Patents

Literature

64 results about "Pellet Product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coating for fertilizer

InactiveUS20050076687A1Maintain reaction temperatureImparts physical strengthBiocideGas treatmentVegetable oilPolymer chemistry

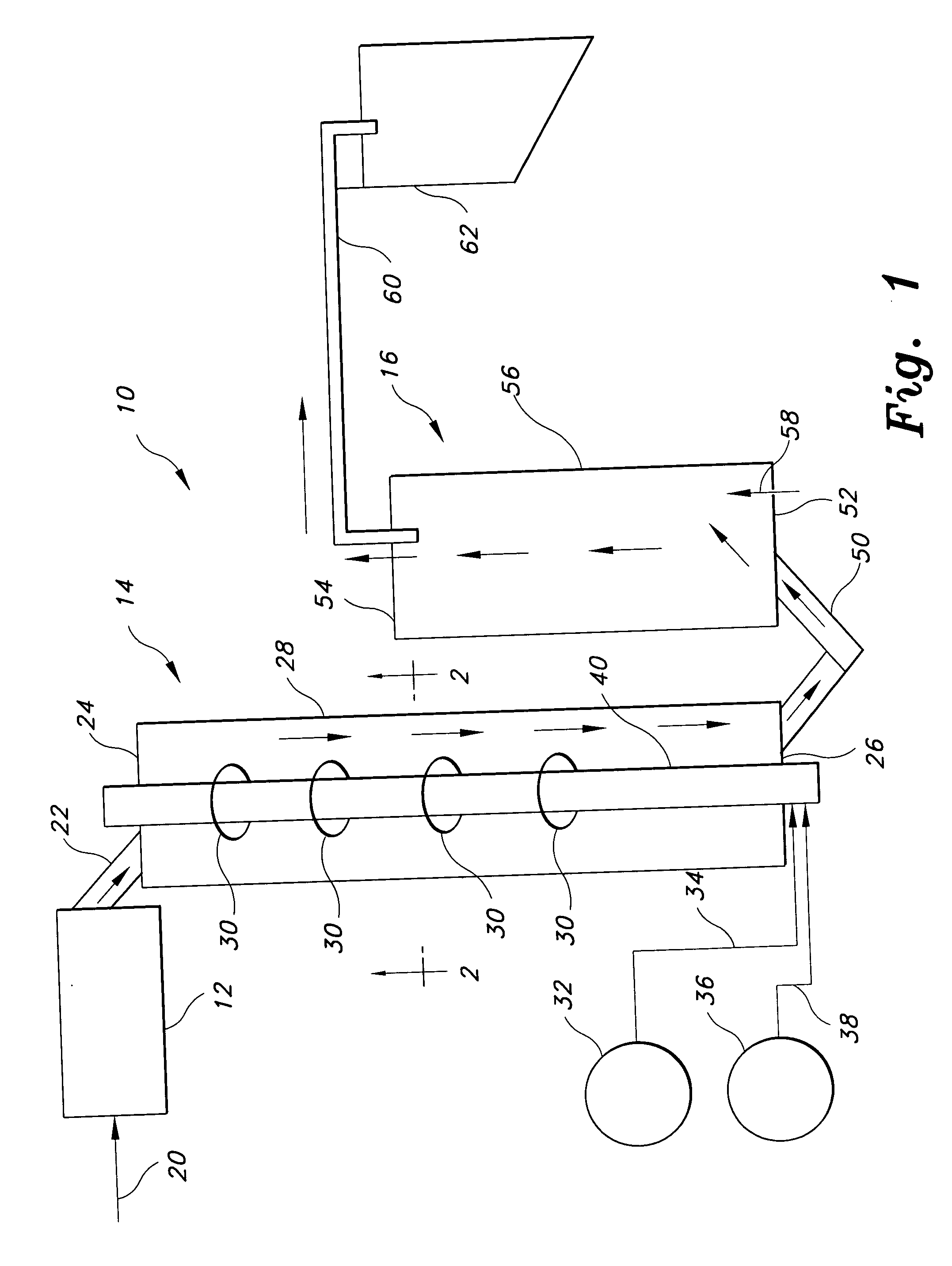

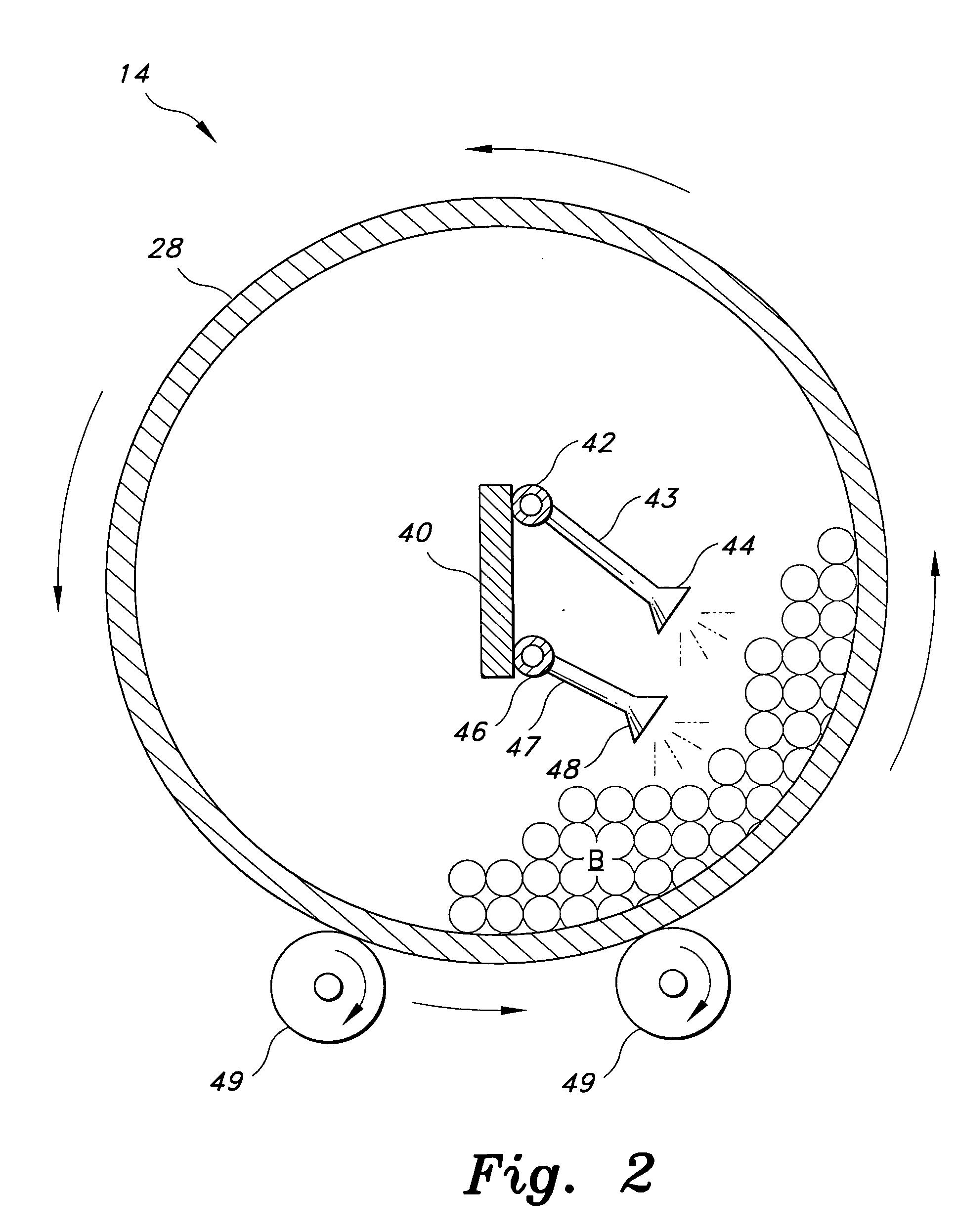

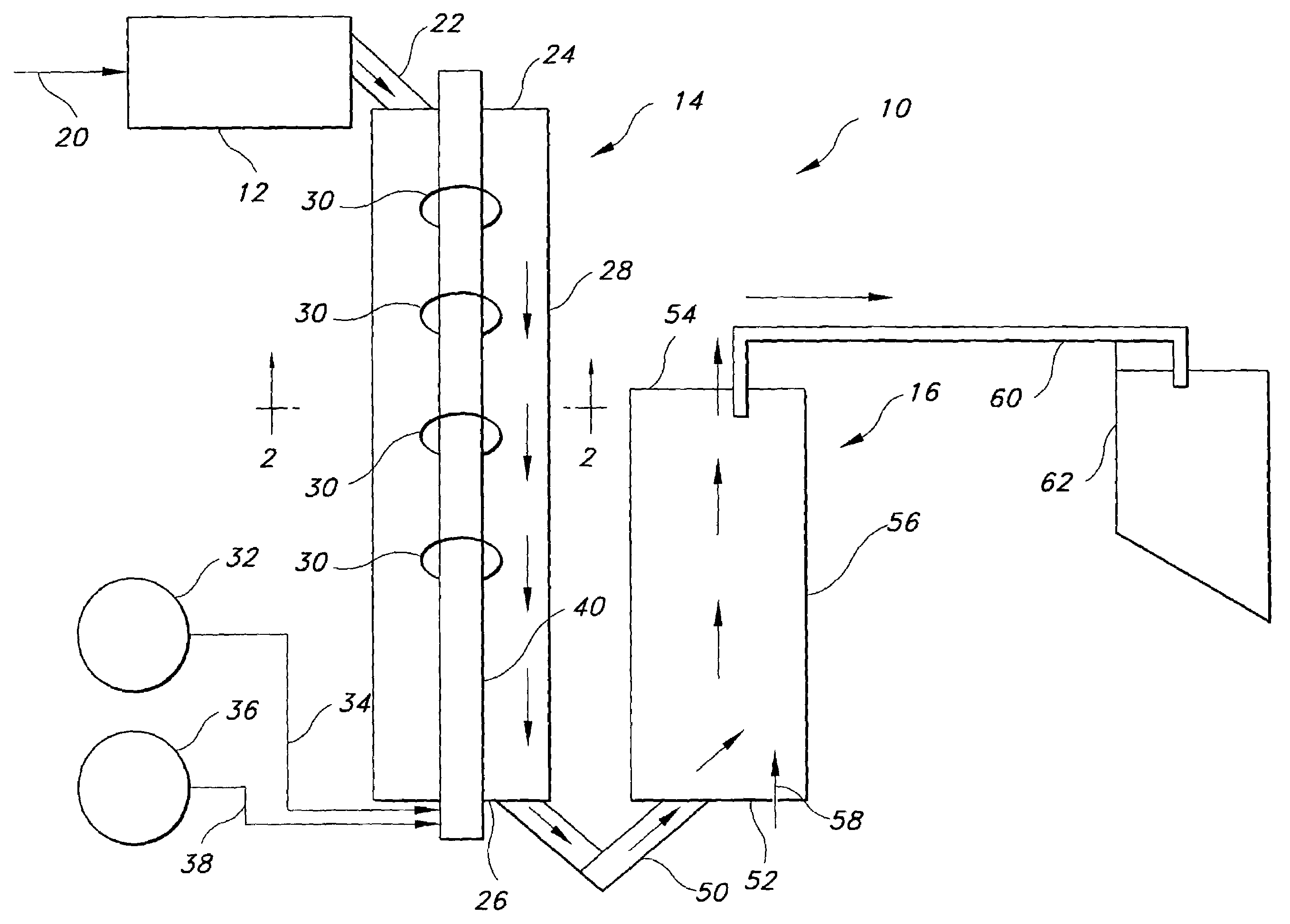

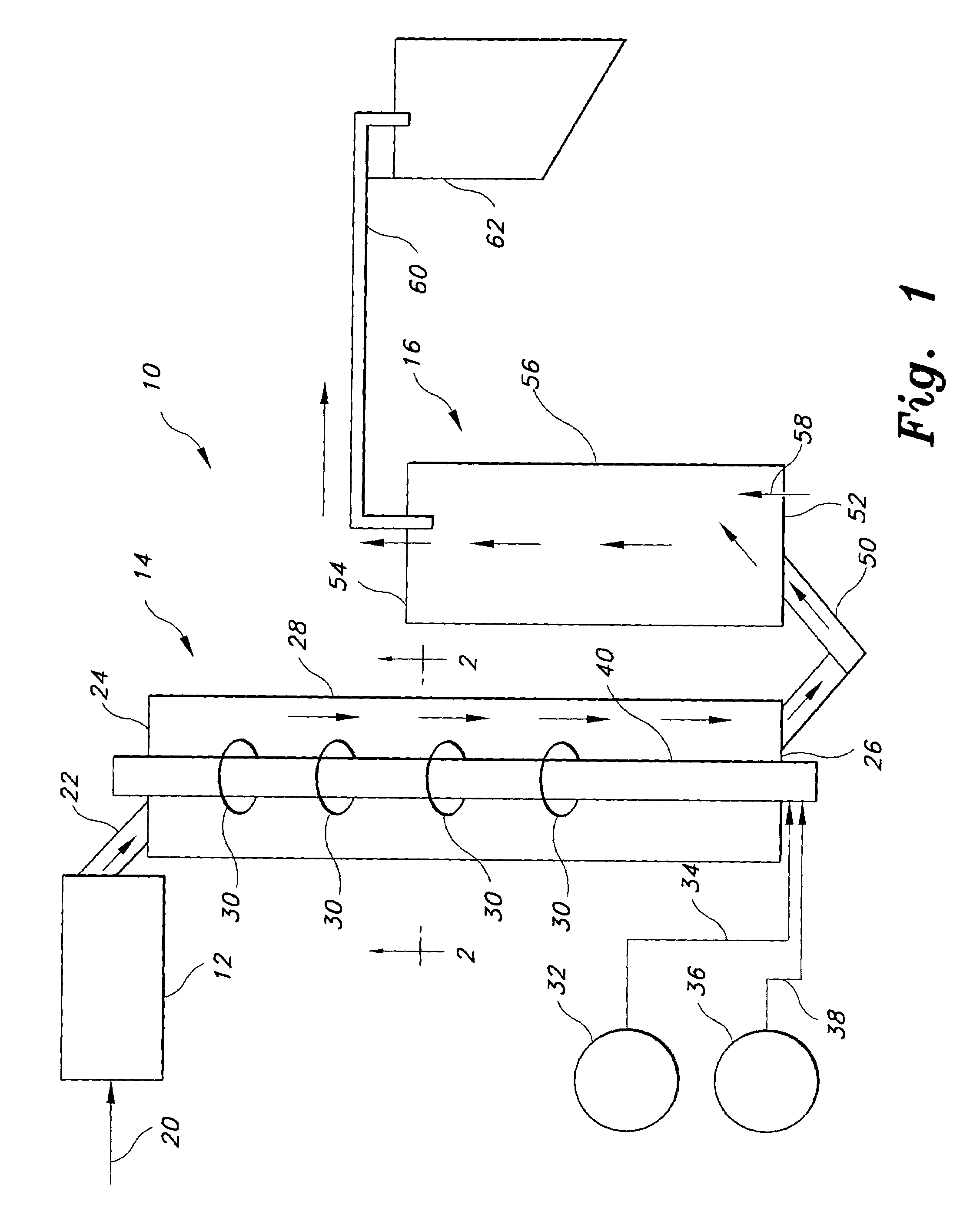

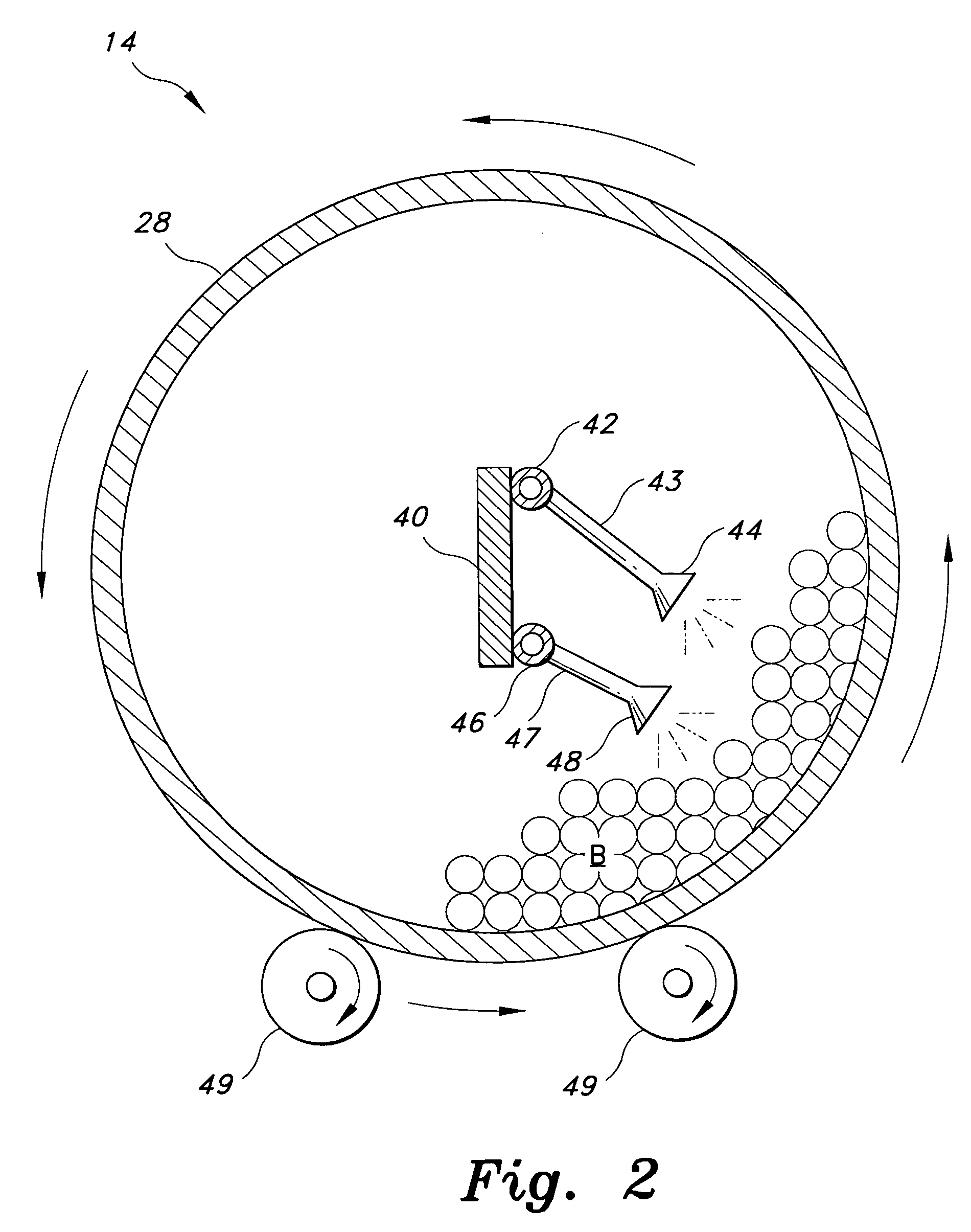

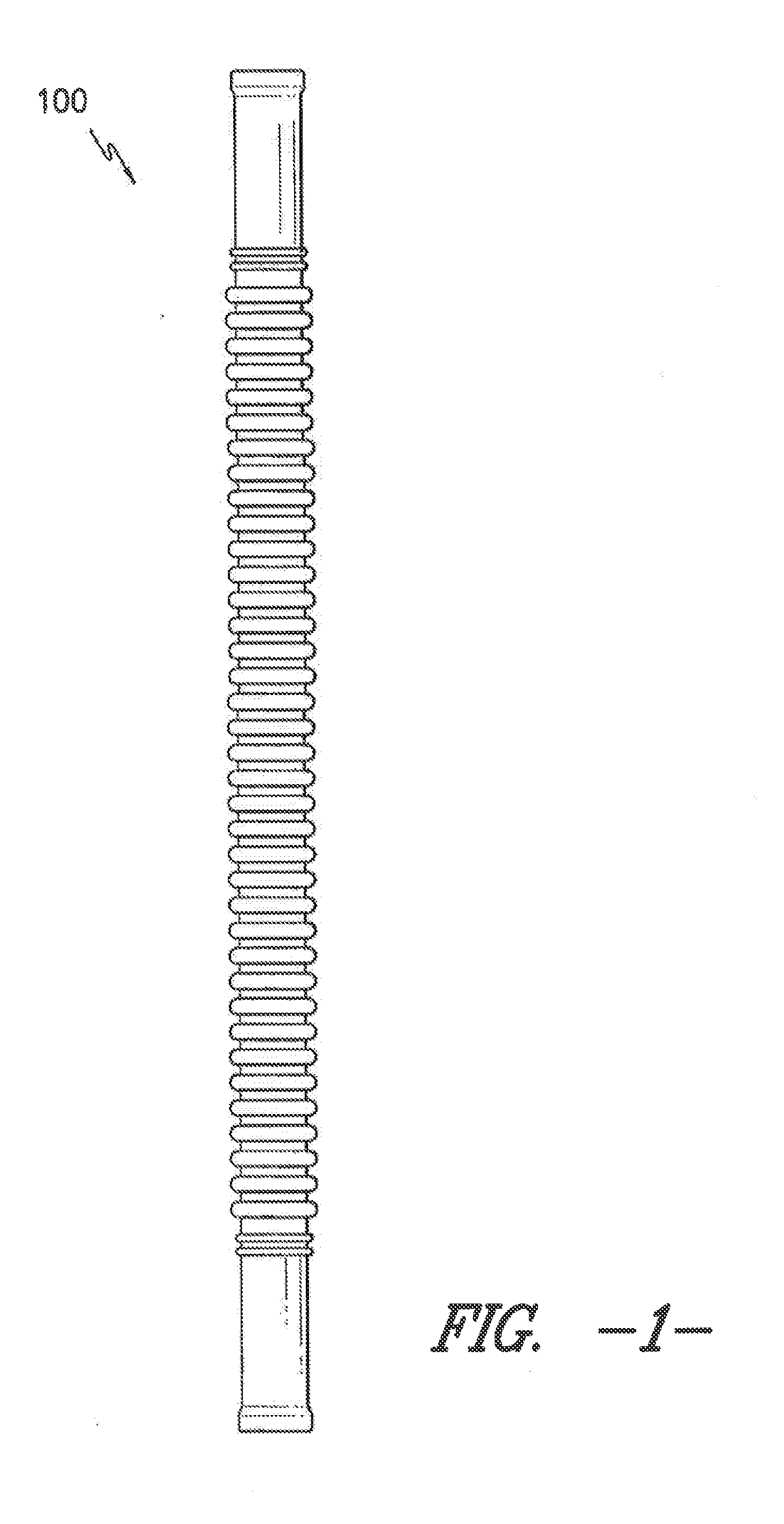

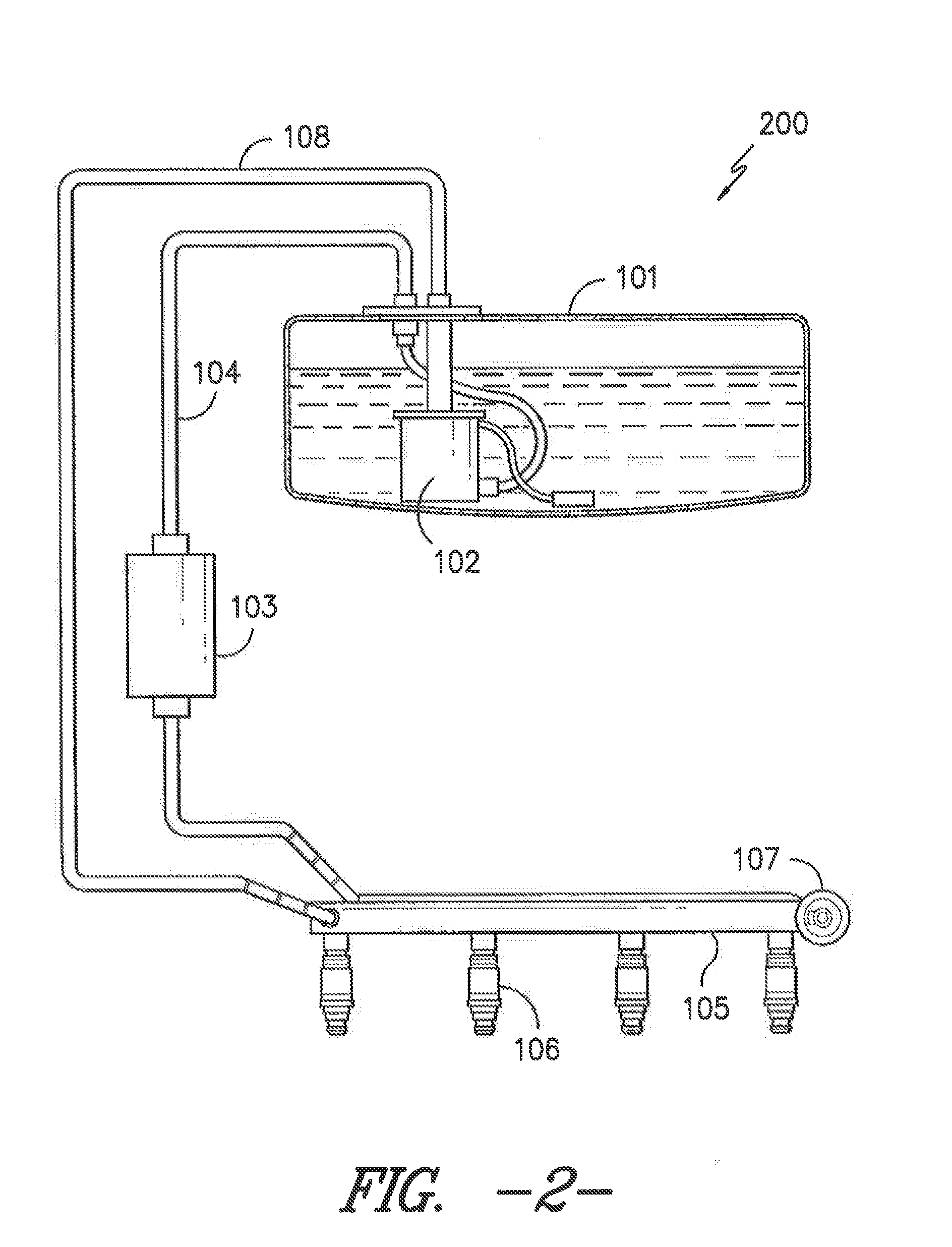

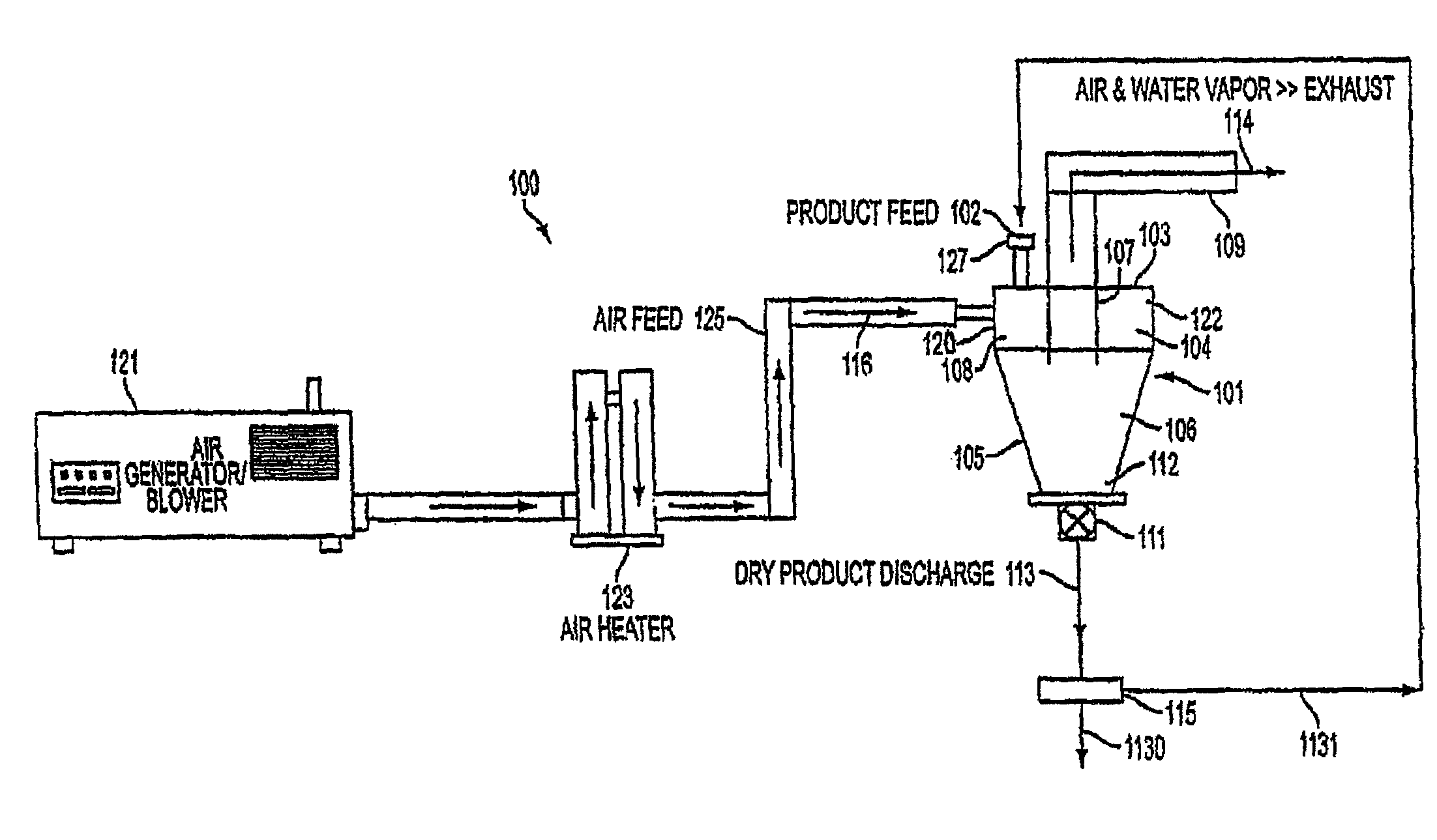

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

Method for utilizing iron containing metallurgical dust

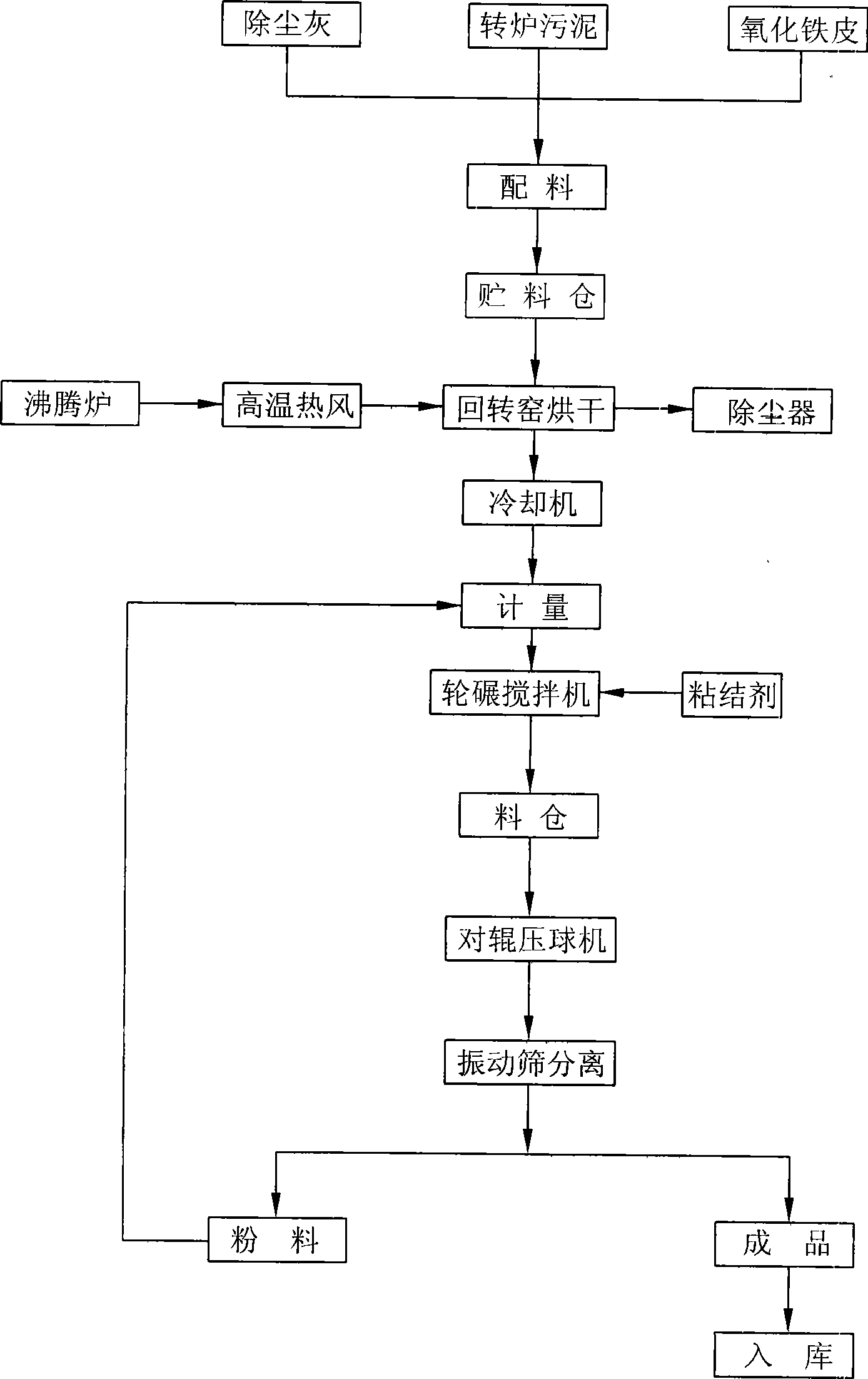

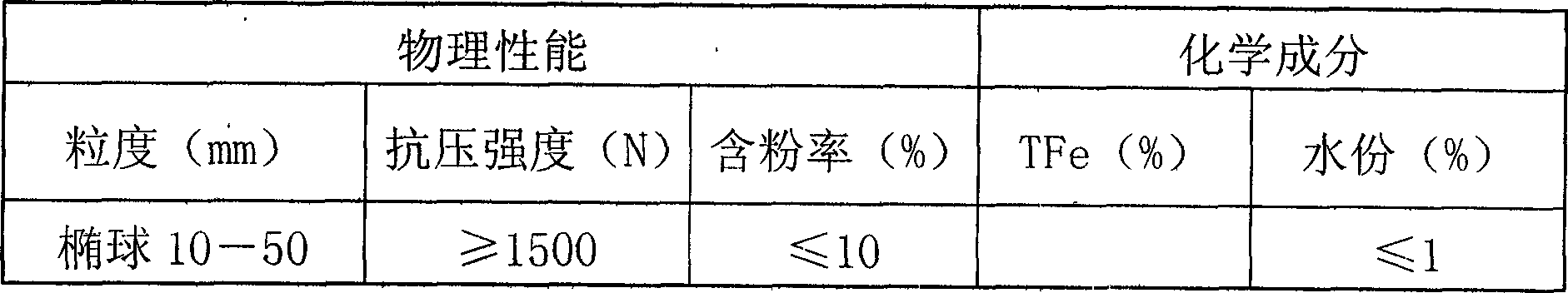

The invention relates to a method for utilizing iron containing metallurgical dust, which comprises that: steel-making sludge, metallurgical dust-removing powder and iron scale are mixed; the mixed raw materials are sent into a rotary kiln and dried, and the drying temperature is determined according to moisture content of the raw materials and controlled to be between 300 and 500 DEG C; the dried materials are cooled by a cooler, the cooled materials are added with 5 to 10 percent of caking agent by weight, and the material and the caking agent are fully stirred evenly by a wheel-rolling mixer; and finally, the mixture is pressed into cooled agglomerated pellet products by a twin-roller machine, the pressure of the twin-roller machine is more than or equal to 500 Kg / cm<2>, and the cooled agglomerated pellet products are prepared into finished products after separation by a vibration sieve. The method has the advantages of low production energy consumption, high product strength, low moisture content and good quality, and can realize full effective utilization of resources; and the finished products of cooled agglomerated pellets can be directly used as a cooling agent and a slag former in steel making, can improve smelting effect and achieve functions of cooling and slag forming, and can be also used for blast furnace process.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

Coating for fertilizer

InactiveUS7452399B2Imparts physical strengthAbrasion resistance is very highBiocideGas treatmentVegetable oilPolymer chemistry

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

Method for reinforcing preparation and reduction of carbon-containing pellets in iron ore

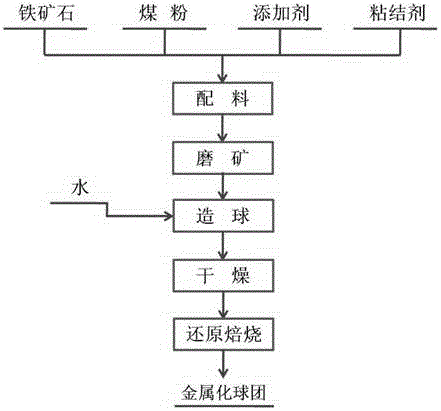

The invention relates to a method for reinforcing preparation and reduction of carbon-containing pellets in iron ore. The method for reinforcing preparation and reduction of the carbon-containing pellets in the iron ore comprises the following steps that (1) the iron ore, a reducing agent, a bonding agent and an additive are prepared according to a certain proportion; (2) prepared mixtures are sent into a ball mill to be crushed, fine ground, evenly mixed and the like, so that fine-sized evenly-mixed materials are obtained; (3) pelletizing or briquetting is conducted by means of the fine-sized evenly-mixed materials, so that the carbon-containing pellets in the iron ore are obtained; and (4) the prepared carbon-containing pellets in the iron ore are subjected to reducing roasting treatment, and thus metallized pellet products can be obtained. According to the method for reinforcing preparation and reduction of the carbon-containing pellets in the iron ore, in the way that the raw materials including the iron ore, the reducing agent, the bonding agent, the additive and the like enter