Patents

Literature

170results about How to "Improve incineration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

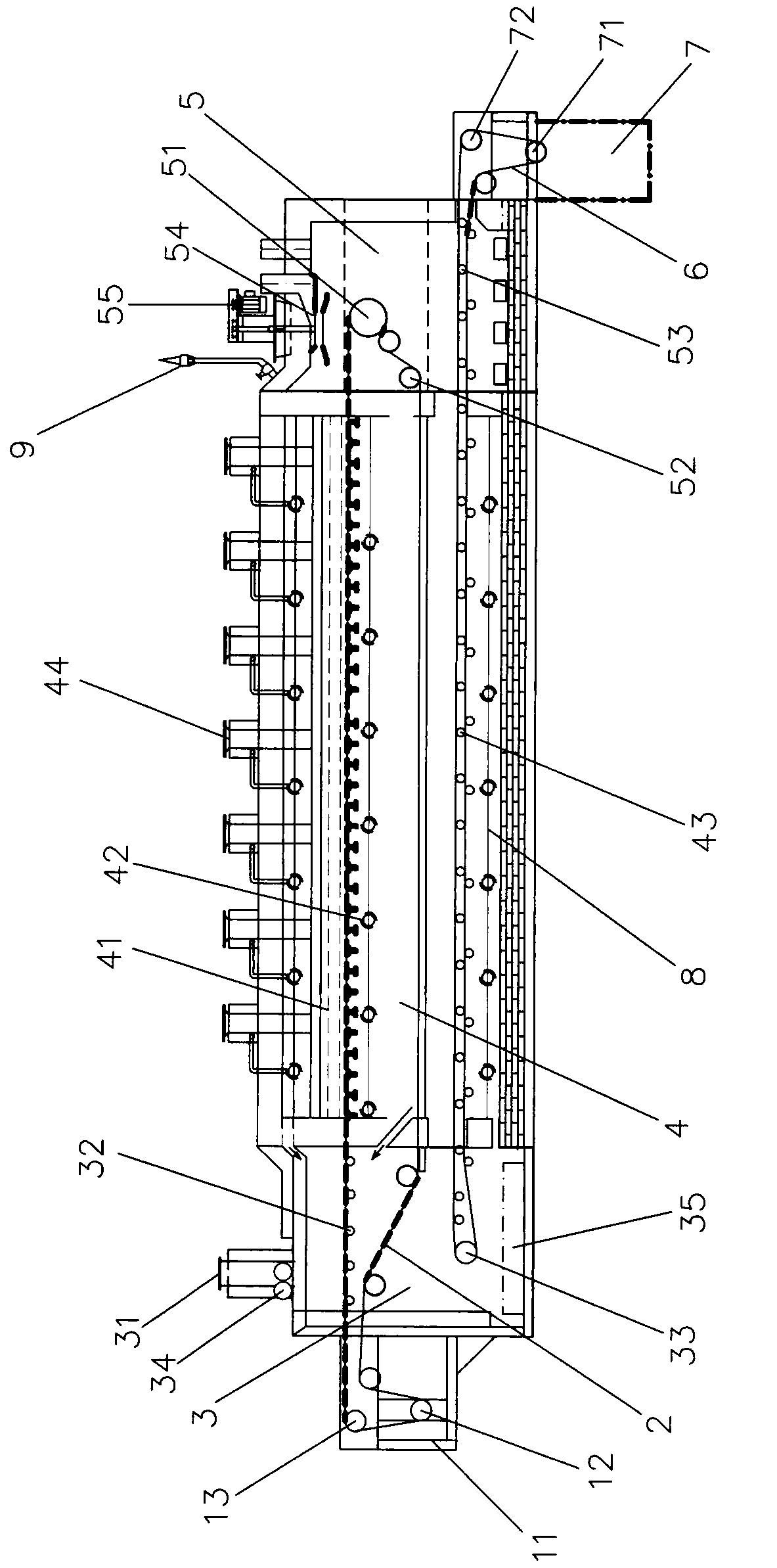

Continuous type transmission sludge burning caking furnace

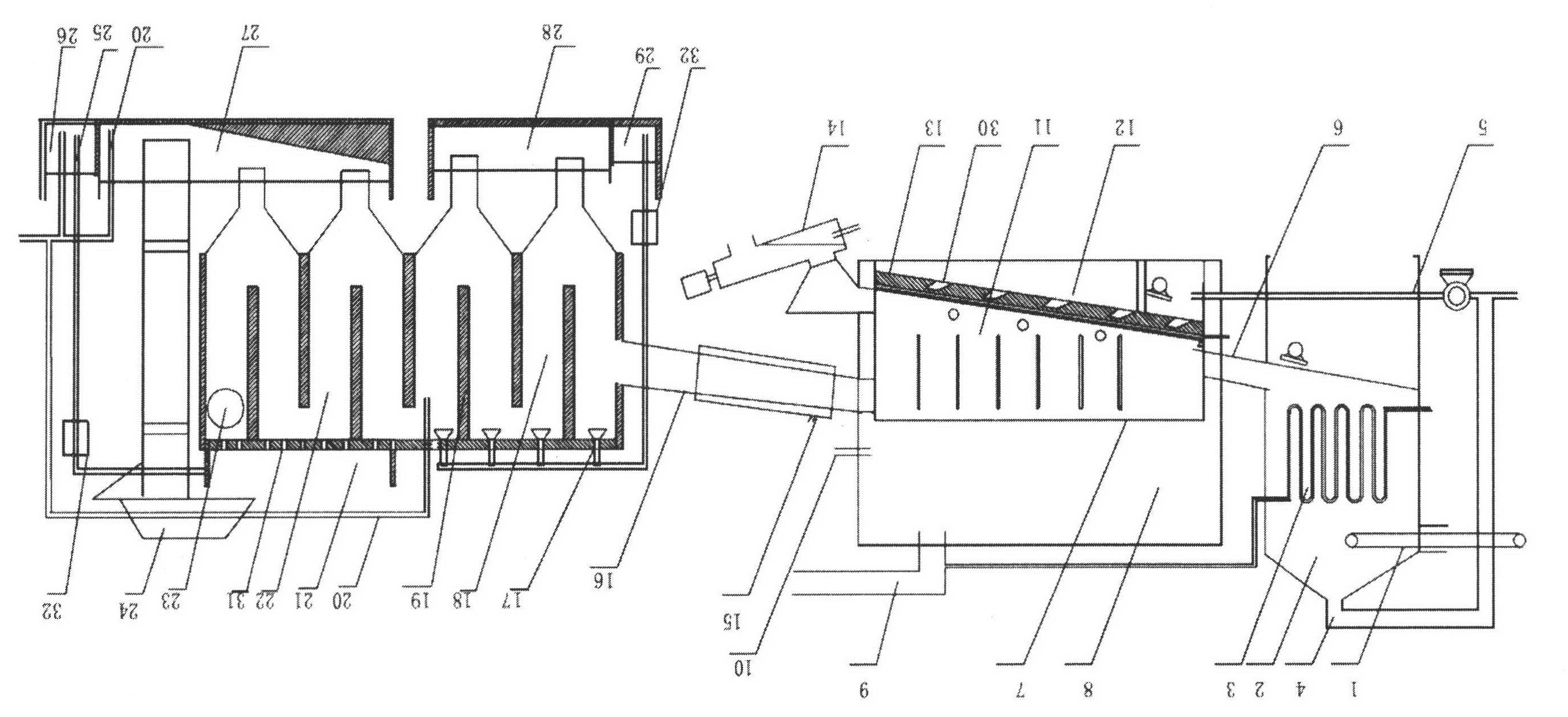

The invention discloses a continuous type transmission sludge burning caking furnace which comprises a feeding device, a transmission wire belt, a furnace body system, a sideward discharging connecting wire belt and a wire belt naturally extending ditch. The feeding device comprises a support, a feeding machine and a feeding guide roller. The furnace body system comprises a preheating chamber, a heating chamber and a steam chamber. A preheating roller and a sideward discharging connecting wire belt driving roller are arranged inside the preheating chamber. A burner nozzle and a heatproof carrier roller are arranged inside the heat chamber. A transmission roller, a tensioning roller and a carrier roller are arranged inside the steam chamber. A driving roller and a support roller are arranged inside the wire belt naturally extending ditch. The transmission wire belt twines the feeding machine, the feeding guide roller, the preheating roller, the transmission roller and the tensioning roller and penetrates the heating chamber in the middle. The sideward discharging connecting wire belt twines the sideward discharging connecting wire belt transmission roller, the heatproof carrier roller, the driving roller and the support roller and penetrates the heating chamber and the steam chamber in the middle. High temperature smoke produced after burning is transmitted to the preheating chamber so that wet sludge is heated and then dried, waste heat is used, energy is saved and burning effect is good.

Owner:苏州瑞翔三禾科技有限公司

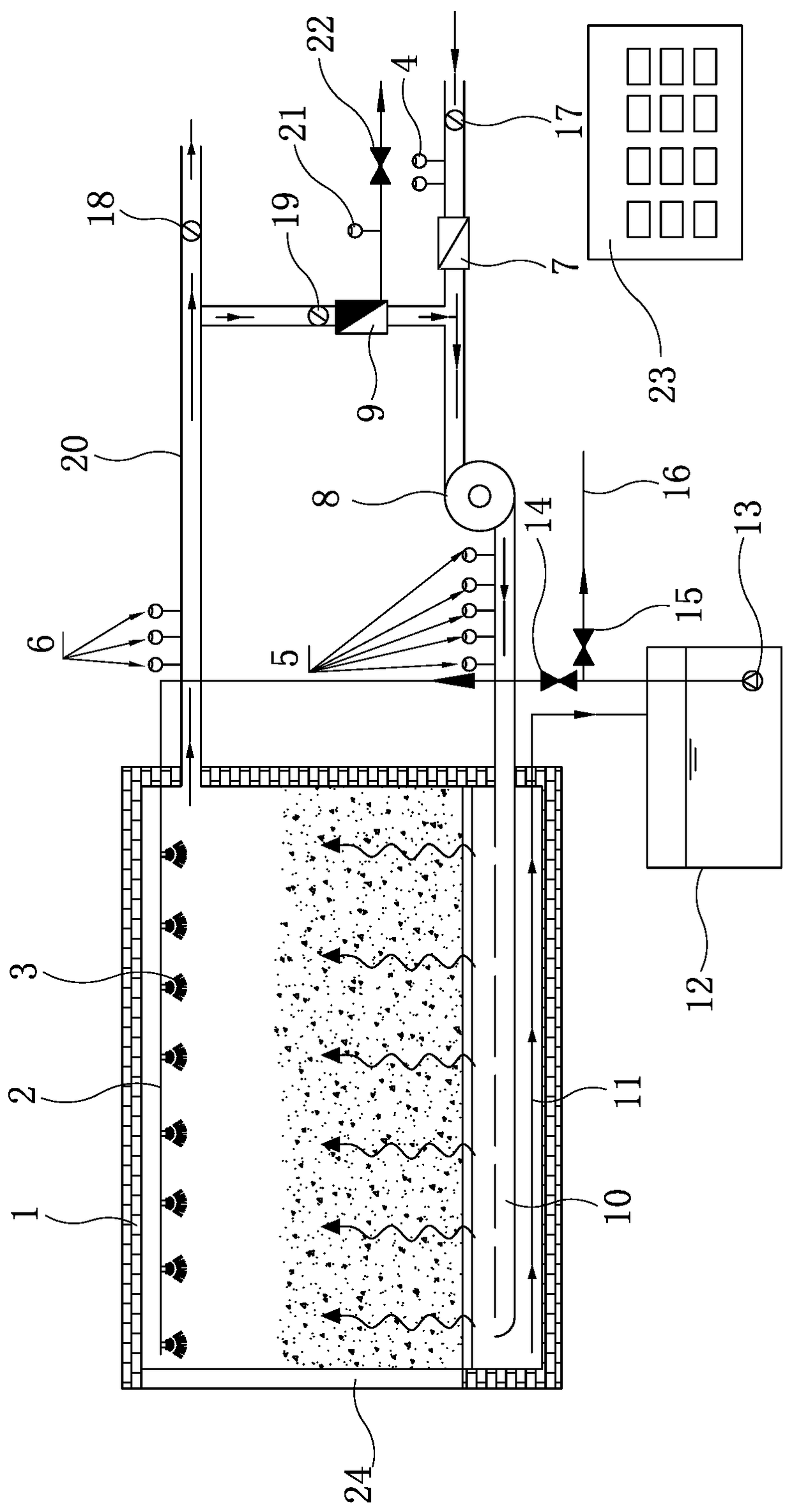

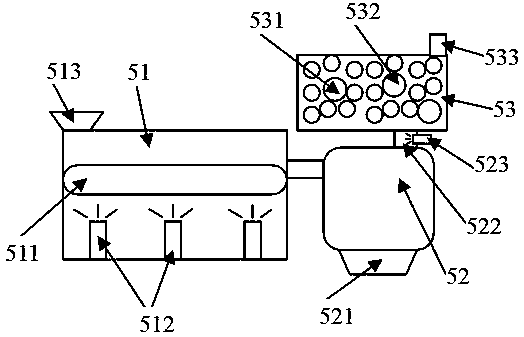

Biological drying treatment device and method for domestic garbage

PendingCN109201706AAchieve harmless purposeTo achieve the purpose of reducingSolid waste disposalHigh concentrationAir monitoring

The invention discloses a biological drying treatment device and method for domestic garbage. The biological drying treatment device comprises a biological drying chamber, a wastewater evaporation system, a condensation conversion system, an auxiliary system, an online exhaust gas and supply air monitoring system, an exhaust gas and supply air cyclic utilization system, and an automatic productionand distribution control system. According to the invention, wastewater evaporation and condensation conversion technologies of the invention can convert high-concentration percolate wastewater intolow-concentration condensed wastewater, so wastewater treatment difficulties and treatment cost are lowered; online monitoring and cyclic utilization technologies can reduce the supply volume of a fresh air source, decrease the amount of exhaust gas treated by an end exhaust gas treatment system and lower the cost of exhaust gas treatment; and an automatic distribution control system (DCS) can realize on-line monitoring of the parameters of a biological drying production process, centralized control of remote terminals and automatic execution of procedures, so the automation management level of a project is improved.

