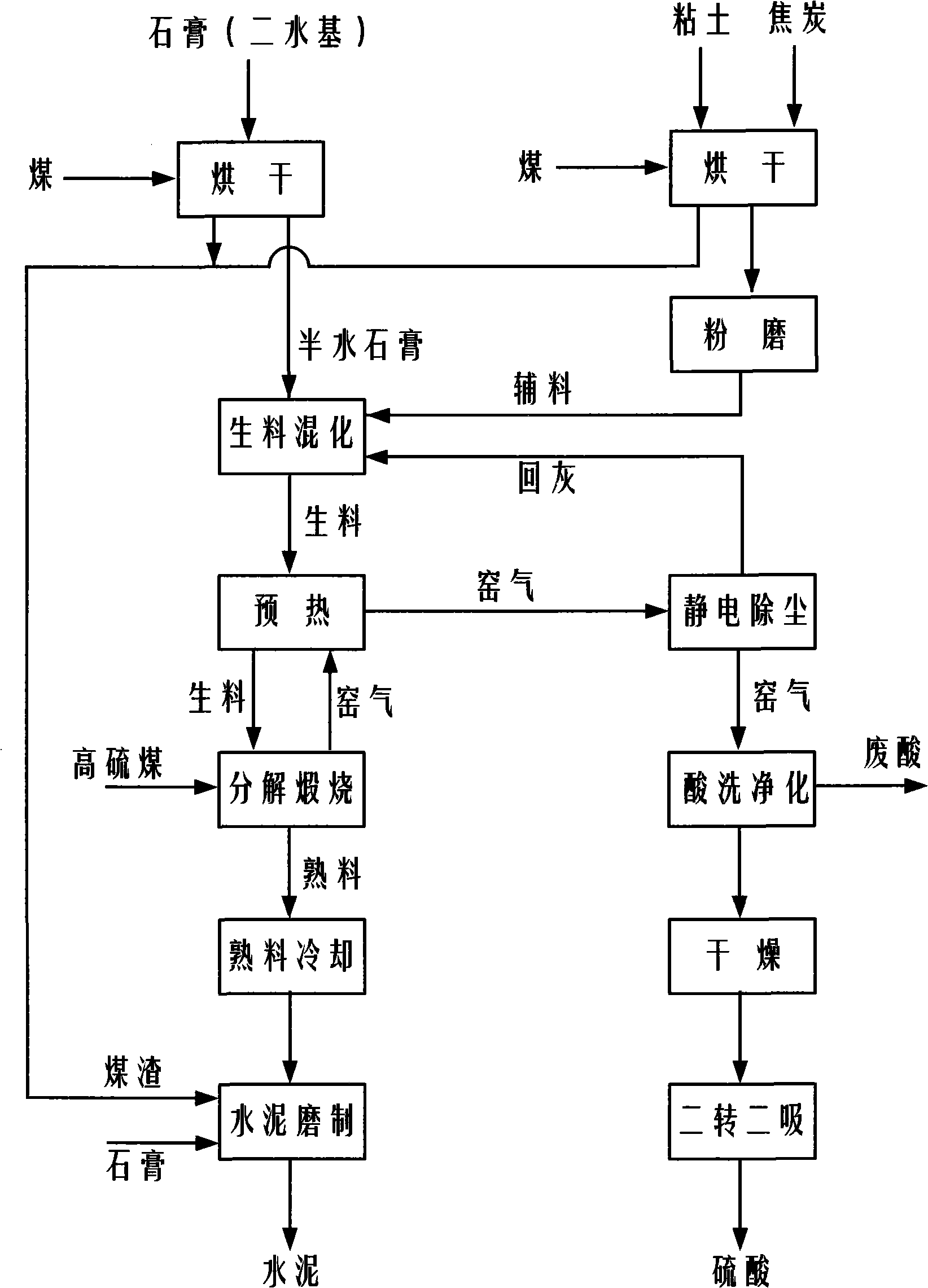

Improved preparation technique for preparing sulphuric acid and cement with gypsum

