Patents

Literature

65results about How to "Strong raw material adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

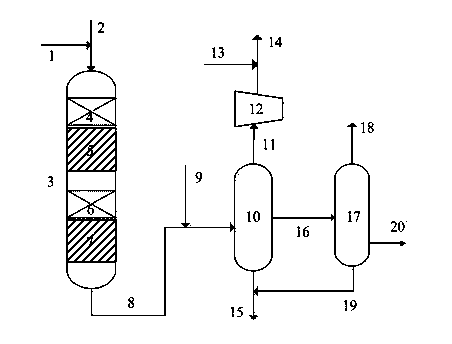

Crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparing method

PendingCN109575982AStrong raw material adaptabilityStrong resistance to metal pollutionCatalytic crackingCatalystsChemistryMetal contamination

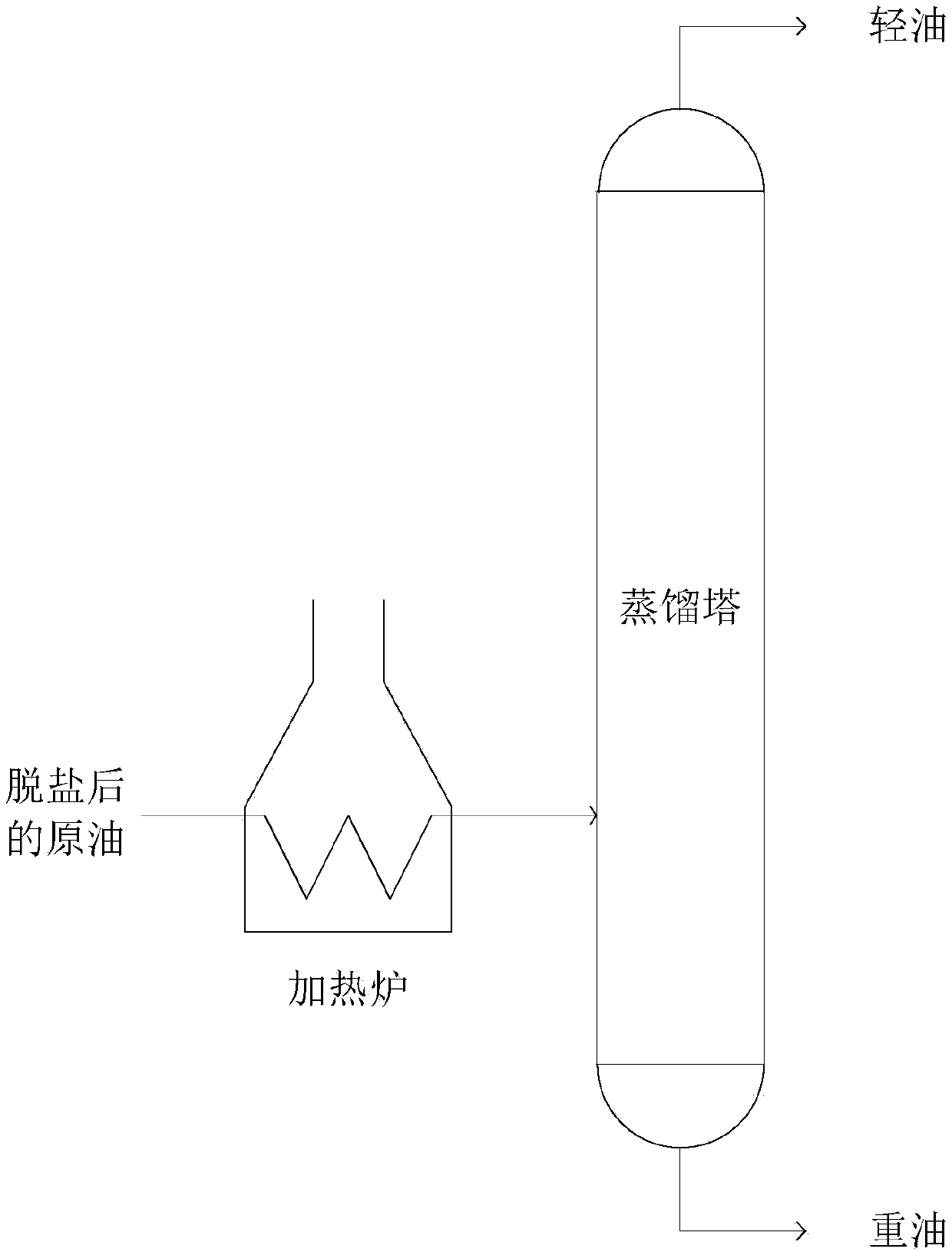

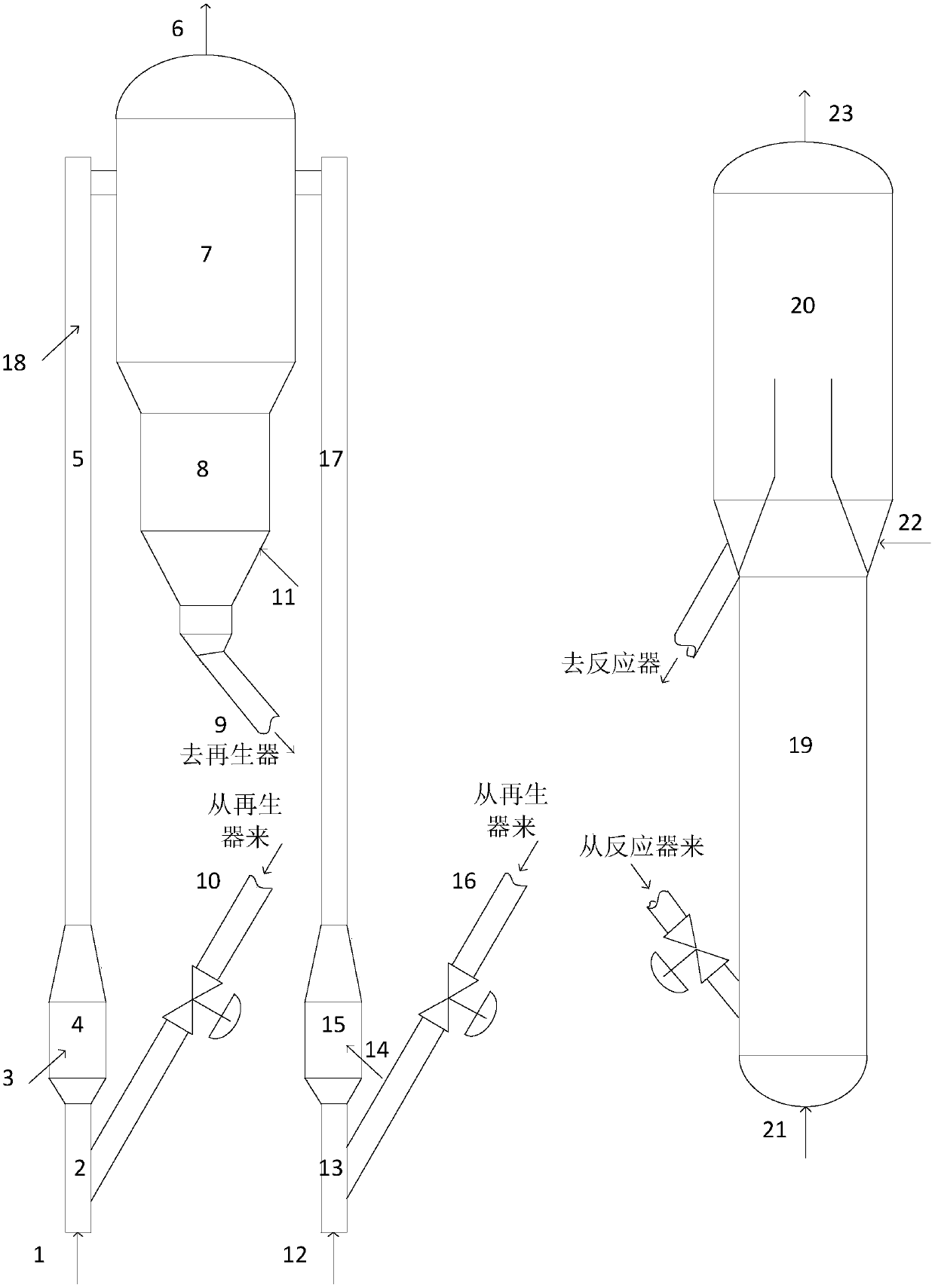

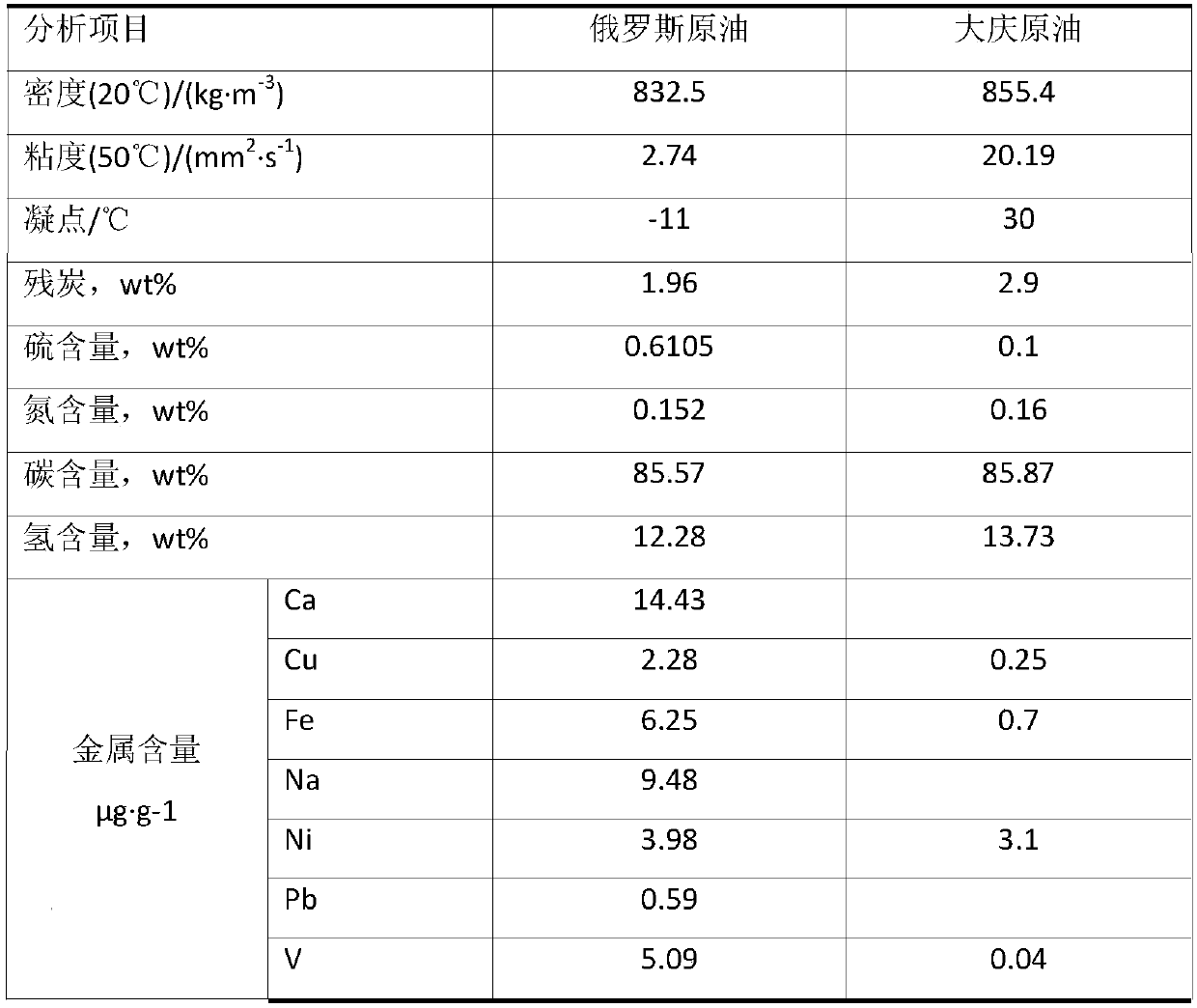

The invention provides a crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparing method. The crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparingmethod is characterized by comprising the following steps of 1), desalinating and dewatering crude oil, then heating the crude oil in a heating furnace, and then dividing the heated crude oil into heavy components and light components in a distillation tower at a cut point of 150-300 DEG C; 2) subjecting the light components discharged from the top of the distillation tower, namely a fed light material, and the heavy components discharged from the bottom of the distillation tower, namely a fed heavy material, to contact reaction with high-temperature catalysts under a vapor atmosphere in tworeactors separately. Compared with the prior art, the crude oil catalytic cracking low carbon olefin and aromatic hydrocarbon preparing method has the advantages of 1) high raw material adaptability,2) high metal contamination resistance of the catalysts, no hydrothermal deactivation and low reagent consumption, 3) lower energy consumption compared with steam cracking, and 4) high per-pass conversion rate and high olefin selectivity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

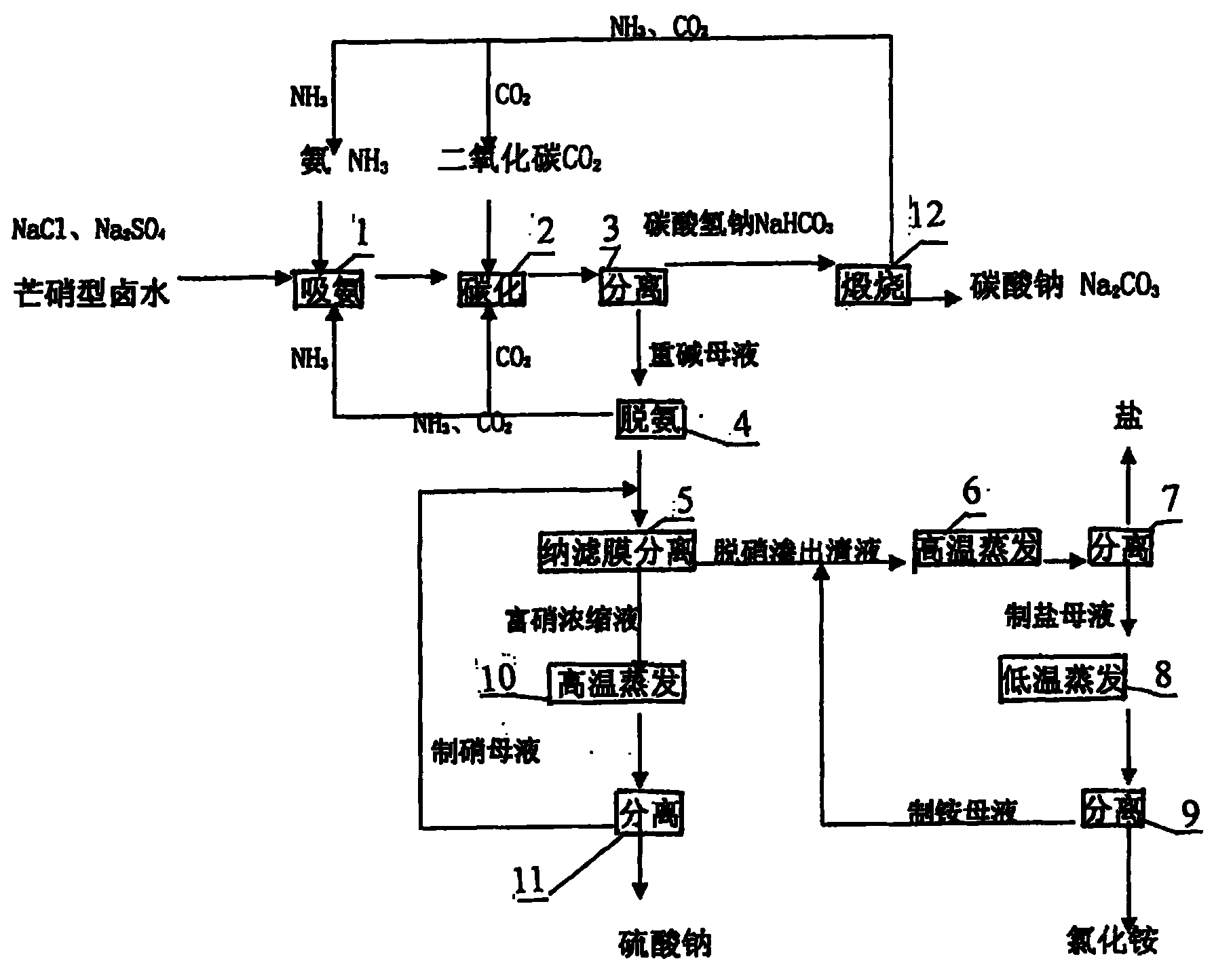

Process for producing mirabilite type bittern, sodium carbonate, sodium chloride, sodium sulfate and ammonium chloride

ActiveCN102153113AHigh quality main and by-productsStrong raw material adaptabilityAmmonium halidesAlkali metal chloridesDecompositionChemistry

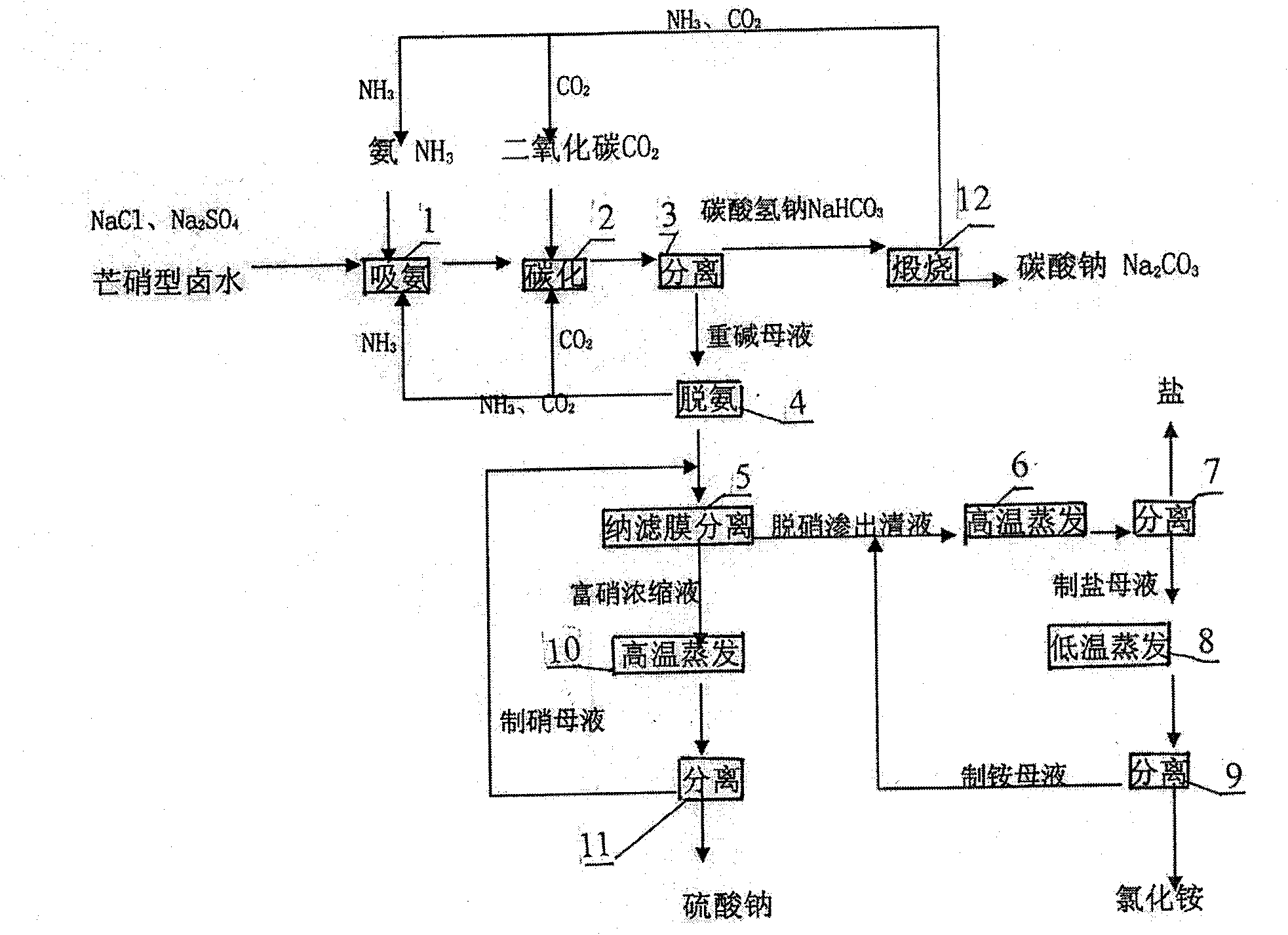

The invention provides a process for producing mirabilite type bittern, sodium carbonate, sodium chloride, sodium sulfate and ammonium chloride. The process comprises the following steps of: performing double decomposition reaction by using mirabilite type bittern, ammonia and carbon dioxide as raw materials, and then separating the reaction products to obtain sodium bicarbonate and sodium bicarbonate mother solution; performing preheating and high-temperature ammonia removal on the sodium bicarbonate mother solution to obtain ammonia removed mother solution; separating the ammonia removed mother solution through a nano-filtration membrane to obtain denitration seeped clear solution and mirabilite rich concentrated solution; performing high-temperature evaporation and separation on the mirabilite rich concentrated solution to obtain solid sodium sulfate and mirabilite preparation mother solution, and circularly mixing the mirabilite preparation mother solution and the ammonia removed mother solution to perform the nano-filtration membrane separation process; performing high-temperature evaporation and separation on the denitration seeped clear solution and the circular ammonium preparation mother solution to obtain solid sodium chloride and salt preparation mother solution; performing low-temperature evaporation and separation on the salt preparation mother solution to obtain solid ammonium chloride and ammonium preparation mother solution; and mixing the ammonium preparation mother solution and the denitration seeped clear solution, and performing circular evaporation and separation to obtain solid sodium chloride and salt preparation mother solution. The process has the characteristics of high main product and byproduct quality, low steam energy consumption and production cost, no three-waste discharge in closed cycle and the like.

