Patents

Literature

950results about "Sulfur-trioxide/sulfuric-acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

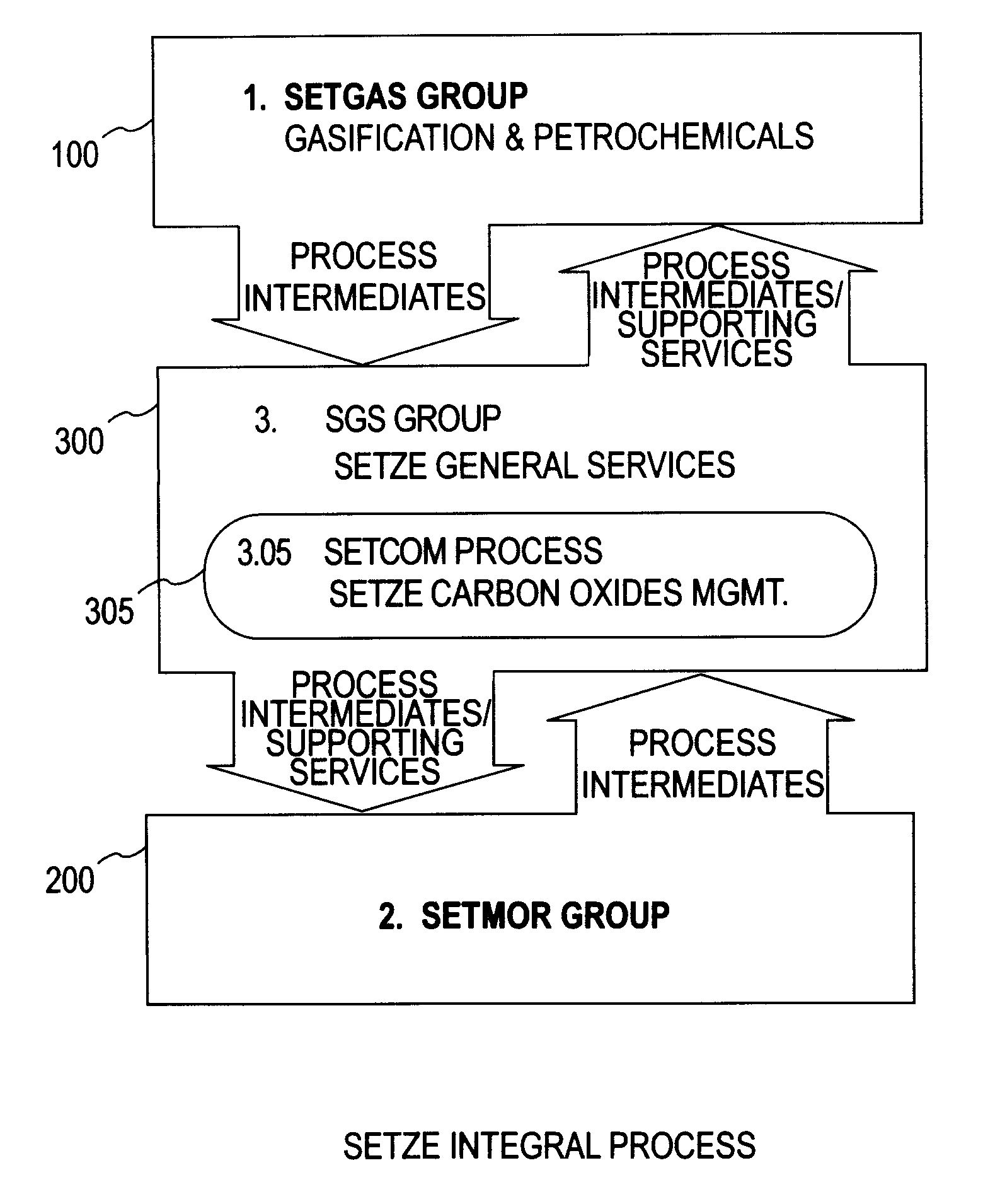

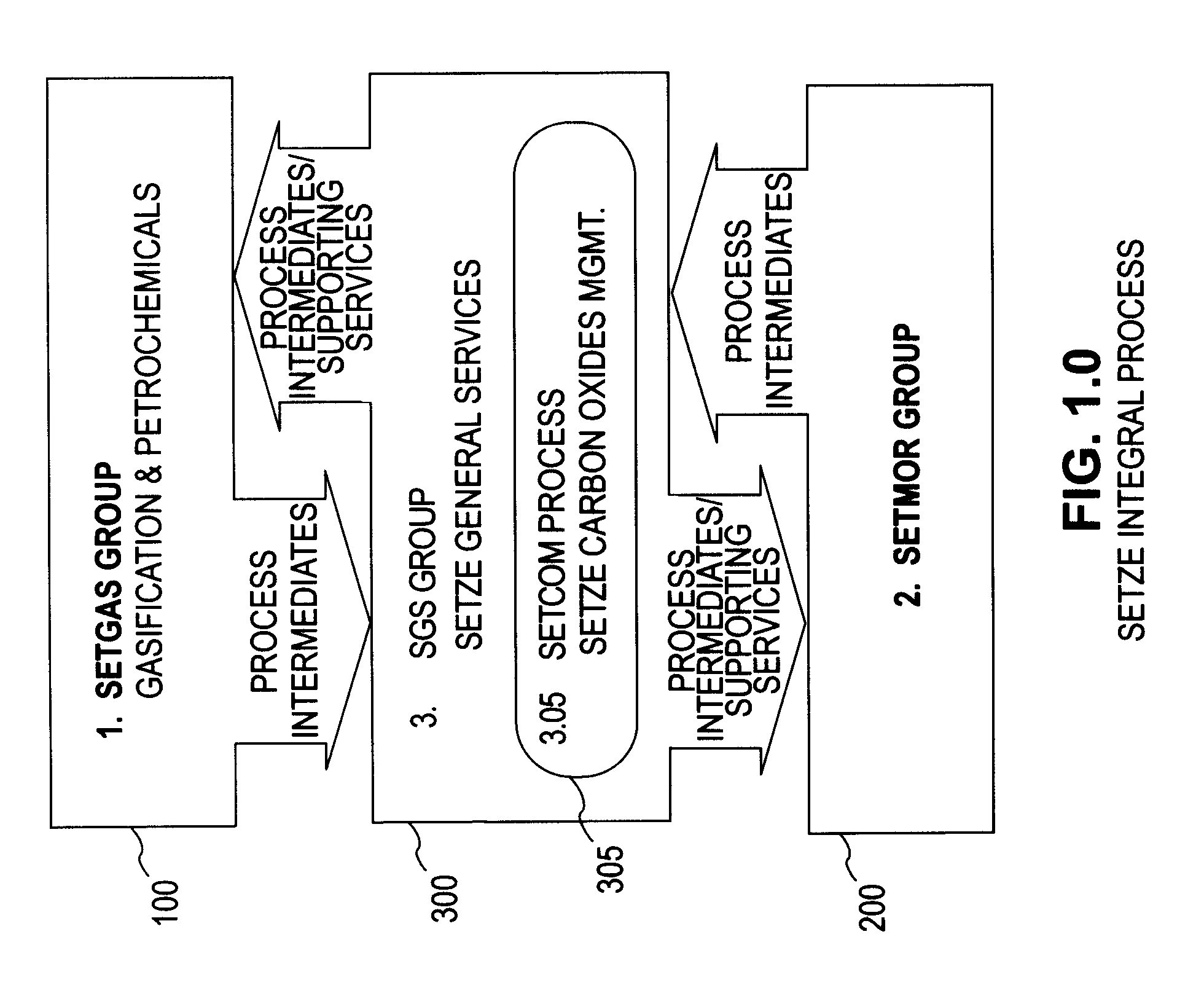

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

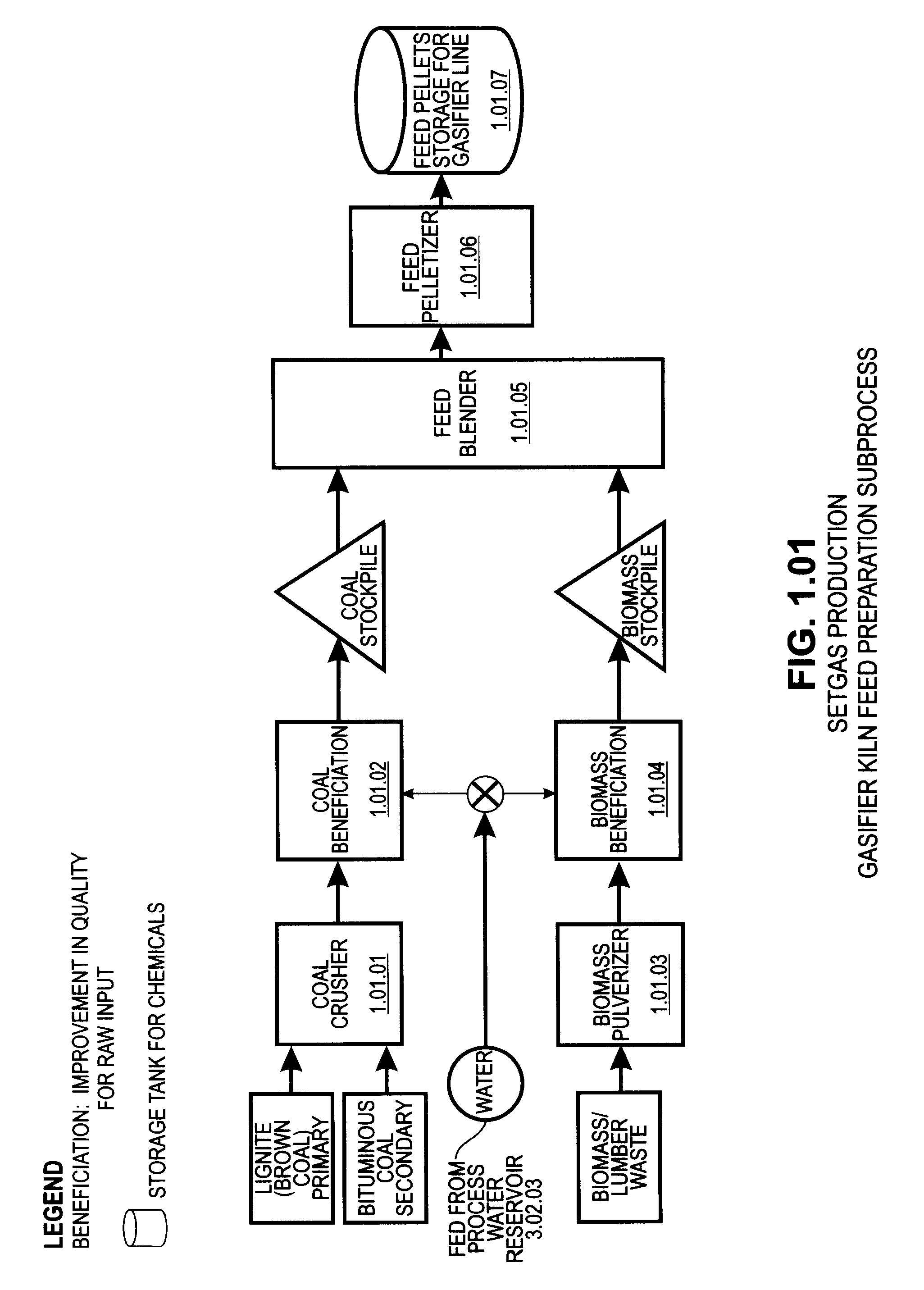

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

Flue gas purification process using a sorbent polymer composite material

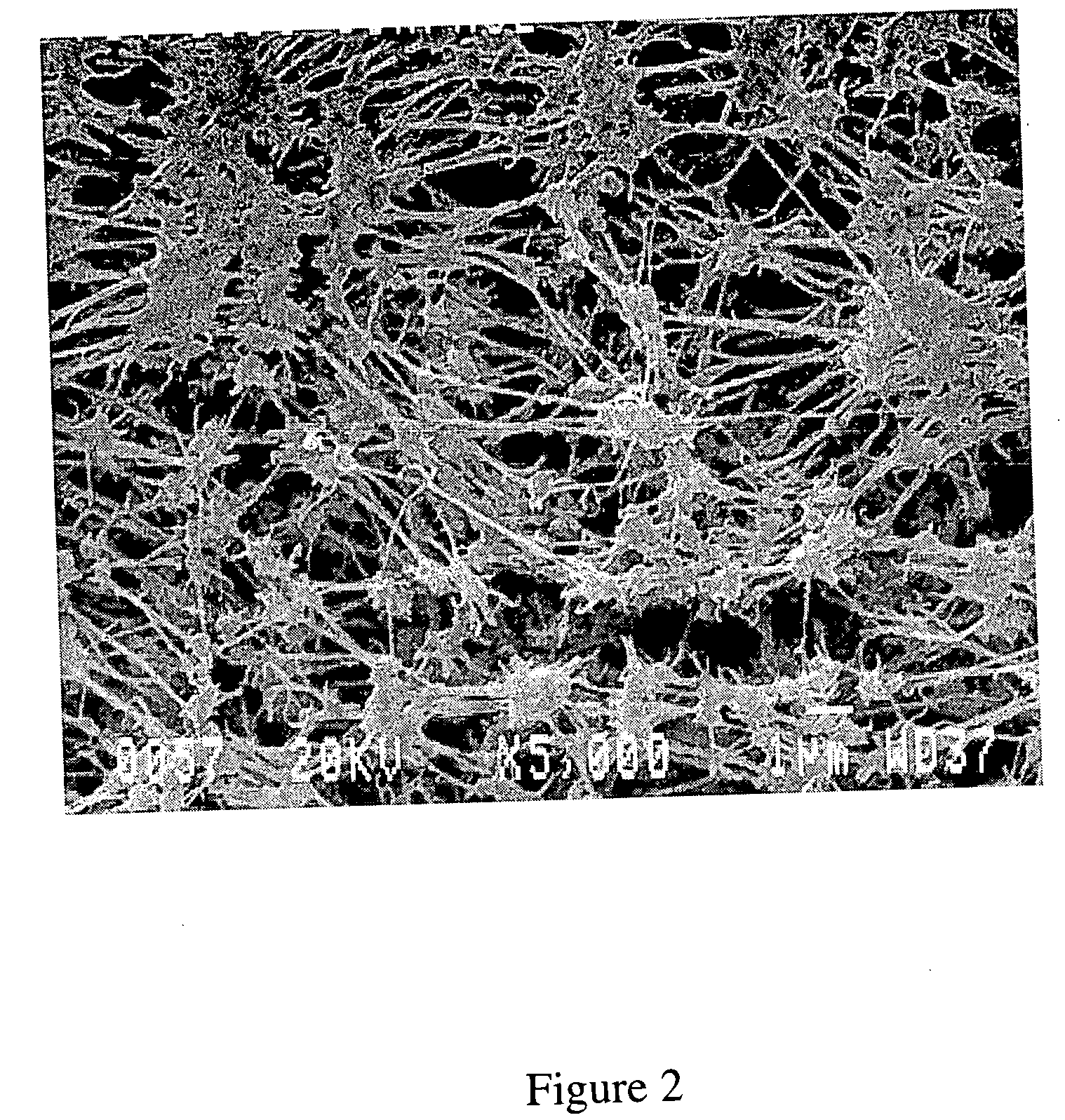

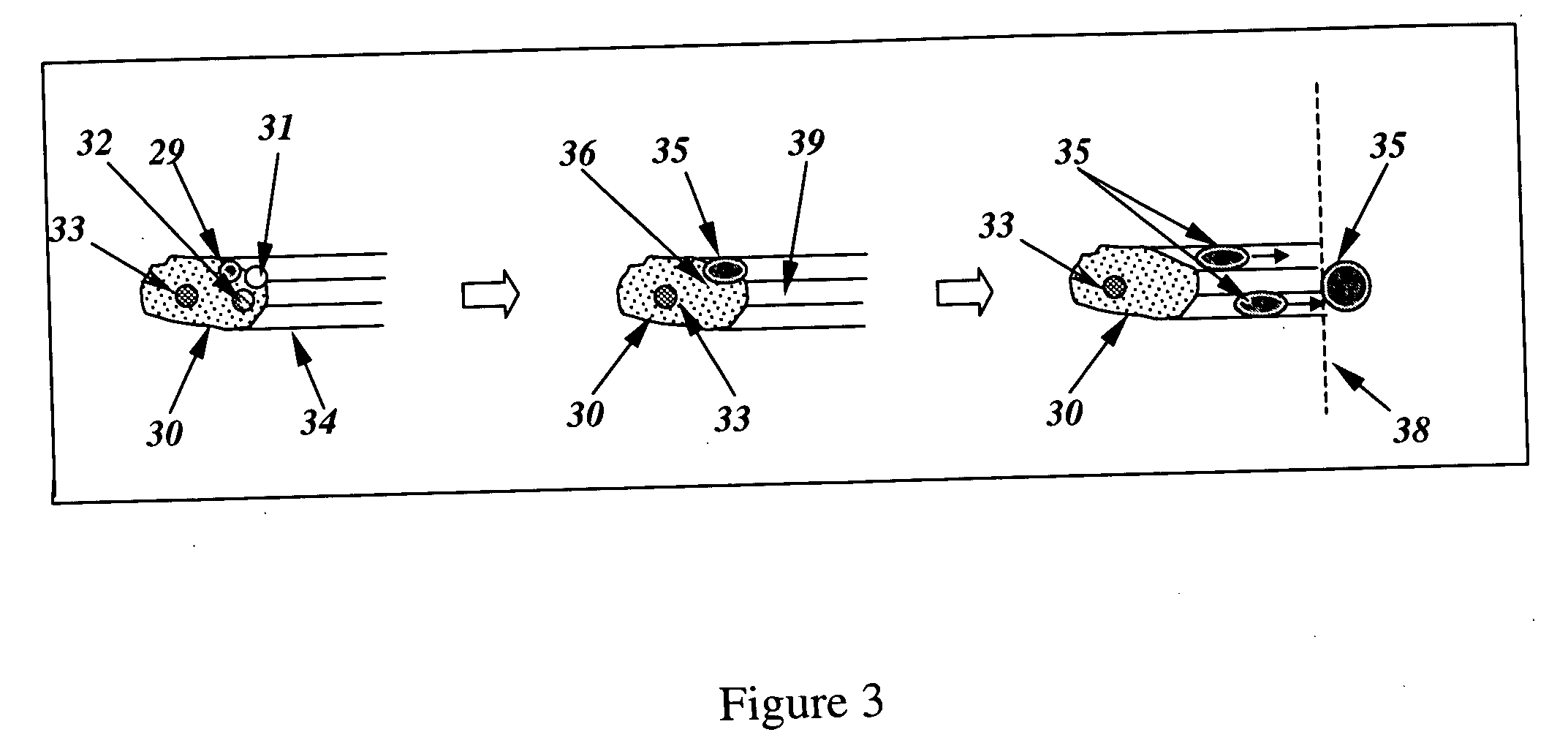

ActiveUS20050019240A1Easy to fixImprove removal efficiencyGas treatmentNitrogen compoundsSorbentFluoropolymer

This invention provides a process of removing sulfur oxides, mercury vapor, and fine particulate matters from industrial flue gases that contain such pollutants. The pollutants are removed by modules, which contain microporous adsorbent (i.e., sorbent) material that is held within a polymer matrix. The preferred polymers are fluoropolymers. The composite material that contains the microporous absorbent material held within a polymer matrix removes sulfur oxides by converting them into high concentration sulfuric acids. It also removes mercury vapor by chemically adsorbing the mercury into the matrix. It also removes fine particulate matters by surface filtration. The sulfuric acid that is produced inside the composite material is automatically expelled onto the external surfaces of the composite material and is drained into an acid reservoir together with the fine particulate matters which are washed from the external surfaces of the composite material by the constant dripping of the sulfuric acid along the external surfaces of the composite material.

