Method for preparing TiC mTiO sosoloid using titanium complex ore as material

A compound ore and solid solution technology, applied in the field of non-ferrous metallurgy, can solve the problems that the price of titanium cannot be greatly reduced, and achieve the effects of broad industrial application prospects, quick results, and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

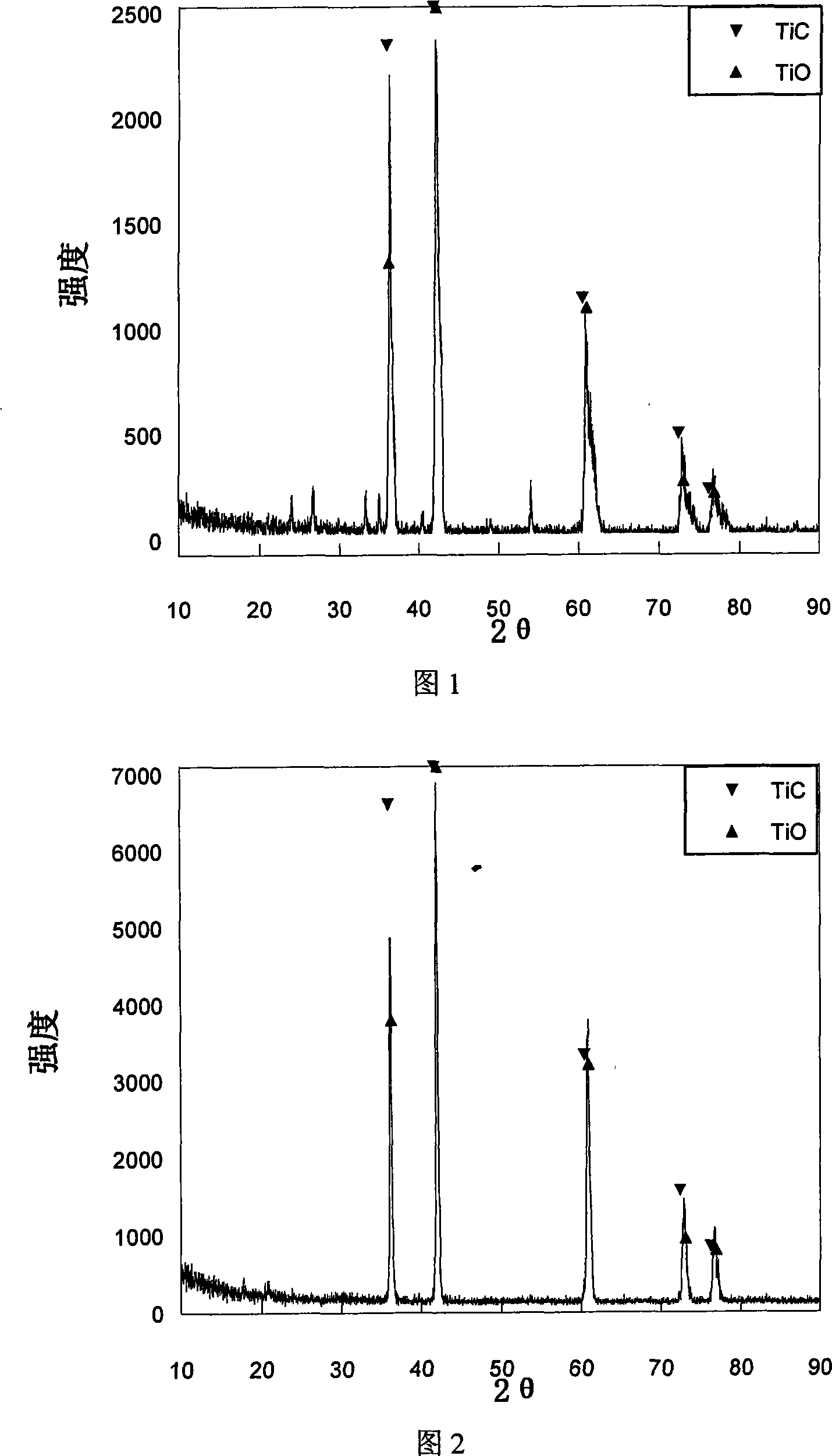

[0021] Weigh 200 grams of rutile concentrate, its composition is 95.96% TiO 2 , 1% Fe 2 O 3 , The rest is in trace amounts. Weigh 58.68 grams of graphite powder according to the following chemical reaction ratio

[0022] Fe 2 O 3 +3C=2Fe+3CO

[0023] TiO 2 +4C=TiC·TiO+3CO

[0024] The mixture is uniformly mixed, placed in a graphite crucible, and reacted at 1400° C. for 5 hours under vacuum to obtain a TiC·TiO-rich mixture. The mixture is crushed and pulverized to 44-150 microns, which accounts for 90%. The product is impregnated with dilute hydrochloric acid, the impregnation temperature is 80°C, the impregnation time is 100 minutes, the liquid-solid ratio is 16:1, the hydrochloric acid concentration is 20%, and the stirring speed is 80 revolutions per second. The product was filtered and dried, and then washed once under the same conditions to obtain a TiC·TiO solid solution (elemental analysis carbon to oxygen atom ratio of 1:1.02) powder with a content of 97.92%.

