Patents

Literature

317results about How to "Expand area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

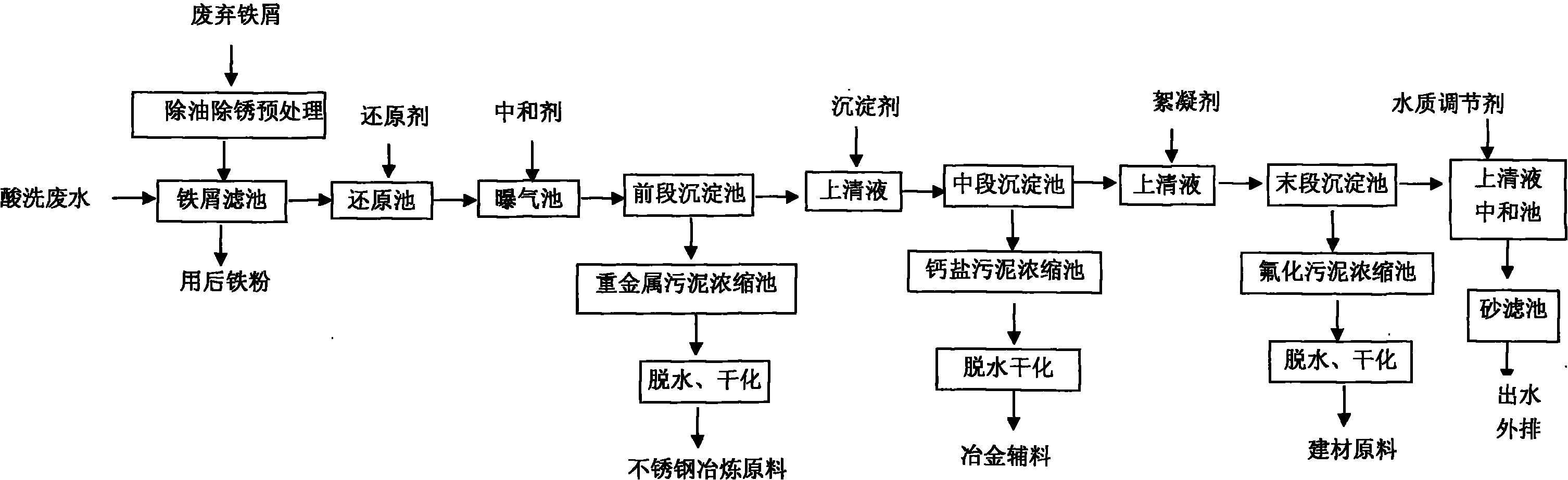

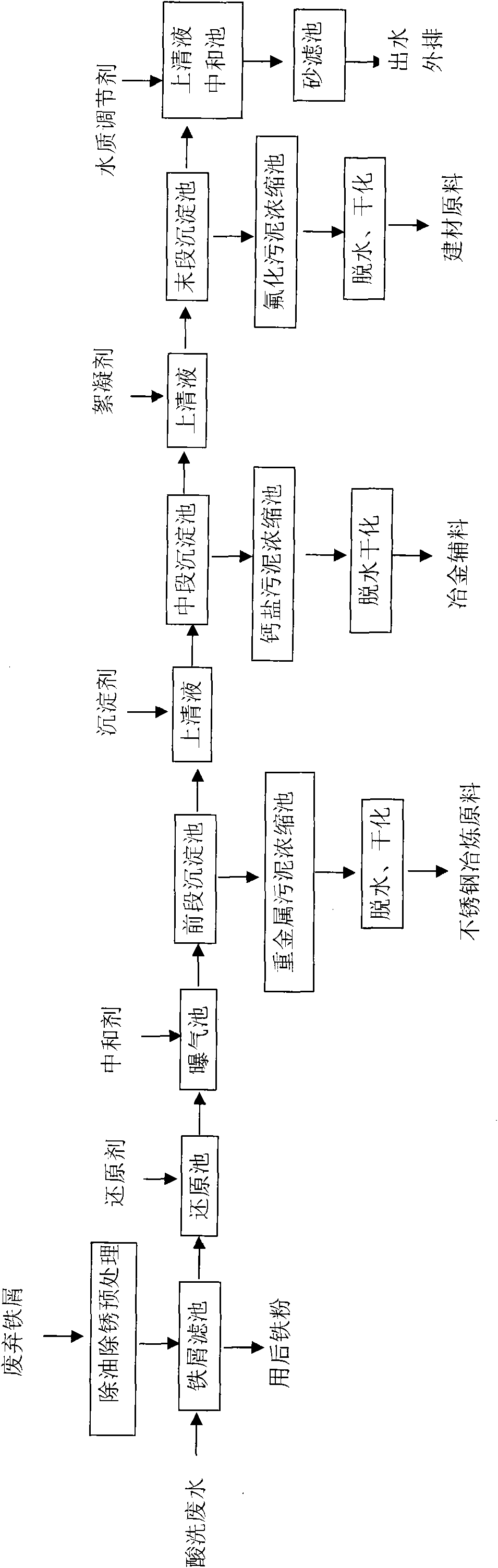

Processing method of stainless steel cold rolling pickling wastewater

ActiveCN101811792AIncrease dosageIncrease productionSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processScrapHexavalent chromium

The invention relates to a processing method of stainless steel cold rolling pickling wastewater. The pickling wastewater enters a hexavalent chrome secondary reduction pool after the actions of micro-electrolysis and hexavalent chrome preliminary reduction of a scrap iron filtering pool; the reduced wastewater enters a front-segment precipitation tank after neutralization and aeration, heavy metal sludge is concentrated and dehydrated, and the heavy metal sludge and scrap iron after the use of the scrap iron filtering pool are recycled and used as stainless steel smelting raw materials; middle-segment precipitation is carried out after a primary supernatant acts with a precipitant, and dehydrated and dried fluoride sludge is recycled and used as a metallurgical adjuvant material; final-segment precipitation is carried out after a secondary supernatant continues to act with a flocculating agent to obtain calcium salt which can be used as a building material raw material; and after the three segments of precipitation of acidic wastewater, the final third level supernatant reaches a standard and is discharged through water quality regulation and sand filtering. The invention has the advantages of less investment, low wastewater processing cost, convenient maintenance and the like, and not only can effectively utilize discarded scrap iron of a stainless steel enterprise, but also can greatly lower the subsequent wastewater processing cost and the operating load.

Owner:BAOSHAN IRON & STEEL CO LTD

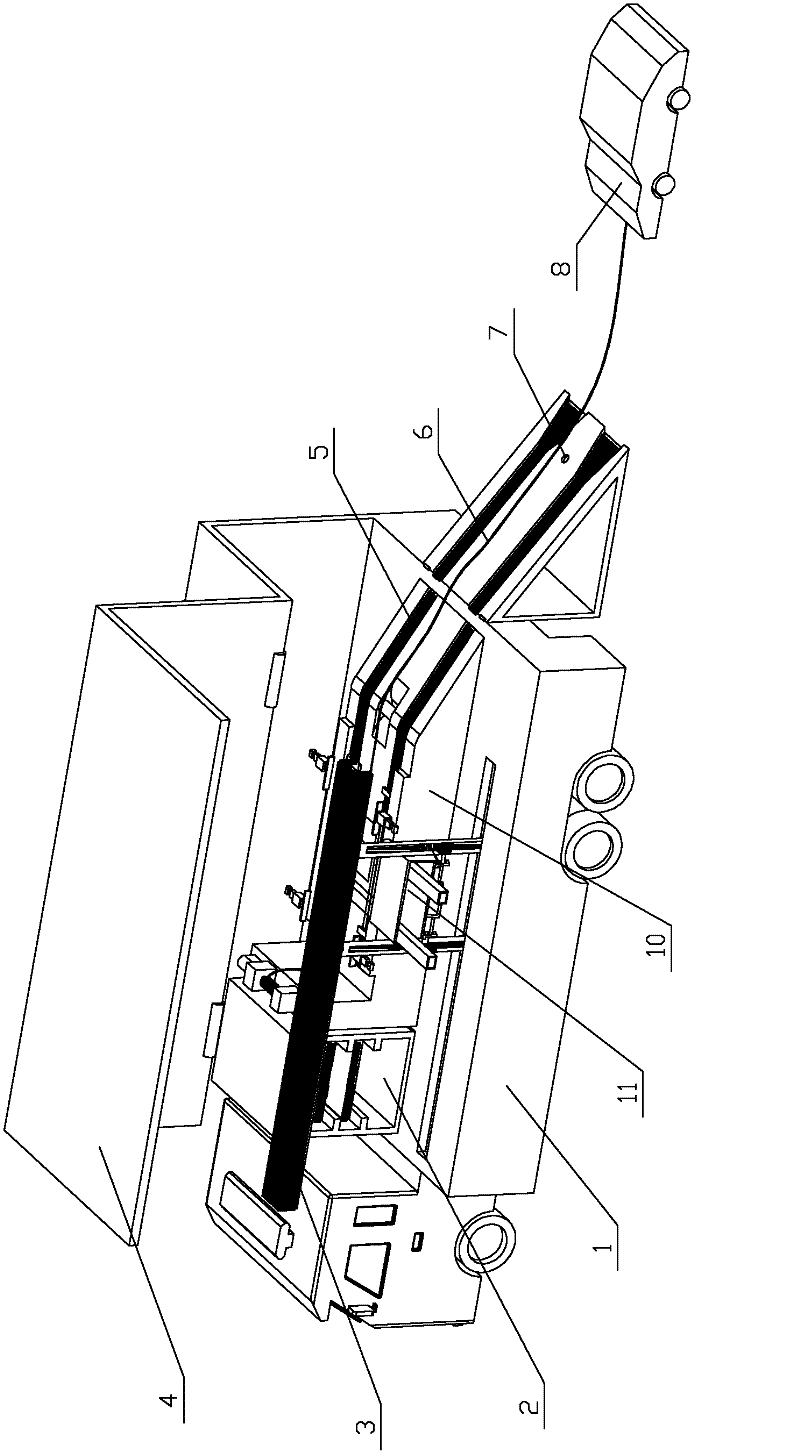

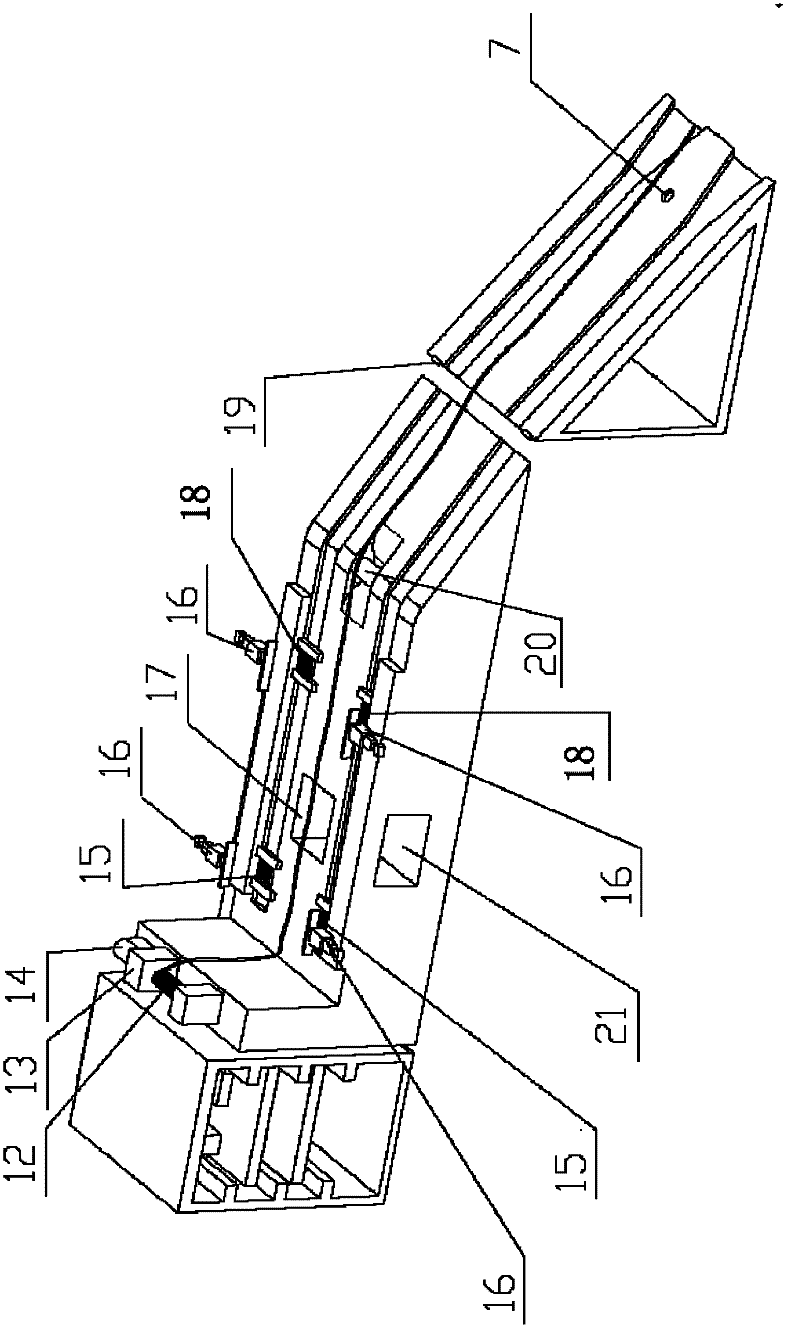

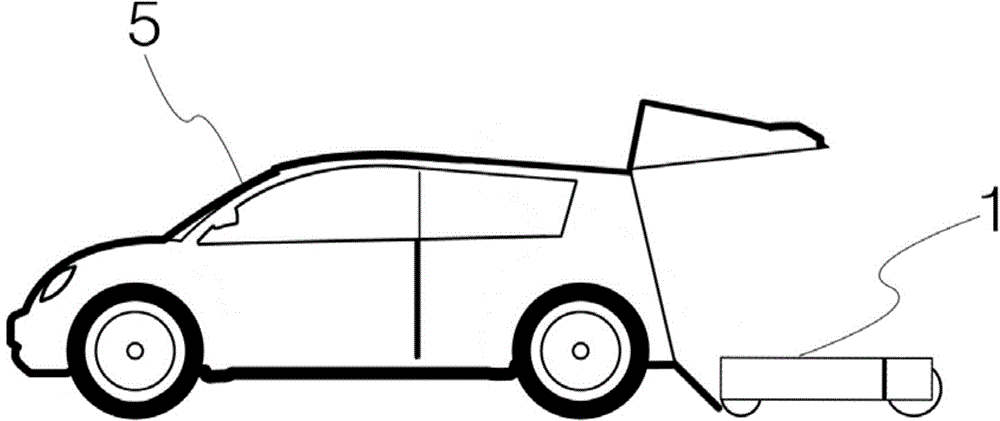

Emergency movable battery replacing vehicle and battery replacing method thereof

ActiveCN102358266AFully automatic intelligent emergency battery replacement serviceHigh degree of automationElectric propulsion mountingItem transportation vehiclesElectricityTraction system

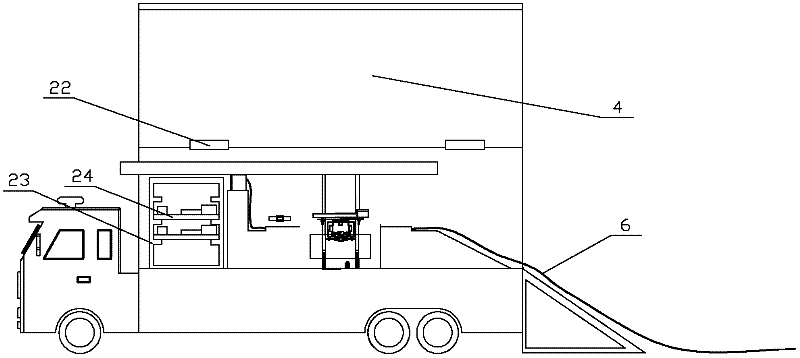

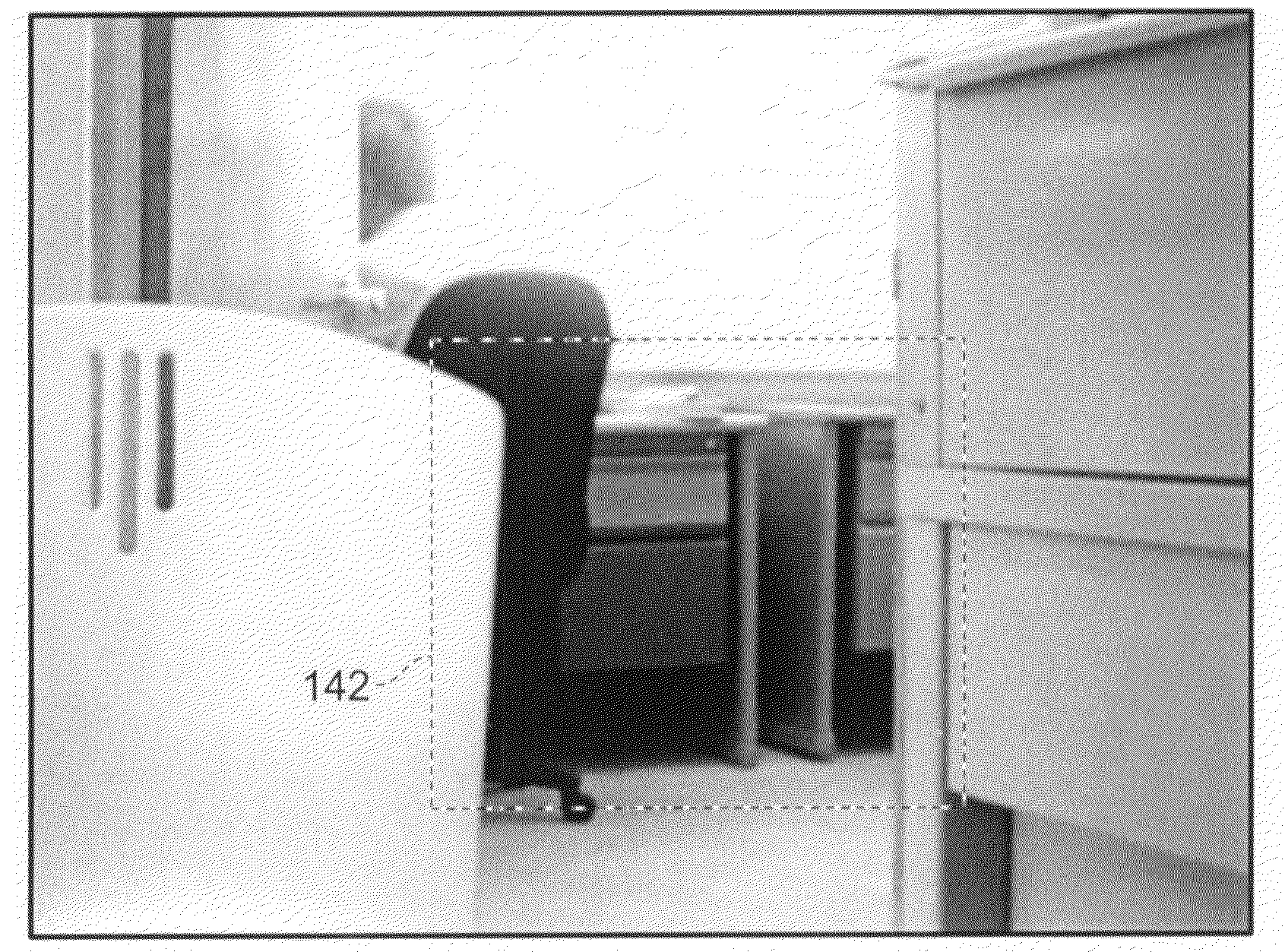

The invention relates to an integrally distributing and replacing emergency movable battery replacing vehicle and a battery replacing method thereof, which are used for solving the problem that an electric passenger car can not reach a special concentrated charging power station for replacing batteries due to stoppage (no power of the battery, fault and emergency use). The emergency movable battery replacing vehicle comprises a battery replacing car. A battery storing frame is arranged on the upper front portion of the battery replacing car and adjacent to a trapezoid stand. A traction systemis further arranged on the trapezoid stand. A folded slope is matched with a slope face of the trapezoid stand, the trapezoid stand is hinged with the folded slope, the height of the folded slope ensures that when the folded slope is arranged on the ground, the folded slope is connected with the lower edge of the slope face of the trapezoid stand, and the battery storing frame, the trapezoid stand and the folded slope are distributed horizontally. A battery replacing robot is arranged in front of the trapezoid stand and the battery storing frame and matched with the battery storing frame and the trapezoid stand, and the traction system and the battery replacing robot are both connected with a control system.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