Owner:WL GORE & ASSOC INC

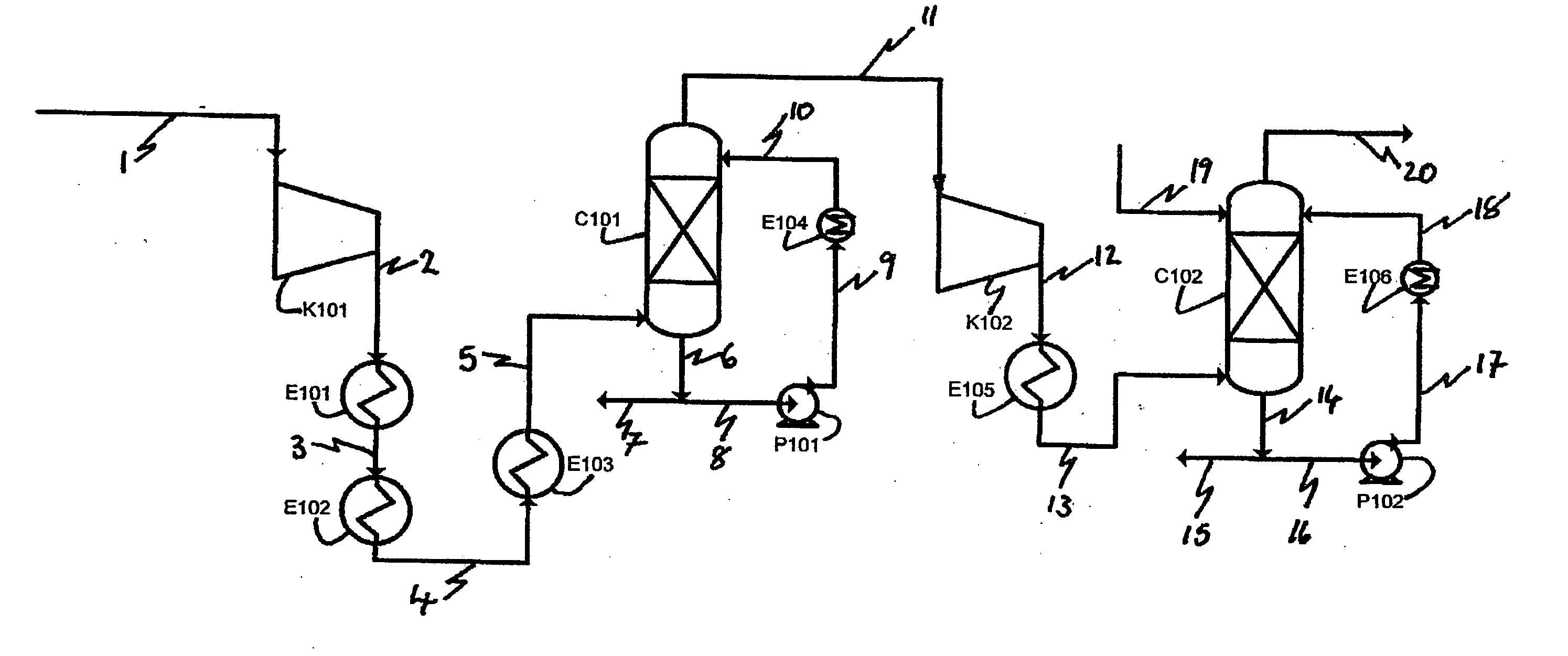

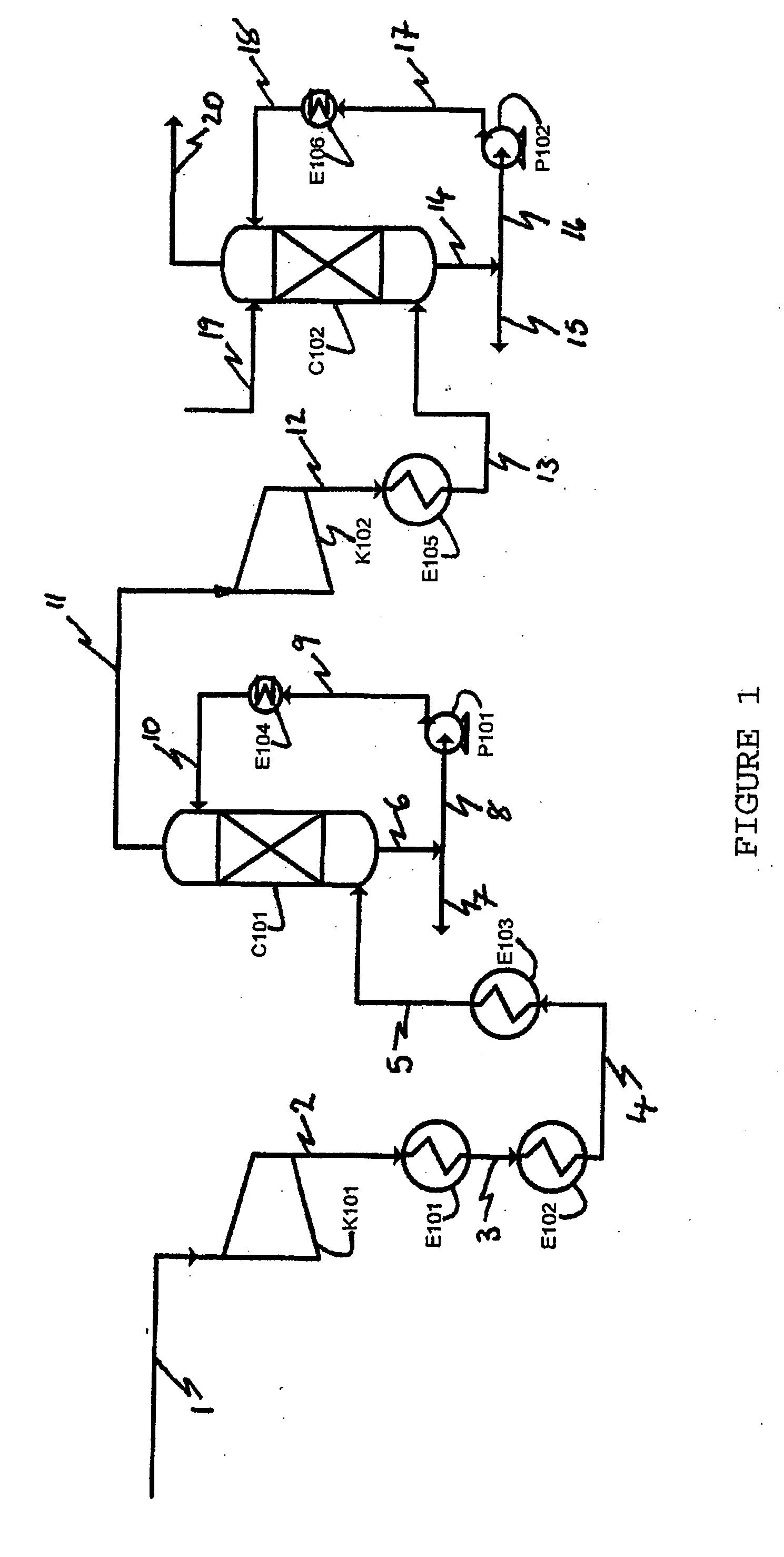

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

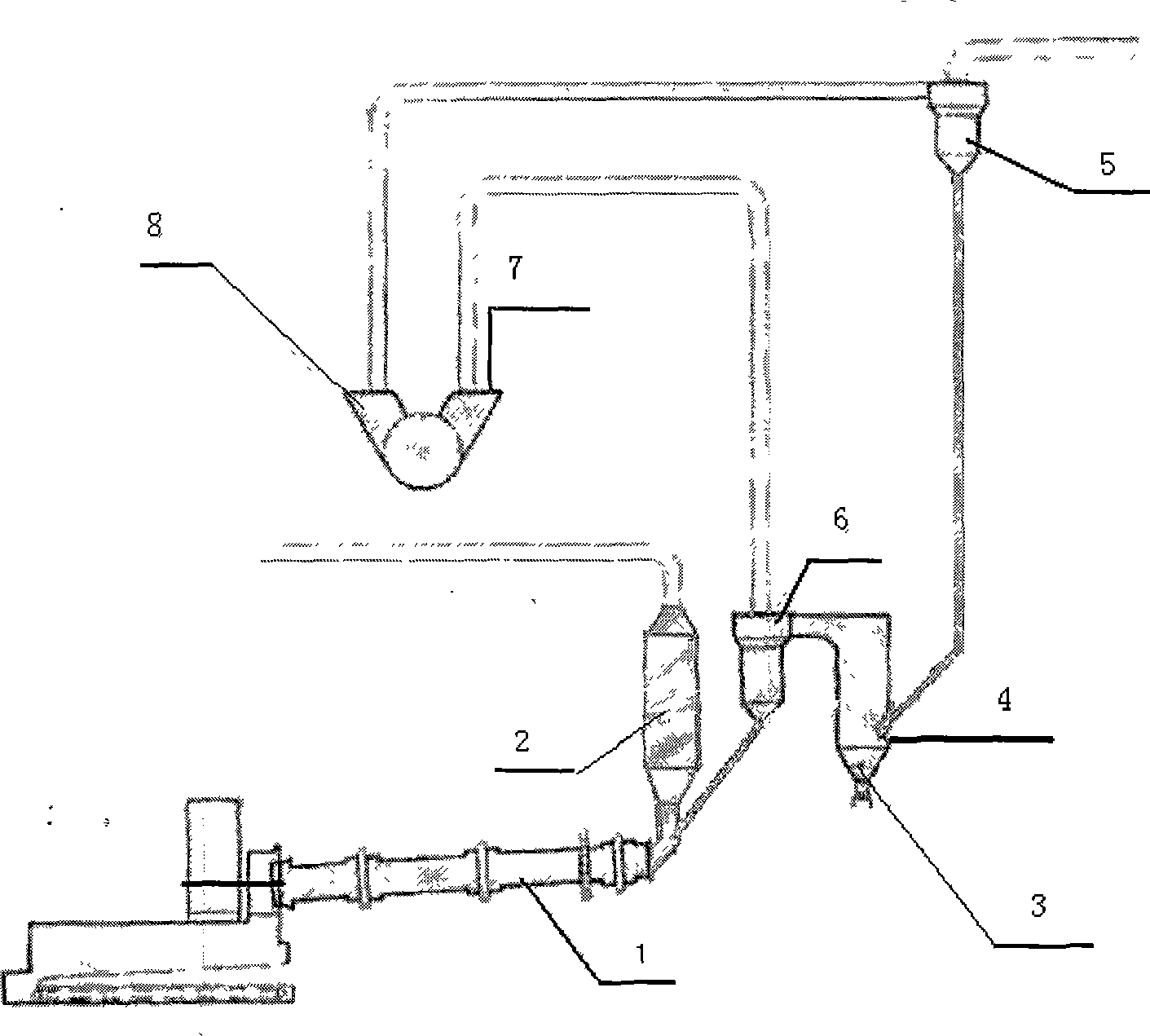

Treatment technology of producing sulfuric acid from alkylated spent sulfuric acid through high temperature decomposition

ActiveCN1751984ARealize lysis treatmentAvoid secondary pollutionSulfur-trioxide/sulfuric-acidDecompositionContact method

A process for preparing sulfuric acid from used alkylating sulfuric acid by high-temp cracking includes such steps as heating to 1000-1100 deg.C, cracking, acid washing for cleaning, converting twice by contact method, and absorbing twice to obtain qualified sulfuric acid for reuse. It has high recovering rate.

Owner:PETROCHINA CO LTD

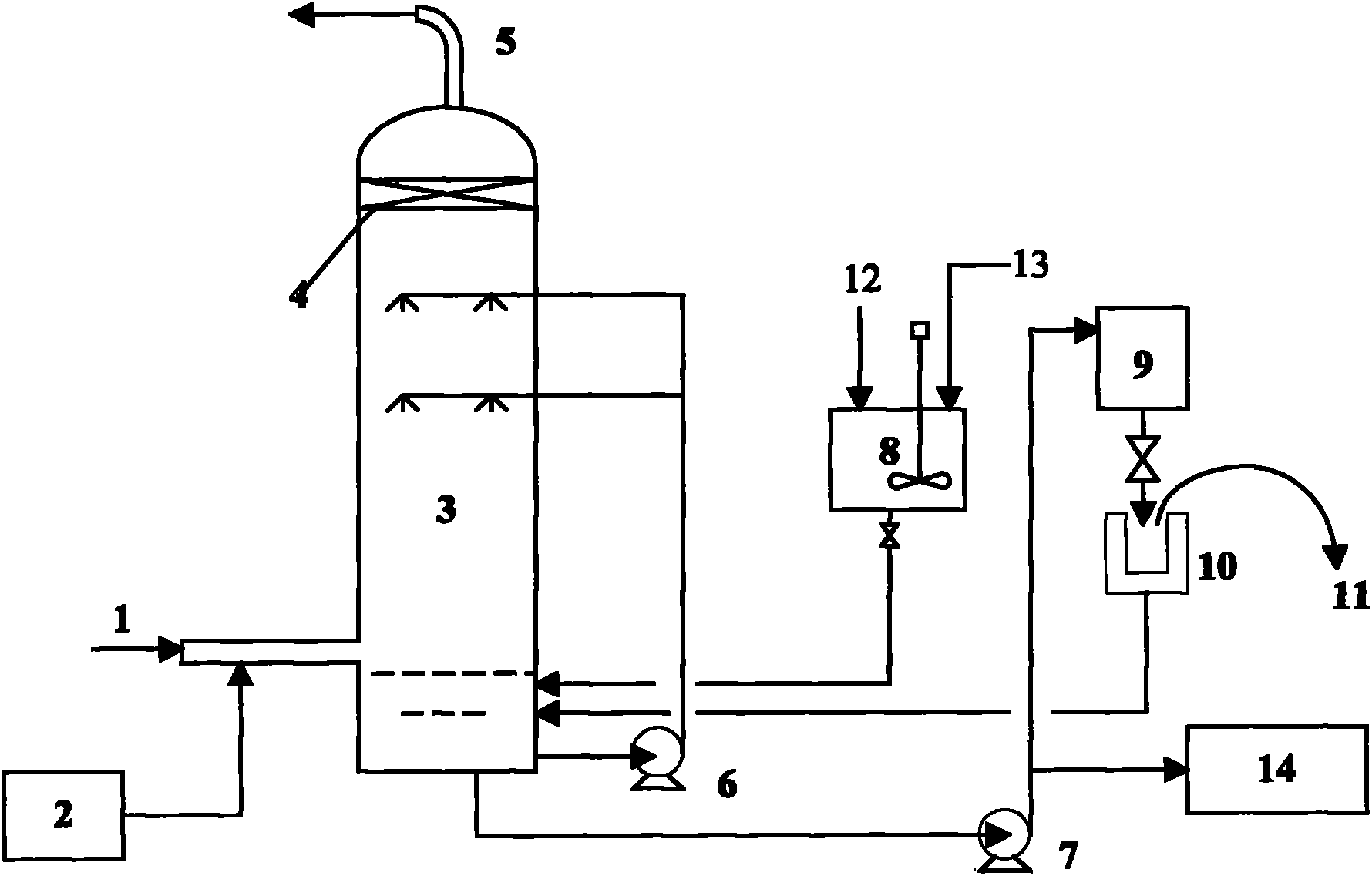

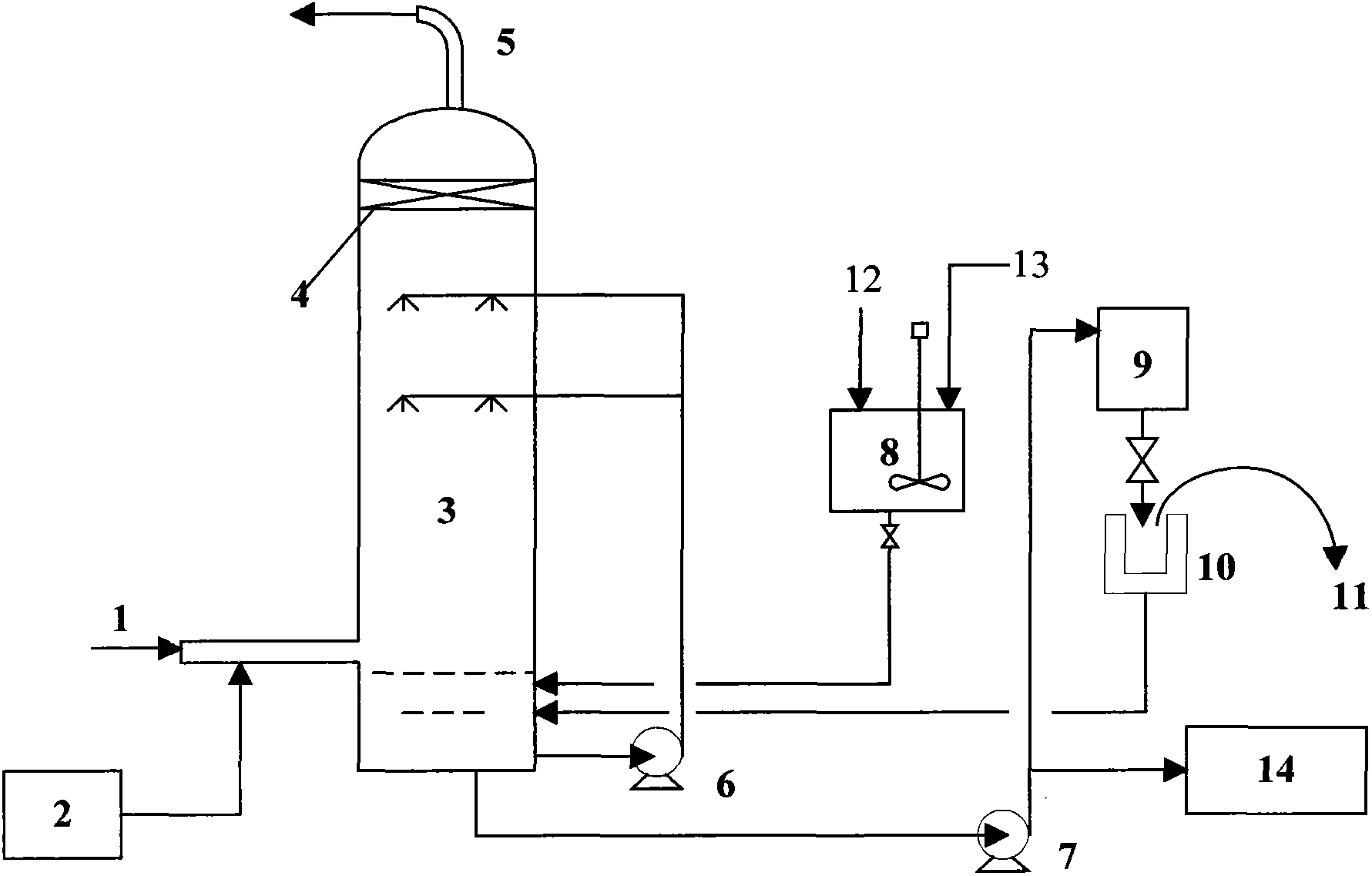

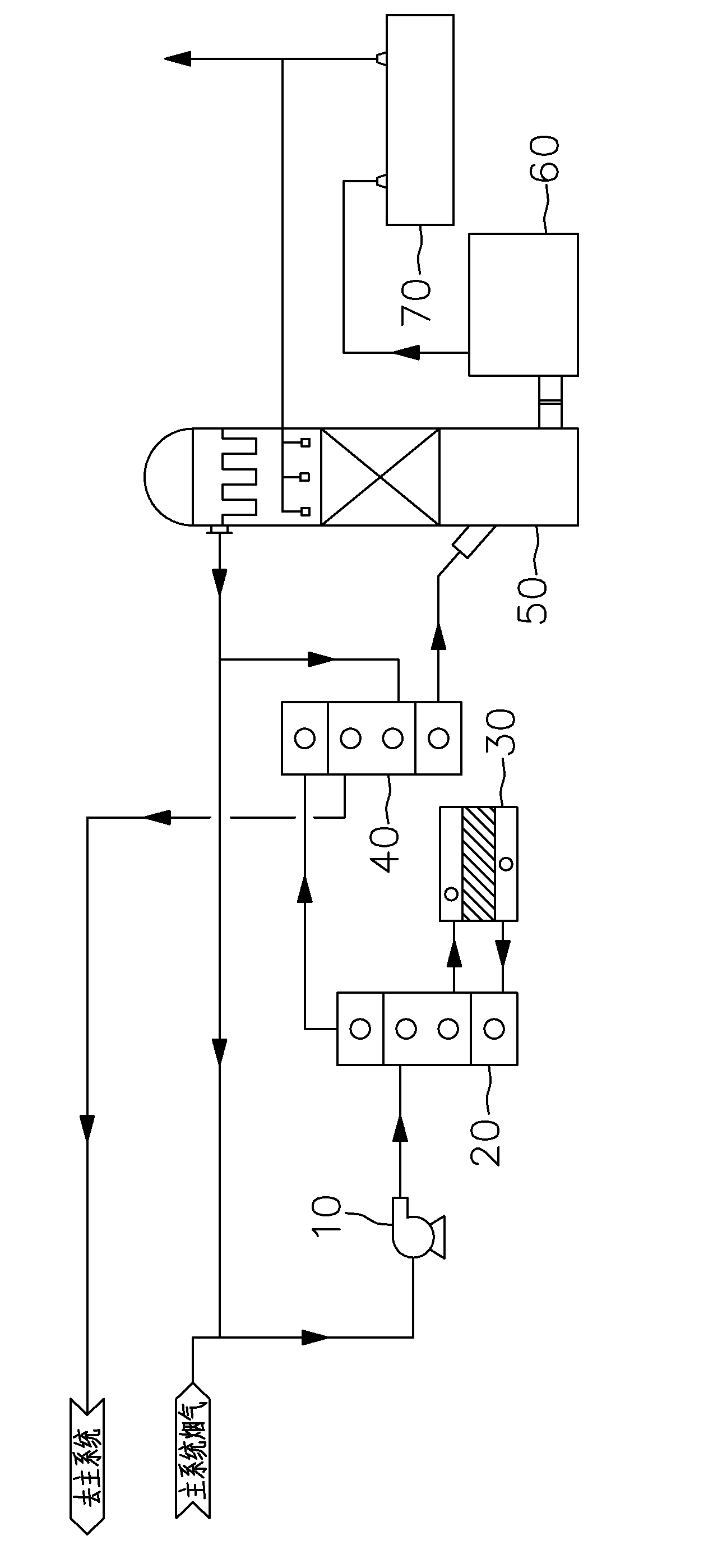

Device and method for simultaneously desulfurizing and denitrifying flue gas by ozone catalytic oxidation process

InactiveCN102247750AEfficient oxidationDispersed particle separationSulfur-trioxide/sulfuric-acidCatalytic oxidationAbsorption of water

The invention relates to a flue gas pollutant treatment process and aims to provide a device and method for simultaneously desulfurizing and denitrifying a flue gas by ozone catalytic oxidation process. The device comprises a desulfurization and denitrification tower, an ozone generator, absorption liquid circulating equipment and desulfurization and denitrification by-product post-treatment equipment. Ozone enters from a flue or the lower part of the desulfurization and denitrification tower, a catalyst is added to an absorption liquid, and the absorption liquid is injected in from the upper part of the desulfurization and denitrification tower, so that SO2 and NO in the flue gas are oxidized by ozone with high efficiency under the action of the catalyst, and in combination with the absorption of water or alkaline substances, SO2 and NOx in the flue gas are recovered in the form of high value-added sulfuric acid and nitric acid products, or ammonium sulfate / ammonium nitrate mixed nitrogen fertilizers, potassium sulfate / potassium nitrate mixed potassium fertilizers or ammonium / potassium compound fertilizers respectively, thereby achieving resource recovery and value maximization of the desulfurization and denitrification process. The desulfurization and denitrification process provided by the invention has the advantages of simple structure, low investment and low operation cost. The desulfurization rate and the denitrification rate of the desulfurization and denitrification process provided by the invention can reach more than 96% and more than 90% respectively.

Owner:EAST CHINA UNIV OF SCI & TECH

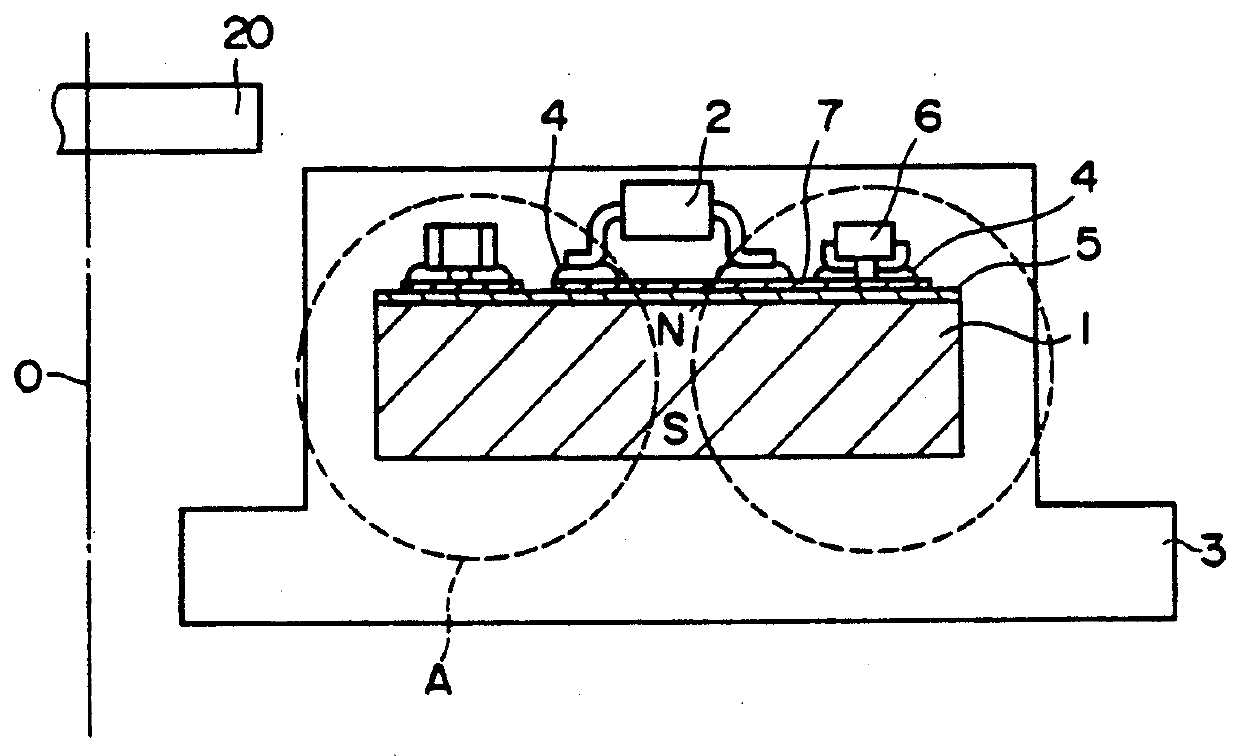

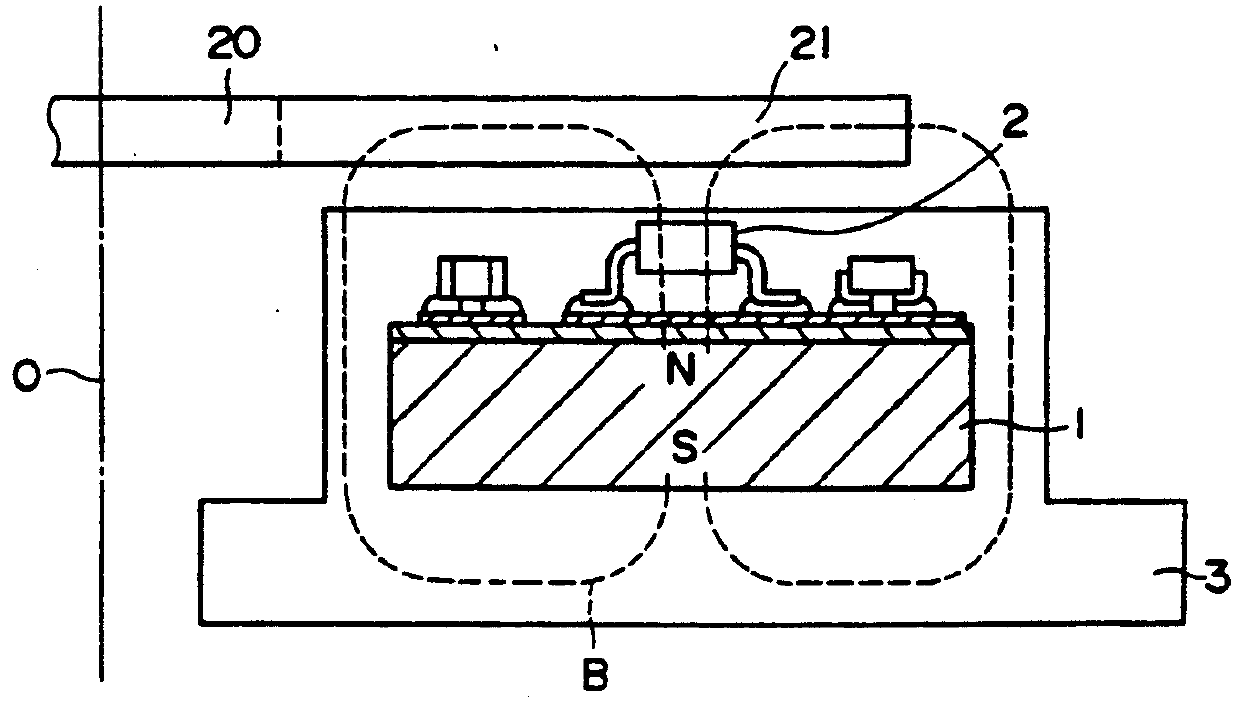

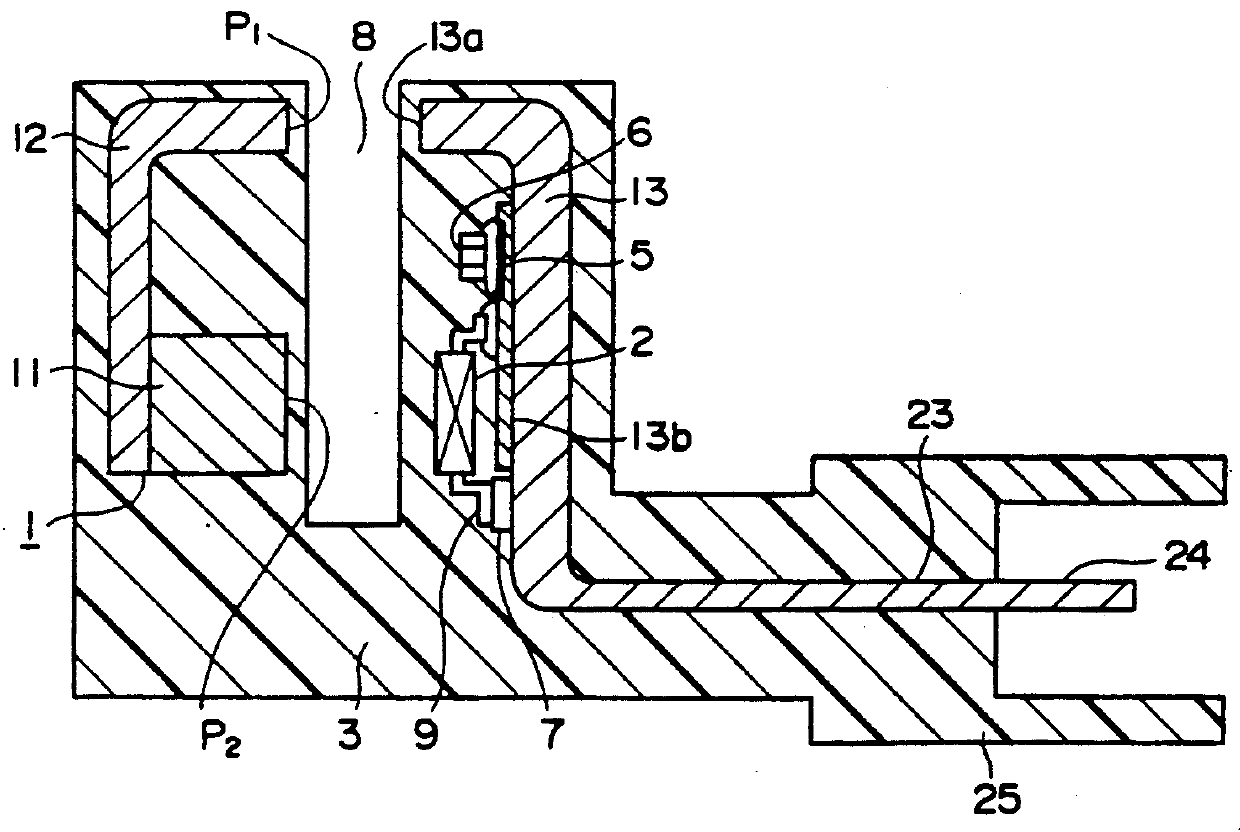

Hall-effect sensor having integrally molded frame with printed conductor thereon

A Hall-effect sensor, wherein a Hall element is disposed in a magnetic path being formed by a magnet and a flux guide, and the magnet, flux guide, and Hall element are integrally held with a molded frame, and the Hall element is fixed to the magnet (or flux guide) or the molded frame. This Hall-effect sensor can easily position the Hall element with higher sensitivity.

