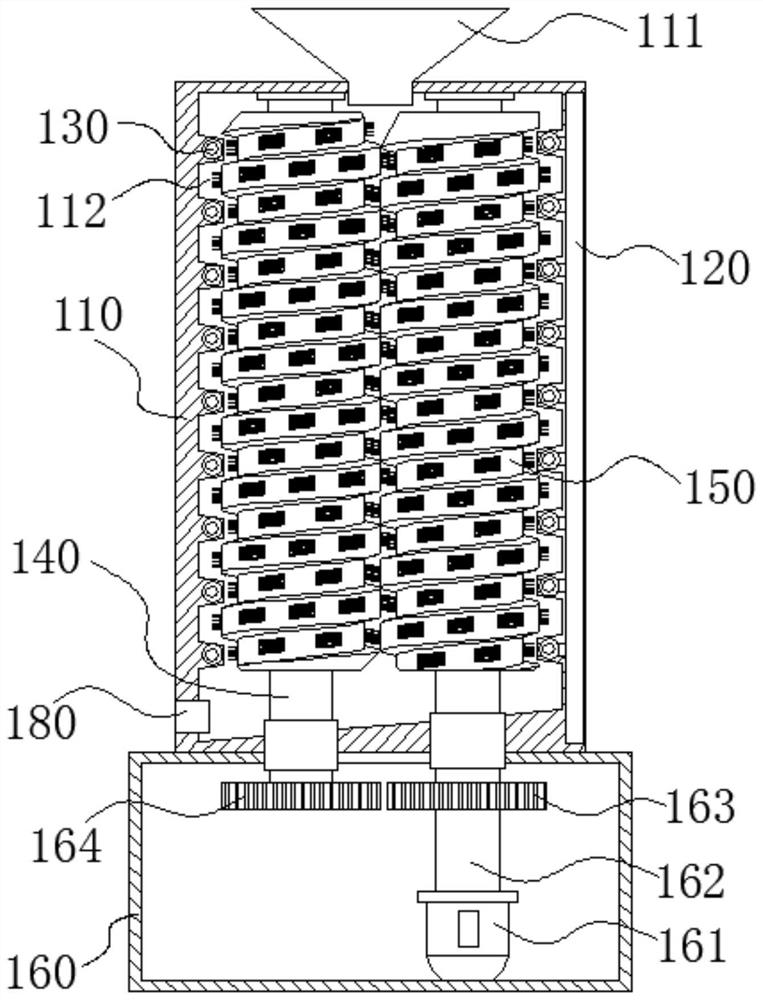

Garbage recycling device and recycling method thereof

PendingCN111167843AAchieve cleaningEasy to clean and maintainSolid waste disposalClimate change adaptationEnvironmental engineeringScrew conveyor

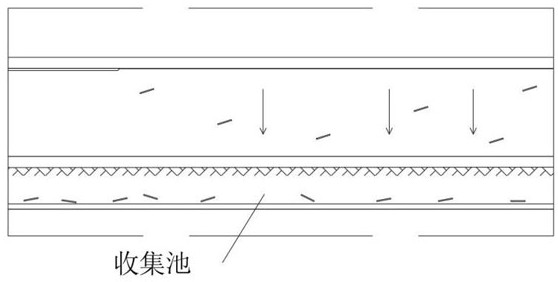

The invention discloses a garbage recycling device and a recycling method thereof. The garbage recycling device is used for processing kitchen waste and dry garbage, wherein the recycling device comprises a screw conveyor, a cleaning device, a crusher and a dryer; the screw conveyor comprises a material groove with high and low differences at two ends, the low end of the material groove is provided with a feed port, the bottom part of the barrel wall of the high end of the material groove is provided with a discharge port, and the bottom of the material groove is provided with a liquid discharge hole at the low end; the cleaning device is located above a screw conveying shaft in the material groove; the feed end of the crusher is hermetically connected to a discharge port of the screw conveyor, the dryer is connected with the discharging end of the crusher. According to the scheme, the garbage recycling device allows the liquid in the wet garbage to concentrate at a drainage hole underthe action of gravity to achieve emissions, so that the area of the drainage hole can be greatly reduced, in addition, a large size liquid collection groove is not required, and the difficulty of waste liquid collection is reduced; meanwhile, compared with existing oil and salt removing equipment, the design of the structure of the screw conveyor and the cleaning device is more reasonable, easier to realize, save a delivery crushing mechanism at the front end and more simple in structure.

Owner:深圳市君颂自动化科技有限公司

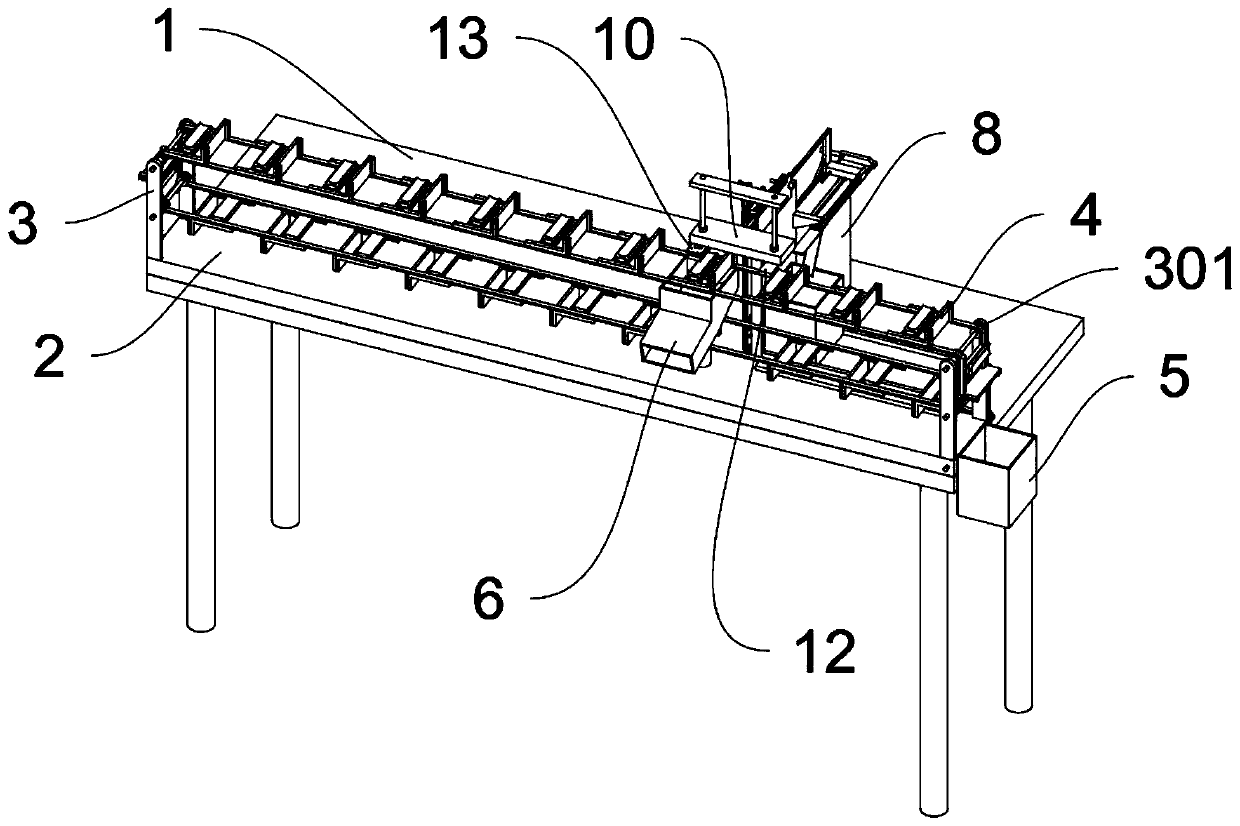

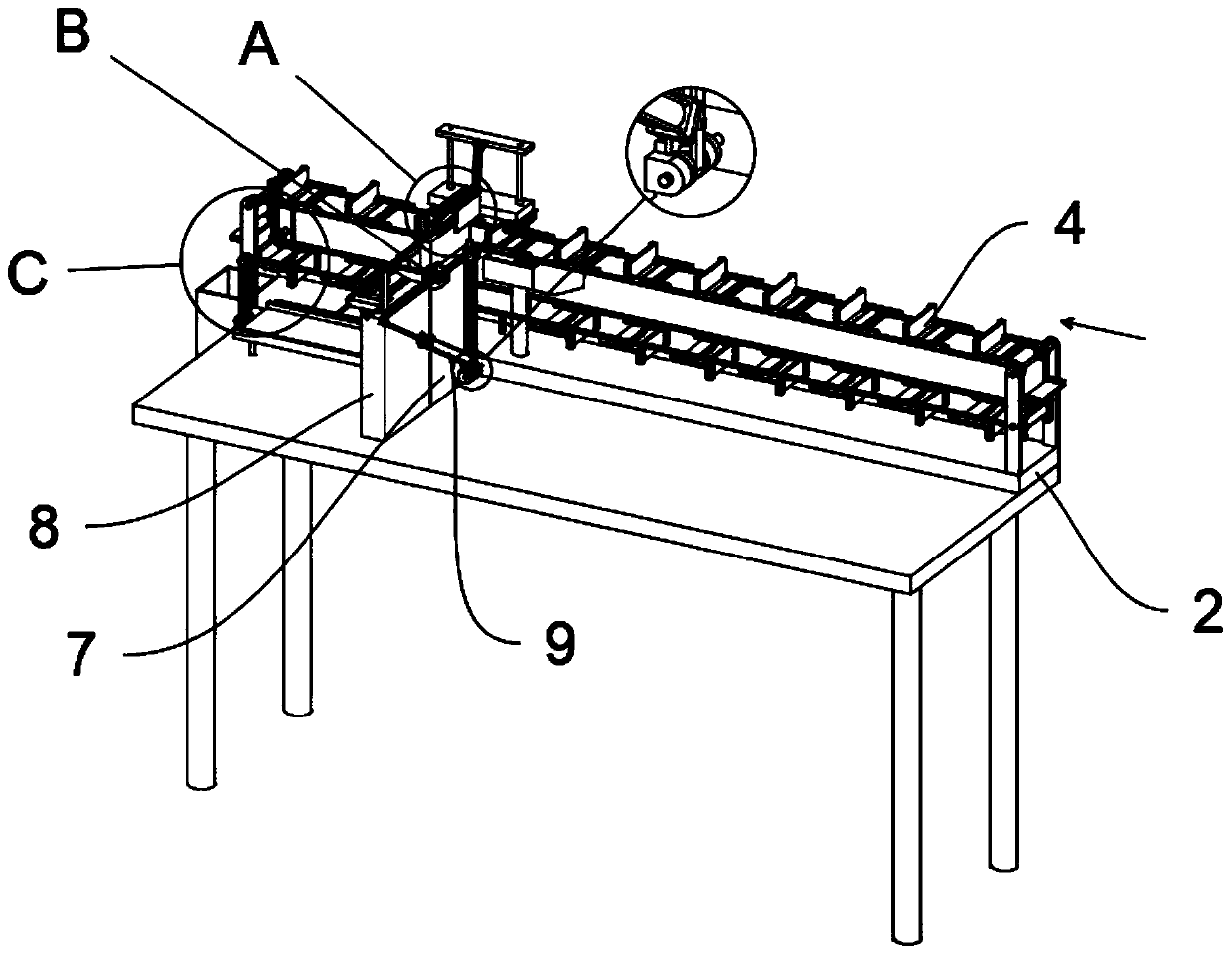

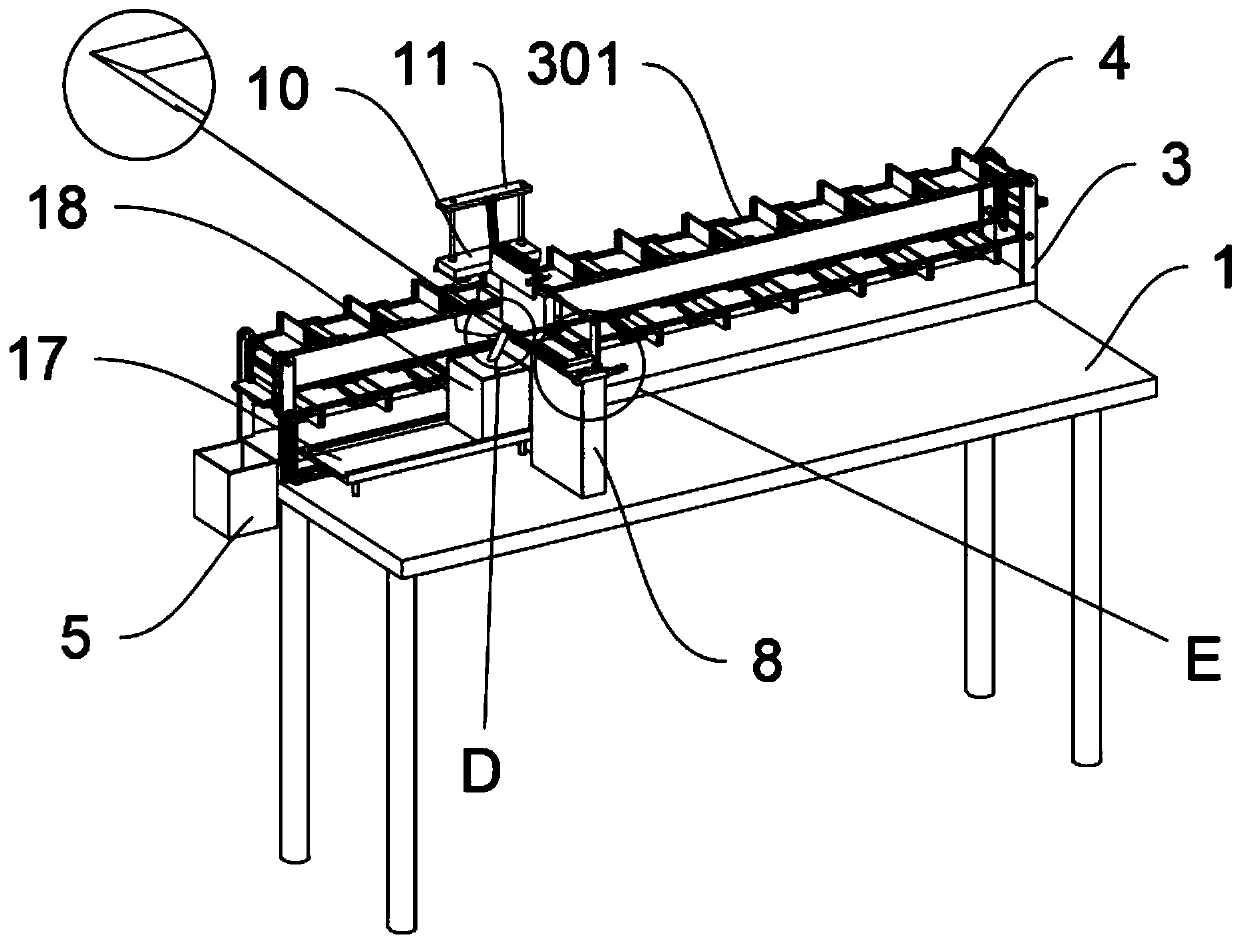

Automatic peeling and sorting device for aloe flesh in previous working procedure of cosmetic production

InactiveCN111202252AEasy to recycle separatelyRealization of automatic peeling and sortingVegetable peelingMetal working apparatusProcess engineeringMechanical engineering

The invention discloses an automatic peeling and sorting device for aloe flesh in a previous working procedure of cosmetic production, and relates to the technical field of cosmetic processing. The automatic peeling and sorting device solves the problems that the peeling on aloes by an existing peeling device is not accurate enough; much colloid is wasted; a fine sorting function cannot be realized; meanwhile, the linkage capability is poor; a plurality of power sources are needed for completing peeling and feeding actions; and the operation is extremely inconvenient. The automatic peeling andsorting device for aloe flesh in the previous working procedure of cosmetic production comprises a processing table, wherein a feeding table is fixedly arranged at one side of the top of the processing table through screw bolts; four groups of conveying frames are fixedly arranged at the top of the feeding table; the middle of the top of the processing table is connected and fixedly provided withan inner power table and an outer power table; and the inner power table is in contact with the feeding table. Through the arrangement of a straight knife, an arc knife and a cutting device, diversified multi-step differentiation processing is provided for the peeling device; the automatic sorting in the peeling process is realized; useful aloe peels can be conveniently and singly recycled for other purposes; and convenience and environment protection are realized.

