Patents

Literature

666results about "Contact materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

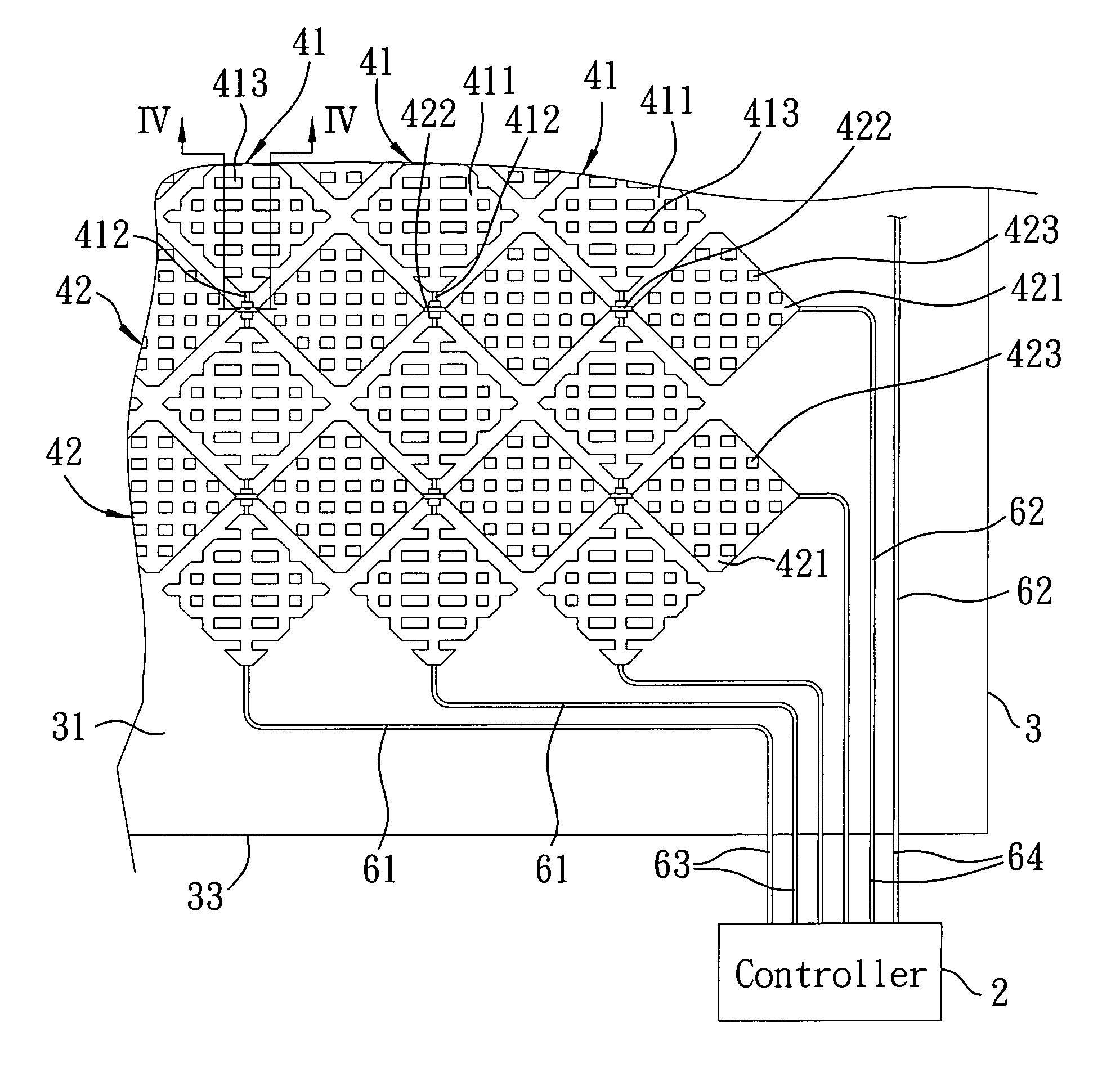

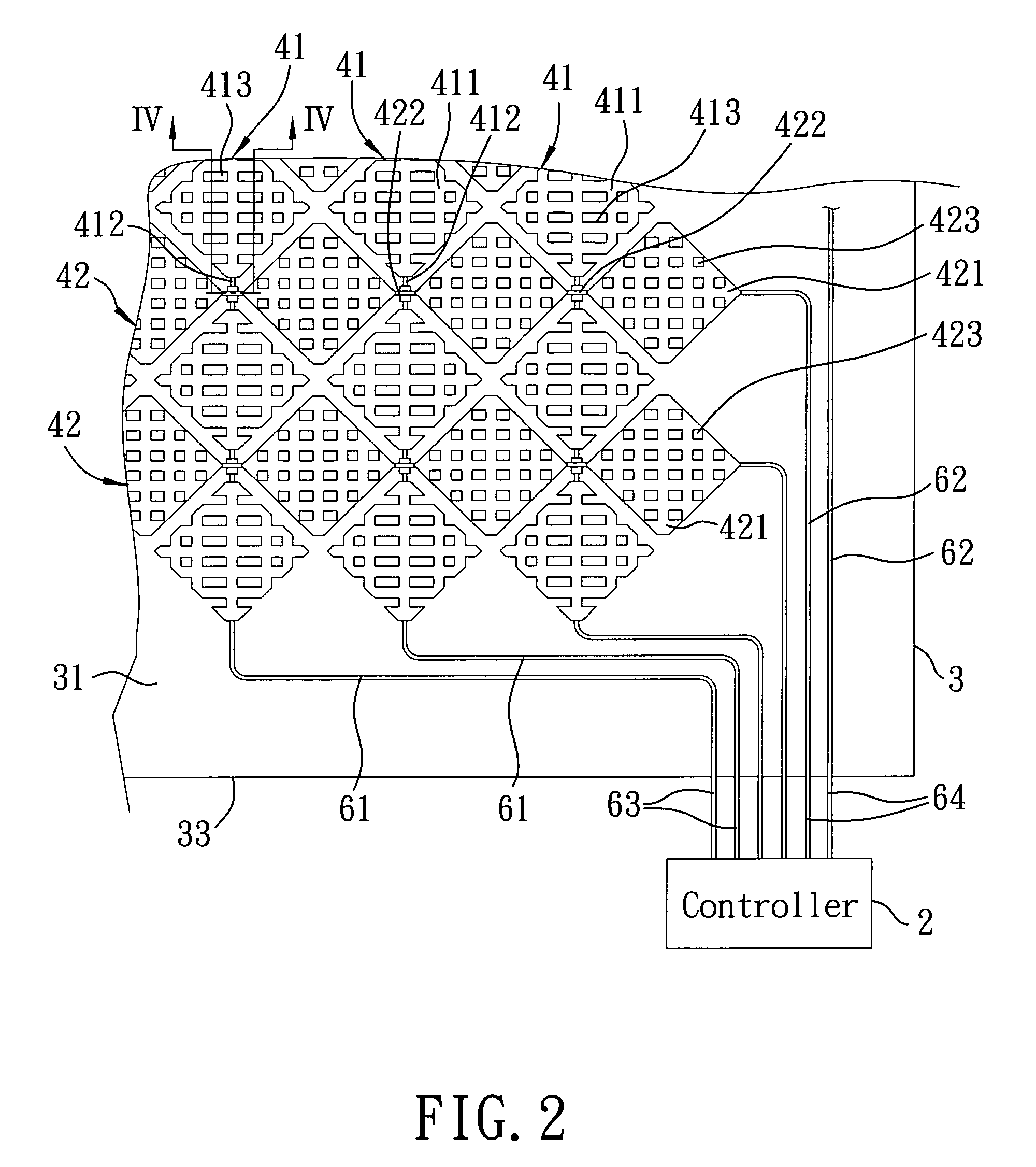

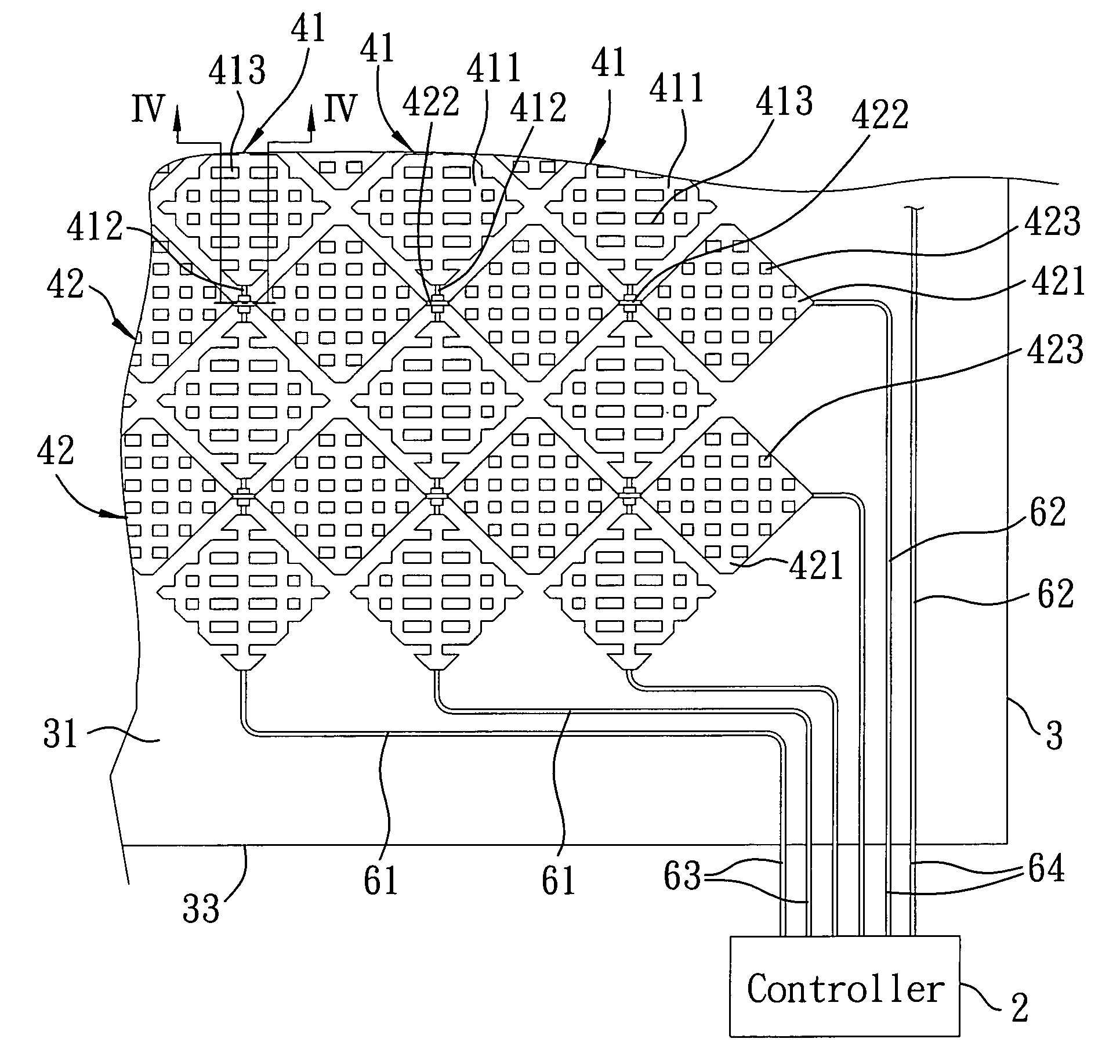

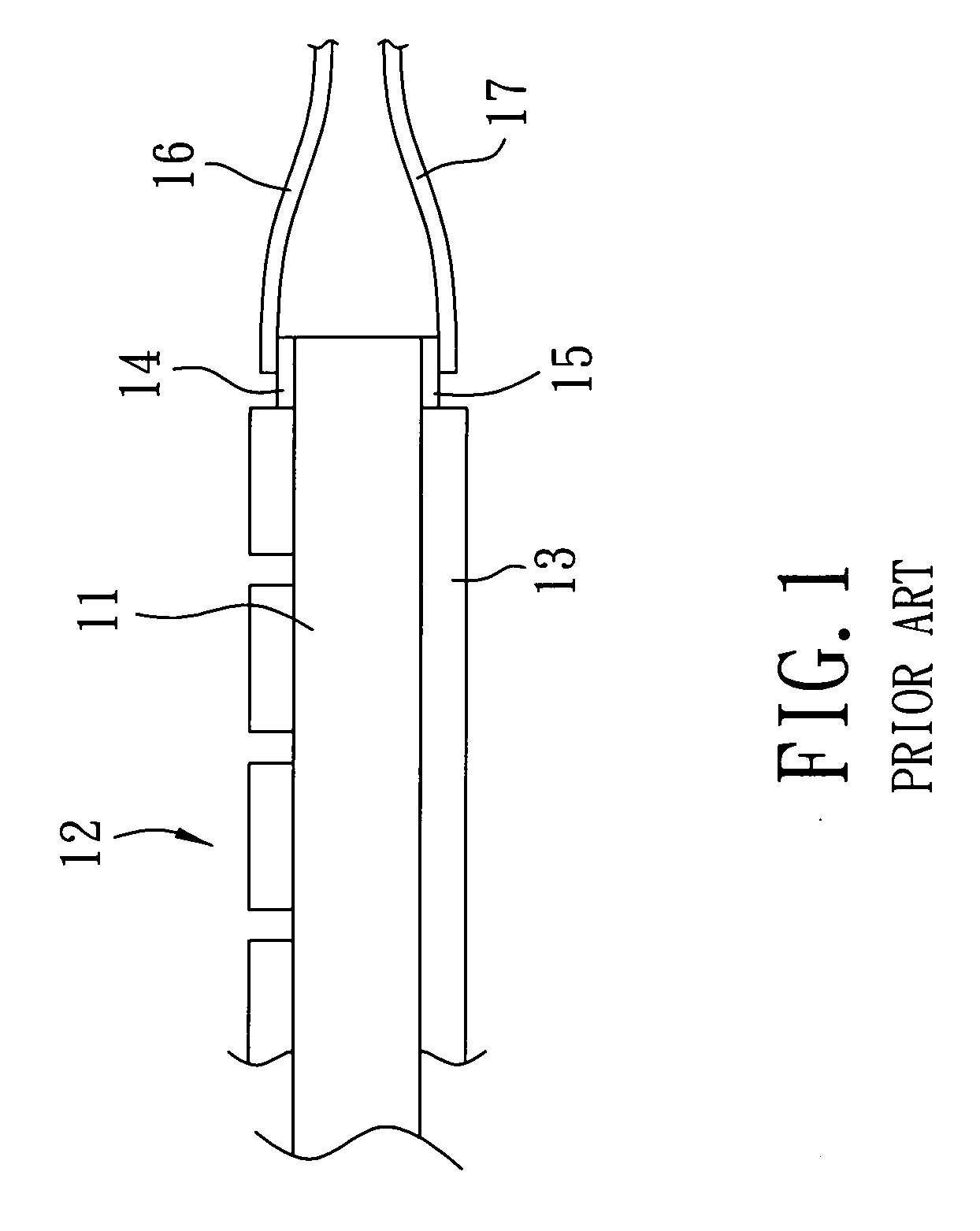

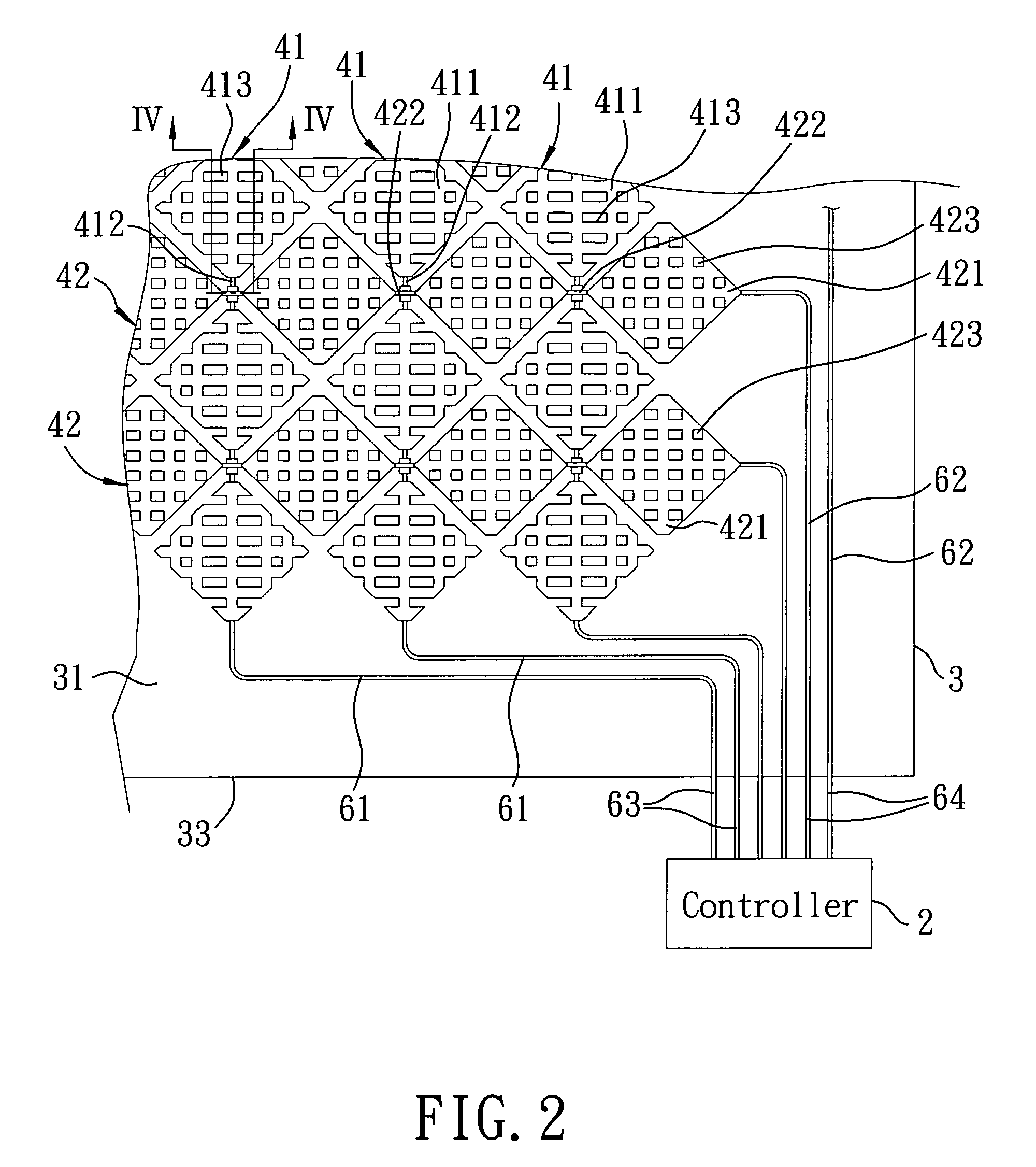

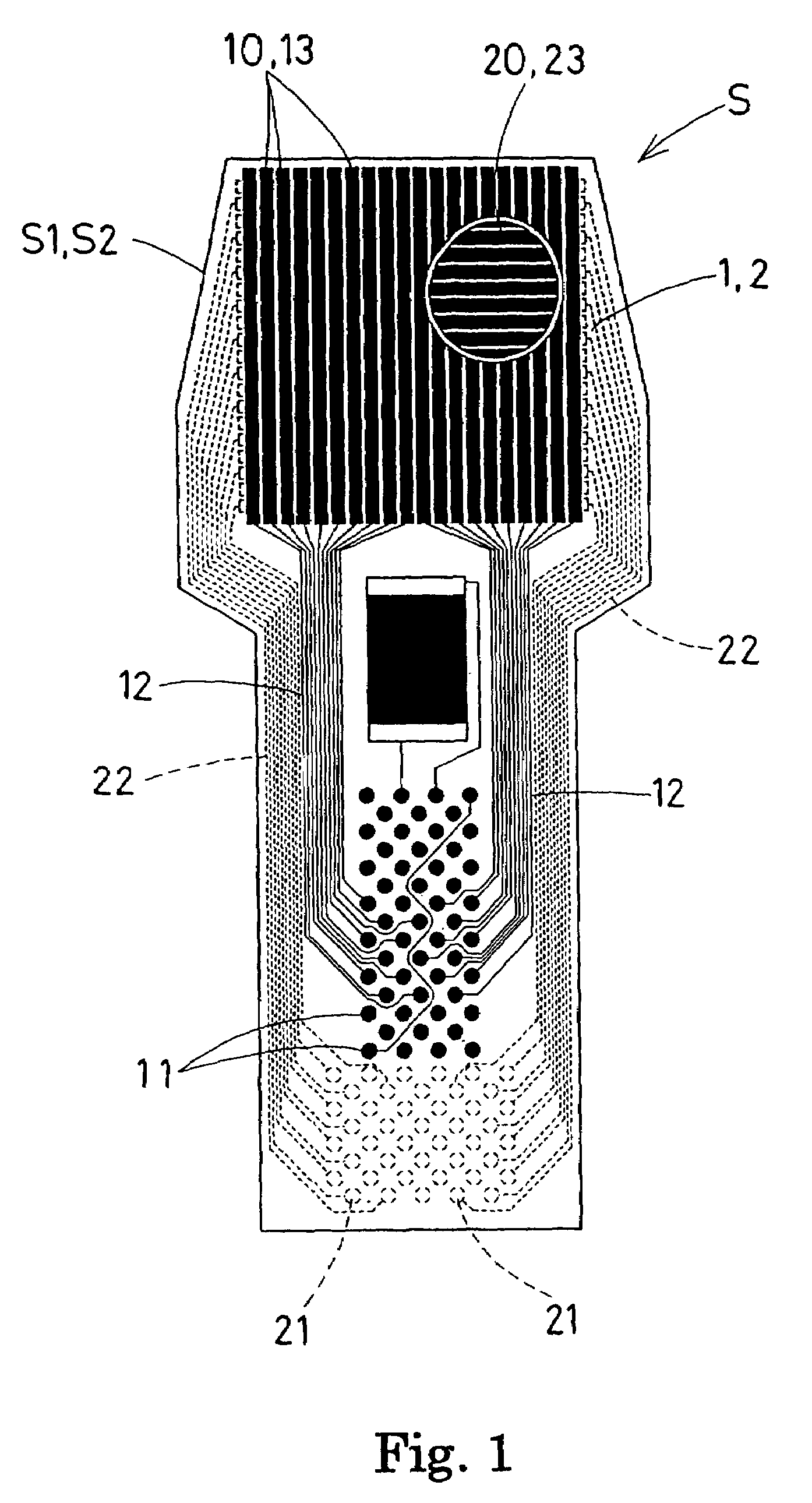

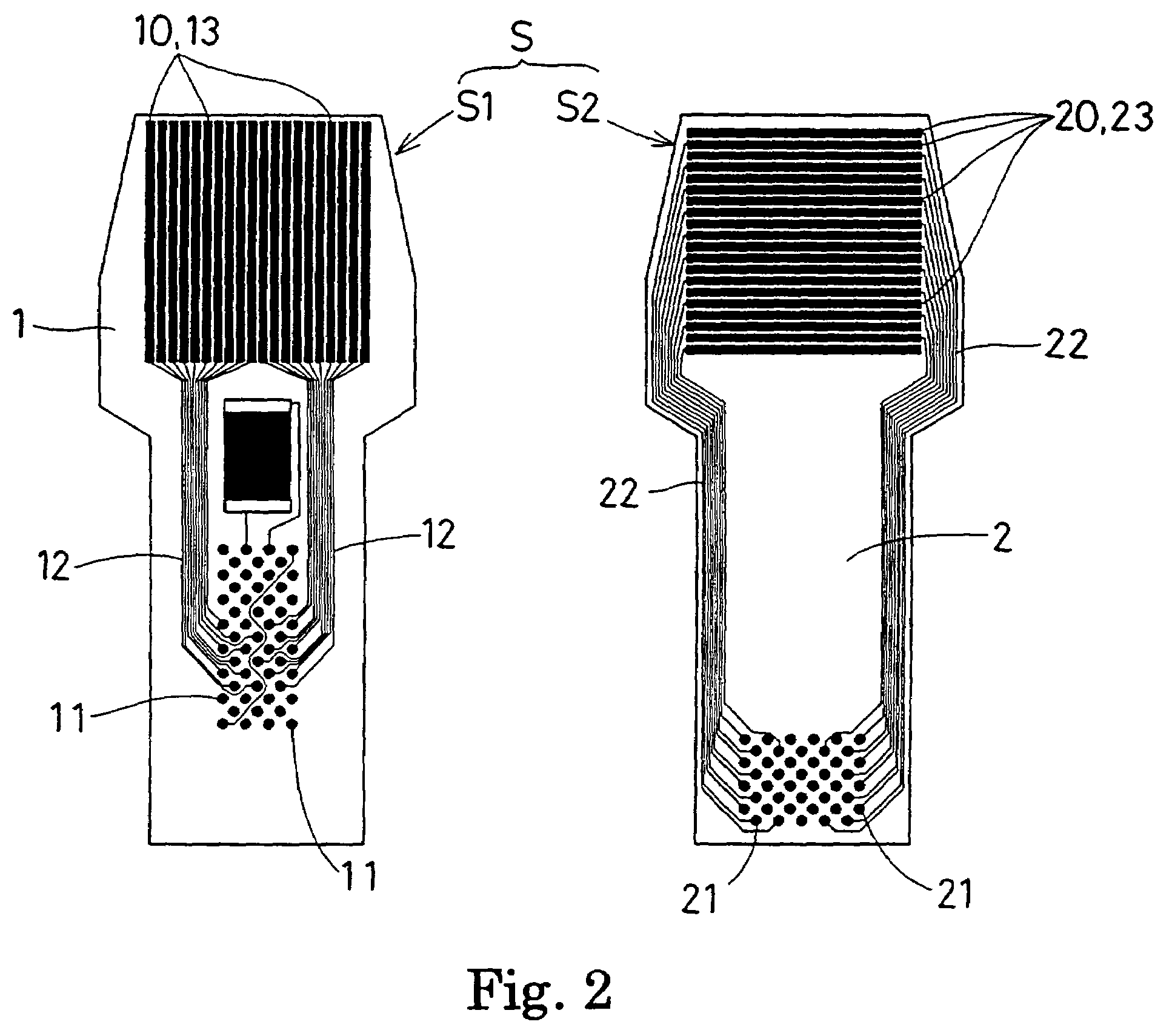

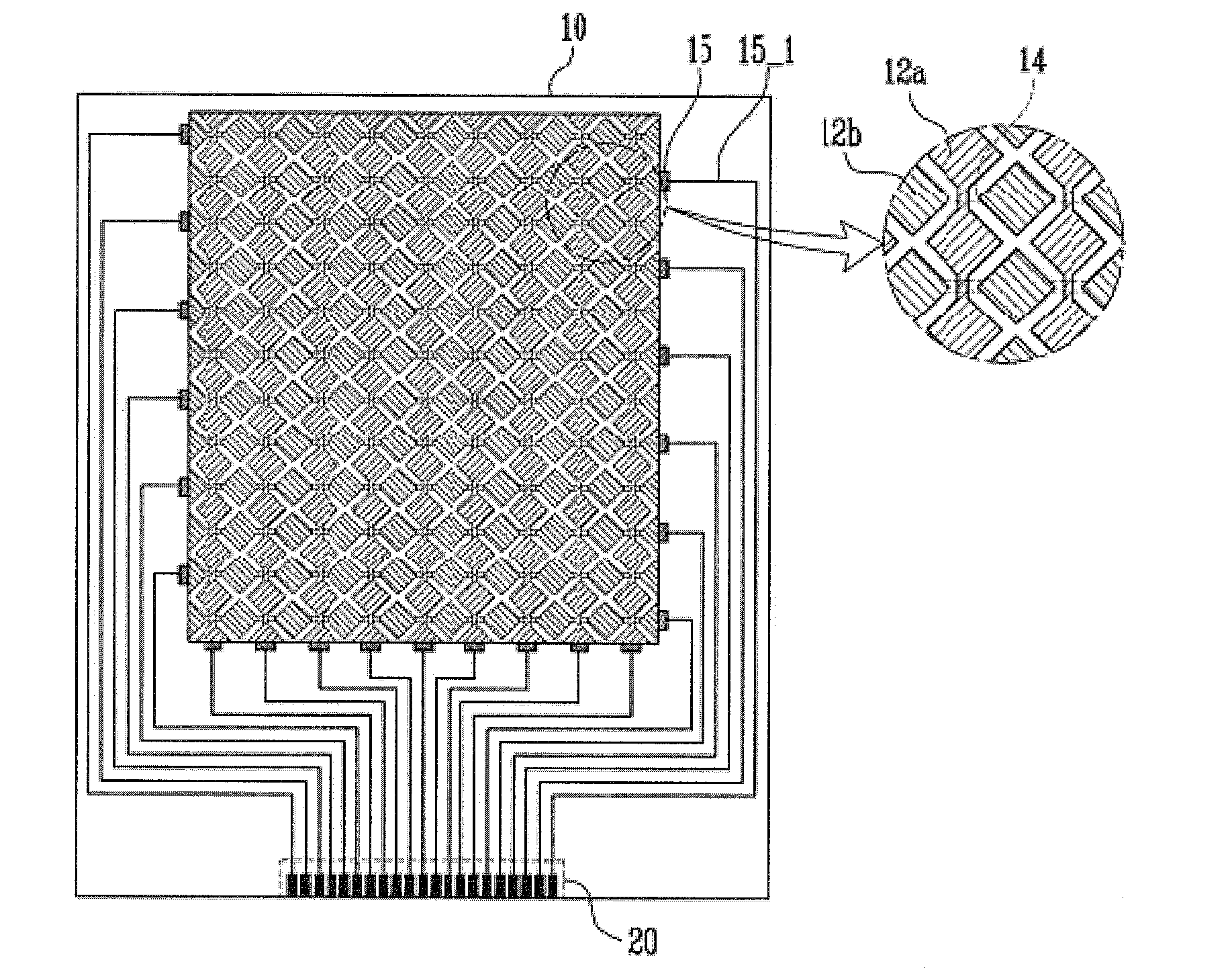

Capacitive type touch panel

ActiveUS7864503B2Overcomes drawbackContact materialsMechanically variable capacitor detailsElectrical conductorEngineering

A capacitive type touch panel includes: a transparent substrate; an array of first conductors formed on a surface of the transparent substrate; an array of second conductors formed on the surface of the transparent substrate; a plurality of conductive first bridging lines, each of which interconnects two adjacent ones of the first conductors; a plurality of conductive second bridging lines, each of which interconnects two adjacent ones of the second conductors and each of which intersects insulatively a respective one of the first bridging lines; and a plurality of spaced apart insulators, each of which is disposed at an intersection of a respective one of the first bridging lines and a respective one of the second bridging lines to separate the respective first and second bridging lines.

