Patents

Literature

502 results about "Pellet fuel" patented technology

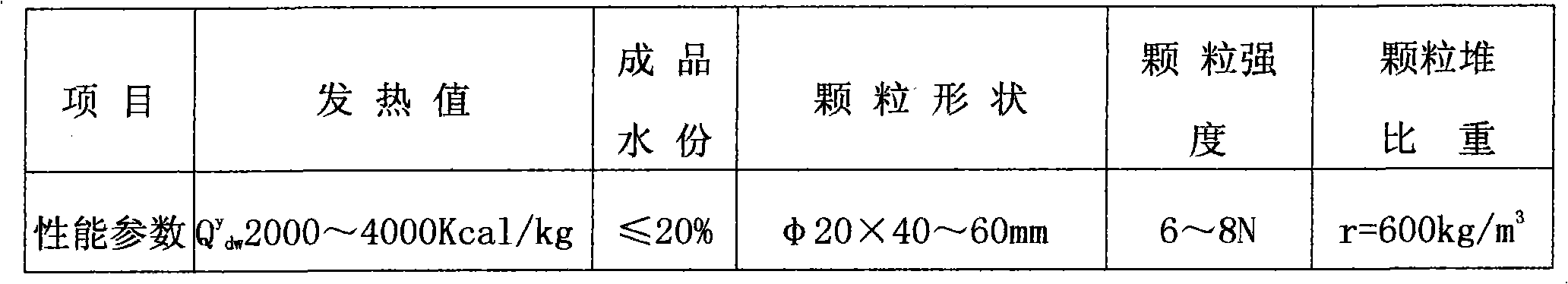

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pellet fuels (or pellets) are biofuels made from compressed organic matter or biomass. Pellets can be made from any one of five general categories of biomass: industrial waste and co-products, food waste, agricultural residues, energy crops, and virgin lumber. Wood pellets are the most common type of pellet fuel and are generally made from compacted sawdust and related industrial wastes from the milling of lumber, manufacture of wood products and furniture, and construction. Other industrial waste sources include empty fruit bunches, palm kernel shells, coconut shells, and tree tops and branches discarded during logging operations. So-called "black pellets" are made of biomass, refined to resemble hard coal and were developed to be used in existing coal-fired power plants. Pellets are categorized by their heating value, moisture and ash content, and dimensions. They can be used as fuels for power generation, commercial or residential heating, and cooking. Pellets are extremely dense and can be produced with a low moisture content (below 10%) that allows them to be burned with a very high combustion efficiency.

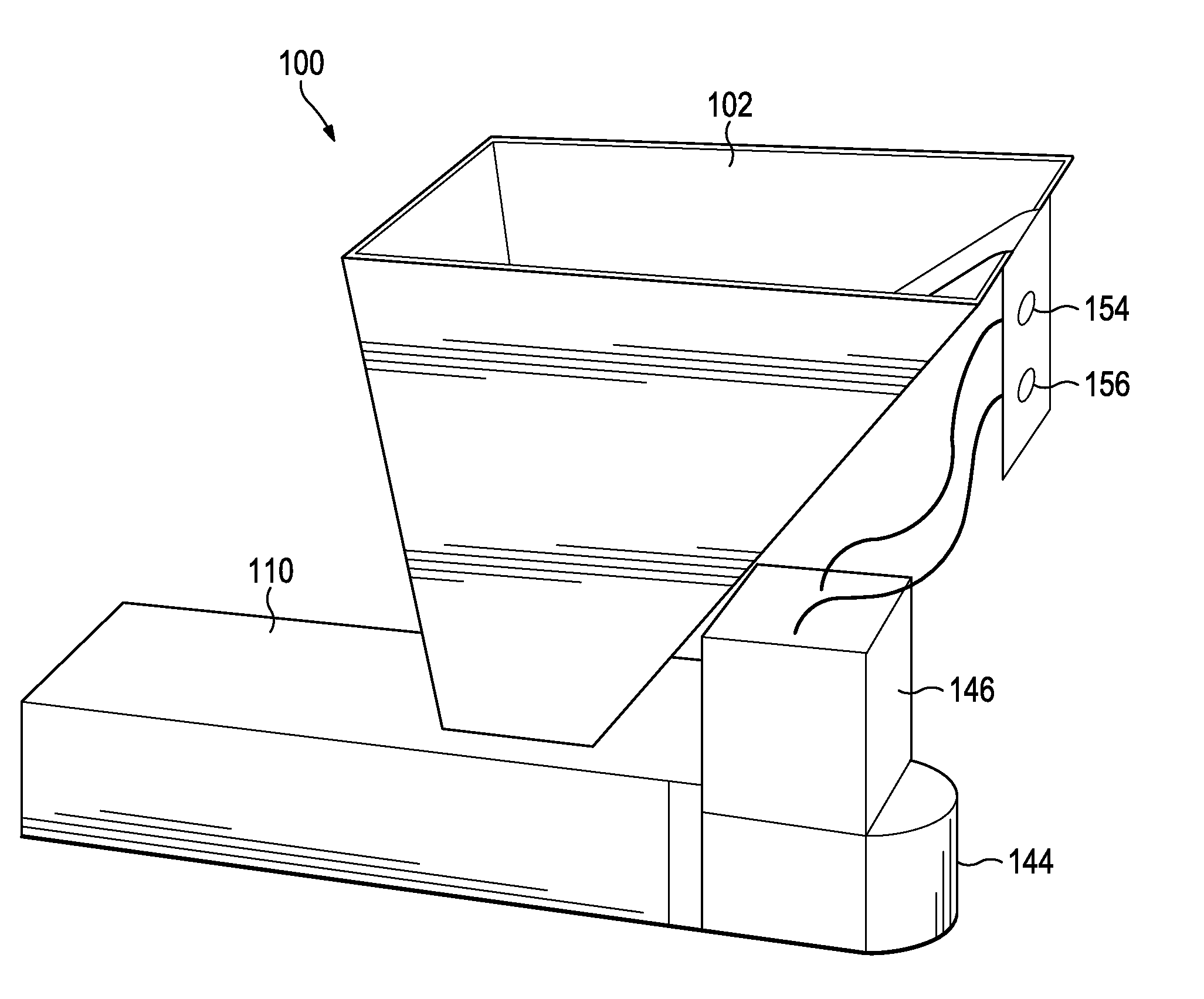

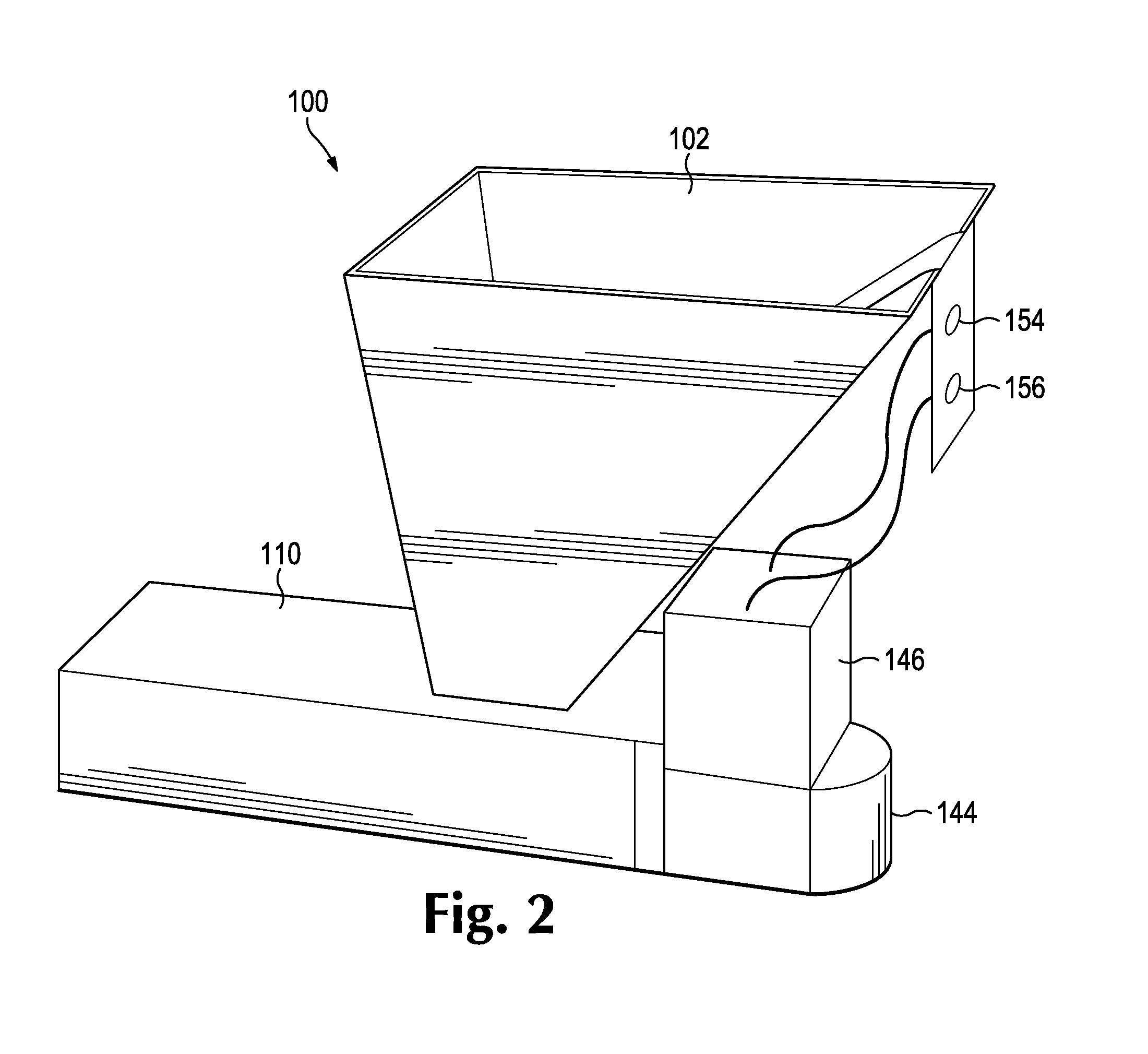

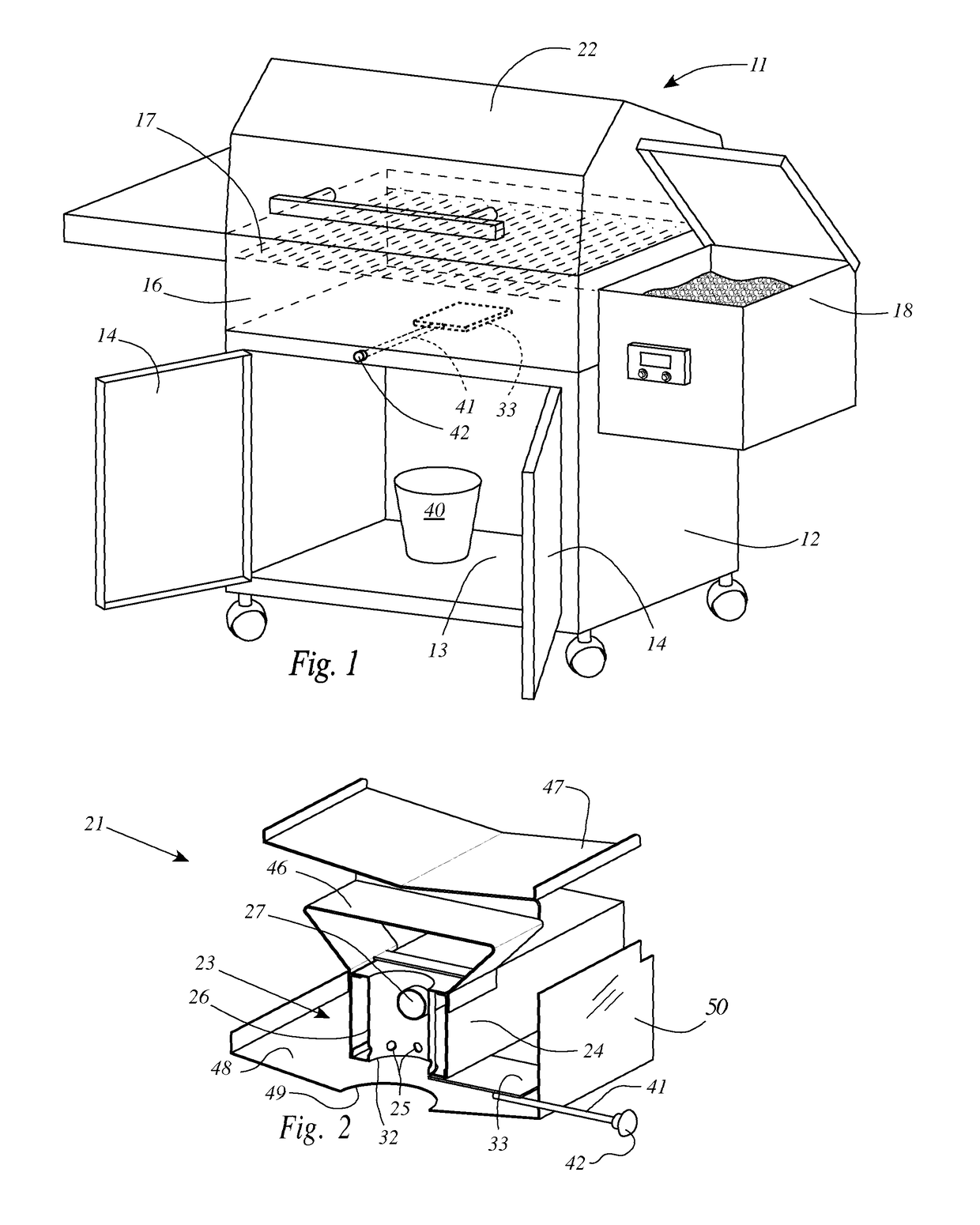

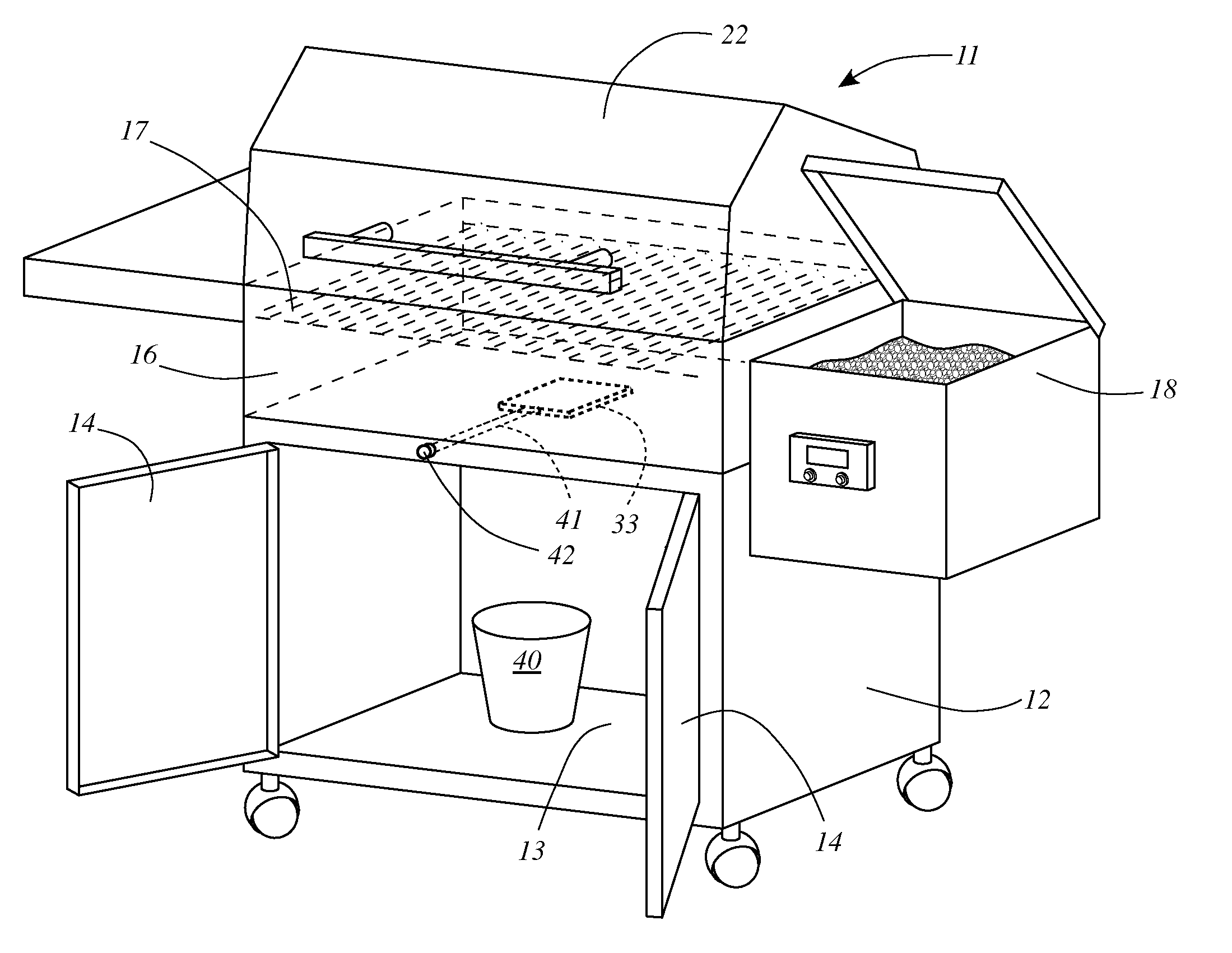

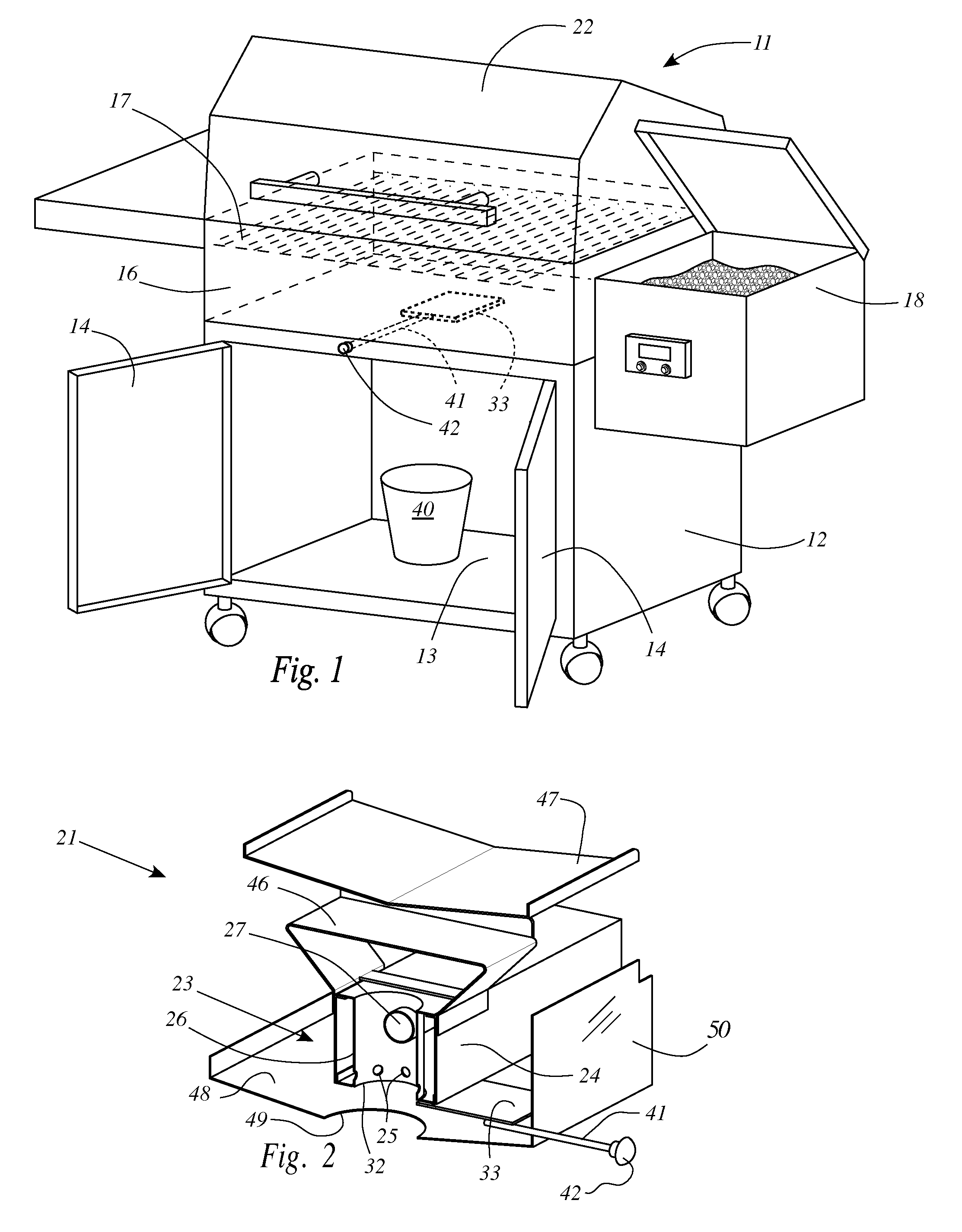

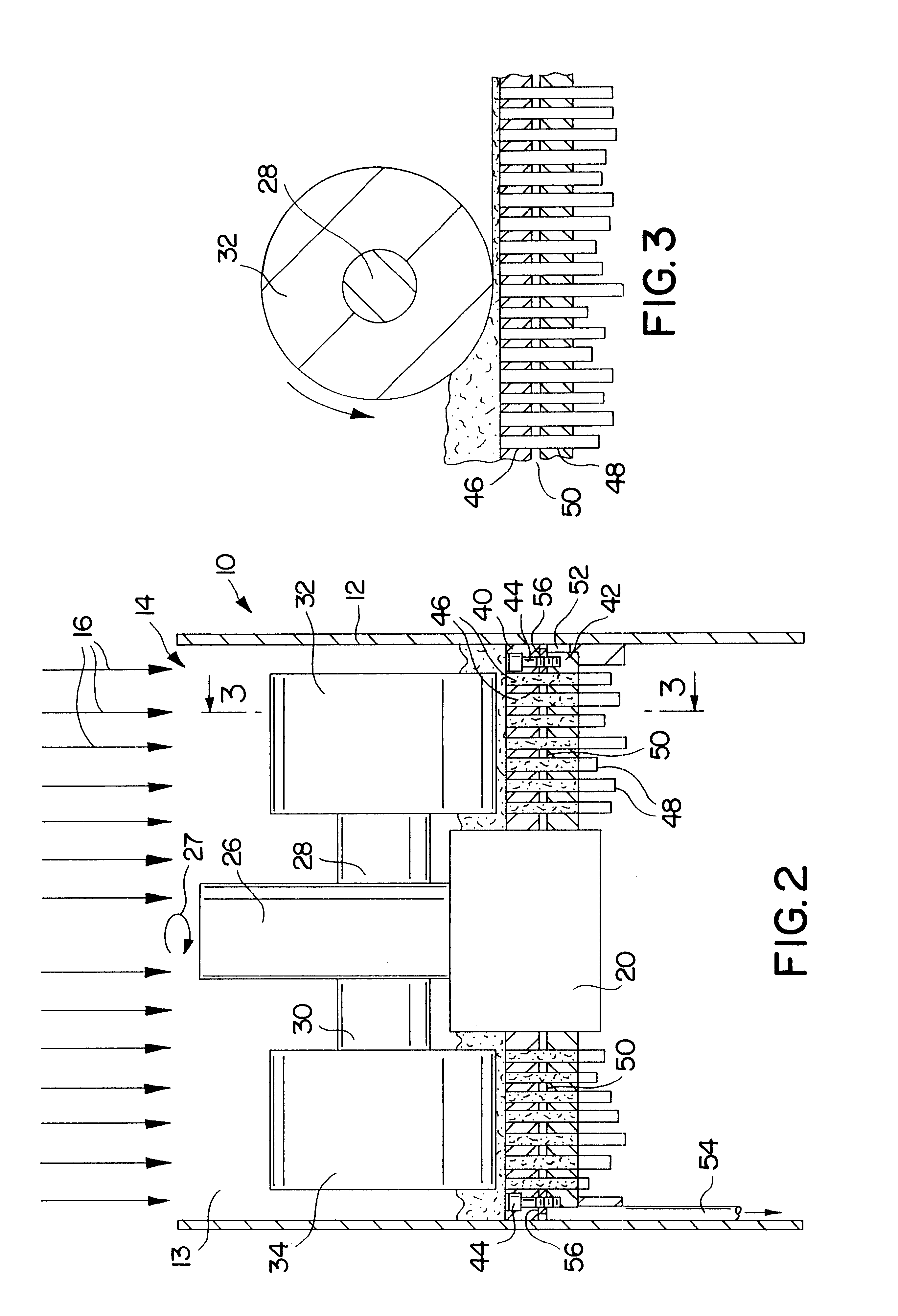

DC pellet burner assembly

InactiveUS20140326233A1Improve portabilityProvide such operationDomestic stoves or rangesLighting and heating apparatusCombustorEngineering

A wood-fuel pellet burner assembly, such as for barbecues, includes a gravity-feed pellet fuel hopper positioned in alignment with a pellet fuel intake and a perforated pellet fuel slide that extends to a combustion region. A DC ignitor has a heating element that extends into the combustion region, and a DC fan is positioned to direct a flow of air through the perforated pellet fuel slide and into the combustion region. A DC power source, such as a vehicle-grade 12-volt battery, is coupled to and powers the DC ignitor and the DC fan.