Embodiment 2

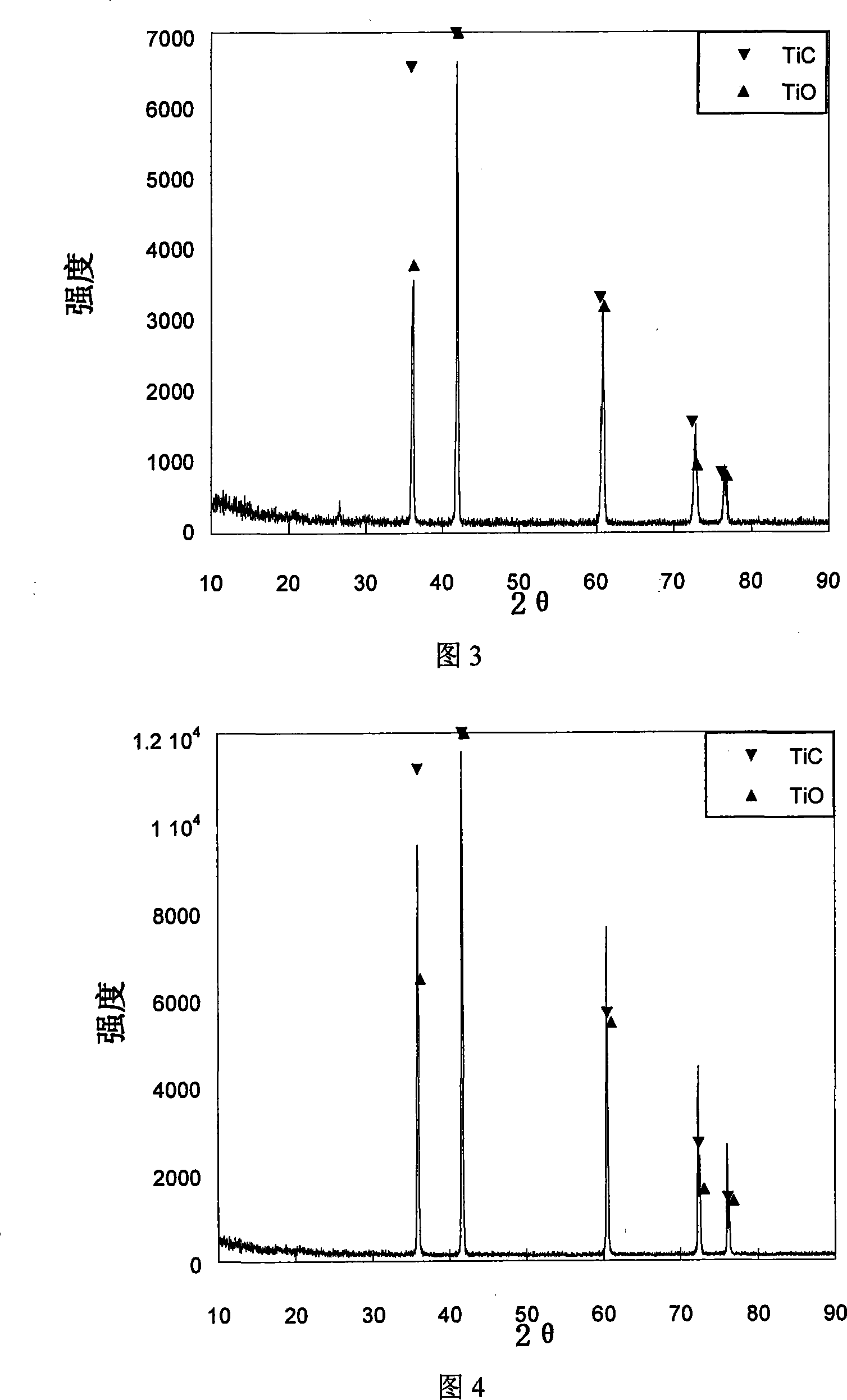

[0026] Weigh 200 grams of rutile concentrate, its composition is 97.13% TiO 2 , 0.9% Fe 2 O 3 , And the rest is in trace amounts. Weigh 87.82 grams of graphite powder according to the following chemical reaction measurement ratio:

[0027] Fe 2 O 3 +3C=2Fe+3CO

[0028] TiO 2 +3C=TiC+2CO

[0029] They are mixed uniformly, placed in a graphite crucible, and reacted at 1500° C. for 8 hours under the protection of argon to obtain a TiC-rich mixture. The mixture is crushed and pulverized to 44-150 microns, which accounts for 90%. The product is impregnated with dilute hydrochloric acid, the impregnation temperature is 60°C, the impregnation time is 60 minutes, the liquid-solid ratio is 12:1, the hydrochloric acid concentration is 15%, and the stirring speed is 100 revolutions per second. The product was filtered and dried, and then washed once under the same conditions to obtain a powder with a TiC (elemental analysis carbon to oxygen atomic ratio of 1:0.02) content of 98.15%.

