Patents

Literature

387results about "Granulation in rotating drums" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating for fertilizer

InactiveUS20050076687A1Maintain reaction temperatureImparts physical strengthBiocideGas treatmentVegetable oilPolymer chemistry

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

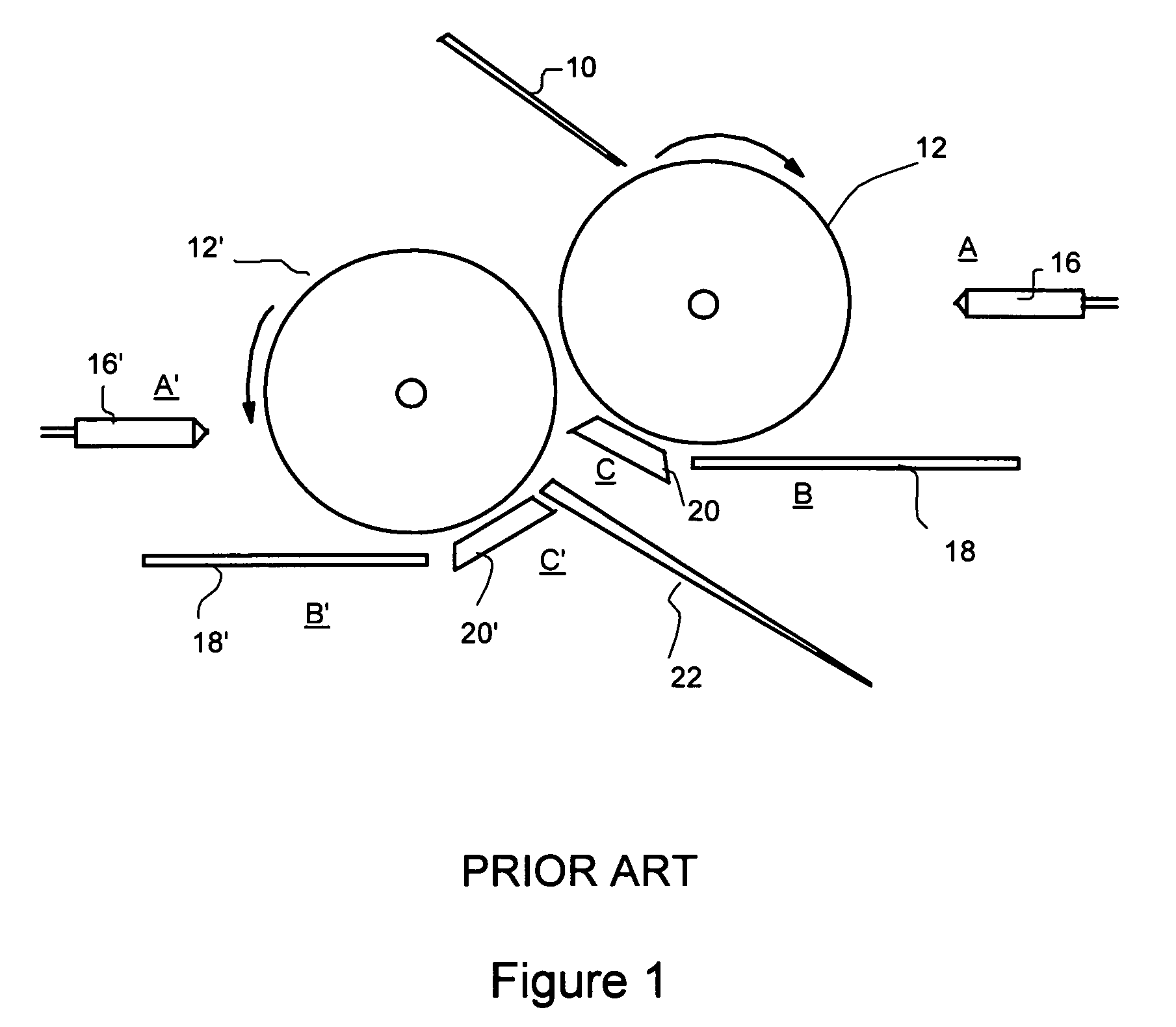

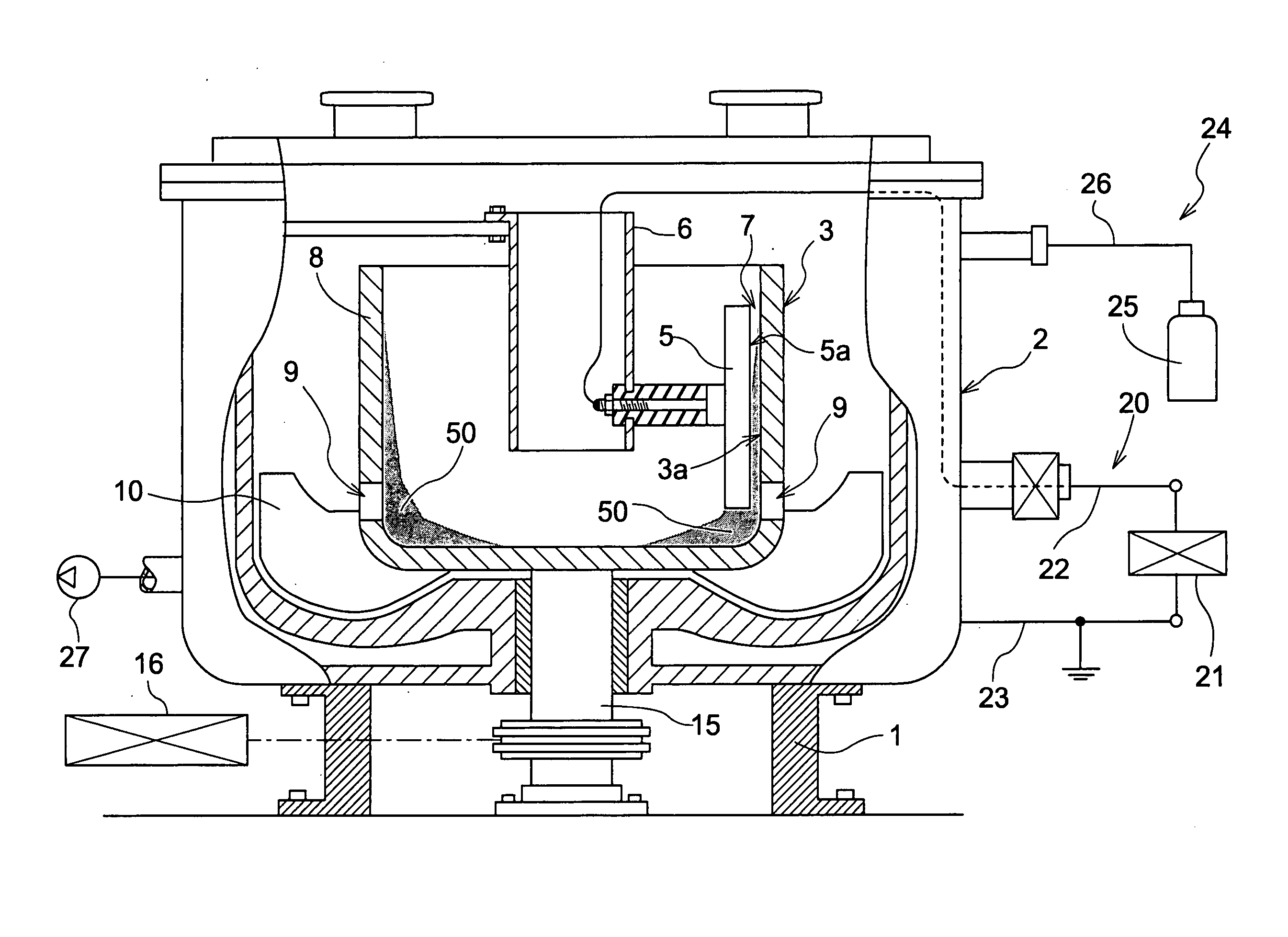

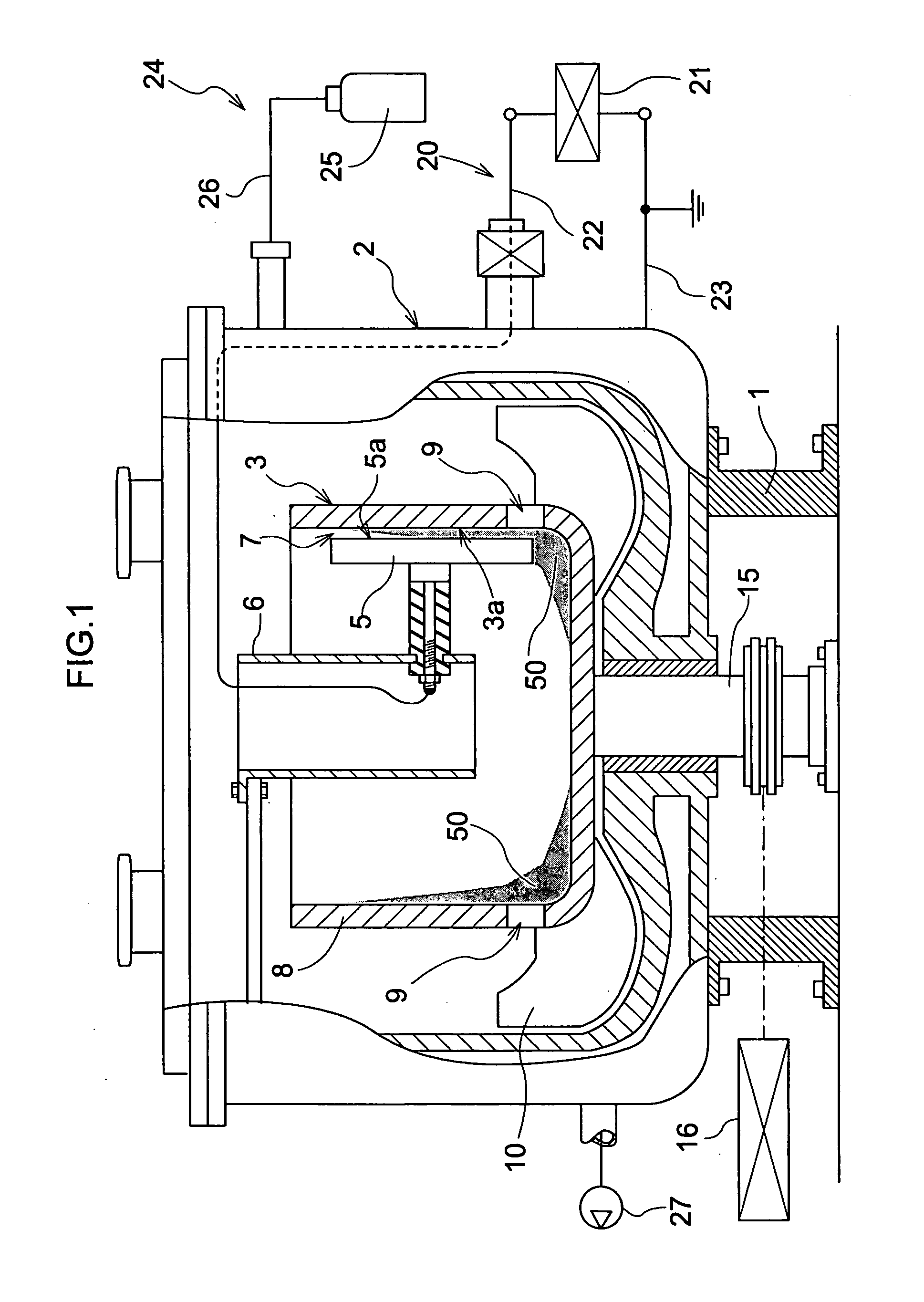

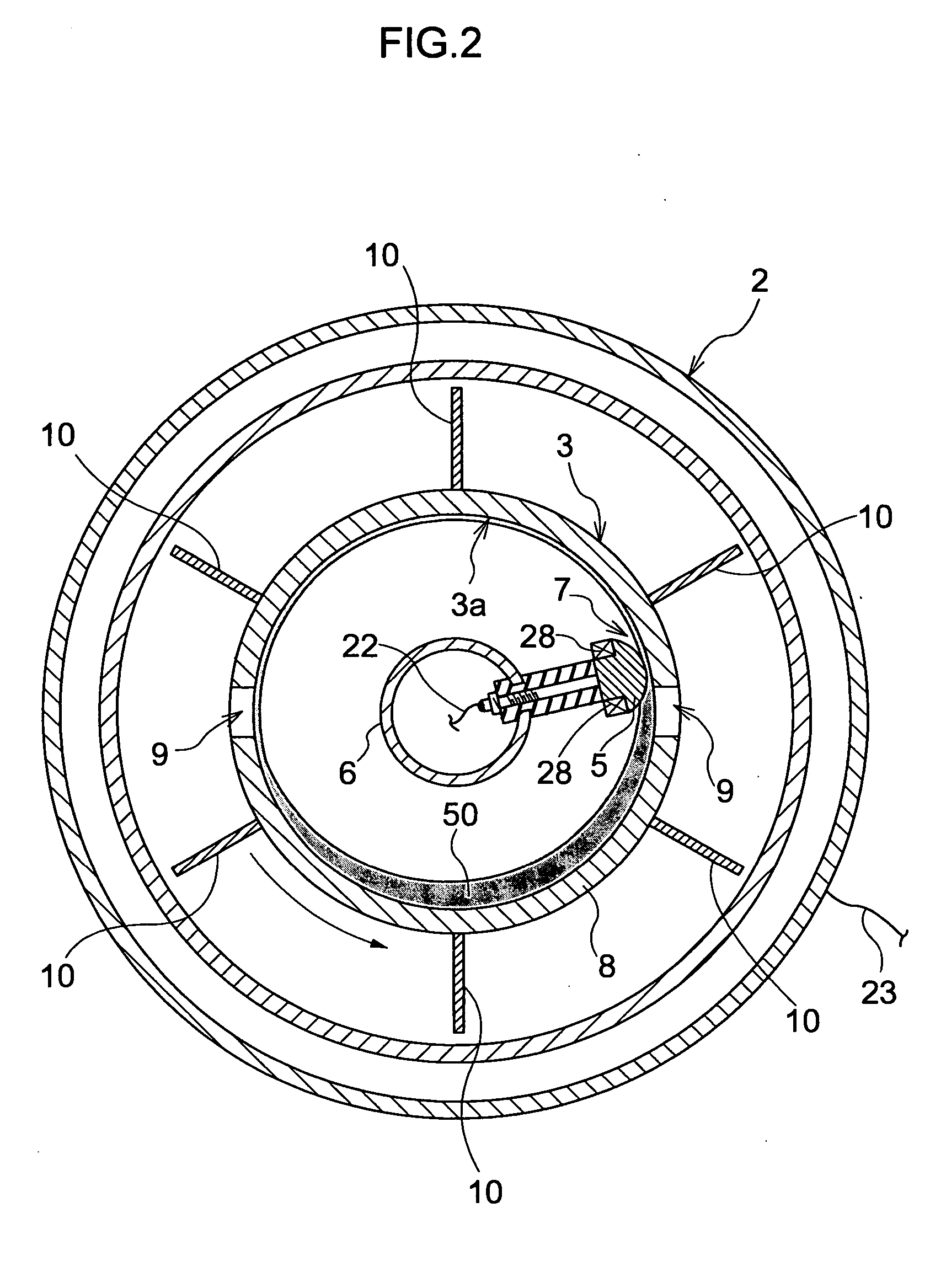

Direct coating solid dosage forms using powdered materials

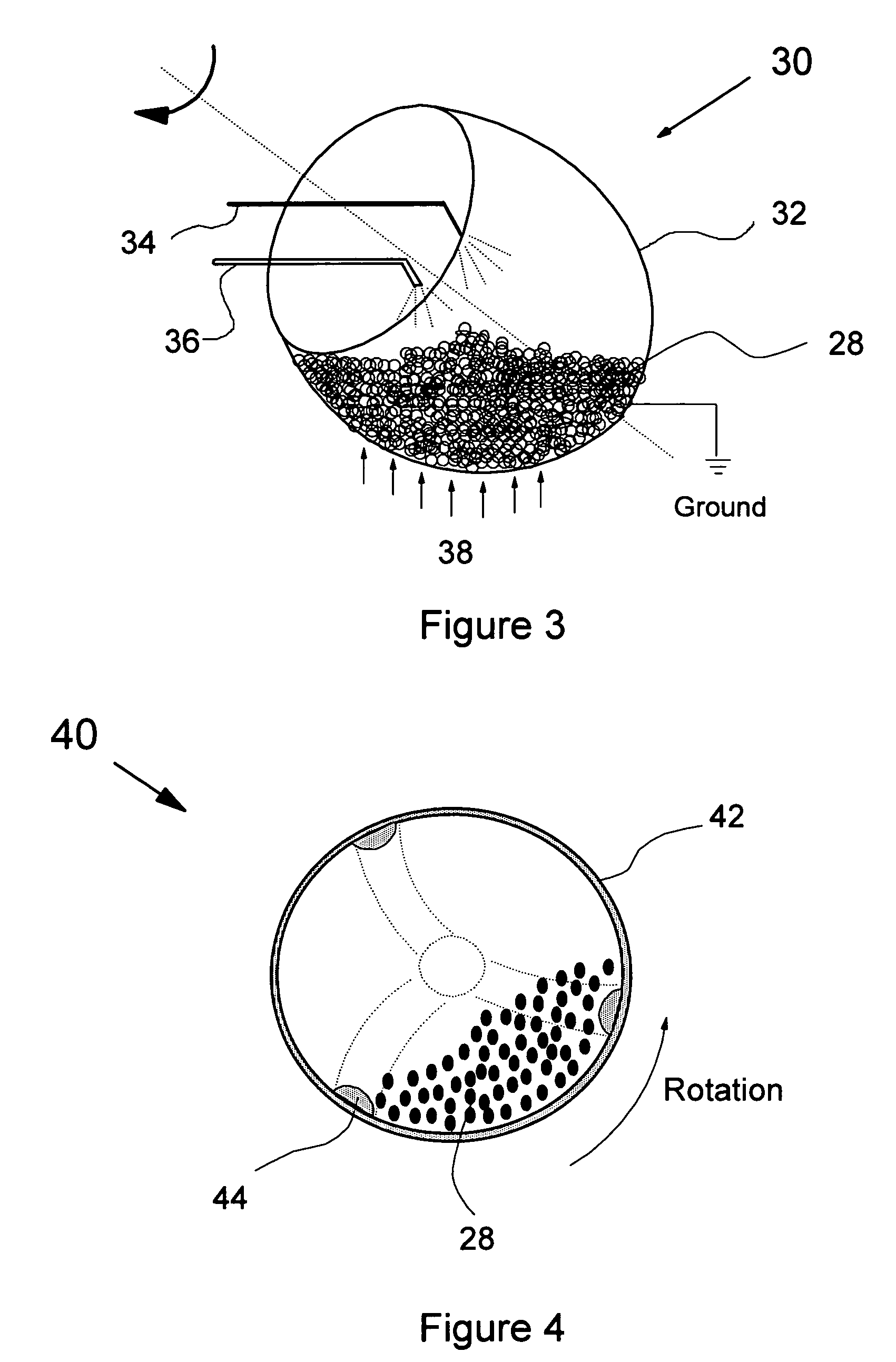

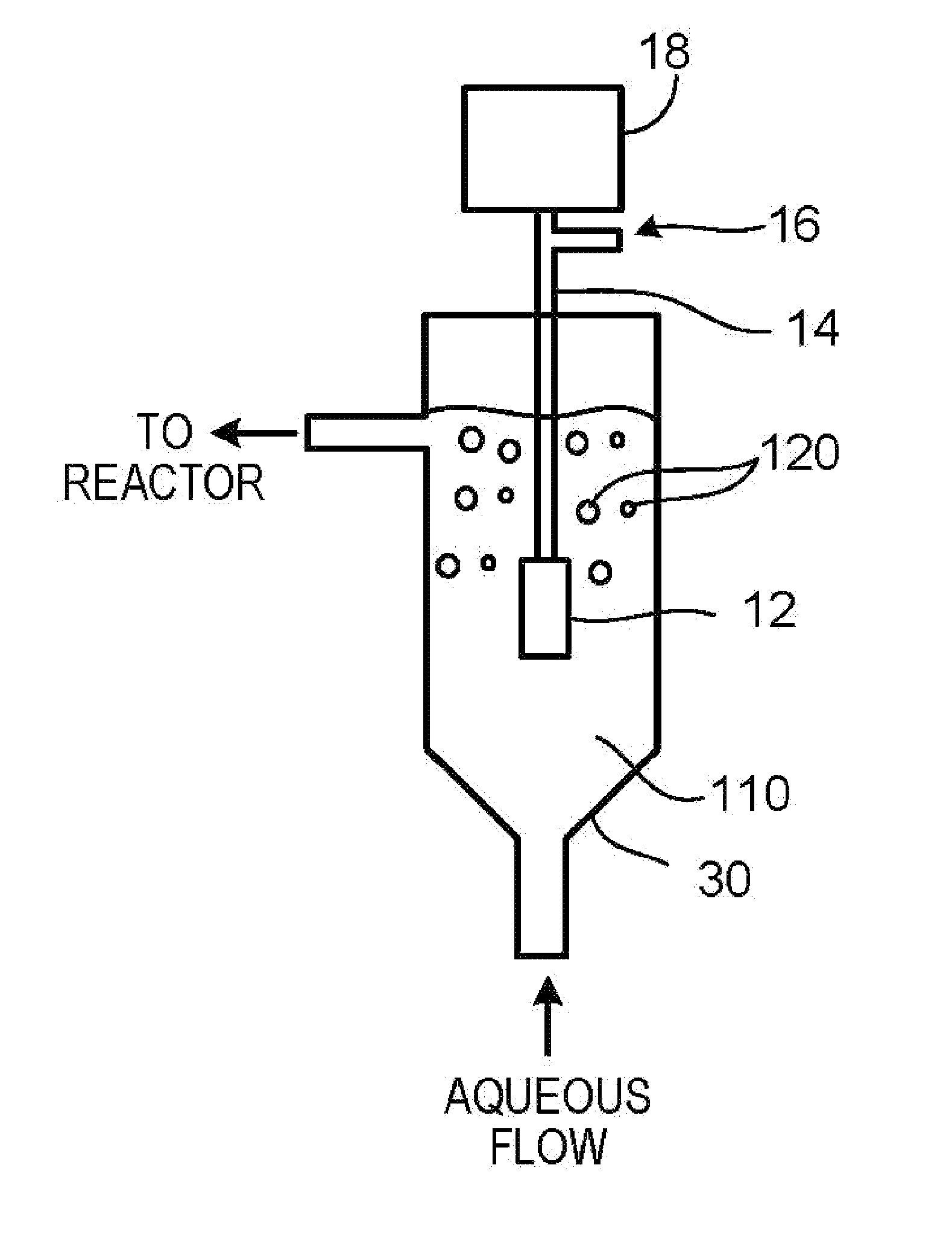

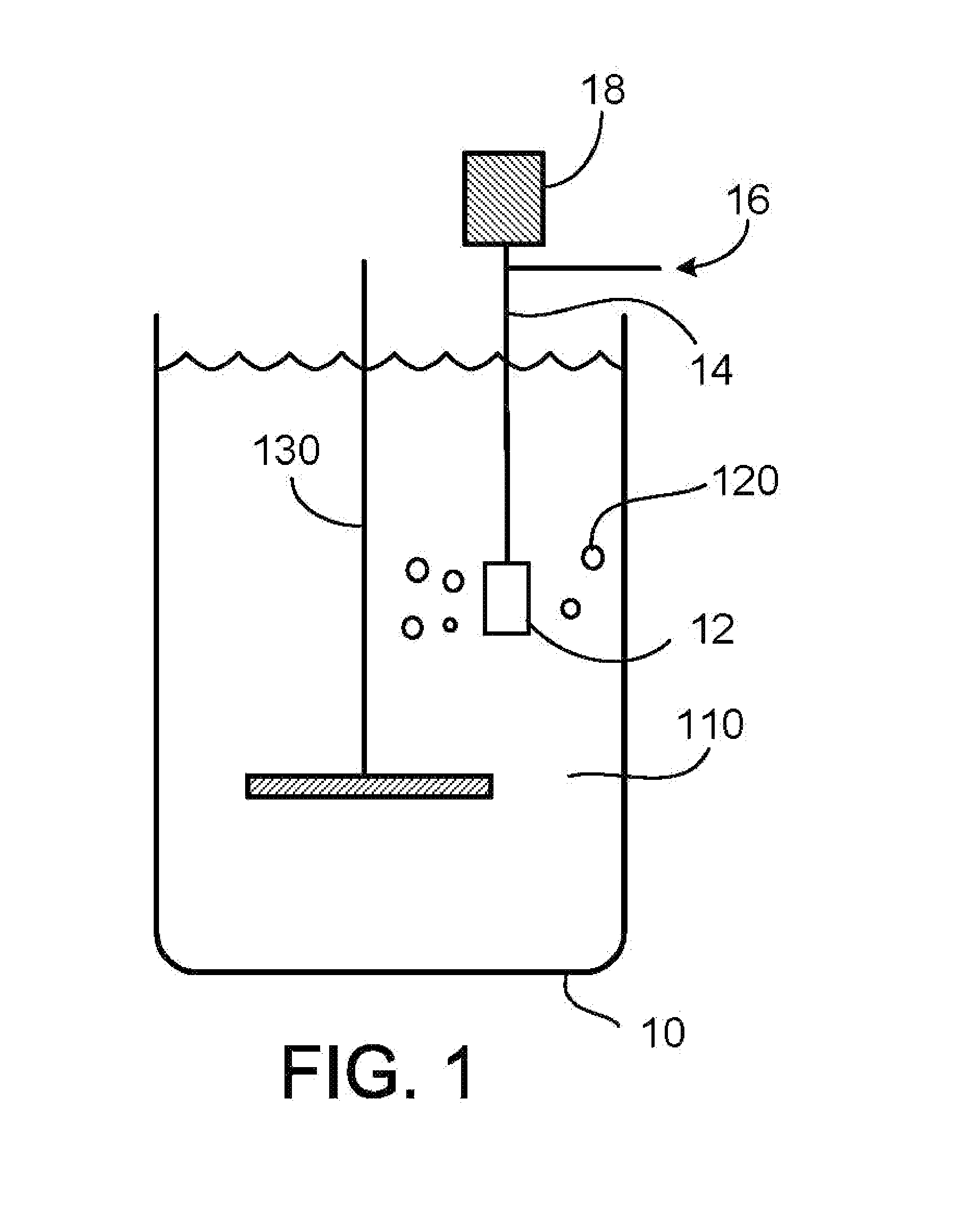

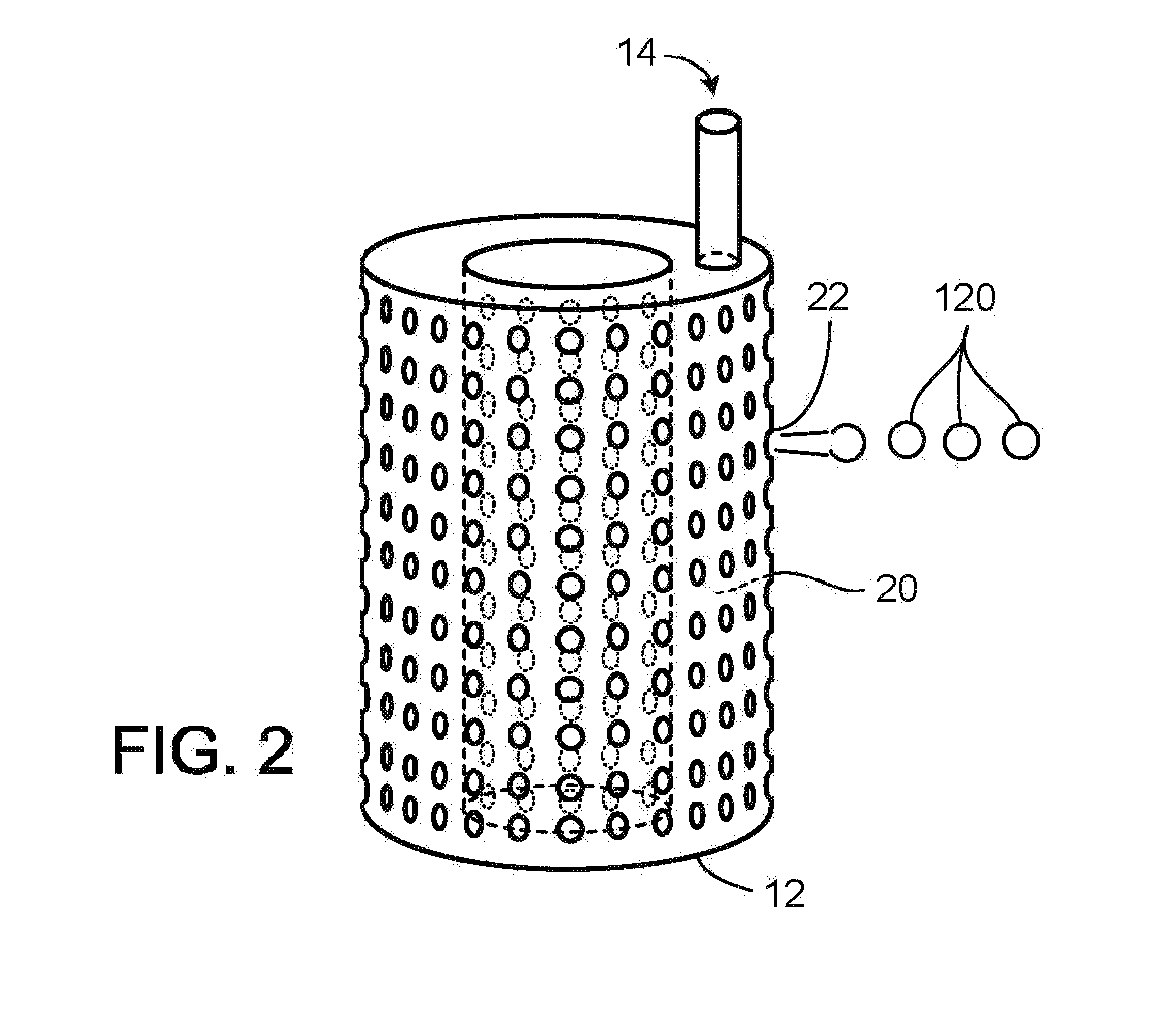

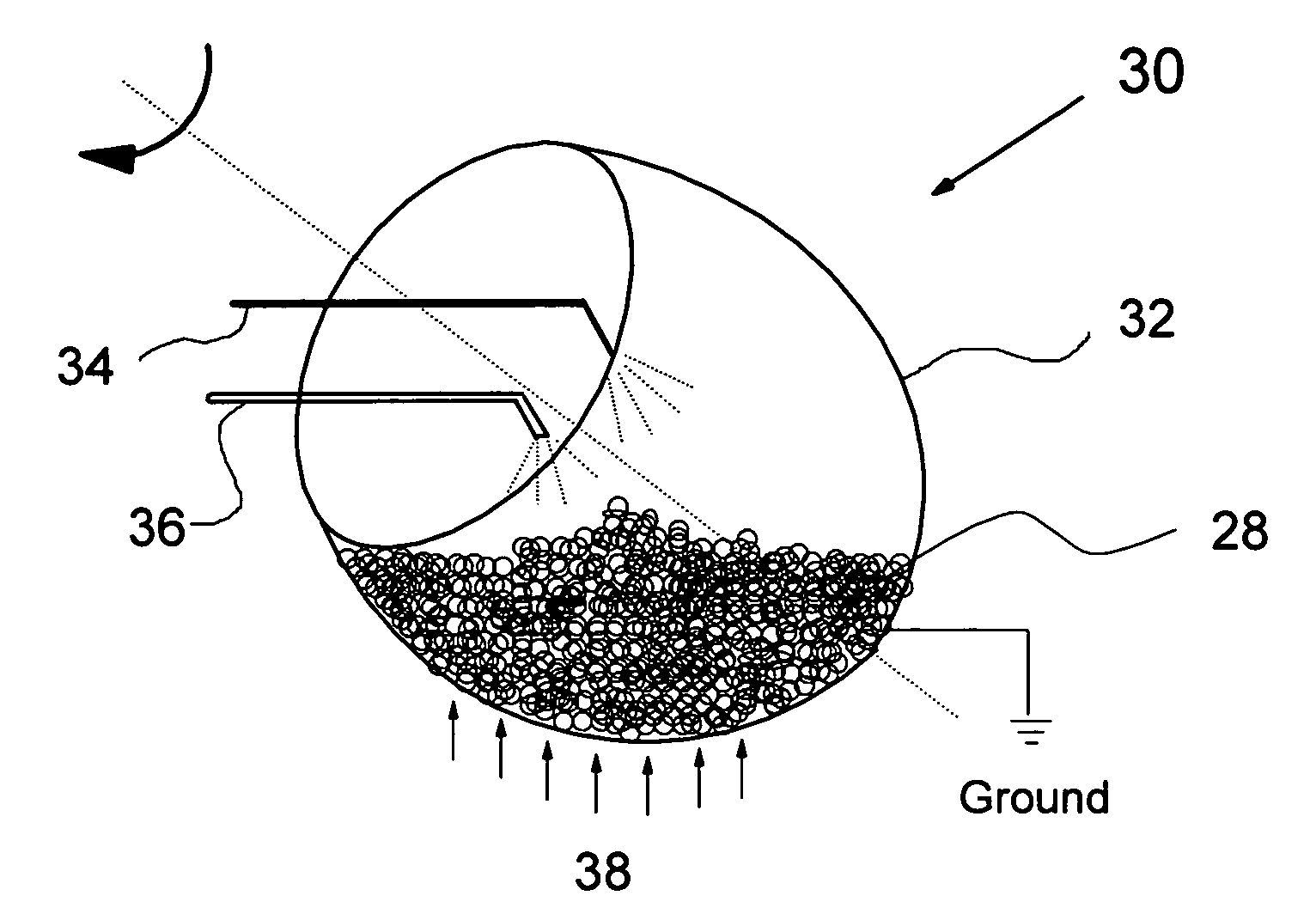

The present invention provides a method and apparatus for dry coating solid dosage forms. The method includes the steps of placing solid dosage forms in a rotatable, electrically grounded housing, and spraying a film forming polymer powder composition into the housing during rotation thereof to form a polymer coating on the solid dosage forms, the polymer powder composition being sprayed using an electrostatic spray gun, and curing the coated solid dosage forms.

Owner:WESTERN ONTARIO THE UNIV OF +1

Method of Producing Uniform Polymer Beads of Various Sizes

ActiveUS20140264984A1Simple and highly methodShaking/oscillating/vibrating mixersTransportation and packagingPolymer scienceDouble wall

Speriodal polymer beads having a uniform size are prepared by polymerizing uniformly sized monomer droplets formed by dispersing a polymerizable monomer phase over double-walled cylindrical cross-flow membrane into an aqueous phase. A shear force is provided at a point of egression of the polymerizable monomer phase into the aqueous phase, the direction of shear substantially perpendicular to the direction of egression of the monomer phase. The polymer beads can be employed in applications where beads having uniform diameters of 10 to 200 μm are useful.

