Mixed waste disposal system

A garbage treatment system and garbage technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing the actual treatment amount of leachate, low moisture content calorific value, and reducing sludge Dealing with issues such as effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

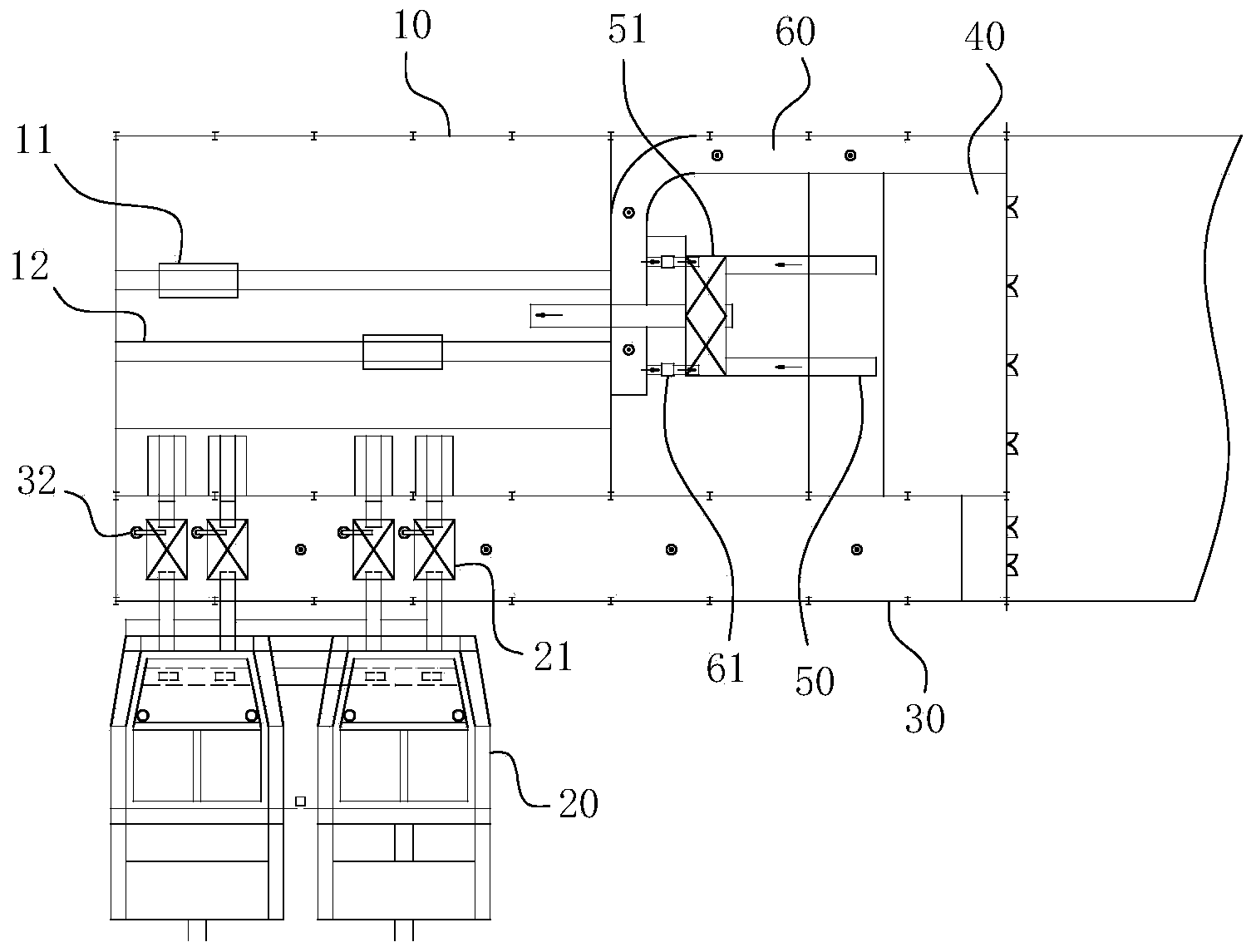

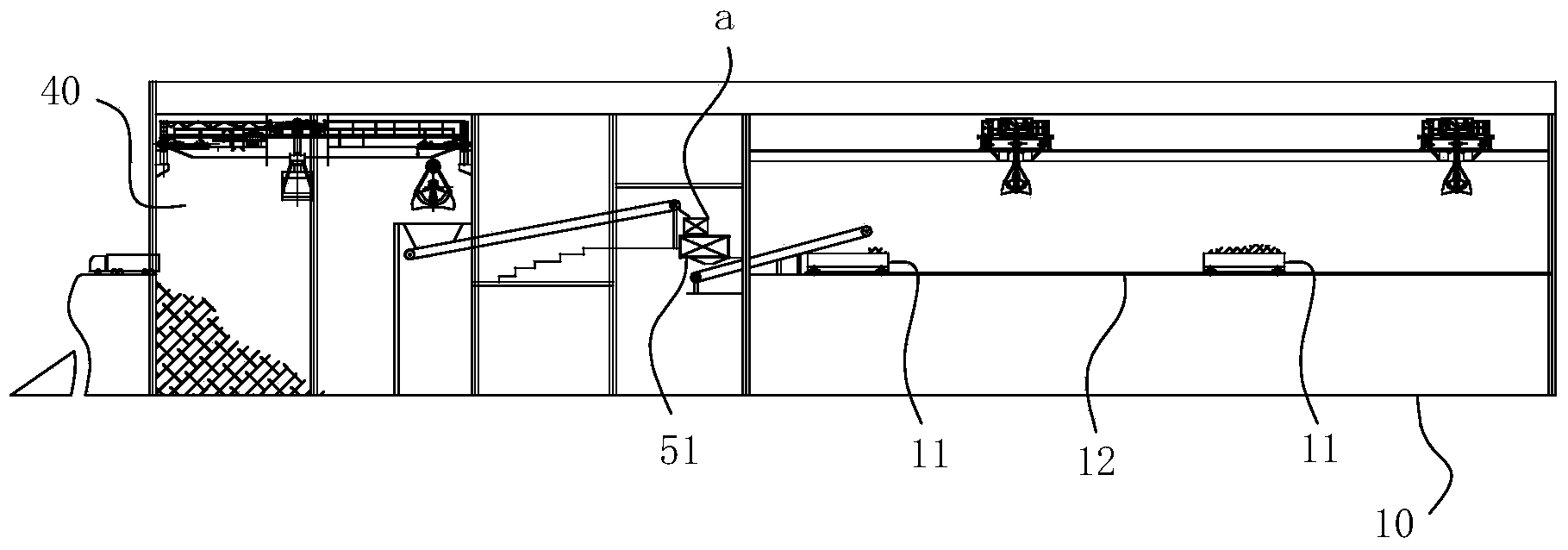

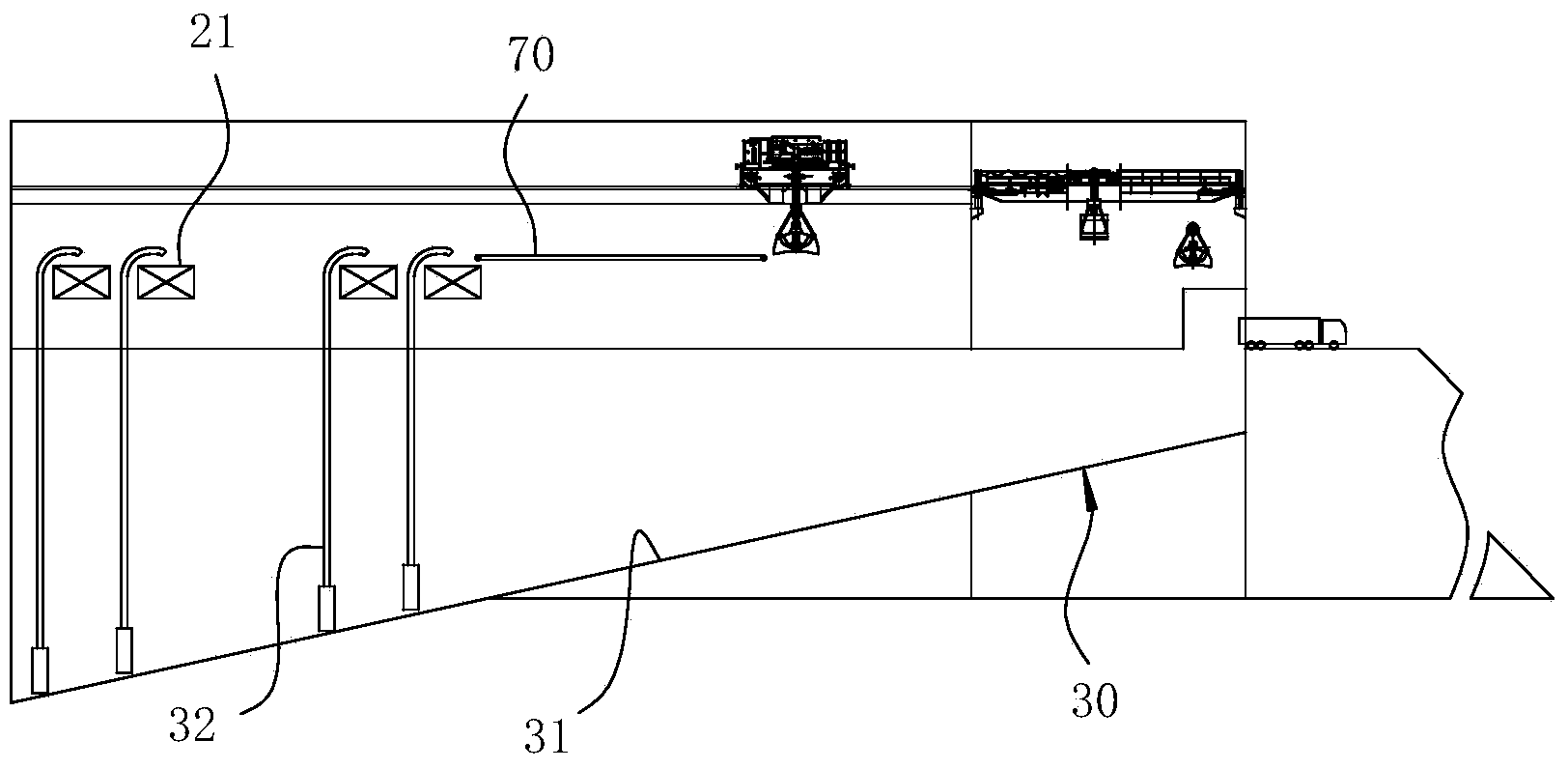

[0044] For ease of understanding, combined here Figure 1-9 Concretely set forth the specific implementation structure and workflow of the present invention:

[0045] Concrete structure of the present invention, as Figure 1-4 As shown, it includes a temporary domestic waste storage 40, a garbage conveying unit 50, and a garbage stacking unit 10 arranged end to end in sequence, wherein a temporary storage for food waste 60 is arranged side by side with the temporary storage for domestic waste 40, and a temporary storage for kitchen waste 60 The discharge end of the discharge end is erected at the garbage conveying unit 50 to ensure that the garbage in the temporary food waste storage 60 and the domestic garbage temporary storage 40 can be simultaneously discharged to the garbage conveying unit 50 and stirred to form mixed garbage. In addition, on the other side of the temporary kitchen waste storage 60 on the domestic waste temporary storage 40, the sludge storage and treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com