Owner:厦门市联谊吉源环保工程有限公司

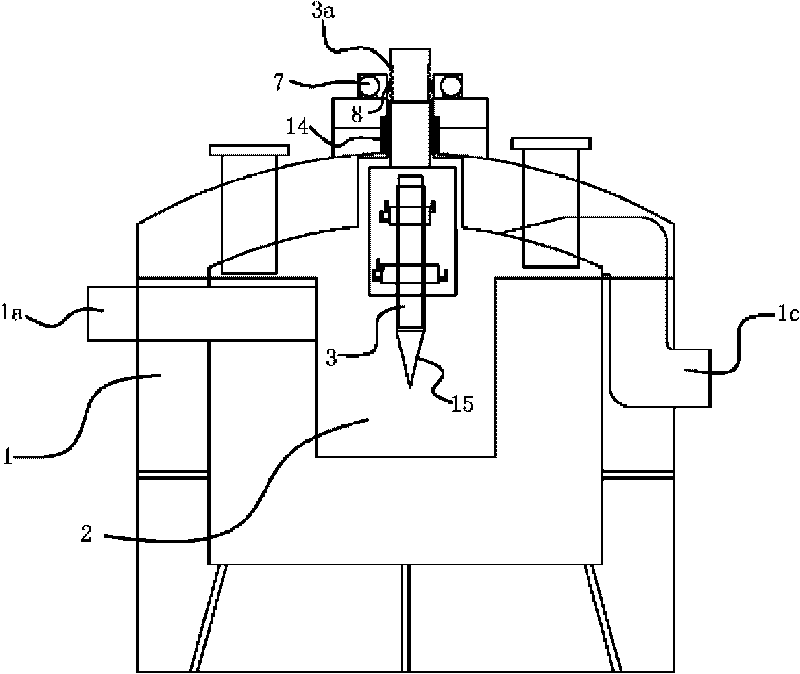

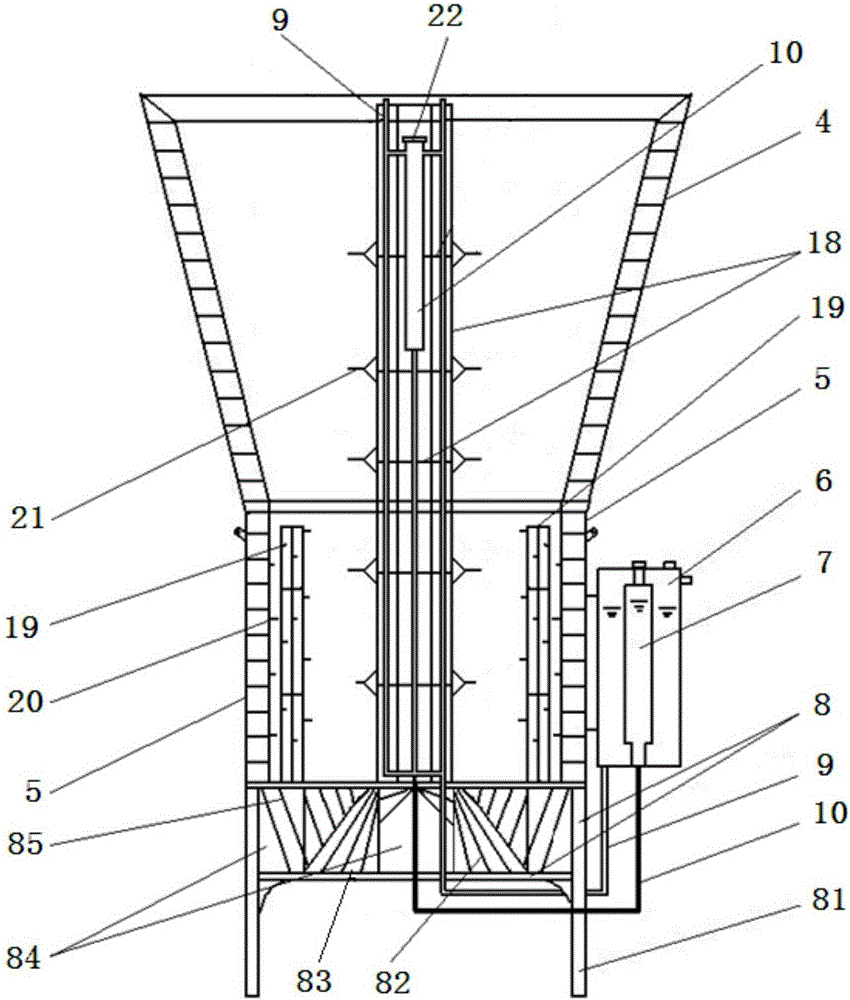

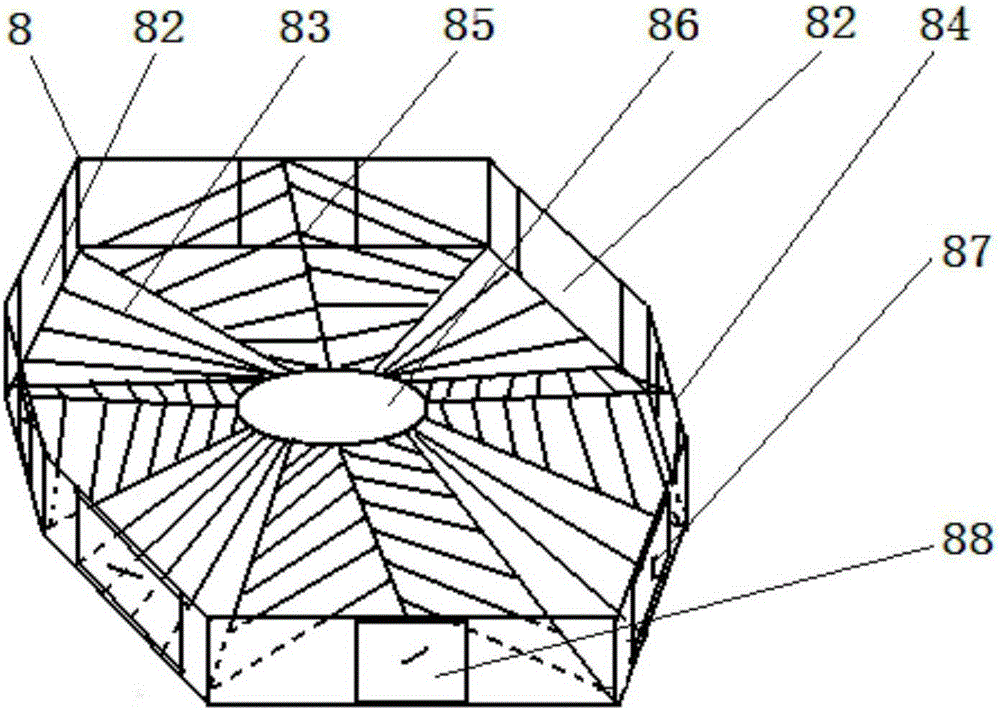

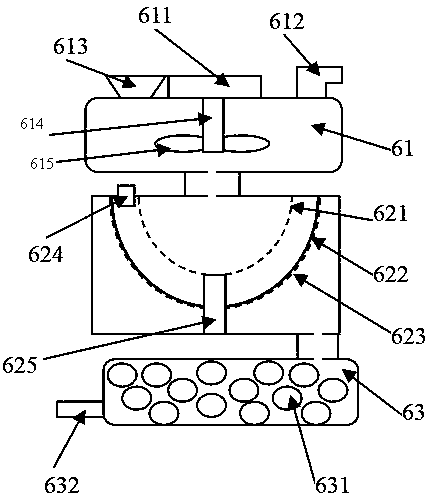

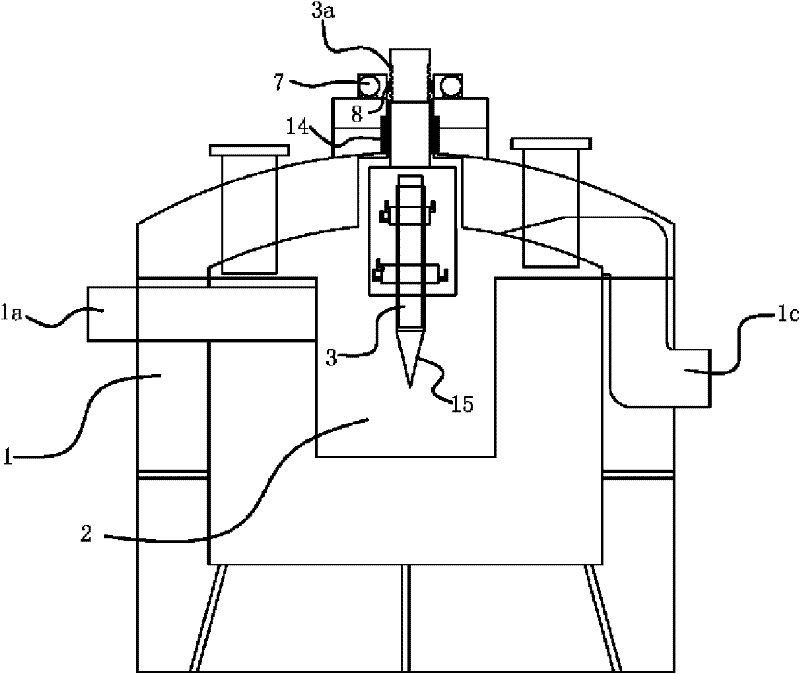

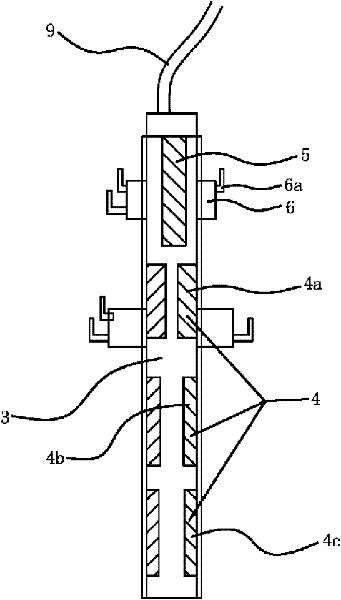

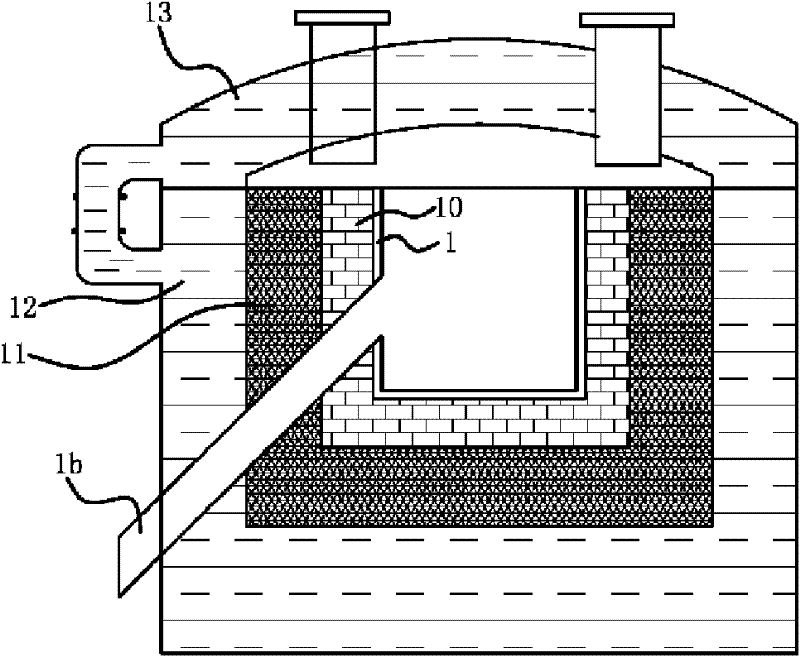

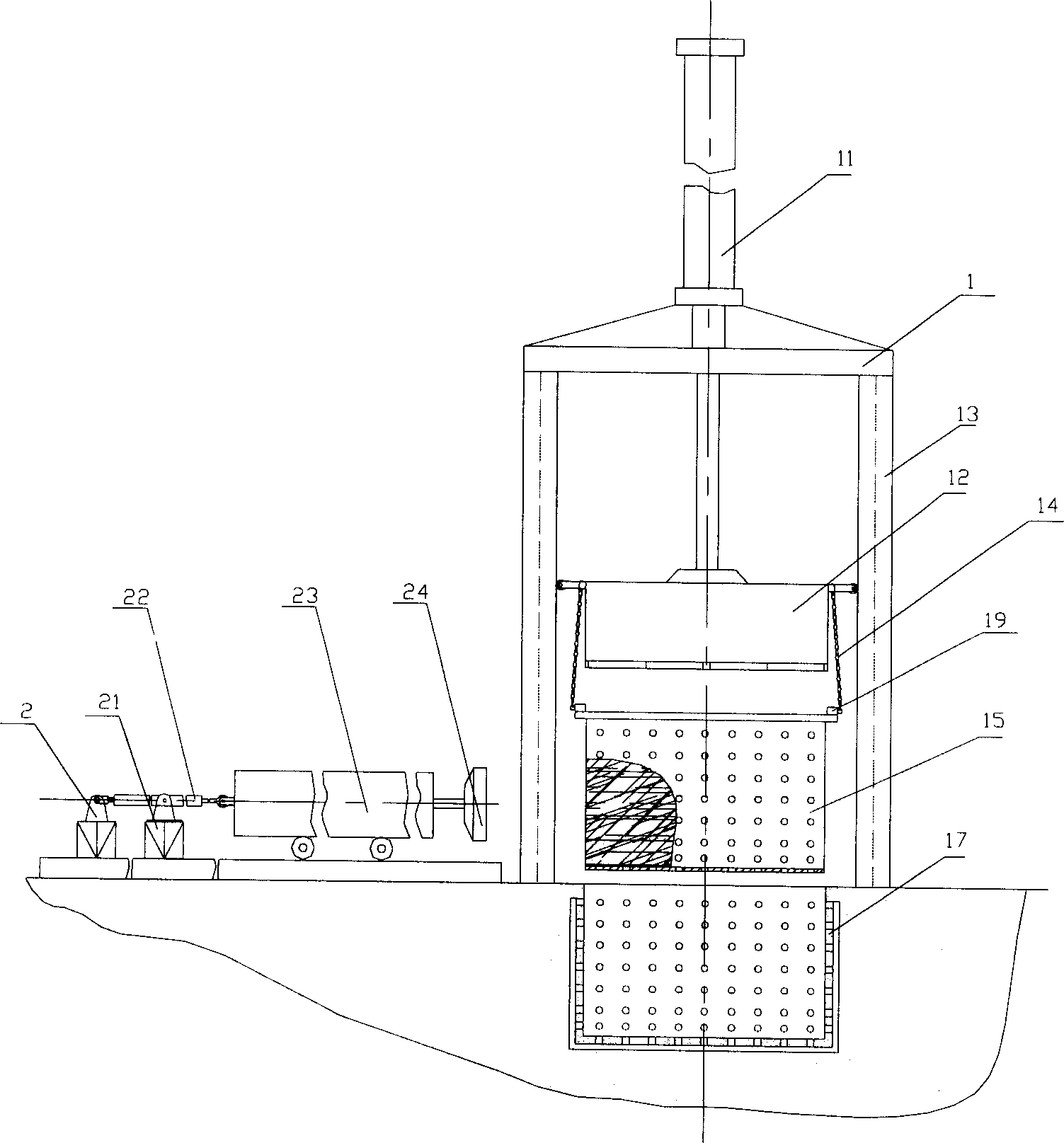

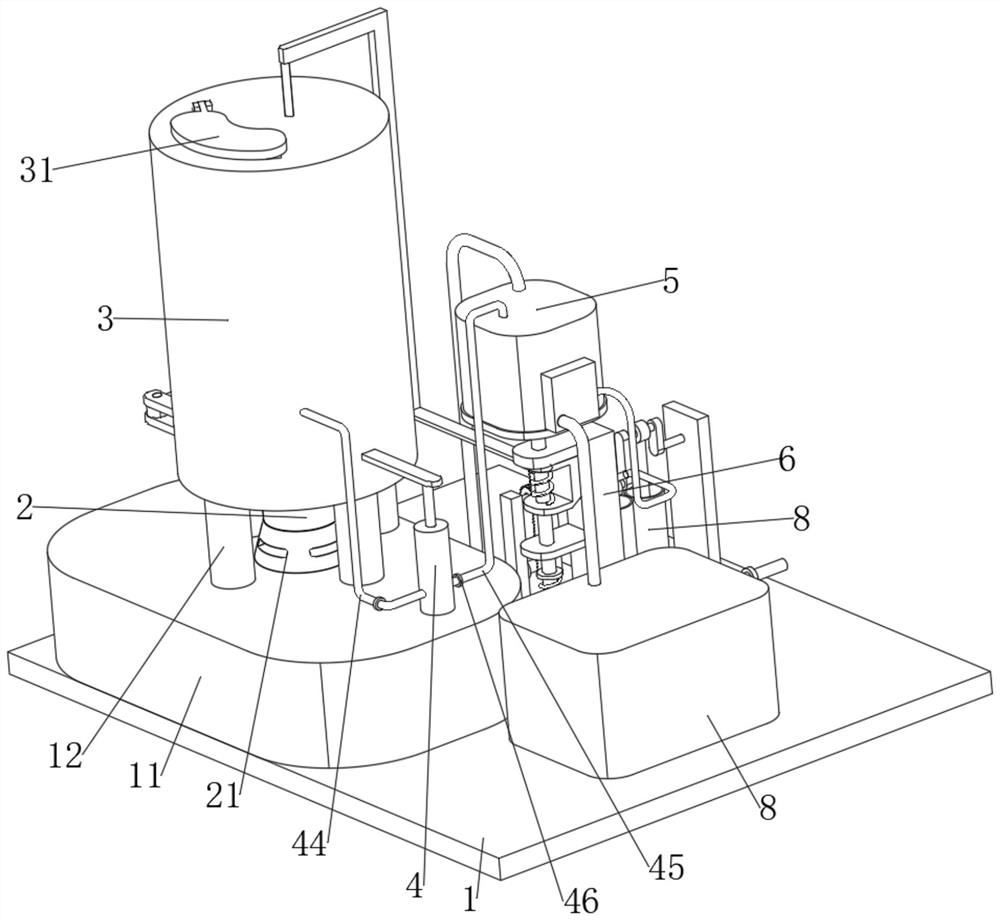

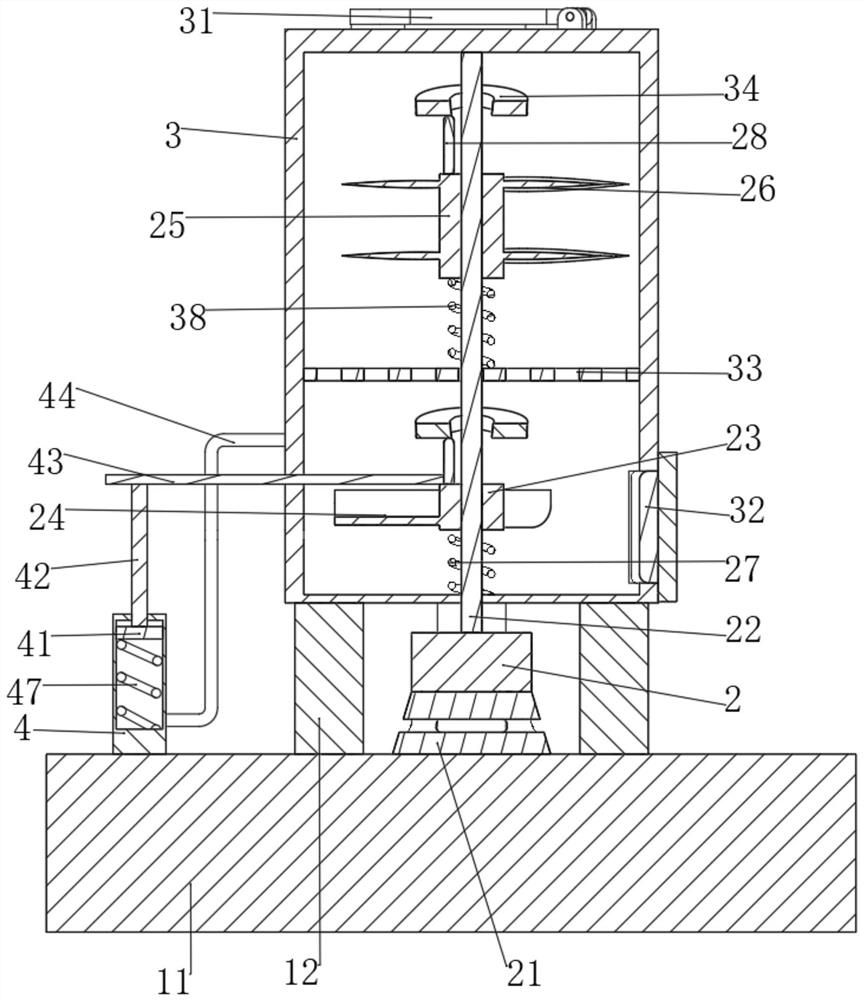

Plasma melting cracking treating equipment

ActiveCN101737786ABurn completelyImprove incineration effectIncinerator apparatusPlasma flameIncineration

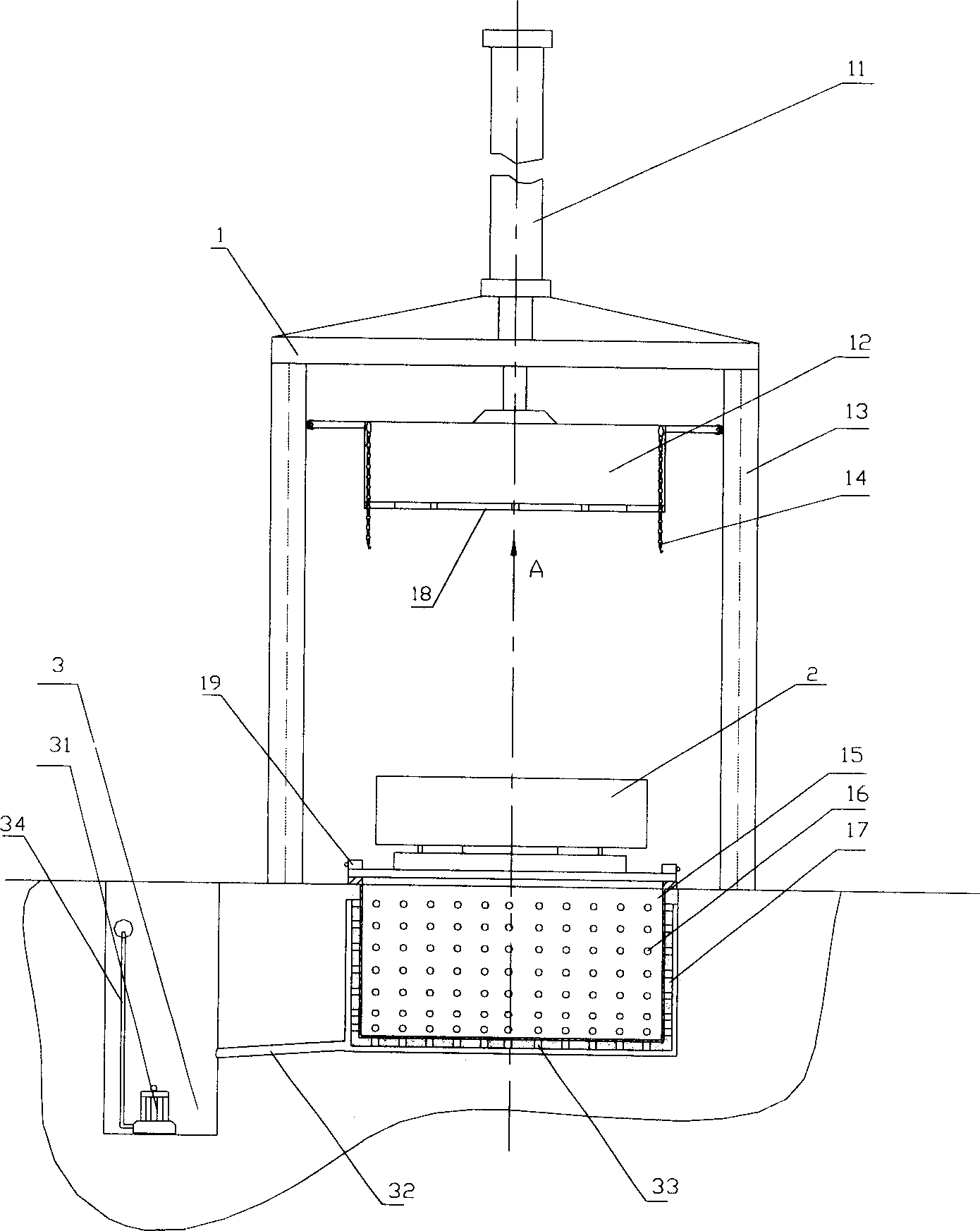

The invention provides plasma melting cracking treating equipment belonging to the technical field of machines and solving the technical problems of low incineration temperature, poor incineration effect, insufficient incineration and the like of a traditional incineration furnace. The plasma melting cracking treating equipment comprises a furnace body with a charging port and a discharging port, wherein the furnace body is internally provided with an incineration cavity communicated with the charging port and the discharging port; the furnace body is also provided with a gas outlet communicated with the incineration cavity; the top of the furnace body is also provided with a plasma torch generator capable of generating plasma flames; one end of the plasma torch generator penetrates into the incineration cavity; and the other end penetrates out of the furnace body and is connected with a lifting mechanism capable of driving the plasma torch generator to lift upwards and downwards. The treating equipment has the advantages of higher flame temperature, more sufficient incineration, higher incineration efficiency and the like.

Owner:TAIZHOU WEIBO ENVIRONMENTAL PROTECTION EQUIP TECH

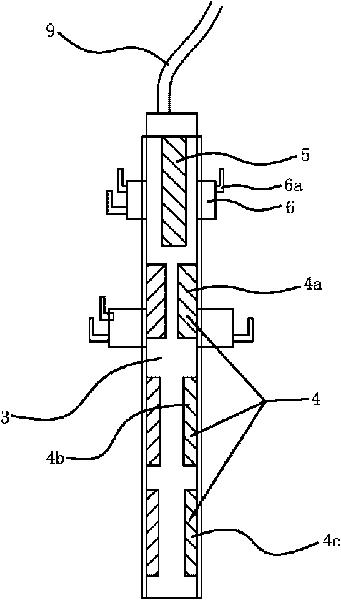

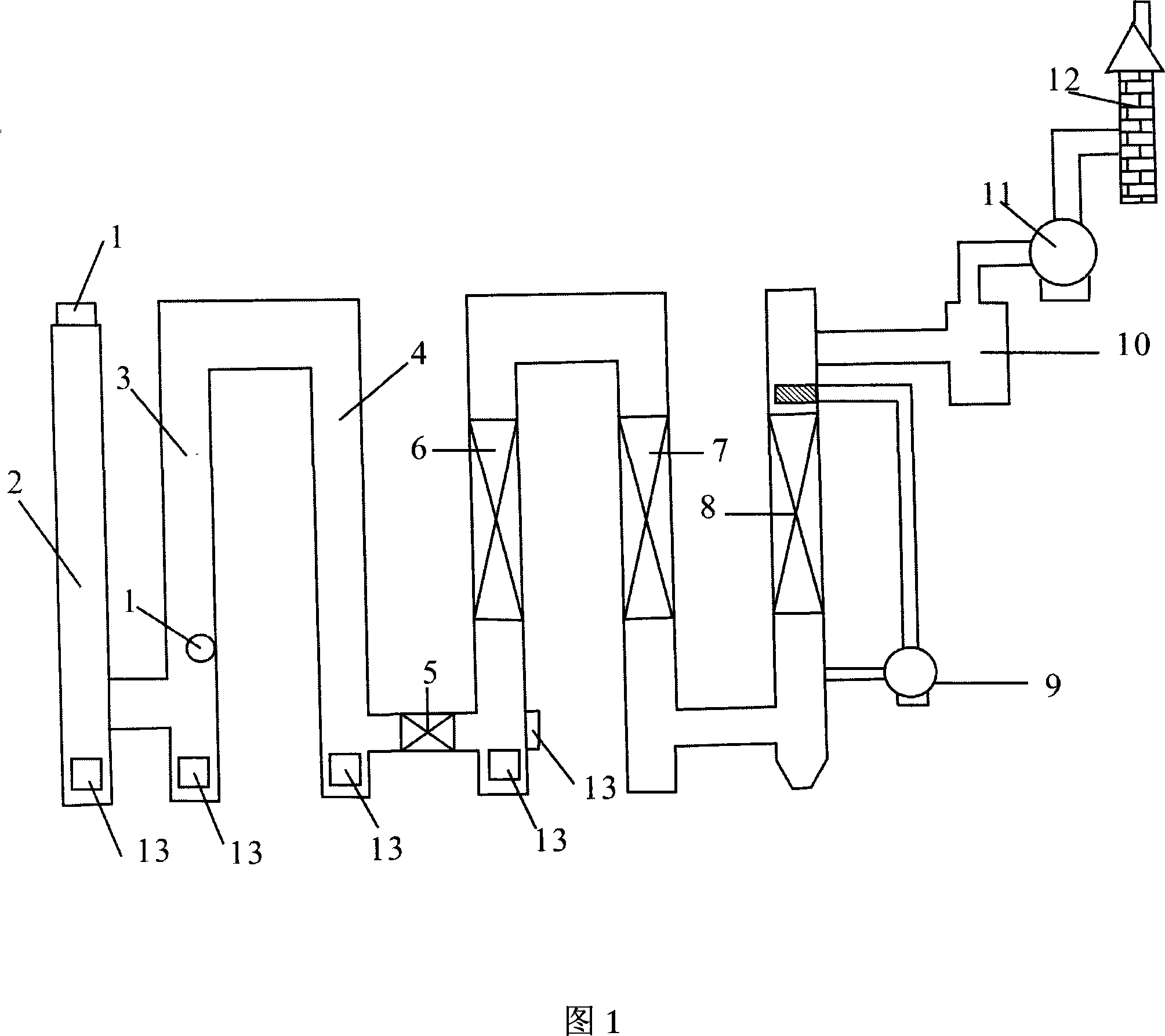

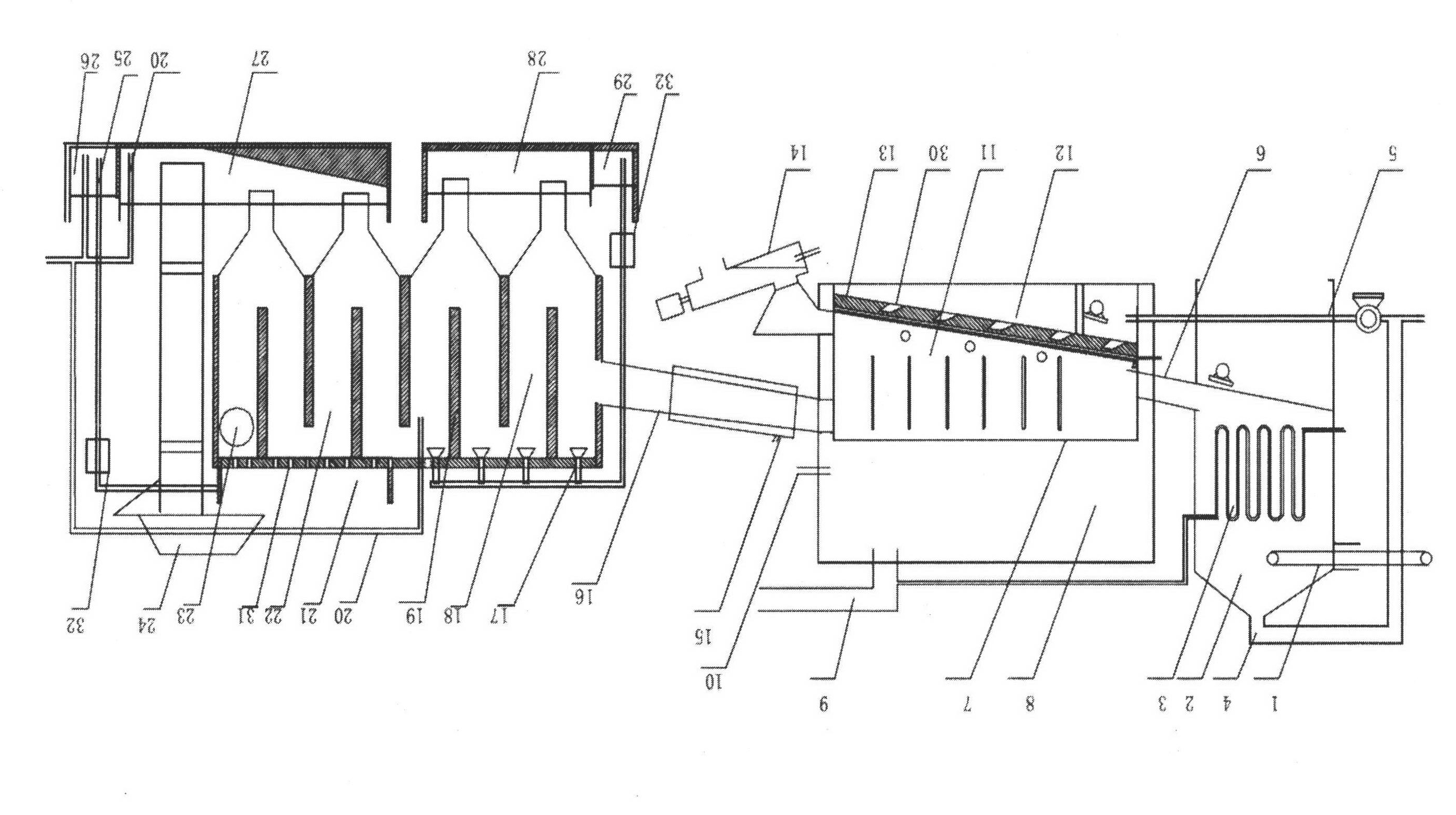

High concentration organic waste liquid burning process and device

ActiveCN101078520AReduce generationIncineration effect is goodIncinerator apparatusHigh concentrationLiquid waste

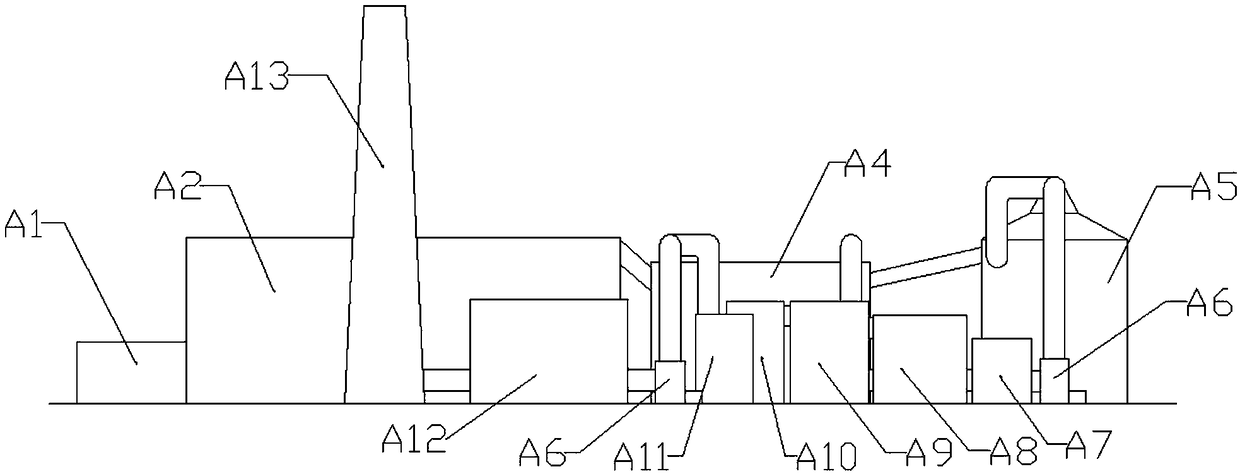

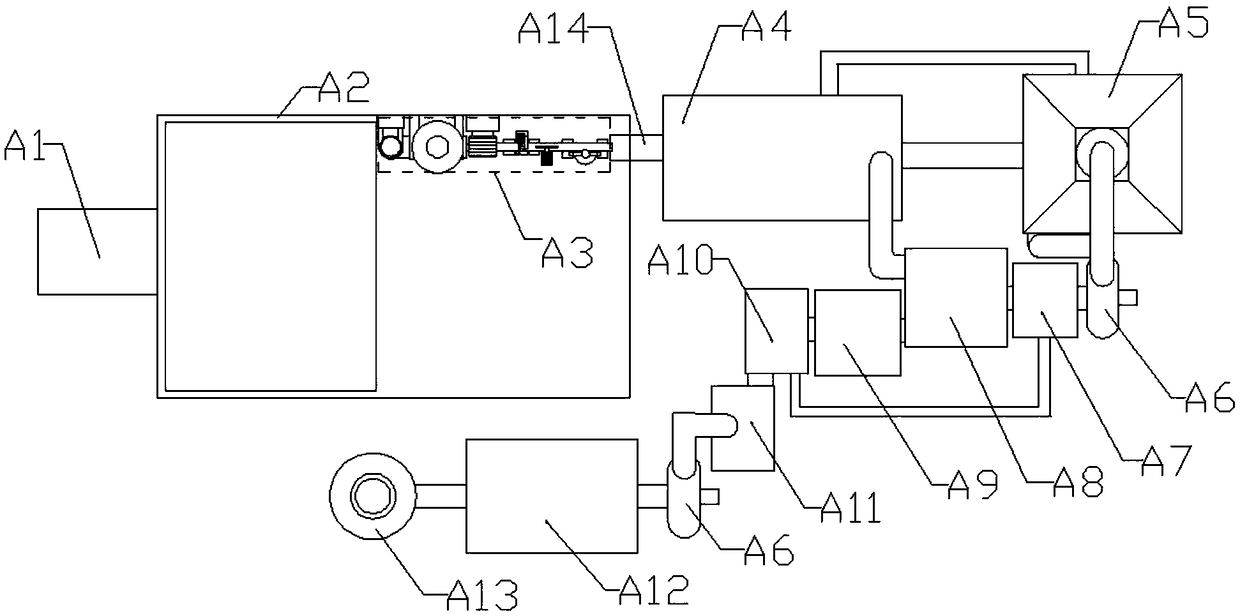

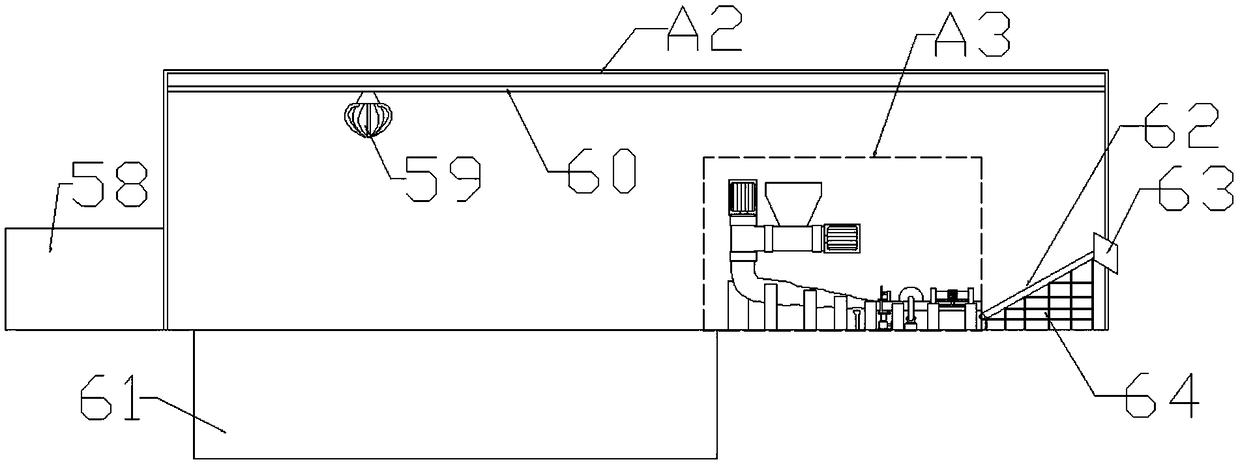

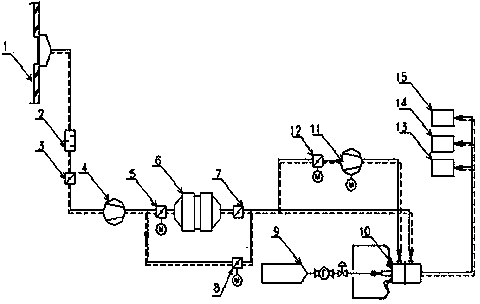

The invention discloses a burning process for high-concentration organic waste liquid and the device, characterized in that (1)double incinerators, which are incinerator 2 and incinerator 3, are set; burning machine 1 is set at the top of incinerator 2 and the middle-lower end of incinerator 3; whereinto lower ends of incinerators 2 and 3 are connected with pipes; (2) sedimentation house 4 is set, whose top end is connected with the top of incinerator 3; the bottom end of sedimentation house 4 is connected with the recovery section for residual heat; the other end of said recovery section for residual heat is connected with washing tower 8; the top end of washing tower 8 is connected with separating jar 10, induced fan 11 and chimney 12 in turn. The technology adopts high-efficiency spraying burning technology, waste heat recovery technology and smoke treating technology integrally and creatively under the foundation that waste burning technology is developed successfully. It has good treating effect for high-concentration refractory organic waste water, high-concentration salt-contained organic waste water, and residual liquid and waste oil in rectifying reactor. And it can make use of waste heat to generate steam. The effect of energy saving is obvious.