Owner:TAZIK SOLUTIONS (SUZHOU) LTD

Capacitive type touch panel

ActiveUS20080277259A1Overcomes drawbackContact materialsMechanically variable capacitor detailsElectrical conductorTouch panel

A capacitive type touch panel includes: a transparent substrate; an array of first conductors formed on a surface of the transparent substrate; an array of second conductors formed on the surface of the transparent substrate; a plurality of conductive first bridging lines, each of which interconnects two adjacent ones of the first conductors; a plurality of conductive second bridging lines, each of which interconnects two adjacent ones of the second conductors and each of which intersects insulatively a respective one of the first bridging lines; and a plurality of spaced apart insulators, each of which is disposed at an intersection of a respective one of the first bridging lines and a respective one of the second bridging lines to separate the respective first and second bridging lines.

Owner:TAZIK SOLUTIONS (SUZHOU) LTD

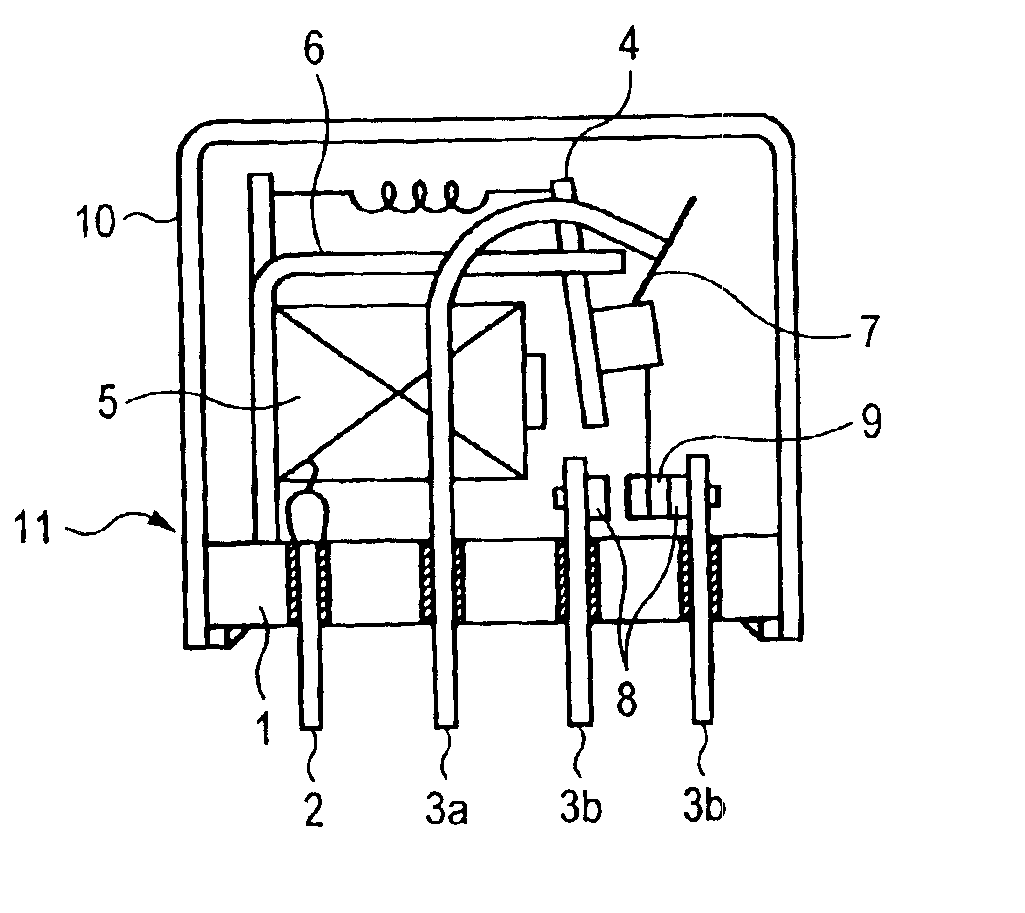

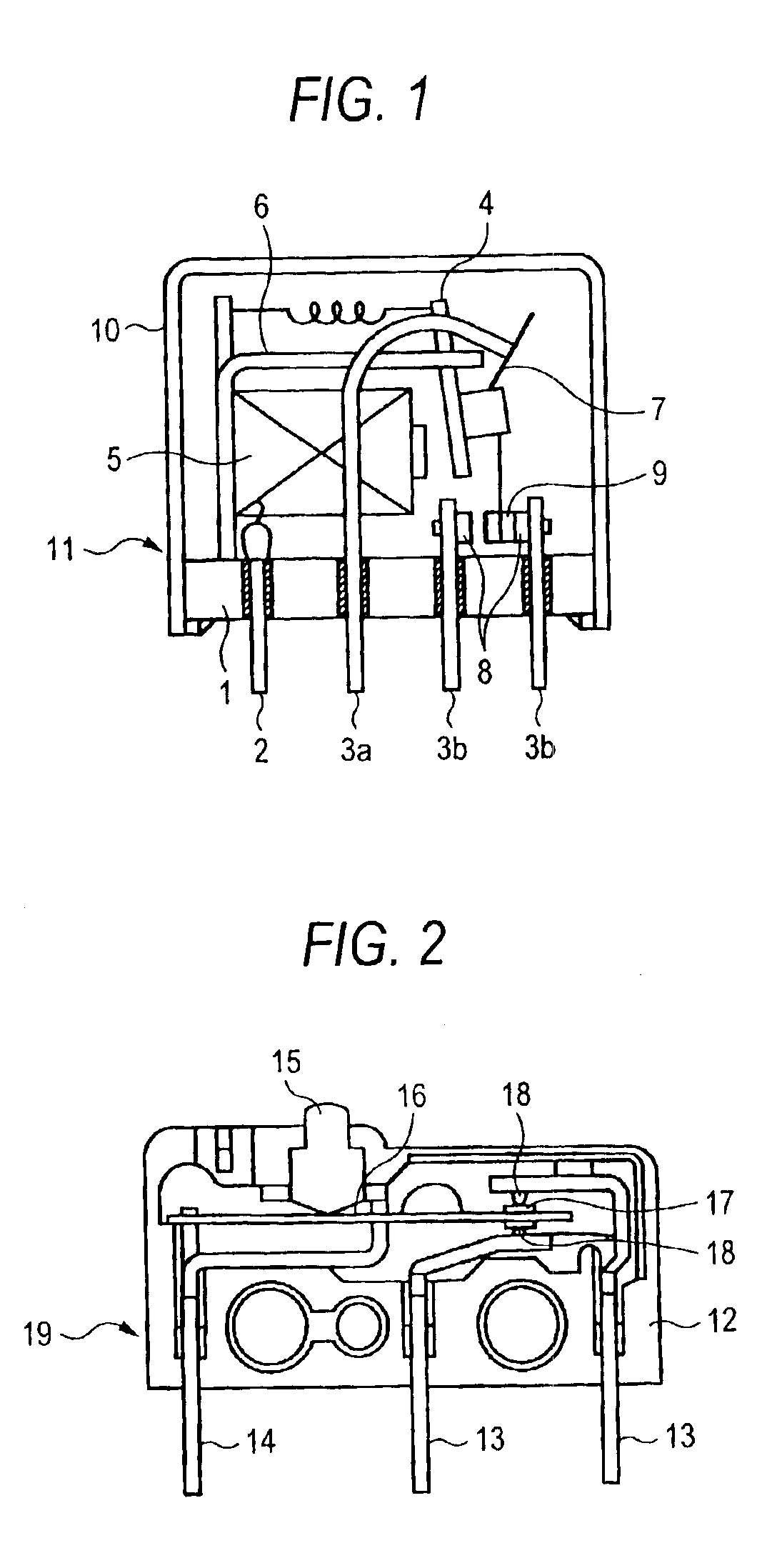

Direct current load breaking contact point constitution and switching mechanism therewith

InactiveUS6934134B2Contact materialsCircuit-breaking switches for excess currentsElectrical resistance and conductanceElectrical polarity

The invention intends to provide a direct current load breaking contact point constitution that can make and break an electrical circuit under both direct current loads of direct current resistance load and direct current inductance load over a long period of time without causing problems such as ① the conduction defect due to the consumption of the contact point, ② the locking due to material transfer from one contact point to the other contact point, ③ the welding between the contact points, and ④ the abnormal arc continuation, and a direct current load breaking switching mechanism such as a relay, a switch and so on that has the contact point constitution. The direct current load breaking contact point constitution according to the invention comprises a movable contact point and a stationary contact point that face each other; wherein the movable contact point is made of AgSnO2In2O3 alloy that contains at least Ag, 8 to 15% by weight in total of metal oxides including SnO2 and In2O3, 6 to 10% by weight of SnO2 and 1 to 5% by weight of In2O3; the stationary contact point is made of AgZnO alloy that contains at least Ag and 7 to 11% by weight of ZnO; and polarity of a movable side is (+) and that of a stationary side is (−).

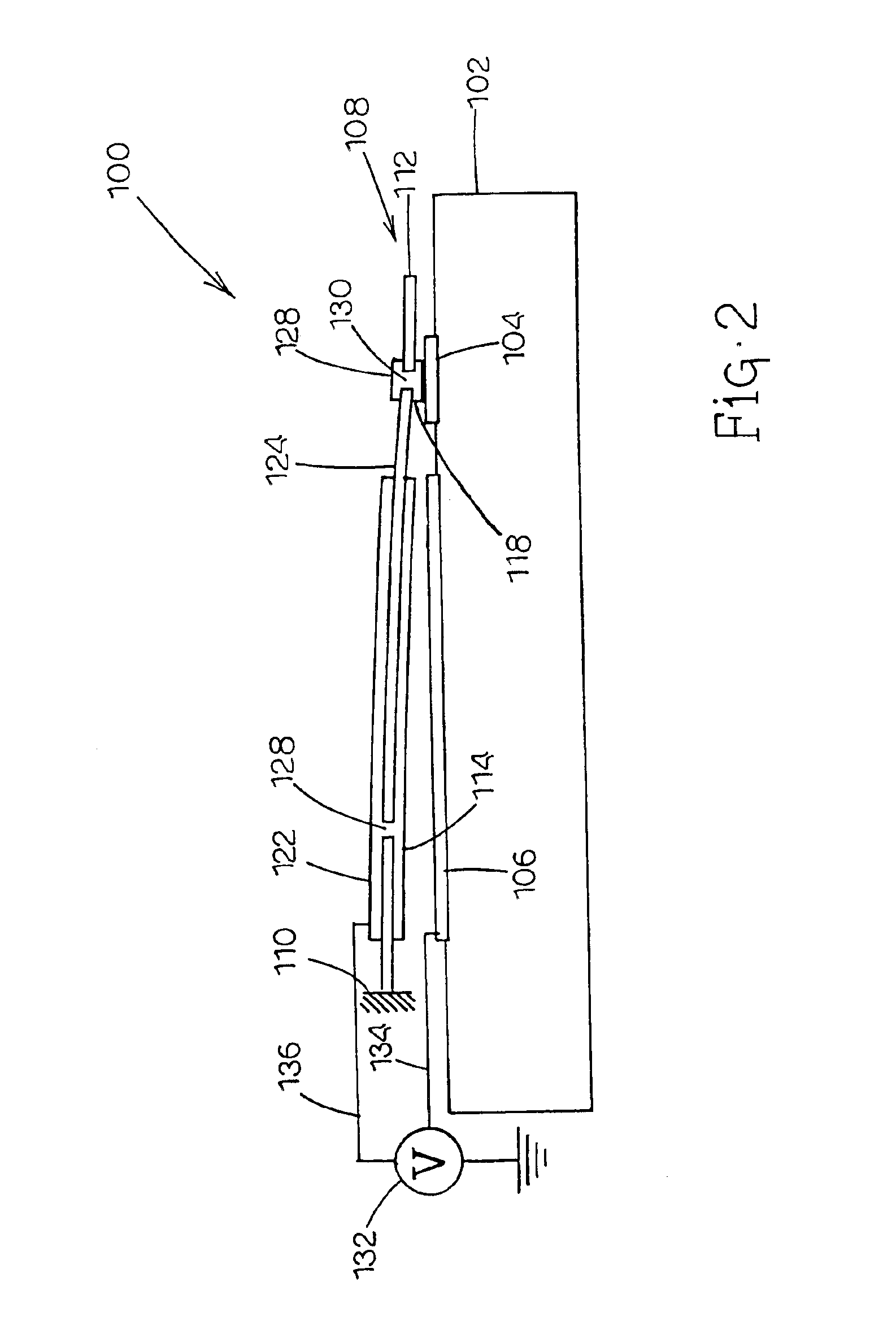

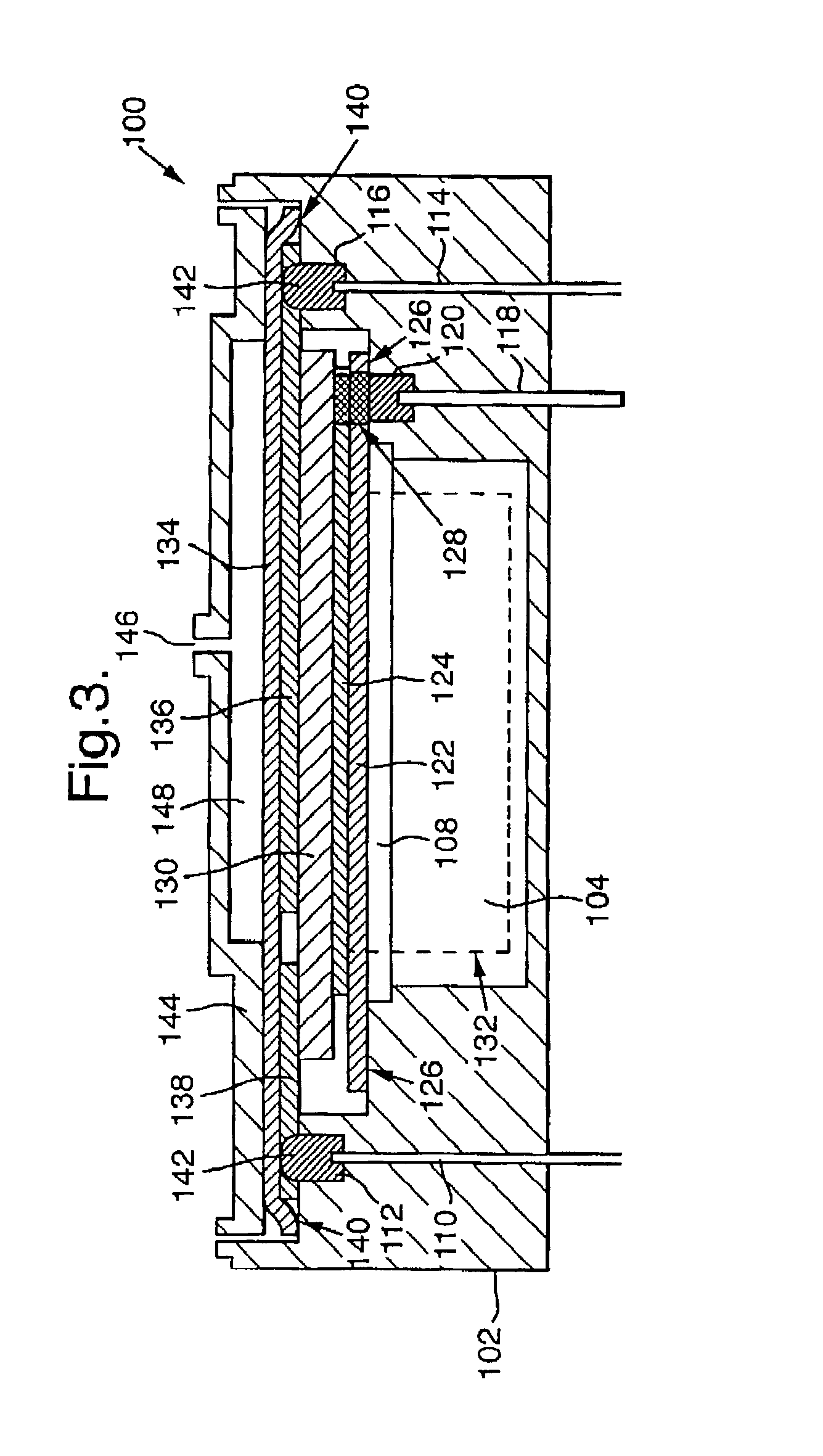

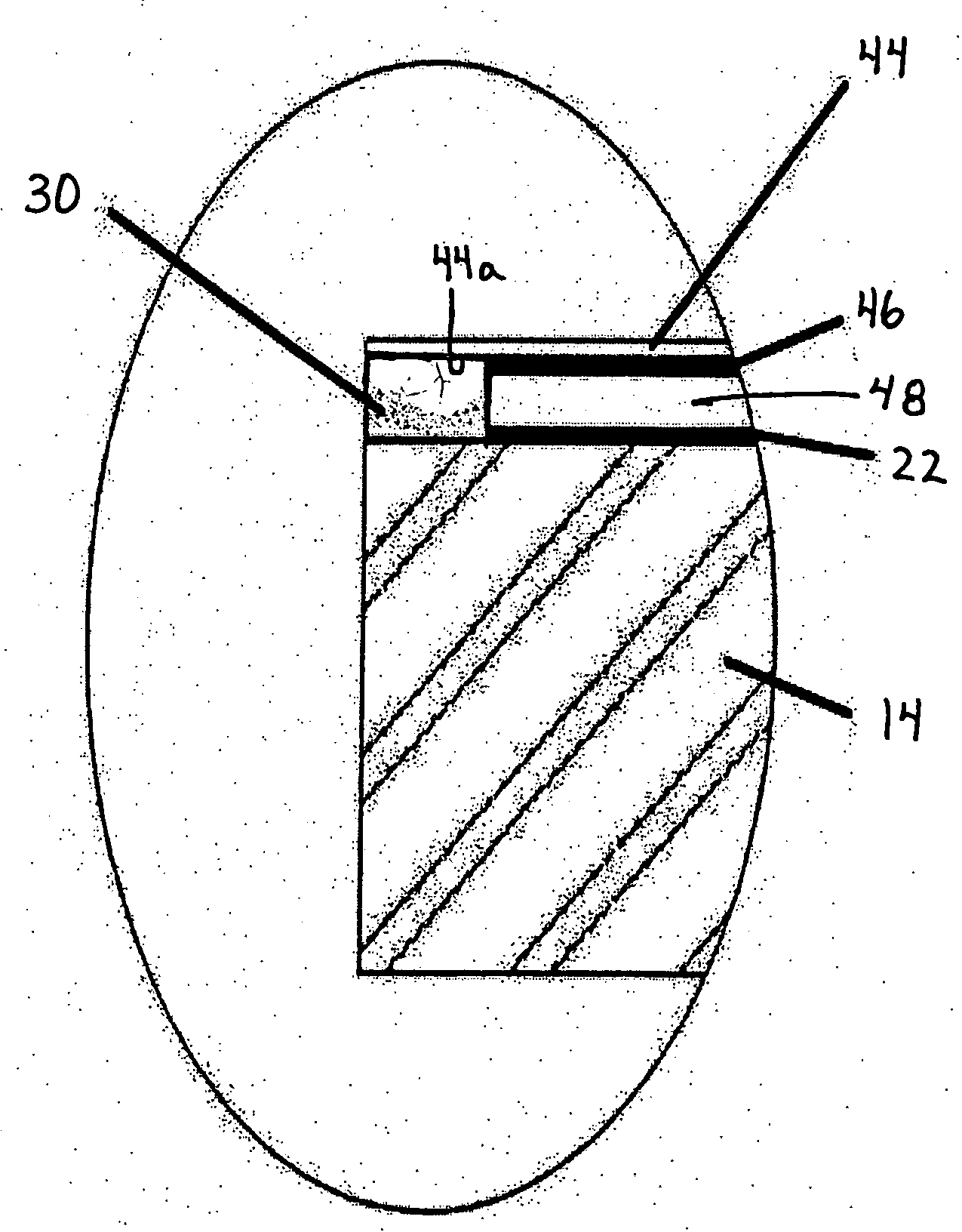

MEMS device having a trilayered beam and related methods

MEMS Device Having A Trilayered Beam And Related Methods. According to one embodiment, a movable, trilayered microcomponent suspended over a substrate is provided and includes a first electrically conductive layer patterned to define a movable electrode. The first metal layer is separated from the substrate by a gap. The microcomponent further includes a dielectric layer formed on the first metal layer and having an end fixed with respect to the substrate. Furthermore, the microcomponent includes a second electrically conductive layer formed on the dielectric layer and patterned to define an electrode interconnect for electrically communicating with the movable electrode.

Owner:AAC TECH PTE LTD

Low current high temperature switch contacts

A low ampere mechanical switch has a contact design creating a line of contact between the moveable and stationary contacts. The stationary contacts are stainless steel and the moveable contact is Inconel TM . Both contacts have a thin plating of gold alloy to provide for good mechanical strength at high temperature with a natural lubricating ability. The contact physical design provides good wiping action and mechanical contact while preventing troughing.

Owner:HONEYWELL INC

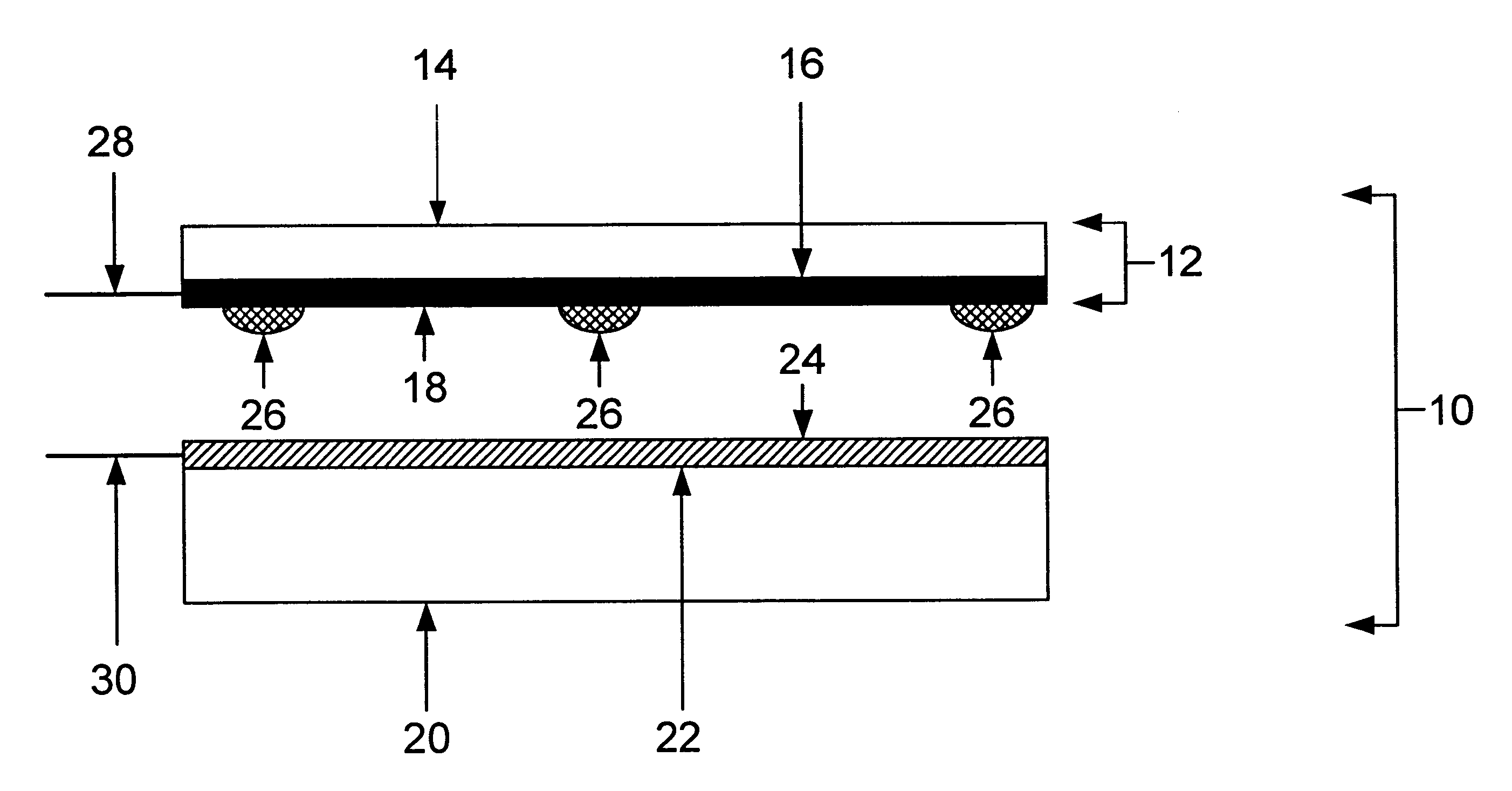

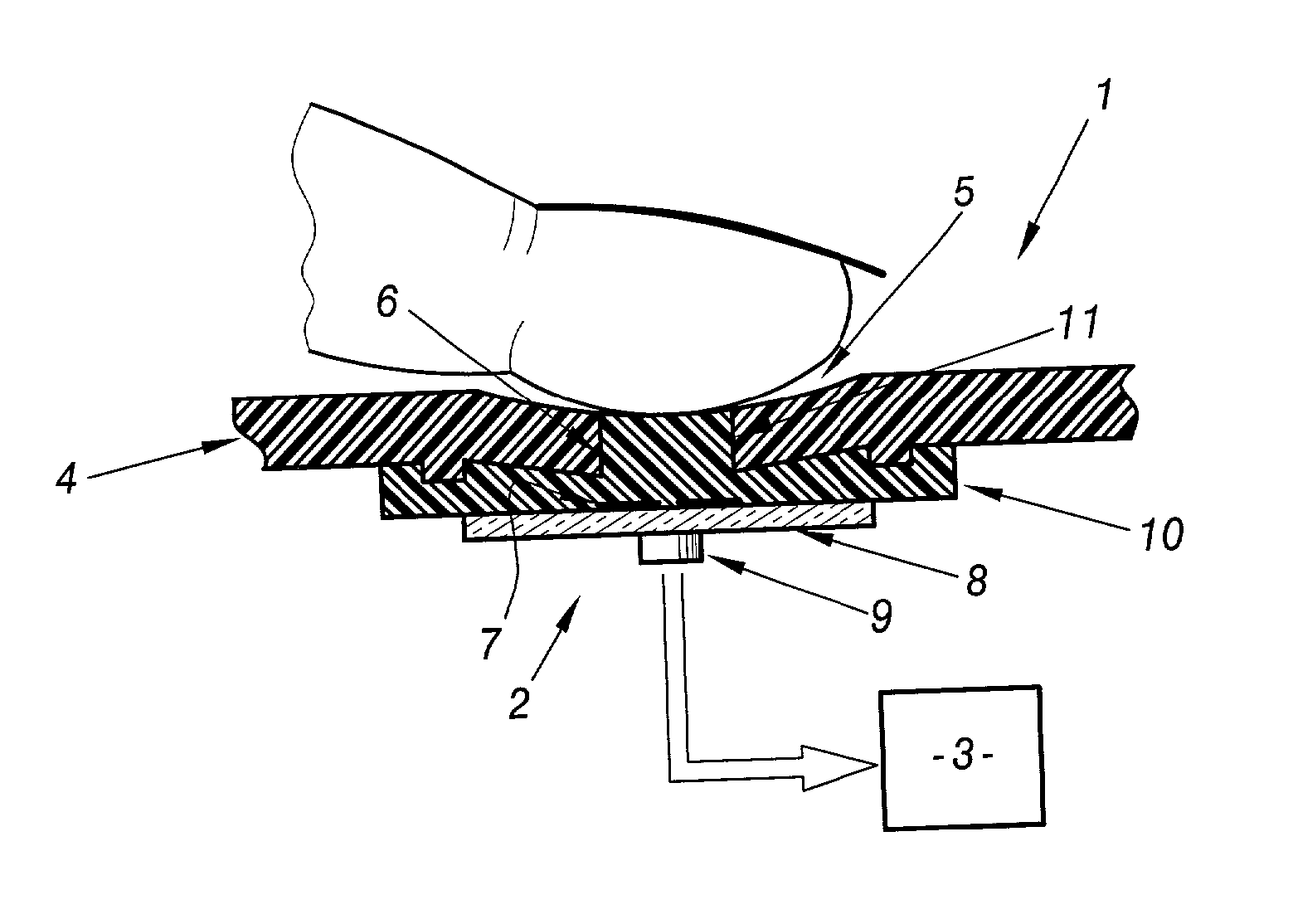

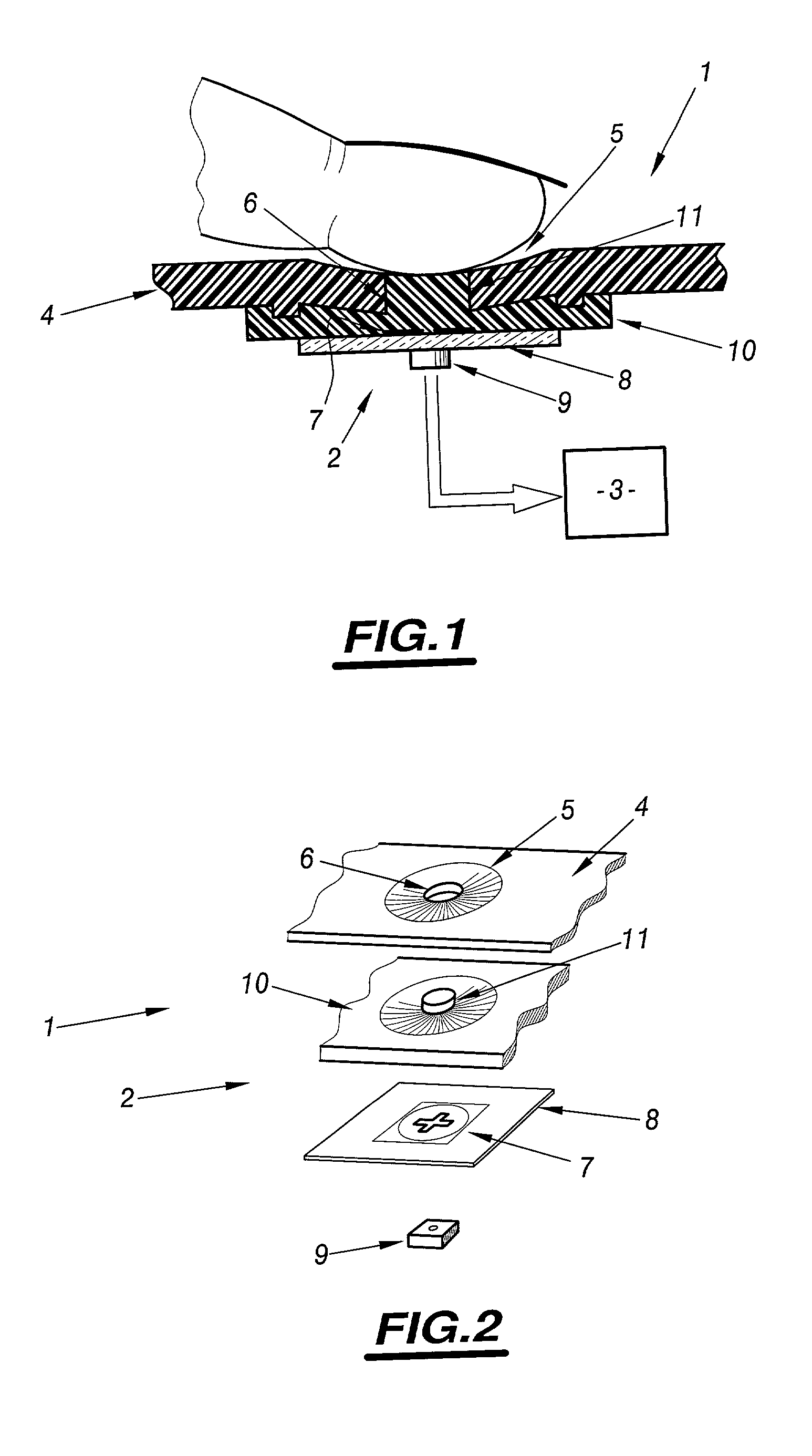

Pressure-sensitive sensor

InactiveUS7112755B2Improve output stabilityReduced output irregularityContact materialsContact surface shape/structureConductive coatingSilicone Elastomers

The pressure sensitive sensor includes a sheet base, an application-side and a receiving-side electrode provided on the sheet base and conducting coatings provided on the electrodes. The conductive electrodes have pressure-sensitive conductive ink containing conductive carbon black. Resistance between the application-side electrode and the receiving-side electrode changes by a contact area between the conductive coatings on the electrodes. The pressure-sensitive conductive ink has an enhanced strength as a resin and an enhanced effect of dispersion of the conductive carbon black by adding 30 to 70 parts by weight of silicon dioxide to 100 parts by weight of silicone elastomer component as a binder. The pressure-sensitive sensor has output stability and linearity at temperatures in a wide range from −40° C. to 85° C.