Owner:PUROLITE CORP

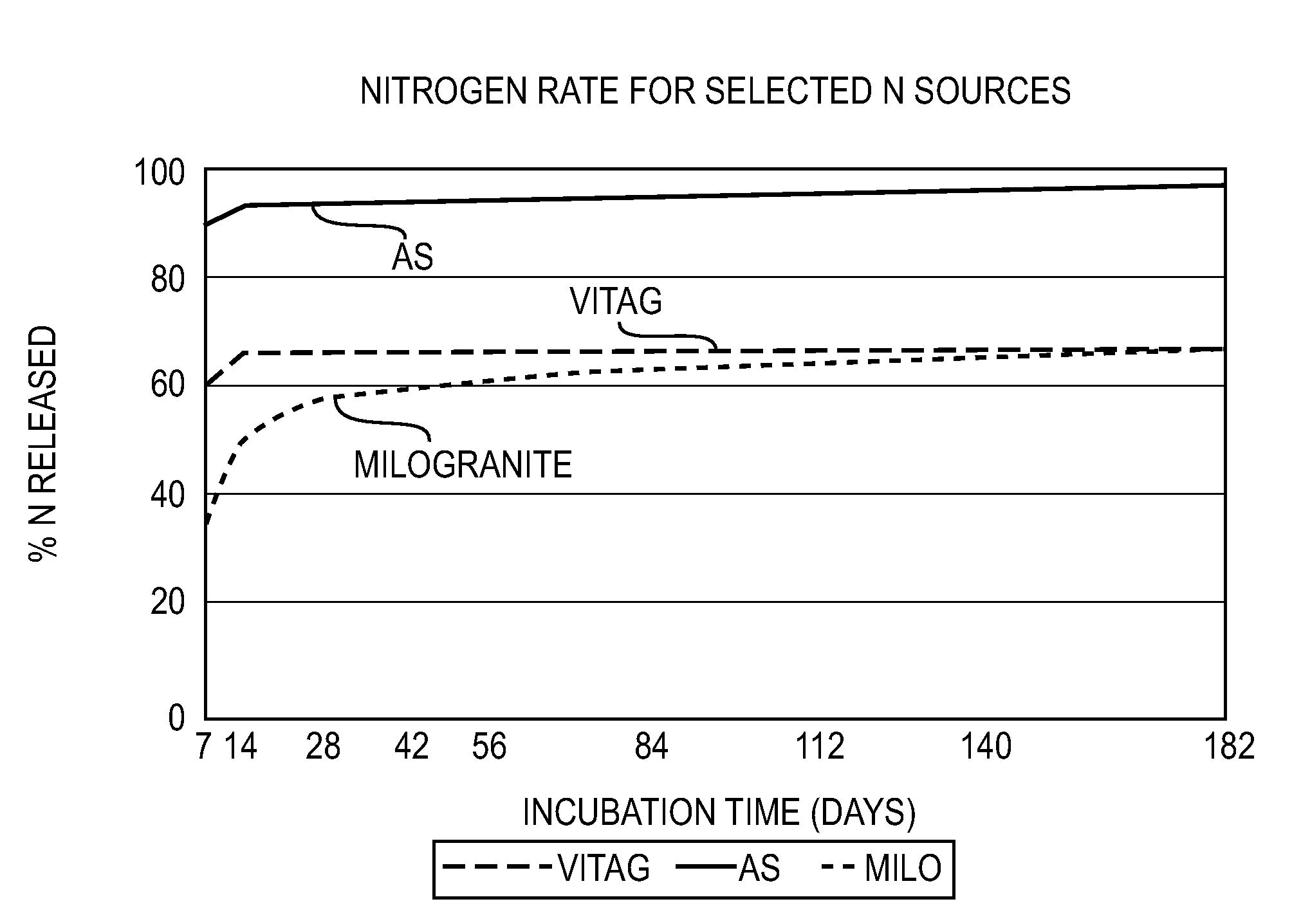

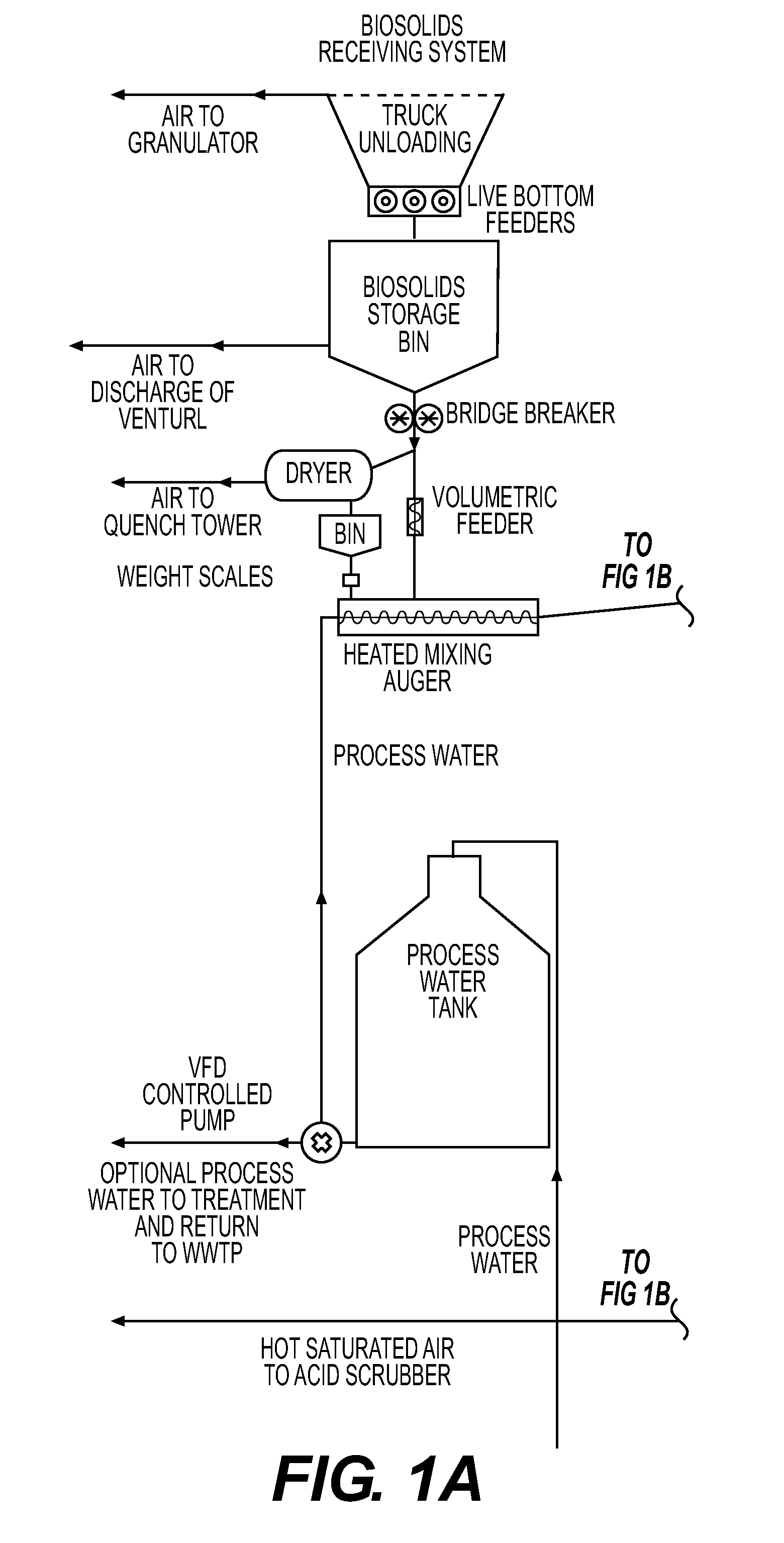

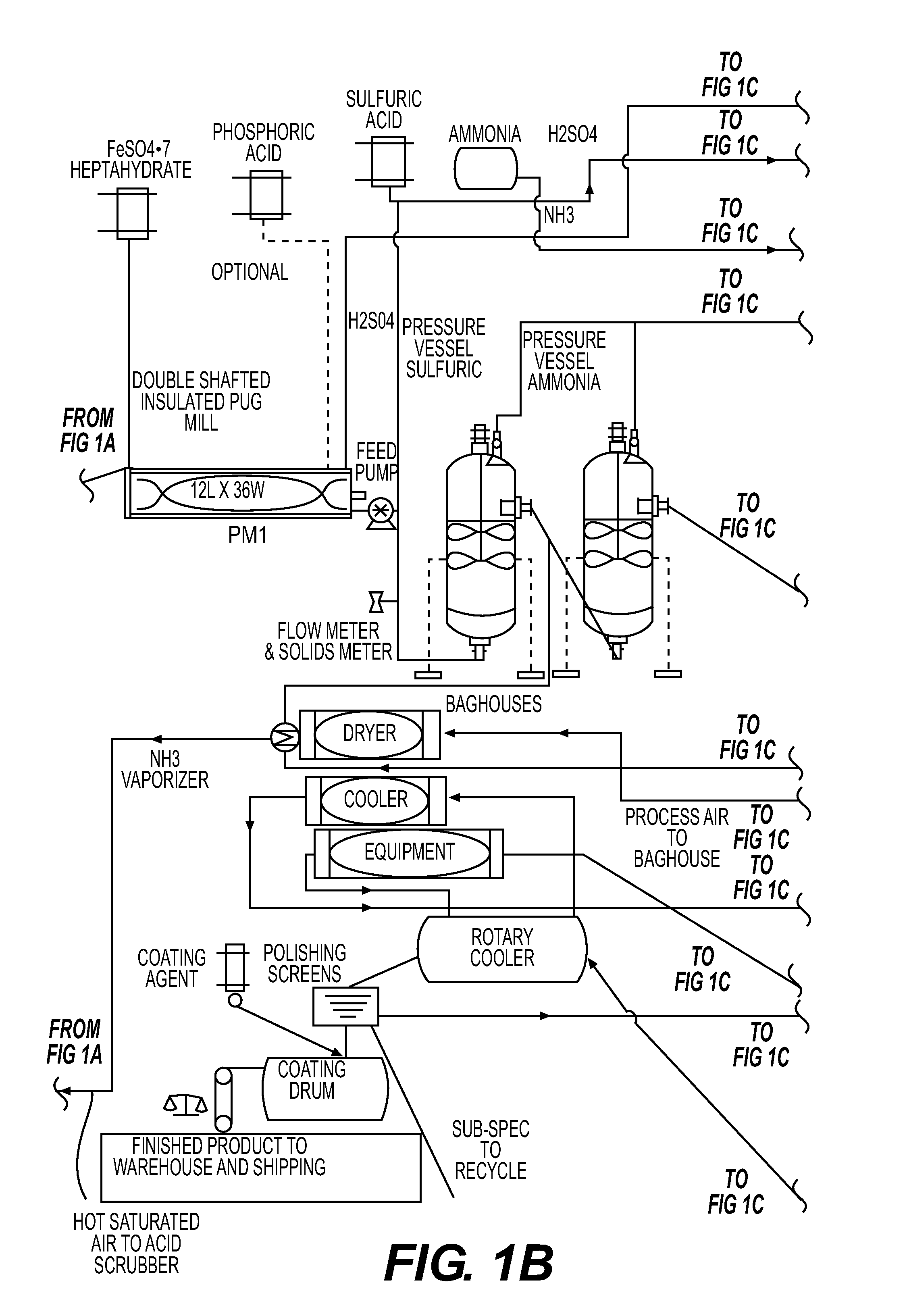

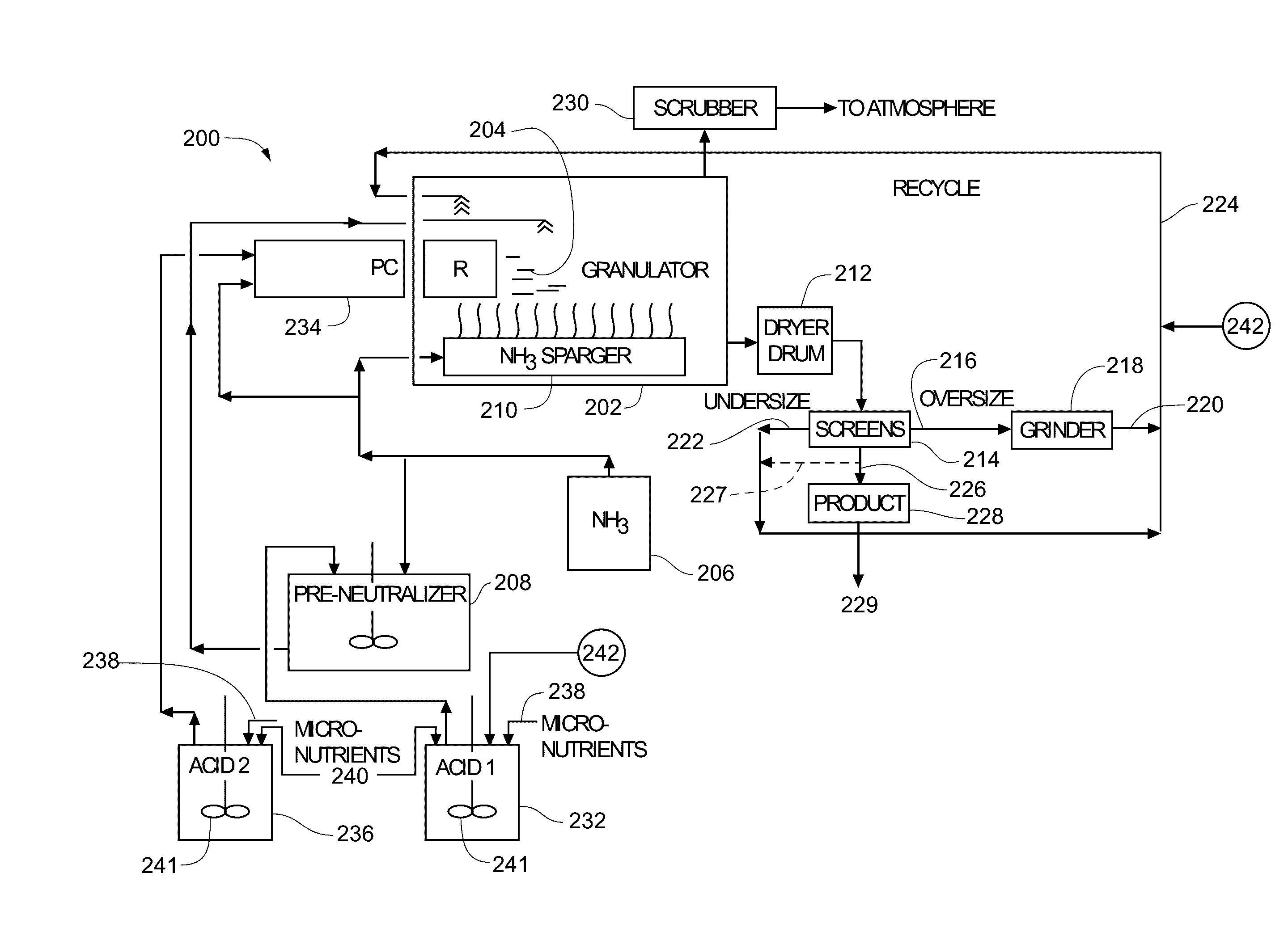

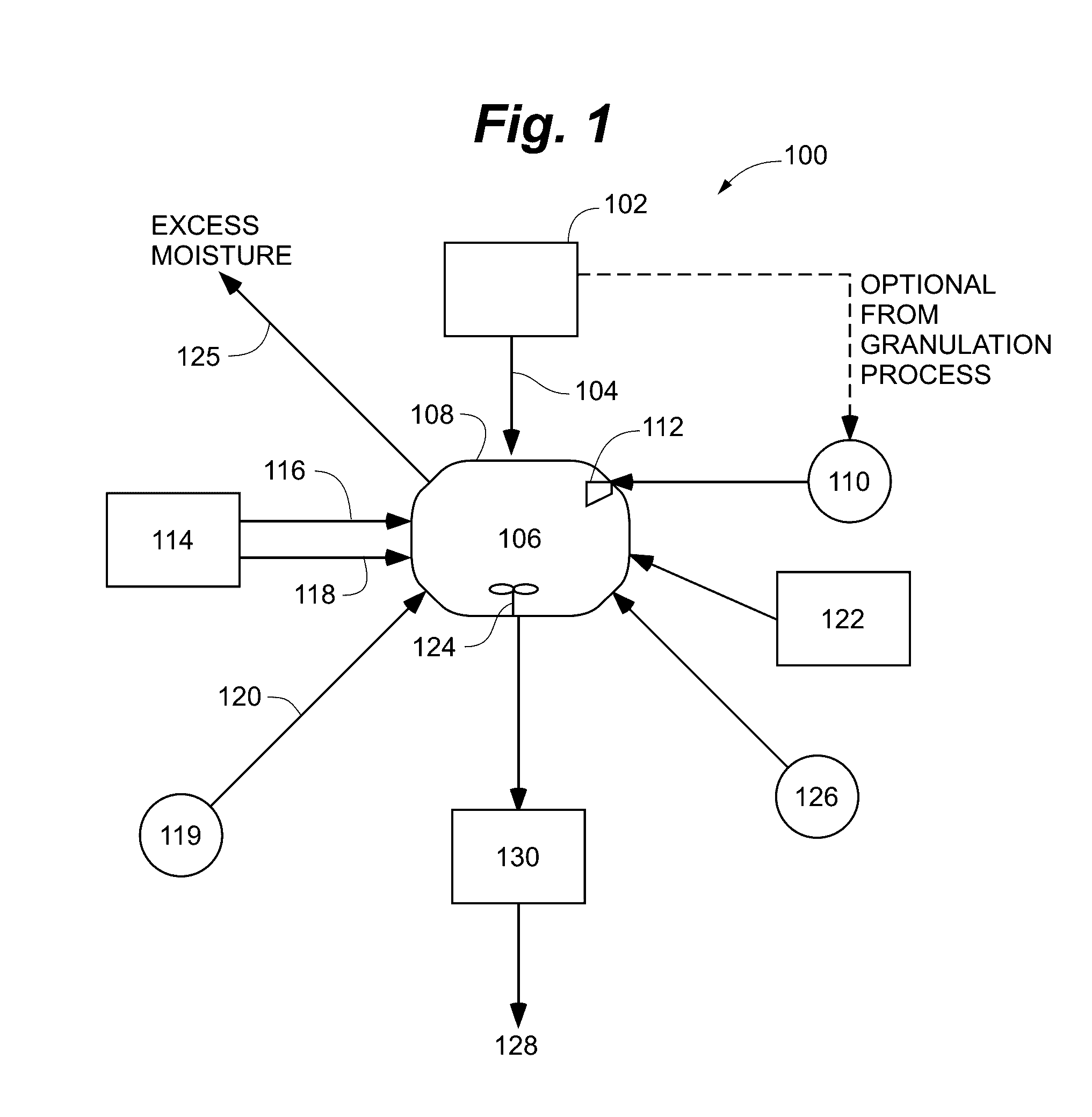

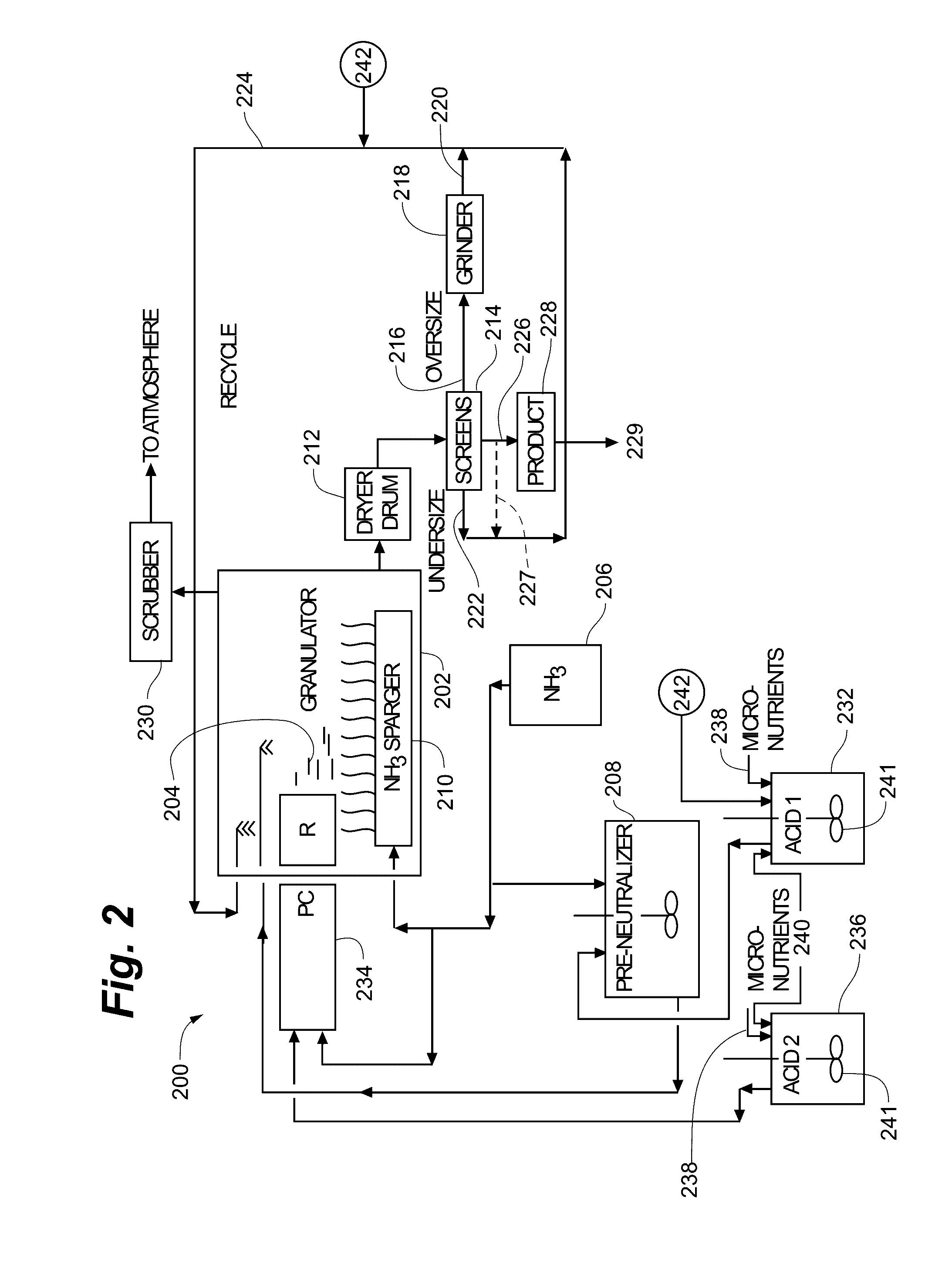

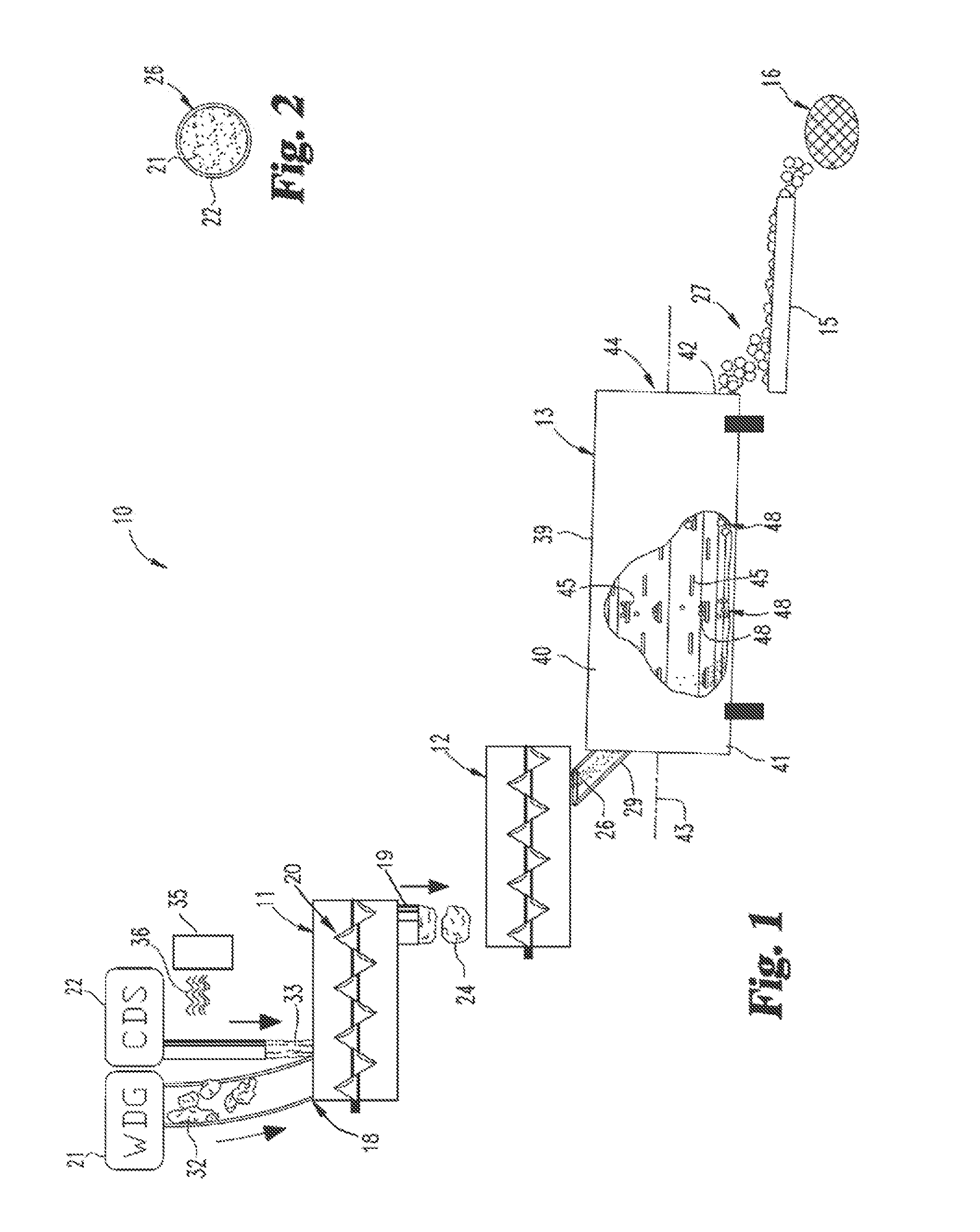

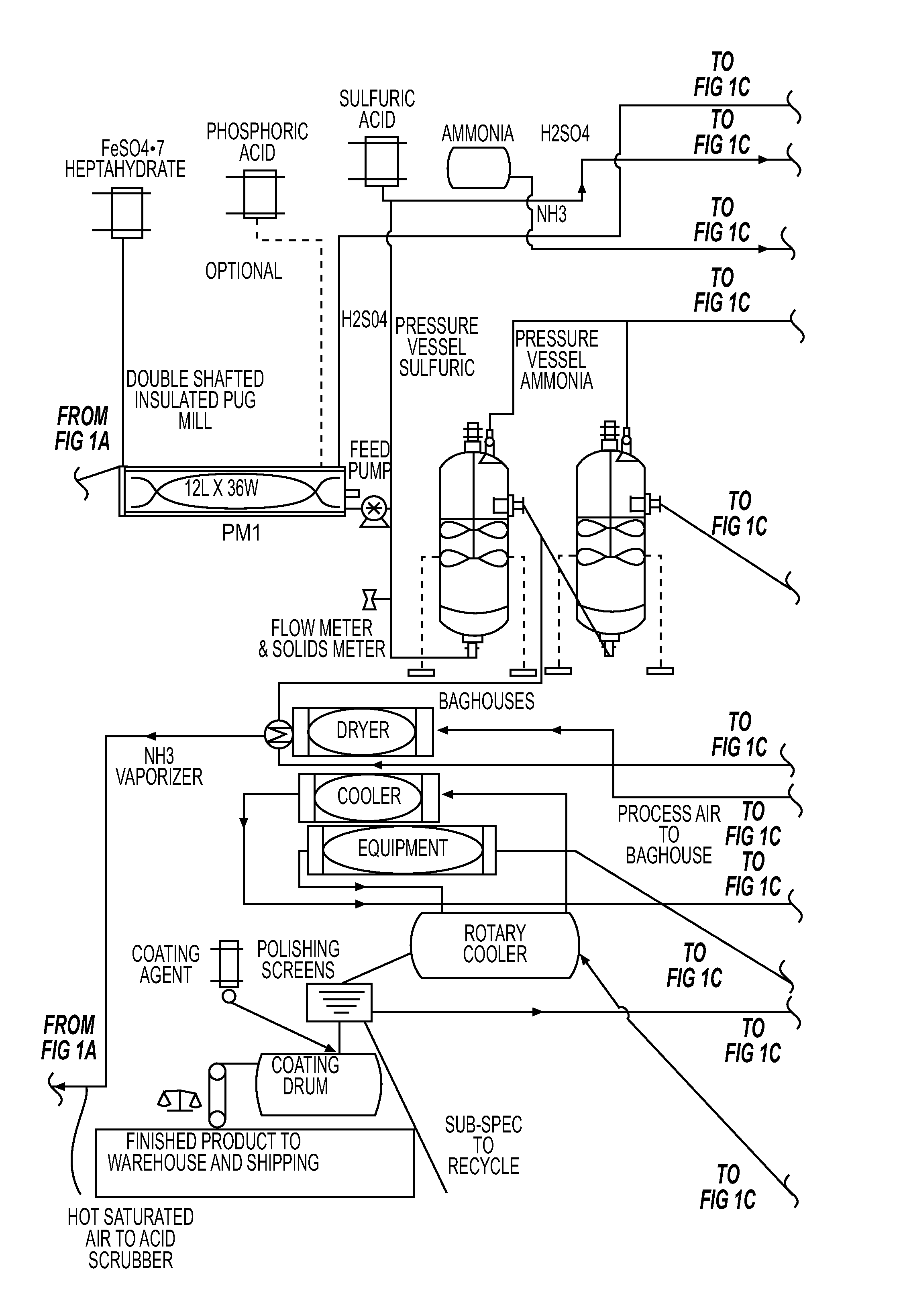

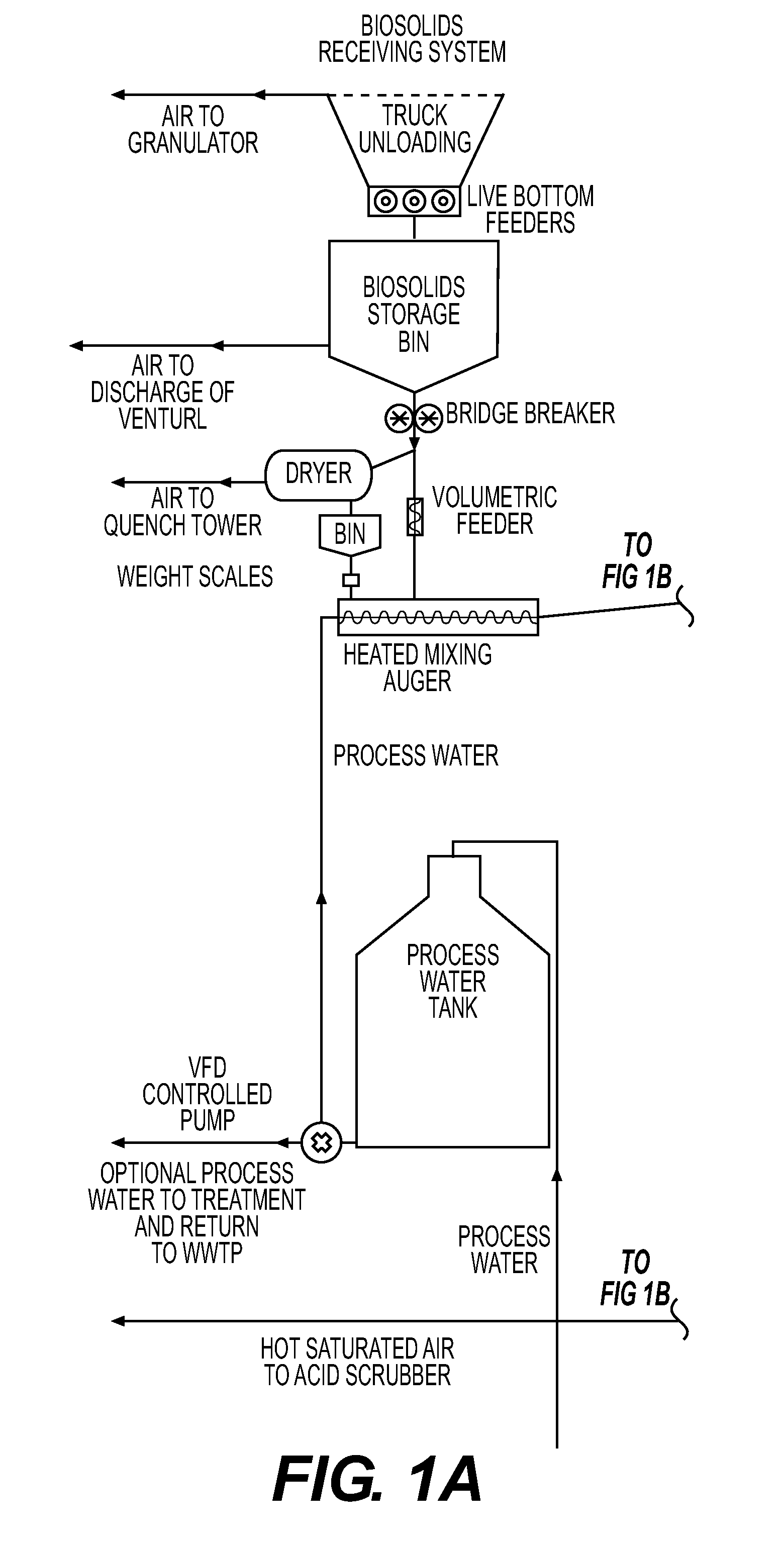

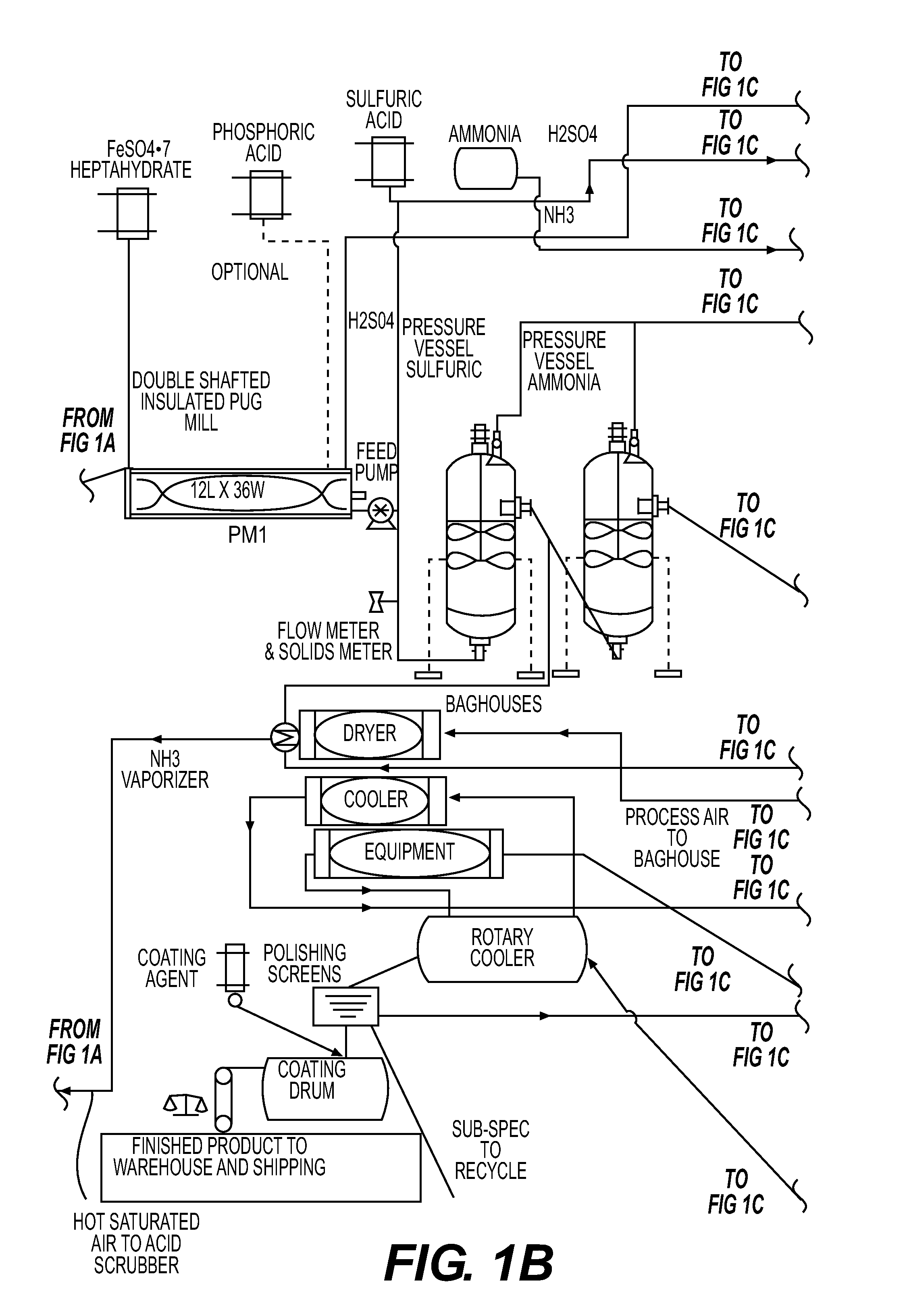

High value organic-enhanced inorganic fertilizers

ActiveUS20120247164A1Increase valueEasy to containCalcareous fertilisersGranule coatingSoil organic matterNitrogen

The invention is directed to manufacture of fertilizer having commercial levels of nitrogen supplemented with organic substances. The process treats organic matter with acid causing hydrolysis of organic polymers after which the mix is injected with nitrogen. The resultant sterilized and liquefied organic matter is disbursed over recycled material for the production of granules. Because the process allows for the controlled addition of acids and ammonia, desired levels of components can be achieved. The process is scalable, odor controlled and safe thereby allowing for the location of biosolid processing facilities in most any location. Further, the fertilizer of the invention provides a dual nitrogen-release profile when applied to crops. After application to soil, fertilizer of the invention releases an immediate bolus of nitrogen, similar to traditional ammonium sulfate, followed by continued slow release of nitrogen typically over a season.