Owner:MITSUBISHI ELECTRIC CORP

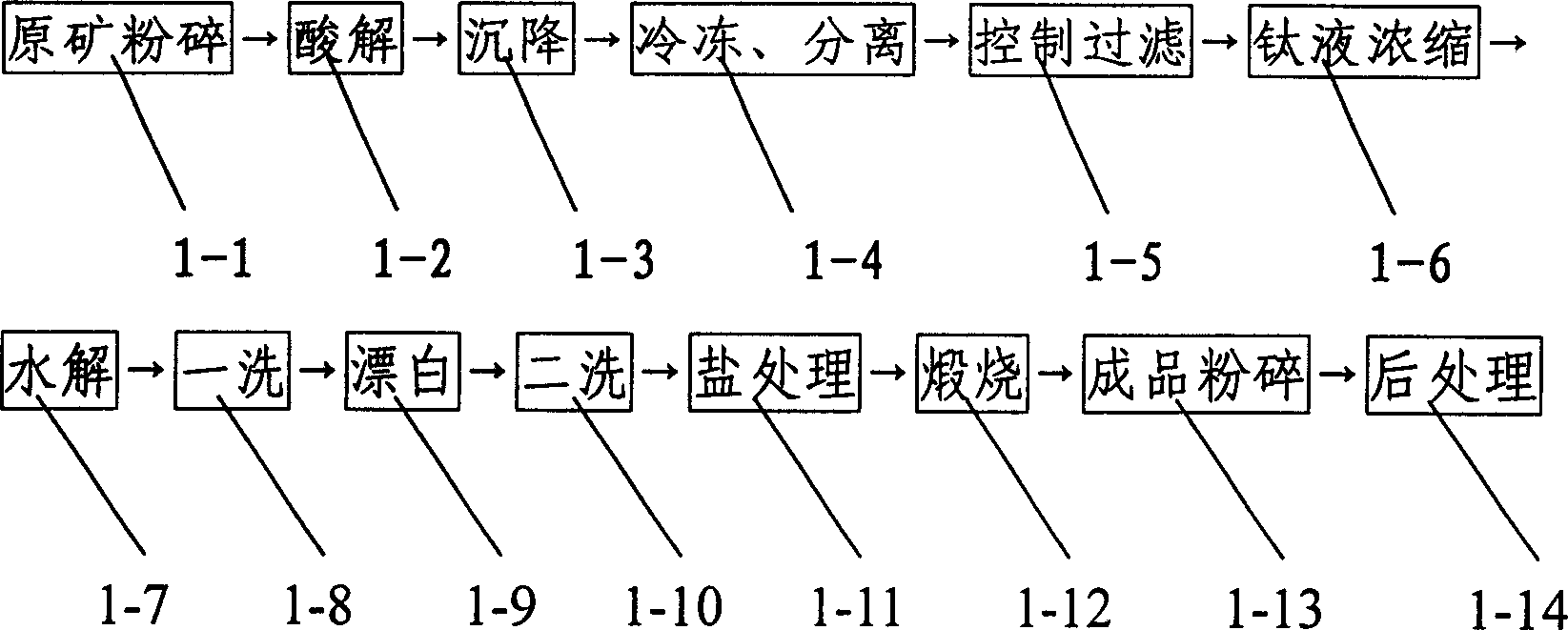

Treatment and recovery process of acid wastewater in titanium dioxide production process

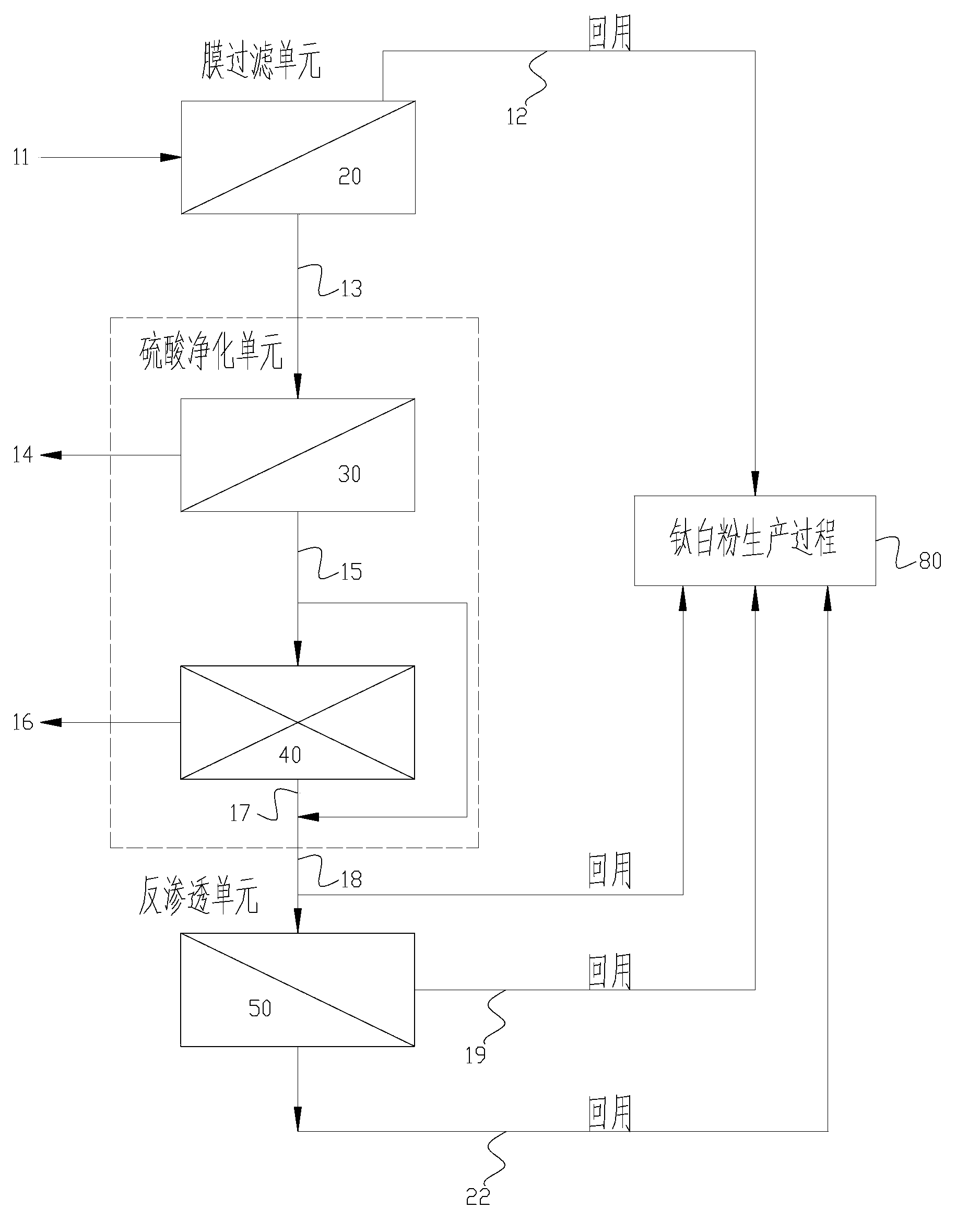

ActiveCN103663547AEmission reductionEasy to meet environmental protection requirementsWater/sewage treatment bu osmosis/dialysisSulfur-trioxide/sulfuric-acidSludgeFiltration

The invention discloses a treatment and recovery process of an acid wastewater in a titanium dioxide production process. The treatment and recovery process mainly comprises the following steps: A, pumping the acid wastewater into a membrane filtration unit, filtering by using a filtering membrane, wherein a membrane intercept object is titanium dioxide particle concentrate, and is fed to the system to be reused, and membrane permeate is a crude sulphuric acid, and enters the next step to be treated; B, pumping the crude sulphuric acid obtained in the step A into a sulphuric acid purification unit, decontaminating and purifying the crude sulphuric acid to obtain pure dilute sulphuric acid, wherein a part of pure dilute sulphuric acid is directly reused, and the other part enters the next step to be treated; C, pumping the dilute sulphuric acid obtained in the step B into a reverse osmosis unit, filtering by a reverse osmosis membrane, wherein the intercept object is concentrated sulfuric acid and is fed to a titanium dioxide production system to be used, the permeate is water and can be directly reused as process water, and 99.9% of titanium dioxide particles, 80-90% of sulfuric acid and 60-80% of water can be recovered after the titanium dioxide acid wastewater is processed by the process disclosed by the invention, so that the production cost of an enterprise can be reduced, and the discharge amount of the wastewater and the sludge waste emission are greatly reduced.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

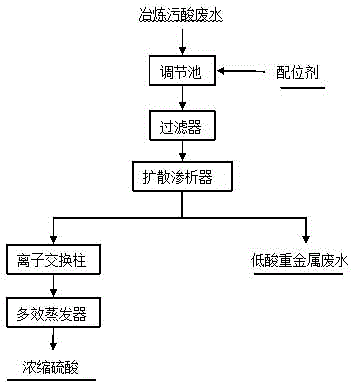

Method for purifying smelting waste acid

ActiveCN104445095AEfficient removalAchieve separationSulfur-trioxide/sulfuric-acidSmall footprintIon-exchange resin

The invention discloses a method for purifying smelting waste acid. The method comprises the following steps: adding a coordination agent into a centralized inflow adjusting pool of waste acid discharged from a sulfuric acid smelting system, stirring uniformly, and filtering the mixture in a filter to further remove insoluble granular impurities; separating dilute acid nearly containing no metal ion and low-acid wastewater through a diffusion dialyzer; adsorbing such residual anion impurities as fluorine and chlorine in the dilute acid through ion exchange resin, concentrating the dilute acid in a multi-effect evaporator and recycling the dilute acid in the sulfuric acid system; further treating the low-acid wastewater to reach the national sewage drainage standard. The method disclosed by the invention can be used for quickly and efficiently separating acid from heavy metal ions in the smelting waste acid, the separated dilute acid can be recycled in a sulfuric acid production procedure after being concentrated, and the method has the advantages of low energy consumption and few residues, and can be used for effectively and comprehensively recycling resources in the waste acid. The wastewater treatment cost is low, and the economic benefit is good. The process is simple, the occupation area of equipment is small and industrialized application is easy to achieve.

Owner:CENT SOUTH UNIV

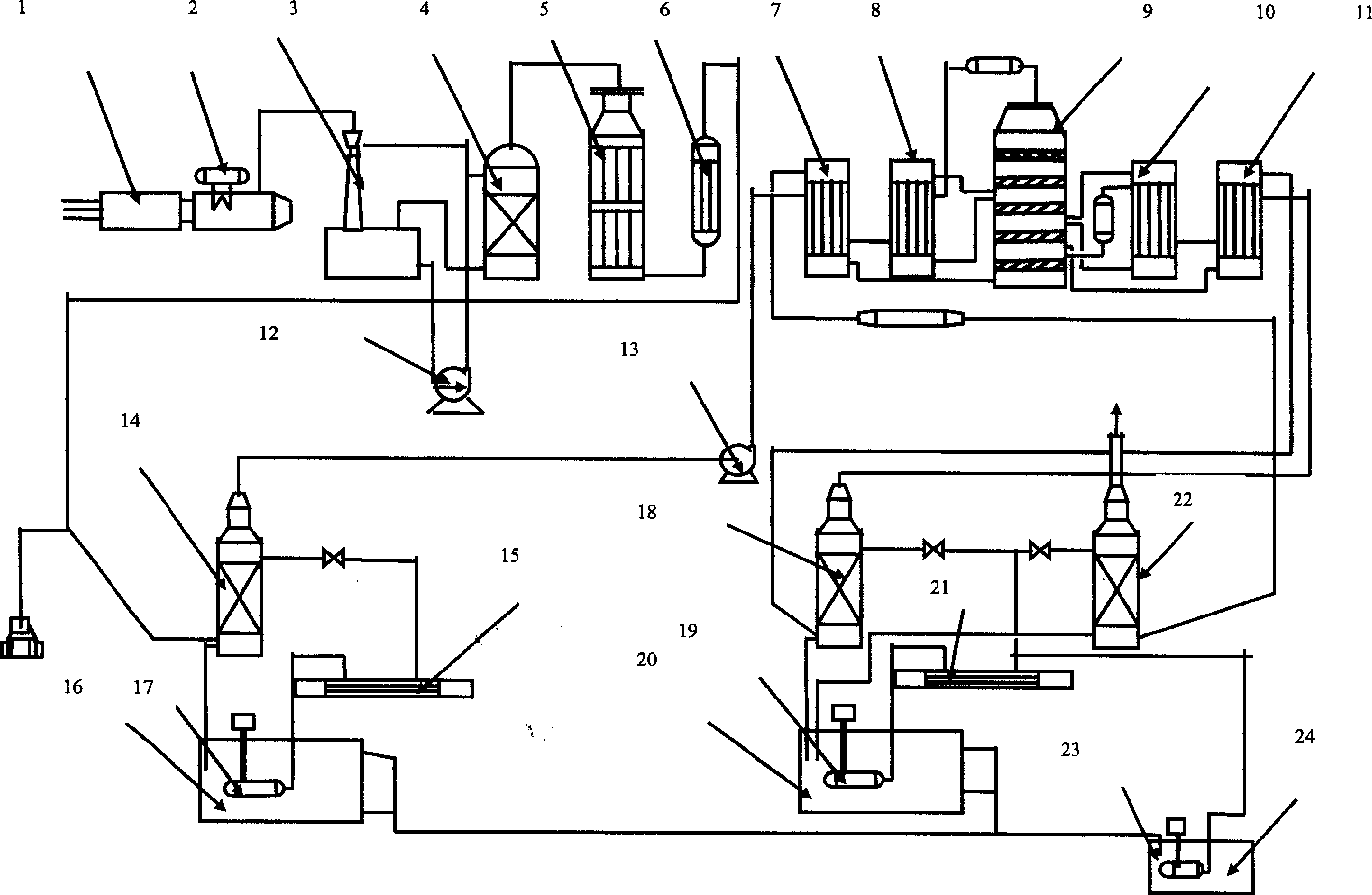

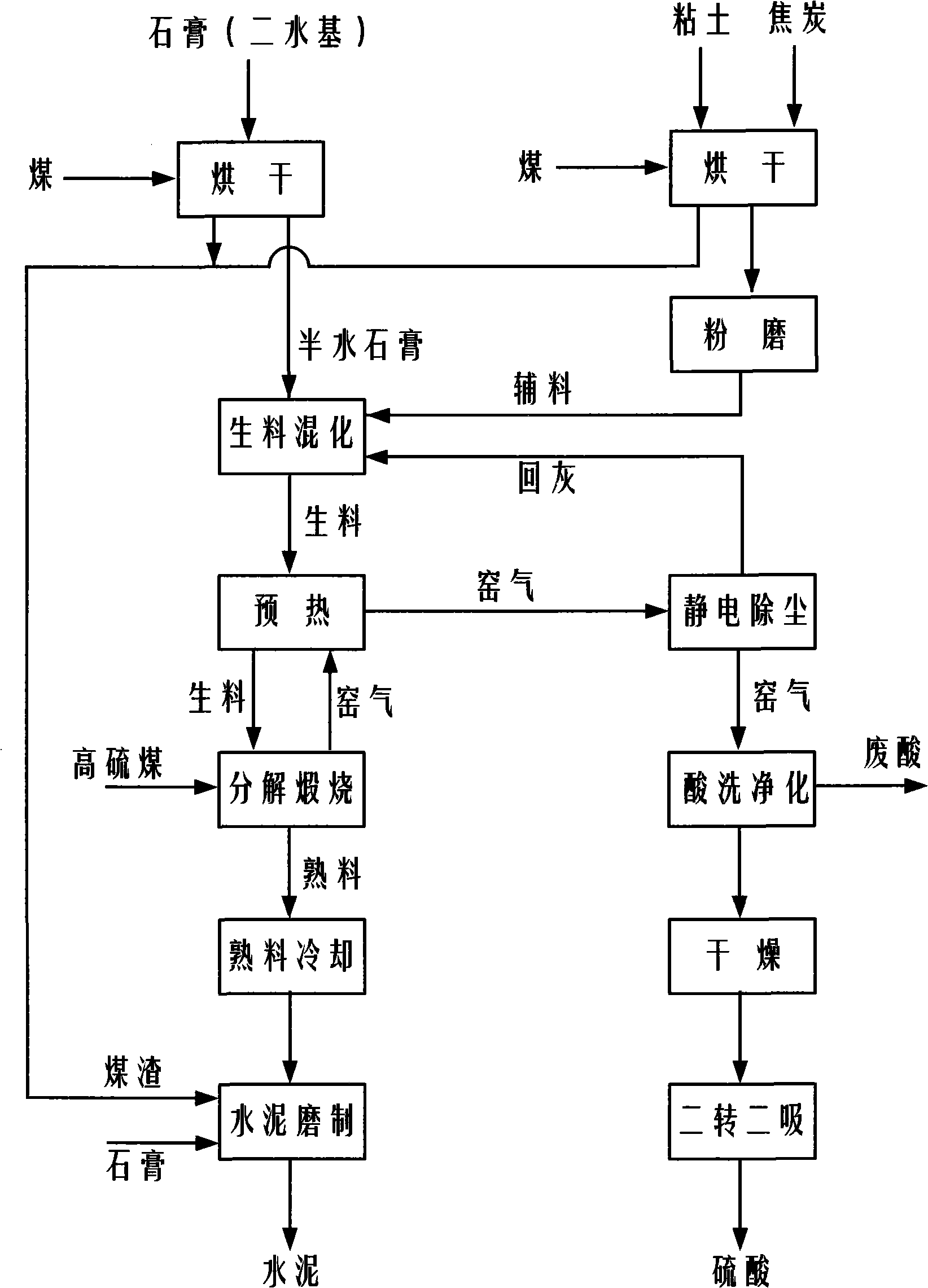

Improved preparation technique for preparing sulphuric acid and cement with gypsum

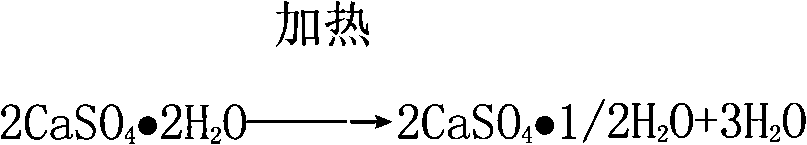

ActiveCN101343047AEliminate pollutionAlleviate supply shortagesCement productionSulfur-trioxide/sulfuric-acidSource materialAcid washing

The invention provides an improved production process of utilizing gypsum to produce sulfuric acid and cement, which relates to the sulfuric acid and cement industry production technology, and the resource comprehensive utilization and environmental protection governing field of the industrial byproduct gypsum. The improved production process is characterized in that natural gypsum with the CaSO4*2H2O as the main composition or the industrial byproduct gypsum is adopted as the main source material; clay, coke and fly ash clinker are used as supplementary materials; the half-water drying gypsum flow, the single stage powder grinding, raw material mixing melting, suspension preheater kiln decomposing calcination, closing diluted acid washing and purification, two-turning and two-suction processes are adopted; the sulfuric acid and cement products are prepared through six steps of source material homogenizing, drying and dehydration, raw material preparation, clinker burning, kiln gas acid production and cement grinding; the improved production process has the advantages of wide range source material, solving the land occupation and environmental pollution problems of the gypsum waste residue, realizing the circulation utilization of sulfur resource, adopting a plurality of new processes and devices, realizing the large scale production easily, advanced technology, mature process, easy operation in production control, low energy consumption, high benefit, no waste water and waste residues exhaust.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