Owner:NITTA CORP

Pitted-surface metal and rubber composite conductive particle

The invention provides a pitted-surface metal and rubber composite conductive particle, which is formed by adhering a metal surface layer to a rubber basic body or slitting after adhesion, wherein the metal surface layer is a pitted surface and has pits or bumps or both the pits and the bumps; the pits or the bumps are formed on an external surface of the metal surface layer or an internal surface or both the external surface and the internal surface; the depths of the pits are smaller than the thickness of the metal surface layer; the heights of the bumps are greater than or equal to one tenth of the thickness of the metal surface layer; the metal surface layer is made of metal or alloy; gold, silver, copper or nickel can be coated on the external surface of the metal surface layer; the rubber basic body is made of silicon rubber or polyurethane rubber; an adhesion layer can be arranged between the metal surface layer and the rubber basic body; the adhesion layer is made of a heat vulcanization adhesive, a prime coating agent or a material which is the same as that of the rubber basic body; and aids such as a coupling agent can be coated on the internal surface of the metal surface layer. The metal surface layer is high in strength, stable in conductivity, high in strength of the adhesion layer and high in elasticity of the rubber basic body; and the pitted-surface metal and rubber composite conductive particles can serve as conductive parts of various kinds of keys of a mobile phone, an automobile and the like, and the cost can be controlled.