Owner:曹乐季

Environment-friendly efficient waste incinerator

The invention discloses an environment-friendly efficient waste incinerator. The environment-friendly efficient waste incinerator comprises a lower incinerator body part, an upper incinerator body part, an internal chimney, a base, an incinerator cover and an external chimney. The upper incinerator body part and the lower incinerator body part of an incinerator body are welded into a whole. The internal chimney is arranged in the middle of the lower incinerator body part and the middle of the upper incinerator body part. A combustion chamber is formed by the lower incinerator body part and the internal chimney. Refractory bricks are arranged on the periphery of the lower incinerator body part and the periphery of the upper incinerator body part. The bottom end of the lower incinerator body part is connected with the base. Both the upper surface and the lower surface of the base are open. The incinerator cover is arranged on the upper incinerator body part. The external chimney is arranged at the top of the incinerator cover in a connected mode. A water tank is arranged outside the lower incinerator body part. An oil tank is further arranged in the water tank. A water pipe and an oil pipe are arranged in the internal chimney. The water pipe is communicated with the water tank. The oil pipe is communicated with the oil tank. According to the environment-friendly efficient waste incinerator, oil in the oil pipe can be gasified by means of heat generated during waste combustion, so that waste on the upper portion of the incinerator body can be combusted for the second time, continuous waste combustion is achieved, incineration is thorough and rapid, and the incineration effect is good; pollution to the environment is small, and the environment-friendly efficient waste incinerator is suitable for waste treatment in village and town communities, schools and hospitals.

Owner:都安通达环保设备制造厂(普通合伙)

Medical waste recovery treatment device

ActiveCN108435755AAchieving processing powerAchieve partial recyclingSolid waste disposalMedical waste disposalMedical wasteClassification treatment

The invention relates to a medical waste recovery treatment device. The medical waste recovery treatment device comprises a rough crushing cavity, a fine crushing cavity, a grinding cavity, a sedimentchamber, a flotage treatment device, a liquid treatment device and a sediment treatment device. Crushing is optimized, crushed materials are directly divided into three kinds through comparison withthe water density, classification treatment is carried out on different kinds of waste, medical waste is treated more deeply, and the environment friendliness degree is high.

Owner:张言敏 +1

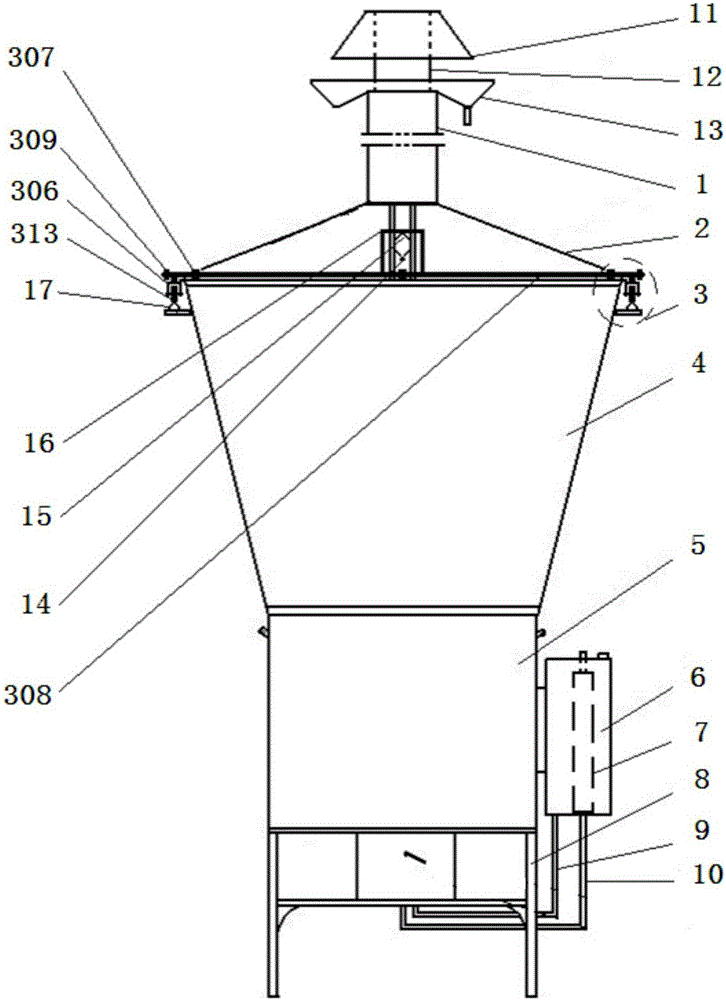

Flue gas recirculation type garbage pyrolysis gasification oxygen-rich incinerator

ActiveCN105333440AImprove heat utilization efficiencyReduce consumptionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberFlue gas

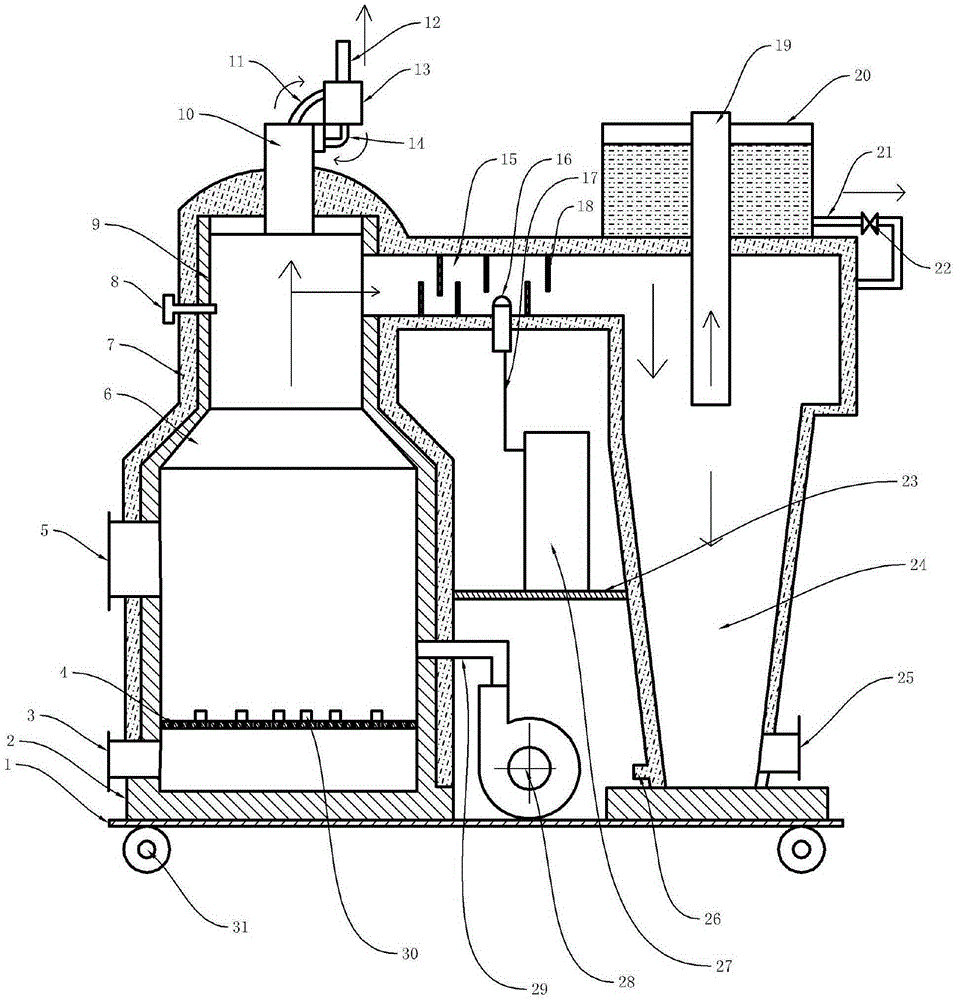

The invention discloses a flue gas recirculation type garbage pyrolysis gasification oxygen-rich incinerator which comprises an incinerator main body, a flue gas recirculation type air feeding system, a flue gas filter device, an oxygen-rich air feeding system, a flue gas waste-heat heat exchanger and a flue gas purifying device, wherein the incinerator main body comprises a combustion chamber I and a combustion chamber II which are respectively used for garbage pyrolysis gasification and incineration of combustible materials; the circulated flue gas is injected into the incinerator through the flue gas recirculation type air feeding system, so that turbulivity in the incinerator is improved, garbage incineration is strengthened, incompletely-combusted pollutants such as a dioxin precursor and the like are reduced, and discharge of the pollutants is reduced. The oxygen-rich air feeding system can increase an incineration temperature, and can reduce consumption of auxiliary fuels; the flue gas filter device and the flue gas purifying device can further reduce discharge of pollutants; and the flue gas waste-heat heat exchanger can recycle flue gas waste heat. The flue gas recirculation type garbage pyrolysis gasification oxygen-rich incinerator can effectively solve the problems that a garbage thermal value is low, water content is high, an incineration temperature caused by low oxygen content in air is low, combustion efficiency is poor, consumption of auxiliary fuels is high, discharge of pollutants is not up to standard, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

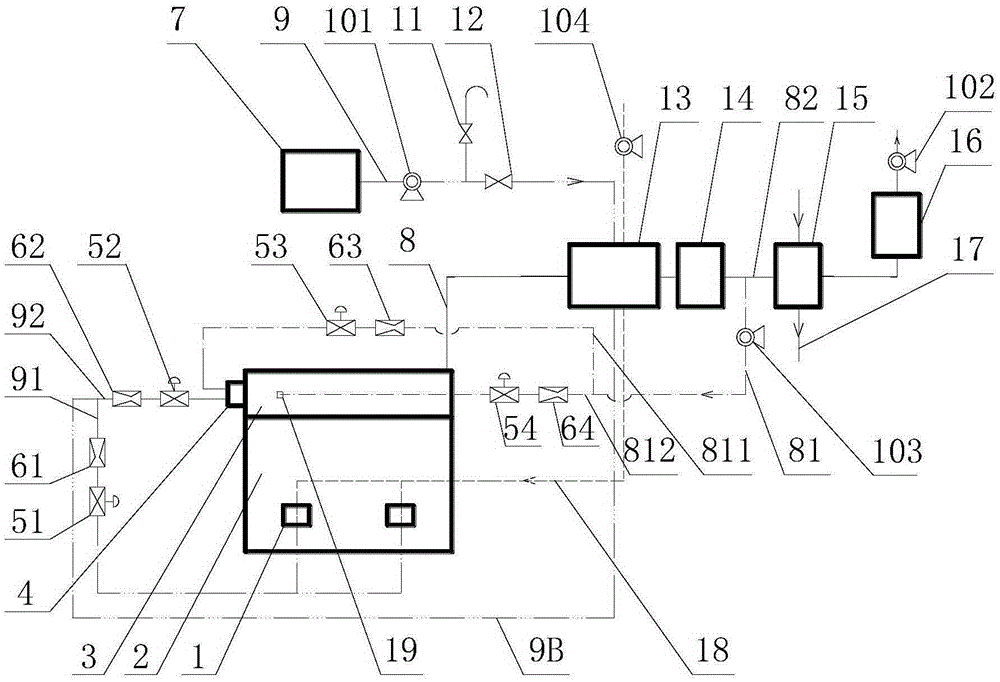

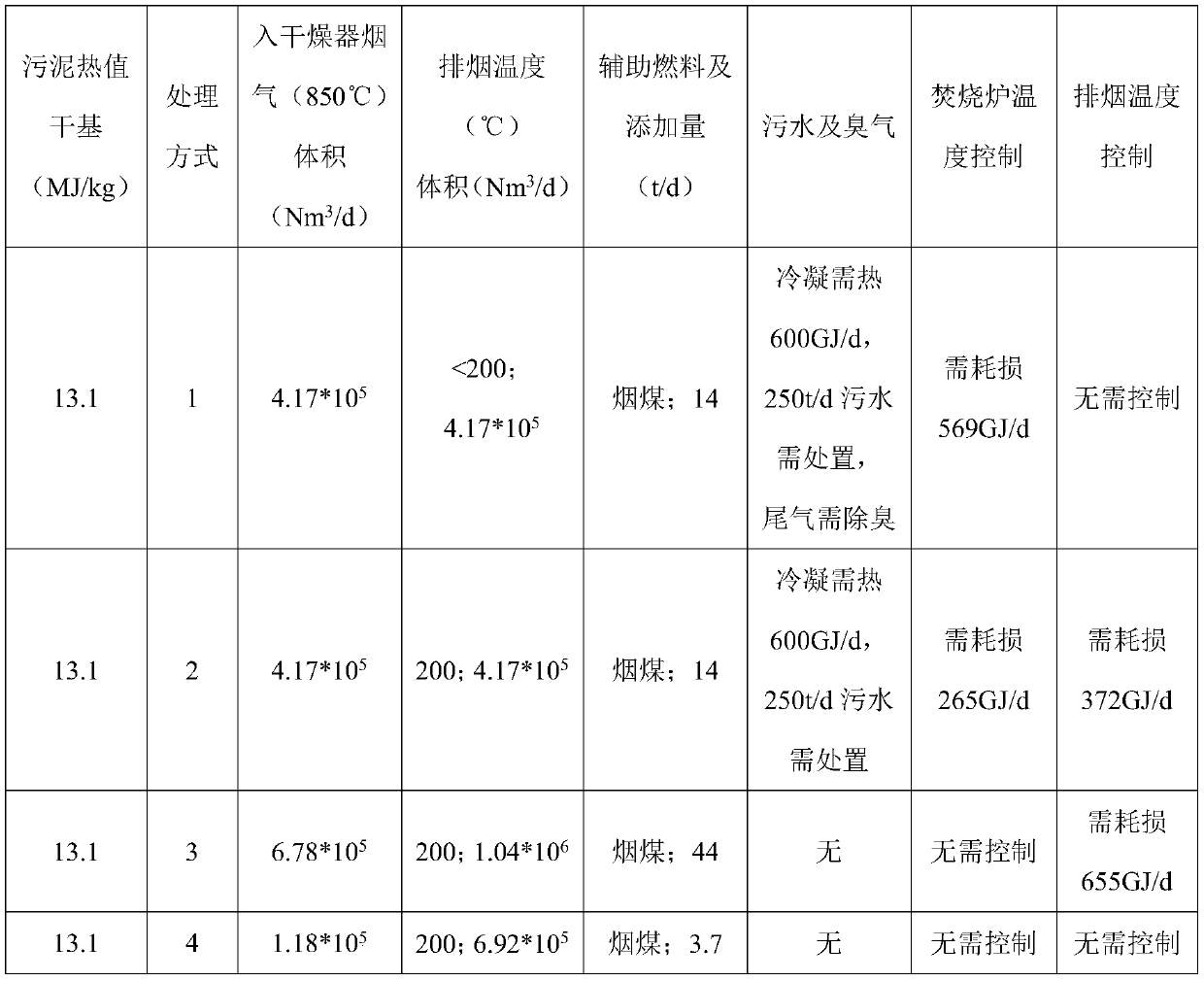

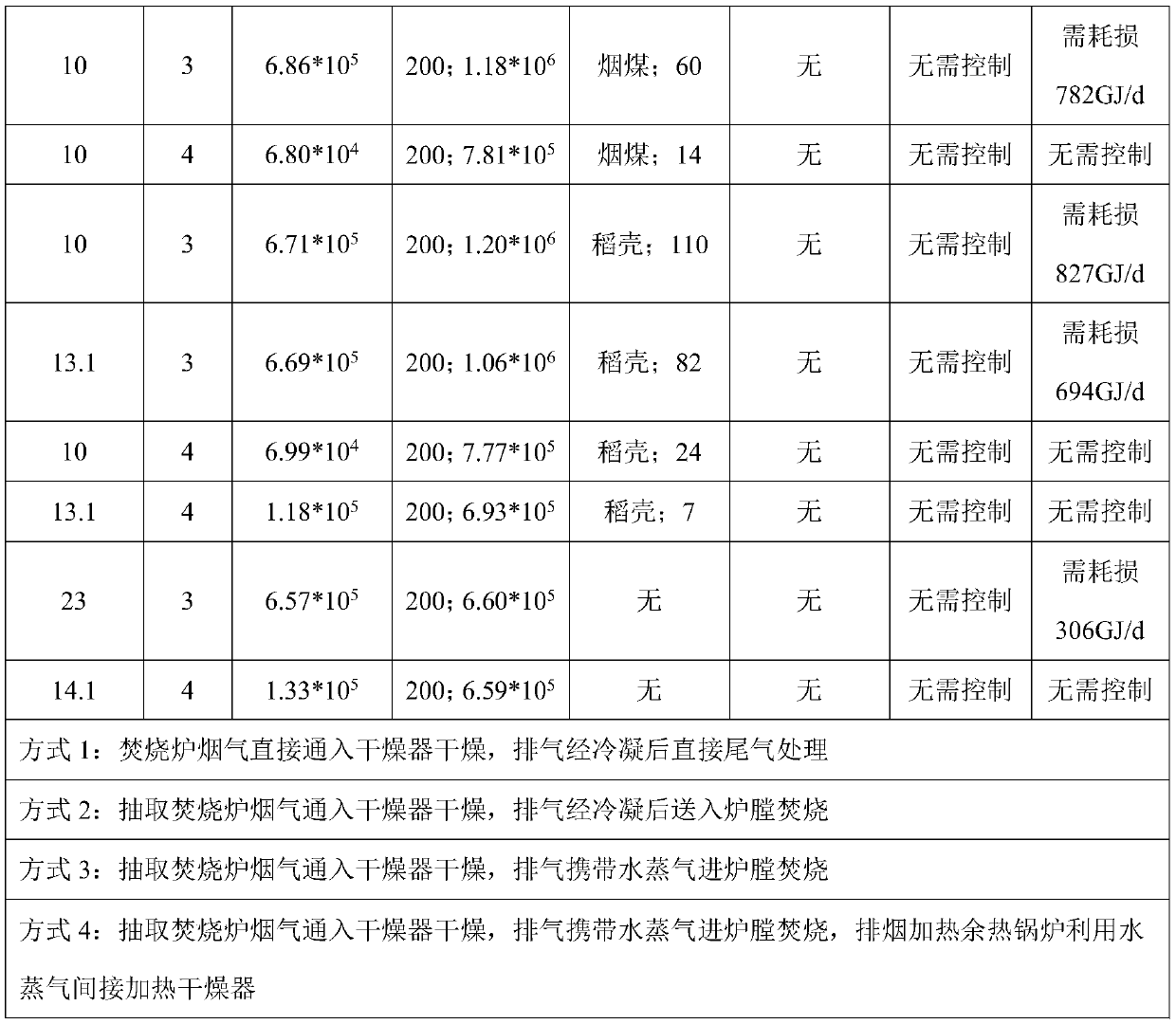

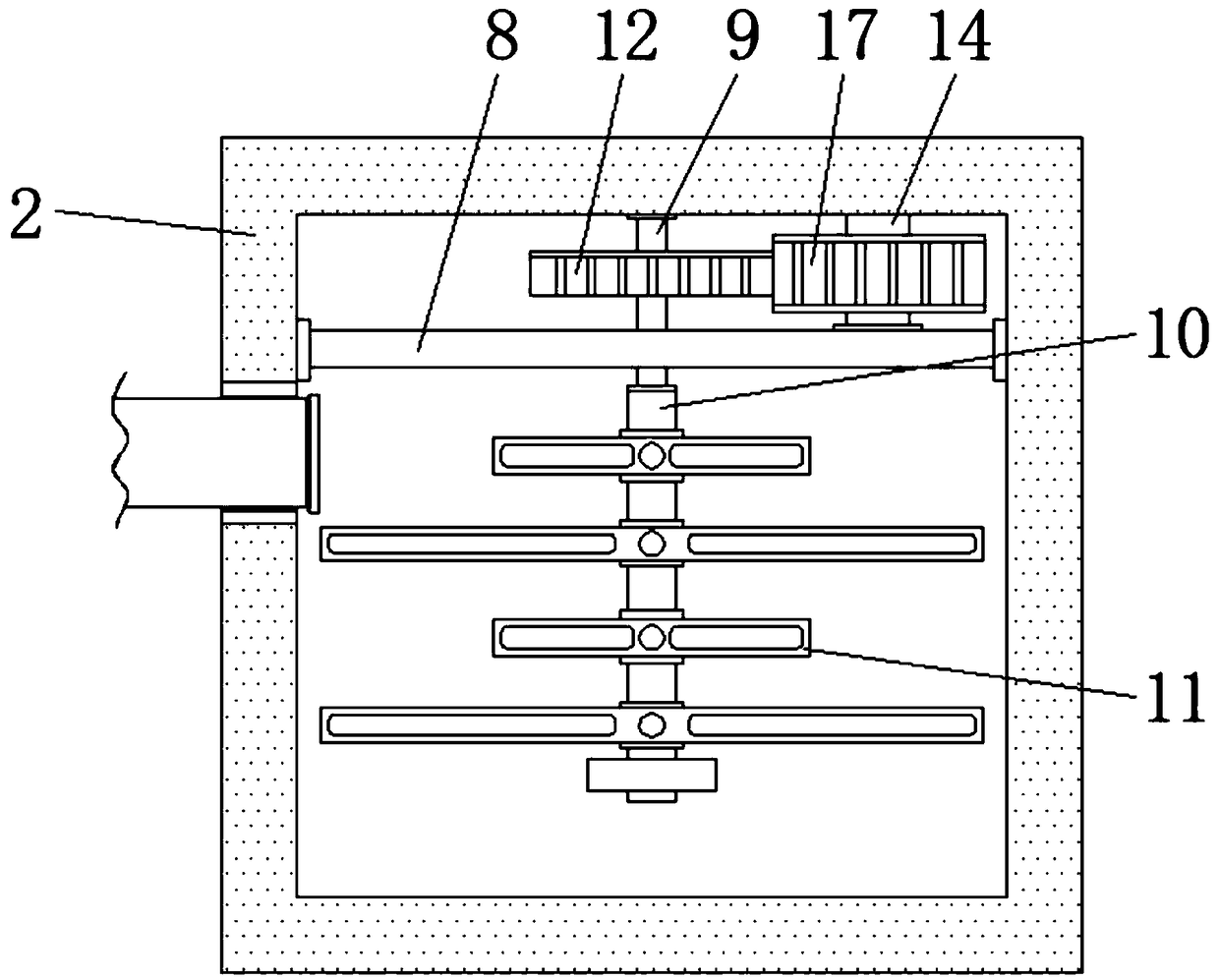

Drying and incineration system, and drying and incineration method for sludge

InactiveCN111288463ASave dehumidification and deodorization costsSave heating mediumSludge treatment by de-watering/drying/thickeningSludge dryingAir preheaterCombustion

The invention discloses a drying and incineration system, and a drying and incineration method for sludge. The system comprises a dryer used for drying wet sludge, a fluidized bed incinerator used forcarrying out incineration treatment on the dried sludge and exhaust gas of the dryer, a waste heat boiler used for recovering and utilizing high-temperature smoke waste heat generated due to incineration, an air pre-heater used for re-recovering the smoke waste heat and providing hot air combustion-supporting wind for the incinerator, and a tail gas treatment device used for purifying smoke subjected to waste heat utilization and then discharging the smoke, wherein one path of a high-temperature smoke outlet of the incinerator communicates with the dryer, and carries out contact drying on thewet sludge, the other path is connected with a flue of the waste heat boiler, and an exhaust port of the dryer communicates with the incinerator. A part of the high-temperature smoke is circulated inthe dryer and the incinerator, odor of the sludge is brought into the incinerator and directly treated while the sludge is dried by virtue of hot smoke energy, and the system does not need to carry out tail gas deodorization, so that the tail gas dehumidification and deodorization costs are saved; and the whole system realizes adequate energy utilization, and is safe and capable of running for along time.