the mill simultaneously after being prepared, the dual effects of fine grinding and sufficient and even mixing of the raw materials are achieved at the same time in the single ore grinding procedure, and the procedure links of fine grinding raw materials separately in advance, then preparing the raw materials in proportion and finally conducting even mixing of traditional operation are greatly simplified; and the quality of the carbon-containing pellets in the iron ore is remarkably improved, and the subsequent reduction process is reinforced.

Owner:CENT SOUTH UNIV

Chewable tablets containing mannitol and aspartame

InactiveUS6296868B1Increase surface areaLiquify rapidlyPowder deliveryConfectioneryAdditive ingredientDietary supplement

Chewable tablets and particulate food and pharmaceutical products are disclosed which are made from agglomerates comprising an alcohol sugar such as mannitol and a high intensity sweetener such as Aspartame from which agglomerate tablets may be directly compressed, and processes for making the agglomerates and tablets. The tablets or particulate product containing the agglomerate may contain active ingredients blended with the agglomerate or as part of the agglomerate structure. Tablets and particulate products according to the invention can contain active ingredients such as pharmaceuticals (e.g., antacids, analgesics, cough medicine, drugs, etc.) breath sweeteners, vitamins and dietary supplements, to name a few. The high intensity sweetener containing agglomerates can also be used to make solid food mix type products such as sugar free ice tea mixes.

Owner:ADVANCED TECH PHARMA CORP

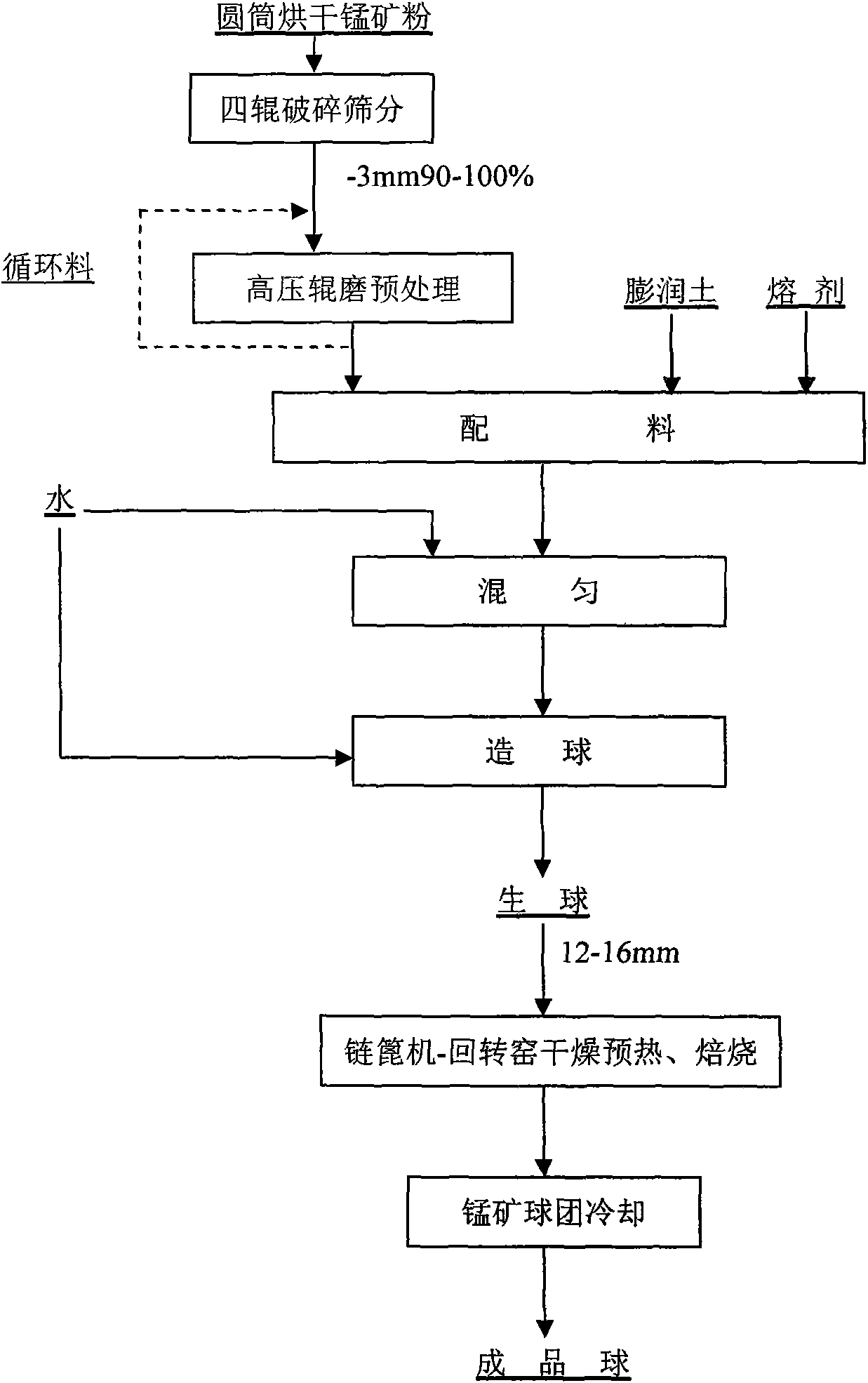

Complex manganese ore powder pelletization process

The invention relates to a complex manganese ore powder pelletization process. High-crystal-water manganese powder ore is treated by a cylindrical drier for drying, a four-roll crusher for coarse crushing and a high-pressure roller mill for fine milling pretreatment, bentonite and flux are added in finely milled manganese ore concentrate obtained after pretreatment for pelletization, green pelletsare dried and preheated on a chain-grate machine, preheated pellets enter a rotary kiln for high-temperature roasting and then is cooled to obtain a pellet product. Compared with ball milling process, the invention can reduce the energy consumption in pretreatment flow, improve the ballability index of finely milled material, eliminate thermal explosion of pellets and solve the technical problemsthat narrow manganese ore softening temperature area affects pellet roasting. The adoption of two-segment preheating effectively prevents cracks on the preheated pellets and improves the performancesof the preheated pellets; the addition of limestone or dolomite as flux changes the alkalinity and the slagging property of raw material and enhances the pellet roasting and next melting; and the produced manganese ore pellet has high strength, large output and high manganese grade.

Owner:CENT SOUTH UNIV

Preparation method of high-chromium high-vanadium type vanadium-titanium ore pellets