Owner:GENERATE LENDING LLC +1

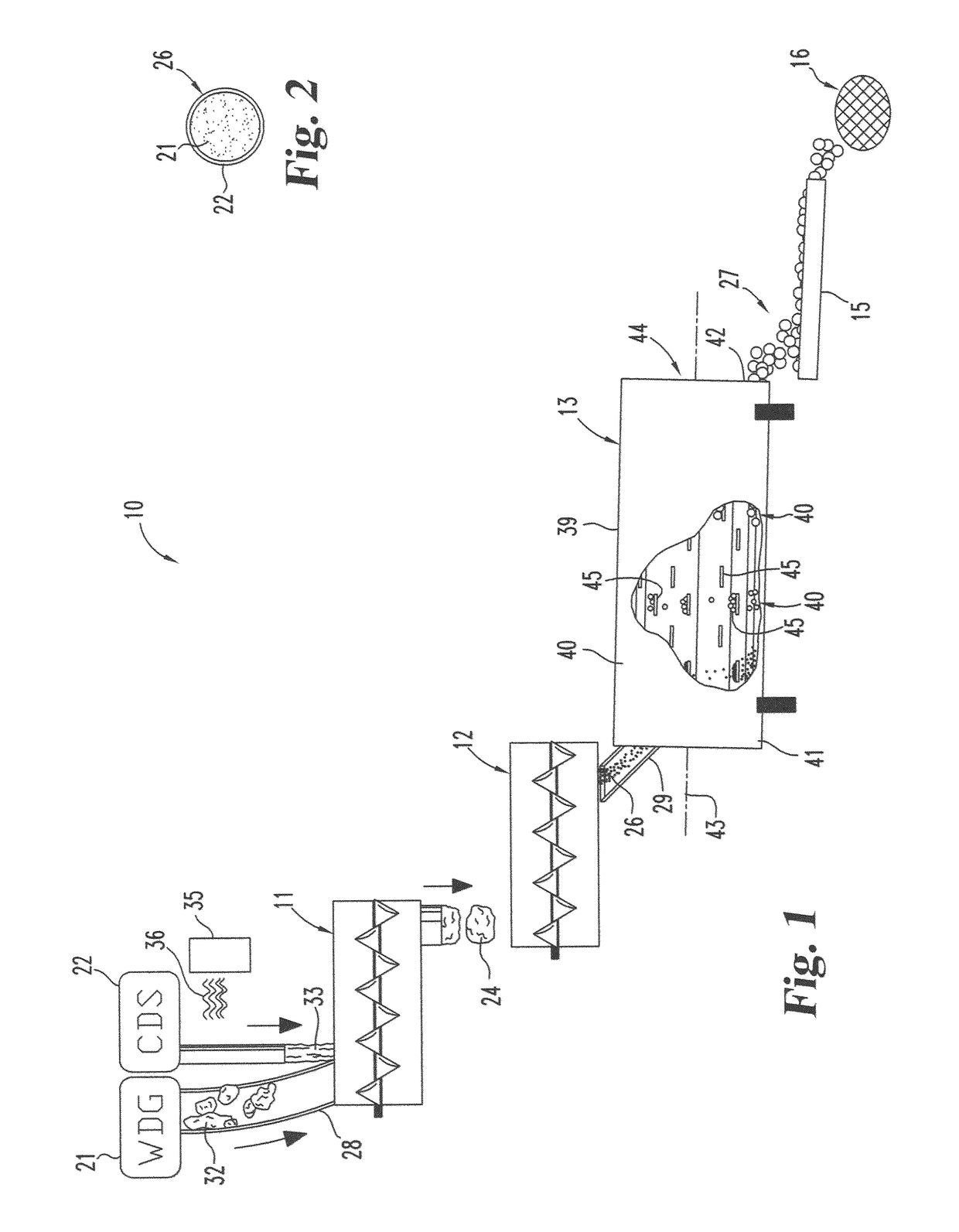

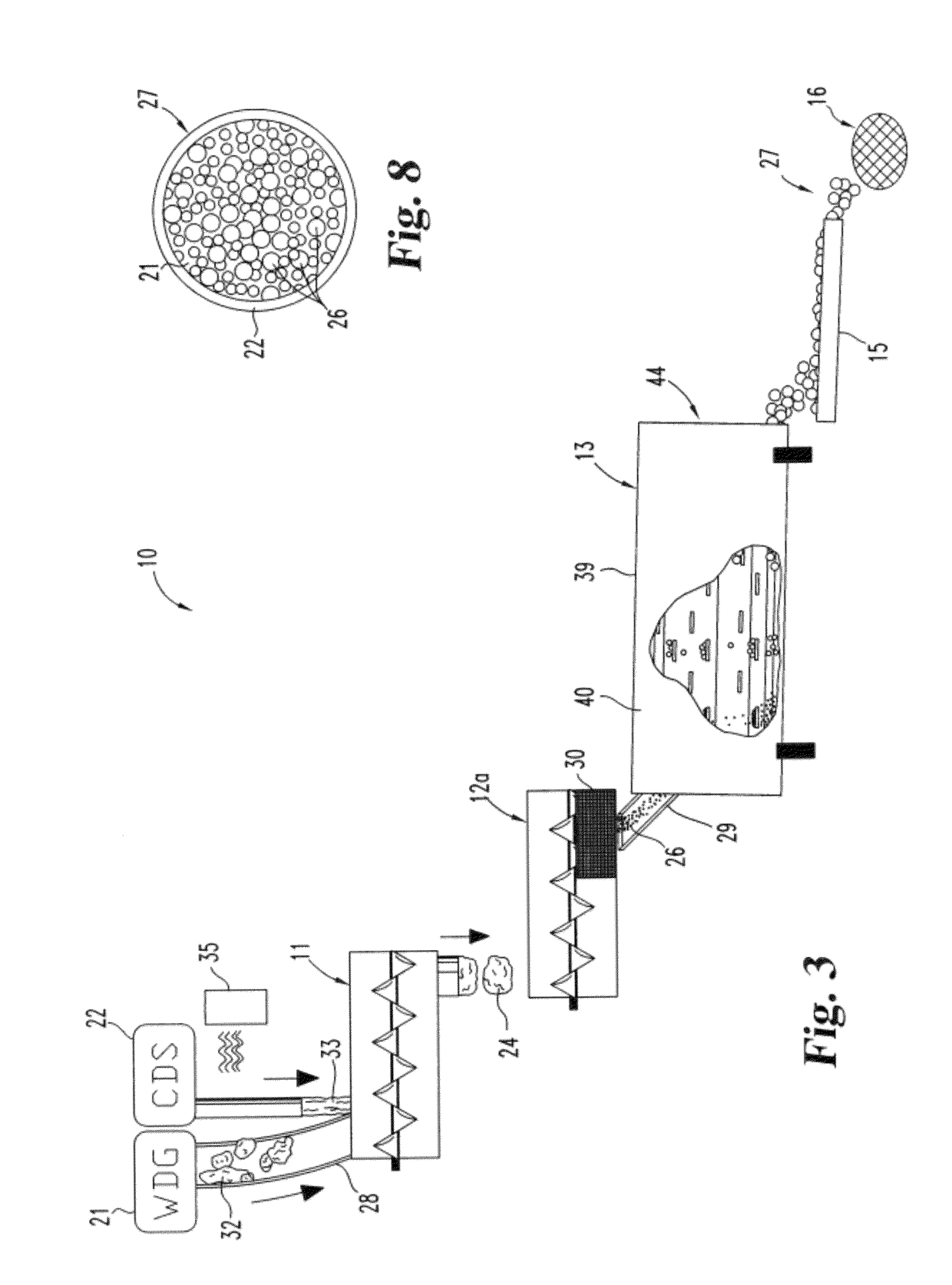

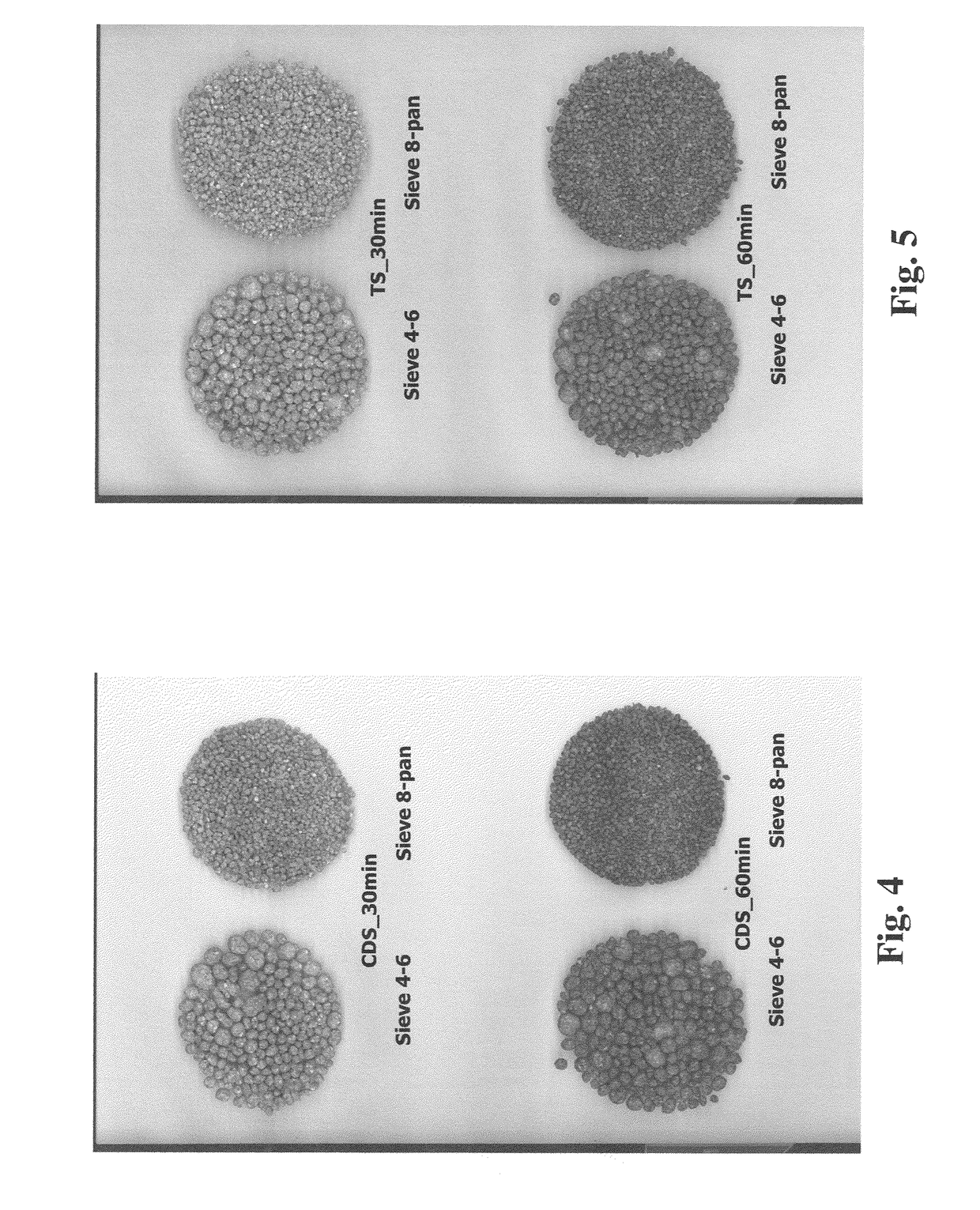

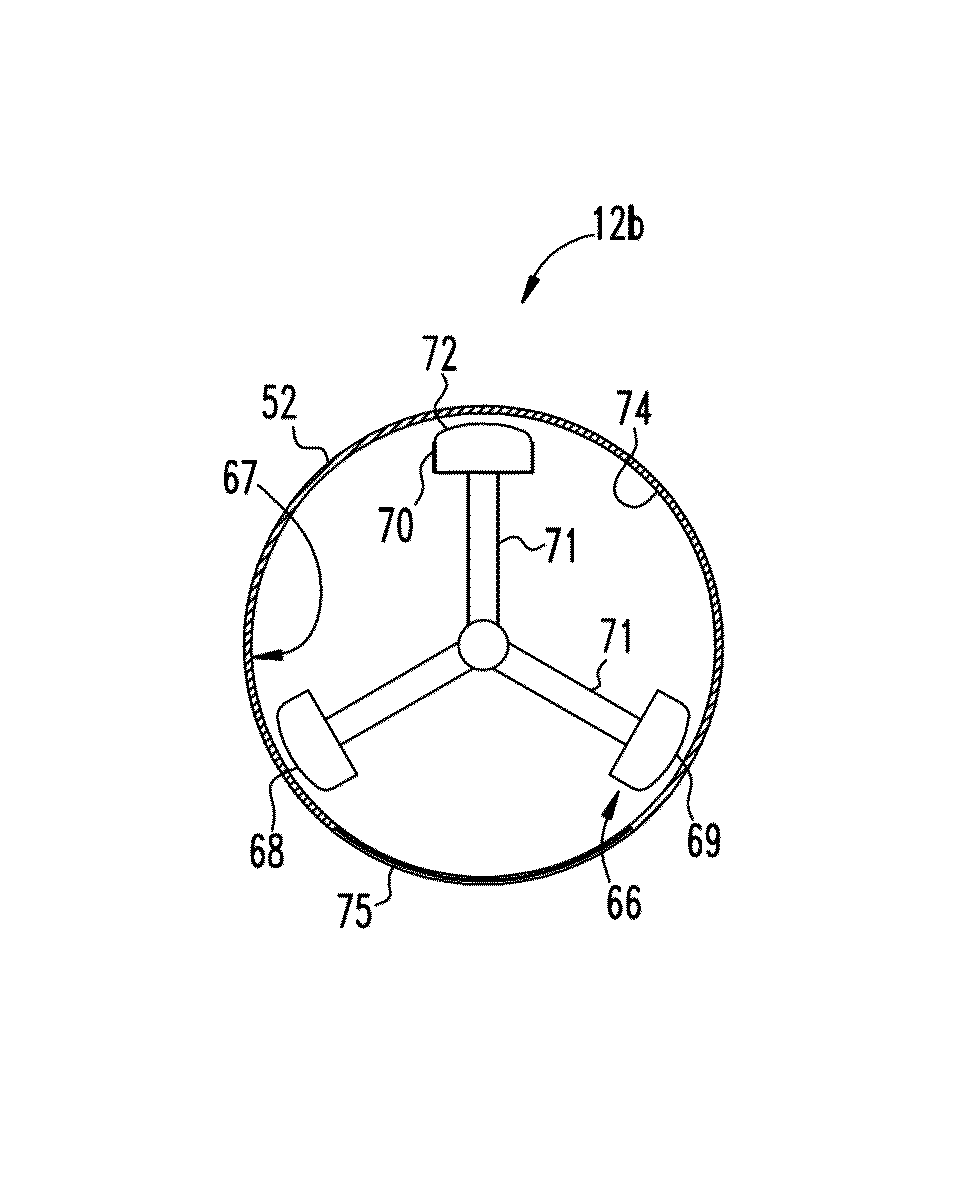

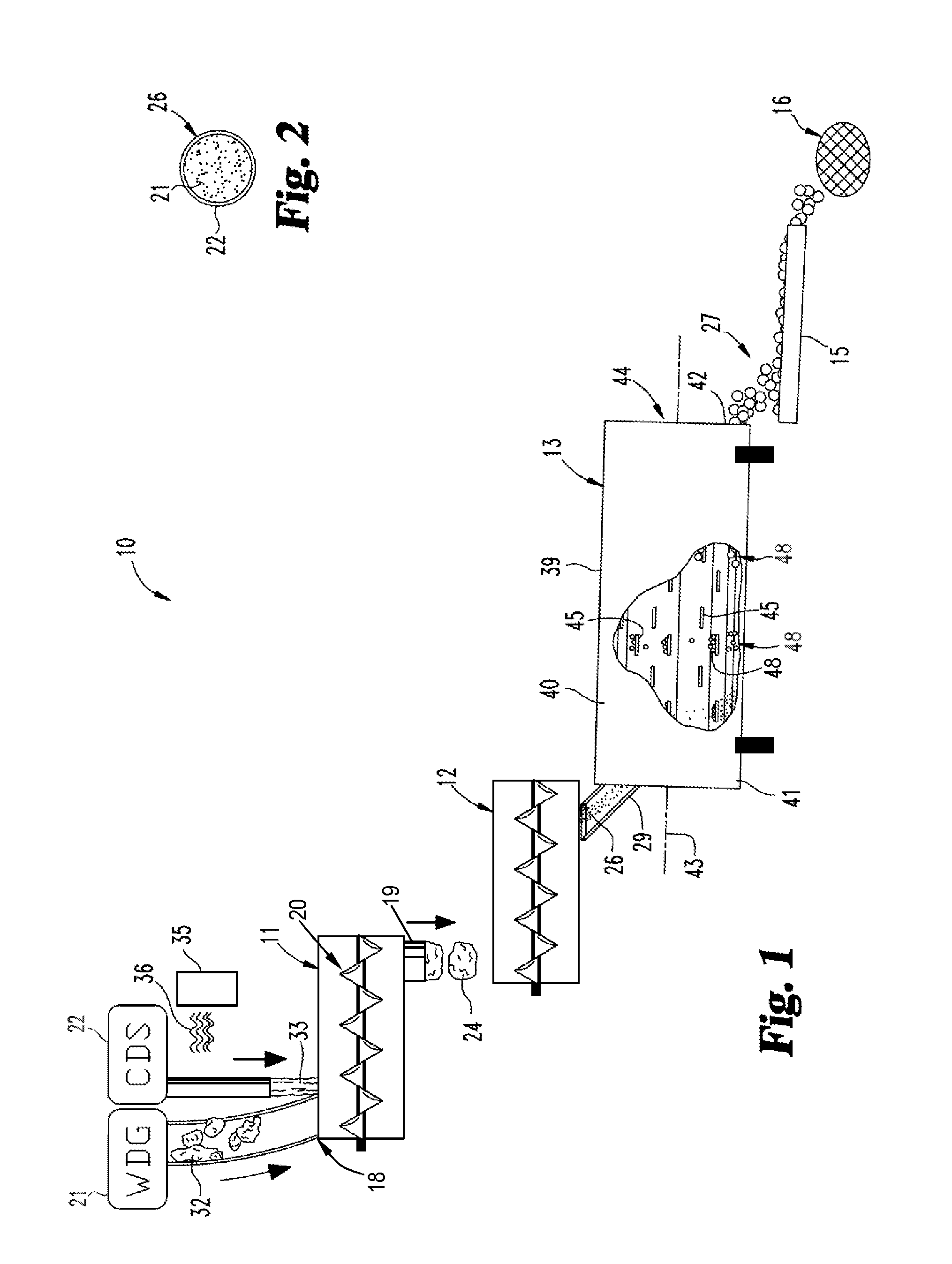

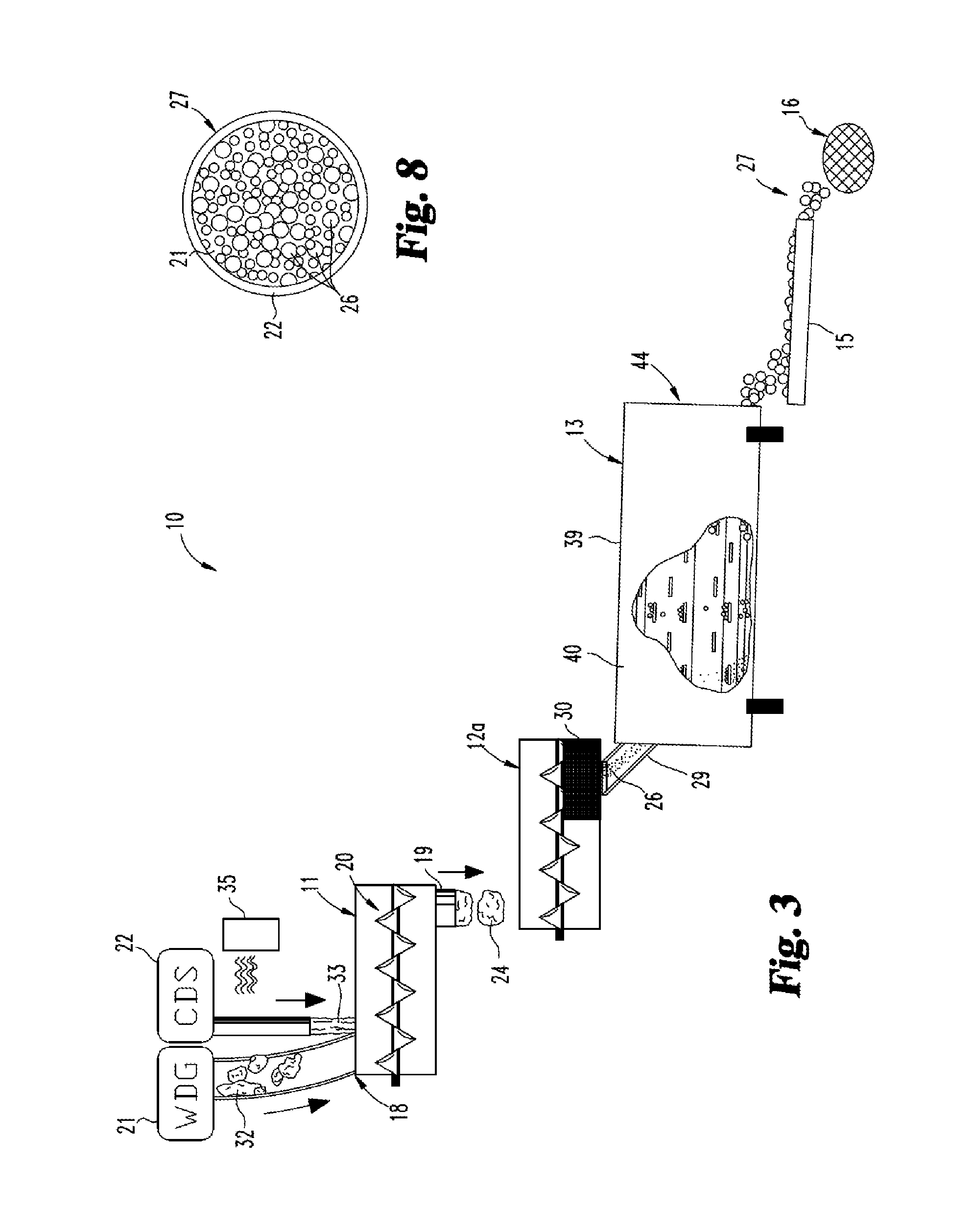

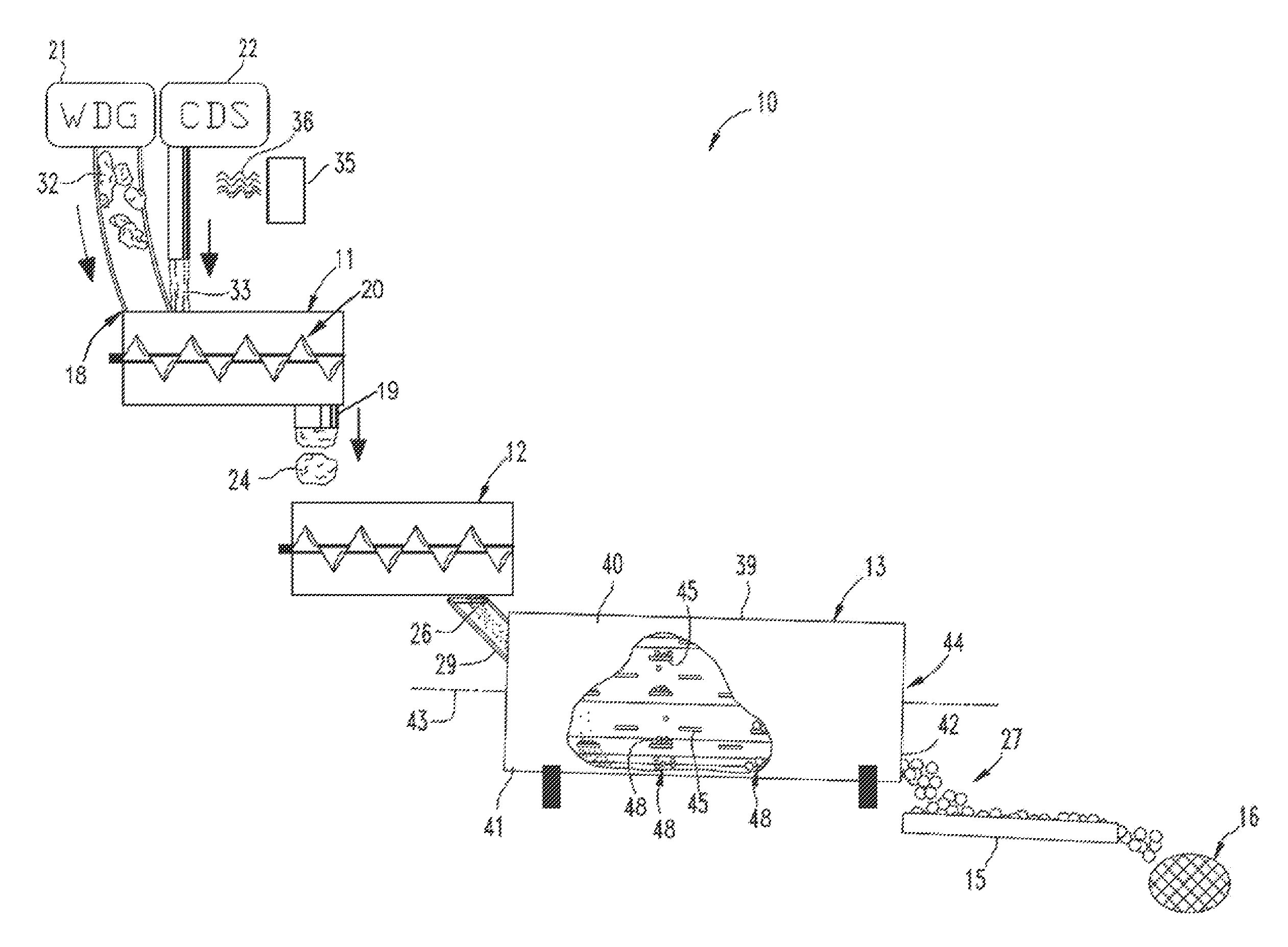

Method and apparatus for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a cavity for receiving a coproduct of a wet biomass process and a binder and being operable to premix the coproduct and binder to produce a substantially homogeneous DDGS mixture; a high shear mixer having a receptacle for receiving the DDGS mixture and being operable to shear mix the mixture and produce very small DDGS particles; and, an agglomerator having an interior chamber sized and configured to receive and transform the DDGS particles into substantially spherical DDGS pellets.

Owner:PURDUE RES FOUND INC

Coating for fertilizer

InactiveUS7452399B2Imparts physical strengthAbrasion resistance is very highBiocideGas treatmentVegetable oilPolymer chemistry

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

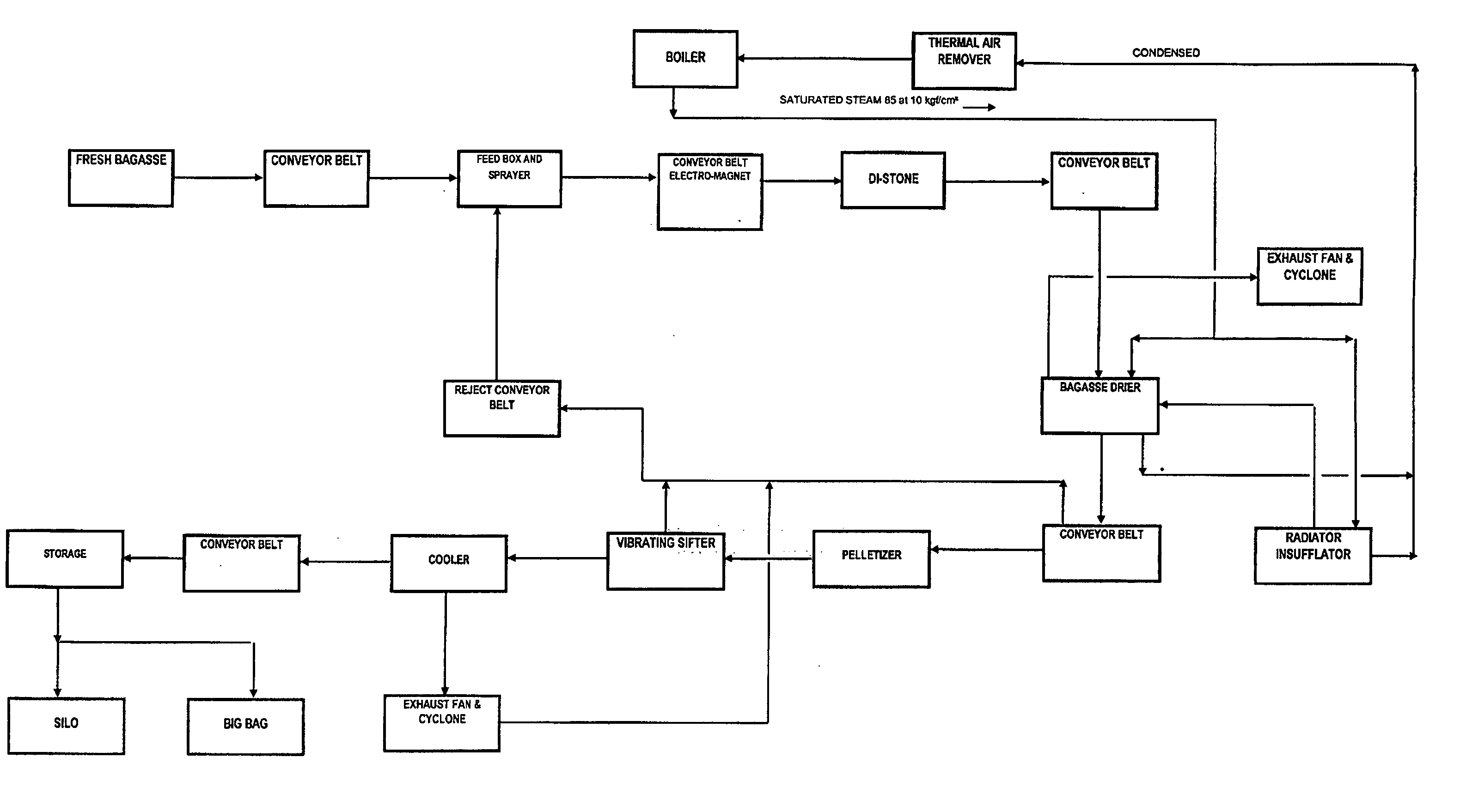

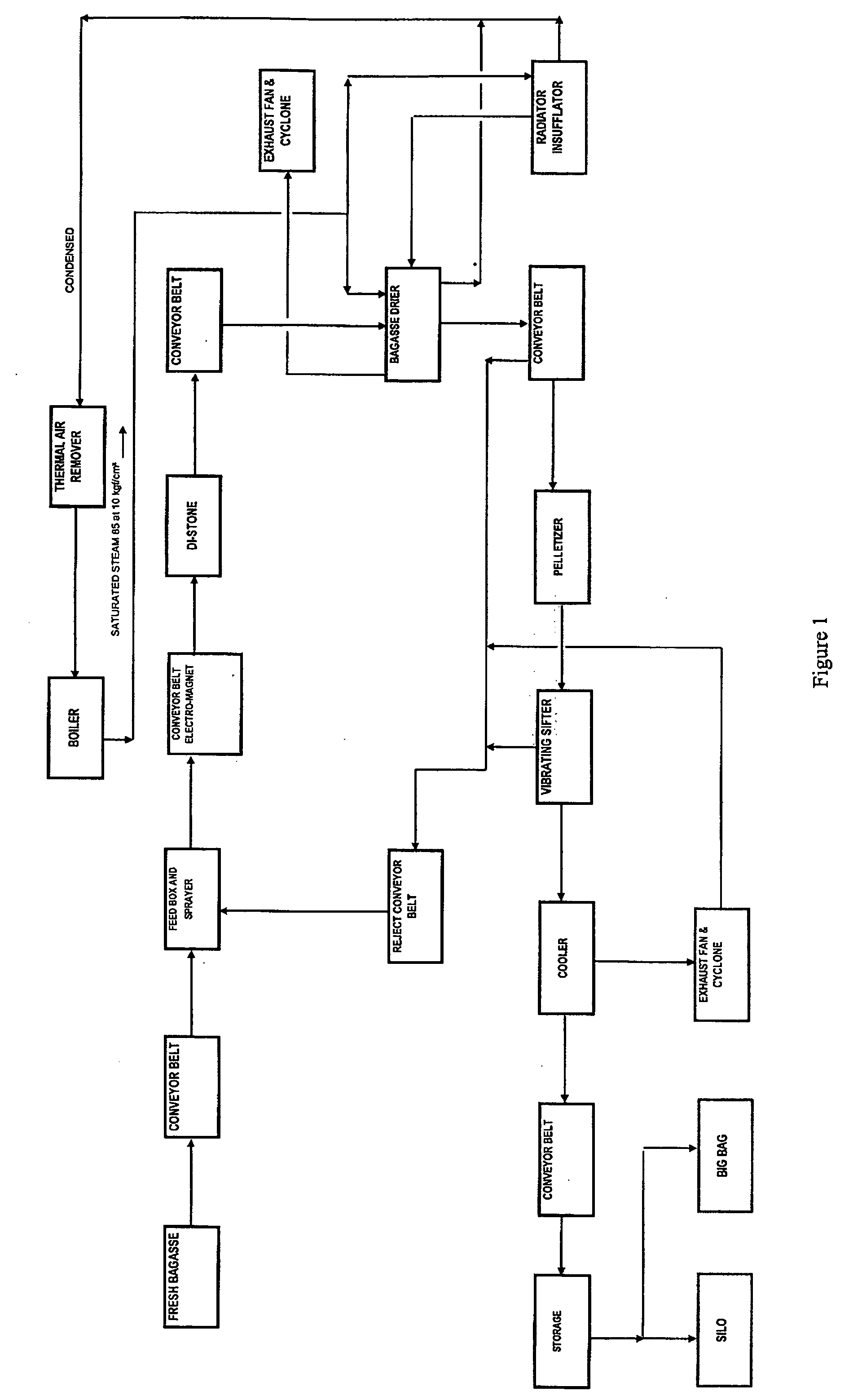

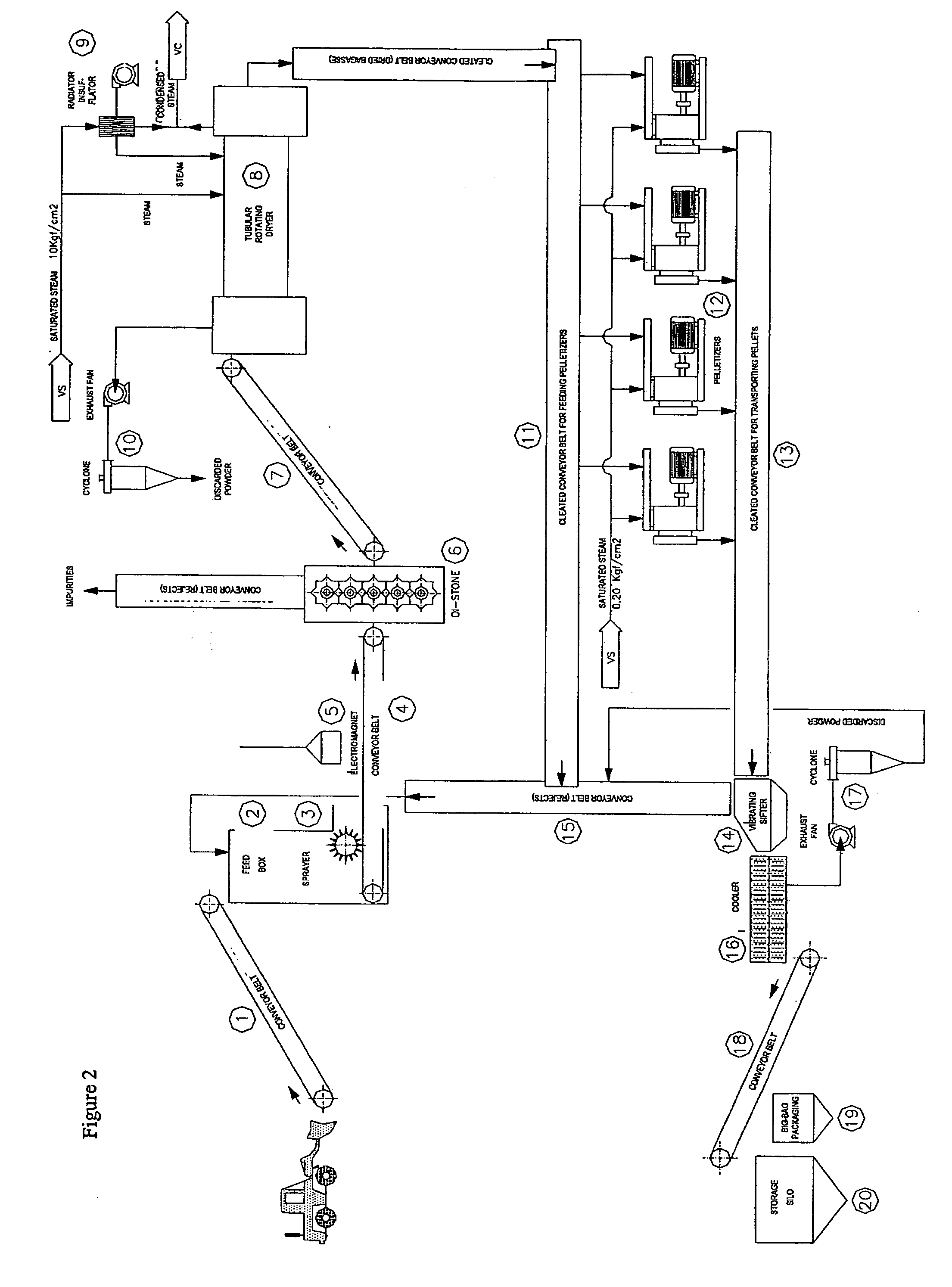

Method and device for pelletizing unprocessed cellulosic fibrous material

InactiveUS20070084385A1High risk of fireHigh calorific valueBiofuelsGranulation in rotating drumsPulp and paper industryCellulose fiber

The present invention relates to a method and a device for pelletizing unprocessed cellulosic fibrous material on an industrial scale, and in particular to the use of said unprocessed cellulosic fibrous material pellets as a combustible fuel product.