Owner:冯文豪

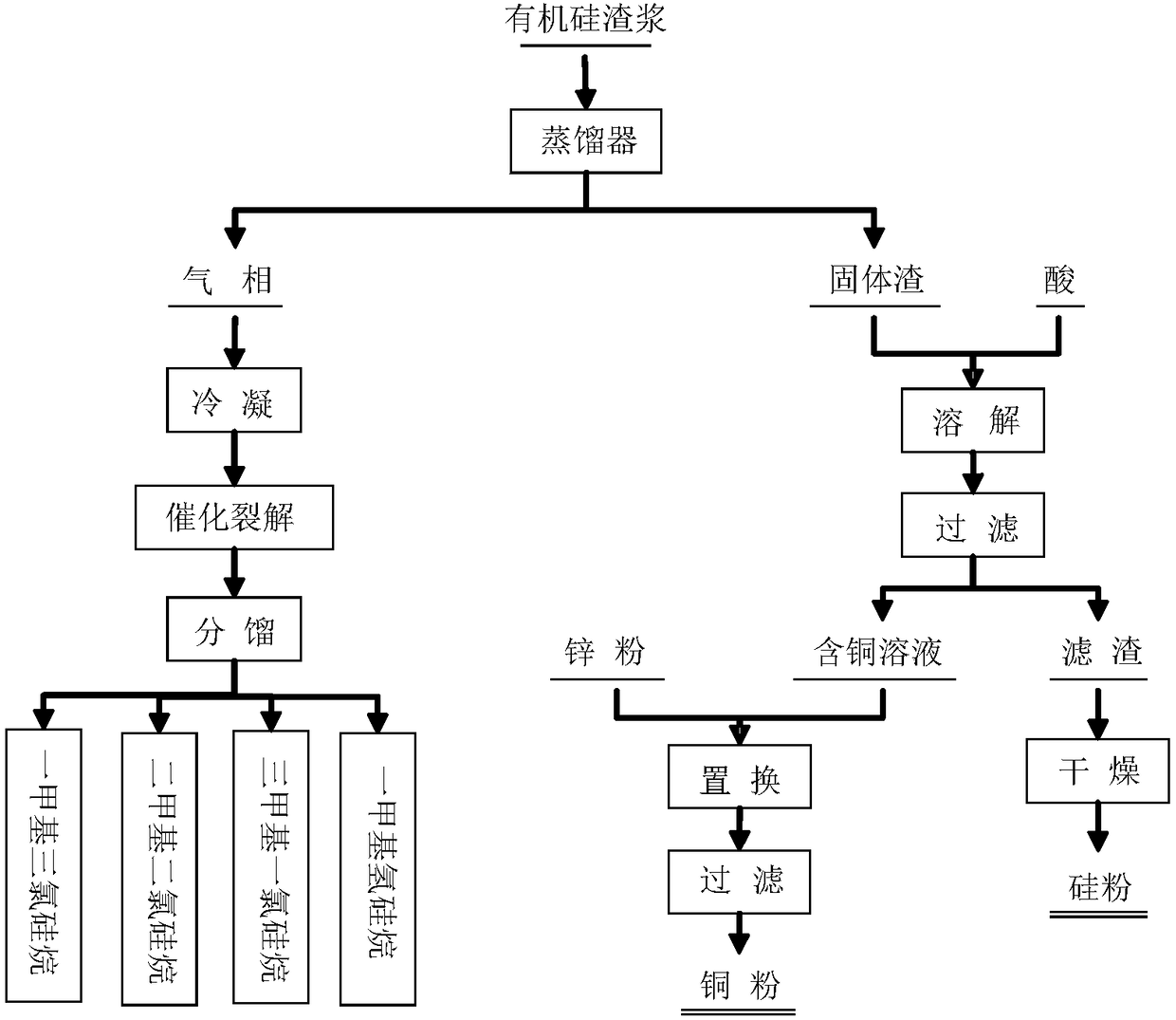

Method and equipment for comprehensive recycling treatment on organic silicon slag slurry

ActiveCN108558928AAchieve separationEasy to recycle separatelySilicon organic compoundsSilicon compoundsGas phaseSlag

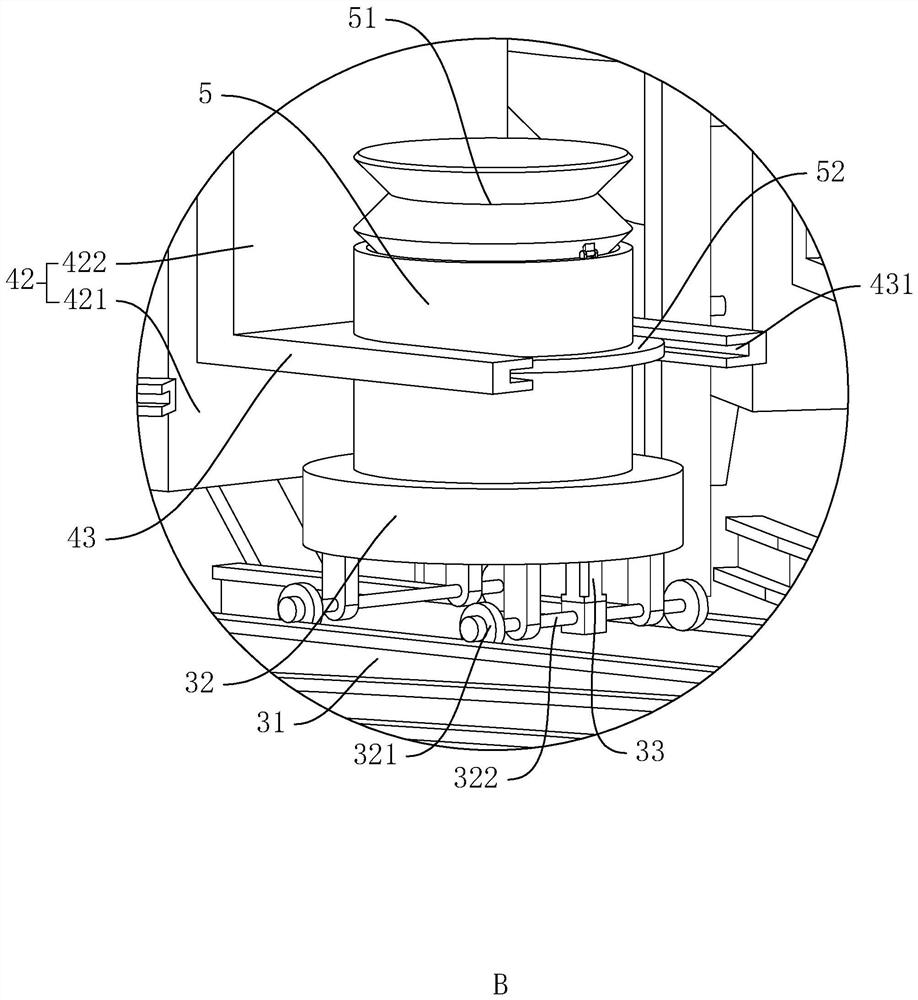

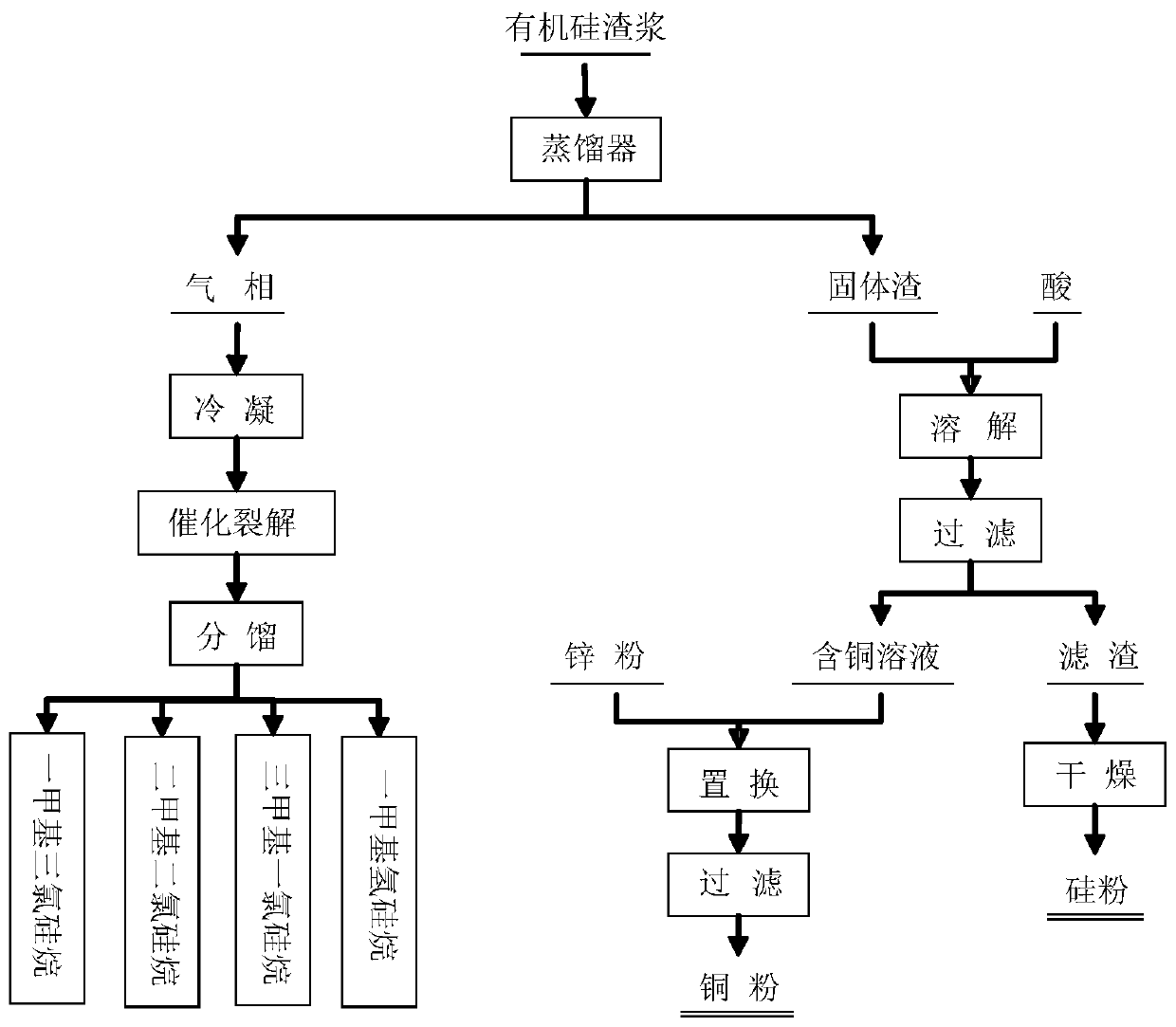

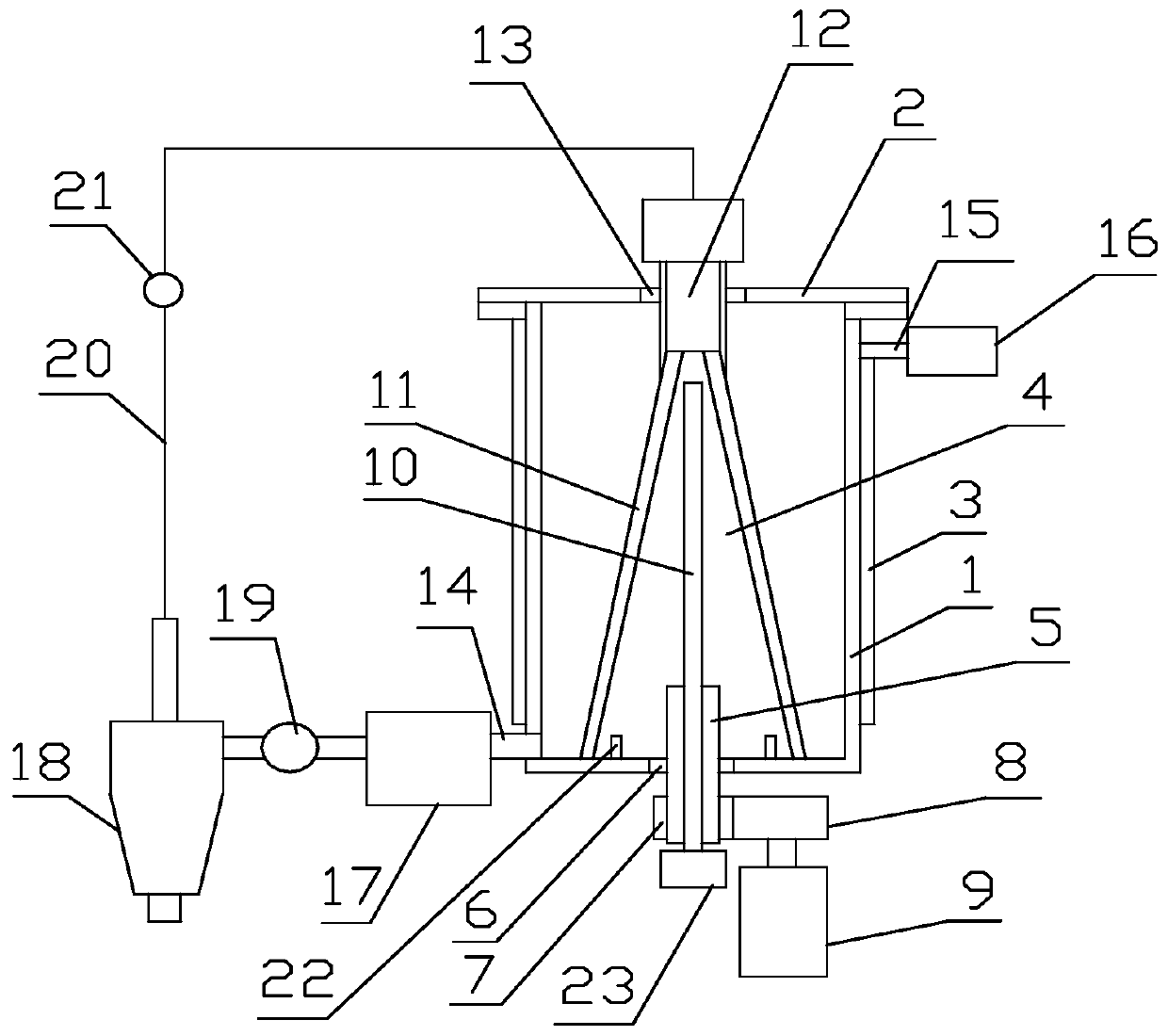

The invention discloses a method and equipment for comprehensive recycling treatment on organic silicon slag slurry. The method comprises the following steps: 1, separating organic silicon slag slurryby using a distiller so as to obtain gas-phase high-boiling residues and solid residues; 2, dissolving the solid residues with an acid, and after dissolution is completed, carrying out filtration andseparation so as to obtain a copper-containing solution and filter residues; 3, washing the filter residues obtained in the step 2, and drying so as to obtain silicon powder; 4, putting zinc powder into the copper-containing solution separated in the step 2 to carry out replacement so as to obtain metallic copper powder; 5, condensing the gas-phase high-boiling residues obtained in the step 1 soas to obtain liquid high-boiling residues, and carrying out catalytic cracking on the liquid high-boiling residues with a catalyst; 6, carrying out fractionation on a gas phase obtained through catalytic cracking in the step 5, and collecting monomethyl trichlorolsilane, dimethyl diclorossilane, trimethylchlorosilane and monomethyl hydrosilane. By adopting the method and the equipment, copper andsilicon resources in organic silicon slag can be effectively recycled, thus being environmental-friendly and economic.

Owner:CHENGDU SILICON TECH CO LTD

Container

ActiveUS8960491B2Improve sealingEasy to recycle separatelyCapsClosure using stoppersEngineeringMechanical engineering

Owner:AIRNOV INC

Concrete mixing plant stock bin dust collection device

ActiveCN111716541AImprove energy saving and environmental protection performanceEasy to recycleMixing operation control apparatusPretreatment controlElectrostatic precipitatorMechanical engineering

The invention relates to the technical field of dust recovery devices, in particular to a concrete mixing plant stock bin dust collection device. The concrete mixing plant stock bin dust collection device comprises a plurality of raw material bins and a dust collection mechanism, wherein a plurality of raw material bins are connected with the dust collection mechanism through a plurality of connecting pipes, the dust collection mechanism comprises a collection bin and fans, the collecting bin comprises a plurality of independent bin chambers, the multiple bin chambers communicate with the connecting pipes correspondingly, a plurality of fans are arranged, and are correspondingly connected with the plurality of bin chambers, electrostatic dust collectors are arranged inside the bin chambers, each electrostatic dust collector comprises two oppositely-arranged electrode plates, the electrode plates are arranged in the air flowing direction, and dust collecting filter cartridges are arranged on the outer sides of the bin chambers. The fans can introduce raised dust in different raw material bins into different bin chambers, and the electrostatic dust collectors in the bin chambers canadsorb the raised dust in the air, so that the purpose of collecting different types of raised dust is achieved, and the raised dust can be independently recycled.