Owner:CHINA LIGHT IND INT ENG CO LTD

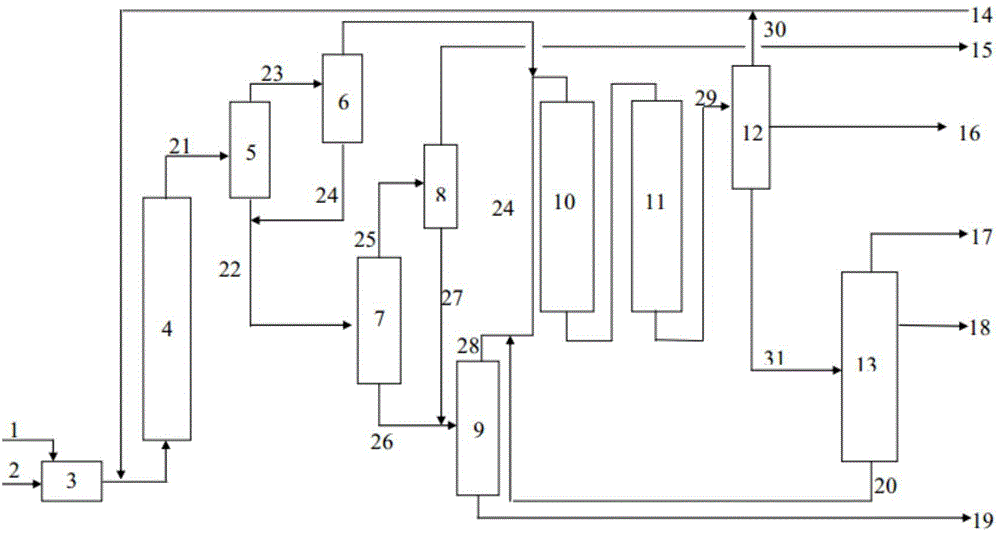

Method for producing high-quality fuel oil by heavy oil hydrocracking

ActiveCN104388117AStrong raw material adaptabilitySimple effectTreatment with hydrotreatment processesChemistryFuel oil

The invention discloses a method for producing high-quality fuel oil by heavy oil hydrocracking. The method comprises the following steps: heavy oil, a catalyst and hydrogen gas are mixed to enter a plug-flow suspension bed hydrocracking reactor; the gas-liquid mixture product is separated in a hot high-pressure separator and a cold high-pressure separator, the gas-phase product directly enters a two-stage fixed-bed reactor, and the liquid-phase product enters a vacuum distillation tower; the residues on the bottom of the vacuum tower are directly discharged out of the device, and the gas phase enters a fixed-bed reactor; and the fixed bed reaction product is subjected to hydrogen gas and light hydrocarbon separation to enter a fractionating tower so as to obtain high-grade gasoline and diesel, and the bottom oil is circulated to enter the fixed-bed reactor. By combining the plug-flow suspension bed, fixed-bed reactor and on-line hydrogenation, the method enhances the adaptability of the raw materials and the yield and quality of the liquid product, and lowers the reaction energy consumption and operation difficulty.

Owner:SHAANXI YANCHANG PETROLEUM GRP

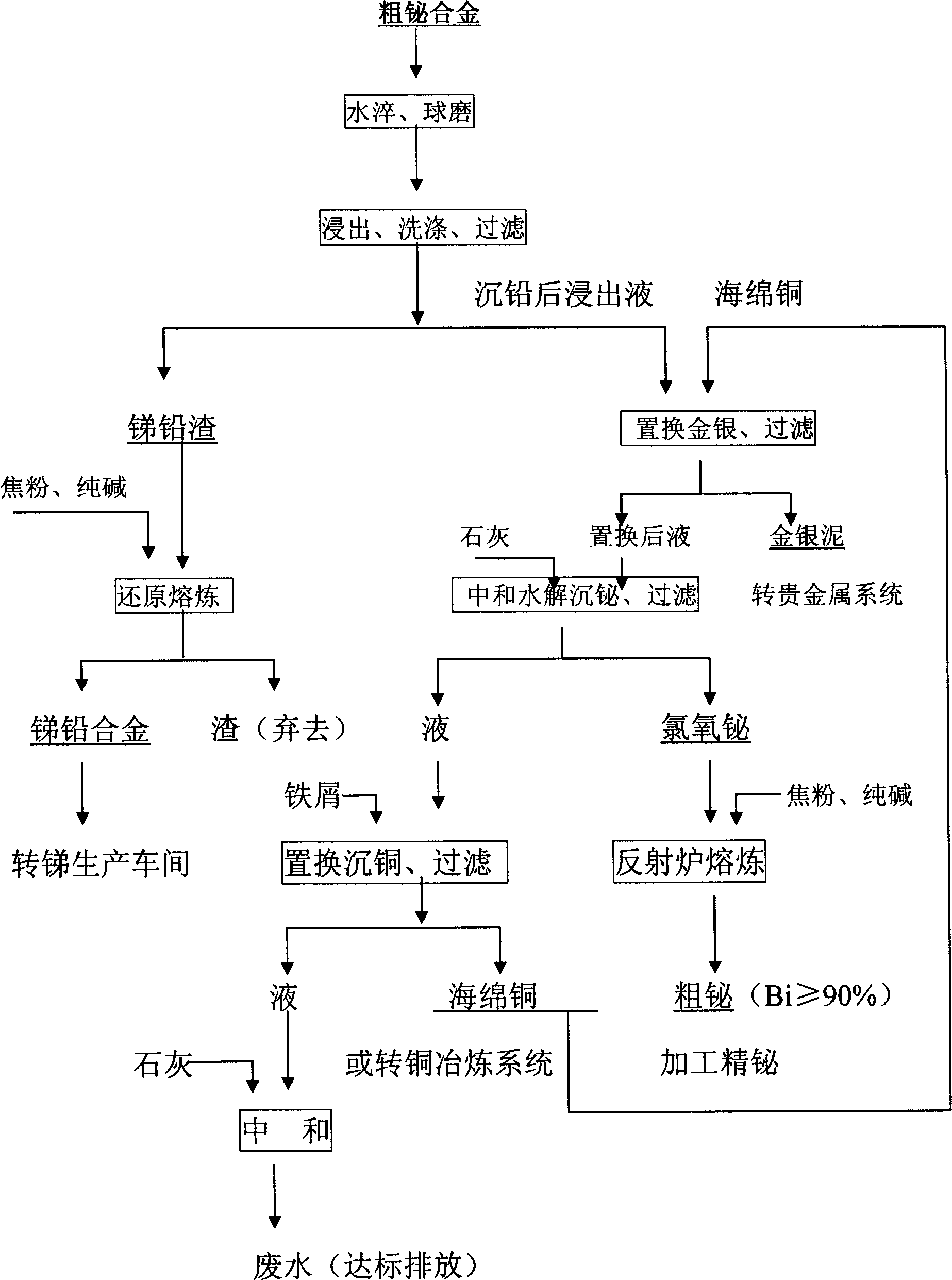

Recovering process of valent metal from crude bismuth

ActiveCN1800421AStable production processStrong raw material adaptabilityProcess efficiency improvementQuenchingSlag

The invention relates to a crude bismuth metal recovery technology which adopts wet process and pyrogenic process craft to recover the mental. It first dose water quenching, ball milling, extracting, scouring and filtering to the crude bismuth alloy to obtain the antimony lead skim and leaching solution; the antimony lead skim returns to the pyrogenic process system and then to the lead smelt system; it uses spongy copper to displace the Au and Ag of the leaching solution to produce the gold silver earth which returns to the noble metal smelting system; the liquid after displacing the gold silver earth dose hydrolytic precipitation bismuth and uses limestone and water to inactive it to pH=3-3.5, it filters the solution to obtain the bismuth oxide chloride and obtains the crude bismuth by smelting and then obtains the purified bismuth; it uses iron slag to displace the Cu to produce the spongy copper; adding limestone in the liquid after depositing Cu to inactive it and discharges it.

Owner:HENAN YUGUANG GOLD & LEAD

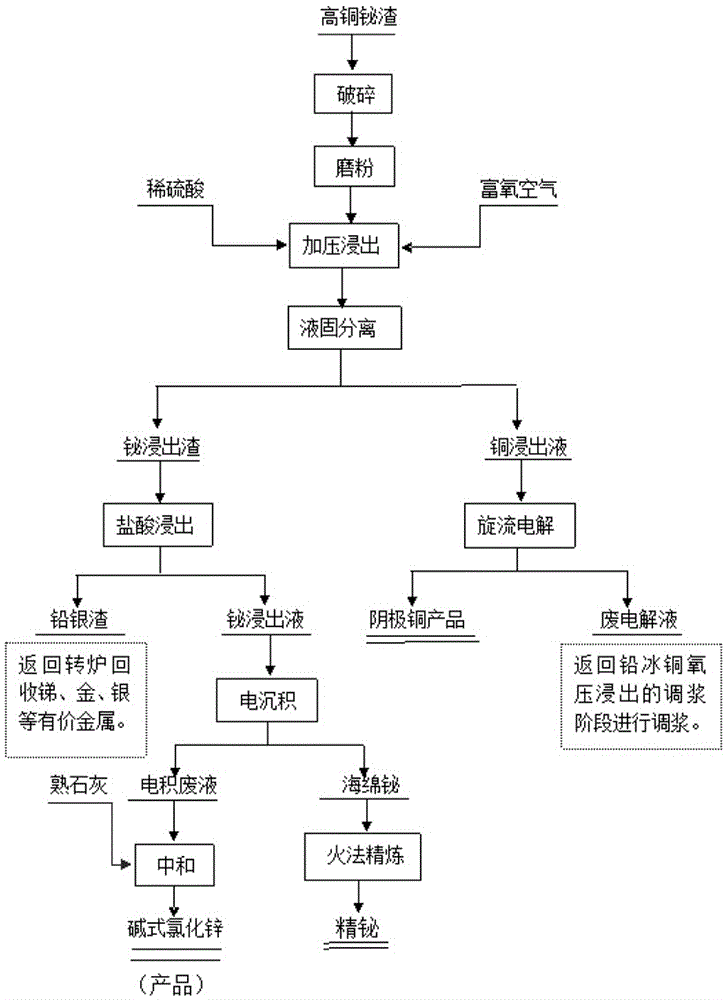

Method used for selective high-efficiency extraction of copper and bismuth from high-copper bismuth slag

InactiveCN106566928AStrong raw material adaptabilityEasy to operateProcess efficiency improvementBismuthPyrometallurgy

The invention discloses a method used for selective high-efficiency extraction of copper and bismuth from high-copper bismuth slag. According to the method, high-copper bismuth slag is taken as a raw material; high-copper bismuth slag powder obtained via smashing, grinding, and sieving and a sulfuric acid solution are subjected to size mixing at a certain ratio, and are delivered into a high-pressure autoclave; rich oxygen is introduced into the high-pressure autoclave, and oxygen pressure in the high-pressure autoclave is controlled for oxidizing leaching, wherein in the oxidizing leaching process, leaching of Cu in the form of Cu2+ is realized, and selective separation of copper with other non-zero valent elements is realized; a copper-containing leachate is subjected to acid adjusting, and is subjected to rotational flow electrolysis directly so as to extract copper in the copper-containing leachate and obtain copper products; a leaching residue is subjected to leaching separation of bismuth with concentrated hydrochloric acid, sponge bismuth is obtained via electro-deposition, and product refined bismuth is obtained via refining of sponge bismuth; and the rest slag is delivered into a lead pyrometallurgy system for comprehensive recycling of non-zero valent elements such as Pb, Ag, and Au. No environment pollution is caused by the method, no three wastes are discharged, and the method is a clean metallurgy technology.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

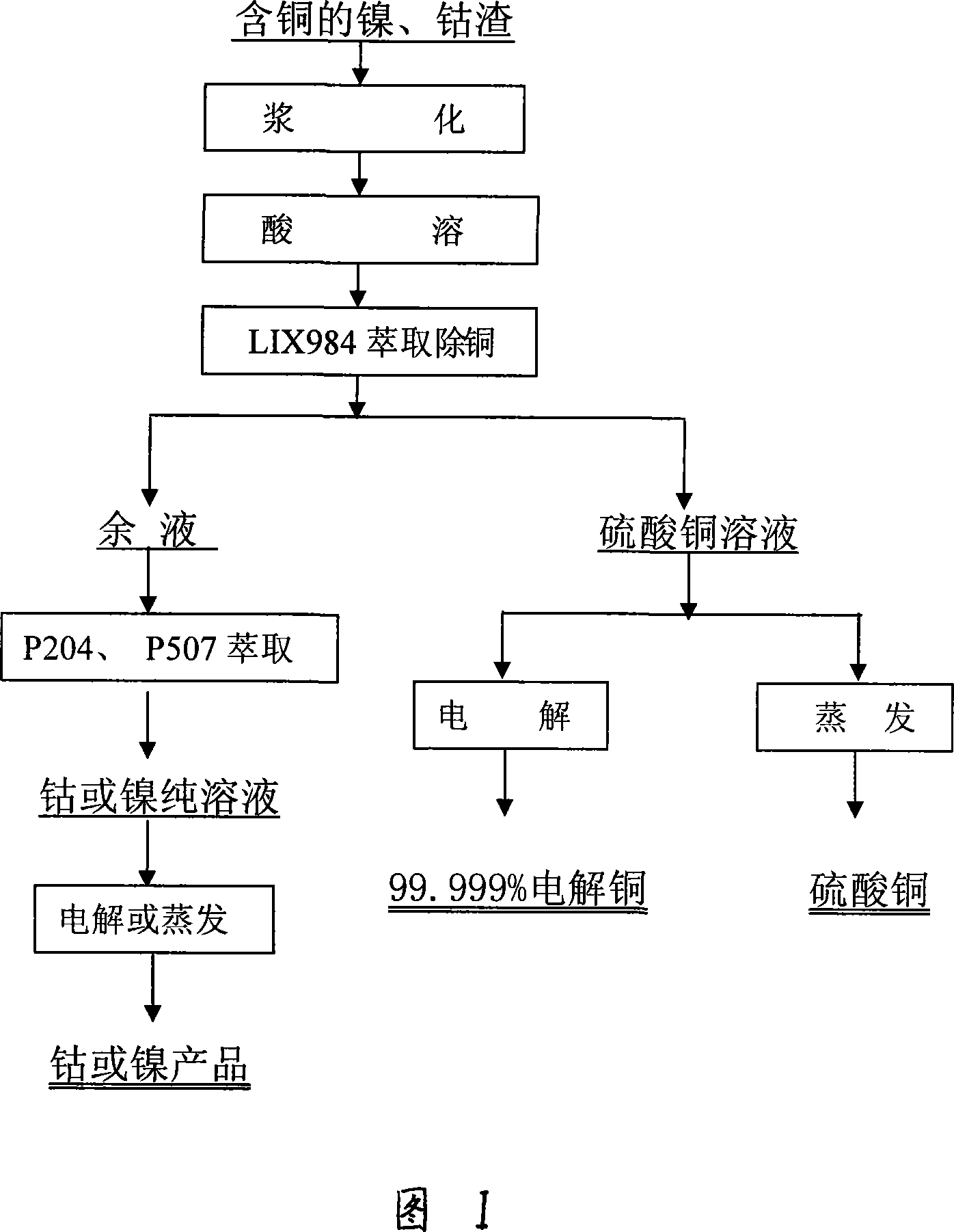

Method for separating copper from nickel and cobalt solution

InactiveCN101195861AReduce consumptionHigh recovery rateProcess efficiency improvementKeroseneHydrometallurgy

The invention discloses a method of separating copper from nickel cobalt solution, which relates to a method of separating copper from nickel cobalt solution during the technical process of producing high quality nickel or cobalt through a hydrometallurgy method. The invention is characterized in that LIX<QUESTION MARK> series of extracting agent is adopted to extract and separate copper in the nickel cobalt solution, the conditions of the extracting process are as follows: firstly, the pH value of the feed solution of the nickel cobalt solution is 1.5 to 2.5; secondly, the organic compounding ratio is 5 percent to 35 percent; thirdly, organic thinning agent is number 260 solvent oil or sulfonated kerosene; fourthly, the copper in the feed solution is extracted out through adopting two to three-stage countercurrent extraction; loading organic phase is washed through adopting zero to two-stage diluted acid solution; the copper in the loading organic phase is circularly and back washed through adopting 1 to 3 stages; fifthly, the concentration of the washing loading organic dilute sulfuric acid is 0 to 50 g / l; the concentration of the sulfuric acid for back washing the copper in the loading organic phase is 140 to 190 g / l; sixthly, the temperature during the extracting process is controlled to 15 to 35 DEG C. Compared with the traditional copper removal process, the method of the invention has the advantages that the process flow is short, the adaptability of the raw material is strong, the raw material consumption and energy consumption are few, the metal recovery ratio is high, and the comprehensive utilizing effect is good.

Owner:JINCHUAN GROUP LIMITED

Method for producing diesel oil with low condensation point by catalyst gradation technology

ActiveCN103805257ALow yieldGuaranteed yieldTreatment with hydrotreatment processesHydrogenation reactionSulfur

The invention discloses a method for producing diesel oil with a low condensation point by catalyst gradation technology. The method comprises the following steps: mixing a diesel oil raw material with hydrogen, orderly passing through at least two hydrogenation reaction zones connected in series, wherein in the material flowing direction, each hydrogenation reaction zone orderly comprises a hydro-refining dewaxing catalyst composite bed layer filled with a mixture of a hydro-refining catalyst and a hydro-upgrading isodewaxing catalyst, and a hydrodewaxing catalyst bed layer; performing separation and fractionation of the reaction effluent from the last hydrogenation reaction zone to obtain the diesel oil product with a low condensation point. The method of the invention reasonably combines and utilizes the temperature increase of the hydro-refining and hydro-upgrading dewaxing process with the temperature decrease of the hydrodewaxing process, improves the diesel oil yield and the cetane value while producing diesel oil with a low condensation point and low sulfur, reduces the hot-spot temperature of the device, prolongs the running period, also reduces the cold hydrogen consumption or the combustion gas loss of a heating furnace, and saves operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

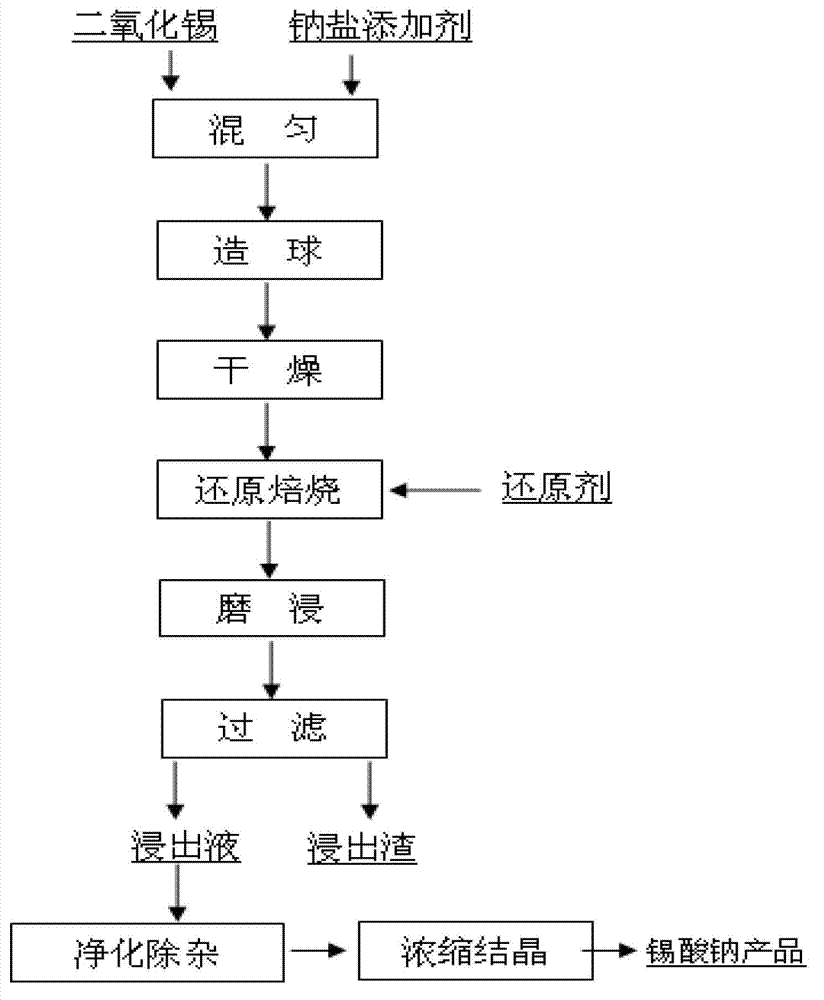

Method for preparing sodium stannate from stannic oxide and sodium salt in reduction roasting manner

The invention discloses a method for preparing sodium stannate from stannic oxide and sodium salt in a reduction roasting manner. The method comprises the following steps of firstly and respectively grinding stannic oxide and sodium salt additive to meet the following requirement that the mass percent of grinded stannic oxide and sodium salt additive with particle grade of -0.1mm is not less than 90%, and uniformly mixing grinded stannic oxide and sodium salt additive according to a mass ratio of 1:(0.8-1.6); blocking the mixture, drying and placing the mixture under reduction atmosphere to heat and roast, wherein coke powder or anthracite is served as a reduction agent, the roasting temperature is 800-950 DEG C, and the roasting time is 30-90min; and after cooling down the roasted blocks, sequentially carrying out treatments of grinding and soaking, filtering, purifying and impurity removing, and concentrating and crystallizing to obtain products of sodium stannate. Compared with the traditional sodium stannate preparation process, the method for preparing sodium stannate from stannic oxide and sodium salt in the reduction roasting manner, disclosed by the invention, has the characteristics of strong raw material suitability, high tin conversion rate, low cost, small investment, simple operation, environmental friendliness and the like; the whole reduction roasting process is carried out under a solid condition without special requirements in a roasting device; and the industrial production is easy to be realized.