Owner:CARGILL INC

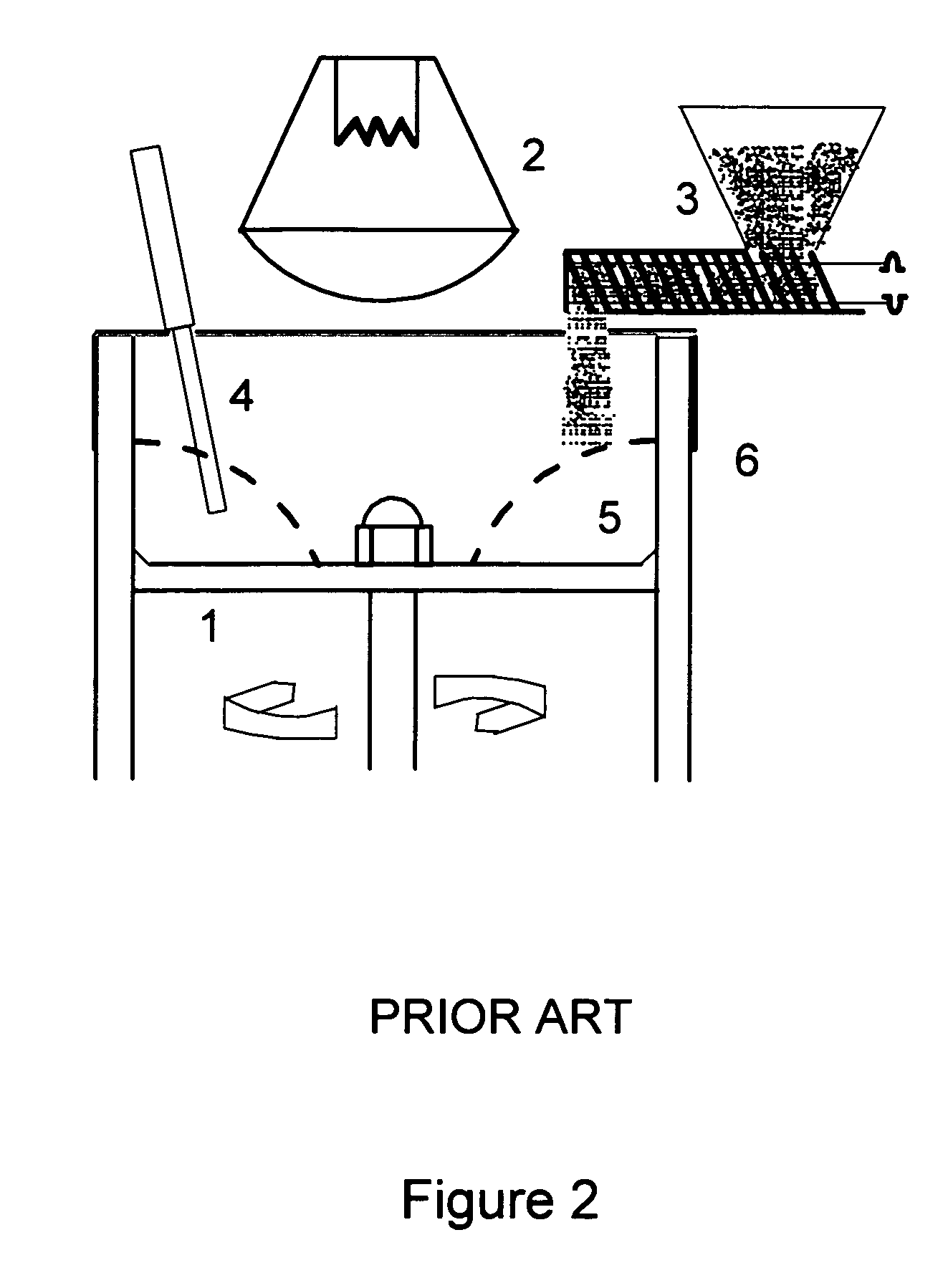

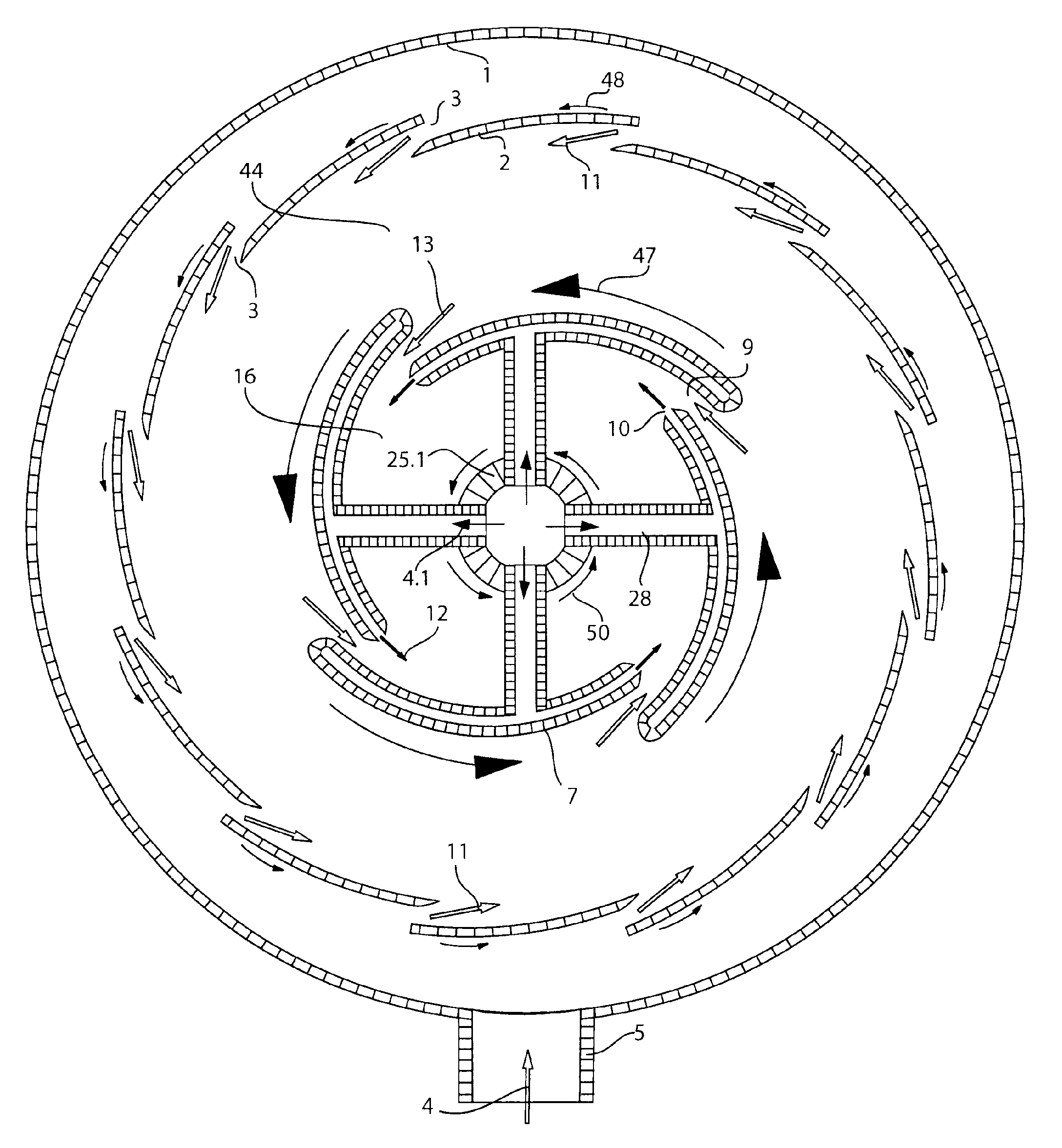

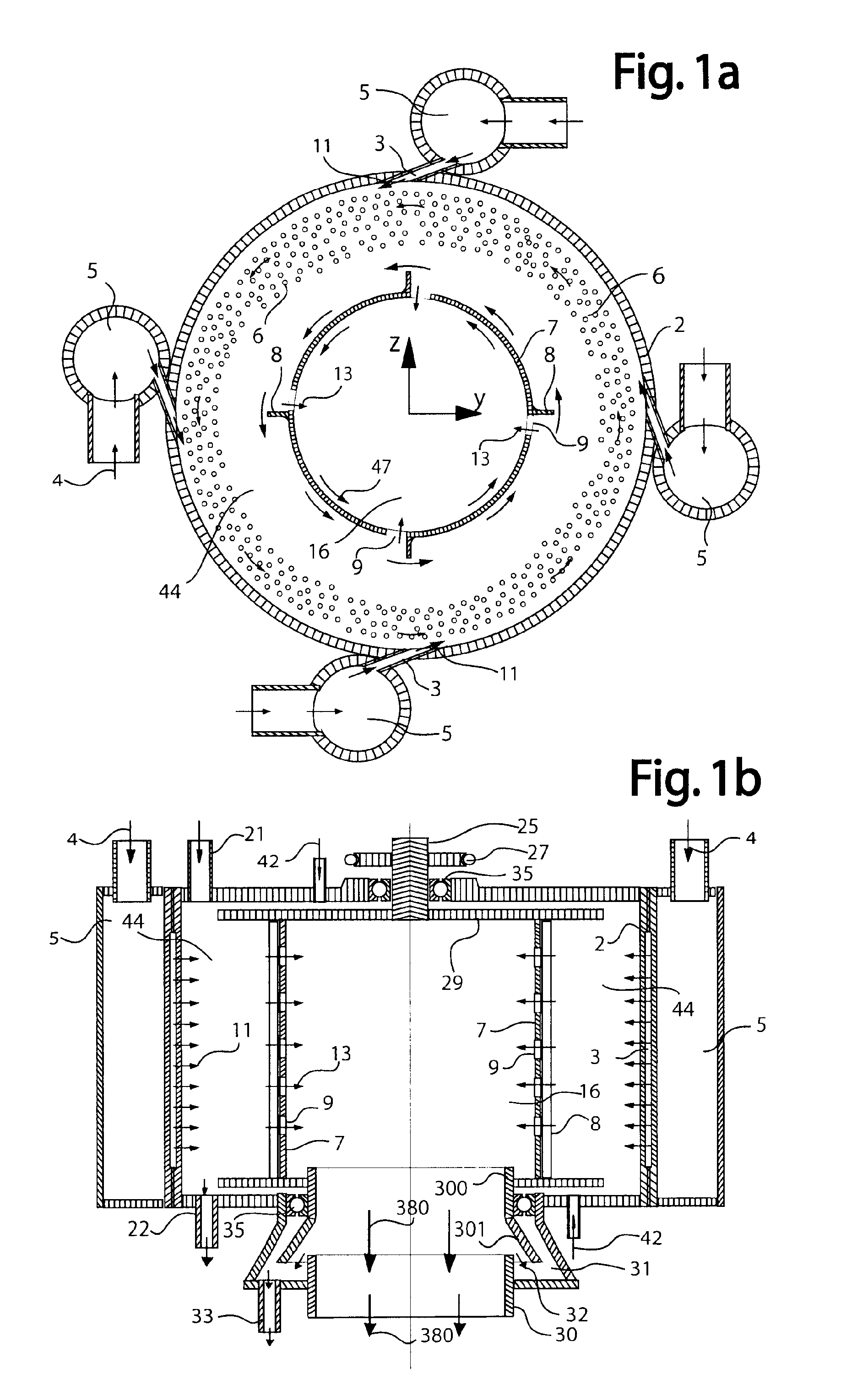

Device and method for injecting fluid into a rotating fluidized bed

A device for discharging, through a central rotating chimney, fluids from a fluidized bed driven in a rotational movement in the same direction by the rotation of the outer circular wall of a reaction chamber and / or by injection of part of these fluids along the circular wall of a fixed or rotating chamber, and methods for catalytic polymerization, drying, or other treatments of solid particles in suspension in a rotating fluidized bed or for cracking or other catalytic conversions of fluids using this device.

Owner:TOTAL RES & TECH FELUY

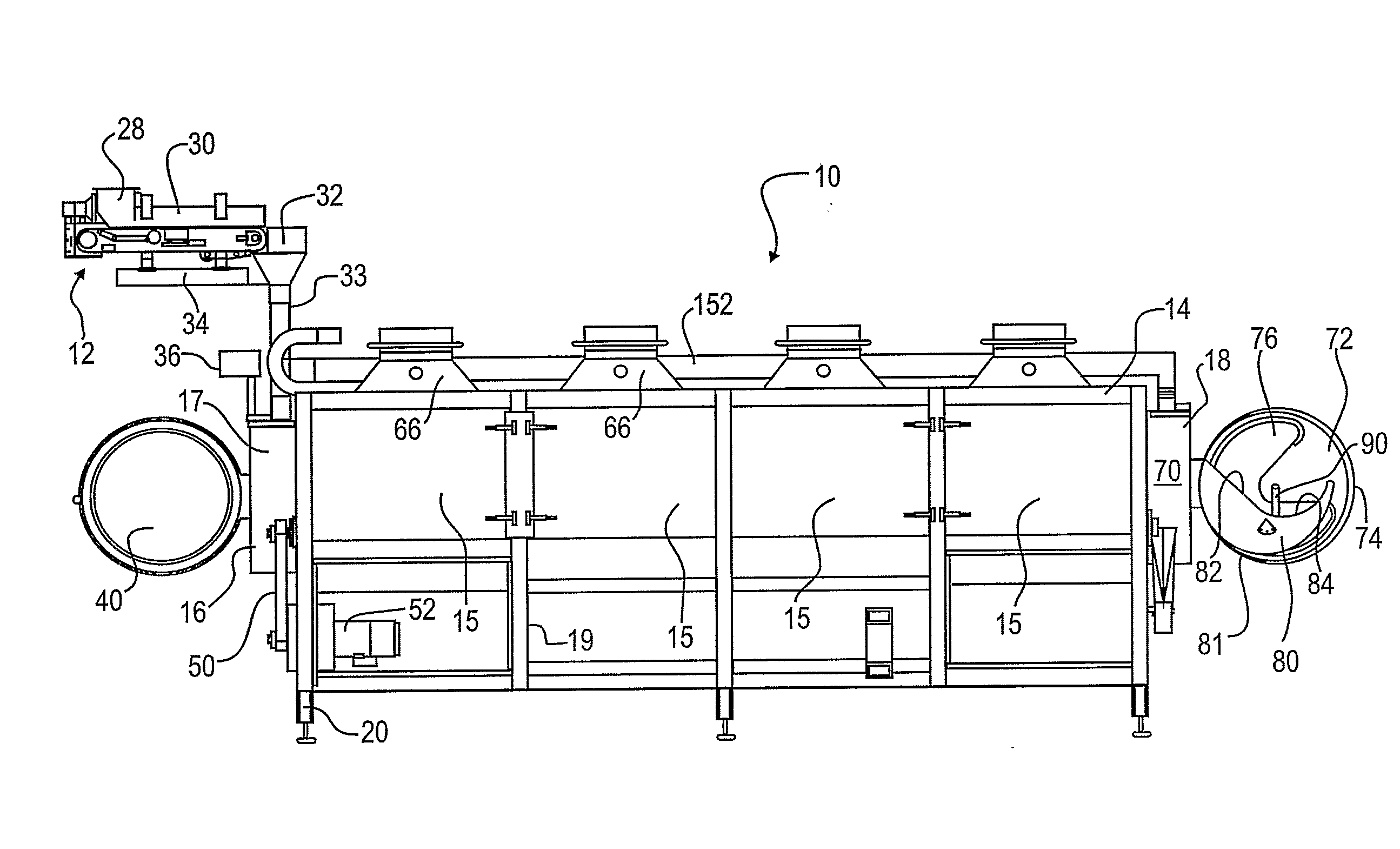

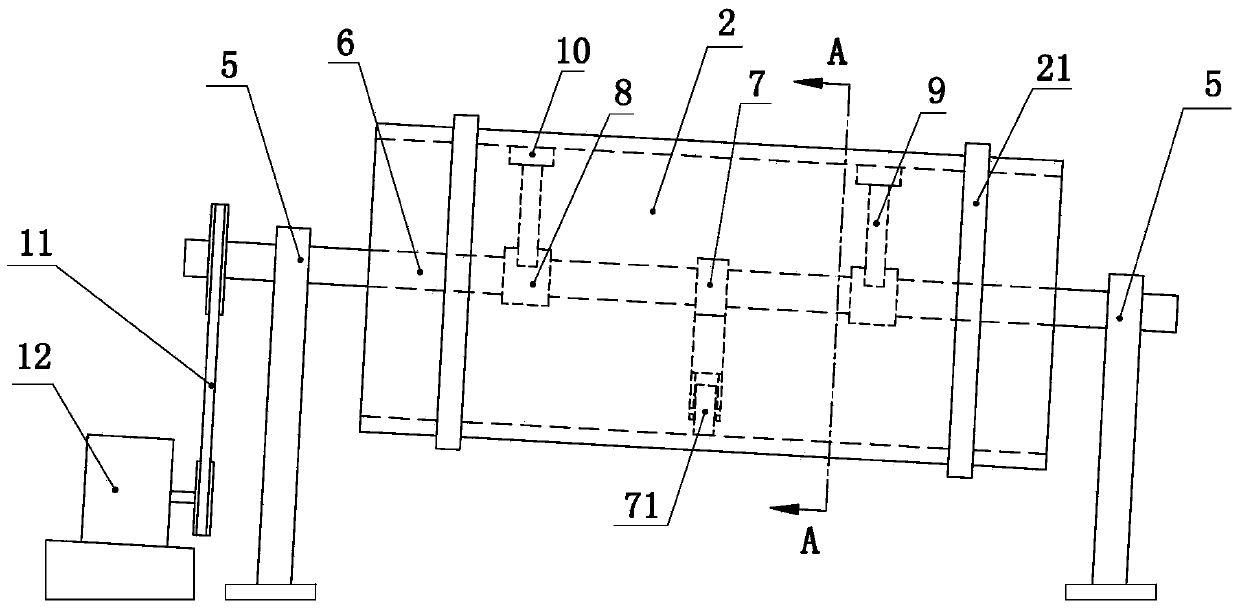

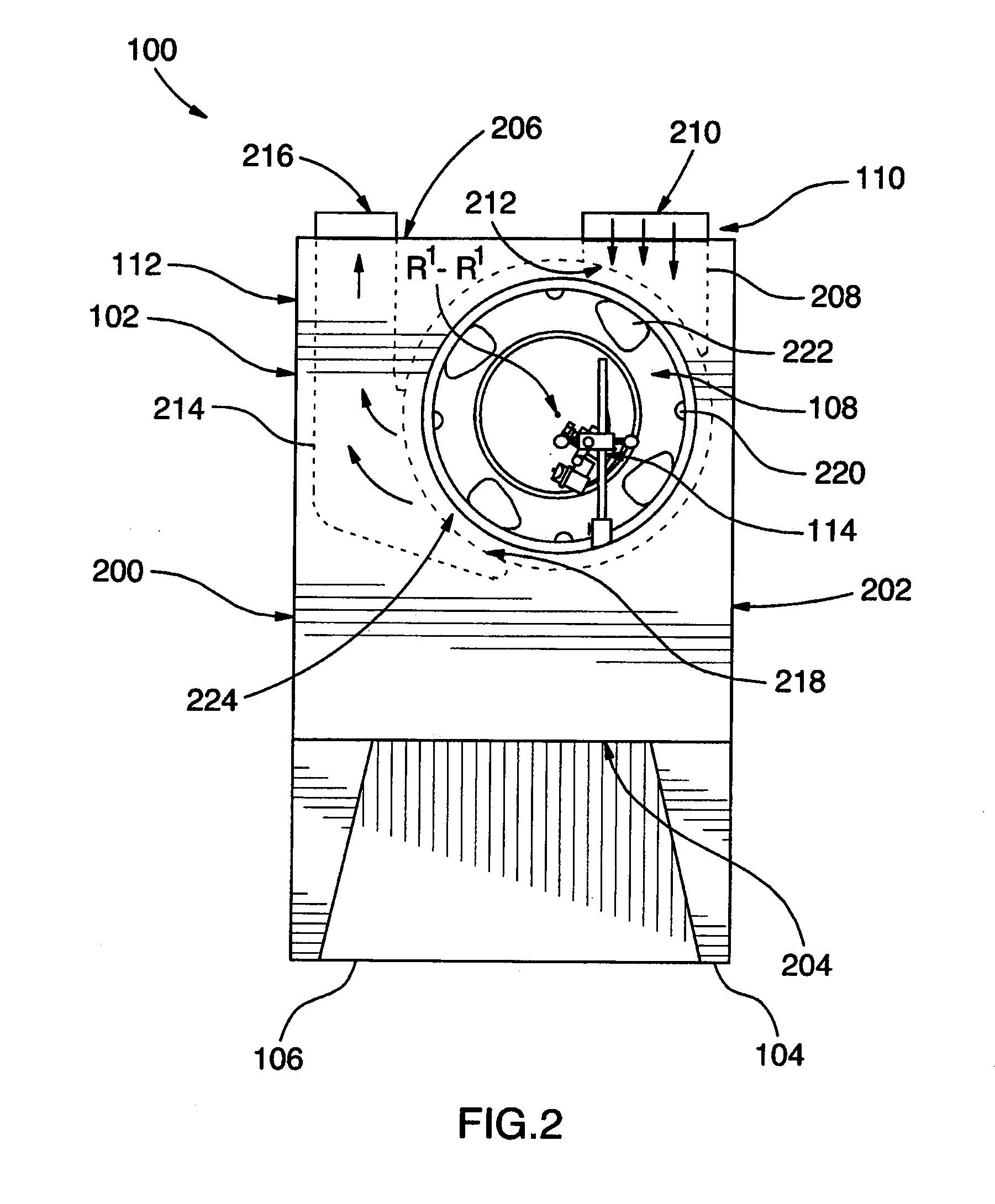

Continuous Feed Tablet Coating System

ActiveUS20080193632A1Widen meansExtended stayGranule coatingConfectioneryCoating systemHorizontal axis

A system for coating tablets and other small articles is provided. The system is comprised of an elongate housing containing a drum journalled for rotation about a horizontal axis. The drum has two open ends that receive and discharge a supply of tablets respectively. The drum is rotated about the axis by a drive means to tumble the tablets and advance the tablets through the drum. The system also includes a system for delivering a selected amount of coating to the tablets while they are being tumbled and a feeder for continually feeding tablets at a first end of the housing. The system employs a weir plate for maintaining a depth of tablets within the drum and for controlling the time that the tablets remain in the drum. Finally, the system has a tablet discharge region for receiving tablets for discharge.

Owner:OHARA TECH INC

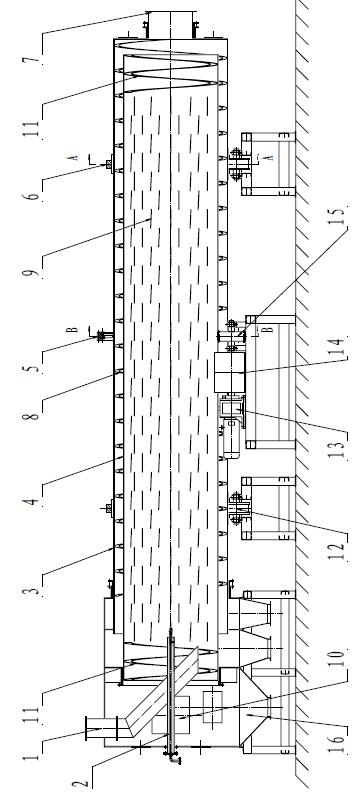

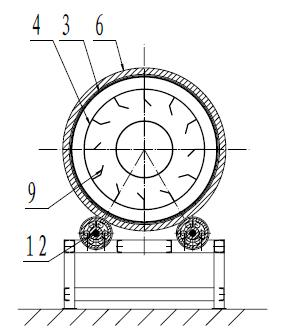

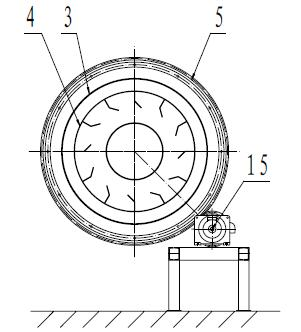

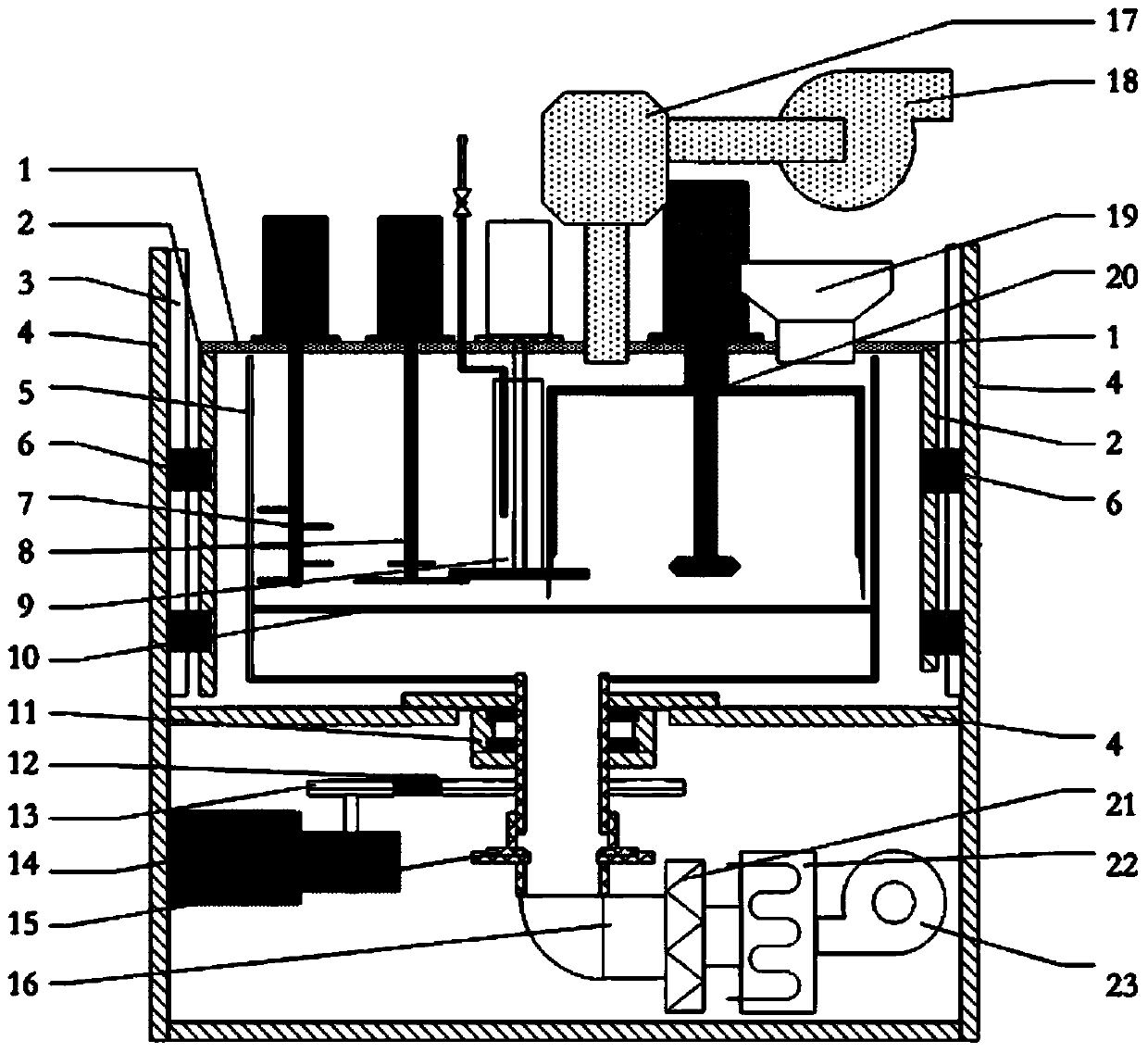

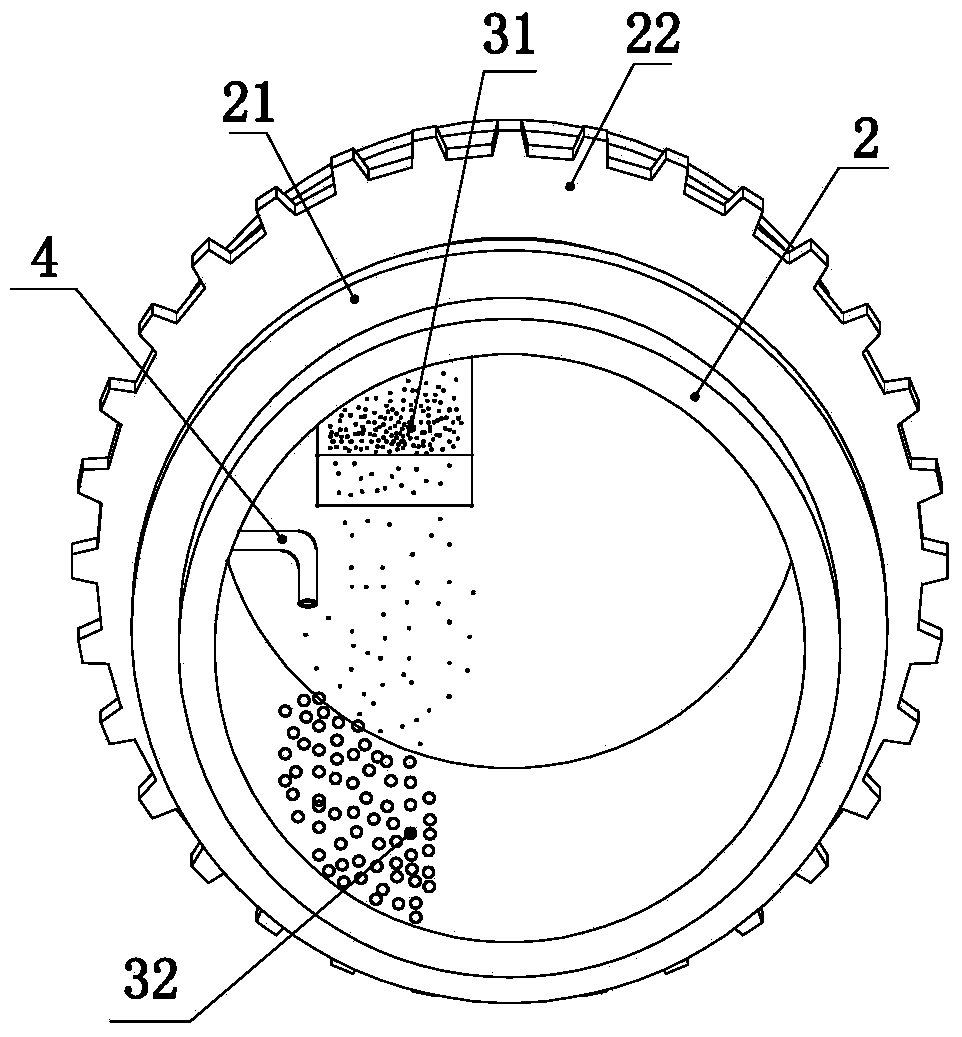

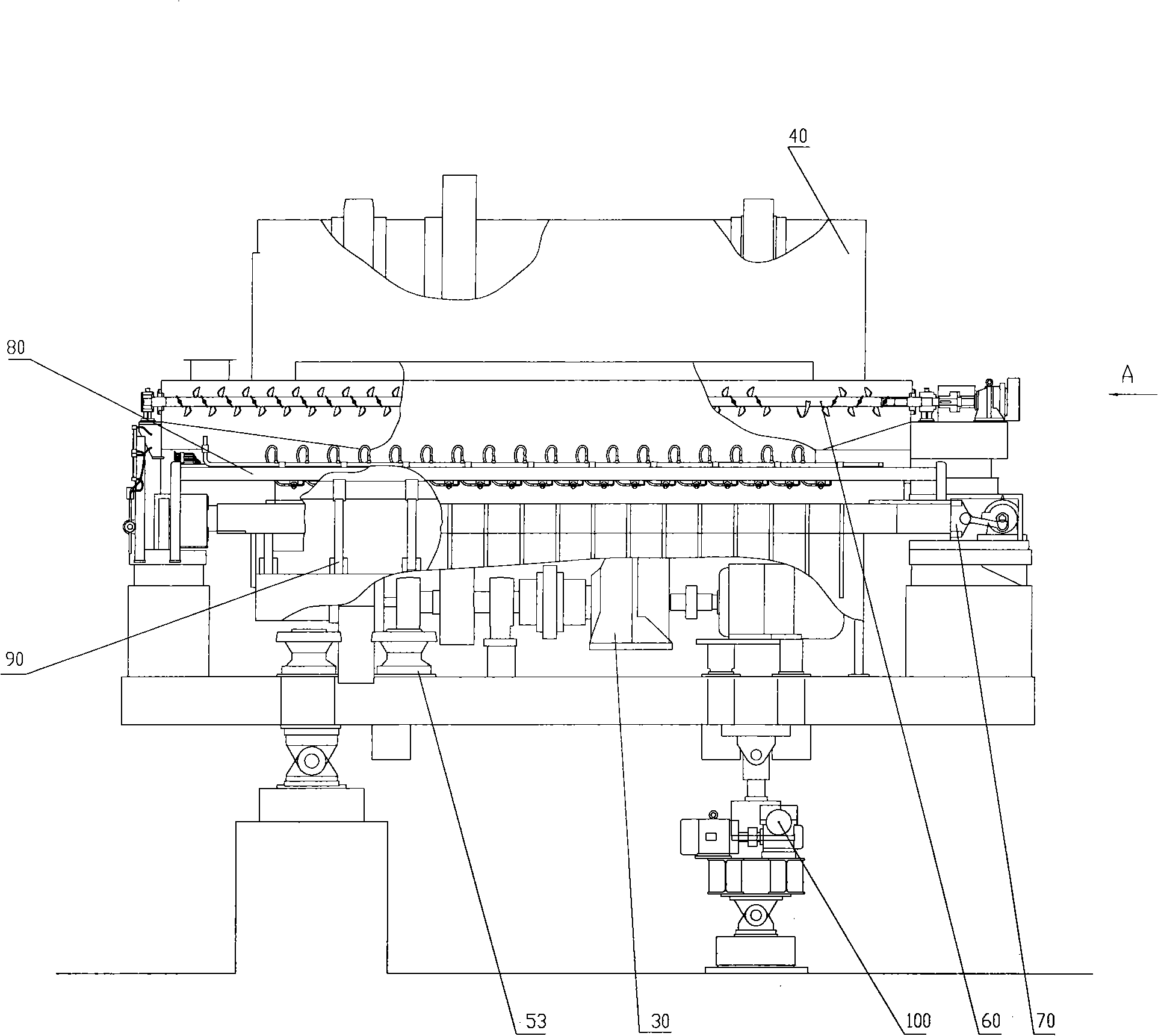

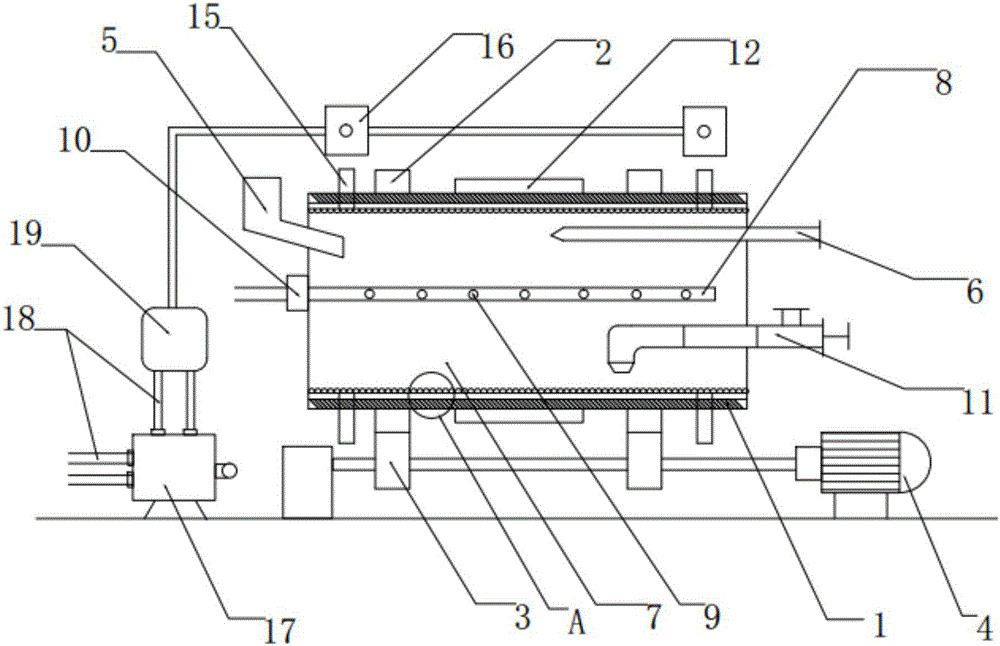

Slurry-spraying rotary granulator

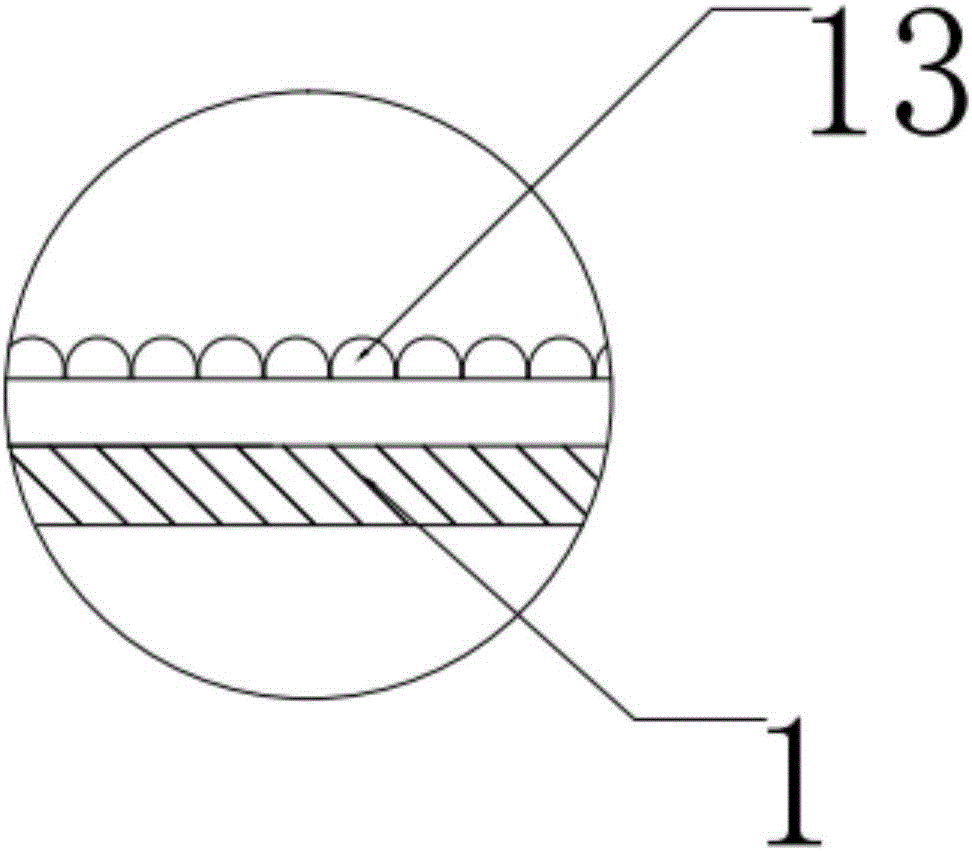

ActiveCN102120160AWell mixedReduce processGranulation in rotating drumsFertiliser formsThermal energyBarrel Shaped