Embodiment 3

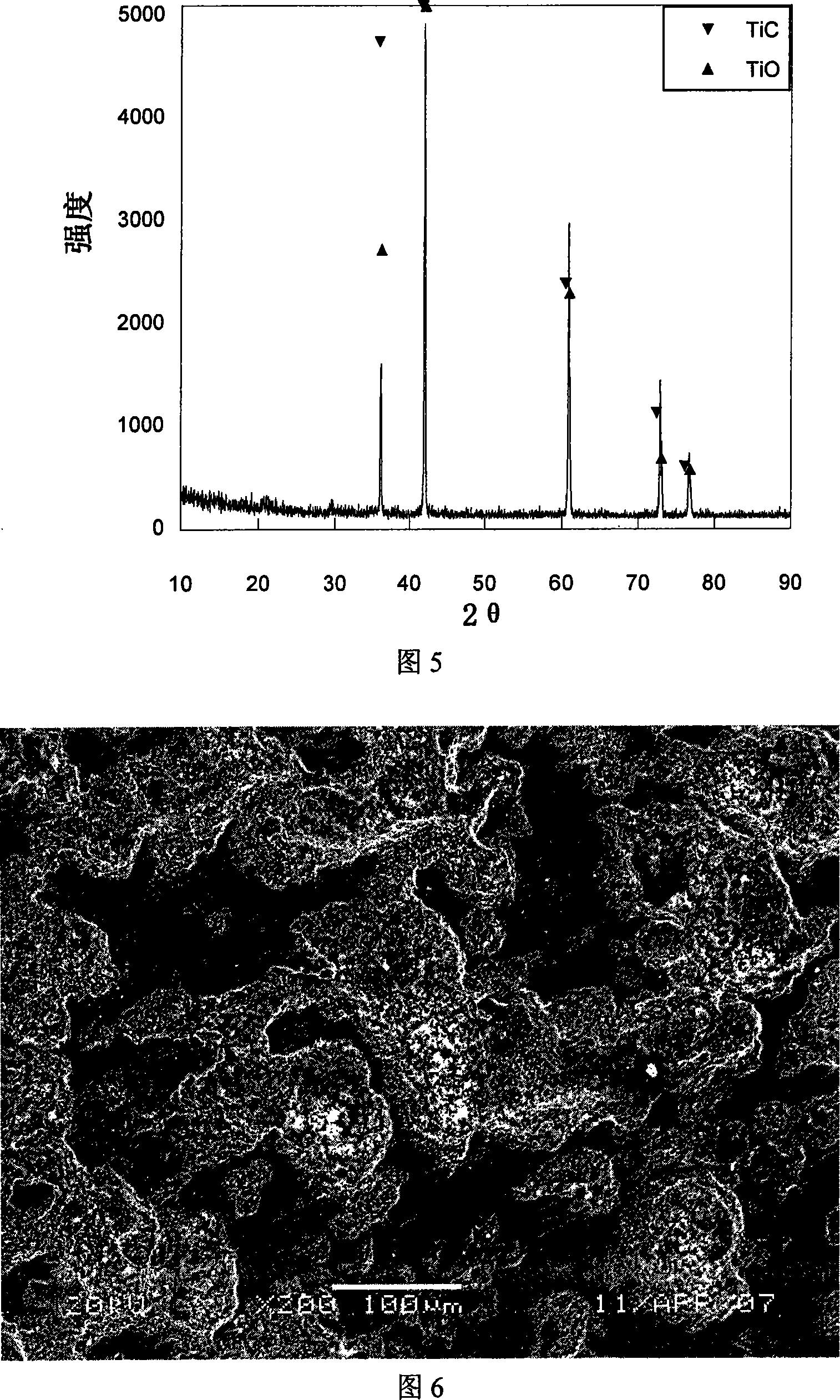

[0031] Weigh 200 grams of high-titanium slag, its composition is 77.26% TiO 2 , 10.28% FeO, 5.68% MgO, 3.21% SiO 2 , 1.69% CaO, 1.26% Al 2 O 3 , Weigh 49.78 grams of graphite powder according to the following chemical reaction metering ratio:

[0032] FeO+C=Fe+CO

[0033] 2TiO2 +4C=TiC·TiO+3CO

[0034] They are mixed uniformly, placed in a graphite crucible, and reacted at 1500° C. for 4 hours under the protection of argon to obtain a TiC·TiO-rich mixture. This mixture is crushed and pulverized to 44-150 microns, which accounts for 90%. The product is impregnated with dilute hydrochloric acid, the impregnation temperature is 90°C, the impregnation time is 60 minutes, the liquid-solid ratio is 20:1, the hydrochloric acid concentration is 15%, and the stirring speed is 100 revolutions per second. Filter and dry the product, and then wash it twice under the same conditions, and finally obtain TiC·TiO solid solution (elemental analysis shows that the carbon to oxygen atomic ratio is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com