Owner:CENT SOUTH UNIV

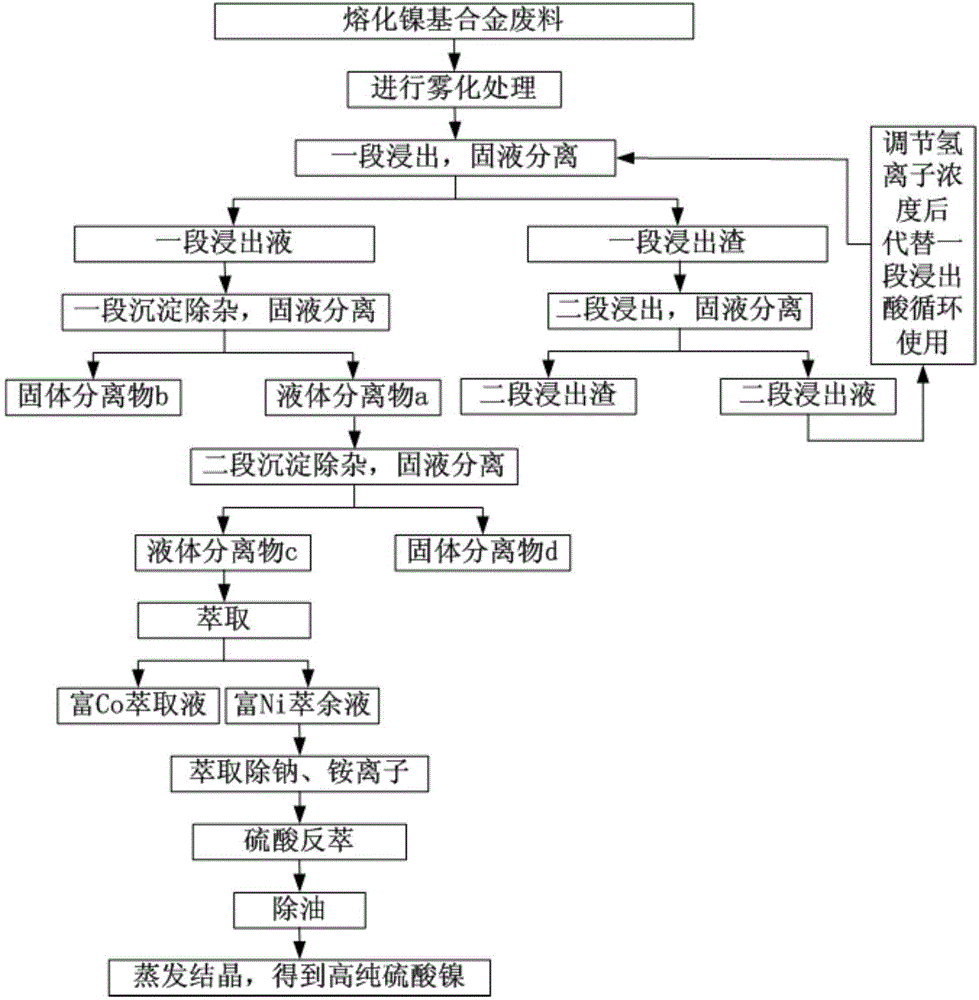

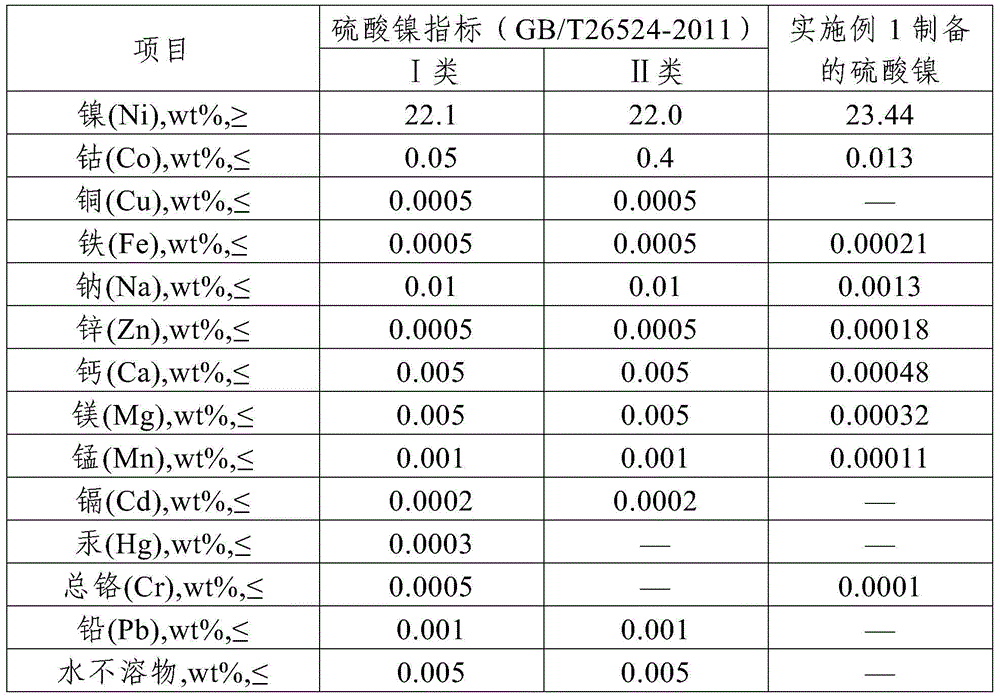

Method for regenerating high-purity nickel sulfate from nickel-based alloy waste material

The invention provides a method for regenerating high-purity nickel sulfate from a nickel-based alloy waste material. The method comprises the following steps of: 1, fusing the nickel-based alloy waste material; 2, atomizing; 3, carrying out first-stage leaching treatment to obtain a first-stage leaching solution and a first-stage leaching residue; 4, respectively treating the first-stage leaching solution and the first-stage leaching residue, carrying out second-stage leaching on the first-stage leaching residue, then regulating the concentration of hydrogen ions contained in a second-stage leaching solution, and then substituting for first-stage leaching acid for recycling; sequentially carrying out first-stage precipitation impurity removal, second-stage precipitation impurity removal, nickel and cobalt extraction separation, sodium ion or / and ammonium ion extraction removal, sulfuric acid reverse extraction, oil adsorption removal and evaporative crystallization treatment on the first-stage leaching solution to obtain the high-purity nickel sulfate. The method provided by the invention can be used for effectively recovering nickel contained in the nickel-based alloy waste material so as to be prepared into the high-purity nickel sulfate and directly applying the high-purity nickel sulfate to related industries, such as accumulators and electroplating, and has the characteristics of high raw material adaptability, high product purity, less environmental pollution and the like.

Owner:XIAN RAREALLOYS

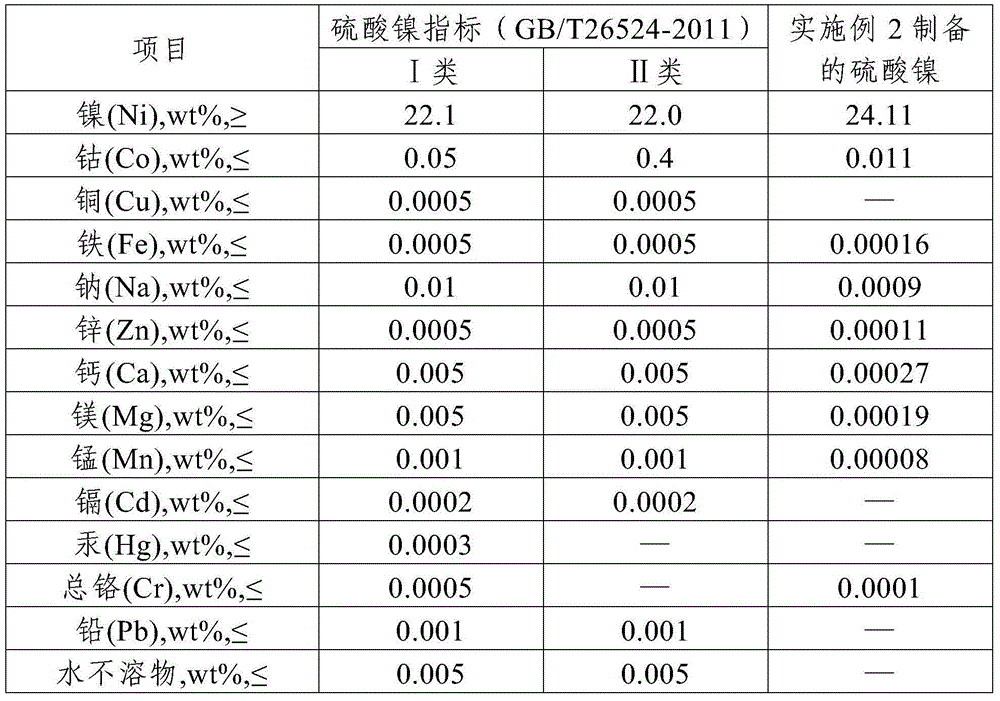

Integrated process method of producing low-carbon aromatic hydrocarbons and olefins from gas oil

ActiveCN110938464ALow yieldRealize oil reduction and increaseTreatment with hydrotreatment processesHydrocarbon oils treatment productsFuel oilProcess engineering

The invention provides an integrated process method of producing low-carbon aromatic hydrocarbons and olefins from gas oil. The method includes: feeding gas oil to a gas oil hydrogenation refining unit to perform a refining reaction to obtain refined gas oil; feeding the refined gas oil to a hydrocarbon adsorption separation unit to prepare a non-aromatic hydrocarbon component and a heavy aromatichydrocarbon component; feeding the non-aromatic hydrocarbon component to a non-aromatic hydrocarbon cracking unit to obtain olefin-rich gas, cracked gasoline and cracked heavy oil through catalytic cracking or vapor cracking; feeding the heavy aromatic hydrocarbon component and the cracked heavy oil into a heavy aromatic hydrocarbon mild-hydrogenation cracking unit to perform a selective crackingreaction, thus obtaining an extract raw material; feeding the cracked gasoline to a cracked gasoline hydrogenation refining unit to perform a refining reaction to obtain the extract raw material; feeding the extract raw material into an aromatic hydrocarbon extract unit to prepare the low-carbon aromatic hydrocarbons. In the invention, firstly, the hydrocarbons in the gas oil are separated, and secondly, a processing technology is selected specifically to maximumly produce the low-carbon aromatic hydrocarbons and olefins. The method has advantages of strong raw material adaptability, high target product yield and mild operation conditions.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