Owner:SOUTHEAST UNIV

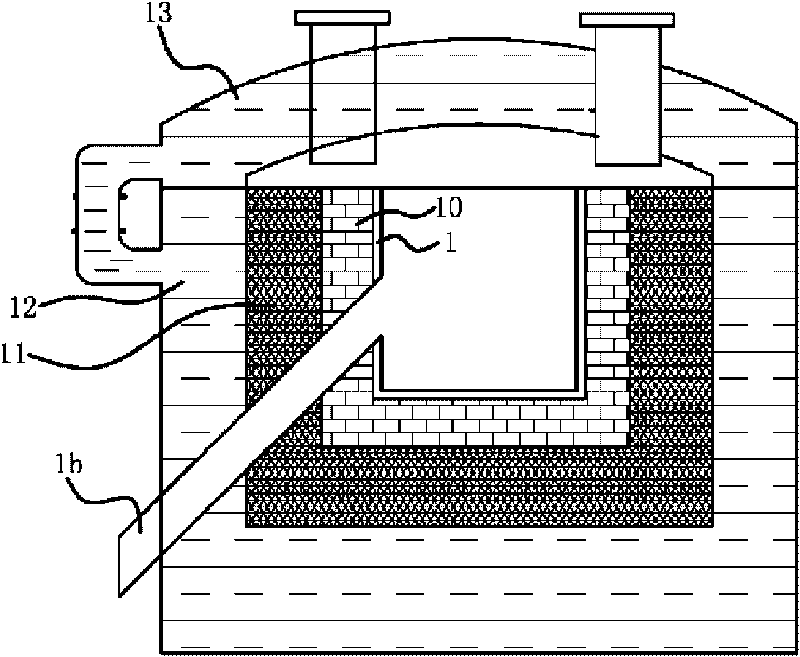

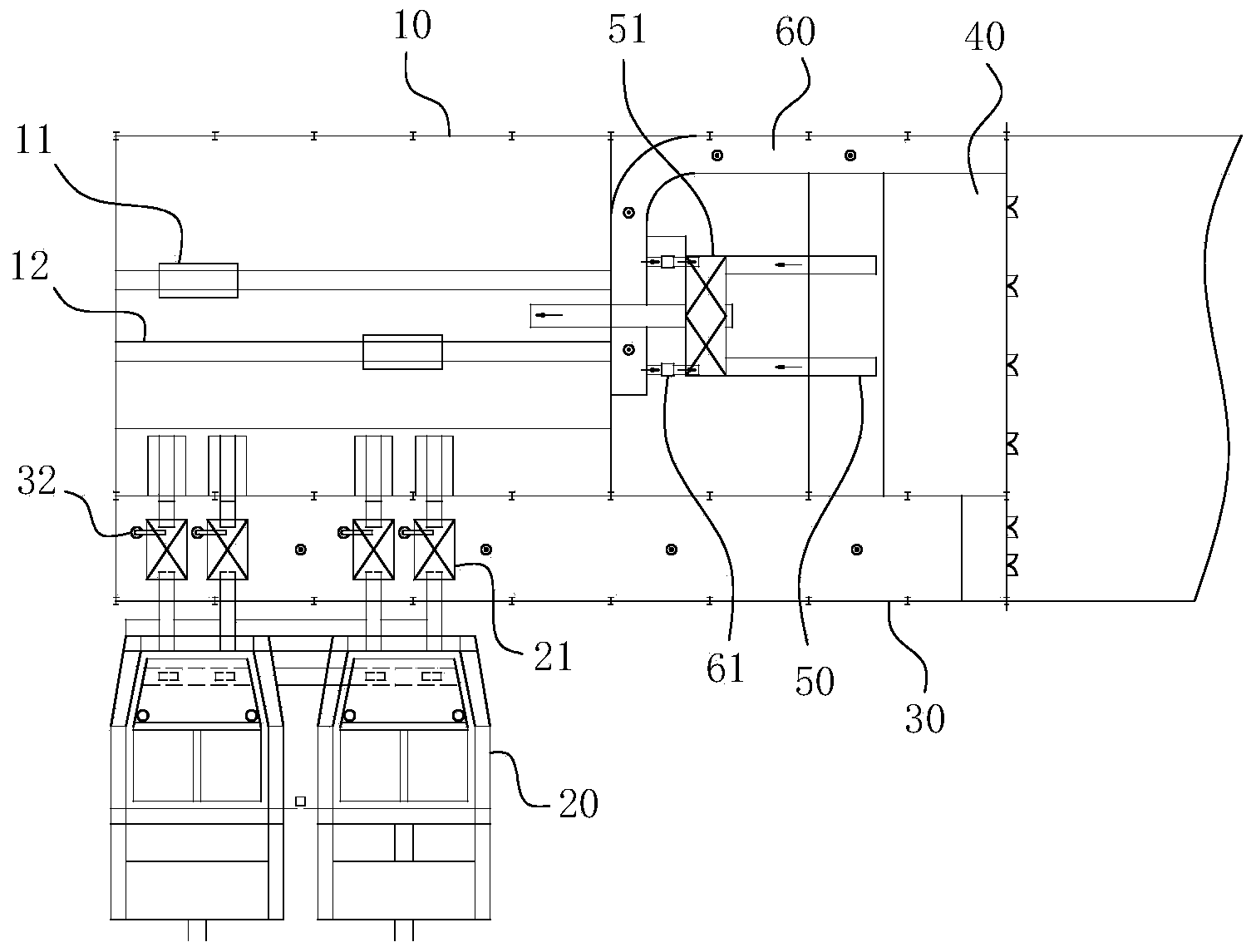

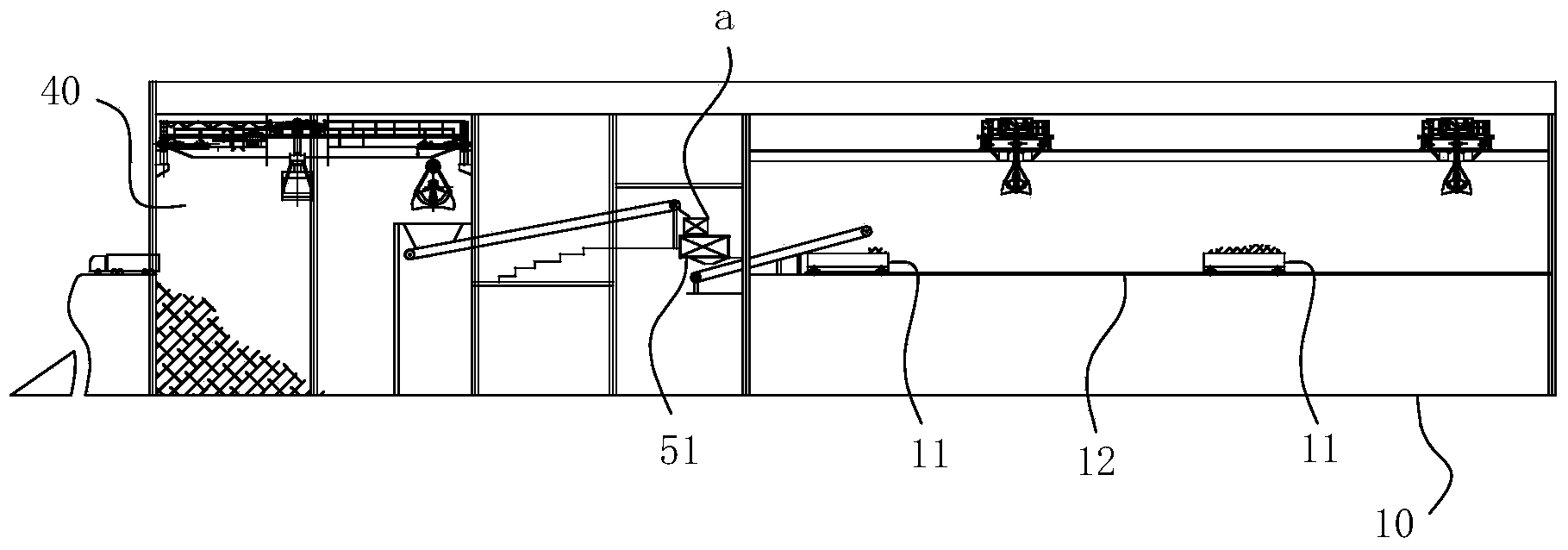

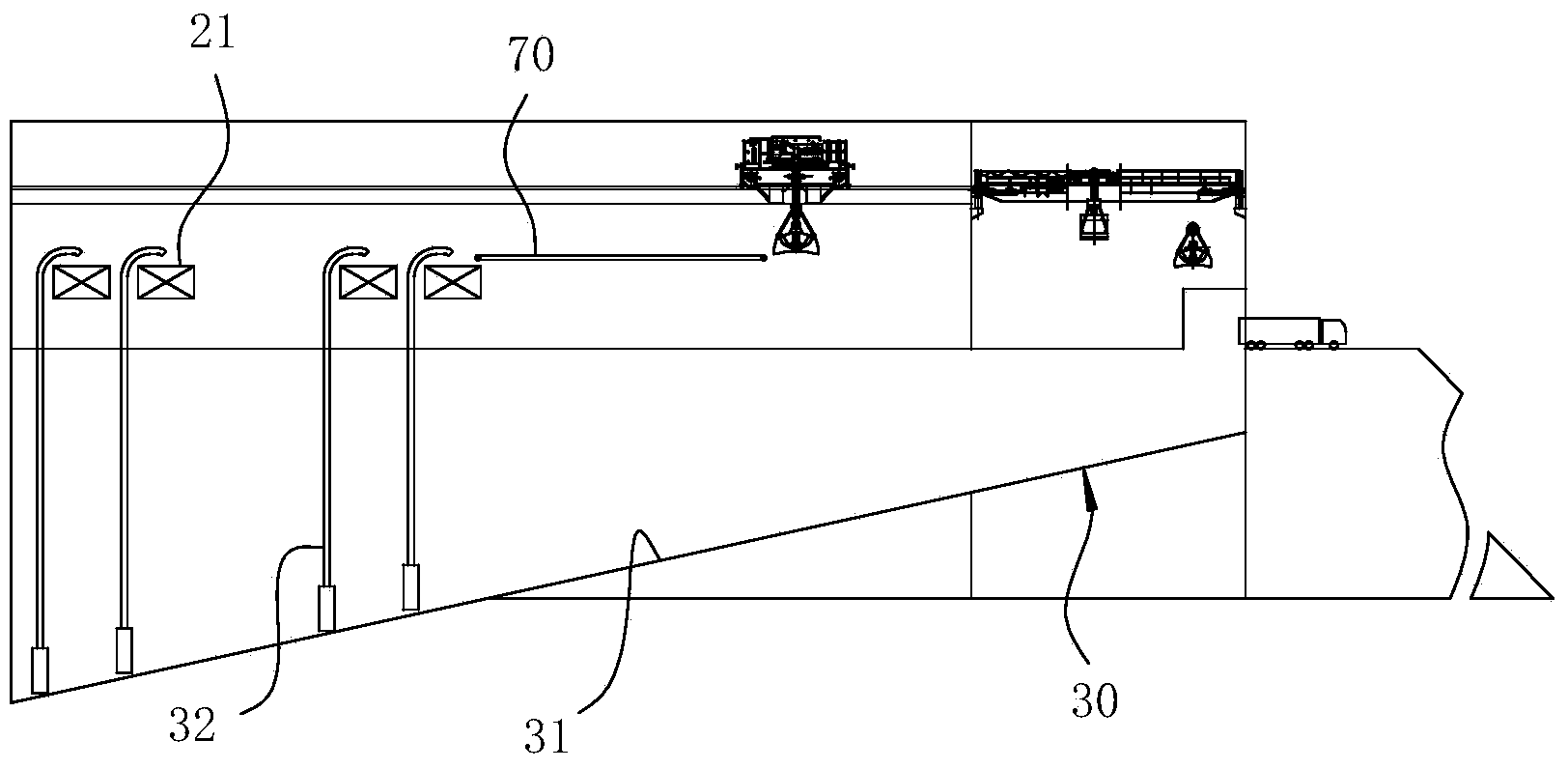

Mixed waste disposal system

InactiveCN103759273AReduce moisture contentHigh calorific valueSolid waste disposalIncinerator apparatusMixed wasteMunicipal solid waste

The invention belongs to the field of municipal solid waste disposal and particularly relates to mixed waste disposal system. The mixed waste disposal system at least comprises a waste pile-up unit used for waste pile-up fermentation and a waste incineration unit used for waste incineration. The mixed waste disposal system further comprises a sludge storage disposal pool, a material sliding ramp used for conveying materials is arranged in the sludge storage disposal pool, and the material sliding ramp is in the shape of an inclined face or a step-shaped structure becoming lower gradually. A sludge feeding end is arranged at the higher end of the material sliding ramp, and the lower end of the material sliding ramp forms a sludge discharging end. The time for sludge to flow from the sludge feeding end to the sludge discharging end along the material sliding ramp is longer than or equal to the number of days for the sludge to undergo set pile-up and warm-up fermentation and aerobic reaction. Both the waste pile-up unit and the discharging end of the sludge storage disposal pool are communicated with the feeding end of the waste incineration unit. Due to the simple and practical structure, mixed incineration disposal effect on municipal sludge and household waste can be achieved efficiently.

Owner:南京溧水石湫机场科技工业园开发有限公司

Plasma melting cracking treating equipment

ActiveCN101737786BBurn completelyImprove incineration effectIncinerator apparatusIncinerationTest equipment

Owner:TAIZHOU WEIBO ENVIRONMENTAL PROTECTION EQUIP TECH

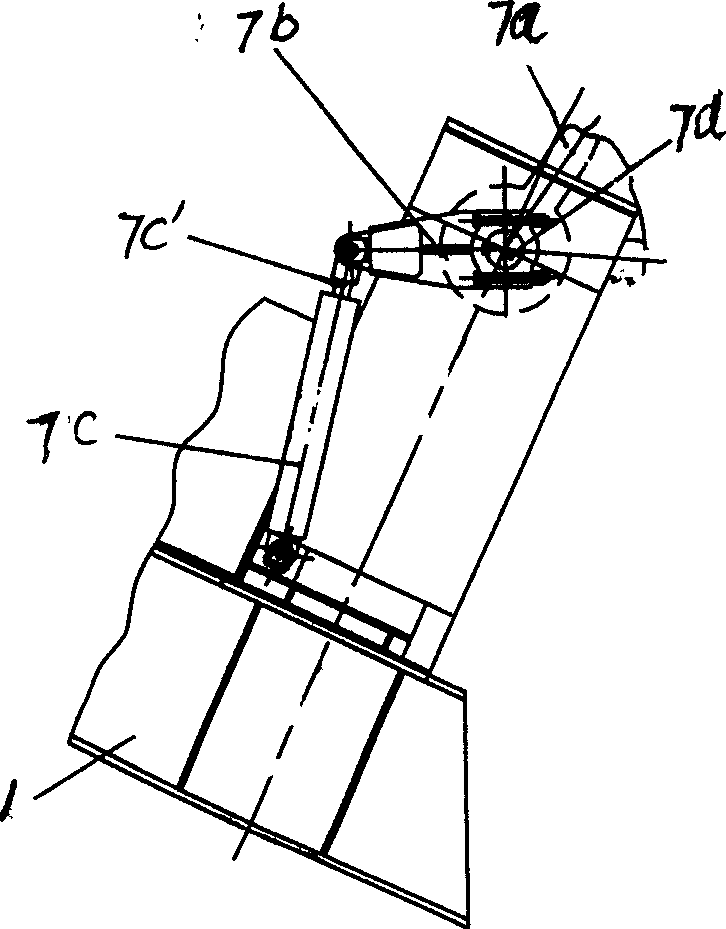

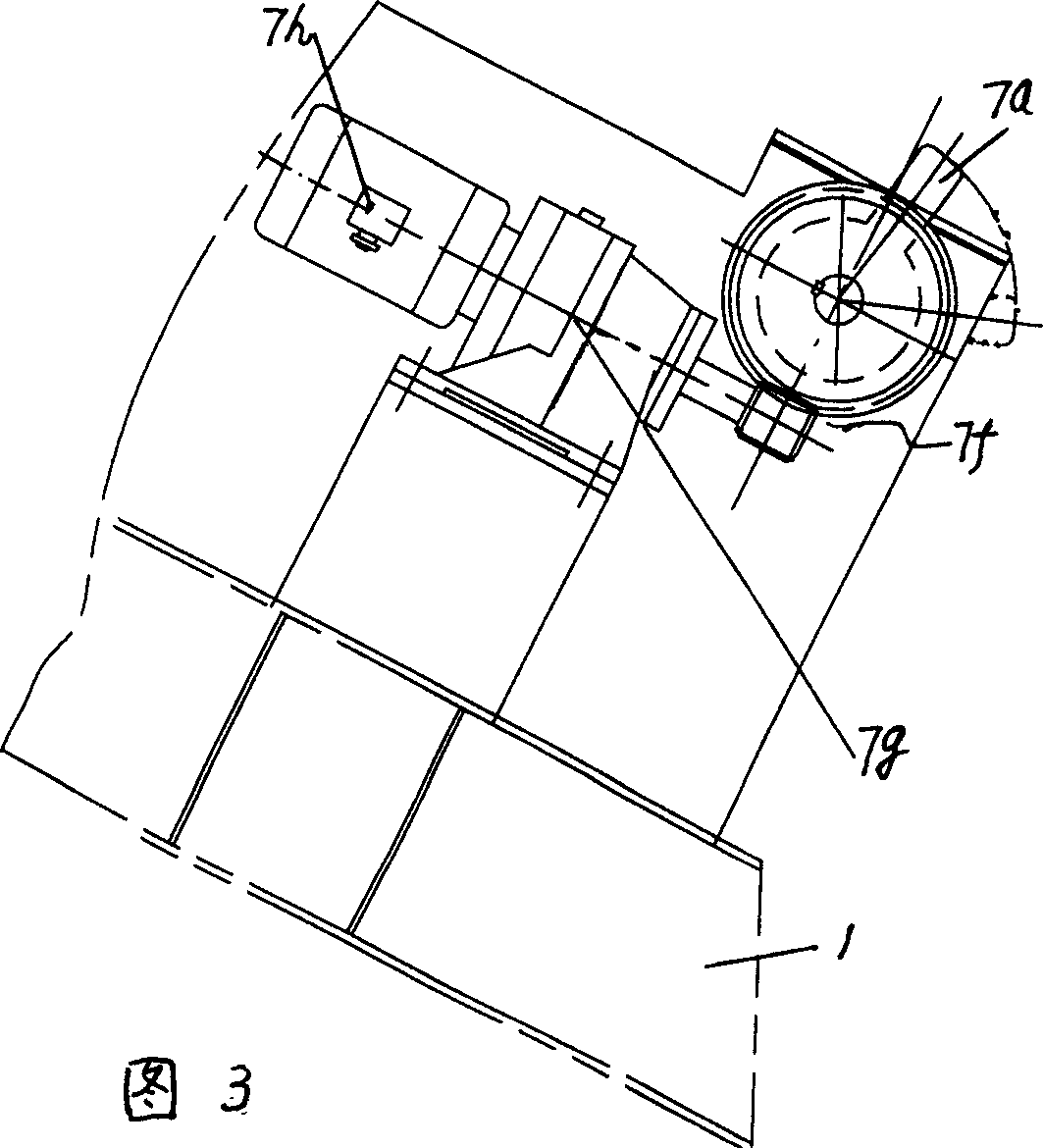

Invers propeller garbage furnace capable of regulating height of bed of material

A garbage incinerator of inverse pushing type with material layer height being able to be adjusted consists of incinerator body, material feeder, fire grate of inverse pushing type, ash basin and wind chamber under fire grate, slag releasing channel and slag releasing device. It is featured as setting device adjusting height of material layer at position of incinerator body set with tail end of fire grate in inverse pushing type and forming said adjusting device by baffle shaft set in bearing base and baffle used to changer height of material layer by its rotation as well as driving unit for driving baffle shaft.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

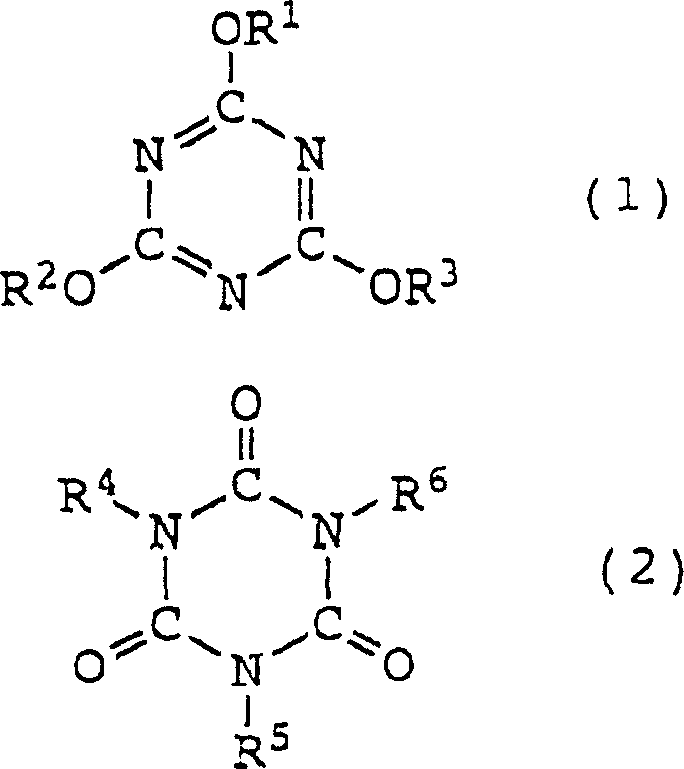

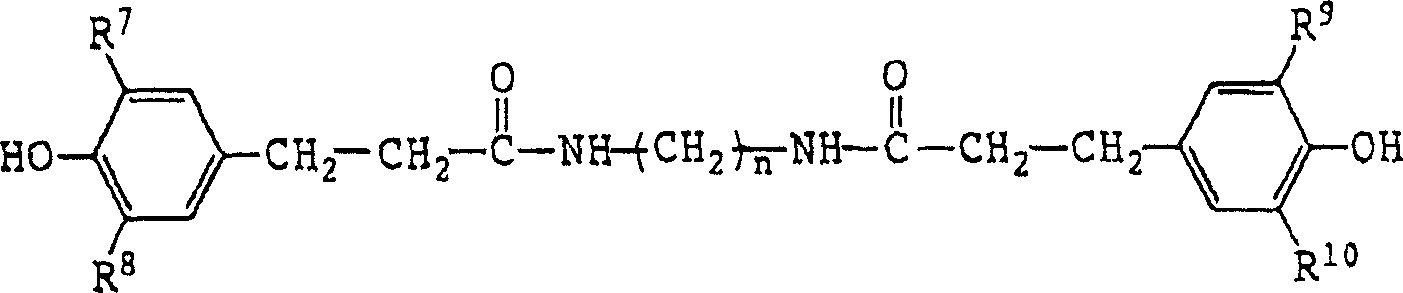

Flame-retardant polyamide resin composition and extrusion-molded product

InactiveCN1667023AIncrease flame retardancyGood flexibilityTubular articlesCarbon numberHexamethyldiamine

The present invention relates to a polyamide resin composition comprising 99 to 80 parts by weight of a polyamide base resin and 1 to 20 parts by weight of a triazine-based flame retardant, said polyamide base resin having constituting units comprising (a) polyamide 6 constituting units comprising a polycondensate of epsilon -caprolactam and (b) two or more kinds of polyamide constituting units comprising a polycondensate of hexamethylenediamine and a dicarboxylic acid having a carbon number of 6 to 11.

Owner:MITSUBISHI ENG PLASTICS CORP

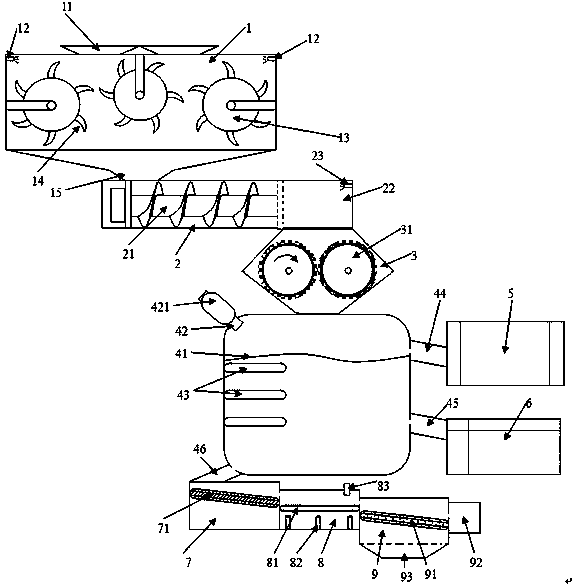

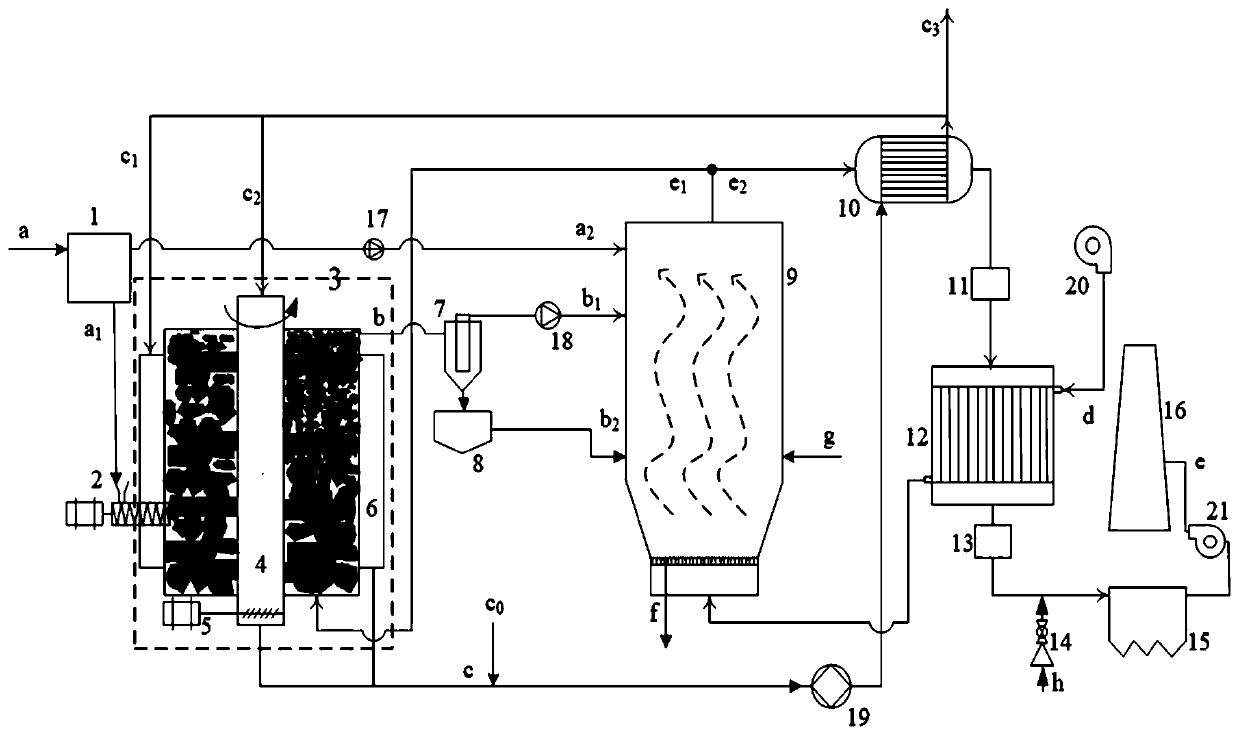

Method for preventing and controlling flue gas pollutant and domestic refuse incineration system

PendingCN108826303AAdsorption reductionReduction of passive governance measuresEmission preventionCombustion technology mitigationCombustion chamberGreenhouse

The invention discloses a domestic refuse incineration system for preventing and controlling flue gas pollutant. A material grabbing hopper of a refuse storage vault feeds materials into a compressionand crushing system, the compression and crushing system is connected with a drying system through a conveying system, a refuse discharging opening of the drying system is connected with a refuse feeding opening of an integrated incinerator, a hot bad smell outlet of the drying system is connected with an air inlet of the integrated incinerator, a combustible gas outlet and a flue gas discharge opening of the integrated incinerator and a hot air outlet of a second-stage heat exchanger are connected with a second combustion chamber, and the second combustion chamber, a first-stage heat exchanger, a quick cooling chamber, the second-stage heat exchanger and a flue gas desulfurization device are connected in sequence; and a hot air outlet of the first-stage heat exchanger is connected to anair inlet of the drying system. The domestic refuse incineration system is rigorous and reasonable in structure, the flue gas pollutant can be prevented and controlled in key processes including refuse drying, gasification burnout, flue gas burning purification and flue gas cooling, heat energy, combustible gas and combustion-supporting air needed by the system in all processes are provided, and the direct cost is almost zero.