A production process, gypsum technology, applied in cement production, sulfur trioxide/sulfuric acid, etc., can solve the problems of low concentration, high power consumption, low gypsum decomposition rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Embodiment 1 (making raw material with phosphogypsum):

[0098] 1. The main raw materials of phosphogypsum, clay, coke and coal are as follows:

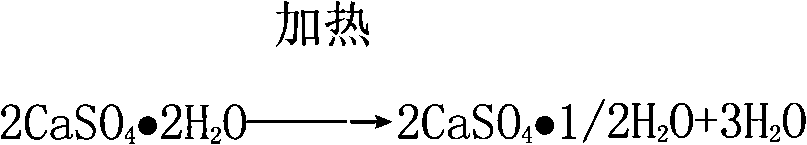

[0099] (1) Main chemical components of phosphogypsum (dihydrate base)

[0100] Phosphogypsum

LOSS

SiO 2

Fe 2 o 3

al 2 o 3

CaO

MgO

SO 3

P 2 o 5

F -

∑

[0101] Wt, %

19.23

3.81

0.27

0.29

31.40

0.44

43.34

0.72

0.16

99.79

[0102] (2) Main chemical components of clay

[0103] clay

LOSS

SiO 2

Fe 2 o 3

al 2 o 3

CaO

MgO

∑

Wt, %

9.10

62.37

4.69

12.15

5.89

2.34

96.54

[0104] (3) Coke industrial analysis, ash analysis

[0105]

[0106] (4) Industrial analysis and ash analysis of burning coal

[0107]

[0108] 2. Main chemical components of...

Embodiment 2

[0136] Embodiment 2 (make raw material with desulfurization gypsum):

[0137] 1. The main raw materials of desulfurization gypsum, clay, coke and coal are as follows:

[0138] (1) Main chemical components of desulfurized gypsum (dihydrate base)

[0139] Phosphogypsum

LOSS

SiO 2

Fe 2 o 3

al 2 o 3

CaO

MgO

SO 3

∑

Wt, %

18.37

0.96

0.22

0.28

32.72

1.13

45.17

98.85

[0140] (2) Main chemical components of clay

[0141] clay

LOSS

SiO 2

Fe 2 o 3

al 2 o 3

CaO

MgO

∑

Wt, %

7.4

70.1

3.0

10.46

5.19

1.64

97.79

[0142] (3) Coke industrial analysis, ash analysis

[0143]

[0144] (4) Industrial analysis and ash analysis of burning coal

[0145]

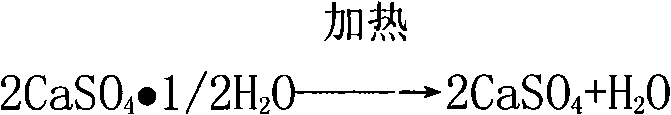

[0146] 2. Main chemical components of hemihydrate desulfurization gypsum

[0147] Hemihydrate desulfurized gy...

Embodiment 3

[0173] Embodiment 3 (making raw material with salt gypsum):

[0174] 1. The main raw materials of salt gypsum, clay, coke and coal are as follows:

[0175] (1) Main chemical components of salt gypsum (dihydrate base)

[0176] Phosphogypsum

LOSS

SiO 2

Fe 2 o 3

Al 2 o 3

CaO

MgO

SO 3

∑

Wt, %

22.49

7.54

0.55

1.04

31.31

0.10

33.75

96.78

[0177] (2) Main chemical components of clay

[0178] clay

LOSS

SiO 2

Fe 2 o 3

al 2 o 3

CaO

MgO

∑

Wt, %

7.4

70.1

3.0

10.46

5.19

1.64

97.79

[0179] (3) Coke industrial analysis, ash analysis

[0180]

[0181] (4) Industrial analysis and ash analysis of burning coal

[0182]

[0183] 2. Main chemical components of hemihydrate salt gypsum

[0184] Hemihydrate desulfurized gypsum

LOSS

SiO 2

Fe 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com