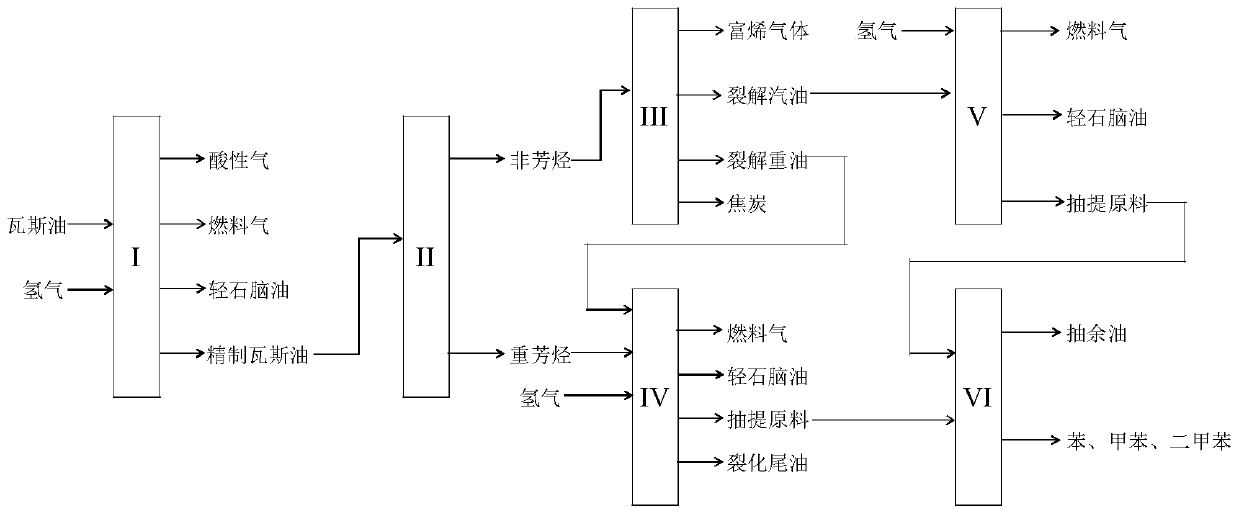

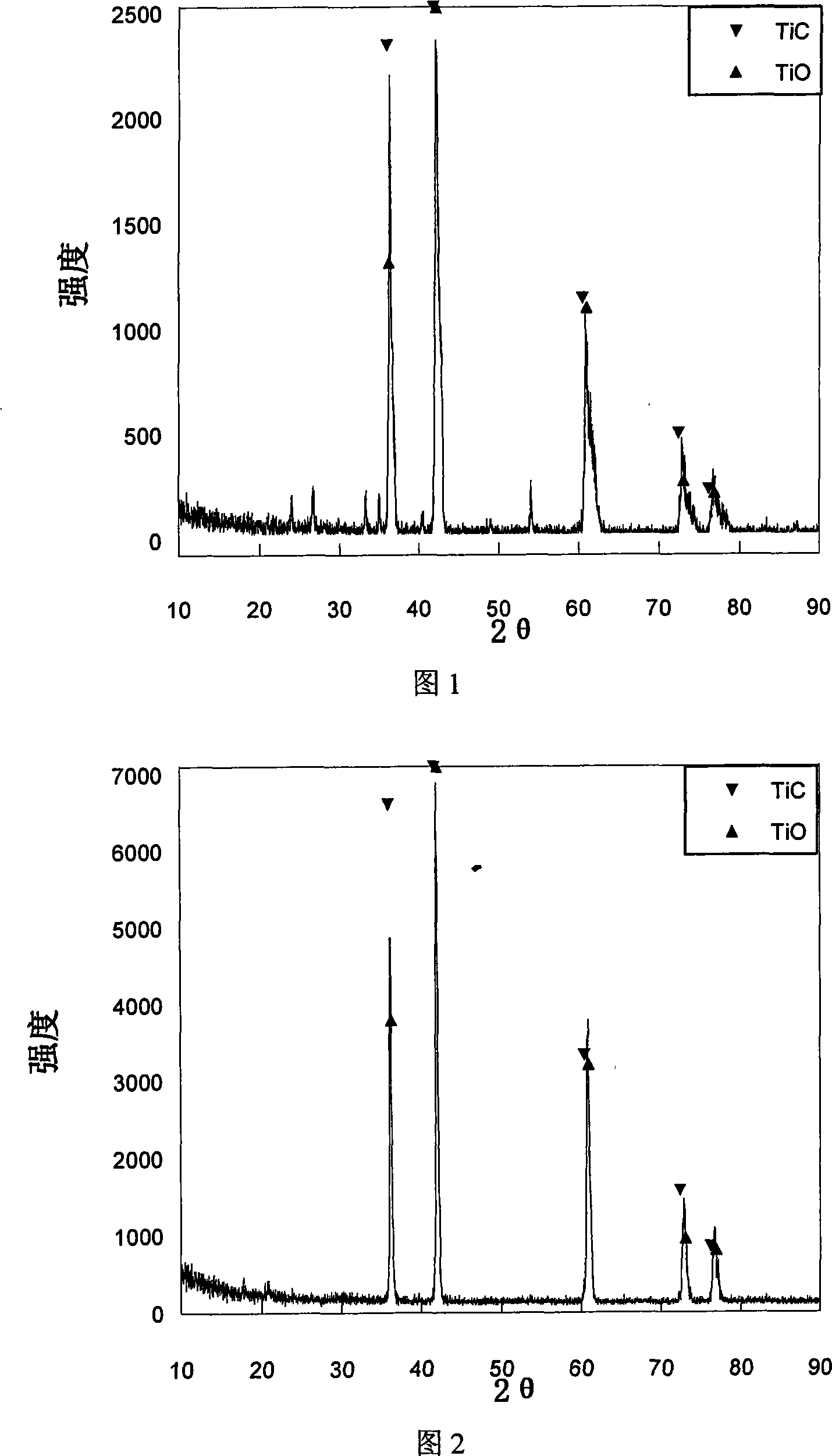

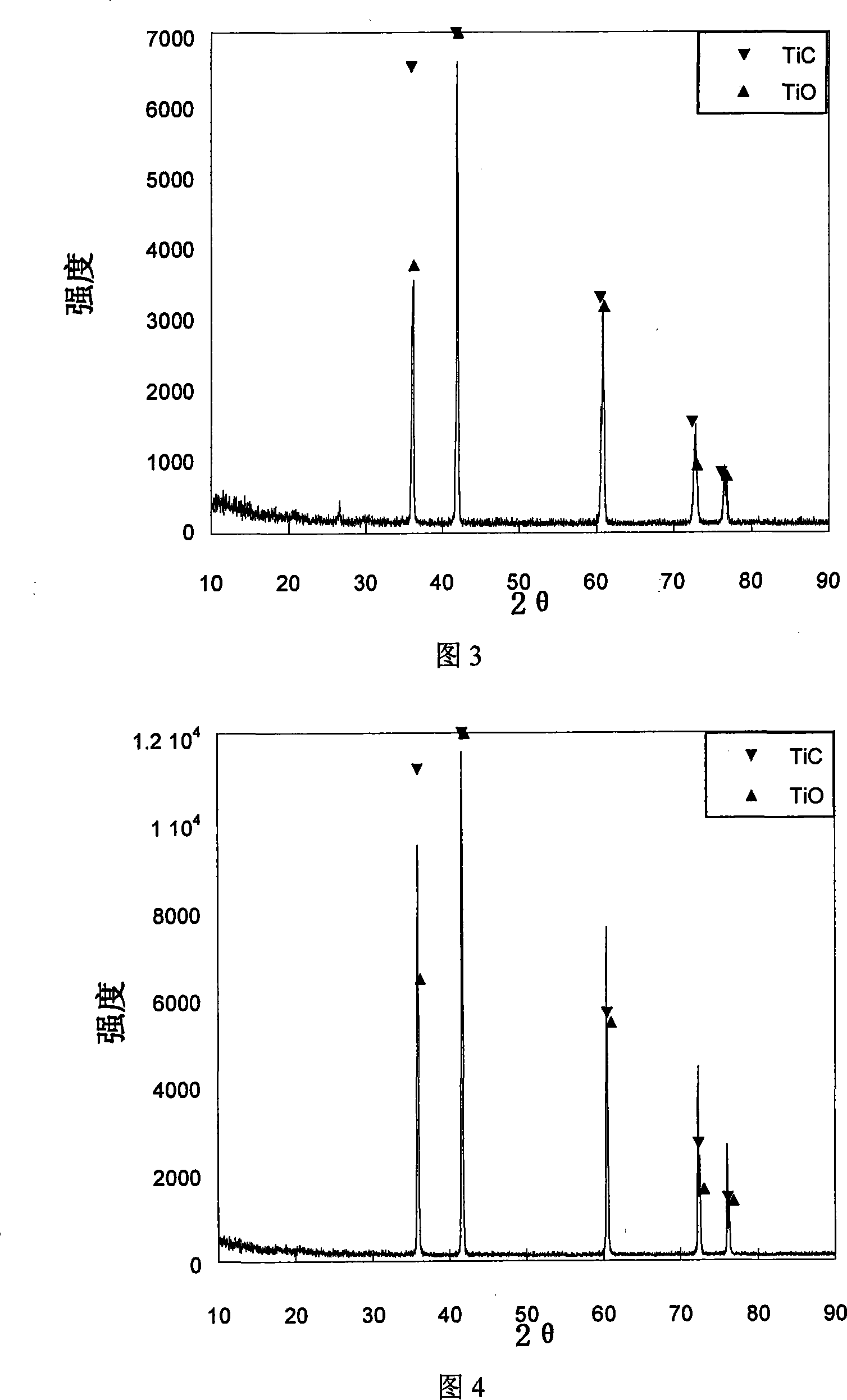

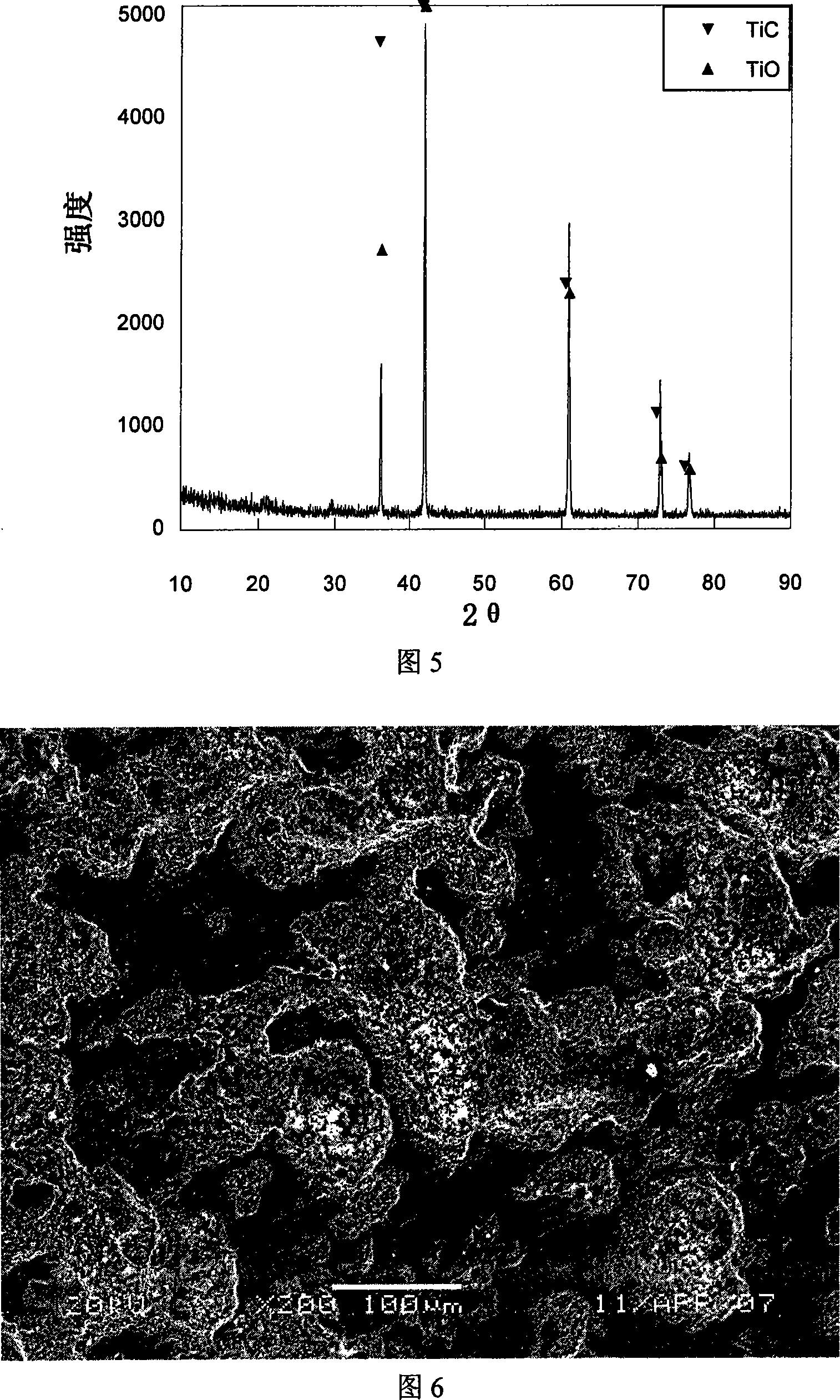

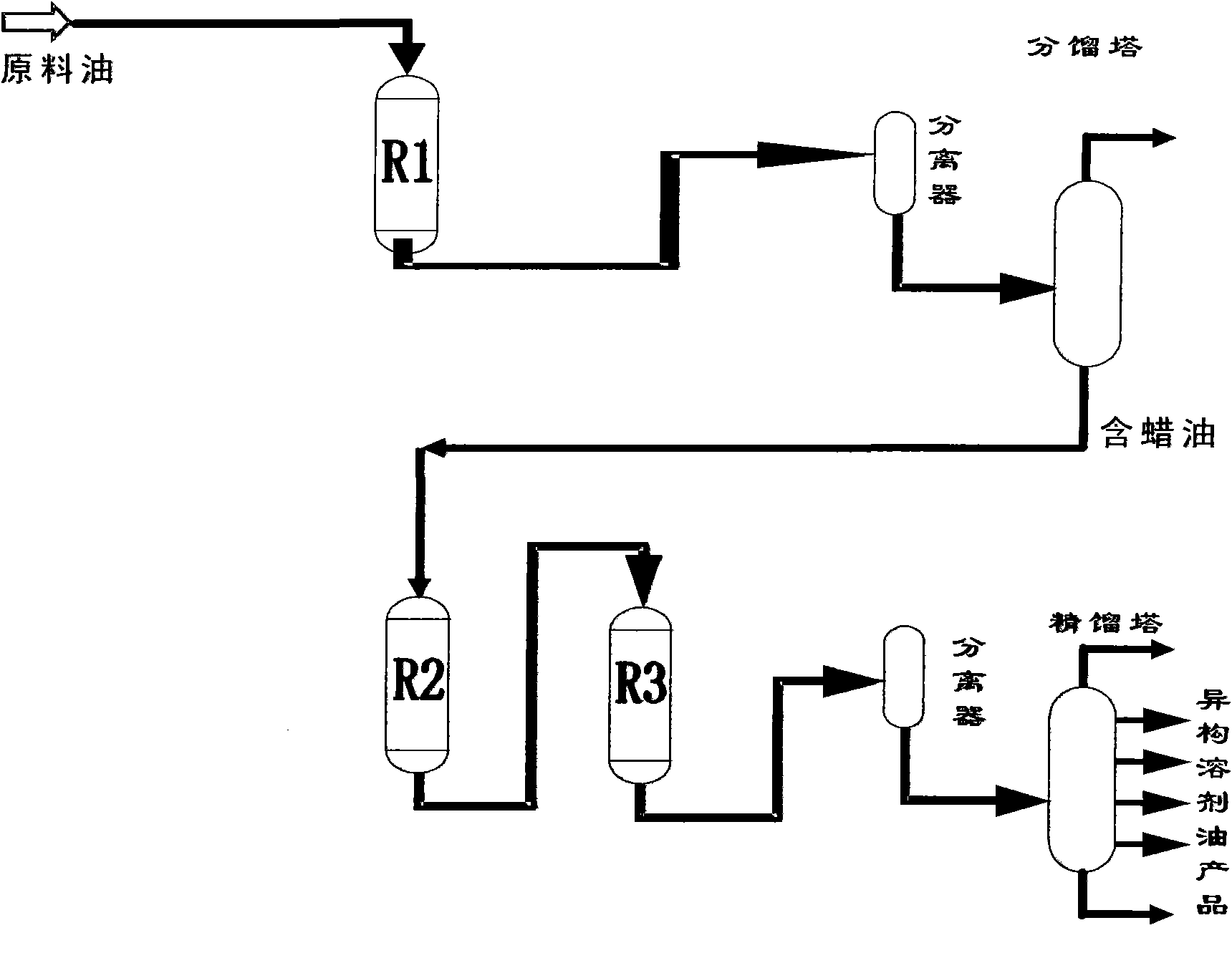

Method for preparing TiC mTiO sosoloid using titanium complex ore as material

The invention relates to a method of making TiC,mTiO sosoloid by using a plurality of common titanium complex ores as raw materials, such as rutile, high-titanium slag, titanium concentrate, ilmenite rock mine, ilmenite placer, rich ferrotitanium concentrate ore and the like. The invention is characterized in that titanium complex ores and a proportion of carbonaceous materials of carbite, coke and coal are uniformly mixed and reacted in the device with hot vacuum or inert gas and then the product is separated and purified after wet treatment, and at last achieve high-purity TiC,mTiO(0<=m<íÌ) sosoloid. The technical procedures of the invention are that carbonaceous materials are utilized to deacidize titanium complex ores at a temperature of 1000-2000 DEG C under the protection of the vacuum or inert gas. To ensure the purity and the utilization ratio of the product, titanium complex ores and carbonaceous materials are uniformly mixed at a certain proportion and the mixture rich in TiC,mTiO is achieved, the product with more than 95% content of TiC,mTiO is achieved after acid pickling and alkali washing. The method has the advantages of strong application of material, short technological process, simple device, small investment, fast effect, low energy consumption and continuous production and the like.

Owner:UNIV OF SCI & TECH BEIJING

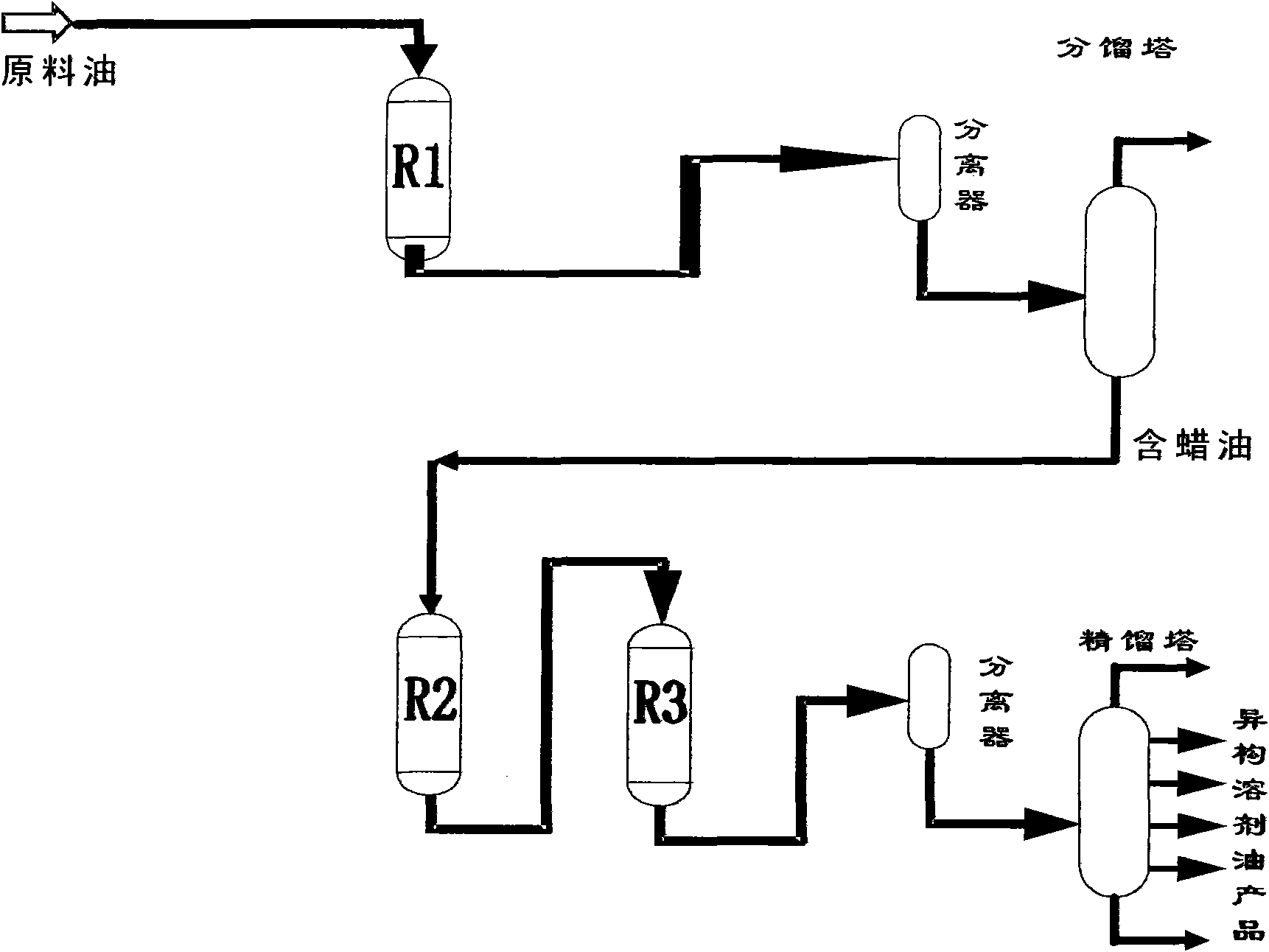

Method for manufacturing isoparaffin solvent oil

ActiveCN101921621AStrong raw material adaptabilityGood product qualityRefining to change hydrocarbon structural skeletonTreatment with hydrotreatment processesSolventChemistry

The invention discloses a method for manufacturing an isoparaffin solvent oil. By utilizing distillate or light deasphalted oil and the like as a raw material, the isoparaffin solvent oil is manufactured by the integrated process of hydroprocessing-hydrogenation isomerization-hydrofinishing. With the method of the invention, high-quality isoparaffin solvent oil products of various fractions can be manufactured with ordinary raw oil. The method has the characteristics of good raw material adaptability, good quality of products, flexible manufacturing and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

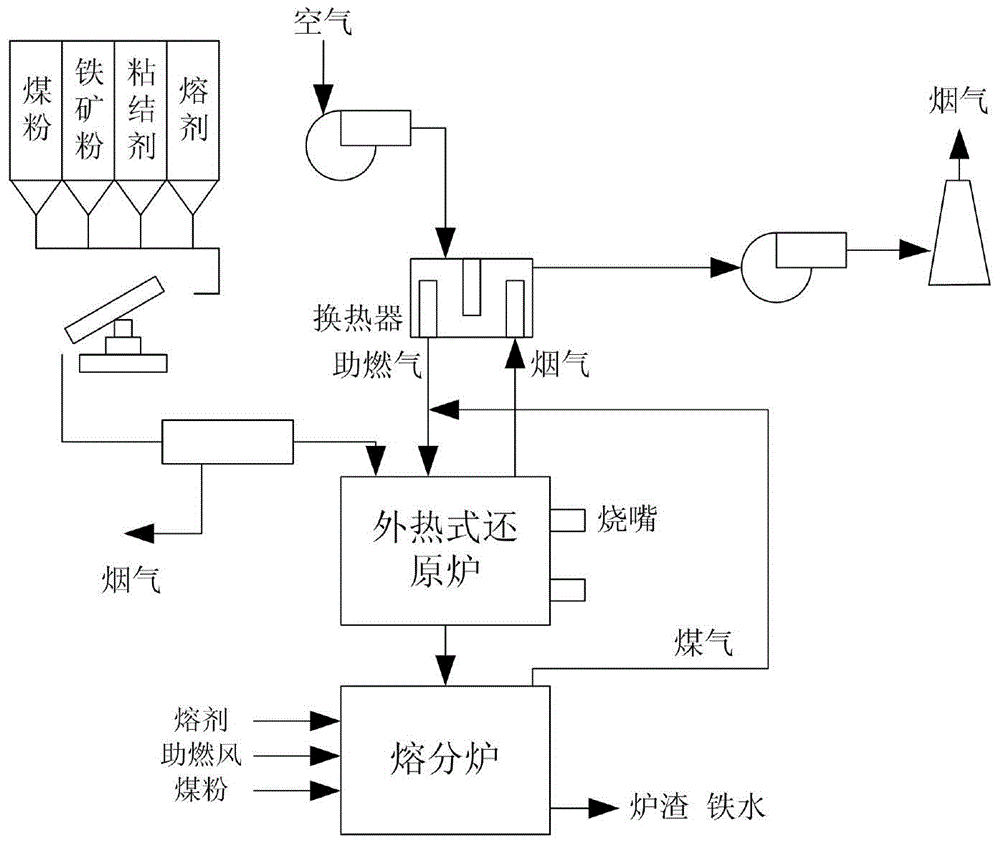

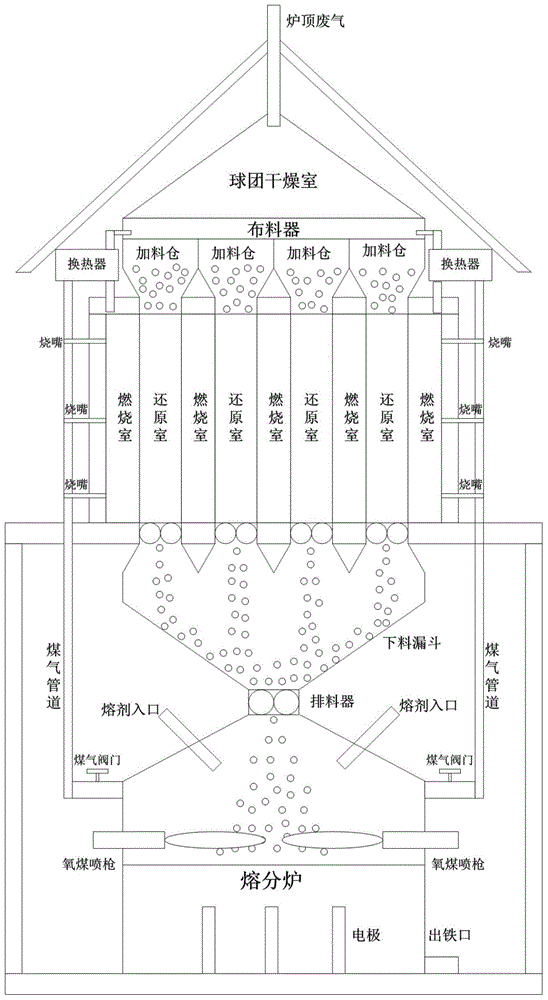

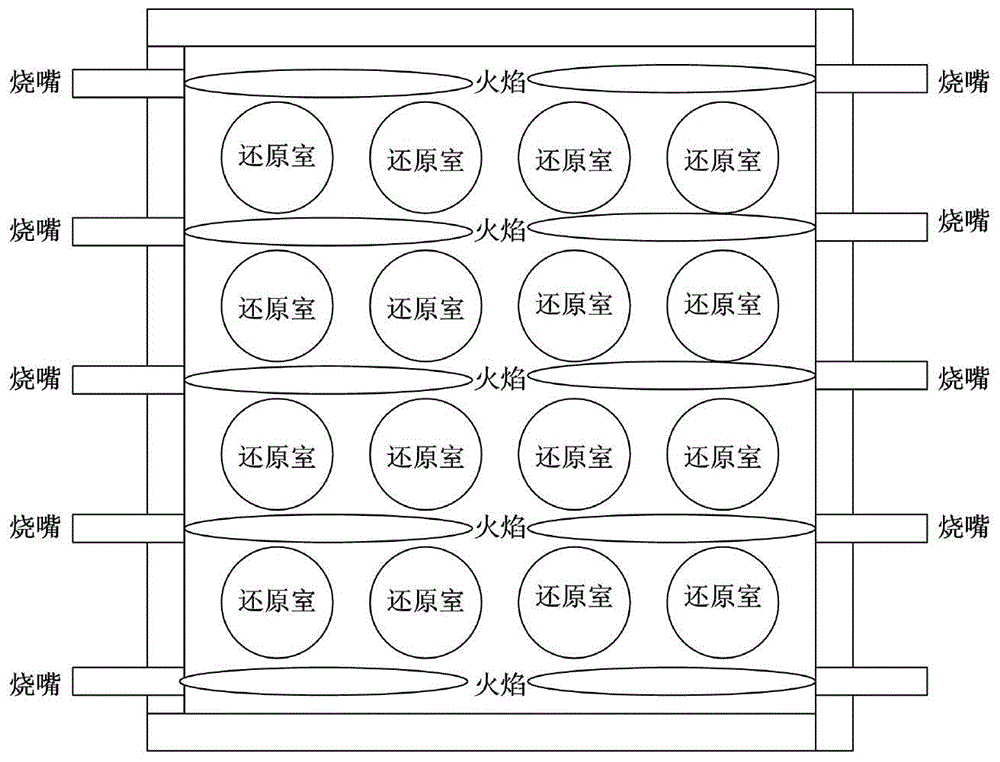

Coal-based direct reduction-melt separation furnace smelting reduction iron-making process using external heating mode

The invention relates to a coal-based direct reduction-melt separation furnace smelting reduction iron-making process using an external heating mode. Equipment used in the process comprises a pellet drying chamber, a distributing device, an external heating type reduction furnace and a melt separation furnace which are arranged from top to bottom. The process includes the steps that S1, carbon-bearing pellets are preheated and dried in the pellet drying chamber; S2, the carbon-bearing pellets in a reduction chamber are continuously and evenly heated, and the carbon-bearing pellets are quickly reduced in the reduction chamber; S3, high-temperature metallized pellets are obtained after the carbon-bearing pellets in the reduction chamber are reduced, and the high-temperature metallized pellets are charged into the melt separation furnace in a hot-delivery and hot-charging mode to be subjected to reduction smelting; S4, after the metallized pellets enter the melt separation furnace, the melting point, the viscosity and the separating effect of slag iron are controlled through the content of added flux and pulverized coal, reduction smelting of the metallized pellets is completed, and accordingly high-quality molten iron and high-temperature furnace slag are obtained. By the adoption of the process, iron ore which is low in grade and difficult to reduce is utilized comprehensively, the technological process is shortened, production cost is lowered, product quality is improved, and production efficiency is effectively improved.