The invention relates to a granulator, in particular to a double-layer barrel-shaped slurry-spraying rotary granulator. The device comprises an inner barrel and an outer barrel, which are arranged coaxially and opposite in conveying directions, and is characterized in that: one end of the inner barrel is provided with a feed inlet and the other end of the inner barrel is communicated with the outer barrel; an air inlet is formed on one side of the feed inlet of the inner barrel; the opening on the other side of the inner barrel is communicated with the outer barrel; an air outlet is formed on the outer barrel on the opening side of the inner barrel; and thus, a drying air duct running through the inner barrel is formed. In the invention, grain finishing and drying can be performed in a granulating process, a plurality of processes are performed in one machine, process steps are reduced, the production efficiency is improved and the production cost is reduced; and grain finishing is performed in the interlayer between the inner barrel and the outer barrel, the drying heat can be reused, energy consumption is reduced, and external working environment is improved.

Owner:浙江钱江伟岸干燥设备有限公司 +2

Air conditioner

InactiveUS20090211284A1Avoid normal workHigh placementAmino compound purification/separationMechanical apparatusEngineeringAir blower

An air conditioner is installable in a ceiling of an air-conditioned room and is disposed with a casing in whose top surface is formed a suction opening and in whose bottom surface are formed blowout openings, and in which is formed an air flow path that leads from the suction opening to the blowout openings, a blow fan that is disposed in the air flow path, and a heat exchanger that is disposed in the air flow path.

Owner:DAIKIN IND LTD

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

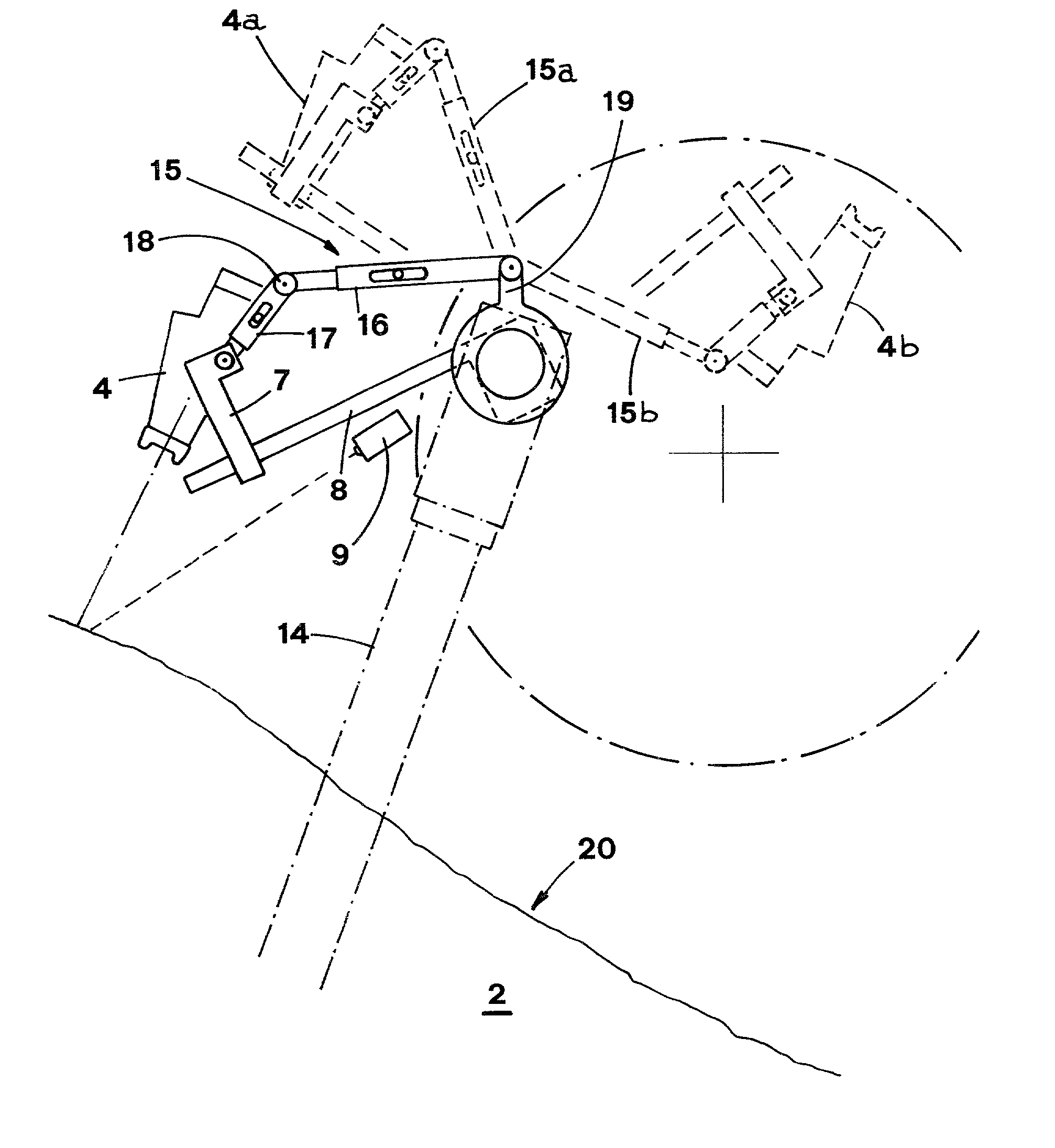

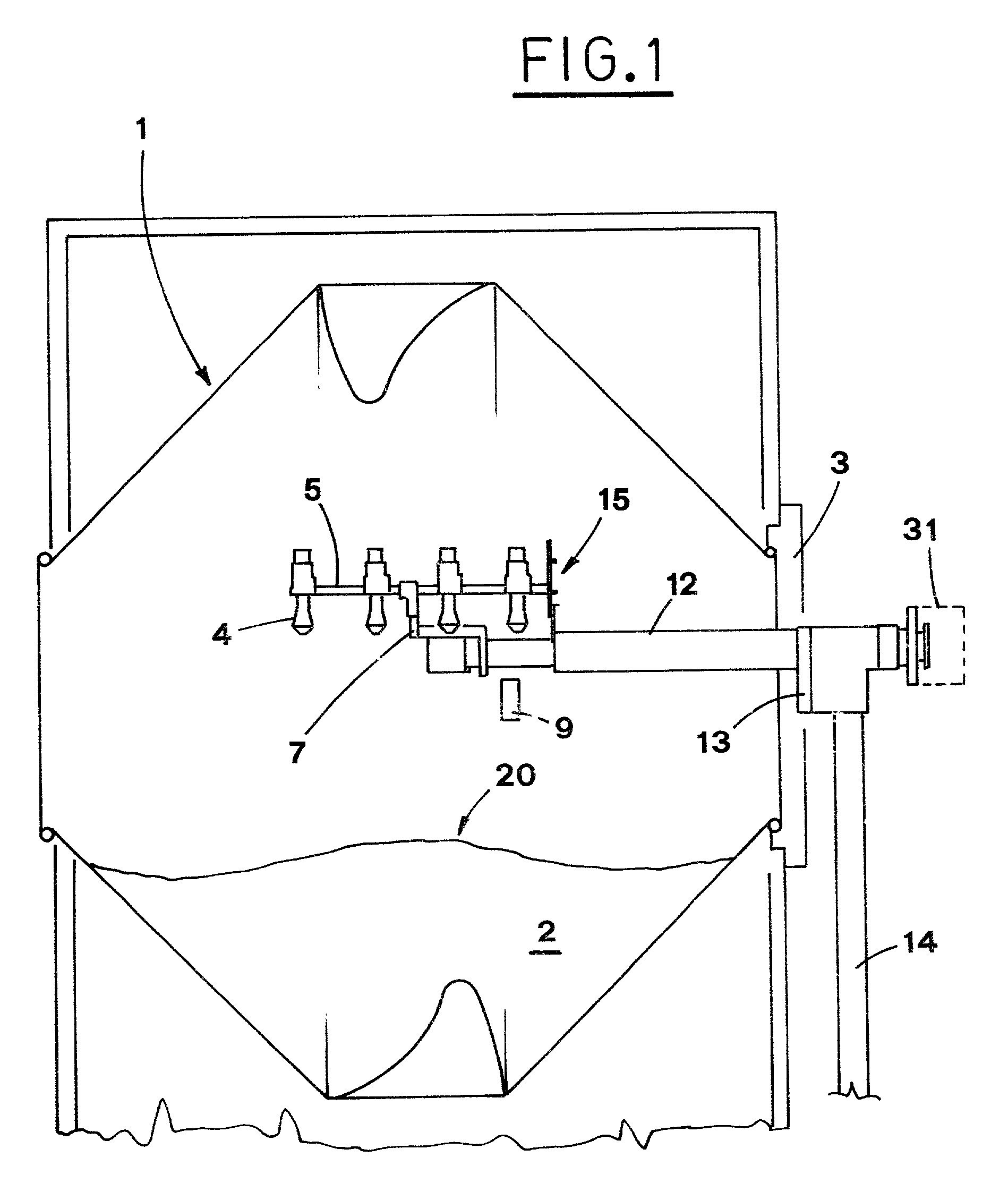

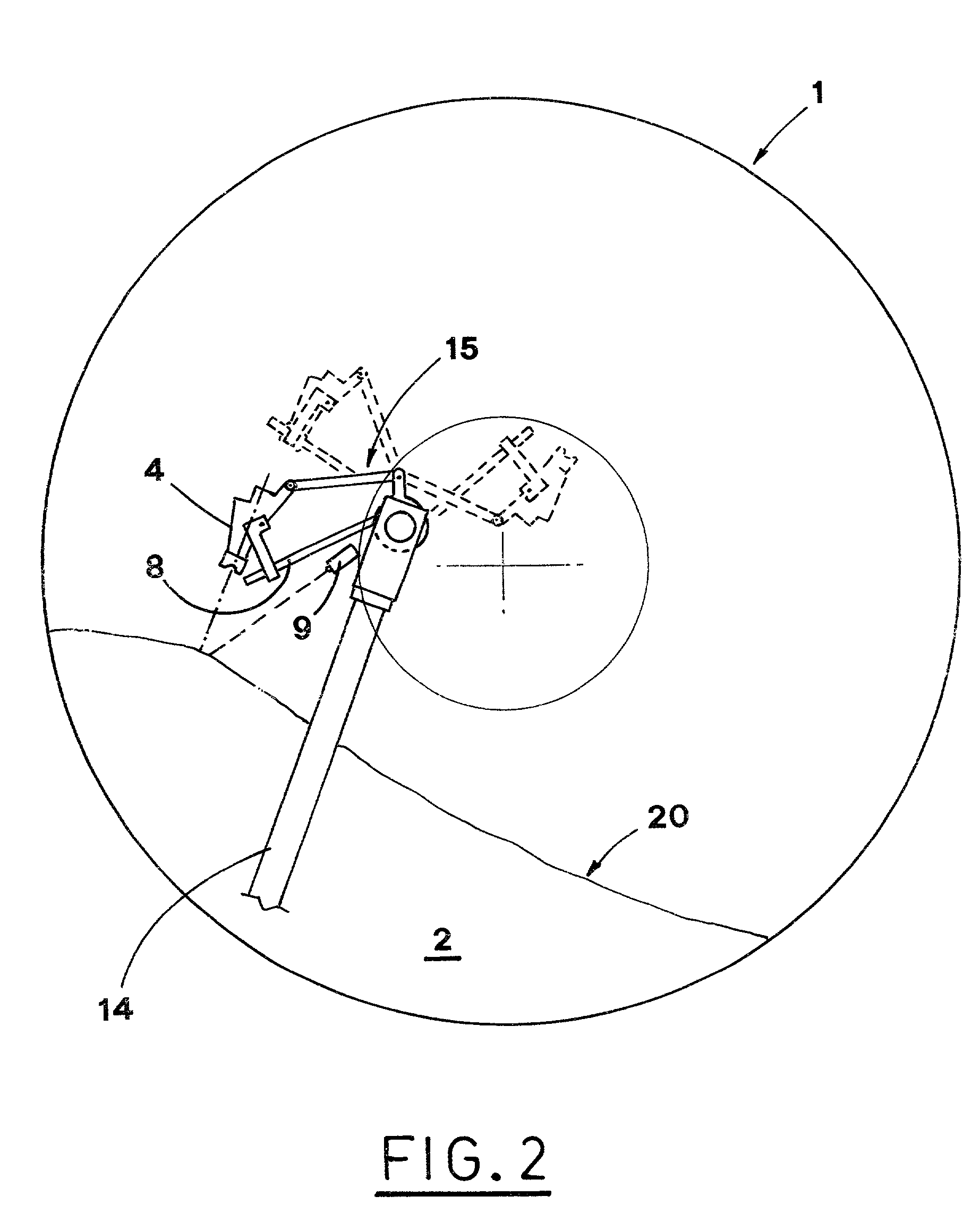

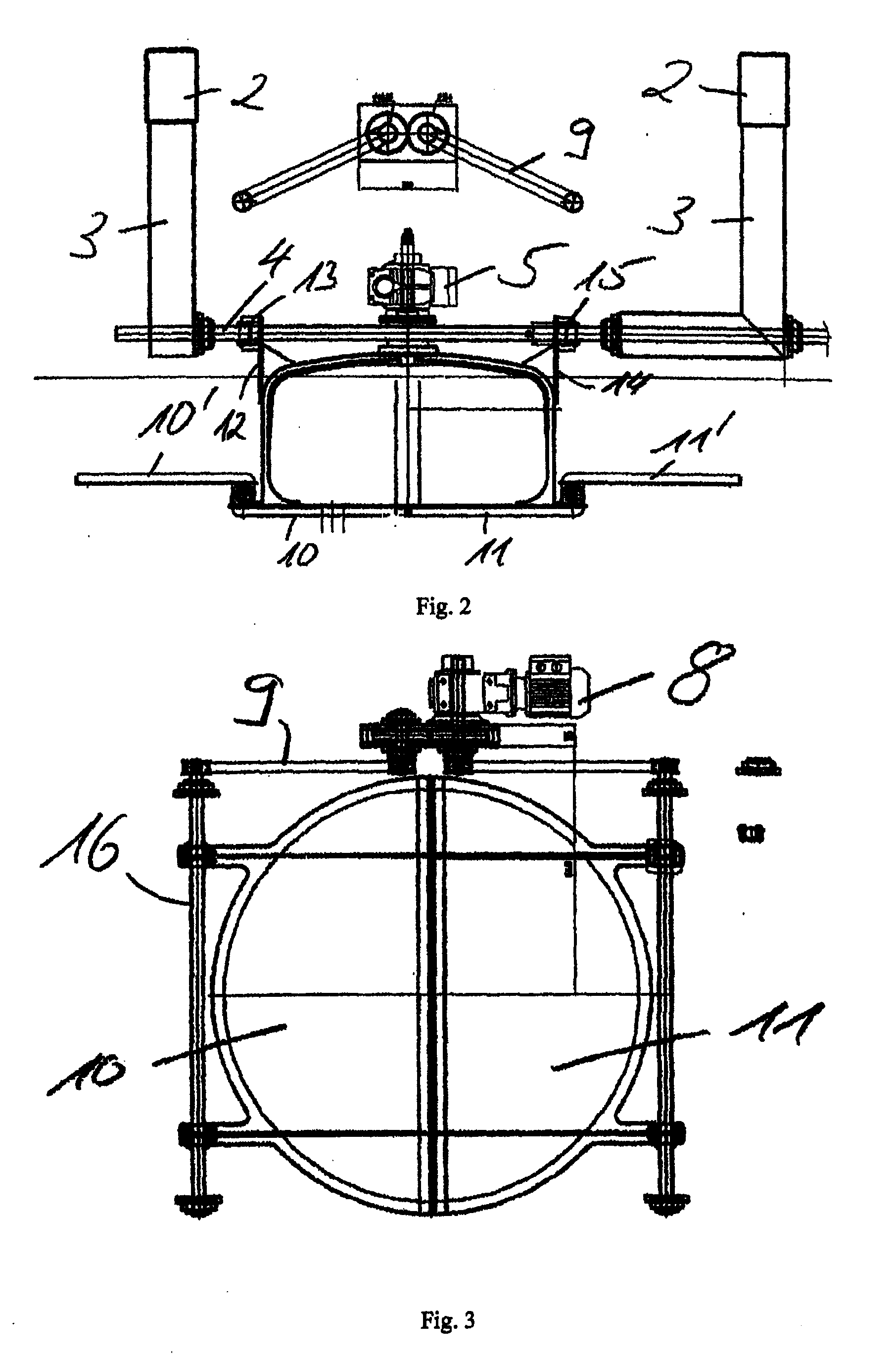

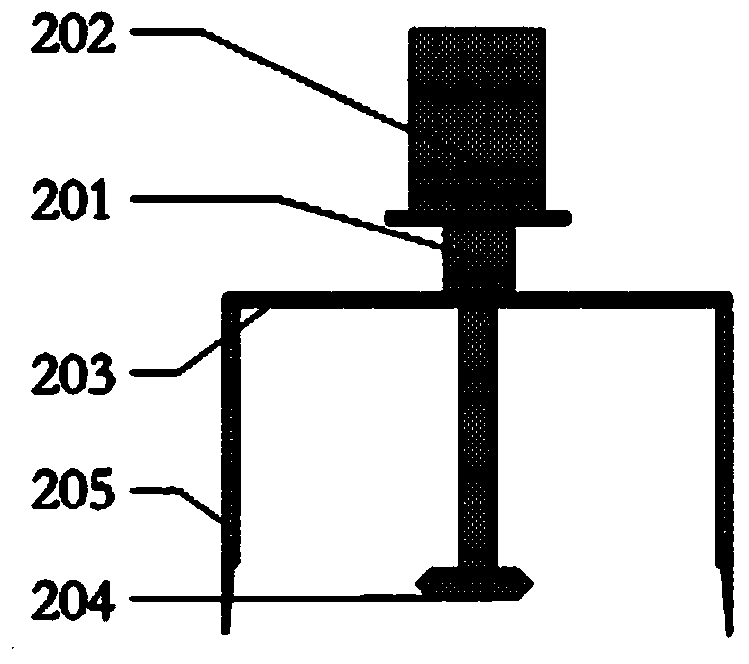

Device for moving and orienting spraying nozzles in a coating pan

InactiveUS20020134303A1Function increaseLiquid surface applicatorsGranule coatingHorizontal axisSpray nozzle

A device moves and orients spraying nozzles (4) inside a coating pan (1). The spraying nozzles (4) are carried, arranged in a line, by a shaft (5), which rotates on a horizontal axis parallel to the axis of the rotating drum (1). The shaft (5) is supported by a support frame (7), which is fastened to a bar (10), which is rotated to adjust the distance between the spraying nozzles (4) and the free surface (20) of said mass of articles (2) being treated. The shaft (5) is fastened to the lever mechanism (16,17) of a positioning member (15) for changing the inclination of the spraying nozzles (4), so as to maintain constant their orientation with respect to said free surface (20) of the mass of articles (2).

Owner:G S S R L COATING SYST

Device and method for coating small parts

ActiveUS20090017224A1Fast and economical coatingImprove surface qualityRadiation applicationsConfectioneryEngineeringRadiation

The present invention relates to a coating device for small parts, in particular for lacquering mass produced small parts, like e.g. bolts, small plastic parts and similar, and it relates to a method for this purpose with a movable receiver element for receiving and moving the small parts, and a dispenser device, located at the receiver element for continuous or portioned dispensing the coating material into the receiver element, wherein a radiation emitter device is provided in the receiver element for emitting radiation for drying and / or hardening the coating material.

Owner:SPECIAL COATINGS

Acid treatment for fertilizers to increase zinc solubility and availability

ActiveUS20170044078A1Improve availabilityGood water solubilityMaterial granulation and coatingAlkali orthophosphate fertiliserSolubilityZinc uptake

Methods and system for increasing the water solubility and availability of zinc in granular fertilizers using acid treatments. The treatment of granular fertilizers with an acidic solution increases an amount of water-soluble zinc, which in turn, increases the efficiency of zinc uptake and reduces the costs and equipment otherwise needed to mitigate zinc deficiencies.

Owner:THE MOSAIC COMPANY

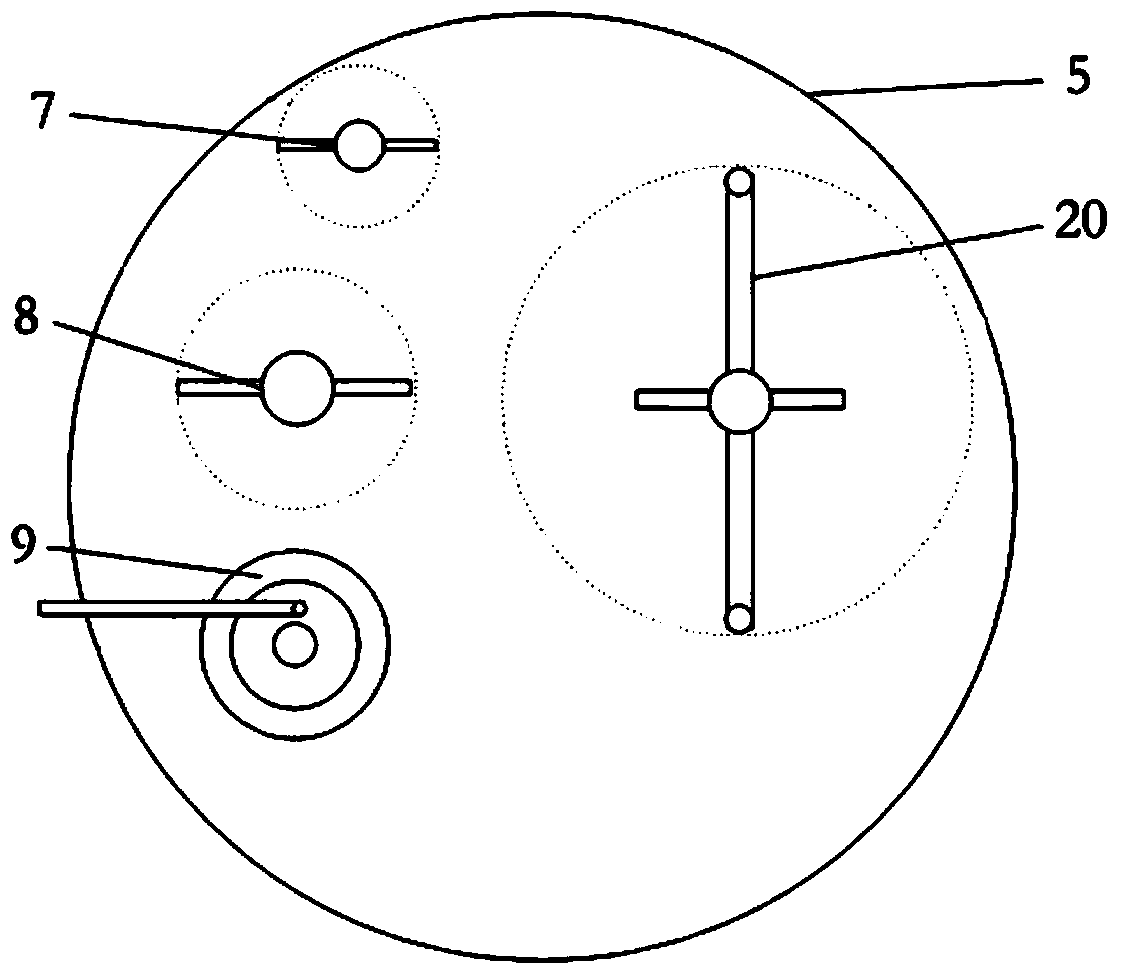

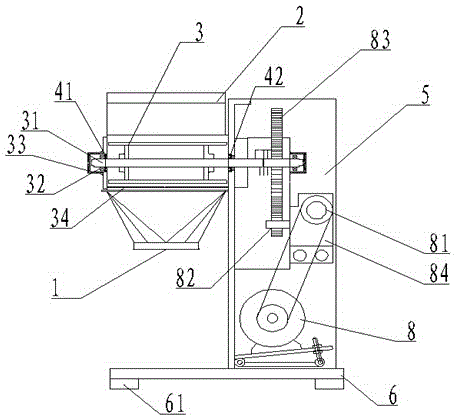

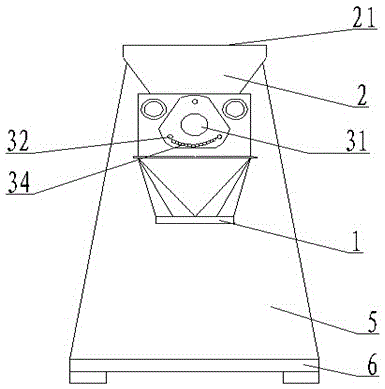

Rotating bucket type granulator

ActiveCN104001450AReduce the risk of contaminationAvoid stickingGranulation in rotating drumsDrying gas arrangementsMechanical engineeringEnergy consumption

The invention discloses a rotating bucket type granulator. The rotating bucket type granulator is characterized by comprising a machine frame, a rotating bucket, a bucket cover and a screen plate. The rotating bucket is connected with the machine frame through a hollow main shaft assembly, and the lower end of the main shaft assembly is communicated with an air supplying mechanism. The bucket cover is connected with the machine frame through a vertical lifting assembly, and the bucket cover is provided with a feeding hopper, a dust collector, a material distributing device, a scraper assembly and a plurality of sets of rotating cutter assemblies. The rotating center of the scraper assembly is located in the middle point of the radius of the rotating bucket, the rotating centers of the rotating cutter assemblies deviate from the axis of the rotating bucket, and the distances between the rotating centers of the rotating cutter assemblies and the axis of the rotating bucket are not equal. The rotating bucket type granulator has the advantages that the structure is compact and reasonable, the yield is large, the energy consumption is low, the dust is little, and the functions are multiple; in the granulating process, the scraper assembly and the rotating cutter assemblies break produced large particles in time, the material is effectively prevented from adhering to the surfaces and blocking, the produced particles are spherical or in the shape close to a ball, fluidity is good, the number of large particles and the amount of fine powder in the product are small, and the rate of finished particles is high.

