Method for preparing additive agent electrolyte for electrolyzing aluminium from lithium-containing waste liquid

A technology for waste liquid and aluminum electrolysis, which is applied in the field of preparing aluminum electrolytic electrolyte additives, can solve the problems of complex process flow, hidden dangers of environmental protection, low recovery efficiency, etc., and achieves the effects of short process flow, convenient production scale adjustment and high recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

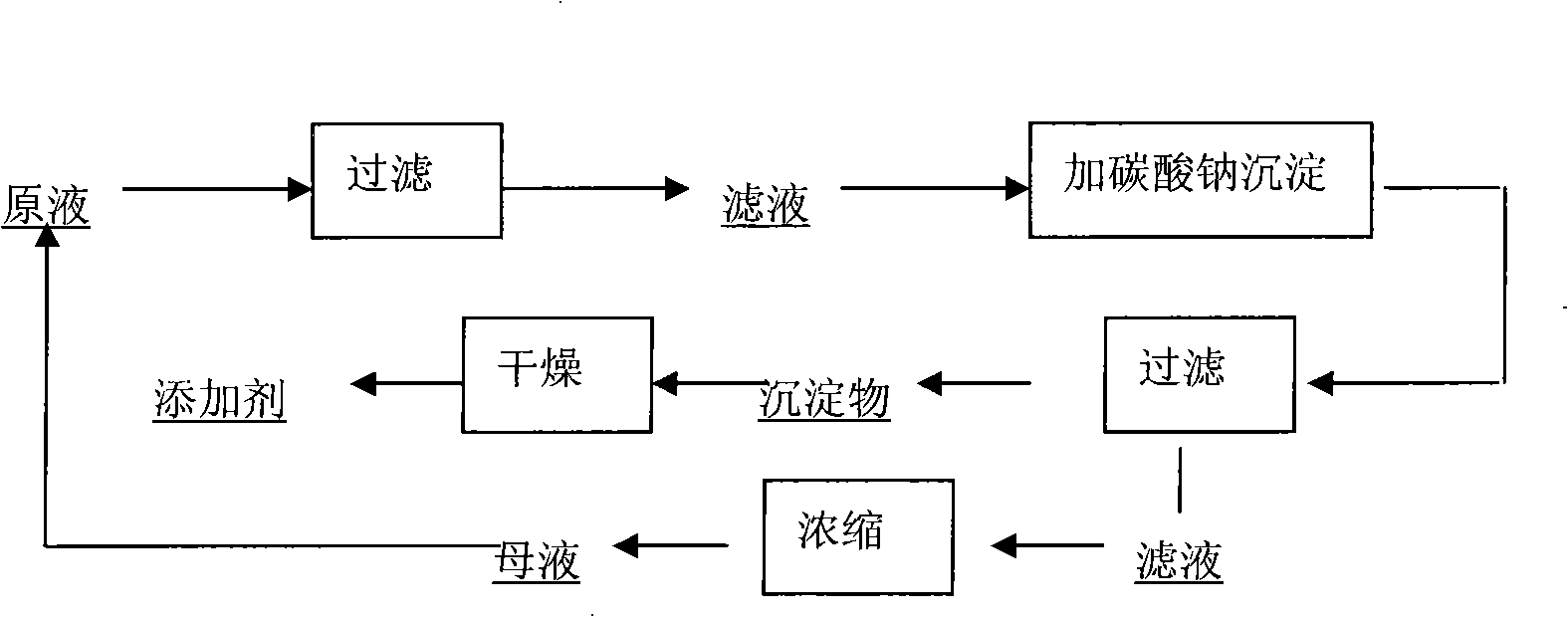

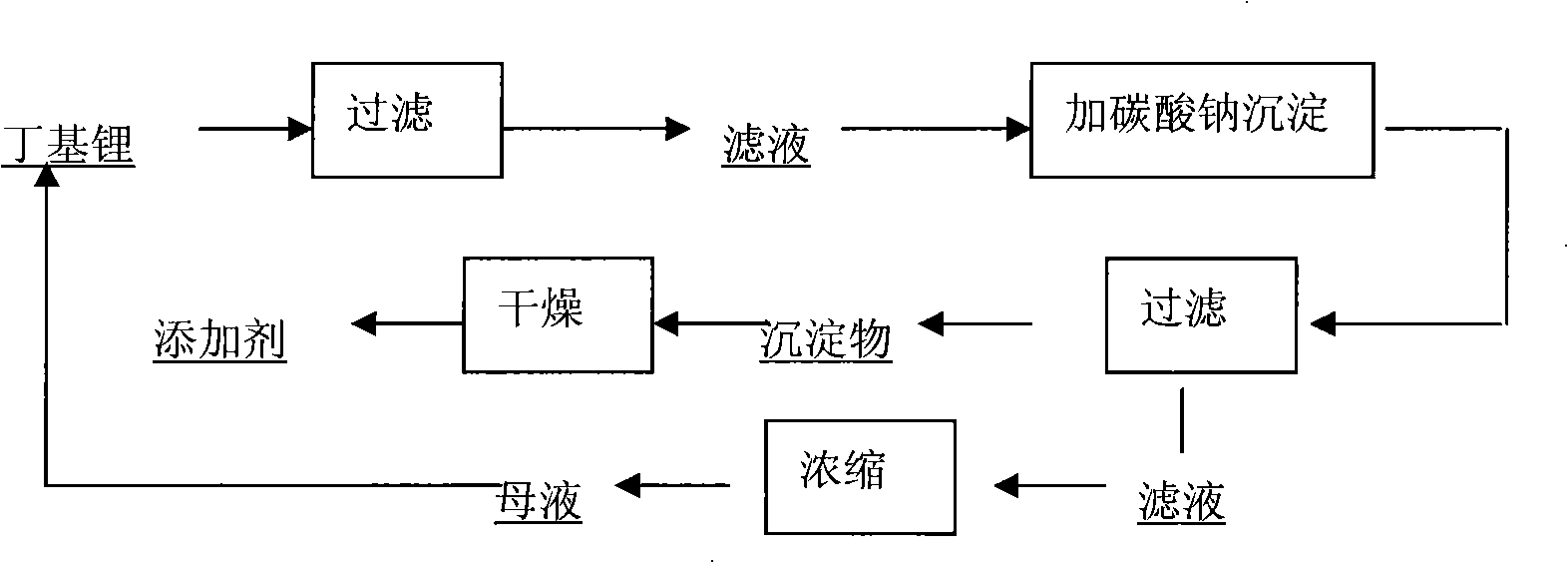

[0018] 1. Treatment of catalyst waste liquid

[0019] A factory uses lithium metal to produce n-butyllithium, and produces a waste liquid containing a mixture of lithium chloride and lithium hydroxide. The typical composition is: lithium chloride: 80%, lithium hydroxide: 15%, and the others are impurities. The specific process plan is as follows:

[0020] Main process conditions:

[0021] Precipitation by adding sodium carbonate: 110% to 120% of the chemical reaction volume;

[0022] Reaction temperature: 70~90℃, reaction time 2~3h;

[0023] Drying temperature: 300~450℃;

[0024] Primary recovery rate of lithium: >50%;

[0025] Lithium recycling rate: >95%.

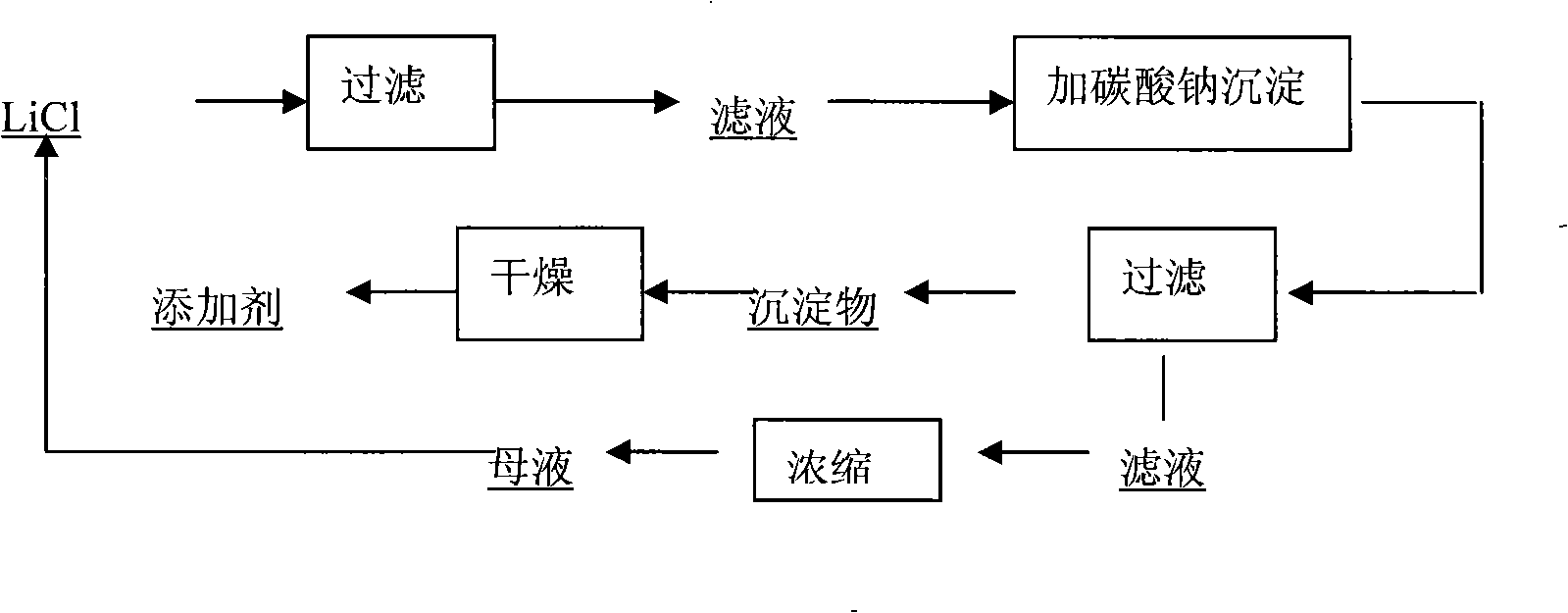

[0026] 2. Chemical raw material lithium halide waste liquid treatment

[0027] LiCl aqueous solution is often used as a desiccant in desiccant cooling systems, and its regeneration after disposal is also a difficult problem. The concentration of LiCl in the waste liquid is between 20% and 25%, and a small amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com