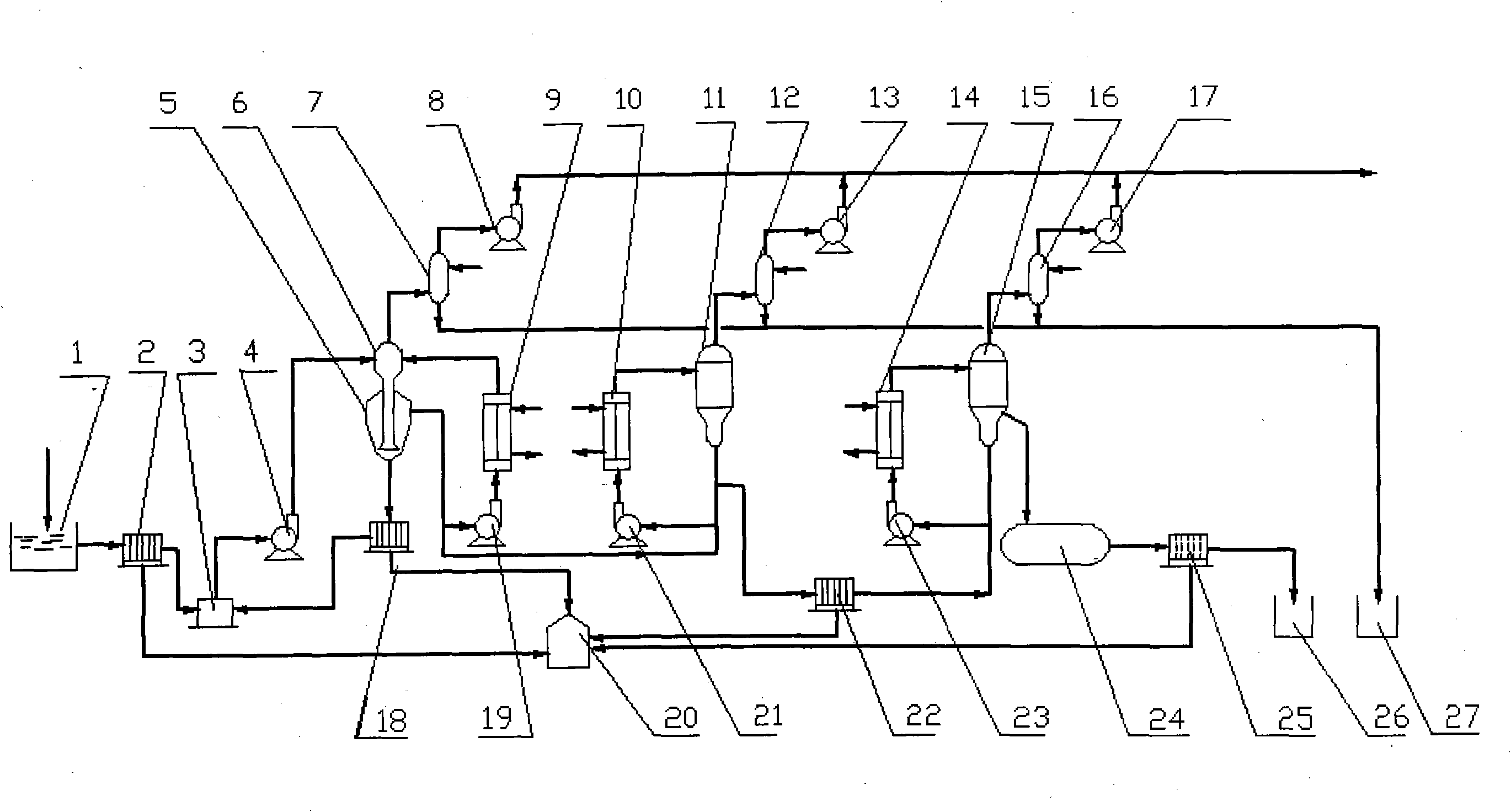

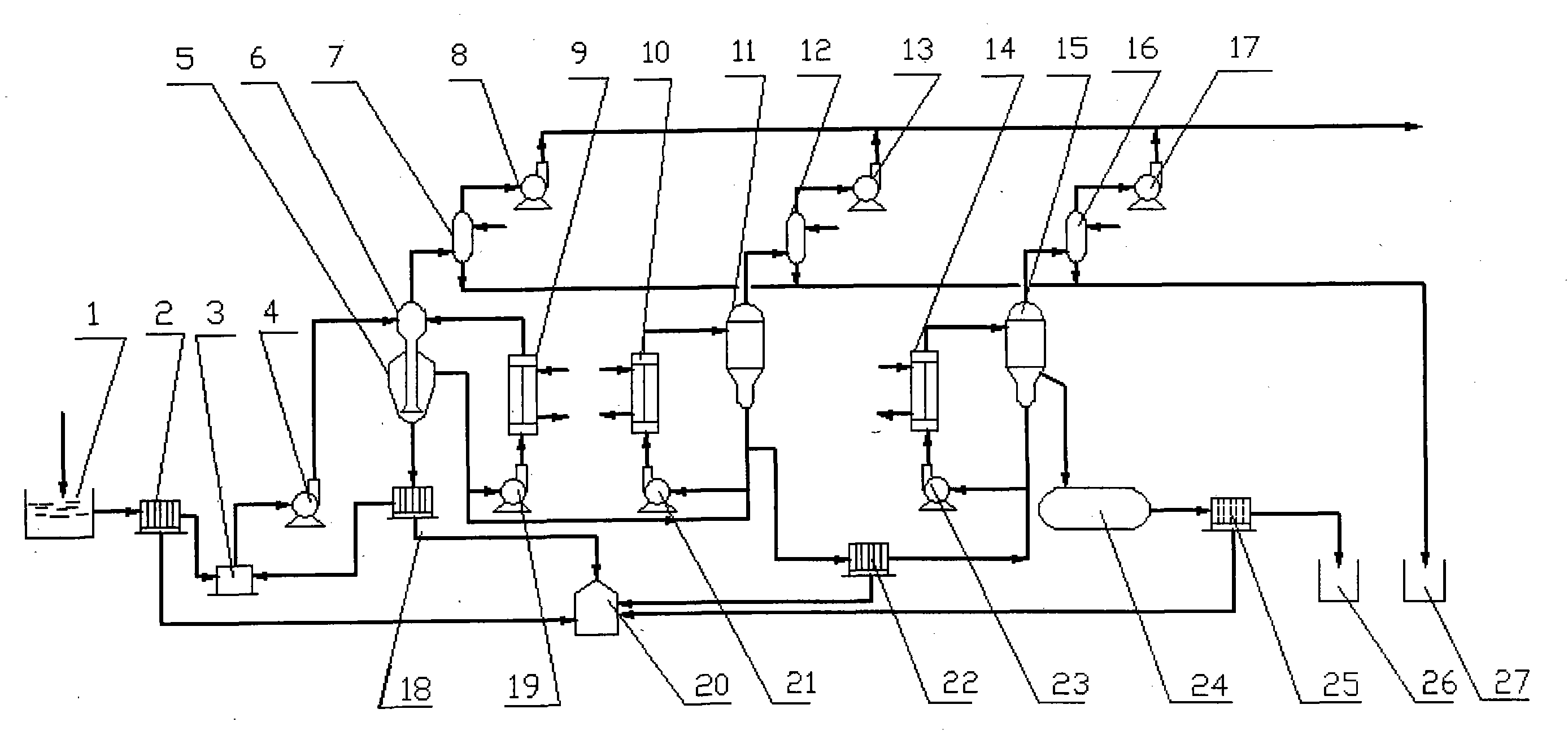

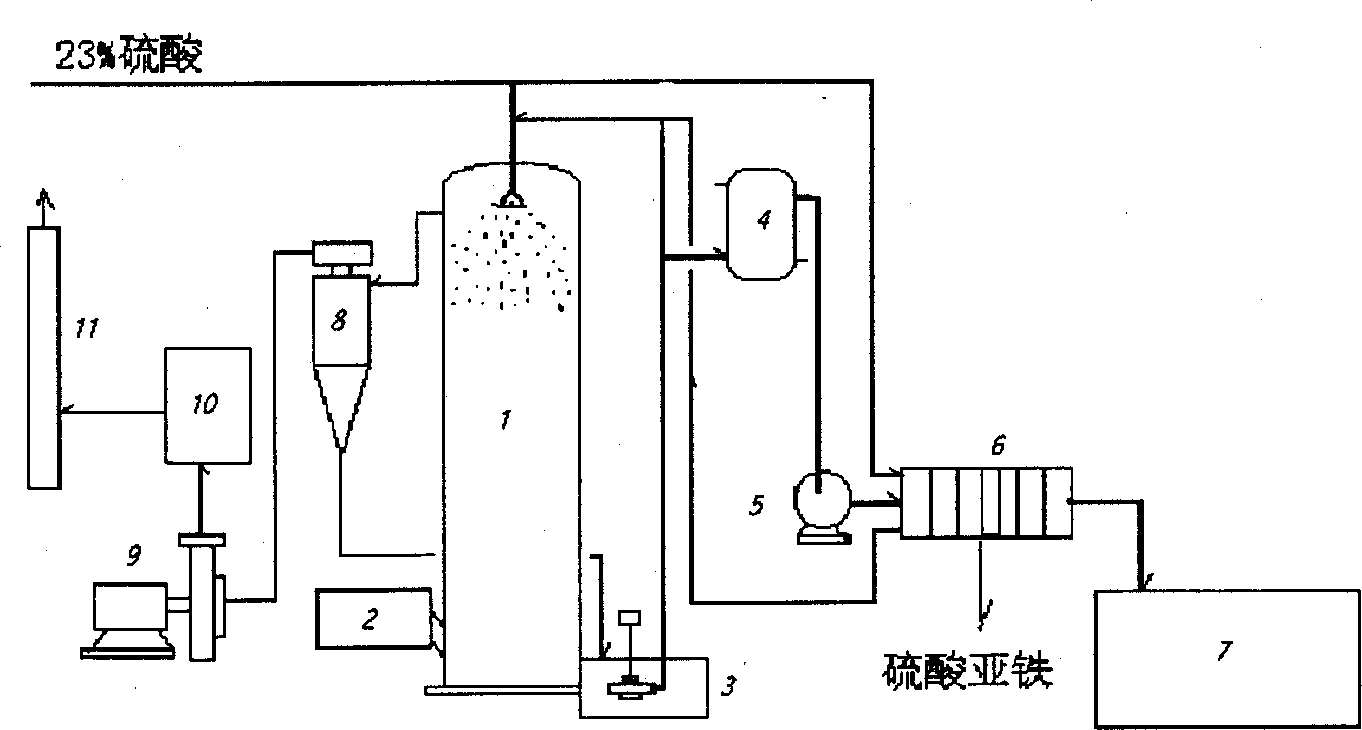

Process for recovering sulfuric acid and sulfate from waste acid generated in preparation of titanium dioxide by using sulfuric acid method

InactiveCN102079512AImprove recycling ratesIncrease concentrationSulfur-trioxide/sulfuric-acidIron sulfatesHigh concentrationWater vapor

The invention relates to a process for recovering sulfuric acid and sulfate from waste acid generated in the preparation of titanium dioxide by using a sulfuric acid method, belonging to the technical field of waste acid treatment in the industrial production. The invention recovers sulfuric acid and sulfate products from waste acid generated in the production process for preparing the titanium dioxide by using the sulfuric acid method through the sedimentation pretreatment and the simple process including the first segment of flash evaporation-crystallization, concentration and separation, the second segment of vacuum evaporation, concentration and separation and the third segment of vacuum evaporation, concentration and separation. The invention has simple process, convenience of operation, simple equipment, high performance price ratio and high yield, high concentration and less impurities of the product acid, can recycle resources without waste liquid or waste residue emission and can be favorable to environmental protection and energy saving, and emitted exhaust mainly contains air and less vapor, is non-toxic to the environment and can effectively overcome the difficulties of fouling and clogging of the equipment. The invention can be widely applied to the recovery of waste acid in the industrial production and be particularly suitable for recovering the waste acid generated in the preparation of titanium dioxide by using the sulfuric acid method.

Owner:CHONGQING UNIV

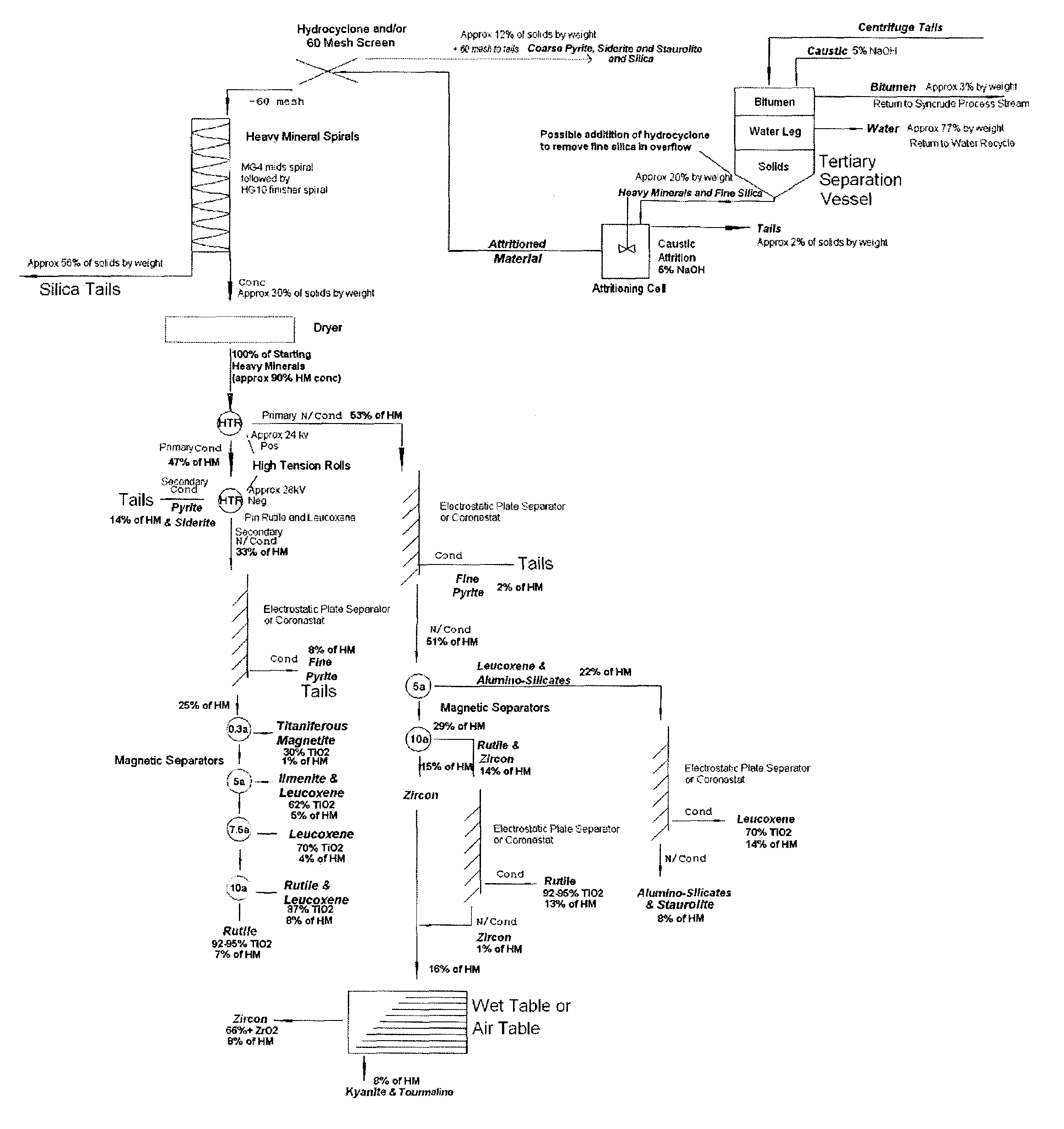

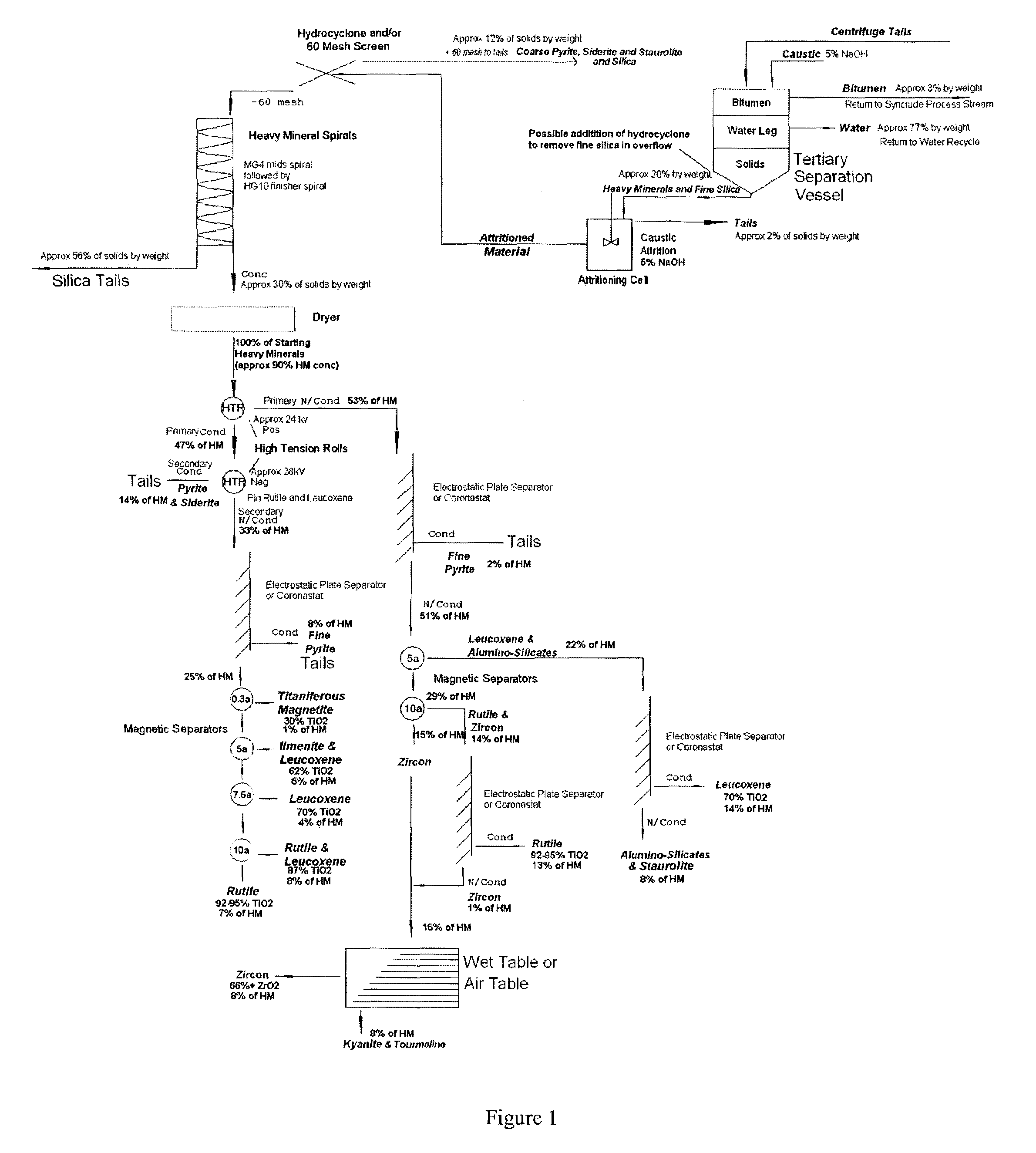

Recovery of heavy minerals from a tar sand

A process for recovering heavy minerals (e.g., titanium minerals such as TiO2) from a feedstock comprising tar sands or a tar sands-derived solids fraction. The feedstock comprises bitumen and heavy minerals. The process comprises the steps of: (i) contacting the solids fraction with water at a temperature of at least about 100° F. to cause production a bituminous phase and a heavy minerals phase; and (ii) separating the heavy minerals phase from the bituminous phase. Optionally, these steps may be preceded by one or more steps used to produce a tar-sands derived solids fraction from a tar sands feedstock.

Owner:TITANIUM CORP

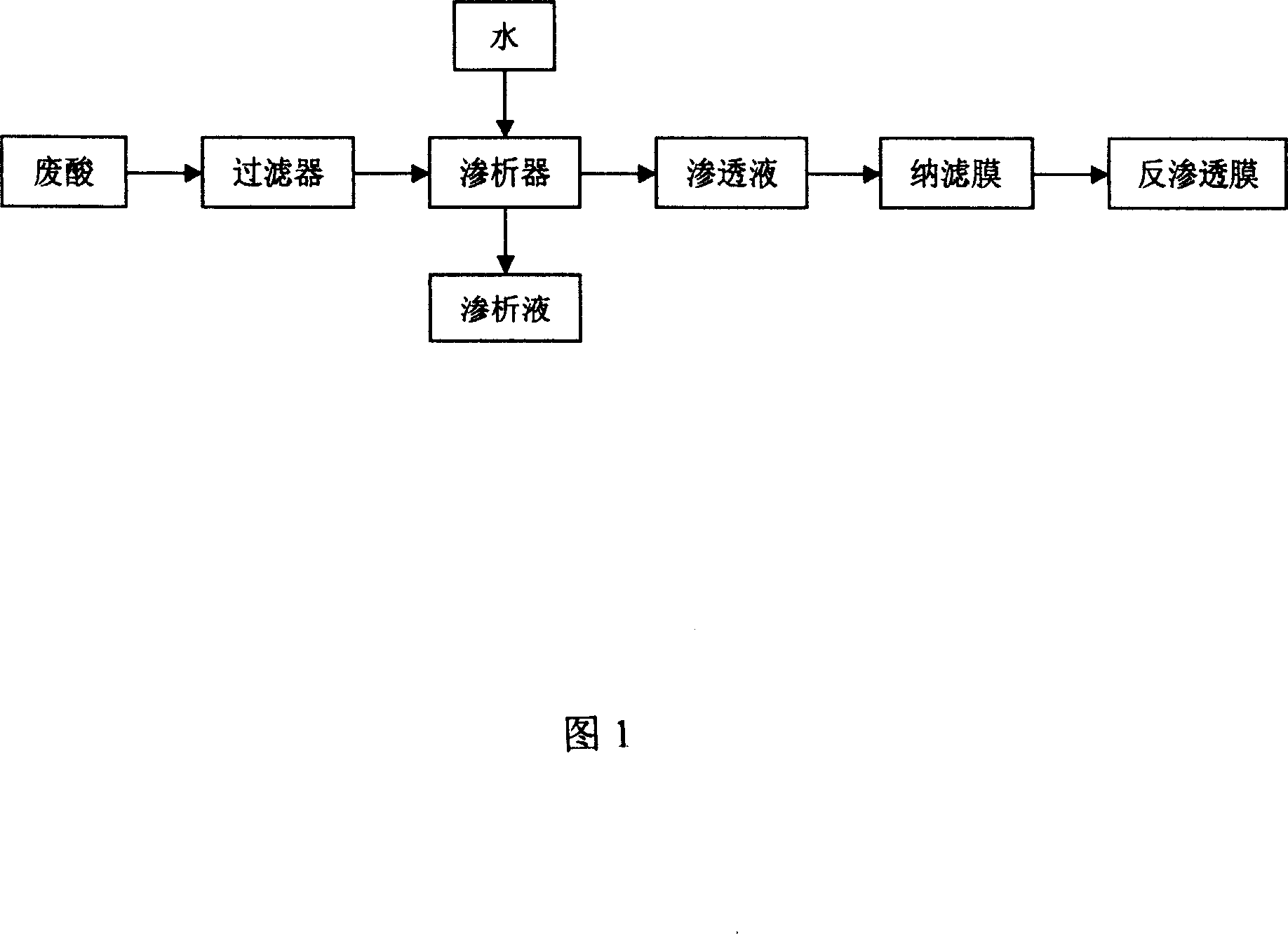

Method for treating waste acid produced from titanium dioxide production using vitriol method

InactiveCN1966400AReduce pollutionEfficient separationWater/sewage treatment bu osmosis/dialysisSulfur-trioxide/sulfuric-acidReverse osmosisTitanium

The invention relates to a way to treat spent acid in the sulfuric acid method to produce titanium pigment. The characteristic of the invention: the method includes the following steps: pulping the spent acid into the sophisticated filtrator through the high pressure anti-corrosion pulp, the filtrate entering the container; the tap water and filtered spent acid going separately into the two inlets of the diffuse dialyzator, separating for the first time the strong H2SO4 from FeSO4 in the permeating solution, the separated strong permeating solution is pulped into the nano-filter membrane to separate H2SO4 for the second time, the content of FeSO4 in the solution is 0.1% or less; the separated permeating solution H2SO4 goes into the reverse osmosis membrane device and the concentrated solution is the dilute sulfuric acid product. The advantage of the invention includes high spent acid recovery rate, high purity, low processing cost and high holding-up rate.

Owner:上海闵欣环保设备工程有限公司

Oxide gas absorbing arrangement and method

InactiveUS6274106B1Improve long-term stabilityNitrogen compoundsInternal combustion piston enginesMetal foilMetal

In the oxide gas absorbing arrangement disclosed in the specification, metal foils having a thickness <=0.05 mm are coated with an oxide gas absorbing layer containing gamma aluminum oxide. One metal foil is corrugated and joined to a smooth foil and the combined foils are rolled into a cylinder to provide parallel gas passages in which exhaust gases are exposed to the oxide gas absorbing layer. To enhance absorption turbulence is created in the gas passages by twisting the cylinder to narrow and contort the individual passages.

Owner:VOLKSWAGEN AG

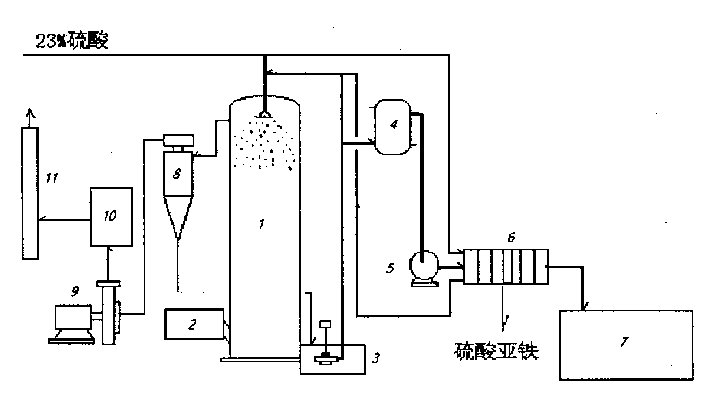

Process for concentrating diluted sulfuric acid and removing impurities

InactiveCN1376633AReduce recycling production costsLess investmentSulfur-trioxide/sulfuric-acidNuclear chemistryImpurity

A process for concentrating diluted sulfuric acid while removing impurities includes such steps as counter-current contact between hot air and atomized diluted sulfuric acid in drying-concentrating tower for heating, evaporating and concentrating, cooling, and separating the educed or deposited impurities for sulfuric acid. Its advantages are low cost and simple process.