Owner:吴江市恒泰混凝土制品有限公司

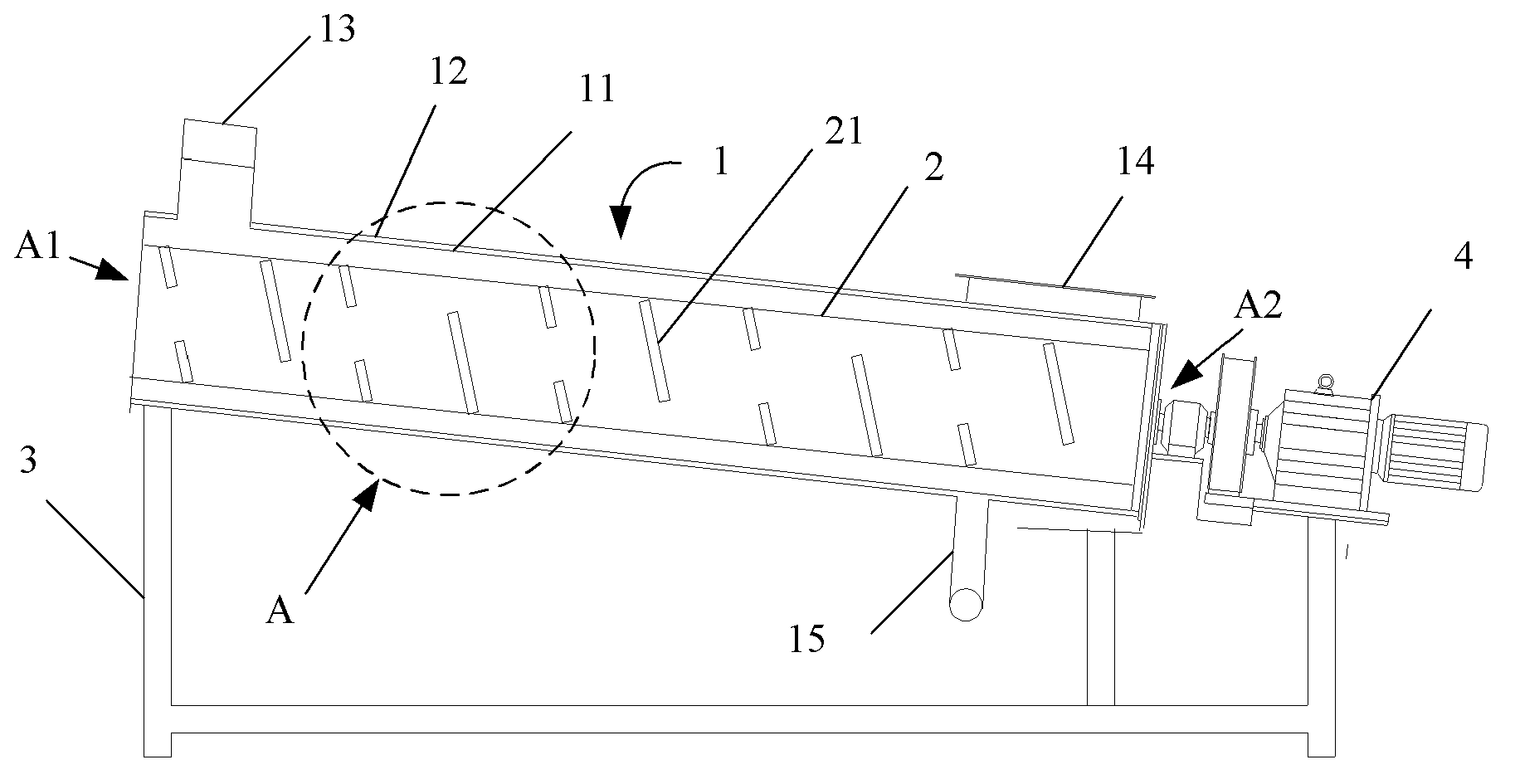

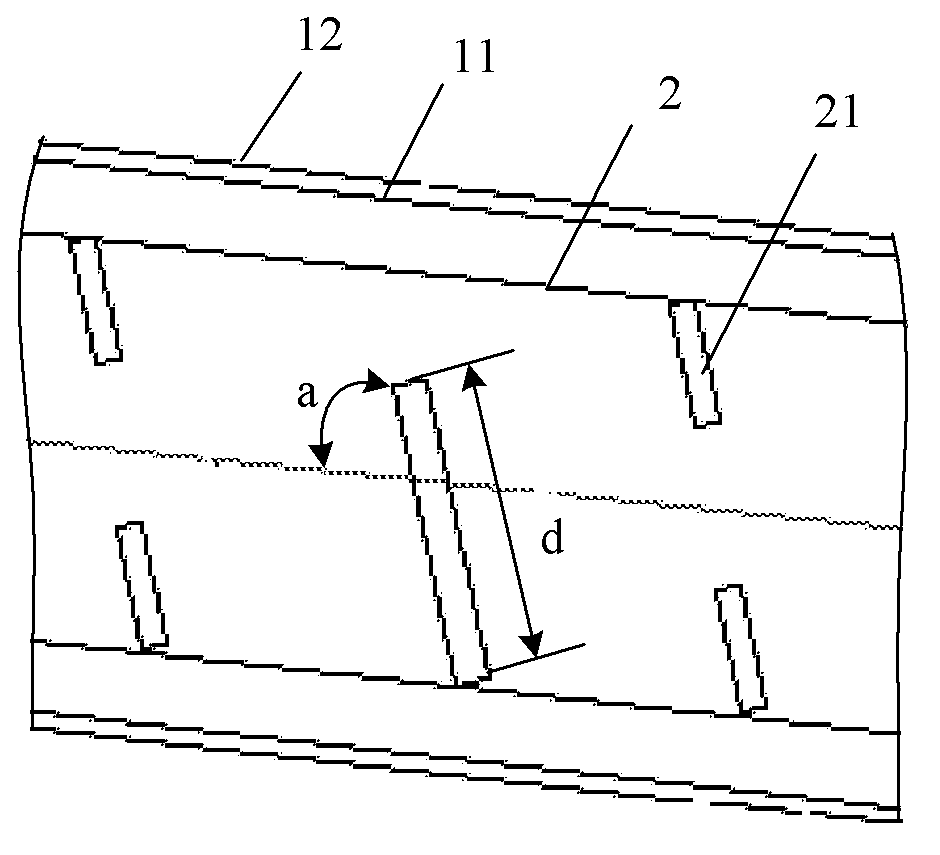

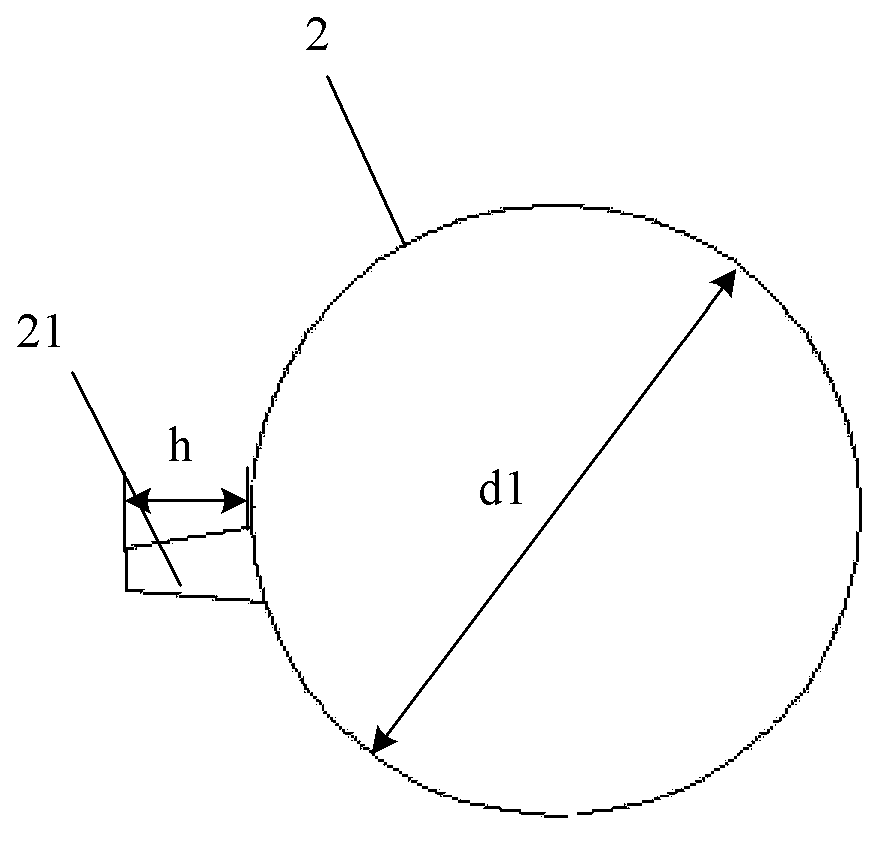

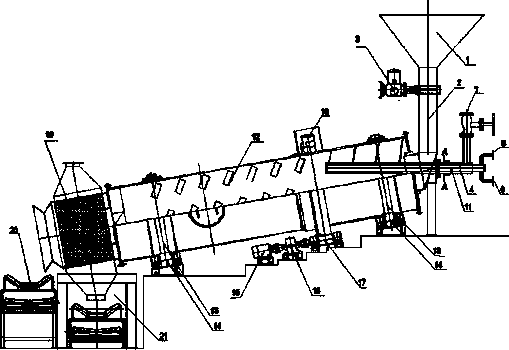

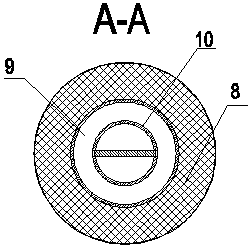

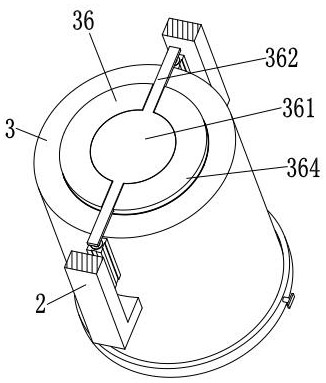

Horizontal type continuous separating and spin-drying device for aluminum plastic composite packing material

ActiveCN102794295AEasy to separateEasy to recycle separatelySievingScreeningPack materialPhysical separation

The invention provides a horizontal type continuous separating and spin-drying device for aluminum plastic composite packing materials, which comprises a barrel body that is arranged in an inclined way; the barrel body comprises an inner barrel body and an outer barrel body which are arranged at an interval; the wall of the inner barrel body is provided with sieve meshes; a first discharge hole passing through the inner barrel body and the outer barrel body is formed in a position on the barrel body and close to a first end; a feeding hole passing through the inner barrel body and the outer barrel body is formed in a position on the barrel body and close to a second end; a second discharge hole passing through the outer barrel body is formed in a position on the barrel body and close to the second end; the first end is higher than the second end; a cavity of the inner barrel body is internally provided with a rotating shaft which is provided with a plurality of sickle-shaped blades at intervals; the plurality of sickle-shaped blades are distributed on the rotating shaft in a spiral way; and the second end of the barrel body is provided with a motor connected with the rotating shaft. The horizontal type continuous separating and spin-drying device can realize continuous aluminum plastic physical separating and plastic spin-drying at the same time, so that the handling capacity of the aluminum plastic physical separating can be effectively improved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Horizontal type continuous separation spin-drying device of aluminum-plastic composite packing material

InactiveCN108214993AEasy to separateEasy to recycle separatelyPlastic recyclingCentrifugesBall bearingBiochemical engineering

The invention discloses a horizontal type continuous separation spin-drying device of an aluminum-plastic composite packing material. The horizontal type continuous separation spin-drying device comprises a base, wherein the upper end of the base is provided with a support frame; the upper end of the support frame is provided with a fixing tube; a motor is arranged at one side of the fixing tube;a feeding opening is formed in one side of the upper end of the fixing tube; a No.1 discharging opening is formed in the other side of the upper end of the fixing tube; a No.2 discharging opening is formed in one side of the lower end of the fixing tube; two ends inside the fixing tube are respectively provided with fixing seats; a separation spin-drying tube is arranged inside the fixing tube; ball bearings are arranged between the separation spin-drying tube and the fixing tube; the two ends of the separation spin-drying tube are provided with rotating shafts; a plurality of groups of bladesare arranged on the inner side wall of the separation spin-drying tube; the lower end of the base is provided with support feet. The horizontal type continuous separation spin-drying device has the advantages that the structure is simple; the use is simple; aluminum and plastics are respectively recovered and utilized; the spin-drying degree is high; the yield is high; the industrial popularization and application can be convenient; better popularization values are realized.