Owner:ORIGINAL PELLET GRILL CO LLC

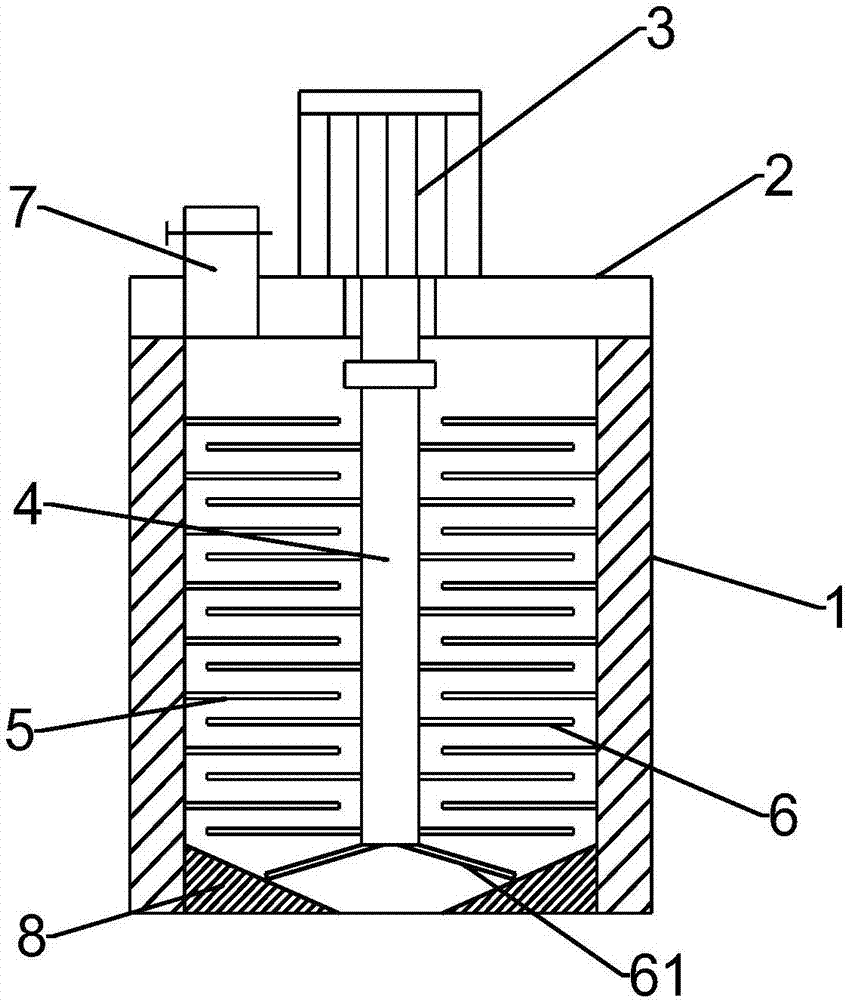

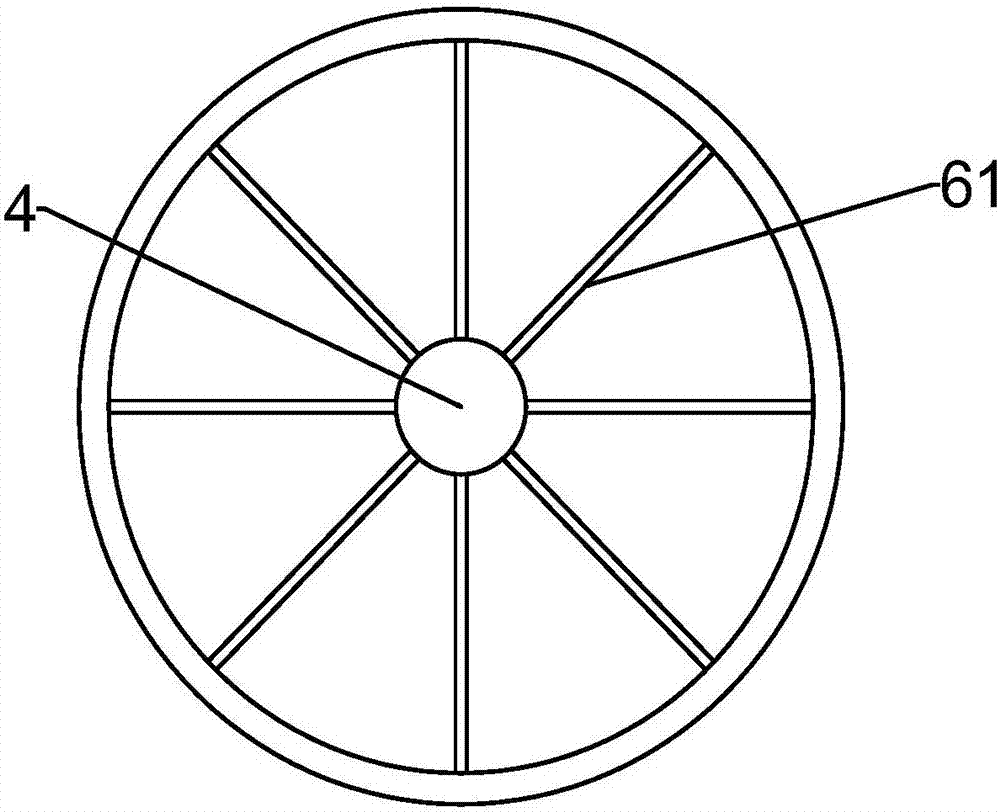

Raw material cleaning and crushing device for biomass pellet fuel

InactiveCN106914318AAvoid incomplete crushingEfficient crushingGrain treatmentsPressesCamWater collection

The invention discloses a raw material cleaning and crushing device for biomass pellet fuel. The device of the invention comprises a crushing tank, a support backing plate, a dehydration chamber, a discharging baffle plate, a dehydration baffle plate, a dehydration push pedal, a water collection chamber, a material collection chamber, a second motor and a cam. The crushing tank is provided with an upper cover, a first motor, a crushing shaft, a fixed blade, a moving blade, a feed pipe, a guide baseboard and a circular cutter group. The support backing plate, the dehydration chamber and the discharging pipe are welded at the lower end of the crushing tank. The discharging baffle plate and a backing plate are movably arranged at the left part of the support backing plate. A sliding groove, a discharge opening, a telescopic rod, the dehydration baffle plate, a push rod and the dehydration push pedal are arranged inside the dehydration chamber. The lower end of the dehydration chamber is provided with the water collection chamber and the material collection chamber. The right wall of the material collection chamber is provided with a movable cover. The upper end of the water collection chamber is equipped with the second motor, a rotating rod, a connecting rod, a support plate, a rotating shaft and the cam. Through the motors for controlling the push rod and the cam, intermittent discharging and automatic extruding-dehydration discharging can be achieved.

Owner:广西众新环保科技有限公司

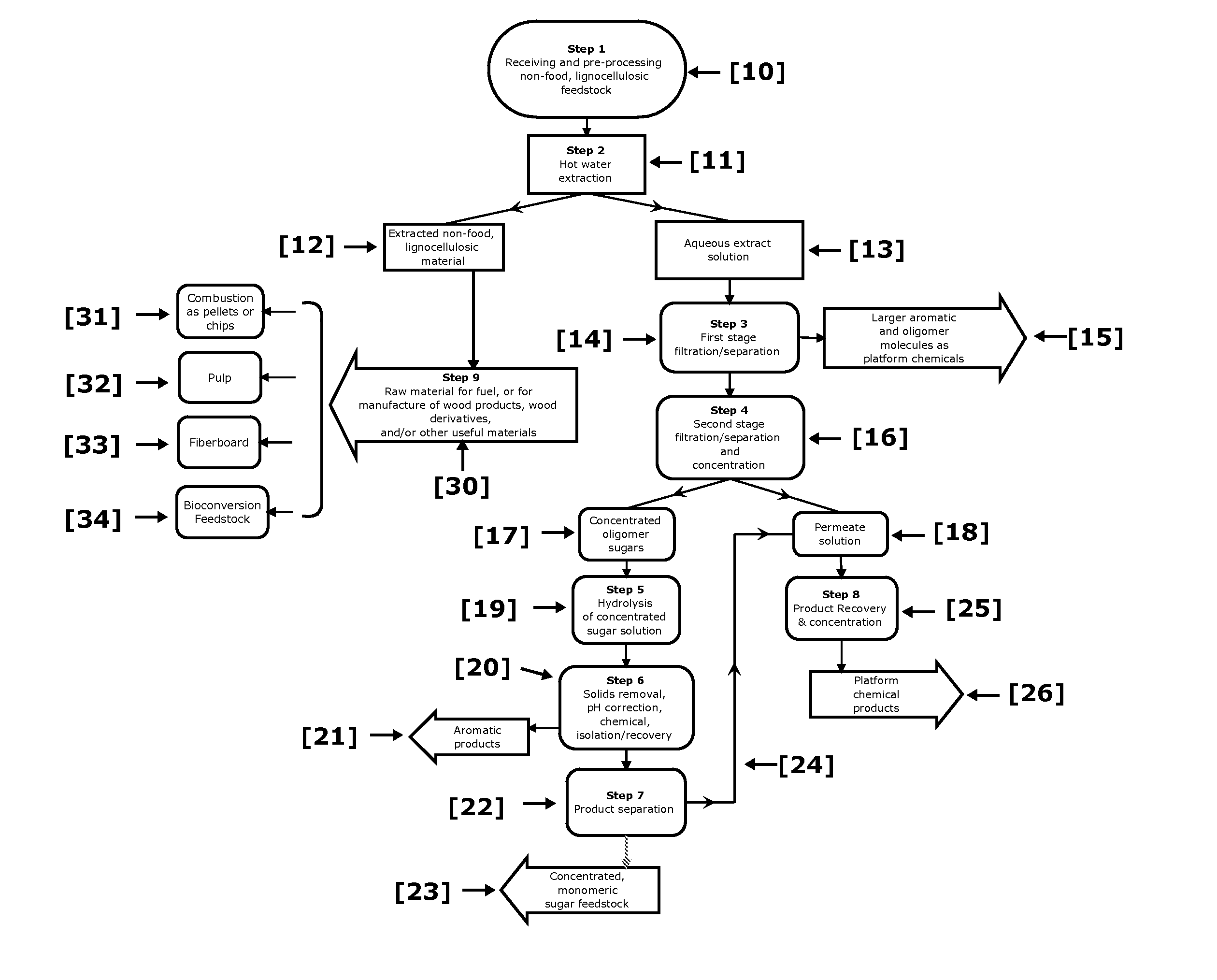

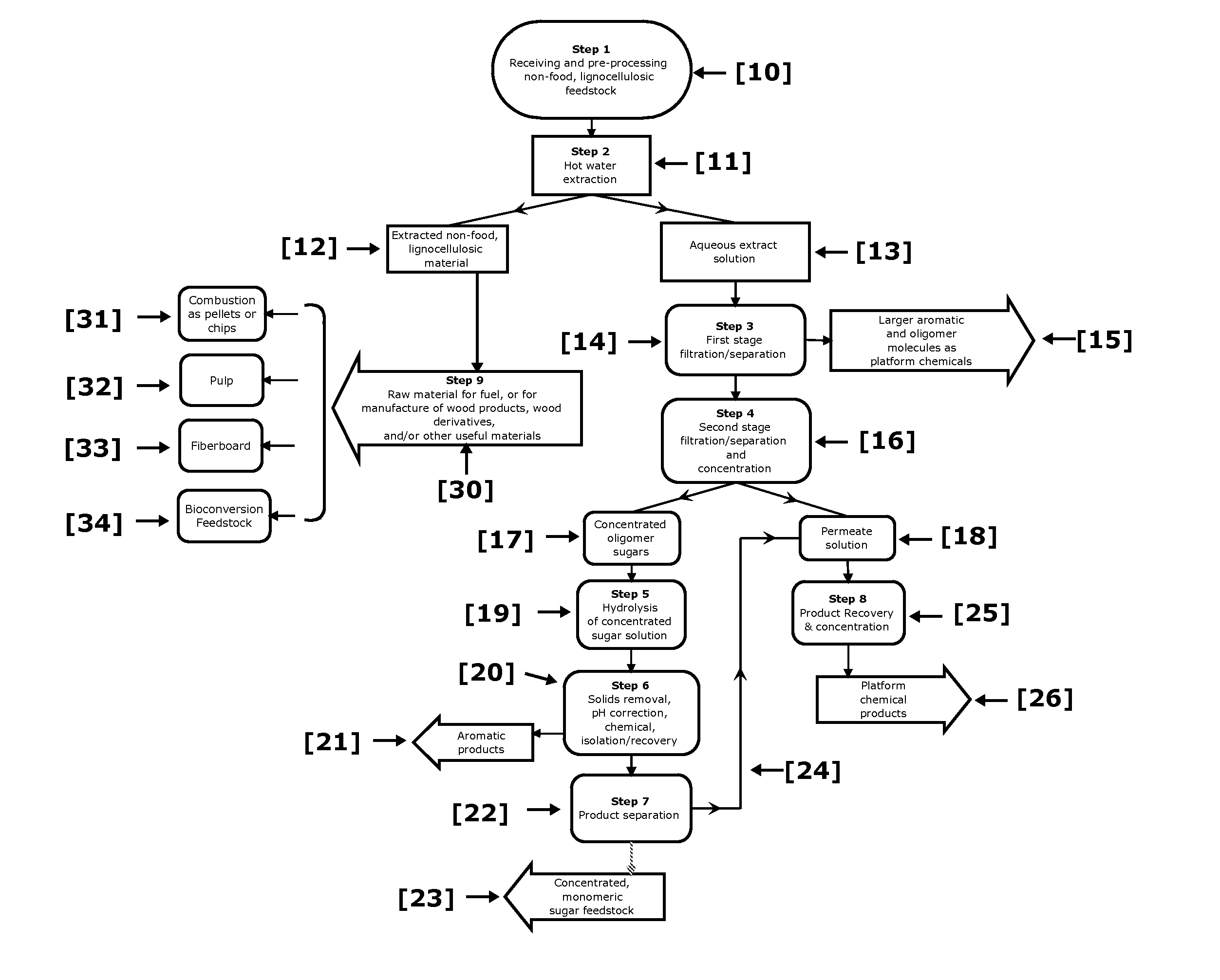

Biorefinery Process for Extraction, Separation, and Recovery of Fermentable Saccharides, other Useful Compounds, and Yield of Improved Lignocellulosic Material from Plant Biomass

ActiveUS20110129886A1Increase diversityIncrease probabilityCellulosic pulp after-treatmentBiofuelsFurfuralAqueous extract

Non-food plant biomass is subjected to hot-water extraction in a pressurized vessel at an elevated temperature up to about 250° C. and at a pH below about 7.0, to yield an aqueous extract containing hemicellulosic components, other wood-derived compounds, and a lignocellulosic residue. The separated aqueous extract or liquor is purified and concentrated through a multi-step process producing fermentable sugars. At each stage, inhibitory chemicals such as acetic acid, lignin, and furfural are separated and eventually recovered as commercial chemicals. The lignocellulosic residue may be further processed, as a material with enhanced resistance to sorption of water, for manufacture of improved pulp and paper, construction materials, pellet fuel, and / or other useful products.

Owner:APPLIED BIOREFINERY SCI

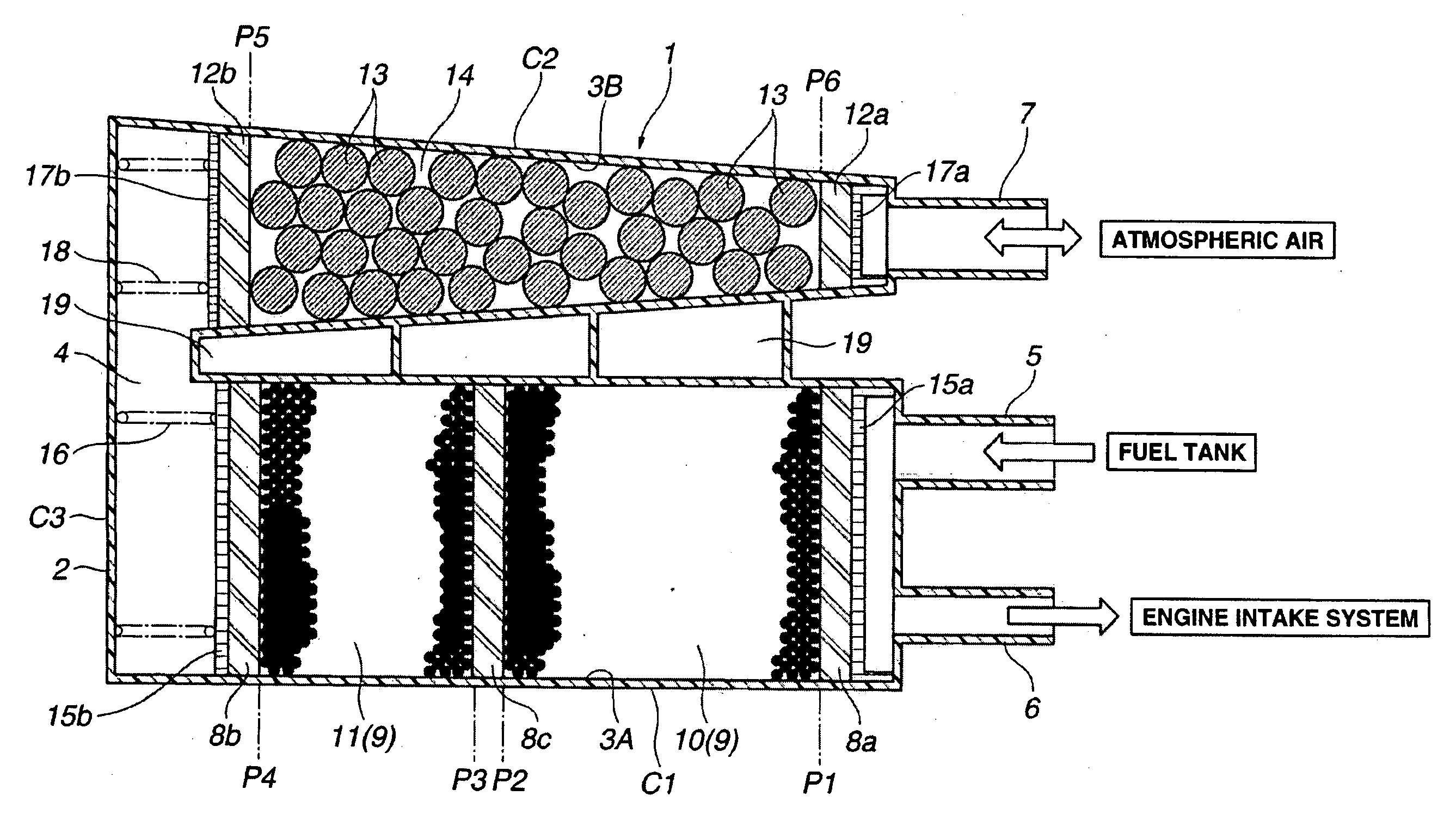

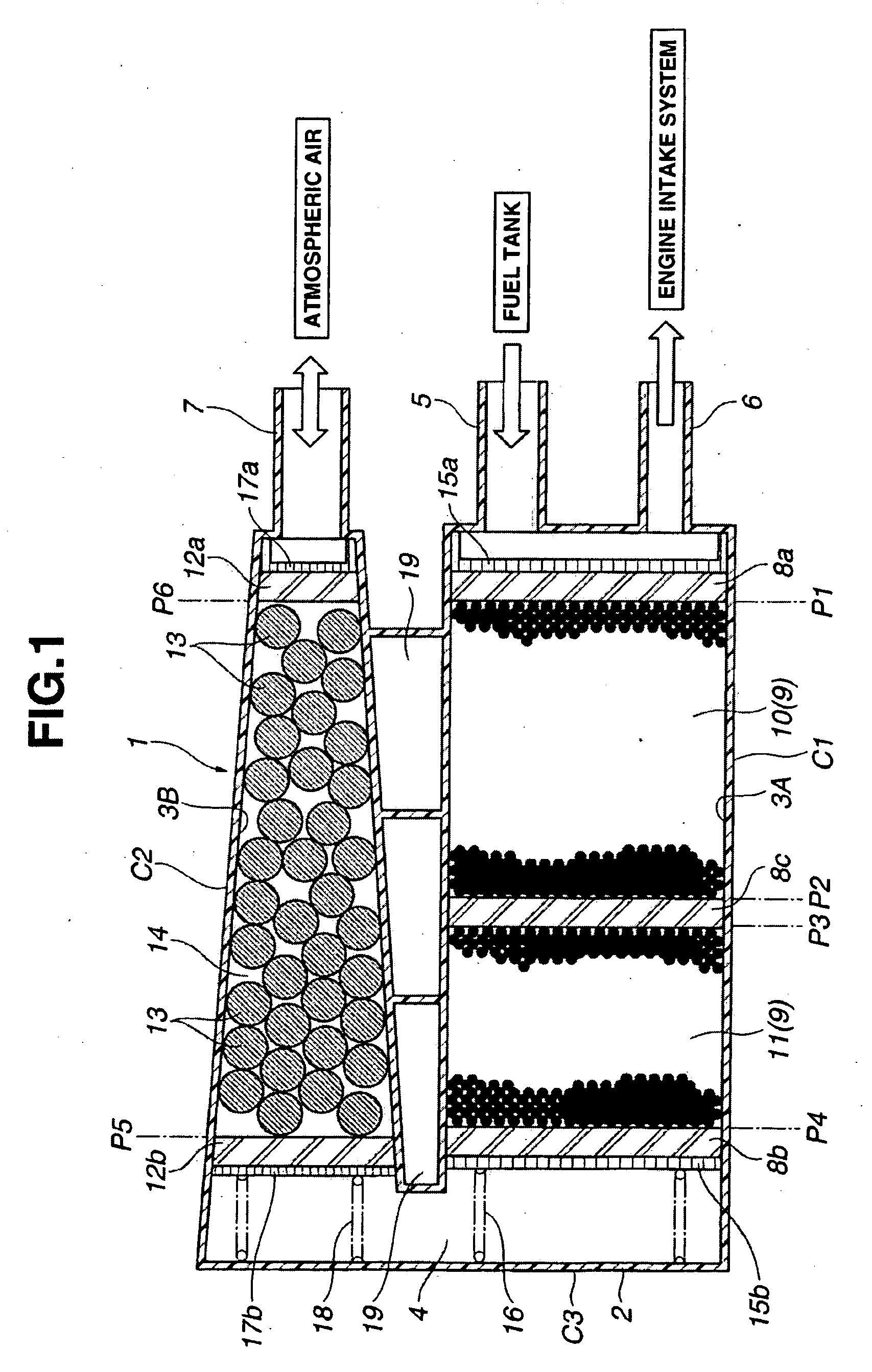

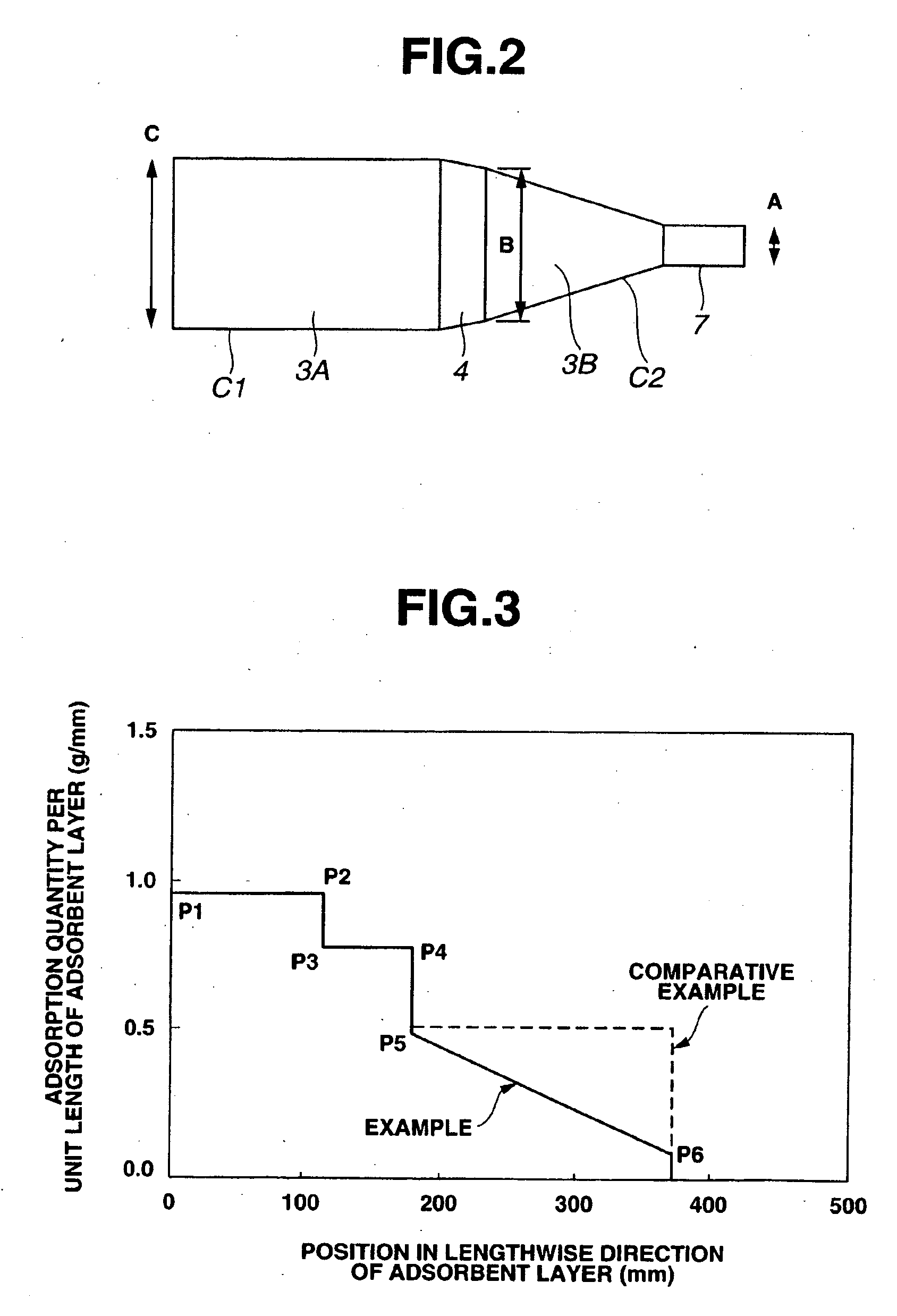

Fuel vapor storage canister, fuel vapor adsorbent for canister, and method of producing fuel vapor adsorbent