Owner:SICHUAN LOMON CORP

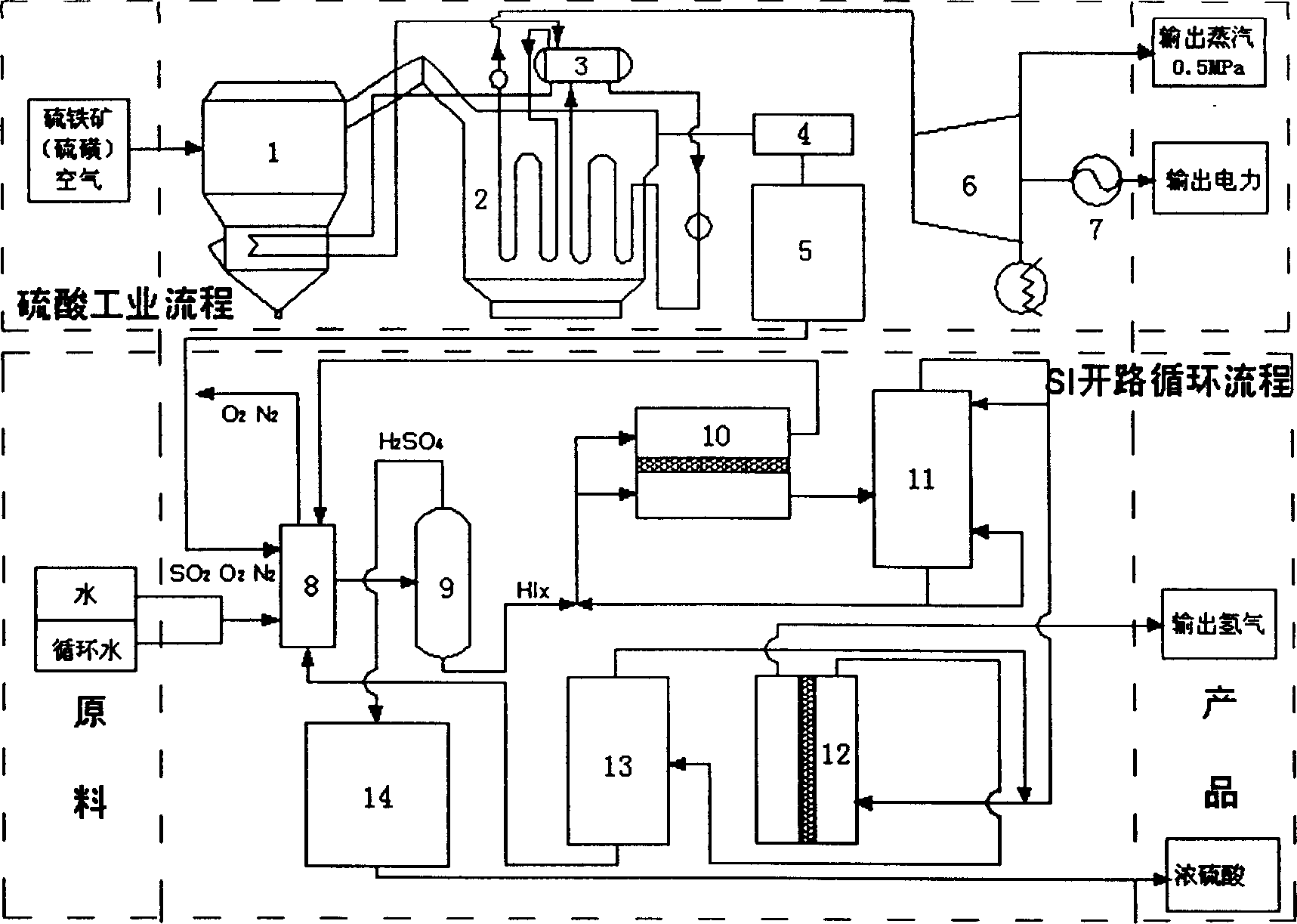

Technical method of sulfur iodine open circuit circulation hydrogen manufacture and its equipment

ActiveCN1785796AReduce the temperatureReduce energy consumptionIodine/hydrogen-iodideSulfur-trioxide/sulfuric-acidIt equipmentHydrogen

The present invention relates to a process for preparing hydrogen gas, and is aimed at providing a technological process capable of combining sulfur-iodine open-circuit circulation and sulfuric aid industry to simultaneously produce hydrogen gas and sulfuric acid and provide electric power and its equipment. Said method includes the following steps: roasting sulfur-bearing mineral, Bunsen reaction, separating HIx phase and H2SO4 phase solution, using electroosmose process to concentrate and purify HIx phase and utilizing HI membrane catalytic decomposition reactor to make decomposition to obtain I2 and find product H2.

Owner:ZHEJIANG UNIV

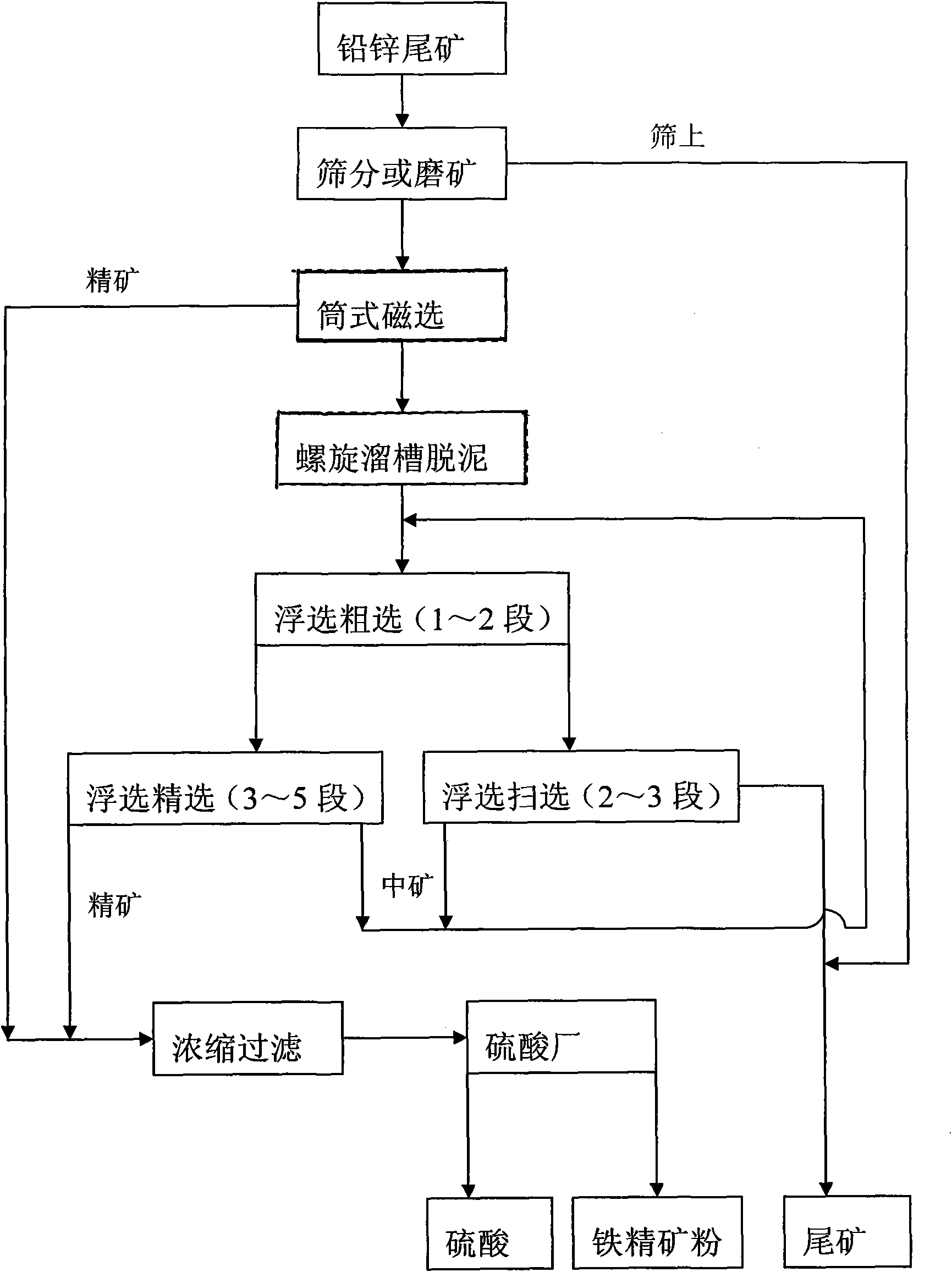

Process of using sulphur lead-zinc containing tailings to prepare sulphur iron ore concentrate

InactiveCN101549322ATake advantage ofStable in natureSulfur-trioxide/sulfuric-acidFlotationNational standardSulfur containing

The objective of the invention is to provide a process of using sulphur lead-zinc containing tailings to prepare sulphur iron ore concentrate, using magnet-floating combination process or magnet-gravity-floating combination process to produce sulphur iron ore concentrate containing more than 90% sulphur and iron, using the sulphur iron ore concentrate to produce sulphuric acid, getting 98% sulphuric acid of national standard while getting iron ore concentrate power containing more than 60% iron, and sulphur in the tailings is reduced to less than 2%, recovery rate of sulphur iron in ore concentrate is more than 86%. The invention make comprehensive recovery and use of sulphur iron in the lead-zinc tailings.

Owner:KUNMING UNIV OF SCI & TECH +1

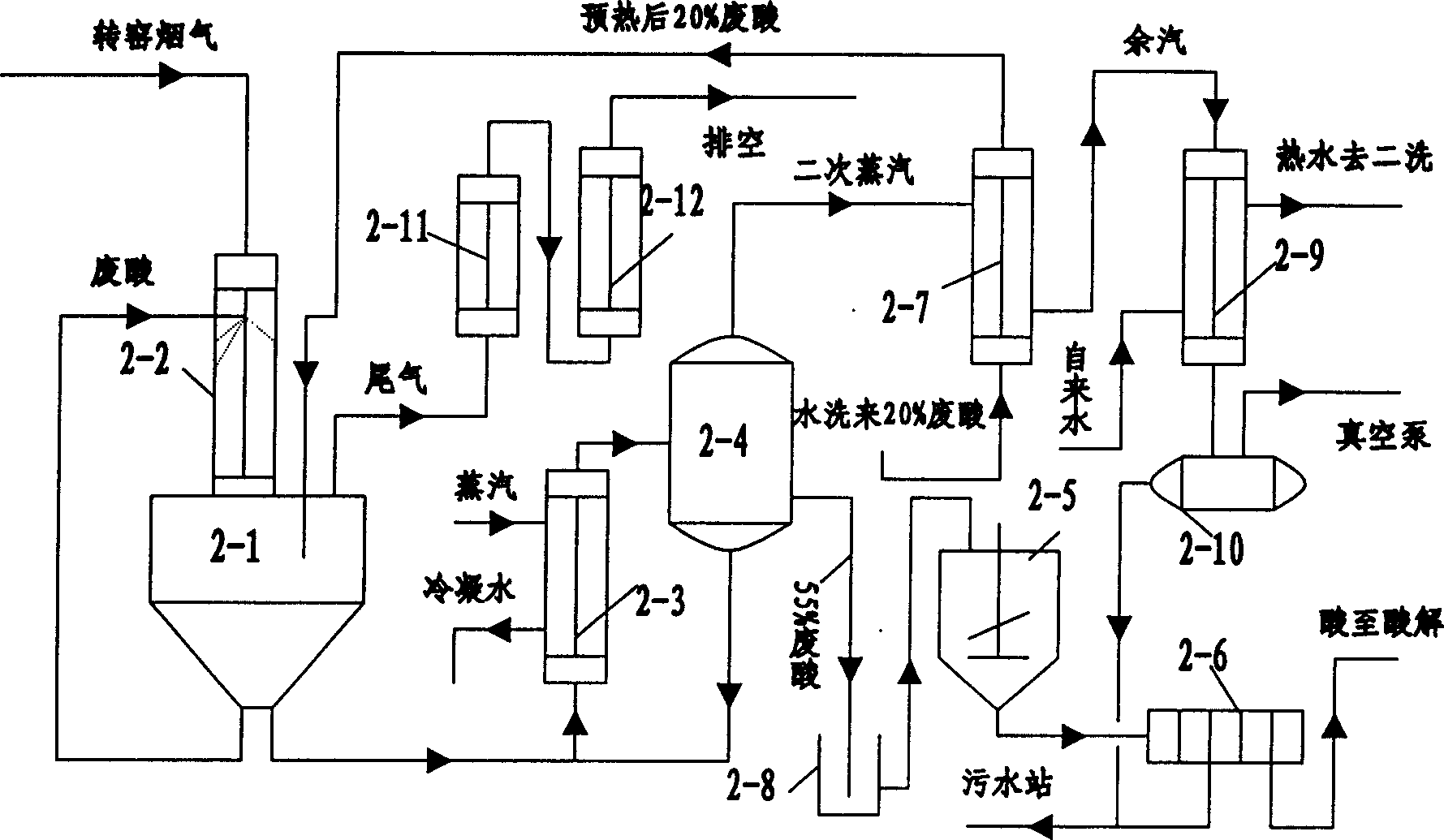

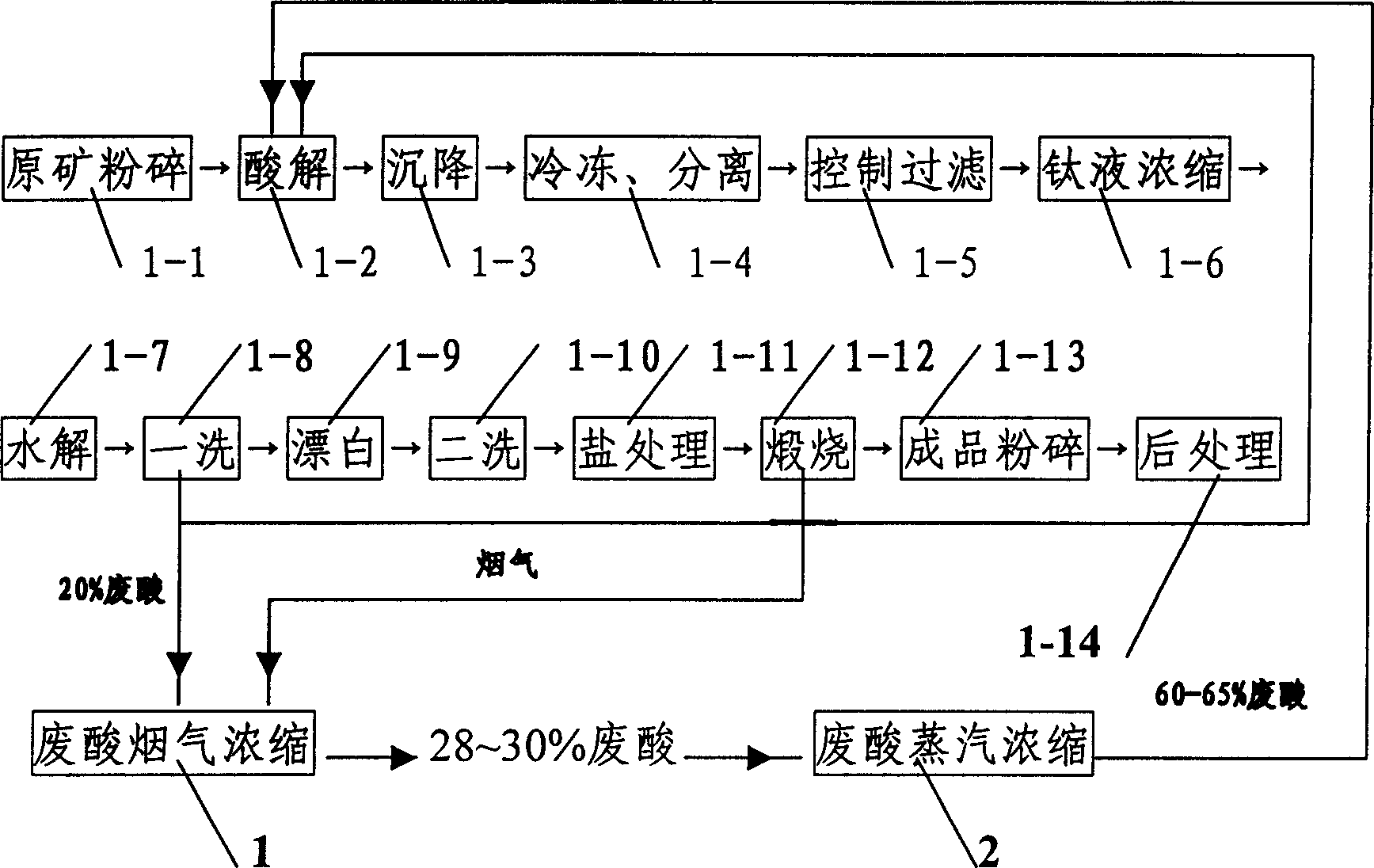

Process of industrialize for waste acid concentrition recovering used in titanium white production by sulfuric acid method

ActiveCN1724339AReduce energy consumptionReduce dosageSulfur-trioxide/sulfuric-acidTitanium dioxideWhite powderTitanium

An industrial process for reclaiming the waste acid in the production of titanium white powder by sulfuric acid method features that the waste acid is concentrated by fume and then by steam. Its advantages are high efficiency, low cost, and no environmental pollution.

Owner:潜江方圆钛白有限公司

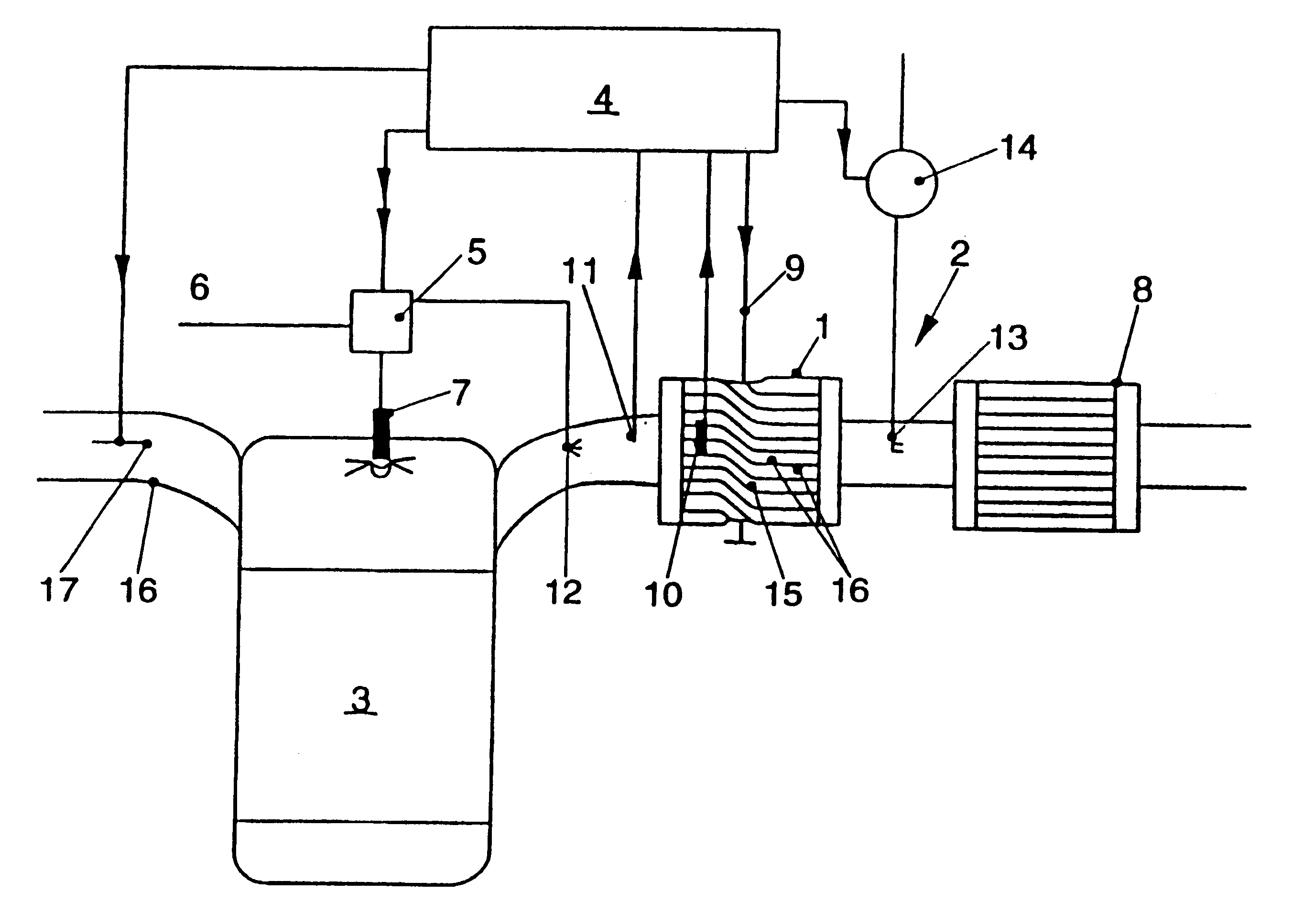

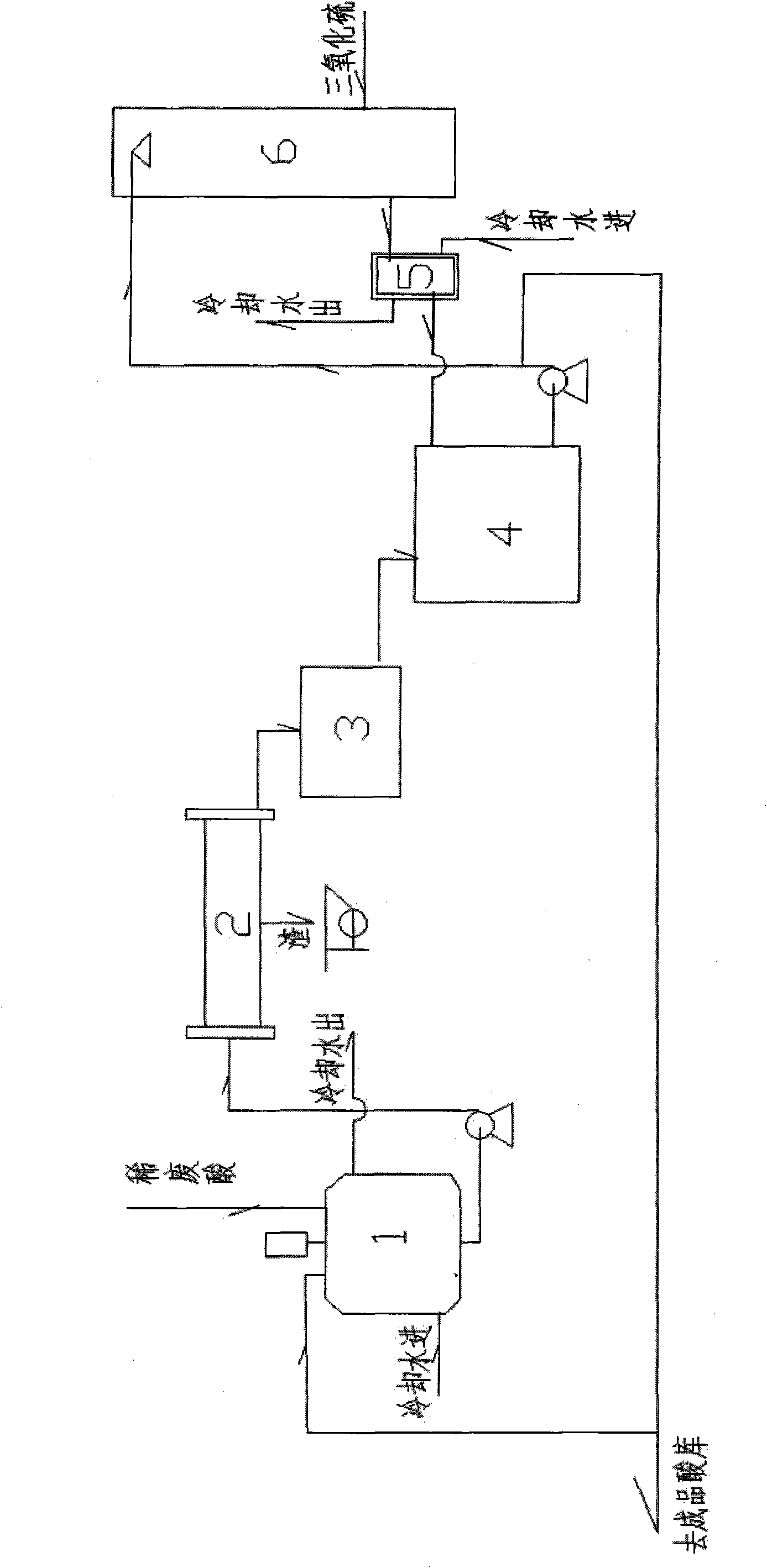

Method and device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production

ActiveCN101538021ASolving production challenges of reuseIncrease productionSulfur-trioxide/sulfuric-acidSulfurSulfate

The recycling of diluted waste acid produced in the production process of sulfate process titanium dioxide is a bottleneck limiting the development of the sulfate process titanium dioxide. In addition, manufacturers of sulfate process titanium dioxide usually have sulfate acid production devices due to the need of a large amount sulfate acid. The invention relates to a method and a device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production. The method comprises the following steps: firstly, performing the pre-concentration of the diluted sulfate acid; secondly, removing most impurities carried by the diluted sulfate acid through settlement; and finally, using the sulfate acid subjected to pre-concentration and impurity removal to replace make up water of a sulfate production system, adding the sulfate acid into a sulfate circulating tank of a sulfate acid absorption tower to produce concentrated sulfate acid after sulfate acid absorption tower absorbs sulfur trioxides, and thus recycling the diluted sulfate acid. The method has the advantages of making a plurality of achievements at one time, namely changing pre-concentrated diluted sulfate acid into concentrated sulfate acid without extra energy consumption and equipment addition while reducing the cooling load of sulfate acid flowing out from the tower at the same time.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Recycling method for waste sulfuric acid of dye intermediate product

InactiveCN102219191ANo secondary pollutionSimple methodSulfur-trioxide/sulfuric-acidSulfateRoom temperature

The invention relates to a recycling method for waste sulfuric acid of a dye intermediate product, which comprises the following steps of: recovering waste sulfuric acid with a mass fraction of 40+ / -2%, settling, filtering, dewatering and concentrating, then oxidizing with an oxidant (oxyful or ozone) at 80-200 DEG C to obtain colorless transparent sulfuric acid, removing exhaust gases generated during the oxidation process under negative pressure, cooling to room temperature, storing, and directly using for producing an inorganic fertilizer, a sulfate, or a water treatment agent; or mixing the oxidized sulfuric acid with fuming sulfuric acid or sulfur trioxide to obtain 98wt% sulfuric acid, storing, and reusing for synthesizing a dye intermediate product or producing a sulfate. The waste sulfuric acid is acquired by oxidizing 1,4-diamino-2,3-dicyano anthraquinone as a raw material with sulfuric acid, then hydrolyzing to obtain a dye intermediate product namely 1,4-diaminoanthraquinone-2,3-dicarboxyl imine and hydrolyzing the dye intermediate product. The recycling method is simple and practical, the recovery rate of the waste sulfuric acid of the dye intermediates is up to 96.9%, and the recovered sulfuric acid can be used as fresh industrial sulfuric acid.