Owner:庞礴 +2

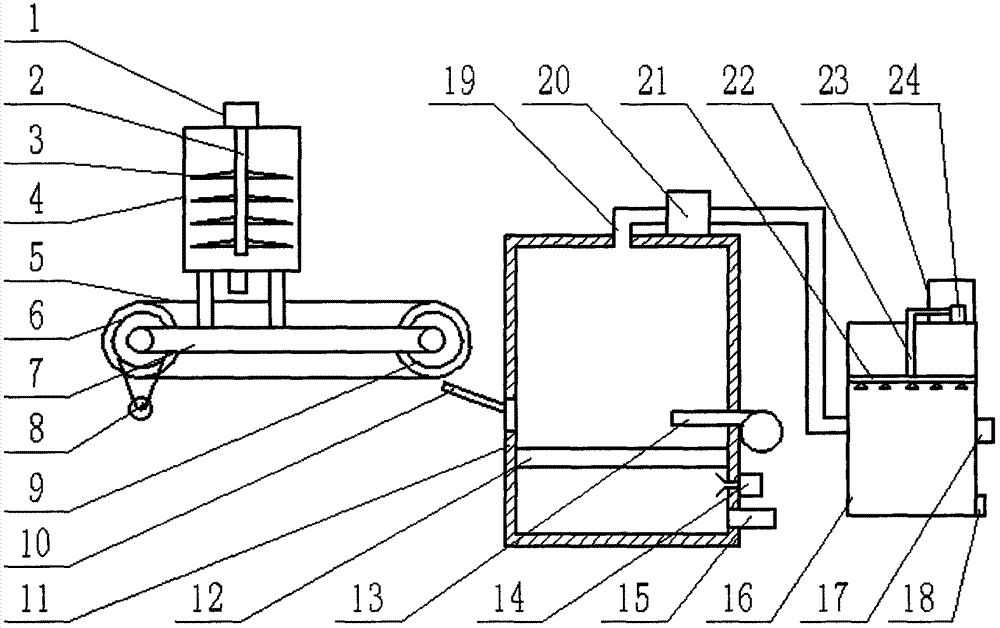

Squeezing type dehydration system adapted for waste paper residue with high water content

ActiveCN1704646AImprove incineration effectLow investment costIncinerator apparatusInlet channelSlag

This invention relates to an expression dehydration system fit for waster paper slag, which comprises compressor, pusher and sewage collecting well, characterized in that the compressor comprises frame, hydraulic oil cylinder 1 setting vertically in the frame, a stripper plate connecting to the bottom of the cylinder 1 and excavation masonry under the ground; in the steel die wall surface it distributes ports for passing water evenly, and the in the lateral of the stripper plate it hinges the steel link which can be active connected with the steel die; the pusher comprises the hydraulic oil cylinder 2, roll vehicle and push plate, which hinges horizontally with the ground seat; the sewage collecting well is set in the bottom adjacent to the excavation, having pump and the inlet, outlet channel of the pump, wherein on end of the inlet channel connected with the discharging slot between the excavation and the steel die.

Owner:TSINGHUA UNIV +1

Domestic garbage incineration equipment

InactiveCN107152687AImprove incineration effectImprove incineration efficiencyIncinerator apparatusLitterExhaust fumes

The invention discloses a domestic waste incineration equipment, which comprises a crushing box, an incineration box and an air purification box. The lower end of the crushing box is fixedly connected with a crossbeam through a support column, the left end of the crossbeam is connected with a driving roller through a rotating shaft, and the right end of the crossbeam passes through the The rotating shaft is connected with a driven kun, the driving kun and the driven kun are connected by a belt, and the right side of the driven kun is connected with a feed plate, which communicates with the inside of the incineration box. There are multiple ash holes on the top, and an air purification box is installed on the right side of the incineration box. The incineration box and the air purification box are connected through pipelines. The end is connected with a branch water pipe. The invention has a simple structure and a reasonable design, and can break large-volume garbage into small-volume garbage, improve incineration efficiency, and simultaneously process waste gas generated to reduce environmental pollution.

Owner:桐乡市大麻正扬家纺经营部

Municipal solid waste incineration device

ActiveCN109708119AImprove incineration effectFully dryIncinerator apparatusSlagMunicipal solid waste incineration

The invention belongs to the technical field of waste processing equipment, and particularly relates to a municipal solid waste incineration device. The municipal solid waste incineration device comprises an outer shell. The outer shell is internally provided with an incineration chamber and a slag discharging chamber. An incineration plate is arranged in the incineration chamber. A slag guide plate is obliquely arranged in the slag discharging chamber. An oxygen conveying pipe is arranged on the lateral face of the bottom end of the incineration plate. The incineration plate comprises an upper incineration plate and a lower incineration plate. Slag discharging holes are formed in the upper incineration plate. Air inlets are formed in the lower incineration plate. A cavity is formed between the upper incineration plate and the lower incineration plate. A drying chamber is arranged on the lateral face of the outer shell. The drying chamber is connected with the incineration chamber by afeeding chamber. An air inlet pipe is arranged on the drying chamber. The air inlet pipe is connected with the cavity. Heat generated by the upper incineration plate can heat oxygen in the cavity. The heated gas enters the drying chamber through the air inlet pipe. Stirring blades in the drying chamber stir the waste, and therefore the heated gas can dry the waste in the drying chamber more fully, and the municipal solid waste incineration effect can be improved.

Owner:LISHUI INST OF ECOLOGY ENVIRONMENT NANJING UNIV

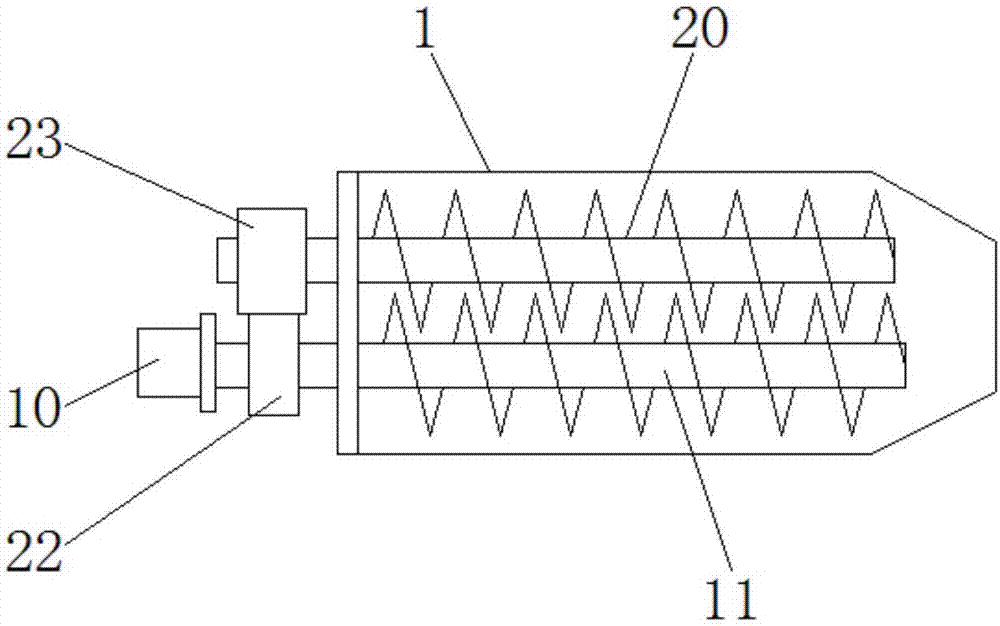

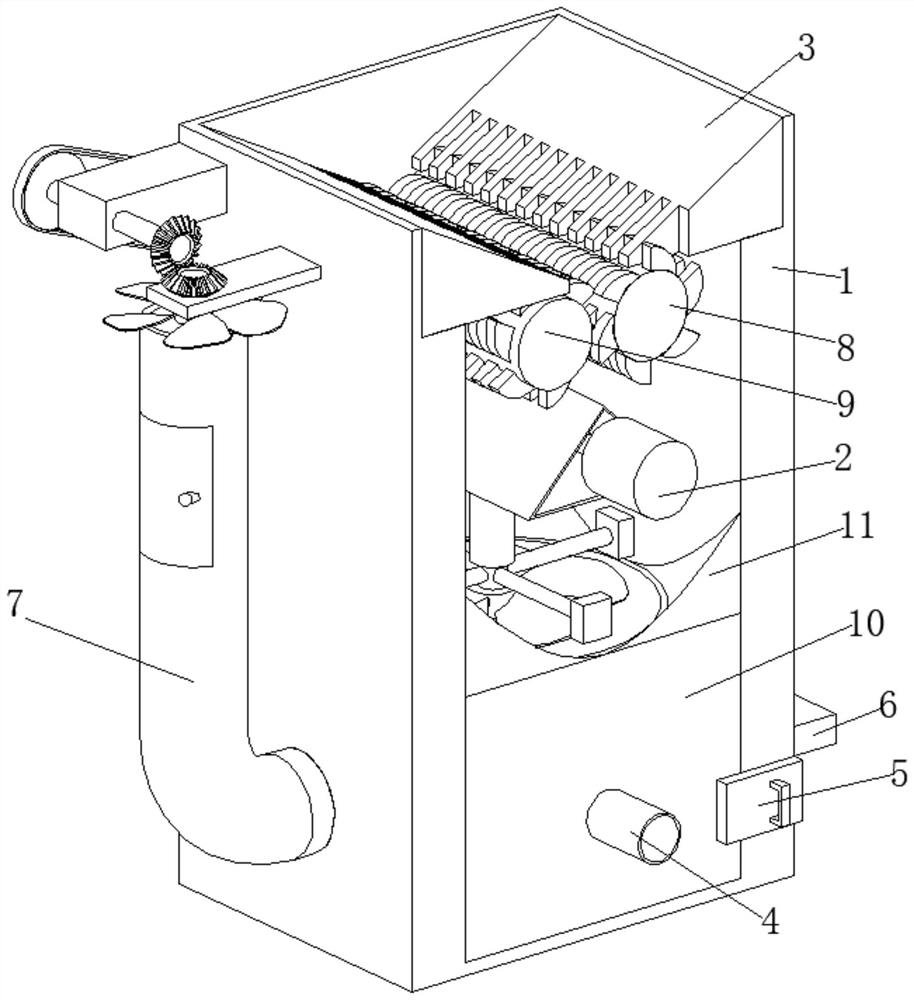

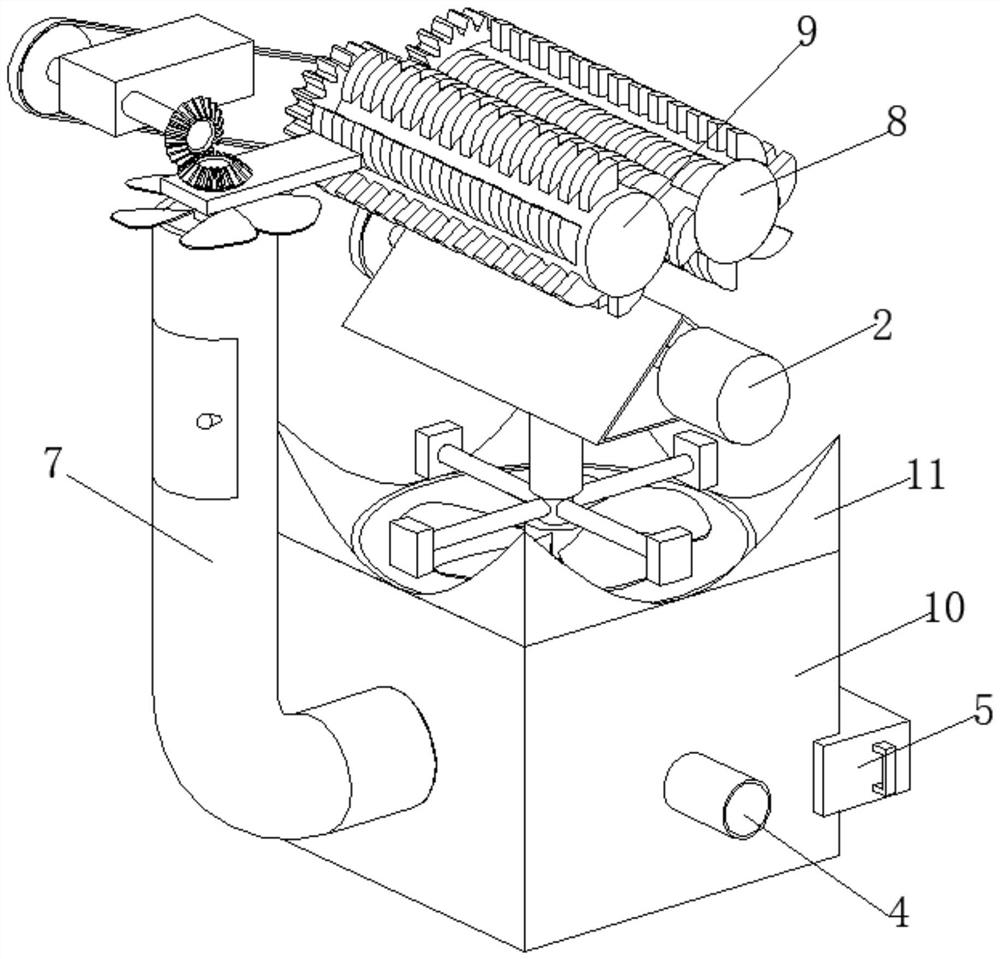

Waste incineration device capable of achieving double-screw crushing

InactiveCN107270294AReasonable structureEasy to operateIncinerator apparatusCombustionPulp and paper industry

The invention discloses a double-screw crushing garbage incineration device, which comprises a garbage double-helix incinerator, a heating furnace body, a garbage storage hopper and a smoke collection cover. The bottom of the garbage double-helix incinerator is equipped with a heating furnace body. A flue gas collection hood is installed on the top of the spiral incineration cylinder; a spiral crushing push rod A and a spiral crushing push rod B are installed inside the double spiral incineration cylinder of garbage, and the screw crushing push rod A and the spiral crushing push rod B are both worn at the same end. Garbage output double-helix incinerator; it is convenient to crush and push the garbage falling from the garbage introduction tube, and the flame passes through the incineration through hole to fully incinerate the turned garbage during the crushing and pushing process; Full combustion; facilitate the collection of residue after combustion and the collection and discharge of flue gas after combustion, and improve the incineration effect.

