Automatic feeding and discharging gas combustion-supporting garbage incinerator

A garbage incinerator, automatic loading and unloading technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problem of reducing the efficiency of garbage incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

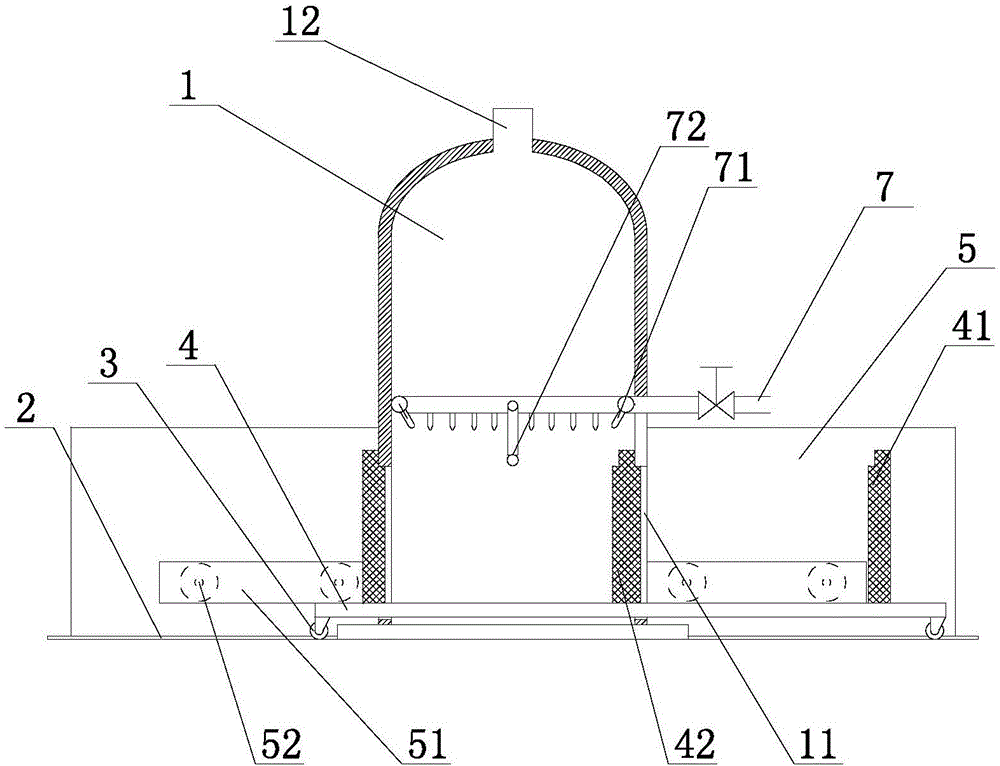

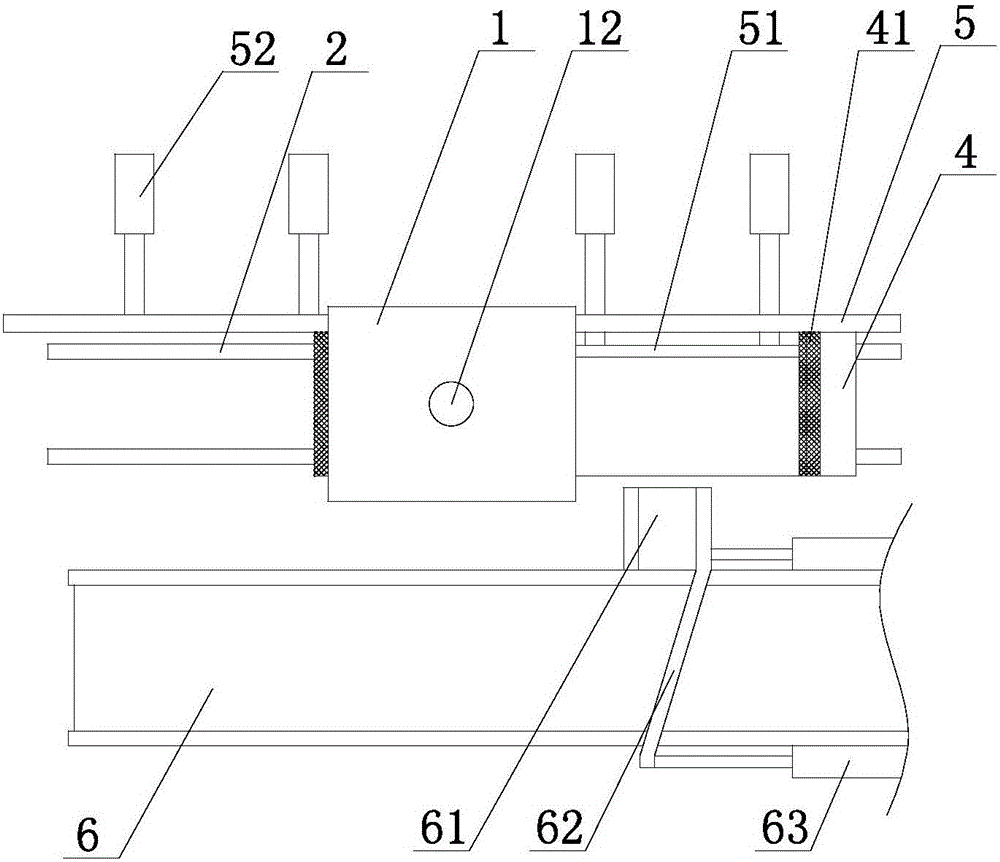

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0011] like figure 1 , figure 2 As shown, the automatic loading and unloading gas-fired combustion-supporting garbage incinerator of this embodiment includes a combustion chamber 1, feeding through holes 11 are provided on both sides of the combustion chamber 1, horizontal rails 2 are arranged on both sides of the combustion chamber 1, and driving wheels are arranged on the horizontal rails 2 3. The driving wheel 3 is fixedly connected to the bottom plate 4, the connecting bottom plate 4 passes through the feeding through hole 11 and runs through the entire combustion chamber 1, the outer sealing door 41 is fixed on both sides of the connecting bottom plate 4, and the connecting bottom plate 4 is located in the combustion chamber 1 and the inner sealing door 42 is fixed. A tailgate 5 is arranged on one side of the horizontal track 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com