Owner:NANTONG MEMTECH TECH

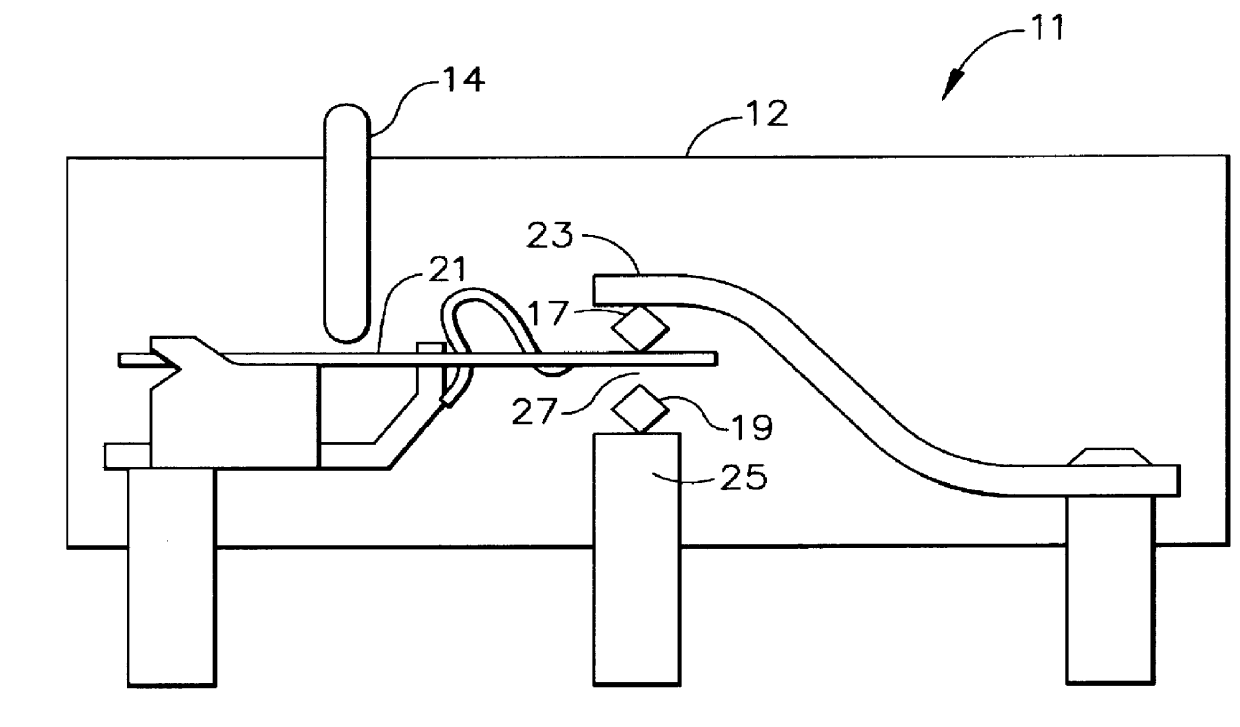

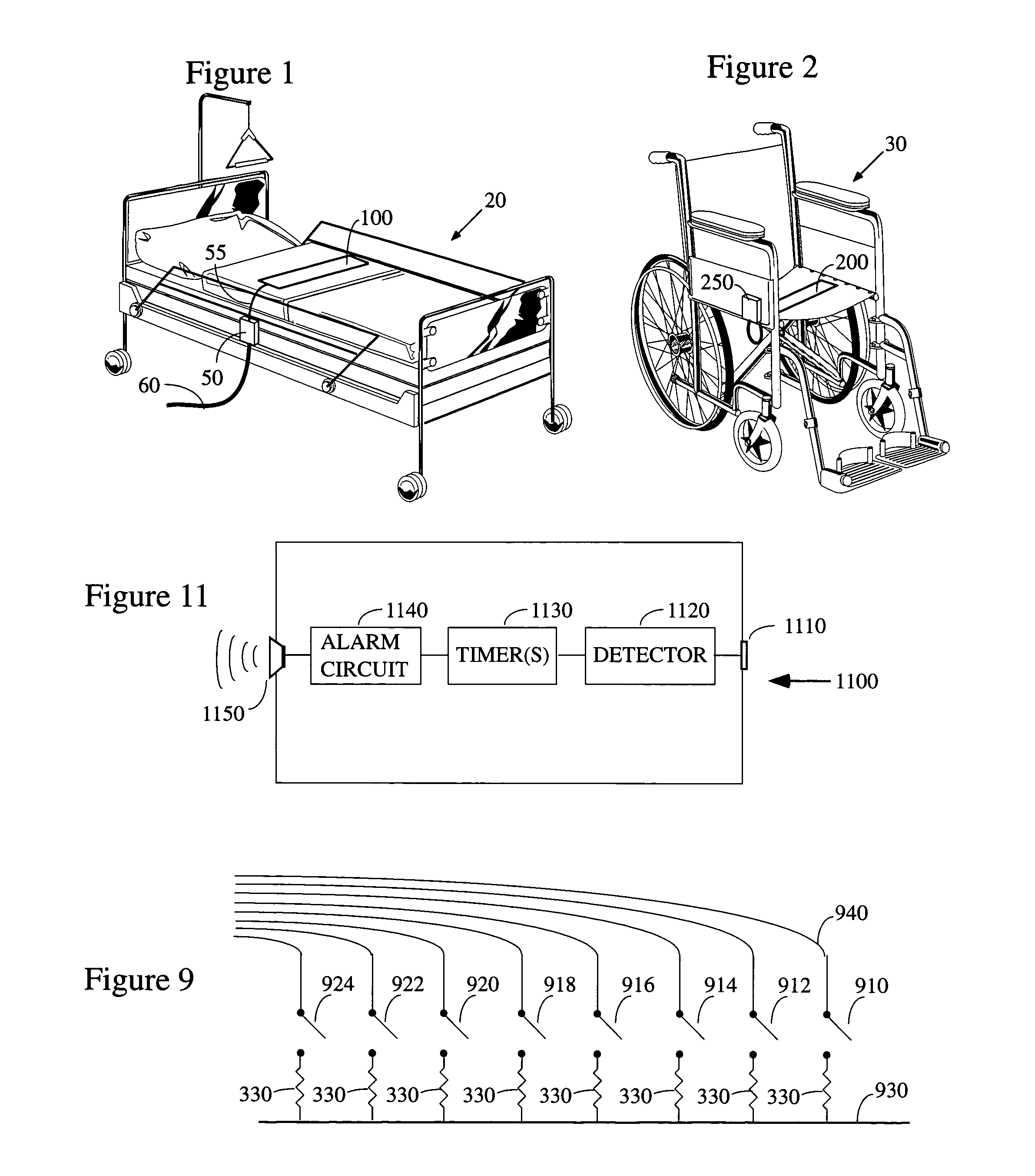

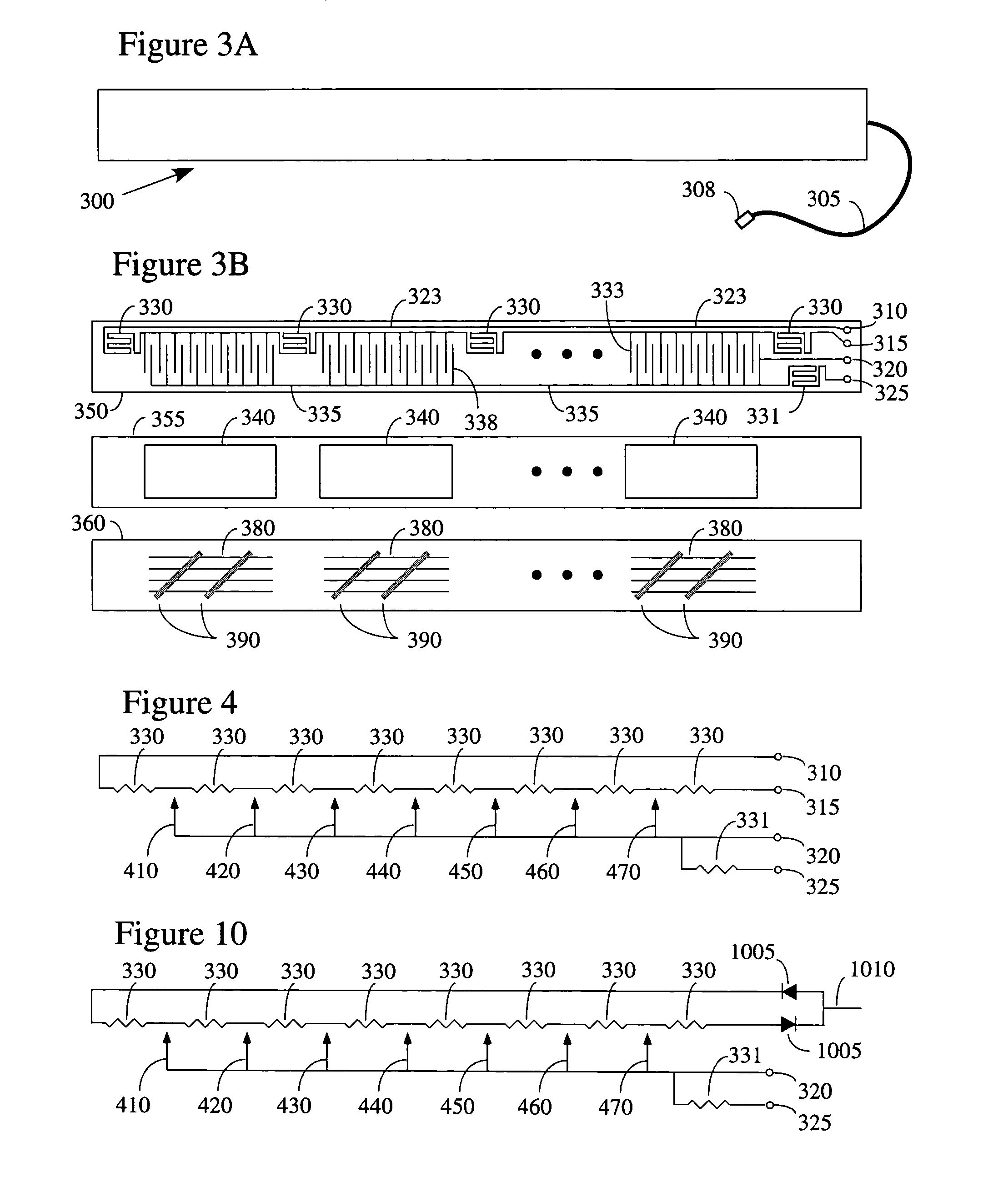

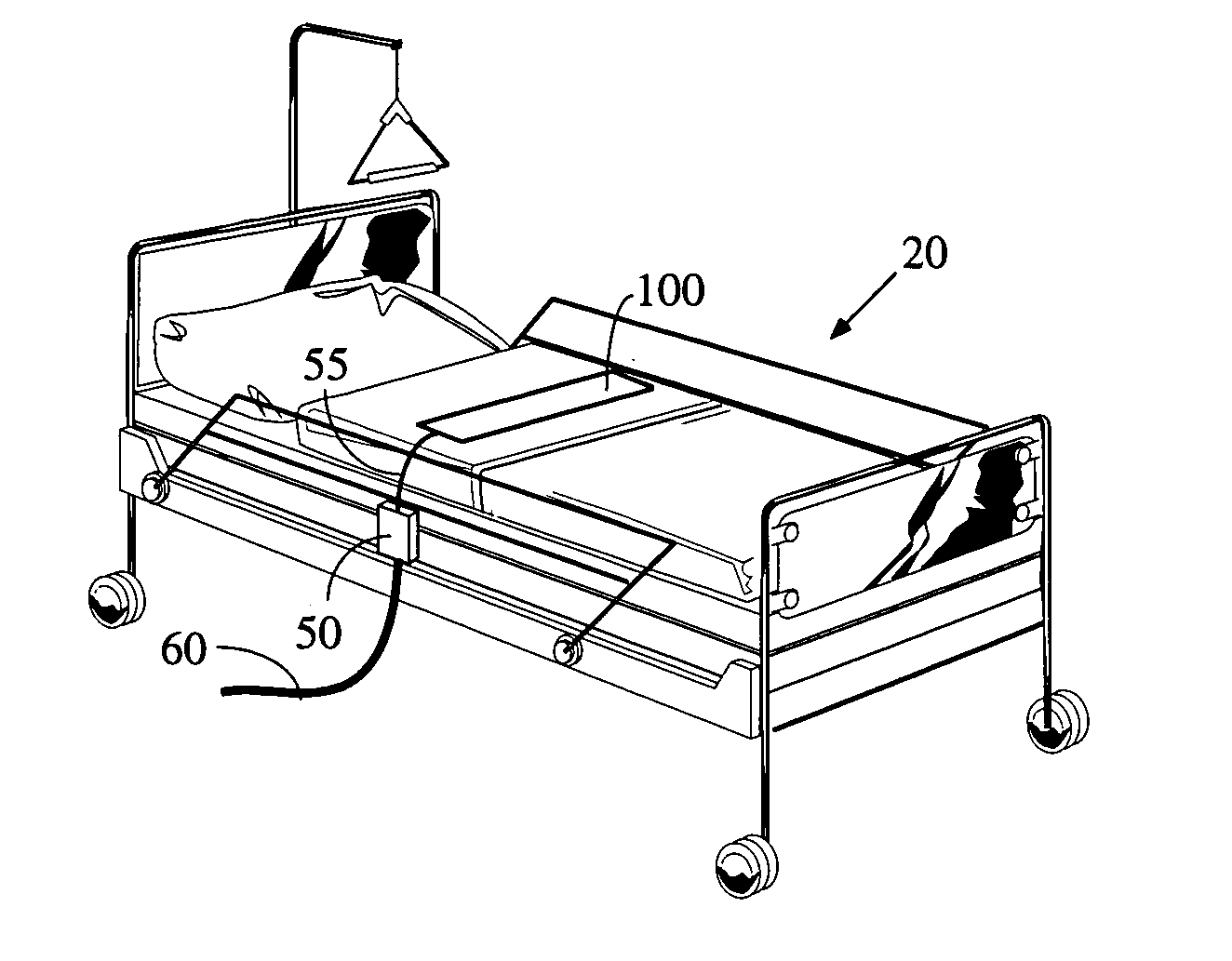

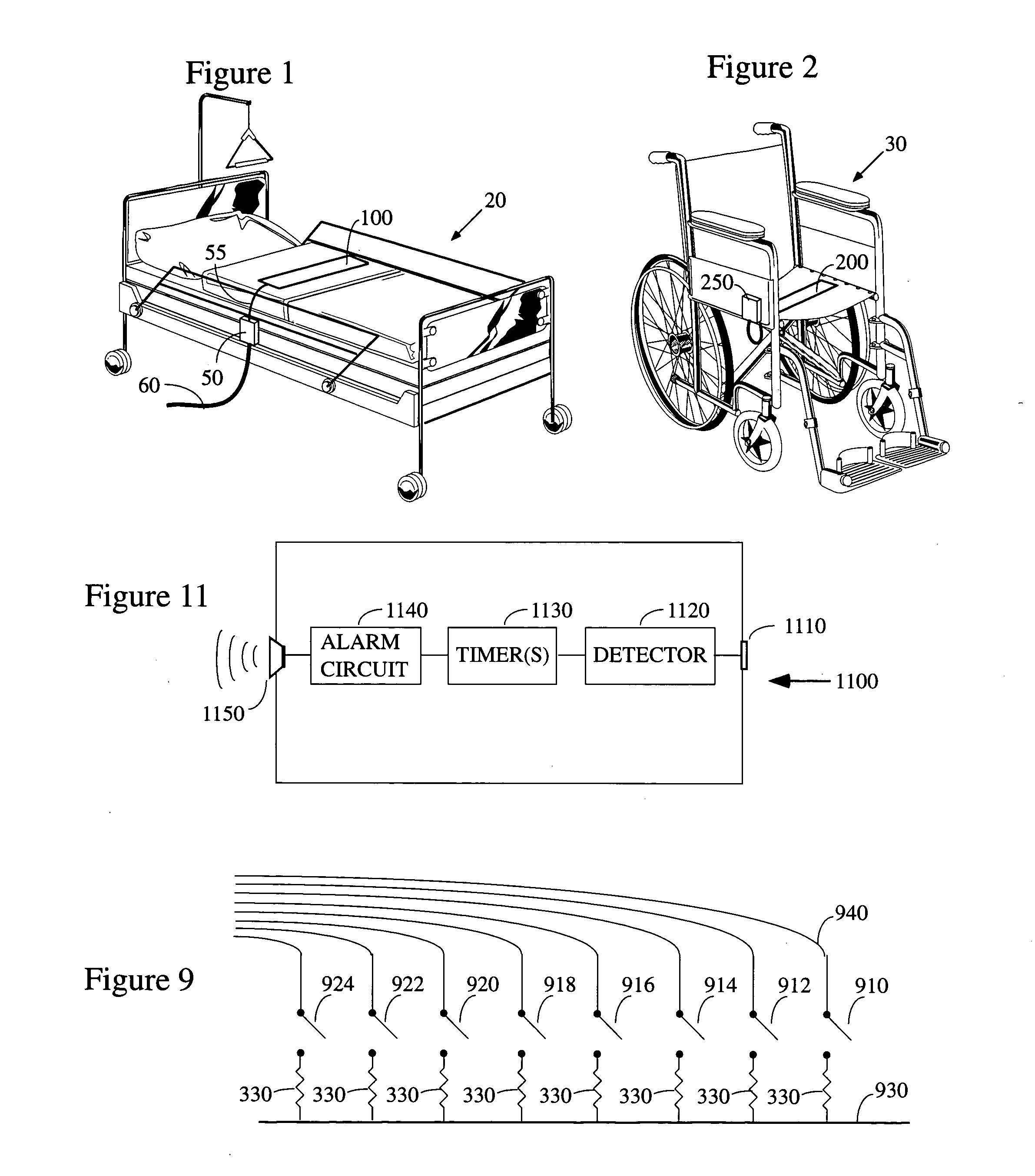

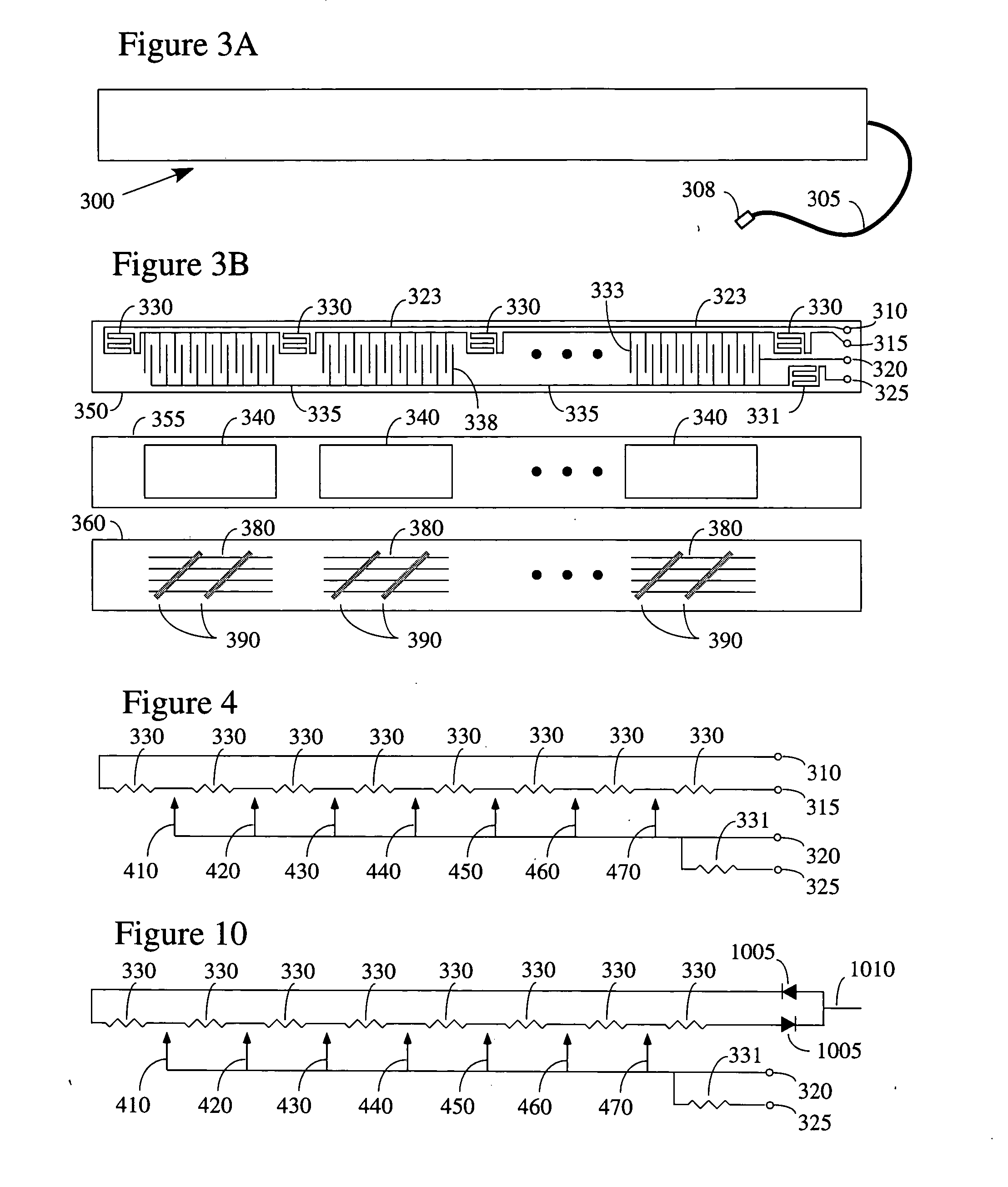

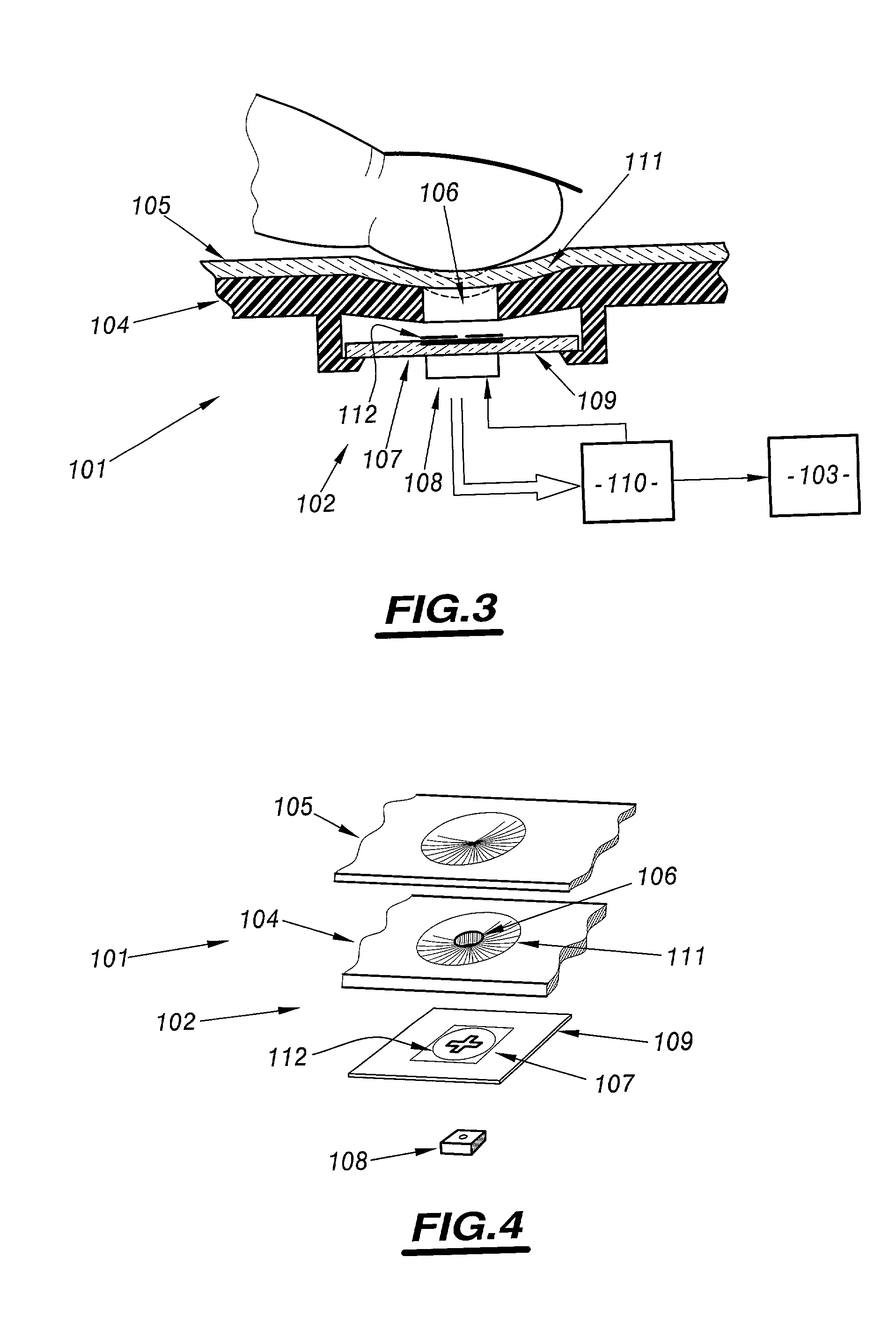

Sensor and method for detecting a patient's movement via position and occlusion

Owner:BED CHECK CORP

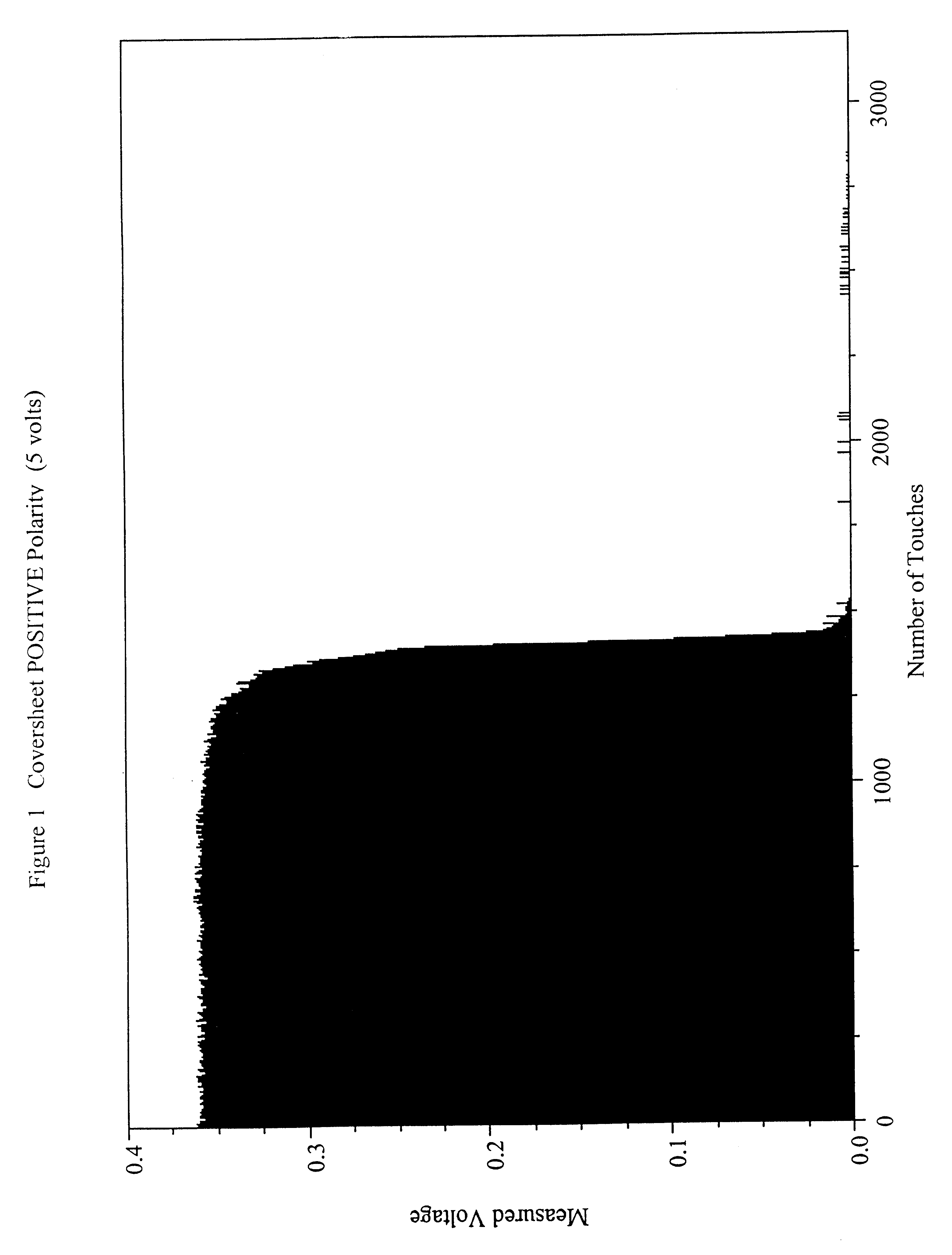

Switch with at least one flexible conductive member

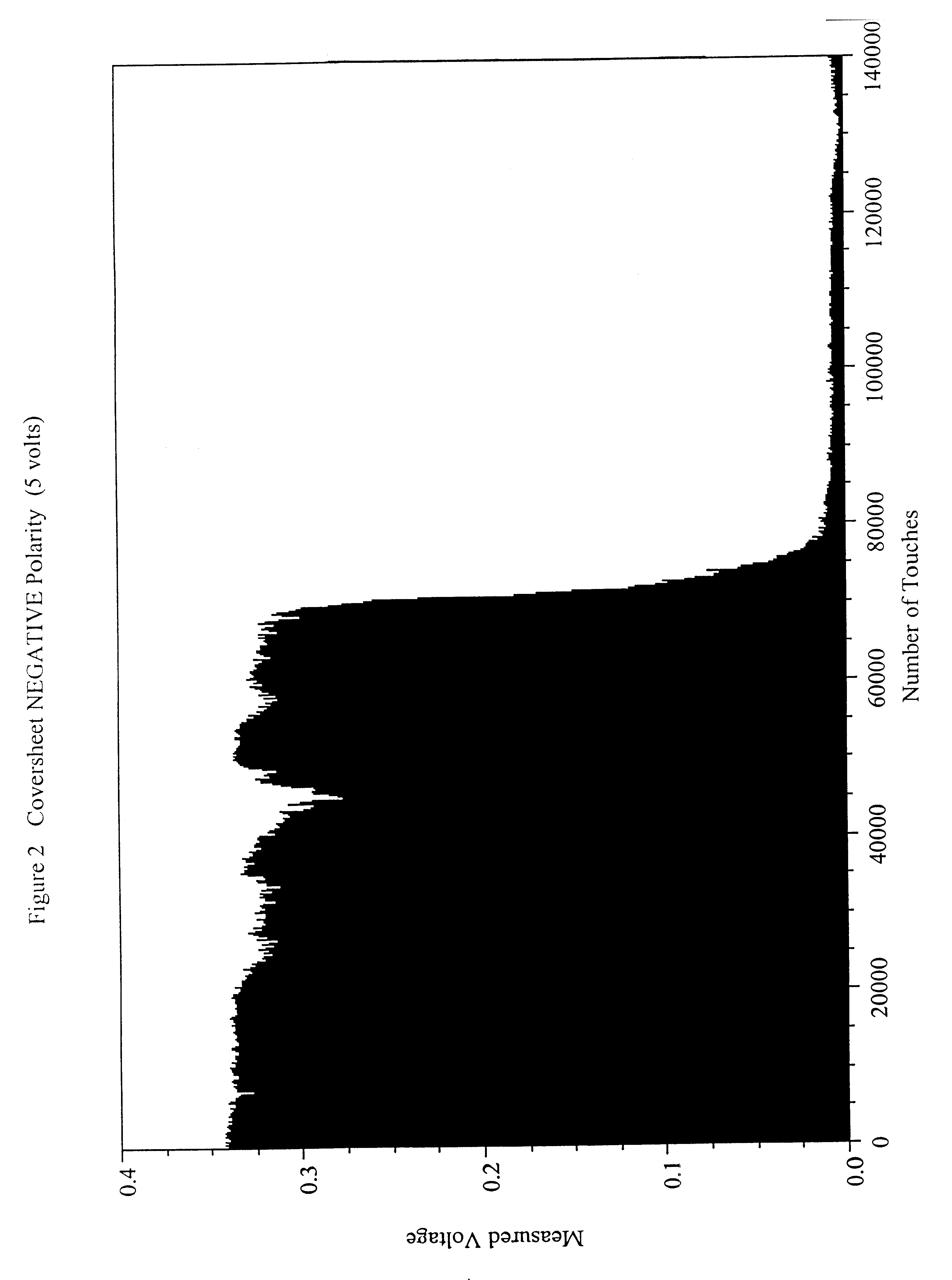

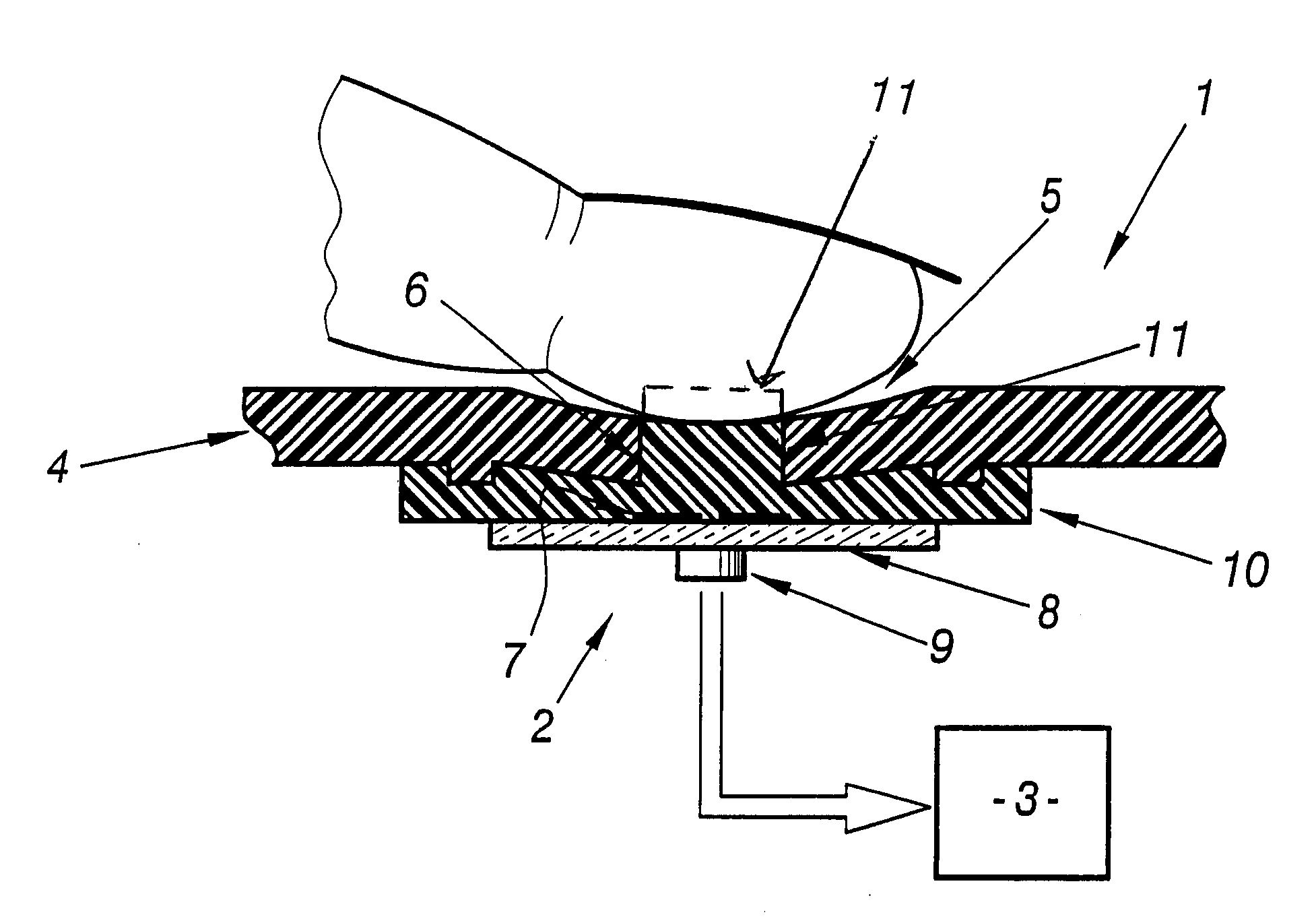

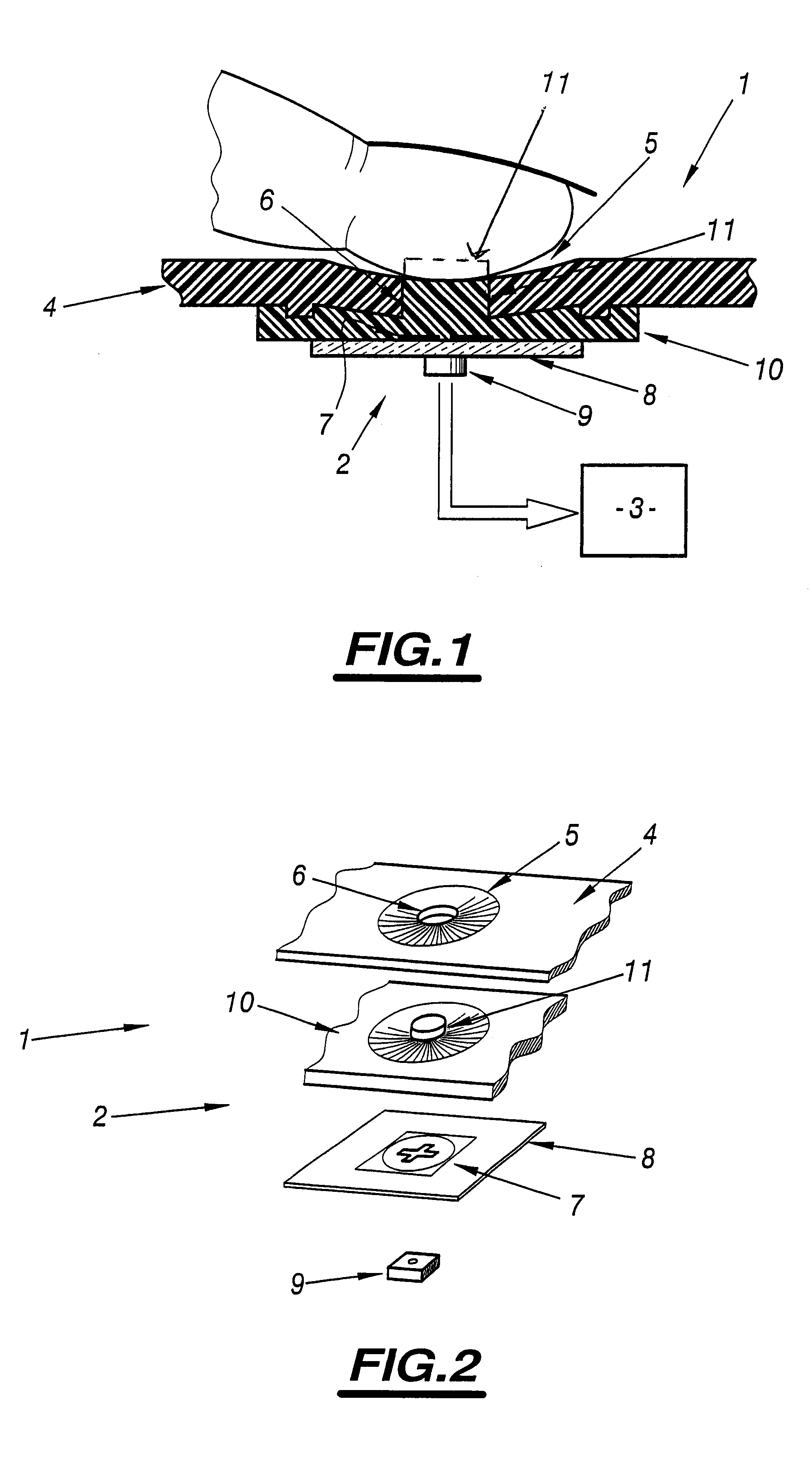

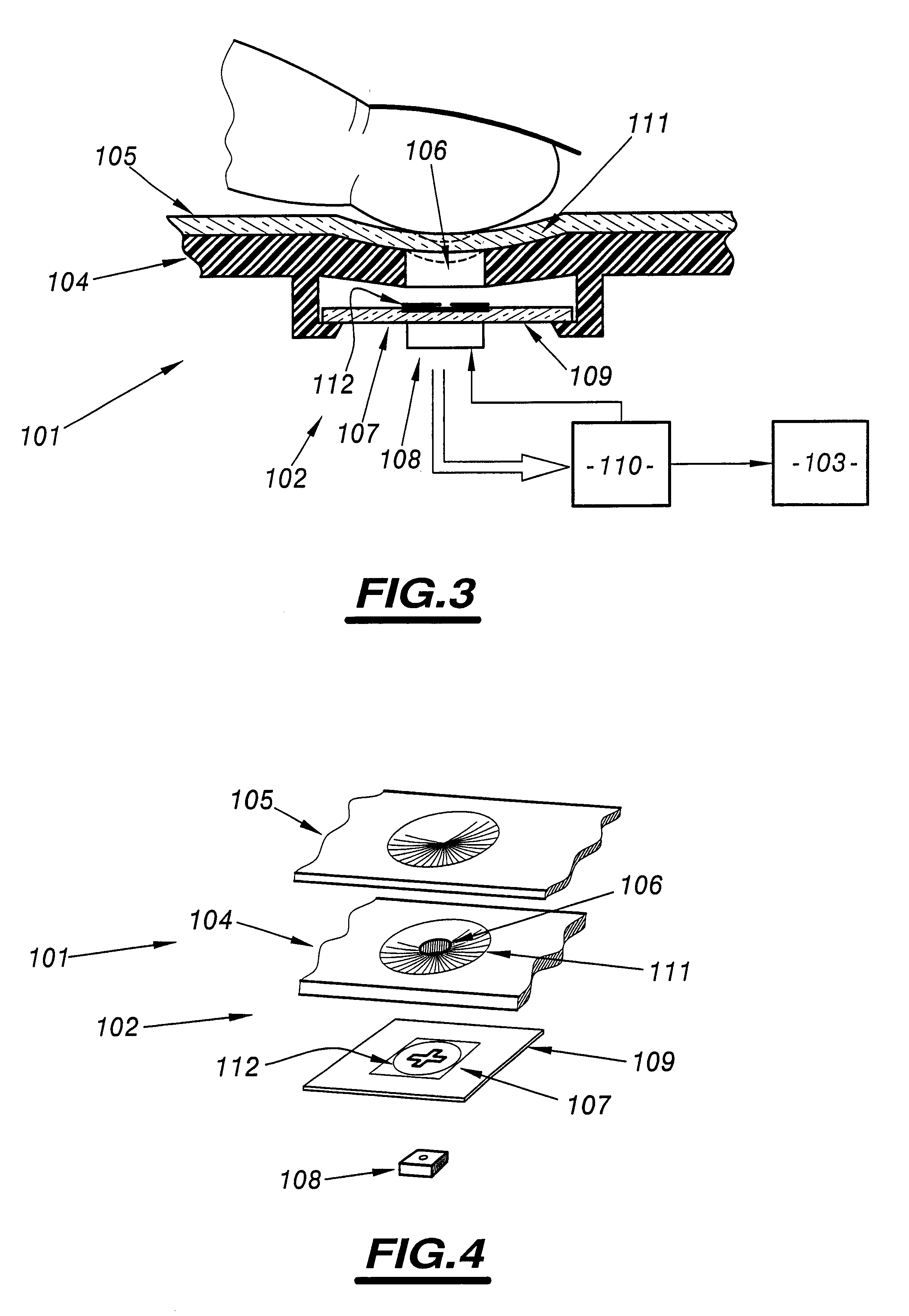

InactiveUS6469267B1Improve mechanical propertiesMaximize the benefitsContact materialsContact surface shape/structureConductive polymerElectrical polarity

A switch comprises two substrates coated with conductive elements opposed to each other across a gap. At least one of the conductive elements comprises an intrinsically conductive polymer. The switch completes an electrical circuit when one of substrates is pressed toward the other of the substrates and the two conductive elements touch. The polarity applied to the intrinsically conductive polymer coating is, preferably, negative. The voltage applied to the electrical circuit, is, preferably, less than five volts; more preferably, the voltage applied to the electrical circuit is less than three volts; even more preferably, the voltage applied to the electrical circuit is less than one volt.

Owner:ELO TOUCH SOLUTIONS INC +1

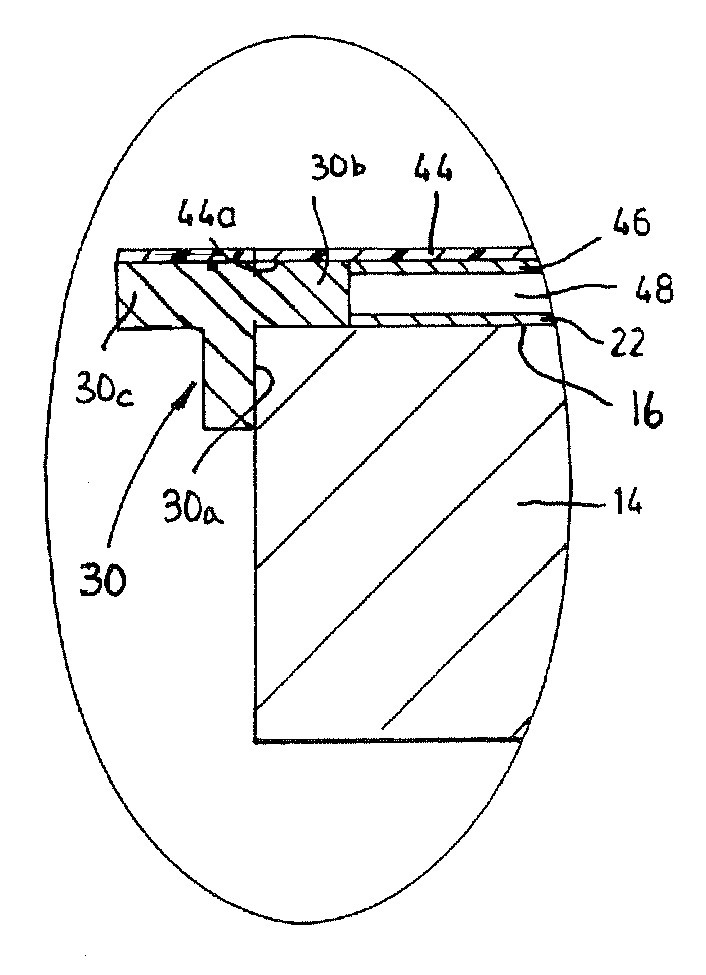

Switch with capacitive control member and pictogram

A control member of the capacitive type for controlling at least one functional member in particular of a motor vehicle, the control member including a rigid support structure, at least one capacitive touch-sensitive detection cell located on or close to one of the faces of the support structure, and at least one control operating zone located on or close to the other face of the support structure in registration with the capacitive touch-sensitive detection cell, wherein the control operating zone includes an elastically deformable part.

Owner:FAURECIA IND

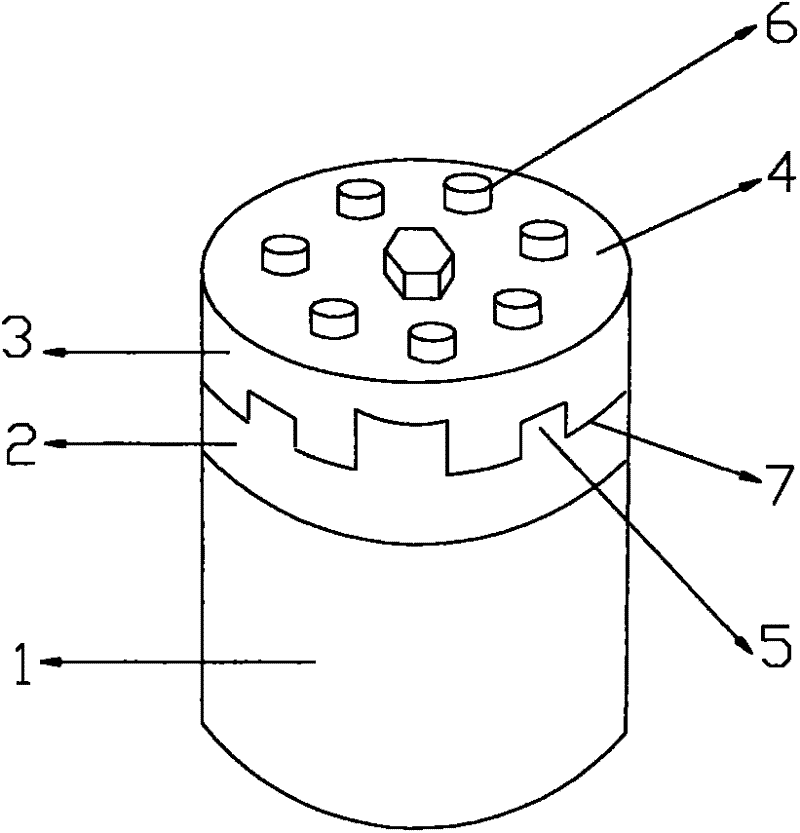

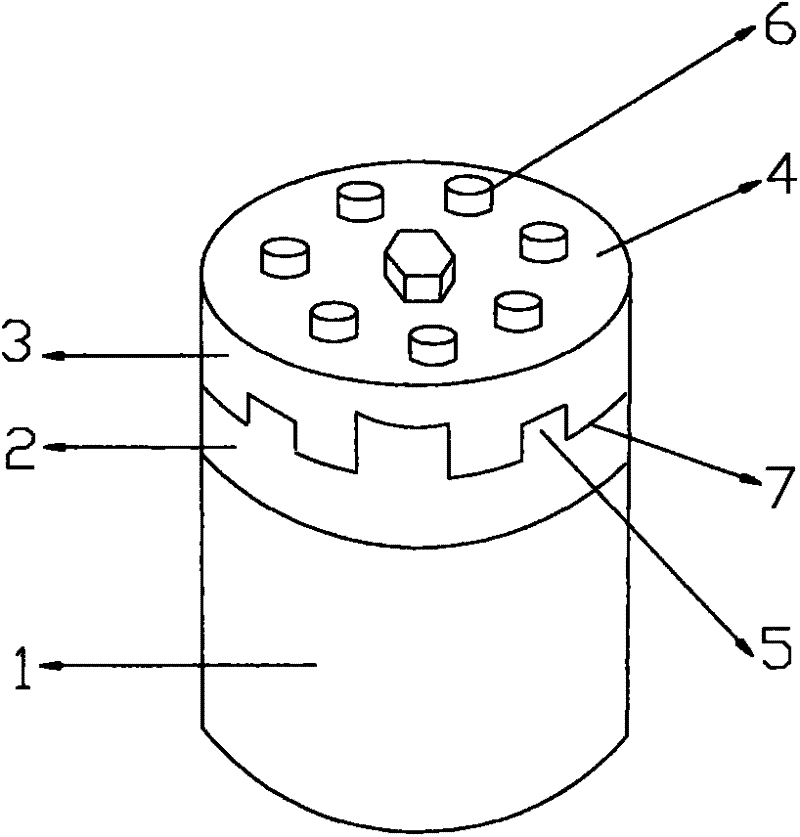

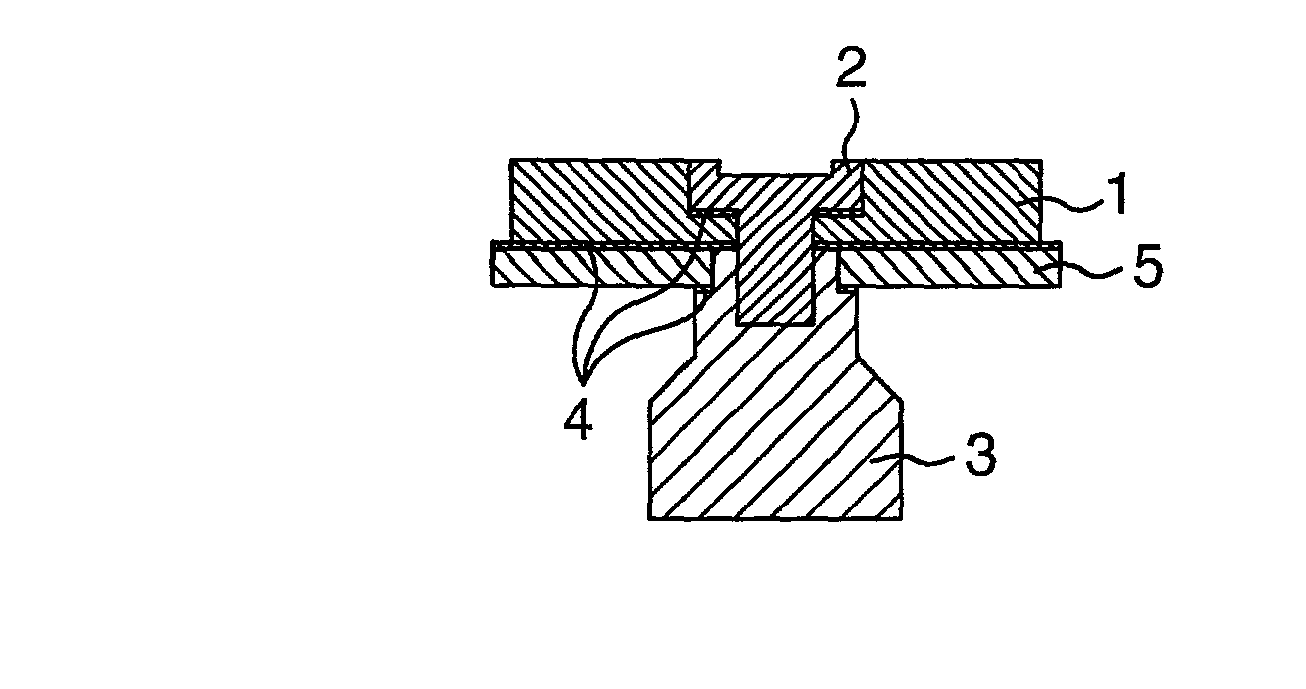

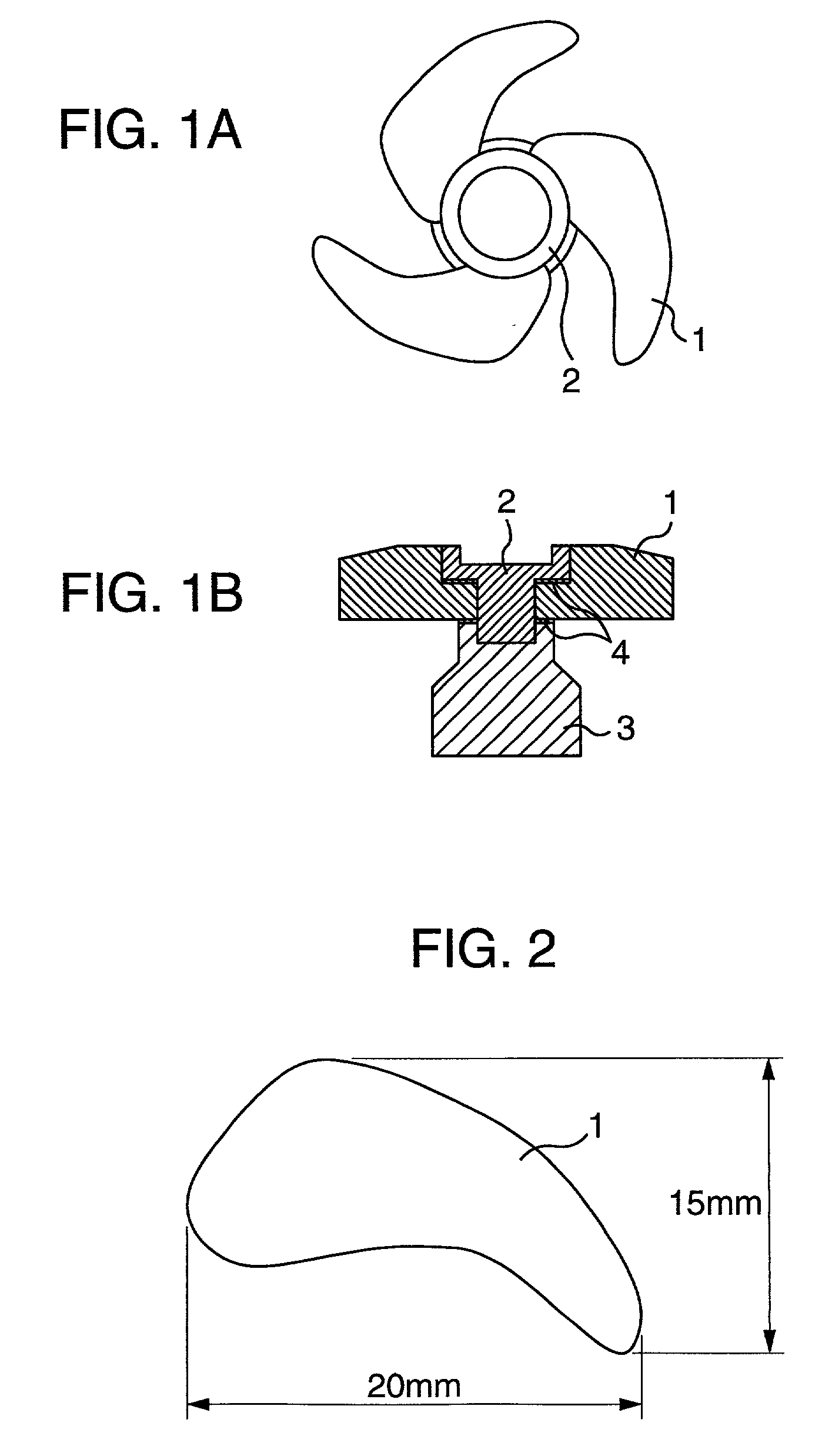

Electrode of a vacuum valve, a producing method thereof, a vacuum valve, a vacuum circuit-breaker and a contact point of the electrode

InactiveUS20020144977A1Improve circuit performanceWell formedContact materialsContact member manufacturingHigh conductivityMetal

The inventive electric contact point of a vacuum valve is made of a sintered alloy containing a heat-resistant metal and a high-conductivity metal. The contact point has at least three slit grooves which extend from the central region to the peripheral region of the contact point, and is soldered to an electrode rod which is connected to the contact point. The contact point includes at least three radially extending vane type contact point members each made of a sintered alloy containing a heat-resistant metal and a high-conductivity metal, and soldered to the electrode rod.