Owner:陈琦

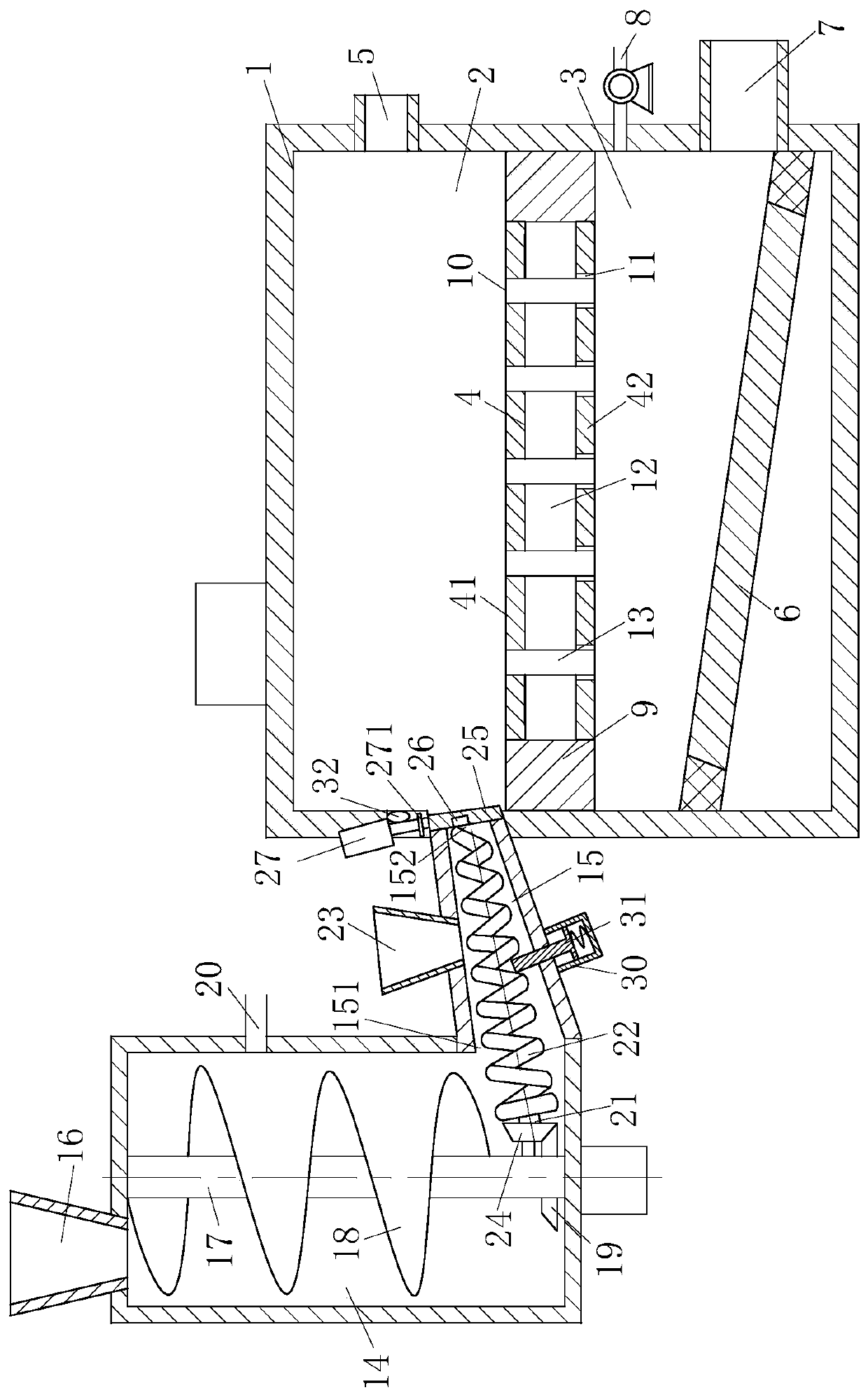

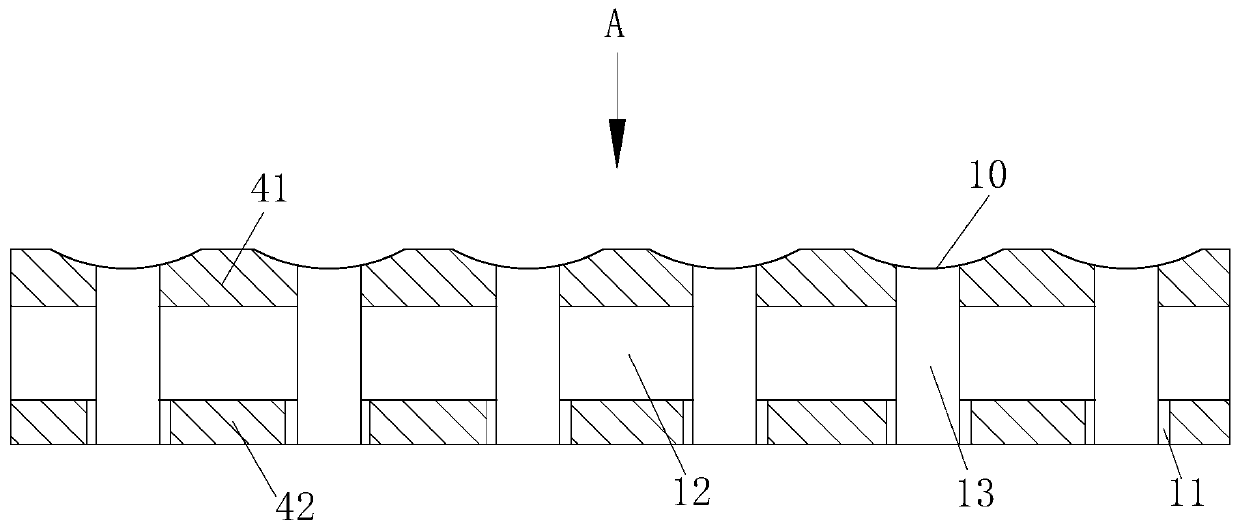

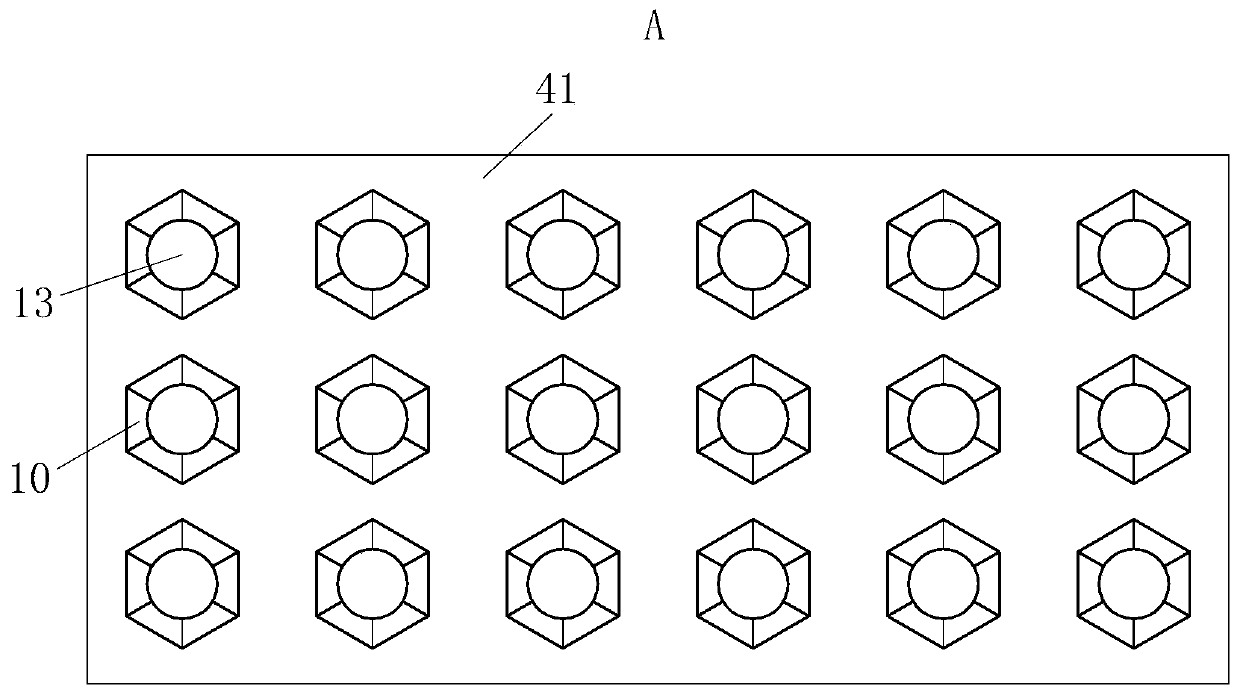

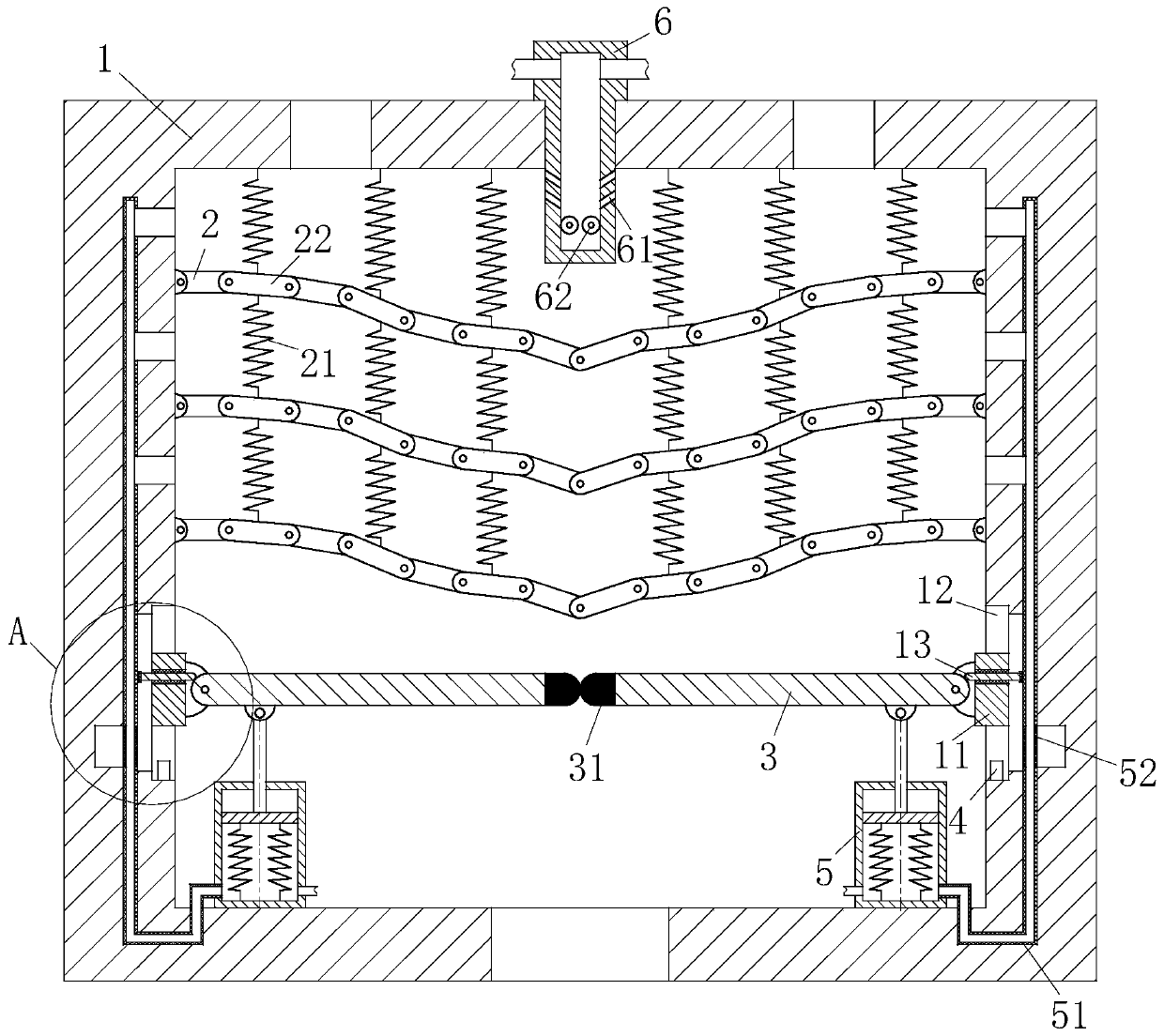

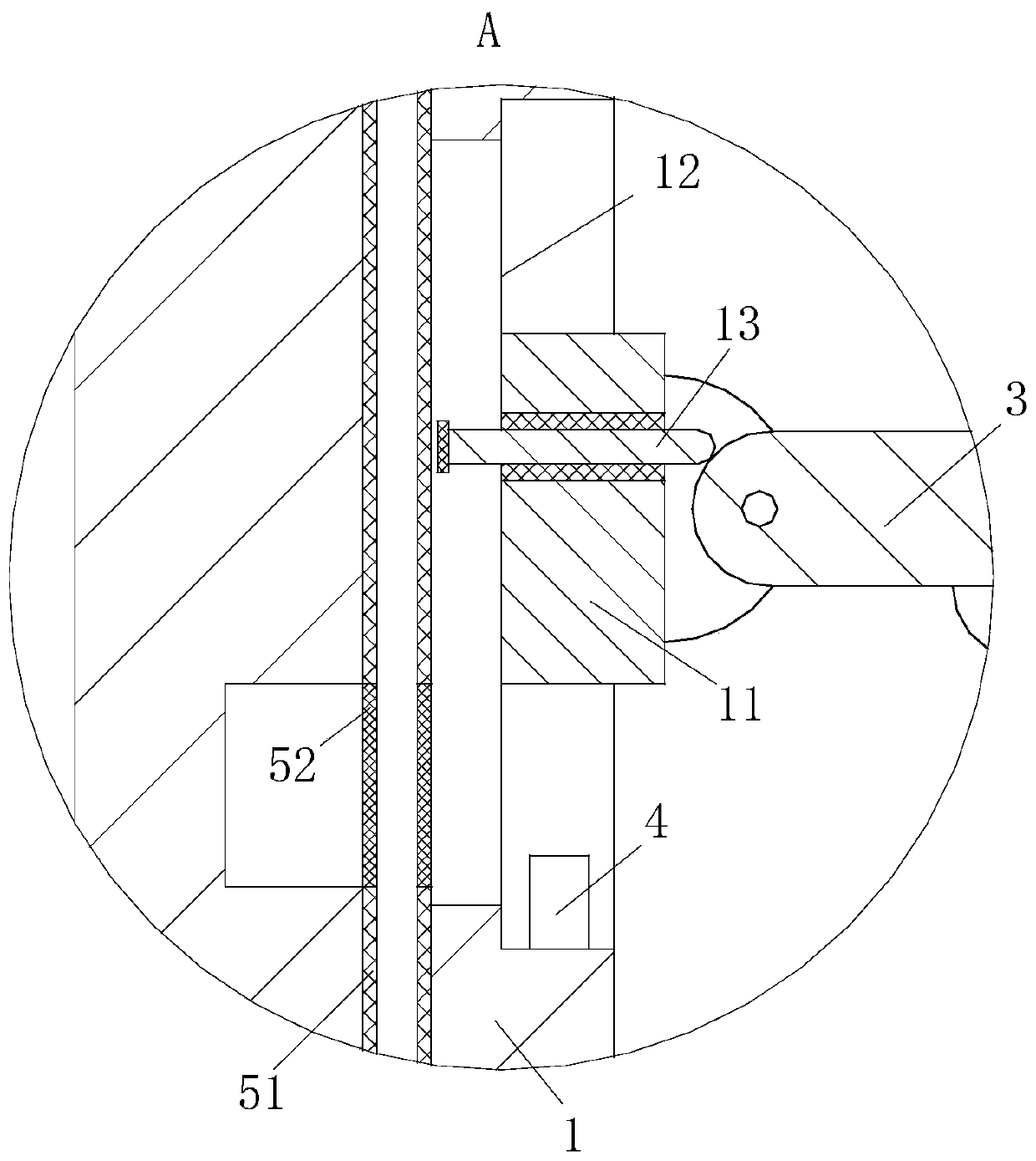

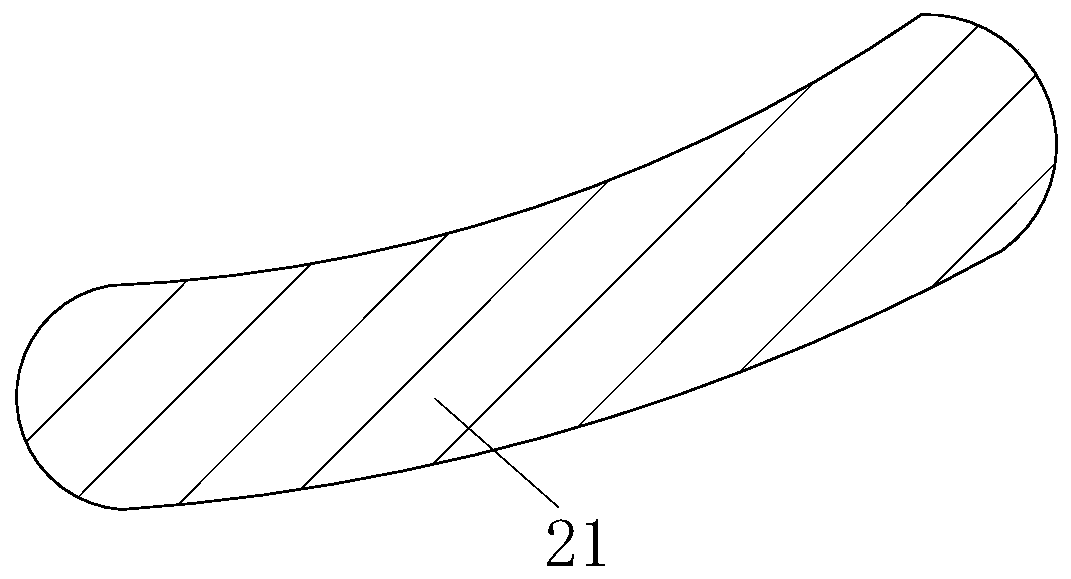

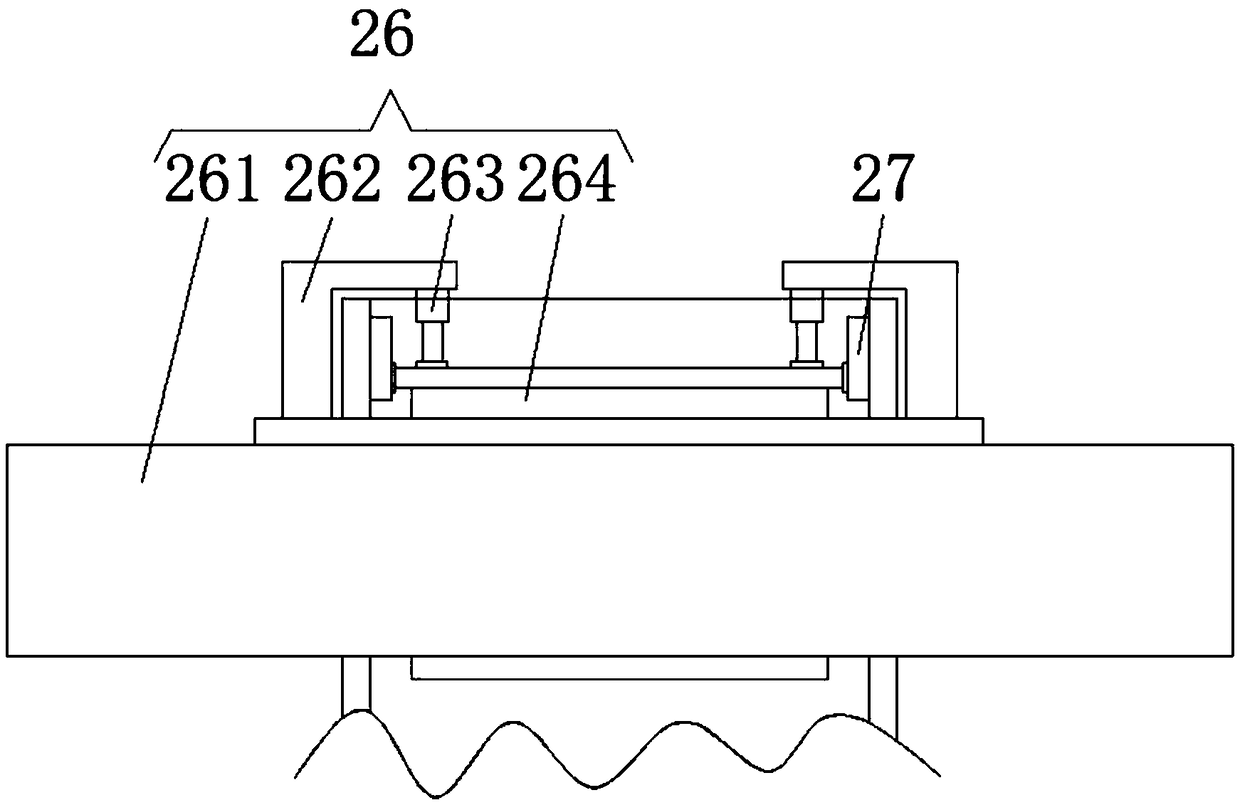

Vibration type furnace chamber garbage incinerator

The invention belongs to the technical field of garbage incinerators, and particularly relates to a vibration type furnace chamber garbage incinerator. The vibration type furnace chamber garbage incinerator comprises a furnace body, a plurality of fire grates are arranged above the furnace body, combustion-supporting springs are among the fire grates, and combustion-supporting blocks are arrangedon the combustion-supporting springs; sliding grooves for mounting sliding blocks are symmetrically arranged on the left inner wall and the right inner wall of the furnace body, sealing plates are correspondingly hinged to the opposite ends of the sliding blocks, electromagnets are arranged at the end parts of the sealing plates, and travel switches are arranged at the lower ends of the sliding grooves; and the lower surfaces of the sealing plates are hinged to piston rods of two air cylinders which are symmetrically arranged on a bottom plate of the furnace body left and right, springs are arranged between pistons of the air cylinders and inner bottom plates of the air cylinders, air outlets of the air cylinders are connected with air outlet pipes, the upper ends of the air outlet pipes penetrate into the furnace wall of the furnace body and communicate with cavities formed among the fire grates through a channel formed above the furnace body, the air outlets of the air cylinders areprovided with one-way valves with a one-way air outlet function, air inlets of the air cylinders are provided with one-way valves with a one-way air inlet function, the air inlets of the air cylindersare connected through air inlet pipes, and the other ends of the air inlet pipes are positioned at the top of the furnace body.

Owner:徐海军

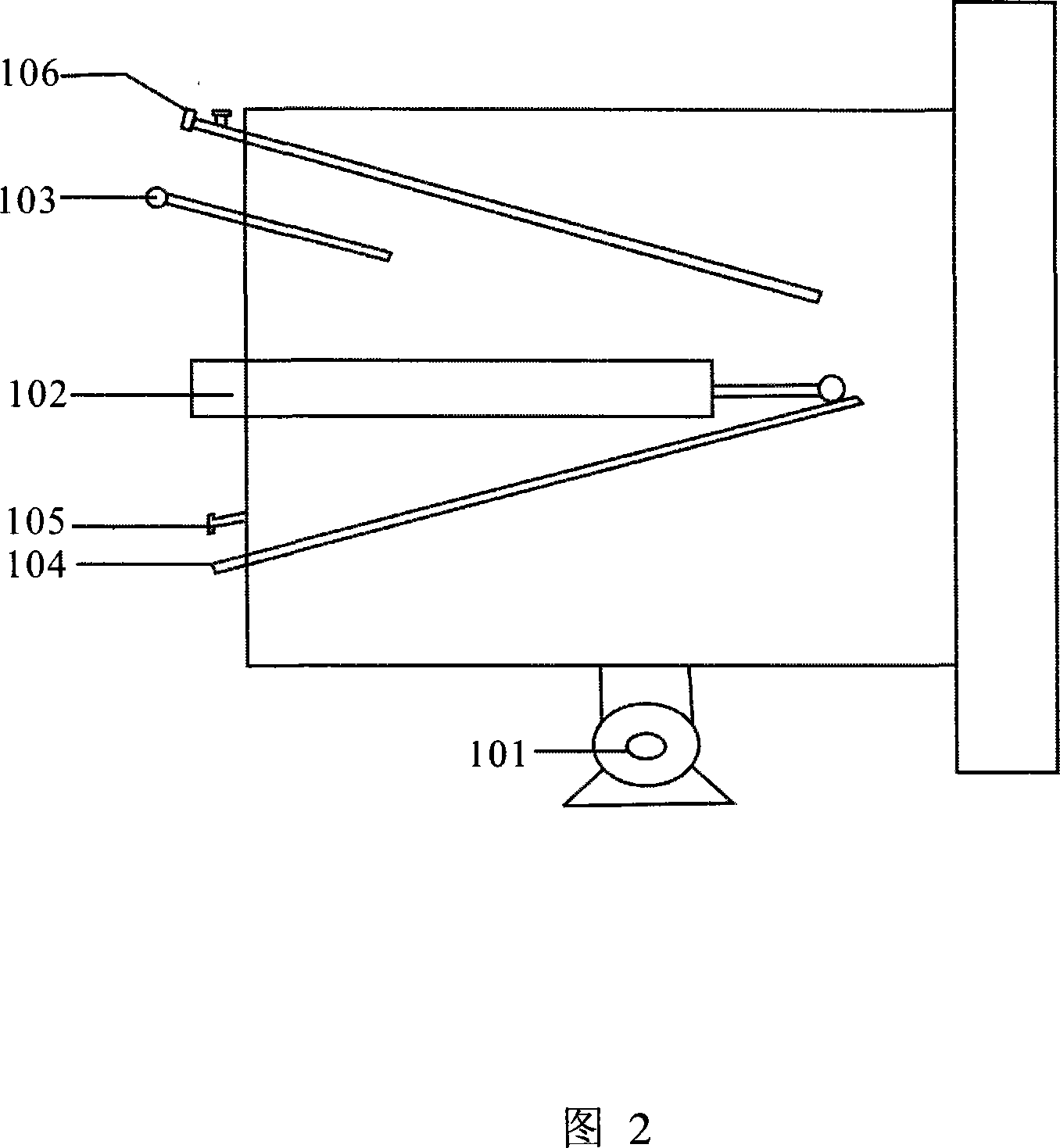

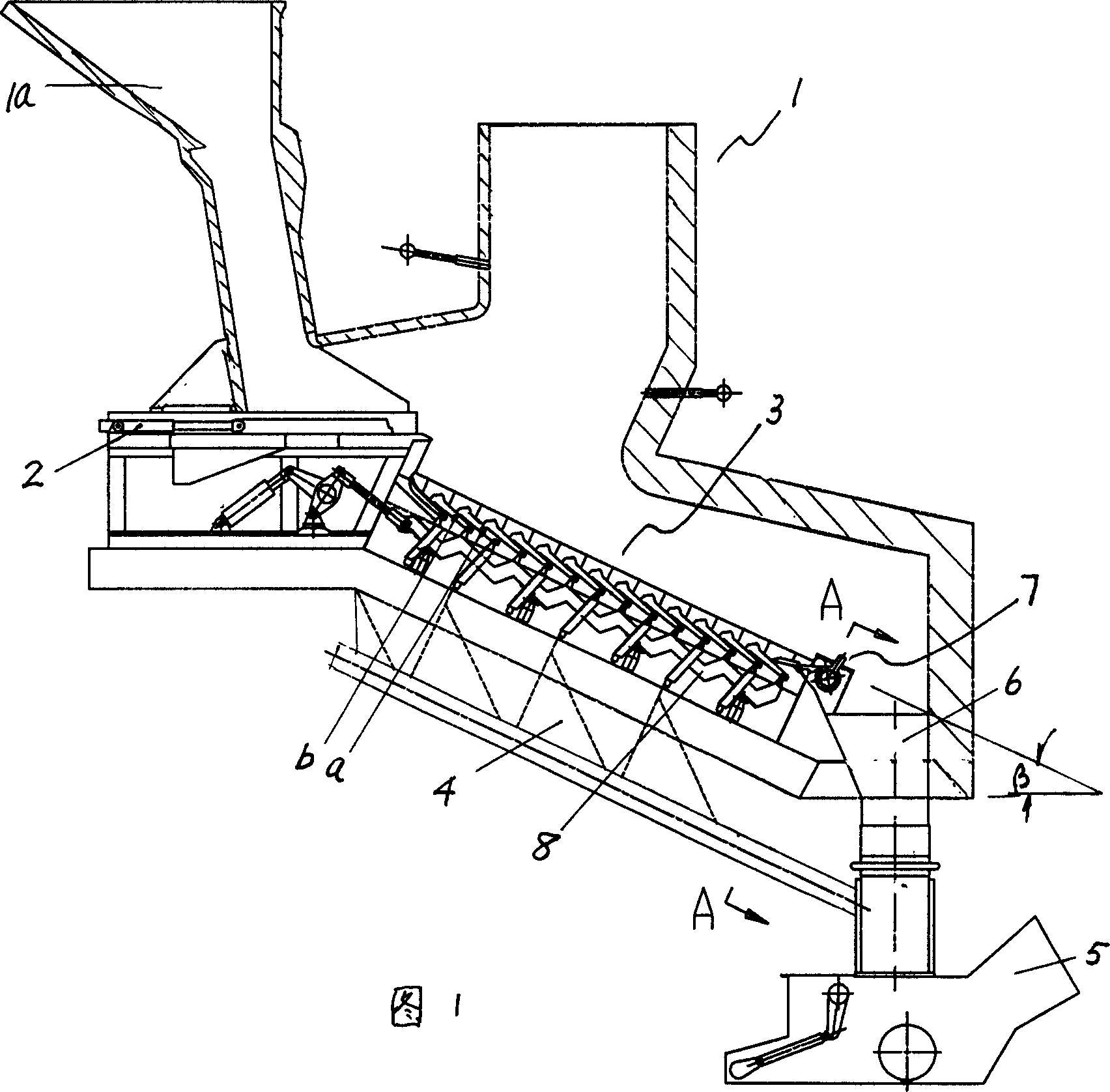

Air distributing device and method for household rubbish incinerating furnace

InactiveCN103672913AIncrease temperatureImprove incineration effectIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterAir volume

The invention relates to the field of household rubbish incinerating processing, in particular to an air distribution device for a rubbish incinerating furnace. The air distribution device is suitable for severely-cold environment regions. A rubbish pit is connected with a fan through a pipe, an adjustment stop plate ventilation door A is arranged in an inlet of the fan, an outlet of the fan is connected with an air pre-heater and an adjustment stop plate ventilation door D in parallel and then respectively connected with a drying furnace air discharging chamber, a combustion furnace air discharging chamber and an after-combustion furnace air discharging chamber of the three-section-type household rubbish incinerating grate furnace through a direct-type air pre-heater, an inlet and an outlet of the air pre-heater are provided with an adjustment stop plate ventilation door B and an adjustment stop plate ventilation door C respectively, and an adjustment stop plate ventilation door E, a direct-type air pre-heater fan and a fuel system are connected to the direct-type air pre-heater. According to the air distribution device, an improvement is carried out on the basis of a conventional air distribution device of the three-section type grate furnace; as the direct-type air pre-heater is additionally arranged, the temperature of combustion air is raised, air distribution of three-section grates is improved, the air inlet amount of the drying-section grate is increased, the air pressure of an inlet of the incinerating furnace is increased, the incinerating furnace can adapt to the characters of rubbish in the severely-cold environment regions, and the intra-incinerating-furnace rubbish combustion effect is improved.

Owner:SHANGHAI SUS ENVIRONMENT

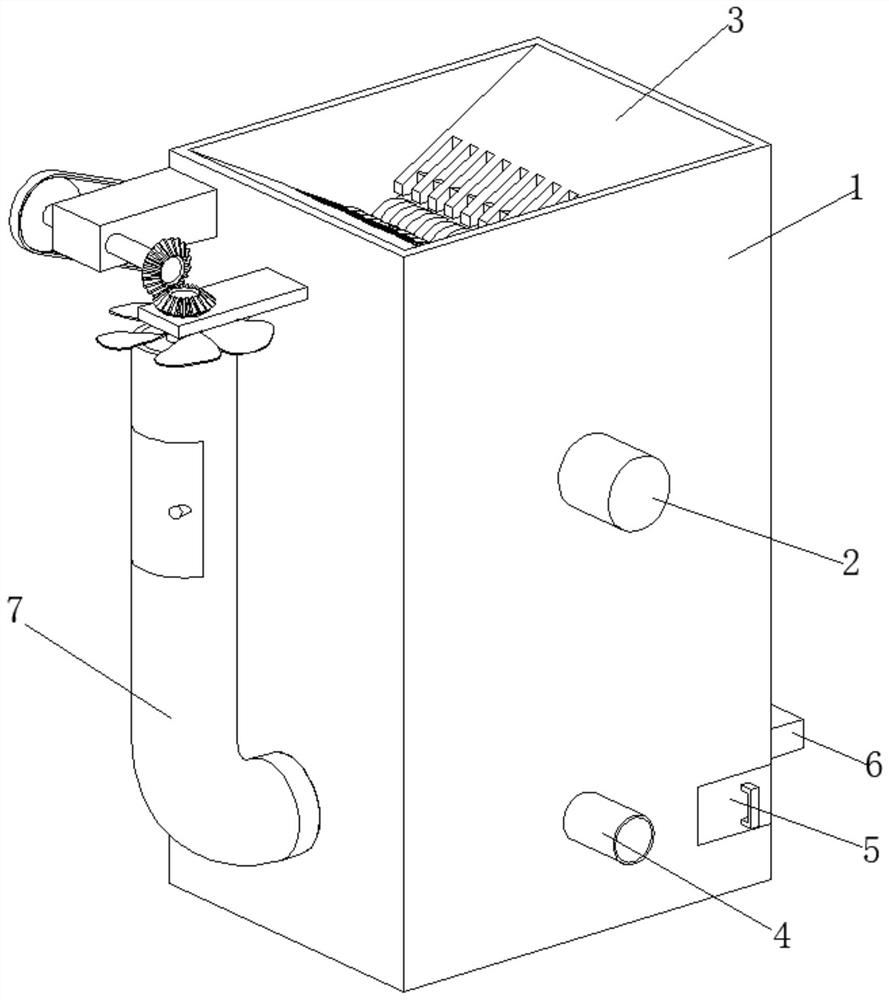

Straw incineration processing device with waste gas processing function

InactiveCN109307272AImprove purification effectPlay a role in combustionIncinerator apparatusCombustionIncineration

The invention discloses a straw incineration processing device with a waste gas processing function. The straw incineration processing device with the waste gas processing function comprises a bearingvehicle body, an incineration furnace, a smashing roller, an air blowing device, a smoke purifying box, mist sprayers and a vertical type chimney. A plurality of groups of moving wheels are installedon the lower side of the bearing vehicle body. A incineration furnace is further fixedly installed on the upper surface of the bearing vehicle body. The air blowing device is further installed on theouter wall of the left side of the incineration furnace. The smoke purifying box is arranged on the right side of the incineration furnace. Air in an inner cavity of the air blowing device is pressedinto the incineration furnace, so that the combustion supporting function is achieved, the incineration effect is improved, and the incomplete incineration phenomenon is avoided. In the incinerationprocess, an exhaust fan and a water pump are switched on to work, the exhaust fan exhausts smoke in the incineration furnace into the smoke purifying box, the mist sprayers spray water mist to adsorbdust in the smoke, and harmless gas is discharged from the vertical chimney. Compared with an existing straw incineration device, the straw incineration processing device with the waste gas processingfunction is higher in smoke purifying capacity and achieves the environmental protection function.

Owner:湖南米笠农业科技有限公司

Fixed grate and incineration system applying same

InactiveCN104595907AGuaranteed structural rigidityGuaranteed to be constantInclined grateIncinerator apparatusCombustion chamberHot blast

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate and an incineration system applying the same. The fixed grate at least comprises grate plates; the arrangement heights of the grate plates are gradually reduced so as to form a step type grate body structure of the fixed grate; a spacing is formed between plate bodies of each two adjacent grate plates in the perpendicular direction so as to form a ventilation pore running through a grate body; the grate plates are provided with extending plates; the plate faces of each extension plate and the plate body of the previous grate plate are crossed mutually to form a wind guide port structure. The incineration system comprises a main combustion chamber, the fixed grate and a grate ejector rod, wherein the main combustion chamber is isolated and divided into a combustion cavity and a hot blast cavity by the fixed grate; the air inlet end of the hot blast cavity is also the feed end of the fixed grate; the grate ejector rod is used for overturning and ejecting materials on the incineration face; the grate ejector rod passes through a through hole and runs through the material layer on the fixed grate in the maximum lift range. The fixed grate and the incineration system have reasonable and practical structures; the grate body has a good ventilation effect; material incineration efficiency is high.

Owner:安徽盛燃焚烧炉科技有限公司

Incineration method for domestic, medical and building solid waste

ActiveCN106765158AEfficient dryingEnough contact areaIncinerator apparatusIncinerationMedical treatment

The invention discloses an incineration method for domestic, medical and building solid waste. A fixed smoke baffle is vertically arranged at the joint of an upper chamber and a lower chamber. The upper end of the fixed smoke baffle is fixed to the inner top surface of the lower chamber, and a waste passing port for allowing the waste to pass is reserved between the lower end of the fixed smoke baffle and the bottom surface of the upper chamber. A waste inlet pipe is arranged at the top of the upper chamber, and a discharge outlet of the waste inlet pipe communicates with a feed inlet of the top of the upper chamber. A set of burning nozzles are densely arranged on the inner wall of the lower chamber, the uppermost burning nozzles are close to the lower end of a movable smoke baffle, and the bottommost burning nozzles are located at the bottom of the lower chamber. Air nozzles are densely arranged on the inner bottom surface of the lower chamber, are vertically disposed and spay air upwards, and the same air pump arranged outside a furnace body supplies air to all the air nozzles through an external pipeline. By means of the method, sufficient waste incineration is guaranteed, meanwhile, the effect that the waste is pre-dried by high-temperature hot air is improved, and the environmental-friendly performance is good.

Owner:XUZHOU CITY YUANHENG NEW ENERGY DEV

Energy-saving incinerator special for chemical industry

PendingCN114353092AImprove crushing efficiencyImprove incineration efficiencyIncinerator apparatusChemical industrySulfide

The invention discloses an energy-saving chemical industry special incinerator which comprises a bearing plate and a supporting plate, the bearing plate is fixedly connected with the supporting plate, the upper surface of the supporting plate is fixedly connected with four supporting columns, the four supporting columns are fixedly connected with a shell, and the shell is provided with a smashing combustion-supporting mechanism used for smashing chemical industry waste and accelerating incineration of the chemical industry waste. A feeding port is formed in the upper surface of the shell, a feeding cover matched with the feeding port is hinged to the upper surface of the shell through a pin shaft, a discharging port is formed in the side, close to the supporting column, of the shell, a discharging cover matched with the discharging port is hinged to the side, close to the supporting column, of the shell through a pin shaft, and a sieve plate is fixedly connected to the inner wall of the shell. And a neutralizing mechanism for neutralizing sulfide gas generated by incineration is arranged on the supporting plate. According to the crushing and incineration device, through cooperation of the overall structure, the crushing and incineration efficiency is improved, and the effect of purifying generated hydrogen sulfide gas is achieved.