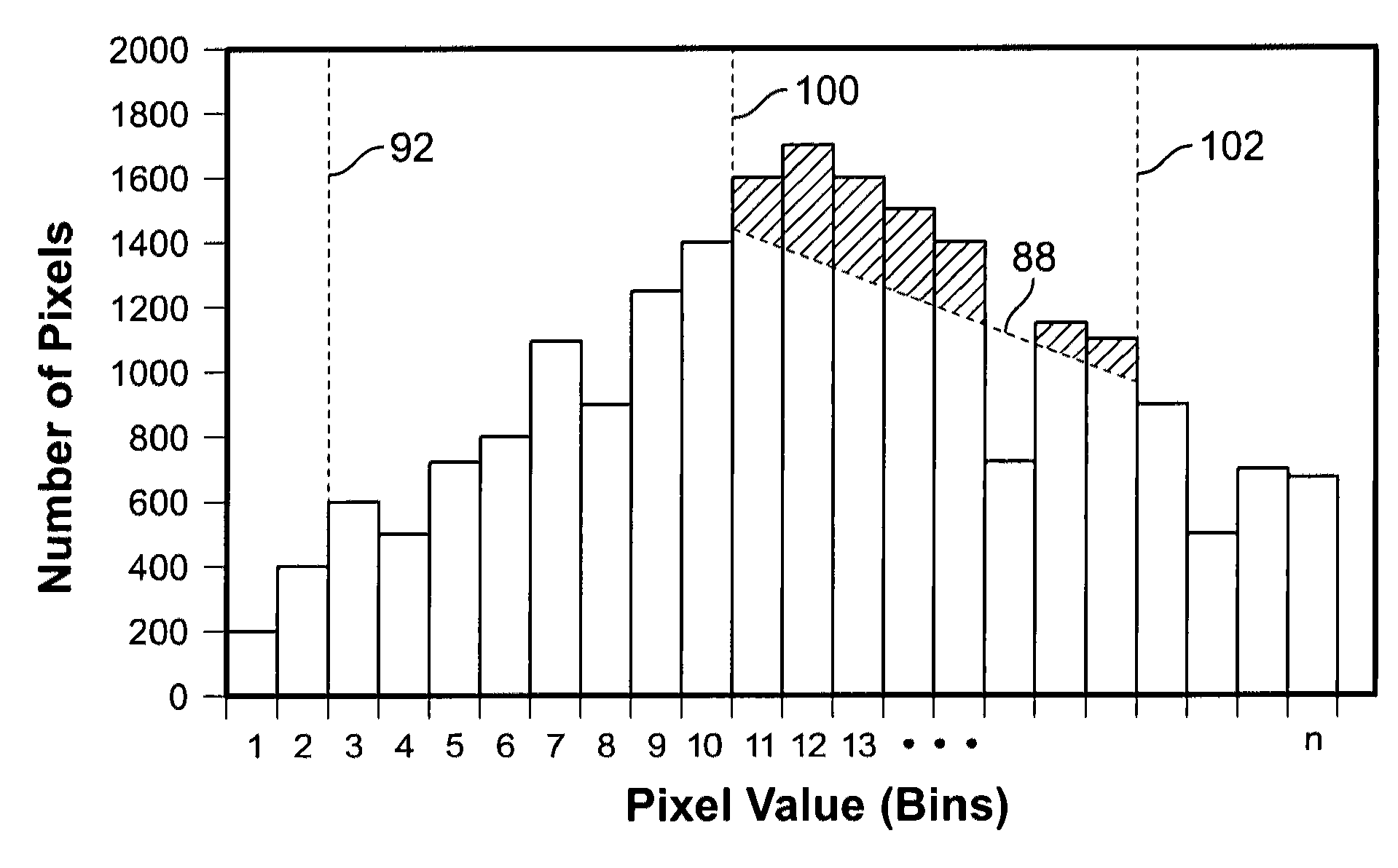

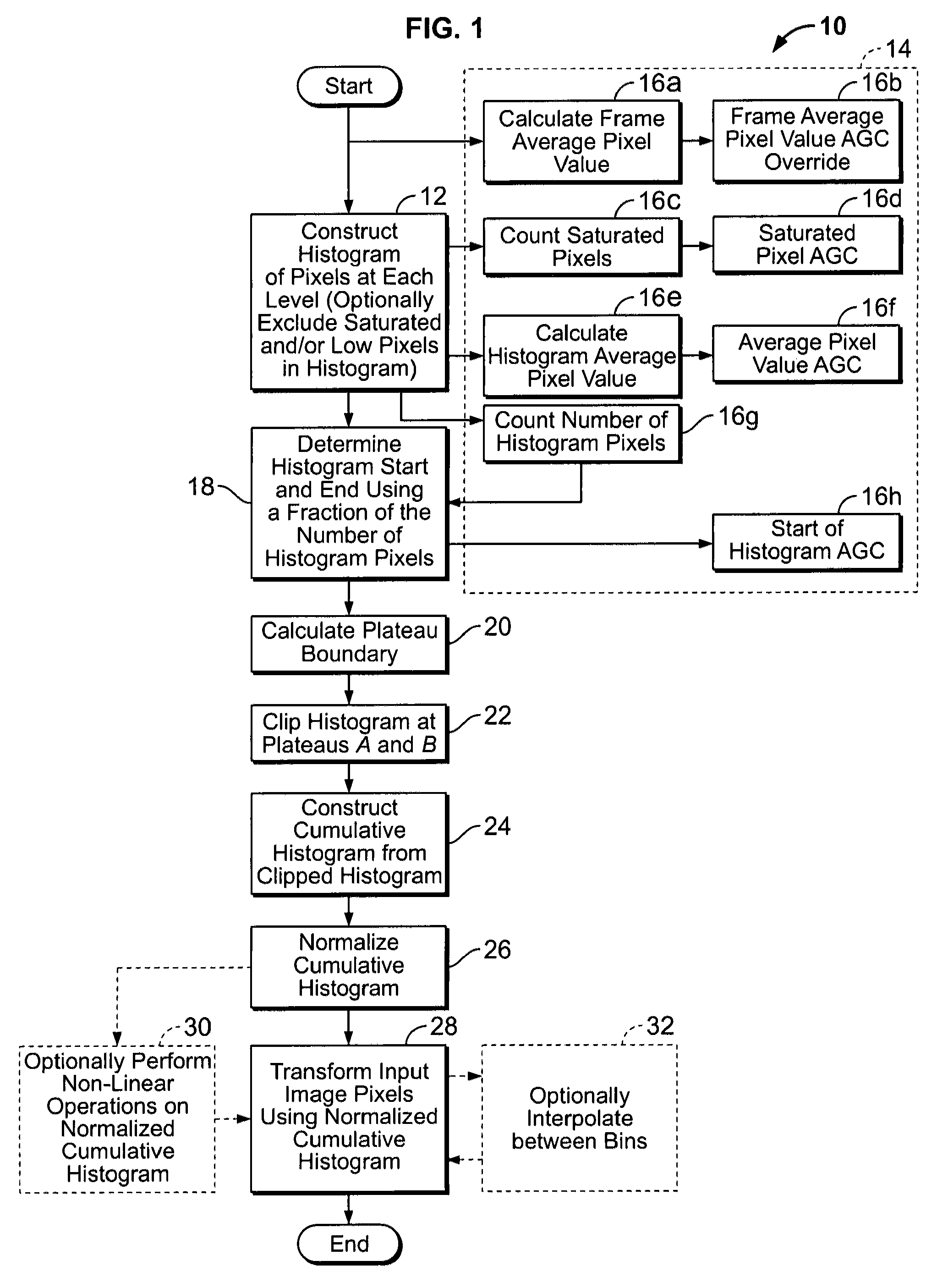

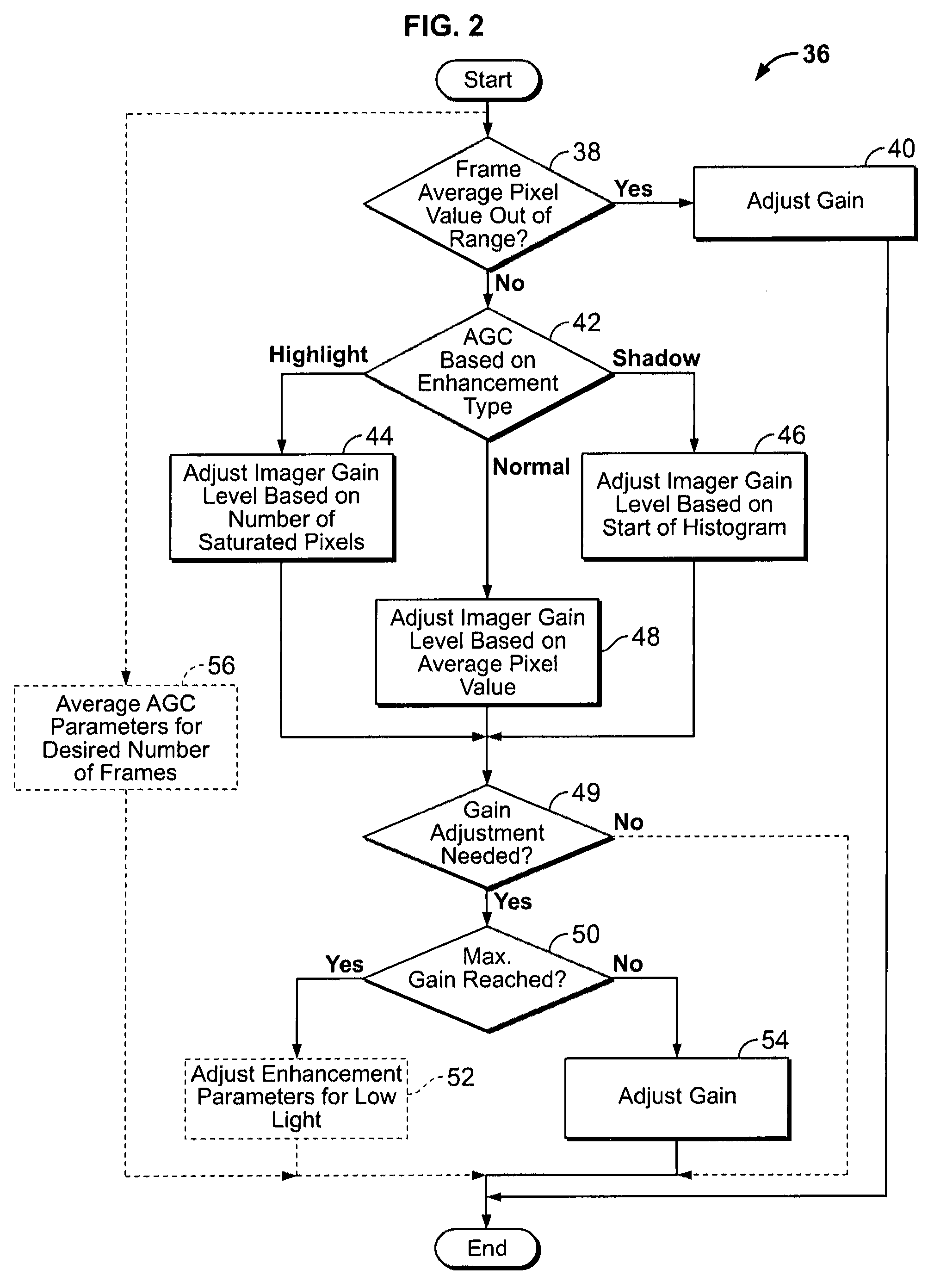

Method and Apparatus for Enhancing Images

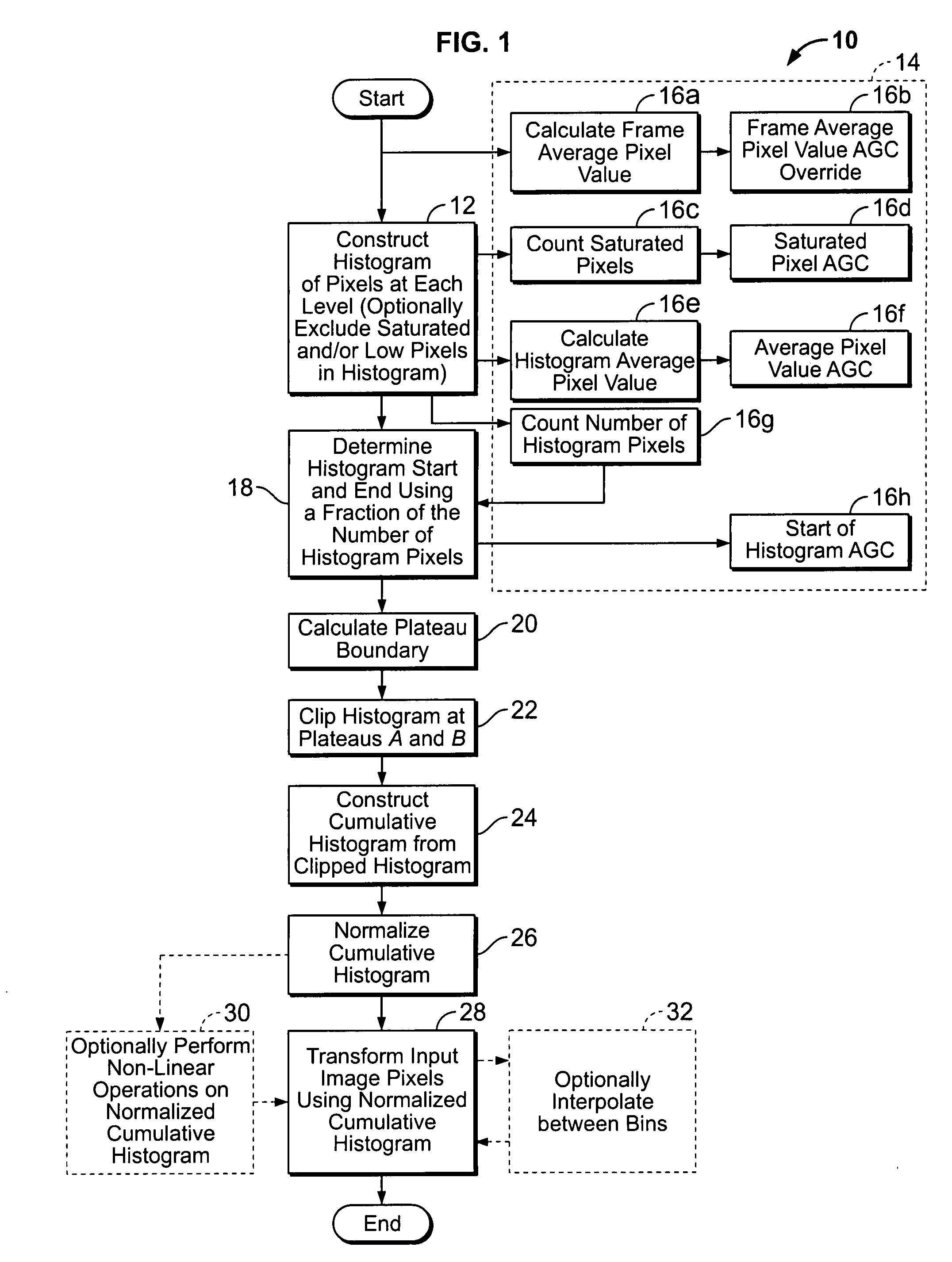

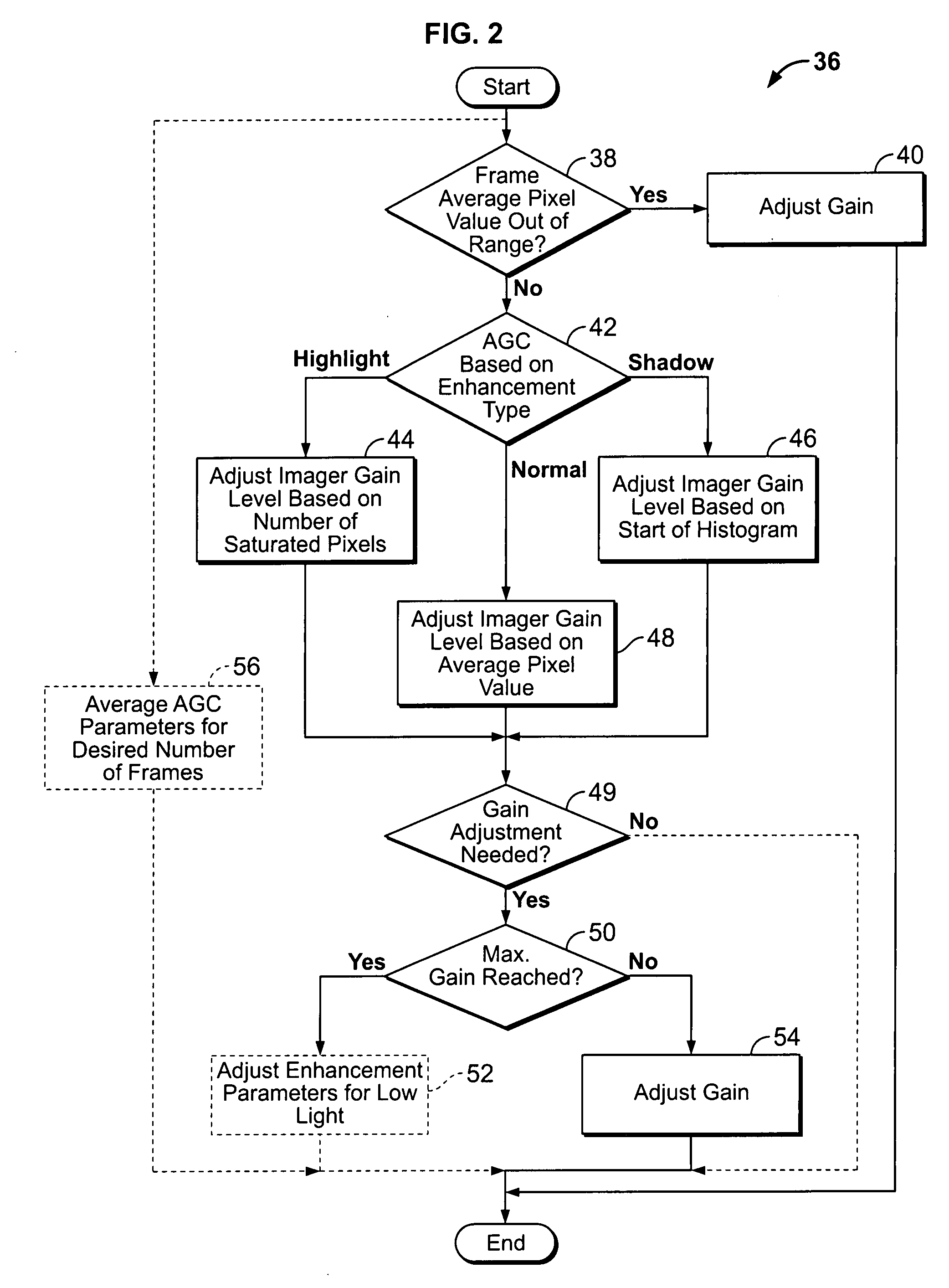

A method and an apparatus for enhancing images are provided. An input image generated by an imaging device, such as a short-wavelength infrared (SWIR) camera, sensor, or any other imaging device, is processed to produce an input histogram representing the distribution of pixel intensities in the input image. Histogram start and end points are determined, and a variable plateau profile is calculated depending upon the type of enhancement desired. The plateau profile could take on any desired shape or size, and two or more plateau regions could be included in the profile. The input histogram is clipped along the variable plateau profile. A cumulative histogram is constructed from the clipped histogram, and is normalized. The input image is then transformed into an enhanced output image using the normalized cumulative histogram as a look-up table.

Owner:SENSORS UNLTD

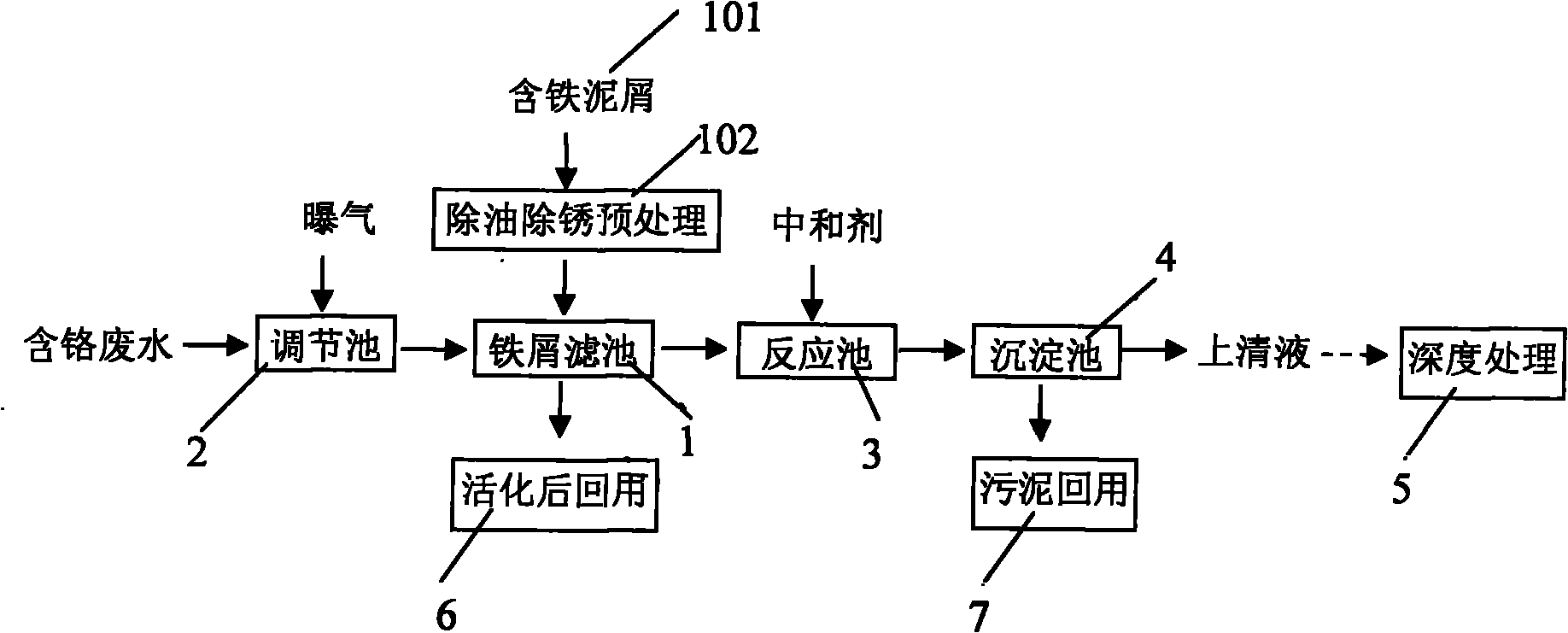

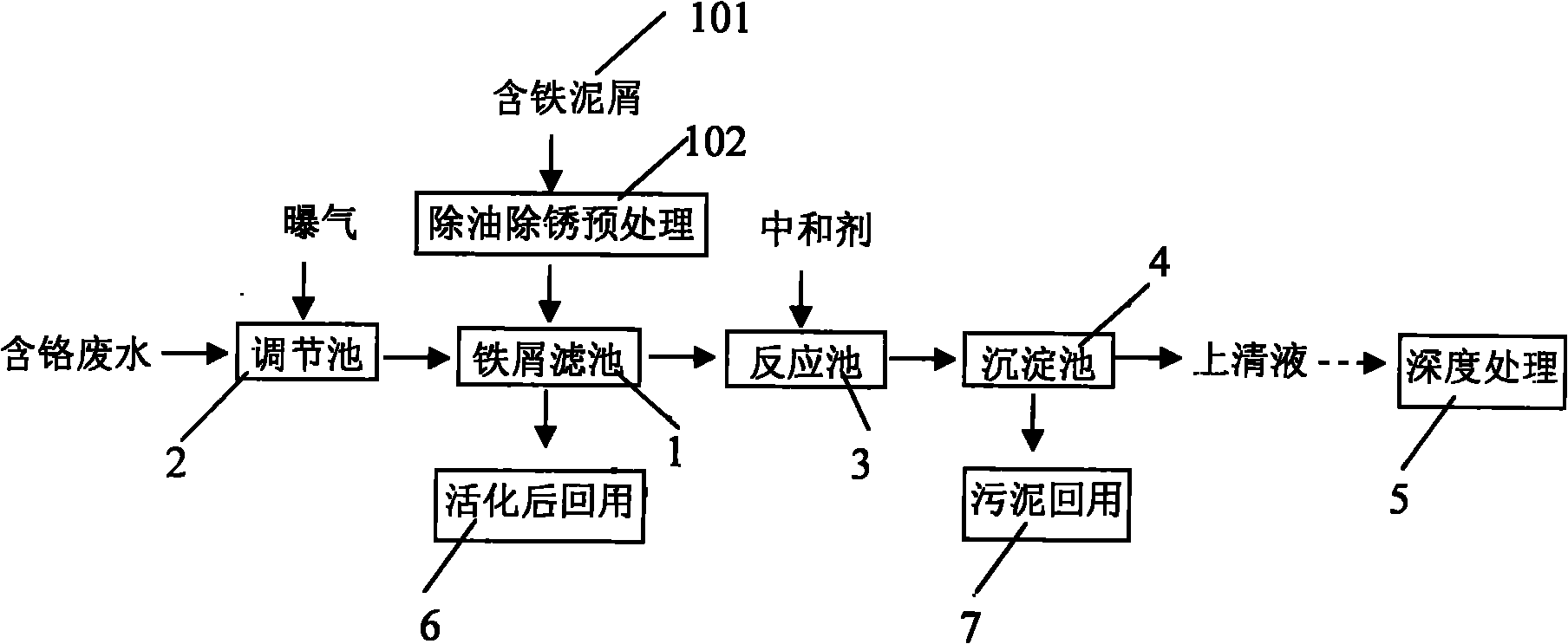

Pretreatment process of chromium-containing wastewater

InactiveCN101811793AIncrease productionDrive up processing costsWater contaminantsMultistage water/sewage treatmentElectrolysisResource utilization

The invention relates to a pretreatment process of chromium-containing wastewater, which comprises the following steps that: 1) scrap iron filter tank is established, iron-containing spare is mixed with carbon-containing particles and porous filler to form a scrap iron filter tank after being washed by alkali so as to remove the oil and being washed by acid to remove the rust and to be activated; 2) chromium-containing wastewater is introduced into the scrap iron filter tank to be undertaken the micro electrolysis reaction after being aerated by an adjusting tank, and pH value and the oxidation reduction potential level ORP value are adjusted by acid liquid, so major hexavalent chrome is reduced to trivalent chromium; 3) the water which is discharged from the filter tank is guided to a reaction tank, neutralizing agent is added, heavy metal complex-precipitation happens, and discharged water is guided into a sedimentation tank; 4) after the majority of heavy metal pollutant inside the sedimentation tank is removed, the upper clean liquid is undertaken the advanced treatment and is discharged after reaching the standard. The pretreatment process not only realizes the resource utilization of waste scrap iron and waste acid liquid, but also greatly reduces the cost of the medicine, reduces the quantity of the following mud, and is easier to realize the resource utilization of the produced mud.