Owner:安徽长正升科技有限公司

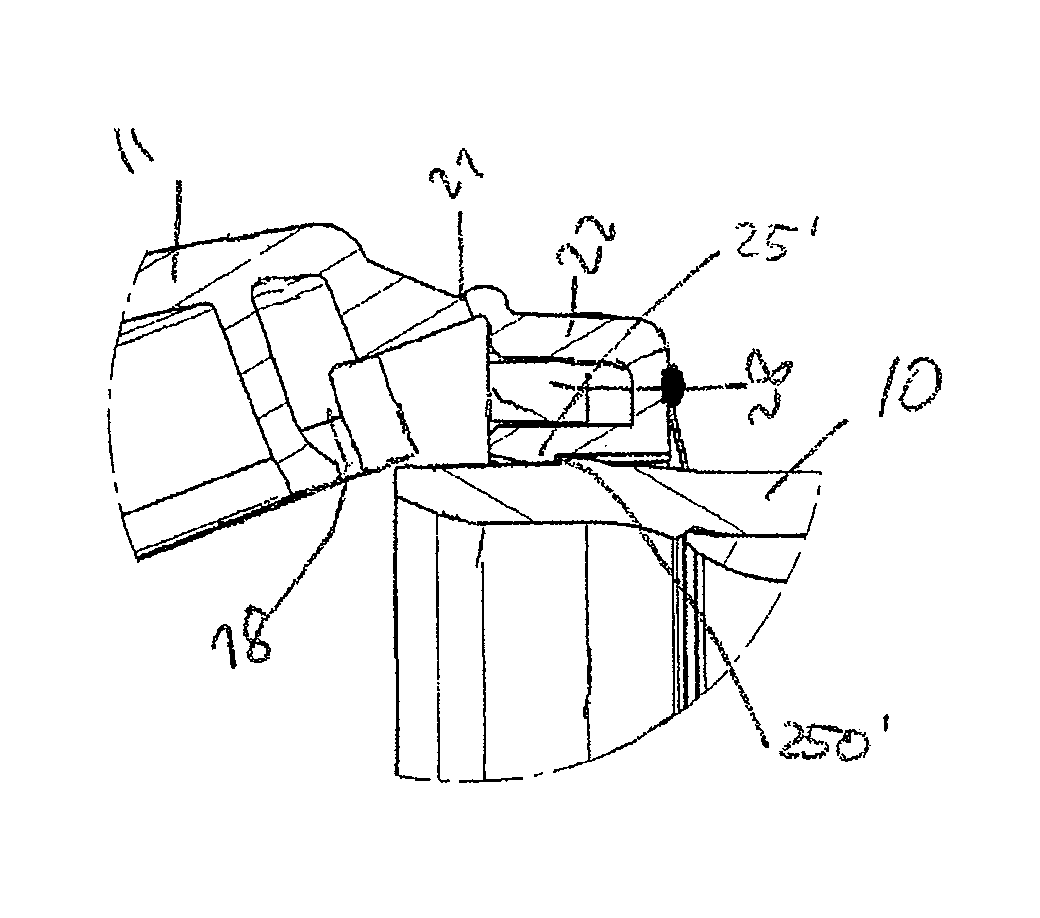

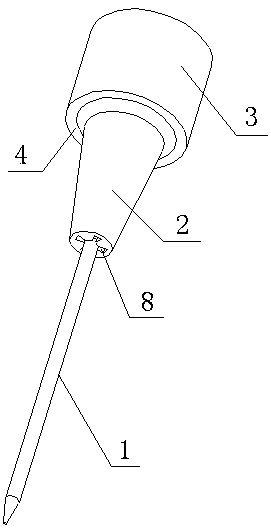

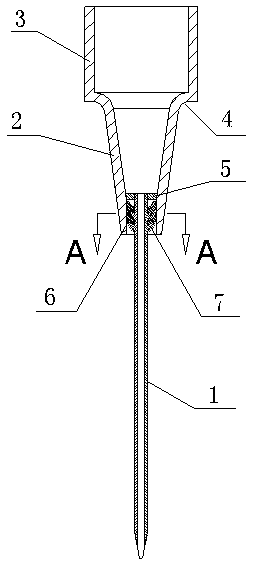

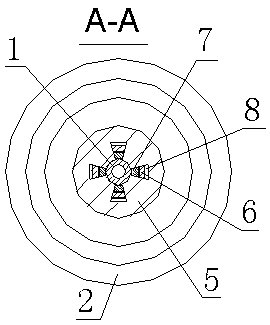

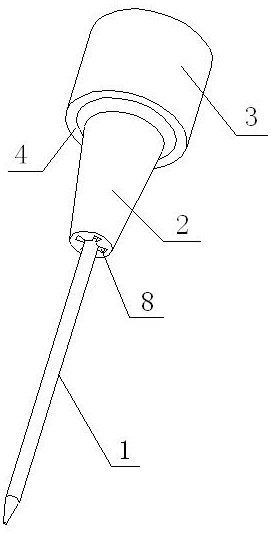

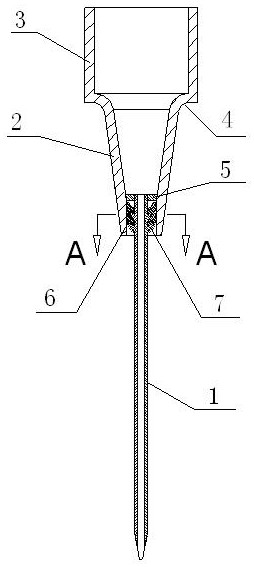

Safe syringe needle device for syringe

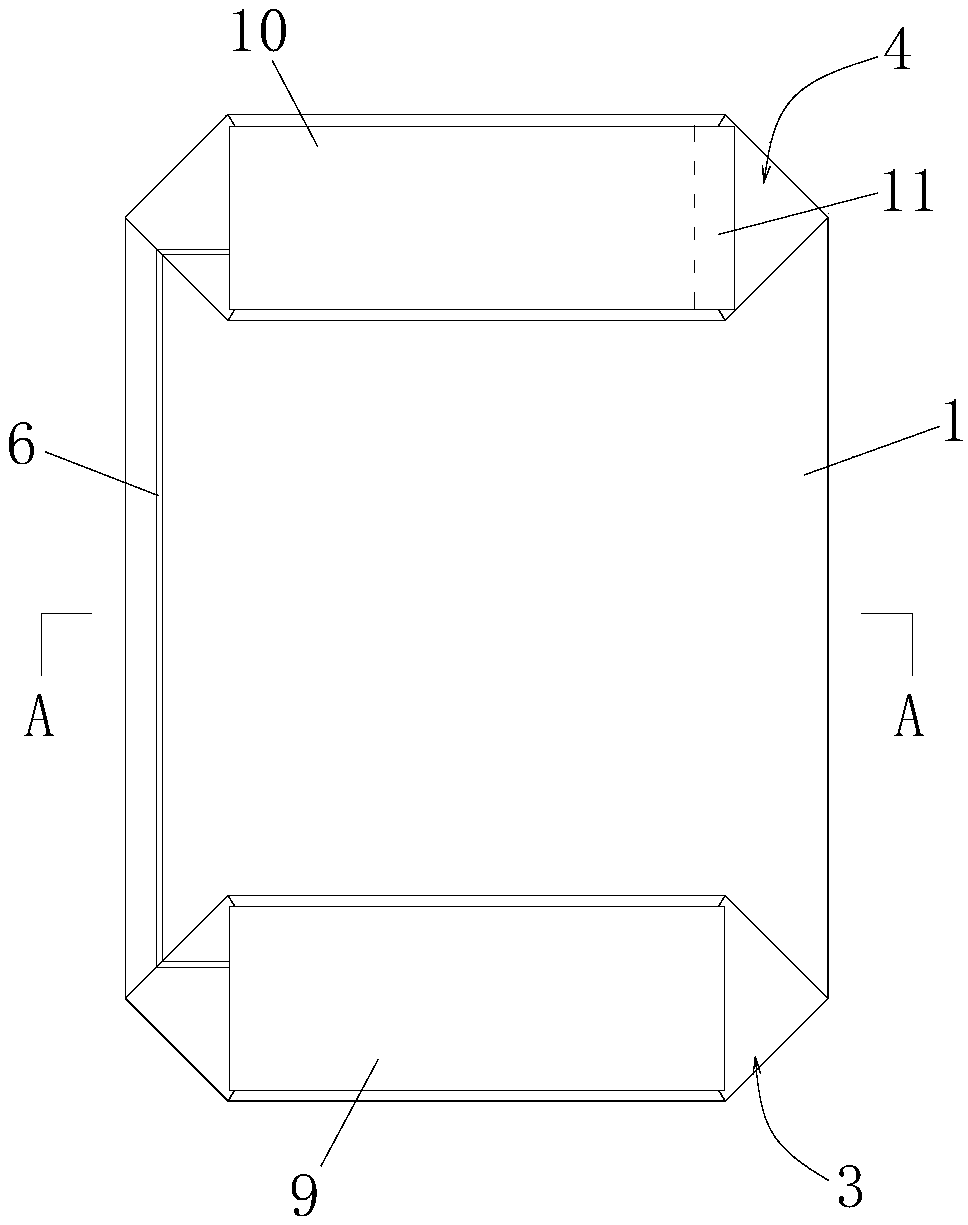

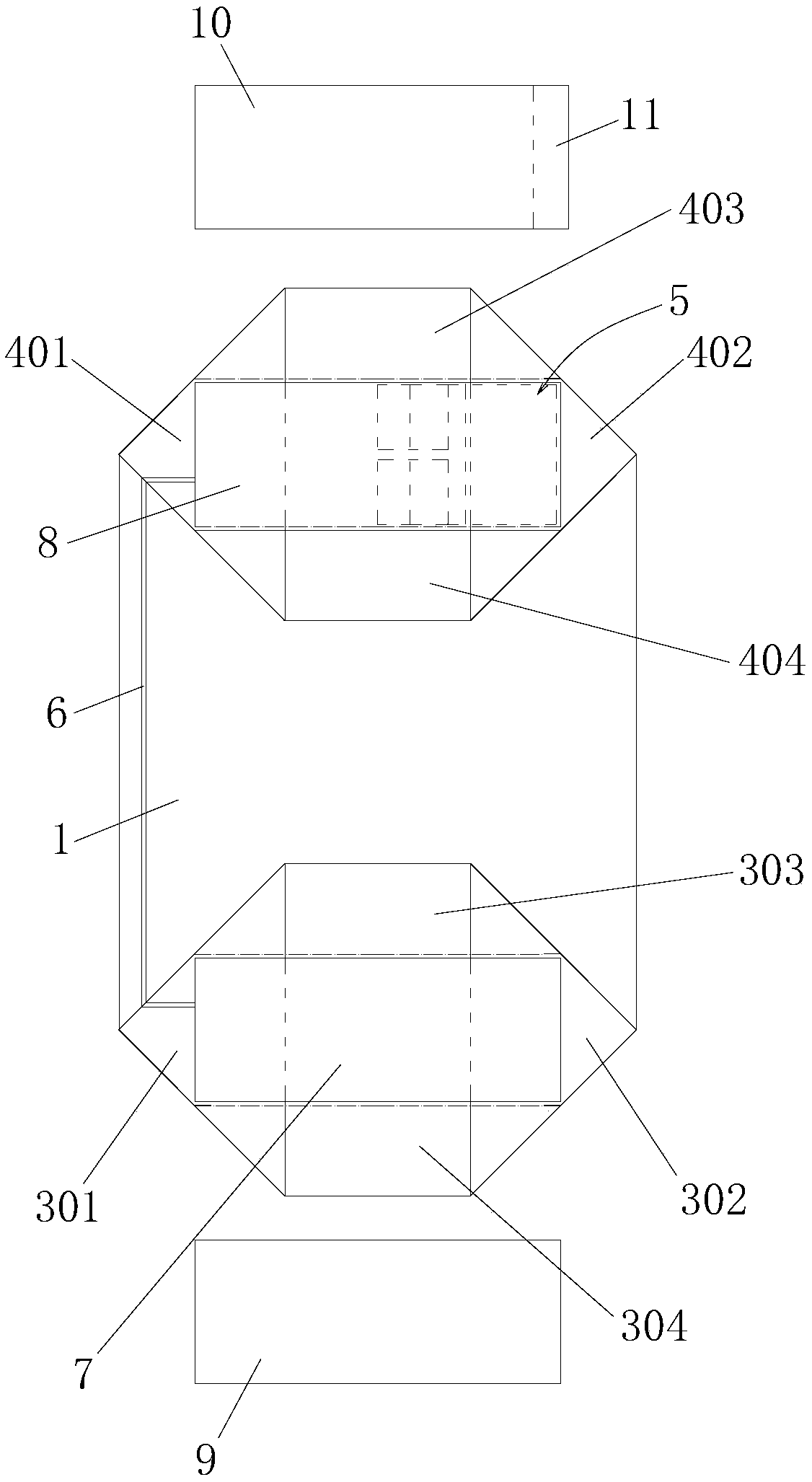

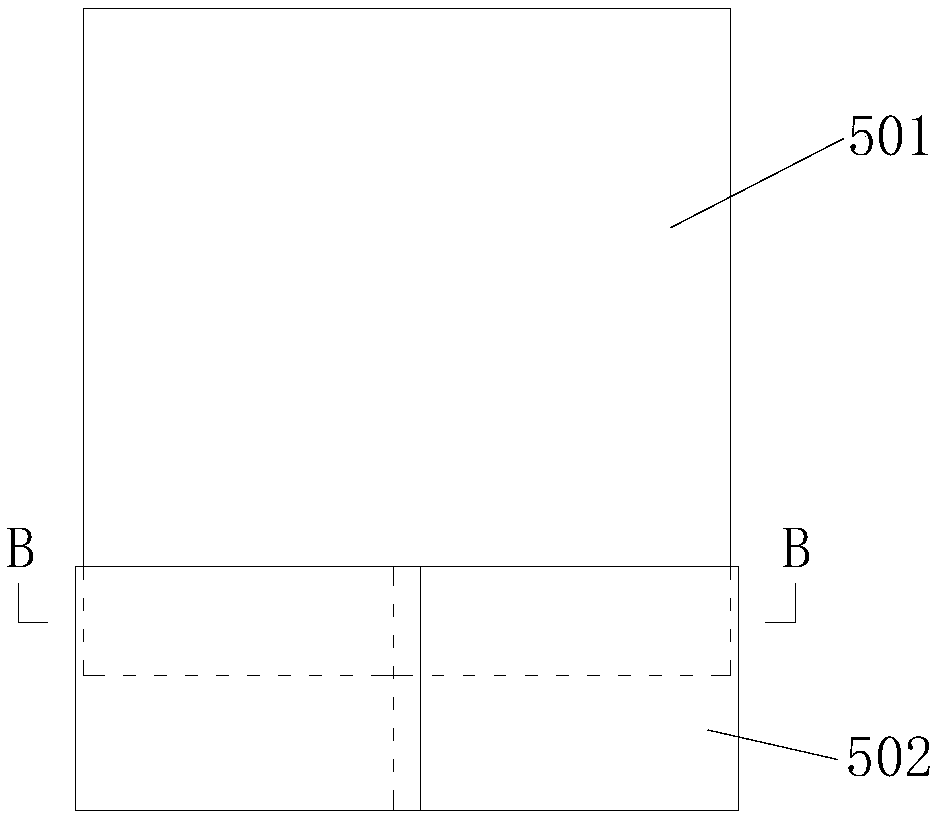

ActiveCN107596509AEasy to recycle separatelyEasy to separateInfusion needlesNEEDLE/SYRINGESyringe needle

The invention discloses a safe syringe needle device for a syringe. The syringe needle device comprises a needle cap and a syringe needle thin tube, multiple groups of pawls are distributed on the periphery of the side wall of the top of the syringe needle thin tube, each group of pawls comprises at least two pawls which are distributed in the length direction of the syringe needle thin tube, multiple pawl insertion grooves where the pawls are correspondingly inserted are formed in the periphery of the inner wall of an inner hole in the bottom end of the needle cap, pawl blocks clamped and matched with the pawls in a one-to-one corresponding mode are fixedly arranged on the inner walls of the pawl insertion grooves, the outer wall of the top end of the syringe needle thin tube is sleeved with a sealing ring in a sealed mode, and the circumferential outer wall of the sealing ring is in sealed connection with the inner wall of the inner hole of the needle cap. The syringe needle device has the advantages that the structural design is reasonable, the structural fixation is firm and reliable, the syringe needle and the needle cap are separated truly and conveniently, and separated recycling of the needle syringe needle is achieved.