Owner:刘存孝

Urban garbage disposal method

InactiveCN102151688AReduce harmful ingredientsReduce the temperatureConstruction waste recoverySolid waste disposalSlurryEngineering

The invention discloses a method for burning urban garbage and disposing fly ash in enclosed environment, comprising the following steps: sorting the urban garbage; crushing the sorted urban garbage; mixing the crushed urban garbage by using a combustible material including fixed carbon; drying the mixed urban garbage; carrying out enclosed burning on the fried urban garbage at a burning temperature above 850 DEG C under mixed oxygen; carrying out low-temperature circular disposal on the dust particles in the burning fly ash of the urban garbage by using fly ash slurry; and carrying out low-temperature circular disposal on the harmful gas in the burning fly ash of the urban garbage by using a harmful gas adsorption material and water. Through the method, the combustion temperature of a burning boiler can be up to 850 DEG C, the garbage burning can be controlled above 2 seconds, the generation of dioxin and furan can be effectively retrained, the dust and harmful gas in the generated fly ash (smoke) are fully adsorbed and the environment around the burning field can be effectively protected.

Owner:李凤山 +2

Municipal solid waste incineration, waste heat recovery and energy storage device

The invention relates to the technical field of city environment protection equipment and discloses a municipal solid waste incineration, waste heat recovery and energy storage device which comprisesa tank, wherein an incinerator body is fixedly arranged on the bottom part of an inner cavity of the tank; a heating tank is fixedly arranged on the top part of the incinerator body; the outer surfaceof the heating tank is fixedly connected with one side of the inner cavity of the tank; an air guiding pipe fixedly communicates to the top part of the heating tank; and a middle pipe fixedly communicates to the top part of the air guiding pipe. According to the municipal solid waste incineration, waste heat recovery and energy storage device, the waste is incinerated through the incinerator body, water in the heating tank is heated so as to produce high-temperature water vapor, the water vapor pushes a blade paddle so as to enable a movable shaft to rotate, the movable shaft favorably drivesa second gear and a first gear to rotate, a transmission shaft drives a stirring roller to rotate, and the waste in the incinerator body can be favorably stirred, so that an incineration effect is improved.