Owner:CHONGQING UNIV

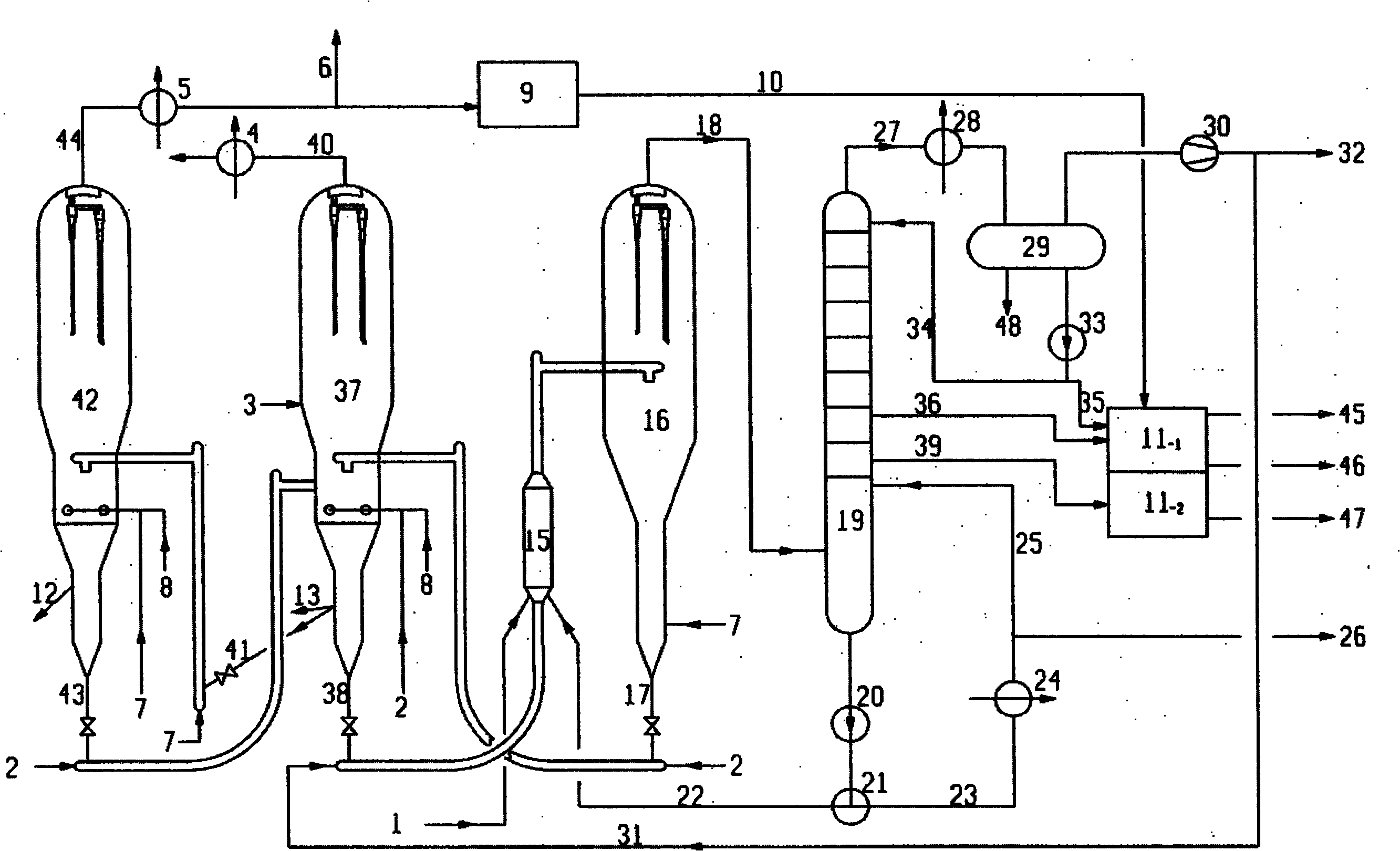

Process for catalytic conversion production of ethylene and propylene

ActiveCN1634811AEasy to separateStrong raw material adaptabilityHydrocarbon by hydrocarbon crackingReactions stressHydrocarbon

The present invention discloses a catalytic conversion method for producing ethylene and propylene. Hydrocarbon material contacts with a catalyst in a reactor under reaction temperature of 450 to 750 degrees centigrade, reaction pressure of 0.03 to 0.20 MPa, weight ratio between water vapour and raw oil of 0.01 to 1.00, weight hourly space velocity of 1 to 15 h-1, weight ratio between catalyst and raw oil of 2 to 20, the reaction product is separated from the catalyst of carbon deposit, which is burned for regeneration and periodic use after stripping, by a reaction product separating system, wherein the particle diameter of the catalyst ranges from 150 to 2000 micrometers. The inventive method can obtain higher ethylene and propylene yield under mild reaction conditions, and the olefin degree of the cracked gas is high, thereby being good for separation and utilization of the cracked product.

Owner:CHINA PETROCHEMICAL CORP +1

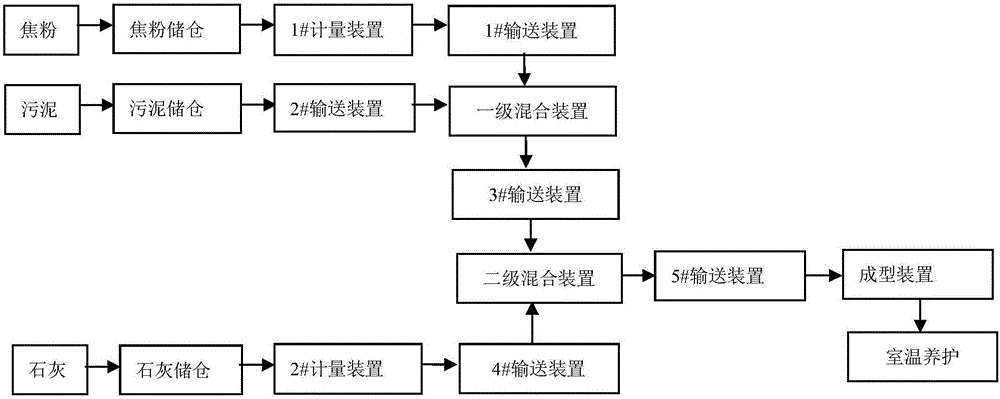

Method and device for preparing fuel by means of mixing coke powder with sludge from sewage plants

InactiveCN105733734AStrong raw material adaptabilityLarge amount of sludge treatmentSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCircular economySewage

The invention relates to a method and a device for preparing fuel by means of mixing coke powder with sludge from sewage plants.The method includes mixing the sludge from the sewage plants with the coke powder which is waste generated in the coking industry to obtain mixed materials; adding lime into the mixed materials and digesting and drying the sludge; carrying out compression molding on the sludge and curing the sludge under room-temperature conditions to obtain the environment-friendly solid fuel.The device comprises a coke powder storage bin, a sludge storage bin, a lime storage bin, metering devices, conveying devices, a primary mixing device, a secondary mixing device and a molding device.The method and the device have the advantages that the method and the device are low in investment and can become effective fast, processes are simple and flexible relatively, the device is low in running cost, high in practicality, treatment capacity and recycling and energy regeneration rate and thorough in harmlessness, ideas of recycling economy and low-carbon economy can be sufficiently embodied, the method and the device have obvious social, economical and environmental benefits, and the like.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Pyrogenic pretreatment method for low-grade laterite nickel mine

InactiveCN101368235ASimple preprocessingStrong raw material adaptabilityWet separationBeneficiationLow graded

The invention relates to a fire pre-processing method for a low-grade lateritic nickel ore which belongs to the field of nonferrous metal. The method includes following steps : the low-tenor lateritic nickel ore mine is cracked; vulcanization pre-processing is carried out; a metal sulfide is generated; the ore concentrate and the tailing of the nickel purite can be obtained through carrying out one time roughing, four time choiceness and three time scavenging on the preprocessed lateritic nickel ore and returning the middling ores in sequence; under a magnetic field intensity of 6000 to 10000 oersted, one time open roughing and three time open choiceness are carried out on the flotation tailing; a magnetic product is iron ore concentrate; the rest products are combined into the total tailing. The technology of the invention has the characteristics of high material suitability, short flow, good vulcanization effect, device investment saving, low production cost, and the like, thus leading the subsequence beneficiation techniques to be greatly simplified and being capable of producing the mixed ore concentrate of nickel and cobalt, the iron ore concentrate and the tailing as well as obtaining a higher metal ore concentrate grade and a high recycling rate.

Owner:KUNMING METALLURGY INST

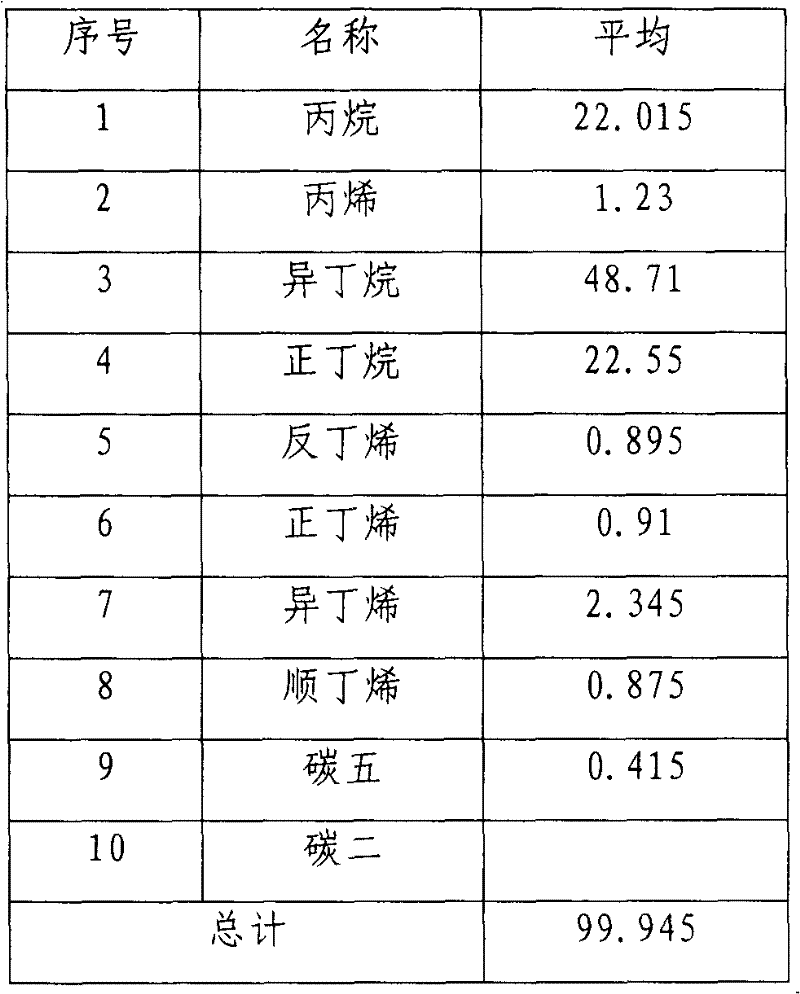

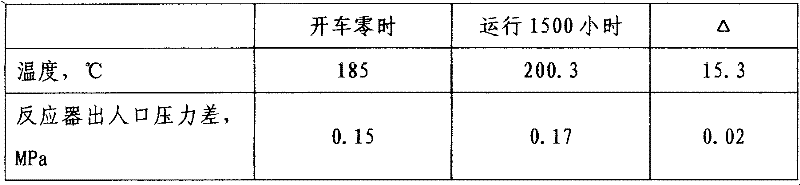

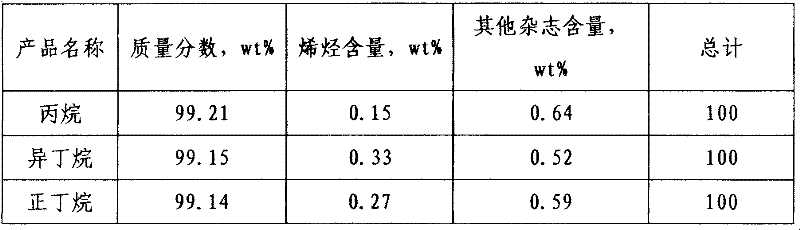

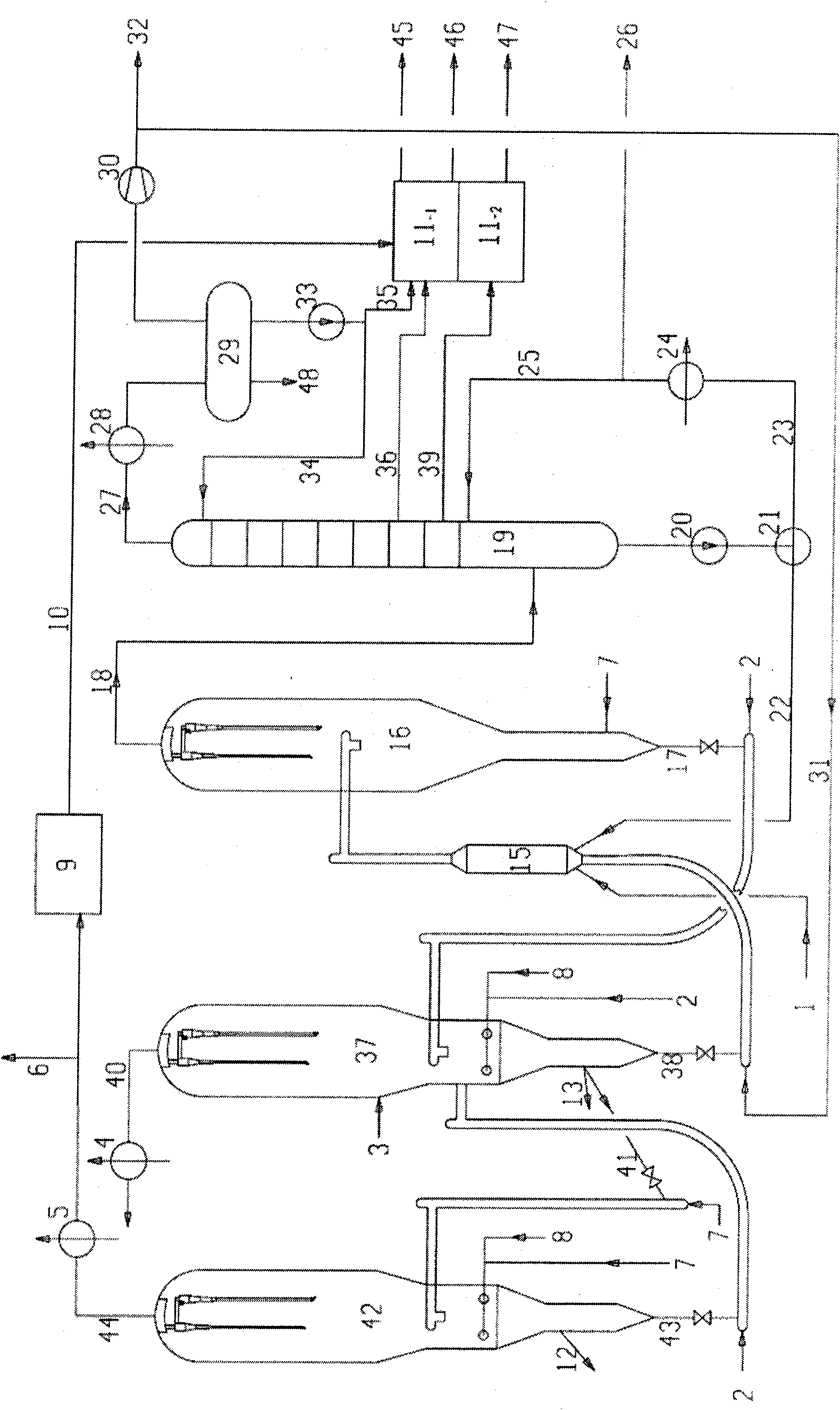

Method for preparing high-purity propane, iso-butane and n-butane

InactiveCN102633585AAdaptableSimple processDistillation purification/separationHydrocarbonsAlkaneAromatization

The invention discloses a method for preparing high-purity propane, iso-butane and n-butane. The method for preparing high-purity iso-butane and n-butane comprises the following steps of: hydrogenating mixed carbon 4 subjected to propylene extraction, etherification and aromatization, and separating the product, wherein olefins are respectively less than 0.5 percent, and the hydrogenating catalyst is a special catalyst comprising a common non-noble metal main catalyst and a noble metal cocatalyst. By adopting a process of hydrogenation and rectification in the method, the obtained alkane components have high purity; and compared with simple thermal processing, the method has the advantages that the method saves a large quantity of investment and is low in operation cost, high in flexibility, flexible and convenient and the products completely meet downstream chemical processes and have remarkable economic benefits.

Owner:NANJING MAISEN SCI & TECH DEV

Method for preparing sponge indium with indium-rich slag produced in lead-zinc smelting process

ActiveCN102586608AStrong raw material adaptabilityProcess configuration is reasonableProcess efficiency improvementIndiumSmelting process

The invention relates to a method for preparing sponge indium with indium-rich slag produced in a lead-zinc smelting process and belongs to the technical field of hydrometallurgy of non-ferrous metals. The method comprises the processing steps as follows: curing and leaching the indium-rich slag, performing secondary high-temperature acid leaching on filtered slag which is cured again, removing impurities in indium-rich liquid, and displacing the sponge indium; and after the displacement, the liquid is recovered and then is used for producing white vitriol or zinc oxide products. The method has the advantages that the process flow is short, the suitability of the raw material is strong, the recovery rate of indium is high, and the energy consumption, the pollution and the production cost are low.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

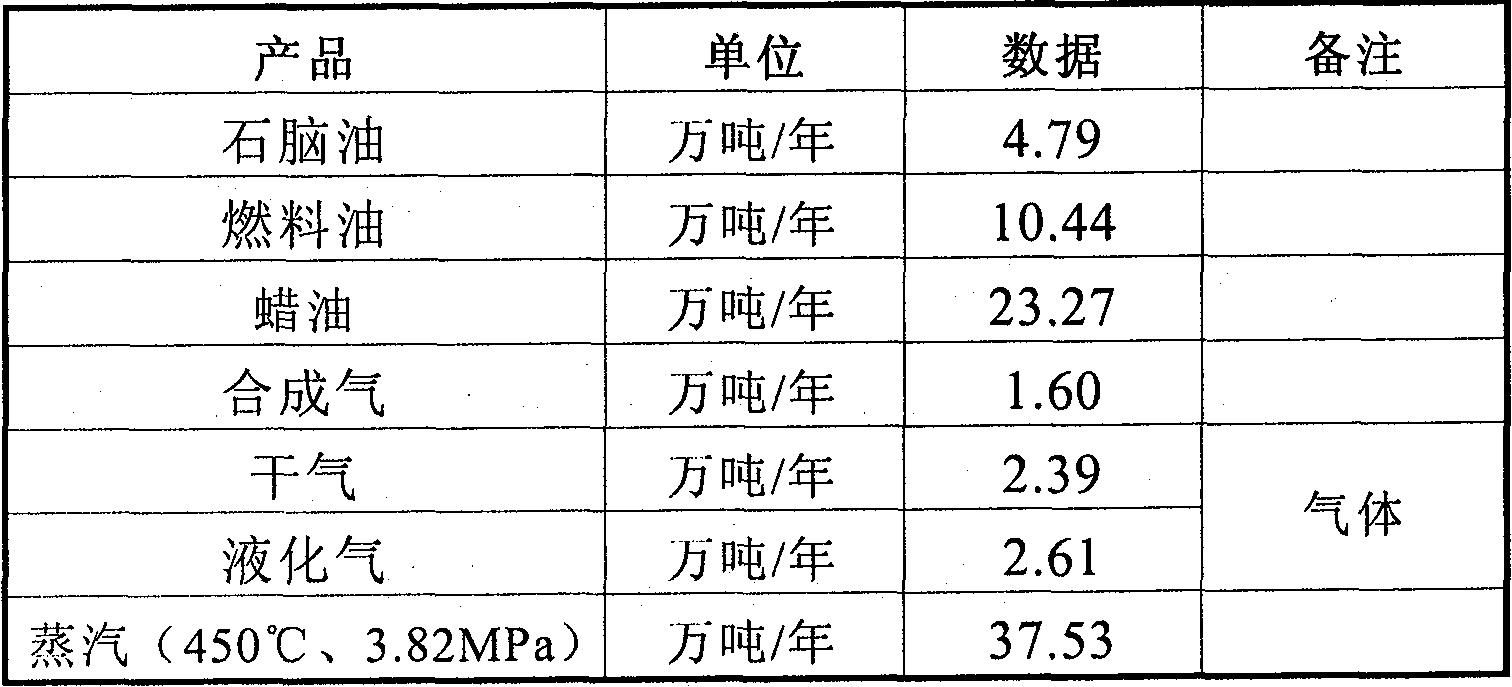

Comprehensive processing and utilizing method for heavy oil

InactiveCN102031135AAchieve rapid lysisImprove light oil yieldThermal non-catalytic crackingHydrogen separationSyngasFuel oil

The invention belongs to the field of petroleum processing and utilization, and relates to a comprehensive processing and utilizing method for heavy oil. By integrating quick cracking of the heavy oil, pre-combustion and gasification of the generated coke, recycling of non-converted heavy oil, hydrogen production by synthetic gas generated through gasification, and a hydrofining process for cracked oil products, light oil can be prepared from the heavy oil to the greatest degree, the light oil is hydrogenated to form high-quality clean oil products, and also can generate the synthetic gas through gasification, and the synthetic gas can serve as a hydrogen production raw material to provide a cheap hydrogen source for oil product hydrofining, and also can serve as fuel gas to provide clean fuel for a refinery. The invention provides a low-cost comprehensive processing and utilizing method for converting the heavy oil into clean light oil products to the greatest degree.