Owner:BEIJINGLANDINGKECHUANG EQUIP TECH CO LTD

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

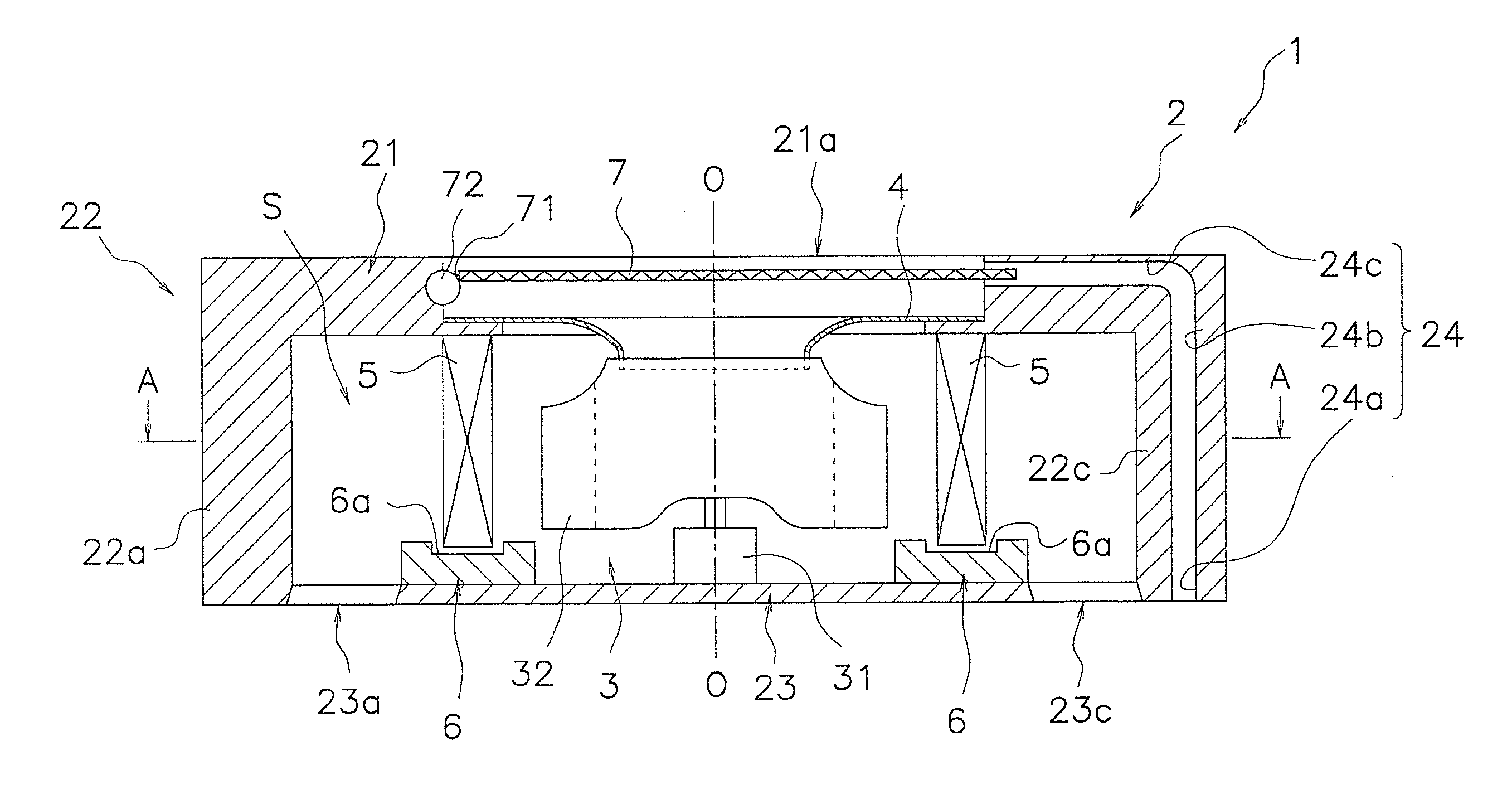

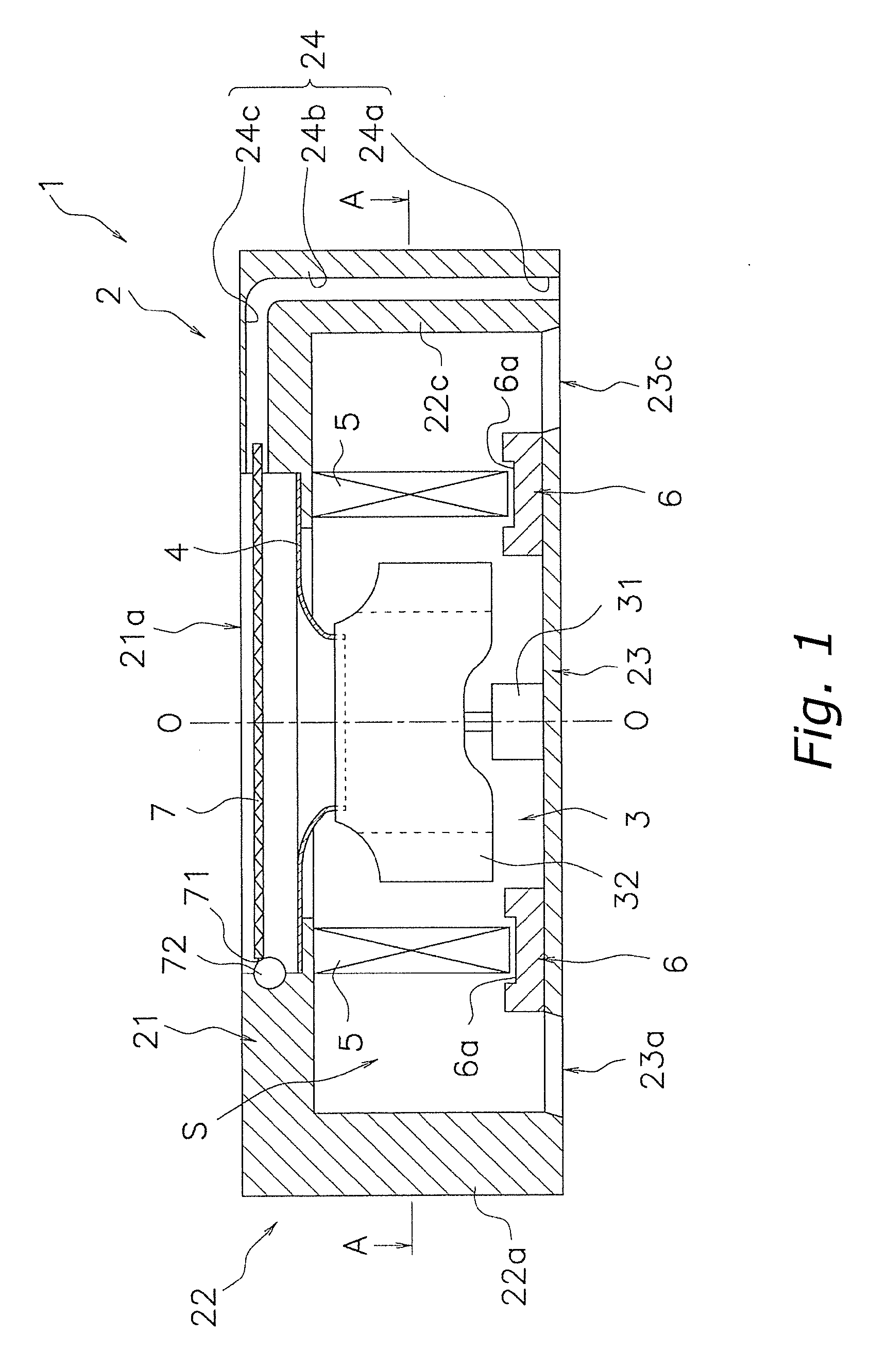

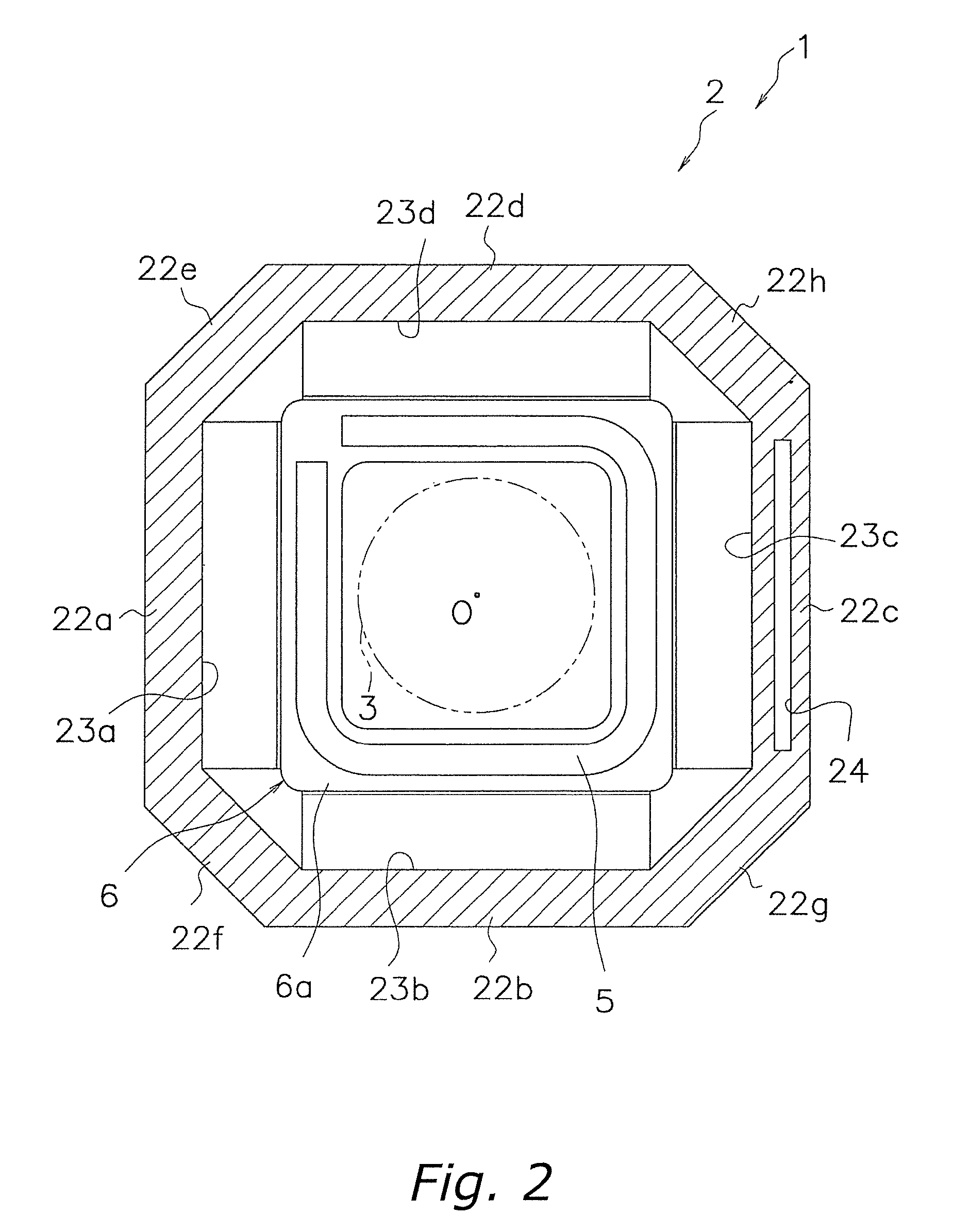

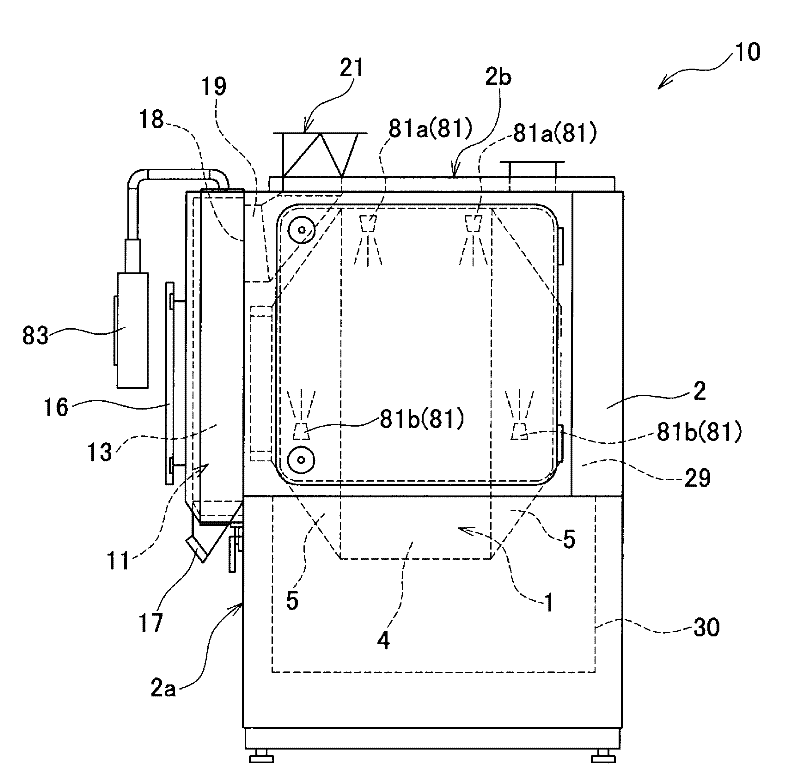

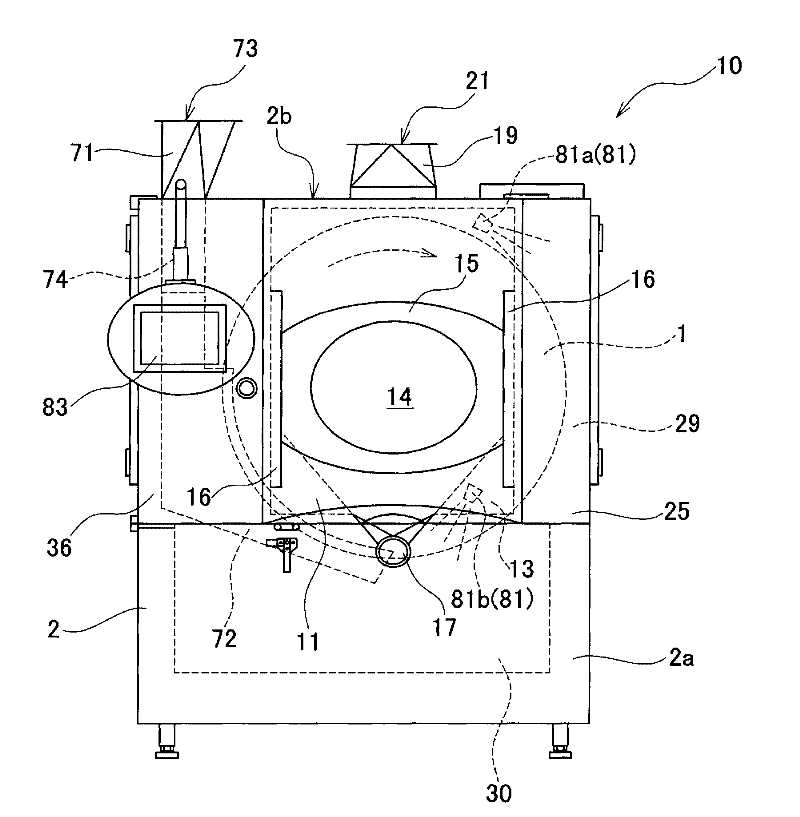

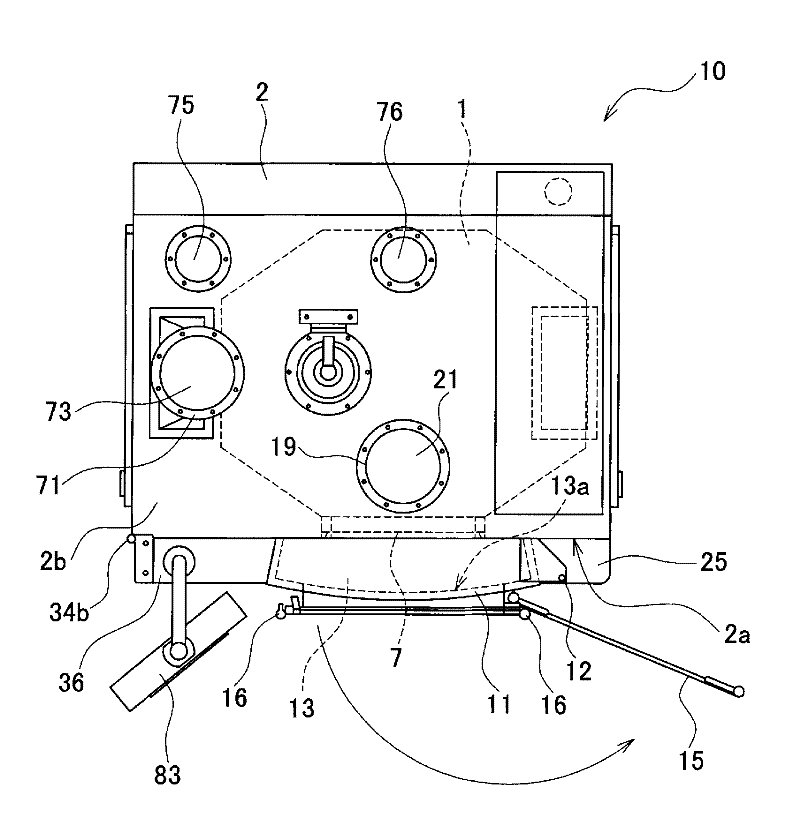

Pan coating device

ActiveCN102202778AReduce cleanup workloadReduce flow rateMaterial granulation and coatingLiquid surface applicatorsStable stateRotational axis

In a pan coating device (10) provided with a rotating drum (1) which rotates about a horizontal rotational axis line (O), an air supply chamber (13) with a larger cross-sectional area than that of an opening (7) in the front surface of the rotating drum is provided at the preceding stage of the opening (7). The air supply chamber (13) is formed inside a chamber door (11) attached to the front of a housing (2) with one end thereof communicating with the opening (7) and the other end thereof connected to an air supply duct (19) via an air supply hole (18). Air flowing into the air supply chamber (13) from the air supply duct (19) is reduced in flow velocity in the air supply chamber (13) and supplied from the opening (7) into the rotating drum (1) with the current thereof in a stable state.

Owner:FREUNT IND

Preparation of a quartz glass body in a standing sinter crucible

The invention relates to a process for the preparation of a quartz glass body comprising the process steps i.) Providing a silicon dioxide granulate, ii.) Making a glass melt out of silicon dioxide granulate in an oven and iii.) Making a quartz glass body out of at least part of the glass melt, wherein the oven comprises a standing sinter crucible. The invention further relates to a quartz glass body which is obtainable by this process. The invention further relates to a light guide, an illuminant and a formed body, which are each obtainable by further processing of the quartz glass body.

Owner:HERAEUS QUARZGLAS

Direct coating solid dosage forms using powdered materials

The present invention provides a method and apparatus for dry coating solid dosage forms. The method includes the steps of placing solid dosage forms in a rotatable, electrically grounded housing, and spraying a film forming polymer powder composition into the housing during rotation thereof to form a polymer coating on the solid dosage forms, the polymer powder composition being sprayed using an electrostatic spray gun, and curing the coated solid dosage forms.

Owner:WESTERN ONTARIO THE UNIV OF +1

Oscillating granulator

InactiveCN105107422AImprove work efficiencyReduce noiseGranulation in rotating drumsGranulation by material expressionBiochemical engineering

The invention discloses an oscillating granulator, which includes: a base, a machine body, a motor, a roller, and a hopper. The base is the supporting platform of the oscillating granulator, the machine body is arranged on the base, the hopper is in the form of a funnel structure, the upper end is provided with a feed inlet, the lower end is provided with a grain outlet, the middle is the roller, the roller is a powder scraping component of material, the roller is equipped with a powder scraping plate, and a roller rotation shaft is arranged in the middle of the roller. The work efficiency of the oscillating granulator provided by the invention is greatly enhanced, a stationary ring and a movable ring are combined for sealing, the seal ring is arranged to avoid pollution of materials by the external environment, and the purity of drugs is improved.

Owner:太仓市友联干燥粉碎设备有限公司

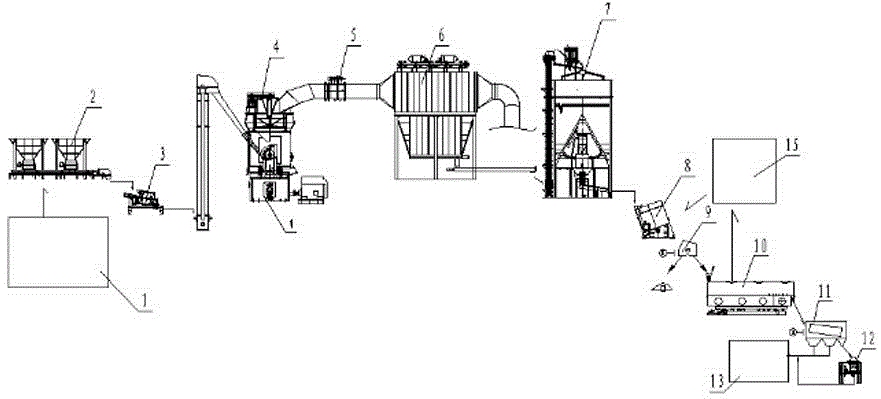

Ceramic raw material dry method granulation production line and production technology

InactiveCN105478056AImprove uniformityImprove pass rateSievingScreeningProduction lineFluidized bed drying

The invention relates to a ceramic raw material dry method granulation production line and a production technology. The production line orderly comprises a raw material field, a raw material bin, a grinding mechanism, a granulation mechanism, a drying mechanism and a screening mechanism. A mixer is arranged between a discharge outlet of the raw material bin and a feeding inlet of the grinding mechanism. A discharge outlet of the grinding mechanism is connected to a dust collector through a powder iron separator. An output end of the dust collector is connected to a powder homogenization mechanism. The powder iron separator is an iron separator with at least two rotary iron separation channels. A feeding end of a reciprocating type fluidized bed dryer is provided with a distributing device. The lower end of the distributing device is provided with an airlock. A ventilation partition plate is arranged in a blast chamber. The blast chamber is divided into a drying zone and a cooling zone through the ventilation partition plate. The screening mechanism is a rotary screen with a demountable screen. The production technology has a high one-step granulation qualified rate, a low production cost and good drying effects.

Owner:SHANDONG ECON ENERGY SAVING TECH

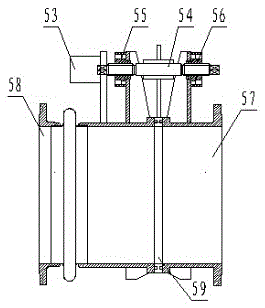

Anti-caking device of drum granulator

InactiveCN104174329AAvoid corrosionClumping in real timeGranulation in rotating drumsFertiliser formsPulp and paper industryCorrosion

The invention discloses an anti-caking device of a drum granulator, relates to the technical field of drum granulators, and aims at solving the problem that a large quantity of chemical fertilizer raw materials are easily clung to the inner wall of a roller after getting damp when a drum granulator is used for fabricating chemical fertilizer particles in the prior art, so that the production efficiency is improved and the corrosion of the chemical fertilizer materials to the roller is reduced. According to the anti-caking device of the drum granulator, disclosed by the invention, a screw rotates to drive a screw nut to move in the rotating process of the roller, so that a scraper blade is driven to move along the axis of the roller, so that the chemical fertilizer raw materials on the inner wall of the roller are scraped in real time, the chemical fertilizer raw materials are prevented from caking on the inner wall of the roller for a long period of time, the high production efficiency is ensured, and the corrosion of the chemical fertilizer raw materials to the roller is prevented.

Owner:JINAN BADUN FERTILIZER

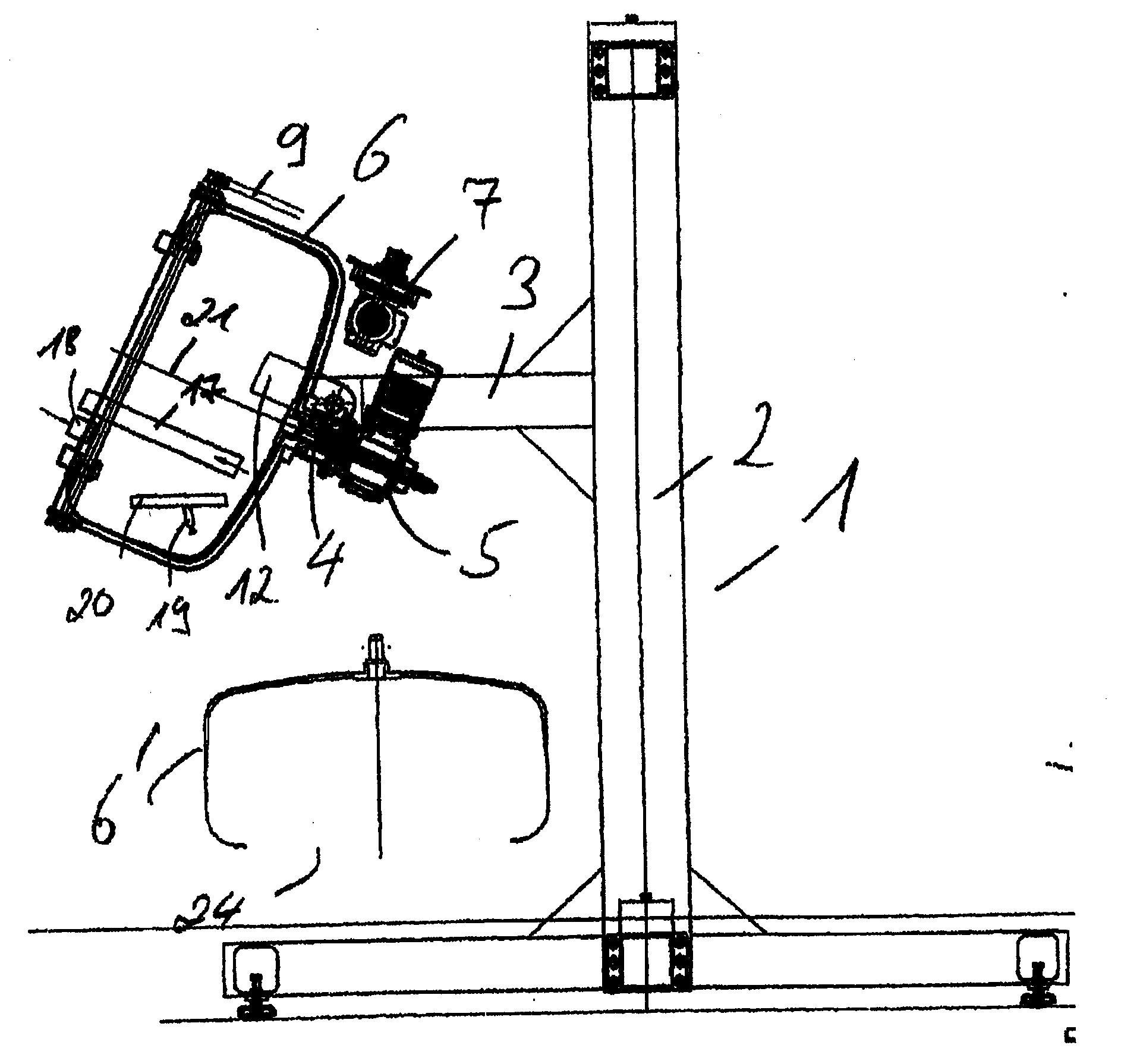

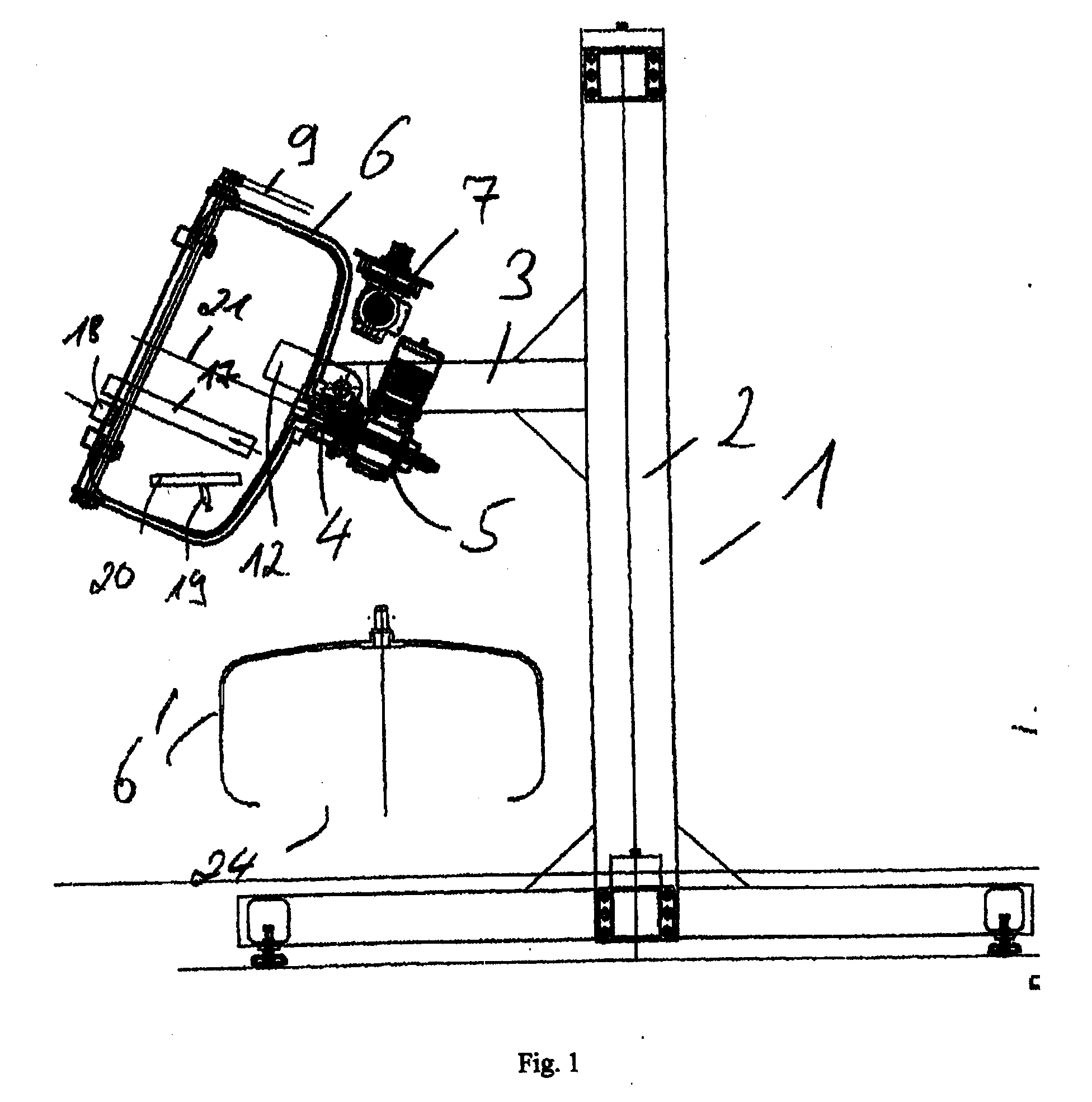

Turbine Coating Apparatus And Spray Gun Assembly Therefor

The present invention generally relates to a turbine coating apparatus and a spray gun assembly therefor. More specifically, the present invention relates to a spray gun assembly comprising a gun support mountable to the turbine coating apparatus and at least one spray gun mounted to the gun support. The spray gun is adapted for providing a spray of a coating substance onto a cluster of solid forms to be coated in the apparatus, where the spray defines a spray angle of less than 90 degrees relative to the coating plane defined by the cluster of solid forms in movement.

Owner:JACQUES WILFRID +1

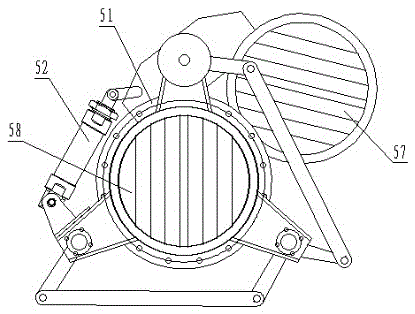

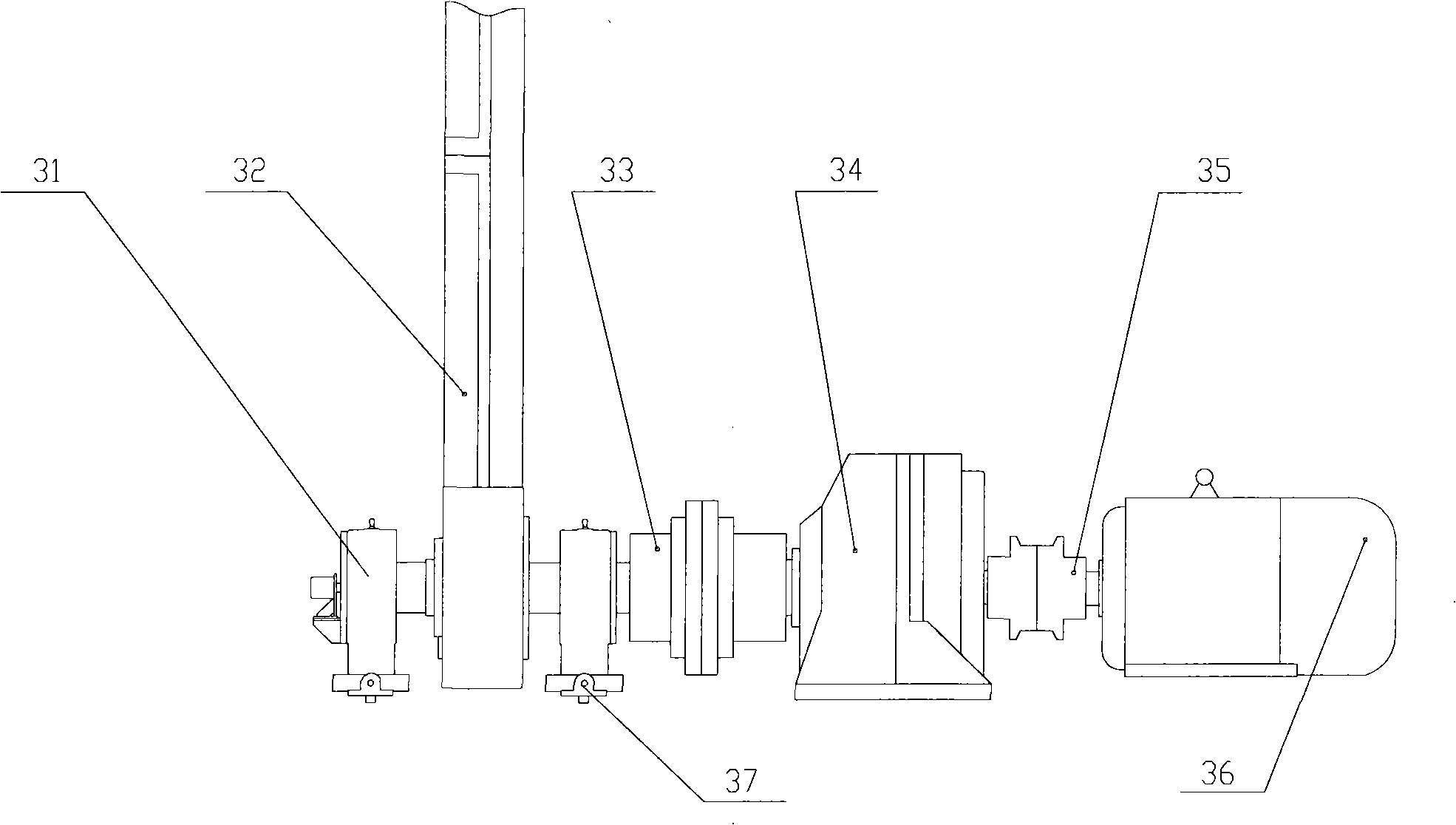

Molecular sieve granulator

InactiveCN101357311AImprove ball forming efficiencyExtend your lifeGranulation in rotating drumsMolecular sieveSprayer

The invention discloses a molecular sieve granulator which comprises a power transmission part, a cylinder part, a screw conveyer, a rake part and a water sprayer; wherein, the power transmission part is connected with the cylinder part, and the screw conveyer, the rake part and the water sprayer are arranged in the cylinder part. The granulator is provided with the screw conveyer which can realize uniform feeding without clogging, a spraying system of adjustable flow which is convenient for controlling the humidity of a molecular sieve, and a rake device which can realize automatic material stirring, thus realizing continuous operation of the device, and the yield is high. The product of the molecular sieve of the invention can be applied to chemical oxygen production and molecular adsorption filtration, and can be widely applied to industrial processes such as gas preparation, filtration of harmful gases, etc.

Owner:SHANGHAI HEAVY MACHINERY PLANT

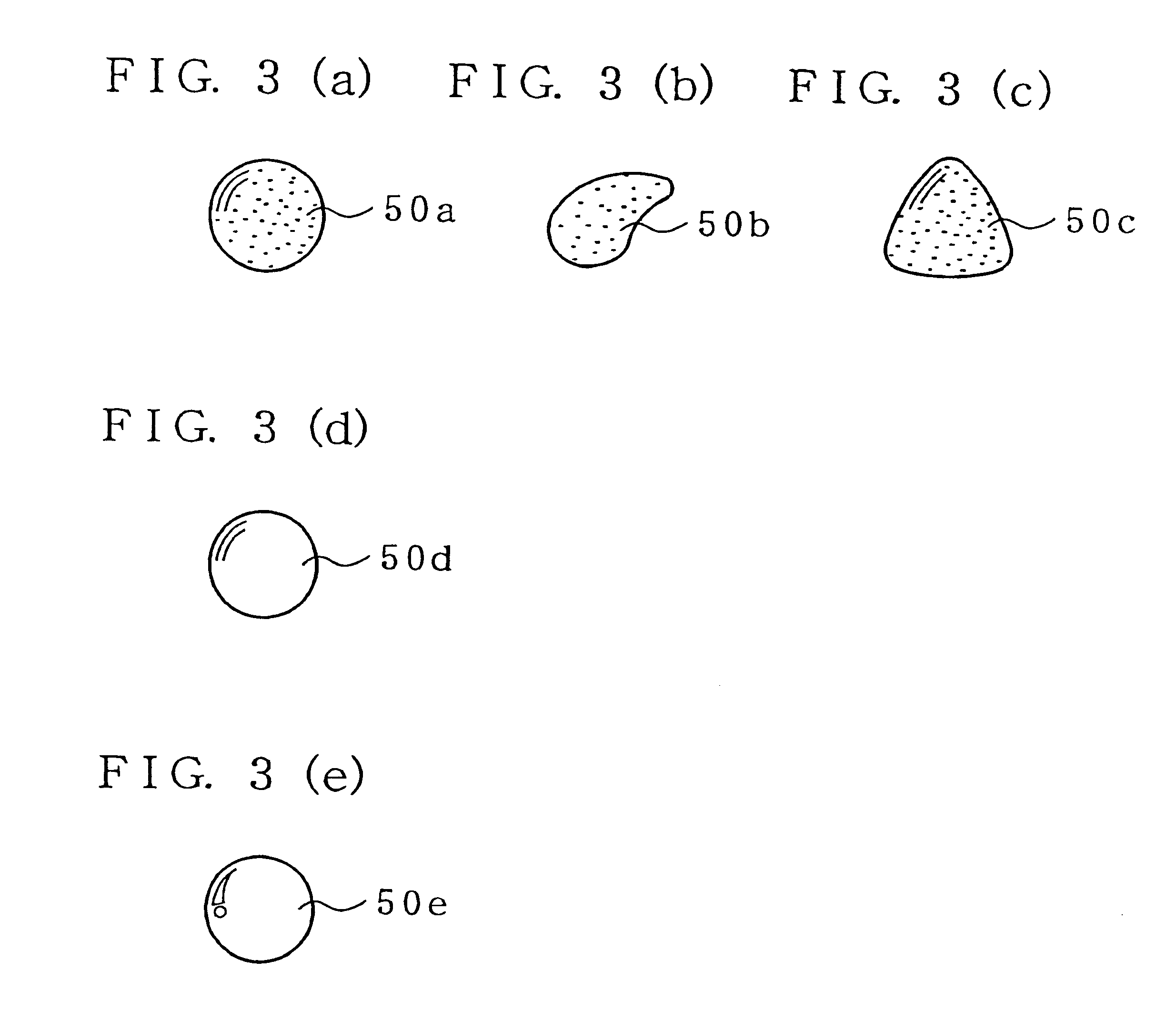

Method of manufacturing spherical bodies by rotation, spherical bodies made by the method and a powder composition for use in the method

InactiveUS6464906B1Low costInexpensive and efficient to manufactureNitrogen compoundsShaftsSolventSpherical form

A method of making spherical bodies from powder, which comprises (1) preparing an adjusted powder so as to have at least one powder characteristic selected from the group consisting of an average particle size, a powder particle size distribution and a BET specific surface area, (2) preparing nuclei having a particle size larger than that of the adjusted powder, (3) rotating the nuclei, and (4) adding the adjusted powder and a solvent to the rotating nuclei so that particles of the adjusted powder accumulate on the nuclei to form granular bodies. Also disclosed is a spherical body having a core or nucleus formed in the spherical body, an adjusted powder composition for forming a spherical body, and a method for manufacturing spherical sintered bodies of silicon nitride.