Owner:JIANGSU YABANG DYE

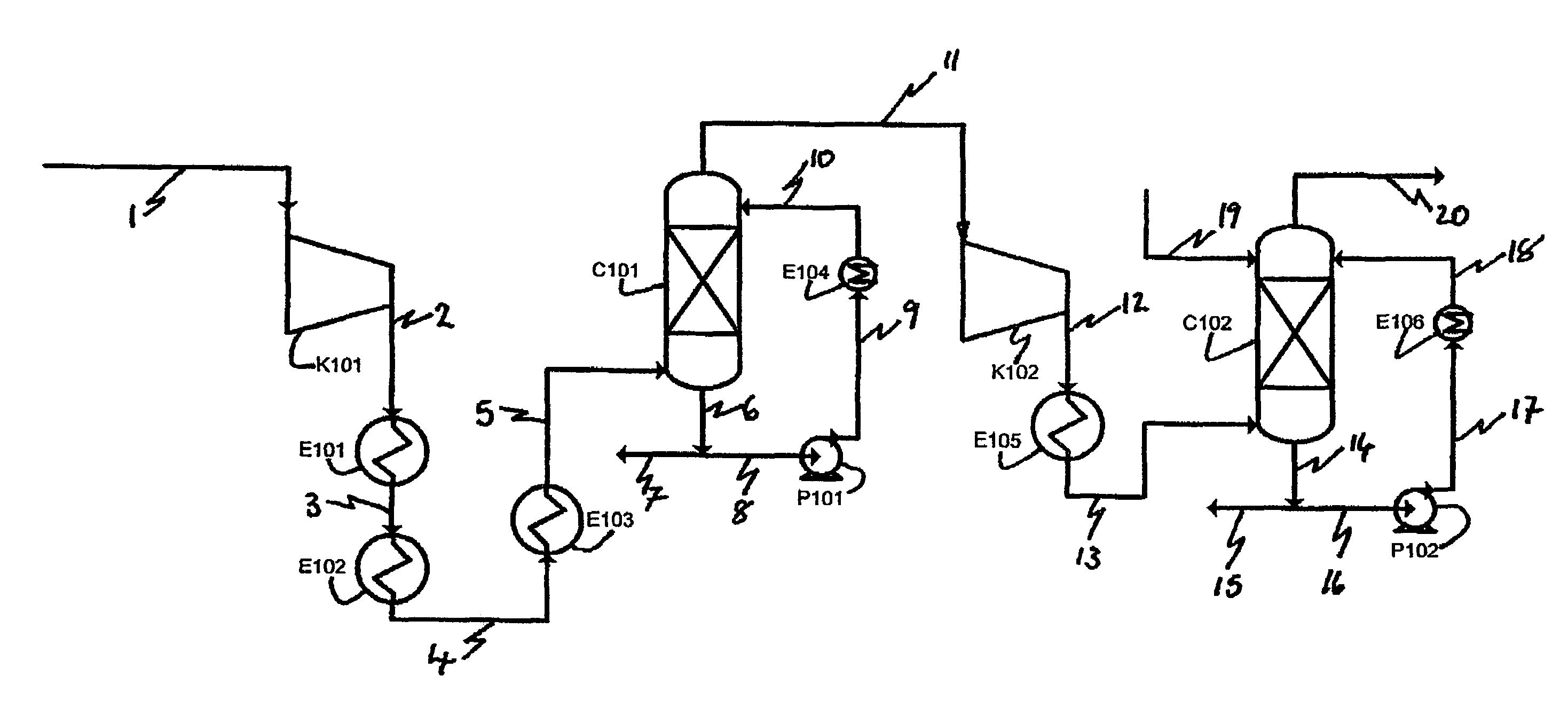

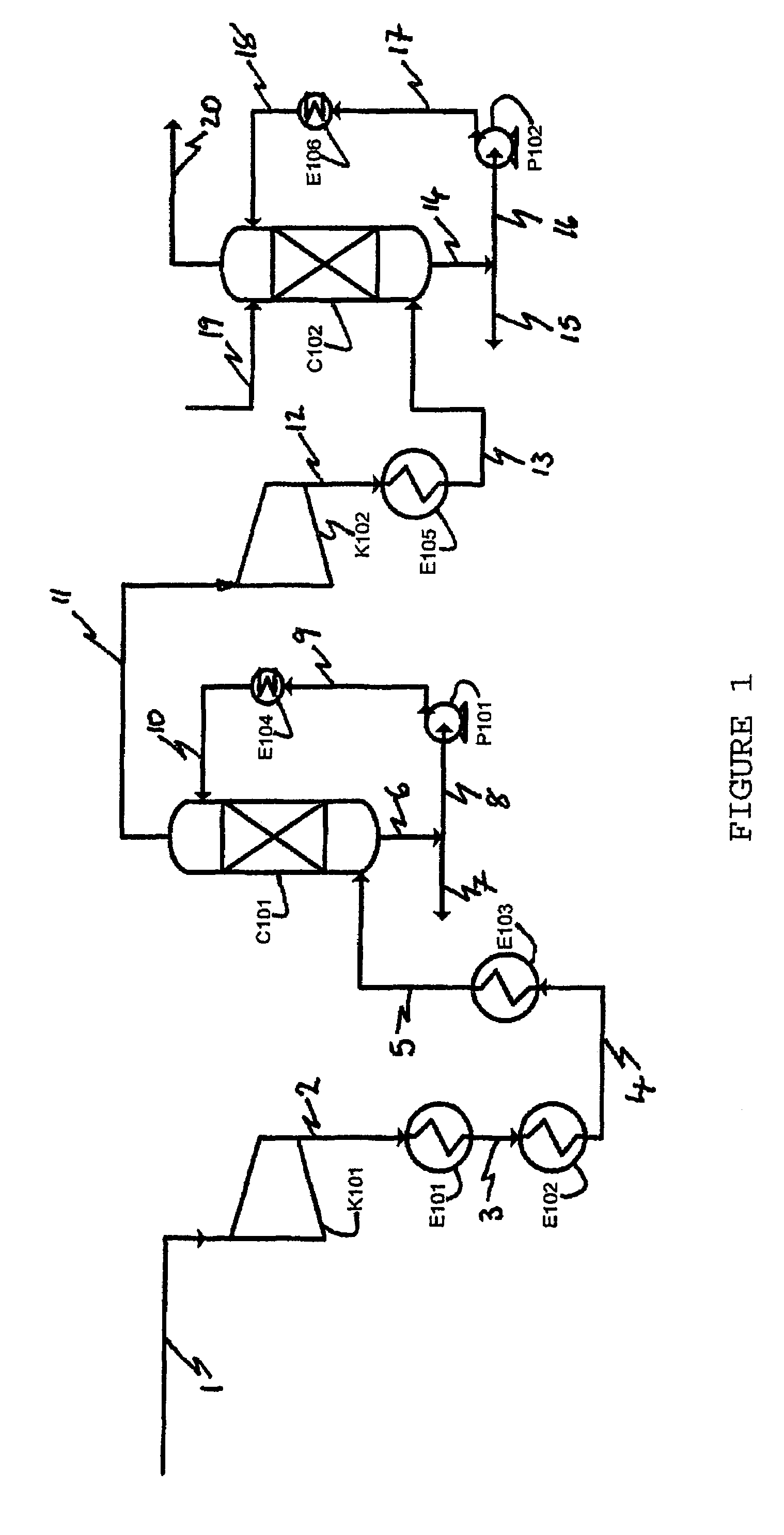

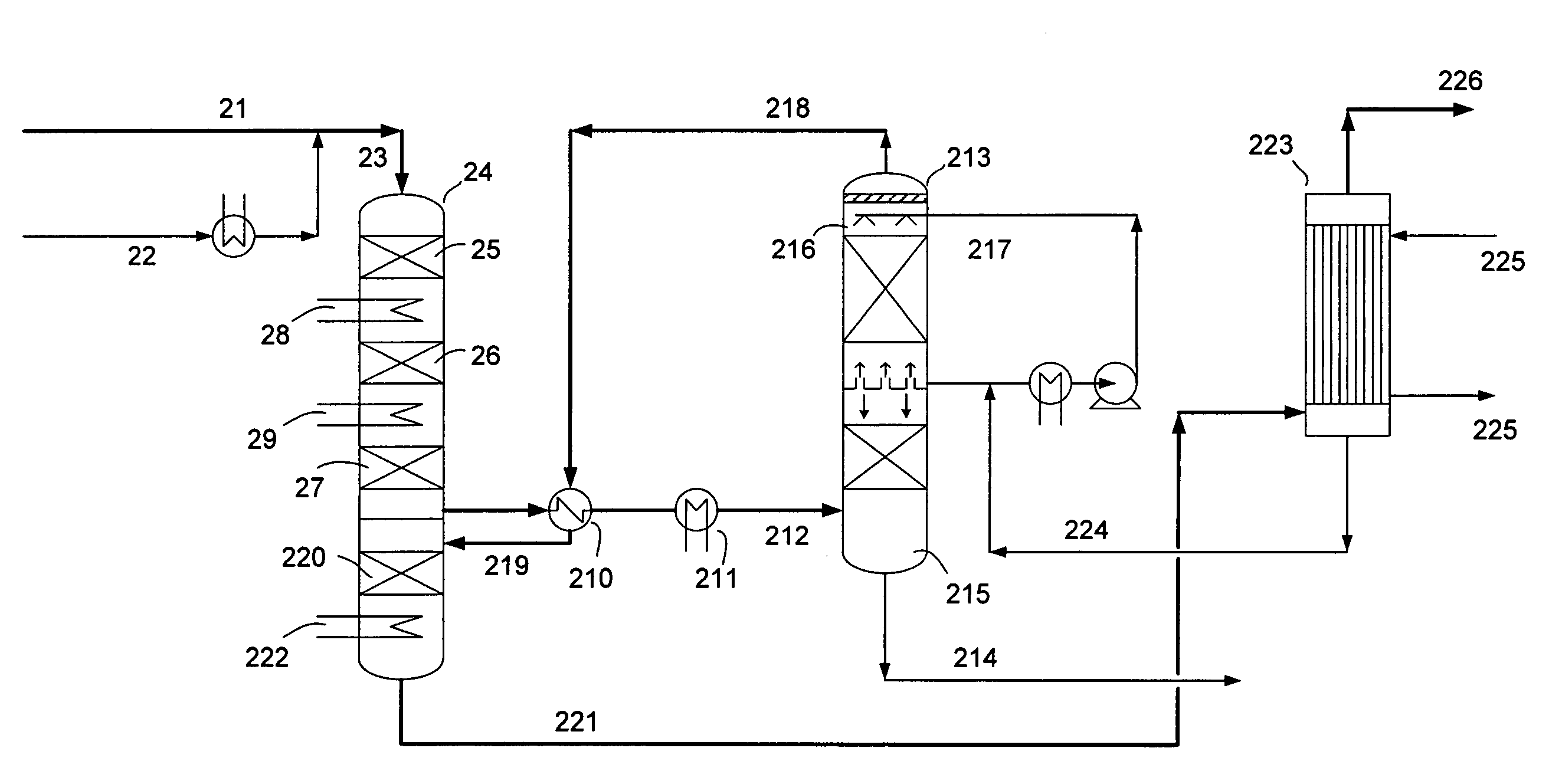

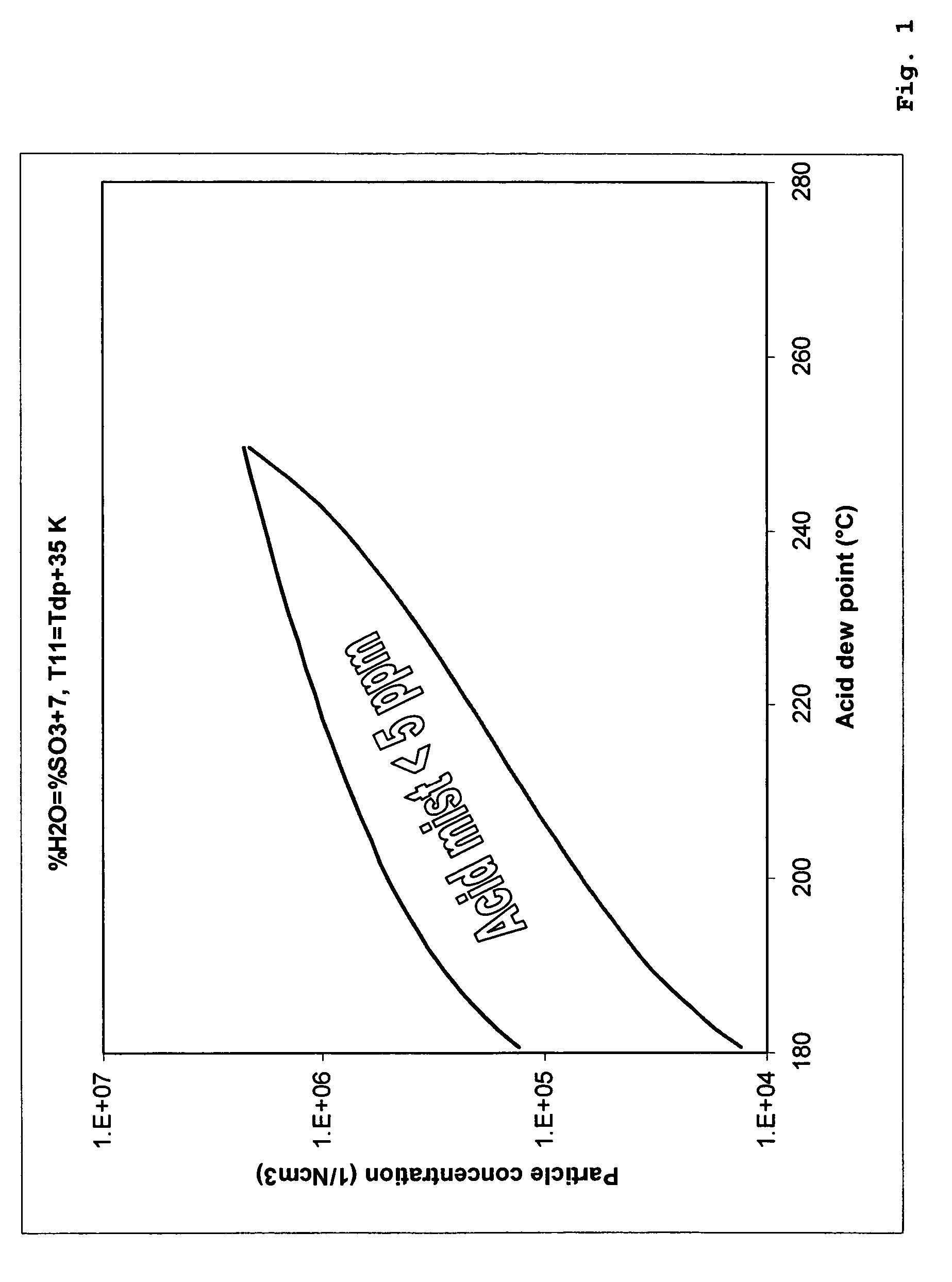

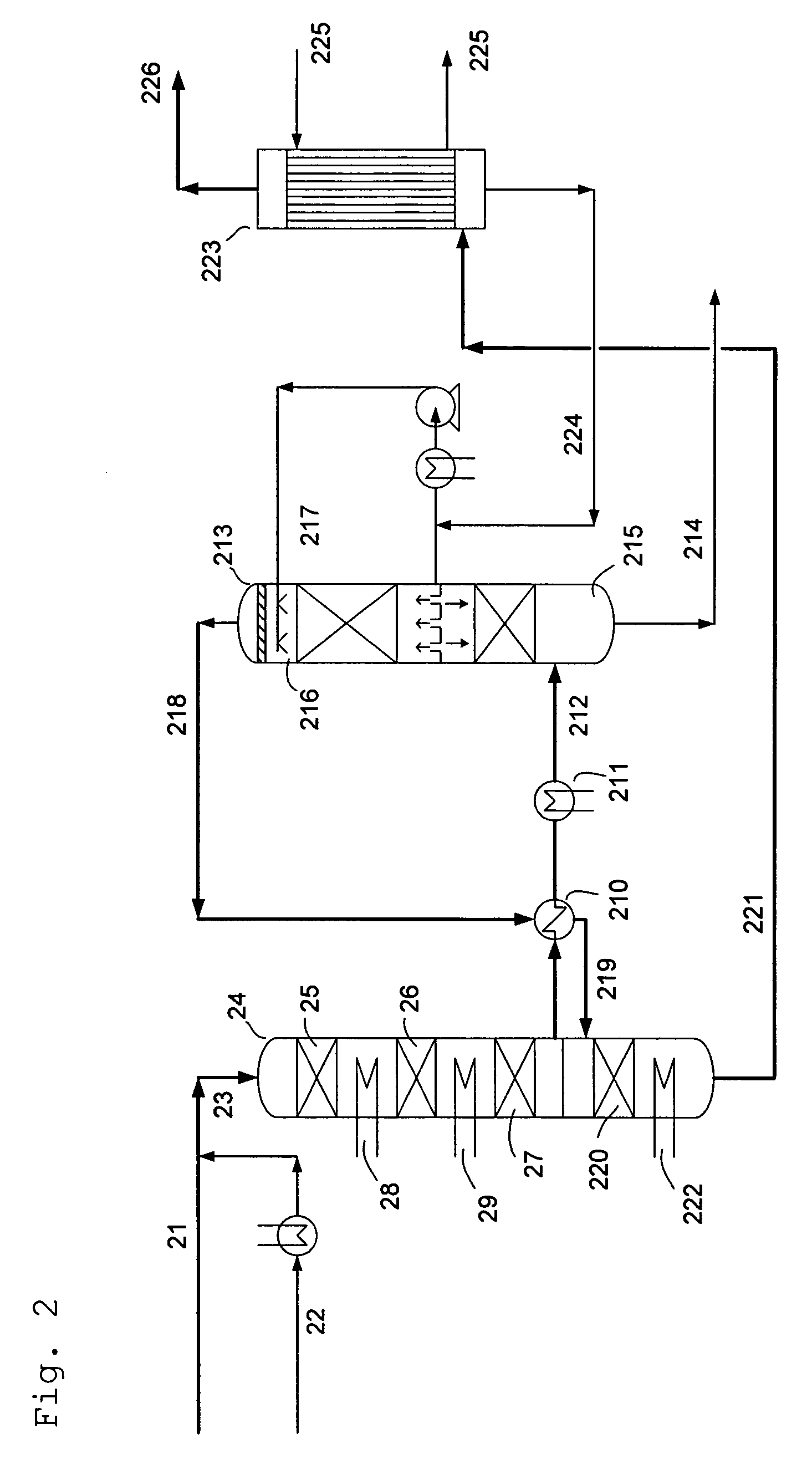

Process for the production of sulfuric acid

ActiveUS7361326B2Strict requirementsSignificant dilutionSulfur-trioxide/sulfuric-acidChemistrySulfuric acid

A process of producing sulfuric acid from feed gases containing 0.1-30% SO2. The process produces concentrated sulfuric acid from a feed gas containing 0.1 vol % to 30 vol % SO2, in particular a strong feed gas containing 6 vol % to 30 vol % SO2, that enables the gas entering the final wet condensing stage to have an acid dew point of below 260° C., while at the same time achieving current requirements of acid mist emissions of about 20 ppmv without resorting to substantial air dilution of the strong feed gas.

Owner:TOPSOE AS

Method for improving SO2 concentration in acid making technique with decomposition of calcium sulphate

ActiveCN101244811AIncrease concentrationStable productionSulfur-trioxide/sulfuric-acidVulcanizationSulfate

The invention relates to a method for improving the concentration of the SO2 in decomposing the calcium sulfate to acid craft and a chemical manufacturing technique of sulphuric acid and cement clinker, in particular to a manufacturing technique of sulphuric acid and cement clinker made from calcium sulfate. The procedures of the invention are as follows: a, under the function of the strong reduction medium, the calcium sulfate is produced into calcium vulcanization in the reactor; b, the reduction product of a procedure is the compound of the calcium vulcanization and the unreacted calcium sulfate; c, the reduction product is transferred to another reaction directly and under the high temperature, the calcium vulcanization and the calcium sulfate react and make into the SO2 and the clinker. The method has the advantages that: the concentration of the SO2 in gas is increased; the production system of sulfate is more stable and the extensive use of phosphogypsum is possible.