The invention relates to a preparation method of high-chromium high-vanadium type vanadium-titanium ore pellets. The invention relates to a preparation method of vanadium-titanium ore pellets. With existing high-chromium high-vanadium type vanadium-titanium ore pellet preparation technologies, pellet superfusion is possible to occur, and pellet caking or nodulation are possible to occur, such that the quality of finished pellet product is influenced. The invention aims at solving the problem. The preparation method of the high-chromium-high vanadium type vanadium-titanium ore pellets comprises the steps of material blending, mixed drying, palletizing, green pellet screening, and shaft furnace roasting. Vanadium content of vanadium-titanium powder in the vanadium-titanium pellets is higherthan 4.5%, such that a requirement by blast furnace vanadium-titanium smelting is satisfied. The high-chromium-high vanadium type vanadium-titanium ore pellet preparation method provided by the invention is used for preparing vanadium-titanium ore pellets.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Trimetazidine dihydrochloride sustained control release pellet and preparation method thereof

InactiveCN102133195AUniform sizeHigh true sphericityOrganic active ingredientsPharmaceutical non-active ingredientsTrimetazidine DihydrochlorideControlled release

The invention relates to trimetazidine dihydrochloride sustained control release pellet and a preparation method thereof. The sustained control release pellet structurally comprises a blank pellet core, a trimetazidine dihydrochloride medicine layer and a sustained control release coating layer from inside to outside; the preparation method comprises the following steps: preparing the blank pellet core by a centrifugal coating pelletizer, putting the blank pellet core in the centrifugal coating pelletizer under a motion state, then spraying mixed liquor of adhesive and wetting agent by a spray gun until the blank pellet core is wetted, uniformly spreading the raw trimetazidine dihydrochloride on the wetted blank pellet core through a powder supplying device to obtain a medicine-containing pellet, and carrying out sustained control release coating on the exterior of the medicine-containing pellet, thus obtaining the trimetazidine dihydrochloride sustained control release pellet. The invention is suitable for preparing the trimetazidine dihydrochloride sustained control release pellet, the preparation process is simple, and a prepared pellet product is scientific and reasonable in structure, uniform in granularity and good in release degree.

Owner:王国栋

Method for preparing oxidated pellets from pure hematite concentrate

A method for preparing oxidated pellets from pure hematite concentrate includes the following steps: after the hematite concentrate is preprocessed until the specific surface area is larger than or equal to 1300cm2.g-1, compound additive which accounts for 0.5 to 1.6 percent by weight of the total amount of hematite concentrate is added, damp milling is then carried out, pelletizing, drying, preheating and roasting are sequentially carried out after damp milling, and thereby the finished oxidated pellet product is obtained. The compound additive is the mixture of humic acid, calcium peroxide and paigeite, the mixture is ground to the grain size of negative 0.074mm after mixing, and the percentage by weight is not lower than 95 percent. The method solves the problems in the preparation of oxidated pellets from the hard-to-pelletize, hard-to-roast hematite concentrate, such as poor pellet quality, high preheating and roasting temperatures, long time, low finished pellet product strength. The method is simple, the quality of the prepared hematite concentrate pellets is high, the preheating and roasting temperatures are low, the time is short, and the method is suitable for the preparation of the oxidated pellets from the hematite concentrate, particularly the preparation of the oxidated pellets from hard-to-pelletize, hard-to-roast spiegeleisen concentrate. The method can realizeindustrialized production.