Owner:WISON ENG

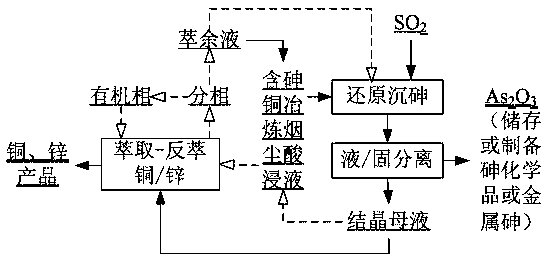

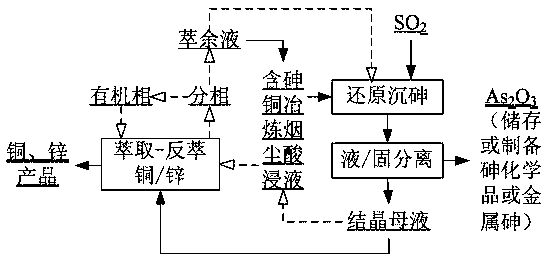

Method of efficiently separating and recovering arsenic, copper and zinc from arsenic-copper-containing smelting smoke dust pickle liquor

PendingCN109913658AStrong raw material adaptabilityFlexible operationProcess efficiency improvementSolventSmoke

The invention relates to a method of efficiently separating and recovering arsenic, copper and zinc from arsenic-copper-containing smelting smoke dust pickle liquor, and belongs to the technical fieldof wet-process metallurgy and environmental protection. The method comprises the steps that SO2 is filled into the arsenic-copper-containing smelting smoke dust pickle liquor for carrying out reduction and settlement of the arsenic, filtering is carried out, and a crystal and crystallized mother liquor are obtained; the crystallized mother liquor is subjected to organic solvent extraction-reverseextraction to recover the copper, and a copper product and extracted copper residual liquor are obtained; and the obtained extracted copper residual liquor is subjected to the organic solvent extraction-reverse extraction to recover the zinc, a zinc product and extracted zinc residual liquor are obtained, and arsenic-copper-containing smelting smoke dust is leached through the extracted zinc residual liquor. The arsenic, copper and zinc are separated and recovered from the arsenic-copper-containing smelting smoke dust pickle liquor with the adoption of a mode that gas reduction and solvent extraction are organically combined, the method is high in separation efficiency and recovery efficiency, the situation that the ecological environment is polluted due to the fact that arsenic-containing hypertoxic gas and arsenic-containing dangerous waste residues are produced is avoided, the copper product and the zinc product do not contain the arsenic, and the additional value is high.

Owner:KUNMING UNIV OF SCI & TECH

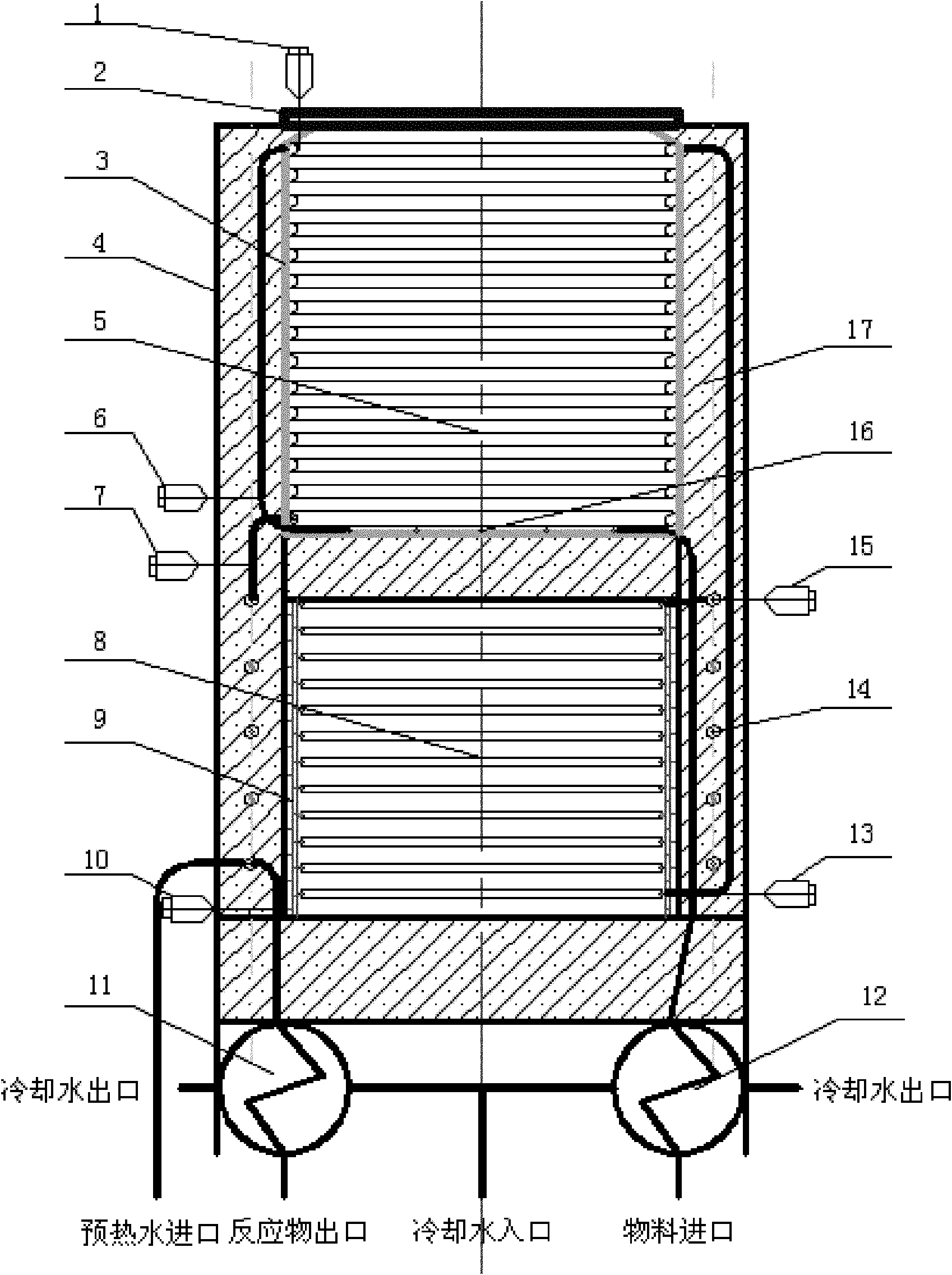

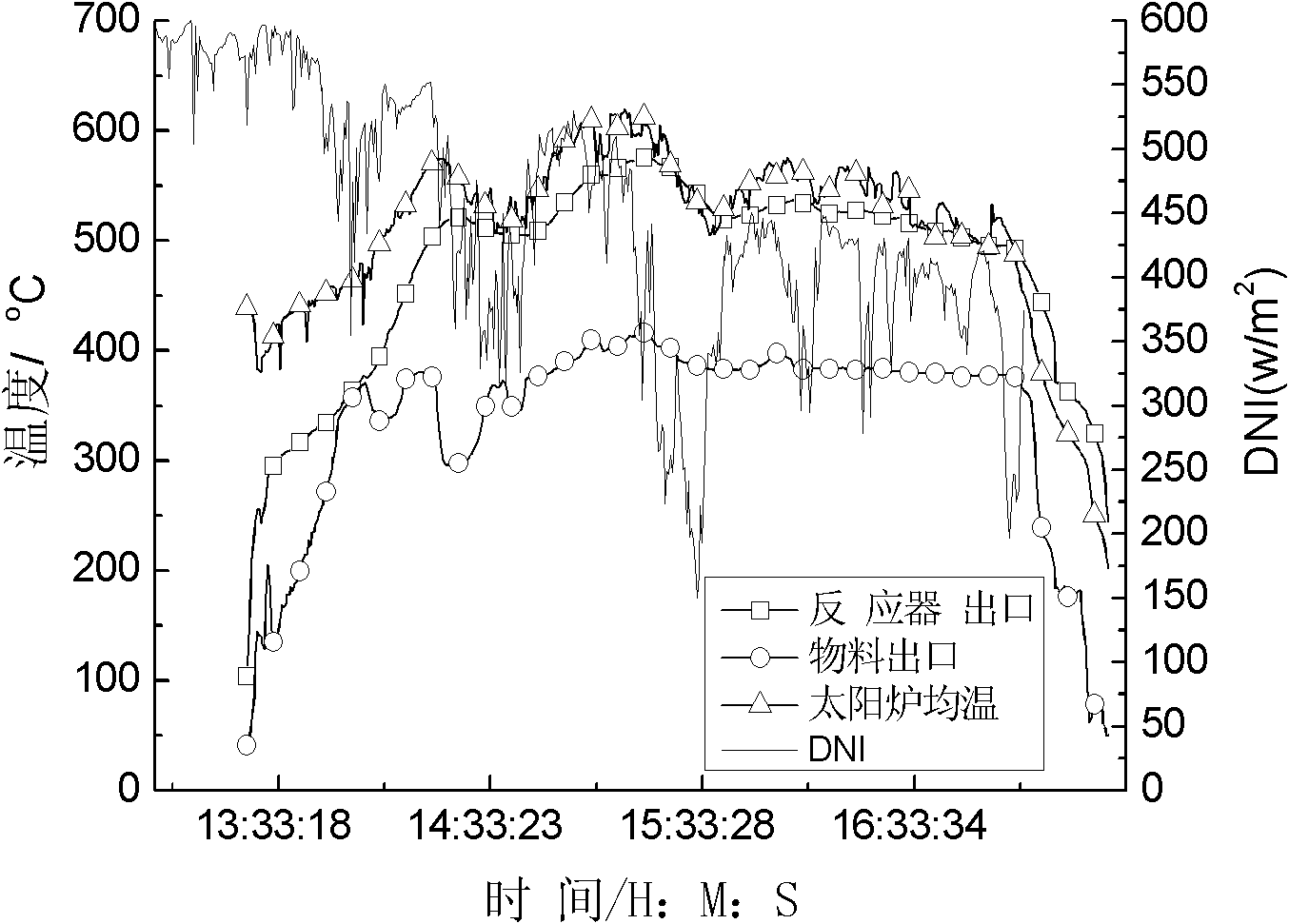

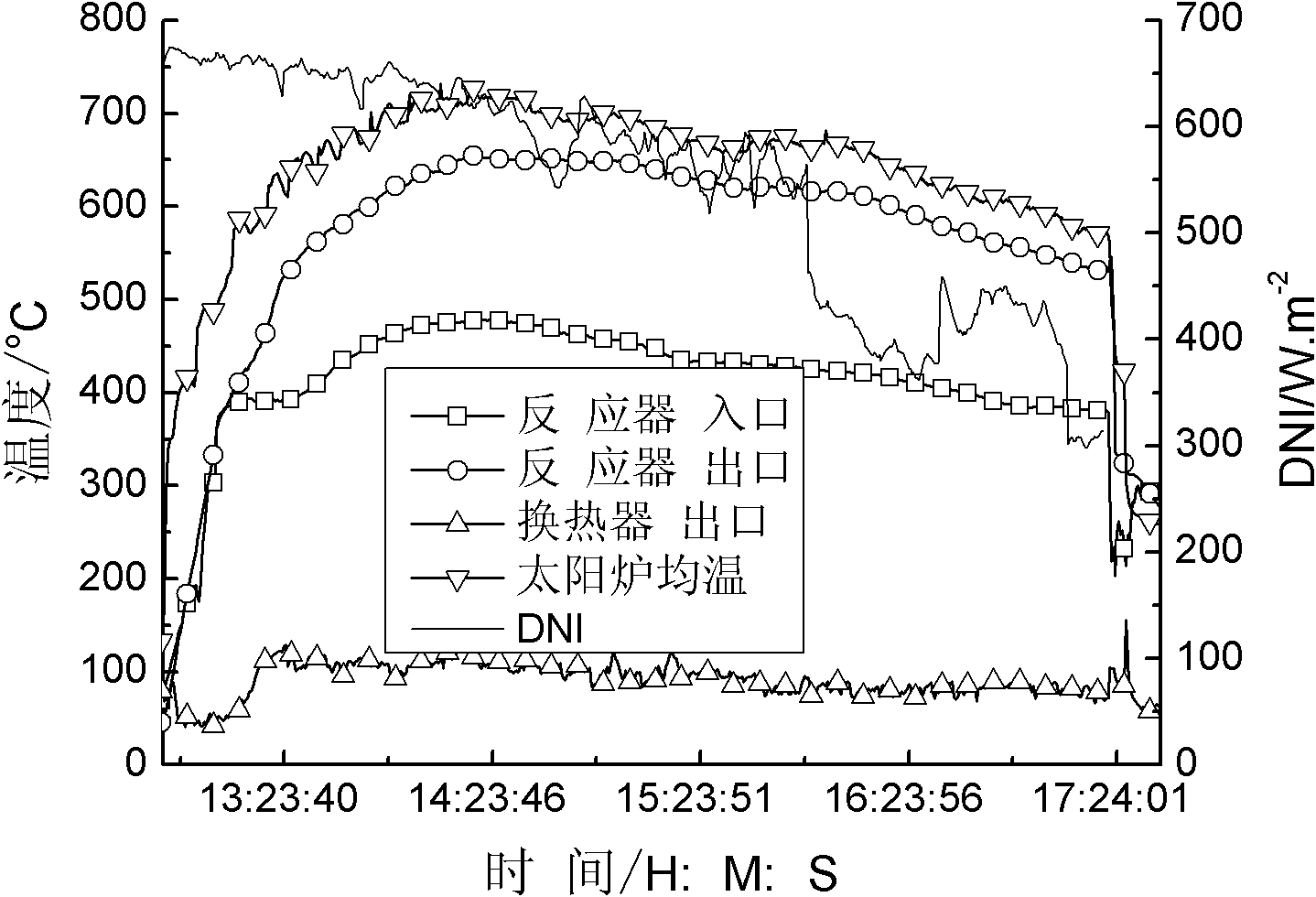

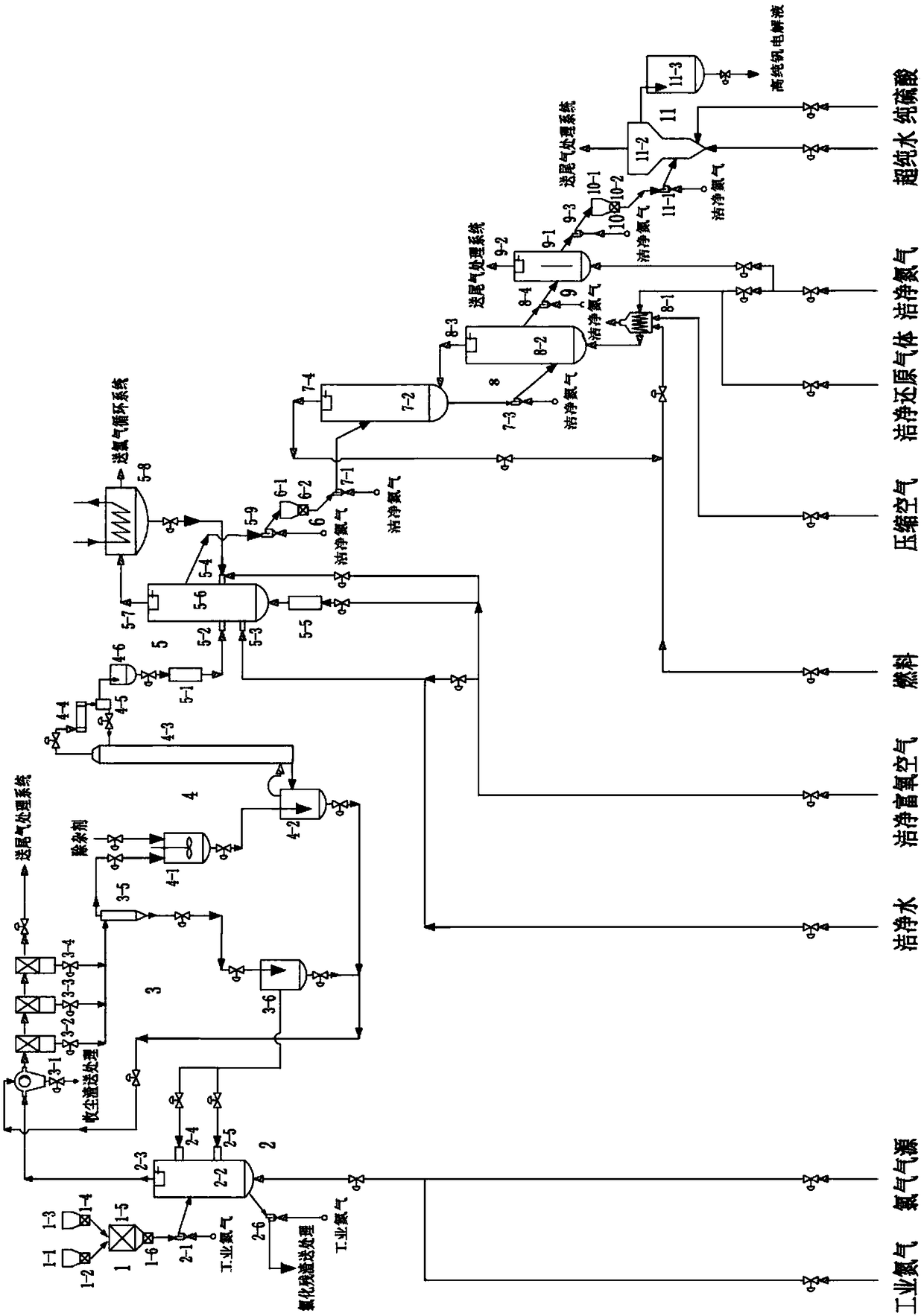

Supercritical water gasification hydrogen production and heat absorption reactor for multi-disk solar heat-collecting coupling biomass

ActiveCN102115030ASmall temperature fluctuationsReduce heat lossHydrogen productionBulk chemical productionHigh energyCoupling

The invention discloses a supercritical water gasification hydrogen production and heat absorption reactor for a multi-disk solar heat-collecting coupling biomass, which comprises a cavity type solar absorption reactor, a first cooler and a second cooler, wherein the cavity type solar absorption reactor comprises an endothermic reaction cavity and a pre-heated water heating cavity, inner cavity walls of the endothermic reaction cavity and the pre-heated water heating cavity are provided with insulating layers, an opening at the upper end of the endothermic reaction cavity is sealed by silica glass, a pipe flow reactor is arranged in the endothermic reaction cavity, and the bottom of the endothermic reaction cavity is provided with a material preheater; the pre-heated water heating cavity is internally provided with a pre-heated water heater, a crawler-type electric heater is used for heating, and a heat storage medium is filled in the pre-heated water heating cavity; and a screw shelltype high-pressure heat exchanger is wound outside the pre-heated water heating cavity. The supercritical water gasification hydrogen production and heat absorption reactor has the advantages of small temperature fluctuation in the solar absorption cavity, high biomass supercritical water gasification rate, high energy comprehensive utilization efficiency and the like, and is beneficial to the realization of efficient, low-cost and massive hydrogen production through supercritical water gasification of focused solar heat coupling biomass.