Owner:李奇元

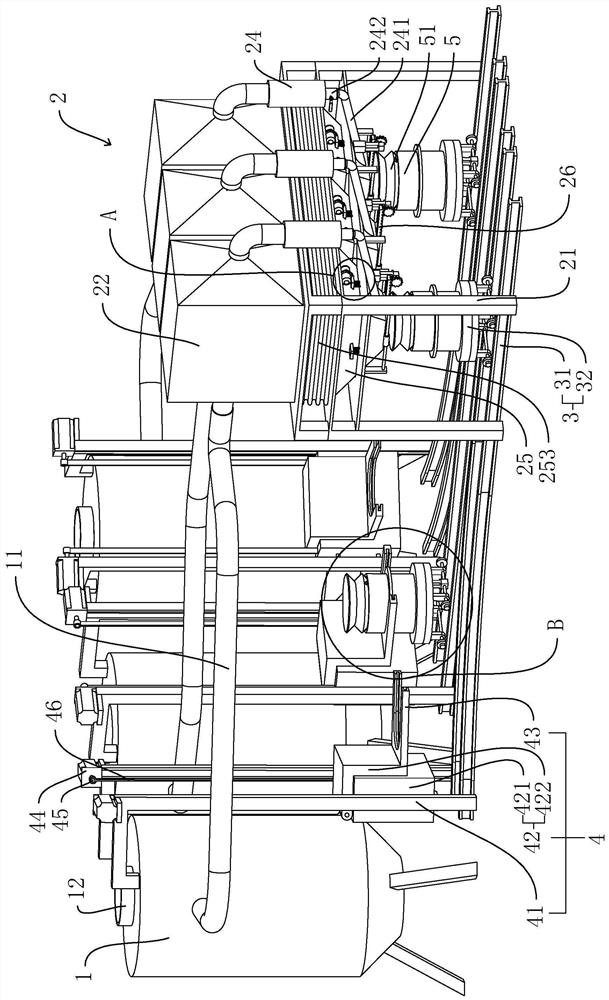

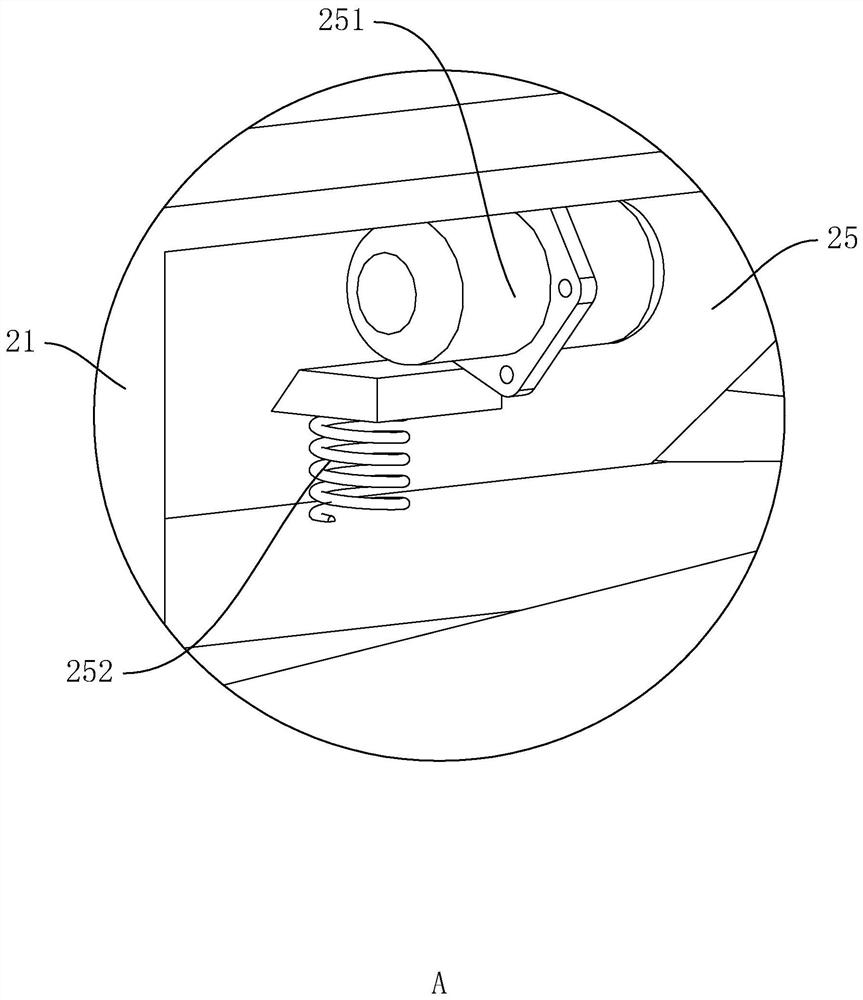

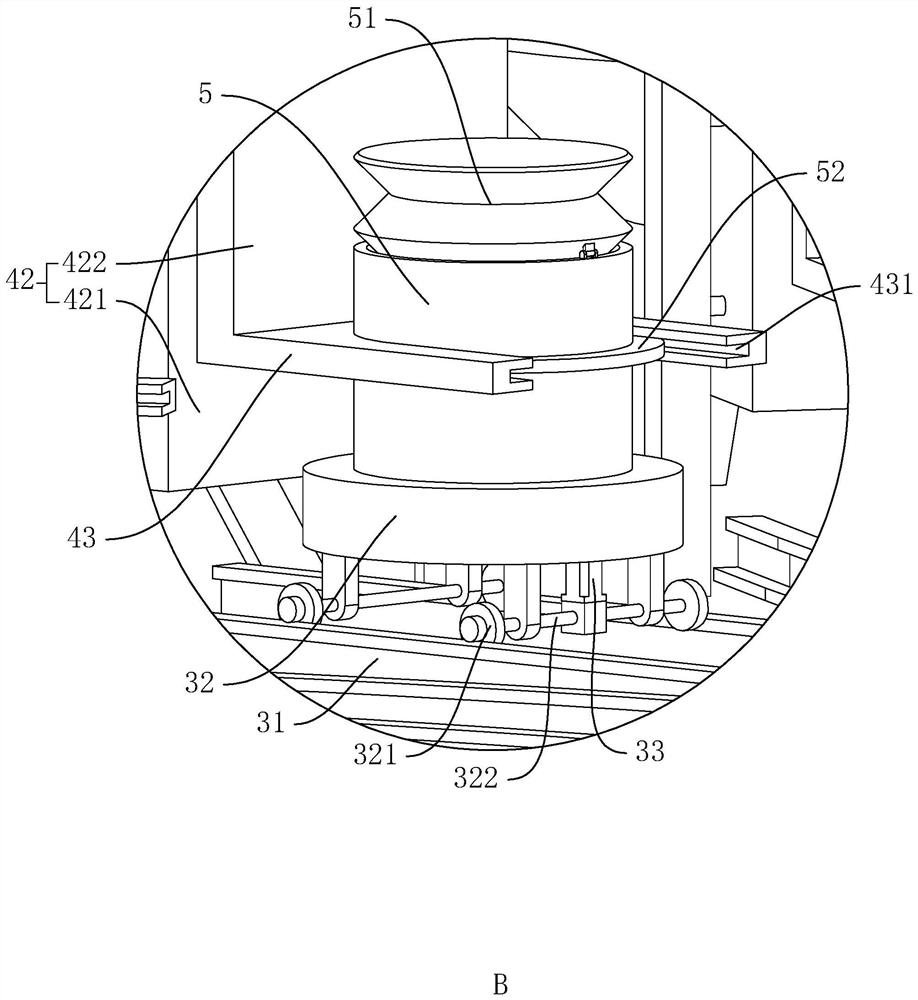

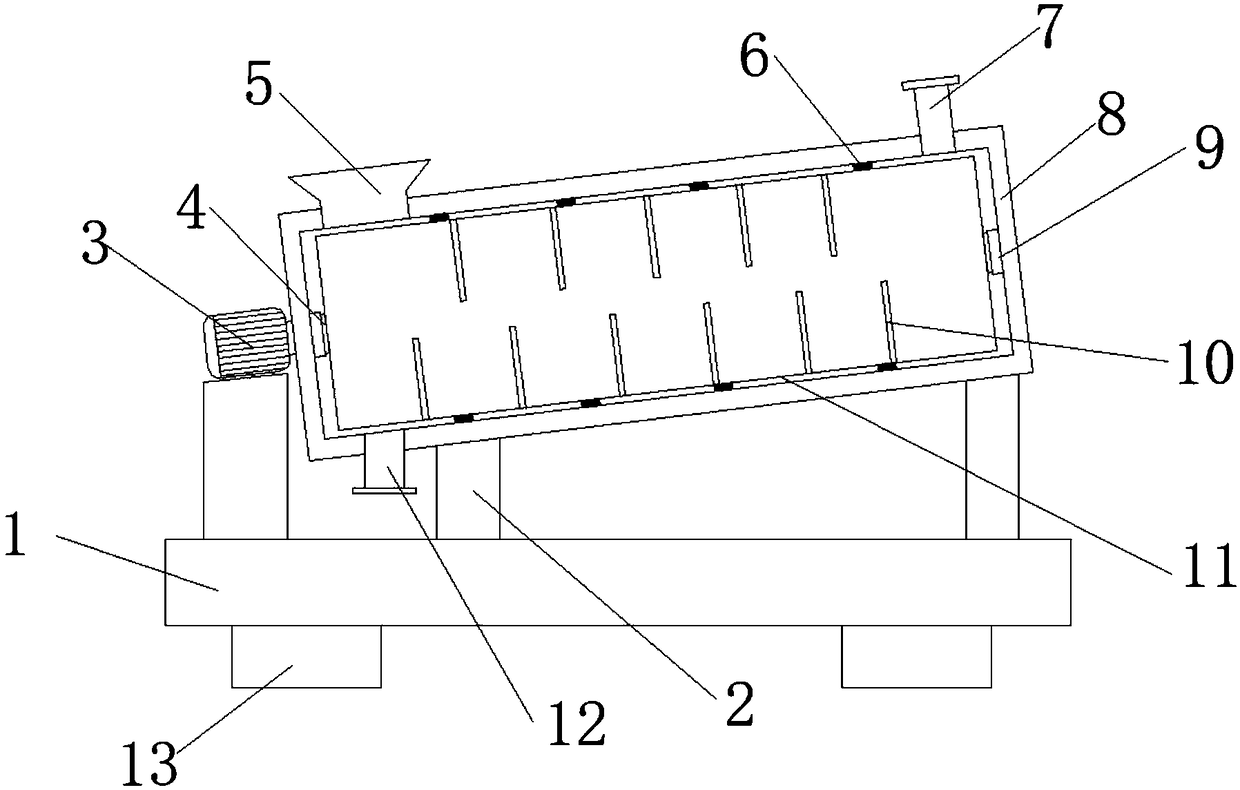

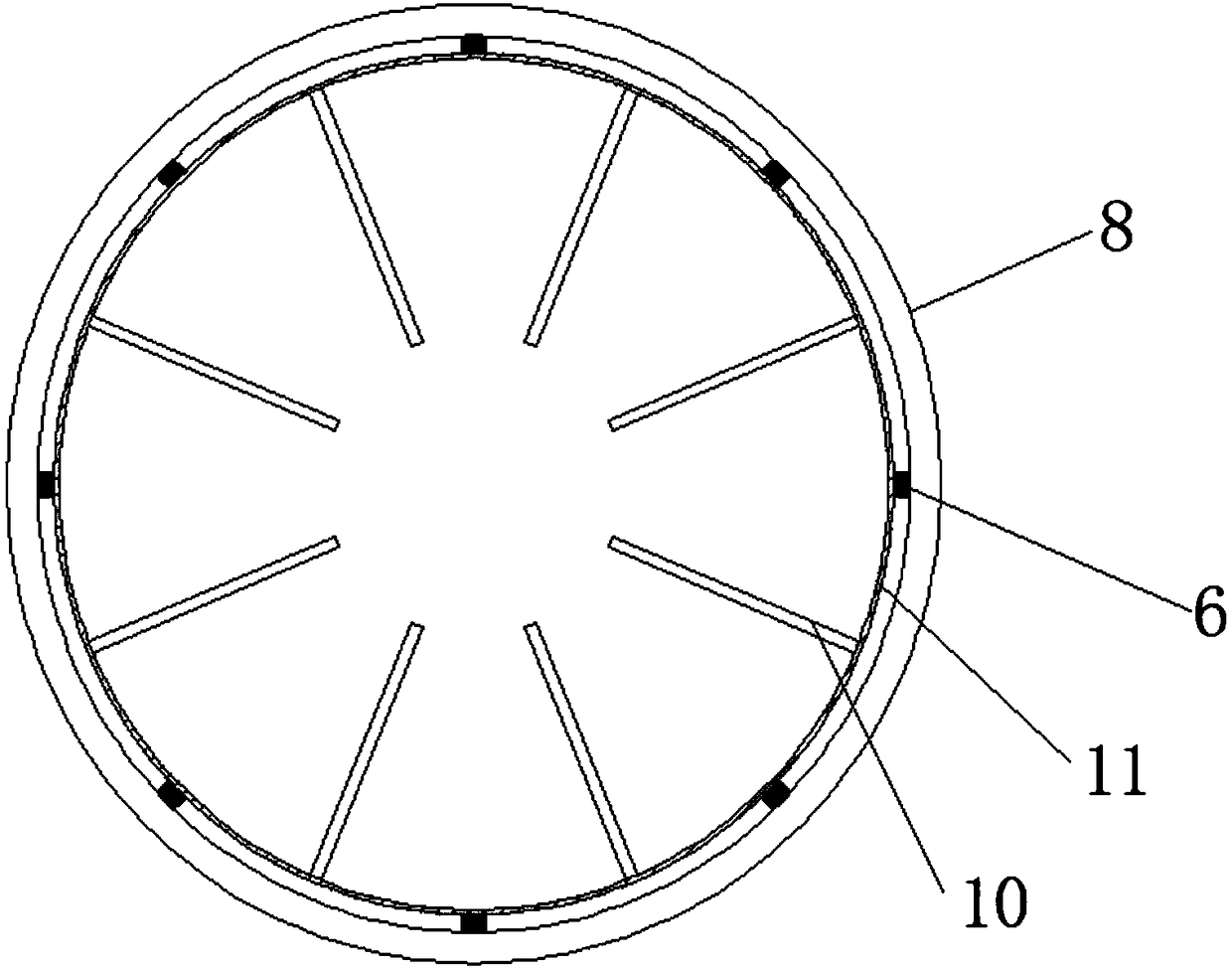

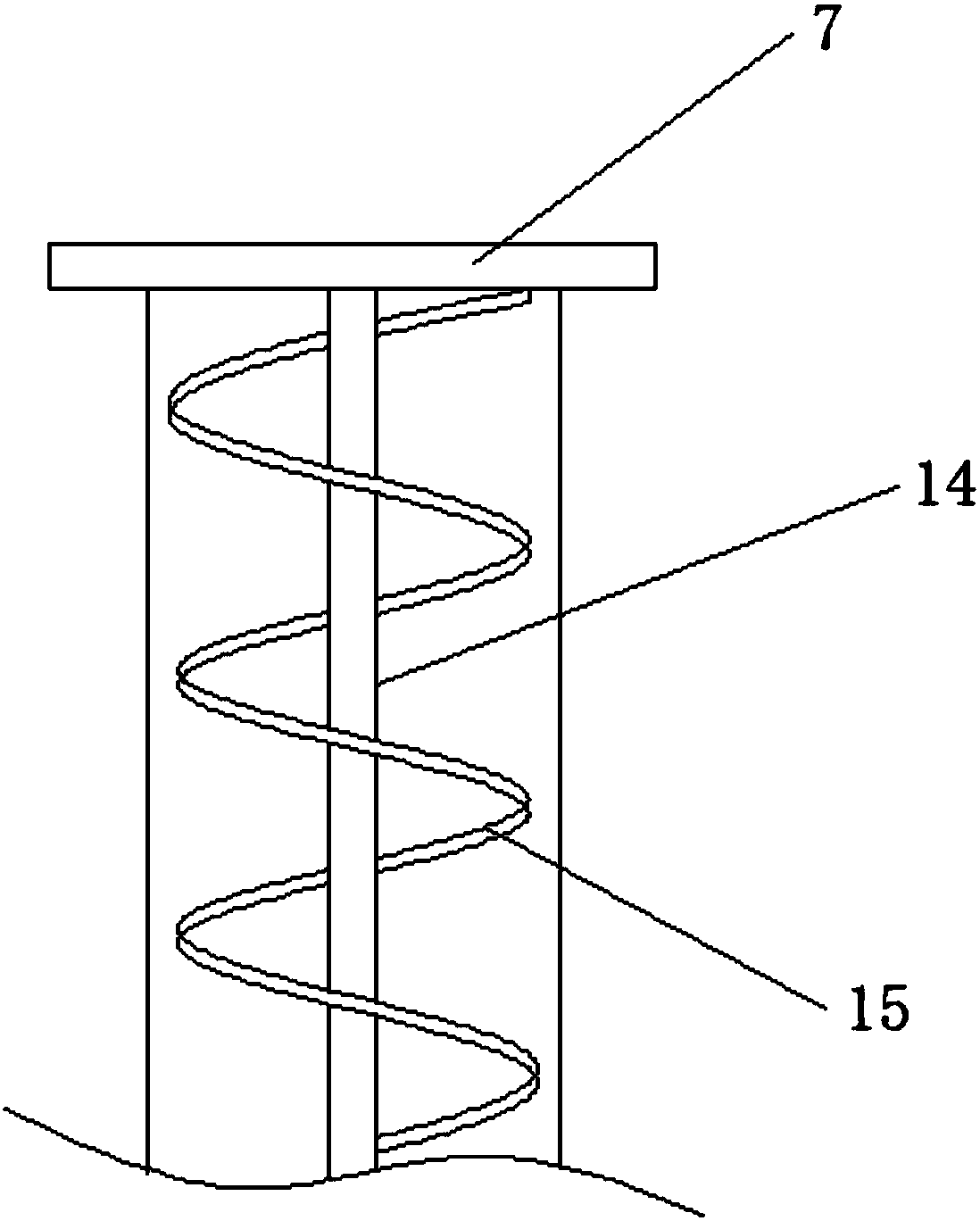

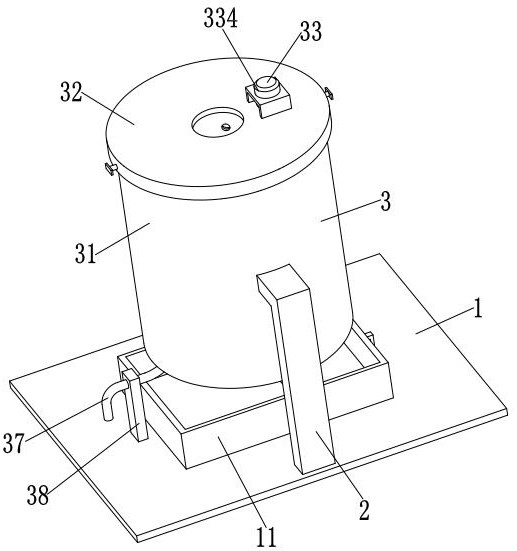

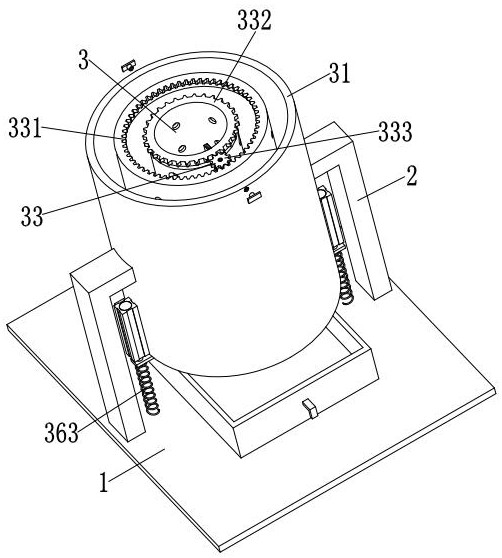

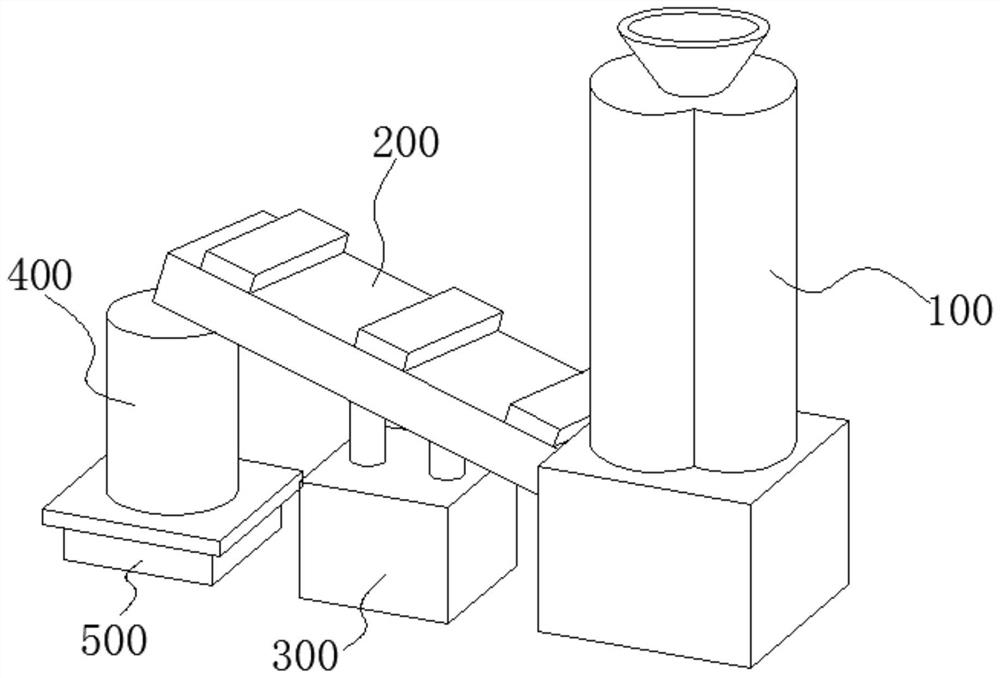

Carbonaceous raw material granulator

InactiveCN103566821AEasy to recycle separatelyReduce consumptionGranulation in rotating drumsWork in processEngineering

The invention relates to a carbonaceous raw material granulator which comprises a material charging mechanism, a heating mechanism, a rotary kiln rotary mechanism, and a recycling mechanism; the material charging mechanism is connected with the rotary kiln rotary mechanism; the heating mechanism is also connected with a material inlet of the rotary kiln rotary mechanism; the rotary kiln rotary mechanism is inclinedly fixed on a pedestal; the recycling mechanism is disposed at a material outlet of the rotary kiln rotary mechanism. The granulator of the invention is compact in structure, low in production cost, and convenient for operation; the heating mechanism can well provide the granulator with heat, and enables uniform heat conduction; heat conduction oil is circulated and recycled, which saves production cost; the rotary kiln rotary mechanism reduces raw material and electrode consumption, and decreases equipment maintenance cost, which realizes energy saving and emission reduction; the recycling mechanism conveniently recycles finished products and semi-finished products separately, and is high in recycling efficiency and high in accuracy.