Owner:HITACHI LTD

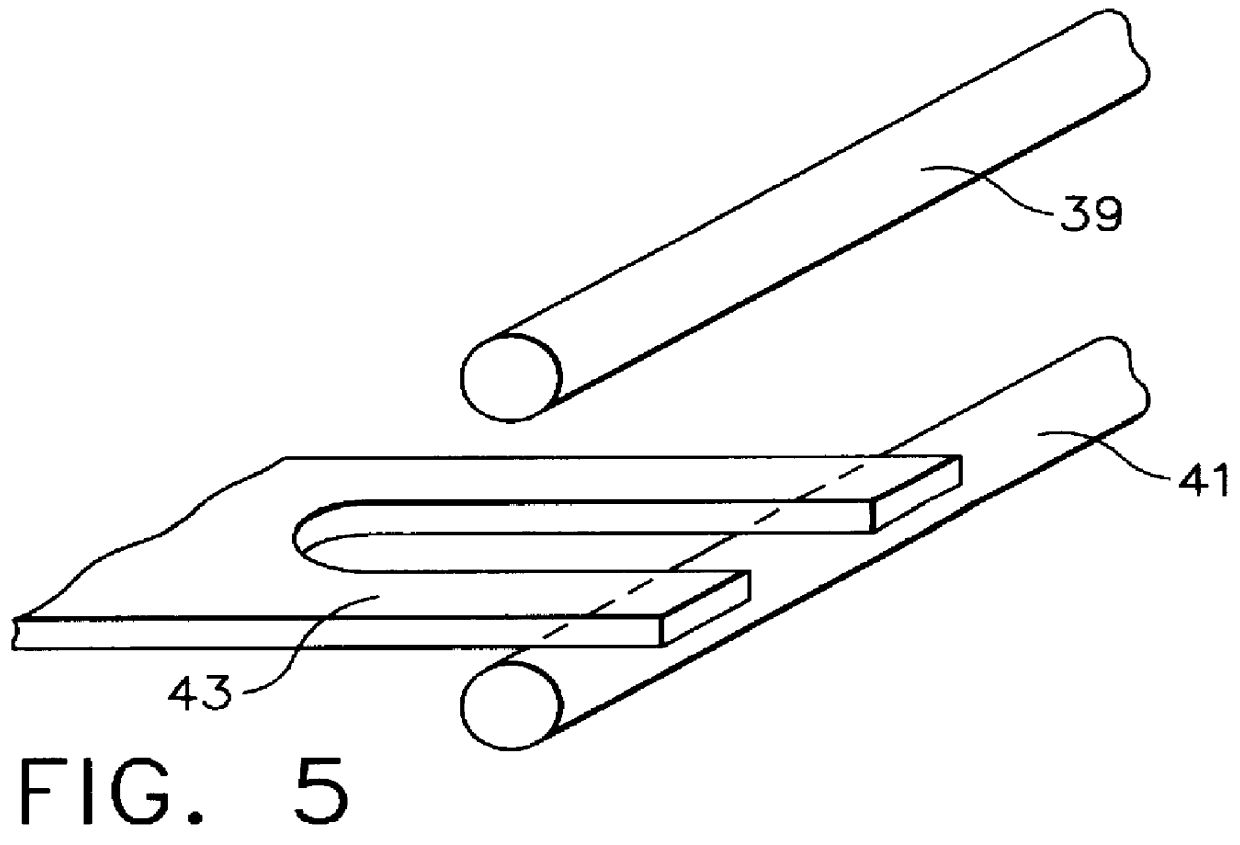

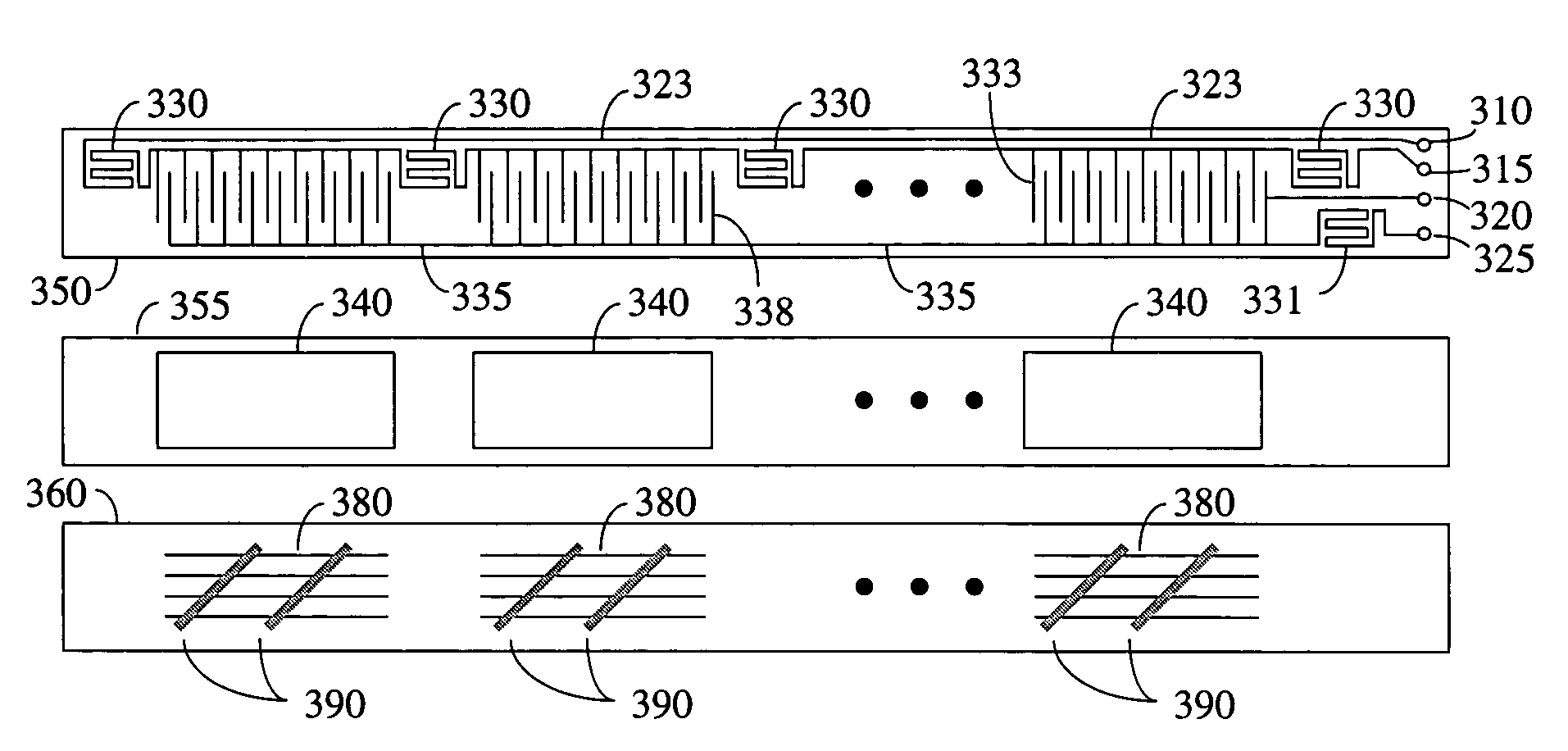

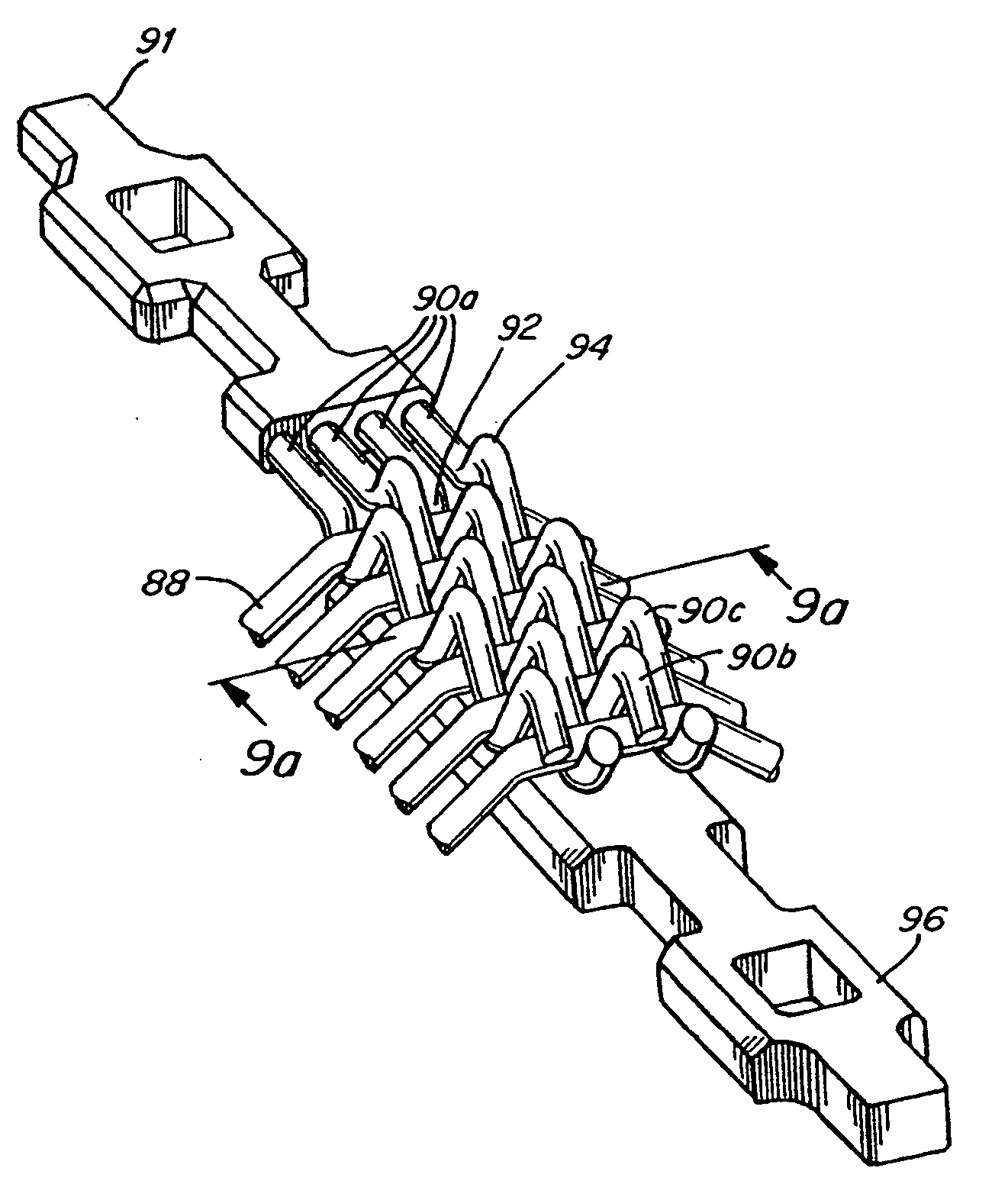

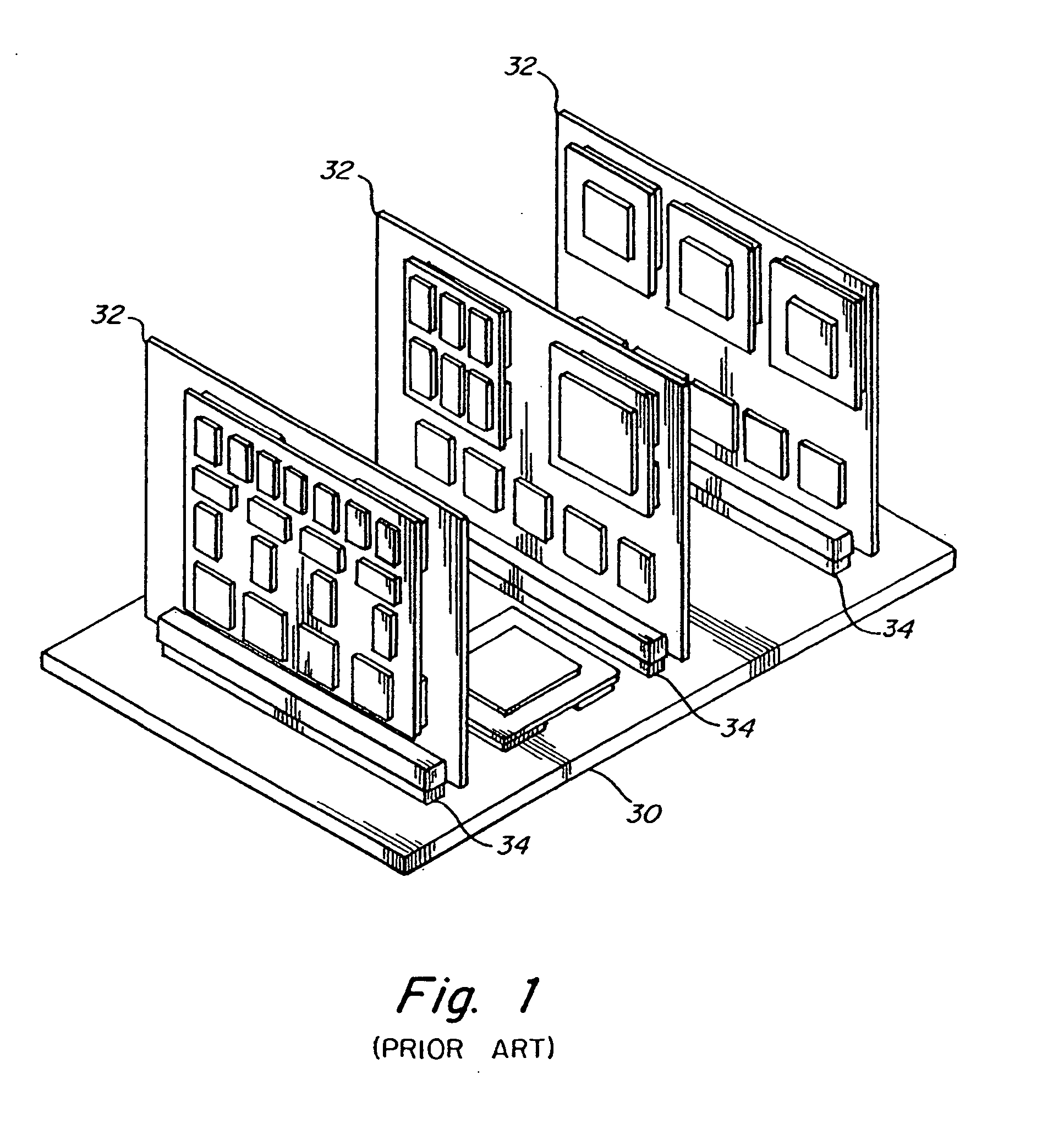

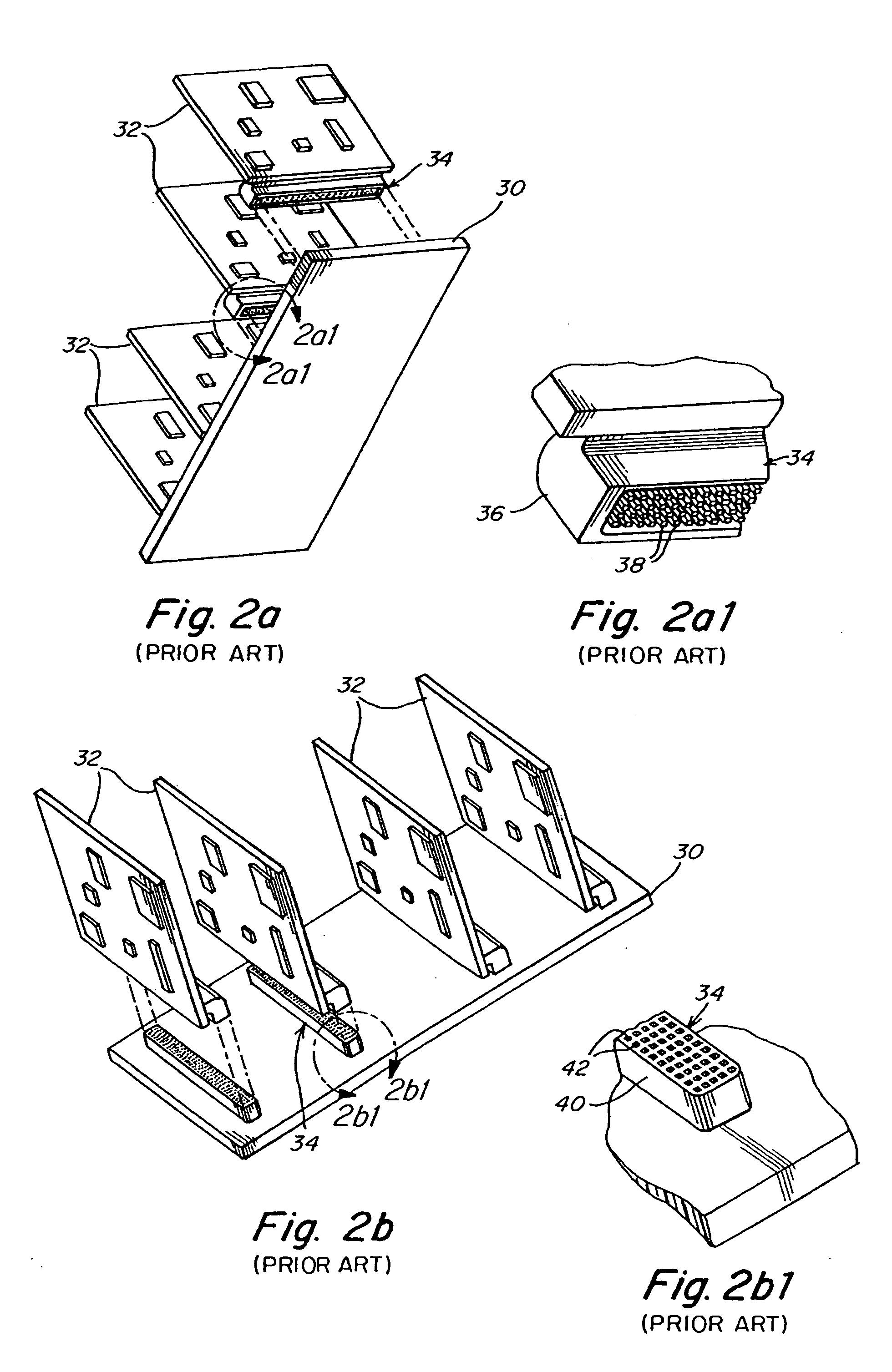

Multiple-contact woven electrical switches

The present disclosure is directed to electrical switches that utilize conductors that are woven onto loading fibers and a mating conductor that has a contact mating surface. Each conductor has at least one contact point. The loading fibers are capable of delivering a contact force at each contact point of the conductors. Electrical connections are established between the contact points of conductors and the contact mating surface of the mating conductor when the conductor-loading fiber weave is engaged with the mating conductor and the electrical connections are terminated when the conductor-loading fiber weave is disengaged from the mating conductor. In one embodiment, the portion of the contact mating surface of the mating conductor where arcing between the conductors and the mating conductor is expected to occur is plated with a conductive arc-tolerant material, such as silver, for example. In another embodiments, the portions of the conductors where arcing is expected to occur are plated with a conductive arc-tolerant material. In an alternate embodiment, the conductors are made thicker where arcing between the conductors and the mating conductor is expected to occur. The contact mating surface of the mating conductor can include a non-conductive portion that assists in guiding the conductor-loading fiber weave when its being engaged and disengaged from the mating conductor.

Owner:METHODE ELETRONICS INC

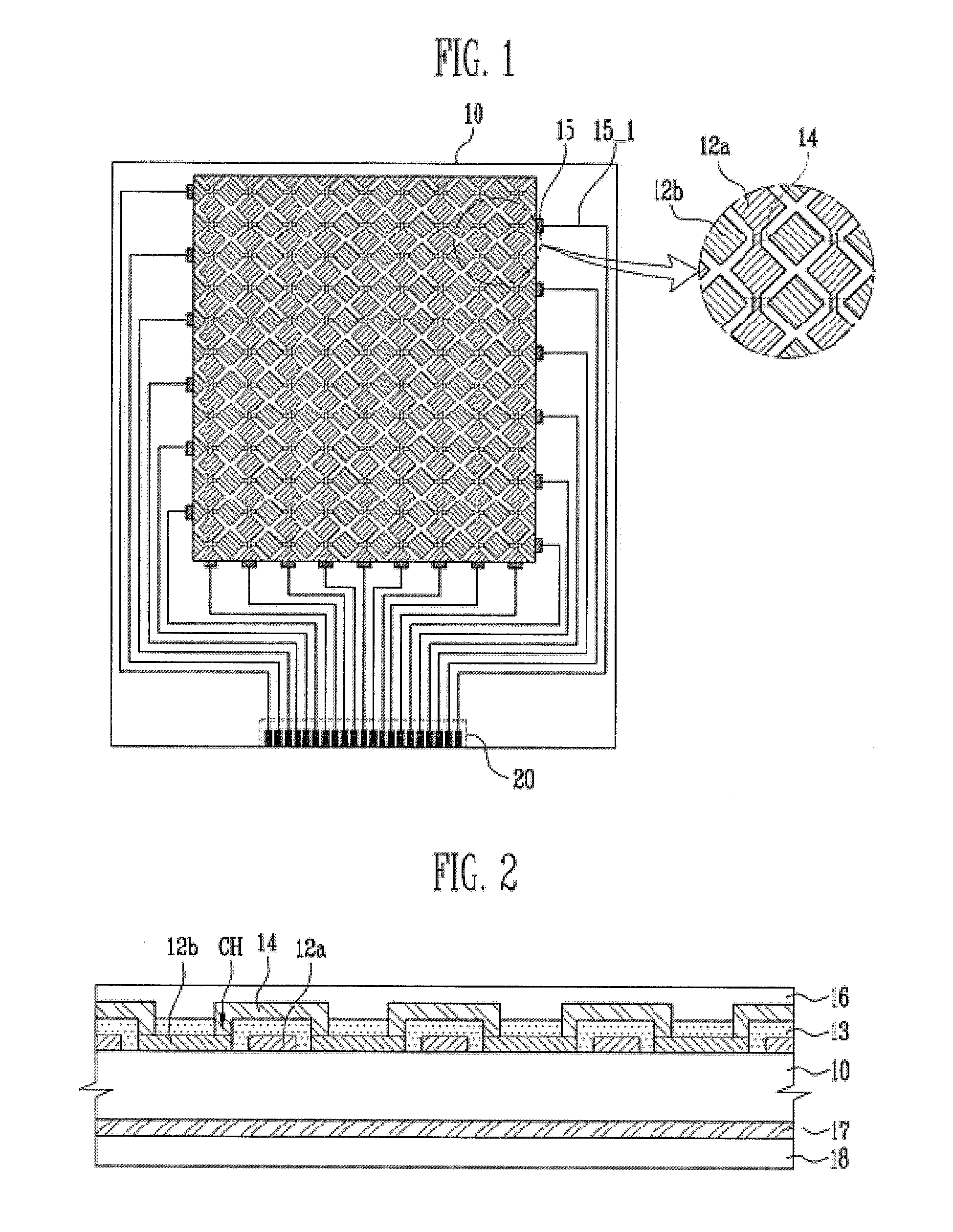

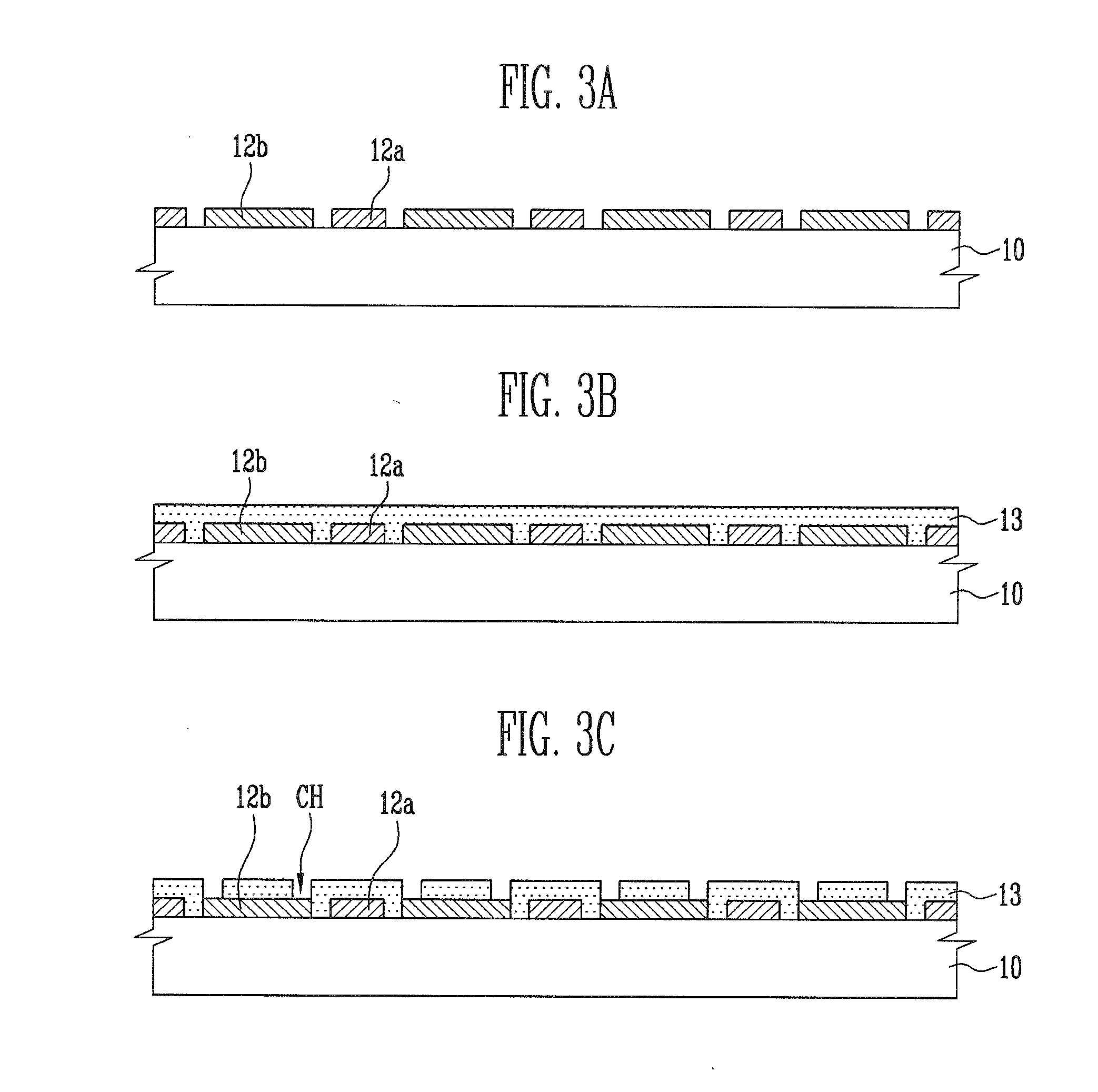

Touch screen panel and method of fabricating the same

InactiveUS20100182272A1Prevent and reduce damageReduce and prevent likelihoodContact materialsSemiconductor/solid-state device manufacturingPhotoresistComputer science

A touch screen panel for an image display device and a method of fabricating the same. The touch screen panel includes: a transparent substrate; a plurality of first and second sensing patterns on one side of the transparent substrate, the first sensing patterns coupled to one another along a first direction, and the second sensing patterns positioned between the first sensing patterns including patterns separated from one another; a first insulating layer on the first and second sensing patterns, the first insulating layer having a plurality of contact holes, and the contact holes exposing portions of the second sensing patterns; and connecting patterns on the first insulating layer, the connecting patterns coupling the second sensing patterns to one another along the second direction through the contact holes. In the touch screen panel, the first insulating layer is formed of a transparent photoresist.