Owner:BAOSHAN IRON & STEEL CO LTD

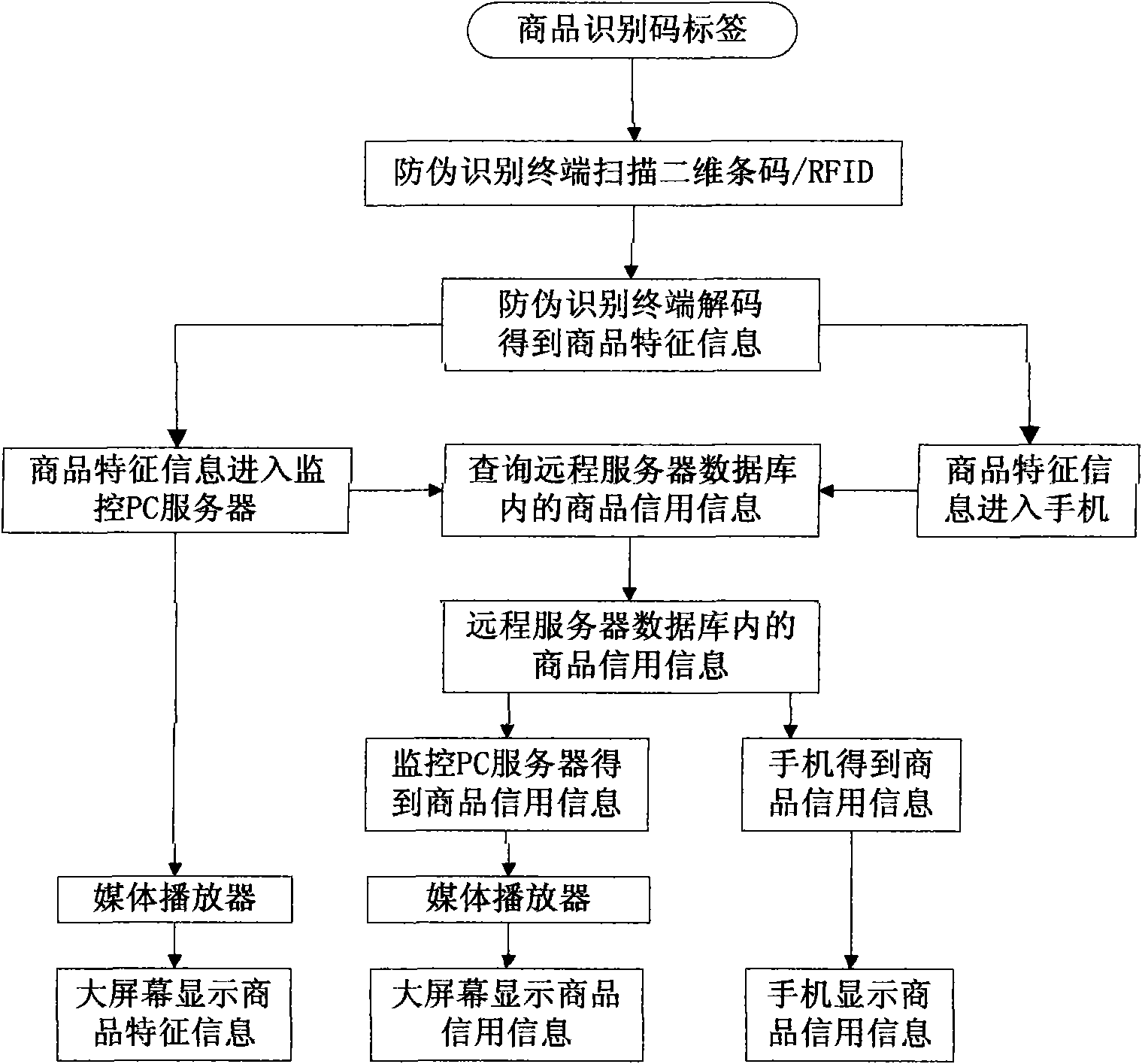

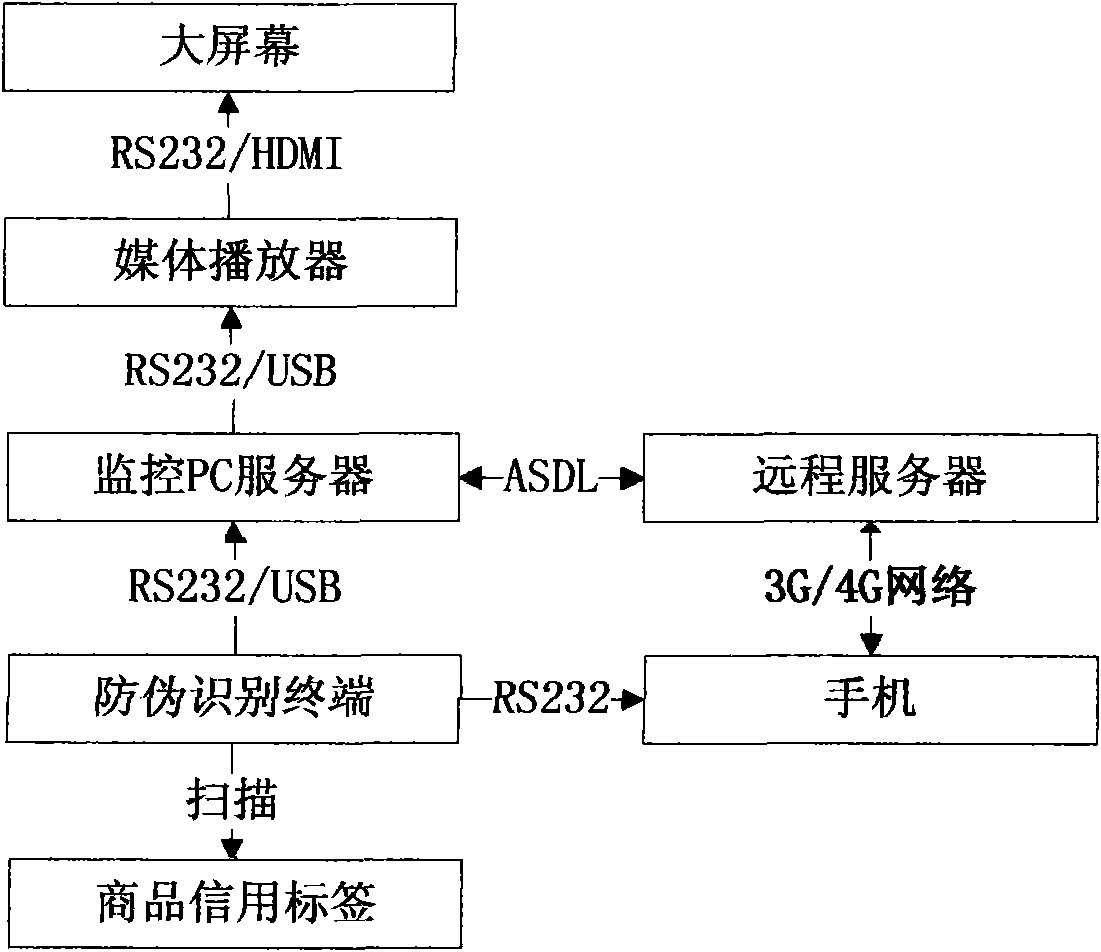

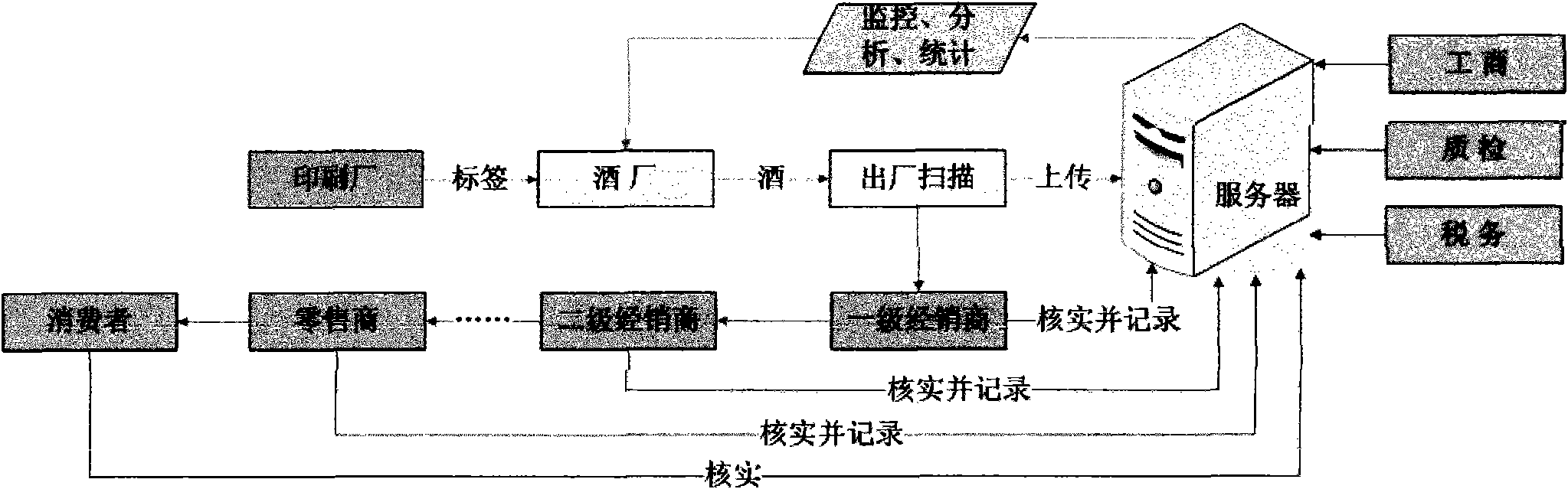

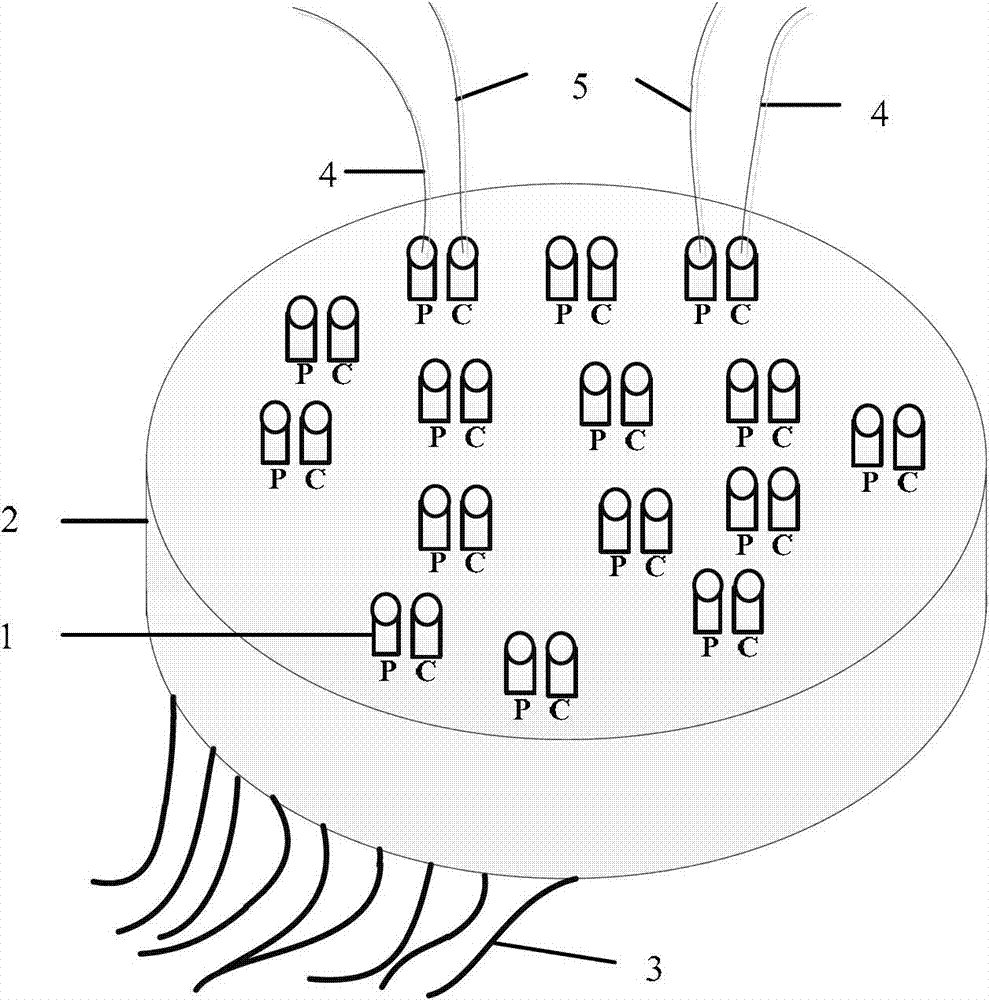

Method and device for monitoring commodity identity and credit in commodity circulation based on Internet of things

InactiveCN102760263AStop Illegal Operations and CounterfeitingProtect premium brandsCommerceInternet of ThingsProcess information

The invention relates to a method and a device for monitoring commodity identity and credit in commodity circulation based on the Internet of things, and solves the problem that the commodity identity and credit are difficult to monitor. In the method, an anti-forgery identification code label is arranged on each commodity, anti-forgery identification code information on the commodities is acquired or edited, original commodity information in anti-forgery identification codes is transmitted to a remote server and an identity and credit management database by using a communication network, proprietary identity and anti-forgery identification code readers of users are used for acquiring the identity and anti-forgery identification code information on the commodities in all circulation links after delivery, and transmitting the information to the remote server and a core database, the remote server compares the two kinds of anti-forgery identification codes, and transmits comparison results or processed information to relevant communication terminals, and the remote server also transmits the comparison results or the processed information to communication terminals of other users according to a protocol. The method and the device have the advantages that the informatization of monitoring the commodity identity and credit in the production and circulation can be realized at the minimum cost, and the difficulty of monitoring the commodity identity and credit is significantly reduced.

Owner:梁剑豪

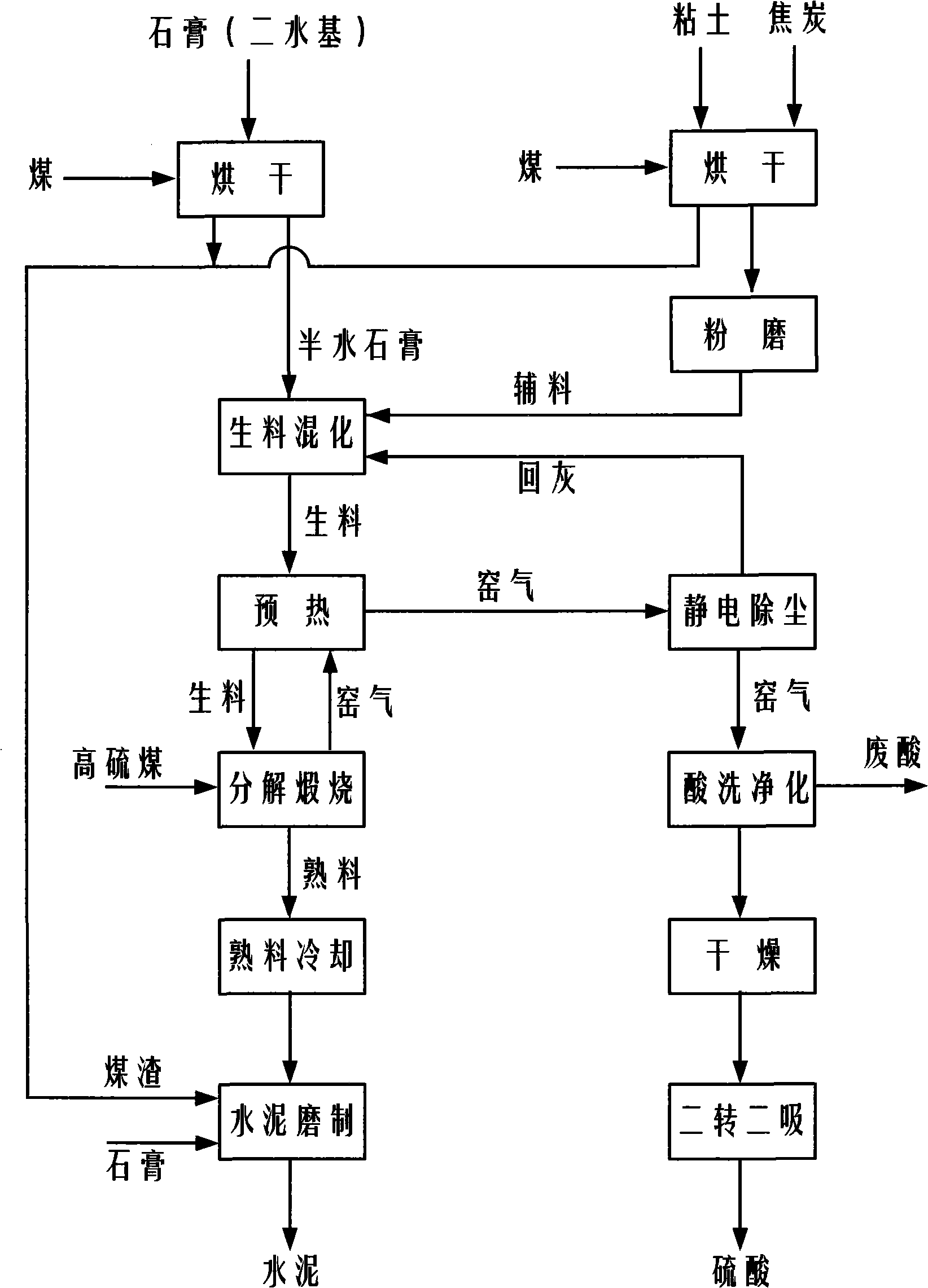

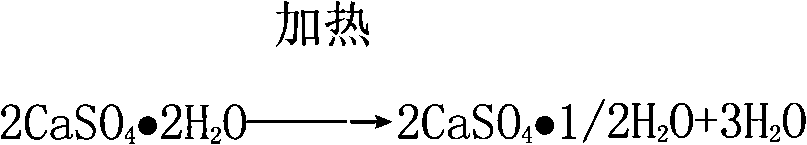

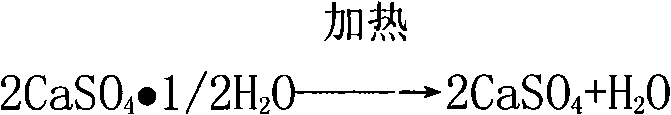

Improved preparation technique for preparing sulphuric acid and cement with gypsum

ActiveCN101343047AEliminate pollutionAlleviate supply shortagesCement productionSulfur-trioxide/sulfuric-acidSource materialAcid washing

The invention provides an improved production process of utilizing gypsum to produce sulfuric acid and cement, which relates to the sulfuric acid and cement industry production technology, and the resource comprehensive utilization and environmental protection governing field of the industrial byproduct gypsum. The improved production process is characterized in that natural gypsum with the CaSO4*2H2O as the main composition or the industrial byproduct gypsum is adopted as the main source material; clay, coke and fly ash clinker are used as supplementary materials; the half-water drying gypsum flow, the single stage powder grinding, raw material mixing melting, suspension preheater kiln decomposing calcination, closing diluted acid washing and purification, two-turning and two-suction processes are adopted; the sulfuric acid and cement products are prepared through six steps of source material homogenizing, drying and dehydration, raw material preparation, clinker burning, kiln gas acid production and cement grinding; the improved production process has the advantages of wide range source material, solving the land occupation and environmental pollution problems of the gypsum waste residue, realizing the circulation utilization of sulfur resource, adopting a plurality of new processes and devices, realizing the large scale production easily, advanced technology, mature process, easy operation in production control, low energy consumption, high benefit, no waste water and waste residues exhaust.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

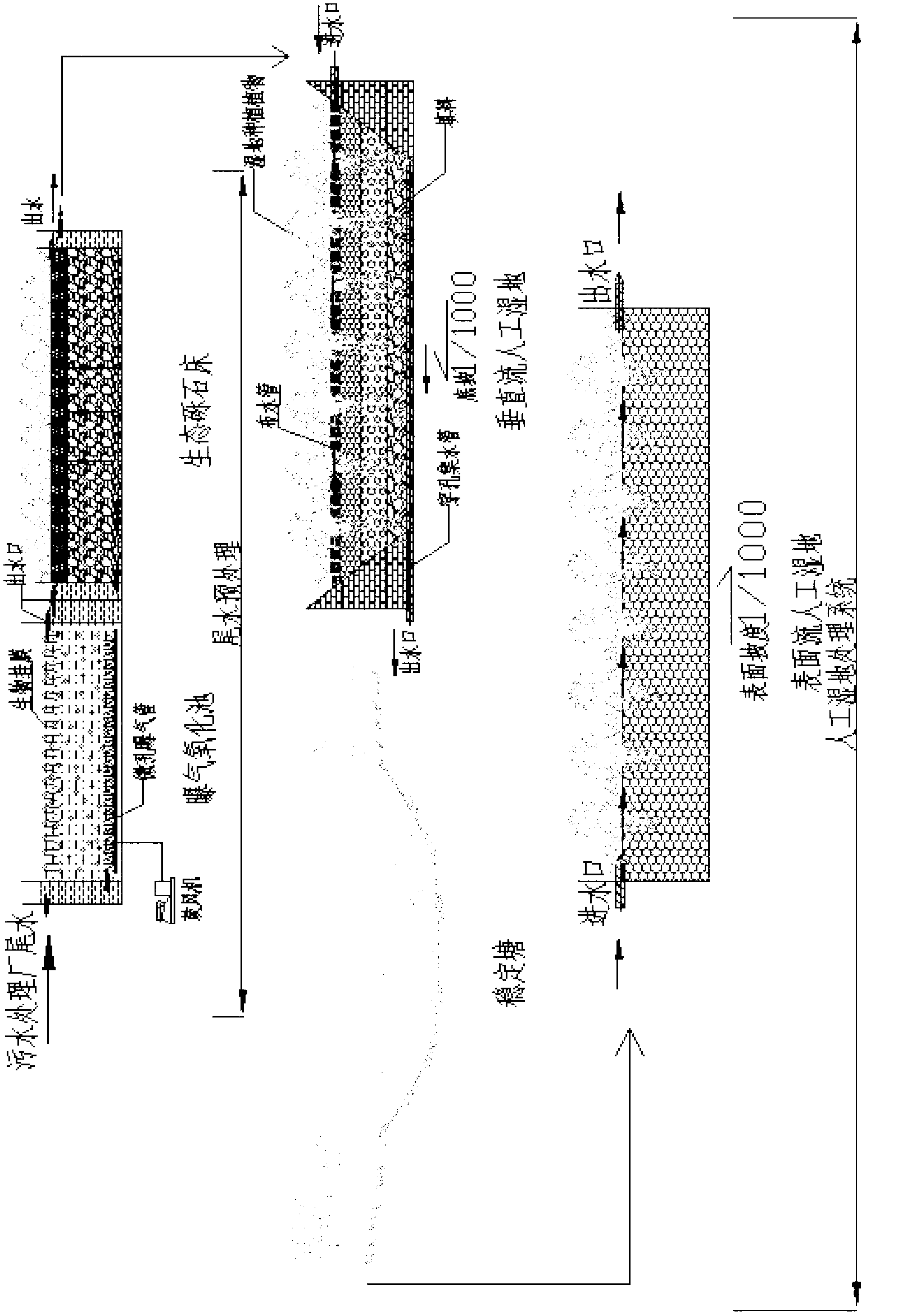

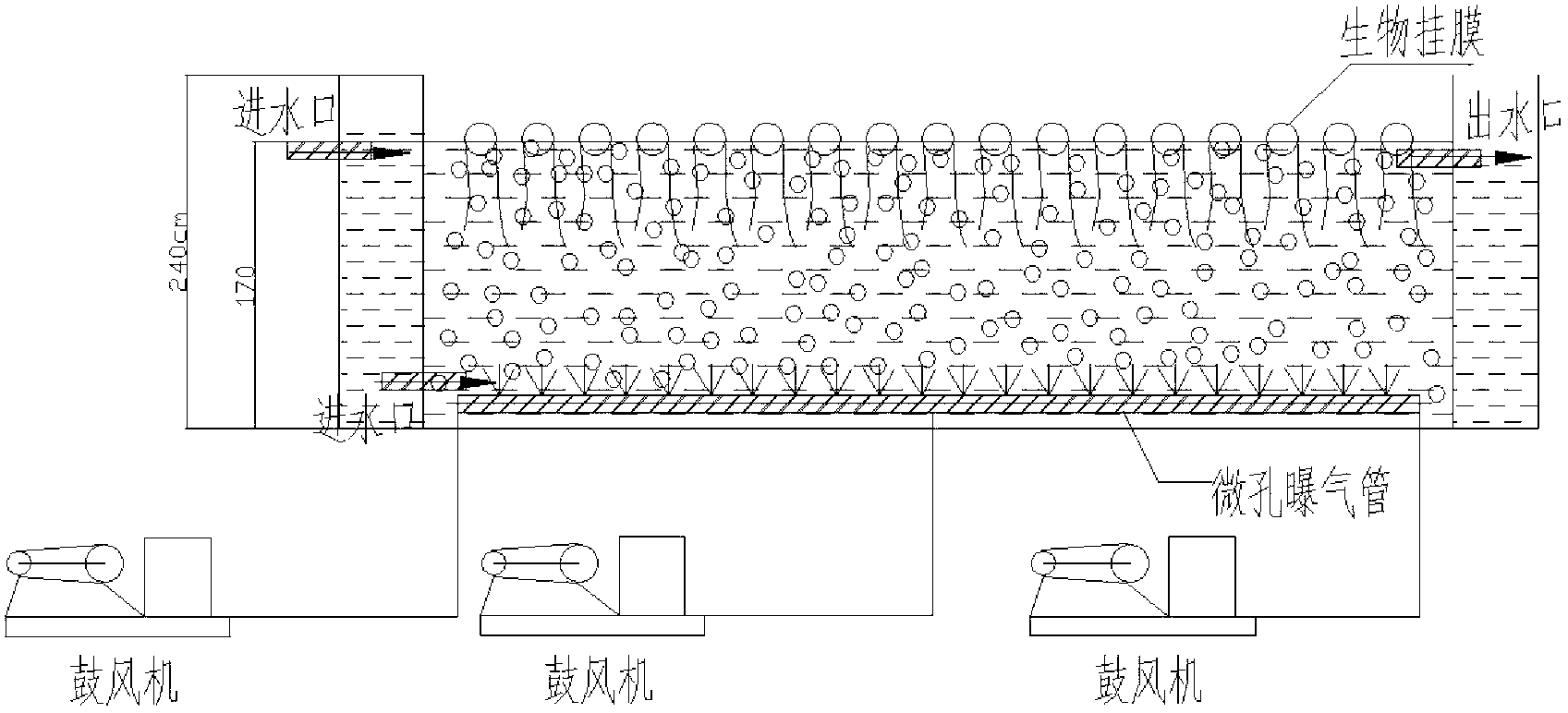

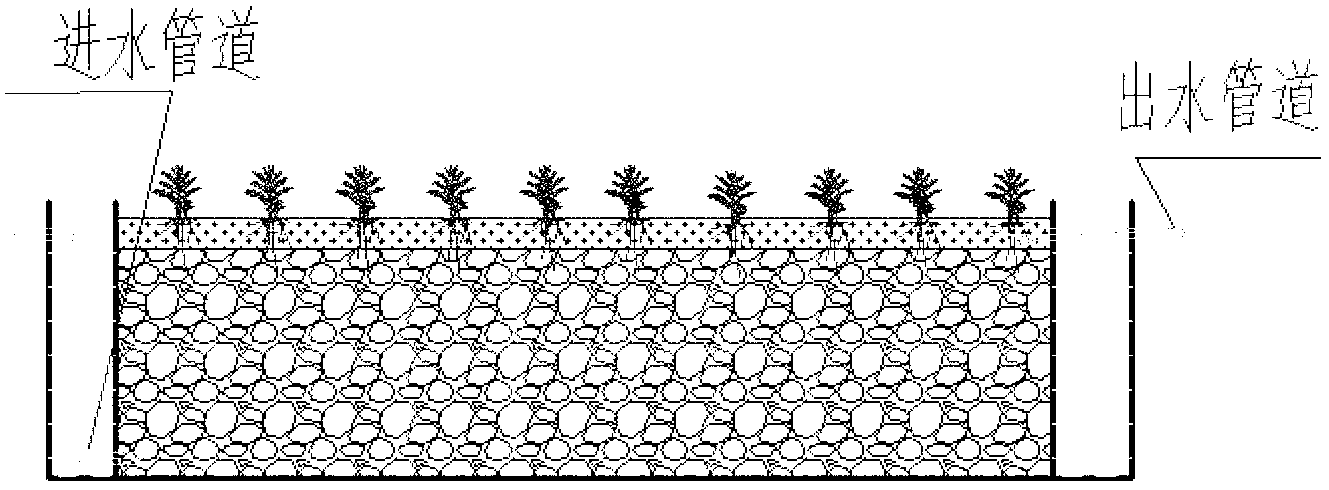

Compound constructed wetland tail water treatment system

InactiveCN103253822AReduce processing sizeIncrease investmentEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandEcological environment

The invention discloses a compound constructed wetland tail water treatment system, which belongs to the field of sewage treatment technology. The system mainly includes a pretreatment and a constructed wetland system. The pretreatment portion comprises an aeration oxidation pool and an ecological gravel bed; The constructed wetland system fuses a design of stabilization lagoon, which combines a vertical current constructed wetland and a surface flow constructed wetland, and a stabilization lagoon is arranged in step in series; the tail water to be treated passes the aeration oxidation pool, the ecological gravel bed, the vertical current constructed wetland, the stabilization lagoon in order, and finally passes the surface flow constructed wetland and flows out. The system combines physical, chemical and biological means organically, thereby effectively improving the tail water quality, and the water quality of water outlet basically reaches the surface water environment standard III grade, and the water outlet can directly returns to river ecological environment for supplementing water and can be used as city miscellaneous water; the invention has the advantages of low investment, simple operation, low energy consumption, high environment benefit and ecological benefit, etc.

Owner:HOHAI UNIV

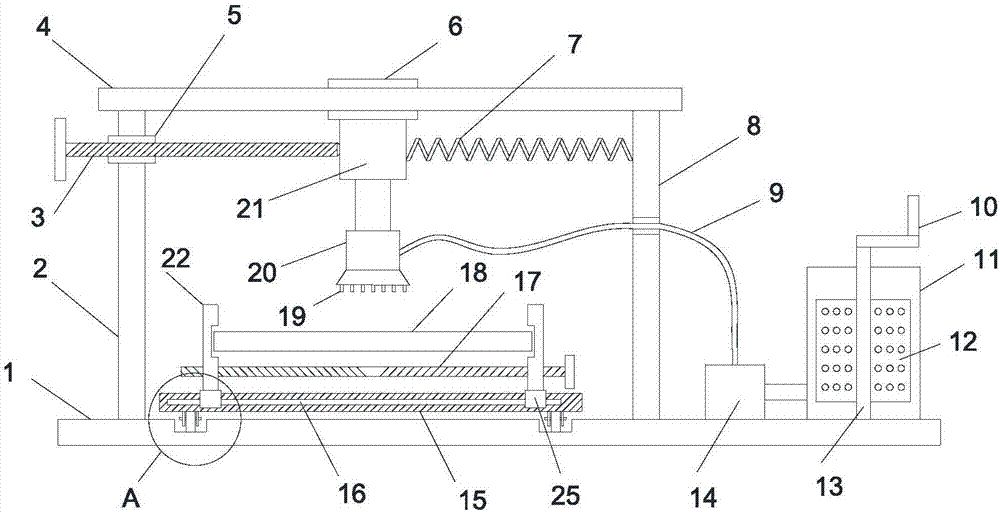

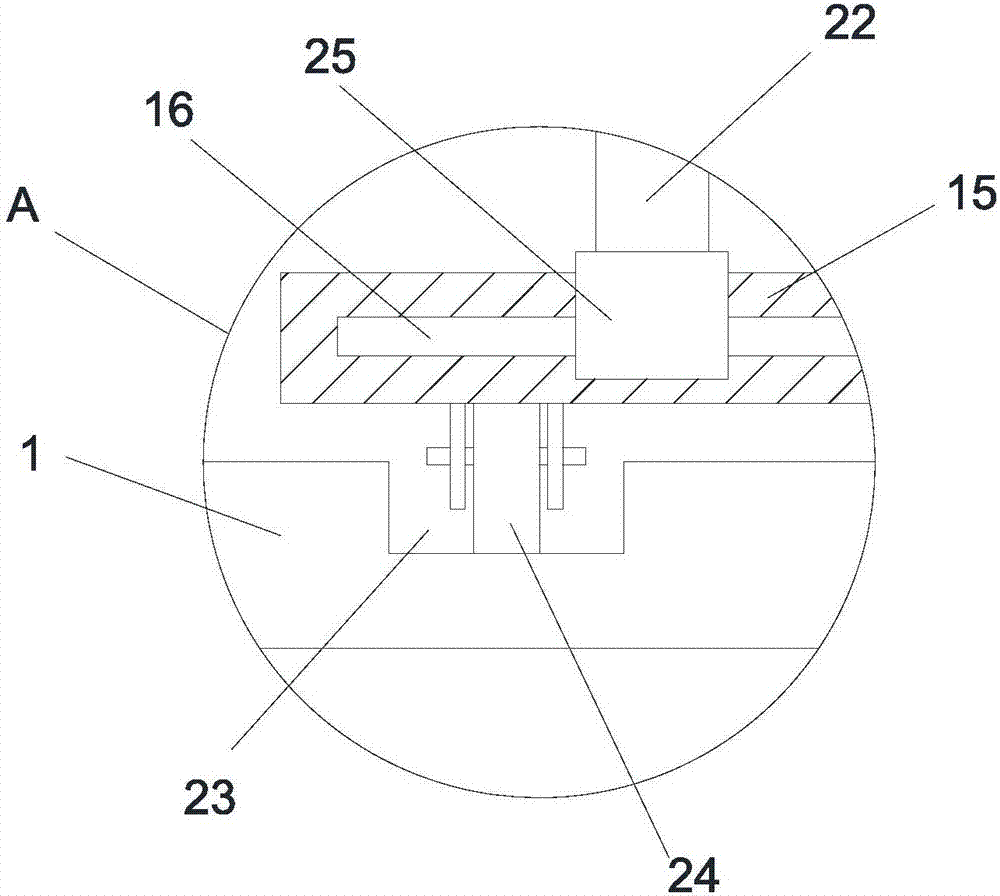

Platy workpiece paint spraying device for machining

The invention discloses a paint spraying device for a plate-shaped workpiece for machining, comprising a bottom plate, a left column and a right column are vertically fixed on the bottom plate, a threaded sleeve is arranged on the left column, and a threaded sleeve is horizontally provided with a thread through a thread fit. The first screw rod, the top plate is fixed horizontally on the left column and the right column, the sliding sleeve on the top plate is provided with a sliding sleeve, the rotating shaft is fixedly installed with a stirring plate, and the inlet end of the conveying pump is connected with the paint bucket through a pipeline; above the bottom plate A sliding plate is arranged horizontally, a chute is horizontally and horizontally opened on the side of the sliding plate, and two limit sliders are matched and connected to the chute, and a splint is vertically fixed on each of the limit sliders, and the splint is horizontally and horizontally installed. A second screw rod is threadedly connected, and the left half and the right half of the second screw rod have opposite screw threads; the invention is simple and convenient to adjust, and has strong practicability and operability, so that the surface of the plate-shaped workpiece can achieve a uniform painting effect and improve the the quality of the spray paint.

