Garbage incinerator

A waste incinerator and furnace body technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of immovable volume of incinerators, accelerated resource consumption, and insufficient temperature, so as to achieve good incineration effects, facilitate miniaturization, No secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

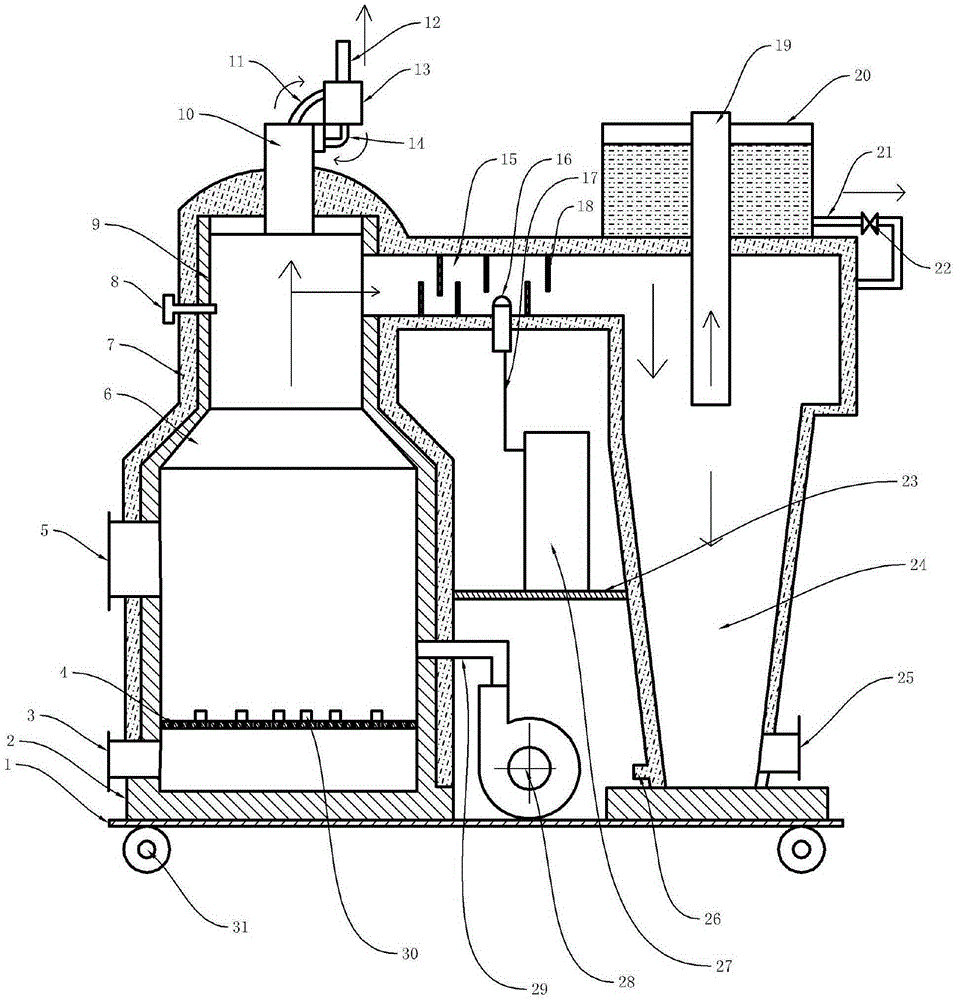

[0028] see figure 1 , a garbage incinerator, comprising a base 1, a furnace body 2 is arranged above the base 1, wheels 31 are arranged below, and a first combustion chamber 6 is arranged in the furnace body 2;

[0029] The wheels 31 can make the whole combustion furnace move conveniently. Of course, it is better to set a braking mechanism on the wheels 31 to prevent them from rotating on their own, which may cause potential safety hazards and inconvenient use;

[0030] The bottom of the first combustion chamber 6 is provided with a fire grate 4, and the bottom of the fire grate 4 is provided with an ash outlet 3. When the garbage is burned in the first combustion chamber 6, the ash will fall through the fire grate 4. To the bottom of the grate 4, and then discharged through the ash outlet 3;

[0031] Also be provided with air intake pipe 29 in the describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com