Owner:SAMSUNG DISPLAY CO LTD

Nano silver-tin oxide electric contact and its prepn

InactiveCN1417817AImprove plasticityImprove conductivityContact materialsMetal/alloy conductorsRare earthTitanium oxide

The present invention belongs to metal-based composite material technology. The electric contact material consists of Ag 70-97 wt%, nanometer tin oxide 3-22 wt% and RE elements 0.1-8 wt%. The electric contact is produced through the processes of preparation of zine oxide or titanium oxide doped nanometer tin oxide, mixing metal oxide powder, pressing the mixture to form, sintering, extruding, drawing wire and forming into rivet type or stripe contact. The pressure in pressing the mixture to form is 150-400 MPa and the sintering temperature is 800-900 deg.c. The electric contact can be used inelectric appliance, instrument and switch.

Owner:TIANJIN UNIV

Gas sensor and its method of manufacture

InactiveUS7022213B1Reduce manufacturing costLess-prone to leakingContact materialsPretreated surfacesElectrolyte leakageElectricity

The invention relates to a gas sensor and its method of manufacture.Electrochemical gas sensors usually comprise an external housing, which acts as a reservoir for electrolyte; a wick to keep electrodes wetted with the electrolyte and external electrical terminals, for making electrical contact with the electrodes. Typically a gas permeable / microporous membrane has been used to seal a gas sensor in order to prevent leakage of electrolyte. A problem with existing sensors has been that there was a risk of electrolyte leaking through the membrane around the region where electrical connectors passed therethrough.The present invention overcomes this by providing a method of urging conductive polymer through the membrane under controlled conditions of heat and pressure, thereby ensuring the integrity of the membrane remains in tact while defining an electrically / conductive pathway therethrough.

Owner:INVENSYS CONTROLS UK

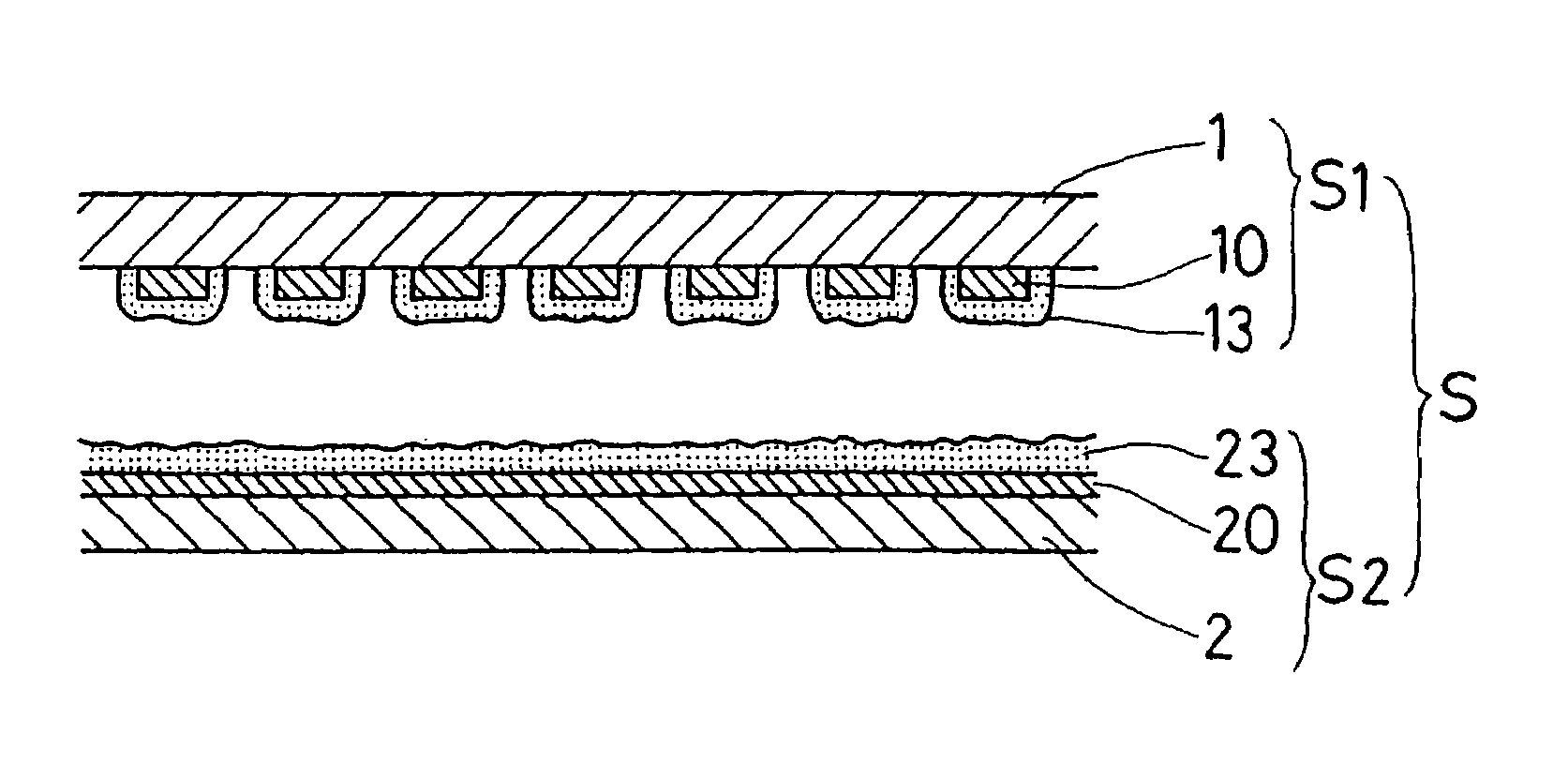

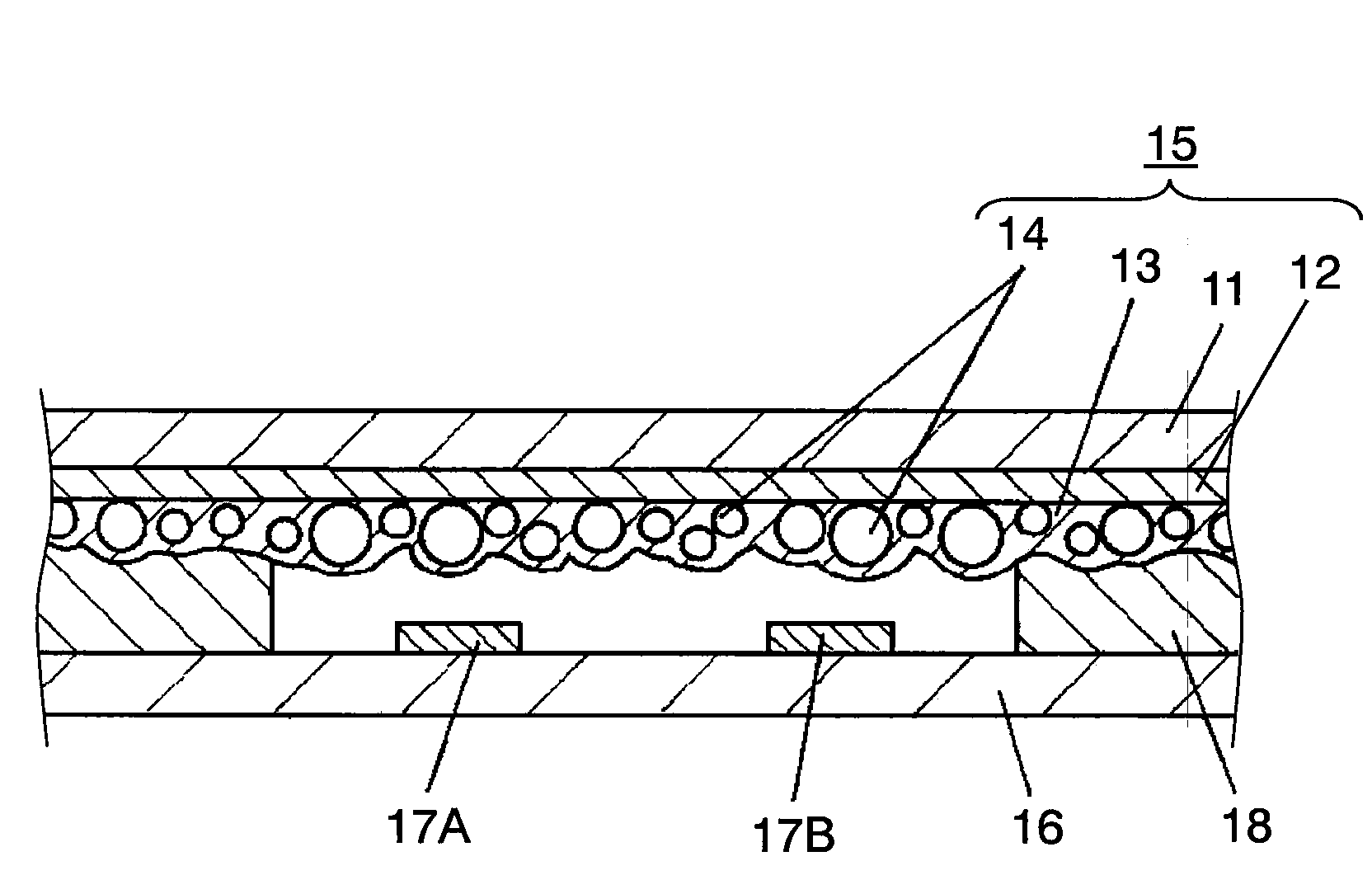

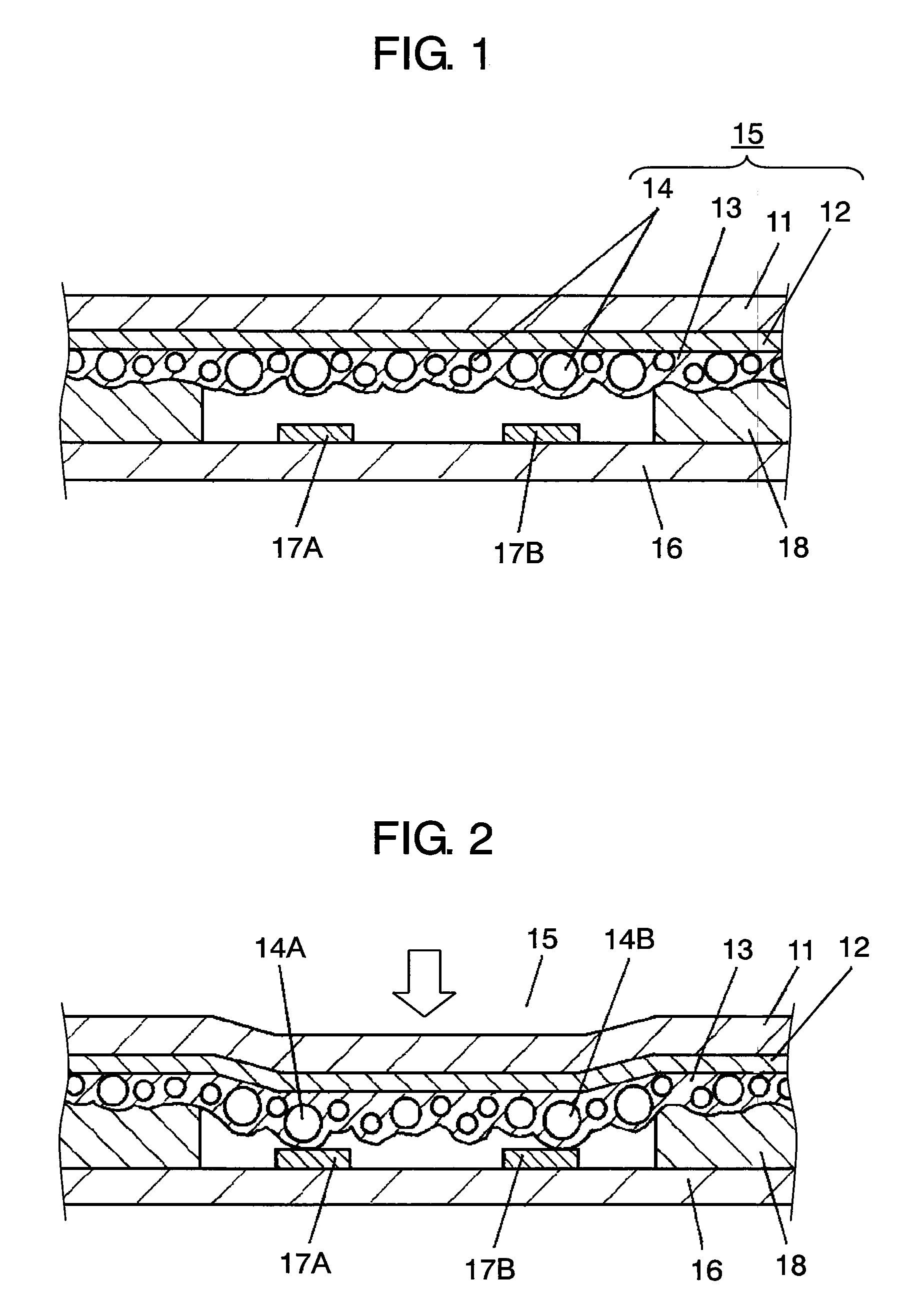

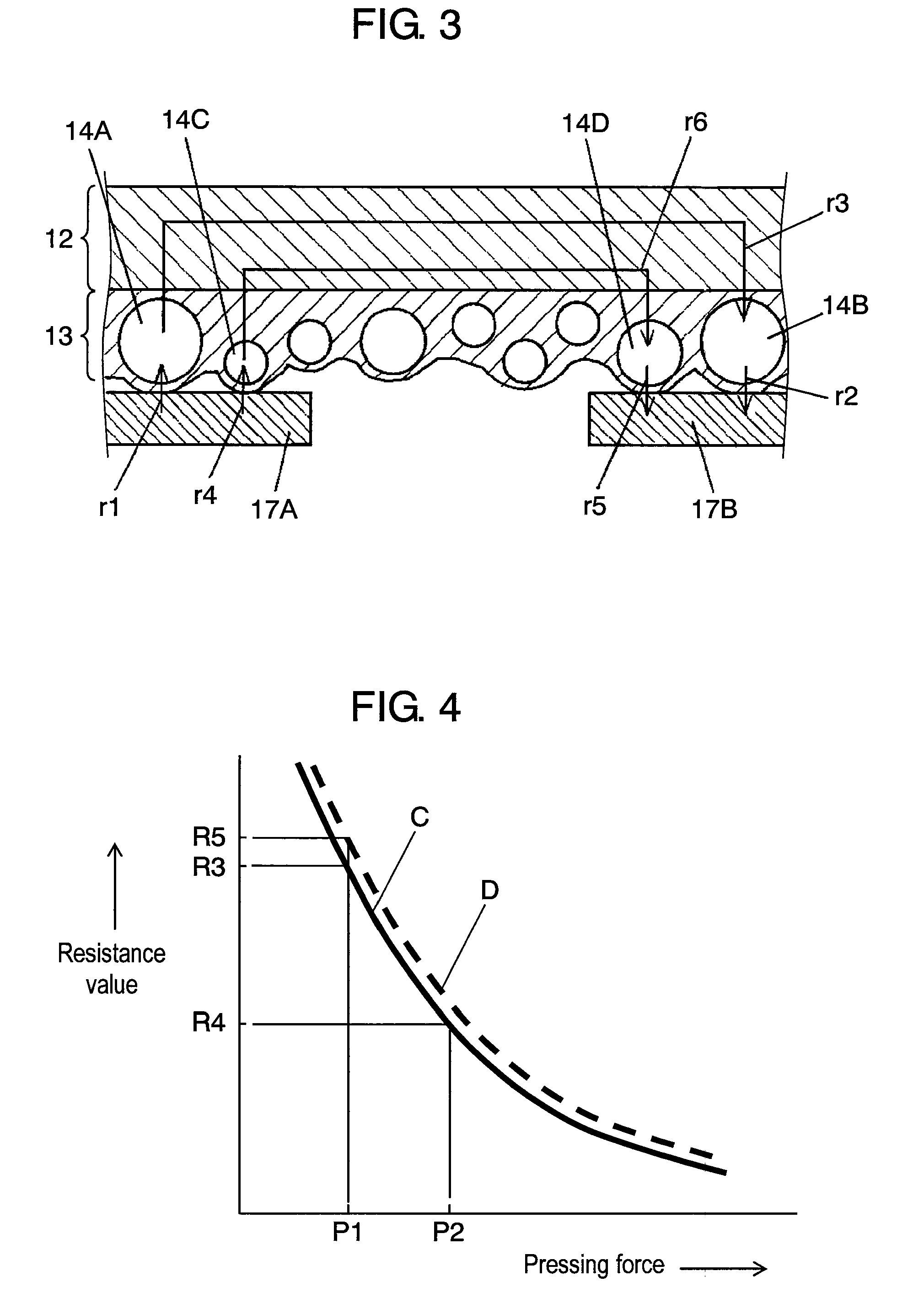

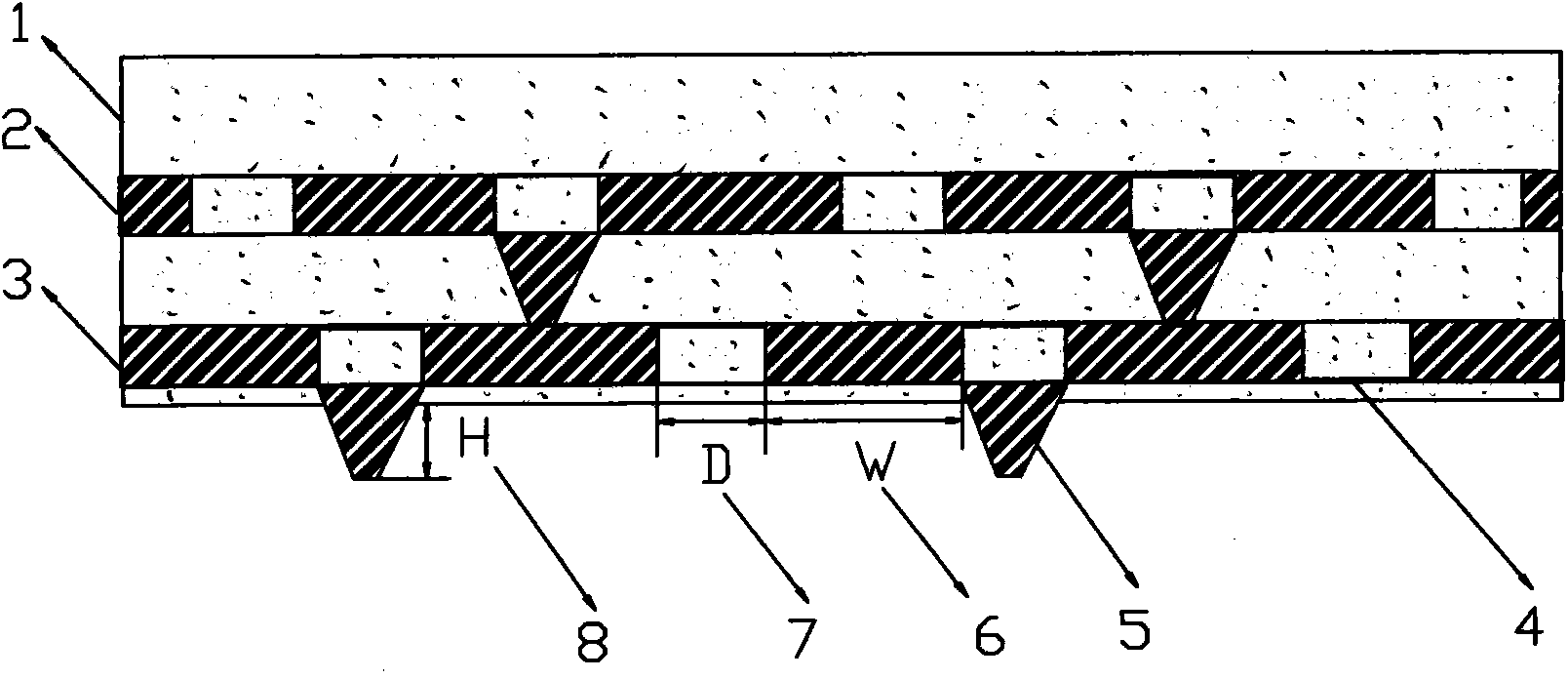

Pressure sensitive conductive sheet and panel switch using same

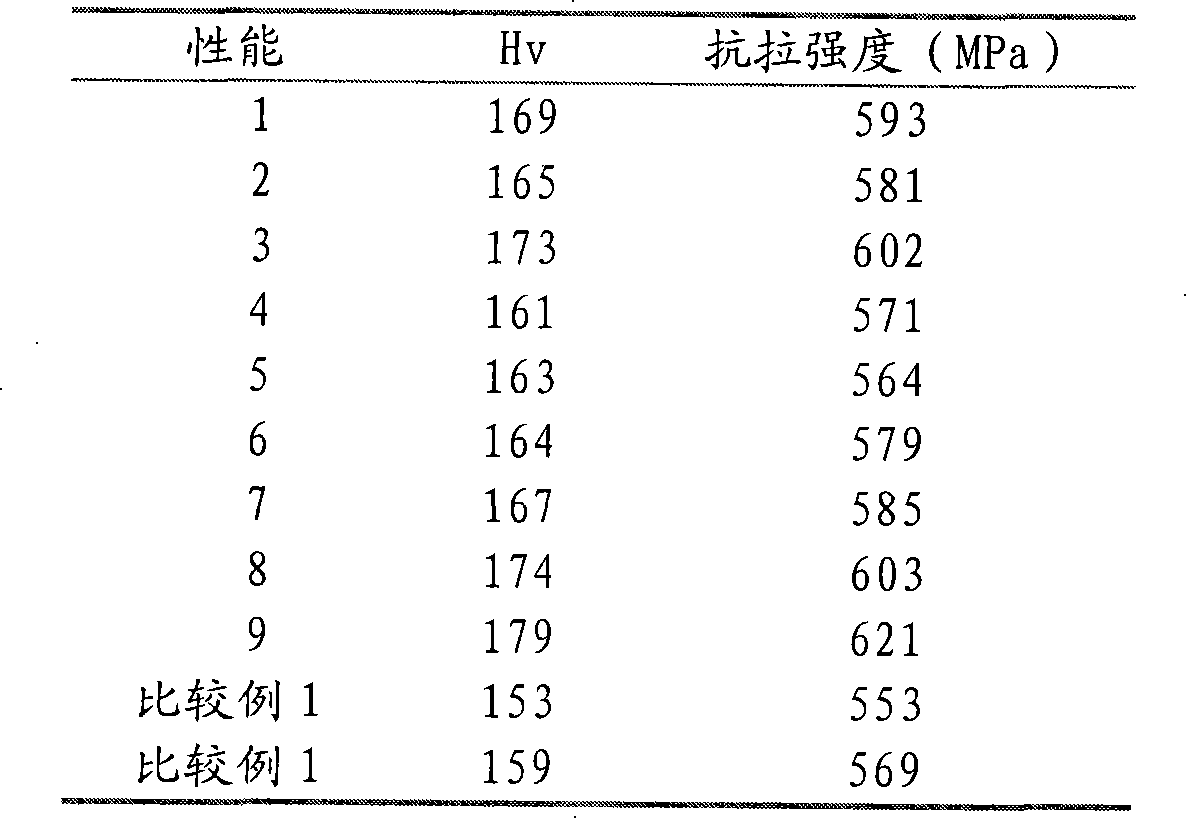

InactiveUS7528337B2Reduce thicknessLittle changeContact materialsContact surface shape/structureElectrical connectionEngineering

A first resistor layer is formed on the lower surface of a base in film form, and at the same time, a second resistor layer in which particles of different particle diameters are dispersed is formed and layered on the lower surface of the first resistor layer, and thus, a pressure sensitive conductive sheet is formed. In this configuration, the second resistor layer in uneven form makes contact with the fixed contacts in accordance with a pressing force so that electrical connection is made via the second resistor layer and the first resistor layer, and therefore, a thin panel switch with little fluctuation in the resistance value resulting from repeated operation where a stable resistance value can be gained can be realized.

Owner:PANASONIC CORP

Sensor and method for detecting a patient's movement via position and occlusion

There is provided herein a sensor for use in connection with an electronic patient monitor, wherein the sensor preferably uses a linearly configured resistive ladder with spaced-apart resistors as a means of determining at least approximately a location of the patient on the sensor as well as an approximate length of the sensor which is compressed by the patient. By continuously determining both of these quantities over time it is possible to track the patient's movement and determine to what extent the patient needs to be manually turned and / or the extent to which a next-scheduled turn can be skipped.

Owner:BED CHECK

Contact material

InactiveUS6210809B1Reduce incidenceLower average currentContact materialsDomestic articlesChemical compoundSolid solution

The contact material of the present invention comprises: an anti-arcing constituent consisting of at least one TiC, V and VC of which the content is 30~70 volume % and whose mean particle (grain) size is 0.1~9 mum; C whose content is 0.005~0.5 weight % with respect to the anti-arcing constituent, whose diameter is 0.01~5 mum when its shape is calculated as spherical, and which is in non-solid solution condition or condition in which it does not form a chemical compound; and a conductive constituent consisting of Cu and constituting the balance.

Owner:KK TOSHIBA

Capacitive control member for a functional member in particular of a motor vehicle, and a piece of equipment including such a member

A control member of the capacitive type for controlling at least one functional member in particular of a motor vehicle, the control member comprising a rigid support structure, at least one capacitive touch-sensitive detection cell located on or close to one of the faces of said support structure, and at least one control operating zone located on or close to the other face of said support structure in register with said capacitive touch-sensitive detection cell, wherein the control operating zone includes elastically deformable means.

Owner:FAURECIA IND

Metal oxide blended silver-tin dioxide electric contactor material and its preparing method

The present invention belongs to the preparation techonlogy of electric alloy material. The electric contactor material consists of Ag 85-90 wt%, SnO2 5-20 wt% and blended metal oxide 0.5-8 wt%. The blended metal oxide is ZrO2, ZnO, TiO2, MnO2, WO3 or Sb2O3. The electric contactor material is prepared through coating oxide through chemical plating with plating liquid with dispersant, mixing the coated pwoder and silver powder, pressing, sintering, hot extruding, cold drawing or cold rolling, and making rivet or punched product. The present invention has the features of homogeneous oxide dispersion, good fusion welding resistance, high arc corrosion resistance and less electric transfer. The production process is simple, practical, low in cost and suitable for large scale production.