Owner:深圳市海帮国际商务服务有限公司

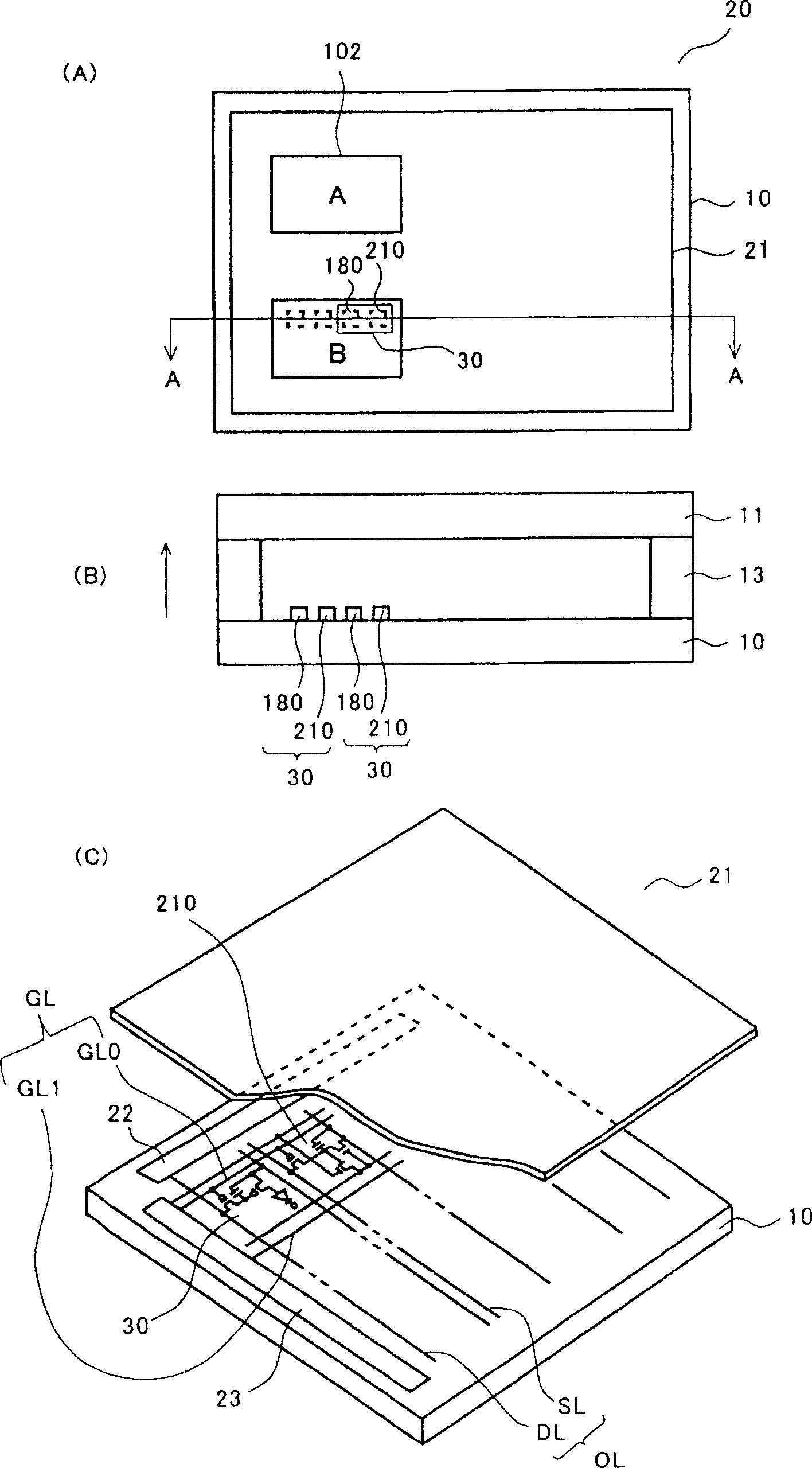

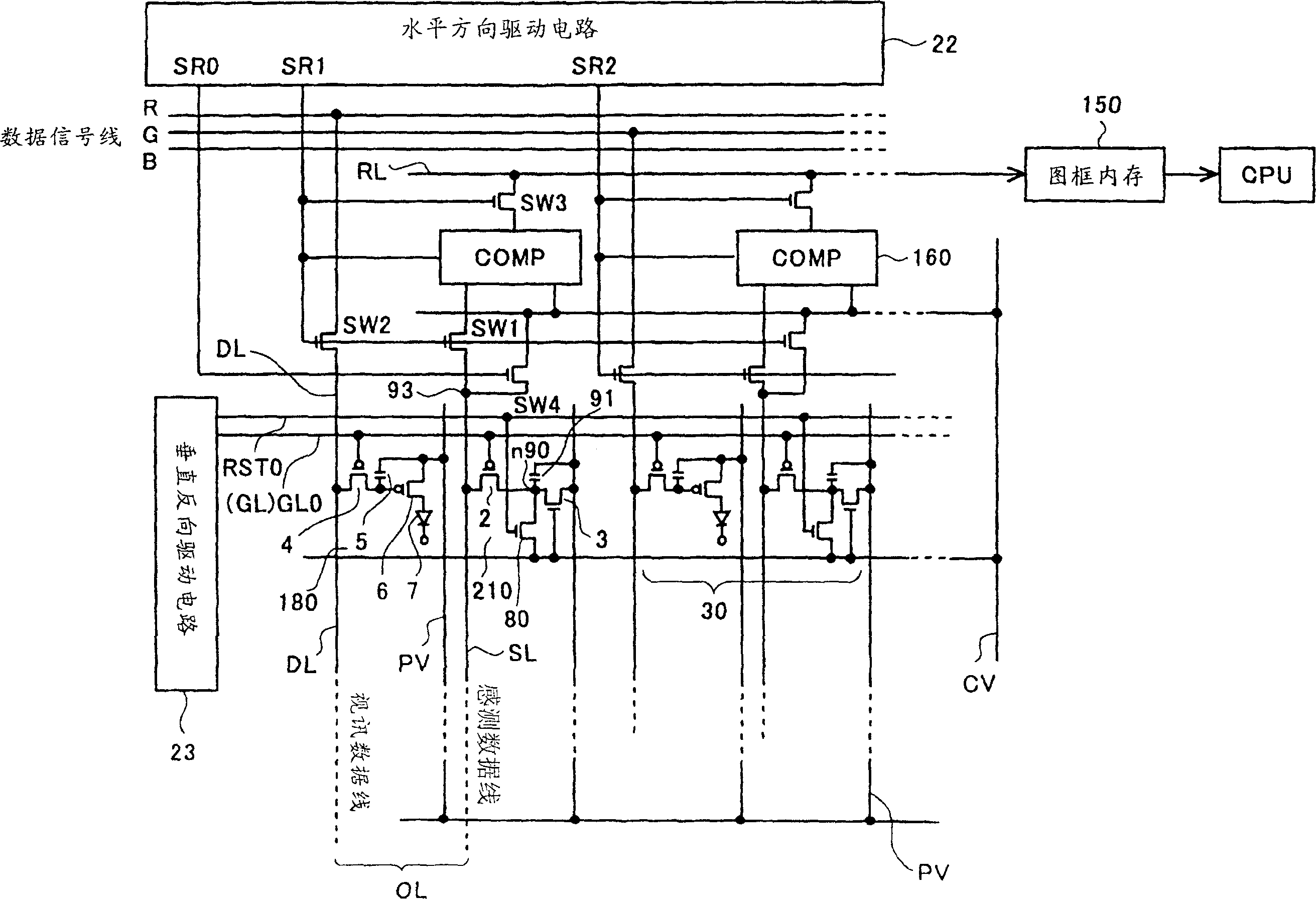

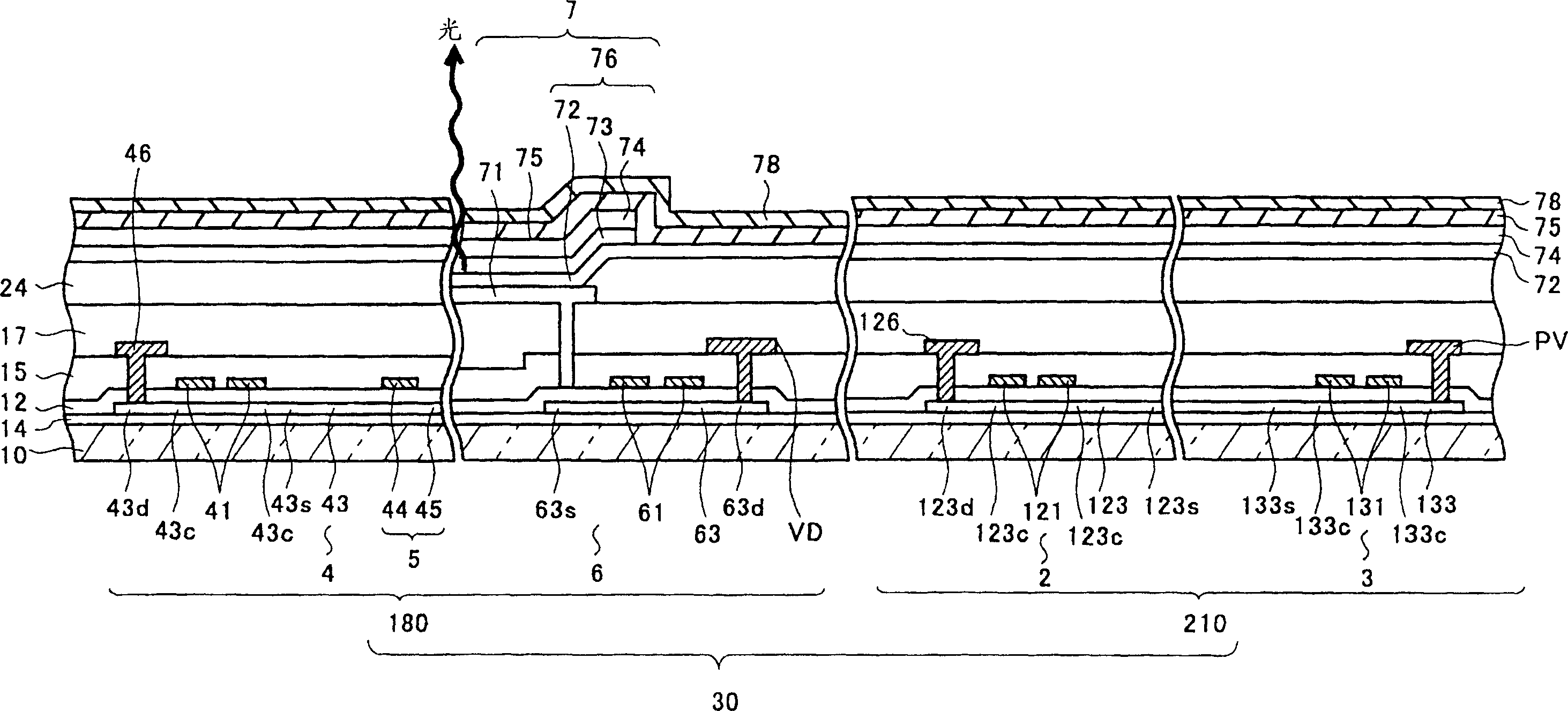

Touch panel

InactiveCN1758197AIncrease the display areaInhibit deteriorationGraph readingMechanical pattern convertionMiniaturizationEngineering

The present invention relates to a touch panel, and a photosensor and the display part are fabricated on the same substrate. Input coordinates are specified by comparing the light quantities among positions (pixels) of contact or non-contact by a finger or the like by using a comparator. This allows TFTs constituting the photosensor to be fabricated on the same substrate in the same process as the pixels, and it is thereby possible to reduce the manufacturing cost and the number of components. A region for disposing a sensor in the outer portion becomes unnecessary, which allows downsizing of the device. Moreover, effective use of the display part is possible because blind spots are eliminated from the display part. It is possible to improve the precision of input recognition and to perform detection uniformly over the entire display part. Furthermore, since the photosensor comprises a photoreceptor circuit capable of adjusting the light-receiving sensitivity, it is possible to achieve uniform light-receiving (detection) sensitivity for the display part.

Owner:SANYO ELECTRIC CO LTD

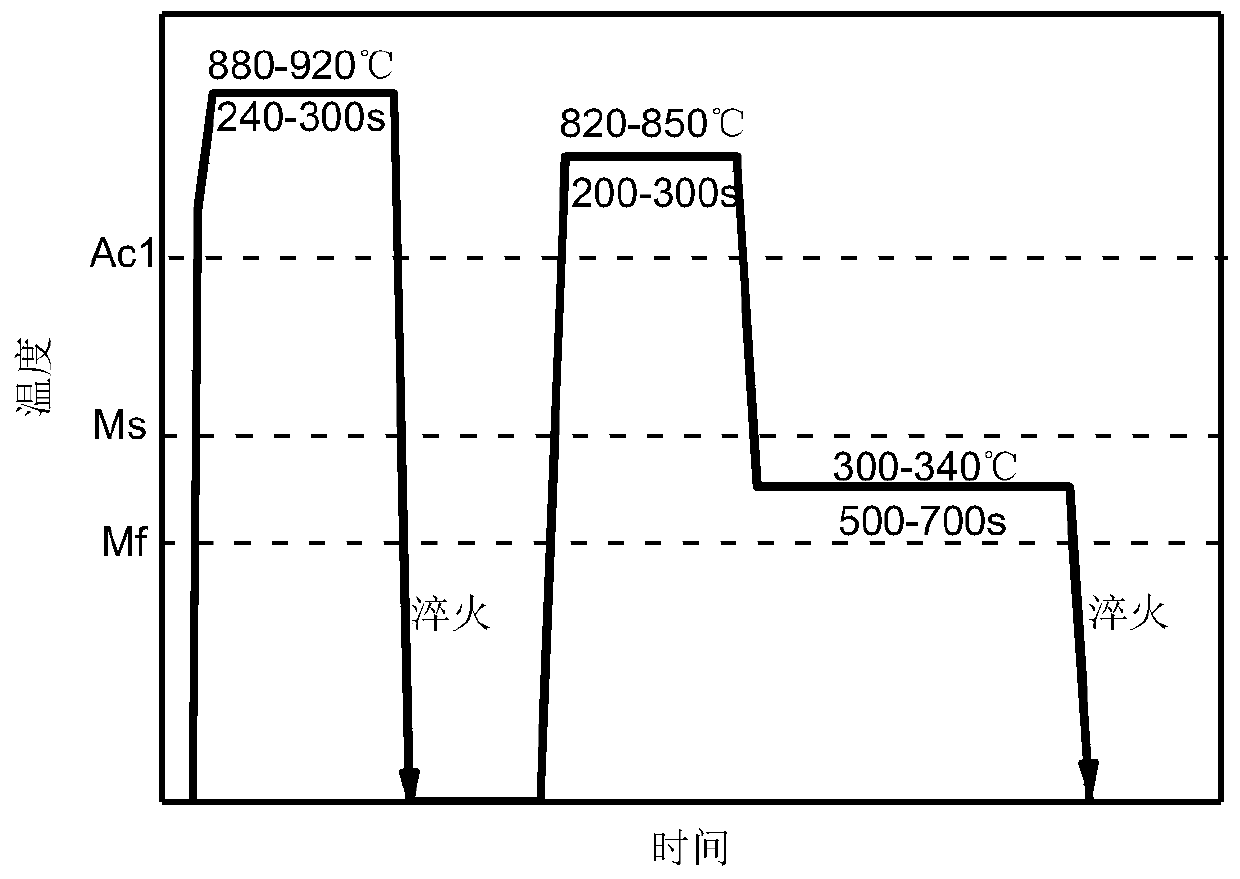

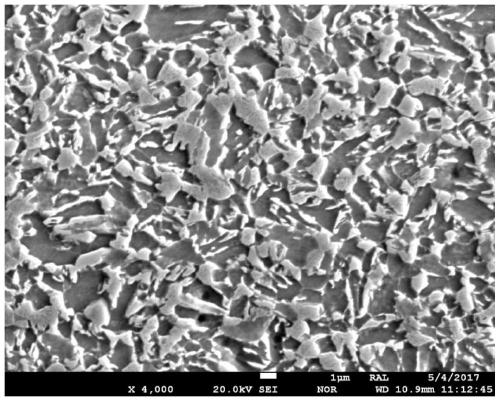

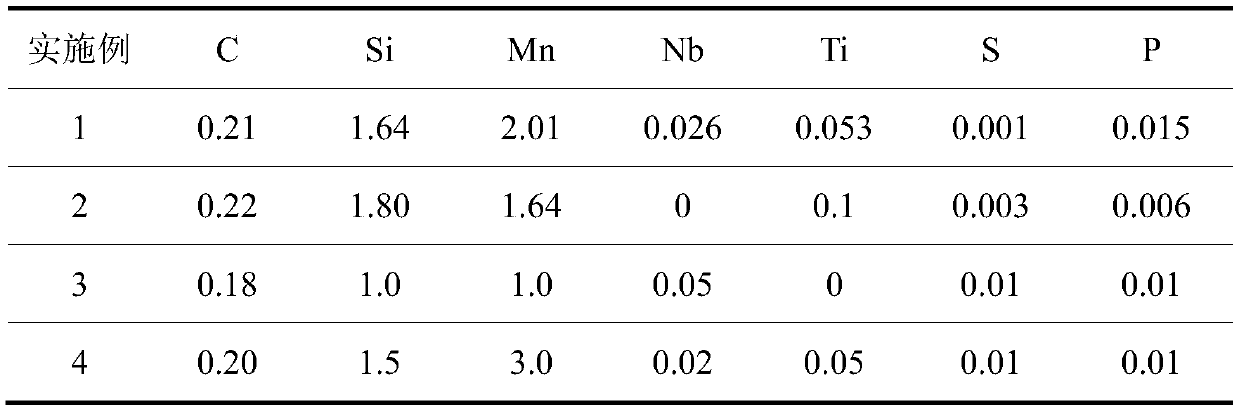

1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and manufacturing method thereof

InactiveCN110093564AIncrease contentOrganizational stabilityUltimate tensile strengthMechanical property

The invention relates to the field of third-generation advanced high-strength steel used for automobiles and discloses 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and a manufacturing method thereof. A steel plate comprises the chemical components including, by mass percent, 0.18-0.22% of C, 1.0-3.0% of Mn, 1.0-2.0% of Si, not greater than 0.05% of P, not greaterthan 0.02% of S, 0-0.05% of Nb, 0-0.2% of Ti and the balance iron and inevitable impurities. The steel plate manufacturing method relates to the process of steel smelting, hot rolling, cold rolling,pre-quenching and heat treatment, and finally, a ferrite-bainite-martensite-retained austenite mixed structure is obtained. According to the 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and the manufacturing method thereof, on the basis of traditional C-Mn-Si series quenched partition steel, Nb and Ti elements are added for refining the structure, pre-quenching treatment and a one-step partition process are adopted, finally the ultrahigh-strength quenched partition steel with the yield strength being 500-800 MPa, the tensile strength not smaller than 1180 MPa, the elongation after fracture not smaller than 20% and the product of strength and elongation not smaller than 24GPa.% is obtained, and the mechanical property is quite excellent.

Owner:NORTHEASTERN UNIV

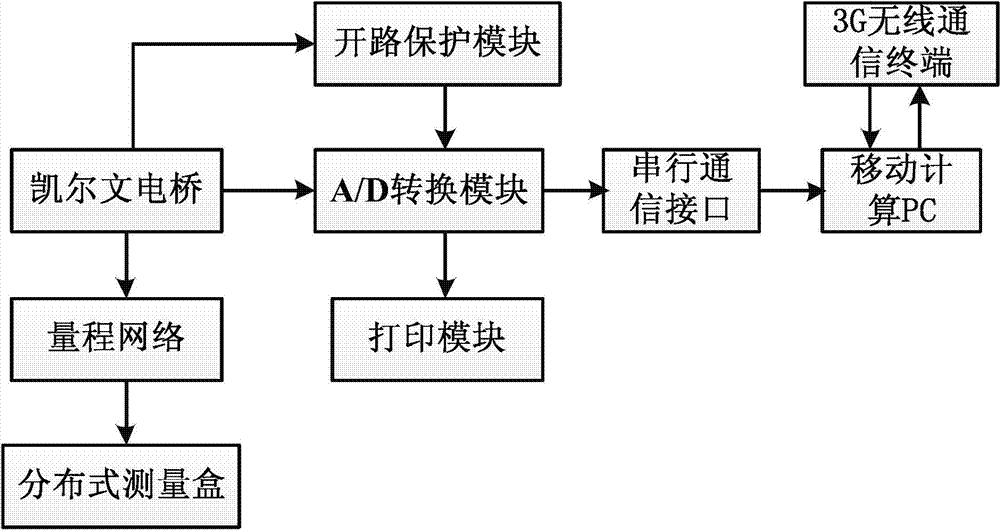

Diagnosis device and diagnosis method for corrosion of earth screen of large-size transformer substation

ActiveCN102707191AReduce security risksEasy to repeat measurements regularlyResistance/reactance/impedenceFault locationCounterpoiseTransformer

The invention provides a diagnosis device for corrosion of an earth screen of a large-size transformer substation. The diagnosis device comprises a distribution type collection box, a signal collection device, a movable calculation PC (personal computer) and a 3G (3rd Generation) wireless communication terminal, wherein the distribution type collection box is formed by a box body, a protection cover, binding posts and a measuring lead wire, wherein the protection cover detachably covers the box body; a plurality of binding posts are vertical in a mutually-insulating manner and pass through a bottom plate of the box body; the measuring lead wire is a two-core flexible lead core; one end of the measuring lead wire is electrically with the lower ends of the binding posts; and the other end of the measuring lead wire is welded with a lead-up wire of a grid node of the earth screen. The diagnosis device and the diagnosis method for the corrosion of the earth screen of the large-size transformer substation can be widely applied to corrosion fault detection of the earth screen of the transformer substation which is put into operation and are particularly suitable for the large-size transformer substation which has a larger occupied area and higher safety requirements. Furthermore, the diagnosis device and the diagnosis method for the corrosion of the earth screen of the large-size transformer substation can also be widely applied to other systems with the earth screens, such as steel, chemical engineering, a power plant and the like and have extremely great required amount and an extremely wide application prospect.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Granular organic composite straw fertilizer

ActiveCN104446775AImprove utilization efficiencyExpand areaFertilising methodsOrganic fertilisersDry weightTrace element

The invention discloses a granular organic composite straw fertilizer. The granular organic composite straw fertilizer comprises the following components in percentage by dry weight: 50-70% of crop straws, 10-15% of straw-prepared bio-char, 10-20% of humic acid fertilizer, 1-3% of bone meal and 3-5% of trace element compounds, and is prepared through the following steps of mixing according to certain weight percentage after smashing all the components in dry weight, sufficiently and uniformly mixing, and then, carrying out granulation treatment. By applying the granular organic composite straw fertilizer, the soil structure can be improved, and the utilization efficiency of the fertilizer can be increased.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

Method and apparatus for enhancing images

Owner:SENSORS UNLTD

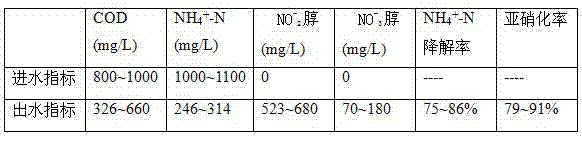

Coupling type sewage purification and regeneration treating method capable of removing phosphorus efficiently

ActiveCN102775020AImplement removal methodEnriched growthMultistage water/sewage treatmentMunicipal sewagePhosphine

The invention discloses a coupling type sewage purification and regeneration treating method capable of removing phosphorus efficiently. The method takes municipal sewage as a treatment object and includes: a, preliminary precipitation; b, phosphorous removal through conversion of the phosphorous in the sewage into phosphine; c, conversion of the phosphine; and d, recycling of purified water. According to the method, the municipal sewage is recycled, sludge after the sewage treatment is recycled completely, organic pollutants are removed, denitrification is achieved, and the technical gap of efficient conversion and usage of the phosphine at present is filled.