Owner:CENT SOUTH UNIV

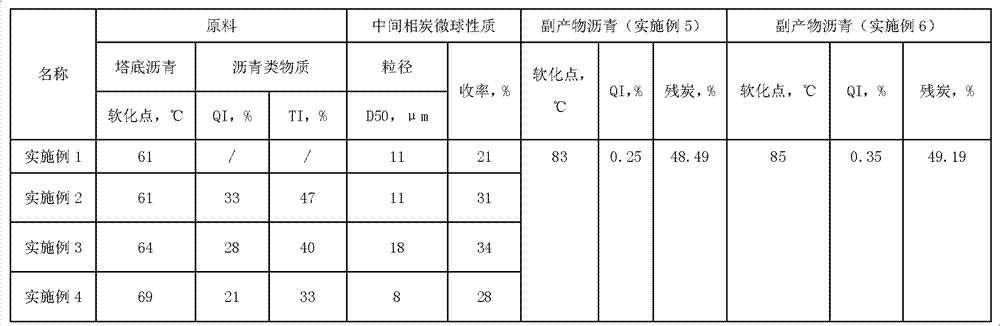

Preparation method of mesophase carbon microspheres with different particle sizes

InactiveCN103359702ASmall particle sizeImprove separation efficiencyChemical industryCarbon preparation/purificationPolymer scienceMicrosphere

The invention relates to a preparation method of mesophase carbon microspheres with different particle sizes. Green pellet products of the mesophase carbon microspheres are obtained by adding asphalt type substances containing high quinoline insoluble matters and high toluene insoluble matters into asphalt, adjusting the composition of raw materials, and performing solvent extraction, filtration, separation and drying on a condensation polymerization reaction product. The preparation method disclosed by the invention has the advantages of simple preparation of the raw materials, low price, high yield of the mesophase carbon microspheres, uniform particle size distribution, and adjustable and controllable particle size. In addition, the byproduct asphalt can be used as soaker asphalt or can be used for preparing spinning asphalt with a high softening point, and the problems of low value of the byproduct and further influence on the cost of the carbon microsphere products can be solved. An extraction, separation and pre-drying integrated process has the advantages of reducing investment in equipment and instruments, shortening process flows, being easy to produce and operate, realizing the closed separation process and being environment-friendly.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof

The invention relates to alloy steel smelting, and particularly relates to a chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof. The pellet comprises the following components according to mass percentage: 40-65 percent of high-carbon ferrochrome powder, 15-40 percent of molybdic oxide powder, 5-15 percent of a reductant and 3-5 percent of a flux. The self reduction pellet product is added to a ladle during electric furnace or convertor tapping, under the action of high-temperature molten steel and a pellet inner reductant, metal elements in the pellet are effectively reduced, as a result, the molten steel is directly alloyed; the self reduction pellet product is applied in alloy steel including stainless steel, wear resistant steel and the like, which contain elements Cr and Mo, and not only is the procedure for the production of ferro molybdenum saved, but also the elements Cr and Mo can be added at one time, so that the cost of adding alloy elements is lowered, the smelting cycle is shortened, meanwhile, the use range of high-carbon ferrochrome is widened, and furthermore, the problem that the element Mo is difficult to add and settle and great in volatilization during the steel smelting is solved.

Owner:JIANGSU UNIV

Novel biomass densification-forming pellet fuel

InactiveCN102115687AAvoid the problem of high demand and difficult collectionImprove molding rateBiofuelsSolid fuelsHuskEngineering

The invention discloses a novel biomass densification-forming pellet fuel. Waste and renewable crop straws, rice husks and corncobs are used as raw materials, and are processed through crushing, mixing, drying, compressing, cooling, screening and packaging into the novel biomass densification-forming pellet fuel. The following components are proportioned according to weight ratios for the fuel preparation: 50 percent of straws, 30 percent of rice husks and 20 percent of corncobs. The preparation method is that the straw length is reduced to 6mm through crushing, the corncob length is reduced to 4mm through crushing, and the rice husks are not crushed; the straws, the corncobs and the rice husks are evenly mixed according to the weight ratios and dried by drying equipment; and after the moisture content reaches 13 percent to 15 percent, the fuel is formed in a compressed manner at a high temperature through a pellet forming machine. The formed biomass densification-forming pellet fuel is a cylindrical pellet of which the diameter is 8mm and the length is 10mm to 50mm. After being formed, the fuel is cooled through a cooler, screened and packaged, and then a finished pellet product can be acquired.

Owner:哈尔滨金石生物质能源发展有限公司 +1

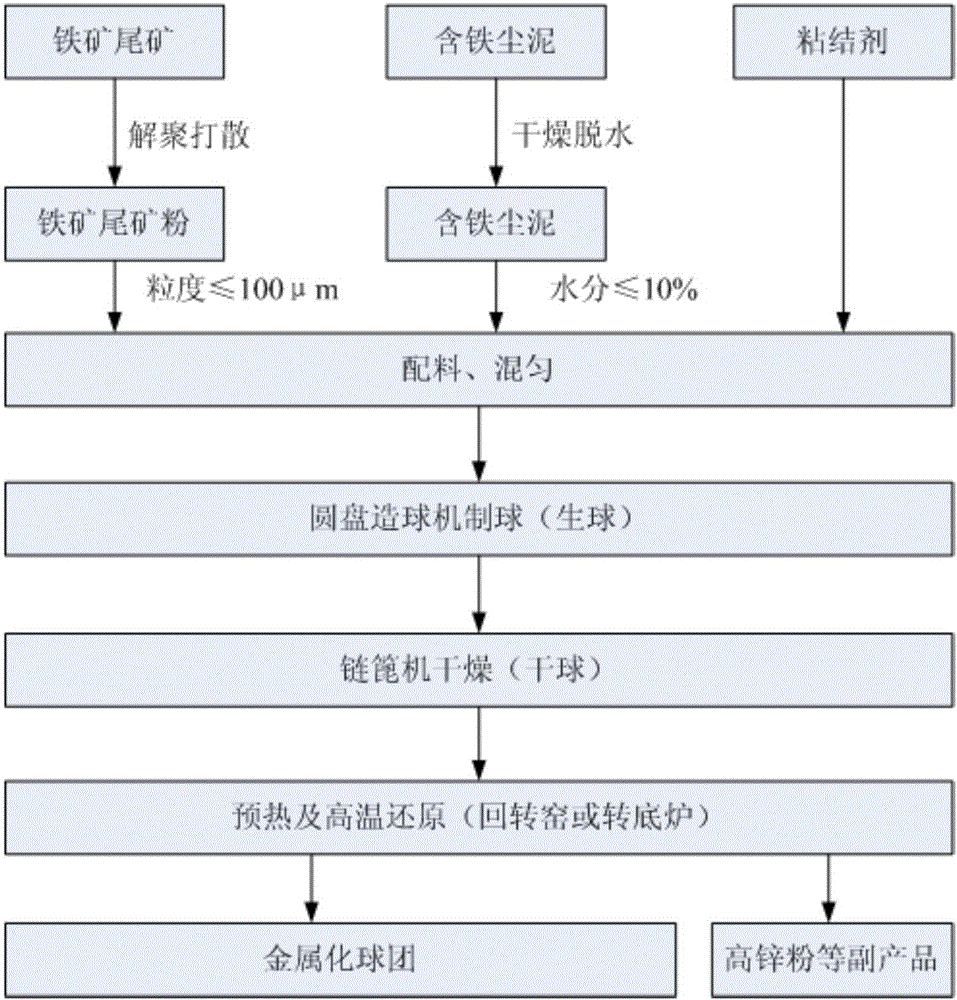

Method for producing metallized pellets through iron mine tailings

ActiveCN106755981AReduce manufacturing costImprove resource utilization efficiencyRotary drum furnacesHearth type furnacesDepolymerizationSodium Bentonite

The invention relates to a method for producing metallized pellets through iron mine tailings. The method mainly comprises the following technology steps that a powder depolymerization and scattering machine is adopted for crushing and scattering the caked iron mine tailings; the iron mine tailings and dried iron containing dust mud are mixed according to the proportion of 1:9-3:7; 1-4% of bentonite and 0-5% of coked dust removing ash or pulverized coal are prepared in the mixture in the second step, and sufficient uniform mixing is conducted through a powerful mixing machine; a certain proportion of water is added in the mixture, and 10-16 mm of green pellets are manufactured through a disc pelletizing machine; after being dried through a chain grating machine, the green pellets are conveyed to a rotary kiln or a rotary hearth furnace to be preheated and roasted at the high temperature, and metalized pellet products are finally obtained and serve as high-quality raw materials for blast furnace iron making or electric furnace steel making. According to the method, the iron mine tailing resource hard to treat is comprehensively utilized, meanwhile, the production cost of the iron containing dust mud metalized pellets is reduced, and very obvious economic benefits and environment benefits are achieved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Plasticized, Conductive Polyoxymethylene for Fuel Applications

InactiveUS20140137975A1Reduce riskNon-metal conductorsLayered productsPolyoxymethyleneTransfer system

Polymer compositions containing a plasticized, impact modified polyoxymethylene composition that is compounded with a conductive filler composition are disclosed that are flexible while also exhibiting electrostatic dissipative (ESD) capabilities. The polymer compositions can be formed into shaped articles such as tubes, hoses, etc. for use in fuel transfer systems. The plasticized, impact modified polyoxymethylene composition includes a functionalized polyoxymethylene, a plasticizer, and an impact modifier. Meanwhile, the conductive filler composition includes a conductive filler and a high flow polyoxymethylene. The compositions can be compounded into a pellet product which can then be formed into a shaped article that complies with the ESD capabilities required by SAE J1645. It is also to be understood that the polymer composition components can be blended and formed into a pellet product in a single step that can be used to produce a shaped article that complies with the ESD capabilities required by SAE J1645.

Owner:TICONA LLC

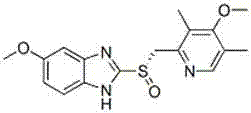

Esomeprazole medicated pellet and preparing method thereof

ActiveCN102824316AAvoid wastingIncrease productivityOrganic active ingredientsDigestive systemPharmaceutical medicineMannitol

The invention discloses an esomeprazole medicated pellet and a preparing method of the esomeprazole medicated pellet. The esomeprazole medicated pellet is mainly prepared from 25-50% of esomeprazole raw material and ramification of the esomeprazole raw material, 20-50% of mannitol and 5-30% of polyvinylpolypyrrolidone according to weight percentage; and in addition, pharmaceutic adjuvant acceptable pharmaceutically is also contained. The ingredients of the esomeprazole medicated pellet are proportioned, and the esomeprazole medicated pellet product can be prepared by virtue of an extruding-rolling preparing method. Compared with the prior art, the technical scheme provided by the invention has the advantages that the efficiency is greatly improved, and waste of a large amount of time, manpower and material resources are avoided; and the method is simple, and the midbody of the obtained product preparation has the advantages of stable medicine, high reproducibility and the like.

Owner:ZHONGSHUAI PHARMA SCI & TECH CO LTD

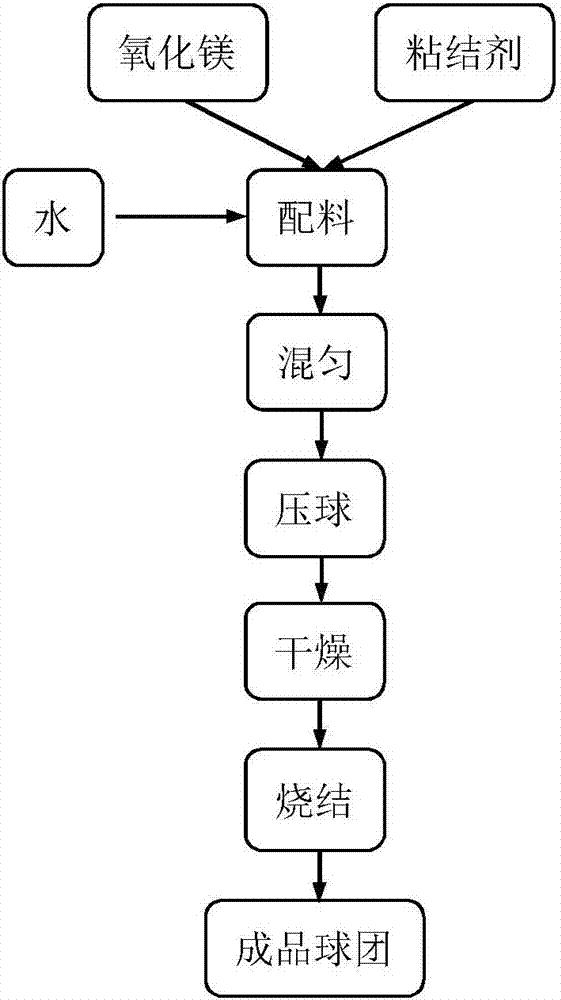

Method of producing light-calcined magnesia with powdery tailings of magnesite

ActiveCN106145716AAvoid pellet pulverizationRealize industrial productionLime productionEconomic benefitsCalcination

A method of producing qualified light-calcined magnesia with powdery tailings of magnesite. In the method, the powdery tailings of magnesite, of which the content of MgO is not less than 44%, is employed as a raw material. The method includes the processes of modifying and aging the powdery tailings of magnesite, pelletizing the powdery tailings of magnesite, and performing light calcination. The method successfully maintains the strength of pellets during calcination, and effectively solves a problem of pulverization during the light calcinations of the magnesite and can produce the qualified light-calcined magnesia pellet product that satisfies the HGT 2573-2012 industrial light magnesia related grade standard. The method tightly combines a magnesite lump ore roasting process in the prior art and achieves utilization of the powdery tailings of magnesite by means of the roasting equipment that is applied for roasting the lump ore in industry at present without much transformation. The method simplifies the recycling utilization process of the powdery tailings of magnesite, greatly reduces production energy consumption and improves economic benefit.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