Owner:YANGZHOU BAFANG ELECTROMECHANICAL EQUIP CO LTD

A sewage treatment filter

ActiveCN113457260BEasy to recycle separatelyGuaranteed Filtration EfficiencyMoving filtering element filtersFiltrationWastewater

Owner:江苏大彭环保科技有限公司

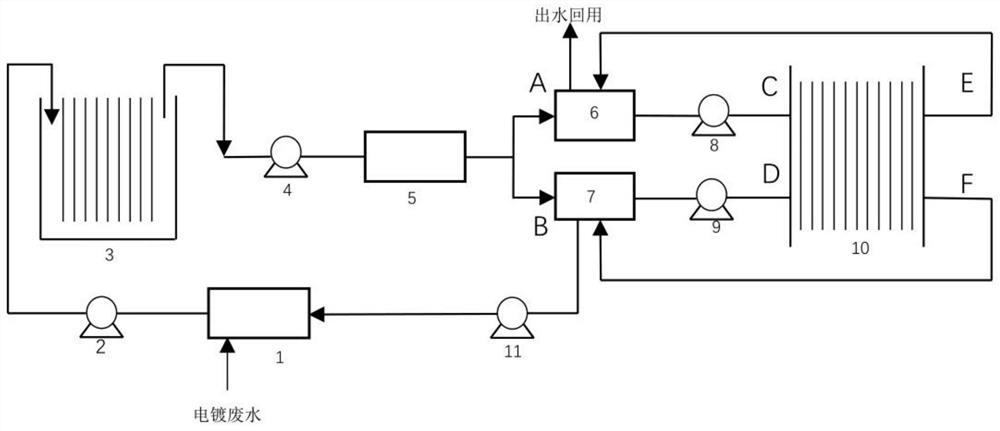

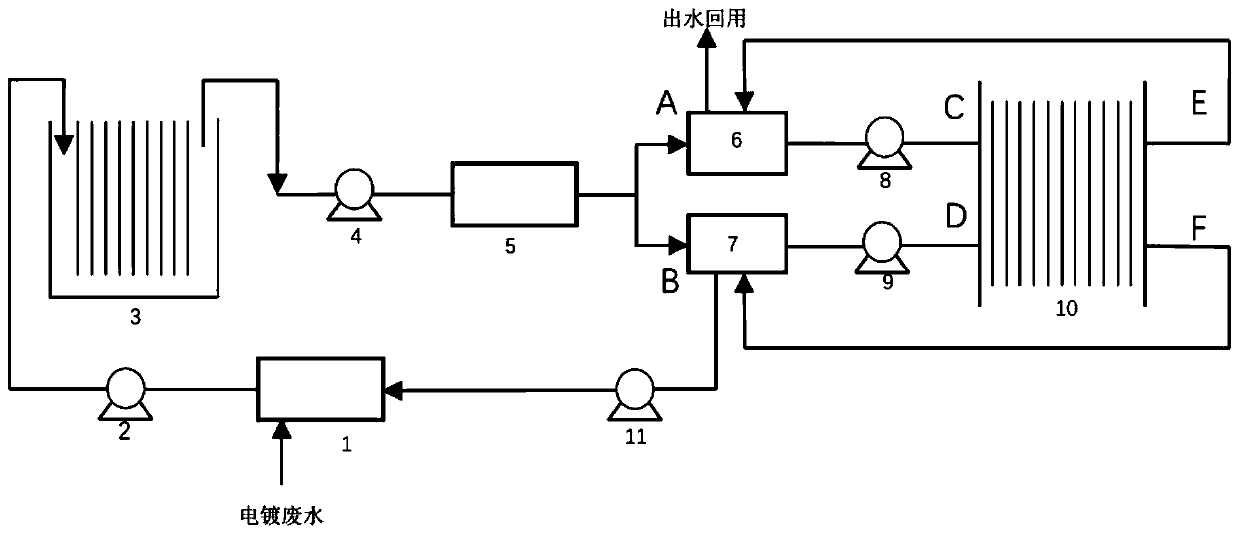

A resource recovery device for nickel-containing heavy metal wastewater

ActiveCN111018203BReduce loadReduce the concentration of nickel ionsWater contaminantsWater/sewage treatmentElectrolytic agentWater storage tank

The invention discloses a resource recovery device for nickel-containing heavy metal wastewater, which belongs to the field of recovery of nickel-containing heavy metal wastewater. The recovery system is composed of a sewage pump, a DC power supply, an electrolytic cell, and an electrode plate; the electrolyte ultrafiltration system is composed of a sewage pump, an ultrafiltration filter reactor, and a water storage tank; the electrodialysis circulation nickel removal system is composed of a sewage pump, a direct current Composed of power supply and electrodialyzer. The invention has the advantages of simple structure, recyclable nickel, recyclable waste water and no secondary pollutants. It is suitable for the treatment of nickel-containing heavy metal wastewater in electroplating enterprises, and has both environmental and economic benefits.

Owner:ZHAOQING UNIV

Method for simultaneous removal of sulfur dioxide and nitrogen oxides in flue gas by double-tower series catalytic-biofilm packed tower system

InactiveCN101708415BEasy to cleanEasy to recycle separatelyDispersed particle separationAir quality improvementBiofilmPh buffering

The invention provides a twin tower tandem exhaust gas purifying processing combination device which adopts a biomembrane packing tower system utilizing catalytic oxidant cyclically spraying liquid in the front and a biomembrane packing tower system utilizing pH buffering agent cyclically spraying liquid in the rear, which can carry out purifying processing to simultaneously remove the SQ2 and the NOx in the exhaust gas and to obtain by-products, namely, the utilizable sulphuric acid and nitrating acid products. The invention is characterized in that desulphuricants and denitrifier complex bacteria with the performance of simultaneously removing SQ2 and NOx in the exhaust gas under the conditions of liquid-phase catalyzed oxidation and pH acid environment can be obtained by screening and culturing and domesticating, and the composite bacteria biofilm to manufacture the biomembrane packing tower which is arranged in the tandem front end and is mainly used for removing SQ2; and the biomembrane packing tower which is mainly used for removing NOx in the rear is manufactured by adopting the denitrifier complex bacteria biofilm with the performance of removing NOx in the exhaust gas under the condition of pH neutral environment through screening and culturing and domesticating.

Owner:NANJING JIANGDAO INST OF ENVIRONMENT RES CO LTD

A needle device for a safety syringe

ActiveCN107596509BEasy to recycle separatelyEasy to separateInfusion needlesEngineeringSafety syringe

Owner:李奇元

Metal cutting device for machining center and working method of metal cutting device

ActiveCN114700796AAvoid pollutionEasy to recycle separatelyMeasurement/indication equipmentsMaintainance and safety accessoriesStructural engineeringCooling fluid

The invention belongs to the technical field of metal cutting, and particularly relates to a metal cutting device for a machining center and a working method.The metal cutting device comprises a cutting mechanism, a collecting mechanism and a filtering mechanism, the cutting mechanism comprises a rack, the middle of the rack is of a hollow structure, and two symmetrical sliding rails are arranged on the top of the rack in the length direction; by means of the device, environmental pollution can be avoided, cooling liquid and chippings can be recycled and treated conveniently, and therefore the cost is saved; and in addition, defective products or defective products of corresponding batches can be quickly found for key screening, so that the quality inspection efficiency is effectively improved.

Owner:XIANGNAN UNIV

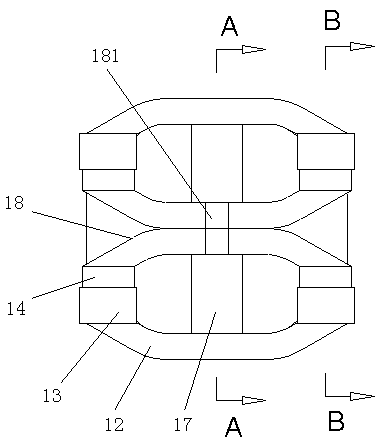

A liquid-liquid separation chromatography device

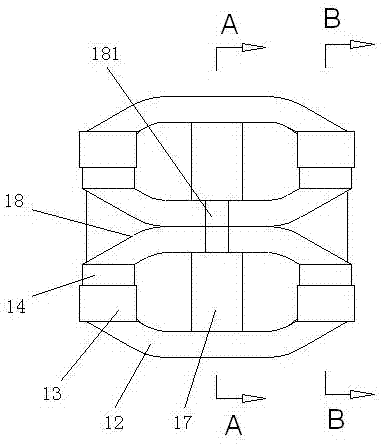

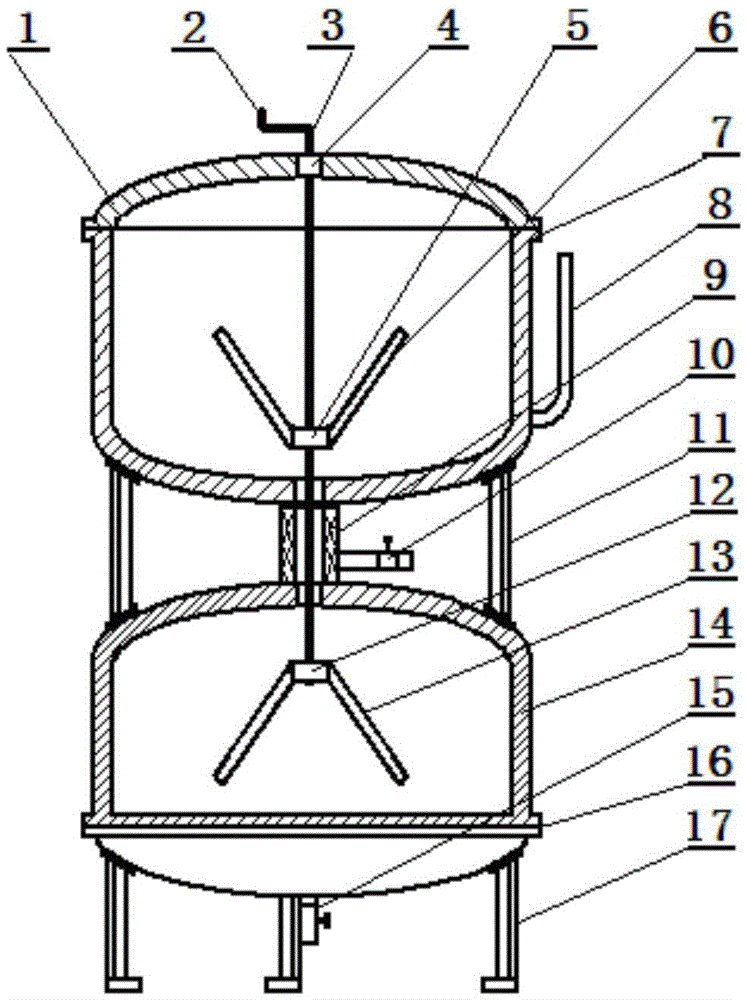

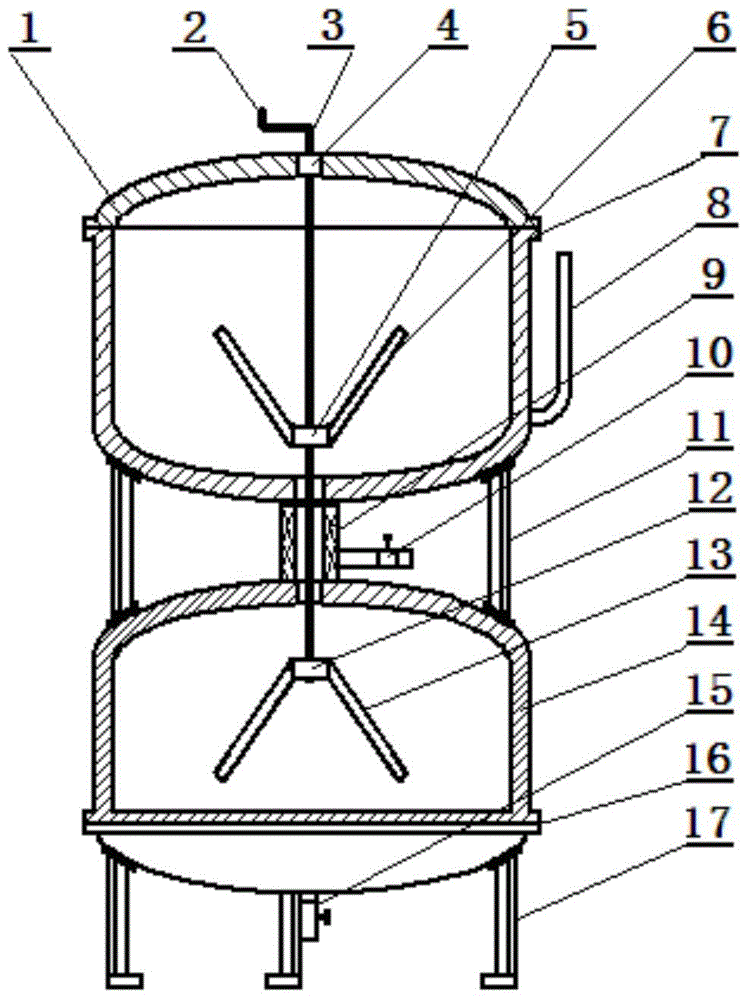

ActiveCN104623928BThe connection interface is smallEasy to recycle separatelyLiquid separationAntineoplastic agentsSocial benefitsFluid phase

The invention discloses a liquid-liquid separation and chromatography device, which includes an upper liquid tank 1 and a lower liquid tank 14. The upper liquid tank 1 and the lower liquid tank 14 are connected through a visual bell 9, and the upper liquid tank 1 and the lower liquid tank 14 are connected by a tank connecting column 11. The liquid tank 1 and the lower liquid tank 14 are fixed, and the upper liquid tank 1 and the lower liquid tank 14 are respectively provided with an upward slope paddle 5 and a downward slope paddle 12, and the upward slope paddle 5 and the downward slope paddle 12 are fixed on the vibration shaft 3 superior. Described visual clock 9 is a conventional visual clock, and the middle section of visual clock 9 is provided with upper liquid valve 10, and fixes with the top of connecting rod and lower liquid tank 14. A watch clock with an upper liquid valve is set between the two liquid tanks of this device. The connection interface between the upper liquid tank and the lower liquid tank is small, and the bottom of the lower liquid tank is equipped with a lower liquid valve, which is easy to control the flow of the upper and lower liquid phases. Recycle separately. The liquid-liquid separation device has a simple structure, is easy to process, is easy to operate, occupies a small area, has good practicability, is economical and reasonable, has good liquid-liquid separation effect, and has good economic and social benefits.

Owner:桂平市市场监督管理局

Liquid-liquid separation chromatography device

ActiveCN104623928AOvercoming the difficulty of judgingOvercoming separationLiquid separationAntineoplastic agentsSocial benefitsFluid phase

The invention discloses a liquid-liquid separation chromatography device which comprises an upper liquid container 1 and a lower liquid container 14, wherein the upper liquid container 1 is connected with the lower liquid container 14 by a visual clock 9; the upper liquid container 1 and the lower liquid container 14 are fixed by a container connecting column 11; an upper oblique paddle 5 and a lower oblique paddle 12 are arranged in the upper liquid container 1 and the lower liquid container 14, and are fixed on a vibration shaft 3; the visual clock 9 is conventional; an upper liquid valve 10 is arranged at the middle section of the visual clock 9; and the upper liquid valve 10 and the top of the lower liquid container 14 are fixed by a connecting rod. According to the device, the visual clock of the upper liquid valve is arranged between the two liquid containers, the interface of a connecting end between the upper liquid container and the lower liquid container is small, and a lower liquid valve is arranged at the bottom of the lower liquid container, so that the respective recovery of upper and lower liquid phases can be controlled easily. The device is simple in structure, easy to process and operate, small in floor area, relatively good in practicability, economic benefits and social benefits, good in liquid-liquid separation effect, economic and reasonable.