Owner:SOUTH CHINA UNIV OF TECH

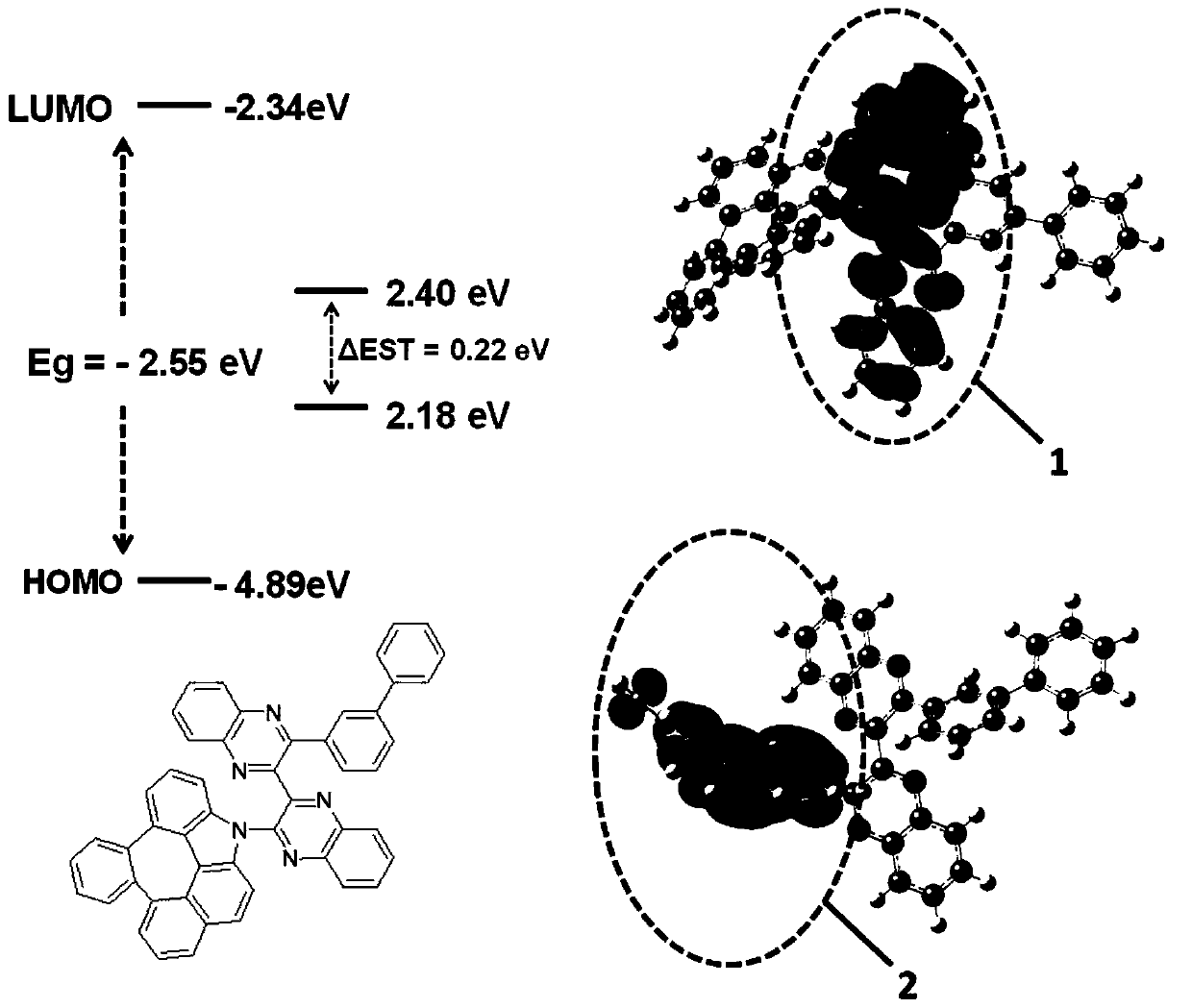

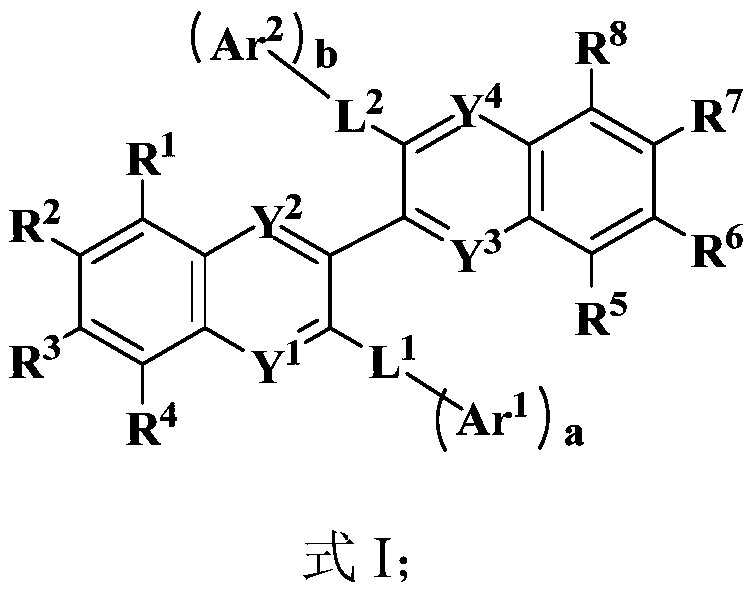

Organic electroluminescent compound, preparation method and application thereof

ActiveCN110862381AImprove balanceReduce concentrationGroup 4/14 element organic compoundsSolid-state devicesElectron holeHost material

The invention provides an organic electroluminescent compound, a preparation method and application thereof. The organic electroluminescent compound has a structure shown as formula I, is suitable foruse as a luminescent layer host material of an organic electroluminescent device, has double dipolarity, wherein the HOMO energy level and LUMO energy level are respectively positioned on different electron donating groups and electron withdrawing groups, and can match adjacent hole transport layer and electron transport layer, and the charge-hole transport balance is good, thus enlarging the area for compounding holes and electrons into electrons in the luminescent layer, reducing the exciton concentration, preventing triplet state-triplet state annihilation of the device, and improving thedevice efficiency. As a luminescent layer host material, the organic electroluminescent compound makes the area where carriers are compounded far from an adjacent interface of the luminescent layer and the hole or electron transport layer, improves the color purity of an OLED device, and at the same time can prevent excitons from passing back to the transport layer, thus further improving the device efficiency.

Owner:NINGBO LUMILAN NEW MATERIAL CO LTD

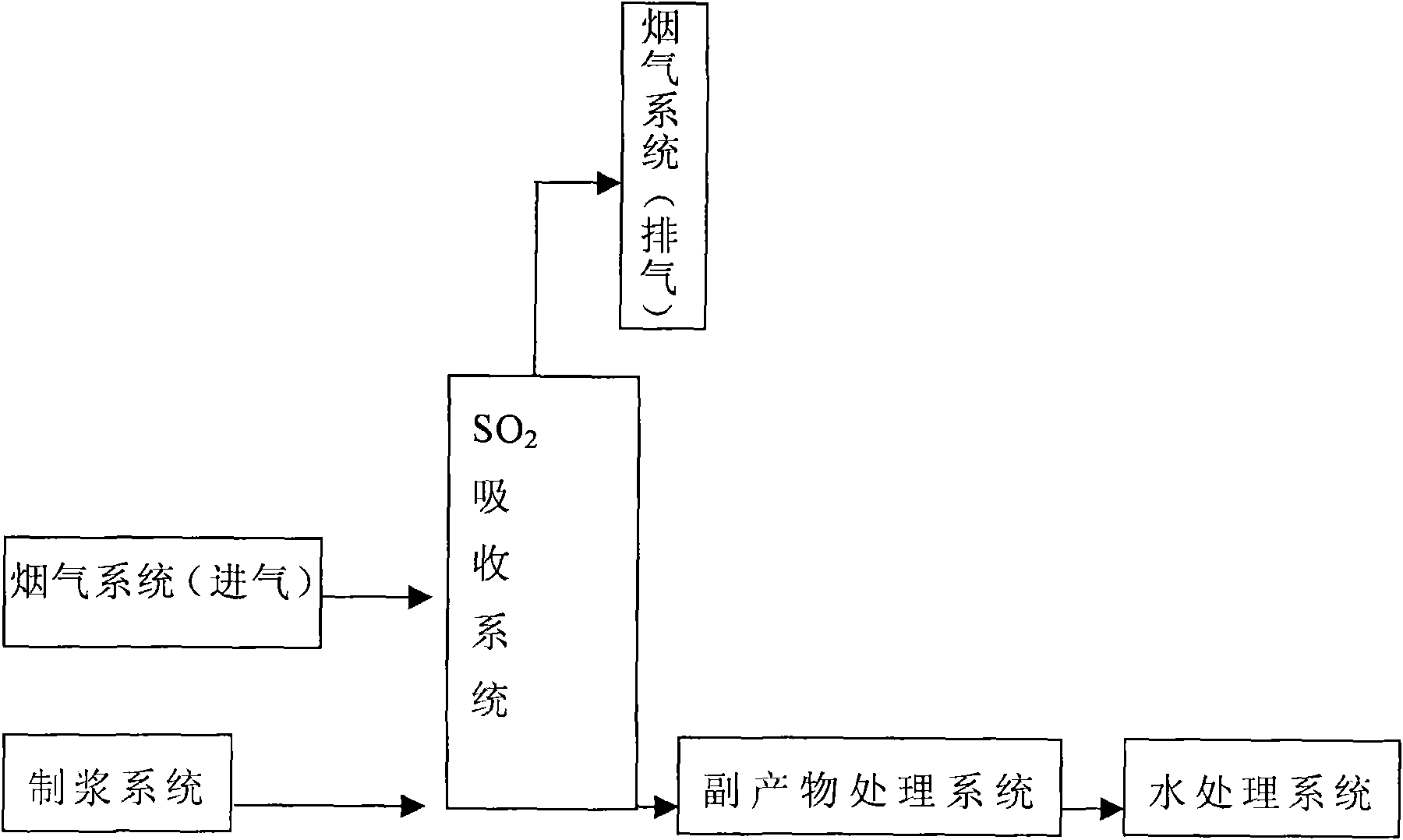

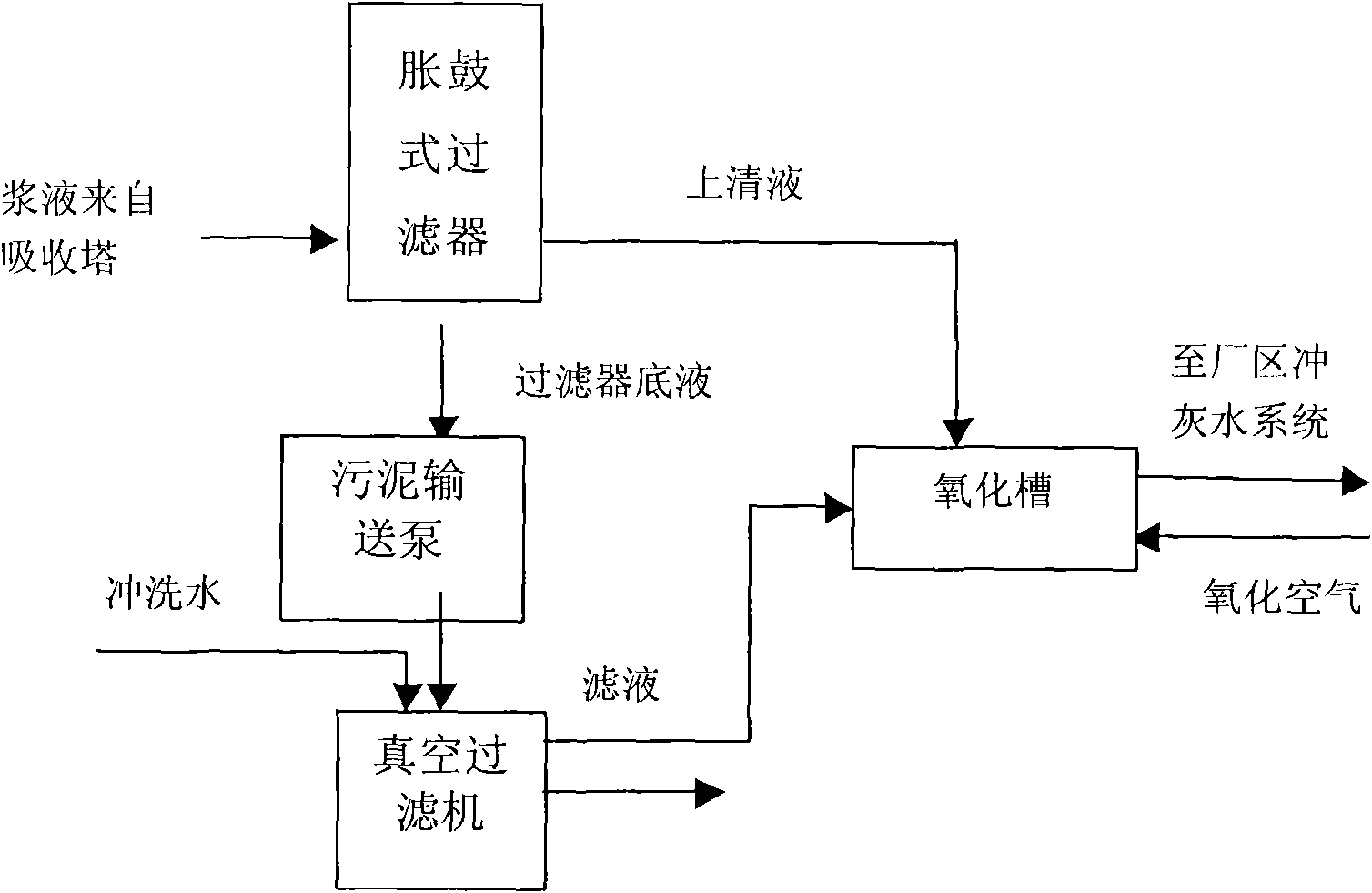

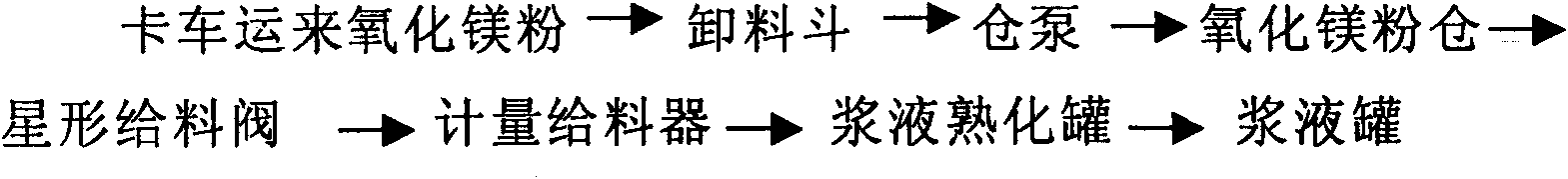

Improved magnesium method flue gas desulphurization technique

InactiveCN101628199AHigh desulfurization activityReduce energy consumptionDispersed particle separationWater vaporFlue gas

The invention provides an improved magnesium method flue gas desulphurization technique, which comprises the following steps: (a) mixing 1 portion of magnesium oxide desulfurizing agent with 2.3 to 5 portion of water and 0.1+ / -0.05 portion of water vapor in portion by weight at a temperature of between 0 and 20 DEG C so as to generate a magnesium hydroxide slurry; (b) ageing the magnesium hydroxide slurry obtained in the step (a) at a temperature of between 50 and 80 DEG C for 2 to 4 hours to obtain a desulfurizing agent slurry; and (c) spraying the desulfurizing agent slurry obtained in the step (b) to perform contact reaction with a flue gas containing sulfur dioxide so as to obtain a magnesium sulfite slurry or a magnesium sulfate slurry and the flue gas without the sulfur dioxide. The process has good reactivity and high desulphurization efficiency, and effectively avoids the problems of scaling, blockage and the like in a desulphurization system.

Owner:SINOPEC NINGBO ENG +1

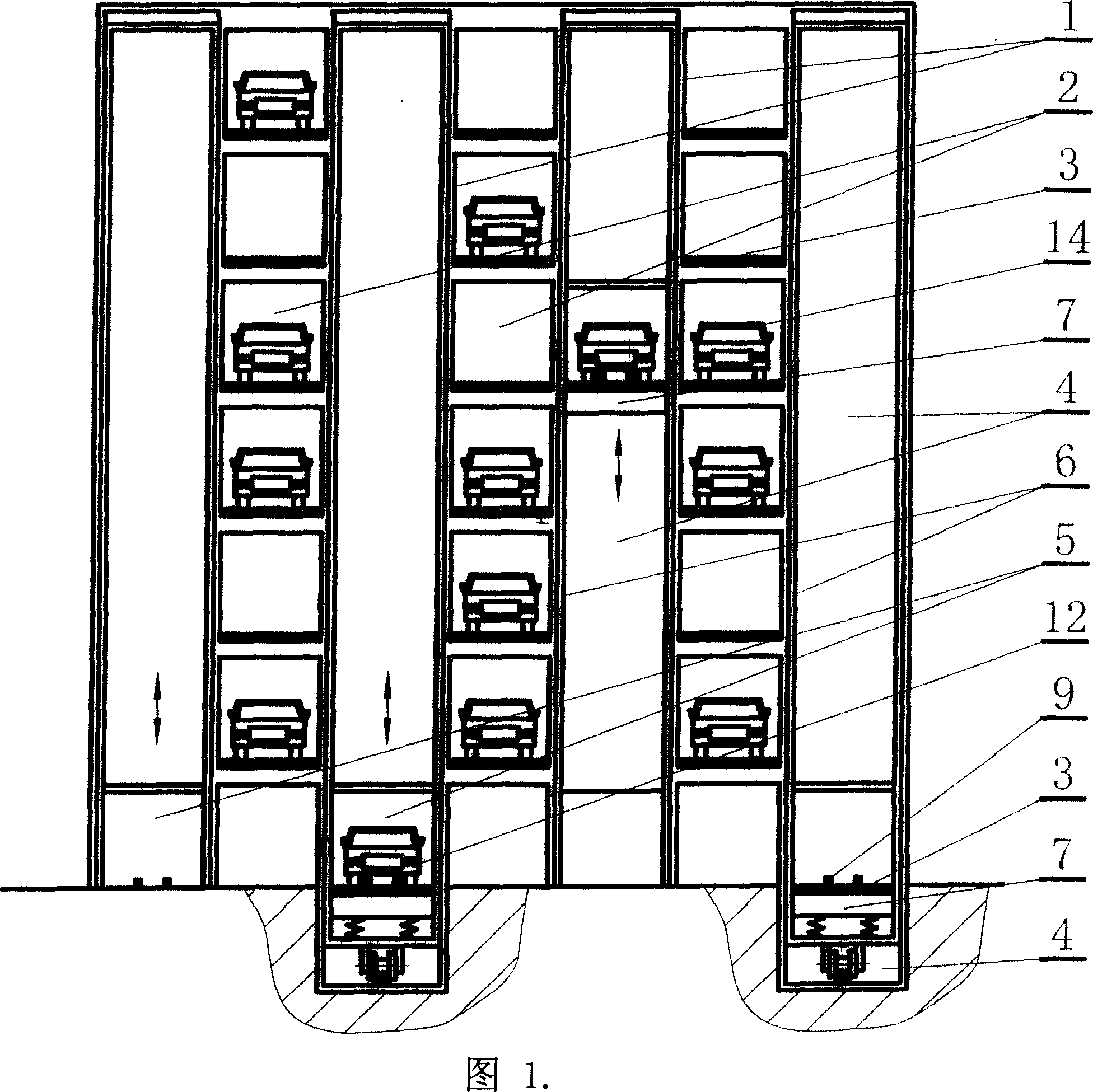

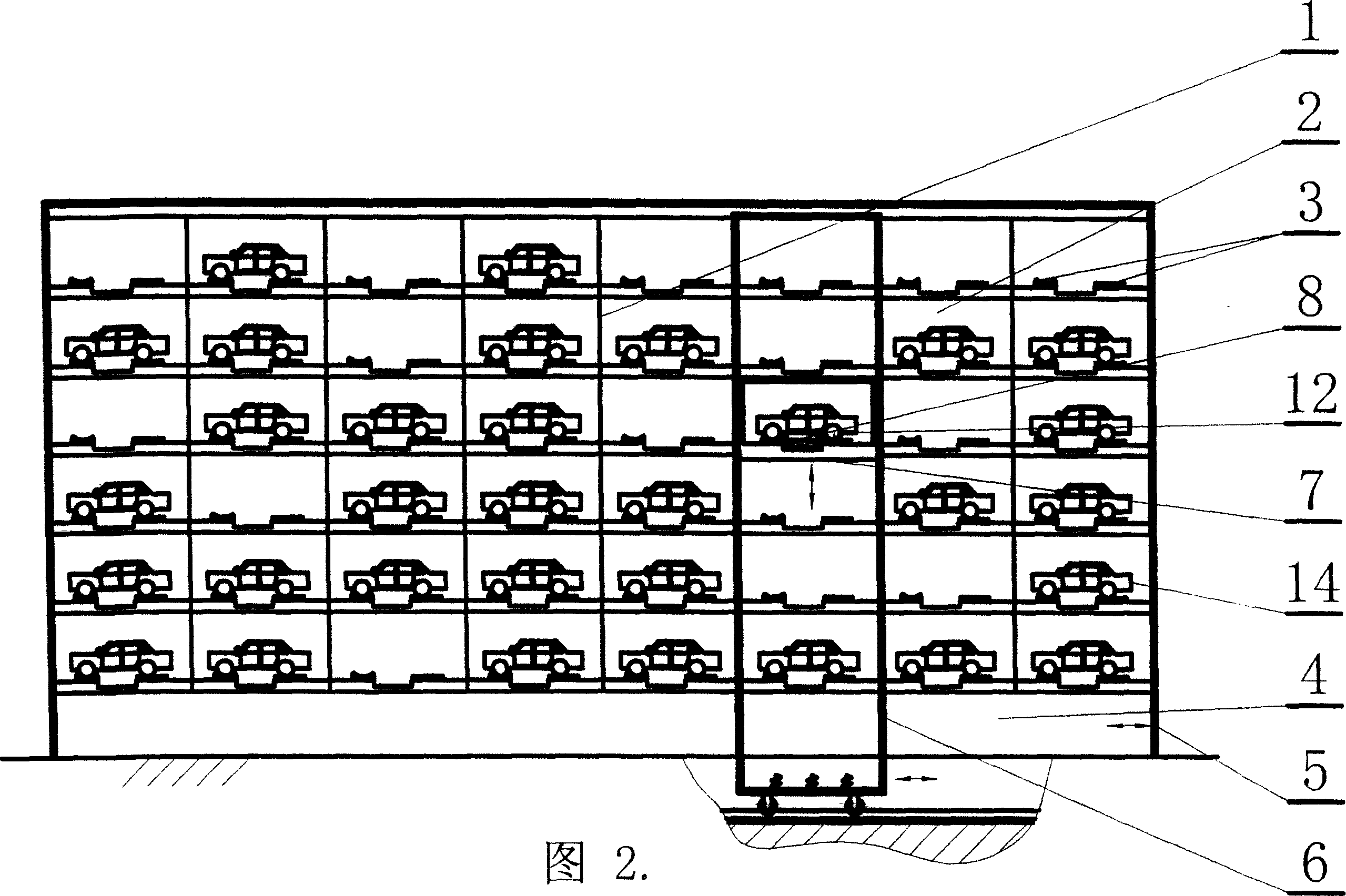

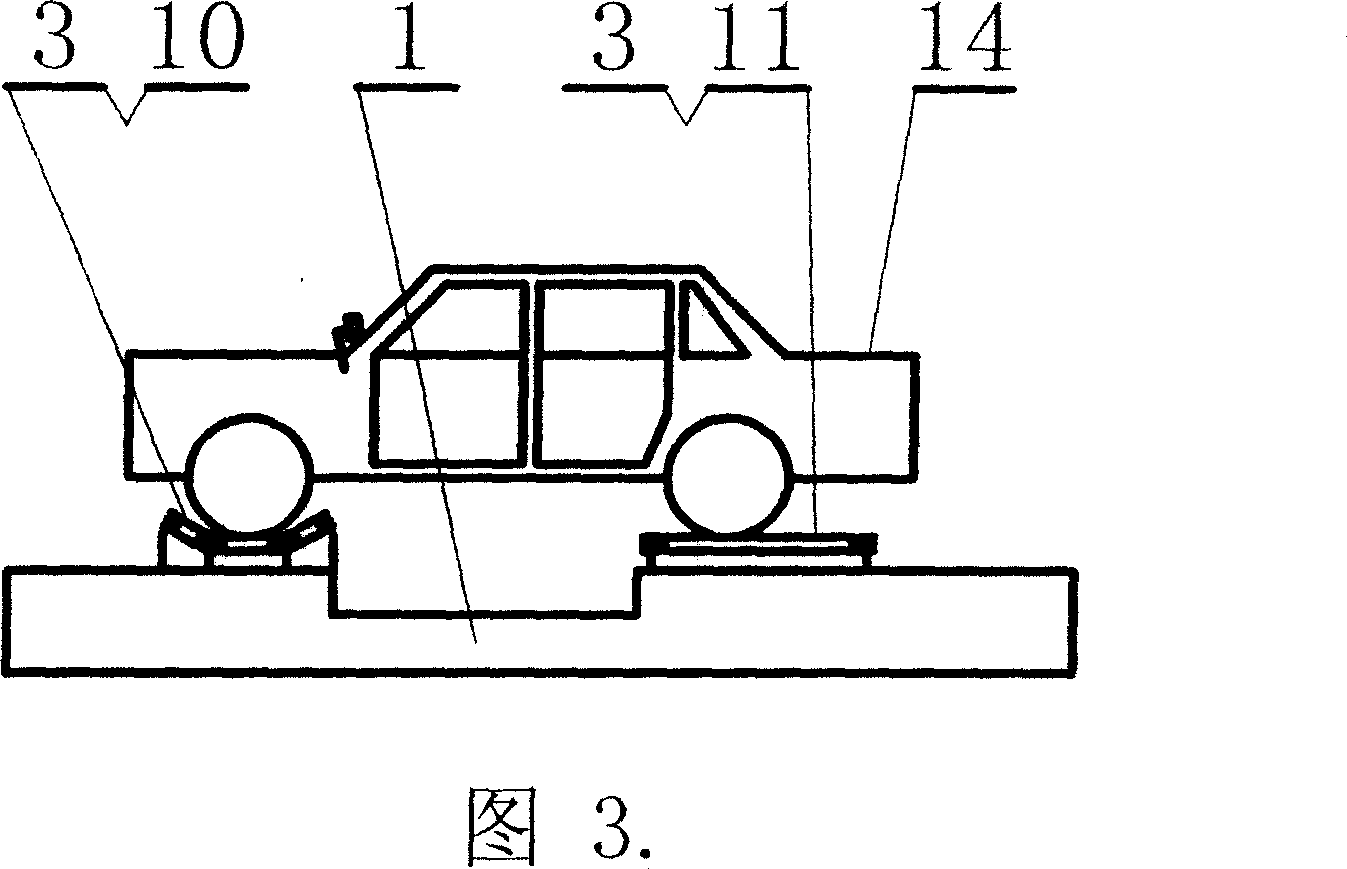

Multilane spacing parallel arranging stacker transport apparatus taking sending type rollaway parking equipment

A traffic engineering equipment parking areas over the roadway alongside stacker interval for handling delivery barrel road store parking equipment, includes : steel-storage, parking, child care up roller wheels, roadway, run stacker, vehicle handling devices, delivery vehicles; roadway with a number of storage-type steel parallel staggered side-by-side arrangement, all of the roadway or the bottom of the top set up run-steel storage in the adjacent roadway between the two, its every vertical layer along the roadway to set up a number of parking areas, each parking zone on the wheel set up child care can be entrusted Raceway up a car, each roadway with a vertical stacker can be mobile, stacker removal vehicles are equipped with lifting devices can be mobile, all the vehicles moving on the same set of wheels asked Raceway up and there can be a two-way horizontal left-to-right move to enter into the parking vehicles delivery agencies for access to super vehicle operations. This present invention vehicles are large space, covers little fields, structure is simple and cost is low, operates high efficiency and reliable.