ActiveUS20090013973A1Low flow resistanceReduce adsorption speedGas treatmentNon-fuel substance addition to fuelSorbentPellet fuel

A fuel vapor storage canister for adsorbing fuel vapor evaporated from a fuel tank of an automotive vehicle. The fuel vapor storage canister includes a casing provided with charge and purge ports at its first end and an atmospheric port at its second end. At least first and second fuel vapor adsorbent layers are respectively located near the first and second ends of the casing. In this arrangement, the first fuel vapor adsorbent layer is larger in cross-sectional area perpendicular to flow direction of fuel vapor than the second fuel vapor adsorbent layer. The first and second fuel vapor adsorbent layers respectively include first and second granular fuel vapor adsorbents. The first granular fuel vapor adsorbent has a microporous structure, while the second granular fuel vapor adsorbent has a macroporous structure.

Owner:MAHLE JAPAN LTD

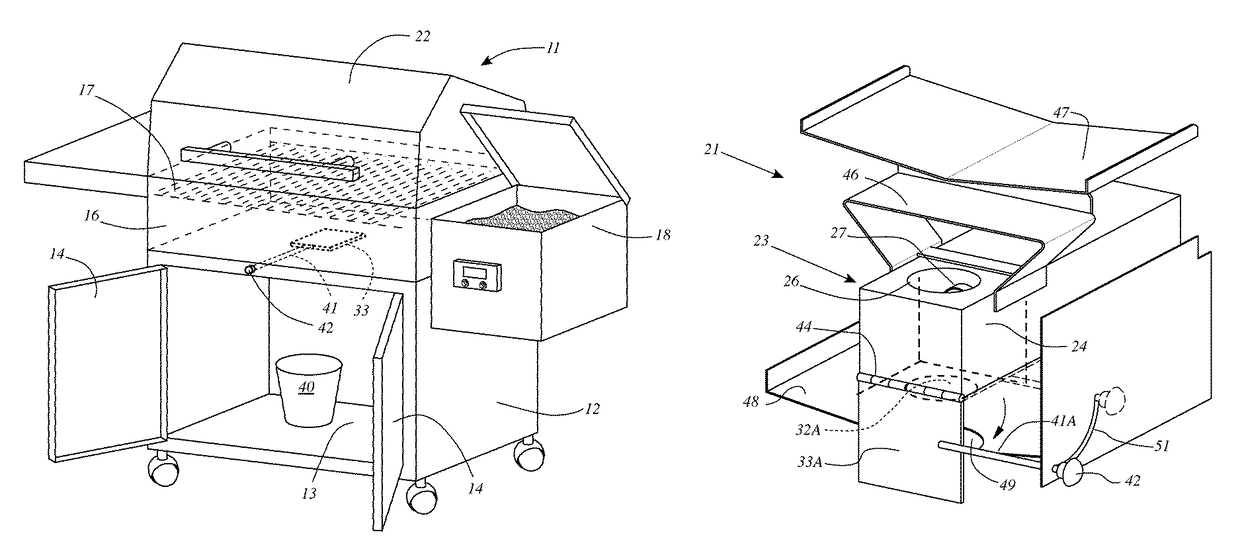

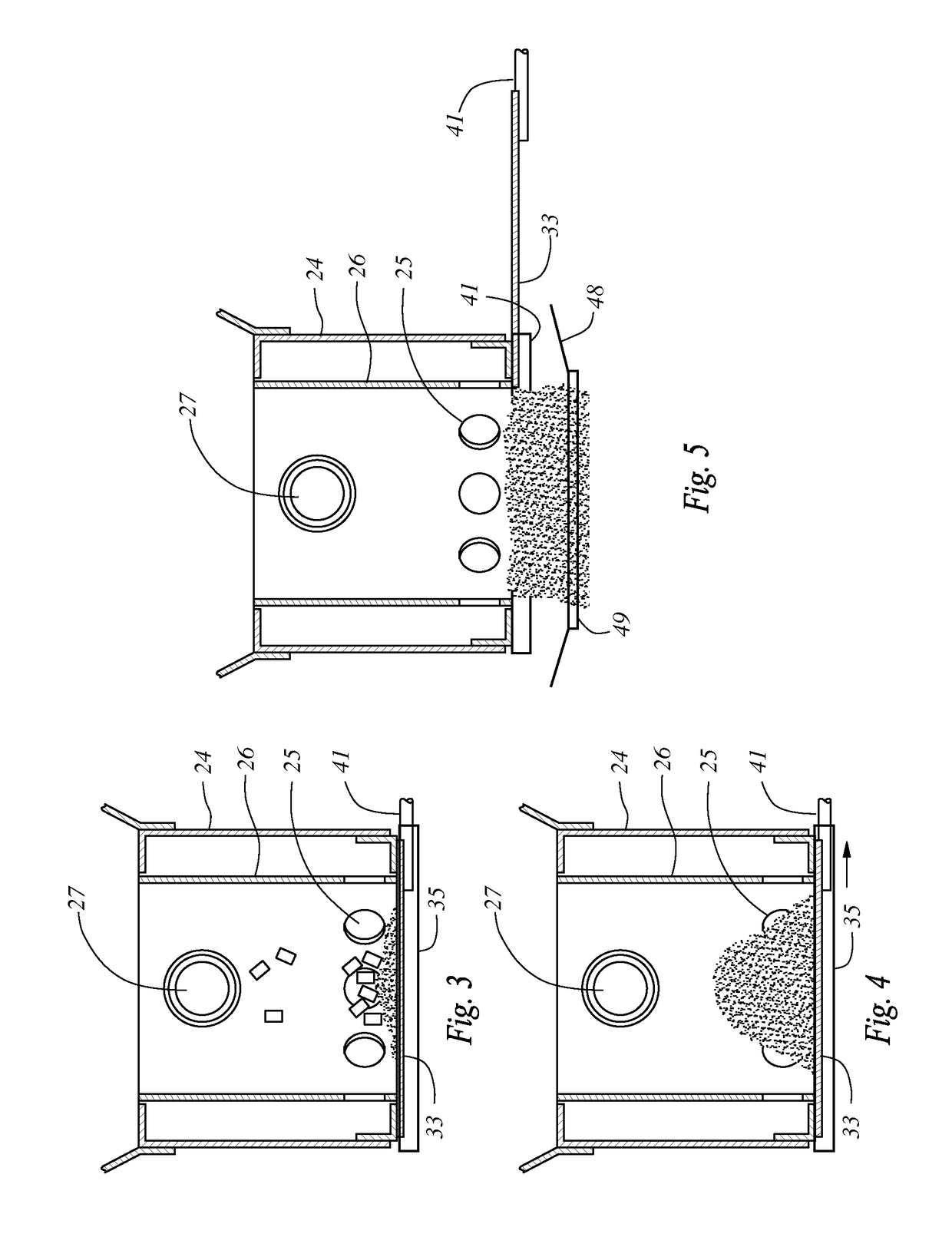

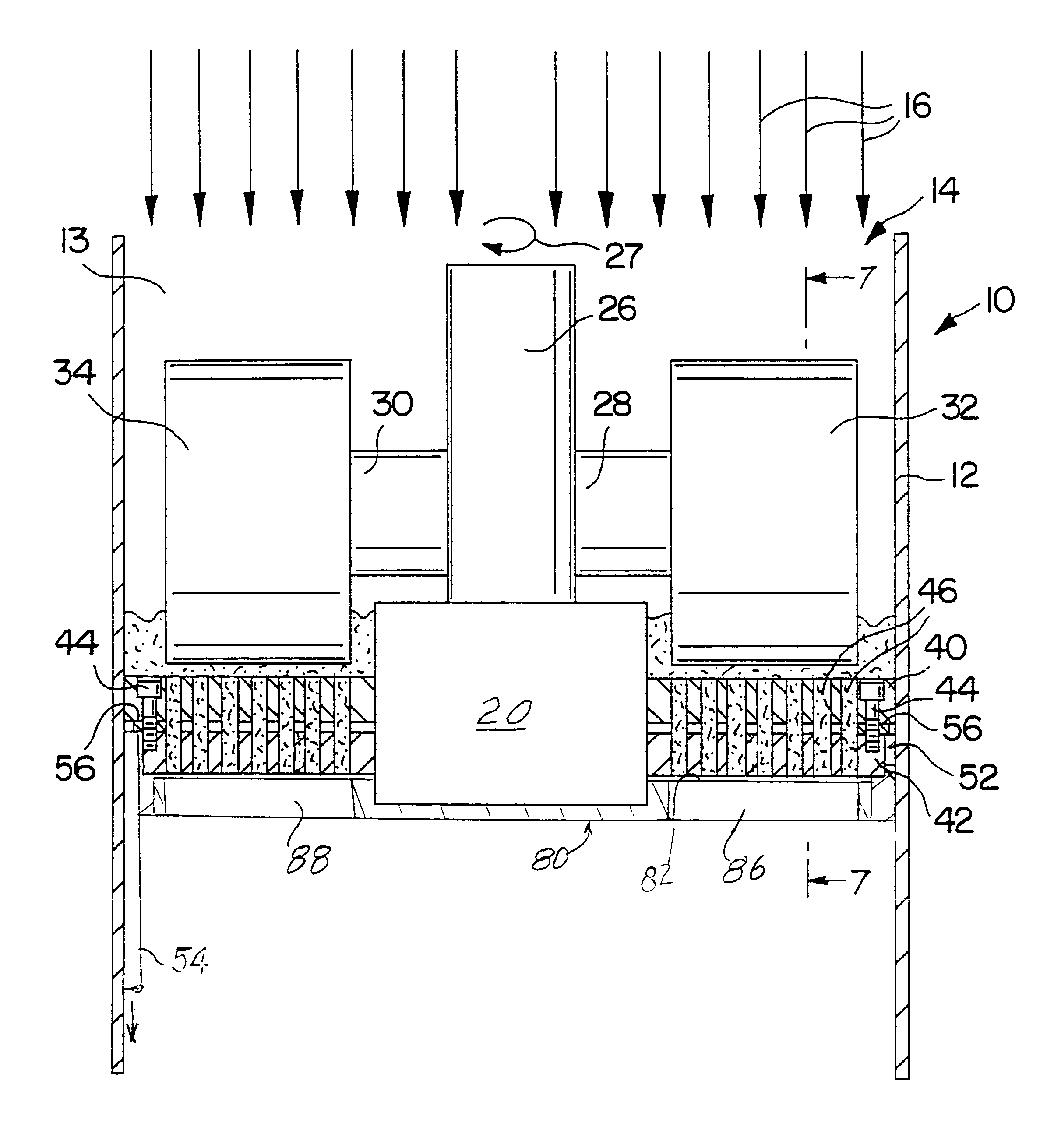

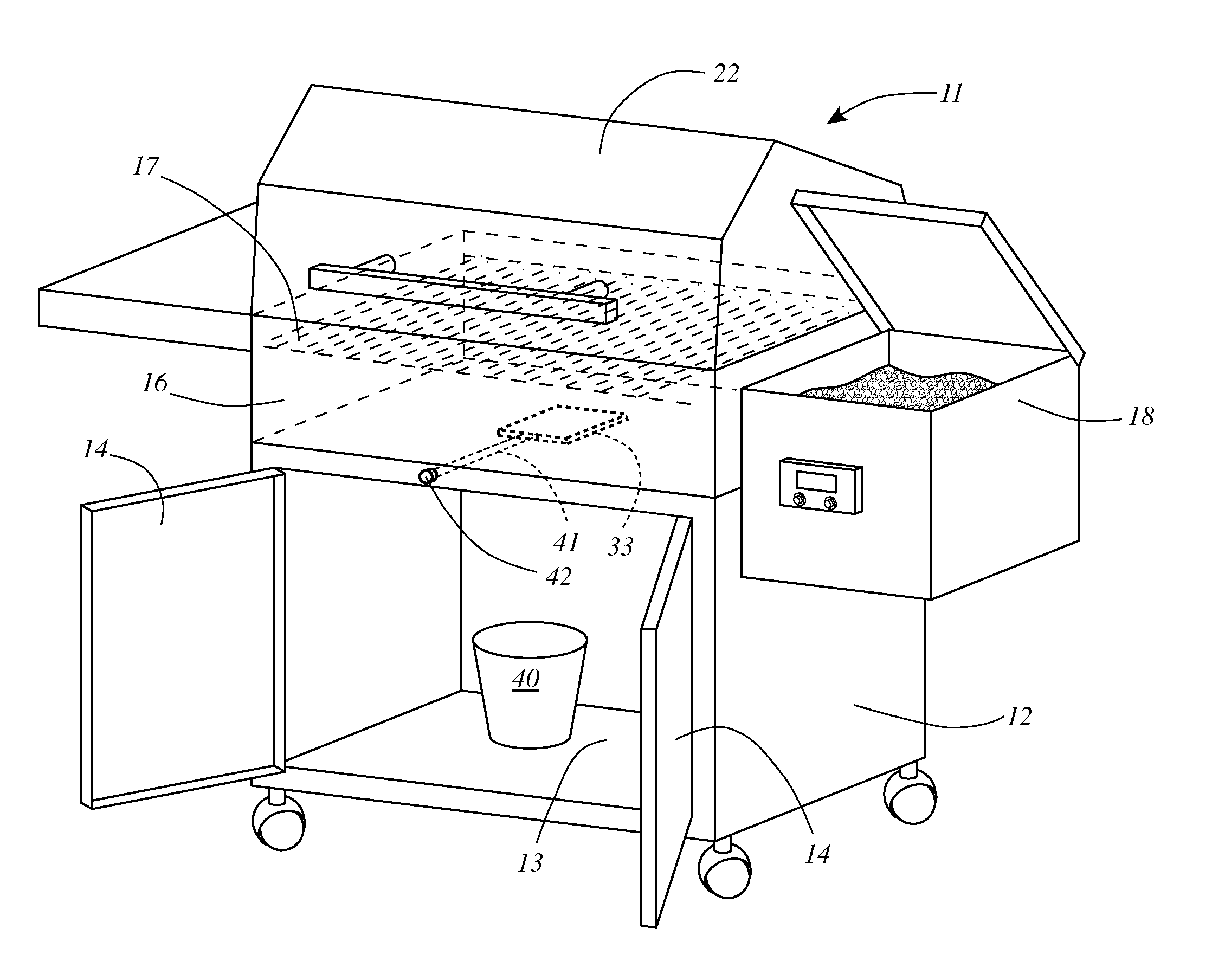

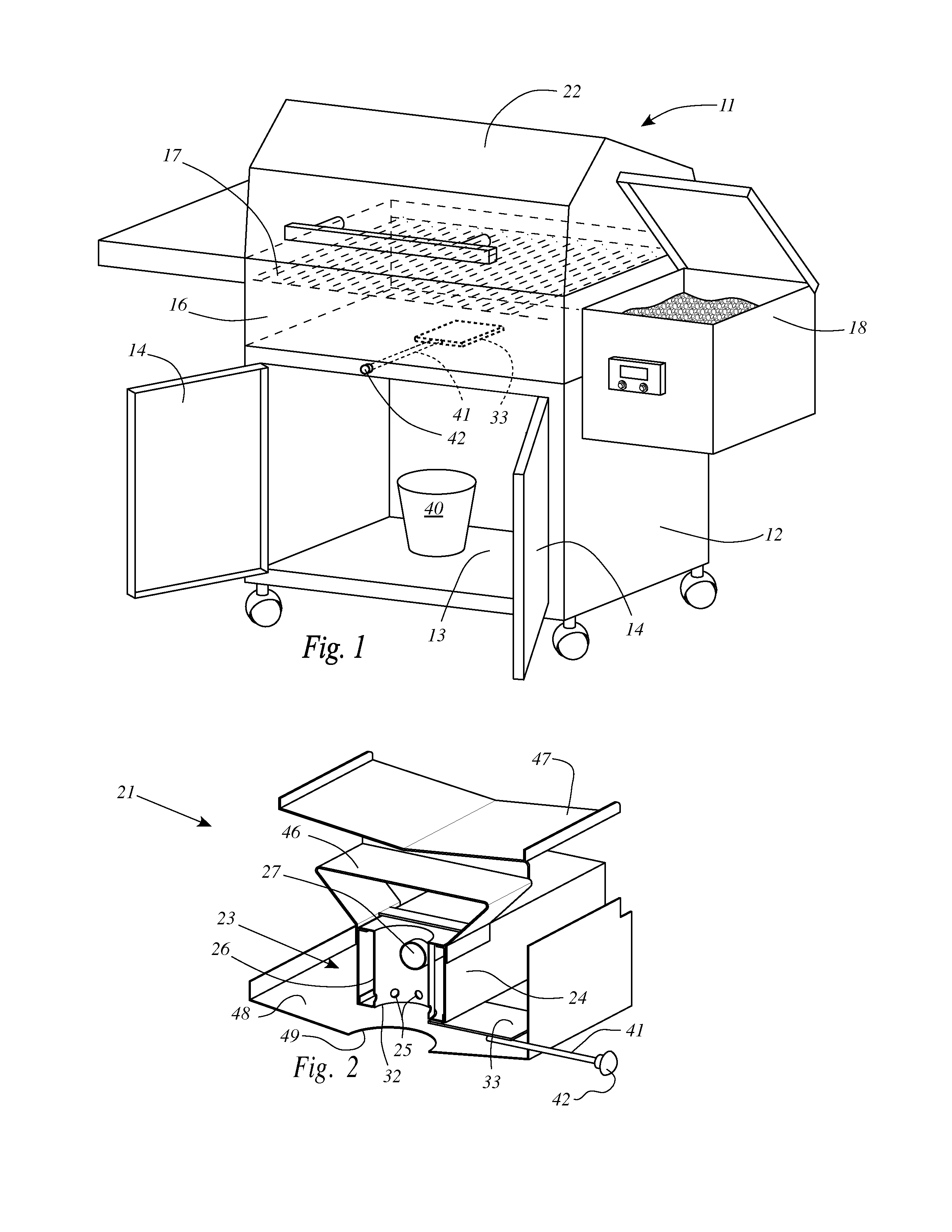

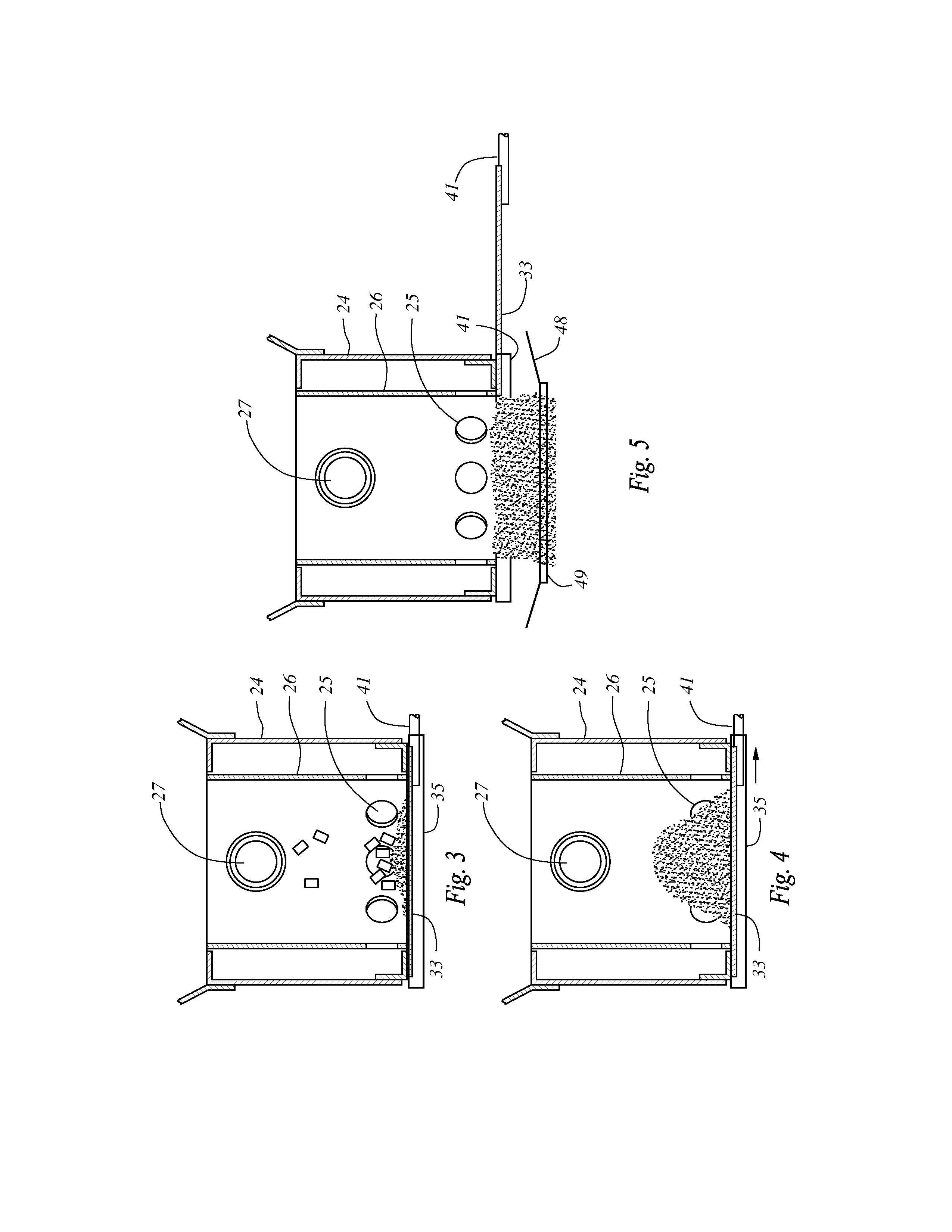

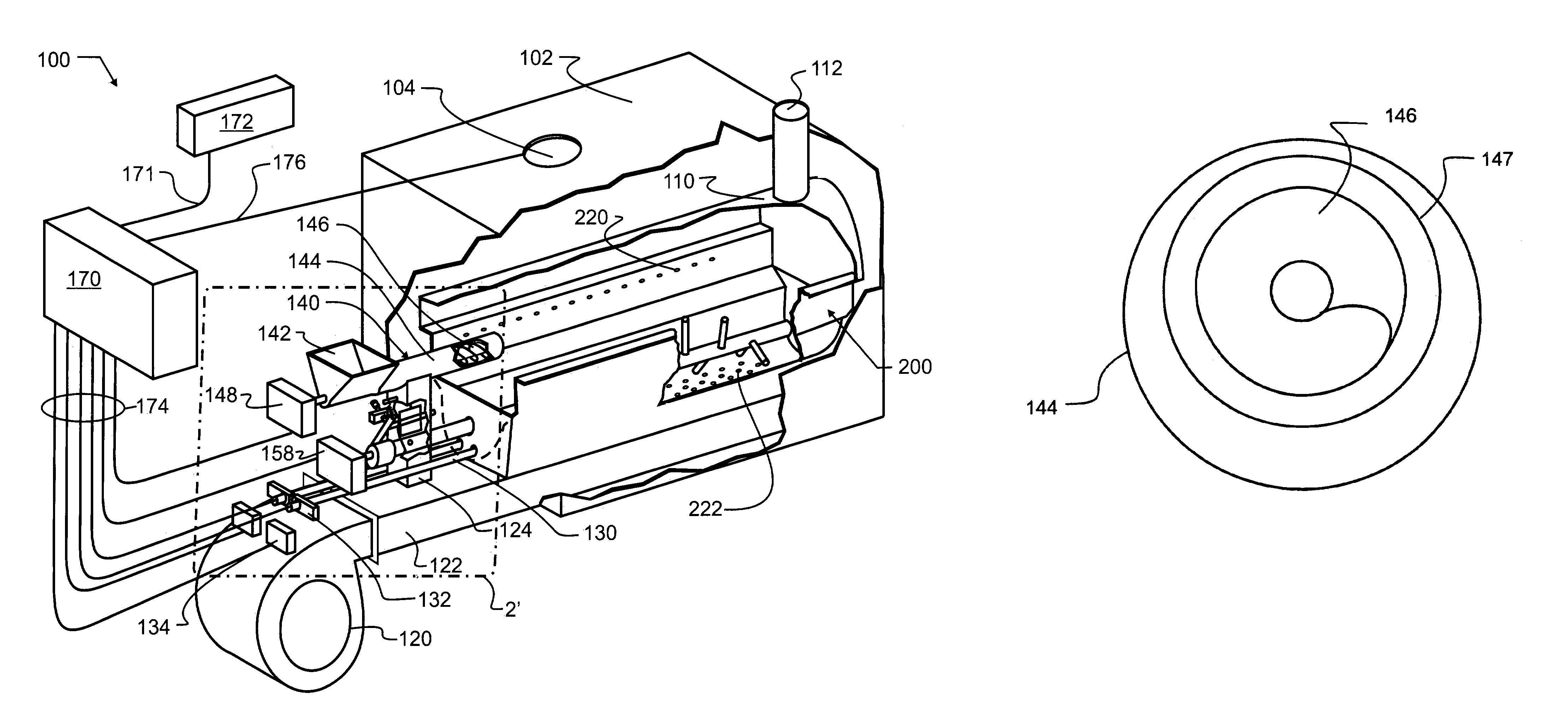

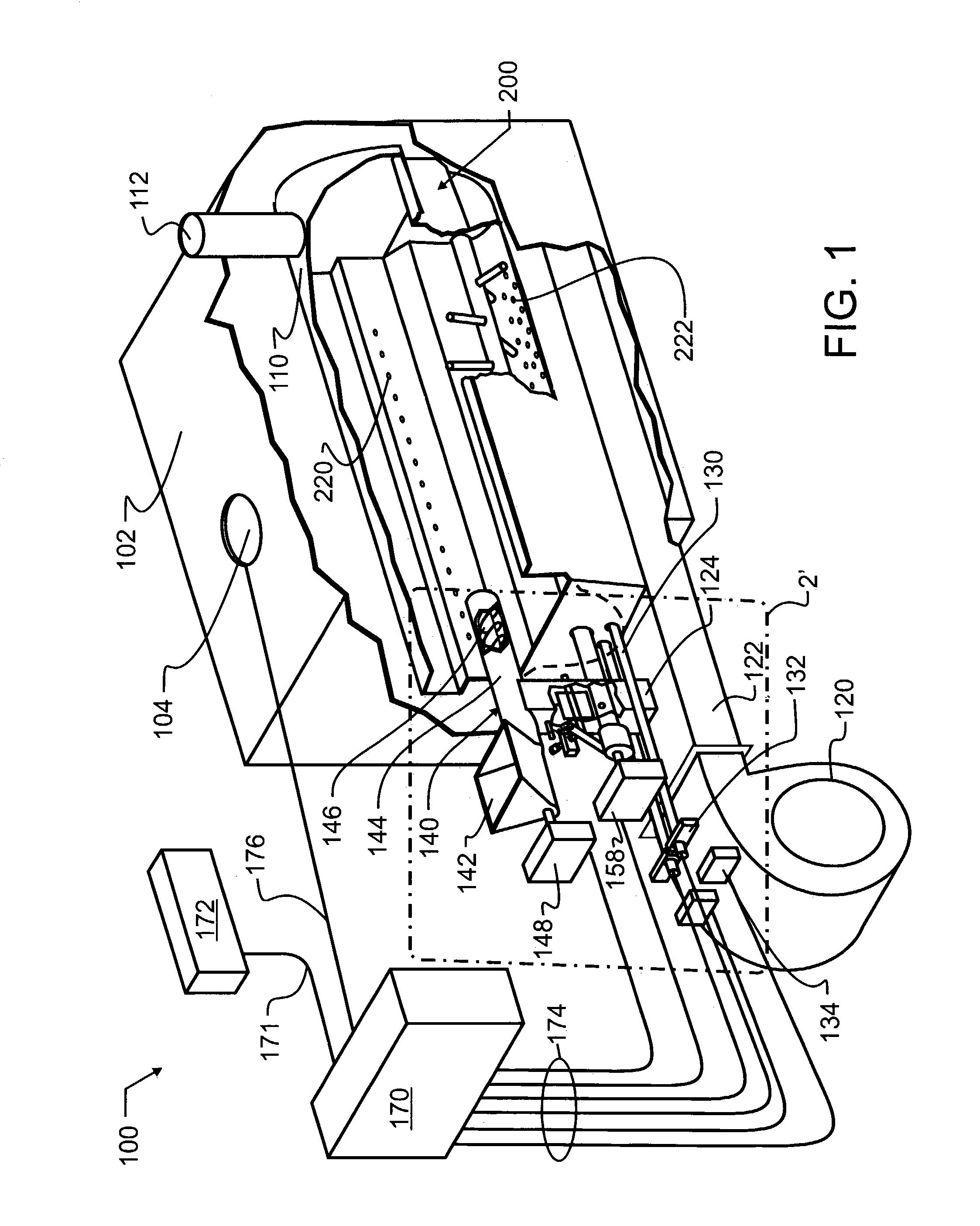

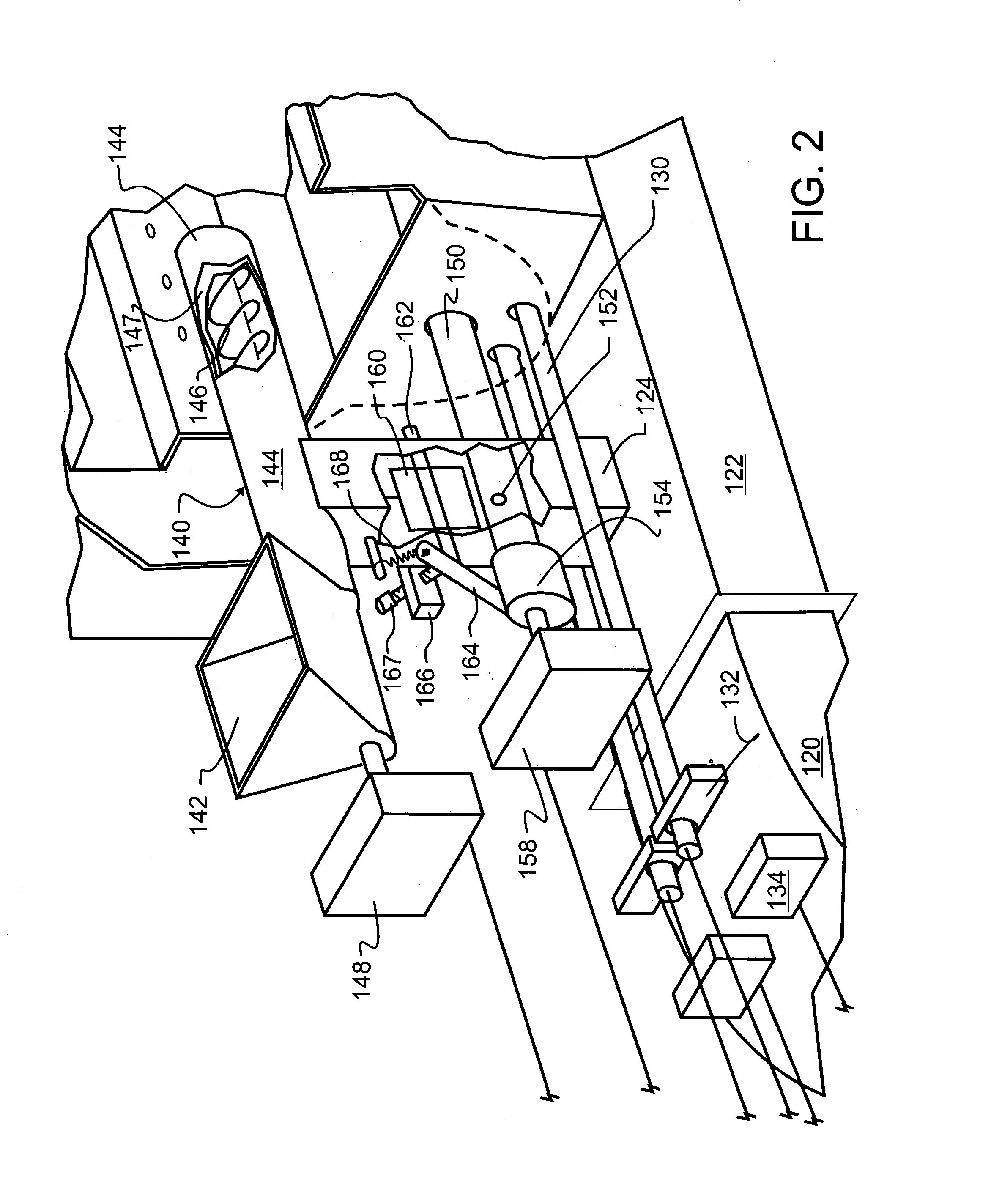

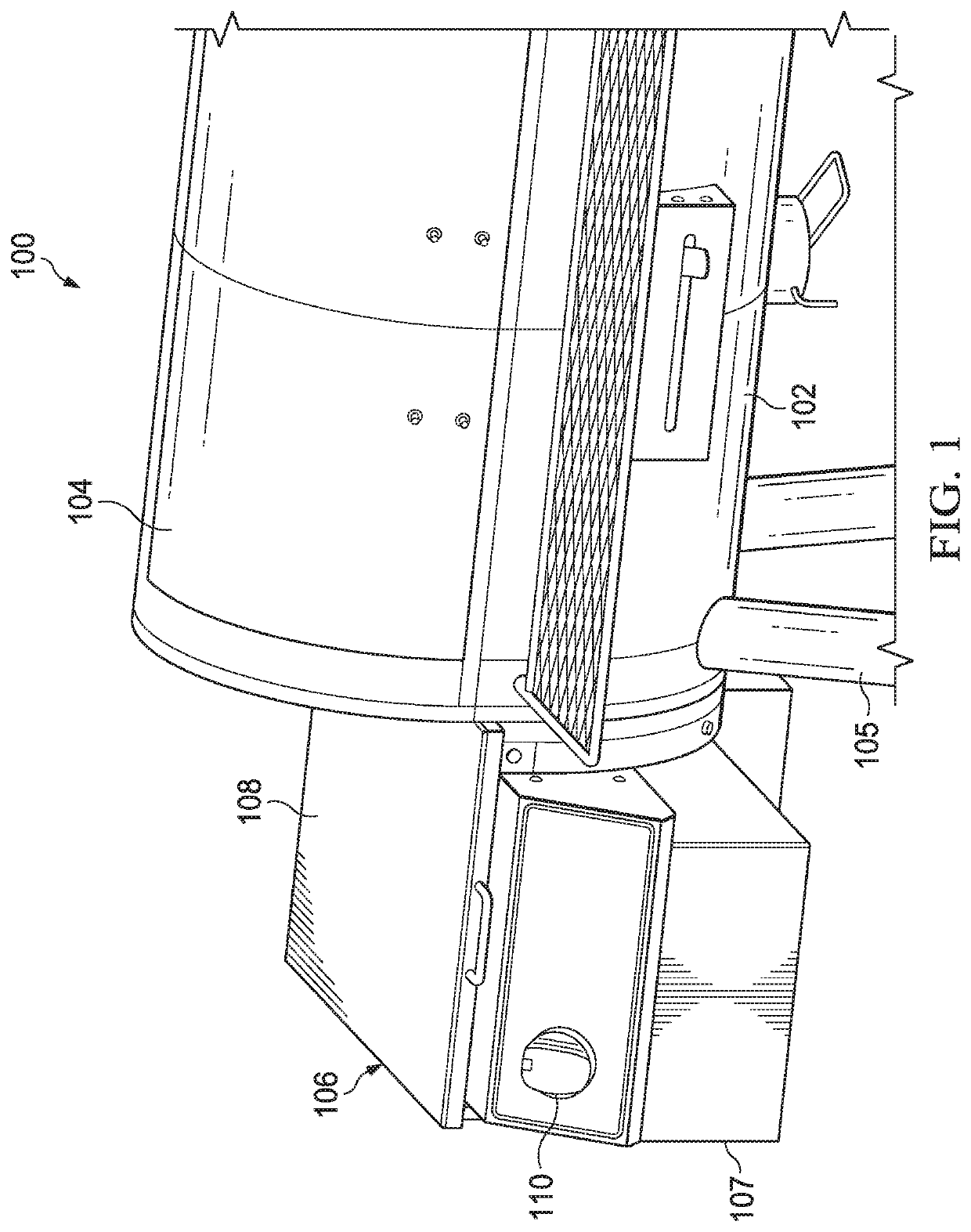

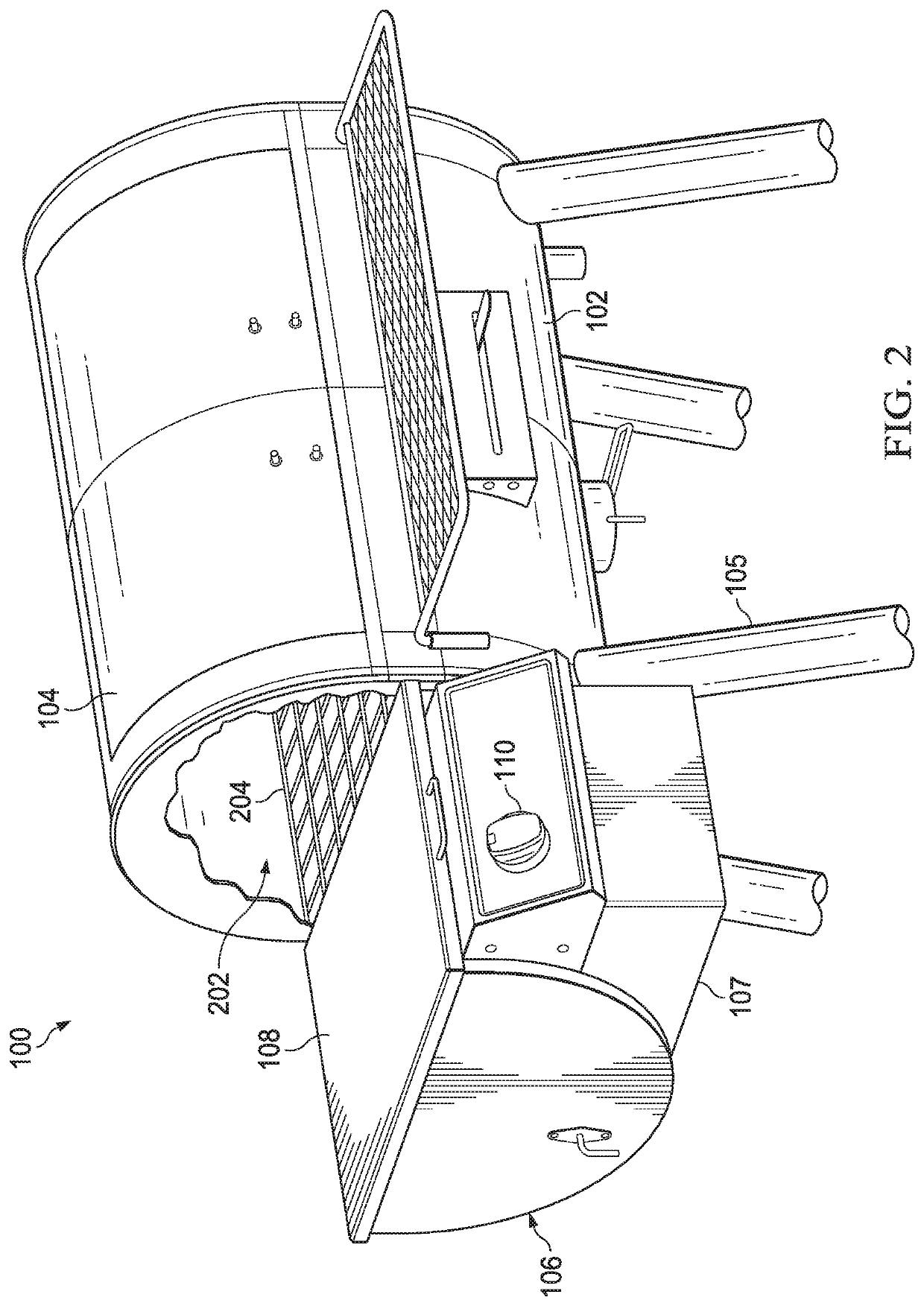

Pellet fueled grill with cleanout port

ActiveUS9635978B2Prevents unintended and accidental actuationDomestic stoves or rangesLighting and heating apparatusCombustion chamberEngineering

A pellet-fired grill for barbecue cooking includes a cleanout port in the bottom of the combustion chamber and an access door so that the ash may be cleaned out and removed from the grill without necessitating disassembly of the upper components of the grill. The access door is operated by a pull link, and a stop catch mechanism adjacent to the pull link enables actuation of the pull link assembly only when the stop catch mechanism is released.

Owner:LOGAN OUTDOOR PRODS

Pellet fueled grill with cleanout port

ActiveUS20140318524A1Prevents unintendedPrevents accidental actuationDomestic stoves or rangesLighting and heating apparatusPellet fuelMechanical engineering

A pellet-fired grill for barbecue cooking includes a cleanout port in the bottom of the combustion chamber and an access door so that the ash may be cleaned out and removed from the grill without necessitating disassembly of the upper components of the grill. The access door is operated by a pull link, and a stop catch mechanism adjacent to the pull link enables actuation of the pull link assembly only when the stop catch mechanism is released.

Owner:LOGAN OUTDOOR PRODS

Apparatus for dewatering and pelletizing particulate fuel

An apparatus for pelletizing a feed material containing finely divided solids and water by compressing the feed material in the die cavities of a pellet mill and permitting excess water to escape from the material being compressed through at least one water escape opening in each die cavity.