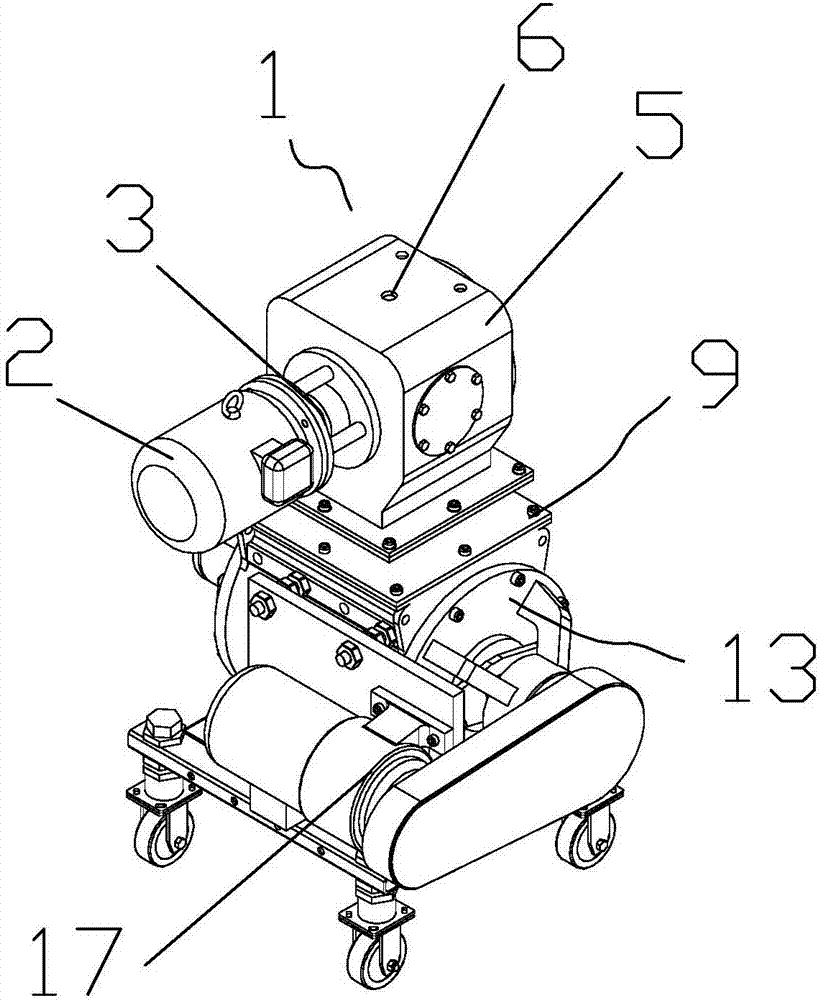

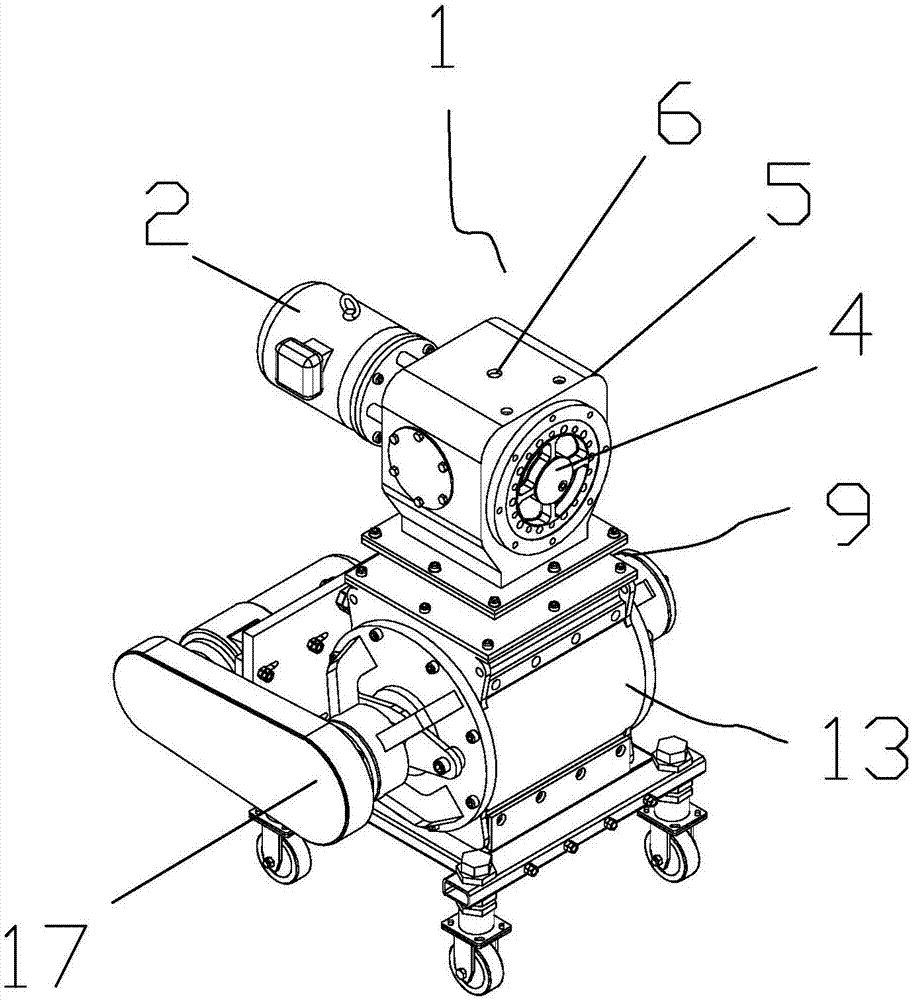

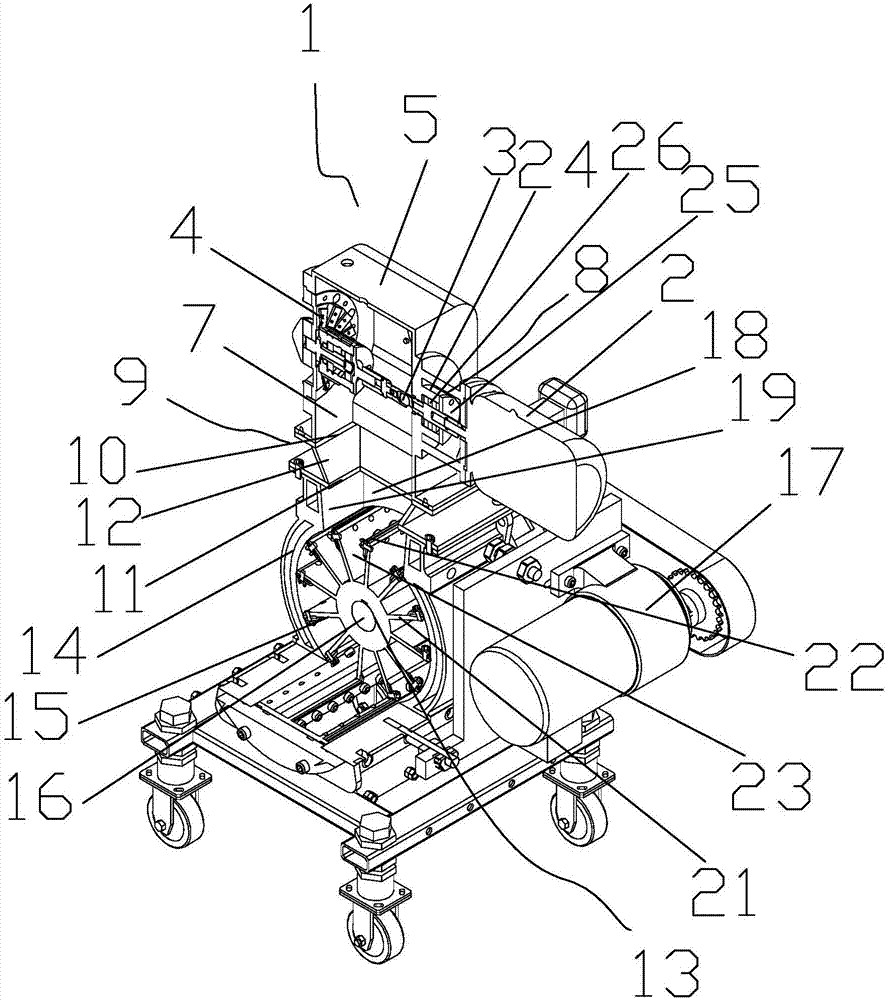

Density control equipment for aquatic puffed pellet feed

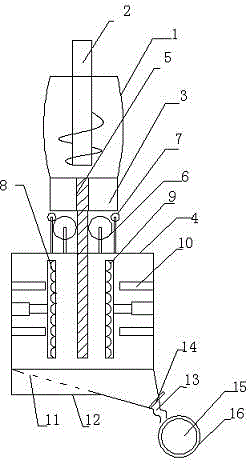

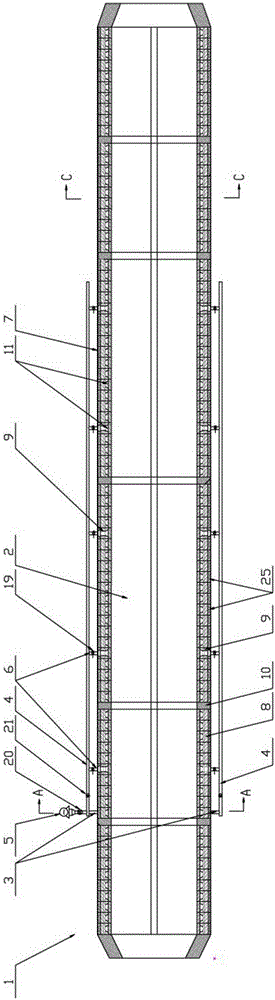

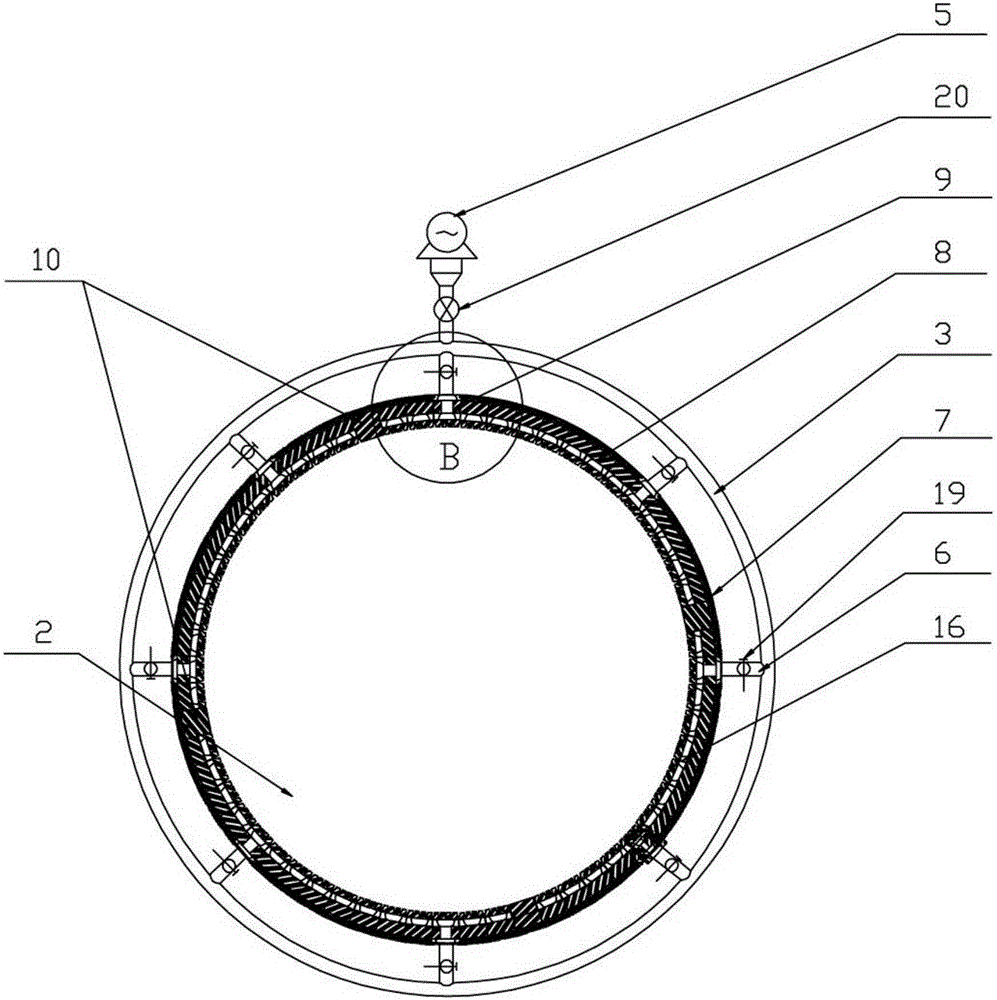

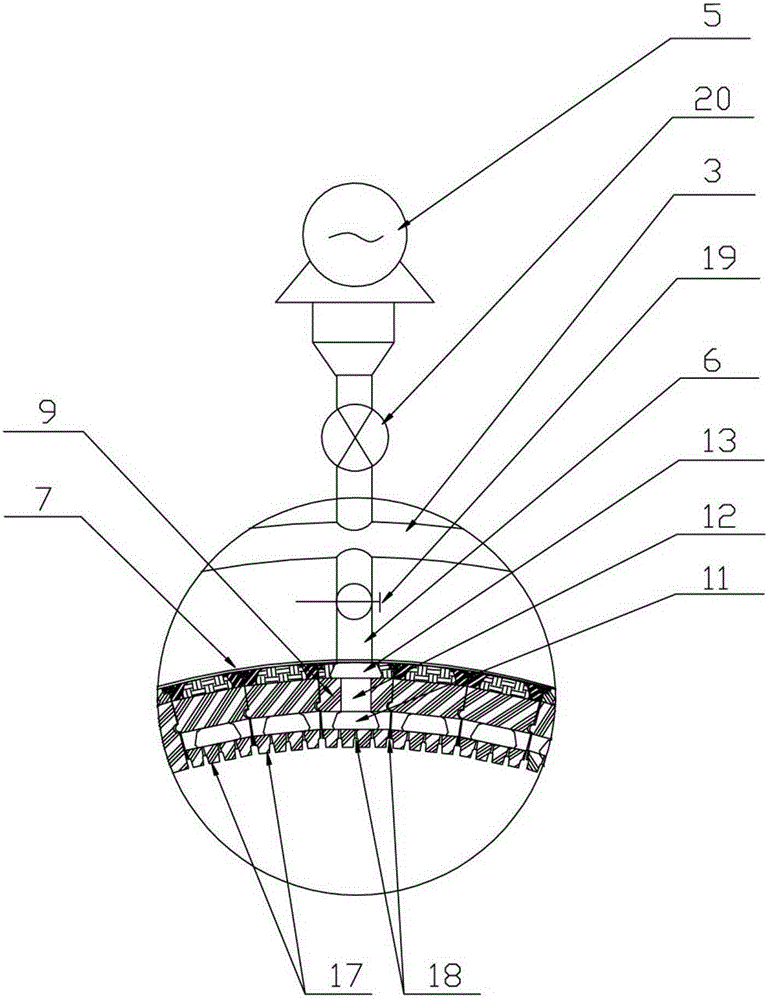

InactiveCN106983169AIntegrity guaranteedIncrease usageFeeding-stuffMetal working apparatusEnvironmental engineeringMechanical engineering

The invention discloses density control equipment for aquatic puffed pellet feed. The equipment includes a cutting device, a buffer feeding device and a sealed pressurizing device, wherein the cutting device is used for cutting puffed pellet feed discharged from a puffing cavity into pellets; the buffer feeding device is used for buffering the falling pellets, and the sealed pressurizing device is used for performing pressurization, sealing and volume-weight increasing on the pellets falling in the sealed pressurizing device; the sealed pressurizing device comprises a sealed pressure stabilizing chamber, an impeller body, a spindle and a drive component; the lower end of the sealed pressure stabilizing chamber is provided with a discharge hole; a plurality of blades are arranged on the impeller body, and the blades are provided with sealing pieces matched with the sealed pressure stabilizing chamber; a pressurizing chamber is formed between every two adjacent blades; and a sealed pressurizing space is formed among a cutter housing, the buffer feeding device, the sealed pressure stabilizing chamber and the impeller body. According to the density control equipment for aquatic puffed pellet feed, positive pressure air is introduced into the sealed pressure stabilizing chamber to make pellet texture denser, the volume-weight is increased, and required heavy pellet products are finally obtained.

Owner:嘉兴润阳机械有限公司

Vanadium-titanium pellet ore roasting control method

The invention discloses a vanadium-titanium pellet ore roasting control method and particularly relates to a vanadium-titanium pellet ore roasting control method used in the field of pellet ore oxidizing roasting. According to the vanadium-titanium pellet ore roasting control method, the roasting process conditions can be adjusted according to the field production situation in time, the product quality can be remarkably improved, and the pass percent of a pellet product can be improved. The vanadium-titanium pellet ore roasting control method comprises the steps that (A) finished pellet ores are sampled in a production field; (B) the sampled finished pellet ores are split; (C) the cross sections of the split finished pellet ores are inspected, and process parameters are adjusted. Professional observers detect the cross sections of the vanadium-titanium pellet ores, judge simulated oxidation behaviors of the pellet ores, find out the problems existing in the pellet production process, adjust and optimize preheating temperature, calcination temperature, heating speed, high-temperature duration time and other parameters in time, and the pellet product quality is remarkably improved.

Owner:PANZHIHUA GANGCHENG GROUP

Composite binder and powder pellet obtained through same

The invention relates a composite binder and a powder pellet obtained through the same, in particular to a binder used for preparing a powder pellet, especially a magnesium oxide pellet binder, and the pellet of the binder. The composite binder and the powder pellet are characterized in that the composite binder comprising sodium carboxymethylcellulose, humic acid, corn starch, acrylic resin, syrup, polyvinylpyrrolidone, polyacrylamide, sodium silicate and slaked lime is prepared; a magnesium oxide powder raw material is mixed with the composite binder to obtain a mixed material; then the mixed material is subjected to pellet pressing, drying and sintering, and then a finished pellet product is obtained; and the magnesium oxide powder raw material is high-purity magnesium oxide, and the MgO chemical component of the magnesium oxide powder raw material is larger than 92 wt%. The powder pellet or the magnesium oxide pellet obtained through the composite binder is high in strength and not prone to being broken in the electric smelting process, the preparation technology is simple and can be directly applied to industrial mass production, and furnace condition deterioration and environmental pollution which are caused by the fact that powder directly enters a furnace are avoided; and the magnesium oxide pellet prepared through the binder can be directly used for preparing electric smelting magnesia.