Owner:TIANJIN UNIV

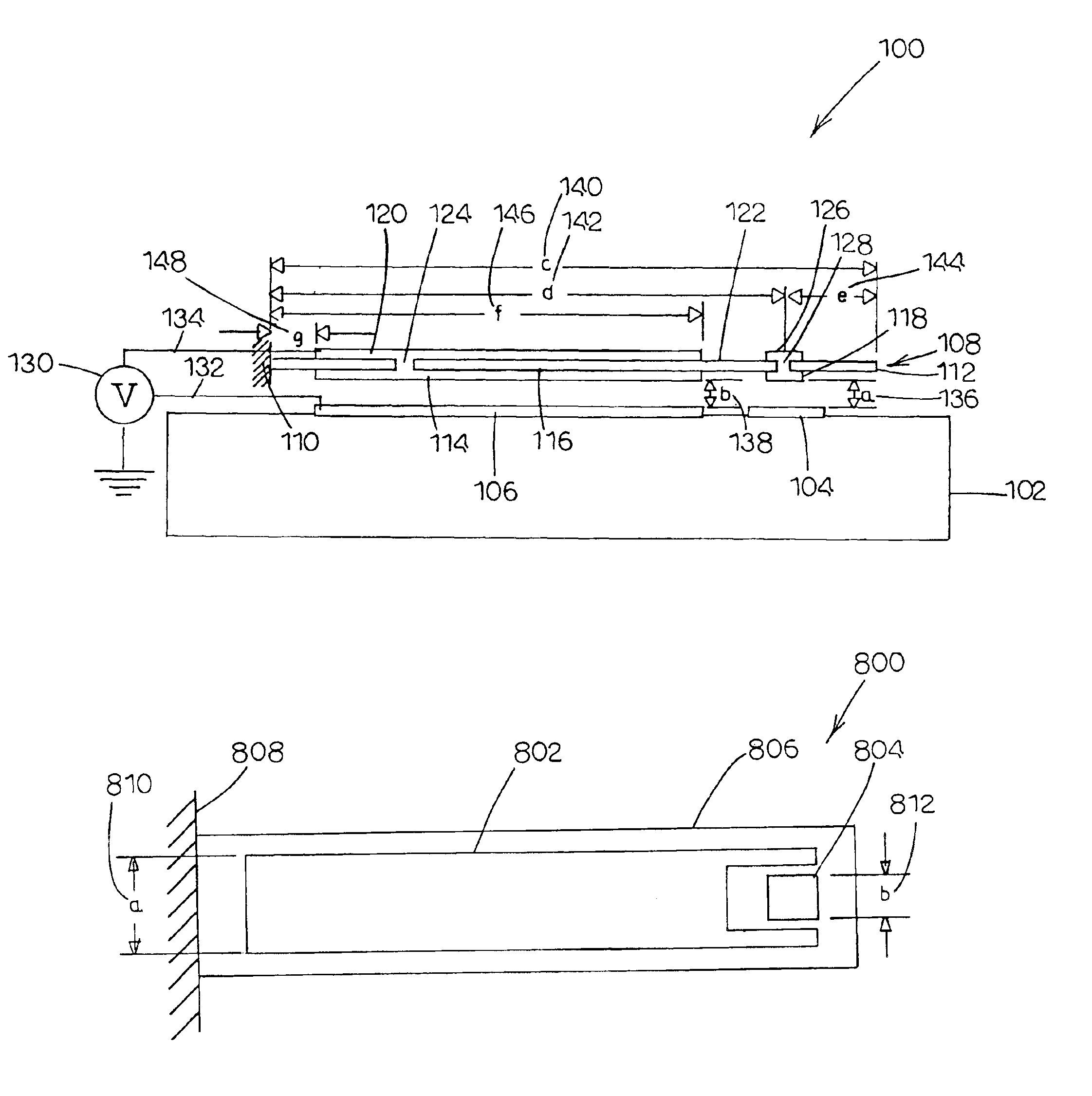

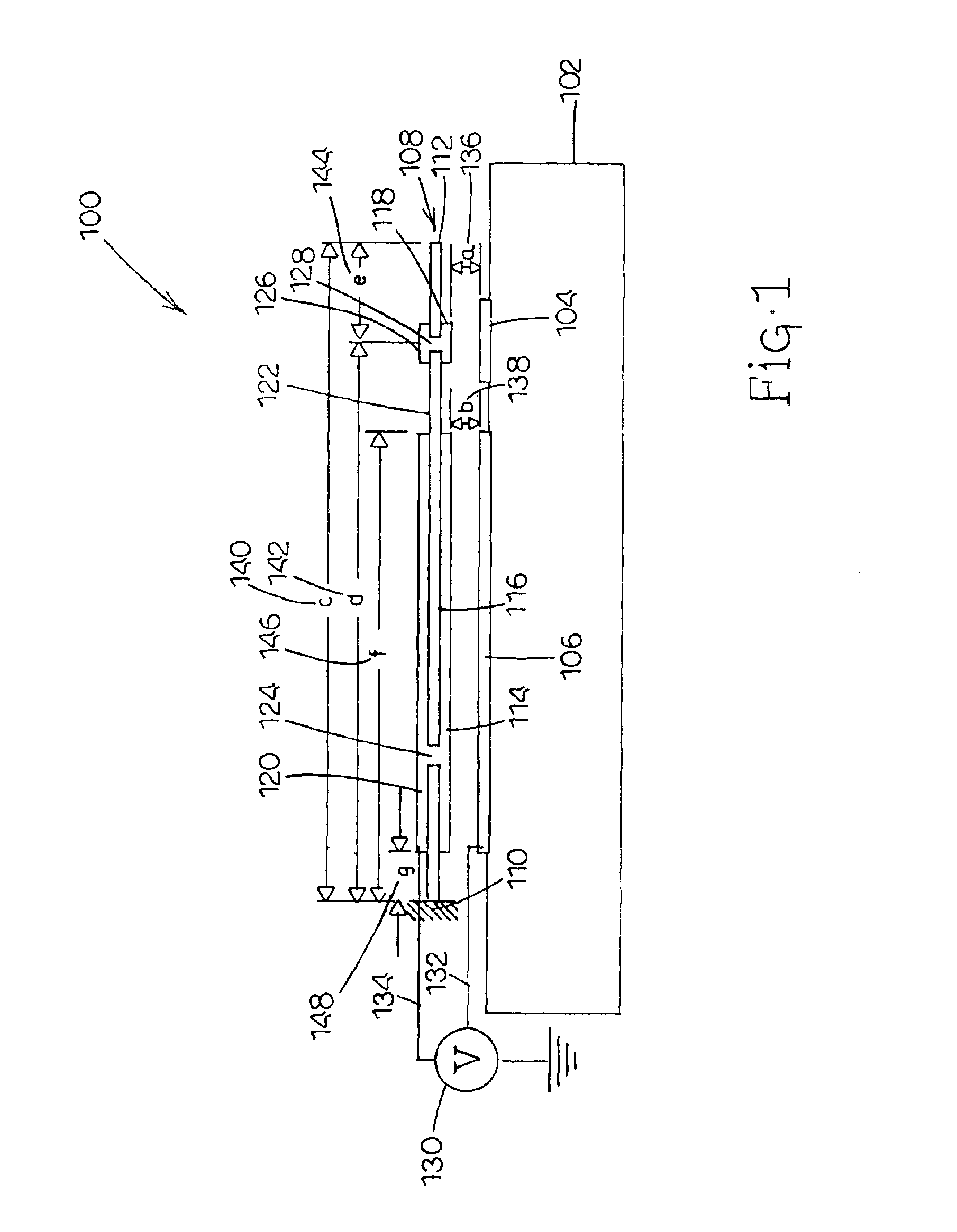

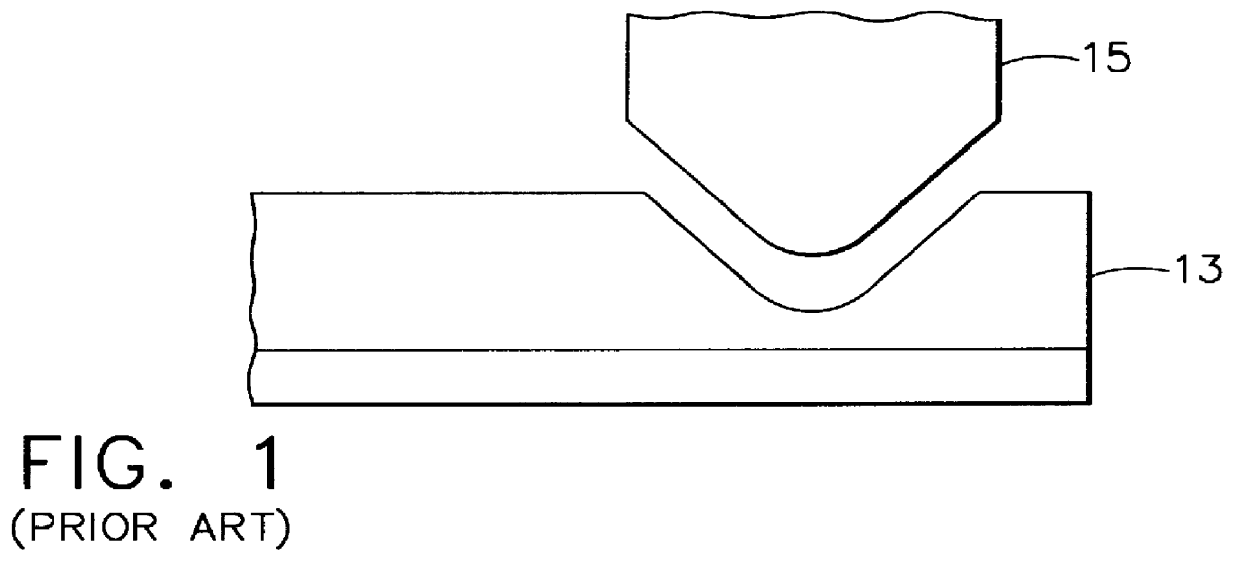

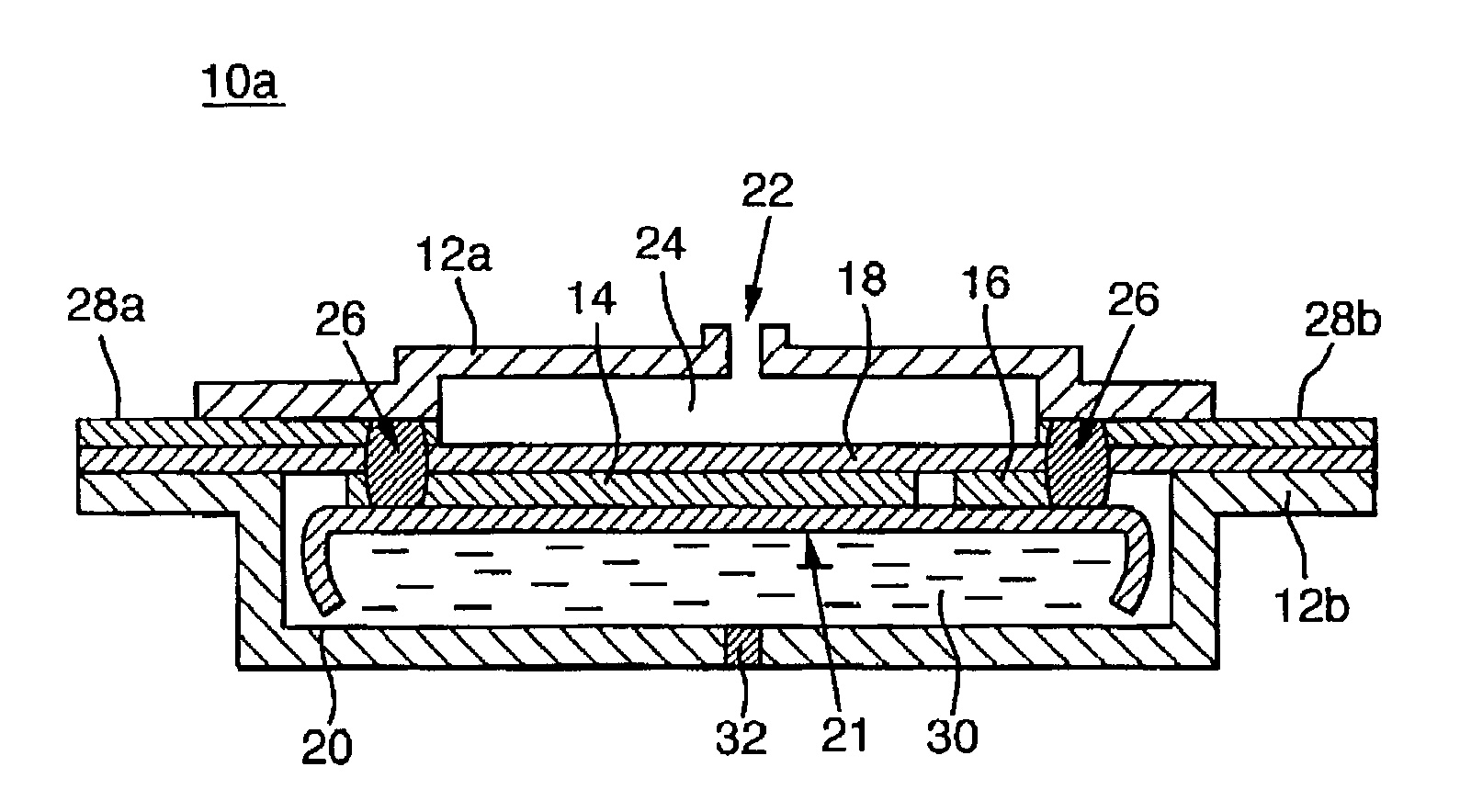

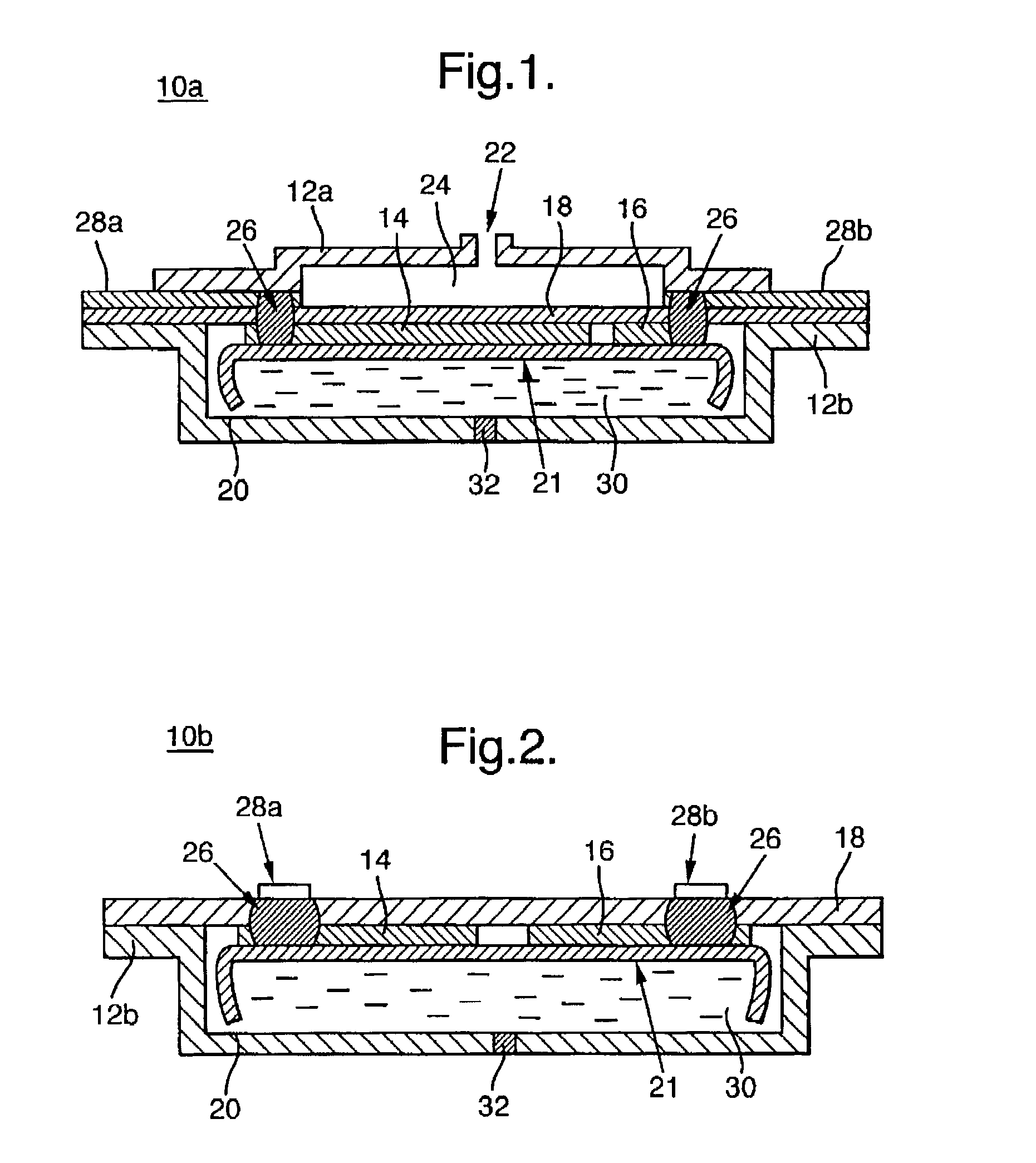

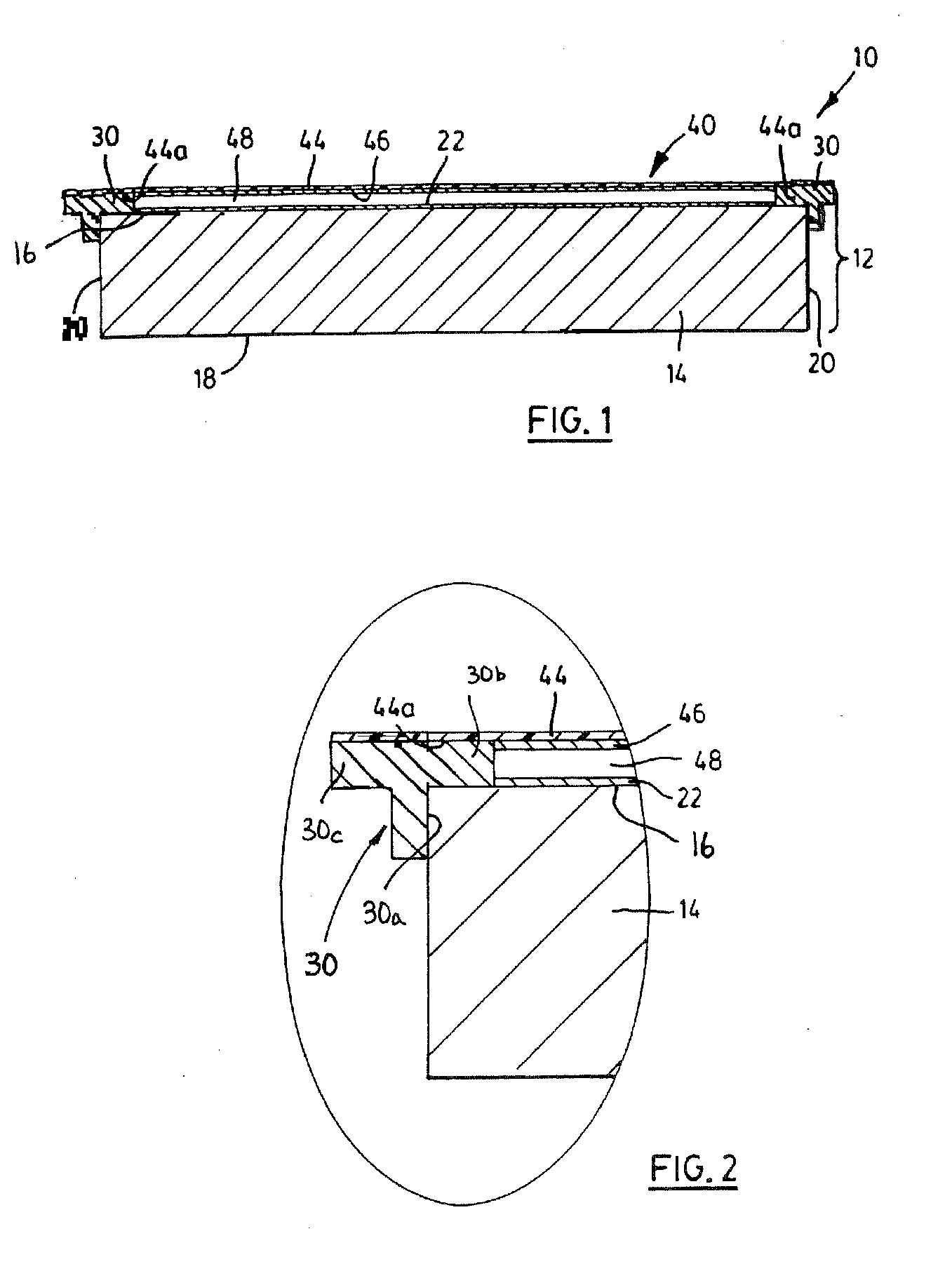

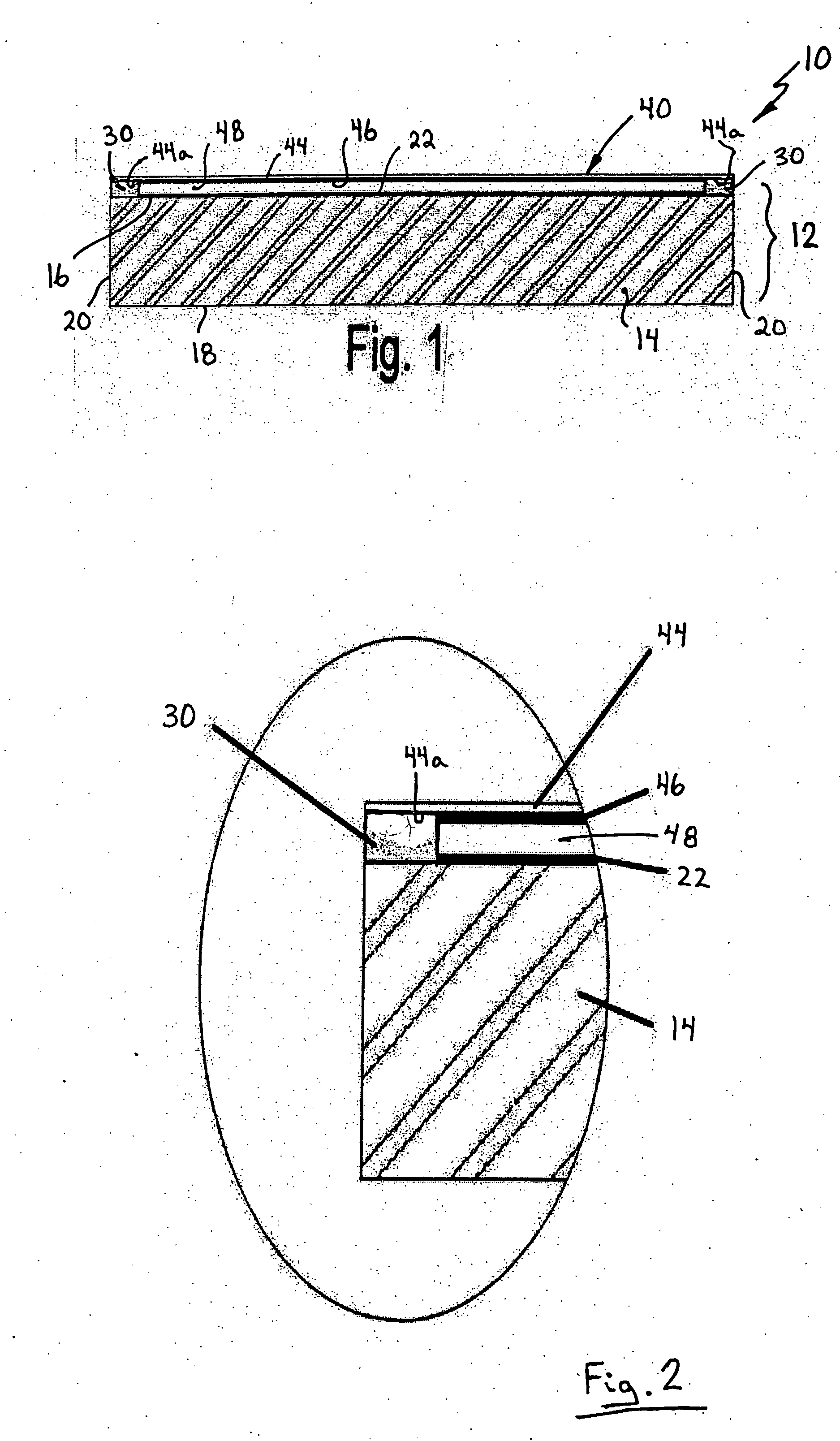

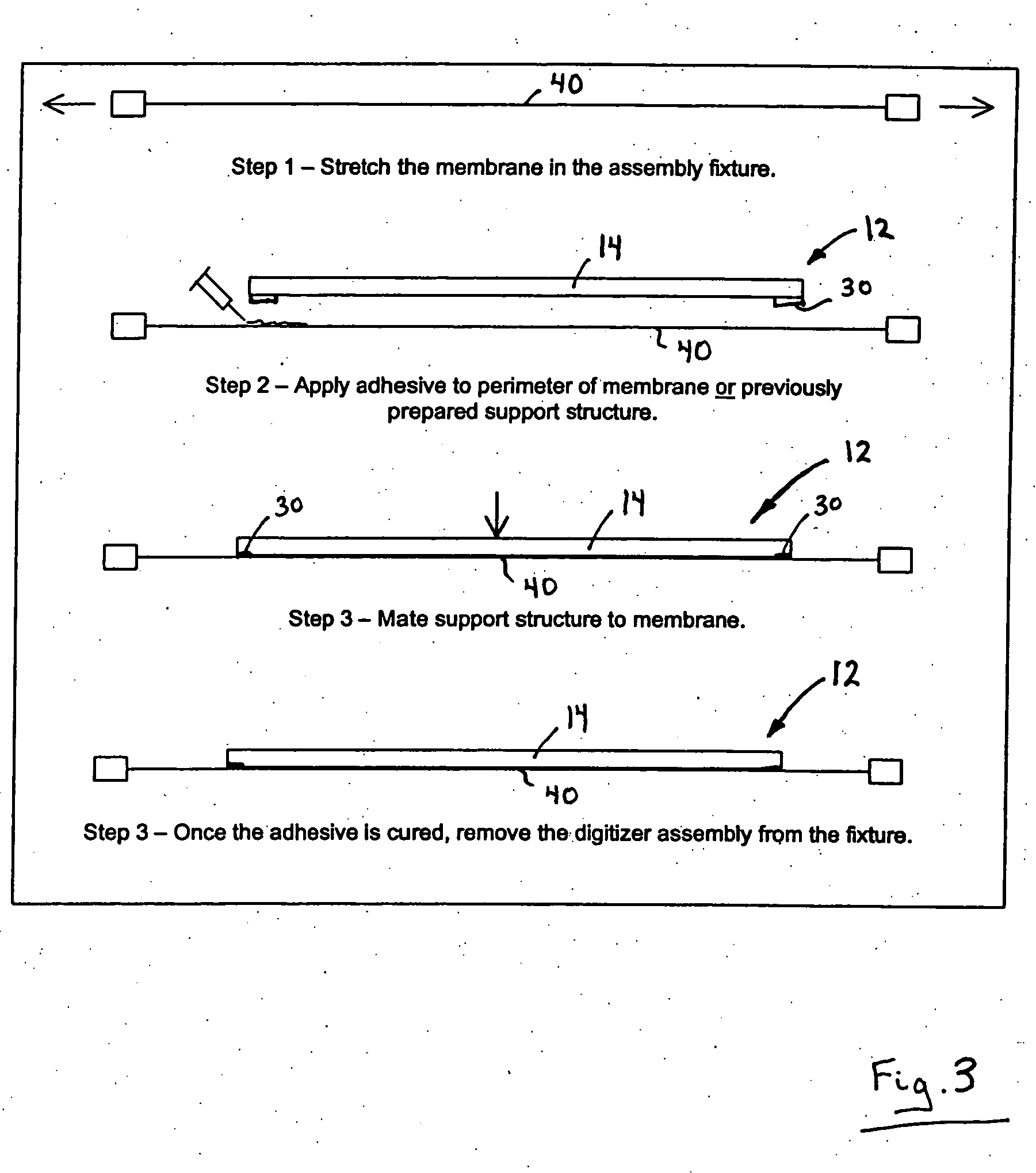

Tensioned touch panel and method of making same

ActiveUS20080083602A1Reducing manufacturing and labour costUniform tensionContact materialsLine/current collector detailsTouchscreenTouch panel

A tensioned touch panel includes a support structure having a substrate with a generally planer conductive surface disposed thereon and an insulating spacer generally about the periphery of the substrate. A pretensioned conductive member overlies the support structure. The spacer separates the conductive membrane and the conductive surface thereby to define an air gap therebetween. A conductive membrane is secured to the support structure under sufficient tension to inhibit slack from developing in the conductive membrane as a result of changes in environmental conditions. A method of assembling a tensioned touch panel is also provided.