Owner:ZITRON ZALMAN

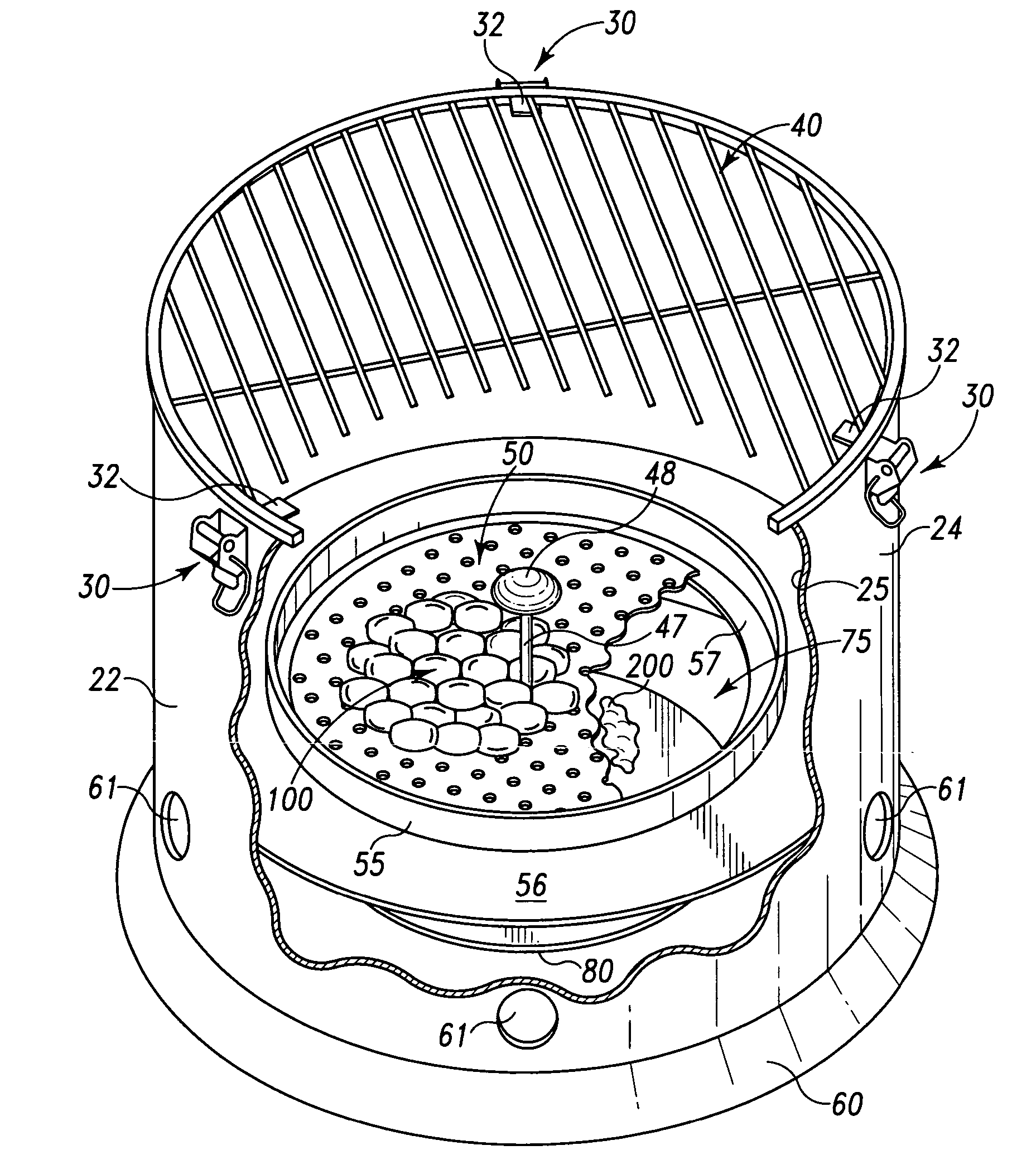

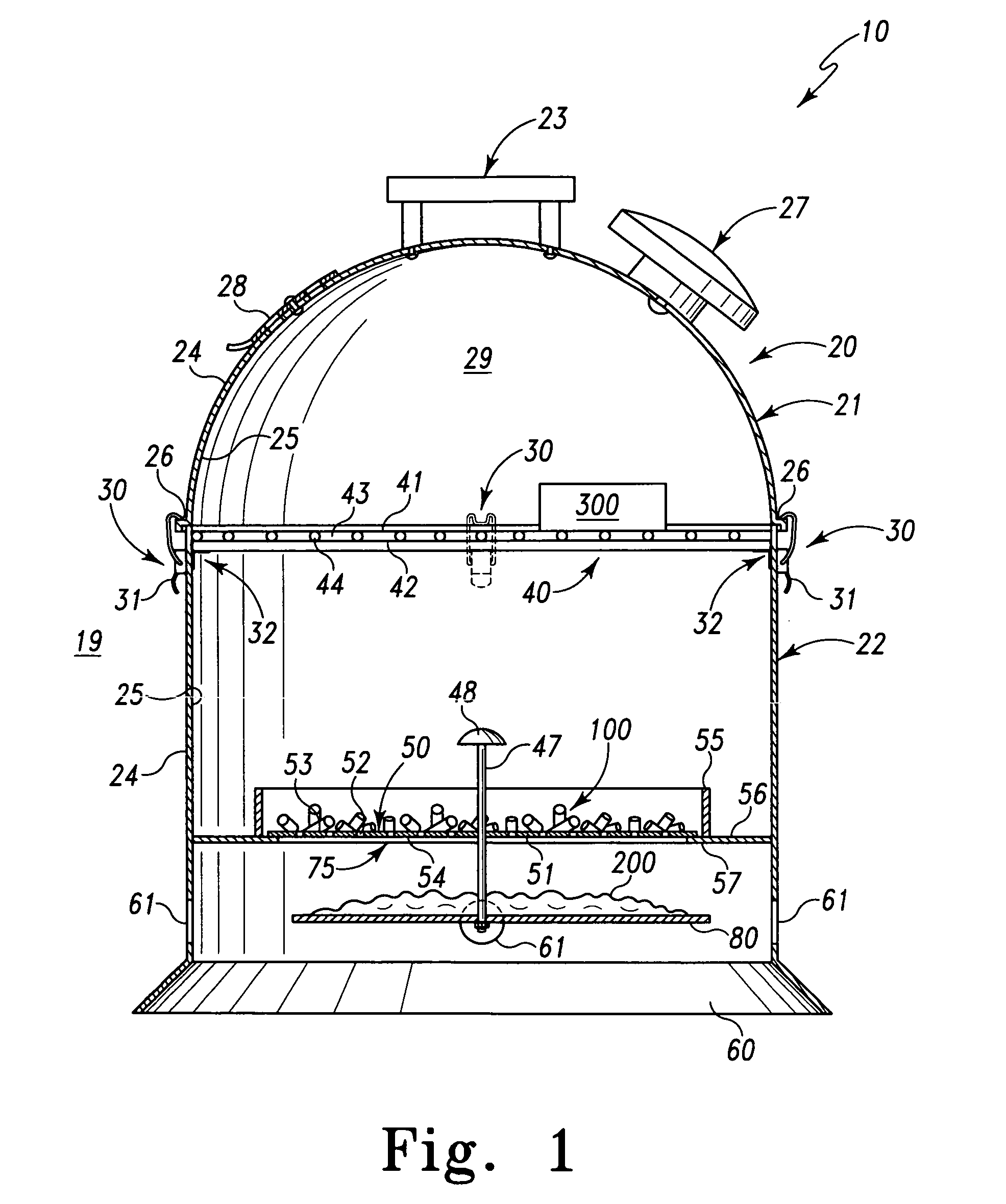

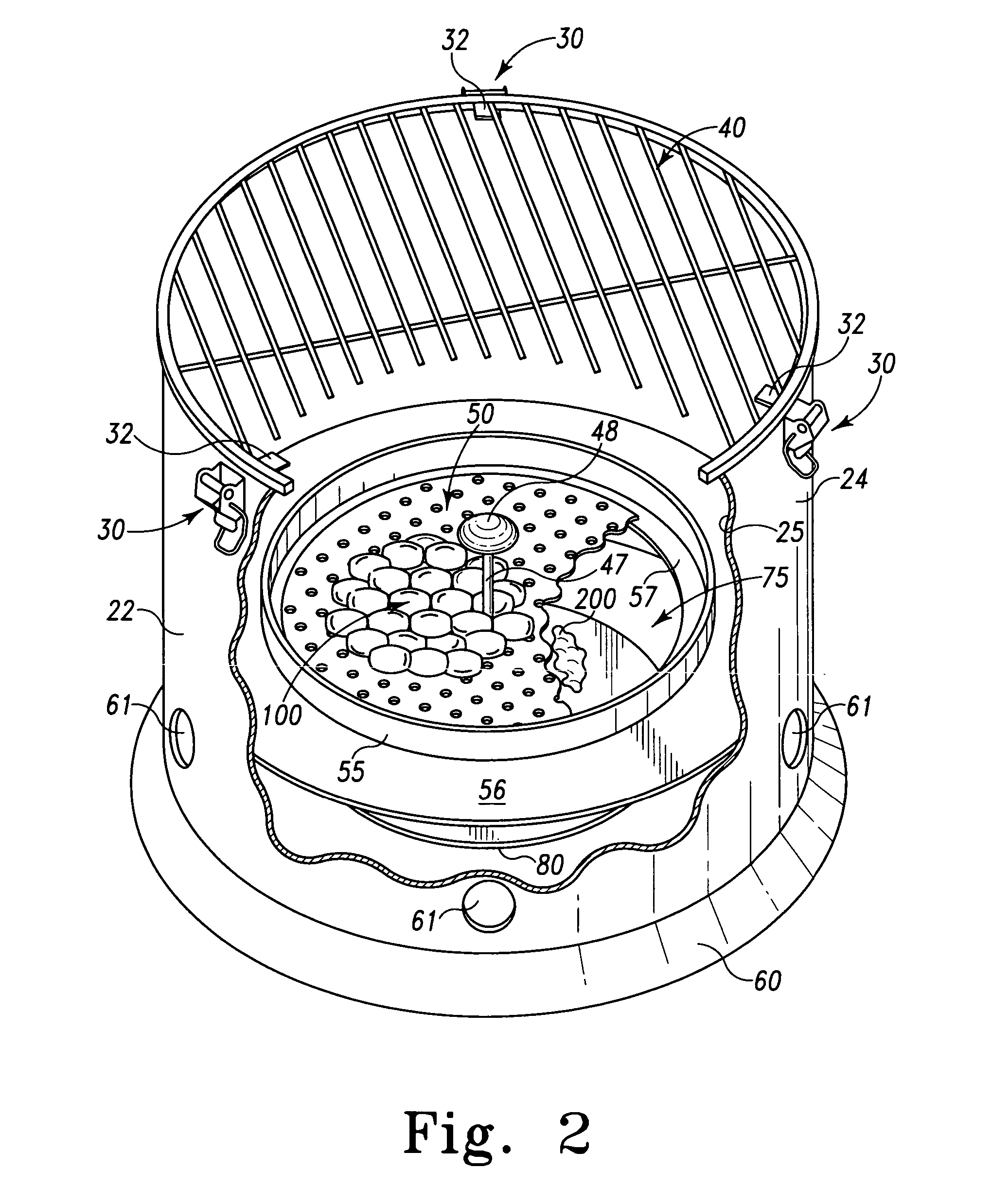

Pellet-fired BBQ

A pellet-fired cooking apparatus is provided. The cooking apparatus may include an outer shell into which are mounted at least a fuel support member and a food support member. Pellet fuel may be placed on the fuel support member and may be used to cook food placed on the food support member. The fuel support member may have a construction that allows for controlled combustion of the pellet fuel, providing for desired cooking characteristics of the pellet fuel. Intake air for combustion may be provided to the pellet fuel through one or more hollow supports for the cooking apparatus.

Owner:TRAEGER PELLET GRILLS LLC

Preparation method of anti-slagging biomass solid granular fuel

The invention discloses a preparation method of an anti-slagging biomass solid granular fuel and solves problems that a biomass solid granular fuel, which is prepared through a preparation method in the prior art, is poor in quality, is liable to crush, is poor in durability, is liable to slag during a combustion process, can causes corrosion to a heating surface and is low in combustion rate. The preparation method in the invention mainly comprises following steps: (1) smashing raw materials; (2) pre-processing crop straws and bagasse; (3) drying the raw materials; and (4) mixing the raw materials and performing a moulding process. The preparation method in the invention is simple in processes. Variety and content of each raw material are strictly selected and optimized during preparation processes, and meanwhile granularity and moisture content of the raw materials are strictly controlled. The prepared biomass solid granular fuel is good in durability and an anti-slagging effect and is high in combustion rate.

Owner:江山华隆能源开发有限公司

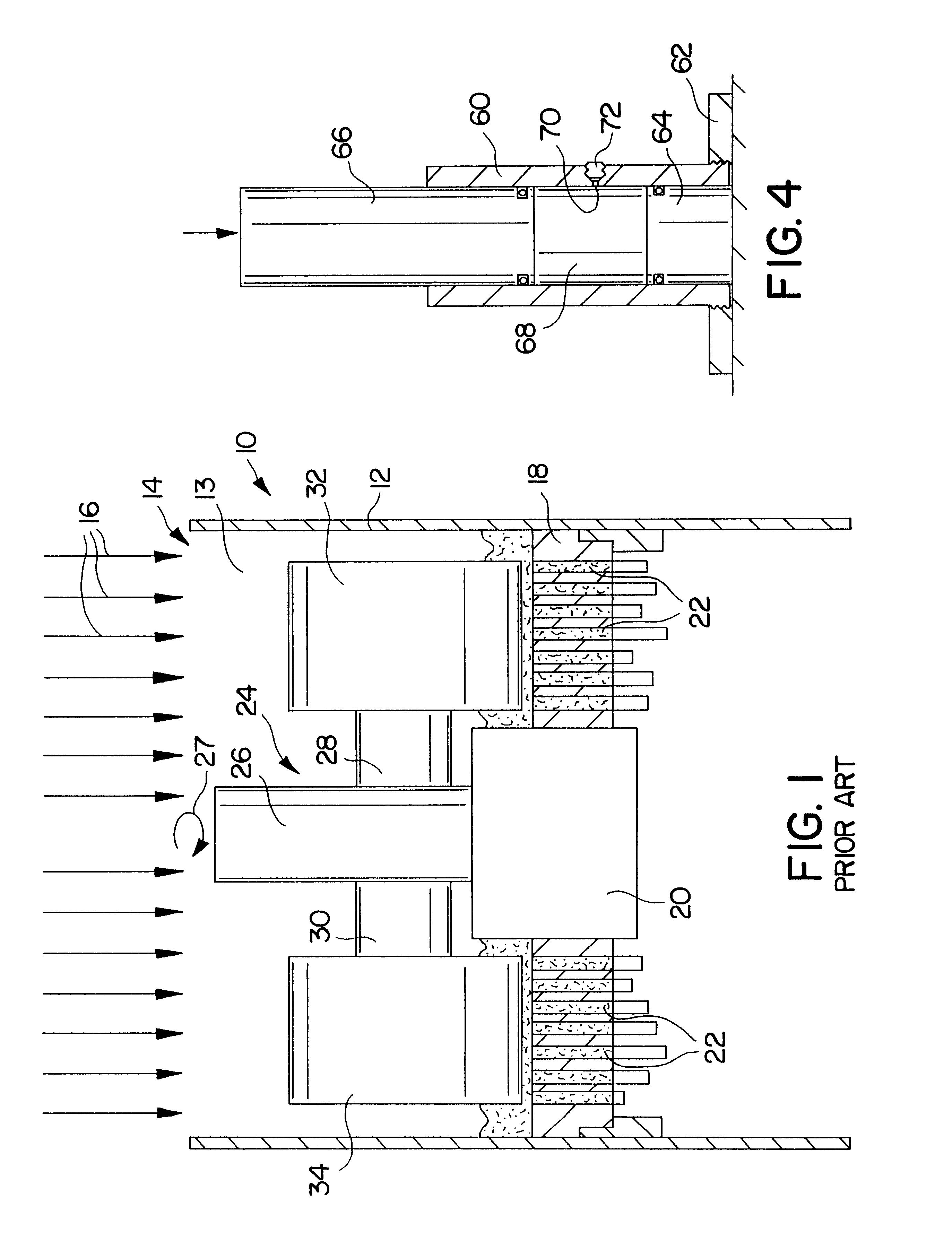

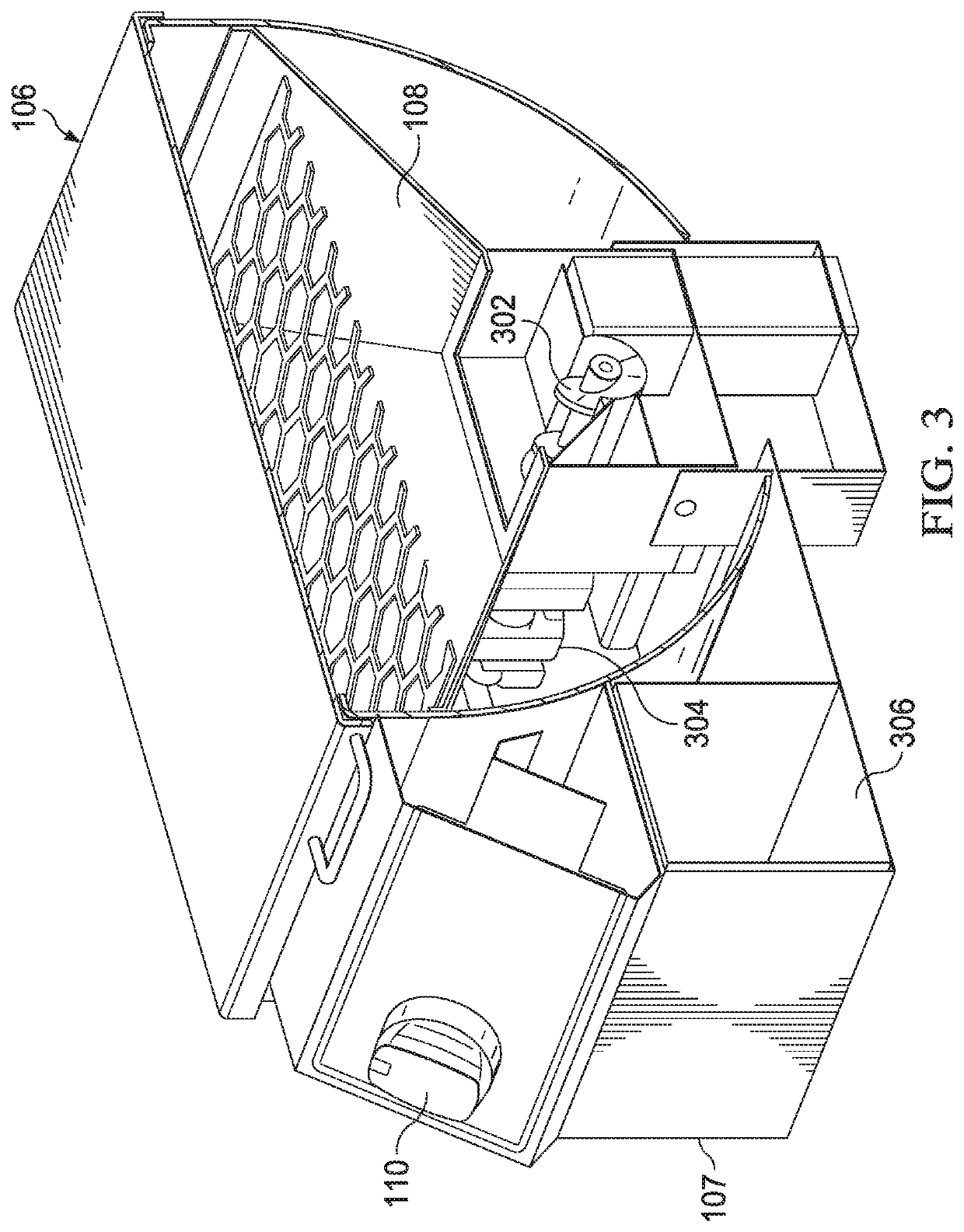

Pellet fueled grill with cleanout port

InactiveUS20130174834A1Domestic stoves or rangesLighting and heating apparatusCombustorCombustion chamber

A pellet-fired grill for barbecue cooking includes a cleanout port in the bottom of the combustion chamber that enables access to the ash that falls from the burner unit, so that the ash may be cleaned out and removed from the grill without necessitating disassembly of the upper components of the grill. The access door is slidably secured adjacent to the cleanout opening and connected to a knob or pull link so that it may be slidably translated longitudinally to open for ash removal and close the cleanout opening so that the airflow through the burner assembly is not disrupted from its designed path.