Owner:EAST CHINA UNIV OF SCI & TECH

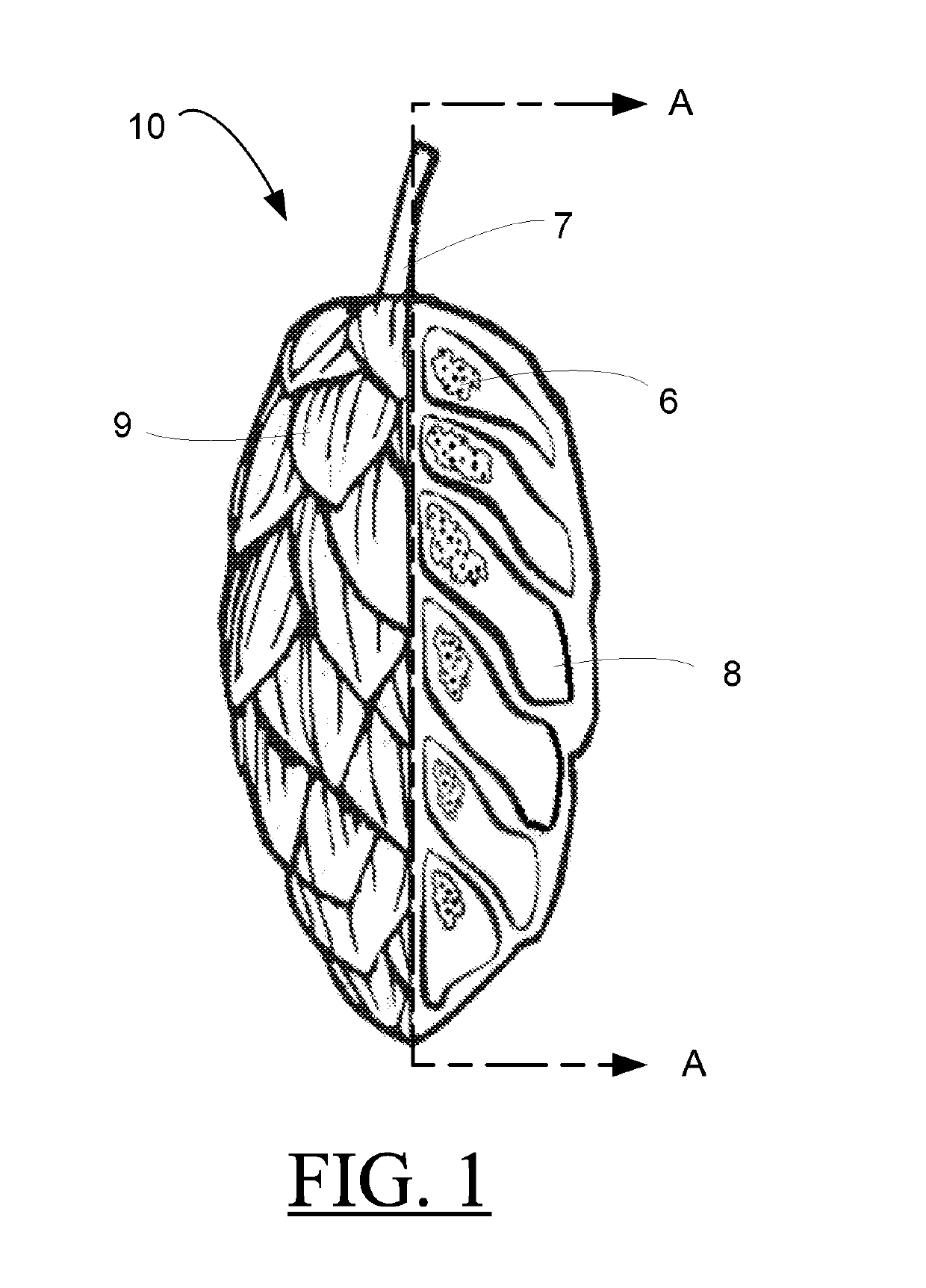

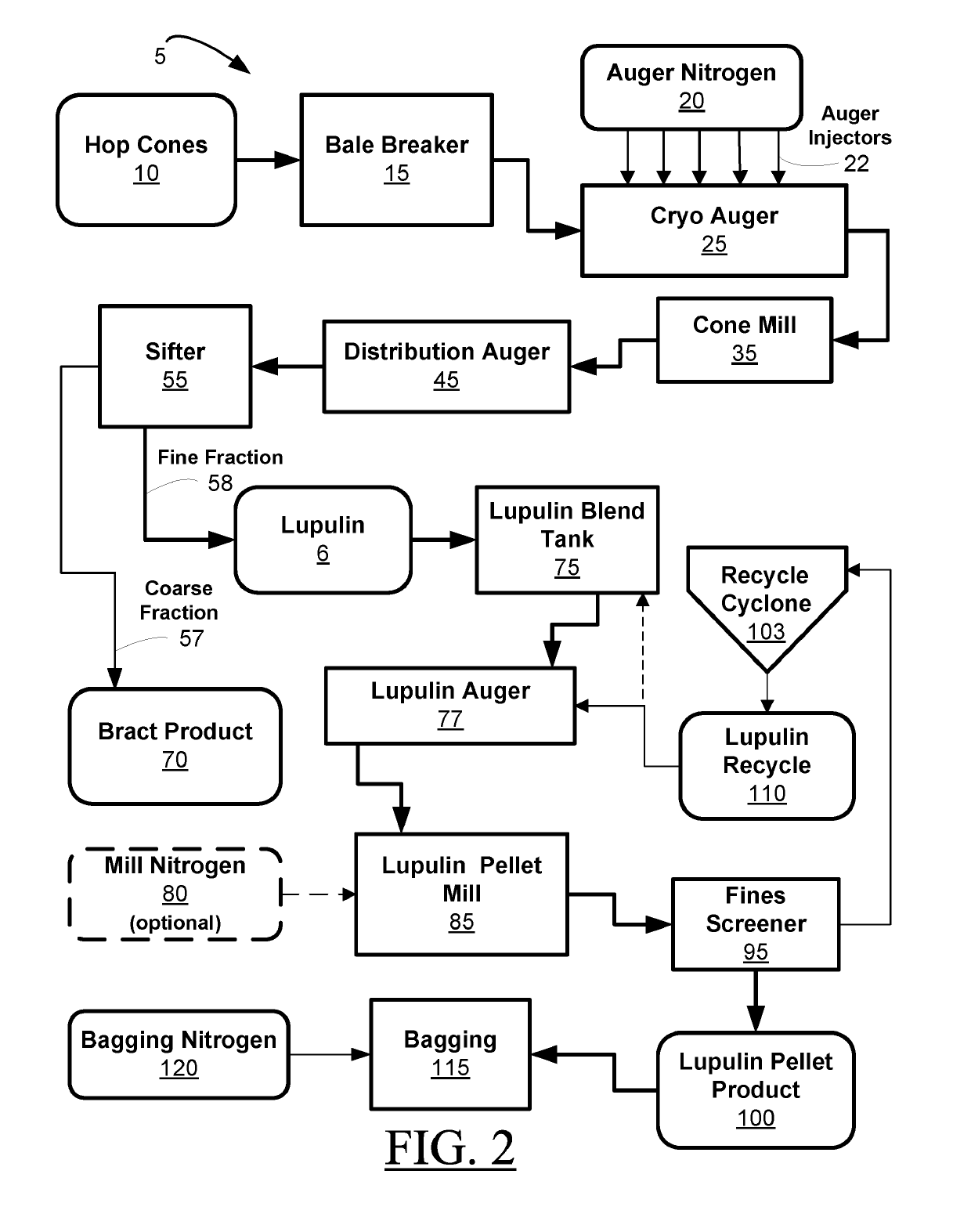

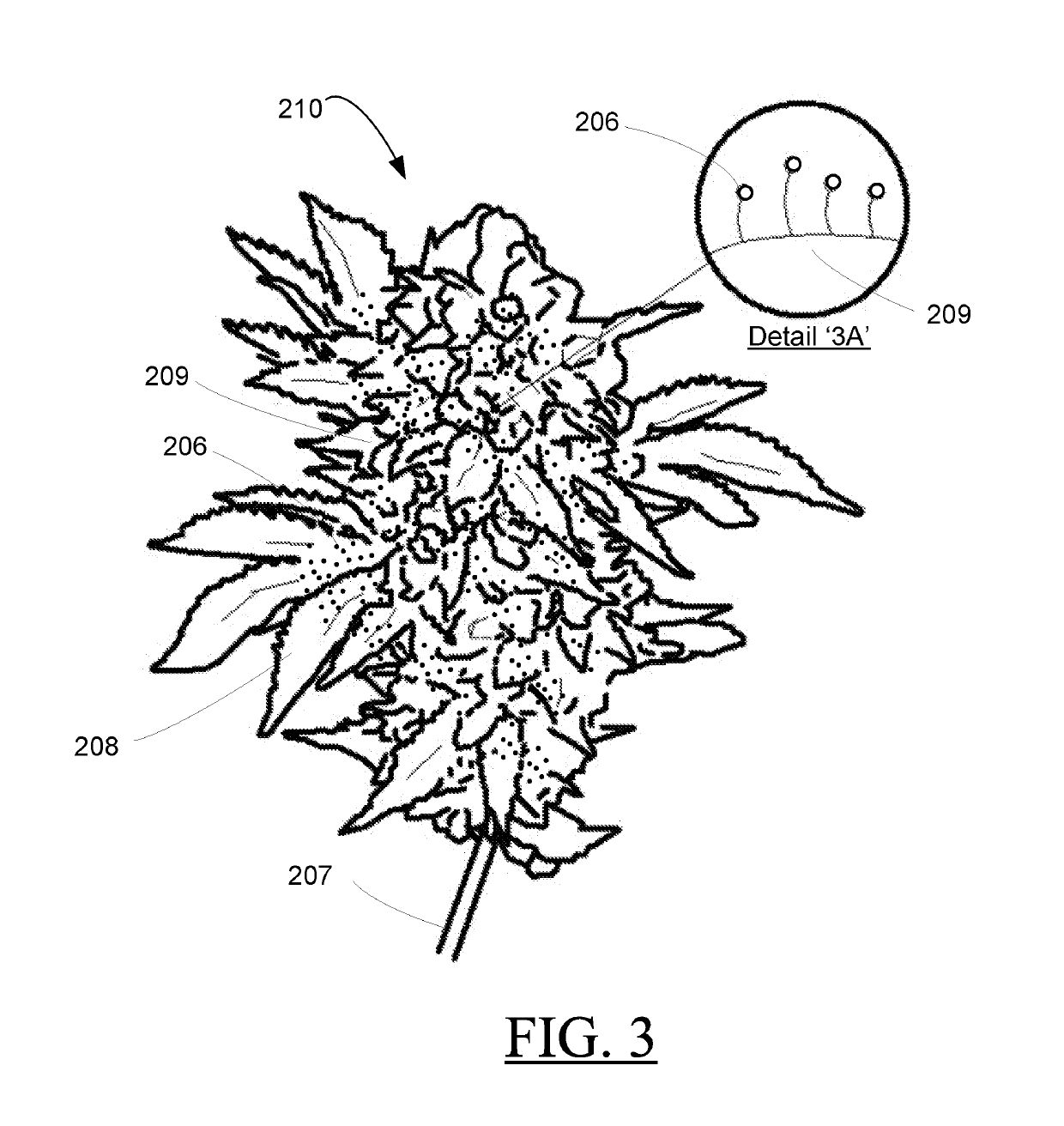

Cryogenic hop lupulin or cannabis trichome pellets

An enriched trichome pellet product including either a hop derived lupulin component or a cannabis derived trichome component, and the associated cryogenic and mechanical method for the efficient production of the pellet product. The pellet is produced at low temperatures, which aids in pellet production eliminating degradation of the hop lupulin having a high alpha acid and essential oils content that is especially suited for use in the brewing of beer and hop flavored beverages, and aids in eliminating degradation of the cannabis trichome having aromatic oils, and terpenoids and terpenes as well as therapeutic and psychoactive cannabinoids including THC, CBG, and CBD that is especially suited for use in cannabis component or “cannabinoid” enriched products.

Owner:YAKIMA CHIEF HOPS LLC

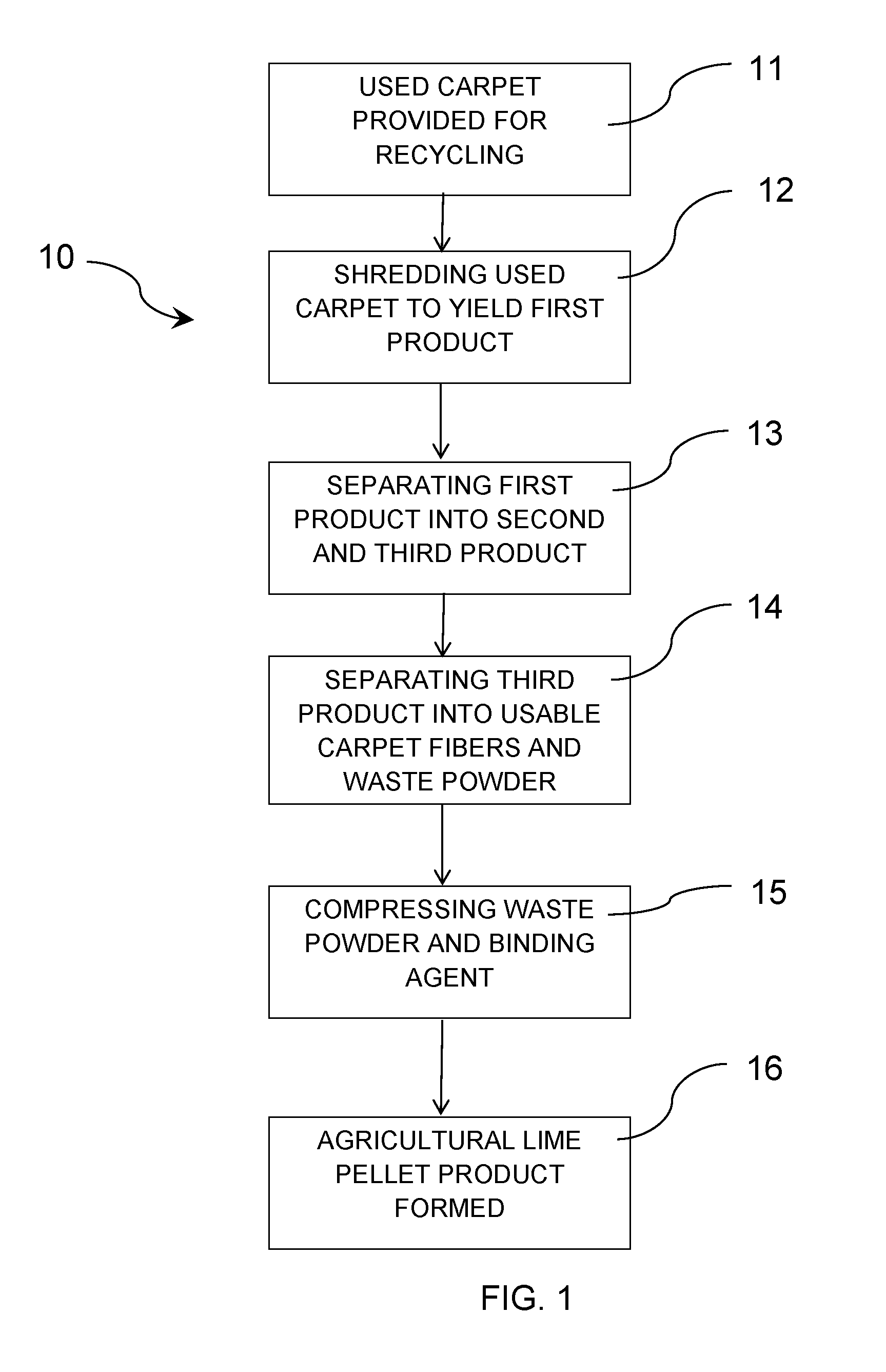

Process for making pellet product for use in soil neutralization and other applications

InactiveUS20170044346A1Reduce dust emissionsEasy to handleOther chemical processesAnimal housingFiberPrill

Recycled carpet mineral filler material is processed to form pellets that can be used in a variety of applications, such as an agricultural lime product, an asphalt paving additive, a loss control material, or cat litter. Used carpet undergoes a shredding process separating valuable resin fibers from the mineral filler and the residual glue. The mineral filler / residual glue undergoes a screening process and then a pelletizing process to produce an agricultural lime product. A liquid or dry adhesive binder can be added to facilitate compaction of the mineral filler in such a manner as to form a pellet, which reduces dust and increases the ease of handling.