Owner:陕西中核交大超洁能源技术有限公司

Technology using calcium and magnesium mud purified by brine to produce magnesium sulfate and calcium sulfate

InactiveCN106745115AImprove product qualityStrong raw material adaptabilityCalcium/strontium/barium carbonatesMagnesium sulfatesCalciums magnesiumMagnesium sulphate heptahydrate

The invention relates to a technology using calcium and magnesium mud purified by brine to produce magnesium sulfate and calcium sulfate. The technology comprises the following steps of sequentially adding caustic soda and pure soda into raw materials to remove Ca<2+> and Mg<2+>, so as to simultaneously obtain a magnesium hydroxide and calcium sulfate precipitate and refined brine; separating soil and liquid, so as to obtain a magnesium hydroxide and calcium sulfate mixing precipitate and a refined brine clarifying liquid; sending the refined brine clarifying liquid into a sodium nitrate production system; adding sulfuric acid and water into the magnesium hydroxide and calcium sulfate mixing precipitate, and reacting with magnesium hydroxide, so as to obtain a magnesium sulfate solution and a calcium sulfate precipitate; separating solid and liquid, so as to obtain a magnesium sulfate clarifying liquid and the calcium sulfate precipitate; freezing and cooling the magnesium sulfate clarifying liquid, so as to obtain magnesium sulfate heptahydrate and a freezing and cooling magnesium mother liquid; or, evaporating at high temperature, so as to obtain magnesium sulfate monohydrate; cycling the freezing and cooling magnesium mother liquid to a sulfuric acid and water reaction system; washing the calcium sulfate precipitate by fresh water, and drying, so as to obtain a calcium carbonate product. The technology has the advantages that the product quality is high, the suitability of raw materials is high, the technology is continuous and concise, the cost is low, and the environment-friendly effect is realized.

Owner:CHINA LIGHT IND INT ENG CO LTD

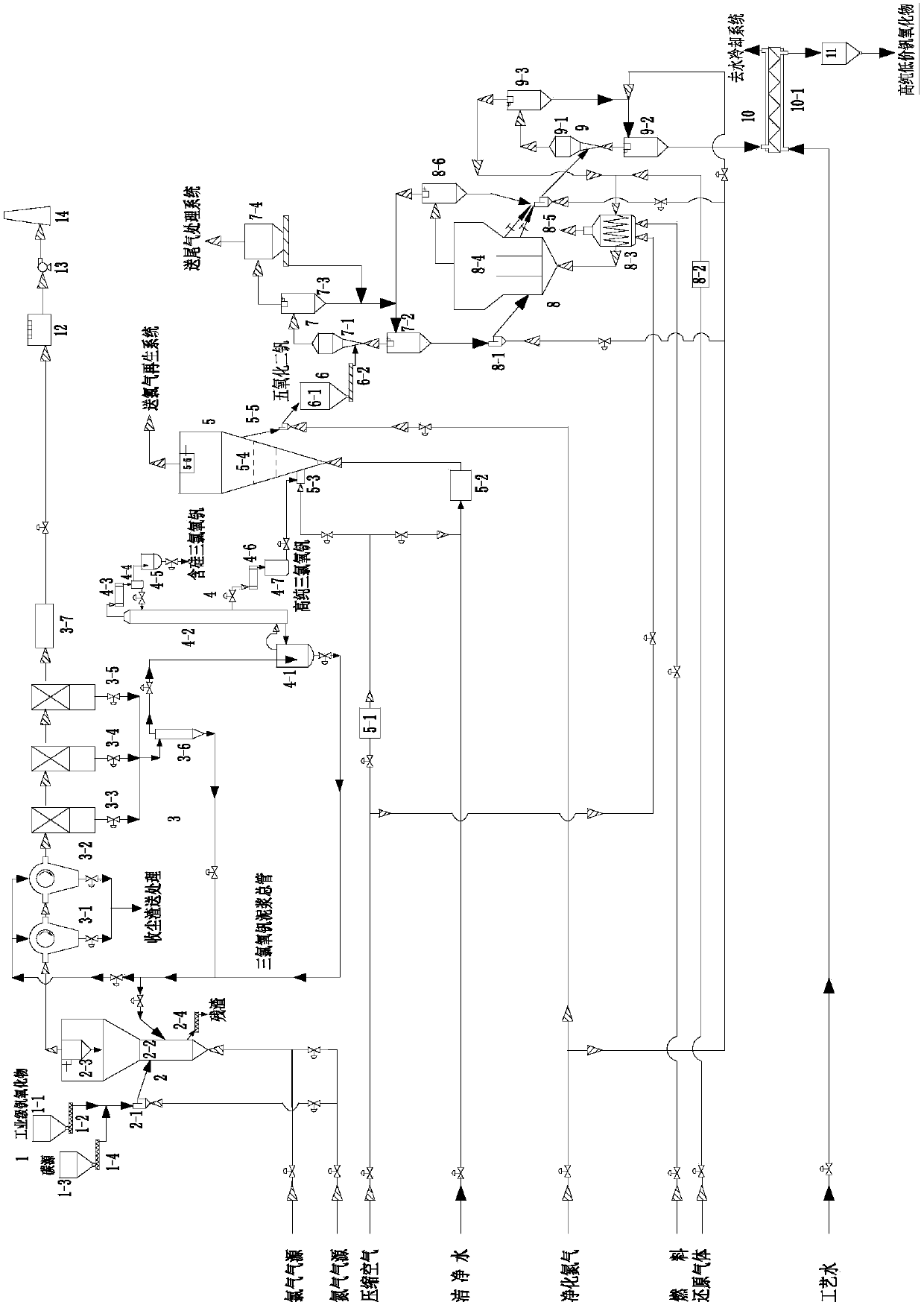

System and method for preparing high-purity vanadium electrolytic solution through efficient clean chlorination method

ActiveCN108630973AReduce pollutionReduce manufacturing costFinal product manufactureRegenerative fuel cellsChemical industryOxygen enrichment

The invention belongs to the fields of metallurgy and chemical industry, and specifically discloses a system and a method for preparing a high-purity vanadium electrolytic solution through an efficient clean chlorination method, wherein high-purity and low-valence vanadium oxide powder is prepared by using a process comprising chlorination, dust removal leaching, purification, catalytic oxidation,fluidization reduction and fluidized bed dissolution, the equivalent average valence of vanadium can be any one value selected from 3.0-4.0, and the low-valence vanadium oxide is subjected to low-temperature dissolving by adding ultrapure water and pure sulfuric acid to a liquid-solid fluidized bed to obtain the high-purity vanadium electrolytic solution capable of being directly used for all-vanadium redox flow batteries. According to the present invention, the chlorine gas is regenerated by introducing clean oxygen-rich air into the catalytic oxidation fluidized bed, such that the chlorinegas circulation is achieved, and the production cost is reduced; the hydrogen chloride in the catalytic oxidation tail gas is recovered by the hydrochloric acid condensation absorption tower, such that the generation of vanadium-containing hydrochloric acid is eliminated, and the environmental protection cost is substantially reduced; and the system and the method have advantages of strong raw material adaptability, low production energy consumption, low operation cost, stable product quality and the like, and are suitable for the large-scale industrial production of high-purity vanadium electrolytic solutions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

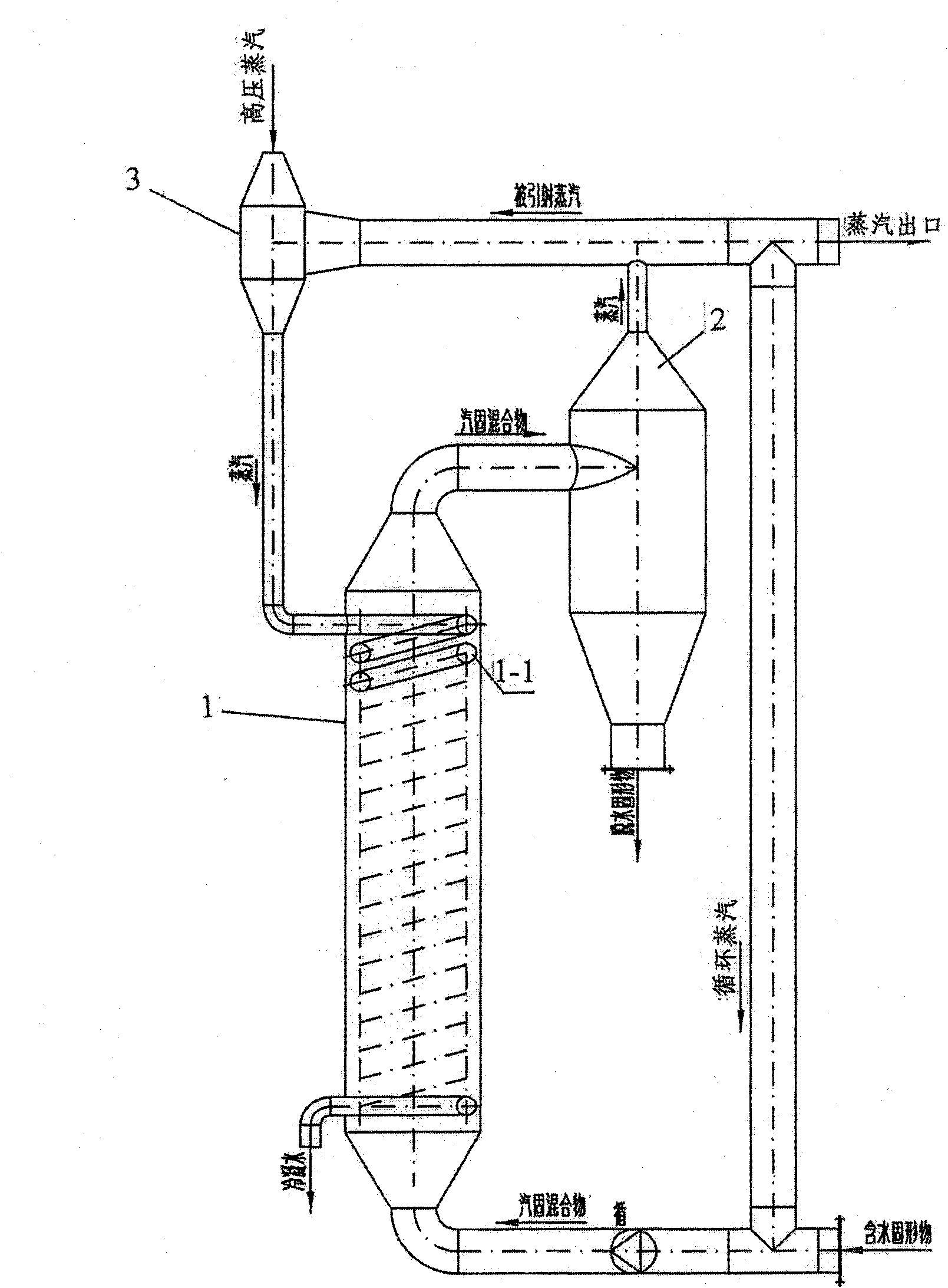

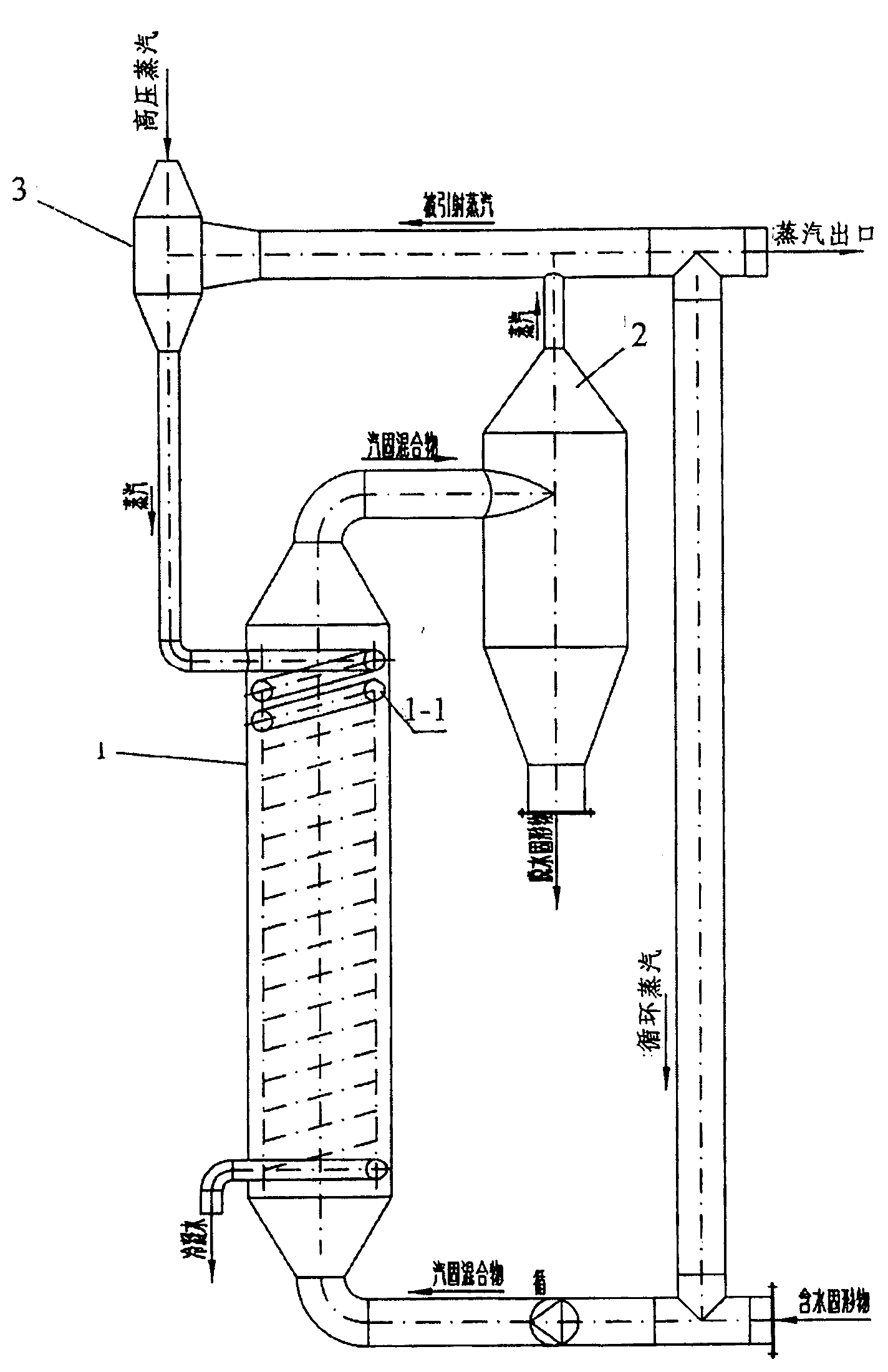

Drying dehydration steam-recycle process and device for solid containing water

InactiveCN102183122ASolve unusable problemsStrong raw material adaptabilityDrying solid materials with heatHearth type furnacesChemical industryProcess engineering

The invention provides a drying dehydration steam-recycle process and device for solid containing water, belonging to the fields of a chemical industry technology and a heat exchanging device. Mixing steam is taken as a heat source, heat is indirectly transferred between the mixing steam and the solid containing water through a heat exchanger to evaporate the mixing steam, the mixture of the generated secondary steam and the solid is subjected to gas-solid separation by a body dry dust collector; the solid after dehydration is a dry finished product; a part of the secondary steam is injected into mixing steam by high-pressure working steam for a steam injection pump to serve as a heat source of indirect heat transfer and evaporation of the next circulation heat exchanger and the solid containing water, a part of the secondary steam is injected out to serve as a heat source to be utilized, and the other part of the secondary steam is circulated, is mixed with the solid containing water and exchanges heat with the heat exchanger. The adaptability raw materials used by the device has strong adaptability and low cost, the device has the characteristics of low energy consumption, no pollution and the like, and heat energy can be recycled.

Owner:CHINA LIGHT IND INT ENG CO LTD

Vanadium-containing pig iron and method for preparing vanadium-containing pig iron by smelting vanadium-containing steel slag

The invention belongs to the technical field of metal smelting, and particularly relates to vanadium-containing pig iron and a method for preparing the vanadium-containing pig iron by smelting vanadium-containing steel slag. The method for preparing the vanadium-containing pig iron by smelting the vanadium-containing steel slag comprises the following steps that (1) granulating and sintering are conducted on the vanadium-containing steel slag, vanadium ore fines, coke powder and fly ash to obtain sintered ore; (2) after the sintered ore, vanadium-titanium magnet lump ore, coke and silica are prepared into furnace burden, the furnace burden is added into a furnace for smelting; and (3) deslagging and tapping are conducted. The method for preparing the vanadium-containing pig iron by smelting the vanadium-containing steel slag has the advantages of being short in process, high in raw material adaptability and capable of effectively recycling vanadium resources in the steel slag.

Owner:BERIS ENG & RES CORP

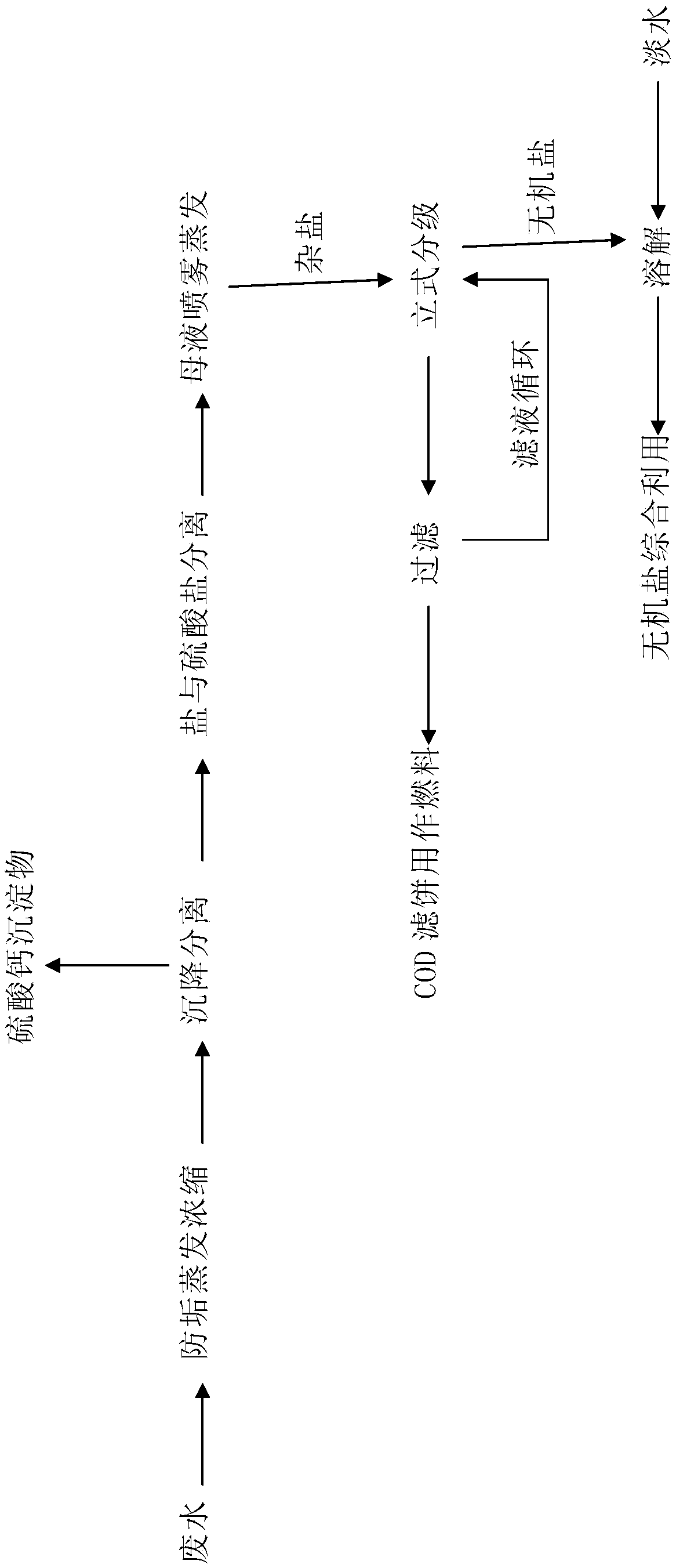

Recovery process for wastewater with high salt COD (chemical oxygen demand)

ActiveCN109437243AStrong raw material adaptabilityLess miscellaneous saltBiofuelsTreatment involving filtrationEvaporationMagnesium ion

Disclosed is a recovery process for wastewater with high salt COD (chemical oxygen demand). Wastewater with sodium chloride, sulfate, calcium ions, magnesium ions, nitrate, COD ions and the like is adopted as a raw material which is then vapored and concentrated to produce fresh water and a nearly-saturated solution in a condition that concentration is controlled by an antiscale agent; the nearly-saturated solution is subjected to clarification for solid-liquid separation to obtain calcium sulfate sediment and sulfate brine clarified liquid; the brine clarified liquid is subjected to a salt and sulfate separation process to obtain the sodium chloride, the sulfate, the fresh water and high-COD salt-making mother liquid; the salt-making mother liquid is subjected to high-temperature spray evaporation to obtain mixed abraum salt with the COD, the sodium chloride, the sulfate, nitrate and the like; circulating filtering liquid with ingredients similar to that of the salt-making mother liquid is adopted to separate the COD from inorganic salt including the sodium chloride, the sulfate, nitrate and the like in the mixed abraum salt through a vertical separator; the inorganic salt including the sodium chloride, the sulfate, nitrate and the like obtained at the bottom can be dissolved by the fresh water and then subjected to comprehensive utilization, COD filtering cakes in overflowingliquid are utilized as fuel, and the filtering liquid can be utilized cyclically.