Owner:浙江绿保再生资源科技有限公司

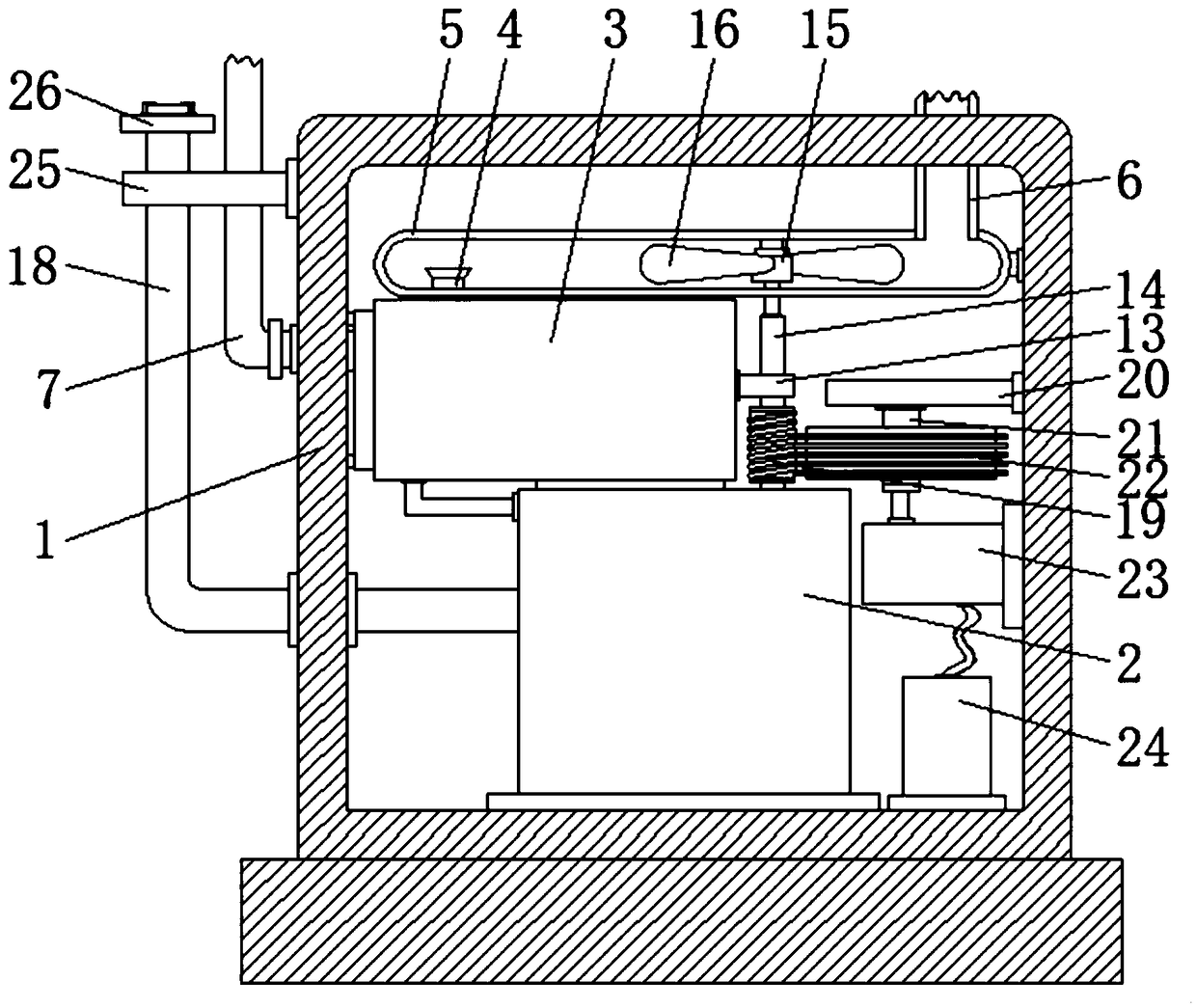

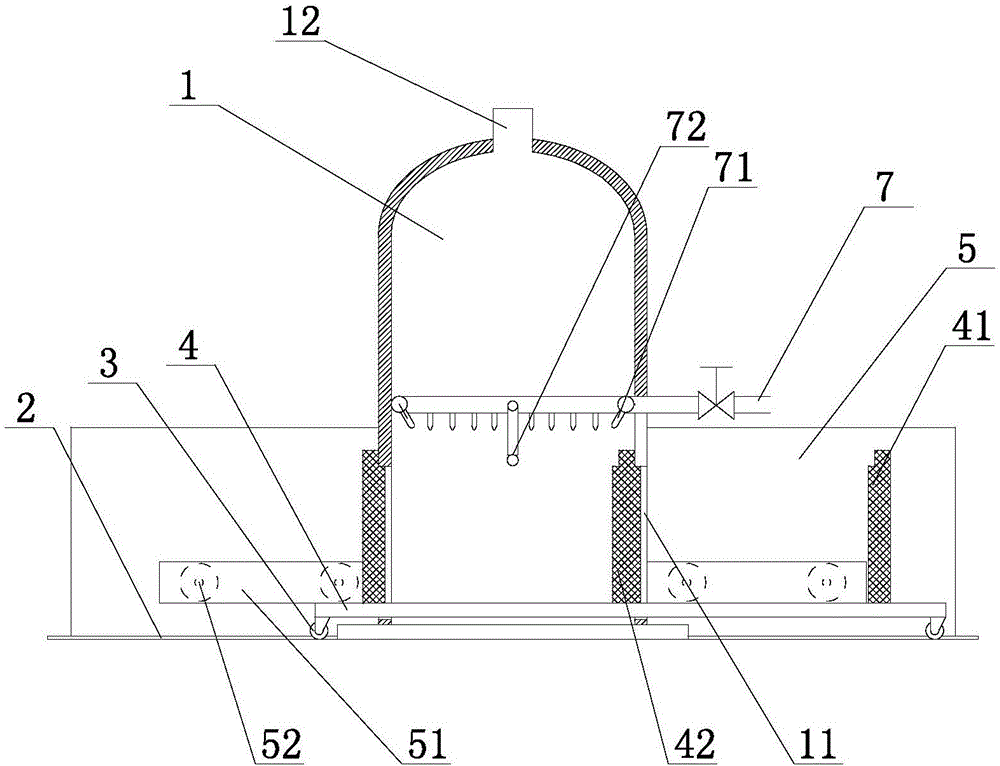

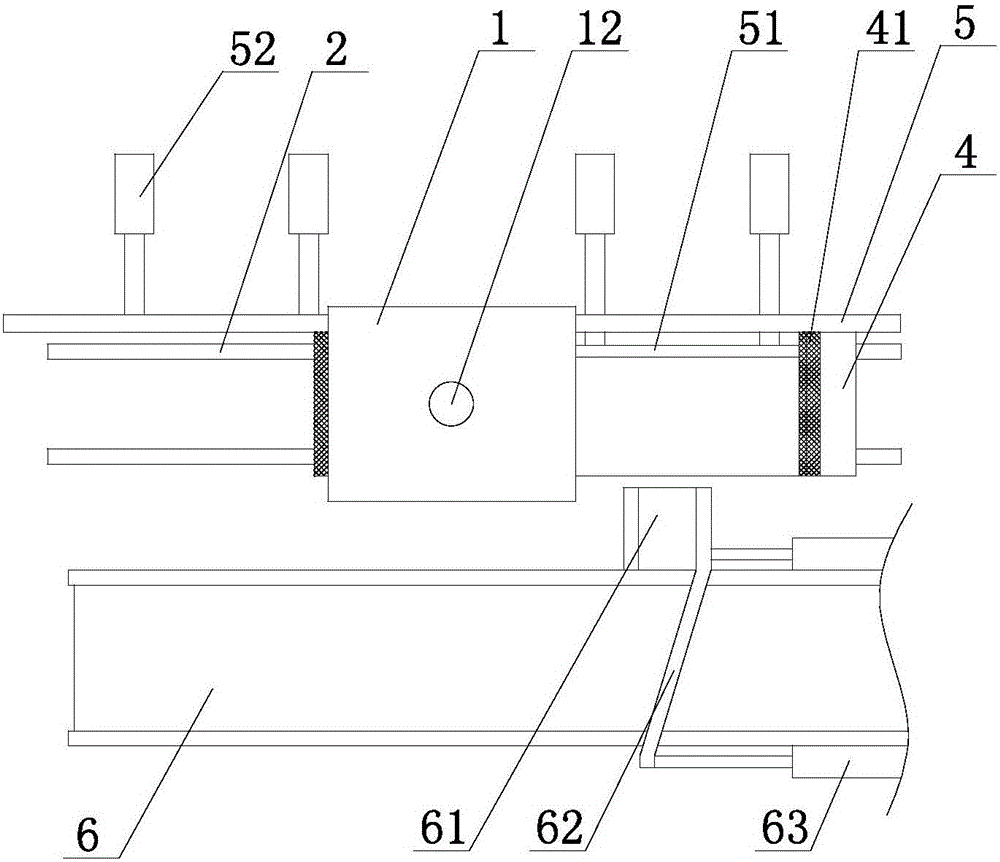

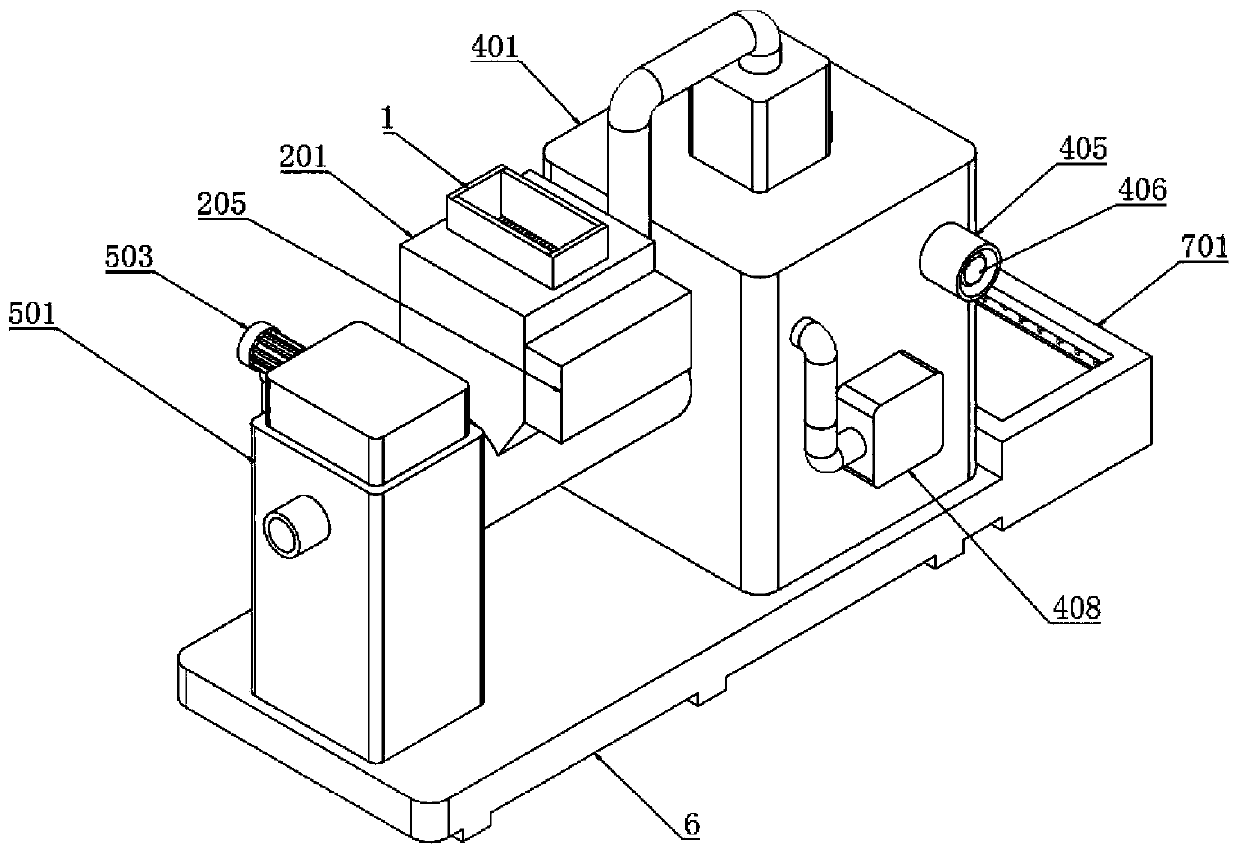

Automatic feeding and discharging gas combustion-supporting garbage incinerator

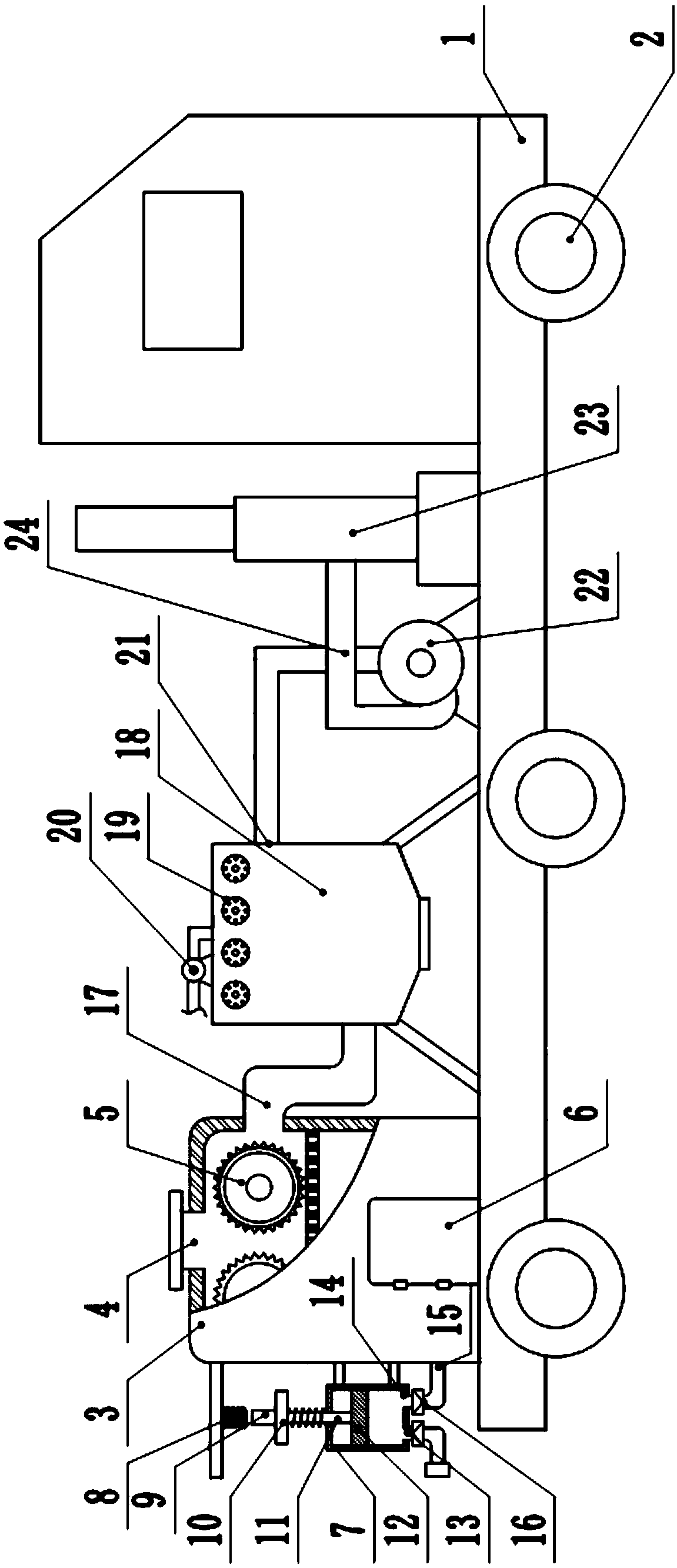

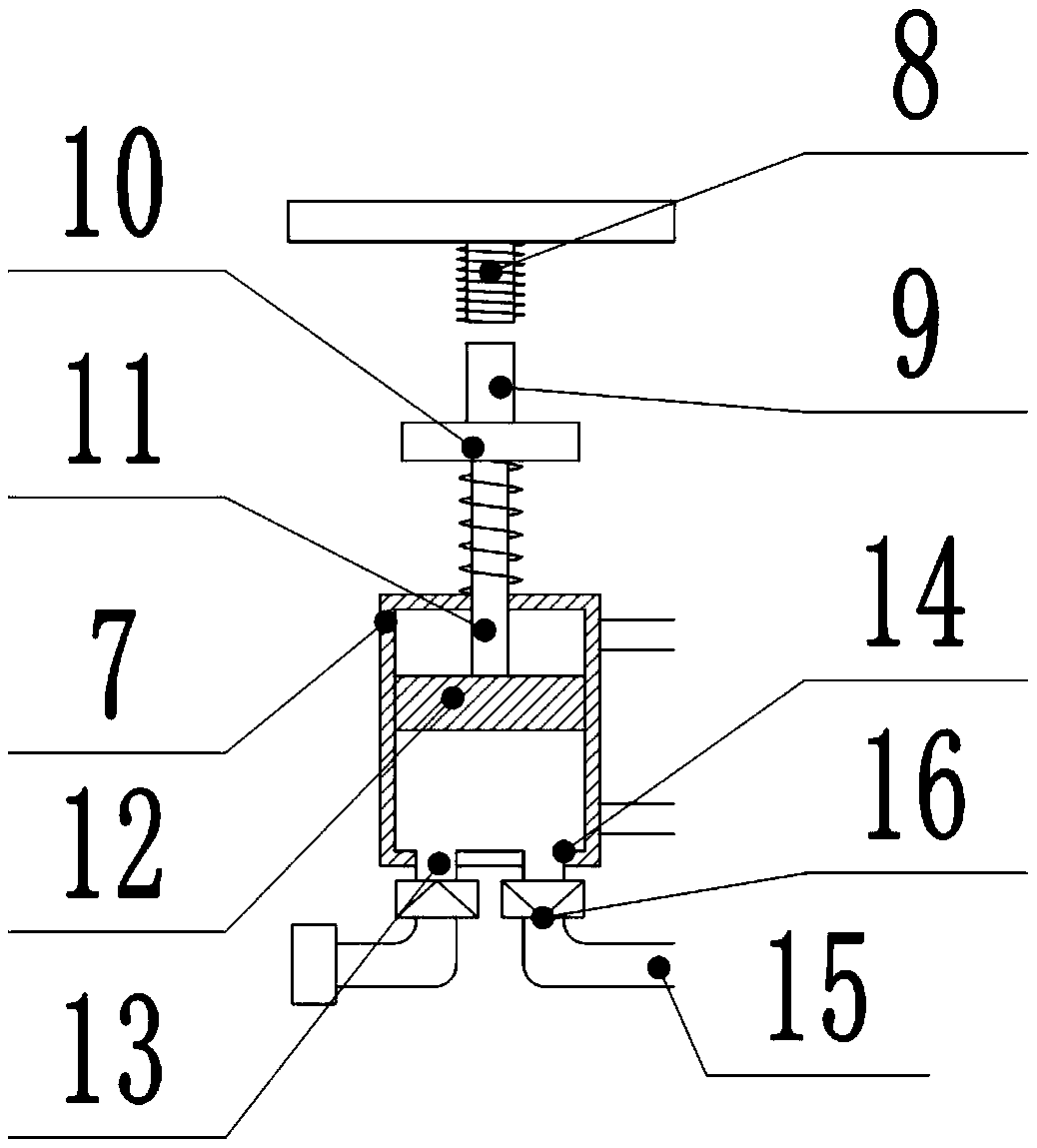

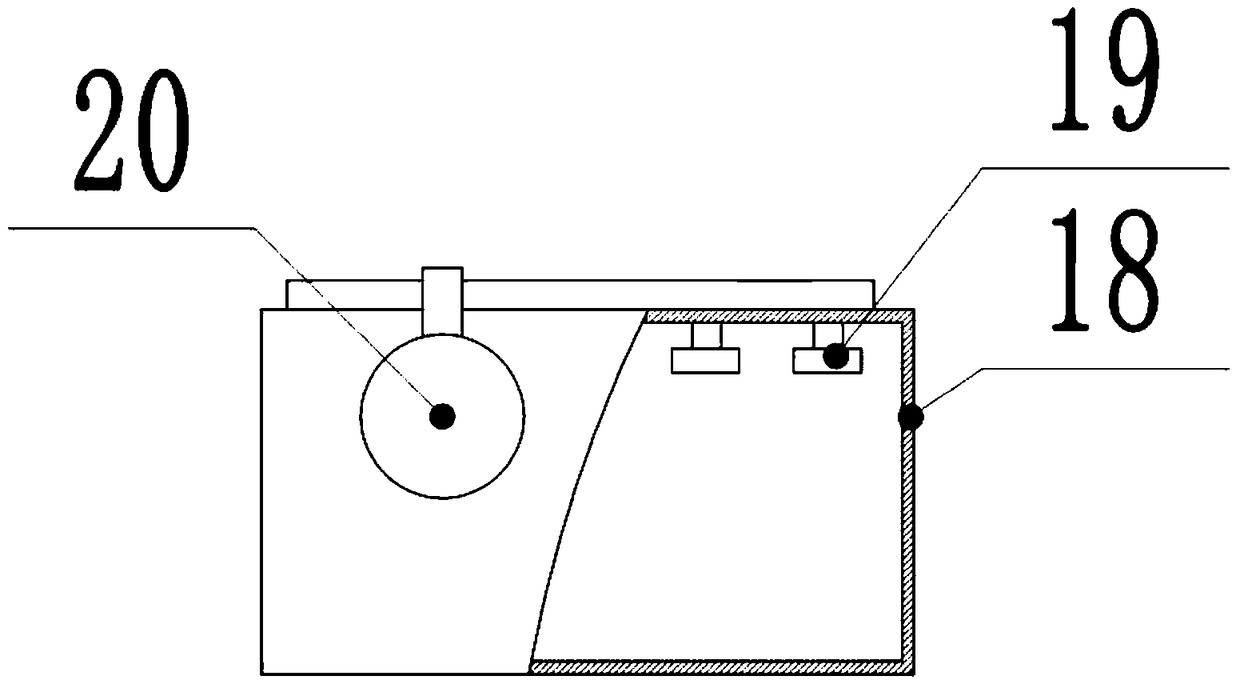

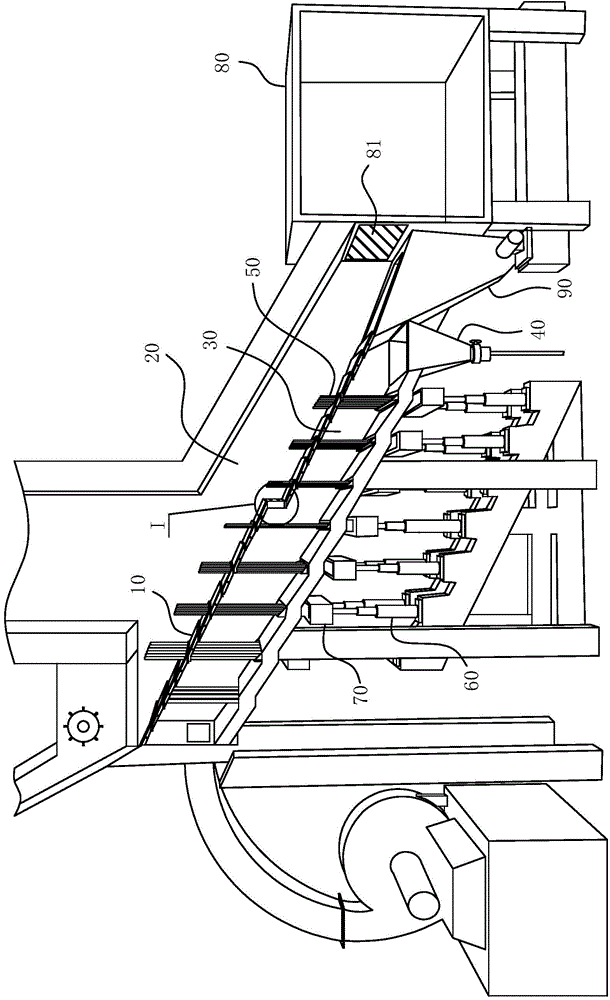

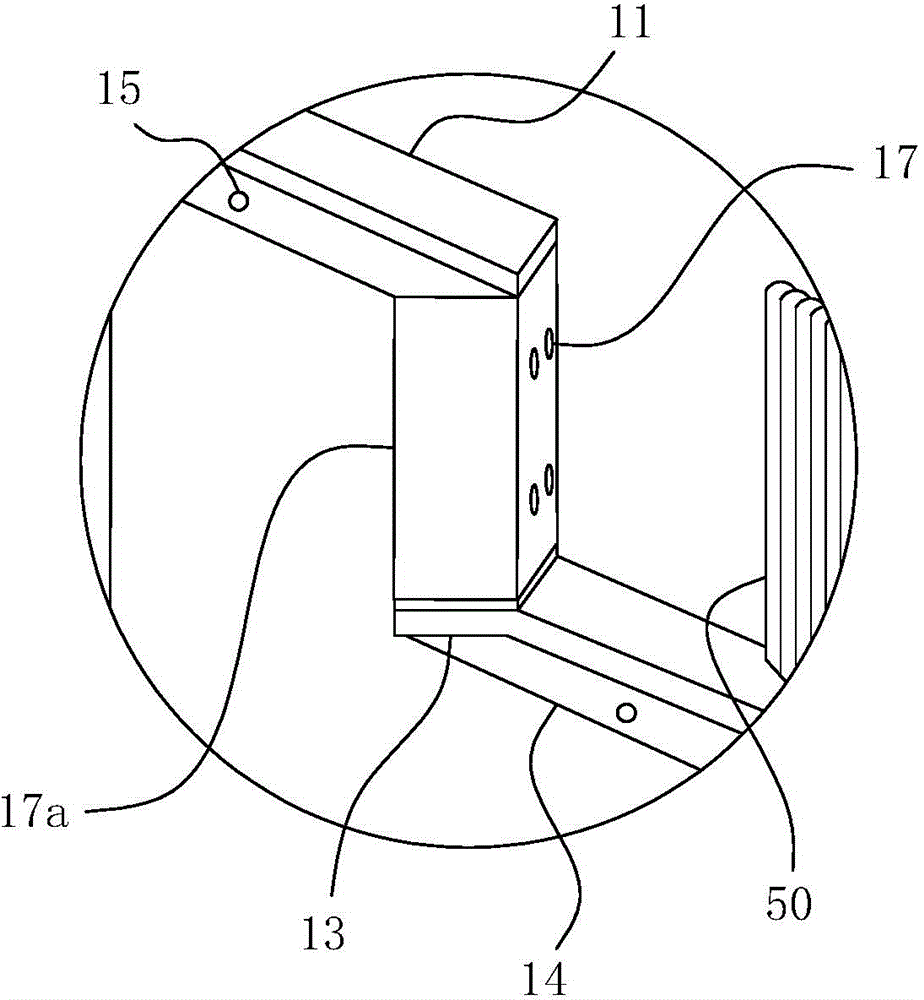

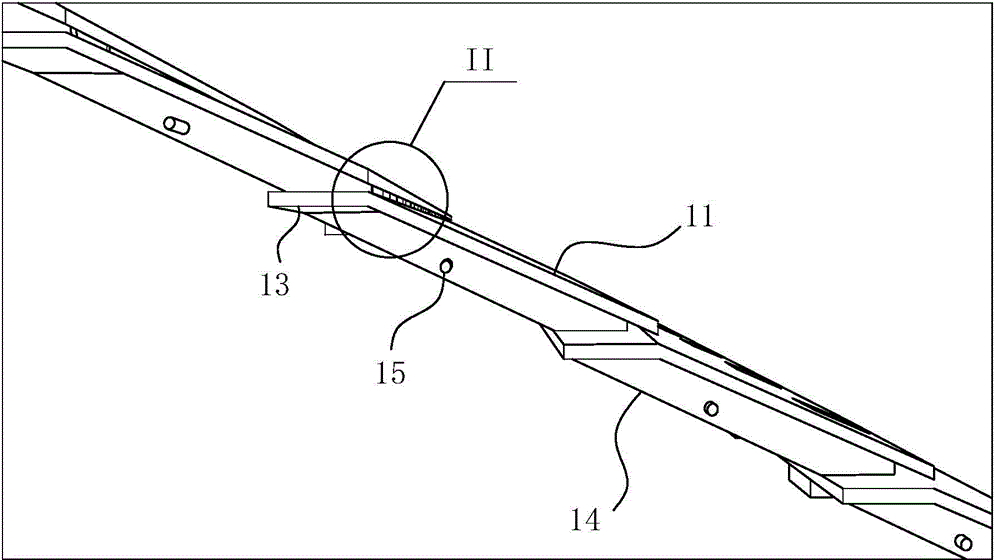

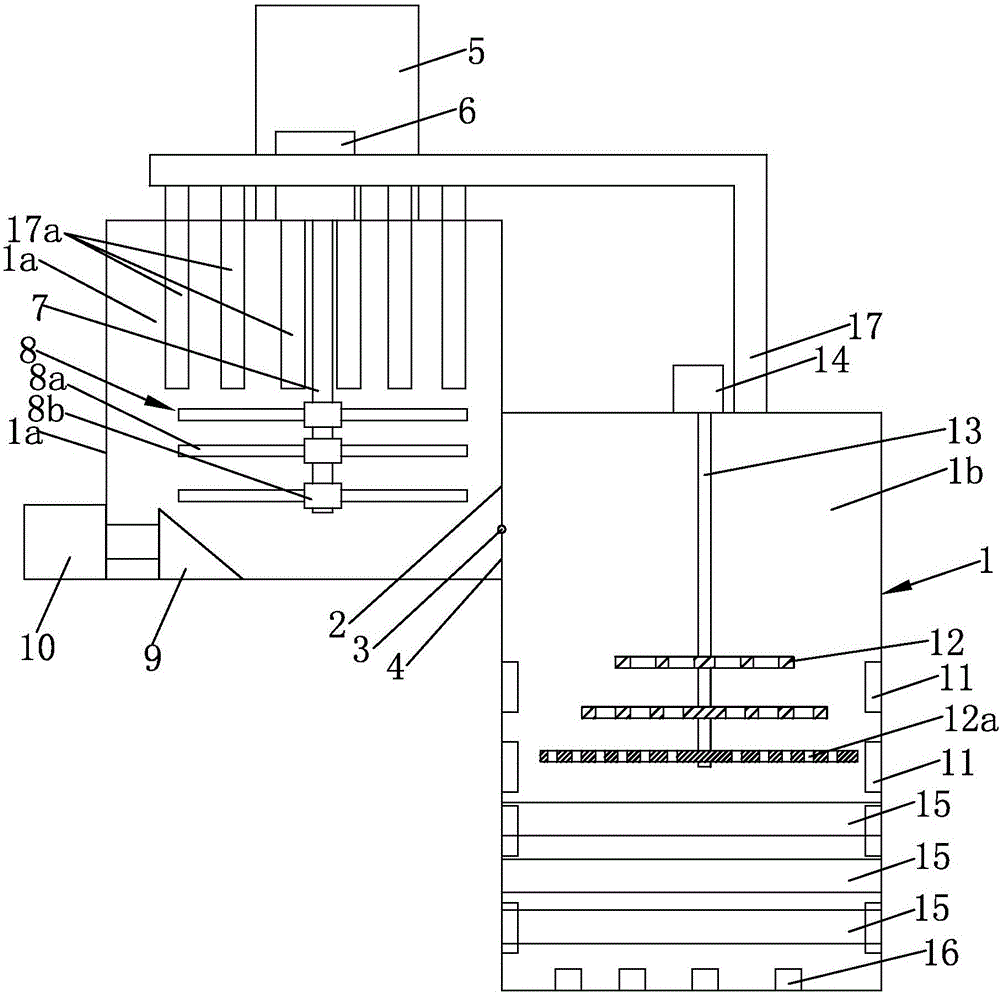

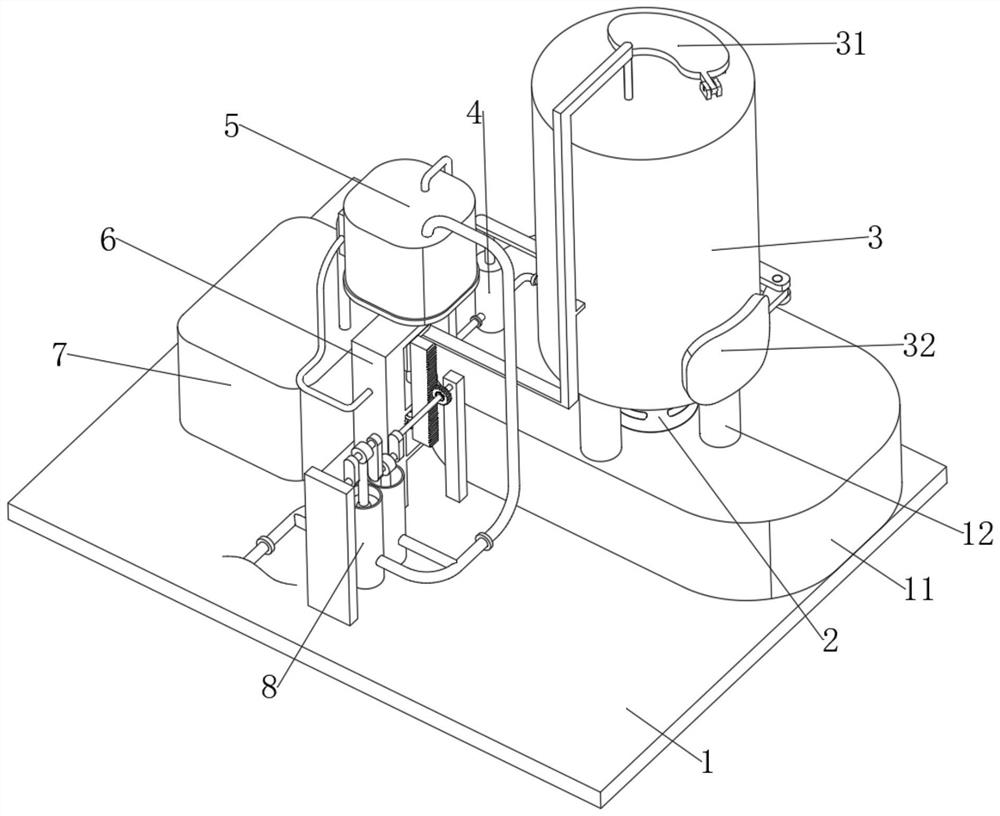

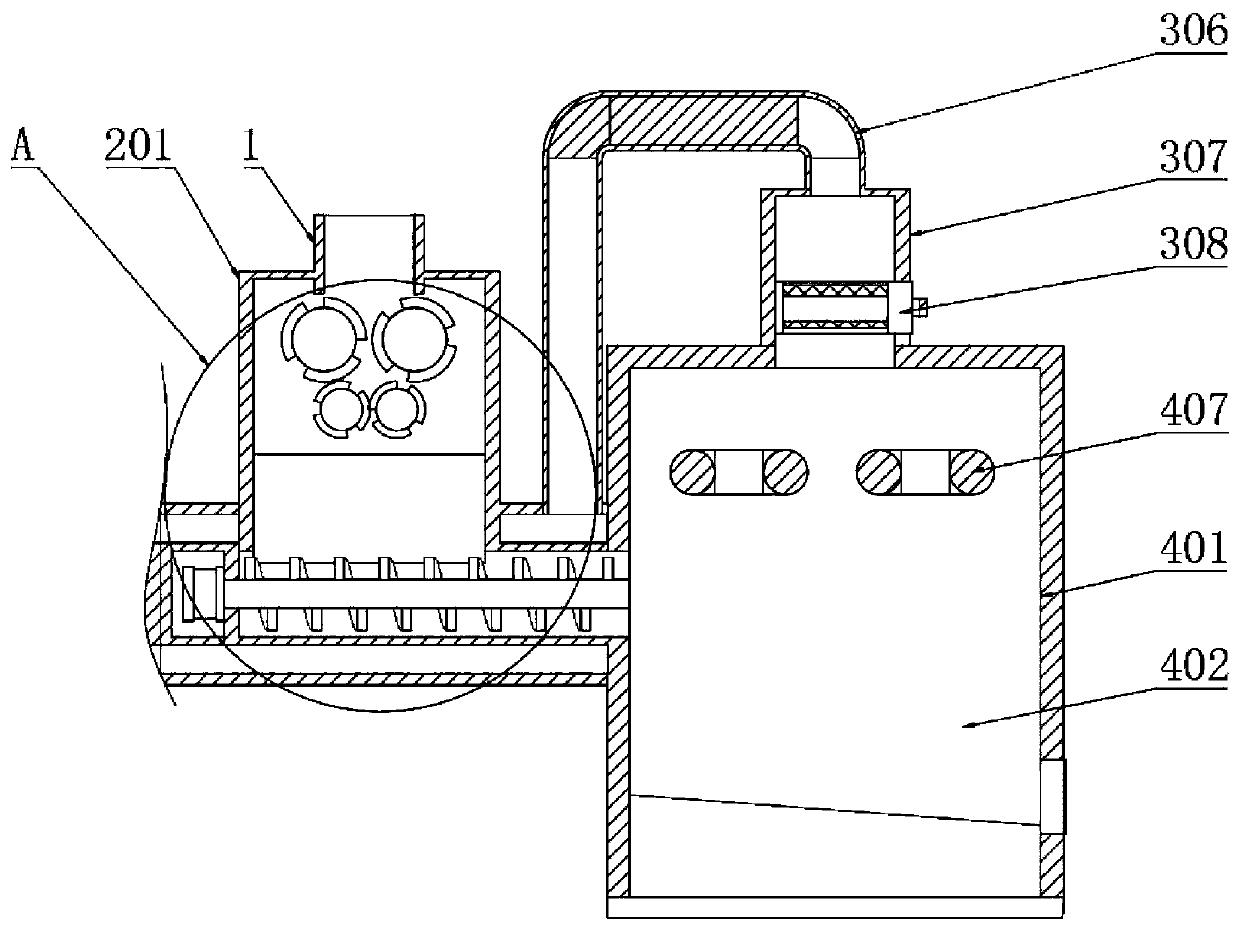

ActiveCN106402893AImprove incineration effectEasy to operateIncinerator apparatusDrive wheelIncineration

The invention relates to an automatic feeding and discharging gas combustion-supporting garbage incinerator. The automatic feeding and discharging gas combustion-supporting garbage incinerator comprises a combustion cavity. Feeding through holes are formed in the two sides of the combustion cavity. Horizontal tracks are arranged on the two sides of the combustion cavity and provided with drive wheels. A connecting bottom plate is fixed to the drive wheels. The connecting bottom plate penetrates the feeding through holes and then penetrates the whole combustion cavity. The connecting bottom plate is connected with an inner sealing door and an outer sealing door. A baffle is arranged on one sides of the horizontal tracks and provided with a push plate. The rear side of the push plate is connected with a first drive air cylinder, and a garbage conveying belt is arranged on the other sides of the horizontal tracks and provided with a movable guiding groove and a baffle, wherein the guiding groove and the baffle are connected with second drive air cylinders on the two sides of the garbage conveying belt. The combustion cavity is internally provided with a circle of gas pipeline with gas nozzles. The gas pipeline is connected with a gas source. An ignition valve is further arranged in the combustion cavity. A smoke discharging pipeline is further arranged at the upper end of the combustion cavity. The automatic feeding and discharging gas combustion-supporting garbage incinerator conducts automatic feeding and deslagging, and is high in incineration efficiency.

Owner:JINGMEN TUODA TECH CO LTD

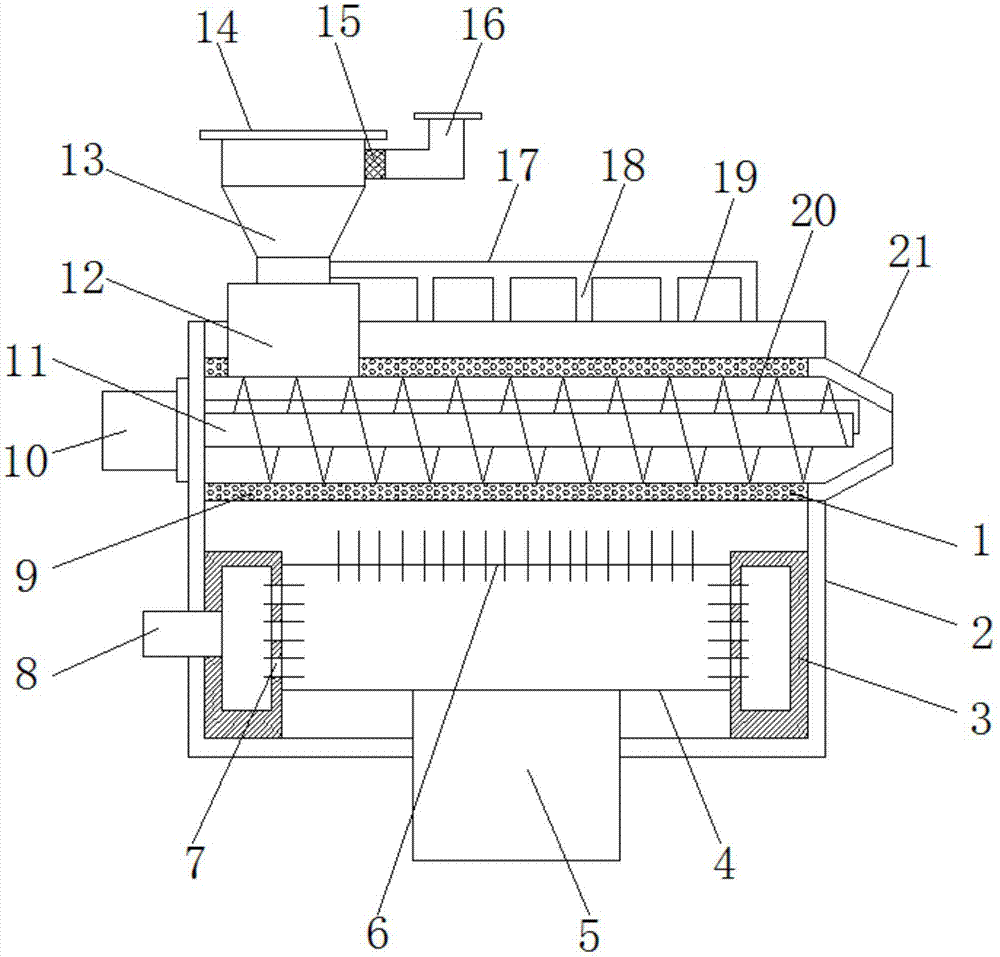

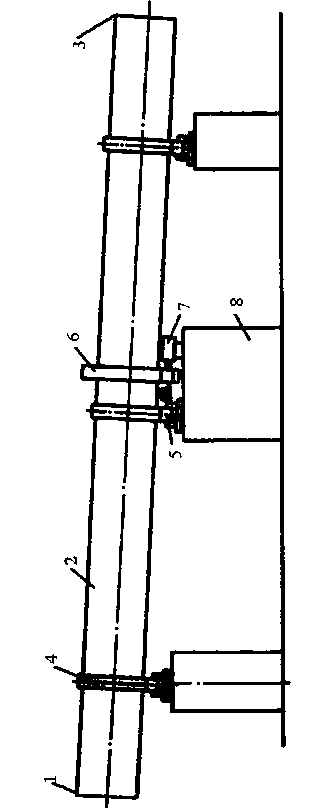

Rotary kiln

InactiveCN103528072AImprove drying efficiencyStable temperatureIncinerator apparatusActivated sludgeCombustion

The invention discloses a rotary kiln which comprises a kiln head, a kiln body, a kiln tail, rim bands, riding wheels, a big gear ring, a transmission device and a foundation. The riding wheels are arranged on the foundation through bearings, the rim bands penetrate through the kiln body in a sleeved mode and are fixedly connected to the kiln body, and the kiln body is arranged on the riding wheels through the rim bands. The big gear ring penetrates through the kiln body in a sleeved mode and fixed on the kiln body, the transmission device is arranged on the foundation, and an output end of the transmission device is in gear mesh with the big gear ring. A lifting board is arranged in the kiln body, and a kiln head cover is arranged on the kiln head. The kiln head is provided with an activated sludge feed device and a combustible waste feed device. The lifting board is an O-shaped hanging chain which is arranged on the inner wall of the kiln body. A sealing structure between the kiln head and the kiln body is in a labyrinth seal mode and a scale seal mode. The sealing structure between the kiln tail and the kiln body is in a labyrinth seal mode and a scale seal mode. A smoke outlet is formed above the kiln head cover, and a temperature measuring device is arranged on the smoke outlet. The rotary kiln is used for drying PTA process activated sludge, the combustion is sufficient, burning effects are good, sludge drying efficacy is good, energy is saved, and sealing performance is good.

Owner:YIZHENG MAORUI CHEM

Medical waste treatment equipment with cleaning function

InactiveCN112902179AReduce the risk of contact infectionImprove work efficiencyElectrostatic separationBlast-producing apparatusMedical wasteEnvironmental engineering

The invention relates to the technical field of waste treatment, and discloses medical waste treatment equipment with a cleaning function. The equipment comprises a box body, wherein a transmission mechanism is arranged on the right side of the box body, two sliding blocks are welded on the inner wall of the box body, the right side of the box body communicates with a feeding pipe, the feeding pipe is positioned below the transmission mechanism, a sliding block is slidably connected to the inner wall of the rear portion of the box body, an electromagnet is fixedly installed on the rear portion of the box body, a purification mechanism is arranged on the front portion of the box body, a first smashing roller and a second smashing roller are rotatably connected to the inner wall of the box body, a treatment box is fixedly installed on the bottom wall inside the box body, and an inclined block is welded to the top of the treatment box. According to the equipment, cleaning liquid is injected into the feeding pipe, and then the inner wall of the treatment box can be automatically cleaned through the transmission mechanism, so that manual cleaning by workers is not needed, the risk of contact infection is reduced, and the working efficiency is further improved.

Owner:邵欠欠

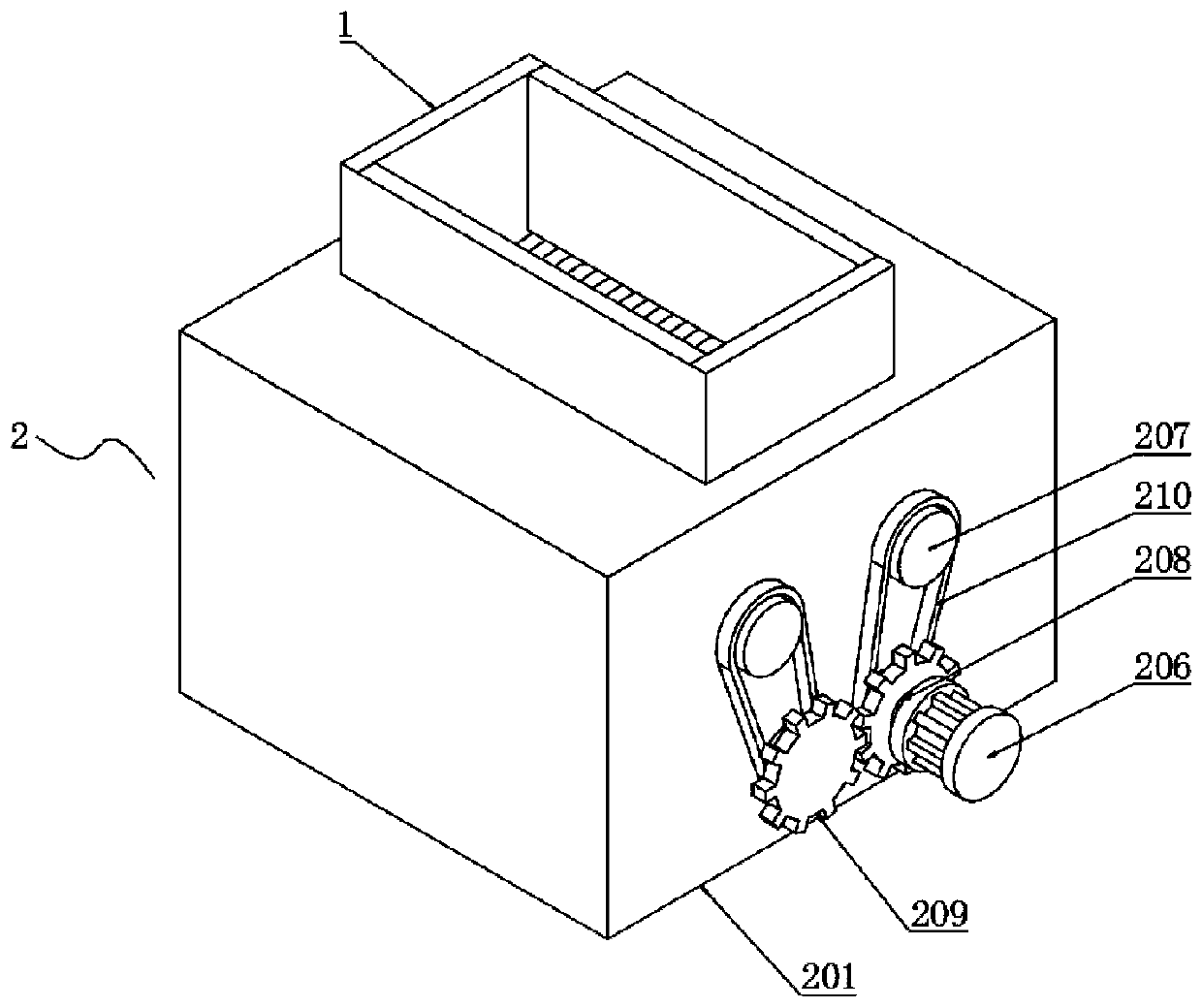

Efficient incineration equipment for waste incineration processing

InactiveCN111594849AScientific and reasonable structureEasy to useIncinerator apparatusElectric machineGear wheel

The invention discloses efficient incineration equipment for waste incineration processing. The bottom end of a feeding channel is fixedly connected with a pulverization mechanism; the pulverization mechanism comprises a pulverization box, a pulverization chamber, thick grinding rollers, thin grinding rollers, a transmission box, a rotary motor, upper rotary shafts, lower rotary shafts, gears andbelts, wherein the bottom end of the feeding channel is fixedly connected with the pulverization box; the pulverization chamber is arranged in the pulverization box; and the top position of the innerwall of the pulverization chamber is symmetrically rotatably connected with the thick grinding rollers. The efficient incineration equipment has a scientific and reasonable structure, and is safe andconvenient to use. Since the efficient incineration equipment is provided with the pulverization mechanism, waste can be pulverized into tiny scraps through the pulverization mechanism, so that the waste can be fully burnt, an incineration effect is improved, meanwhile, the rotary motor drives the lower rotary shafts, through the cooperation of the gears and the belts, the rotary motor can simultaneously drive the thick grinding rollers and the thin grinding rollers to rotate together, transmission efficiency is improved, and waste pulverization efficiency is improved.

Owner:那玉金

Garbage incinerator

ActiveCN106594756AIncineration effect is goodImprove combustion efficiencyIncinerator apparatusSmall footprintCombustion chamber

The invention discloses a garbage incinerator which is convenient to move, low in consumed energy, high enough in combustion temperature and free of generation of harmful substances. The garbage incinerator comprises a base; a furnace body is arranged above the base and is internally provided with a first combustion chamber; a fire grate is arranged at the bottom of the first combustion chamber, and an ash discharging port is formed below the fire grate; an air inlet pipe is further arranged in the first combustion chamber, and a draught fan blows air into the first combustion chamber through the air inlet pipe; the first combustion chamber is further provided with a garbage inlet and an exhaust pipe; the side face of the first combustion chamber is further connected with a second combustion chamber which is internally provided with mutually-staggered flow baffles and a plasma injecting head, and the plasma injecting head is connected with a plasma converter through a special through connection pipe; the fire grate is provided with plasma spray nozzles which are connected with the plasma converter through a plasma connecting pipe; and the second combustion chamber is connected with a flue gas separation cavity which is internally provided with a chimney, and a flue gas separation cavity ash discharging port is formed in the bottom of the flue gas separation cavity. The garbage incinerator is simple, capable of achieving miniaturization conveniently, small in floor space, low in operating cost and suitable for popularization.

Owner:SUNKUN ENVIRONMENTAL PROTECTION TECH SHANGHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com