Owner:NGK SPARK PLUG CO LTD

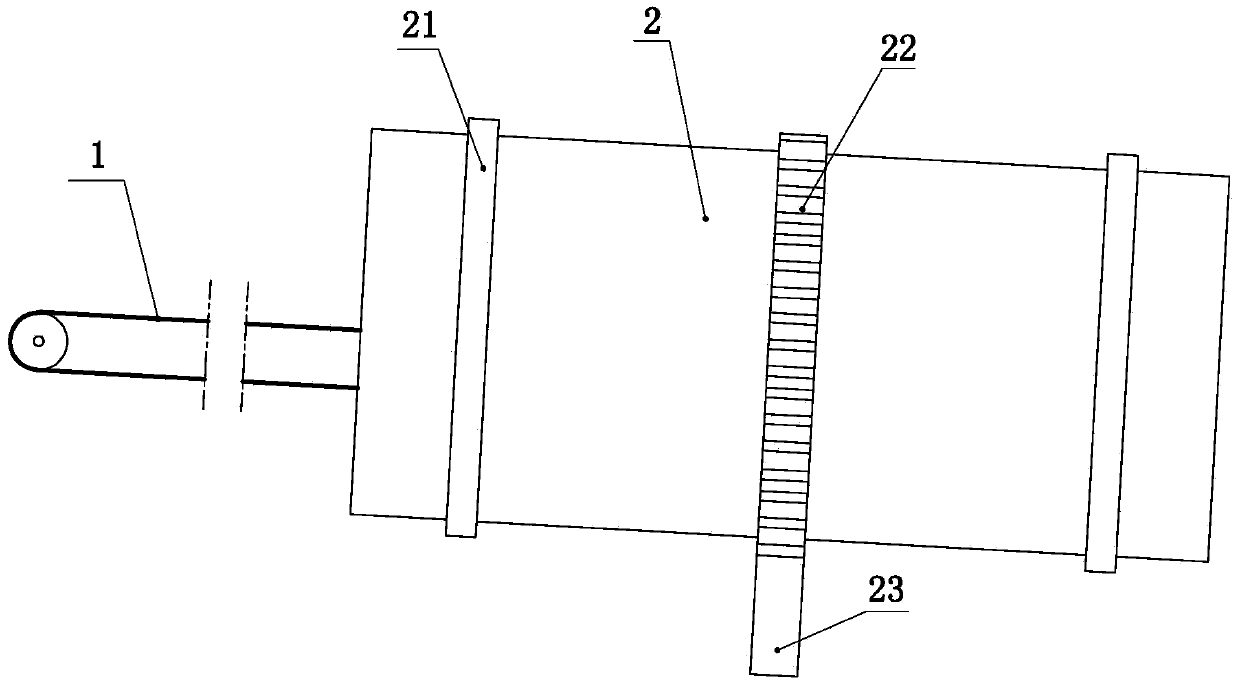

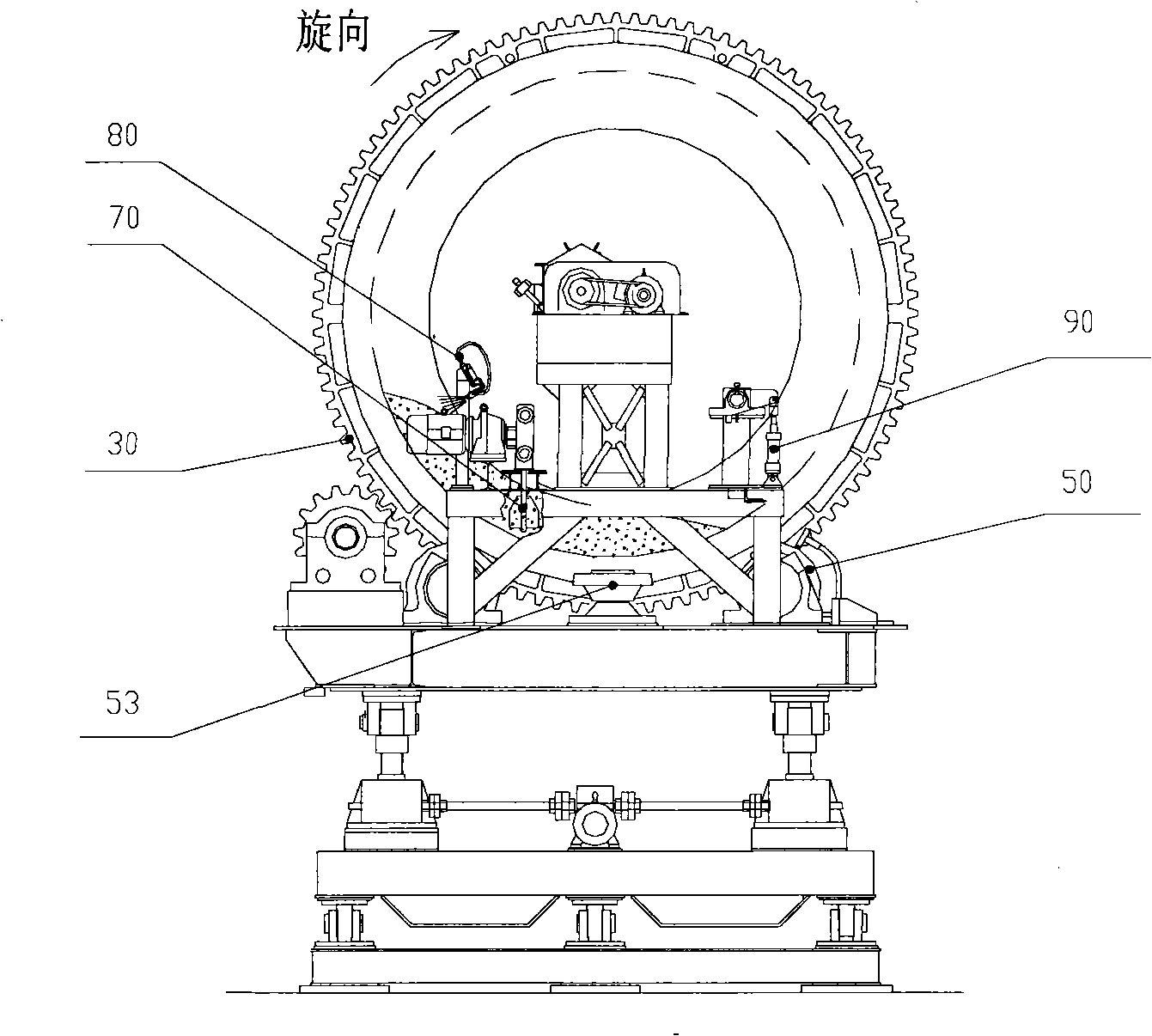

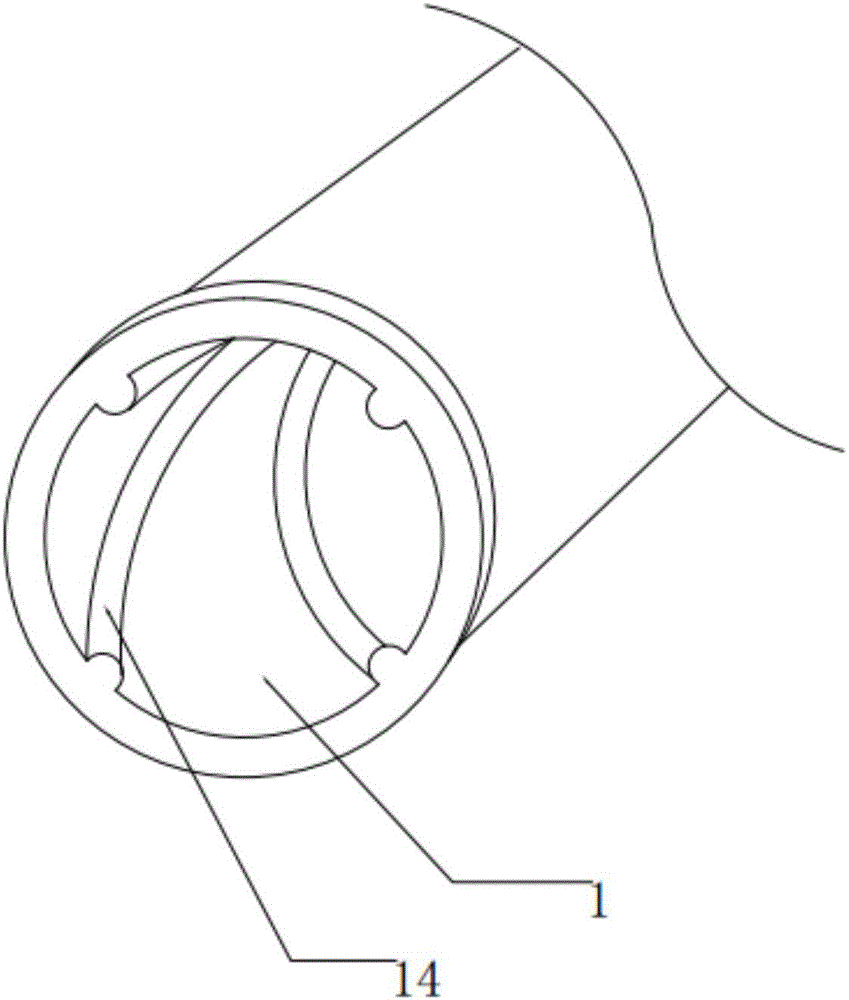

Roller pelletizer for producing controlled-release compound fertilizer with ammonia-acid method

InactiveCN106311076AAvoid stickingImprove liquidityGranulation in rotating drumsGranulation using vibrationEngineeringDrive motor

The invention provides a roller pelletizer for producing a controlled-release compound fertilizer with an ammonia-acid method. The roller pelletizer comprises a roller, a driven gear arranged on the outer wall of the roller and a driving gear connected onto the output shaft of a driving motor, wherein a charging hole is formed in one end of the roller, and a steam distribution pipe and an ammonia-acid tubular reactor are arranged at the other end of the roller; the roller is internally provided with a pelleting lining, the pelletinglining is internally provided with an air blowing pipeline and a humidity sensor, and the humidity sensor is electrically connected with the controller; a silencing barrel is arranged on the outer side of the middle part of the roller, and the pelletizer is provided with multiple stages of anti-sticking structures: the first stage of anti-sticking structure comprises wavy bulges fixedly arranged in the pelleting lining; the second stage of anti-sticking structure comprises elastic raised lines uniformly distributed on the inner wall of the roller; the third stage of anti-sticking structure comprises convex blocks fixedly arranged on the outer side of two ends of thepelleting lining, vibrating drums are arranged at the corresponding positions above the convex blocks, and the vibrating drums are connected to a hydraulic driving mechanism. The roller pelletizer adopts the multiple stages of anti-sticking structures, the fluidity of particles is improved, and simultaneously a self-adaptive humidity control system is formed, so that the product quality is improved.

Owner:天津亚泰昊德科技有限公司

High value organic-enhanced inorganic fertilizers

ActiveUS8992654B2Easy to containReduce and eliminate disagreeable odorCalcareous fertilisersBiocideSoil organic matterNitrogen

The invention is directed to manufacture of fertilizer having commercial levels of nitrogen supplemented with organic substances. The process treats organic matter with acid causing hydrolysis of organic polymers after which the mix is injected with nitrogen. The resultant sterilized and liquefied organic matter is disbursed over recycled material for the production of granules. Because the process allows for the controlled addition of acids and ammonia, desired levels of components can be achieved. The process is scalable, odor controlled and safe thereby allowing for the location of biosolid processing facilities in most any location. Further, the fertilizer of the invention provides a dual nitrogen-release profile when applied to crops. After application to soil, fertilizer of the invention releases an immediate bolus of nitrogen, similar to traditional ammonium sulfate, followed by continued slow release of nitrogen typically over a season.

Owner:GENERATE LENDING LLC +1

Method and Apparatus for Processing Powder and Method of Manufacturing Porous Granulated Substance

InactiveUS20070228201A1Effective controlLow thermal conductivitySolid waste disposalGranulation in rotating drumsEnergy supplyMaterials science

In order to manufacture the compound powder or the porous granulated substance in an efficient manner, a powder processing apparatus has an accumulating face on which the processing target powder is to be accumulated and a processing face disposed in opposition to the accumulating face and convexly curved, and a moving means for moving the accumulating face and the processing face along the accumulating face relative to each other. The apparatus comprises an excitement treatment means capable of applying an excitation energy to the processing target powder accumulated on the accumulating face from an excitation energy supplying portion disposed in opposition to the accumulating face or an oscillation means for oscillating the accumulating face or the processing face in a direction intersecting the accumulating face.