Owner:PEAK TRADES

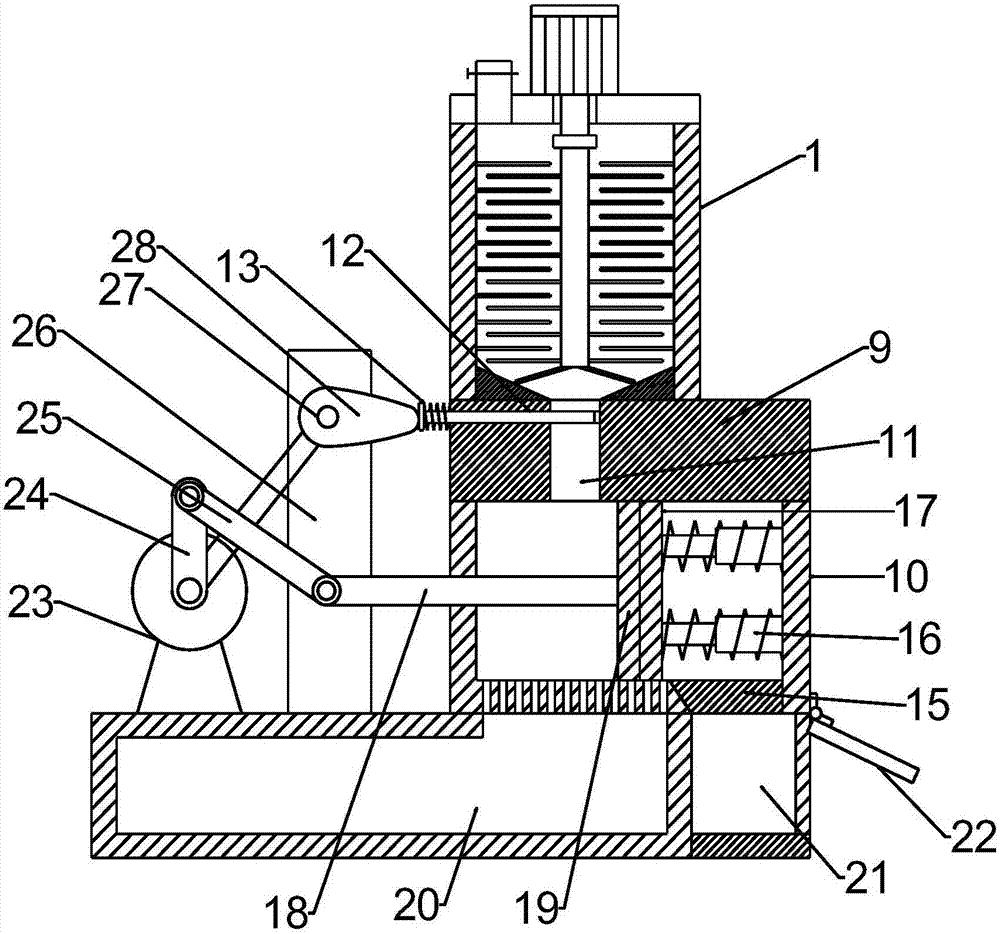

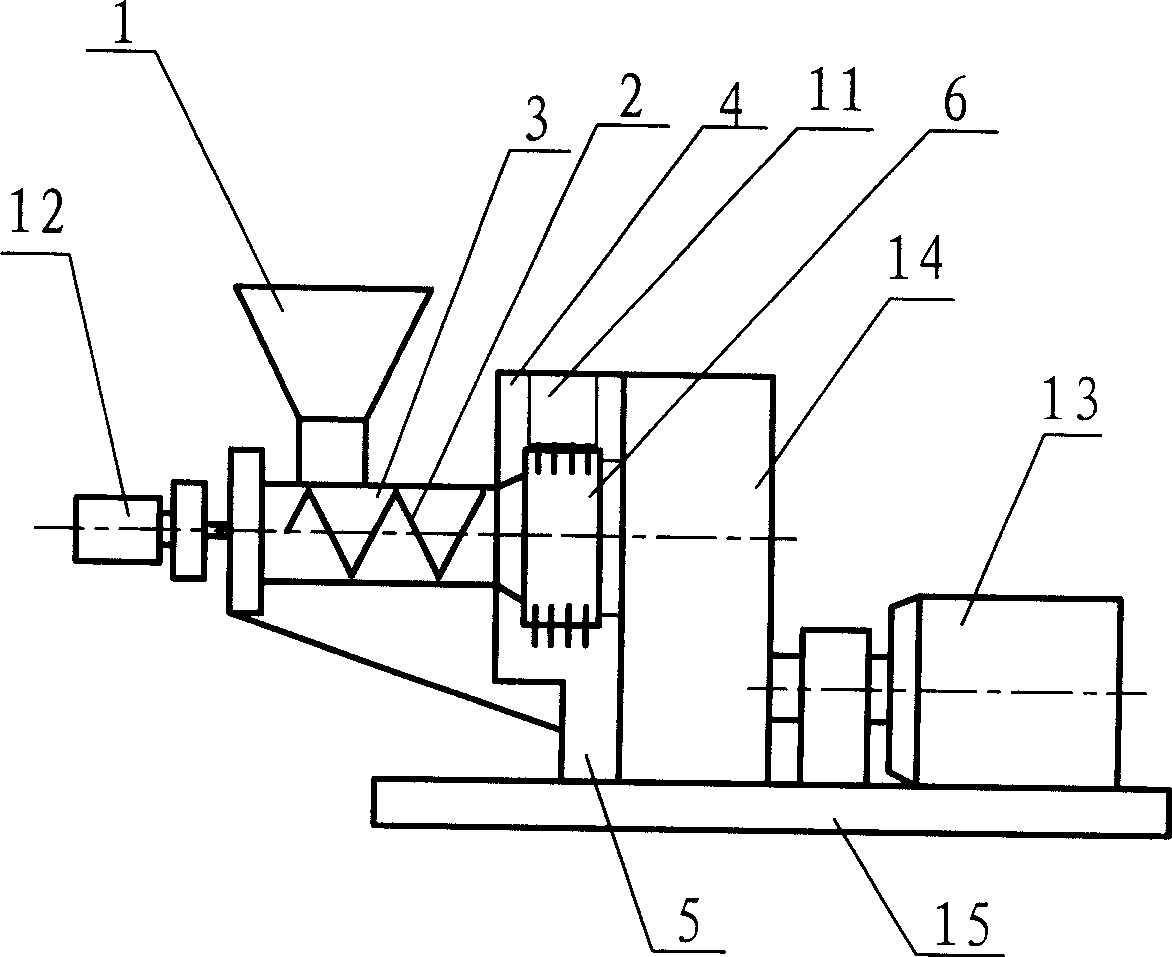

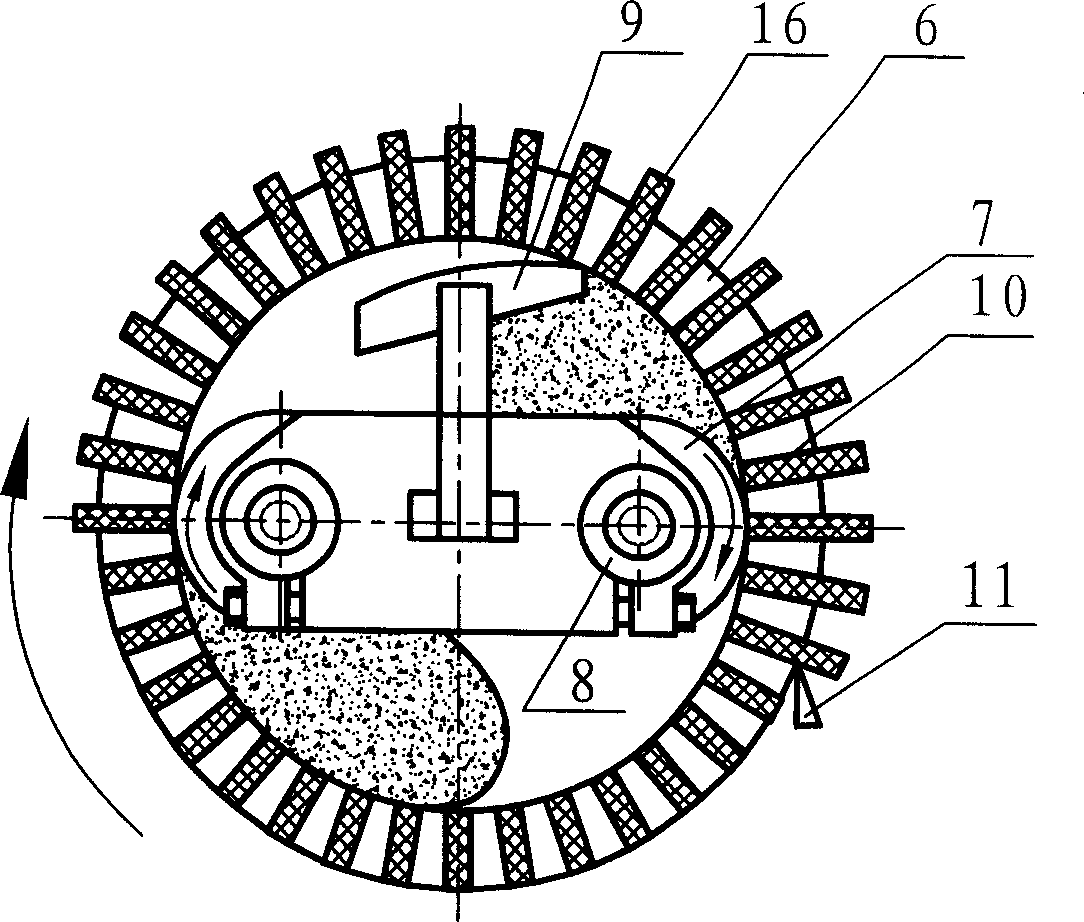

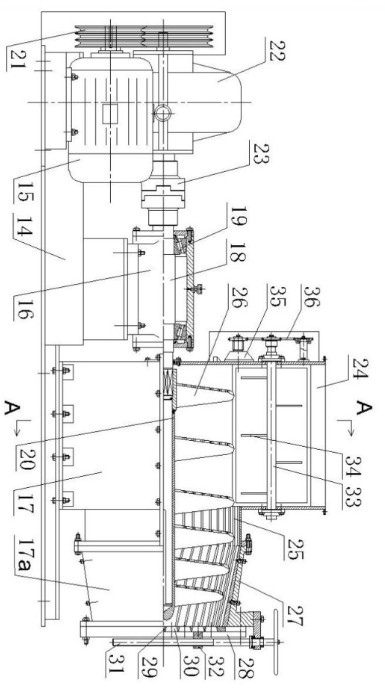

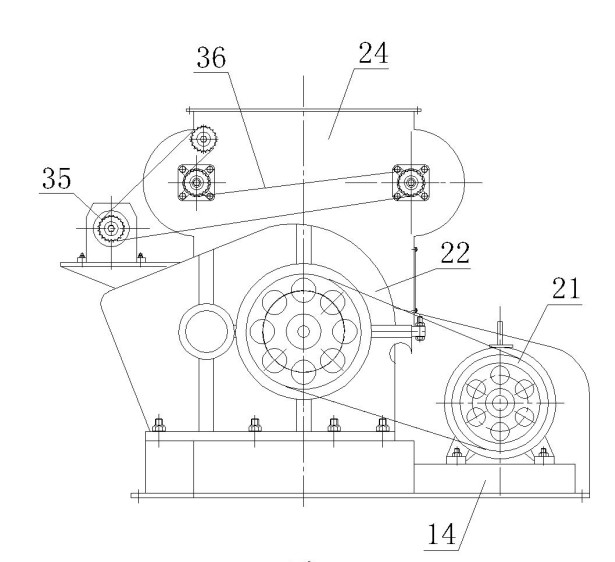

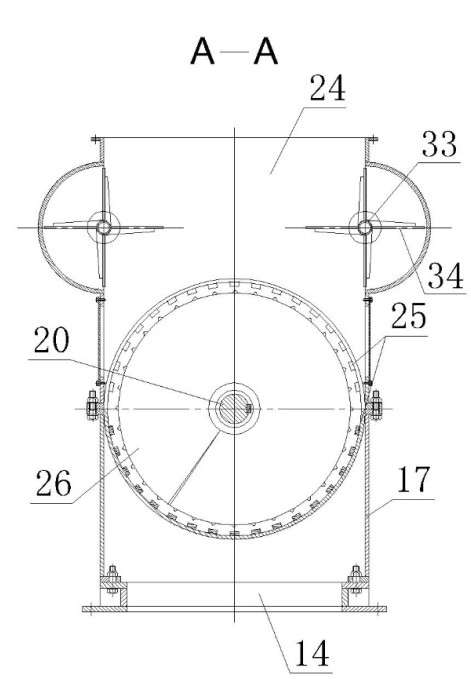

Biomass pellet fuel forming machine

The granular biomass fuel forming machine belongs to the field of biomass utilizing technology. It includes a feeding bin, a feeding chamber with feeding conveyer, a pelletizing chamber with pelletizing mechanism and material exhaust port, and a power mechanism connected to the feeding conveyer and the pelletizing mechanism. The pelletizing mechanism includes annular pressing mold with closed outer end and conic radial forming hole, at least two press rollers on bearing, feeding hood, material dispersing board, and cutter outside the annular pressing mold. The present invention has simple structure, and may be used to produce biomass grain for burning together with coal or other fossil fuel.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

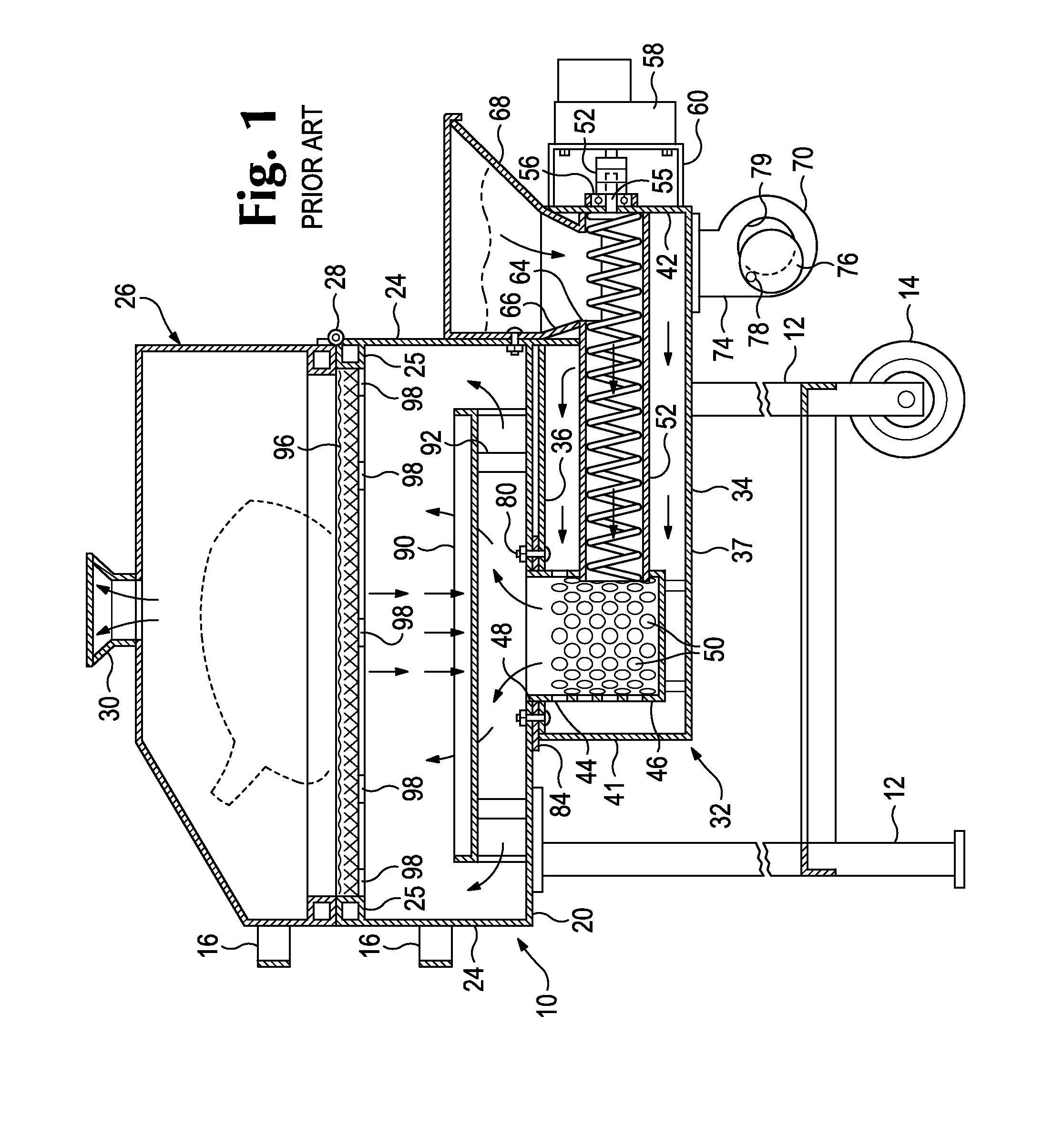

Corn burner

InactiveUS7004084B1Inhibition formationMaximize capacityFuel supply regulationSolid fuel combustionCombustorProcess engineering

A corn-burning stove provides cooling for the corn in-feed auger and other adjacent components by combustion inlet air flow patterns. The inlet air flow transports pellet fuel through a distance within the fire pot which varies responsive to the flow rate of the inlet air flow. A fire pot and agitator ensure, in combination with the inlet air flow, complete burning of the corn, with almost no ash production and while avoiding the formation of clinkers. The agitator is toothed, having teeth closely adjacent the burn pot for moving burning corn kernels or solid pellets across the fire pot. Retractable ignitors have handles and furnace function interlocks. A process control is associated with the corn burner that includes some logic, including interlock, power control, speed controls, sensing inputs / devices, and user interface.

Owner:ANDERSON C MERTON +1

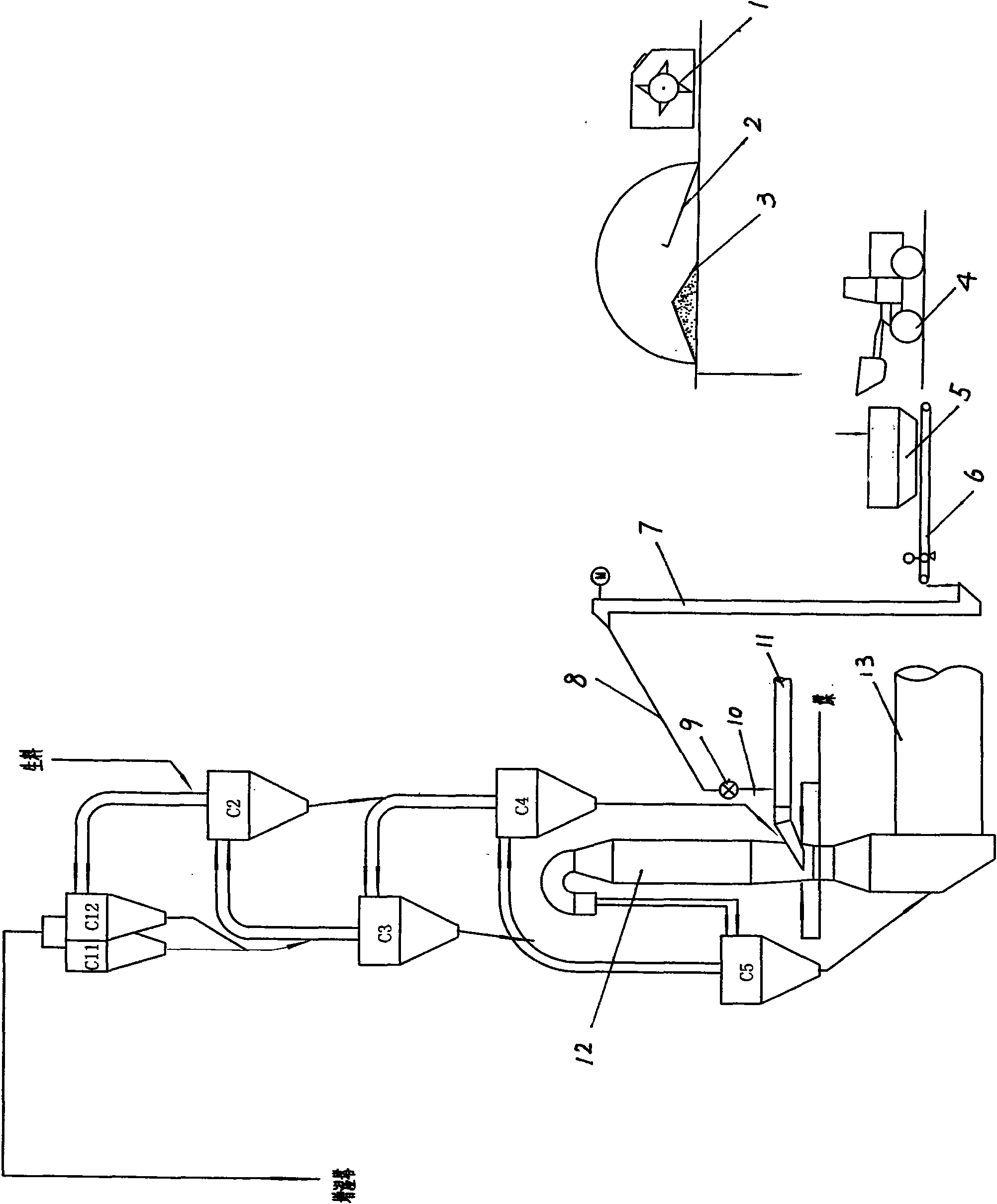

Biomass composite granular fuel, and manufacturing method and device thereof

InactiveCN101824347AHigh calorific valueMaintain particle shapeBiofuelsSolid fuelsAdhesivePellet fuel

The invention relates to a biomass composite granular fuel, and a manufacturing method and device thereof. Crop straws with low lignin content and heat value and wood materials with high lignin content and heat value are used as the raw materials, pulverized, mixed in a random ratio and granulated to obtain the granular fuel. The manufacturing method comprises the following steps: using crop straws with low lignin content and heat value and wood materials with high lignin content as the raw materials, respectively pulverizing and drying the crop straws and wood materials, mixing, softening with steam, molding, cooling and packaging to make the granular fuel. The manufacturing device comprises a wood chipping and pulverizing system, a pulverized wood drying system, a straw cutting and pulverizing system, a pulverized straw drying system, a granulating system and a product processing and packaging system. The composite granular fuel of the invention does not need adhesive or other additives with high heat value, thereby keeping the fixed granule shape and enhancing the heat value of the fuel.

Owner:北京泛欧瑞德科技有限公司 +1

Biomass particle fuel and preparation method

InactiveCN102796586AHigh activityImprove cementing performanceBiofuelsSolid fuelsEngineeringPellet fuel

The invention provides a biomass particle fuel and a preparation method. The method comprises the following steps: cleaning and removing the impurities of the agricultural wastes such as wood chips and straws, and then crushing to obtain a raw material with the particle size of 0.02-20mm, drying the raw material to obtain the water content between 5-15%; reshaping to obtain the biomass particle fuel through an extrusion molding device; cooling and screening, removing the loose particles; drying through an air-flow machine and then packing and storing, wherein the water content is between 5-15%. The drying temperature is between 200 and 300 DEG C, the extrusion molding pressure is between 5 and 100 MPa, and the compression ratio is 1:4.5-1:9. According to the biomass particle fuel, the natural cementation component in the raw material is used for tightly combining the raw material, no extra chemical additive is required as a bond medium, the biomass particle fuel is environment-friendly type biomass fuel, the diameter of the biomass particle fuel is between 6-20mm, the length of the biomass particle fuel is 3-5 times of the diameter of the biomass particle fuel, and the water content of the biomass particle fuel is 5-10%.

Owner:SHANDONG HONGYI BIO FUEL

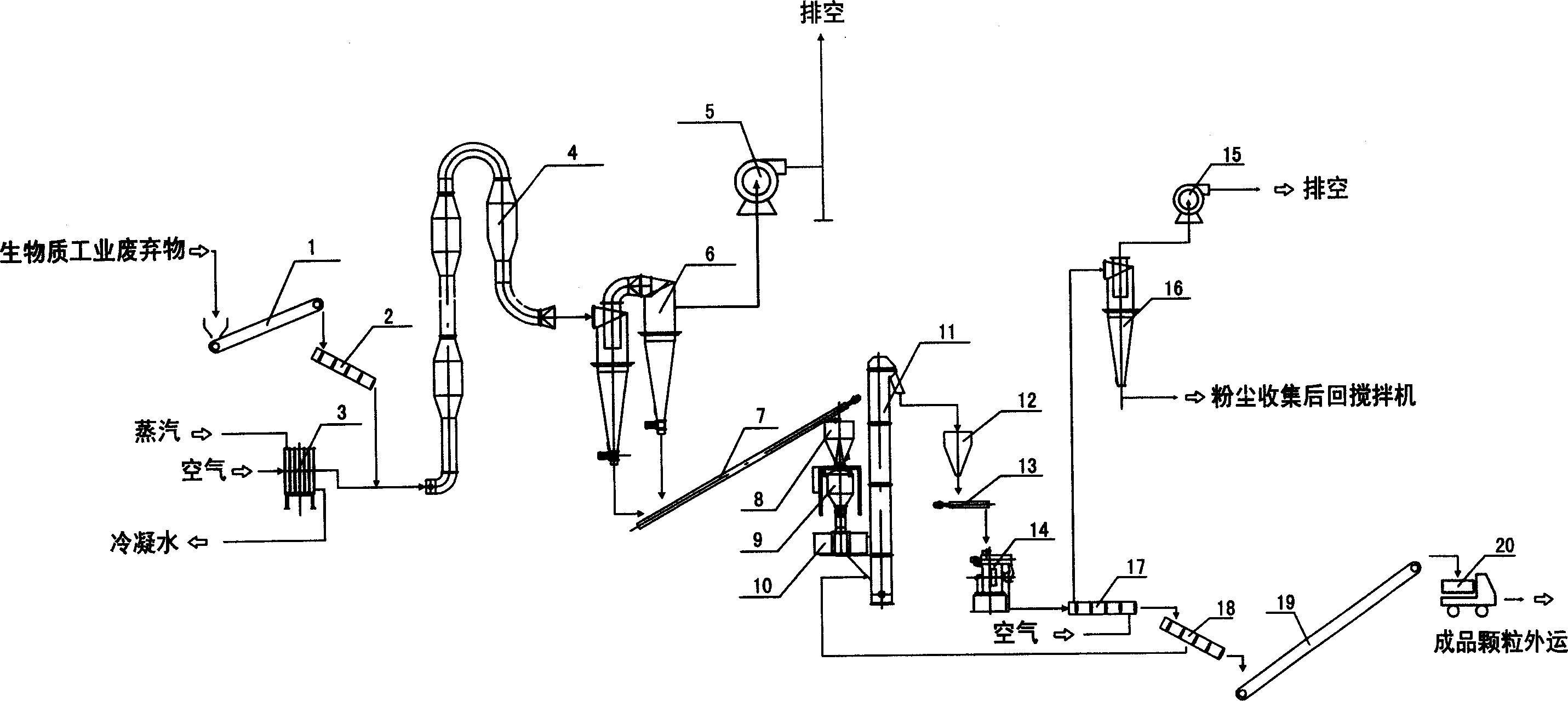

Production process of biomass pellet fuel and complete equipment

The invention discloses a production process of a biomass pellet fuel and complete equipment. The production process comprises the following steps of: 1, crushing: crushing biomass raw materials until the granularity is below 200nm; 2, tempering and curing: helically stirring, pressurizing and extruding, mutually rubbing, kneading and crushing, and mechanically crushing the crushed biomass, wherein the granularity and the flexibility of the biomass are improved, at this moment, the biomass can be naturally raised, the active organic matters of bound water, tar oil and the like inside the biomass can be extruded out to become a natural bonding agent; 3, drying and stirring: stirring and drying the tempered and cured biomass raw materials to ensure that the water content is controlled to be 15-25 percent; 4, extruding and forming, wherein the biomass pellet fuel with granularity of below 20nm is obtained; and 5, air-cooling and drying, wherein the water content of the biomass pellet fuel is controlled to be below 10 percent. The invention has the advantages of good continuity of produced biomass pellet fuel, wide application range of the biomass raw materials, lower energy consumption, easiness of formation and high production efficiency; and the formed granule has smaller volume and is convenient for transportation and storage.