Owner:CHINA LIGHT IND INT ENG CO LTD +3

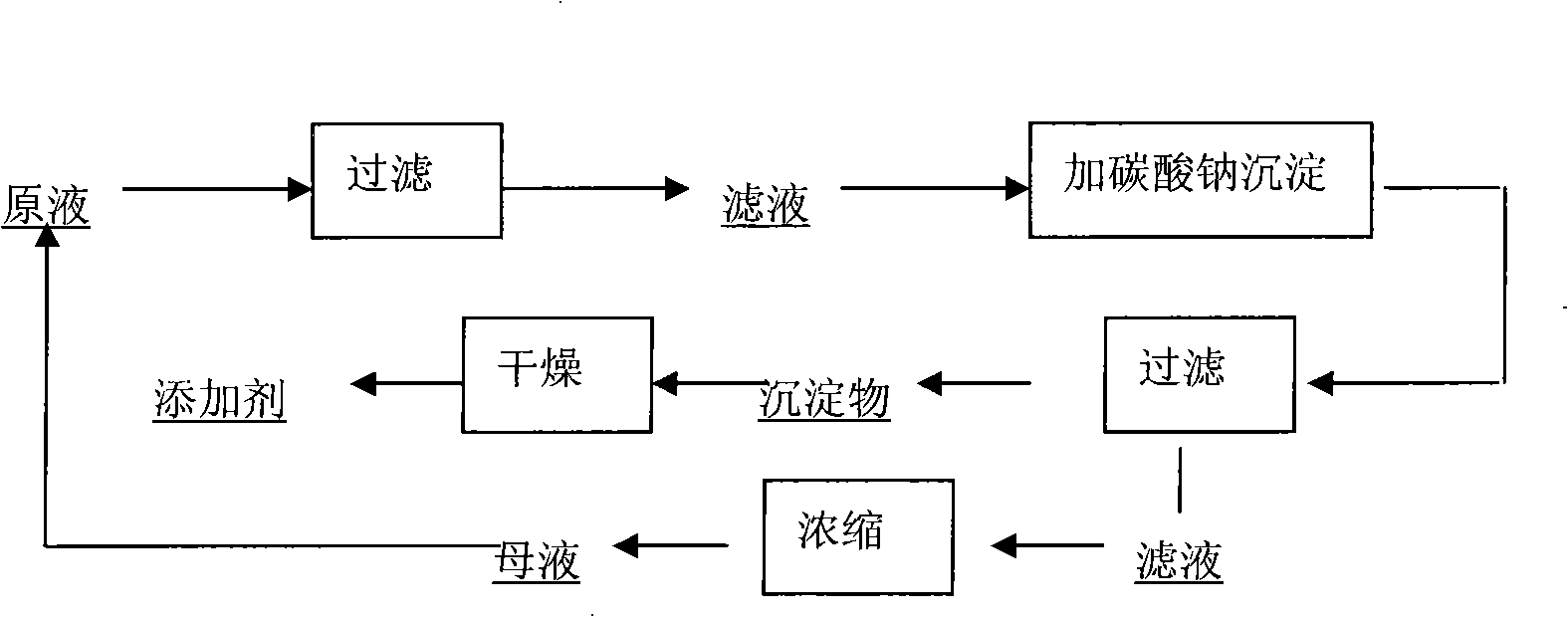

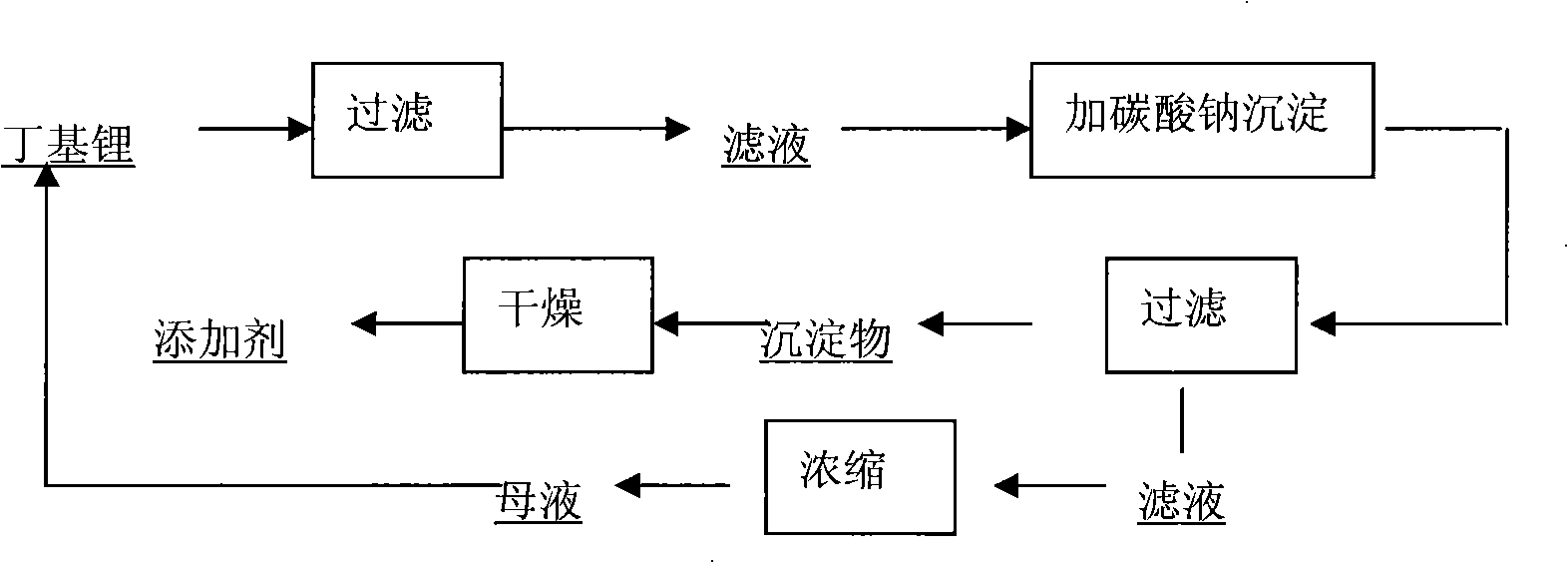

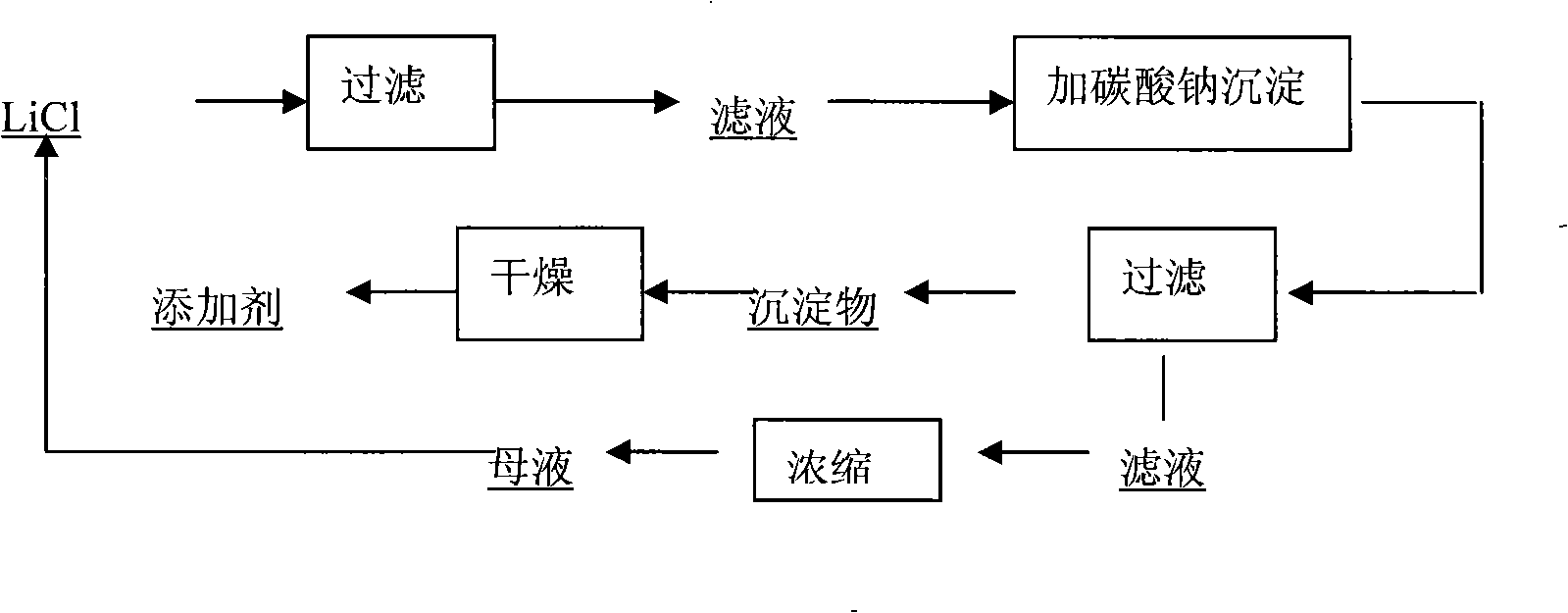

Method for preparing additive agent electrolyte for electrolyzing aluminium from lithium-containing waste liquid

InactiveCN101307469AEasy to adjust production scaleStrong raw material adaptabilitySodium carbonateChemistry

The invention relates to a method for preparing an additive for aluminum electrolysis electrolytes by lithium-containing waste liquid. The method is characterized in that in the preparation process, the lithium-containing waste liquid are filtered and added with sodium carbonates for precipitation reaction, and the mixed liquid are filtered and dried to be used as the additive for aluminum electrolysis electrolytes. In the method of the invention, the scale of production is conveniently adjusted and raw materials are good in adaptability; simultaneously the product of the invention is a complex additive of a plurality of substances, thereby reducing technological process, lowering technological requirement, greatly lowering manufacturing cost and improving recovery ratio of resources; compared with the prior process of preparing the additive for aluminum electrolysis electrolytes by directly utilizing carbonates and fluoride salts, the technical proposal of the invention has the advantages of cheap material, resource conservation, cyclic utilization of resources, short technological process, simple operation and high recovery ratio.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

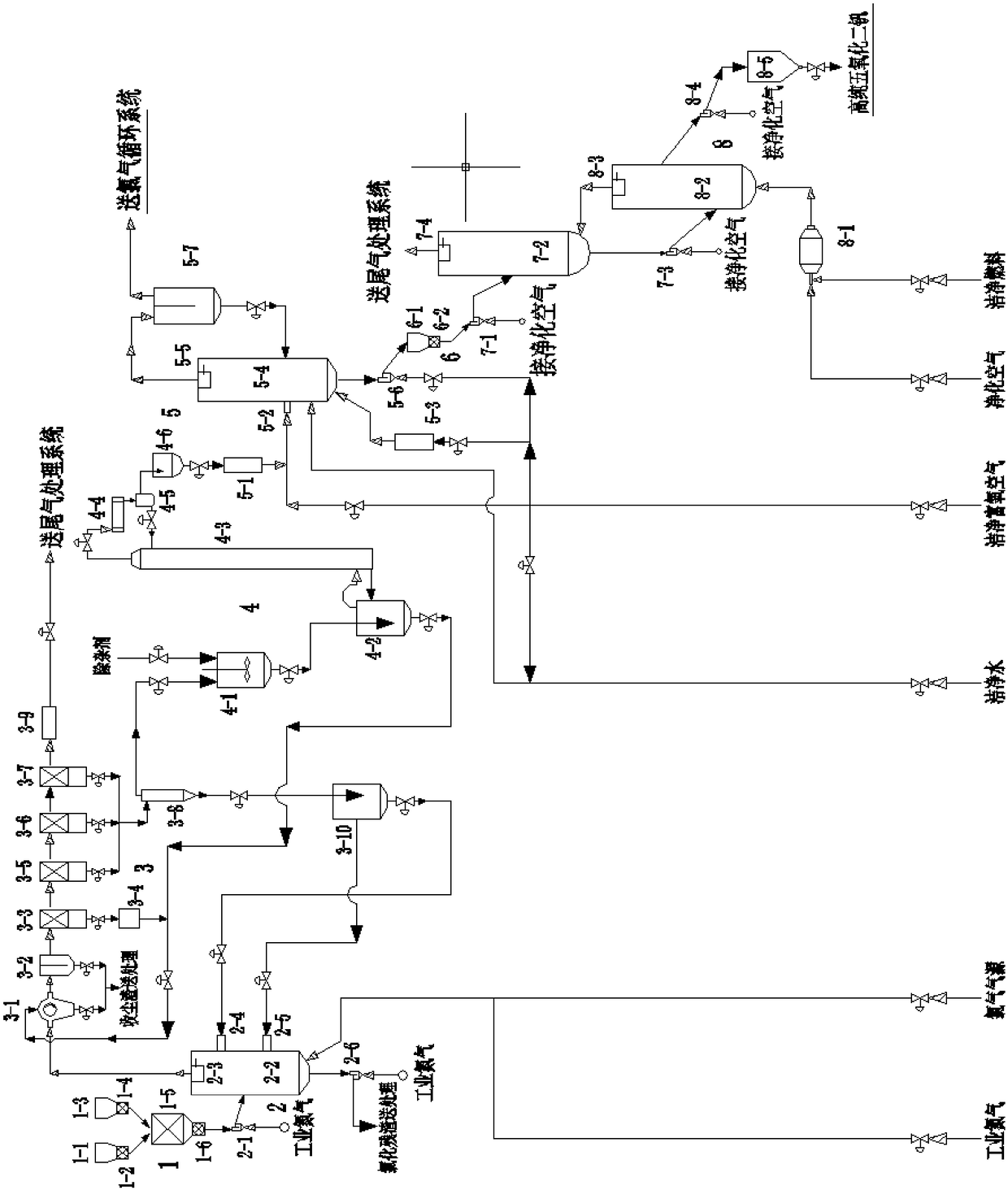

System and method for preparing high-purity vanadium pentoxide powder through efficient clean chlorination method

ActiveCN108622936AUniform temperature distributionStrong chlorination selectivityVanadium oxidesFurnace temperatureChemical industry

The invention belongs to the fields of metallurgy and chemical industry, and specifically discloses a system and a method for preparing high-purity vanadium pentoxide powder through an efficient cleanchlorination method, wherein industrial-grade vanadium oxide is converted into vanadium oxytrichloride by combing fluidization and carbon chlorination, two-stage dust removal and four-stage leachingare performed to obtain crude vanadium oxytrichloride, and the crude vanadium oxytrichloride is subjected to purification, catalytic oxidation and calcination to obtain the high-purity vanadium pentoxide powder. According to the present invention, the too high furnace temperature is prevented by spraying the vanadium oxytrichloride slurry into the boiling chlorination furnace; the chlorine gas isregenerated by blowing clean oxygen-rich air into the catalytic oxidation fluidized bed; the hydrogen chloride is recycled by returning the hydrochloric acid to the catalytic oxidation fluidized bed;and the system and the method have advantages of strong raw material adaptability, self-circulation of chlorine gas, no vanadium-containing hydrochloric acid emission, low production energy consumption, low operation cost, stable product quality and the like, are suitable for the large-scale industrial production of high-purity vanadium pentoxide powder with the purity of more than 4N, and have good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

System and method for preparing high-purity and low-valent vanadium oxide through chlorination method

ActiveCN107555479ASolve temperature balance problemsUniform temperature distributionVanadium oxidesSocial benefitsThree stage

The invention belongs to the field of chemical industry and metallurgy, and provides a system and a method for preparing a high-purity and low-valent vanadium oxide through a chlorination method. According to the method, an industrial grade vanadium oxide is converted into vanadium oxytrichloride by using fluidization chlorination; two-stage dust removing and three-stage leaching are performed toobtain crude vanadium oxytrichloride; and rectification, catalytic oxidation and precise reduction control are performed to obtain the high-purity and low-valent vanadium oxide, wherein the average valence of vanadium can be any one selected from 3.0-4.5. According to the present invention, the furnace temperature is controlled by spraying the vanadium oxytrichloride mud into the chlorination fluidized bed; the reaction efficiency is improved by arranging the inner member on the catalytic oxidation fluidized bed; the reduction degree is regulated by arranging the vertical baffle and the material discharging ports with different heights on the reduction fluidized bed so as to obtain the high-purity and low-valent vanadium oxide with the specific valence; and the system and the method have advantages of strong raw material adaptability, no pollution, low production energy consumption, low operation cost, stable product quality and the like, are suitable for the large-scale industrial production of high-purity and low-valent vanadium oxide with more than 4N, and have good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

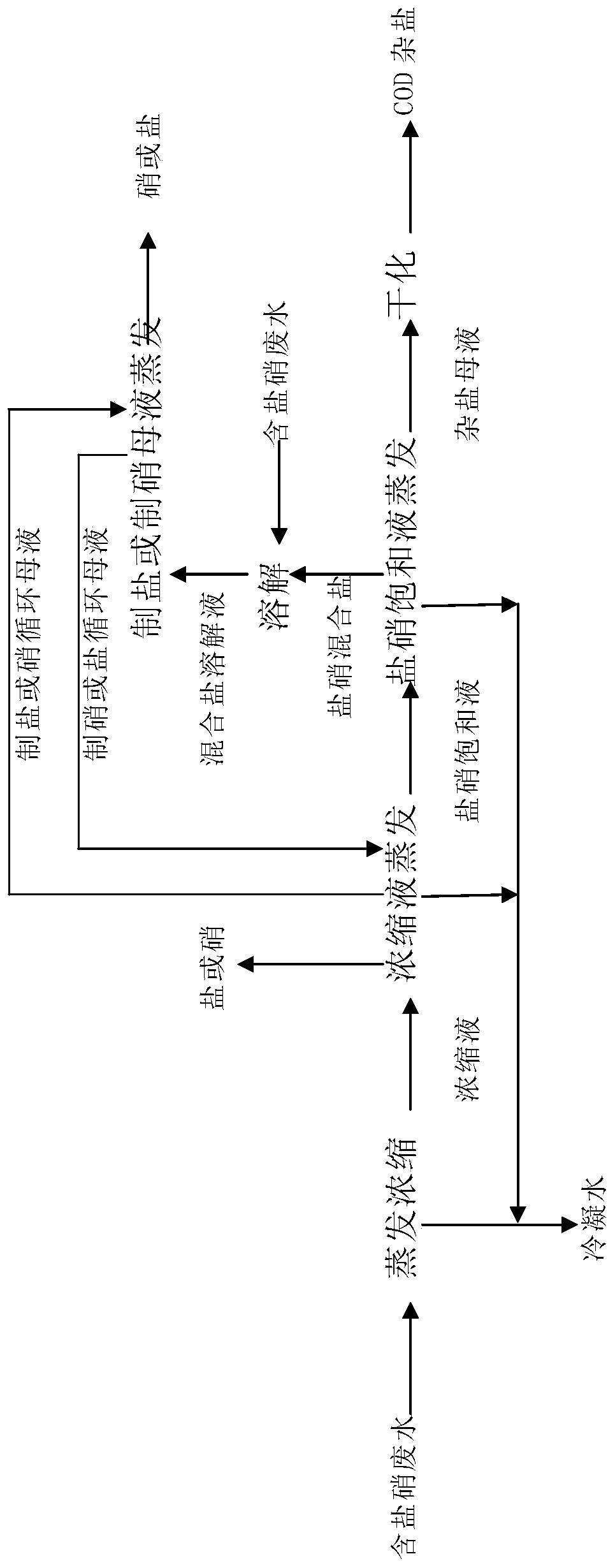

Process for separating nitrates, COD salts and sulfates by evaporating wastewater containing nitrates, COD salts and sulfates

InactiveCN110790331AStrong raw material adaptabilitySimple processWater contaminantsAlkali metal sulfite/sulfate purificationProcess engineeringMother liquor

A process for separating nitrates, COD, salts and sulfates by evaporating wastewater containing nitrates, COD salts and sulfates is provided. The process includes A) performing evaporation concentration on wastewater containing salts and sulfates and adopted as a raw material to obtain fresh water and a concentrated solution; B) evaporating the concentrated solution to obtain salts or sulfates, fresh water and a salt-sulfate saturated solution; C) evaporating the salt-sulfate saturated solution to obtain a salt-sulfate mixture and a mixed salt mother liquor, drying the mixed salt mother liquorto obtain mixed salts containing nitrates, reductive compounds corresponding to CODs, salts and sulfates; D) dissolving the salt-sulfate mixture with the wastewater to obtain a mixed salt solution; E) evaporating the mixed salt solution at 40-140 DEG C and crystallizing to obtain sulfates or salts, and a circulating mother liquor for sulfate or salt preparation; F) allowing the circulating motherliquor for sulfate or salt preparation to participate in evaporation in the next cyclic process step B at an evaporation temperature of 40-140 DEG C to evaporate, crystallize and precipitate salts orsulfate and to obtain a circulating mother liquor for salt or sulfate preparation, with the circulating mother liquor for salt or sulfate preparation participating in evaporation in the step E of thenext cyclic process.

Owner:CHINA LIGHT IND INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com