Owner:YUNNAN YUNTIANHUA

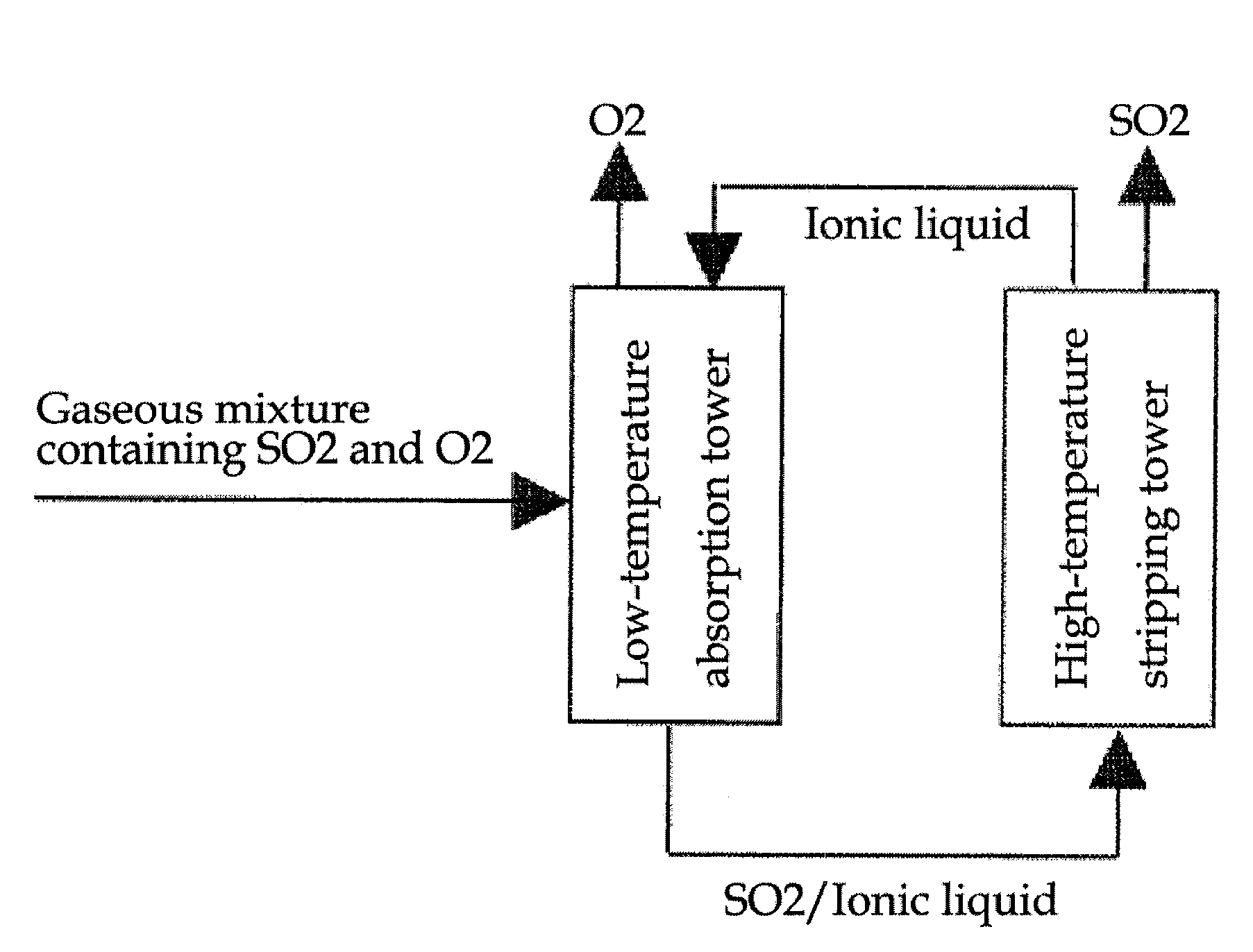

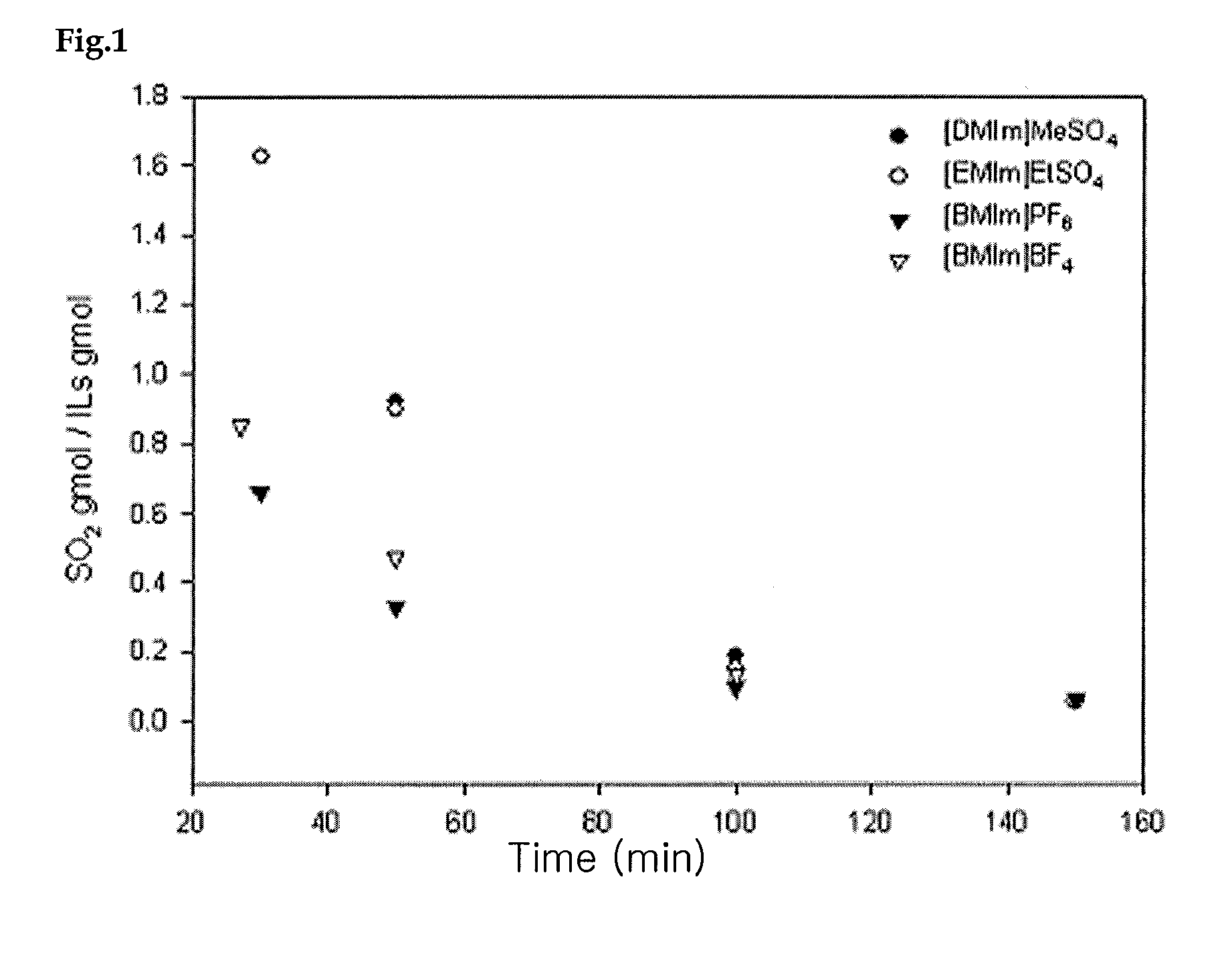

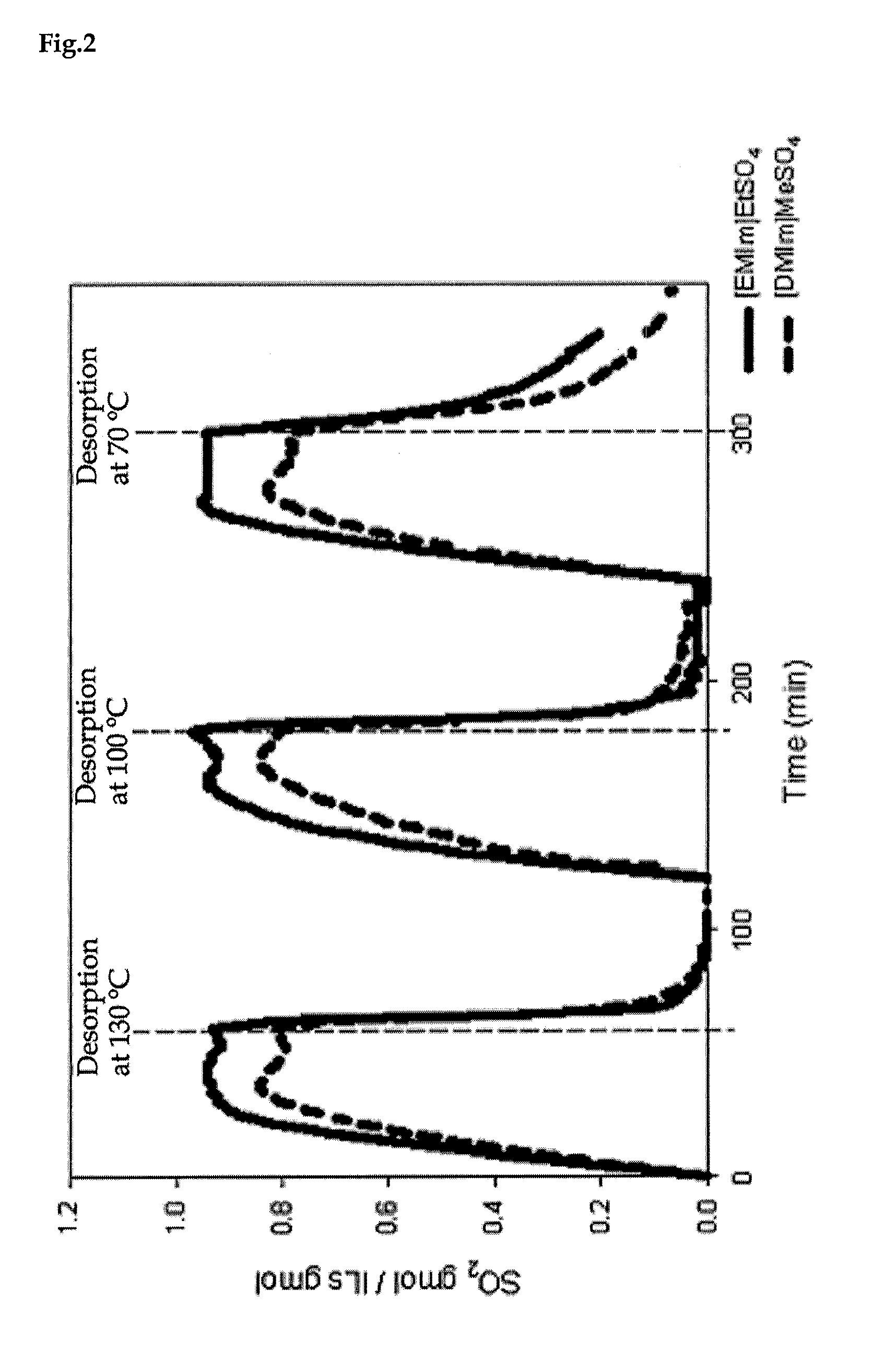

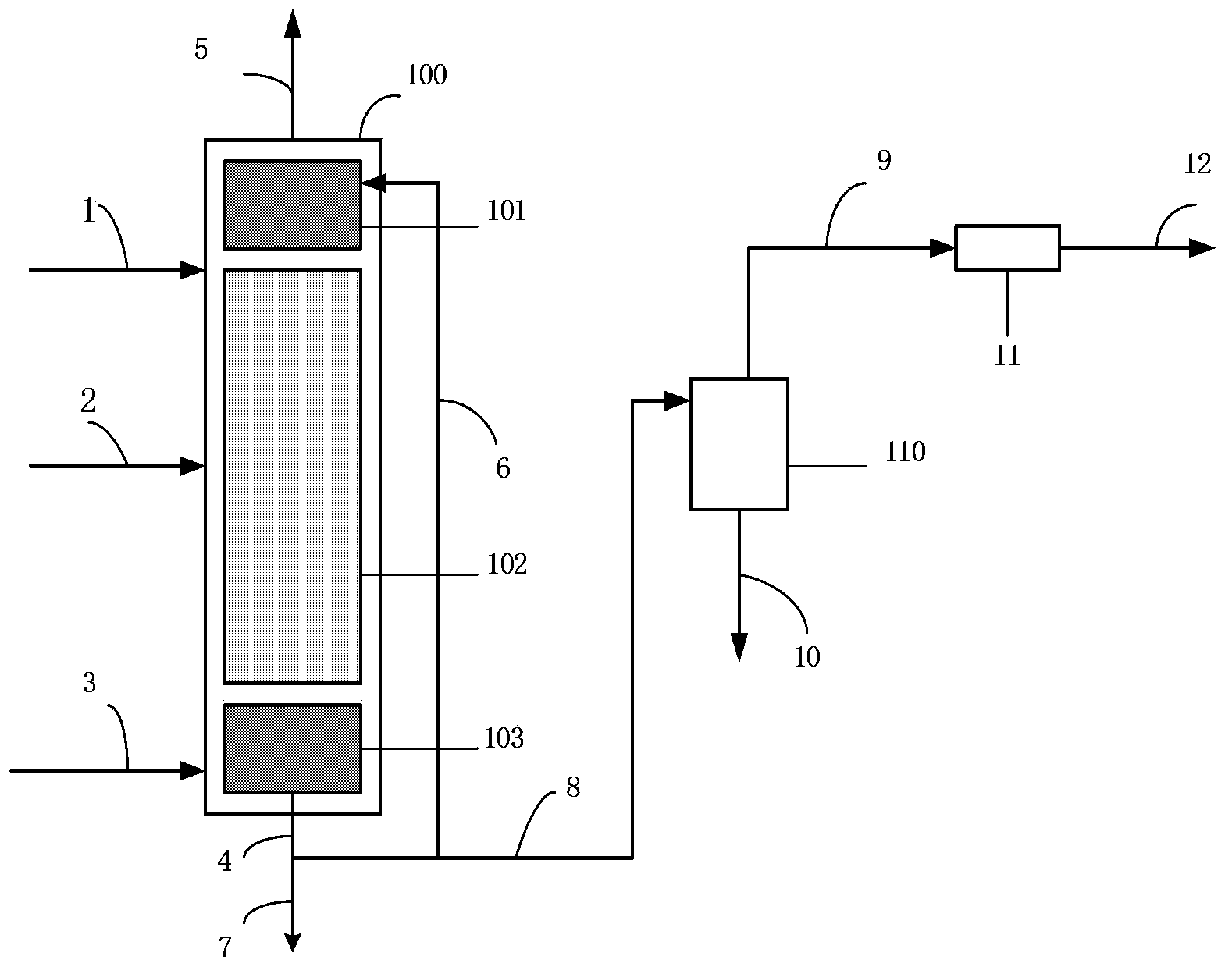

Method for separation and recycle of pure sulfur dioxide from a gaseous mixture in is cycle with ionic liquids

InactiveUS20100015040A1Improve processing efficiencyGood chemical stabilityChlorine/hydrogen-chlorideOxygen/ozone/oxide/hydroxidePhysical chemistryIonic liquid

The present invention relates to a method for separation and recycling of pure sulfur dioxide from a gaseous mixture in the IS cycle. More specifically, the present invention relates to a method for separation and recycling of pure sulfur dioxide from a gaseous mixture in the IS cycle using an ionic liquid under a specific condition. When compared with the conventional amine-based absorbent, the use of the ionic liquid enables continuous absorption and stripping of SO2 even at high temperature, and enables a reversible absorption of SO2 without loss, decomposition or degradation of a solvent due to good chemical stability, thereby enabling separation and recycling of pure SO2 from a gaseous mixture in the IS cycle.

Owner:KOREA INST OF SCI & TECH

Regeneration method for alkylated waste sulfuric acid

ActiveCN103771353ALower operating temperatureHigh removal ratePhysical/chemical process catalystsSulfur-trioxide/sulfuric-acidRedoxOrganic matter

Provided is a regeneration method for alkylated waste sulfuric acid. The regeneration method comprises: under redox conditions, waste sulfuric acid and oxidants are contacted, organic matters or tiny carbon particles in the waste sulfuric acid are reacted with the oxidants and converted into CO2, N2 and H2O, after steam stripping removal, regenerated sulfuric acid is obtained. The method can be carried out at a low pressure and at a low temperature, device operation energy consumption is low, investment is saved, operation is simple, and device maintenance cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

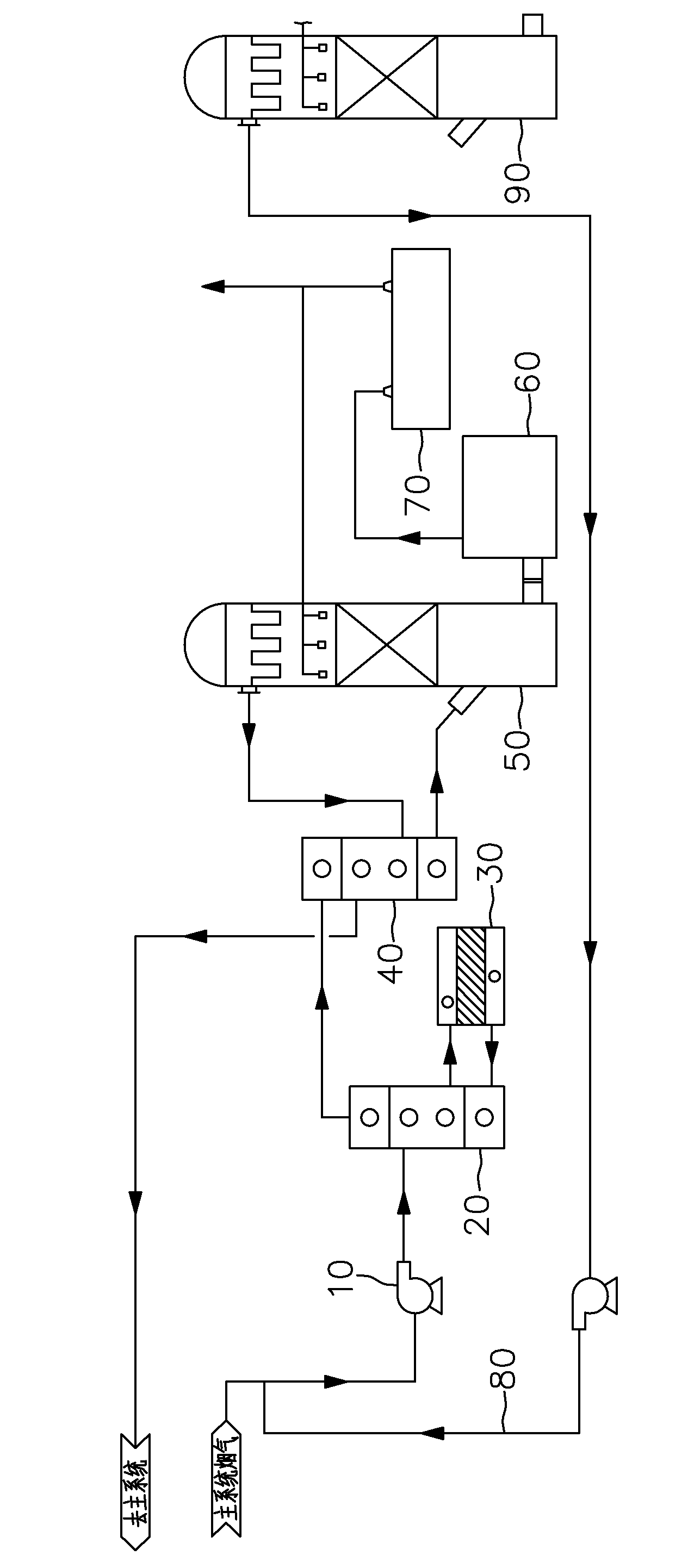

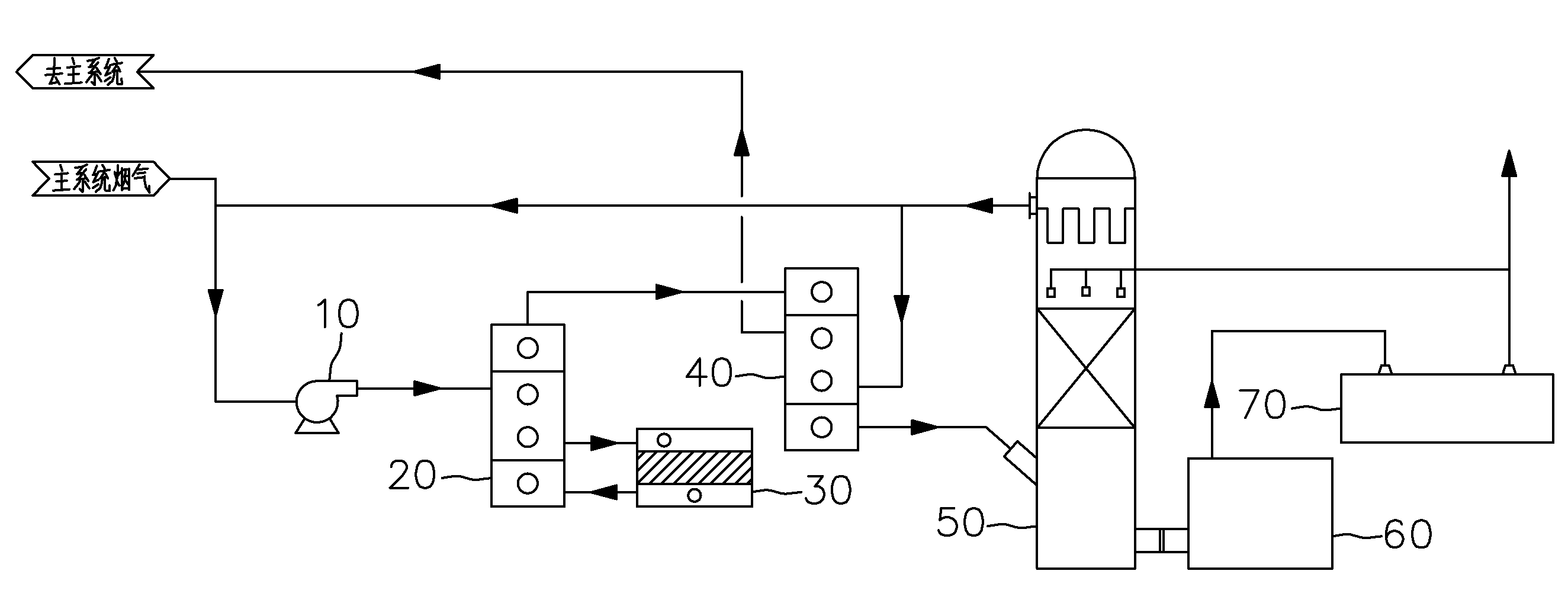

Acid making system suitable for high-concentration sulfur dioxide-containing flue gas

ActiveCN102079511AReduce concentrationReduce loadDispersed particle separationSulfur-trioxide/sulfuric-acidHigh concentrationFlue gas

Owner:JINLONG COPPER +1

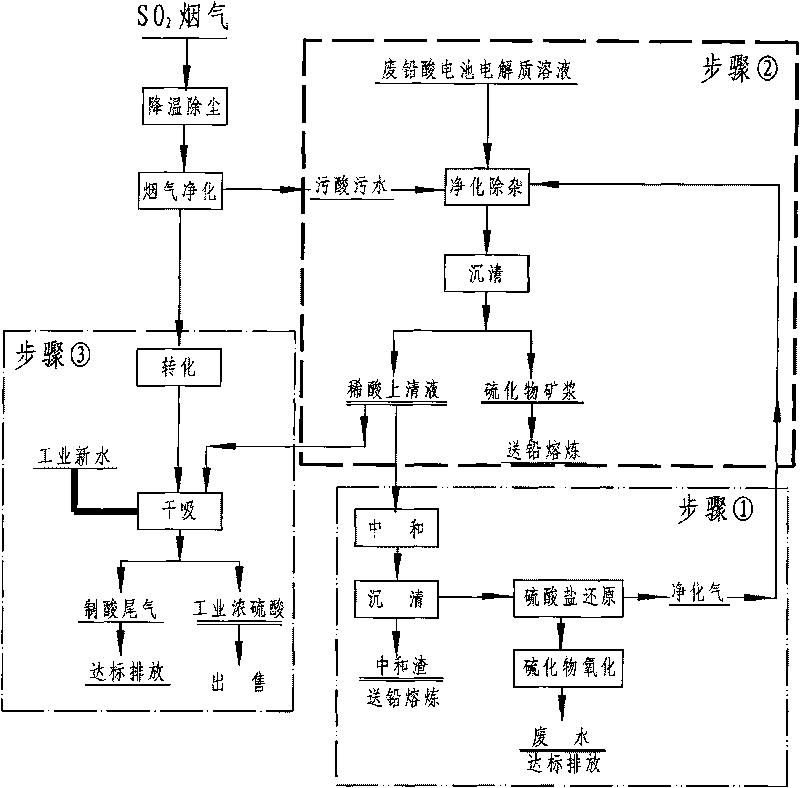

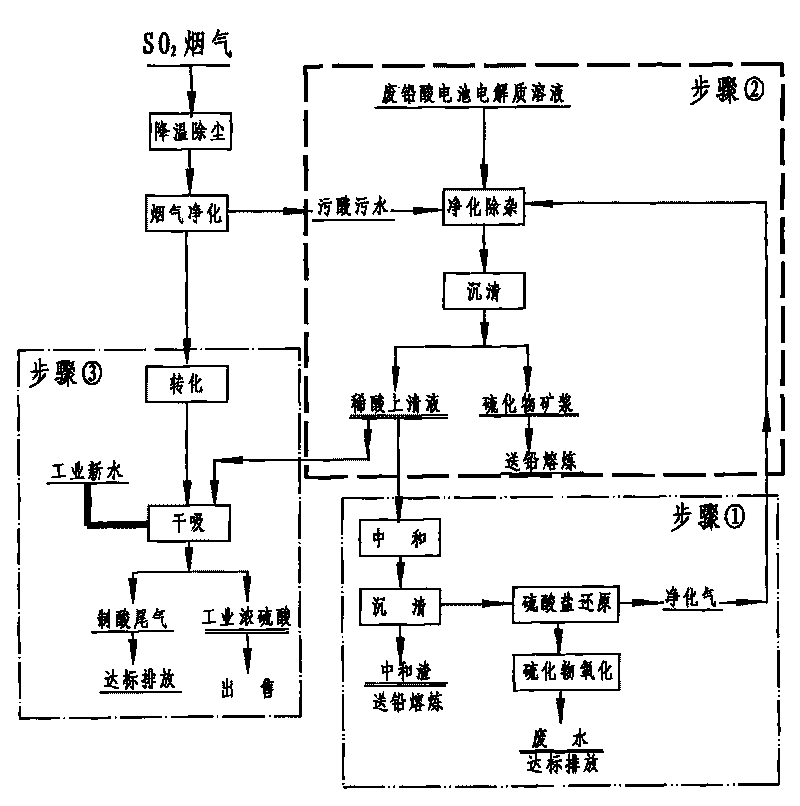

Method for regenerating and recovering sulfuric acid from waste acid

ActiveCN101759158AAvoid pollutionReduce processing costsWater contaminantsSulfur-trioxide/sulfuric-acidFlue gasNuclear chemistry

The invention relates to a method for regenerating and recovering sulfuric acid from waste acid generated in the production of the sulfuric acid or waste acid collected from waste lead-acid storage batteries, comprising the following steps of: firstly preparing purified gas containing H2S with volume percent of 2.5%-5%, CO2 with volume percent of 20%-45% and N2 with volume percent of 50%-77.5; supplying the purified gas to a waste acid solution with the flow rate of 10-20 m3 / h and the stirring speed of 300-400 rpm at the speed of 400-600 L / h so that heavy metal impurities in the waste acid solution and S2+ react to generate a sulfide; precipitating, filtering and separating the generated sulfide so that the sulfide is purified and removed from a dilute sulfuric acid solution; and replenishing the filtered dilute sulfuric acid solution which replaces new water into the dry-adsorbing procedure of a flue gas acid making systemso that the sulfuric acid in the waste acid solution is recovered into industrial sulfuric acid. The method has the advantages of low production cost, short flow, high cyclic utilization rate, low energy consumption, treatment of wastes by using wastes, small environmental pollution and high level of automation.