Owner:四川雷鸣生物环保工程有限公司

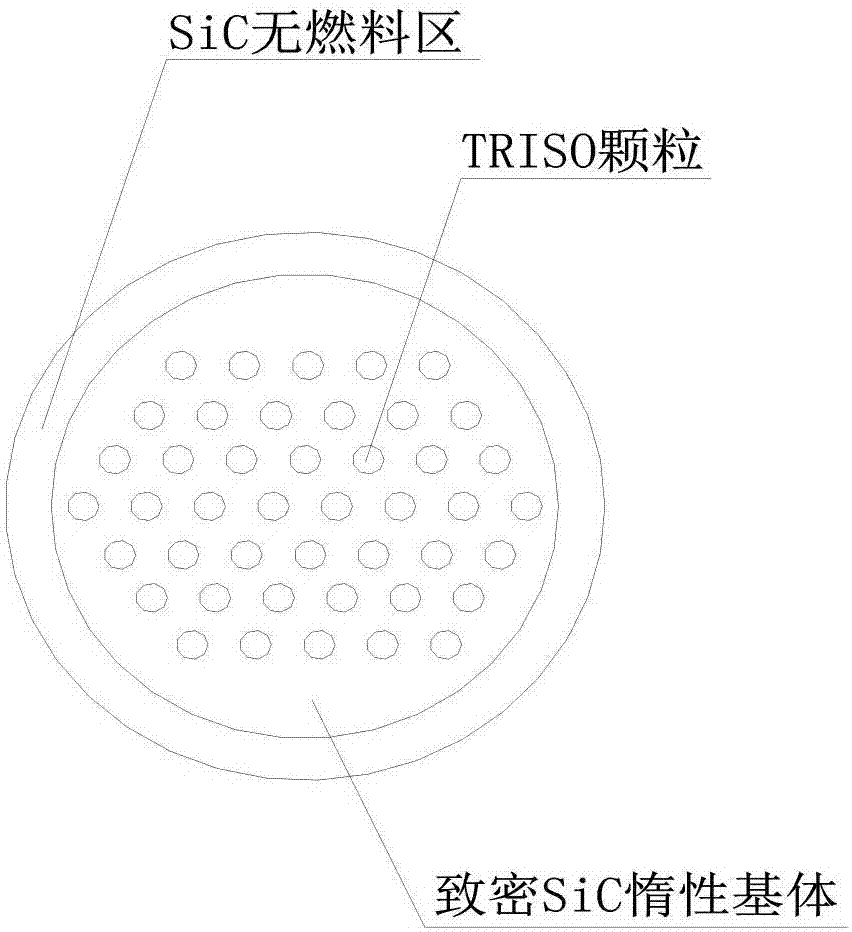

Inertia-based dispersion pellet fuel and preparation method and application thereof

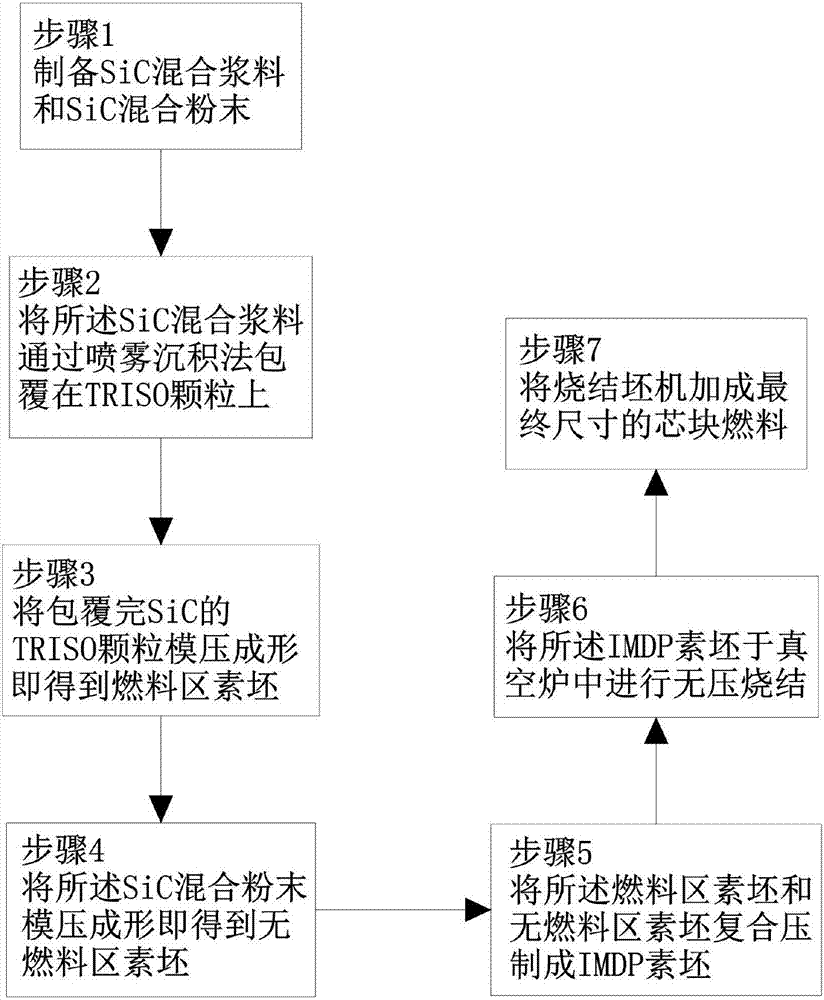

ActiveCN106981318AAchieve densificationRealize mass productionFuel elementsNuclear energy generationHigh volume manufacturingNuclear reactor

The invention discloses an inertia-based dispersion pellet fuel and a preparation method and application thereof, which solve the problems of poor anti-radiation property, containment of fission gas and heat conductivity, and difficulty in realizing of large-batch industrialized production in the prior art. The pellet fuel comprises a fuel area and a fuel-free area protecting layer, wherein the fuel-free area protecting layer wraps the periphery of the fuel area. The preparation method comprises the following steps of coating the surface of a TRISO particle with SiC by a spraying and depositing method, and uniformly distributing the pressed TRISO particles into a fuel core blank in an inertia substrate; preparing a SiC fuel-free area blank by die pressing, and combining and pressing the fuel-free area blank and the fuel core blank; finally, performing non-pressure sintering on the combined and pressed fuel core and the protecting layer blank at high temperature, and machining a sintering blank, so as to obtain a fuel assembly of a water reactor and a melting salt reactor in a nuclear reactor. The IMDP has the characteristics that the anti-radiation property is excellent, the containment of the fission gas is good, and the heat conductivity is high.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

Biomass pellet fuel and preparation method thereof

ActiveCN105542893AReduce moisture contentHigh lignin contentBiofuelsSolid fuelsPropanoic acidSodium Bentonite

The invention provides a biomass pellet fuel and a preparation method thereof. The biomass pellet fuel comprises the following components, by weight: herbivorous animal manure, agricultural waste, illegal cooking oil, calcium oxide, calcium sulfate, propionic acid, kaolin, diatomaceous earth, bentonite, calcium peroxide, aluminum hydroxide, propylene glycol, polyvinyl alcohol, an oxygenate, an antiknock agent, a combustion improver, and a bulking agent. The biomass pellet fuel has low water content and high lignin content. According to the invention, a large amount of agricultural waste and animal manure are utilized. Air pollution caused by the activities of burning agricultural waste is greatly reduced, and animal manure can be effectively treated, such that recycling application value is improved, and the fuel is more environment-friendly. Compared to conventional biomass pellet fuels, the biomass pellet fuel provided by the invention has the advantages of high combustion value, long combustion time, no harmful gas emission after combustion, and no corrosion to combustion equipment.

Owner:太仓东浔生物科技有限公司

Method for producing granular fuel from biomass industrial produced wastes

InactiveCN1858166ASolve the problem of not being able to burnAvoid pollutionBiofuelsSolid fuelsPulp and paper industryPellet fuel

The method of producing granular fuel with industrial biomass waste belongs to the field of comprehensive utilization technology. Industrial biomass waste with water content of 30-35% is first extruded to form in a ring mold type pelletizing machine while softening material with the heat generated during extruding formation, and then cooled and sieved to obtain the product. The present invention utilizes industrial biomass waste effectively and is environment friendly, and the produced granular fuel may be used to replace charcoal for warming, barbecue, etc.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Anti-slagging biomass solid granular fuel

The invention discloses an anti-slagging biomass solid granular fuel and solves a problem that a biomass solid granular fuel in the prior art is liable to slag and is low in combustion efficiency. The anti-slagging biomass solid granular fuel is prepared from following raw materials, by weight, 60-70 parts of crop straws, 10-15 parts of wood chips, 5-10 parts of bagasse, 3-5 parts of a combustion-promoting agent and 1-3 parts of an anti-slagging agent. The anti-slagging biomass solid granular fuel is simple in components, reasonable in formula, low in cost, high in combustion efficiency and low in slagging rate.

Owner:江山华隆能源开发有限公司

Granular fuel with crop straw and production thereof

InactiveCN1746274AWide range of materialsSimple processSolid fuelsWaste based fuelHigh densityEngineering

A crop straw particle fuel and its production are disclosed. The fuel is prepared by drying crop or plant waste under moisture content 16%, crushing them into powder with grain size under 8mm from side-rub multifunctional crusher, mixing one material or several materials with water, steam vaporizing, compression forming from special straw granulating flat die machine, cooling, and packing into particle fuel of which grain size is 6-9mm, length is 20-30mm and moisture content <=14wt%. Its advantages include low cost, high density, heat value and forming rate, simple process and no environmental pollution.

Owner:张建超

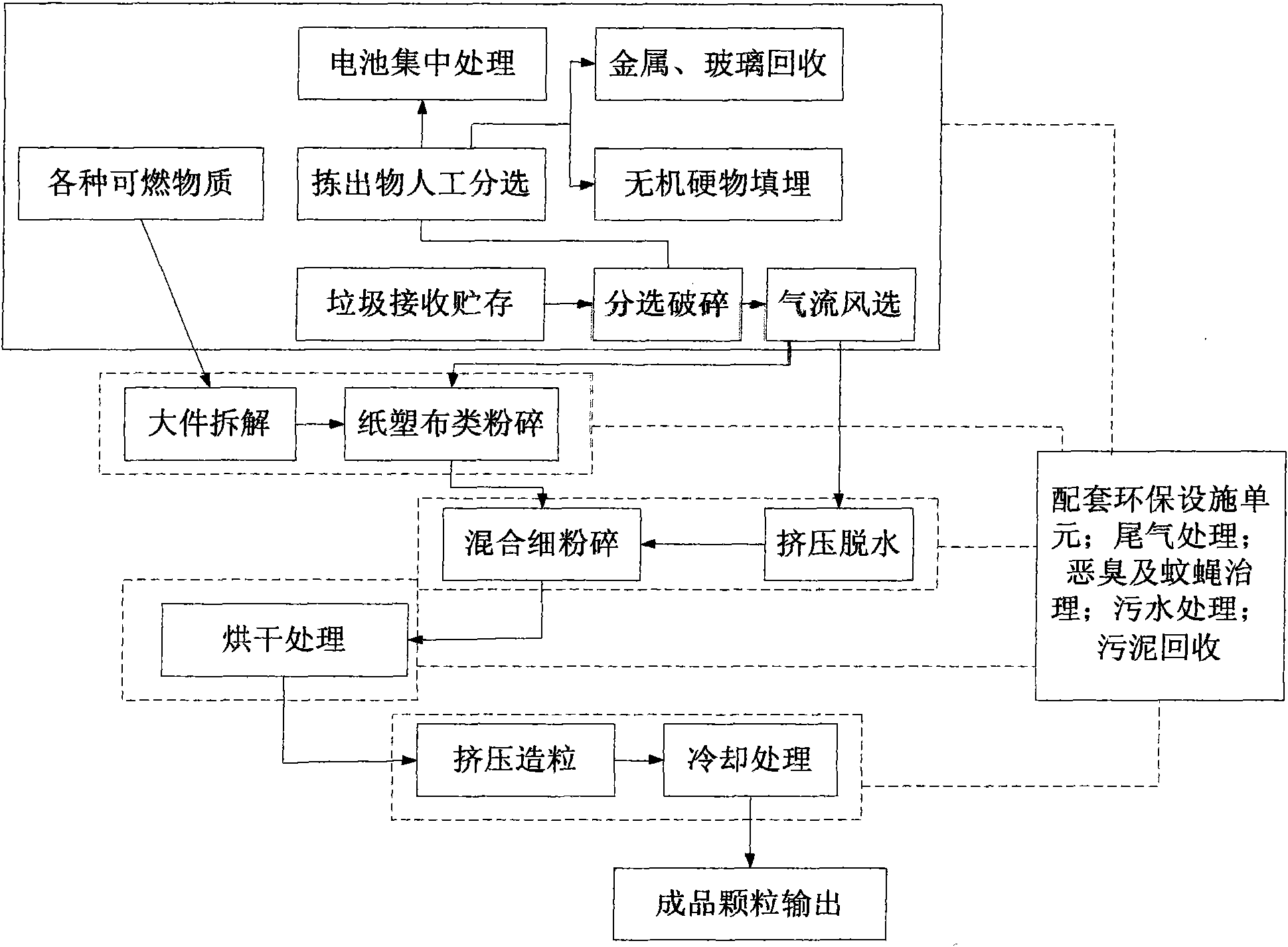

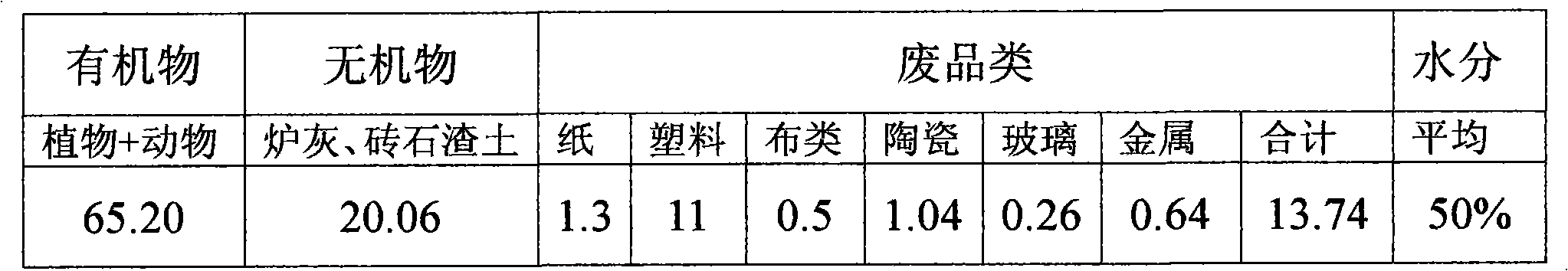

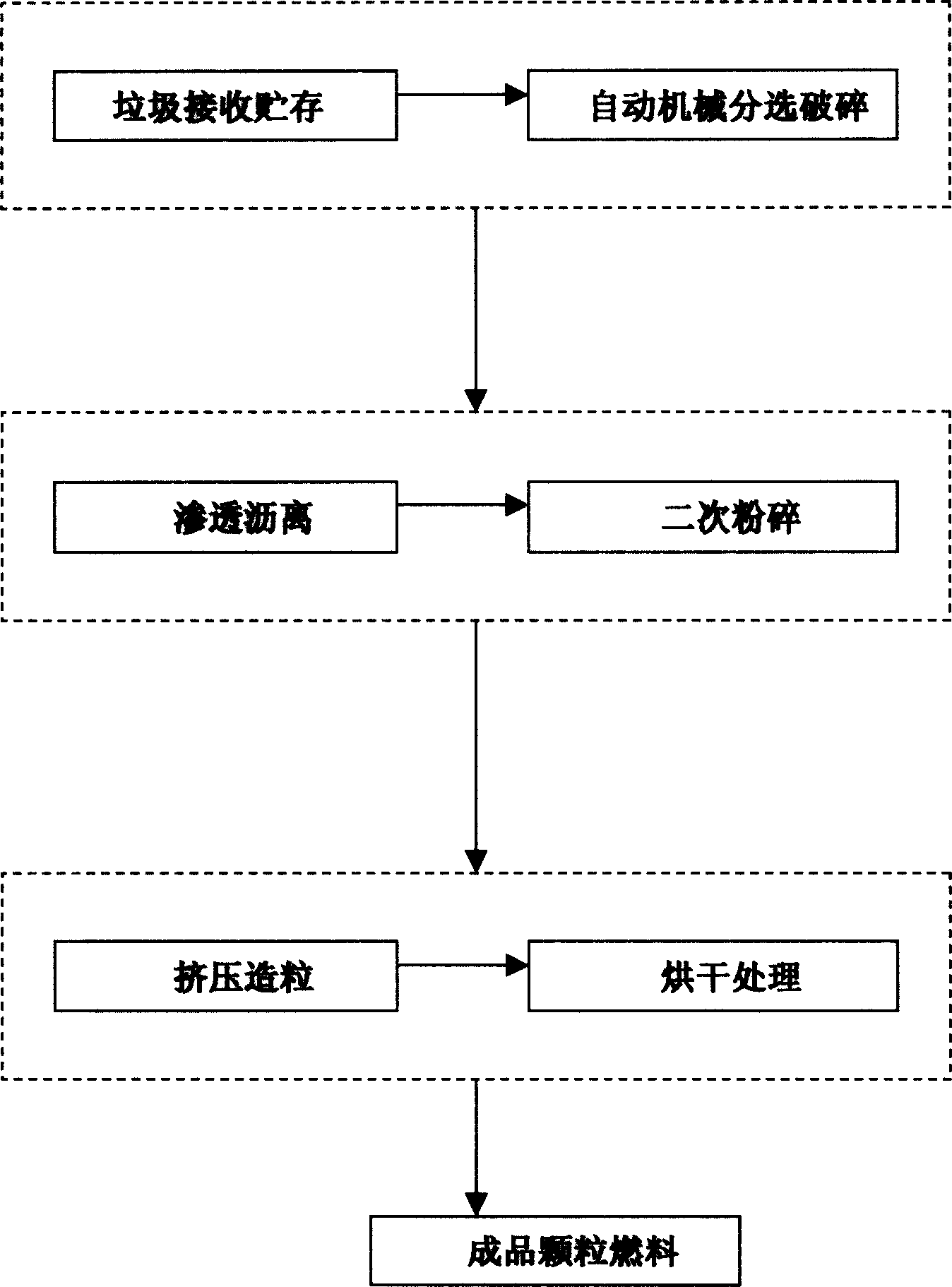

Method for preparing regeneration pellet fuel of urban household garbage

InactiveCN101886010AImprove recycling efficiencyReduce labor costsBiofuelsSolid fuelsLower limitLitter

The invention provides a method for preparing the regeneration pellet fuel of urban household garbage, which adopts the following steps of: comprehensive treatment of household garbage, burdening, secondary mixing and crushing, material drying, fuel forming, cooling and packaging and the like. The regeneration pellet fuel of the urban household garbage prepared by the method has the advantages that: the burdening process is adopted in the process of preparing garbage fuel to balance a heat value of the garbage fuel; the garbage fuel is prepared by adopting fully-mechanized assembly line operation, the process of garbage disposal has no phenomenon of material retention, no secondary pollution and no generation of garbage percolate and reduces mosquitoes and flies and the stench grade to the lowest limit, and simultaneously, the heat value of combustible matters in the processing process is not lost basically; and the fuel is dried first before forming, and has the high heat efficiency.

Owner:深圳市兖能环保科技有限公司

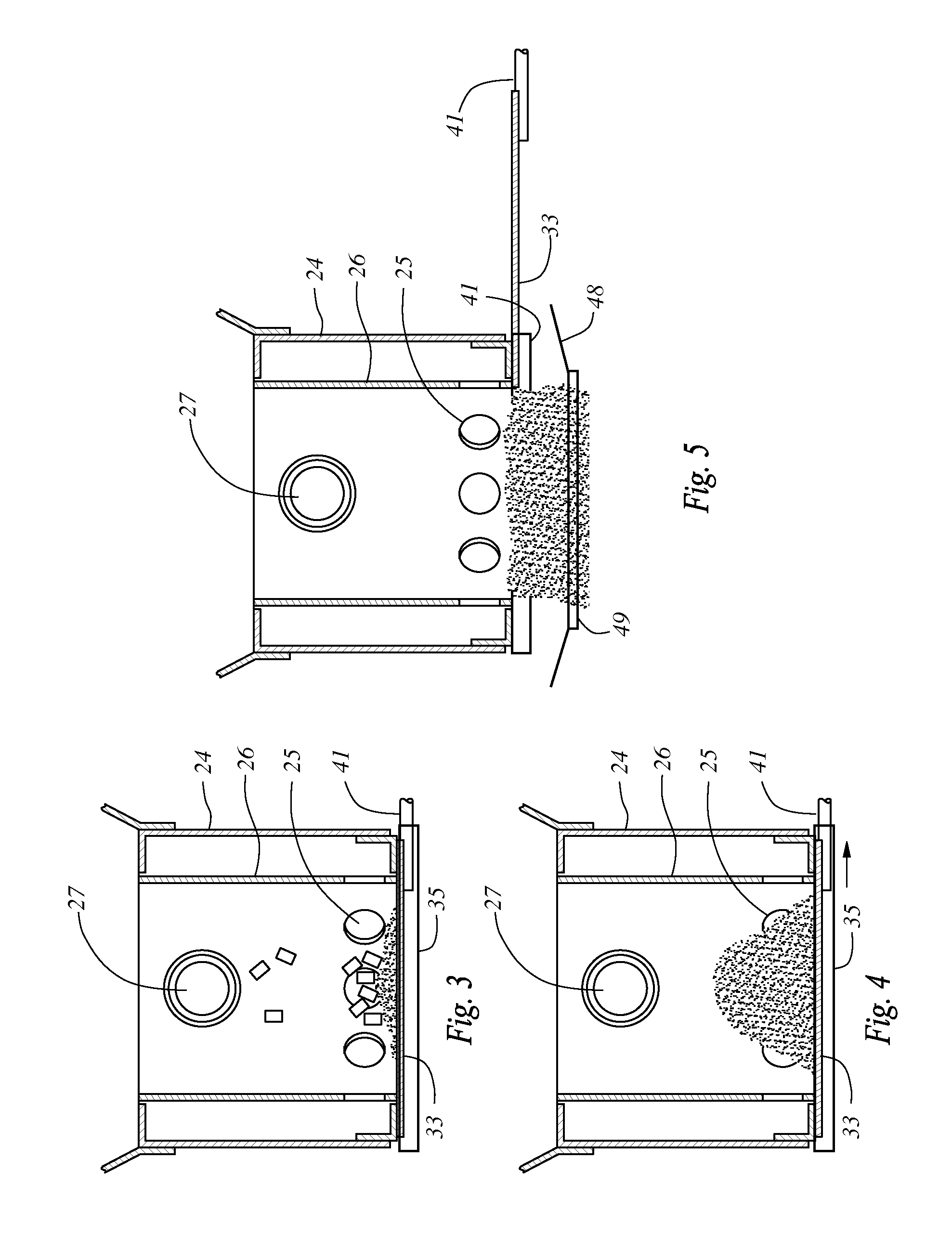

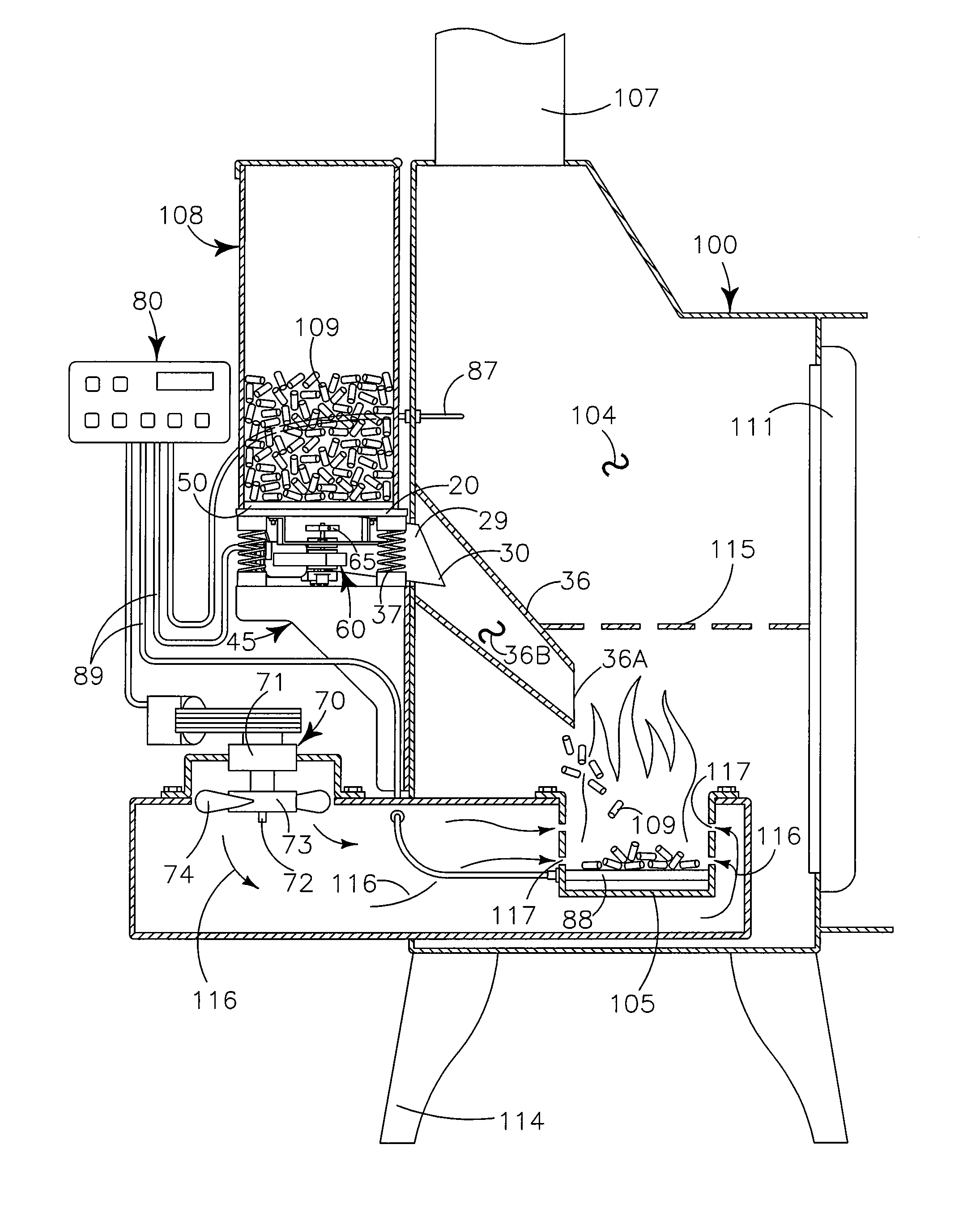

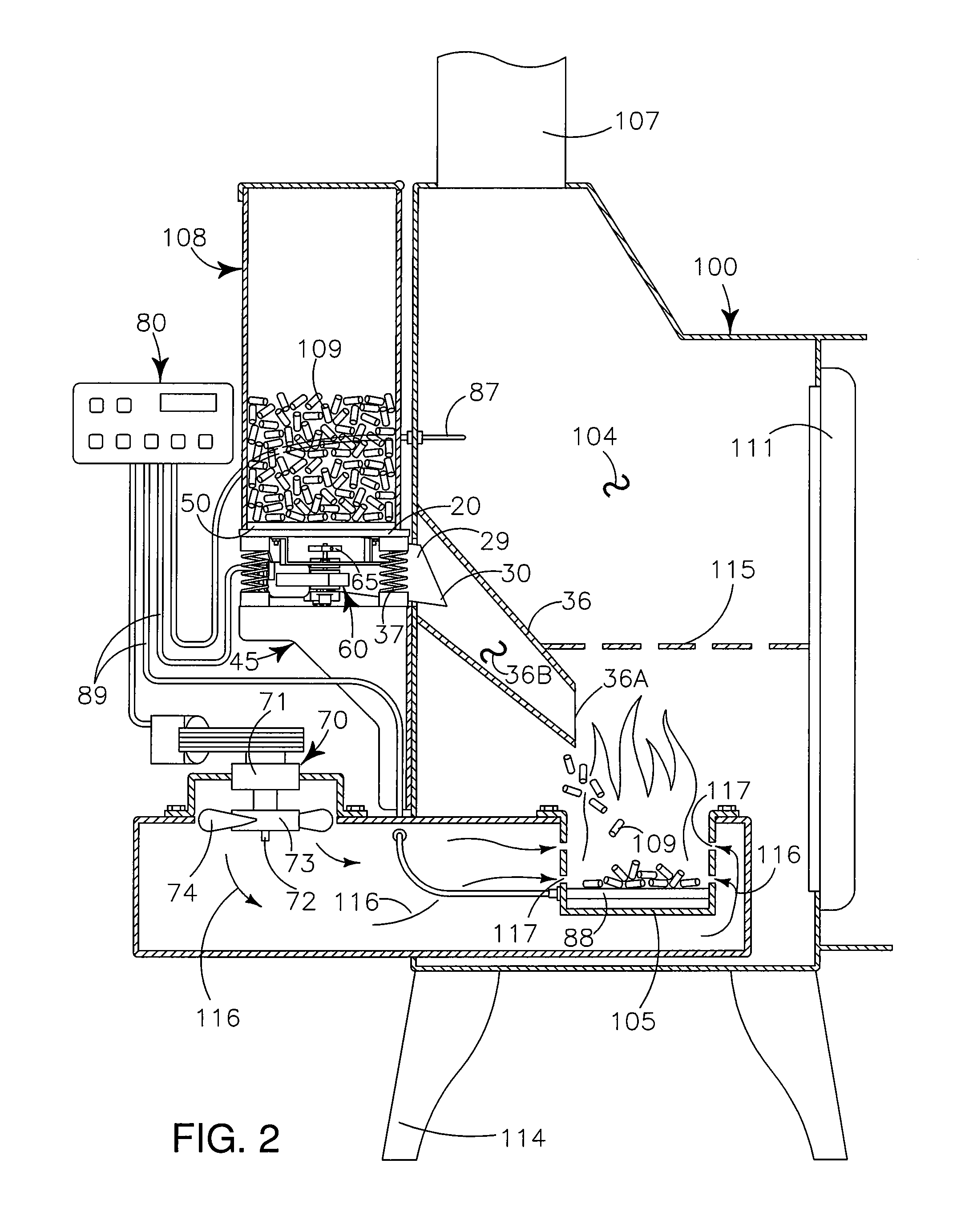

Vibratory feed mechanism for pellet fuel combustion device

ActiveUS9140448B2Accurate measurementEasy to controlDomestic stoves or rangesSolid fuel combustionEngineeringThermocouple device