Owner:SHANGHAI JIAO TONG UNIV

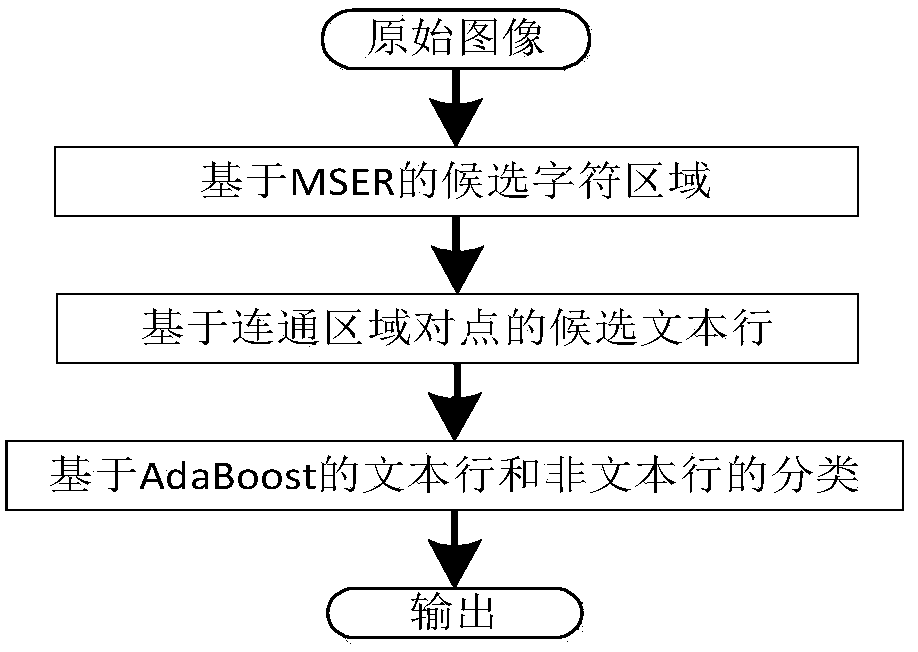

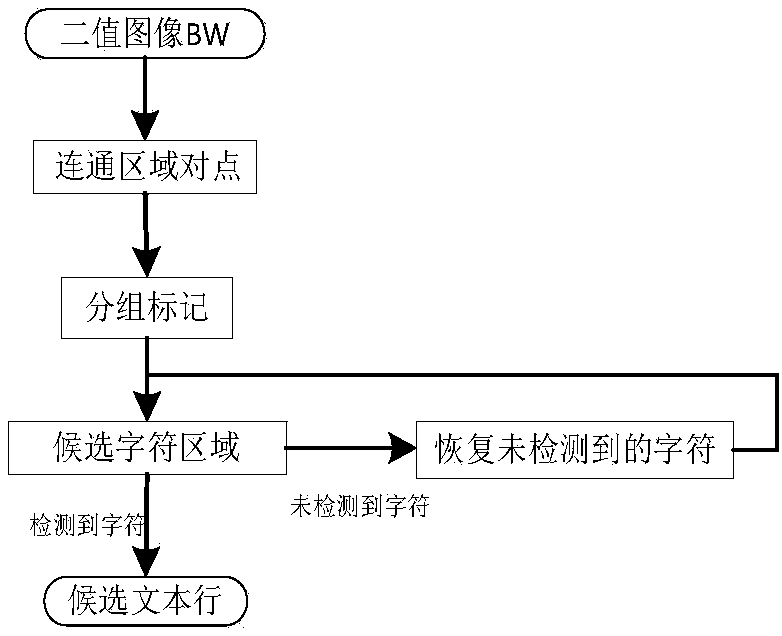

Fast multidirectional text line detection method

ActiveCN108154151AFast extractionReduce computational complexityCharacter and pattern recognitionComputation complexityAdaboost algorithm

The invention discloses a fast multidirectional text line detection method. The method comprises the steps that a candidate connected region of a natural scene picture to be detected is extracted by an MSER algorithm; connected region counter point algorithm is carried out on the candidate connected region to acquire a candidate character region; a connection rule is used for grouping; a lost character recovery algorithm is used to acquire candidate text lines; and finally according to the features of candidate multidirectional text lines, an AdaBoost algorithm is used to classify text lines and non-text lines. According to the invention, the connected region counter point algorithm is used to process the candidate connected region acquired through the MSER, which reduces the computationalcomplexity and speeds up scene text extraction; and the Adaboost algorithm is used to extract the features of the candidate multidirectional text lines, which can greatly improve the accuracy of textdetection.

Owner:NANJING UNIV OF POSTS & TELECOMM

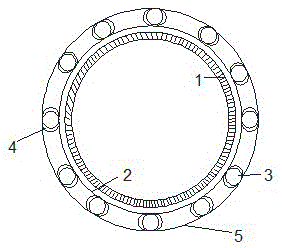

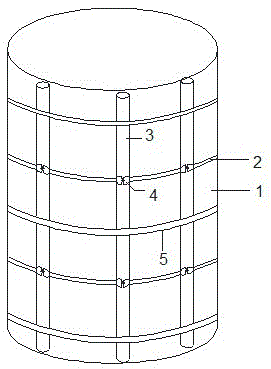

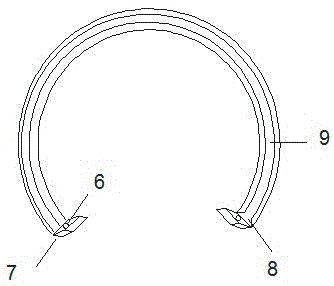

Simple supporting method for cylindrical concrete formwork

ActiveCN105569331AEasy to processImprove turnover rateForms/shuttering/falseworksMaterials scienceSteel tube

The invention discloses a simple supporting method for a cylindrical concrete formwork, and belongs to the technical field of building concrete formworks. An inner flat iron hoop, supporting steel tubes and an outer flat iron hoop are involved in the method. The method is characterized in that a bamboo wood formwork is further involved in the method and is of a cylindrical structure formed by splicing two or more composite bamboo glue formworks; the inner flat iron hoop is fixedly installed on the periphery of the bamboo wood formwork, and the supporting steel tubes are fixed to the inner flat iron hoop through steel tube fasteners and are sleeved with the outer flat iron hoop. The cylindrical concrete formwork is compact in structure, easy to machine, not prone to deformation, light in weight and low in cost, the surface of poured concrete is smooth, and dimension errors are small; the supporting components are high in circulation rate, convenient to assemble and disassemble and high in working efficiency; no complex outer supporting structure is needed, and the cylindrical concrete formwork is suitable for narrow sites and is convenient to maintain and clean after being dismantled.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

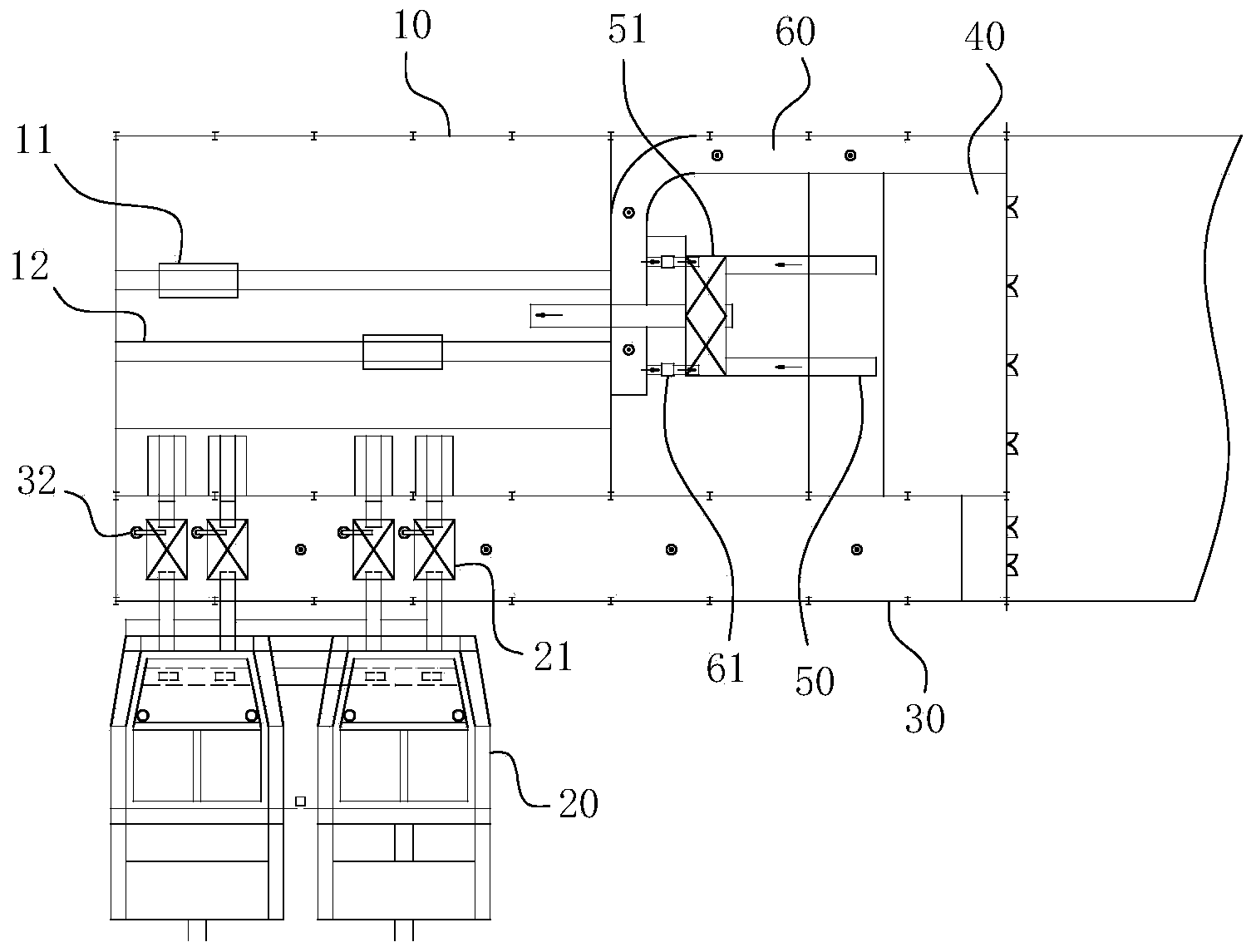

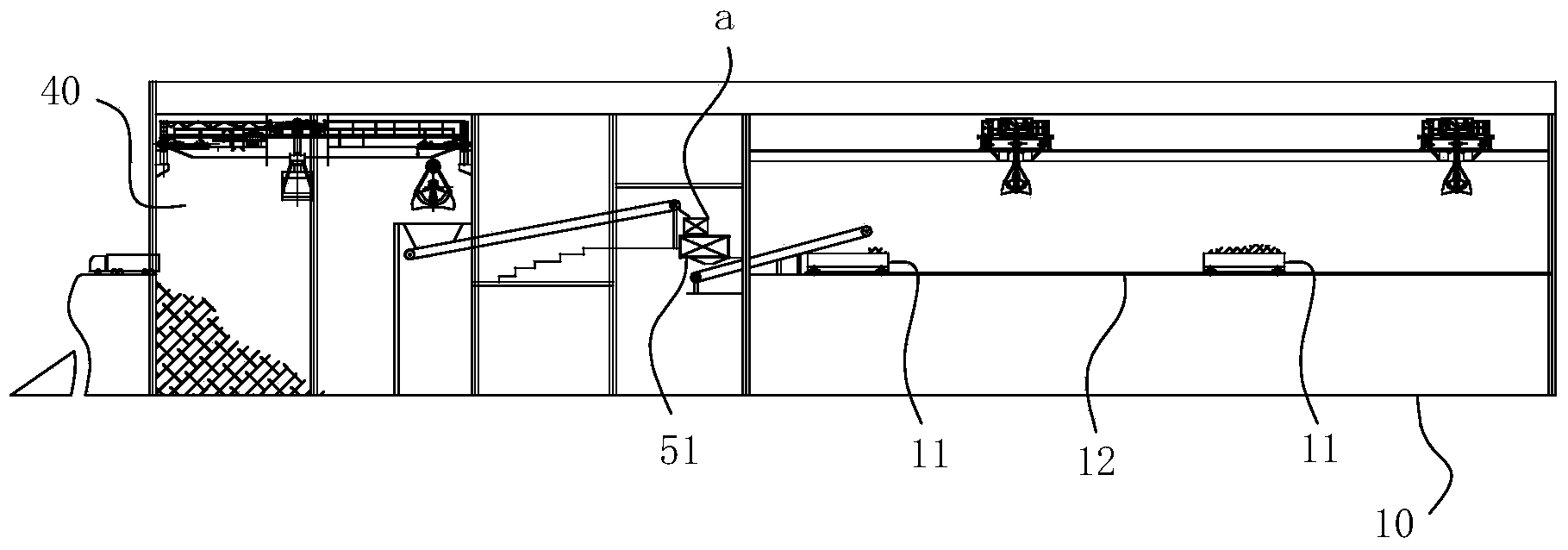

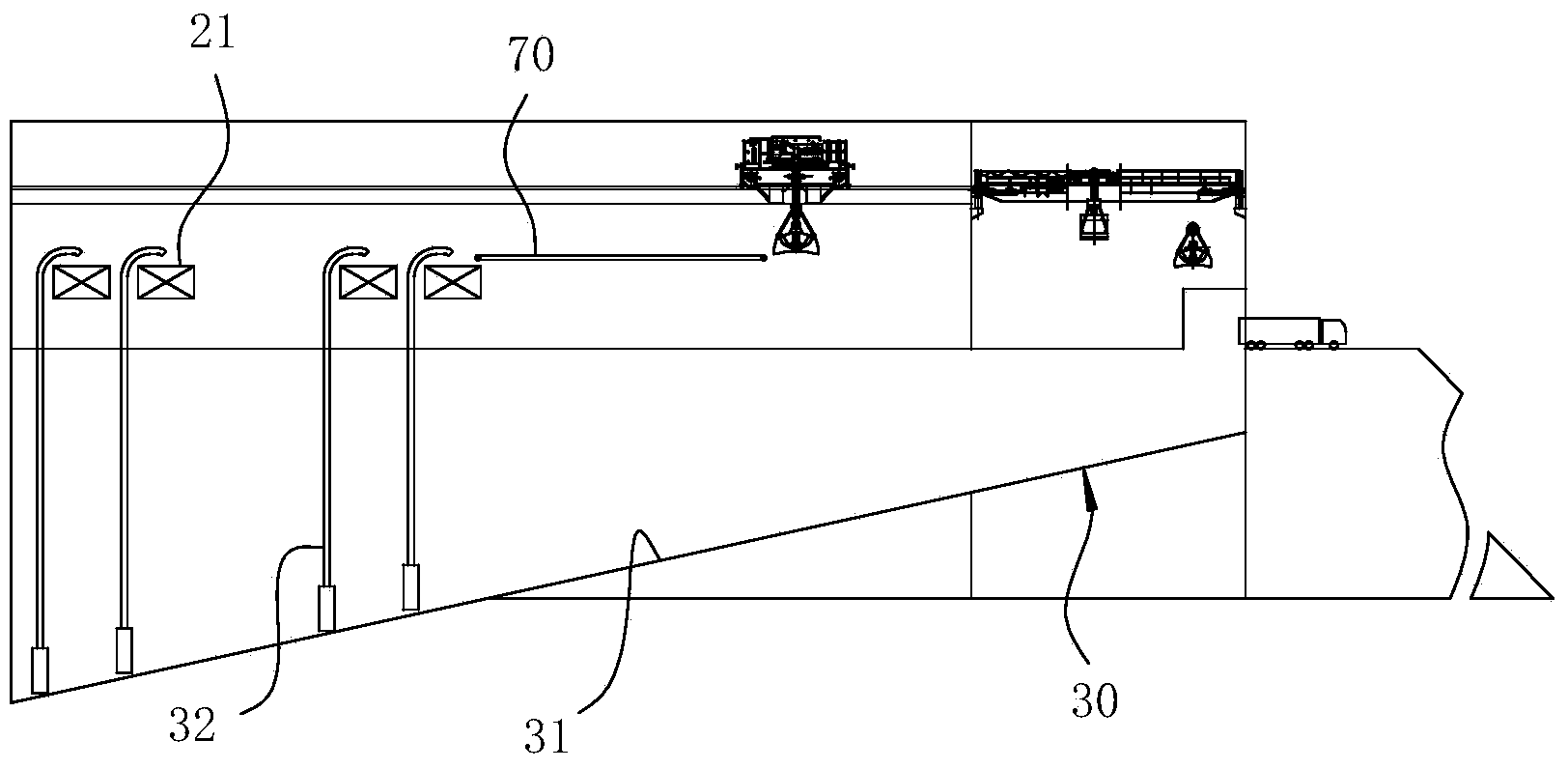

Mixed waste disposal system

InactiveCN103759273AReduce moisture contentHigh calorific valueSolid waste disposalIncinerator apparatusMixed wasteMunicipal solid waste

The invention belongs to the field of municipal solid waste disposal and particularly relates to mixed waste disposal system. The mixed waste disposal system at least comprises a waste pile-up unit used for waste pile-up fermentation and a waste incineration unit used for waste incineration. The mixed waste disposal system further comprises a sludge storage disposal pool, a material sliding ramp used for conveying materials is arranged in the sludge storage disposal pool, and the material sliding ramp is in the shape of an inclined face or a step-shaped structure becoming lower gradually. A sludge feeding end is arranged at the higher end of the material sliding ramp, and the lower end of the material sliding ramp forms a sludge discharging end. The time for sludge to flow from the sludge feeding end to the sludge discharging end along the material sliding ramp is longer than or equal to the number of days for the sludge to undergo set pile-up and warm-up fermentation and aerobic reaction. Both the waste pile-up unit and the discharging end of the sludge storage disposal pool are communicated with the feeding end of the waste incineration unit. Due to the simple and practical structure, mixed incineration disposal effect on municipal sludge and household waste can be achieved efficiently.

Owner:南京溧水石湫机场科技工业园开发有限公司

Railway wash water recovery and utilization method

InactiveCN1765778AImprove biodegradabilityImprove operational efficiencyTreatment with anaerobic digestion processesMultistage water/sewage treatmentChemistryCarbon dioxide

The recycle method for railway washing sewage comprises steps shown below: (1) removing the seston in sewage by grid screen to flow into anaerobic hydrolysis pond; (2) acidifying the LAS in sewage and organic into micromolecular organic by anaerobic active sludge; (3) entering membrane bioreactor, oxidizing said organic into carbon dioxide and water totally by aerobic active sludge, and recycling the residual clear water with material less than intercept diameter. This method uses MBR as main body and has high efficiency with low cost.

Owner:SHANGHAI JIAO TONG UNIV +1

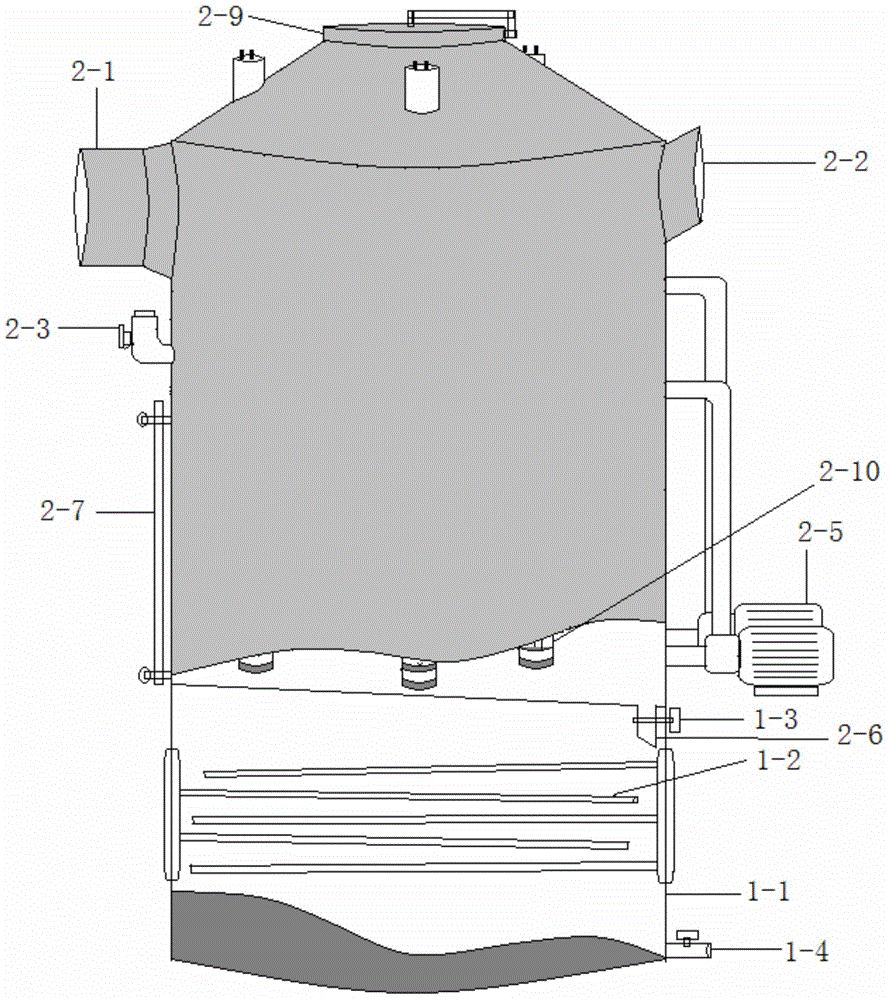

Method and device for purifying flue gas by utilizing photochemical Fenton reaction

ActiveCN103949153ASend each other quicklyExponentially faster chemical reactionsCombination devicesCoalIndustrial market

The invention discloses a method and a device for purifying flue gas by utilizing photochemical Fenton reaction. The method comprises the steps of converting particle powder into carbon dioxide and converting sulfur dioxide into sulfuric acid by utilizing the photochemical Fenton reaction. The device comprises a luminous energy bin and a purifying bin, so that the sulfuric acid recycling benefit of the device exceeds the running cost of the device, and users can obtain the relatively large profit. Additionally, the method is very flexible, can be accepted in existing systems of coal combustion boilers for improving the effectiveness of the coal combustion boilers, or can completely replace the original old system. The method and the device for purifying the flue gas by utilizing the photochemical Fenton reaction can be suitable for being used in any coal combustion boiler industrial market comprising cement plants, iron and steel plants, municipal government rubbish combustion plants, medical treatment rubbish combustion plants, chlorine manufacturers, paper pulp and paper production factories and the like.

Owner:林小晓 +1

Baking-free brick with waste rubber and coal ash as major raw materials

ActiveCN102976686AImprove brittle defectsLow elastic modulusSolid waste managementWaste rubberFreeze and thaw

The invention discloses a baking-free brick with waste rubber and coal ash as major raw materials. The baking-free brick is composed of the following raw materials in parts by weight: 3-10 parts of waste rubber, 30-45 parts of coal ash, 20-25 parts of yellow sand, 5-10 parts of cement, 10-15 parts of calcium oxide, 3-5 parts of calcium sulfate, 1-2 parts of sodium sulfate, 1.5-2 parts of sodium hydroxide, 0.01-0.05 parts of sodium metaaluminate and 8-15 parts of water. The baking-free brick has the advantages that (1) the major problems that the coal ash baking-free brick is high in water absorption and poor in resistance to freezing and thawing resistance are solved, and the application field and region of the coal-ash baking-free brick are greatly expanded; (2) the production process is simple, the investment is low, the cost is low, the benefit is good, the market competitiveness is strong and the capacity of the market is great; and (3) the solid wastes such as waste tire and coal ash are used for making bricks instead of the traditional clay bricks, so that the baking-free brick is a green novel building material and is an important development project in China.