Owner:WATERS JOHN HINTON

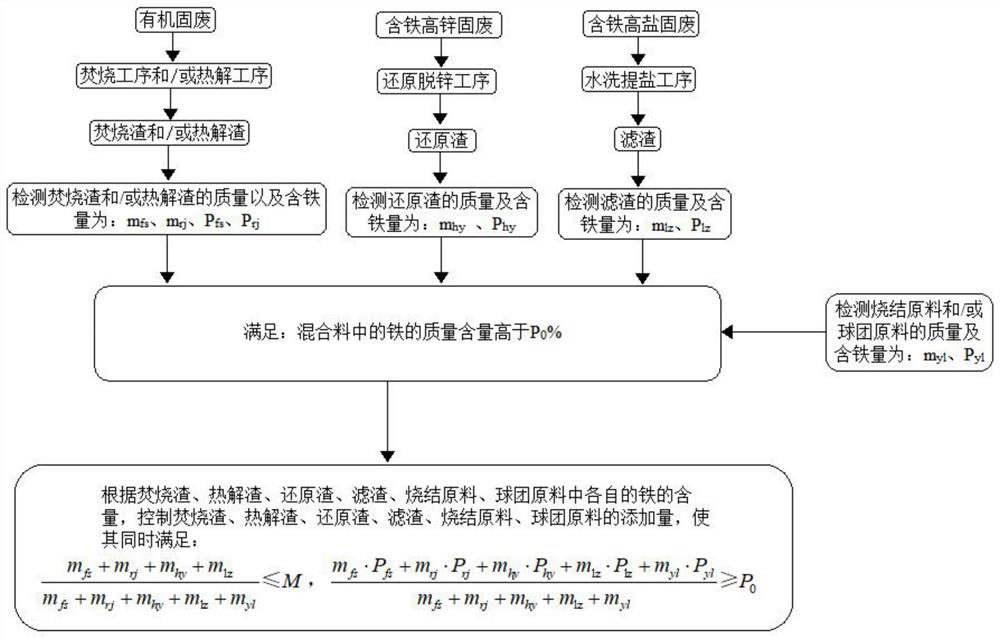

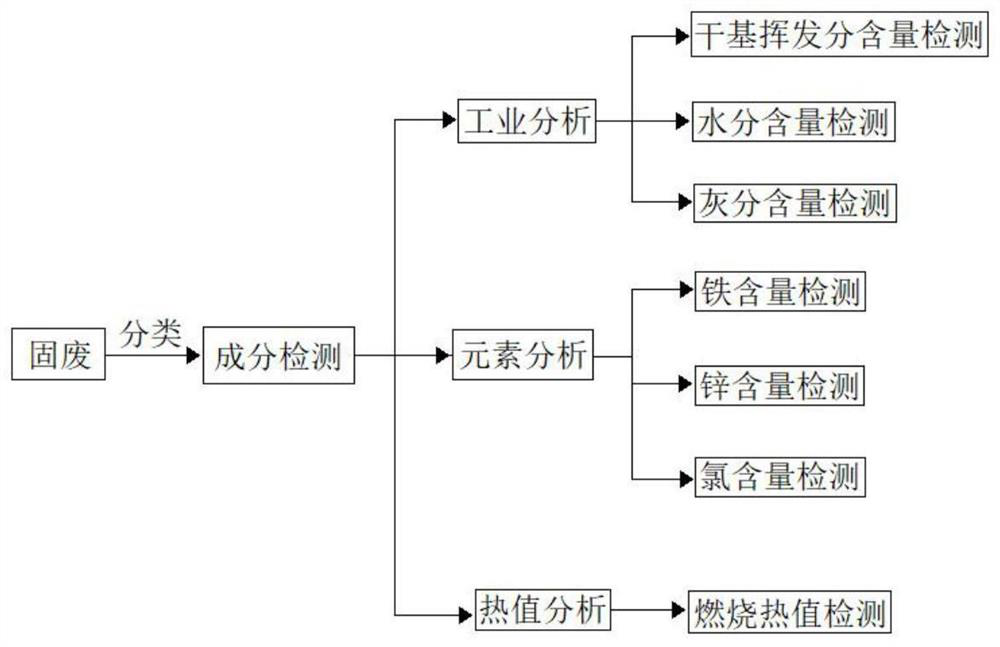

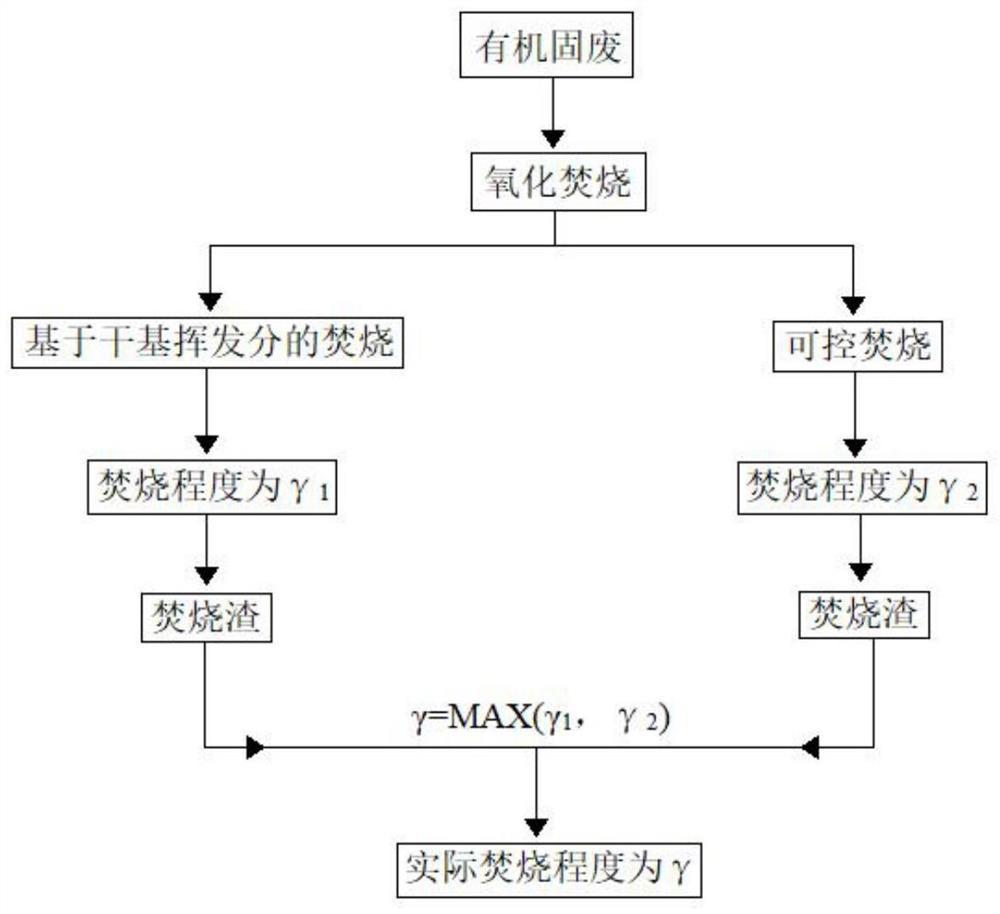

Solid waste, sintering and pelletizing co-treatment process capable of guaranteeing iron grade

ActiveCN113122709AEliminate the effects ofEliminate the risk of secondary pollutionProcess efficiency improvementSlagMixed materials

The invention discloses a solid waste, sintering and pelletizing co-treatment process capable of guaranteeing the iron grade. The process comprises the following steps that the adding amount of incineration slag, pyrolysis slag, reducing slag, filter residues, sintering raw materials and pelletizing raw materials is controlled according to the respective iron content in the incineration slag, pyrolysis slag, reducing slag and filter residues obtained after solid waste pretreatment, the sintering raw materials and the pelletizing raw materials. Therefore, the mass content of iron in the mixed material is controlled to meet the production requirement of actual working conditions on the mass content of iron, cooperative treatment of various solid wastes is achieved, finally, full-process treatment of the various solid wastes is achieved, and the influence of the solid wastes on the environment and the risk of secondary pollution are thoroughly eliminated. Besides, the quality of sintered and / or pellet products is ensured.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Chromium-molybdenum metal self-reducing pellets and method for preparing and directly alloying molten steel

The invention relates to alloy steel smelting, and particularly relates to a chrome-molybdenum metal self reduction pellet and preparation and direct steel liquid alloying methods thereof. The pellet comprises the following components according to mass percentage: 40-65 percent of high-carbon ferrochrome powder, 15-40 percent of molybdic oxide powder, 5-15 percent of a reductant and 3-5 percent of a flux. The self reduction pellet product is added to a ladle during electric furnace or convertor tapping, under the action of high-temperature molten steel and a pellet inner reductant, metal elements in the pellet are effectively reduced, as a result, the molten steel is directly alloyed; the self reduction pellet product is applied in alloy steel including stainless steel, wear resistant steel and the like, which contain elements Cr and Mo, and not only is the procedure for the production of ferro molybdenum saved, but also the elements Cr and Mo can be added at one time, so that the cost of adding alloy elements is lowered, the smelting cycle is shortened, meanwhile, the use range of high-carbon ferrochrome is widened, and furthermore, the problem that the element Mo is difficult to add and settle and great in volatilization during the steel smelting is solved.

Owner:JIANGSU UNIV

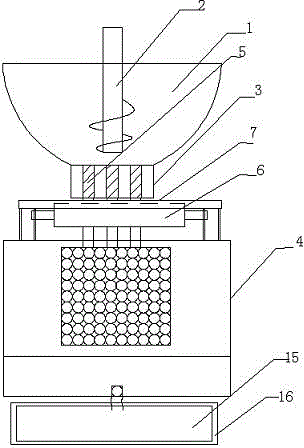

Pelleting device for processing food

The invention relates to a pelleting device for processing food. The pelletinng device comprises a feeding hopper, wherein a stirring shaft which is driven by a motor to rotate is inserted into the feeding hopper, a forming plate with a plurality of cylindrical holes is arranged below the feeding hopper, a box body is arranged below the forming plate, a left circle formation template and a right circle formation template which are driven by an air cylinder are respectively arranged on the left side and the right side in the box body, the left side wall and the right side wall of the box body are respectively provided with a plurality of knocking blocks, the lower end of the box body is provided with an oblique bottom surface, a plurality of impurity drain holes are formed in the oblique bottom surface, a waste chute is arranged below the box body and below the impurity drain holes, a circle formation discharging opening is formed below the box body, a curing rotation box is arranged below the circle formation discharging opening, and a heating layer is arranged at the outer side of the curing rotation box. The pelleting device is simple in structure and reasonable in design; not only can the product quality be improved, but also the circle formation rate is high, and a product is not prone to scatter. The pelleting device is suitable for producing different pellet products and also can be used for producing dumpling stuffing.

Owner:DALIAN DONGLIN FOOD

Method and process for preparing Huahua pellet

InactiveCN101874541ATake advantage ofAvoid pollutionConfectionerySweetmeatsMaterials preparationResource saving

The invention relates to a method and a process for manufacturing Huahua pellets, belonging to the technical field of food processing processes. A raw material can comprises plum grains or other conserved fruit product leftovers. The main process comprises the steps of material preparation, powder grinding, powder screening, sugar liquor addition, seasoning, polishing, Huahua pellet model preparation, Huahua pellet enlarging, Huahua pellet flavoring, Huahua pellet polishing, drying, screening for grading and packaging. The invention has the advantages of waste utilization, environmental protection and resource saving, and the prepared pellet product has the effects of comforting, palatability, cooling, body fluid generation and thirst pacification when being kept in the mouth and is convenient for carrying.

Owner:GUANGDONG KANGHUI GROUP

Preparation method of hollow pellet containing boron zirconium alloy burnable poison

ActiveCN103160706AIncrease fuel consumptionSolve technical problems that are difficult to form with steel moldsOptical rangefindersNuclear energy generationZirconium hydrideSuperhard material

The invention provides a preparation method of a hollow pellet containing boron zirconium alloy burnable poison. The method is as below: mixing boron carbide particles with size less than 5mum with a zirconium hydride-2 powder; pressing the mixture by a steel mold into a hollow pellet blank; and conducting dehydrogenation sintering and machining on the hollow pellet blank, so as to prepare a hollow pellet product containing boron zirconium alloy burnable poison. The hollow pellet containing boron zirconium alloy burnable poison prepared by the method provided by the invention has thickness less than 2mm, density higher than 95% and opening pore rate less than 2%, satisfies relevant technological requirements of pellet containing boron zirconium alloy burnable poison used in reactors; the method solves a technical problem that a powder containing a superhard material is difficult to be molded by a steel mold, and greatly improves molding precision and utilization rate of pellet containing superhard particle material; and compared with rubber molding preparation of a solid boron carbide zirconium alloy combustible poison pellet, the method reduces consumption of the raw material zirconium hydride by more than 60%.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for directly reducing and producing metallized pellets by utilizing sensible heat of high-temperature oxidized pellets

InactiveCN105177292AEmission reductionReduce coal consumptionDestructive distillationHot Temperature

The invention belongs to the technical field of metallurgy, in particular to a method for directly reducing and producing metallized pellets by utilizing sensible heat of high-temperature oxidized pellets. The method comprises the following steps: preparing high-temperature oxidized pellets by adopting a single-chain grate-rotary kiln process, and utilizing the sensible heat of the high-temperature oxidized pellets to directly carry out reduction reaction with a reducing agent (coals); then, adopting normal-temperature reducing coal to carry out heat exchange and cool, and obtaining metallized pellet products and a dried reducing agent (including destructive distillation cokes) after magnetic separating. The method can be used for recycling the destructive distillation cokes and recycling high-purity coal gas; the recycled destructive distillation cokes can be used as a reducing agent; the high-purity coal gas can provide energy resources for an oxidized pellet rotary kiln and a muffle type deep-reduction rotary kiln without additionally introducing energy resources for heating. The method can reduce coal consumption by 40%-60%; and the burnt high-purity coal gas can be used for reducing carbon emission, saving energy and protecting environment.