A vibratory feed mechanism for pellet fuel combustion device provides a spring-mounted feed plate communicating with a fuel reservoir and vibrated by an electric motor carrying an offset counterweight to move pelletized fuel from a first position on the feed plate to a feed orifice defined in the feed plate for communication of the pelletized fuel to a metering channel and a drop tube for conveyance to a fire pot. A control board communicating with an igniter, at least one thermocouple, a combustion fan, and the electric motor allow a user to set a desired parameter which controls the rate of pelletized fuel feed and temperature and operating conditions.

Owner:FREEMAN MARK D

Preparation method of city refuse incineration furnace granular fuel

The invention discloses a produce method for grain fuel used in municipal refuse incinerator, which comprises: separating, breaking, draining, evaporating, secondary breaking, granulating and drying. This invention reduces the require to material, heat value and moisture, enlarges scope of application, cuts energy consumption and cost, decreases pollution greatly, and can be used to restart stop-production incinerator.

Owner:雷丰源

Battery enabled pellet grill

A system includes a cooking chamber defining a space for food to be cooked, a firepot inside the cooking chamber that is configured to utilize pelletized fuel to provide heat or smoke within the cooking chamber for cooking the food, and a fuel hopper defining a storage space for the pelletized fuel before delivery to the firepot. A battery powered auger interposes the fuel hopper and the firepot and is configured to selectively convey the pelletized fuel from the fuel hopper to the firepot for combustion. A rechargeable battery selectively provides power to the auger.

Owner:W C BRADLEY CO

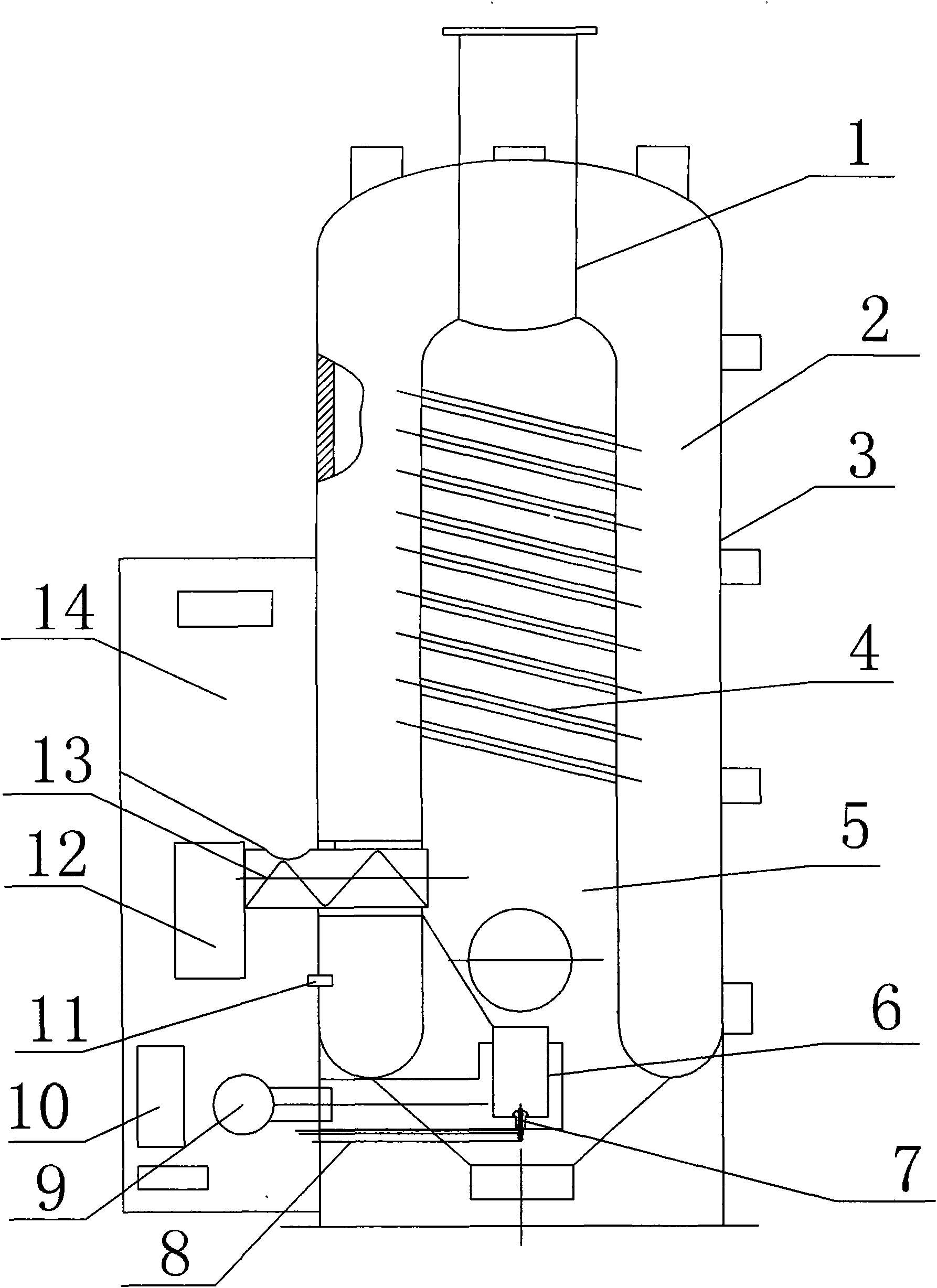

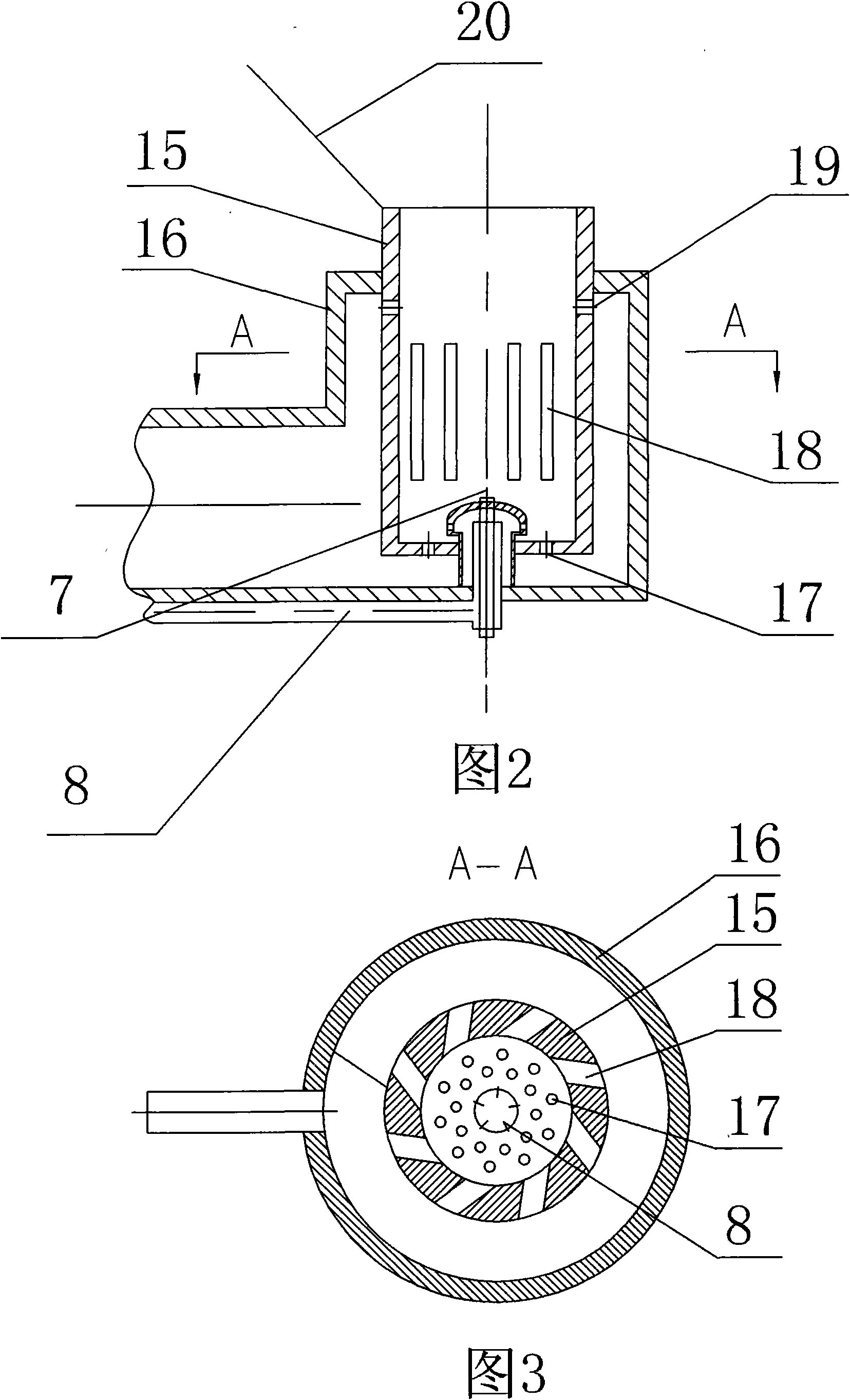

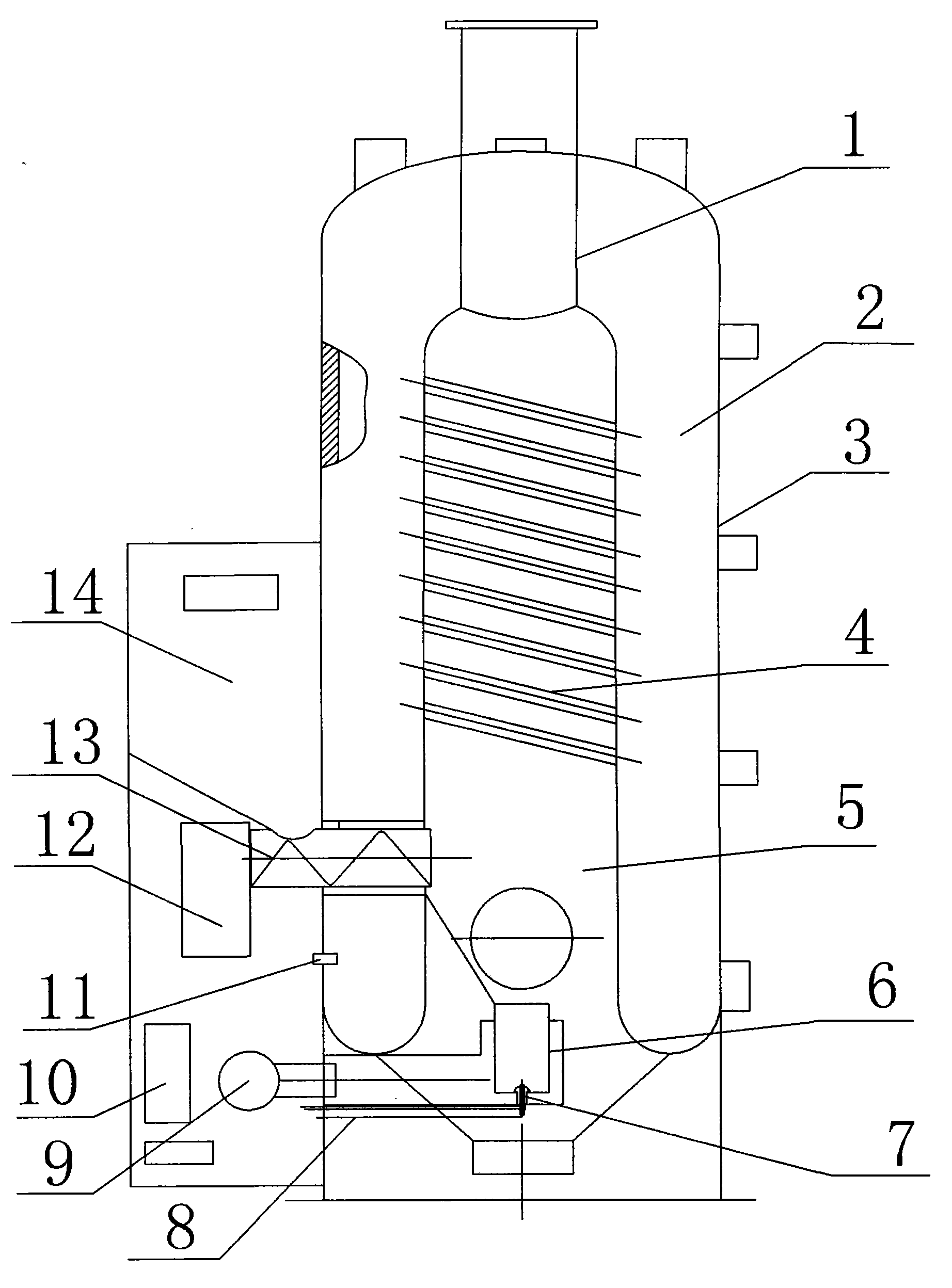

Biomass fuel boiler

InactiveCN101846386ABurn fullySolve the problem of stickingSteam generation plantsWater heatersCombustion chamberCombustor

The invention discloses a biomass fuel boiler which is equipped with an outer shell and an inner combustion chamber, wherein, a water storage room is arranged between a barrel and the combustion chamber, and a burner is arranged at the lower part of the combustion chamber. The biomass fuel boiler is characterized in that the burner is of a double-layer sleeve structure, wherein, the inner layer thereof is a cylinder with an open on the upper surface, and an ignition device is arranged in the middle of the bottom; an outer layer is a closed body which is communicated with a fan and is used for enclosing the inner-layer cylinder besides an open mouth; and air intakes are arranged at the middle part and the upper part of the bottom and the side of the inner-layer cylinder; and a particle fuel tank is arranged at the side of the shell, and particle fuel is connected to the burner through a twisting cage. In the invention, three types of combustion air such as upper straight air, middle spiral air and bottom raising air are formed in the burner by changing the mode of air supply, wherein, the bottom raising air enables biomass particles to suspend in the burner; the middle spiral air enables biomass fuel more dispersed and more fully burned; and the upper straight air performs secondary oxygen supply to achieve more thorough combustion and improve thermal efficiency.

Owner:范家文

Process for producing cement by using organic garbage to substitute partial fuel coal

The invention discloses a process for producing cement by using organic garbage to replace partial fuel coal, which comprises the following steps that: 1) the organic garbage is pretreated into granular fuel; and 2) the granular fuel of the organic garbage is sent into a fuel decomposition furnace of a cement production device for decomposition to ensure that organic components in the granular fuel are volatilized into a gas phase, and then the granular fuel enters a cement kiln for oxidizing combustion. The process can solve the way problem of the organic garbage and can also reduce cement cost.

Owner:四川利森建材集团有限公司

A new method for comprehensive utilization of waste materials from rubber tree processing boards

ActiveCN102260506AHigh calorific valueIncrease production capacityCarbon compoundsSolid waste disposalSolid carbonWater vapor

The invention relates to a novel method for comprehensively utilizing waste materials of rubber tree processing sheets. The method specifically comprises the following steps of: (1) crushing the waste materials, drying, and performing extrusion molding to produce biomass pellet fuel; (2) pyrolyzing the dried waste materials at the temperature of between 420 and 550 DEG C to produce biomass oil and solid carbon; and (3) activating the solid carbon by water vapor to produce activated carbon. The advancement of the method is that: (1) the composition of solid, liquid and gas phases of a product is controlled by controlling pyrolysis temperature, gas obtained after gas phase combustion reaches the temperature required by the pyrolysis and is used for biomass drying and pyrolysis after being regulated and controlled, and energy sources are not required to be added additionally; (2) the condensing temperature is improved, the biomass oil is upgraded in situ, and the calorific value is 28 to30MJ / kg; (3) the biomass oil is added into raw materials which are then processed into particles, so that the calorific value and the production capacity of equipment are improved, and the energy consumption is reduced; and (4) the biomass oil is taken as the energy source for producing the activated carbon, so that the fossil energy is saved, the discharge of harmful gas is reduced, and the environment is protected.

Owner:JILIN UNIV

Method for preparing biomass pellet fuel by mulberry branch fermentation wastes

InactiveCN104845696AGood technical effectImprove molding rateBiofuelsSolid fuelsWoody plantCaloric values

The invention discloses a method for preparing biomass pellet fuel by mulberry branch fermentation wastes. The method comprises the following steps of crushing the mulberry branch fermentation wastes into 1 to 3mm, and crushing the woody plant leftovers into 3 to 6mm; uniformly stirring and mixing 5 to 40 parts of mulberry branch fermentation waste powder and 60 to 95 parts of woody plant leftover powder, heating and drying to the 14 to 25% of water content, and sending the dried material into a press roll type annular die to form. The method has the advantages that by mixing the mulberry branch fermentation wastes with low caloric value and the woody plant leftovers with high caloric value, the biomass raw material can be formed under the condition of lower aperture and length ratio of the annular die, the abrasion of the annular die is reduced, and the forming rate, product density, durability and lower caloric value of the pellet fuel can be effectively improved.

Owner:GUANGXI ACAD OF SCI +1

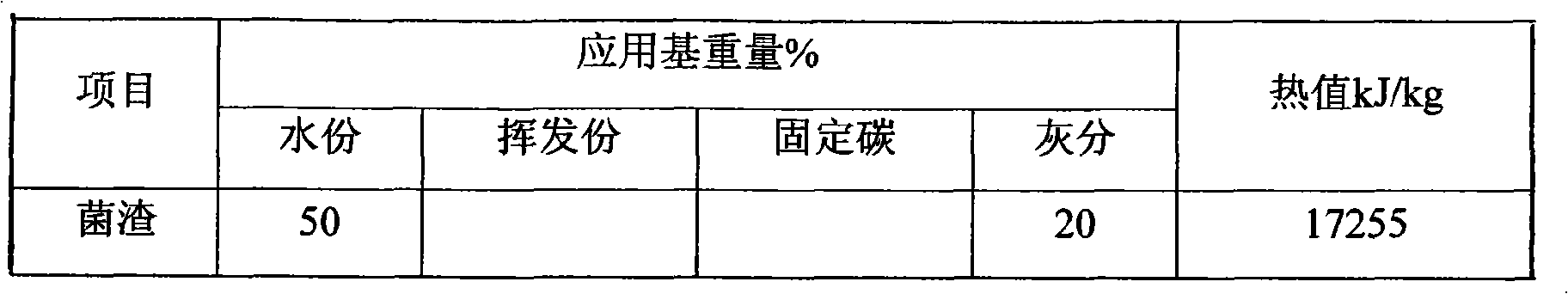

Novel biomass solid particle fuel

ActiveCN104673425ACompatibility is reasonablePromote combustionBiofuelsSolid fuelsPotassiumSolid particle

The invention relates to a novel biomass solid particle fuel. The novel biomass solid particle fuel is prepared by the following raw materials in parts by weight: 20-50 parts of crop straw, 10-20 parts of bacteria stick, 10-15 parts of pig manure, 10-20 parts of saw dusts, 10-20 parts of corncobs, 5-10 parts of carbon rock, 1-2 parts of potassium chloride and 1-5 parts of combustion improver. The preparation process comprises the following steps: drying, crushing, extruding at high temperature to granulate, cooling, packaging and storing; with the reasonable raw material proportion of the solid particle fuel, the problems that the quantity demand of single raw material is high and the single raw material is difficult to collect are avoided, the forming rate in a processing process is improved effectively, meanwhile, the moisture-proof effect is good, the durability and combustion endurance of the fuel are favorable, and the heat of combustion and the combustion ratio are high.

Owner:山西惠民新能源股份有限公司

Biomass granular fuel and processing method thereof

The invention discloses a biomass granular fuel. Raw materials comprises the following components in proportions by weight: 4 to 6 parts of shaving, 12 to 18 parts of wood chip, 0.1 to 0.4 part of swelling agent and 0.1 to 0.4 part of flame accelerator, wherein the water content of the shaving is 4 to 6 percent; the wood chip is a mixture of a wood chip of which the water content is 25 to 35 percent and a wood chip of which the water content is 8 to 10 percent according to a weight ratio of 1 to 2. The invention also provides a processing method of the biomass granular fuel. The processing method comprises pulverization, primary mixing, secondary mixing, tertiary mixing and granulation. The biomass granular fuel which is provided by the invention and is processed by utilizing the production waste of a timber is more convenient to use and transport; the resource utilization rate is improved; the heat value of the biomass granular fuel can reach 4500 to 4700 kilocalories per kilogram; a liquid fuel is added into the raw materials in a spraying manner as the flame accelerator; sodium hydrogen carbonate and ammonium hydrogen carbonate are used as the swelling agent; the combustion performance of the biomass granular fuel is further improved; according to the biomass granular fuel and the processing method thereof, the raw materials are subjected to the primary mixing and the secondary mixing; the uniform distribution of moisture is facilitated; the flame accelerator is atomized and sprayed into a secondary mixture; the uniform distribution of the flame accelerator is promoted.

Owner:玉溪加宝生物能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com