Owner:河南盖森材料科技有限公司

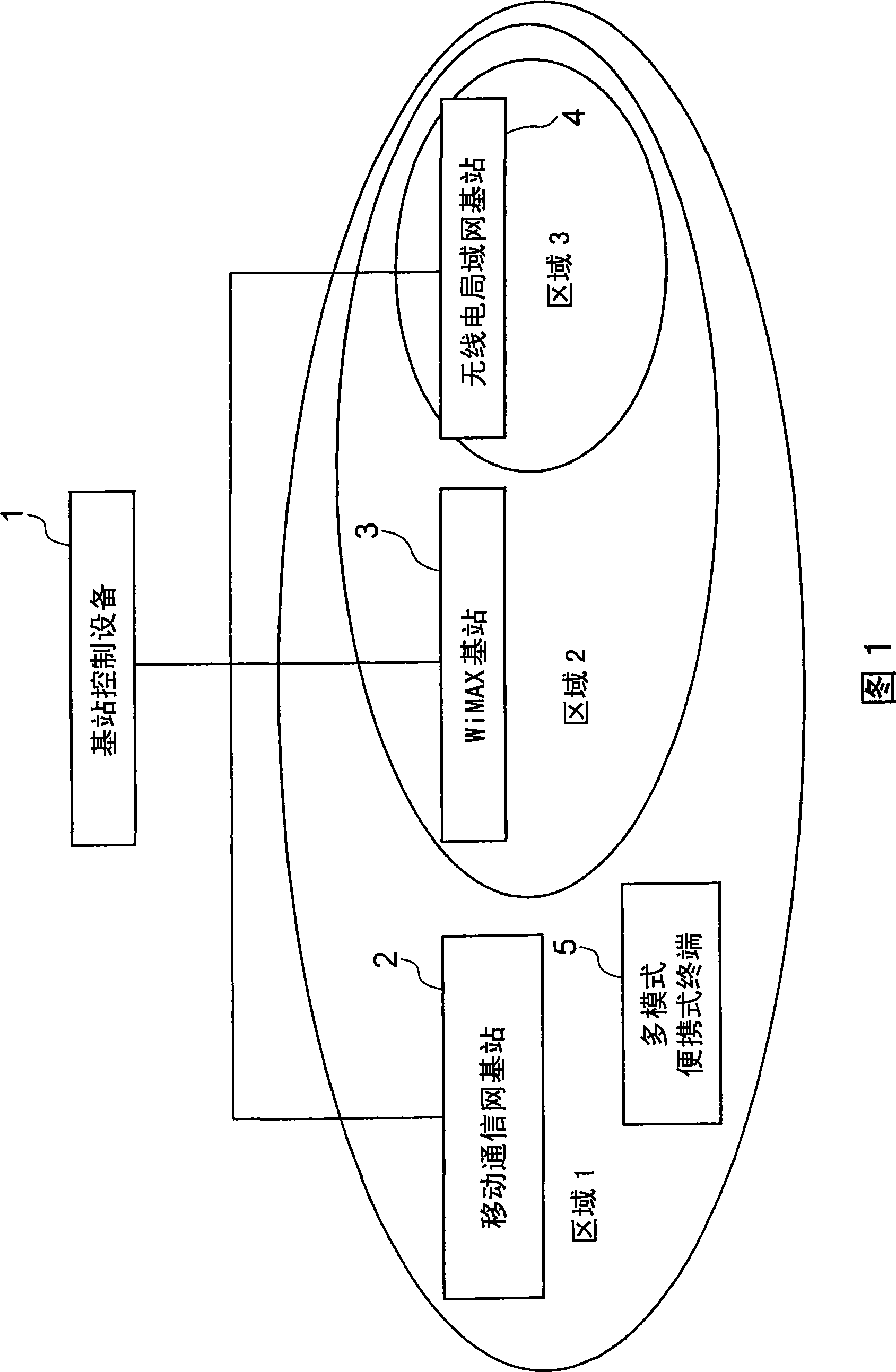

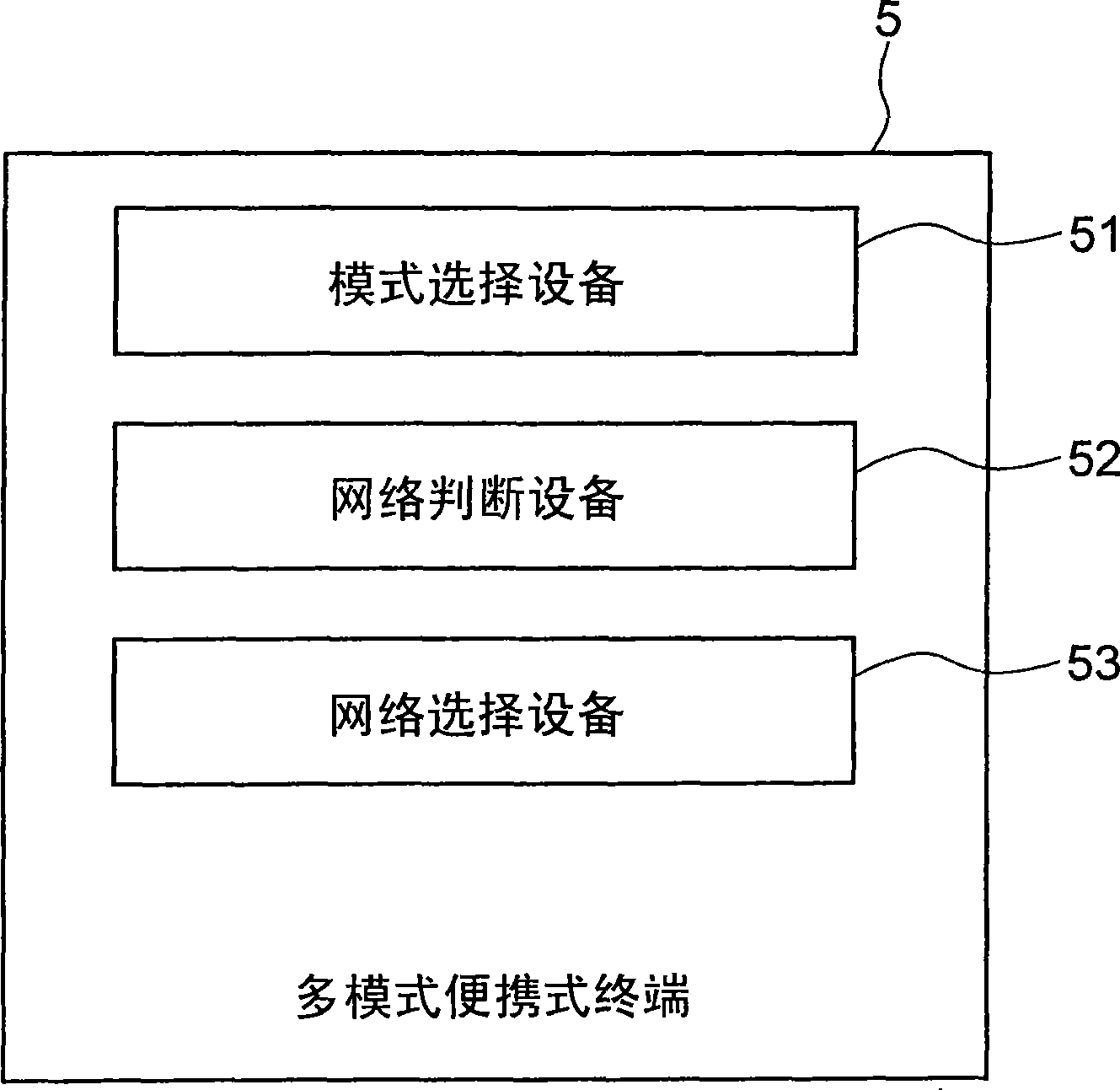

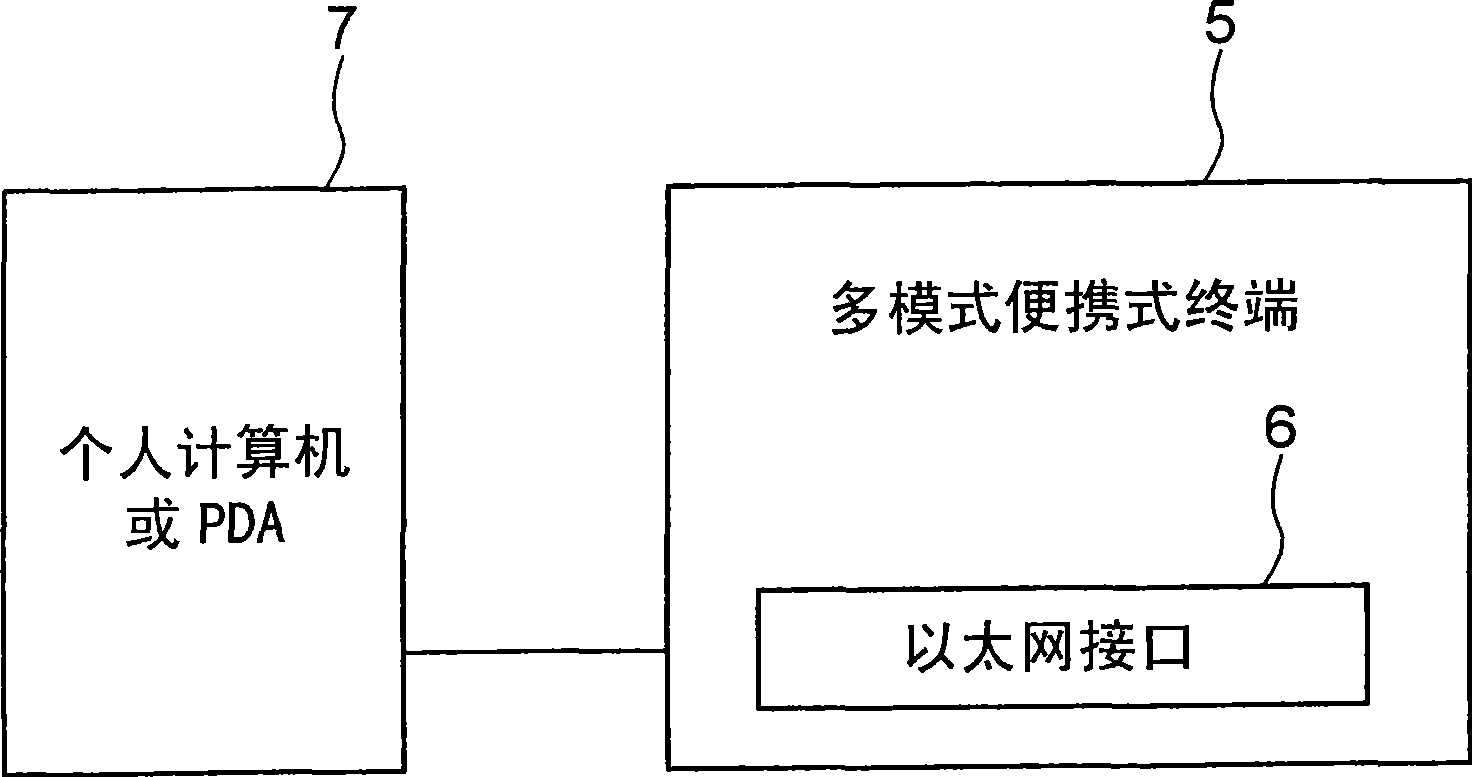

Multimode portable terminal and mode switch-over method

InactiveCN101427600AAvoid settingProjected increase in number of subscribersAssess restrictionTelecommunicationsUser input

To provide a multimode portable terminal capable of variously switching over the mode of a network connection according to various needs such as high-quality and high-speed data communication or inexpensive data communication, and a mode switch-over method. [MEANS FOR SOLVING PROBLEMS] A multimode portable terminal connectable to any one of a plurality of radio communication networks with different standards comprises a mode selecting means (51) for presetting mode selection information by the user input, a network judging means (52) for judging in which area of which radio communication network the multimode portable terminal is present on the basis of whether or not there is a radio communication network unique control signal, and a network selecting means (53) for selecting one of the radio communication networks in whose area the multimode portable terminal is present in the order of priority according to the mode selection information.

Owner:NEC CORP

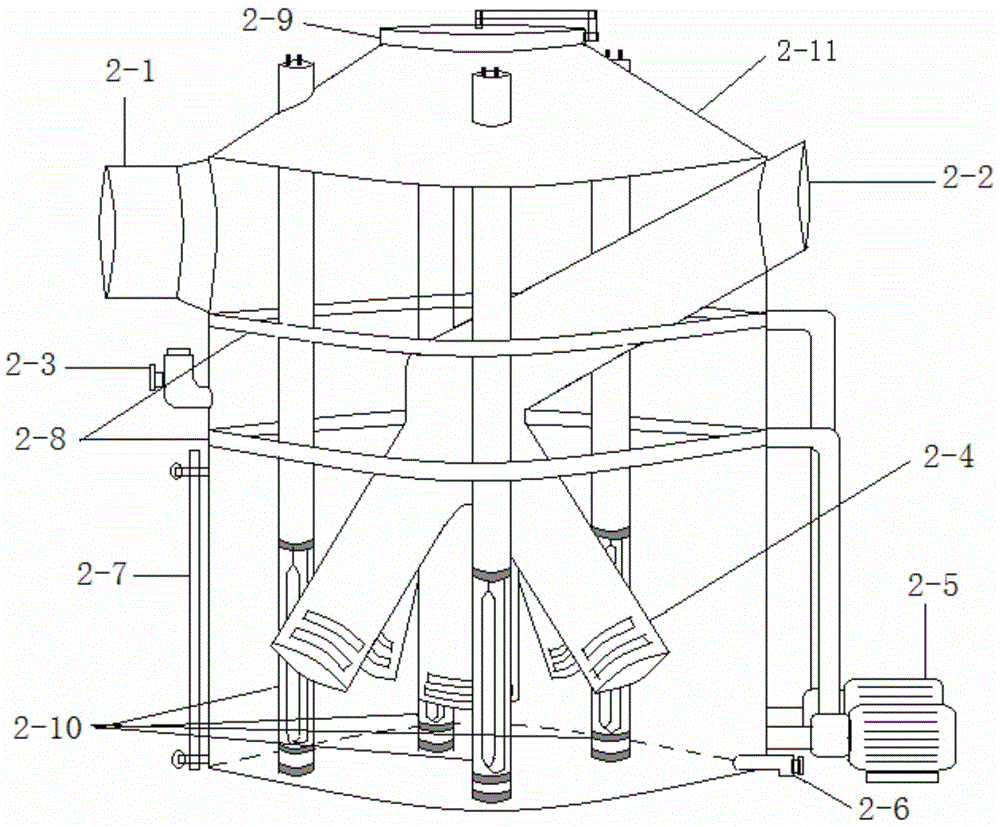

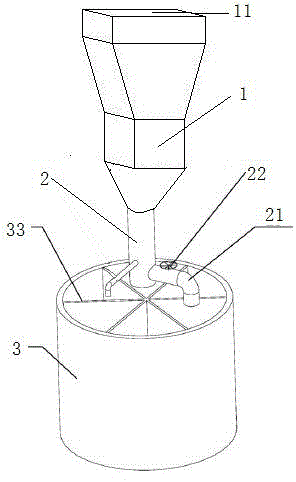

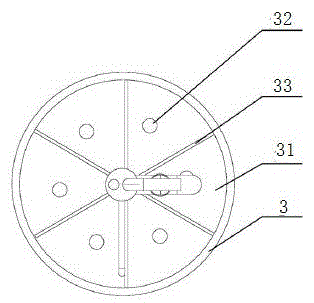

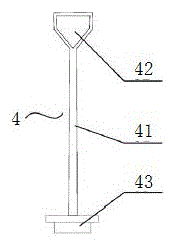

Granular fertilizer distribution device

InactiveCN106583256AOptimize allocationExpand areaLarge containersGradingEngineeringMaterial distribution

The invention discloses a granular fertilizer distribution device. The granular fertilizer distribution device is characterized in that the device comprises a collection hopper, a distribution mechanism and a distribution barrel; a plurality of material troughs are formed in the distribution barrel; the bottom face of each material trough is provided with a discharging outlet; the collection hopper is arranged above the distribution barrel; and the distribution mechanism is connected between the collection hopper and the distribution barrel. According to the granular fertilizer distribution device provided by the invention, by arranging the multiple material grooves in the distribution barrel and forming the discharging outlets in the bottom of all the material troughs, granular fertilizers are injected into all the material troughs through the collection hopper, and the fertilizers with different granules are collected in the material troughs. Through the material distribution device, the fertilizers can be distributed quite conveniently, the occupied space is small, and the space utilization rate is high.

Owner:东兴易新环保科技有限公司

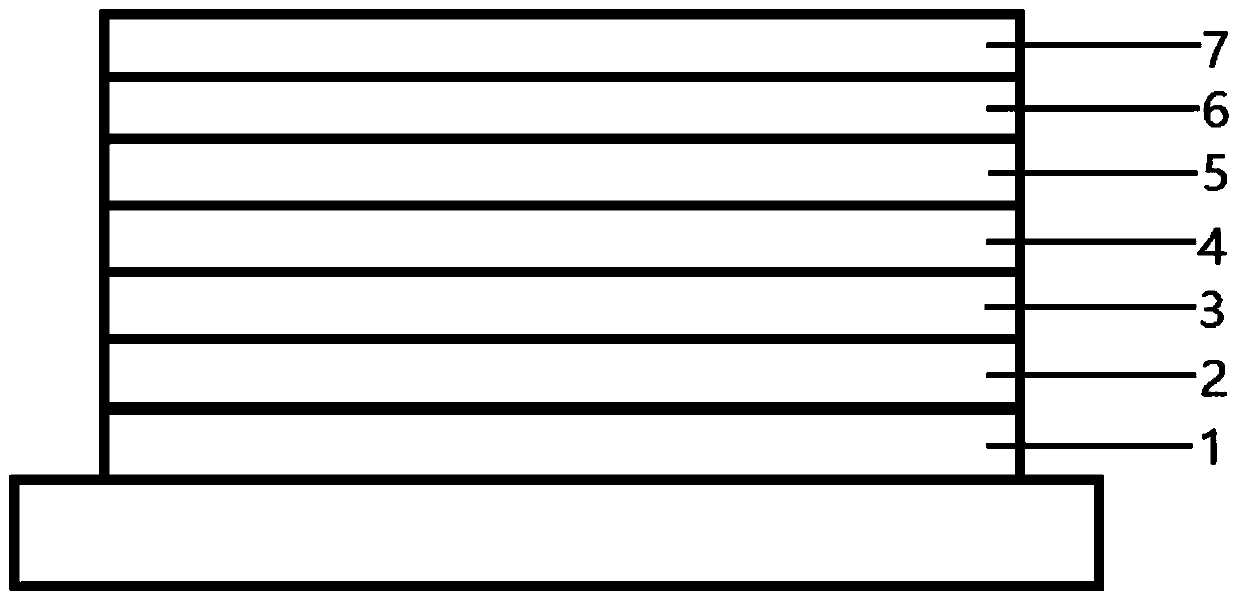

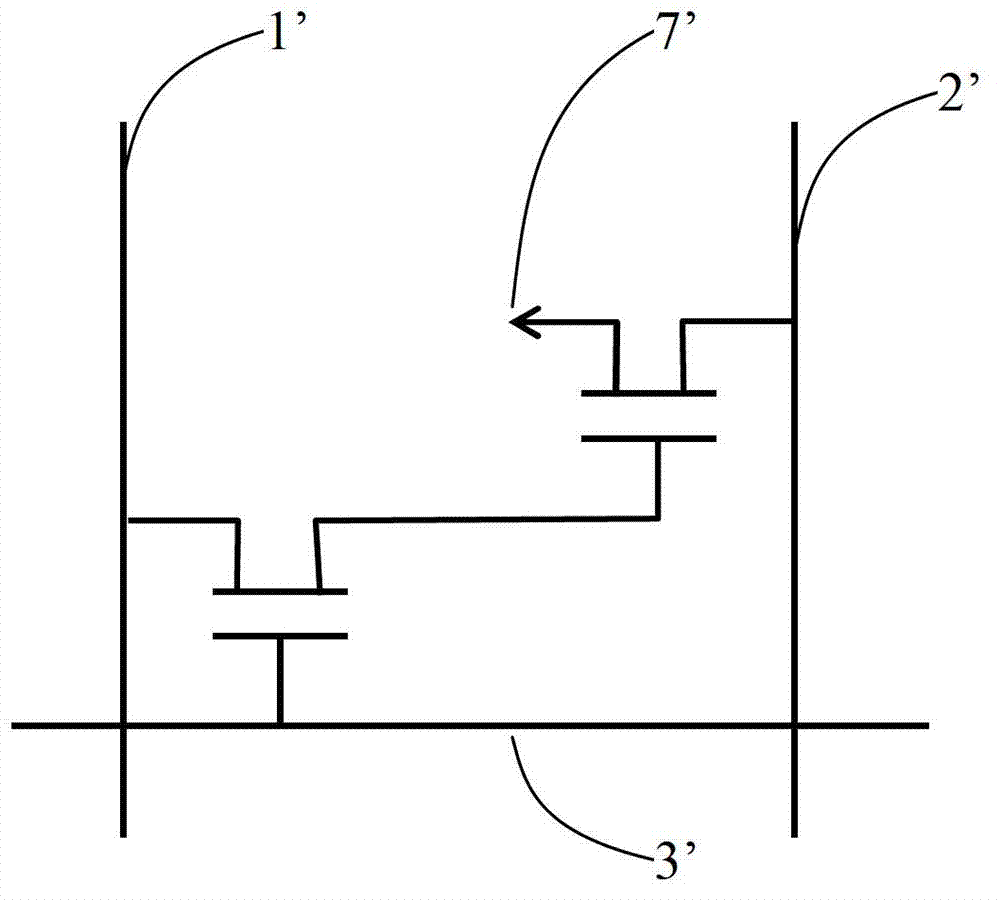

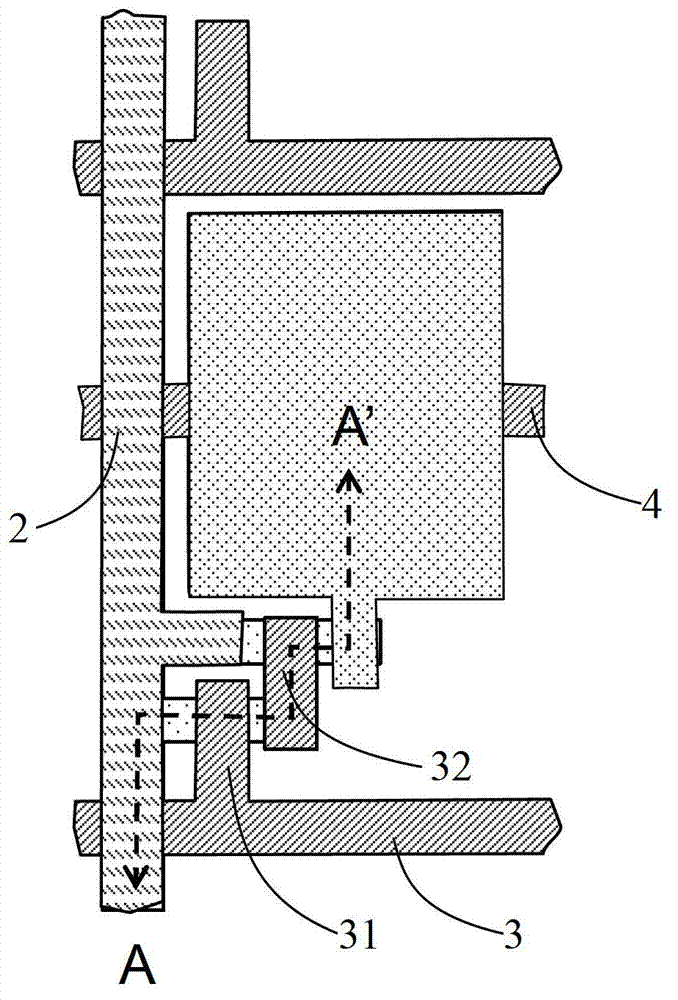

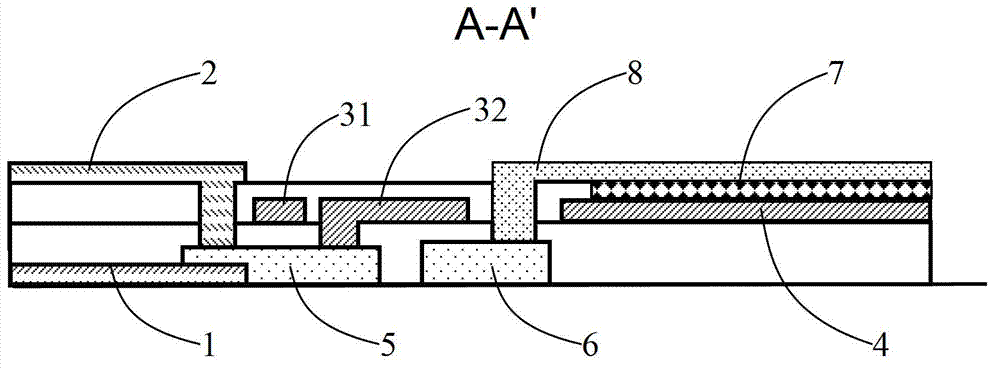

Active organic light emitting diode (OLED)

ActiveCN102881711AImprove OLED brightnessEasy to prepareStatic indicating devicesSolid-state devicesData linesOLED

The invention discloses an active organic light emitting diode (OLED), which comprises a data line, a power supply line, a scanning line, a common electrode, a data thin film transistor (TFT), a current TFT, an organic luminous layer and a transparent electrode layer, wherein the data TFT, the current TFT and the data line are formed in the same layer; the organic luminous layer is formed on the common electrode, and coats the transparent electrode layer; the data line and the power supply line are made of different-layer metals and are overlapped; and the common electrode and the data line or the scanning line are formed in the same layer. According to the active OLED, the data line and the power supply line are made of different-layer metals and configured at the same position, and by the framework, an opaque area occupied by metal wires can be decreased, and the area of the luminous layer can be effectively increased to improve the brightness of the OLED in a top emitting OLED framework or a bottom emitting OLED framework.

Owner:NANJING CEC PANDA LCD TECH

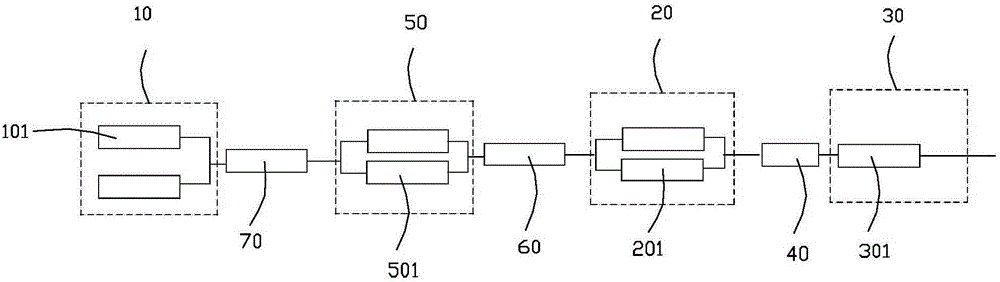

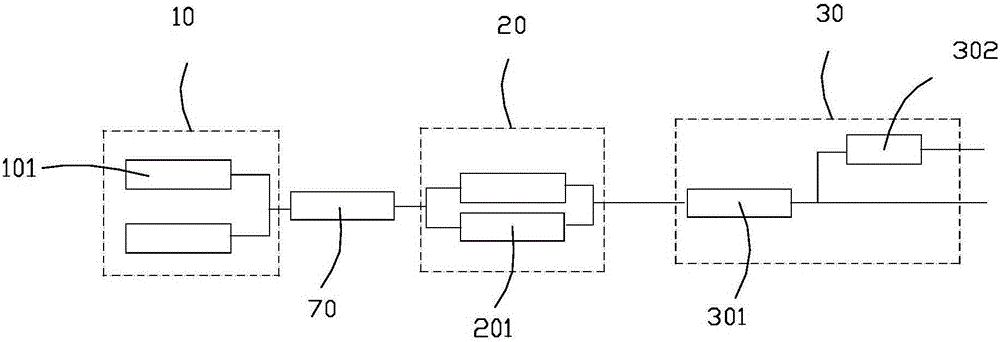

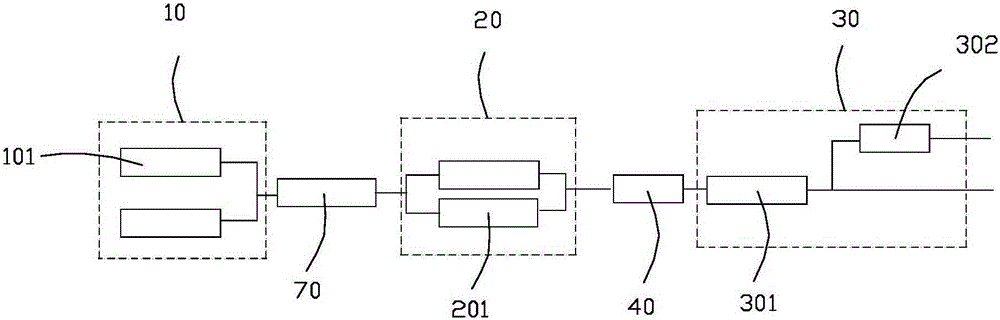

Nitrogen making system for ship

ActiveCN105197898ASimple structureReduce equipment investment and energy consumptionNitrogen purification/separationChemical industryEngineeringNitrogen gas

The invention relates to a nitrogen making system for a ship. The nitrogen making system comprises a compressor, a nitrogen making machine and / or a nitrogen buffer tank as well as a flow pressure regulating device which are sequentially connected through pipelines, wherein the compressor comprises at least one compression unit and is used for providing compressed air; the nitrogen making machine comprises at least two nitrogen making units and is used for making nitrogen; the nitrogen buffer tank is used for storing and buffering the nitrogen; the flow pressure regulating device is used for regulating flow and pressure. Compared with a conventional nitrogen making system, the nitrogen making system is not equipped with an air dryer, an air buffer tank or a nitrogen buffer tank and can output the small-flow and high-pressure nitrogen, and the pressure of the nitrogen is higher than the highest output pressure of an air compressor. With the adoption of the means, the structure of the nitrogen making system in the prior art is simplified, device operation and nitrogen yield cannot be influenced, and device investment and energy are saved.