Owner:泉州寰锋冶金技术有限责任公司

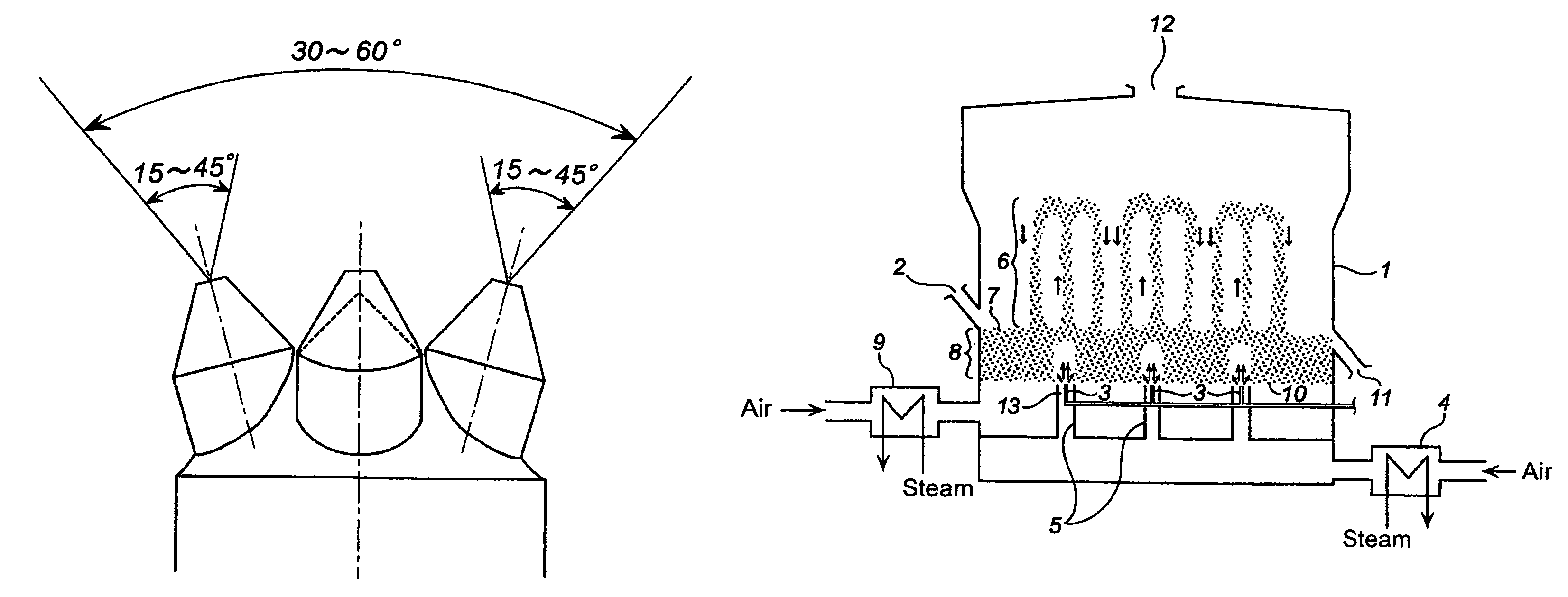

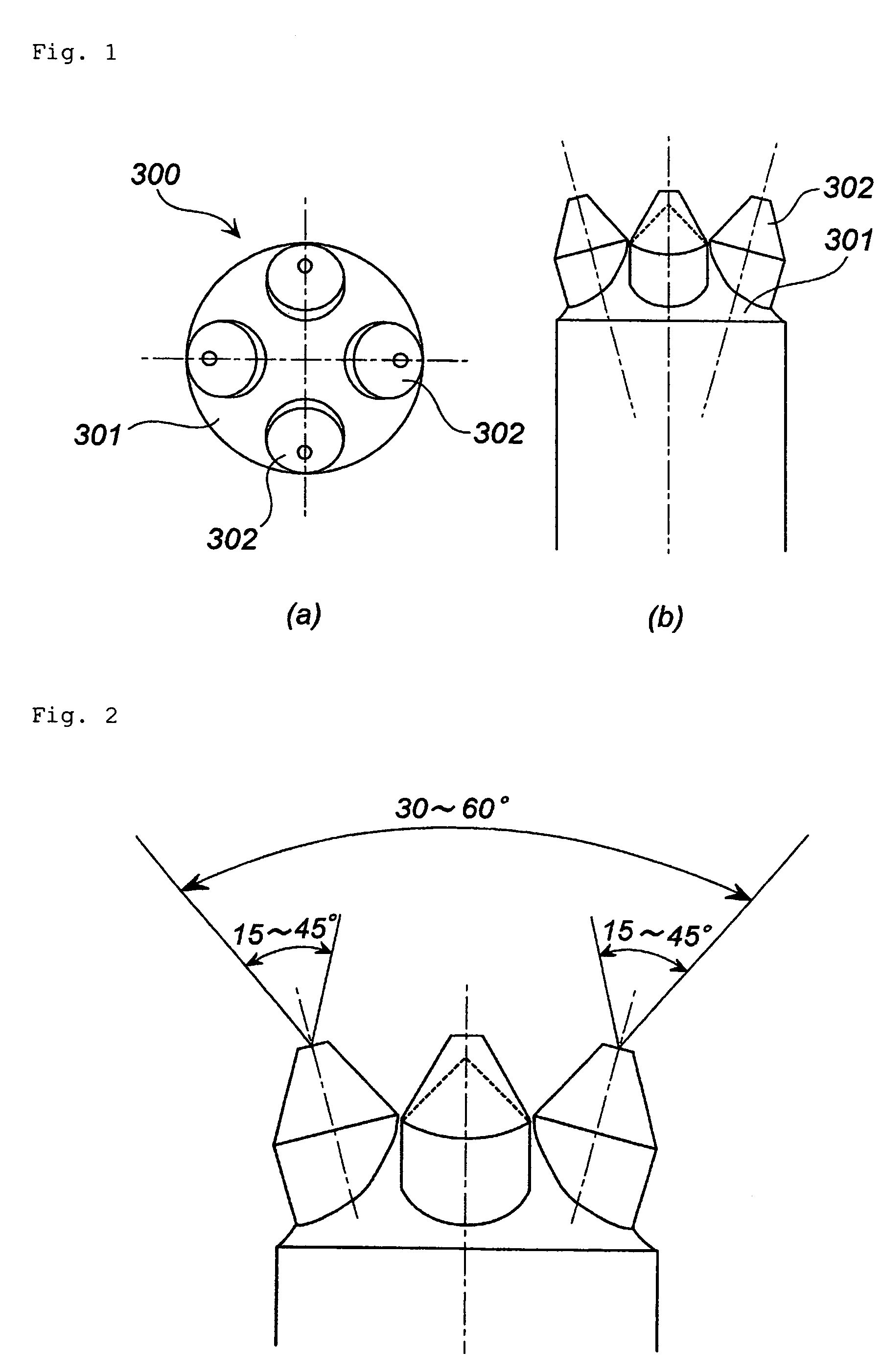

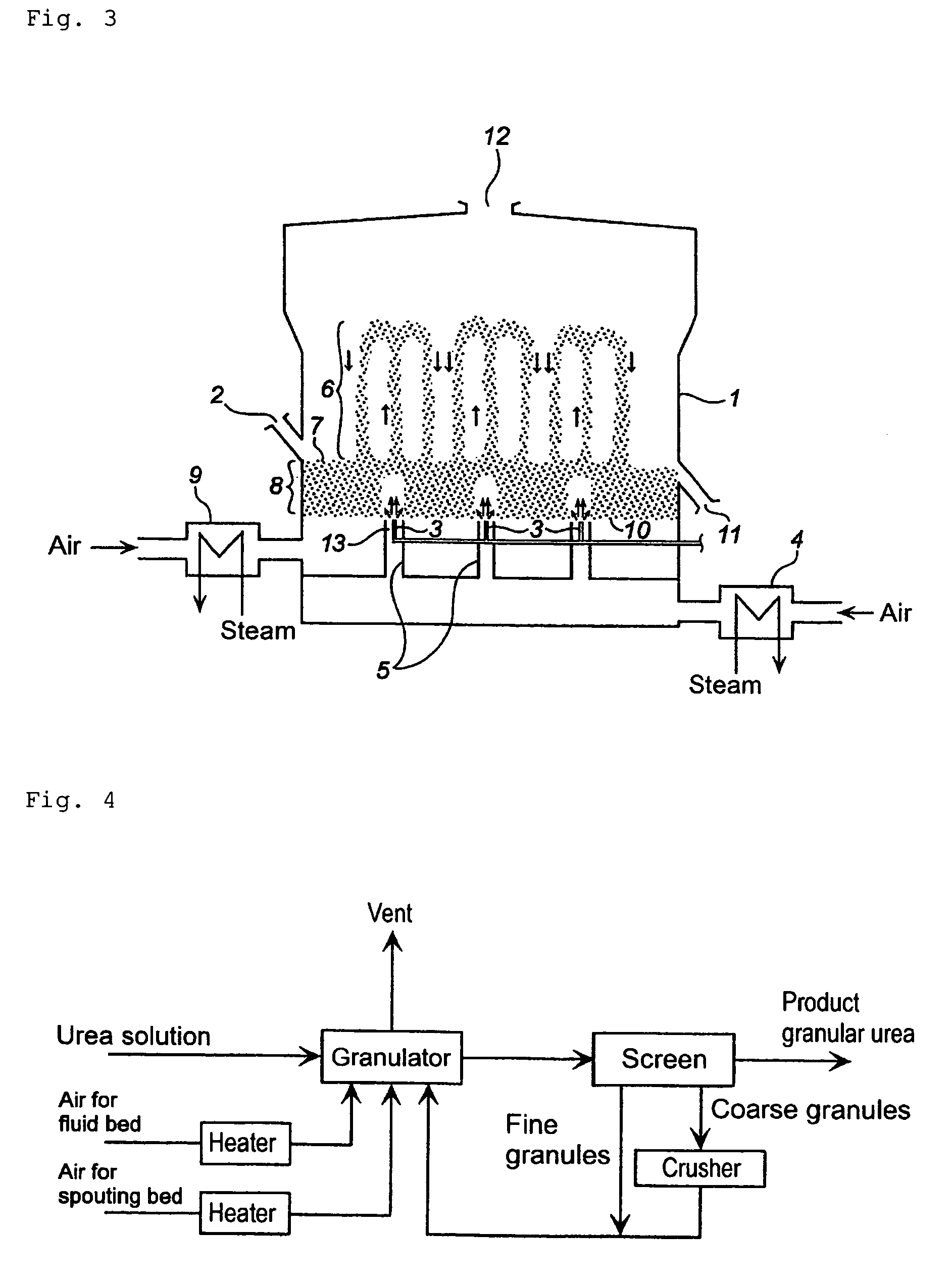

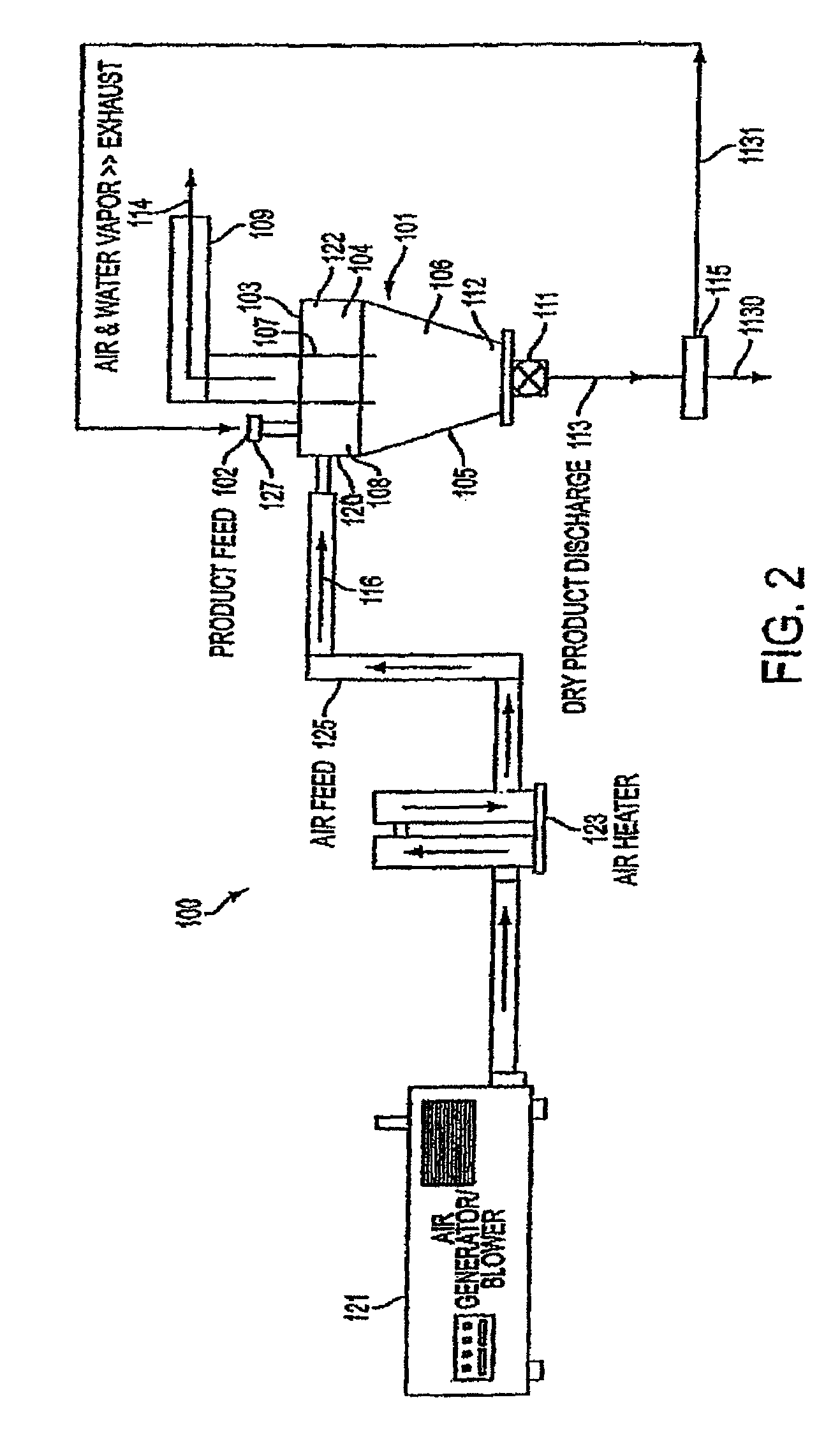

Multi-nozzle for granulation and method for manufacturing granular product

ActiveUS7344663B2Keep dryDrying solid materials with heatPretreated surfacesEngineeringAqueous solution

The present invention provides a granulation method with increased drying effect while assuring the pressure for spraying the aqueous solution and the necessary number of nozzles equivalent to those of conventional design. Specifically, the granulation method uses a granulator structured by a fluid bed which fluidizes the granulating-particles, an air feed pipe to introduce air, a nozzle for spraying the raw material aqueous solution being located at center part of the air feed pipe, and a perforated plate to feed a fluidization air to the fluid bed, thus granulating the raw material aqueous solution by spraying thereof from the nozzle into a granulation part, wherein a multi-nozzle in a specified shape having a plurality of nozzle ends thereon is used as the nozzle for spraying the raw material aqueous solution.

Owner:TOYO ENG CORP

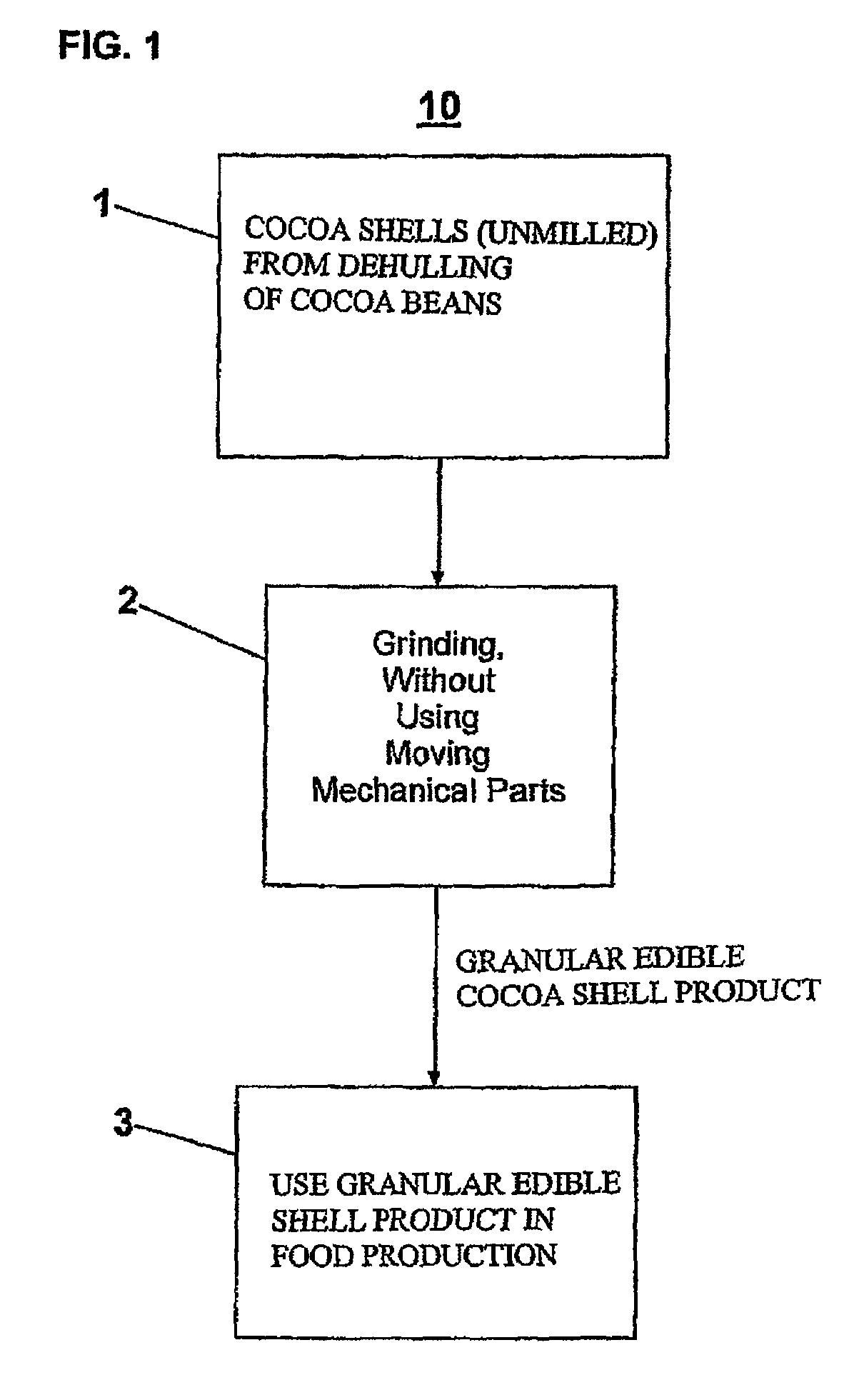

Process for milling cocoa shells

A process for preparation of milled cocoa shell including grinding cocoa shell in a single unit operation in a short-duration manner without the need for moving mechanical parts. The milled cocoa shell product obtained from the grinding treatment has reduced heat degradation and avoids equipment maintenance concerns otherwise associated with mechanical milling of the cocoa shells while providing an edible granular product useful for food manufacture such as chocolate food production.

Owner:KRAFT FOODS SCHWEIZ HLDG AG

Method for reducing high-density metallized pellet

ActiveCN102936653BReduce consumptionReduce manufacturing costFluidised-bed furnacesHigh densityFree cooling

The invention relates to a method for reducing a high-density metallized pellet, belonging to the technical field of metallurgy. The method comprises the following steps: (1) preparing a pellet by proportionally and uniformly mixing iron ore powder to be reduced, carbon powder to be contained and a bonding agent; (2) preparing a material to be reduced by proportionally mixing the pellet and a reducer; (3) putting the material to be reduced into a reduction container, then transferring into a reduction kiln, and performing reduction reaction at 1220-1260 DEG C for 6-8 hours; and (4) after the reaction, naturally cooling the material in a kiln car to 200 DEG C, separating the reducer tailing and the metal pellet, performing surface sanding, and cleaning to obtain the high-density metallized pellet product of which the density is 3.8-4.2 t / m<3>. According to the method provided by the invention, the original kiln reduction operation is not changed, the reduced iron does not need to be crushed and subjected to cold briquetting, the production cost can be lowered, the energy consumption can be reduced, the steel making application is facilitated, the production process is stable, and the metallization rate is improved. Thus, the method provided by the invention has favorable application prospects.

Owner:江苏靖隆合金钢机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com