Owner:SMART TECH INC (CA)

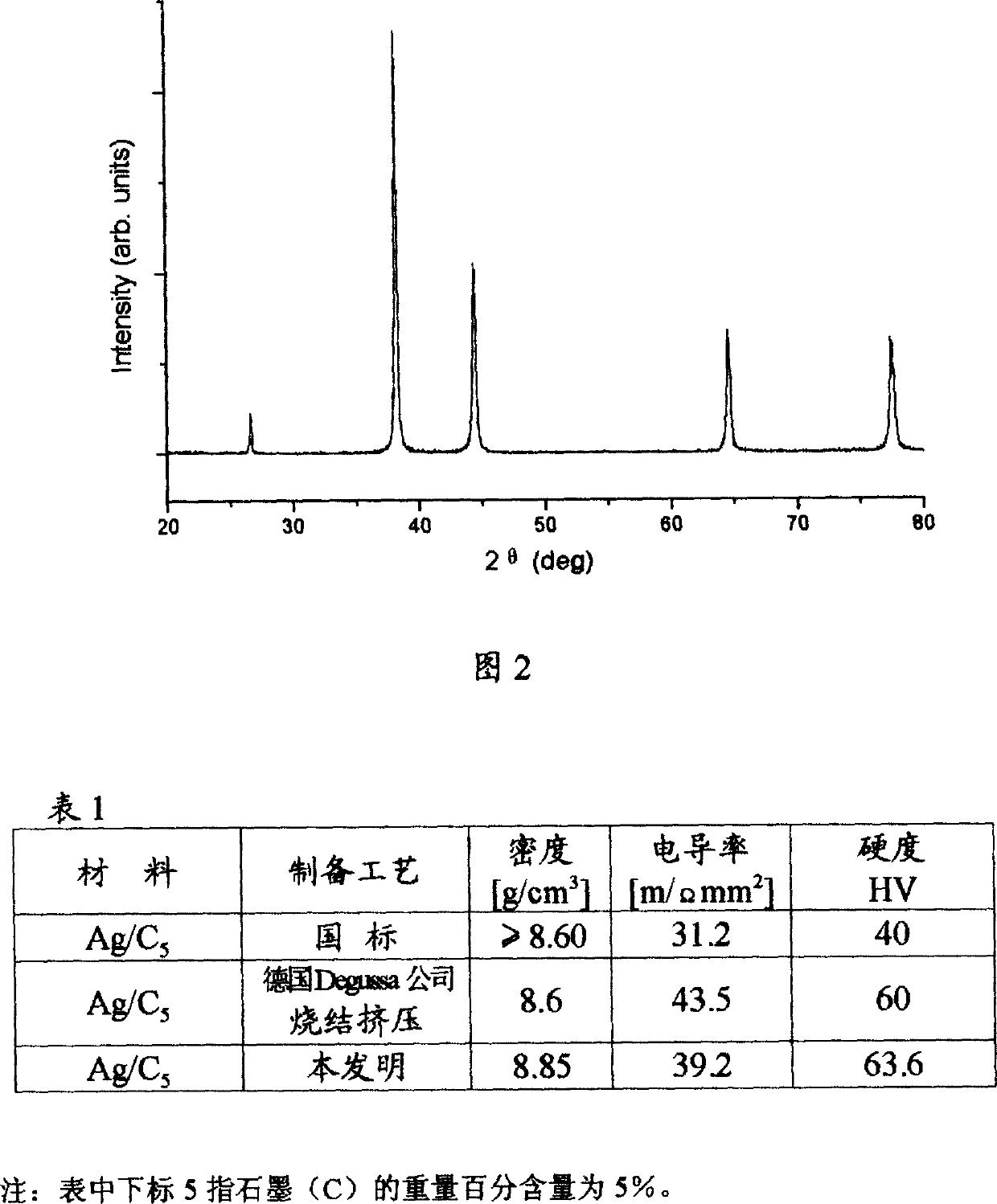

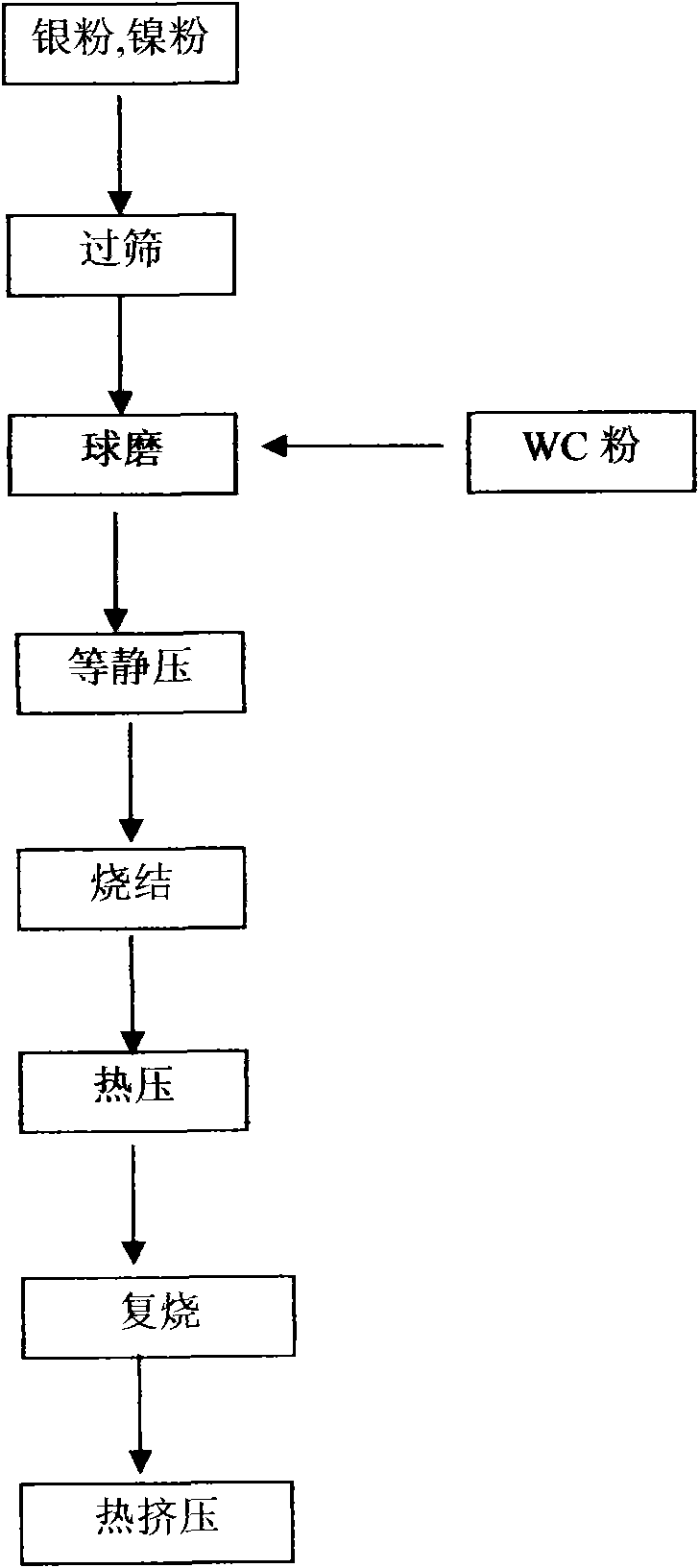

Manufacturing method of silver-tungsten carbide-carbon electrical contact material

InactiveCN1658346AImprove compactnessHigh hardnessContact materialsManufacturing technologyCircuit breaker

This invention relates to a manufacturing method of a silver-tungsten carbide-carbon electric contactor. It adopts silver powder, tungsten carbide and graphite powder as the raw materials and manufactures the silver-tungsten carbide-carbon electric contactor material through chemical coating and solid agglomeration techniques, and belongs to the field of electric components breaker switch manufacturing technology. The characteristic of this invention is: adopt silver powder, slab tungsten carbide powder, graphite powder and a little additive metal powder as the raw materials. At first mix the slab tungsten carbide powder, the graphite powder and the additive metal powder, and use chemical coating technique to get silver coating compound powder, and then pass through cold roll forming, agglomeration, re-rolling to get AgWC12C3 electric contactor material with tungsten carbide grains arrayed directionally. The AgWC12C3 electric contactor material made by this invention has fine compactness, high rigidity and conductive power. This material can be applied to many kinds of breakers with large capacity, the breakers with plastic covers and automatic switches.

Owner:SHANGHAI UNIV

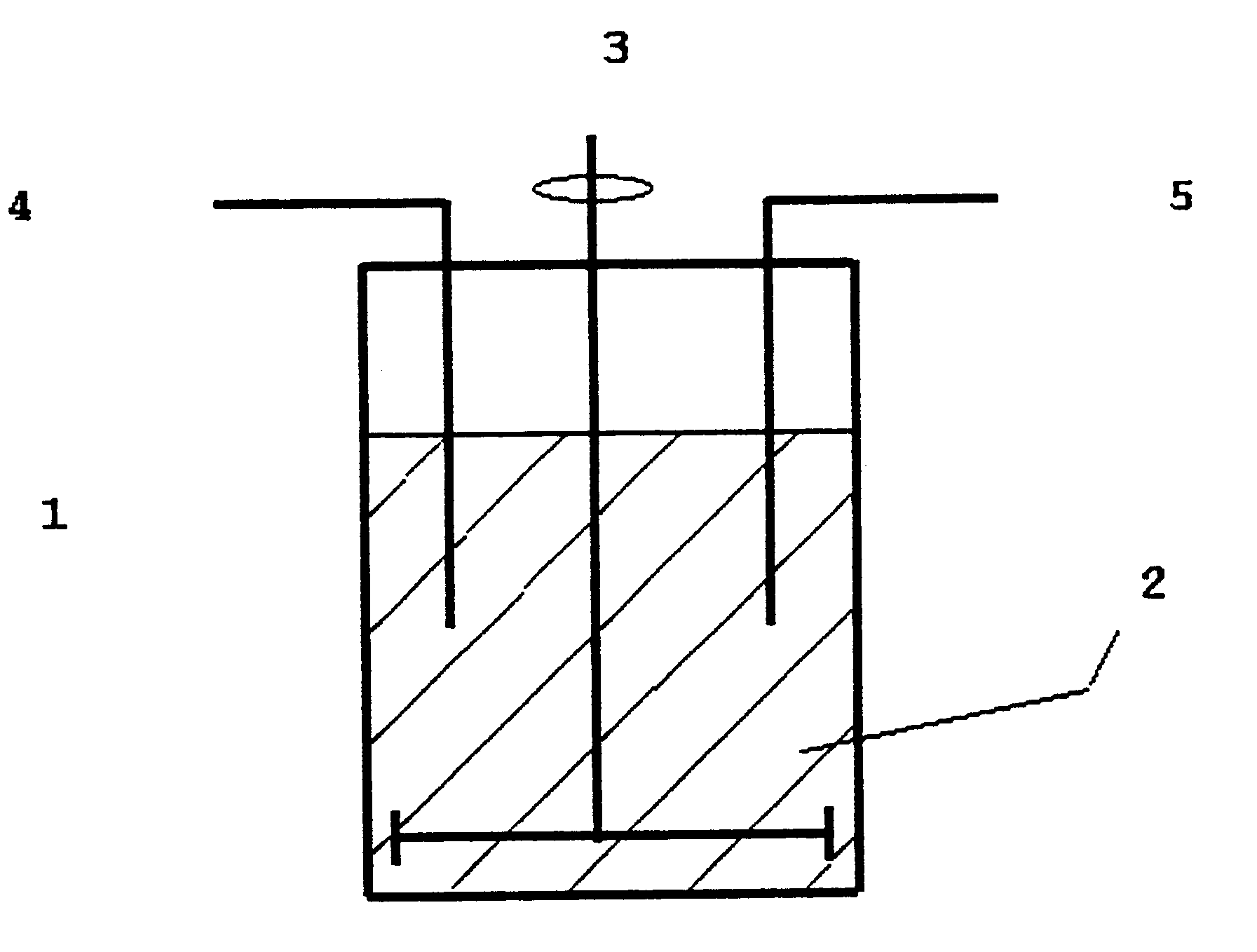

Silver-nanotin oxide electric contact material and its preparing process

ActiveCN101071687AImprove electrical performanceImprove wettabilityContact materialsLiquid/solution decomposition chemical coatingPowder mixtureHYDROSOL

This invention disclose silver - nanometer tin oxide contact material and their, and preparation of the electrical contact materials SnO2 the weight percentage of 8 to 12 percent, with an average particle size of less than 100 nanometers, but also a 0.1 to 1% CuO, MS volume Ag. Preparation of its major include: stannic chloride and citric acid solution was prepared by adding ammonia Sn (OH) 4 hydrosol; Ag powder dissolved by adding ammonia from AgNO3 solution after mixing uniform joined Sn (OH) 4 hydrosol, sprayed the hydrazine hydrate reaction after cleansing, concentration, drying in the Ag-Sn (OH) 4-coated powder; coated milling and baking powder, as treatment with Ag powder mixture and processing; in the Ag-nanometer SnO2 powder processed by a conventional process, Contact Materials. Silver Powder used by the copper powder can be added to the Ag-Cu-Sn (OH) 4-coated powder. This process Sn (OH) 4 Sol a good dispersion, coated Ag, calcined SnO2 particles dispersed in the matrix of Ag, income, life expectancy and electrical contact materials tensile strength, hardness has risen markedly, and the stability and processing sexual better.

Owner:桂林金格电工电子材料科技有限公司

Process for preparing electric silver/graphite contact material by nano technique

InactiveCN1396025AImprove sinterabilityImprove the bonding strength of the interfaceContact materialsGraphiteNanometre

A process for preparing the silver / graphite material as electric contact by use of nanometre technique includes such steps as preparing graphite nanometre powder; adding silver nitrate solution; chemical coating; washing with water; drying and sintering. Its advantages are simple process, low cost and high quality of product.

Owner:EAST CHINA NORMAL UNIV

Tensioned touch panel and method of making same

ActiveUS20050241929A1Lower manufacturing requirementsReduce labor costsContact materialsContact surface shape/structureTouchscreenTouch panel

A tensioned touch panel includes a support structure having a substrate with a generally planer conductive surface disposed thereon and an insulating spacer generally about the periphery of the substrate. A pretensioned conductive member overlies the support structure. The spacer separates the conductive membrane and the conductive surface thereby to define an air gap therebetween. A conductive membrane is secured to the support structure under sufficient tension to inhibit slack from developing in the conductive membrane as a result of changes in environmental conditions. A method of assembling a tensioned touch panel is also provided.

Owner:SMART TECH INC (CA)

AgNi electrical contact material and preparation method thereof

InactiveCN101608272AExtended service lifeImprove welding resistanceContact materialsElectricityHardness

The invention discloses an AgNi-base electrical contact material and a preparation method thereof and the electrical contact material comprises nickel, tungsten carbide and silver; wherein, the weight percent of nickel is not less than 5% and not more than 10%, the weight percent of tungsten carbide is not less than 0.1% and not more than 5% and the allowance is silver. In the invention, the distribution of nickel particles and the fiber orientation are considered; the manufacturing process adopts the processes of ball-milling, pressing, sintering and extruding. Owning to the high hardness, high strength and high melting point of tungsten carbide, tungsten carbide / silver bonding strength is better; comprised with the traditional AgNi electrical contact material, the AgNi electrical contact material prepared by the method of the invention has higher welding resistance and arc deterioration resistance and longer electrical life.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Method for producing composite powders based on silver-tin oxide, the composite powders so produced, and the use of such powders to produce electrical contact materials by powder metallurgy techniques

InactiveUS6409794B2Contact materialsLiquid/solution decomposition chemical coatingMaterials scienceReducing agent

Owner:UMICORE AG & CO KG +1

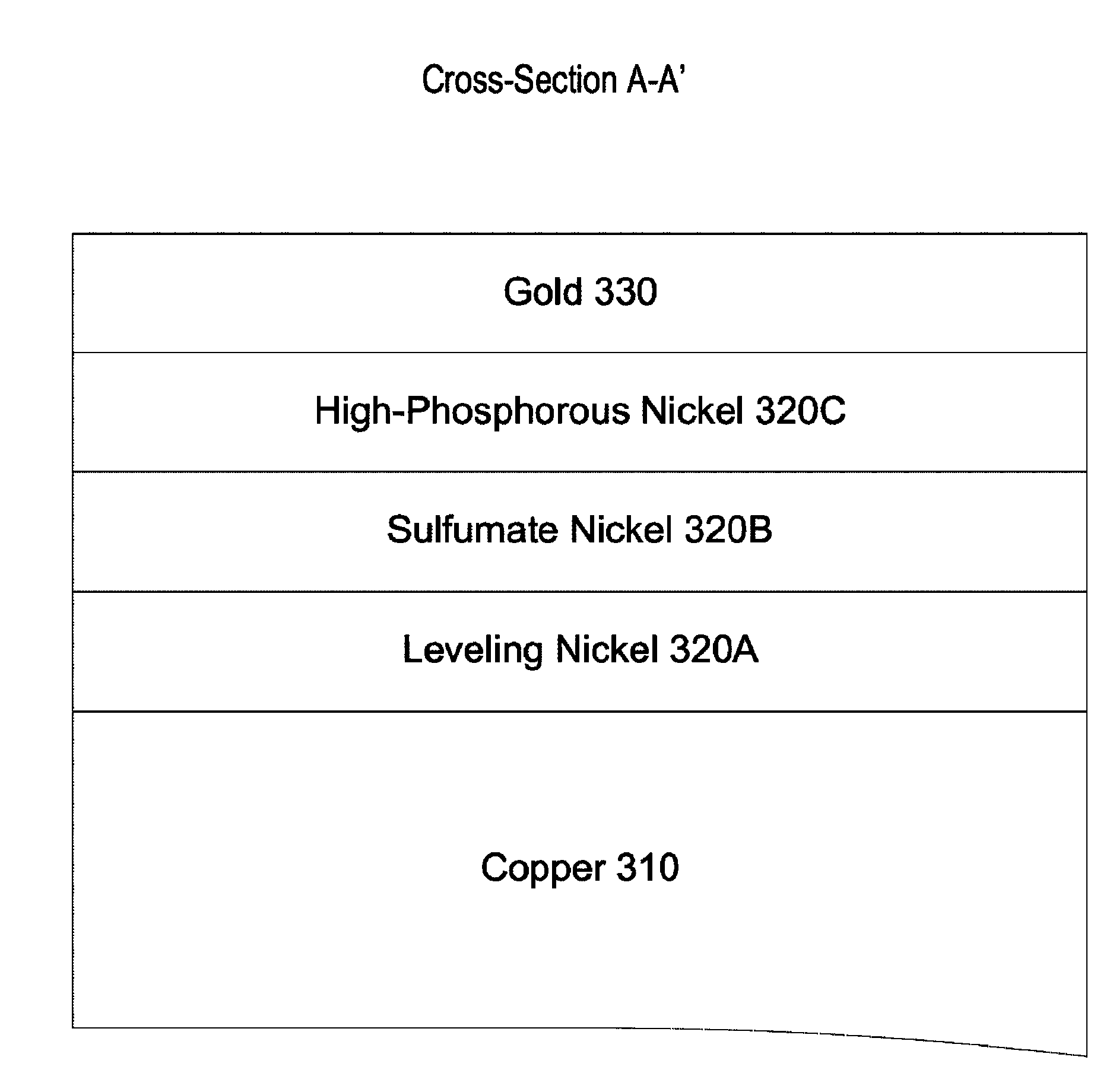

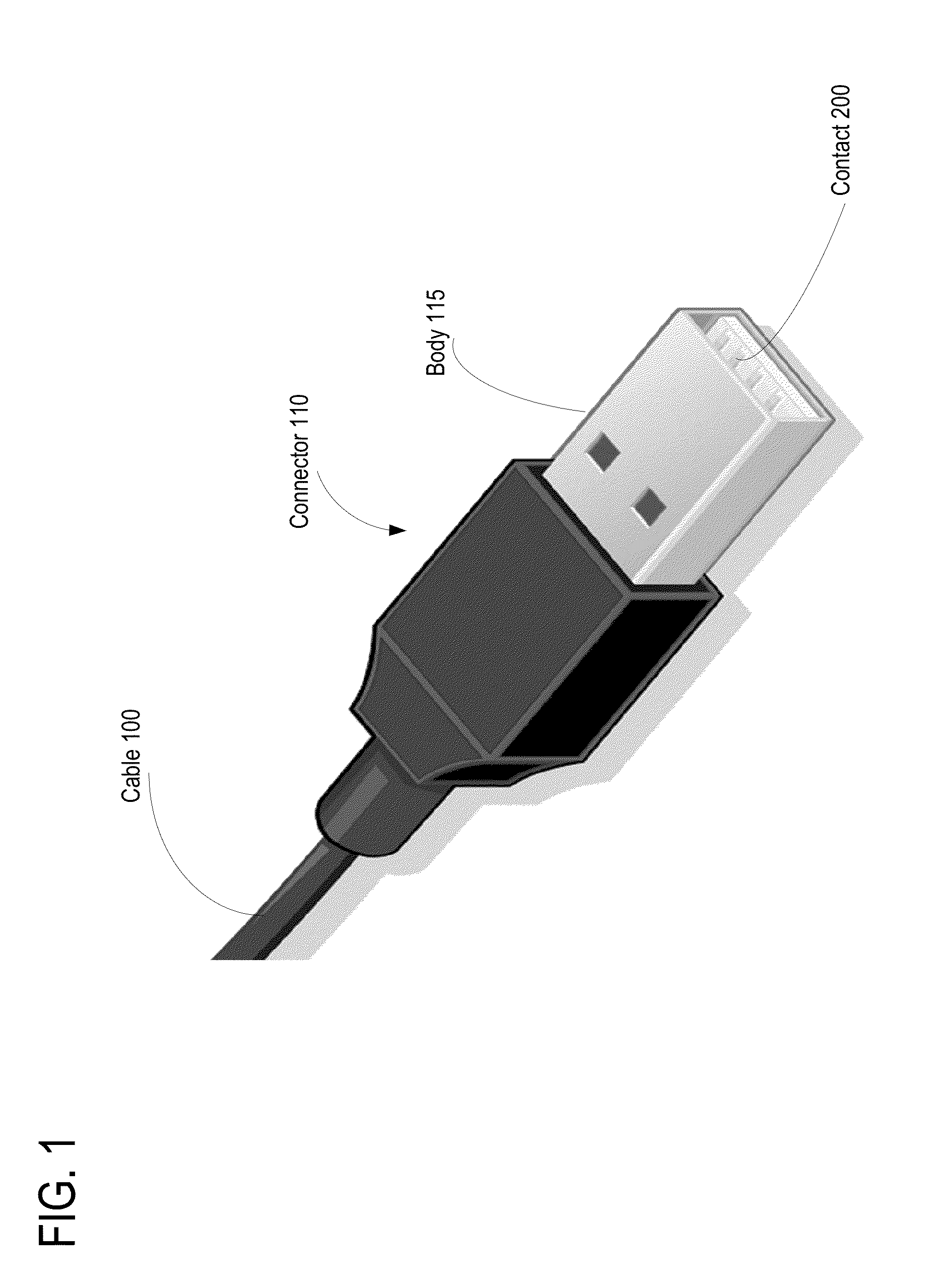

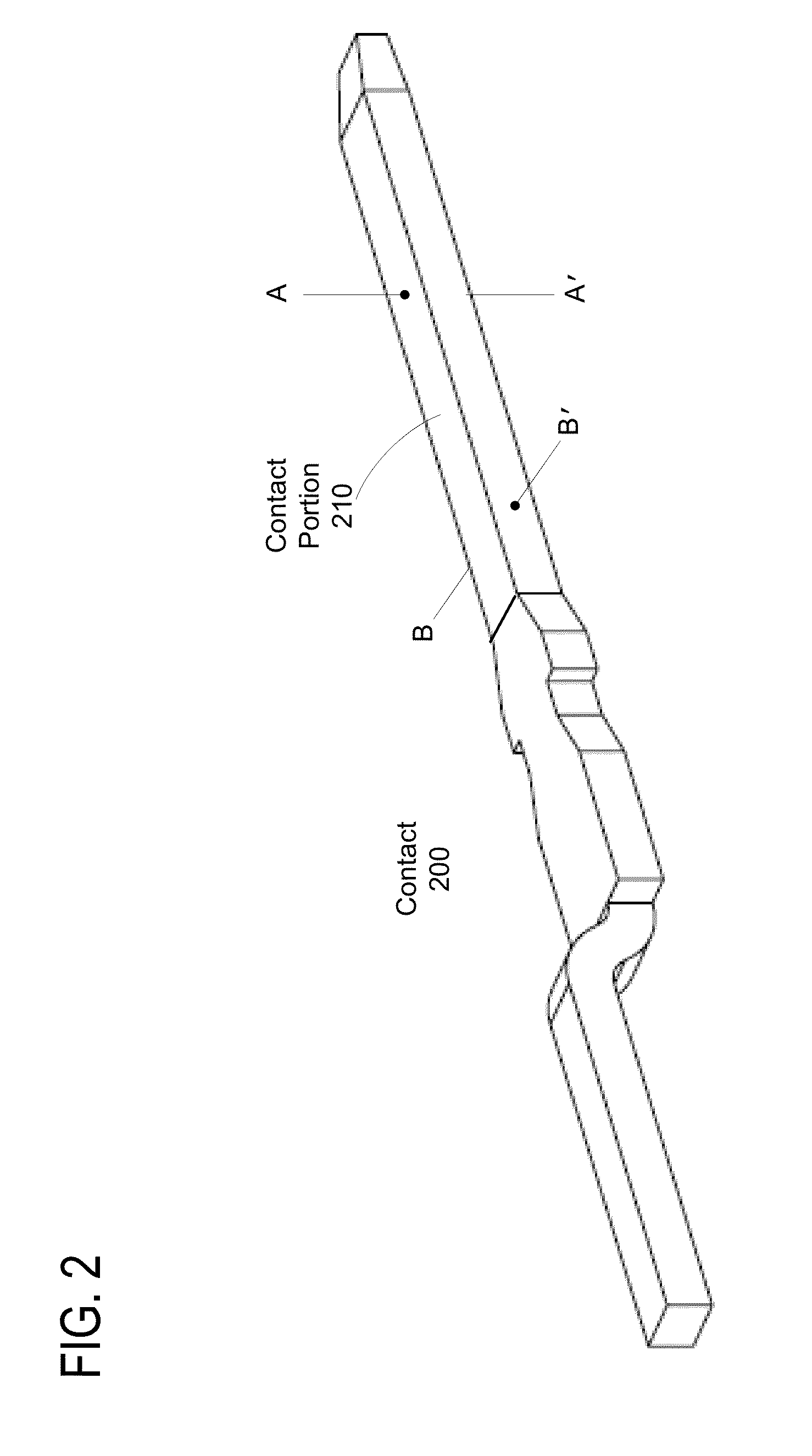

Connector with multi-layer Ni underplated contacts

InactiveUS8637165B2Contact materialsElectrically conductive connectionsElectrical connectorCorrosion resistant

A corrosion-resistant electrical connector is disclosed. A multi-layer nickel underplating is applied to the substrate material of the connector contacts. The three layers of nickel include a leveling nickel layer, a sulfumate nickel layer, and a high-phosphorous nickel layer. A layer of gold is applied to the nickel underplating in an embodiment.

Owner:APPLE INC

Sliding electric contact material for low current

ActiveCN101246758ASmall and stable contact resistanceQuality improvementContact materialsMetal/alloy conductorsElectricityWeak current

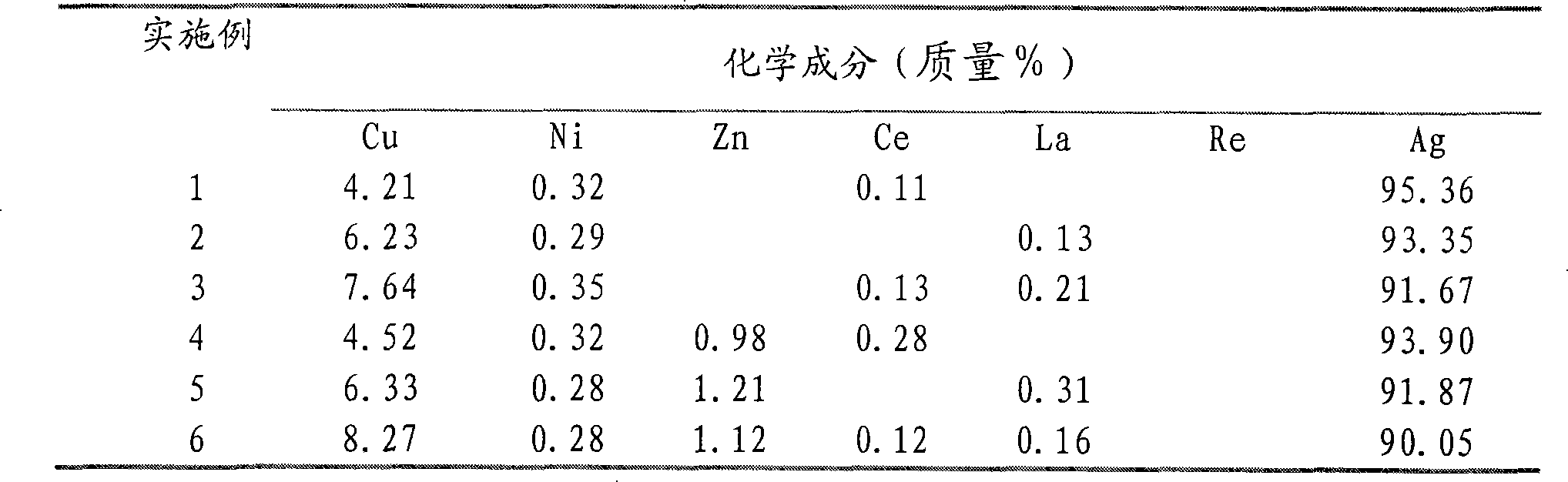

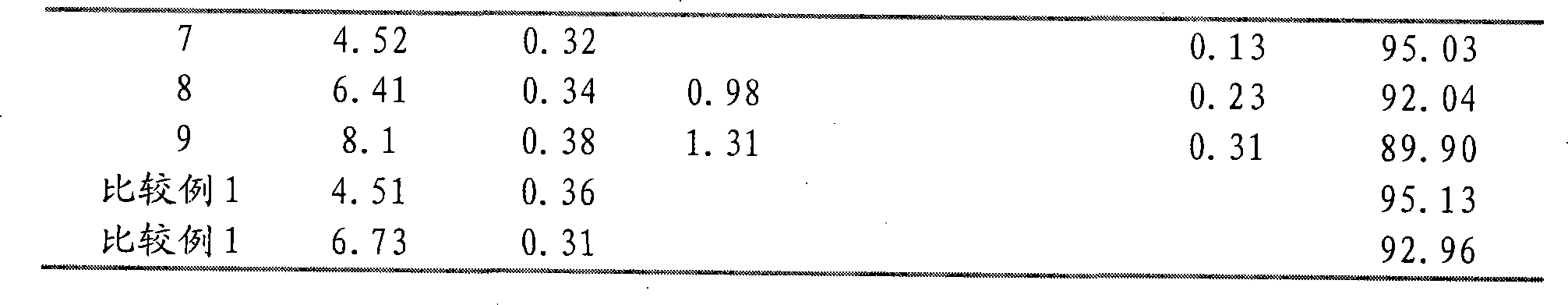

The invention relates to a slip electrical contact material for feeble current, the material is Ag-Cu-Ni-Re alloy, Ag-Cu-Zn-Ni-Re alloy or Ag-Cu-Pd-Zn-Ni-Re alloy, wherein Cu has a mass percentage of 0.1-10.0%, Ni has mass percentage of 0.01-0.6%, Re has a mass percentage of 0.01-0.5%, Zn has a mass percentage of 0.1-5.0%, Pd has a mass percentage of 0.1-105%,and the balance Ag. The invention solves the following problems of feeble current slip contact alloy under high: unstable contact resistance, low contact reliability, low hard and low wearing quality. The slip electrical contact material prepared by combining the material with copper or copper alloy has good quality and long life in a temperature scope ranging from -40 DEG C to 80 DEG C.

Owner:CHONGQING CHUANYI AUTOMATION

Composite conducting strip

InactiveCN102169760AGood conduction current performanceAntistaticContact materialsMetal layered productsMetal foilCopper foil

The invention provides a composite conducting strip which comprises a high-polymer matrix and one or two or more than two layers of communicated metal foils composited therein; and the total thickness of the composite conducting strip is 0.3-3mm. The surfaces of the metal foils are uneven and have protruding contacts which are exposed to one surface of the high-polymer matrix. The high-polymer matrix includes silicon rubber, nitrile rubber, ethylene propylene rubber, natural rubber, rubber and plastic materials, thermoplastic plastics, thermosetting plastics, fiber reinforced plastics and thelike and can contain 0.1-5% of coupling agent and other auxiliaries. The metal foils are nickel foils, copper foils, aluminum foils, stainless steel foils, gold foils, silver foils with holes or meshgrids. The composite conducting strip has the advantages of being high in composite strength, good in corrosion resistance and good in current conduction performance, can be divided into random shapes and specifications and can be widely used for manufacturing the conductive base materials of various buttons in an electronic industry.

Owner:NANTONG MEMTECH ELECTRONIC INDUSTRY CO LTD +1

Popular searches

Capacitor with electrode area variation Capacitor with electrode distance variation Input/output processes for data processing Non-mechanically variable capacitors Emergency protective arrangements for automatic disconnection Semiconductor/solid-state device details Solid-state devices Fluid speed measurement Flexible microstructural devices Thermal electric motor

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com