Owner:桂平市市场监督管理局

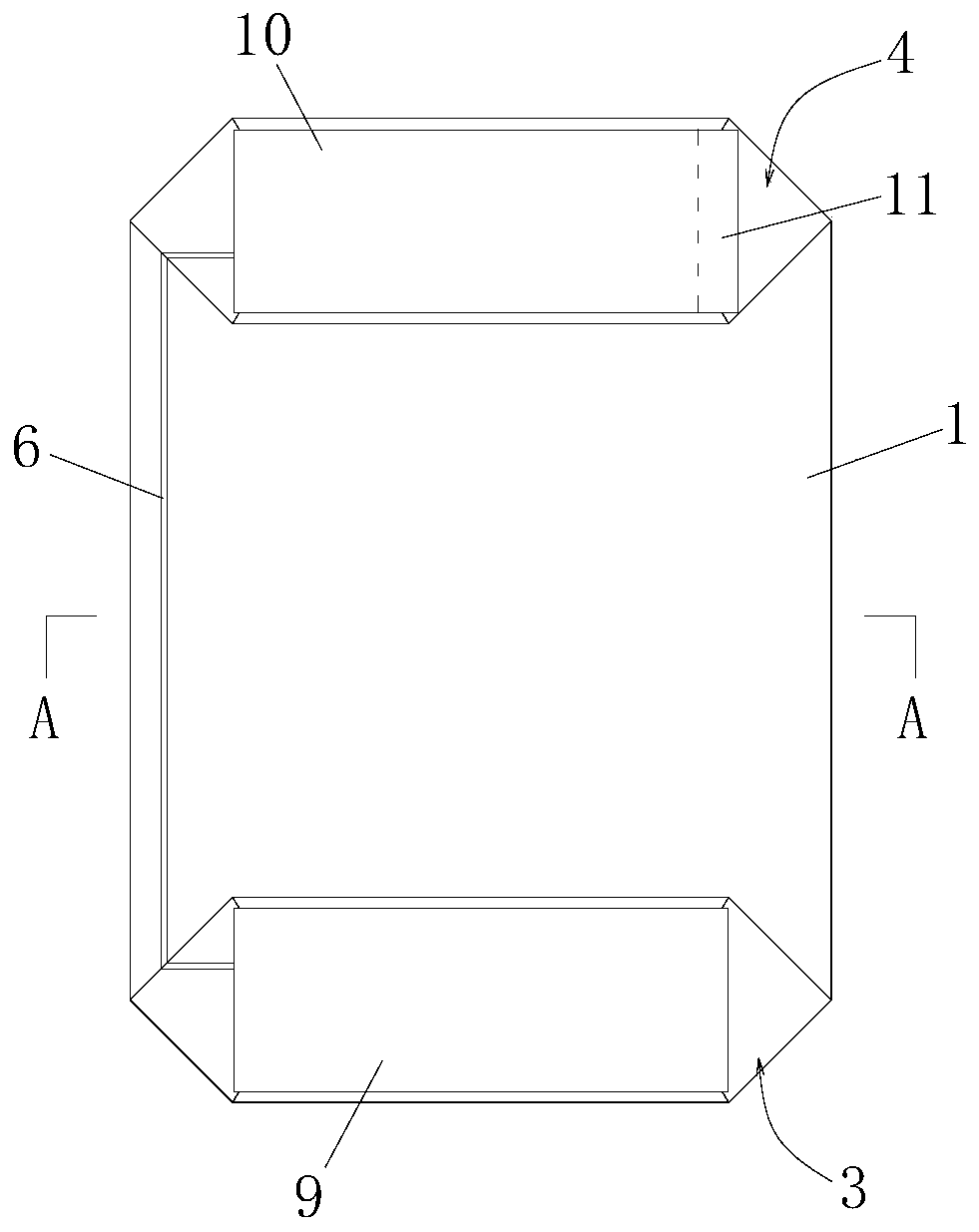

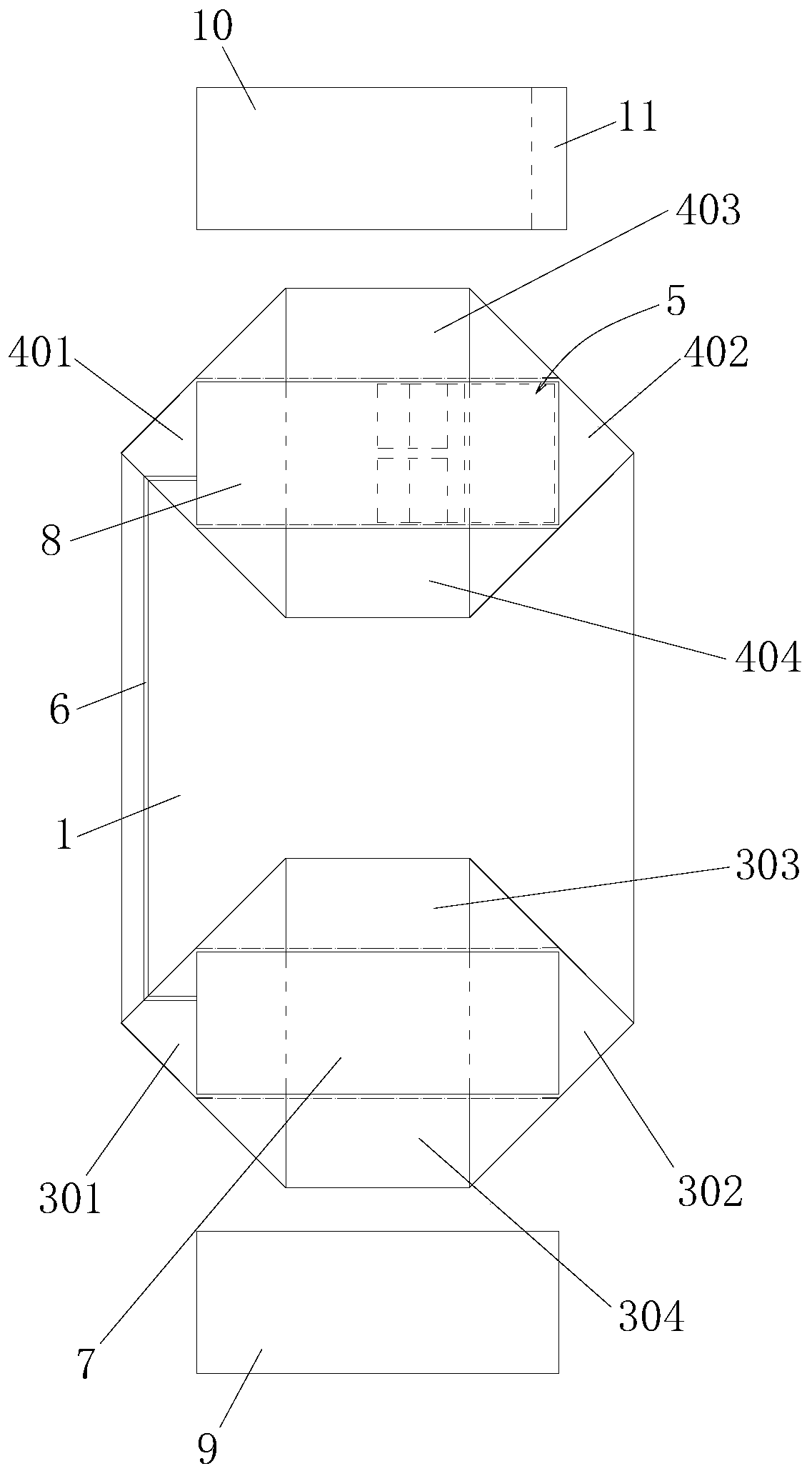

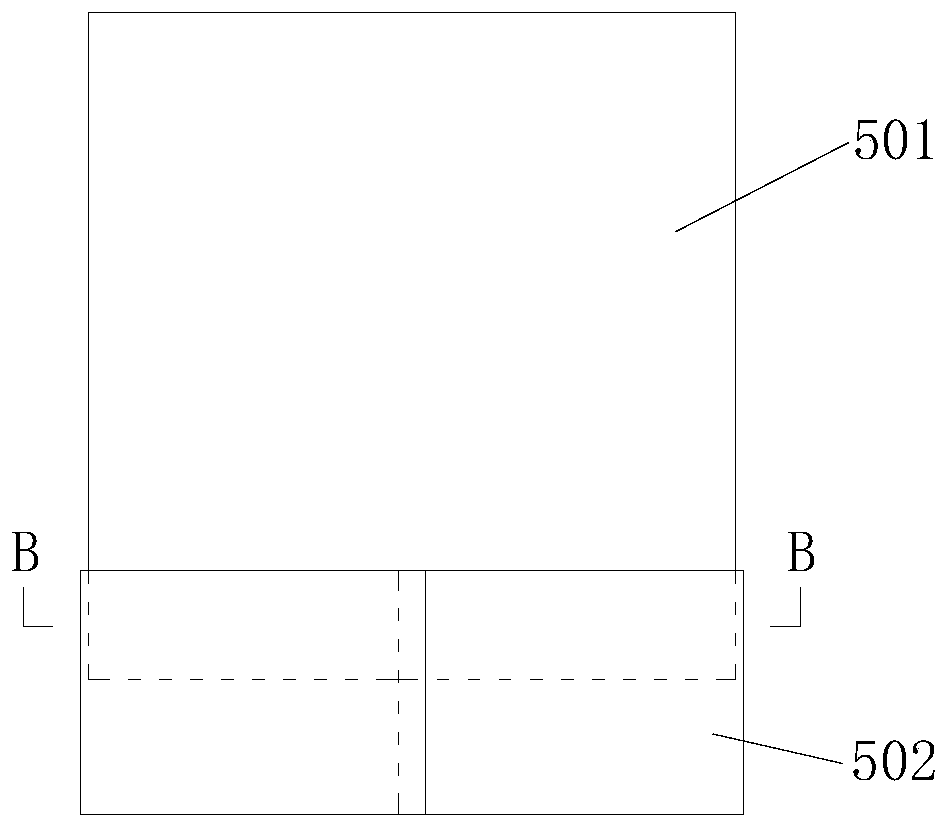

Packaging bags and packaging bag production process

ActiveCN109160069BExquisite appearanceEasy to recycleBag making operationsPaper-makingPulp and paper industryBrightness perception

The invention provides a packaging bag, and belongs to the field of packaging. The packaging bag comprises a paper layer, a plastic layer and a valve structure, wherein the bottom of the paper layer is bonded with the bottom of the plastic layer; the top of the paper layer is bonded with the top of the plastic layer; and the middle part of the paper layer and the middle part of the plastic layer are separated. According to the packaging bag, only the tops and the bottoms of the paper layer and the plastic layer are bonded, the middle parts are separated, the plastic layer and the paper layer are separately recycled, and the packaging bag is more energy-saving and environmentally-friendly; and patterns can be printed on the flat paper layer in advance, the printed patterns are flat and bright, and the appearance of the packaging bag is more beautiful. The invention further provides a production technology of the packaging bag. The production technology comprises the steps of printing the patterns on the paper layer; arranging the paper layer on the periphery of the plastic layer; bonding the top of the paper layer with the top of the plastic layer; bonding the bottom of the paper layer with the bottom of the plastic layer; forming a lower bottom and an upper bottom; and arranging the valve structure. According to the production technology, flatness and brightness of the printedpatterns of the packaging bag are guaranteed, and separated recovery of the plastic layer and the paper layer is facilitated.

Owner:河北立广新型材料科技有限公司

Dust collection device for silo of concrete mixing station

ActiveCN111716541BAchieve the purpose of collectionAvoid mixing with each otherMixing operation control apparatusPretreatment controlProcess engineeringSilo

The present invention relates to the technical field of dust recovery devices, in particular to a dust collection device for a concrete mixing station silo, which includes a plurality of raw material bins and a dust collection mechanism, and a plurality of raw material bins are respectively connected to the dust collection mechanism through a plurality of connecting pipes. The dust collection mechanism includes a collection bin and a fan; the collection bin includes a plurality of mutually independent compartments, and the plurality of compartments communicate with a plurality of connecting pipes; The interior of the warehouse is equipped with an electrostatic precipitator, and the electrostatic precipitator includes two oppositely arranged electrode plates. The electrode plates are arranged along the direction of air flow, and a dust collection filter cartridge is arranged outside the warehouse. The fan can pass the dust in different raw material warehouses into different warehouses, and the electrostatic precipitator in the warehouse can absorb the dust in the air, so as to achieve the purpose of collecting different types of dust, and it is convenient to separate the dust Recycle.

Owner:吴江市恒泰混凝土制品有限公司

A method and equipment for comprehensive recovery and treatment of organic silicon slurry

ActiveCN108558928BAchieve separationEasy to recycle separatelySilicon organic compoundsSilicon compoundsPtru catalystSlag

The invention discloses a method and equipment for comprehensive recycling treatment on organic silicon slag slurry. The method comprises the following steps: 1, separating organic silicon slag slurryby using a distiller so as to obtain gas-phase high-boiling residues and solid residues; 2, dissolving the solid residues with an acid, and after dissolution is completed, carrying out filtration andseparation so as to obtain a copper-containing solution and filter residues; 3, washing the filter residues obtained in the step 2, and drying so as to obtain silicon powder; 4, putting zinc powder into the copper-containing solution separated in the step 2 to carry out replacement so as to obtain metallic copper powder; 5, condensing the gas-phase high-boiling residues obtained in the step 1 soas to obtain liquid high-boiling residues, and carrying out catalytic cracking on the liquid high-boiling residues with a catalyst; 6, carrying out fractionation on a gas phase obtained through catalytic cracking in the step 5, and collecting monomethyl trichlorolsilane, dimethyl diclorossilane, trimethylchlorosilane and monomethyl hydrosilane. By adopting the method and the equipment, copper andsilicon resources in organic silicon slag can be effectively recycled, thus being environmental-friendly and economic.

Owner:CHENGDU SILICON TECH CO LTD

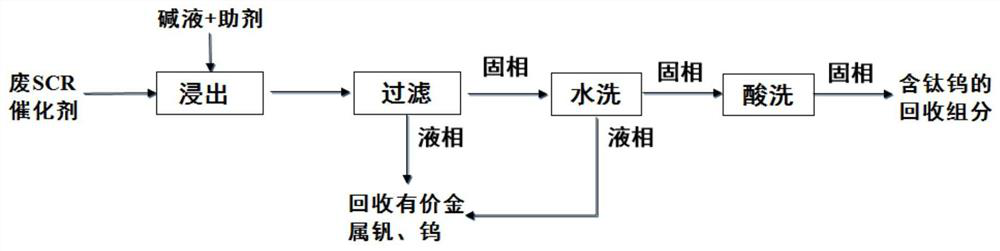

A method for desiliconization and arsenic removal of spent SCR catalyst

ActiveCN110385044BEfficient removalImprove leaching rateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention provides a method for removing arsenic and silicon from a spent SCR catalyst. The method comprises: leaching the spent SCR catalyst in an alkaline solution containing additives, and then separating the solid from the liquid; The recovered components are used in the preparation of SCR catalysts. The present invention can effectively remove the arsenic and silicon in the spent SCR catalyst by adding additives in the lye, the removal rate of arsenic can reach more than 95%, and the removal rate of silicon can reach more than 50%; the leaching method The leaching rate of vanadium and tungsten in the active components of the catalyst is also improved, and the active components and the carrier are separated to a certain extent, which is convenient for recycling respectively; the method has simple operation steps, mild leaching conditions, low raw material and operating costs, and wide application wide.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