Owner:HOSOKAWA MICRON CORP

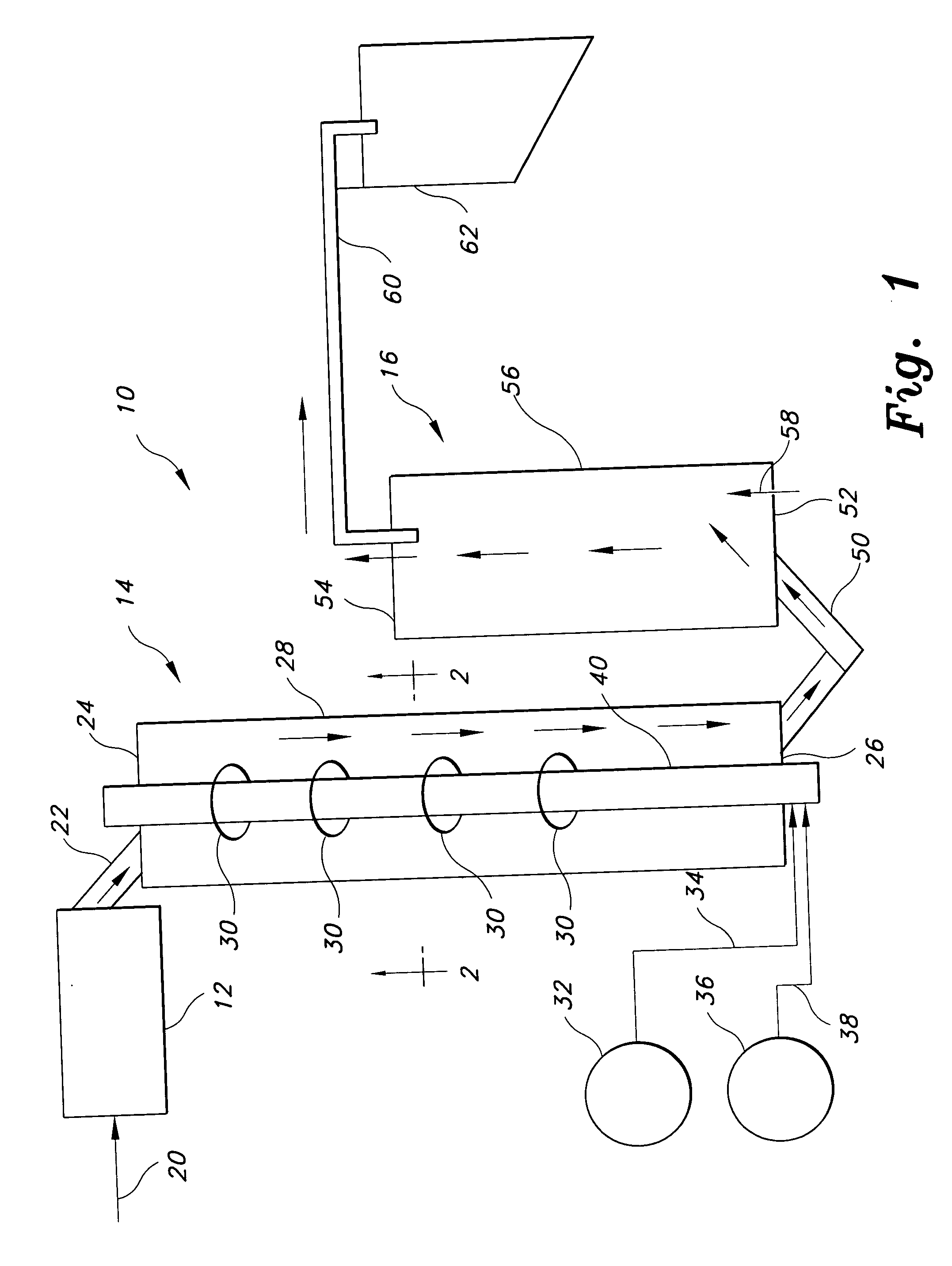

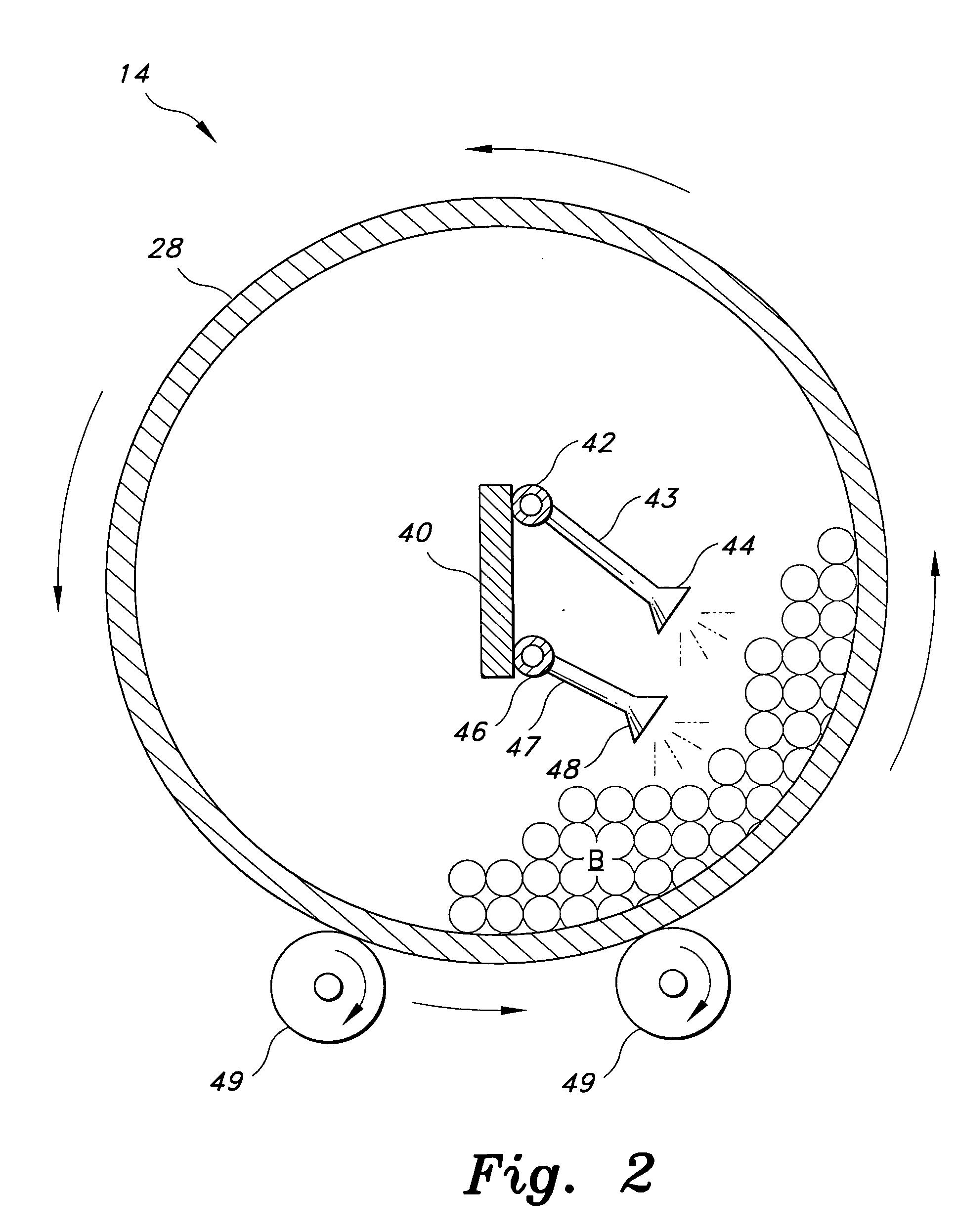

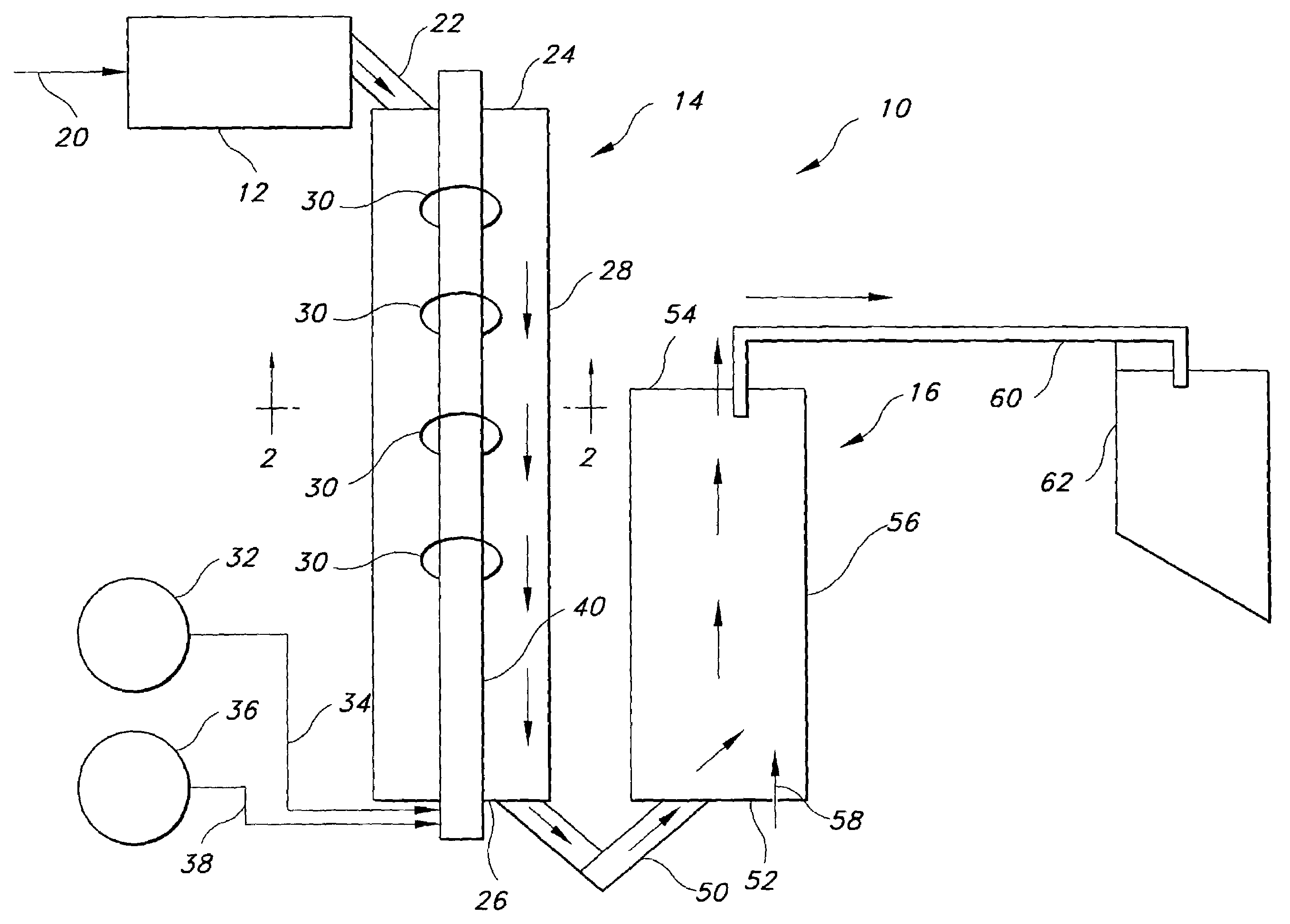

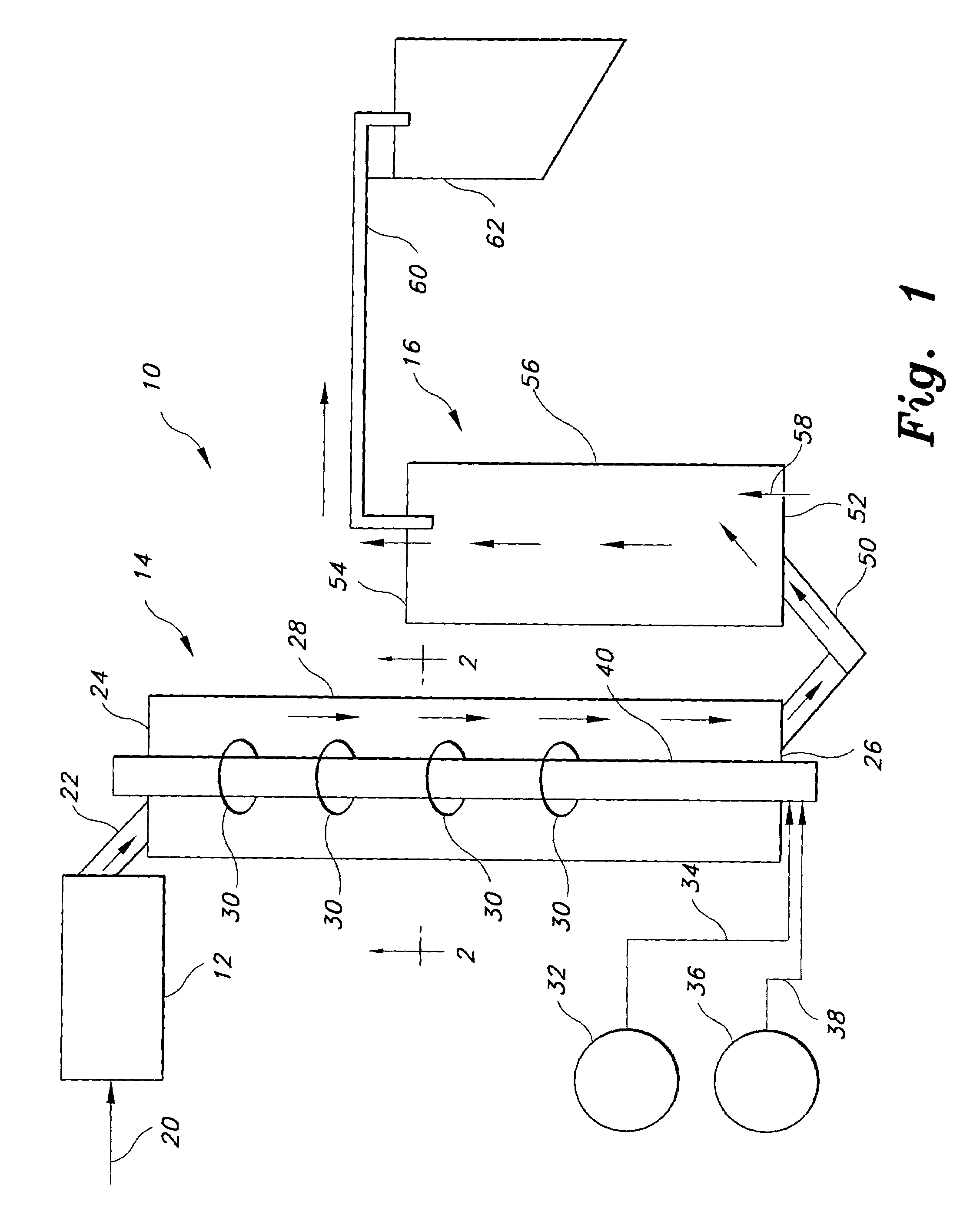

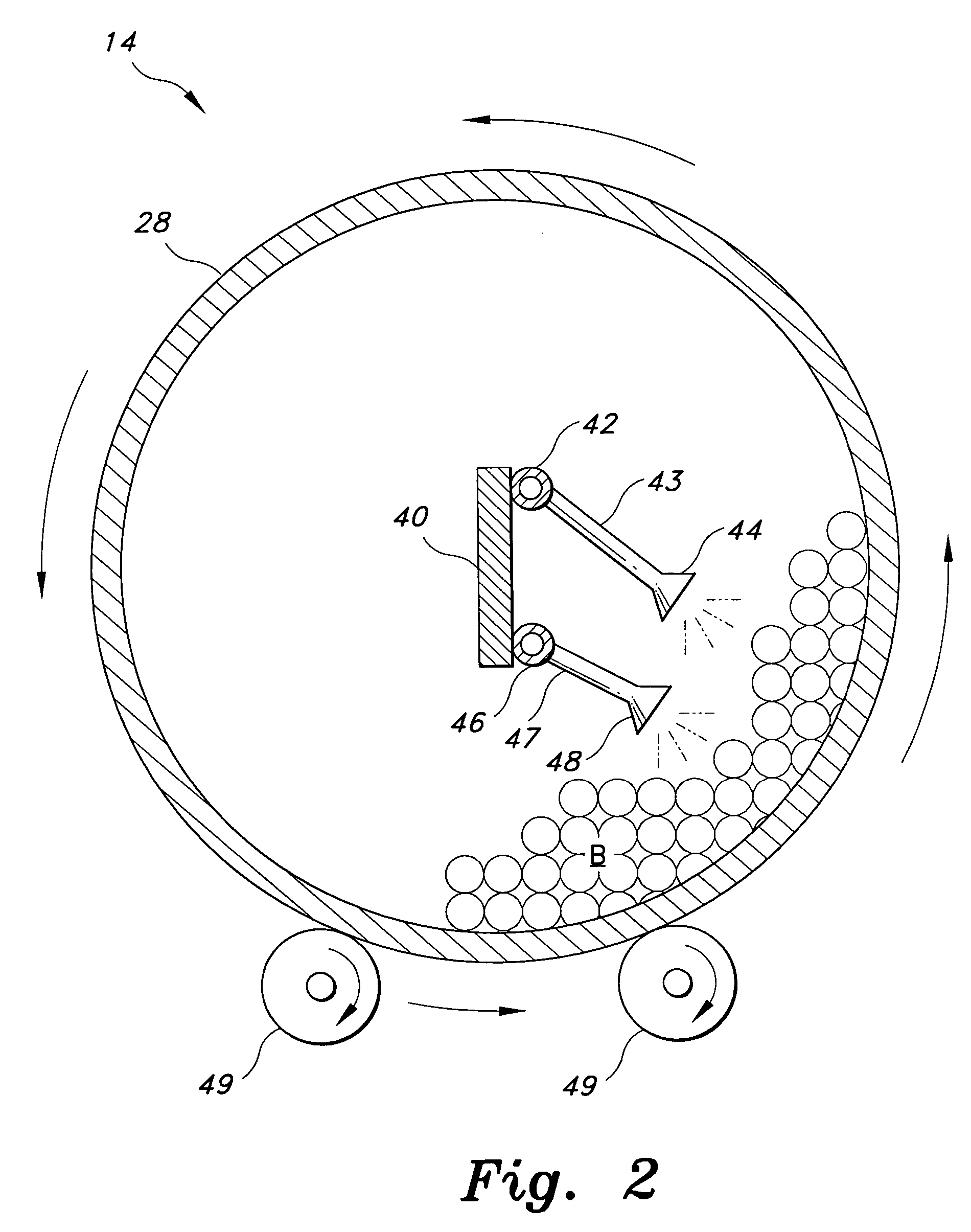

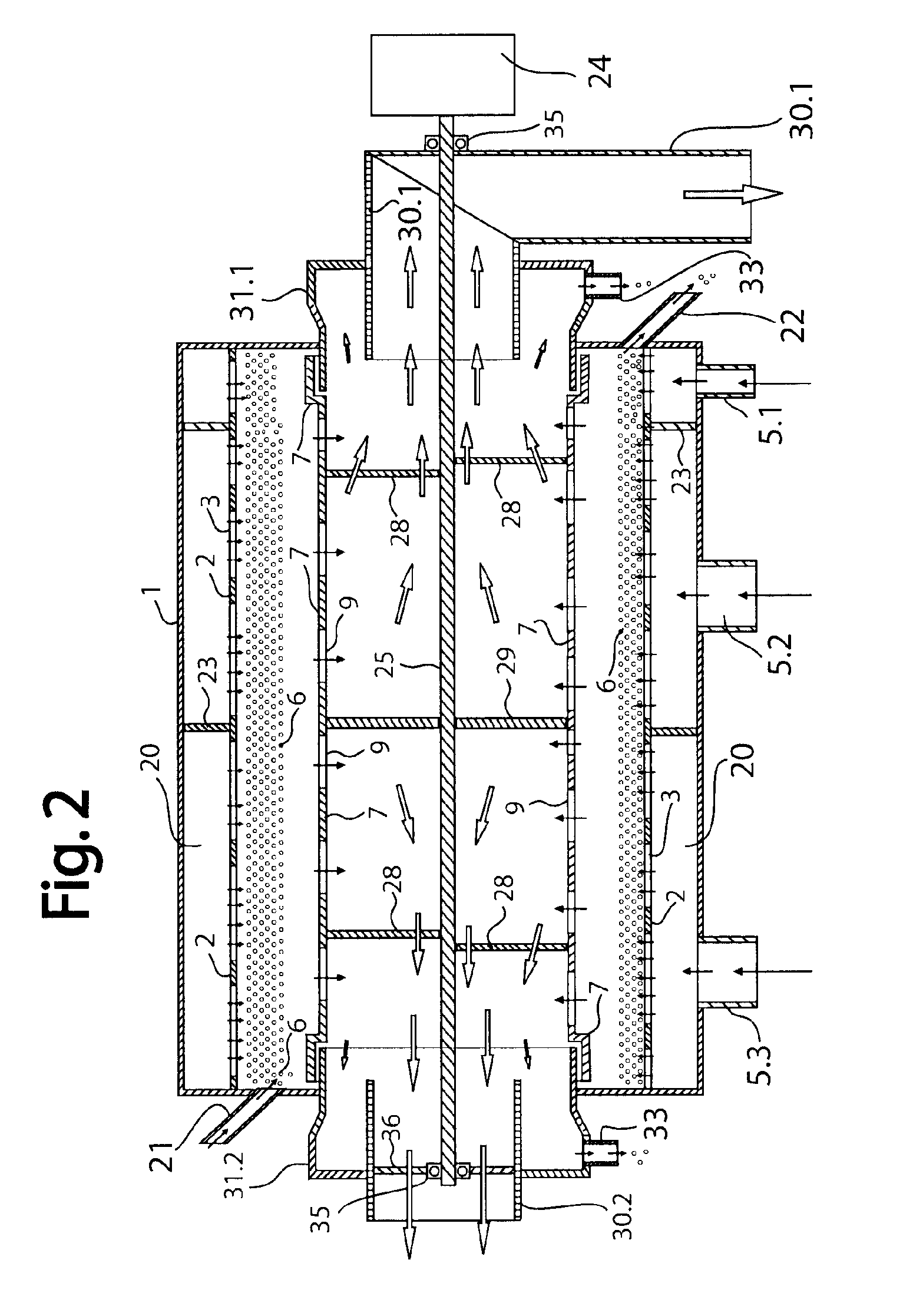

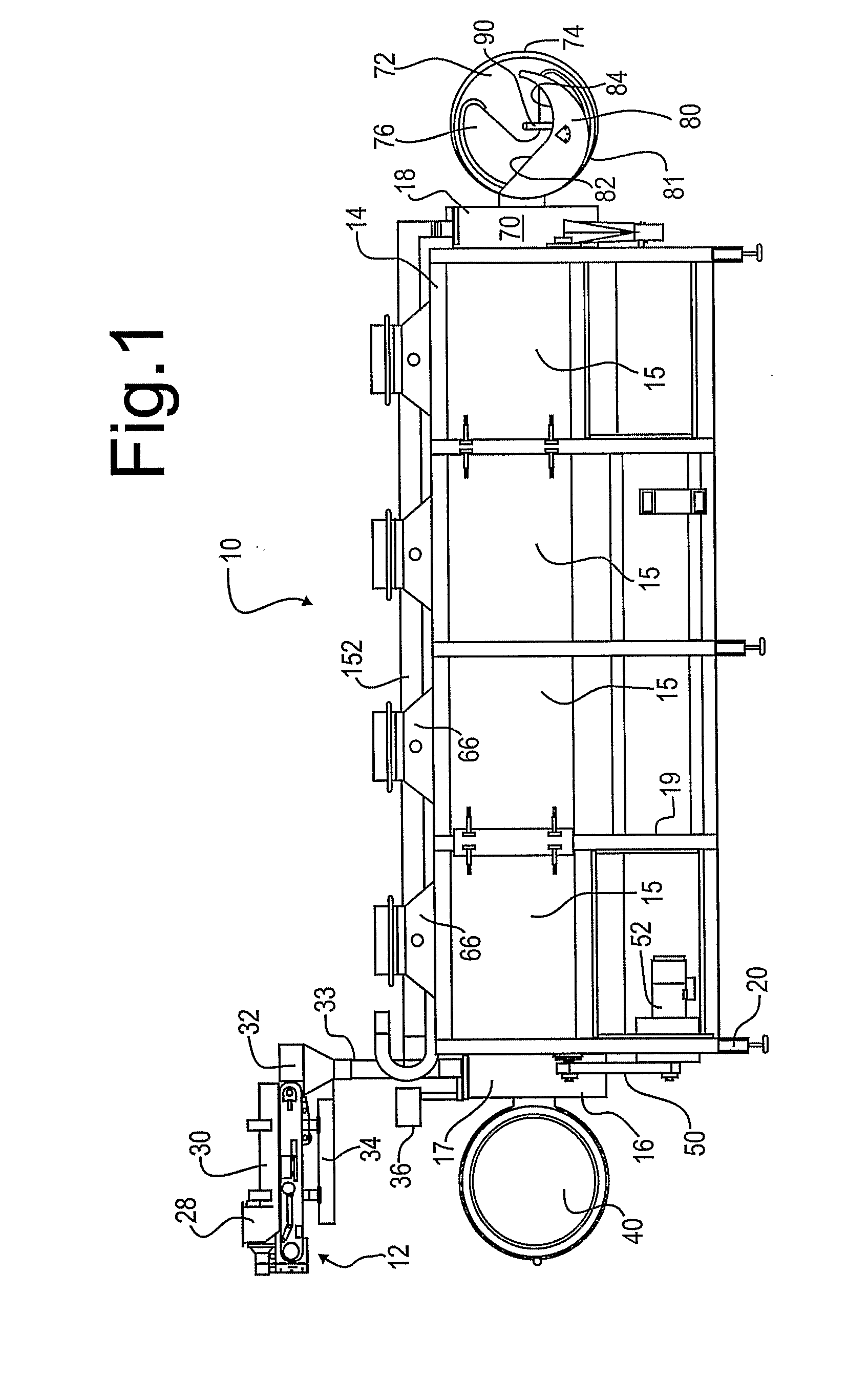

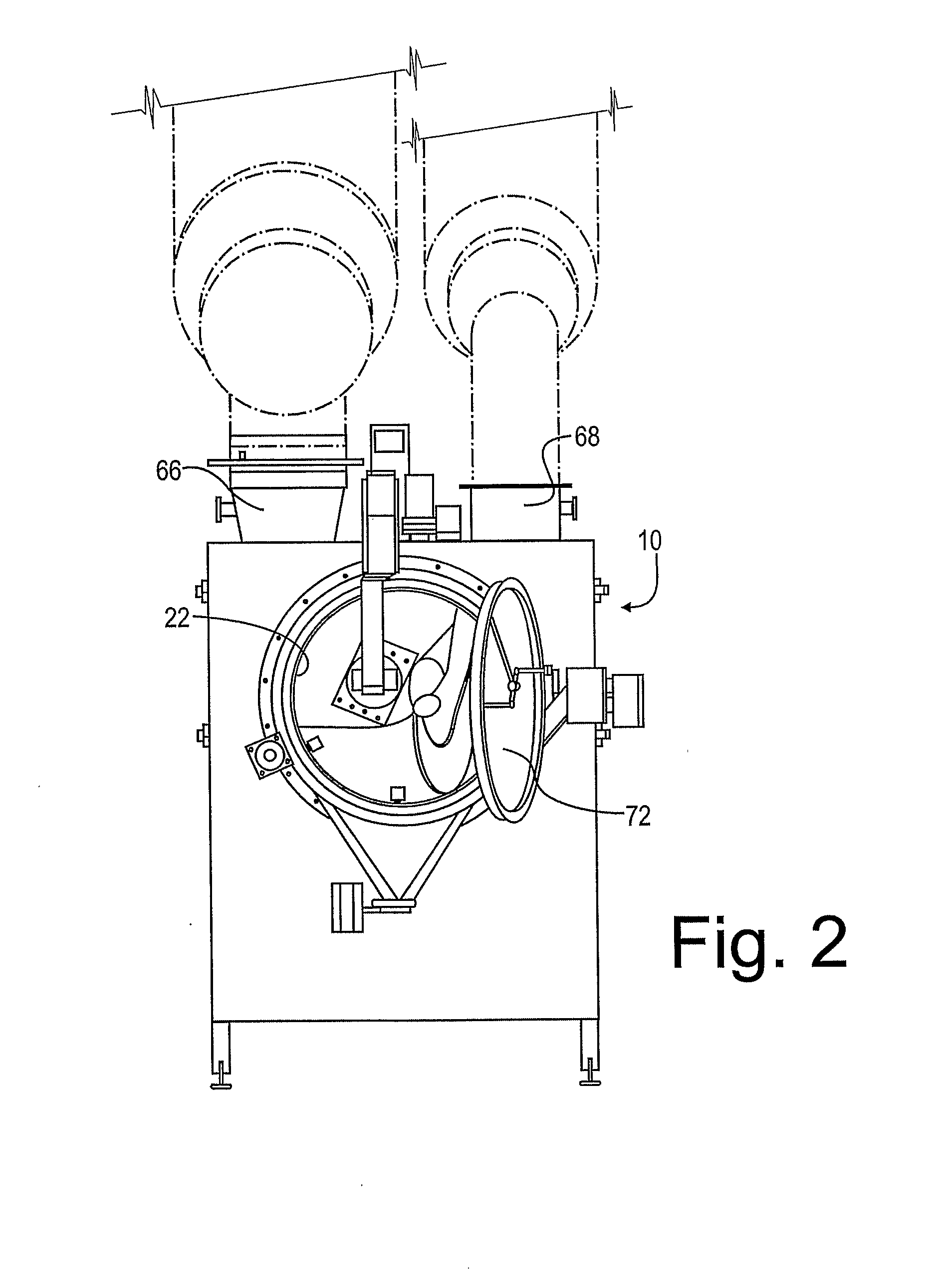

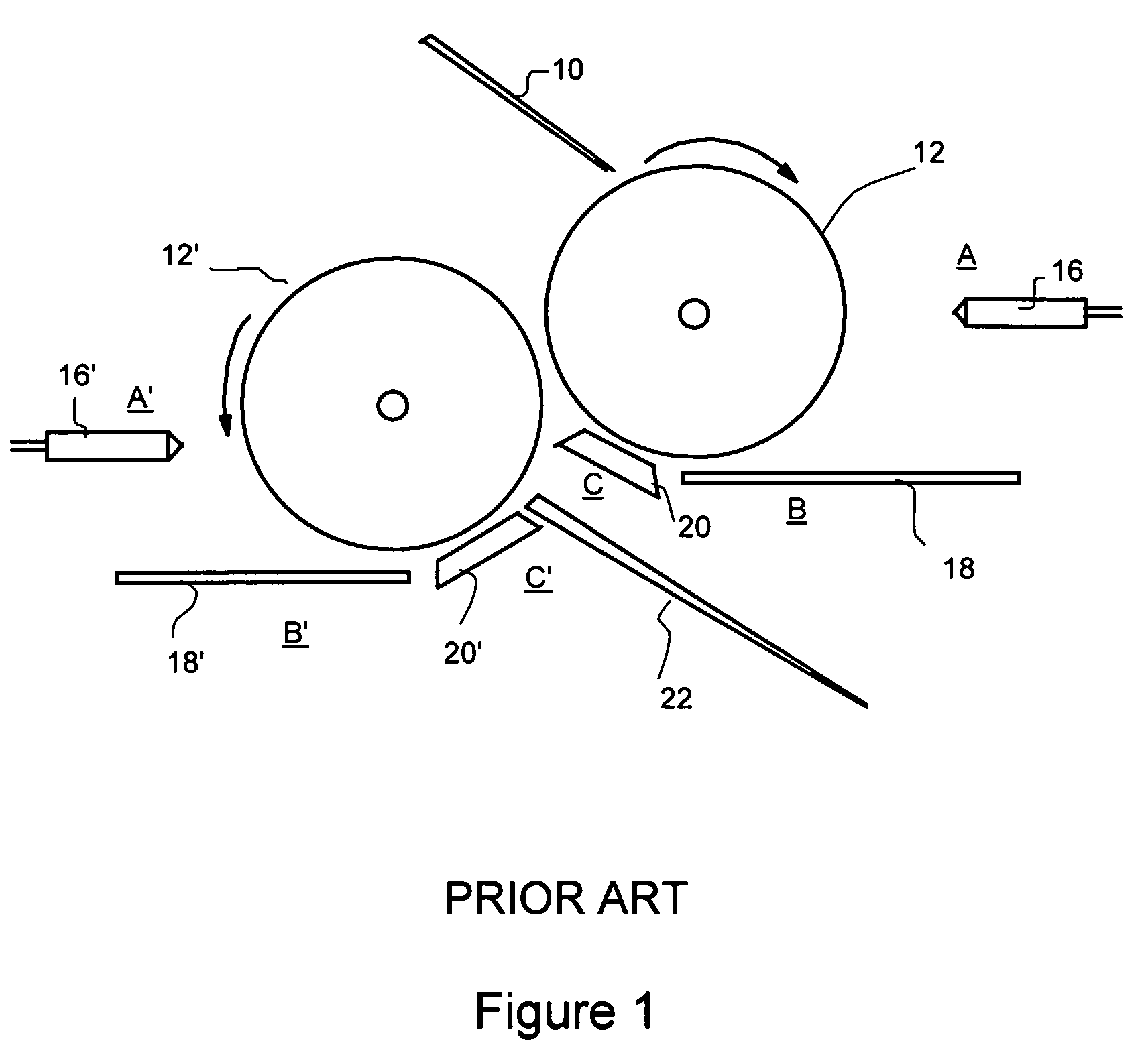

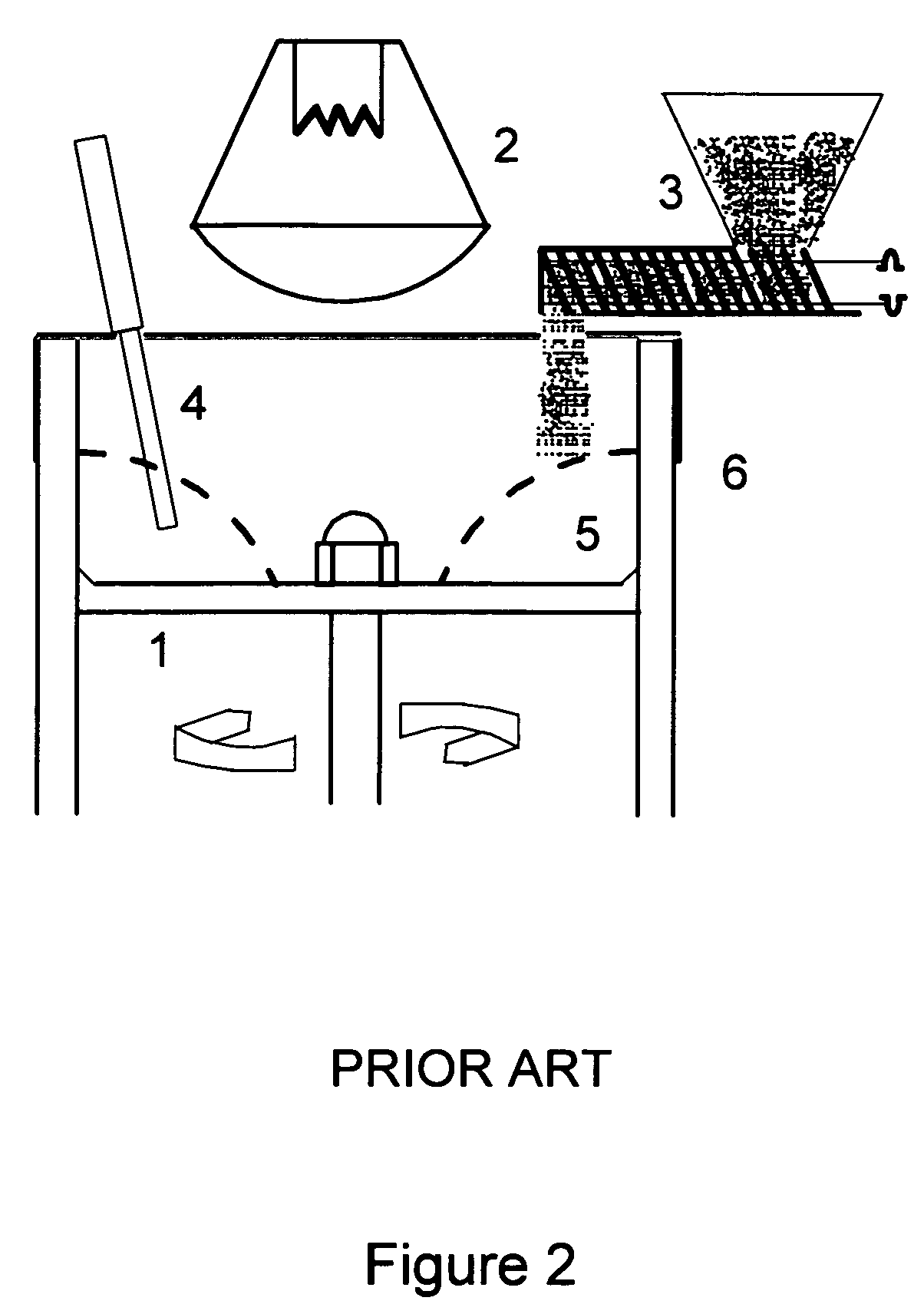

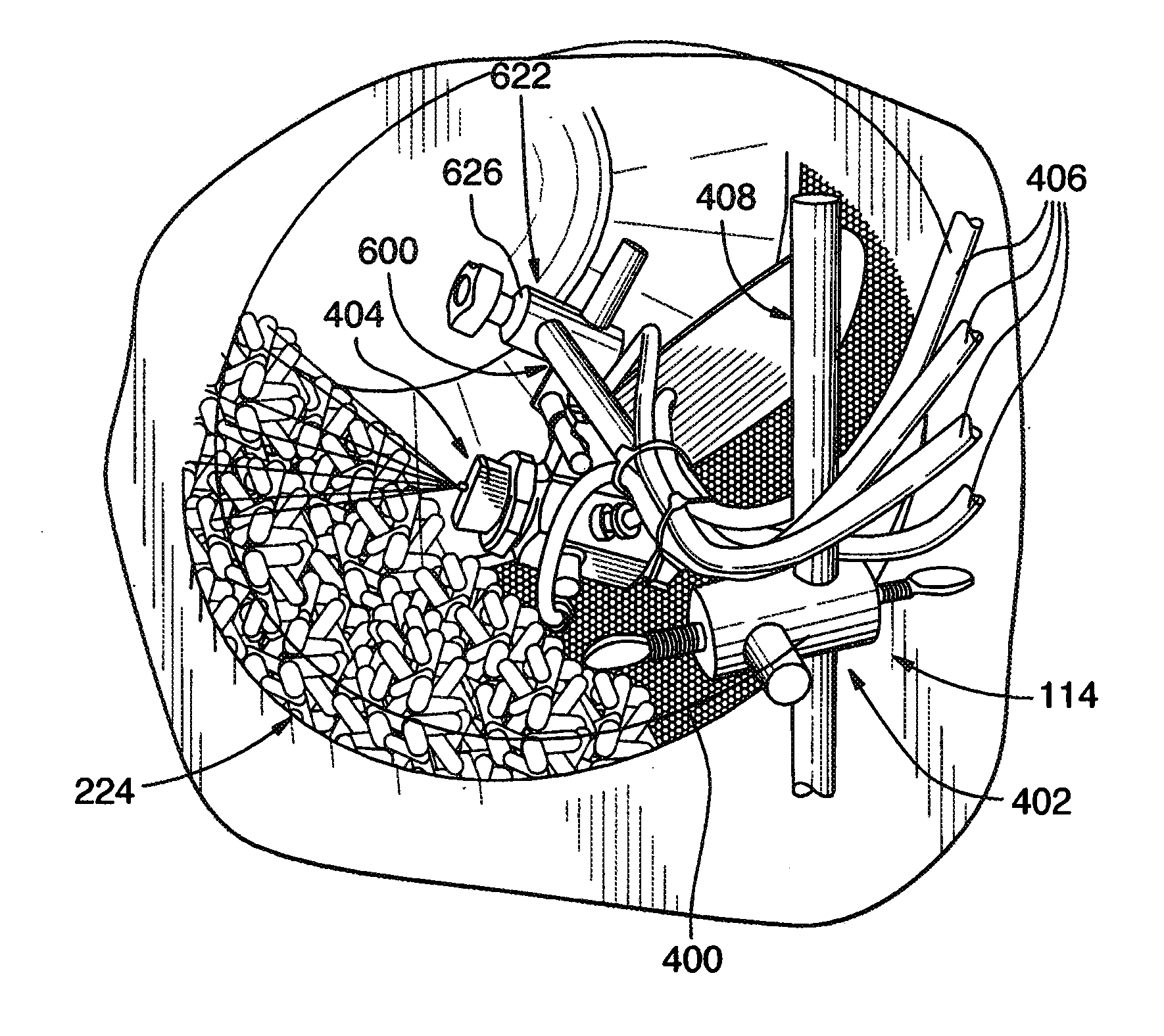

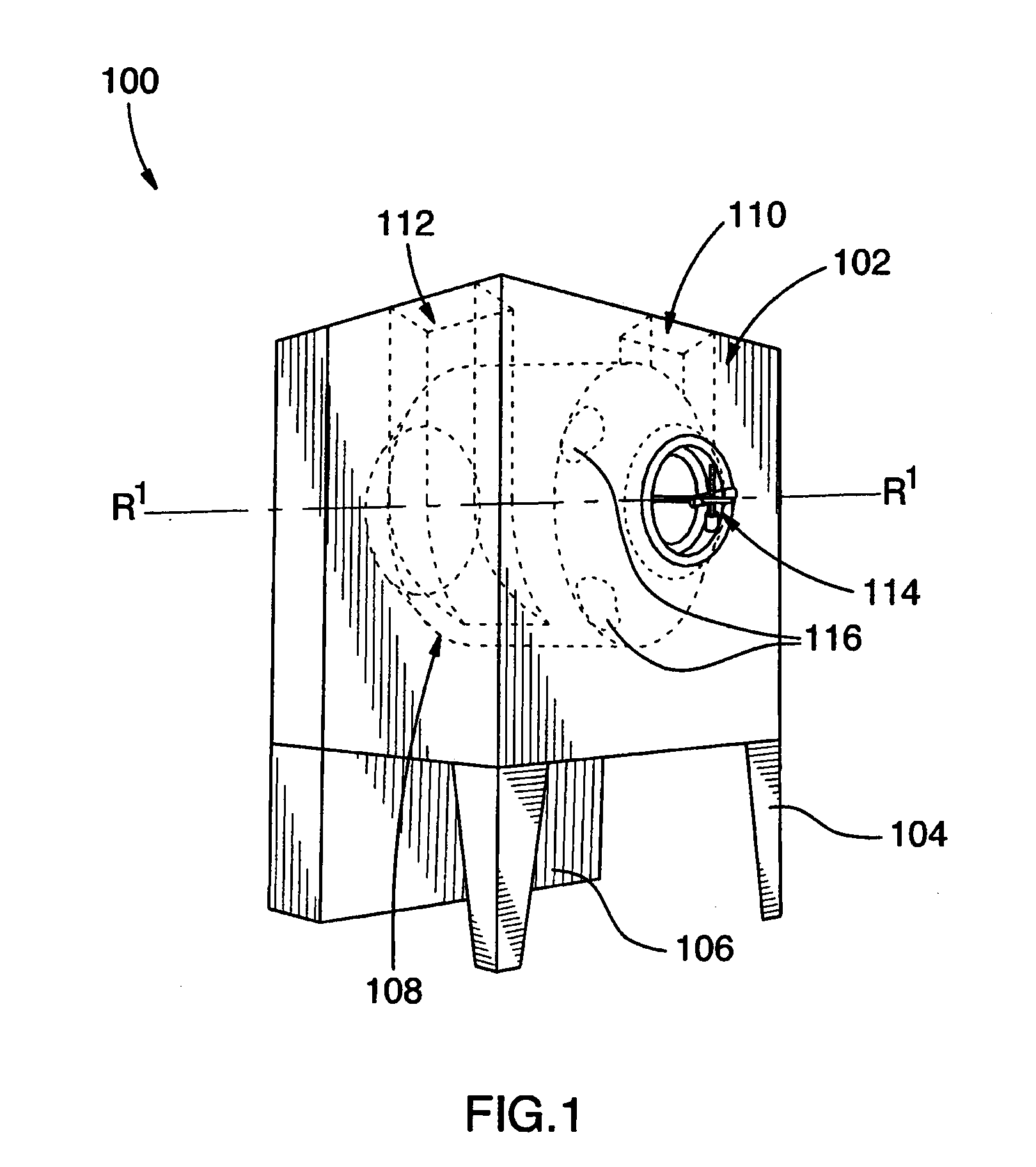

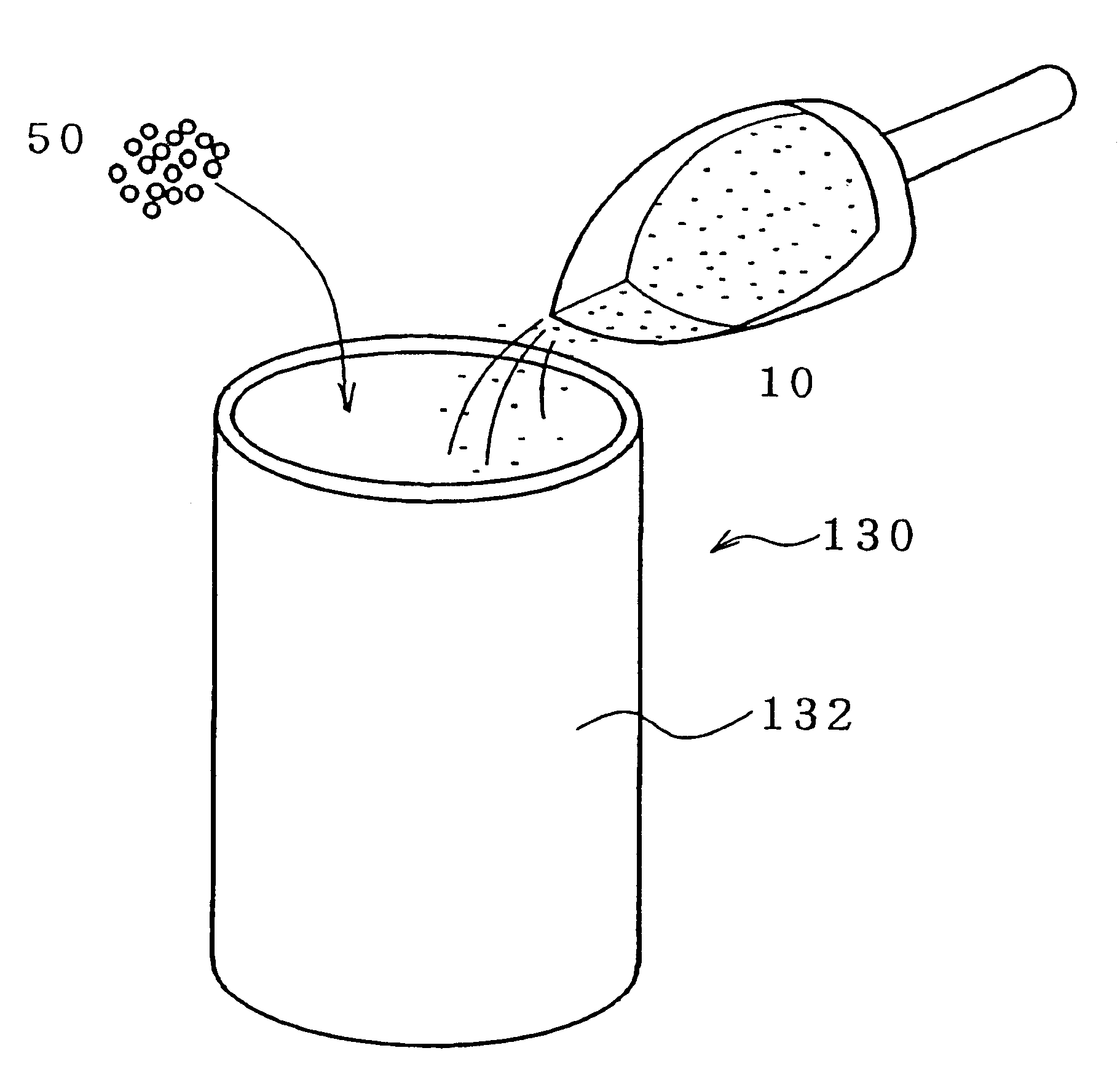

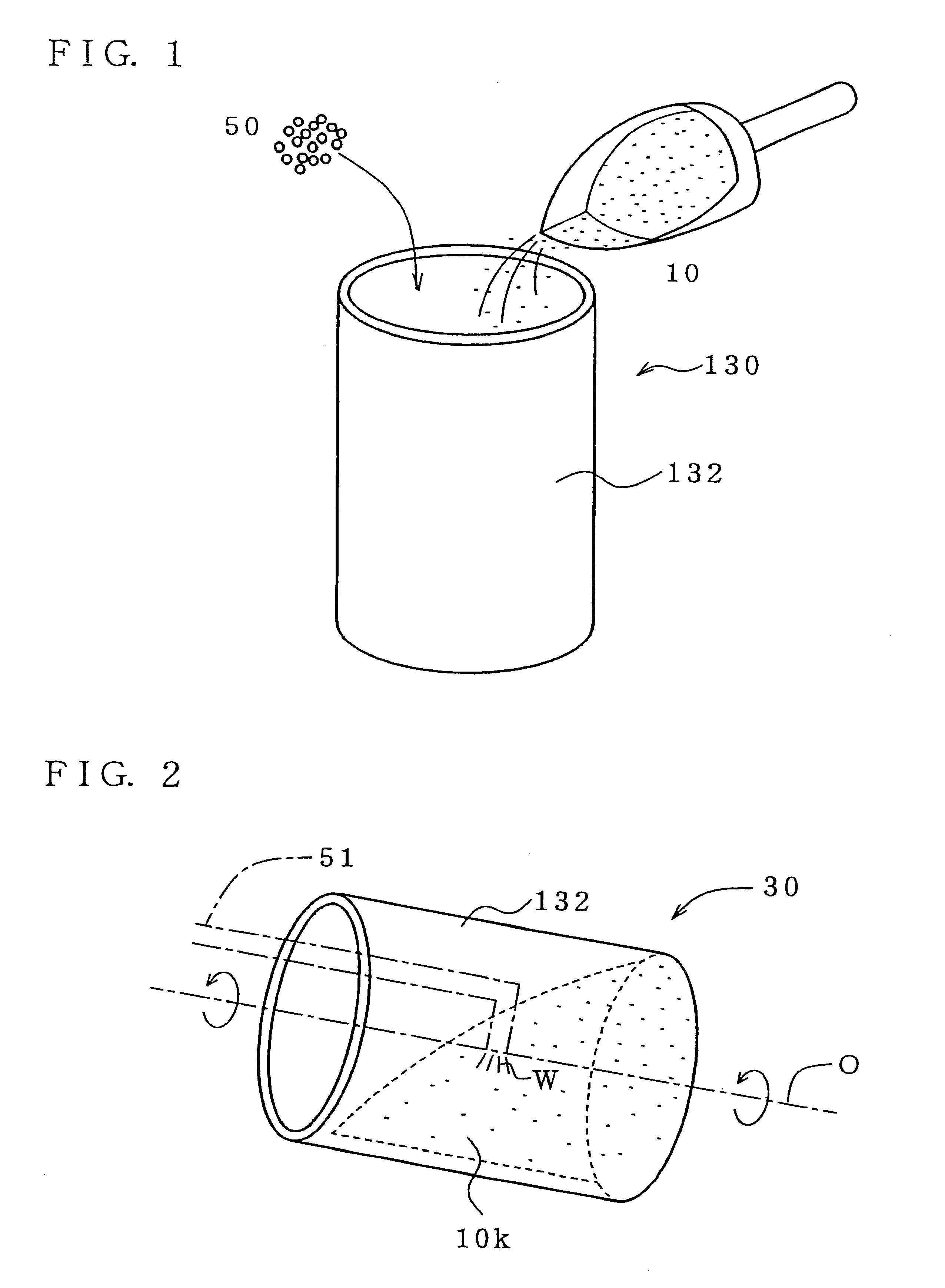

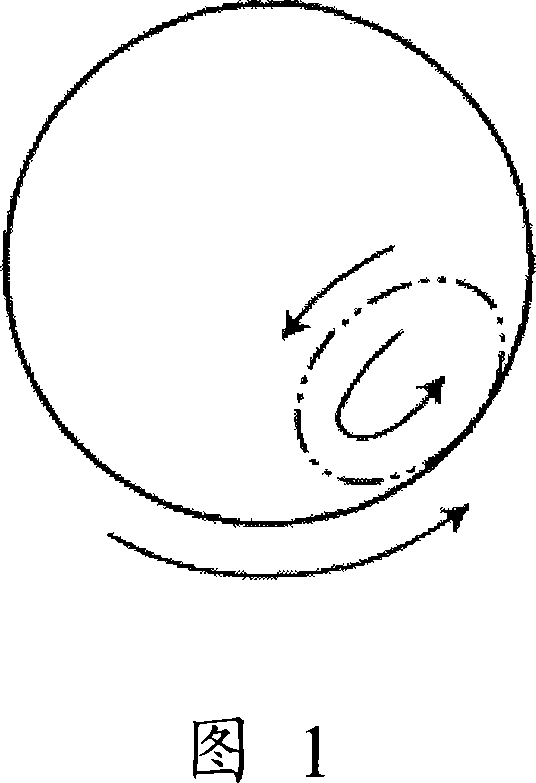

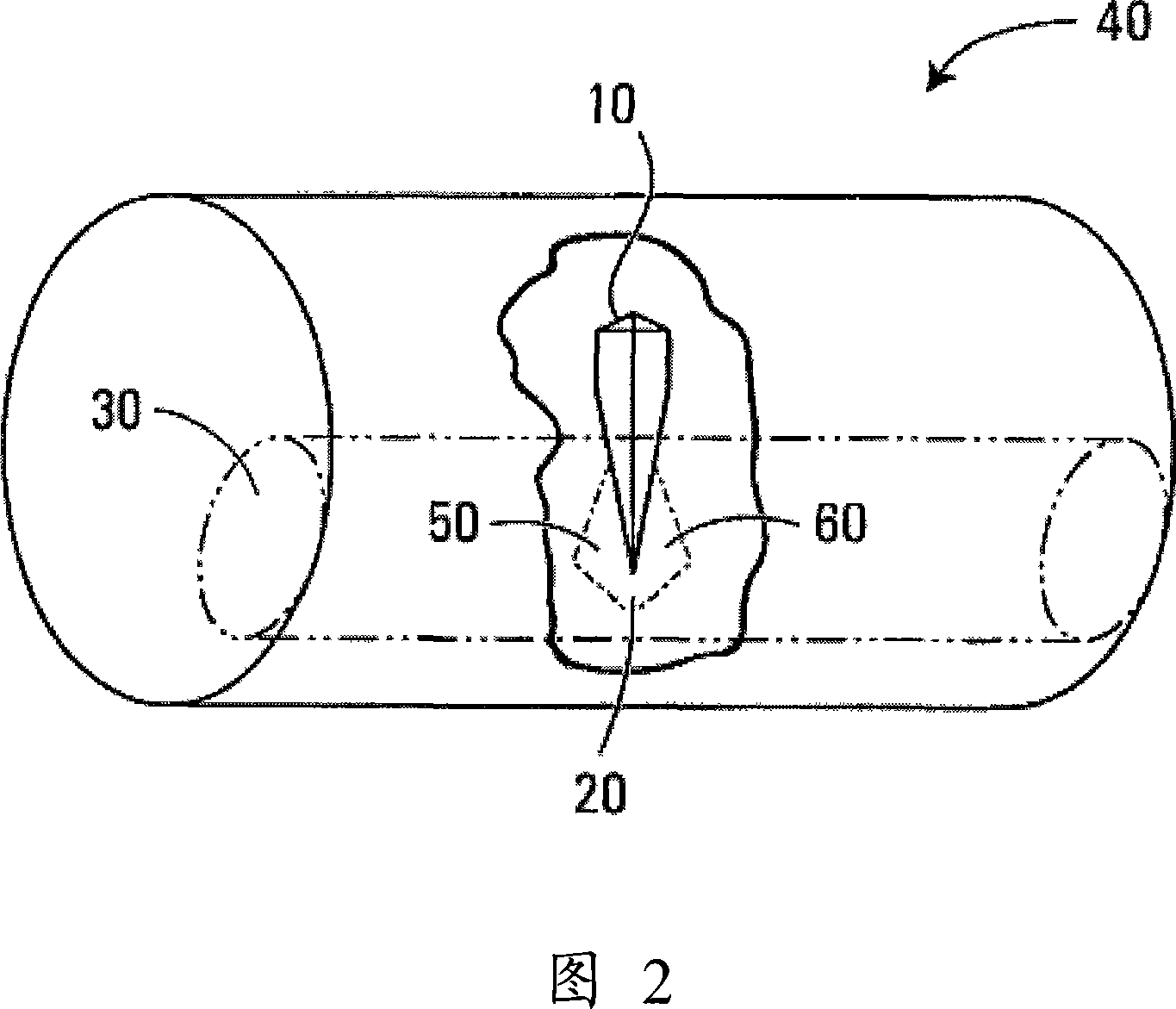

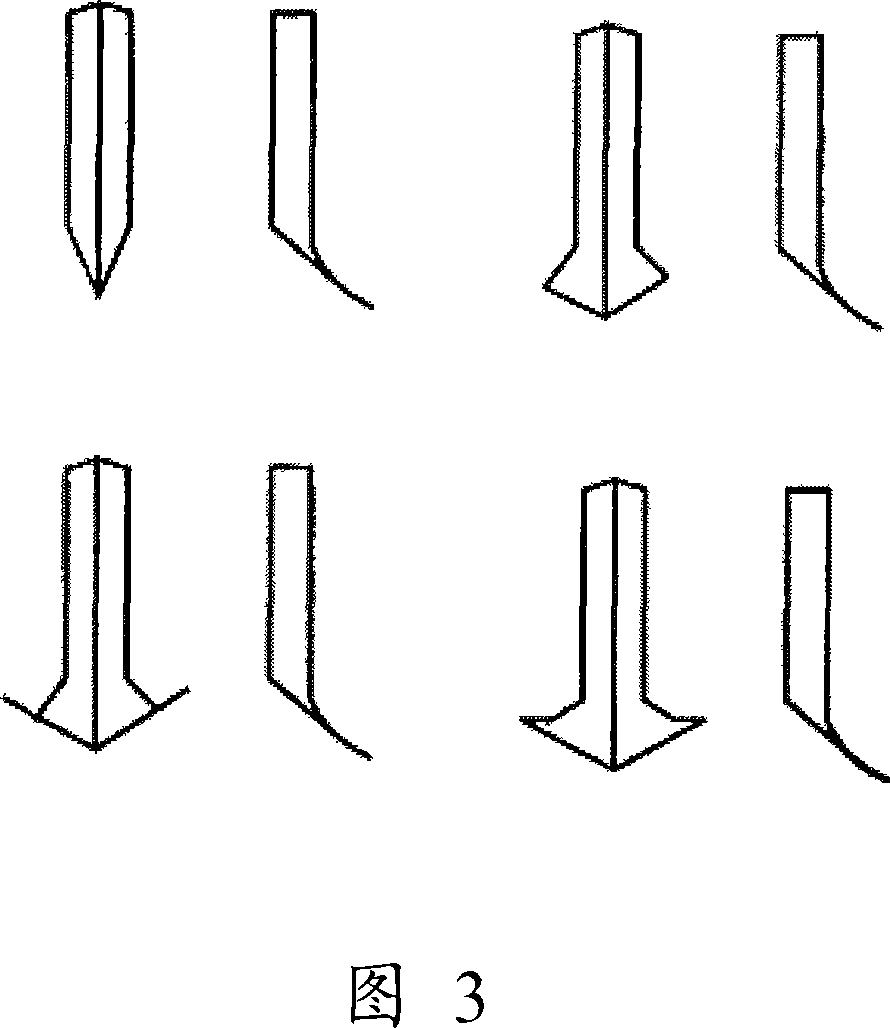

Process and apparatus for coating a controlled release product in a rotating drum

The present invention is directed to a process for coating a substrate in a rotating drum, wherein a pocket is created in a substrate bed into which pocket coating materials are delivered. Also provided is a controlled release product produced according to this process, and an apparatus for carrying out the process.

Owner:爱禾瑞公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com