Process for producing cement by using organic garbage to substitute partial fuel coal

A technology of organic waste and replacement parts, which is applied in the field of dry suspension preheater rotary kiln cement production system, can solve the problems of waste of resources, high calorific value, and short residence time, so as to reduce the cost of cement, avoid re-diffusion, and meet the The effect of environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

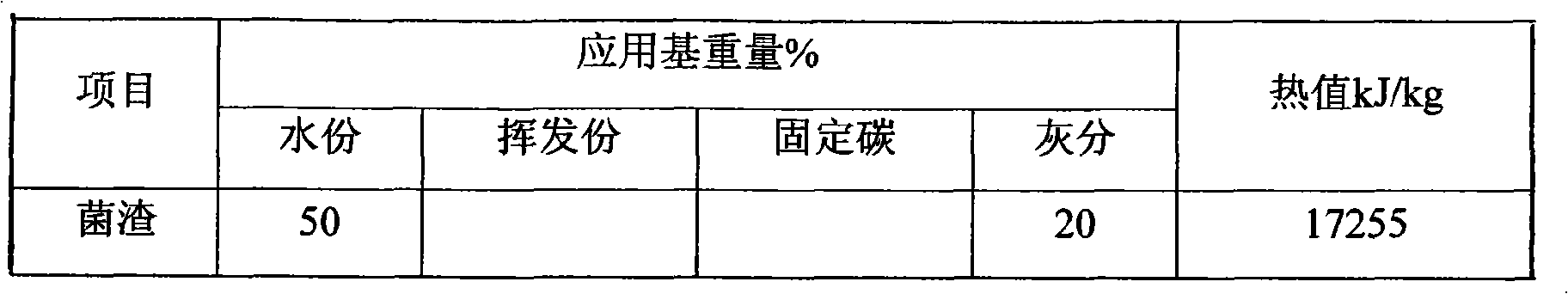

[0031] Mushroom residue is the residue of edible fungi after harvesting. It has not been crushed and homogenized, and its composition is complex. It mainly contains combustible components such as sawdust and cottonseed hulls, and has a high calorific value. See Table 1 and Table 2.

[0032] Table 1 Composition of fungal residue

[0033] Element

Rice hulls, cottonseed hulls, etc.

quicklime, gypsum, etc.

other ingredients

percentage content

80%

5%

15

[0034] Table 2 Calorific value table of fungal slag

[0035]

[0036] It can be seen from the above table that the fungus residue has a high calorific value and a high utilization value.

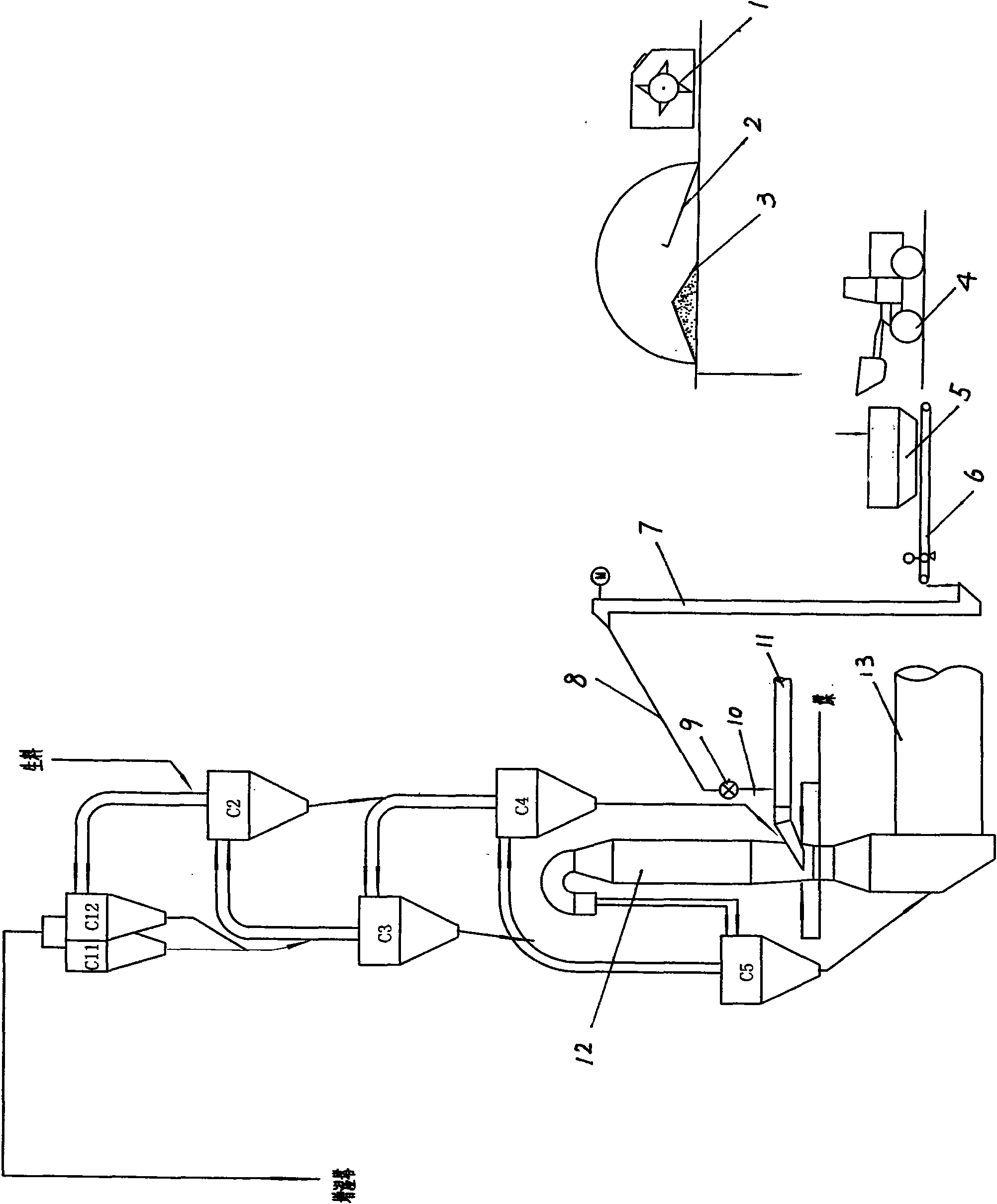

[0037] The present invention replaces part of coal-fired calcined cement with fungal slag, and its technological process is shown in figure 1 After collecting and packing the fungus residues to the factory area, they are dried and crushed into granules with a pulverizer 1 with a drying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com