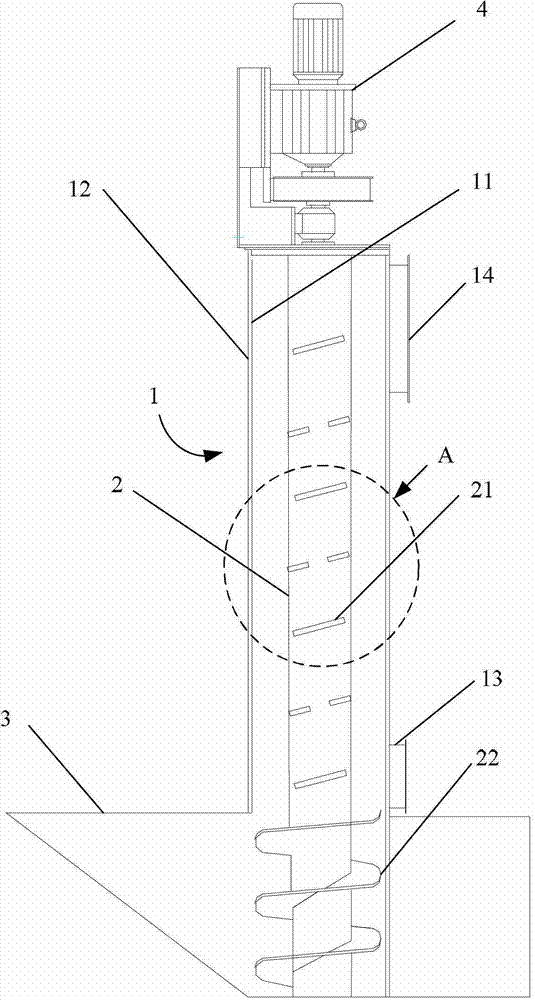

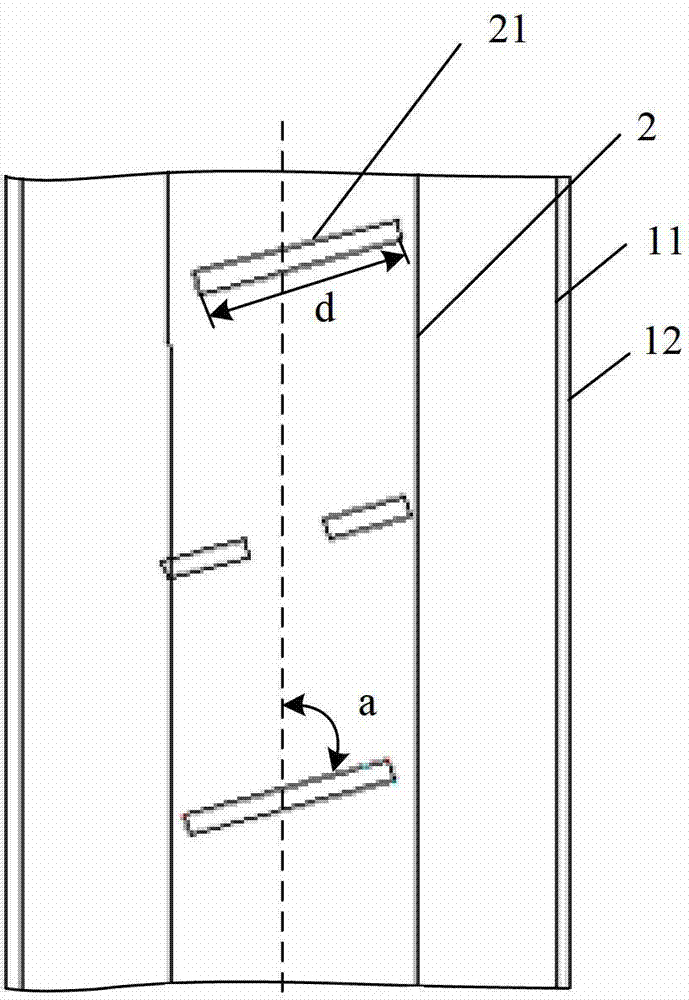

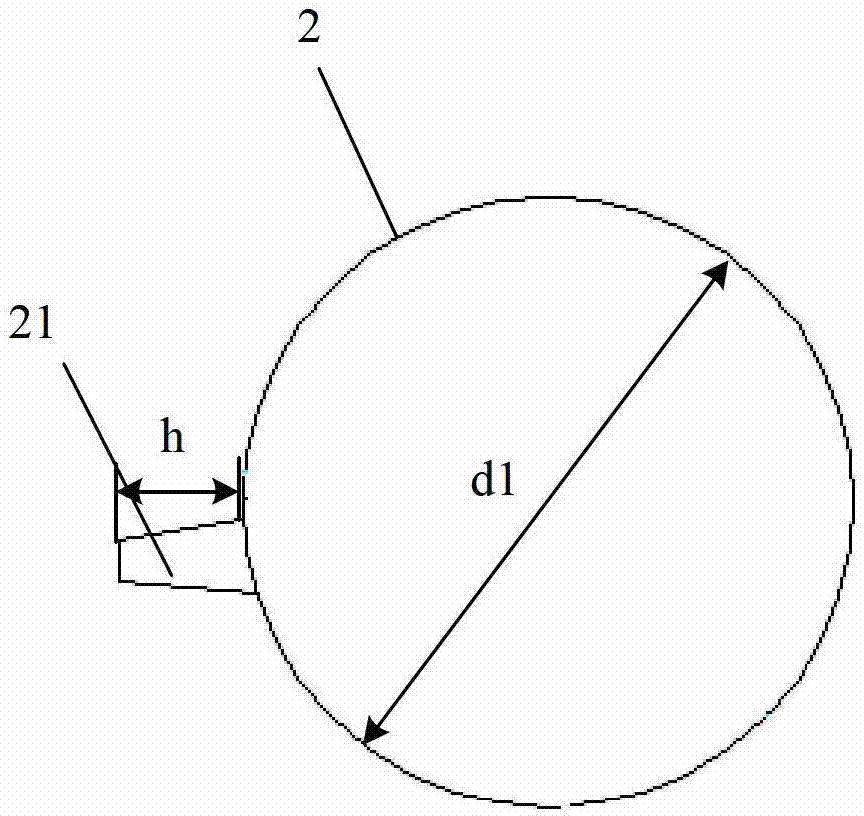

Vertical type continuous separating drying device for aluminum-plastic composite package material

ActiveCN102755922BEasy to separateEasy to recycle separatelyPlastic recyclingGrain treatmentsSpiral bladeEngineering

The invention provides a vertical type continuous separating drying device for an aluminum-plastic composite package material. The device comprises a vertically arranged barrel body, wherein the barrel body comprises an inner barrel body and an outer barrel body which are arranged with each other at an interval, and the wall of the inner barrel body are provided with sieving holes; a cavity of the inner barrel body is internally provided with a rotating shaft, a plurality of sickle type blades are arranged on the rotating shaft at intervals, and the plurality of sickle type blades are spirally distributed with one another from bottom to top; the lower end of the barrel body is provided with a feed bin, the lower end of the rotating shaft goes deep into the feed bin, and the part (which goes deep into the feed bin) of the rotating shaft is provided with a continuous spiral blade; a first discharging opening is arranged on the position (which is near to the lower end of the barrel body) on the outer barrel body, and a second discharging opening which penetrates through the outer barrel body and the inner barrel body is arranged on the position (which is near to the upper end of the barrel body) on the barrel body; and the upper end of the barrel body is provided with a motor connected with the rotating shaft. According to the vertical type continuous separating drying device provided by the invention, the continuous aluminum-plastic physical separation can be simultaneously realized, plastic can be dried, and the treatment capability for the aluminum-plastic physical separation can be effectively improved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

Resource recycling device for nickel-containing heavy metal wastewater

ActiveCN111018203AReduce loadReduce the concentration of nickel ionsWater contaminantsWater/sewage treatmentElectrolytic agentWater storage tank

The invention discloses a resource recycling device for nickel-containing heavy metal wastewater, belonging to the field of nickel-containing heavy metal wastewater recovery. The resource recycling device comprises an electrolytic nickel recovery system, an electrolyte ultrafiltration system and an electrodialysis circulation nickel removal system, wherein the electrolytic nickel recovery system comprises a sewage pump, a direct current power supply, an electrolytic bath and an electrode plate; the electrolyte ultrafiltration system consists of a sewage pump, an ultrafiltration reactor and a water storage tank; and the electrodialysis circulation nickel removal system consists of a sewage pump, a direct-current power supply and an electrodialyzer. The device has the advantages that the structure is simple, nickel can be recycled, wastewater can be recycled, and secondary pollutants are not generated. The method is suitable for treatment of nickel-containing heavy metal wastewater in electroplating enterprises, and has environmental and economic benefits.

Owner:ZHAOQING UNIV

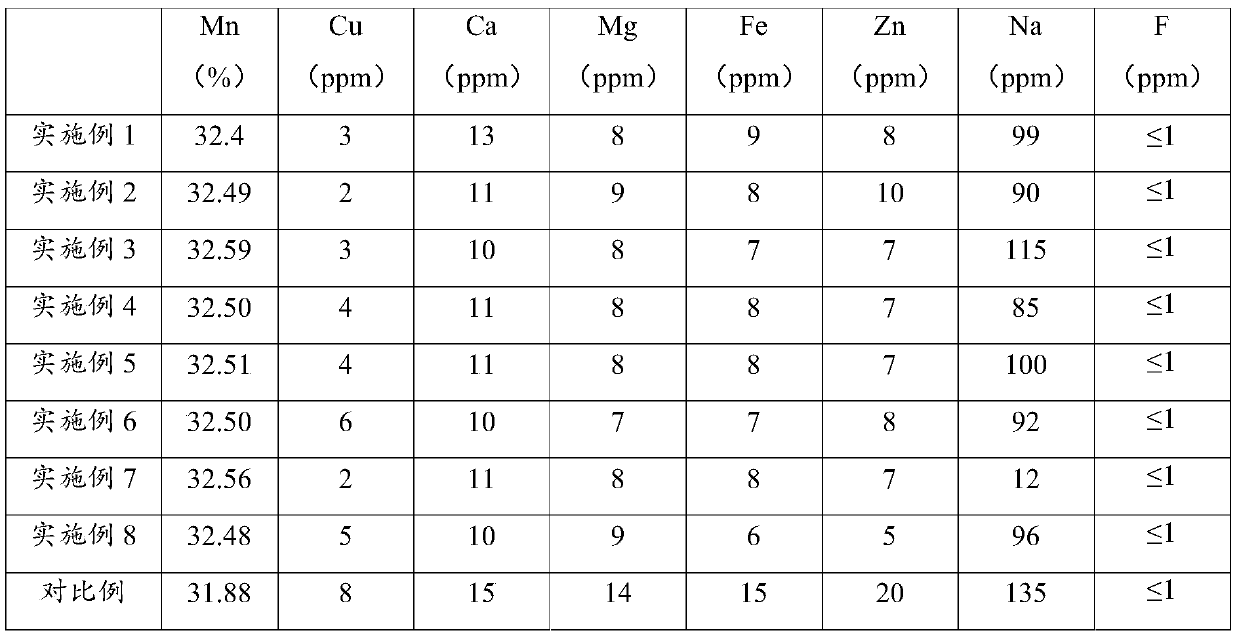

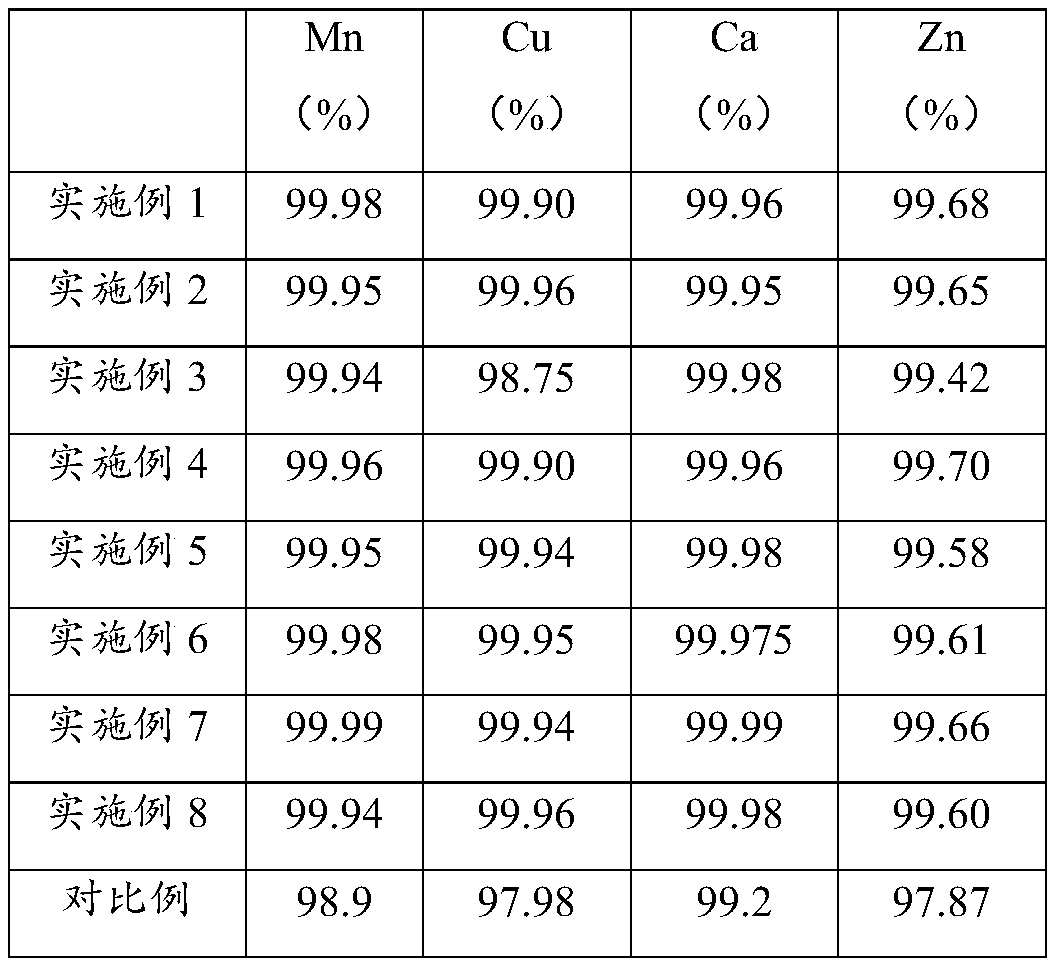

Preparation method and application of battery grade manganese sulfate

ActiveCN109650458BGuaranteed purityReduce the process of extraction and removal of impuritiesCell electrodesSecondary cellsManganese sulphateCu2 ions

The invention belongs to the technical field of hydrometallurgy, and relates to a preparation method and application of battery grade manganese sulfate. The preparation method of the battery grade manganese sulfate comprises the following steps of: (A) precipitating copper ion, calcium ion and zinc ion in a copper chloride manganese solution to obtain first filtrate; (B) in a protective atmosphere, mixing the first filtrate, a precipitating manganese agent and a base solution for manganese precipitation reaction and separation of solid and liquid to obtain manganese hydroxide; (C) mixing themanganese hydroxide with concentrated sulfuric acid for neutral reaction to obtain coarse manganese sulfate, and refining the coarse manganese sulfate to obtain the battery grade manganese sulfate; wherein in step (B), the precipitating manganese agent comprises ammonia water; and the base solution comprises the ammonia water and soluble hydroxide. The preparation method of the battery grade manganese sulfate can not only achieve preparation of the battery grade manganese sulfate, but also benefit recovery of zinc, copper, calcium and the like, thereby maximizing utilization of copper-manganese chloride waste liquor, reducing cost and conforming to a concept of sustainable development.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD

Environment-friendly waste collecting device with disinfection function for cardiology department nursing

PendingCN114798101ARealize the paving effectAvoid distractionMedical waste disposalMagnetic separationUv disinfectionMedical waste

The invention relates to the technical field of medical waste recovery, in particular to an environment-friendly waste collecting device with a disinfection function for cardiology department nursing. Comprising a crushing unit, the crushing unit comprises a crushing box, a second liquid conveying pipe is arranged on the inner wall of the crushing box, and a plurality of sets of spraying openings are distributed in the second liquid conveying pipe; the output end of the crushing unit communicates with a disinfection unit. The disinfection unit comprises a disinfection box. A conveying belt is arranged in the disinfection box, and a plurality of groups of spreading grooves are distributed on the conveying belt at equal intervals; a permeable net is arranged at an opening in the bottom of the spreading groove; a water outlet is formed in the inner wall of the disinfection box, and the other end of the water outlet is communicated with a liquid storage box; and a plurality of groups of ultraviolet disinfection lamps are distributed in the disinfection box along the conveying direction of the conveying belt at equal intervals. According to the device, the disinfection effect is improved, the environment-friendly collection purpose is achieved, and meanwhile the working efficiency is improved due to the fact that no extra disinfection procedure needs to be set.

Owner:中国人民解放军西部战区总医院

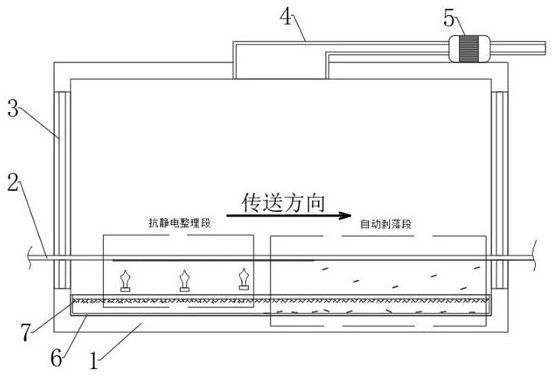

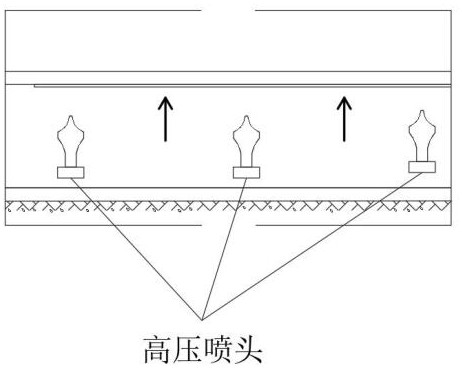

Antistatic finishing device for polyester fabrics

InactiveCN113373616AReduce pollutionLess likely to be seriously affectedTextile treatment machine partsTextile treatment by spraying/projectingPolyesterPolymer science

The invention discloses an antistatic finishing device for polyester fabrics and belongs to the field of antistatic finishing devices. According to the scheme, antistatic finishing work is conducted on the polyester fabrics by means of spraying, a bearing ball is doped into traditional antistatic finishing liquid, the working environment is adjusted to be in a low-pressure and high-temperature environment, and the antistatic finishing device has the characteristics of of being small in water consumption and low in wastewater output, so that pollution of polyester fabric antistatic finishing can be greatly reduced, and serious influence on the environment cannot be caused easily; after the bearing ball is sprayed by a high-pressure spray head, a bearing ball shell is adhered to the lower side of a polyester fabric body to achieve a single-side sealing effect; in a high-temperature and low-pressure environment, a solvent of antistatic finishing liquid can generate a transpiration effect, and part of solute is brought to the upper surface of the polyester fabric body, so that the polyester fabric body with the upper surface and the lower surface subjected to antistatic treatment is obtained; and the bearing ball shell automatically falls off from the surface of the polyester fabric body along with reduction of the antistatic finishing liquid solvent.

Owner:南通缘喜纺织品有限公司

Packaging bag and production technology of packaging bag

ActiveCN109160069AExquisite appearanceEasy to recycle separatelyBag making operationsPaper-makingPulp and paper industry

The invention provides a packaging bag, and belongs to the field of packaging. The packaging bag comprises a paper layer, a plastic layer and a valve structure, wherein the bottom of the paper layer is bonded with the bottom of the plastic layer; the top of the paper layer is bonded with the top of the plastic layer; and the middle part of the paper layer and the middle part of the plastic layer are separated. According to the packaging bag, only the tops and the bottoms of the paper layer and the plastic layer are bonded, the middle parts are separated, the plastic layer and the paper layer are separately recycled, and the packaging bag is more energy-saving and environmentally-friendly; and patterns can be printed on the flat paper layer in advance, the printed patterns are flat and bright, and the appearance of the packaging bag is more beautiful. The invention further provides a production technology of the packaging bag. The production technology comprises the steps of printing the patterns on the paper layer; arranging the paper layer on the periphery of the plastic layer; bonding the top of the paper layer with the top of the plastic layer; bonding the bottom of the paper layer with the bottom of the plastic layer; forming a lower bottom and an upper bottom; and arranging the valve structure. According to the production technology, flatness and brightness of the printedpatterns of the packaging bag are guaranteed, and separated recovery of the plastic layer and the paper layer is facilitated.

Owner:石家庄康益包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com