Owner:HENAN YUGUANG GOLD & LEAD

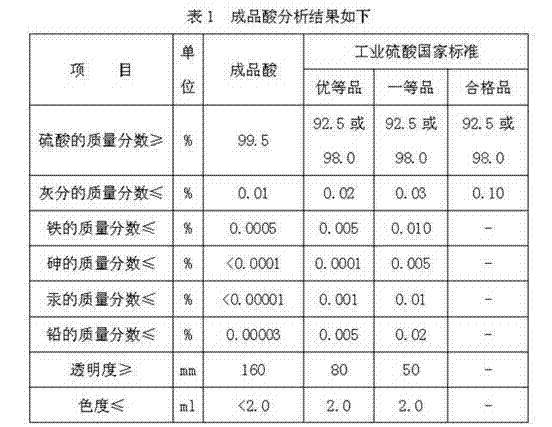

Method for decolorizing sulfuric acid by using hydrogen peroxide

InactiveCN102757021ANo change in qualityEliminate ChromaSulfur-trioxide/sulfuric-acidFlue gasEconomic benefits

The invention relates to a method for decolorizing sulfuric acid by using hydrogen peroxide. The method includes the following steps of injecting a hydrogen peroxide solution to the sulfuric acid in a closed sulfuric acid decolorizing tank at a speed of 6-18L / min*t with a volume ratio of the sulfuric acid to the hydrogen peroxide solution being 100: (6-22); and simultaneously continuously stirring a mixture at a speed of 8-15 revolutions per minute to obtain the finished sulfuric acid. By means of the hydrogen peroxide solution, the method is strong in oxidizability, good in selectivity, simple in process, convenient, flexible and capable of decolorizing tawny or black brown sulfuric acid; under acidic conditions, reduzate of the hydrogen peroxide is water, other metal ions can not added to the sulfuric acid finished product, and the quality of the sulfuric acid finished product can not be changed; therefore, the problem that the chromaticity and the transparency of the sulfuric acid finished product prepared by gypsum flue gases can't reach the standard can be eliminated, the quality of gypsum flue gas acid can reach the standard of high-class products of industrial concentrated sulfuric acid, the market competitiveness of the gypsum acid is improved, and economic benefits of enterprises are increased.

Owner:刘立文

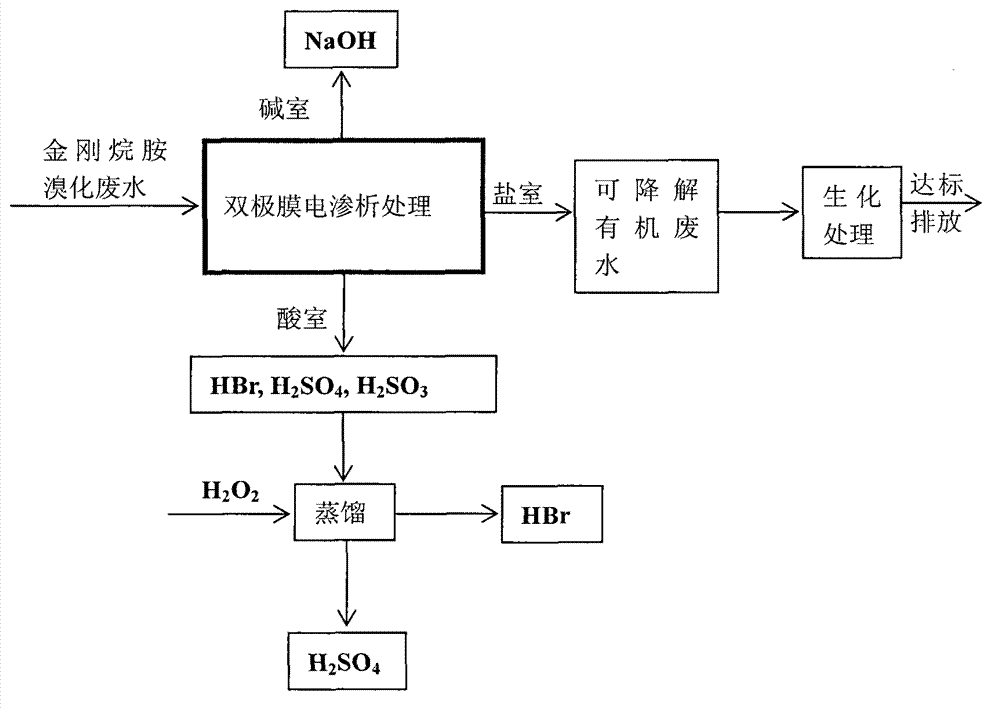

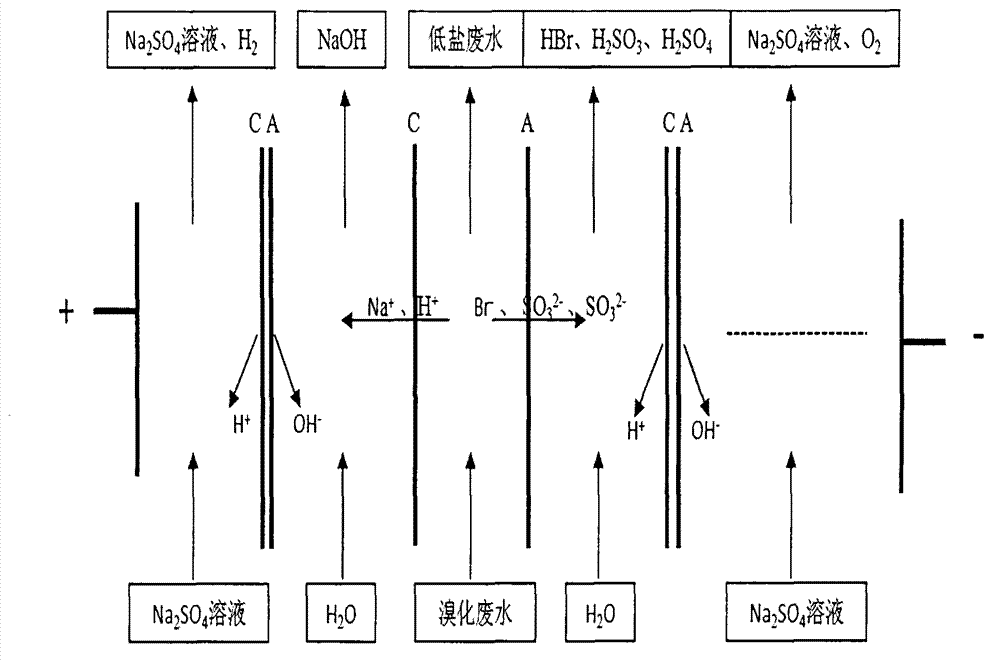

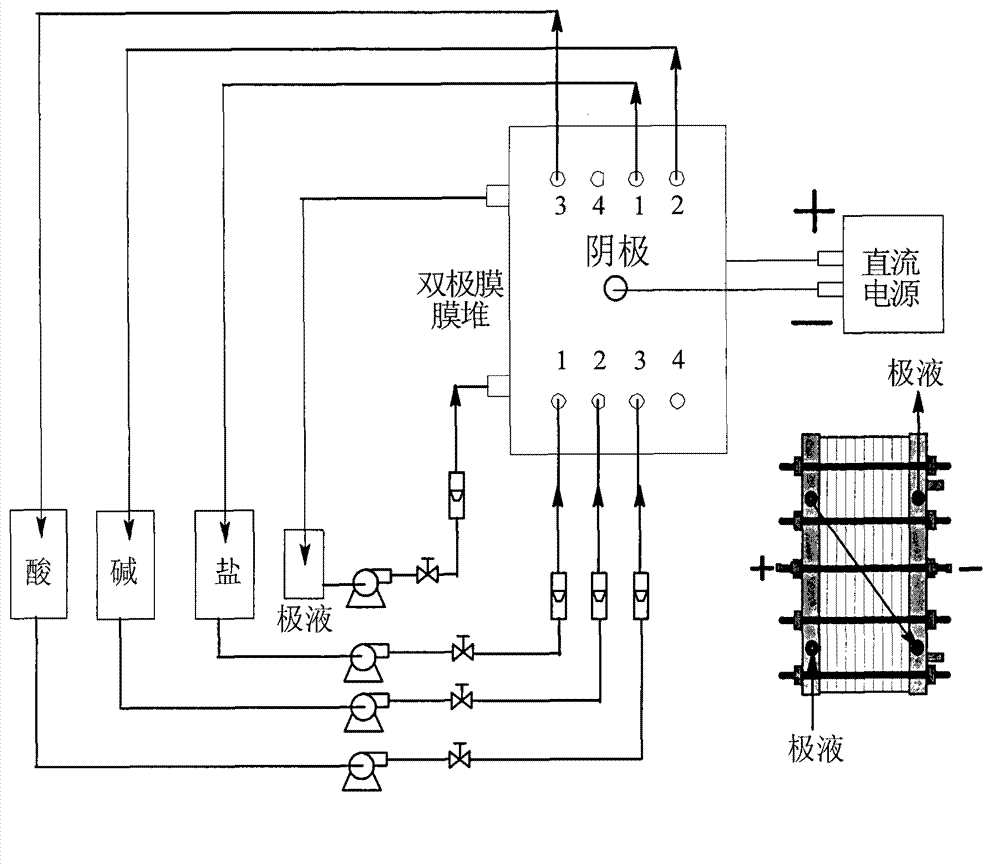

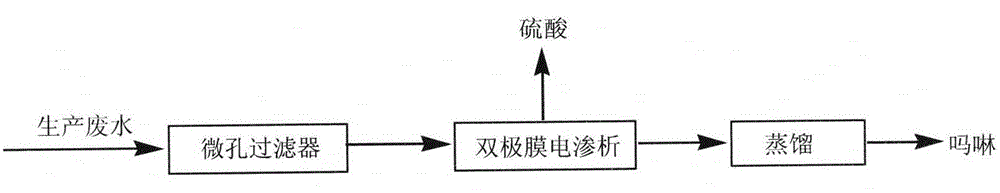

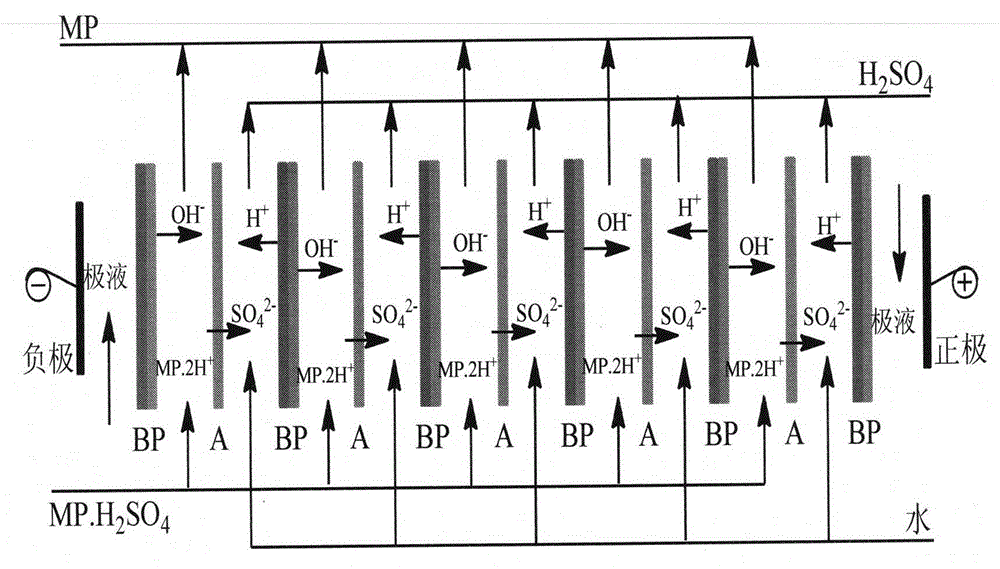

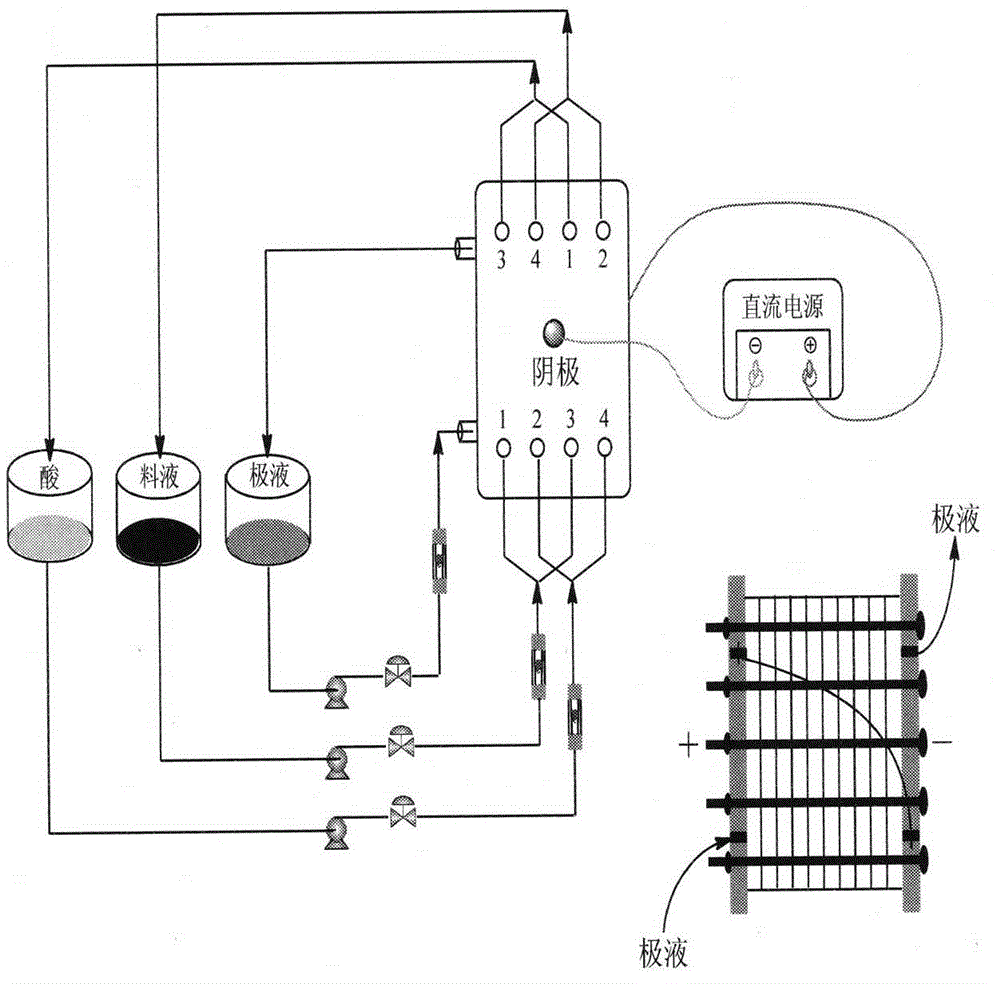

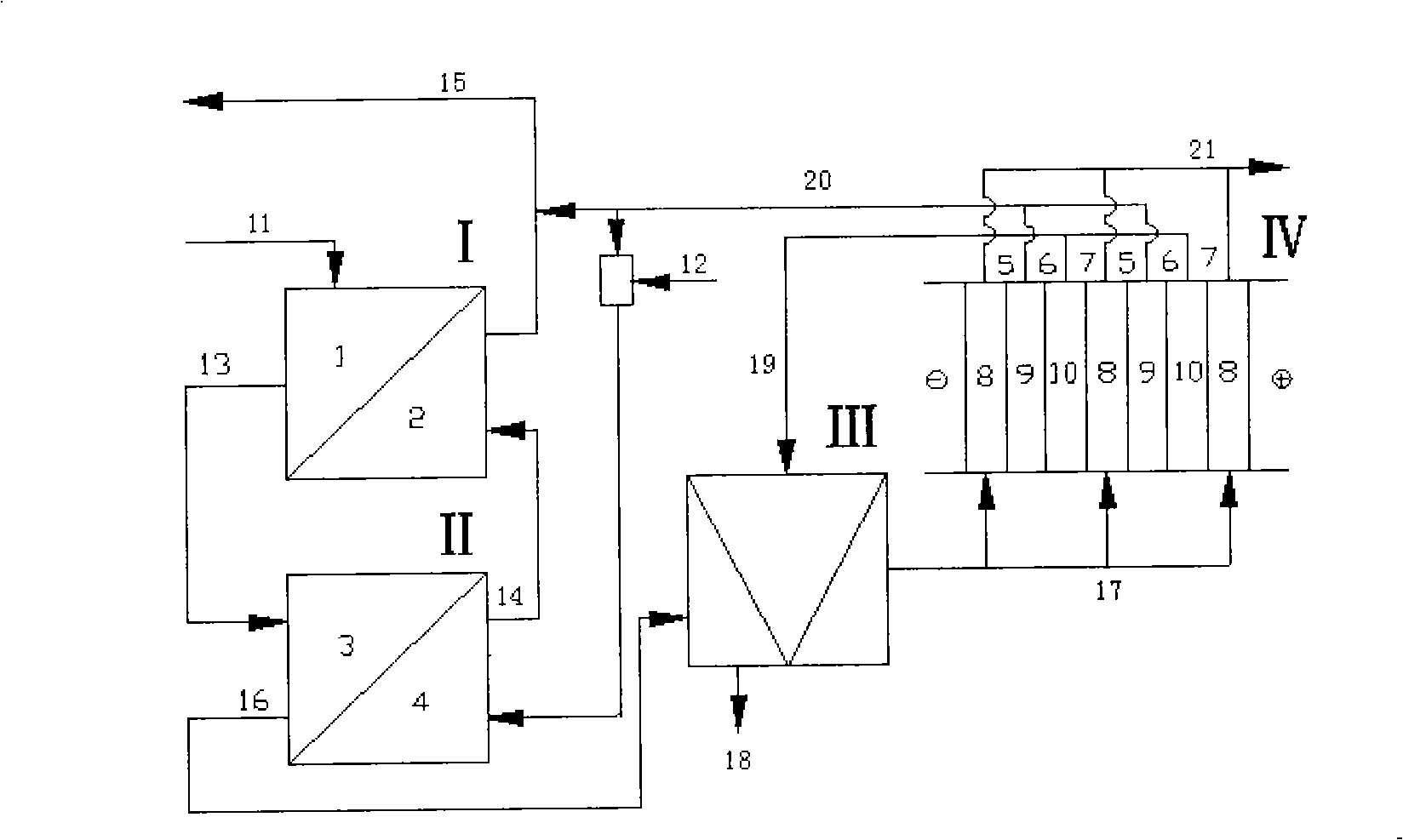

Process for treating amantadine bromination waste water and mineral acid and alkali recycling through bipolar membrane electrodialysis process

InactiveCN103073131AHas recycling valueGood governanceGeneral water supply conservationDispersed particle separationDesalinationBromine

The invention relates to a process for treating amantadine bromination waste water and mineral acid and alkali recycling through a bipolar membrane electrodialysis process, which comprises the following steps: firstly, filtrating bromination waste water through micropore filtration film; then pumping the bromination waste water into a salt chamber of the bipolar membrane electrodialysis device, pumping tap water into an acid chamber and an alkali chamber of the bipolar membrane electrodialysis device, and pumping Na2SO4 solution into electrode liquid of the two ends of the bipolar membrane electrodialysis device; and finally, starting the bipolar membrane electrodialysis device and recycling the acid and the alkali. According to the invention, a bipolar membrane electrodialysis technology is used for the treatment of degradation-resistant amantadine bromination waste water, and realizes the recycle of the mineral acid and the alkali in waste water. The process has the following advantages: bromine irons in waste water containing bromine can be removed, the desalination rate is higher than 95 percent, the hydrogen ion concentration is decreased from 2.95 mol / L to 0.003 mol / L below, and avoids secondary contamination; the process enables the degradation-resistant pharmaceutical wastewater to become biochemical degradable organic wastewater, and emits qualified waste water after the biochemical treatment; and the control effectiveness is good, the operation is convenient, and the process has a favorable application prospect.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for bipolar membrane electrodialysis treatment of 3-aminopyrazole-4-carboxamide hemisulfate production wastewater and recycling of sulfuric acid

InactiveCN103936214ANo pollutionImprove pollutionOrganic chemistryDispersed particle separationMorpholineElectrodialysis

The invention discloses a method which does not pollute the environment and is used for bipolar membrane electrodialysis treatment of 3-aminopyrazole-4-carboxamide hemisulfate production wastewater and recycling of sulfuric acid. The method comprises the following steps: the 3-aminopyrazole-4-carboxamide hemisulfate production wastewater is filtered by a microporous filter with the accuracy of 0.1-0.45; the filtered wastewater is pumped into one of a salt chamber or a salt / alkali chamber or a salt / acid chamber of a bipolar membrane electrodialysis device, and an electrolyte solution with a certain concentration is injected into other compartments; a cathode and an anode of the bipolar membrane electrodialysis device are respectively connected with a negative electrode and a positive electrode of a direct-current power source, the current density of a direct-current electric field is controlled to be 10-500 mA / cm<2>, the temperature is controlled at 5-40 DEG C, the bipolar membrane electrodialysis device is started, sulfuric acid in the wastewater is removed and recycled, the sulfuric acid removal rate is above 90%, and the concentration of the recycled sulfuric acid reaches more than 4%; and the wastewater after deacidification is subjected to morpholine recycling by a distillation method.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

Method for recycling pure acid from metallic ion containing waste acid and regenerating alkali

ActiveCN101343039AHigh recovery rateReduce manufacturing costChlorine/hydrogen-chloride purificationSulfur-trioxide/sulfuric-acidFiltrationAcid concentration

Disclosed is a method which recovers pure acid from the waste acid contains metallic ion and reproduces alkaline, and belongs to the environmental protection field. The process steps include that: (a) the waste acid solution with the acid concentration 10%-40% is processed with the first level diffusion dialysis; (b) the residue after the step a is processed with the second level diffusion dialysis; the volume ratio of the first level (or the second level) waste acid (or the first level diffusion residue) in the first level (or the second level) diffusion dialysis groove residue and the acid recovery chamber collected solution is 1:0.5-1:3.0; the flow rate of the waste acid (or the first level diffusion residue) is enabled to be 0.2-0.6L / h; the flow rate of the acid recovery chamber collected solution is 0.1-1.8L / h; (c) the second residue after the step b is processed with neutralization and deposition; (d) the neutralized filtrate after the solid-liquid separation-filtration is fed to the three compartment electrodialysis groove middle chamber, the electrodialysis is processed for 1-3h under the voltage 5-15V to obtain the reproduction acid and reproduction alkaline. The method which recovers pure acid from the waste acid contains metallic ion and reproduces alkaline has the advantages of high acid recovery rate, low production cost and energy-consumption, less film pollution, saving water, reducing discharge and no secondary pollution.

Owner:HARBIN COSLIGHT STORAGE BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com