Owner:PANASIA GAS TECH WUXI CO LTD

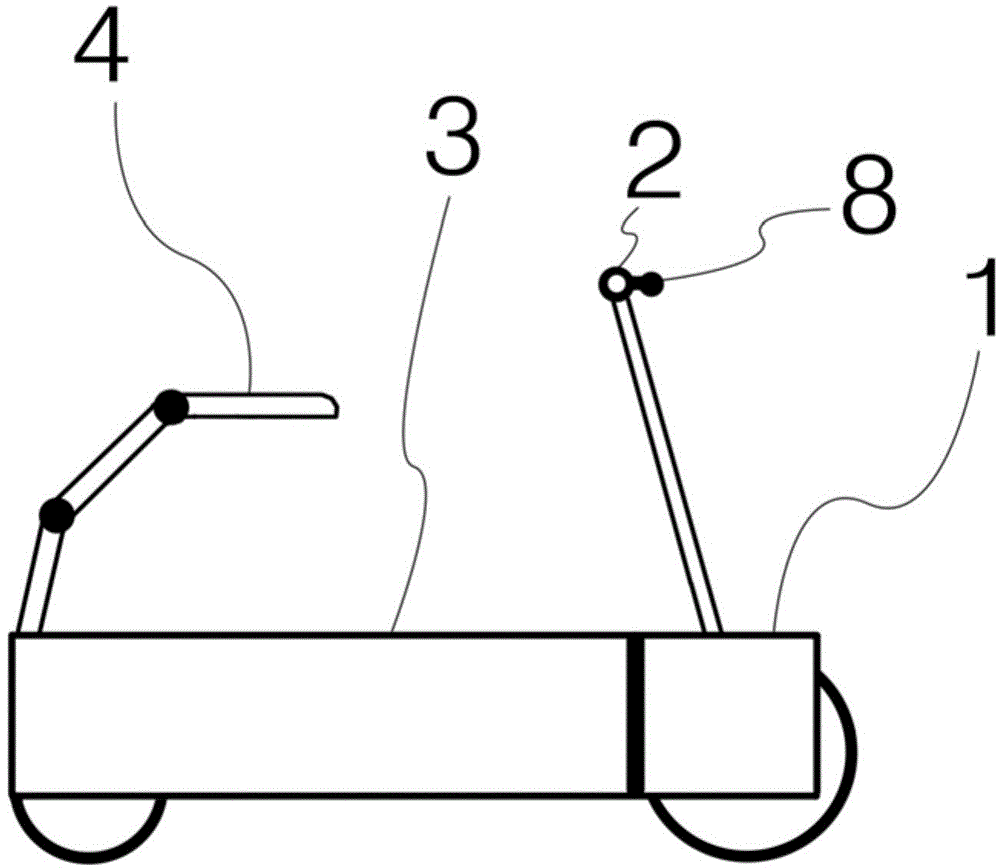

Power supply cart capable of supplying power for electric vehicle and electric vehicle capable of accommodating power supply cart

InactiveCN104890710ALow costEasy to manufactureBatteries circuit arrangementsElectric powerElectrical batteryBattery electric vehicle

The invention discloses a power supply cart capable of supplying power for an electric vehicle. The power supply cart comprises a battery, wherein the battery can supply the power for driving the power supply cart to run, and the power supply cart can be placed in the electric vehicle and supplies the power for the electric vehicle. The power supply cart is characterized in that the power supply cart can carry people.

Owner:陈龙

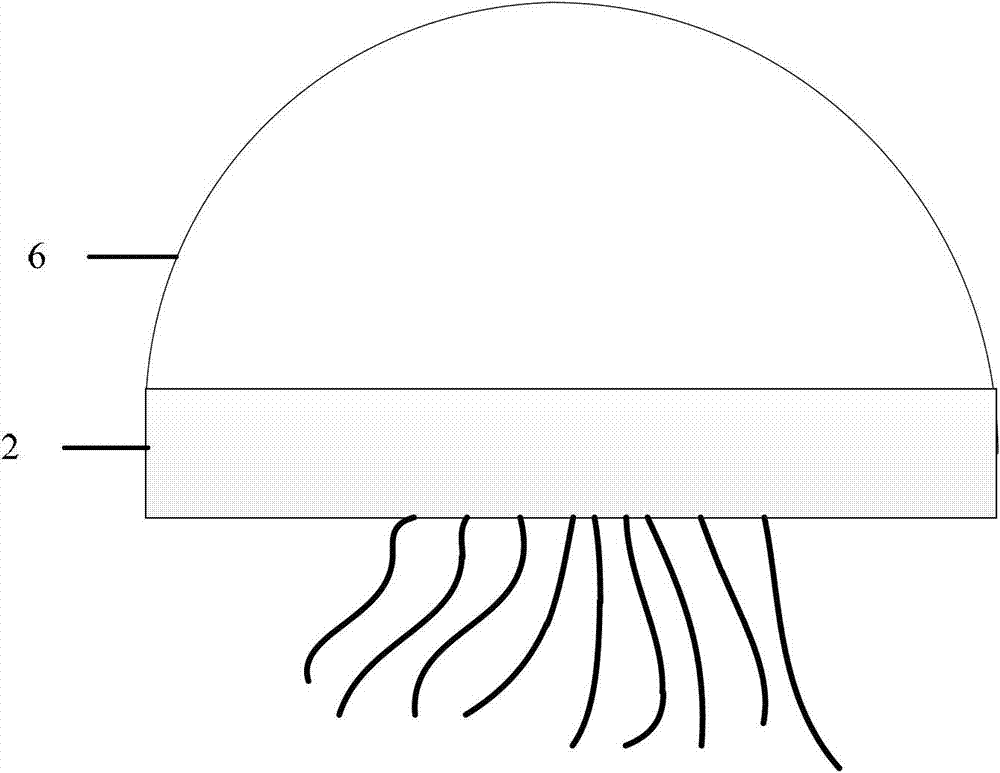

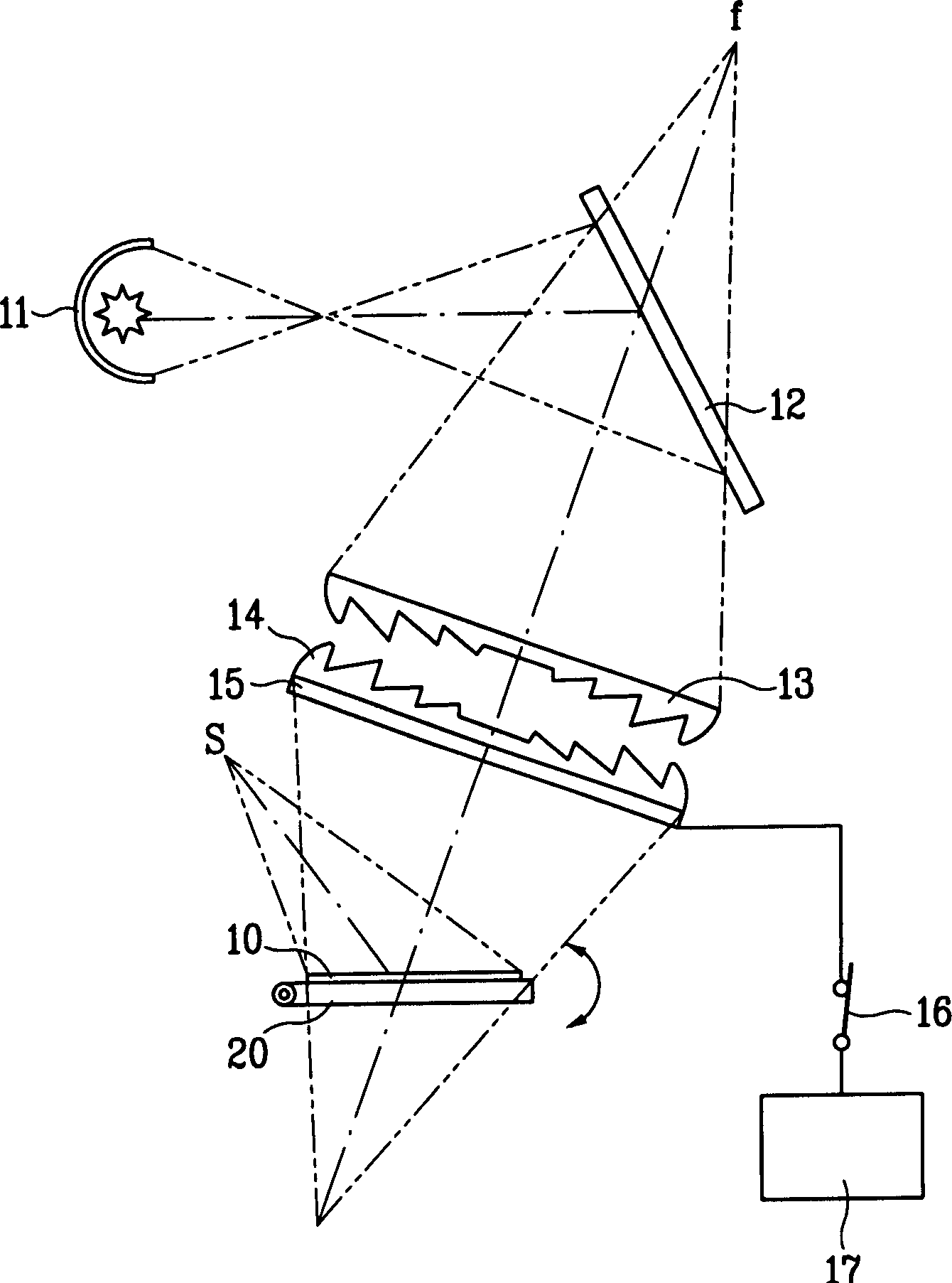

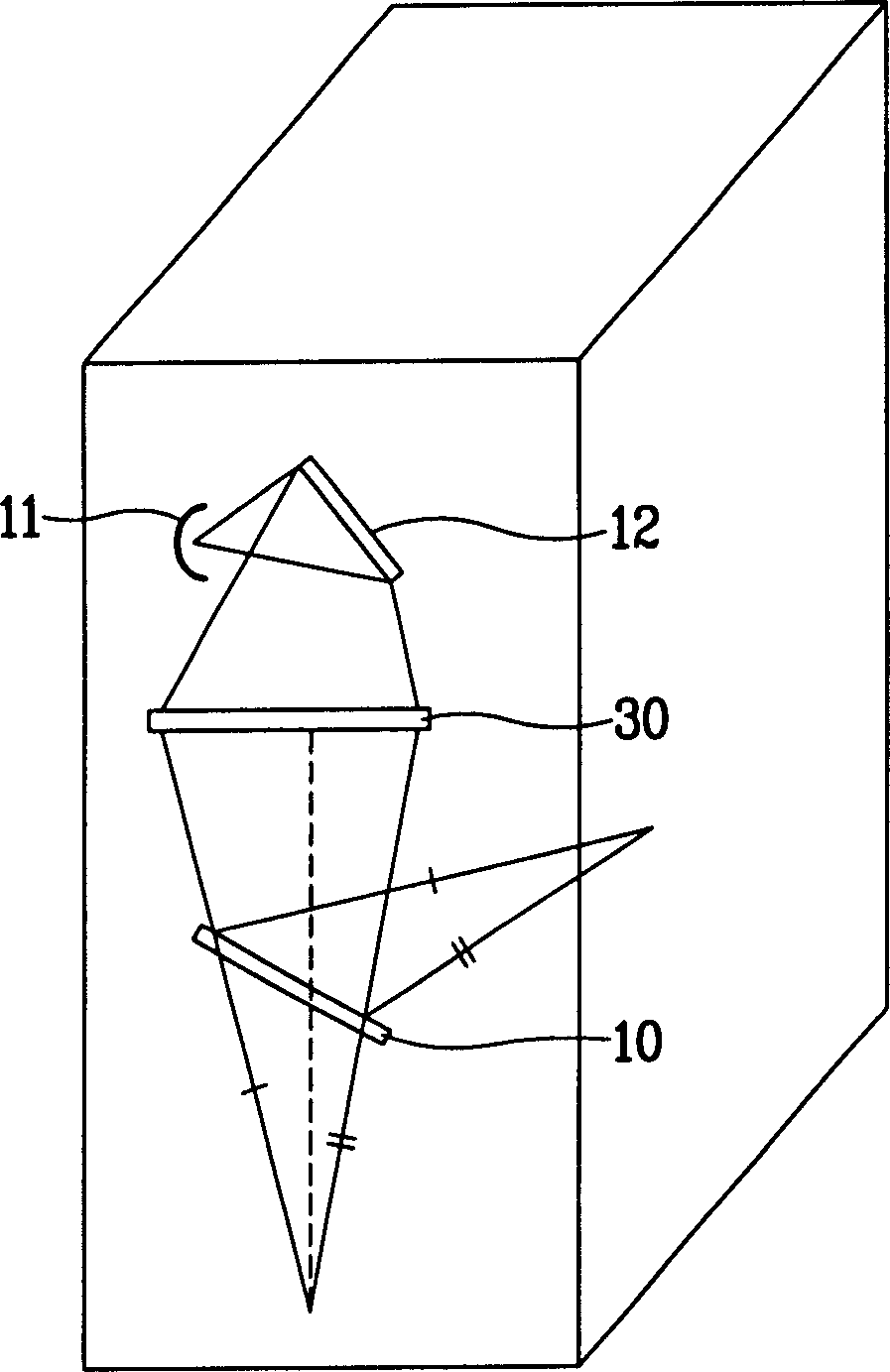

Lighting device for testing substrate

InactiveCN1548947AGood visual conditionImprove reliabilityRadiation pyrometryScattering properties measurementsFresnel lensEffect light

A lighting apparatus is provided to simplify the movement structure of the lighting apparatus by lighting the wide area of a substrate through the use of plural lightings. A lighting apparatus comprises a plurality of mirrors(130,140) for reflecting the light beams generated from a plurality of light sources(110,120); and first and second Fresnel lens(200,210) for focusing the diffused light beams reflected from each of the mirrors to a single focusing point, and radiating the focused light beams to a substrate(100) mounted on a stage. The light beams radiated to the substrate from the first Fresnel lens and the second Fresnel lens are partially overlapped.

Owner:DE&T

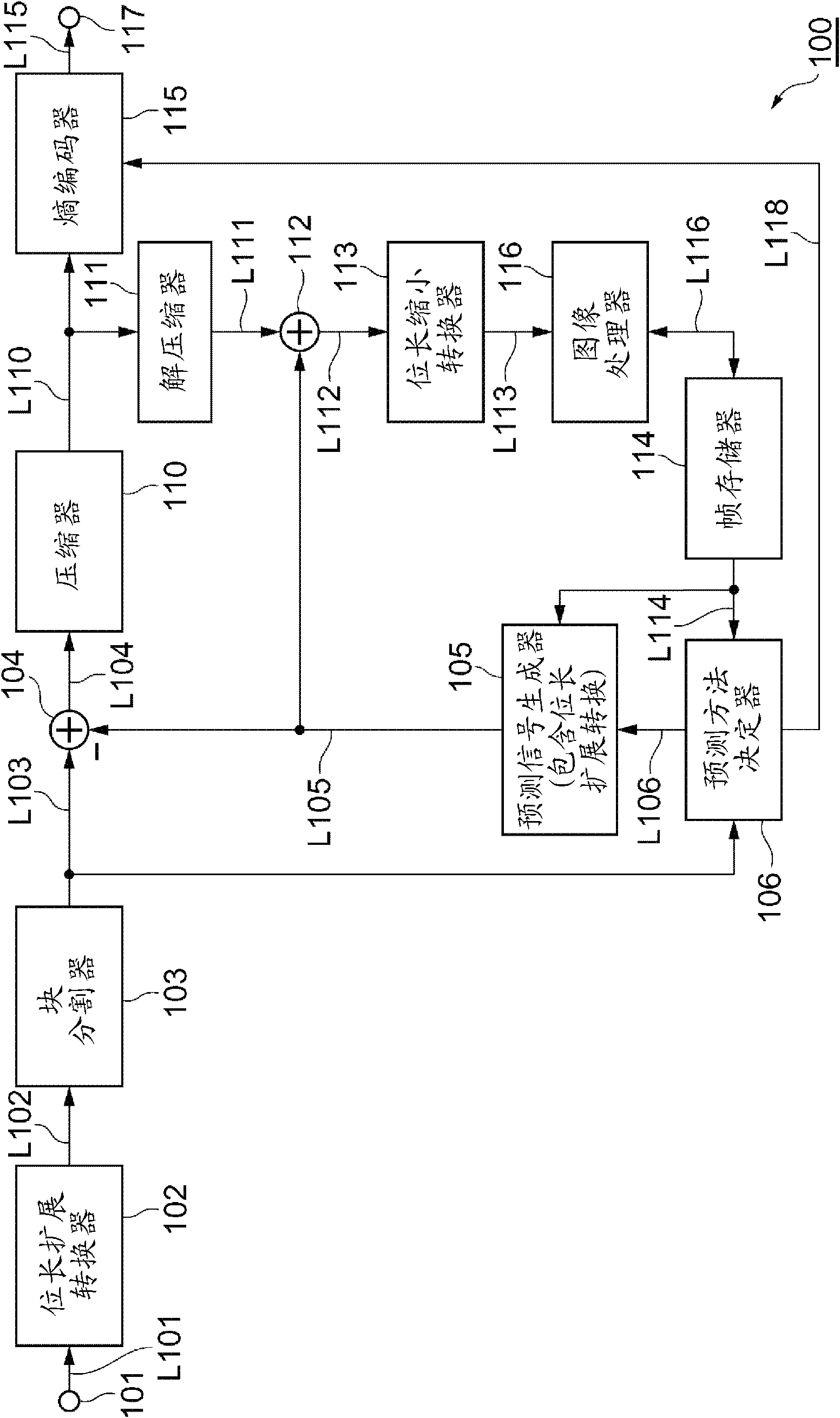

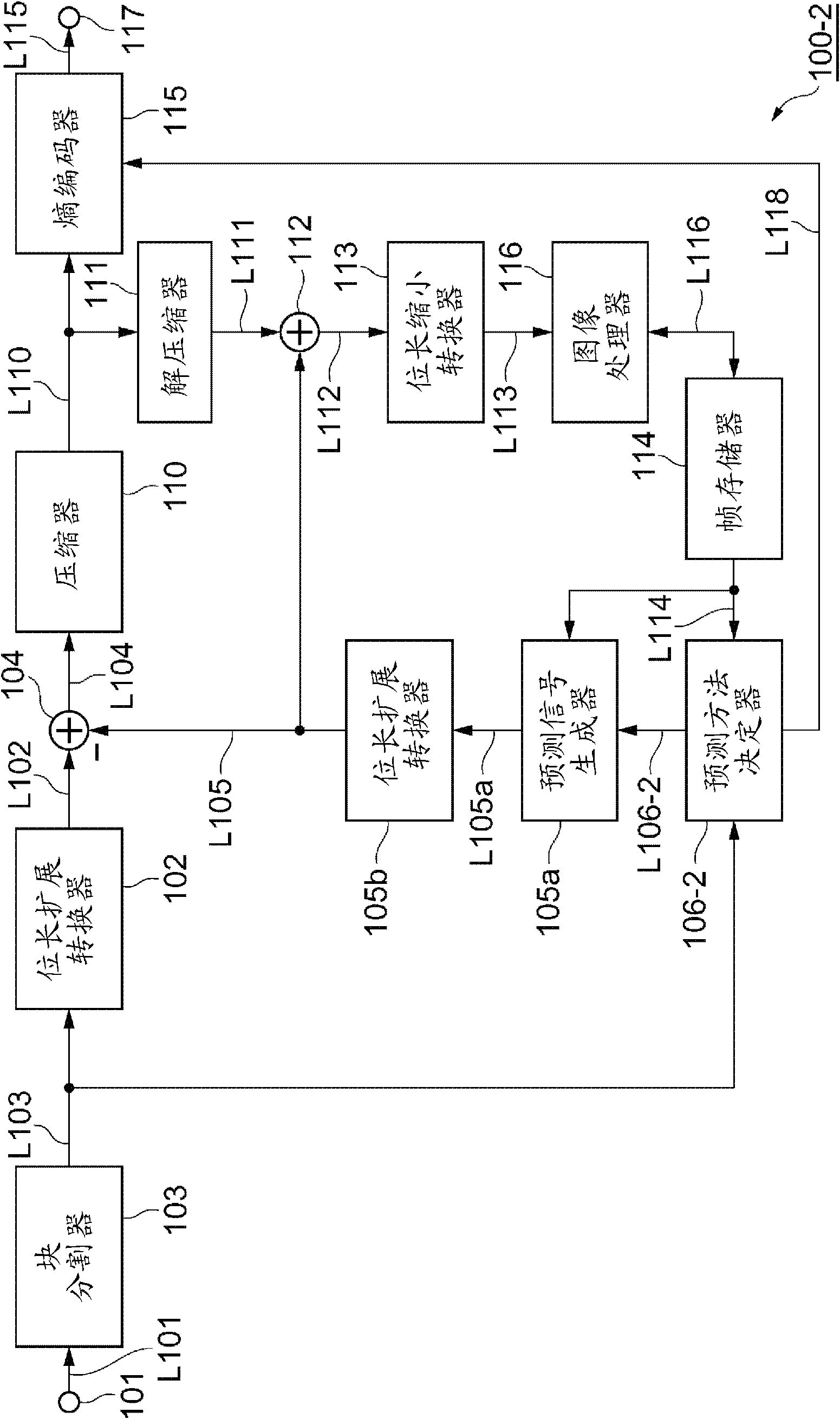

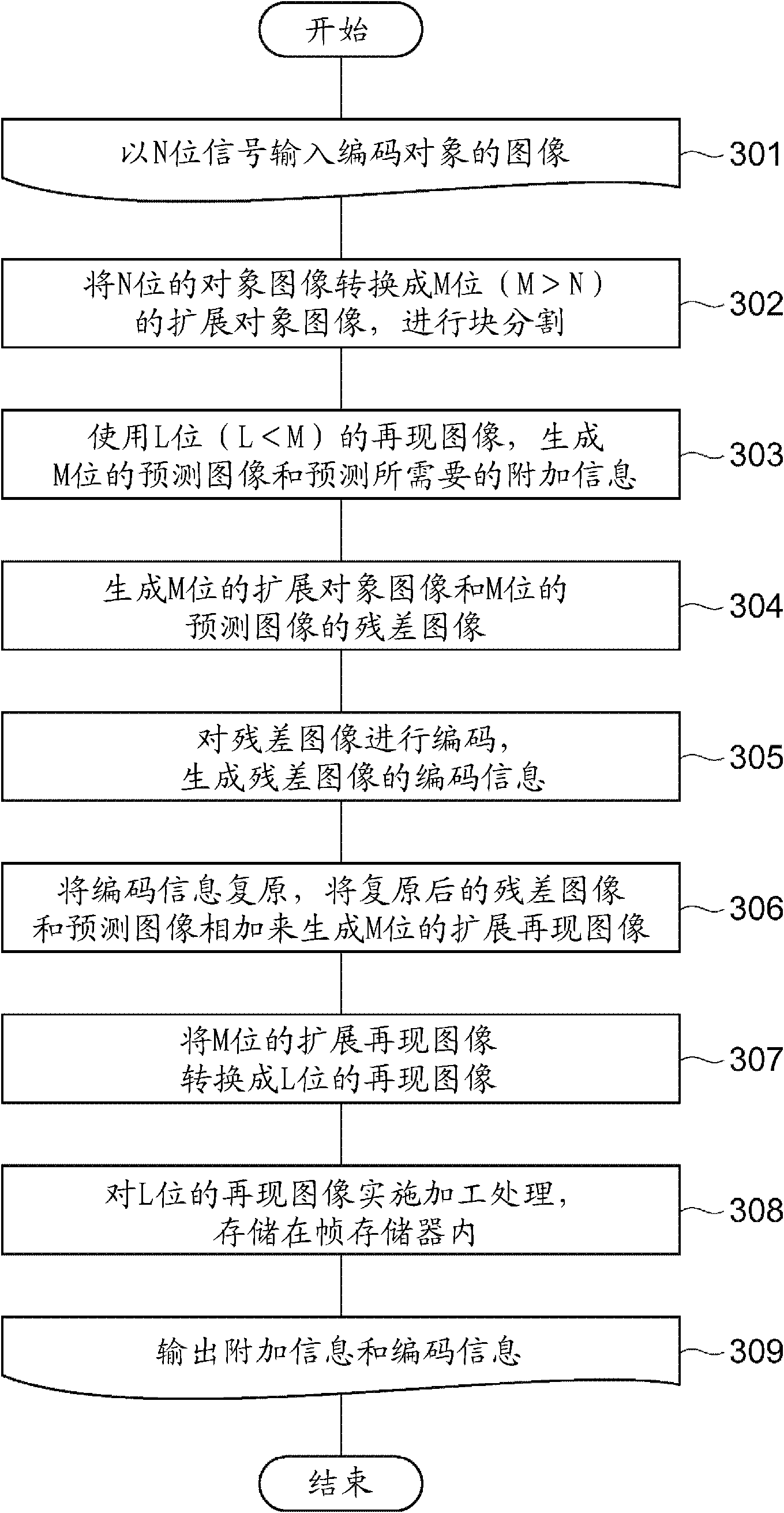

Moving image encoding apparatus, moving image decoding apparatus, moving image encoding method, moving image decoding method, moving image encoding program, moving image decoding program, and moving image encoding/decoding system

InactiveCN102172029AIncrease capacityExpand areaTelevision systemsDigital video signal modificationBit-lengthReference image

In encoding / decoding of moving images, the efficiency of encoding is enhanced and the expansion is facilitated, while the increases in the capacities of frame memories and in bands are suppressed. A bit length expanding converter (102) converts a target image, the pixel values of which are expressed by use of a bit length (N), to an image the pixel values of which are expressed by use of a bit length (M). A compressor (110) encodes the image converted. A decompressor (111) decompresses the image encoded. A bit length contracting converter (113) converts the image decompressed to a reproduced image the pixel values of which are expressed by use of a bit length (L) shorter than the bit length (M). The reproduced image is then stored, as a reference image, into a frame memory (114).

Owner:NTT DOCOMO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com